Treatment system and treatment method for biochemical effluent of industrial wastewater

A treatment system and industrial waste water technology, applied in water/sewage treatment, oxidized water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of low concentrated water concentration, low recovery rate of fresh water, high treatment cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0114] Example 1: Treatment system for industrial wastewater biochemical effluent

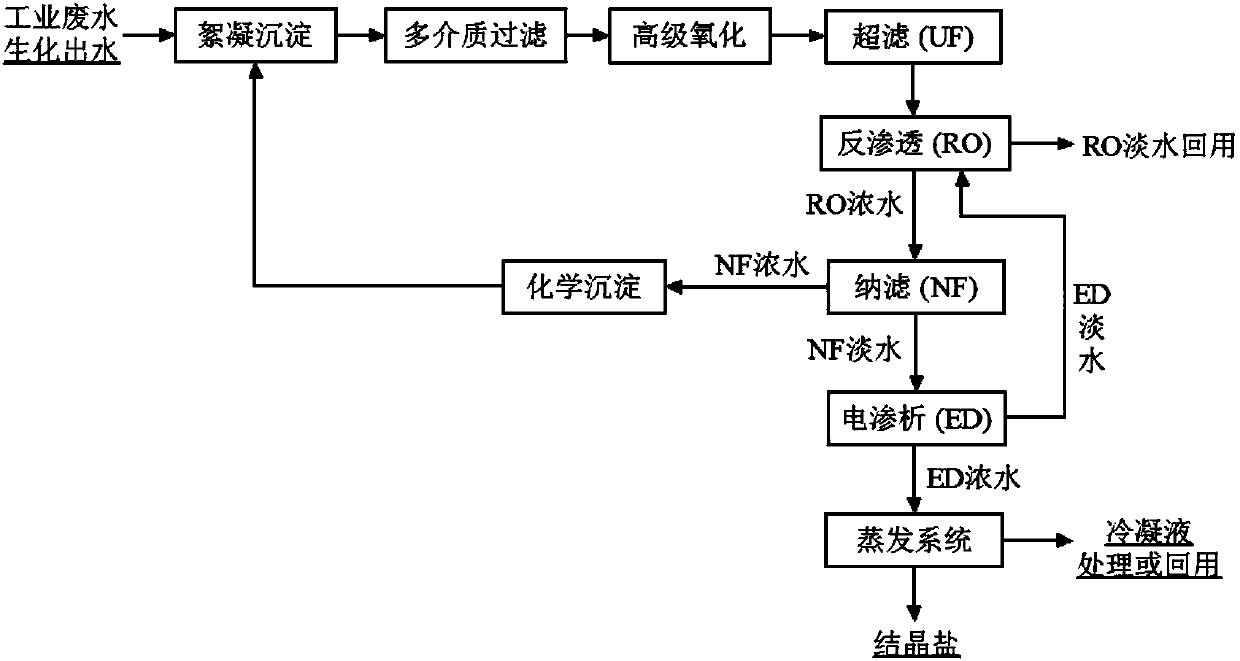

[0115] A treatment system for biochemical effluent of industrial wastewater, the treatment system includes a chemical precipitation unit and a flocculation sedimentation unit connected in sequence, a multimedia filtration unit, an advanced oxidation unit, an ultrafiltration unit, a precision filter, a reverse osmosis unit, and a nanofiltration unit , electrodialysis unit, evaporation unit and condensation unit;

[0116] The produced water outlet of the ultrafiltration unit is connected to the water inlet tank of the reverse osmosis unit, the concentrated water outlet of the reverse osmosis unit is connected to the water inlet of the nanofiltration unit, and the fresh water outlet of the nanofiltration unit is connected to the inlet of the electrodialysis unit. The water tank is connected, the concentrated water outlet of the nanofiltration unit is connected with the water inlet of the chemical ...

Embodiment 2

[0124] Example 2: Advanced treatment and desalination reuse of salty wastewater from coal chemical industry

[0125] Although the coal chemical industry saline wastewater treated by traditional technology can meet the discharge standard, the wastewater still contains a small amount of organic matter, colloid, suspended particles, Ca 2+ and Mg 2+ and other high-valent ions (if there is no special description in the present invention, high-valent ions all refer to ions with a valence of 3 or more), a large amount of other soluble inorganic salts, etc., the efflux will cause waste of water resources and environmental pollution. To realize this type of industrial For wastewater reuse, it is necessary to further remove residual organic matter and inorganic salts in wastewater. The existing ultrafiltration-reverse osmosis double-membrane treatment still has disadvantages such as low recovery rate of fresh water, low concentration of concentrated water, secondary pollution, and high...

Embodiment 3

[0136] Example 3: Advanced treatment and desalination reuse of salty wastewater from coal chemical industry

[0137] The coal chemical industry saline wastewater is the same as the coal chemical industry saline wastewater described in Example 2. Its processing method includes the following steps:

[0138] (1) The salty wastewater from the coal chemical industry after biochemical treatment is first treated by flocculation and sedimentation. The flocculant used is an inorganic flocculant and an organic flocculant with a mass ratio of 2000:1. The inorganic flocculant is polyaluminium chloride, and the organic flocculant The agent is polyacrylamide; flocculation and sedimentation treatment can effectively remove impurities such as total cyanide, small particle suspended matter, organic matter and colloid in coal chemical industry saline wastewater, among which the removal rate of total cyanide is 95%, and the removal rate of organic matter can reach 50%;

[0139] (2) The waste wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com