Equipment for treating waste emulsion

A waste emulsion and equipment technology, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. The effect of reducing stress and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

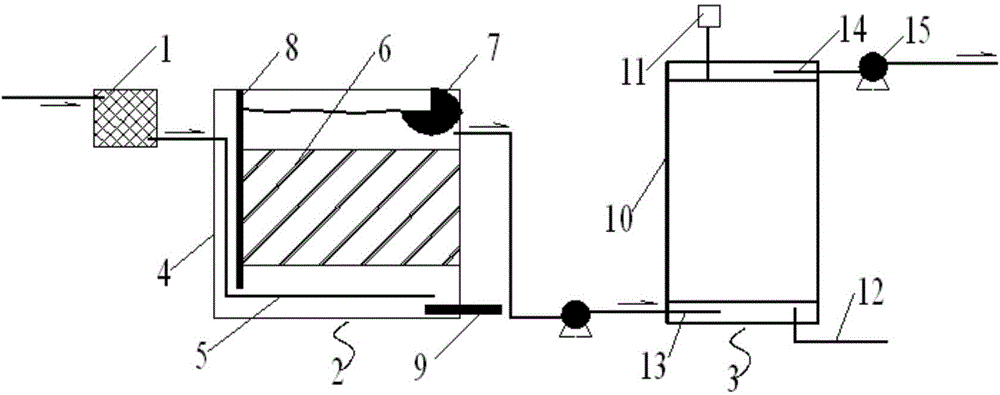

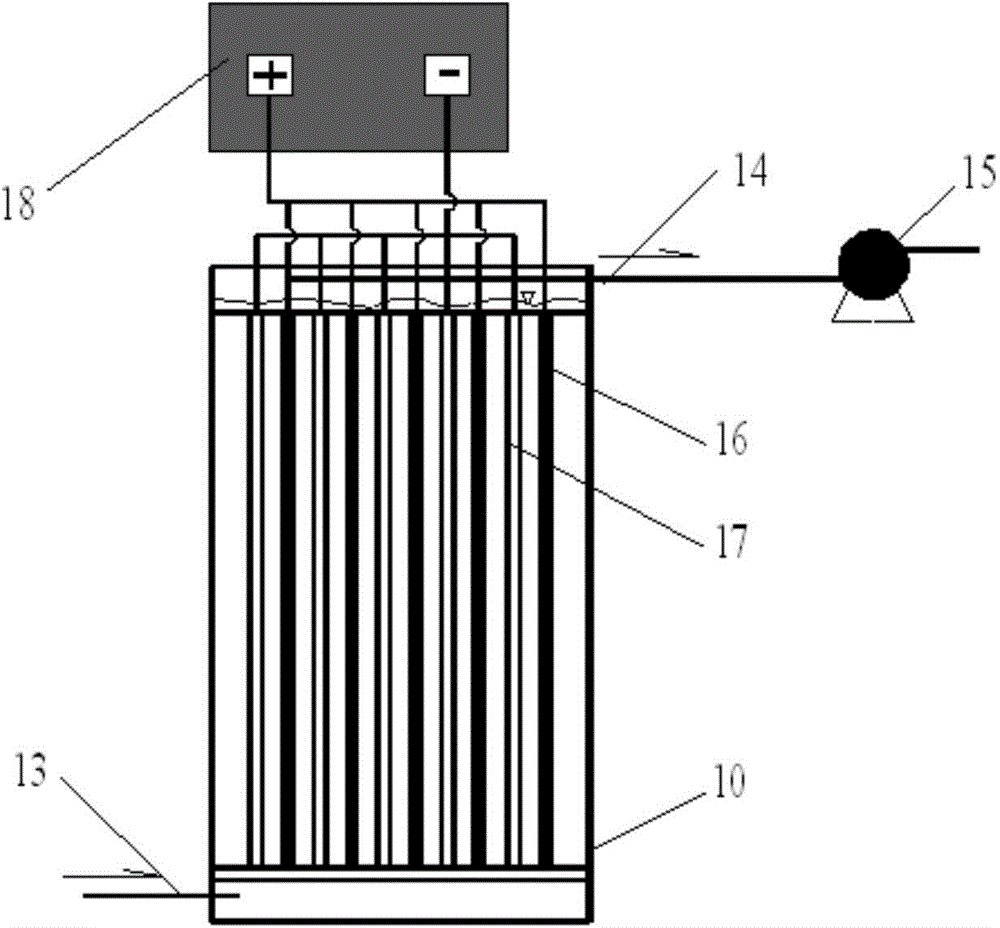

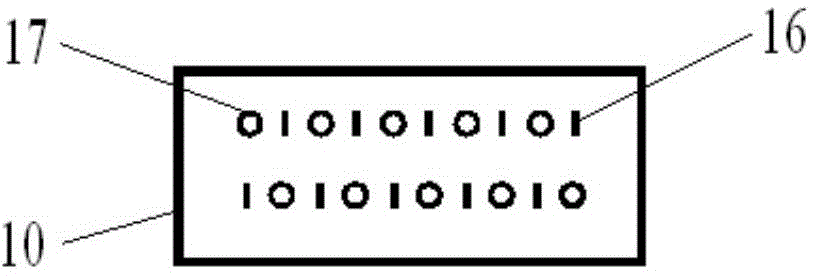

[0083] 1. Pass the waste emulsion to be treated through a fine mesh filter to filter it, wherein the filtration accuracy of the fine mesh filter is 90 μm; after filtering through the fine mesh filter, the waste emulsion with a particle size greater than 90 μm Oil slicks are removed.

[0084] 2. The waste emulsion that has removed the floating oil is introduced into the grease trap through the water distribution pipe, so that the waste emulsion flows through the oil-water separation pipe from bottom to top; after passing through the oil-water separation pipe, the dispersed oil and water in the waste emulsion have different specific gravity , the dispersed oil floats to the water surface to form oil-water separation, and the dispersed oil floating to the water surface is collected by the oil coalescing pipe; wherein, the angle between the oil-water separation pipe and the horizontal plane is 60°.

[0085] 3. Introduce the waste emulsion after the oil-water separation treatment i...

Embodiment 2

[0094] 1. Let the waste emulsion to be treated pass through the fine mesh filter to filter it, wherein the filtration accuracy of the fine mesh filter is 100 μm; after filtering through the fine mesh filter, the waste emulsion with a particle size greater than 100 μm Oil slicks are removed.

[0095] 2. The waste emulsion that has removed the floating oil is introduced into the grease trap through the water distribution pipe, so that the waste emulsion flows through the oil-water separation pipe from bottom to top; after passing through the oil-water separation pipe, the dispersed oil and water in the waste emulsion have different specific gravity , the dispersed oil floats to the water surface to form oil-water separation, and the dispersed oil floating to the water surface is collected by the oil coalescing pipe; wherein, the angle between the oil-water separation pipe and the horizontal plane is 55°.

[0096] 3. Introduce the waste emulsion treated by the grease trap into th...

Embodiment 3

[0105] 1. Pass the waste emulsion to be treated through a fine mesh filter to filter it, wherein the filtration accuracy of the fine mesh filter is 80 μm; after filtering through the fine mesh filter, the waste emulsion with a particle size greater than 80 μm Oil slicks are removed.

[0106] 2. The waste emulsion that has removed the floating oil is introduced into the grease trap through the water distribution pipe, so that the waste emulsion flows through the oil-water separation pipe from bottom to top; after passing through the oil-water separation pipe, the dispersed oil and water in the waste emulsion have different specific gravity , the dispersed oil floats to the water surface to form oil-water separation, and the dispersed oil floating to the water surface is collected by the oil coalescing pipe; wherein, the angle between the oil-water separation pipe and the horizontal plane is 65°.

[0107] 3. Introduce the waste emulsion treated by the grease trap into the electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| filtration accuracy | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com