Patents

Literature

385 results about "Wastewater reuse" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite reagent for treating recycled water of printing and dyeing wastewater and application method of composite reagent

InactiveCN104108775AAchieve efficiencyAchieve economyWaste water treatment from textile industryWater/sewage treatment by flocculation/precipitationSolubilityFlocculation

The invention discloses a composite reagent for treating recycled water of printing and dyeing wastewater and an application method of the composite reagent. The composite reagent comprises the following components by weight percent: 20% to 70% of aluminum salt coagulant, 5% to 30% of iron salt coagulant, 5% to 40% of mineral material and 5% to 45% of activated carbon. The method comprises the following steps: preparing the composite reagent for treating the recycled water of the printing and dyeing wastewater into powder or an aqueous liquid in which the content of effective components accounts for 5% to 30%; regulating a pH value of effluent in a printing and dyeing wastewater biochemical system to be within 3 to 9; adding the powder or the aqueous liquid of the composite reagent into the effluent in the printing and dyeing wastewater biochemical system under the condition that the adding quantity of the effective components is between 20mg / L and 1000mg / L after the pH value of the effluent is regulated; and stirring for 0.2 to 2 hours and then standing so as to obtain the recycled water conforming to the water quality standard in textile industry. According to the method, macromolecular colloidal pollutants in the biochemical effluent of the printing and dyeing wastewater, which are difficult to degrade, can be removed by utilizing the coagulation / flocculation performance of aluminum salts and iron salts in the composite reagent; and meanwhile, soluble inert pollutants in the wastewater are removed by utilizing the adsorbability of the activated carbon and the mineral material in the composite reagent.

Owner:HANGZHOU DIANZI UNIV

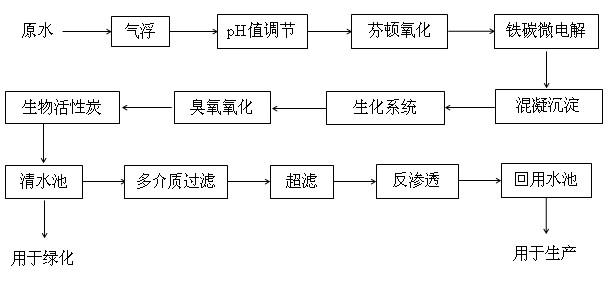

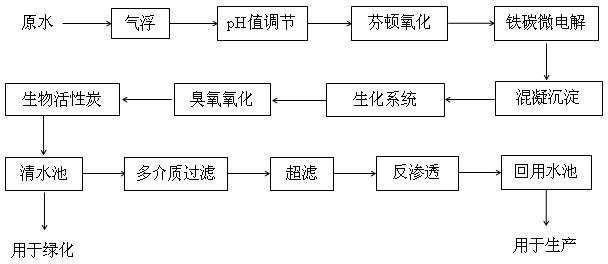

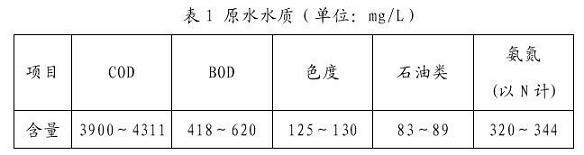

Treatment method for recycling complex waste water in coal chemical industry

InactiveCN102515442AImprove biodegradabilityRealize resourcesMultistage water/sewage treatmentWater useBiological activated carbon

The invention provides a treatment method for recycling complex waste water in the coal chemical industry and relates to recycling technologies for enhanced pretreatment, biochemical treatment, deep purification and regeneration process of waste water. The invention provides the process scheme as follows: first enhanced pretreatment for the complex waste water in the coal chemical industry is carried out by using the combined process of air floatation, Fenton oxidation and ferric-carbon micro-electrolysis, so as to improve the biodegradability of the waste water; then the waste water is poured into a biochemical system comprising a hydrolyze acidification zone pool, an anoxic pool and an aerobic pool; the biodegraded water is discharged into a deep purification system with the function ofozone-biological activated carbon filtration, so that materials which are difficult to degrade are further removed, and the discharged water can be used for green spaces and other landscapes; after that, most of salt ions are removed by using a regeneration recycling system with the functions of multi-media filtration, ultrafiltration and reverse osmosis, so as to obtain water can be reused for production.

Owner:蓝星环境工程有限公司

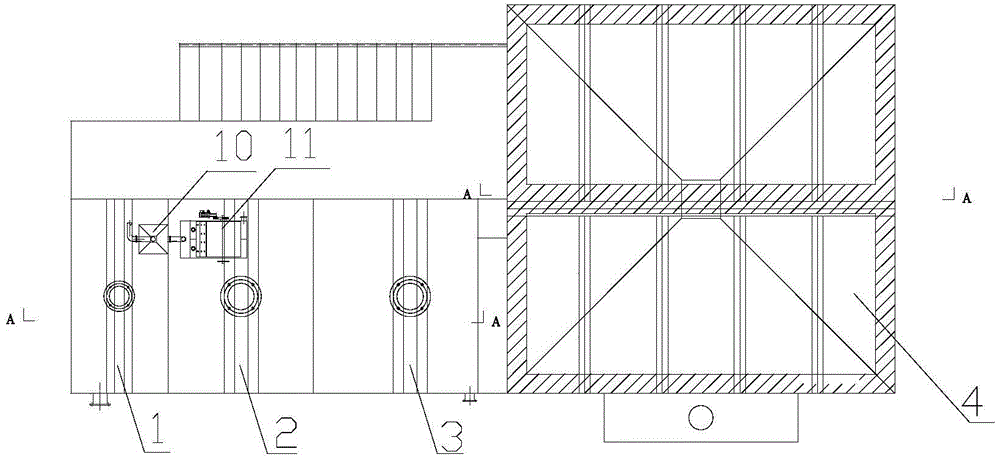

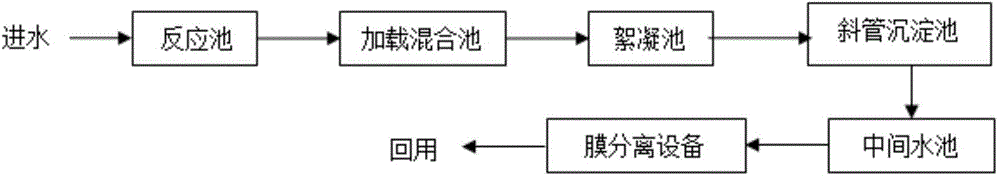

Wastewater reuse method combining magnetic loading coagulation clarification and membrane separation

ActiveCN103819045AAvoid or reduce pollutionLow costMultistage water/sewage treatmentParticulatesSolubility

The invention discloses a wastewater reuse method combining magnetic loading coagulation clarification and membrane separation. The method comprises the following steps: (1) a coagulant is added into a reaction tank to form small flocs; (2) the small flocs enter a loading and mixing tank to generate magnetic coagulation cores with magnetic carriers; (3) after the magnetic coagulation cores enter a flocculation tank, a flocculant is added to generate large-particle magnetic floccules; (4) after the magnetic floccules are stirred and dispersed strongly by a high-speed dispersion machine, magnetic carriers which are recycled via a magnetic drum separator return to the step (2), supernatant liquor enters a middle water tank via the collection by a water collecting pipe, after being pressurized by a water pump, the supernatant liquor enters membrane separating equipment for fine filtration, and filtered water is discharged for reusing. The method is used for removing particulate matters, colloid and a part of dissolved organic matters in advance before membrane filtration, so that membrane pollution degrees can be effectively avoided or reduced, and the cleaning period and the service life of membrane components are increased. The method can be used for the resource reutilization of the wastewater in industries of printing and dyeing, electroplating, paper-making and the like, as well as the upgrading and reconstruction and the tail water reuse of sewage treatment plants.

Owner:浙江立丰环保设备有限公司

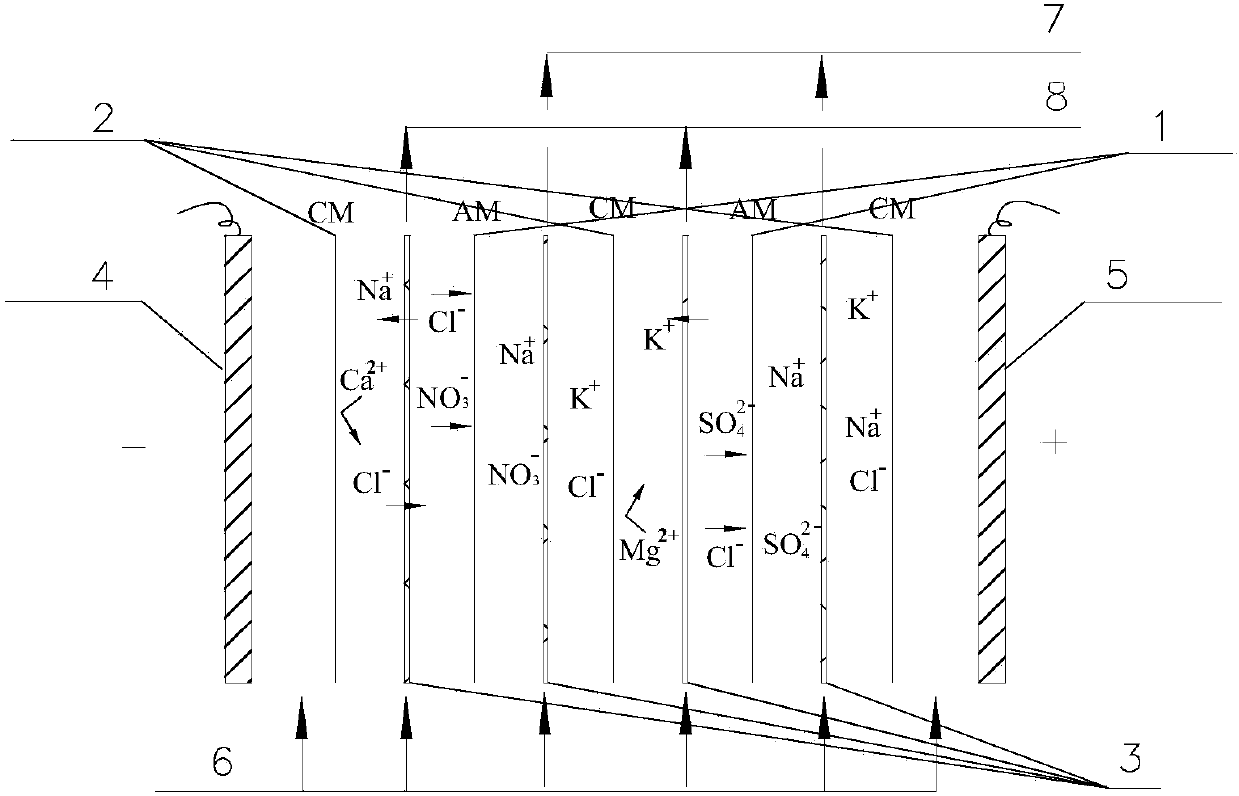

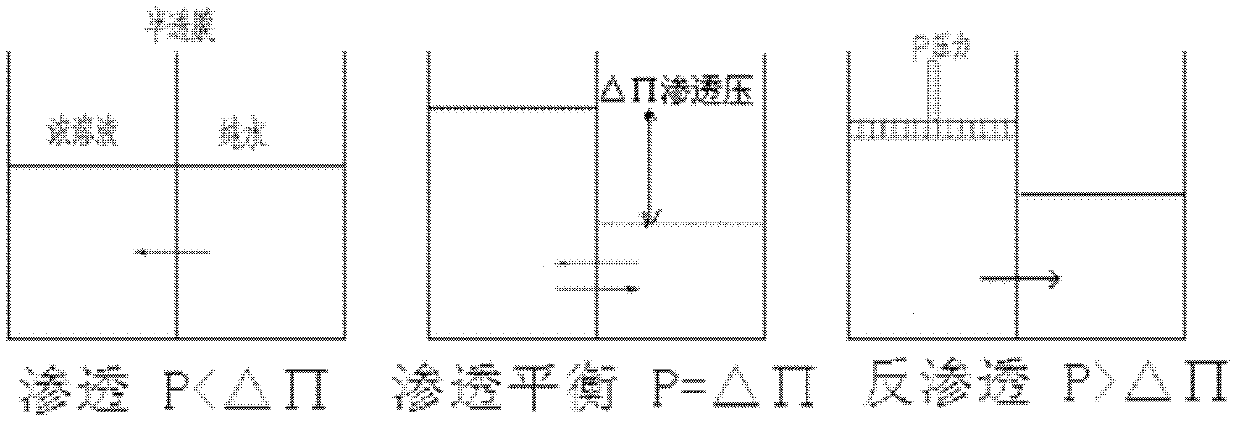

Electrodialyzer and near-zero-release industrial wastewater recycling technique

ActiveCN103723799AGeneral water supply conservationDispersed particle separationIndustrial waste waterElectrolysis

The invention relates to an electrodialyzer and a near-zero-release industrial wastewater recycling technique. The electrodialyzer is arranged vertically; the electrodialyzer is in an asymmetrical water inlet-outlet channel structure, and the water inlet channel is more narrow than the water outlet channel; the cation-exchange membrane adopts a univalent ion exchange membrane, and the anion-exchange membrane adopts a general-purpose ion exchange membrane; and the negative plate and positive plate of the electrodialyzer adopt noble-metal-coated titanium base electrodes. The technique comprises the following steps: carrying out electric flocculation treatment on industrial wastewater, carrying out electrolysis and flocculation reaction under the actions of an electric field and air floatation, and pretreating the industrial wastewater by precipitation and filtration; directly recycling fresh water by an ultrafiltration+reverse osmosis combined technique; and carrying out deep concentration on concentrated water by using the electrodialyzer, recycling the produced fresh water, and sending the concentrated water into an evaporation crystallizer to perform evaporation crystallization. The technique is mainly used for treating circulating water sewage, satisfactory sewage, primary reverse osmosis concentrated water and other types of industrial sewage.

Owner:BEIJING JINGRUN NEW TECH DEV

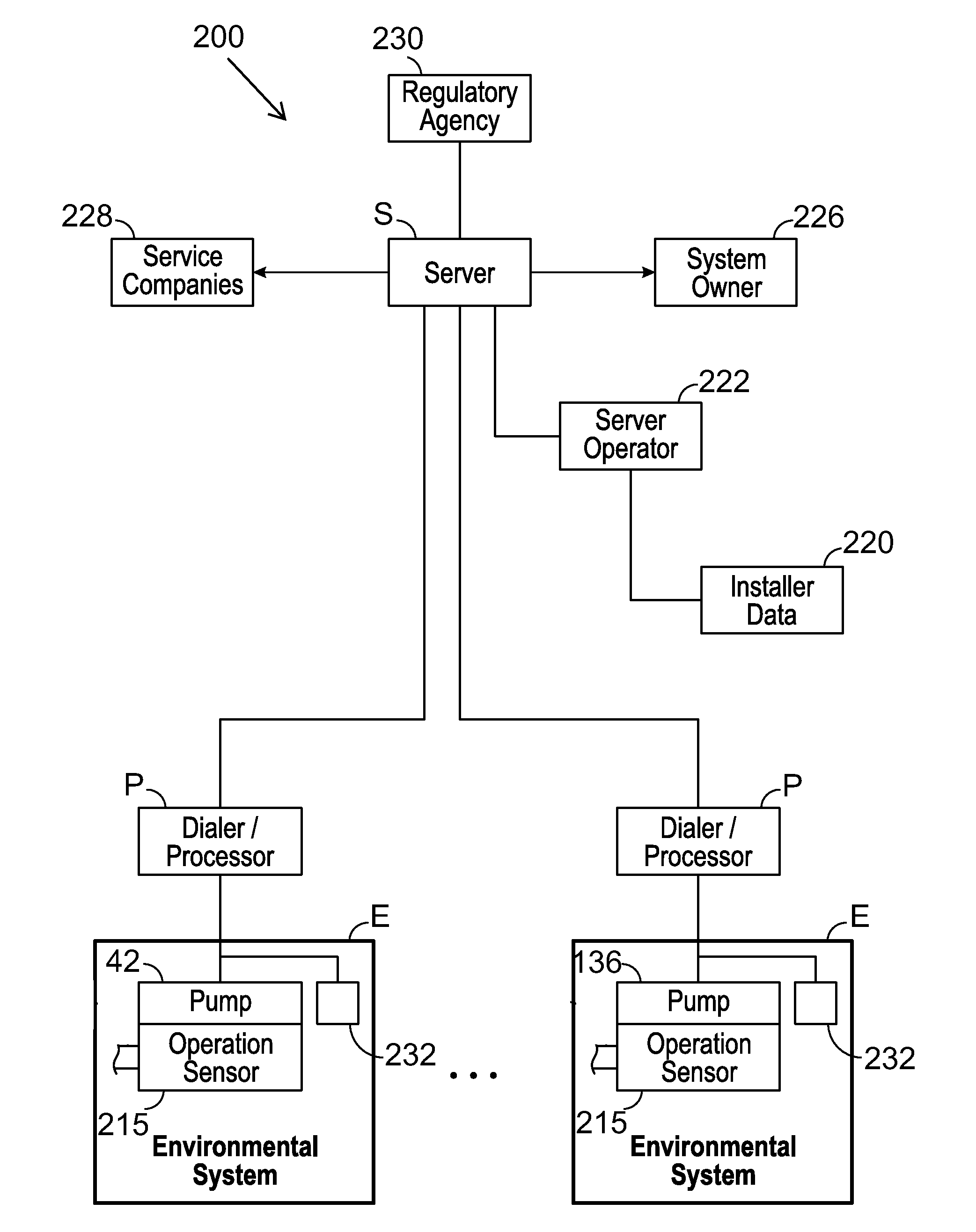

Wastewater Use and Monitoring System

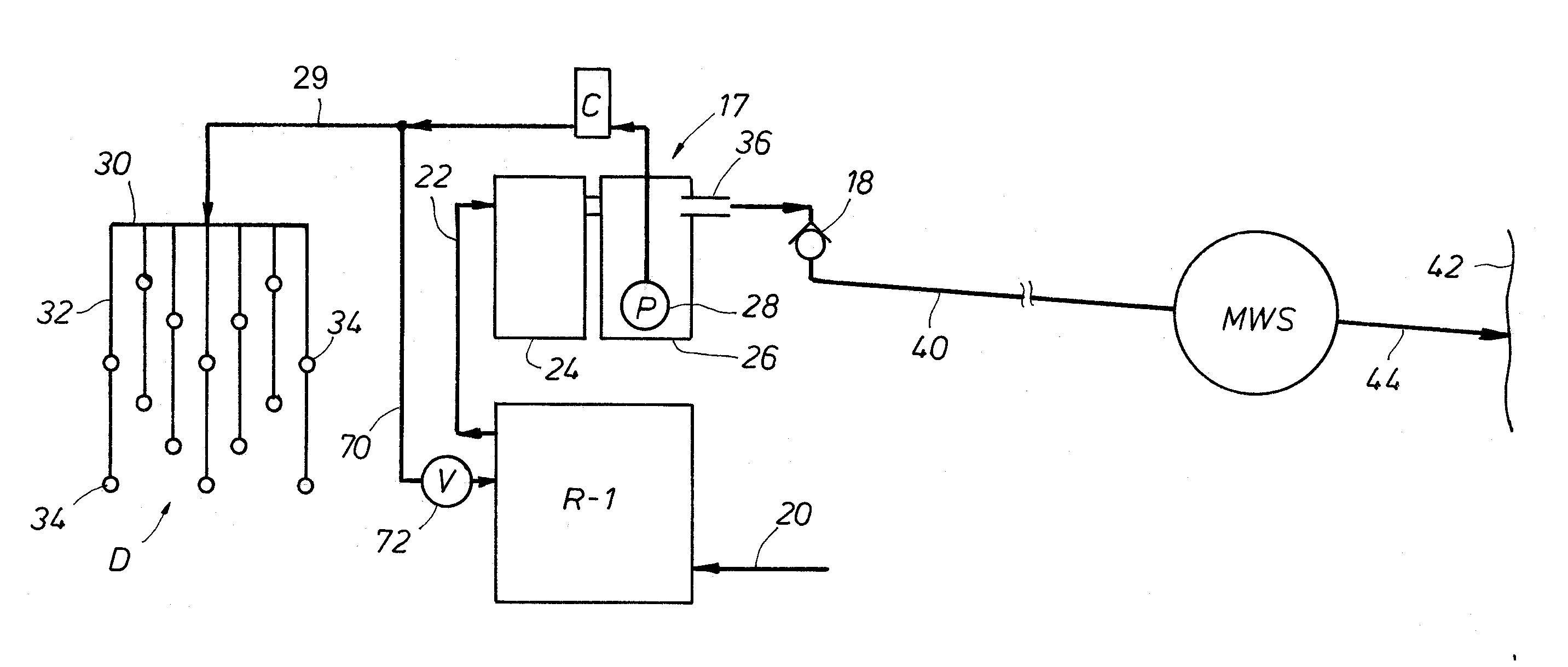

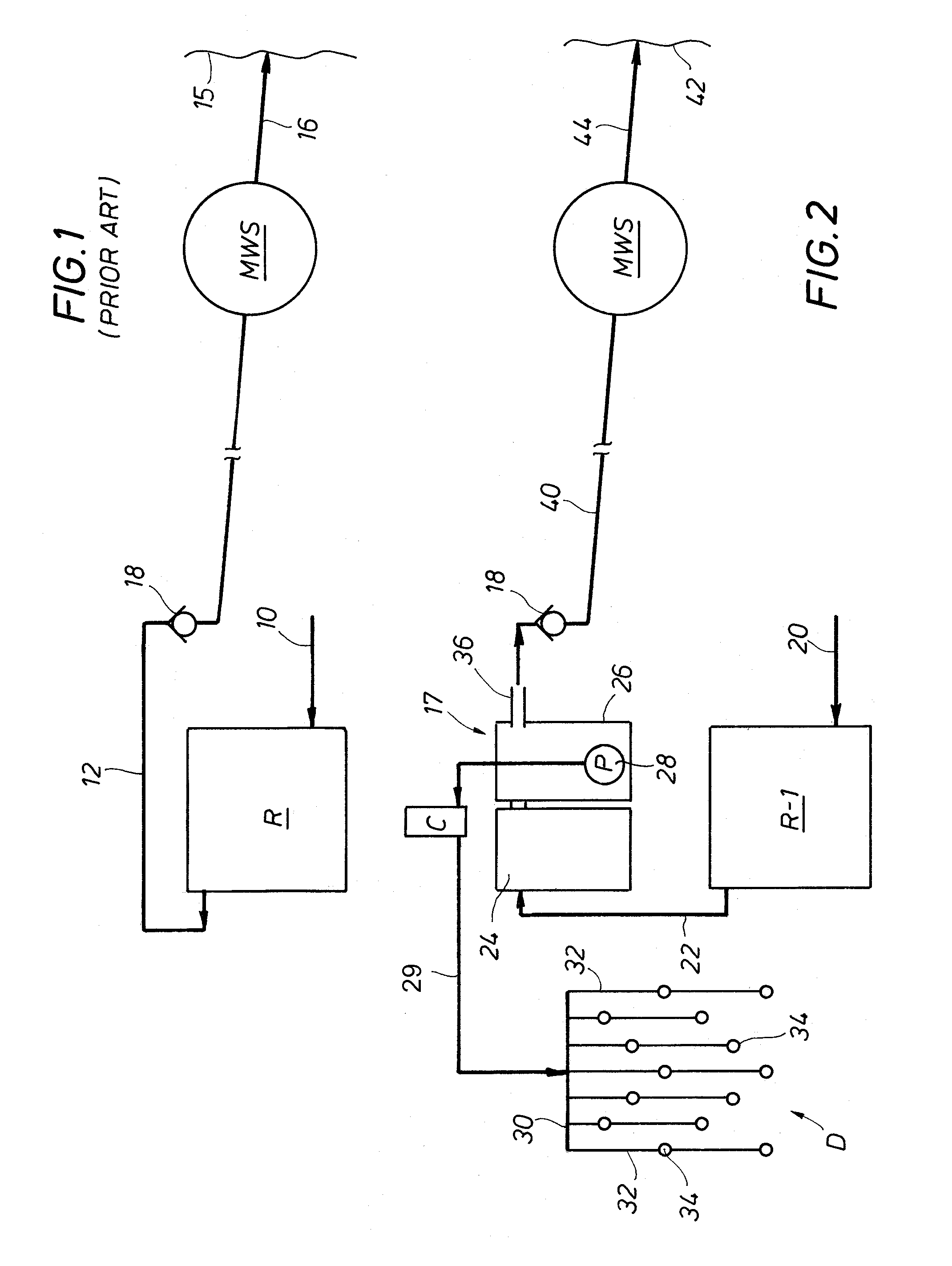

ActiveUS20150100169A1Easy to disinfectConserveWater treatment parameter controlComputer controlWater useCollection system

A wastewater reuse system has a wastewater treatment system connected to a dwelling for receiving wastewater therefrom. The wastewater treatment system has a pump tank with an outlet that can be connected to a central wastewater collection system and / or a reuse recipient of treated wastewater, such as an irrigation system. A monitoring system for tracking the water used and / or reused by a dwelling. The monitoring system using a dialer system to transmit operating data to a server which is configured to determine the amount of water used and / or reused by a dwelling.

Owner:MCKINNEY JERRY L

Recycling and processing method for printing and dyeing wastewater

ActiveCN103011524AImprove preprocessing effectSimple processMultistage water/sewage treatmentWaste water treatment from textile industryWater useActivated carbon

The invention relates to a recycling and processing method for printing and dyeing wastewater, which comprises the following steps of: mixing, neutralizing and coagulating the wastewater of acid wax and jacquard workshops and then performing biochemical treatment, so as to discharge the wastewater reaching the required standards; processing the wastewater of blanching and coloring workshop by the processes of adjusting, coagulating, hydrolytic-acidification, contact-oxidization, coagulation and chemical adding processes, so as to discharge the wastewater reaching the required standards; and then producing recycled water by adopting active carbon adsorption and then using ultra-filtration membrane and reverse osmosis membrane. The recycle water recovering rate of the recycled water treatment system is greater than 50%, the water quality index is better than that of tap water, and the influence to the printing and dyeing is avoided.

Owner:HUBEI JUNJI WATER TREATMENT

Artificial wet land and uses thereof

ActiveCN101293708ALow construction costReduce processing costsWaste water treatment from metallurgical processSustainable biological treatmentConstructed wetlandWater use

The invention provides a constructed wetland and the application thereof; wherein, the constructed wetland takes gravels and manganese sands as combined packing and can be used for treating wastewater in industries, such as iron and steel industry, etc., the wetland can reduce the nutrient content of organics, nitrogen, phosphorus, etc. in water, and meanwhile can remove metal ions, such as Fe, Mn, Cd, Pb, etc., more particularly, can reduce higher content of ions of Fe and Mn in iron and steel industry wastewater so that the index achieves the water quality standard of reclaimed water used as cooling water and the water intake quality requirement of reverse osmosis desalination process in Code for Engineering Design of Wastewater Reclamation and Reuse. The wetland has less engineering investment, simple management, low operation and maintenance cost, stable processing effect, so as to have better environmental, economic and social benefits. The wetland has better wastewater processing effect, stronger treatment capacity and stronger shock resistance loading capability, so the wetland can greatly solve the problem of excessively high concentration of Fe and Mn ions in wastewater reuse of the iron and steel industry, etc.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Reclamation and comprehensive treatment method for paper-making waste water

ActiveCN101337750ASolve the problem of large water consumptionWater/sewage treatment by irradiationWater/sewage treatment bu osmosis/dialysisInorganic saltsMicrowave

The invention discloses a comprehensive processing method of paper-making wastewater reuse. By adopting the method, after being pre-processed, paper-making wastewater discharged enters ultra-filtration, reverse osmosis or nanofiltration; membrane permeation liquid can be directly reused for power plants or taken as process water; due to being rich in inorganic salt, various additives, lignin, fibrin, hemicellulose and other organisms, as well as various colonies, concentrated solution which is subjected to membrane interception can not be discharged directly. The concentrated solution is processed by adopting the microwave technique; the concentrated solution after being processed can achieve State Discharge Standards, thereby being discharged directly. Particularly, the pollution prevention and the recovery of a membrane system and the microwave treatment of the membrane concentrated solution can be discharged according to standards. A majority of paper-making wastewater can be reused by adopting the method, and a small amount of residual wastewater can be discharged according to standards, thereby completely solving the problem that the water consumption is large in a paper-making industry.

Owner:ZHEJIANG CREATION ENVIRONMENT TECH

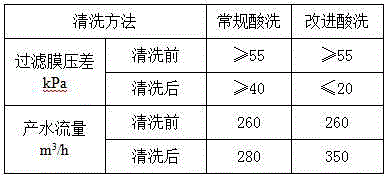

Method for cleaning immersed ultrafiltration membrane in wastewater reuse

ActiveCN103949163AGood water flowGood operating differential pressureSemi-permeable membranesOXALIC ACID DIHYDRATEUltrafiltration

The invention discloses a method for cleaning an immersed ultrafiltration membrane in wastewater reuse. The method comprises the following step of chemical cleaning. The method is characterized in that the step of chemical cleaning comprises the following substeps of alkali cleaning, acid cleaning or combined alkali cleaning and acid cleaning, wherein each of the alkali cleaning method and the acid cleaning method is of a method combining the circulatory cleaning with the immersed cleaning, and an alkali cleaning agent comprises sodium hypochlorite, sodium dodecyl benzene sulfonate and sodium tripolyphosphate; an acid cleaning agent comprises citric acid, hydrochloric acid and oxalic acid. The method has the advantages that sodium dodecyl benzene sulfonate and sodium tripolyphosphate are added in the process of alkali cleaning by sodium hypochlorite, so that the cleaning effect of the method on ultrafiltration organic matters and oil pollutants is obviously better than that of a normal alkali cleaning method, the polluting and plugging degree of the cleaned ultrafiltration membrane can be reduced, and stability in operation can be realized; the acid cleaning is adopted as required after alkali cleaning, and the oxalic acid agent is added in the process of acid cleaning, so that the ultrafiltration membrane can be thoroughly cleaned, and the produced water flow and the running differential pressure of the ultrafiltration membrane can be recovered to be the optimal effect.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

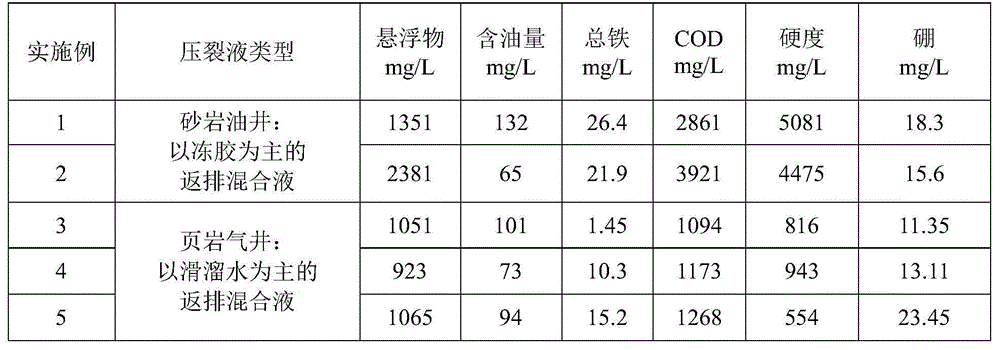

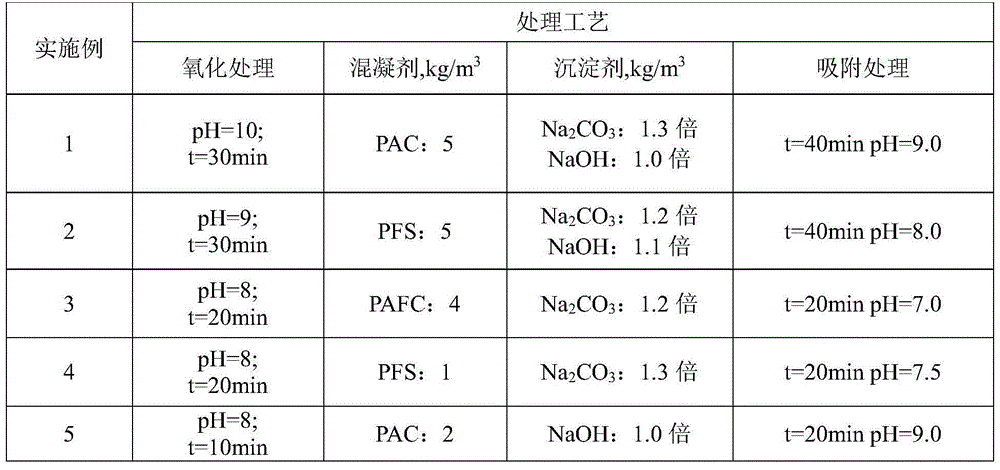

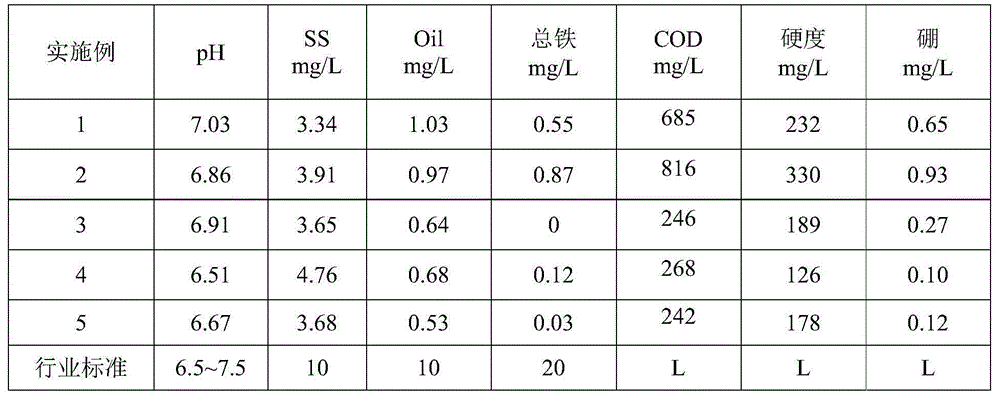

Reutilization method of water-base fracturing flowback fluid

InactiveCN104310628AReduce interventionHigh recovery rateMultistage water/sewage treatmentDrilling compositionLiquid wasteWater based

The invention relates to a reutilization method of a water-base fracturing flowback fluid, and belongs to the field of cyclic utilization technologies for water-base fracturing flowback fluids generated in non-routine oil and gas reservoir resource exploitation, especially wastewater reuse processing technologies of oil and gas fields. A mixed waste liquid of the water-base fracturing flowback fluid is subjected to ozone oxidation, flocculation precipitation processing and filter adsorption processing for removing harmful compositions in the wastewater, and the discharged water can be used to prepare slick water normally used in unconventional oil and gas wells, linear glue and gelling fracturing fluids. The method is simple in technology, continuous in operation, rapid and efficient, and helps to realize repeated reuse of fracturing flowback fluids and save water resource.

Owner:CHINA PETROCHEMICAL CORP +1

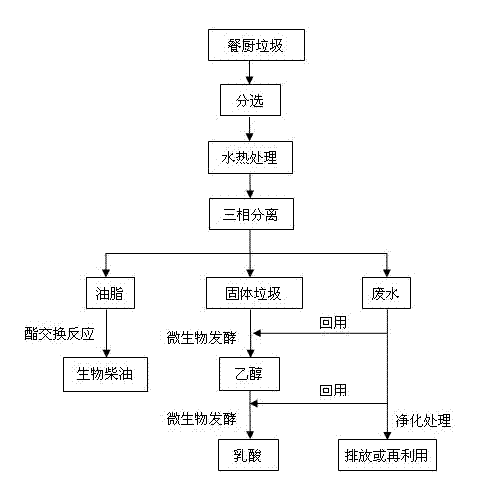

Method adopting hydro-thermal treatment to facilitate producing ethyl alcohol and lactic acid through kitchen waste

ActiveCN103484521ASimple configurationThe fermentation process is simpleMicroorganism based processesChemical recyclingEngineeringChemical products

The invention discloses a method adopting hydro-thermal treatment to facilitate producing ethyl alcohol and lactic acid through kitchen waste. The kitchen waste is used as raw materials for producing energy sources and chemical products, so that waste is fully utilized while energy-from-waste and recycling utilization of biomass is realized. According to the method, the kitchen waste is subjected to sorting, hydro-thermal treatment and three-phase separation, and then solid waste obtained after the separation is added with microorganisms, so as to be fermented and generate the ethyl alcohol and the lactic acid; waste water obtained after the separation can be reused in a fermentation tank, and residual waste water of the kitchen waste can be purified and then be discharged or reused; grease obtained after the separation can be used for preparing biodiesel after being subjected to the transesterification. According to the invention, the kitchen waste is more thoroughly hydrolyzed as the hydro-thermal treatment technology is adopted; meanwhile, mixed florae are adopted for fermentation to produce the ethyl alcohol, selected cultures are simple and can be easily obtained, the preparation method is simple, the fermentation technology is simple and convenient, the fermentation effect is excellent, and the method is particularly suitable for industrialized application.

Owner:SOUTH CHINA AGRI UNIV

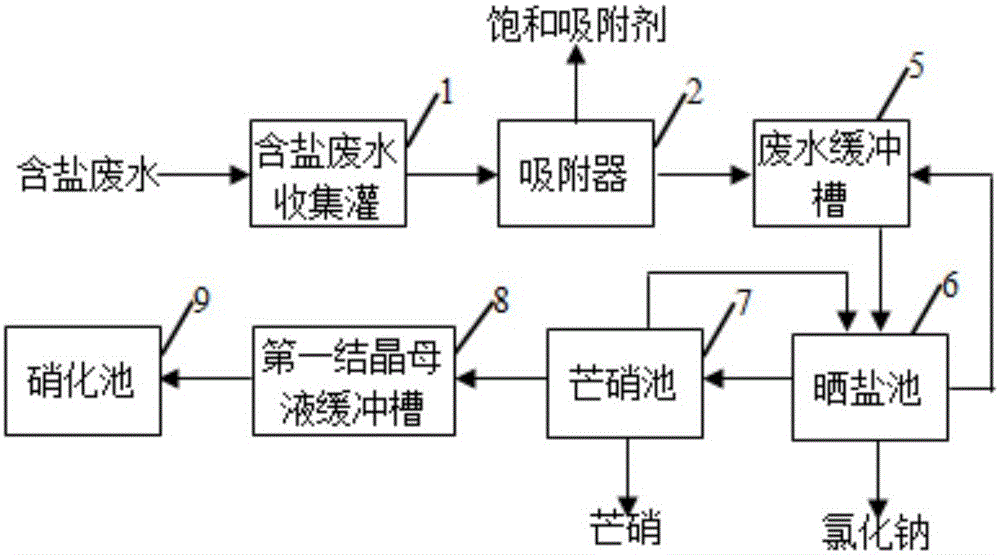

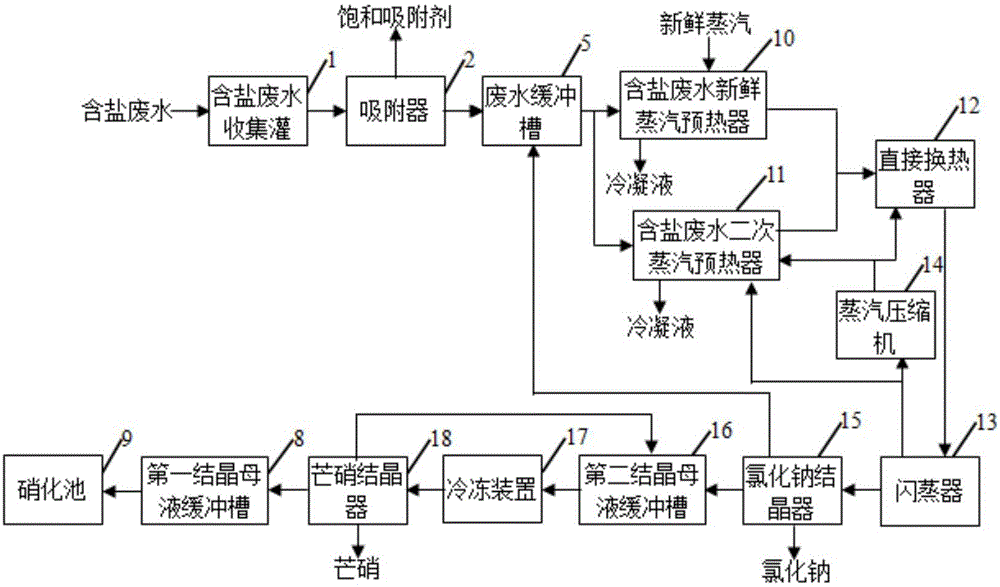

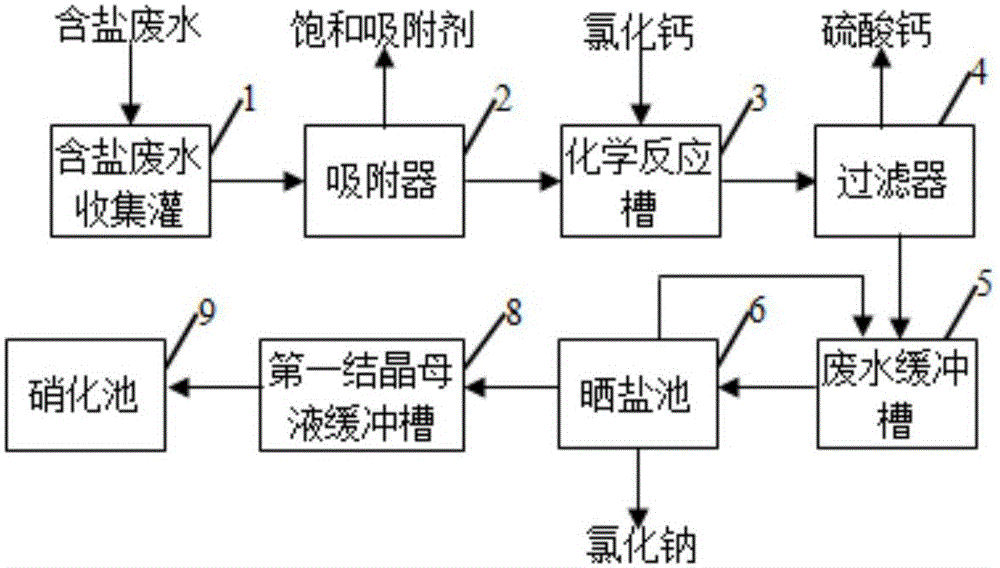

Purification treatment and pure-salt recovery process for strong-salt wastewater in coal chemical industry

ActiveCN105084651ARemove and reduce chromaRemove and reduce turbidityGeneral water supply conservationEnergy inputSulfate radicalsReverse osmosis

Provided is a purification treatment and pure-salt recovery process for strong-salt wastewater in the coal chemical industry. According to the purification treatment and pure-salt recovery process, a working procedure of absorption treatment is additionally conducted on organic matter macromolecules and heavy metals contained in high-concentration salt water after a wastewater reuse multistage reverse osmosis treatment process is carried out; working procedures of evaporation, freezing and desalination are additionally carried out to achieve the purposes of effective utilization of natural energy and industrial low-grade waste heat resources and effective removal of salt-containing wastewater after the working procedure of absorption treatment; a working procedure of chemical separation is added between the working procedure of absorption treatment and the working procedure of desalination to completely convert sulfate radical ions in the salt-containing wastewater into chloride ions and collect and reuse obtained solid, and a nitrate-rich mother solution subjected to crystallization and desalination is returned to a biochemical treatment stage for denitrification treatment. By means of the purification treatment and pure-salt recovery process, salt contained in the salt-containing wastewater is effectively separated out, meanwhile nitrate is returned for biochemical treatment, and secondary steam condensate is evaporated for recycle, so that the whole process achieves the purposes of zero discharge and effective resource utilization.

Owner:山西诺凯化工技术有限公司 +1

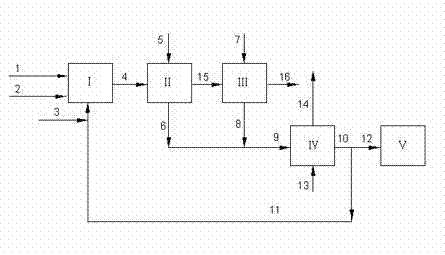

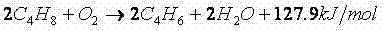

Recycling method for butylene oxidative dehydrogenation wastewater

ActiveCN103086829AEmission reductionReduced distribution water usageHydrocarbonsNature of treatment waterOrganic acidSaline water

The invention relates to a recycling method for butylene oxidative dehydrogenation wastewater, which is mainly used for solving the problems that the wastewater quantity is large and the dosage of water vapor is much in the prior art. The recycling method comprises the following steps of: (a) enabling butylenes, oxygen gas or air and water vapor to carry out oxidative dehydrogenation reaction under certain conditions, wherein reaction products enter a water-cooling tower after being cooled, so as to countercurrent contact washing water from the tower top for removing organic acid; (b), pressurizing water-cooling tower top gas to 0.5 Mpa-2.0MPa, enabling the pressurized water-cooling tower top gas to enter an aldehyde washing tower kettle and countercurrent contact fresh desalted water from the tower top for removing aldehyde impurities in the generated gas; and feeding the aldehyde-containing wastewater of the tower kettle and wastewater of the water-cooling tower to a wastewater pretreatment tower; and (c), removing part of aldehyde and micro hydrocarbon in the wastewater pretreatment tower to obtain aldehyde-deficient water, returning the part of aldehyde-deficient water to a butylene oxidative dehydrogenation reaction system, recycling part the aldehyde-deficient water as water distribution, and discharging part of the aldehyde-deficient water to a wastewater treatment site. According to the technical scheme, the technical problems are solved, and the recycling method can be used for industrial production process of butylene oxidative dehydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

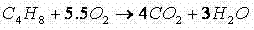

Method for circularly processing hot boiler flue gas and desulfurization wastewater

InactiveCN103058435AReduce water consumptionConserve waterLighting and heating apparatusElectrostatic separationFlue gasProcess engineering

The invention discloses a method for circularly processing hot boiler flue gas and desulfurization wastewater and a device for circularly processing the hot boiler flue gas and the desulfurization wastewater. The method comprises the following steps of: 1) storing the desulfurization wastewater in a sedimentation basin; 2) feeding the hot glue gas into an electrostatic precipitator, and introducing the desulfurization wastewater into an atomizing spray gun; 3) introducing air into the atomizing spray gun, mixing the air and the desulfurization wastewater in the atomizing spray gun, thereby obtaining wastewater foam flow; 4) injecting the wastewater foam flow into the desulfurization wastewater, and obtaining cooled flue gas with desulfurization wastewater precipitates; 5) feeding the cooled flue gas into an adsorption tower for the desulfuration treatment; 6) changing the cooled flue gas into desulfurized purified gas, and feeding the wastewater, namely the desulfurized wastewater generated in the desulfurizing process, into the sedimentation basin; and 7) obtaining a continuous recycling process of using the hot boiler glue gas to evaporate the desulfurized wastewater and using the desulfurized wastewater to cool and dedust the hot boiler glue gas. The method for circularly processing the hot boiler flue gas and the desulfurization wastewater and the device for circularly processing the hot boiler flue gas and the desulfurization wastewater can be used for improving the treatment rate of wastewater and wastewater reuse rate, improving the dedusting efficiency, reducing the waste gas discharge, and reducing the desulfuration treatment cost.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

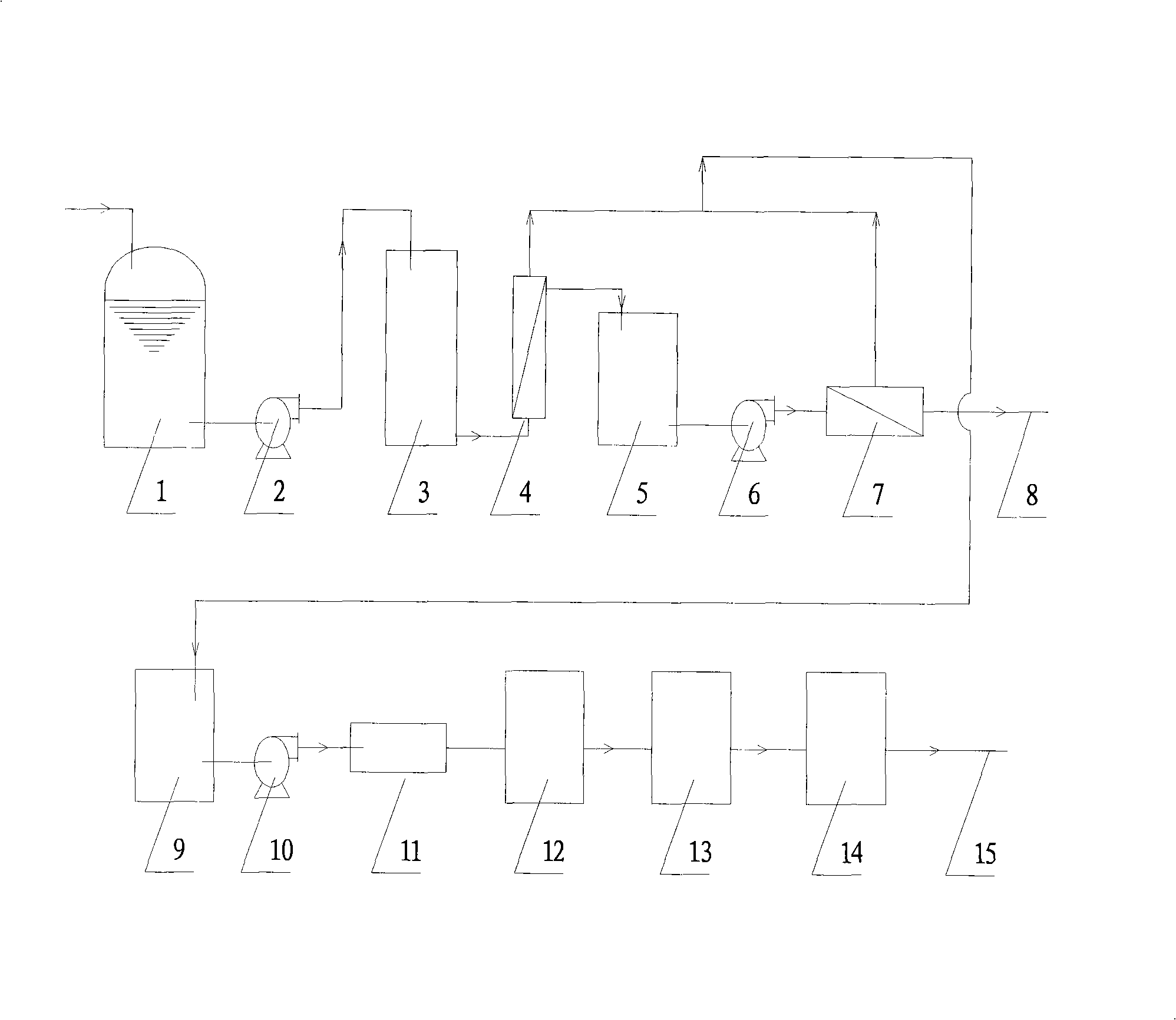

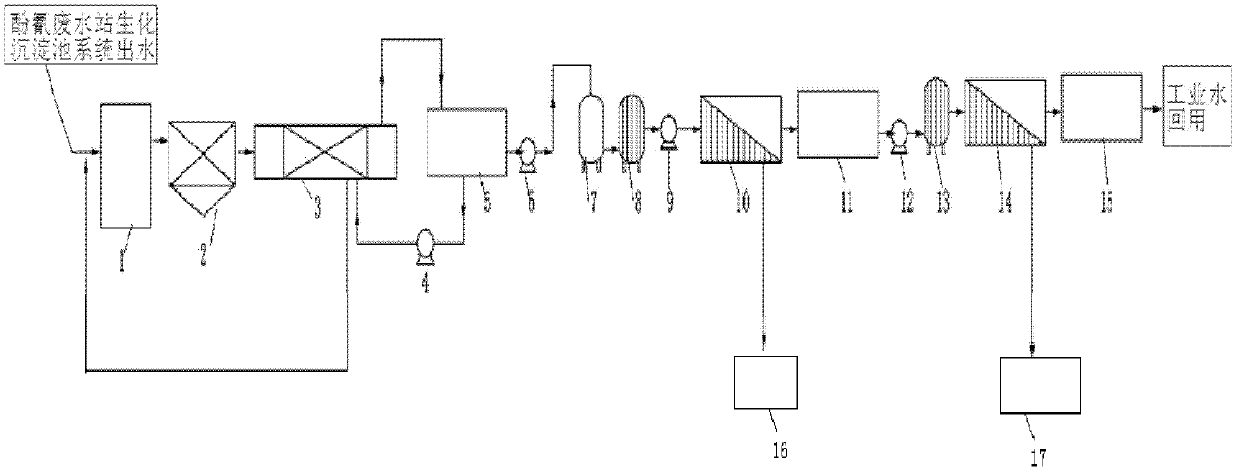

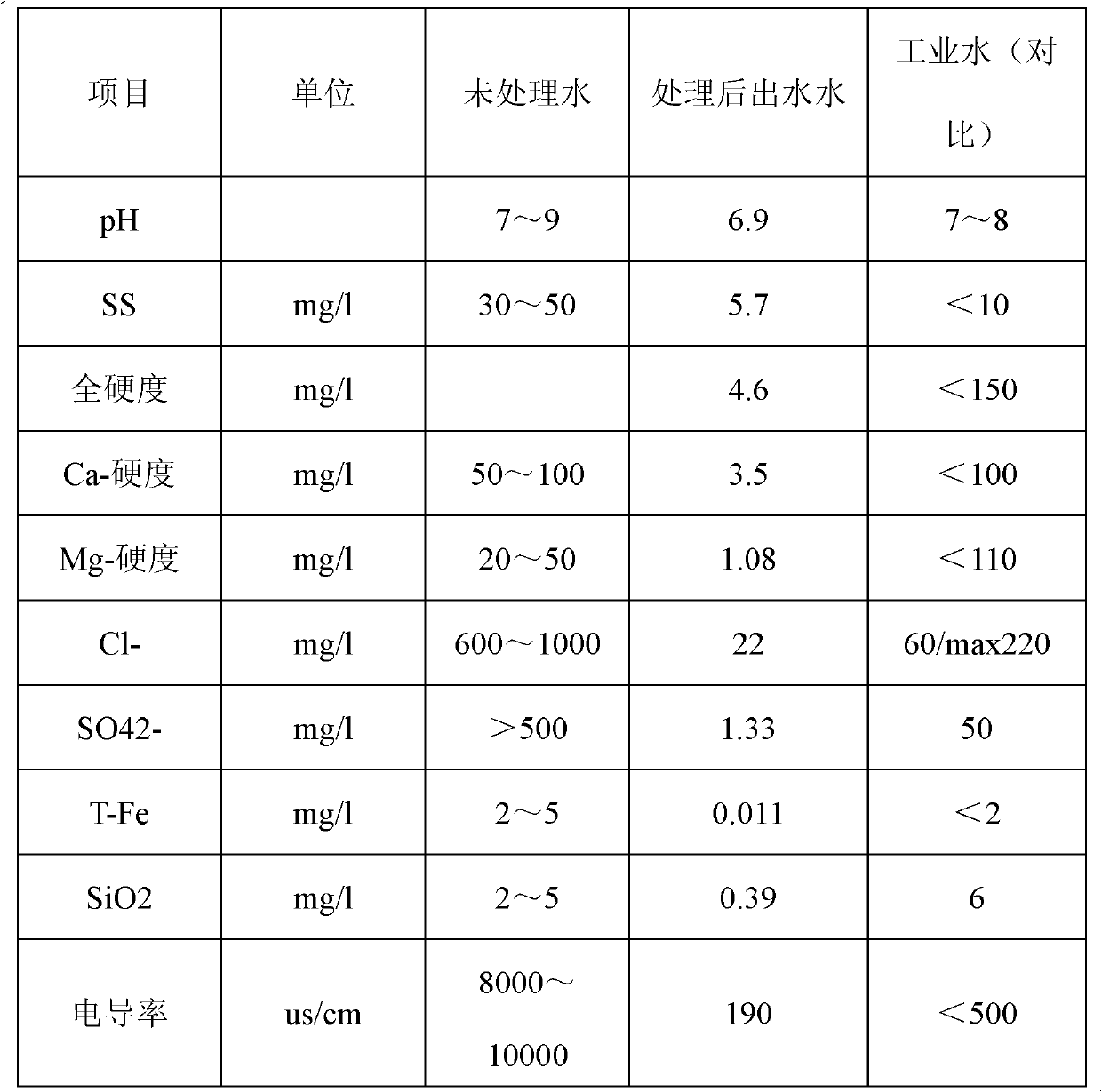

Coking wastewater reuse treatment system and method thereof

ActiveCN103304049AReduce processingReduce processing operating costsGeneral water supply conservationWater/sewage treatment bu osmosis/dialysisUltrafiltrationSludge

The invention relates to a coking wastewater reuse treatment system. The system is characterized in that the system comprises a coagulation pool (1), and the coagulation pool (1) is sequentially connected with an inclined plate sedimentation pool (2), an ultrafiltration device (3), an ultrafiltration water production pool (5), a first pump (6), a first filter (7), a second filter (8), a second pump (9), a nanofiltration device (10), a nanofiltration water production pool (11), a third pump (12), a third filter (13), a reverse osmosis device (14) and a reverse osmosis water production pool (15) through a pipeline. The invention also provides a coking wastewater reuse treatment method. The system has the advantages of stable treatment effect, low production running cost, simple operation running, realization of the water discharge through adopting a biochemical sedimentation pool, avoiding of the physical-chemical treatment segment after routine biochemical treatment, avoiding of the massive application of agents, reduction of the sludge throughout of the system, and reduction of the wastewater treatment running cost.

Owner:BAOWU CHARCOAL MATERIAL TECH CO LTD

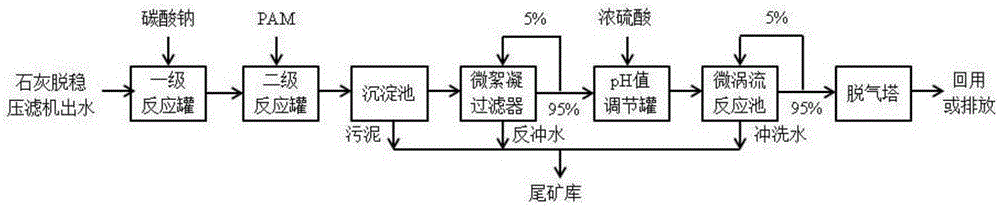

Wolframine beneficiation wastewater treatment process

ActiveCN105254069AReduce flotation rateRealize solid-liquid separationWaste water treatment from quariesMultistage water/sewage treatmentSludgePrecipitation

The invention discloses a wolframine beneficiation wastewater treatment process, and belongs to the field of industrial wastewater treatment. The method comprises the following steps of A, adding lime into wolframine beneficiation wastewater, so that the pH value is regulated to 11 to 12; B, performing solid-liquid separation after destabilization precipitation; C, discharging solid into a tailing pond, putting inlet and outlet water into a first-stage reaction tank, and adding sodium carbonate; D, putting into a second-stage reaction tank, adding coagulant aids PAM into the second-stage reaction tank to take flocculation reaction with the PAM; E, performing self flowing to put into a precipitation pool, and discharging the bottom layer concentration sewage into the tailing pond; F, putting supernatant fluid into a micro-flocculation filter, using 5-percent outlet water as reverse flushing water to be discharged into the tailing pond; G, adding concentrated sulfuric acid into 95-percent outlet water to regulate the pH value to 6 to 9; H, putting the outlet water into a micro eddy current reaction pool, and using the 5-percent outlet water as flushing water to be discharged into the tailing pond; I, eliminating carbon dioxide from 95-percent outlet water through a degassing tower, so that the water can be reused for wolframine beneficiation or can be directly discharged. The process has the advantage that the wolframine beneficiation wastewater reuse rate is improved.

Owner:NANJING UNIV +1

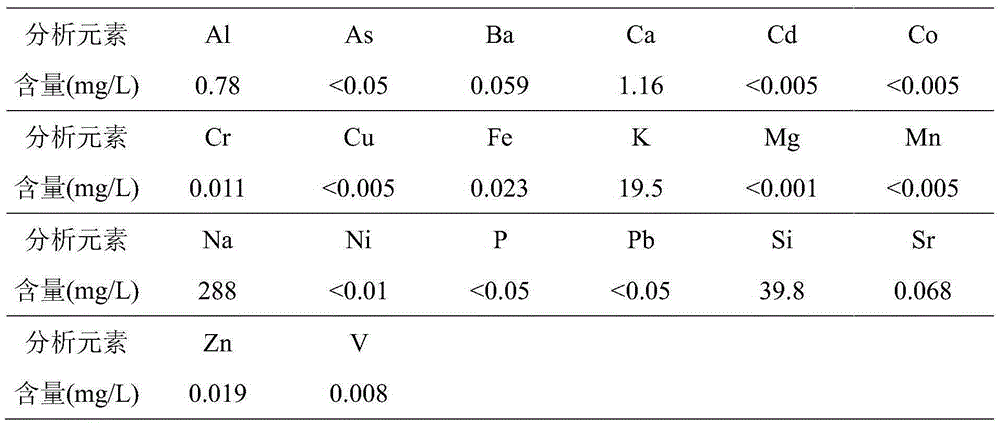

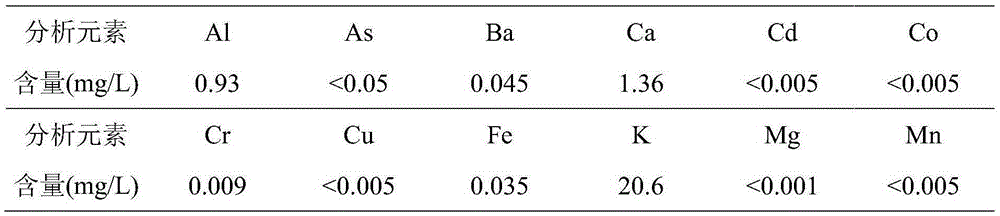

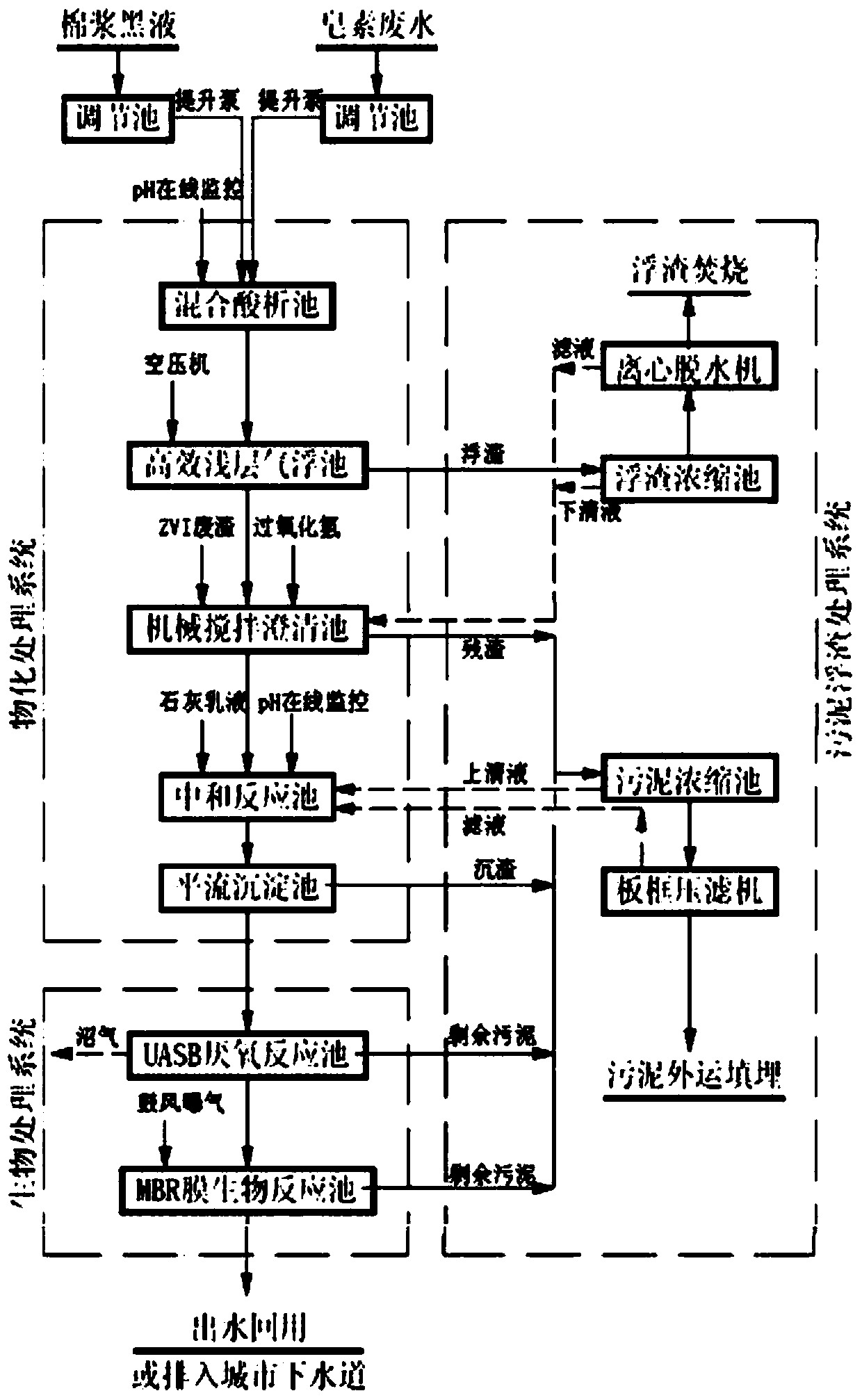

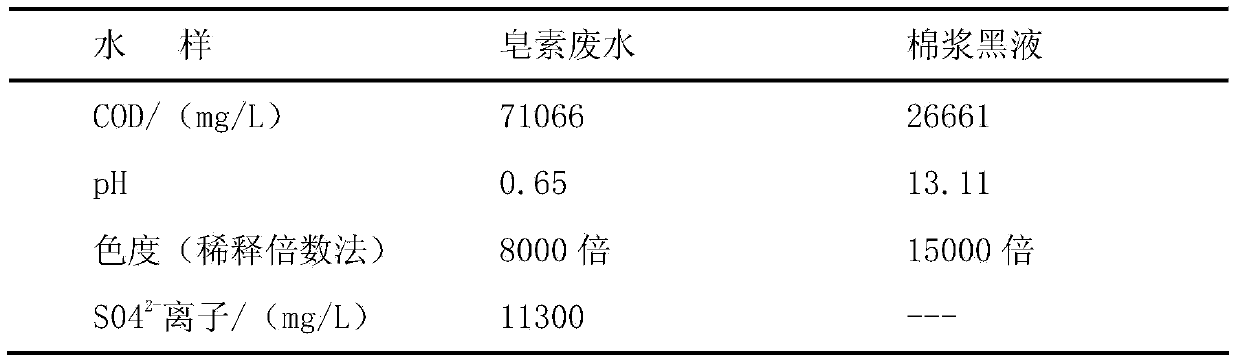

Combined treatment process for cotton pulping black liquid and saponin wastewater

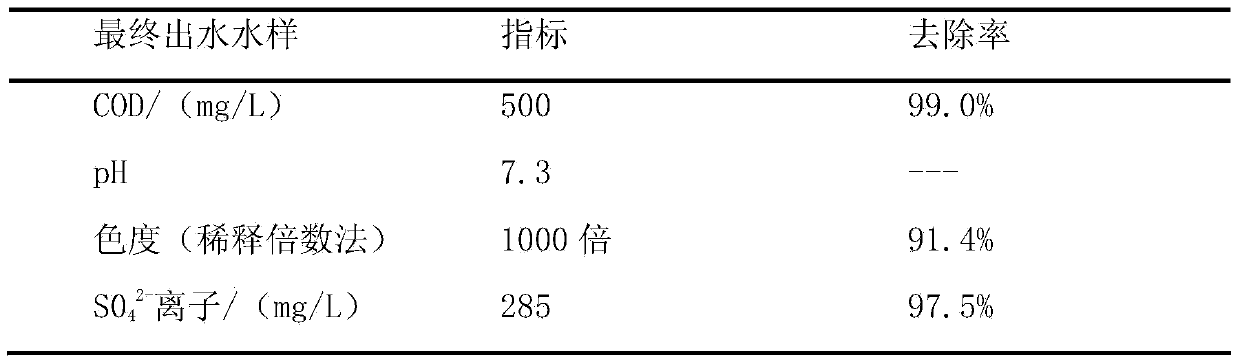

The invention provides a combined treatment process for cotton pulping black liquid and saponin wastewater. The combined treatment process comprises the steps of mixing the cotton pulping black liquid and the saponin wastewater, carrying out acidification on the mixed liquid, separating the mixed liquid and removing lignin and suspended solids dissolved out in the mixed liquid to obtain treating fluid A; adding zero-valent iron and hydrogen peroxide into the treating fluid A, stirring for reaction and completing the reaction to obtain treating fluid B, wherein the structures of complex macromolecule organic matters in the treating fluid B are damaged; adding lime slurry into the treating fluid B, regulating pH value of the treating fluid B to be neutral, converting sulfate ions in the treating fluid into calcium sulfate to be precipitated out and dissolved out, separating to remove the calcium sulfate to obtain treating fluid C; treating the treating fluid C by an anaerobic UASB (Upflow Anaerobic Sludge Blanket) reactor and an MBR (Membrane Biological Reactor) for aerobic biological treatment, separating by a membrane separation system to obtain final yielding water, and reutilizing the final yielding water or discharging. The combined treatment process can realize treatment of wastes with processes of wastes against one another, is energy-saving, reduces energy consumption, improves the wastewater reuse rate and reduces the water consumption.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

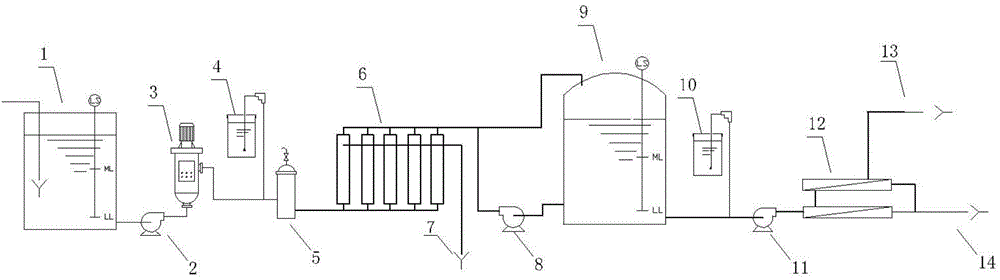

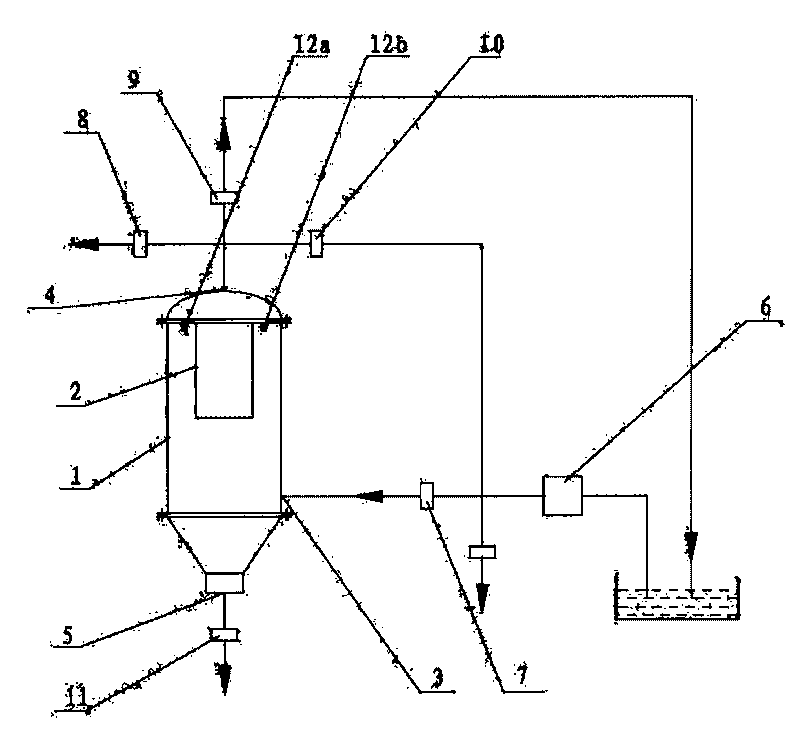

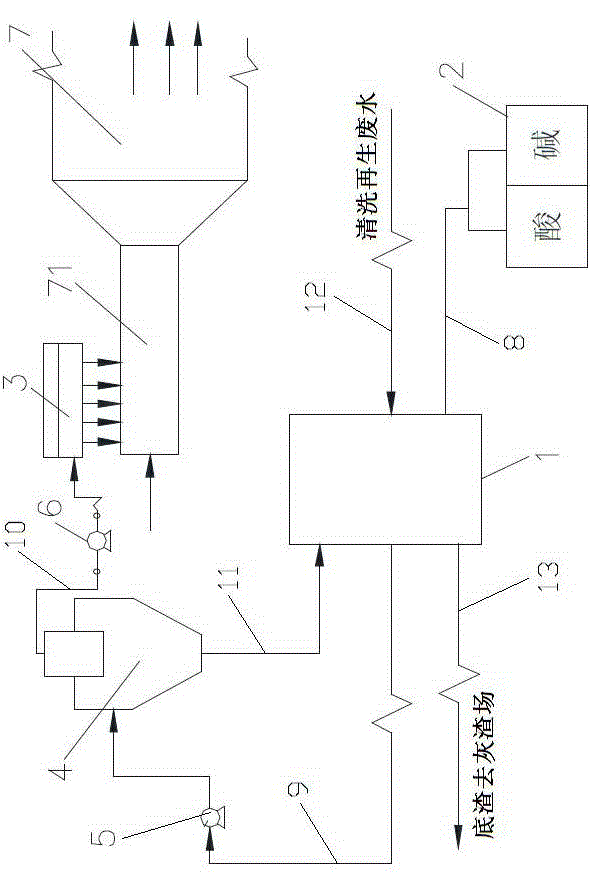

Complete plant for treating and recovering printing light polluted waste liquid

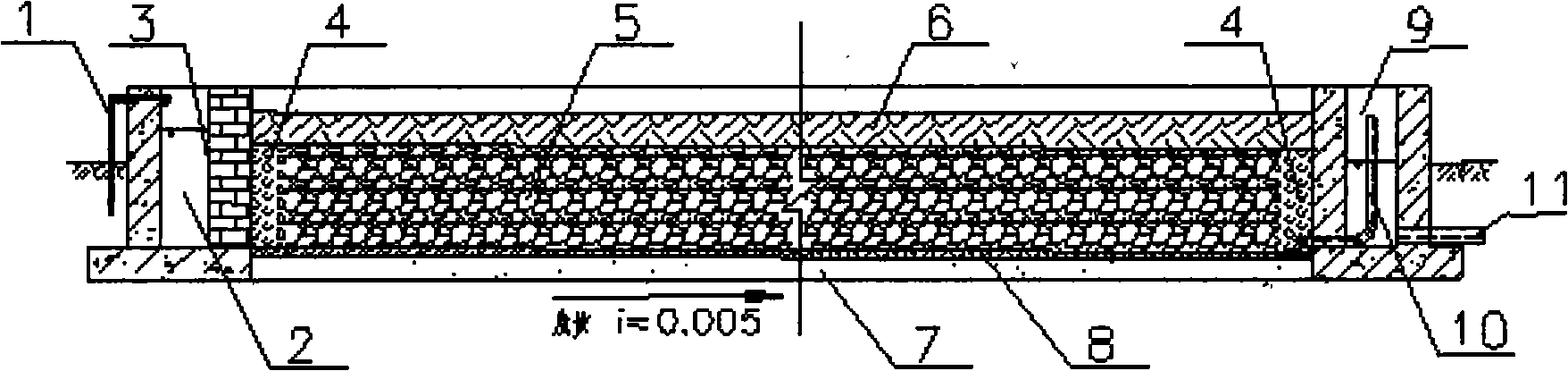

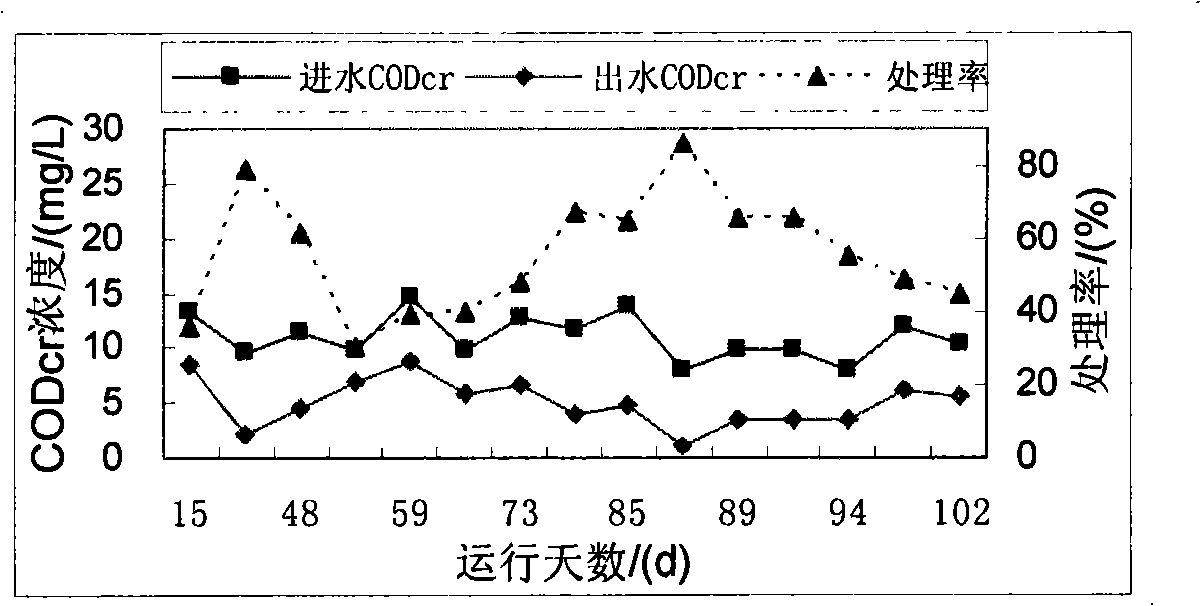

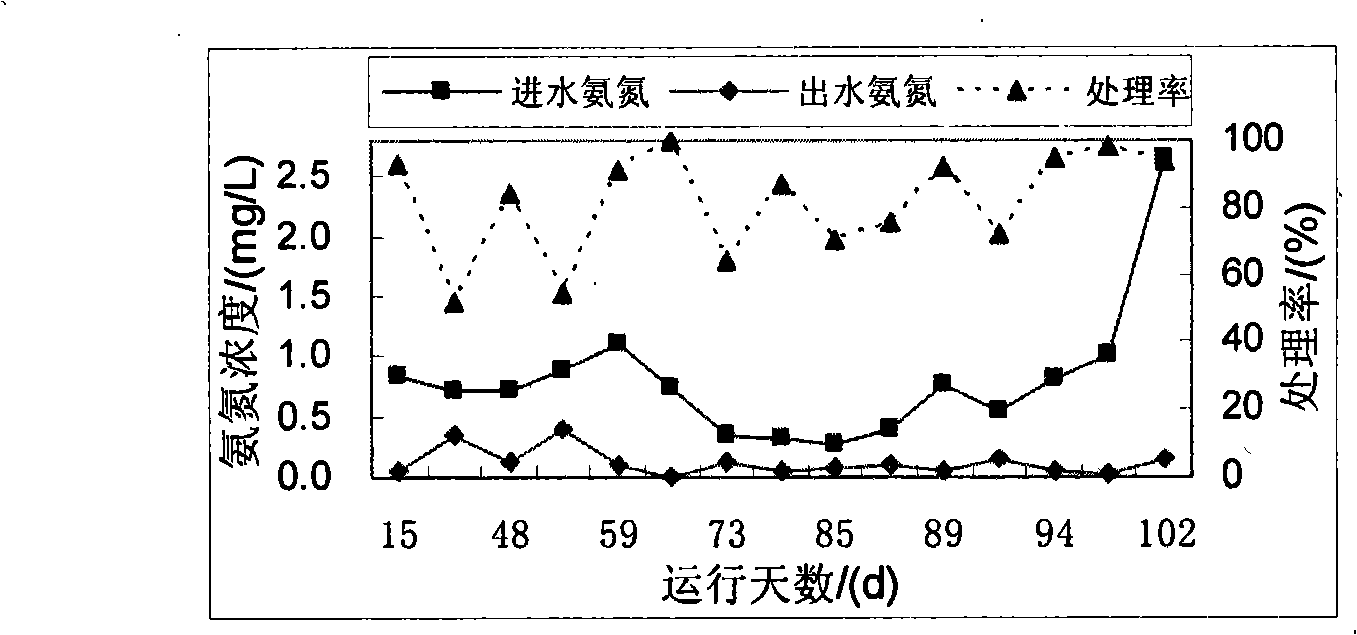

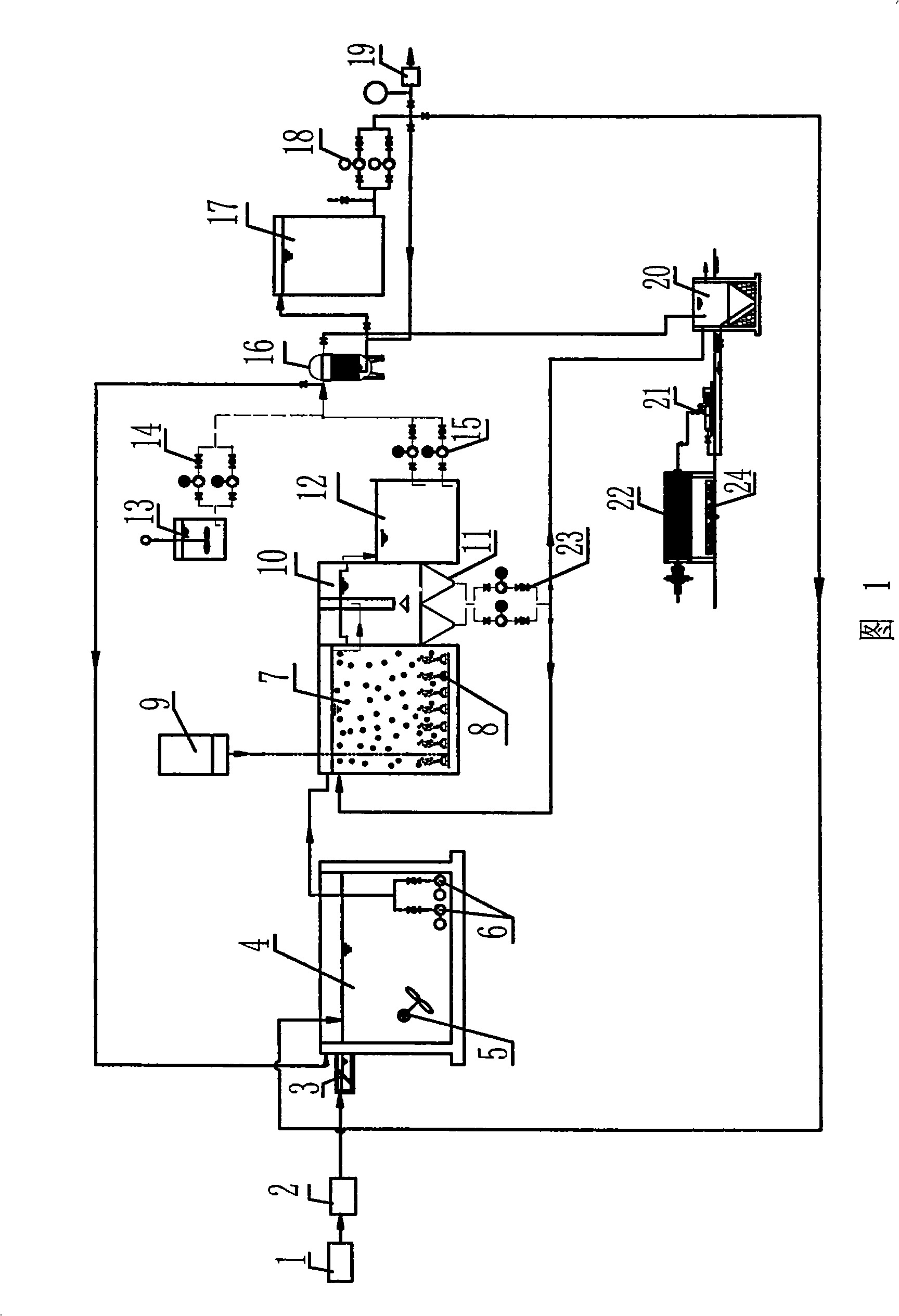

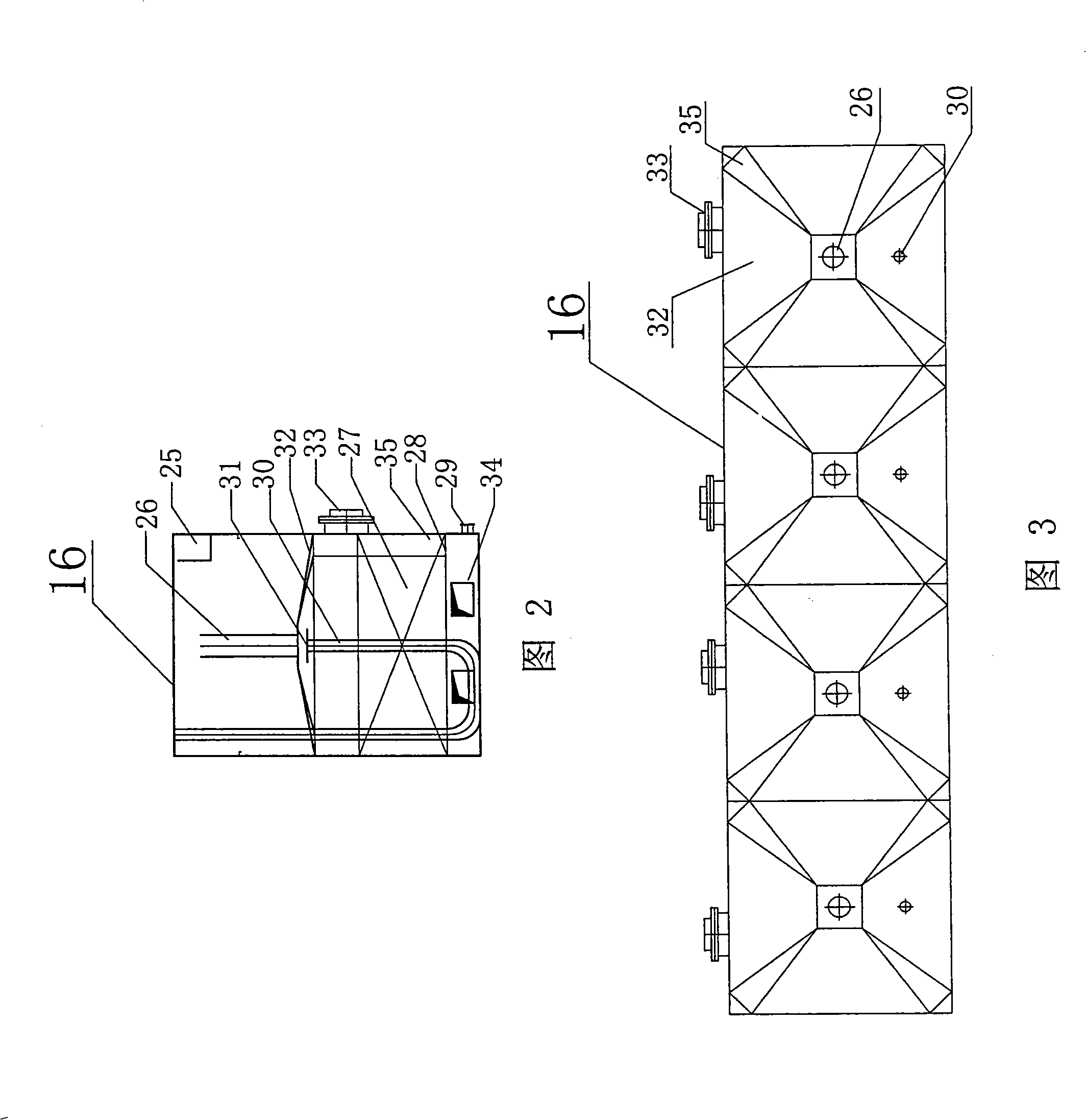

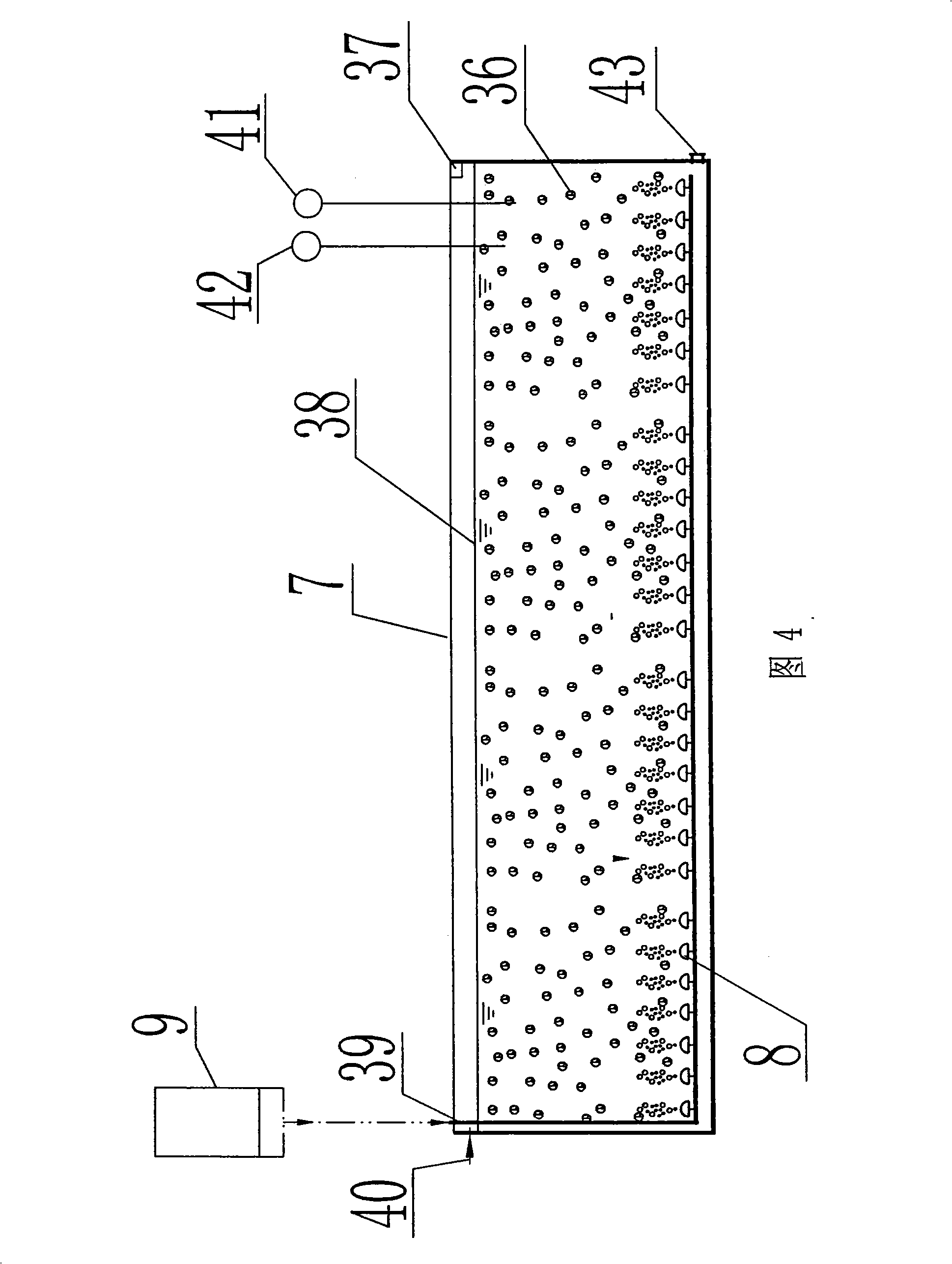

InactiveCN101333055AExtended stayIncrease contact areaMultistage water/sewage treatmentSustainable biological treatmentManufacturing technologyTreatment effect

A complete set of equipment used for printing and dyeing light polluted wastewater treatment and reuse belongs to the manufacturing technical filed of printing and dyeing wastewater treatment and reuse equipment and is mainly composed of a workshop wastewater collecting tank (1), an automatic diversion pipe (2), a screen (3), an adjusting pool (4) with a diving mixer (5) and a lift pump (6) arranged inside, a moving bed bioreactor (7), a precipitation-separation tank (10) with a sludge discharge bucket (11) at the bottom, a middle water pool (12), a secondary lift pump (15), a backwashing self-cleaning filter (16), a reuse water pool (17), a reuse lift pump (18) and an automatic reuse system (19); a dosing device (13) and a dosing pump (14) are arranged between the secondary lift pump (15) and the backwashing self-cleaning filter (16). The complete set of equipment disclosed in the invention has rational design, compact overall structure and good treatment effect, and saves energy sources, which can ensure stable water quality indexes of the reuse water after treatment to achieve the purpose of wastewater reuse, and can meet the production requirements of enterprises.

Owner:龚先木

Device and method for realizing printing and dyeing dyed wastewater reuse and dye recovery

ActiveCN104609605AAchieve retentionAchieve reuseMultistage water/sewage treatmentSeparation technologyUltrafiltration

The invention relates to a printing and dyeing wastewater reuse, and particularly relates to a device and a method for printing and dyeing wastewater water-soluble dye recovery on the basis of a membrane separation technology. The device comprises a raw water booster pump, a self-cleaning filter, a precise filter, an ultrafiltration membrane assembly, an ultrafiltration backwash pump, an ultrafiltration water tank, a high-pressure pump, a nanofiltration membrane assembly, and a reducer and scale inhibitor pouring system which are communicated with a wastewater collection pool. The method comprises the steps of draining the dyed wastewater to the wastewater collection pool and pumping the dyed wastewater in the self-cleaning filter through the raw water booster pump to remove large-particle suspended matters and impurities, then entering the wastewater into the precise filter to remove the remainder suspended matters, then entering the wastewater into an ultrafiltration membrane to remove bacteria, colloids and macromolecular organic compounds, finally pumping the wastewater in a nanofiltration membrane device through the high-pressure pump to remove micromolecular organic compounds and divalent ions, thereby producing high-quality reclaimed water and simultaneously intercepting and recovering most of activated dye molecules.

Owner:DALIAN UNIV OF TECH

Process method for reusing wastewater of coal mine well

InactiveCN105217844AReduce wasteReduce energy consumptionWaste water treatment from quariesMultistage water/sewage treatmentWater sourceActivated carbon filtration

The invention provides a process method for reusing wastewater of a coal mine well, relating to the field of mine well wastewater treatment. The process method comprises the following steps: wastewater is pumped by virtue of a water pump and sequentially flows through a quartz sand filter and an activated carbon filter; wastewater enters a softening system and then enters a disinfection system after the total hardness of wastewater is decreased through ion exchange; a precision filter with filtration precision of 5 microns is arranged behind the disinfection system and is used for removing inactivated hyphae and other impurities, which are remained in the water body after being disinfected, by virtue of a micro-hole filter element, and effluent, which meets the water quality requirement of domestic water, of the precision filter enters a reservoir. The process method has the beneficial effects that the energy consumption is low, the investment and operation costs are low, pretreated mine water can be subjected to advanced treatment and then can be used as production and domestic water for factories, so that partial water source wells can be replaced; the water resource is effectively protected, the water resource of underground mine wells is reasonably utilized, and the wasting of the water resource is reduced.

Owner:安徽洋森环保节能科技有限公司

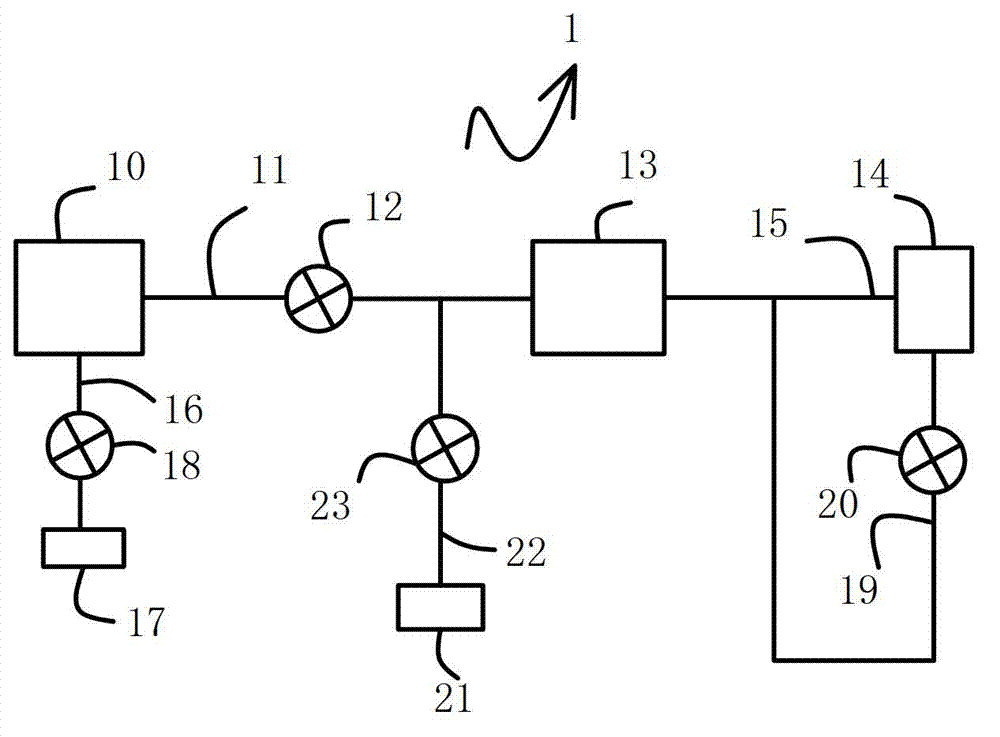

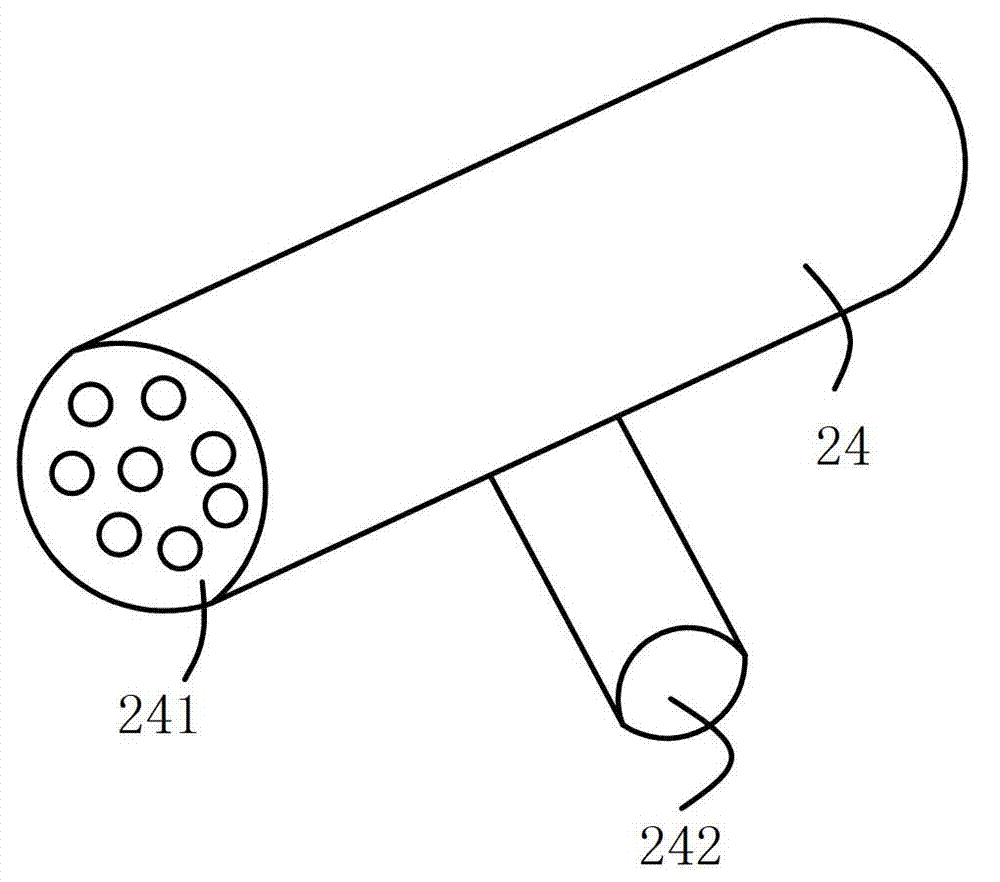

Grinding wastewater reuse and silica powder recovery device with tubular micro-filtration membrane assembly

InactiveCN103028329AGood chemical resistanceContinuous solid-liquid separation effectSiliconUltrafiltrationFiltration membraneAutomatic control

The invention provides a grinding wastewater reuse and silica powder recovery device with a tubular micro-filtration membrane assembly. The device comprises a raw water tank, the tubular micro-filtration membrane assembly, a first delivery pipe, a circulating pump, a water production tank, a second delivery pipe, a silica mud recovery device, a third delivery pipe, a mud delivery pump, a fourth delivery pipeline, a back washing pump and an automatic control system, wherein the raw water tank is used for containing wastewater; the first delivery pipe is used for communicating the raw water tank with the tubular micro-filtration membrane assembly; the circulating pump is arranged on the first delivery pipe; the second delivery pipe is used for communicating the tubular micro-filtration membrane assembly with the water production tank; the third delivery pipe is used for communicating the lower end of the raw water tank with a pressure filter; the mud delivery pump is arranged on the third delivery pipe; the fourth delivery pipeline is communicated with the water production tank; and the back washing pump is arranged on the fourth delivery pipeline. According to the grinding wastewater reuse and silica powder recovery devic, the wastewater enters the tubular micro-filtration membrane assembly under the action of the circulating pump, is purified and enters the water production tank through the tubular micro-filtration membrane assembly after being purified, generated concentrated water flows back to the raw water tank, and the purified water enters the tubular micro-filtration membrane assembly and is subjected to back washing, and particles in the raw water tank enter the silica mud recovery device, are dehydrated to form mud cakes and are discharged. The grinding wastewater reuse and silica powder recovery device with the tubular micro-filtration membrane assembly has a good pollution cleaning effect and high efficiency.

Owner:无锡凝洋环保科技有限公司

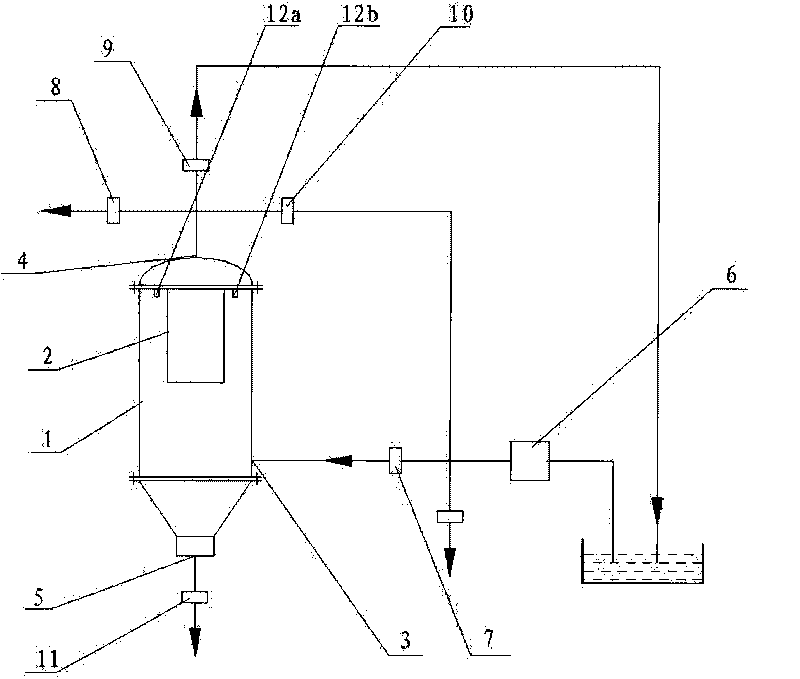

Ultrasonic-pulse self-cleaning wastewater reusing device and treatment method

InactiveCN101703852AReduce pollutionControl processing timeStationary filtering element filtersAutomatic controlTreatment effect

The invention relates to the field of energy conservation and environmental protection and provides an ultrasonic-pulse self-cleaning wastewater reusing device and a method, the whole filtration and the washing processes are automatically controlled through a PLC control system, thereby greatly improving the degree of automation of the treatment processes; and a back-wash way combining the pulse way and the ultrasonic cleaning is adopted, thereby changing the traditional cleaning way of adding a chemical cleaning agent and having the constant-flow backwash, avoiding the possible secondary pollution, greatly improving the backwash effect and also cleaning oily dirt adhered to a filter core. The wastewater reusing device and the method have the advantages of reasonable structure, good treatment effect, convenient cleaning and maintenance of the filter core and convenient realization of automatic control.

Owner:JIANGSU UNIV

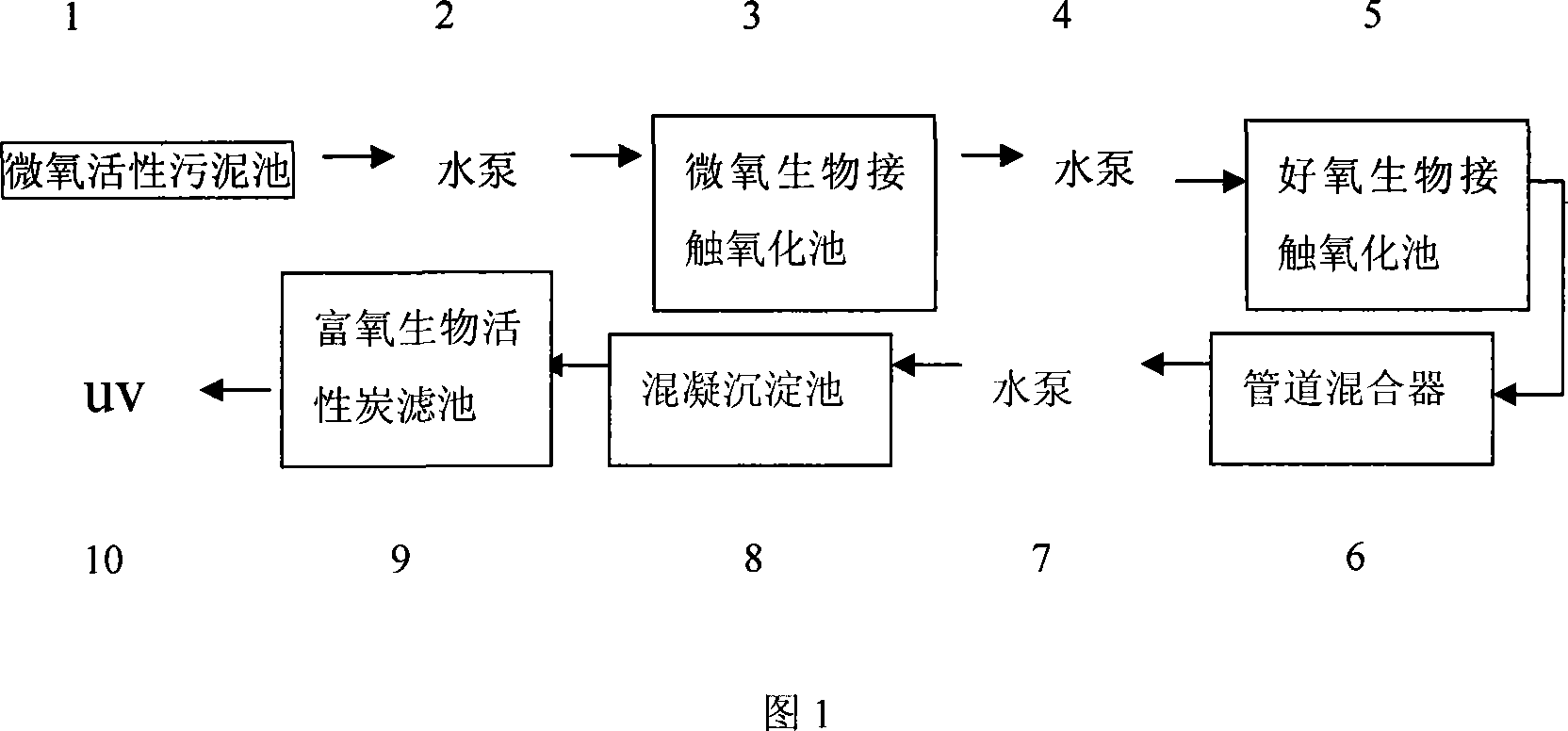

Process method for dimethyl ether production wastewater recycled for cooling water

InactiveCN101172744AWith biodegradable functionAchieve reflowTreatment using aerobic processesWater/sewage treatment by irradiationActivated sludgeBactericidin

The invention relates to a processing method for recovering the organic waste water exhausted from the dimethyl enther procedure to be used for industry circulation cooling water, and adopts the integrated system technique of anoxic activated sludge pool-anoxic biological contact oxidation pond-oxygen biological contact oxidation pond-coagulation sedimentation tank-oxygenrich biological activated carbon filtrating pool-UV bactericidin disposal technique. The biological contact oxidation pond adopts a biological filling and micropore aerating system. The anoxic biological contact oxidation degrades the organic matter under the condition of DO is 0.5 to 1.0 mg / L, and the oxygen biological contact oxidation effectively eliminates CODcr under the condition of the DO is 2 to 4mg / L. The outputted water from the oxygen biological contact oxidation pond is used for eliminating the suspended matter by coagulating and precipitation, and further is deeply processed through oxygenrich biological activated carbon filtrating pool to eliminate suspended matter and organic matter, and is finally sterilized through uv to be repeatedly used as circulation cooling water makeup water. Compared with the normal anaerobic technique, the anoxic biological processing technique eliminates the producing of the peculiar smell of H2S, and compared with the aerobic technique, the aeration quantity is reduced, the powder consumption is saved, and the anoxic biological processing technique is a new technique of biological processing. The method has the advantages of simple operation, low running expenses, small device investment and zero exhausting of waste water, and without secondary pollution.

Owner:NANJING INST OF GEOGRAPHY & LIMNOLOGY

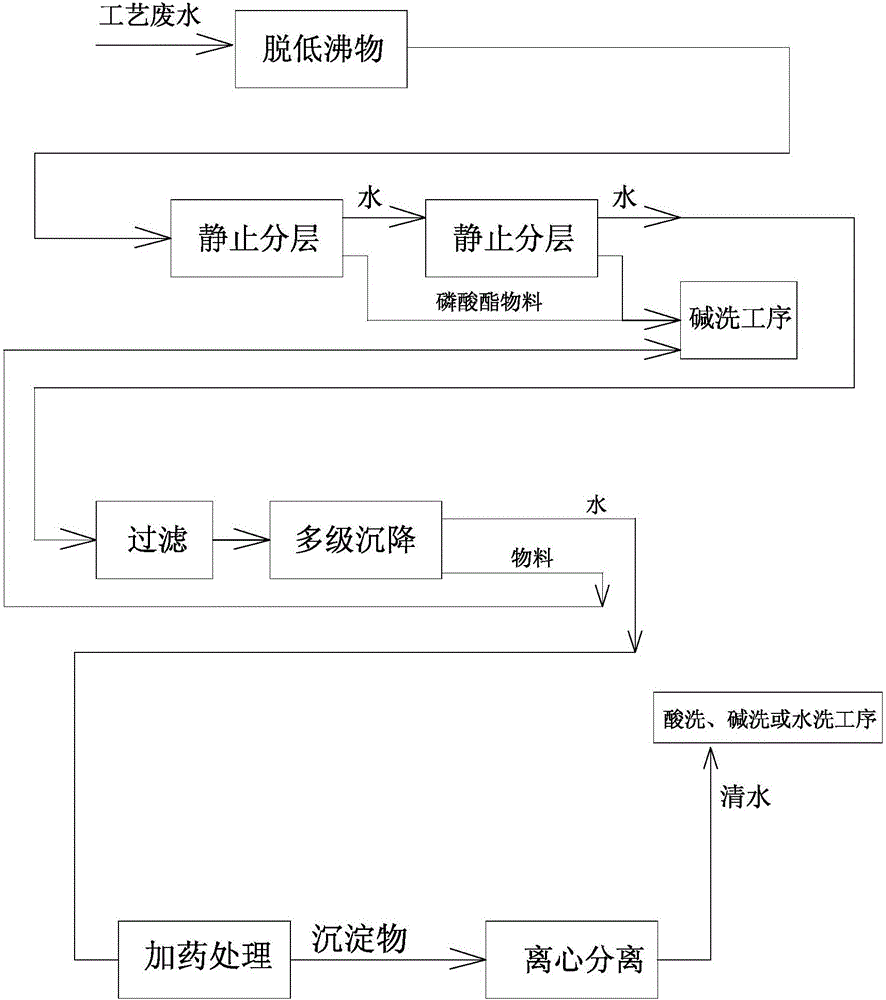

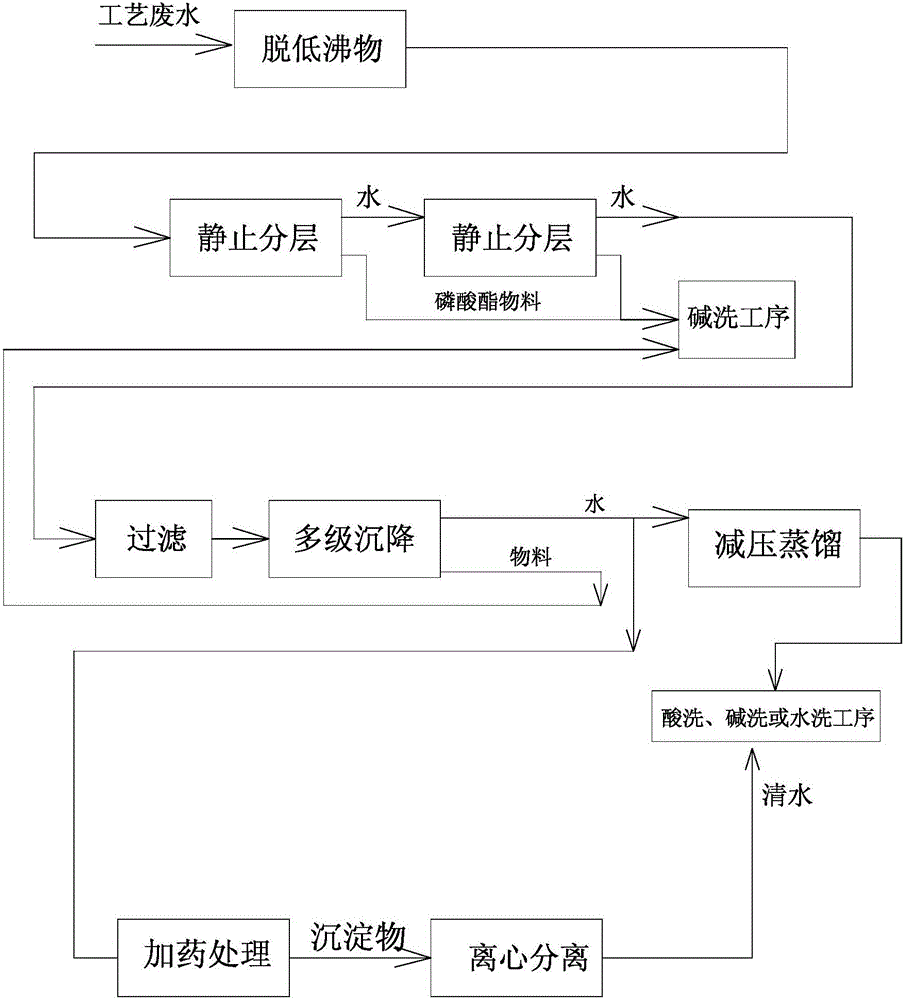

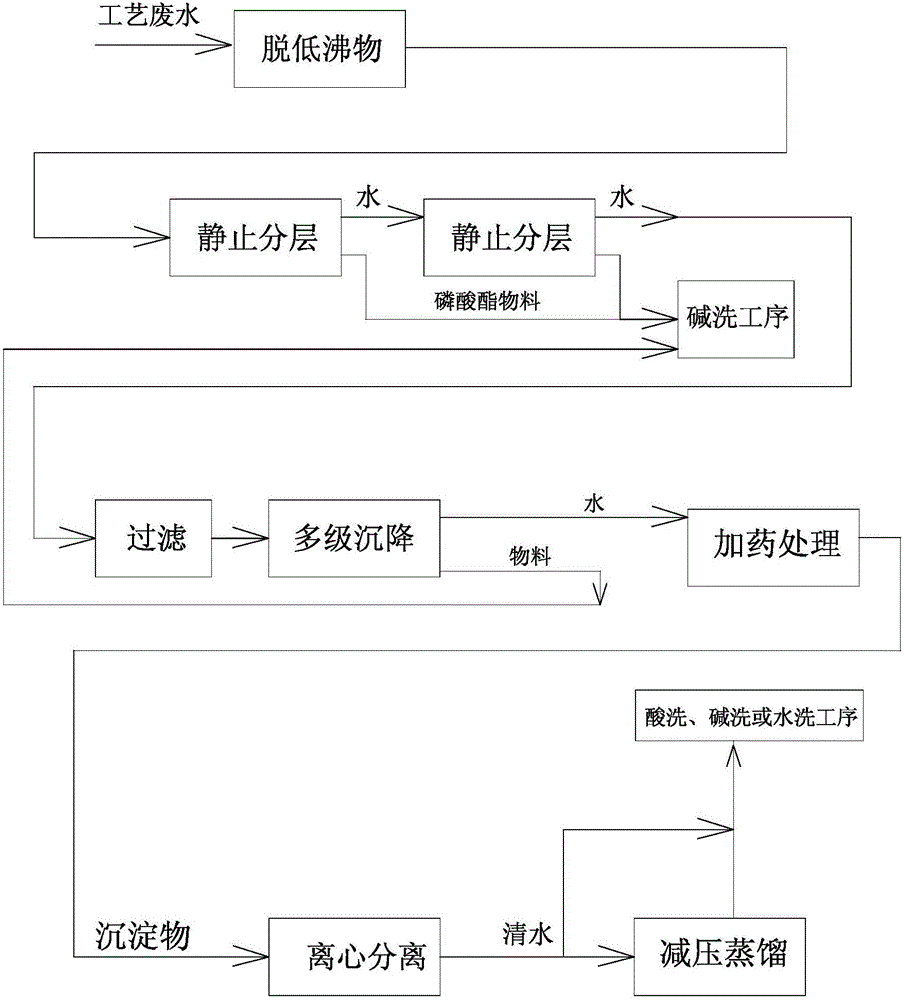

Method for treating wastewater of phosphate fire retardant production process

ActiveCN106336059AReduce contentHigh yieldWater/sewage treatment by centrifugal separationTreatment involving filtrationHigh concentrationEnvironmental resistance

The invention discloses a method for treating wastewater of a phosphate fire retardant production process. The wastewater of the phosphate fire retardant production process is high-concentration salt-containing organic phosphorus wastewater, wastewater treatment is always a difficult problem in the industry, and at present there is no feasible method. The method includes the following steps that 1, process wastewater produced in the phosphate fire retardant preparation process is subjected to low-boiling-point substance removal treatment; 2, the wastewater is fed into a wastewater layering box for static layering; 3, the wastewater is fed into a multistage sedimentation pool for sedimentation, the lower-layer material of the multistage sedimentation pool is recycled, and the upper-portion wastewater is subjected to subsequent treatment; 4, dosing treatment is performed, and organic phosphorus and inorganic phosphorus in the wastewater precipitate in the form of solid; 5, centrifugal separation or filtering is performed. The various impurities in the wastewater of the phosphate fire retardant production process are effectively removed through low-boiling-point substance removal, static layering, multistage sedimentation and dosing treatment, process wastewater reuse is achieved, and the method is economic and environmentally friendly.

Owner:福建新安科技有限责任公司

Wastewater treatment and reusing membrane separation treatment technology

InactiveCN102583831AEasy to controlSafe and reliable controlWater contaminantsWater/sewage treatment bu osmosis/dialysisWater useSludge

The invention relates to a wastewater treatment and reusing membrane separation treatment technology which is characterized by treating heavy metal wastewater by using the pretreatment of 'preformed precipitation + fiber filter + ultrafiltration' and the membrane separation technology of 'nanofiltration + reverse osmosis + mixed bed', so that the treated wastewater can reach the boiler water standards, and equipment and electrified control is beneficial to accurately and safely controlling wastewater treatment equipment. In the invention, the purpose of real wastewater zero emission is realized by the application of the membrane technology, the reuse rate of wastewater reaches 75-80%, the rest wastewater is conveyed back to a regulating pool for continued circular treatment, metal ions are finally transported outwards or reused in the main form of sludge, and the possibility of affecting environment by heavy metal wastewater can be reduced as much as possible.

Owner:GUANGXI YUDA WATER PROCESSING ENVIRONMENTAL PROTECTION ENG CO LTD

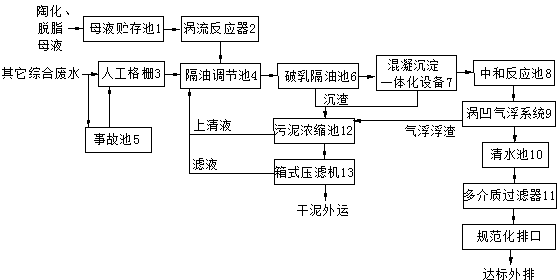

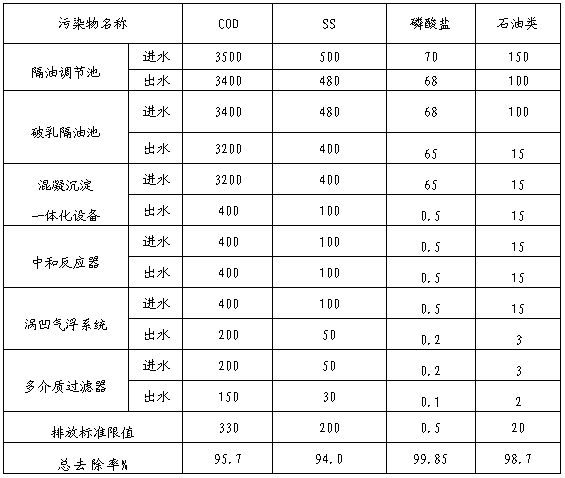

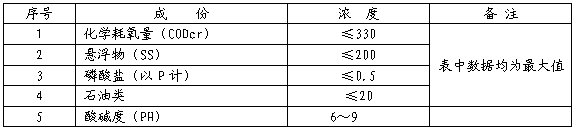

Treatment process for wastewater of household appliance product degreasing process

ActiveCN103739107AReduce shock loadGuaranteed uptimeMultistage water/sewage treatmentCavitationPhosphate

The present invention discloses a treatment process for wastewater of a household appliance product degreasing process. According to the treatment process, wastewater of a household appliance product degreasing process enters an oil isolation adjustment pool to isolate part of the surface floating oil, and the mixed wastewater enters a demulsification oil isolation pool to carry out demulsification on emulsified oil in the wastewater; the oil-isolated wastewater enters coagulation and precipitation integrated equipment to carry out a coagulation reaction, and the pH value is adjusted to more than 12 so as to remove phosphates, suspended solids and organic matters; the mixed solution after the coagulation reaction is subjected to precipitation, the obtained supernatant sequentially flows into a neutralization reaction pool and a cavitation air flotation system, and the wastewater is subjected to secondary phosphorus and oil removal through aeration; and the wastewater treated by the cavitation air flotation system sequentially flows into a clear water pool and a multi-media filter so as to be filtered, and the filtered clear water is subjected to standard discharge so as to be discharged into the municipal drainage pipeline network through the standardization discharge port. According to the present invention, the removal effects on phosphates and other pollution factors in the wastewater of the degreasing process are good, the treated wastewater can achieve the comprehensive sewage discharge standard, and enterprises can easily achieve wastewater reuse.

Owner:ANHUI GREEN TITAN ENVIRONMENTAL TECH

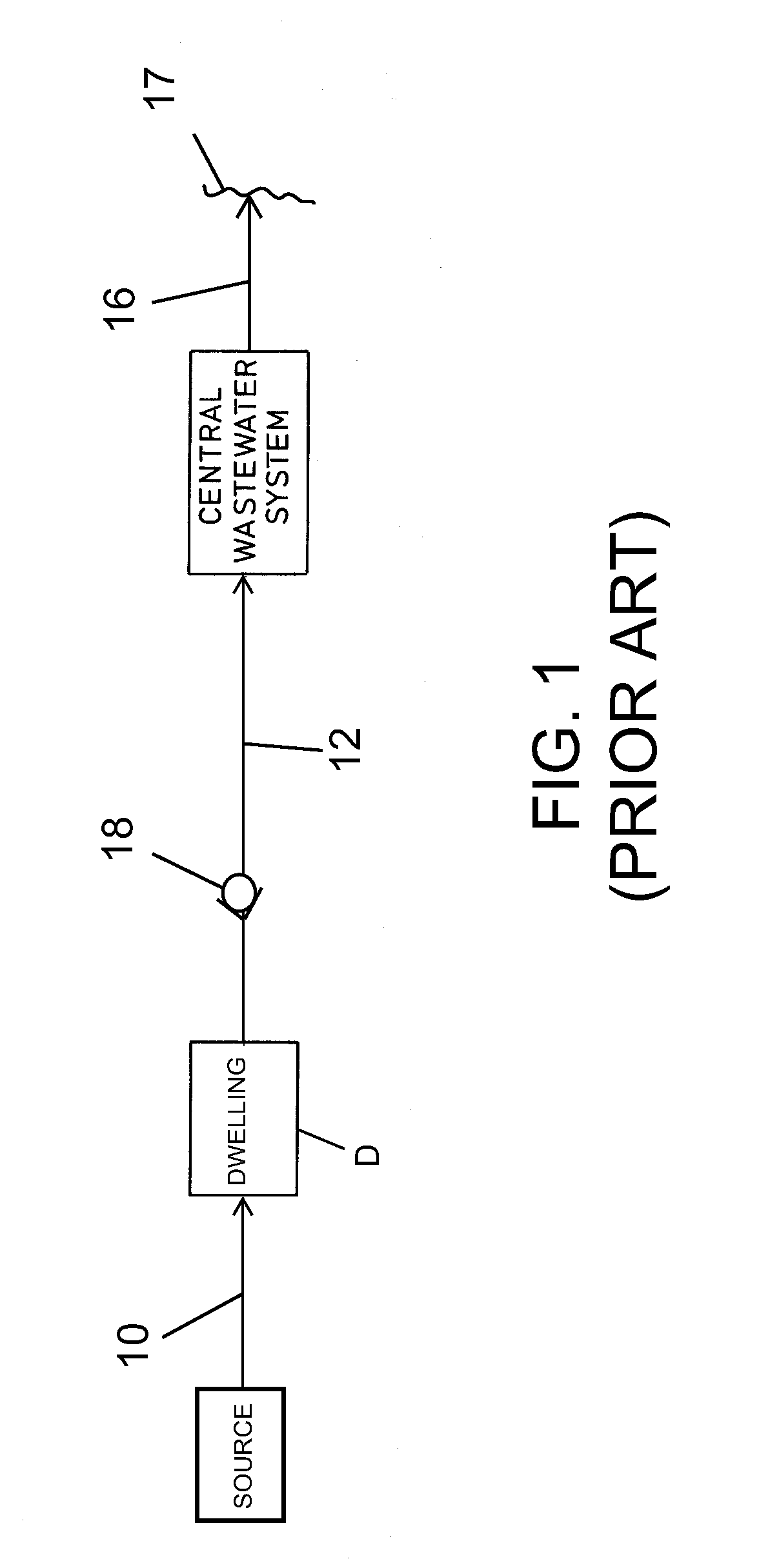

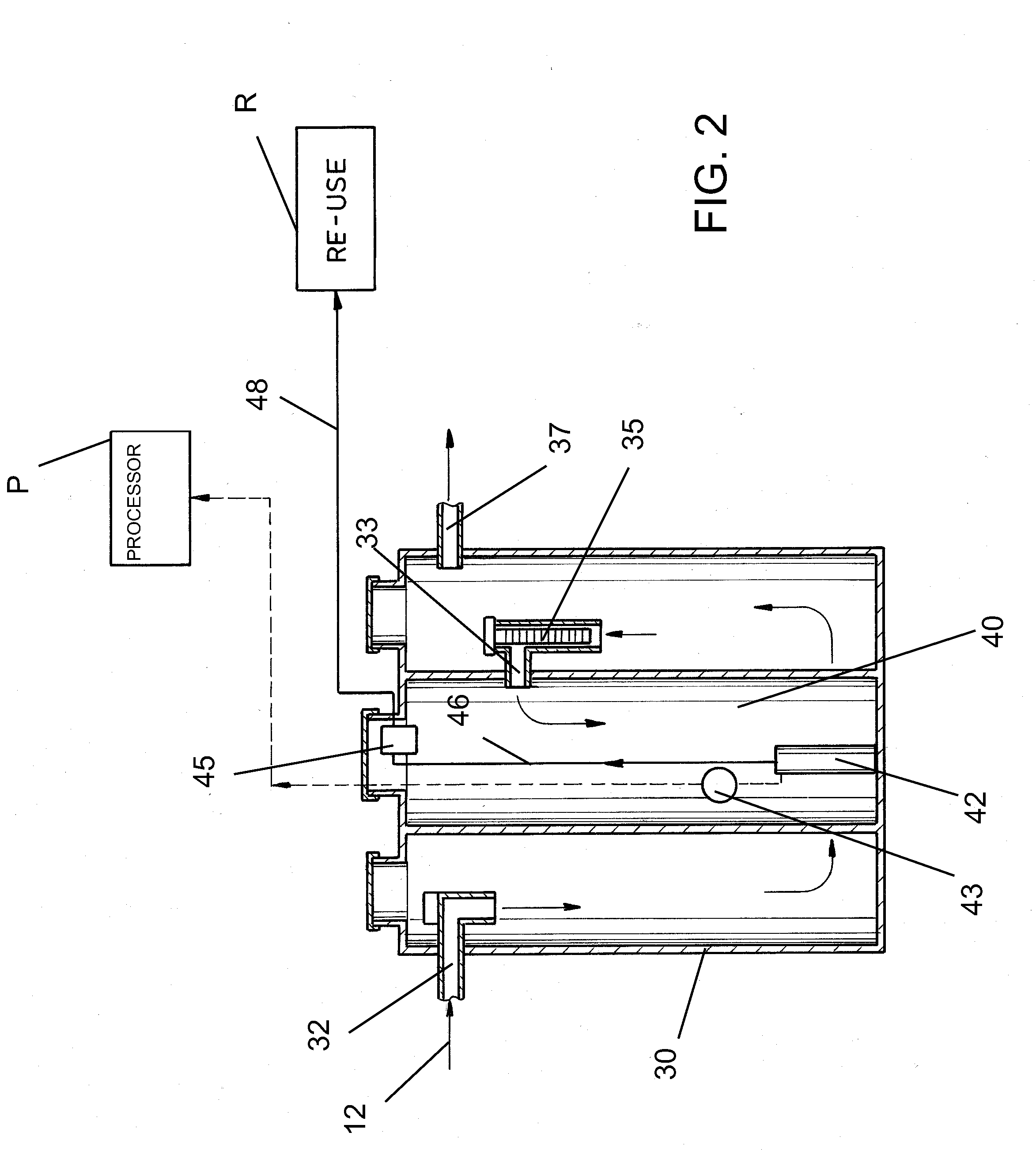

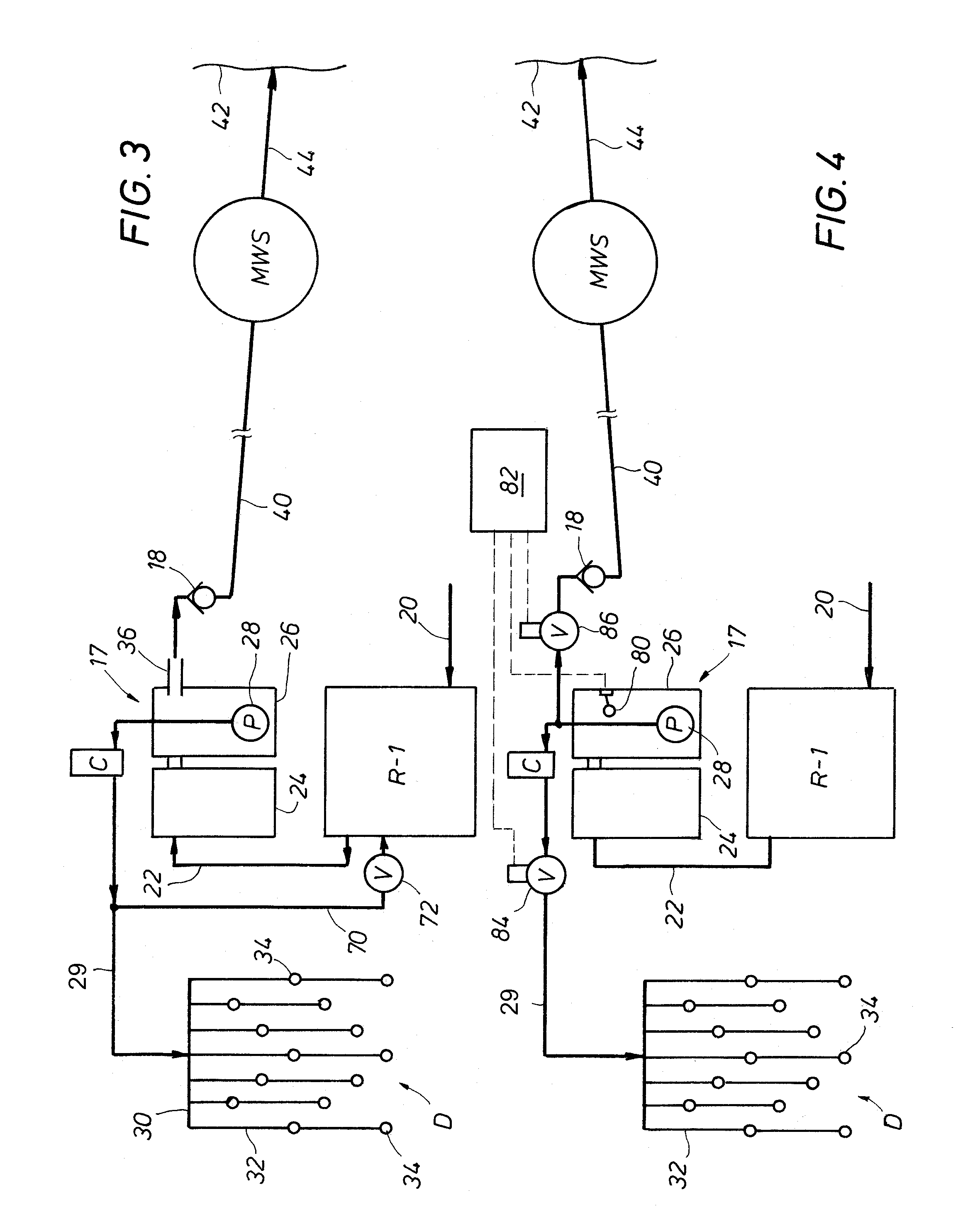

Wastewater Re-Use Systems

ActiveUS20120024766A1Reduce pollutionReduce loadTreatment using aerobic processesSolid sorbent liquid separationCollection systemWastewater reuse

A wastewater reuse system has a wastewater treatment system connected to a dwelling for receiving wastewater therefrom. The wastewater treatment system has a pump tank with an outlet that can be connected to a central wastewater collection system. There can be a pump in the pump tank for pumping water from the pump tank to a use recipient of treated wastewater such as an irrigation system.

Owner:MCKINNEY JERRY L

Treatment device and treatment technology for denitration catalyst cleaning regeneration wastewater and waste residue

ActiveCN104591460AAchieve reuseImprove applicabilityUsing liquid separation agentMultistage water/sewage treatmentHigh energyWastewater

The invention relates to a treatment device and a treatment technology for denitration catalyst cleaning regeneration wastewater and waste residue. A treatment device and a treatment technology for denitration catalyst cleaning regeneration wastewater and waste residue, which have high energy utilization rate and can realize recycling of the denitration catalyst cleaning regeneration wastewater, are unavailable now. The treatment device is characterized by comprising a wastewater buffer sedimentation tank, an acid-base dosing box, an ultrasonic atomizing nozzle, a wastewater hydrocyclone, a liquid conveying pump, a deduster, an acid-base supply pipe and an underflow return pipe, wherein a cleaning regeneration wastewater conveying pipe and a bottom residue conveying pipe are both connected to the wastewater buffer sedimentation tank; and the acid-base dosing box is connected to the wastewater buffer sedimentation tank through the acid-base supply pipe. The treatment technology comprises the following steps: conveying the denitration catalyst cleaning regeneration wastewater into the wastewater buffer sedimentation tank; adjusting the pH value; standing for sedimentation; performing solid-liquid separation of the supernate; and atomizing the overflow filtrate and spraying into the deduster. The treatment device and treatment technology provided by the invention can be used for realizing recycling of the denitration catalyst cleaning regeneration wastewater.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

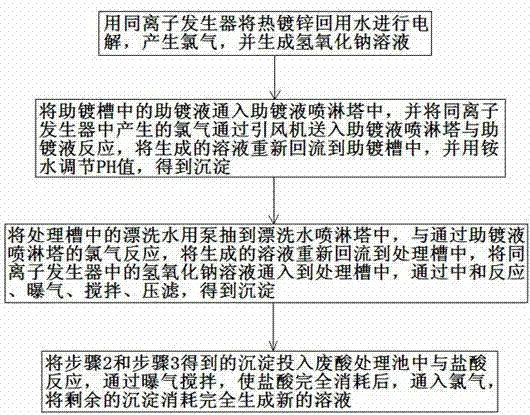

Waste acid and wastewater reuse production process for hot galvanizing

ActiveCN103755080AReduce usageReduce investmentWaste water treatment from metallurgical processMultistage water/sewage treatmentRinse waterSpray tower

The invention discloses a waste acid and wastewater reuse production process for hot galvanizing. The production process comprises the following steps: (1) electrolyzing reuse water of hot galvanizing to generate chlorine and sodium hydroxide liquor; (2) introducing assistant plating liquor to a spraying tower and sending the chlorine to the spraying tower to react with the assistant plating liquor, returning the generated liquor to an assistant plating tank, and adjusting pH value by ammonium water to obtain a precipitate; (3) pumping rinse water to the spraying tower by a pump to react with the chlorine, returning the generated liquor to a treatment tank, introducing the sodium hydroxide liquor into the treatment tank for treatment to obtain a precipitate; and (4) inputting the precipitates obtained in the steps 2 and 3 into a waste acid treatment pool to react with hydrochloric acid, and after the hydrochloric acid is fully consumed, introducing the chlorine, and completely consuming the residual precipitate to generate new liquor. The production process disclosed by the invention has the advantages that the investment of integral equipment of waste acid and wastewater assistant liquor treatment in the hot galvanizing industry is reduced, thus the cost is reduced, the resources are saved, and waste is turned into wealth by recycling.

Owner:CHANGSHU FENGFAN POWER EQUIP

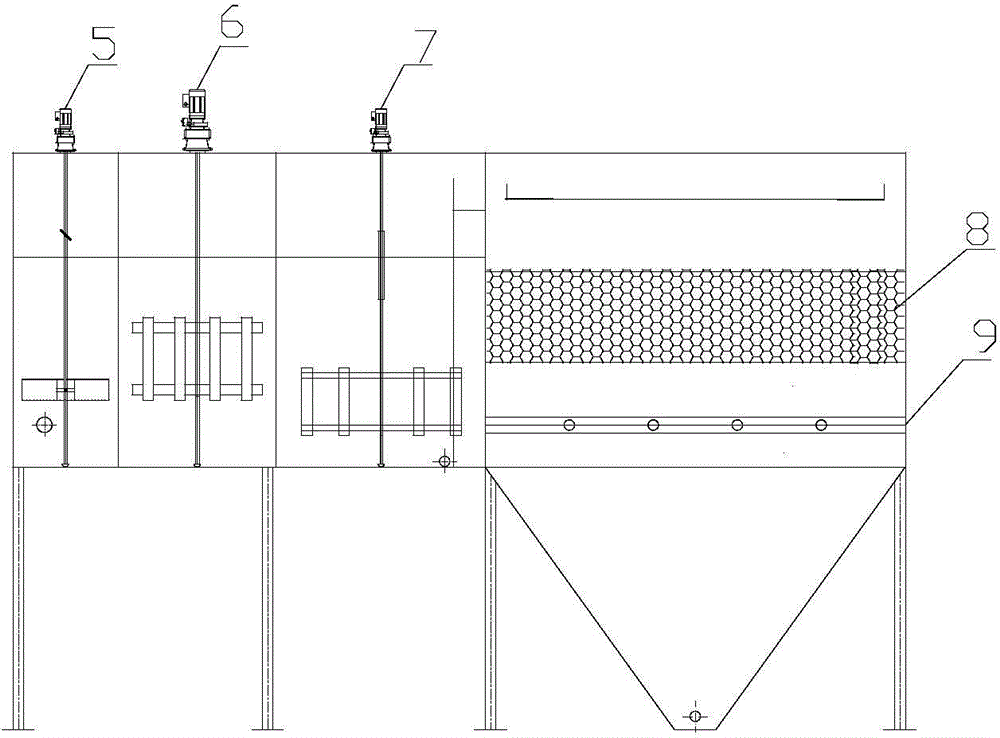

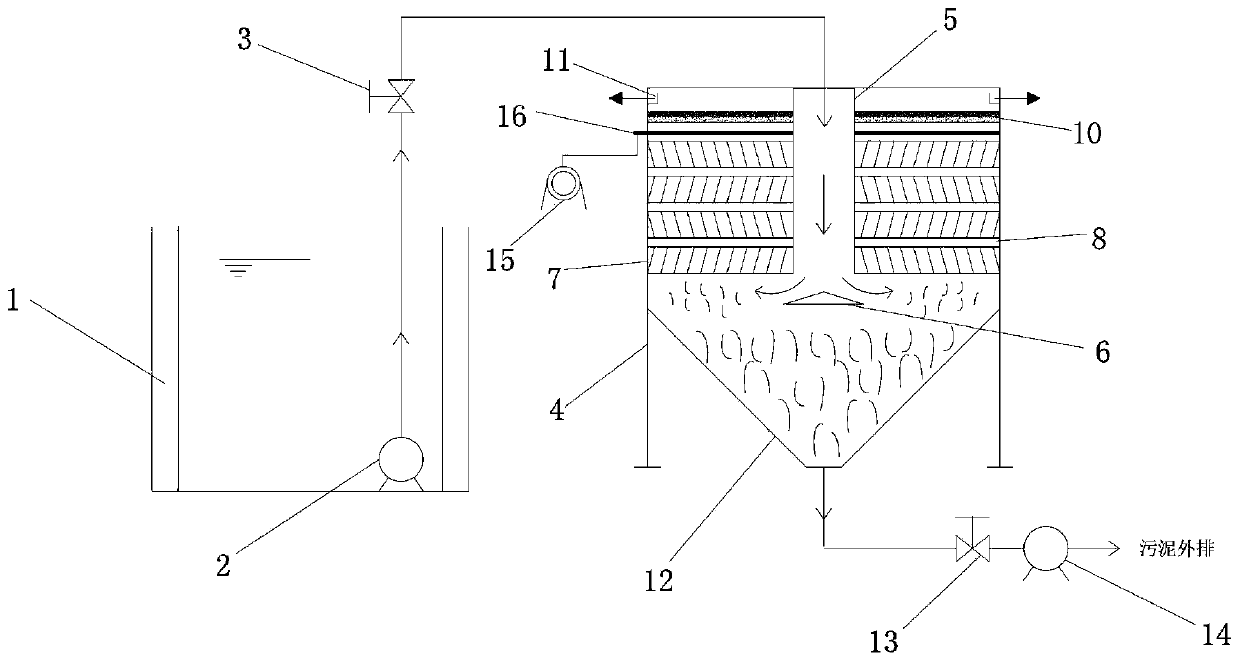

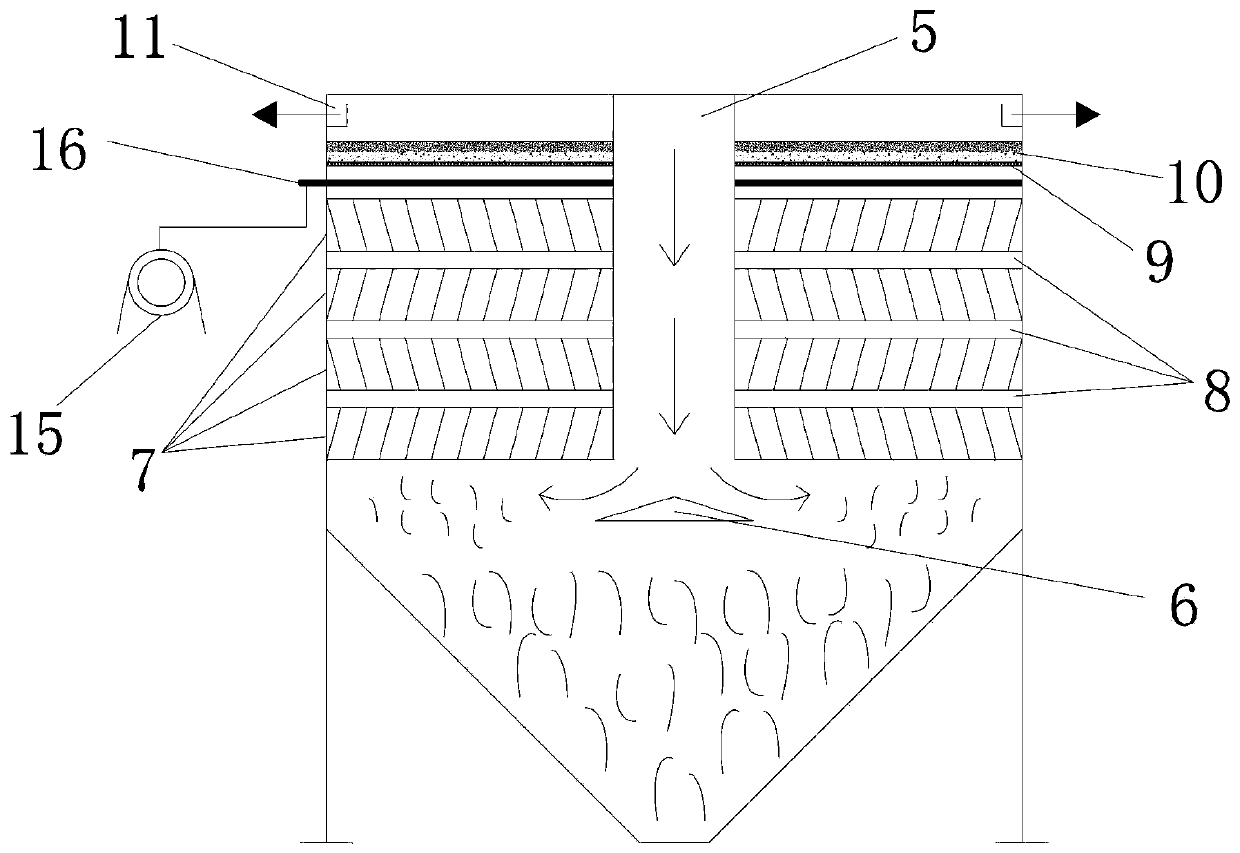

SS multilayer mixed flow precipitation device and precipitation method thereof

PendingCN111437636AEasy to handleReduce flow rateSettling tanks feed/dischargeLoose filtering material filtersDiaphragm pumpMixed flow

The invention discloses an SS multilayer mixed flow precipitation device and a precipitation method thereof. Due to the fact that the social industry develops rapidly, the problem of water resource shortage becomes more and more serious, wastewater reuse treatment engineering has great significance in cyclic utilization of water resources, and industrial water pressure can be effectively relieved.The SS multilayer mixed flow precipitation device comprises a water inlet module, an efficient precipitation module and a backwashing module. The water inlet module comprises a wastewater collectingtank, a sewage lifting pump and a first on-off valve; the efficient precipitation module comprises a precipitation device main body, a wastewater inlet central pipe, a water retaining weir plate, a multi-layer water purification inclined plate, a variable-speed mixing area, a fine grid, filter sand, a second on-off valve and a pneumatic diaphragm pump; and the backwashing module comprises an aeration fan and a porous aeration pipe. The process characteristics of the inclined pipe and the vertical flow sedimentation tank are integrated, the treatment capacity and the treatment effect on high SSwastewater are effectively improved, and the sedimentation advantage is obvious in comparison with the devices and the methods in the prior art.

Owner:ENVIRONMENTAL PROTECTION TECH CO LTD HANGZHOU DING HUI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com