Patents

Literature

154 results about "Emission limit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The emissions licence specifies two limits – a ‘normal’ operating limit, which emissions must be below for 96% of the time and a ‘cap’ limit, which emissions must never exceed. For example, Lethabo Power Station’s licence limits are: Normal limit: 75 mg/Nm3. Cap limit: 300 mg/Nm3.

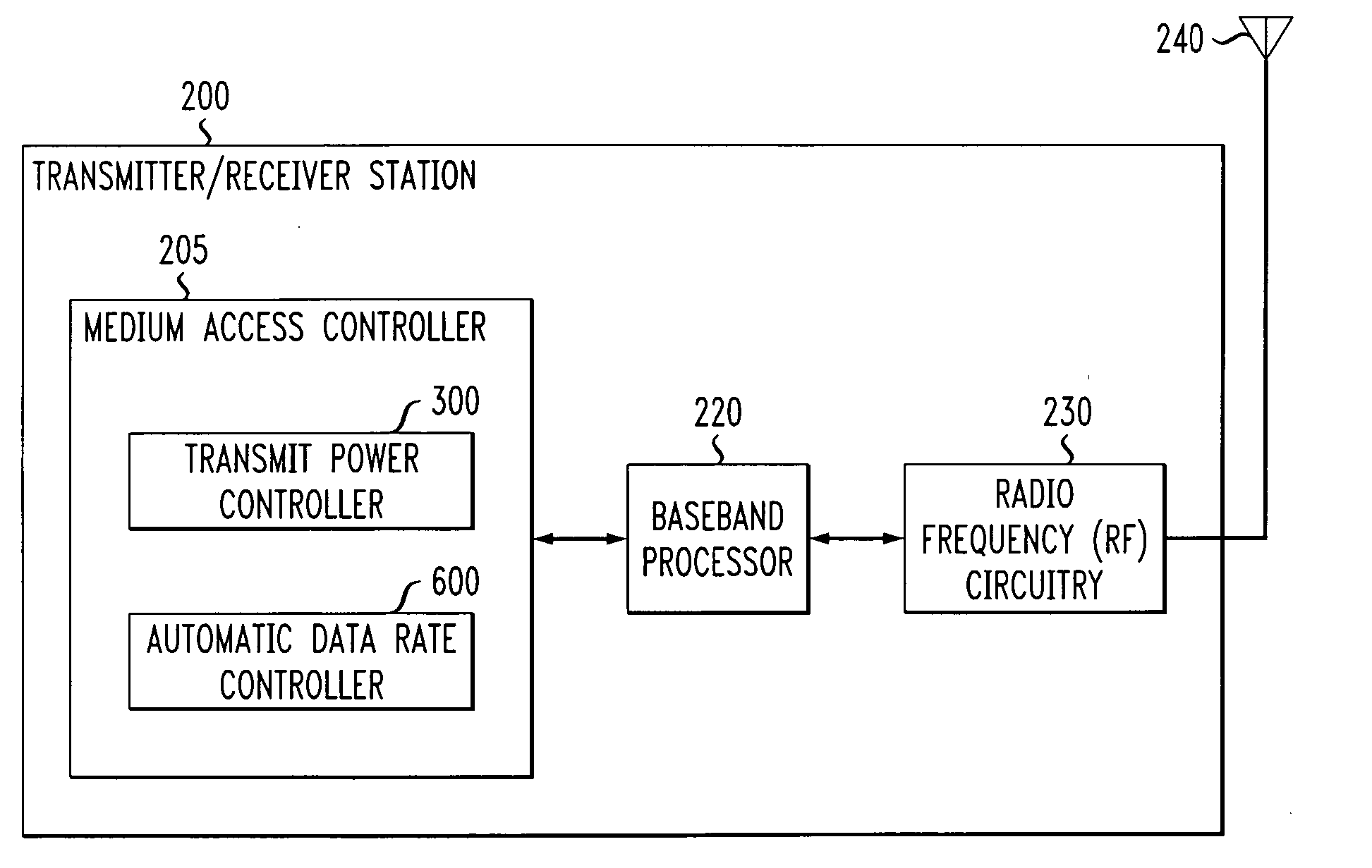

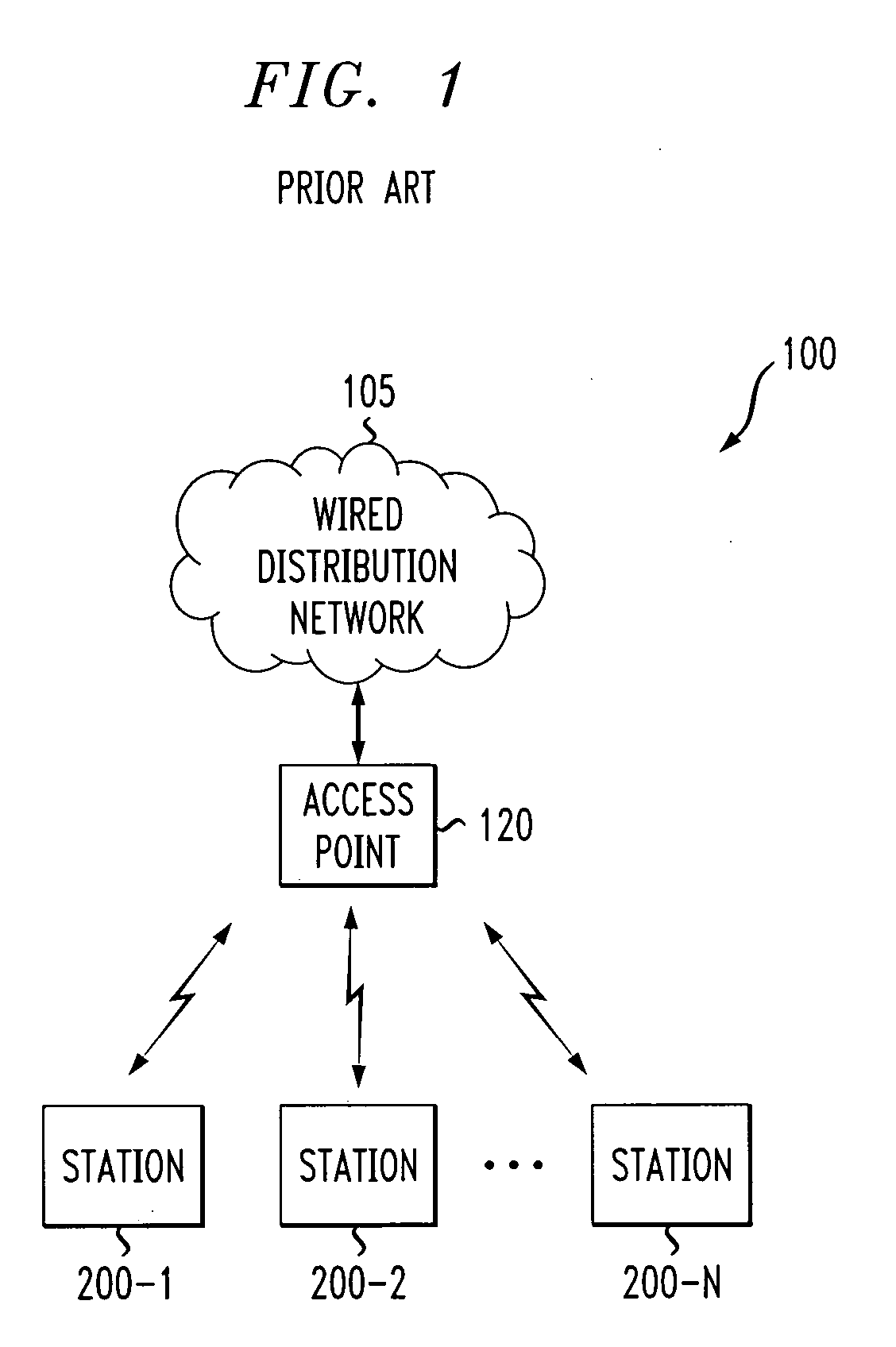

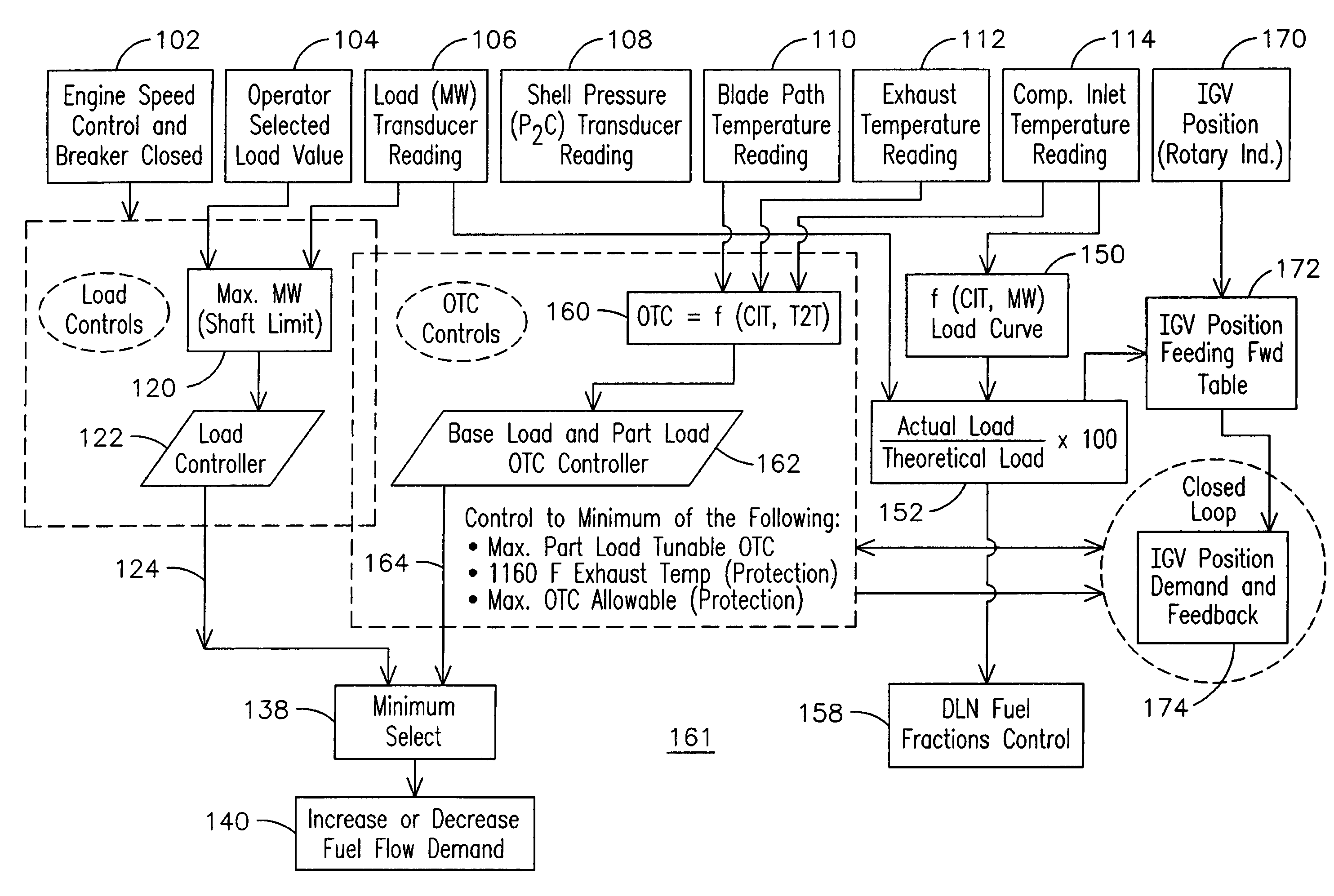

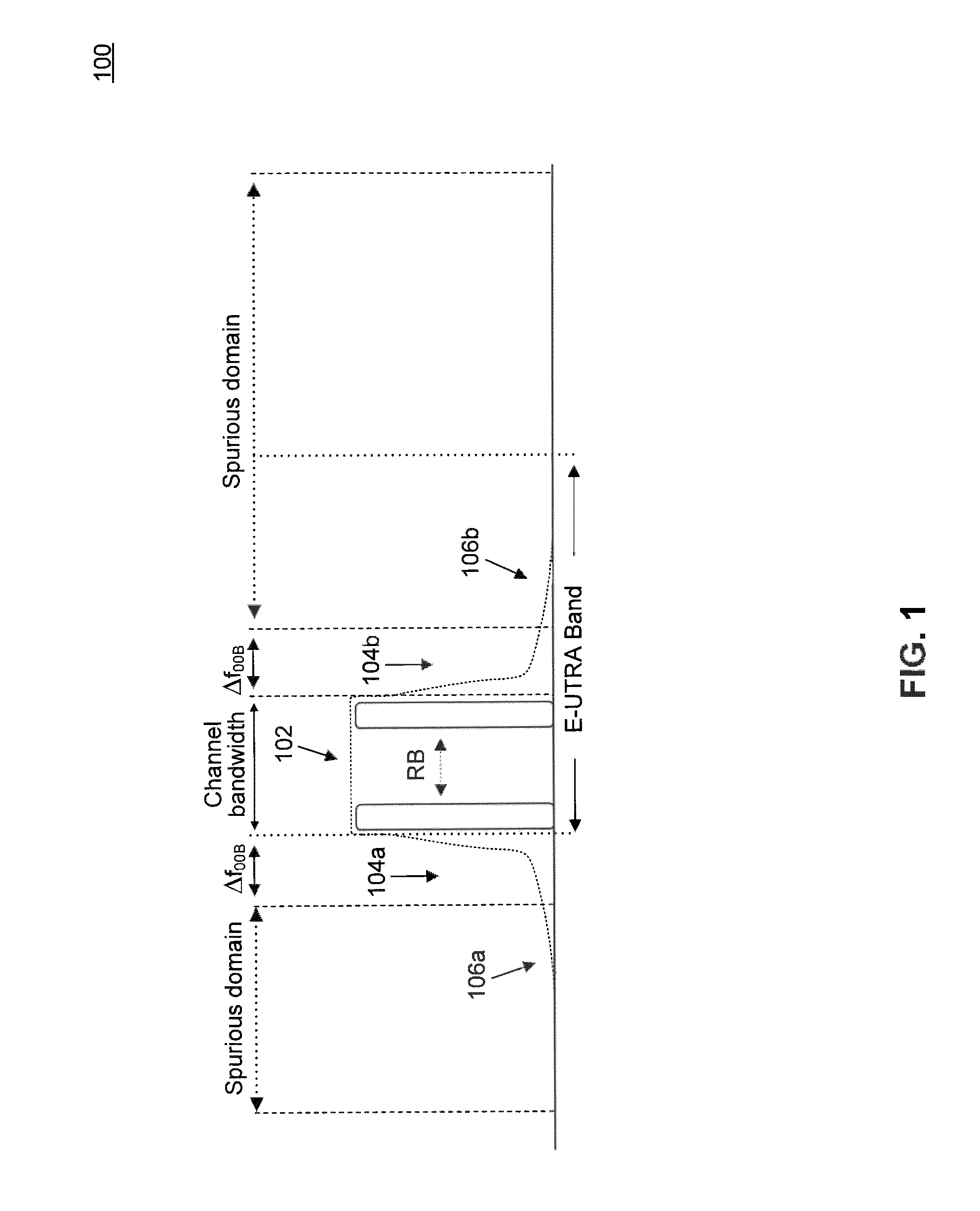

Method and apparatus for automatic data rate control in a wireless communication system

InactiveUS20050143027A1Low transfer rateError prevention/detection by using return channelPower managementSignal qualityHigh rate

A method and apparatus are provided for automatic data rate control in wireless communication systems, such as wireless LANs. A data rate controller adapts a transmission rate of said data based on a signal quality and a transmit power level. The data rate controller can also adapt the transmission rate based on one or more of amplifier non-linearities, anticipated signal quality for a next frame transmission, regulatory emission limits and data rate advice. The data rate advice will decrease a data rate if a current signal quality is below a minimum required signal quality for a given data rate and increase a data rate if a current signal quality is above a minimum required signal quality for a given data rate. A probation mechanism allows a higher rate to be evaluated before switching to the higher rate permanently. A retry balance mechanism forces a rate fallback when a number of failed transmission exceeds a predefined threshold. A rate fallback feature reduces the transmission rate when a number of failed transmission exceeds a predefined threshold.

Owner:AGERE SYST INC

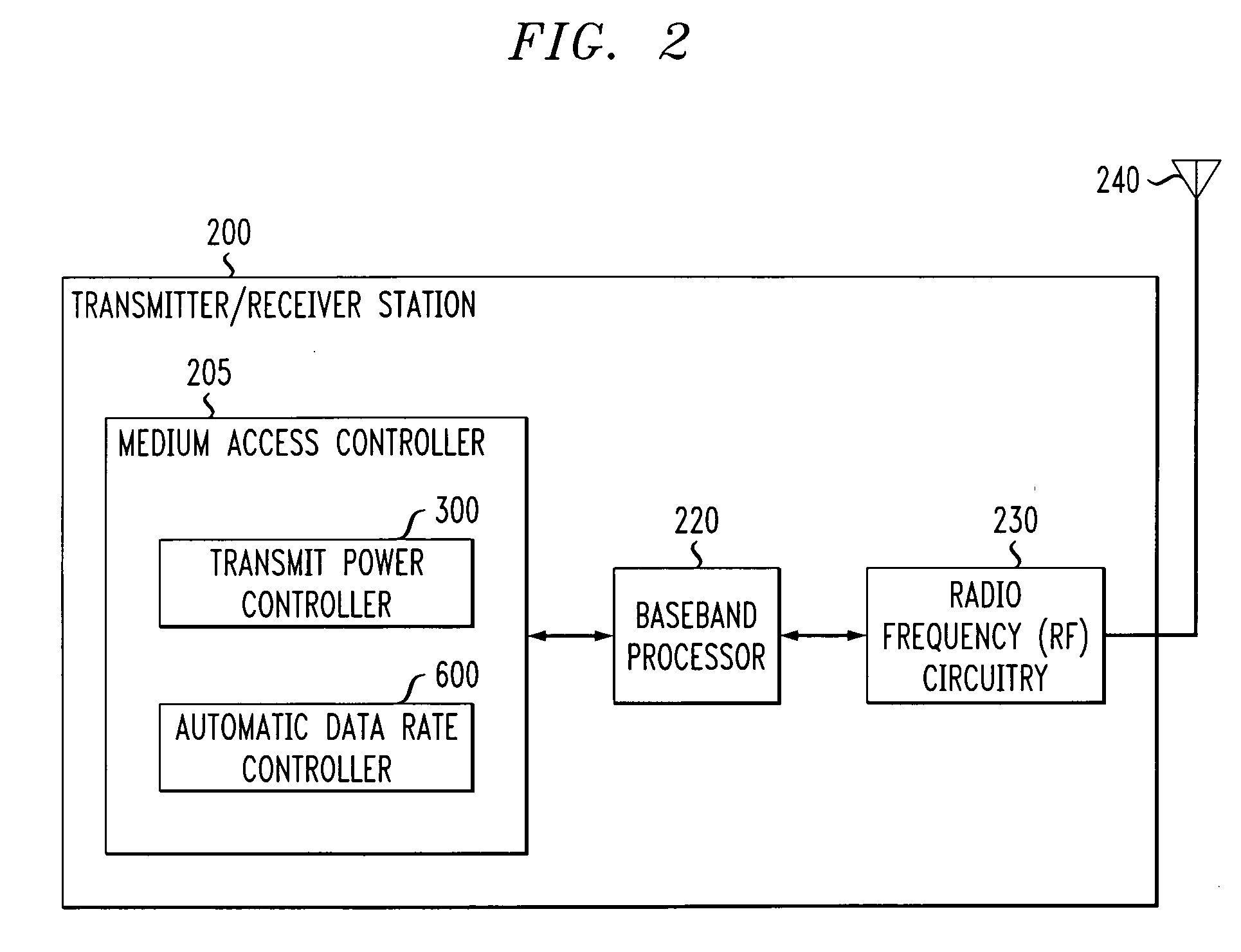

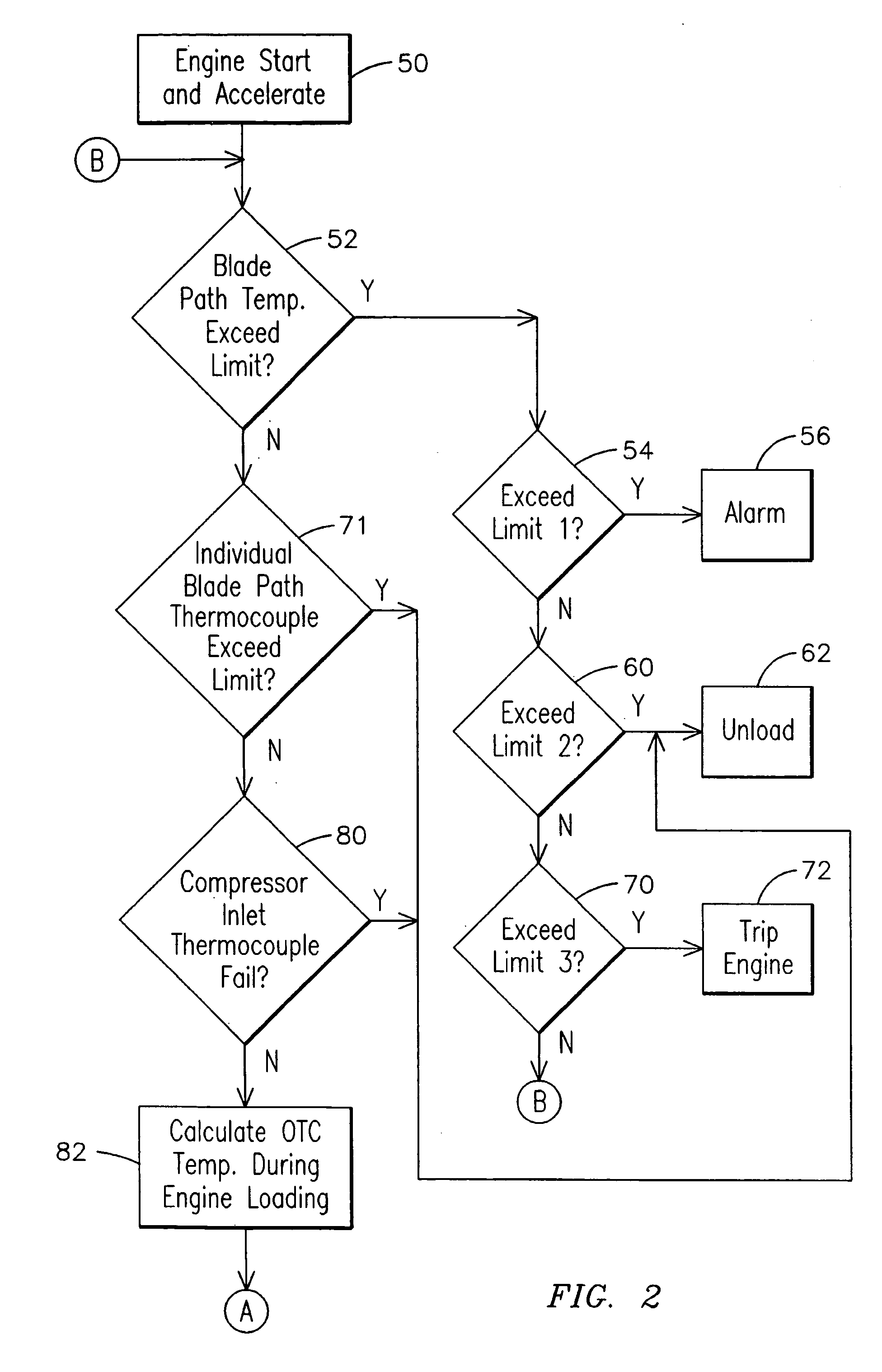

Method of controlling a power generation system

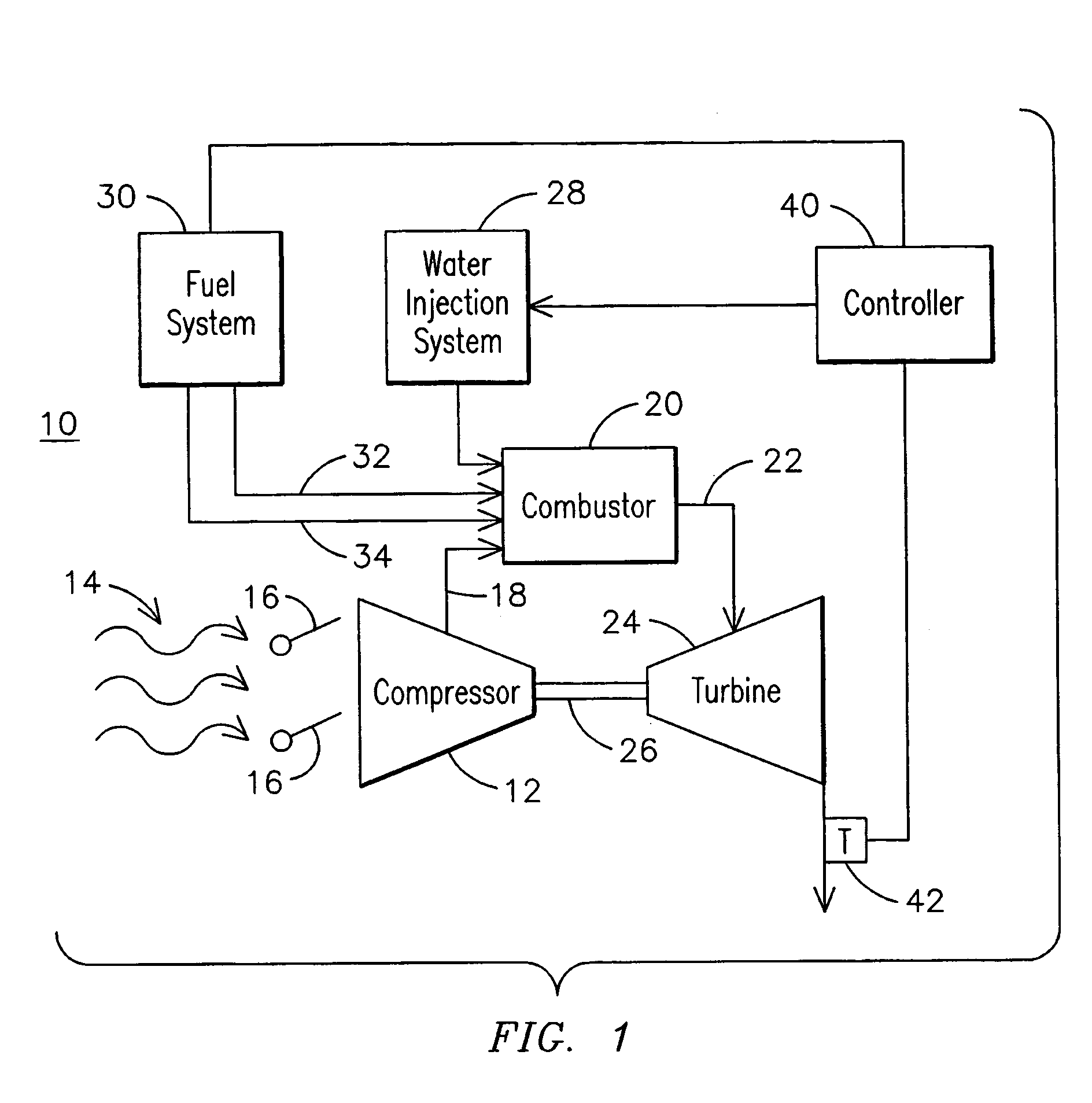

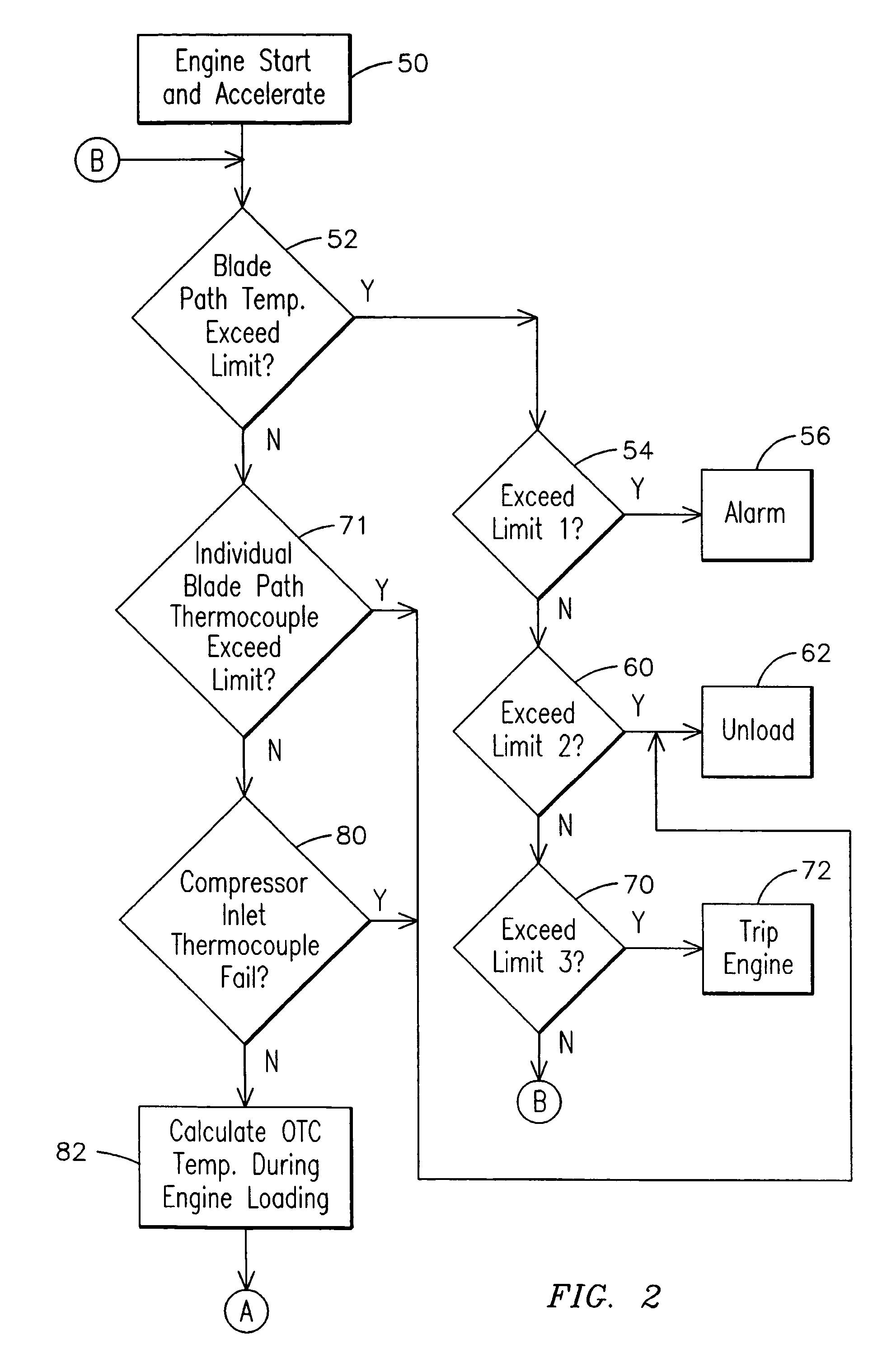

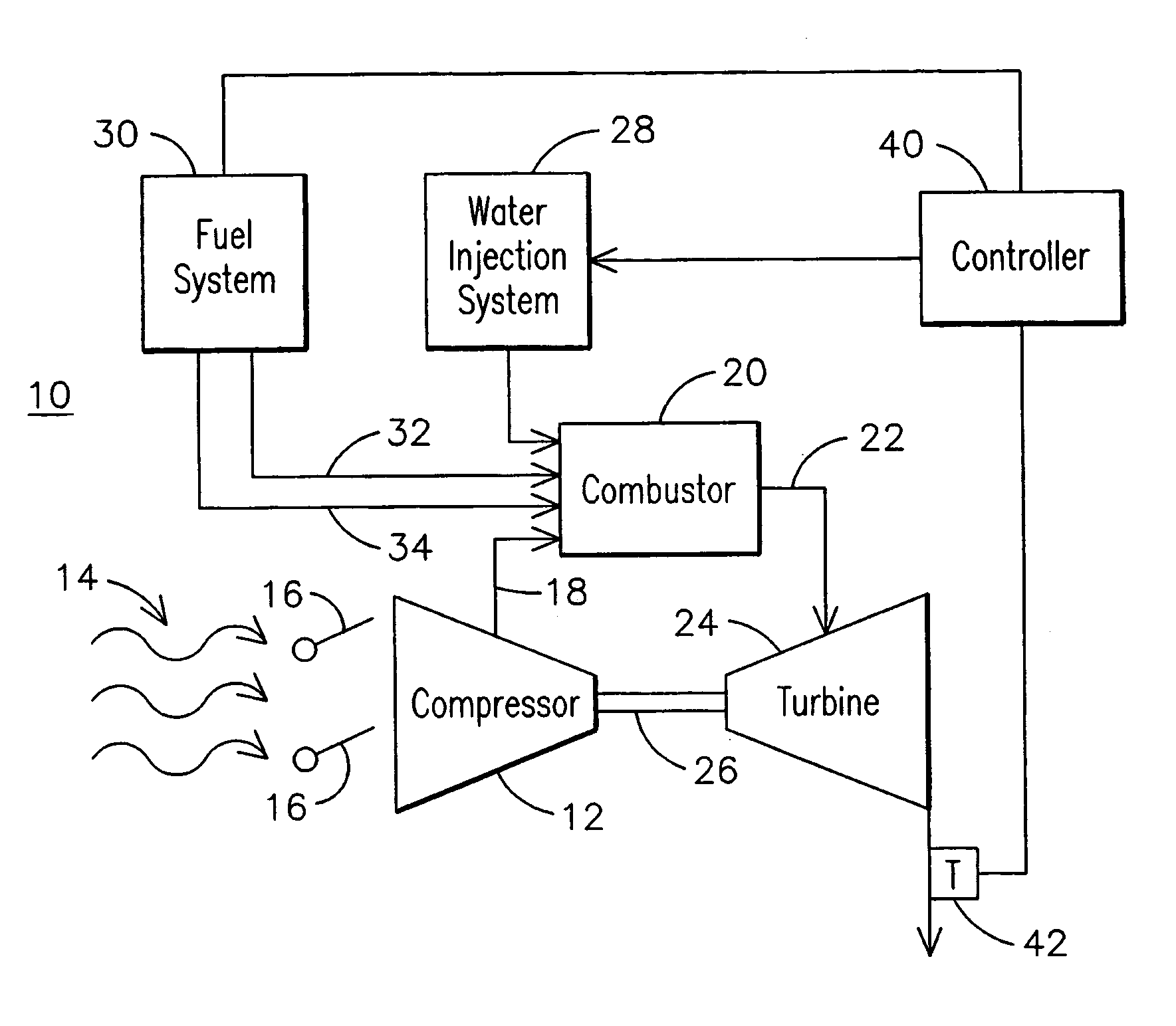

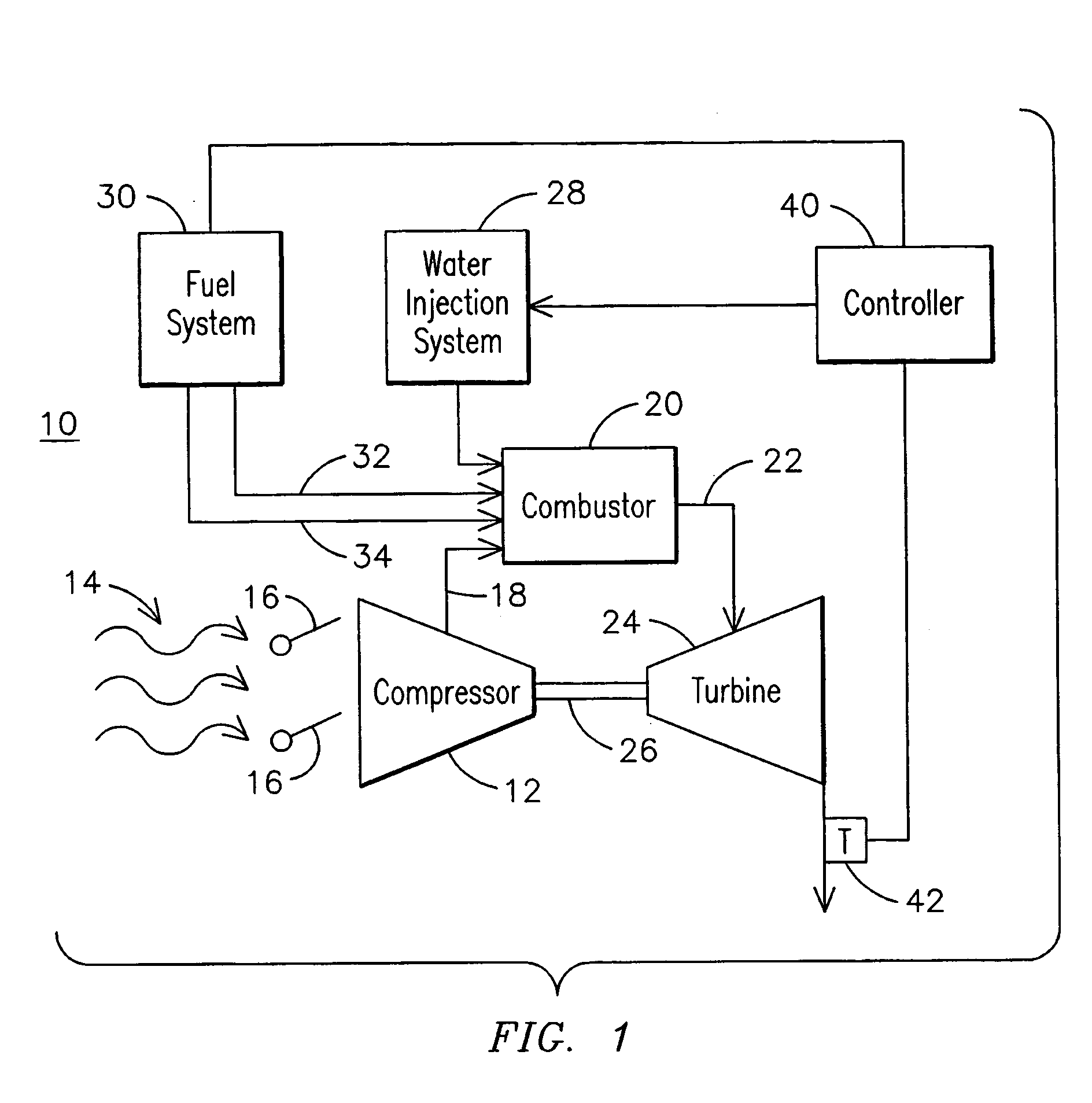

ActiveUS7269953B2Well mixedAccelerate emissionsGas turbine plantsTurbine/propulsion fuel controlCombustorTurbine

A method of controlling a gas turbine system (10) may include controlling an inlet guide vane position (98) to maintain a turbine (24) exhaust temperature at a corrected value that is a function of a compressor (12) inlet temperature and a turbine (24) normalized load. The method may include selecting the minimum value (138) of a part load tunable value, a part load maximum value and a fixed maximum value of a turbine (24) exhaust temperature for the corrected value. A corrected value setpoint may be determined (94) for the gas turbine system (10) operating at a part load condition where at least one of a fuel flow rate and the inlet guide vane position is controlled (98) so the corrected value does not exceed the corrected value setpoint. The corrected value may prevent a turbine (24) engine from exceeding its firing temperature during operation and ensure the engine operates within combustor dynamics and emissions limits.

Owner:SIEMENS ENERGY INC

Method of controlling a power generation system

ActiveUS20060042258A1Well mixedAccelerate emissionsGas turbine plantsTurbine/propulsion fuel controlCombustorTurbine

A method of controlling a gas turbine system (10) may include controlling an inlet guide vane position (98) to maintain a turbine (24) exhaust temperature at a corrected value that is a function of a compressor (12) inlet temperature and a turbine (24) normalized load. The method may include selecting the minimum value (138) of a part load tunable value, a part load maximum value and a fixed maximum value of a turbine (24) exhaust temperature for the corrected value. A corrected value setpoint may be determined (94) for the gas turbine system (10) operating at a part load condition where at least one of a fuel flow rate and the inlet guide vane position is controlled (98) so the corrected value does not exceed the corrected value setpoint. The corrected value may prevent a turbine (24) engine from exceeding its firing temperature during operation and ensure the engine operates within combustor dynamics and emissions limits.

Owner:SIEMENS ENERGY INC

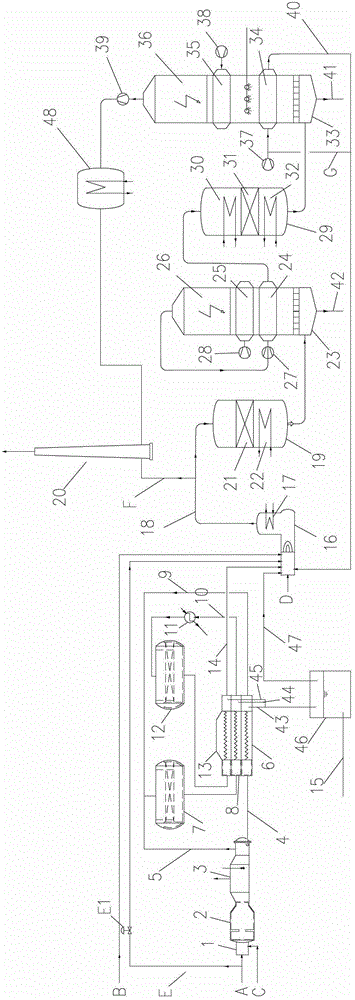

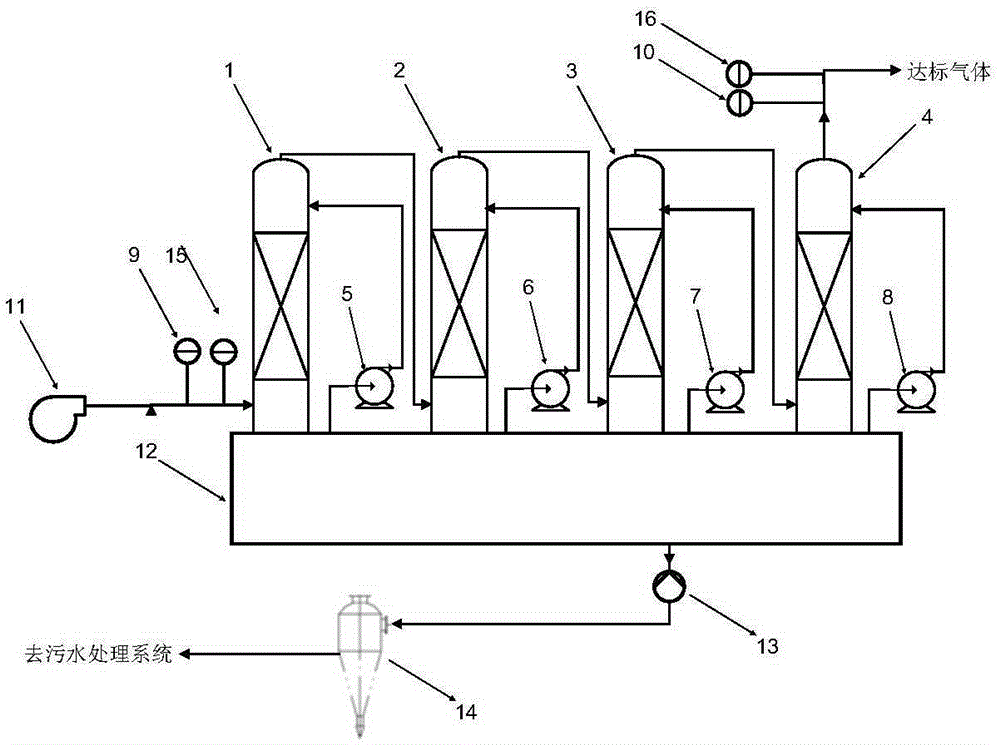

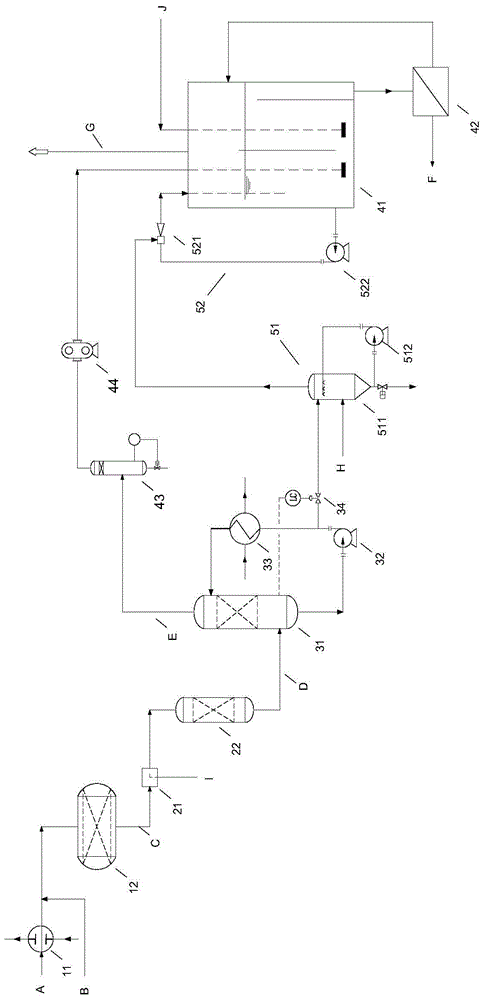

System and method for treating waste acid gas

ActiveCN102910593ANo emissionsLower requirementEnergy inputSulfur preparation/purificationLiquid wasteSulfur

Owner:美景(北京)环保科技有限公司

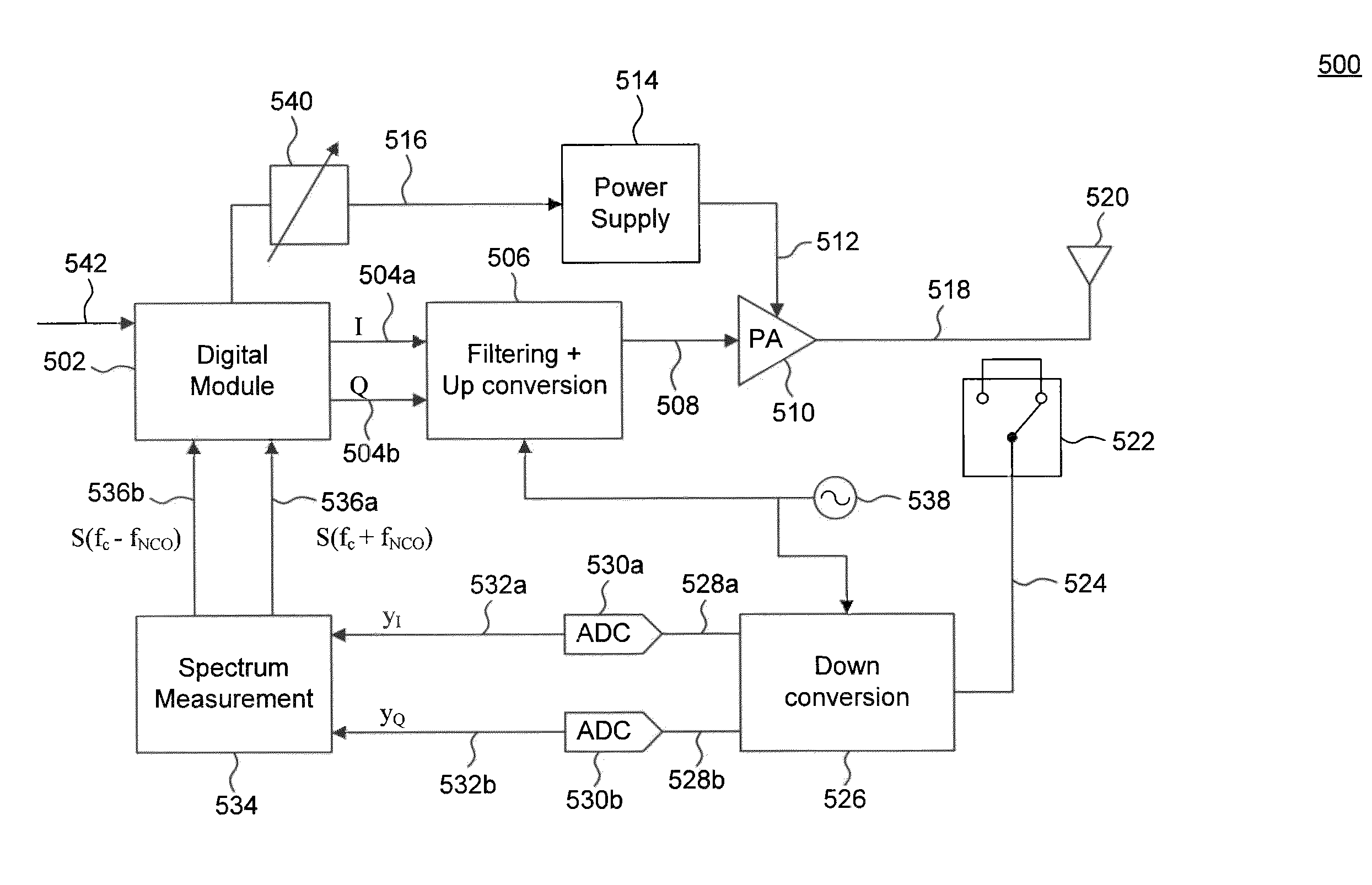

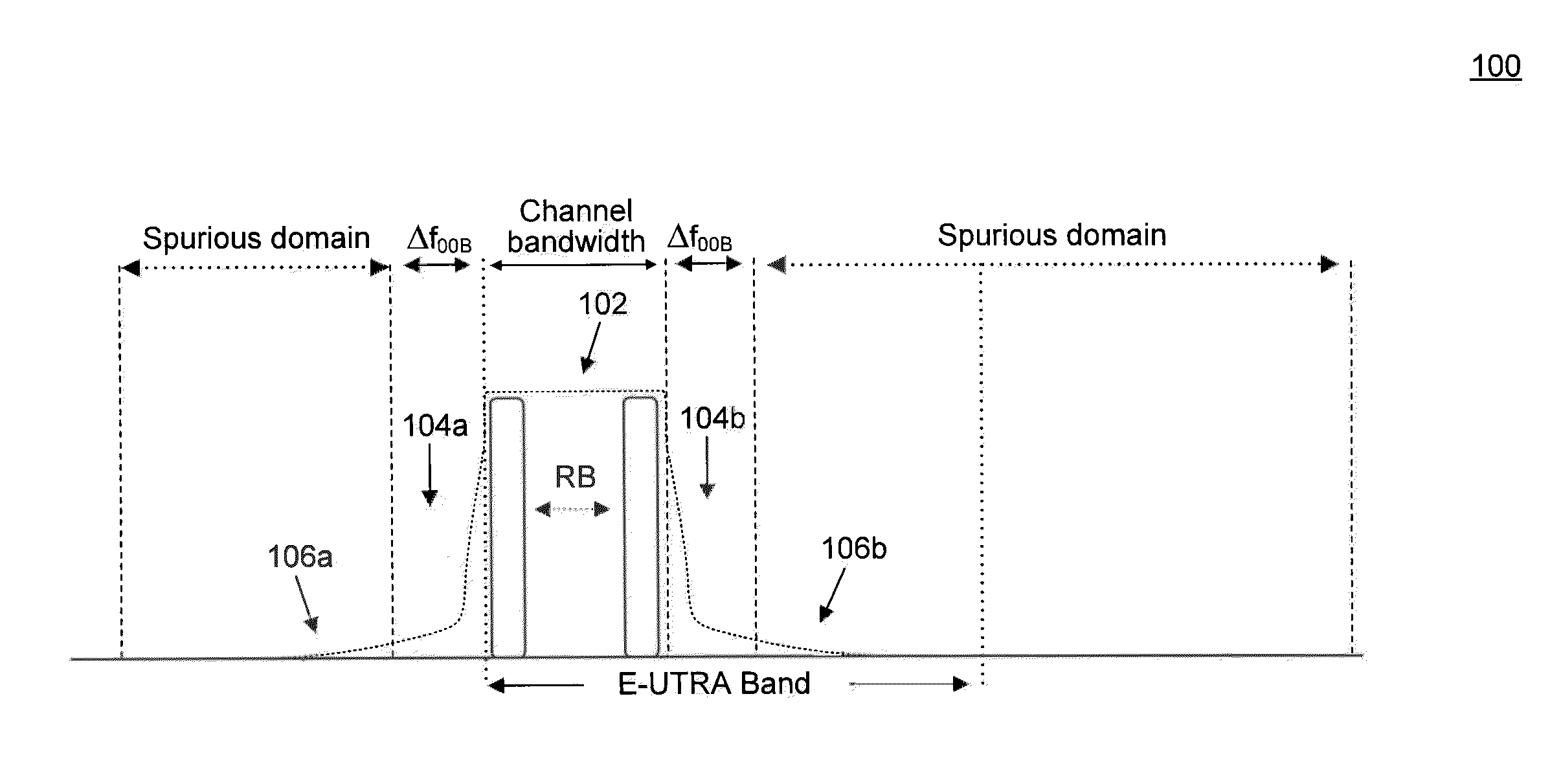

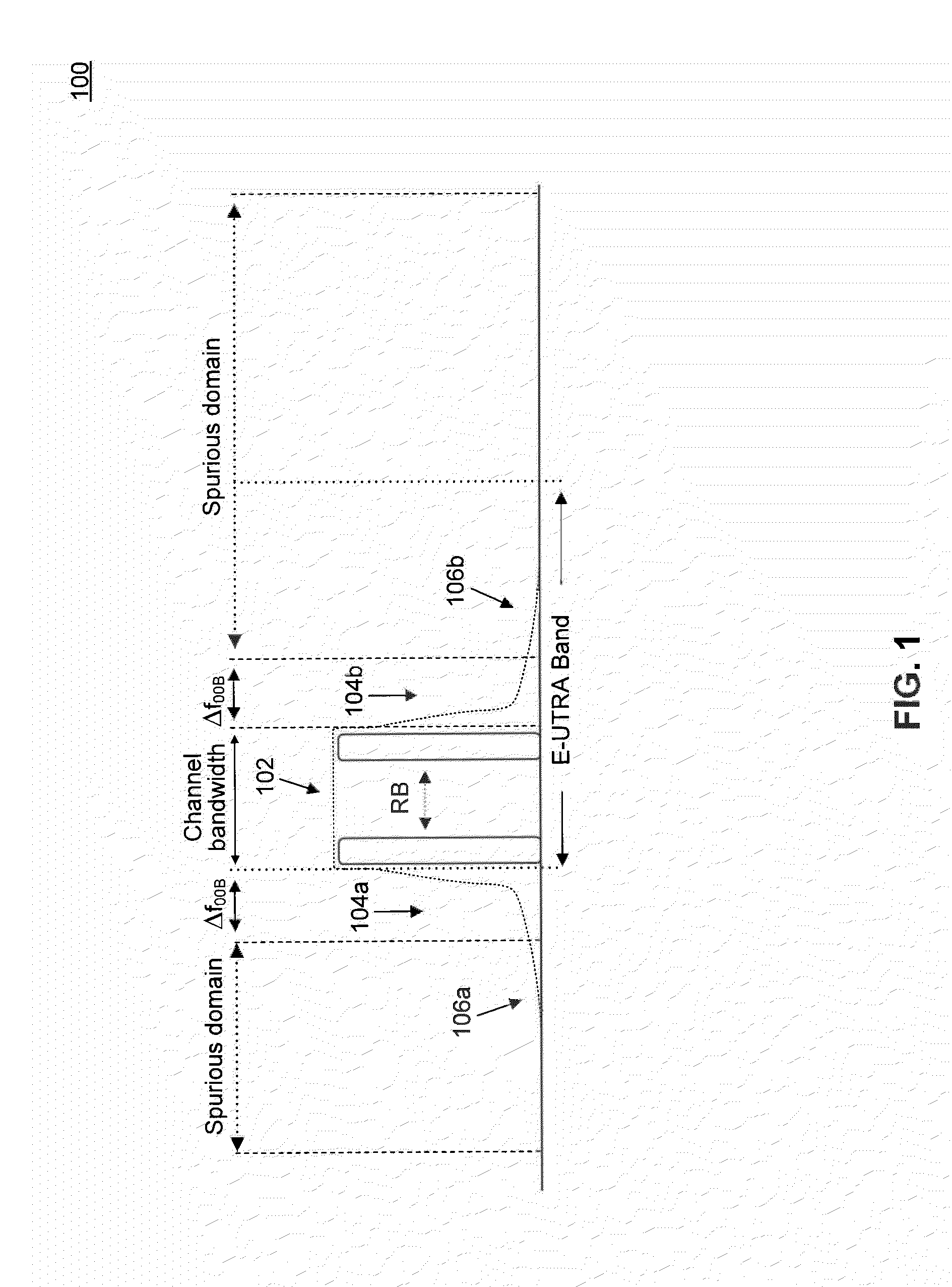

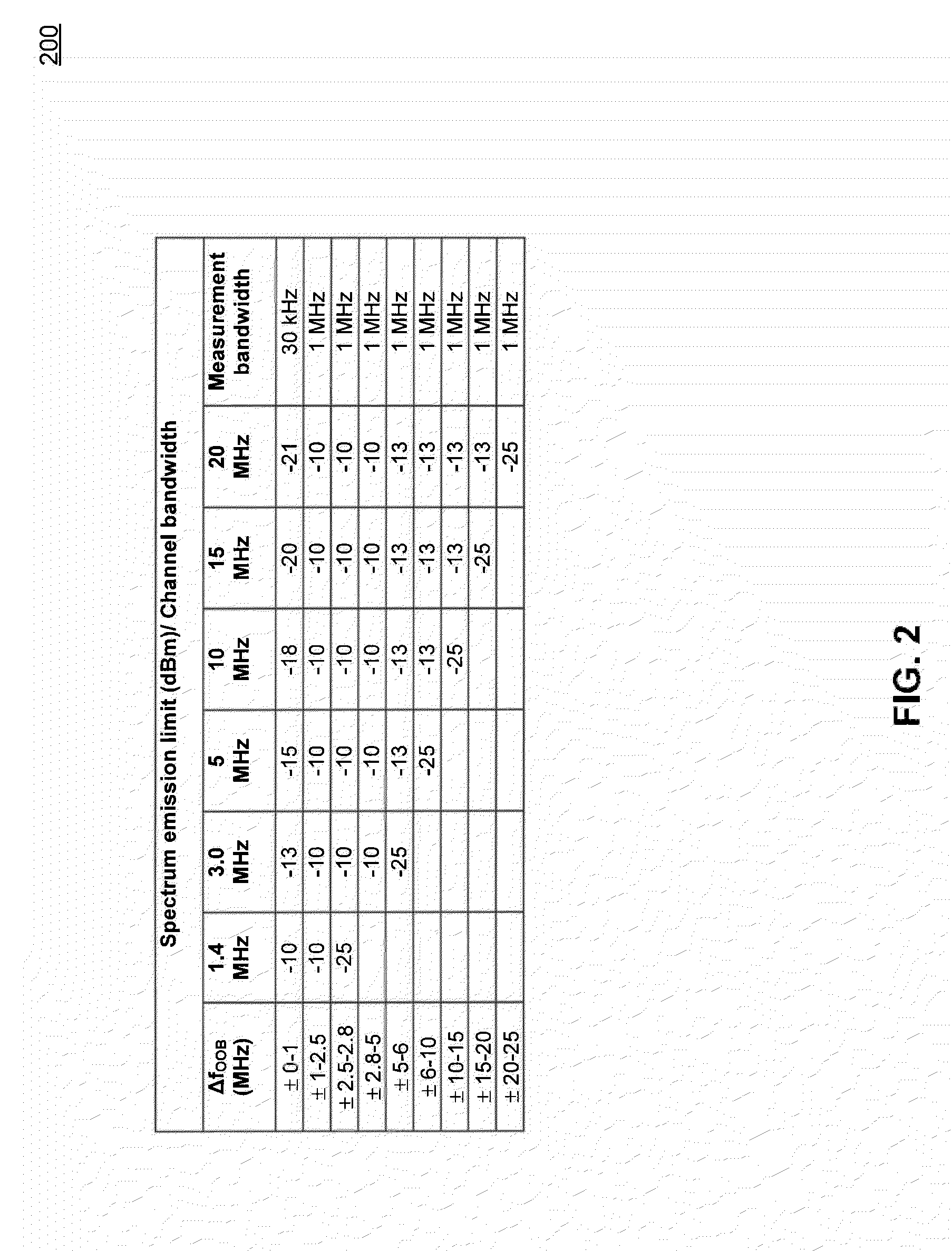

Controlling a power amplifier based on transmitter output emissions

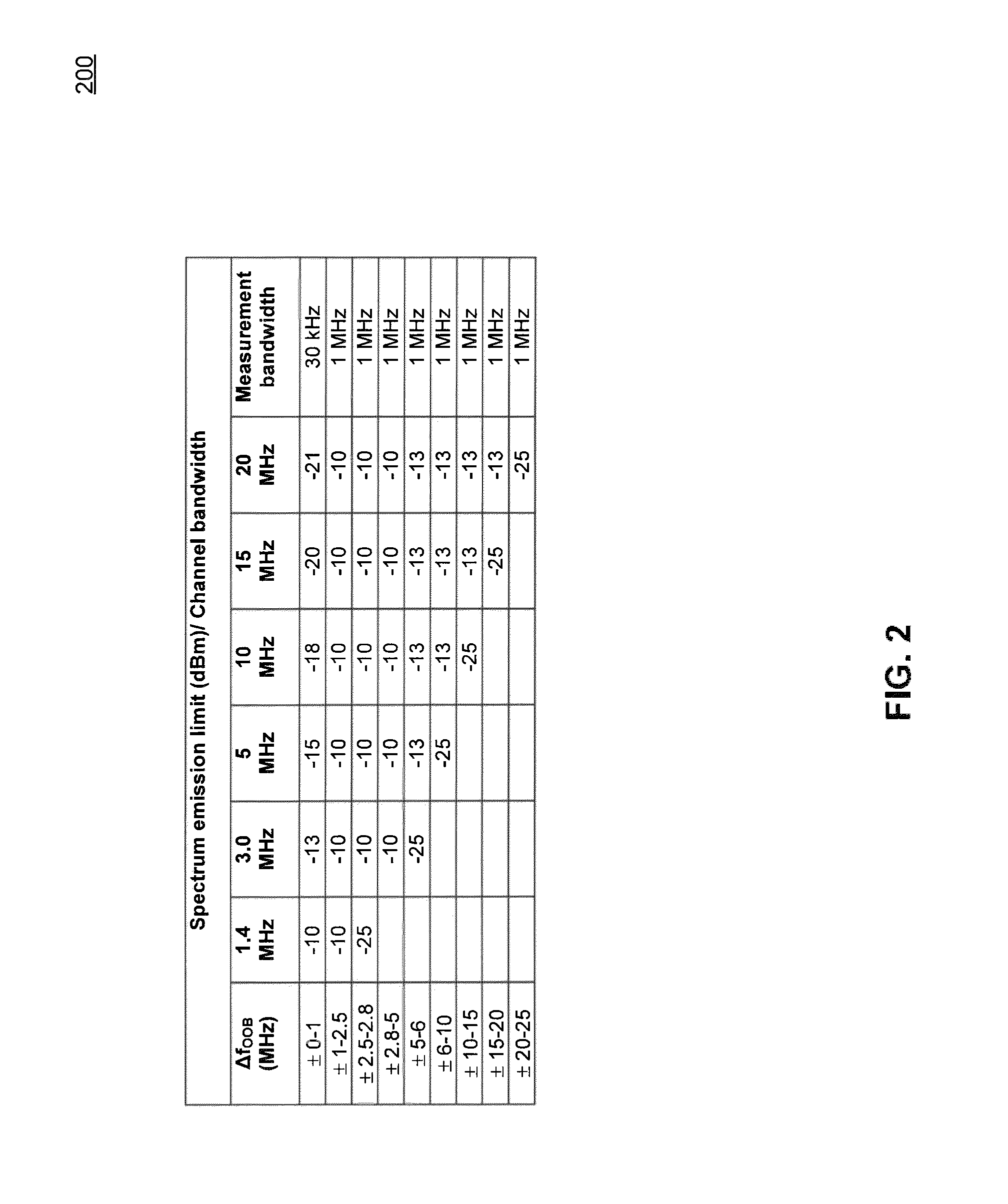

Methods and systems for controlling the supply voltage provided to a power amplifier (PA) in a radio frequency (RF) transmitter based on measured output spectrum emissions are provided. In an embodiment, the PA supply voltage is adjusted such that spectrum emission limits are satisfied with predetermined margins. In another embodiment, the predetermined margins are reduced to lower power consumption of the PA.

Owner:AVAGO TECH INT SALES PTE LTD

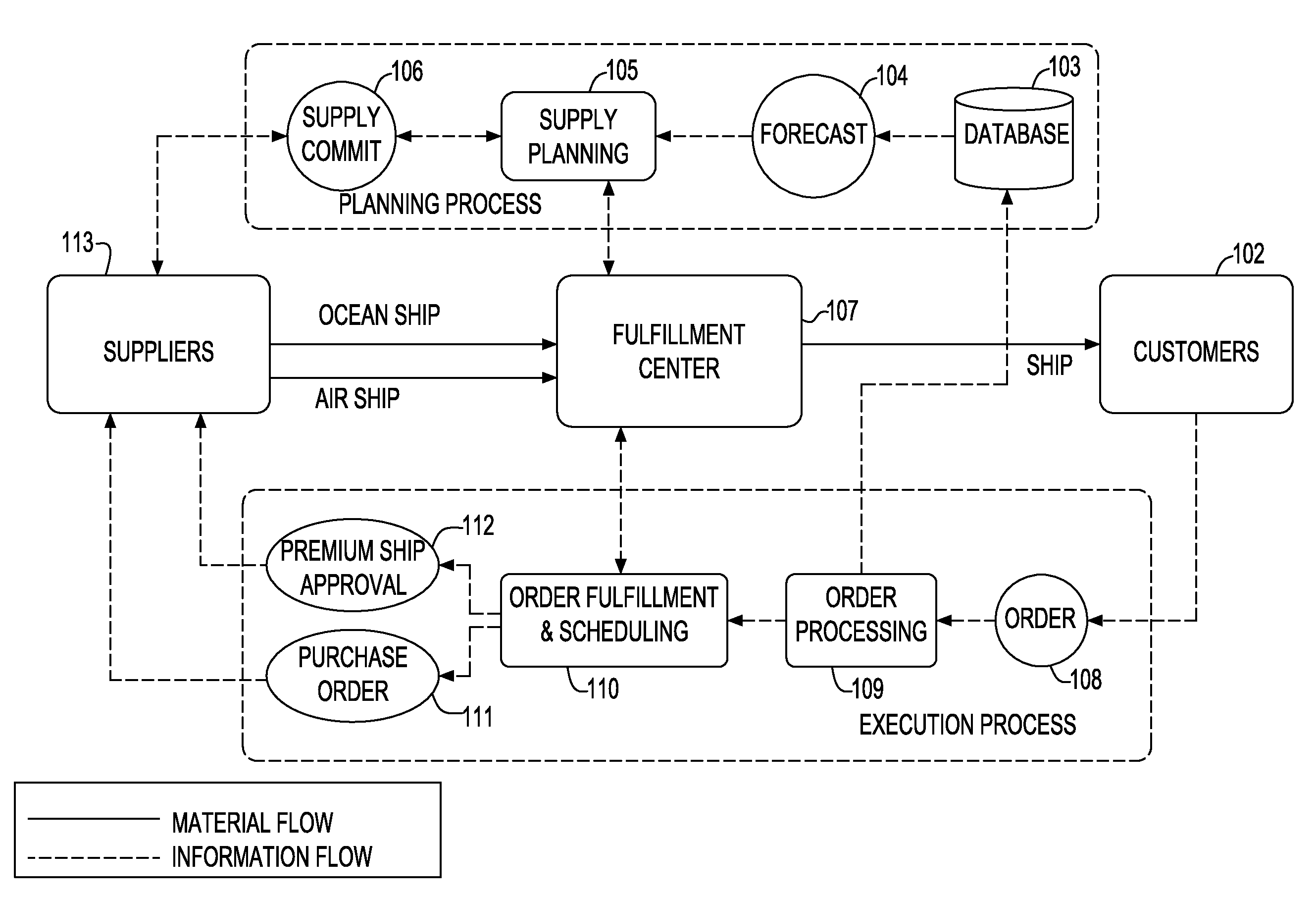

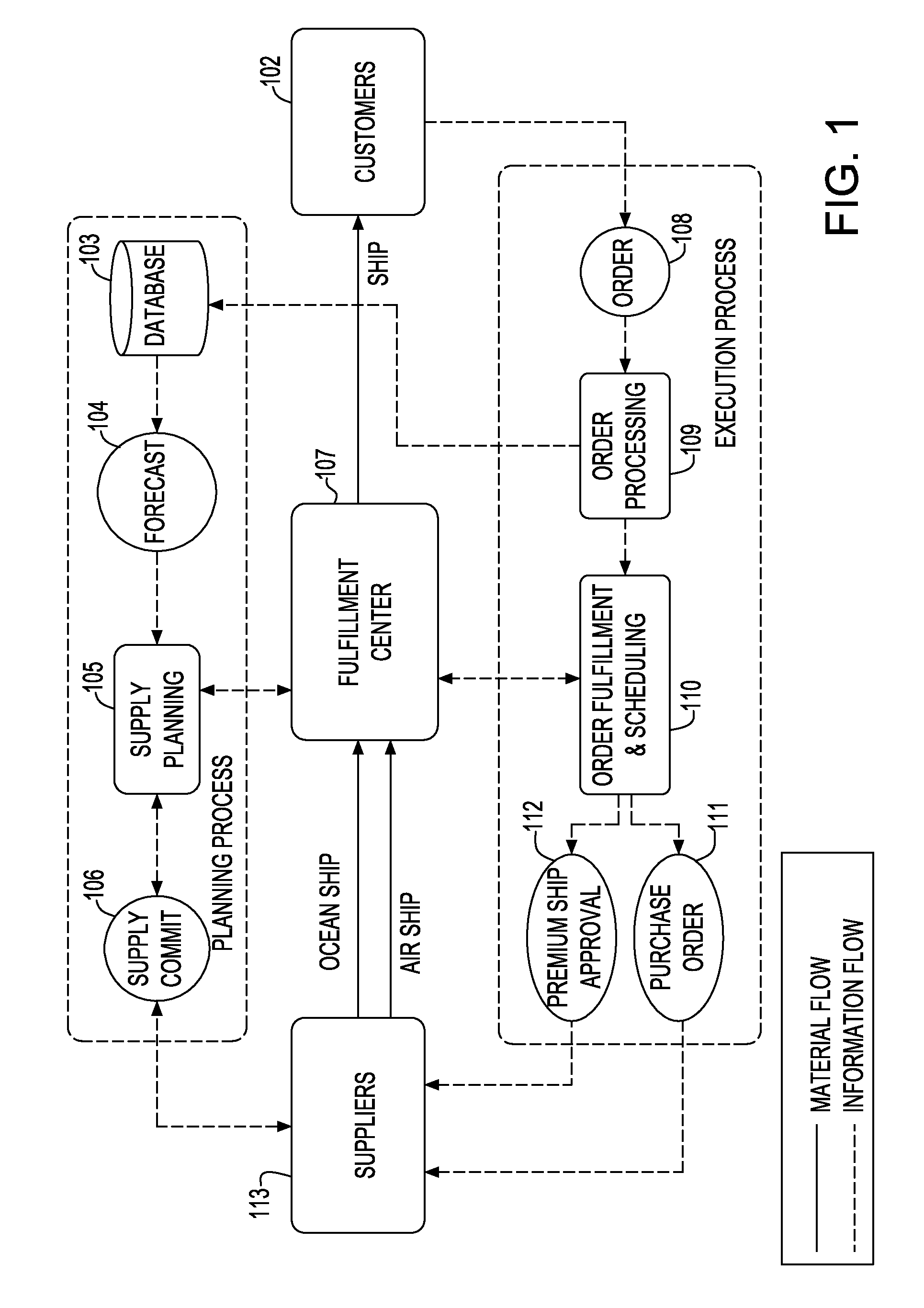

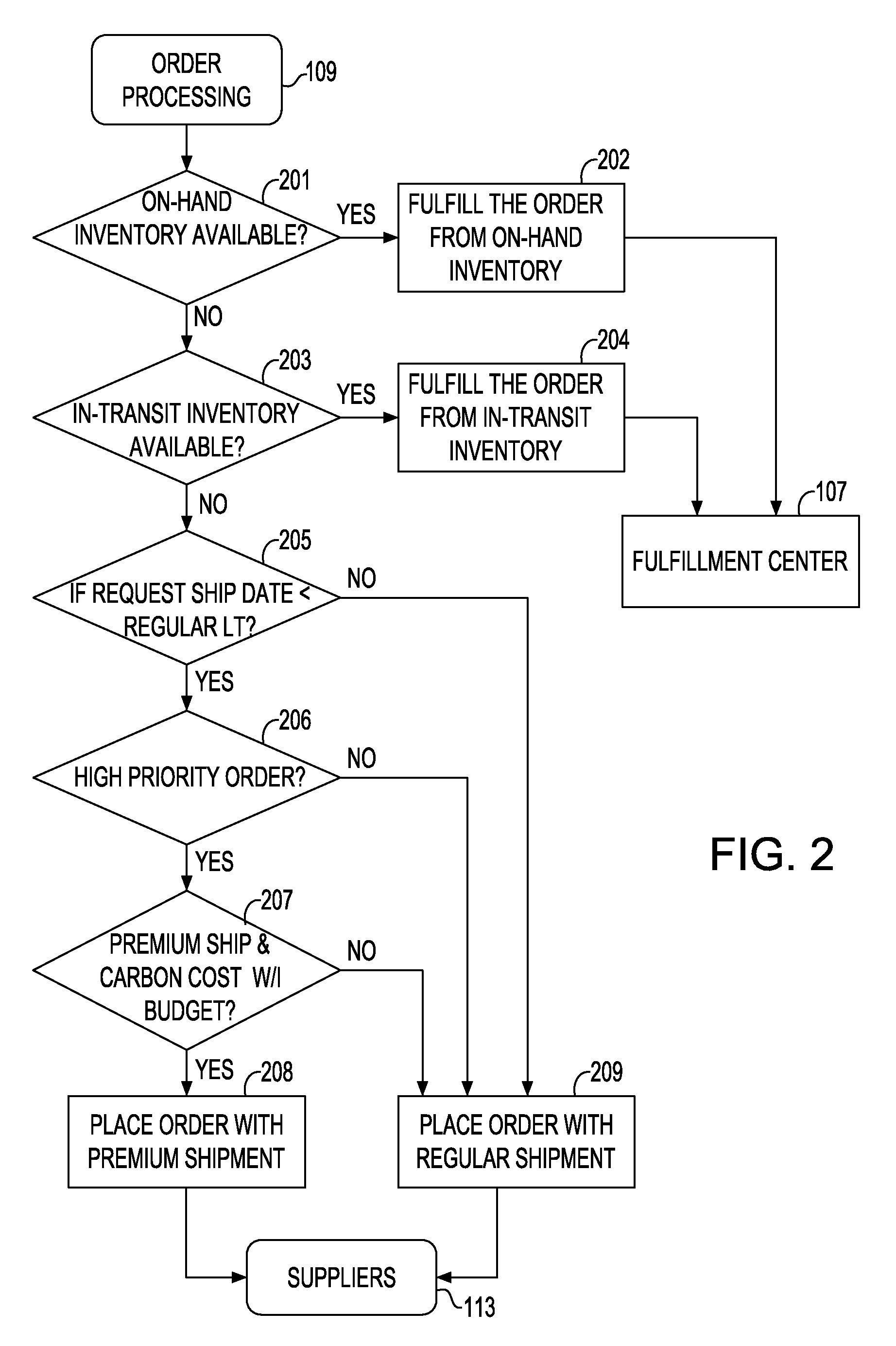

System and method for determining carbon emission-conscious order fulfillment alternatives with multiple supply modes

InactiveUS20100088136A1Hand manipulated computer devicesTicket-issuing apparatusOrder fulfillmentMode of transport

A system and method for optimizing order fulfillment by considering multiple supply modes in one aspect, plans supply of inventory by forecasting demand, estimating accuracy of said forecasted demand, and establishing reorder point policy based at least on said accuracy of said forecasted demand, a plurality of supply transportation modes, cost of carbon emissions and limit on carbon emission credits. Current inventory position is monitored and if the current inventory position is below the reorder point policy, orders are placed according to a selected shipping method. The selected shipping method may be based at least on customer order priority, transportation budget, and carbon emission limit.

Owner:IBM CORP

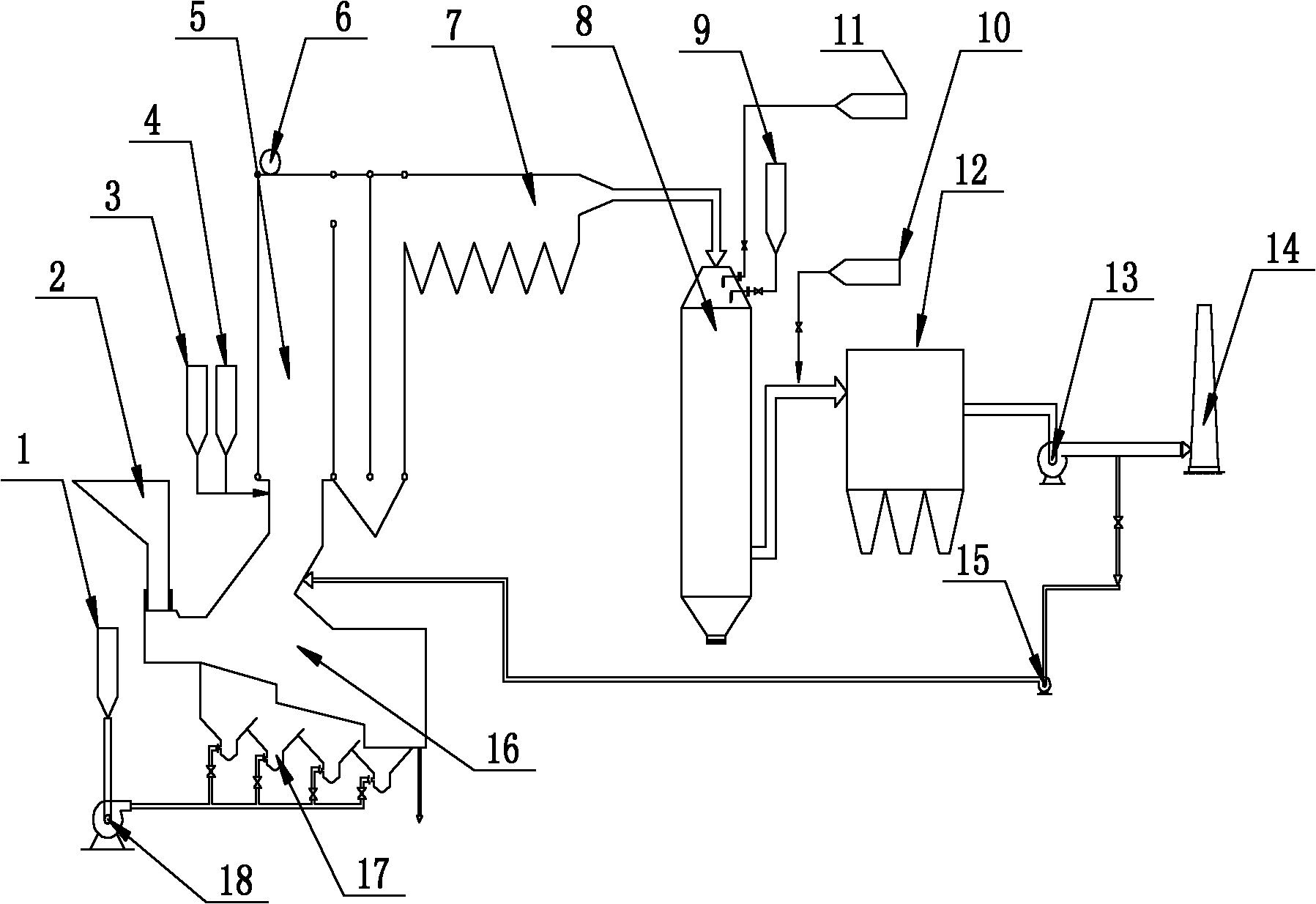

Method and device for reducing emission limits of nitrogen oxides in waste incineration flue gas

InactiveCN102168852APromote harmlessnessImprove utilizationDispersed particle separationIncinerator apparatusFlue gasNitrogen oxide

The invention relates to a method and a device for reducing emission limits of nitrogen oxides in waste incineration flue gas. In the method, processes of a waste incineration processing device, an optimizing air supply device, an exhaust-heat boiler device, a selective non-catalytic reduction (SNCR) device, a tail gas processing device and the like are integrated into a whole; by combining clean flue gas serving as secondary air supply and the SNCR device, the situation that the nitrogen oxides in the discharge of tail gas generated after wastes are processed by national waste incineration equipment is not removed effectively in low cost can be changed, and the removal ratio of the nitrogen oxides can be improved; and the removal rate of the nitrogen oxides after the device is optimized is more than 70 percent, so that the concentration of the tail gas discharged finally is lower than 150 mg / Nm<3> specified in the European Union standard 2000. Simultaneously, the optimizing device requires less increment investment and low running cost and is suitable to be applied and popularized in waste incineration equipment at home and abroad, and a denitration device is small in newly increased floor space.

Owner:BMEI

Effective printing and dyeing sewage treatment method

InactiveCN102659280AEconomic treatmentEasy to handleTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentSludgeWater quality

The invention discloses an effective printing and dyeing sewage treatment method, belongs to the field of industrial sewage treatment and is suitable for treating sewage difficult to degrade. The effective printing and dyeing sewage treatment method comprises the steps of automatically flowing printing and dyeing sewage into a primary settling tank to remove settleable substances and floaters in the sewage; pumping water out of the primary settling tank into a hydrolysis and acidification tank for hydrolysis and acidification; carrying out biological treatment on water out of the hydrolysis and acidification tank in an A2O reaction tank in which powdered activated carbon is fed; and carrying out coagulative precipitation on sewage subjected to biological treatment in a coagulative precipitation tank and discharging. After the printing and dyeing sewage is treated by the method, various effluent water indexes can basically reach the discharge standards of Major Water Pollutant Emission Limit of Urban Sewage Treatment Plants and Key Industries in Taihu (DB32 / T1072-2007). Through the method, the problems of bad treatment effect, unstable effluent water quality, large floor area, large sludge yield and high treatment cost of a traditional process are solved, and the economic and efficient treatment of the printing and dyeing sewage is realized.

Owner:CHANGSHU RES INSTITUE OF NANJING UNIV OF SCI & TECH

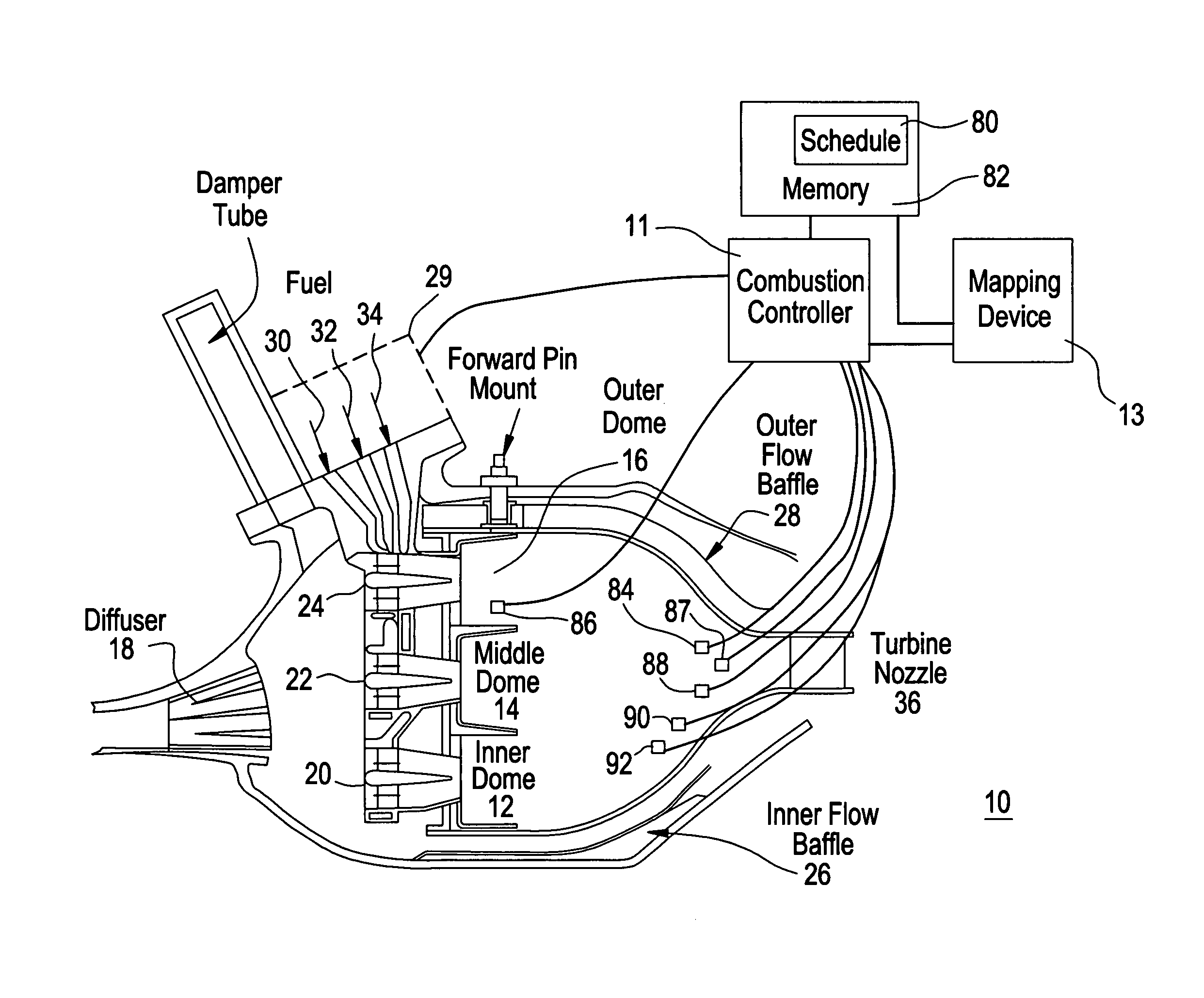

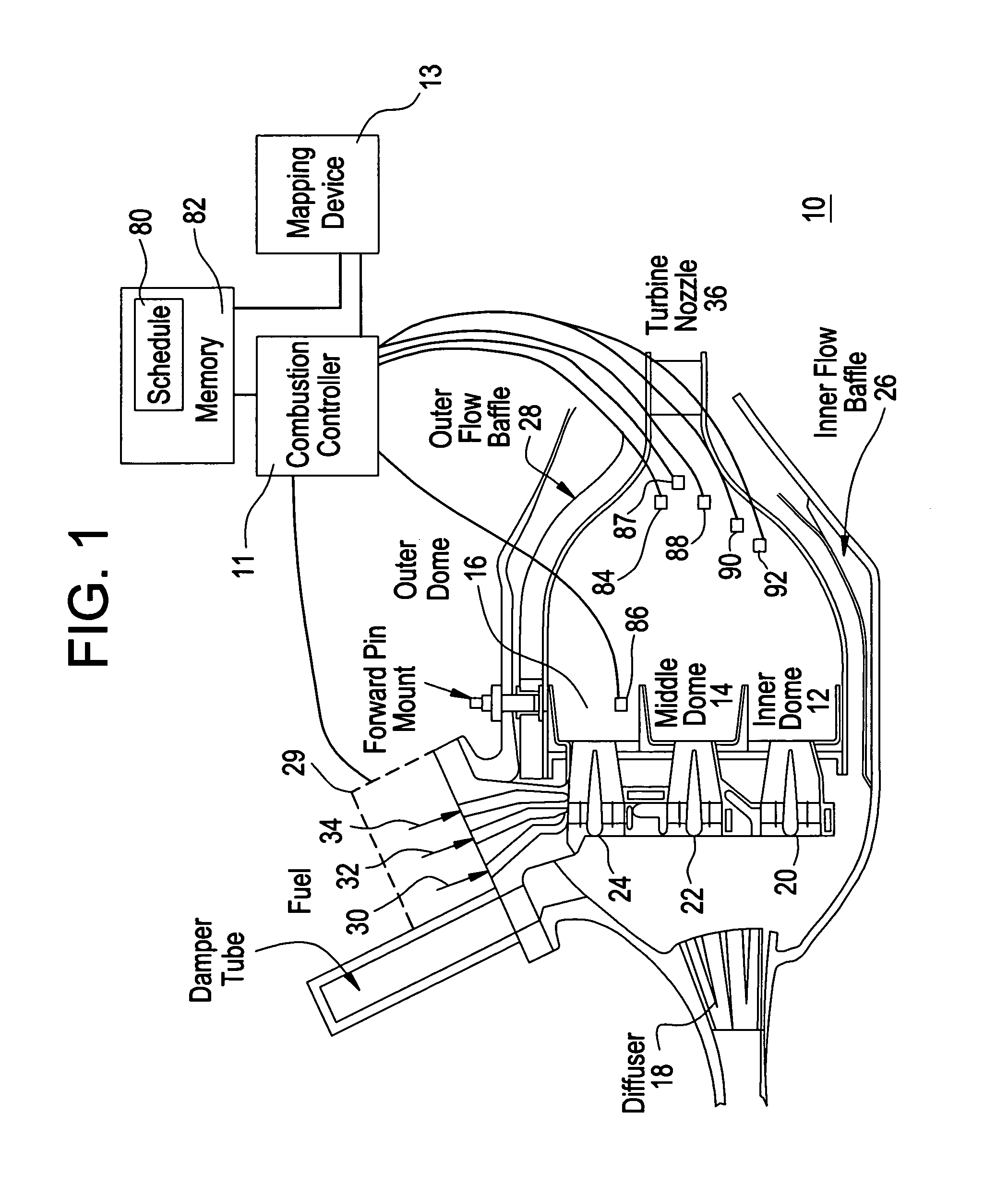

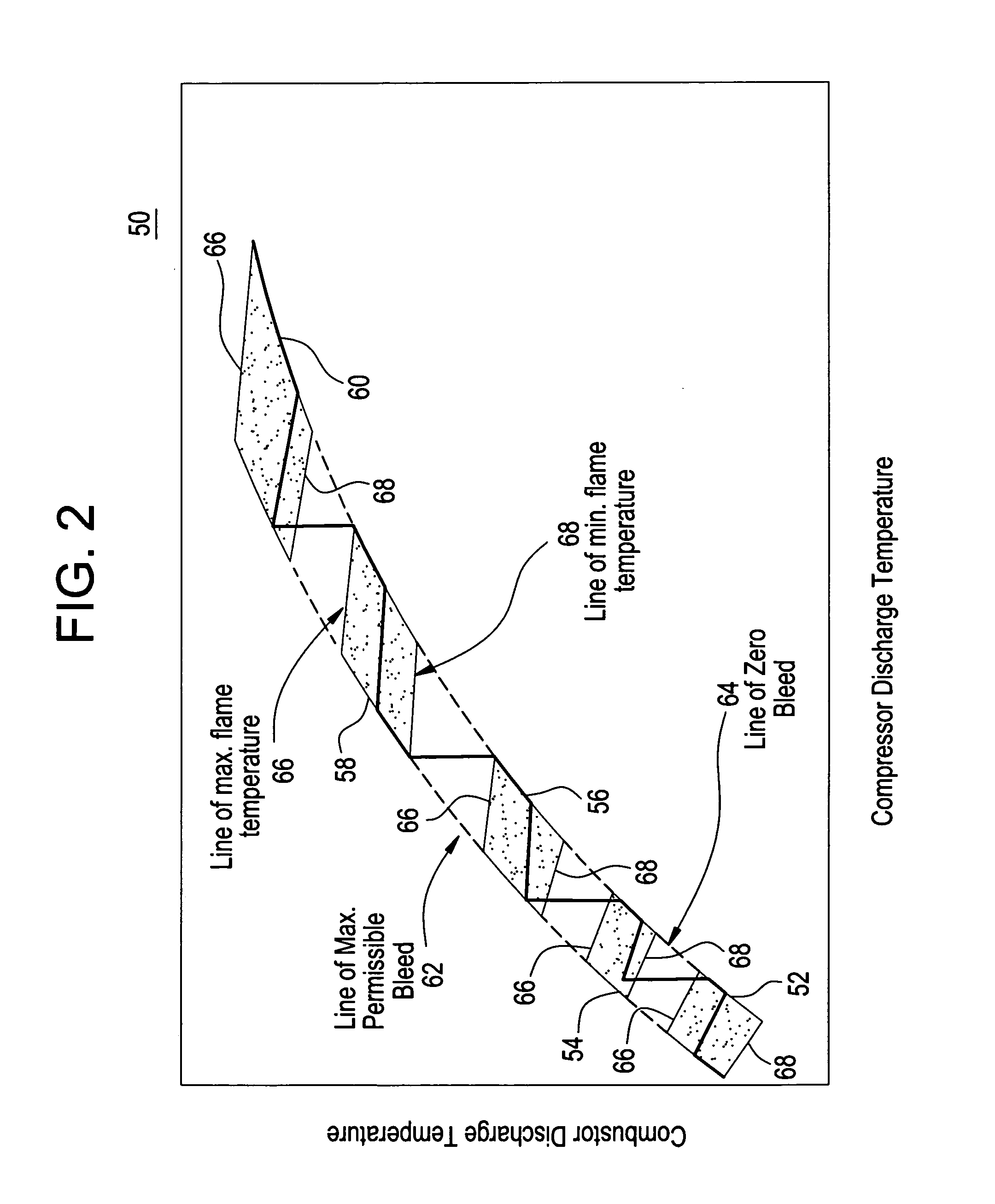

Automatic mapping logic for a combustor in a gas turbine engine

ActiveUS7302334B2Analogue computers for vehiclesContinuous combustion chamberCombustorCombustion chamber

A mapping device maps each burner mode at various bleed settings to generate control schedules for a combustion controller that ensure combustion dynamic (acoustic) pressures, and emissions limits and ring flame temperatures are within operational limits. In general, a method of combustor mapping involves adjusting the bulk ring flame temperature to meet emissions and acoustic requirements. The dome (ring) ring flame temperature is then adjusted to determine maximum and minimum ring flame temperature boundary limits. At both the maximum and minimum ring flame temperatures, the emissions levels and acoustic pressures are checked to see that they are within specification limits. If they are not, the bulk ring flame temperature is adjusted, and the entire process is repeated for that bleed setting and burner mode. If the emissions levels and acoustic pressures are within specification limits, then the power is increased to a different mode and bleed setting combination, and the process is again repeated. During each of these steps, mapping data are recorded.

Owner:GENERAL ELECTRIC CO

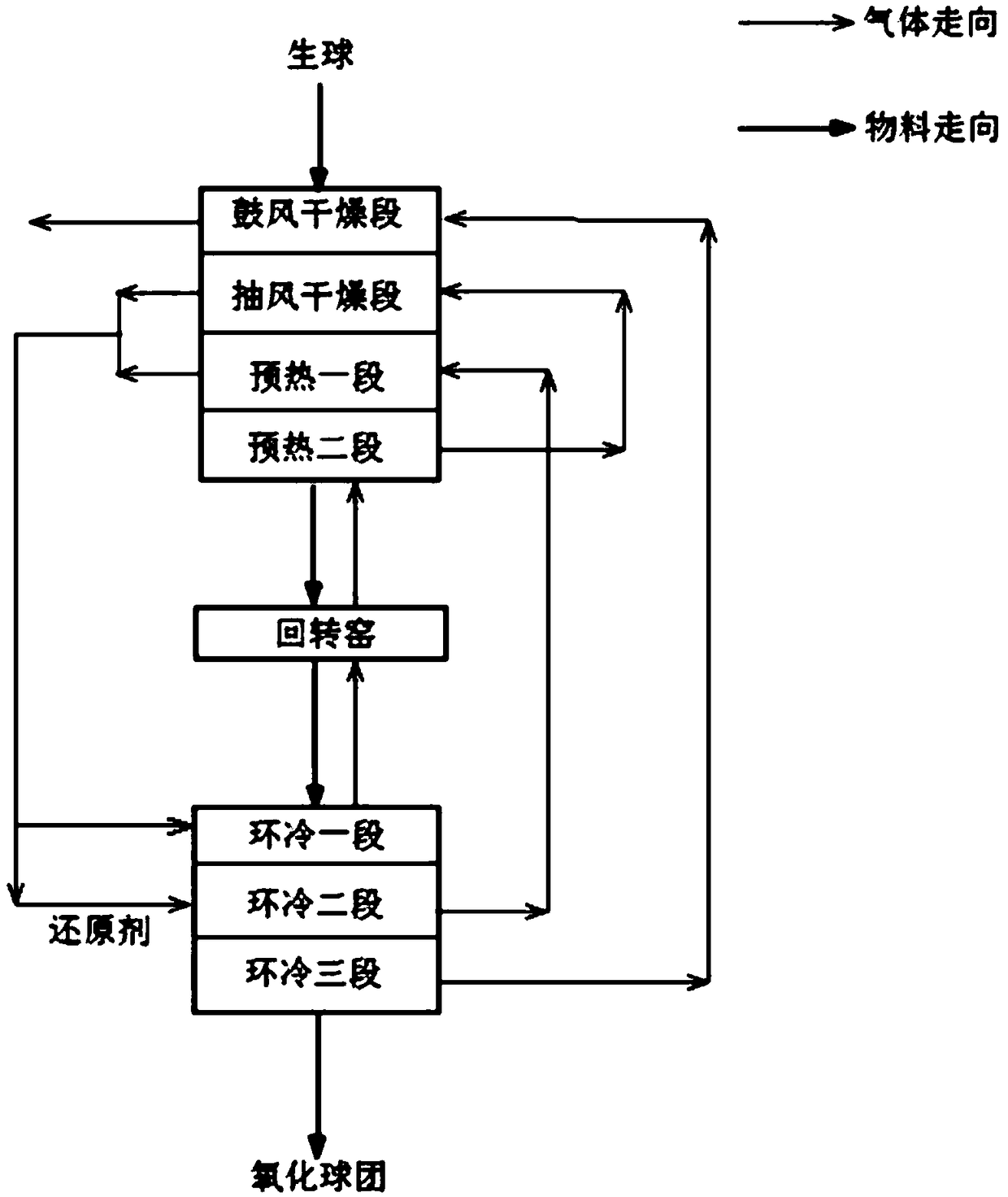

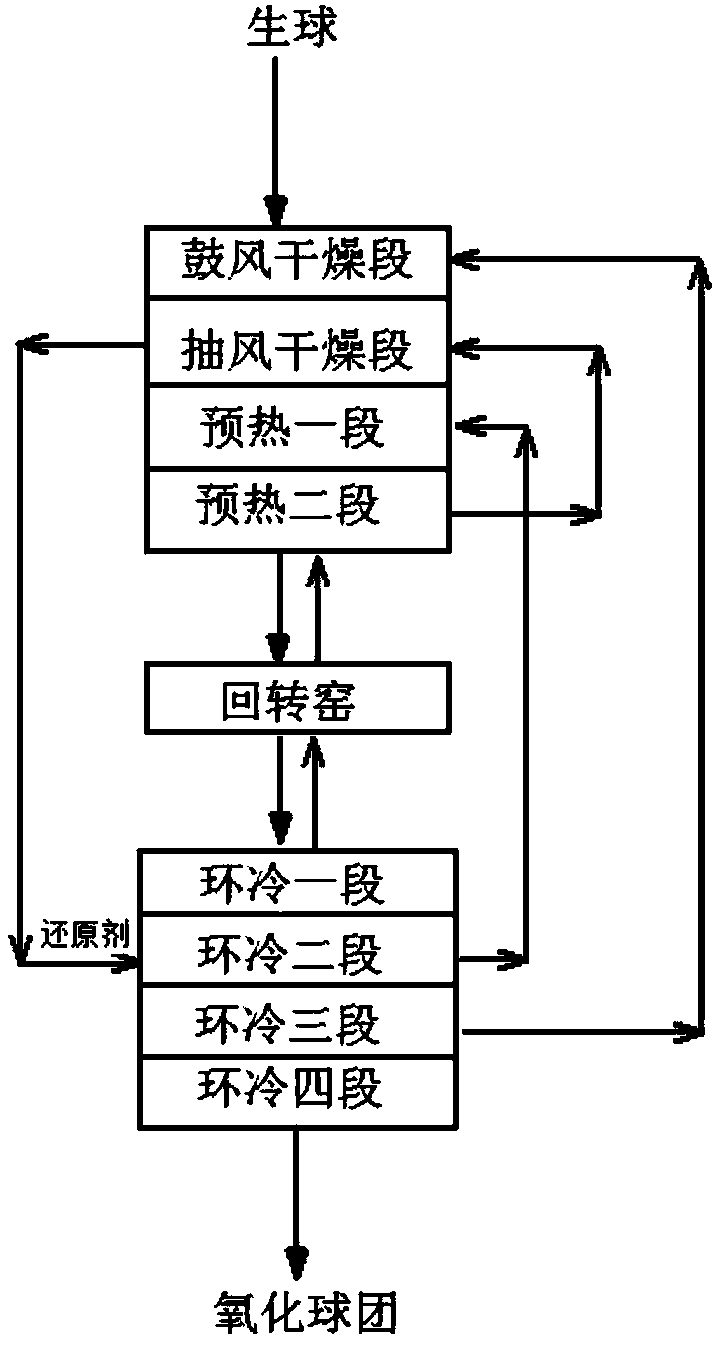

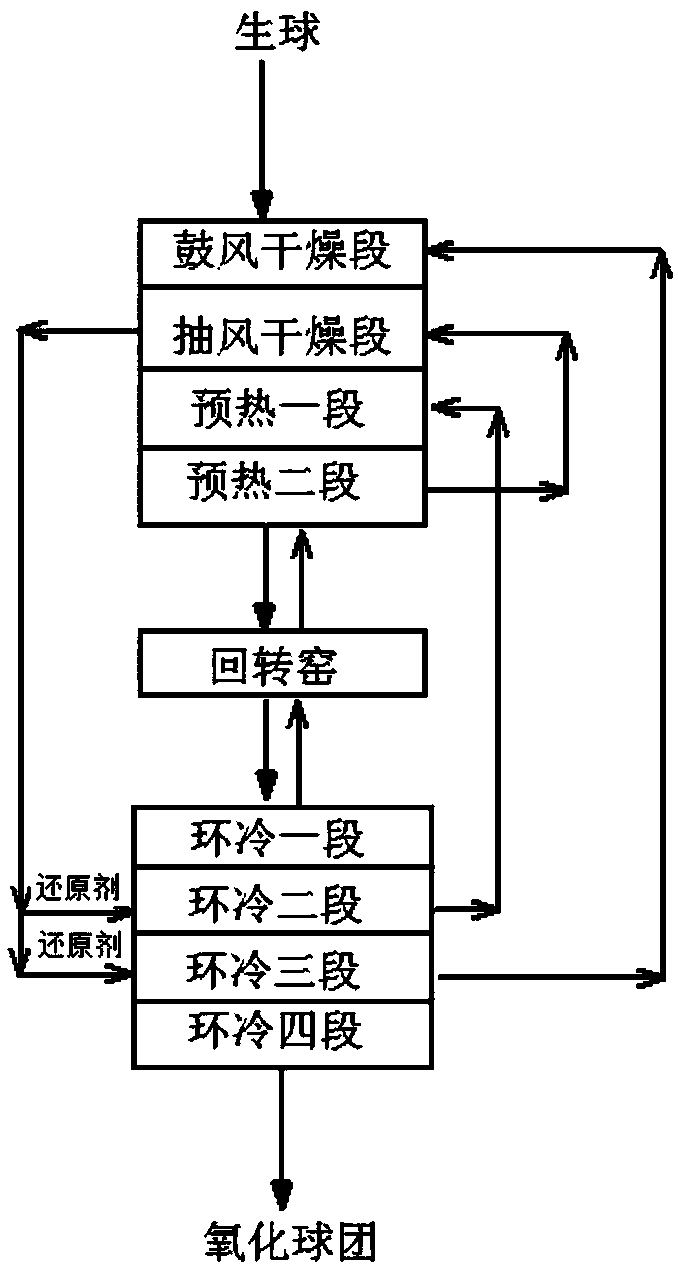

Low-NOx grate-rotary kiln pellet production technology and low-NOx grate-rotary kiln pellet production system

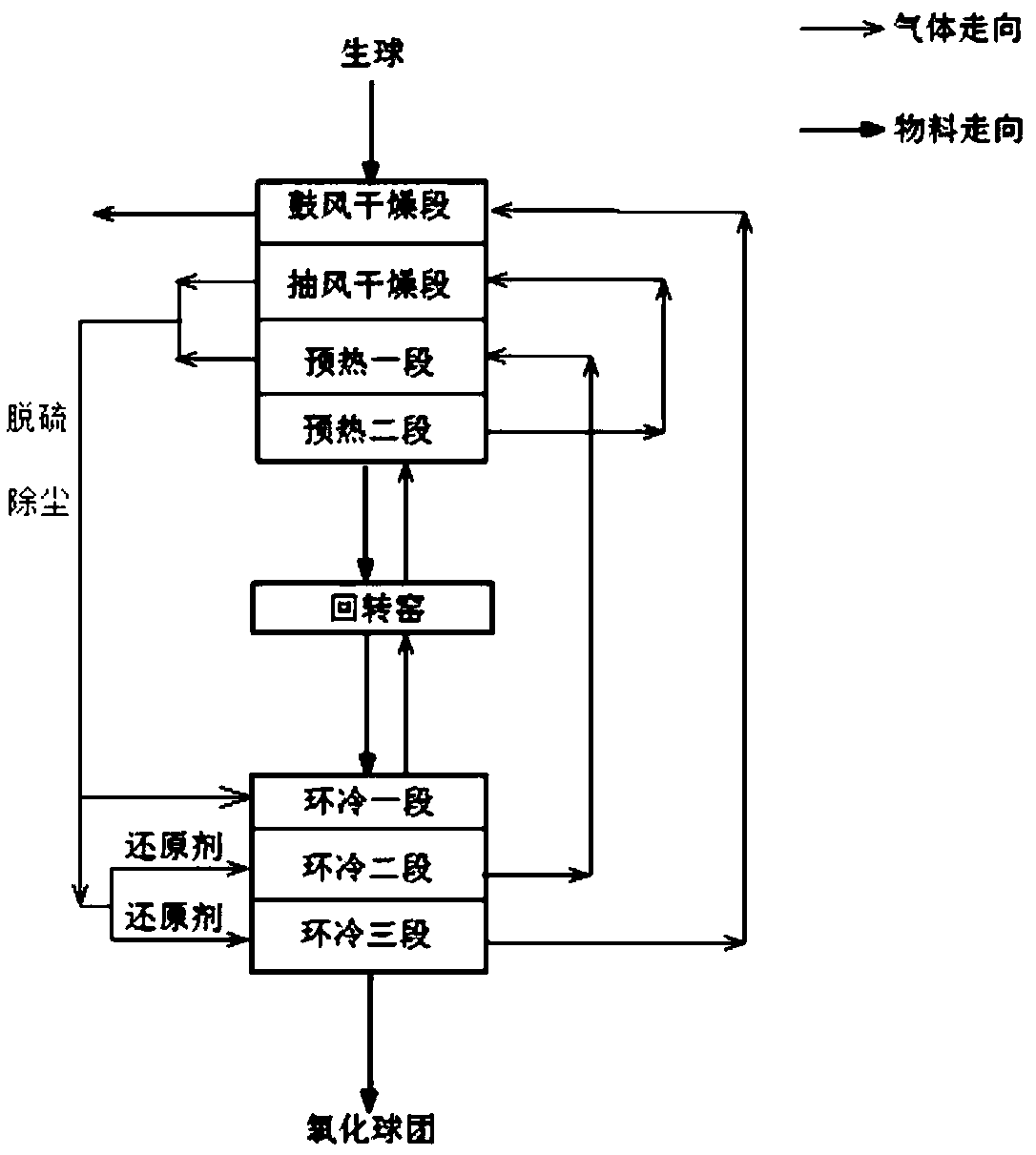

ActiveCN109136545AReduce generationReduce contentRotary drum furnacesDispersed particle separationFlue gasEngineering

The invention provides a low-NOx grate-rotary kiln pellet production technology. The production technology includes utilizing blended flue gas W exhausted from a down-draft drying section (DDD) and aprimary preheating section (TPH) as cooling air to be delivered to an air inlet of (1) a primary circular cooling section (C1) and (2) an air inlet of a secondary circular cooling section (C2), spraying a reducer into a bottom air box of the circular cooling section (C2), making the reducer and the blended flue gas exhausted from the down-draft drying section (DDD) and the primary preheating section (TPH) to react with NOx so as to achieve SNCR (selective non-catalytic reduction) denitration. The low-NOx grate-rotary kiln pellet production technology has the advantages that the production pressure of enterprise atmospheric pollutant emission limits on pellet calcination equipment can be reduced to a certain degree, and the production technology is saving in investment, low in running costand remarkable in NOx emission reduction effect.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

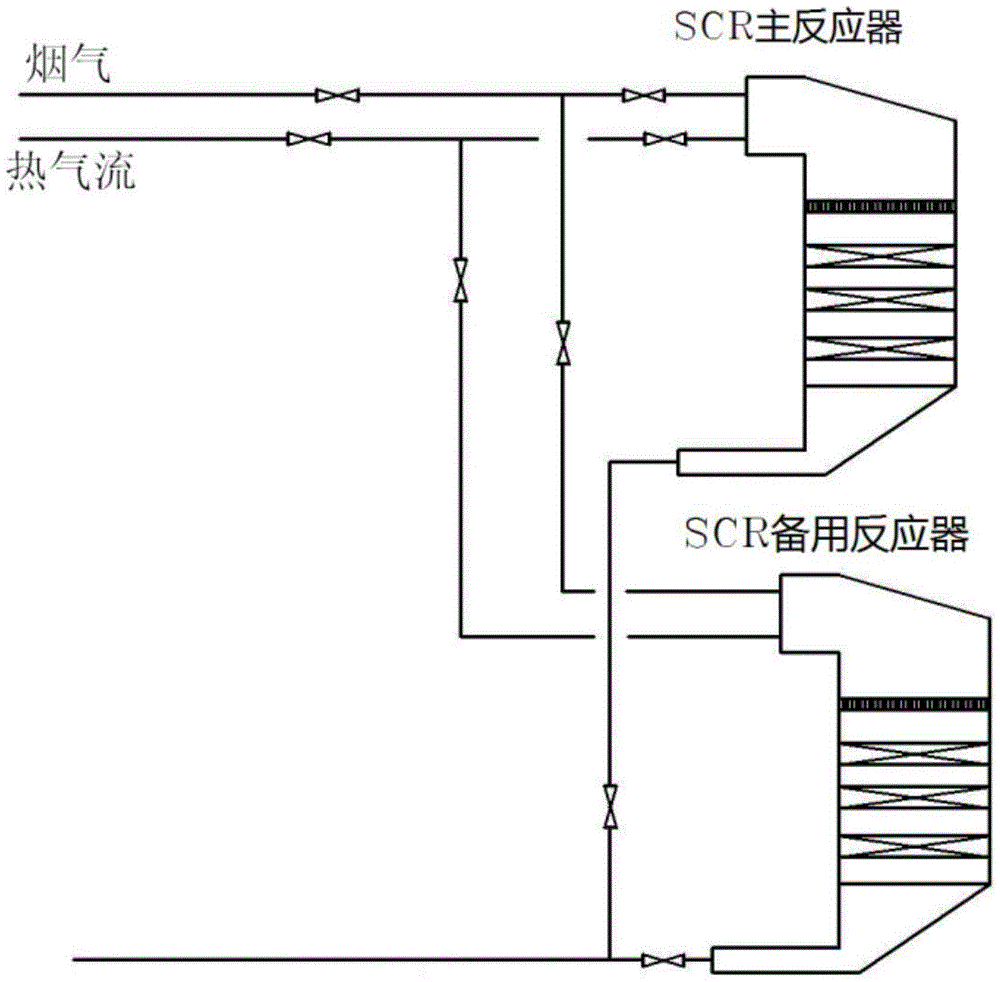

In-situ regeneration method of ammonium sulfate poisoning denitration catalyst

InactiveCN105688936AEasy to operateShort regeneration timeHeterogenous catalyst chemical elementsDispersed particle separationNitrogen oxidesFlue gas

The invention relates to an in-situ regeneration method of an ammonium sulfate poisoning denitration catalyst and belongs to the technical field of an industrial denitration catalyst. The in-situ regeneration method comprises the following steps: (1) when the concentration of nitrogen oxide in outlet flue gas of an SCR (Semiconductor Control Rectifier) main reactor is close to an emission limit value, switching the flue gas to an SCR reserved reactor; (2) introducing hot gas flow into the SCR main reactor and decomposing an ammonium sulfate layer deposited on the surface of the catalyst under the action of the hot gas flow; continuously introducing the hot gas flow for 1 hour to 8 hours to finish regeneration of the denitration catalyst; (3) switching the flue gas back to the SCR main reactor and continually carrying out a denitration reaction. Under the action of the hot gas flow, ammonium sulfate is decomposed into ammonia gas, sulfur trioxide and water steam and is removed along the flowing of the hot gas flow, so that the denitration performance of the catalyst can be recovered. The in-situ regeneration method of the ammonium sulfate poisoning denitration catalyst has the advantages of simplicity in operation, short regeneration time, low regeneration cost, safety and environmental friendliness, high denitration efficiency of the regenerated catalyst, and no changes of the strength and pore structure of the catalyst.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

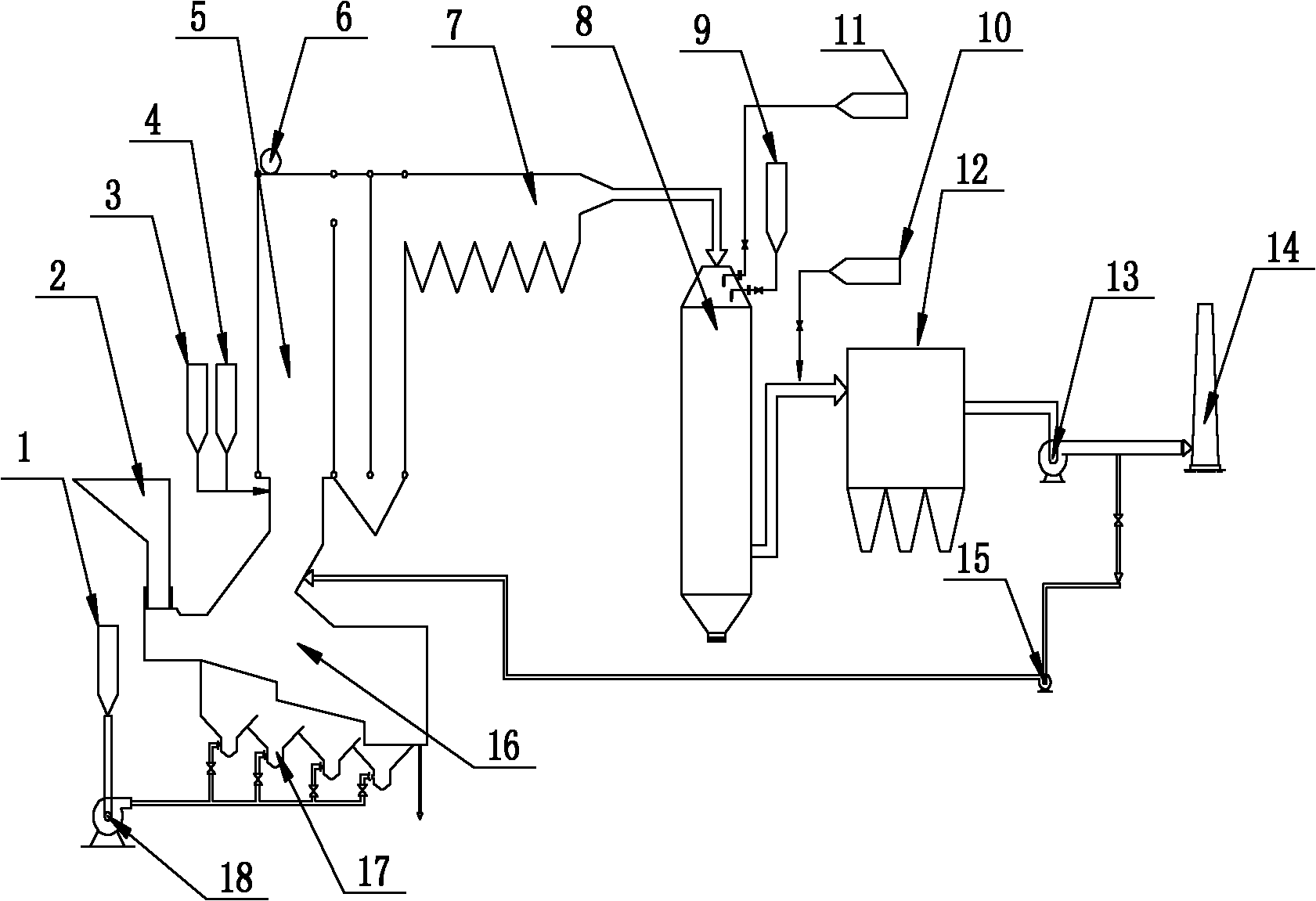

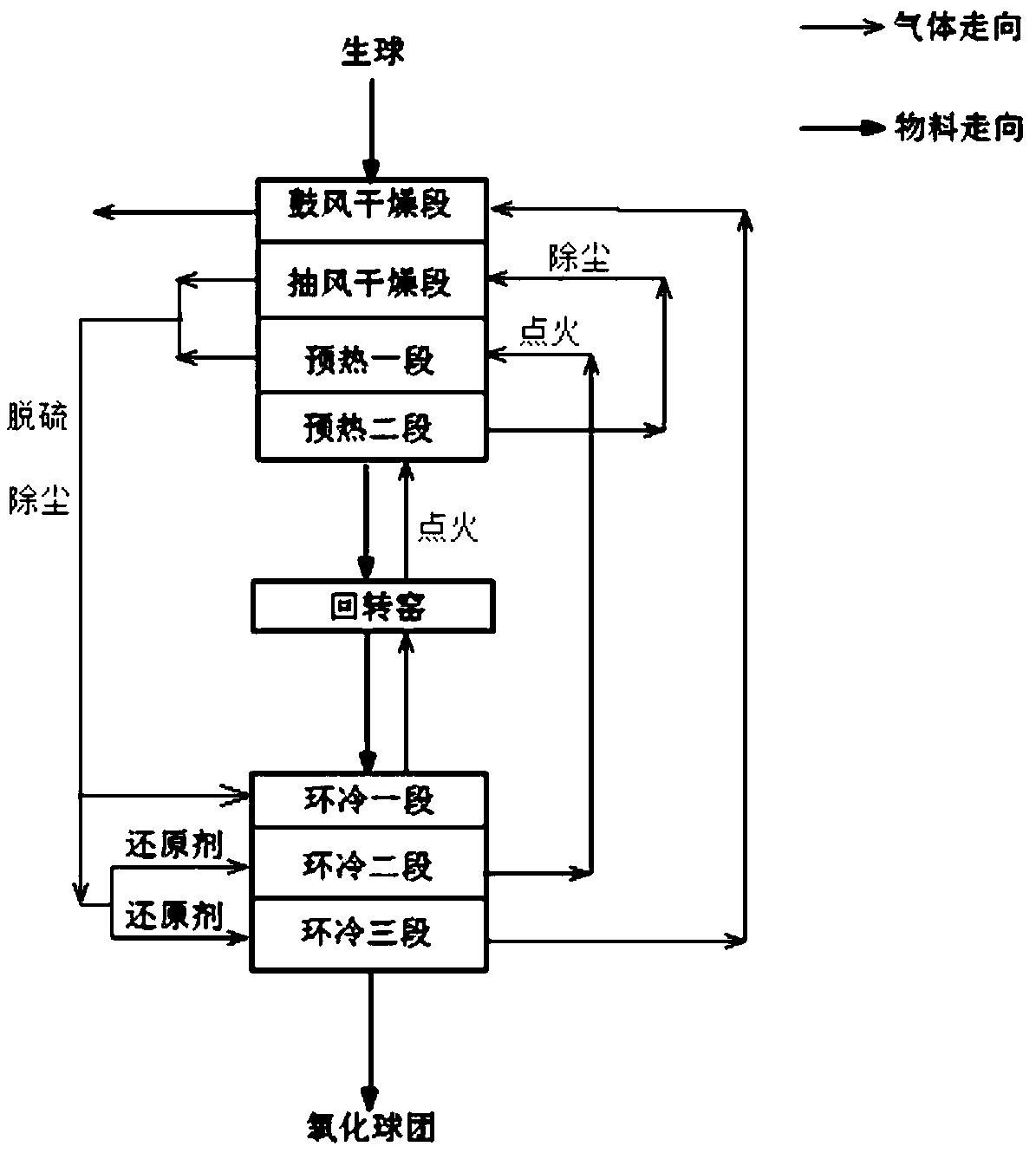

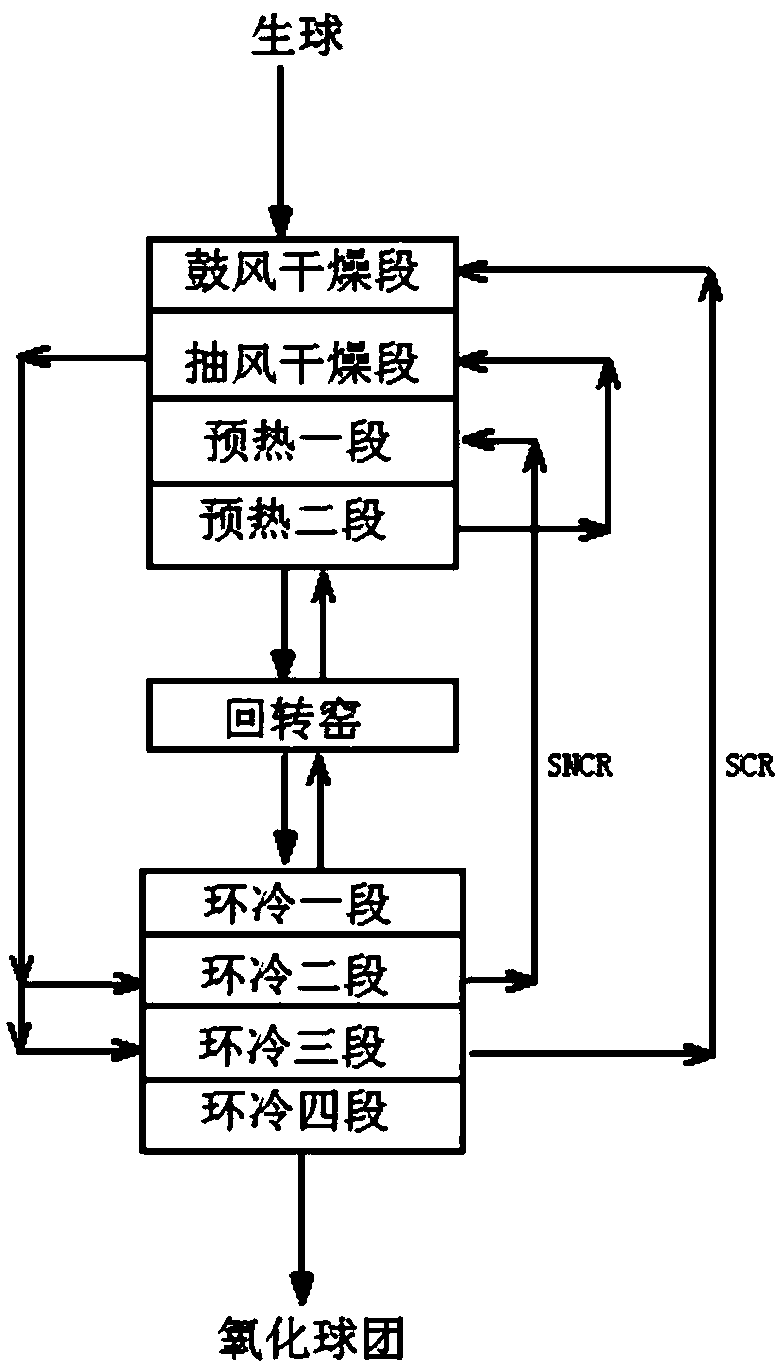

Production process and system of ultralow NOx emission of pellet flue gas

ActiveCN109373767AReduce concentrationReduce contentRotary drum furnacesIncreasing energy efficiencyFlue gasProcess engineering

The invention provides a production process and a system of ultralow NOx emission of pellet flue gas. A set of flue gas circulation system is additionally arranged, the flue gas discharged from an airdraft drying section is taken as cooling air to be further conveyed to an air inlet of an annual cooling two-section, meanwhile, a reducing agent is sprayed at the top located at the annular coolingtwo-section, the reducing agent reacts with NOx in the flue gas subjected to the annular cooling two-section, and SNCR denitration is realized; and or the gas discharged from an air outlet of the annular colling two-section is conveyed to a preheating one-section of a chain grate machine after passing through a SNCR treatment system; the high-temperature characteristic of discharging the flue gasfrom the air draft drying section is utilized, meanwhile, the condition of high-temperature sintering ore in the annual colling two-section is utilized, and the part of the flue gas is treated by adopting the SNCR. By the adoption of the technical means, an enterprise atmospheric pollutant emission limit value on the production pressure of pellet roasting equipment requirements can be reduced to acertain extent, and the process and the system have the characteristics of being decreasd in investment, low in operation cost and remarkable in NOx emission reduction effect.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

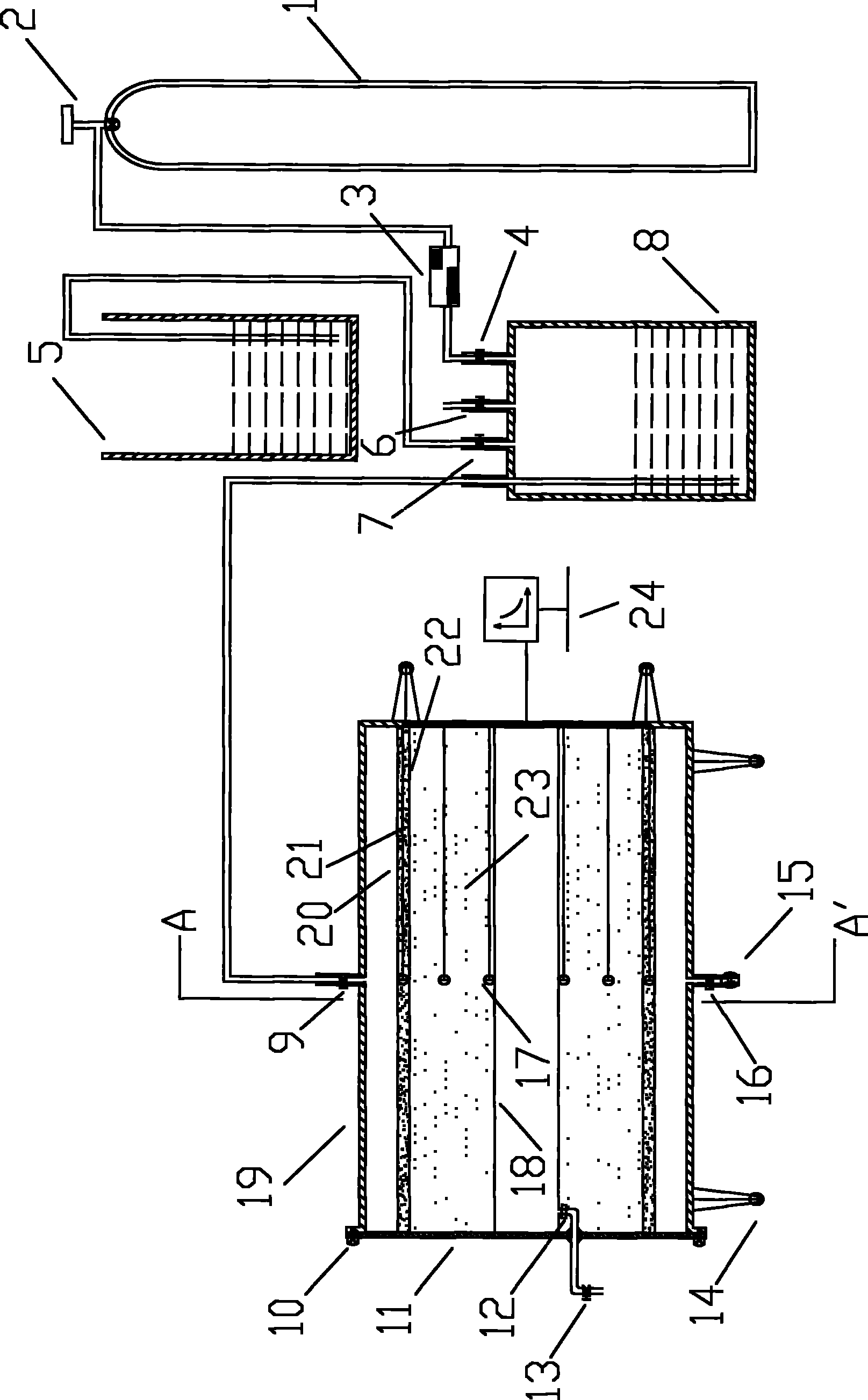

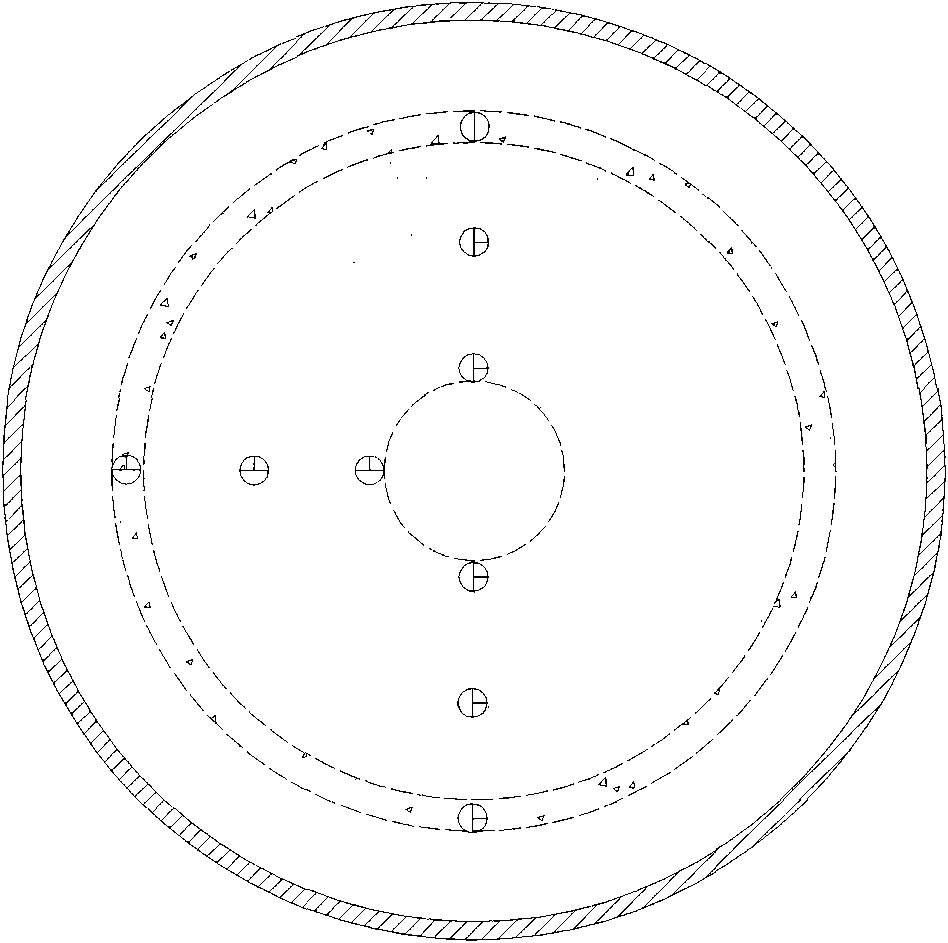

Tester for testing discount rule of water pressure of grouting circle of anti-water pressure emission-limit tunnel

InactiveCN101893617ARealize simulationEasy to controlUnderground chambersFluid pressure measurementPore water pressureEngineering

The invention relates to a tester for testing a discount rule of a water pressure of a grouting circle of an anti-water pressure emission-limit tunnel, comprising a pressure chamber, a simulation tunnel, pressurized equipment and measurement equipment, wherein the pressurized equipment comprises a nitrogen cylinder, a control valve, a pressure regulating valve, a switch, a water tank and an air-water exchange tank; the pressure chamber is a cylindrical container, comprising a switch, a flange plate, a support and a pressure chamber sleeve; the pressurized equipment utilizes the nitrogen cylinder combining with the air-water exchange tank for pressurization to provide a stable osmotic pressure for the pressure chamber; the simulation tunnel, a simulation grouting material and stimulation wall rock are placed in the pressure chamber; the diameter of the grouting material can be converted according to test requirements and geometric similarity; and the simulation tunnel can be precasted into be of different shapes and sizes according to the test requirements and geometric similarity. The measurement equipment can realize accurate measurement on pressure and flow rate. The tester can be used for researching the discount rule of hydraulic pressure of the grouting circle of the anti-water pressure emission-limit tunnel.

Owner:TONGJI UNIV

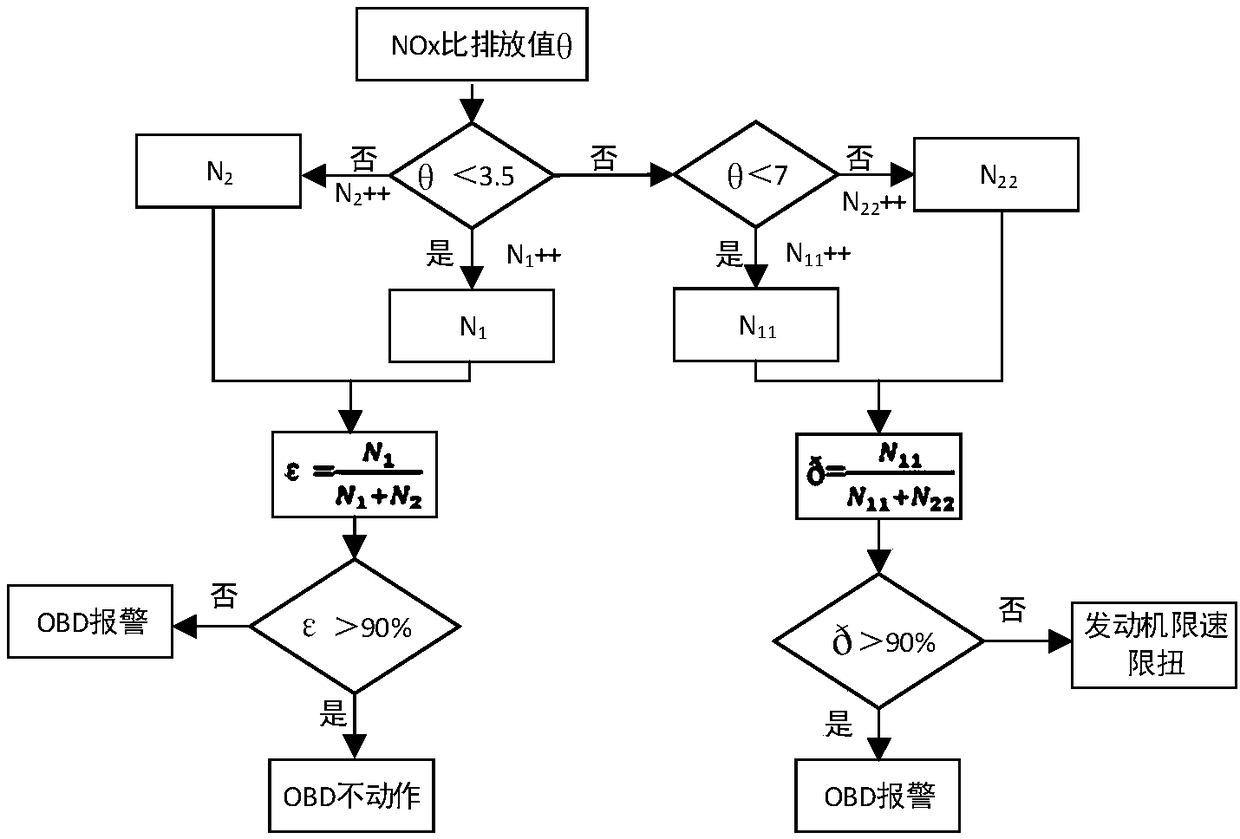

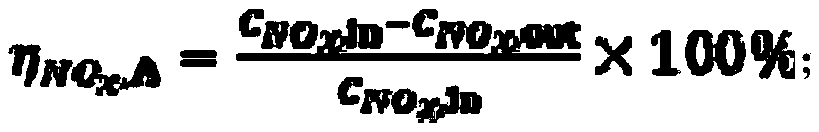

Ageing correction method based on dual NOx sensors for SCR catalyst

ActiveCN108952901AReal-time calculation of conversion efficiencyCalculate emissions in real timeInternal combustion piston enginesExhaust apparatusCorrection methodDiagnostic strategy

The invention provides an ageing correction method based on dual NOx sensors for an SCR (Selective Catalytic Reduction) catalyst. The NOx sensors are correspondingly arranged at the upstream and downstream of the SCR catalyst of an engine exhaust system to calculate actual conversion efficiency of the SCR catalyst in real time, and the degree of ageing of the catalyst is calculated according to the actual conversion efficiency and ideal conversion efficiency of the SCR catalyst; the feed-forward control quantity of urea is corrected according to the degree of ageing of the catalyst; the brakespecific NOx emission of an engine is calculated in real time; and an OBD (On Board Diagnostics) diagnostic strategy judgment method is provided based on an OBD emission limit. The degree of ageing ofthe catalyst is reflected by a deterioration factor of the catalyst, the ejection amount of urea can be fed back and corrected according to the degree of ageing of the catalyst, the brake specific NOx emission of a vehicle on road is calculated in real time, and an emission OBD monitoring and judging method is put forward.

Owner:CHINA AUTOMOTIVE TECH & RES CENT +1

Controlling a Power Amplifier Based on Transmitter Output Emissions

Methods and systems for controlling the supply voltage provided to a power amplifier (PA) in a radio frequency (RF) transmitter based on measured output spectrum emissions are provided. In an embodiment, the PA supply voltage is adjusted such that spectrum emission limits are satisfied with predetermined margins. In another embodiment, the predetermined margins are reduced to lower power consumption of the PA.

Owner:AVAGO TECH INT SALES PTE LTD

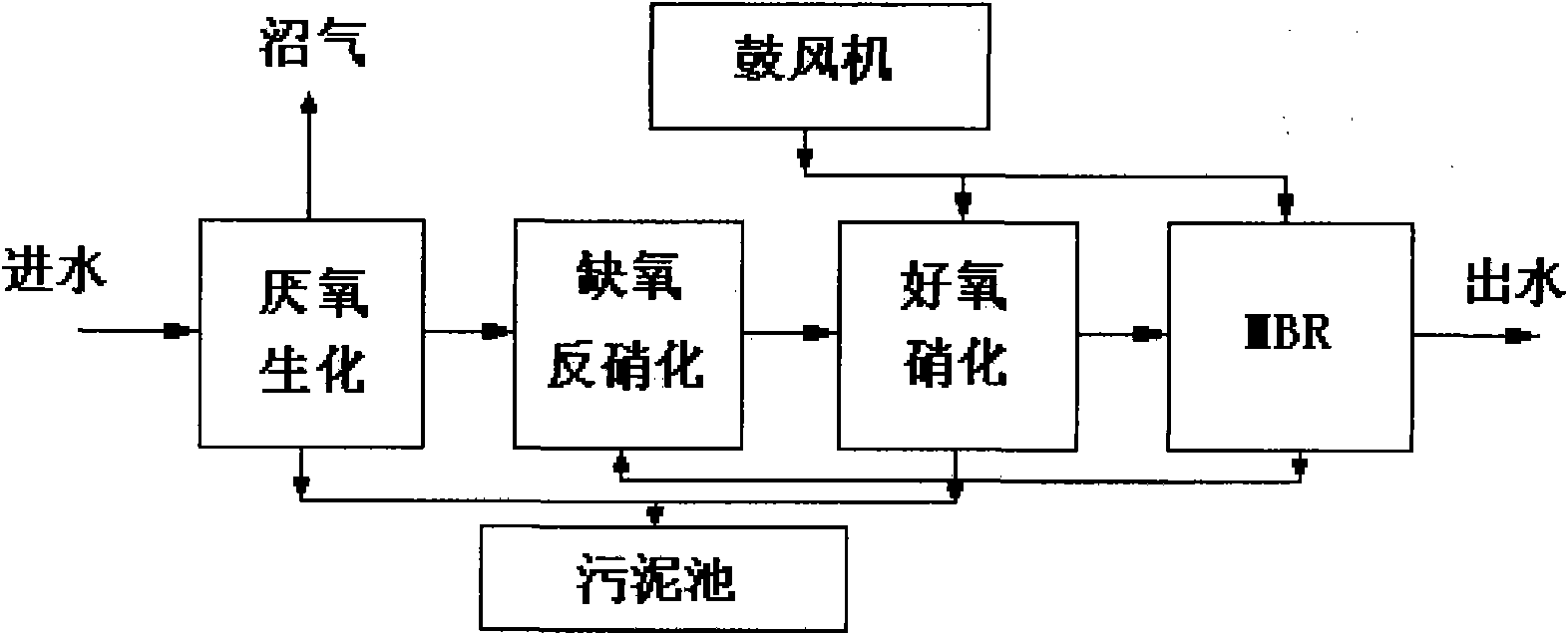

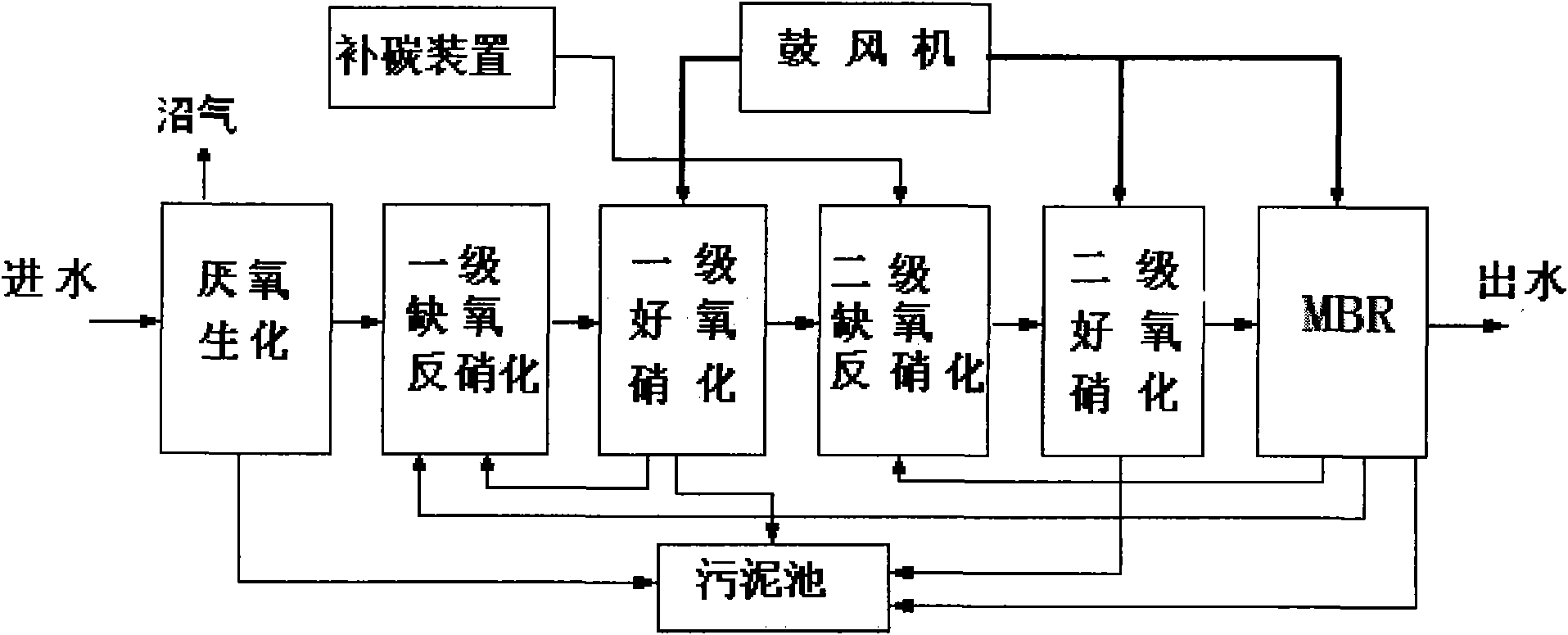

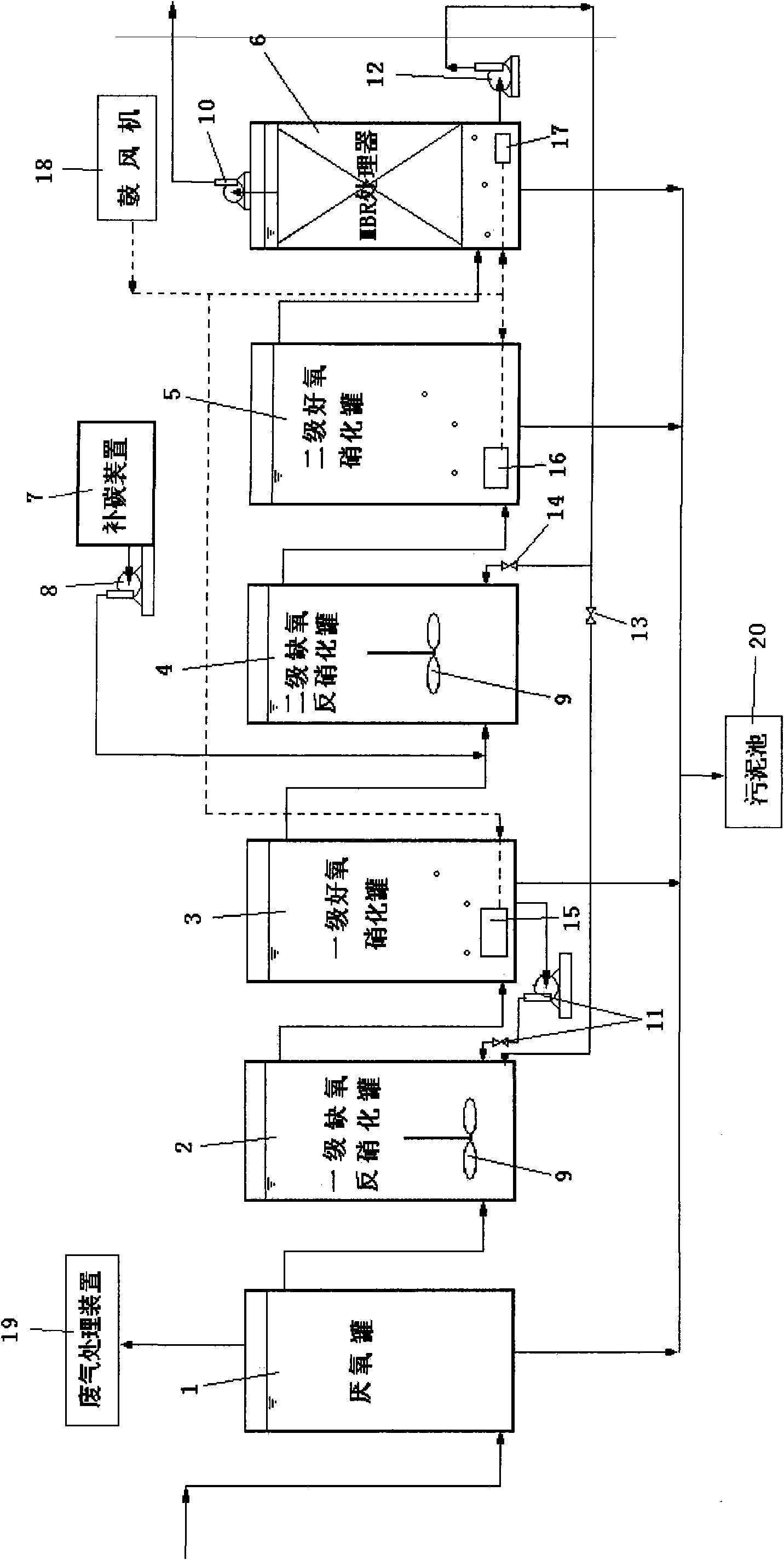

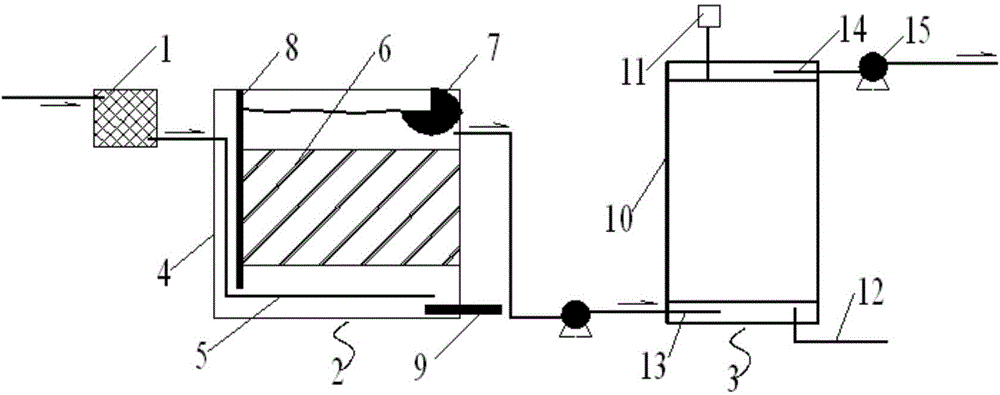

Rubbish leachate biological nitrogen removal process and device

InactiveCN101811803AImprove nitrogen removal efficiencyIncrease concentrationWater contaminantsWater/sewage treatment bu osmosis/dialysisNitrogen removalReflux

The invention relates to a rubbish leachate biological nitrogen removal process and a rubbish leachate biological nitrogen removal device. The process comprises the steps of water feeding, anaerobic biochemical treatment, primary anoxic denitrification, primary aerobic nitrification, secondary anoxic denitrification, secondary aerobic nitrification, MBR treatment and subsequent treatment. The device comprises an anaerobic tank, a primary anoxic denitrification tank, a primary aerobic nitrification tank, a secondary anoxic denitrification tank, a secondary aerobic nitrification tank and an MBR treatment device which are connected in turn through a water through pipeline, wherein a reflux pipe is led out from the primary aerobic nitrification tank to the primary anoxic denitrification tank; two reflux pipes led out from the MBR treatment device are connected to the primary and secondary anoxic denitrification tanks respectively; the anaerobic tank, the primary and secondary aerobic nitrification tanks and the MBR treatment device are connected with a sludge pipe respectively; the anaerobic tank is connected with a waste gas treatment device; the secondary anoxic denitrification tank is connected with a carbon supply device; and an aerating device is arranged in the primary and secondary aerobic nitrification tanks and the MBR treatment device respectively. The process can meet the requirement of GB16889-2008 'Domestic Rubbish Percolate (Leachate) Emission Limit' on nitrogen.

Owner:BEIJING JIELV ENVIRONMENTAL TECH CO LTD

Treatment and resource-utilizing technology of tert-butyl peroxy benzoate production wastewater

InactiveCN102092906AHigh purityQuality improvementPreparation from carboxylic acid saltsSulfur-trioxide/sulfuric-acidBenzoic acidHigh concentration

The invention discloses a treatment and resource-utilizing technology of the production wastewater of tert-butyl peroxy benzoate (initiator is C). The technology is as follows: high concentration production wastewater is collected from the sewage outlet of a production device to perform stabilization treatment, and after the risk that the organic peroxide in wastewater is violently decomposed when heated is basically eliminated, the mixture of tertiary butanol and tert-butyl peroxide, sulfuric acid, benzoic acid and sodium chloride are recycled from wastewater. the mixture of tertiary butanol and tert-butyl peroxide, benzoic acid and sulfuric acid can be used repeatedly in production and sodium chloride is a by-product. After most of tertiary butanol and tert-butyl peroxide are removed and benzoic acid, sulfuric acid and sodium chloride are recycled, the wastewater performs hydrolysis-contact oxidation and C-Fe micro-electrolysis decoloring treatment and the main indexes of discharged water meet the requirements of the discharge standard of water pollutants for pharmaceutical industry chemical synthesis products category (GB21904-2008) on the water pollutants emission limits of new business.

Owner:NORTHWEST NORMAL UNIVERSITY

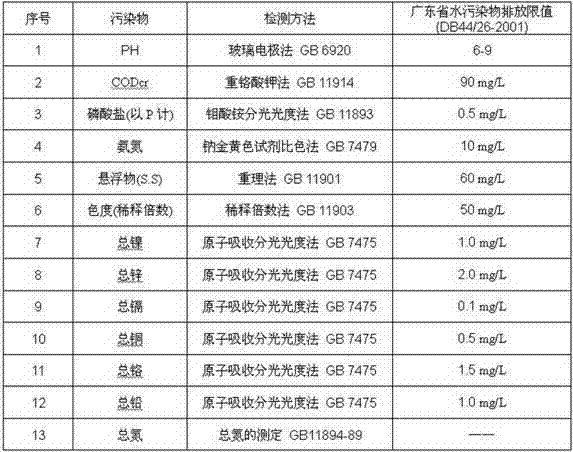

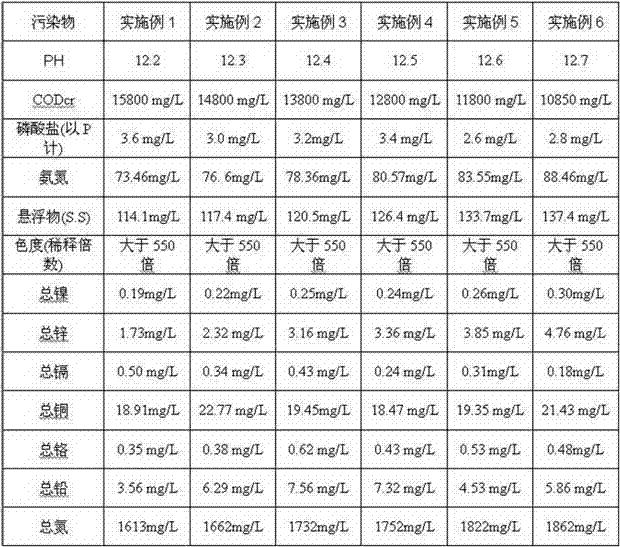

Treatment method of printing ink wastewater generated in circuit board production

ActiveCN103787551AEfficient removalFacilitate solid-liquid separationWater/sewage treatment by irradiationWater/sewage treatment bu osmosis/dialysisElectrolysisFiltration

The invention discloses a treatment method of printing ink wastewater generated in circuit board production. The treatment method comprises the following steps: firstly guiding printing ink raw wastewater generated in circuit board production into a raw water collecting tank, carrying out water quality equalization, then pumping into a reaction tank in the step two, coagulating so as to form muddy water mixed liquid of flocs, feeding the muddy water mixed liquid into a plate-and-frame filter press, carrying out solid-liquid separation, pumping filtrate into a Fenton oxidization / ultraviolet tank in the step four, carrying out oxidative degradation, electrolyzing, entering the electrolyzed wastewater to a membrane filtration device, and further carrying out biochemical treatment on the wastewater filtered by using a membrane. The treatment method can be used for effectively removing COD, ammonia nitrogen, total phosphorus and heavy metals in the printing ink wastewater generated in circuit board production, effectively preventing membrane pollution, continuously and effectively carrying out wastewater treatment and ensuring the final discharged water of the printing ink wastewater generated in circuit board production to meet the primary standards of Guangdong province water pollutant emission limits (DB44 / 26-2001).

Owner:GUANGDONG VICDI TECH +1

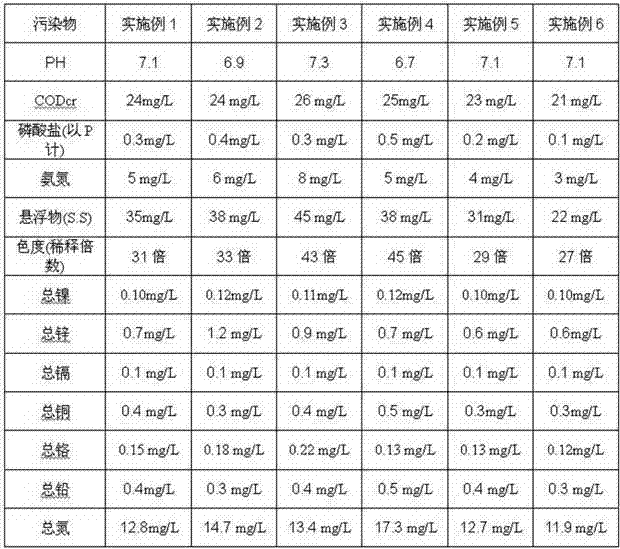

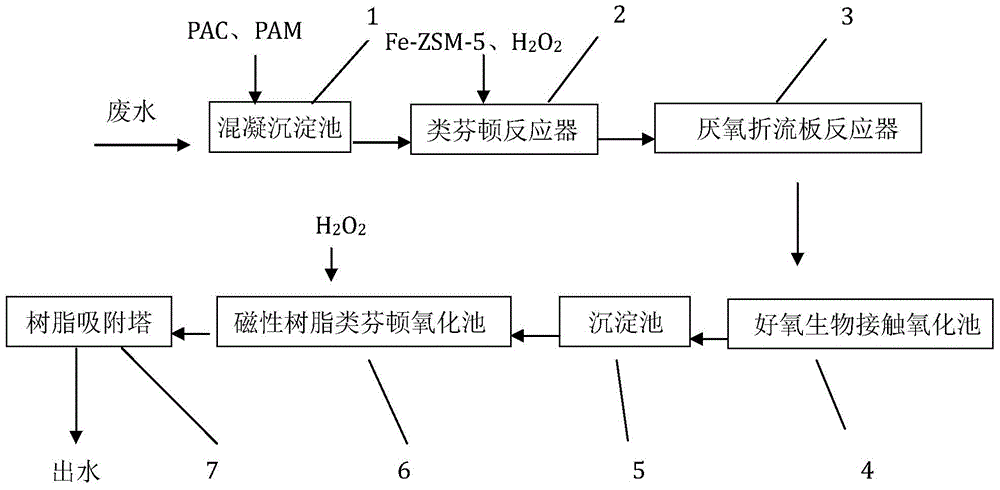

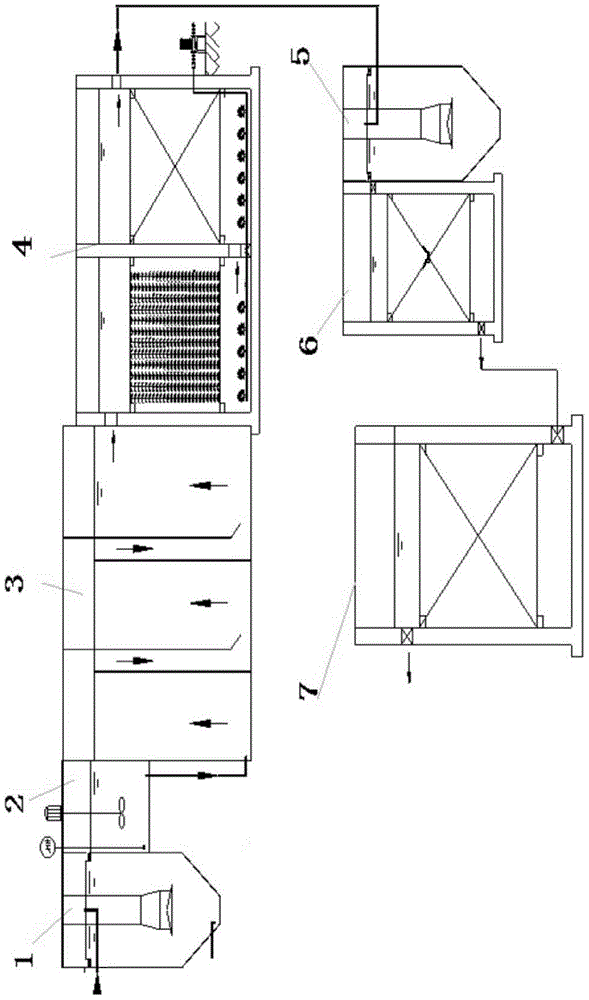

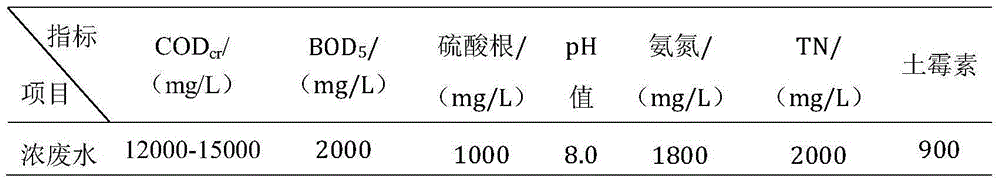

Method for deeply treating antibiotic pharmaceutical wastewater based on magnetic Fenton-like resin

ActiveCN105036486AAchieve removalEfficient removalMultistage water/sewage treatmentNature of treatment waterPollutant emissionsWastewater

The invention discloses a method and a device for deeply treating antibiotic pharmaceutical wastewater based on magnetic Fenton-like resin. The device comprises a coagulative precipitation tank, a Fenton-like reactor, an anaerobic baffle plate reactor, an aerobic biological contact oxidation tank, a sedimentation tank, a magnetic resin Fenton-like oxidation tank and a resin adsorption tower which are sequentially communicated by virtue of pipelines. By using the method and the device, the antibiotic pharmaceutical wastewater can be deeply treated; and effluent obtained after the antibiotic pharmaceutical wastewater is treated by using the method and the device disclosed by the invention can stably reach up to the emission limit regulated by Fermented Pharmaceutical Industrial Water Pollutant Emission Standard (GB21903-2008).

Owner:TAIZHOU UNIV +1

Styrene exhaust gas treatment method

ActiveCN105344224AEmission reductionEliminate environmental risksGas treatmentDispersed particle separationAtmospheric airSmall footprint

The invention discloses a styrene exhaust gas treatment method including the following steps: carrying out countercurrent contact of styrene exhaust gas with an alkaline solution of potassium permanganate, carrying out an oxidation reaction of styrene with the alkaline solution of potassium permanganate in the contact process, and after completion of the reaction, discharging the exhaust gas having styrene consumed into the atmosphere. With adopting of the technological process of spraying the potassium permanganate solution to absorb styrene, styrene-containing exhaust gas generated by refinery enterprise styrene materials and generated in highway car loading, wharf shipment, storage tank breathing and other various places can be treated at the same time, and the method has higher treatment efficiency, besides, is simple in flow, small in occupied land area and low in energy consumption, can meet the national latest environmental protection standard requirements for styrene emission limit values, effectively reduces the styrene emission and eliminates environmental risks and security risks at refinery enterprise styrene workplaces.

Owner:CHINA PETROLEUM & CHEM CORP +1

Radioactive wastewater treatment technology and synthesis of treatment agent of radioactive wastewater

The invention discloses a radioactive wastewater treatment technology and the synthesis of a treatment agent of radioactive wastewater. A modified product Y3-8103 is used for chemically reacting with radioactive wastewater, all heavy metal elements and all radioactive elements, namely cesium137, uranium 235, thorium, plutonium, thallium, protium, deuterium, tritium, radon, Sr-90 and radium, listed in the periodic table of elements and wastewater generated by all artificial nuclides. Alpha radioactive rays, beta radioactive rays, gamma radioactive rays and neutron radioactive rays are attenuated in a nationally specified mode. The radioactive wastewater treatment technology and the synthesis of the treatment agent of the radioactive wastewater can also be used for treating radioactive seawater or waste residues generated by wastewater treatment and can be used for treating heavy metal wastewater discharged by a lead-acid battery enterprise and an electronic plant and mine nucleus waste residues. The treatment cost of the radioactive wastewater is different along with different radioactive element concentration contents or different waste residue radioactive element concentration contents and different atomic weights in the wastewater, and the treatment cost of the wastewater and the waste residues ranges from RMB 90 yuan / m<3> to RMB 680 yuan / m<3>, radioactive energy with the alpha, beta and gamma radioactive ray radiant quantity smaller than or equal to 0.01Bq / 1-1.10Bq / 1 can be discharged to the ambient environment by the wastewater and the waste residues, the emission limit standard allowed by the international is reached, and secondary pollution is avoided. The radioactive wastewater treatment technology and the synthesis of the treatment agent of the radioactive wastewater are suitable for treating wastewater and waste residues of a nuclear power plant and treating wastewater and waste residues in mining with the radioactive elements, and are also suitable for treating wastewater containing heavy metal, namely lead, cadmium, mercury, arsenic, chromium, nickel, copper and manganese.

Owner:叶绍朋

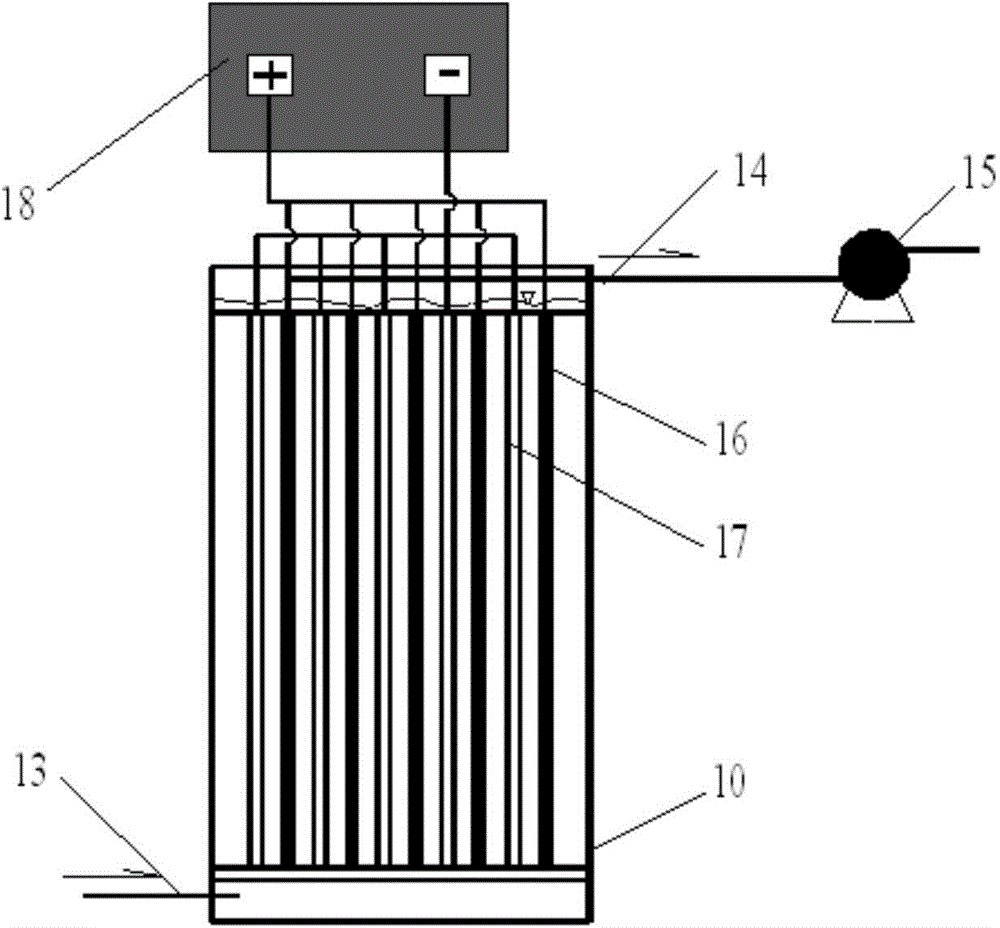

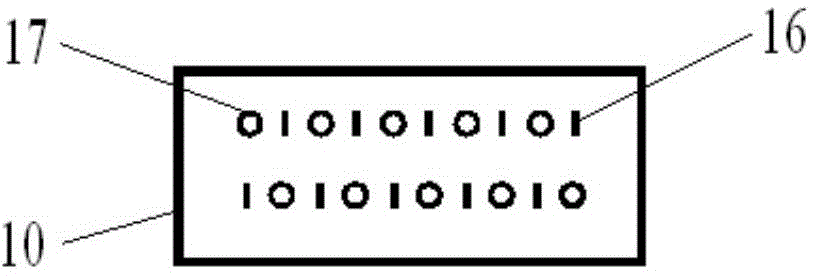

Equipment for treating waste emulsion

ActiveCN104649481AGood removal effectExtended service lifeFatty/oily/floating substances removal devicesMultistage water/sewage treatmentWater treatment systemEmulsion

The invention provides equipment for treating waste emulsion. The equipment is characterized by comprising a floating oil removal device, an oil-water separation device, and an electrochemical treatment device, wherein the floating oil removal device is used for removing floating oil from to-be-treated waste emulsion, and removing the floating oil floating on the level of the waste emulsion; the oil-water separation device is used for performing oil-water separation to the waste emulsion without floating oil, and removing the dispersion oil suspending in the waste emulsion; and the electrochemical treatment device is used for performing electrochemical treatment to the waste emulsion which is subjected to oil-water separation treatment, so that emulsifying oil and dissolved oil are flocculated, wherein an electrified aluminum plate and a nanoceramic membrane are used for performing electrochemical treatment; a disconnected nanoceramic membrane is used for performing ultrafiltration treatment to the stand and precipitated crude emulsion. After being treated through the equipment, the quality of effluent water is good, and the effluent water can completely meet the emission limit requirement of a public sewage treatment system in Beijing Integrated discharge standard of water pollutants DB11 / 307-2013.

Owner:BEIJING SINORICHEN ENVIRONMENTAL PROTECTION

Claus tail gas treatment system and treatment method

The invention provides a Claus tail gas treatment system. The system comprises a hydrogenation unit, a fast cooling unit, a desulfurization unit, an optional hydrolysis unit and an optional liquid sulfur degassing gas supply unit. The invention further provides a Claus tail gas treatment method. According to the tail gas treatment system and treatment method provided by the invention, the sulfur removal rate can be greater than 99.99%; H2S concentration of exhaust gas emitted into the atmosphere is less than 10 ppm, and is, when converted into the SO2 concentration, less than 50 mg / m3; the removal rate and emission concentration can meet the current highest emission limit standard. Furthermore, the system and method have the advantages of: being environmentally-friendly, stable and reliable, less in investment and low in operating cost.

Owner:美景(北京)环保科技有限公司

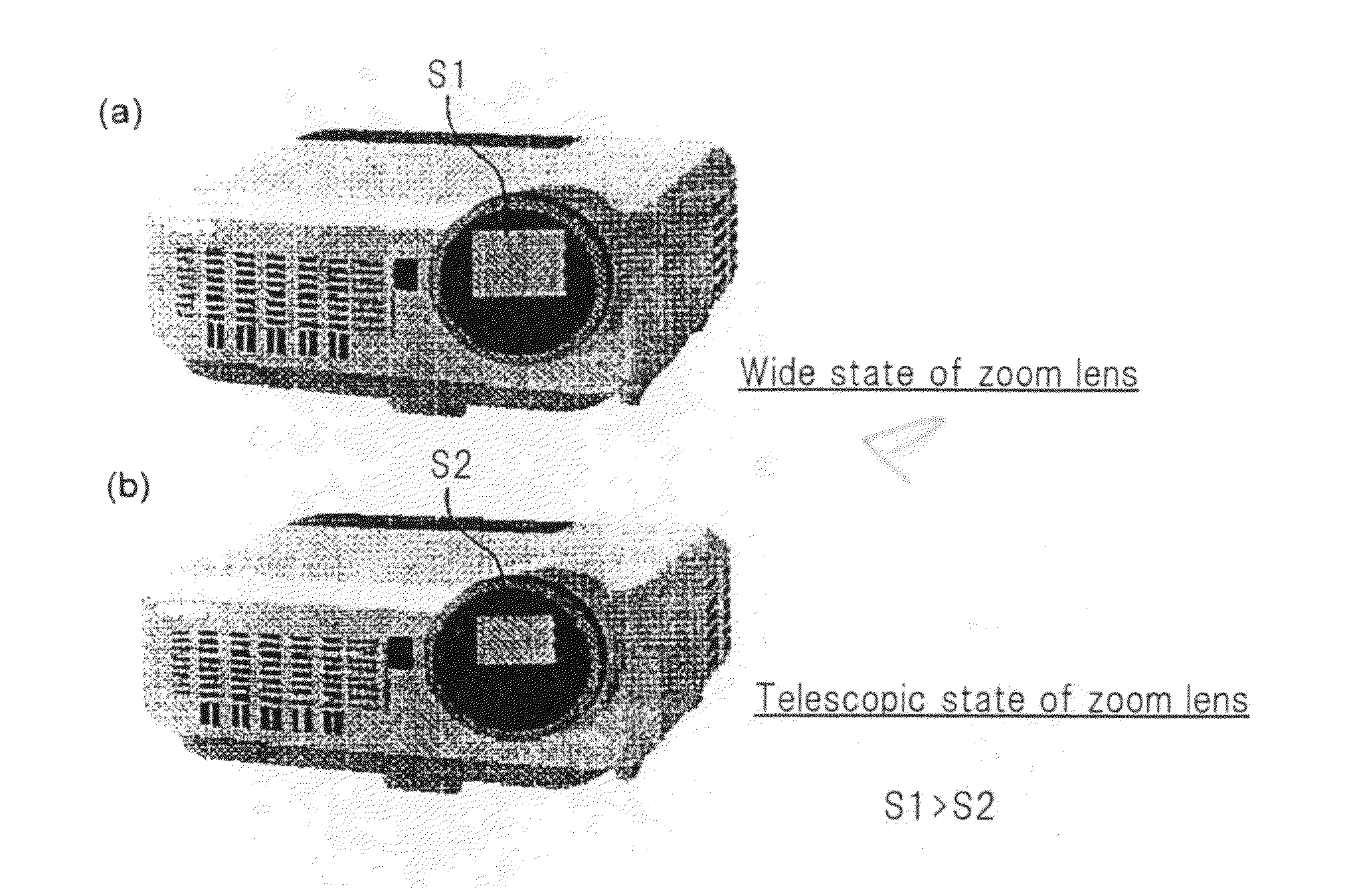

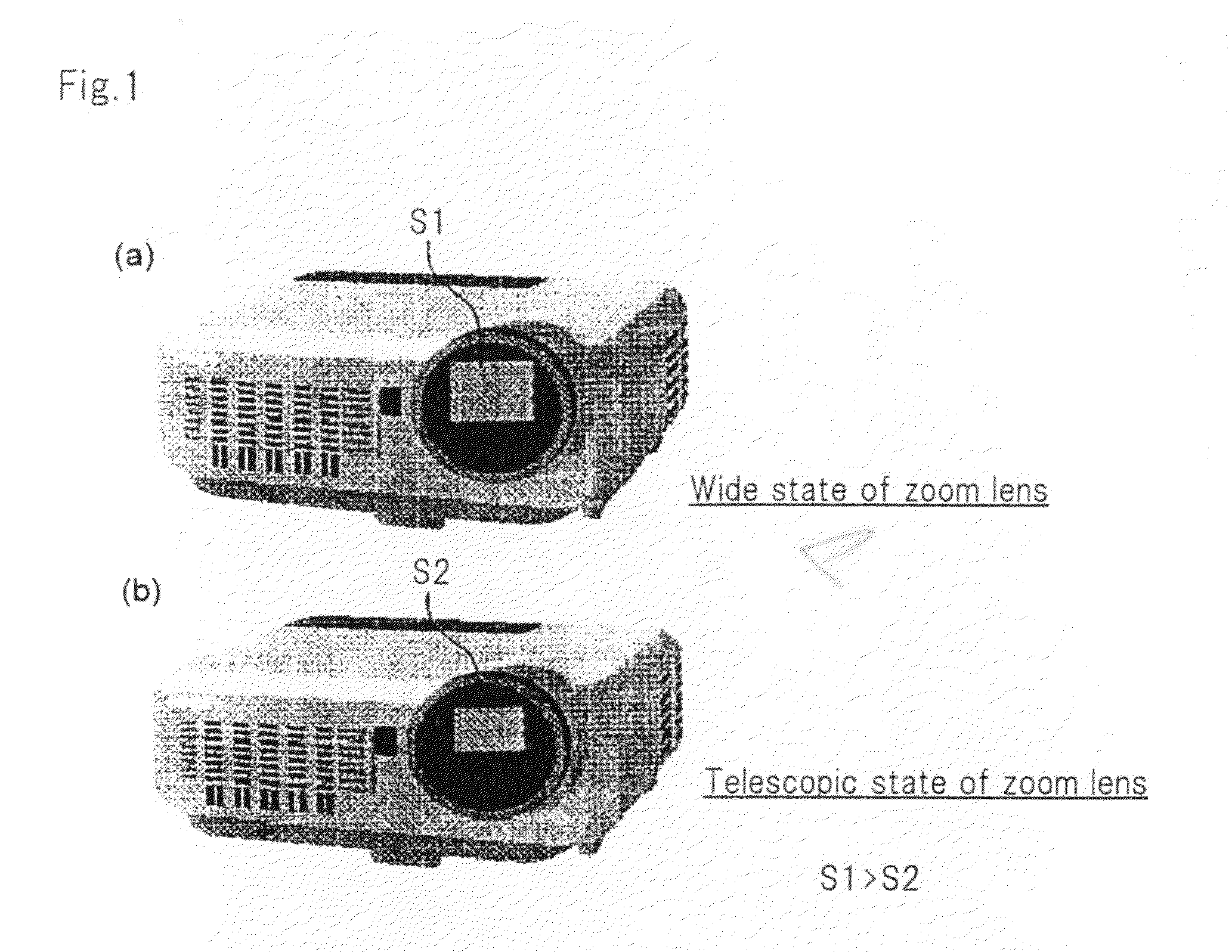

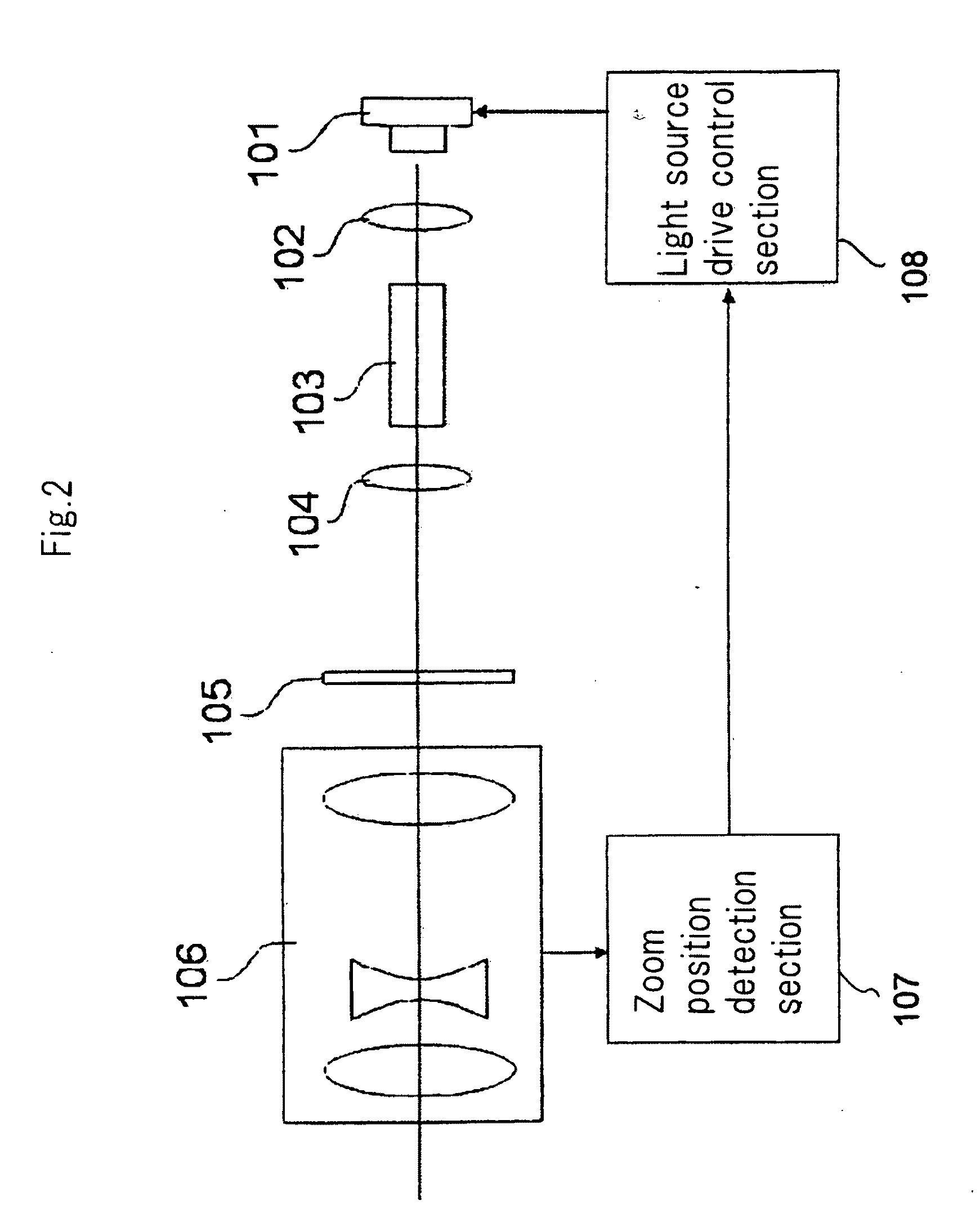

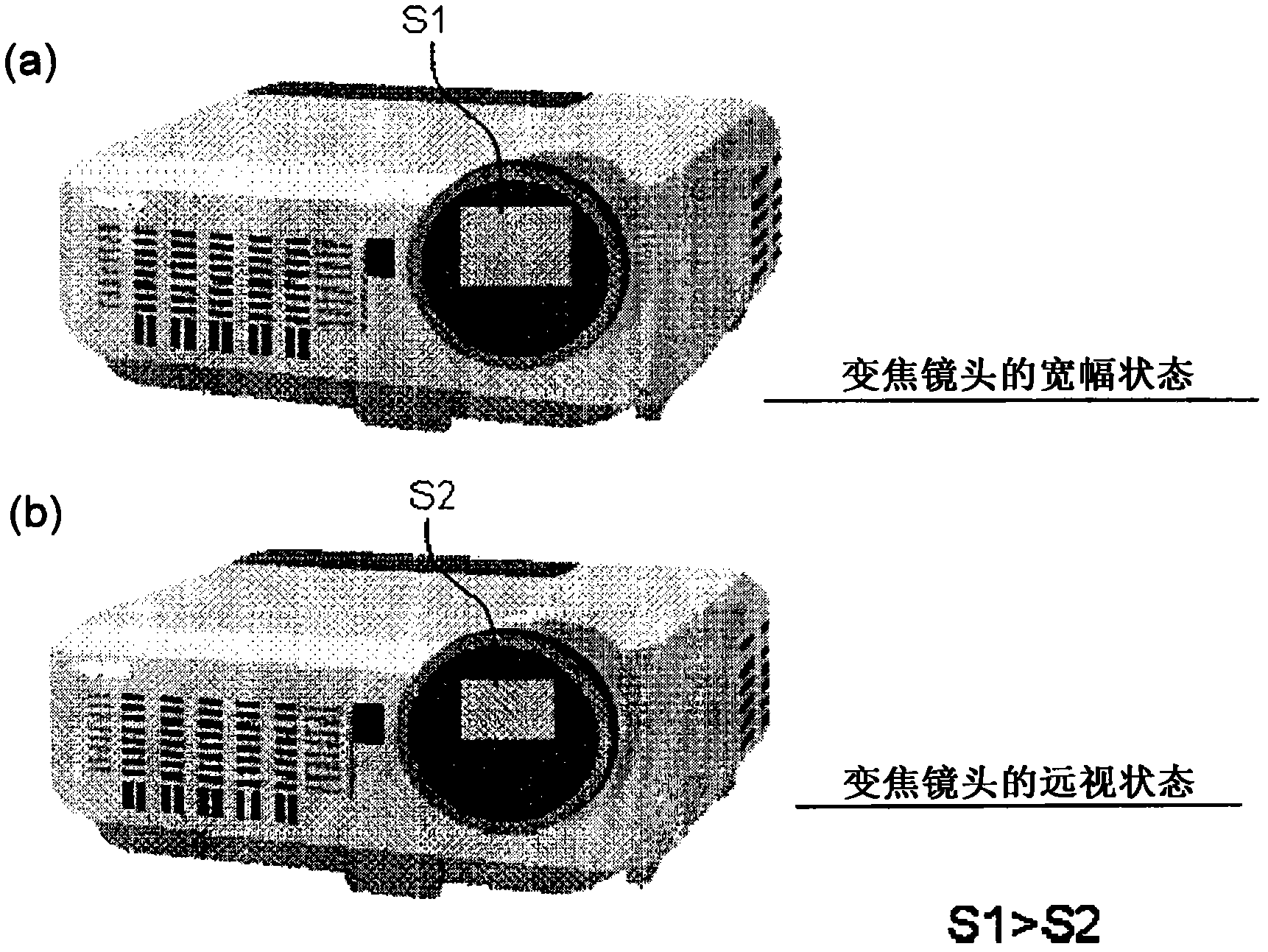

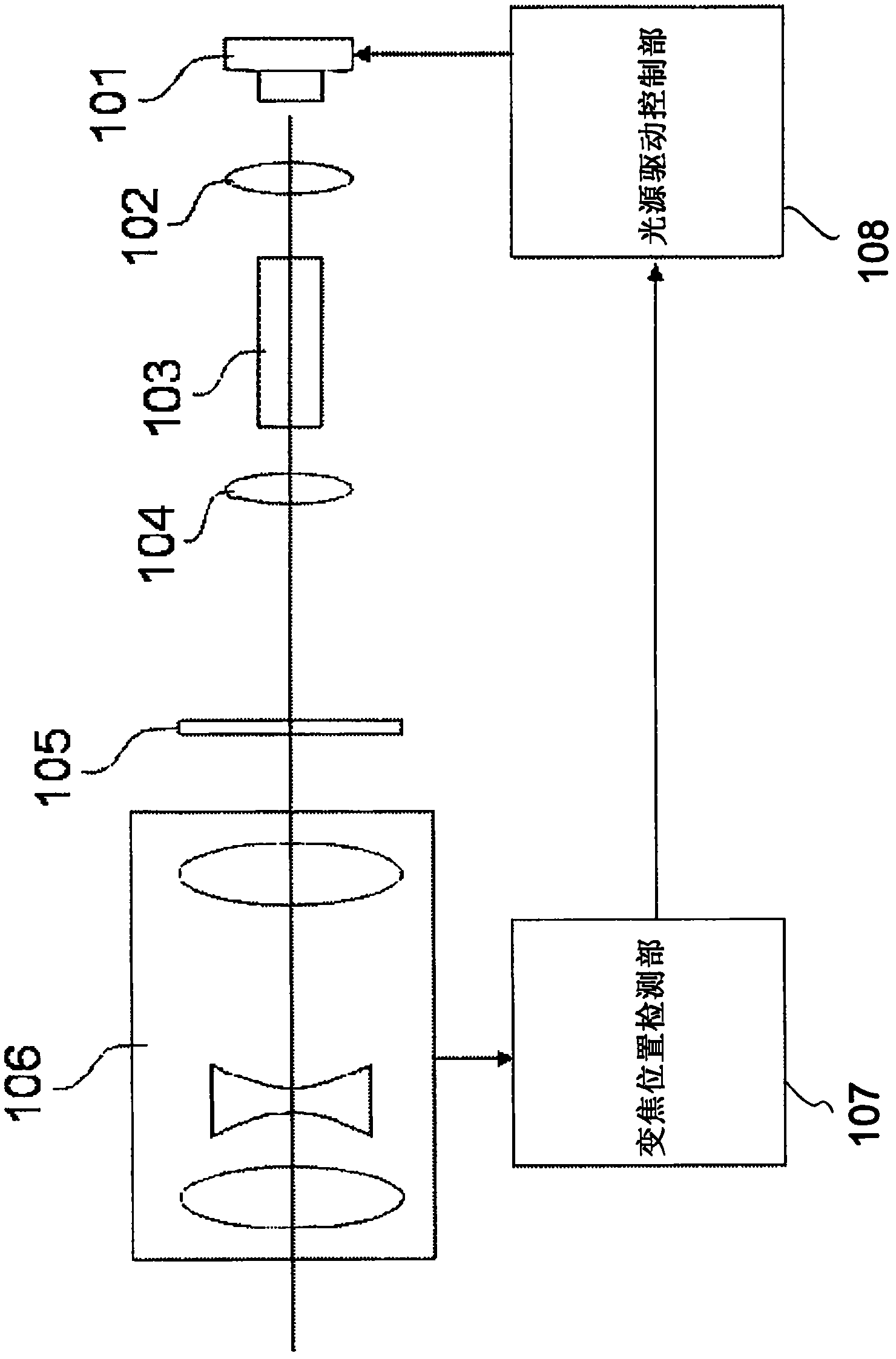

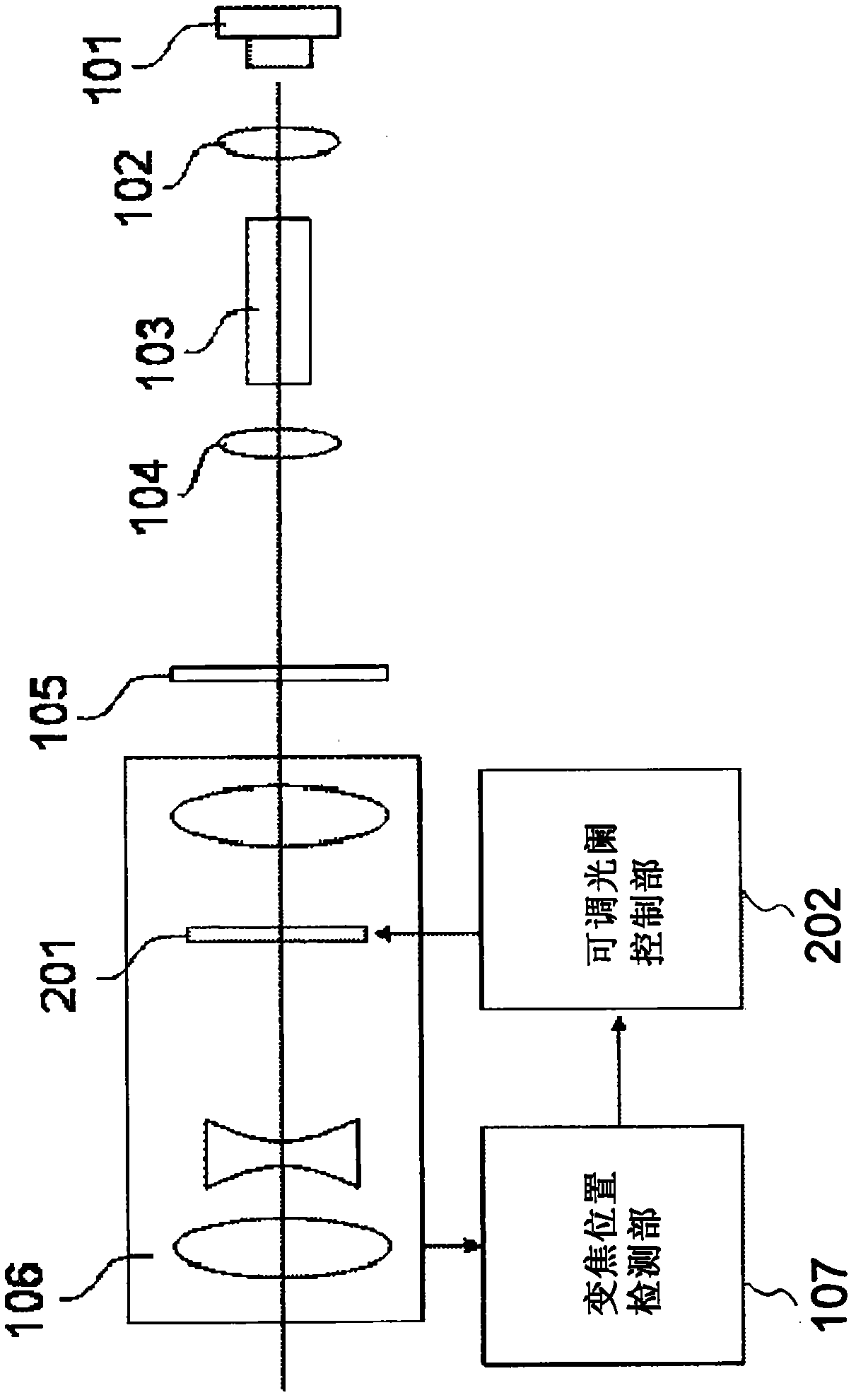

Projector and method for controlling the same

ActiveUS20120008105A1Increase brightnessStay safeProjector focusing arrangementCamera focusing arrangementLaser lightOptoelectronics

There is provided a projector that uses a laser light source and is safe and realizes high brightness. The projector applies a laser beam emitted from a laser light source (101) to an image modulation device (105) and magnifies and projects an image formed in the image modulation device (105) by a zoom lens (106). The projector includes a control mechanism (108) for controlling the amount of energy of the light beam in response to a change in a focal distance of the zoom lens (106) in such a way that an energy density of the laser beam developed on a light emitting surface of the zoom lens (106) is kept at a specified value or smaller than the specified value. The specified value is the energy density of the laser beam in a case where the focal distance of the zoom lens (106) is set to the shortest value and is an accessible emission limit value (AEL value) that satisfies the laser safety class of the projector.

Owner:SHARP NEC DISPLAY SOLUTIONS LTD

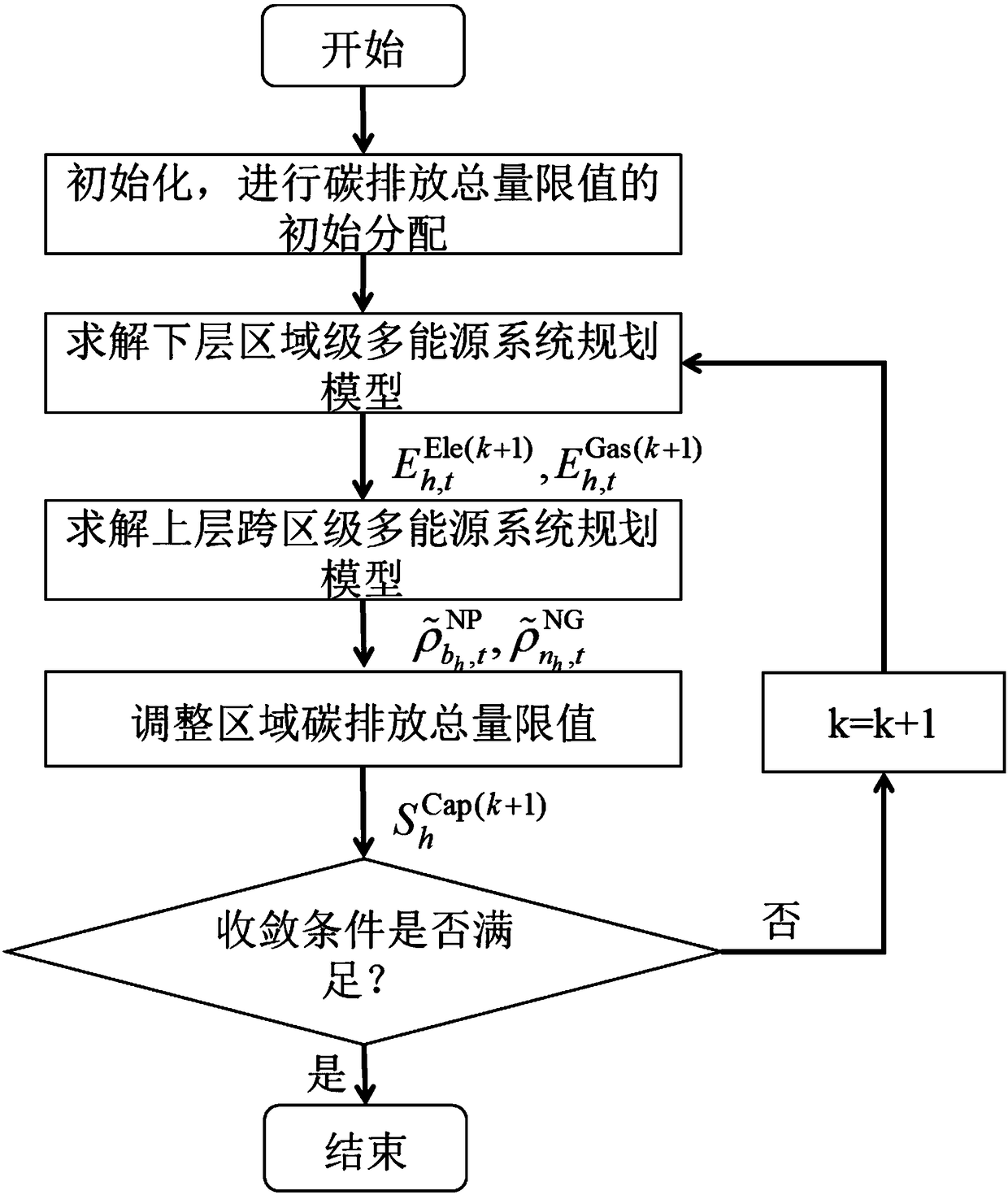

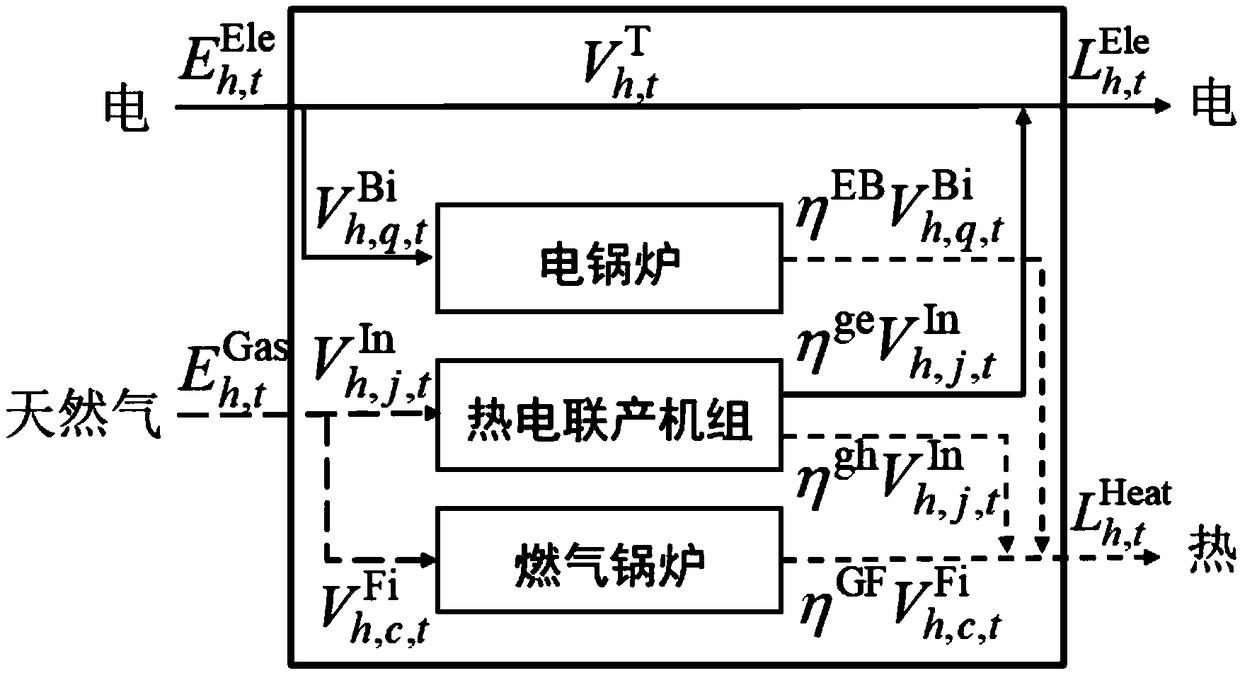

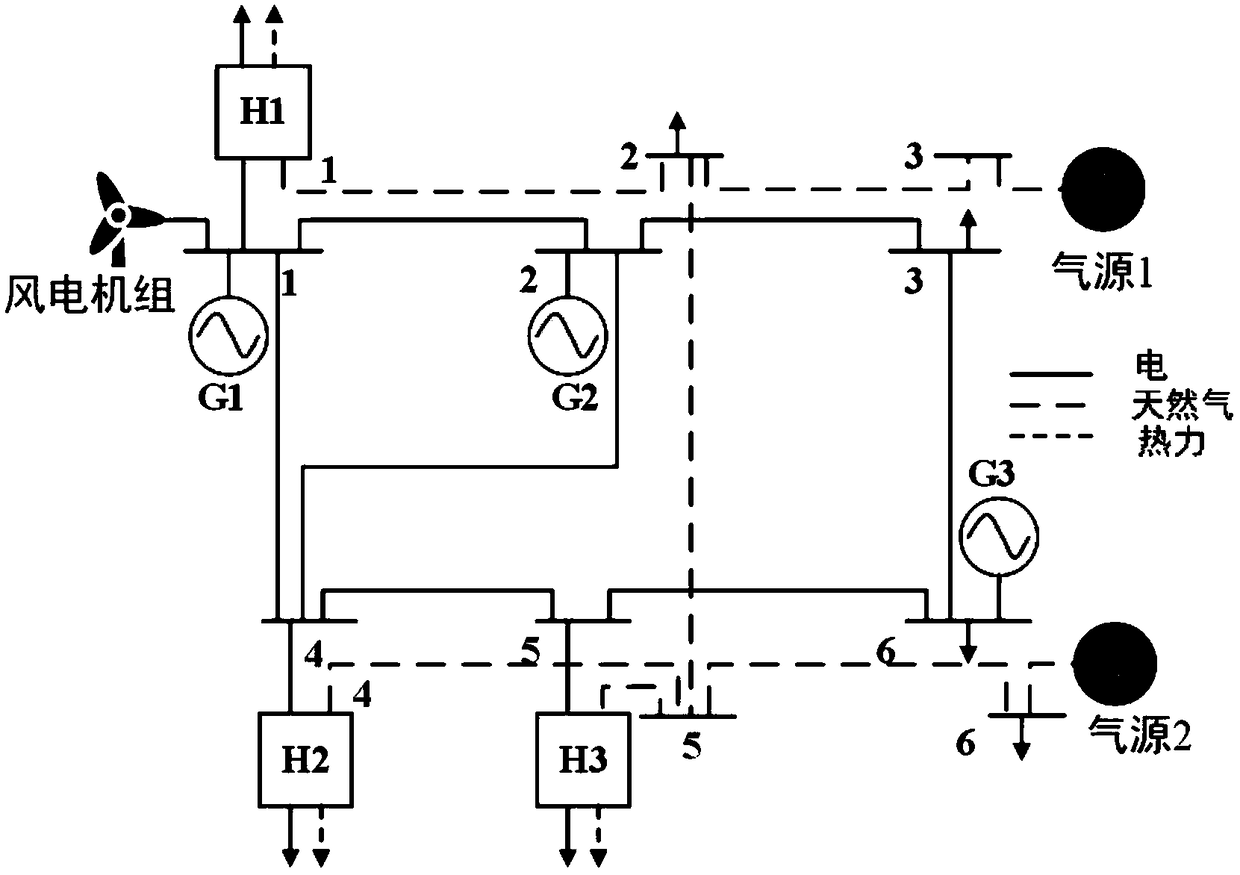

A collaborative low-carbon planning method for multi-energy system based on carbon emission stream

ActiveCN109102104ARealize a reasonable distributionRealize collaborative planningForecastingResourcesElectric power systemProcess engineering

The invention discloses a multi-energy system cooperative low-carbon planning method based on carbon emission flow belonging to the technical field of power system optimization analysis. The method comprises the following steps of: initial allocation of a total carbon emission limit value is performed; a regional multi-energy system model is used to optimize the optimal allocation of regional multi-energy system; transmission lines, natural gas pipelines and power points in the multi-energy system are optimized by using the multi-energy system model at the cross-region level; the carbon emission of each regional multi-energy system is determined by solving the carbon emission flow distribution of the multi-energy system, and the total carbon emission limits of each regional multi-energy system are compared with those of the regional multi-energy system, and the total carbon emission limits of each regional multi-energy system are adjusted and re-planned, and the collaborative low-carbon planning of the multi-energy system is realized through iteration. The invention obtains an overall optimal multi-energy system coordinated low-carbon planning method by reasonably distributing thetotal carbon emission limit value of the overall energy system, and lays a good foundation for the low-carbon planning of the energy system.

Owner:TSINGHUA UNIV

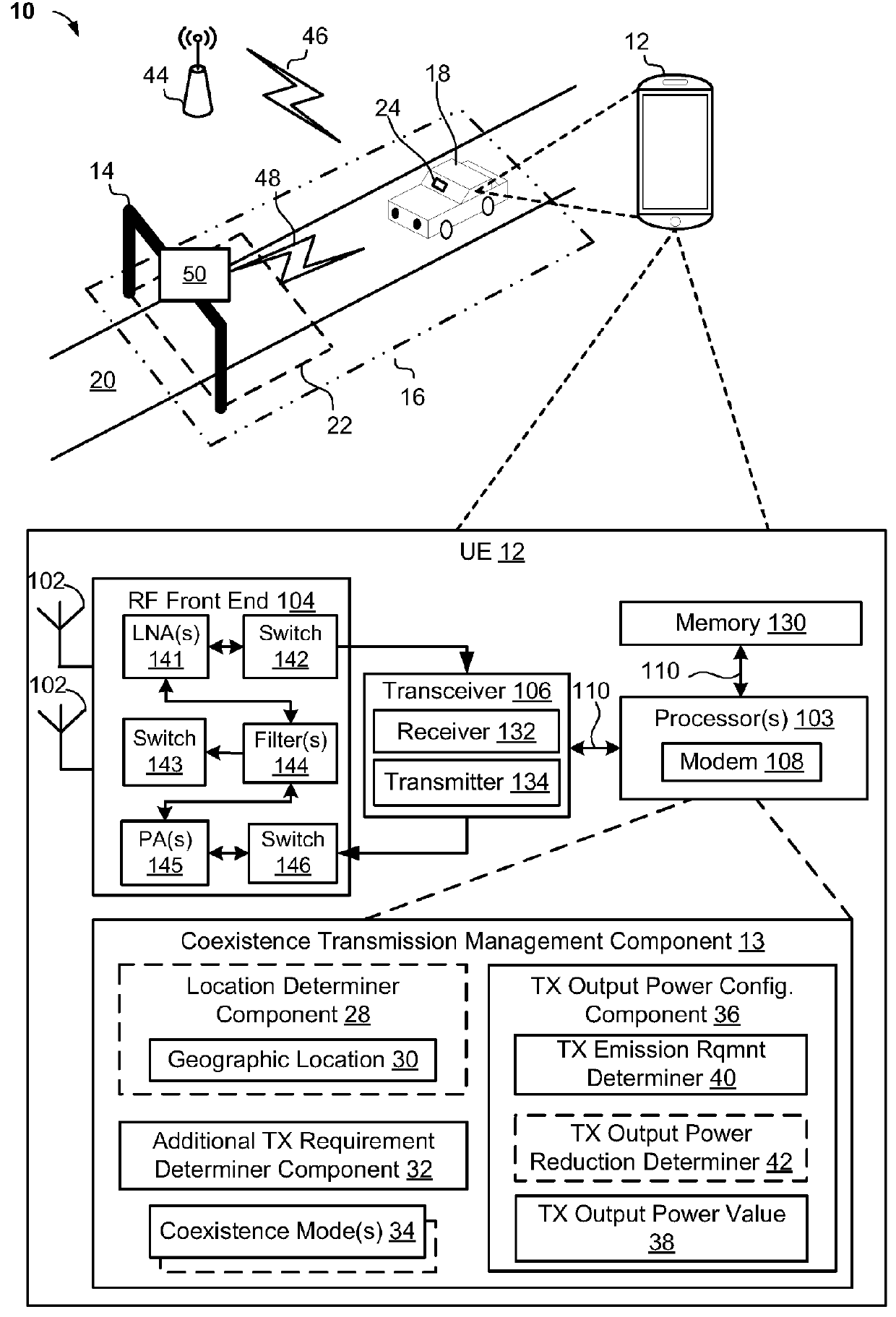

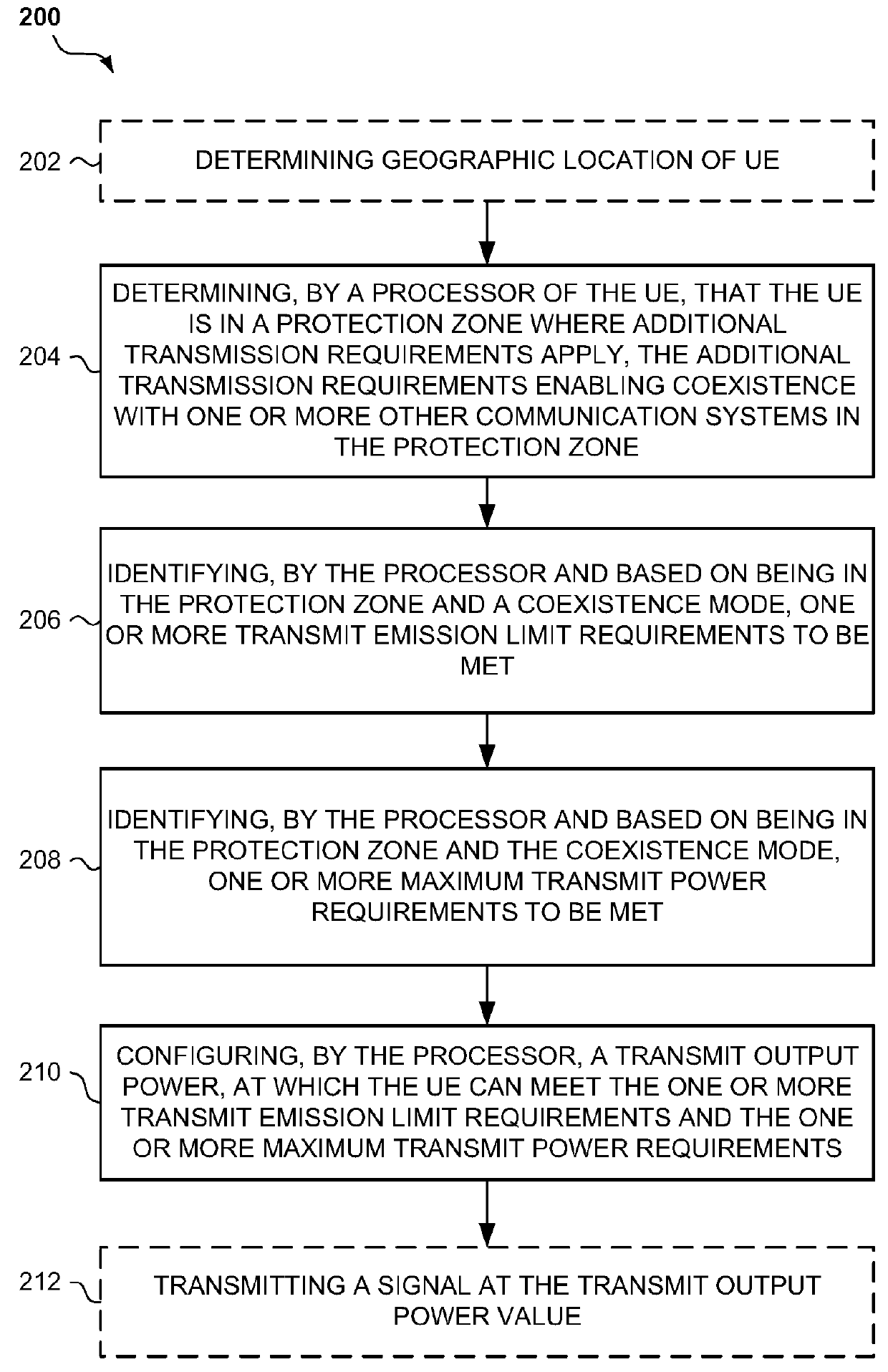

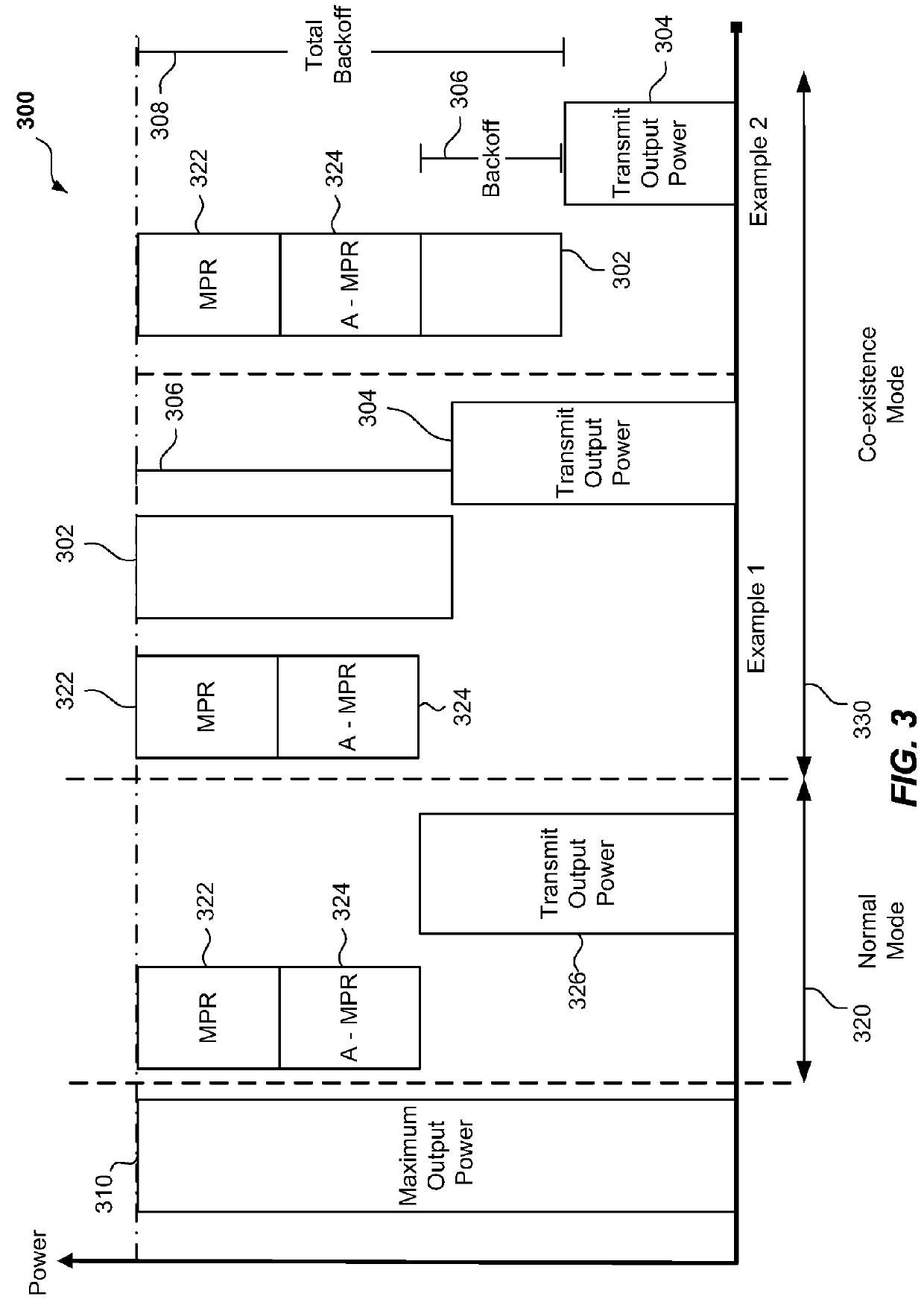

User equipment transmission management for dynamically varying transmission emission requirements

ActiveUS20180098292A1Well formedFast data throughputPower managementRadio transmissionCommunications systemTransmitted power

A method, computer-readable medium, and apparatus operate to reduce or eliminate interference with one or more other communication systems having specific transmission requirements within a specific geographic area. For example, aspects operate by determining that a user equipment (UE) is in a protection zone where additional transmission requirements apply. The additional transmission requirements enable coexistence with one or more other communication systems in the protection zone. The UE may identify, based on being in the protection zone and a coexistence mode, one or more transmit emission limit requirements to be met. The UE may identify, based on being in the protection zone and the coexistence mode, one or more maximum transmit power requirements to be met. The UE may configure a transmit output power, at which the UE can meet the one or more transmit emission limit requirements and the one or more maximum transmit power requirements.

Owner:QUALCOMM INC

Pretreatment method of heavy metal sludge

InactiveCN104496139AReduced LeachabilitySolve excessive heavy metal contentSludge treatment by de-watering/drying/thickeningWater contaminantsPretreatment methodSludge

The invention relates to a pretreatment method of heavy metal sludge. The specific method comprises the following steps: firstly, adjusting the pH of sewage sludge to be 7-9 with slaked lime, and treating with a heavy metal stabilization medicine; adding cement and a flocculating agent, and stirring; finally separating out a lot of water from which metals are removed by virtue of mud-water separation equipment; and naturally drying a mud cake for 1-2 days until the mud cake becomes hard, wherein the moisture content is lower than 40%, the mud cake can be directly subjected to landfill disposal, and the content of heavy metals in the separated sewage accords with the related emission limit in the 'integrated wastewater discharge standard'. Therefore, the method can be used as a pretreatment unit before landfill disposal of high-water sludge and heavy metal-containing sludge.

Owner:扬州杰嘉工业固废处置有限公司

Projector and method for controlling the same

InactiveCN102362220AEnsure safetyIncrease brightnessProjectorsColor television detailsShortest distanceLaser light

A projector using a laser light source is obtained with safety and high brightness. The projector irradiates a laser beam emitted from a laser light source (101) to an image modulation device (105) and enlarges and projects an image formed on the image modulation device (105) by using a zoom lens (106). The projector has a control means (108) for controlling, according to the focal distance change of the zoom lens (106), the energy amount of the laser beam so that the energy density of the laser beam emerging on the light exit surface of the zoom lens (106) is maintained to be a predetermined value or less. The predetermined value is equal to the energy density of the laser beam obtained when the focal distance of the zoom lens (106) is set to the shortest distance and also equal to an accessible emission limit value (AEL value) that satisfies a laser safety class of the projector.

Owner:NEC DISPLAY SOLUTIONS LTD

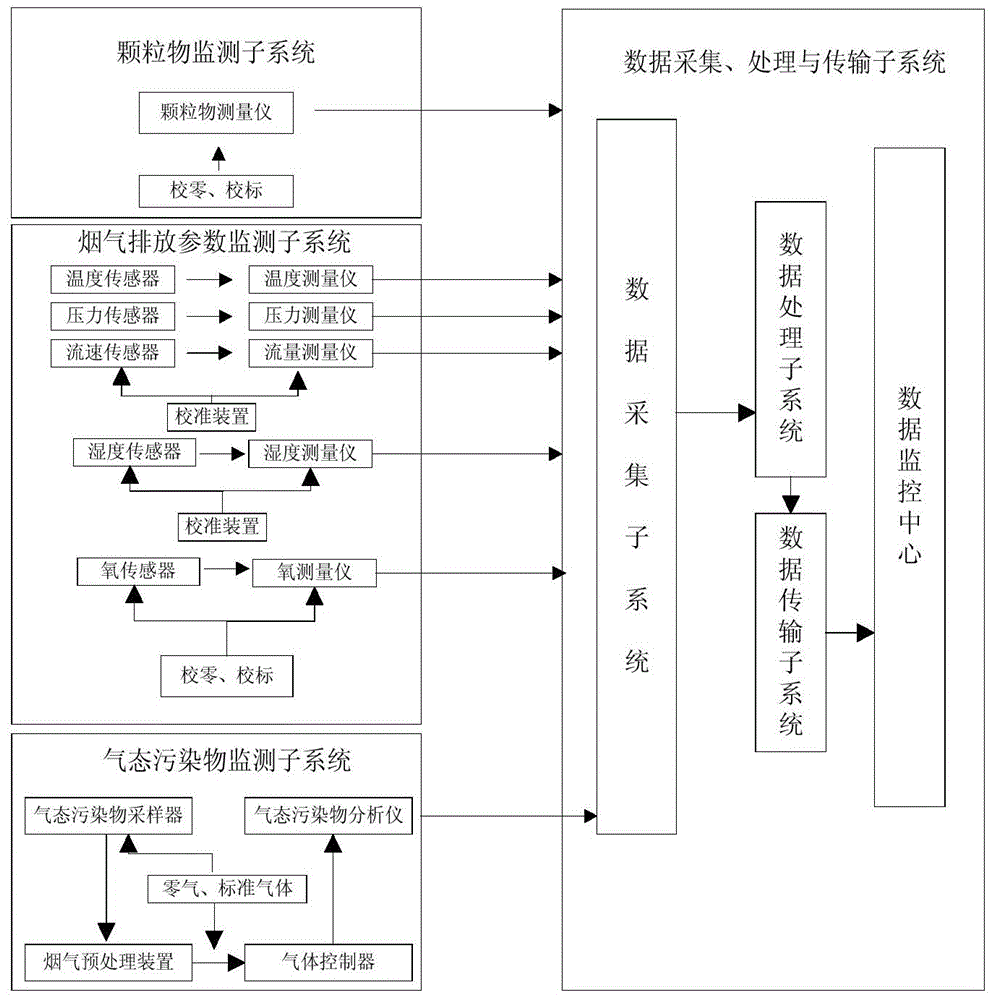

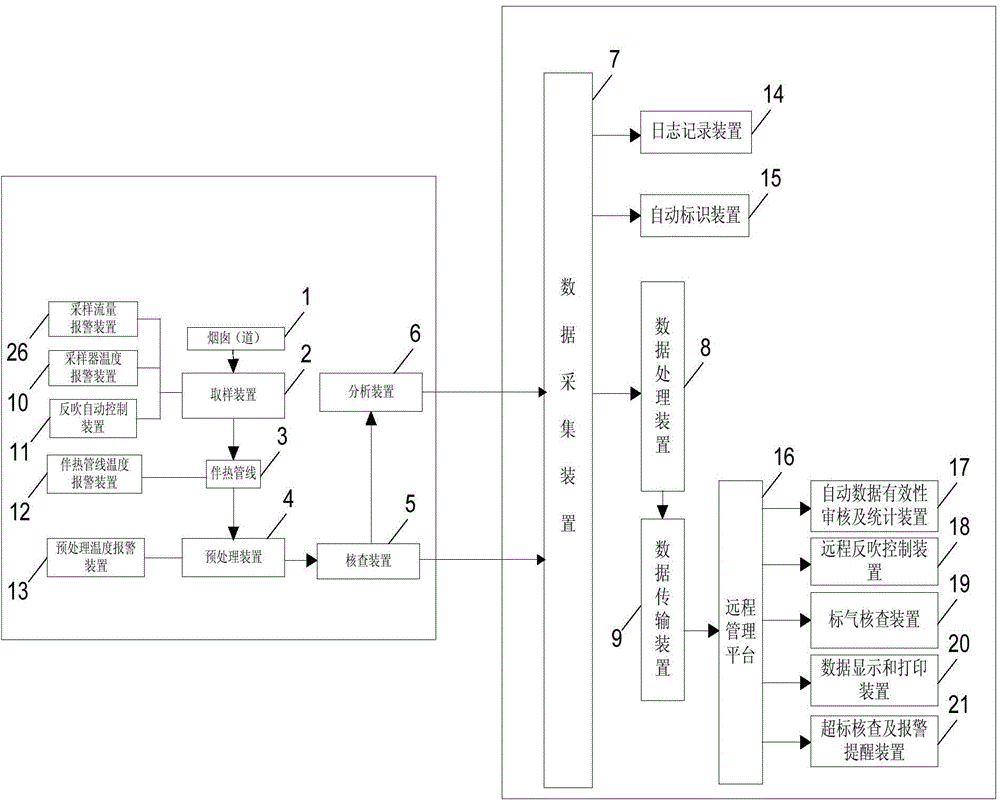

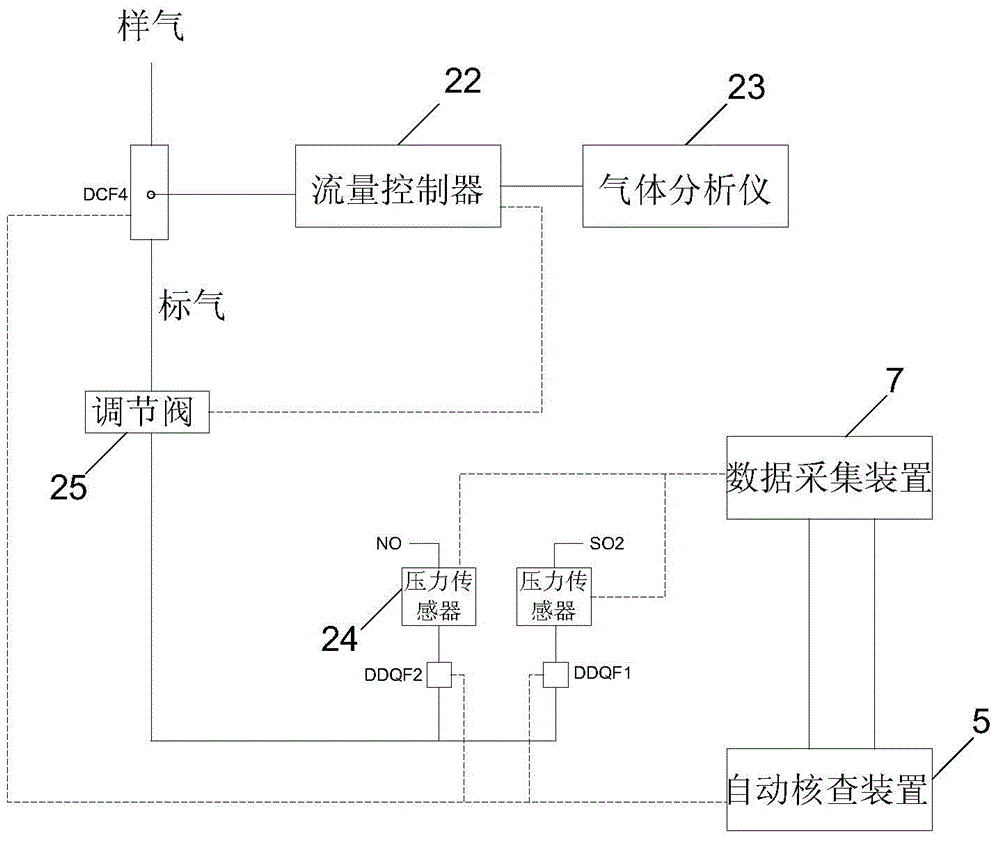

Continuous monitoring device for flue gas emissions and automatic verification method for validity of monitoring data

ActiveCN104678058AImprove data measurement accuracySolve technical problems that cannot prove the accuracy of measurement dataMaterial analysisFlue gasData acquisition

The invention discloses a continuous monitoring device for flue gas emissions and an automatic verification method for the validity of monitoring data. The device comprises a sampling device, a pretreatment device, an analysis device, a data acquisition device and a verification device, wherein the sampling device is connected with a flue, the pretreatment device is connected with the sampling device, the analysis device is connected with the pretreatment device, the data acquisition device and the verification device are connected with the analysis device, and a verification control device carries out automatic verification on the analysis device regularly and / or when the flue gas measured value monitored by the data acquisition device exceeds an emission limit value. According to the automatic verification method for the validity of monitoring data disclosed by the invention, through carrying out automatic verification on a gas analyzer regularly and / or when the flue gas measured value exceeds an emission limit value, and judging whether the instrument error of the gas analyzer is in an allowed range, valid data is identified, so that the technical problem that existing continuous monitoring devices for flue gas emissions can not evidence the accuracy of measurement data is solved, the evidencing to the accuracy of measurement data is realized, and the accuracy of data measuring of the continuous monitoring device for flue gas emissions is improved.

Owner:LIHE TECH (HUNAN) CO LTD

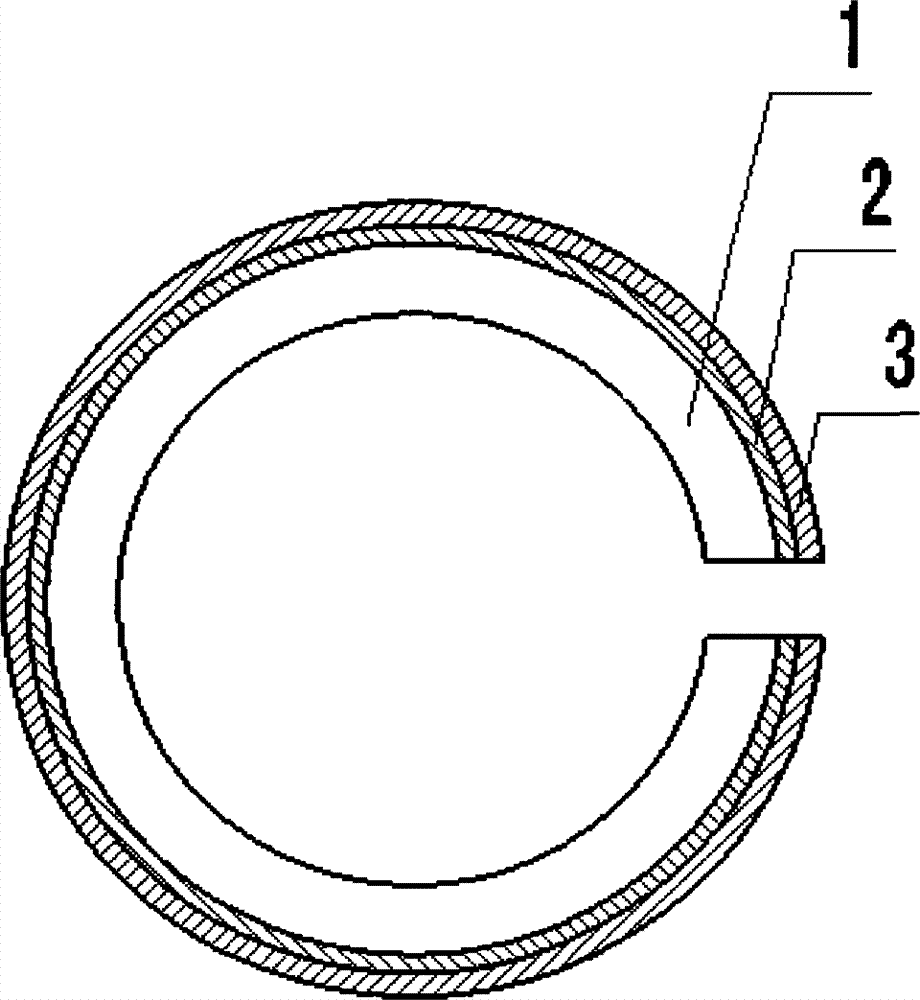

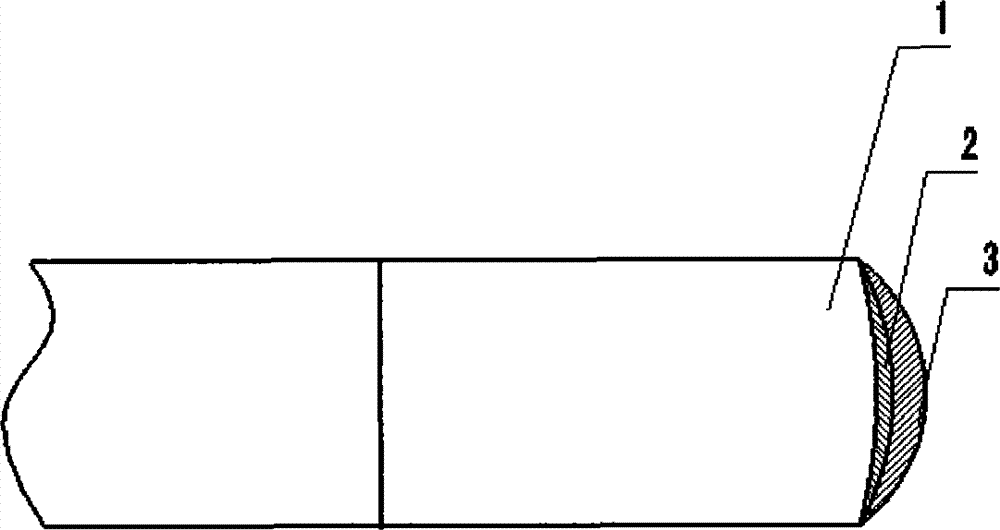

Ceramic thin film cast iron piston ring and manufacturing method thereof

InactiveCN103836186AImprove wear resistanceImprove anti-sintering performancePiston ringsGas phasePiston ring

The invention discloses a ceramic thin film cast iron piston ring. According to a manufacturing method, a thin chromium layer is arranged on the outer circle surface of a ring body in an electroplating or physical vapor deposition mode, and then a hard ceramic thin film coating is formed on the outer circle surface of the thin chromium layer in a physical vapor deposition mode. The problem that abrasion resistance and anti-sintering performance of an existing cast iron piston ring can not meet the requirement for high output and high emission limit of a modern automobile is solved, and the ceramic thin film cast iron piston ring is particularly suitable for the requirements of modern automobile development.

Owner:ANQING TP GOETZE PISTON RING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com