Patents

Literature

6365results about How to "Improve running stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

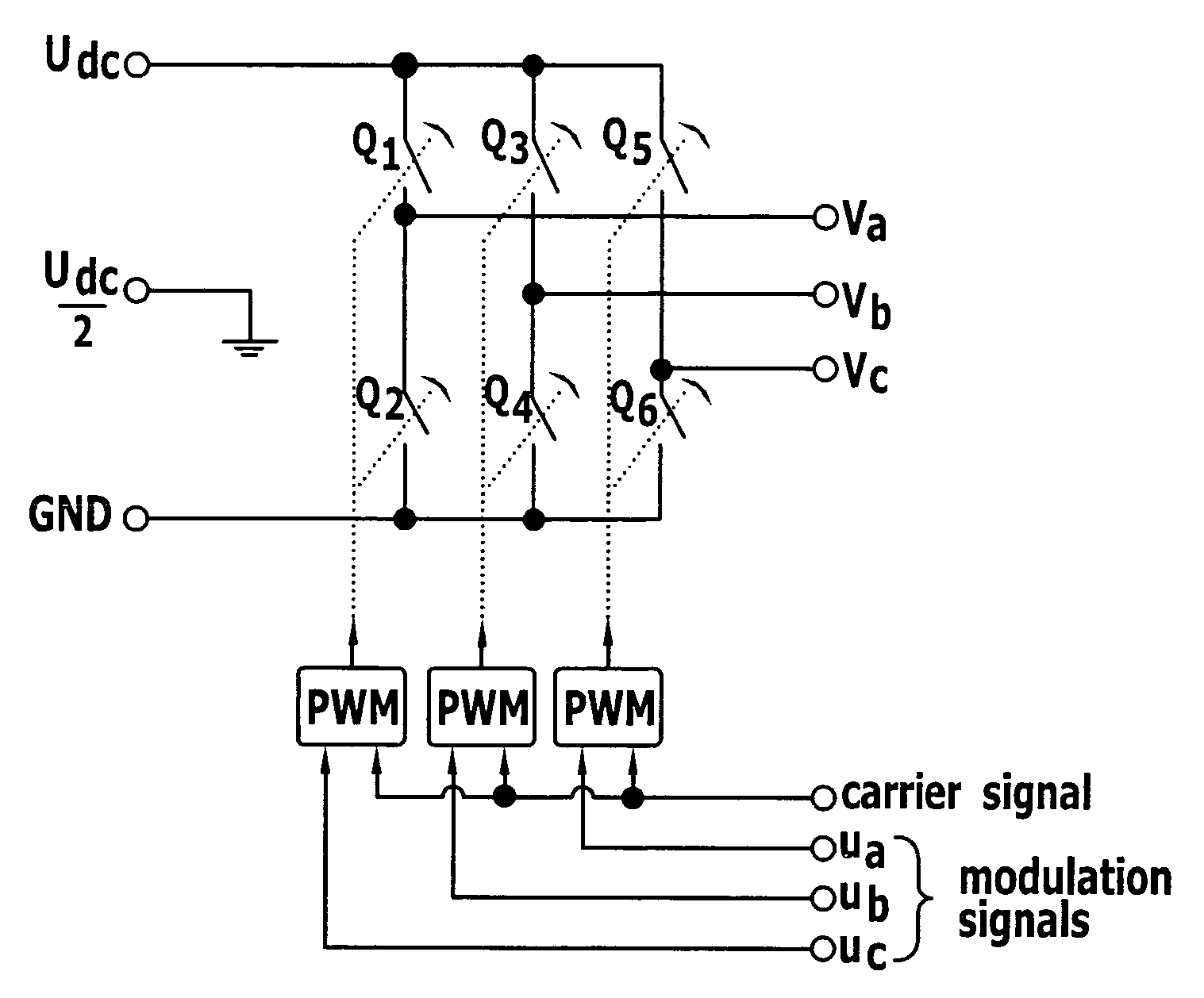

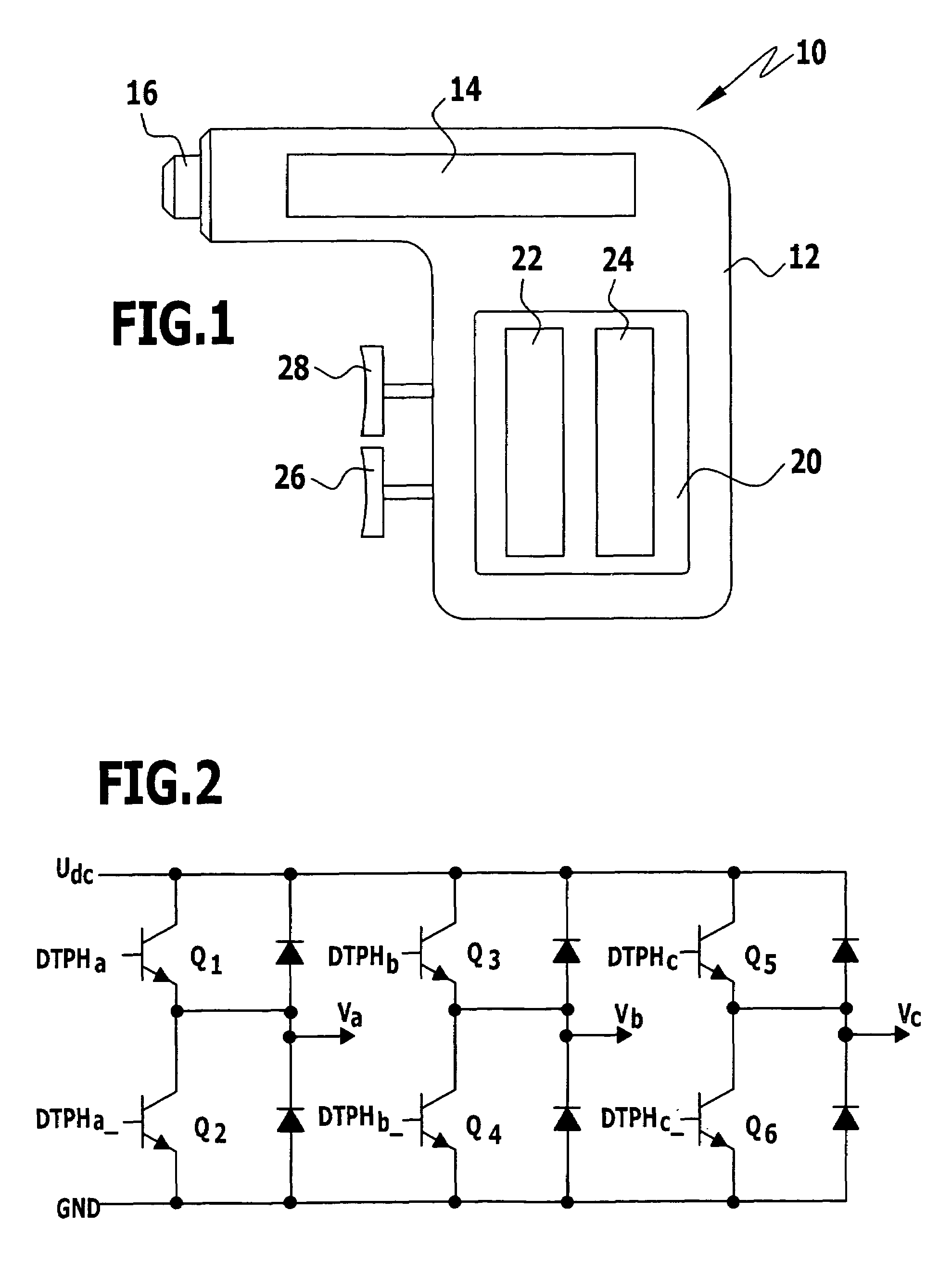

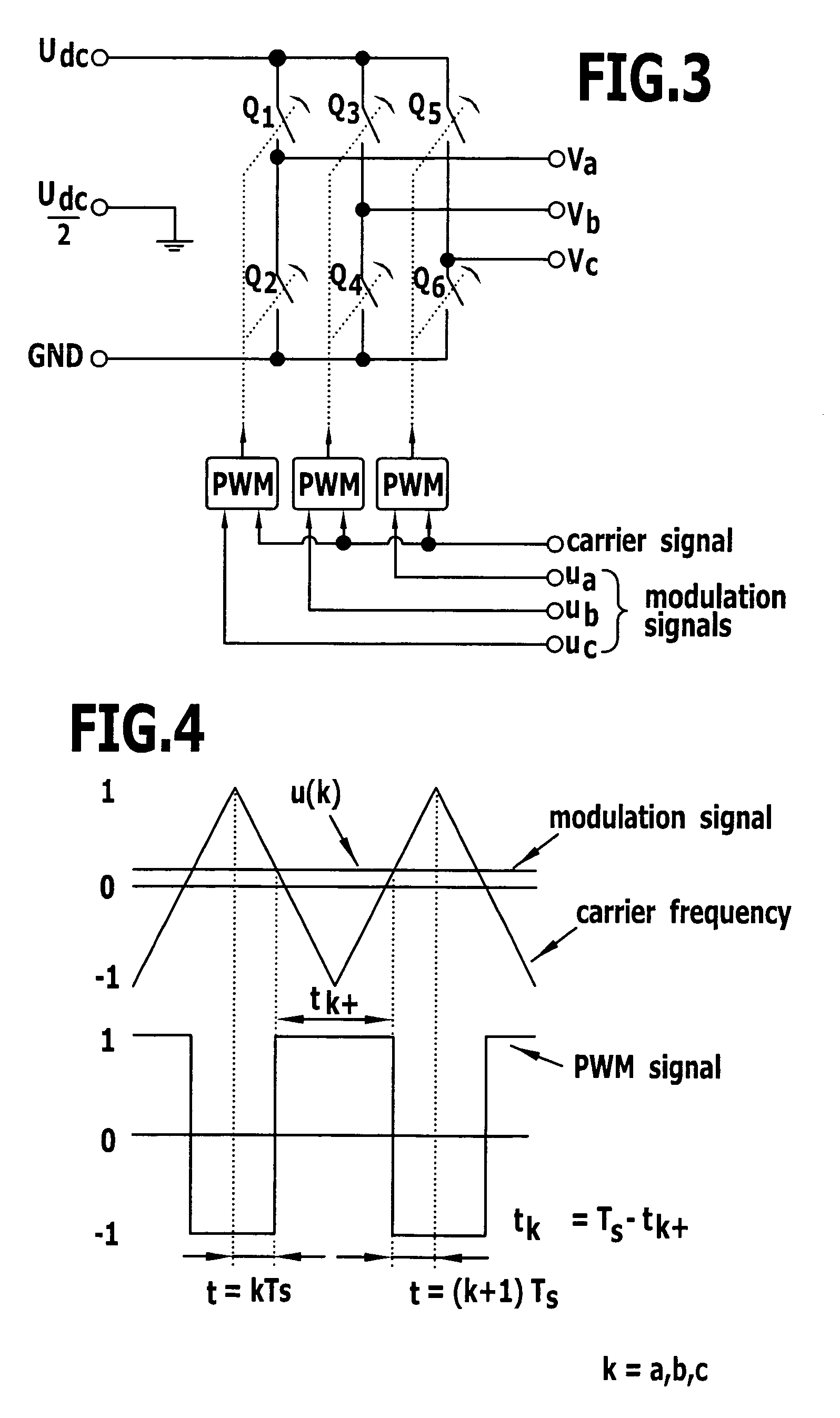

Surgical machine and method for controlling and/or regulating a surgical machine

ActiveUS7362062B2Guaranteed uptimeEasy to startElectronic commutation motor controlDC motor speed/torque controlMotor controllerControl theory

To improve a surgical machine with a sensorless electric motor comprising a rotor and at least two motor windings, and with a motor controller for controlling and / or regulating the electric motor, so that the electric motor is operable with optimum efficiency at low rotational speeds and a starting of the motor in accordance with the purpose, also under load, is enabled, it is proposed that a space vector pulse width modulation (SVPWM) method for controlling and / or regulating the electric motor, in which all motor windings are able to be simultaneously supplied with electric current, be performable with the motor controller. A method for controlling and / or regulating a surgical machine is also proposed.

Owner:AESCULAP AG

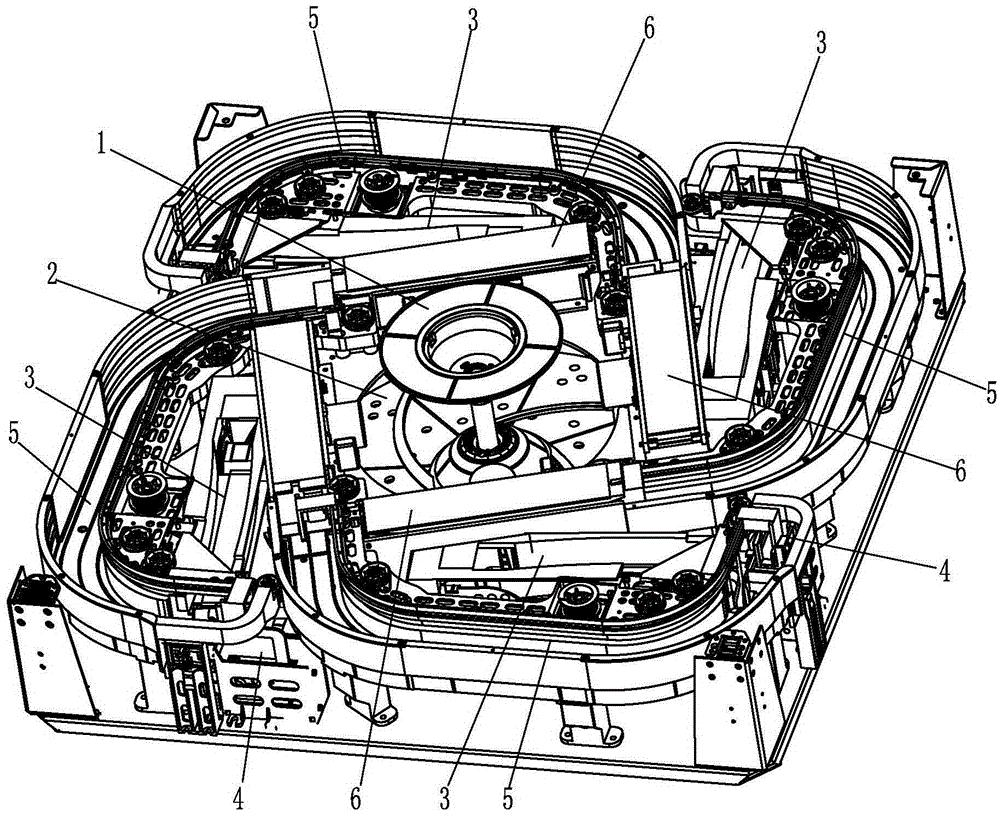

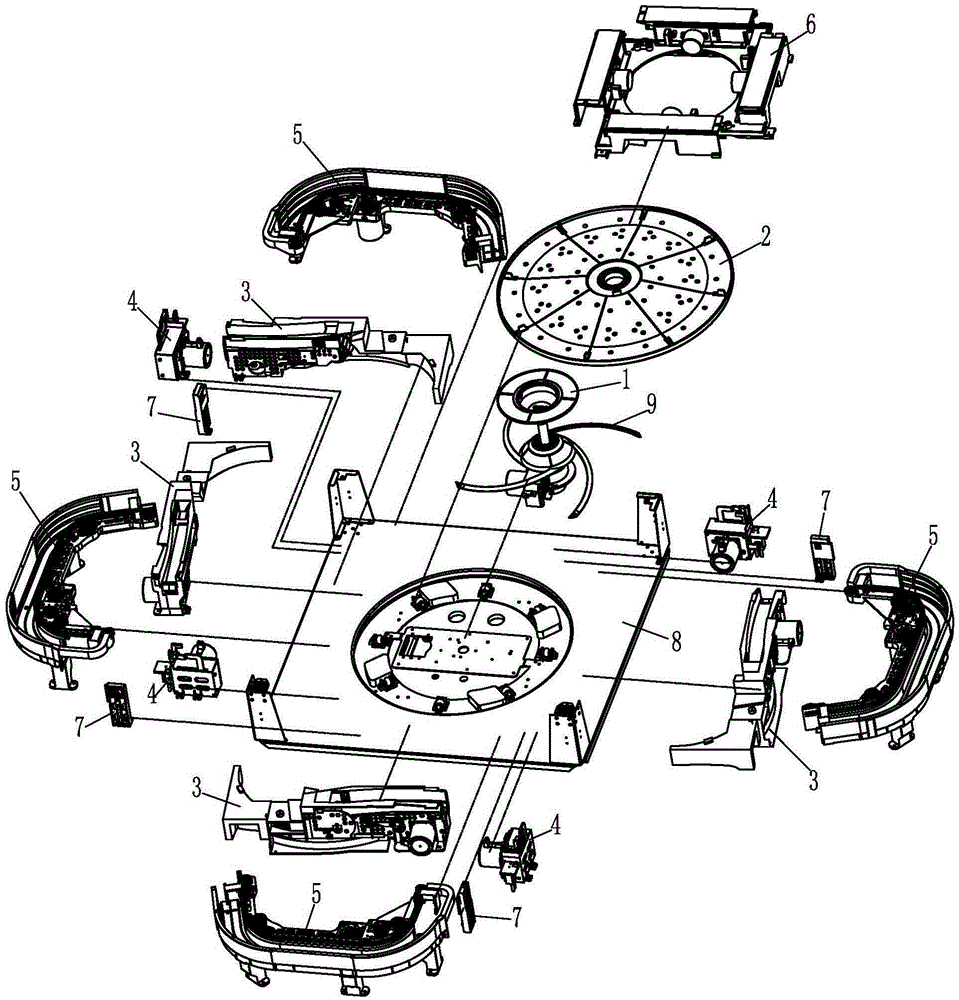

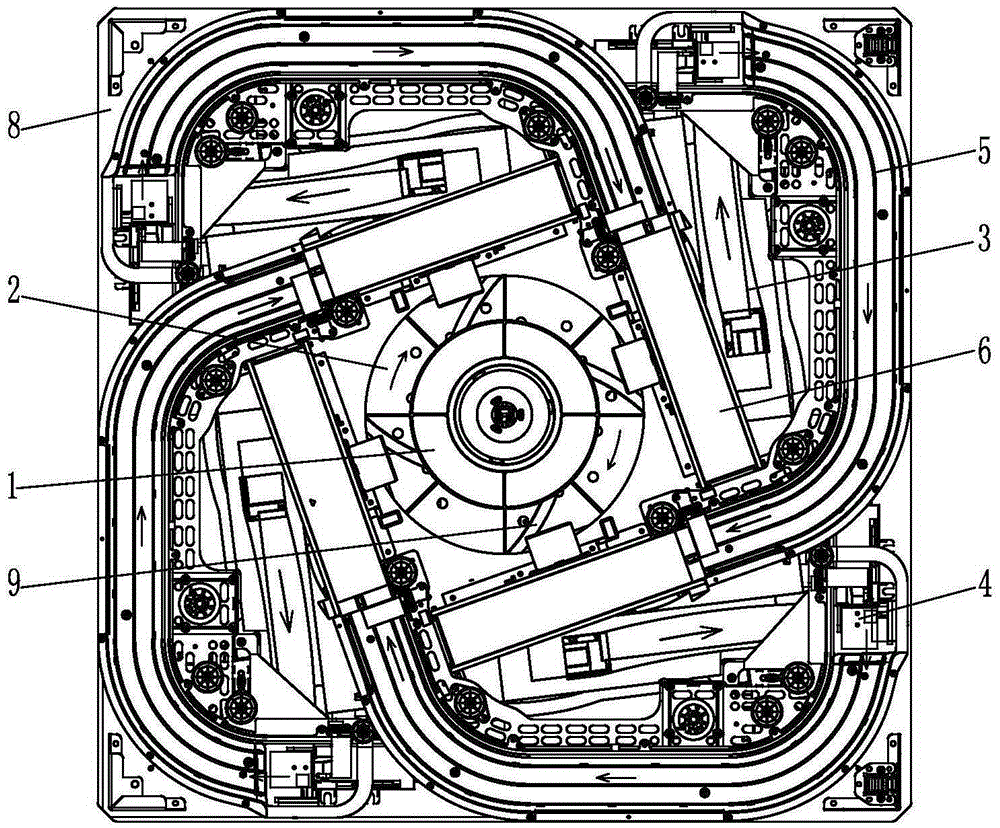

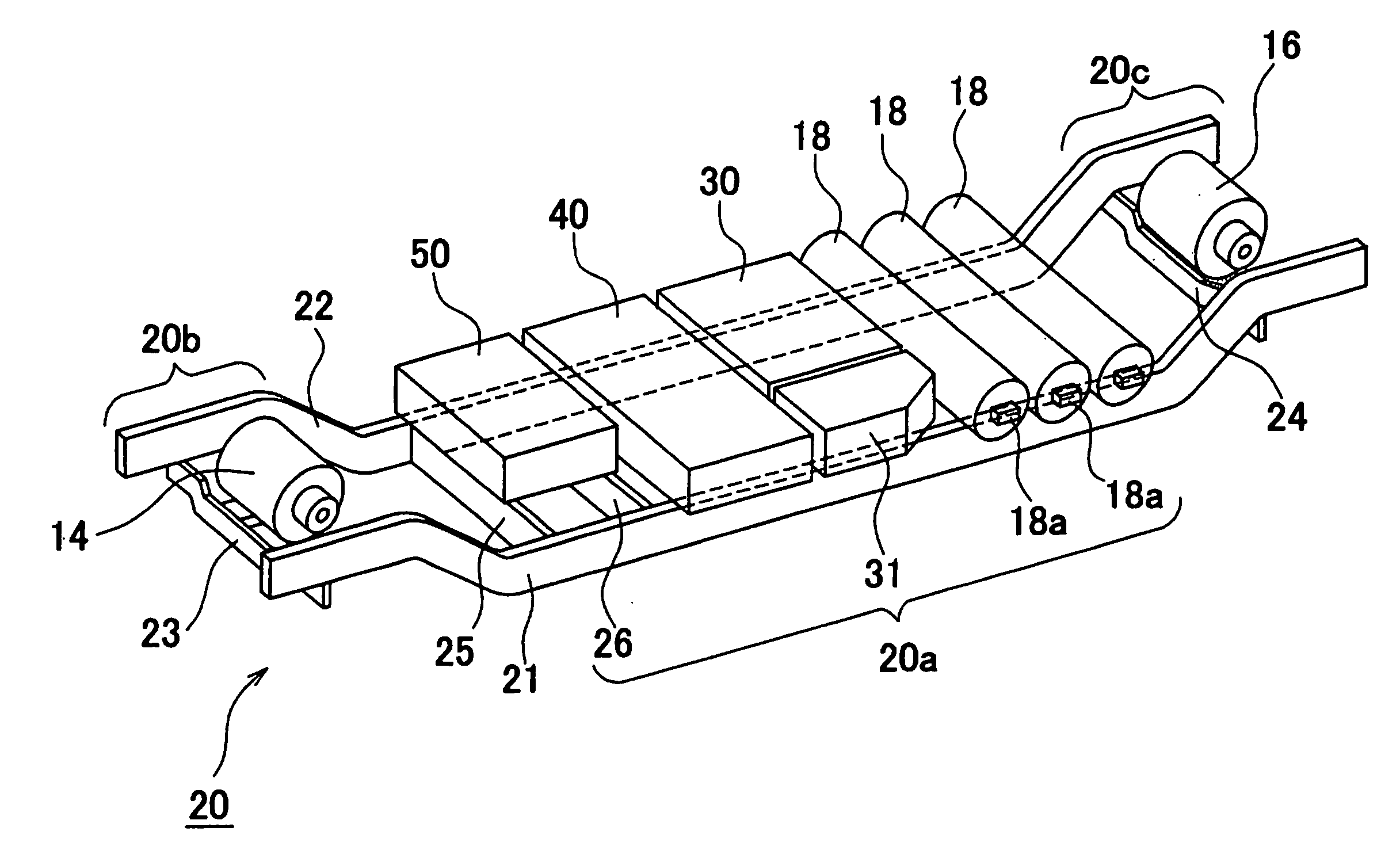

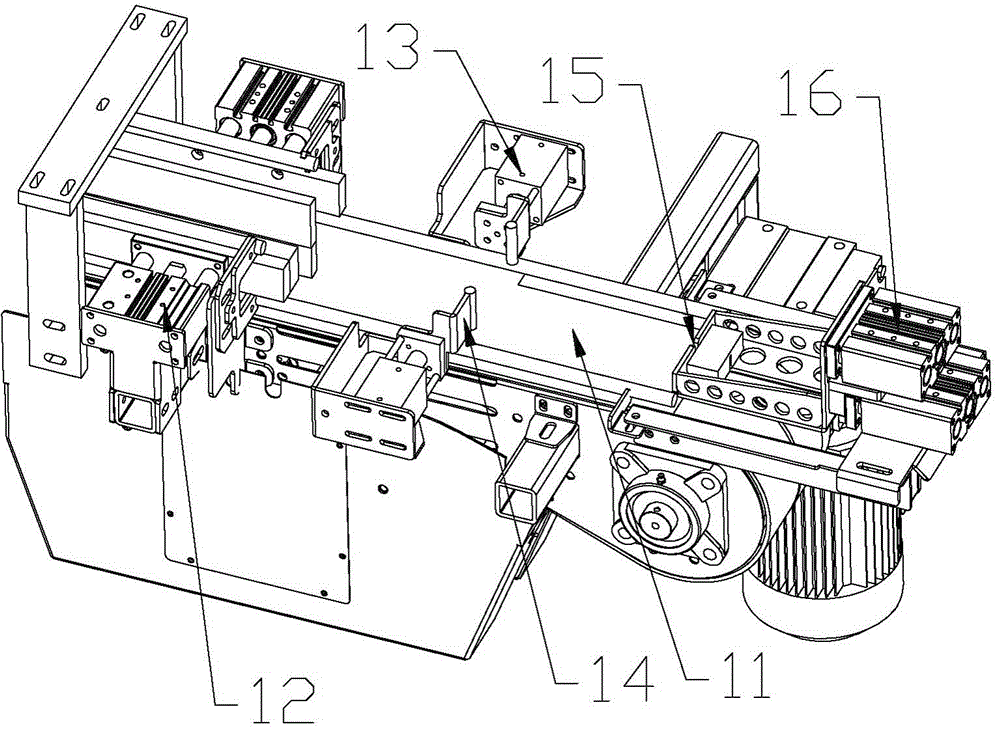

Tile feeding driving mechanisms, tile feeding assemblies and mahjong machine

The invention discloses tile feeding driving mechanisms, tile feeding assemblies and a mahjong machine. Each tile feeding driving mechanism of the mahjong machine comprises a tile feeding support, a tile storage groove, a tile feeding guide rail, a tile feeding pushing head and a steel wire rope, rolling parts are arranged at the position, close to the corresponding tile feeding guide rail and / or the corresponding tile storage groove, of each steel wire rope, each rolling part is installed on the corresponding tile feeding guide rail or the corresponding tile feeding support in a rotatable mode, the part, located in the corresponding tile storage groove, of each steel wire rope are in rolling contact with the multiple rolling parts, and a gap is maintained between the part, located in the corresponding tile storage groove, of each steel wire rope and the corresponding tile feeding guide rail and / or the side wall of the corresponding tile storage groove. According to the scheme, sliding friction of steel wire ropes in the prior art is replaced with rolling friction of the steel wire ropes, friction resistance in the operation process of the steel wire ropes is greatly decreased, and the situation that the service life and operation stability of the steel wire ropes are influenced due to sliding friction contact between the part, located in the corresponding tile storage groove, of each steel wire rope and the corresponding tile feeding guide rail and / or the arc-shaped bent side wall of the corresponding tile storage groove is avoided.

Owner:ZHEJIANG CHAOSHENG ELECTROMECHANICAL TECH CO LTD

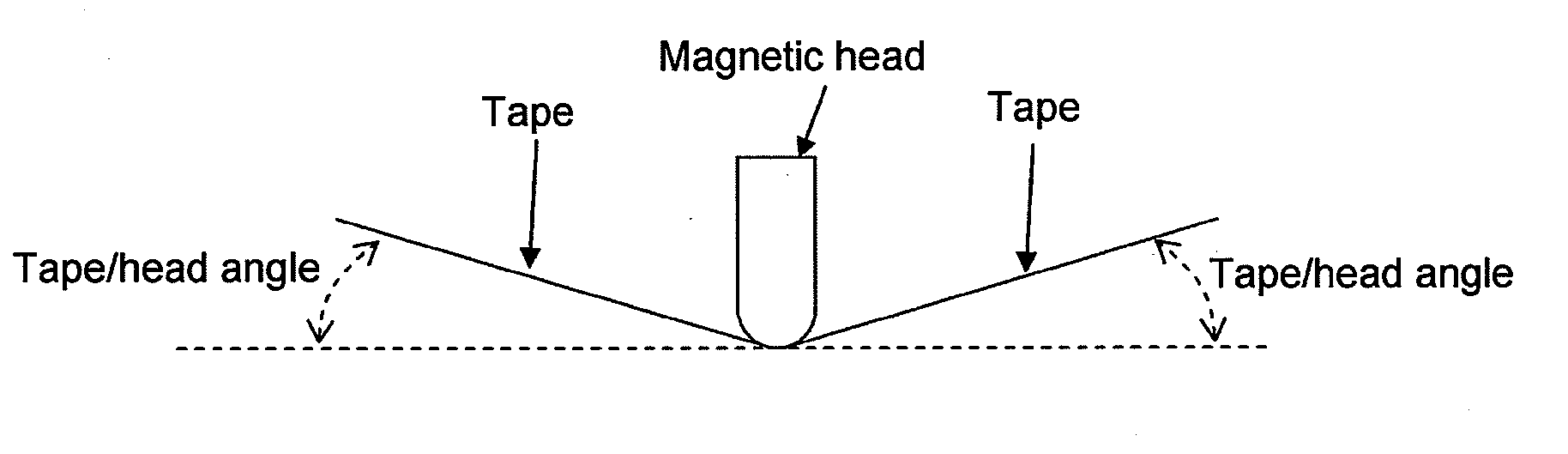

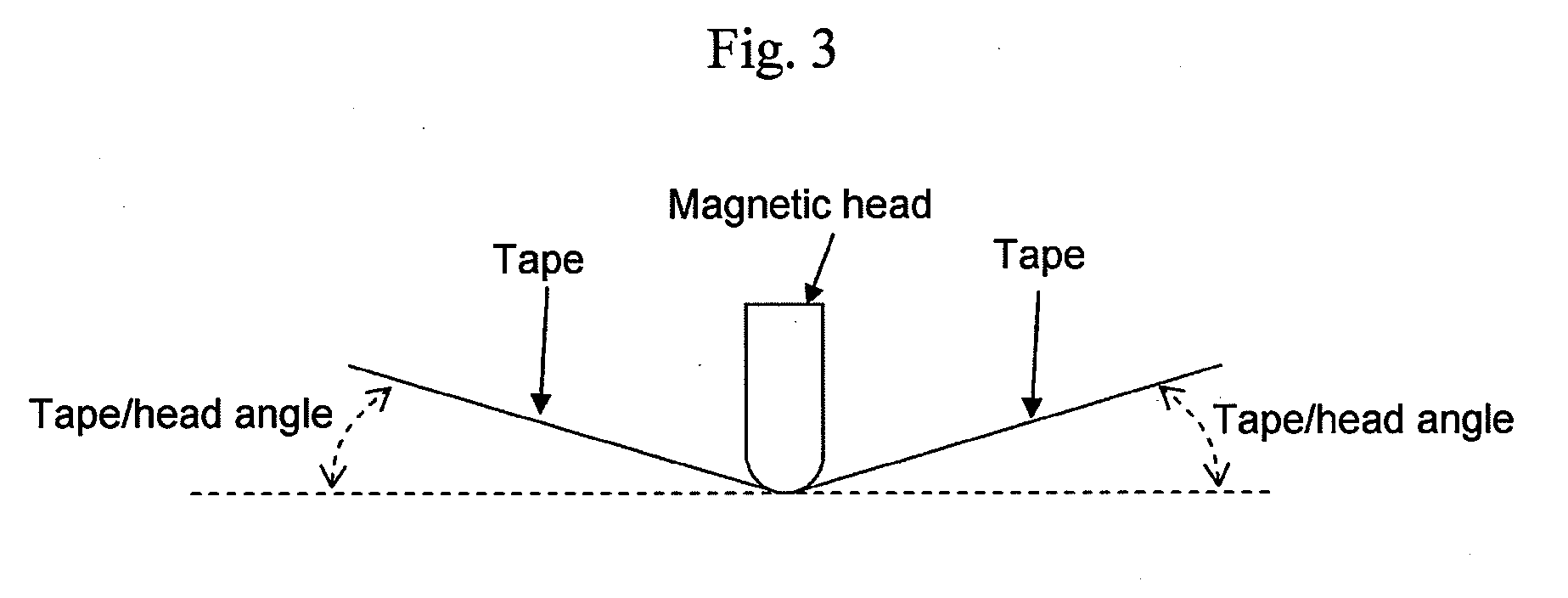

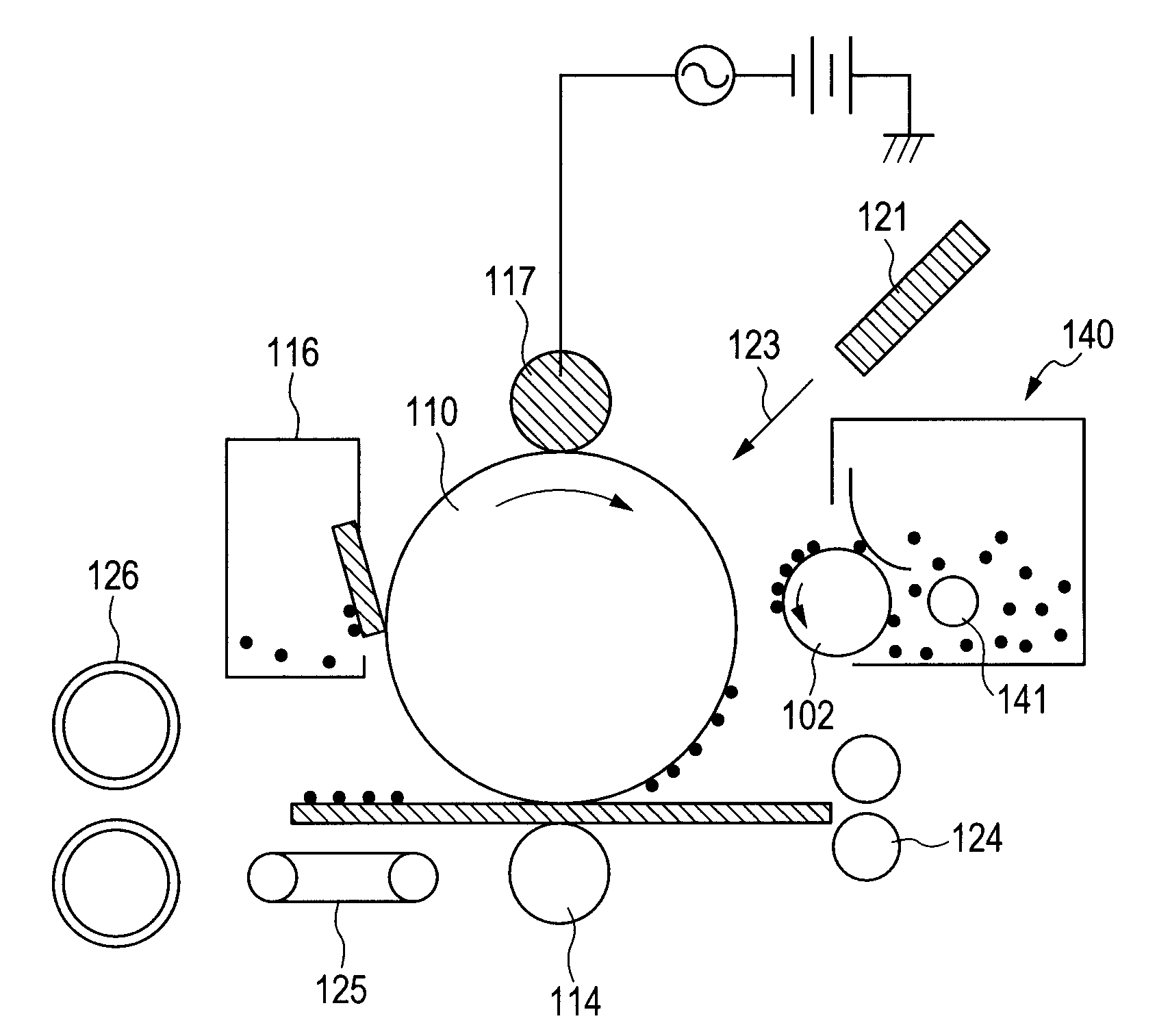

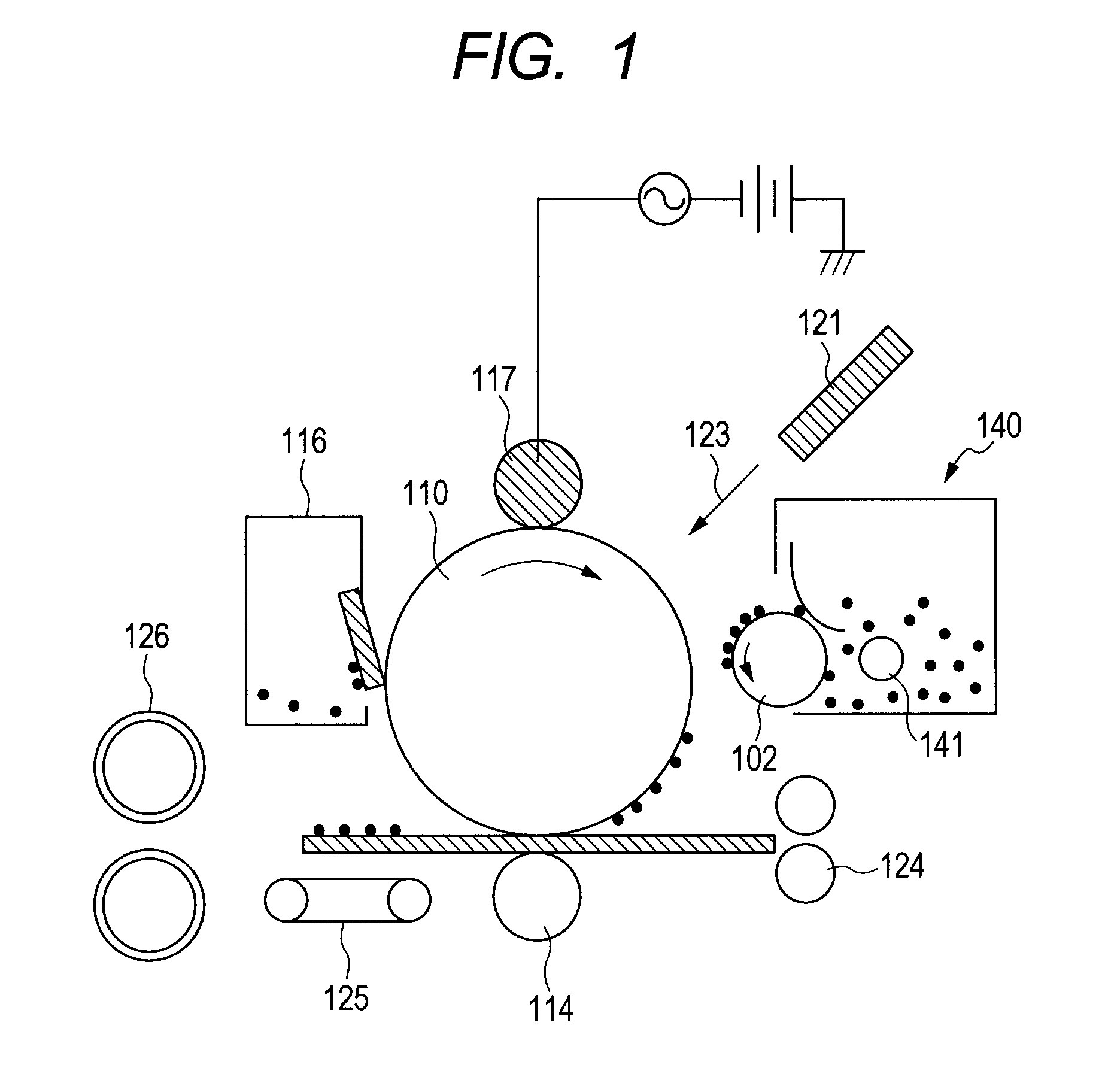

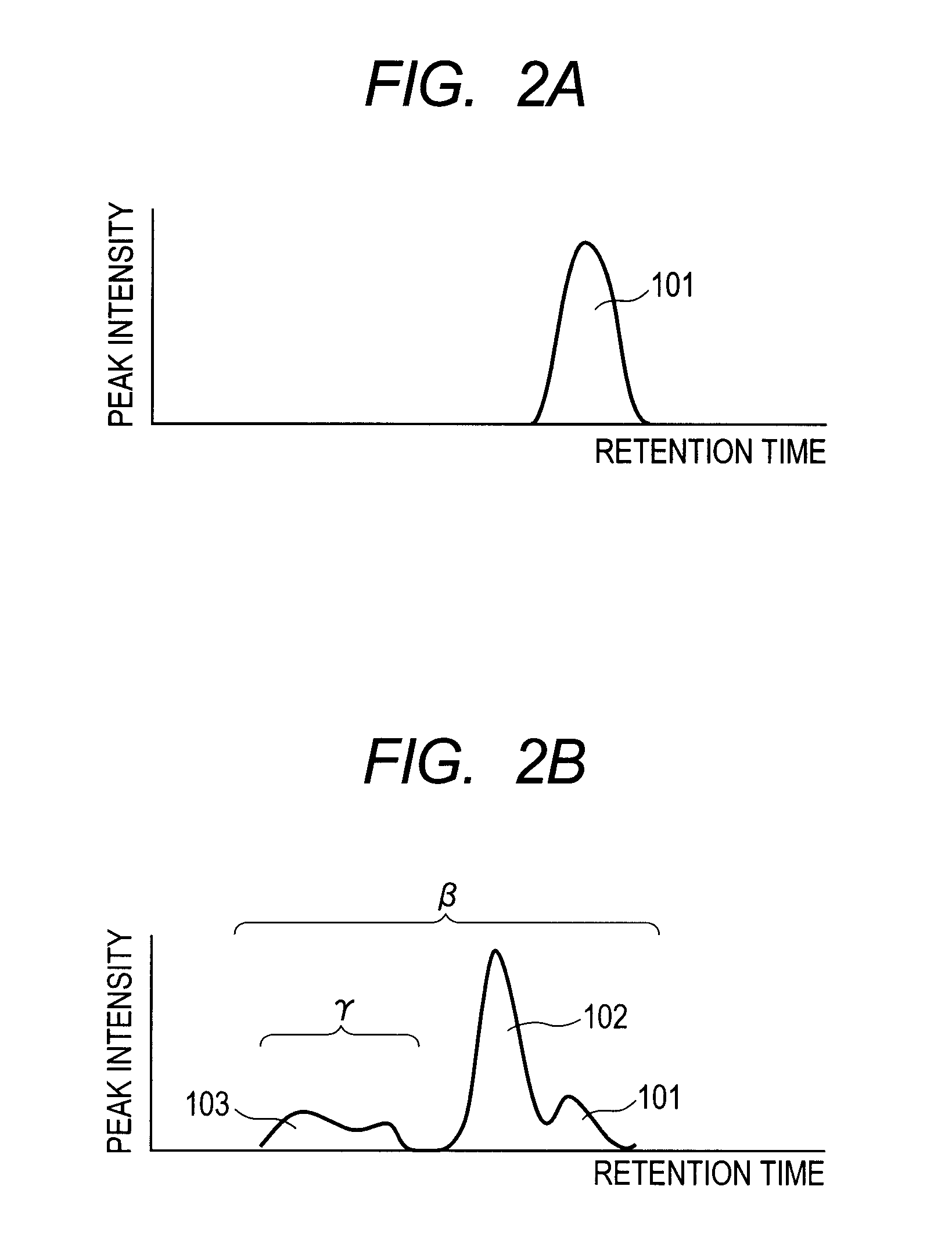

Magnetic signal reproduction system and magnetic signal reproduction method

ActiveUS20080297950A1Good electromagnetic characteristicImprove running stabilityTape carriersRecord information storageNuclear magnetic resonanceMicroscope

The magnetic signal reproduction system comprises a magnetic recording medium comprising a magnetic layer comprising a ferromagnetic powder and a binder on a nonmagnetic support; and a reproduction head, wherein a number of protrusions equal to or greater than 10 nm in height on the magnetic layer surface, as measured by an atomic force microscope, ranges from 50 to 2500 / 10,000 μm2, a quantity of lubricant on the magnetic layer surface, denoted as a surface lubricant index, ranges from 0.5 to 5.0, a surface abrasive occupancy of the magnetic layer ranges from 2 to 20 percent, and the reproduction head is a magnetoresistive magnetic head comprising a spin-valve layer.

Owner:FUJIFILM CORP

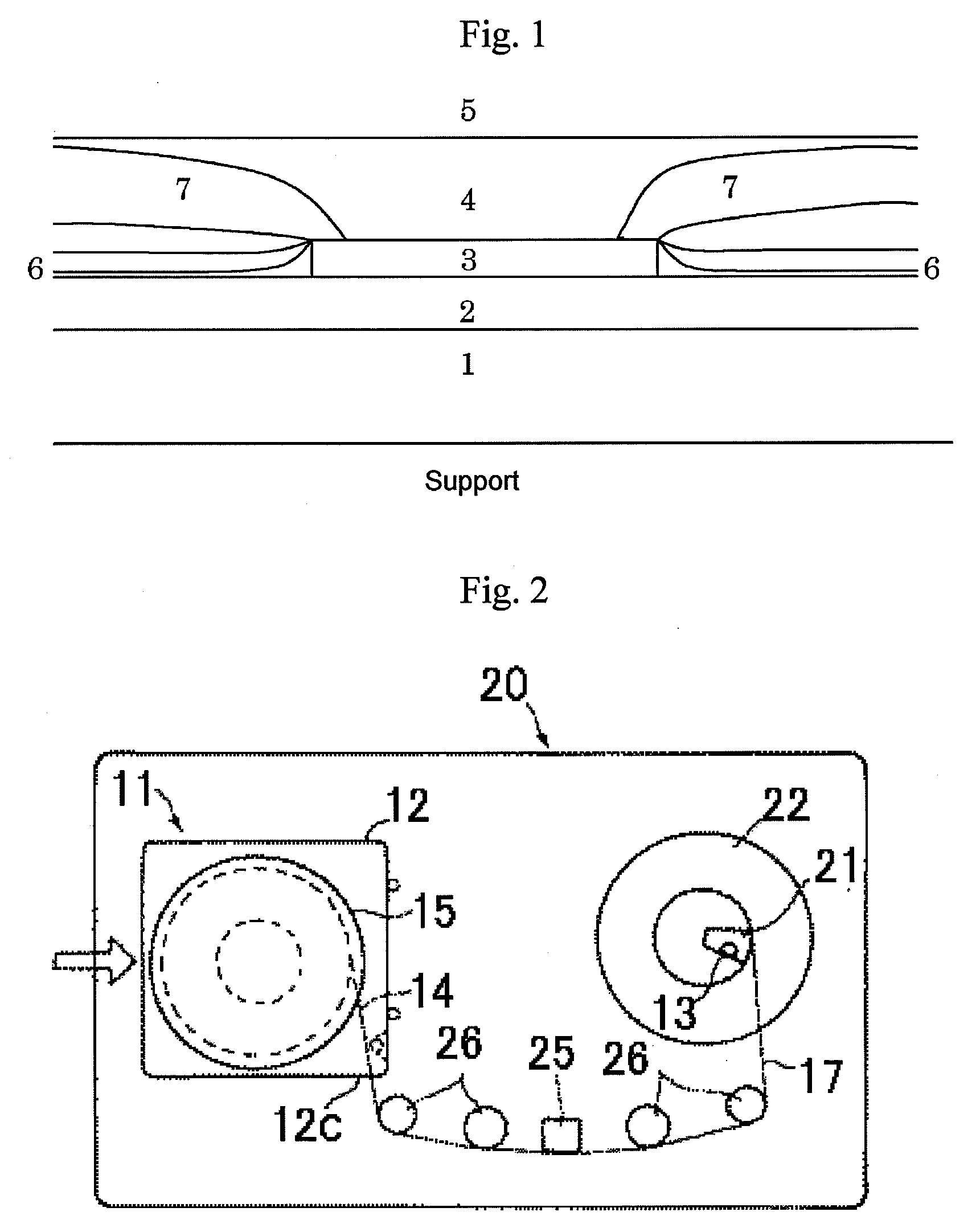

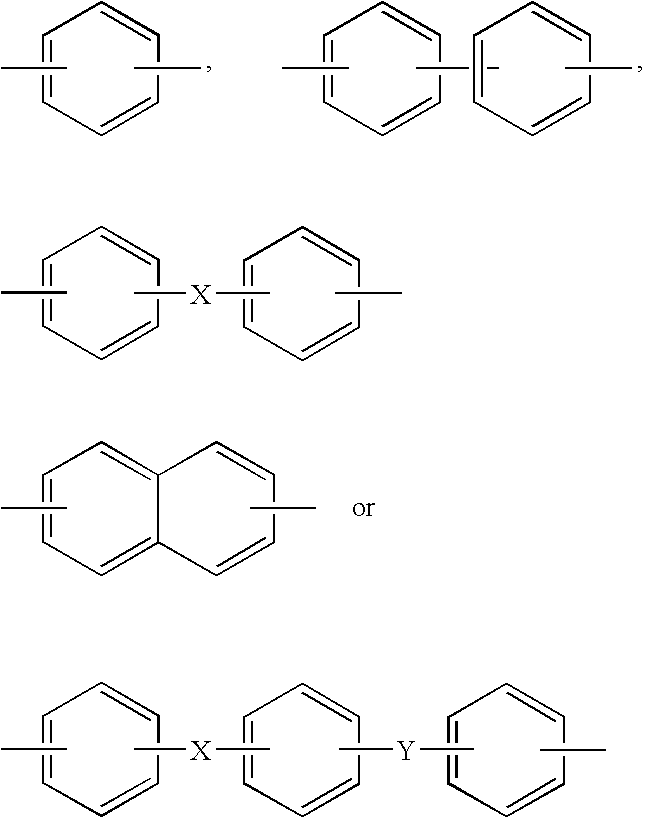

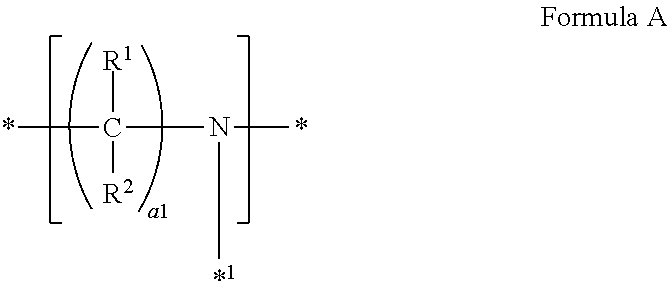

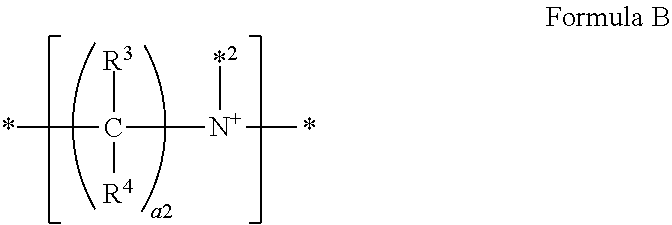

Magnetic recording medium

InactiveUS20100081011A1Secure run stabilityIncrease in dropout and error rateRecord information storageMagnetic recordingMagnetic layerAgglomerate

A magnetic recording medium includes, in the following order: a backcoat layer; a nonmagnetic support; a nonmagnetic layer containing a nonmagnetic powder and a binder; and a magnetic layer containing a ferromagnetic powder and a binder, wherein the backcoat layer contains particles having an average primary particle size D50 of from 0.05 to 1.0 μm and forming substantially no aggregates nor agglomerates in the backcoat layer.

Owner:FUJIFILM CORP

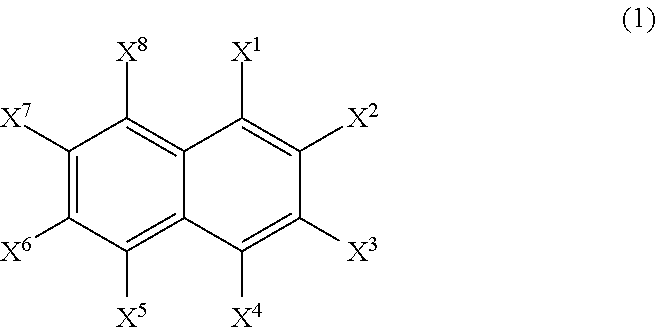

Magnetic recording medium

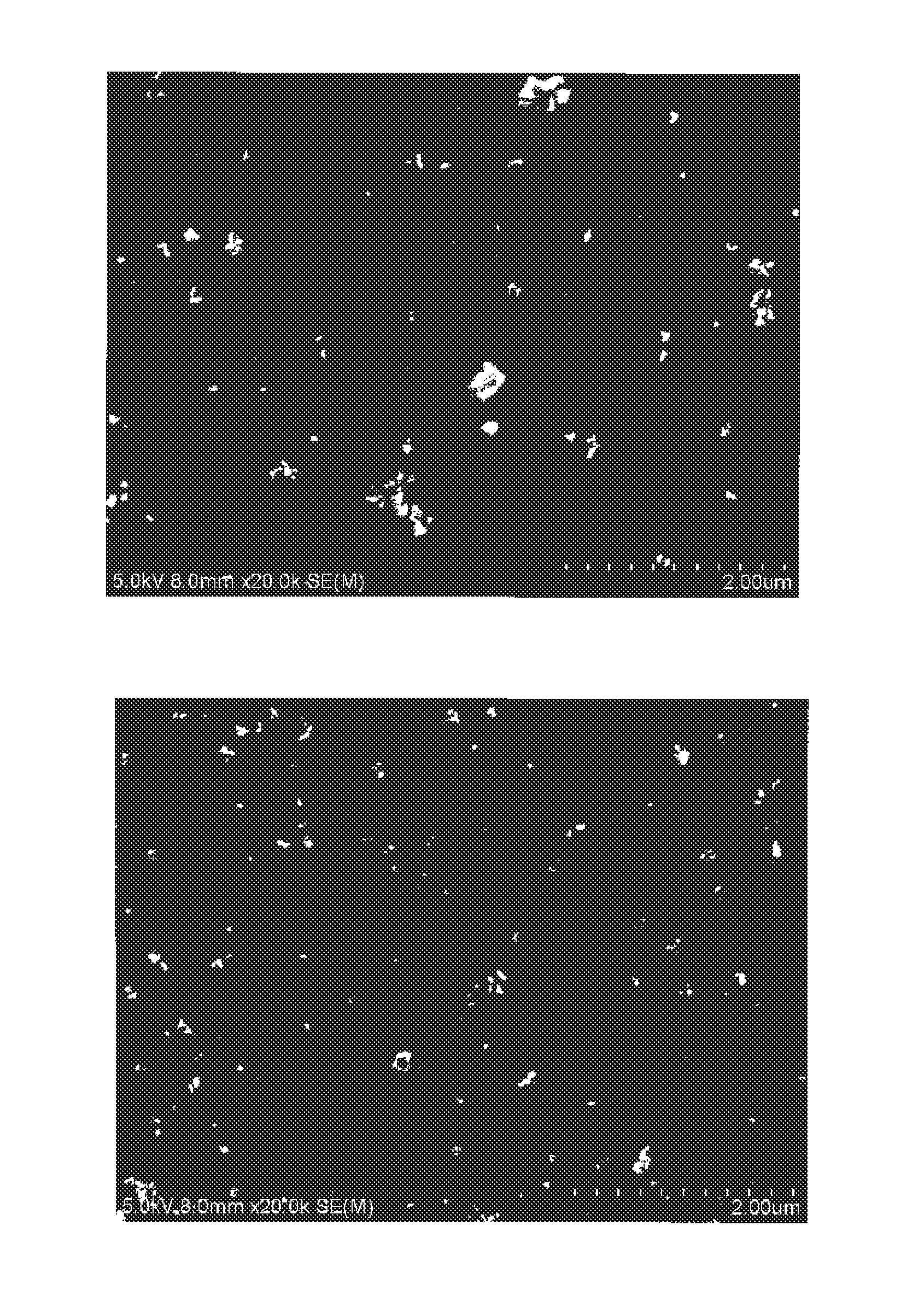

ActiveUS20140272474A1Increased durabilityReduce runningRecord information storageMaterials with non-metallic substancesScanning electron microscopeElectron microscope

An aspect of the present invention relates to a magnetic recording medium, which comprises a magnetic layer comprising ferromagnetic powder and binder on a nonmagnetic support, wherein the ferromagnetic powder is ferromagnetic hexagonal ferrite powder comprising 3 to 12 weight percent of Al, based on Al2O3 conversion, relative to 100 weight percent of a total weight of the powder, the magnetic layer further comprises abrasive, and a maximum plan view surface area of the abrasive as determined for a 4.3 μm×6.3 μm rectangular region of the magnetic layer by a scanning electron microscope is less than 0.06 percent relative to 100 percent of a total surface area of the region.

Owner:FUJIFILM CORP

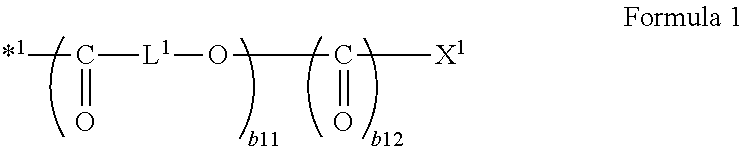

Magnetic recording medium and method of manufacturing the same

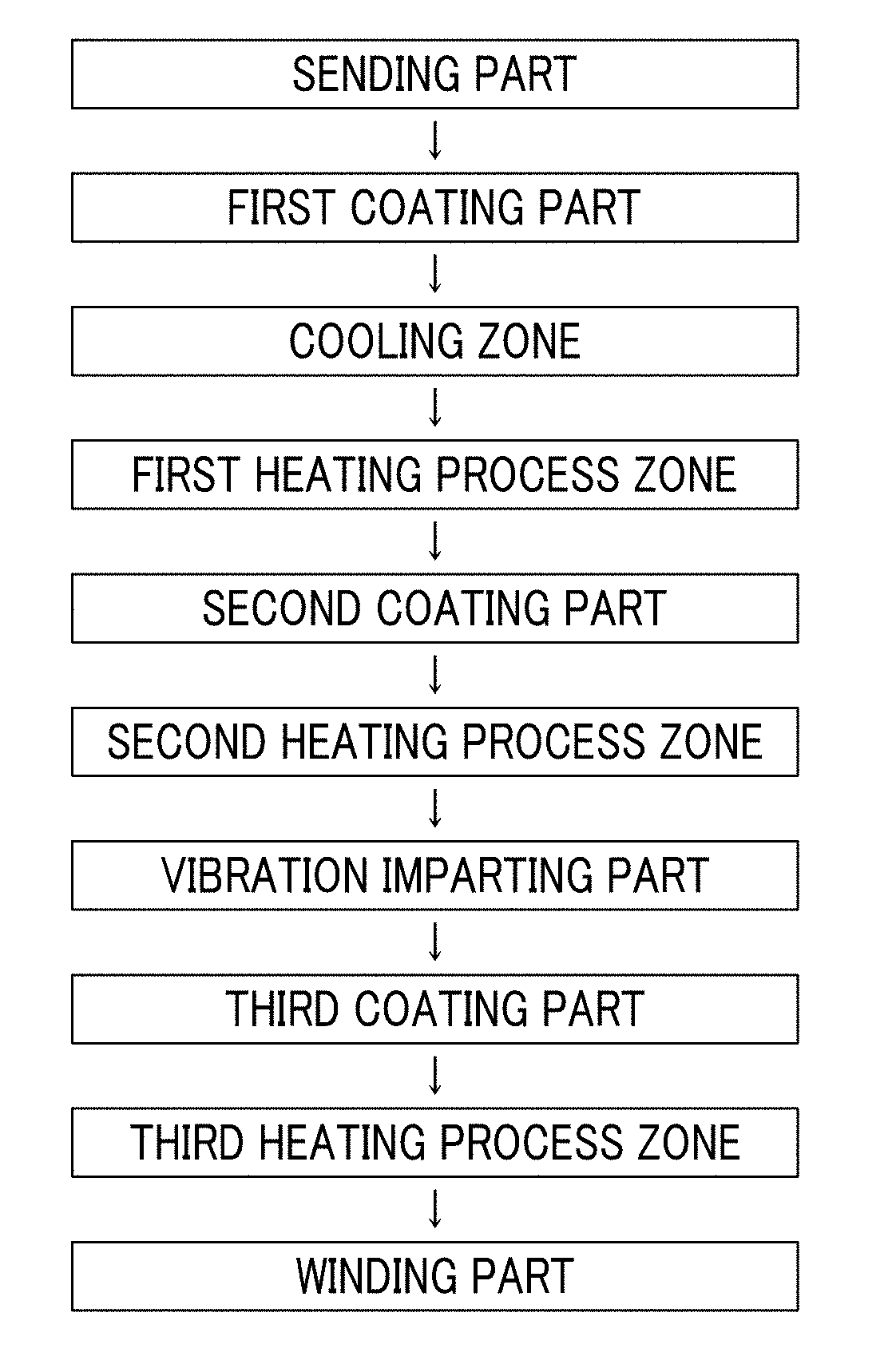

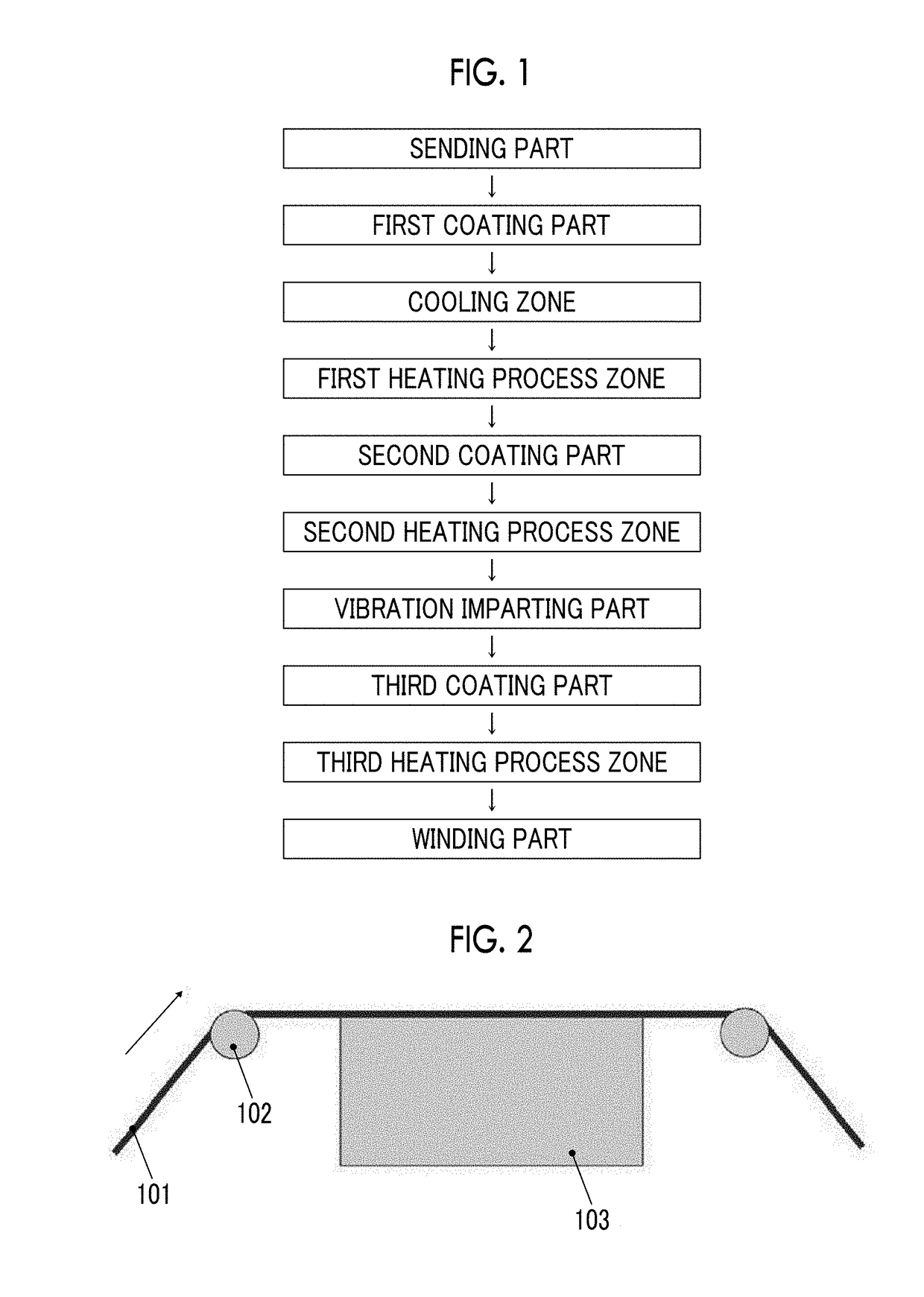

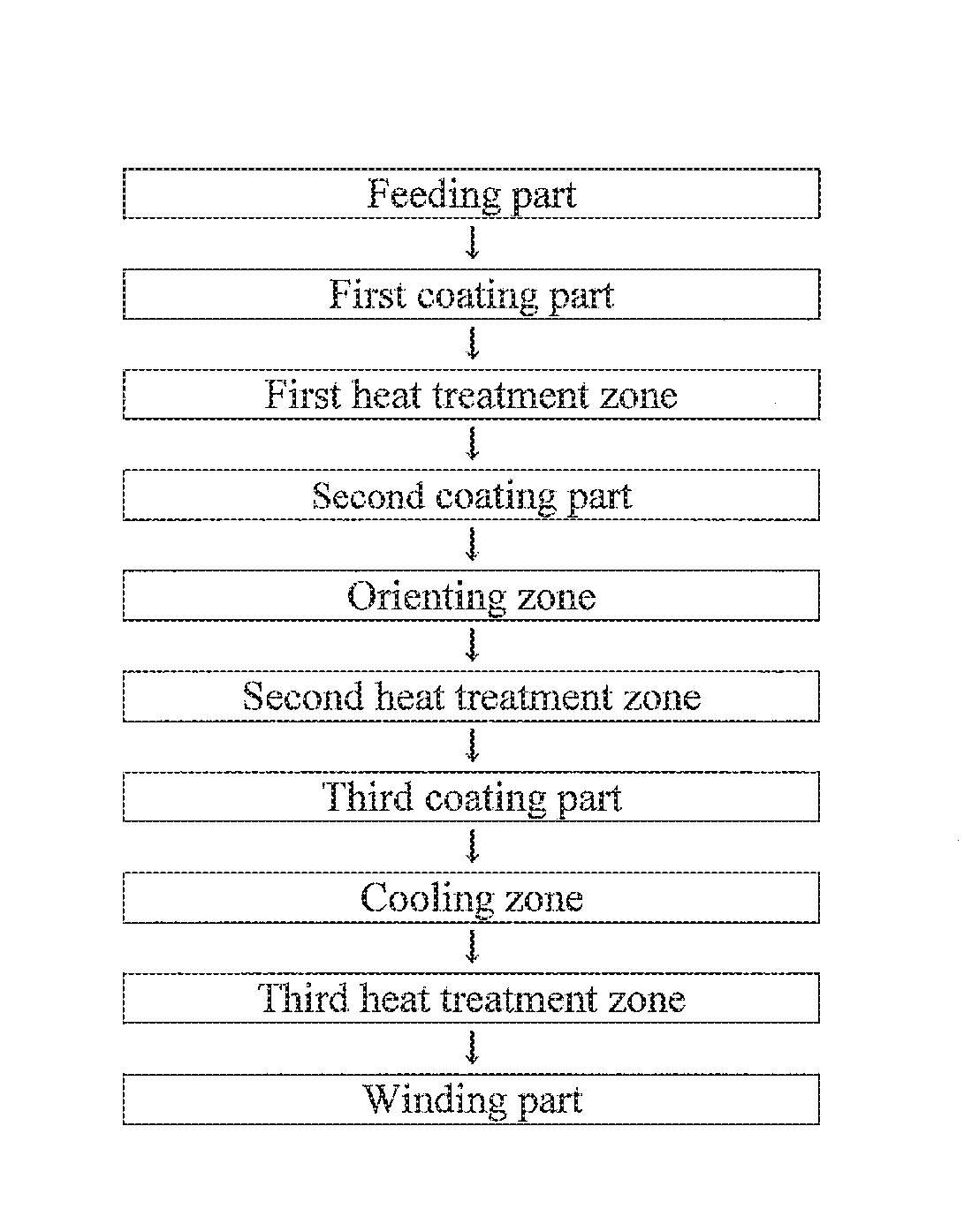

ActiveUS20130260179A1Excellent characteristicsImprove running stabilityRecord information storageCoating by liquid dispersionNon magneticMaterials science

An aspect of the present invention relates to a magnetic recording medium, which comprises a nonmagnetic layer containing a nonmagnetic powder and a binder and a magnetic layer containing a ferromagnetic powder and a binder in this order on a nonmagnetic support, wherein the nonmagnetic layer has a thickness of equal to or less than 300 nm; a composite elastic modulus as measured on a surface of the magnetic layer ranges from 6.0 to 8.0 GPa; the magnetic layer comprises an abrasive with a specific surface area by BET method ranging from 14 m2 / g to 40 m2 / g; and a surface abrasive occupancy on a surface of the magnetic layer ranges from 0.2% to 2%.

Owner:FUJIFILM CORP

Magnetic tape

ActiveUS20170372739A1Improve running stabilityBase layers for recording layersRecord information storageMagnetic tapeFull width at half maximum

Provided is a magnetic tape with the total thickness of a non-magnetic and magnetic layers is equal to or smaller than 0.60 μm, a C—H derived C concentration calculated from a C—H peak area ratio of C1s spectra by ESCA on the surface of the magnetic layer at a photoelectron take-off angle of 10 degrees is equal to or greater than 45 atom %, full widths at half maximum of spacing distribution measured by optical interferometry regarding the surface of the magnetic layer before and after vacuum heating with respect to the magnetic tape are respectively greater than 0 nm and equal to or smaller than 7.0 nm, and a difference between a spacing measured after the vacuum heating and a spacing measured before the vacuum heating is greater than 0 nm and equal to or smaller than 8.0 nm.

Owner:FUJIFILM CORP

Magnetic recording medium

ActiveUS9530444B2Increased durabilityReduce runningMagnetic materials for record carriersRecord information storageScanning electron microscopeElectron microscope

Owner:FUJIFILM CORP

Magnetic recording medium

InactiveUS20090087689A1Improve high-speed running stabilityMaintain good propertiesMagnetic materials for record carriersRecord information storageAtomic force microscopyMagnetic force microscope

The magnetic recording medium comprises a magnetic layer comprising a ferromagnetic powder and a binder on a nonmagnetic support. In the magnetic recording medium, a number of protrusions equal to or greater than 10 nm in height on the magnetic layer surface, as measured by an atomic force microscope, ranges from 50 to 500 / 1,600 μm2, the binder comprises a polyurethane resin with a weight average molecular weight ranging from 100,000 to 200,000, and the magnetic layer further comprises a carbonic ester having a molecular weight ranging from 360 to 460.

Owner:FUJIFILM CORP

Magnetic tape and method of manufacturing the same

ActiveUS9704527B2Increase coefficient of frictionReduced stabilityRecord information storageMetals or alloysMagnetic tapeNon magnetic

Owner:FUJIFILM CORP

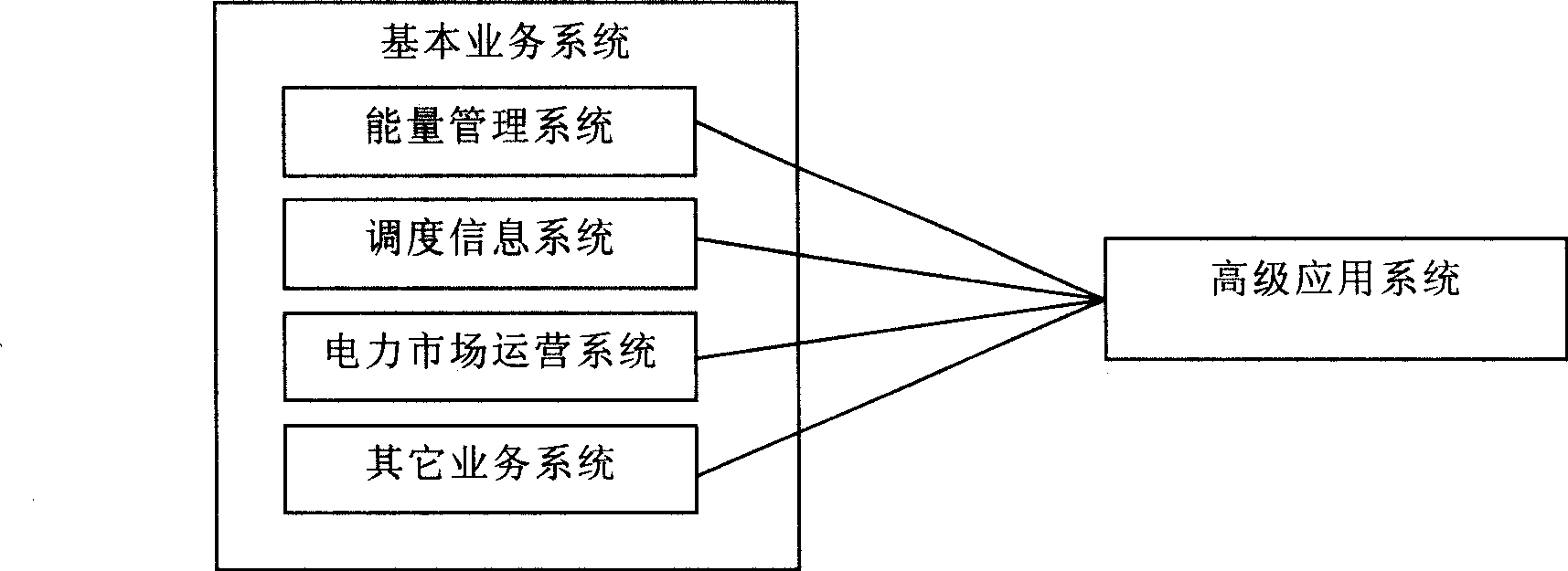

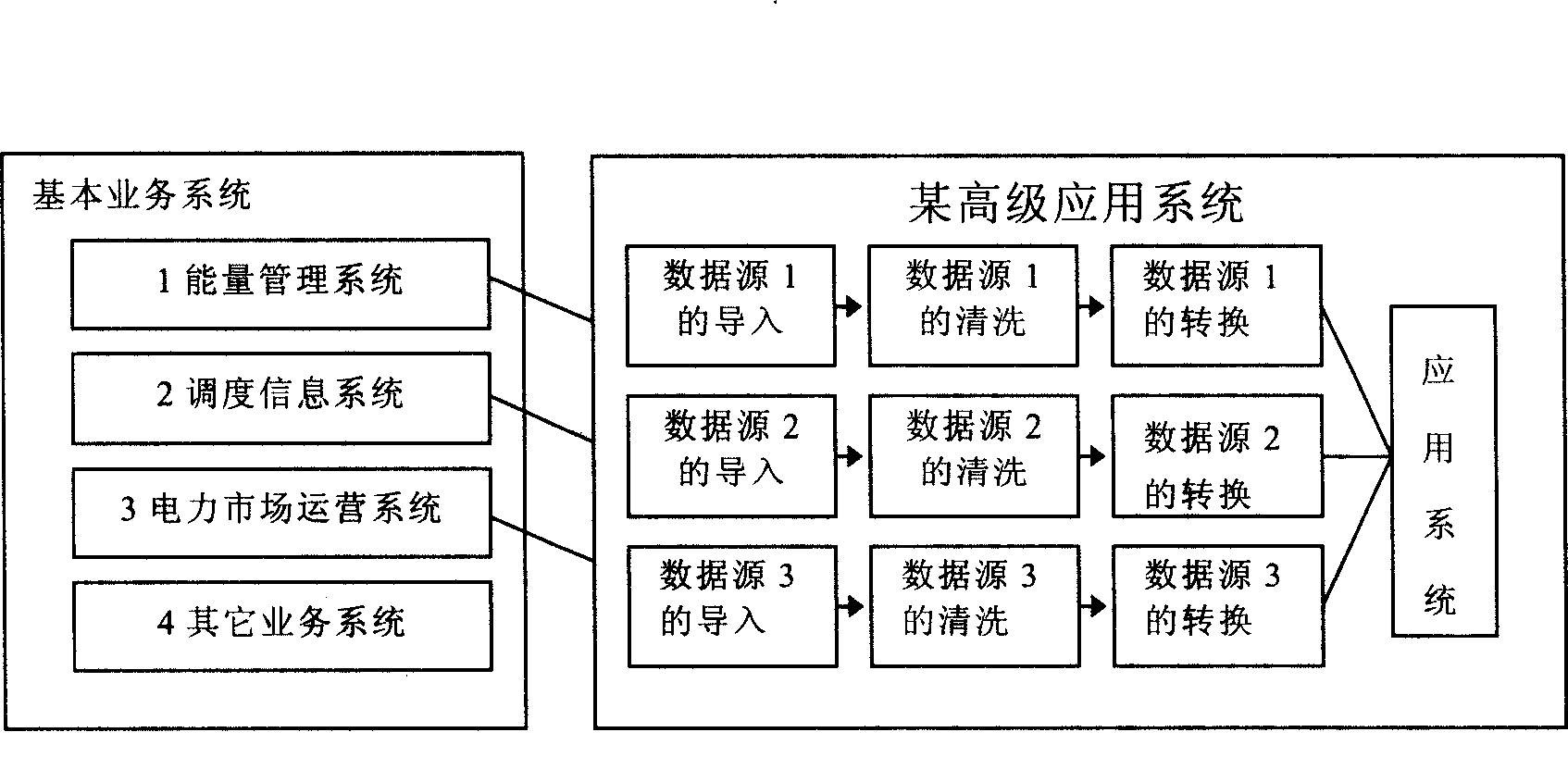

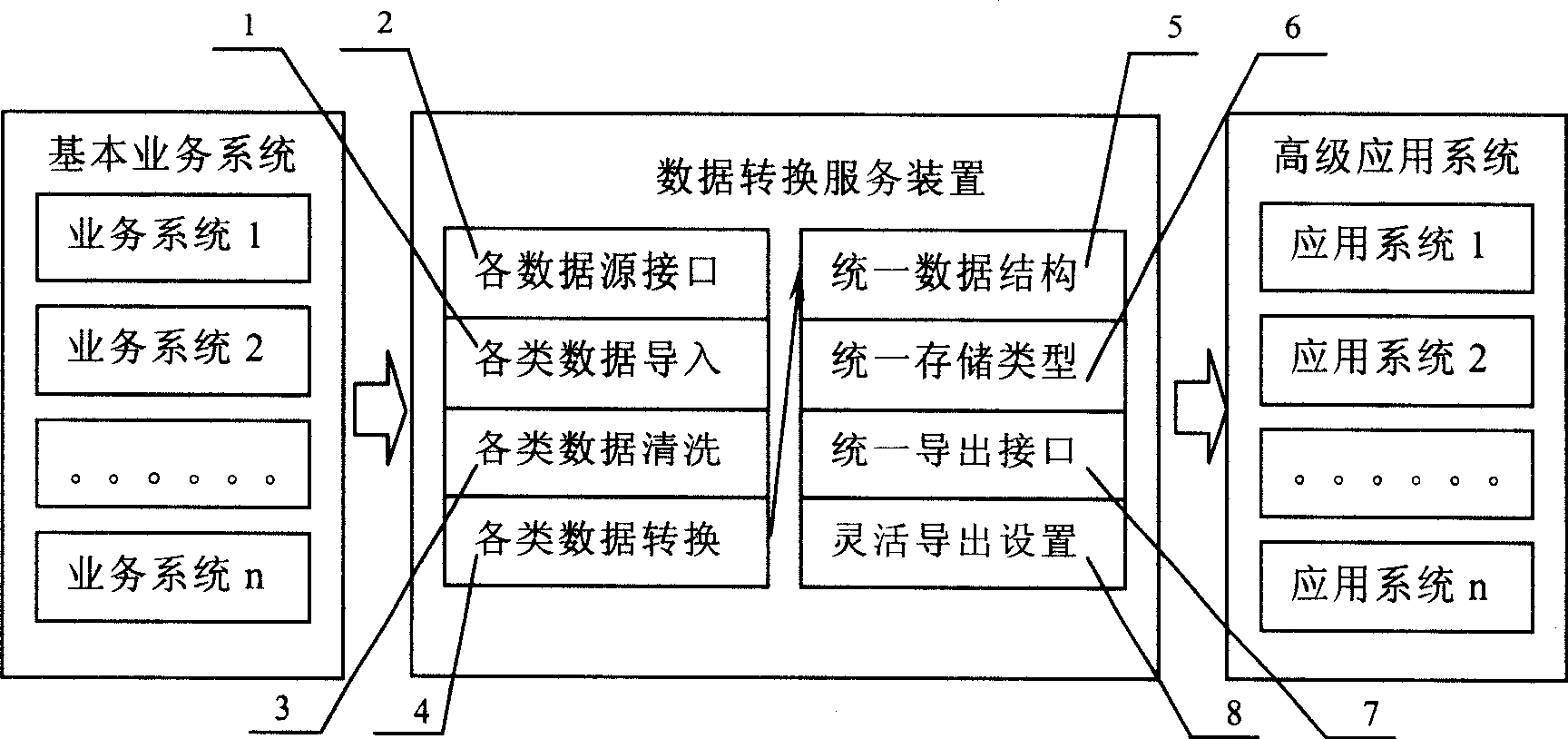

Multiple source data conversion service method and apparatus thereof

InactiveCN101452450AGuaranteed correctnessImprove data conversion efficiencyData processing applicationsSpecial data processing applicationsData sourceBasic service

The invention relates to a service method and a service device for converting multi-source data. The device comprises a data source interface module, a data importing module, a data cleaning module, a data converting module, a consolidated data structure module, a consolidated storage type module, a consolidated exporting interface module and a flexible export setting module. The service method and the service device for converting the multi-source data have the following advantages: 1) an independent device is specially responsible for operations, such as data exchange of various advanced application systems and various basic service systems in a power dispatching center, thereby improving efficiency of data conversion, and ensuring correctness and timeliness of the data conversion; 2) each advanced application system only needs to acquire data from a data conversion service device, thereby saving complicated workload of data conversion, and saving development cost and maintenance cost; and 3) the advanced application system is separated from data conversion, thereby saving hardware resource, and improving operating efficiency and operating stability of the application system.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

Magnetic tape

ActiveUS20170249965A1Increase recording capacityReduce thicknessBase layers for recording layersTape carriersMagnetic tapeMaterials science

The magnetic tape has a magnetic layer containing ferromagnetic powder and binder on one surface of a nonmagnetic support and has a backcoat layer containing nonmagnetic powder and binder on the other surface thereof, wherein the thickness of the backcoat layer is less than or equal to 0.20 μm, and the contact angle for 1-bromonaphthalene that is measured on the surface of the backcoat layer falls within a range of 10.0° to 30.0°.

Owner:FUJIFILM CORP

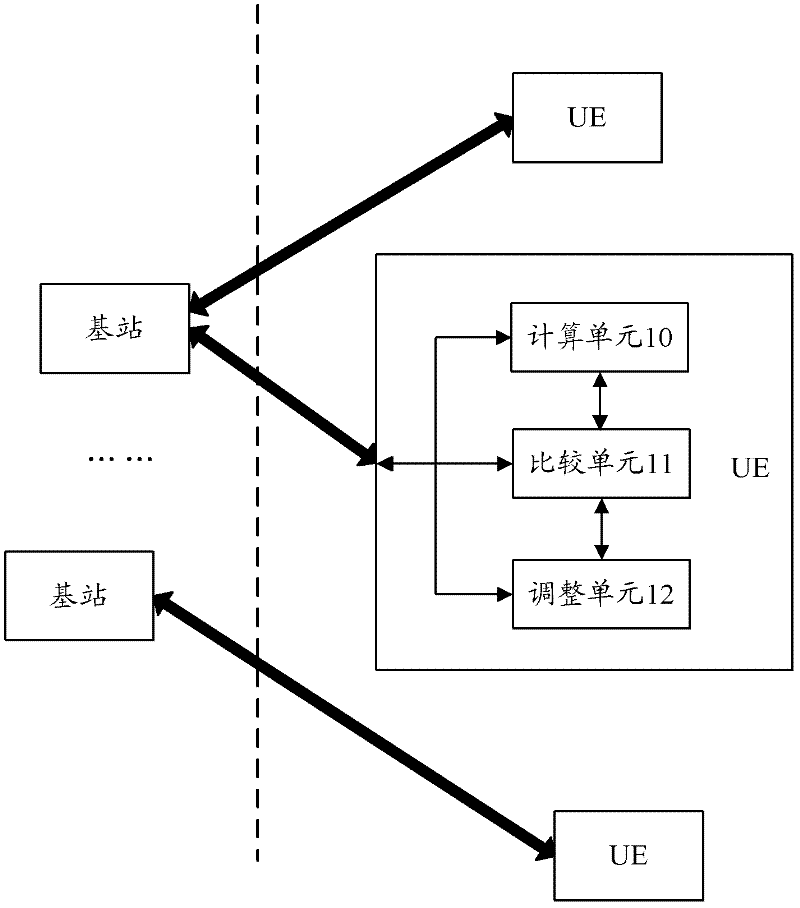

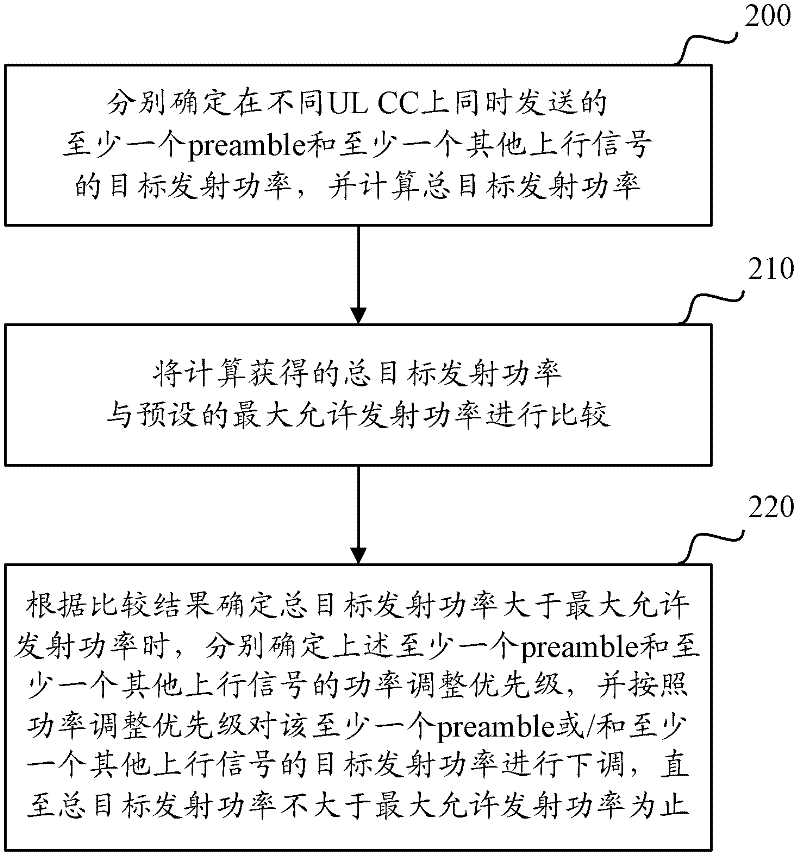

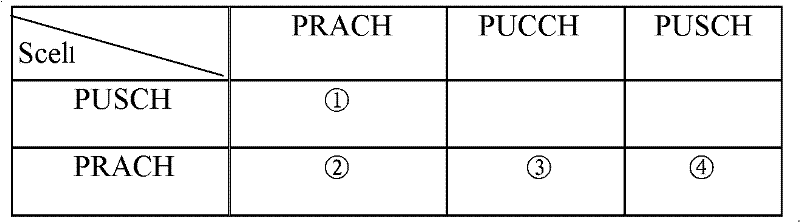

Method and device for adjusting transmitting power

InactiveCN102238716ACircumstances affecting deliveryRealize a reasonable distributionPower managementTransmitted powerCarrier signal

The invention discloses a method and device for adjusting transmitting power, belonging to the field of communication. The method and the device are used for realizing the reasonable distribution of transmitting power between uplink component carriers (ULCC). The method comprises the following steps: when UE (User Equipment) transmits at least one preamble and at least one of other uplink signals at different ULCCs simultaneously and the total target transmitting power is greater than the maximum allowable transmitting power, the UE requires to determine the power adjustment priority of each uplink signal according to a preset rule and adjusts the target transmitting power of at least one preamble and / or at least one of other uplink signals according to the power adjustment priority until the total target transmitting power is not greater than the maximum allowable transmitting power. Thus, the UE can realize the reasonable distribution of transmitting power among different ULCCs, the situation that the transmission of uplink signals is influenced due to too large total target transmitting power is avoided, the operating stability and the robustness of the system are enhanced, and the overall performance of the system is also enhanced.

Owner:CHINA ACAD OF TELECOMM TECH

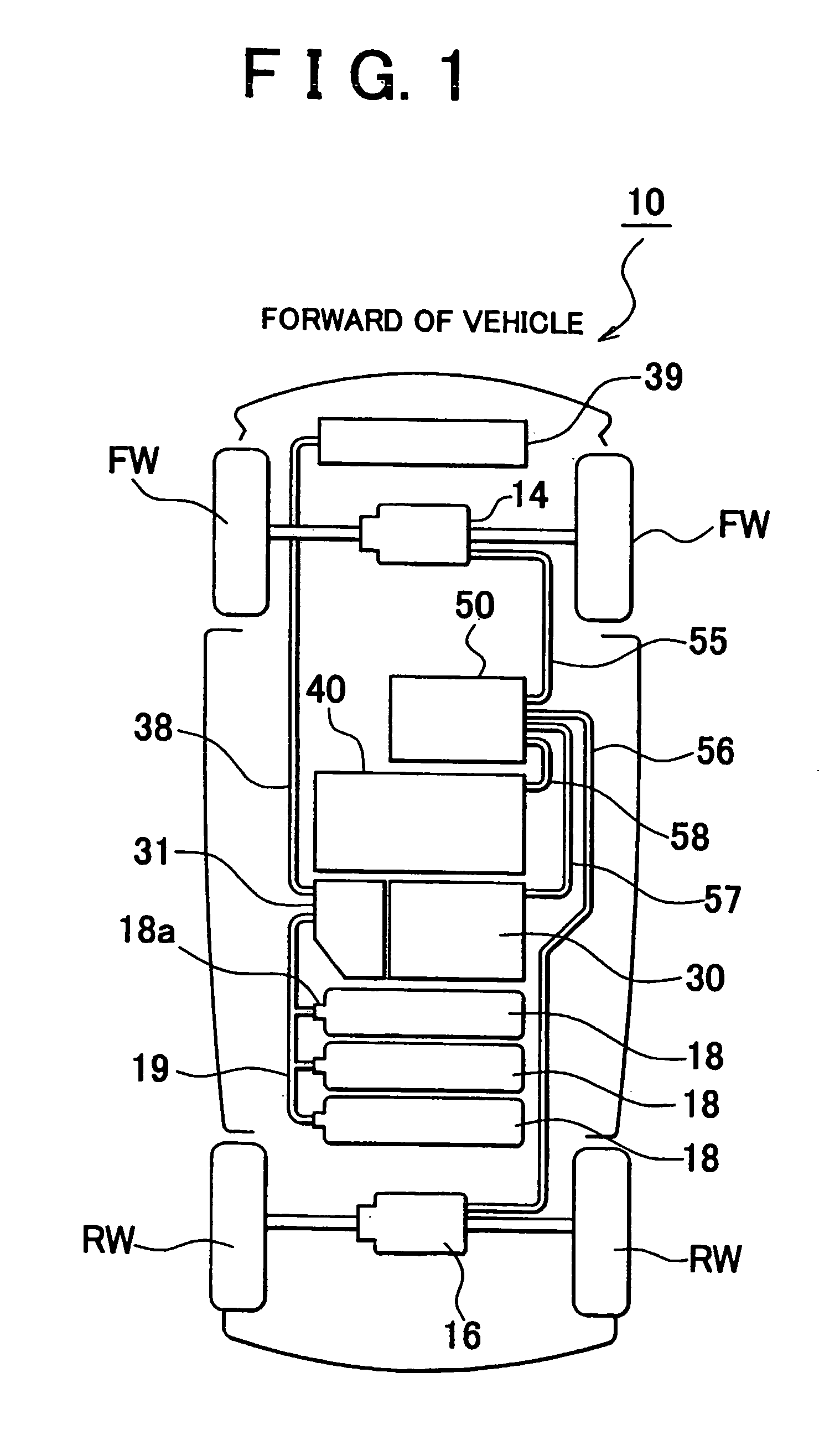

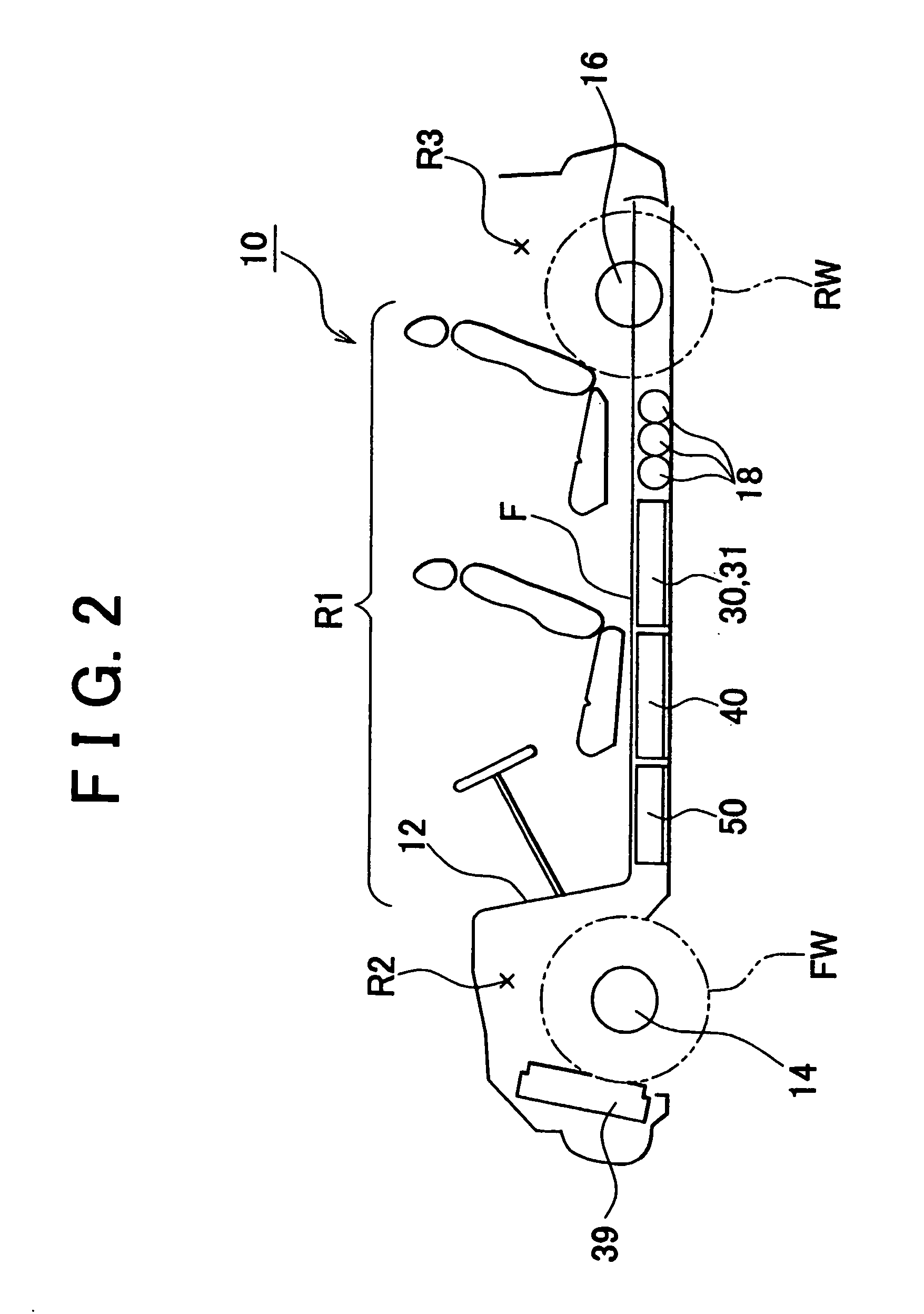

Fuel cell equipped vehicle

InactiveUS20060102398A1Appropriate center of gravityAppropriate connectionRailway vehiclesFuel cell auxillariesFuel cellsHydrogen

In a fuel cell equipped vehicle (10), hydrogen cylinders (18) storing hydrogen gas to be supplied to a fuel cell battery (30), a fuel cell (30), fuel cell accessories (31), a storage battery (40), and a PCU (50) that controls the supply of electric power from the fuel cell (30) and the storage battery (40) to a front wheels-driving electric motor (14) and a rear wheels-driving electric motor (16) are arranged in that order under a floor of a passenger compartment (R1). Therefore, these major component devices do not reduce the spaces of a passenger compartment (R1), a forward compartment (R2), and a rearward compartment (R3). Since the component devices disposed under the floor of the passenger compartment (R1) have relatively great weights, the center of gravity of the vehicle comes to a low position in a central portion of the vehicle, thus achieving good running stability of the vehicle.

Owner:TOYOTA JIDOSHA KK

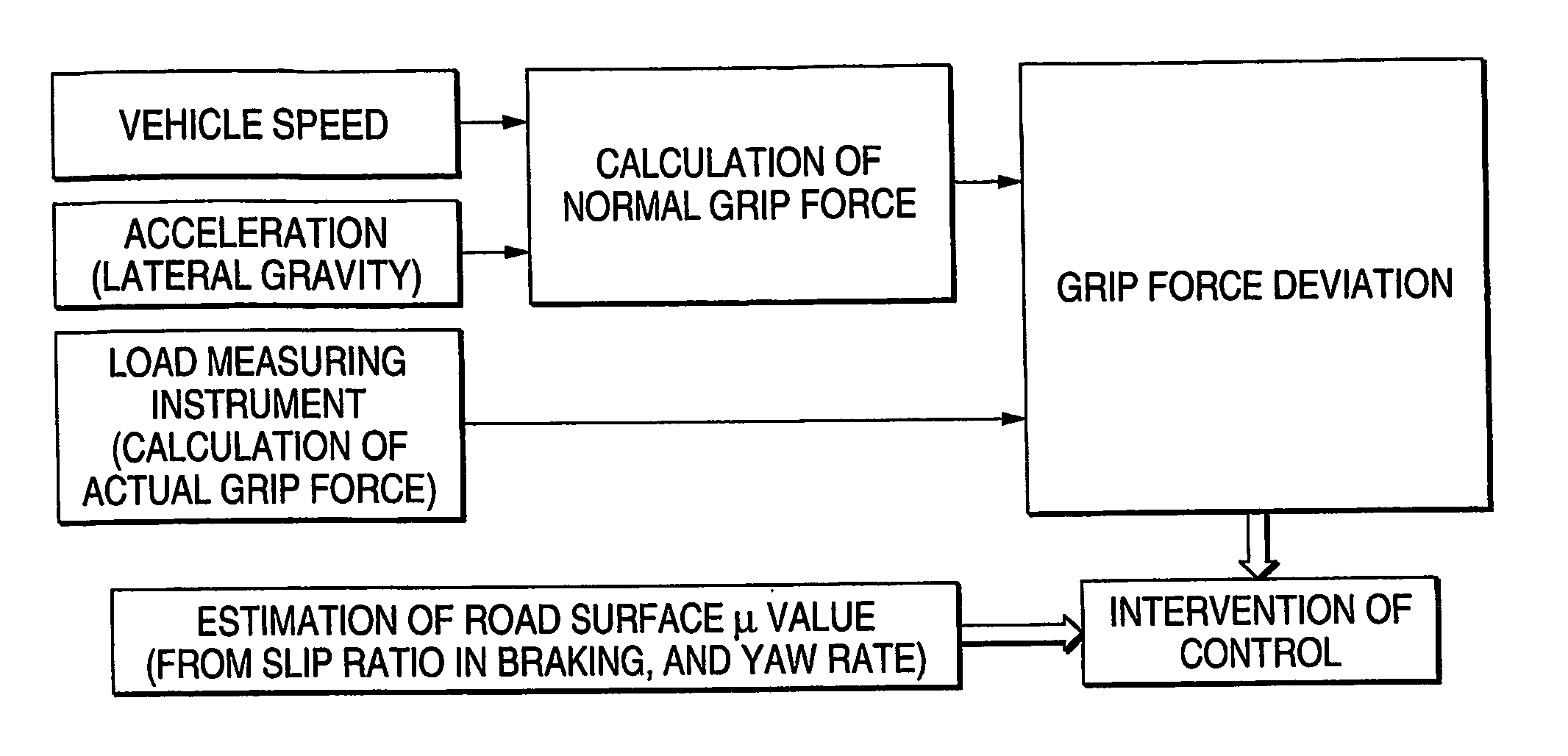

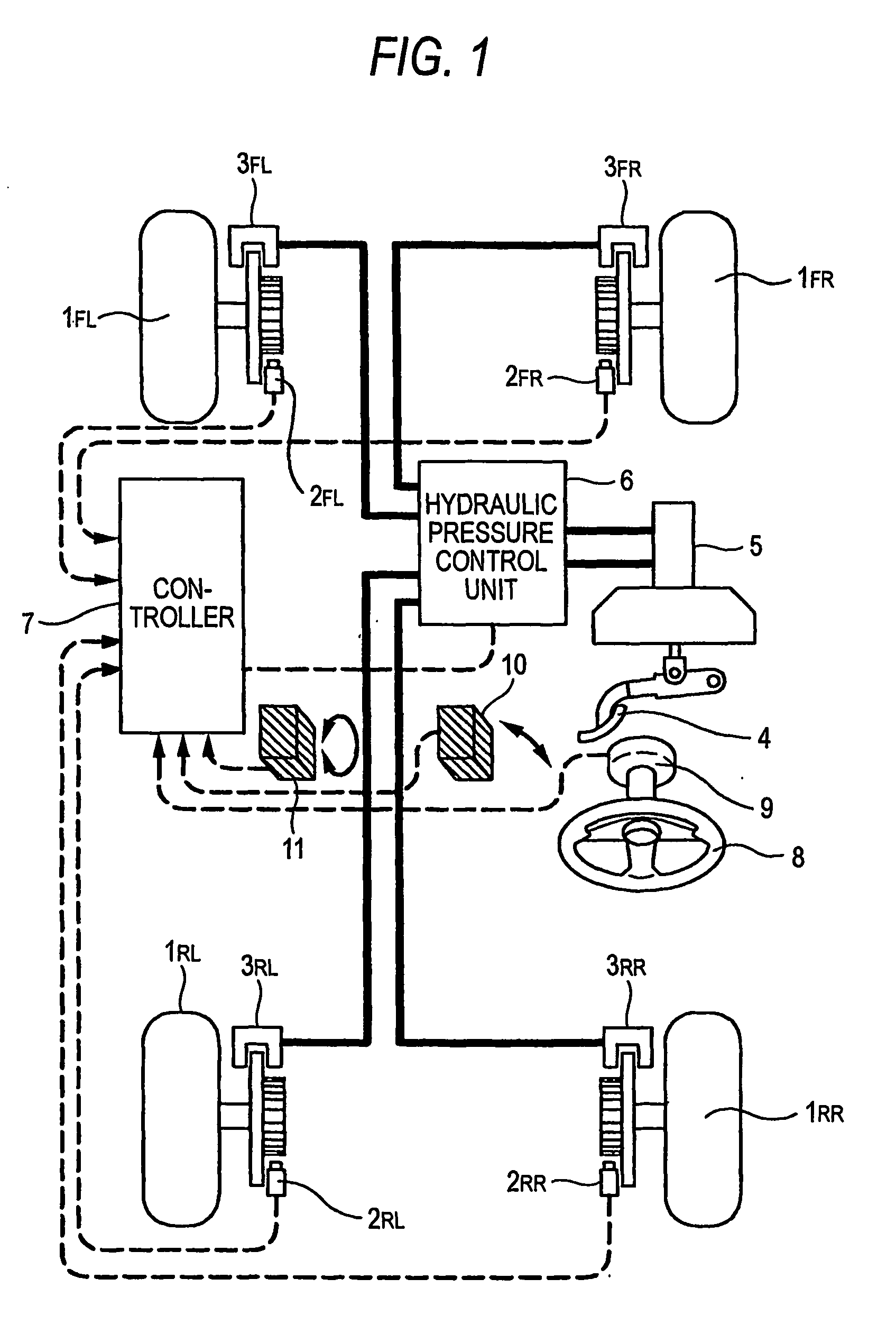

Stability control apparatus and load measuring instrument for wheel supporting rolling bearing unit

ActiveUS20060259225A1Enhancing responsibility of controlImprove running stabilityRotary bearingsBearing assemblyGrip forceMeasuring instrument

A stability control apparatus, includes: a grip detector that changes an output based on a grip force applied in a direction hindering a slippage of a wheel, acting on a contact face between the wheel supported by a wheel supporting rolling bearing unit and the road surface, the wheel supporting rolling bearing unit for supporting freely rotatably the wheel to a vehicle body; and a controller that performs a control for keeping a running stability of the vehicle in response to an input of a detection signal of the grip detector.

Owner:NSK LTD

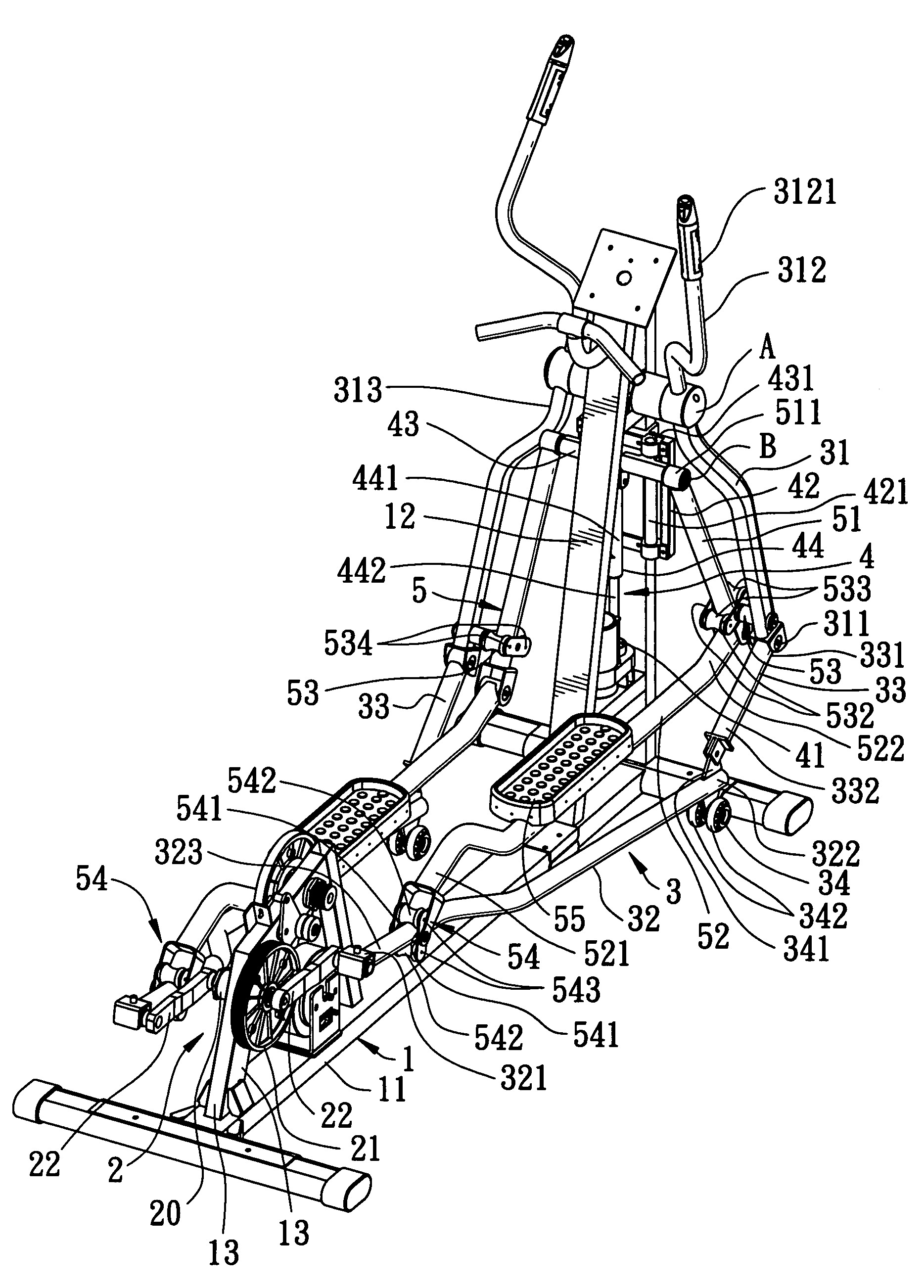

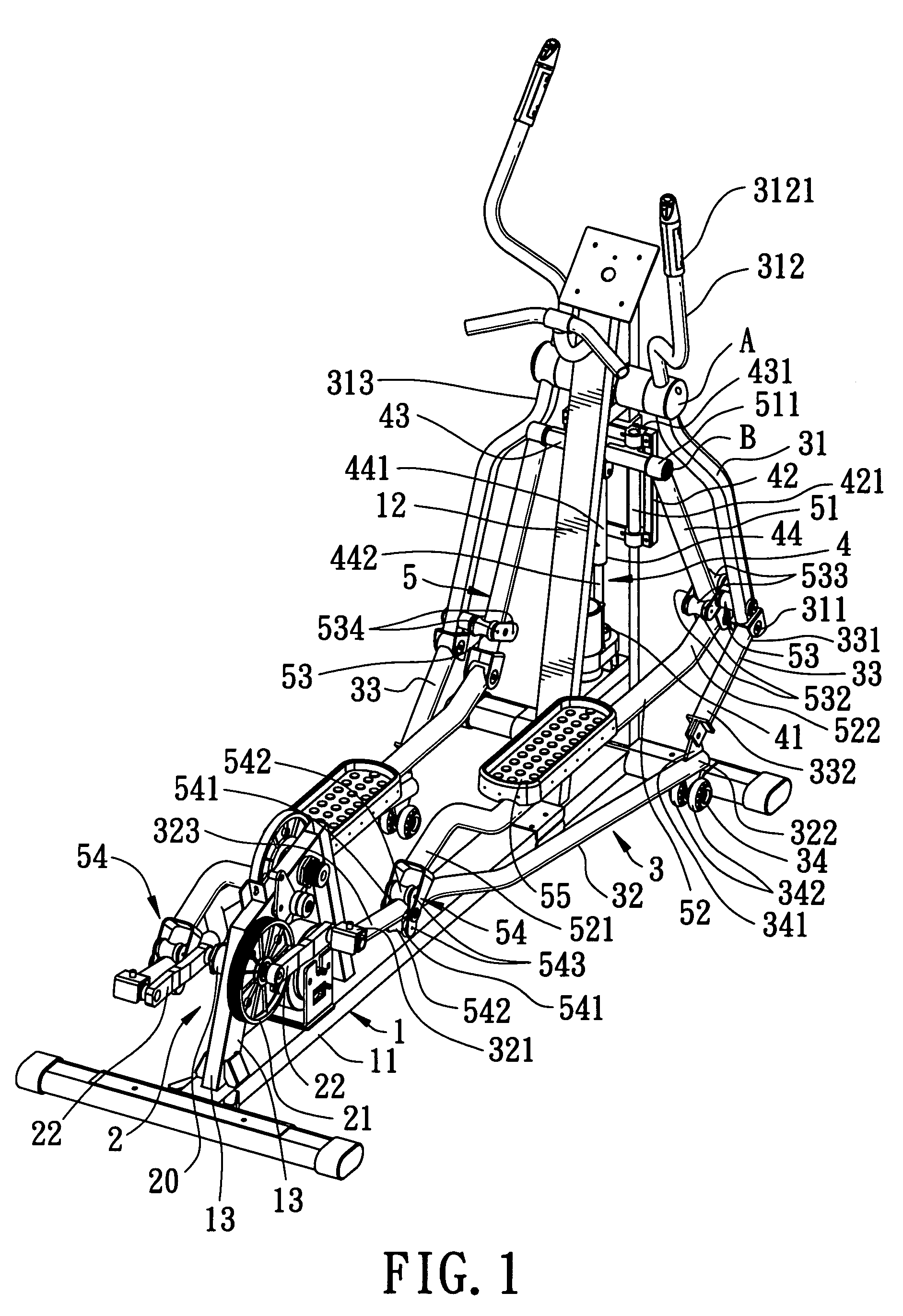

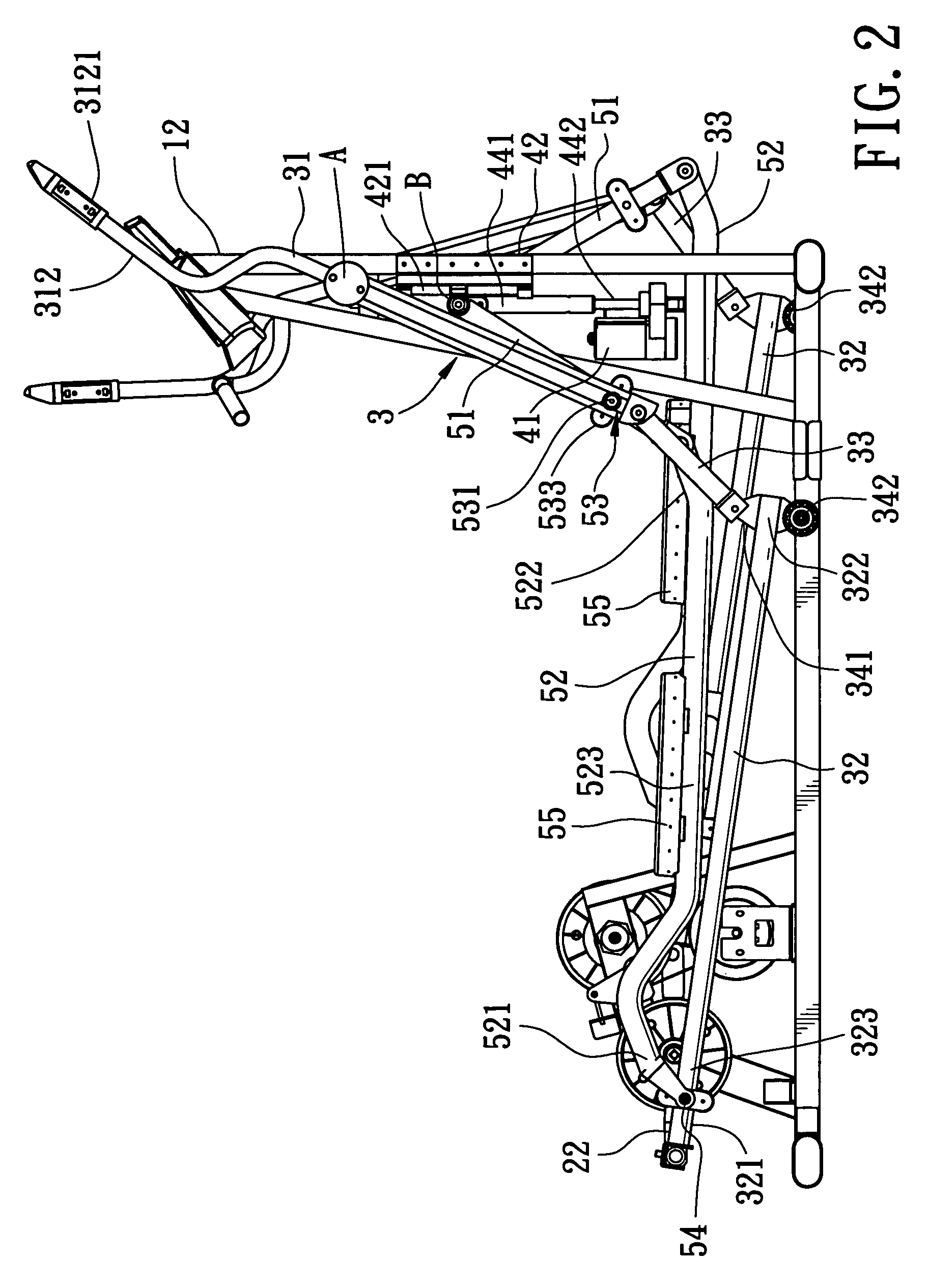

Exercise apparatus

InactiveUS6994656B2Improve stabilityImprove running stabilityMovement coordination devicesMuscle exercising devicesBraced frameEngineering

An exercise apparatus includes a support frame, a crank assembly, two swing units, and two pedal assemblies. The crank assembly is mounted on the rear of the support frame, and has a crankshaft and a pair of crank members. Each swing unit includes a lever mounted on the front of the support frame, and a longitudinal connecting unit connected to a respective crank member. Each pedal assembly includes a rocking arm with a pivot end mounted pivotally on the front of the support frame, and a pedal axle having a rear end making relative sliding movement with the connecting unit when the pedal axle is moved. The pedal assemblies are respectively connected to the swing units for swinging synchronously with the swing units.

Owner:JOHNSON TECH CO LTD

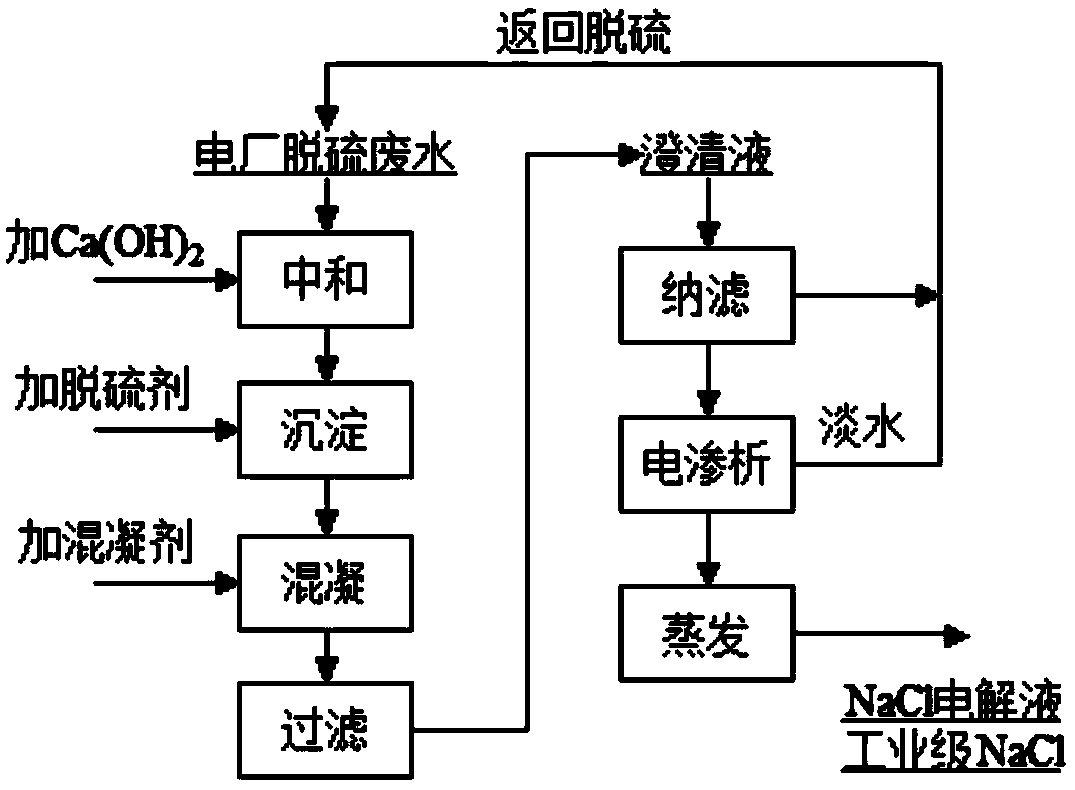

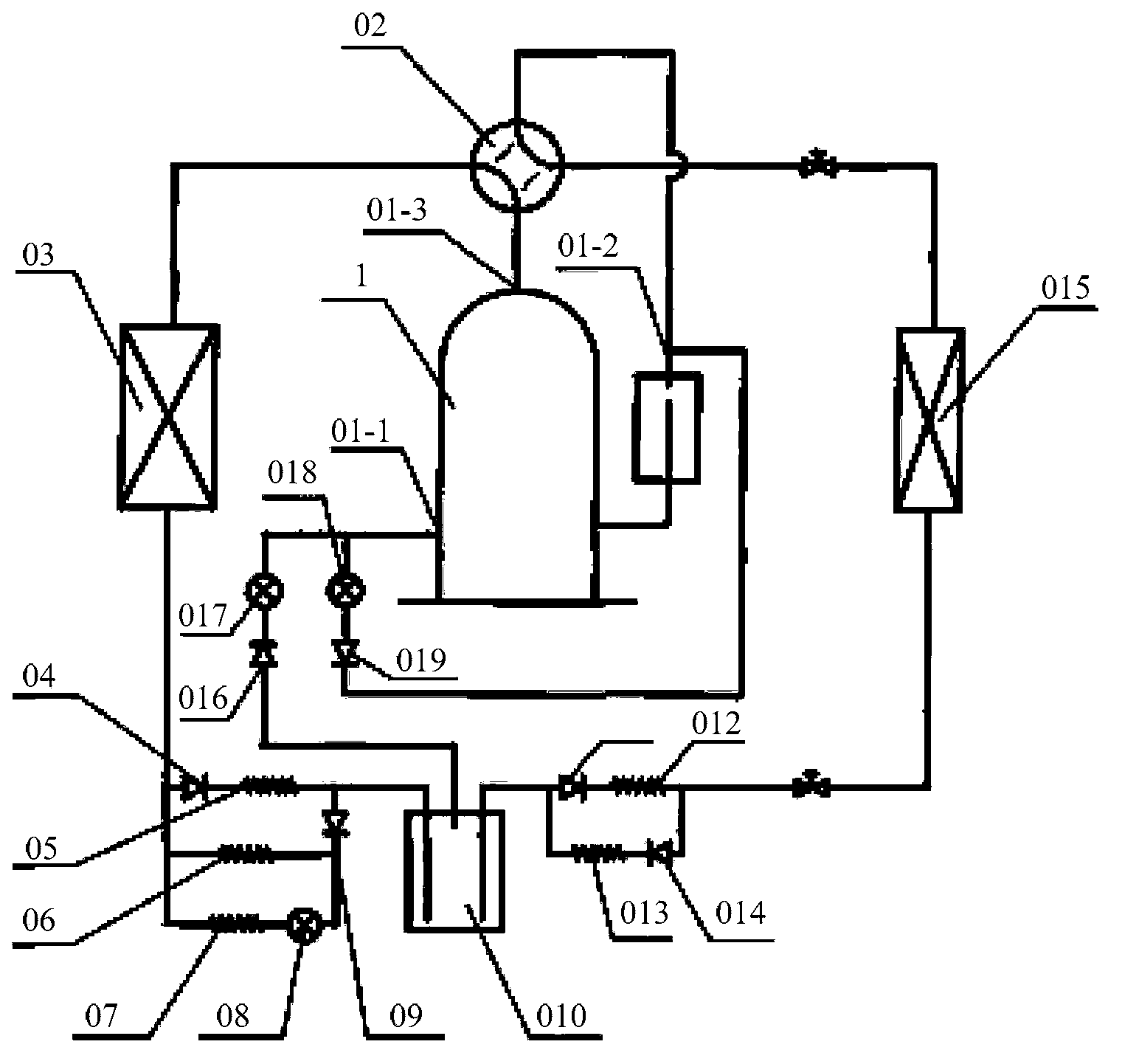

Method for carrying out desalination and zero-discharge processing of power plant desulphurization wastewater by adopting electrodialysis technology

ActiveCN104355473AMeet water requirementsImprove running stabilityGeneral water supply conservationDispersed particle separationChemical oxygen demandResource utilization

The invention relates to a method for carrying out desalination and zero-discharge processing of power plant desulphurization wastewater by adopting an electrodialysis technology. The method comprises the following steps: neutralizing, precipitating, coagulating and filtering the power plant desulphurization wastewater and removing CODs (Chemical Oxygen Demands), heavy metals, F-ions, gypsum, silicon dioxide, hydroxide of iron and aluminum and other insoluble particles in waste water; separating C1-ions and other monovalent ions in clear liquid from SO3<2->, SO4<2-> and other divalent ions through nanofiltration; desalinating and concentrating water produced by the nanofiltration by adopting a multistage countercurrent reverse electrodialysis method. The method has the advantages that the concentration of the Cl-ions in nanofiltration concentrated water and electrodialysis freshwater generated by the method is lower, and the nanofiltration concentrated water and the electrodialysis freshwater can be returned for flue gas desulfurization; the content of NaCl in a small amount of electrodialysis concentrated water produced reaches above 12 percent, the bivalent ions and other impurities are removed by nanofiltration, and the electrodialysis concentrated water is further evaporated and concentrated, so that chlorine-alkali industry electrolytes and NaCl salt can be obtained. Through the method, the zero-discharge treatment and the resource utilization of the desulfurization wastewater can be realized.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

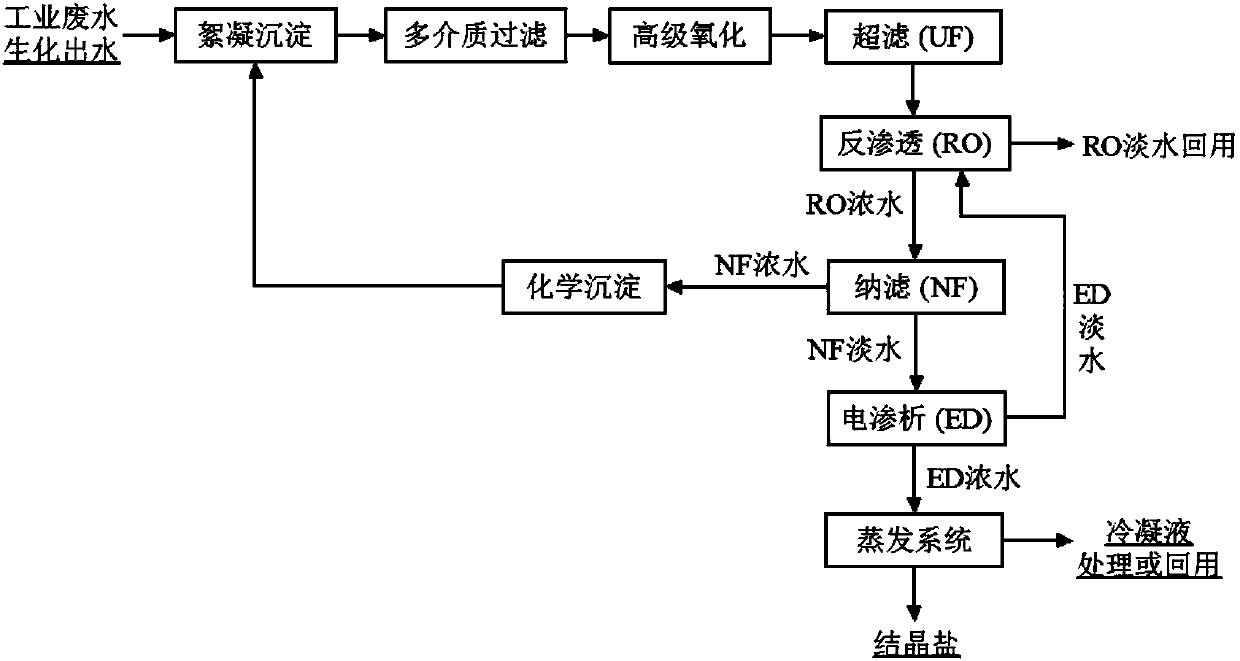

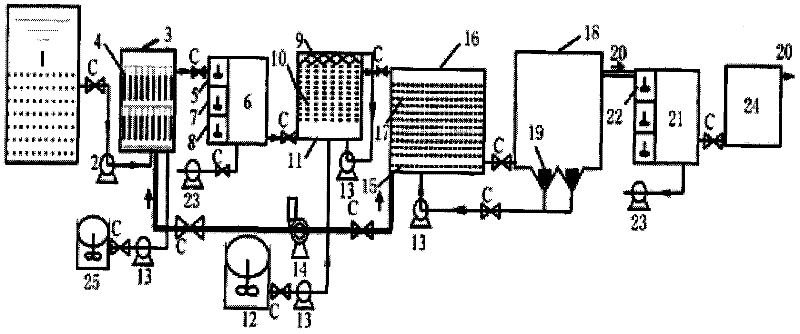

Treatment system and treatment method for biochemical effluent of industrial wastewater

InactiveCN107651794AEfficient removalHigh recovery rate of fresh waterGeneral water supply conservationTreatment involving filtrationHigh concentrationFiltration

The invention provides a treatment system and treatment method for biochemical effluent of industrial wastewater. The treatment system comprises a flocculation sedimentation unit, a filtration unit, an advanced oxidation unit, an ultrafiltration unit, a reverse osmosis unit, a nanofiltration unit, an electrodialysis unit and an evaporation unit which are sequentially connected; and the water production outlet of the ultrafiltration unit is connected with the water inlet tank of the reverse osmosis unit, and the concentrated-water outlet of the reverse osmosis unit is connected with the water inlet of the nanofiltration unit. According to the invention, the treatment system and the treatment method utilize the coupling and synergistic effects of a physical-chemical method and a membrane technology to overcome the limitation of using a single technology, and the advanced treatment and desalination reuse of the industrial wastewater are realized; and the treatment system and the treatmentmethod have the advantages of strong adaptability to raw water, a high recovery rate of fresh water, a high concentration multiple of concentrated water, low energy consumption of evaporation and crystallization and the like, greatly improve the reuse rate of the industrial wastewater, reduce the amount of wastewater discharging, can be applied to the deep treatment and desalination reuse of various effluent wastewater, and promote the promotion and application of the technology in related industries.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

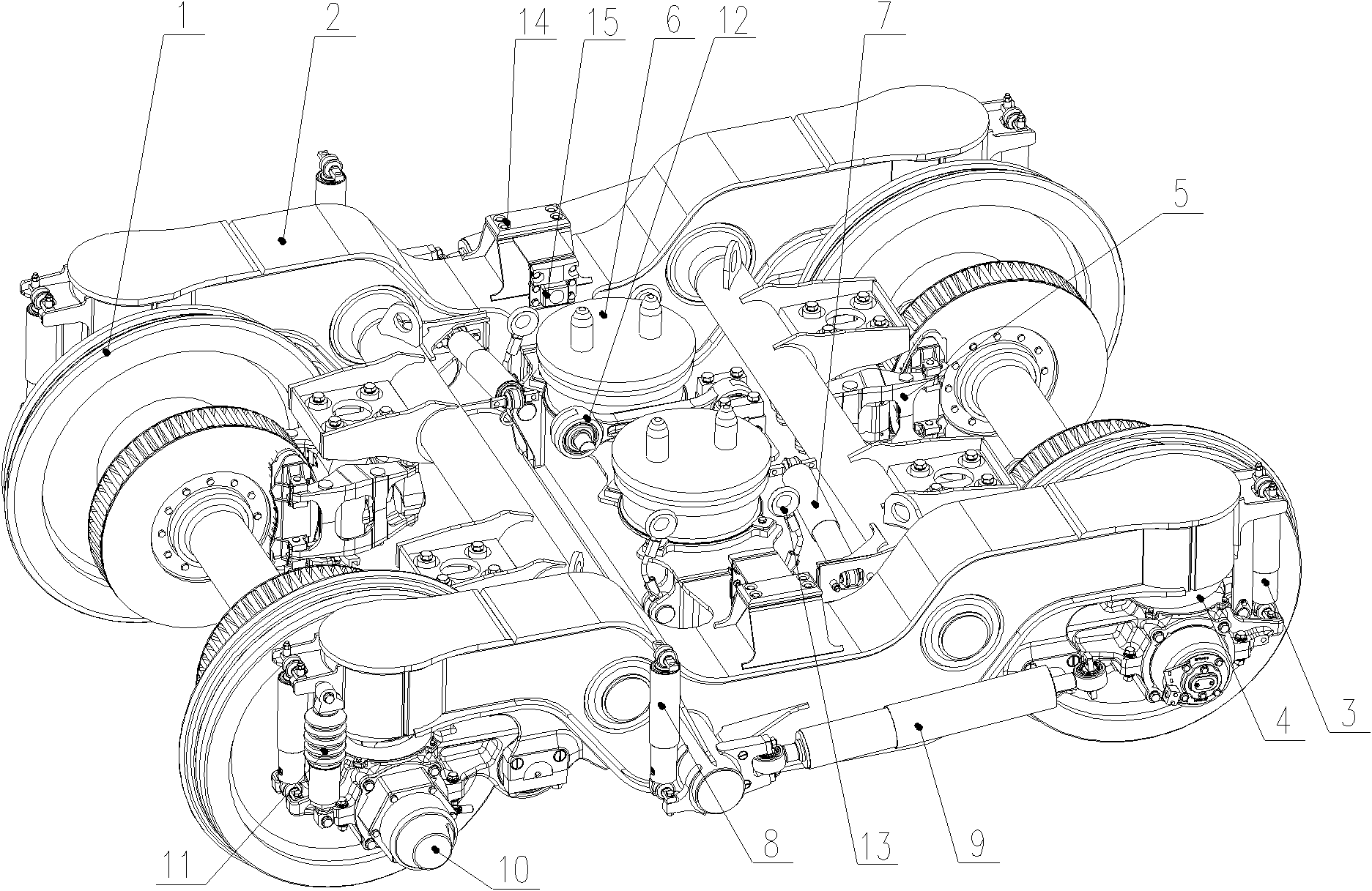

Bogie for high-speed rail wagon

ActiveCN102490755AImprove operational safety indicatorsSimple structureBogiesBogie-underframe connectionsTruckDouble stage

The invention discloses a bogie for a high-speed rail wagon. The bogie comprises a framework, wherein two transverse ends of the framework are connected with a wheel set through two single-stage suspension systems respectively; a double-stage suspension system and a foundation brake device are arranged on the framework; and the front side and the rear side of the framework are provided with an anti-snakelike damper respectively. By the bogie, two-grade requirements that the shaft weight is 16.5t when the speed of the wagon is 200km / h as well as the shaft weight is 18t when the speed of the wagon is 160km / h can be met simultaneously; and the bogie has the remarkable characteristics of simple structure, high popularity and reliable performance.

Owner:CRRC SHANDONG CO LTD

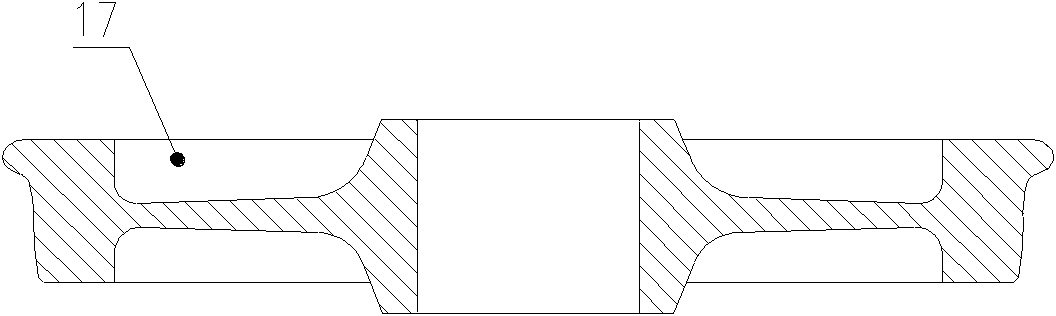

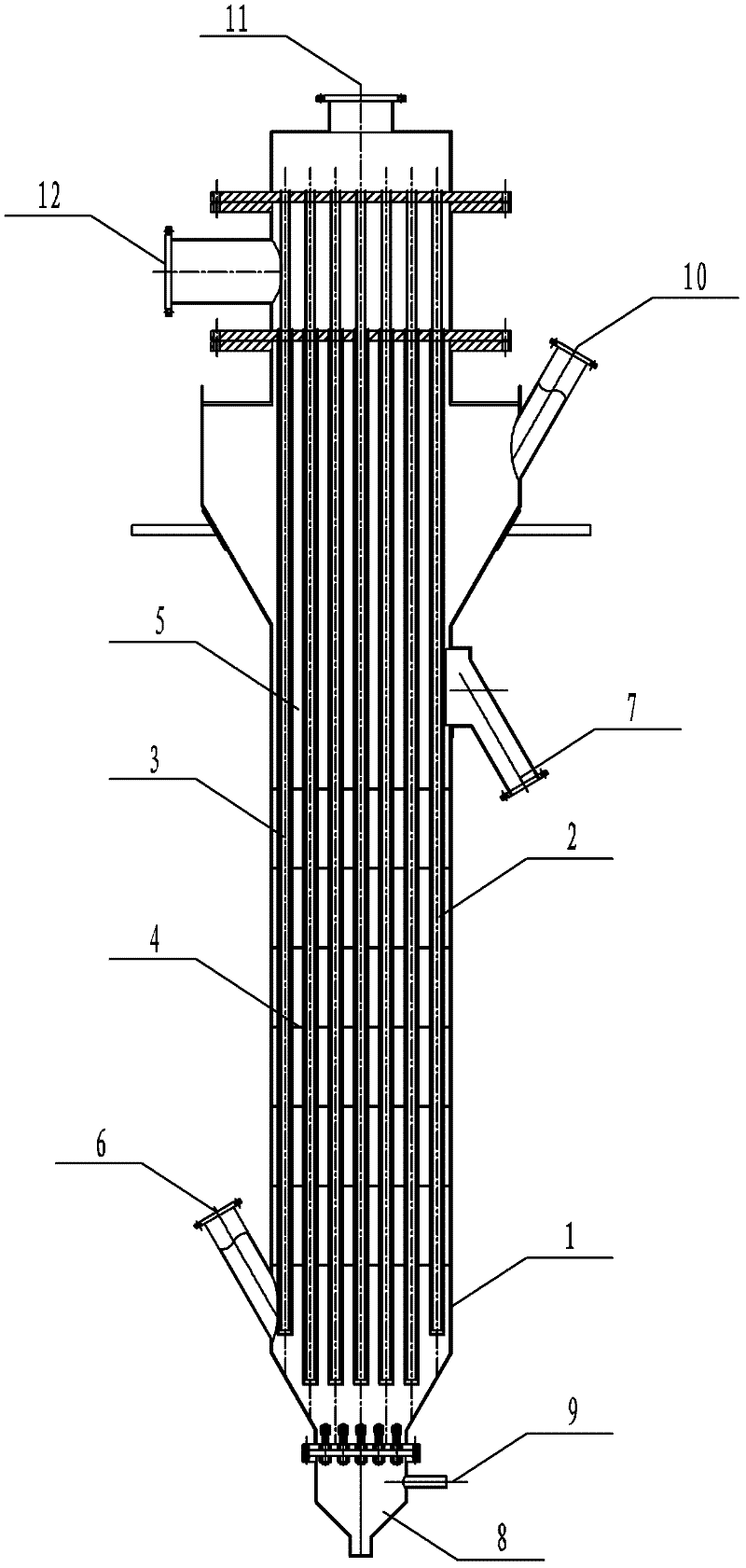

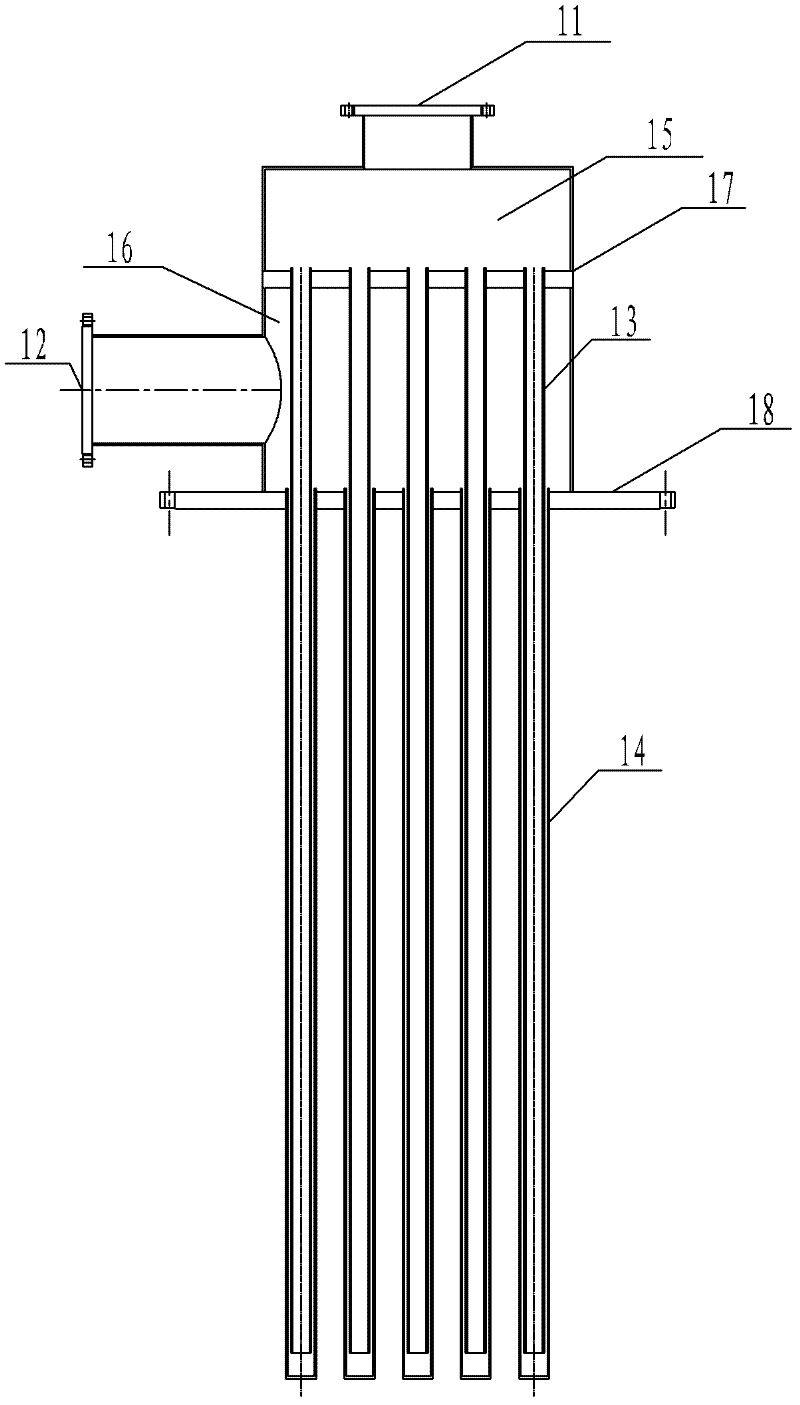

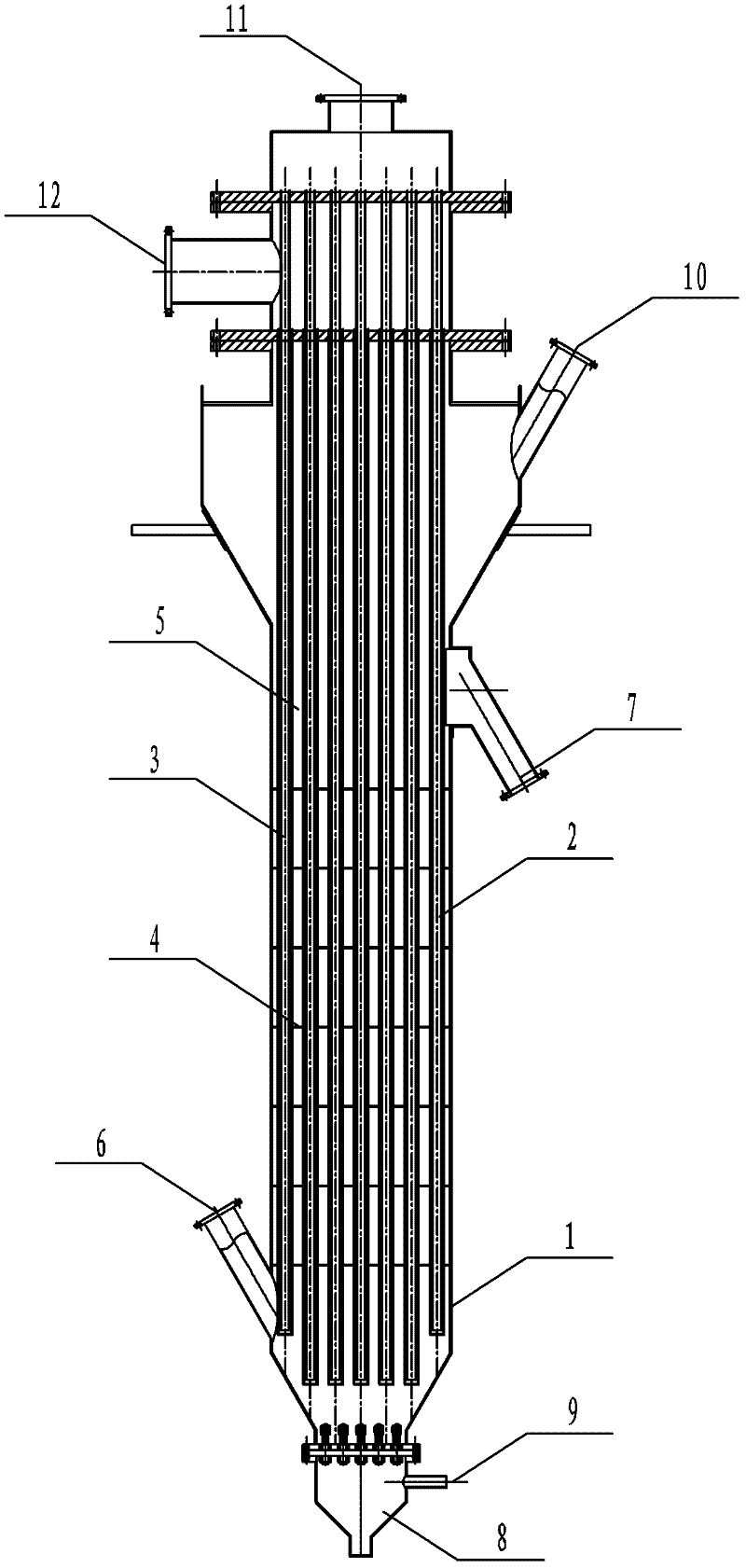

Fluidized reduction furnace for producing high-purity vanadium trioxide and production method

The invention relates to a fluidized reduction furnace for producing high-purity vanadium trioxide, which comprises a fluidized bed reactor and a built-in heat exchange component, wherein the heat exchange component is a tube type heat exchanger, and a heat exchange tube is vertically provided with at least two layers of sieve mesh plates to form at least three layers of fluidized reaction chambers. The invention also provides a fluidized reduction method for producing the high-purity vanadium trioxide. The fluidized reduction furnace and the fluidized reduction method have the advantages that firstly, materials in each layer are in a fully-mixed state, and material flow among the layers is in a plug flow state; secondly, the multi-stage fluidized reduction conditions are provided, raw materials enter from the lowermost layer, are reduced step by step and are purified gradually, and the running stability and the operating rate of equipment are improved in a manner of reduction step by step; and thirdly, the fluidized reduction furnace can be used for producing the high-purity vanadium trioxide, and the vanadium grade is larger than 67.9 percent.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

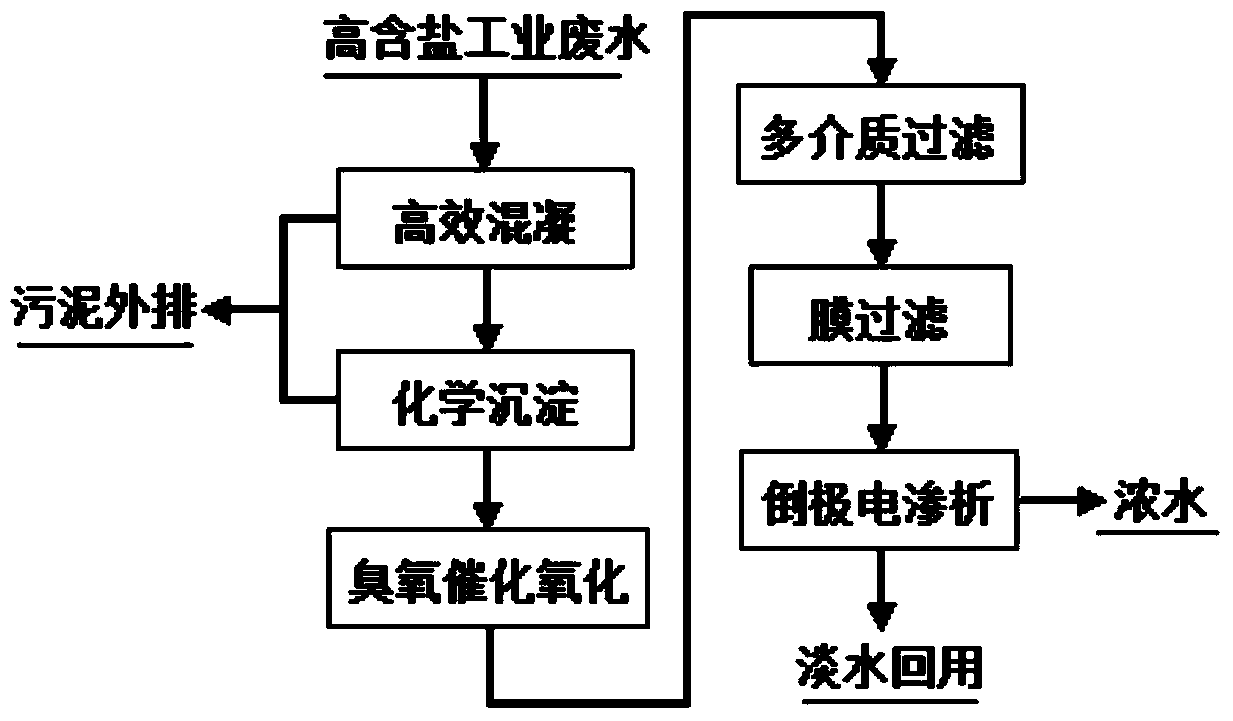

Method for deeply treating, desalting and recycling industrial wastewater with high salt content

ActiveCN104016530AImprove catalytic oxidation efficiencyGood removal effectMultistage water/sewage treatmentSuspended particlesFiltration

The invention relates to the field of industrial wastewater treatment processes and provides a method for deeply treating, desalting and recycling industrial wastewater with high salt content. The method comprises the following steps: 1) carrying out efficient coagulation treatment on the industrial wastewater with high salt content to obtain supernatant; 2) carrying out chemical precipitation on the supernatant obtained in the step 1) to remove high valence ions with valence higher than bivalence in the wastewater; 3) carrying out catalytic ozonation treatment on the supernatant subjected to chemical precipitation in the step 2); 4) carrying out multi-media filtration, precise filtration and membrane filtration treatment on the wastewater subjected to catalytic ozonation in the step 3) in sequence; and 5) carrying out electrodialysis reversal treatment on the effluent obtained after membrane filtration in the step 4). By adopting the method, organic matters, bacteria, colloids, suspended particles, Ca<2+>, Mg<2+> and high valence ions, other soluble inorganic salts and the like in the industrial wastewater with high salt content are removed by utilizing the coupling and synergistic effects of different unit technologies, thus achieving deep treatment, desalting and recycling of the industrial wastewater with high salt content.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Magnetic toner

A magnetic toner has magnetic toner particles, each of the magnetic toner particles containing a binder resin and a magnetic material, and an inorganic fine powder. The magnetic material is prepared by treating the surface of magnetic iron oxide with a silane compound. When the magnetic iron oxide is dispersed in an aqueous solution of hydrochloric acid and dissolved until the dissolution proportion of the iron element reaches 5% by mass based on the total amount of the iron element contained in the magnetic iron oxide, the amount of silicon eluted by that point of time is 0.05% by mass or more and 0.50% by mass or less based on the magnetic iron oxide. The magnetic material has a moisture adsorption amount per unit area of 0.30 mg / m2 or less.

Owner:CANON KK

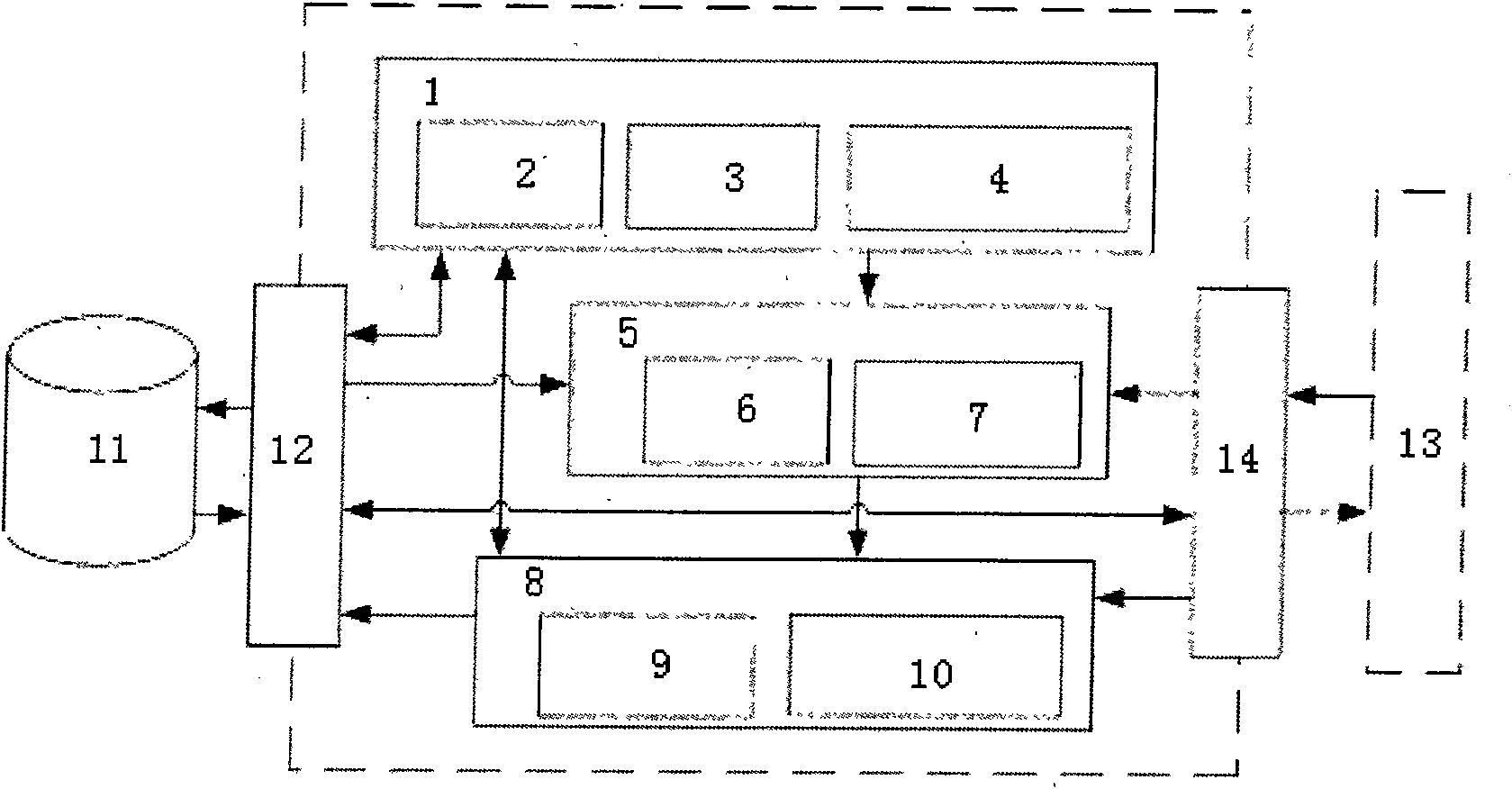

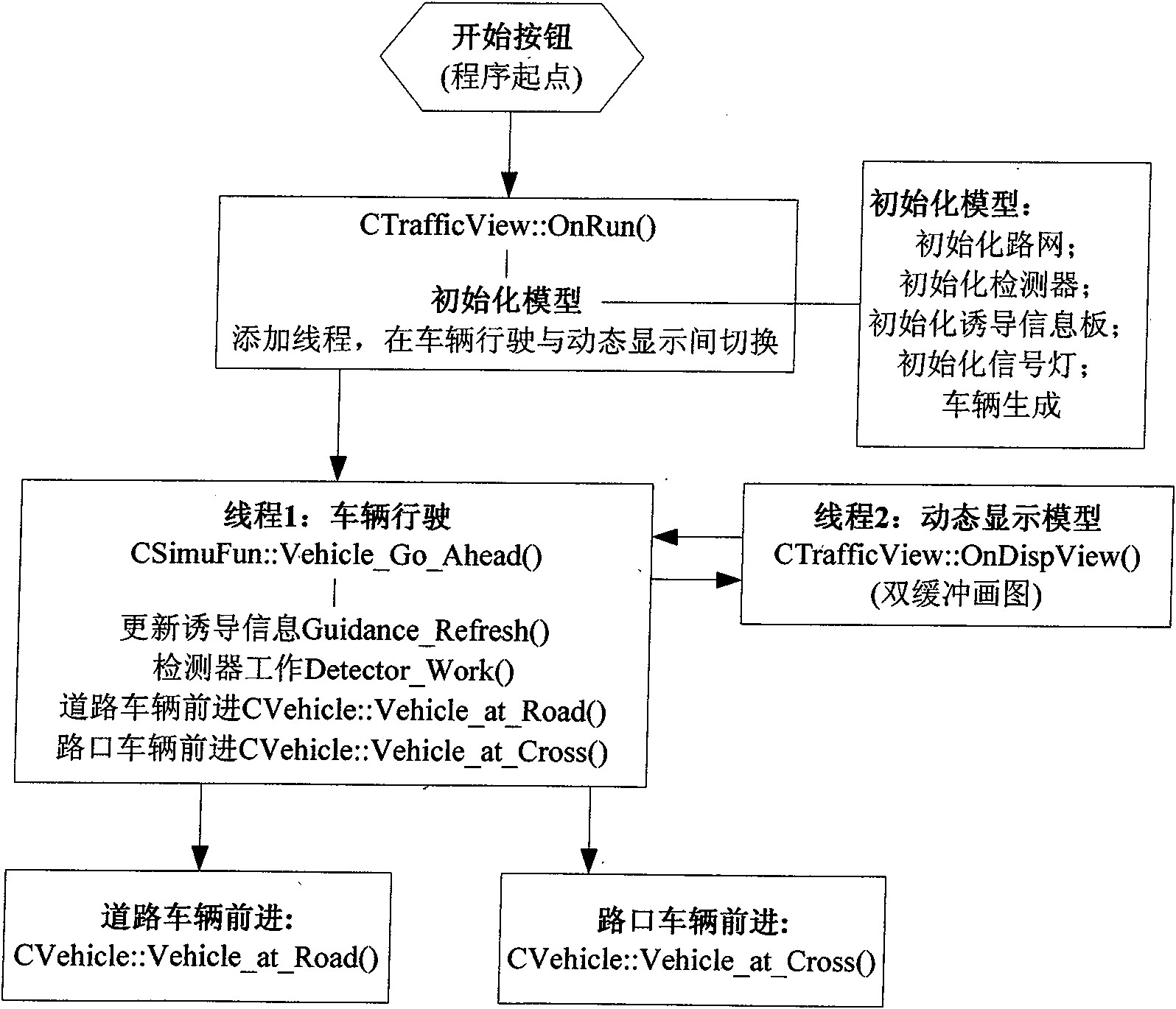

Urban microscopic traffic flow simulation system based on cellular machine

InactiveCN101561836AResolve import conflictsSolve flickeringControlling traffic signalsSpecial data processing applicationsTraffic networkRoad networks

The invention discloses an urban microscopic traffic flow simulation system based on a cellular machine, which comprises a simulated inner core, an initialization model, a human-computer interaction model, a database management system and an induction and control coordination system. The initialization model consists of a road network generating model, a vehicle generating model and a control and induction device generating model; the simulated inner core consists of a vehicle running model and a control and induction device running model; and the human-computer interaction model is in charge of the setting of a user on various parameters in the simulation system and the screen display work of a whole traffic network. The invention researches the overall design of the urban microscopic traffic flow simulation system, various running rules of vehicles at different road network positions and other necessary component parts for constructing the simulation system, mainly starts with the realization of the whole microscopic traffic flow simulation system to provide an overall framework of program running, and carries out corresponding simplification for certain complex independent parts so that the realization of the system is more feasible.

Owner:TIANJIN UNIV

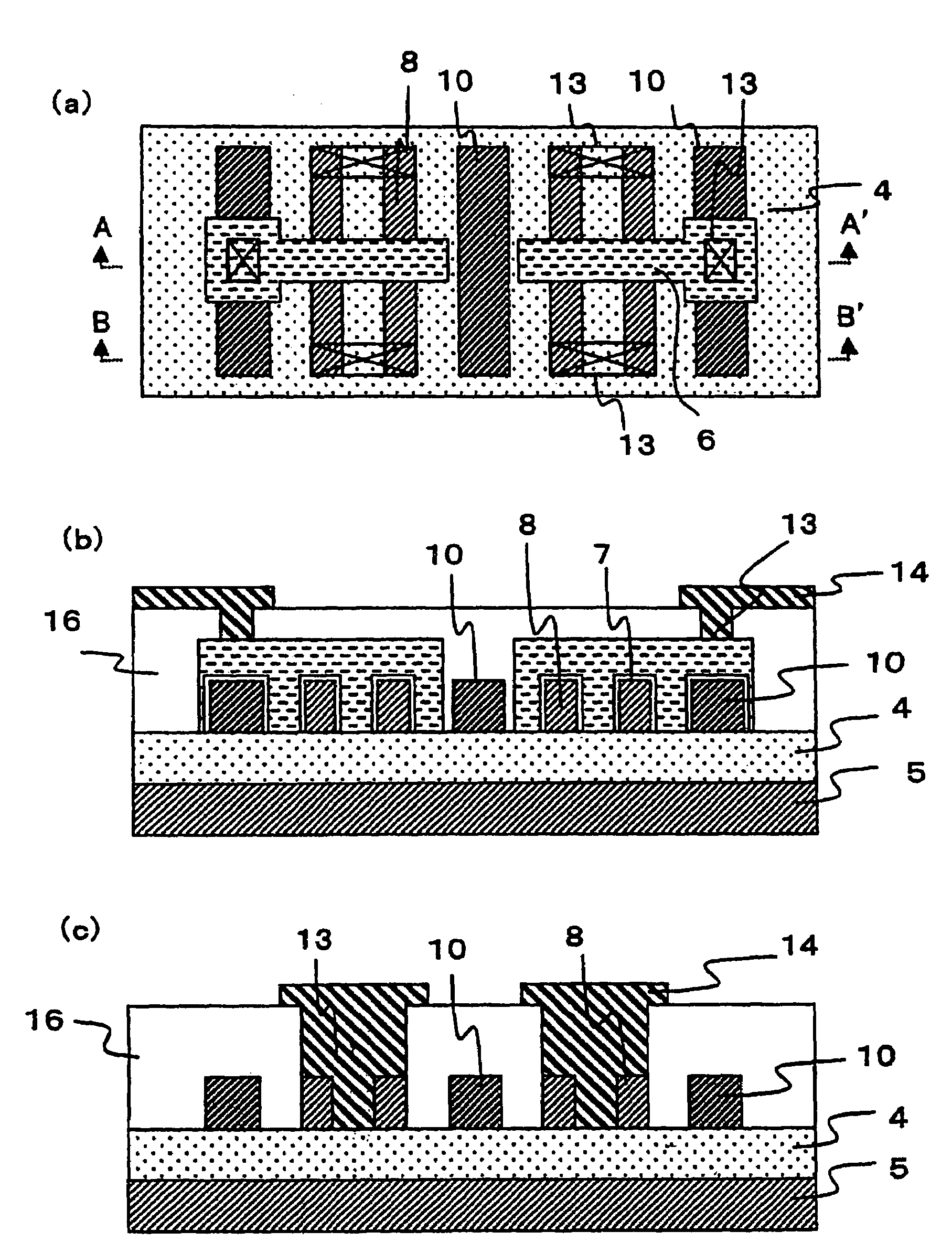

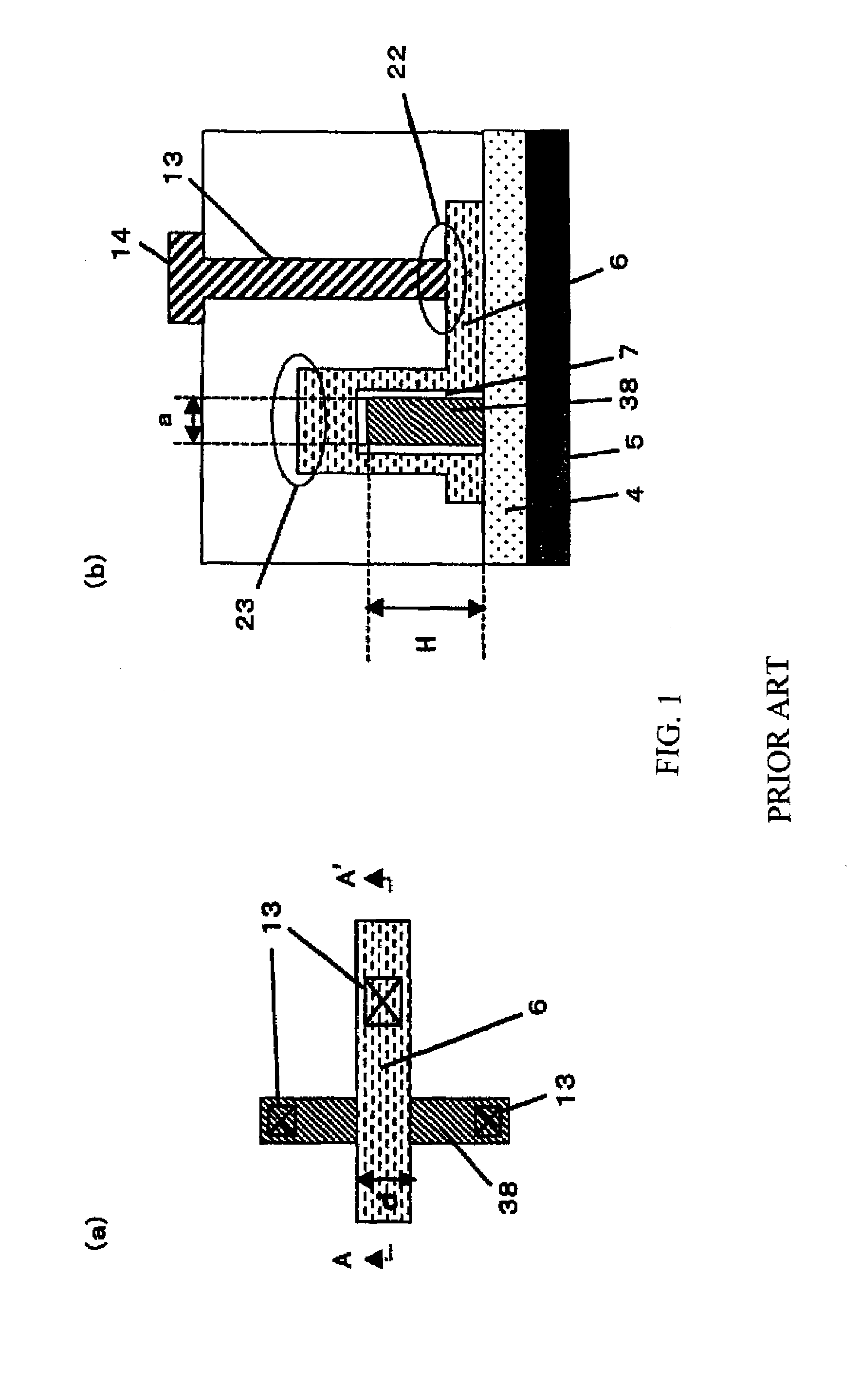

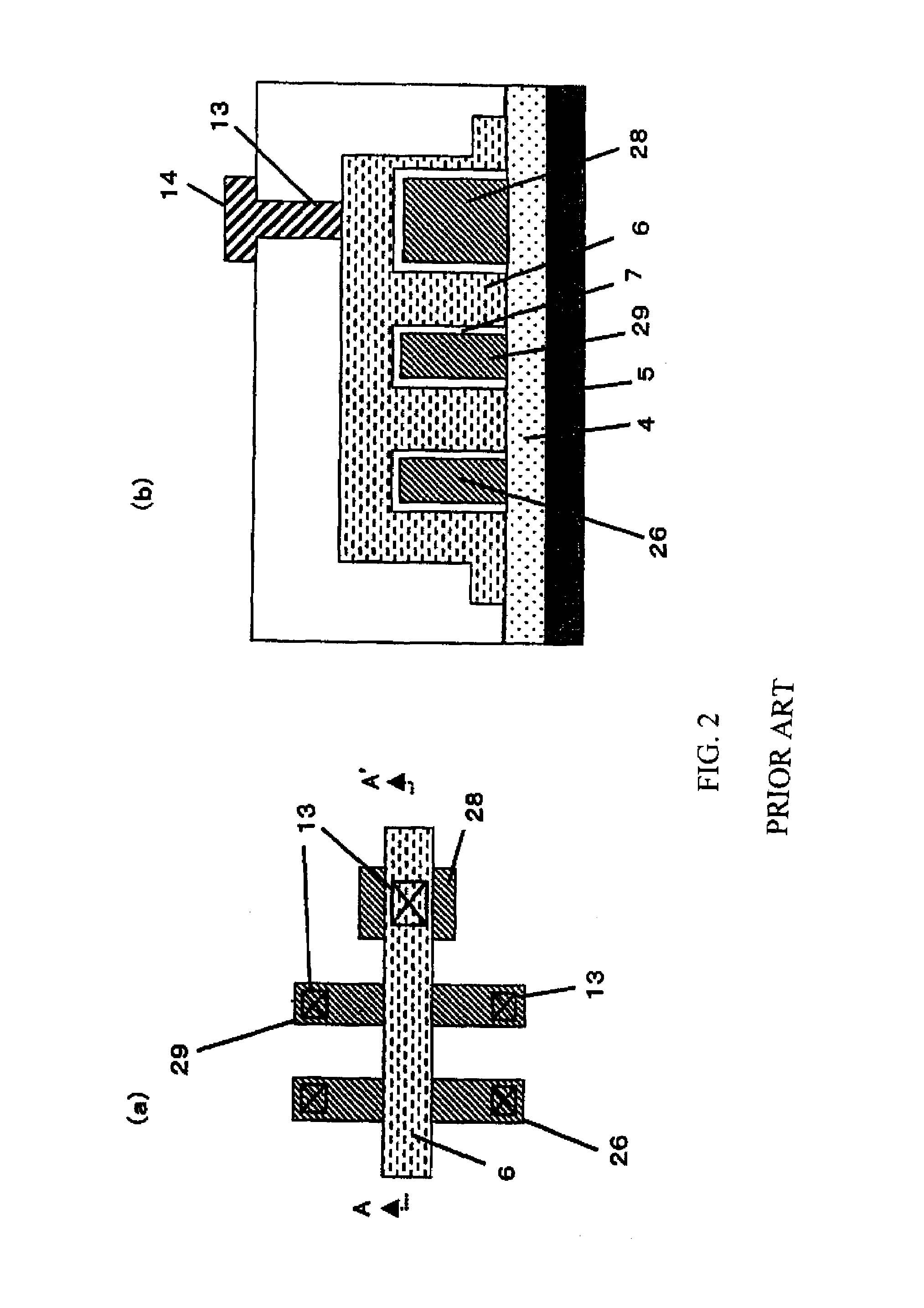

Semiconductor device and method for manufacturing same

ActiveUS7701018B2Easy alignmentImprove running stabilityTransistorSolid-state devicesEngineeringField-effect transistor

A semiconductor device comprising a first semiconductor region and a second semiconductor region,(a) wherein a field effect transistor is comprised of the first semiconductor region comprising at least one semiconductor layer(s) protruding upward from a substrate, a gate electrode(s) formed via an insulating film such that the gate electrode(s) strides over the semiconductor layer(s) and source / drain regions provided in the semiconductor layer(s) on both sides of the gate electrode(s), whereby a channel region is formed in at least both sides of the semiconductor layer(s),(b) wherein the second semiconductor region comprises semiconductor layers protruding upward from the substrate and placed, at least opposing the first semiconductor region at both ends in the direction perpendicular to a channel current direction and the side surface of the semiconductor layers facing the first semiconductor region is parallel to the channel current direction.

Owner:GK BRIDGE 1

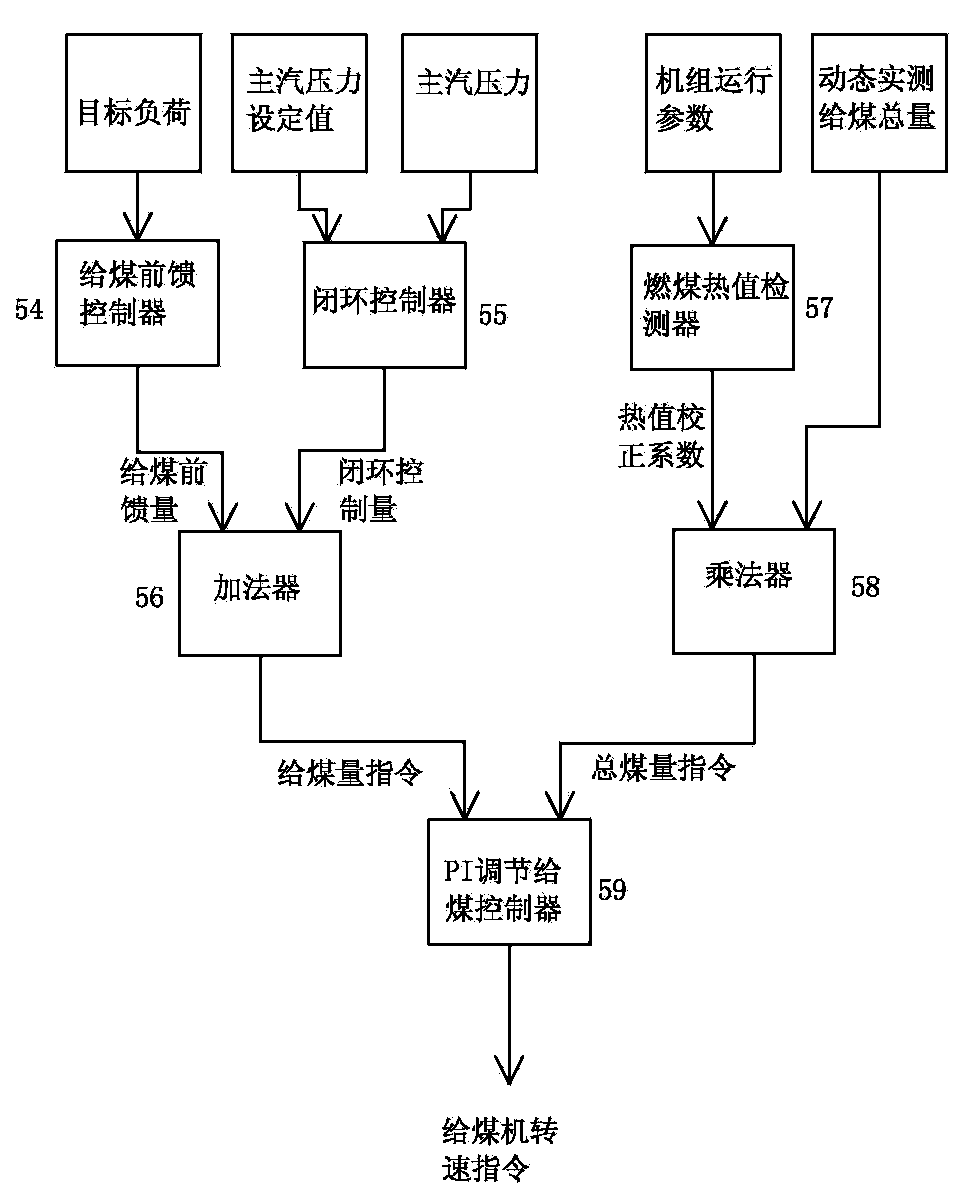

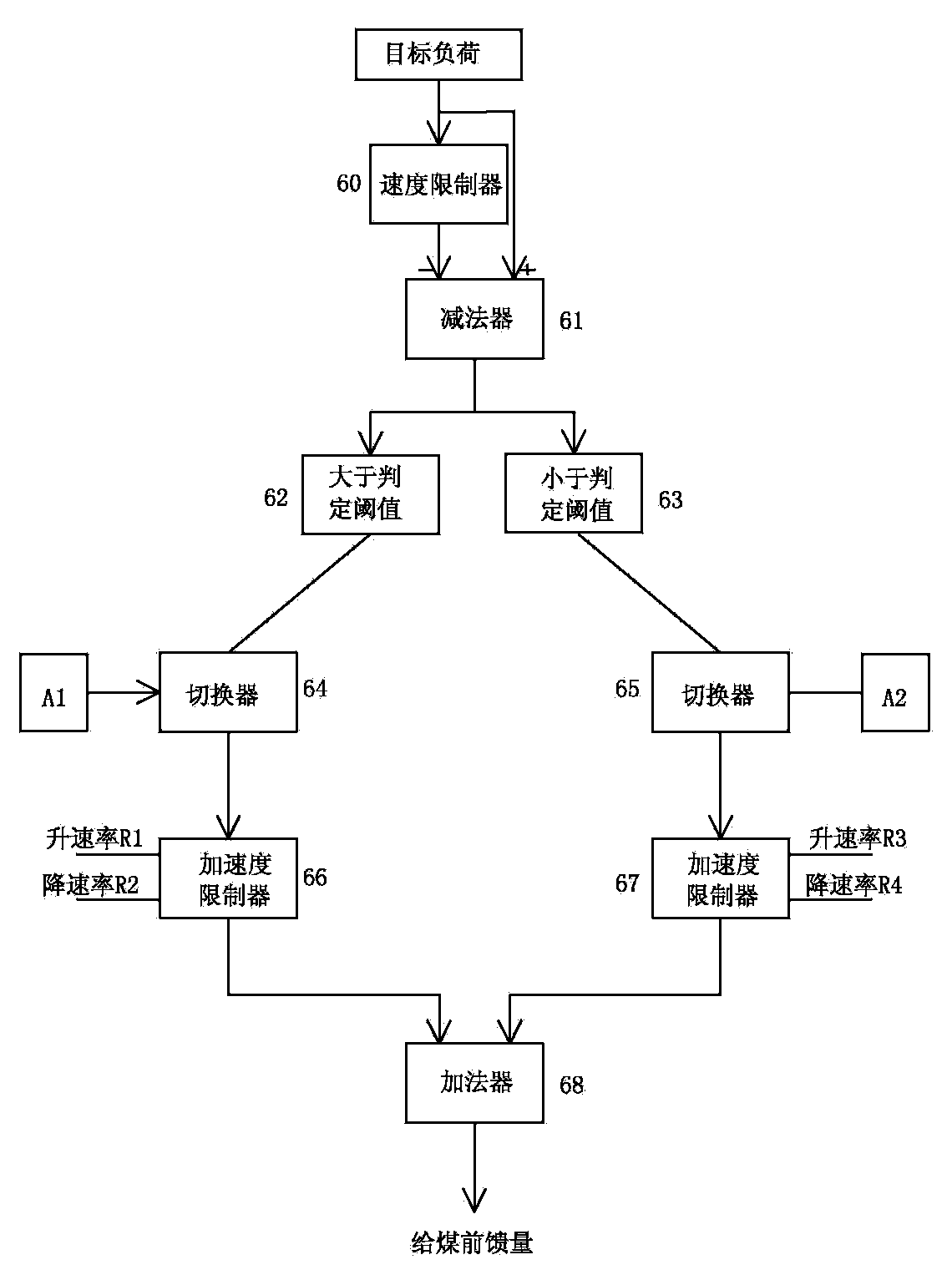

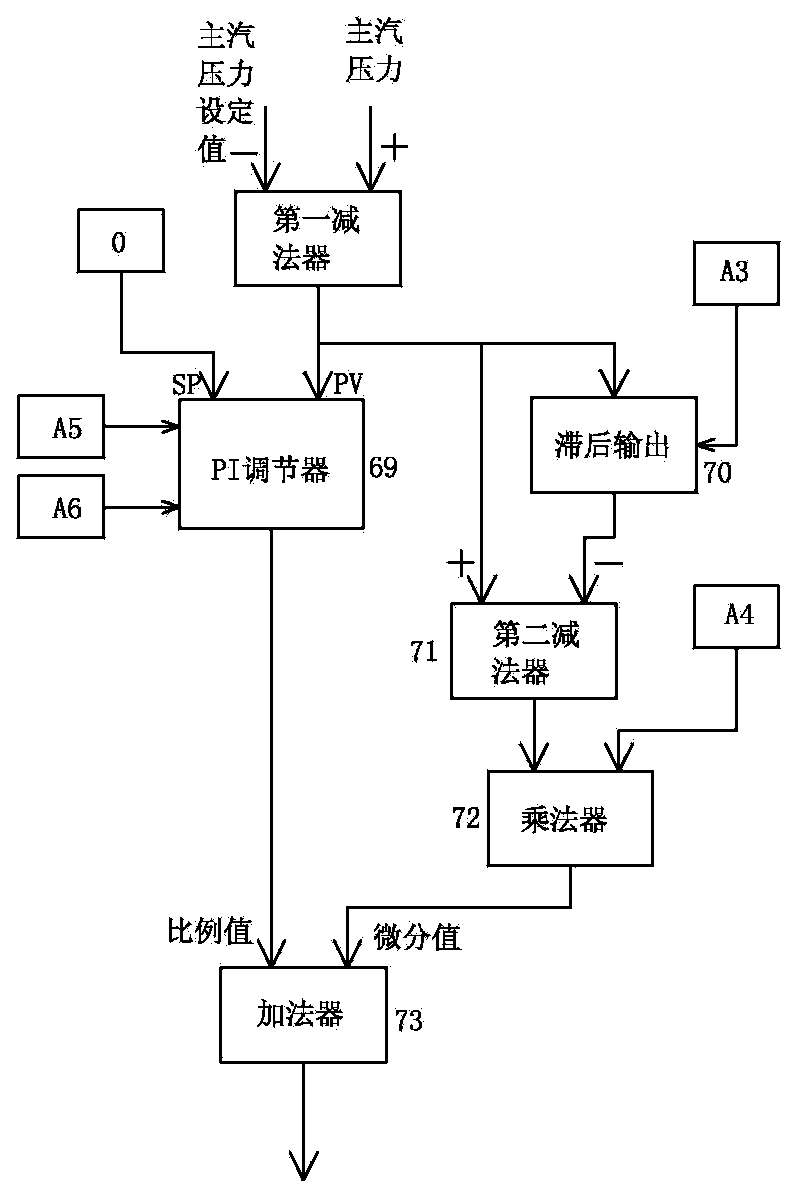

Supercritical boiler fire coal heat value self-balance control loop distributed control system implementation method

ActiveCN104238520AImprove running stabilityImprove operating economyProgramme total factory controlSupercritical steam generatorCombustion

The invention discloses a supercritical boiler fire coal heat value self-balance control loop distributed control system implementation method. The method comprises the steps of outputting a final coal feeder rotation speed command after PID adjustment is carried out on a received coal feed quantity command and a total coal quantity command with a heat value corrected, wherein the total coal quantity command with the heat value corrected is a total coal quantity command output by multiplying a dynamically-measured total coal feed quantity by a heat value balance correction coefficient, and the heat value balance correction coefficient is a delayed heat value balance correction coefficient. According to the method, soft measurement of a fire coal heat value can be achieved based on a unit DCS platform, additional investment is not needed, and a soft measurement signal of the fire coal heat value makes it convenient for operating personnel to monitor the quality of fired coal in real time and guides boiler combustion adjustment. A fire coal heat value self-balance control loop is designed, and therefore a unit coordinated control system has the ability to adapt to various types of coal, and the operation stability and the economy of a unit are improved.

Owner:ANHUI XINLT POWER TECH CONSULTING +3

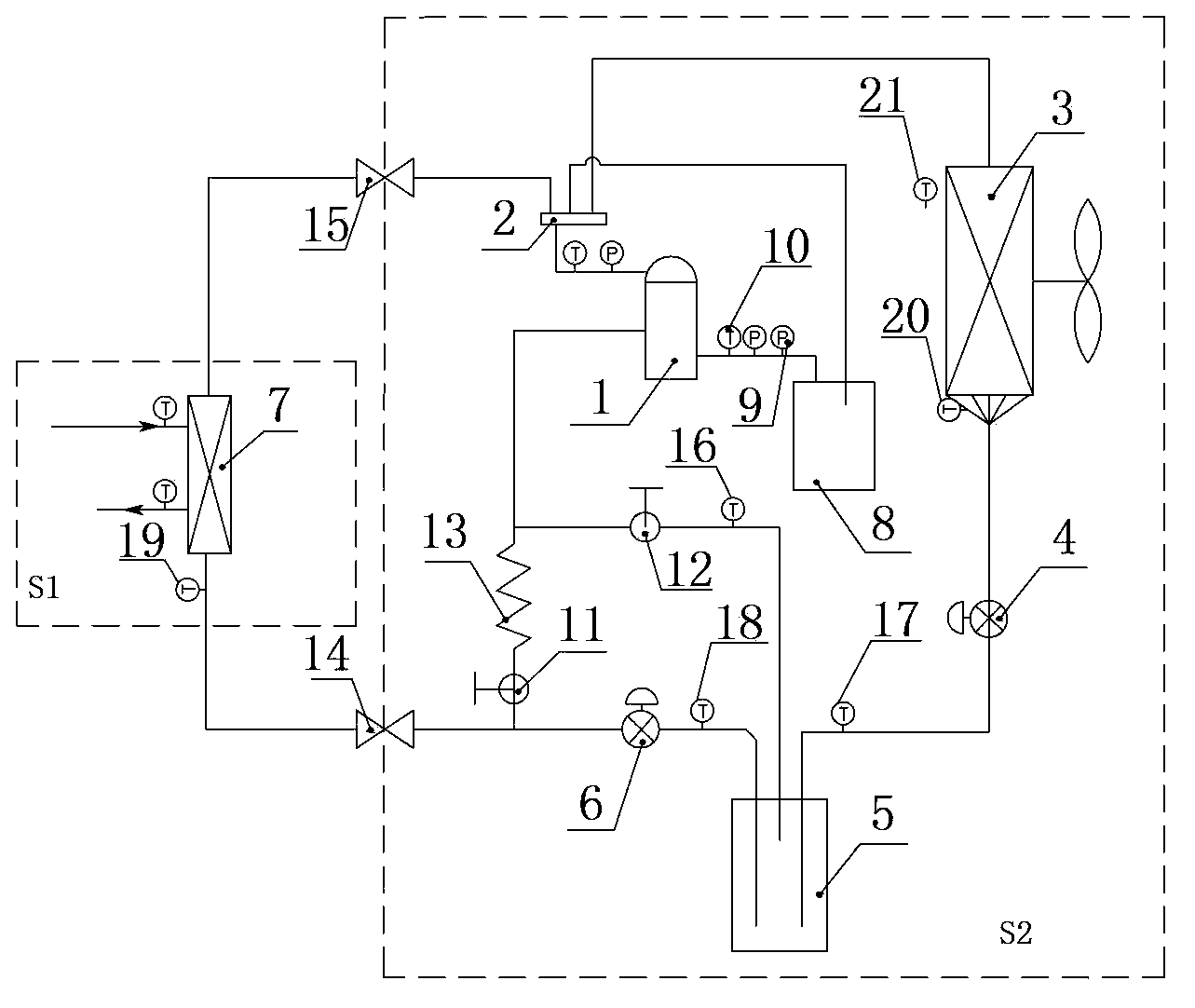

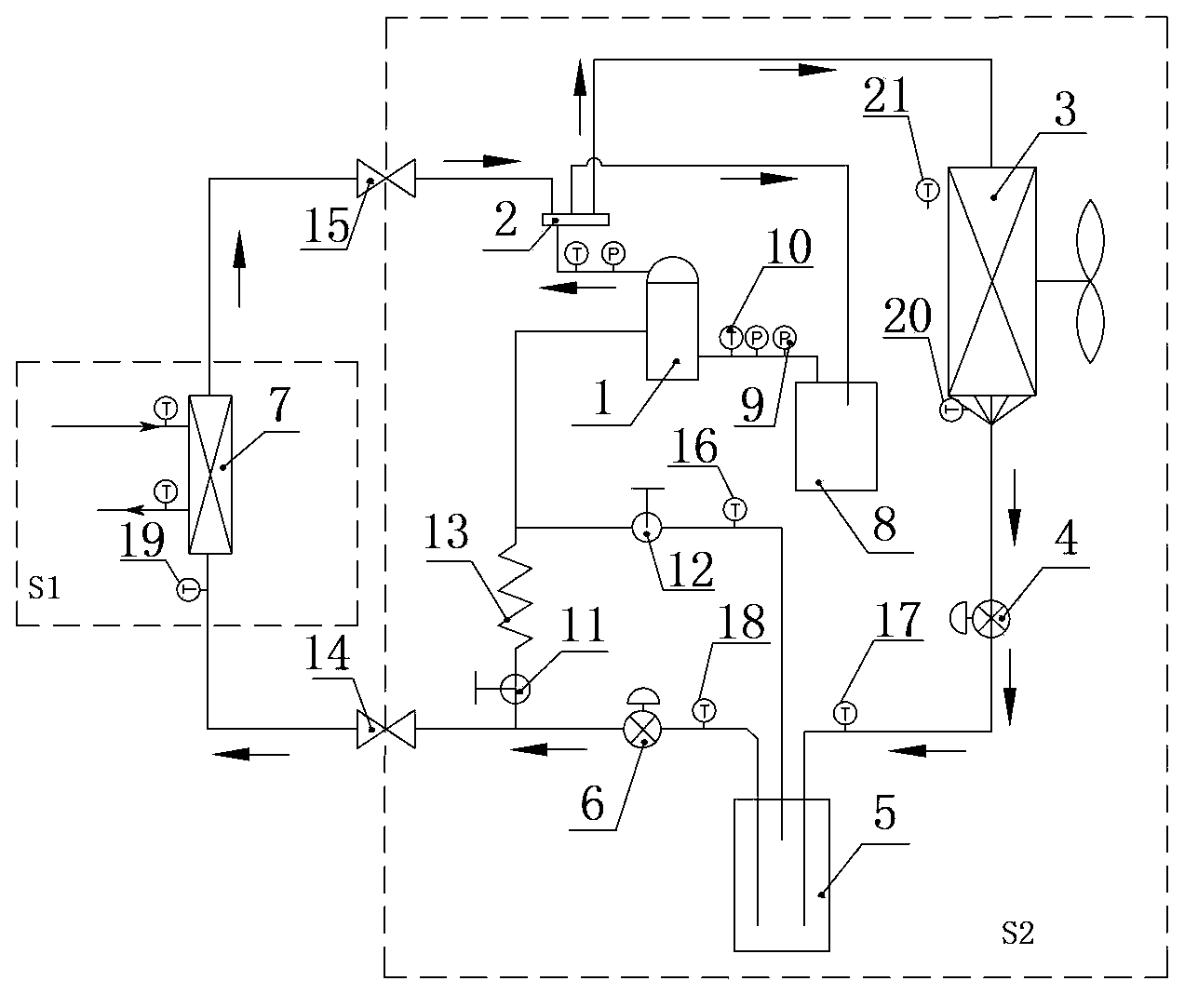

Air conditioner and air supply control method used for air conditioner

ActiveCN103807917AGuaranteed circulation volumeGuaranteed uptimeMechanical apparatusSpace heating and ventilation safety systemsFour-way valveProcess engineering

The invention discloses an air conditioner and an air supply control method used for the air conditioner. The air conditioner comprises a compressor, a four-way valve, an indoor heat exchanger, an outdoor heat exchanger, a liquid accumulator, a first throttling element, a second throttling element and a third throttling element, wherein the compressor is provided with a suction end, a discharge end and an air supply end; a first end of the indoor heat exchanger is connected with a third interface of the four-way valve; a first end of the outdoor heat exchanger is connected with a fourth interface of the four-way valve; the liquid accumulator is connected with a second end of the outdoor heat exchanger by a first liquid pipe, is connected with a second end of the indoor heat exchanger by a second liquid pipe, and is connected with an air supply end of the compressor by an air pipe; the first throttling element is arranged on the first liquid pipe; the second throttling element is arranged on the second liquid pipe; the third throttling element is connected between a first node and the air supply end of the compressor. The problem that the normal operation of the air conditioner in a low temperature environment cannot be ensured by a single air supply loop in the prior art is solved, the operation effect of the air conditioner is thus ensured, and the stability and the reliability of the operation of a unit are improved.

Owner:GREE ELECTRIC APPLIANCES INC

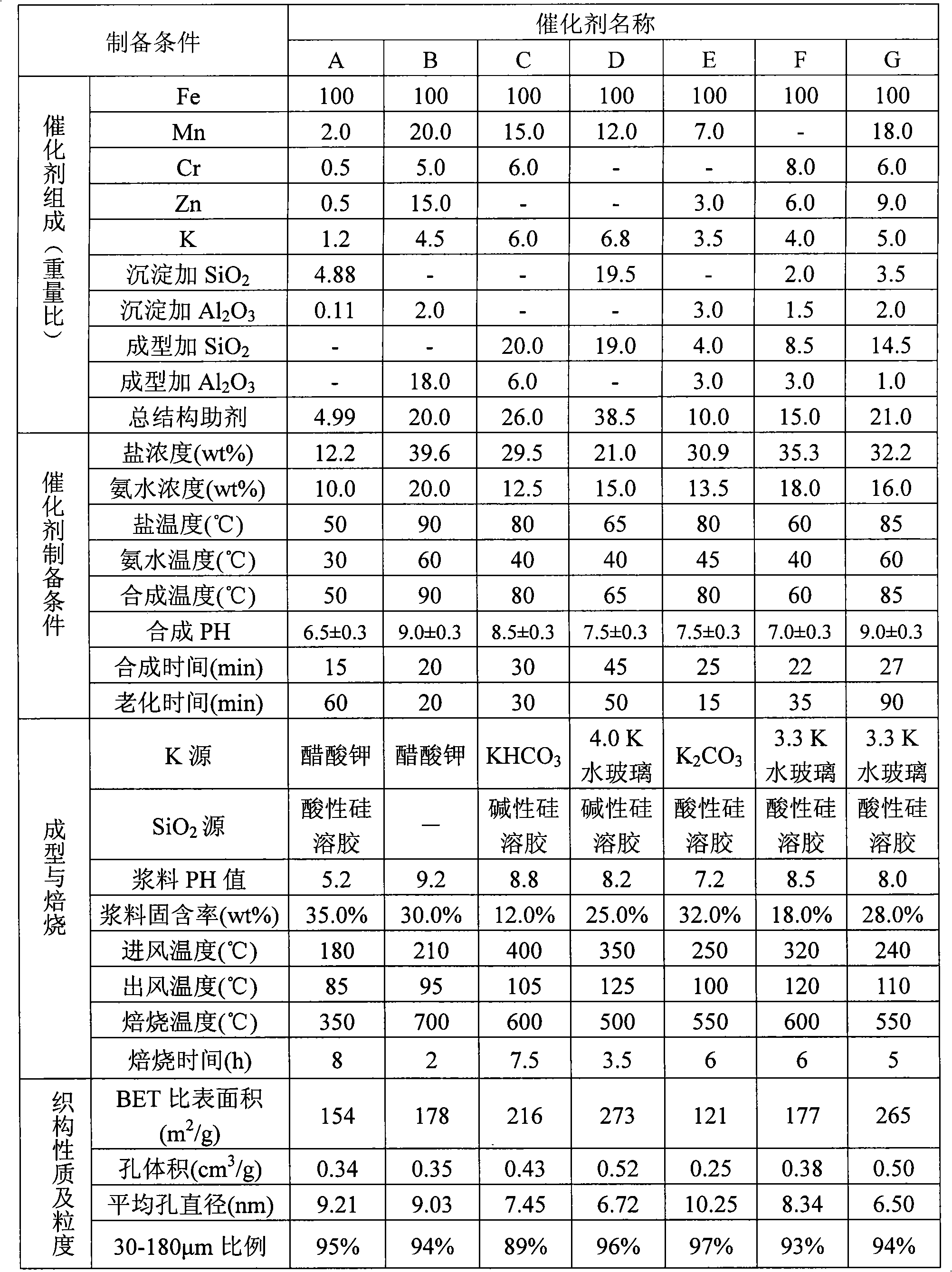

Fischer-Tropsch synthesis catalyst and preparation method and application thereof

InactiveCN101869840AHigh activityOptimize electronic structureHydrocarbon from carbon oxidesHeterogenous catalyst chemical elementsSlurry reactorPtru catalyst

The invention relates to a micro-spherical iron-based catalyst which contains transition metal additive, has high performance and is applicable to the Fischer-Tropsch synthesis of a slurry reactor, and a preparation method and the application thereof; and the weight composition of the catalyst is as follows: Fe: transition metal additive M: structural additive (SiO2 or / and Al2O3):K=100:1 to 50:1 to 50:0.5 to 10. The preparation method of the catalyst comprises the following steps: adding the structural additive into Fe / M mixed nitrate solution, co-precipitating with ammonia to prepare slurry; filtering and washing the slurry to obtain a filter cake; and adding the required amount of K additive and water into the filter cake, beating, spraying, drying and calcining to obtain the Fischer-Tropsch synthesis iron-based catalyst of the micro-spherical slurry reactor. The catalyst prepared by the method has good anti-wear performance, the distribution scope of the grain size of the catalyst is narrow, the synthesis gas conversion capability is high, the product selectivity is good and the time-space yield is high, and the Fischer-Tropsch synthesis reaction of the slurry reactor can be carried out within a wider scope of temperature simultaneously.

Owner:SYNFUELS CHINA TECH CO LTD

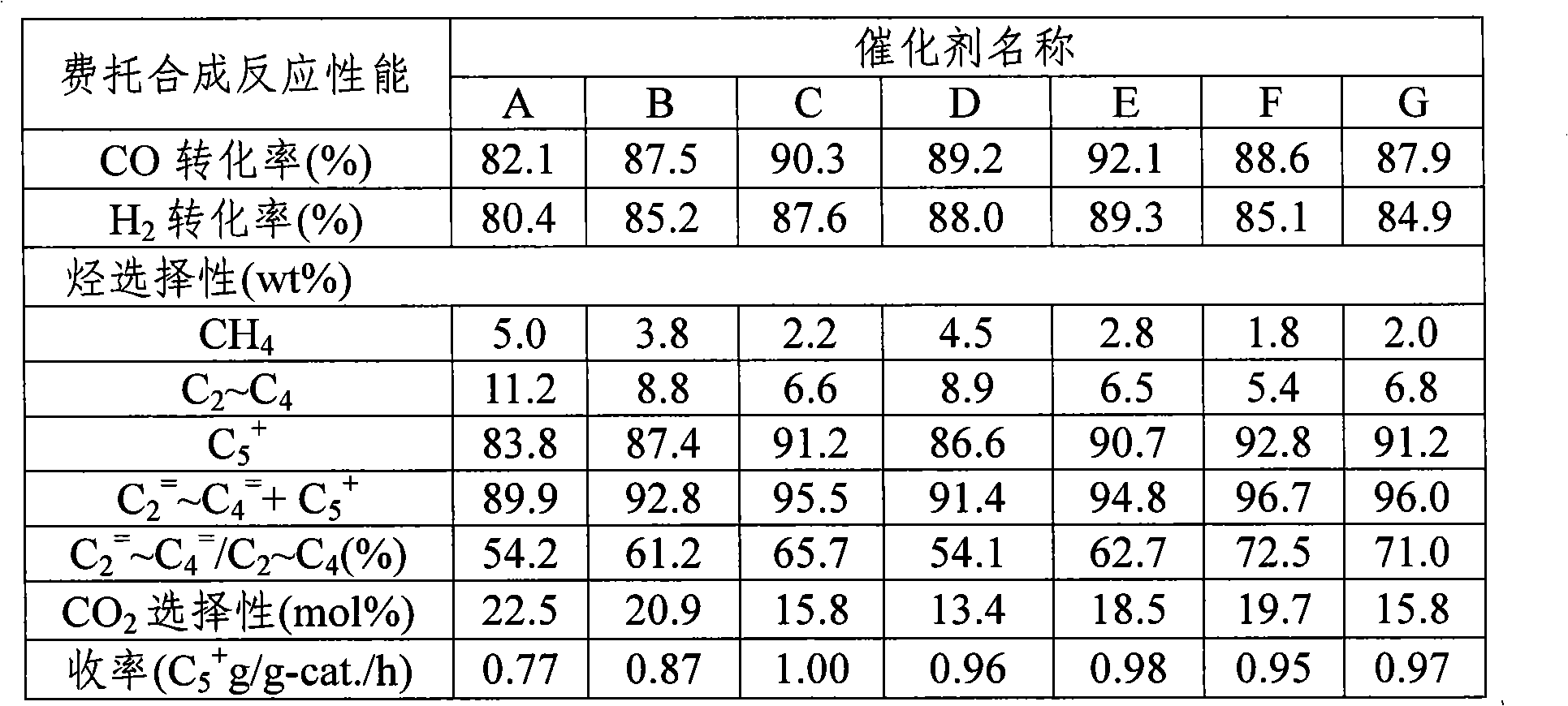

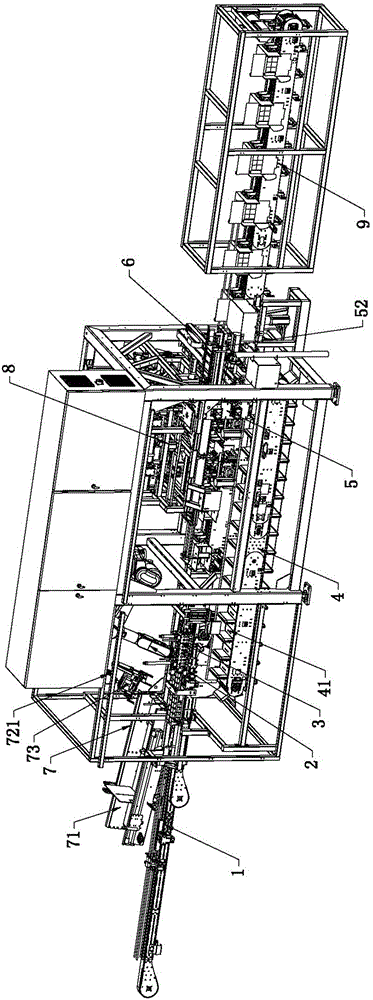

Automatic encasement system for Lilezuan milk bag gift boxes

ActiveCN104828288ASolve the problem that it is difficult to vertically transport automatic packingPrecise movement controlIndividual articlesEngineeringWorkload

The invention discloses an automatic encasement system for Lilezuan milk bag gift boxes. The automatic encasement system comprises a milk bag integration conveying line (1), a milk bag robot (2) and a milk bag unit conveying line (4), wherein a milk bag clamp (3) at the lower end of a manipulator of the milk bag robot (2) catches a milk bag unit on the milk bag integration conveying line (1) and pushes the milk bag unit into a corresponding milk bag unit separation slot (41) under the condition that the milk bag unit is in a horizontal state; then a small baffle plate insertion machine (5) inserts a small baffle plate into a middle clearance of the milk bag unit, and a horizontal pushing mechanism (6) is used for horizontally pushing the milk bag unit with the inserted small baffle plate into a packaging case already provided with a large lining plate on a packaging case conveying line (9); finally the packaging case already provided with the large lining plate, the small baffle plate and the milk bag unit is covered and encased to finish the whole automatic encasement process. According to the automatic encasement system for the Lilezuan milk bag gift boxes, the milk bag encasement operation is creatively changed from vertical encasement into horizontal encasement, so that the production operation is more stable, the maintenance is easy and convenient, and the workload can be reduced to the maximum extent.

Owner:苏州澳昆智能机器人技术有限公司

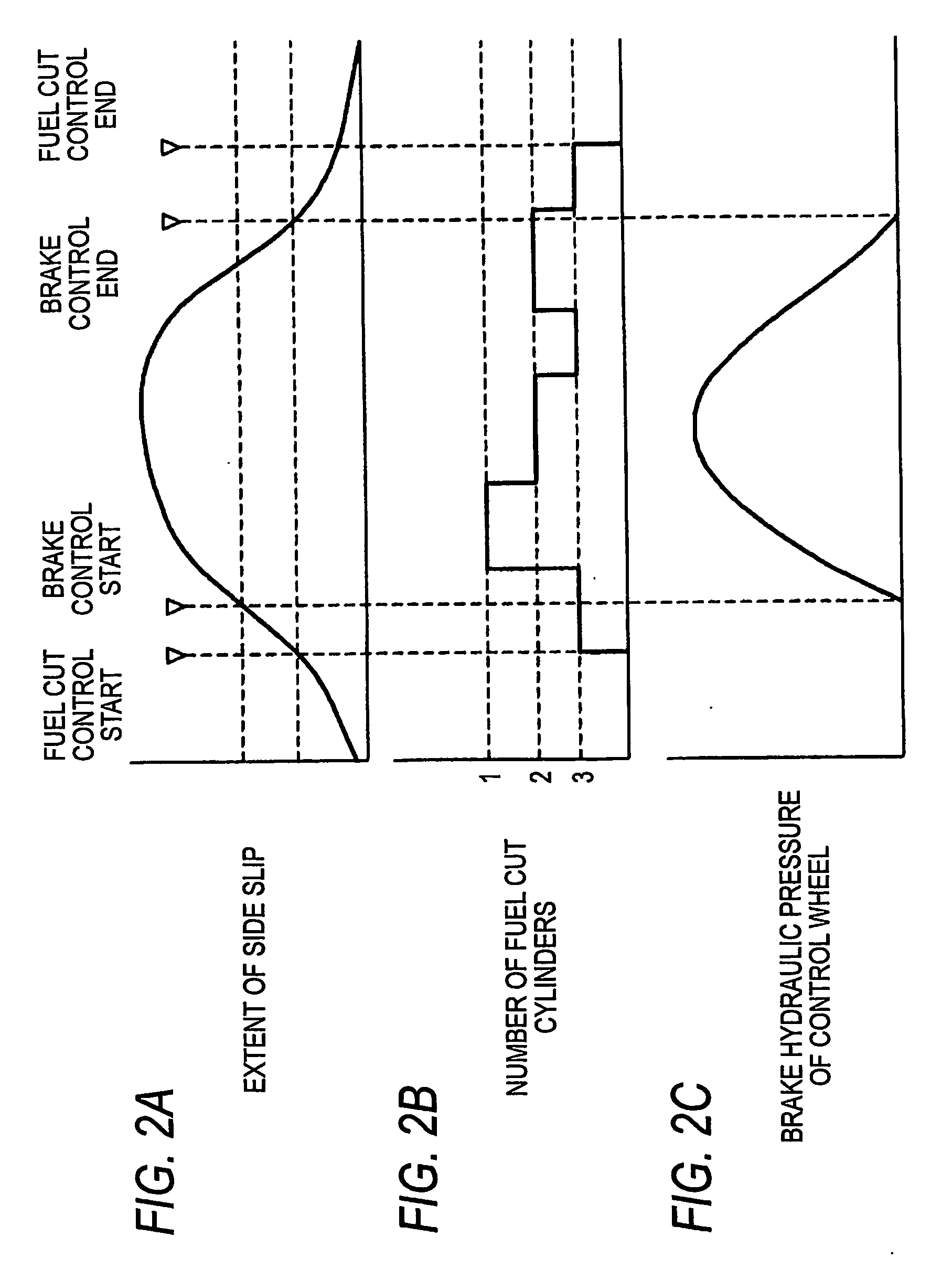

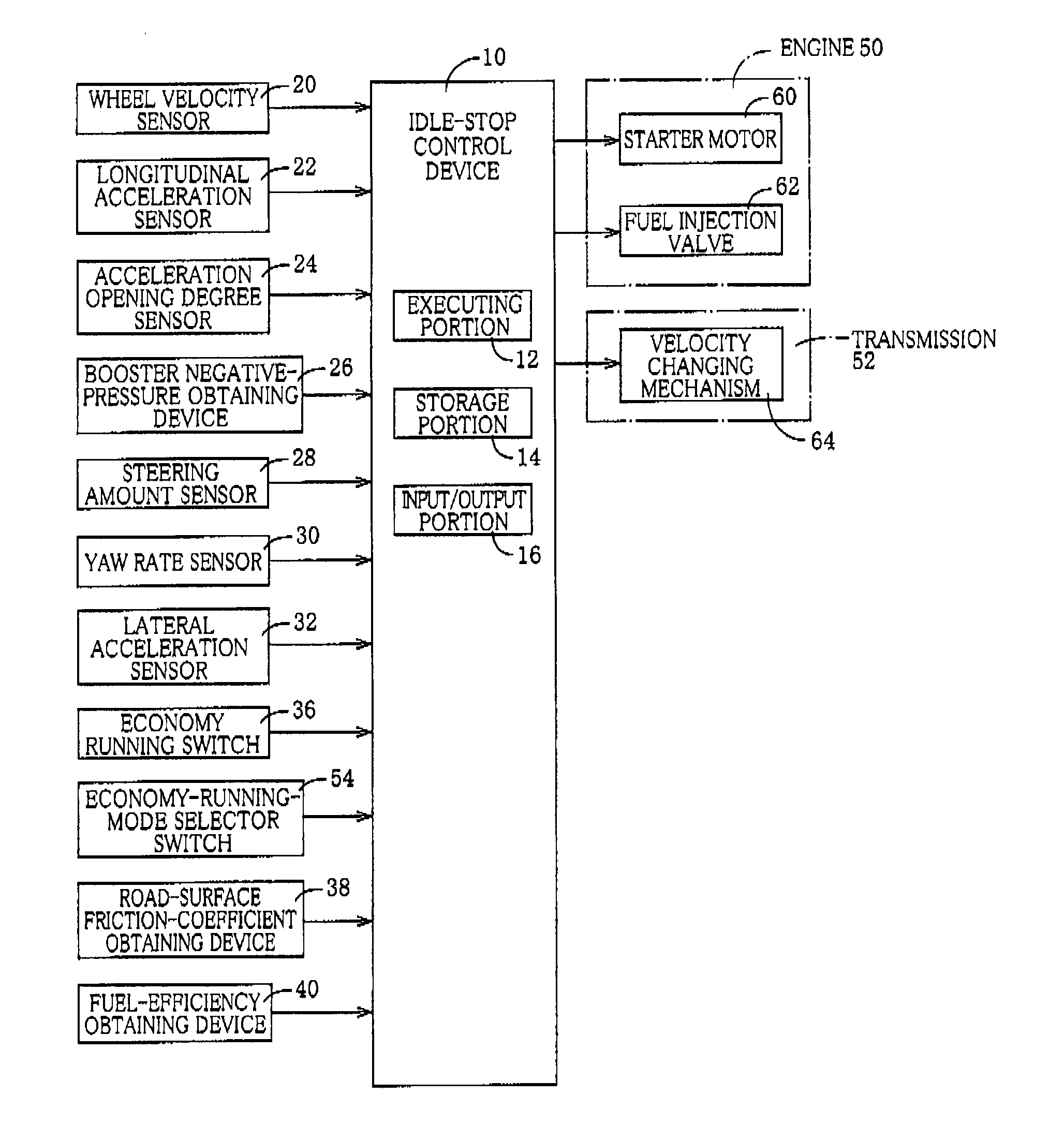

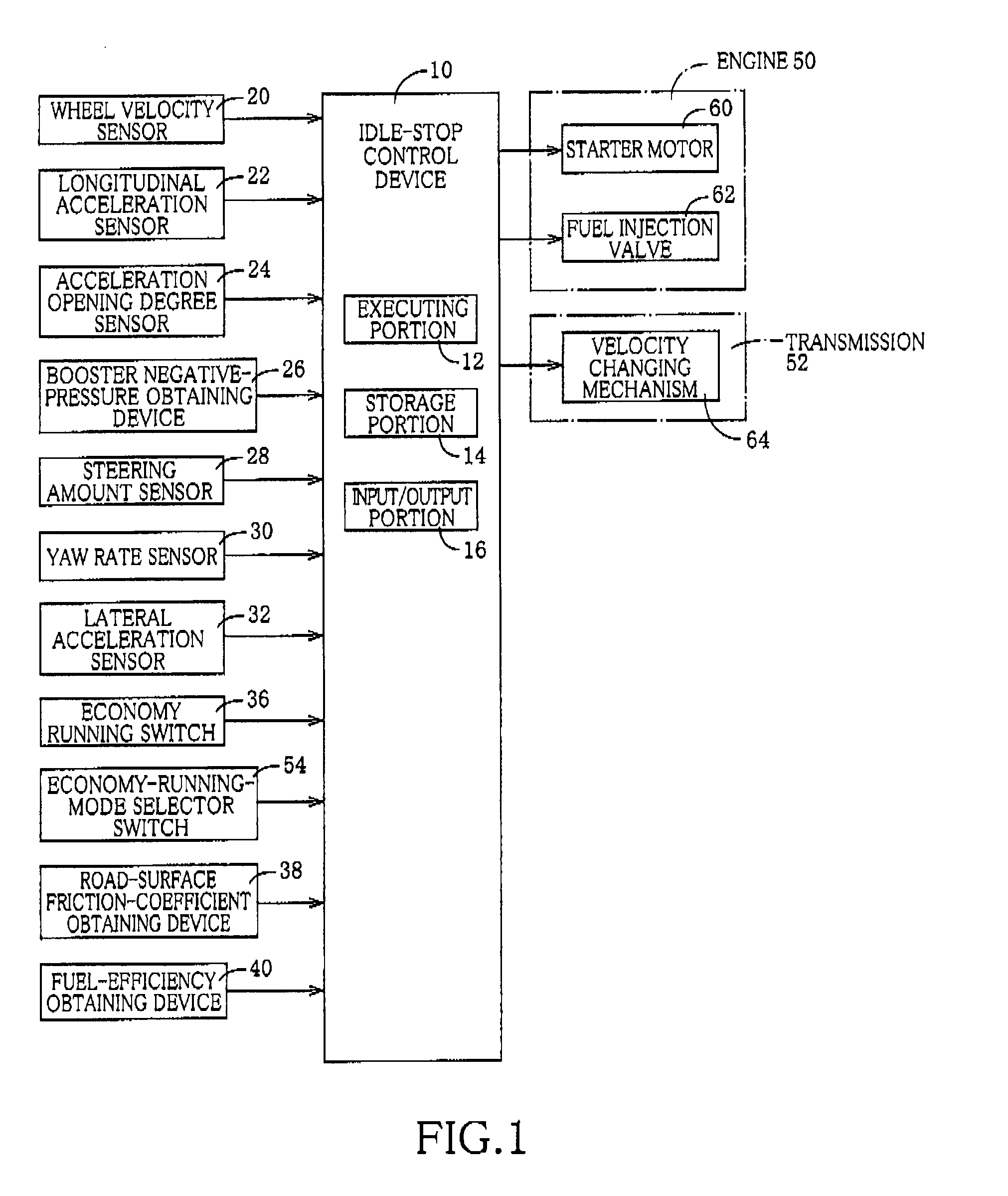

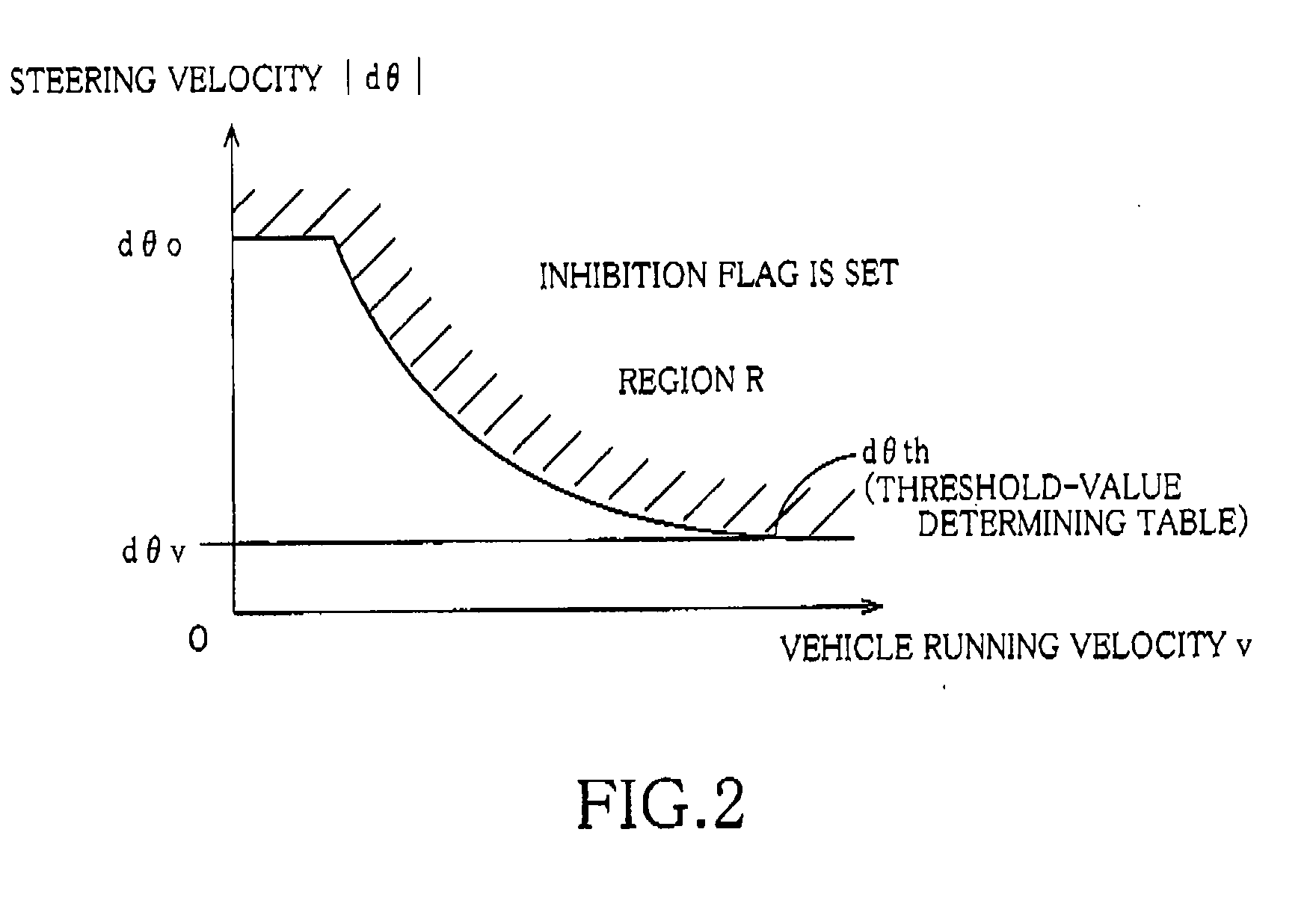

Engine controlling apparatus

InactiveUS20110046864A1Stop runningImprove fuel efficiencyAnalogue computers for vehiclesElectrical controlPhysical quantityAutomotive engineering

Owner:TOYOTA JIDOSHA KK

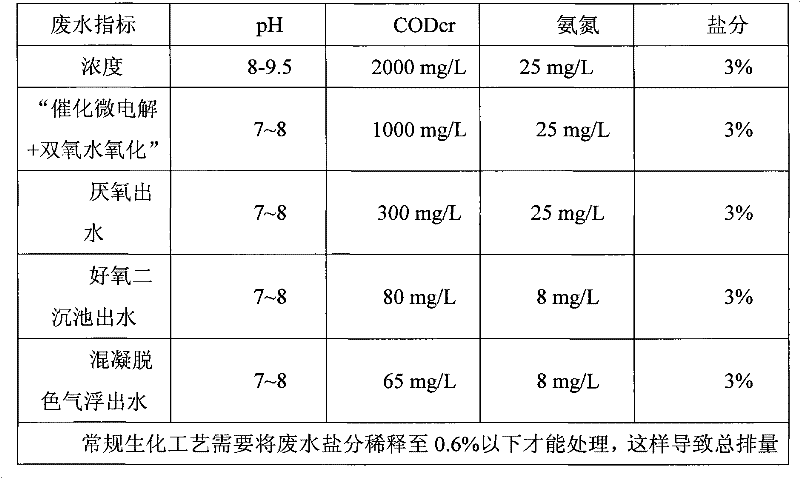

High salinity pharmaceutical wastewater processing system

ActiveCN102363546AImprove processing efficiencyImprove running stabilityMultistage water/sewage treatmentElectrolysisWater treatment system

The invention discloses a high salinity pharmaceutical wastewater processing system, wherein the salinity tolerance range of the system of the invention is that the total salinity is less than 5%, and is generally less than 3%. The system which adopts a processing technology with "a catalytic micro-electrolysis device, a hydrogen peroxide catalytic oxidation tank, a photosynthetic bacterium anaerobic system, a photosynthetic bacterium aerobic system and a coagulation decoloring tank" allows COD, BOD, ammonia nitrogen, and the chroma to be furthest reduced, the processing effect to be uninfluenced by the salinity, and outlet water to reach discharge standards. The system which allows various high salinity pharmaceutical wastewaters to be effectively processed, abuses of dilution or evaporation (burning) processing technologies for the routine processing to be avoided and the total pollutant discharge amount to be reduced and has the advantages of strong operation stability, low investment cost, high processing efficiency and low operation cost is a high salinity pharmaceutical wastewater processing system with development potential.

Owner:上海明诺环境科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com