Patents

Literature

145results about How to "Reduce shrinkage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium silicate glass ceramic

ActiveUS20090038344A1High chemical durabilityReduce shrinkageDental implantsOther chemical processesHigh intensityLithium

Owner:IVOCLAR VIVADENT AG

Lithium silicate glass ceramic

ActiveUS20090038508A1High chemical durabilityReduce shrinkageDental implantsImpression capsHigh intensityLithium

Owner:IVOCLAR VIVADENT AG

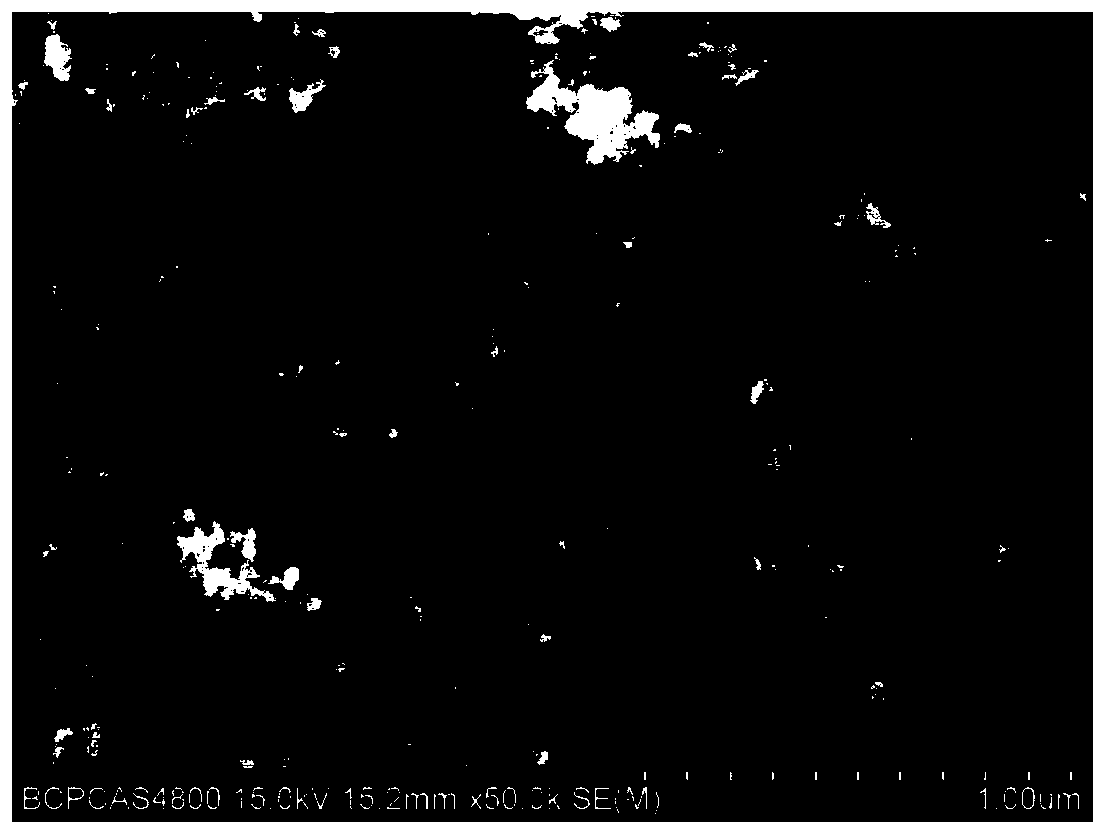

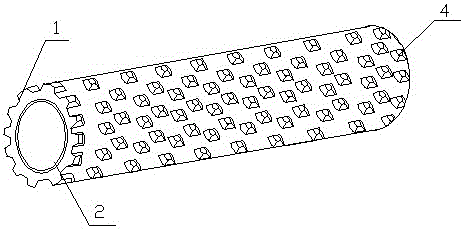

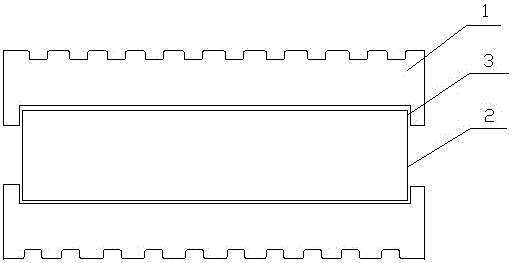

Lithium ion battery diaphragm and preparation method thereof

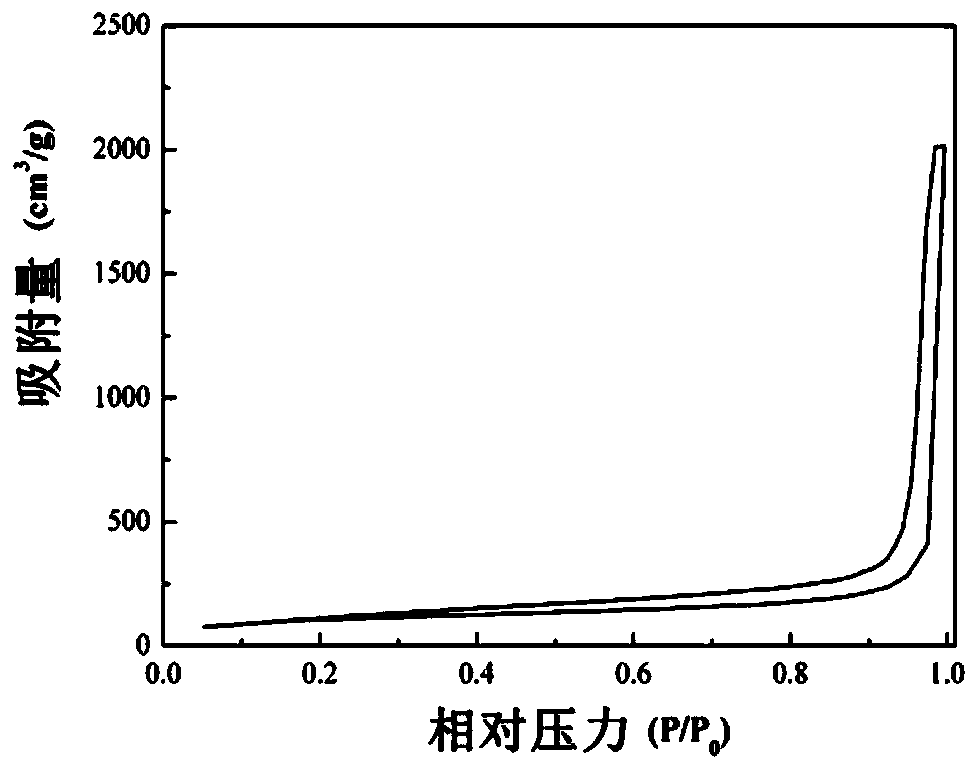

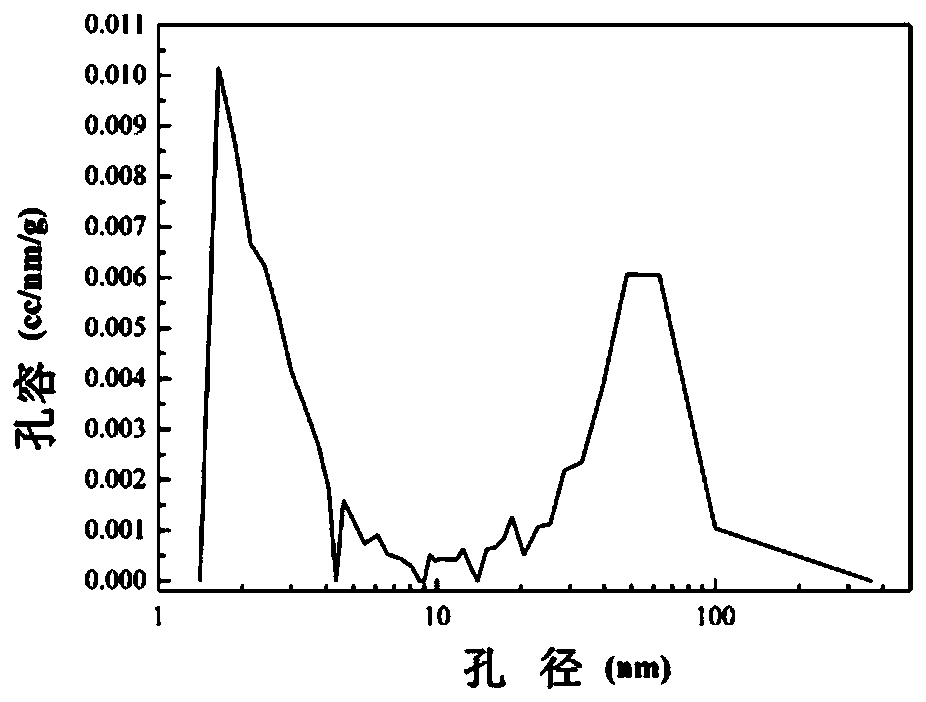

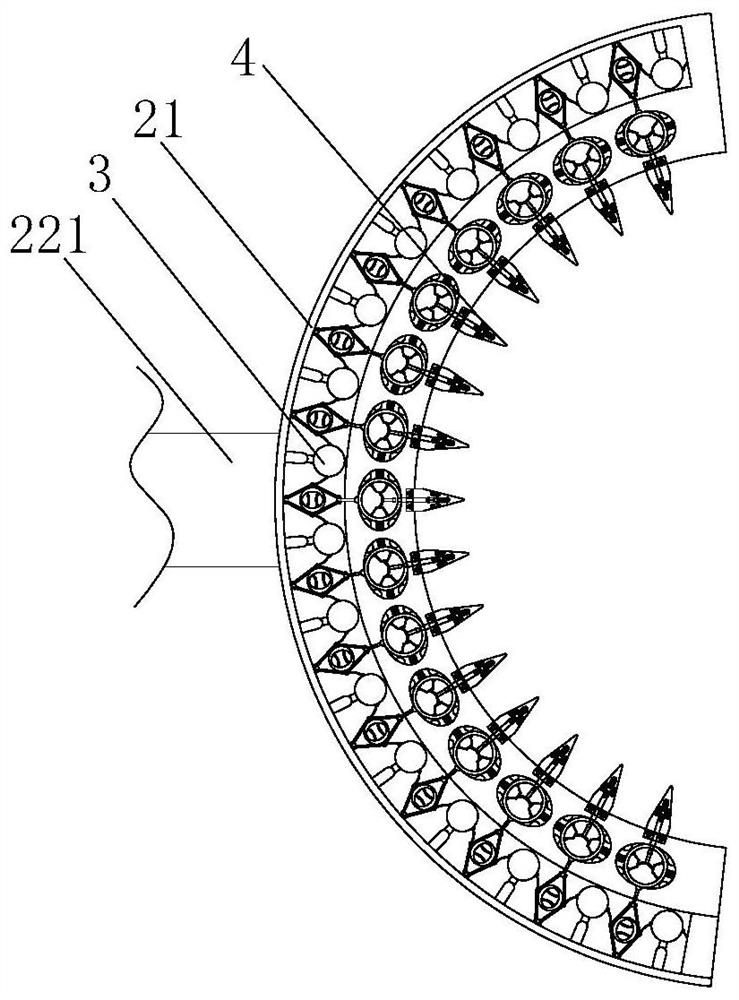

The invention relates to a lithium ion battery diaphragm. The lithium ion battery diaphragm comprises a polyolefin substrate and a composite coating, wherein the coating is connected with the polyolefin substrate through a binder, the coating is formed by stacking a plurality of inorganic particle layers, and each two adjacent inorganic particle layers of the coating are connected with each other through a binder; each inorganic particle layer consists of flaky inorganic particles, and the flaky inorganic particles are distributed in parallel or at a small angle in the coating. The invention also relates to a preparation method of the lithium ion battery diaphragm. The preparation method comprises the following steps: preparing flaky inorganic particles; screening first inorganic particles and second inorganic particles; preparing coating slurry; coating the polyolefin substrate with the coating slurry, and drying the polyolefin substrate with the coating to obtain a product. The lithium ion battery diaphragm is high in flatness, low in coarseness, low in water absorption rate, low inn coating expansion degree, capable of effectively reducing the natural crimpness of single-side coated diaphragm and capable of improving the assembling efficiency and rate of finished products of a laminated battery.

Owner:河南惠强新能源材料科技股份有限公司

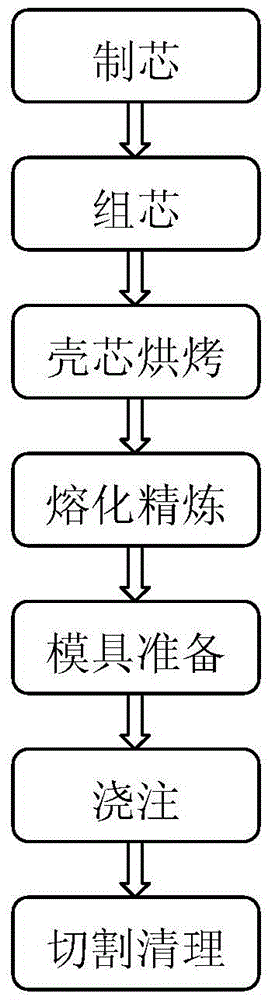

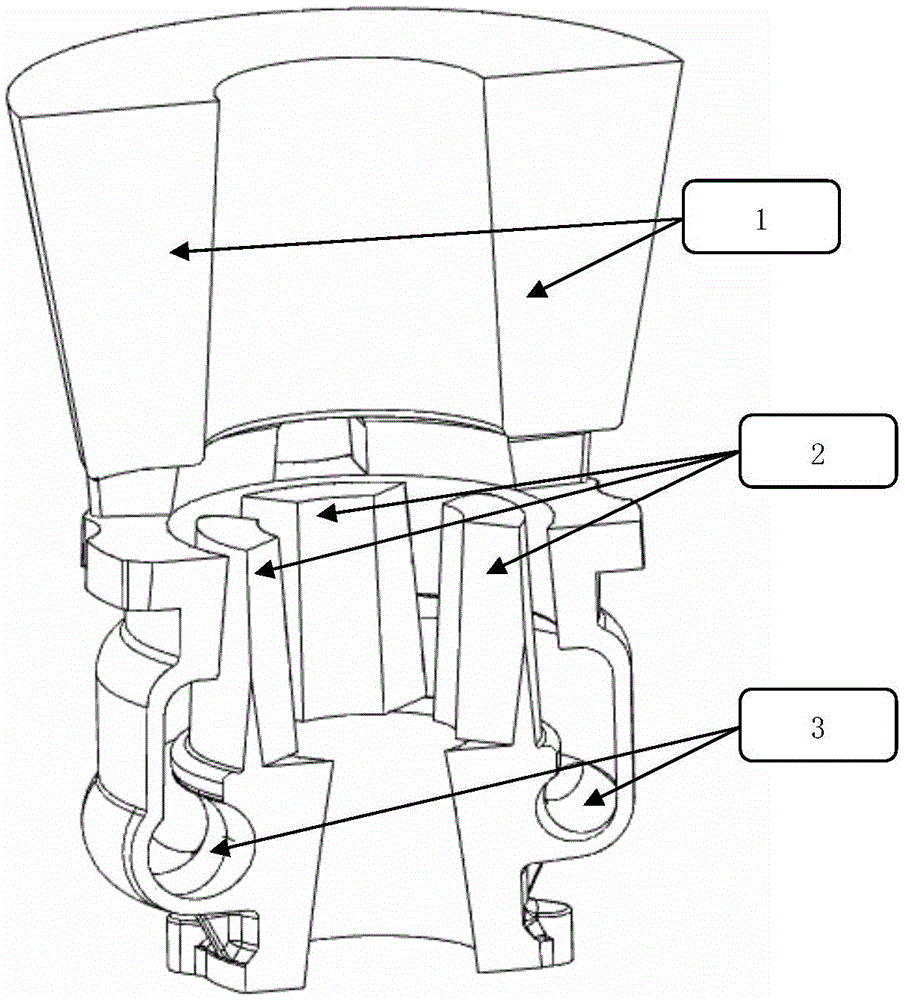

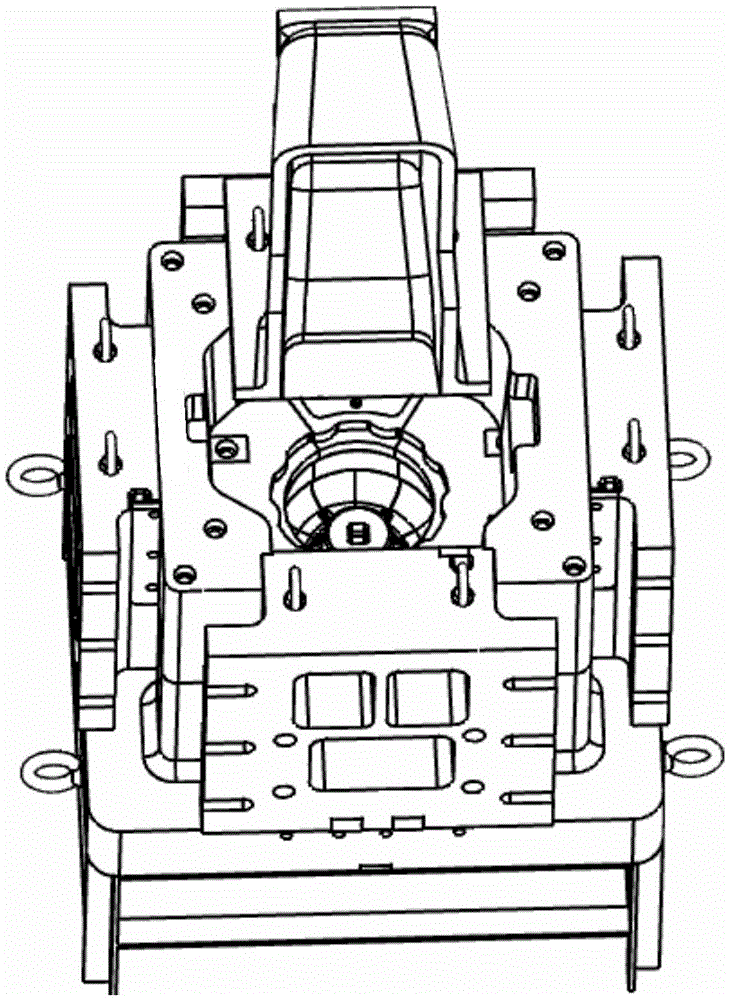

Casting method of turbine housing

ActiveCN105458182AIncrease productivityEffective control of solidification sequenceFoundry mouldsFoundry coresSlagTurbine

The invention provides a casting method of a turbine housing. The casting method includes the following steps of firstly, core manufacturing, secondly, core assembly, thirdly, shell core baking, fourthly, smelting and refining, fifthly, mold preparation, sixthly, casting and seventhly cutting and cleaning. In the core manufacturing process, a riser sand core mold is arranged on a core shooting machine, the core shooting machine is powered on to heat the mold, a layer of precoated sand is cured on a cavity of the riser sand core mold, and a riser sand core is obtained after mold opening. In the core assembly process, the riser sand core and a turbine housing core are assembled and bonded. In the shell core baking process, shell cores painted with coatings are put into a baking kiln. In the smelting and refining process, raw materials are added to a melting and heat preservation furnace, and the melting and heat preservation furnace is powered on for melting. In the casting process, the shell cores are put in a mold, and tilt casting is conducted after mold combination. In the cutting and cleaning process, a casting is cut, the riser is cast, and burrs and fins of the casting are ground and cleaned. The metal tilt casting method of an aluminum alloy turbine housing body can solves the problems of shrinkage porosities and cavities and slag holes in a big flange face of the aluminum alloy turbine housing; open risers and blind risers are arranged, in combination with the riser sand core, an ideal temperature field is formed after the casting is cast, and solidification can be conducted from the casting to the risers in sequence.

Owner:XIAN AERO ENGINE CONTROLS

Filled fiber reinforced thermoplastic composite

InactiveUS20050238864A1Low densityReduce shrinkageSynthetic resin layered productsCeramic layered productsThermoplastic compositesFiber reinforcement

Fiber-reinforced thermoplastic composites containing hollow bubbles provide surprisingly low density and retention of robust physical properties.

Owner:3M INNOVATIVE PROPERTIES CO

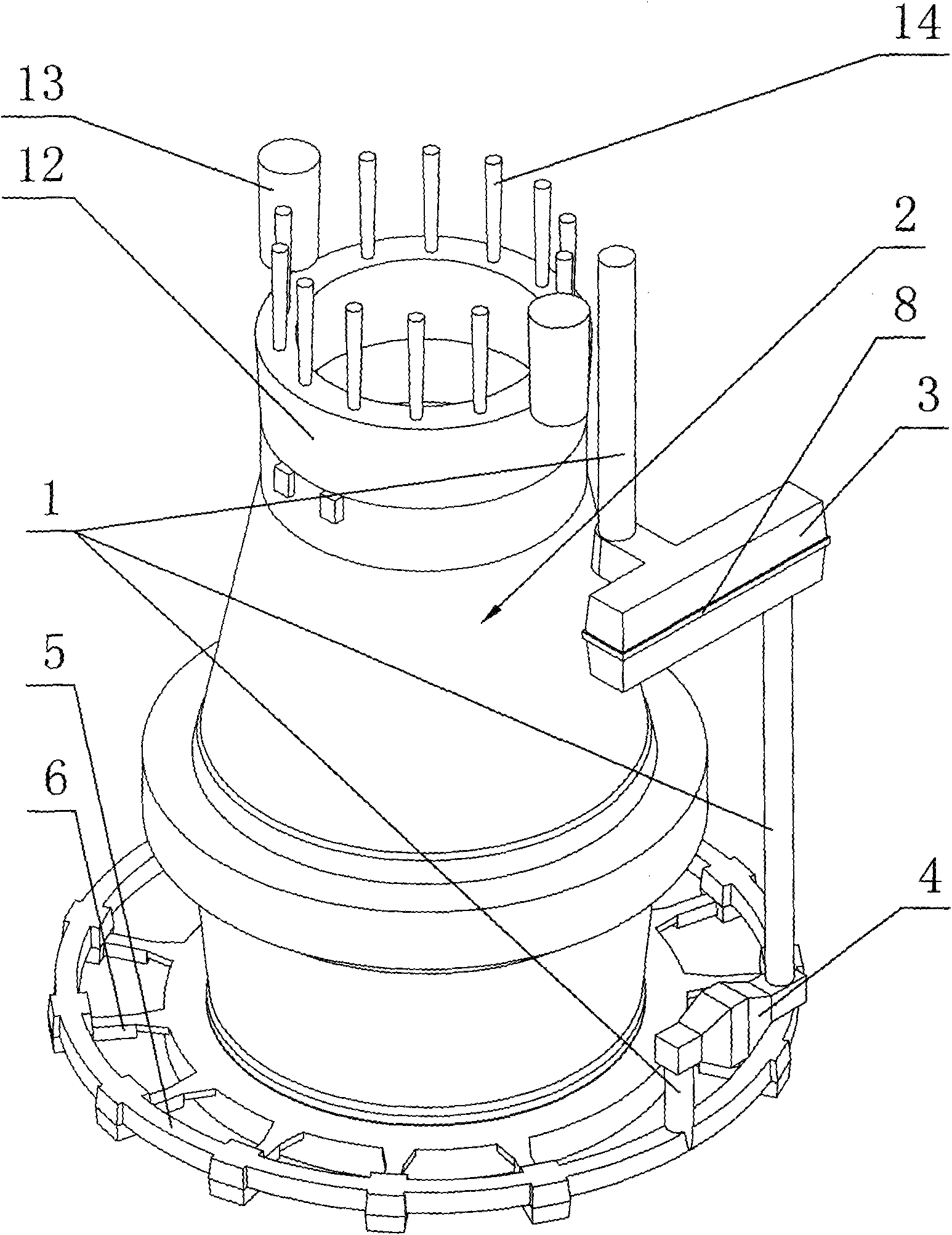

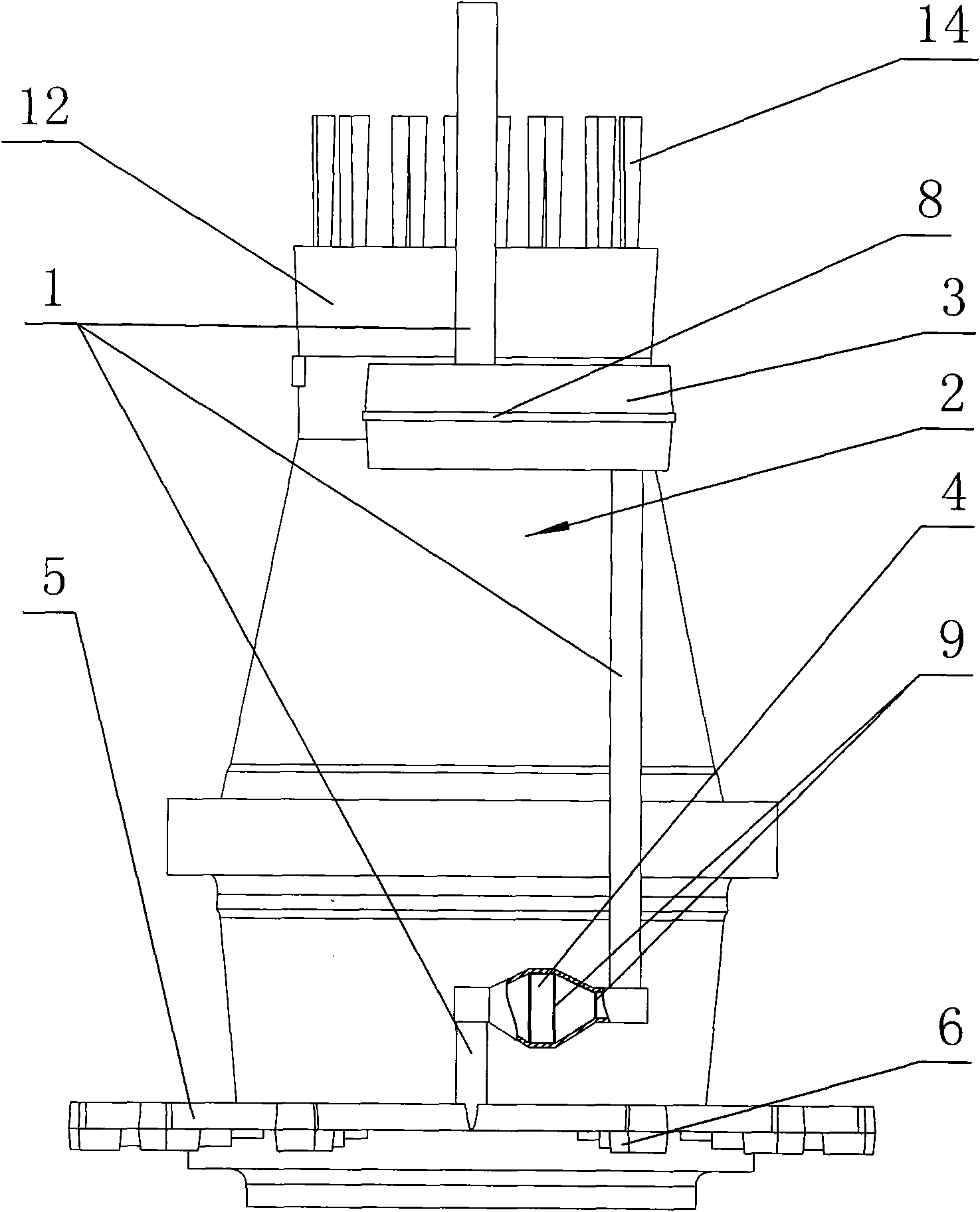

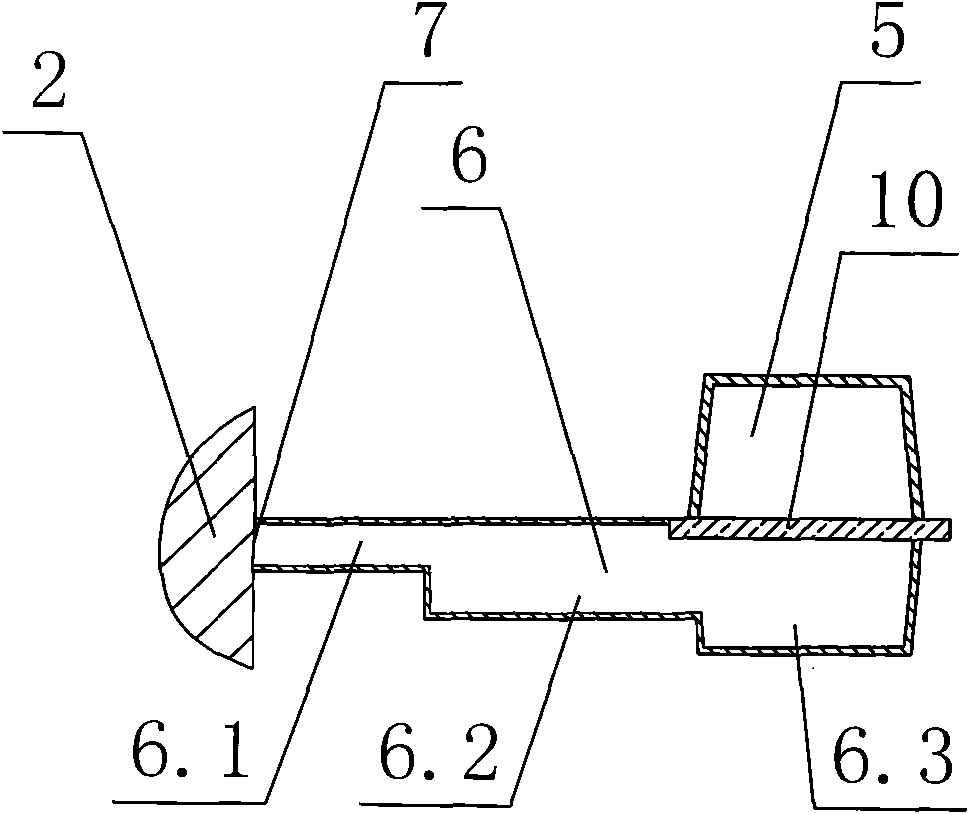

Method for casting rotary axis casts of aerogenerators

The invention discloses a method for casting rotary axis casts of aerogenerators, which comprises the steps of mould manufacture, the manufacture of sand moulds and moulding by casting. In the step b of the manufacture of sand moulds, a top sprue (1) is used as an inlet of iron liquor, and is alternately communicated with runners; a bottom runner is communicated with an ingate communicated with a cast mould cavity; the runners are designed into a first runner (3), a second runner (4) and a circular runner (5); the ingate is designed into a plurality of radial runners (6) for communicating the circular runner (5) and the cast mould cavity; filtering apparatuses are arranged on the first runner (3) and the second runner (4), and are also arranged between each radial runner (6) and the circular runner (5); and in the step c of moulding by casting, the casting temperature is controlled from 1310 DEG C to 1350DEG C; and finally, a cast (2) is obtained. The method for casting rotary axis cast of aerogenerator has the advantages of good residue blocking effect and low production cost.

Owner:RIYUE HEAVY IND

Single-component, high-solid-content and low-volatility organic compound and environment-friendly type varnish composition and preparation method and application of varnish composition

The invention discloses a single-component, high-solid-content and low-volatility organic compound (VOC) and environment-friendly type varnish composition. The varnish composition comprises at least one polymer with a hyper-branched or tree-shaped structure, at least one hydroxyl acrylic resin or hydroxyl methacrylic resin, at least one cross-linking curing agent, at least one acid catalyst, at least one rheology control agent and at least one auxiliary agent. With the adoption of the varnish composition and application of the varnish composition, disclosed by the invention, the viscosity of a varnish coating system can be effectively reduced, and the solid content of the construction can be easily improved to be 58 percent or above; construction VOC emission is reduced to be smaller than or equal to 420g / L; varnish film shrinkage caused in a curing process can also be effectively reduced and a cured multi-coating varnish film has better appearance effect; particularly, the effect in a wet-on-wet process, a three-coating and one-drying process of curing three coatings together or an IPP system of primers, paints and varnishes is obvious.

Owner:LANGFANG NIPPON PAINT

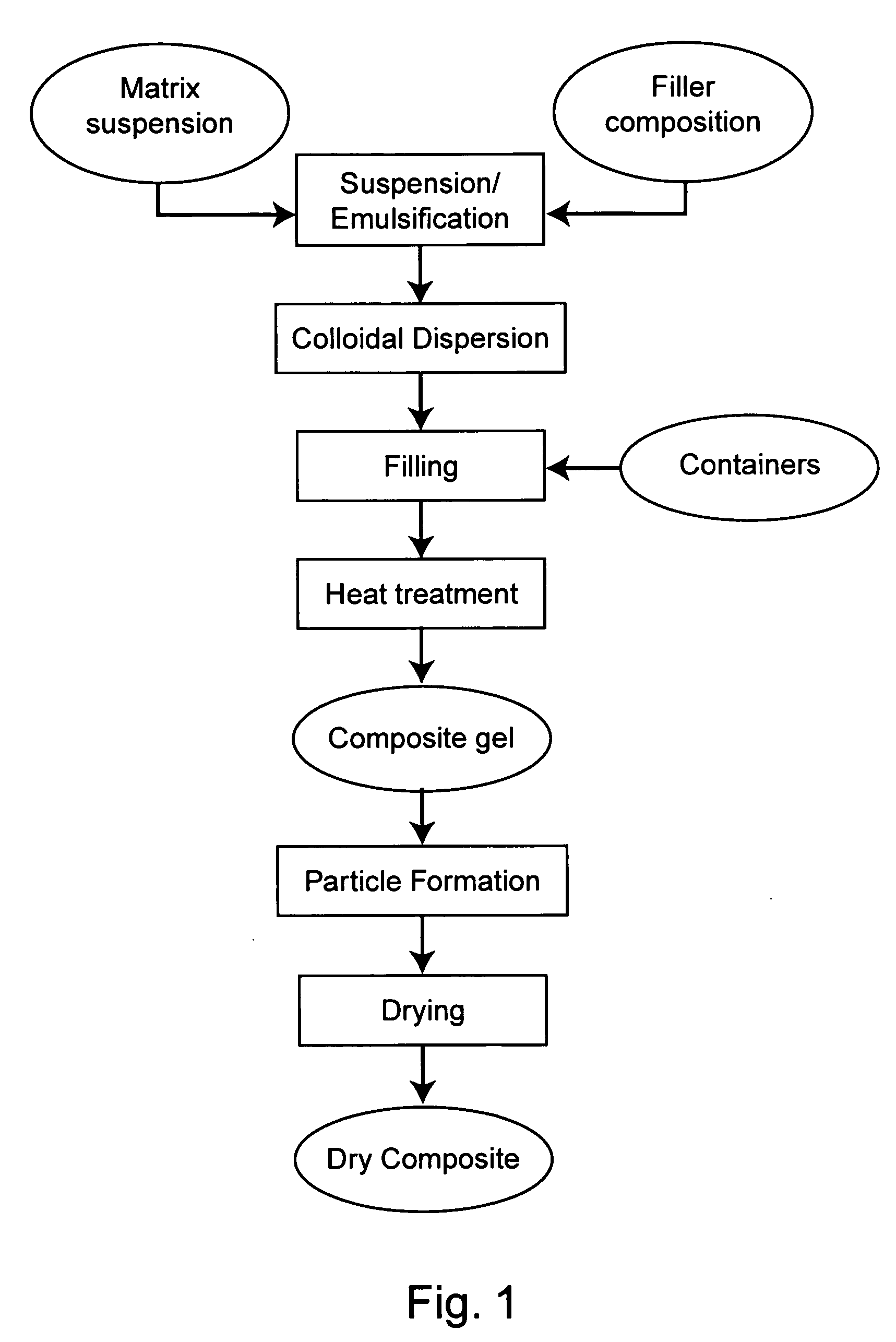

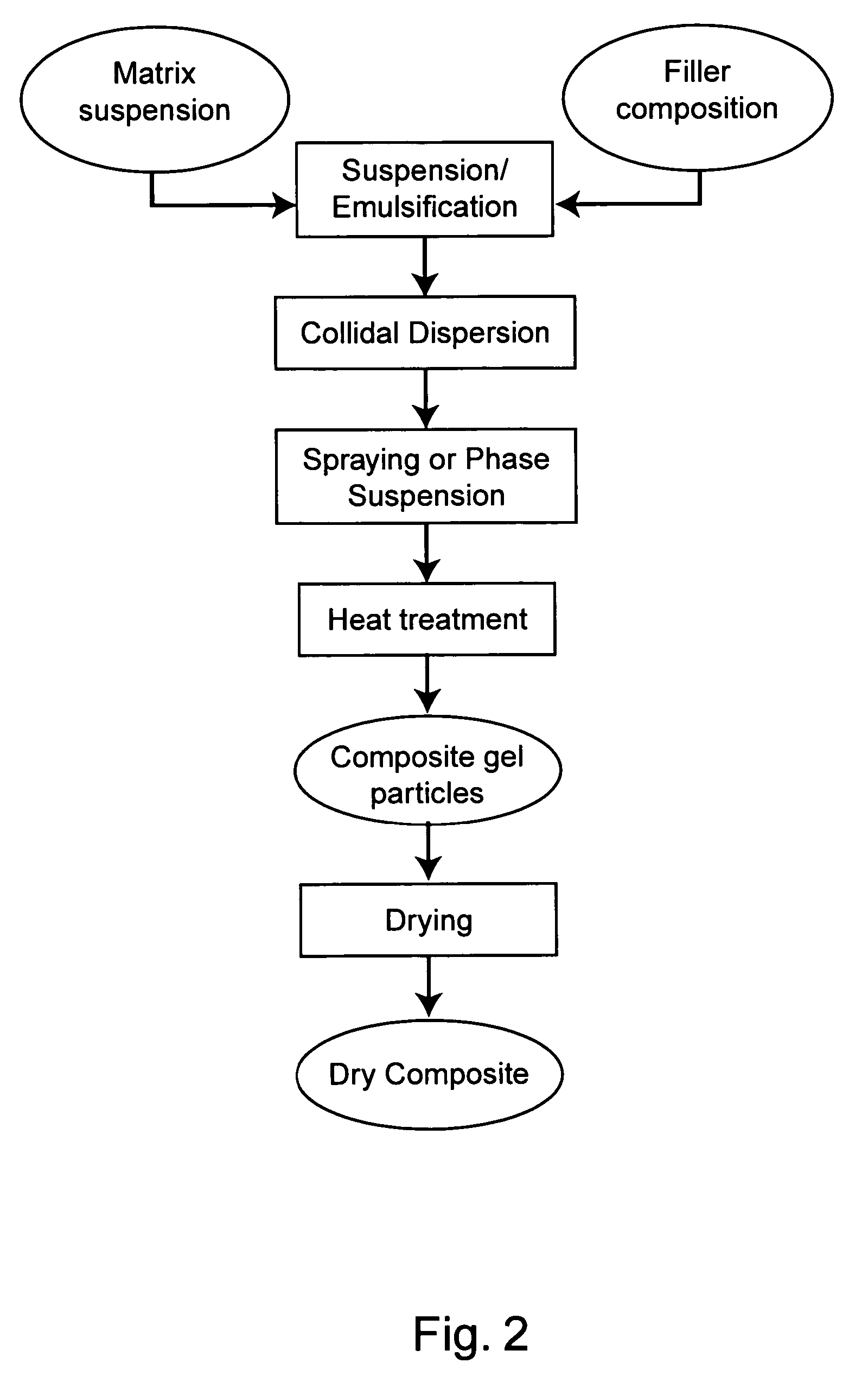

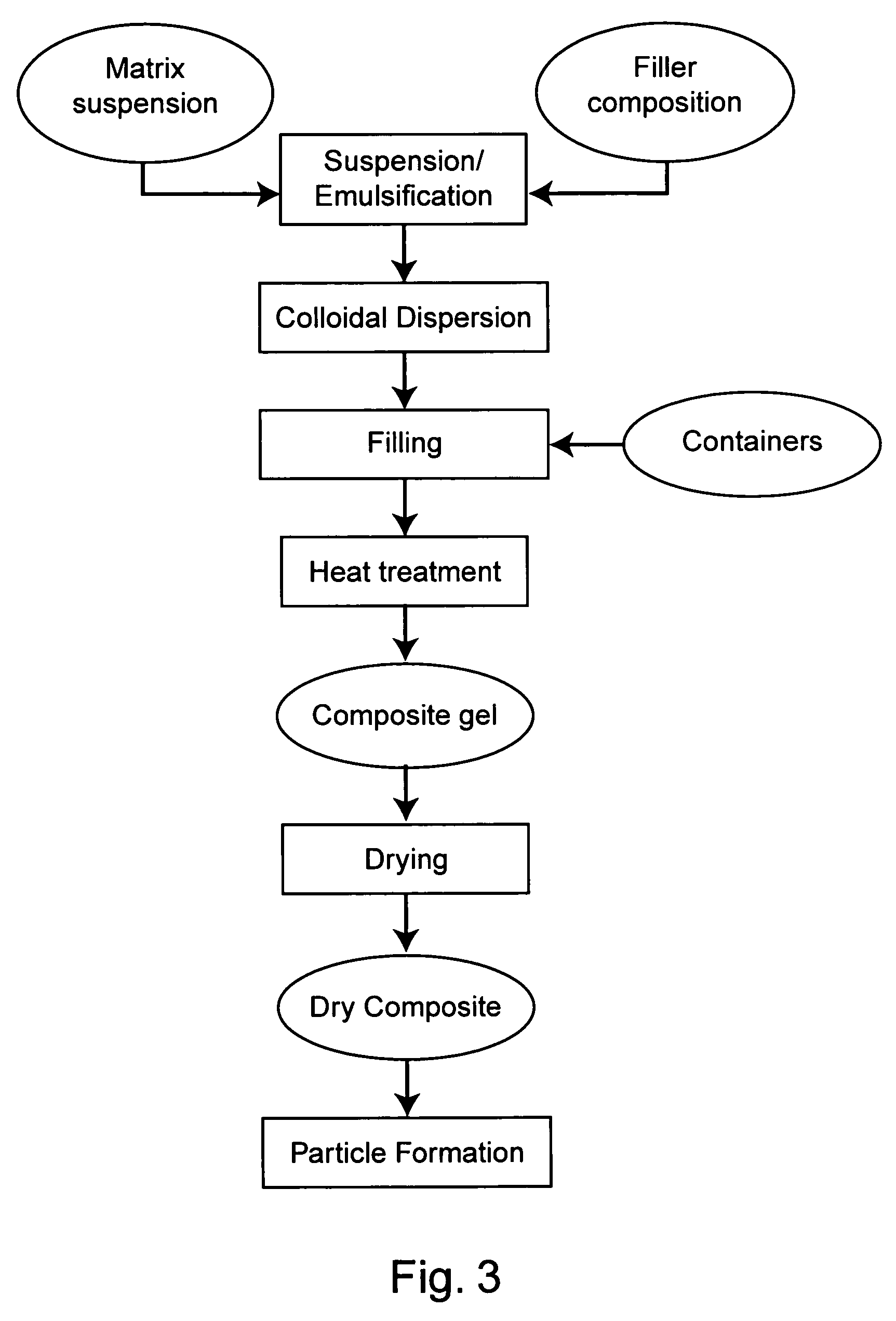

Protected dry composites

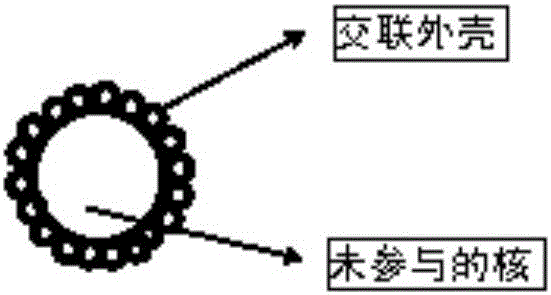

InactiveUS20050186305A1Reduce shrinkageReduce migrationAnimal feeding stuffAccessory food factorsBiologyAmino acid

This invention provides dry composites to, e.g., efficiently deliver unmodified amino acids, lipids, and / or feed supplements through the upper digestive tract of an animal. The invention also provides methods and systems to make and use protected dry composites.

Owner:RGT UNIV OF CALIFORNIA

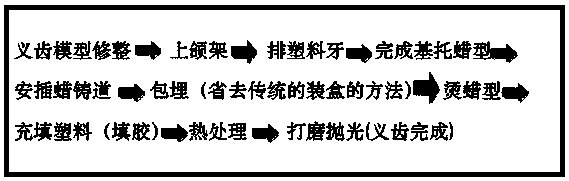

Manufacturing method of removable dentures

ActiveCN107854187AAvoid Coitus HeighteningAvoid Shrinkage Bubble PhenomenonArtificial teethWater bathsDental cast

The invention relates to a manufacturing method of removable dentures. Currently, the removable-denture manufacturing methods in all countries in the world are a thermos-coagulation packing method, need steps such as casing, filling, squeezer pressurizing and water bath polymerization (dental cast cooking pot), are complex in process, time-consuming and labor consuming, are non-uniform in moldingcase pressurizing and are difficult in precise mastering and control of heating speed and heating maintaining time during heat processing. The method has the advantages that the manufacturing flow oftraditional removable dentures is improved, joint height increasing and contraction bubbles of the removable dentures manufactured by the traditional manufacturing process are avoided, and the base-material filling of the partial removable dentures and attachment dentures can be performed; the models of the attachment dentures does not need to be pressurized on a squeezer, and the subfissure or deformation of the fixing-part porcelain teeth of the attachment dentures is avoided.

Owner:程昕

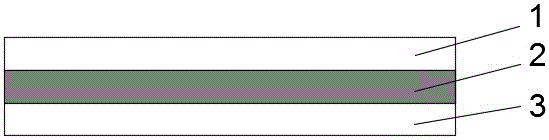

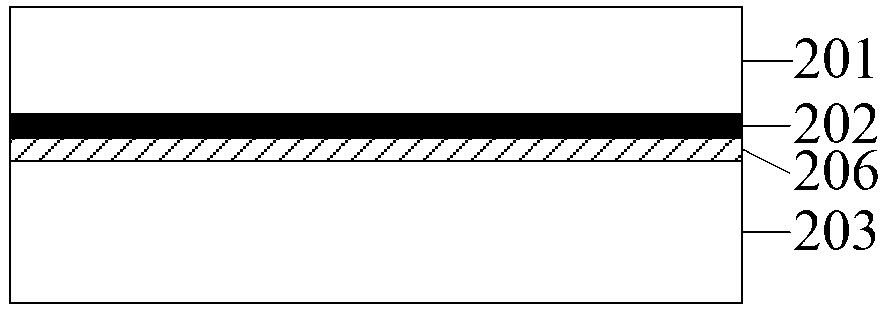

Ceramic metal composite substrate and production method thereof

The invention relates to a ceramic metal composite substrate and a production method thereof. The substrate mainly comprises an ultrathin ceramic sheet, a heat conduction glue and a metal substrate; the ceramic powder of the ultrathin ceramic sheet is a micropowder and a nanopowder mixture, and the volume proportion of nanopowder in the ceramic powder is 15-25%; and the heat conduction glue comprises, by volume, 20-30% of a one-dimensional high heat conduction material. The production method mainly comprises the following steps: making the ultrathin ceramic sheet; carrying out surface treatment on the metal substrate, coating the metal substrate with the heat conduction glue through a coating technology, and carrying out drying semi-solidification; and carrying out hot pressing on the ultrathin ceramic sheet and the glued metal substrate. The ceramic metal composite substrate has a good heat conduction performance, and has a good heat matching performance with chips, and the method has a high production efficiency, and is in favor of realizing development of the substrate to a small, light and thin direction. Tape casting makes the production efficiency of the ultrathin ceramic sheet be high; and the heat conduction glue comprises the one-dimensional high heat conduction material, so thermal resistance between the ultrathin ceramic sheet and the metal substrate is reduced.

Owner:SHANTOU UNIV

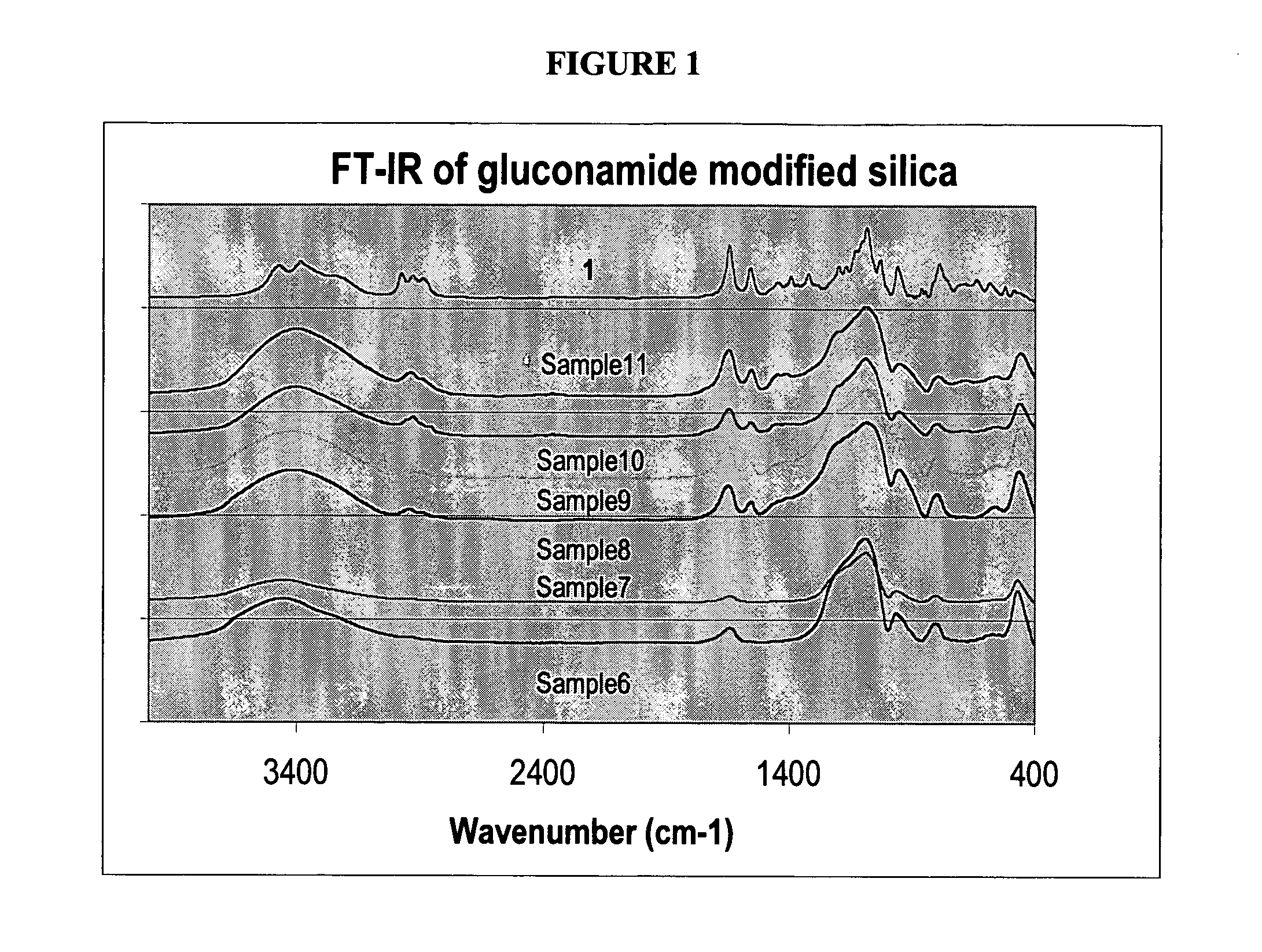

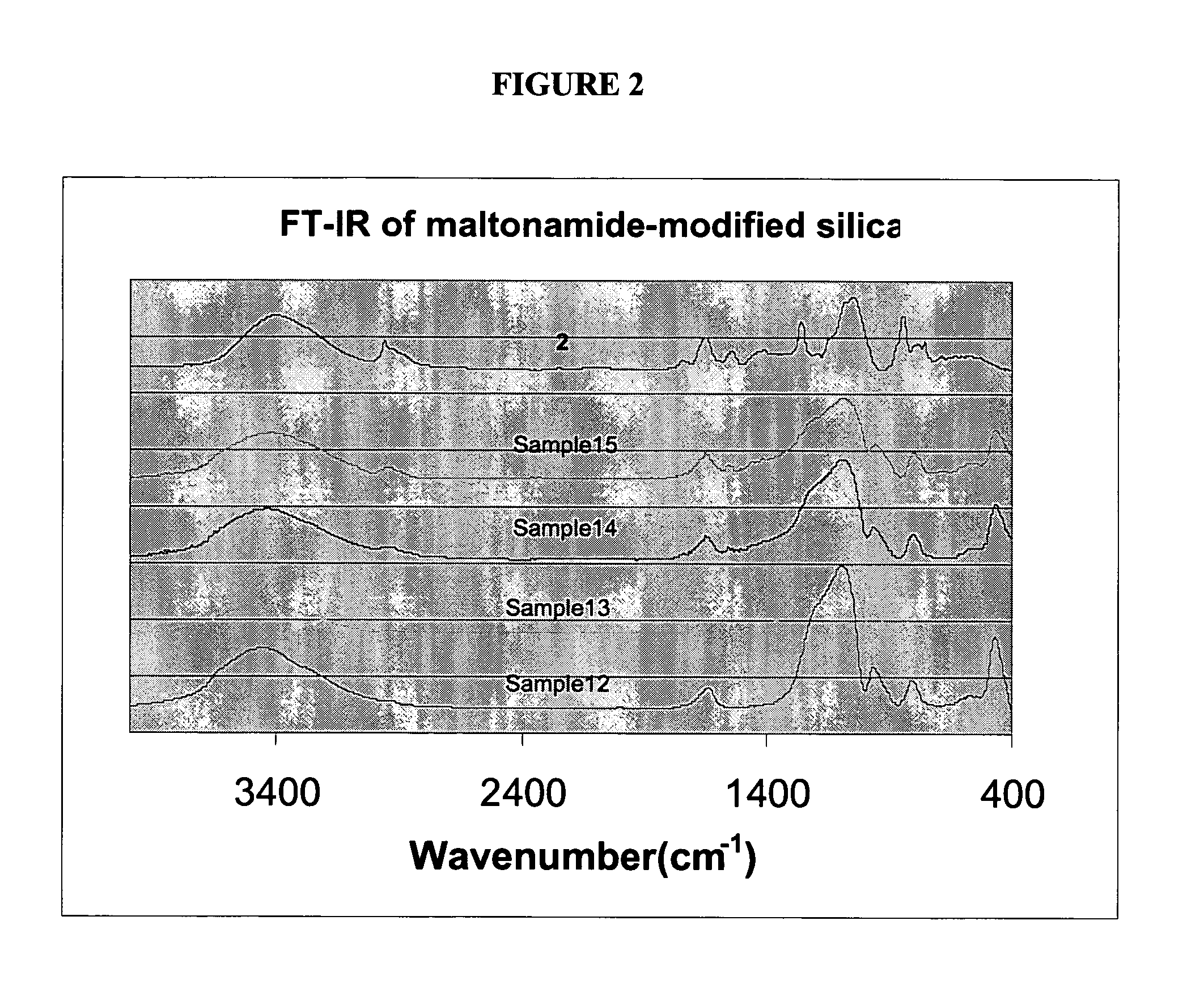

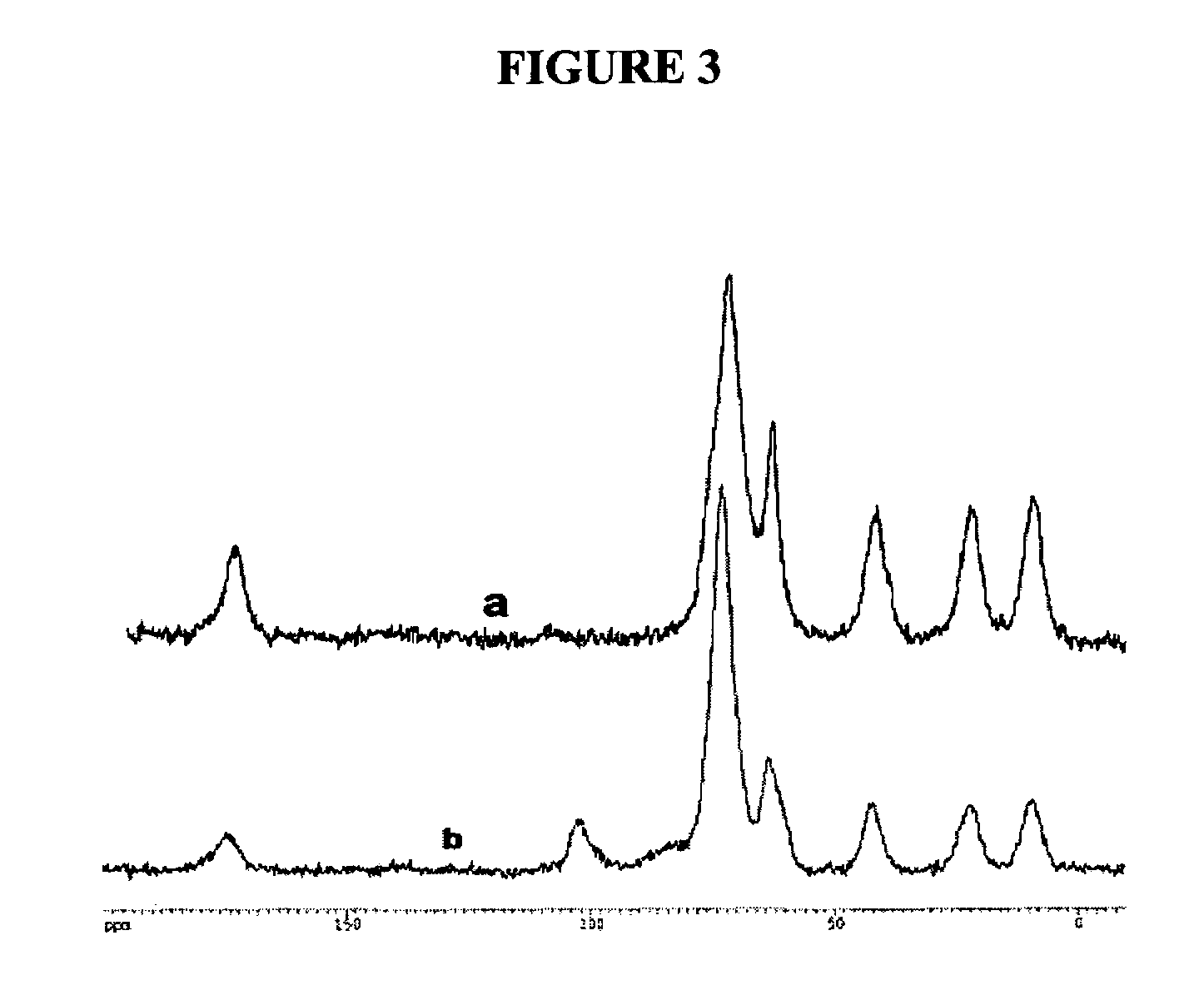

Protein compatible methods and compounds for controlling the morphology and shrinkage of silica derived from polyol-modified silanes

InactiveUS7375168B2Reduce shrinkageReduce Shrinkage ProblemsSilicaComponent separationWater soluble polymersChemistry

Siliceous materials were prepared by adding one or more additives, including one or more water soluble polymers, and derivatives thereof, as well as trifunctional silanes, to sols containing tetraalkoxysilanes derived from polyols. The polymers facilitate phase separation of the growing silica gel matrix, leading to high surface area self-supporting silica gels with cure occurring at ambient temperatures. The materials also show a significant reduction in shrinkage properties and significant protein stabilization abilities.

Owner:MCMASTER UNIV

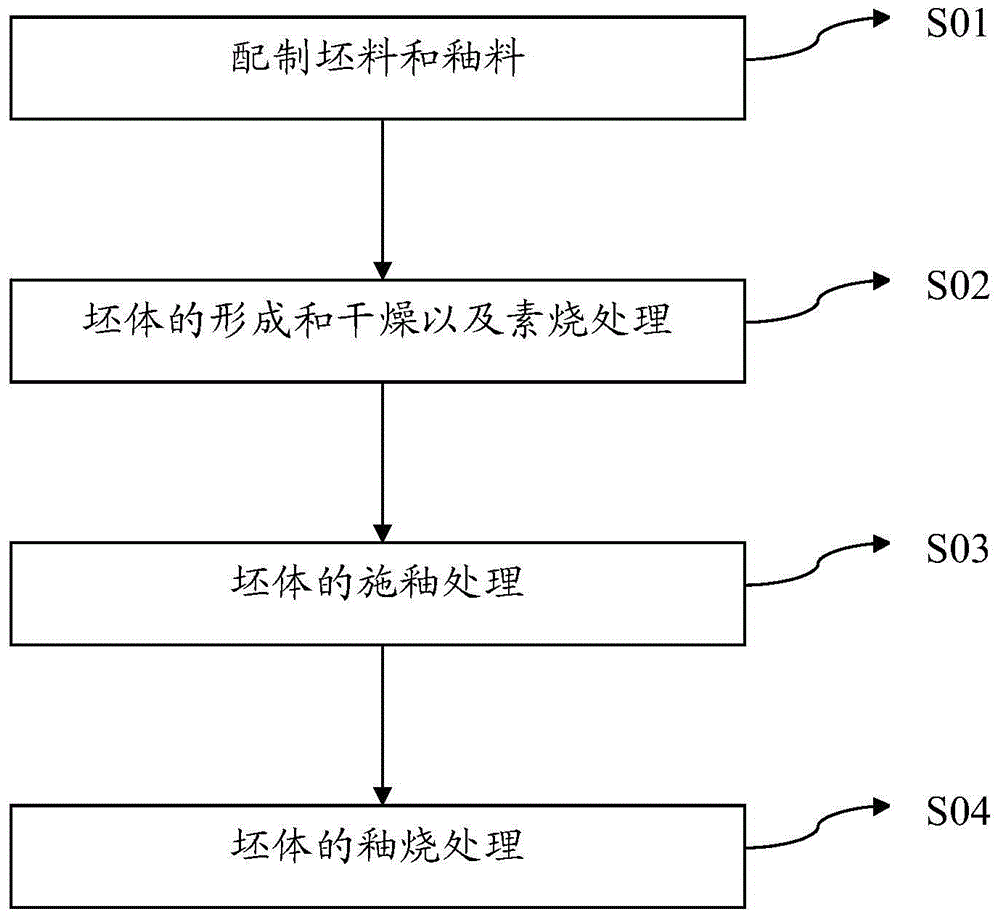

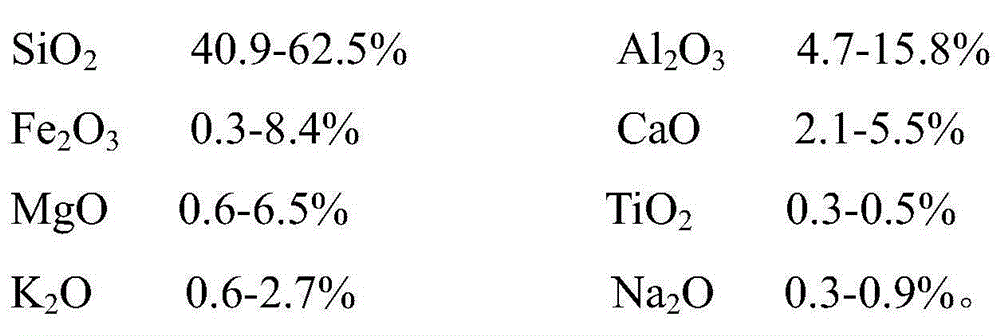

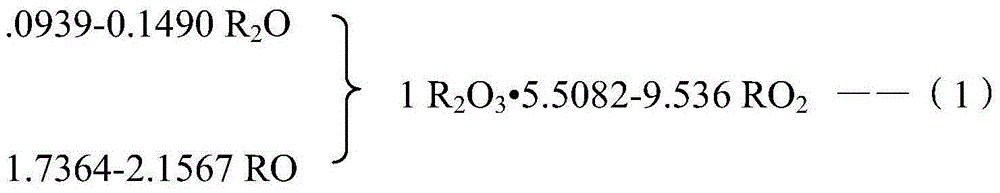

Glazed ceramic tile and preparation method thereof

ActiveCN105130394AHigh strengthReduce shrinkageCeramic materials productionClaywaresCeramic glazeAnaerobic digestion

The invention discloses a glazed ceramic tile and a preparation method thereof. The glazed ceramic tile is prepared by processing a blank material and glaze, and the blank material comprises the following compositions in percent by weight: 50-75% of anaerobic digestion sludge, 10-25% of clay, 5-15% of wollastonite, and 5-10% of talcum. The glazed ceramic tile preparation method comprises preparing blank and glaze, forming a green body, drying, biscuiting, glazing the green body, performing glaze firing on the green body, and the like. The green body of the glazed ceramic tile is high in strength and small in shrinkage degree when being biscuited, the biscuiting temperature scope of the green body is expanded, and phenomena that the green body surface foams, generates black hearts and is reduced in compressive strength and the like because of too large ignition loss are effectively avoided. The glazed ceramic tile preparation method enables the glazed ceramic tile surface to be solid, flat, free of black heart phenomenon, and high in strength, and also the preparation method is simple and easily controllable in technology, high in yield and high in production efficiency, and production cost is effectively reduced.

Owner:深圳市正源清环境科技有限公司

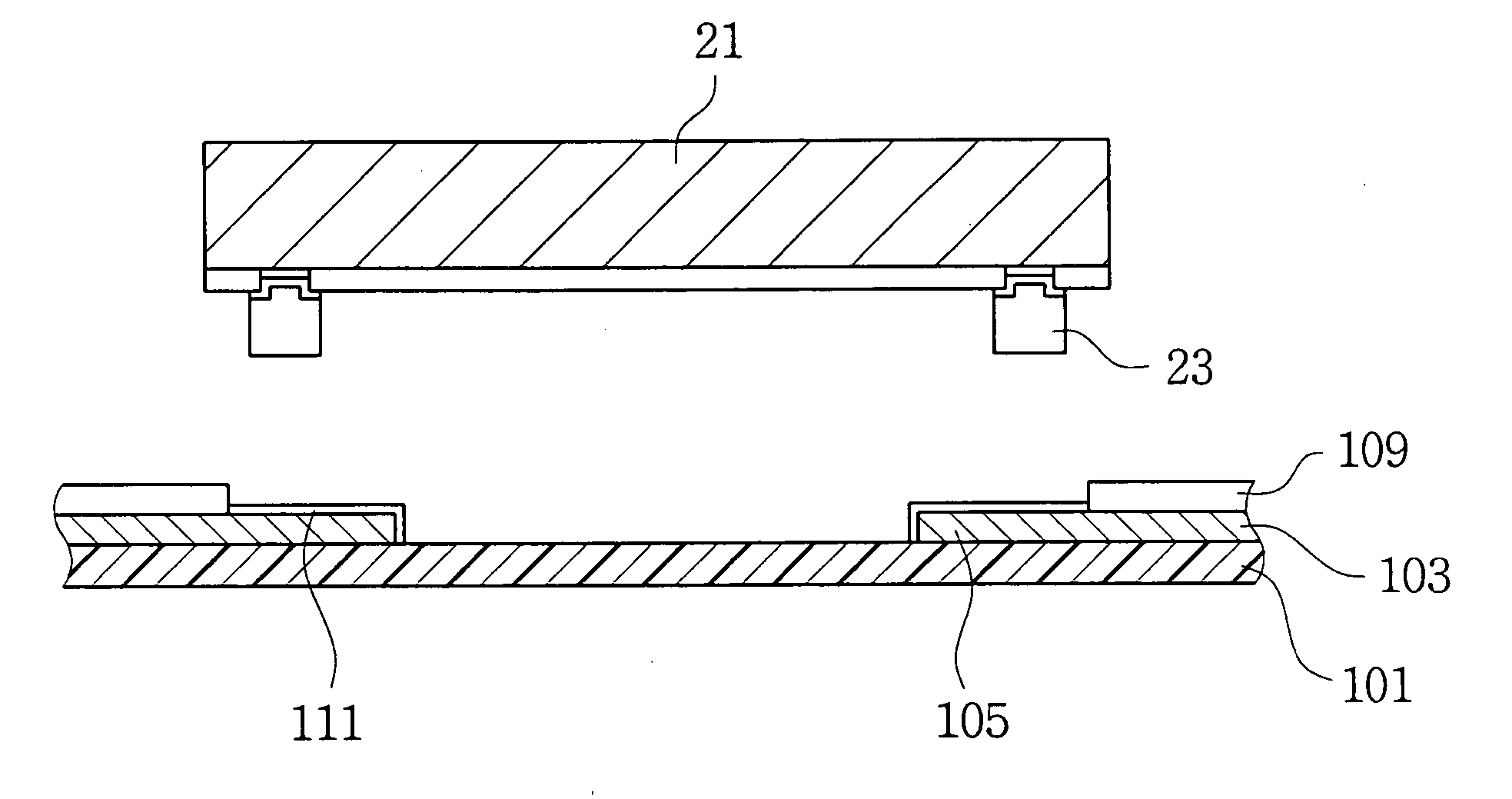

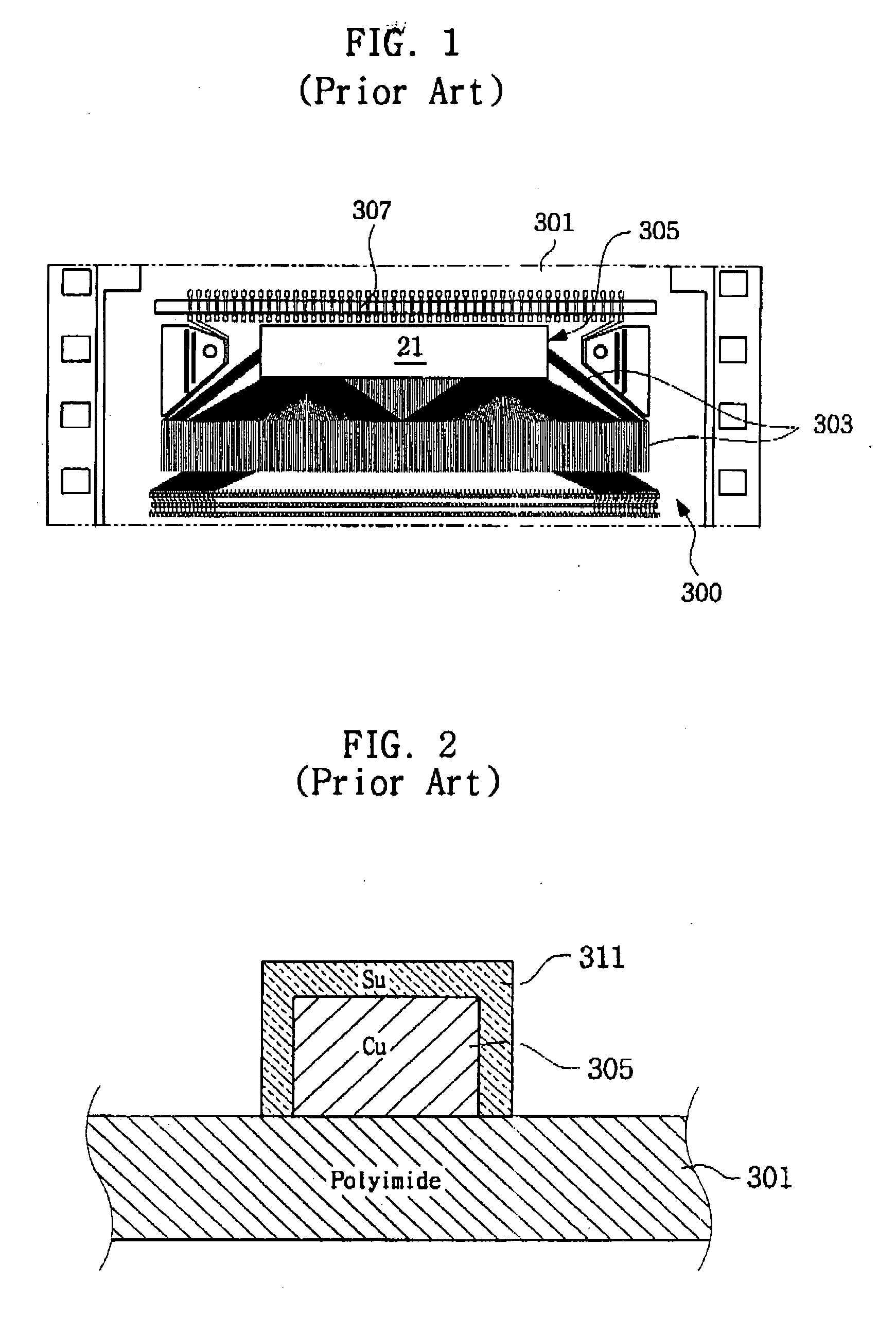

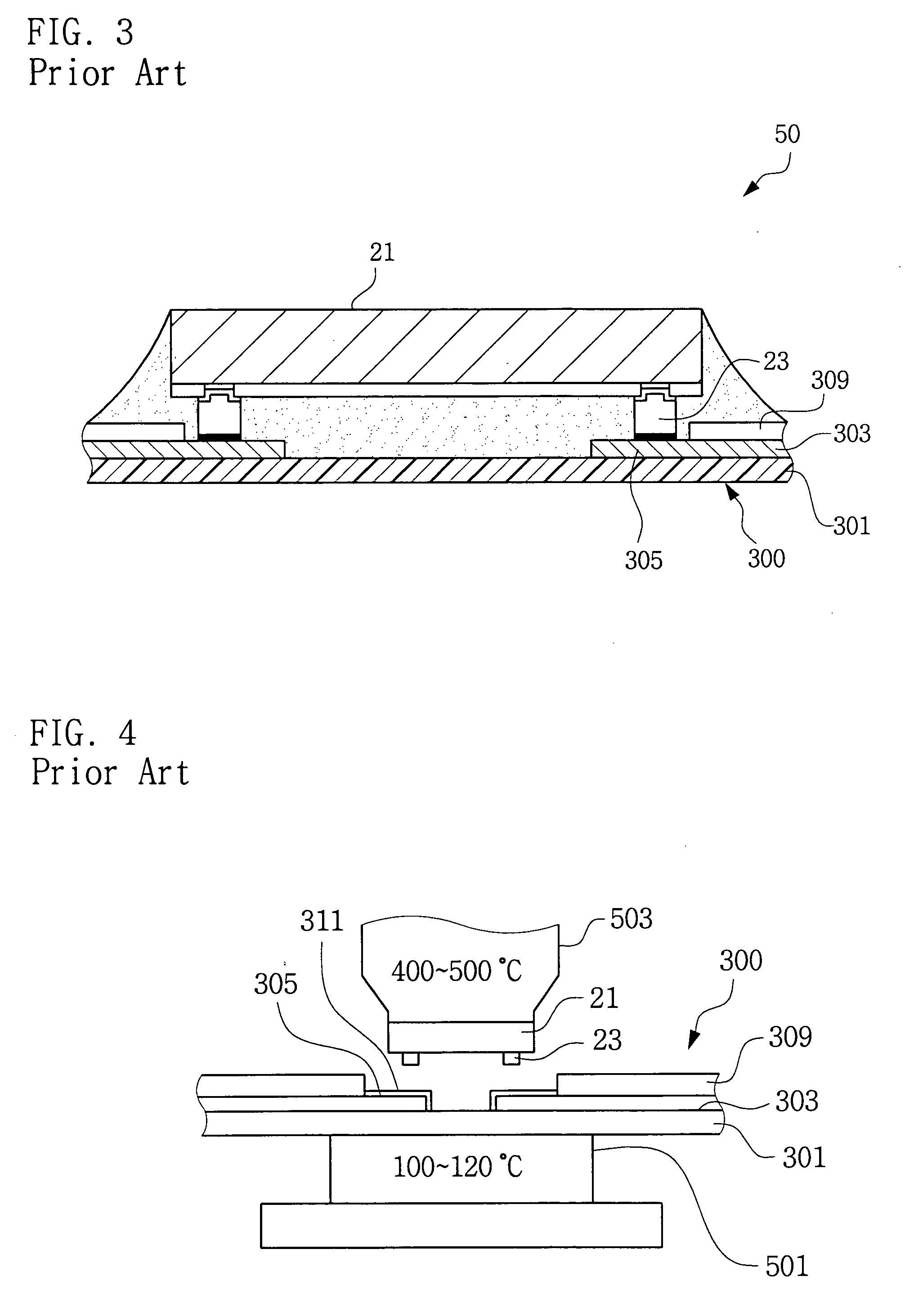

Film circuit substrate having Sn-In alloy layer

InactiveUS20060091504A1Reduce shrinkageAlignment defectSemiconductor/solid-state device detailsPrinted circuit aspectsIndiumBump bonding

In one embodiment, a film circuit substrate comprises an insulating film made of polyimide resin; a conductive circuit pattern formed on the insulating film, the circuit pattern including an inner lead to be connected with a conductive bump of a semiconductor chip through a bump bonding process; and a tin-indium alloy layer formed on the inner lead to produce an inter-metallic compound layer of AuxSn composition during the bump bonding process.

Owner:SAMSUNG ELECTRONICS CO LTD

Total alkaloid of stephania delavayi and preparation and application thereof

ActiveCN101234141AReduce shrinkageNo dysmenorrheaOrganic active ingredientsDigestive systemStrong acidsSteroidal alkaloid

The invention discloses a total alkaloid of Stephania delavayi Diels, the content of which is measured by tetrahydropalmatine. Tetrahydropalmatine occupies 55-95 percent of the total alkaloid extract of Stephania delavayi Diels, wherein the weight percentage of tetrahydropalmatine contained is no less than 2 percent, while the weight percentage of palmatine hydrochloride contained is no less than 0.8 percent. The invention also discloses a preparation method of the total alkaloid of Stephania delavayi Diels, which relates to the steps as follows: adding the Stephania delavayi Diels meal into ethanol for diacolation or reflux to acquire alcohol extract, decompressing and recycling the ethanol and concentrating into a condensed ointment for dissolving and filtrating with acid to acquire a filtrate, passing the filtrate through a macroporous resin column or a strong acid cation exchange resin column for adsorption, washing with water to remove the impurities and extracting with a eluent, collecting the eluent and decompressing and recycling the extract and then concentrating and drying, thus acquiring the total alkaloid of Stephania delavayi Diels; the steps can also be decompressing a percolating liquid to recycle the ethanol, concentrating, dissolving with acid and then filtrating, adjusting the pH value of the filtrate with weak base to produce deposition, filtrating the deposition to acquire a filter residue, adding ethanol into the filter residue to resolve and decompress, recycle the ethanol and then drying, thus acquiring the total alkaloid. The results of a pharmacological study on the acquired total alkaloid show that the total alkaloid of Stephania delavayi Diels has good effect on spasmolysis, pain relieving, antiphlogosis and antibiosis, blood activating and so on, and can combine with the acceptable components in pharmacy to prepare various sustained release or controlled release formulation or other formulations.

Owner:GUANGZHOU BOJI MEDICINE SERVICES

Ambient pressure drying method of silsesquioxane aerogel

ActiveCN110822816AImprove solvent replacement efficiencyReduce capillary forceDrying solid materials with heatDrying solid materials without heatSolventActive agent

The invention discloses an ambient pressure drying method of silsesquioxane aerogel. According to the ambient pressure drying method of the silsesquioxane aerogel, methyltrimethoxysilane is taken as aprecursor, water is taken as a solvent to be combined with a surfactant, silica wet gel with a large aperture size can be prepared through a sol-gel process, after solvent replacement by ethanol is carried out, the silica wet gel is directly and slowly dried at high temperature, and a silsesquioxane aerogel material can be prepared. According to the ambient pressure drying method of the silsesquioxane aerogel, the methyltrimethoxysilane is selected as the precursor, so that the in-situ modification of a gel skeleton surface is realized, the aperture structure is controlled by the surfactant content, the solvent replacement efficiency can be improved, the capillary force during drying can be reduced, the use amount of organic solvent in the ambient pressure drying process is greatly reduced, and the large-scale production is facilitated.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

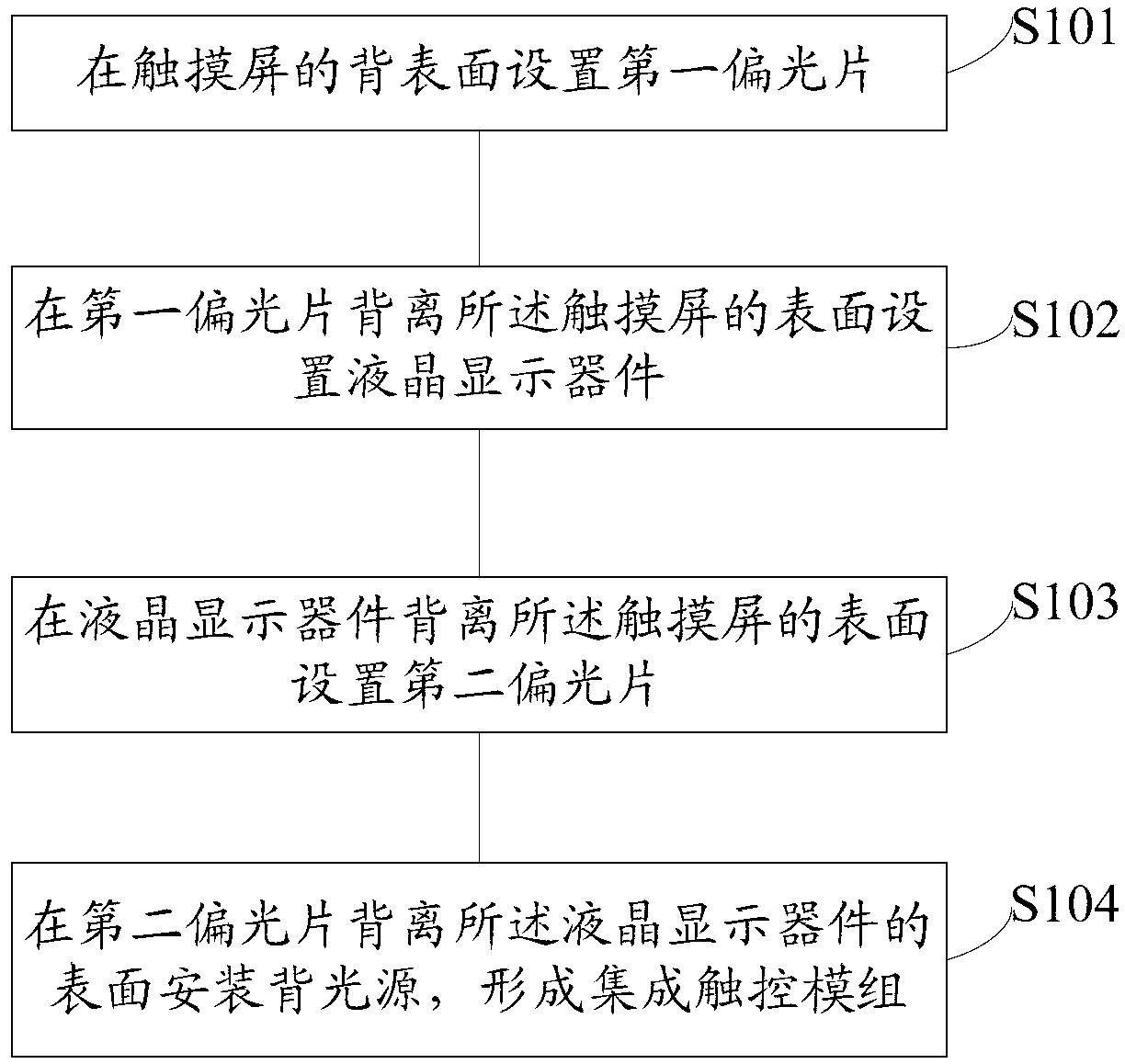

Integrated touch control module, manufacturing method thereof and touch display device

ActiveCN103076694AAvoid warpingGood flatnessNon-linear opticsInput/output processes for data processingLiquid-crystal displayLight source

The invention provides a manufacturing method of an integrated touch control module. The method comprises the following steps of: arranging a first polaroid on the back surface of a touch screen; arranging a liquid crystal display device on the surface, which is deviated from the touch screen, of the first polaroid; arranging a second polaroid on surface, which is deviated from the touch screen, of the liquid crystal display device; and arranging a backlight source on the surface, which is deviated from the liquid crystal display device, of the second polaroid to form the integrated touch module. According to the manufacturing method of the integrated touch control module provided by the invention, the liquid crystal display device can be fully jointed with the touch screen in a relatively flat state in the manufacturing process of the integrated touch module, and the problem of poor flatness between the liquid crystal display device and the touch screen is solved; and on the other hand, the influence of the problem of poor flatness of the backlight source on the display effect of the integrated touch control module can be eliminated, and the problem of displaying of yellow spots on the integrated touch control module is solved on two aspects.

Owner:TRULY OPTO ELECTRONICS

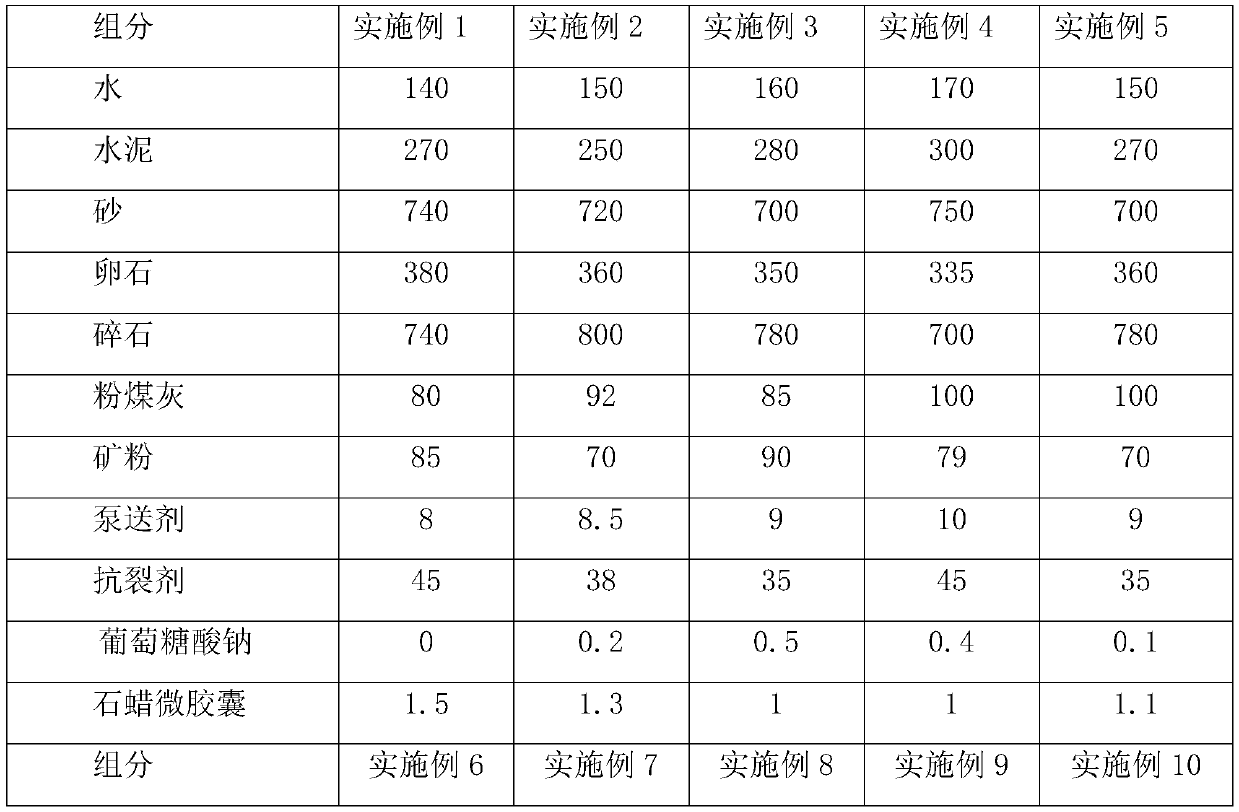

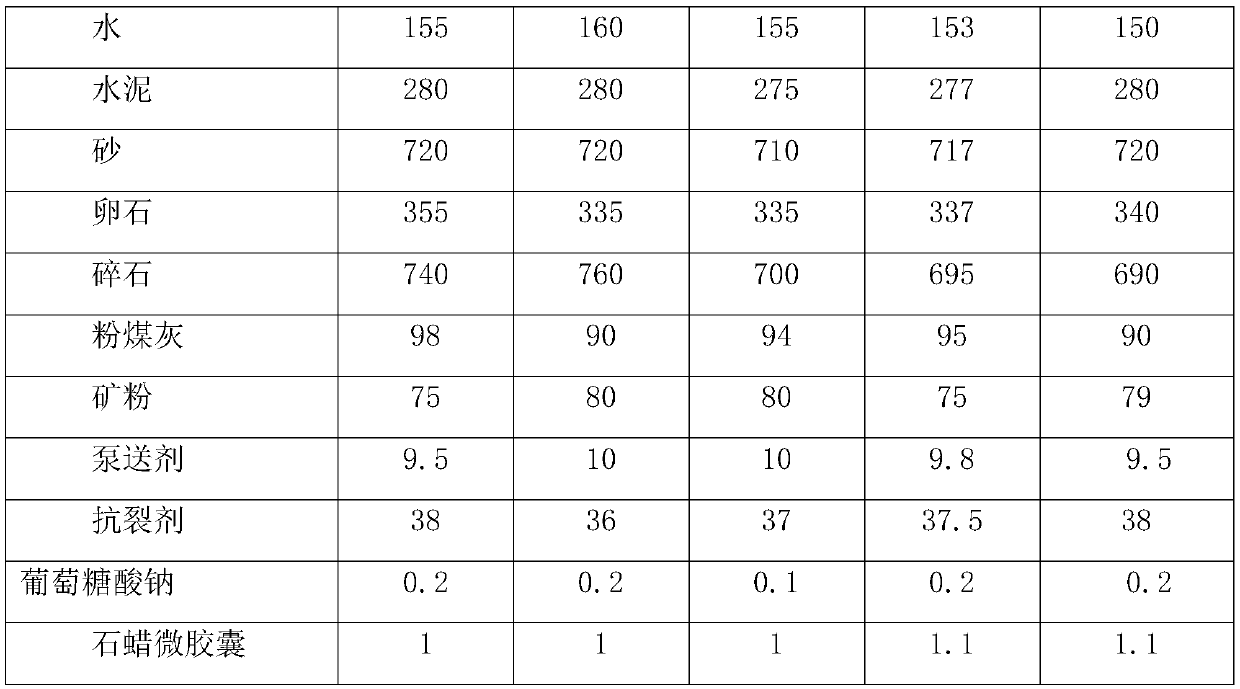

C45 mass concrete and preparation process thereof

The invention relates to C45 mass concrete and a preparation process thereof, wherein the C45 mass concrete comprises: 140-170 parts of water, 250-300 parts of cement, 700-750 parts of sand, 335-380 parts of pebble, 700-800 parts of crushed stones, 80-100 parts of fly ash, 70-90 parts of mineral powder, 8-10 parts of a pumping agent, 35-45 parts of an anti-cracking agent, and 1-1.5 parts of a modifier. The preparation method comprises: 1, uniformly stirring sand, pebble, crushed stone and water to obtain an intermediate product; and 2, adding cement, fly ash, mineral powder, a pumping agent, an anti-cracking agent and a modifier, and uniformly stirring to obtain concrete. According to the technical scheme of the present invention, by simultaneously adding fly ash and mineral powder, the consumption of cement is reduced, such that the release rate of hydration heat is delayed, and the occurrence of shrinkage is reduced; and by adding the paraffin microcapsules, the temperature regulation effect can be achieved, such that the influence of the paraffin phase change volatilization on the environment can be avoided.

Owner:陕西恒盛混凝土有限公司

Preparation method of bombax ceiba three-dimensional dried flowers

The invention discloses a preparation method of bombax ceiba three-dimensional dried flowers. The preparation method comprises following steps: (1), pretreatment, wherein fresh bombax ceiba flowers are immersed in a color retention agent so as to maintain original color and quality of bombax ceiba flowers in subsequent drying processes, and the color retention agent is a mixture of citric acid and glycerin; (2) embedding, wherein gaps of the bombax ceiba flowers processed via step (1) are filled with degreasing cotton, the whole bombax ceiba flowers are coated with degreasing cotton, and the obtained bombax ceiba flowers are coated with granular silica gel; (3) drying, wherein vacuum freeze drying or refrigerator freeze drying are used to dry the coated bombax ceiba flowers so as to remove water in the bombax ceiba flowers; and (4), the granular silica gel and the degreasing cotton are removed so as to obtain the bombax ceiba three-dimensional dried flowers. The preparation method is used for preparing the bombax ceiba three-dimensional dried flowers; original shape, color, texture, softness, and straight shape of the bombax ceiba flowers are basically maintained; the bombax ceiba three-dimensional dried flowers can be further made into bombax ceiba three-dimensional dried flower souvenirs in forms of single flower, flowering branch, or other forms; and supply of the bombax ceiba flowers all year round becomes possible.

Owner:ZHONGKAI UNIV OF AGRI & ENG

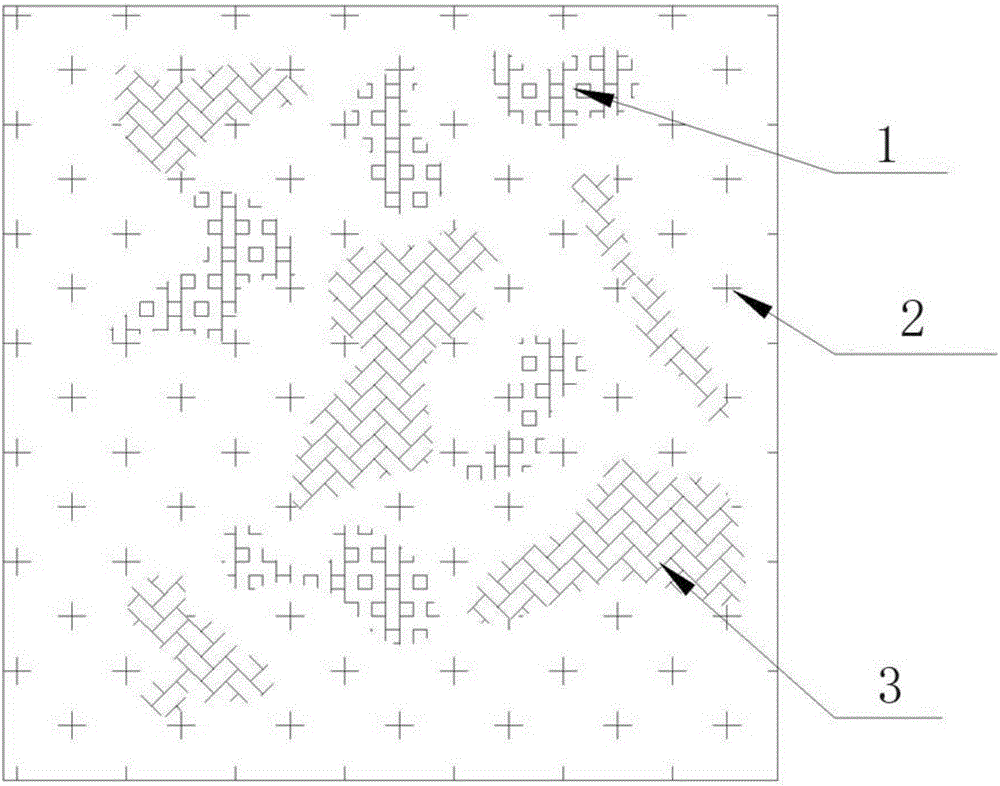

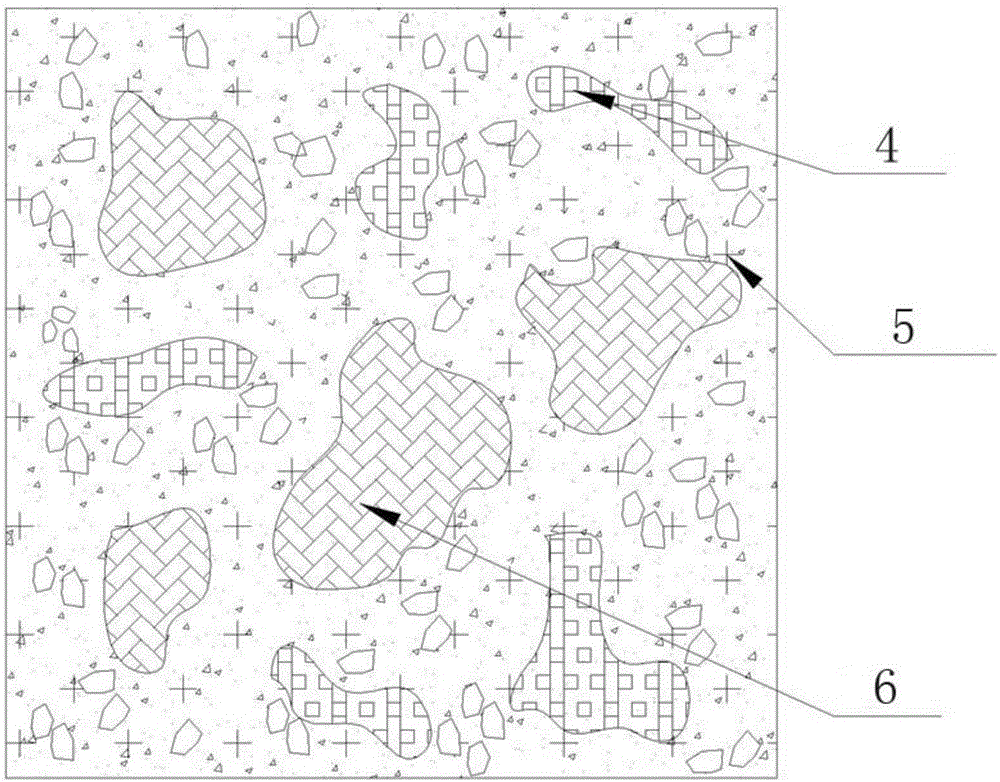

Ceramic tile combining blank patterns with penetration ink patterns and production method of ceramic tile

The invention provides a ceramic tile combining blank patterns with penetration ink patterns. The ceramic tile comprises a bottom blank layer and a surface blank layer. The surface blank layer is 1-5 mm thick. The bottom blank layer and the surface blank layer are integrally stamped to form a tile blank body. Patterns of the surface blank layer are composed of blank colorful pattern areas with different colors and printed pattern areas printed through penetration ink jointly. The blank colorful pattern areas are composed of one or more of colorful bulk particles or ceramic powder materials with ordinary particle sizes or fine powder materials with ordinary particle sizes prepared through ceramic powder materials. The printed pattern areas are shown on the ceramic powder materials and / or the fine powder materials with ordinary particle sizes. The effect that random blank patterns are obtained through blank colorful materials with various dark colors or clear and sharp edges and grains is achieved, and the random blank patterns are combined with the more vivid and exquisite colorful patterns which are obtained through digital printing through the penetration ink to form the ceramic tile with full-page patterns.

Owner:GUANGDONG SUMMIT CERAMIC CO LTD +1

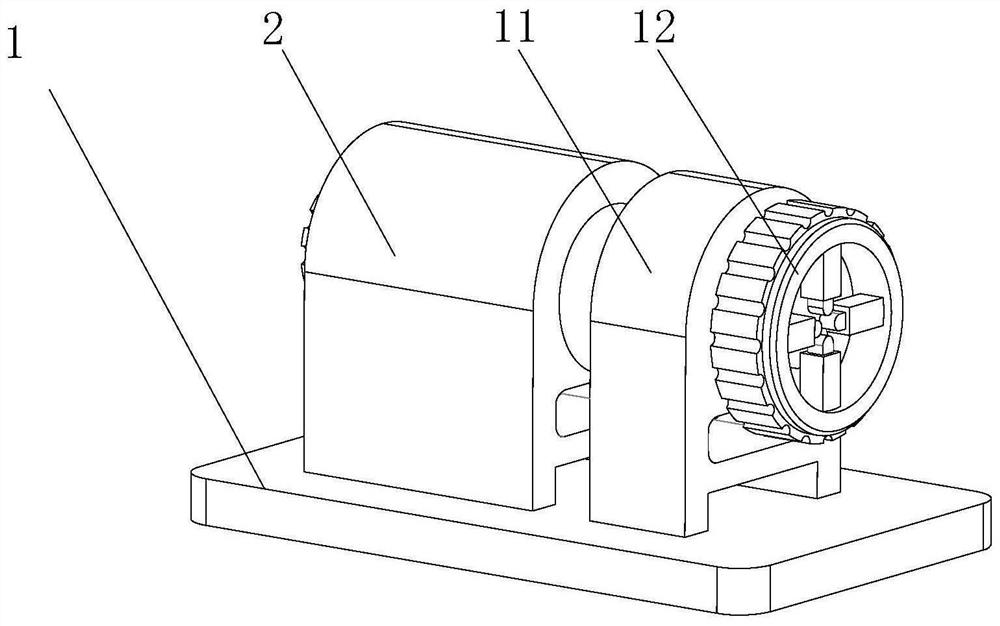

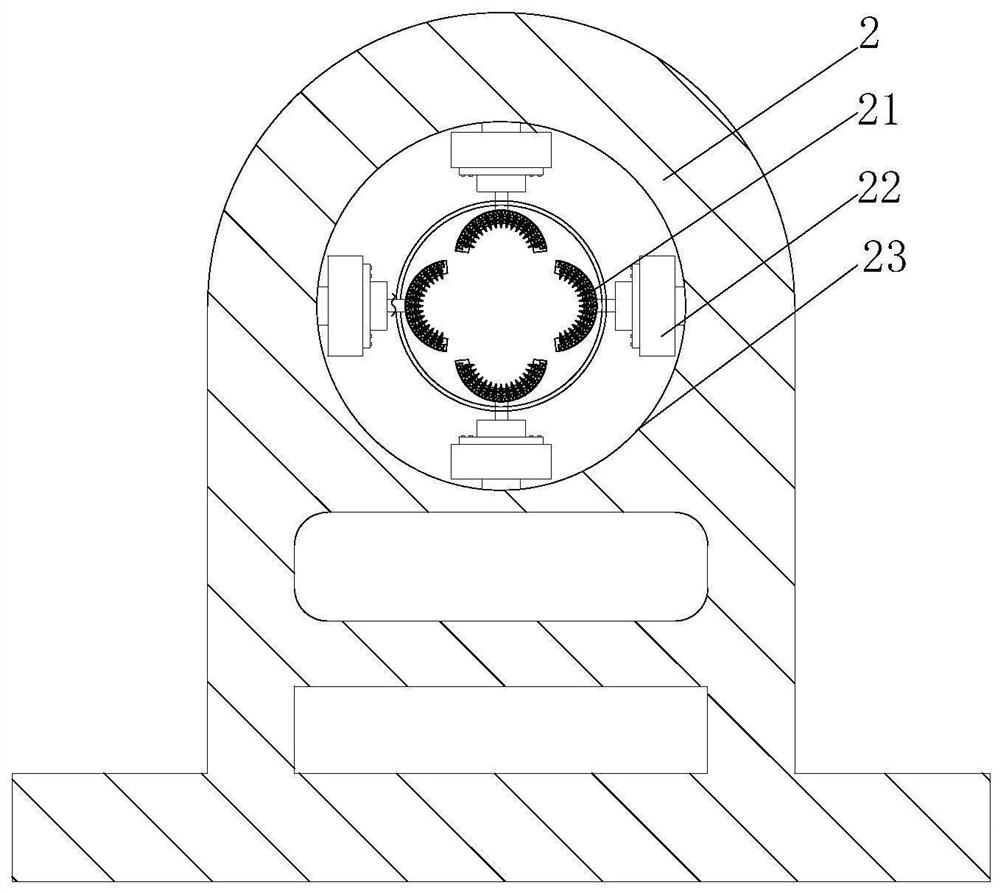

External threaded rod rust removal device

InactiveCN113118083AImprove rust removal effectReduce shockCleaning using toolsScrew threadThreaded rod

The invention discloses an external threaded rod rust removal device. The external threaded rod rust removal device comprises a bottom plate, a clamping seat is fixedly mounted on the bottom plate, a rotating wheel is rotatably arranged on the clamping seat, multiple limiting clamping blocks are mounted on the inner wall of the rotating wheel, a rust removal barrel is fixedly mounted on the bottom plate, one end of the rust removal barrel is fixedly connected with a fixed barrel, one end of the fixed barrel is fixedly connected with the clamping seat, a rust removal cavity is formed in the rust removal barrel, multiple movable tables are movably arranged in the rust removal cavity, a connecting rod is fixed to one end of each movable table, a limiting plate is fixedly connected to one end of each connecting rod, and each limiting plate is in an arc shape and is elastic. Compared with the prior art, gas in extrusion balls is conveyed into a movable groove through connecting gas pipes, the gas pressure in expansion air bags can be increased through the gas, elastic plates deform, rotating plates are pushed to rotate outwards, cleaning barbs can abut against the inner wall of a thread, rust removal cleaning is conducted on the inner wall of the thread, and the rust removal effect on the interior of the thread is further enhanced.

Owner:闻琦

Sol-gel preparation method of barium titanate PTC ceramics

The invention discloses a sol-gel preparation method of barium titanate PTC ceramics, which comprises the following steps that: (1) the materials are measured according to the formula (Ba1-xYx)TiO3, and x is equal to 6 to 20 permillage, barium acetate water solution with the concentration of 1.3 to 1.6 mol / L is prepared, and tetrabutyl titanate solution with the concentration of 1.0 to 1.3 mol / L is prepared; (2) Y(NO3)3.6H2O is incorporated into the Ba(CH3COO)2 water solution, and then the mixed solution is dropped into the Ti(OC4H9)4 solution to obtain the mixed solution; (3) the mixed solution is held at the room temperature to obtain the sol, and the sol is dried to obtain the gel; (4) the gel is smashed, ground and sieved to be pre-burned to synthesize the BaTiO3 powder containing yttrium; (5) the BaTiO3 powder containing the yttrium, the BaCO3 and the BN are measured according to the mol ratio of 1: (0.02 to 0.03) : (0.04 to 0.06) and are mixed and ball milled after being added with deionized water; (6) the BaTiO3 powder containing glass-phase raw material is ball milled with solvent and dispersant, and then the obtained mixture is ball milled with bond and plasticizer to obtain sizing agent for curtain containing; (7) the sizing agent is formed in a curtain coating way; and (8) and flakes are sliced and sintered to obtain the ceramic piece. The prepared PTC ceramic has the advantages of small crystal grains, small room-temperature resistivity and large PTC effect.

Owner:HUAZHONG UNIV OF SCI & TECH

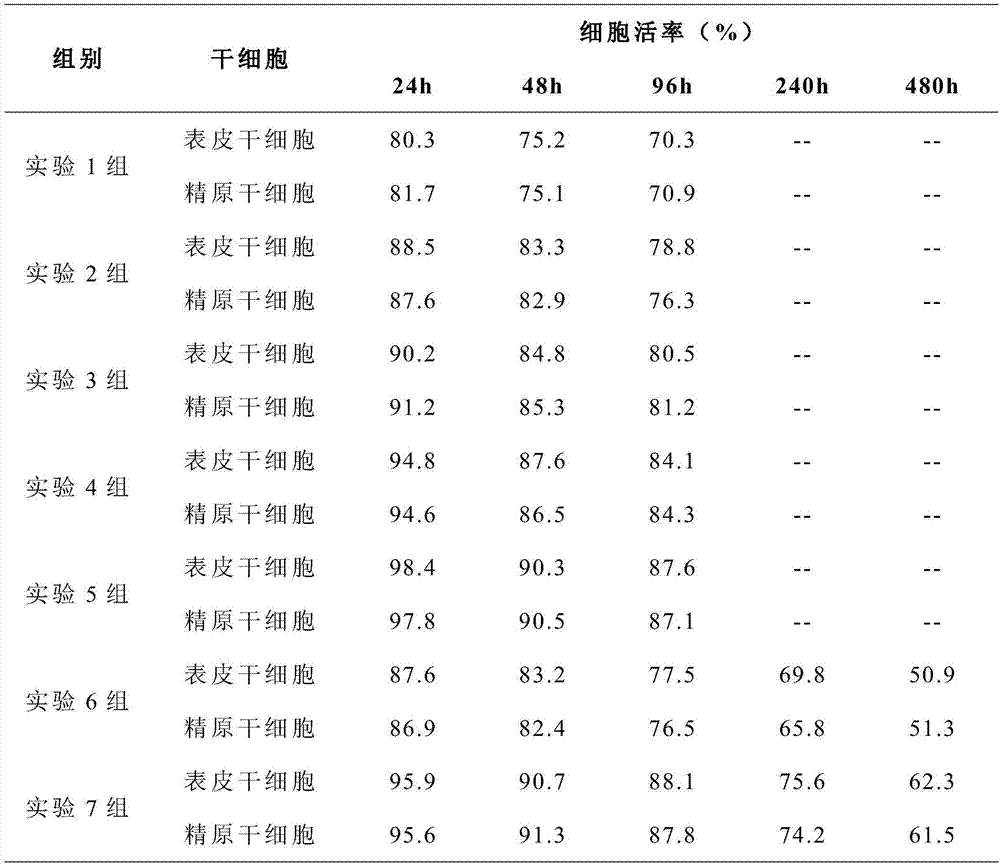

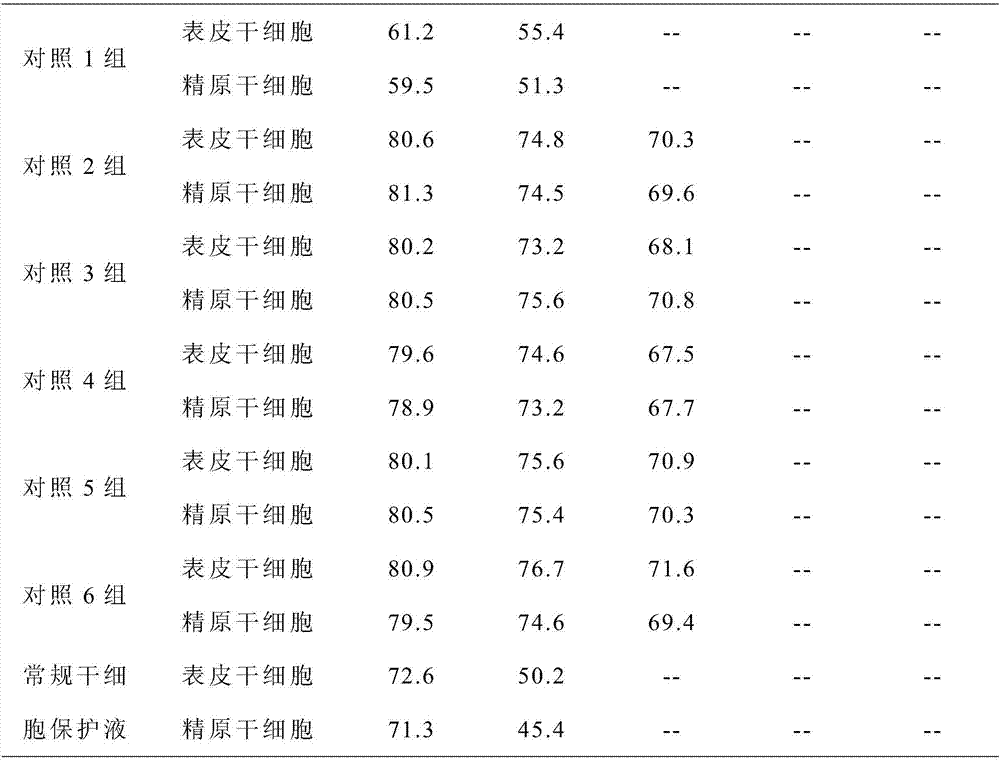

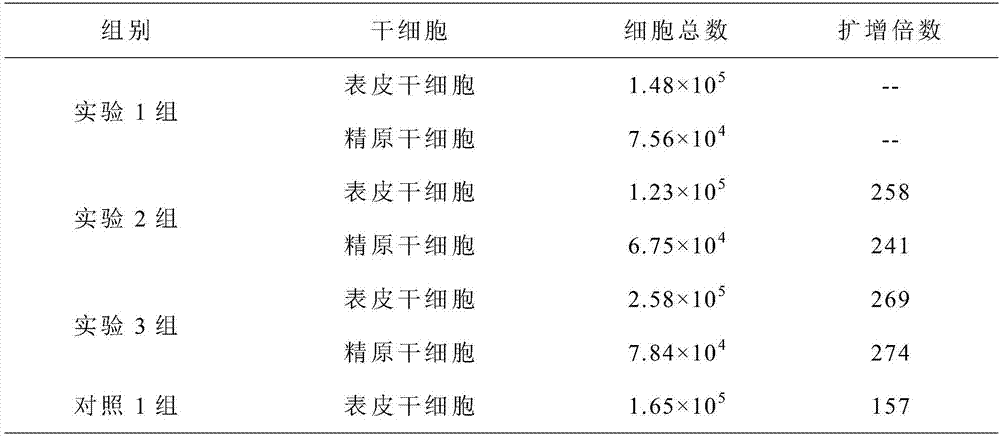

Skin spermatogonium protection liquid and preparation method thereof

InactiveCN107125240ASuitable for preservationHave a bactericidal effectDead animal preservationSpermatogoniumAntibiotic Y

The invention provides skin spermatogonium protection liquid and a preparation method thereof. The protection liquid is mainly formed by dissolving aminoglycoside antibiotics in DMEM (Dulbecco's modified eagle medium) culture medium water solution, 80-120U of the aminoglycoside antibiotics are dissolved in every mL of the DMEM culture medium water solution, and the concentration of the DMEM culture medium water solution is 13-25mg / mL. The skin spermatogonial stem cell protection liquid sufficiently simulates a human internal environment and is more suitable for survival of skin stem cells and spermatogonial stem cells and stable in property, the survival rate of the skin stem cells and the spermatogonial stem cells can be remarkably improved, and cultivation of the skin stem cells and the spermatogonial stem cells can be further enlarged while the skin stem cells and the spermatogonial stem cells are preserved.

Owner:CENTURY BIOSTRENGTH BEIJING PTY LTD

Preparation method for high-strength wheat protein fiber

ActiveCN104532380AHigh strengthHigh tensile strengthMonocomponent protein artificial filamentWet spinning methodsResource utilizationGliadin

The invention relates to a preparation method for high-strength wheat protein fiber, belonging to the field of wheat protein resource utilization. The preparation method comprises the following steps: mixing purified glutenin and wheat gliadin in a mass ratio of (1-2) to (2-1) to obtain a mixture I; adding and dissolving a denaturing agent and a reducing agent in the mixture I to obtain a mixture II, and processing the mixture II under microwaves with certain powder to obtain a spinning solution; and spinning, stretching, performing fumigation treatment by glutaraldehyde or formaldehyde steam to obtain the high-strength wheat protein fiber. The high-strength wheat protein fiber prepared by the preparation method disclosed by the invention has silk gloss, tensile strength and elongation at break which are close to those of wool, dry-state breaking strength of 0.9-1.4cN / dtex, dry-state elongation at break up of 28%-35%, and moisture regain of 10%-12% at 20 DEG C under 65%R.H.

Owner:JIANGNAN UNIV

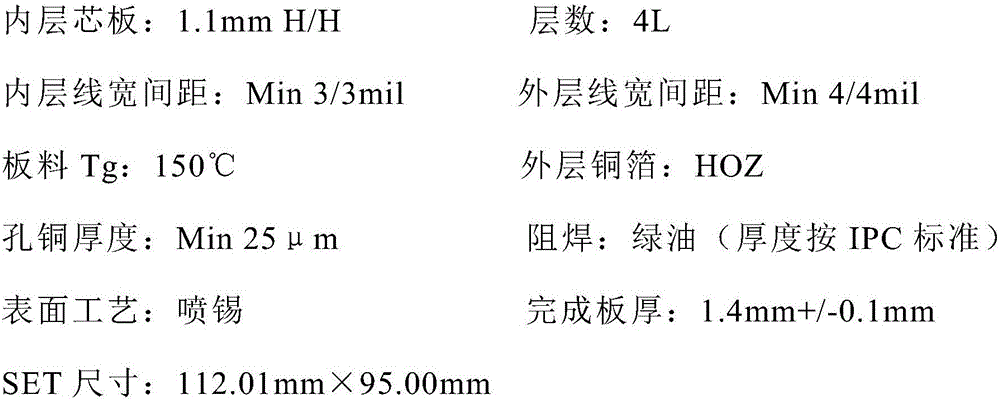

Method for electroplating copper taphole in PCB

InactiveCN106455366AReduce shrinkageOvercome the problem of orifice depression greater than 3μmPrinted circuit aspectsPrinted element electric connection formationProduction lineButt joint

The invention relates to the technical field of circuit board production, in particular to a method for an electroplating copper taphole in a PCB. The method comprises the steps of forming a first metalized blind hole from a first surface of a multi-layer working panel, forming a second metalized bind hole from a second surface, making the bottom of the first metalized blind hole connect with the bottom of the second metalized blind hole in a butt-joint mode so that an existing porefilling electroplating production line can be used to conduct via-filling-plating on the first metalized blind hole and the second metalized bind hole and finally forming the copper taphole tamped by electroplating copper. The advantages that roasting is not needed by the electroplating copper taphole and a stuffing material coincides with a hole wall metal are used to solve the problem that a porthole sunken depth is larger than 3 micrometers caused by roasting in the prior art; meanwhile, due to the fact that copper is used as the stuffing material and expansion coefficient of the stuffing material coincides with that of a hole wall copper layer can sharply lower risks of stratified plate blasting in a welding process. The number of plate grinding times in a production process can be lowered by using the electroplating copper to tamp metalized through holes, thus expansion-shrinkage degree of the multi-layer working panel can be lowered; meanwhile, the method is beneficial to improvement of the quality of the product.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

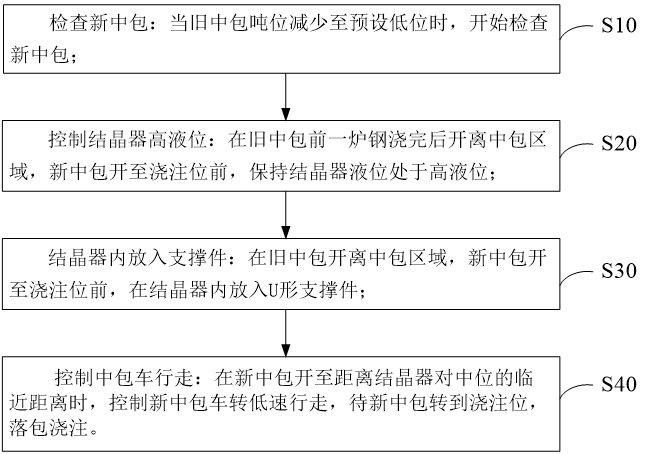

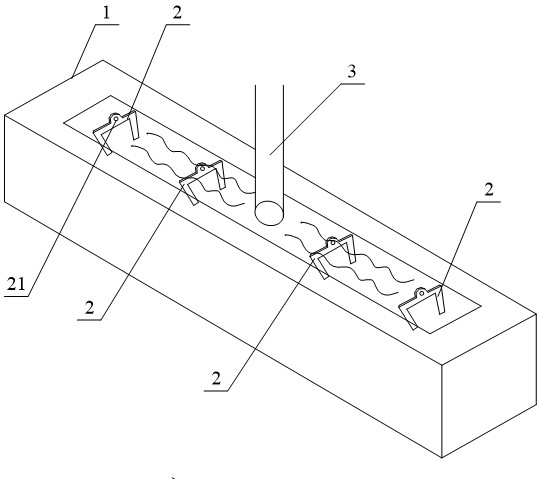

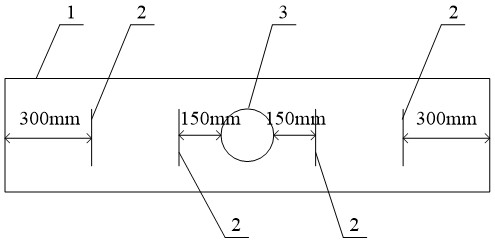

Method for improving wide section tundish changing success rate of plate blank and manufacturing method of method

ActiveCN113210577AReduce shrinkageImprove the success rate of wide-section medium bag replacementLow speedMechanical engineering

The invention discloses a method for improving the wide section tundish changing success rate of a plate blank. The method comprises the following steps that when the tonnage of an old tundish is reduced to a preset low tonnage, a new tundish is started to be checked; after pouring of the previous furnace of steel is finished, the old tundish is separated a tundish area, and before the new tundish is opened to the pouring position, the liquid level of a crystallizer is kept at the high liquid level; when the old tundish is separated from the tundish area and before the new tundish is opened to the pouring position, a U-shaped supporting piece is placed into the crystallizer; and when the new tundish is opened to the position close to the centering position of the crystallizer, a new tundish vehicle is controlled to rotate to walk at a low speed, and when the new tundish rotates to the pouring position, the tundish falls to be poured. According to the technical scheme, by controlling the tundish changing process, the tundish changing time is shortened, the blank shell shrinkage degree is reduced, and the wide section tundish changing success rate of a slab casting machine is improved.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

Solid yoga foam roller and processing method thereof

The invention discloses a solid yoga foam roller which comprises an outer cladding and an inner lined roller, wherein the outer cladding is a hollow cylinder body; a groove is formed in the inner side of the outer cladding; the inner lined roller is arranged in the groove; massage bumps which are distributed in a staggered manner are arranged on the surface of the outer cladding; the inner lined roller is in a shape like a solid cylinder body. The solid yoga foam roller disclosed by the invention has the advantages of low cost, fewer working procedures, short production cycle, scientific processing method, energy conservation and environment friendliness; the produced foam roller has no splicing in a material surface, and is uniform in hardness, high in pattern surface strength, bright in appearance and color of a product and durable; as the inner lined roller is made of a solid EVA (Ethylene Vinyl Acetate) material, the solid yoga foam roller is convenient to use, clean and tidy, dustproof, good in buffer performance and free from deformation after a long time; fascia can be better prevented from being loosened, the contraction degree of muscle is reduced, and the effects of relaxing the body and mind, and building and shaping the body are realized.

Owner:ZHANGJIAGANG HONGLI RUBBER & PLASTIC PROD

Method for casting super-large single-material cast steel bearing roller above 100 ton

ActiveCN101028648AReduce shrinkageReduce shrinkage stressMolten metal conveying equipmentsElectric heatingMetallurgy

A technology for casting the ultra-large (more than 100 tons) bearing steel roller with single material features that a computer simulation method is used to design a metallic mould, such techniques as covering sand on iron mould and the insulating riser head are used for sequential solidifying, casting multiple times, electric heating multiple times and composite riser head are used, top pouring and bottom pouring are combined, and the key parameters are controlled.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

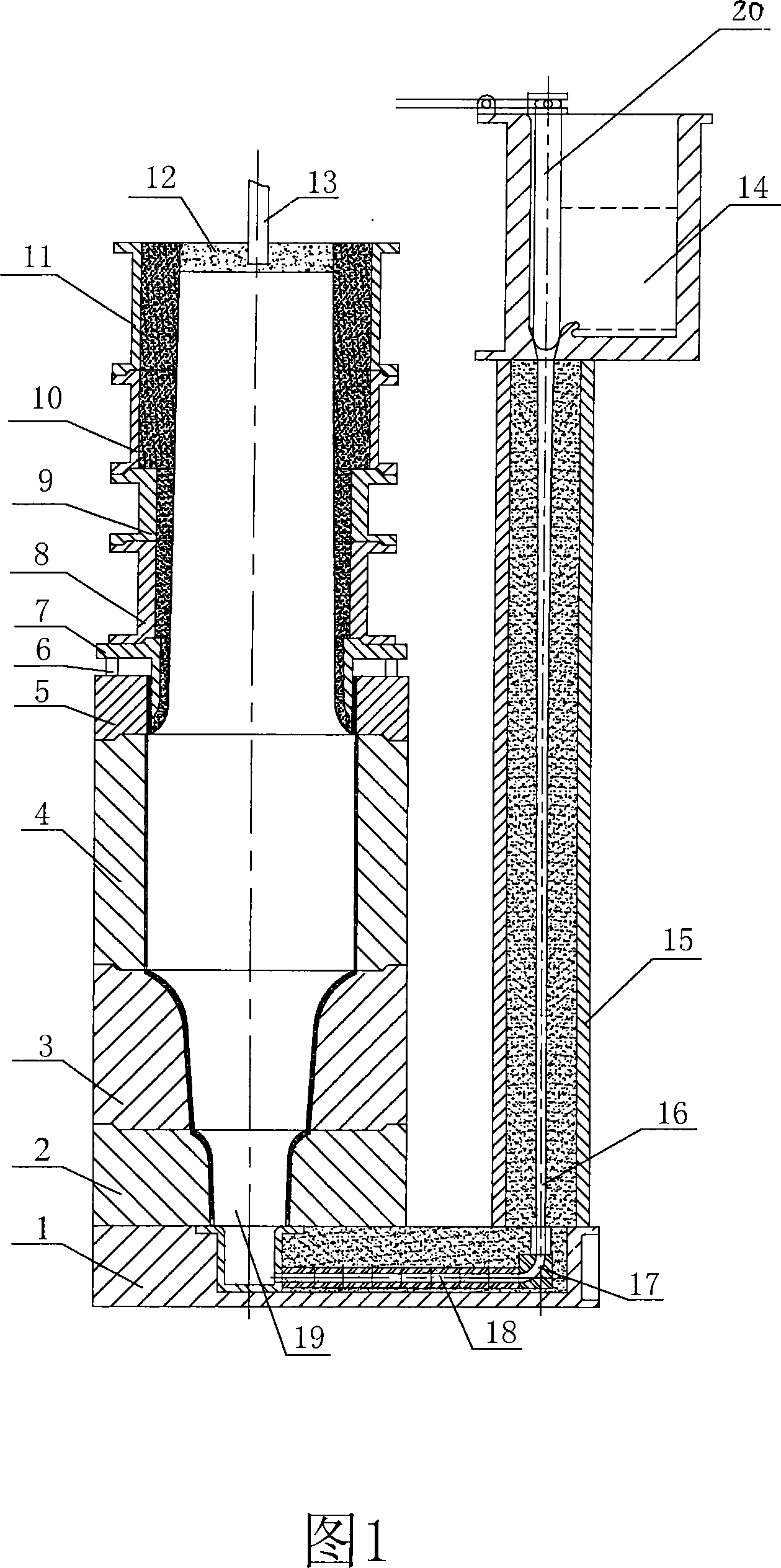

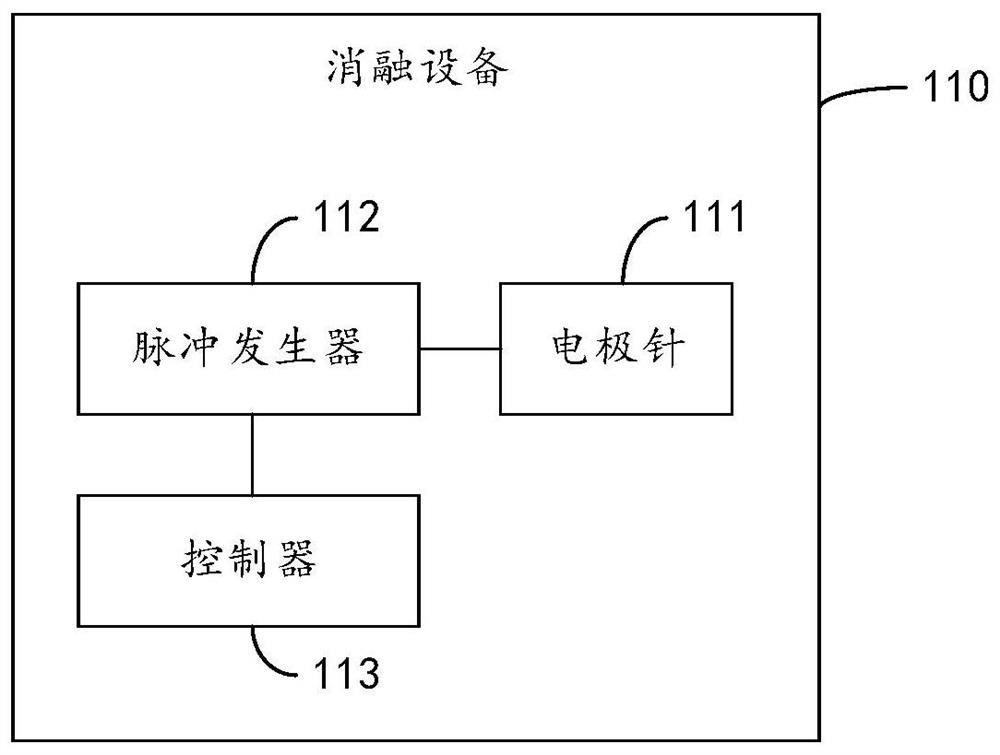

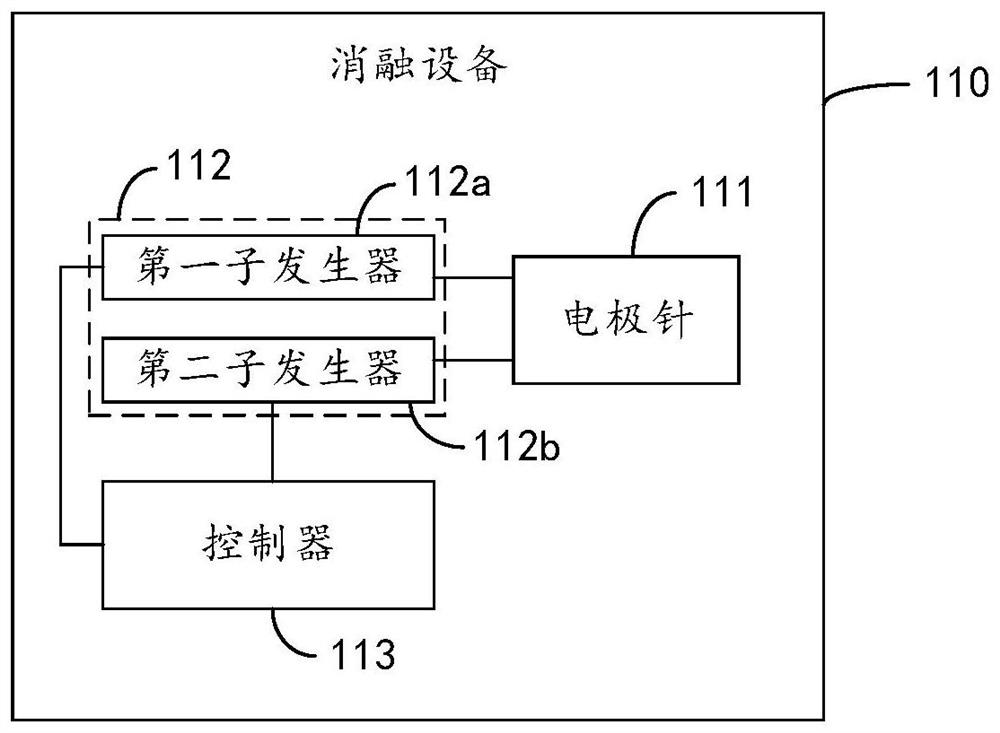

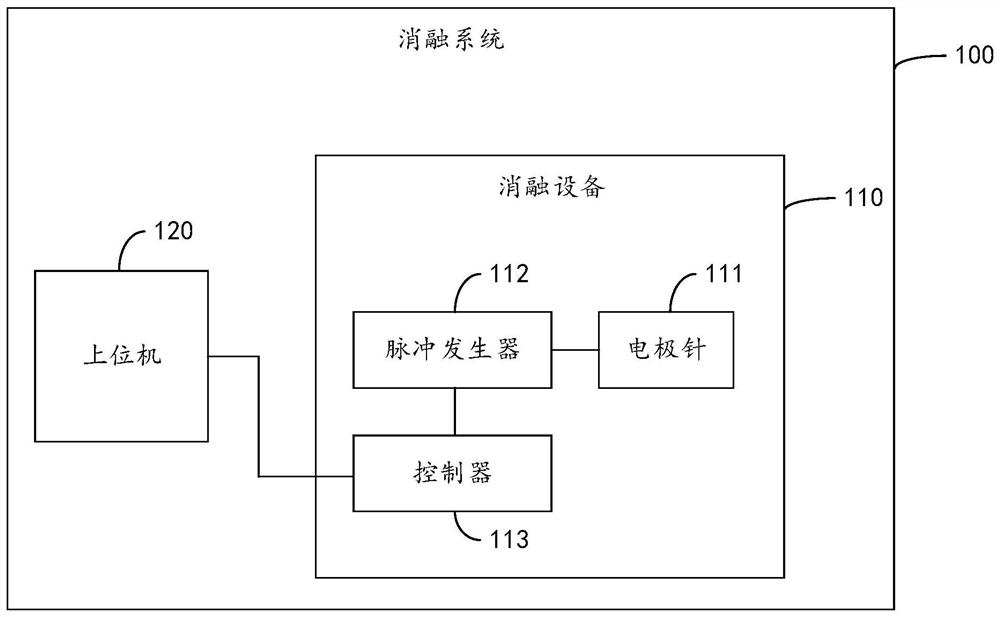

Pulse control method and device thereof, ablation equipment, system and storage medium

PendingCN113100918AReduce shrinkageLow shrinkageSurgical needlesSurgical instruments for heatingAnesthetic AgentPulse control

The provides a pulse control method and a device thereof, ablation equipment, a system and a storage medium. The pulse control method comprises the following steps: outputting a nanosecond pulse sequence and a millisecond pulse sequence to a target biological tissue; the amplitude of the nanosecond pulse sequence is larger than the threshold voltage, and the amplitude of the millisecond pulse sequence is smaller than the threshold voltage. According to the embodiment of the invention, the nanosecond pulse sequence with the amplitude greater than the threshold voltage cooperates with the millisecond pulse sequence with the amplitude less than the threshold voltage, such as the synergistic effect of the high-voltage nanosecond pulse sequence and the low-voltage millisecond pulse sequence, so that the effective ablation range can be enlarged, the ablation is more thorough, the muscle contraction amplitude can be effectively reduced, or the muscle contraction probability is reduced, even the muscle contraction phenomenon is avoided, the treatment experience feeling of a patient can be improved, and the use of anesthetics can be reduced or even not needed, so that the treatment cost is effectively reduced, and side effects are reduced.

Owner:HANGZHOU WKNIFE MEDICAL TECH CO LTD

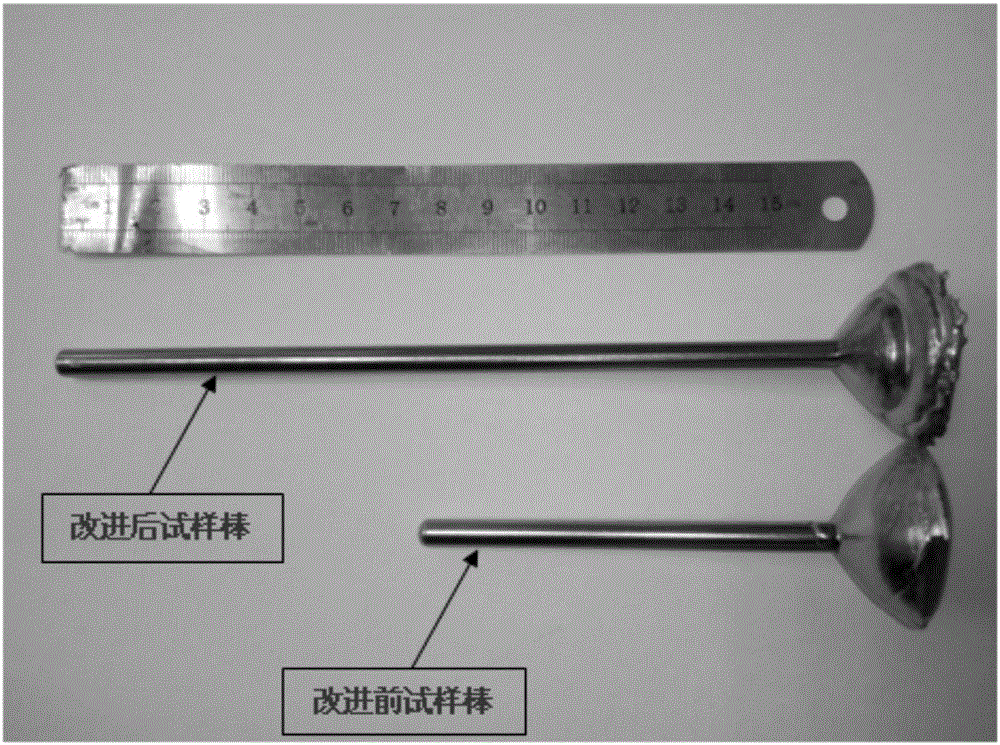

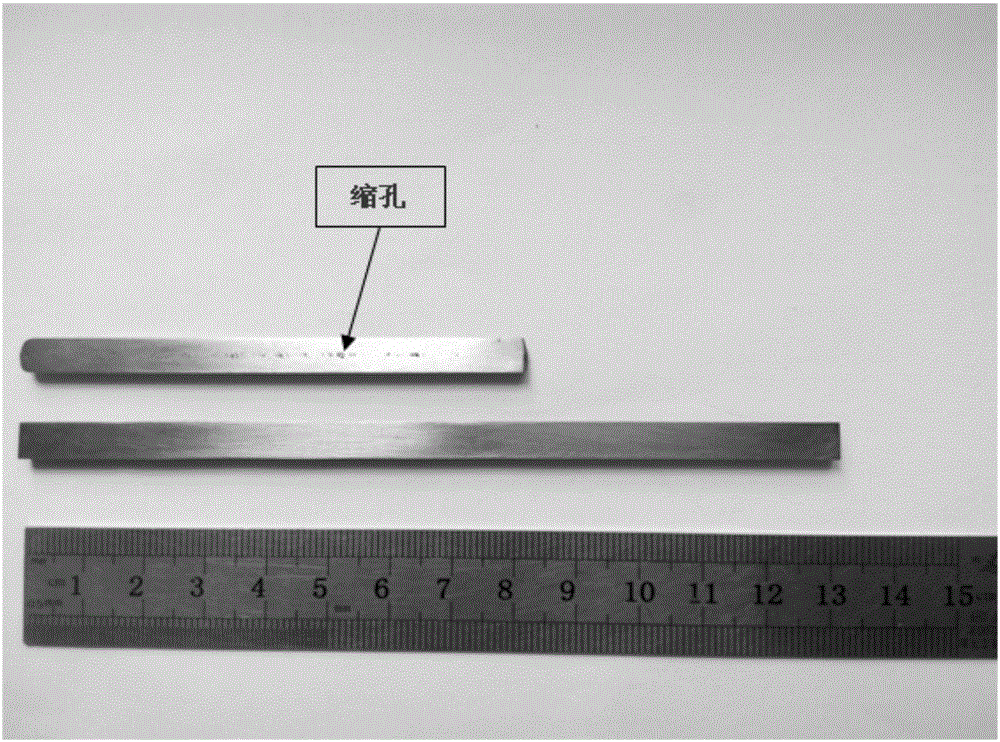

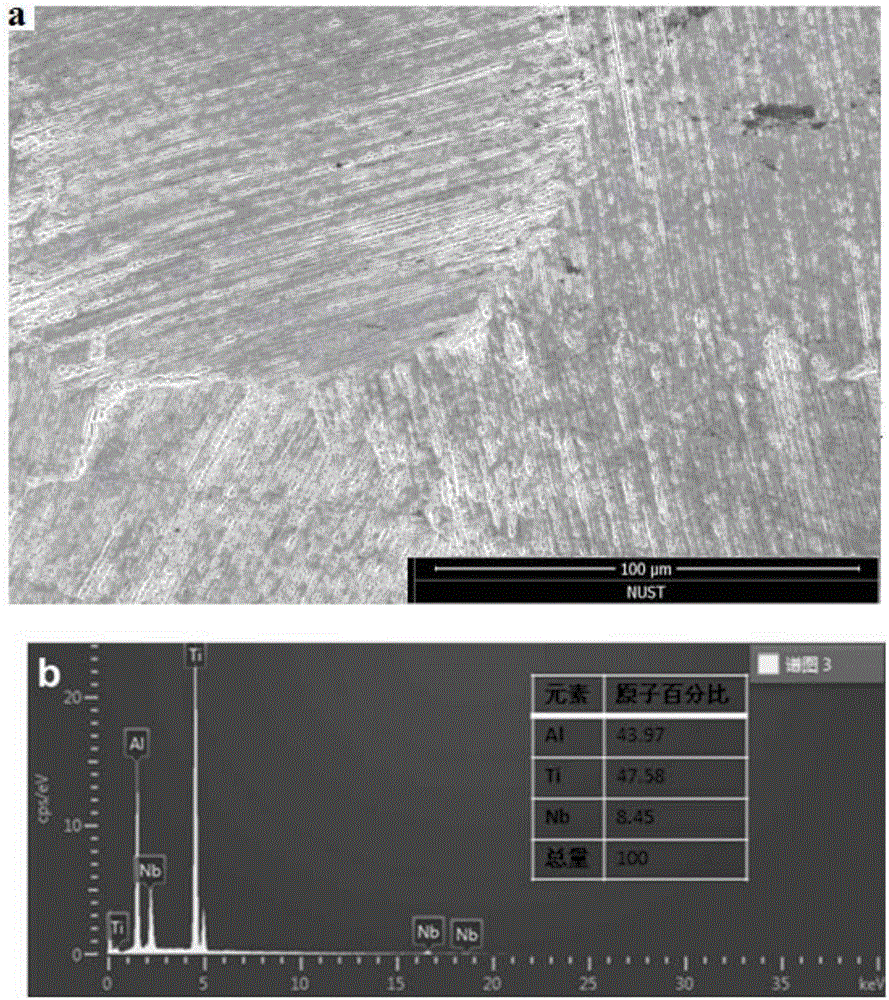

Method for improving liquid-state fluidity of TiAl-Nb alloy

The invention discloses a method for improving liquid-state fluidity of a TiAl-Nb alloy. The TiAl-Nb alloy is Ti-(40-50)Al-(5-10)Nb by atomic percent, and the balance is Ti. The method comprises the following steps: a water-cooled copper crucible is adopted to electromagnetically induce a suspension-smelted TiAl-Nb master alloy ingot; firstly, niobium is put at the bottom of the copper crucible, titanium is put along the wall of the crucible, and aluminum is put in middle; the power is adjusted to 10 kw for keeping 20 S, and is adjusted to 15 kw until niobium, titanium and aluminum are totally molten and suspended; then, the power is adjusted to 20 kw for keeping 180 S, and the smelting is repeated by 4-5 times; the ingot is put in an arc furnace for gravity casting; after arc striking of the arc furnace, the current is adjusted to 150 A; after the surface of the master alloy ingot totally becomes a liquid state, the current is increased to 230 A, and the alloy totally becomes the liquid state; a tungsten electrode rod rotates from center to periphery; and when the current is increased to 320-350 A, the liquid level is descended to obtain a sample rod. The method can guarantee no burning loss of elements of the sample rod, is uniform in components, effectively improves the liquid-state fluidity of the TiAl-Nb alloy, and reduces such defects as shrinkage and porosity.

Owner:NANJING UNIV OF SCI & TECH

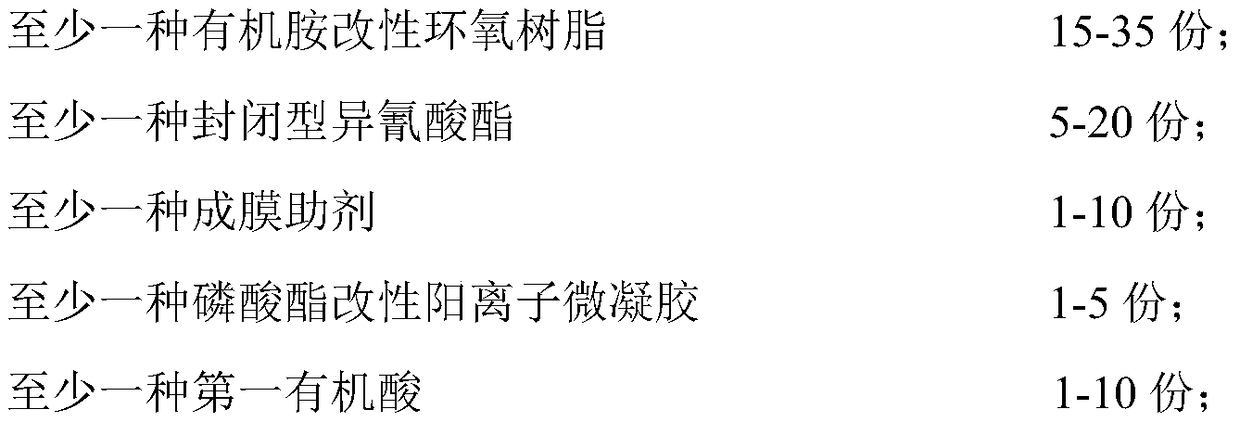

Edge anticorrosive electrophoretic coating composition, preparation method and application

ActiveCN109504264AIncrease coverageReduce shrinkageAnti-corrosive paintsPolyurea/polyurethane coatingsEpoxyOrganic acid

The invention provides an edge anticorrosive electrophoretic coating composition, coating and application. The edge anticorrosive electrophoretic coating composition comprises component A: 15 to 35 parts of at least one organic amine modified epoxy resin; 5 to 20 partof at least one blocked isocyanate; 1 to 10 parts of at least one film-forming auxiliary; 1 to 5 parts of at least one phosphate-modified cationic microgel; 1 to 10 parts of at least one first organic acid; 0.5 to 5 parts of at least one auxiliary solvent; and 30 parts of deionized water; and component B: 10 to 25 parts of at least one epoxy resin containing quaternary ammonium salt and / or tertiary sulfonium salt group; 5-40 parts of at least one pigment; 5 to 40 parts of at least one filler; 0.5 to 5 parts of at least one dispersing aid; 30 to 70 parts of second deionized water. By adopting the invention, the coverage of the electrophoretic coating on the edge of a workpiece can be greatly improved, and the edge corrosionresistance can be improved.

Owner:NIPPON PAINT GUANGZHOU +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com