Patents

Literature

560 results about "Nanosecond pulse" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nanosecond Pulsed Fiber Laser. MPBC’s line of Nanosecond Pulsed Fiber Lasers have been designed to allow users flexibility in their application refinement. With user selectable pulse-widths and repetition rates, these lasers put more options into the hands of the user than traditional lasers with fixed parameters.

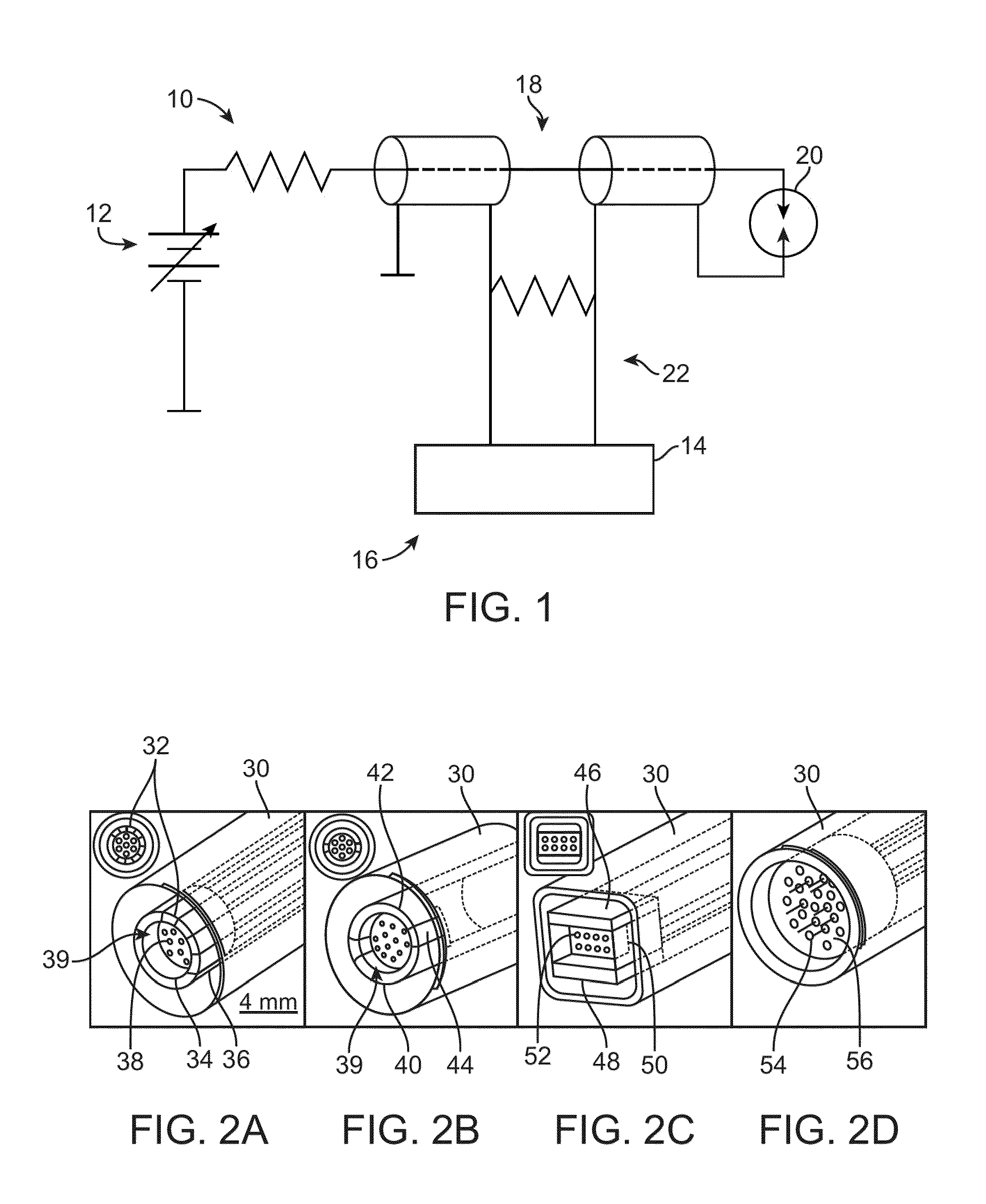

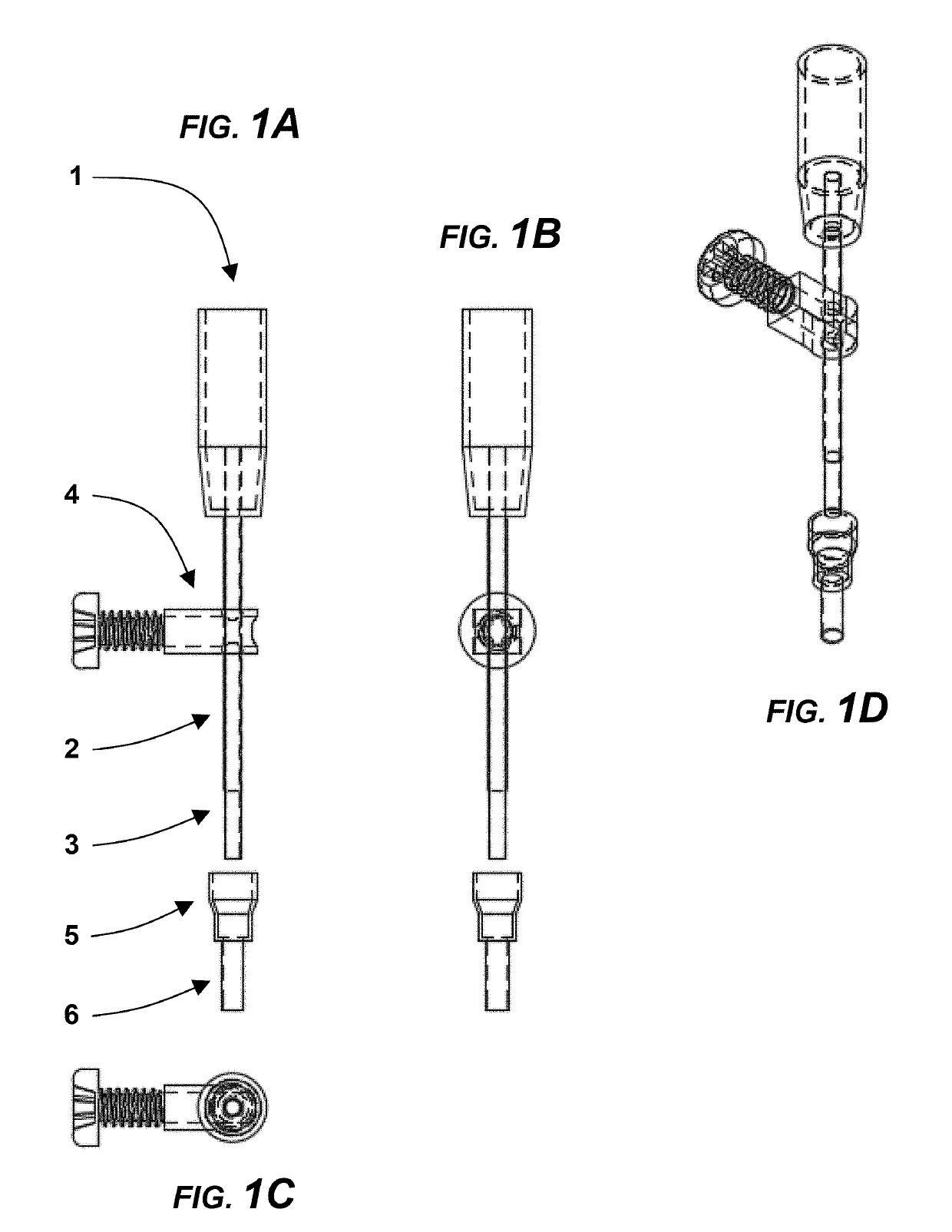

Apparatus for generating electrical pulses and methods of using the same

InactiveUS20060269531A1Increase gene expressionFacilitate entryBiocideElectrotherapyLow voltageShort duration

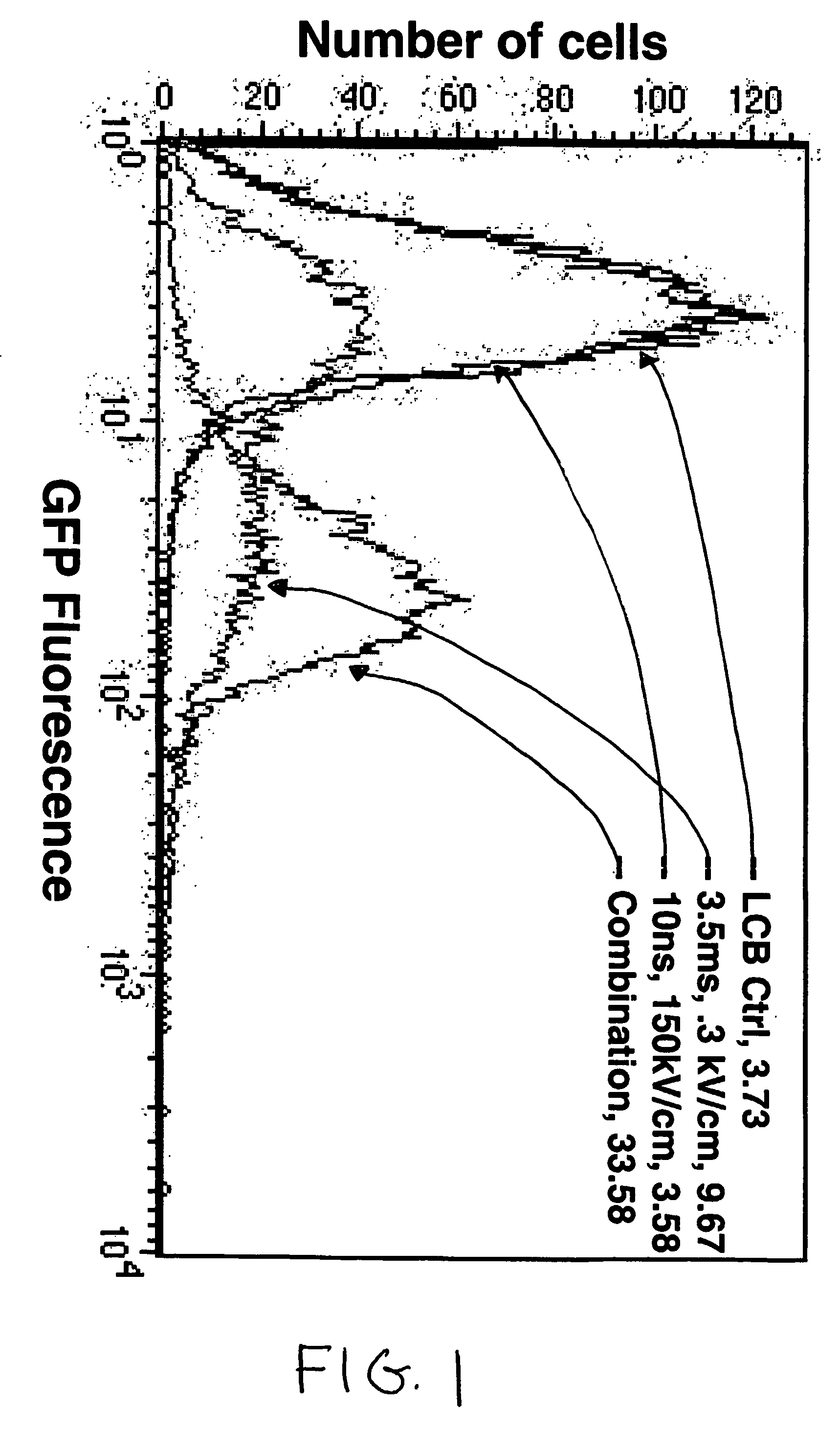

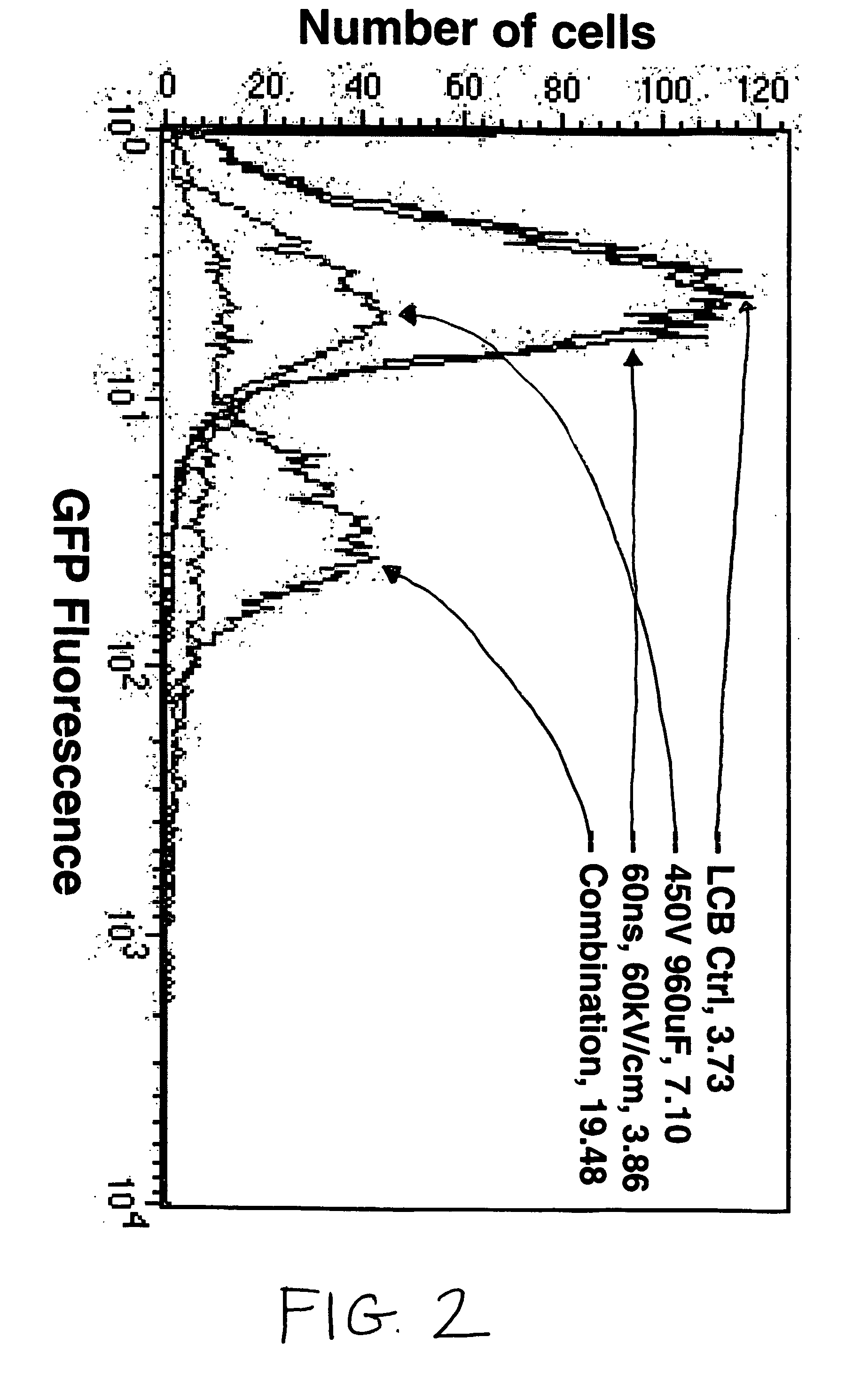

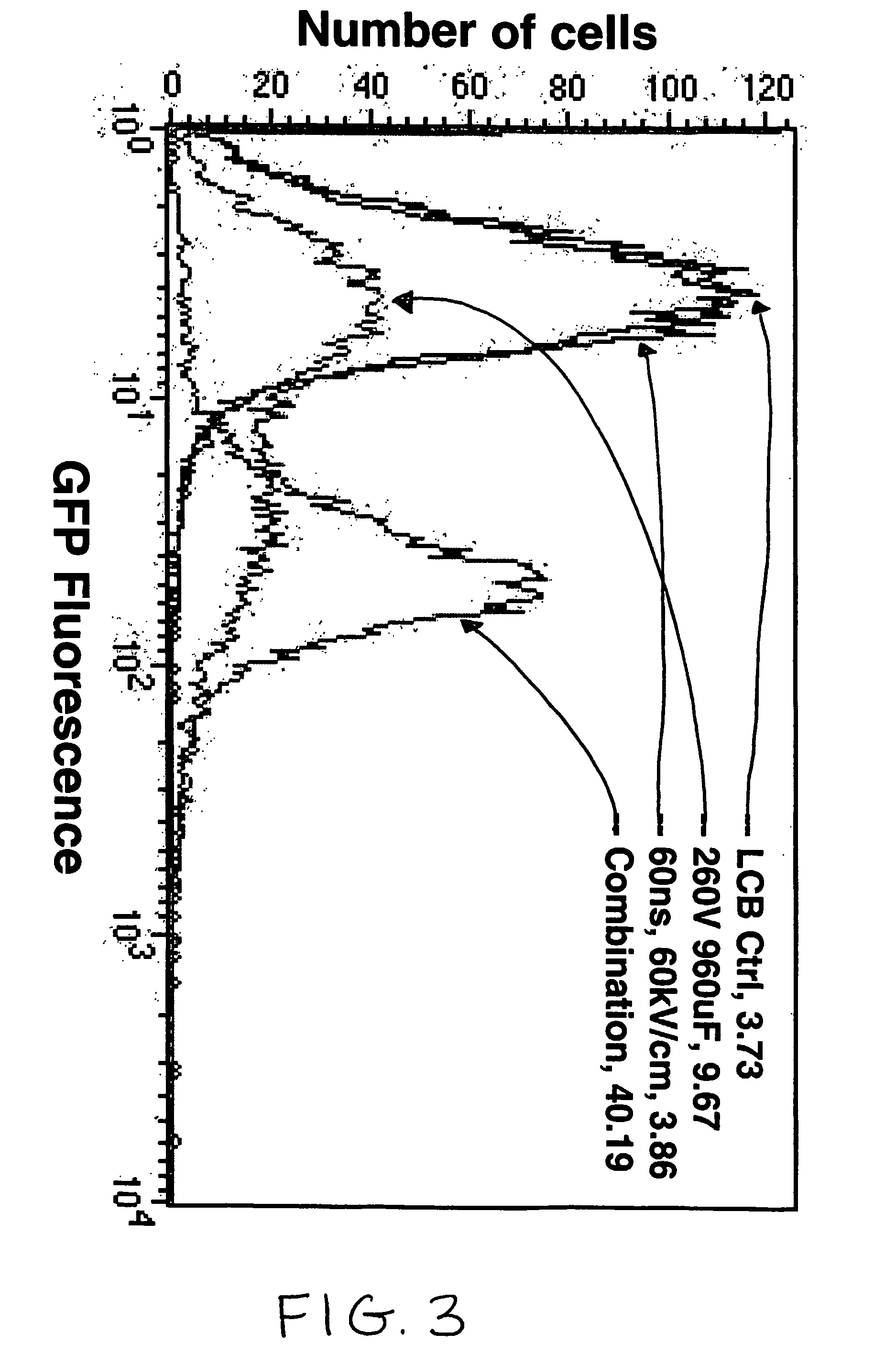

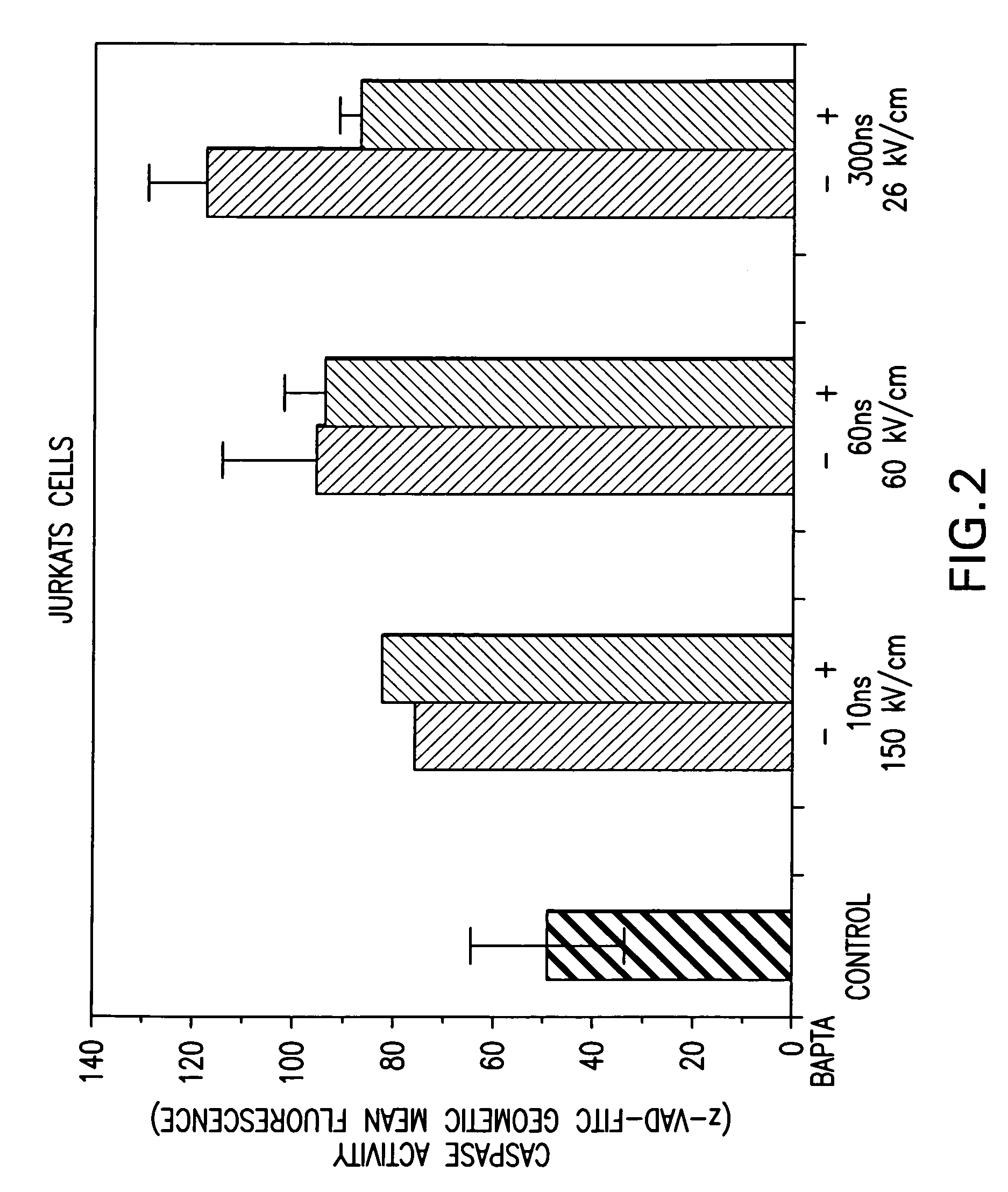

A method and apparatus are provided for delivering an agent into a cell through the application of nanosecond pulse electric fields (“nsPEF's”). The method includes circuitry for delivery of an agent into a cell via known methods followed by the application of nanosecond pulse electric fields to said cell in order to facilitate entry of the agent into the nucleus of the cell. In a preferred embodiment, the present invention is directed to a method of enhancing gene expression in a cell comprising the application of nanosecond pulse electric fields to said cell. An apparatus for generating long and short pulses according to the present invention is also provided. The apparatus includes a pulse generator capable of producing a first pulse having a long duration and low voltage amplitude and a second pulse having a short duration and high voltage amplitude.

Owner:EASTERN VIRGINIA MEDICAL SCHOOL

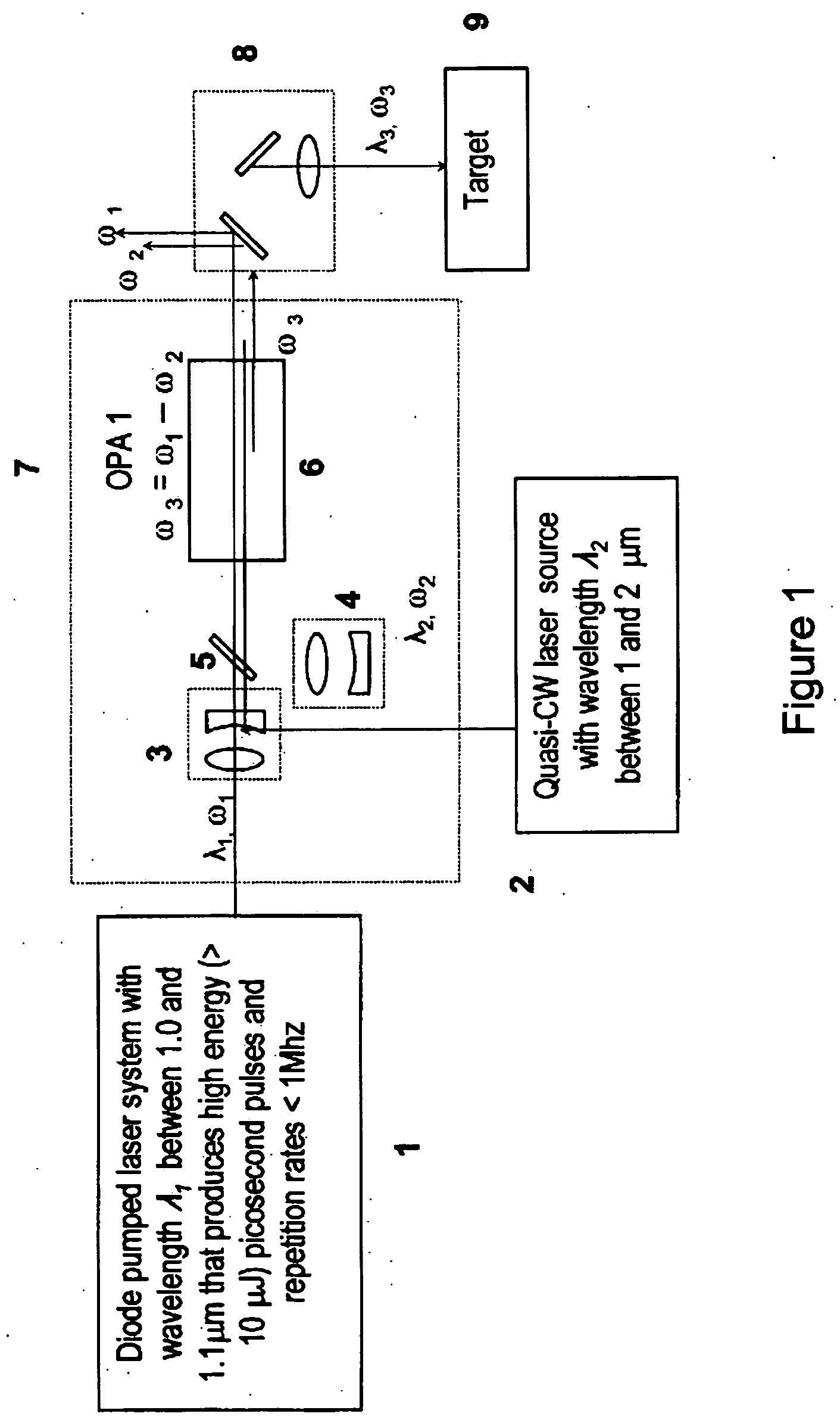

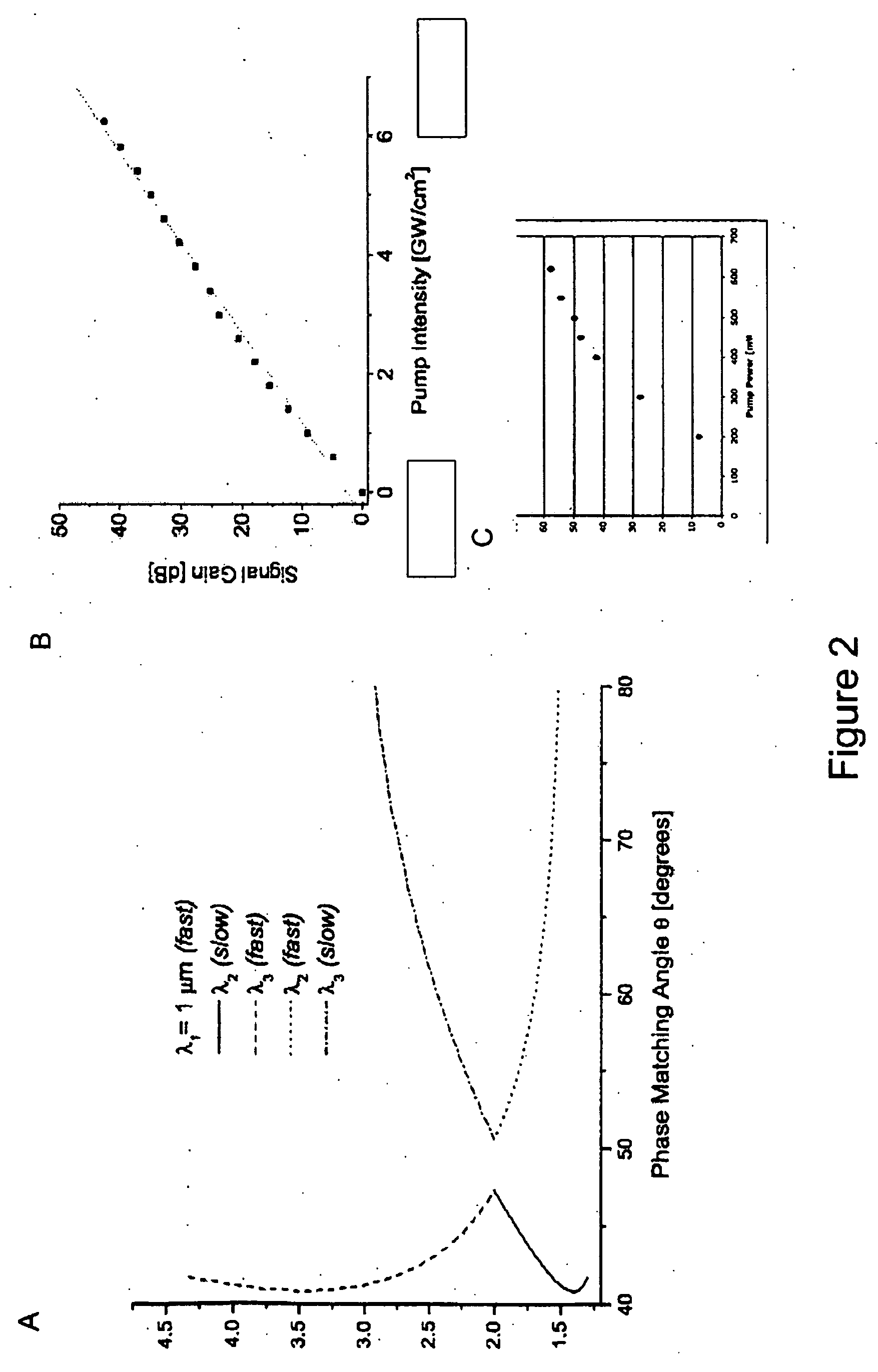

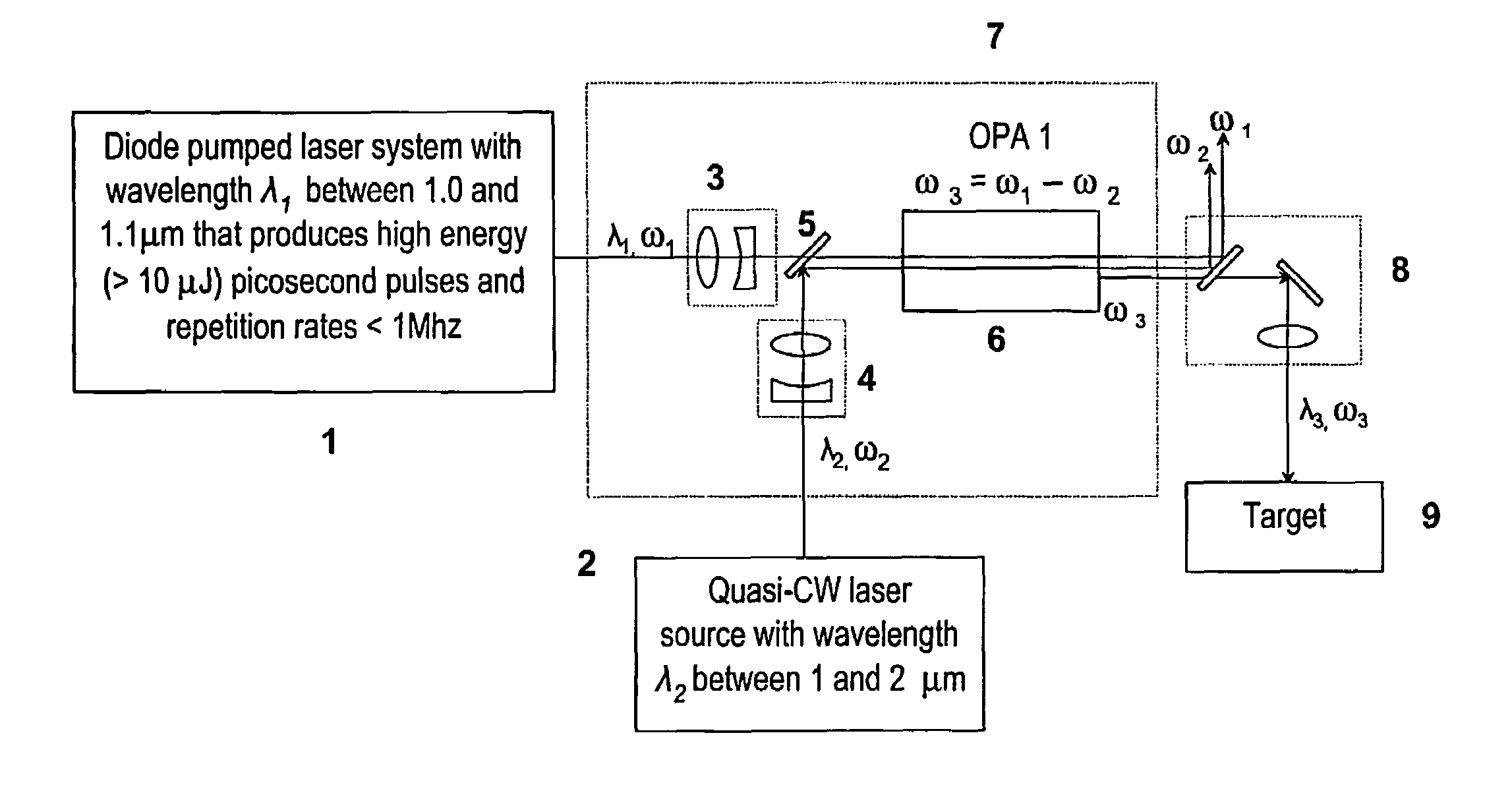

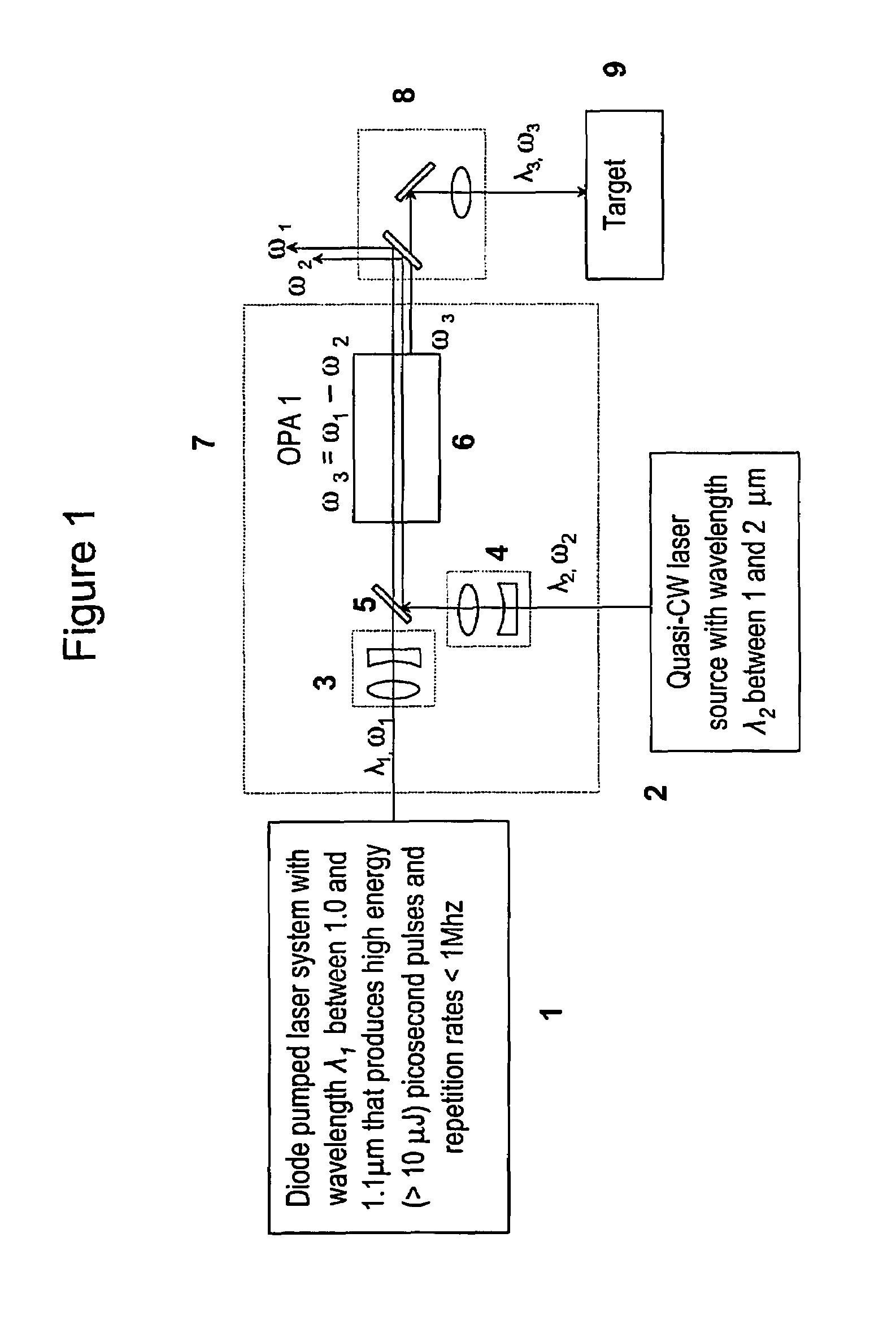

Laser system for generation of high-power sub-nanosecond pulses with controlable wavelengths in 2-15 mum region

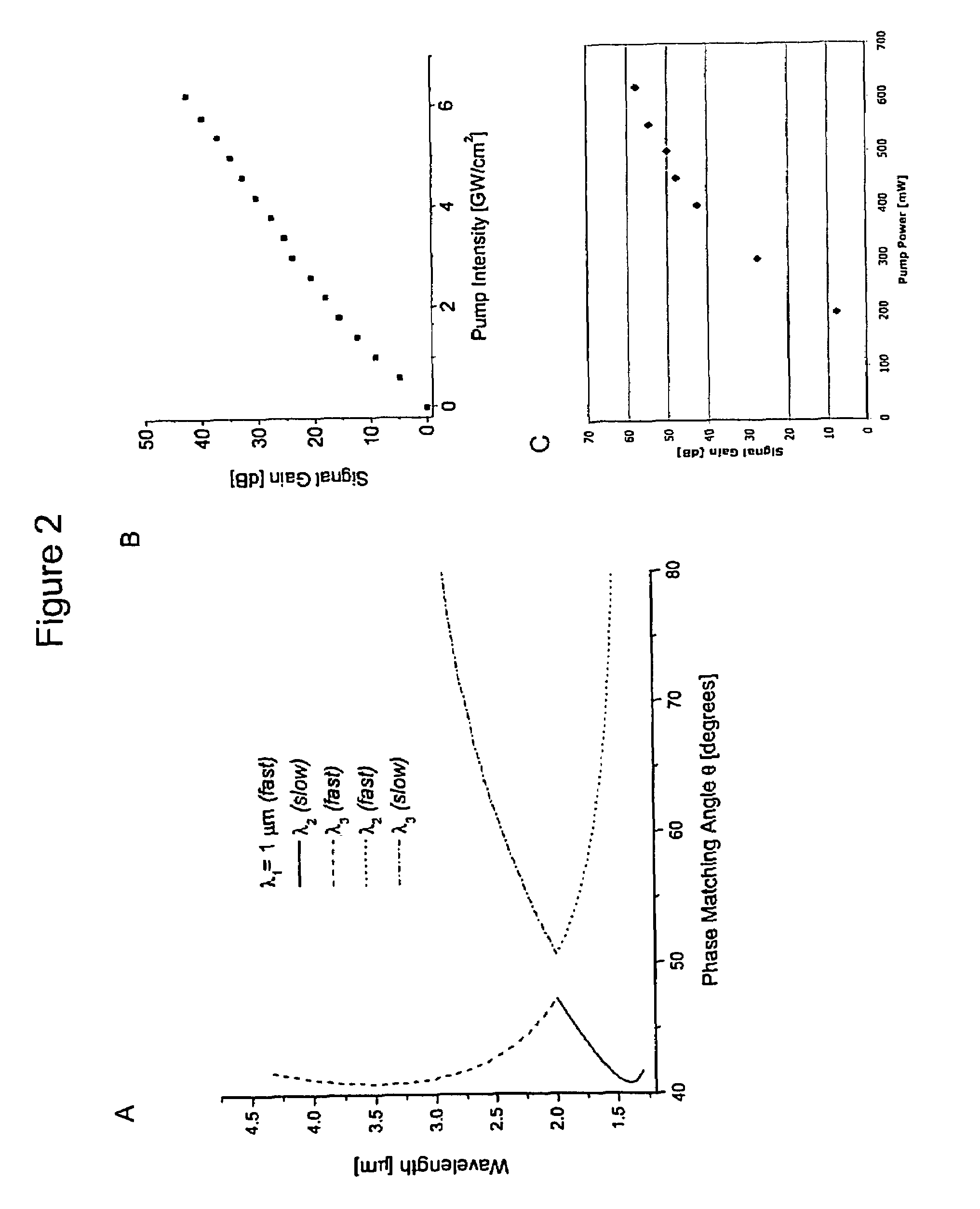

ActiveUS20060153254A1Big spaceSubstantial temporal overlapLaser using scattering effectsSurgical instrument detailsSystems designHigh energy

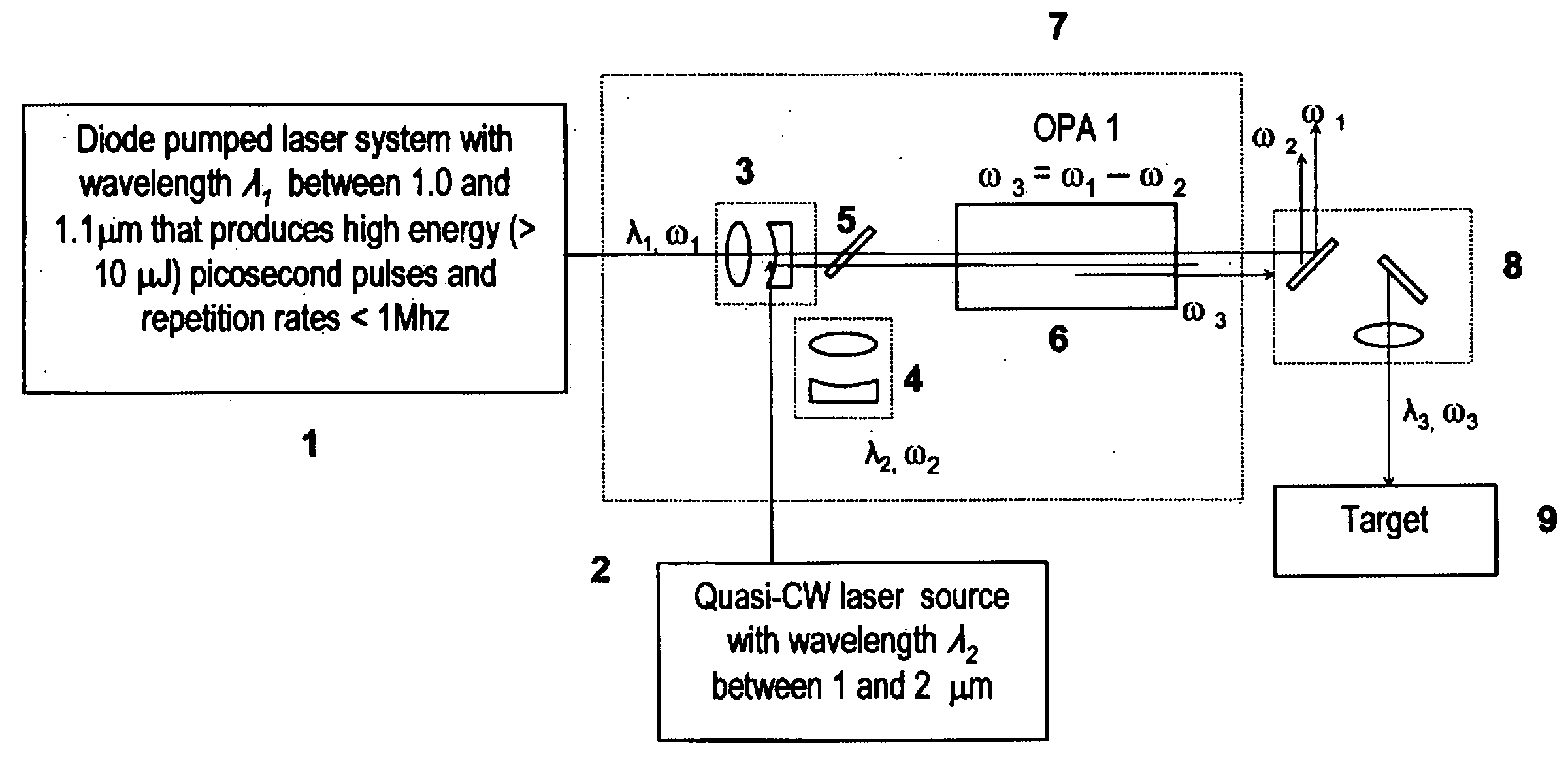

A laser system capable of efficient production of high energy sub-nanosecond pulses in the 2-15 μm spectral region is disclosed. Diode pumped solid state lasers are used as pump sources. The system design is simple, reliable and compact allowing for easy integration. The laser system includes a combination of compact solid-state ˜1 micron laser sources, producing high power picosecond pulses, with optical parametric amplification and a quasi-continuous wave laser for seeding the amplification process that enables the efficient conversion of the high power ˜1 micron laser radiation to tuneable mid-infrared sub-ns pulses. New parametric processes are presented for achieving high gains in bulk nonlinear crystals. Furthermore, a method of exceeding the fundamental conversion efficiency limit of direct three wave mixing is presented. The compact and robust nature of this novel laser system opens up the use of high power and high peak power mid-infrared laser pulses to a wide variety of important medical and dental applications.

Owner:LIGHT MATTER INTERACTION

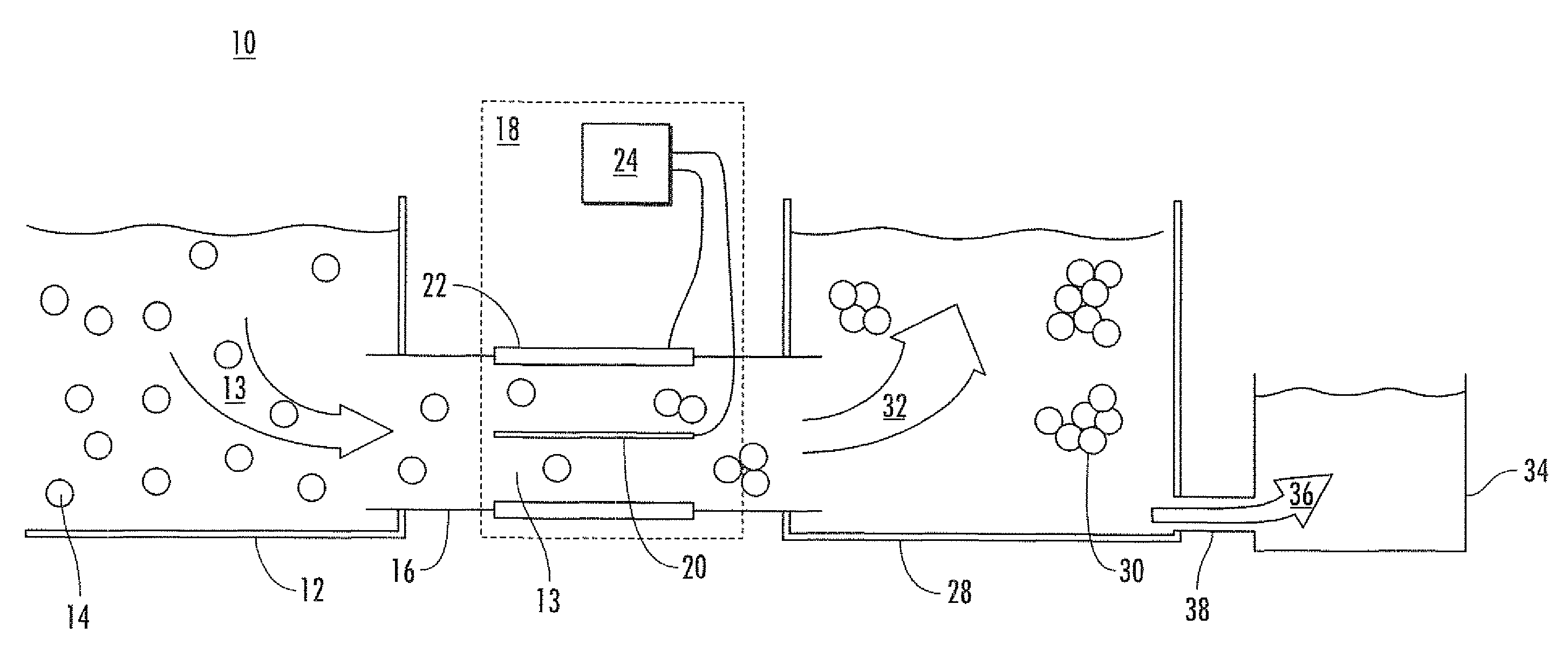

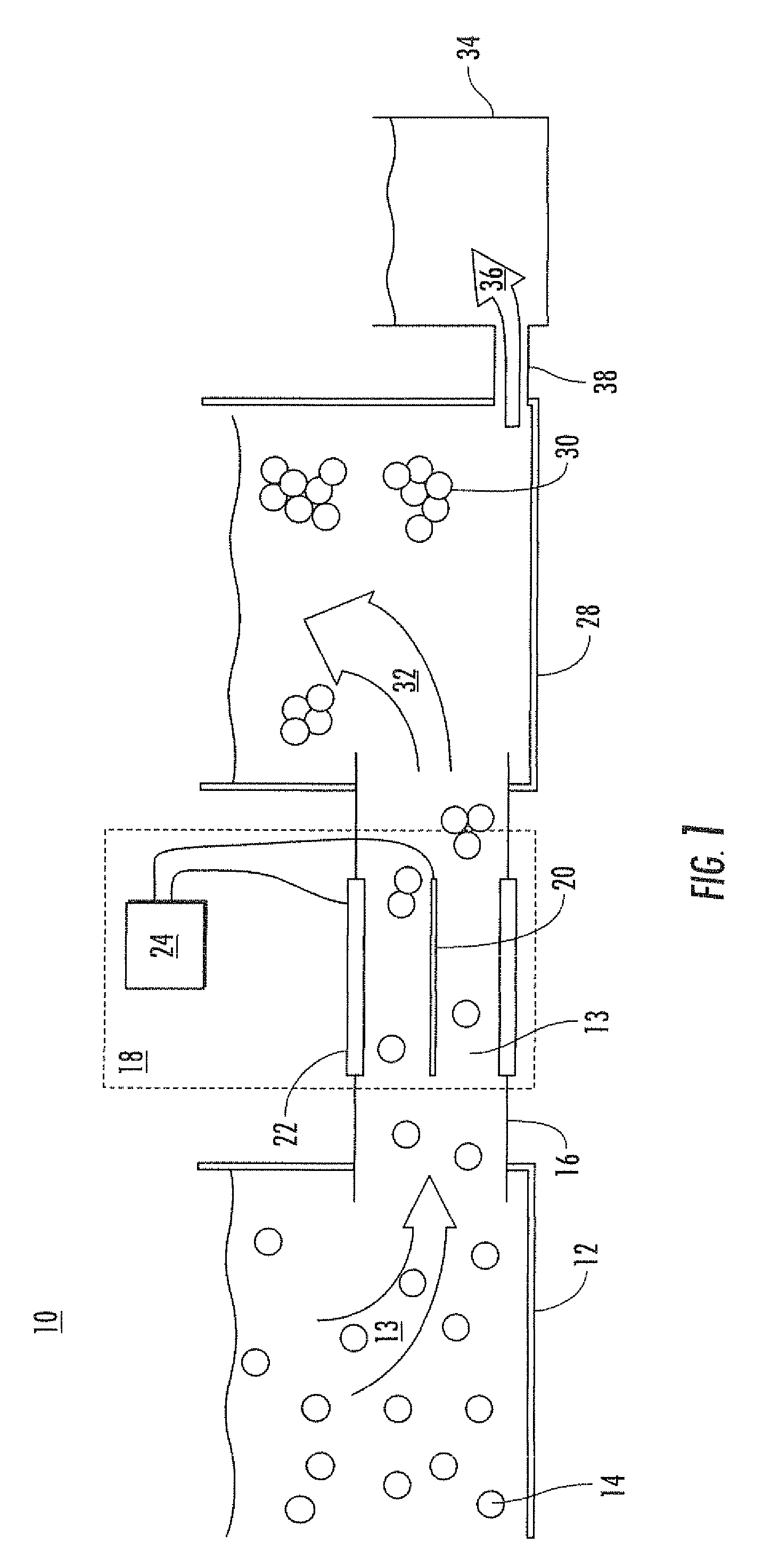

System and method for high-voltage pulse assisted aggregation of algae

ActiveUS20110003350A1Bioreactor/fermenter combinationsBiological substance pretreatmentsNanosecondNanosecond pulse

A method and device for aggregating algae in an aqueous solution is disclosed. The method can include providing an algae feed comprising a liquid and algae dispersed therein. The algae feed can be aggregated by applying a nanosecond pulsed electric field to the algae feed. The nanosecond pulsed electric field can include a plurality of electric pulses having a pulse duration ranging from 1 to 1,000 nanoseconds. The method can also include separating an aggregated algae stream from the algae feed and feeding the aggregated algae stream to a lipid extraction operation.

Owner:OLD DOMINION UNIVERSITY RESEARCH FOUNDATION

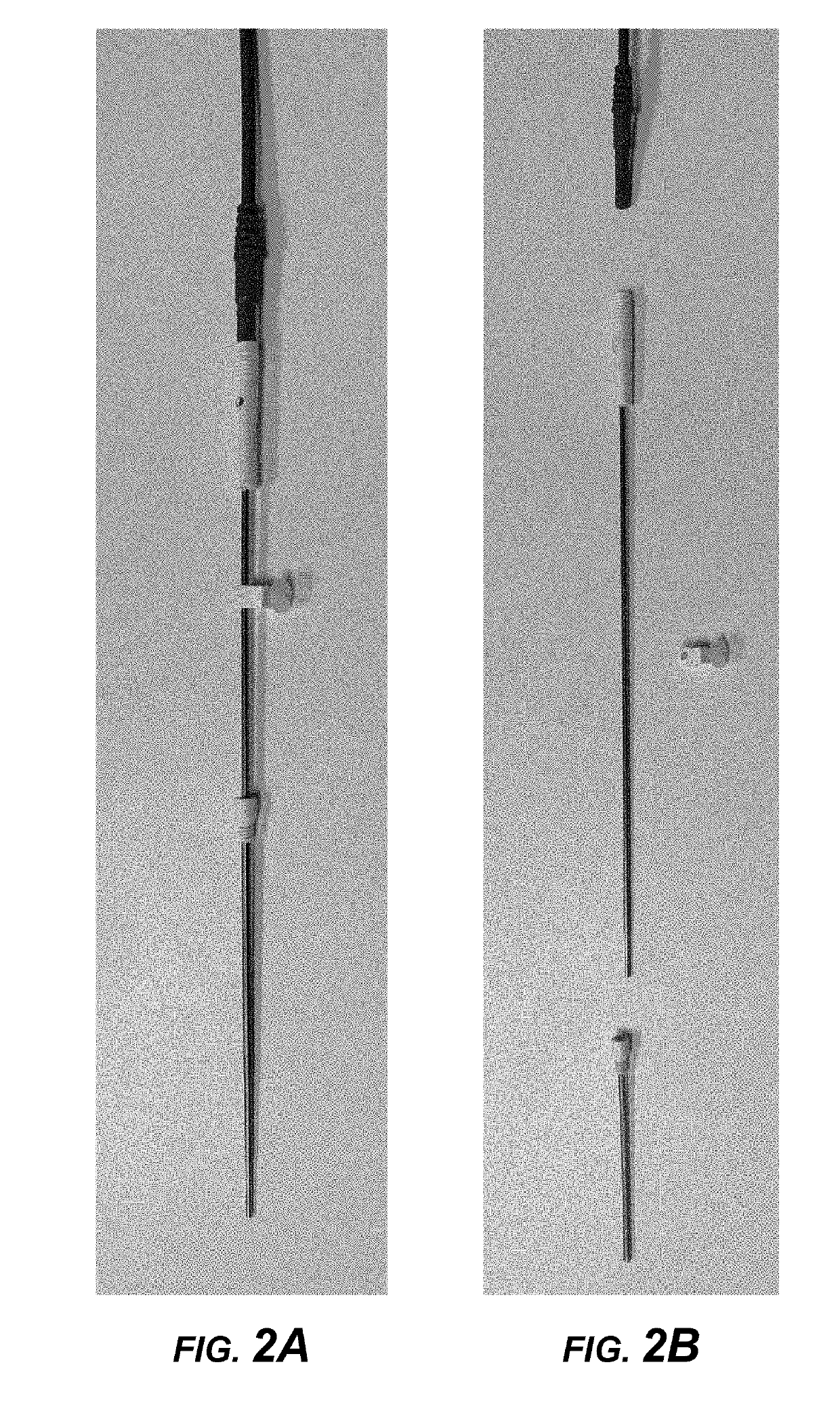

System and method for treating tumors

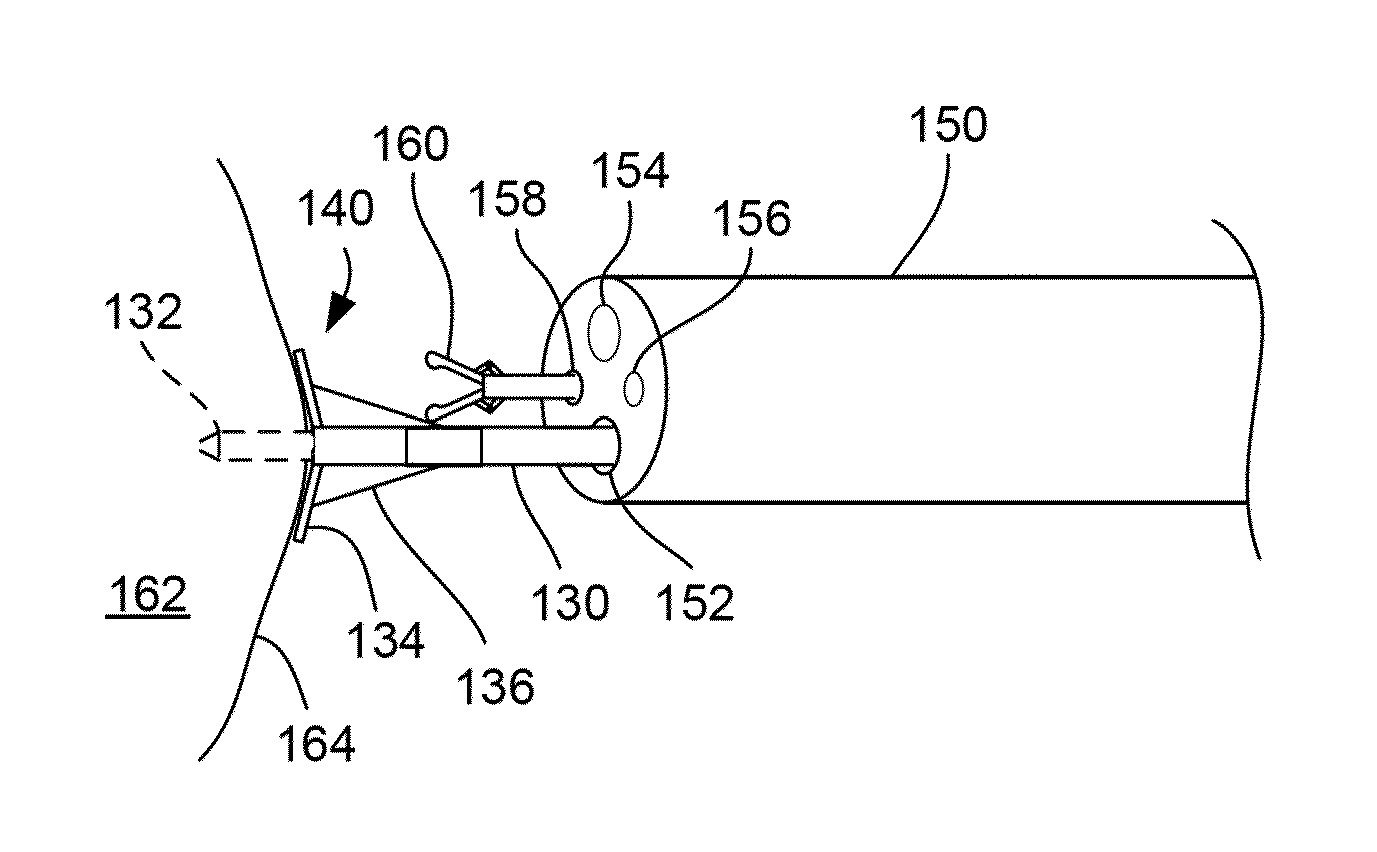

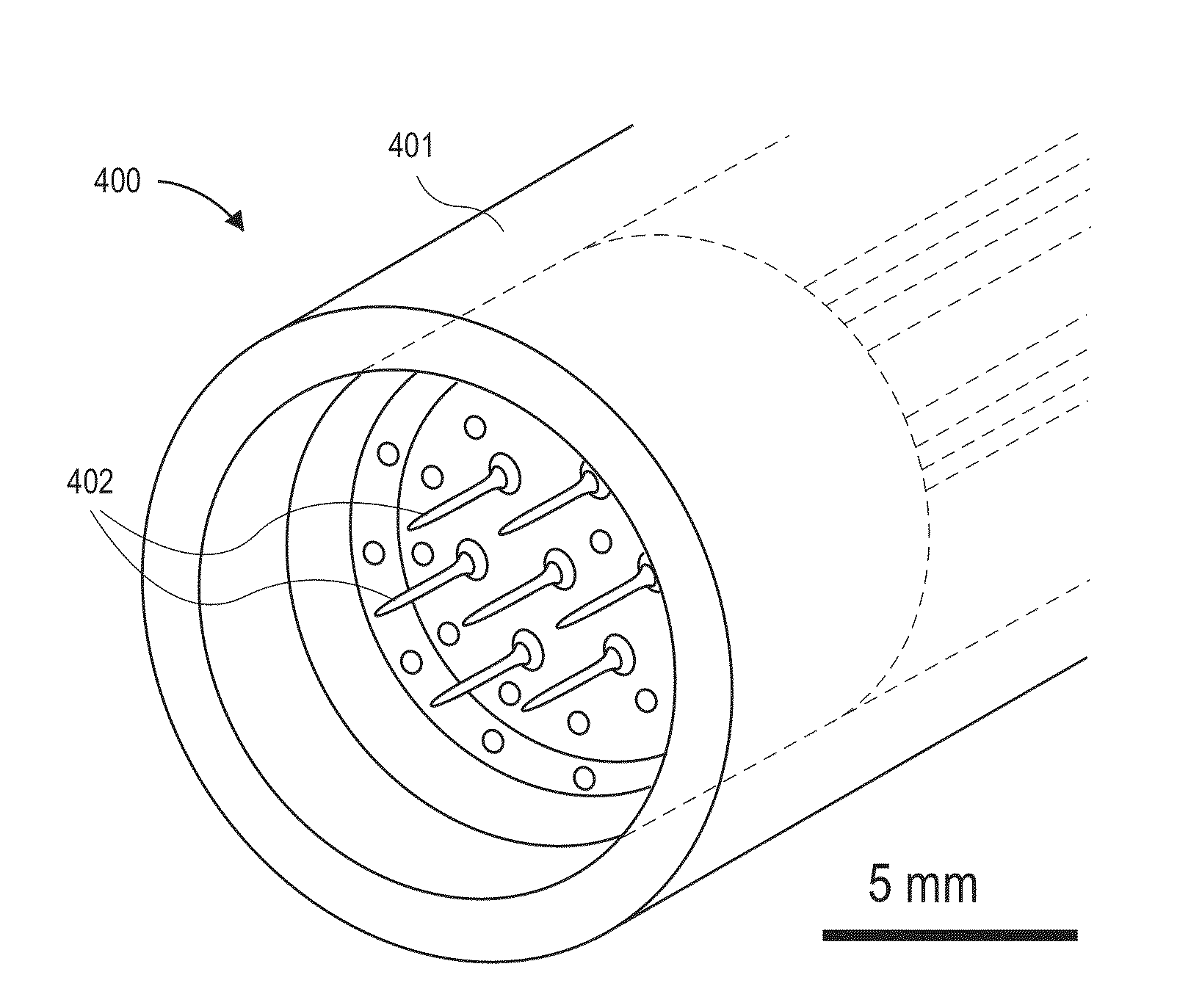

InactiveUS20100240995A1Easy to controlAvoid damageUltrasonic/sonic/infrasonic diagnosticsSurgical needlesIntestinal structureAbnormal tissue growth

Systems and methods for treating tumors on or within internal organs of mammals that have been imaged with endoscopic ultrasound are described. The system uses an expandable bipolar electrode assembly that can be imaged by ultrasound and can penetrate, e.g., the stomach, intestine or bowel wall, etc. and be positioned in or around the tumor on an internal organ while being guided by an operator who visualizes its position with ultrasound imaging. It utilizes an electrode assembly that extends down an internal cavity in the endoscope to allow the operator to spread the electrodes for pulse delivery of a nanosecond pulsed electric field (nsPEF) to the tumor.

Owner:PULSE BIOSCI INC

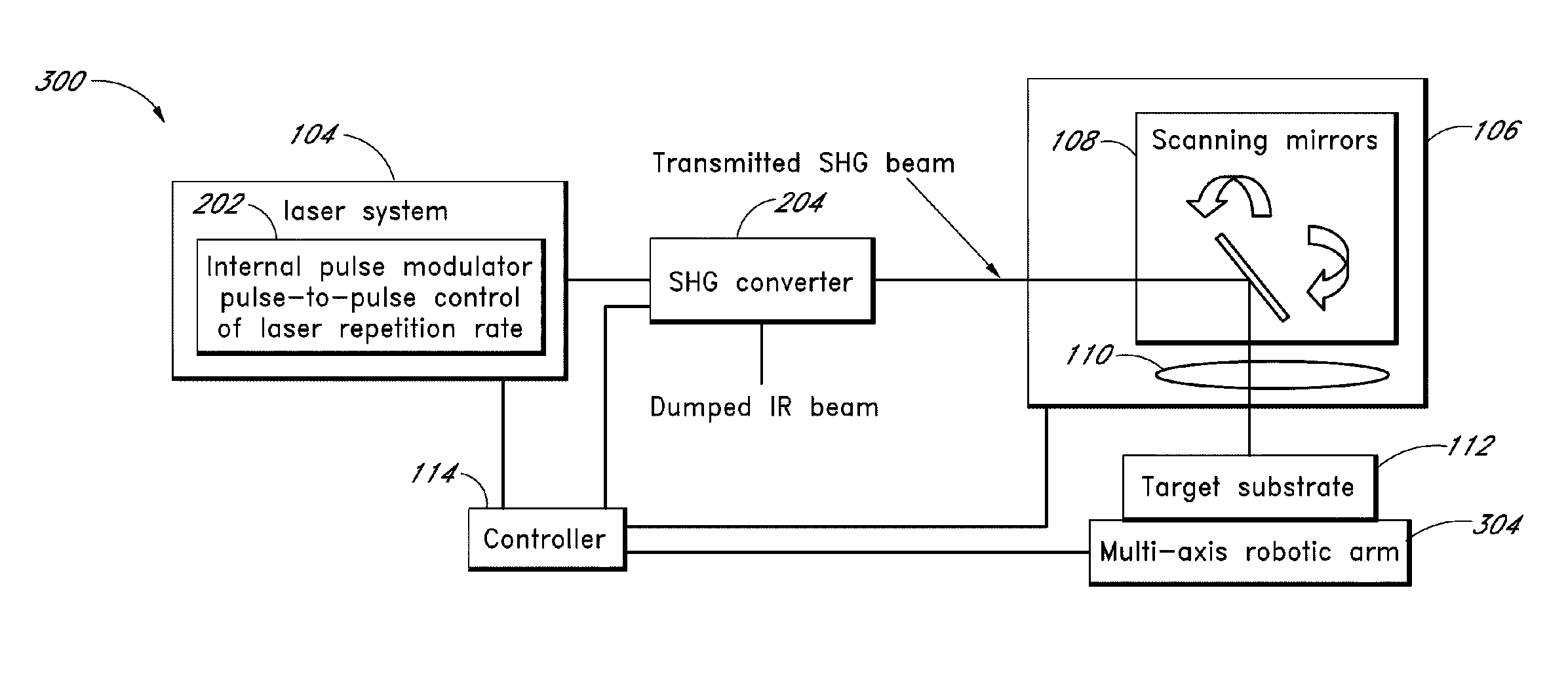

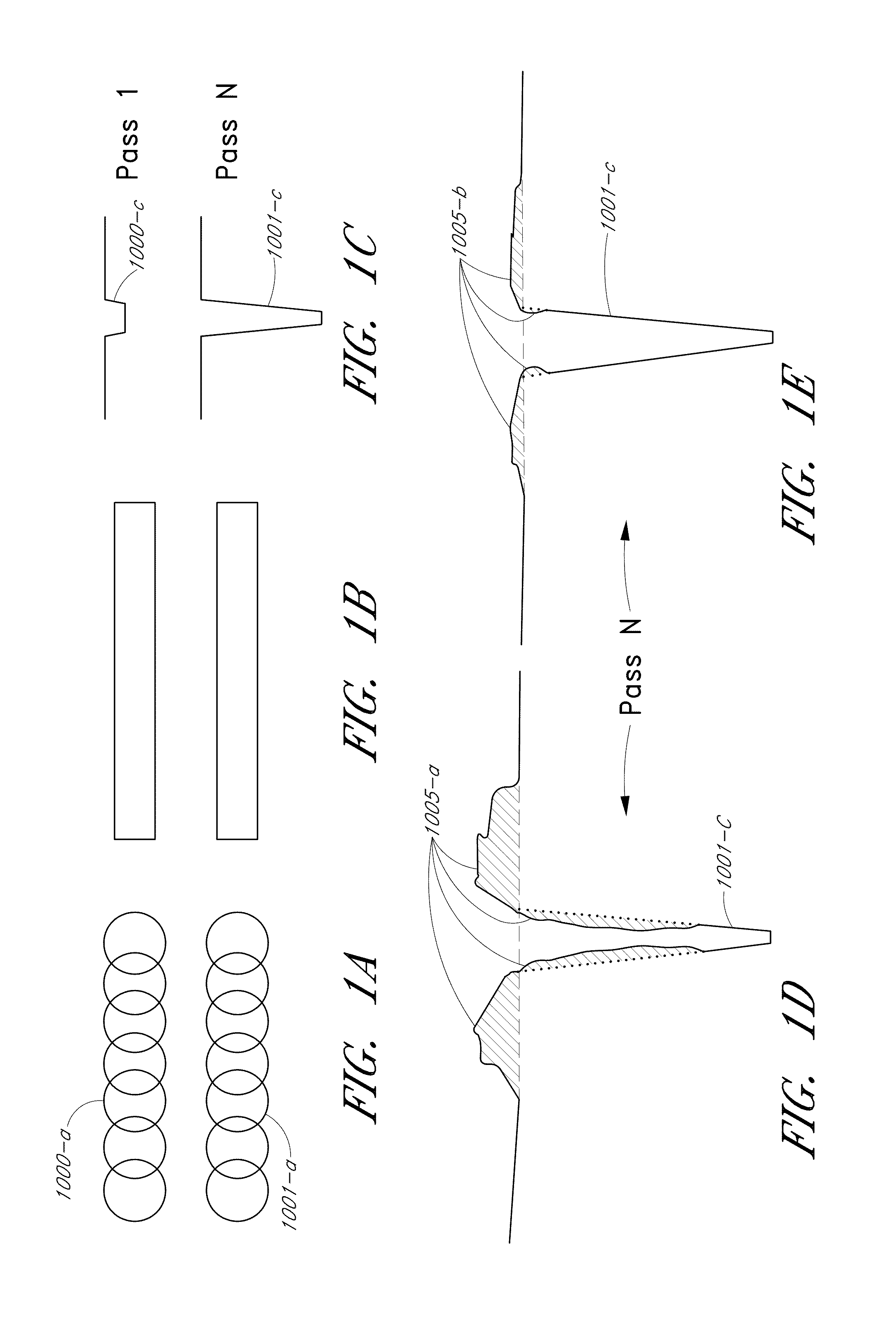

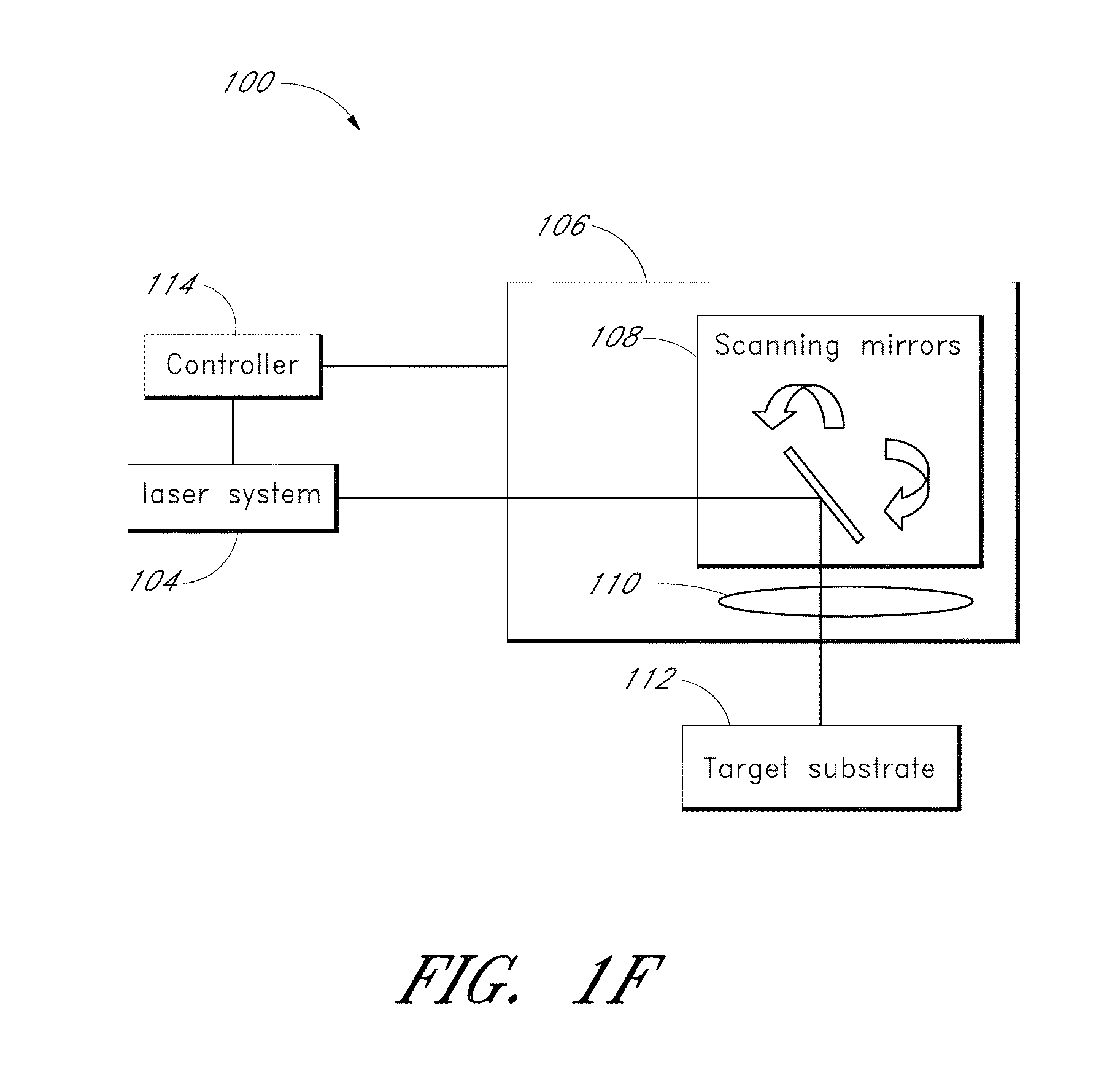

Laser-based material processing methods and systems

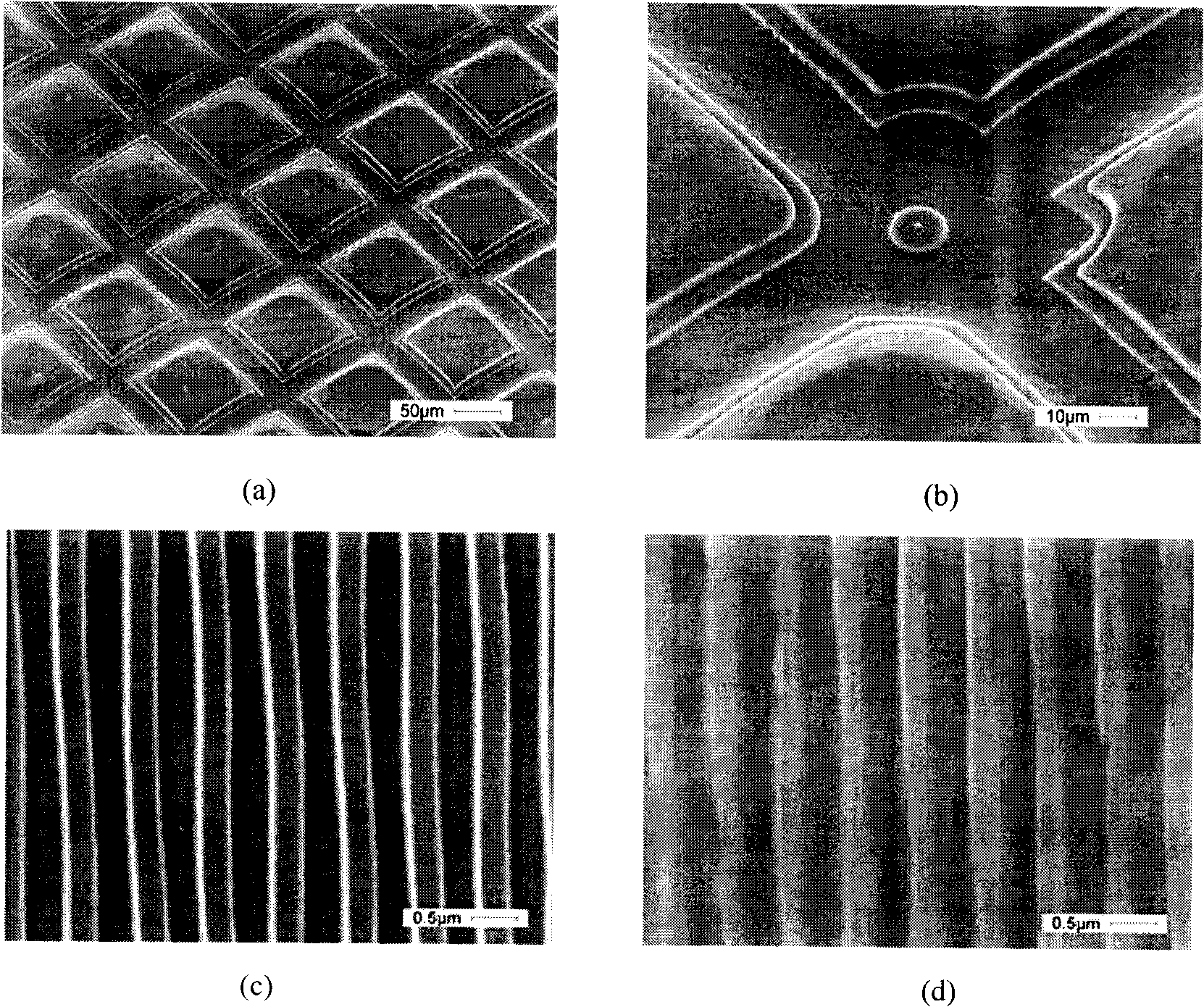

ActiveUS8158493B2Avoid insufficient heatingAvoid layeringSemiconductor/solid-state device manufacturingWelding/soldering/cutting articlesDielectricPicosecond

Various embodiments may be used for laser-based modification of target material of a workpiece while advantageously achieving improvements in processing throughput and / or quality. Embodiments of a method of processing may include focusing and directing laser pulses to a region of the workpiece at a pulse repetition rate sufficiently high so that material is efficiently removed from the region and a quantity of unwanted material within the region, proximate to the region, or both is reduced relative to a quantity obtainable at a lower repetition rate. Embodiments of an ultrashort pulse laser system may include at least one of a fiber amplifier or fiber laser. Various embodiments are suitable for at least one of dicing, cutting, scribing, and forming features on or within a semiconductor substrate. Workpiece materials may also include metals, inorganic or organic dielectrics, or any material to be micromachined with femtosecond, picosecond, and / or nanosecond pulses.

Owner:IMRA AMERICA

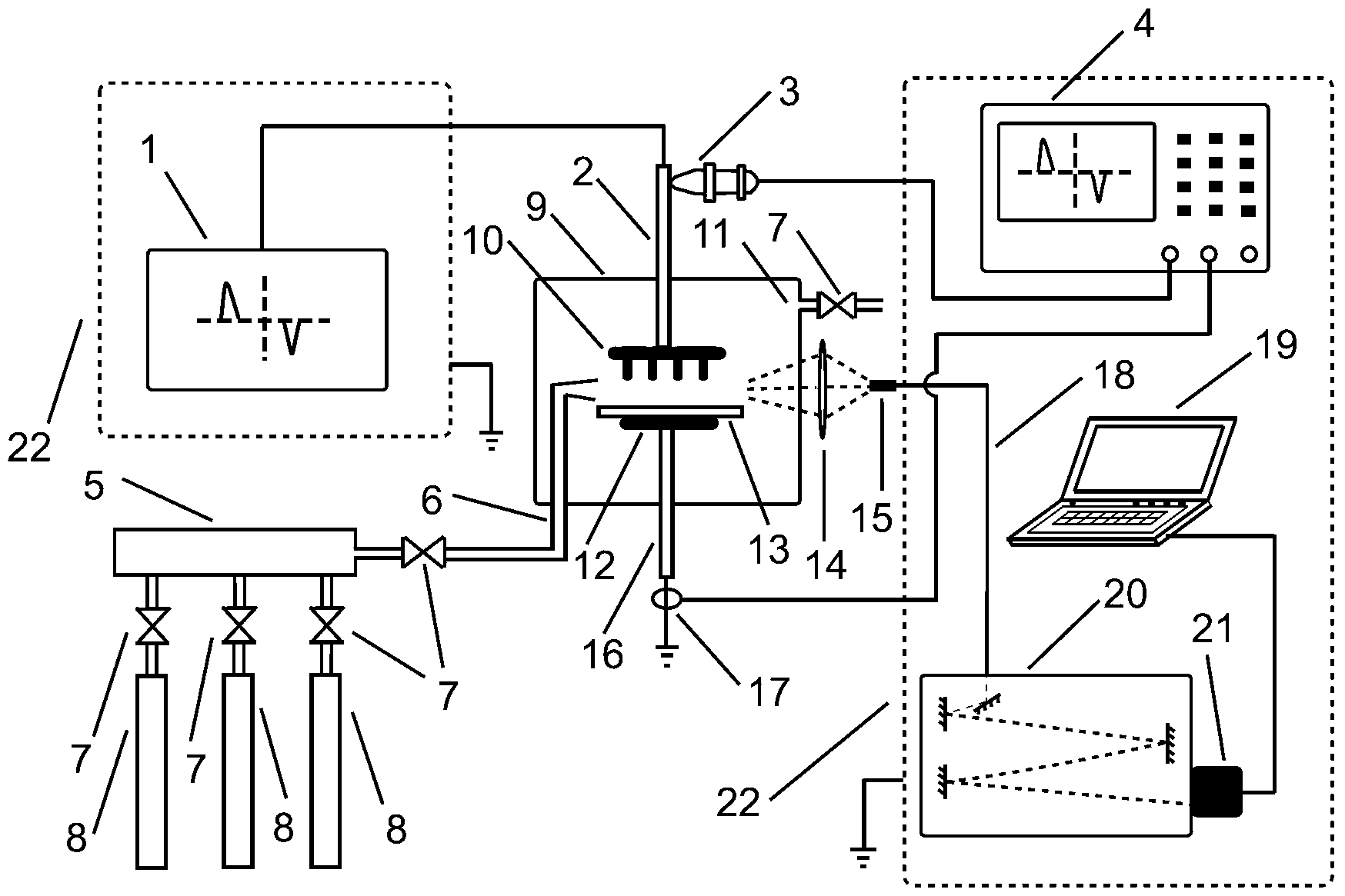

Experimental apparatus for acquiring large-area uniform discharge plasmas

InactiveCN103245655AIncrease electron densityImprove energy utilizationAnalysis by thermal excitationPlasma techniqueDischarge measurementsElectron density

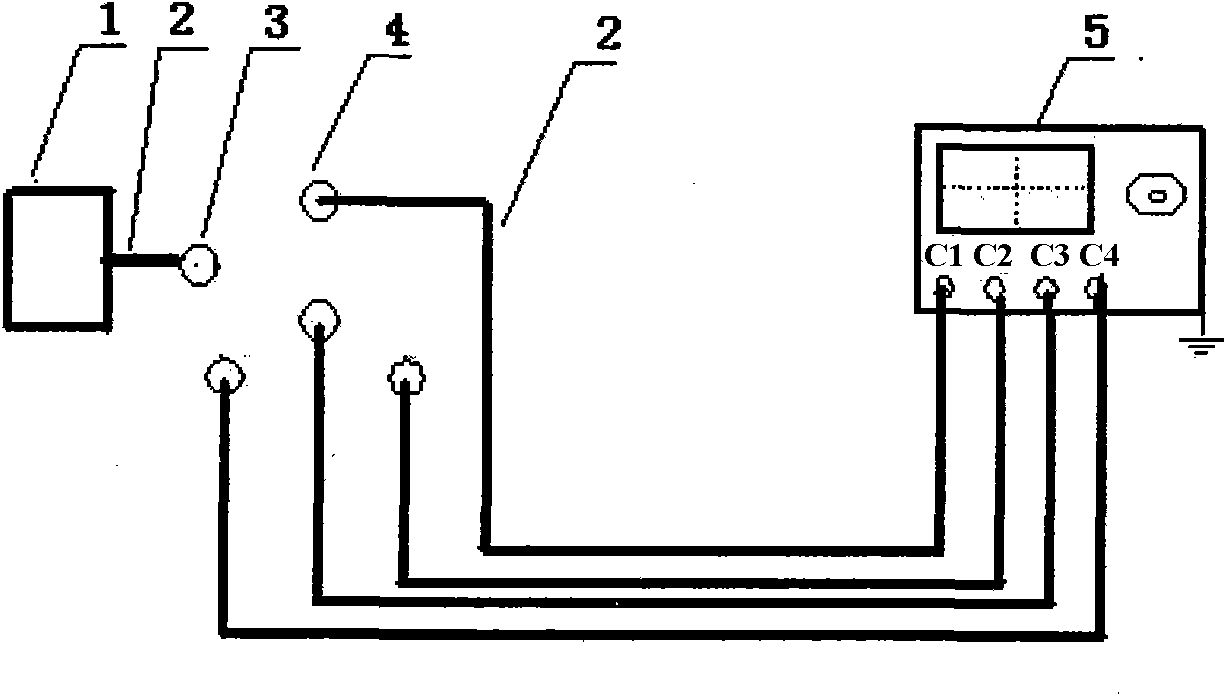

The invention relates to an experimental apparatus for acquiring large-area uniform discharge plasmas, which belongs to the technical field of plasmas. The experimental apparatus comprises a bipolar nanosecond pulse power supply, a reactor, multi-needle-to-plate electrodes, a gas distribution system, a spectral measurement system and a discharge measurement system, wherein the bipolar nanosecond pulse power supply drives dielectric barrier discharge of air and other gas mixtures among the multi-needle-to-plate electrodes in the reactor, and the gas mixtures are input to the reactor through the gas distribution system; the spectral measurement system collects photonic information of plasma discharge in real time and inputs the photonic information to a computer for spectral analysis; and the discharge measurement system collects discharge voltage and current of the high-voltage nanosecond pulse power supply in real time, and the discharge voltage and current are displayed through a digital oscilloscope. By virtue of the bipolar nanosecond narrow-pulse power supply, the large-area discharge plasmas are generated without a magnetic field; and the generated plasmas are uniform, diffusive, high in electron density, high in energy utilization ratio, low in energy consumption and easy to control in a discharge process.

Owner:DALIAN UNIV OF TECH

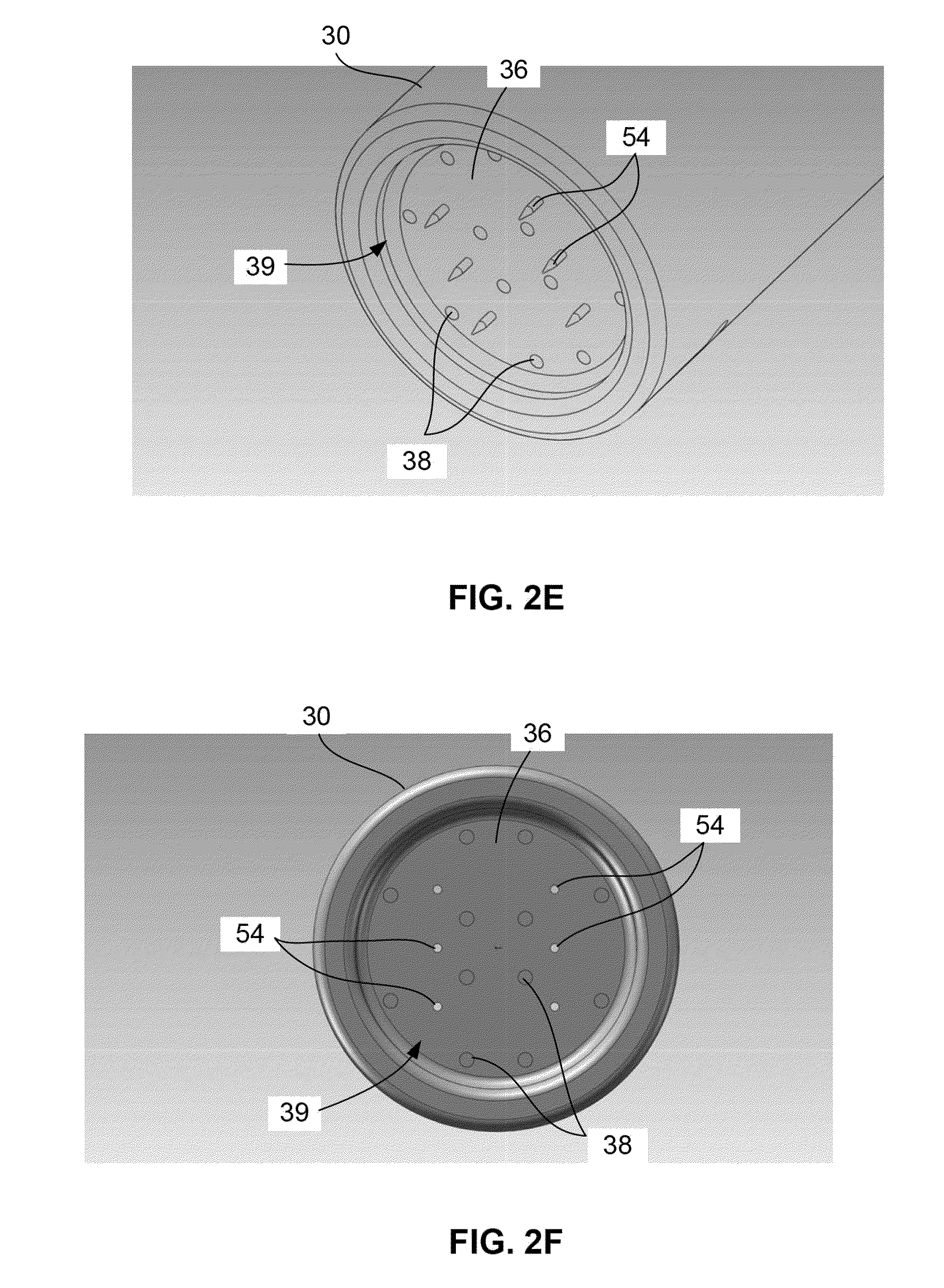

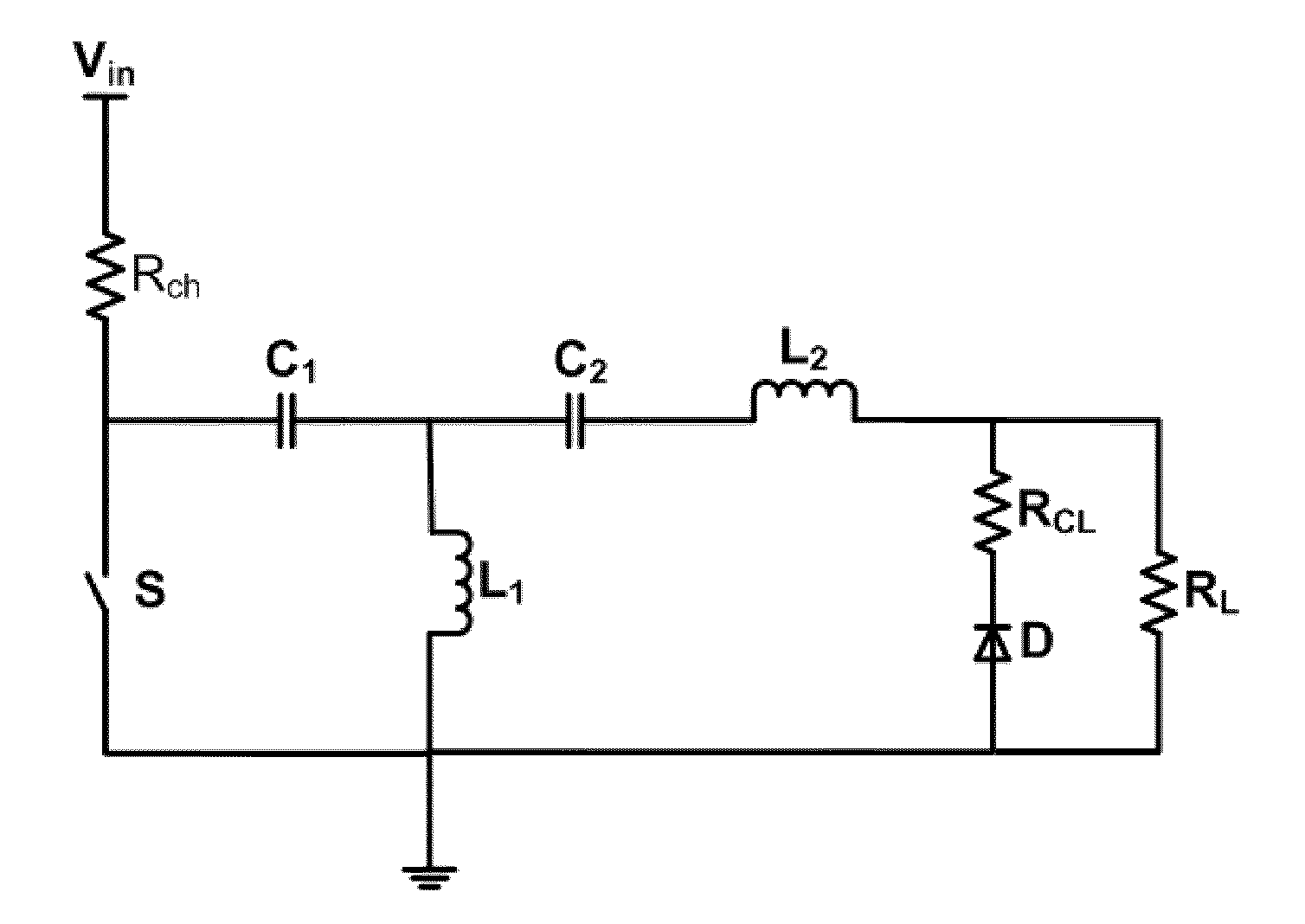

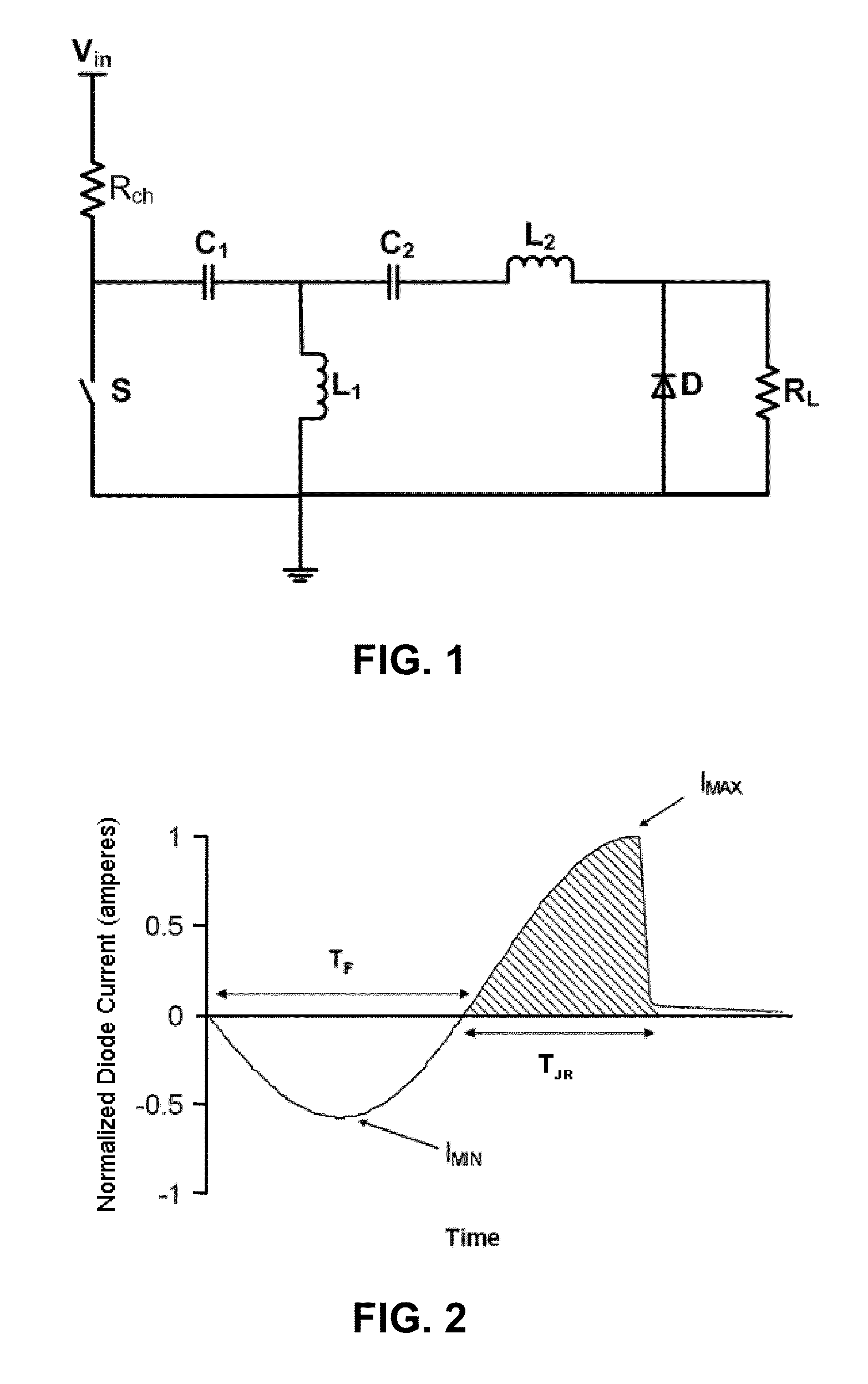

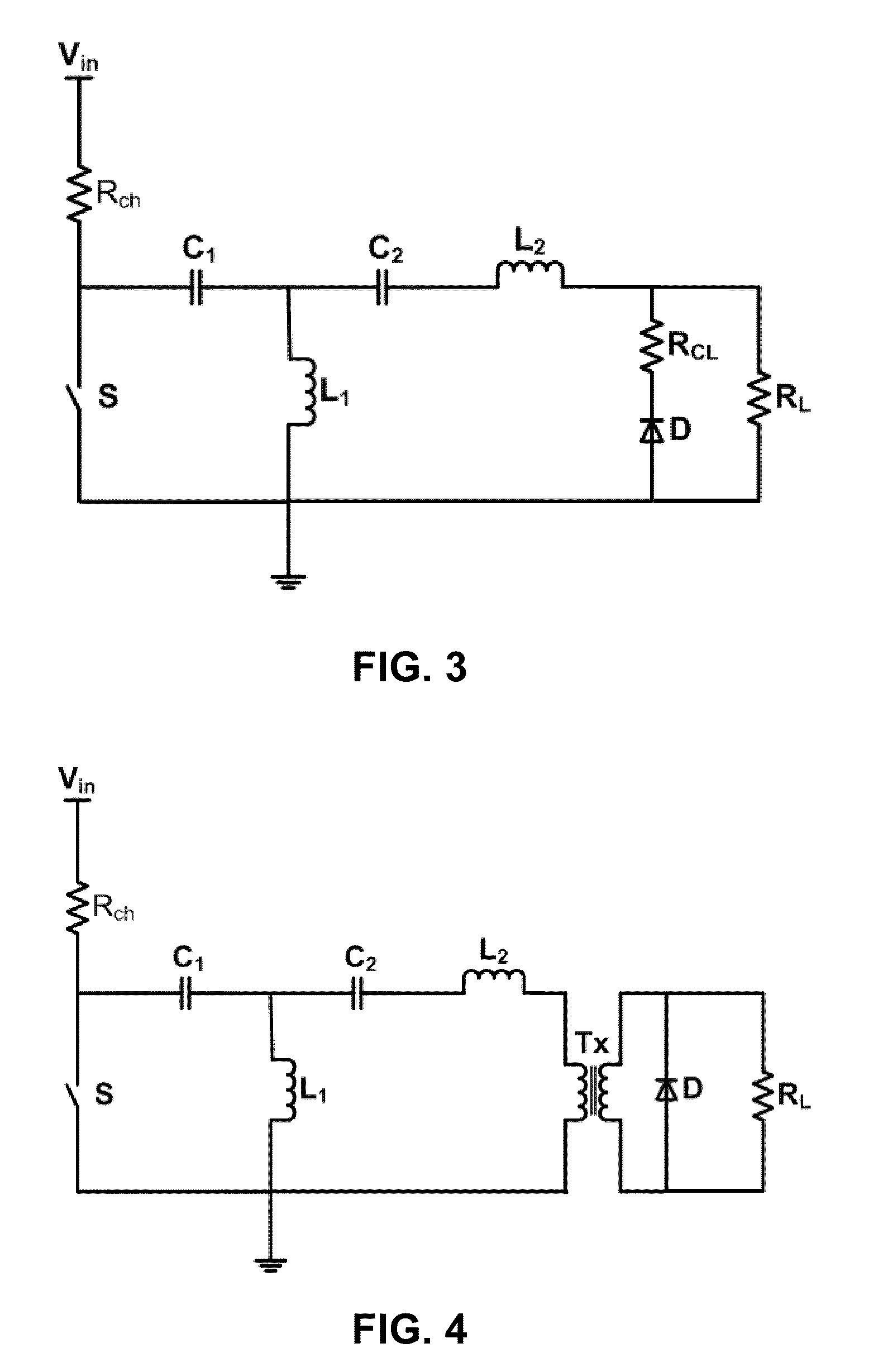

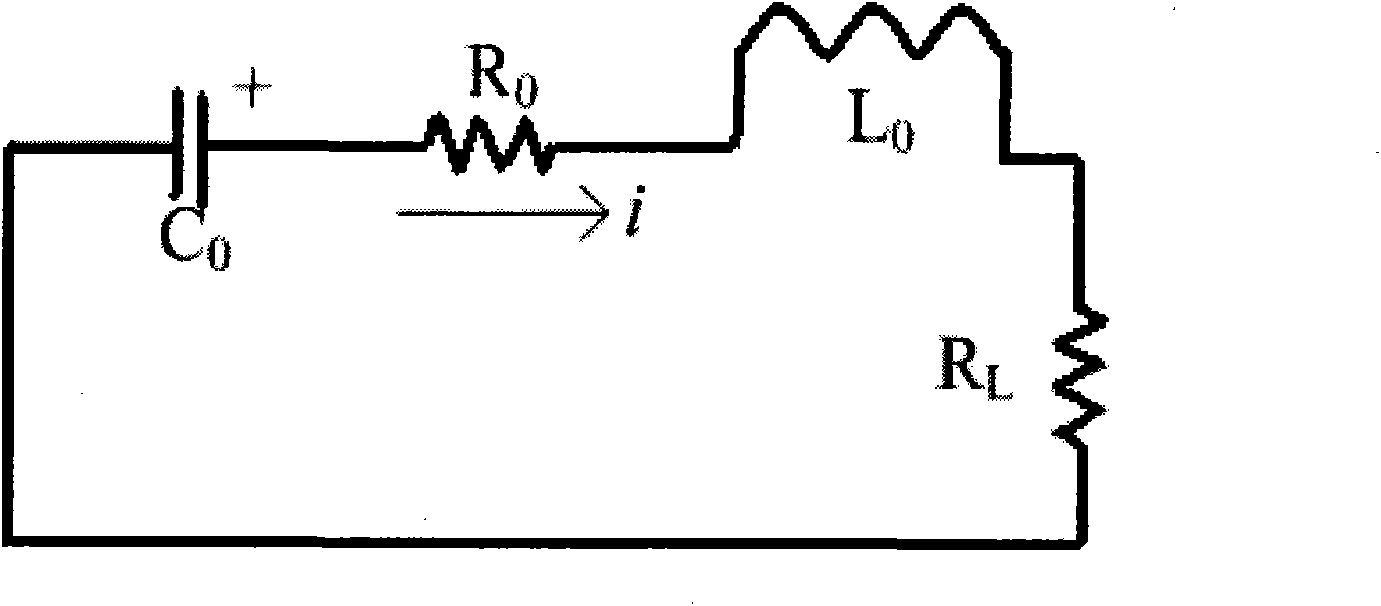

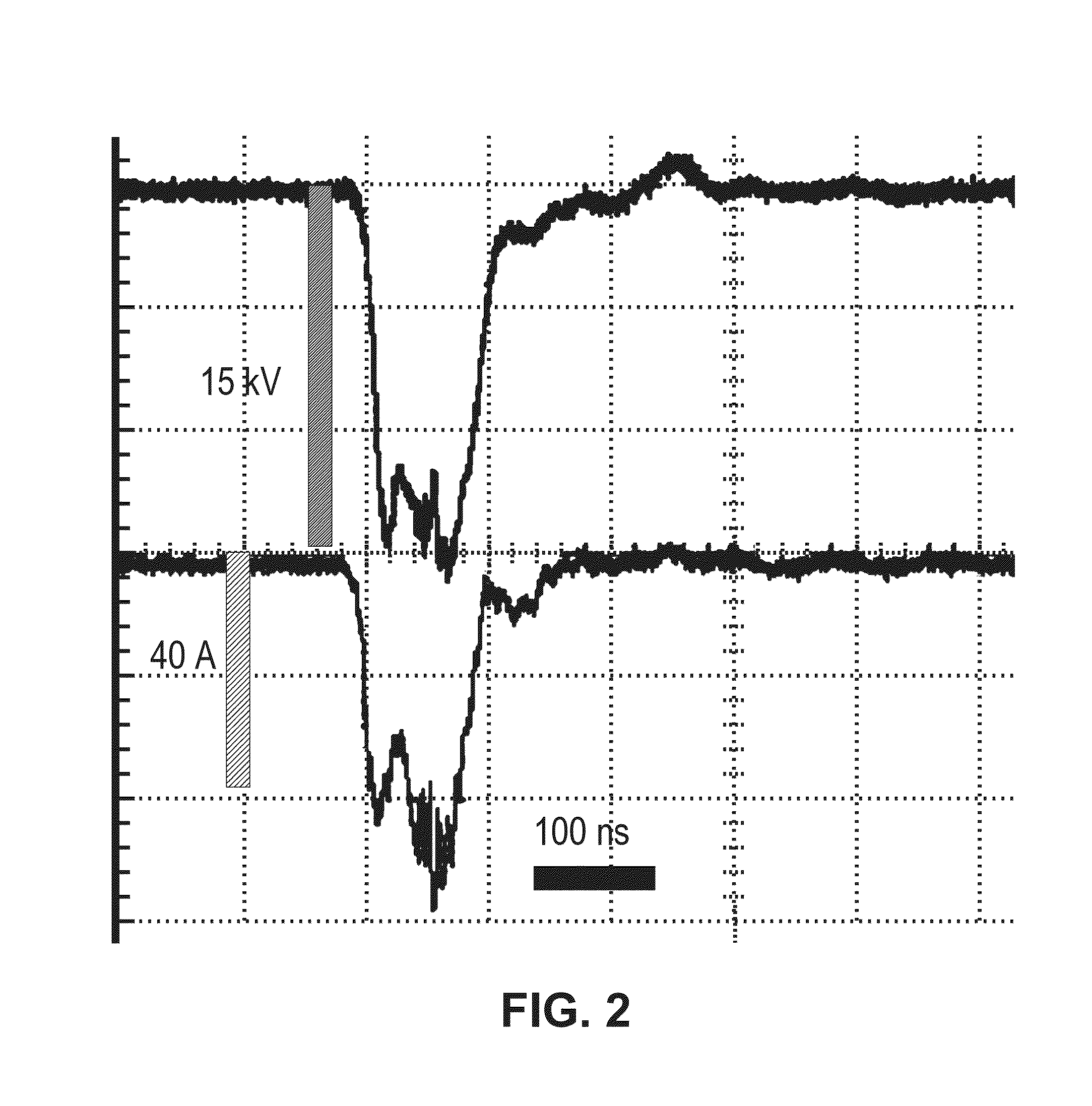

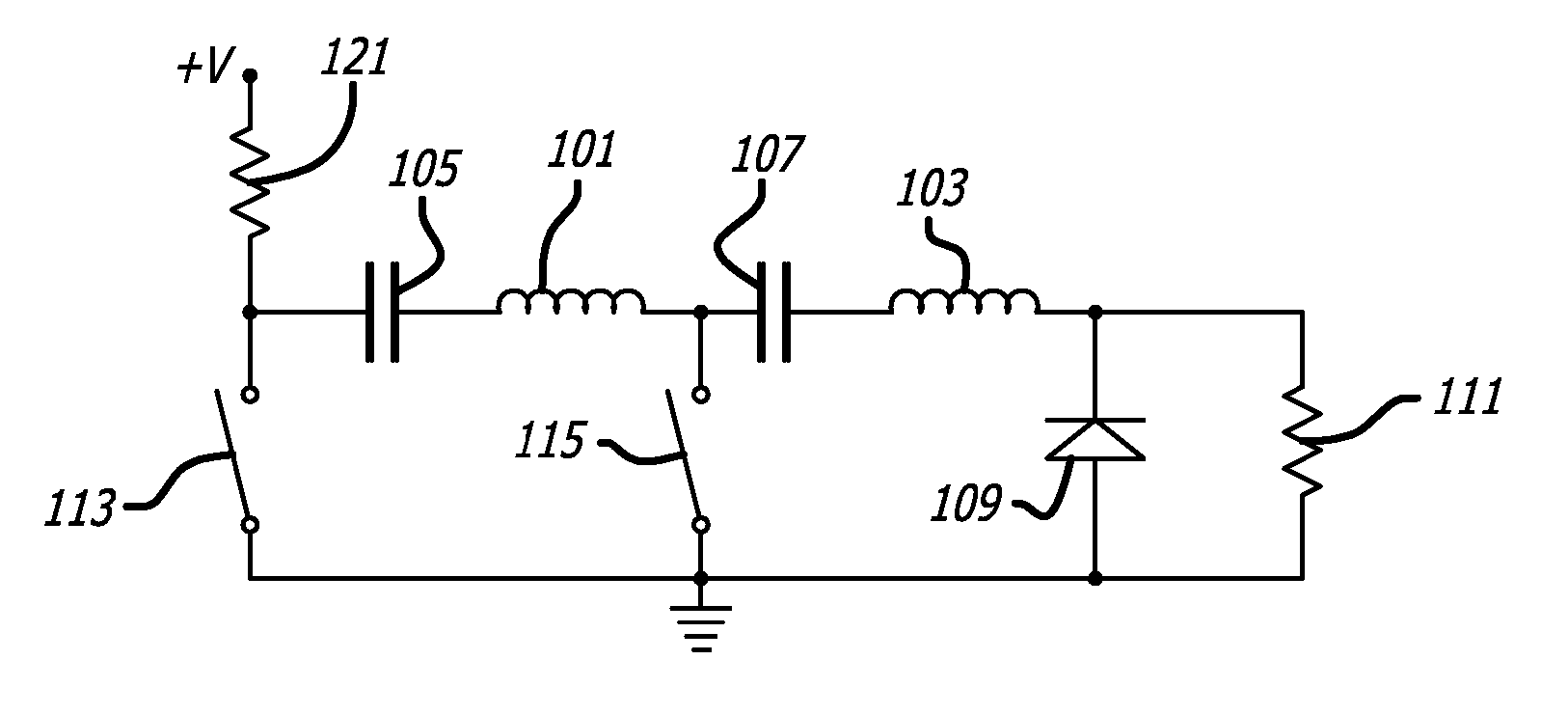

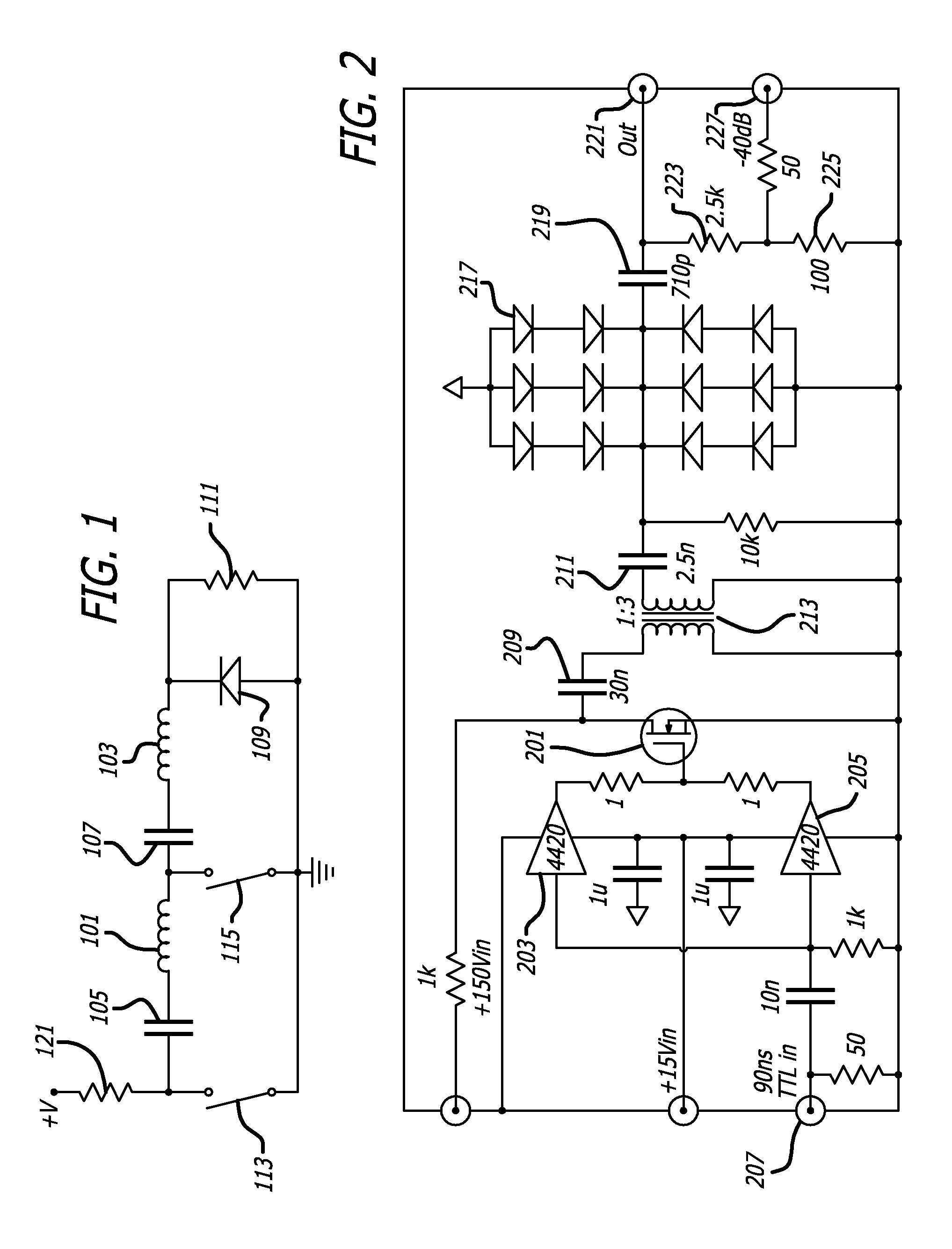

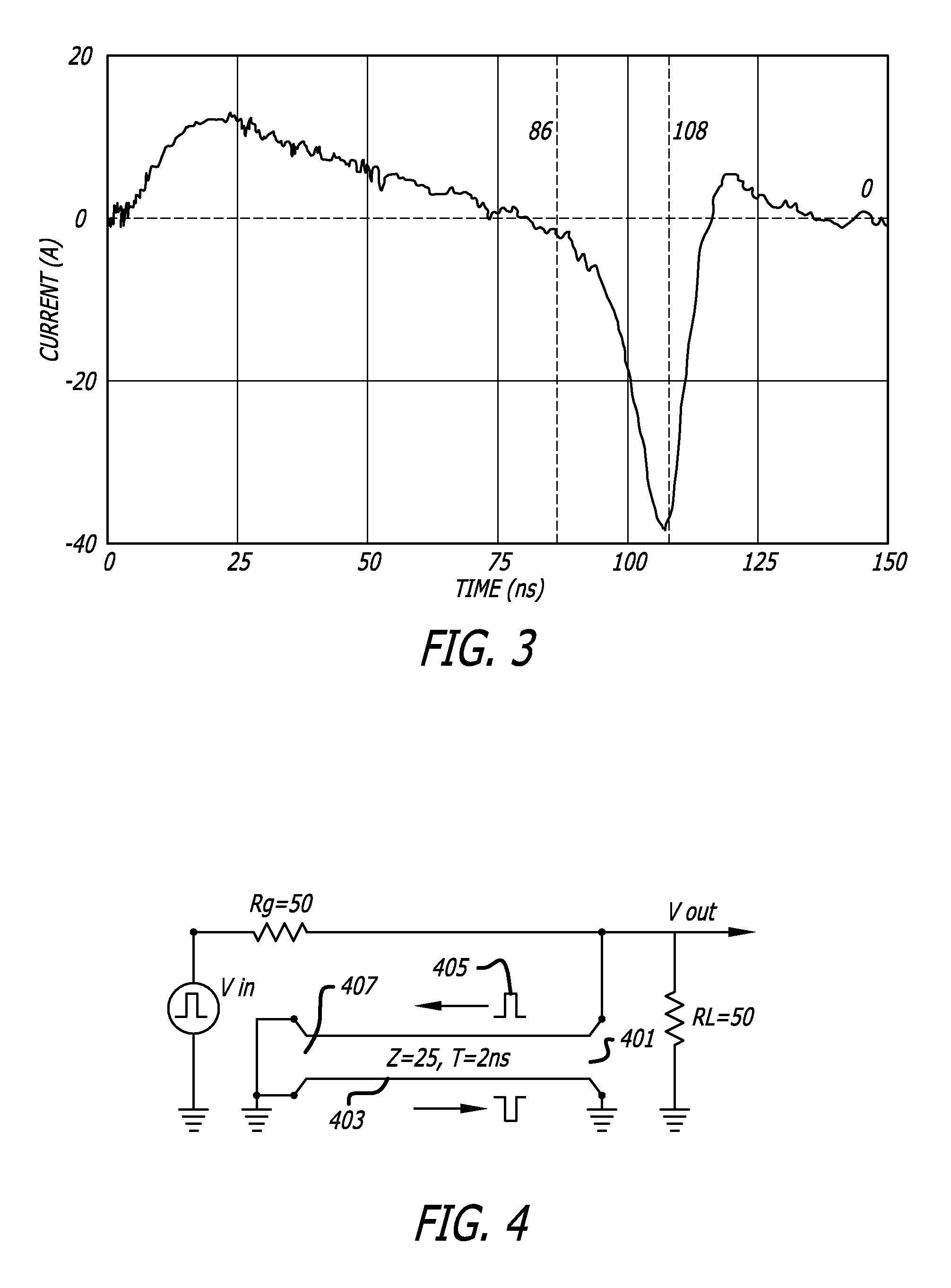

Nanosecond pulse generator

ActiveUS20100038971A1DiodePulse generation by energy-accumulating elementFull width at half maximumPhysics

This invention relates to a pulse generator circuit for delivering a short high current pulse to a load. This pulse generator comprises a junction recovery diode, a switch, a first resonant circuit and a second resonant circuit. The diode may be configured to store charges in its depletion layer when there is a forward flow of a current and to rapidly switch open after the depletion layer is discharged by a reverse flow of a current. After the diode rapidly switch opens, the pulse generator may provide a reverse current to the load. This pulse generator may be configured to generate at least one pulse that is having a length of no more than 100 nanoseconds at the full-width-at-half-maximum and an amplitude of at least 1 kilovolt. Electrodes may be connected to the pulse generator to deliver one pulse or plurality of pulses to biological cells such as tumor cells.

Owner:ALFRED E MANN INST FOR BIOMEDICAL ENG AT THE UNIV OF SOUTHERN CALIFORNIA

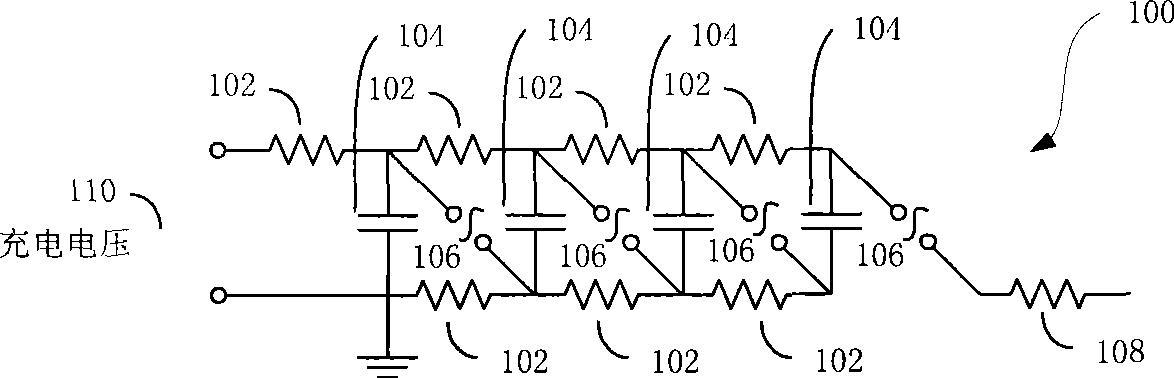

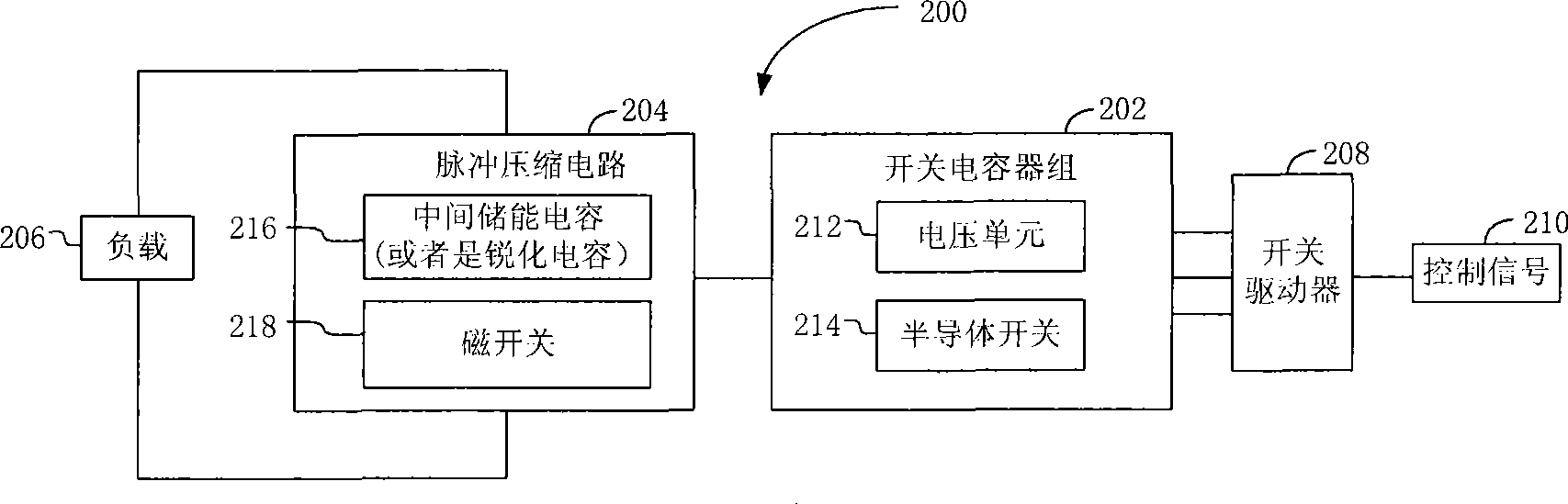

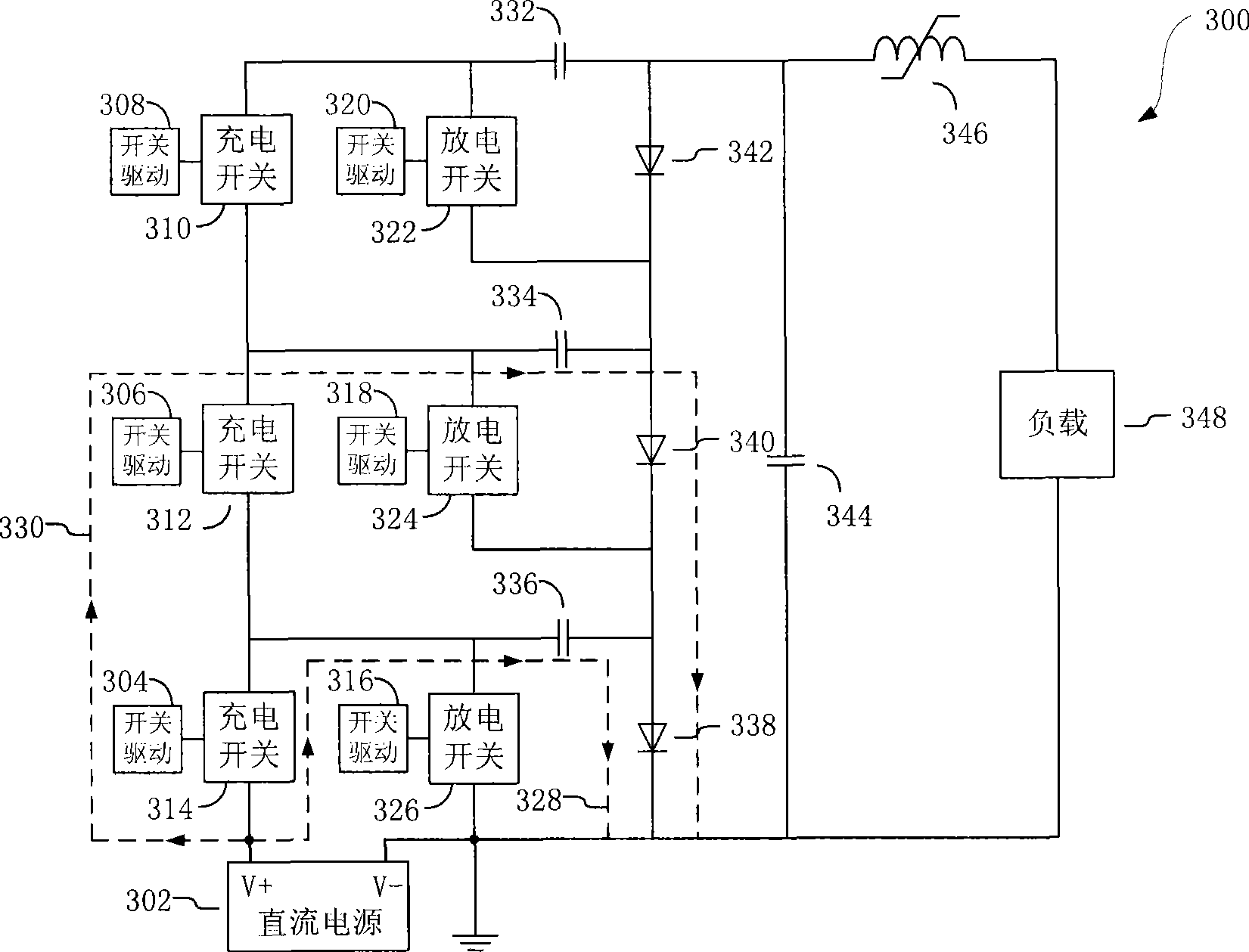

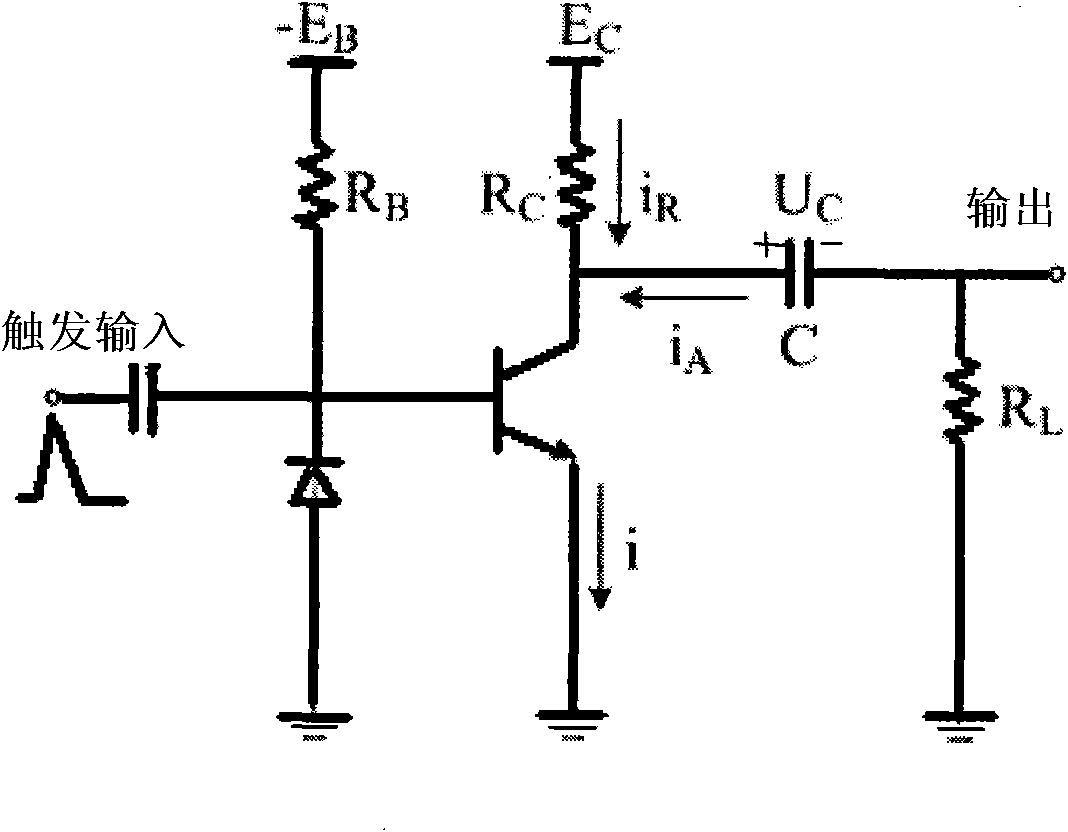

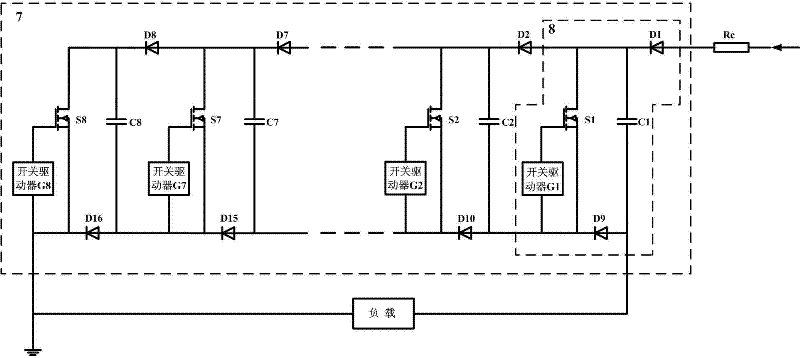

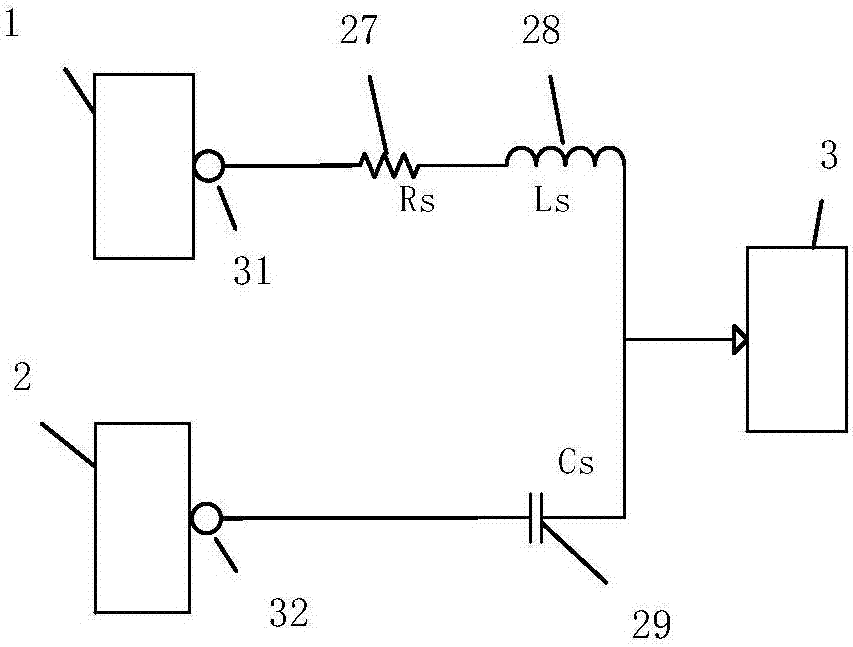

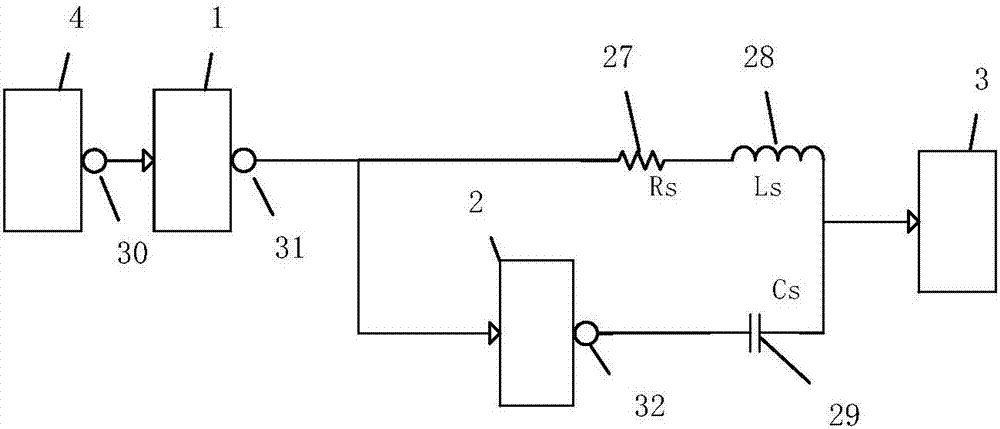

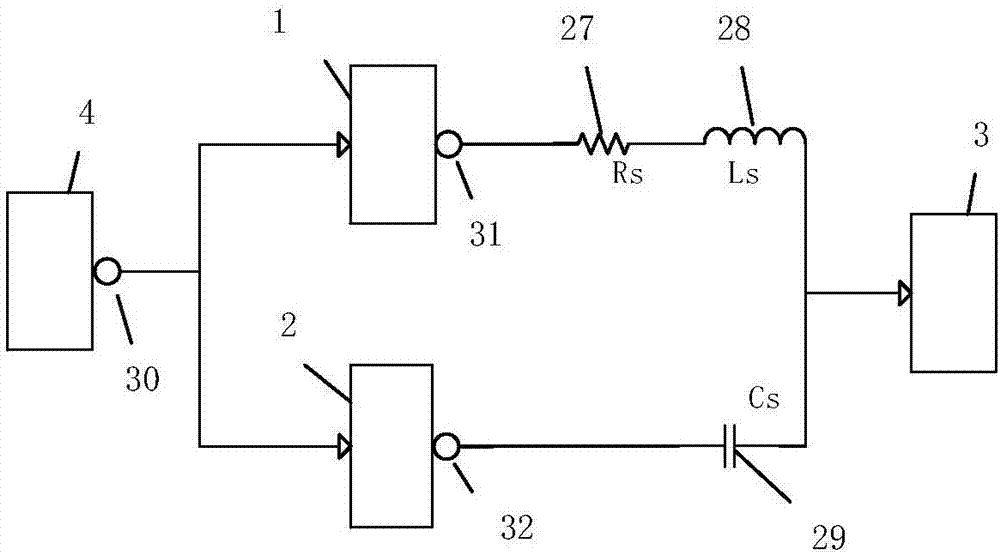

All solid state high voltage nanosecond pulse power supply

The invention belongs to the technical field of the power supply, in particular to an all solid state high voltage nanosecond pulse power supply. The power supply is divided into the following two parts: a series voltage booster circuit and a pulse compression circuit, wherein the series voltage booster circuit consists of a series of voltage units which are connected in series to realize the function of voltage boost; each voltage unit is provided with a capacitor connected with a switch which can be connected and disconnected, and capacitors of the series of the voltage units form a capacitor unit; one part in the switch is a charge switch to charge the capacitors in parallel, while the other part is a discharge switch to discharge the capacitors in series; the pulse compression circuit is connected with a magnetic switch in a series connection mode by an energy storage capacitor or a sharpening capacitor. The power supply reduces system volume to connect more voltage units in series, and uses a direct current charge power supply with lower voltage to charge a pulse generator; the adopted switch device generator has longer service life and higher frequency; and the used magnetic switch reduces rise time of voltage pulse output by a Marx circuit, and is free of maintenance and has low failure rate.

Owner:FUDAN UNIV

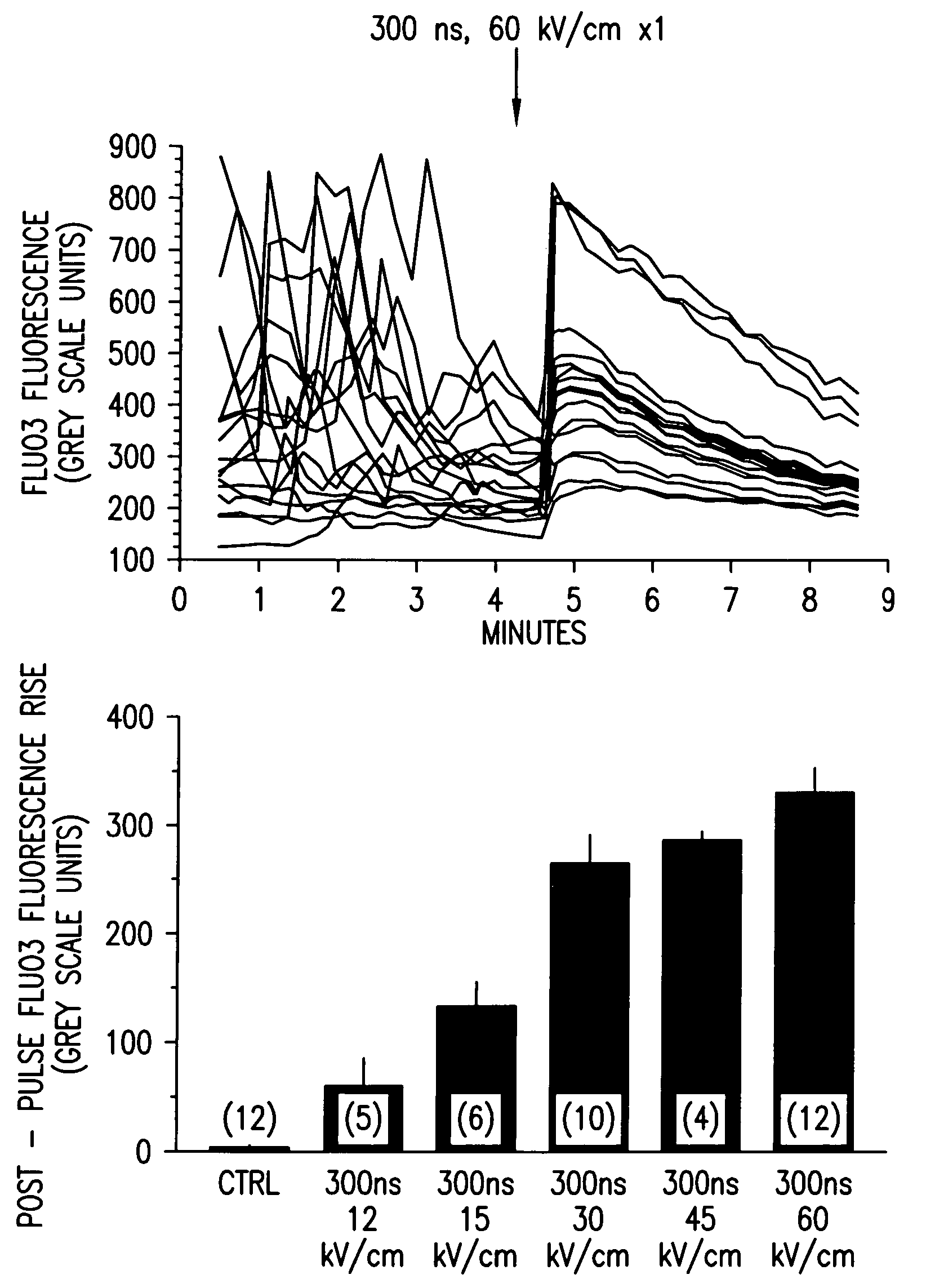

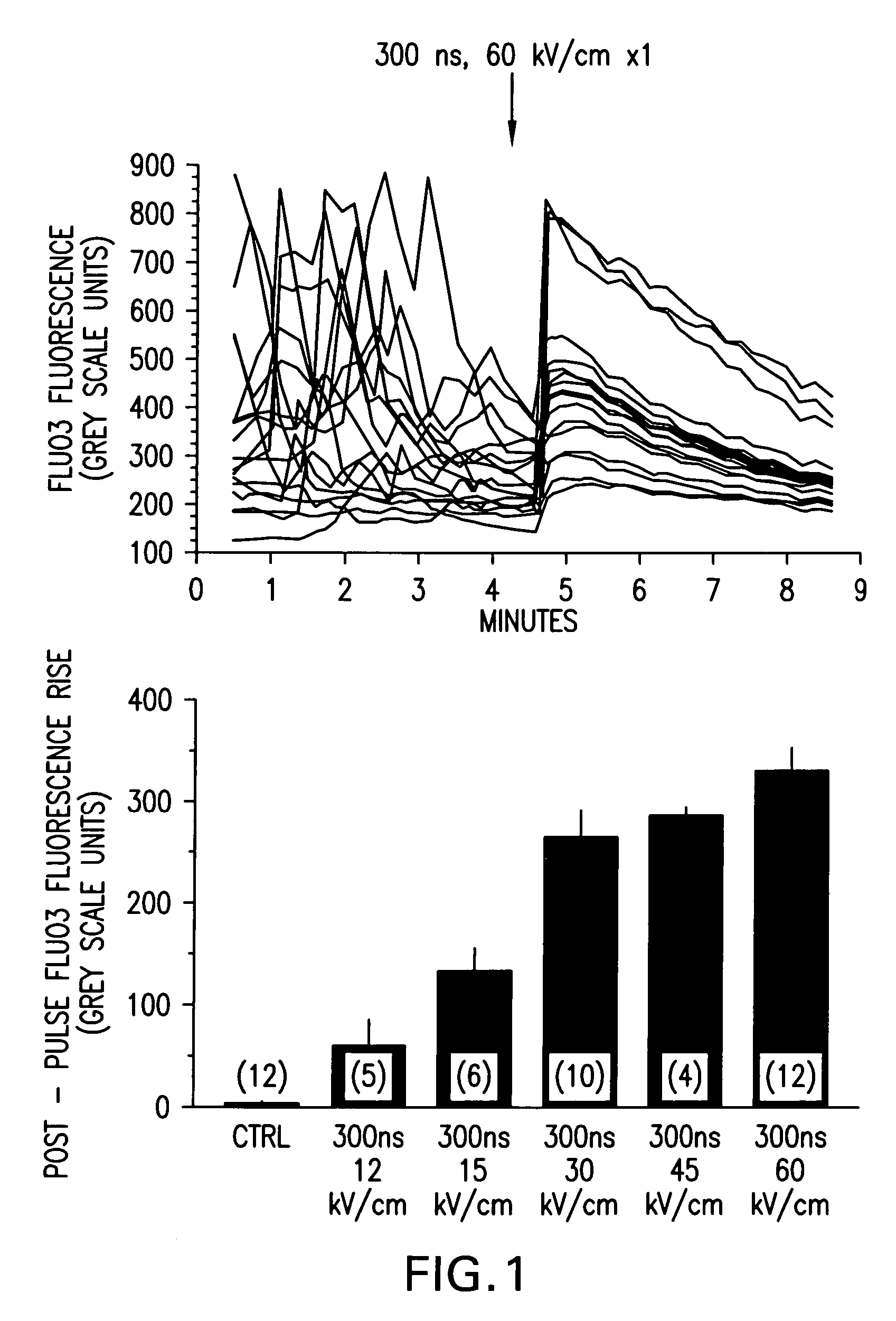

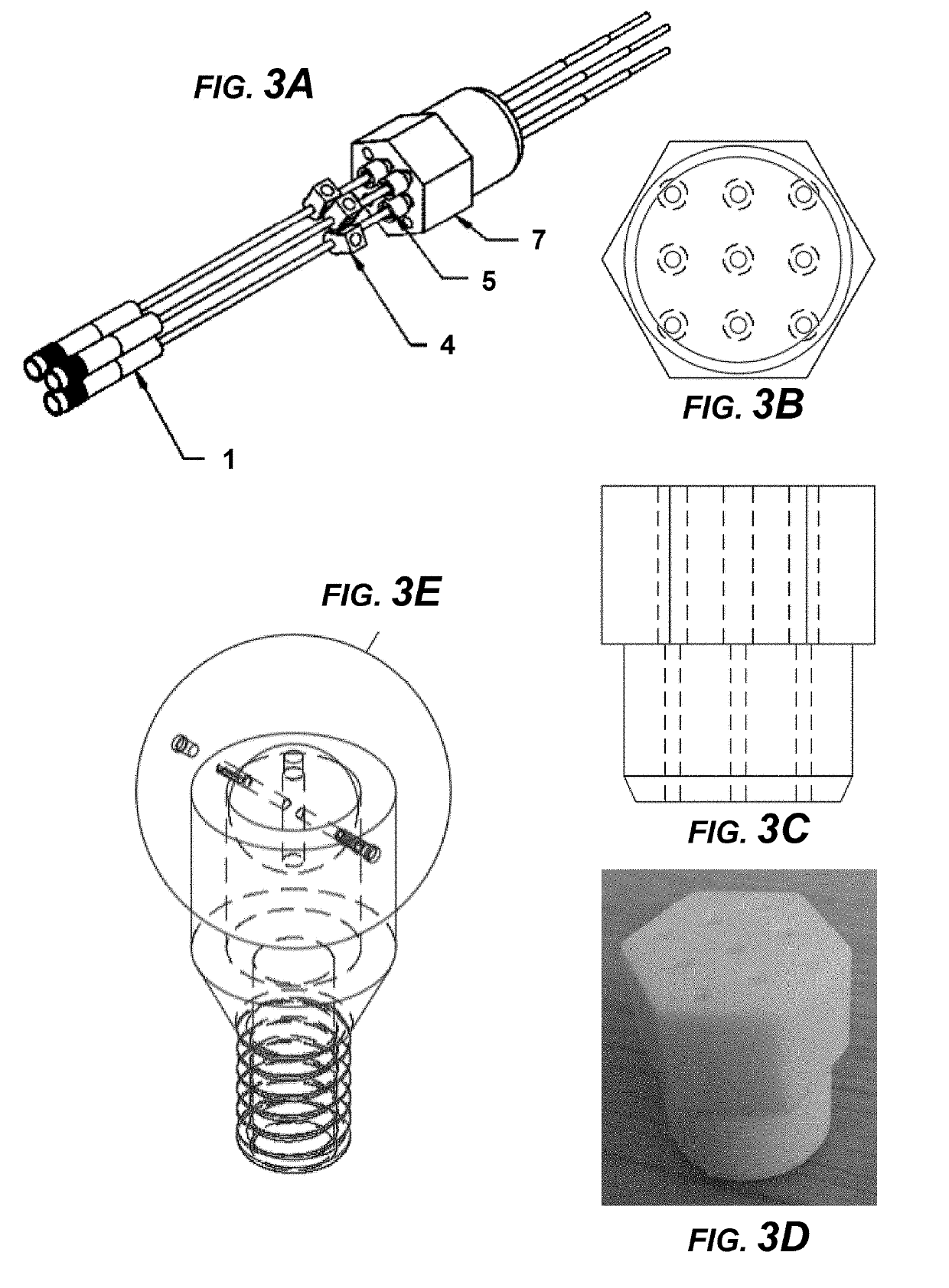

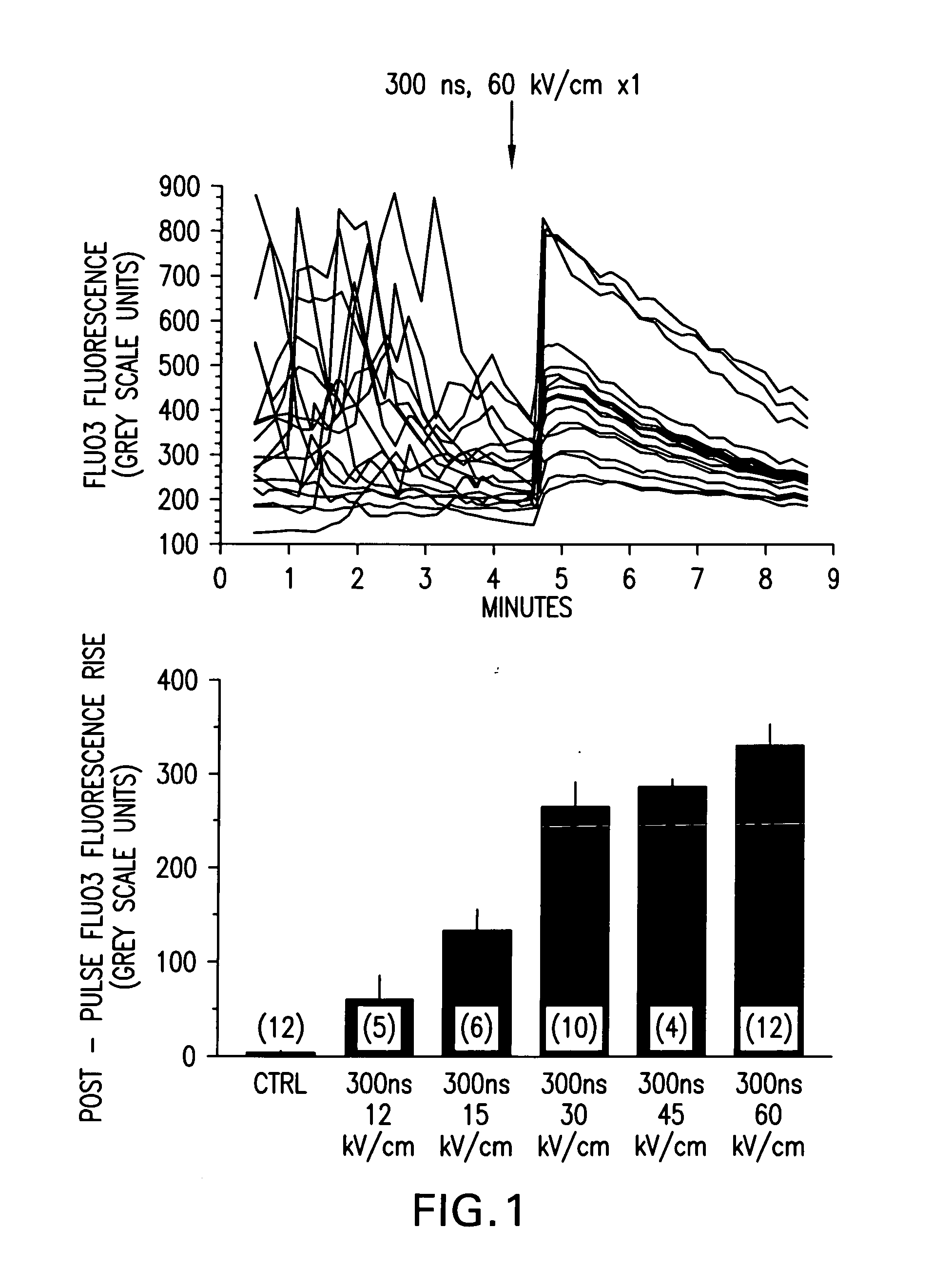

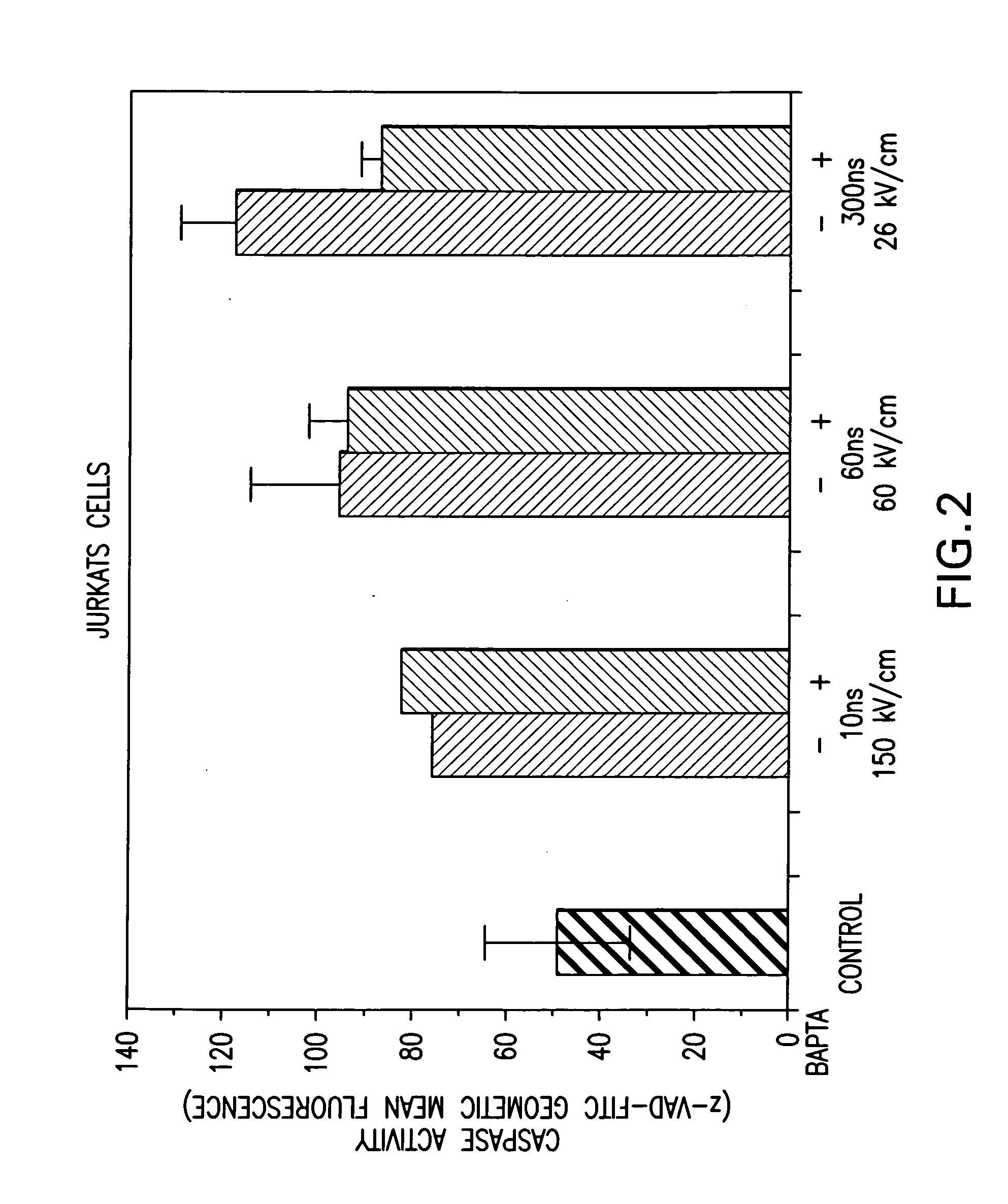

Activation of calcium-mediated cell functions in cells and tissues, including aggregation of human platelets. by nanosecond pulsed electric fields

Methods for inducing calcium mobilization in cells through the application of nanosecond pulsed electric fields (“nsPEFs”) are provided. The invention also provides a method of increasing intracellular calcium in cells through the application of nsPEFs. In one embodiment of the invention, the cells are human platelets, whereby activation and aggregation of the platelets is induced. Methods for treating an injury, trauma, or loss of blood in a subject, through the application of nsPEFs are also provided.

Owner:EASTERN VIRGINIA MEDICAL SCHOOL +1

Ultra-high frequency positioning and detection device of local discharge of electrical equipment and method thereof

InactiveCN101620253AWaveform repeatability is goodReduce distractionsTesting dielectric strengthElectric pulse generator circuitsInterference resistanceCoaxial cable

The invention relates to an ultra-high frequency positioning and detection device of local discharge of electrical equipment and a method thereof, belonging to the technical field of experiments of local discharge of the electrical equipment. The device comprises a steep-sided pulse generator, an ultra-high frequency antenna, a high frequency coaxial cable and a high sampling rate oscilloscope. The device is characterized in that the steep-sided pulse generator is a nanosecond pulse generator. The method performs the positioning computation by using the device and a computer through a program and a positioning principle based on the time difference method. The device has simple connection; nanosecond pulse signals generated by the steep-sided pulse generator can really simulate ultra-high frequency signals of the local discharge of the electrical equipment and have strong interference resistance and high accuracy of read time different signals, thereby improving the positioning accuracy. The invention can be widely applied to the experiment of the ultra-high frequency positioning detection of the local discharge of the electrical equipment.

Owner:CHONGQING UNIV

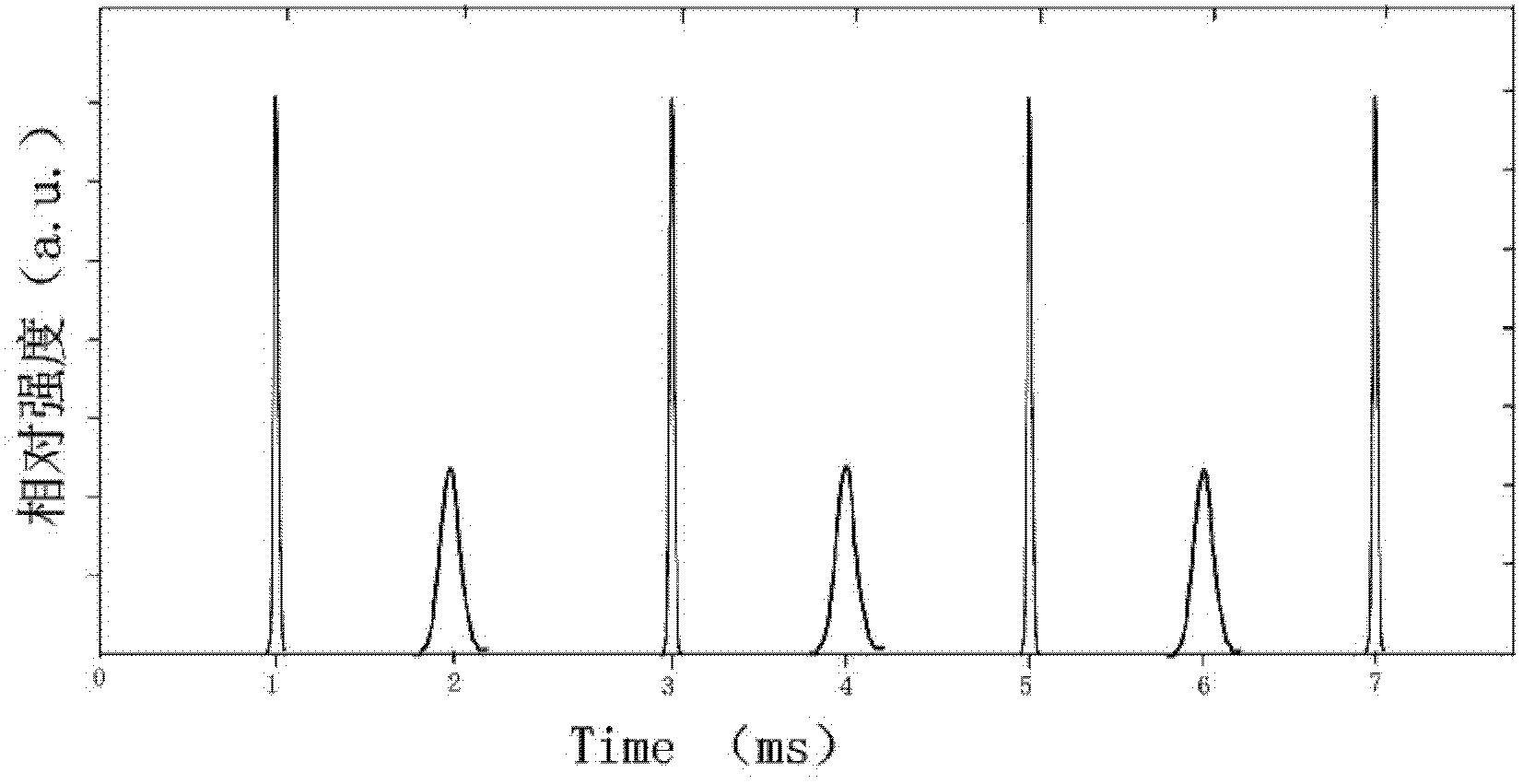

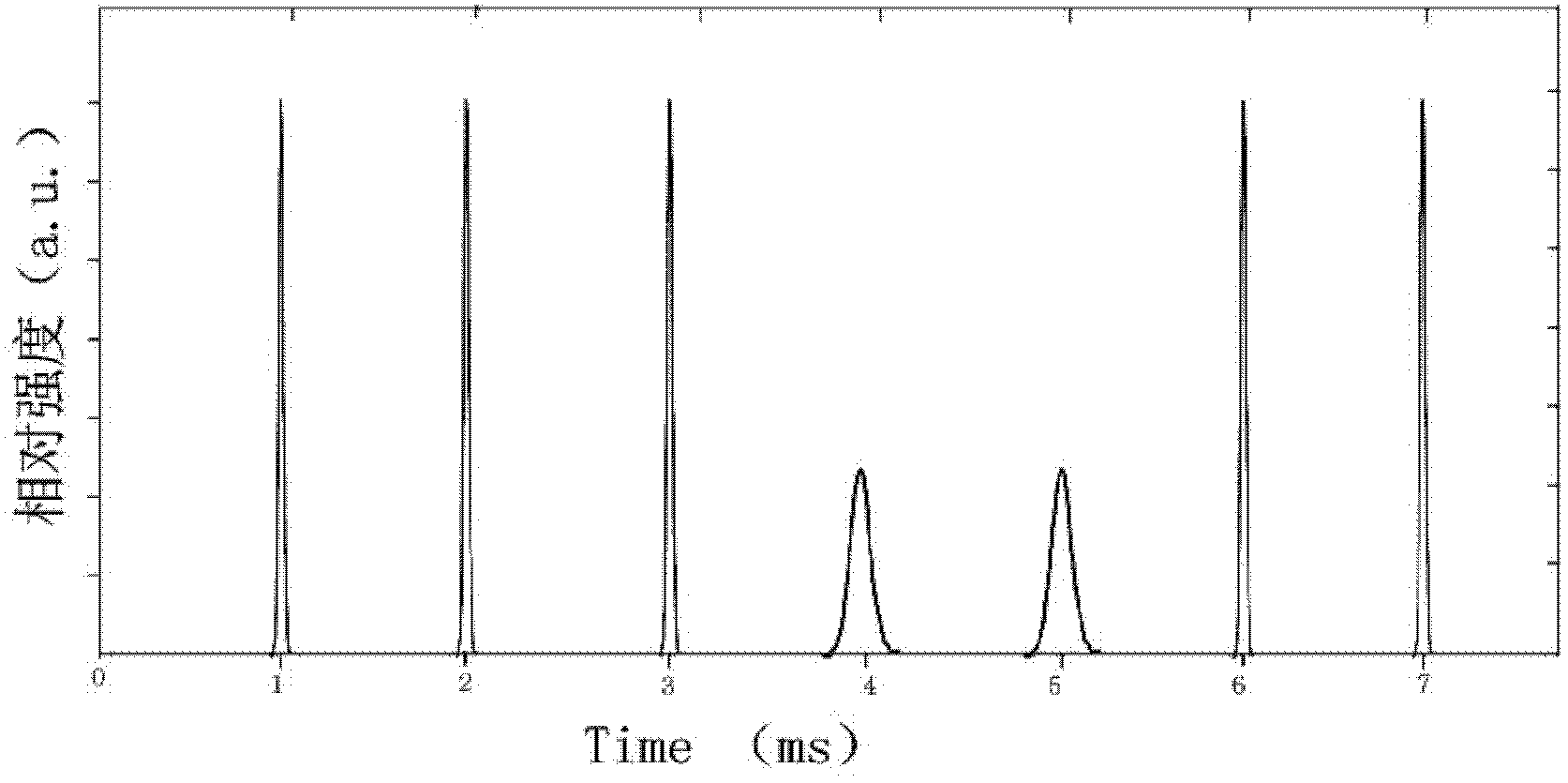

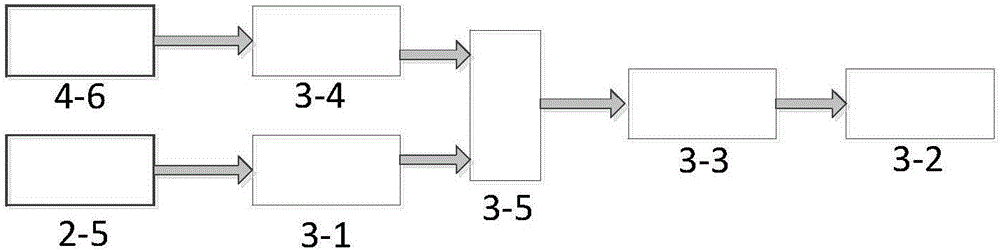

Laser capable of simultaneously outputting nanosecond pulses and pico-second pulses

ActiveCN102709801AImprove utilization efficiencyAvoid complexityLaser detailsChemical reactionHigh energy

The invention discloses a laser capable of simultaneously outputting nanosecond pulses and pico-second pulses. The laser comprises a signal source, a signal isolation system and an amplifier. According to the invention, with an electric light control technology of combining an extra-cavity Pockels cell and intra-cavity Pockels cell, a regenerative amplification process is realized in case of signal light importing so as to obtain high-energy pico-second laser output, and cavity empty process is also realized in case of no signal light importing so as to obtain nanosecond pulse output; and thefree combination of the two processes can be realized according to practical application demand, and as a result, free combination of numbers of the nanosecond pulses and the pico-second pulses in a single laser is realized and is output in an alternative way. The laser provided by the invention has an important application in high-precision high-efficiency fine processing field, as well as basicresearch fields such as plasma excitation, excited state control, chemical reaction control, special radiation excitation and the like.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

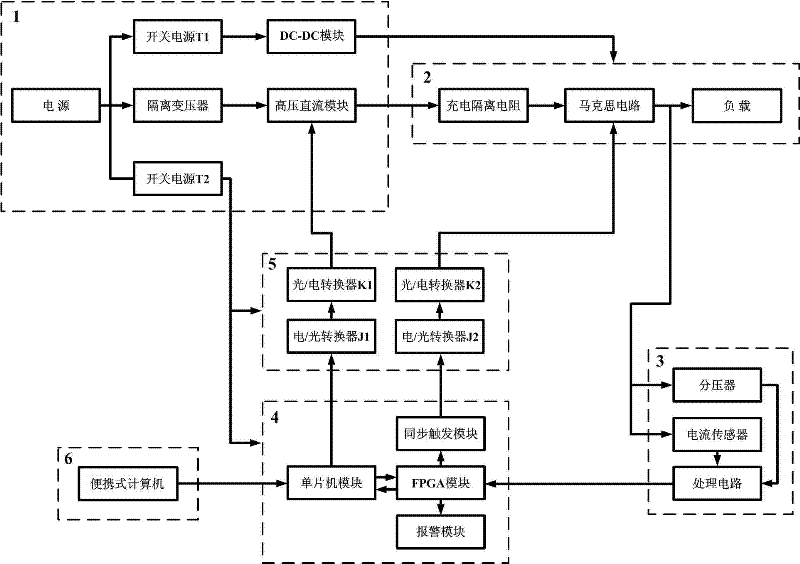

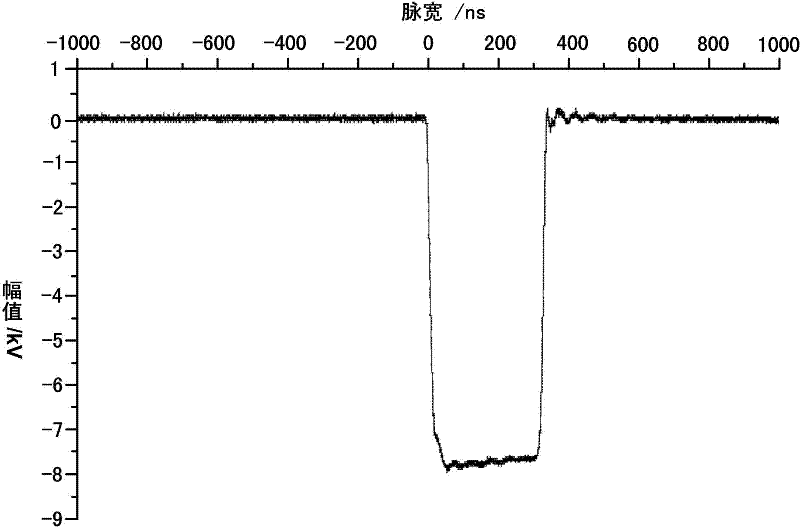

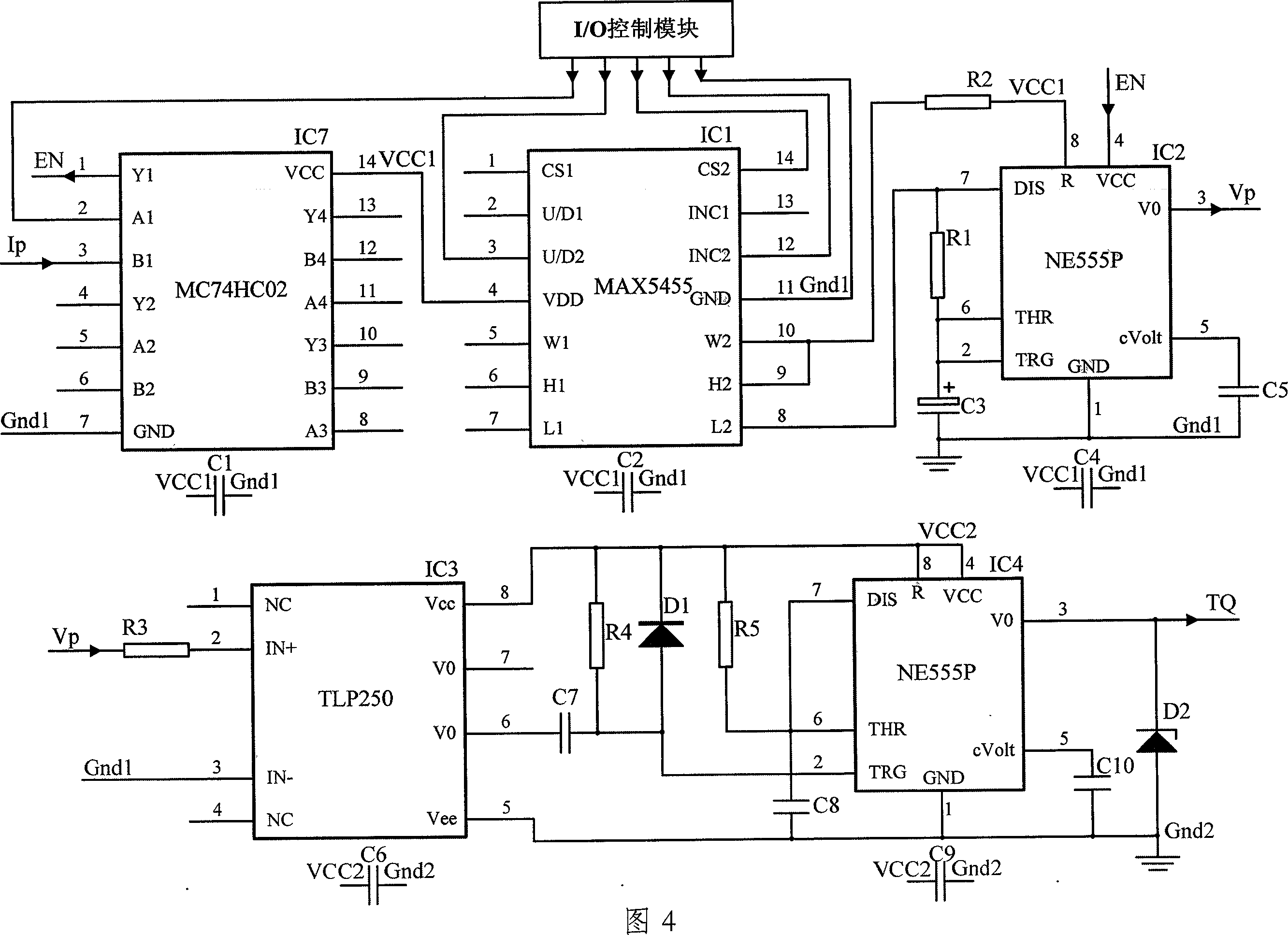

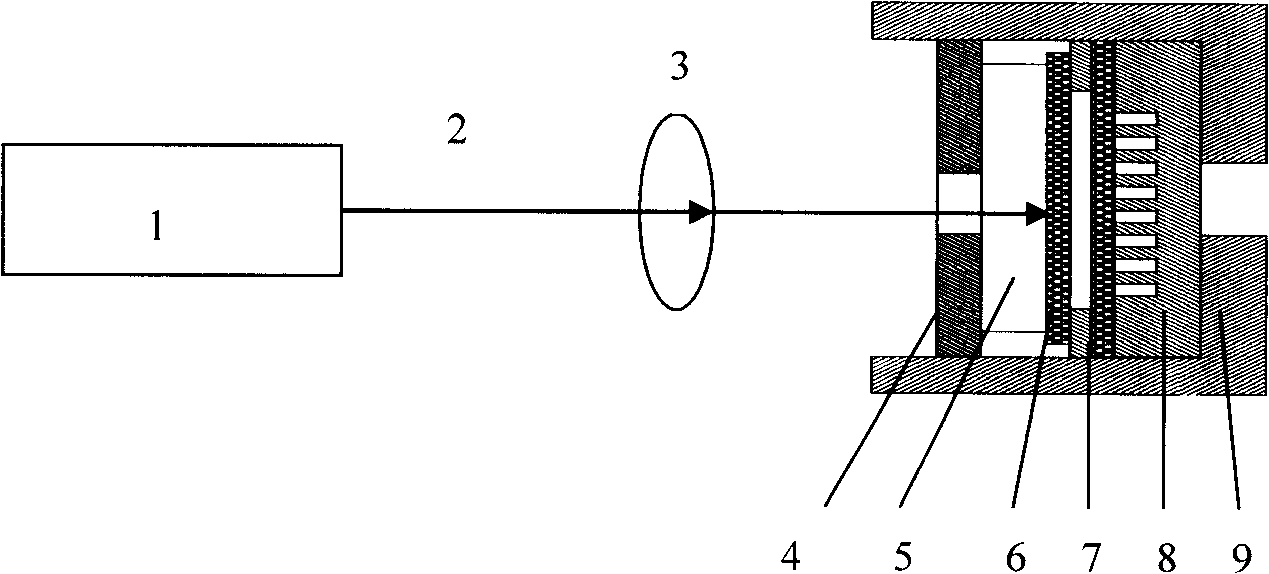

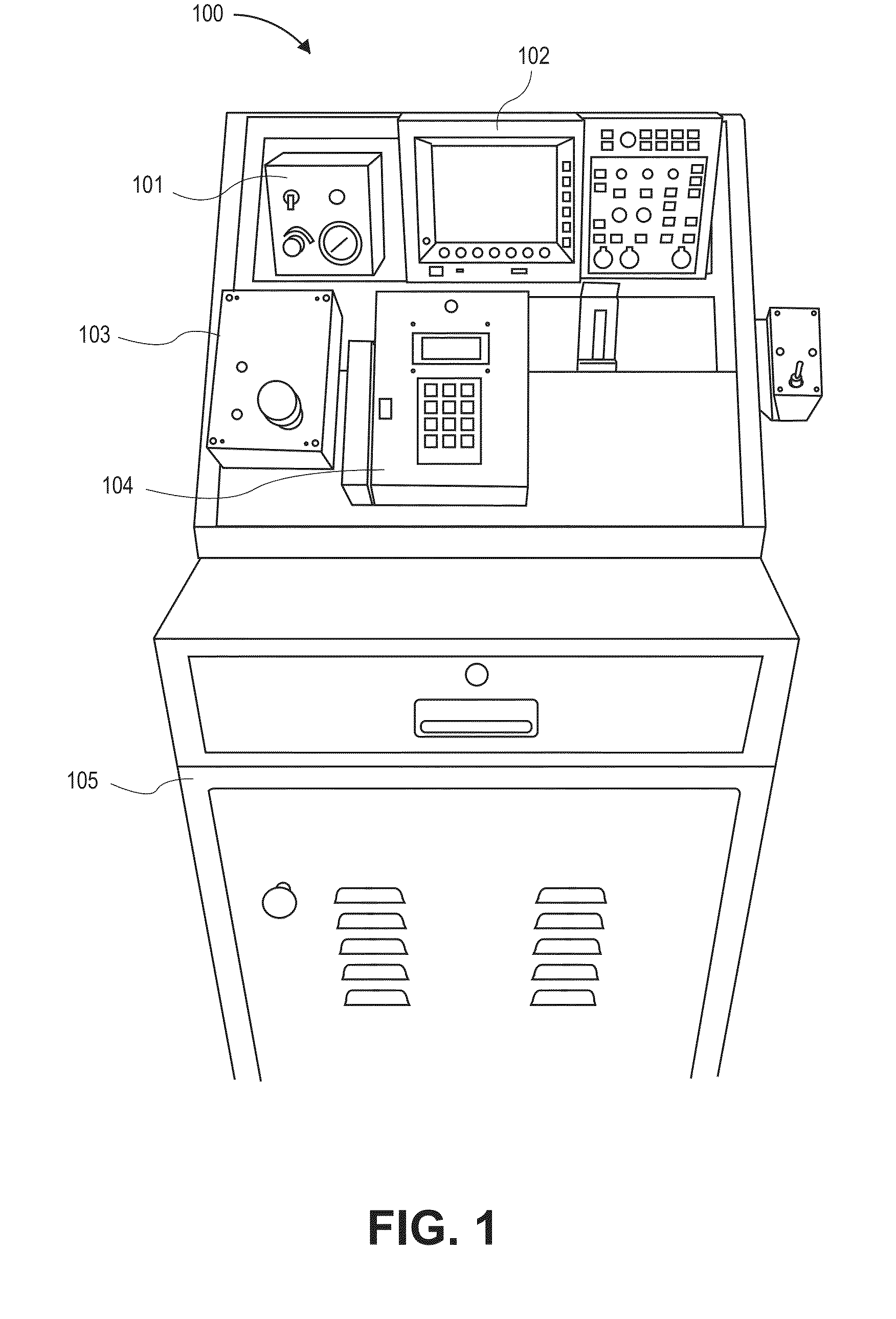

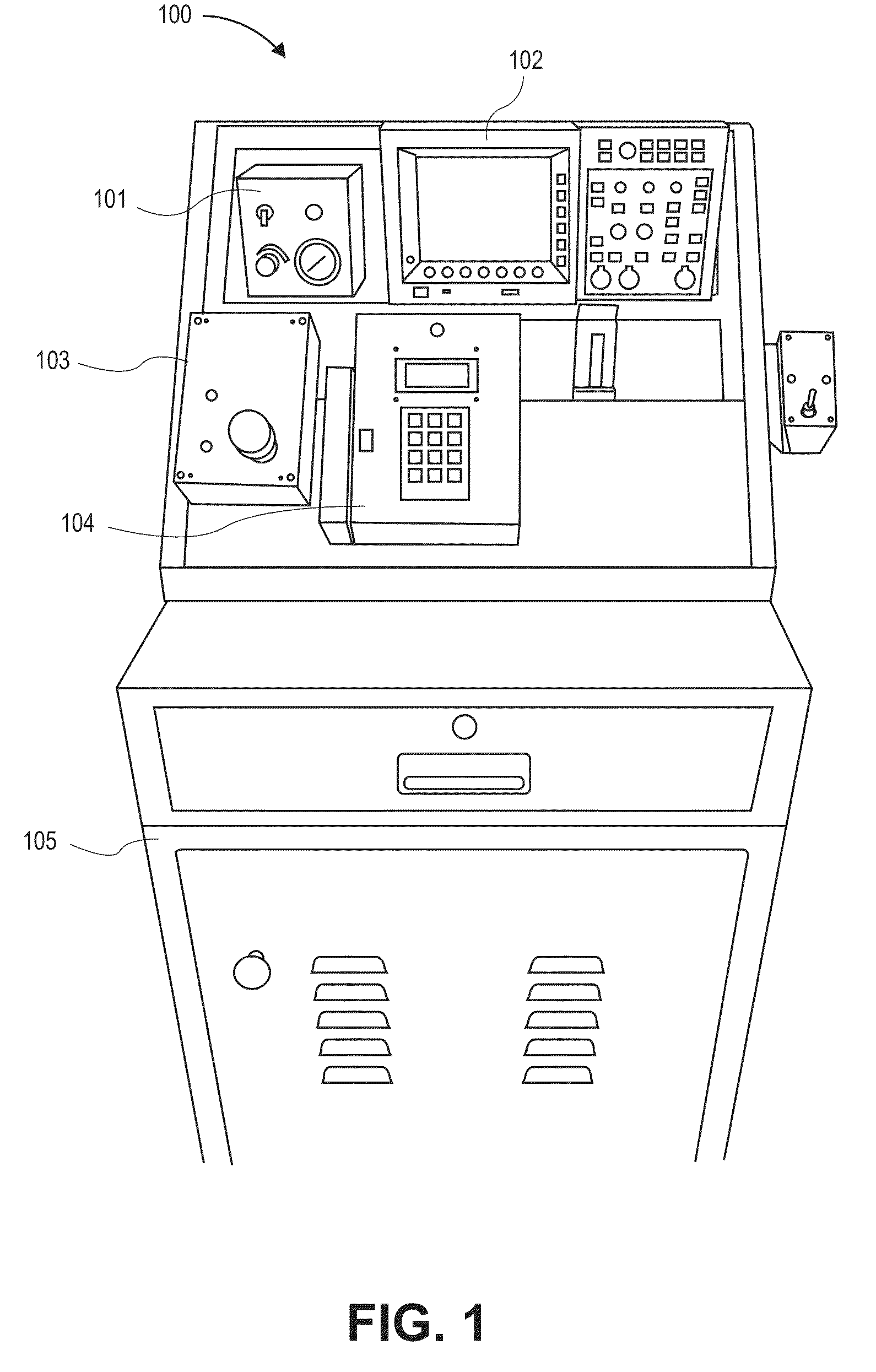

FPGA (field programmable gate array) control-based all-solid-state high-voltage nanosecond pulse generator

ActiveCN102441231AReduce volumeReduce lossElectrotherapyStress based microorganism growth stimulationFailure rateTreatment effect

The invention provides an FPGA (field programmable gate array) control-based all-solid-state high-voltage nanosecond pulse generator, and belongs to the field of bio-electromagnetic technology. The nanosecond pulse generator mainly comprises a power supply system, a pulse forming system, a pulse measurement system, an FPGA control system, a signal conversion system and a portable computer. In the generator, the output pulse amplitude is between 0 and 10kV, the pulse width is between 200 and 1000ns, the pulse frequency is between 1 and 1000Hz, the falling edge is between 30 and 40ns, the number of pulse is between 1 and 1000, and particular parameters are determined according the requirement of tumor treatment. The FPGA control-based all-solid-state high-voltage nanosecond pulse generator has the characteristics of intelligent regulation of pulse parameters (pulse amplitude, width, frequency and number), optical fiber transmission, high parameter accuracy, long service life, small size, low failure rate, good security and the like; and the generator outputs high pulse frequency, and is advantageous to quick searching of the optimal window parameters for inducing tumor cell apoptosis by virtue of intelligent regulation, so that the tumor treatment effect is improved. The FPGA control-based all-solid-state high-voltage nanosecond pulse generator can be widely applied to tumor treatment.

Owner:REMEDICINE CO LTD

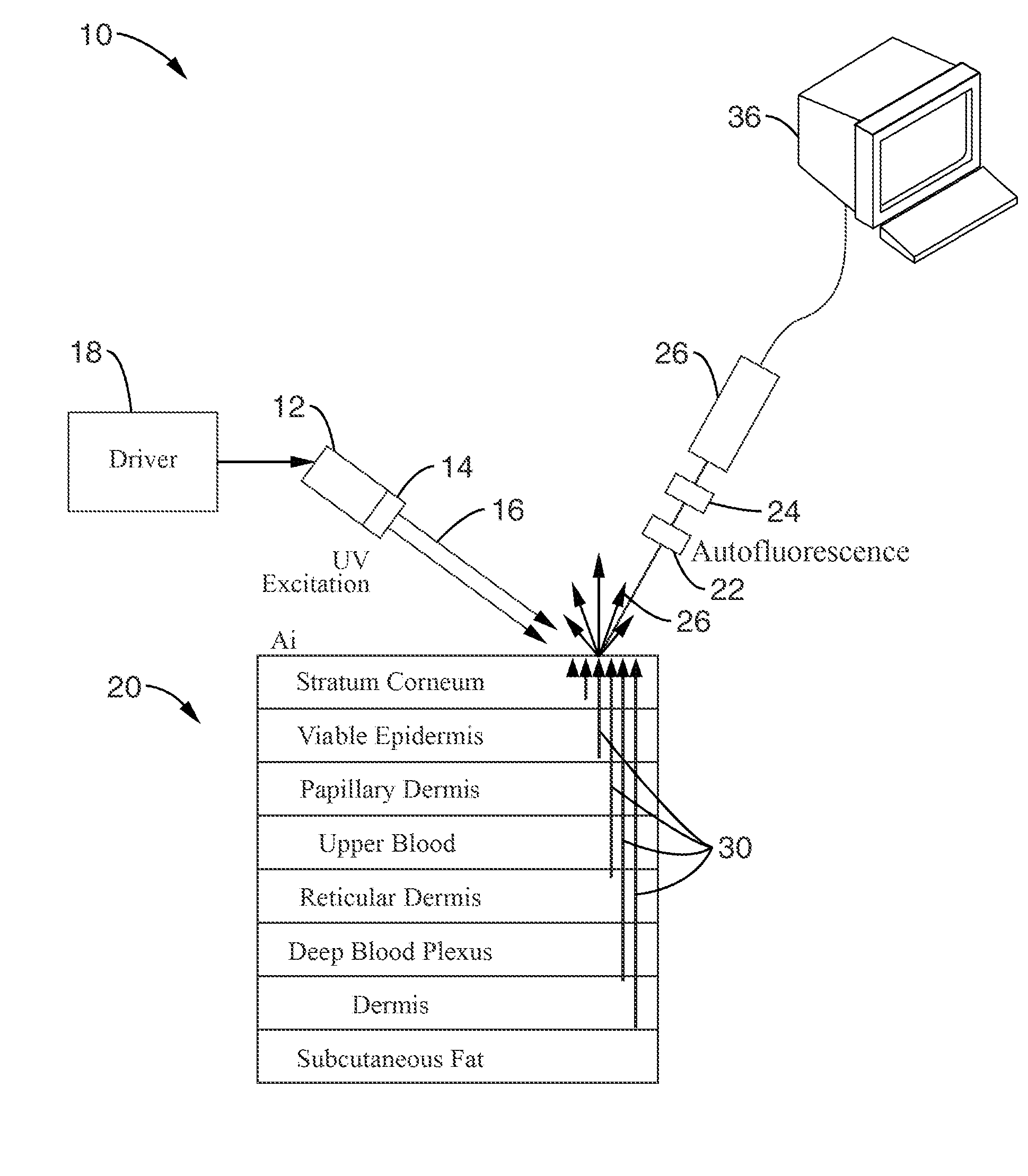

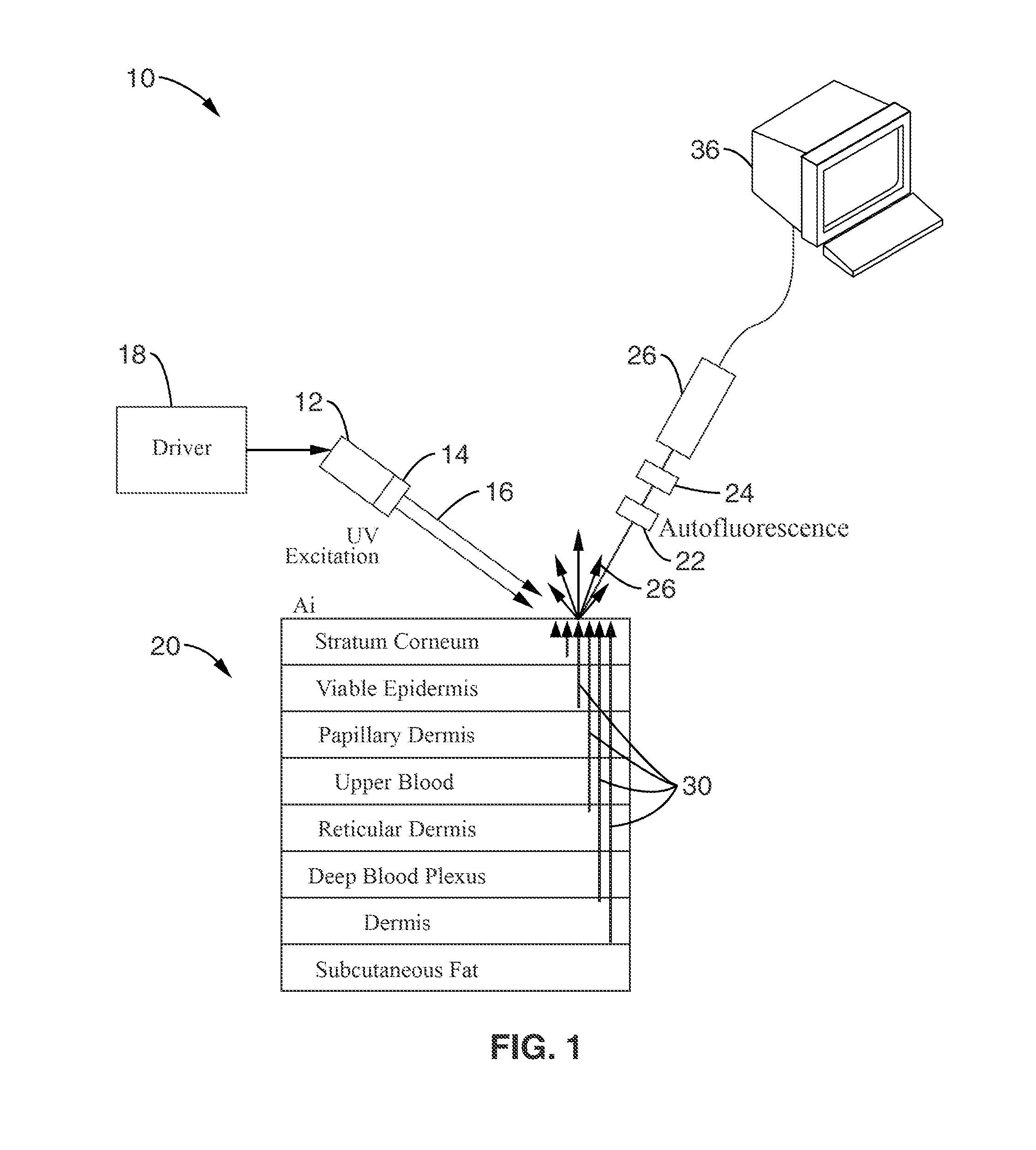

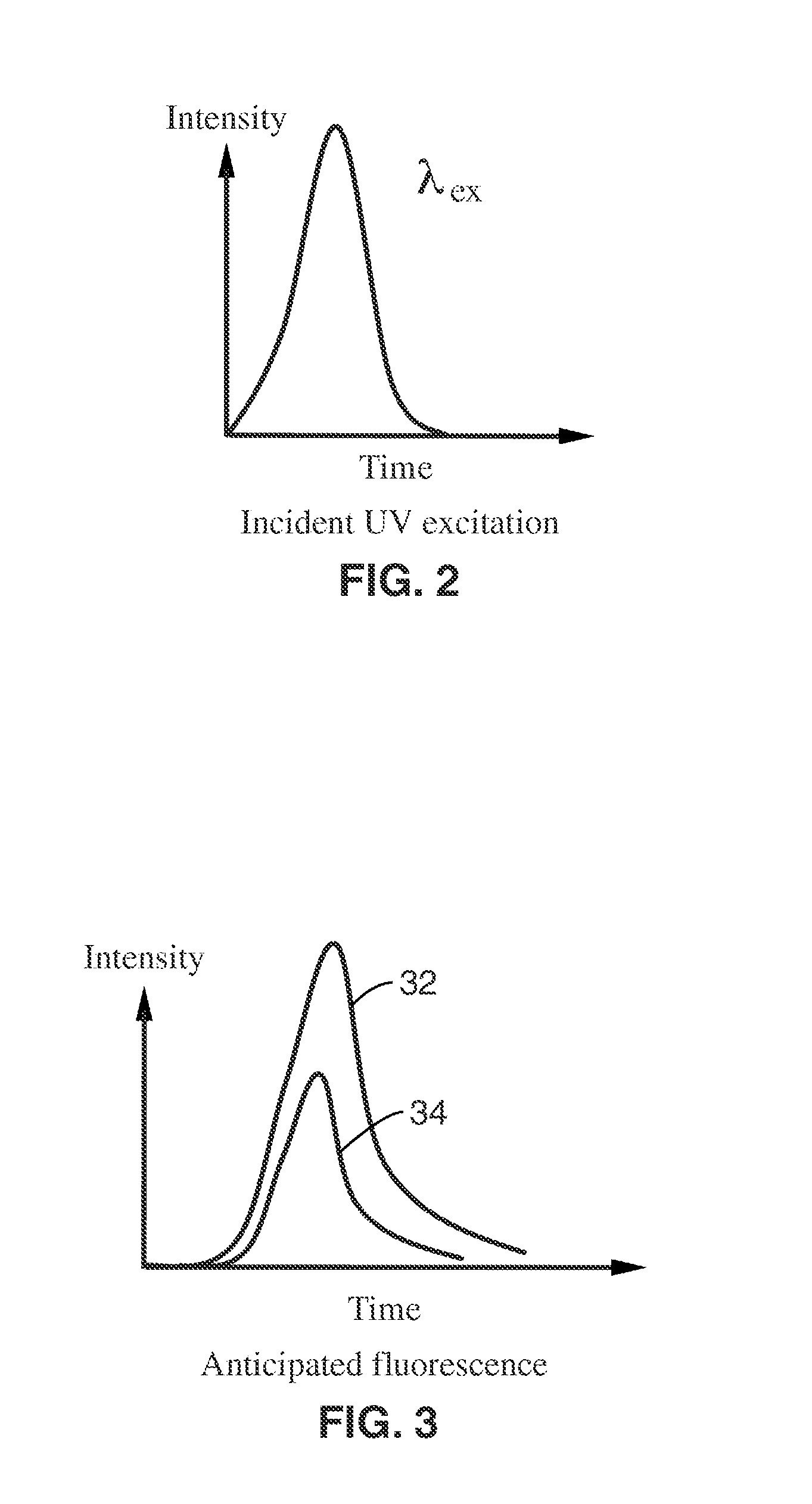

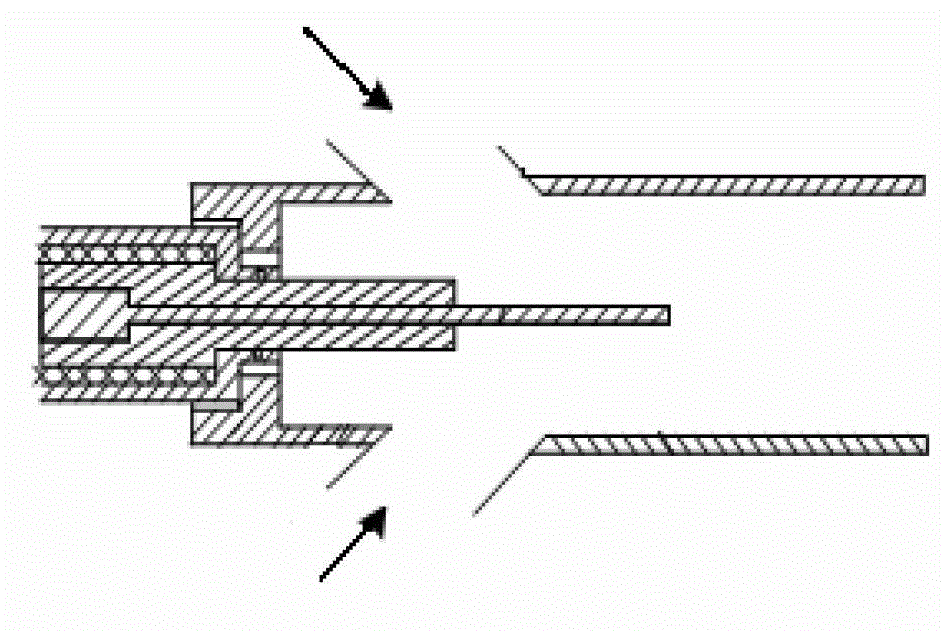

Time-resolved non-invasive optometric device for medical diagnostic

InactiveUS20070156037A1Remove restrictionsDiagnostics using lightMaterial analysis by optical meansDiseaseFluorophore

A time-resolved fluorescence device is described for the detection and diagnosis of various metabolic diseases in a noninvasive or minimally invasive manner. The device uses an ultra-short excitation pulse that comprises of a repetition of nanosecond pulses. The excitation pulse is directed incident onto a strategically selected area of the patient body such as the forearm, the feet, and the palm. This light interacts with the different layers of the skin. The absorbed light excites conditions of interest in the skin, which in turn generate a fluorescence signal, which is collected by a detector. A processor is coupled to the detector to measure the transient fluorescence intensity decay of the skin in terms of lifetimes, and the contribution of individual fluorophores to the overall fluorescence signal.

Owner:RGT UNIV OF CALIFORNIA

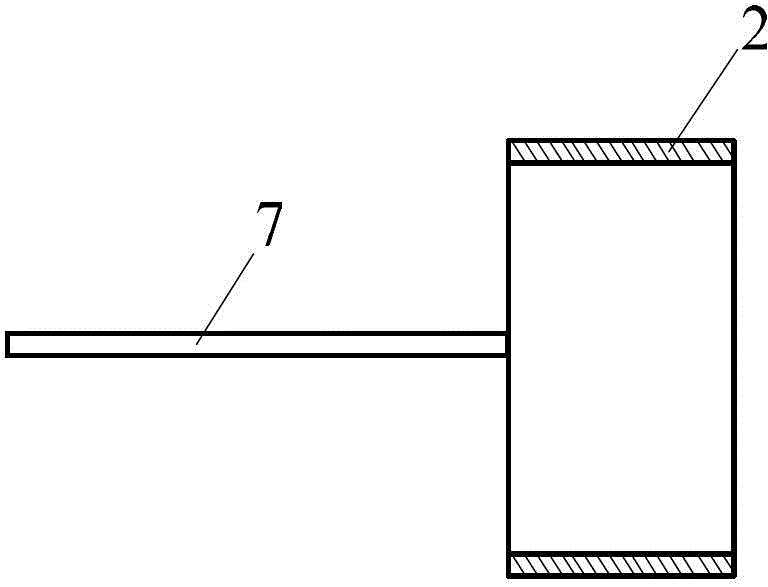

Annular discharge based transient state plasma igniter

ActiveCN102913365AIncrease the ignition areaEasy to igniteEngine ignitionMachines/enginesChemical reactionReaction rate

The invention relates to an annular discharge based transient state plasma igniter. An insulation sleeve is located in an insulation protection sleeve, and one end of the insulation sleeve is located in a cathode. An anode conduction rod is located in the insulation sleeve, and one end of the anode conduction rod is arranged in a center hole of the cathode. One end of the insulation protection sleeve is arranged in a fixing base. The anode is located in the cathode. The transient state plasma igniter is provided with a mixed gas channel. According to the invention, high-energy nanosecond pulse is used to discharge electricity to form a local high temperature area, and a large quantity of active particles are activated to ignite combustible mixed gas in an extremely short period of time. The ignition area is large, and the mixed gas can be ignited by multiple points; the ignition time is extremely short, and the ignition delay time is shorter; the ignition energy can be well coupled with the gas mixture, macromolecule hydrocarbon fuel in the ignition area is ionized as active particles with low activation energy, so that the chemical reaction of the mixed gas is faster, the reaction time is shorter, and the ignition success rate is high.

Owner:AIR FORCE UNIV PLA

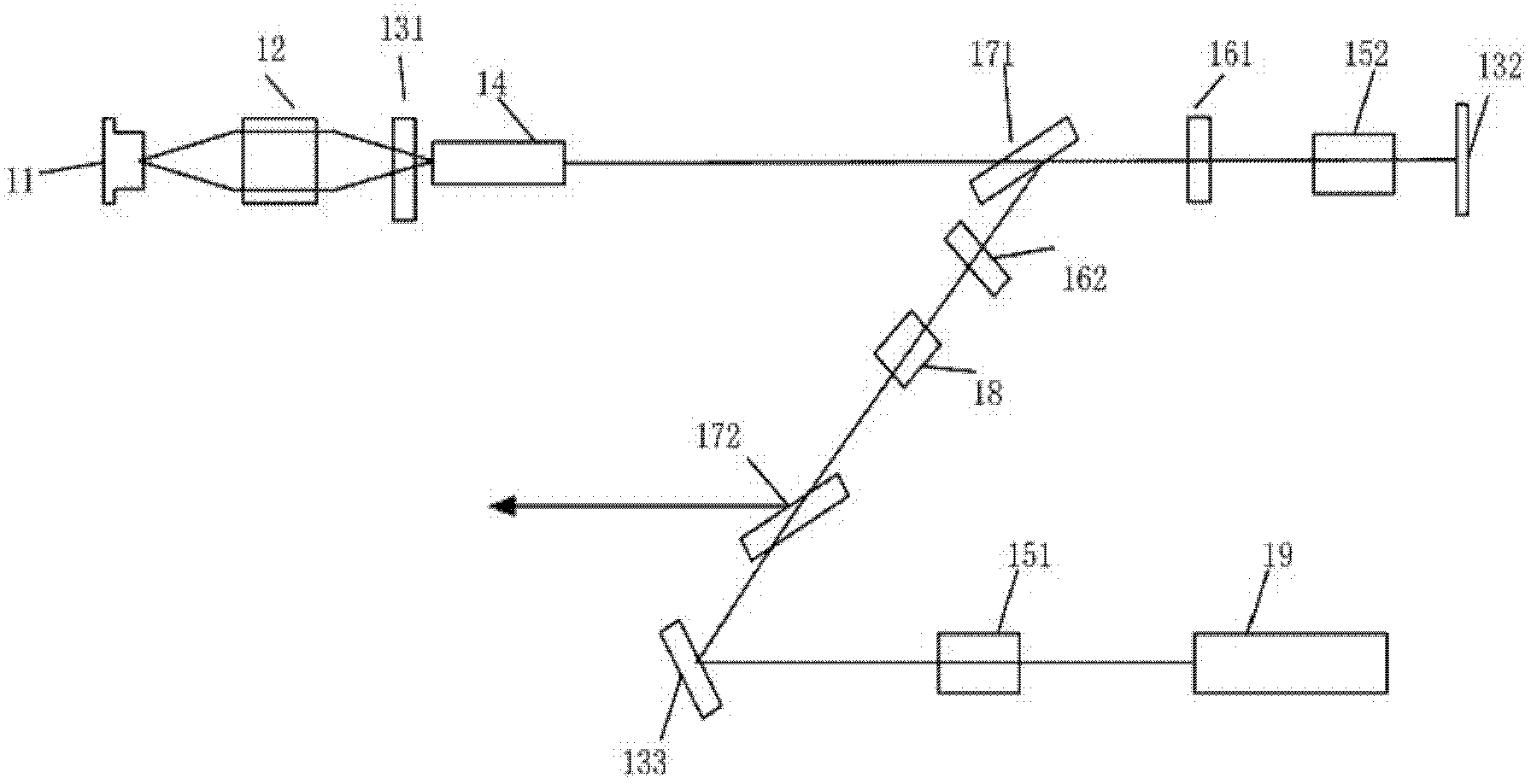

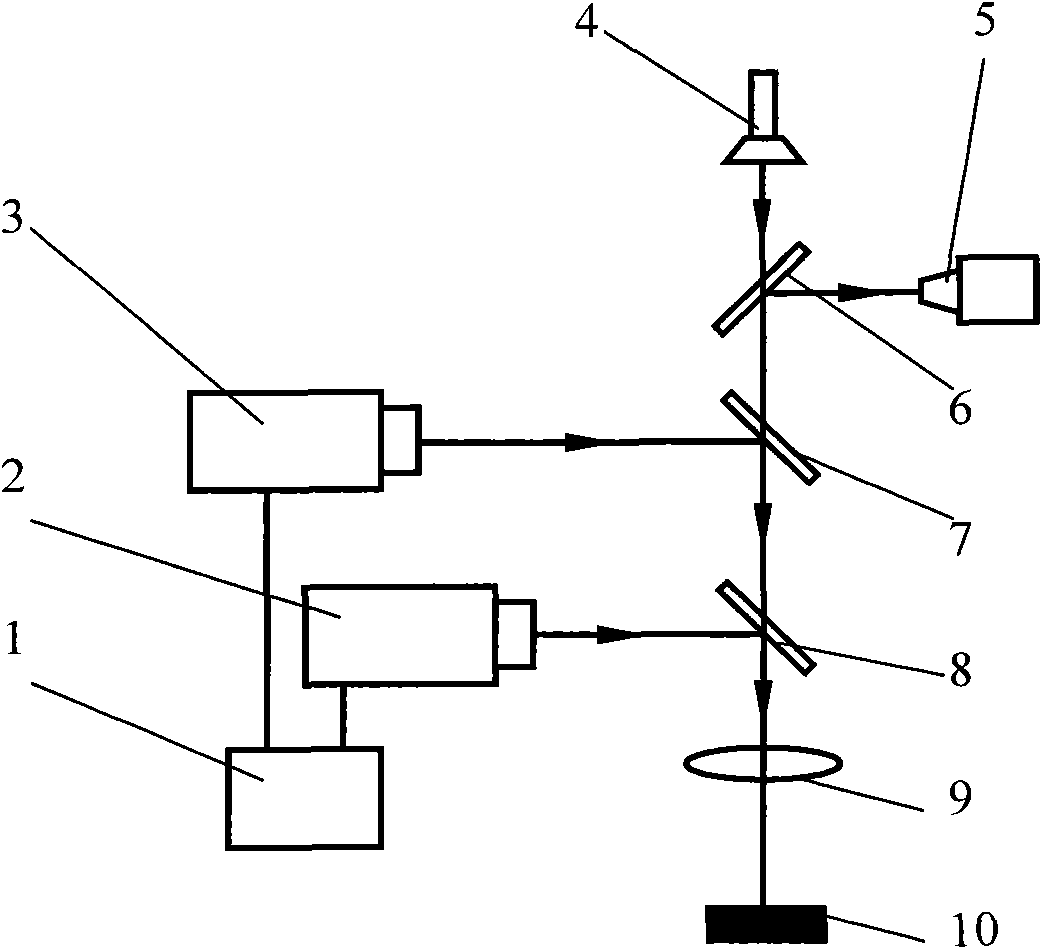

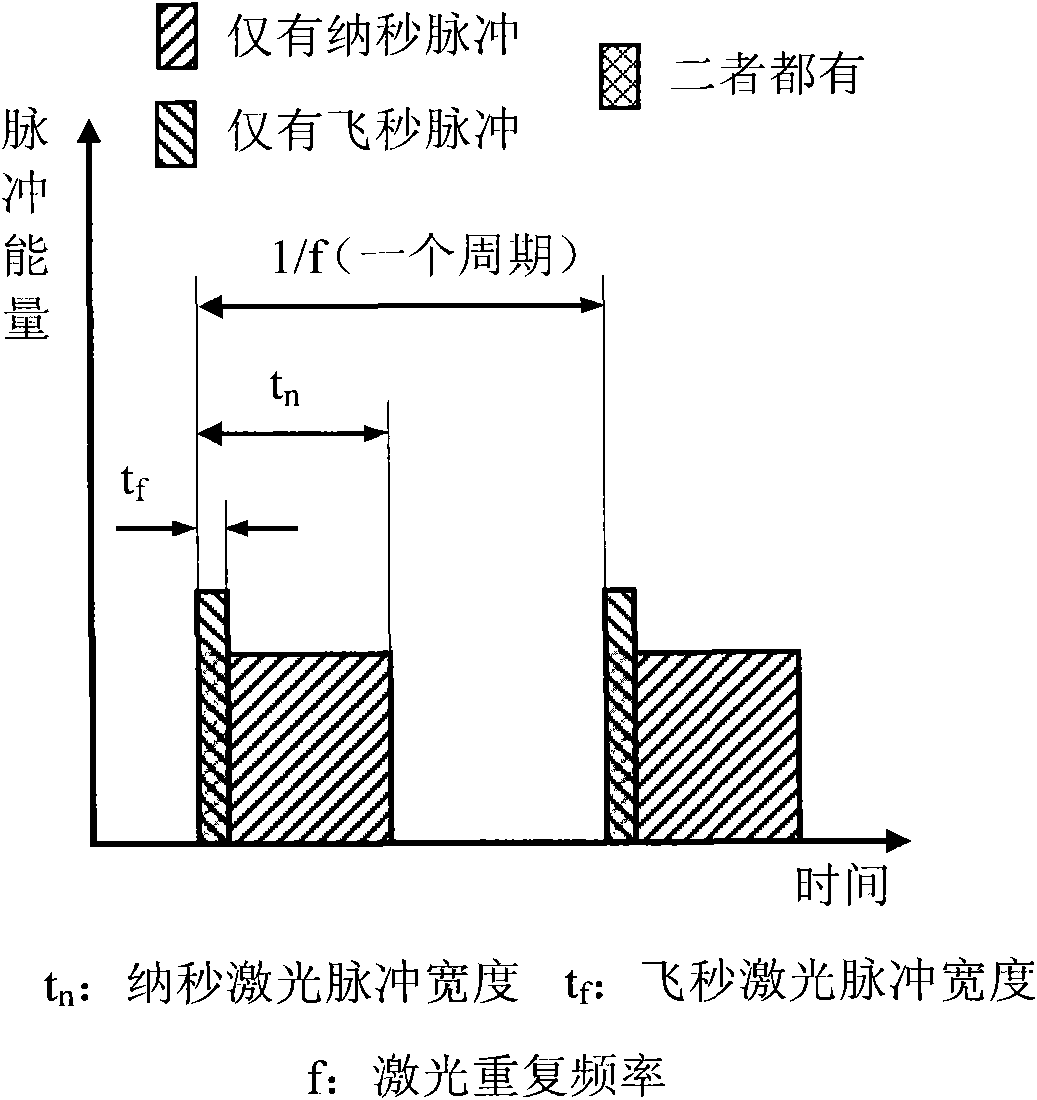

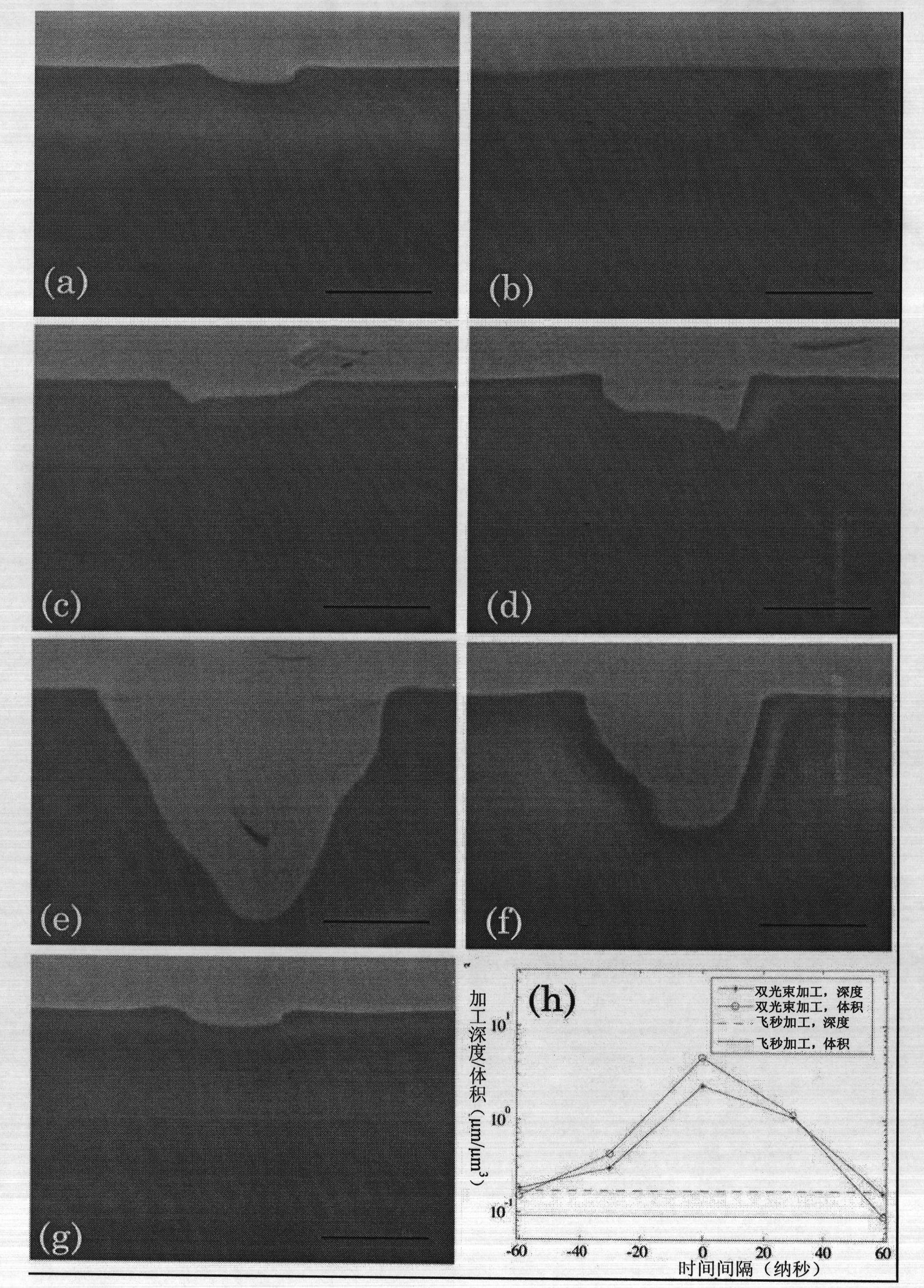

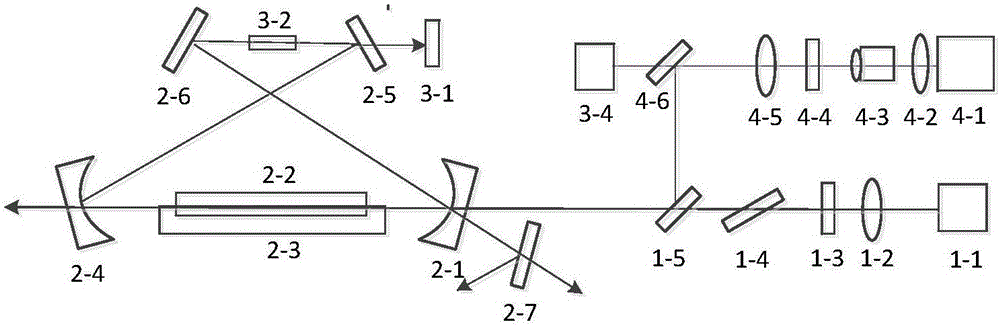

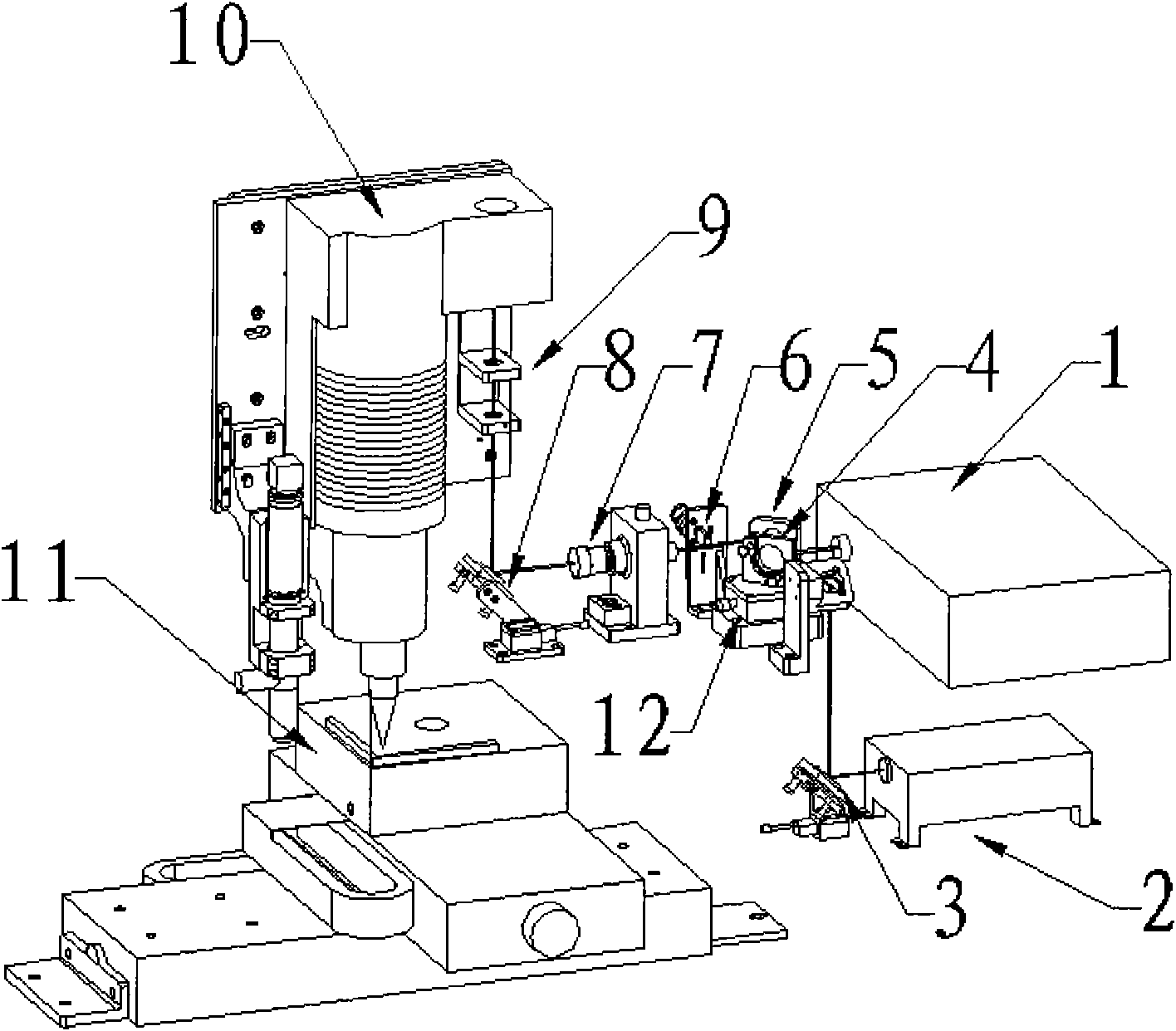

Nano-femtosecond dual-laser composite machining system

InactiveCN102059451AHigh precisionHigh nanosecond laser processing efficiencyLaser beam welding apparatusOptical elementsMicro nanoNuclear fusion

The invention relates to a nano-femtosecond dual-laser composite machining system. The system comprises a femtosecond laser, a nanosecond laser, a synchronous control circuit, an illuminating light source, a semi-transparent semi-reflecting mirror, a first dichroscope, a second dichroscope, a focusing lens and a charge coupled device (CCD) image detector, wherein the synchronous control circuit controls laser pulse output of the femtosecond laser and the nanosecond laser, and accurately adjusts relative time of nanosecond pulse and femtosecond pulse in the aspect of time to synchronize leading edges of the two pulses; the illuminating light source is positioned on one side of the semi-transparent semi-reflecting mirror, and the second dichroscope, the first dichroscope and the focusing lens are coaxially arranged on the other side of the semi-transparent semi-reflecting mirror in turn and are positioned on a straight line together with the illuminating light source; and the CCD image detector is positioned at the tail end of a reflecting light path of the semi-transparent semi-reflecting mirror. Through the system, the advantages of high femtosecond laser machining accuracy and high nanosecond laser machining efficiency are simultaneously integrated, and high-accuracy and high-efficiency micro-nano machining is realized; and the system can be widely applied to the fields such as high-accuracy machining of aviation and aerospace key parts, microstructure machining of a laser fusion ignition target, microstructure machining of a microsensor and the like.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

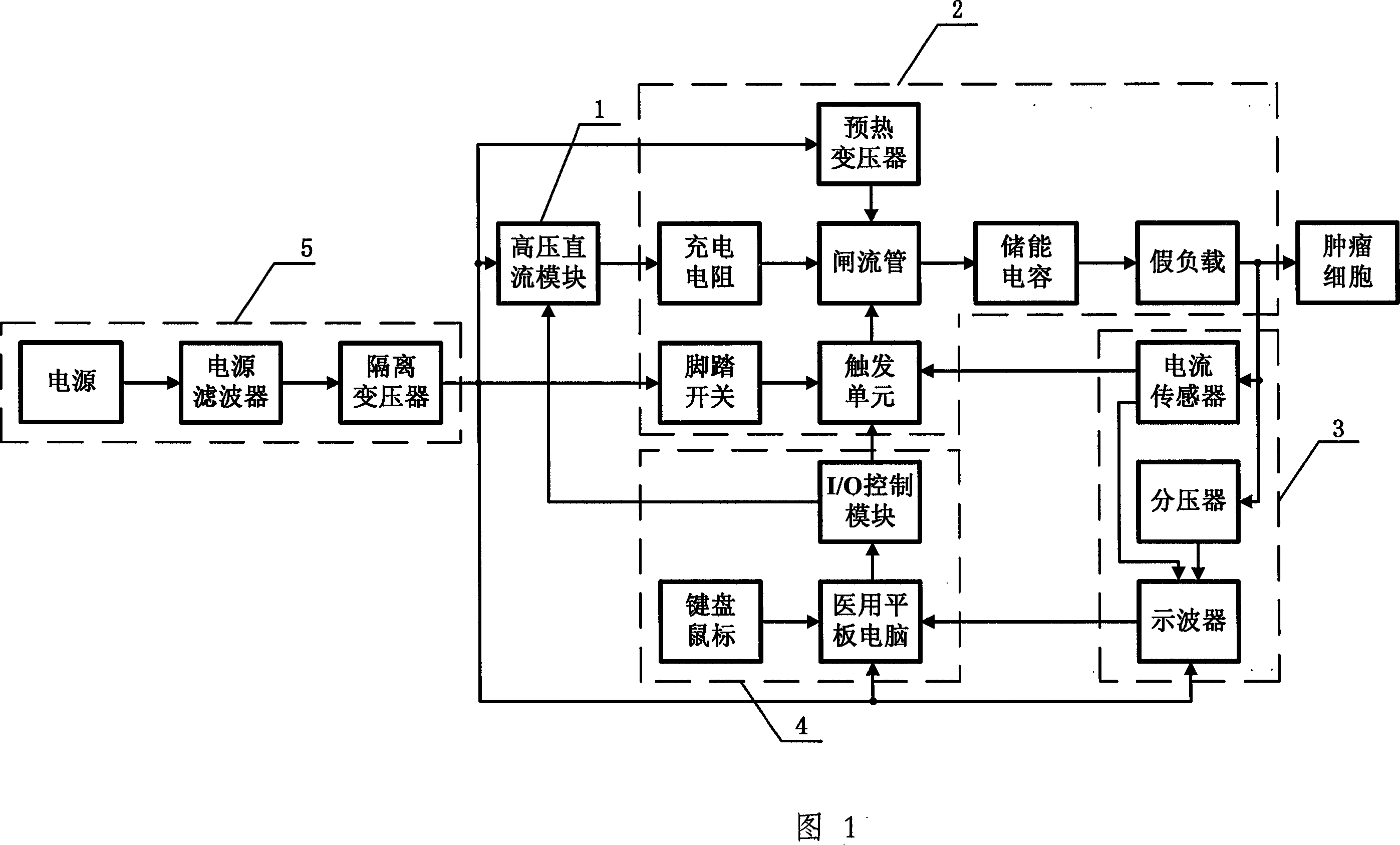

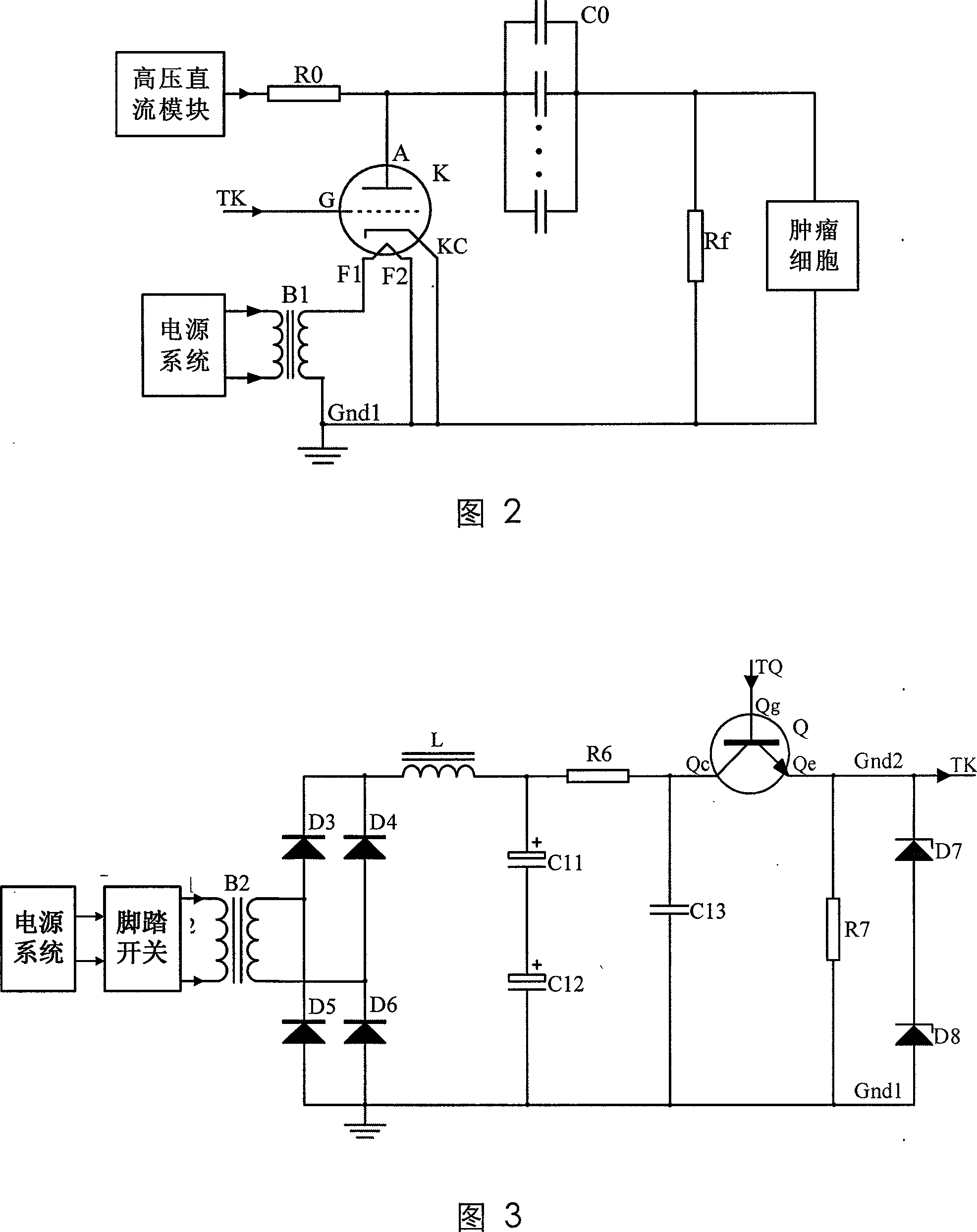

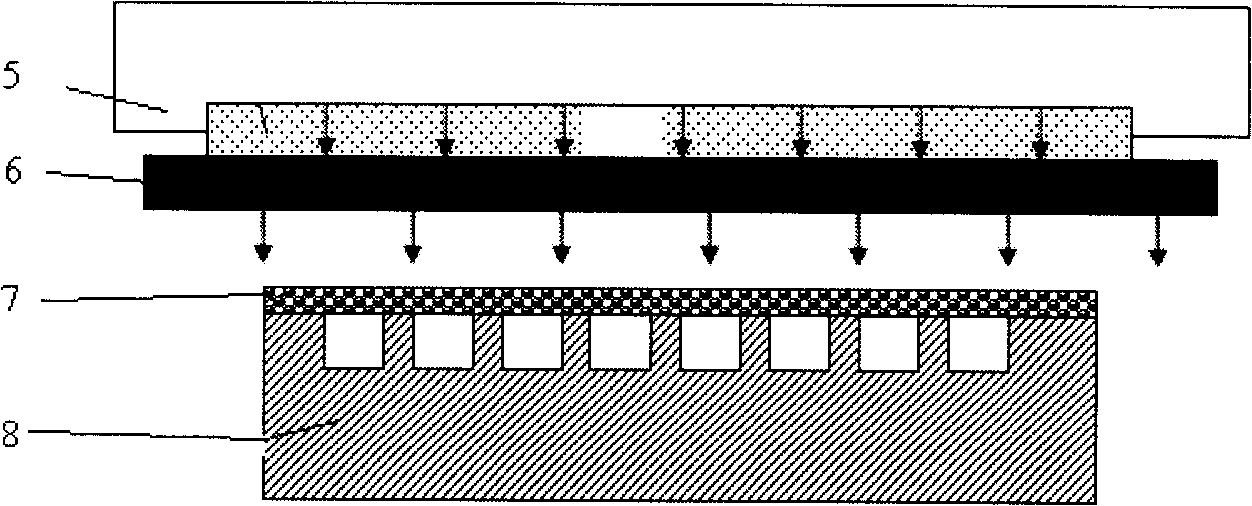

Device for inducing tumor cell apoptosis by high-voltage nanosecond pulse

ActiveCN101085391AReal-time acquisitionReal-time visibilityElectrotherapySurgical instrument detailsAbnormal tissue growthSide effect

A device for inducing apoptosis of tumor cell with high voltage nanosecond pulse belongs to technology field of electric impulse for treatment of tumor. The inventive device mainly comprises high voltage direct current module, pulse formation system, pulse measurement system, computer system, and power system. Amplitude value of high voltage nanosecond pulse is continuously regulated or preset between 0-9.9kV, repetition frequency is continuously regulated or preset between 2-100Hz, width is continuously regulated or preset between 200ns-1 mu s by separating to 7 grades, and numbers is regulated or preset according to treatment requirement. As the inventive device can induce apoptosis of tumor cell, is an unalloyed physical method, has no requirement of medicament assistance, thus can completely avoid toxic and adverse side effect of chemotherapeutics during treatment and adverse reaction such as inflammation, pain, ulcer and stammer, therefore the inventive device can be widely used in oncotherapy and treatment of removing polypus and redundant grease and vulvopathy.

Owner:REMEDICINE CO LTD

Method for impacting micro-plasticity forming with strong laser and device thereof

InactiveCN101254574AHigh surface hardnessHigh sensitivitySemi-permeable membranesPiezoelectric/electrostrictive/magnetostrictive devicesShock waveElectrolysis

A plastic micro-forming method by using strong laser shock and a device thereof belong to the field of micro-electro-mechanical system (MEMS) processing and laser micro-processing technology. The method is characterized in that the method comprises the following steps: polishing both sides of a target for experiment by electrolysis; pressing a transparent optical medium with a thickness of micrometer level on a press plate as a constrained layer; tightly pressing a metal flying plate on the optical medium; fastening the optical medium, the metal flying plate, the target and a template on a special target clamping machine through the press plate; turning on a nano-second pulsed laser; adjusting the optical path to focus the laser outputted from the nano-second pulse laser on the target surface; subjecting the nano-second pulsed laser to single emission to achieve single pulse laser shock on the target. The method can generate ultrahigh pressure and strain rate during production of a sample, and the application of pressure of the generated shock wave has higher planarity, completeness and repeatability, thus improving surface rigidity of micro-metal parts and improving micro-sensing sensitivity. Accordingly, a micro-driving device can provide higher drive force, torsional moment and energy.

Owner:JIANGSU UNIV

Methods and devices for stimulating an immune response using nanosecond pulsed electric fields

ActiveUS20140358066A1Reduce transferOrganic active ingredientsSurgical needlesNanosecondCalreticulin

Nanosecond pulsed electric field (nsPEF) treatments of a tumor are used to cause the tumor to express calreticulin and stimulate an immune response against the tumor and other tumors in a subject. An immune response biomarker can be measured, and further nsPEF treatments can be performed if needed to stimulate or further stimulate the immune response. Cancers that have metastasized may be treated. The treatment can be combined with CD47-blocking antibodies, doxorubicin, CTLA-4-blocking antibodies, and / or PD-1-blocking antibodies. Electrical characteristics of nsPEF treatments can be based on the size, type, and / or strength of tumors and / or a quantity of tumors in the subject.

Owner:PULSE BIOSCI INC

Methods and devices for stimulating an immune response using nanosecond pulsed electric fields

ActiveUS9101764B2Reduce transferOrganic active ingredientsSurgical needlesAbnormal tissue growthNanosecond

Nanosecond pulsed electric field (nsPEF) treatments of a tumor are used to cause the tumor to express calreticulin and stimulate an immune response against the tumor and other tumors in a subject. An immune response biomarker can be measured, and further nsPEF treatments can be performed if needed to stimulate or further stimulate the immune response. Cancers that have metastasized may be treated. The treatment can be combined with CD47-blocking antibodies, doxorubicin, CTLA-4-blocking antibodies, and / or PD-1-blocking antibodies. Electrical characteristics of nsPEF treatments can be based on the size, type, and / or strength of tumors and / or a quantity of tumors in the subject.

Owner:PULSE BIOSCI INC

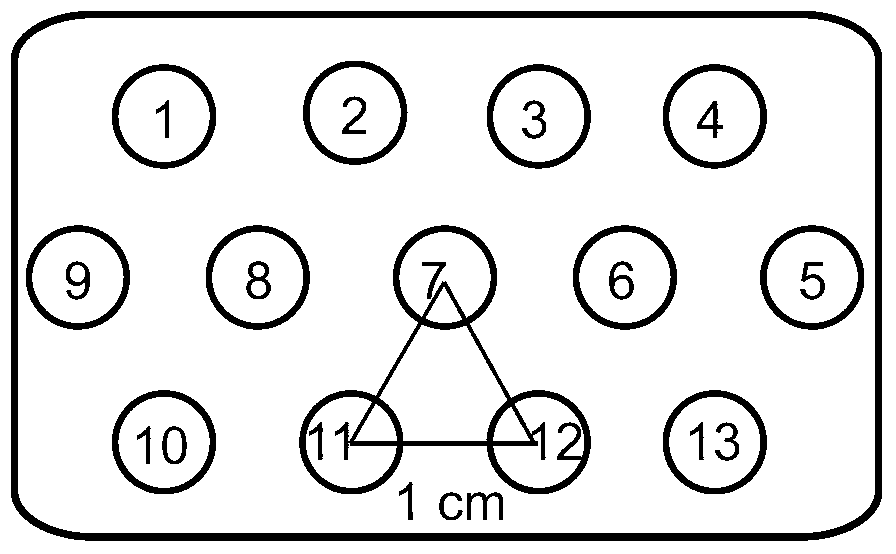

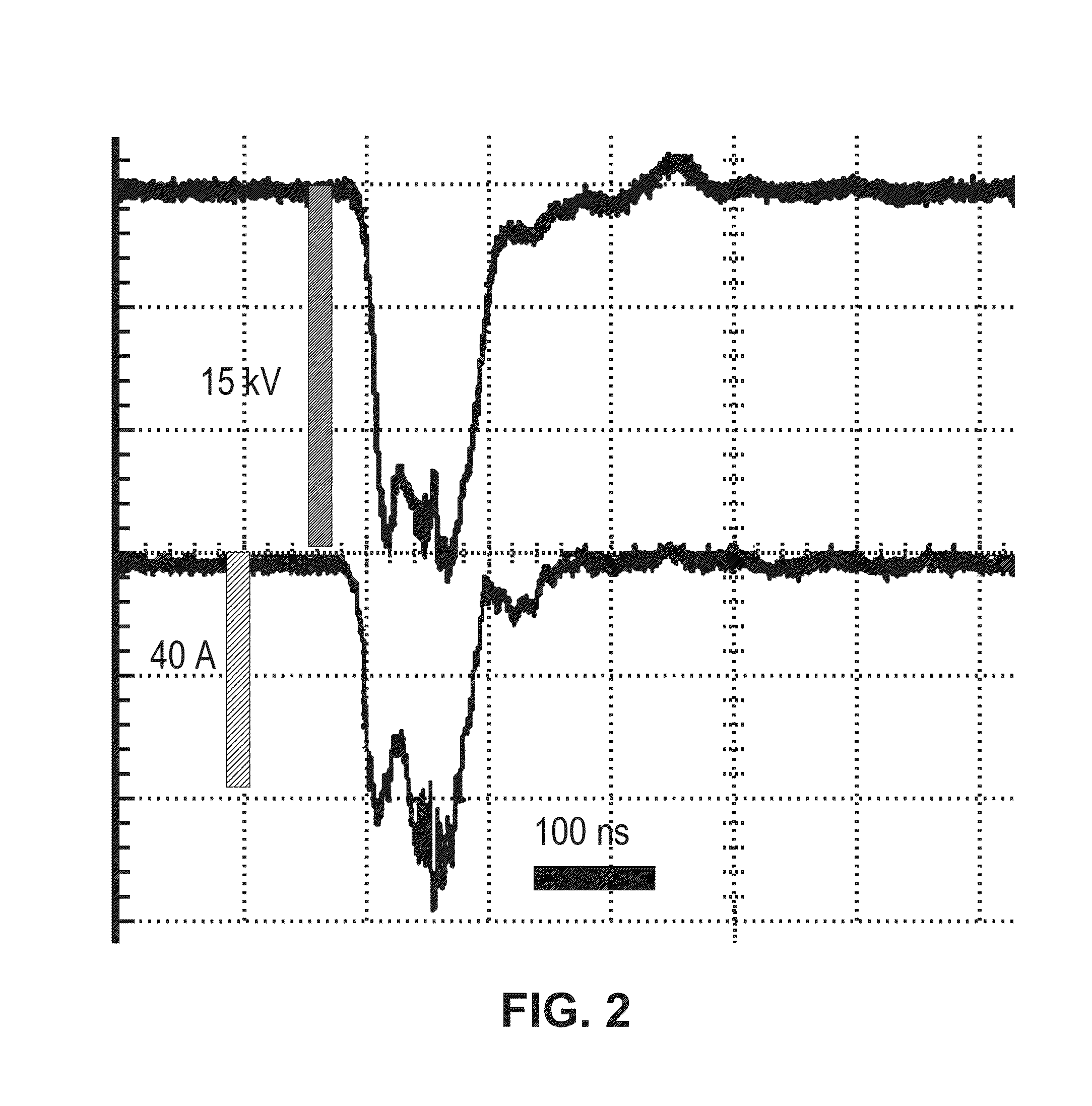

High Voltage Nanosecond Pulse Generator Using Fast Recovery Diodes for Cell Electro-manipulation

ActiveUS20070031959A1Bioreactor/fermenter combinationsBiological substance pretreatmentsBiological cellElectricity

A pulse generator circuit may include a diode configured to operate as an opening switch, a tank circuit in series with the diode having an admittance that is switchable from a first value to a second value that is different from the first value, and a switching system configured to cause the tank circuit to switch between the first value and the second value. The diode may saturate in less than 100 nanoseconds. A saturable core transformer may operate as a switch that controls the opening of the diode. The pulse generator may generate a plurality of pulses, each having a length of no more than 3 nanoseconds and an amplitude of at least 1 kilovolt. Electrodes may be connected to the pulse generator to deliver the plurality of pulses to biological cells.

Owner:UNIV OF SOUTHERN CALIFORNIA

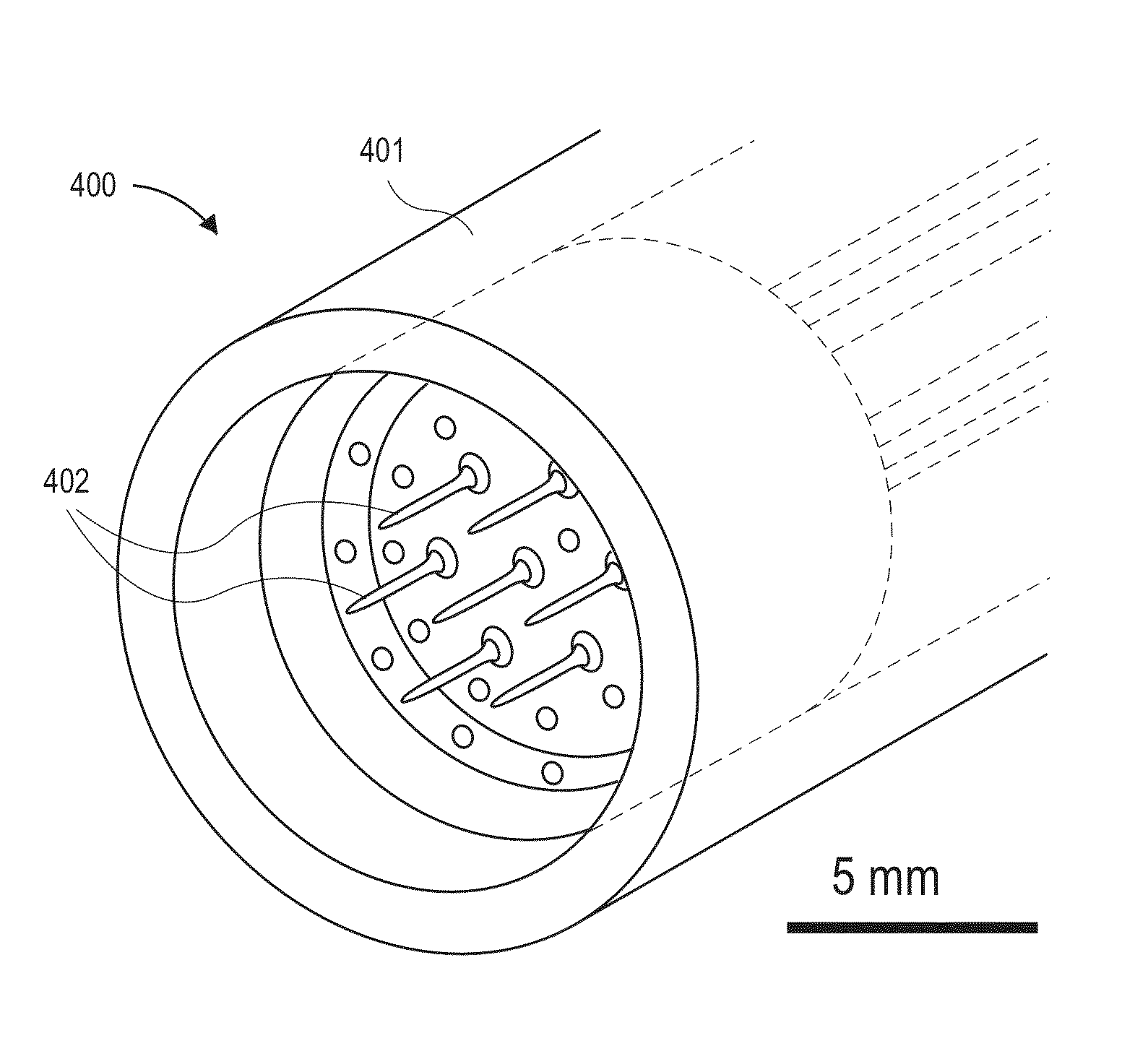

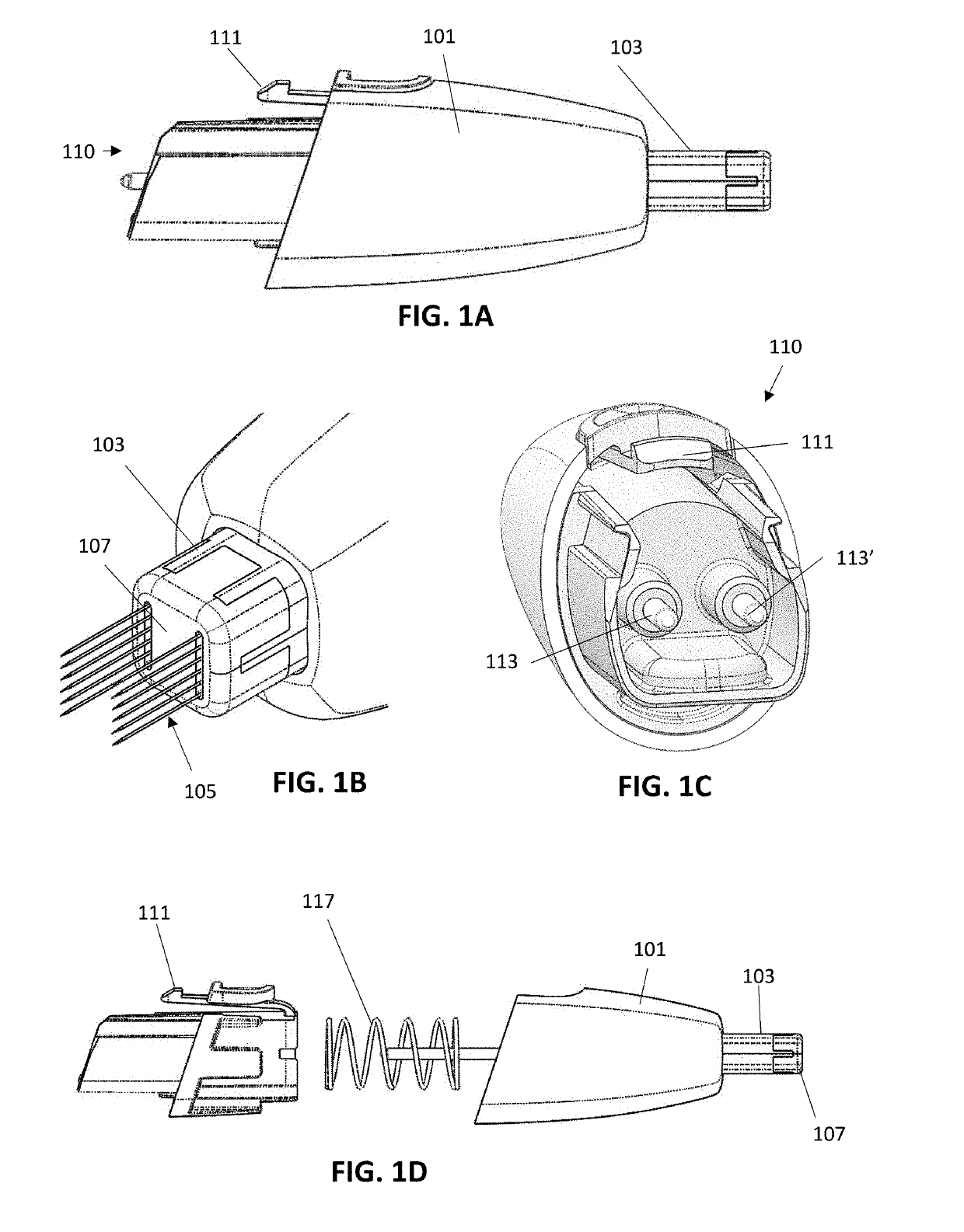

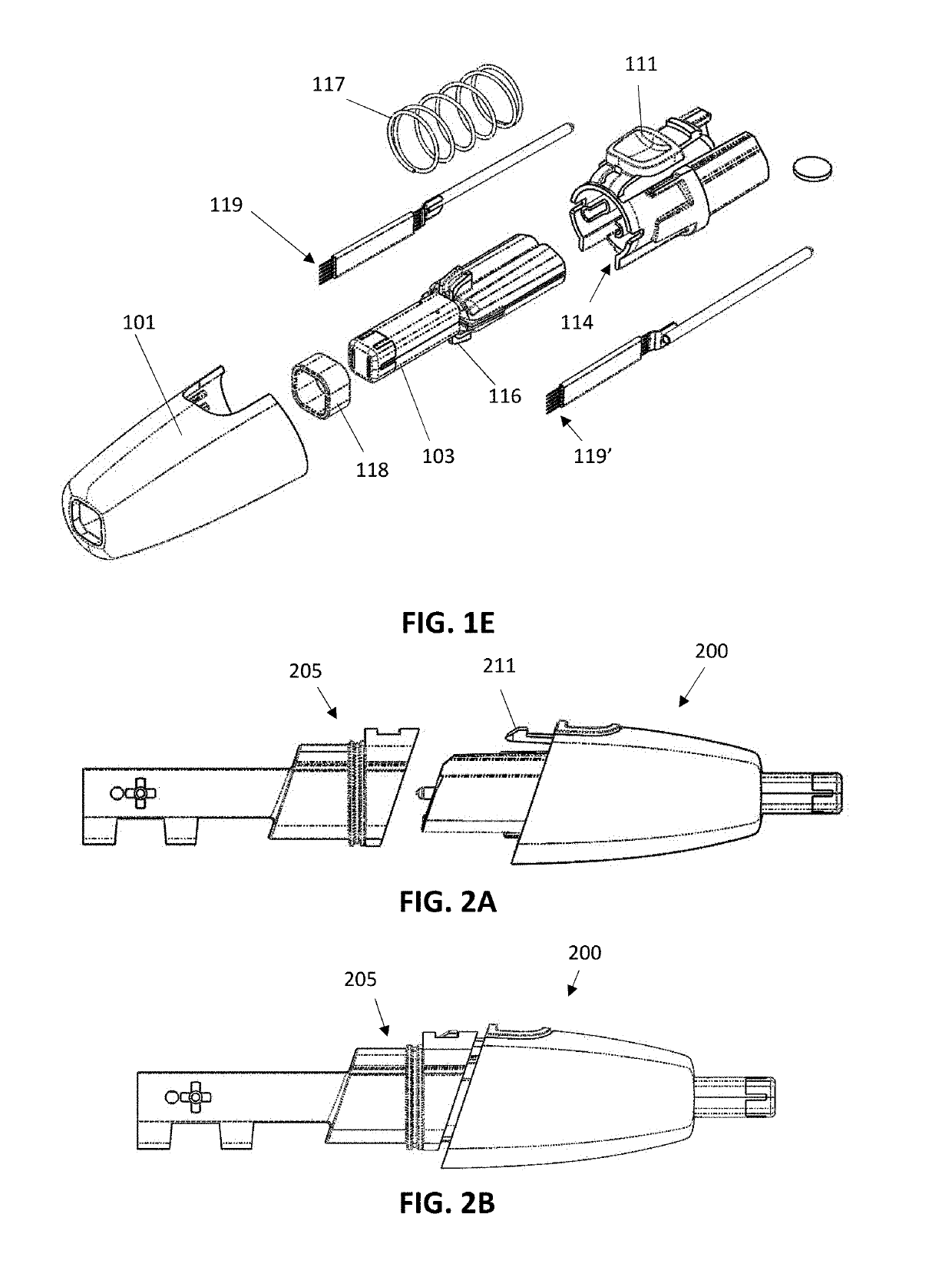

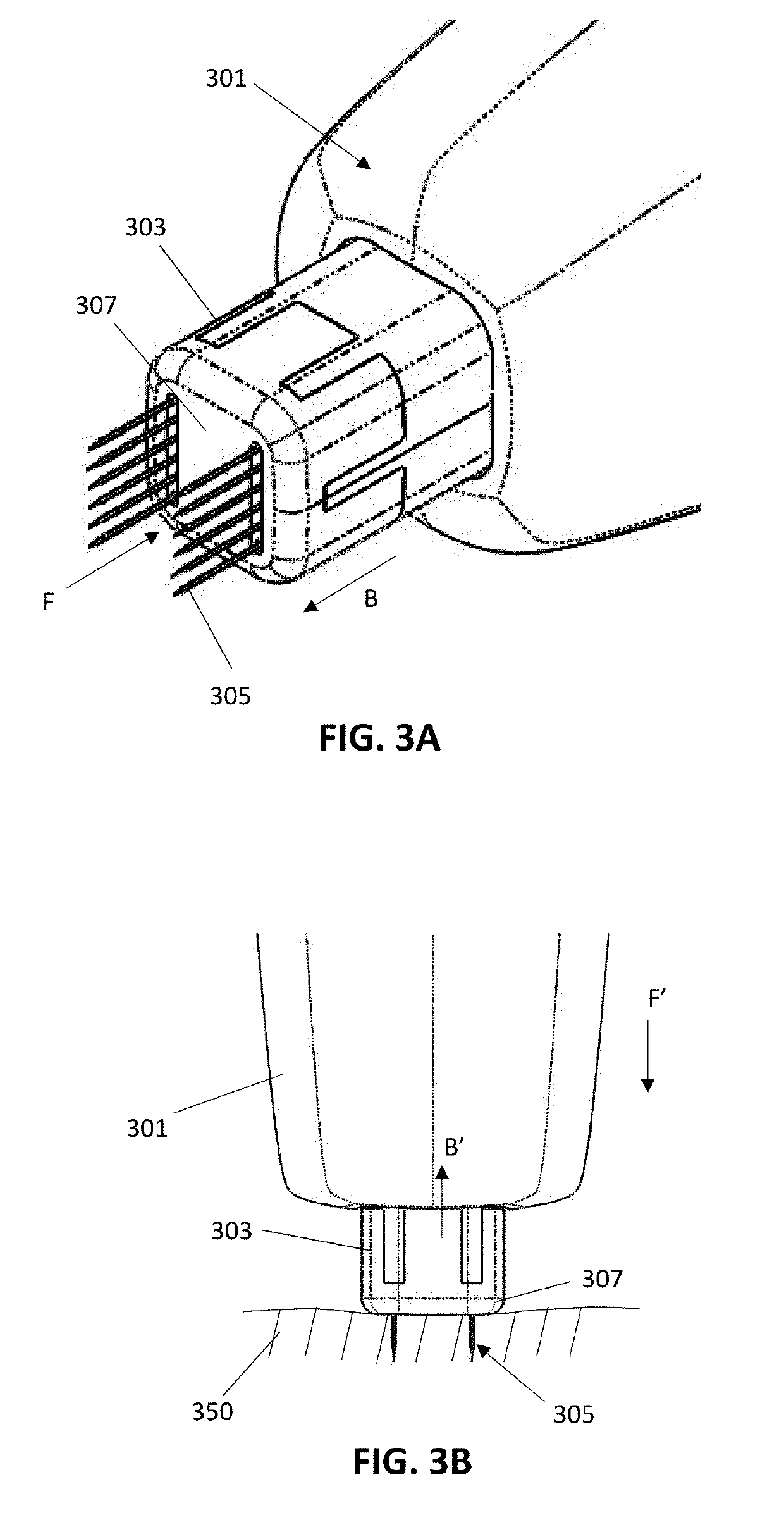

Treatment tip with protected electrodes

ActiveUS20190217080A1Avoiding risk of arcing and otherwise harmingHigh strengthDiagnosticsSurgical instruments for heatingMedicineNanosecond pulse

Described herein are treatment tip apparatuses (e.g., devices, systems, etc.) including one, or more preferably a plurality, of electrodes that are protected by an electrode partition, such as an electrode housing (which may be retractable) until pressed against the tissue for deployment of the electrodes and delivery of a therapeutic treatment. In particular, these apparatuses may include a plurality of treatment electrodes (e.g., needle electrodes) and be configured for the delivery of nanosecond pulsed electric fields.

Owner:PULSE BIOSCI INC

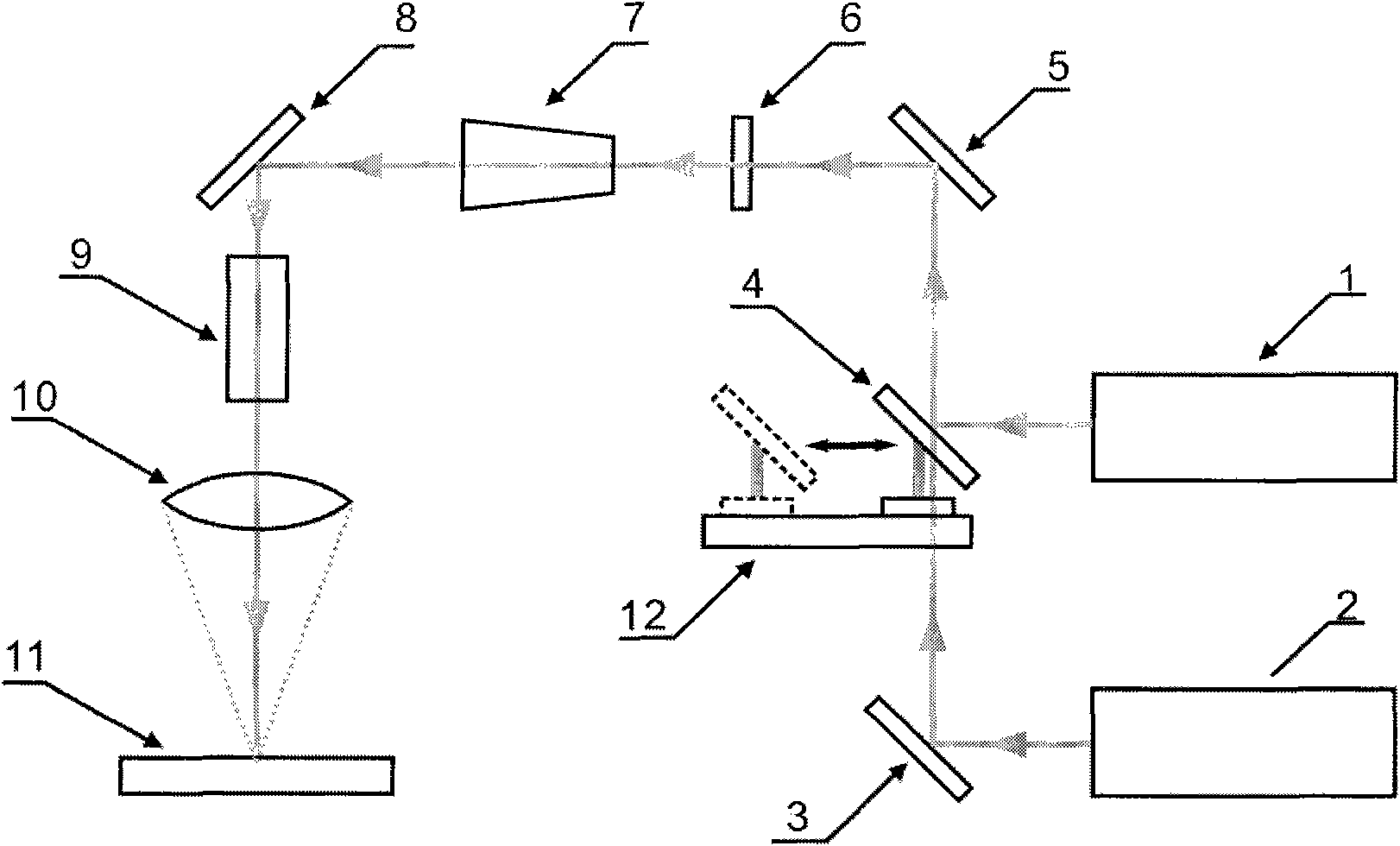

Wide-tuning and narrow-linewidth nanosecond pulse double-resonance medium-infrared parameter oscillator

ActiveCN106711745AEasy to tuneWide coverageOptical resonator shape and constructionActive medium shape and constructionLine widthSpectroscopy

The invention provides a double-resonance, wide-tuning and narrow-linewidth all-solid-state nanosecond pulse medium-infrared optical parameter oscillator comprising four parts including single-frequency pump light, a double-resonance resonant cavity, an electrical control part and seed light. A 1.064 <mu>m single-frequency pulse laser pump quasi-phase matching multi-cycle polarized crystal double-resonance parameter oscillator is adopted to acquire dual-band laser output of wide-tuning range near-infrared signal light and medium-infrared idle light. The output central wavelength is tunable within the wide spectral range, and the cavity length is dynamically adjusted through electro-optical crystal by combining a single-frequency continuous semiconductor laser seed injection technology so as to realize narrow-linewidth laser output of the optical parameter oscillator. The oscillator can be widely applied to the field of high-resolution laser spectroscopy, laser radar, laser remote sensing, environmental detection, optical-electro countermeasure and laser medicine.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Double light path green light micropore processing device

InactiveCN101569962ASimple structureEasy to adjustLaser beam welding apparatusPicosecond pulsed laserOptoelectronics

The invention provides a double light path green light micropore processing device, which comprises a picosecond pulse laser, a nanosecond pulse laser, a light path calibration system and an optical focusing system, wherein the output end of the picosecond pulse laser is provided with a first reflecting mirror; the output end of the nanosecond pulse laser is provided with a second reflecting mirror; the first reflecting mirror and the second reflecting mirror are connected with a third reflecting mirror; the output end of the third reflecting mirror is provided with an optical shutter; the output end of the optical shutter is connected with a beam expanding lens; the output end of the beam expanding lens is connected with a fourth reflecting mirror; and the fourth reflecting mirror is connected with the optical focusing system through the light path calibration system. The two lasers taking the light pulse length as nanoseconds and picoseconds are adopted, the selection of light beams is controlled by a light path selection system, the use of one laser for the processing is allowed, and the two lasers can also be alternately used during the processing. A double light path system maintains the advantage that the laser processes micropores, and can aim at different processing finenesses and cost requirements to flexibly select processing modes.

Owner:SUZHOU DELPHI LASER

Multi-laser polishing and reinforcing method for surfaces of additive manufacturing metal parts

InactiveCN104109860AAchieving Surface Quality Polishing IssuesQuick polishSurface stressLaser scanning

The invention discloses a multi-laser polishing and reinforcing method for surfaces of additive manufacturing metal parts, and the polishing on the surfaces of the additive manufacturing metal parts can be realized by repeatedly scanning and processing the surfaces of the additive manufacturing metal parts through utilizing millisecond pulse laser and nanosecond pulse laser; during the multi-laser scanning polishing process, the additive manufacturing metal parts are subjected to thermal preservation treatment, so that the stress on the surfaces of the additive manufacturing metal parts can be evenly distributed; laser scanning reinforcement is carried out on the surfaces of the laser-polished additive manufacturing metal parts, so that the stress state on the surfaces of the additive manufacturing metal parts can be changed into pressure stress from tensile stress, the anti-fatigue property of the additive manufacturing metal parts can be enhanced, and the usage performance of the metal parts can be met; compared with a manual polishing method, the multi-laser polishing and reinforcement efficiency of the additive manufacturing metal parts is high and is as 20 times as that of the manual polishing, the non-contact rapid polishing of the additive manufacturing metal parts can be realized, the tensile stress, caused by the laser polishing, of the additive manufacturing metal parts can be eliminated, and the anti-fatigue property of the additive manufacturing metal parts can be enhanced.

Owner:XI AN JIAOTONG UNIV

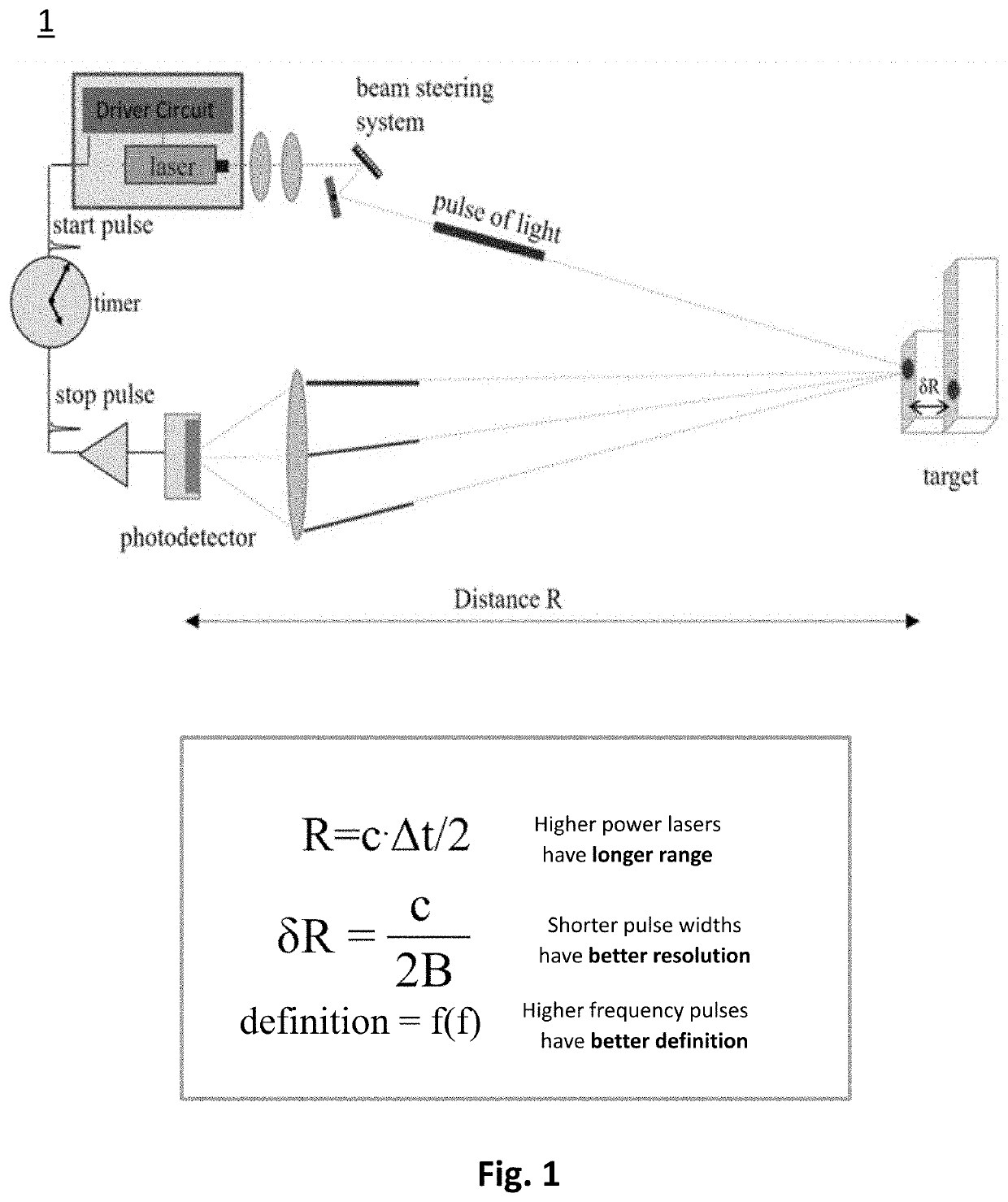

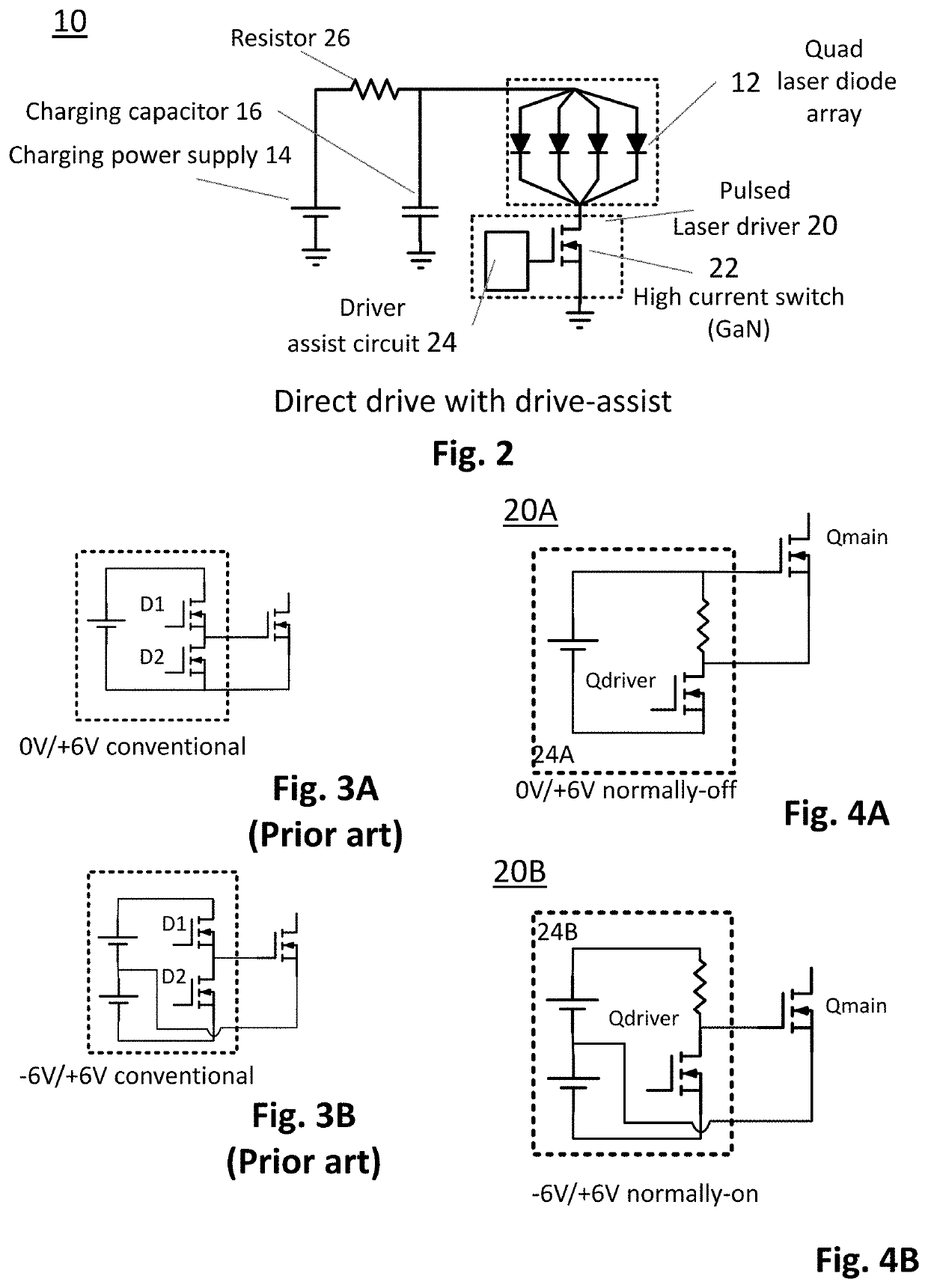

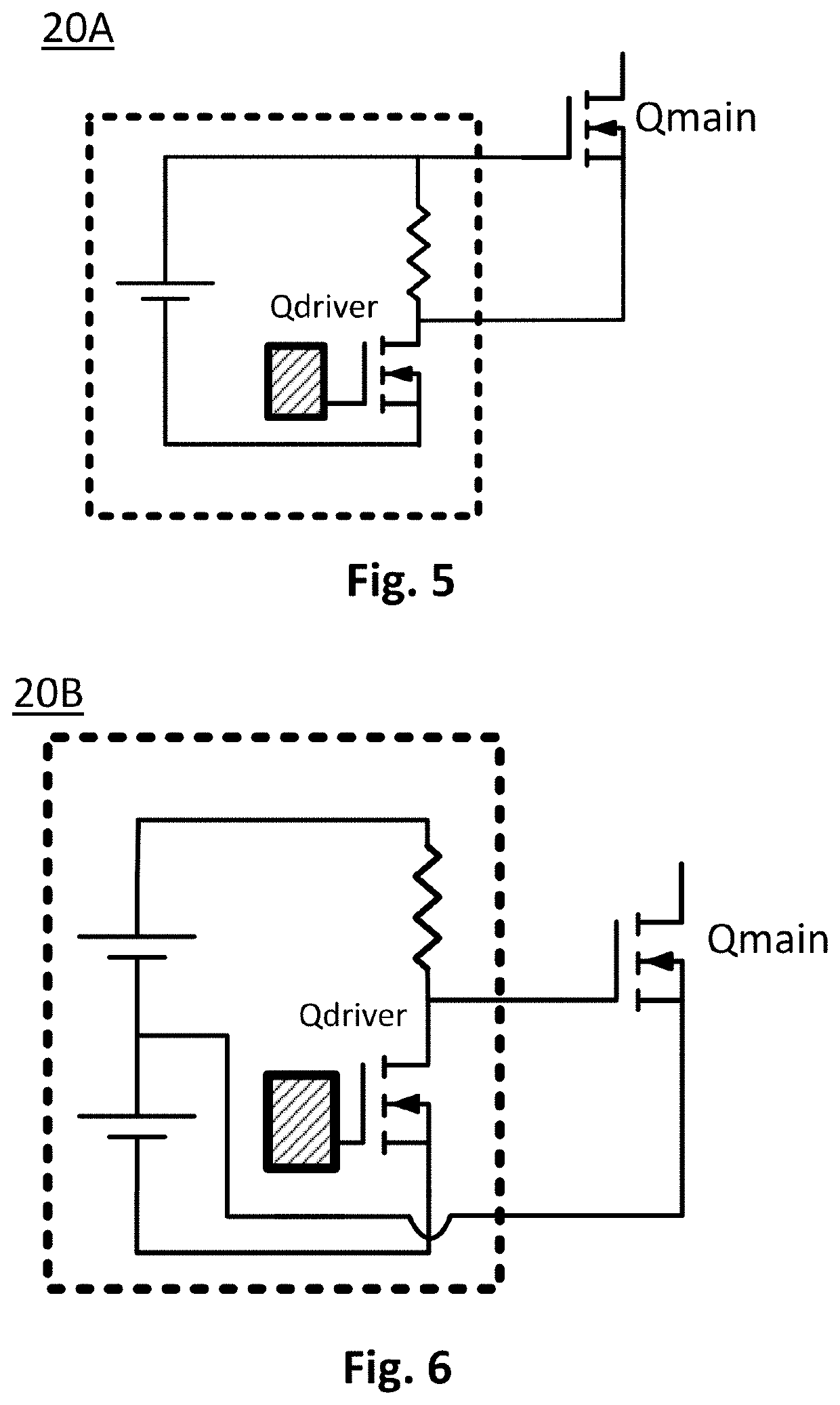

Fast pulse, high current laser drivers

PendingUS20210111533A1Quick switchHigh peak powerSemiconductor laser arrangementsLaser arrangementsHemt circuitsFast charging

Pulsed laser drivers are disclosed comprising Gallium Nitride (GaN) power transistors for driving diode laser systems requiring high current and fast pulses, such as laser drivers for LIDAR (Light Detection and Ranging) systems. Drivers are capable of delivering pulses with peak current ≥100 A, e.g. 170 A to provide high peak power, fast pulses with nanosecond rise times and nanosecond pulse duration, for driving multi-channel laser diode arrays with 40 A per channel for 120 W output per channel for a combined peak output of 480 W. For lower duty cycle, example driver circuits are disclosed comprising a high current power transistor for direct drive with drive assist. For higher duty cycle, example resonant driver circuits are disclosed comprising two high current power transistors. Implementation of resonant driver circuits with GaN technology provides fast charging for short pulse operation at higher repetition rates or for pulse code modulation.

Owner:GAN SYST

Method for treating neurological disorders, including tumors, with electroporation

ActiveUS20190232048A1Accurate and precise mannerAvoiding undesired electroporation of surroundingHead electrodesSurgical needlesAbnormal tissue growthImaging quality

This disclosure describes the methods, devices, and systems of treating diseased tissue with integrated nanosecond pulse irreversible electroporation. Methods and systems as disclosed provide MRI compatible shielded electrodes and electrode leads to prevent emanating radiofrequency noise and improve image quality, disconnecting the electrode from the cable linkage to the pulse generator reduce electromagnetic interference and image artifacts, placing electrodes strategically within a guide cannula to minimize distortion from heterogeneities or maximize ablation within the tissue, utilizing conductive fluids, innate or external, such as cerebral spinal fluid or grounding pads to provide a pathway for current return, and for timing of the electrical waveforms with inherent brain electrical activity.

Owner:VIRGINIA TECH INTPROP INC +1

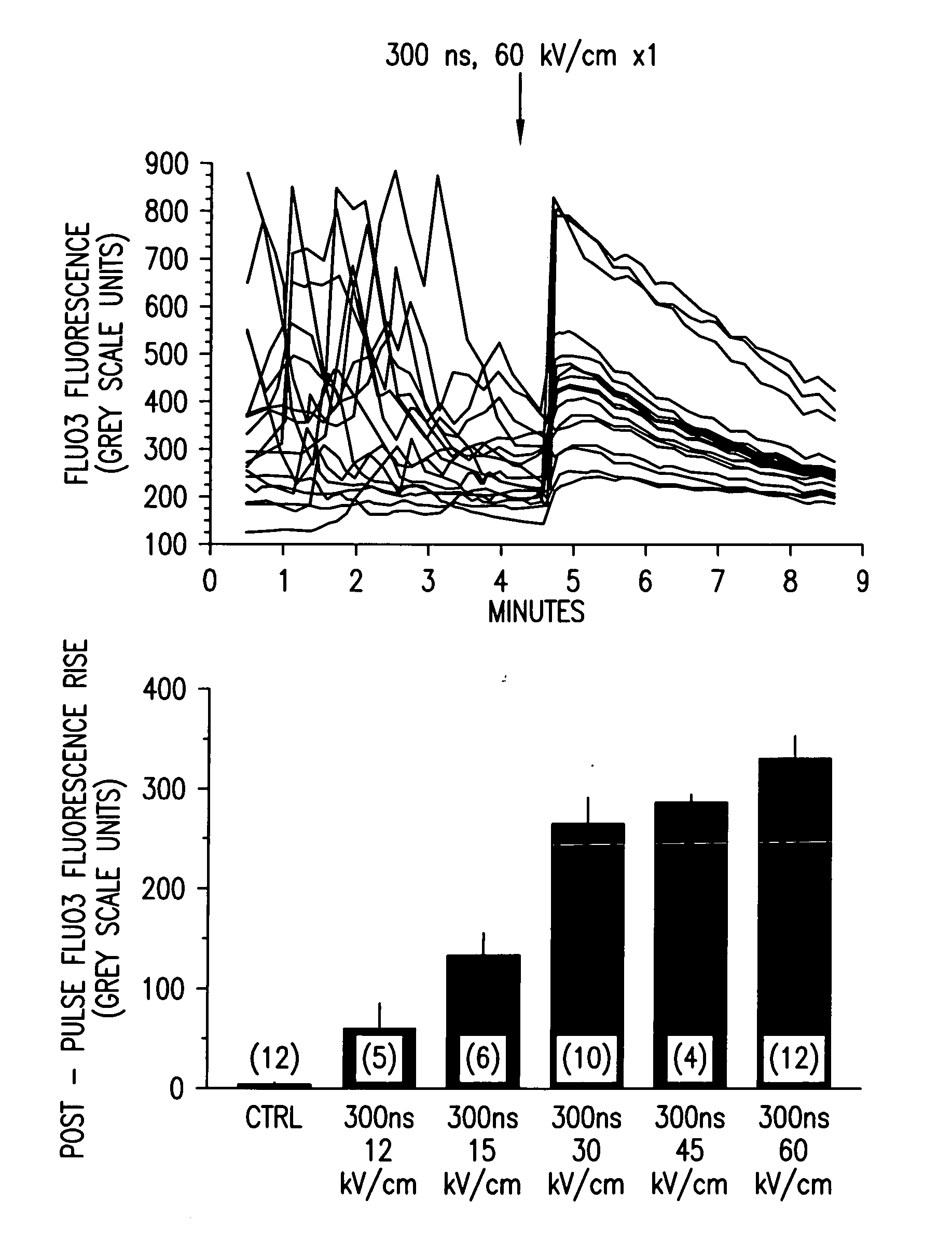

Activation of calcium-mediated cell functions in cells and tissues, including aggregation of human platelets, by nanosecond pulsed electric fields

Methods for inducing calcium mobilization in cells through the application of nanosecond pulsed electric fields (“nsPEFs”) are provided. The invention also provides a method of increasing intracellular calcium in cells through the application of nsPEFs. In one embodiment of the invention, the cells are human platelets, whereby activation and aggregation of the platelets is induced. Methods for treating an injury, trauma, or loss of blood in a subject, through the application of nsPEFs are also provided.

Owner:EASTERN VIRGINIA MEDICAL SCHOOL +1

Laser system for generation of high-power sub-nanosecond pulses with controllable wavelength in 2-15 mum region

A laser system capable of efficient production of high energy sub-nanosecond pulses in the 2-15 μm spectral region is disclosed. Diode pumped solid state lasers are used as pump sources. The system design is simple, reliable and compact allowing for easy integration. The laser system includes a combination of compact solid-state ˜1 micron laser sources, producing high power picosecond pulses, with optical parametric amplification and a quasi-continuous wave laser for seeding the amplification process that enables the efficient conversion of the high power ˜1 micron laser radiation to tuneable mid-infrared sub-ns pulses. New parametric processes are presented for achieving high gains in bulk nonlinear crystals. Furthermore, a method of exceeding the fundamental conversion efficiency limit of direct three wave mixing is presented. The compact and robust nature of this novel laser system opens up the use of high power and high peak power mid-infrared laser pulses to a wide variety of important medical and dental applications.

Owner:LIGHT MATTER INTERACTION INC

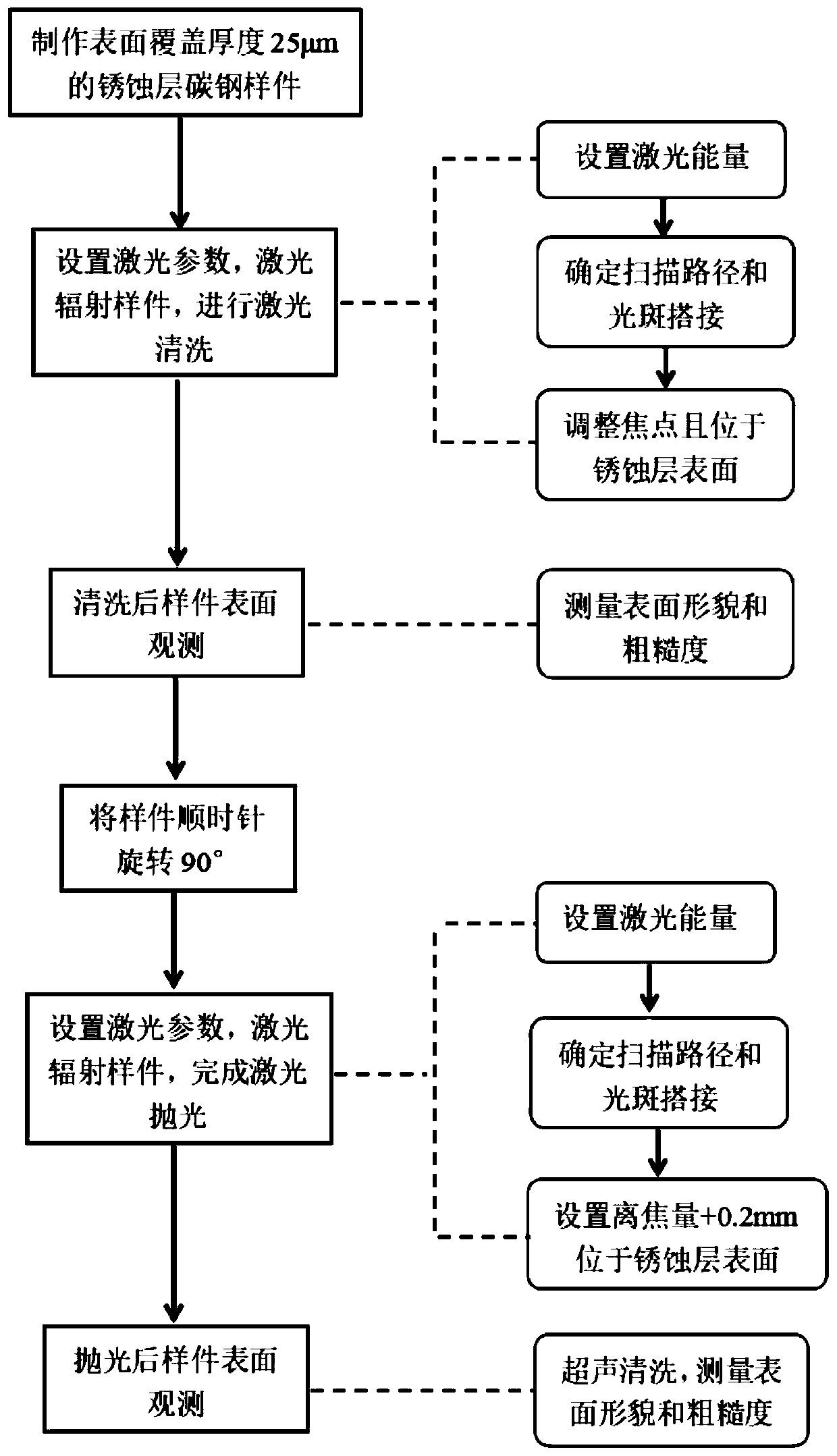

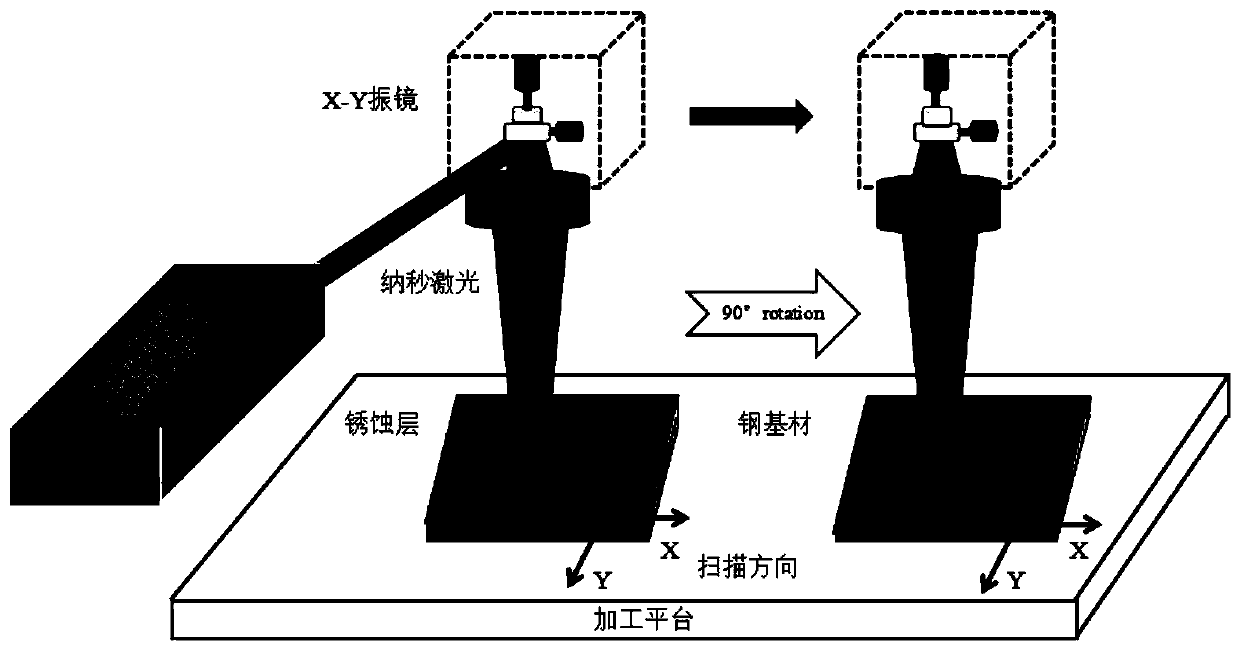

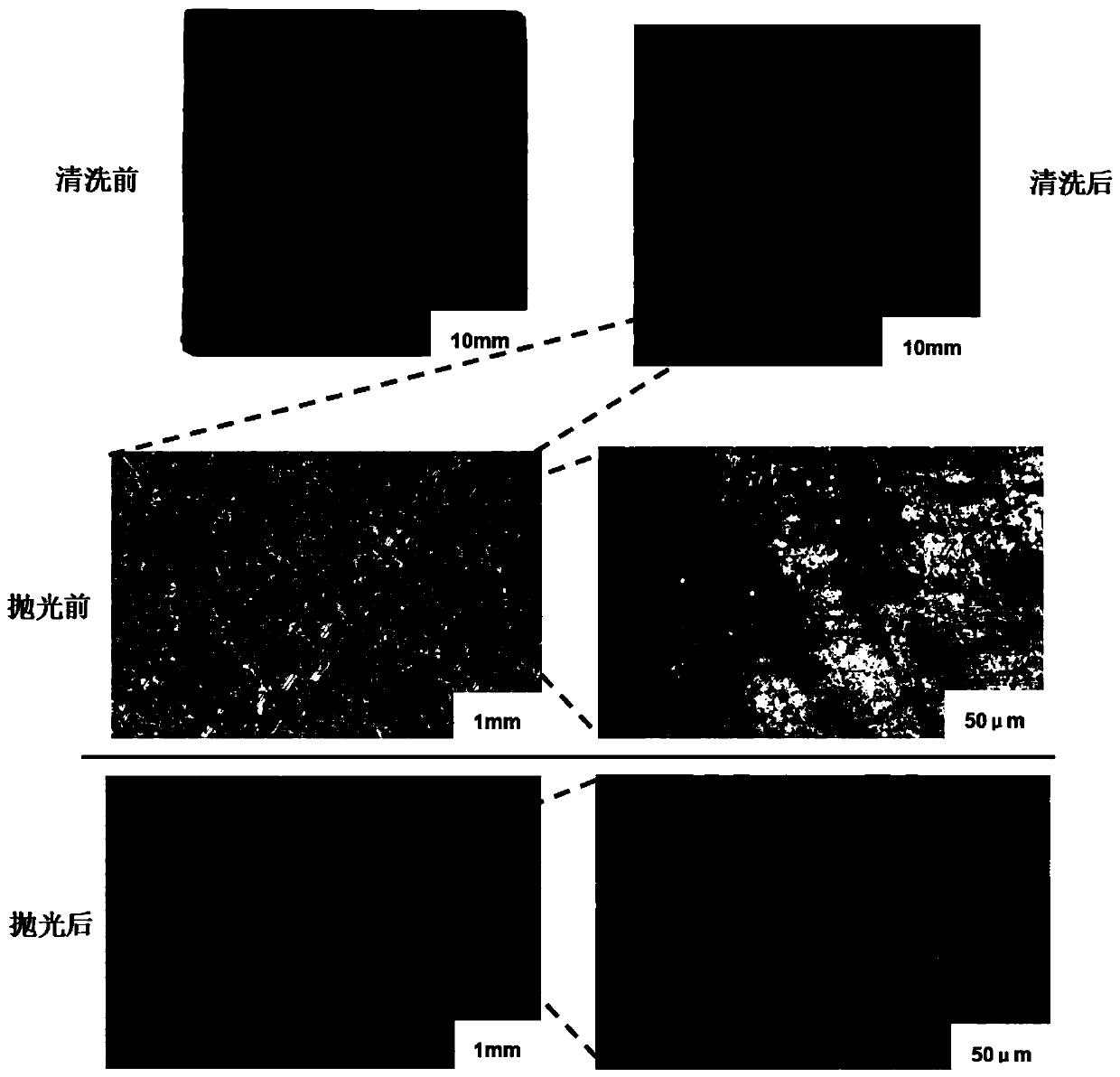

Laser cleaning and polishing composite processing method for surface of carbon steel

ActiveCN109773340AConditions that affect the performance of the matrixAvoid damageWelding/soldering/cutting articlesLaser beam welding apparatusLaser processingNanosecond pulse

The invention discloses a laser cleaning and polishing composite processing method for the surface of carbon steel. By means of the method, laser cleaning and laser polishing processes are seamlesslycombined and used on the same equipment. The method can be widely applied to surface laser processing of steel parts. A nanosecond pulse laser with a certain output energy range is used, so that a corrosion layer can be evaporated; the corrosion layer on the surface of the carbon steel is quickly removed by utilizing primary laser treatment; and then laser parameters are adjusted to radiate a cleaned surface to enable a protruding fused object on the carbon steel to flow and fill and solidify a sunken part, and the polished surface with small roughness and improved performance is obtained. Therefore, defects in the prior art are overcome, fusion pits and micro-scale defects of the surface of the carbon steel after laser cleaning can be effectively repaired, the surface roughness is reduced, and the purposes of improving the laser processing efficiency of the carbon steel and keeping the surface performance are achieved.

Owner:GUANGDONG UNIV OF TECH

Nanosecond pulse superposition direct current power supply device used for plasma ignition

InactiveCN106900135AReduce volumeCompact structureDc-dc conversionPulse generation by energy-accumulating elementHigh energyHigh-voltage direct current

The invention discloses a self-designed-and-constructed power supply device for performing plasma ignition with high-energy nanosecond pulse superposed high voltage direct current, which comprises a DC high voltage power supply, a nanosecond pulse power supply and a nanosecond pulse integrated DC circuit. High voltage DC output and nanosecond pulse output are superposed via nanosecond pulse integrated DC circuit to obtain a nanosecond pulse superimposed DC power supply, applied to the load. The self-designed-and-constructed nanosecond pulse superposed direct current power supply device for performing plasma ignition is small in size, compact in structure and low in cost. The high voltage DC power supply and the nanosecond pulse power supply are integrated, which has the advantages of high discharge energy and device miniaturization and facilitates the usage. In the practical application, the power supply device can be used for internal combustion engine ignition and supersonic-speed airspace engine ignition.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com