Lithium ion battery negative pole size and preparation method thereof

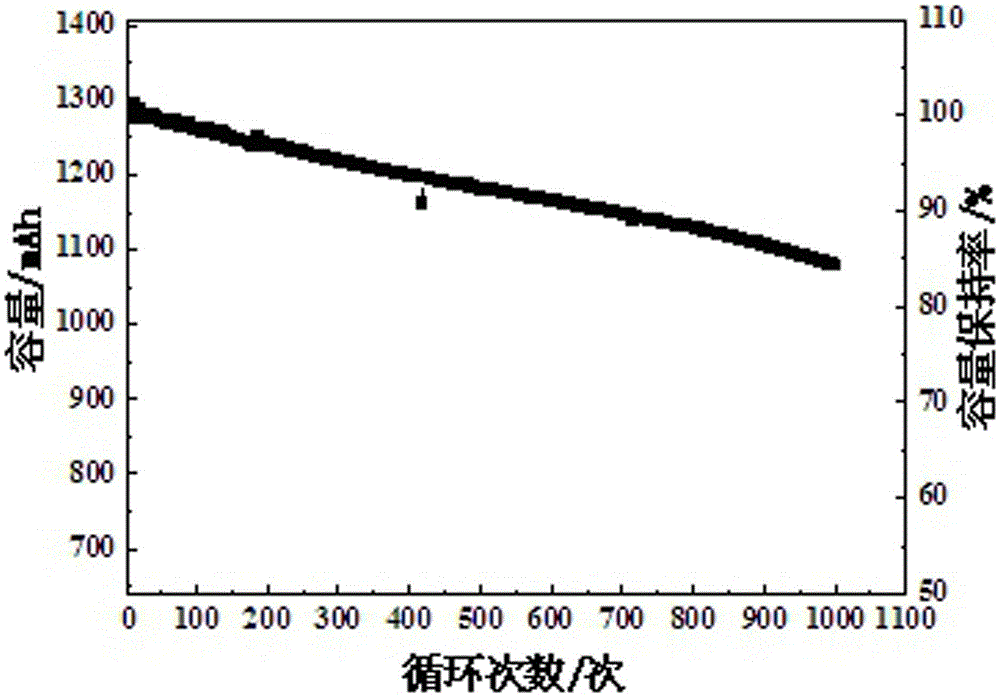

A lithium-ion battery and negative electrode slurry technology, which is applied to battery electrodes, secondary batteries, circuits, etc., can solve the problems of materials and current collectors falling off, poor material cycle performance, etc., and achieve good rate performance and cycle performance, high ratio Effects of capacity, excellent electronic conductivity and chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] First, mix 1.650±0.005kg of CMC and 6.600±0.005kg of NMP into a 200L planetary mixer and stir slowly for 20min, with a revolution speed of 5r / min and an autorotation speed of 0r / min. After the stirring is completed, add 126.000±0.005kg of deionized water Stir at high speed for 90 minutes, revolution speed 20r / min, rotation speed 1000r / min, after the CMC solution is stirred, pass through a 200-mesh sieve and let stand for 12 hours;

[0024] Then mix 1.000±0.005kg Super-p and 122.000±0.005kg CMC solution into a 200L planetary mixer and stir for 120min at high speed, revolution speed 20r / min, rotation speed 1000r / min, then add 95.000±0.005kg layered graphdiyne negative electrode active material Stir at high speed for 120min, revolution speed 20r / min, rotation speed 1500r / min, then add 5.000±0.005kgSBR high speed stirring for 90min, revolution speed 20r / min, rotation speed 1500r / min;

[0025] Finally, 1.000±0.005kg of deionized water was added and stirred to adjust the visc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com