Patents

Literature

115results about How to "Guaranteed desulfurization efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

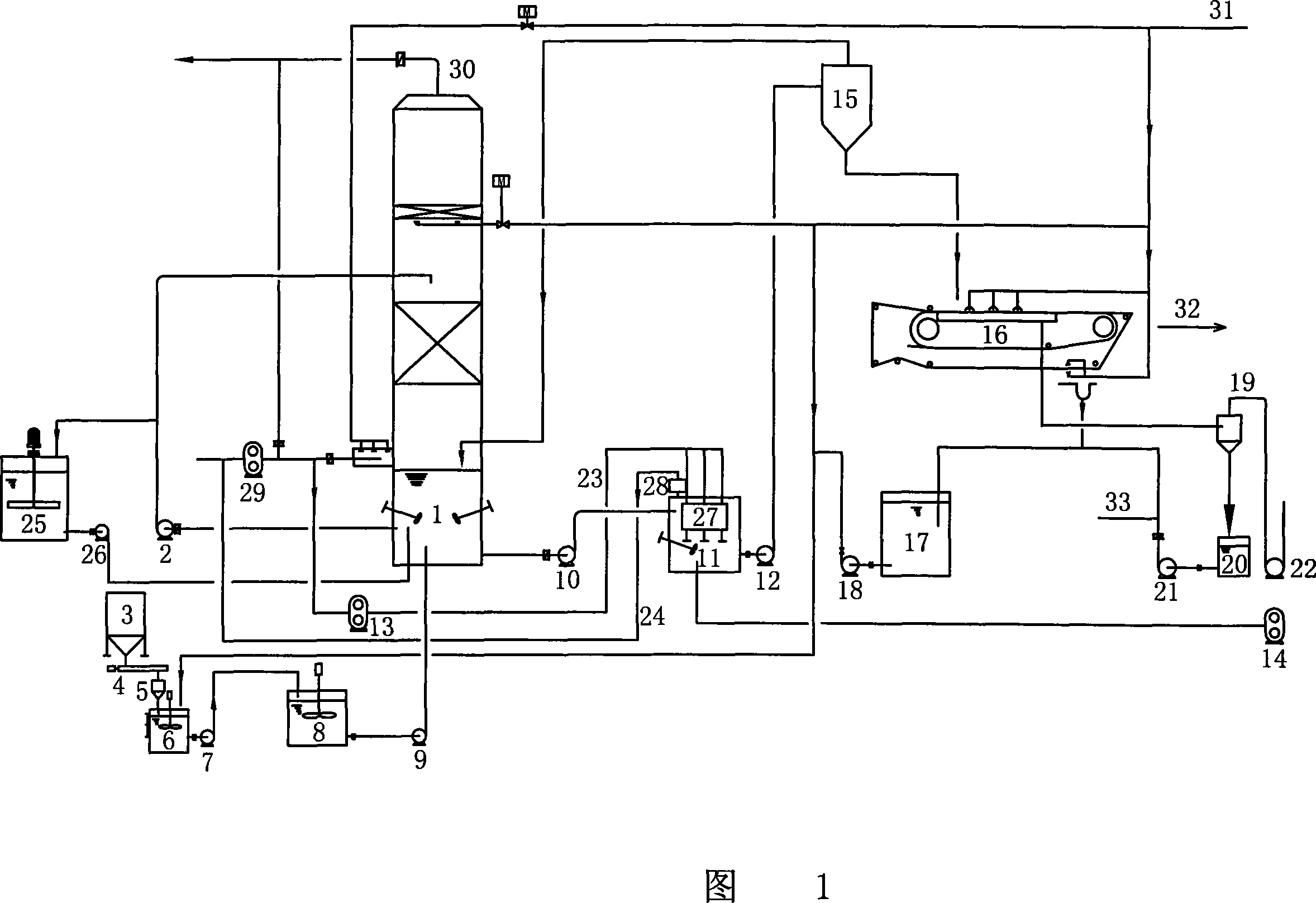

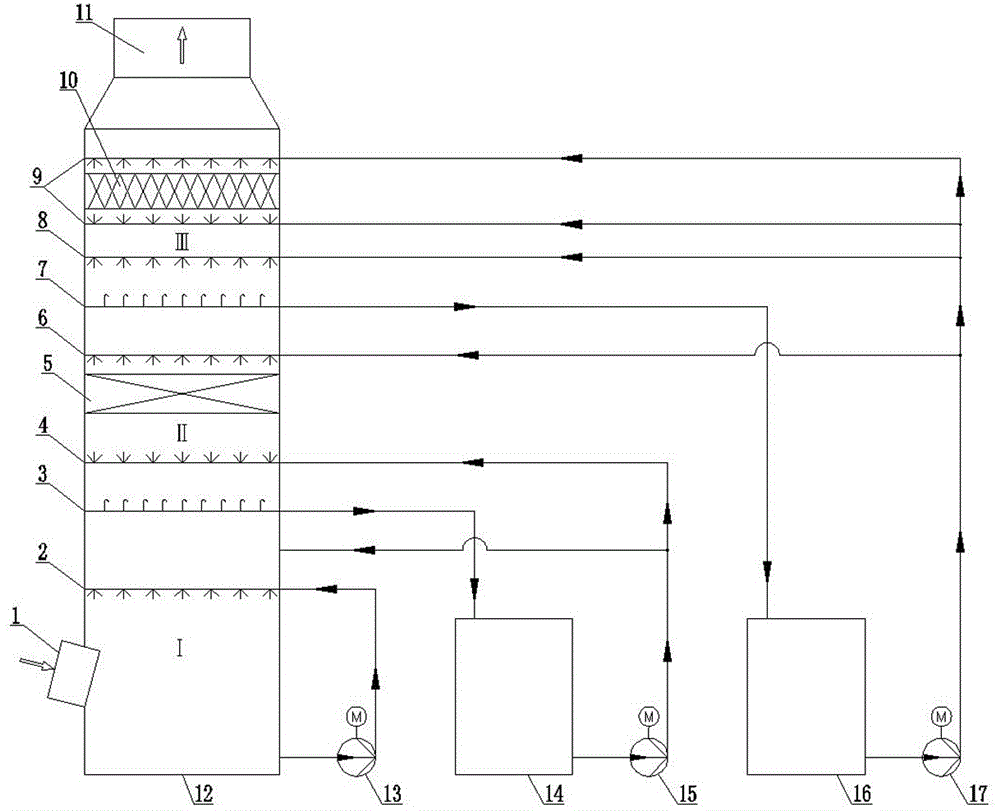

Out tower oxidizing lime/acetylene sludge-gypsum process desulphurization technology and equipment

ActiveCN101229473AImprove qualityGuaranteed desulfurization efficiencyDispersed particle separationSludgeCarbide

The invention discloses a lime oxidation outside tower / carbide-gypsum desulfurization technology and a device thereof, wherein, the technology comprises the steps that initial gas is introduced into a desulfurizing tower and reacted with lime / carbide slurry; sulfur dioxide in the gas is absorbed by the lime / carbide slurry and emitted. The lime / carbide slurry becomes desulfurization slurry after absorbing sulfur dioxide in the desulfurizing tower; the desulfurization slurry is discharged from the desulfurizing tower and introduced into an oxidation tank; one part of the initial gas is introduced into the desulfurizing tower and reacted with the lime / carbide slurry, while the other part is introduced into the oxidation tank to adjust the pH value of the desulfurizing slurry discharged from the desulfurizing tower to 3.0-5.5; then oxygen is introduced into the oxidation tank to carry out oxidation reaction with the desulfurizing slurry, so as to obtain desulfurization gypsum and be recovered. Compared with the prior art, the invention can not only reduce investment and operation cost, but also produce higher-quality desulfurization gypsum as by-product.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

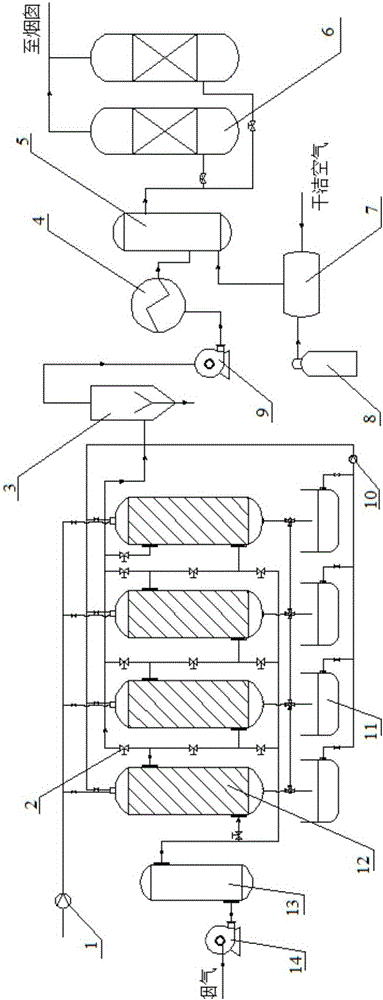

Flue gas low-temperature combined desulfurization and denitration technology method

InactiveCN105327612AAchieve recyclingNo entryDispersed particle separationFlue gasConcentration gradient

The invention discloses a flue gas low-temperature combined desulfurization and denitration technology method mainly including the steps: flue gas after dedusting having a purification temperature and humidity meeting desulfurization conditions is sent into a desulfurization tower to flow through a desulfurization catalyst bed, sulfur dioxide in the flue gas is oxidized into sulfur trioxide under the action of a catalyst, and sulfur trioxide acts with water in the flue gas to generate sulfuric acid; the desulfurization catalyst bed is regenerated through progressively-decreased sulfuric acid concentration gradient washing; the flue gas after desulfurization is sent into a denitration conditioning work section, is dehumidified and heated, and is adjusted to meet requirements of a denitration technology; the flue gas after dehumidification and heating is sent into a mixing tower and is mixed with injected ammonia gas, the mixed flue gas mixed with the ammonia gas is sent into a denitration tower to flow through a denitration catalyst bed, and NOx, NH3 and O2 in the mixed flue gas are converted into N2 and water under the action of a denitration catalyst. The problems that a conventional flue gas desulfurization and denitration technology is narrow in flue gas applicable scope, high in heating energy consumption, high in running cost and the like are overcome.

Owner:SICHUAN UNIV +1

High-efficiency wet-type electric dust removal and desulfuration system and process

ActiveCN102716639AGuaranteed desulfurization efficiencyImprove dust removal system efficiencyCombination devicesGypsumWater balance

The invention discloses a high-efficiency wet-type electric dust removal and desulfuration system and a process. A wet-type electric dust remover is arranged above a demister in a desulfuration tower. First of all, the demister is used for pre-removing mist drops and dust from clean smoke; the wet-type electric dust remover is used for performing fine treatment on the clean smoke; therefore, an extremely high environment-friendly discharging requirement is met; and the desulfuration efficiency is guaranteed, the efficiency of a dust removal system of the desulfuration tower is improved, and the dust discharge concentration at the outlet of the desulfuration tower is reduced, so that the latest discharge standard required in China is met. According to the wet-type electric dust remover, the problem of gypsum rain can be solved; various pollutants can be removed at the same time; furthermore, a water accumulation plate is arranged between the demister and the wet-type electric dust remover and used for collecting and recycling washing water of the wet-type electric dust remover, so that the washing water of the wet-type electric dust remover cannot directly enter into a neutralization oxidation pond of the desulfuration tower; and therefore, the water balance of the whole system is guaranteed.

Owner:CPI YUANDA ENVIRONMENTAL PROTECTION ENG

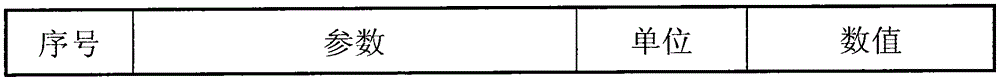

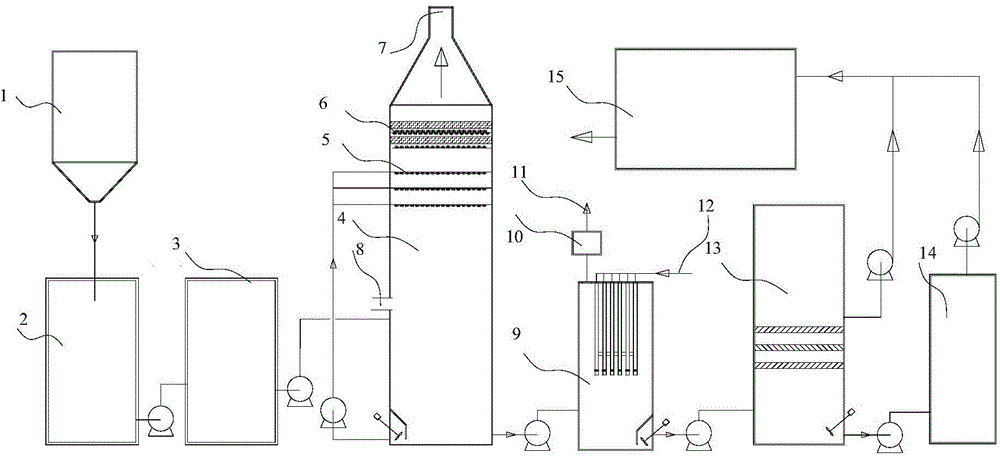

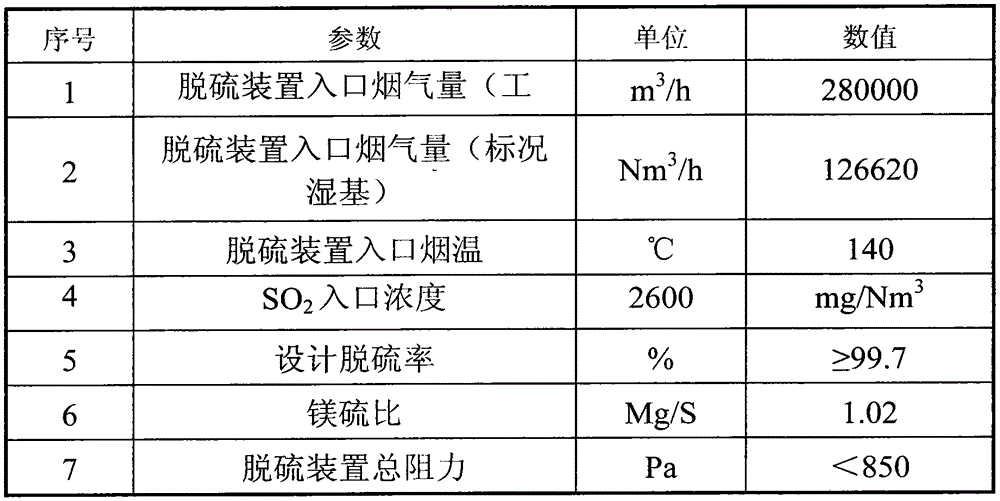

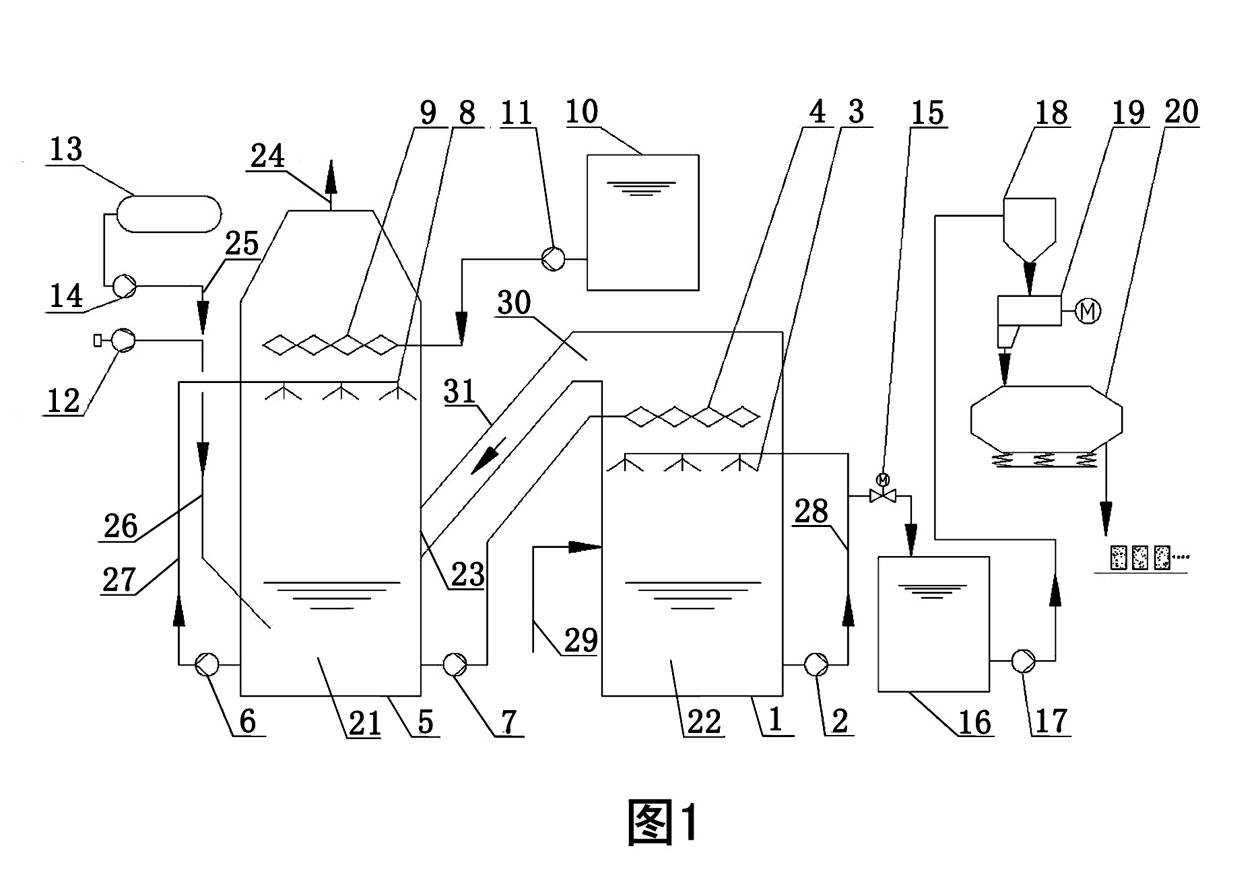

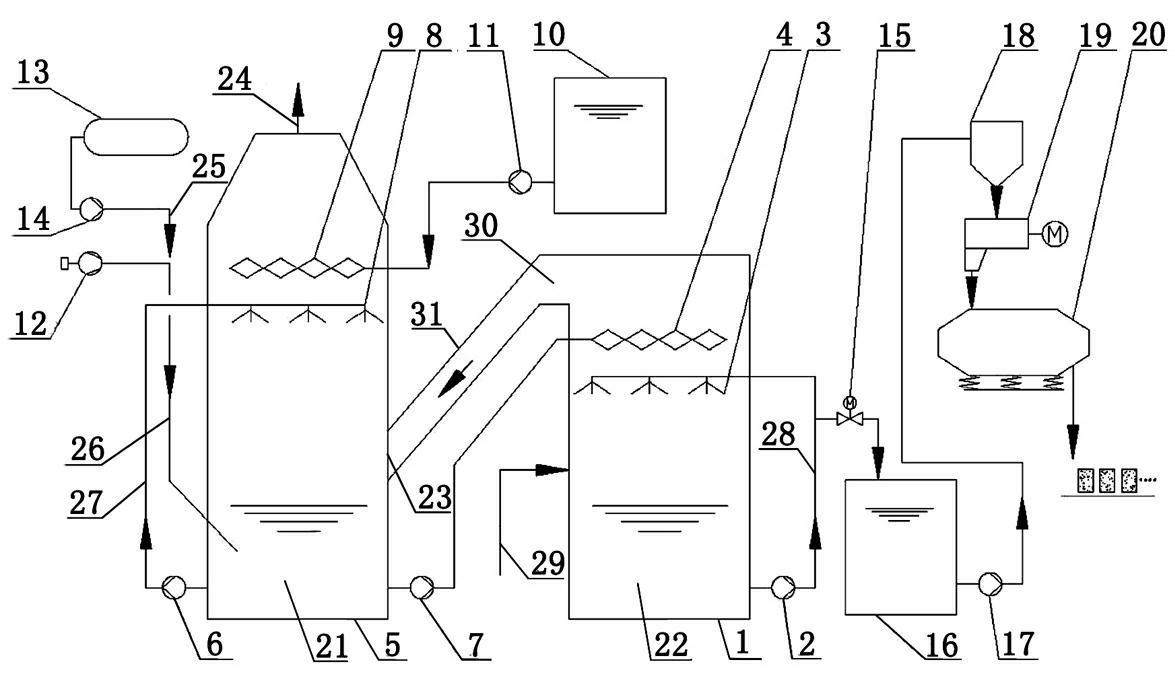

Magnesium sulfate production device and method by flue gas desulfurization

The invention a magnesium sulfate production device and method by flue gas desulfurization, particularly a device and method for producing magnesium sulfate by direct crystallization in a magnesium-oxide-process desulfurization waste liquid tower. The device comprises a flue gas desulfurization apparatus, a slurry circulating tank, an evaporative concentration region, a circulating settling apparatus, a crystallizing apparatus, a centrifugal apparatus, a drying apparatus and the like. The device and method provided by the invention can solve the problems of high steam consumption, higher production cost per ton of ores, and higher desulfurization operating cost when the magnesium-process desulfurization waste liquid is used for producing magnesium sulfate at present.

Owner:ZHONGJING ENVIRONMENTAL TECH CO LTD

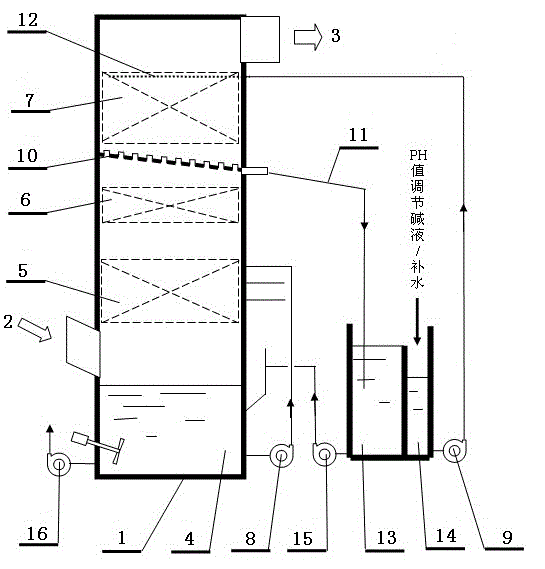

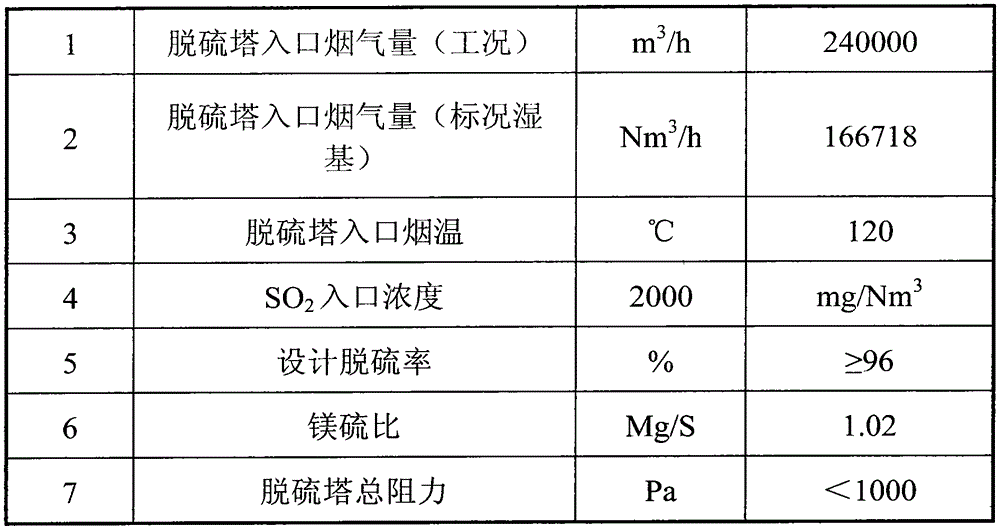

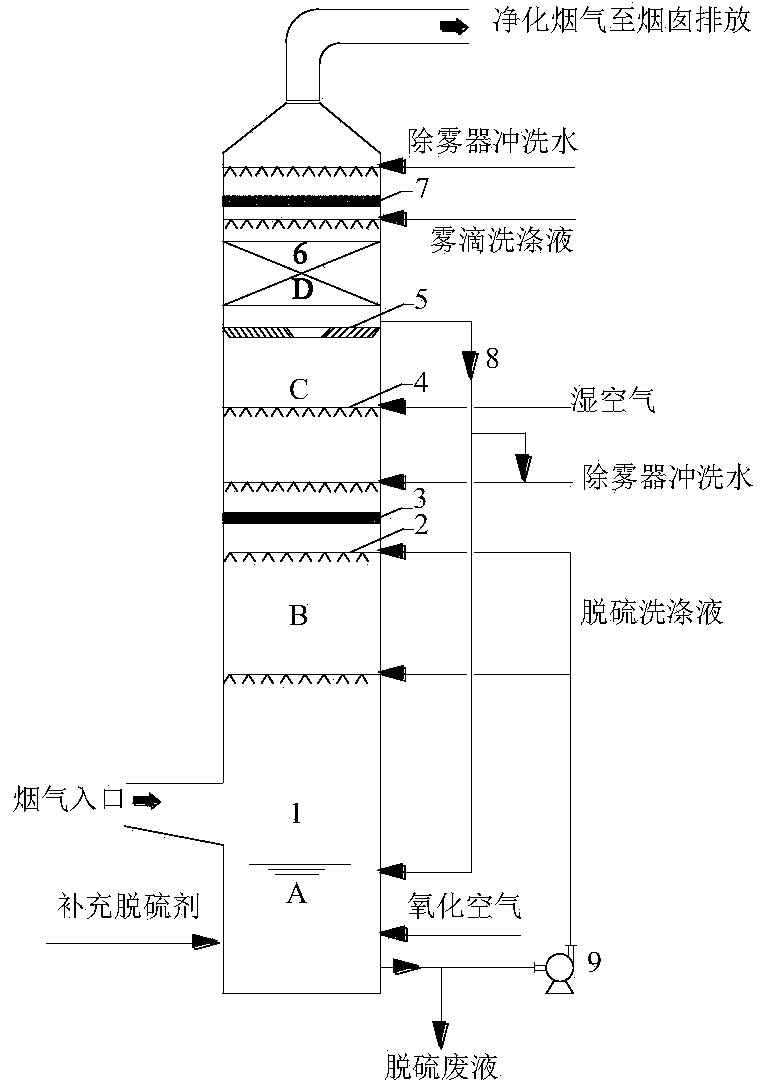

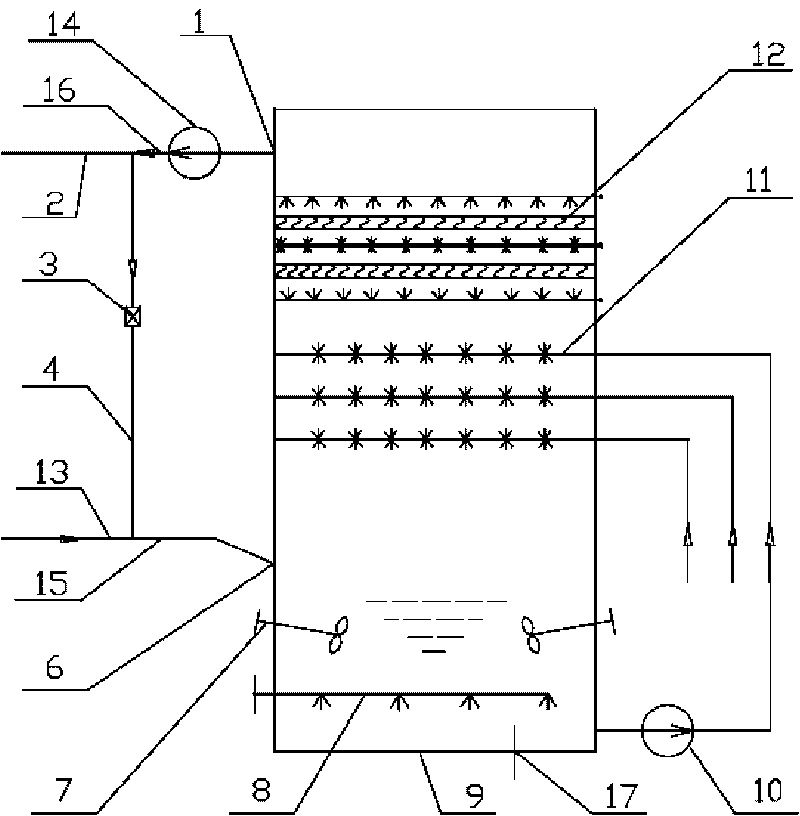

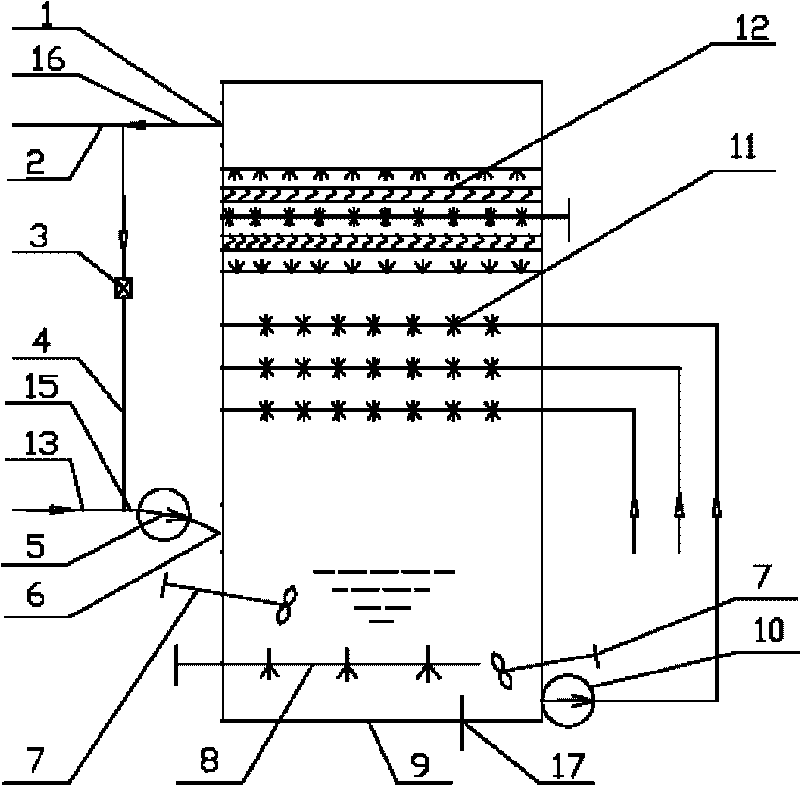

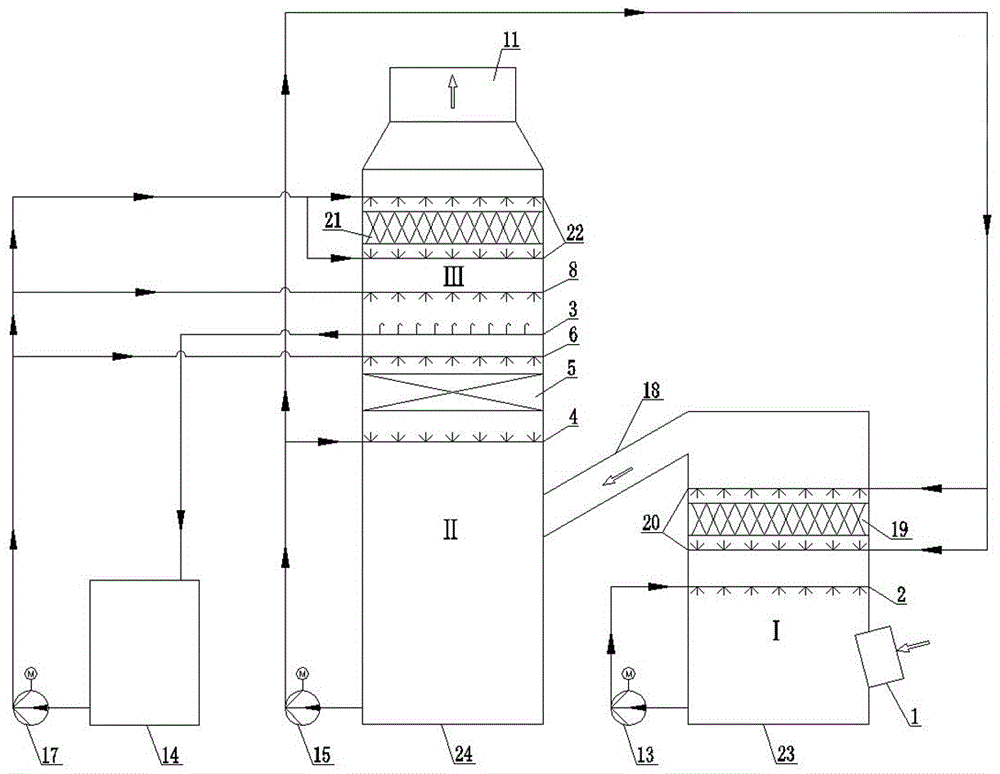

Desulfurization device and desulfurization method for promoting removal of PM2.5 in clean flue gas after wet desulphurization

ActiveCN103721548AReduce energy consumptionSolve the defect of easy cloggingCombination devicesWater vaporFlue gas

The invention discloses a desulphurization device and a desulphurization method for promoting removal of PM2.5 in clean flue gas after wet desulphurization. The desulphurization device comprises a flue gas desulphurization washing device and a fog drop collecting device which are connected in series, wherein the flue gas desulphurization washing device comprises a desulphurization liquid oxidation region, a desulphurization washing region and a water vapor phase change region which are arranged in sequence from bottom to top; the fog drop collecting device forms an integral or split structure together with the flue gas desulphurization washing device and is arranged on the flue gas desulphurization washing device or at an outlet. According to the method, flue gas enters the water vapor phase change region after SO2 is removed through the desulphurization washing region; wet air is filled through a wet air distributor, so that the clean flue gas after the wet desulphurization reaches an oversaturated state; oversaturated water vapor is nucleated and condensed on the PM2.5 surface, so that the PM2.5 is turned into dust fog drops with liquid films on the surfaces and the particle sizes are increased; the condensed expanded dust fog drops enter the fog drop collecting device and are collected through fog drop washing liquid and a defroster of the fog drop collecting device. According to the desulphurization device, the energy consumption for building an oversaturated water vapor environment can be effectively reduced and the PM2.5 emission problem of a wet flue gas desulphurization system is solved.

Owner:SOUTHEAST UNIV

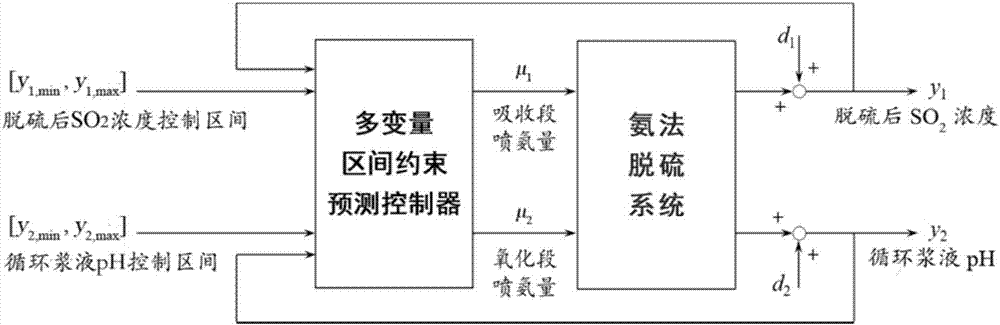

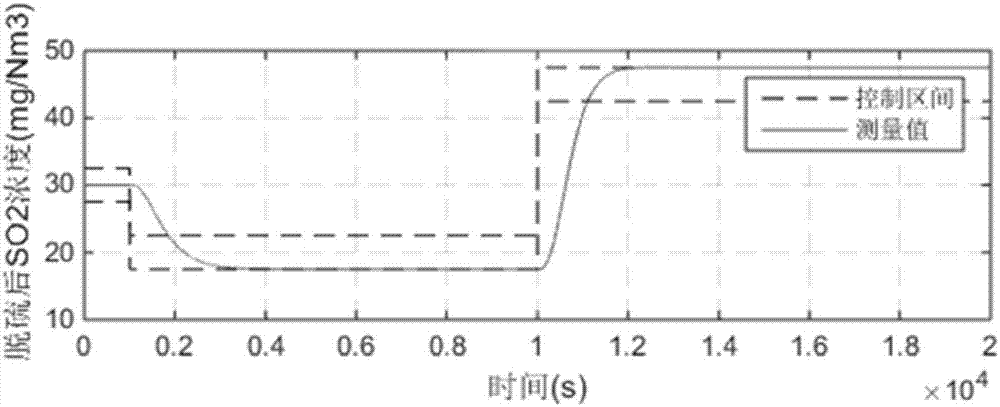

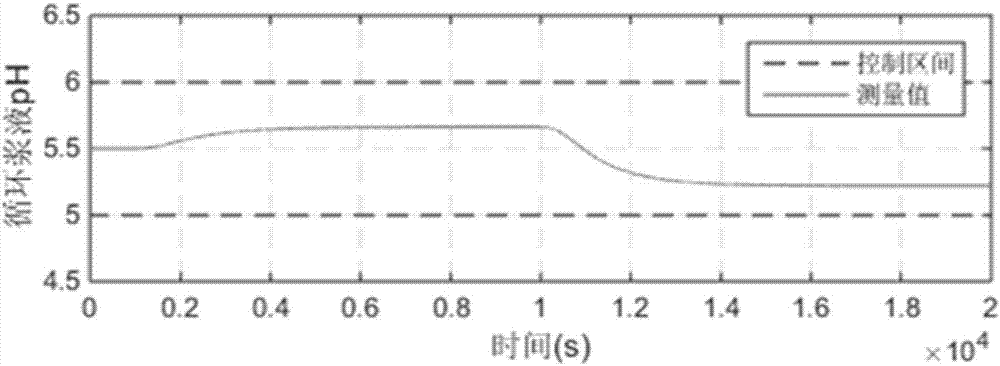

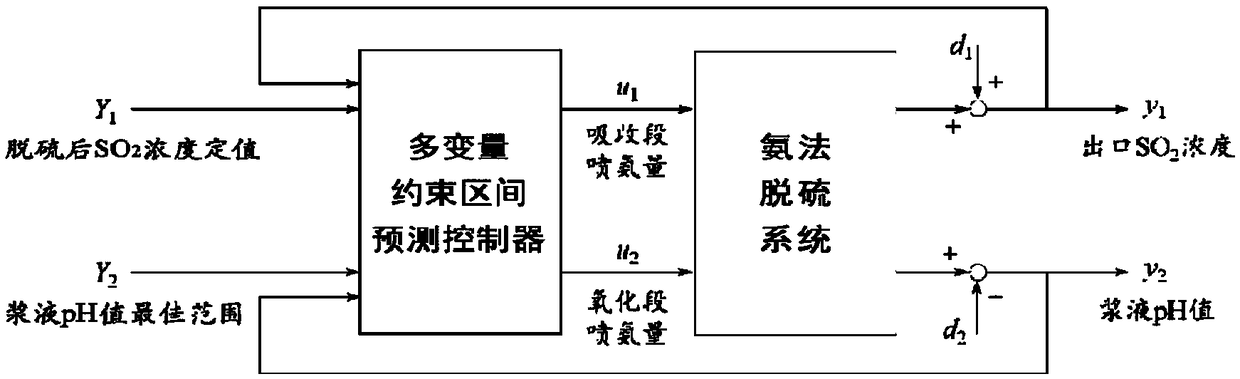

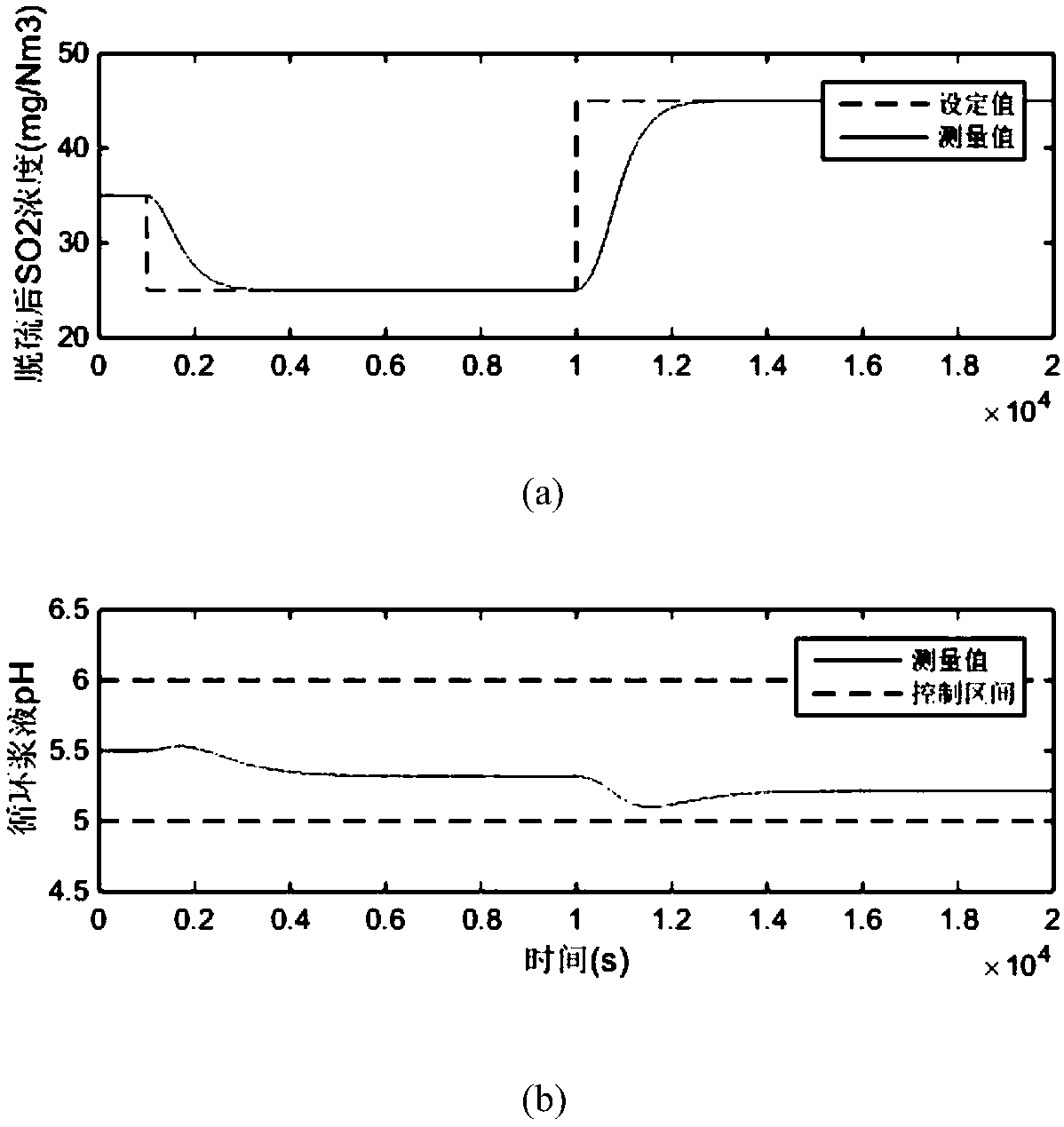

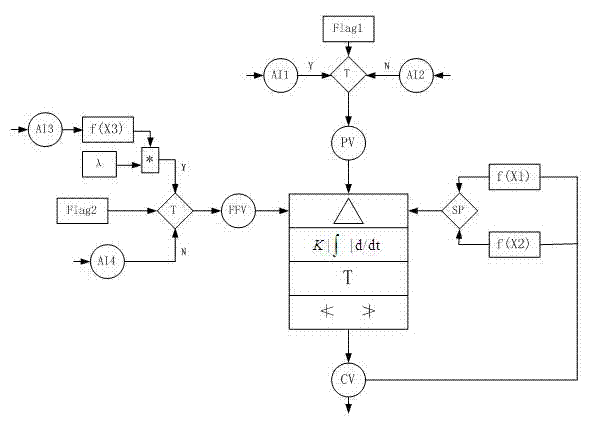

Ammonia desulfurization optimization control method based on multivariable predictive control

ActiveCN107168055ALower requirementImprove robustnessAdaptive controlTraffic volumeState-space representation

The invention discloses an ammonia desulfurization optimization control method based on multivariable predictive control. Firstly, the overall ammonia desulfurization system is regarded as a two-in-two-out multivariable object, and the augmented state space model is obtained through identification; then, in combination of multivariable constrained predictive control and interval control, intake ammonia flows in an absorption section and an oxidation section of a desulfurization tower are controlled, and the SO2 concentration after desulfurization and the pH value of circulating slurry are guaranteed to be maintained in a given interval range. Through adopting the multivariable constrained predictive control method based on interval characteristics, the sensitivity to model errors is weakened, the robustness of the controller is enhanced, distribution of the intake ammonia flow in different reaction stages of the desulfurization tower can be better realized, coordination control demands are reduced on the premise of ensuring the desulfurization efficiency, the dynamic adjustment quality of the system is improved, the actuating frequency of an actuator is reduced, the ammonia consumption amount is reduced, and economic and environmental friendly operation of the desulfurization system is further promoted.

Owner:SOUTHEAST UNIV

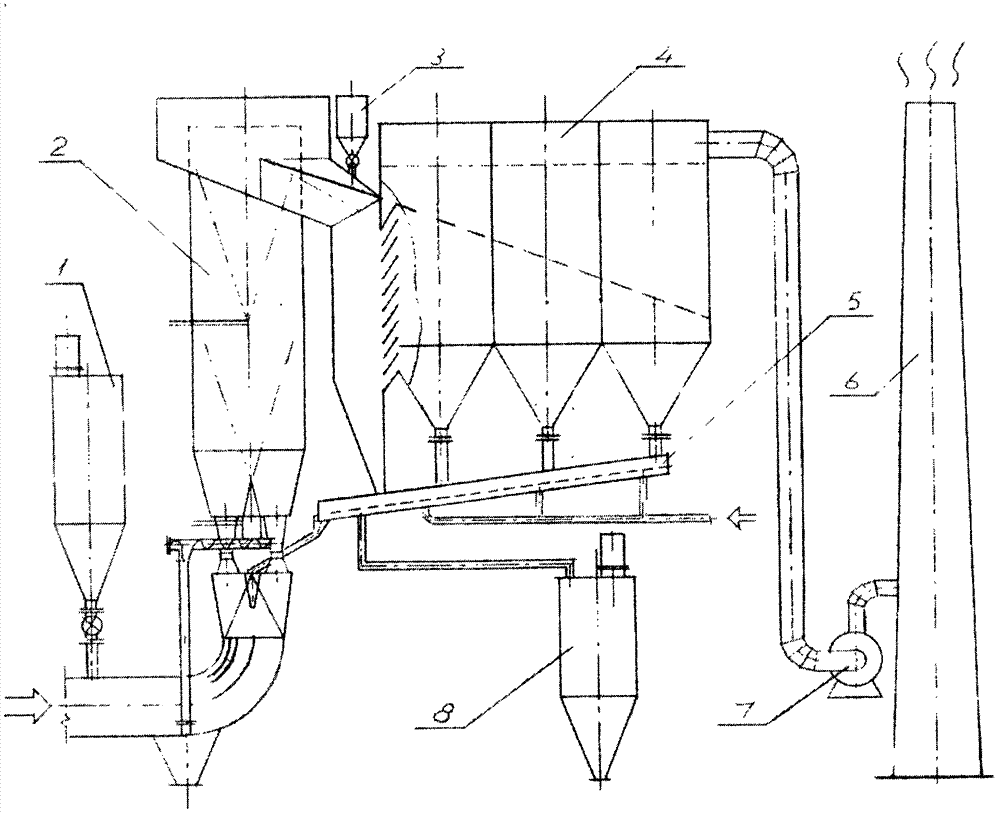

Method for dedusting and desulfurizing catalytic-cracking oil refining regenerated flue gas

The invention relates to a method for dedusting and desulfurizing catalytic-cracking oil refining regenerated flue gas. The method which utilizes a sodium alkali and magnesia combined sodium-magnesium method comprises the following steps: magnesium hydroxide slurry is prepared from magnesia firstly and is mixed with a sodium alkali solution according to a certain ratio so as to prepare a desulfurization solution, and the desulfurization solution is conveyed to each spraying layer from the bottom of a tower by a desulfurization circulating pump; the flue gas is subjected to spraying, humidifying and cooling at an entrance of a desulfurization tower, then rises from the bottom of the desulfurization tower and is subjected to enhanced dedusting, desulfurizing and acid mist trapping by a combination unit, and the flue gas flowing out of the combination unit is then subjected to deep desulfurizing and dedusting by an upper spraying zone; sulfur dioxide in the flue gas is converted into magnesium sulfite and sodium sulfite; desulfurizing waste liquid is subjected to adequate aeration and oxidation, and then, produced magnesium sulfate and waste residues are discharged by a residue slurry pump and enter a subsequent filtration and dewatering system; and slurry concentrated by a cyclone is subjected to dewatering by a filtering machine so as to obtain disposable solid wastes. Compared with the prior art, the method has the advantages that the cost of the desulfurizing liquid can be remarkably reduced, the wastewater output is reduced, and meanwhile, the dedusting and desulfurization of FCC (Fluidized catalytic cracking) regenerated flue gas can be realized efficiently.

Owner:SHANGHAI JIAO TONG UNIV

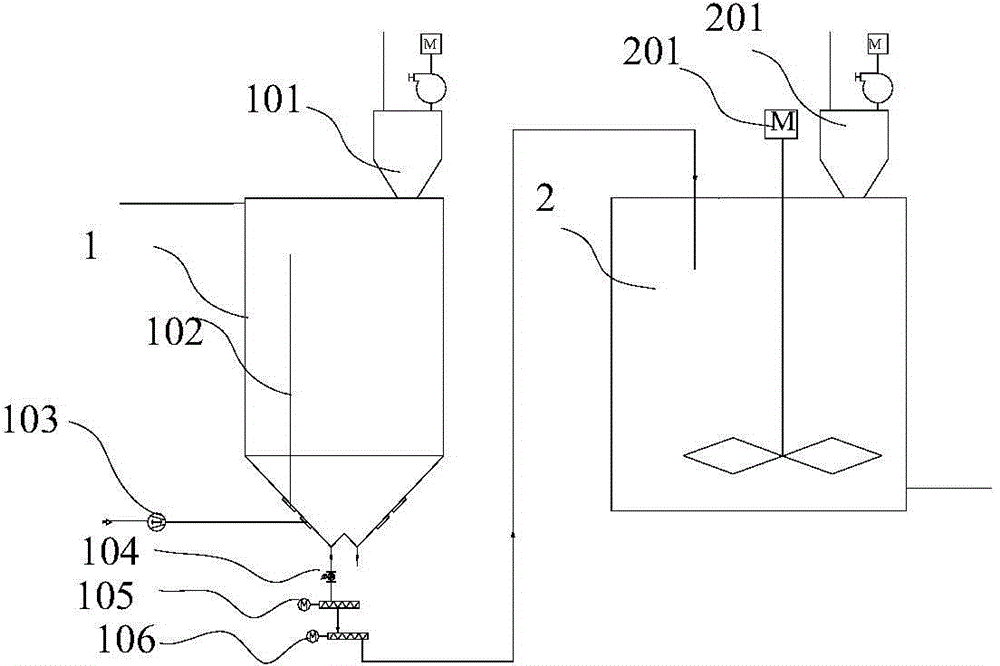

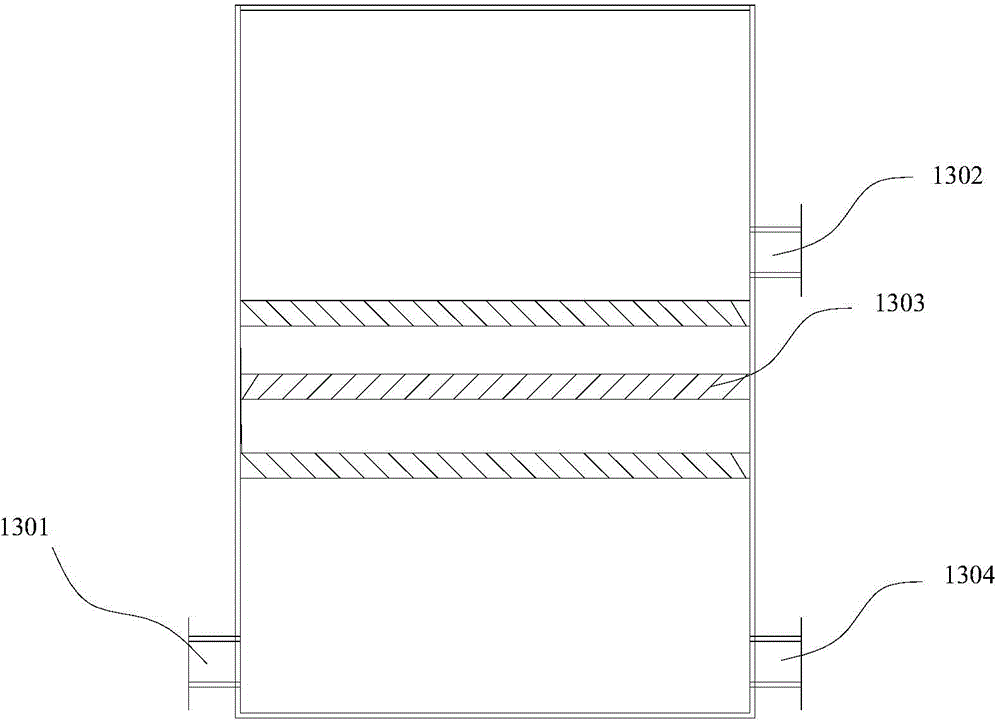

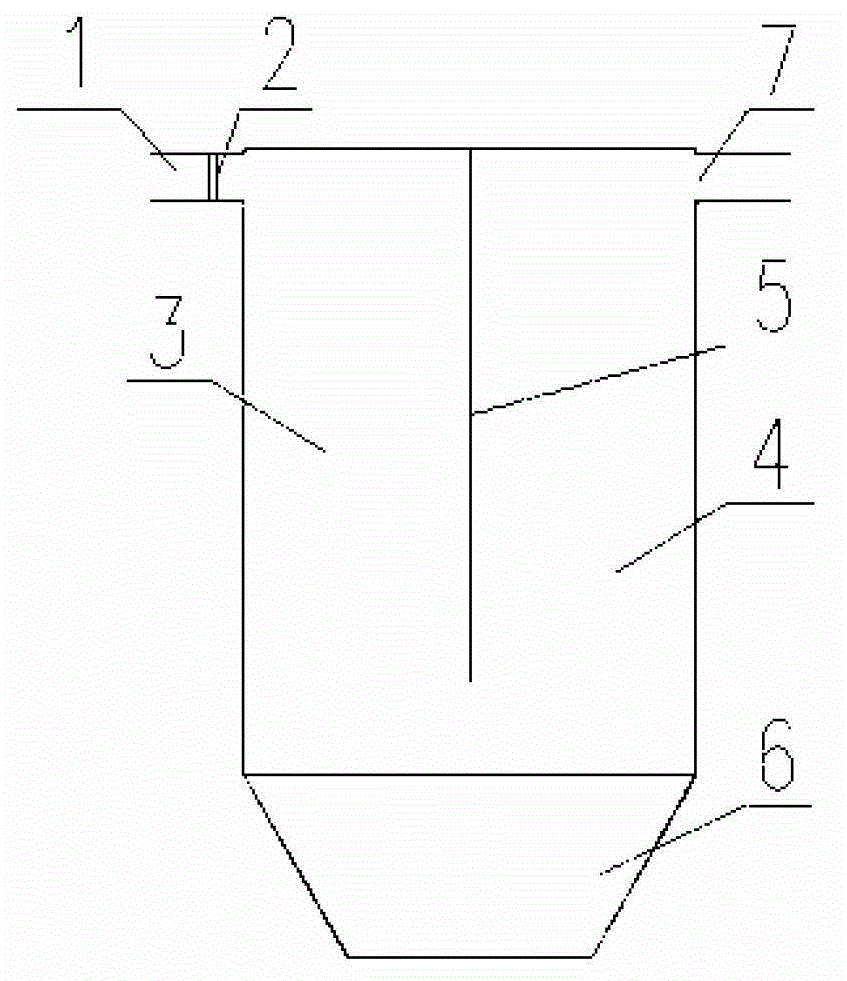

Device and method for redesulfuration with desulfurization ash

InactiveCN104959018AGuaranteed qualityGuaranteed desulfurization efficiencySolid waste disposalCalcium/strontium/barium sulfatesSlurryEngineering

The invention discloses a device and method for redesulfuration with desulfurization ash. The device comprises a desulfurization ash slurrying device, a SO2 absorbing device, an oxidation device, an ash content separating device, a gypsum dehydration device and a wastewater treatment device which are connected in sequence. The desulfurization ash slurrying device comprises a desulfurization ash powder bin provided with a fluidizing air inlet in the lower portion, a vibrator inside, and a dedusting device on the top, and a slurry melting pond connected with the desulfurization ash powder bin and the SO2 absorbing device. The ash content separating device comprises a tank body and multiple layers of baffles, wherein a first slurry liquid outlet is formed in the upper portion of the tank body, a slurry liquid inlet and a second slurry liquid outlet are formed in the bottom of the tank body, and the baffles are horizontally arranged in the tank body and located between the slurry liquid inlet and the first slurry liquid outlet. A desulfurization system is designed according to the characteristics of desulfurization ash, and wet flue gas desulfurization is conducted with desulfurization ash completely, so that desulfurization efficiency is guaranteed and gypsum quality is guaranteed.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

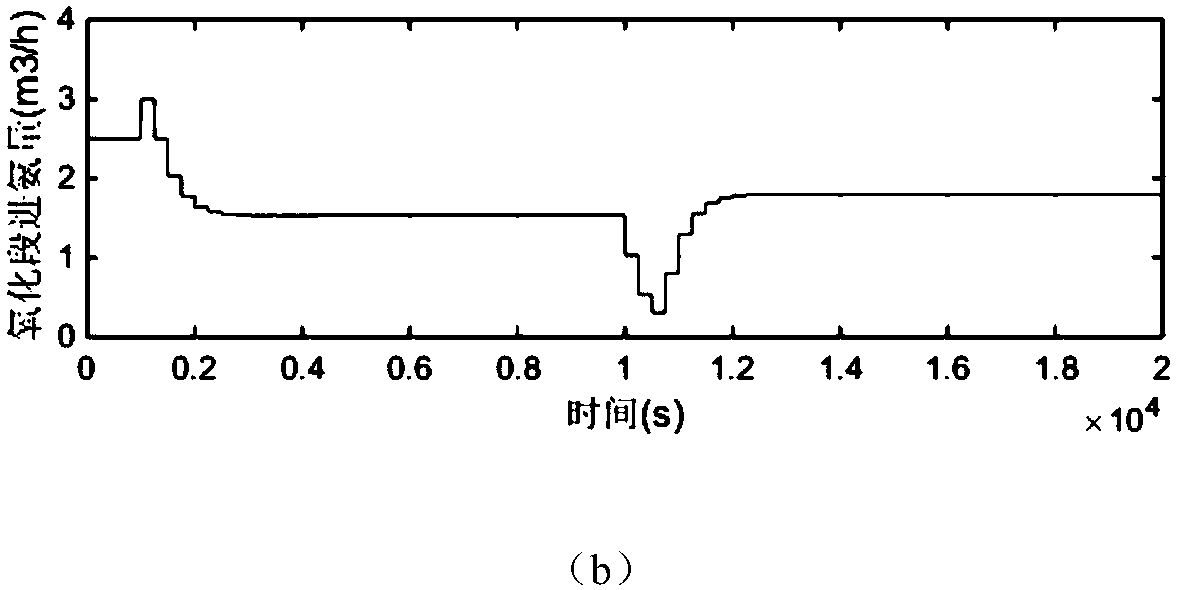

Ammonia-process desulfurization optimum control method based on multi-variable constraint zone predicting control

InactiveCN109224815AImplement schedulingRealize distributionDispersed particle separationProcess engineeringControl quality

The invention discloses an ammonia-process desulfurization optimum control method based on multi-variable constraint zone predicting control. The ammonia-process desulfurization optimum control methodhas the advantages that by adopting the multi-variable constraint zone predicting control method, the intake flow rate of ammonia water between the absorption section and oxidization section of a desulfurization tower can be well coordinated; at the premises of ensuring the desulfurization efficiency, the control quality of the system is improved, the running cost of the system is reduced, and the economic and environment-friendly running of the system is accelerated.

Owner:SINOPEC YANGZI PETROCHEM +1

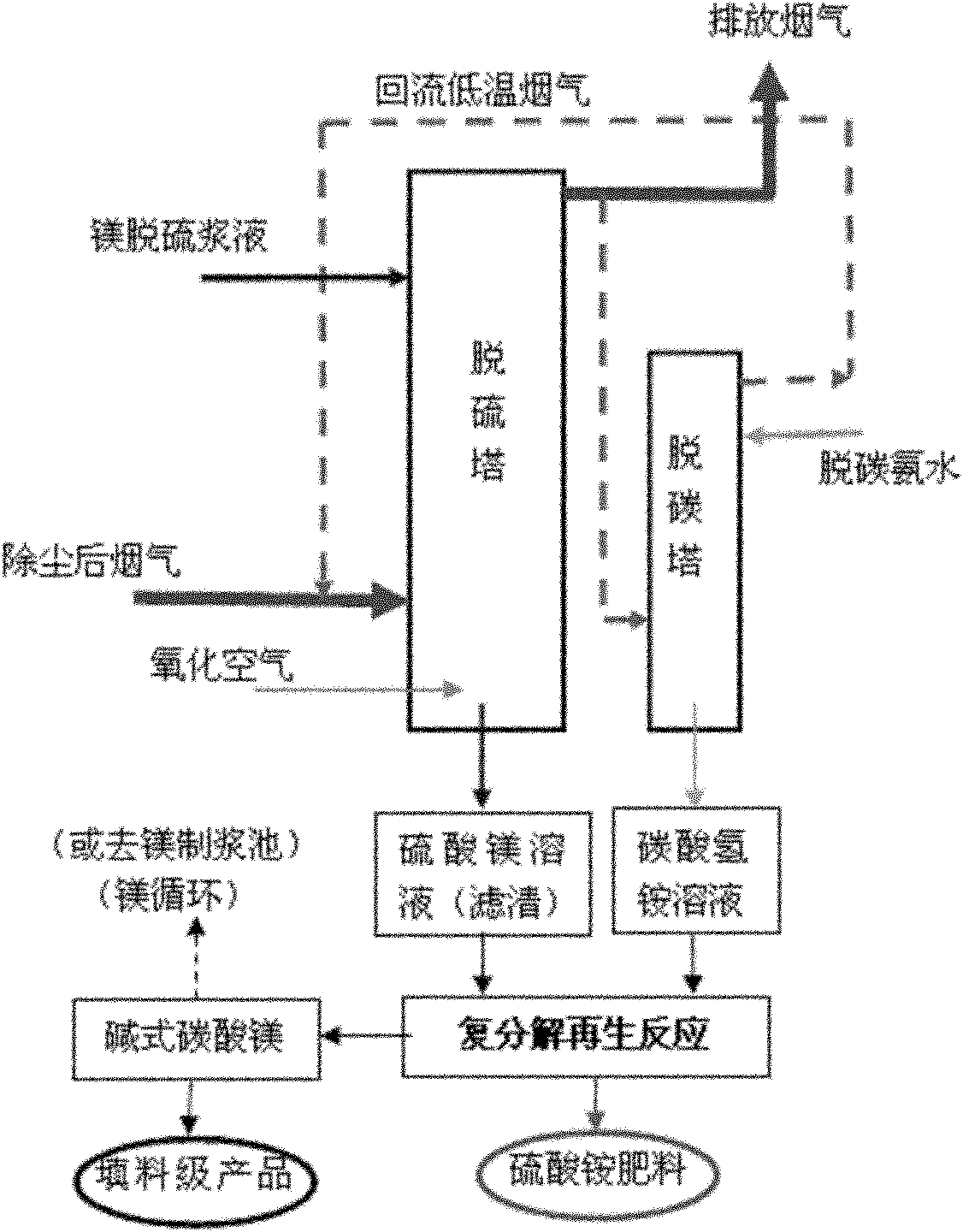

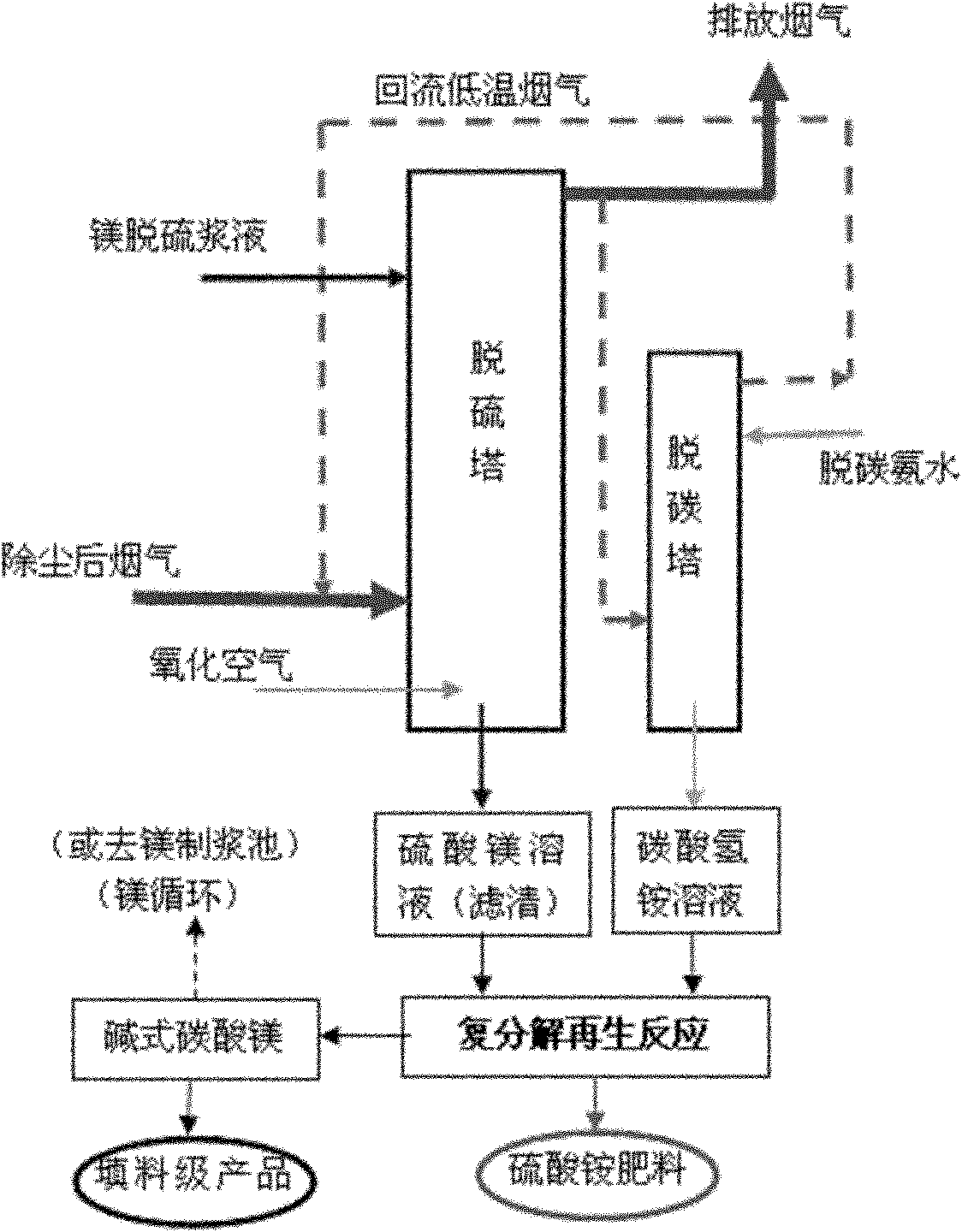

Method for implementing magnesium-ammonia combined flue gas desulfuration and decarbonization and by-product recovery

InactiveCN101972595AGuaranteed desulfurization efficiencyProductsReagentsDiammonium carbonateCarbonate

The invention discloses a method for implementing magnesium-ammonia combined flue gas desulfuration and decarbonization and by-product recovery in the technical field of environment. A method for recycling a desulfurization product of magnesium sulfate through ammonium carbonate / bicarbonate prepared through decarbonization and concentrating ammonium sulfate is utilized, waste liquor subjected to wet magnesium-desulphurization is regenerated on the basis of guaranteeing the desulphurization efficiency, the prepared basic magnesium carbonate solid is used for desulphurization recycling, and simultaneously a by-product of ammonium sulfate solid is prepared. The comprehensive technology for gathering carbon dioxide in the flue gas by using ammonia water so as to produce ammonium carbonate / bicarbonate and treating the magnesium sulfate produced through wet magnesium-desulphurization by using ammonium bicarbonate can simultaneously remove the carbon dioxide in the flue gas and obtain basic magnesium carbonate and ammonium sulfate fertilizers.

Owner:SHANGHAI JIAO TONG UNIV +2

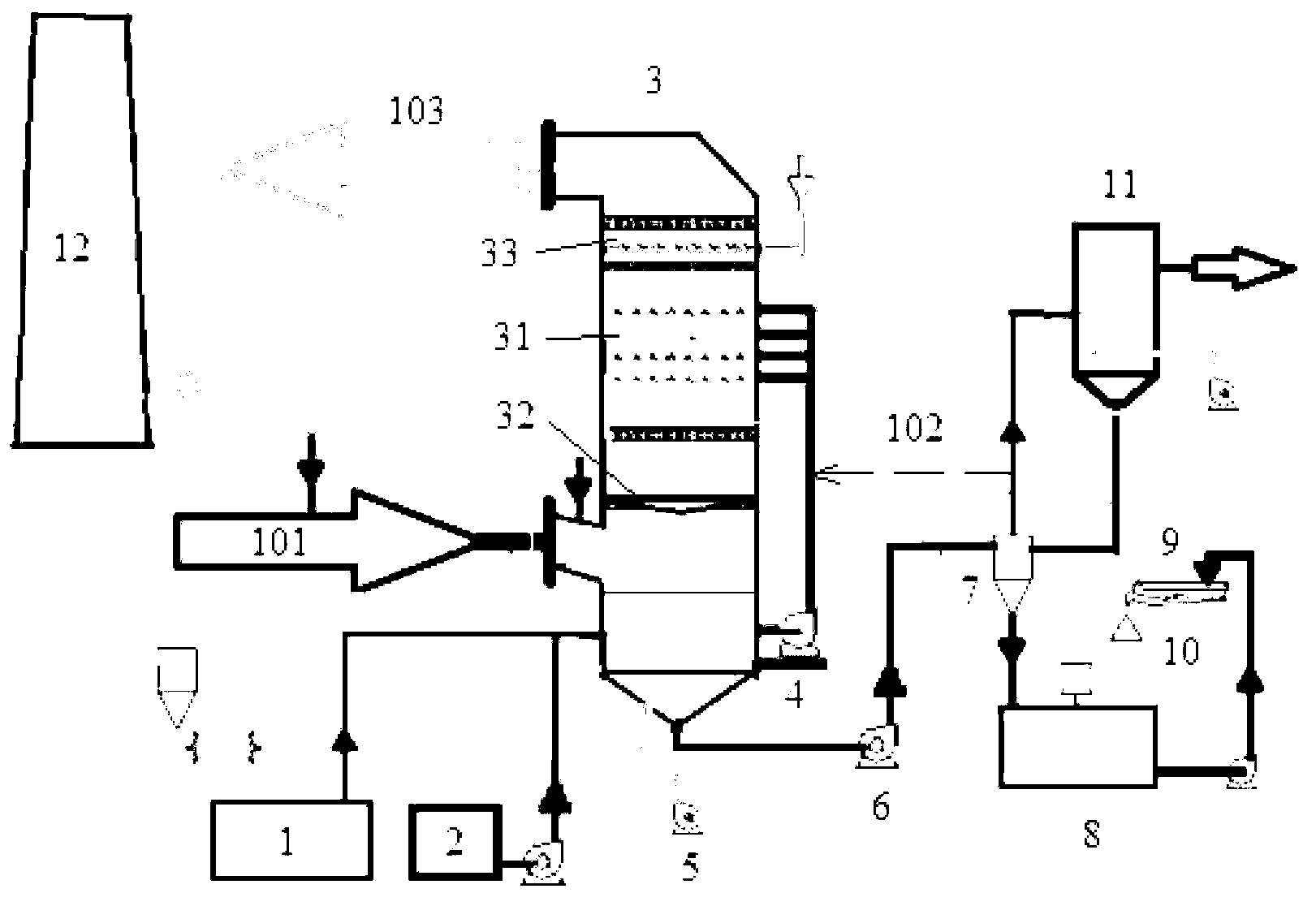

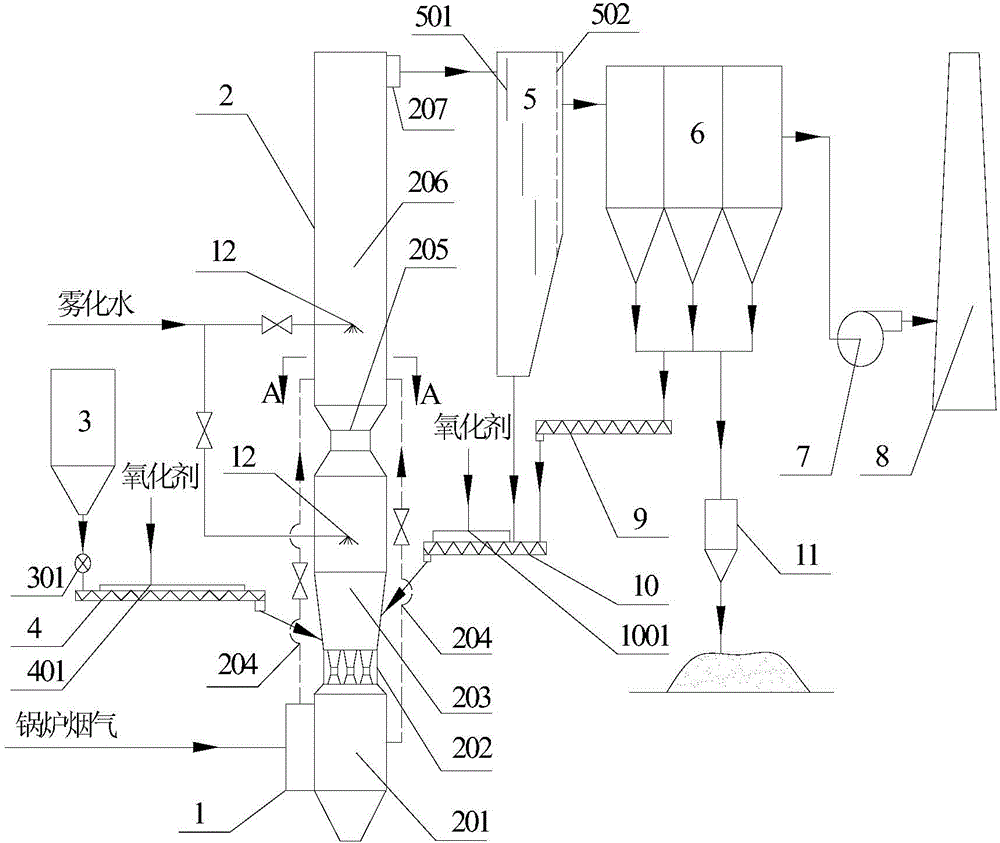

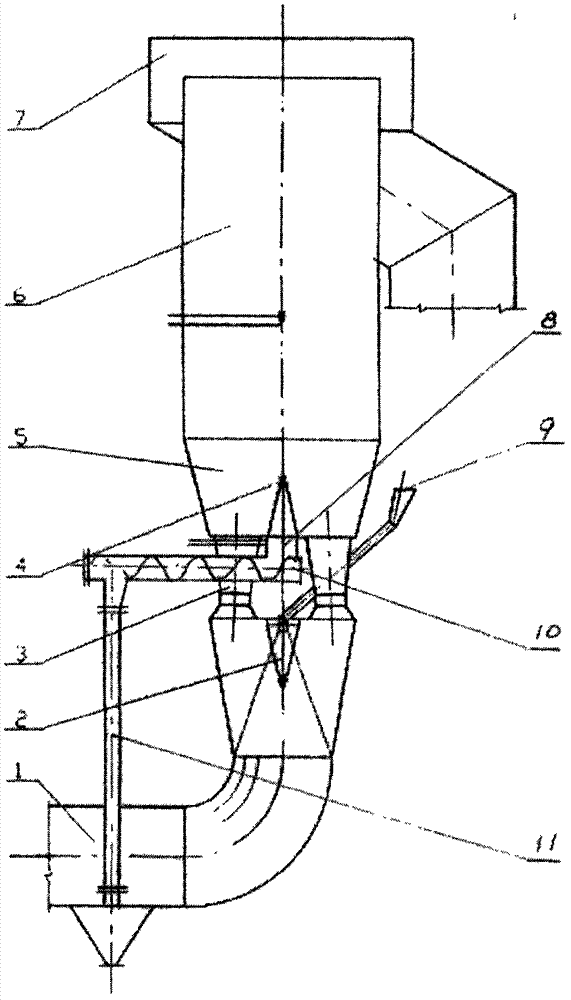

Flue gas desulfurization, denitration and demercuration integrated device with circulating fluidized bed and method

InactiveCN103977702AGuaranteed uptimeReinforce multiple cyclesDispersed particle separationAir quality improvementFluidized bedFirst-order reaction

The invention discloses a flue gas desulfurization, denitration and demercuration integrated device with a circulating fluidized bed and a method. A circulating fluidized bed reaction tower in the device is sequentially provided with a smoke chamber, a venturi tube, a first-order reaction zone, a shrinking opening, a second-order reaction zone and a reaction tower outlet from bottom to top, and atomizing spray guns are respectively arranged in the first-order reaction zone and the second-order reaction zone; 4-6 bypass pipelines are uniformly arranged outside the circulating fluidized bed reaction tower, and an inlet and an outlet of each bypass pipeline are respectively connected with the smoke chamber and the bottom of the second-order reaction zone; oxidizing agent adding openings are formed in an absorbent activator and a returning material activator, and activated absorbents and returning material ash directly enter the bottom of the first-order reaction zone. Through site digestion of calcium-based absorbents, structural improvement of the circulating fluidized bed reaction tower and optimization of operating parameters, on the basis of ensuring the desulfurization efficiency, the device strengthens the catalytic oxidation ability of the absorbents in the first-order reaction zone to NOx and gaseous elemental mercury (Hg0). The device realizes integration of desulfurization, denitration and demercuration through the reasonable combination of the first-order reaction zone and the second-order reaction zone.

Owner:NANJING NORMAL UNIVERSITY

Semi-dry-process desulfurization apparatus

ActiveCN102872712AReduce loadExtended reaction timeDispersed particle separationThermodynamicsFlue gas

The invention belongs to the field of environmental engineering and relates to a semi-dry-process desulfurization apparatus. The apparatus comprises an inlet of an absorption tower, a guide plate, a dense phase chamber, a circulating fluidization chamber, a partition plate, an ash bucket and an outlet of the absorption tower, wherein the absorption tower is of a U-shaped design; the inlet of the absorption tower is arranged at the upper part of the left outer side of the whole apparatus; dust-containing flue gas enters the dense phase chamber from the inlet of the absorption tower via the guide plate; the flue gas and a desulfurizer are subjected to contact reaction in the dense phase chamber; large-grained circulating ash after reaction directly falls into the ash bucket at the bottom of the absorption tower, and fine-grained circulating ash enters the circulating fluidization chamber to be subjected to further reaction along with the flue gas; the desulfurized flue gas and part of the fine grains enter a subsequent dust remover from an outlet of a desulfurization tower; and the circulating ash at the bottom of the absorption tower and in the ash bucket of the dust remover is lifted to the inlet of the absorption tower in a medium-pressure delivery manner, thus finishing the whole cycle. According to the invention, the desulfurization reaction time is increased, the desulfurization efficiency is improved, the amount of the circulating ash is reduced, the load of the dust remover is lowered, the service life of the dust remover is prolonged, the energy is greatly saved, and the maintenance and repair frequency of the apparatus is reduced.

Owner:BEIJING BEIKE ENVIRONMENTAL ENG CO LTD

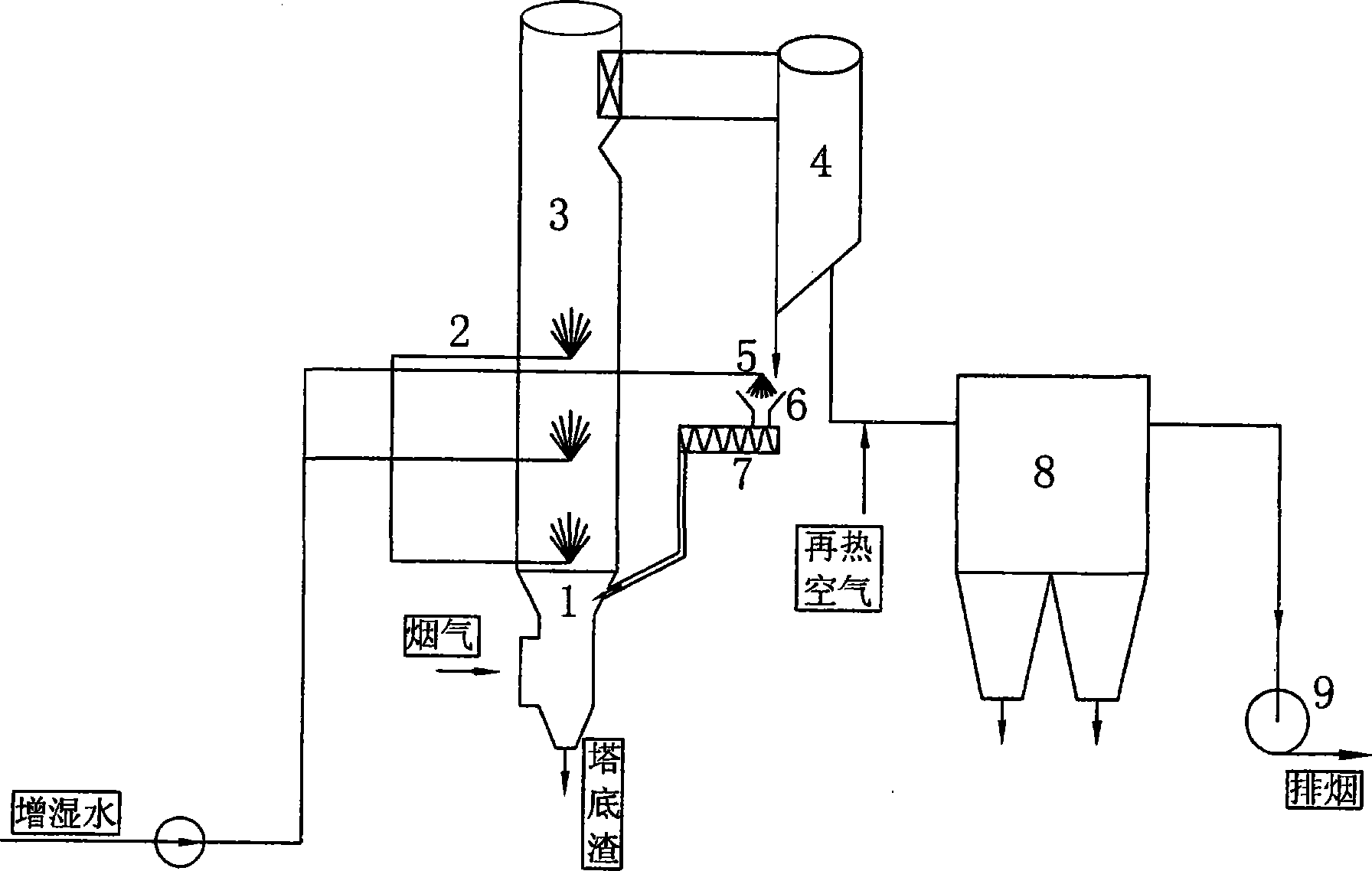

Composite humidifying process suitable for circulating fluid bed semi-drying method flue gas desulfurization

InactiveCN101077470AIncrease profitImprove running stabilityDispersed particle separationIndustrial wasteEngineering

The present invention is one composite humidifying process for semi-dry fume desulfurization in a circulating fluidized bed, and belongs to the field of industrial waste gas purifying, environment protecting and energy source technology. The composite humidifying process includes simultaneous inside-tower humidifying and outside-tower humidifying, the inside-tower humidifying is completed via spraying water directly through nozzle, and the outside-tower humidifying is to humidifying ash for the circulating process. The present invention has reasonably improved complex gas-liquid-solid reaction inside the desulfurizing tower, raised desulfurizing agent utilizing rate and raised running stability of the desulfurizing system.

Owner:SHANDONG UNIV

Wet desulfurization tower based flue gas desulphurization method capable of enhancing adaptability to low load

InactiveCN101703884AGuaranteed uptimeSafe and stable operationDispersed particle separationLower limitLow load

The invention relates to a wet desulfurization tower based flue gas desulphurization method capable of enhancing the adaptability to low load, solving the problems as follows: when the load of the desulfurization tower is lowered (the load is lower than 30% of the amount of flue gas under rated load of the desulfurization tower), the amount of the flue gas flowing through the desulfurization tower is lessened; therefore, the demisting efficiency of a demister can not be maintained, the desulfurization efficiency is reduced and fly ash and liquid drops at the entrance and exit of the tower settle. The method mainly comprises the following steps: exhausting the flue gas desulfurized in the desulfurization tower after being demisted; and separating partial purified flue gas from all the purified flue gas under automatic regulation of a circulatory flue gas regulator when the load of a desulfurization system is lower than 30% of the rated load, and ensuring the partial purified flue gas to return back to the entrance of the desulfurization tower via a circulatory flue gas pipe, thus accelerating the air speed in the tower and ensuring the flue gas load in the desulfurization tower at the lower limit of at least 30% of the rated load under which the desulfurization tower can operate stably. The method enables the wet desulfurization tower to safely and stably operate under the condition of meeting 0%-110% of rated load and obviously enhances the adaptability of the desulfurization system to low load.

Owner:HARBIN INST OF TECH

Flue gas desulfurization system

ActiveCN106621701AReduce mechanical lossReduce desulfurization energy consumptionGas treatmentDispersed particle separationActivated carbonSorbent

The invention discloses a flue gas desulfurization system. The flue gas desulfurization system comprises a first-level absorption tower and a second-level absorption tower which are sequentially communicated, wherein a bubbling bed is arranged in the first-level absorption tower, a fast bed is arranged in the second-level absorption tower, and each of the first-level absorption tower and the second-level absorption tower is loaded with powdered activated carbon. The flue gas desulfurization system has the advantages that fluidized bed double-tower absorption using activated carbon as the desulfurization absorbent is adopted, the bubbling bed is used for first-level absorption, sufficient contact time between the activated carbon and flue gas is guaranteed, and the fast bed is used for second-level absorption to deeply purifying the flue gas; the double-tower design can increase the effective utilization rate of outlet absorbent sulfur capacity on the basis that the overall desulfurization efficiency is guaranteed, the absorbent activated carbon participates in the reaction in a powered state, the mechanical loss of the activated carbon is reduced, the overall utilization rate of the activated carbon is increased, and the activated carbon desulfurization energy consumption and activated carbon consumption can be lowered.

Owner:CHNA ENERGY INVESTMENT CORP LTD +3

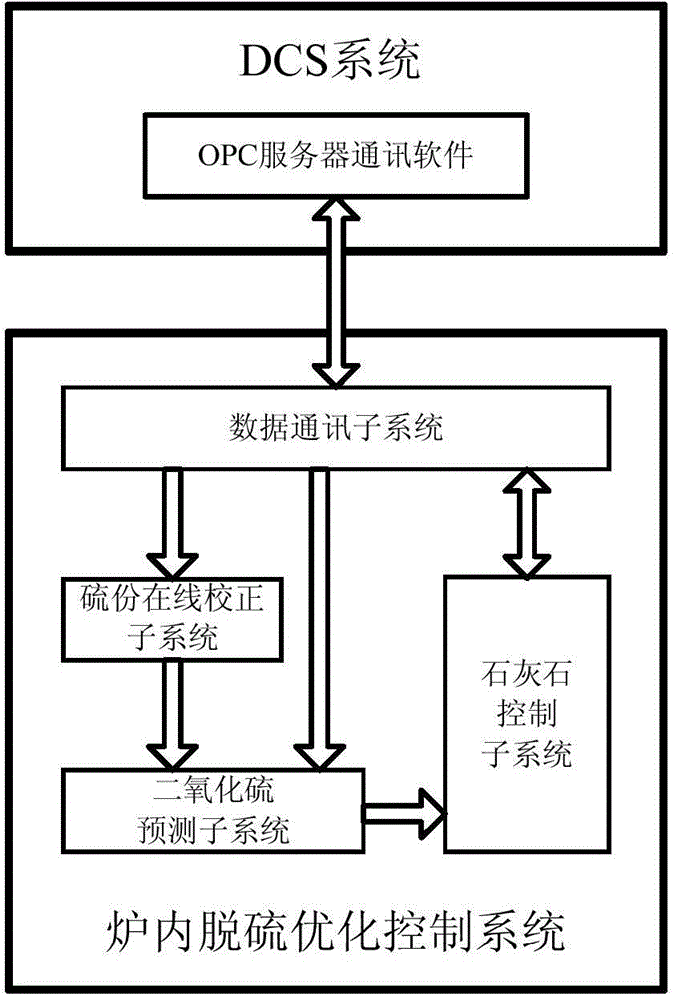

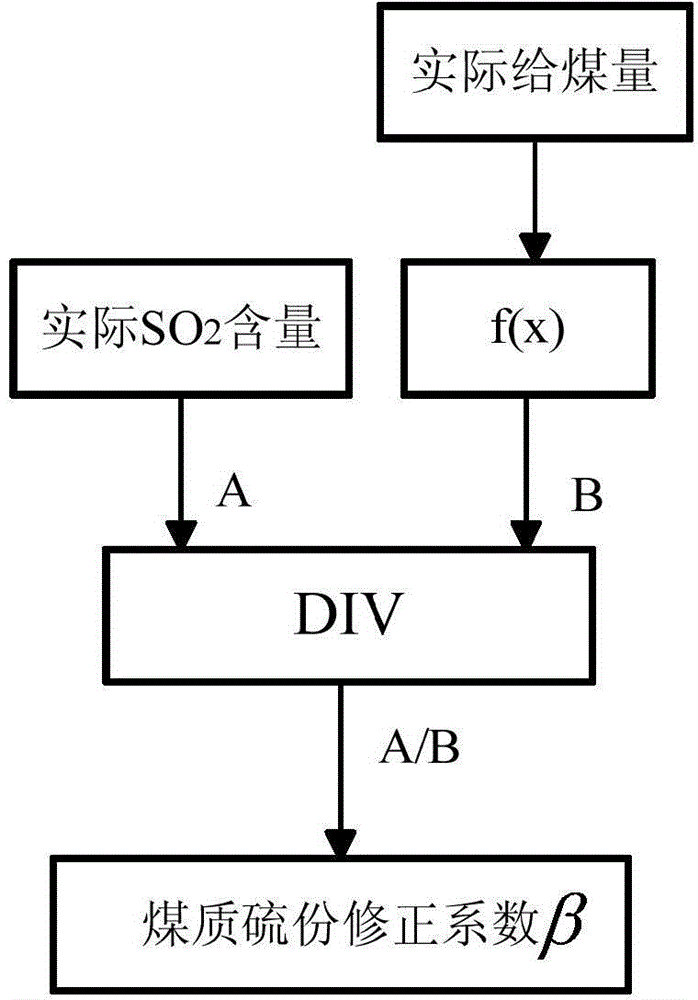

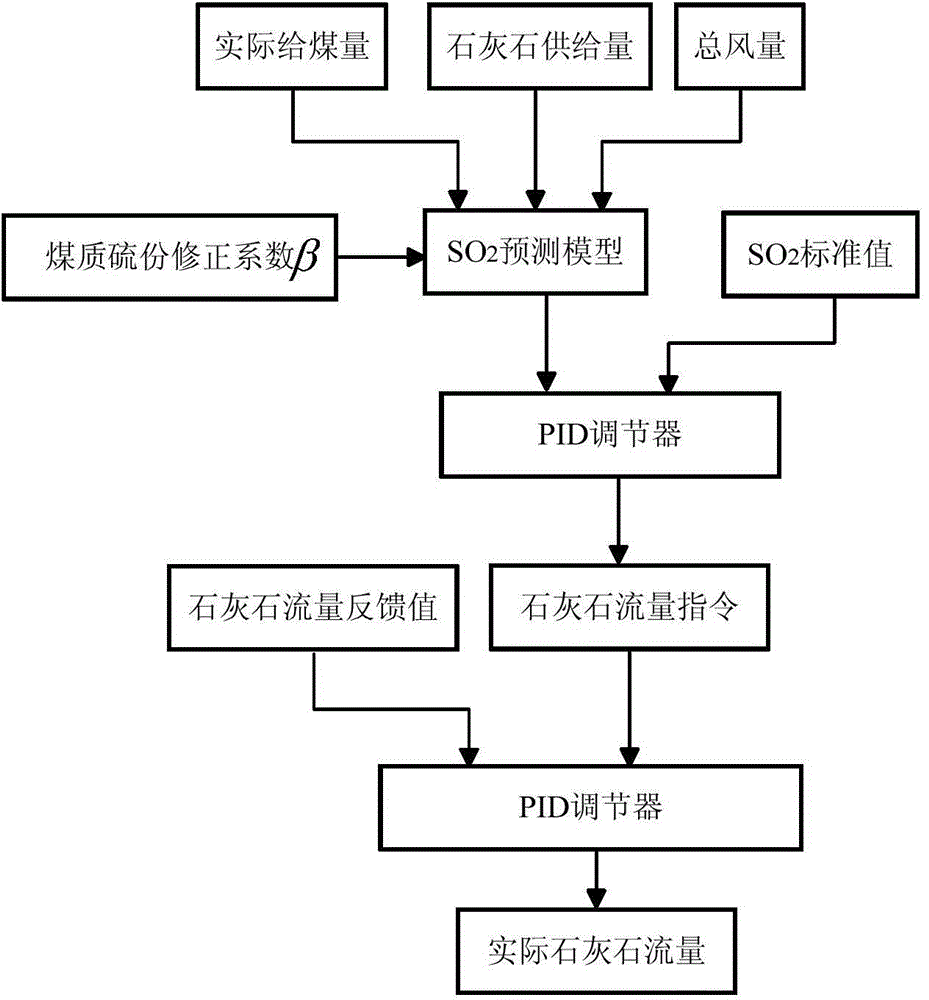

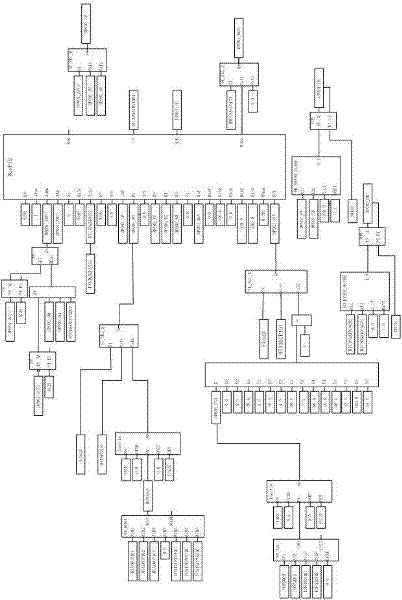

Furnace desulphurization optimization control method for circulating fluidized bed

InactiveCN104615114AAvoid hysteresisSolve the problem of excessive emissionsTotal factory controlProgramme total factory controlControl systemFluidized bed

The invention belongs to the technical field of circulating fluidized bed boilers and discloses a furnace desulphurization optimization control method for a circulating fluidized bed. An optimization control system of the furnace desulphurization optimization control method comprises a data communication subsystem, a sulfur content online correction subsystem, a sulfur dioxide prediction subsystem and a limestone control subsystem; data interaction is performed on the data communication subsystem and OPC server communication software of a DCS system; the sulfur content online correction subsystem is connected with the data communication subsystem; the sulfur dioxide prediction subsystem is connected with the sulfur content online correction subsystem and the data communication subsystem; the limestone control subsystem is connected with the sulfur dioxide prediction subsystem and the data communication subsystem. According to the furnace desulphurization optimization control method for the circulating fluidized bed, a sulfur dioxide prediction model and a coal sulfur content self-adaptive correction method are established and accordingly the feeding amount of the limestone can be timely and dynamically adjusted, the excess emissions of the sulfur dioxide and the excessive use of the limestone and other resources are avoided, and the practical value in engineering is high.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

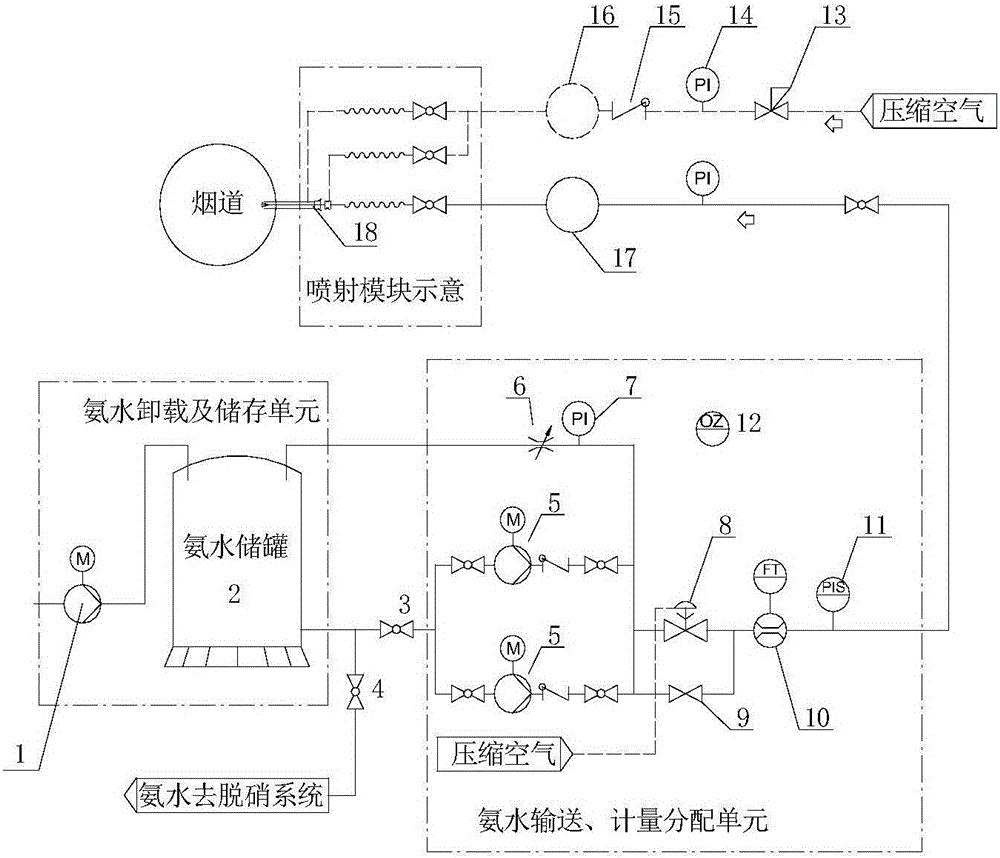

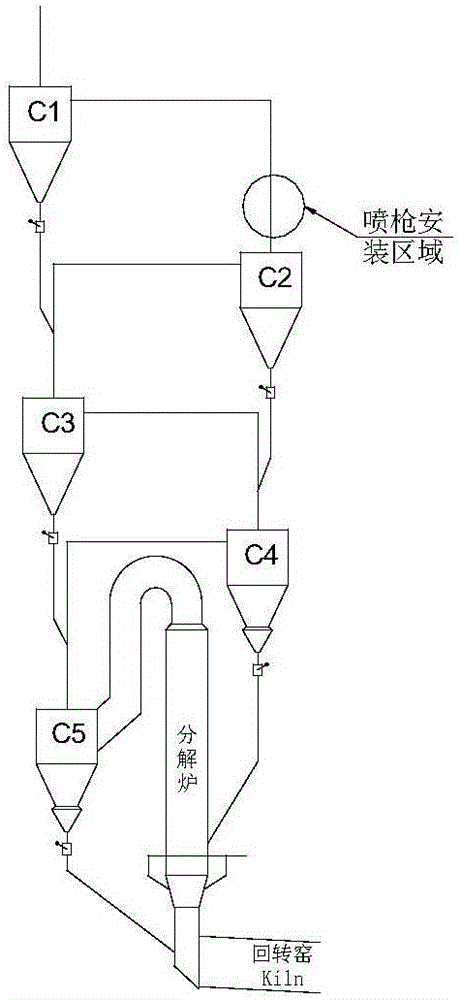

Desulfurization system and method for flue gas of cement kiln furnace

ActiveCN106166437ALess investmentReduce the investment cost onceGas treatmentDispersed particle separationFlue gasSulfur

The invention relates to a desulfurization system and method for flue gas of a cement kiln furnace. The desulfurization system comprises an ammonia water storing tank, conveying pumps, spraying guns, a cement decomposing furnace, a cement kiln pre-decomposing system and an automatic control system, wherein the cement kiln pre-decomposing system comprises a multi-stage pre-heater; the ammonia water storing tank communicates with the spraying guns through the conveying pumps; and spraying points of the spraying guns are located at an outlet of a cyclone barrel of a second-stage pre-heater. The desulfurization method comprises the following steps of I, preparing a 15-25% ammonia water; II, performing real-time detection on the concentration of SO2, and according to the concentration of the SO2 in flue gas, calculating and adjusting the spraying amount of the ammonia water through the automatic control system; and III, according to the spraying amount of the ammonia water, which is obtained through calculation in the step II, injecting the ammonia water which is pressurized through the conveying pumps to the spraying guns, and spraying the ammonia water into the cement kiln pre-decomposing system, wherein the spraying points of the spraying guns are located at the outlet of the cyclone barrel of the second-stage pre-heater. According to the desulfurization system and method disclosed by the invention, the desulfurization efficiency can reach 95% or above, the desulfurization efficiency is high, the ammonia-sulfur ratio is 2-2.5, and the operating cost is low.

Owner:NANJING C HOPE ENVIRONMENTAL SCI & TECH

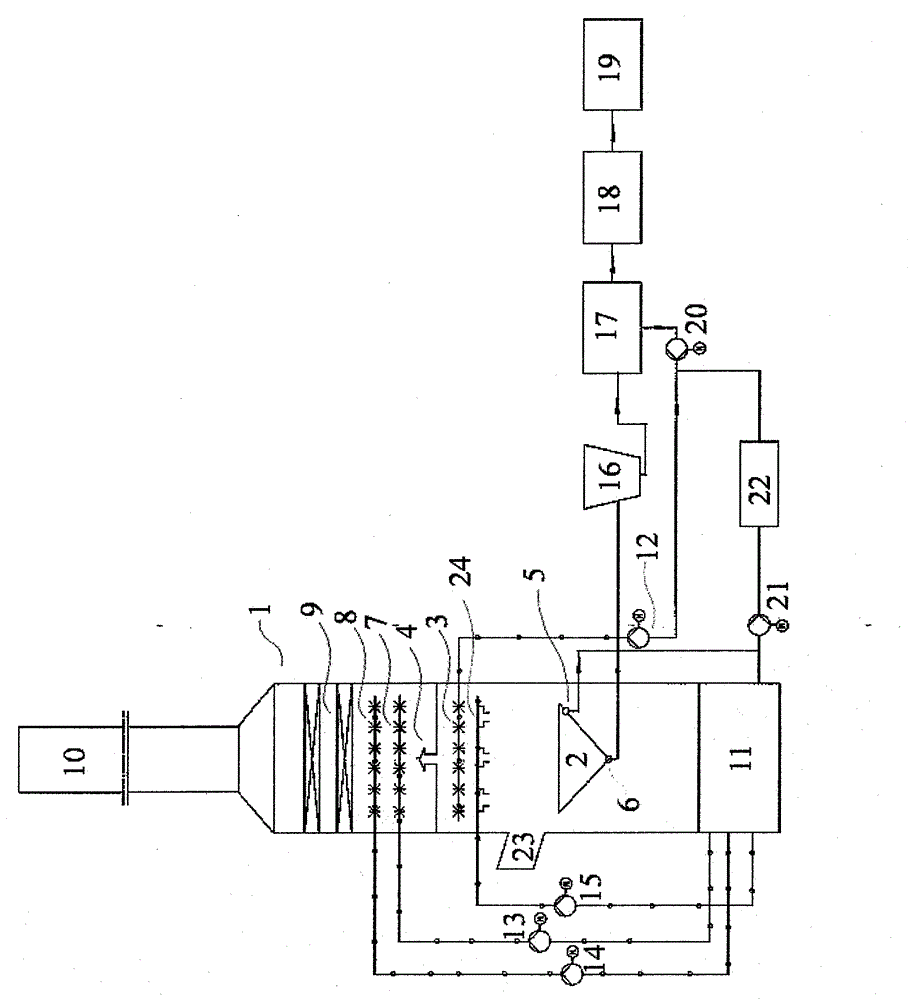

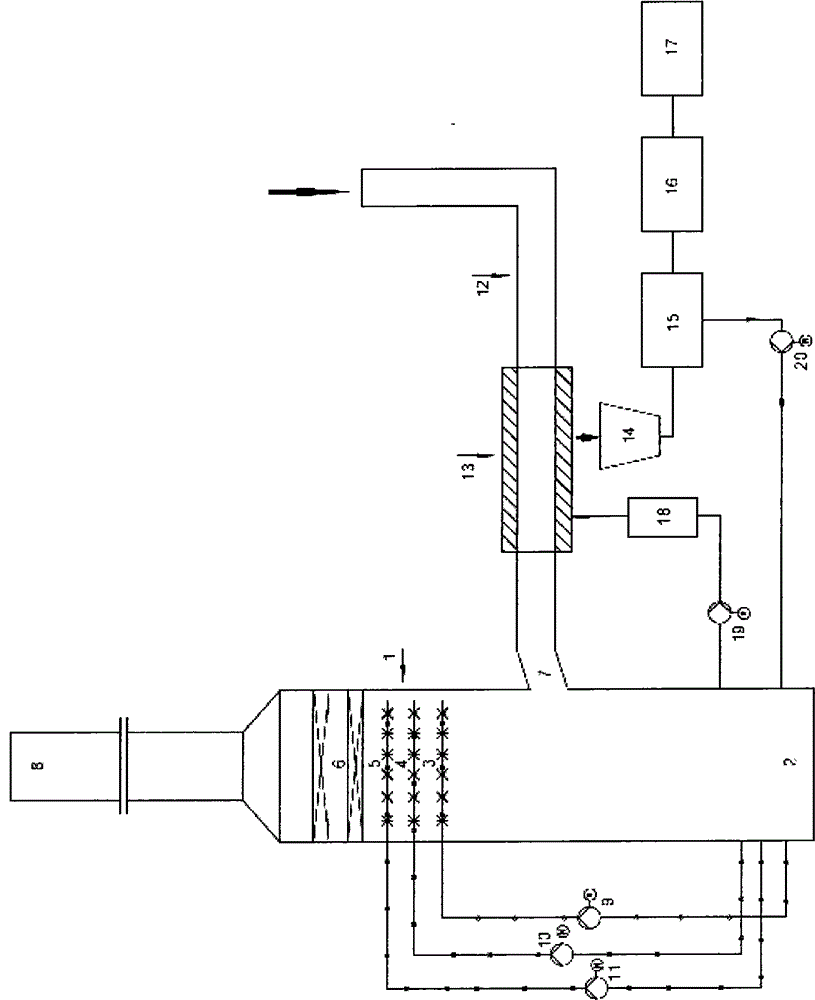

Device and method for producing magnesium sulfate

ActiveCN104445306ALow production costGuaranteed desulfurization efficiencyEnergy inputMagnesium sulfatesFlue gasSystem maintenance

The invention provides a device and a method for producing magnesium sulfate and specifically provides a device and method for producing the magnesium sulfate by use of waste heat of flue gas outside a magnesium oxide process-based desulfurization waste solution tower. The device comprises a desulfurizing tower, a flue, a heat exchanger, a crystallizer and a dryer; the heat exchanger is located at the periphery of at least one section of the flue to evaporate and concentrate a magnesium sulfate-containing solution from the desulfurizing tower under the action of the waste heat of flue gas. According to the device and the method for producing magnesium sulfate, concentration and crystallization are realized without consuming steam in the byproduct production process, and therefore, the byproduct production cost is reduced, the desulfurization operating cost is saved and the system maintenance difficulty is reduced under the premise that the normal desulfurization efficiency is guaranteed.

Owner:ZHONGJING ENVIRONMENTAL TECH CO LTD

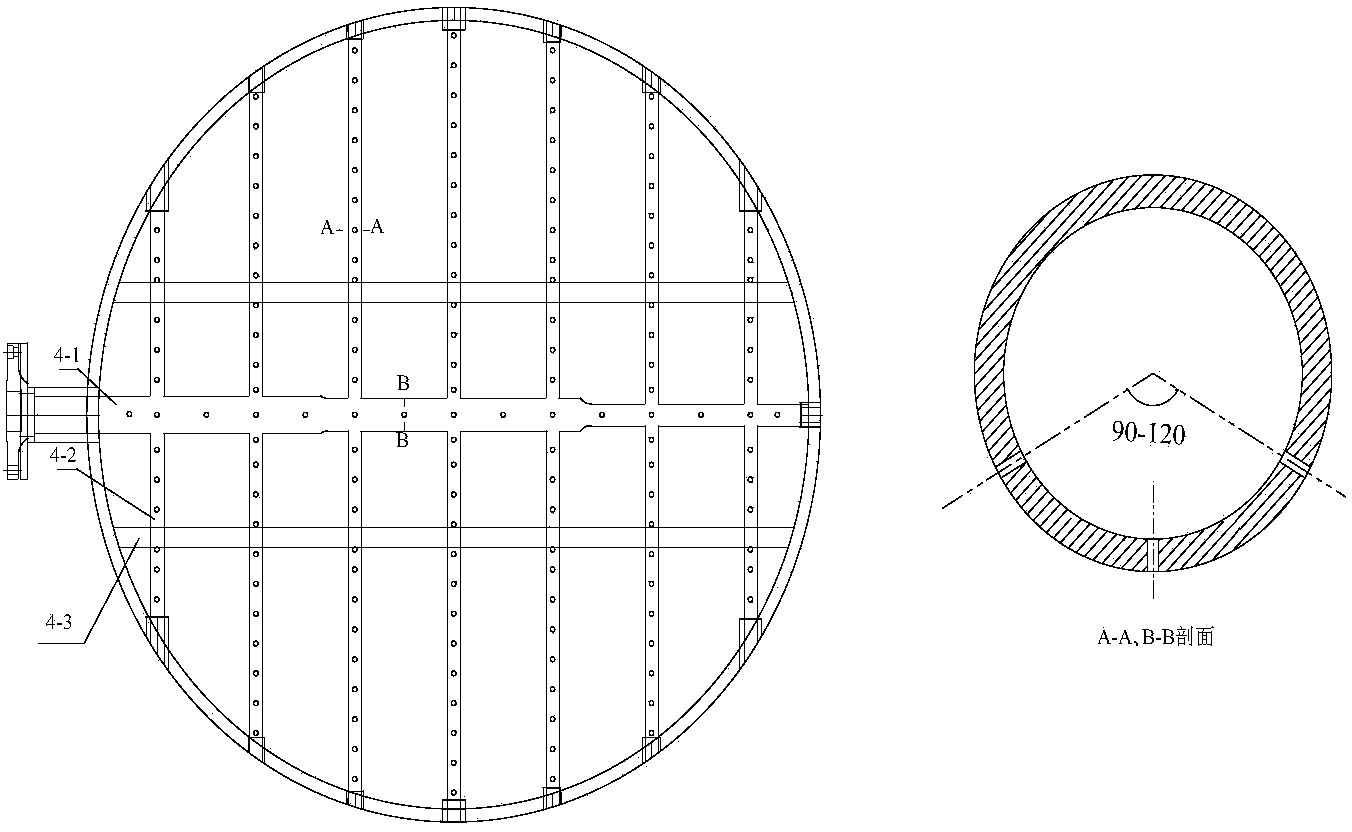

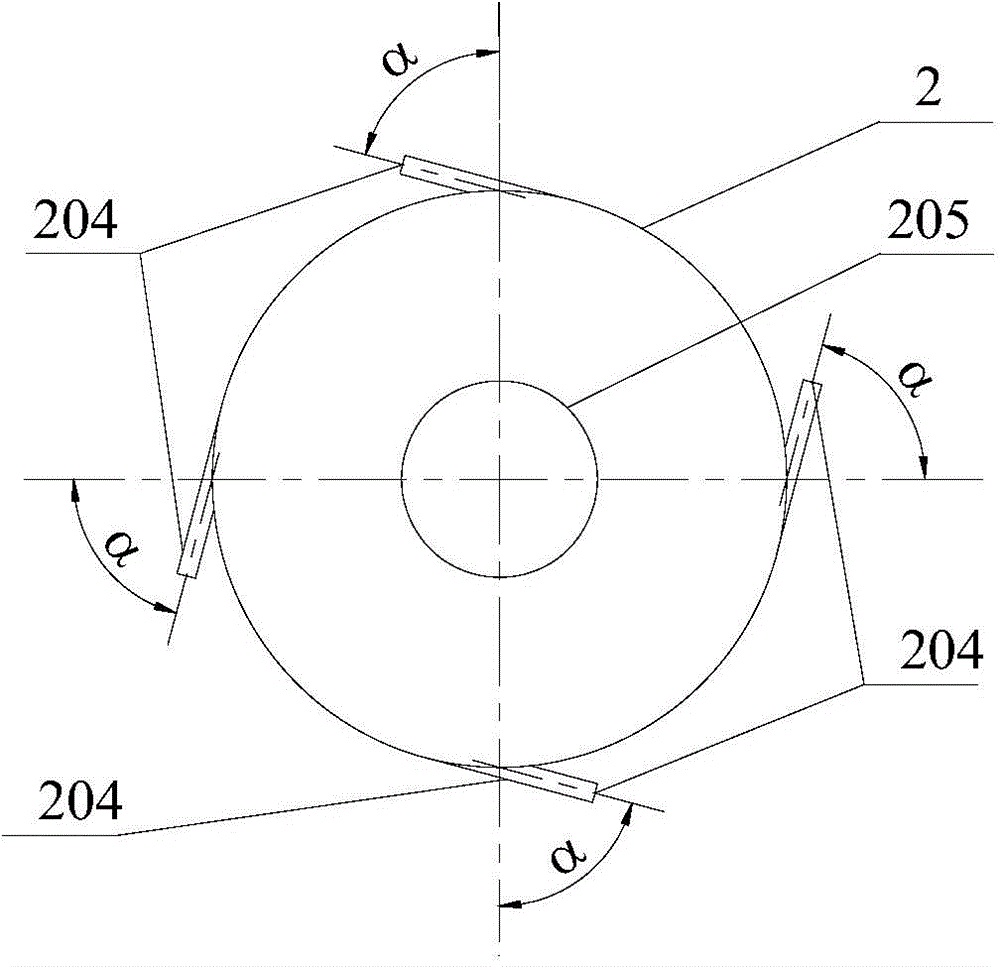

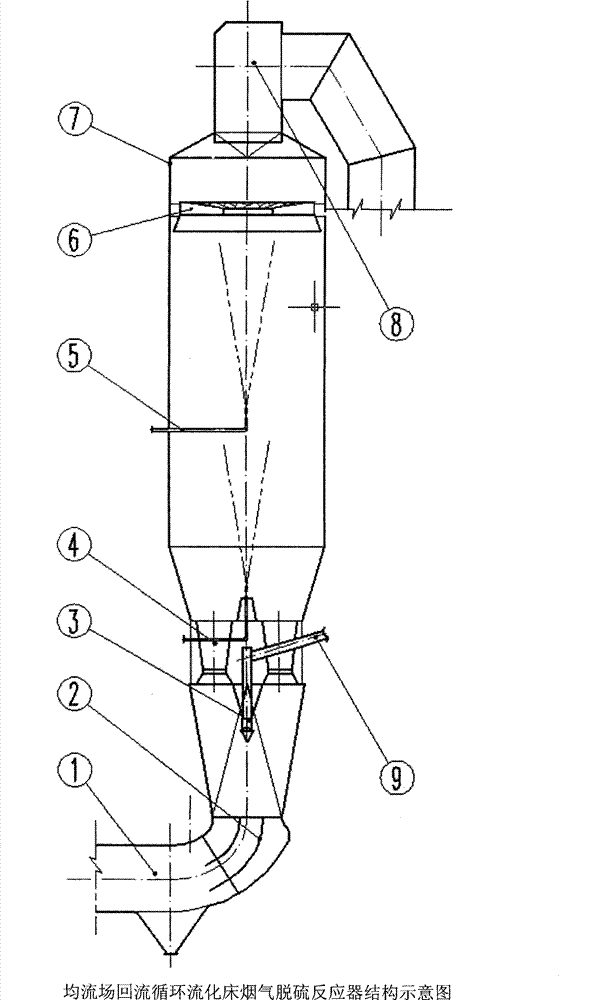

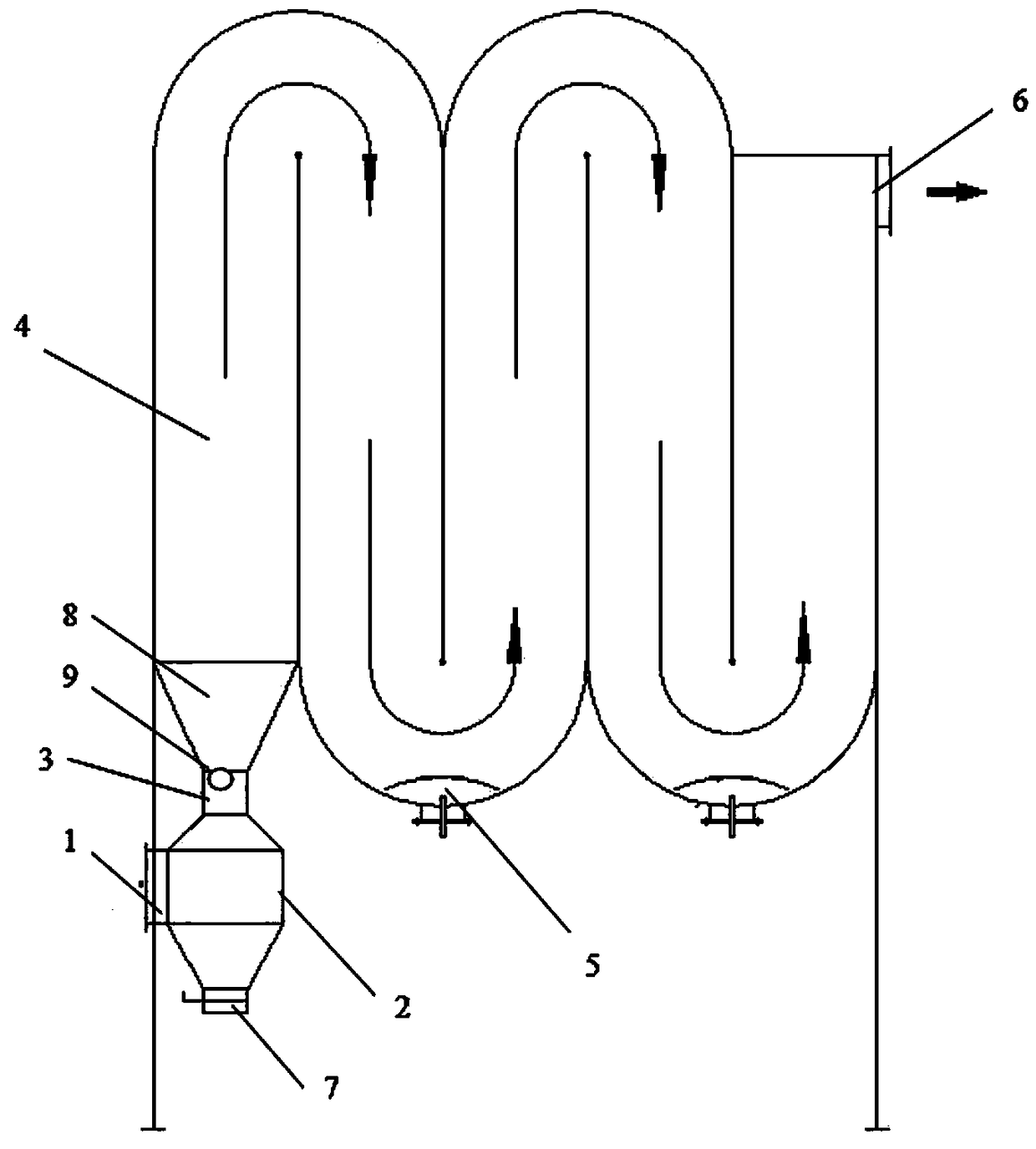

Homogeneous flow-field circulating fluidized bed flue gas desulfurization technology

InactiveCN102784556AGood effectWell mixedLighting and heating apparatusDispersed particle separationBiological activationDistributor

The invention relates to a homogeneous flow-field circulating fluidized bed flue gas desulfurization technology. A homogeneous flow-field circulating fluidized bed flue gas desulfurization reactor adopted by the homogeneous flow-field circulating fluidized bed flue gas desulfurization technology comprises a linear stream line-type flue gas inlet channel, a central built-in (center-explosion type) absorbent distributor, a flue gas accelerator, a humidifying activation nozzle, an annular flue gas outlet channel, an inner reflux circulating ash bin, a screw conveyer and an inner reflux circulating ash downcomer. The homogeneous flow-field circulating fluidized bed flue gas desulfurization technology has the advantages that a design is reasonable so that flue gas in the homogeneous flow-field circulating fluidized bed flue gas desulfurization reactor is acted upon by a homogeneous flow field, a homogeneous pressure field and a homogeneous temperature field; an absorbent has a high circulating ratio and a high utilization rate; a two-stage humidifying process can effectively improve reactivity of an absorbent; the humidifying activation nozzle is located in the center of a homogeneous flue gas flow field and a homogeneous absorbent flow field so that wall wetting, scaling and bed collapse are avoided effectively and flue gas desulfurization efficiency is improved effectively; the annular flue gas outlet channel is conducive to homogenization of a flow field in the homogeneous flow-field circulating fluidized bed flue gas desulfurization reactor and reduces a pressure drop and loads of a bag-type duster; and an inner reflux circulating conveying system can effectively prevent bed collapse and tower blocking so that safety, stability and a long running period of equipment are guaranteed.

Owner:北京博朗环境工程技术股份有限公司 +2

Two-tower ammonia method desulfurization device and method

ActiveCN102151475AImprove purification effectEmission reductionDispersed particle separationAmmonia compoundsEconomic benefitsCircular economy

The invention discloses a two-tower ammonia method desulfurization device and method. A smoke purifying part of the device comprises a desulfurization tower and a pre-scrubbing tower, the lower section inside the desulfurization tower is provided with a desulfurization tower slurry pool, the upper section inside the desulfurization tower is provided with a desulfurization tower spraying layer and a desulfurization tower mist eliminator, the lower section inside the pre-scrubbing tower is provided with a pre-scrubbing tower slurry pool, and the upper section inside the pre-scrubbing tower is provided with a pre-scrubbing tower spraying layer and a pre-scrubbing tower mist eliminator; an absorbing agent supply part comprises a liquid ammonia storage tank, an ammonia supply device and an oxidization fan; and an ammonium sulfate dewatering part comprises an ammonium sulfate slurry discharge valve, a neutralization tank, an ammonium sulfate slurry pump, a swirler, a centrifugal machine and a drying bed. The ammonia method desulfurization device comprises the two towers, system heat source can be effectively utilized through the pre-scrubbing tower, slurry is heated through high-temperature raw smoke so that the purpose of concentration is achieved, and smoke can be primarily purified through circulation of the slurry in the two towers, the emission of aerosol is further reduced, side products with considerable economic benefit can be produced while desulfurization efficiency is ensured, and wastes are changed into valuable, and requirements on circular economy is met.

Owner:BEIJING GUODIAN LONGYUAN ENVIRONMENTAL ENG

Automatic control steady-state undisturbed switching method for desulphurization booster fan

ActiveCN102508432AEnables bumpless switchingAchieve matchingAdaptive controlAutomatic controlEngineering

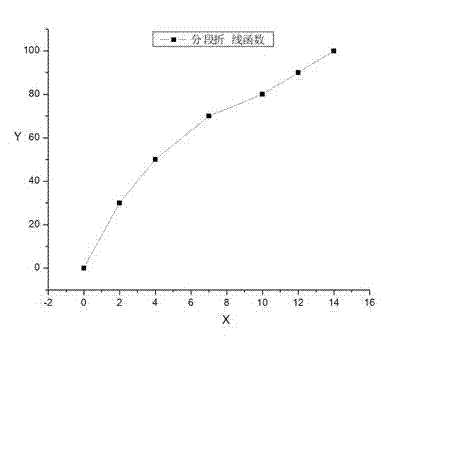

The invention discloses an automatic control steady-state undisturbed switching method for a desulphurization booster fan. According to the method, a controlled quantity is switched and selected flexibly, and a corresponding set value is tracked and set through an object transmission function; furthermore, the openness of a guide blade of a draught fan is used as a feedforward signal; the parameter optimization proportioning is realized by using a segmental polygonal function; and undisturbed adjustment of a static blade or a movable blade of the booster fan can be well realized by setting a proportion parameter. A unit runs securely and stably by rationally adjusting the controlled quantity and the feedforward signal of the booster fan. Under the secure running of a desulphurization system, the desulphurization efficiency of the unit can be guaranteed; desulphurization is automatically performed, so that the unit can generate power securely and stably; therefore, the labor intensity of an operator is reduced greatly, and the labor efficiency is improved. The method is high in practicability; the engineering is easy to implement; and the automatic control steady-state undisturbed switching method is wide in application prospect.

Owner:GUODIAN NANJING AUTOMATION

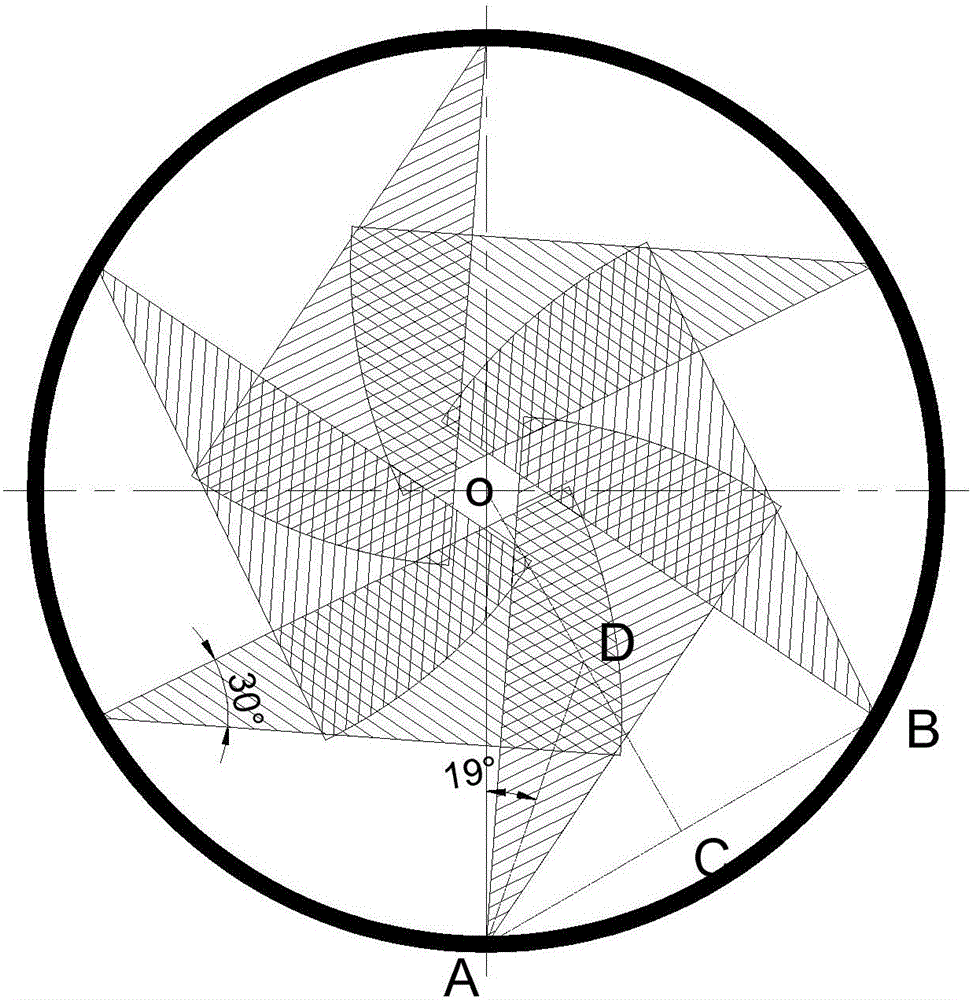

Flue gas desulfurization reactor of return current circulating fluidized bed in flow equalizing field

InactiveCN101402019BGood effectIncrease cycle ratioGas treatmentDispersed particle separationRefluxReturn current

The invention relates to a flue gas desulfurization technology for a uniform flow field internal reflux circulating fluidized bed. Core equipment, namely a reactor, of the flue gas desulfurization technology comprises a direct-current streamline bottom air inlet, a guide plate, a central built-in absorbent distributor, a flue gas accelerator, a humidified activated nozzle, a rotating-stream tray gas-solid separator and a central outlet flue on the upper part of a cylinder body of the reactor form the bottom up in turn, wherein the inside of an inlet flue of the reactor is provided with a dual-chip circular uniform flue gas distribution guide plate; and the inside of the reactor is provided with the central built-in absorbent distributor, the 'Laval nozzle' - type flue gas accelerator, the two-stage double-fluid humidified activated nozzle and the rotating-stream tray gas-solid separator. The flue gas desulfurization technology is reasonable in configuration; flue gas in the reactor obtains ideal and stable uniform fluid field and temperature field; an absorbent obtains high circulation ratio and high utilization rate; and two-stage humidification can effectively improve the reaction activity of the absorbent, and can also effectively avoid wetted wall, fouling and collapsed bed. Moreover, the flue gas desulfurization technology guarantees the desulfurization efficiency, obviously reduces the dust content of the outlet flue, greatly lightens the load of a rear bag-type duster, and solves the technical problems in a flue gas desulfurization technology for a semi-dry circulating fluidized bed.

Owner:北京联合拓展科技有限公司

Three-cycle desulphurization method for wet type ammonia-process desulphurization and flue gas desulfurization tower or system

InactiveCN105727723AGuaranteed oxidationGuaranteed crystallizationGas treatmentUsing liquid separation agentFlue gasProcess engineering

The invention relates to the field of environmental protection and discloses a three-cycle desulphurization method for wet type ammonia-process desulphurization. The desulphurization method is implemented with a first slurry circulating loop, a second slurry circulating loop and a third slurry circulating loop, wherein in the first slurry circulating loop, slurry having mass concentration of 10%-20% and a pH value of 4.0-5.0 is used for carrying out cycle spraying treatment on flue gas, and the temperature of the flue gas treated by the slurry is 50-60 DEG C; in the second slurry circulating loop, slurry having mass concentration of 10%-15% and a pH value of 5.0-6.0 is used for carrying out cycle spraying treatment on the flue gas; and in the third slurry circulating loop, slurry having mass concentration of 3%-10% is used for carrying out cycle spraying treatment on the flue gas. The invention also discloses a flue gas desulfurization tower or system using the three-cycle desulphurization method. According to the three-cycle desulphurization method, the three independent circulating loops are divided according to the concentration of the slurry, the circulating loops separately control the slurry having different concentrations and pH values for treatment of the flue gas, and the contradiction of high desulphurization efficiency and high oxygenation efficiency of by-products is solved.

Owner:SICHUAN JUNHE ENVIRONMENTAL PROTECTION

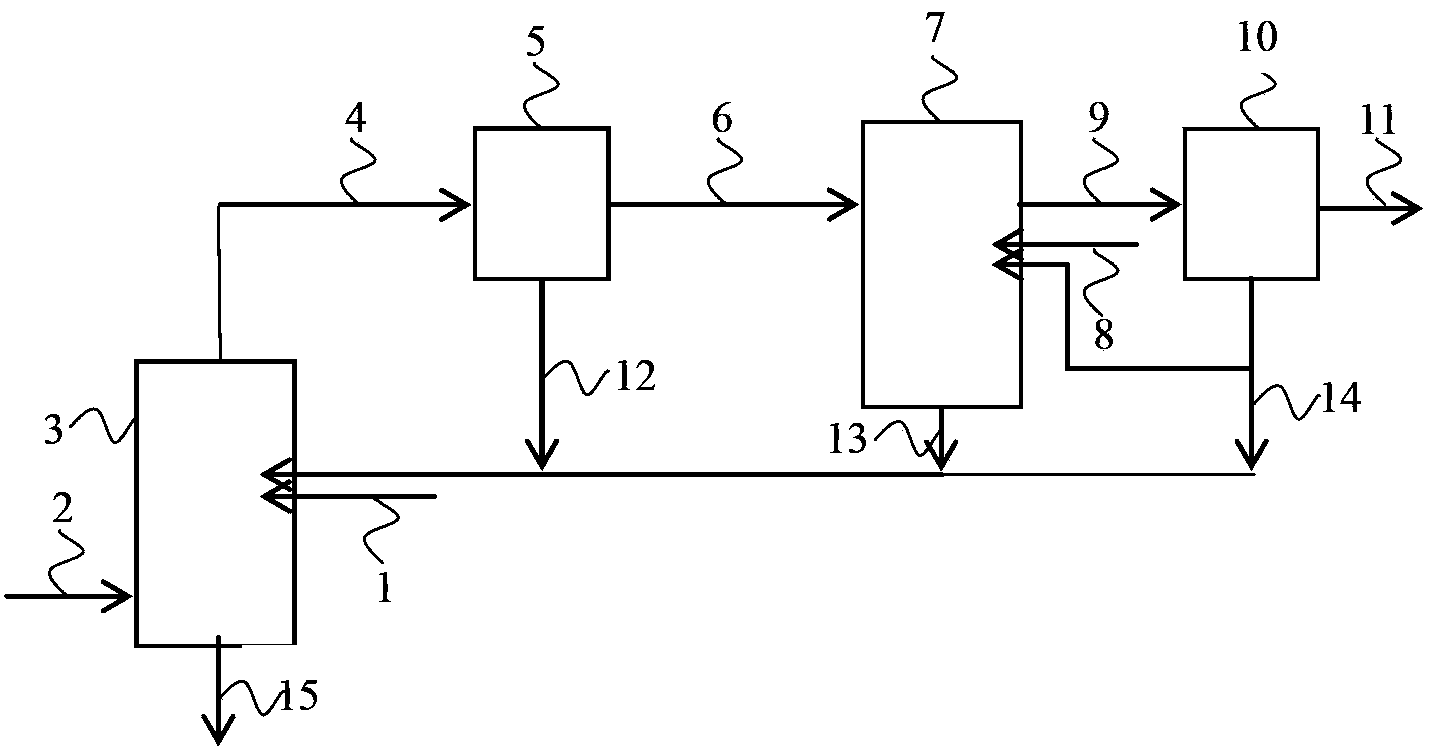

Desulphurization method for lead plaster of waste lead-acid storage battery

InactiveCN107394300AWide range of usesThe desulfurization reaction continuesWaste accumulators reclaimingProcess efficiency improvementLead carbonateAmmonium carbonate

The invention discloses a desulphurization method for lead plaster of a waste lead-acid storage battery, and relates to the technical field of desulphurization. The method disclosed by the invention comprises the steps of: carrying out wet desulphurization on the lead plaster by using ammonium carbonate as a desulphurization agent; cycling and stirring a mixture of the lead plaster, water for diluting the lead plaster and the ammonium carbonate between a desulphurization tank and a forced desulphuriser; feeding the desulphurized lead plaster into a smelting system; reusing desulphurization liquid as liquid for diluting the lead plaster; and enabling the reused secondary desulphurization liquid to enter an evaporative crystallization system and outputting ammonium sulfate. According to the method disclosed by the invention, after the desulphurization liquid is reused, salt concentration of the desulphurization liquid is improved, and thus, cost of enabling the desulphurization liquid to enter the evaporative crystallization system is reduced; according to the invention, the ammonium carbonate is used as the desulphurization agent, so that the produced ammonium sulfate has use value; and according to the invention, in the desulphurizing process, the forced desulphuriser which is of a special structure is used, and newly generated lead carbonate particles coating the surface of lead sulphate can be ground and removed, so that the desulphurizing process is guaranteed to be successfully carried out, desulphurizing efficiency is improved, and environment pollution is reduced.

Owner:HUBEI CHUKAI METALLURGY

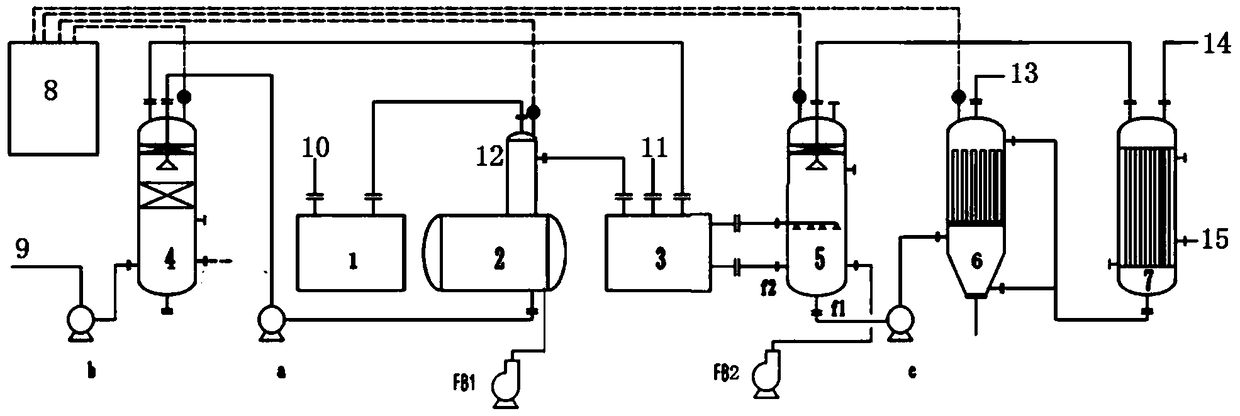

High sulfur-content sewage negative pressure gas stripping desulfurization and sulfur-containing tail gas purifying apparatus and technology thereof

InactiveCN108640385APH real-time monitoringOptimum pH ConditionsWater treatment parameter controlWater contaminantsControl systemSewage

The invention belongs to the technical field of a high sulfur-content gas field natural gas exploitation and sulfur-containing sewage processing technology, and concretely relates to a high sulfur-content sewage negative pressure gas stripping desulfurization and sulfur-containing tail gas purifying apparatus and a technology thereof. The high sulfur-content sewage negative pressure gas strippingdesulfurization and sulfur-containing tail gas purifying apparatus comprises a PLC control system, a pH adjusting device, a pretreatment apparatus, a negative pressure gas stripping apparatus, a finedesulphurization apparatus, an oxidative regeneration apparatus, a sulphur separator, and a heat exchange system. The high sulfur-content sewage negative pressure gas stripping desulfurization and sulfur-containing tail gas purifying apparatus and the technology reduce the energy consumption for processing sulfur-containing sewage, increase the separating efficiency of H2S in the sulfur-containingsewage, and can be widely used for sulfur-containing sewage desulphurization treatment in natural gas exploitation and petroleum exploitation.

Owner:四川沃兹凯兰科技有限公司

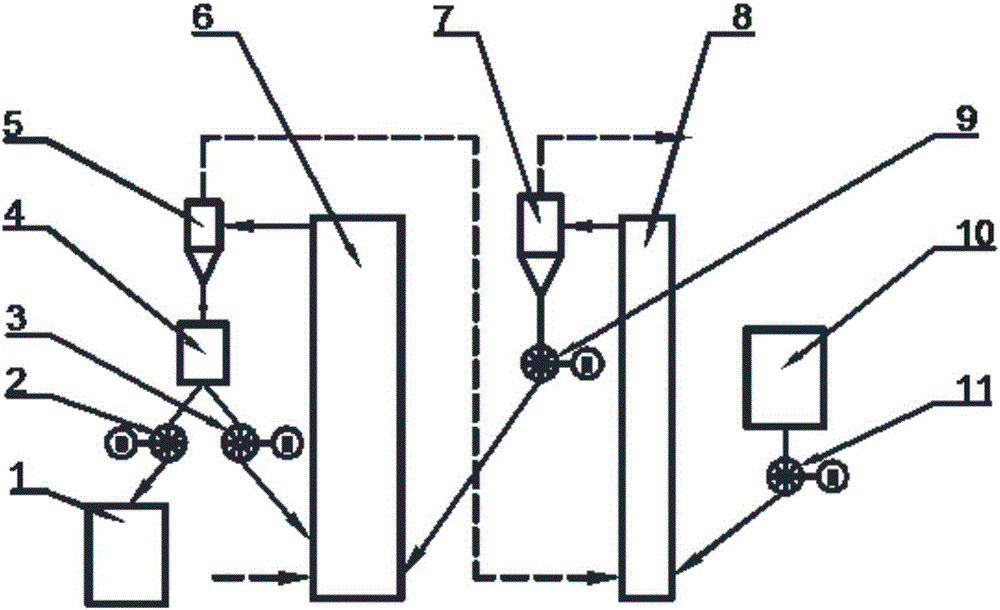

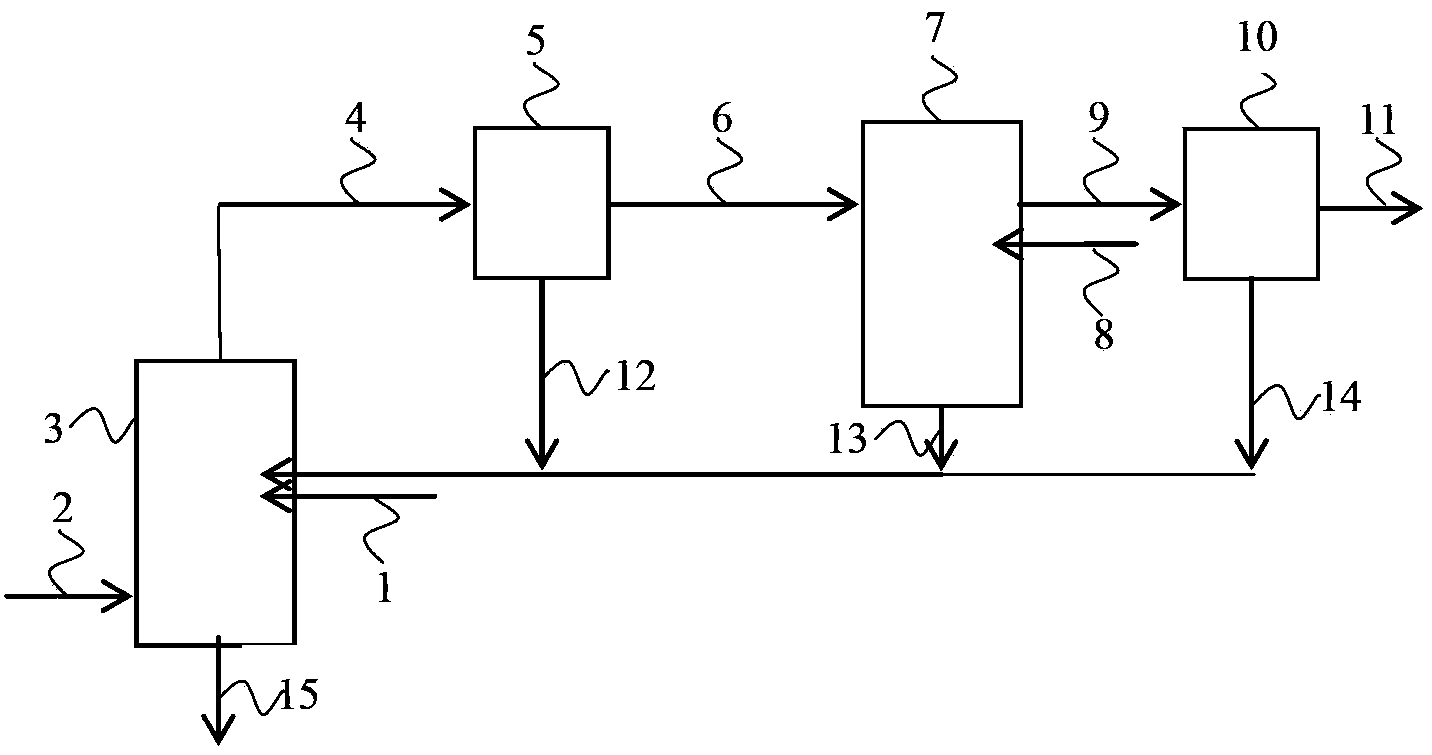

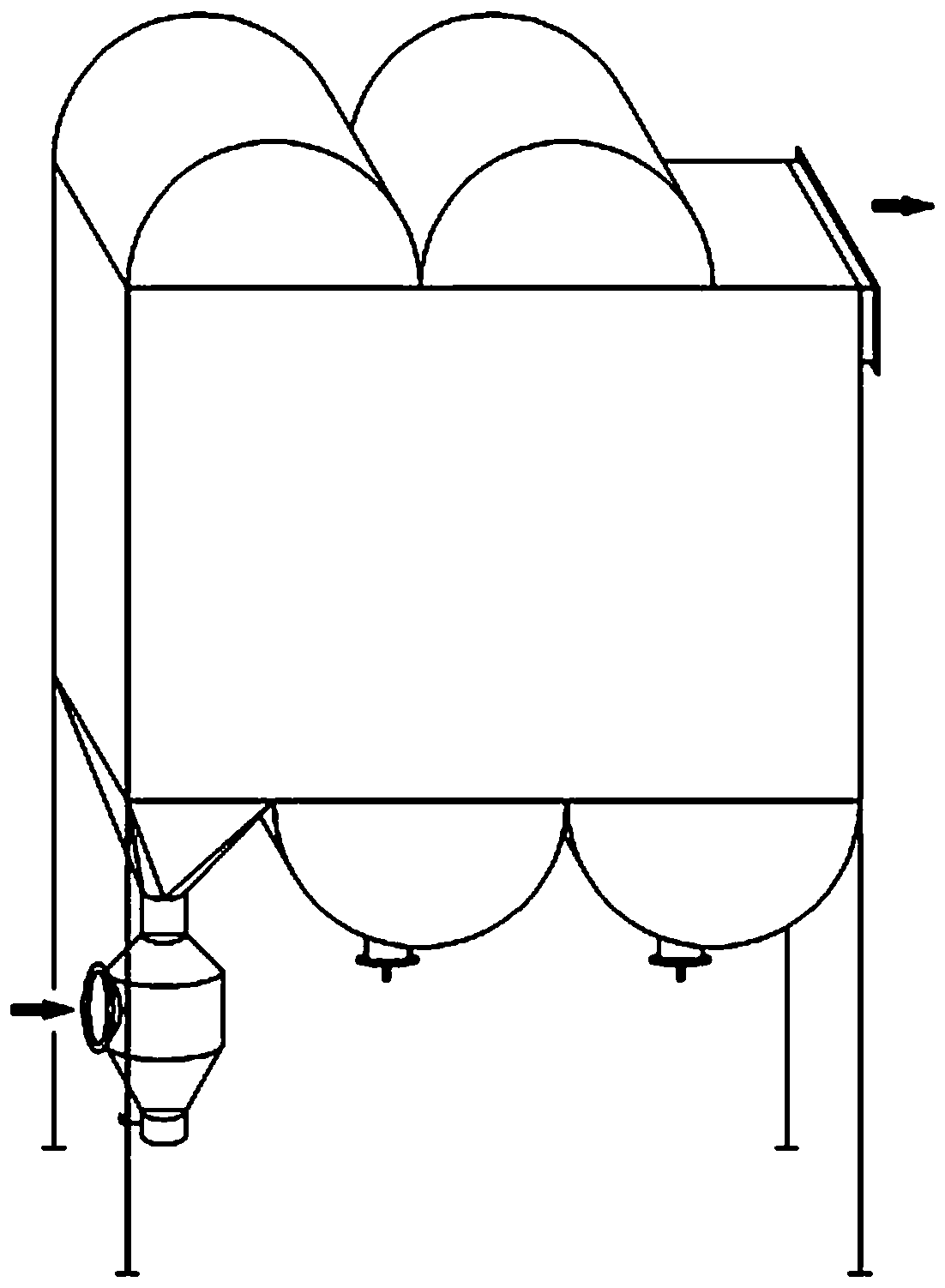

Flue gas semidry desulfurization method and device

InactiveCN103349903AGuaranteed desulfurization efficiencyImprove desulfurization efficiencyDispersed particle separationFlue gasExhaust fumes

The invention relates to a flue gas semidry desulfurization method and a flue gas semidry desulfurization device. Flue gas enters an anterior desulfurization stage, and contacts a desulfurization agent, such that partial sulfur dioxide is removed, and anterior-stage desulfurization is finished; flue gas discharged from the anterior-stage desulfurization process enters a anterior-stage deduster, such that solid particles comprising the desulfurization agent is removed, and anterior-stage dedusting is finished; flue gas discharged from the anterior-stage dedusting process enters a posterior desulfurization stage, such that rest of sulfur dioxide is removed, and posterior-stage desulfurization is finished; flue gas discharged from posterior-stage desulfurization process enters a posterior-stage deduster, such that solid particles comprising the desulfurization agent is removed, and posterior-stage dedusting is finished. According to the invention, through steam humidity regulation and two-stage desulfurization, sulfur dioxide in exhaust gas can be absorbed highly efficiently. The humidity of flue gas or dry-powder desulfurization agent is regulated by using waste steam, such that scaling of the desulfurization agent in the desulfurization tower is avoided, such that system stable operation is facilitated. During the desulfurization process, with the anterior and posterior desulfurization reactions, flue gas desulfurization efficiency is ensured. Desulfurization agent recovered from the deduster and the desulfurization tower is circulated again to the anterior-stage desulfurization tower. With multiple times of circulation, desulfurization efficiency of the desulfurization agent is improved.

Owner:TIANJIN UNIV

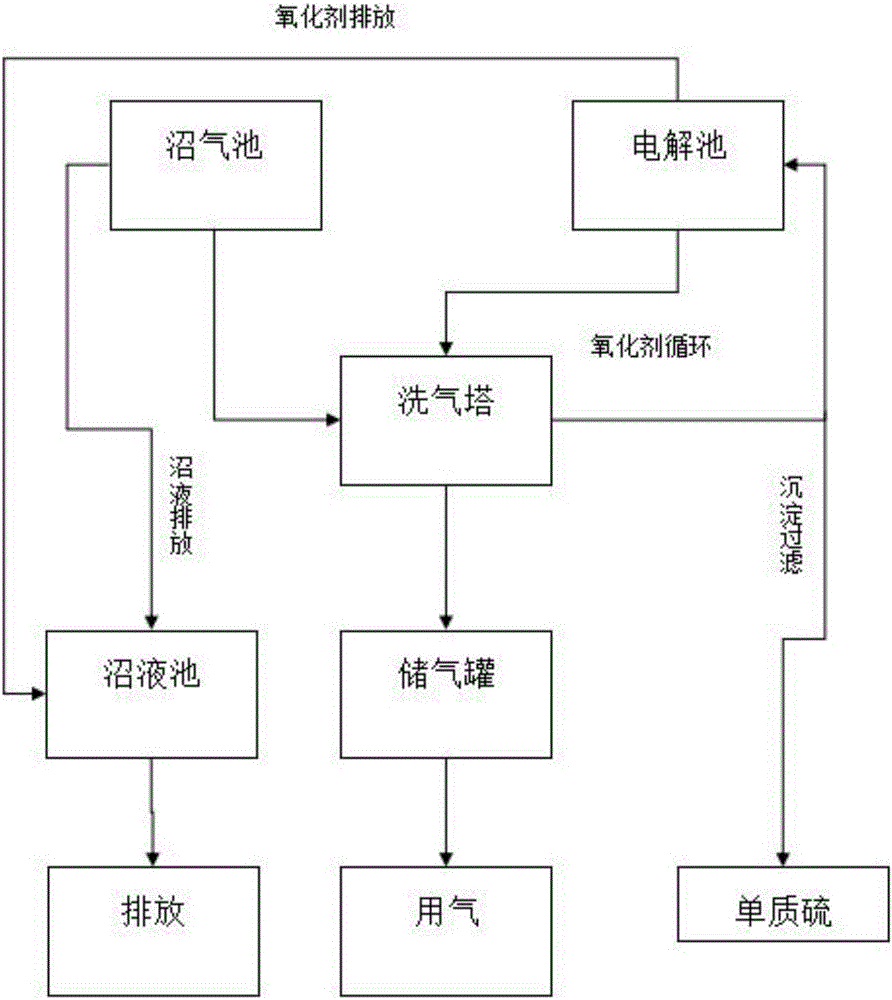

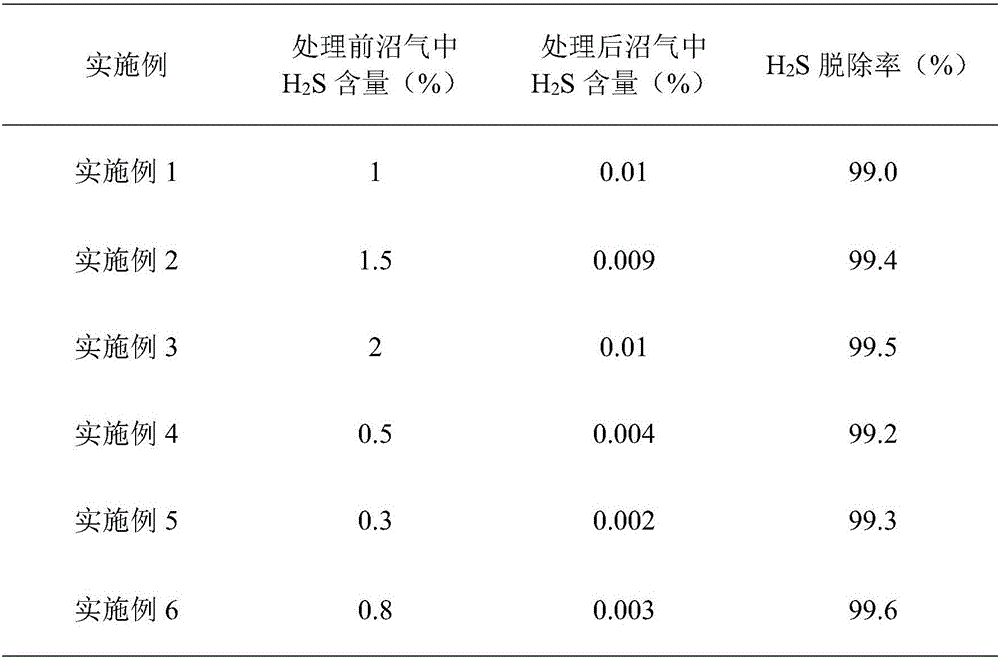

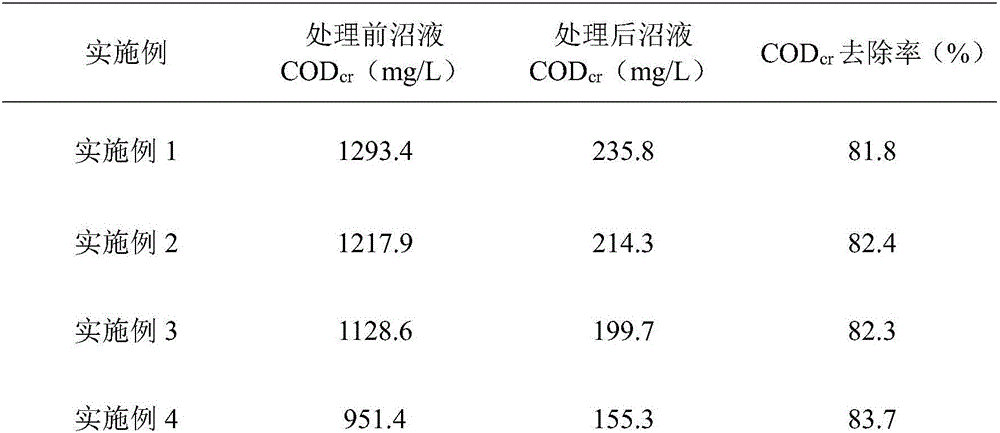

Method for treating marsh gas and marsh liquid by electrolyte

InactiveCN106334431AStrong oxidation abilityPromote oxidationGas treatmentGaseous fuelsMarshLiquid waste

The invention relates to a method for treating marsh gas and marsh liquid by an electrolyte. The method comprises the following steps: (1) introducing the marsh gas to be purified into an oxidizing agent-containing electrolyte for washing, wherein the oxidizing agent comprises sodium hypochlorite and hydrogen peroxide, and the pH of the electrolyte is 6.5 to 7.5; (2) collecting and storing the marsh gas which is treated in the step (1) to obtain the purified marsh gas; (3) refluxing the electrolyte which washes the marsh gas, filtering, and recycling elemental sulphur; (4) treating the marsh liquid by using waste electrolyte, and enabling the waste electrolyte and the marsh liquid to react according to the volume ratio of 1:8 to 10, wherein the reacting time is 40 to 60 minutes. The marsh gas and the marsh liquid are treated by adopting the method provided by the invention, the removal rate of the hydrogen sulphide from the marsh gas is up to 99 percent or above; the marsh liquid is disinfected; the removal rate of COD from the marsh liquid reaches 80 percent or above; the BOD removal rate reaches 85 percent; the ammonium-nitrogen removal rate reaches 92 percent; the marsh liquid which is treated by the method can be directly discharged.

Owner:BIOGAS SCI RES INST MIN OF AGRI +1

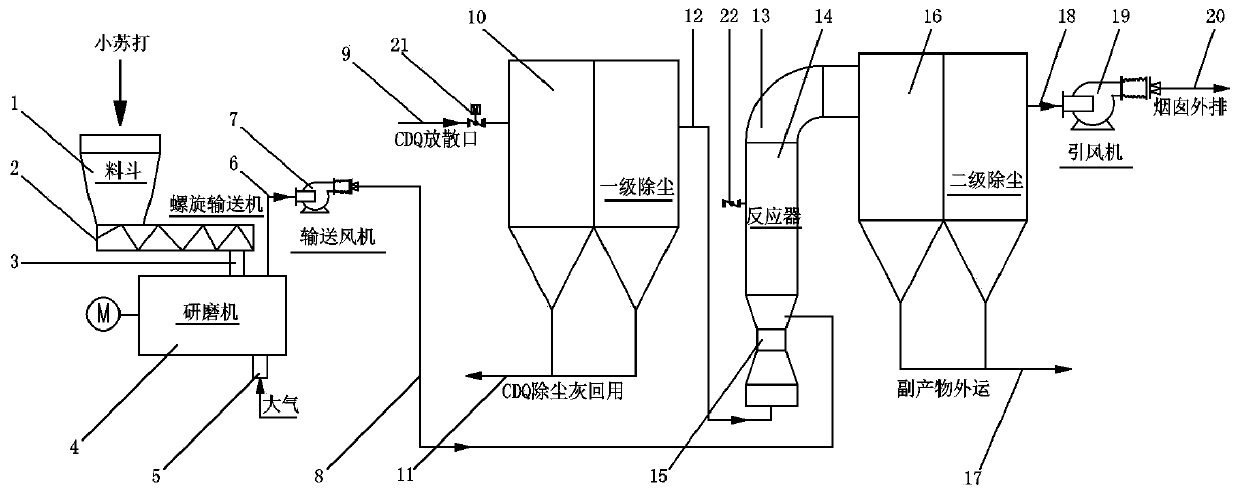

System for CDQ pressure control emitted gas desulfurization and dust removal

PendingCN110280124AEmission reductionNo corrosive effectsDispersed particle separationGrain treatmentsChemical reactionFlue gas

The invention discloses a system for CDQ pressure control emitted gas desulfurization and dust removal, comprising a baking soda hopper, a screw conveyor, a baking soda grinder, a conveying fan, a primary dust remover, a desulfurization reactor, a secondary dust remover and a draught fan. The emitted gas is taken out of an emission port through a pipeline and firstly enters the primary dust remover to remove dust, and the dust-removed emitted gas and the ground baking soda ultrafine powder enter the desulfurization reactor through a Venturi pipe to be uniformly mixed and undergo a chemical reaction in the reactor. The desulfurized flue gas passes through the secondary dust remover and the draught fan and then enters a chimney to be discharged. By the principle of baking soda dry desulfurization and two-stage high-efficiency dust removal, SO2 and dust in the flue gas can be effectively removed to ensure that the treated flue gas meets the latest national special emission limit standard.

Owner:JIANGSU WISDOM ENG TECH

Horizontal semi-dry desulfurization box process technology

InactiveCN108126506AGuaranteed desulfurization efficiencyLess one-time investmentDispersed particle separationFluidized bedFlue gas

The invention discloses a horizontal semi-dry desulfurization box process technology. The technology comprises the following steps: flue gas goes through a flue gas inlet and then enters a desulfurization reactor, the outlet expansion section, externally connected with a Venturi throat, of the desulfurization reactor is provided with a water spray device, and atomized water sprayed by the water spray device reduces the smoke temperature in the desulfurization reactor; the flue gas carrying a desulfurization agent enters a desulfurization box, segment boxes are arranged in the desulfurization box, a fluidized bed is arranged at the bottom of every segment box body, the fluidized beds increase the conversion frequency of a reaction of SO2 and Ca(OH)2, greatly enhance the mass transfer and heat transfer between a gas and a solid, and greatly improve the desulfurization rate; and purified dust-containing flue gas is laterally discharged from the top of an absorption tower connected with aflue gas outlet, enters a desulfurization deduster, goes through a boiler fan and is discharged into a chimney. The design of the desulfurization tower becomes horizontal from horizontal, so the height of the desulfurization tower is greatly reduced, and the use amount of a material is reduced, thereby the production cost is reduced, and the technology has high practical values, and is worth promoting.

Owner:河南环碧环保工程设备有限公司

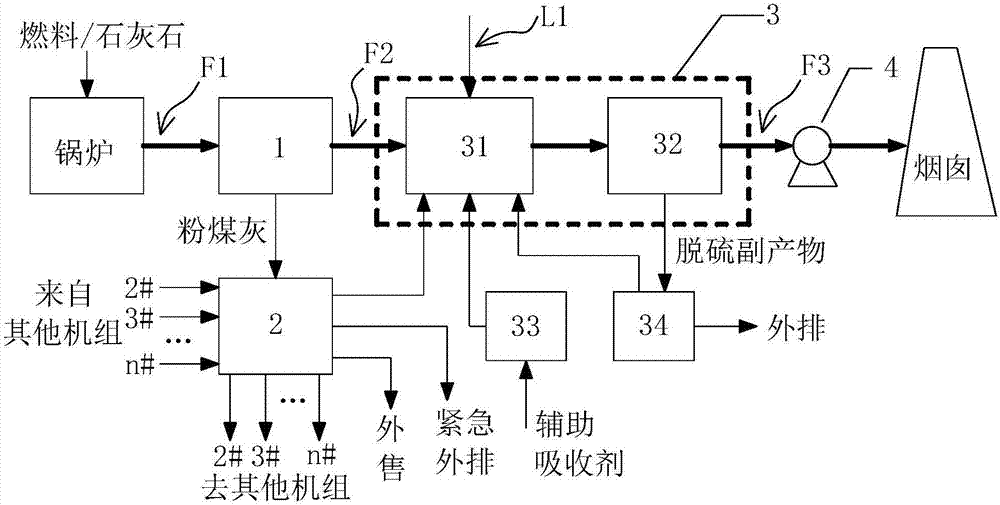

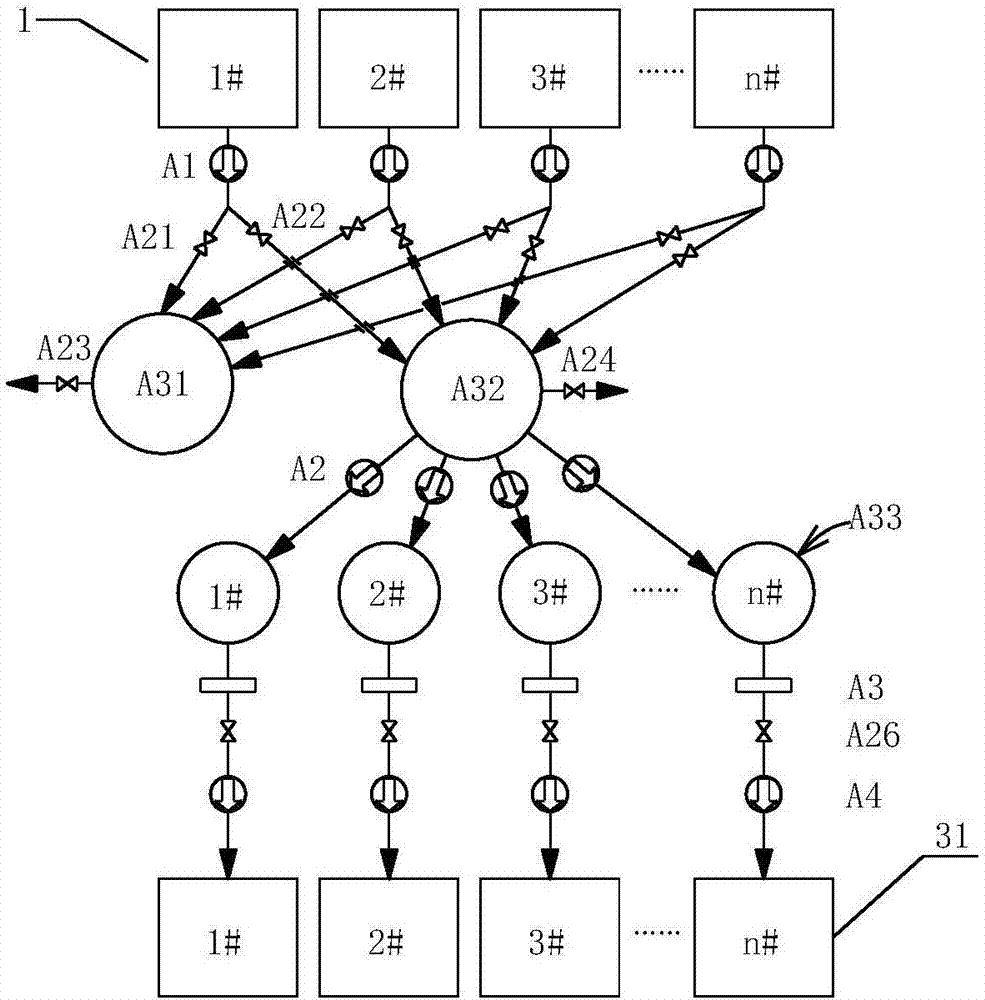

Sharing and resource utilization system and method of high-calcium fly ash for multi-unit plant

PendingCN106861412AEfficient removalFast ionic reactionFluidized bed combustionGas treatmentProcess engineeringCirculating fluidized bed boiler

The invention belongs to the field of flue gas treatment, in particular relates to a sharing and resource utilization system and method of high-calcium fly ash for a multi-unit plant. Each unit of the system comprises a circulating fluidized bed boiler, a front-mounted dust remover, a circulating fluidized bed dry process desulfurization absorbing tower, a rear-mounted dust remover and an induced draft fan, wherein all units share one set of high-calcium fly ash distribution system; the high-calcium fly ash distribution system can feed fly ash collected by the front-mounted dust removers into the circulating fluidized bed dry process desulfurization absorbing towers or externally discharge the fly ash according to the content of calcium oxide of the fly ash. According to the system, the high-calcium fly ash is used as a desulfurizing agent used in a circulating fluidized bed dry process desulfurization process, and the amount of the high-calcium fly ash which is introduced into the circulating fluidized bed dry process desulfurization absorbing towers of a plurality of power generator units and the amount of low-calcium fly ash which is externally discharged to a fly ash storehouse are selected and controlled by utilizing the high-calcium fly ash distribution system according to desulfurization requirements of the plurality of power generator units and the content of the calcium oxide of the fly ash, so that on-site high-efficient resource utilization of the high-calcium fly ash is realized.

Owner:FUJIAN LONGKING DSDN ENGINEERING CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com