Patents

Literature

564 results about "Full width at half maximum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Full width at half maximum (FWHM) is an expression of the extent of function given by the difference between the two extreme values of the independent variable at which the dependent variable is equal to half of its maximum value. In other words, it is the width of a spectrum curve measured between those points on the y-axis which are half the maximum amplitude. Half width at half maximum (HWHM) is half of the FWHM if the function is symmetric.

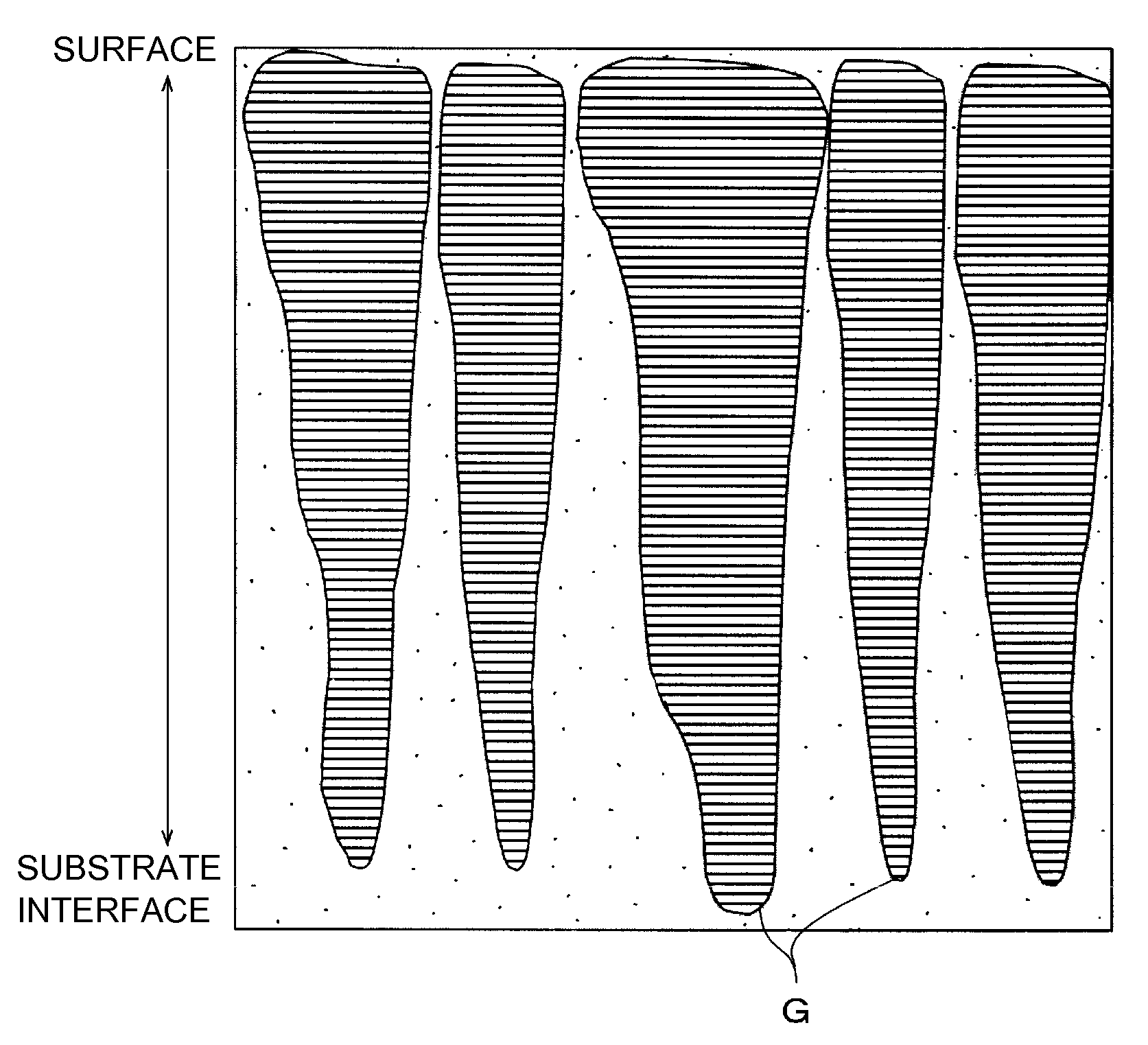

Transparent conductive film and method for manufacturing the same

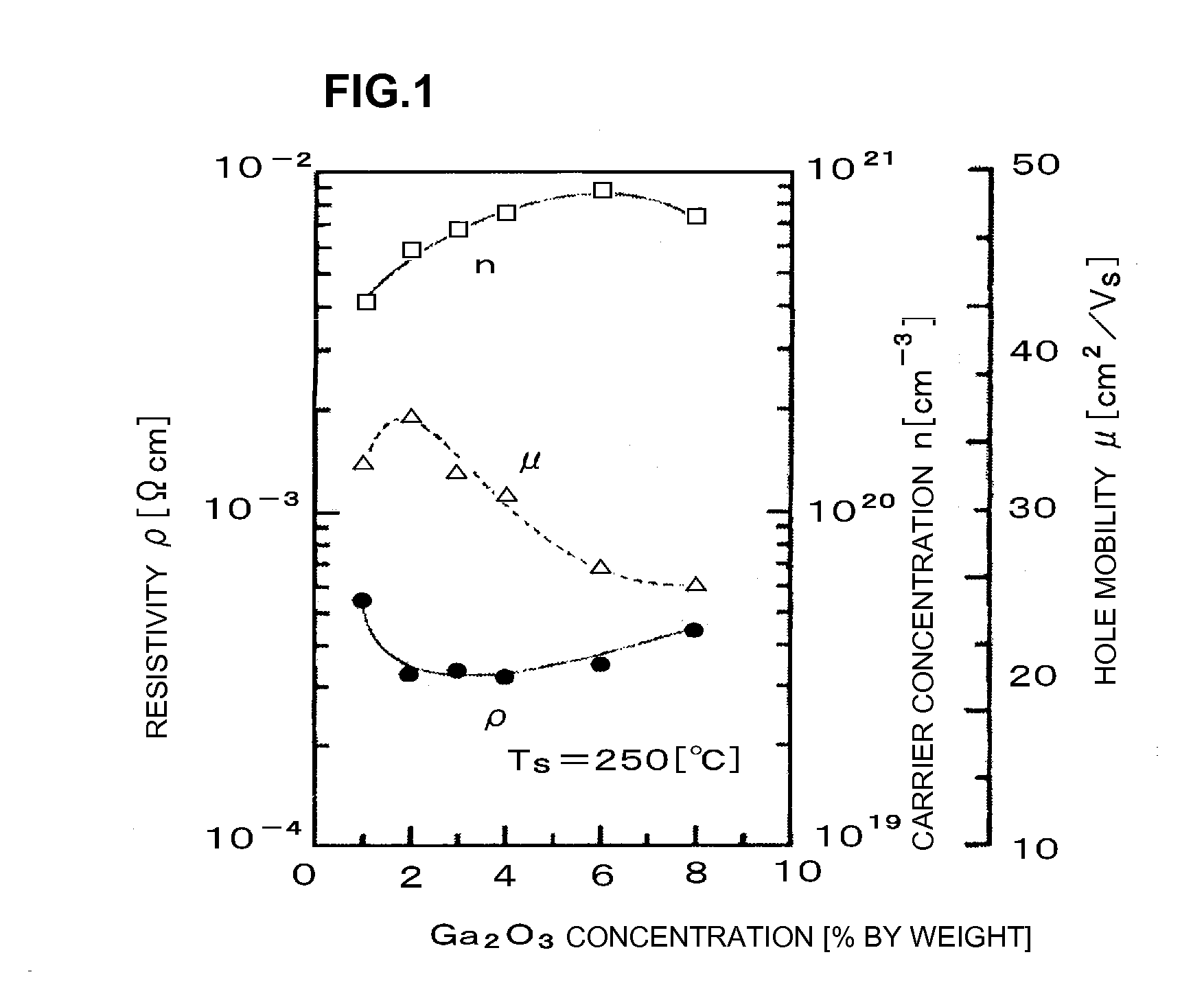

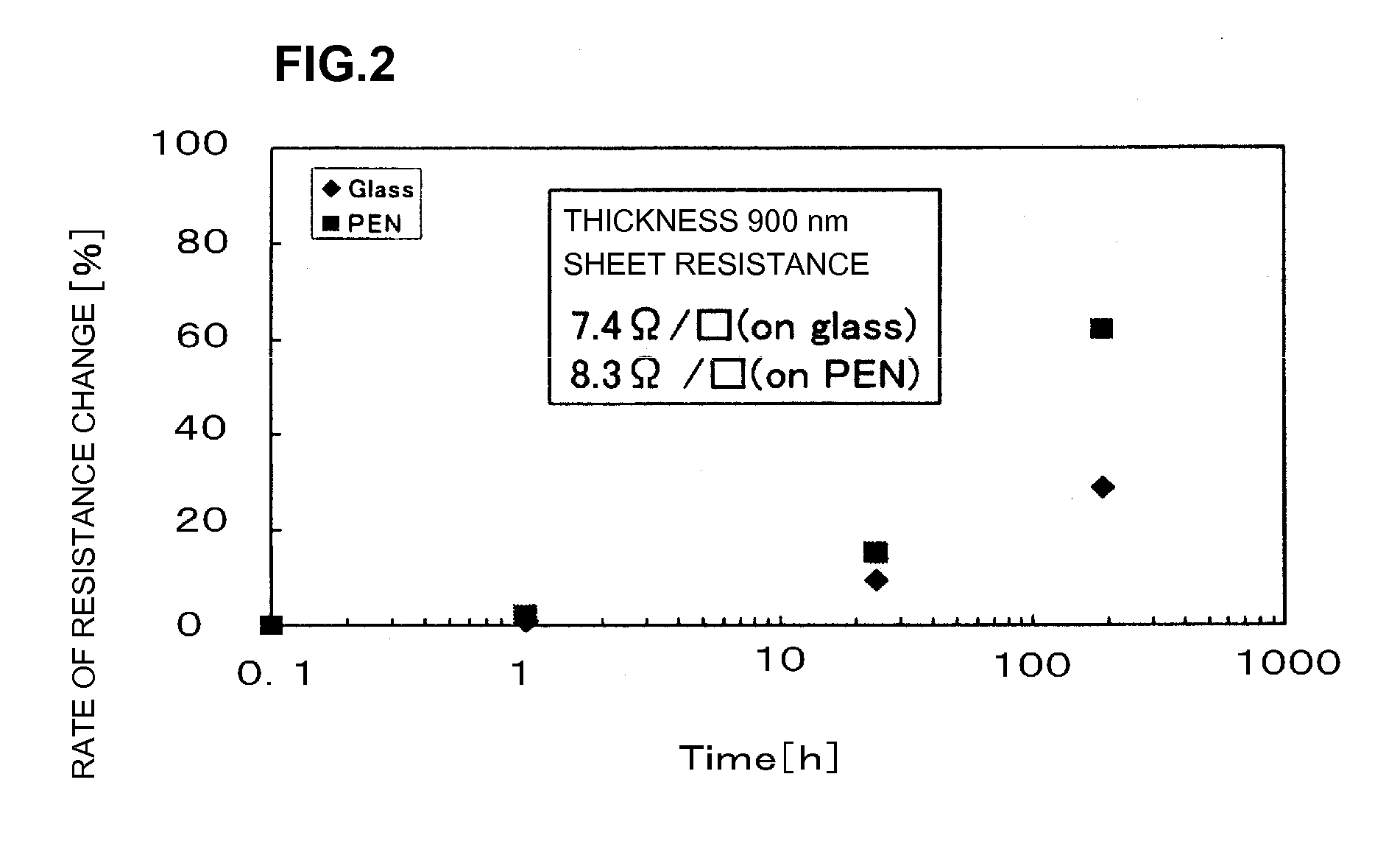

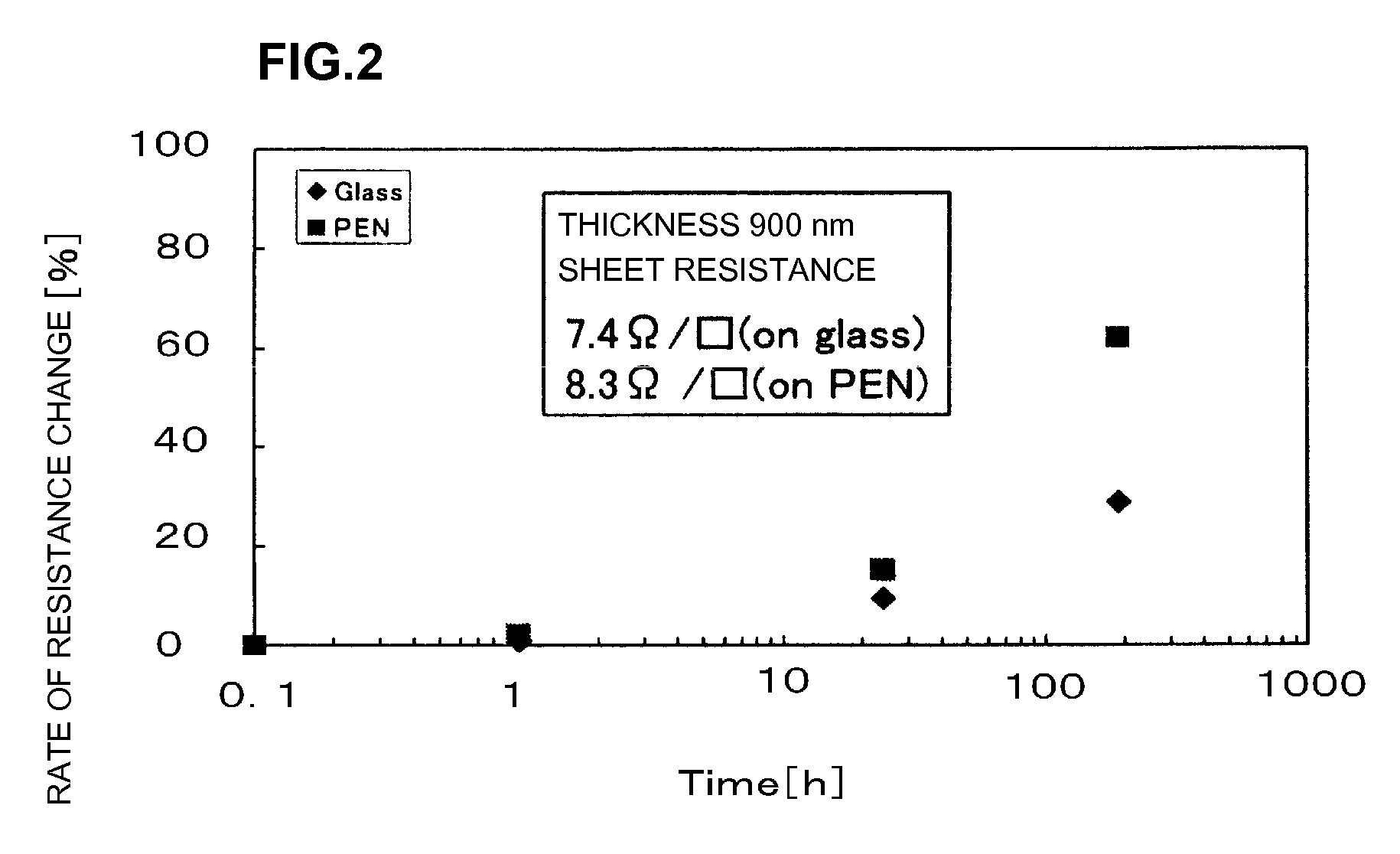

ActiveUS20080050595A1Improve economyConductive layers on insulating-supportsSynthetic resin layered productsRocking curveFull width at half maximum

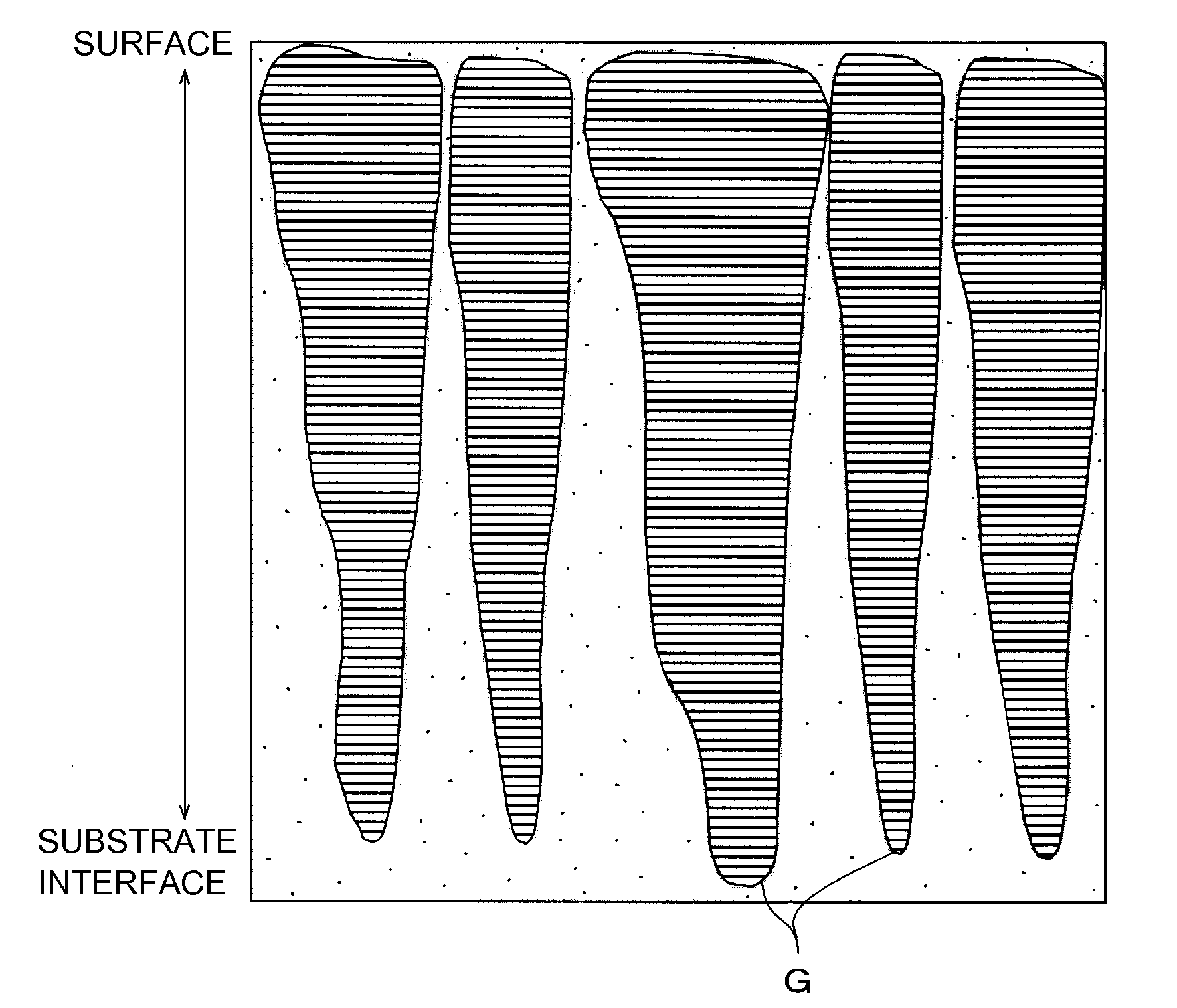

A ZnO-based transparent conductive film has practicable moisture resistance, desired characteristics of a transparent conductive film, and excellent economy. The transparent conductive film is produced by growing ZnO doped with a group III element oxide on a substrate and has a region with a crystal structure in which a c-axis grows along a plurality of different directions. The transparent conductive film produced by growing ZnO doped with a group III element oxide on a substrate has a ZnO (002) rocking curve full width at half maximum of about 13.5° or more.ZnO is doped with a group III element oxide so that the ratio of the group III element oxide in the transparent conductive film is about 7% to about 40% by weight.The transparent conductive film is formed on the substrate with a SiNx thin film provided therebetween.The transparent conductive film is formed on the substrate by a thin film formation method with a bias voltage applied to the substrate.

Owner:MURATA MFG CO LTD

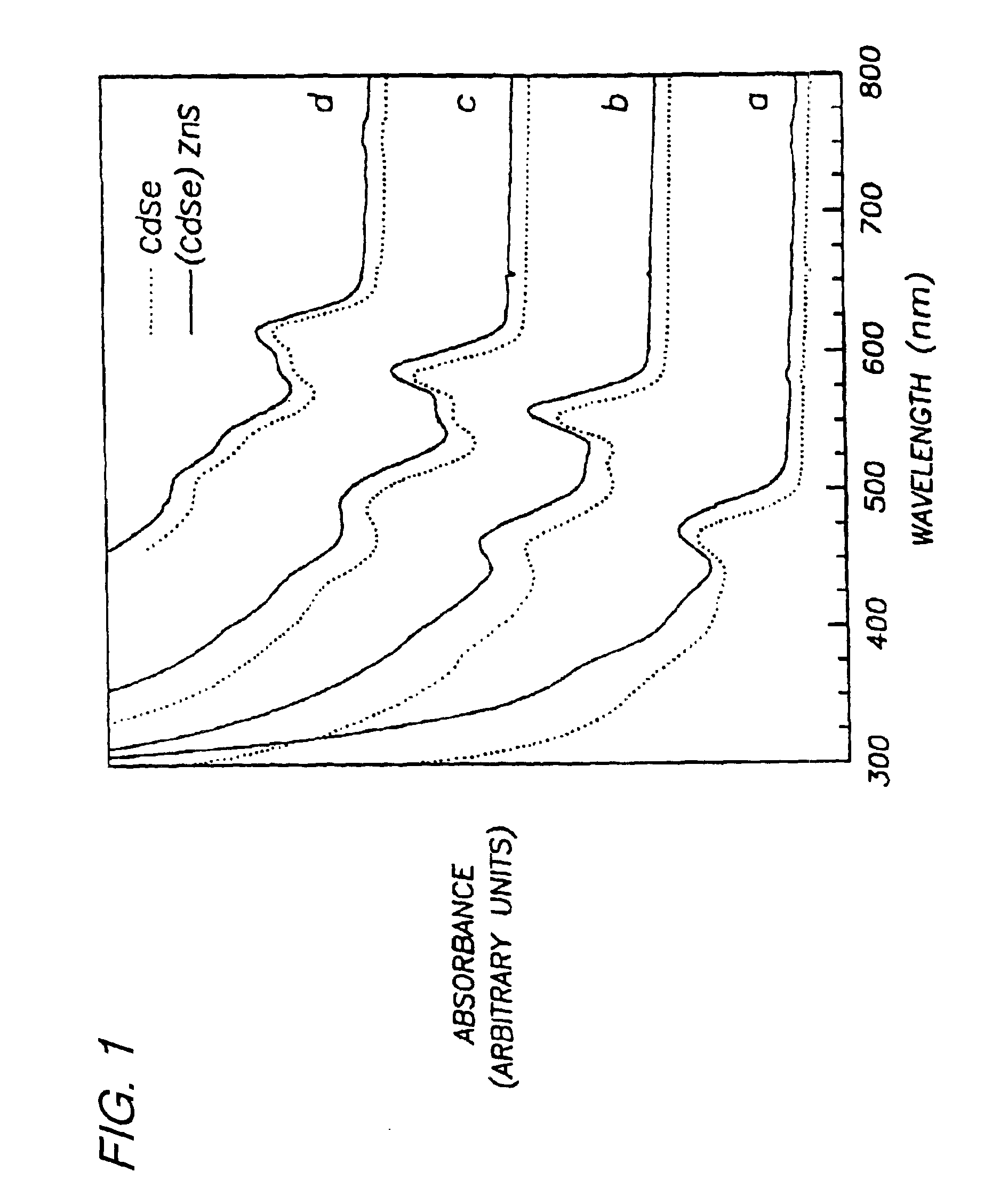

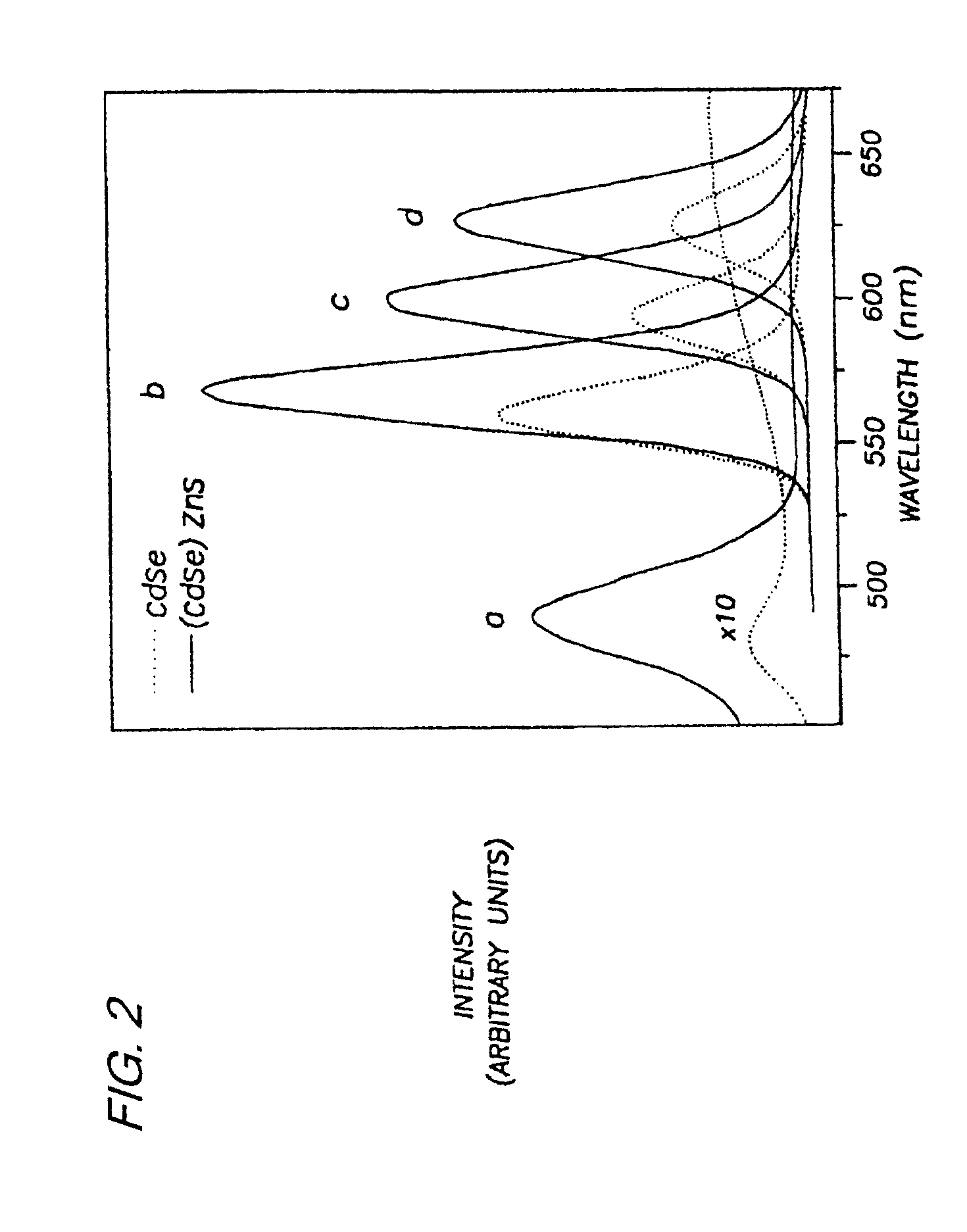

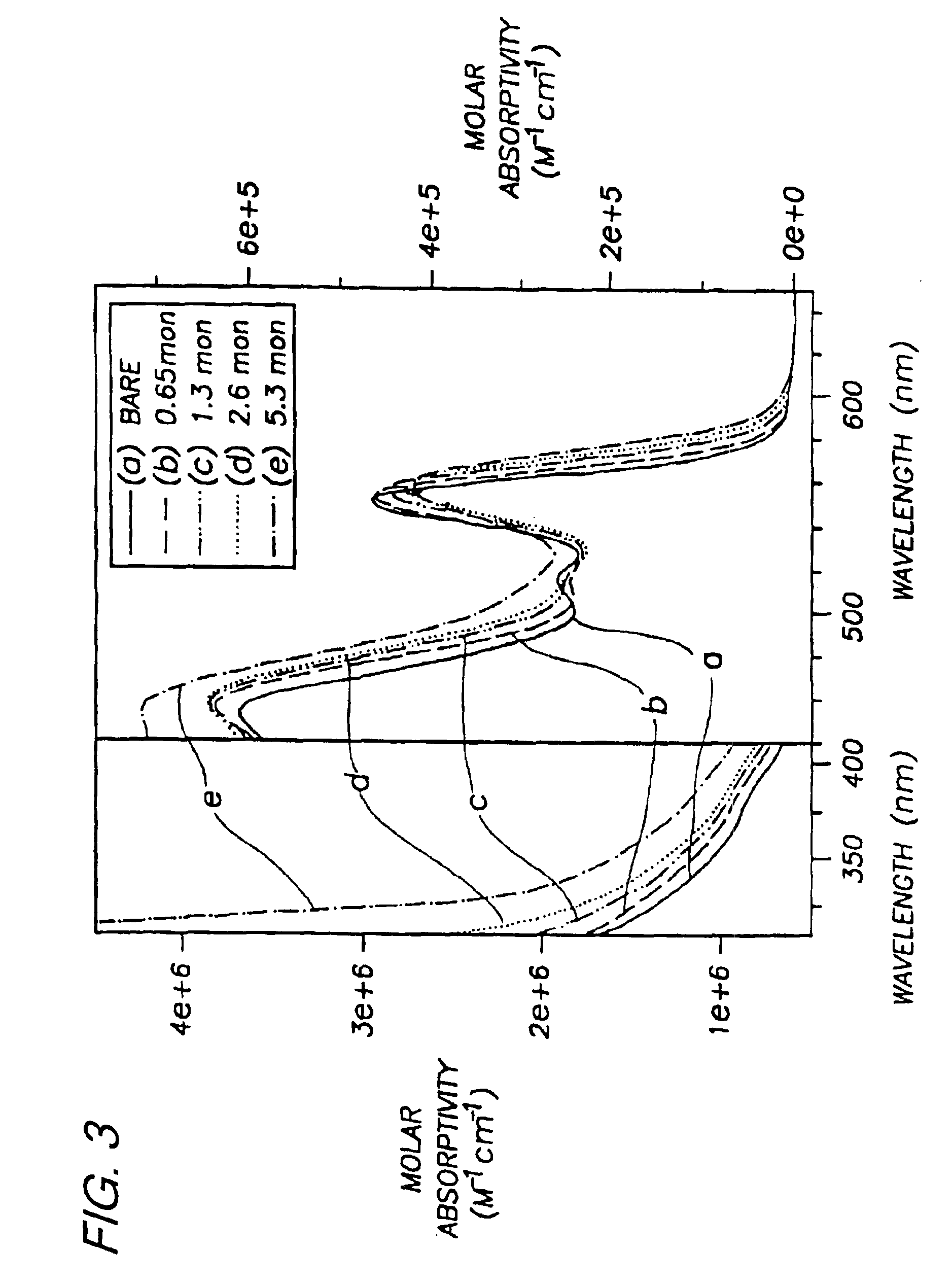

Highly luminescent color selective nanocrystalline materials

InactiveUS6861155B2Improve coordinationMaterial nanotechnologyFrom normal temperature solutionsQuantum yieldPhotoluminescence

A coated nanocrystal capable of light emission includes a substantially monodisperse nanoparticle selected from the group consisting of CdX, where x=S, Se, Te and an overcoating of ZnY, where Y=S, Se, uniformly deposited thereon, said coated nanoparticle characterized in that when irradiated the particles exhibit photoluminescence in a narrow spectral range of no greater than about 60 nm, and most preferably 40 nm, at full width half max (FWHM). The particle size of the nanocrystallite core is in the range of about 20 Å to about 125 Å, with a deviation of less than 10% in the core. The coated nanocrystal exhibits photoluminescence having quantum yields of greater than 30%.

Owner:MASSACHUSETTS INST OF TECH

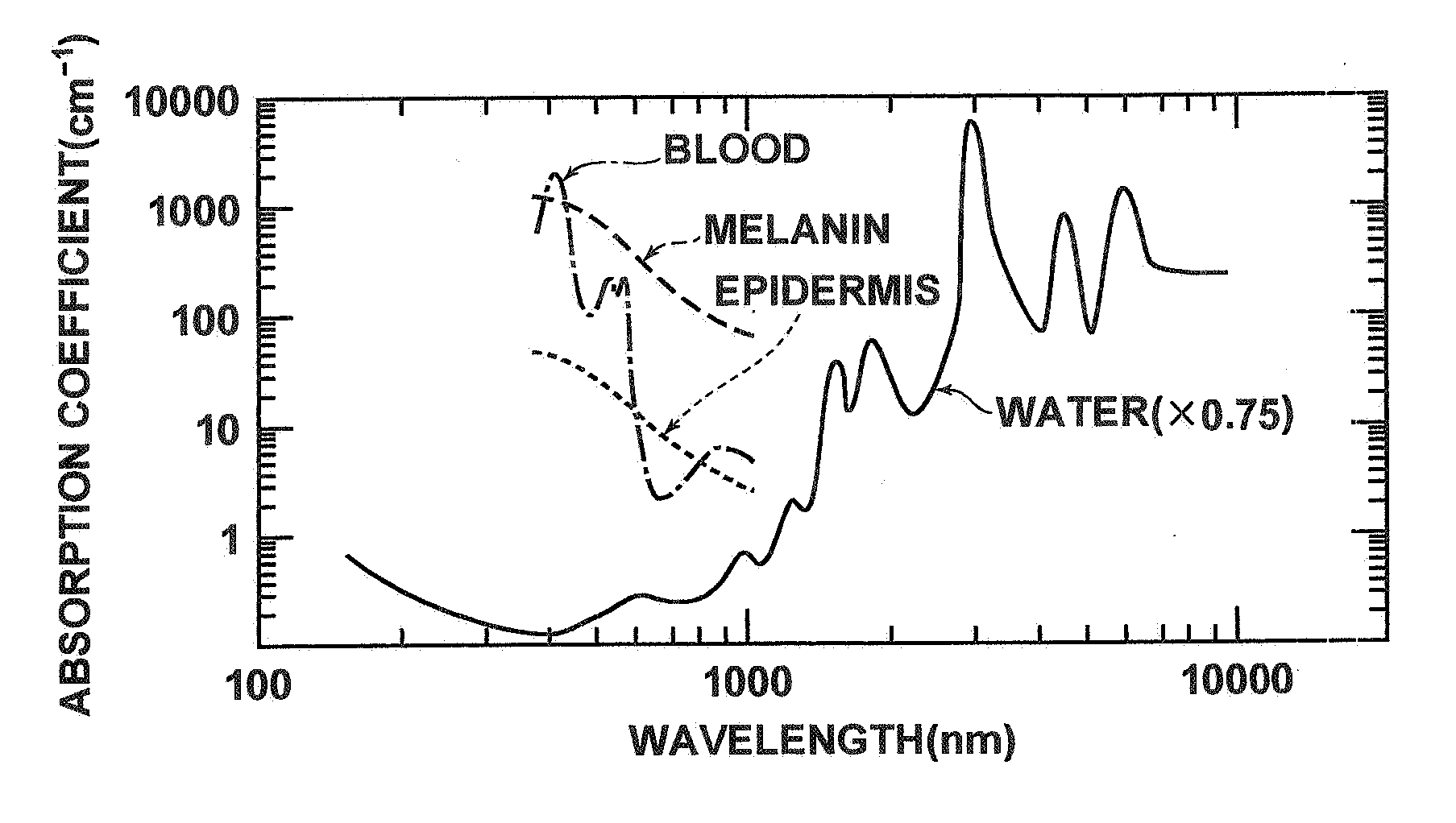

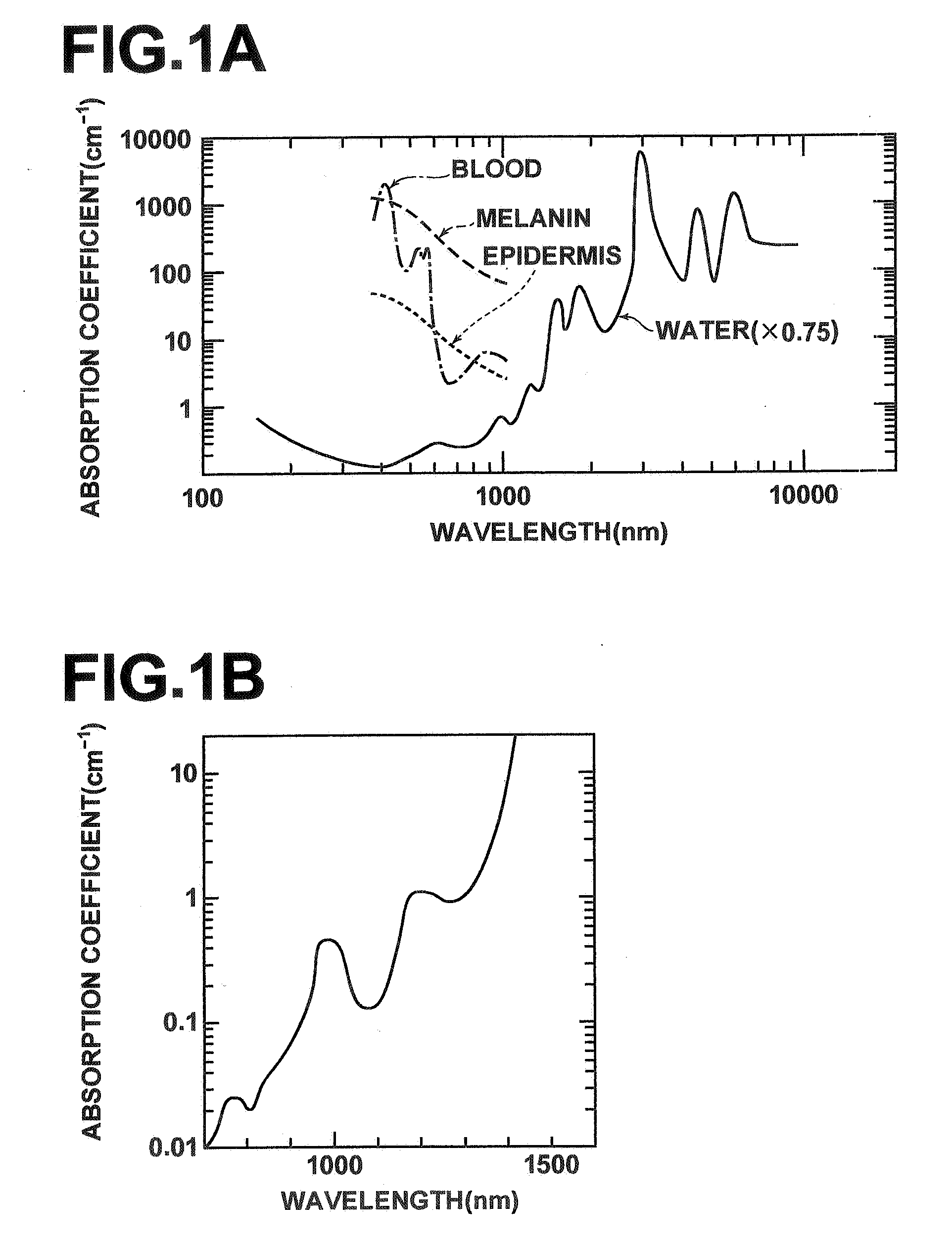

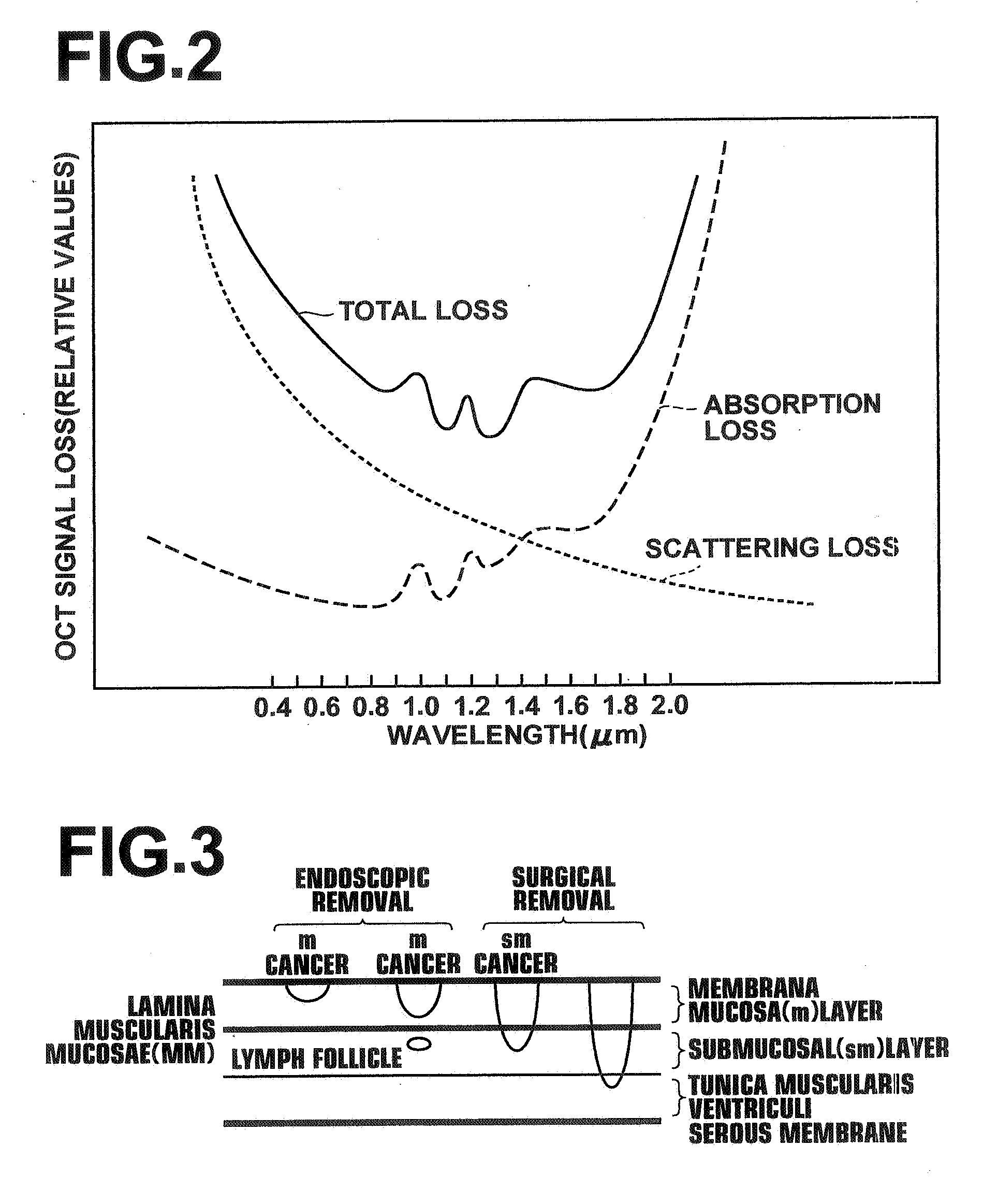

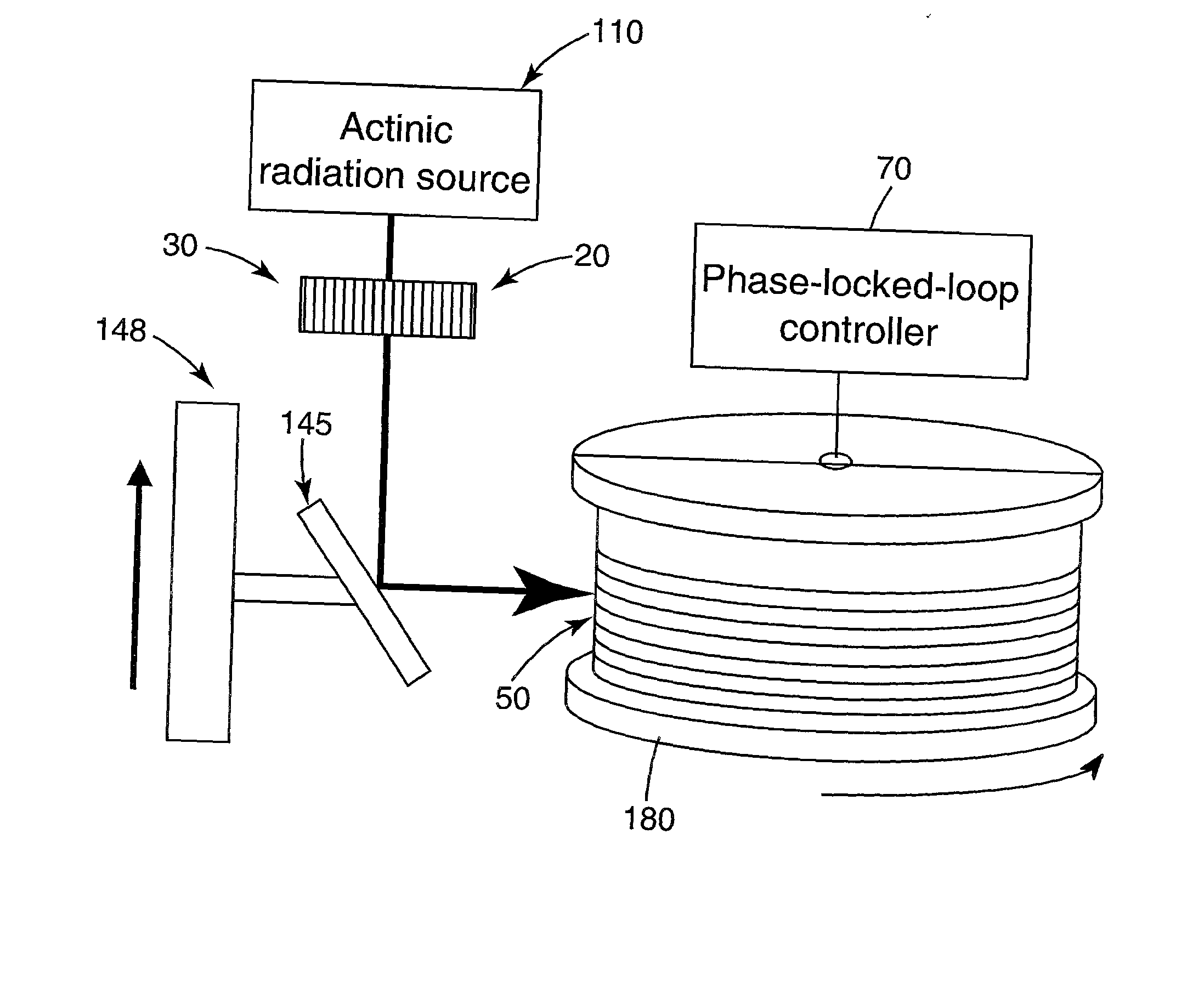

Optical tomography apparatus

ActiveUS20070019208A1High resolutionMaintain good propertiesMaterial analysis by optical meansCatheterMultiplexingDiffusion

Low coherence light having a central wavelength λc of 1.1 μm and a full width at half maximum spectrum Δλ of 90 nm is emitted. The low coherence light has wavelength properties suited for the light absorbing properties, the diffusion properties, and the dispersion properties of living tissue. A light dividing means divides the low coherence light into a measuring light beam, which is irradiated onto a measurement target via an optical probe, and a reference light beam that propagates toward an optical path length adjusting means. A multiplexing means multiplexes a reflected light beam, which is the measuring light beam reflected at a predetermined depth of the measurement target, and the reference light beam, to form coherent light. A coherent light detecting means detects the optical intensity of the multiplexed coherent light. An image obtaining means performs image processes, and displays an optical tomographic image on a display apparatus.

Owner:FUJIFILM HLDG CORP +1

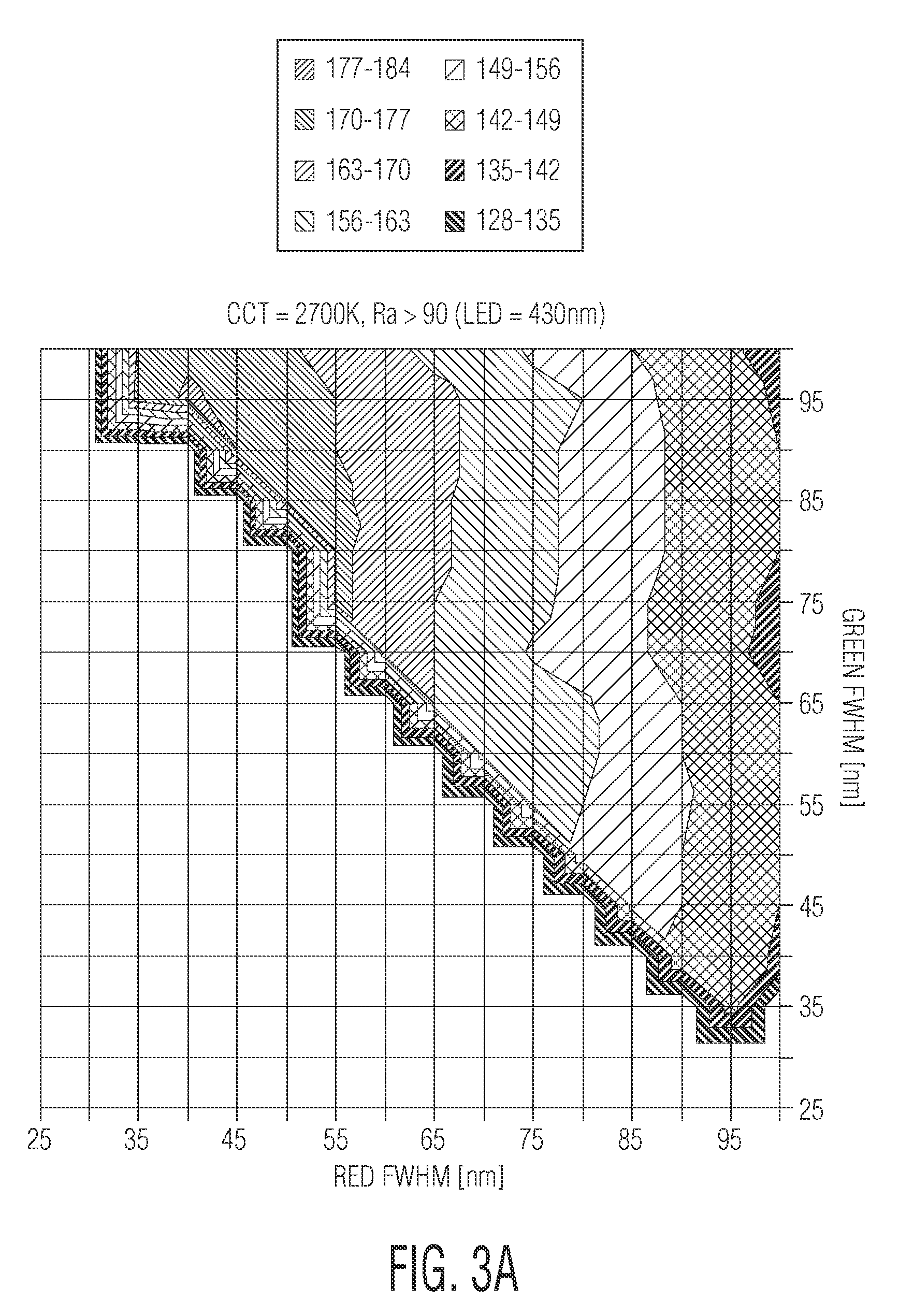

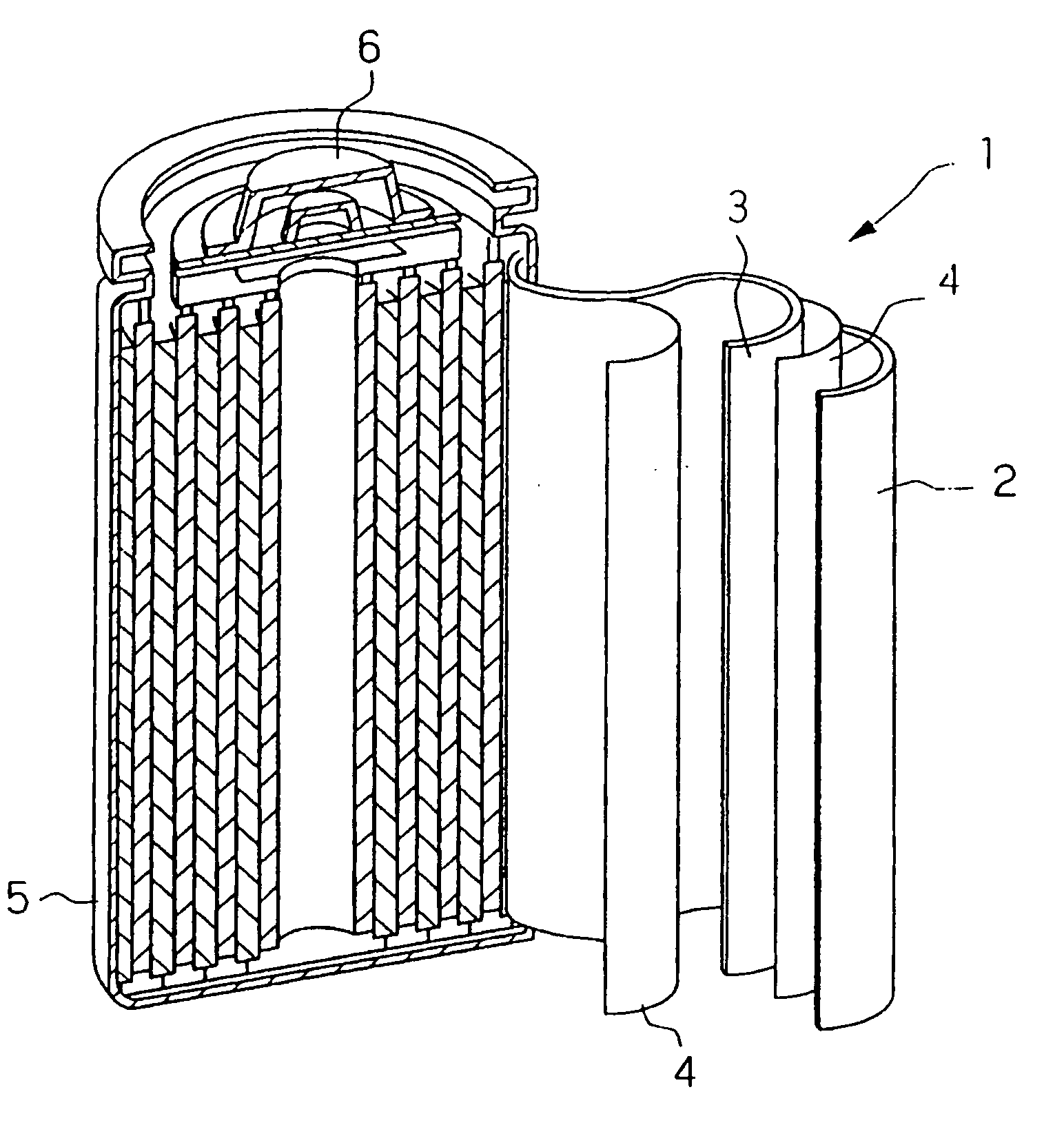

Wavelength conversion for producing white light from high power blue LED

InactiveUS20100289044A1Reduce energy consumptionElectroluminescent light sourcesGas discharge lamp usageFull width at half maximumJunction temperature

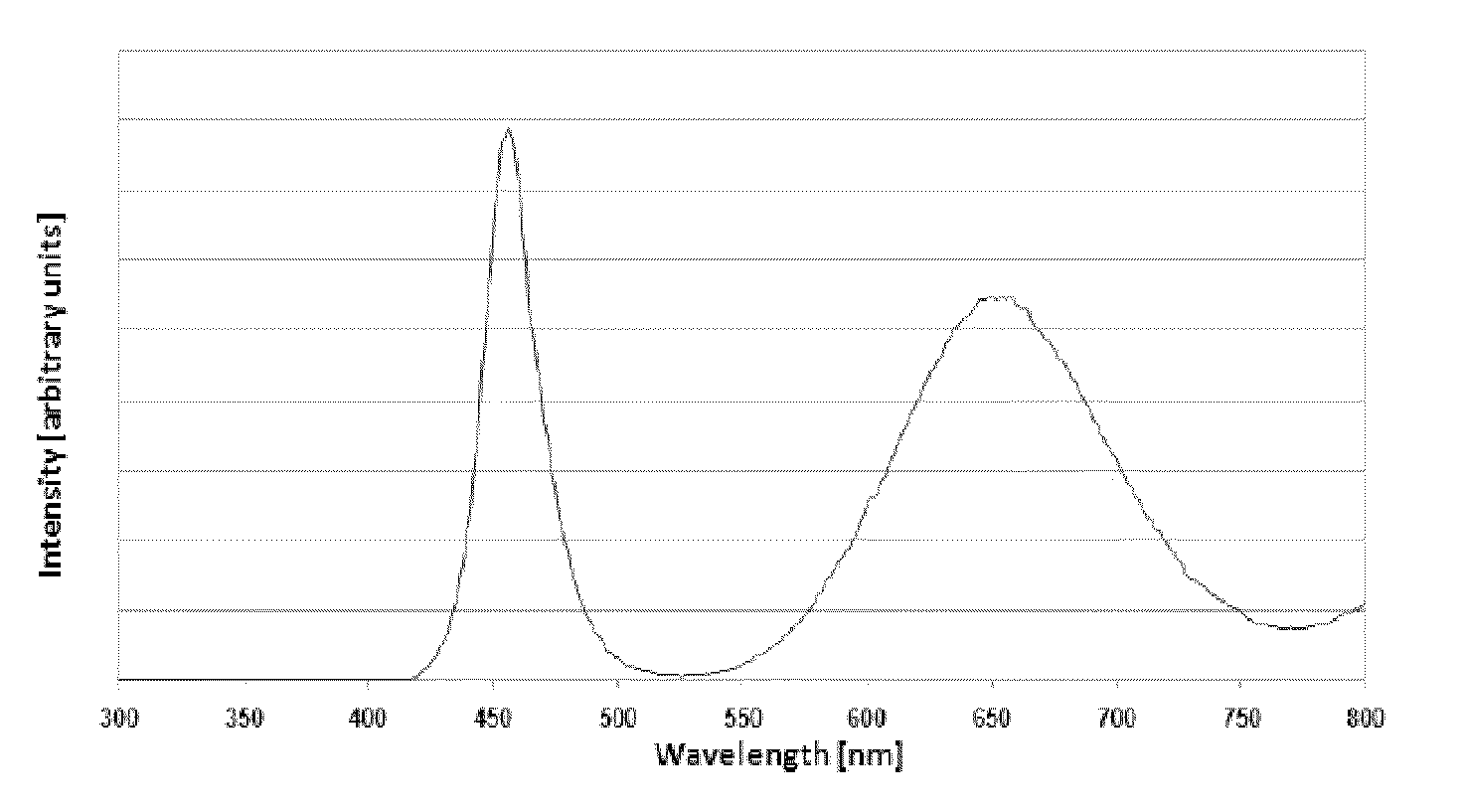

A white light LED is described that uses an LED die that emits visible blue light in a wavelength range of about 450-470 nm. A red phosphor or quantum dot material converts some of the blue light to a visible red light having a peak wavelength between about 605-625 nm with a full-width-half-maximum (FWHM) less than 80 nm. A green phosphor or quantum dot material converts some of the blue light to a green light having a FWHM greater than 40 nm, wherein the combination of the blue light, red light, and green light produces a white light providing a color rendering of Ra,8>90 and a color temperature of between 2500K-5000K. Preferably, the red and green converting material do not saturate with an LED die output of 100 W / cm2 and can reliably operate with an LED die junction temperature over 100 degrees C.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV +1

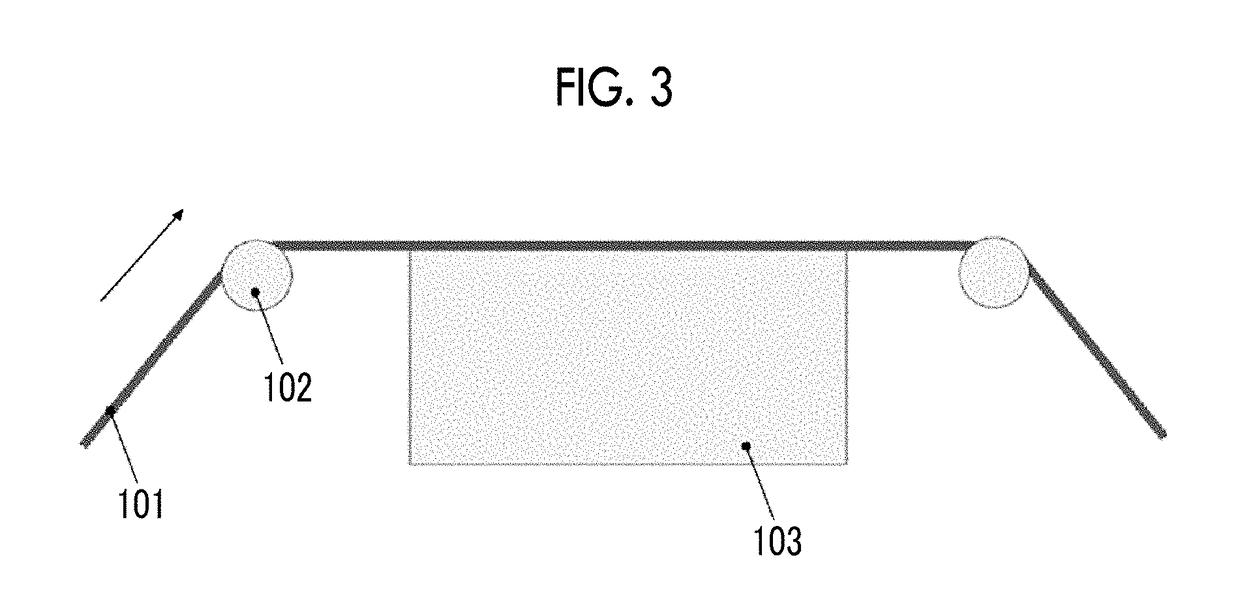

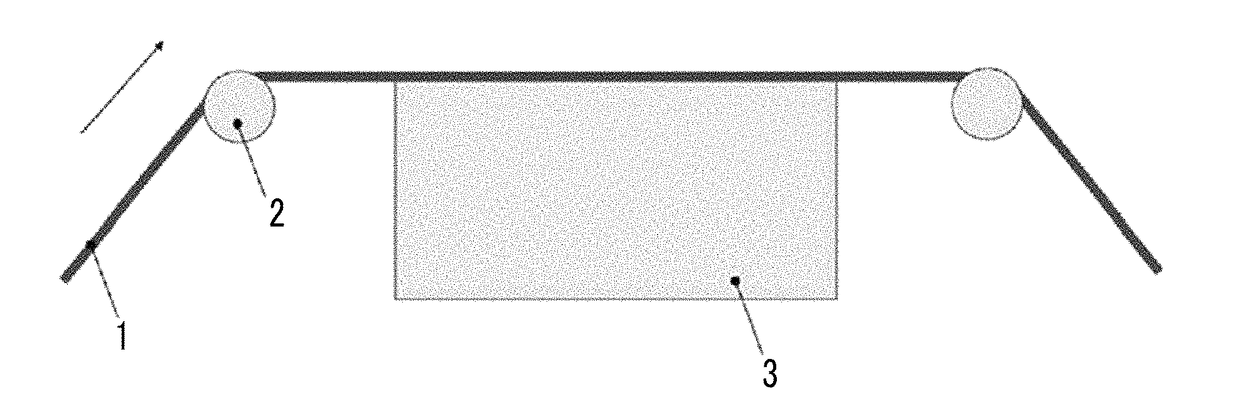

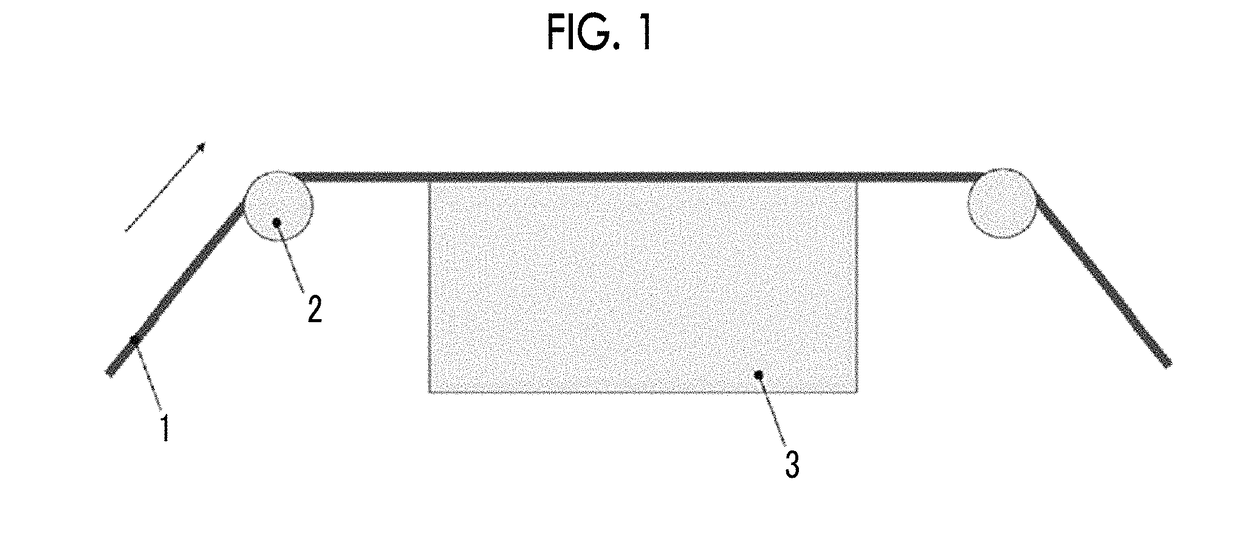

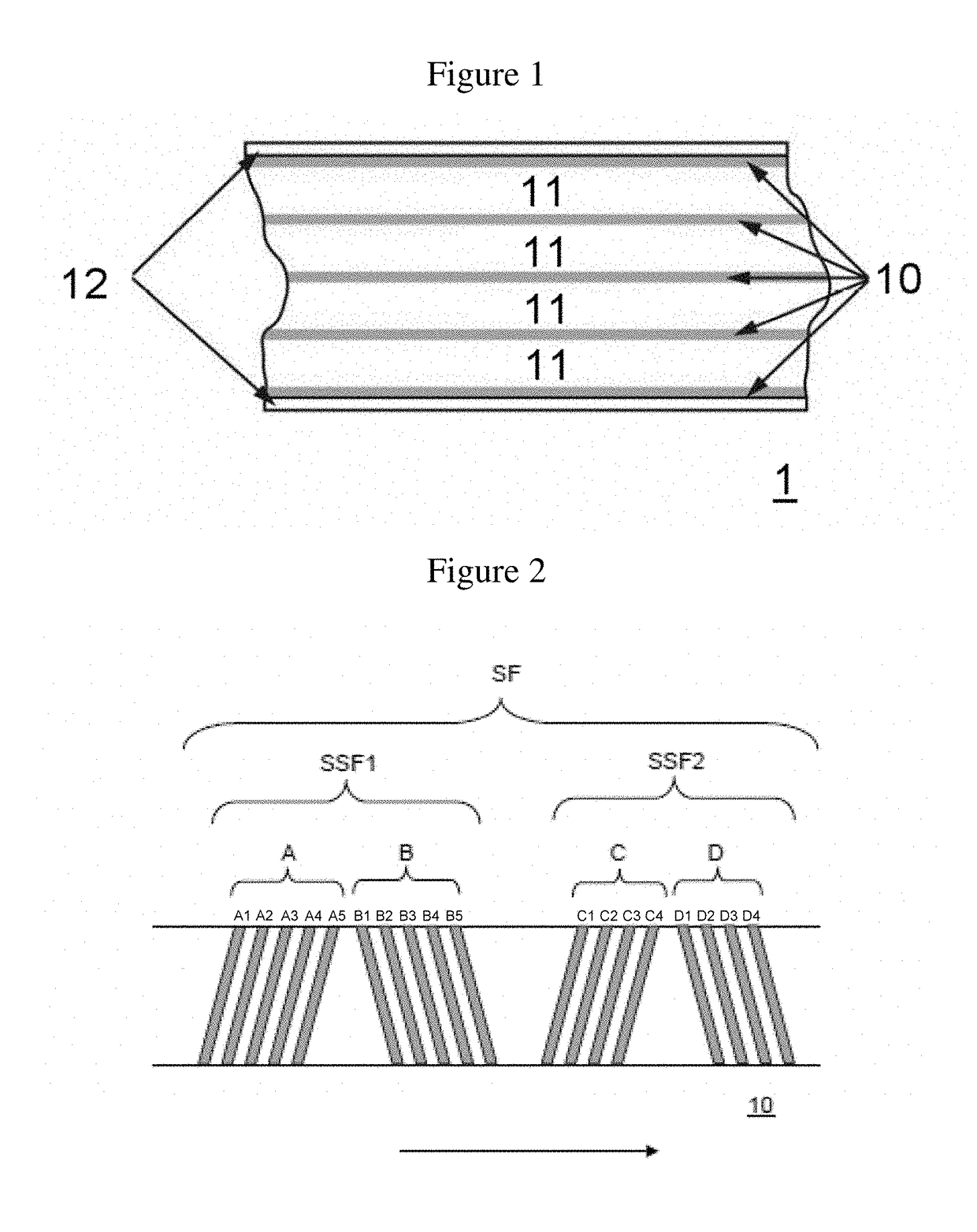

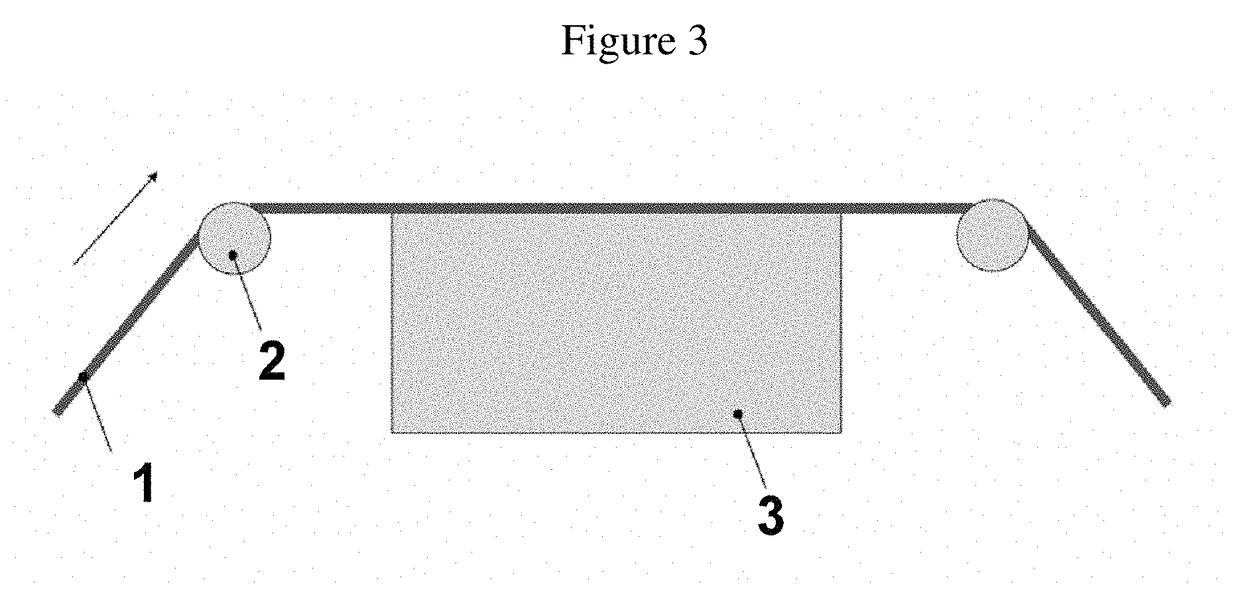

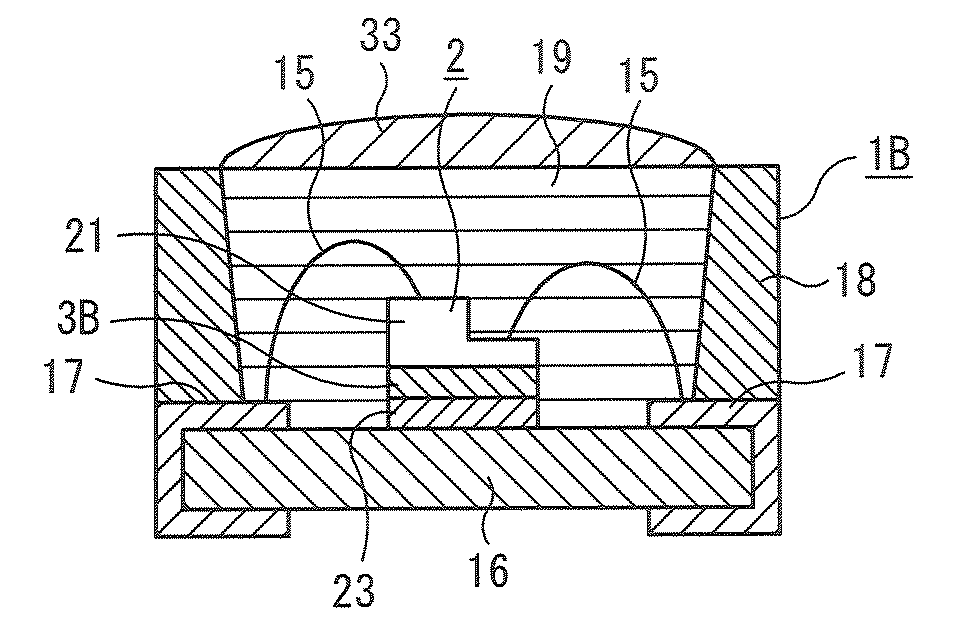

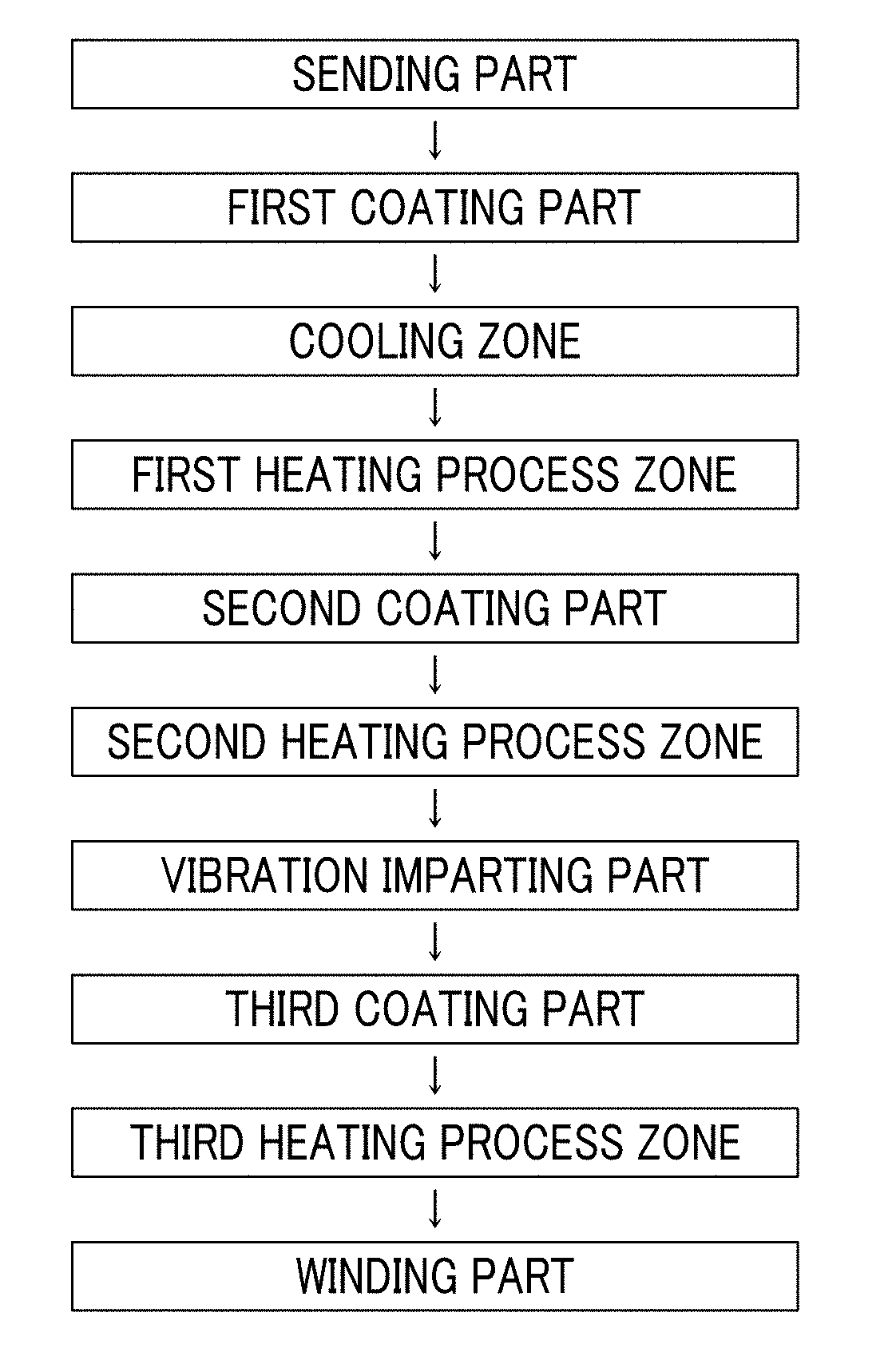

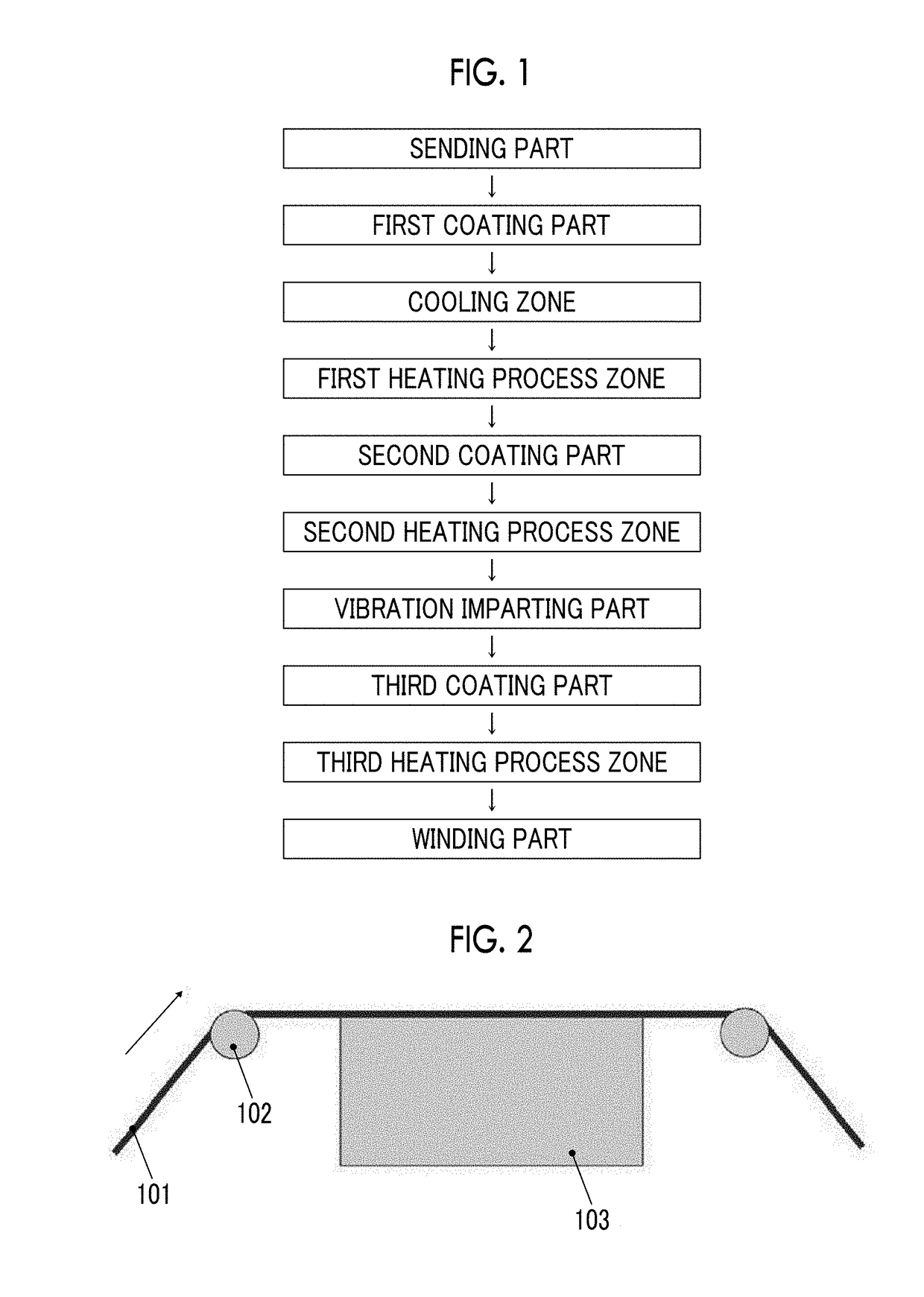

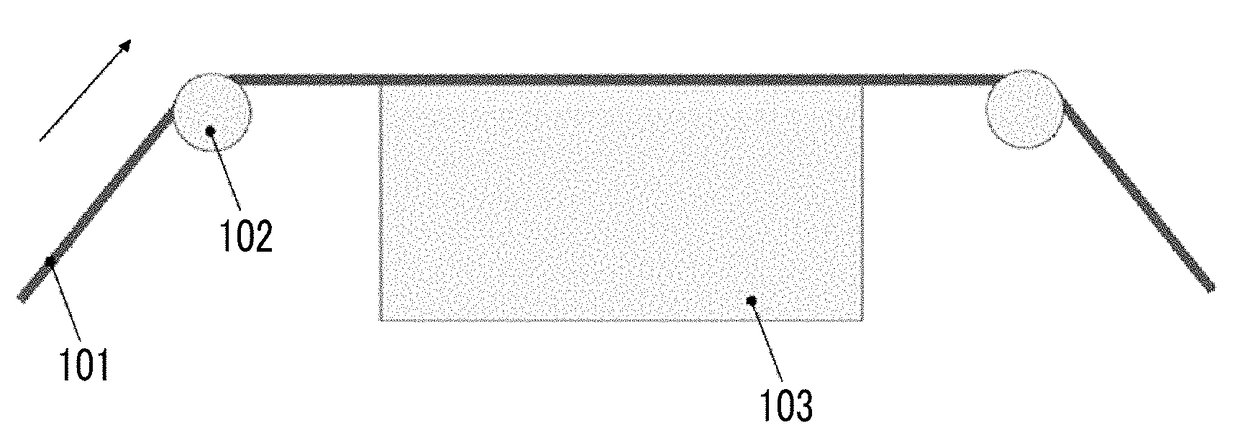

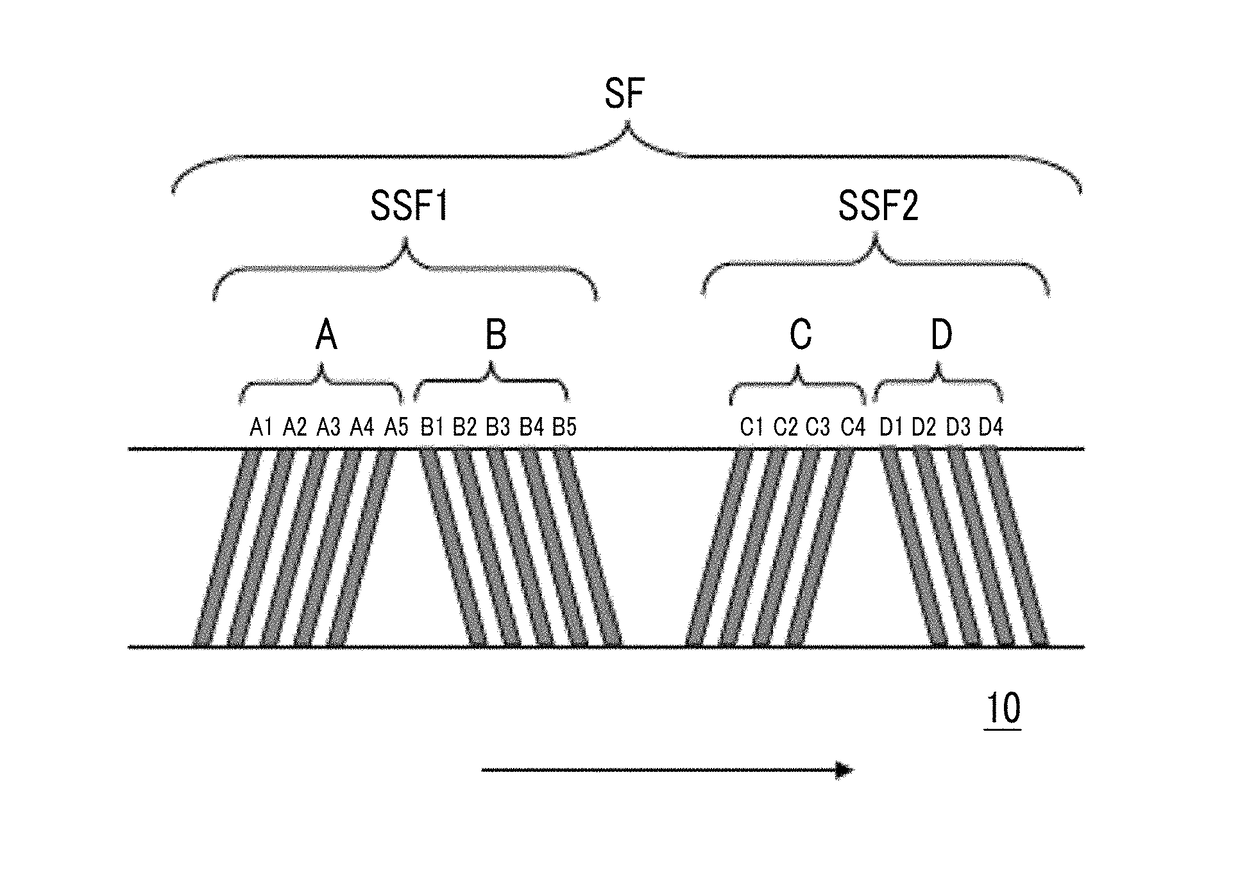

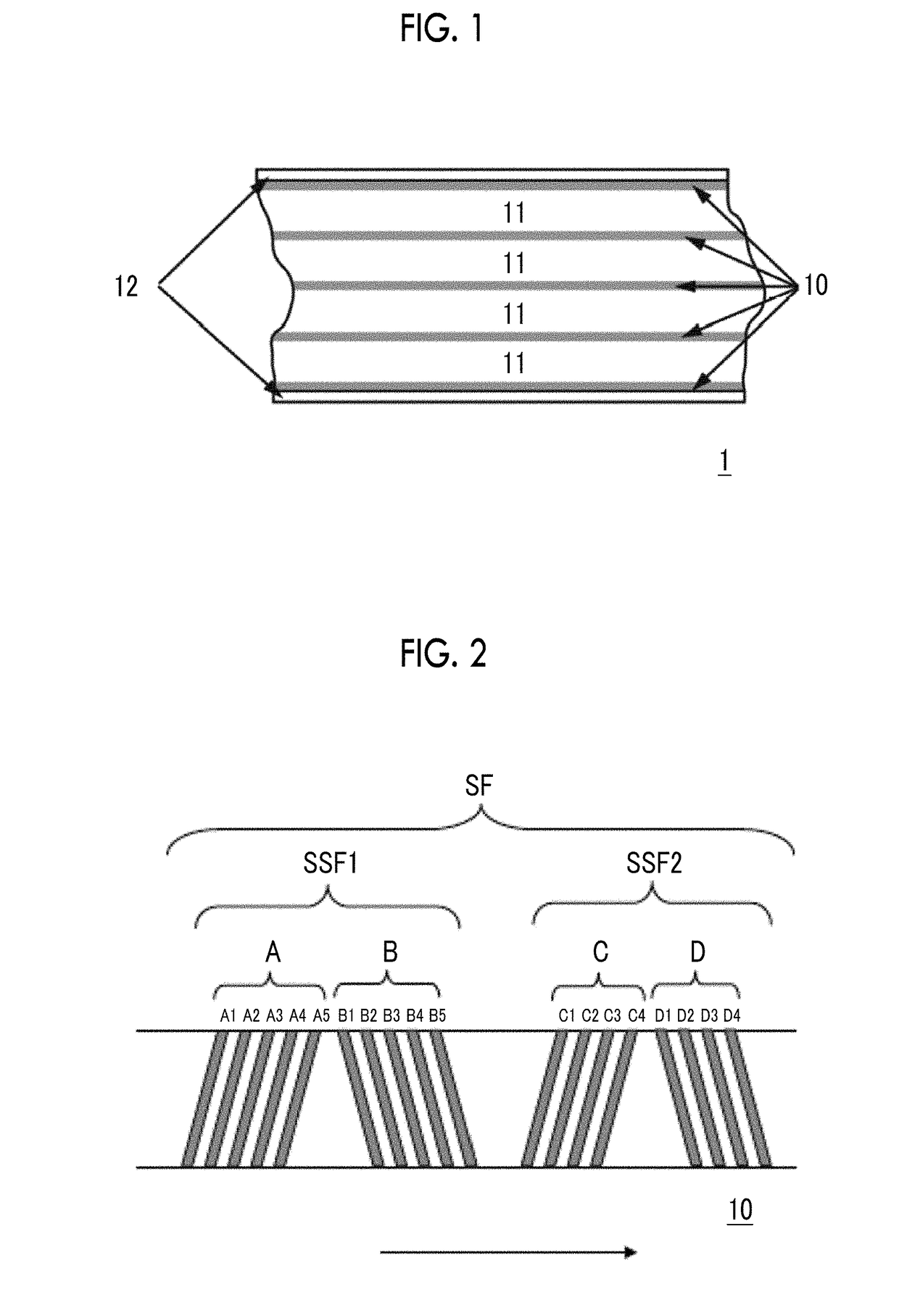

Magnetic tape device and magnetic reproducing method

ActiveUS20180286448A1Improve smoothnessImprove surface smoothnessMaterials with ironTape carriersMagnetic tapeFull width at half maximum

The magnetic tape device includes a TMR head (reproducing head); and a magnetic tape including a magnetic layer including ferromagnetic powder, a binding agent, and fatty acid ester, in which Ra measured regarding a surface of the magnetic layer is equal to or smaller than 2.0 nm, full widths at half maximum of spacing distribution measured by optical interferometry regarding the surface of the magnetic layer before and after performing a vacuum heating with respect to the magnetic tape are greater than 0 nm and equal to or smaller than 7.0 nm, a difference between spacings before and after the vacuum heating is greater than 0 nm and equal to or smaller than 8.0 nm, and ΔSFD (=SFD25° C.−SFD−190° C.) in a longitudinal direction of the magnetic tape is equal to or smaller than 0.50.

Owner:FUJIFILM CORP

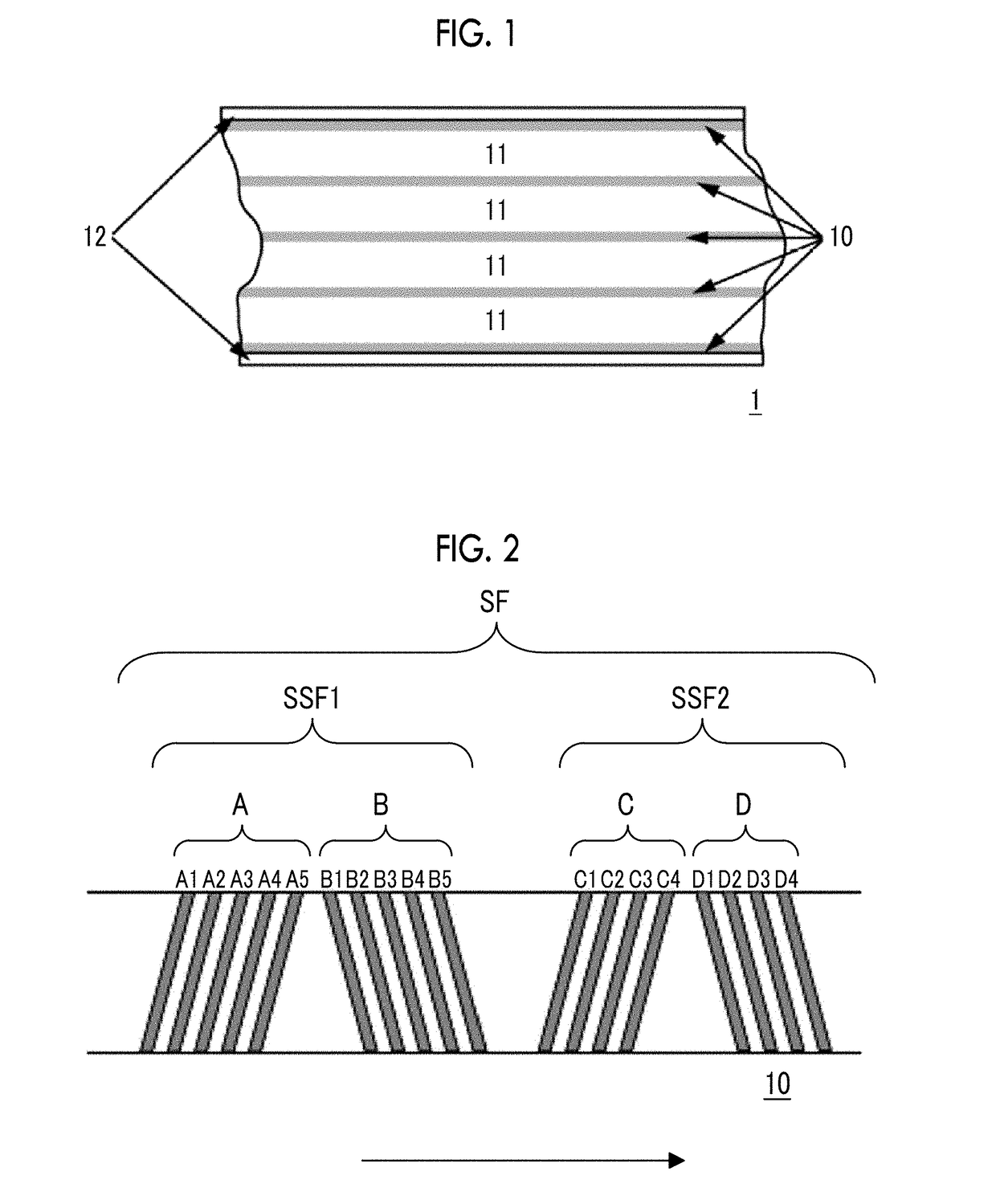

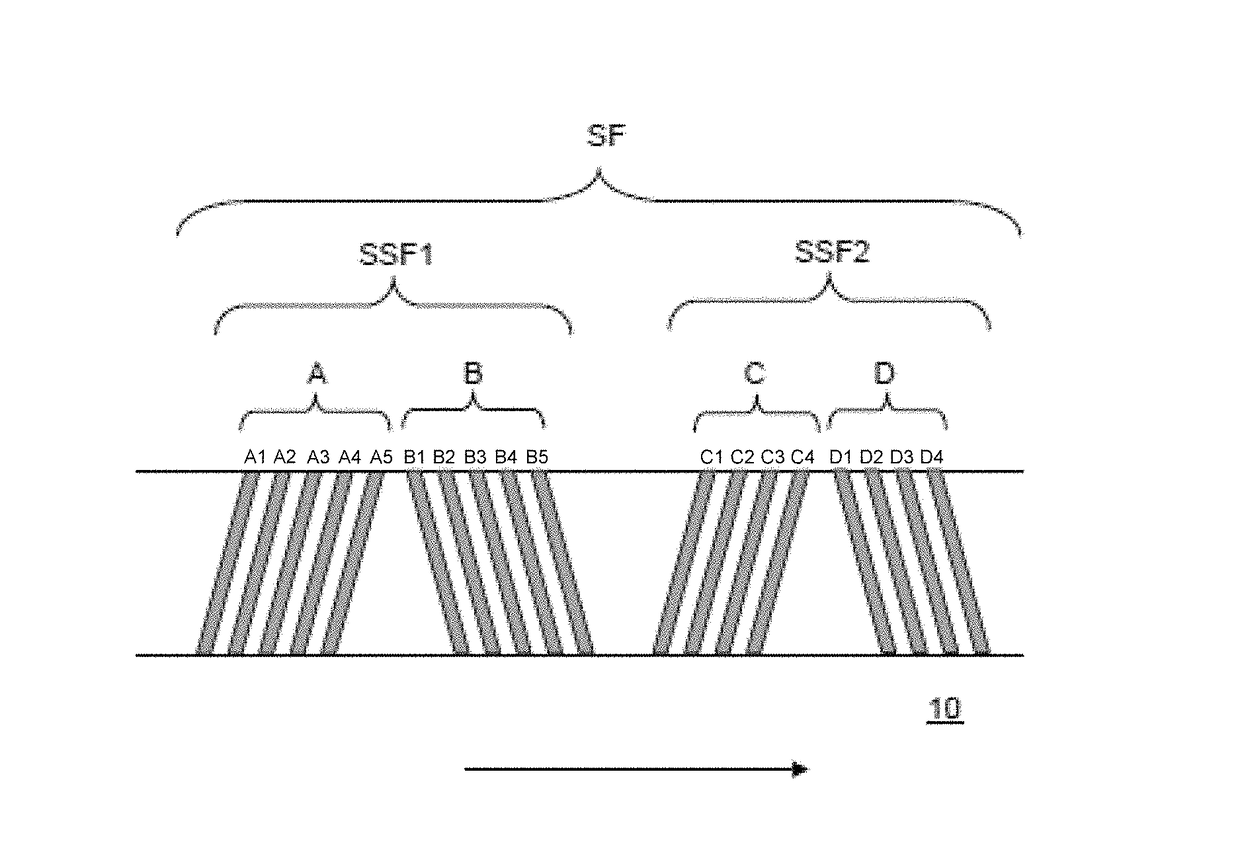

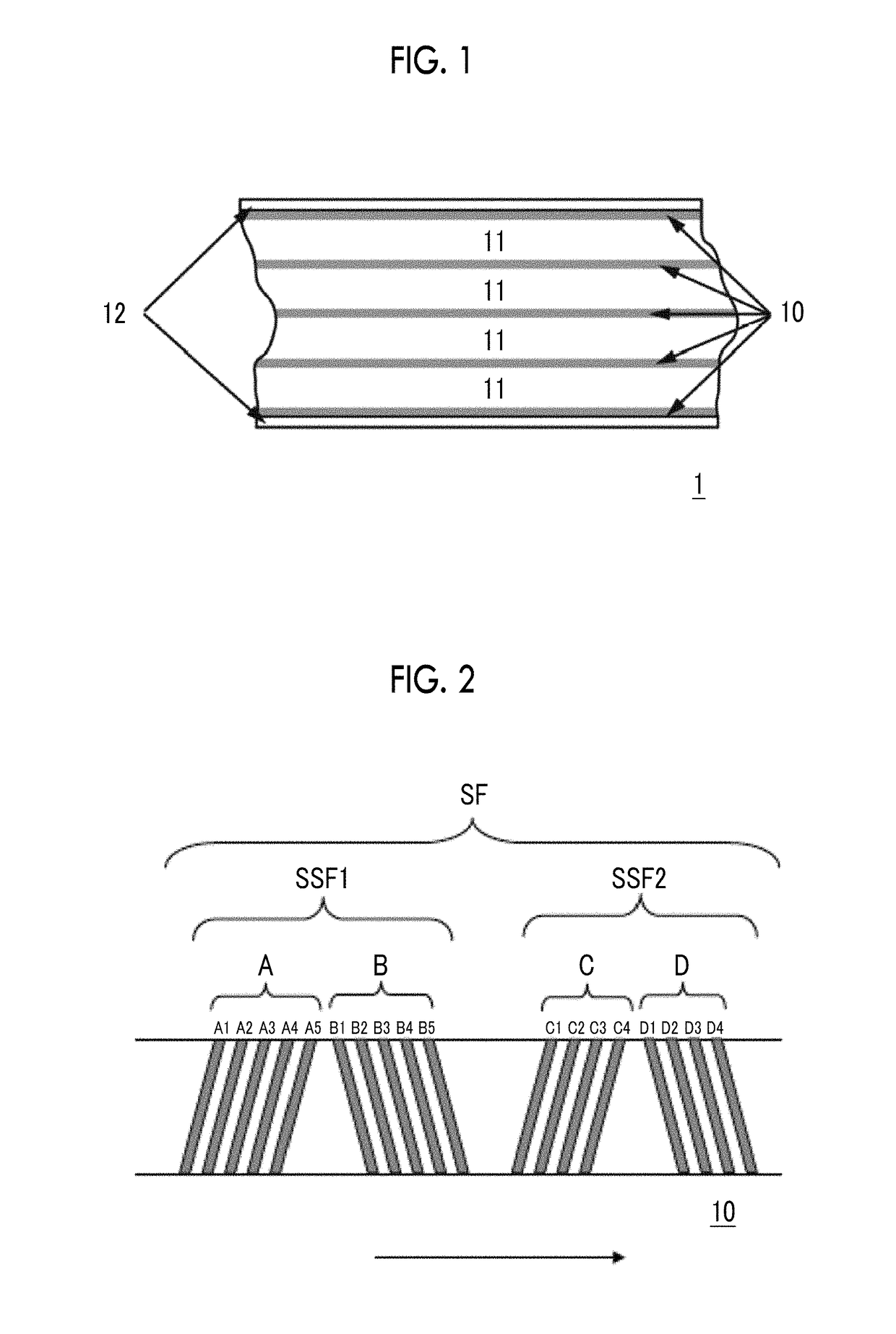

Magnetic tape and magnetic tape device

ActiveUS20170372740A1Improve accuracyAccurate informationBase layers for recording layersAlignment for track following on tapesMagnetic tapeFull width at half maximum

Provided is a magnetic tape in which the total thickness is equal to or smaller than 5.30 μm, the magnetic layer includes a timing-based servo pattern, a magnetic layer surface Ra is equal to or smaller than 1.8 nm, the magnetic layer includes fatty acid ester, a full width at half maximum of spacing distribution measured by optical interferometry regarding the surface of the magnetic layer before performing vacuum heating with respect to the magnetic tape is greater than 0 nm and equal to or smaller than 7.0 nm, a full width at half maximum of spacing distribution measured after performing the vacuum heating is greater than 0 nm and equal to or smaller than 7.0 nm, and a difference between a spacing measured after performing the vacuum heating and a spacing measured before performing the vacuum heating is greater than 0 nm and equal to or smaller than 8.0 nm.

Owner:FUJIFILM CORP

Magnetic tape device and magnetic reproducing method

ActiveUS20180286442A1Improve smoothnessImprove surface smoothnessMaterials with ironRecord information storageIn planeX-ray

The magnetic tape device includes a TMR head (reproducing head); and a magnetic tape including a magnetic layer including ferromagnetic hexagonal ferrite powder, a binding agent, and fatty acid ester, in which an XRD intensity ratio obtained by an X-ray diffraction analysis of the magnetic layer by using an In-Plane method is 0.5 to 4.0, a vertical direction squareness ratio is 0.65 to 1.00, Ra measured regarding a surface of the magnetic layer is equal to or smaller than 2.0 nm, full widths at half maximum of spacing distribution measured by optical interferometry regarding the surface of the magnetic layer before and after performing a vacuum heating with respect to the magnetic tape are greater than 0 nm and equal to or smaller than 7.0 nm, and a difference between spacings before and after the vacuum heating is greater than 0 nm and equal to or smaller than 8.0 nm.

Owner:FUJIFILM CORP

Magnetic tape and magnetic tape device

ActiveUS9837116B2Increase the number ofIncrease recording capacityAlignment for track following on tapesRecord information storageMagnetic tapeSurface roughness

Owner:FUJIFILM CORP

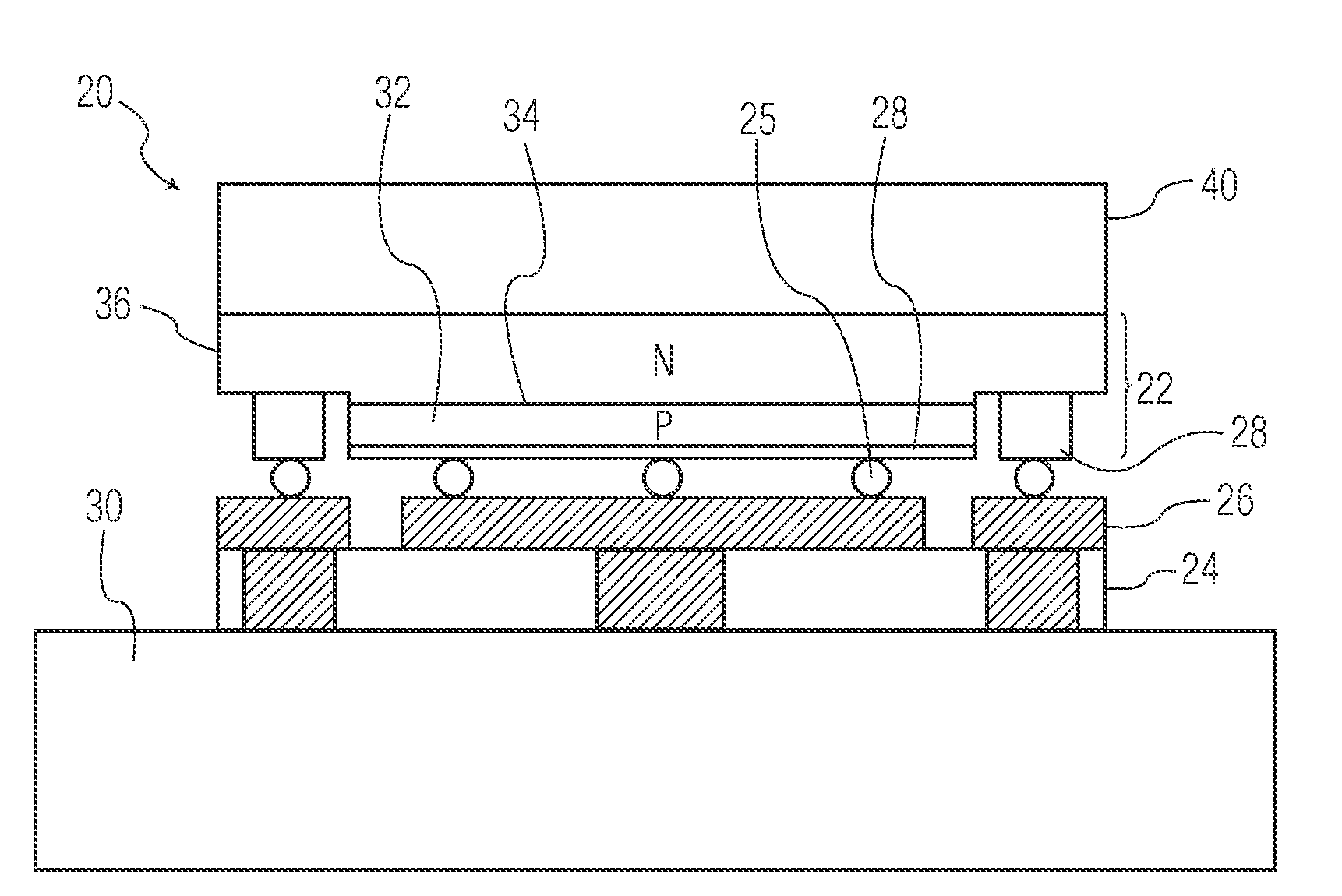

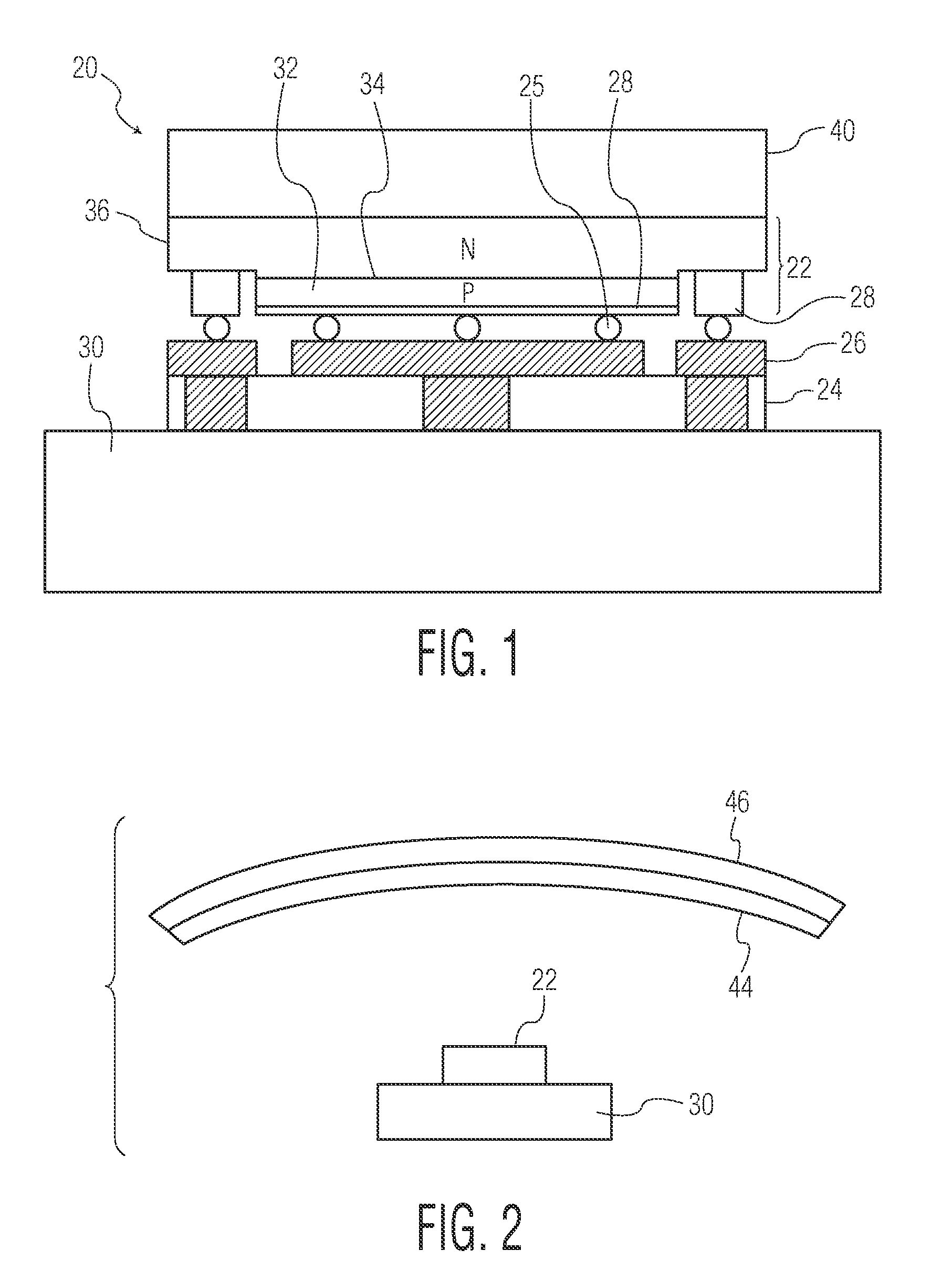

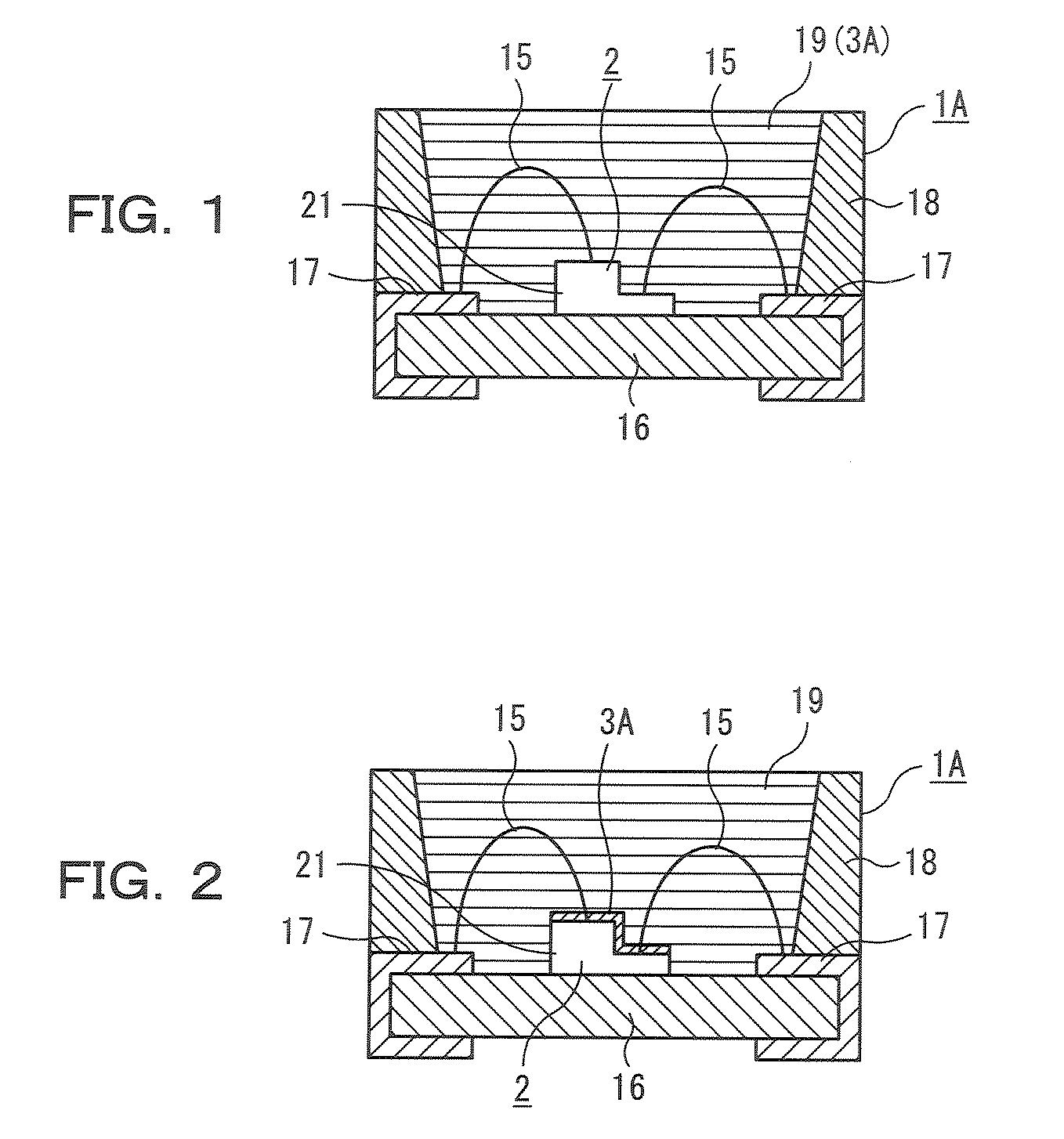

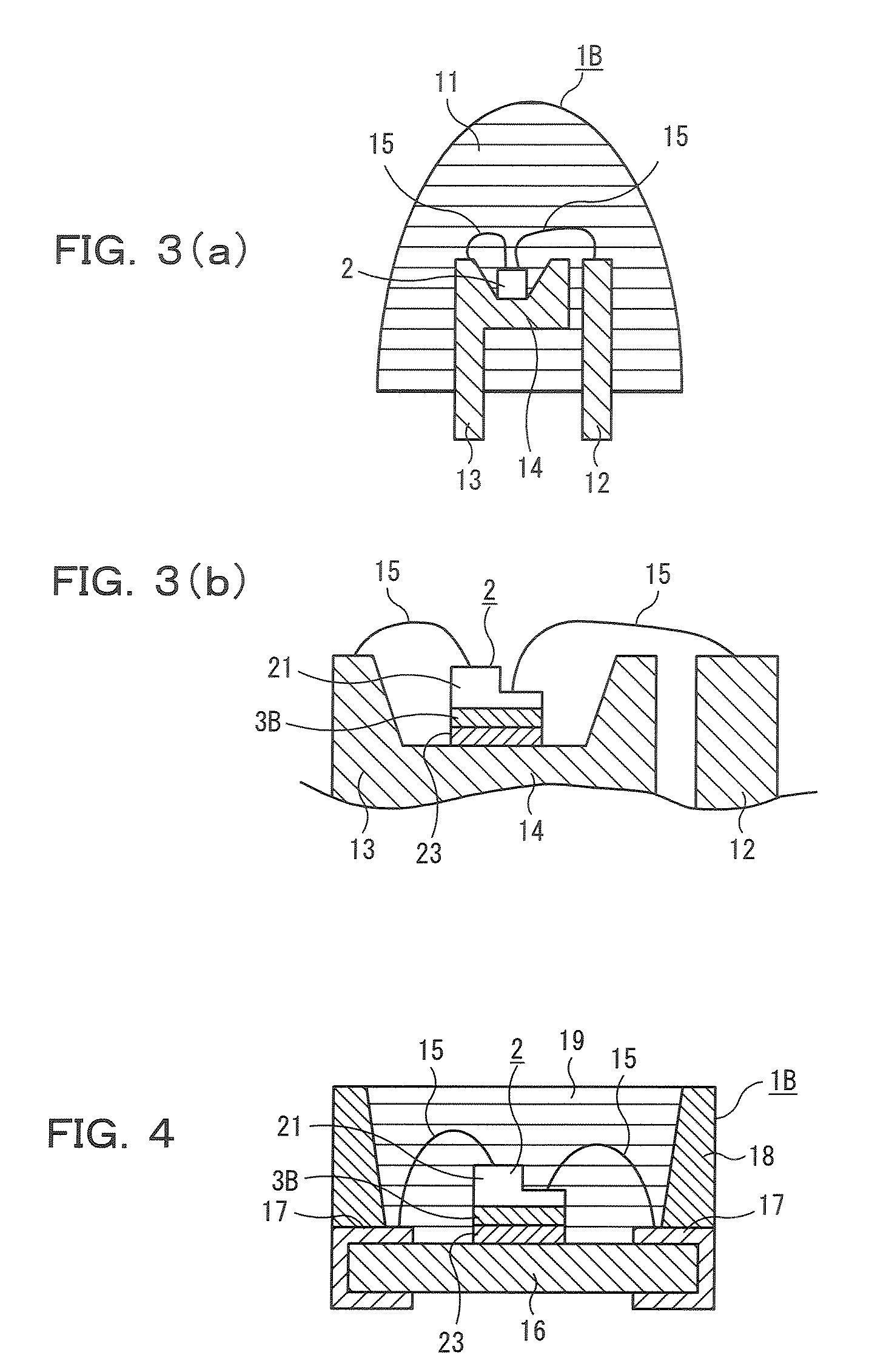

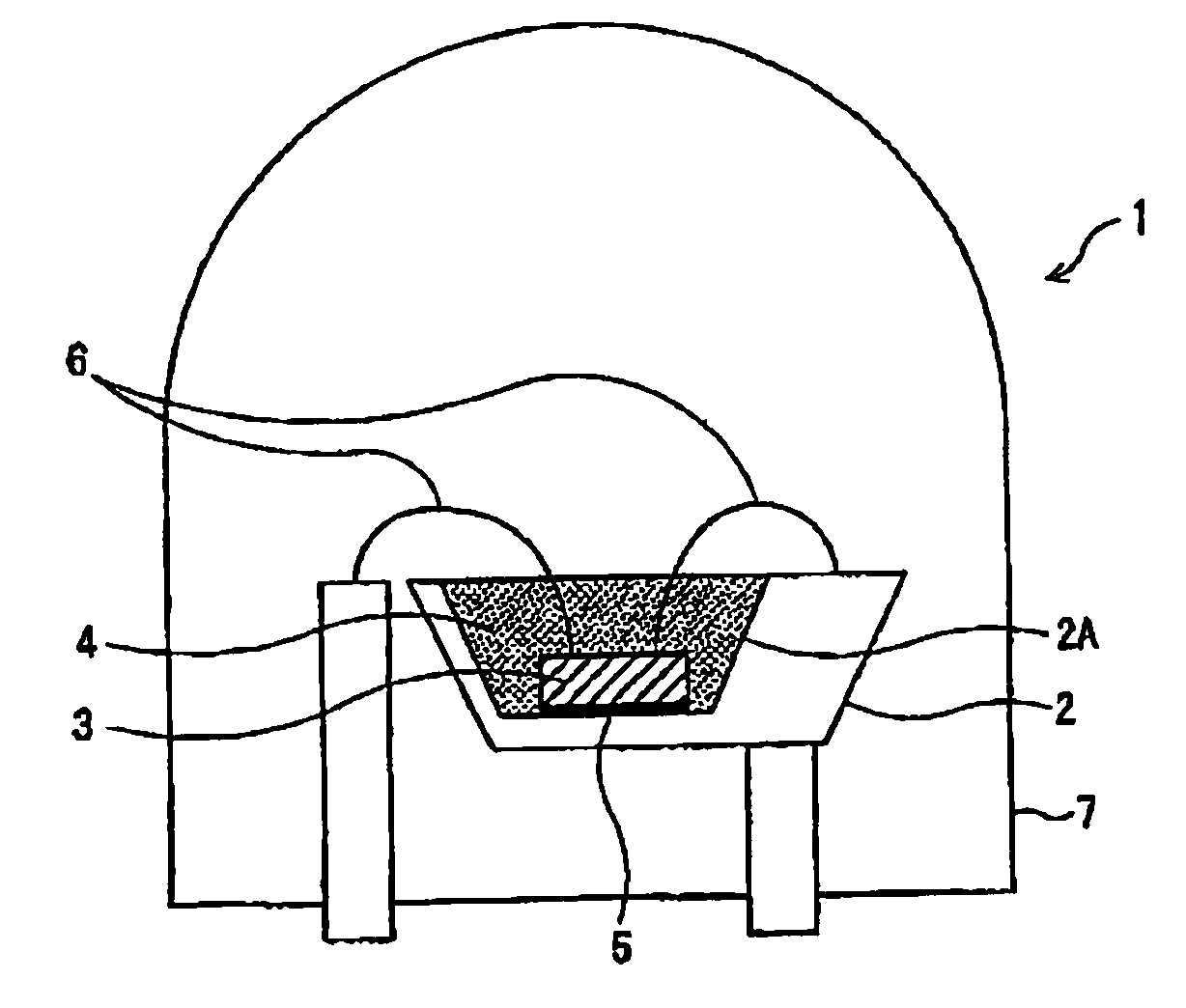

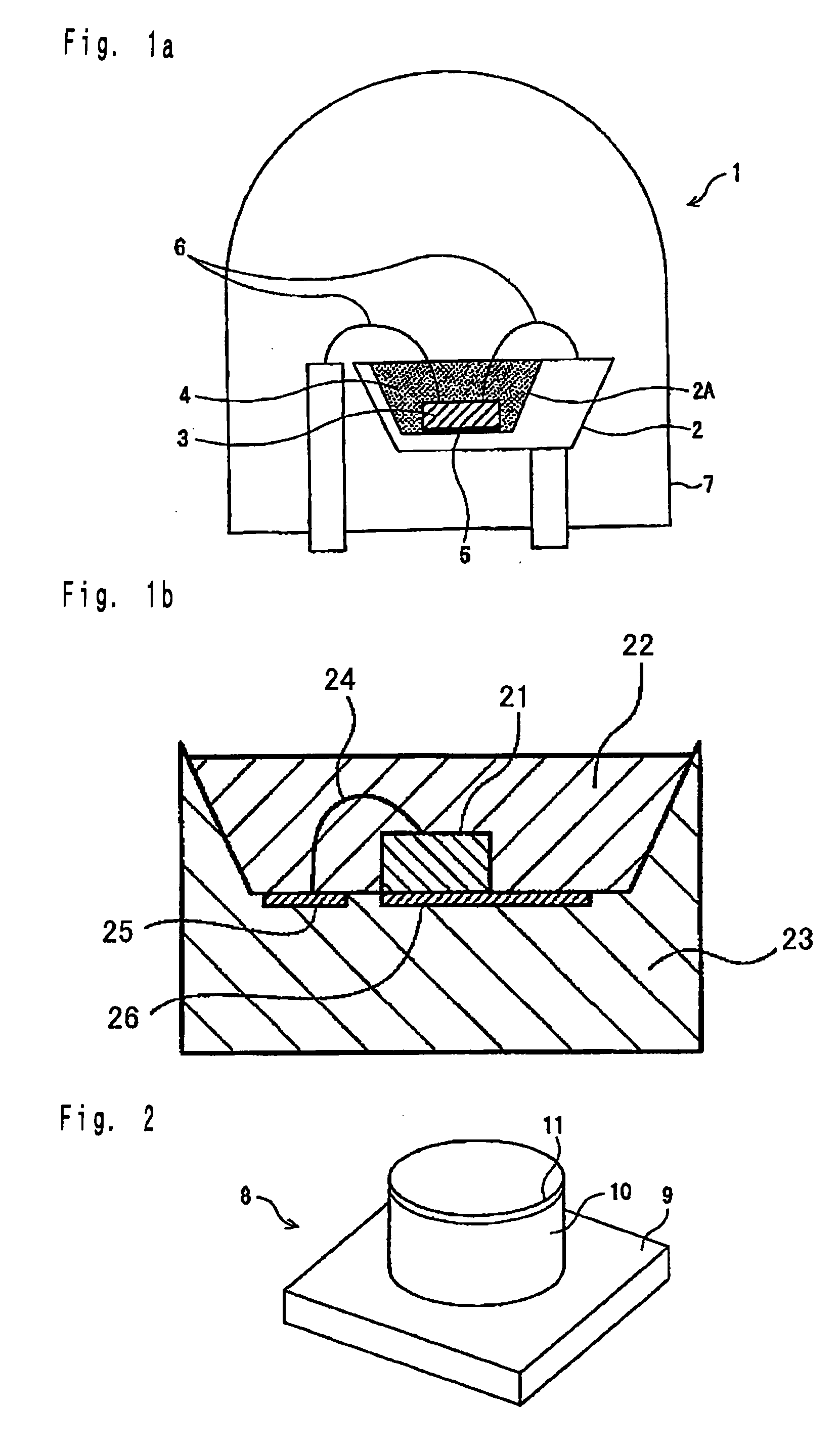

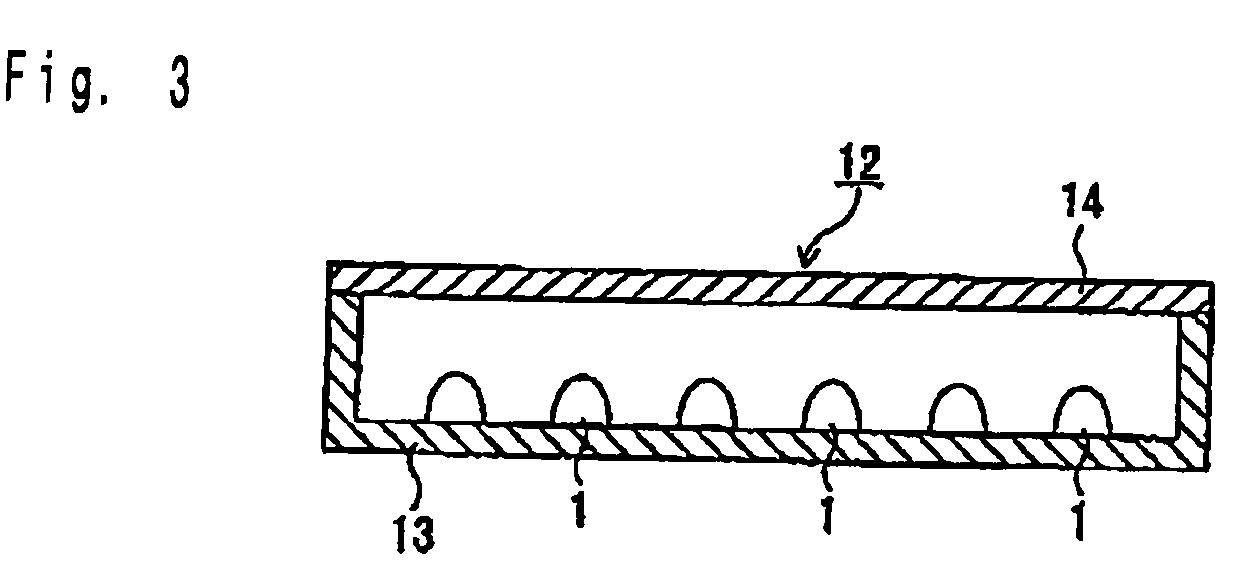

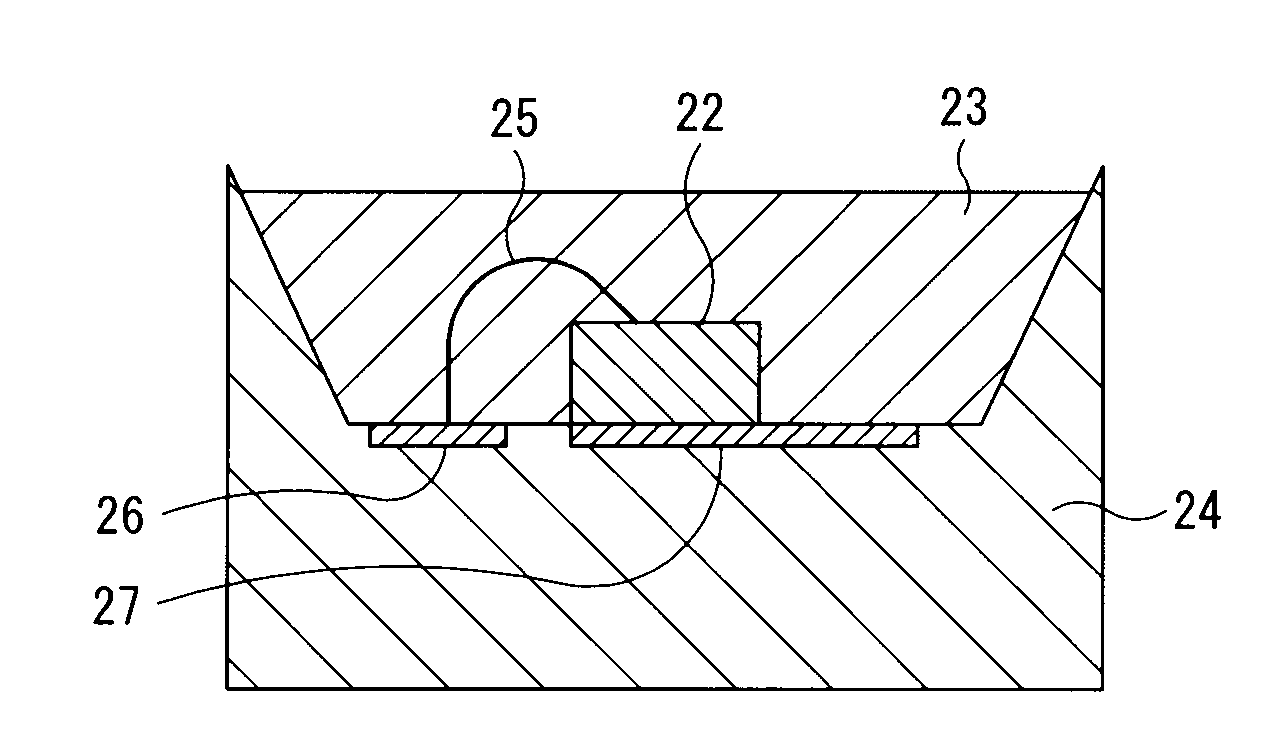

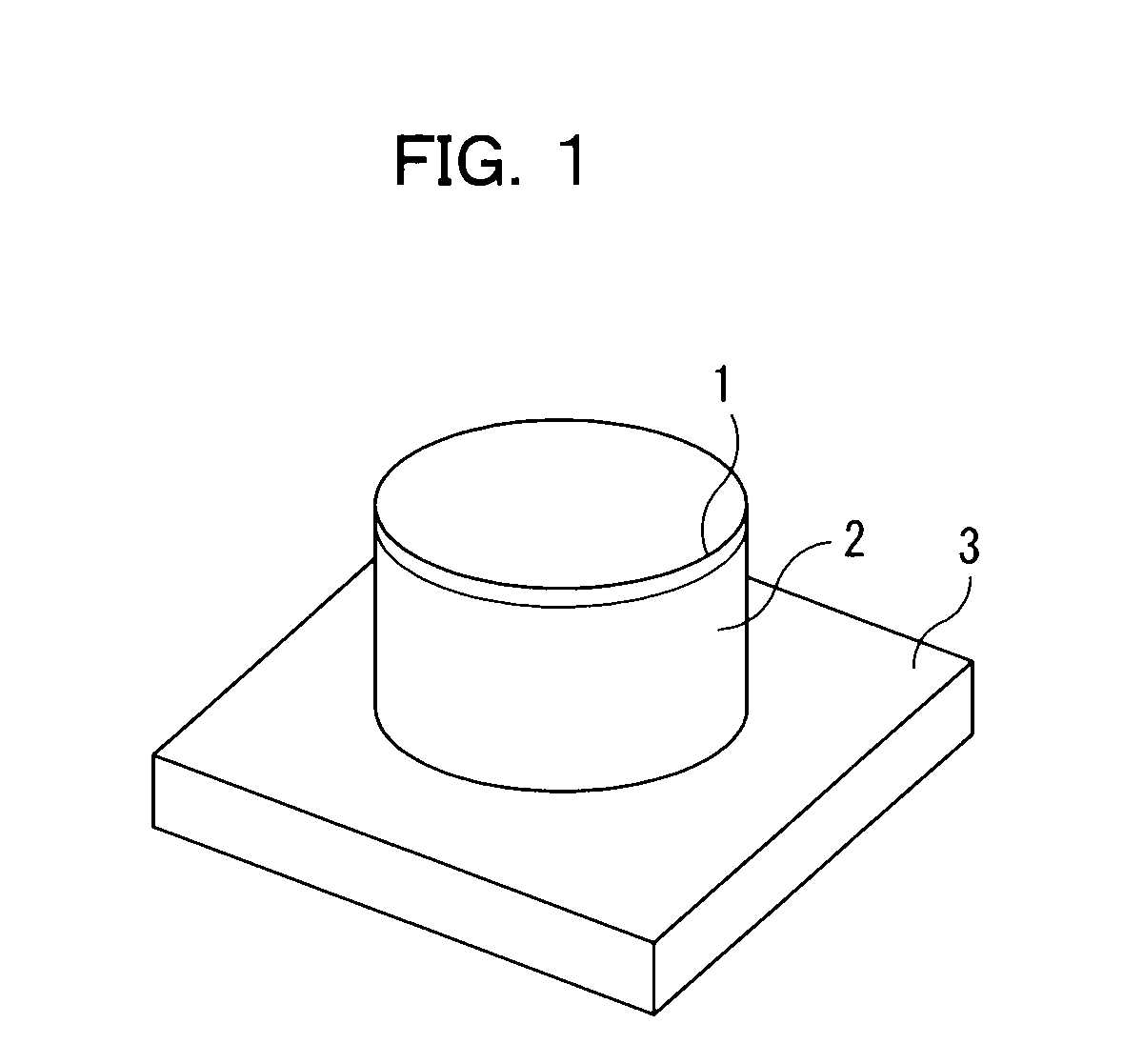

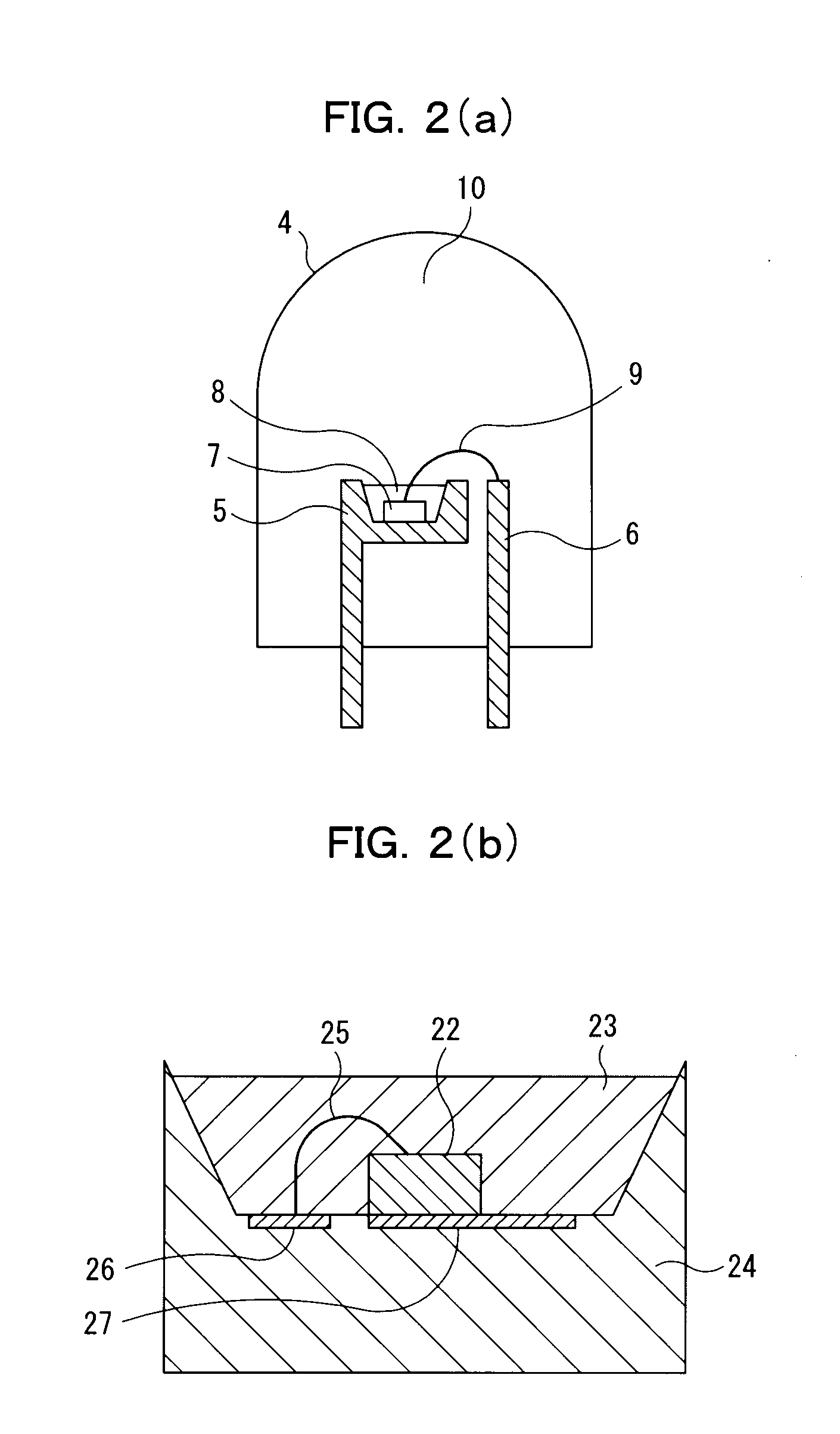

Semiconductor Light Emitting Device Member, Method for Manufacturing Such Semiconductor Light Emitting Device Member and Semiconductor Light Emitting Device Using Such Semiconductor Light Emitting Device Member

ActiveUS20090008673A1Improve sealingImprove heat resistanceSolid-state devicesSemiconductor/solid-state device manufacturingNMR - Nuclear magnetic resonanceHeat resistance

A semiconductor light-emitting device member excellent in transparency, light resistance, and heat resistance and capable of sealing a semiconductor light-emitting device without causing cracks and peeling even after a long-time use is provided. Therefore, a semiconductor light-emitting device member that comprises (1) in a solid Si-nuclear magnetic resonance spectrum, at least one peak selected from a group consisting of (i) peaks whose peak top position is in an area of a chemical shift of −40 ppm to 0 ppm inclusive, and whose full width at half maximum is 0.3 ppm to 3.0 ppm inclusive, and (ii) peaks whose peak top position is in an area of the chemical shift of −80 ppm or more and less than −40 ppm, and whose full width at half maximum is 0.3 ppm to 5.0 ppm inclusive, wherein (2) silicon content is 20 weight % or more and (3) silanol content is 0.1 weight % to 10 weight % inclusive is used.

Owner:MITSUBISHI CHEM CORP

Magnetic tape

ActiveUS20170372739A1Improve running stabilityBase layers for recording layersRecord information storageMagnetic tapeFull width at half maximum

Provided is a magnetic tape with the total thickness of a non-magnetic and magnetic layers is equal to or smaller than 0.60 μm, a C—H derived C concentration calculated from a C—H peak area ratio of C1s spectra by ESCA on the surface of the magnetic layer at a photoelectron take-off angle of 10 degrees is equal to or greater than 45 atom %, full widths at half maximum of spacing distribution measured by optical interferometry regarding the surface of the magnetic layer before and after vacuum heating with respect to the magnetic tape are respectively greater than 0 nm and equal to or smaller than 7.0 nm, and a difference between a spacing measured after the vacuum heating and a spacing measured before the vacuum heating is greater than 0 nm and equal to or smaller than 8.0 nm.

Owner:FUJIFILM CORP

Magnetic tape

ActiveUS20170372741A1Improve running stabilitySuitable compatibilityProtective coatings for layersRecord information storageMagnetic tapeX-ray

Provided is a magnetic tape in which a thickness of a back coating layer is equal to or smaller than 0.20 μm, a C—H derived C concentration calculated from a C—H peak area ratio of C1s spectra obtained by X-ray photoelectron spectroscopic analysis performed on the surface of the back coating layer at a photoelectron take-off angle of 10 degrees, is equal to or greater than 35 atom %, full widths at half maximum of spacing distribution measured by optical interferometry regarding the surface of the back coating layer before and after performing a vacuum heating with respect to the magnetic tape are respectively greater than 0 nm and equal to or smaller than 10.0 nm, and a difference between a spacing measured after performing the vacuum heating and a spacing measured before performing the vacuum heating is greater than 0 nm and equal to or smaller than 8.0 nm.

Owner:FUJIFILM CORP

Magnetic tape and magnetic tape device

ActiveUS20170372744A1Restrain output decreaseImprove accuracyBase layers for recording layersAlignment for track following on tapesMagnetic tapeFull width at half maximum

Provided is a magnetic tape in which the total thickness of a non-magnetic layer and a magnetic layer is equal to or smaller than 0.60 μm, the magnetic layer includes a timing-based servo pattern, the magnetic layer includes fatty acid ester, a full width at half maximum of spacing distribution measured by optical interferometry regarding the surface of the magnetic layer before performing vacuum heating with respect to the magnetic tape is greater than 0 nm and equal to or smaller than 7.0 nm, a full width at half maximum of spacing distribution measured after performing the vacuum heating is greater than 0 nm and equal to or smaller than 7.0 nm, and a difference between a spacing measured after performing the vacuum heating and a spacing measured before performing the vacuum heating is greater than 0 nm and equal to or smaller than 8.0 nm.

Owner:FUJIFILM CORP

Magnetic tape device and head tracking servo method

ActiveUS10008230B1Improve accuracyExact reproductionProtective coatings for layersFilamentary/web record carriersMagnetic tapeFull width at half maximum

The magnetic tape device includes: a magnetic tape; and a servo head, in which the servo head is a TMR head, the magnetic tape includes a non-magnetic support, and a magnetic layer including ferromagnetic powder, a binding agent, and fatty acid ester on the non-magnetic support, the magnetic layer includes a servo pattern, full widths at half maximum of spacing distribution measured by optical interferometry regarding a surface of the magnetic layer before and after performing a vacuum heating with respect to the magnetic tape are greater than 0 nm and equal to or smaller than 7.0 nm, and a difference between a spacing measured by optical interferometry regarding the surface of the magnetic layer after performing the vacuum heating with respect to the magnetic tape and a spacing measured before performing the vacuum heating is greater than 0 nm and equal to or smaller than 9.0 nm.

Owner:FUJIFILM CORP

Magnetic tape

ActiveUS20180286443A1Deterioration of characteristicMaterials with ironRecord information storageMagnetic tapeFull width at half maximum

The magnetic tape has the total thickness of a non-magnetic layer and a magnetic layer of 0.60 μm or smaller, the magnetic layer including an abrasive and fatty acid ester, a percentage of a plan view maximum area of the abrasive confirmed in a region having a size of 4.3 μm×6.3 μm of the surface of the magnetic layer with respect to the total area of the region, obtained by plane observation performed by using an SEM of 0.02% or greater and less than 0.06%, full widths at half maximum of spacing distribution measured by optical interferometry regarding a surface of the magnetic layer before and after performing a vacuum heating with respect to the magnetic tape of greater than 0 nm and 7.0 nm or smaller, and a difference between spacings before and after the vacuum heating of greater than 0 nm and 8.0 nm or smaller.

Owner:FUJIFILM CORP

Magnetic tape device and magnetic reproducing method

ActiveUS20180286439A1Improve smoothnessImprove surface smoothnessTape carriersRecord information storageMagnetic force microscopeMagnetic tape

The magnetic tape device includes a TMR head and a magnetic tape, in which the magnetic tape includes fatty acid ester in a magnetic layer, Ra measured regarding a surface of the magnetic layer is 2.0 nm or smaller, full widths at half maximum of spacing distribution measured by optical interferometry regarding a surface of the magnetic layer before and after performing a vacuum heating with respect to the magnetic tape are greater than 0 nm and 7.0 nm or smaller, a difference between spacings before and after the vacuum heating is greater than 0 nm and 8.0 nm or smaller, and a ratio of an average area Sdc of a magnetic cluster of the magnetic tape in a DC demagnetization state and an average area Sac of a magnetic cluster thereof in an AC demagnetization state measured with a magnetic force microscope is 0.80 to 1.30.

Owner:FUJIFILM CORP

Magnetic tape device and head tracking servo method

ActiveUS20190096437A1Improve accuracyExact reproductionMaterials with ironAlignment for track following on tapesMagnetic tapeFull width at half maximum

The magnetic tape device includes a TMR head (servo head); and a magnetic tape, in which a magnetic layer of the magnetic tape includes fatty acid ester, Ra measured regarding a surface of the magnetic layer is equal to or smaller than 2.0 nm, full widths at half maximum of spacing distribution measured by optical interferometry regarding a surface of the magnetic layer before and after performing a vacuum heating with respect to the magnetic tape are greater than 0 nm and equal to or smaller than 7.0 nm, a difference between spacings before and after the vacuum heating is greater than 0 nm and equal to or smaller than 8.0 nm, and ΔSFD (=SFD25° C.−SFD−#° C.) in a longitudinal direction of the magnetic tape is equal to or smaller than 0.50.

Owner:FUJIFILM CORP

Lighting assembly

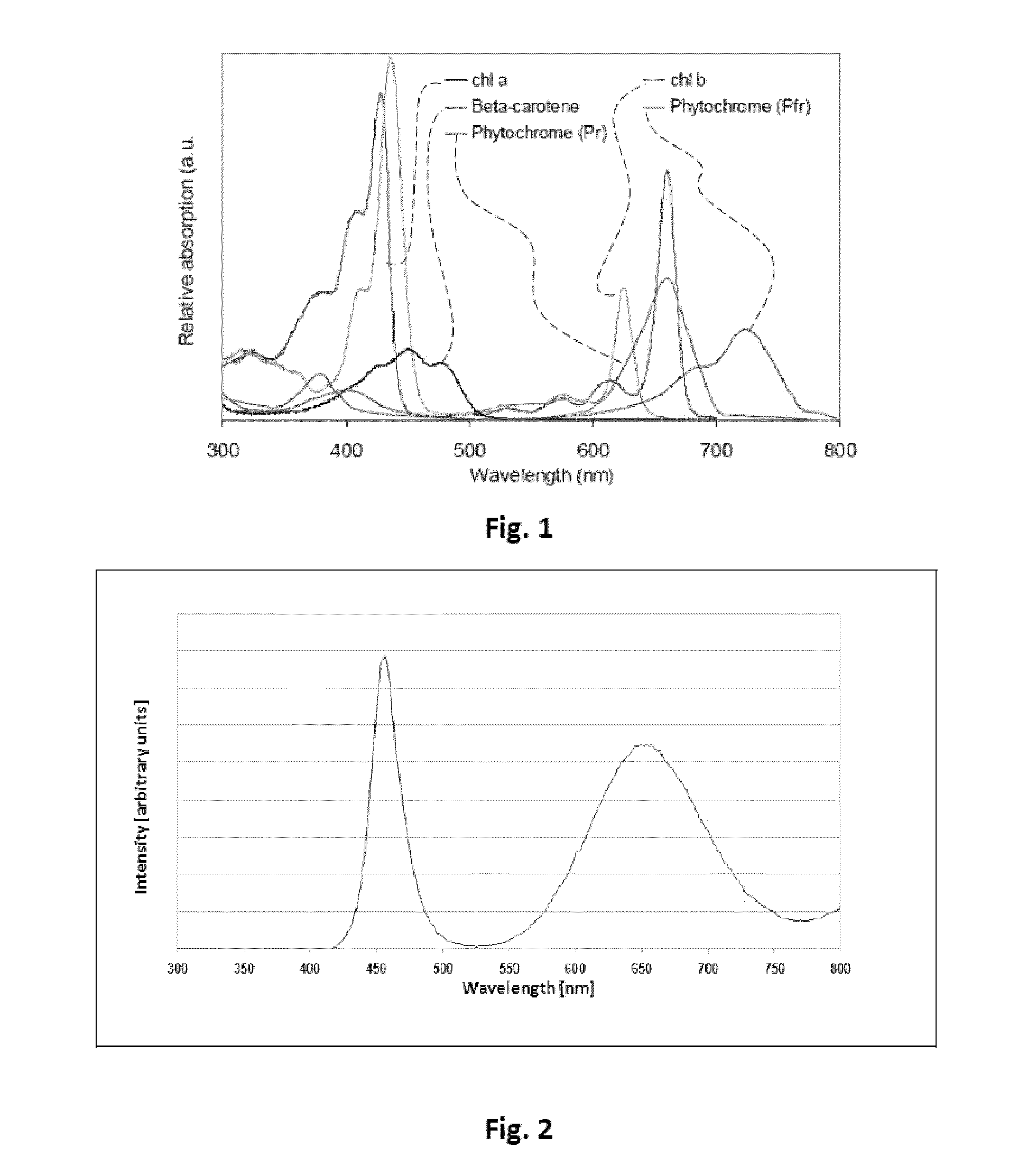

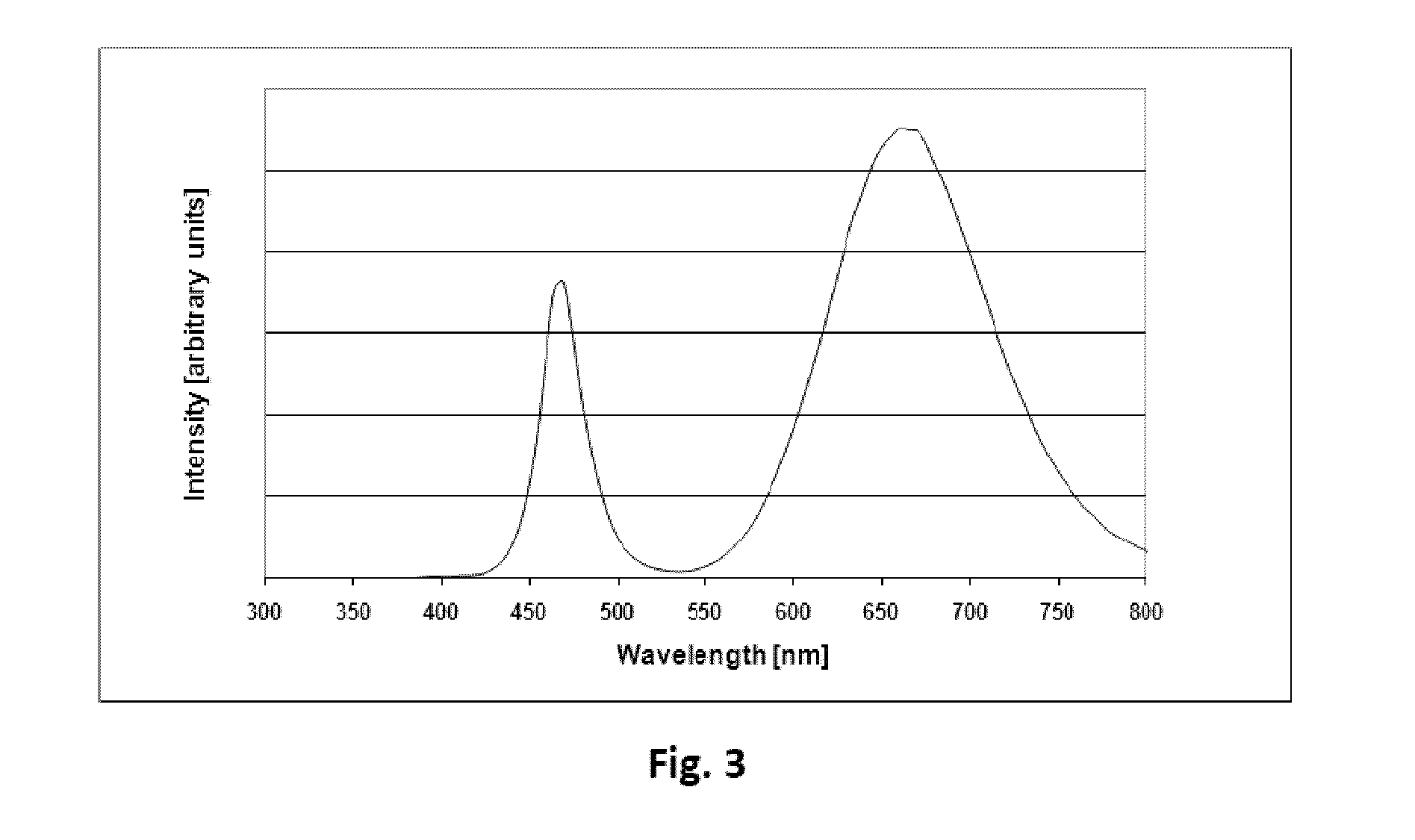

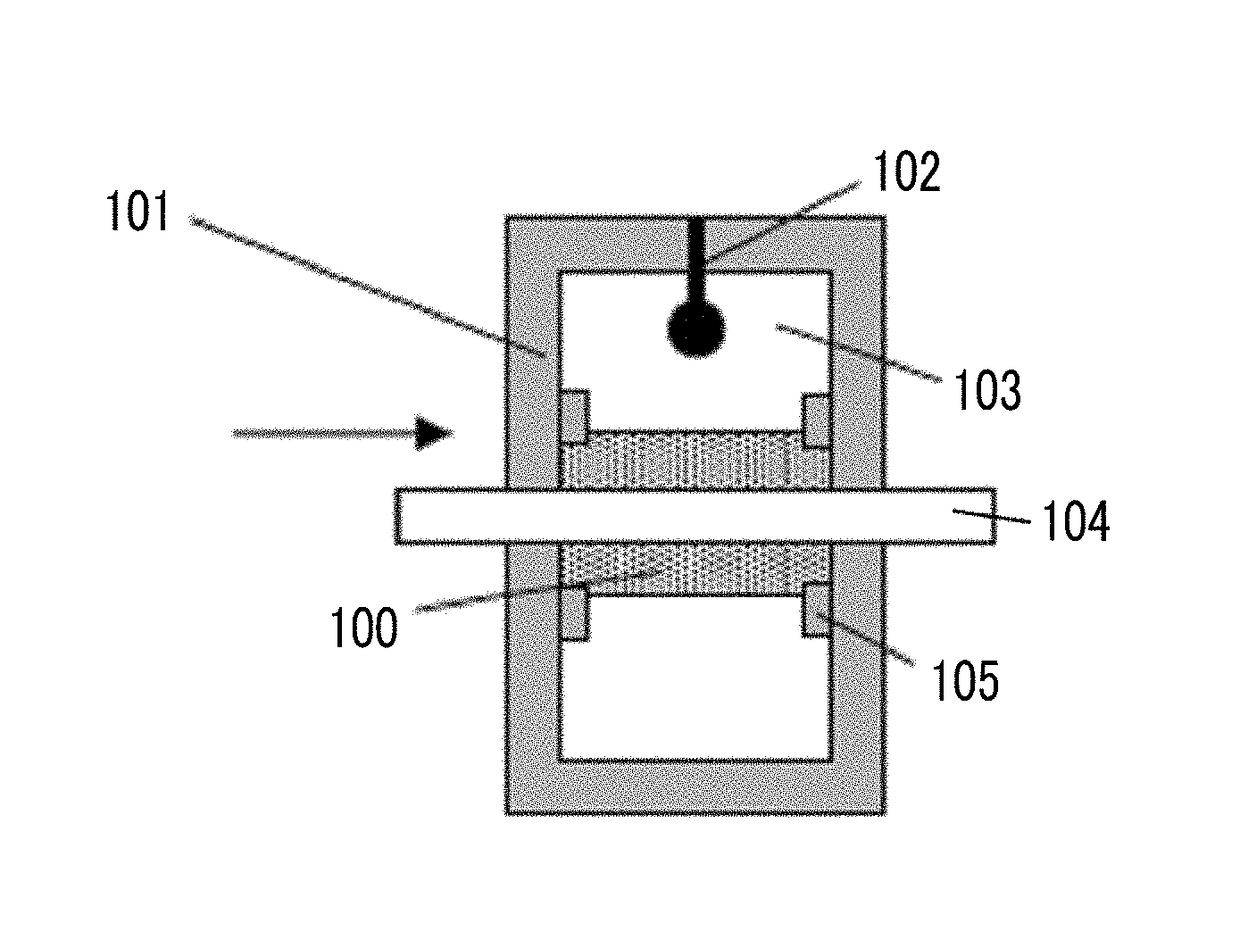

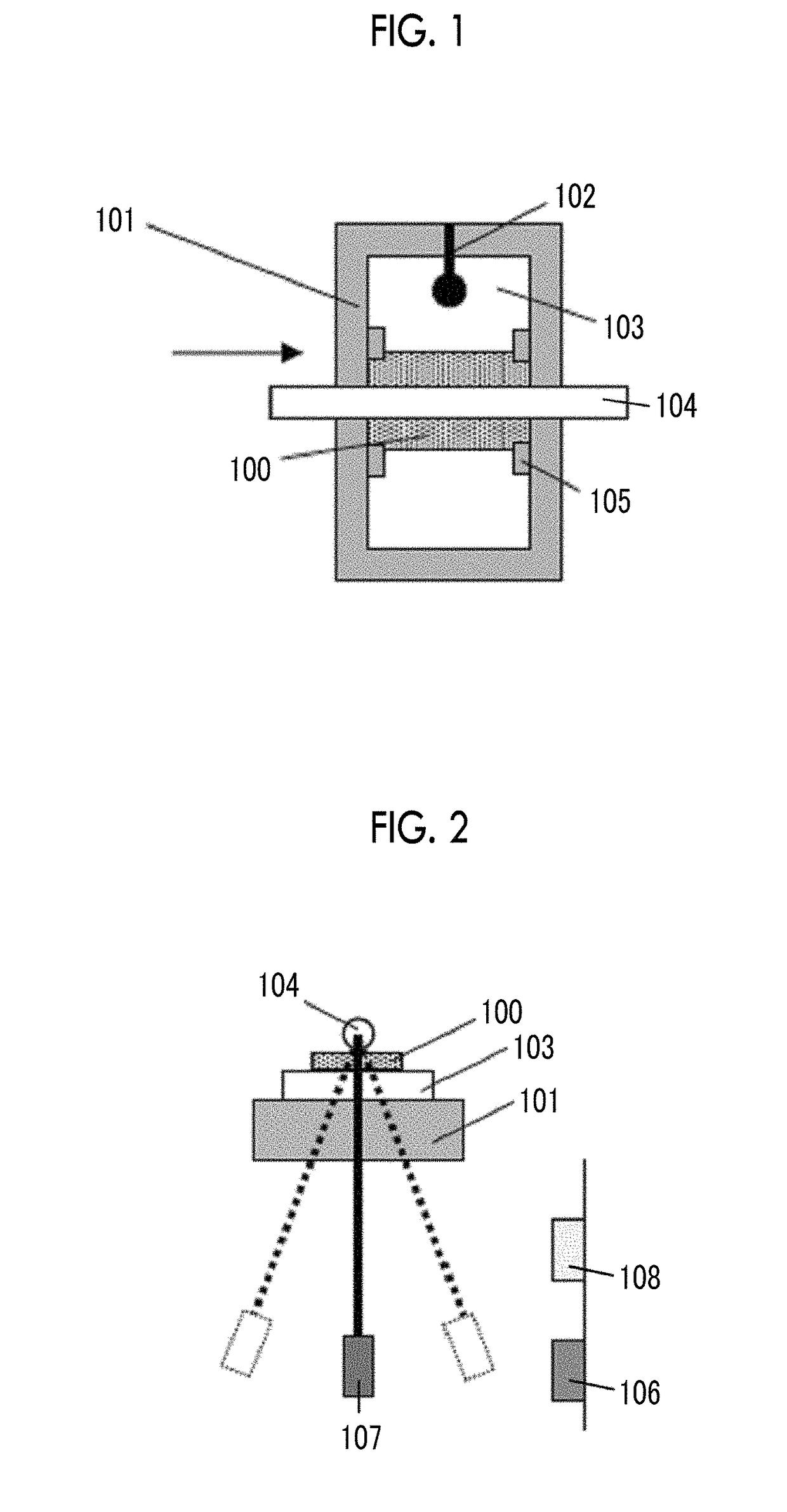

ActiveUS20100259190A1Promote plant growthIncrease valuePoint-like light sourceSolid-state devicesGrowth plantEffect light

A lighting fixture for facilitating plant growth and a light emitting component. The fixture comprises a single light emission source LED device which provides at least two emission peaks in the wavelength range of 300-800 nm and at least one of the emission peaks has Full Width of Half Maximum (FWHM) at least 50 nm or higher. The emission peaks of the LED match well with a plant photosynthesis response spectrum and is therefore particularly suitable for high efficiency artificial lighting.

Owner:VALOYA

Magnetic tape

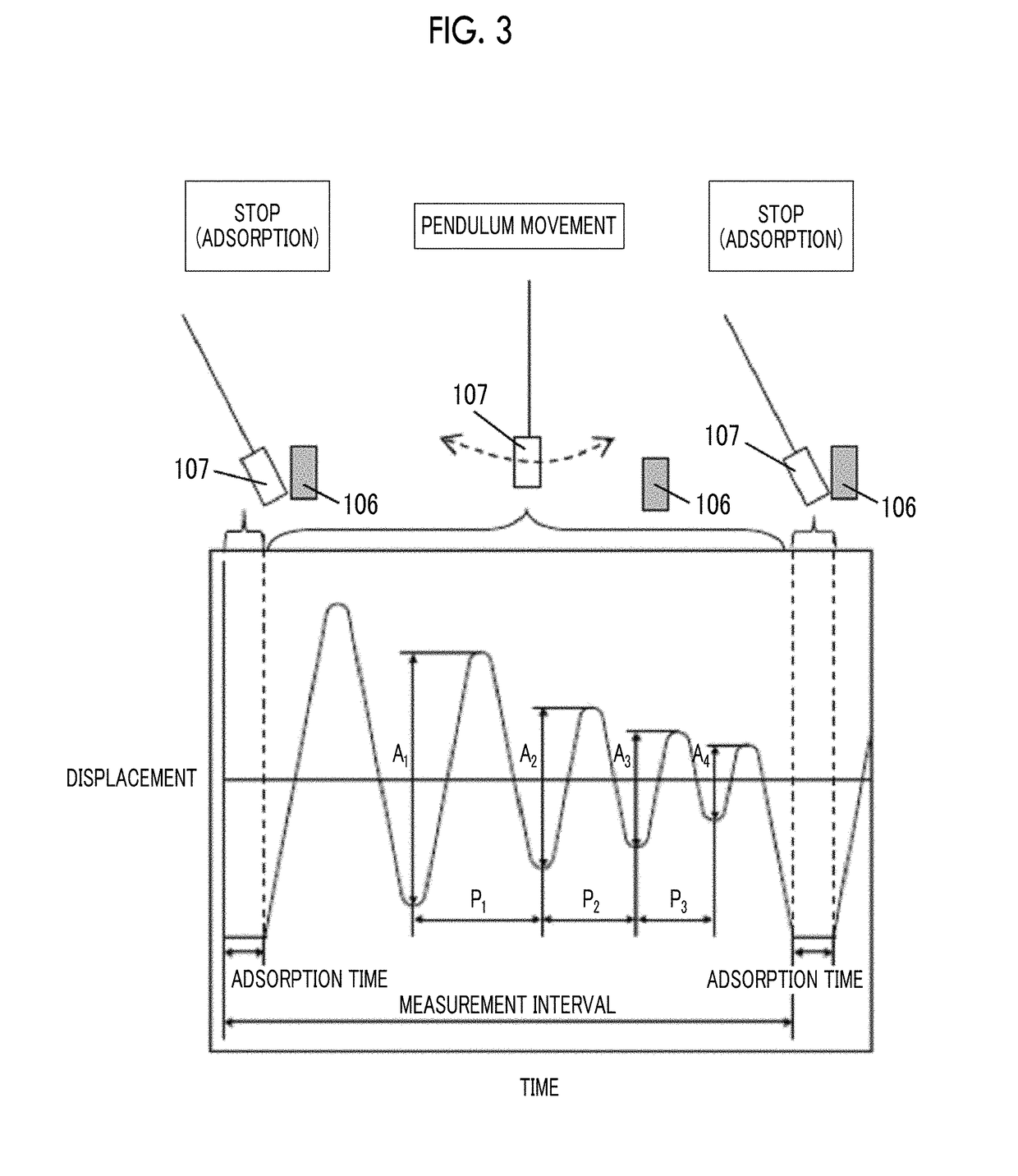

ActiveUS20180240492A1Avoid it happening againRecord information storageTape carriersCoated surfaceMagnetic tape

The magnetic tape includes a back coating layer having a thickness equal to or smaller than 0.30 μm and including fatty acid ester, a logarithmic decrement acquired by a pendulum viscoelasticity test performed regarding a surface of the back coating layer is equal to or smaller than 0.060, a full width at half maximum of spacing distribution measured by optical interferometry regarding the surface of the back coating layer before and after performing a vacuum heating with respect to the magnetic tape is respectively greater than 0 nm and equal to or smaller than 10.0 nm, and a difference between a spacing measured by optical interferometry regarding the surface of the back coating layer after performing the vacuum heating and a spacing measured before performing the vacuum heating is greater than 0 nm and equal to or smaller than 8.0 nm.

Owner:FUJIFILM CORP

Magnetic tape device and magnetic reproducing method

ActiveUS20180182430A1Avoid it happening againReduce resistanceRecord information storageTape carriersMagnetic tapeFull width at half maximum

The magnetic tape device includes: a magnetic tape; and a reproducing head, in which the reproducing head is a TMR head, the magnetic tape includes a non-magnetic support, and a magnetic layer including ferromagnetic powder, a binding agent, and fatty acid ester on the non-magnetic support, a full width at half maximum of spacing distribution measured by optical interferometry regarding a surface of the magnetic layer before performing a vacuum heating with respect to the magnetic tape is greater than 0 nm and equal to or smaller than 7.0 nm, a full width at half maximum of spacing distribution measured after performing the vacuum heating is greater than 0 nm and equal to or smaller than 7.0 nm, and a difference between a spacing measured by optical interferometry regarding the surface of the magnetic layer after performing the vacuum heating with respect to the magnetic tape and a spacing measured before performing the vacuum heating is greater than 0 nm and equal to or smaller than 9.0 nm.

Owner:FUJIFILM CORP

Magnetic tape

ActiveUS20190027181A1Improve surface smoothnessAvoid it happening againMagnetic materials for record carriersRecord information storageIn planeCoated surface

Provided is a magnetic tape in which an Ra measured regarding a surface of a magnetic layer is equal to or smaller than 1.8 nm, Int(110) / Int(114) of a hexagonal ferrite crystal structure obtained by an XRD analysis of the magnetic layer by using an In-Plane method is 0.5 to 4.0, a vertical squareness ratio of the magnetic tape is 0.65 to 1.00, full widths at half maximum of spacing distribution measured by optical interferometry regarding the surface of the back coating layer before and after performing a vacuum heating with respect to the magnetic tape are greater than 0 nm and equal to or smaller than 10.0 nm, and a difference between the spacings measured by optical interferometry regarding the surface of the back coating layer before and after performing the vacuum heating is greater than 0 nm and equal to or smaller than 8.0 nm.

Owner:FUJIFILM CORP

Magnetic tape device and head tracking servo method

ActiveUS10170144B2Improve accuracyExact reproductionMaterials with ironAlignment for track following on tapesMagnetic force microscopeMagnetic tape

The magnetic tape device includes a TMR head and a magnetic tape, in which the magnetic tape includes fatty acid ester in a magnetic layer, Ra measured regarding a surface of the magnetic layer is 2.0 nm or smaller, full widths at half maximum of spacing distribution measured by optical interferometry regarding a surface of the magnetic layer before and after performing a vacuum heating with respect to the magnetic tape are greater than 0 nm and 7.0 nm or smaller, a difference between spacings before and after the vacuum heating is greater than 0 nm and 8.0 nm or smaller, and a ratio of an average area Sdc of a magnetic cluster of the magnetic tape in a DC demagnetization state and an average area Sac of a magnetic cluster thereof in an AC demagnetization state measured with a magnetic force microscope is 0.80 to 1.30.

Owner:FUJIFILM CORP

Magnetic tape device and head tracking servo method

ActiveUS20180286446A1Lower the resistance valueAvoid it happening againMaterials with ironAlignment for track following on tapesIn planeFull width at half maximum

The magnetic tape device includes a TMR head (servo head); and a magnetic tape including a magnetic layer including ferromagnetic hexagonal ferrite powder, a binding agent, and fatty acid ester, in which an XRD intensity ratio obtained by an X-ray diffraction analysis of the magnetic layer by using an In-Plane method is 0.5 to 4.0, a vertical direction squareness ratio is 0.65 to 1.00, Ra measured regarding a surface of the magnetic layer is equal to or smaller than 2.0 nm, full widths at half maximum of spacing distribution measured by optical interferometry regarding a surface of the magnetic layer before and after performing a vacuum heating with respect to the magnetic tape are greater than 0 nm and equal to or smaller than 7.0 nm, and a difference between spacings before and after the vacuum heating is greater than 0 nm and equal to or smaller than 8.0 nm.

Owner:FUJIFILM CORP

Phosphor and light-emitting device using same

InactiveUS20090072255A1Solve low luminous efficiencyIncrease brightnessSolid-state devicesRare earth metal compoundsPhosphorDisplay device

The present invention relates to a phosphor that satisfies requirements (1) to (3):(1) the phosphor satisfies Formula [2] and / or Formula [3]:85≦{R455(125) / R455(25)}×100<110 [2]92≦{R405(100) / R405(25)}×100<110 [3]wherein R455(125) represents an emission peak intensity when the phosphor is excited by light having a peak wavelength of 455 nm at 125° C.,(2) the emission peak wavelength is in the range of 570 nm to 680 nm, and(3) the full width at half maximum of an emission peak is 90 nm or less.The phosphor of the present invention has a high luminous efficiency and emits light of orange to red with high luminance. The use of the phosphor makes it possible to produce a light-emitting device, an illumination apparatus, and an image display, having a high efficiency and excellent color rendering properties.

Owner:MITSUBISHI CHEM CORP

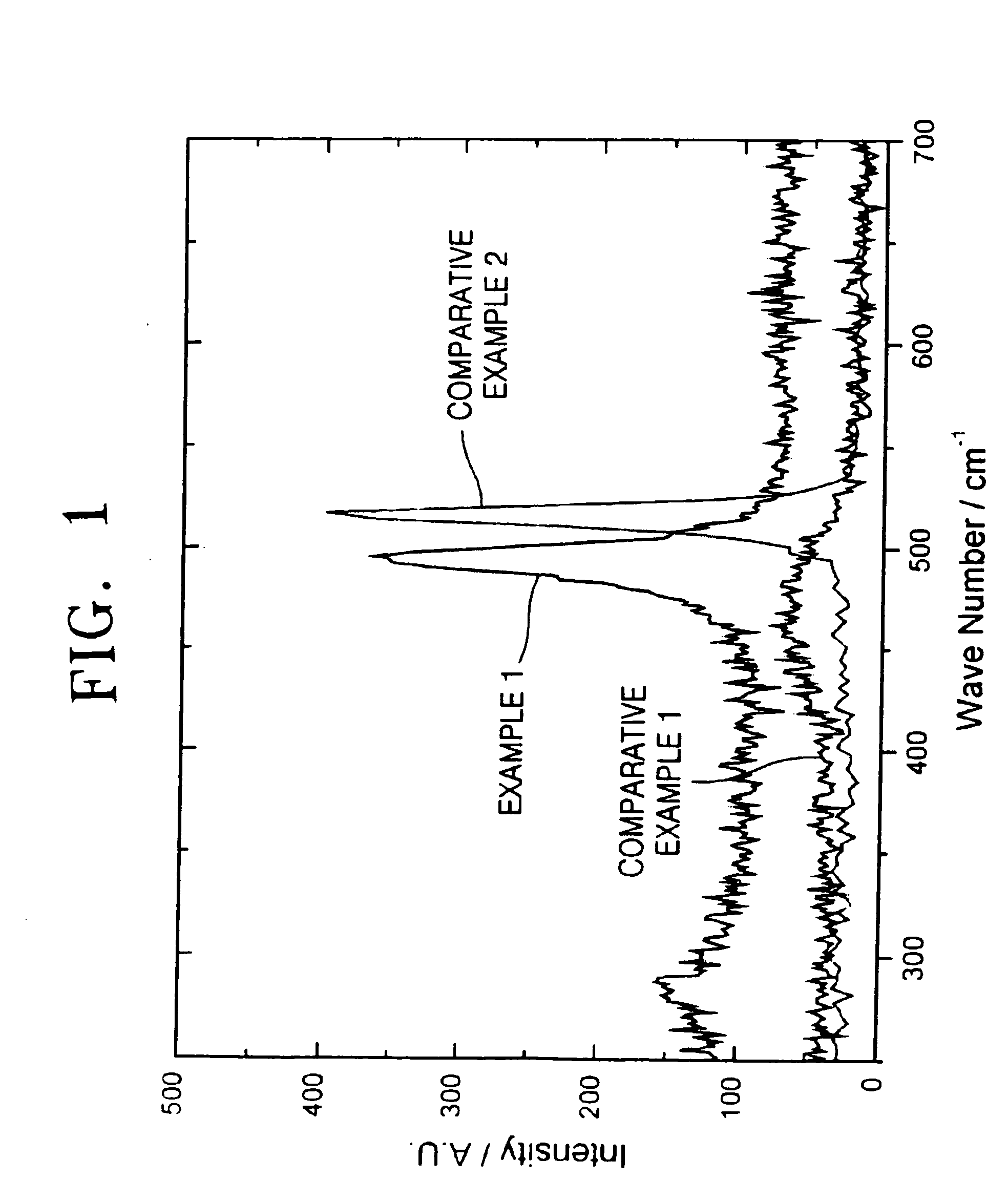

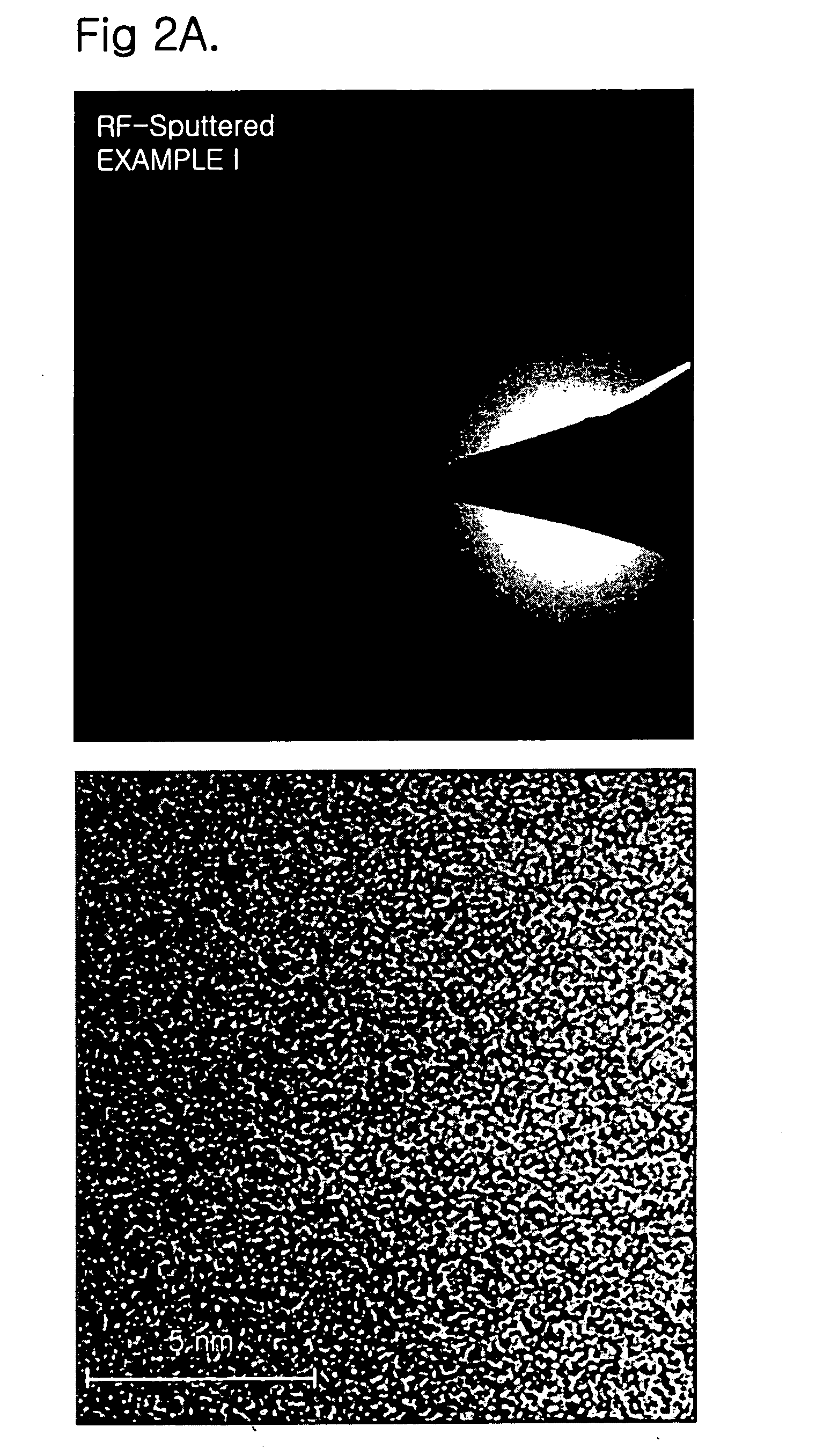

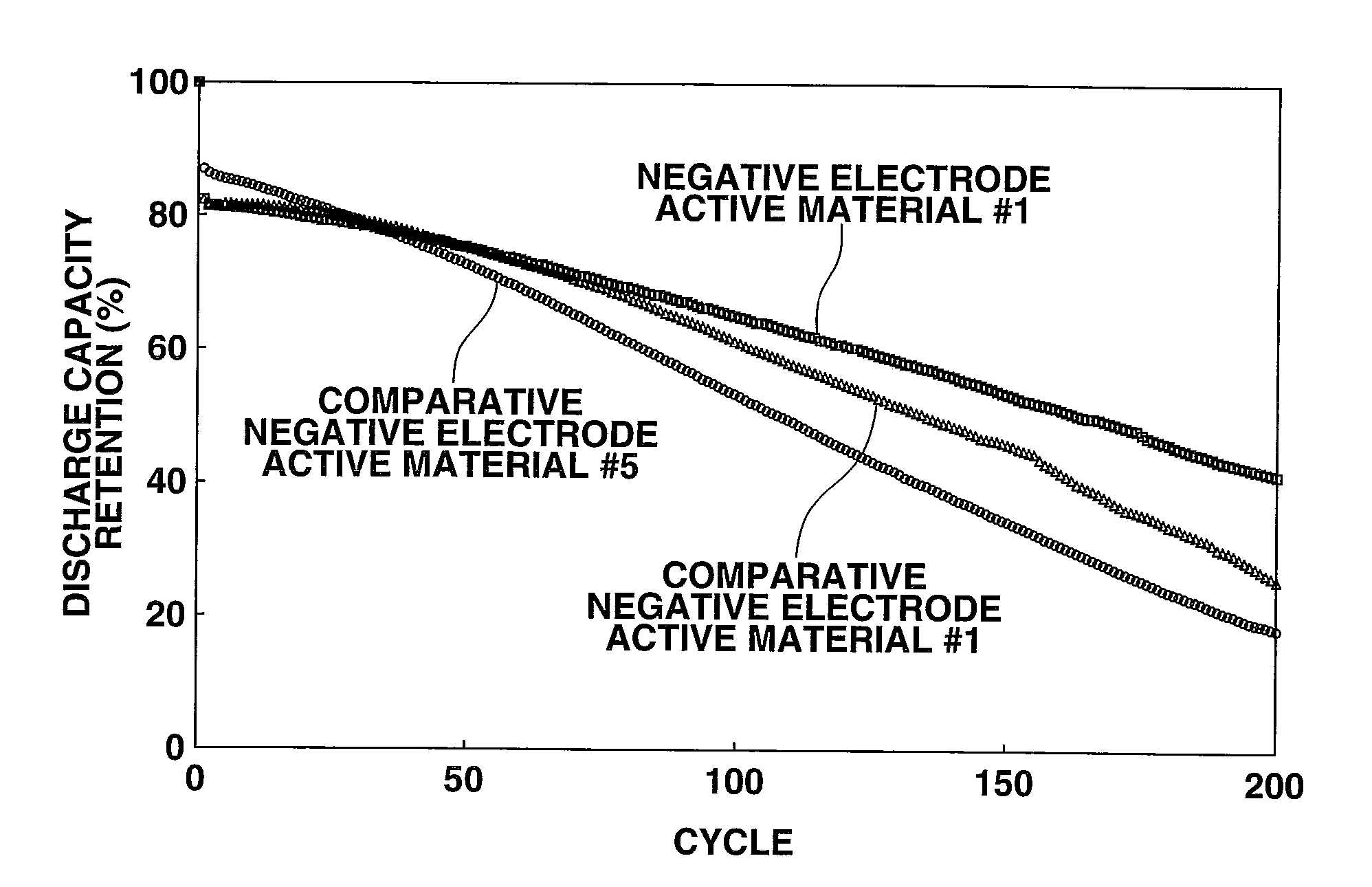

Anode active material, method of preparing the same, and anode and lithium battery containing the anode active material

An anode active material is provided. The anode active material includes a silicon thin film containing crystalline silicon having a Raman shift in a Raman spectrum ranging from about 490 to about 500 cm−1 and a full width at half maximum (FWHM) ranging from about 10 to about 30 cm−1. The volume of the anode active material does not change significantly during charging and discharging. Thus, a lithium battery employing the anode active material has an excellent capacity retention rate and a longer cycle lifetime.

Owner:SAMSUNG SDI CO LTD

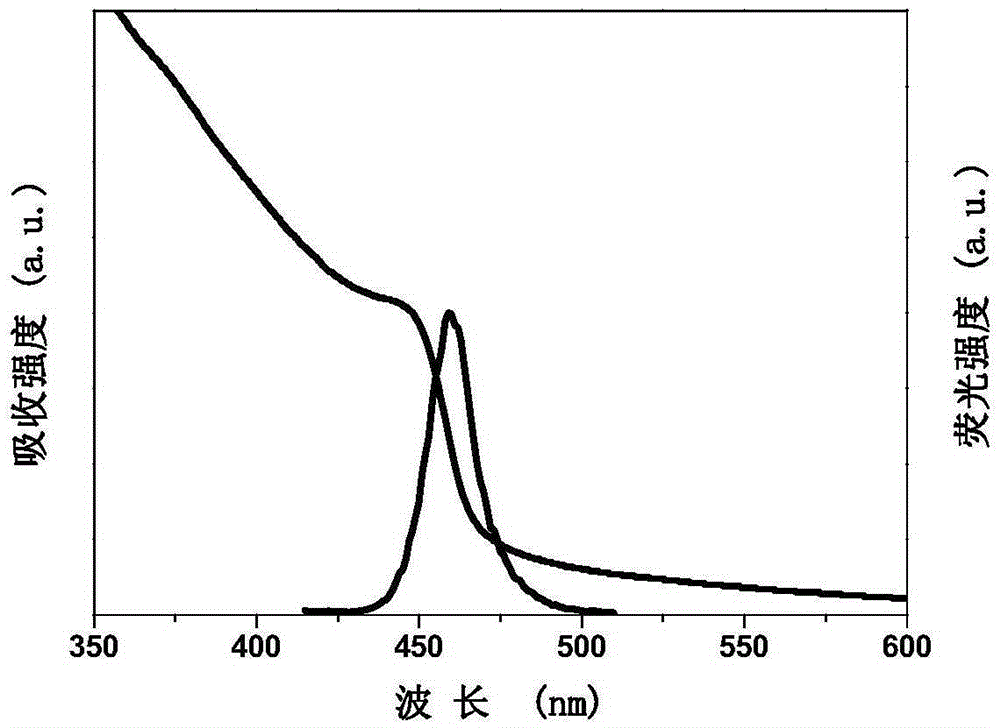

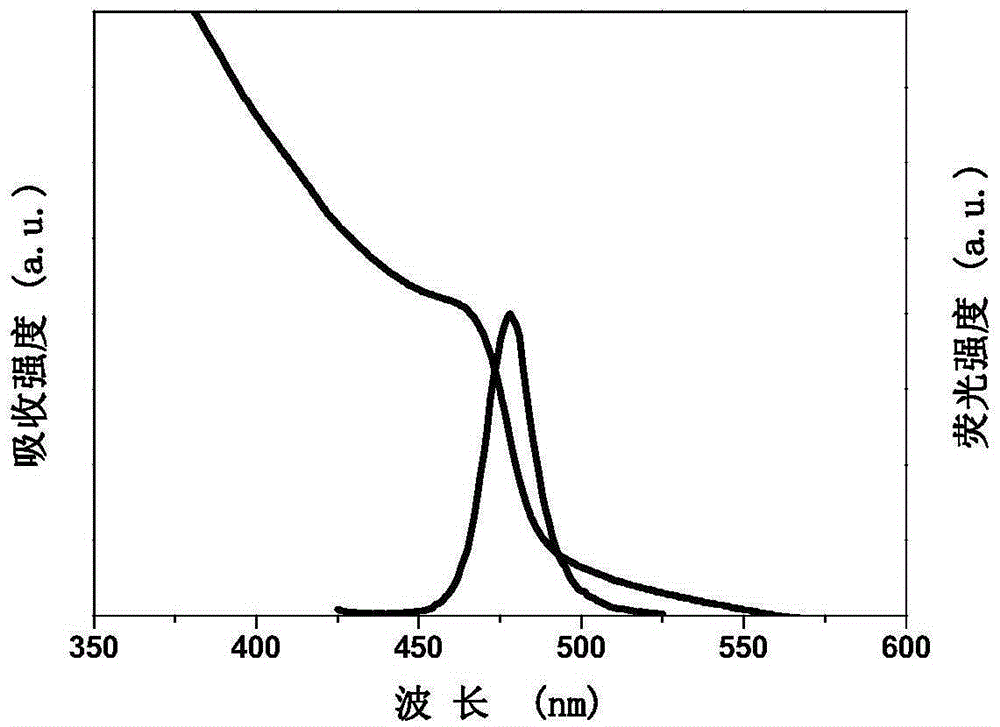

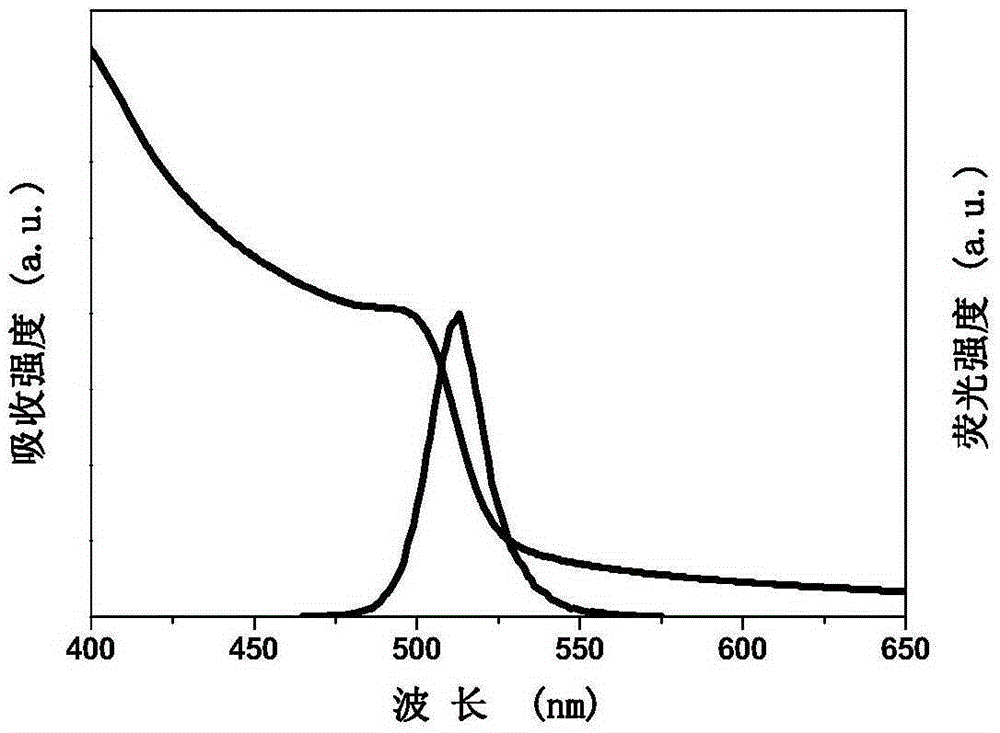

High-yield preparing method for inorganic halogen perovskite fluorescent quantum dots at room temperature

ActiveCN105331362AImprove performanceScalable productionMaterial nanotechnologyNanoopticsFluorescenceShielding gas

The invention discloses a high-yield preparing method for inorganic halogen perovskite fluorescent quantum dots at the room temperature. The fluorescent quantum dots are CsPbX3, wherein X is equal to AxB1-x and is larger than or equal to 0 and smaller than or equal to 1, and A and B are any one of Cl, Br and I. The method comprises the following steps that firstly, lead halide and cesium halide are dissolved into dimethyl formamide, surfactant oleylamine and oleic acid are added, the mixture is stirred until complete dissolution, and a precursor solution is obtained; secondly, the precursor solution is dripped into a poor solvent at the speed of 0.08-0.13 mL / s and stirred evenly at the uniform speed, and the inorganic halogen perovskite fluorescent quantum dots CsPbX3 are obtained. The preparing method is implemented at the room temperature, protection gas is not needed, equipment is simple, mass production can be achieved, and full visible light band shining can be achieved by selecting halogen and adjusting the proportion of halogen. The full width at half maximum of the inorganic halogen perovskite fluorescent quantum dots prepared through the preparing method ranges from 16 nm to 39 nm, the fluorescence quantum efficiency is close to 90%, and the inorganic halogen perovskite fluorescent quantum dots can be stably stored for more than three months, and can be used in the field of solar cells, lasers, light detectors, light-emitting diodes and the like.

Owner:NANJING UNIV OF SCI & TECH

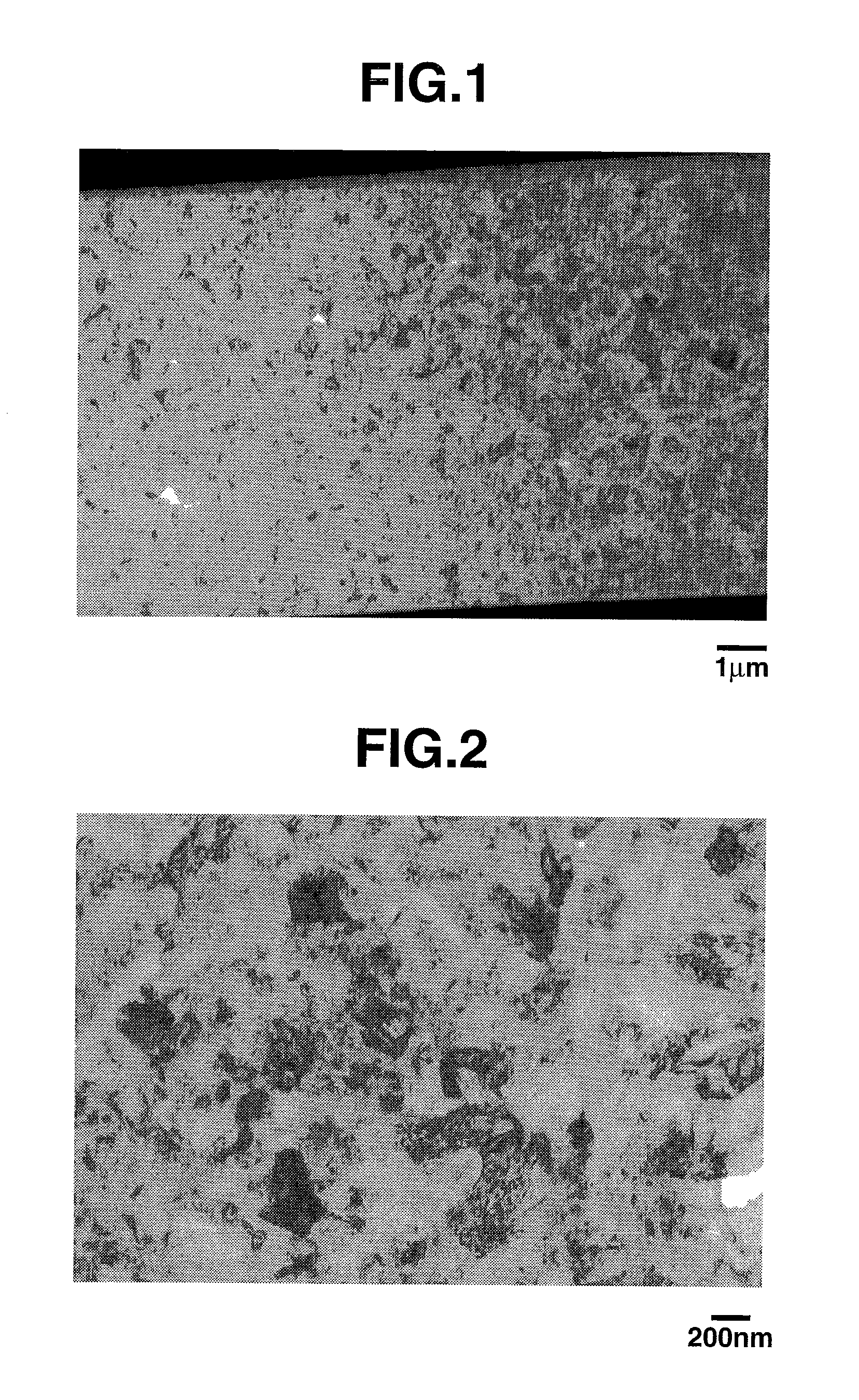

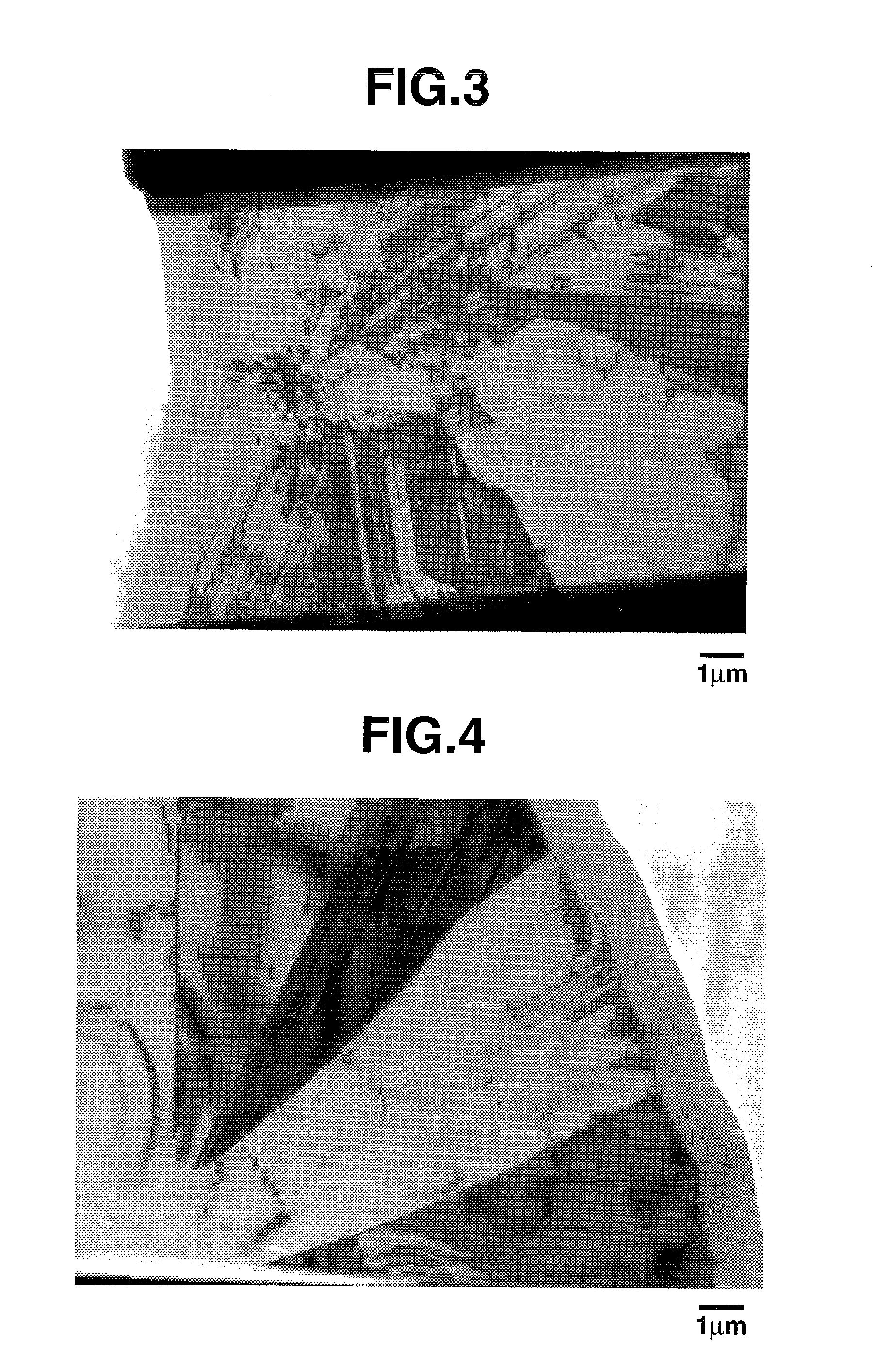

Negative electrode material for rechargeable battery with nonaqueous electrolyte, negative electrode for rechargeable battery with nonaqueous electrolyte, rechargeable battery with nonaqueous electrolyte, and process for producing polycrystalline silicon particles for active material for negative electrode material for rechargeable battery with nonaqueous electrolyte

ActiveUS20100266902A1Increase capacityImprove efficiencyMaterial nanotechnologySiliconX-rayFull width at half maximum

This invention provides a negative electrode material for a rechargeable battery with a nonaqueous electrolyte, characterized in that the negative electrode material contains polycrystalline silicon particles as an active material, the particle diameter of crystallites of the polycrystalline silicon is not less than 20 nm and not more than 100 nm in terms of a crystallite size determined by the Scherrer method from the full width at half maximum of a diffraction line attributable to Si (111) around 2θ=28.4° in an x-ray diffraction pattern analysis, and the true specific gravity of the silicon particles is 2.300 to 2.320.

Owner:PANASONIC ENERGY CO LTD +1

Phosphor, method for producing same, phosphor-containing composition, light-emitting device, image display, and illuminating device

InactiveUS20100164365A1Improve featuresImprove efficiencyDischarge tube luminescnet screensLamp detailsFluorescenceFull width at half maximum

To provide a phosphor emitting green fluorescence and having such superior characteristics as excellent conversion efficiency of blue light or near-ultraviolet light and excellent color purity,a phosphor satisfying the following conditions (i) to (v):(i) the wavelength of emission peak thereof is 510 nm or longer and 542 nm or shorter, when excited with light of 400 nm or 455 nm(ii) the full width at half maximum of emission peak thereof is 75 nm or narrower, when excited with light of 400 nm or 455 nm,(iii) the external quantum efficiency, which is defined by the formula below, is 0.42 or larger, when excited with light of 400 nm or 455 nm,(external quantum efficiency)=(internal quantum efficiency)×(absorption efficiency)(iv) a part of its surface comprises substance containing oxygen, and(v) it contains a bivalent and trivalent metal element (MII element), and its molar ratio to the total bivalent elements is larger than 1% and smaller than 15%.

Owner:MITSUBISHI CHEM CORP

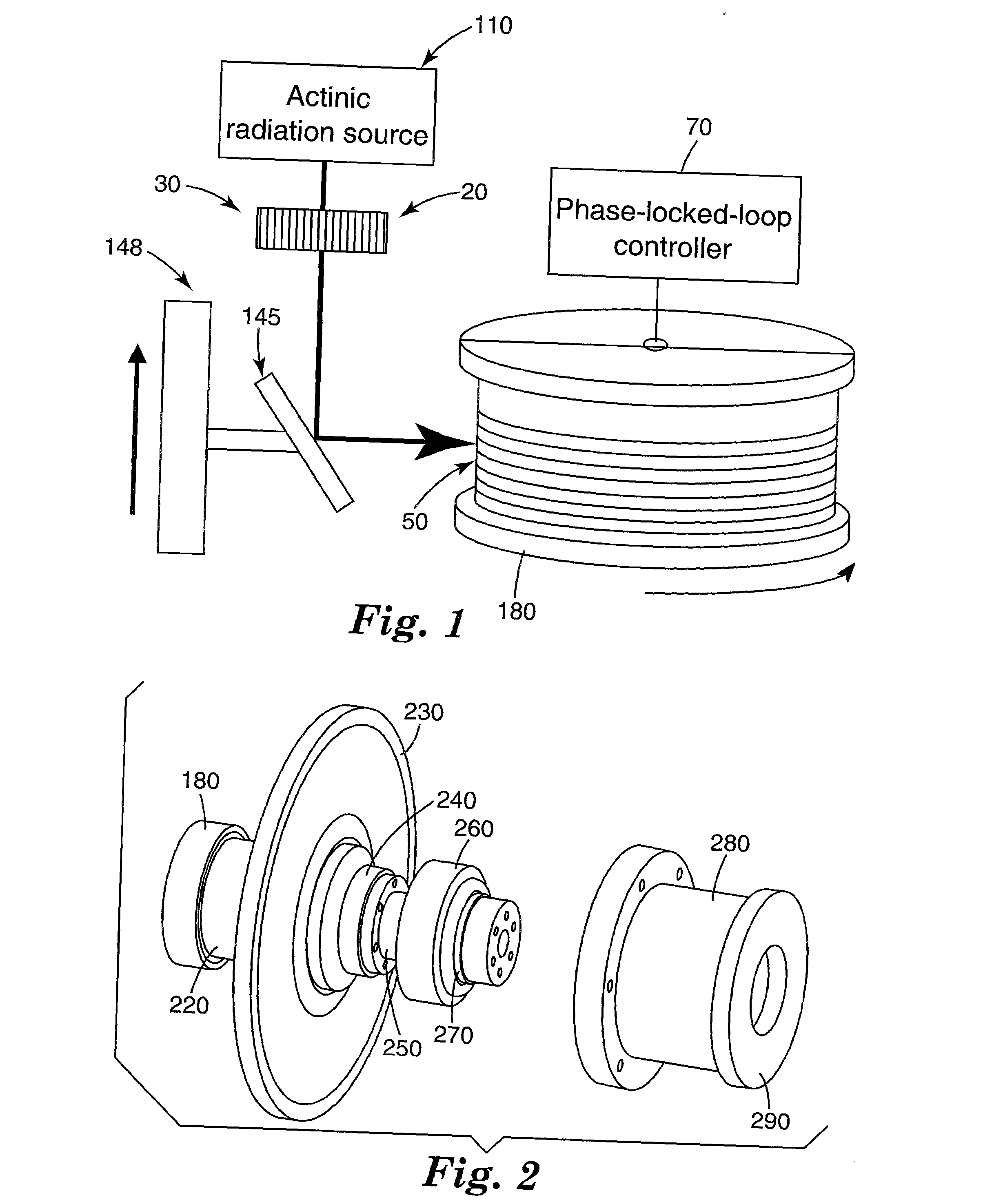

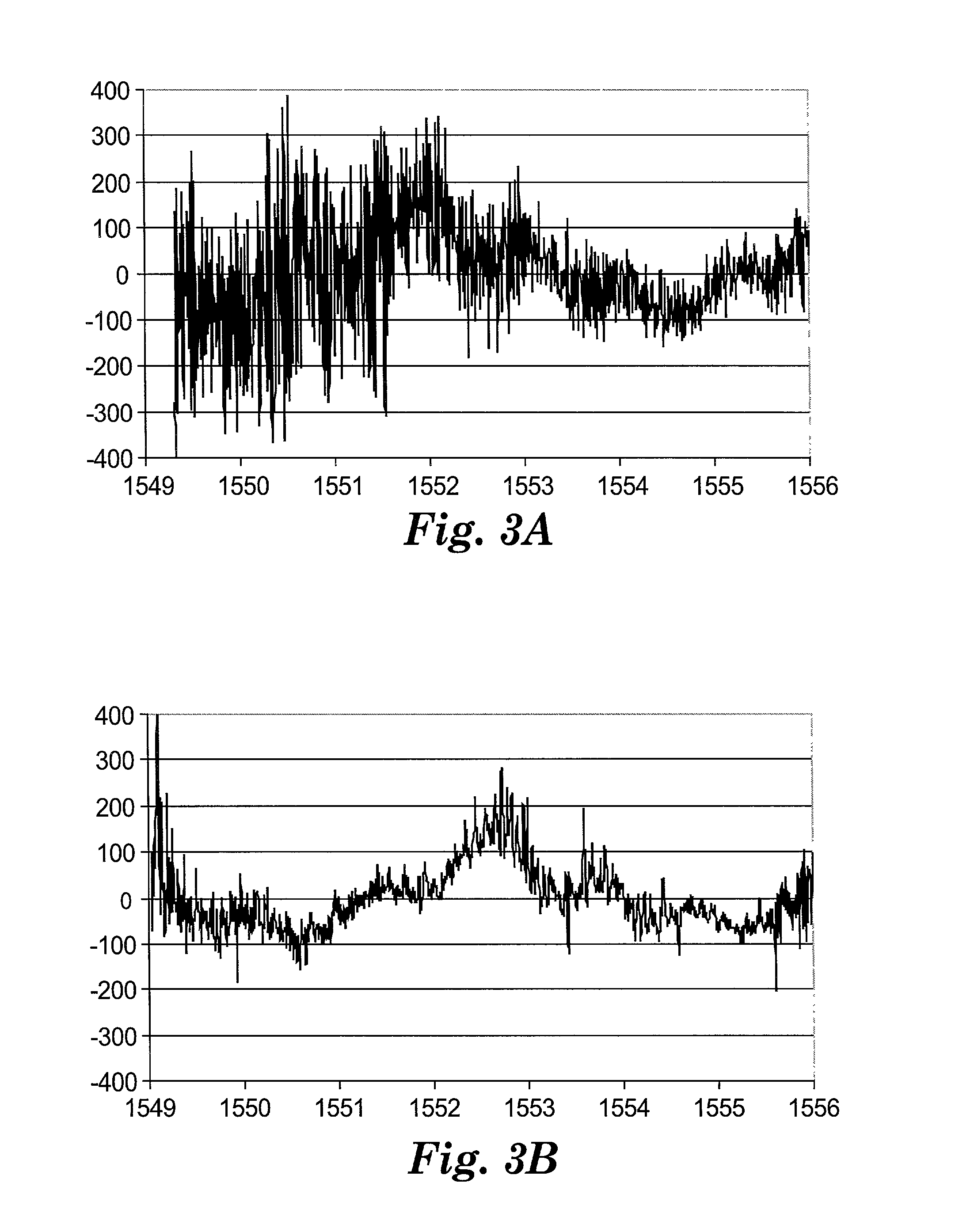

Wide-bandwidth chirped fiber bragg gratings with low delay ripple amplitude

Owner:PROXIMON FIBER SYST

Transparent conductive film and method for manufacturing the same

ActiveUS7867636B2Improve economyConductive layers on insulating-supportsSynthetic resin layered productsRocking curveCrystal structure

A ZnO-based transparent conductive film is produced by growing ZnO doped with a group III element oxide on a substrate and has a region with a crystal structure in which a c-axis grows along a plurality of different directions. The transparent conductive film produced by growing ZnO doped with a group III element oxide on a substrate has a ZnO (002) rocking curve full width at half maximum of about 13.5° or more. ZnO is doped with a group III element oxide so that the ratio of the group III element oxide in the transparent conductive film is about 7% to about 40% by weight. The transparent conductive film is formed on the substrate with a SiNx thin film provided therebetween. The transparent conductive film is formed on the substrate by a thin film formation method with a bias voltage applied to the substrate.

Owner:MURATA MFG CO LTD

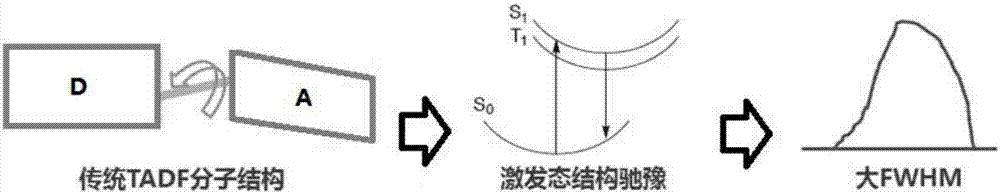

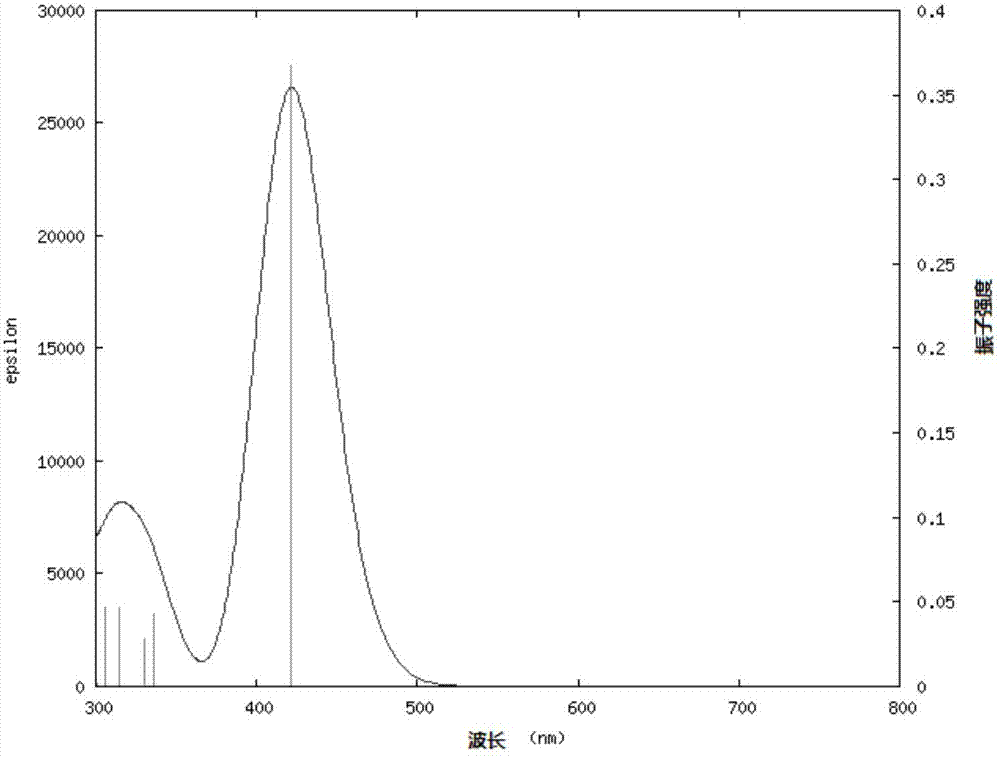

Organic electroluminescent material and luminescent device with same

InactiveCN107417715AImprove consistencyExcellent fluorescence performanceSolid-state devicesSemiconductor/solid-state device manufacturingPush and pullHOMO/LUMO

The invention relates to the technical field of organic luminescent materials, in particular to an organic electroluminescent material and a luminescent device with the same. The organic electroluminescent material comprises selected chemical compounds shown as a general formula I or a general formula II. The organic electroluminescent material and the luminescent device have the advantages that electron pushing and pulling common planes are formed by an electron donating Donor and an electron sucking Acceptor, and accordingly rigid molecular structures can be obtained; HOMO-LUMO (highest occupied molecular orbits-lowest unoccupied molecular orbits) are separated from one another to a certain extent, and accordingly the organic electroluminescent material and the luminescent device are narrow in FWHM (full width at half maximum) and have high transition rate constants Kr.

Owner:AAC TECH NANJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com