Patents

Literature

1769 results about "Rinse water" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flush toilet

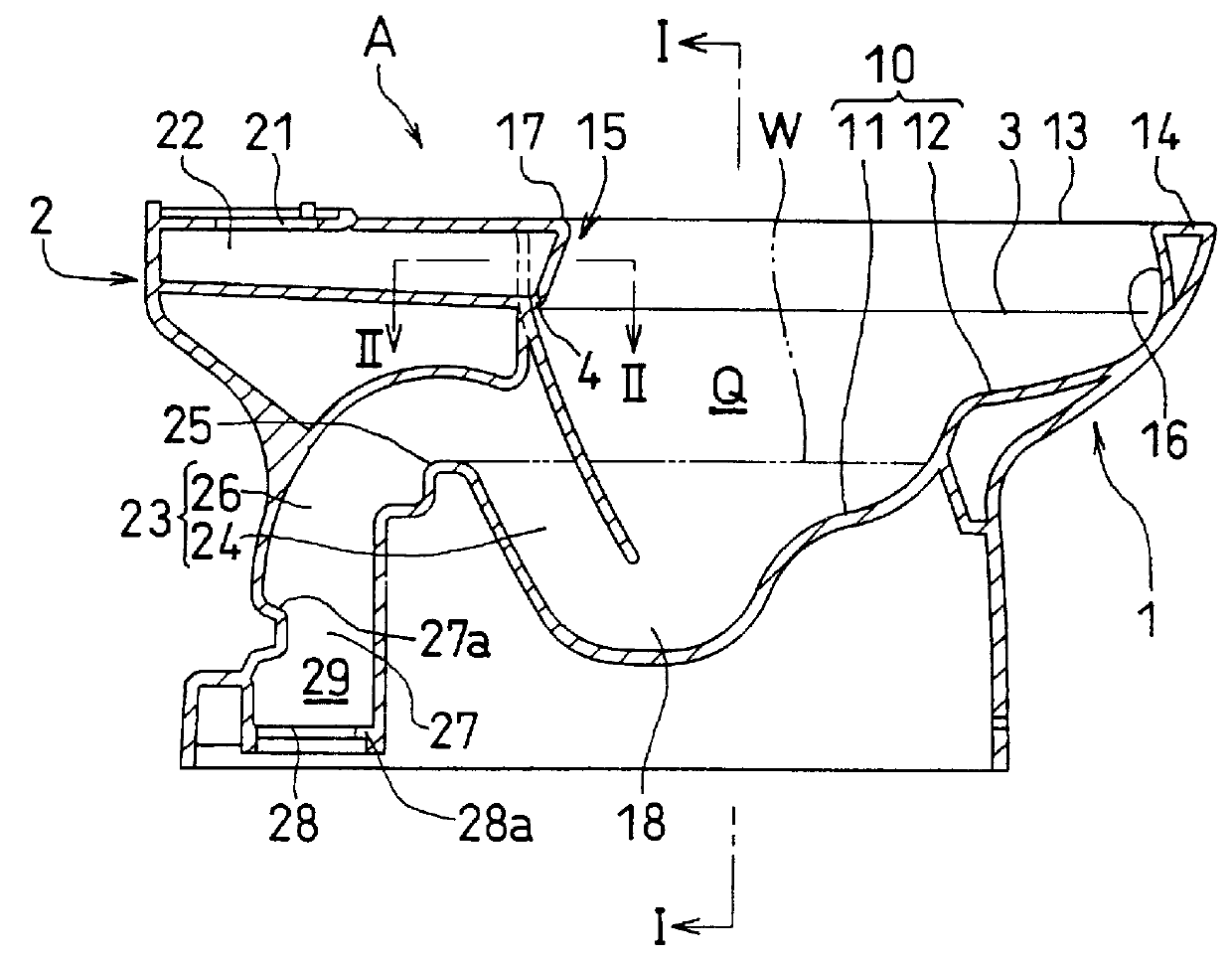

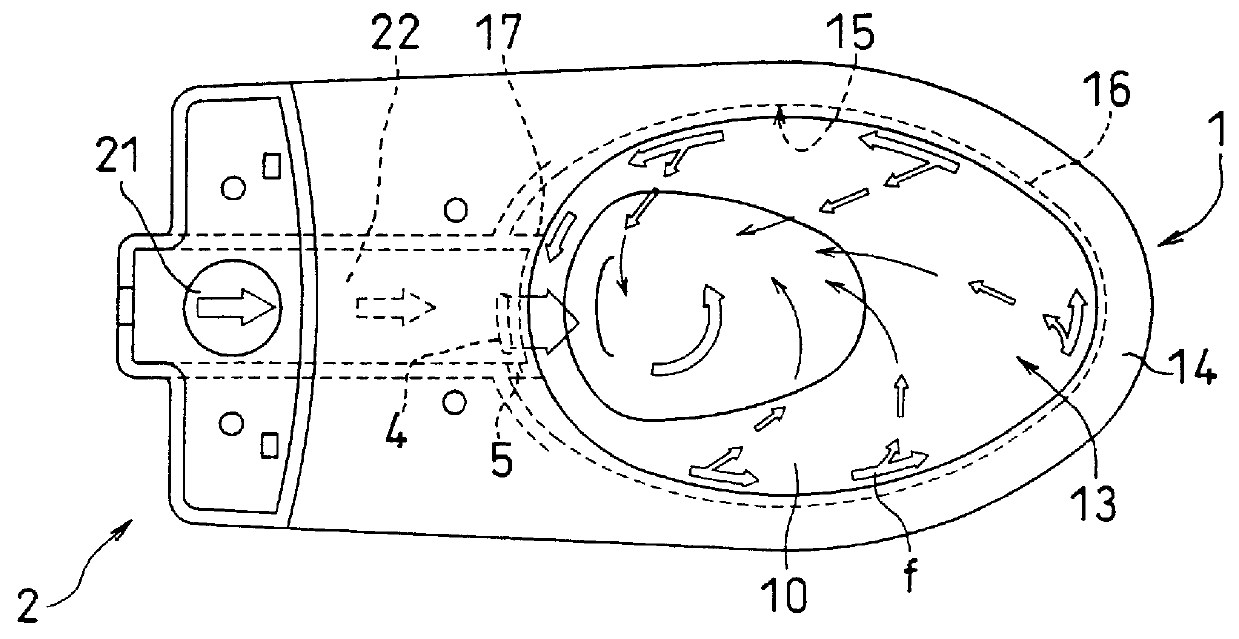

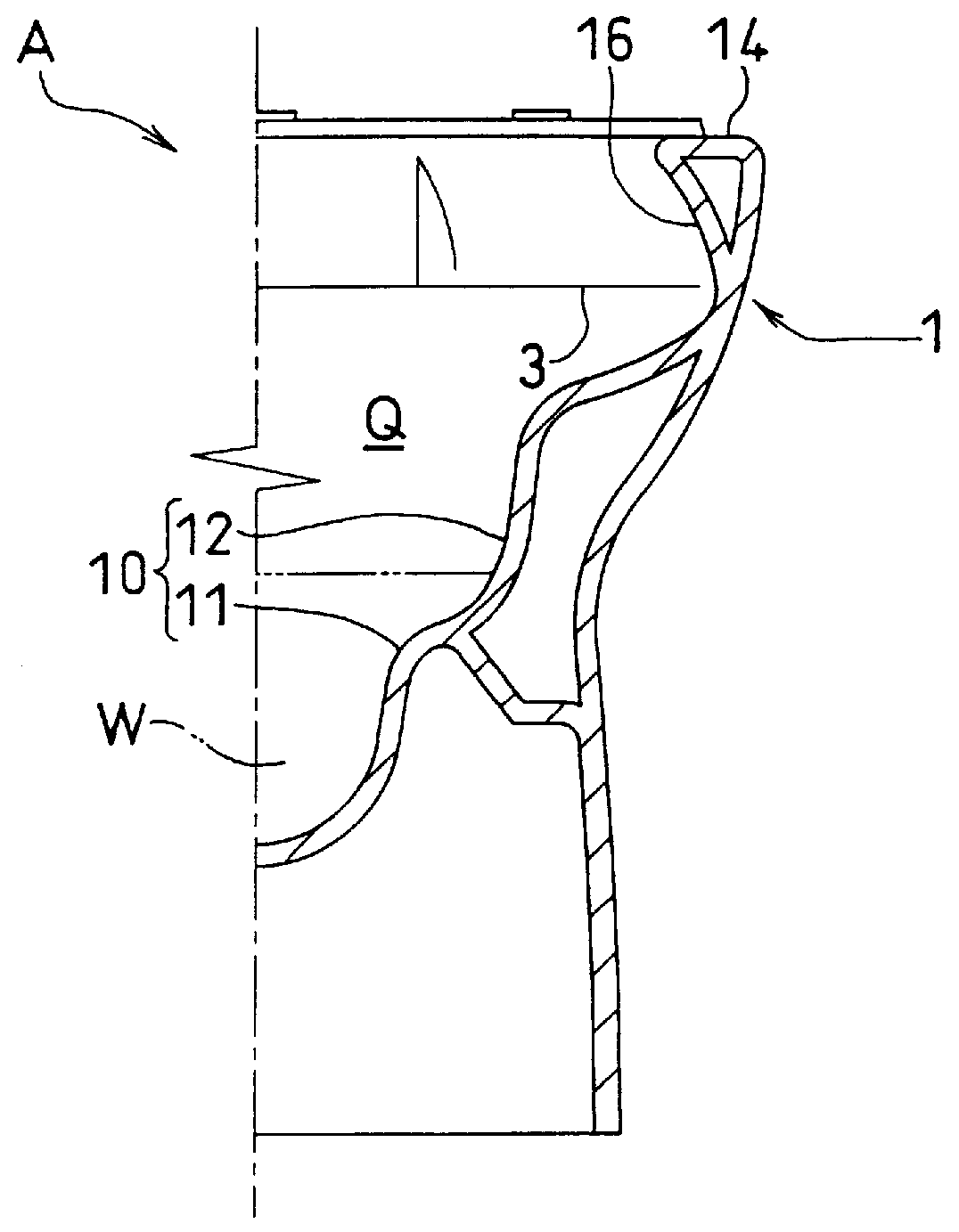

PCT No. PCT / JP97 / 03706 Sec. 371 Date Apr. 14, 1999 Sec. 102(e) Date Apr. 14, 1999 PCT Filed Oct. 14, 1997 PCT Pub. No. WO98 / 16696 PCT Pub. Date Apr. 23, 1998The flush toilet has a waste receipt surface section (10) of a bowl section (1) formed continuously integrally with an inner rim wall surface section (15) of the rim portion disposed at a peripheral edge of an upper opening (13) of the bowl section (1) as a curved surface; and the inner rim wall surface section (15) of the rim portion acts as a flush water passage (16) of the bowl section. The flush water passage (16) of the bowl section is further configured such that the inner rim wall surface section (15) of the rim portion is shaped in an overhanging form inclining so as to hang over inside of the bowl section (1). The flush toilet of this configuration can be cleaned with ease and kept clean in sanitation.

Owner:TOTO LTD

Endoscope system

InactiveUS20070161853A1Improve physician 's diagnosis efficiencyImprove diagnostic efficiencySurgeryEndoscopesInjection portImaging processing

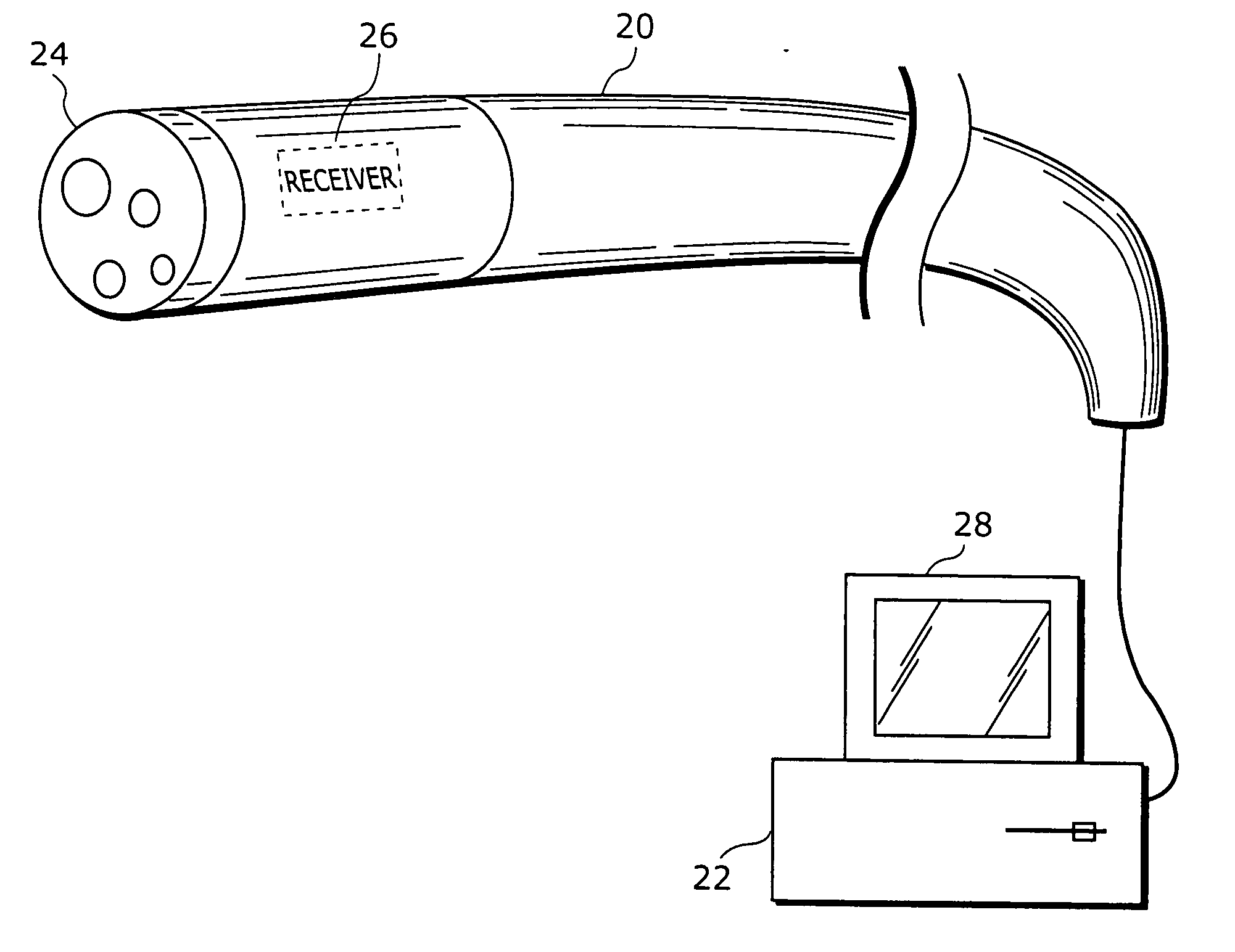

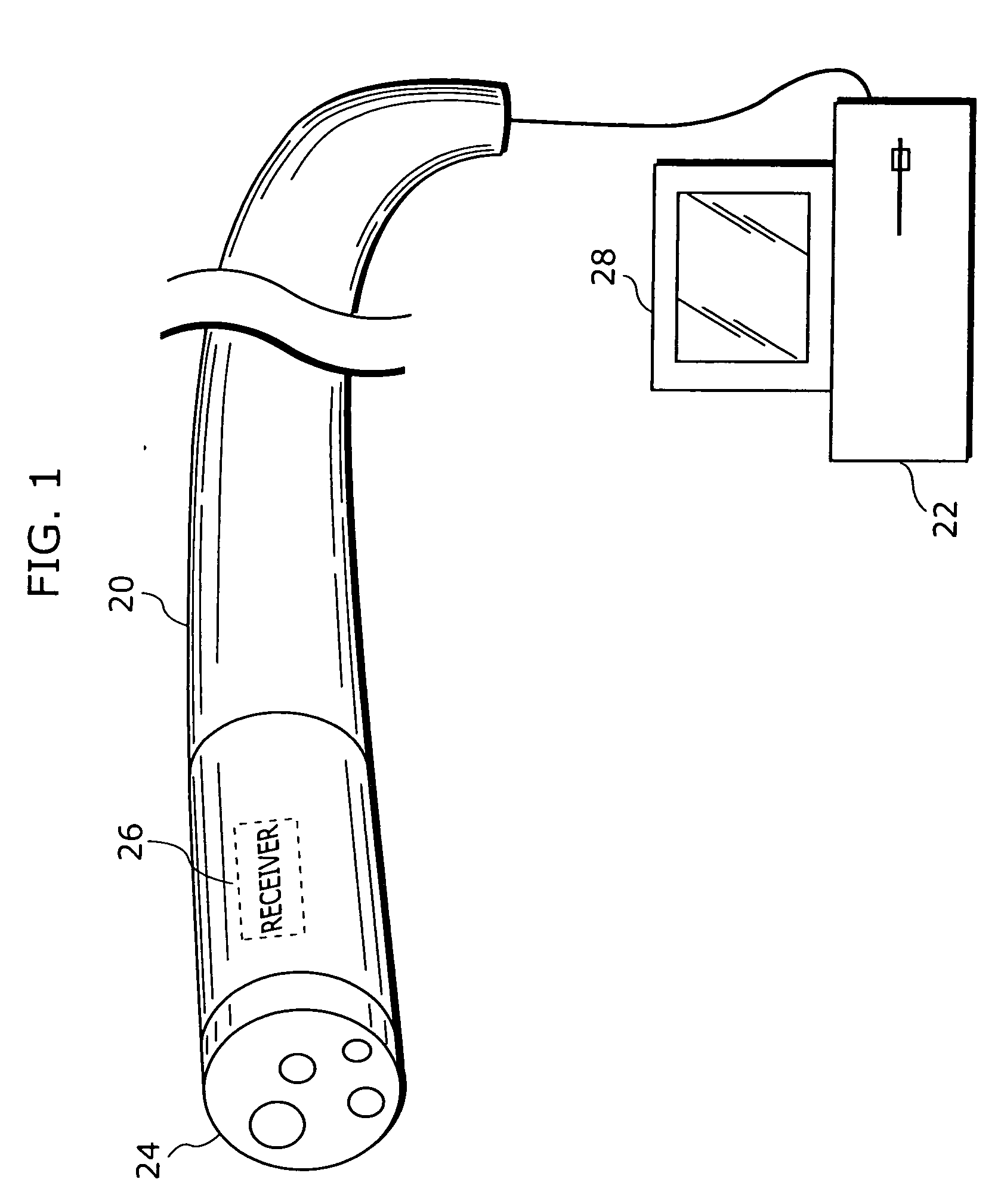

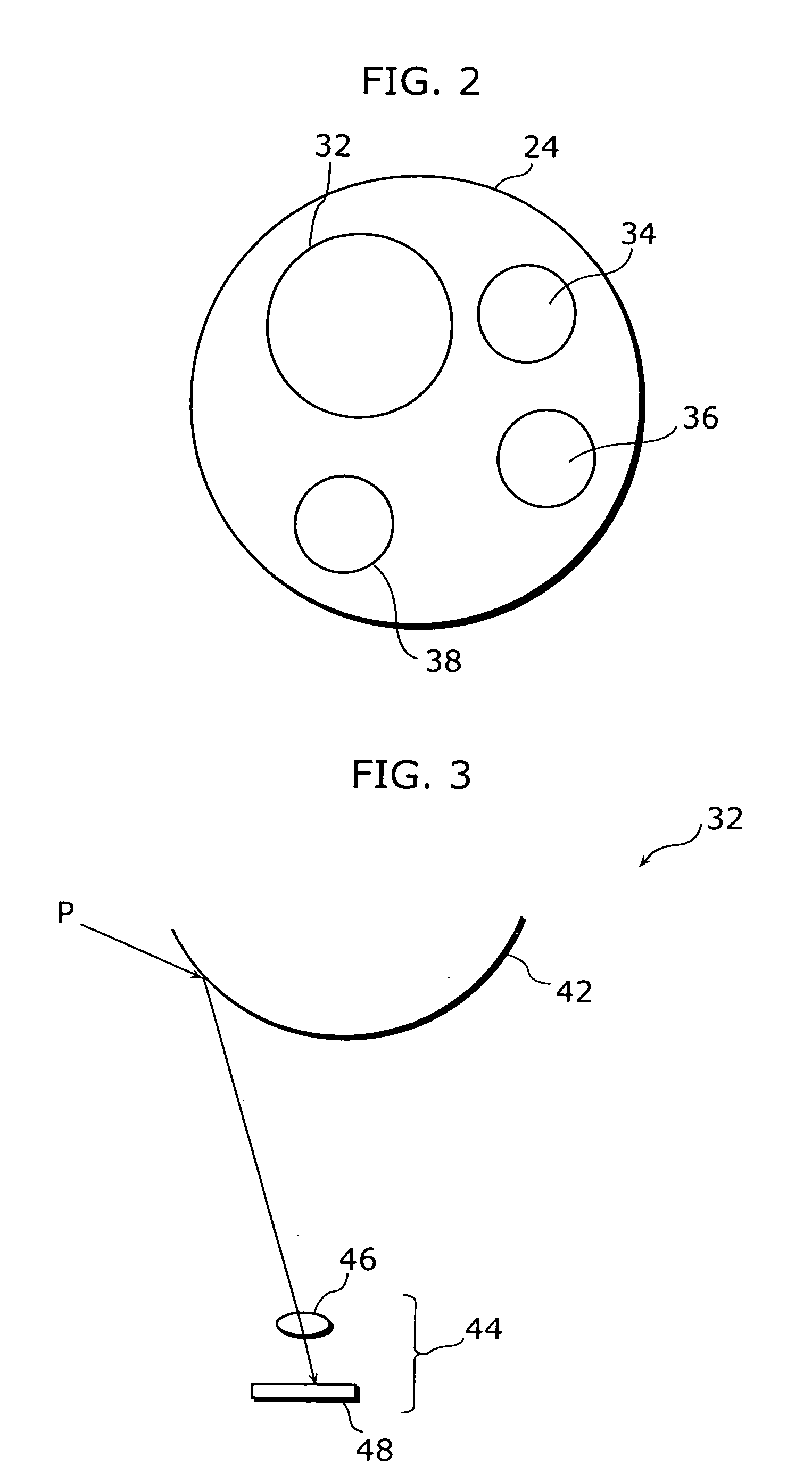

An endoscope that is free from a dead area and capable of preventing the physician from overlooking any nidus is an endoscope for taking the inside of digestive organs, and the endoscope is provided with an omnidirectional camera (32), a light (34), a forceps (36) and a rinse water injection port (38) at the tip (24). The omnidirectional camera (32) is a device for taking the inside of digestive organs, and is able to take 360-degree images of its surroundings. A probe-type endoscope (20) is provided with a receiver (26) composed of orthogonal coils, and the receiver (26) is used for estimating the position and attitude of the probe-type endoscope (20). An image taken by the omnidirectional camera (32) is presented on a display unit (28) of an image processing device (22) connected to the probe-type endoscope (20). In the image processing device, a video mosaicking process is performed on a plurality of images obtained by the omnidirectional camera (32) to generate a panoramic image of the inside of a digestive organ.

Owner:OSAKA UNIV

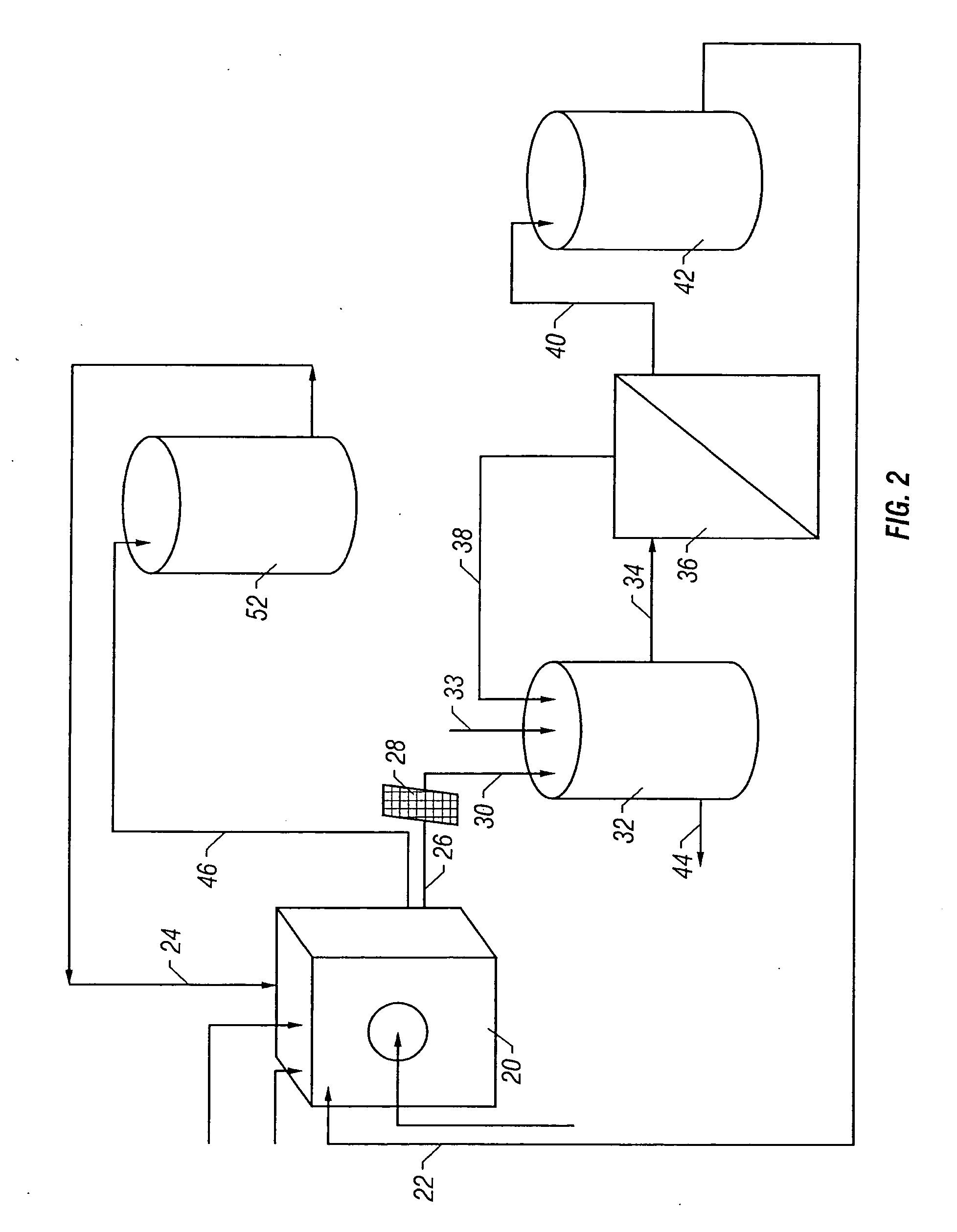

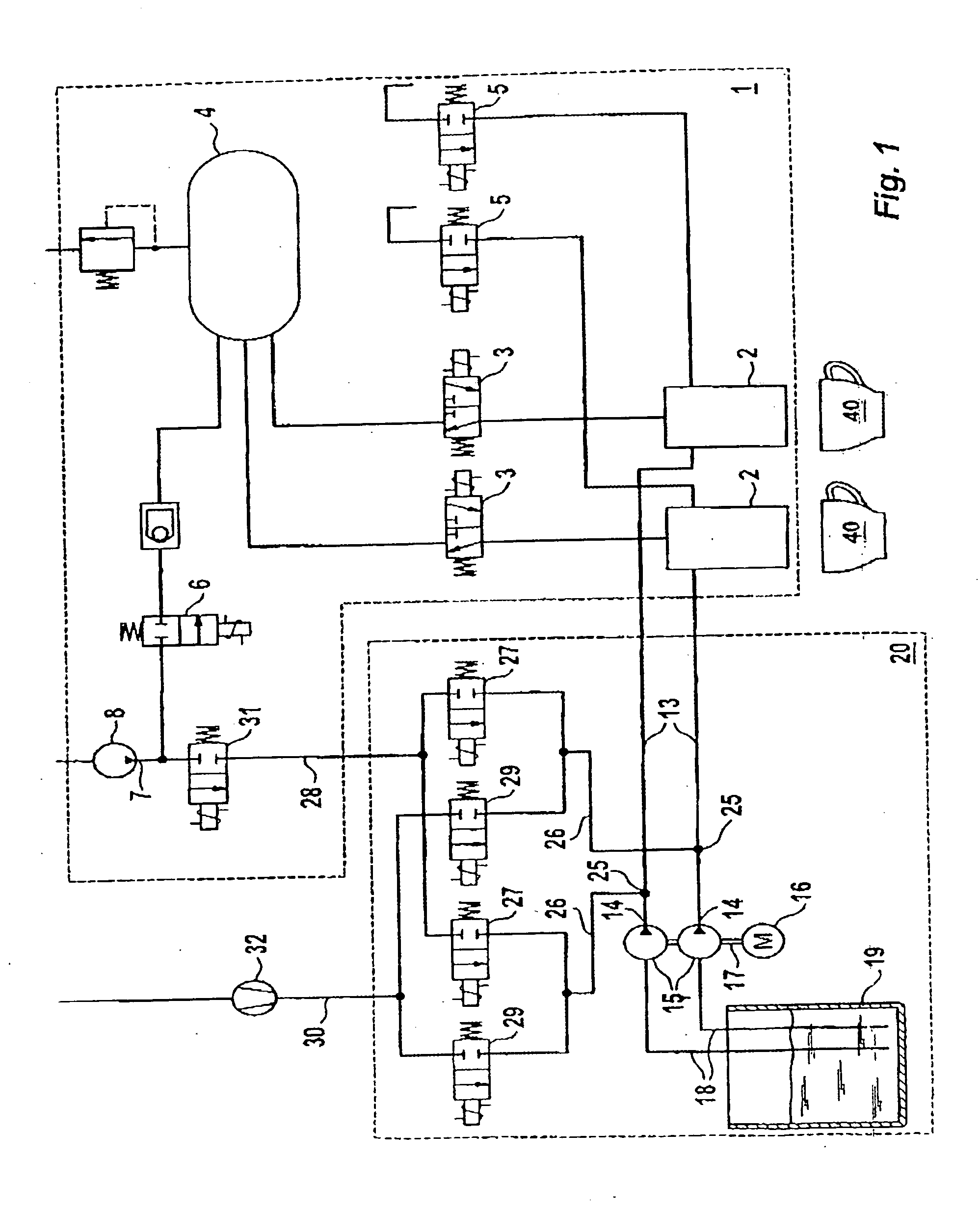

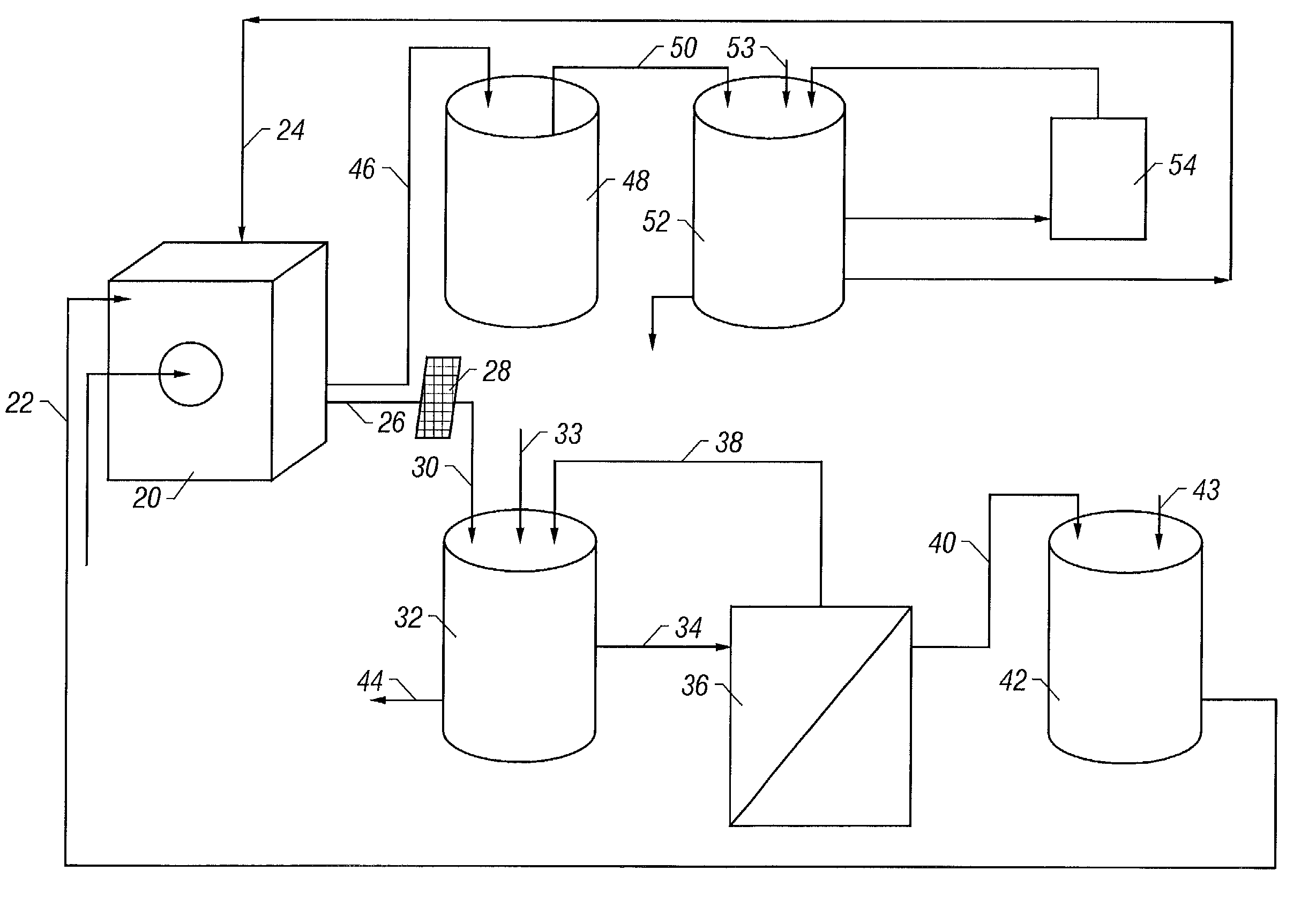

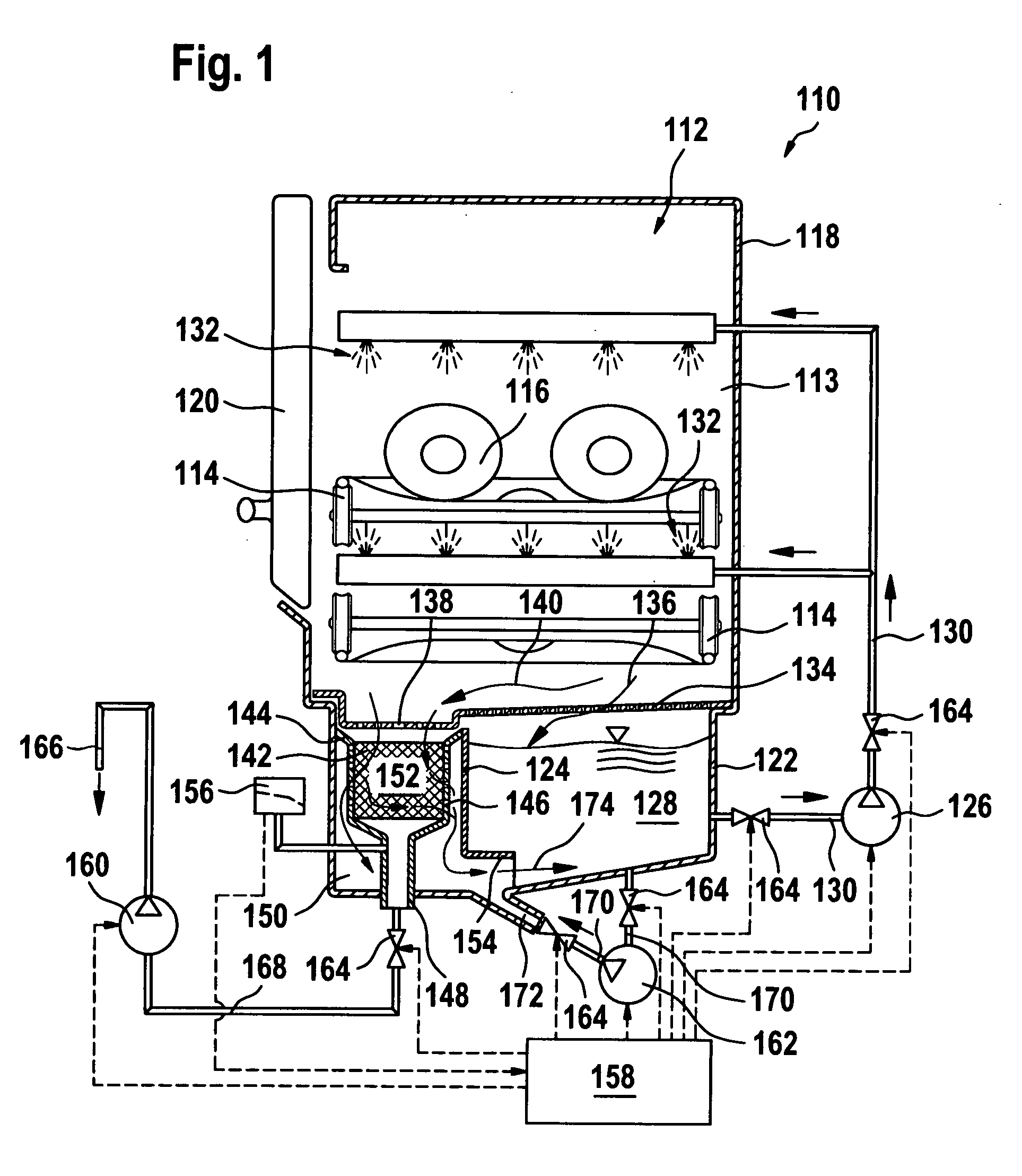

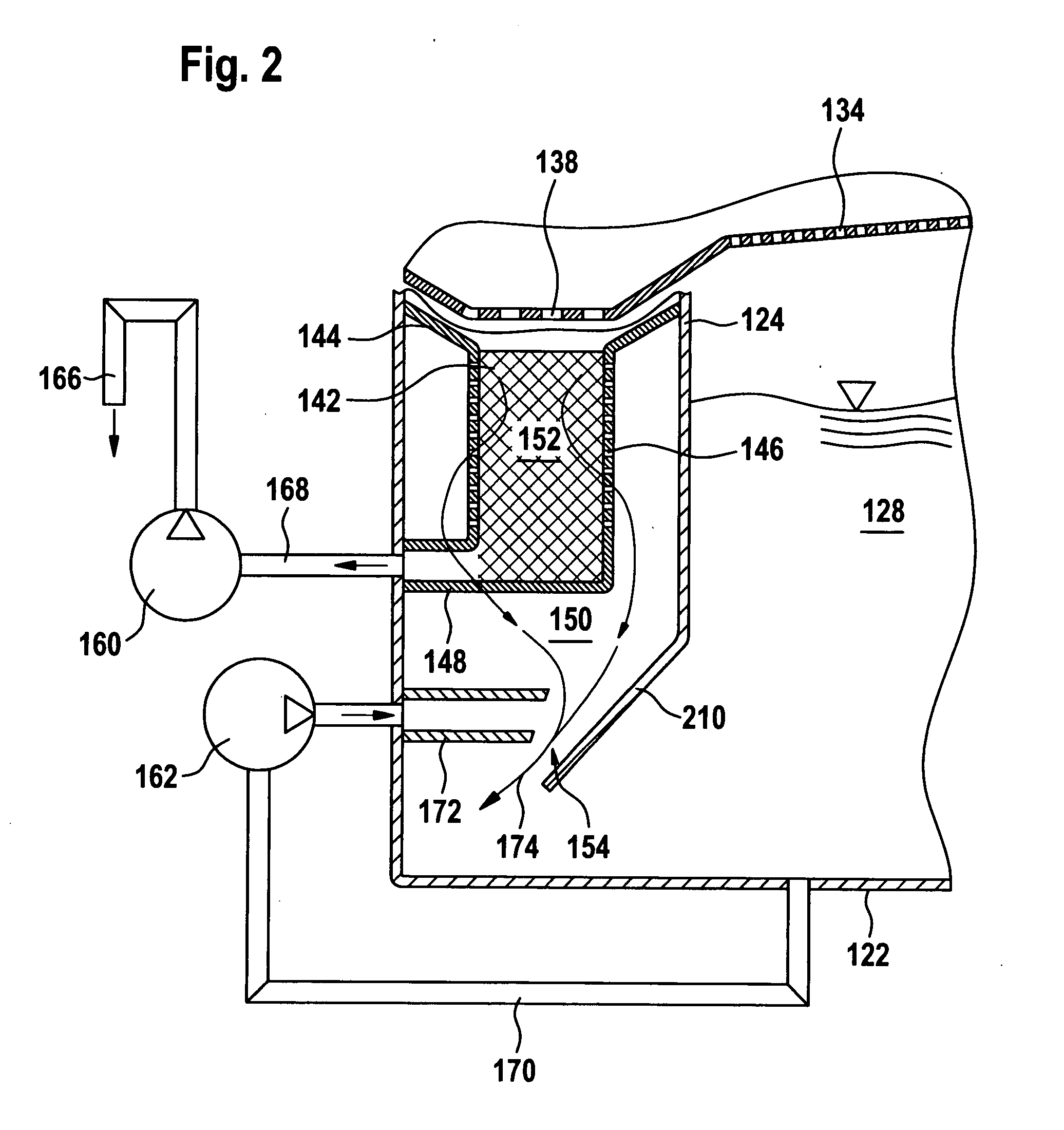

Method for economically viable and environmentally friendly central processing of home laundry

InactiveUS20060123563A1Reduce productionPromote recoveryTableware washing/rinsing machine detailsOther washing machinesEnvironmental effectWash water

An economically viable process and system for centrally processing multiple loads of laundry with minimum environmental impact. A system and method of laundering whereby successive loads of laundry may be washed while continuously providing effective soil removal comprising at least partially recycled wash water from at least one previous wash cycle. The system and the method of using the same comprises filtering wash water with at least one filter to form wash retentate and wash permeate. The use of wash permeate in successive washes provides for reuse of chemicals and water recovery. A similar arrangement may be used with regard to the rinse water. Advantageously, one embodiment of the invention provides for the use of rinse retentate as make up water in the wash loop which increases water recovery and chemical recovery. Ultimately, the invention can reduce the production of gray water and recover chemicals used in the laundering process.

Owner:RANEY KIRK HERBERT +5

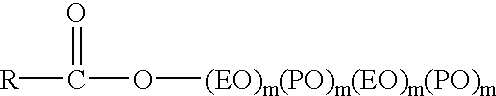

Warewashing system containing nonionic surfactant that performs both a cleaning and sheeting function and a method of warewashing

InactiveUSRE38262E1Inorganic/elemental detergent compounding agentsOrganic detergent compounding agentsActive agentPotable water

We have found an alkaline warewashing detergent composition that can contain a critical amount of a nonionic rinse agent that when used in automatic warewashing machines permits the use of a potable water rinse without the addition of a separate rinse agent. Sufficient residual nonionic surfactant from the alkaline detergent remains on the surface ware and internal machine and rack surfaces after washing to promote adequate sheeting in the rinse cycle. The residual nonionic surfactant on internal surfaces dissolves in the rinse water to create an effective aqueous rinse agent. The nonionic rinse agents can be a single nonionic for both foam reduction cleaning and sheeting or can be a blend of nonionic materials providing these functions. The detergent can be in the form of a particulate, pelletized or block solid. The detergent can be used in a variety of high temperature and low temperature automatic warewashing machines including large multizone conveyor machines, or relatively small institutional machines that have a single washing chamber.

Owner:ECOLAB USA INC

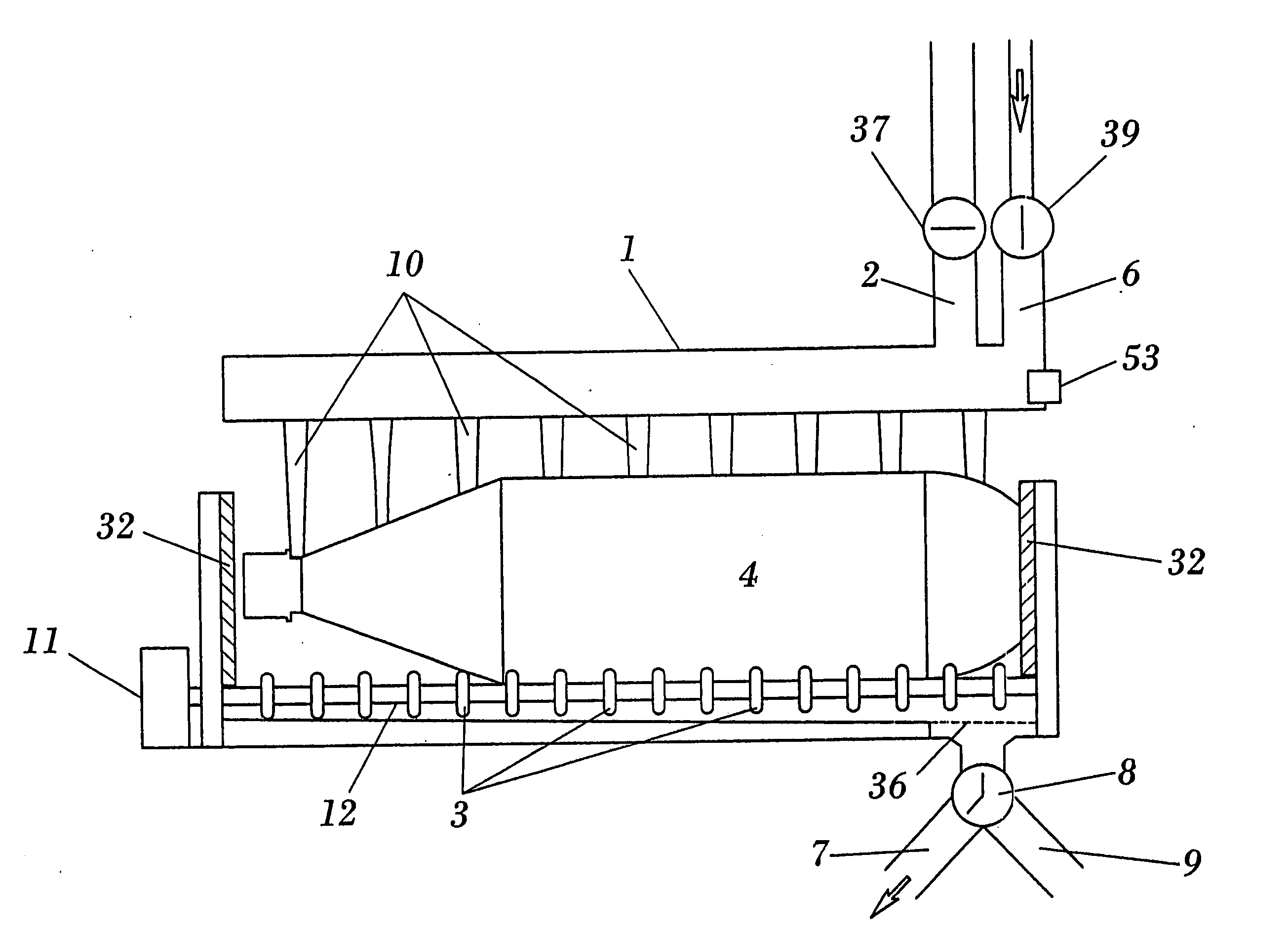

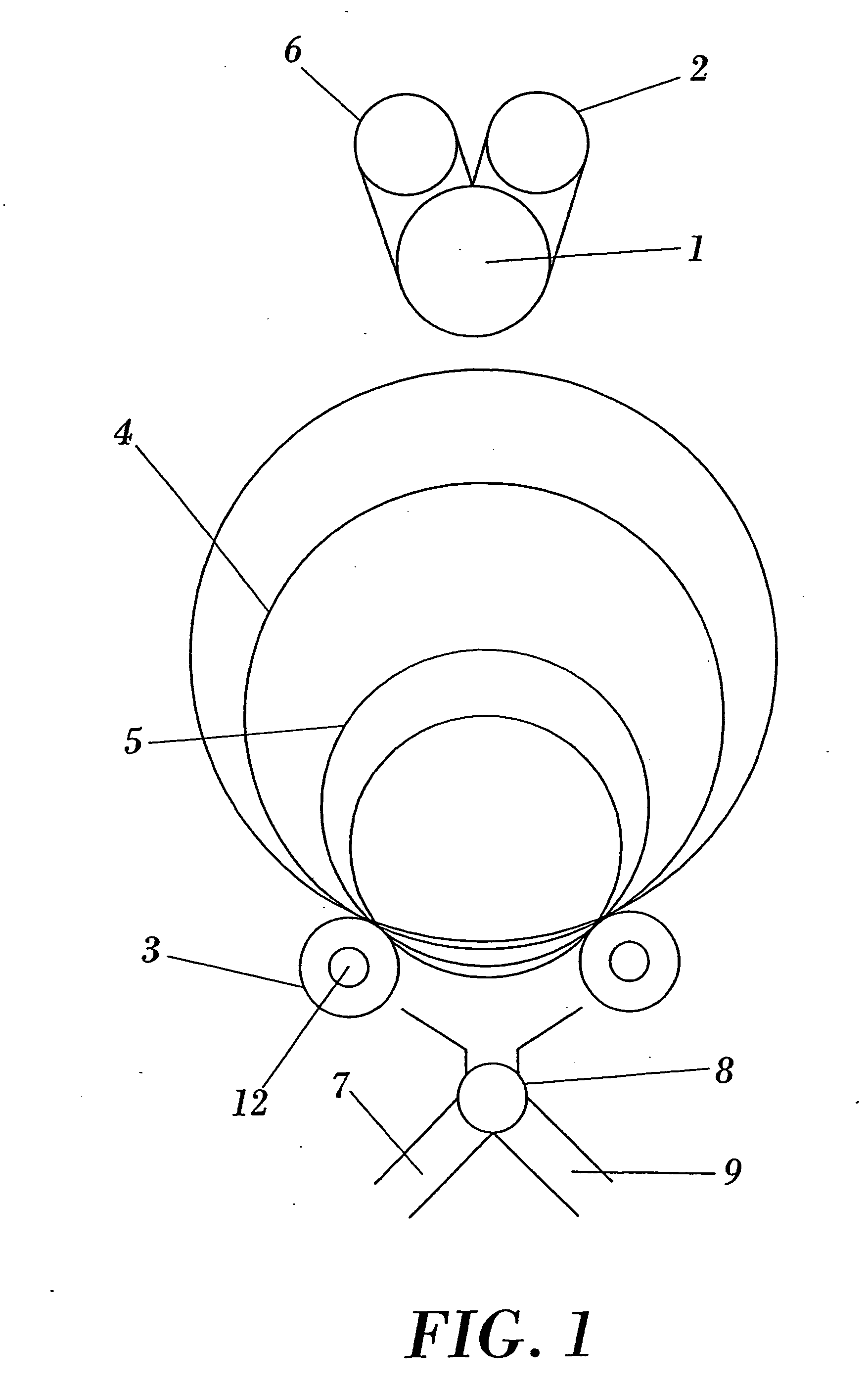

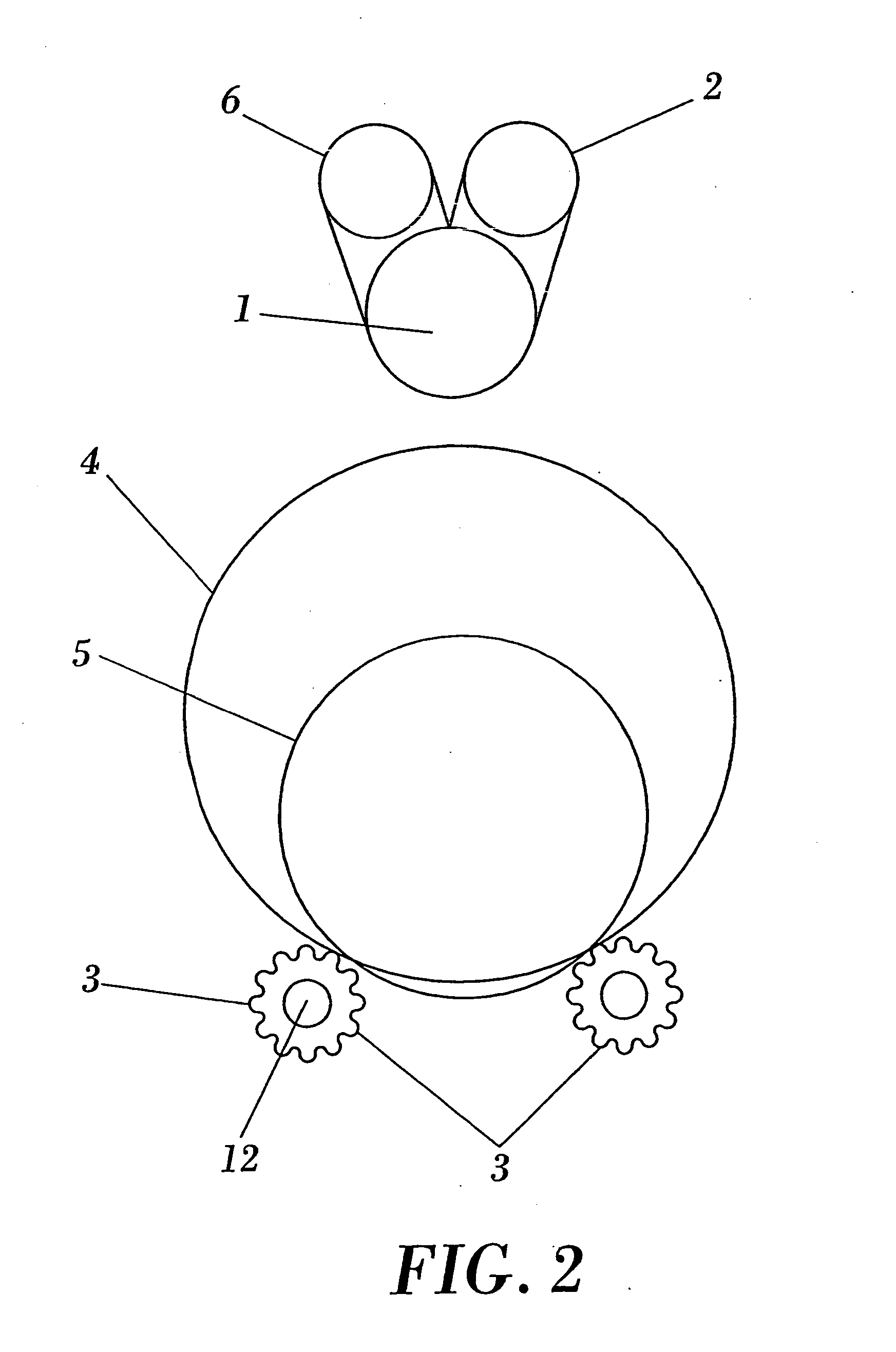

Method and device for rapid cooling of packaged drinks

InactiveUS20060185372A1Smooth rotationLighting and heating apparatusFood preservationSaline waterRinse water

Based on the use of a coolant aqueous liquid, usually brine, maintained at low temperature in a reservoir receptacle, as low as −20° C. if the brine is of Sodium chloride or as low as −50° C. if it is of Calcium chloride, applied on the upper surface of the container, positioned horizontally, rotating about its axis, by means of soft jets, during a time which is calculated from the initial and desired temperatures, the temperatures of the cold solution and of the rinsing water and from the temporal coefficient of the packaged beverage, so that the brine glides over its surface drawn by the force of gravity, surrounding it completely through surface tension adherence to the surface of the container located underneath, where it is detached, determining at all times that the brine coats the greater part of the container during the spraying. By substituting the coolant liquid with hot water the rapid heating of packaged beverages is produced.

Owner:CONDE HINOJOSA JOSE RAMON

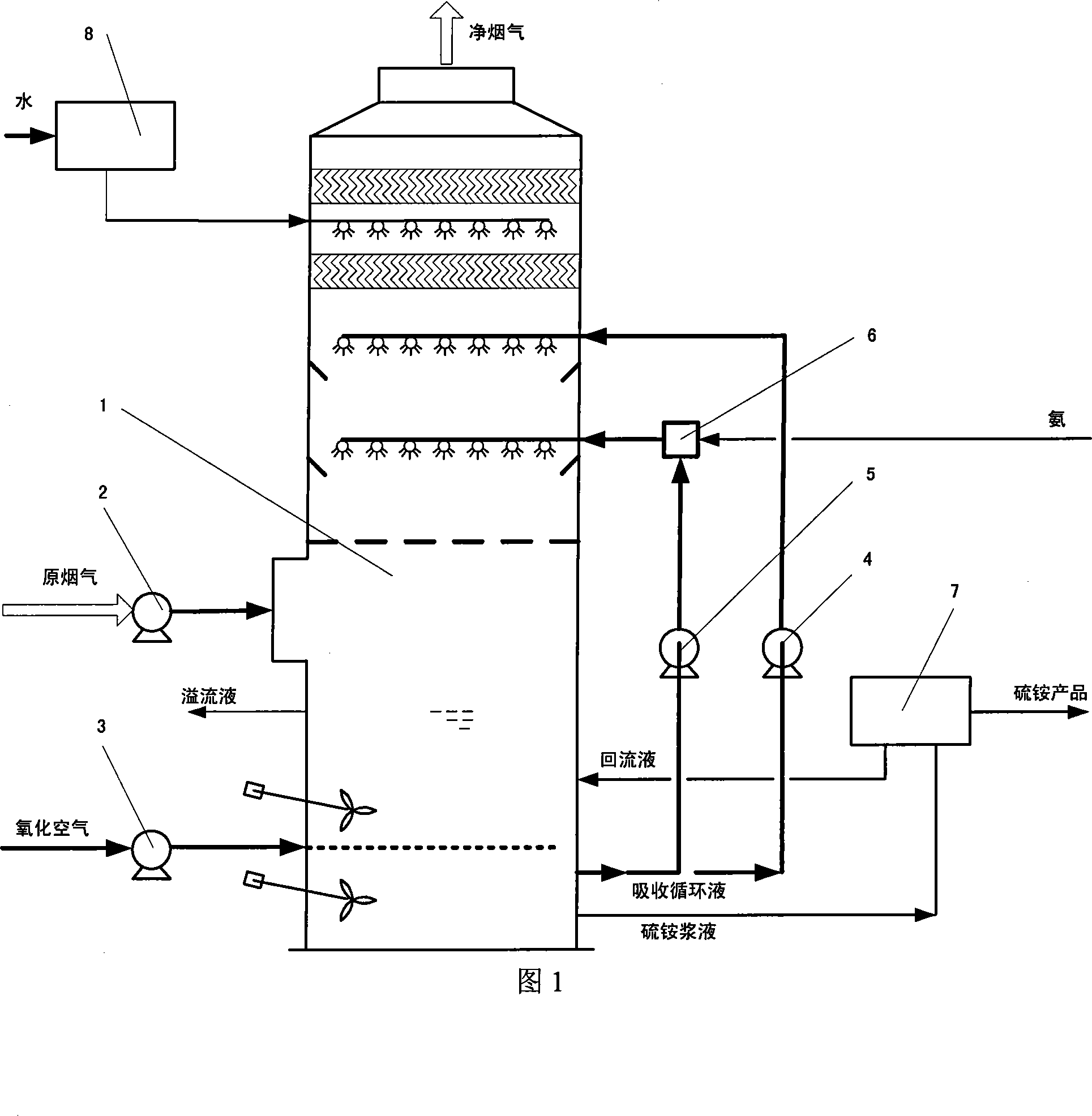

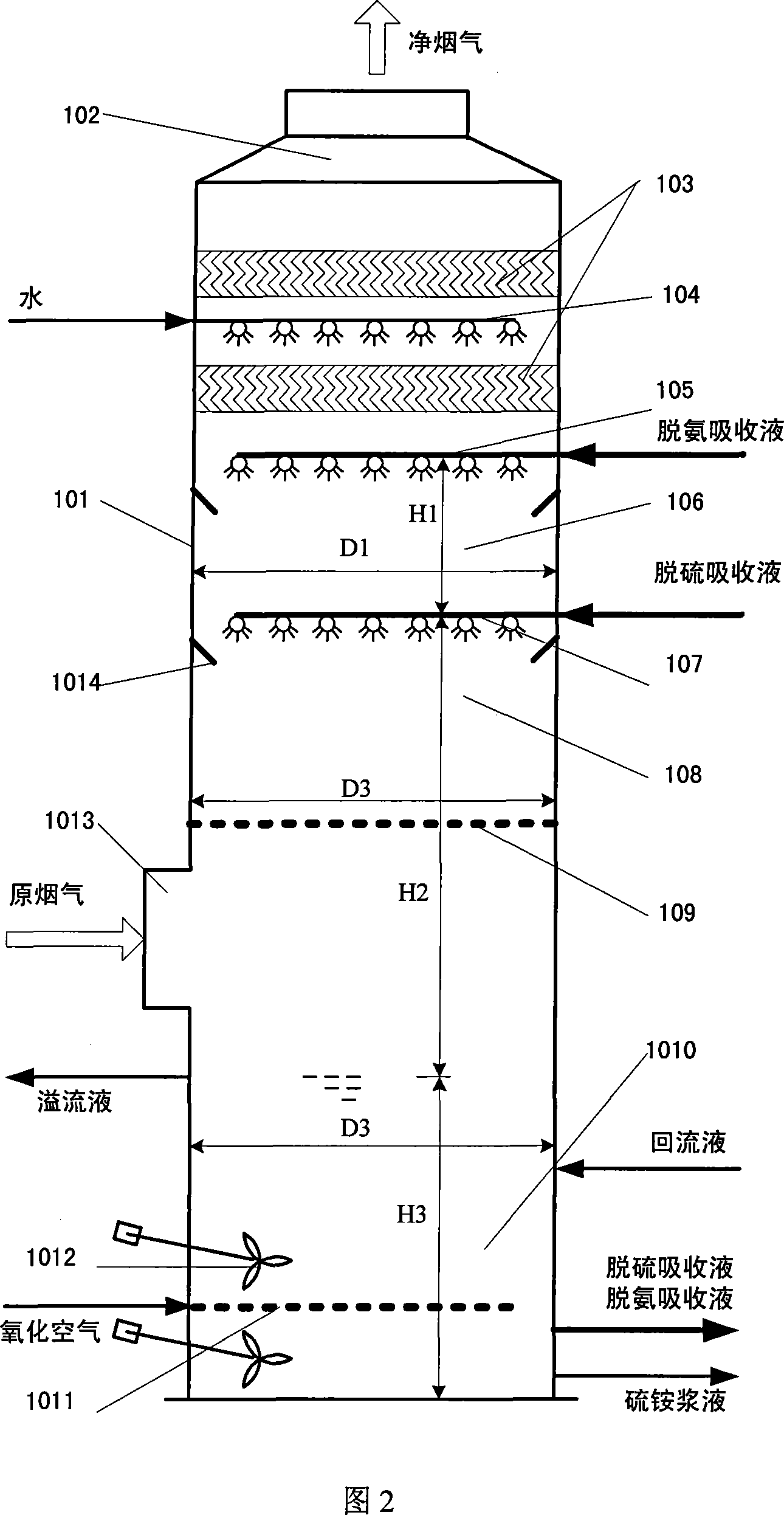

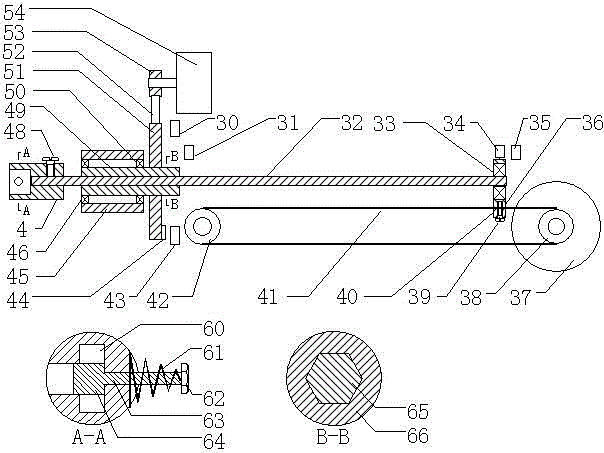

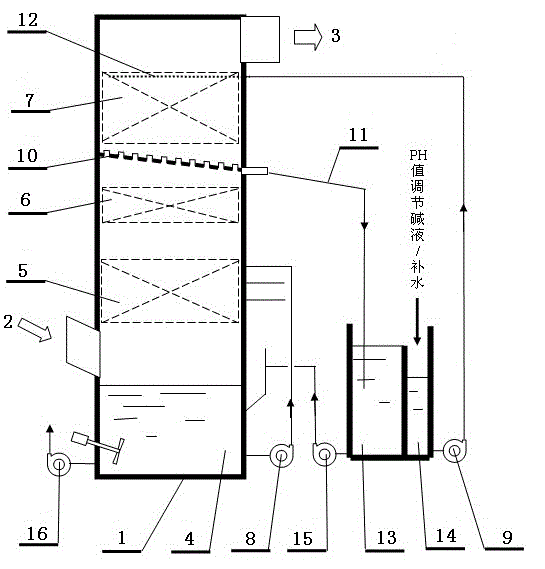

Method and device for reclaiming sulfur dioxide from countercurrent flue gas

InactiveCN101085410AAvoid short circuitImprove efficiencyDispersed particle separationSulfur compoundsSulfur dioxideFlue gas

The invention relates to the new SO2 absorption device with three function areas, namely deamination zone, desulfuration zone and oxidization zone. It has purification air exhaust at the top of the SO2 absorption device, top of the inside of the tower composed of water and liquid separator of the flush water distributor, deamination circulation absorbing distributor connected to its inlet under the air and liquid separation component, under the deamination zone set with desulfuration circulation absorbing outlet connected liquid absorbing distributor, under which set the desulfuration zone, with absorbent liquid overflow outlet on the tower, and oxidization crystallization zone under the overflow outlet. It is low in investment, small in energy consumption, strong in gas treatment ability, high in efficiency, applicable for mass mode industrial application.

Owner:娄爱娟

Cleaning method

InactiveUS6348157B1Strong resistanceSuppress formationSemiconductor/solid-state device manufacturingElectrostatic cleaningCleaning methodsChemical cleaning

A cleaning method capable of processing at room temperatures without conducting heating, uses little chemicals and water, and does not require special devices or materials. The chemical cleaning processes and rinse processes employ pure water or ultrapure water in a semiconductor wet cleaning process, rinse water or chemicals which suppresses formation of surface oxide films, removes particles and prevent their redeposition, and aids in the hydrogen termination of the silicon atoms. The cleaning method of the resent invention includes cleaning which is conducted using pure water containing ozone, cleaning conducted using a cleaning liquid containing HF, H2O, and surfactant, while applying vibration having a frequency of 500 kHz or more, cleaning conducted using pure water containing ozone, cleaning conducted using a cleaning liquid containing HF and H2O in order to remove oxide films, and cleaning which is conducted using pure water. After cleaning a material to be cleaned using chemicals, rinsing is conducted using pure water or ultrapure water containing hydrogen gas in an amount of 0.5 ppm or more and containing oxygen gas in an amount of 100 ppb or less.

Owner:OHMI TADAHIRO +1

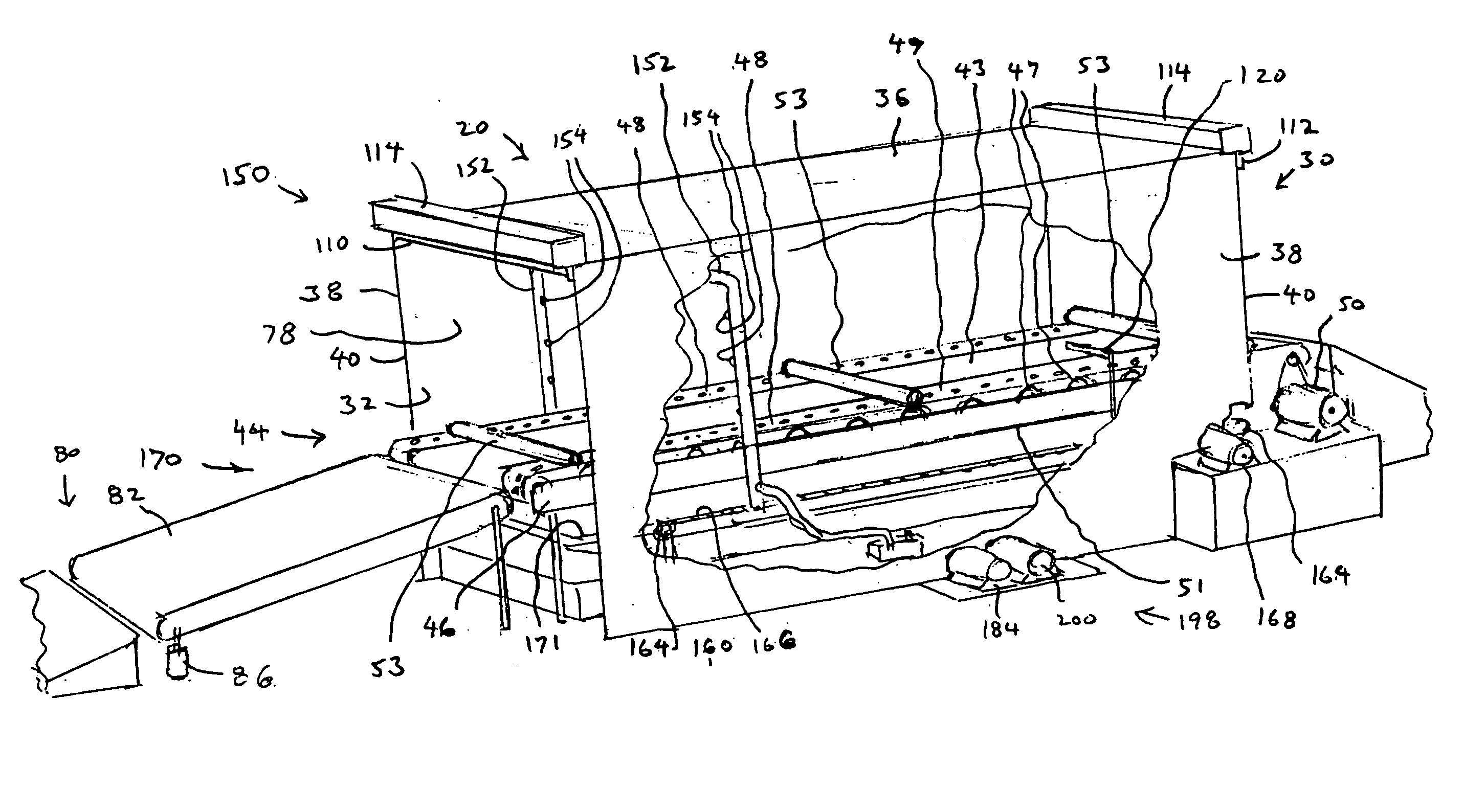

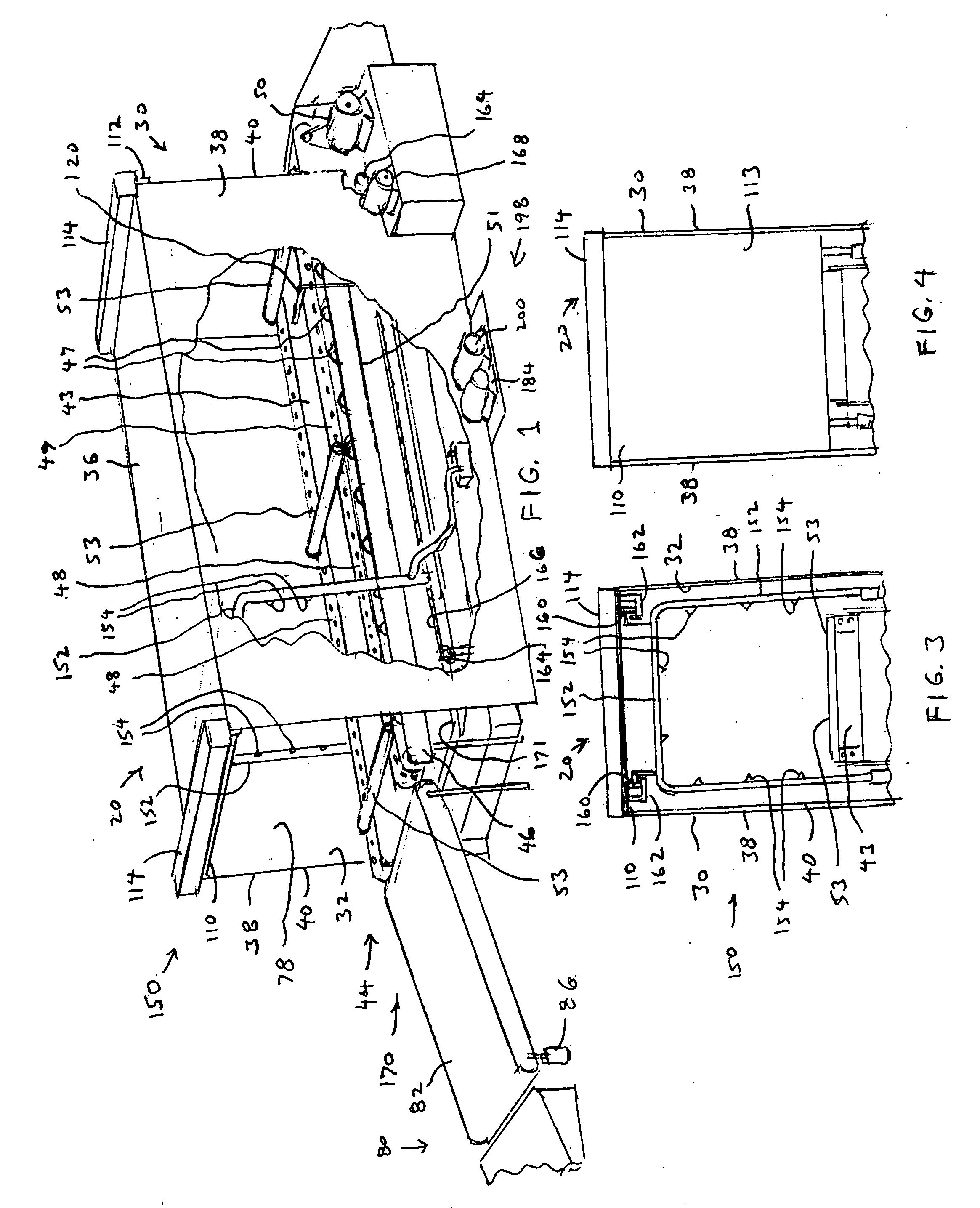

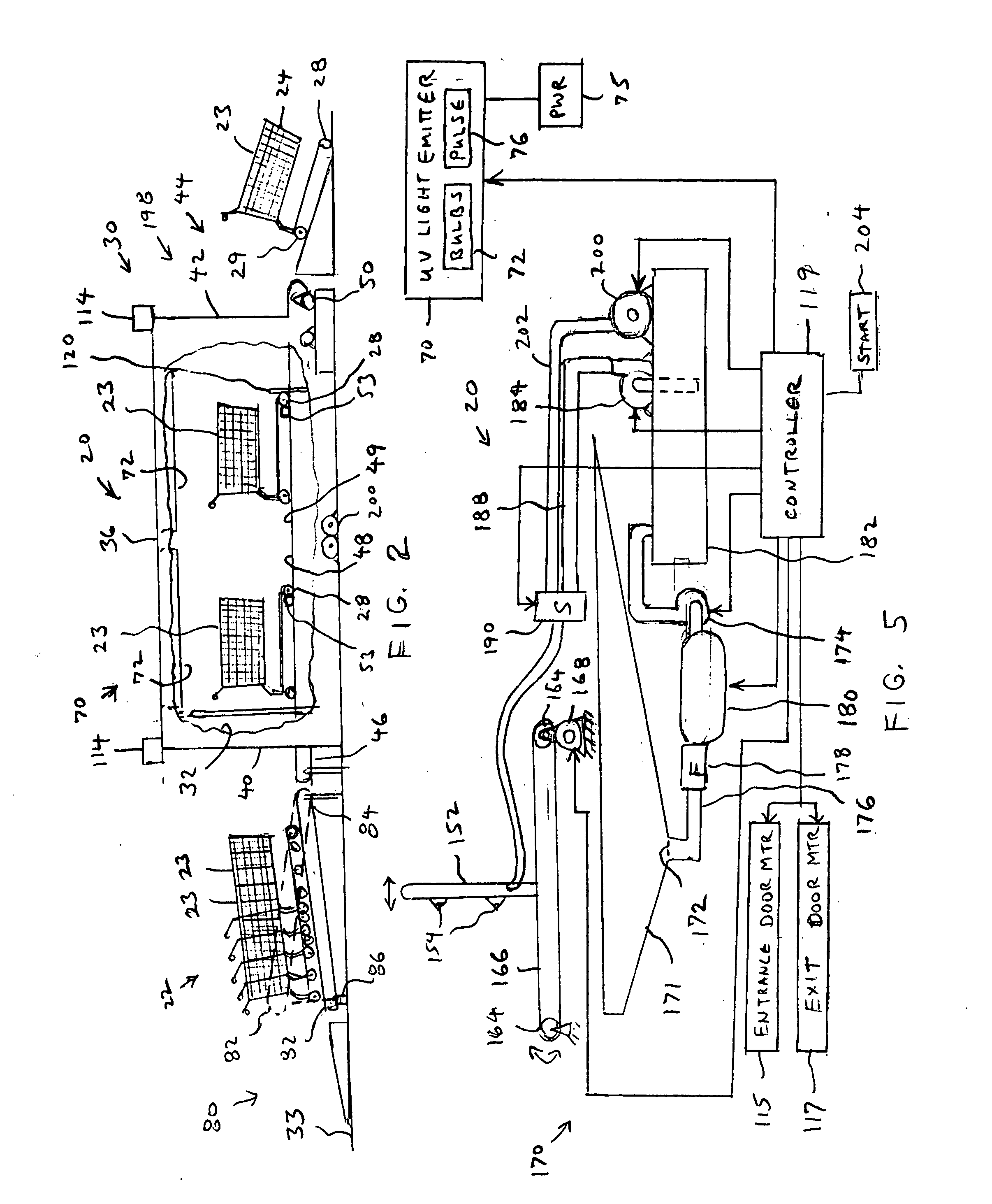

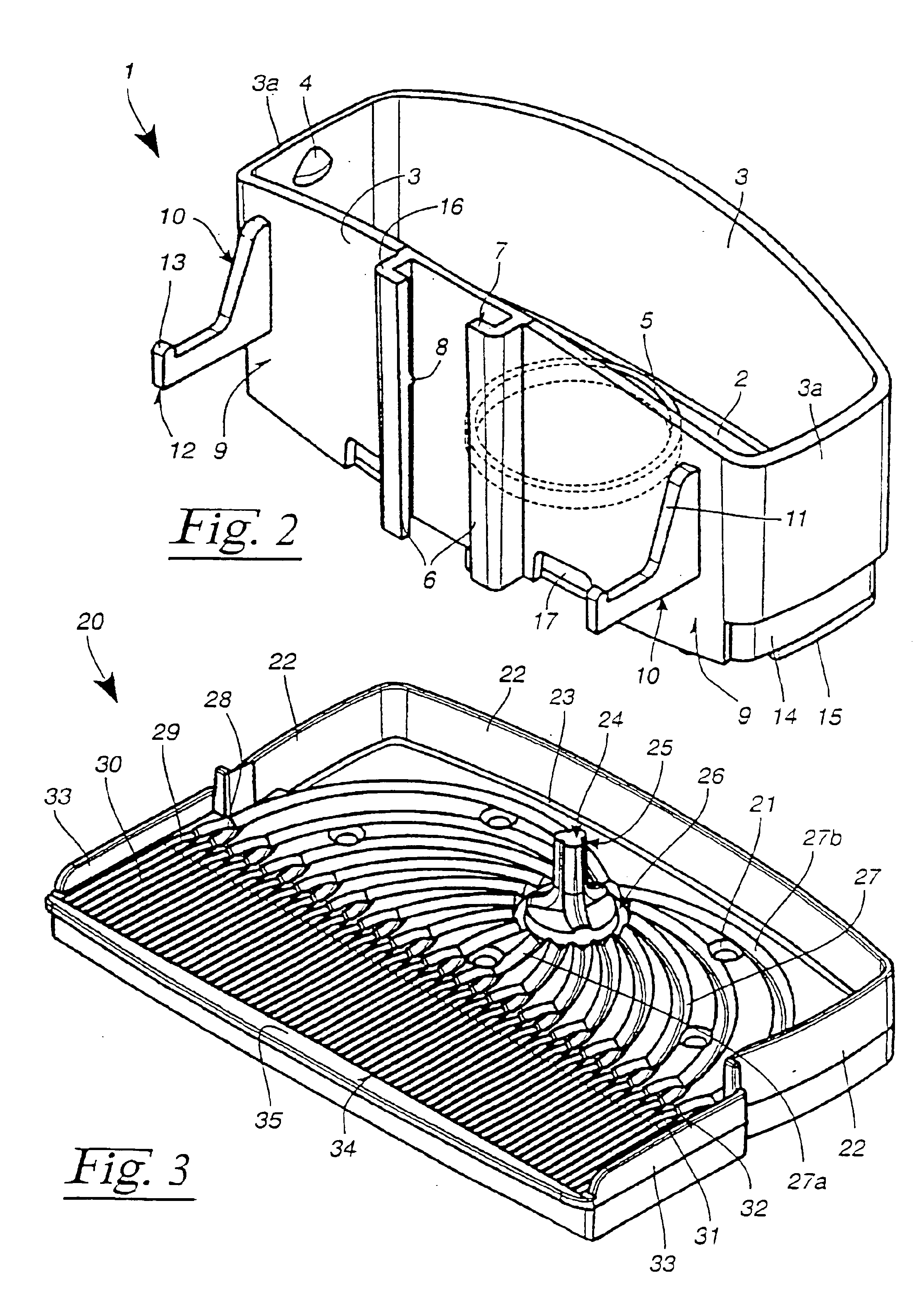

System and method for cleaning or sanitizing items intended for re-use

A system and method for sanitizing or cleaning an item, such as a grocery store shopping cart or a child stroller, for re-use utilizes a passageway having an entrance and an exit and a sanitizing or cleaning station between the entrance and exit. The item is conveyed through the passageway into the station, and pulsating beams of ultraviolet (UV) light are directed toward the item to sanitize the surfaces of the item which are struck by the pulsating beams of light. The system can be supplemented with an arrangement for directing water toward the item for rinsing purposes and for subsequently directing air toward the item for drying purposes. Moreover, the rinse water can be collected and sanitized after it has been directed toward the item during a rinsing operation for subsequent re-use.

Owner:ENVIRONMENTAL CART CLEANING

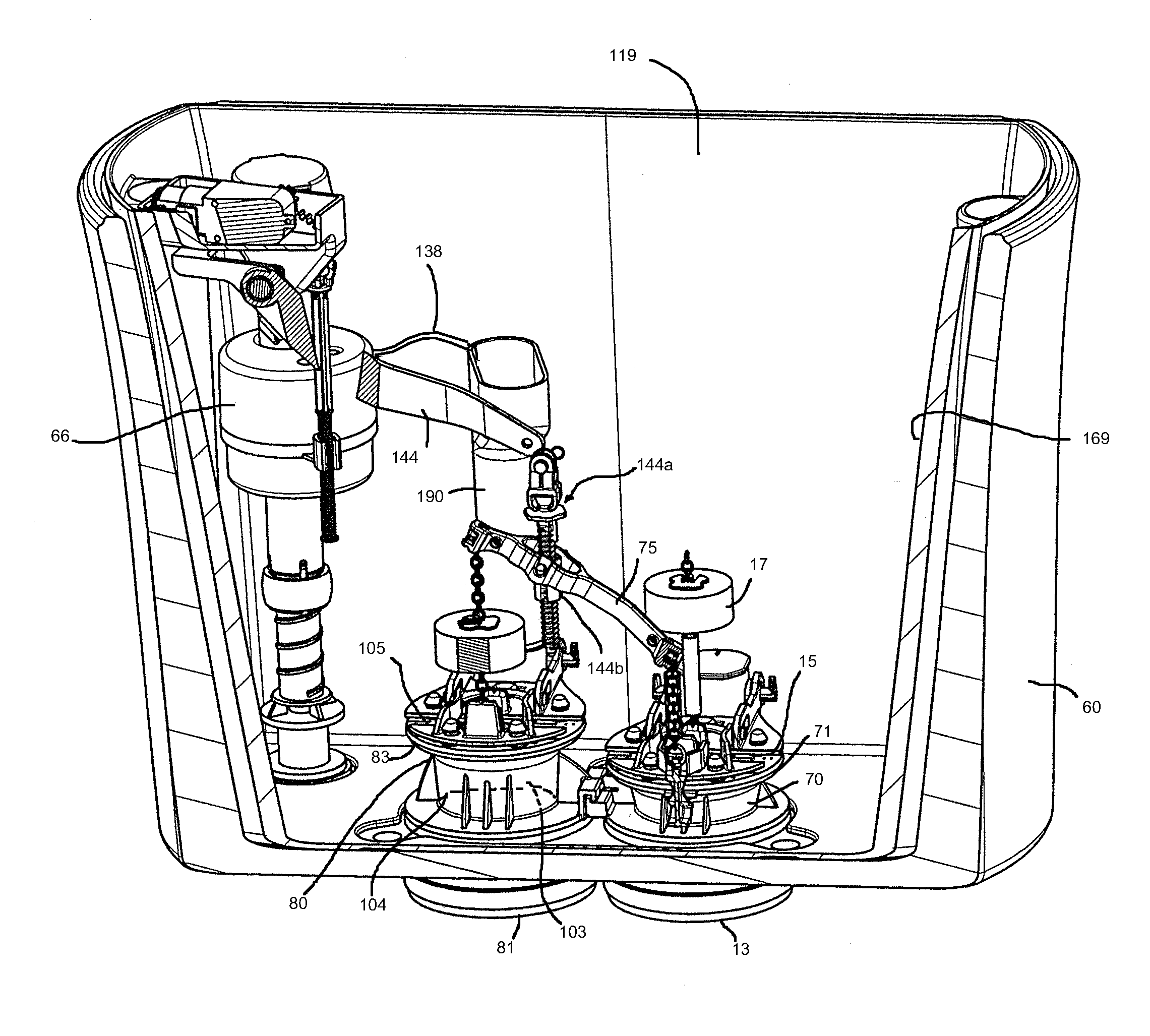

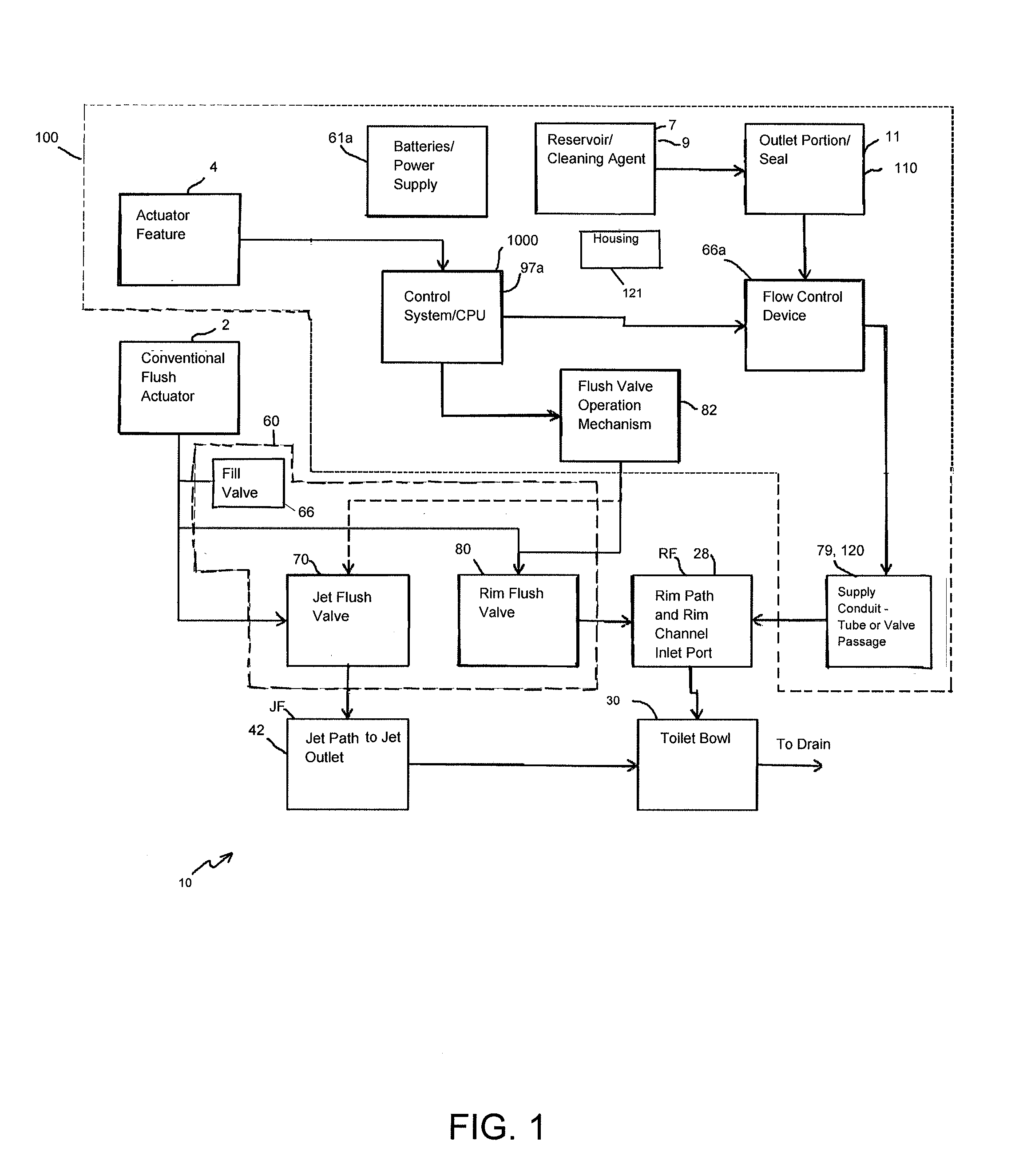

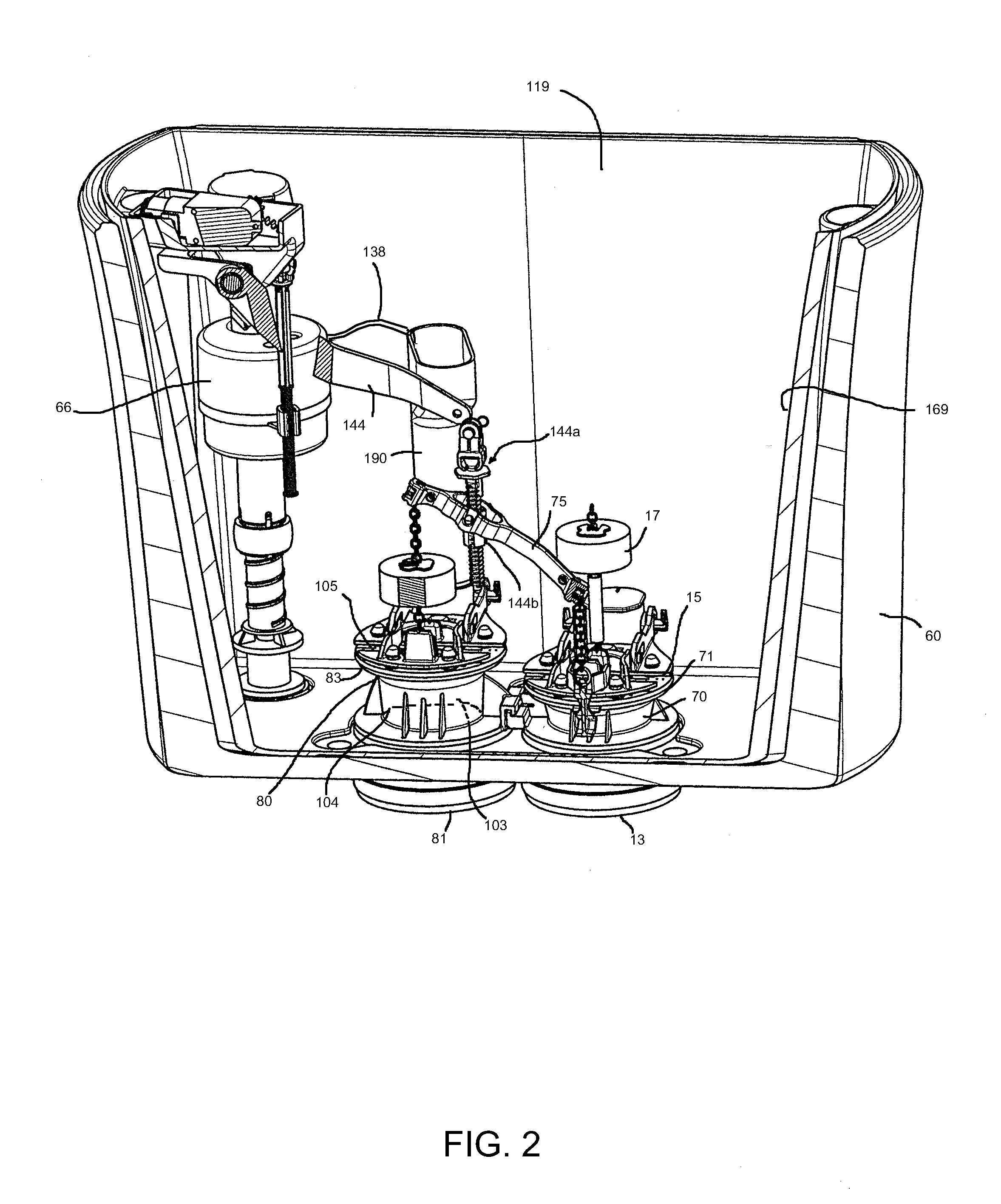

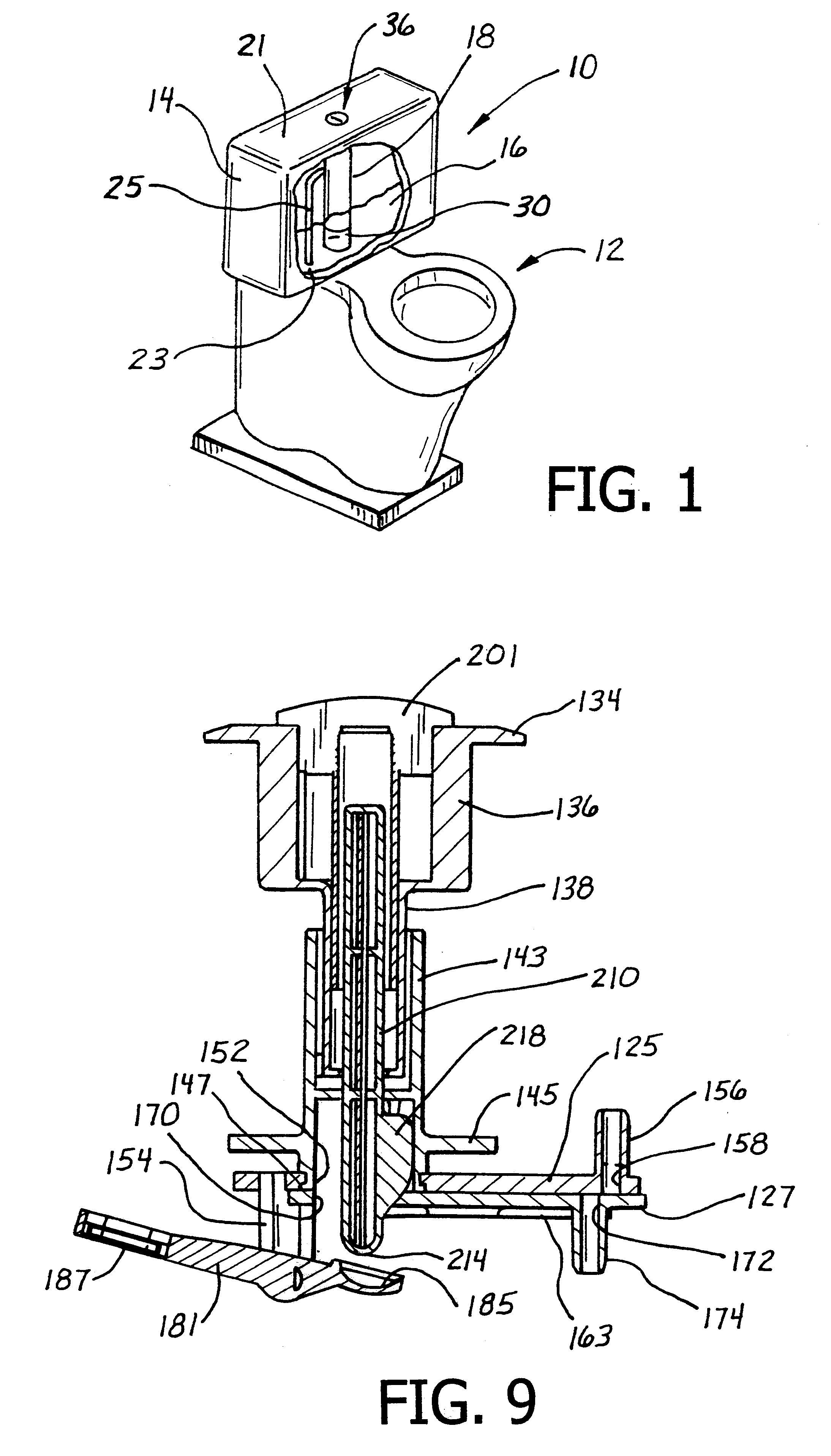

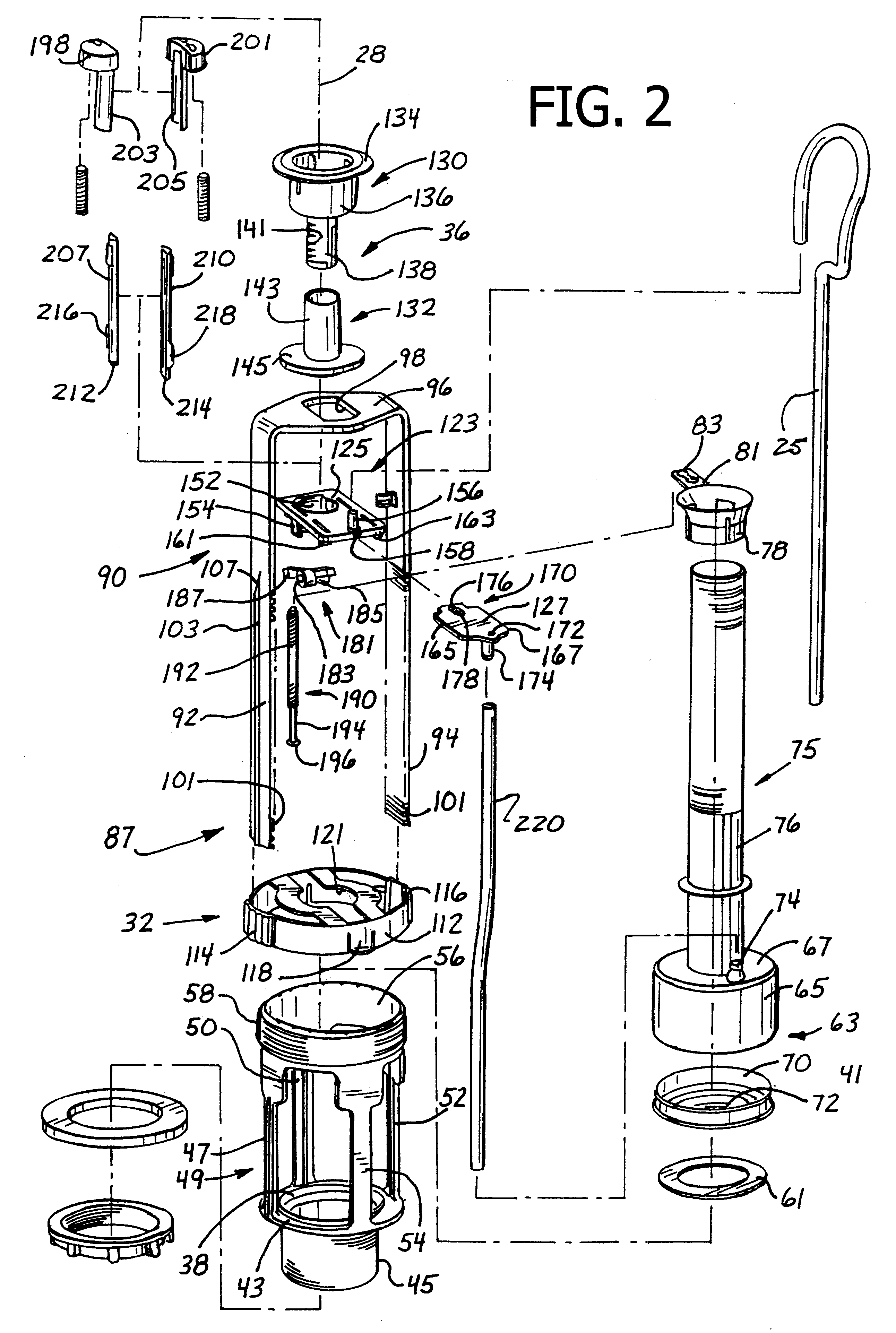

Self-Cleaning Toilet Assembly and System

Toilet assemblies having various embodiments of a cleaning system are described herein which include a toilet assembly and a cleaning system. The toilet assembly has a toilet bowl, a tank, a flush valve, and a rim in fluid communication with the bowl through a rim flow path from an outlet of the flush valve to at least one rim outlet port. The flush valve is configured to operate in a flush actuation mode wherein the flush valve is able to provide flush water flow sufficient for the toilet assembly to initiate a flush siphon or provide a wash down flush and to operate in a cleaning actuation mode wherein the flush valve is only partially opened to allow for introduction of a cleaning agent and flush water mixture to the bowl that is insufficient to initiate a siphon but sufficient for cleaning the bowl. The cleaning system includes a reservoir for a liquid cleaning agent, a housing for the reservoir, a supply conduit for receiving fluid from within the reservoir and delivering it to a flush valve, a flow control device capable of controlling flow of cleaning agent and a control system activatable by an actuator feature to initiate a clean cycle by operating the flow control device to deliver a dose of cleaning agent to one or more rim outlets, and operating the flush valve in cleaning actuation mode to introduce flush water to carry the dose of cleaning agent through the at least one rim outlet port into the toilet bowl at a flow rate insufficient to initiate a siphon but sufficient for cleaning the bowl.

Owner:AS AMERICA

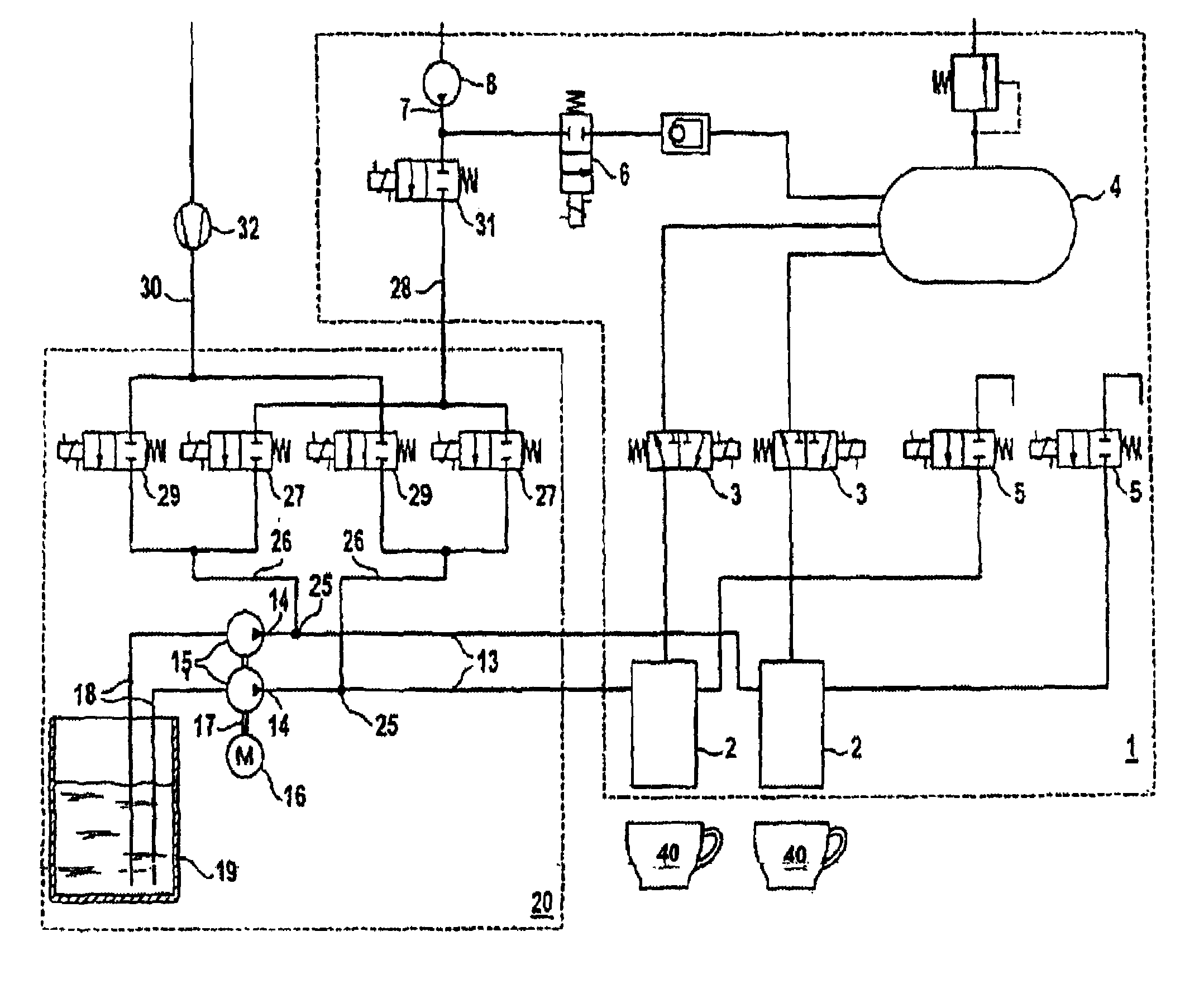

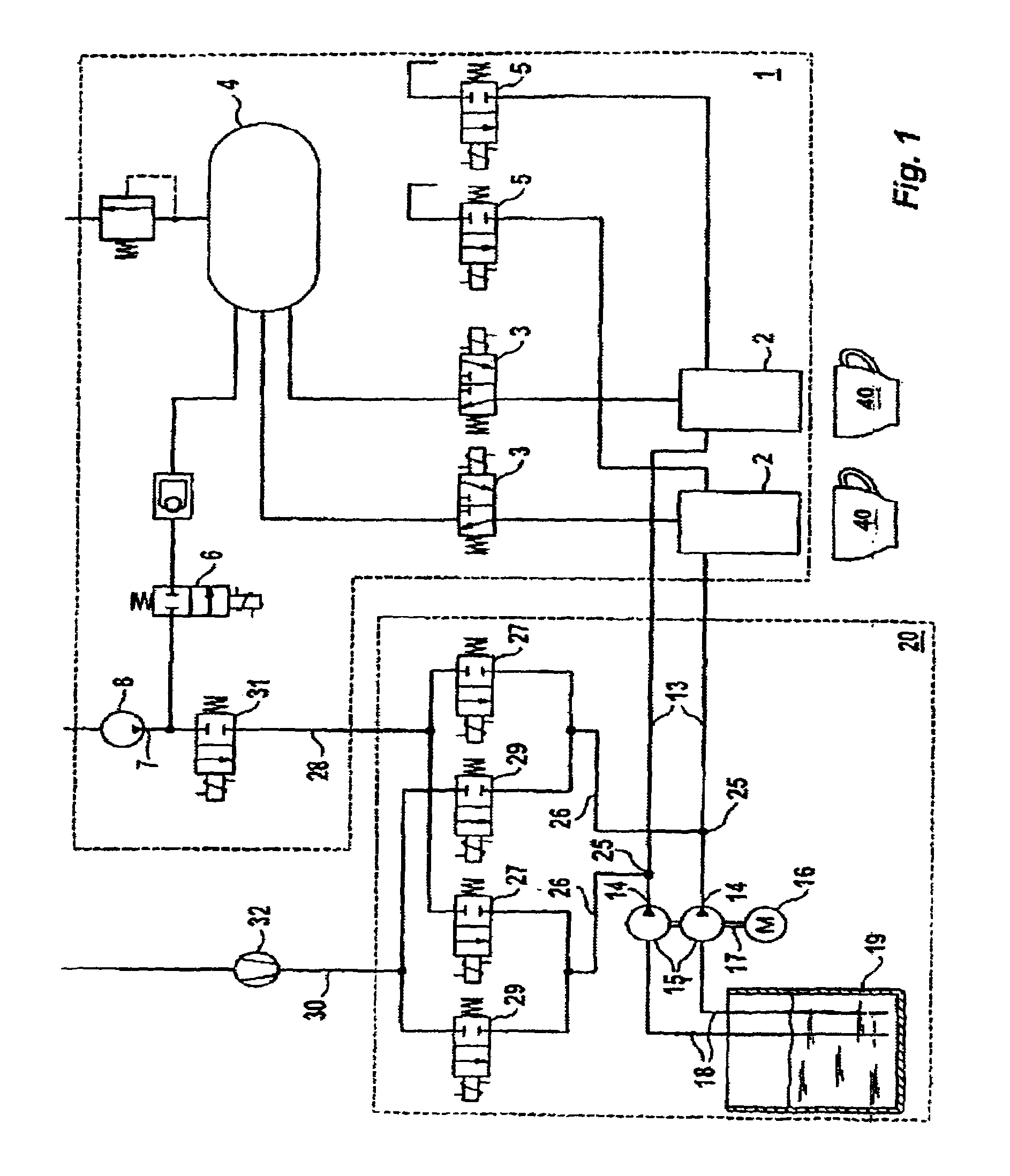

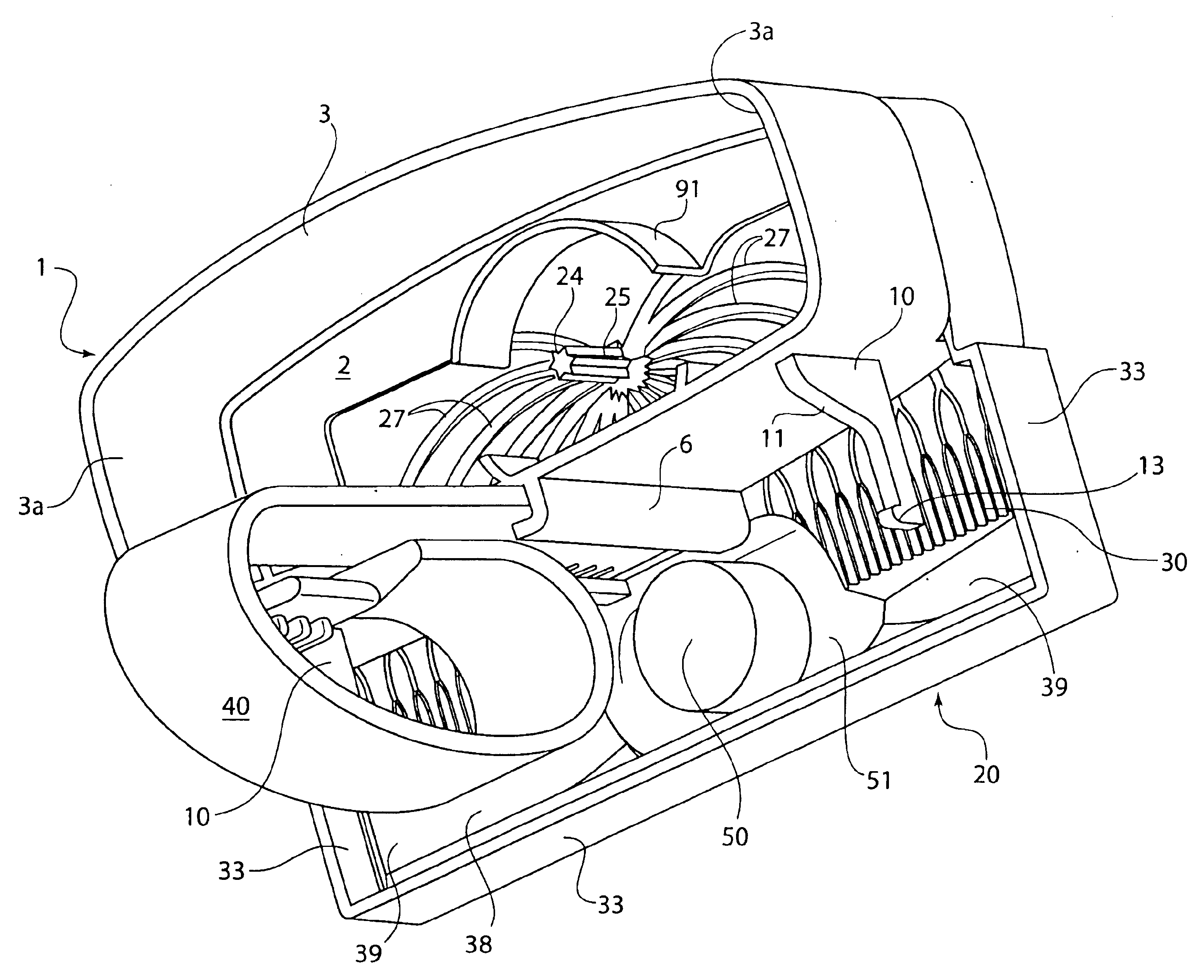

Coffee machine with frothing device and method for cleaning milk suction line

ActiveCN102144892ANo burn hazardReduce the temperatureBeverage vesselsEspresso coffeePulp and paper industry

The invention relates to a coffee machine with a frothing device, especially relates to an automatic espresso coffee machine. The frothing device is provided with an internal milk channel leading to a frothing chamber, a bypass air inlet for operable air supply for the frothing device, a movable milk suction line leading to a milk storing container, and a cleaning device which cleans the frothing device and the milk suction line by using flush water from a continuous type heater of the coffee machine. The flush water from the continuous type heater can be supplied to the bypass air inlet of the frothing device through a valve structure under control. Before the flush water is loaded at the bypass air inlet, the milk suction end of the milk suction line can be directly or indirectly communicated with a remaining water tank of the coffee machine. The invention also relates to a method for cleaning the movable milk suction line connected to the frothing device, especially to the frothing device of the coffee machine.

Owner:EUGSTER FRISMAG

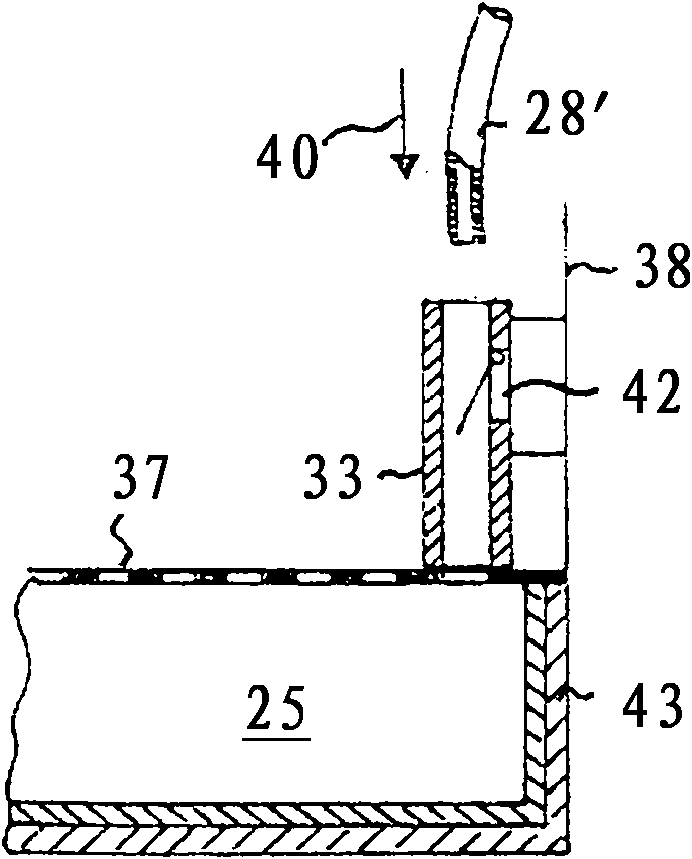

Closed loop cleaning system

InactiveUS6858090B2Hollow article cleaningLiquid hydrocarbon mixture productionDistillationPetroleum product

Railroad tank cars that have contained petroleum products are cleaned of asphalt residues by a closed cleaning system. An initial spray of terpene-based solvent is followed by a water rinse. The solvent extracts hydrocarbons from the asphalt residue. The solvent and hydrocarbon are separated by filtration, stratification, and distillation, allowing reuse of clean solvent and sale of marketable oil products. The rinse water is cleaned by filtration and evaporation of solvent residues, allowing reuse of the water. The asphalt solids such as residual inorganics are removed by filtration as a dry product suited for disposal in a landfill.

Owner:HEBERT SHIRLEY A

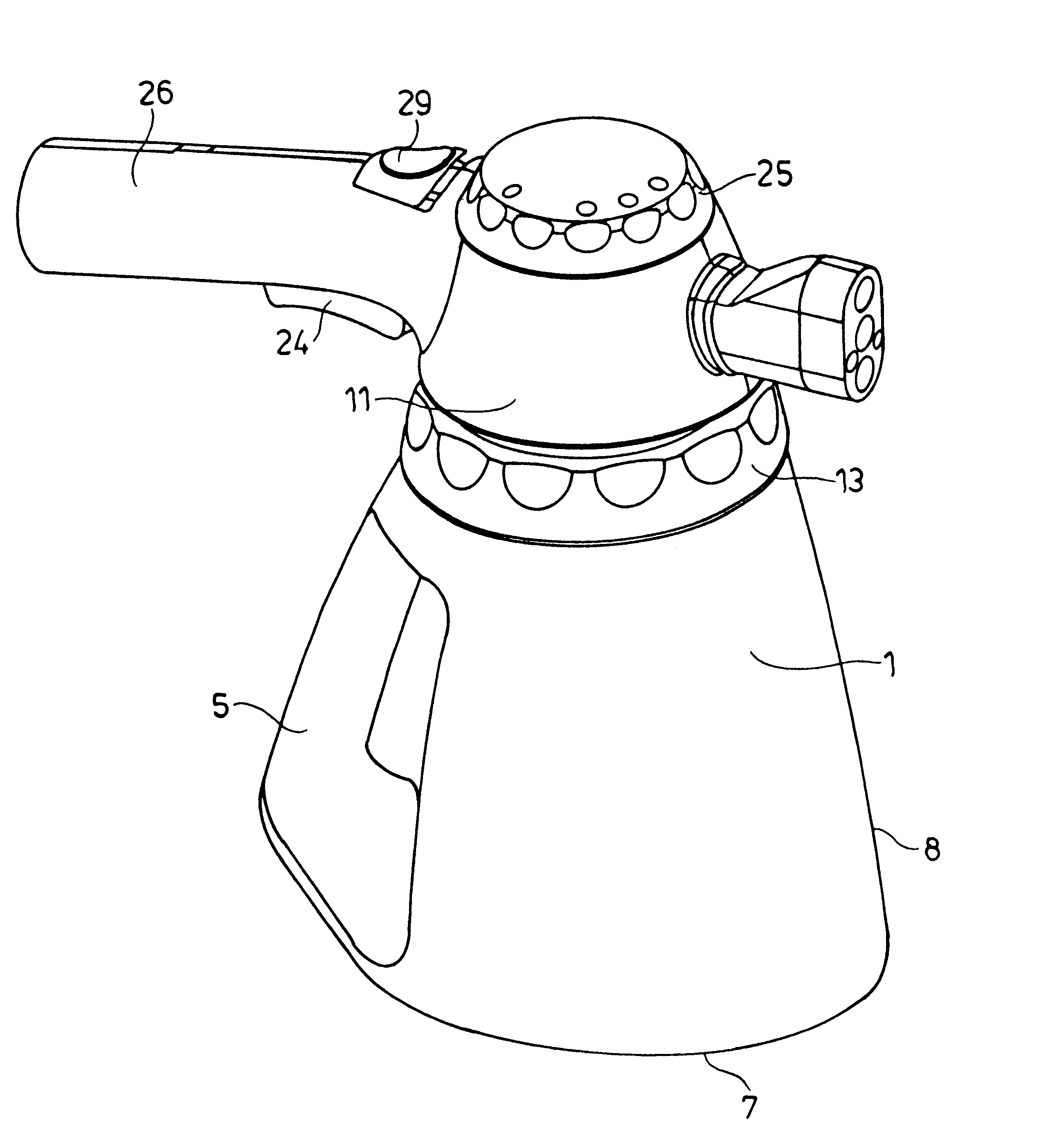

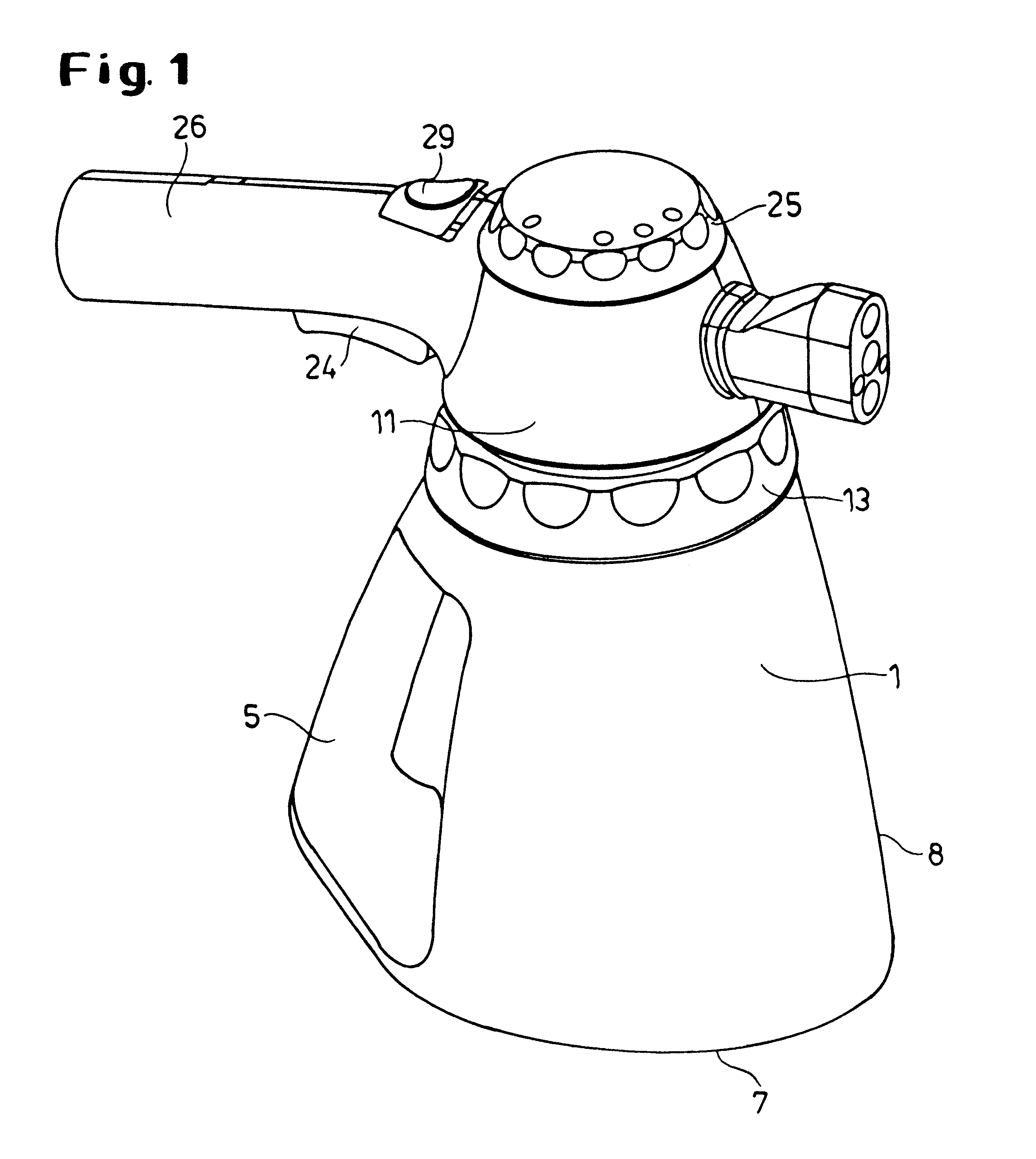

Spraying device

The present invention relates to a spraying device suitable for spraying cleaning compositions and rinse water onto hard surfaces. More particularly the spraying device may be attached to a hose, for example a conventional garden hose, so that the cleaning composition and rinse water can be applied to outside surfaces, such as vehicles or the outside surface of windows. The spraying device comprises a purifier located inside the cavity of a container and a spray head.

Owner:THE PROCTER & GAMBLE COMPANY

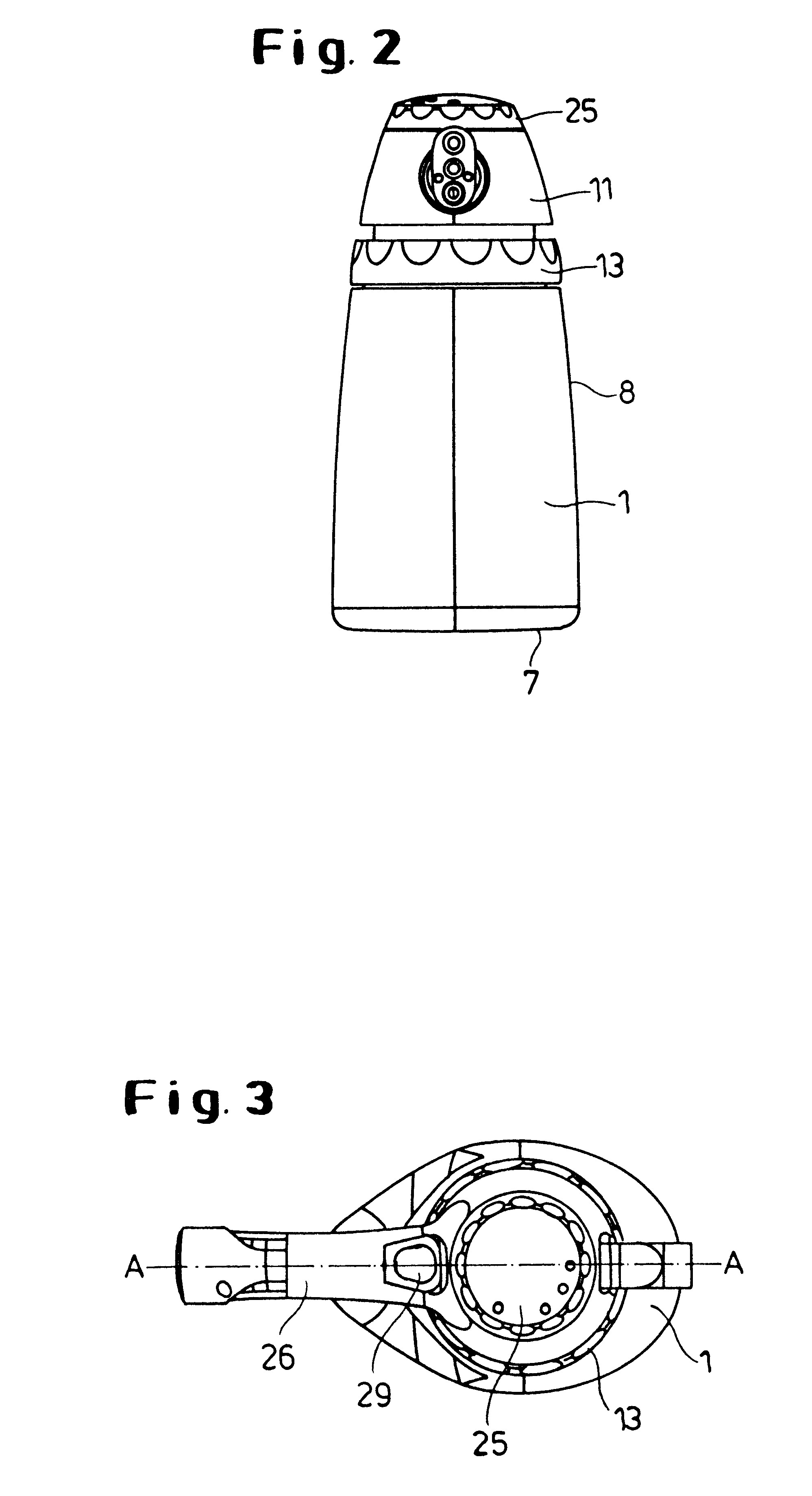

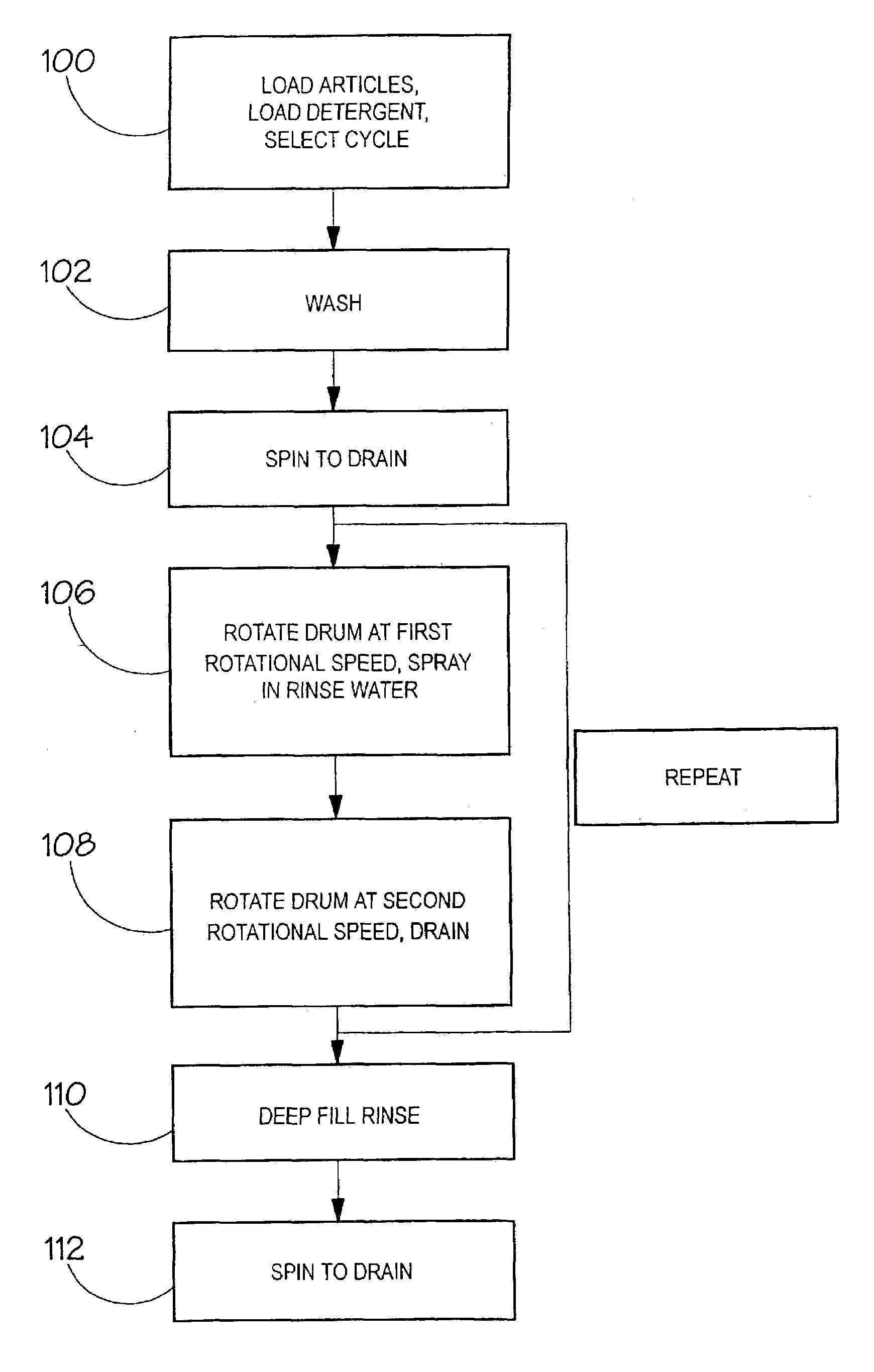

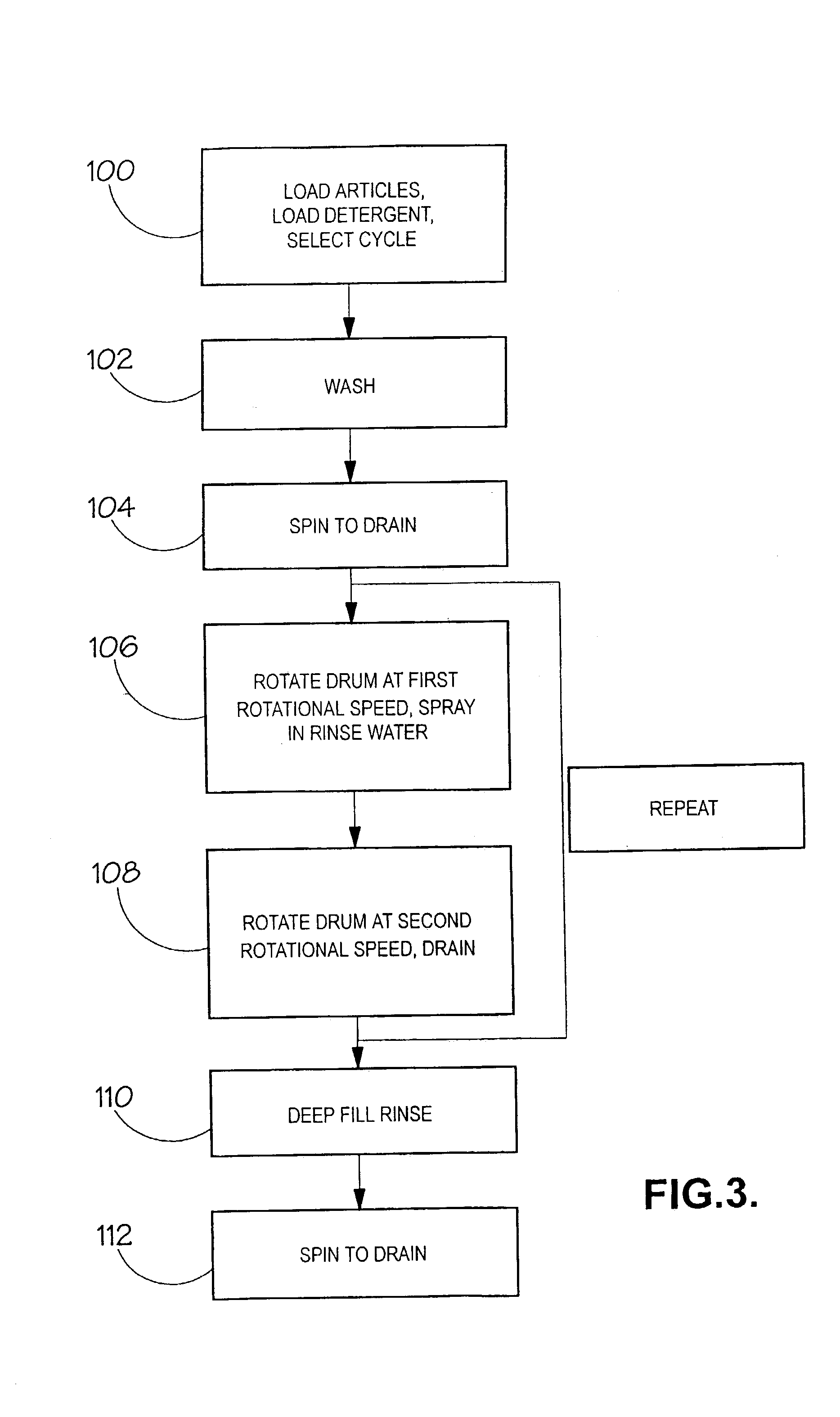

Method of operating a domestic appliance

InactiveUS7146669B2Increase rotation speedImprove the level ofOther washing machinesControl devices for washing apparatusRinse waterMechanical engineering

A method of rinsing a wash load in a washing machine having a perforated drum which is rotatable about an axis and capable of receiving the wash load and having a water inlet which is capable of introducing water to the interior of the rotatable drum includes the steps of rotating the drum about the axis at a first rotational speed sufficient to retain the wash load stationary with respect to the rotating drum; introducing rinse water into the interior of the rotating drum via the inlet so that the rinse water is sprayed from the inlet onto the wash load, the volume of rinse water so introduced being less than the volume required to saturate the wash load; and increasing the speed of rotation of the drum to a second rotational speed sufficient to spin a significant proportion of the rinse water out of the wash load.

Owner:DYSON TECH LTD

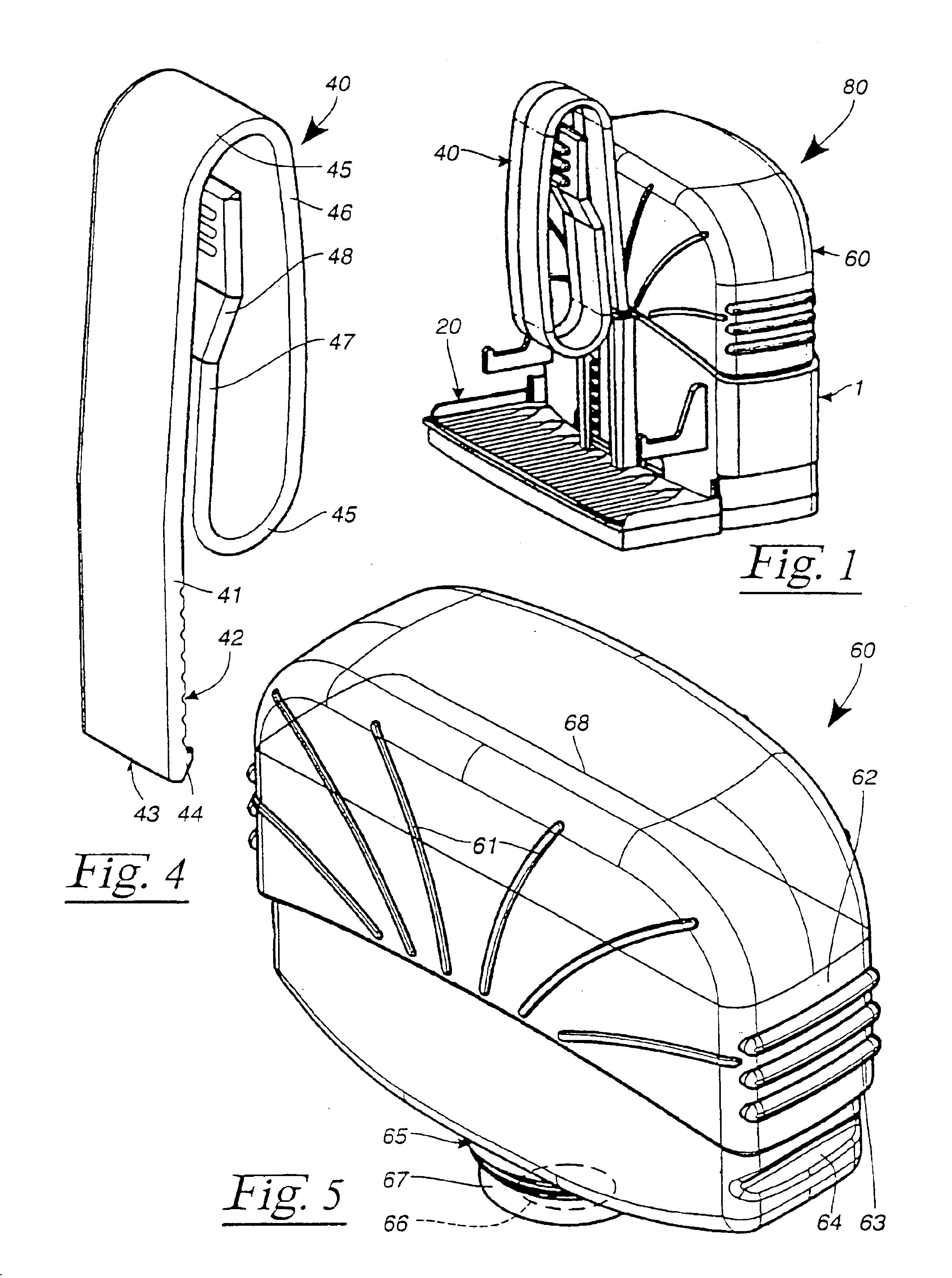

Device for portioned delivery of milk, particularly for cappuccino machines

ActiveUS6959642B1Reliable and efficient rinsingAvoid connectionMilk preparationMilk preservationLine tubingRinse water

A delivery head for delivering a milk portion is connected via a connection line to a milk container in a refrigerator. A rinsing agent source is connected via a first line to a connection part in the connection line. A first on-off valve is inserted in the first line. The connection part is also connected via a second line and a second valve to a fresh air source. The container, the valves, and the connection part are installed in a refrigerator. Through this implementation, complete emptying of the connection line and the delivery head of rinse water after the rinsing procedure, as well as efficient rinsing during the rinsing procedure, are achieved.

Owner:RANCILIO GROUP

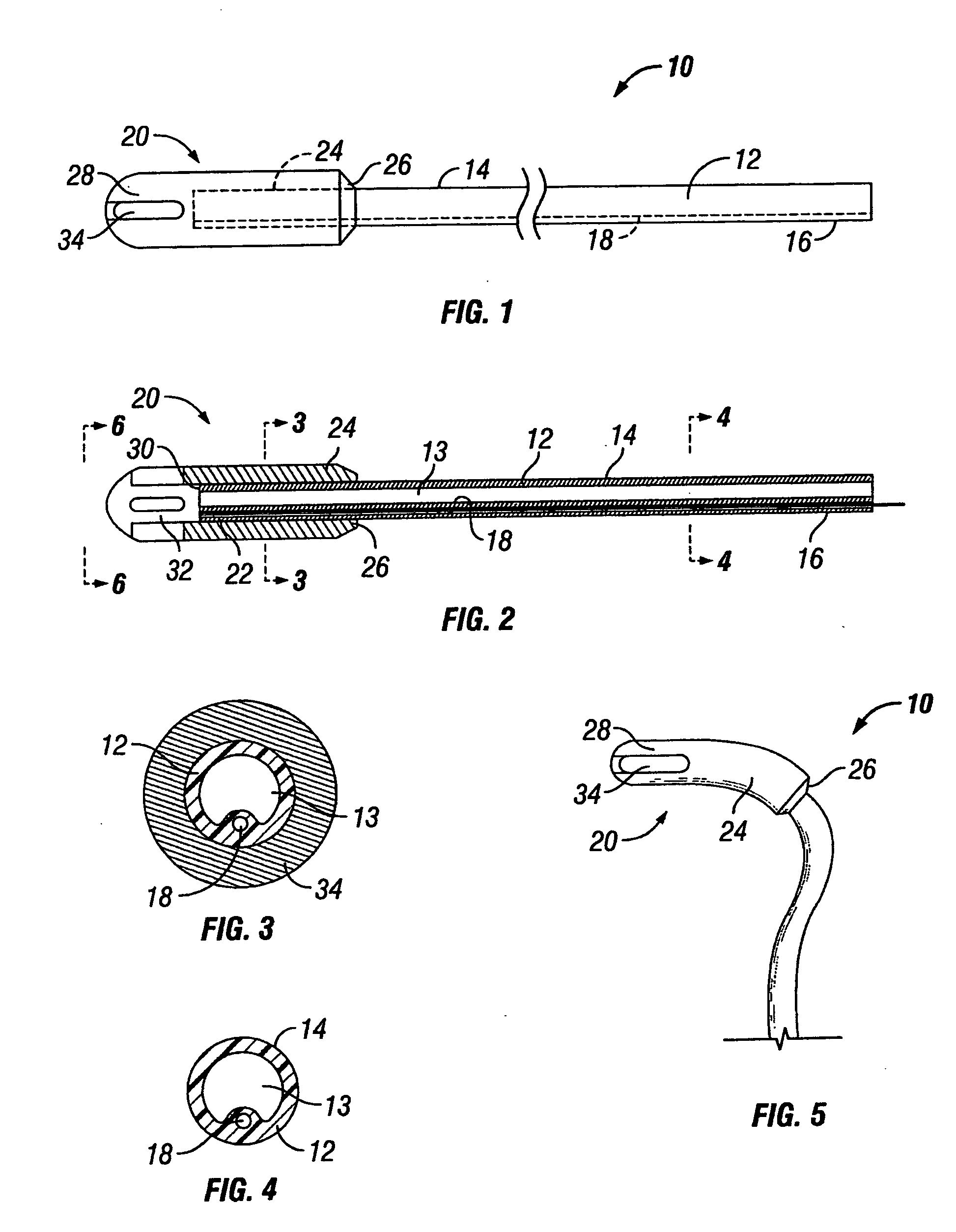

Aspirator having a cushioned and aspiration controlling tip

Owner:MAHLMANN LEE A

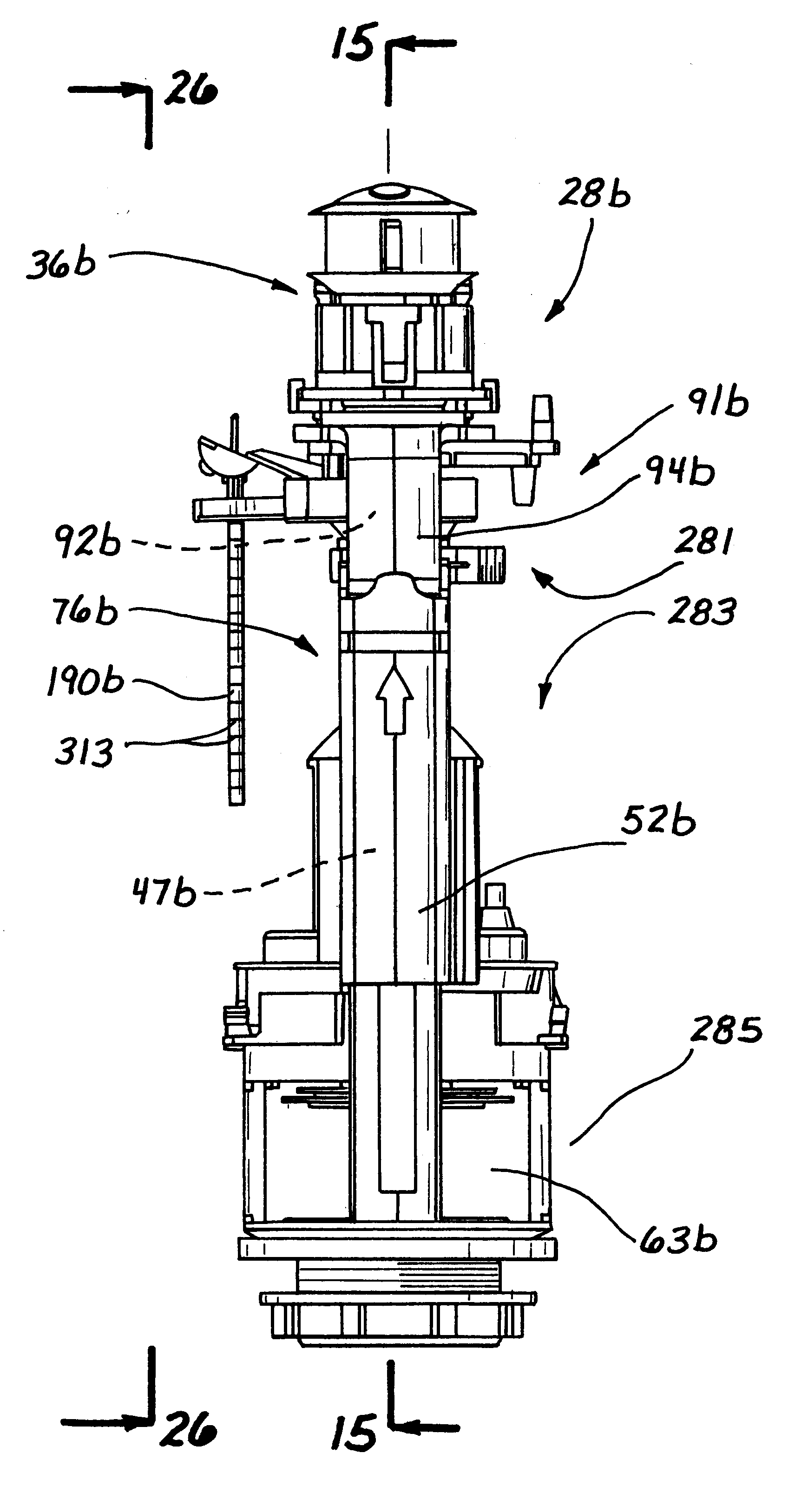

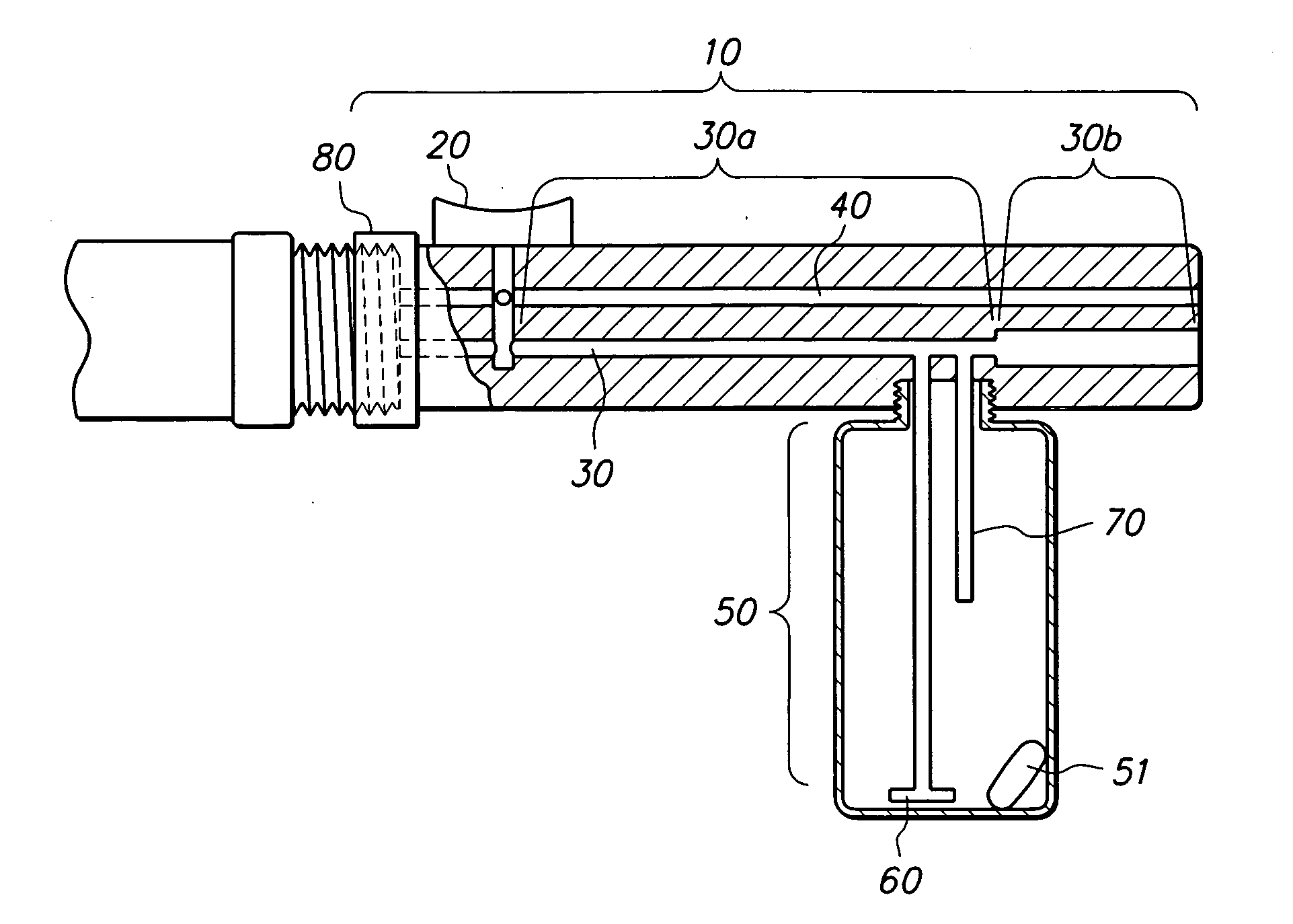

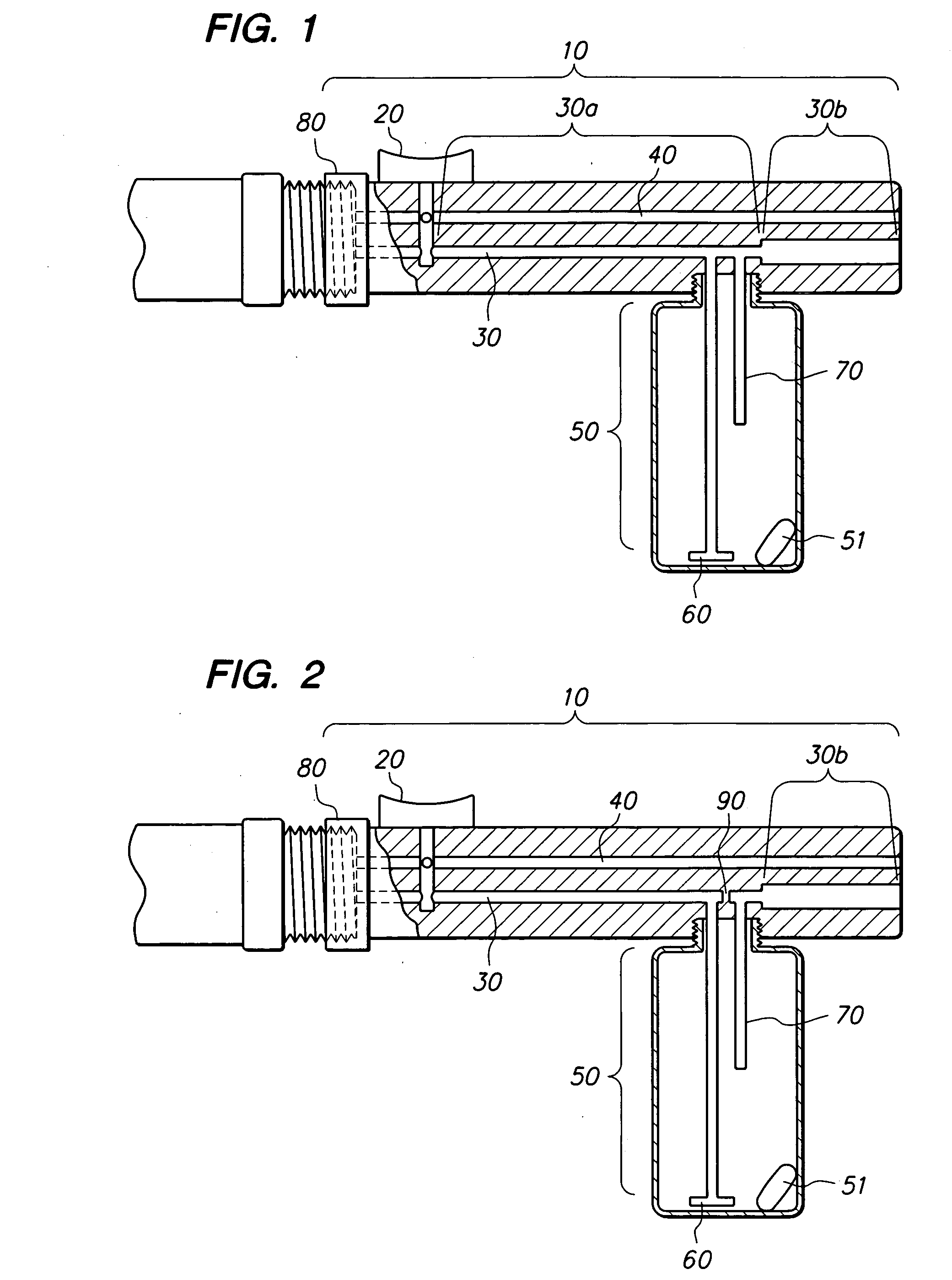

Advanced dual-flush valve

InactiveUS6442772B2Operating means/releasing devices for valvesFlushing devicesRadial motionRinse water

A flush valve is adapted to be mounted in the tank of a toilet and includes a selector assembly and a flush valve. The selector assembly is accessible from outside the toilet and provides for initiation of the flushing operation and an alternative choice between a larger flush water volume and a smaller flush water volume. A support structure provides for both axial and radial movement of the selector assembly relative to the flush valve in order to facilitate mounting and aligning of the flush valve assembly. A slide mechanism provides for variation of at least the smaller flush water volume.

Owner:FLUIDMASTER

Multi-barreled sprayer for selective spraying a plurality of substances and / or rinse water

A multi-barreled sprayer for applying a diluted product such as a diluted cleaning solution to a surface for cleaning thereof and rinsing the diluted product from the surface by spraying a water-only rinse onto the surface from the sprayer. The sprayer can include a flow meter therein for providing a desired product dilution ratio. To provide different spray patterns for the water rinse or diluted product, the sprayer can include a shroud having shaped exit holes. The sprayer includes separate flow paths for the water-only rinse and the diluted product. The flow path for the diluted product includes a mixing chamber in which concentrated tablet product is diluted and mixed with water supplied by a garden hose, for instance. A rotatable valve allows selective application of water or diluted product. Additional embodiments include a trigger assembly that allows selective application of water for either of the water-rinse or diluted product application.

Owner:THE CLOROX CO

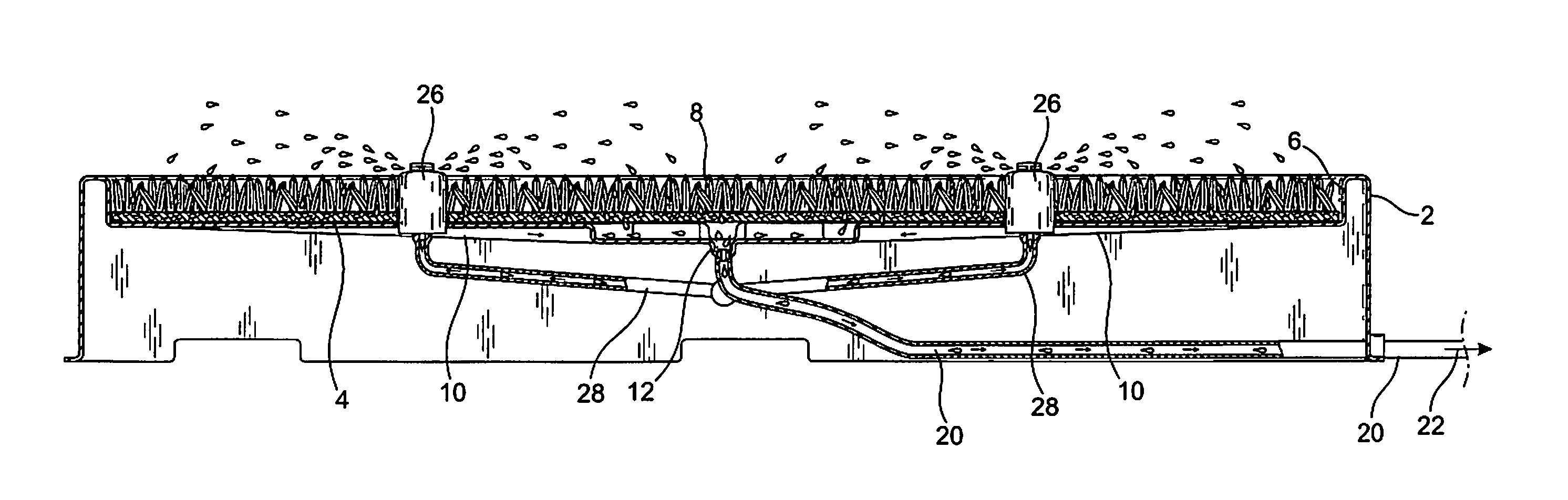

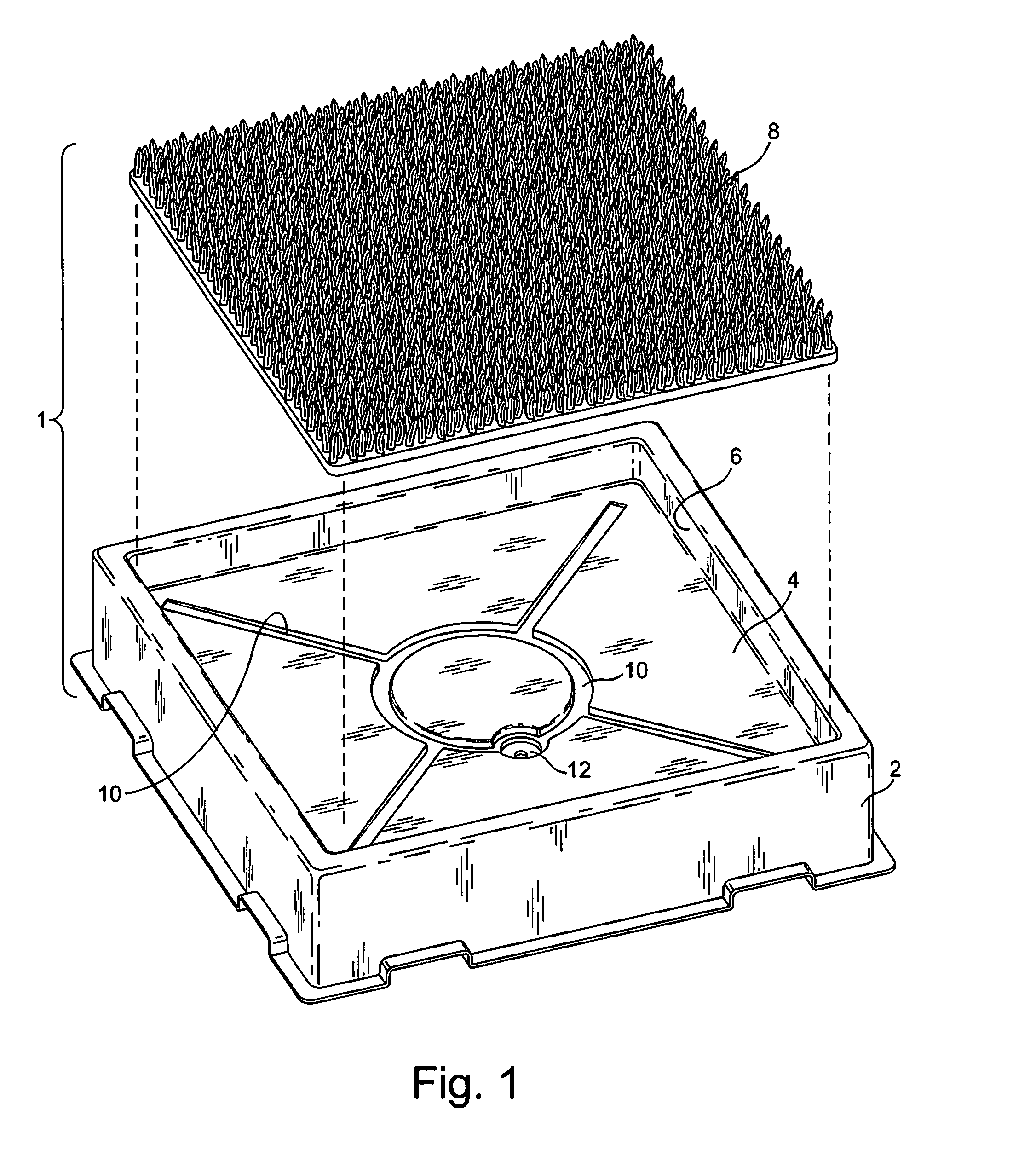

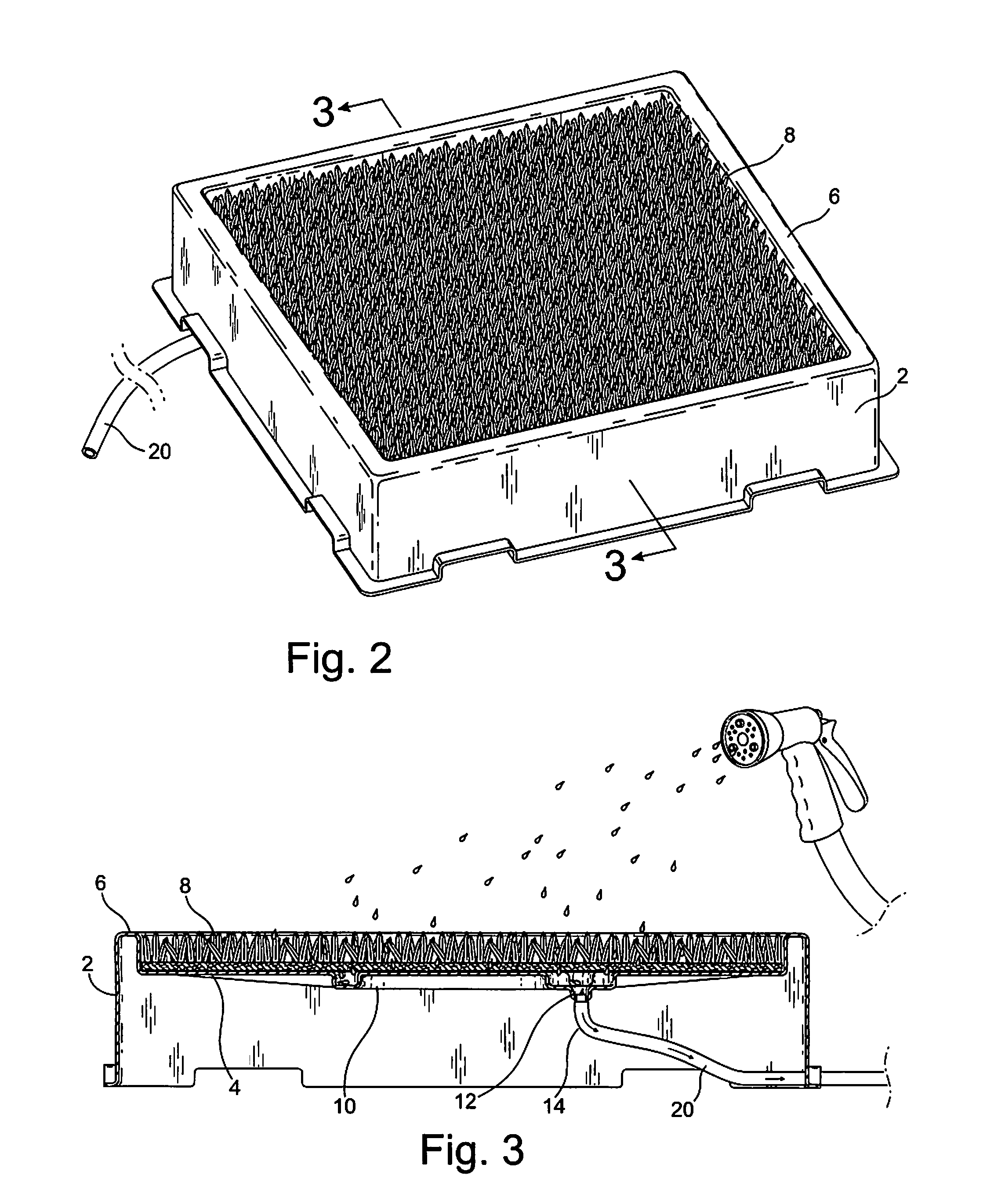

Animal toilet

InactiveUS20100122662A1Prevent over-cyclingPromote degradationAnimal housingChemical/physical/physico-chemical processesRinse waterSolid waste collection

Animal toilets presently do not have an automated method of cleaning the toileting surface and disposing of wastes. The animal toilet disclosed herein is equipped with a permeable toileting surface, a catchment surface underlying the toileting surface to collect and channel liquids, and a drain. The toileting surface may be equipped with a rinsing element to rinse wastes from the toileting and catchment surfaces. The drain may be further equipped with tubing to convey the liquids to a convenient disposal location. The animal toilet may be equipped with a moving toileting surface, which results in improved rinsing, and potential solid waste collection. In all embodiments, absorbent material may be used in place of permeable material for the toileting surface, which may not require any rinsing. The solid waste disposal may be automated through the use of rinse water and disposal tubing routed to the proper disposal location.

Owner:KENNINGTON BRANDON

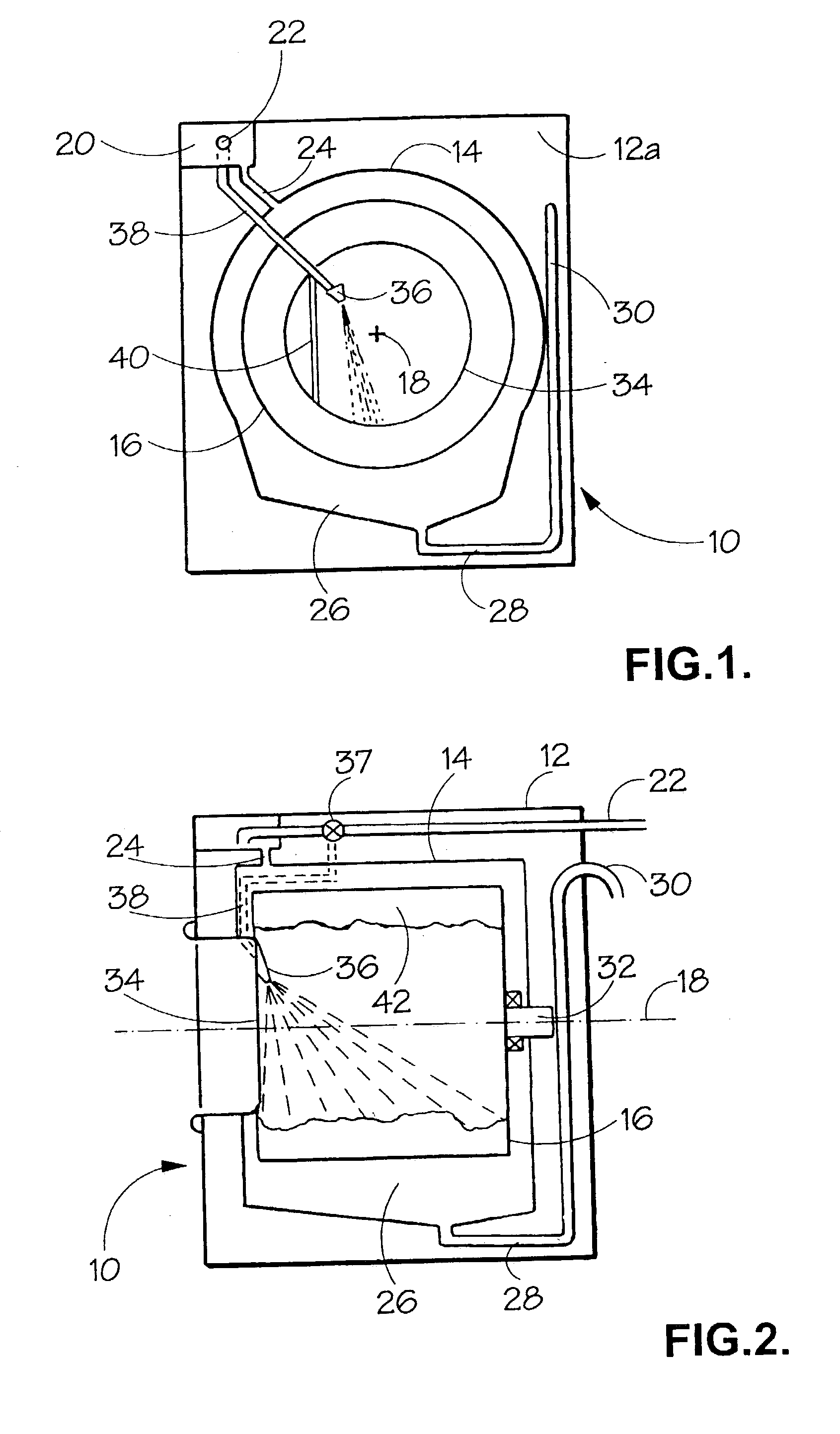

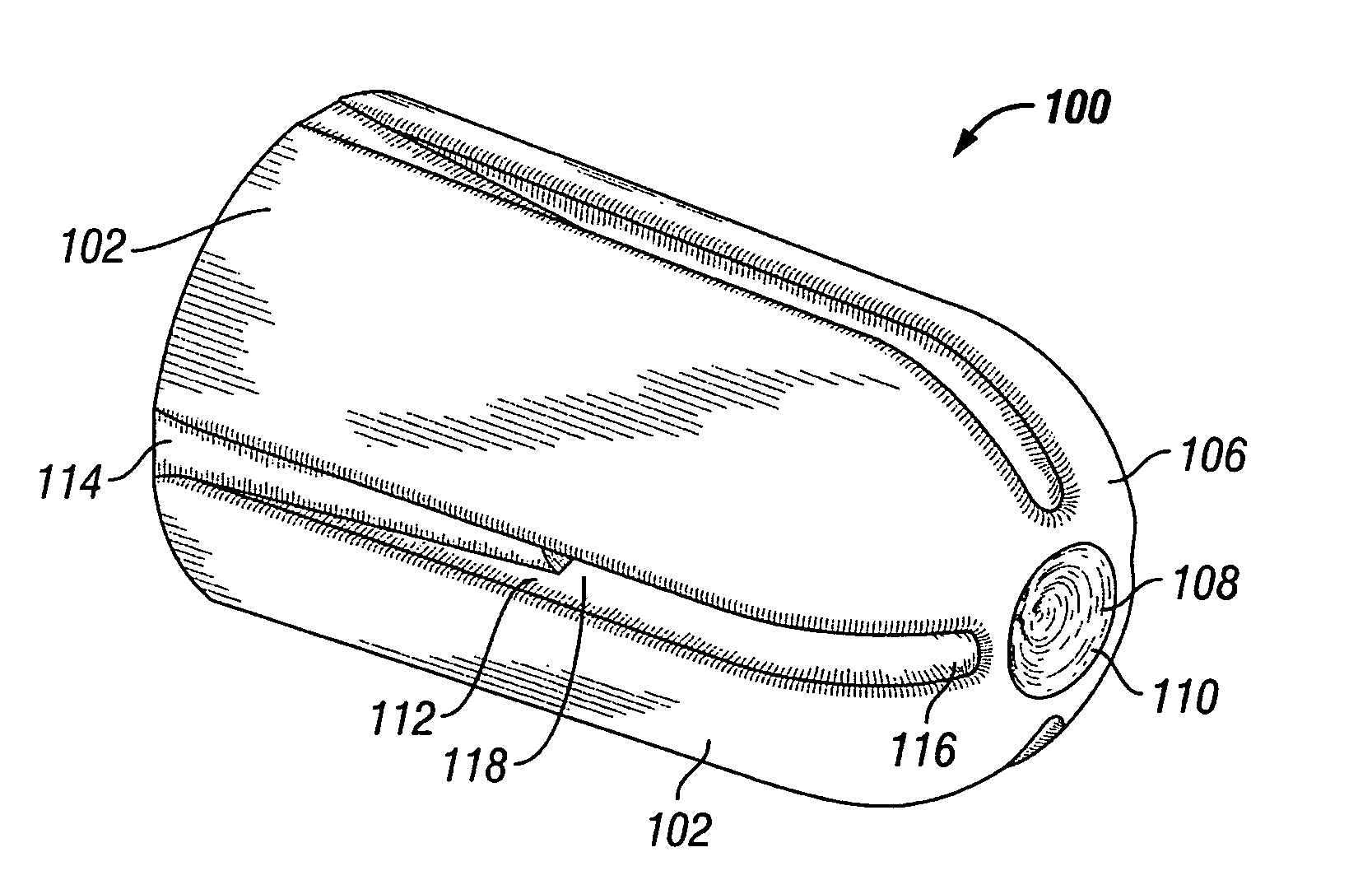

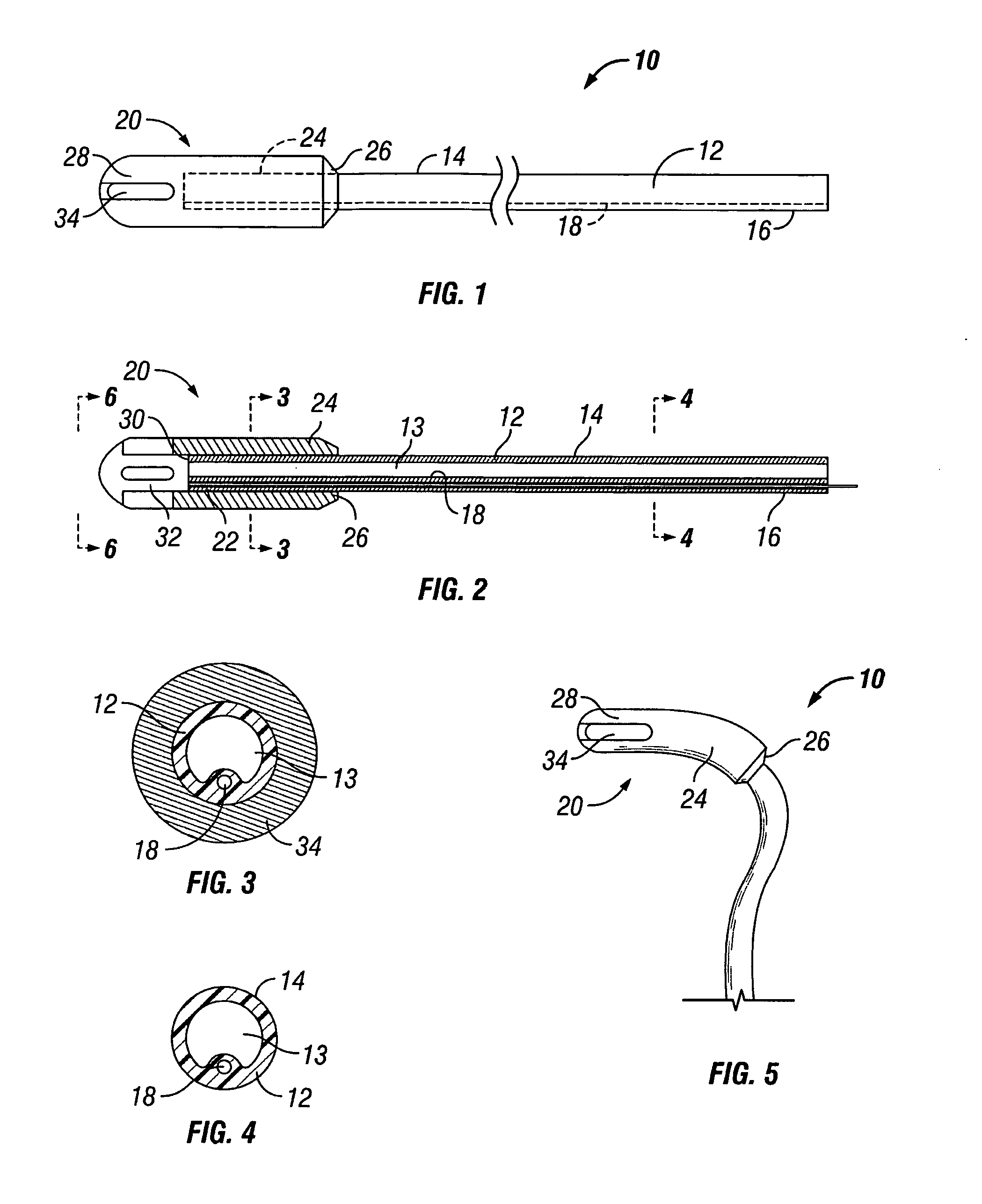

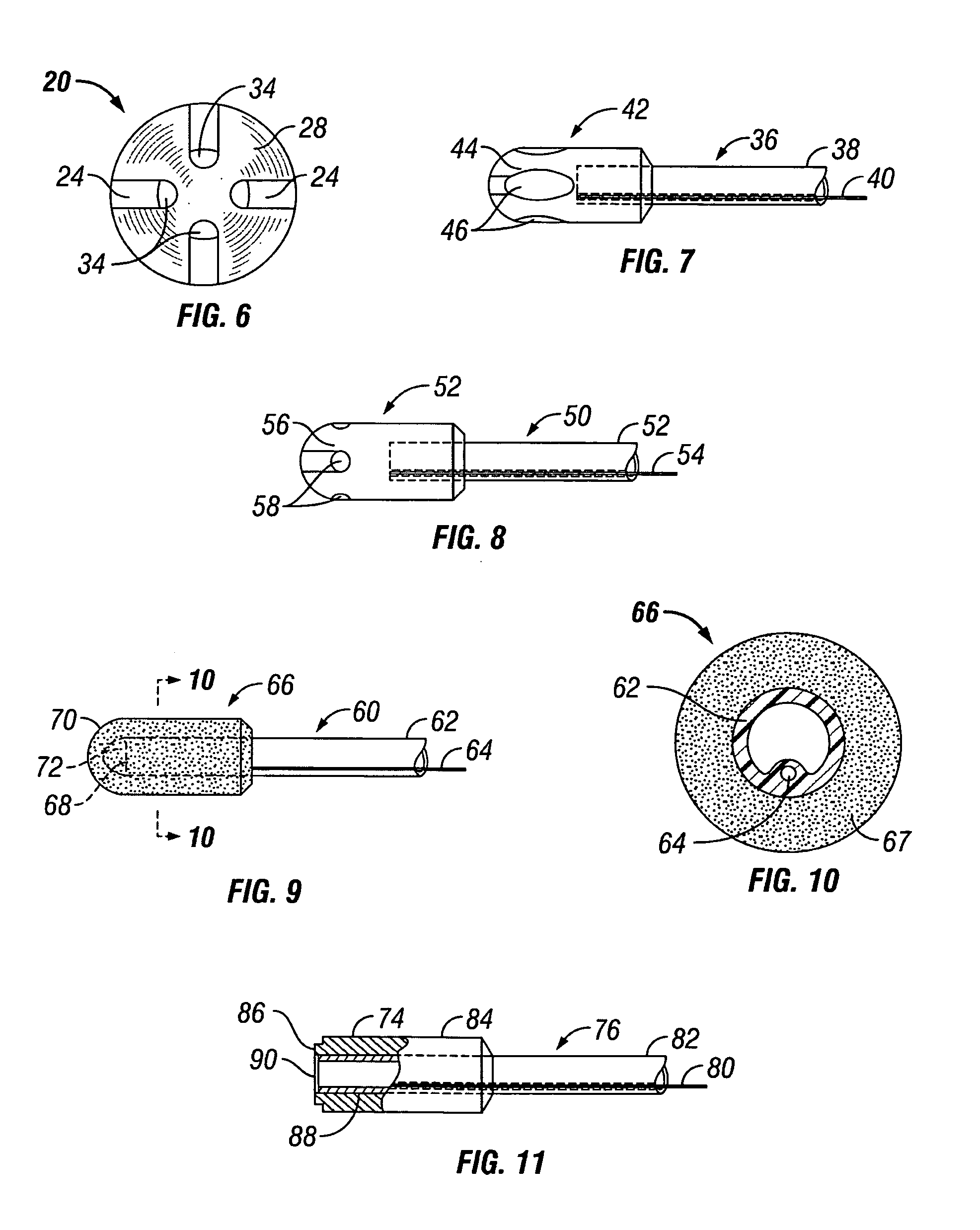

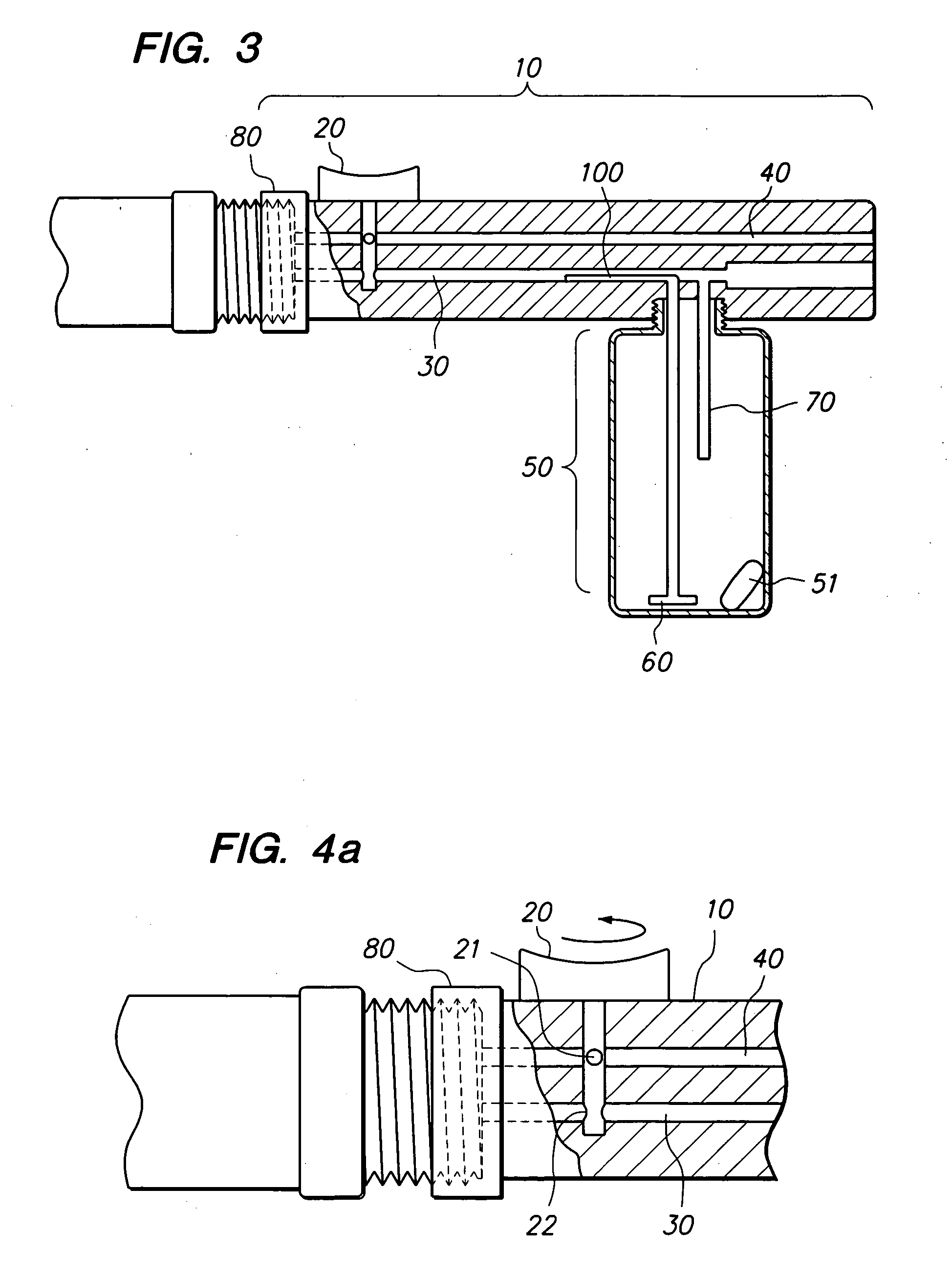

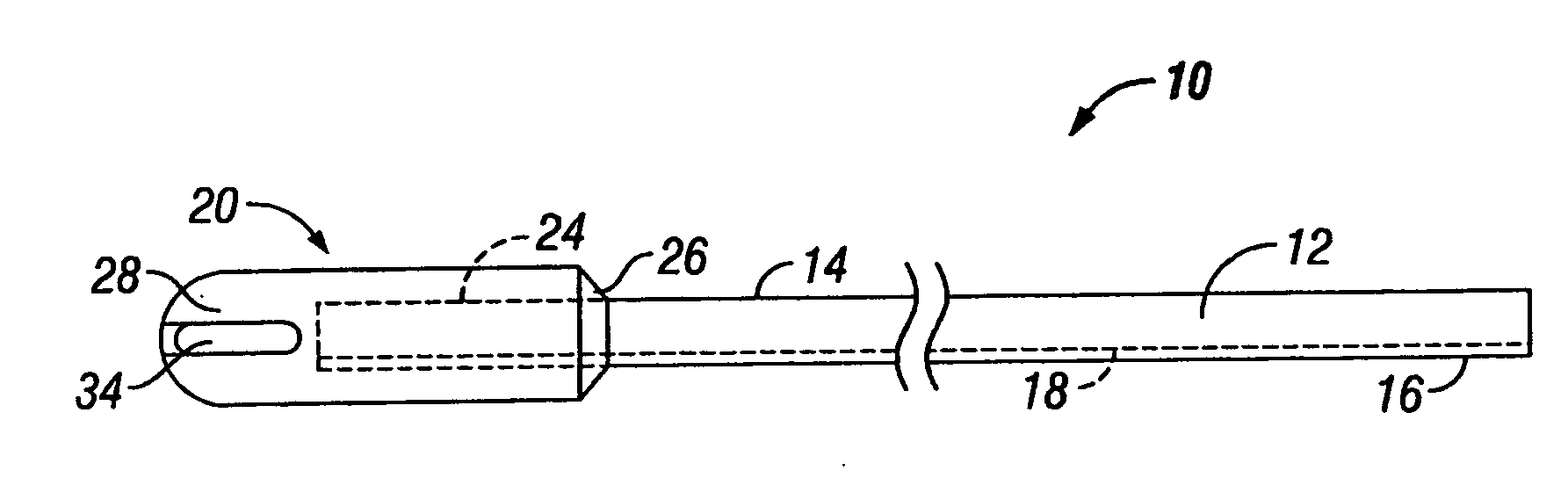

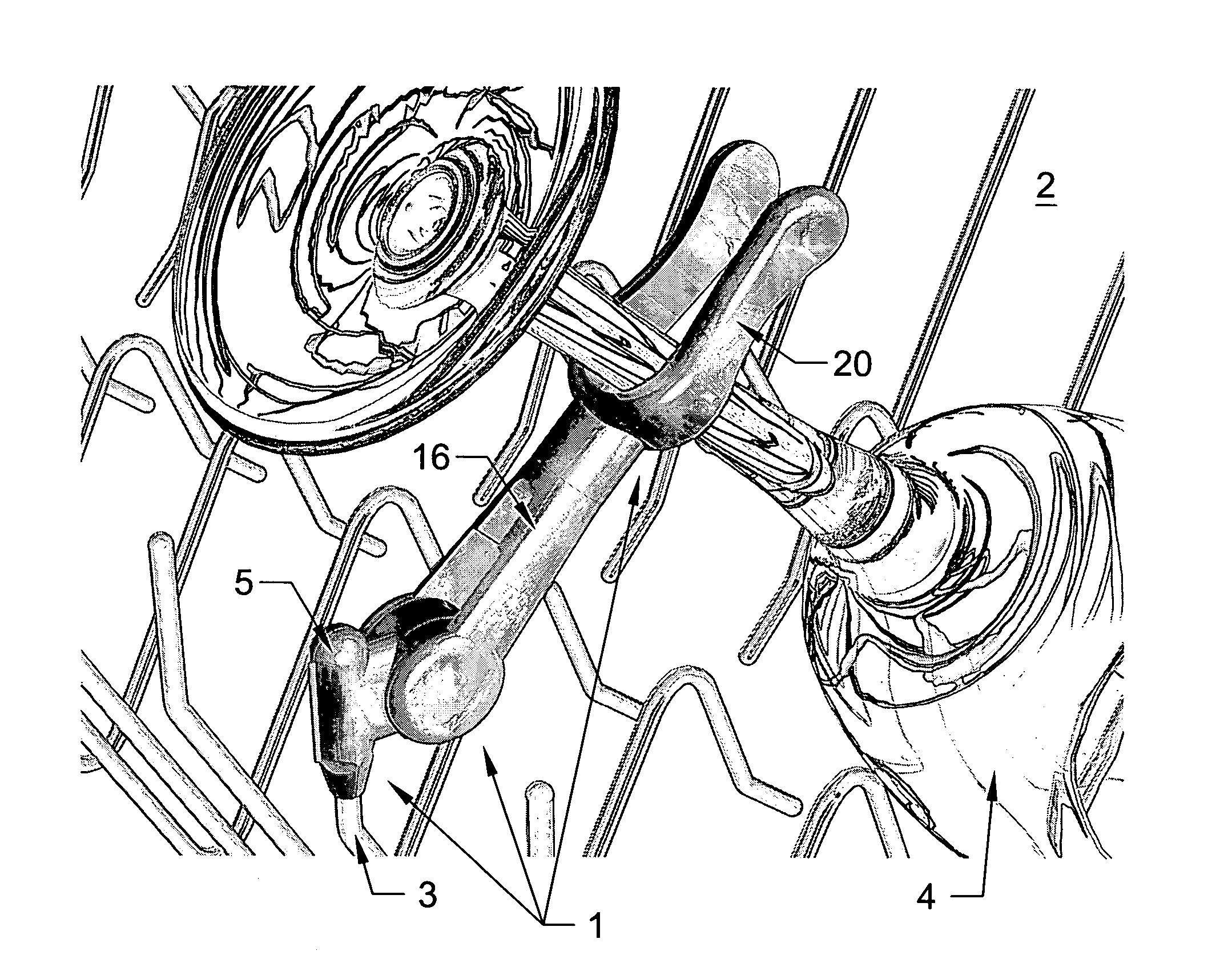

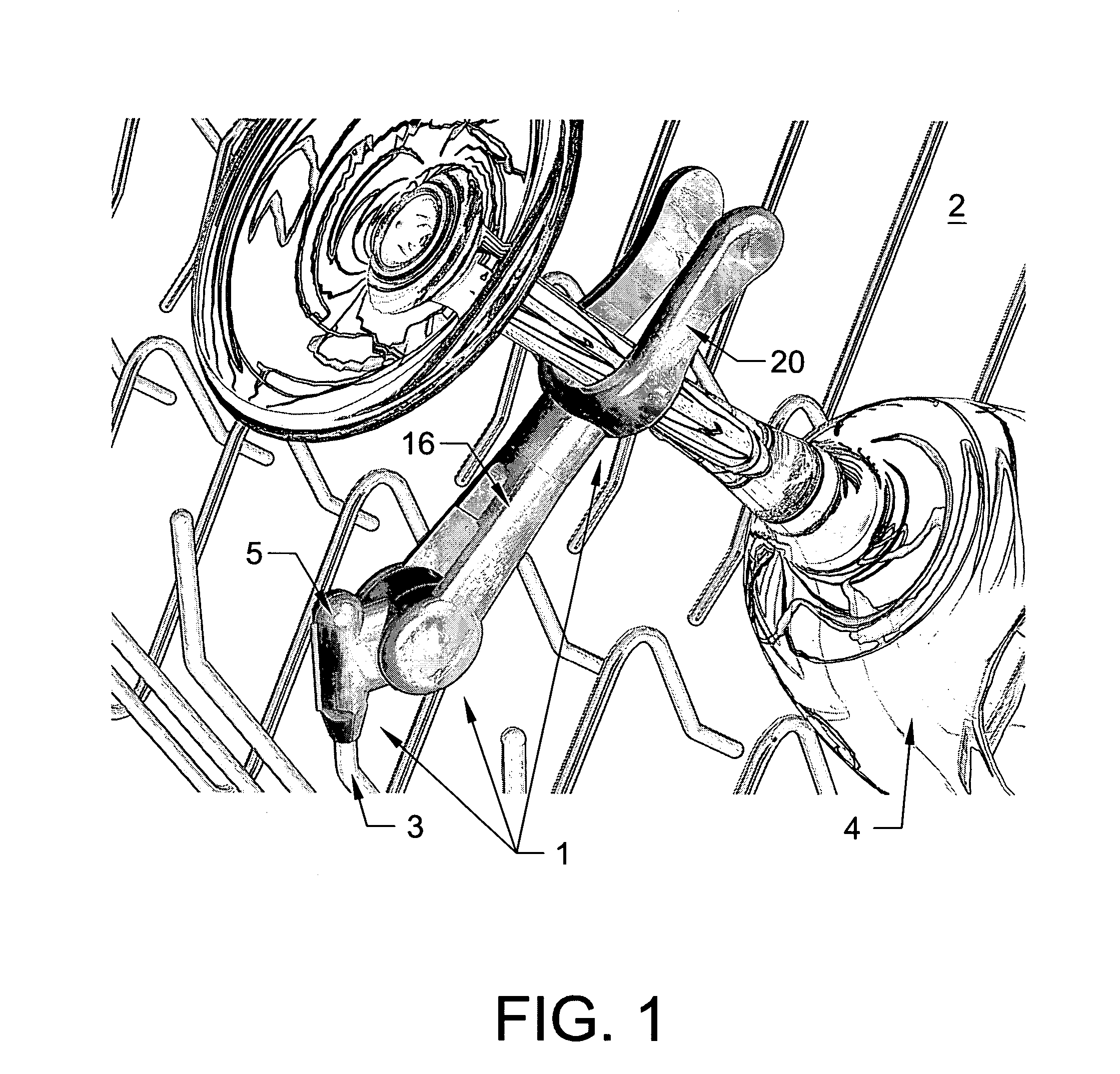

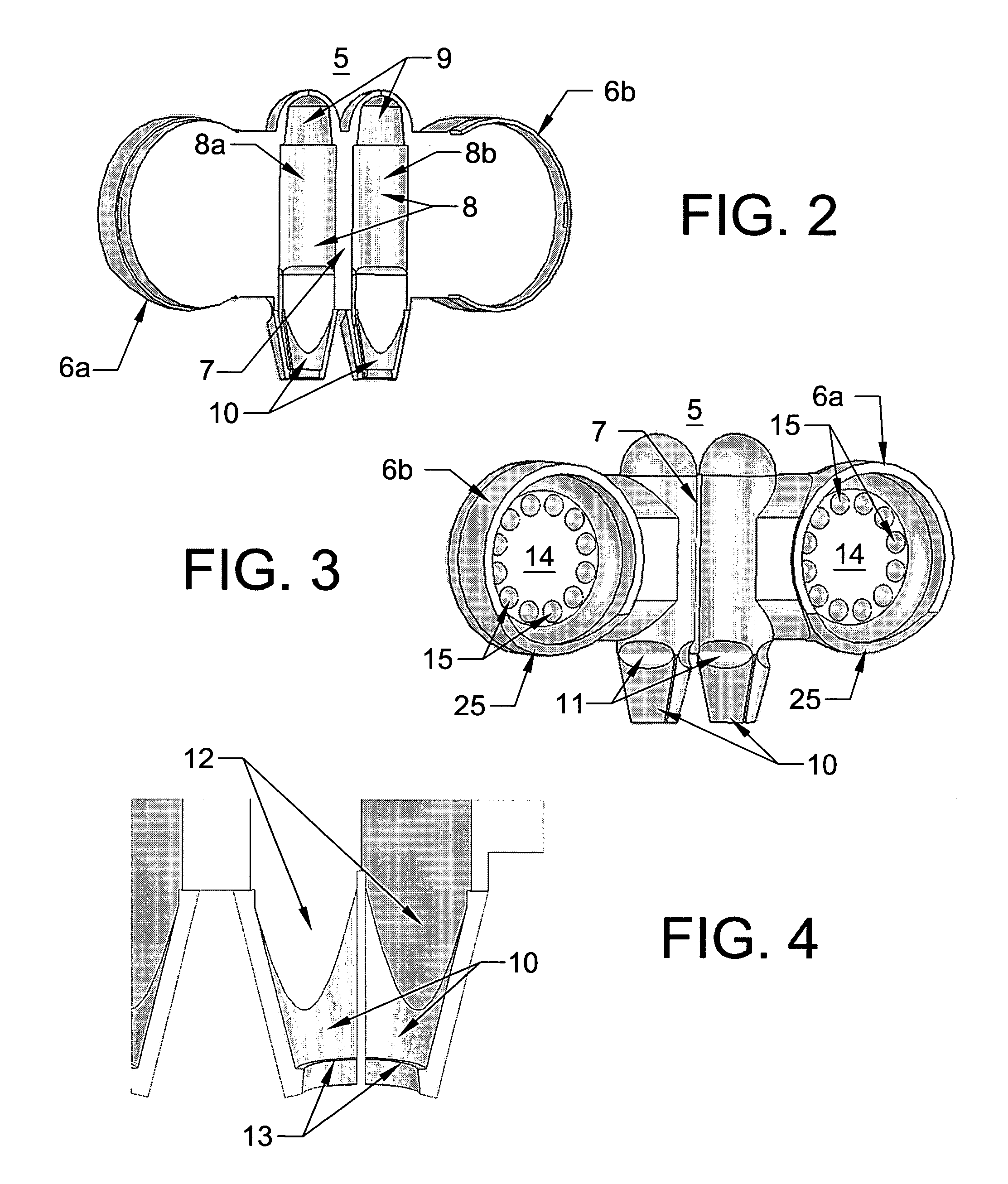

Aspirator having a cushioned and aspiration controlling tip

ActiveUS20060199147A1Minimize potentialEfficient suctionTeeth fillingCatheterMedical procedurePolymer

A disposable cushioned aspirator which forms part of a dental or medical aspirating system. The disposable cushioned aspirator appliance described herein is intended principally to be used in dental and medical procedures where body fluids and rinse water is evacuated from the site of a procedure. An elongate tubular element has a connection end and a patient end. The patient end is exteriorly lined with a layer of soft cushioning material such as a soft thermoplastic elastomers, styrene based polymers, rubber or a porous polymer foam material to define an aspirator tip that protects the soft tissues in and around the mouth of a patient. The soft aspirator tip has external longitudinal pressure relief channels and recessed aspiration openings within the channels for control of aspiration characteristics. The aspirator tube is capable of being manually bent to a desired configuration and has an embedded structural member such as wire extending along its length and being pliable to permit bending and yet of sufficient structural integrity to maintain the aspirator in the desired configuration during use.

Owner:MAHLMANN LEE A

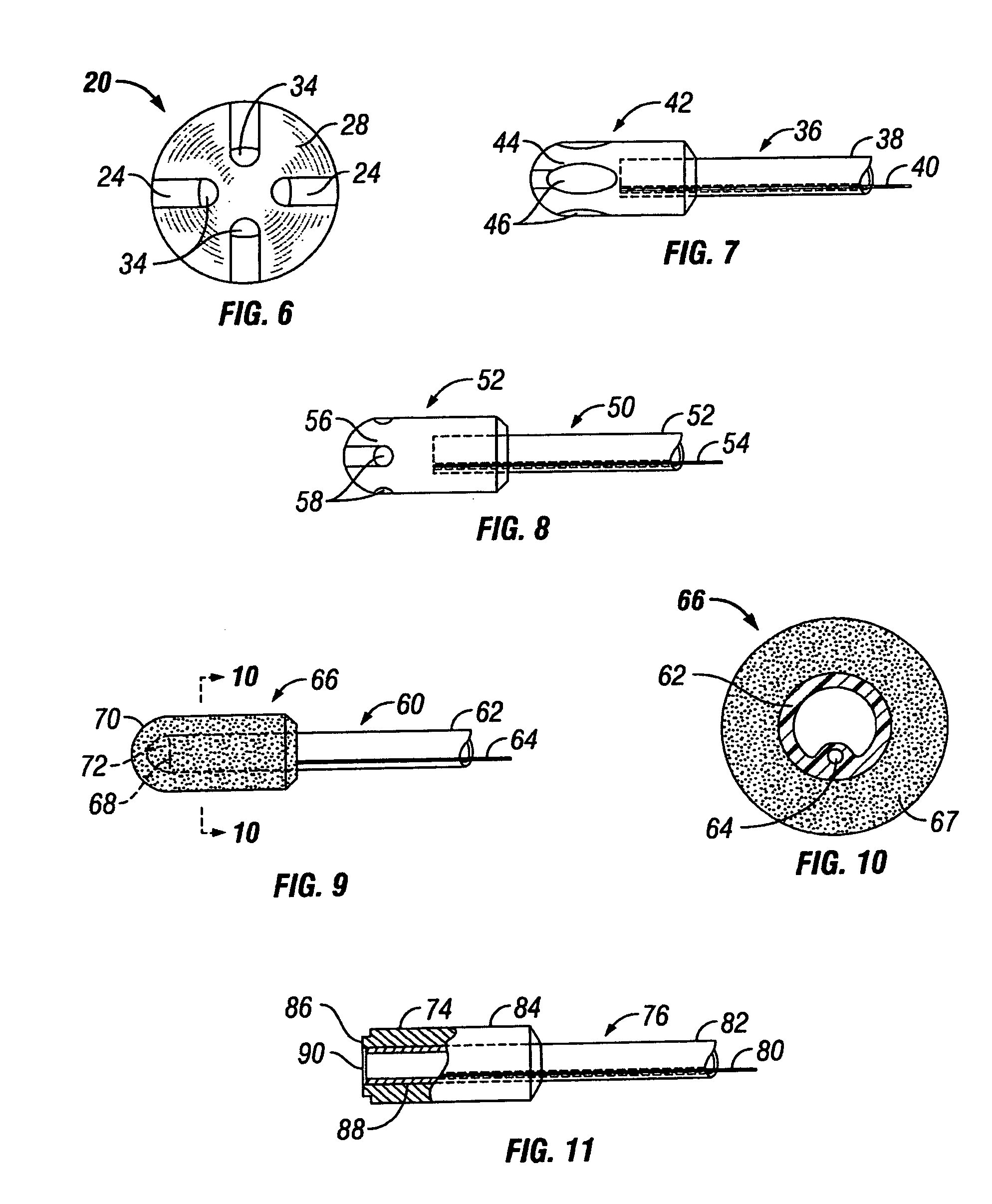

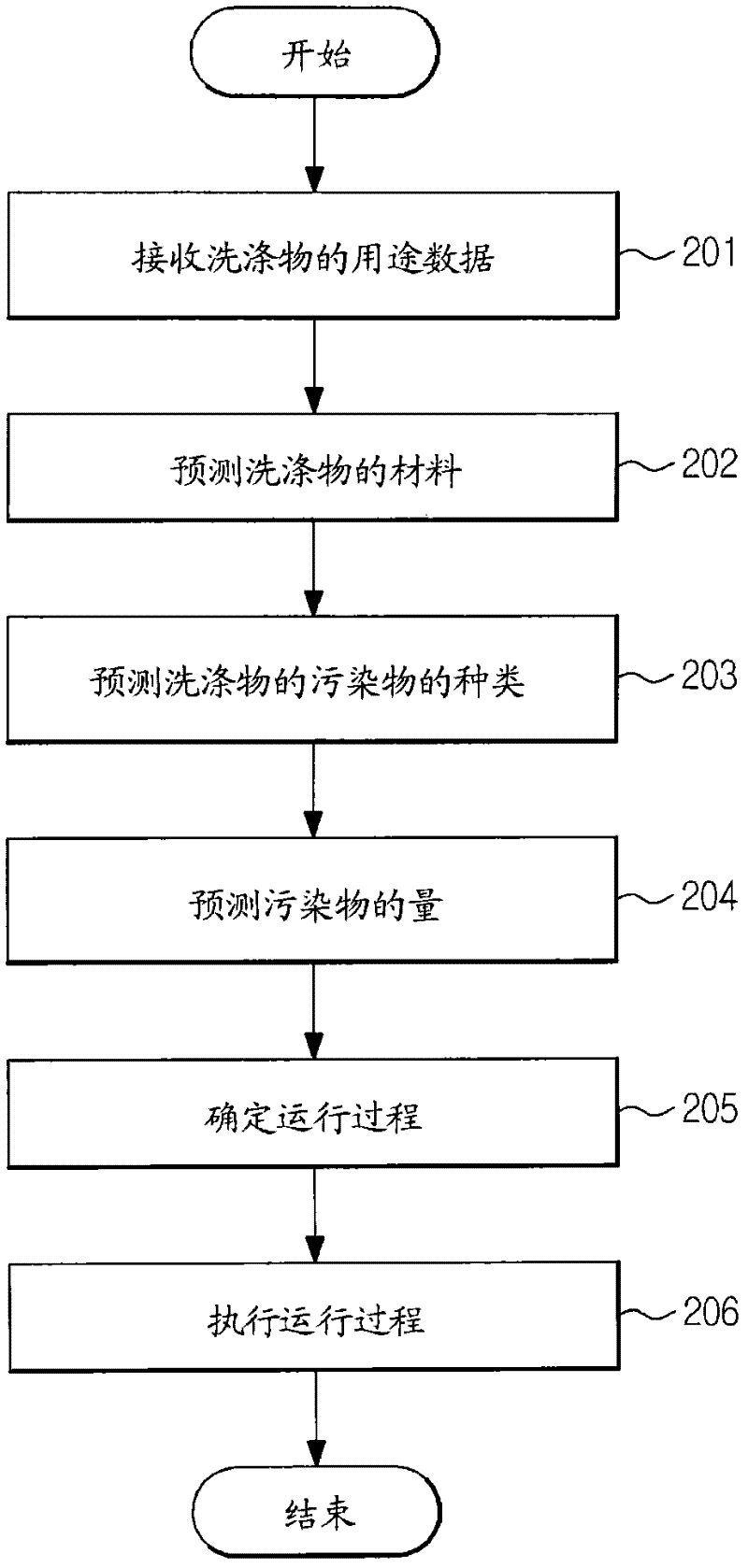

Control method of washing machine

A control method of a washing machine includes receiving purpose data of laundry, determining an operating course based on the purpose data of the laundry, and controlling washing of the laundry according to the determined operating course. The operating course is determined by confirming a material of laundry and predicting kind and amount of contamination of the laundry based on the purpose data of the laundry, thereby performing proper washing according to the purpose of the laundry whenever washing of the laundry is performed. Further, proper washing is performed according to the kind and amount of contamination of the laundry, thereby improving utility of the washing machine. Contamination degrees of wash water and rinse water during washing and rinsing cycles are detected, and a washing time and a frequency of times of the rinsing cycle are adjusted based on the contamination degrees, thereby increasing washing efficiency.

Owner:SAMSUNG ELECTRONICS CO LTD

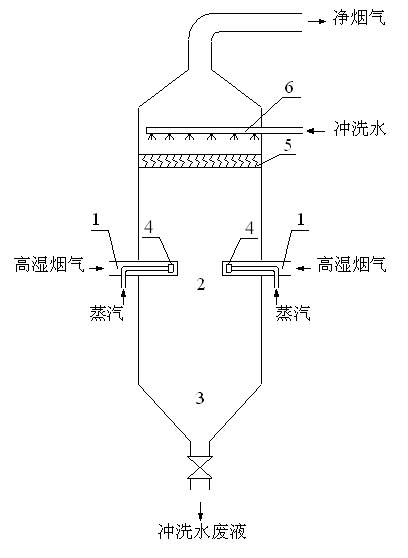

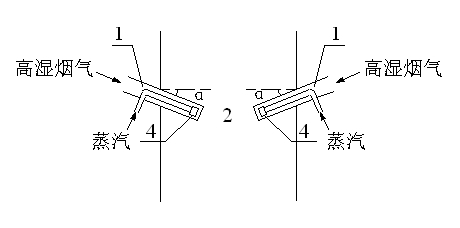

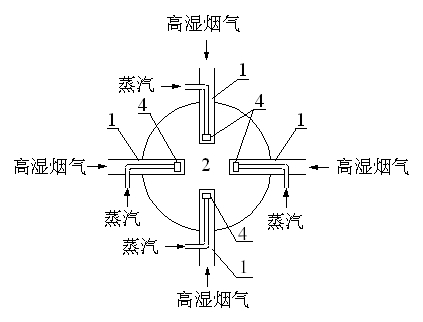

Method and device for removing fine particles in high-humidity gas fume

InactiveCN102059029ASimple processSolve the defect of particle size for efficient removalUsing liquid separation agentRinse waterEngineering

The invention relates to a method and a device for removing fine particles in high-humidity gas fume. The high-humidity gas fume enters a gas fume pipe; saturated steam under normal pressure is injected into the gas fume pipe and is premixed with the high-humidity gas fume; the high-humidity gas fume and the saturated steam under normal pressure enters a bombarding current phase change chamber main body and bombard each other so as to form a highly-turbulent bombardment area with highest concentration of fine particles in the center of the bombarding current phase change chamber main body and promote the saturated steam to be condensed on the surfaces of the fine particles; meanwhile, the fine particles of which the surfaces are condensed with water films collide each other to be coagulated to ensure that the granularity of the fine particles is increased further; and the coagulated and grown fine particles are removed by an efficient demister arranged at the gas fume outlet at the upper end of the bombarding current phase change chamber main body. The device consists of the gas fume pipe, the bombarding current phase change chamber main body, the efficient demister, a demister washing water system, and a washing waste liquor storage tank; a vapor nozzle is arranged in the gas fume pipe; and the efficient demister is arranged at the gas fume outlet at the upper end of the bombarding current phase change chamber main body.

Owner:SOUTHEAST UNIV

Device for portioned delivery of milk, particularly for cappuccino machines

ActiveUS20050223911A1Reliable and efficient rinsingAvoid heatMilk preparationMilk preservationLine tubingRinse water

A delivery head for delivering a milk portion is connected via a connection line to a milk container in a refrigerator. A rinsing agent source is connected via a first line to a connection part in the connection line. A first on-off valve is inserted in the first line. The connection part is also connected via a second line and a second valve to a fresh air source. The container, the valves, and the connection part are installed in a refrigerator. Through this implementation, complete emptying of the connection line and the delivery head of rinse water after the rinsing procedure, as well as efficient rinsing during the rinsing procedure, are achieved.

Owner:RANCILIO GROUP

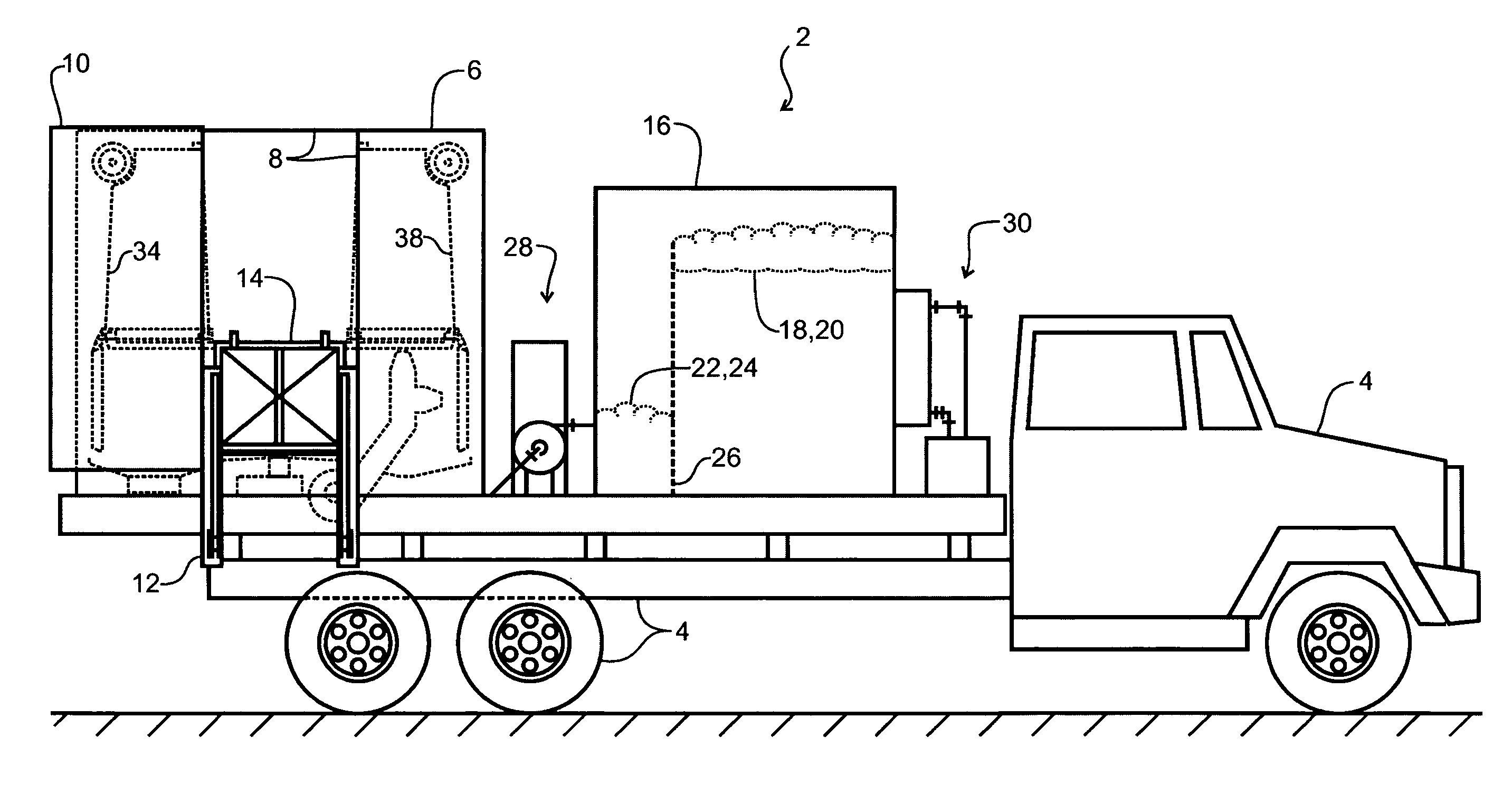

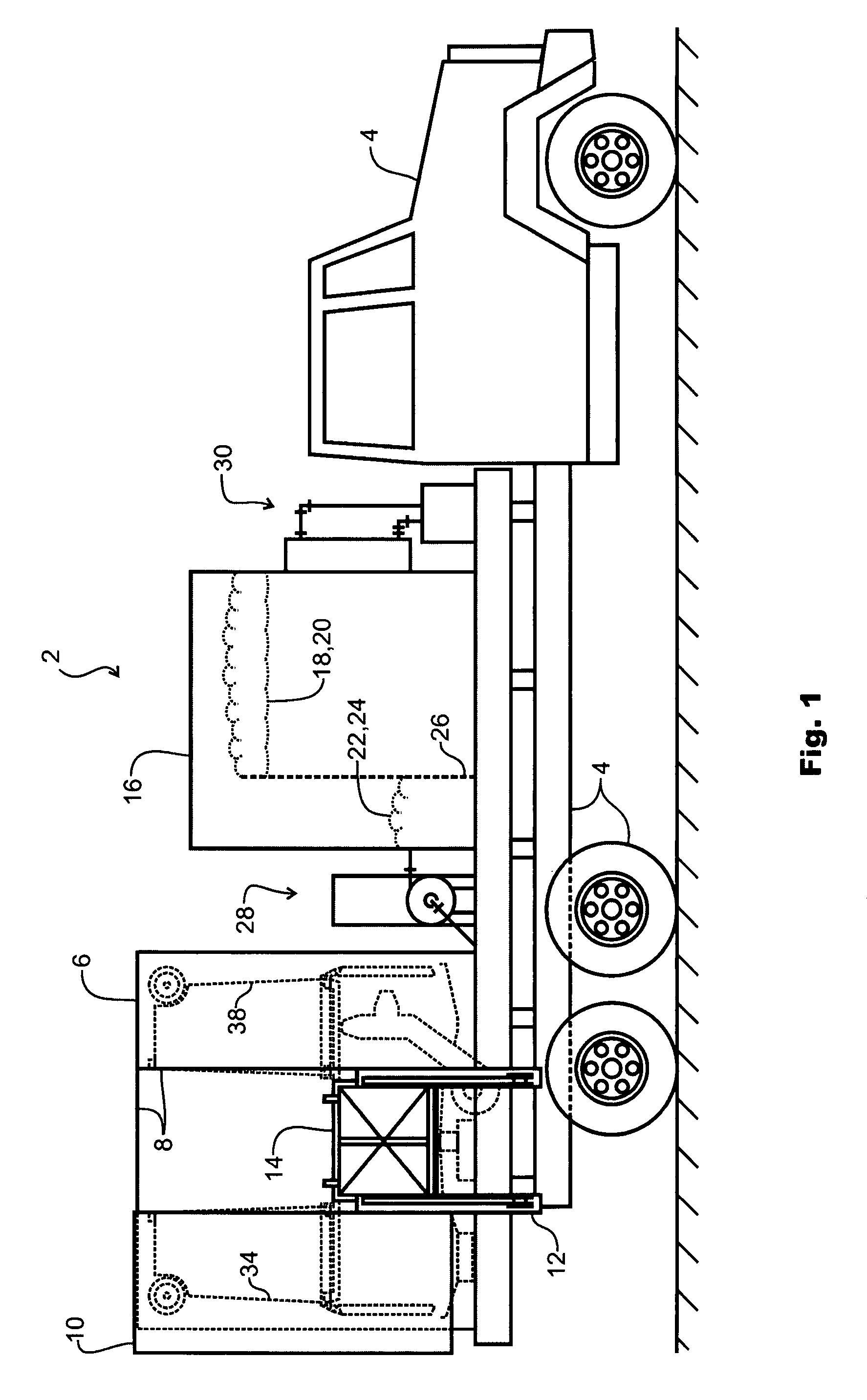

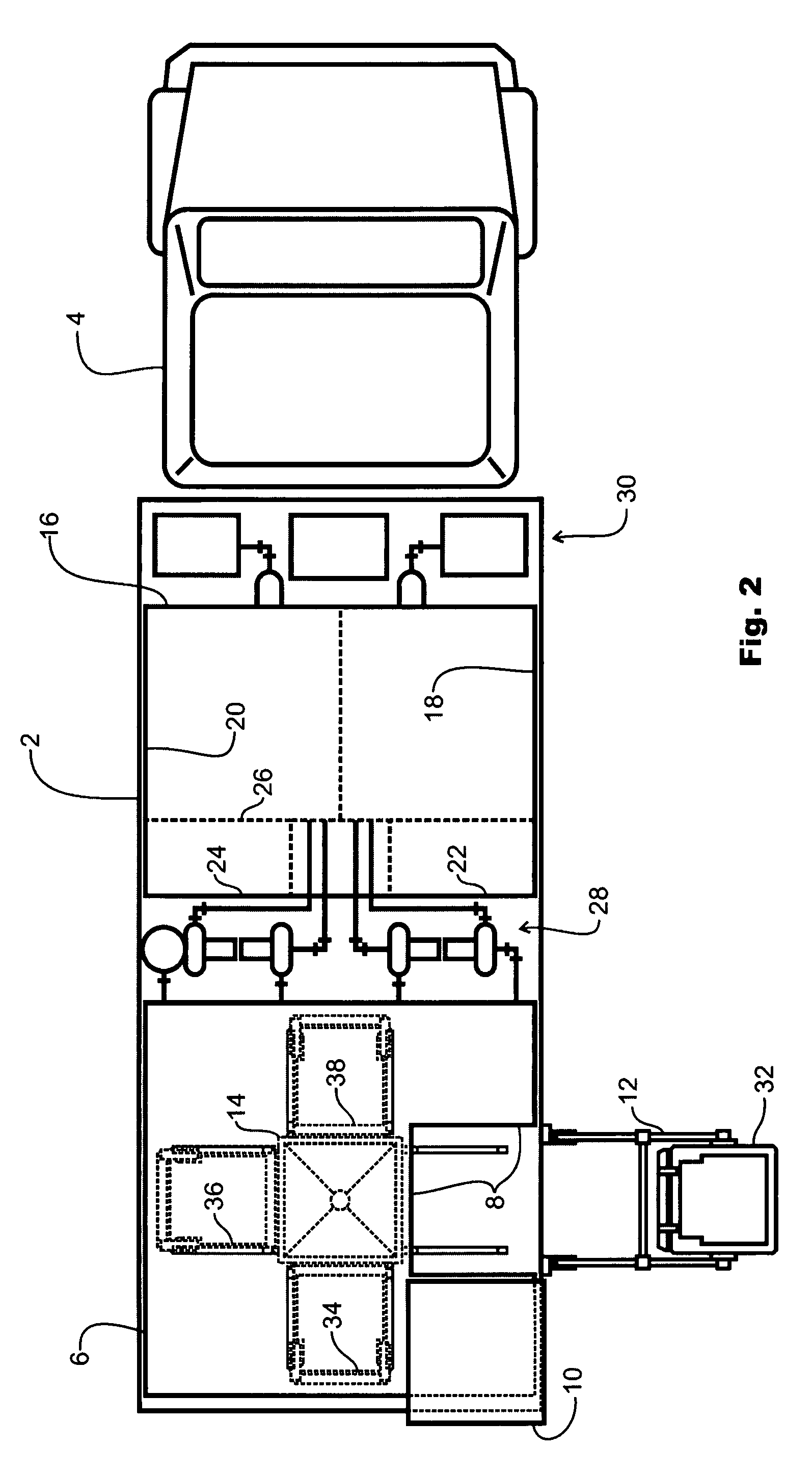

Mobile trash receptacle cleaning system and method

ActiveUS7846263B1Reduces wash-water effluenceReducing wash-water effluence from the enclosureHollow article cleaningRefuse cleaningLitterWash water

A vehicle mountable system for cleaning trash receptacles with wash-water. The system includes an enclosure with an access opening, supported on the vehicle, and a carriage disposed within the enclosure. A spray head is aligned to impinge wash-water against the trash receptacle while it is engaged with the carriage. A basin is aligned to accumulate wash-water drainage from the spraying operation. A spray shield is operated to a closed position that reduces wash-water effluence from the enclosure. The system may include a filter and means for sanitizing wash-water that is accumulated by the basin and recirculated through a holding tank. An automated arm engages a trash receptacle to engage and disengage the trash receptacle with the carriage through the access opening in the enclosure. Plural trash receptacles can be engaged with the carriage and advanced through plural positions within the enclosure. A second spray head aligned to impinge rinse-water against the trash receptacle, and a second basin for accumulating rinse-water drainage may be included in the system. A trash receptacle drying means may also be included within the enclosure.

Owner:PHILLIPS BARRY TOD

Device for dispensing a liquid active substance

A device for dispensing a liquid active substance into the flushing water of a toilet bowl has a supply container for containing the liquid active substance. The supply container has an opening in its underside and is retained in a carrying body which can be fixed on a rim of the toilet bowl. The carrying body has sidewalls and a base having an opening. Tabs disposed around a portion of the perimeter of the base opening project upwardly from the base. A distributor plate is secured to the carrying body and has a plug-in spike projecting upwardly through the base opening and into the supply container opening. The plug-in spike has grooves distributed circumferentially around it which are in fluid communication with the liquid active substance. Distributor channels in the distributor plate are in fluid communication with the grooves and with multiple capillary channels via branching locations in the distributor plate.

Owner:SKOT CHEM PRODS

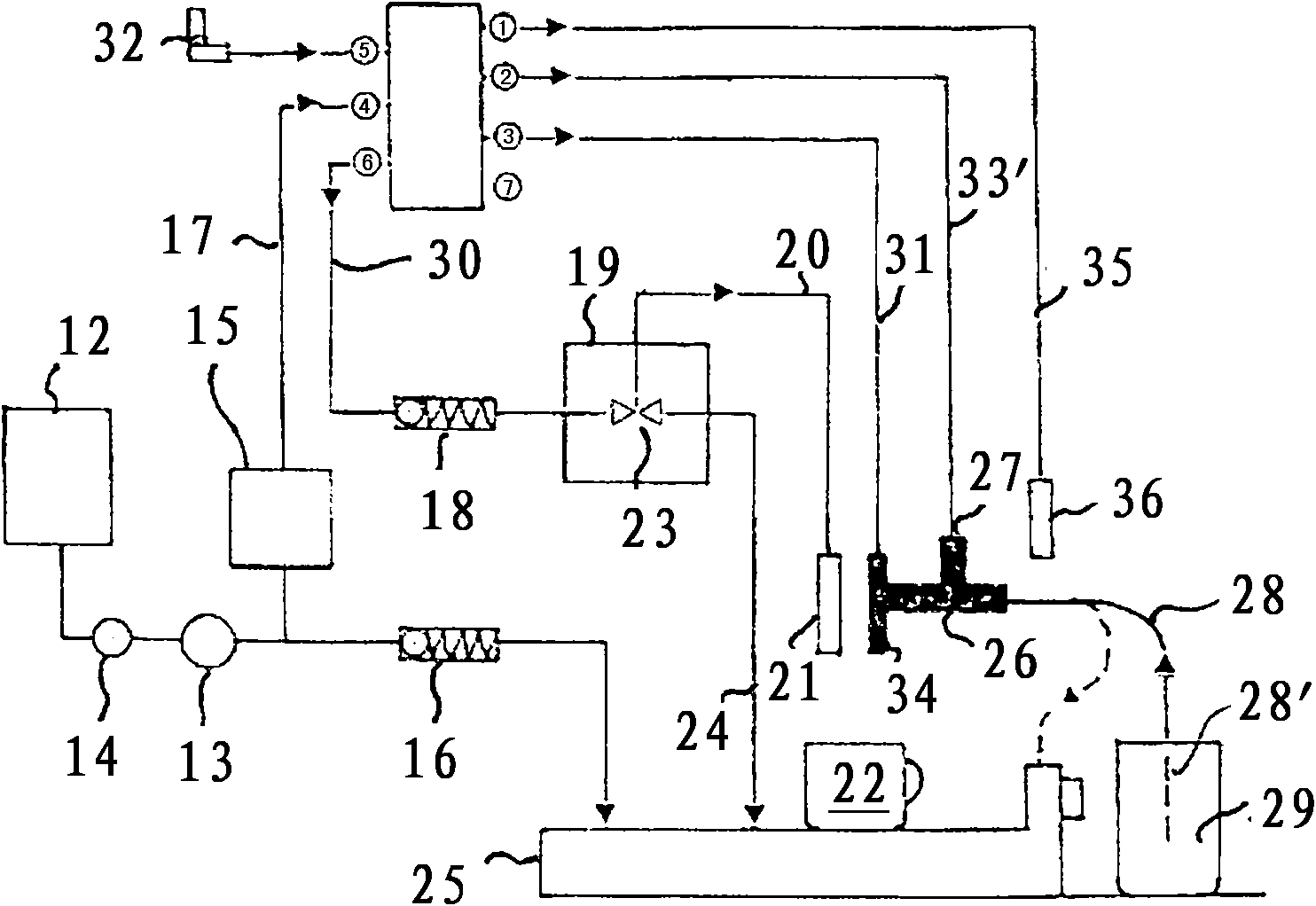

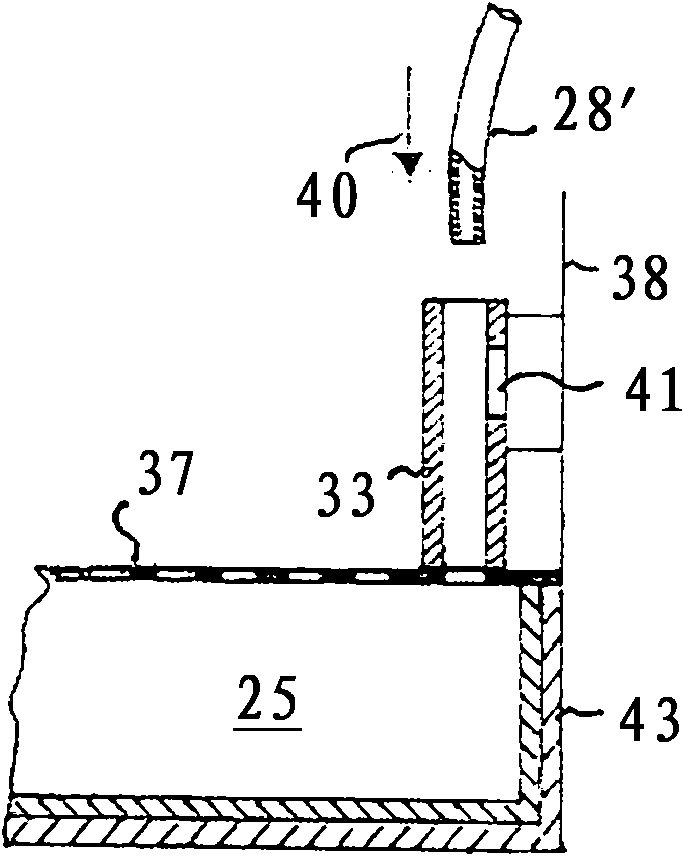

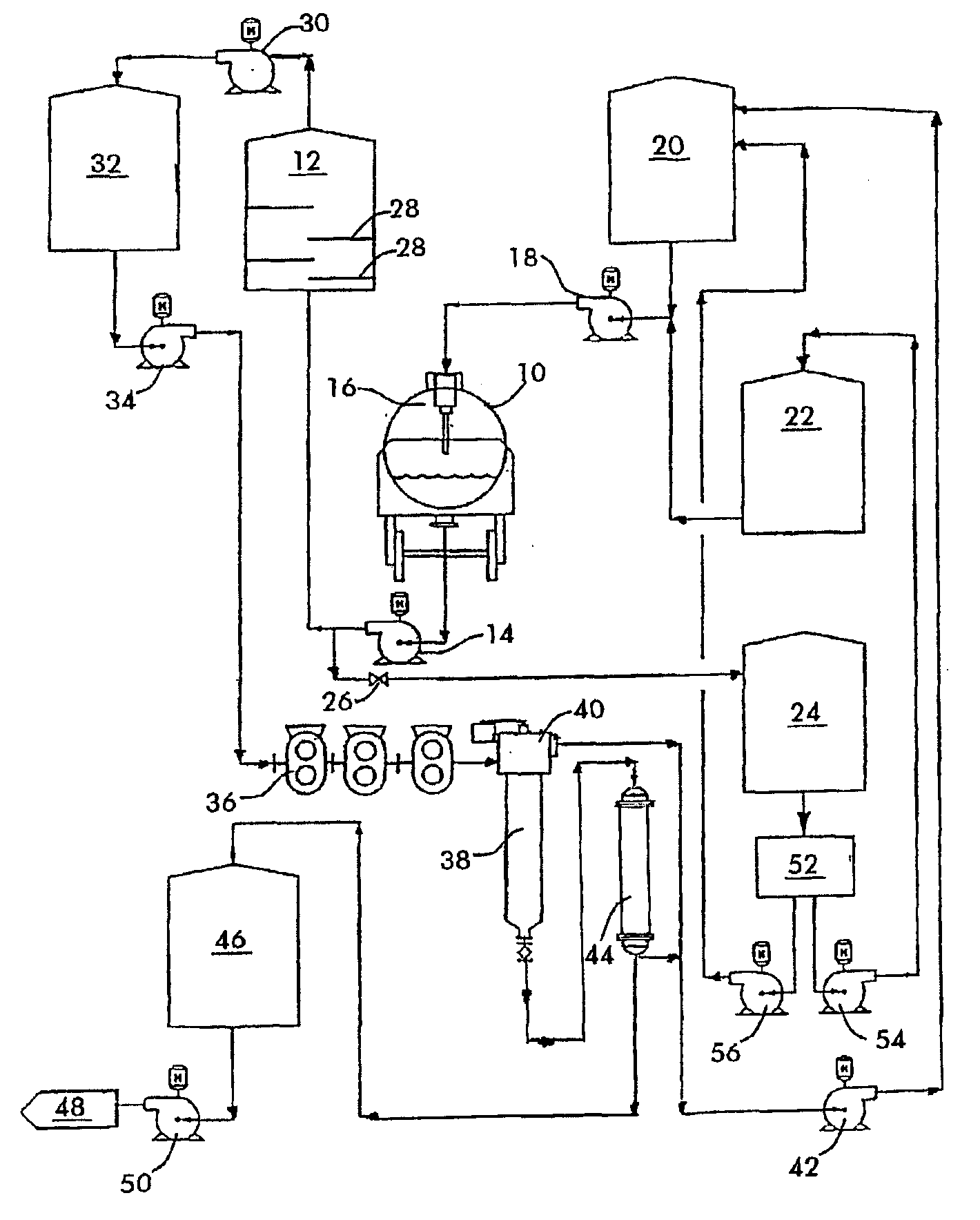

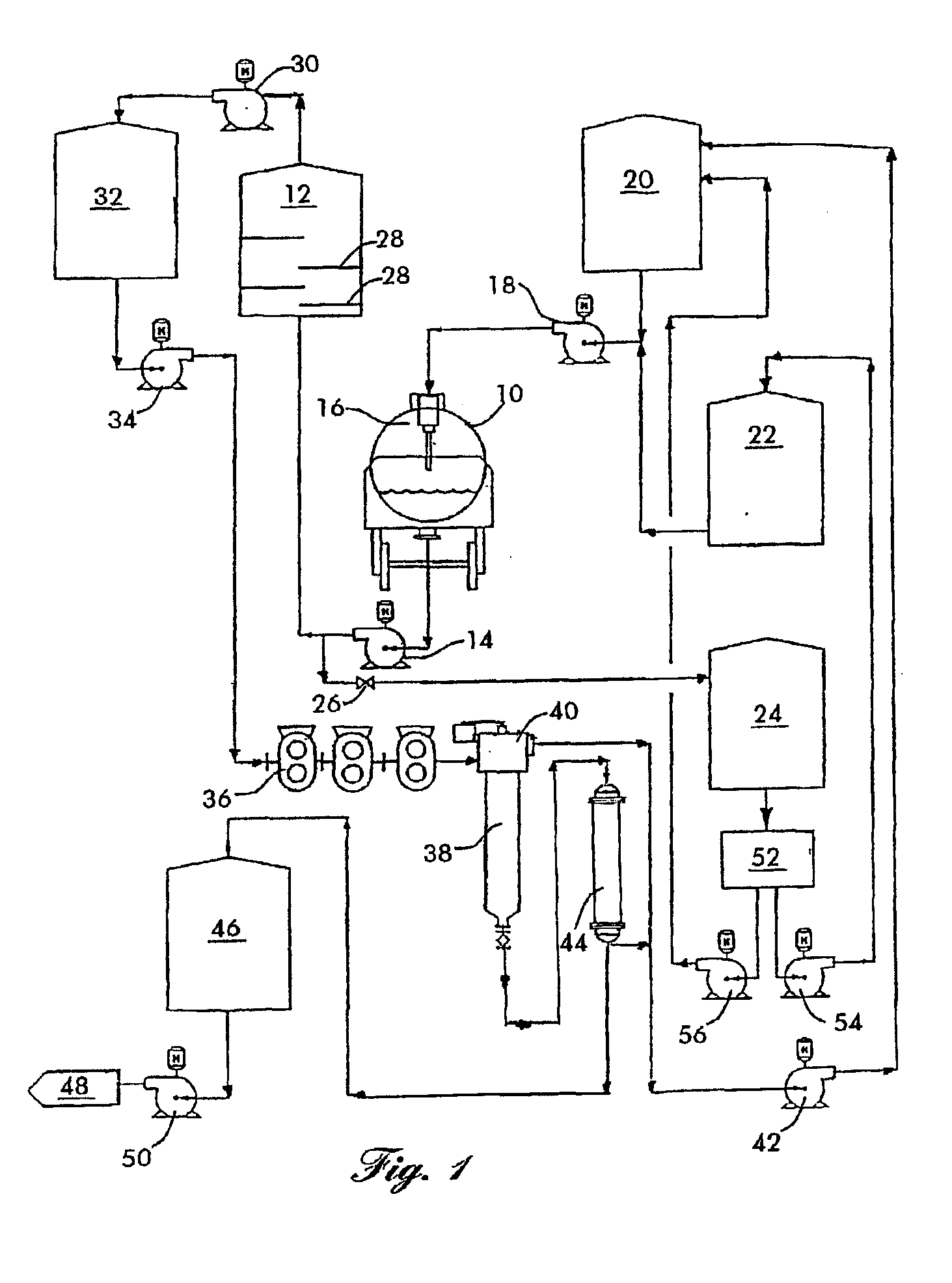

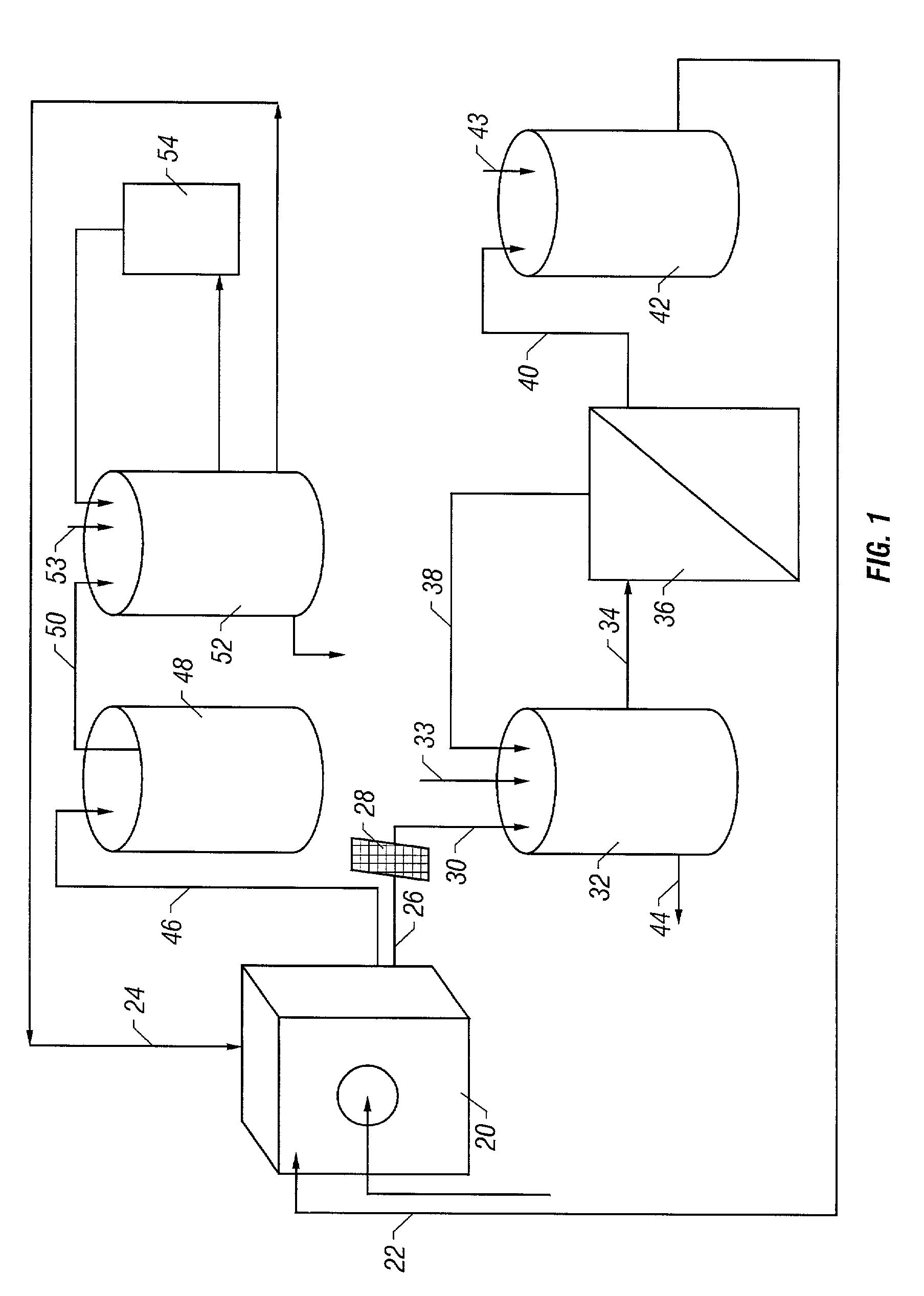

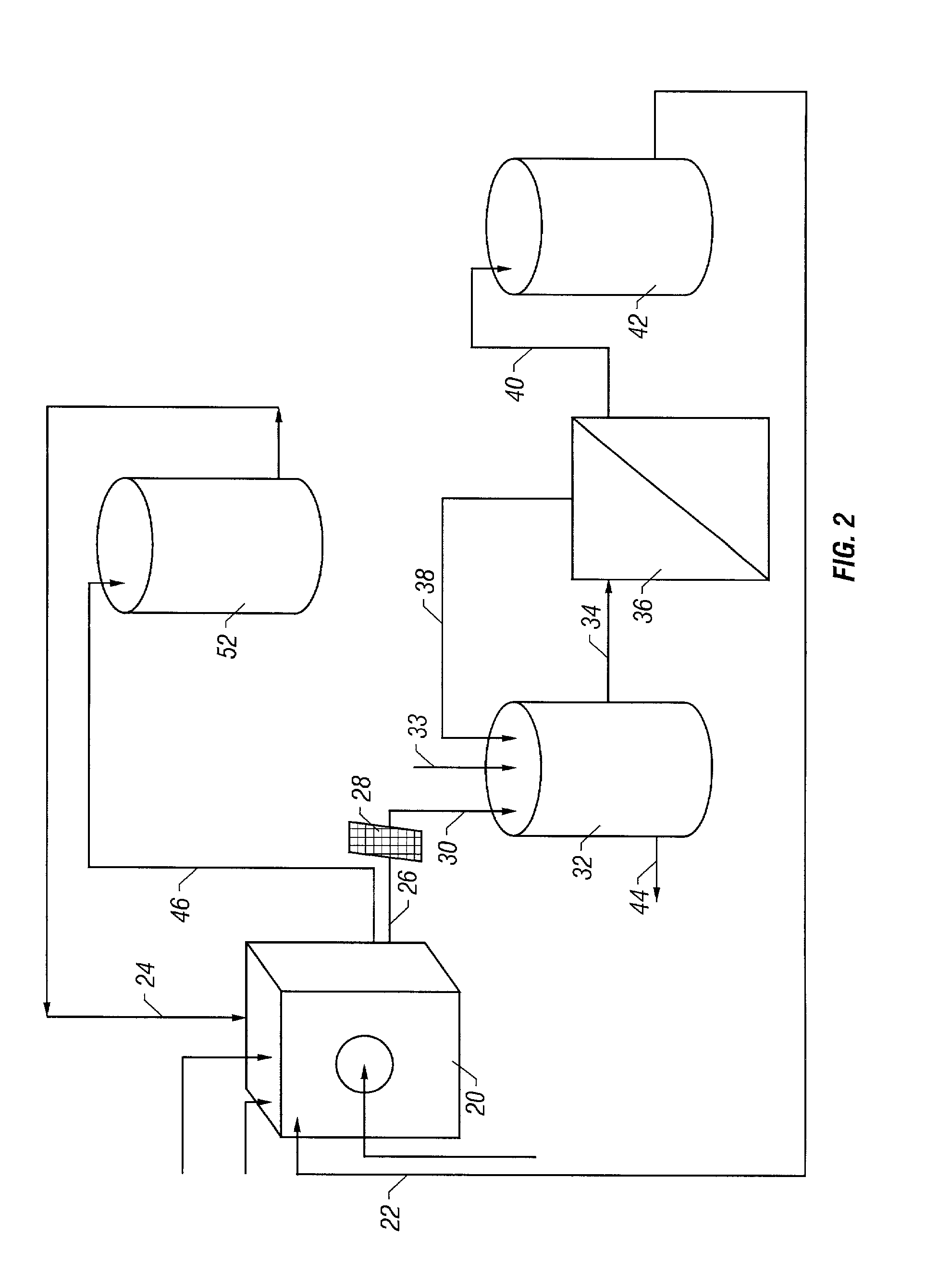

System and method for economically viable and environmentally friendly central processing of home laundry

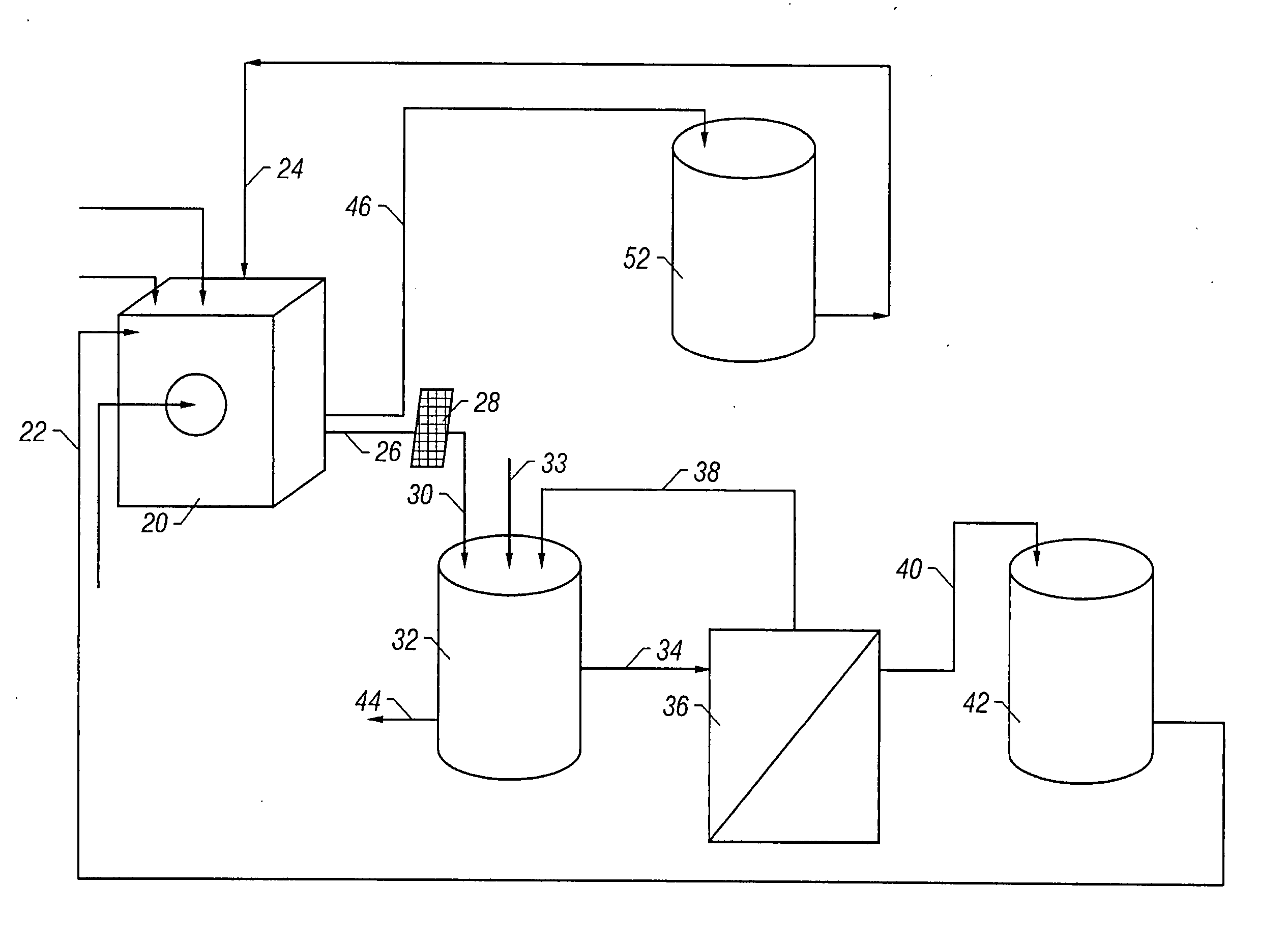

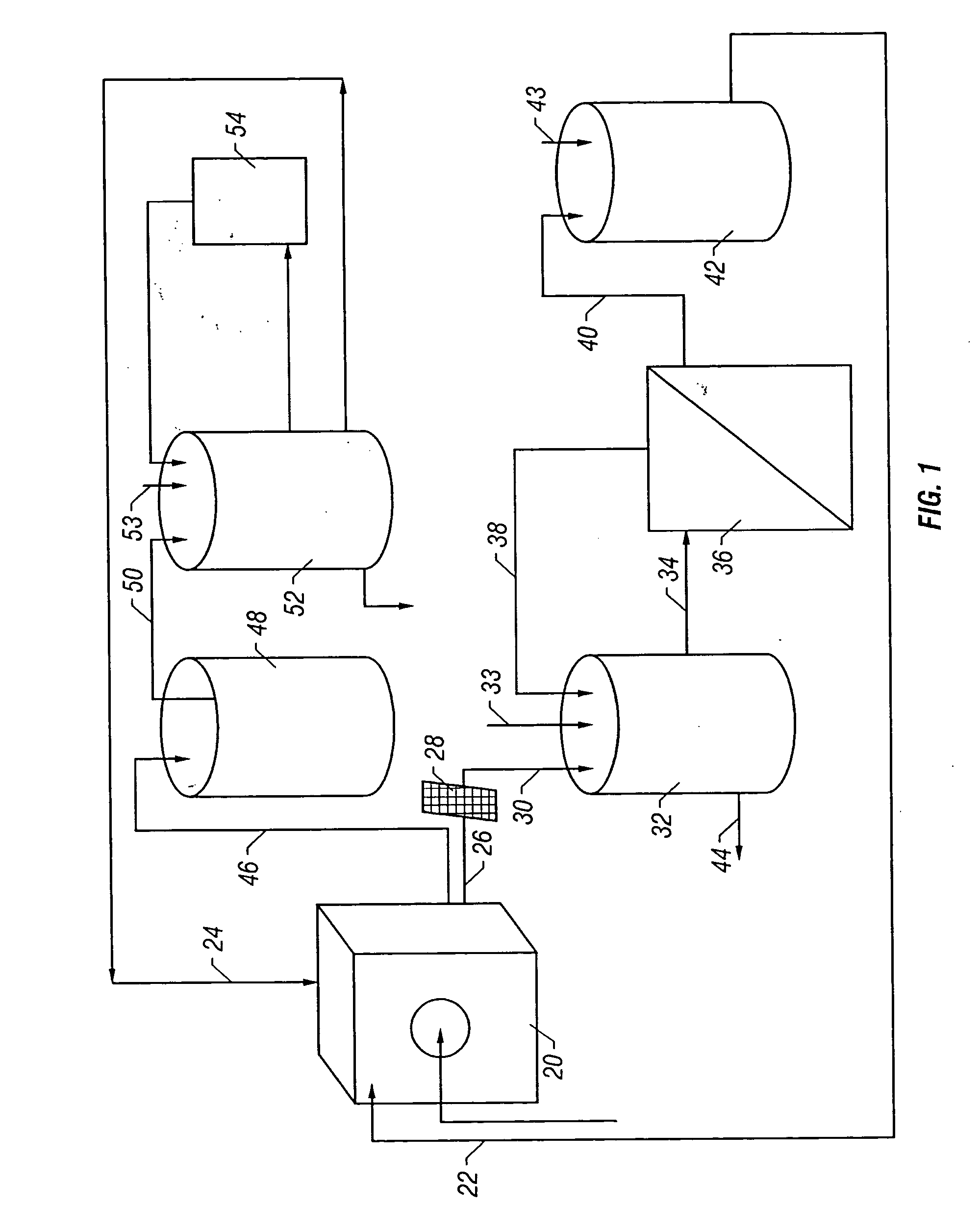

InactiveUS7000437B2Reduce productionPromote recoveryTableware washing/rinsing machine detailsOther washing machinesWash waterChemical recovery

An economically viable process and system for centrally processing multiple loads of laundry with minimum environmental impact. A system and method of laundering whereby successive loads of laundry may be washed while continuously providing effective soil removal comprising at least partially recycled wash water from at least one previous wash cycle. The system and the method of using the same comprises filtering wash water with at least one filter to form wash retentate and wash permeate. The use of wash permeate in successive washes provides for reuse of chemicals and water recovery. A similar arrangement may be used with regard to the rinse water. Advantageously, one embodiment of the invention provides for the use of rinse retentate as make up water in the wash loop which increases water recovery and chemical recovery. Ultimately, the invention can reduce the production of gray water and recover chemicals used in the laundering process.

Owner:SHELL OIL CO

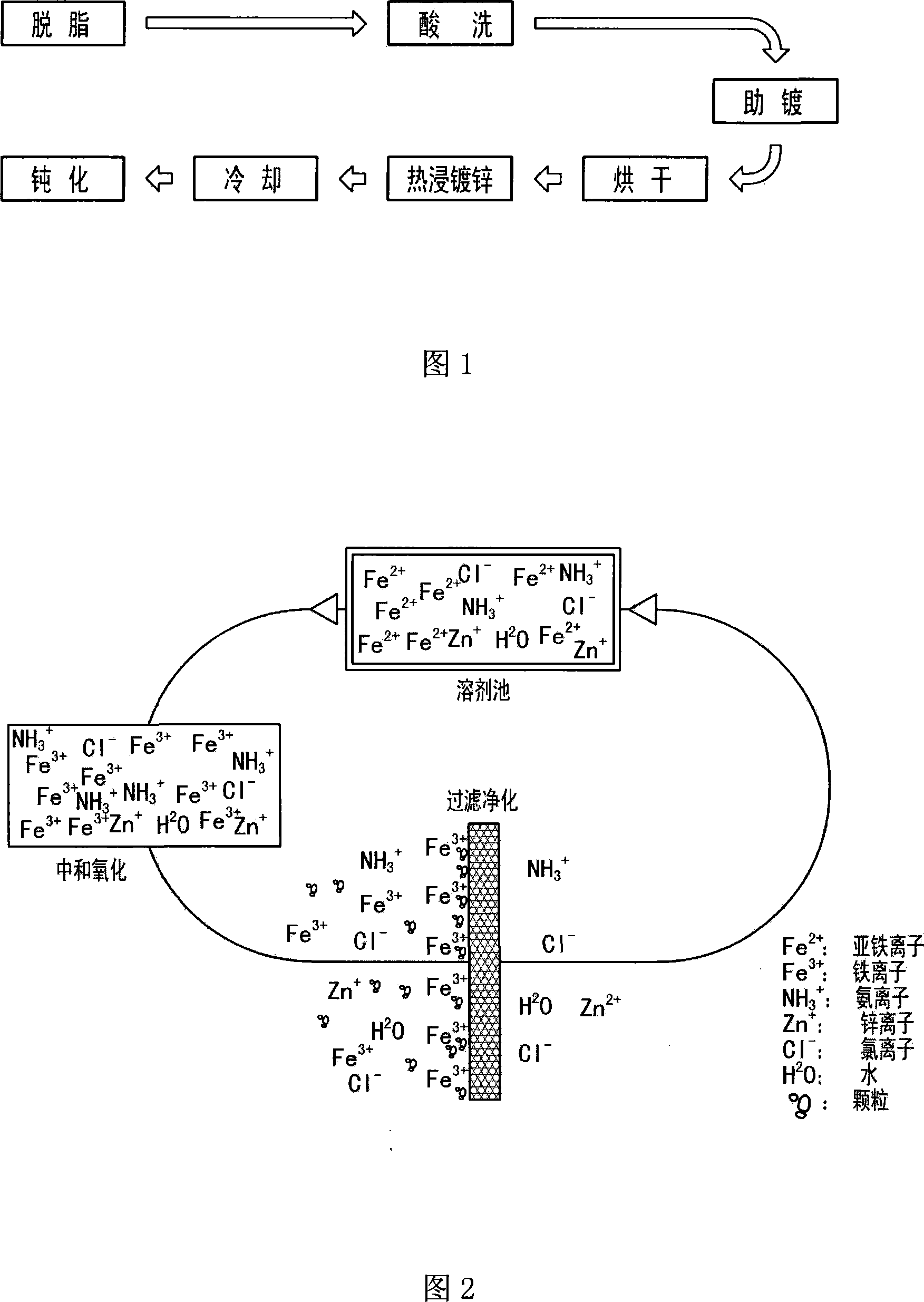

Non-poaching-water common hot-dip galvanizing technique

InactiveCN101215682AZero emissionGuarantee the quality of galvanizingHot-dipping/immersion processesWater sourceRinse water

The invention relates to a hot-dip galvanizing process, in particular to a common hot-dip galvanizing process without rinse water, which aims to solve the technical problems existing in prior art that after being treated, if industrial wastewater which is produced during hot-dip galvanizing is discharged reaching the standard, galvanizing needs to consume a large number of water source, and the treatment cost is greatly increased and the like. The steps of common hot-dip galvanizing process without rinse water of the invention comprises degreasing, cleaning and plating auxiliary, wherein to-be-galvanized workpieces are dipped in assisted plating solution, whose components are aqueous solution of ZnCl2 and NH4Cl, the PH valve of the assisted plating solution is adjusted through adding ammonia water, then Fe2+ on the surface of the workpiece is changed into Fe3+ through hydrogen peroxide solution, and then the Fe3+ is filtered out through a filter purification device, a layer of assisted plating film is formed on the surface of the workpiece, drying, hot-dip galvanizing, cooling and inactivating.

Owner:ZHEJIANG SHENGDA STEEL TOWER +1

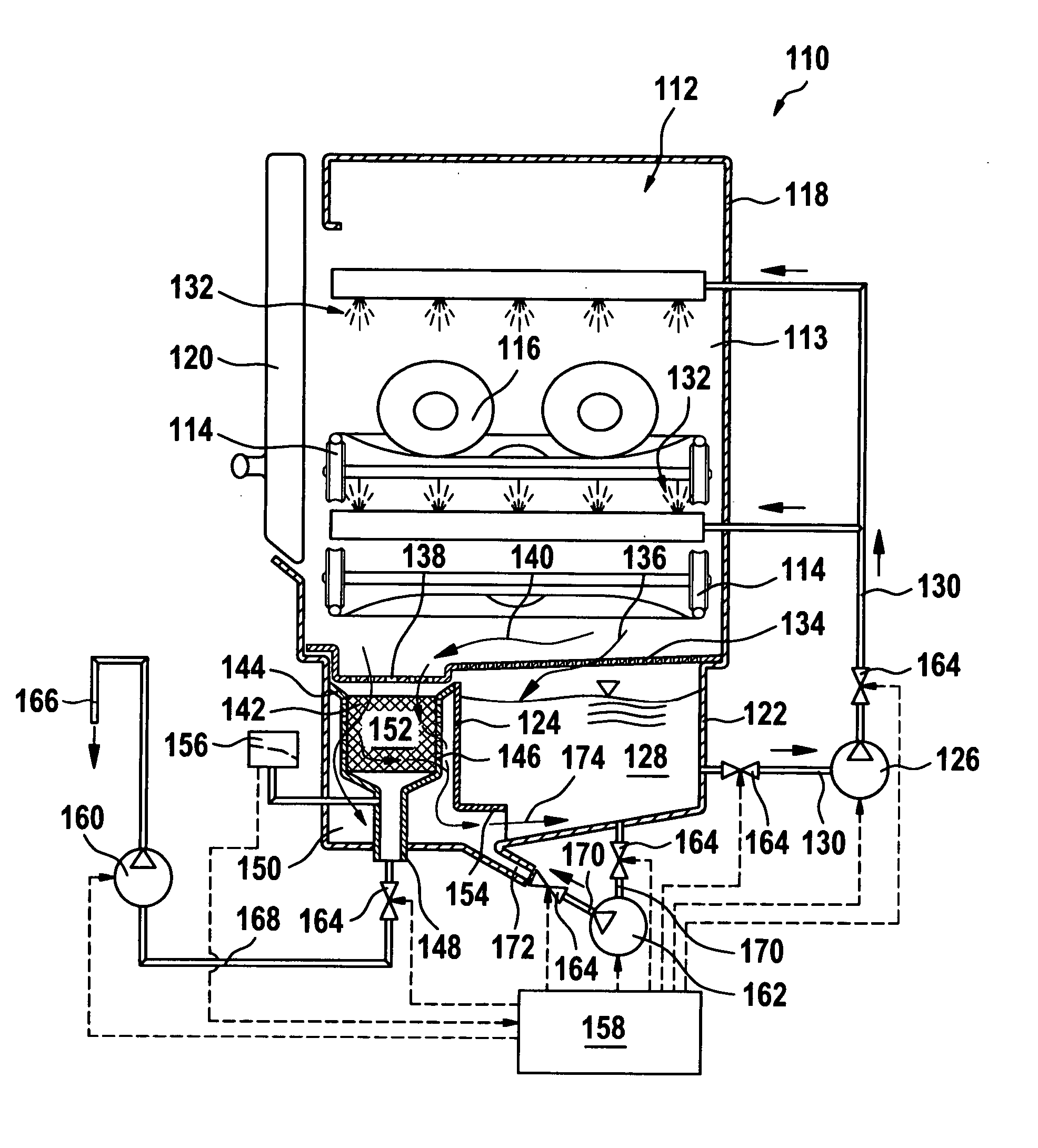

Multi-tank dishwasher comprising a backwash device

ActiveUS20080041419A1Avoid disadvantagesHigh trafficTableware washing/rinsing machinesCleaning using liquidsWater storage tankWastewater

Multi-tank dishwashers are used, in particular, industrially, in order to clean items which are to be washed. The invention relates to a multi-tank dishwasher which is provided with a washing area. The washing area comprises at least one rinsing water storage tank, at least one filter housing, at least one fine filter and at least one backwash device. In the normal mode, a filter wall of the at least one fine filter is cross flown in the direction from a waste water chamber to a pure water chamber. In order to clean the fine filter, the multi-tank dishwasher can be operated in a backwashing mode, without interrupting the washing process. In said backwashing mode, a cross-flow of the at least one filter wall of the rinsing water is reversed by using a backwash pump and a waste water pump. Dirt particles, which are located on the inner side of the filter wall, are rinsed off and are removed by the waste water pump in the waste water outlet.

Owner:MEIKO MASCHENBAU

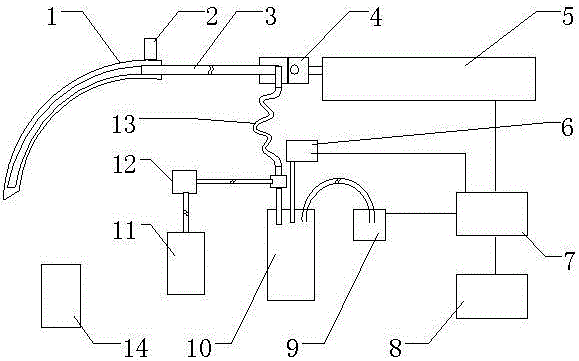

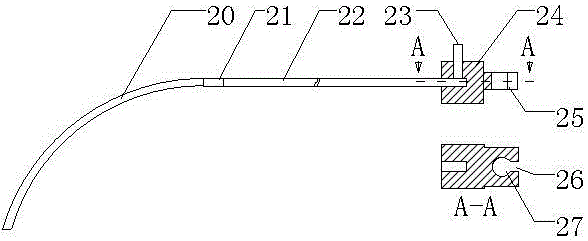

Automatic sputum suction machine

The invention discloses an automatic sputum suction machine, and belongs to automatic medical equipment capable of automatically completing insertion and rotation of a multi-section combined type sputum suction tube, vacuum pump starting for sputum suction, delaying, retreating of the multi-section combined type sputum suction tube and stopping of a vacuum pump. All the sputum suction operation steps can be automatically completed. The automatic sputum suction machine comprises the multi-section combined type sputum suction tube, a motion mechanism, a support, a wireless alarm receiver, the vacuum pump, a microprocessor, a negative-pressure sensor, a liquid storage bottle, a flushing water pump, a flushing liquid bottle and a combined connecting host assembly. If it is detected that the multi-section combined type sputum suction tube is blocked or the liquid level of the liquid storage bottle is too high, a system can automatically send out wireless alarm signals. Medical staff carrying the wireless alarm receiver are informed. When the automatic sputum suction machine is used, contact time between doctors and patients can be shortened, and the labor intensity of medical workers can be lowered.

Owner:李庆喜 +1

Stemware saver for dishwasher

InactiveUS7458471B2Reduce manufacturing costEasy to assemblePlatesTableware washing/rinsing machinesRinse waterEngineering

Owner:CRUDGINGTON JR CLEVELAND B

High-efficiency wet-type electric dust removal and desulfuration system and process

ActiveCN102716639AGuaranteed desulfurization efficiencyImprove dust removal system efficiencyCombination devicesGypsumWater balance

The invention discloses a high-efficiency wet-type electric dust removal and desulfuration system and a process. A wet-type electric dust remover is arranged above a demister in a desulfuration tower. First of all, the demister is used for pre-removing mist drops and dust from clean smoke; the wet-type electric dust remover is used for performing fine treatment on the clean smoke; therefore, an extremely high environment-friendly discharging requirement is met; and the desulfuration efficiency is guaranteed, the efficiency of a dust removal system of the desulfuration tower is improved, and the dust discharge concentration at the outlet of the desulfuration tower is reduced, so that the latest discharge standard required in China is met. According to the wet-type electric dust remover, the problem of gypsum rain can be solved; various pollutants can be removed at the same time; furthermore, a water accumulation plate is arranged between the demister and the wet-type electric dust remover and used for collecting and recycling washing water of the wet-type electric dust remover, so that the washing water of the wet-type electric dust remover cannot directly enter into a neutralization oxidation pond of the desulfuration tower; and therefore, the water balance of the whole system is guaranteed.

Owner:CPI YUANDA ENVIRONMENTAL PROTECTION ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com