Patents

Literature

125results about How to "Reduce COD concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

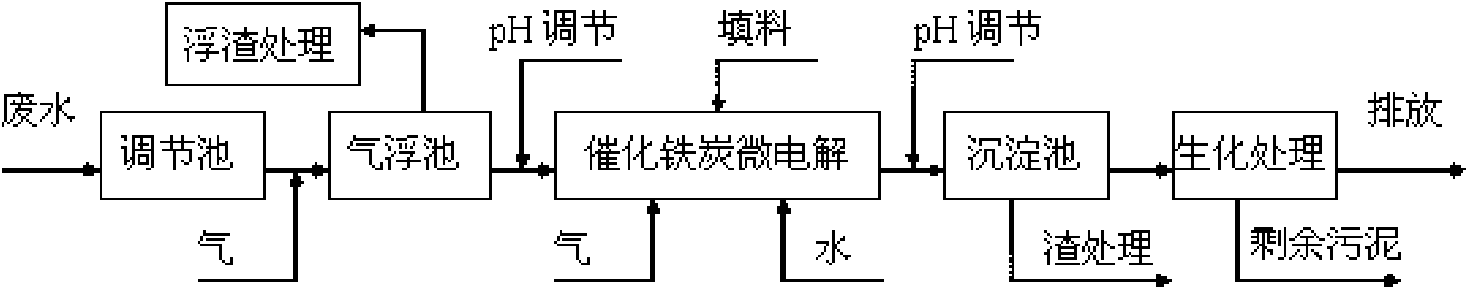

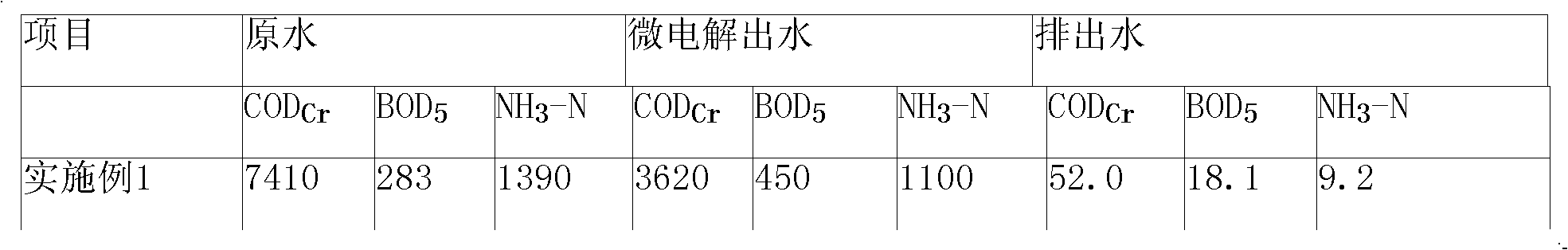

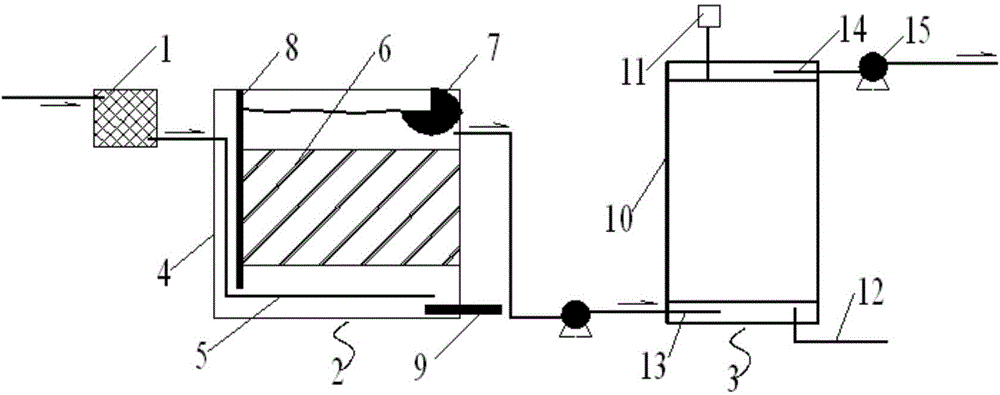

Catalysis and micro-electrolysis combined technology for high-concentration refractory organic wastewater

InactiveCN101665311AReduce processing loadEasy to handleTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentHigh concentrationElectrolysis

The invention relates to a catalysis and micro-electrolysis combined technology for high-concentration refractory organic wastewater; the organic wastewater is collected to an adjusting tank and enters an air floatation tank for air floatation treatment to remove part of the organic matters after the adjustment of water volume and water quality; the scruff is collected or recovered; the wastewatergoes through Ph adjustment and then enters a catalytic iron-carbon and micro-electrolysis unit to improve the biochemical quality; the effluent goes through Ph adjustment and then enters a sedimentation tank; the effluent of the sedimentation tank adopts anoxic-aerobic biochemistry treatment to remove the organic matters and ammonia nitrogen and then is emitted after reaching the standard; and the filler of the catalytic iron-carbon and micro-electrolysis unit comprises iron, carbon and a catalyst, wherein the mass ratio of the iron, carbon and catalyst is 1: (0.3-1.5): (0.01-0.5). The invention can effectively improve the micro-electrolysis electrochemical reaction efficiency and the degrading capability to the organic matters, and reduce the wastewater treatment cost with convenient technological operation.

Owner:CENT SOUTH UNIV

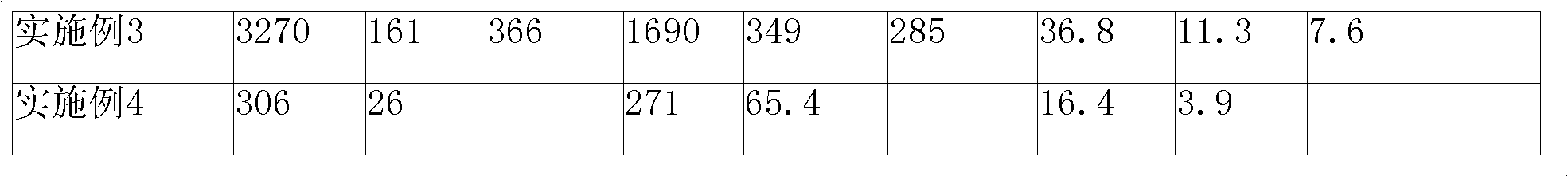

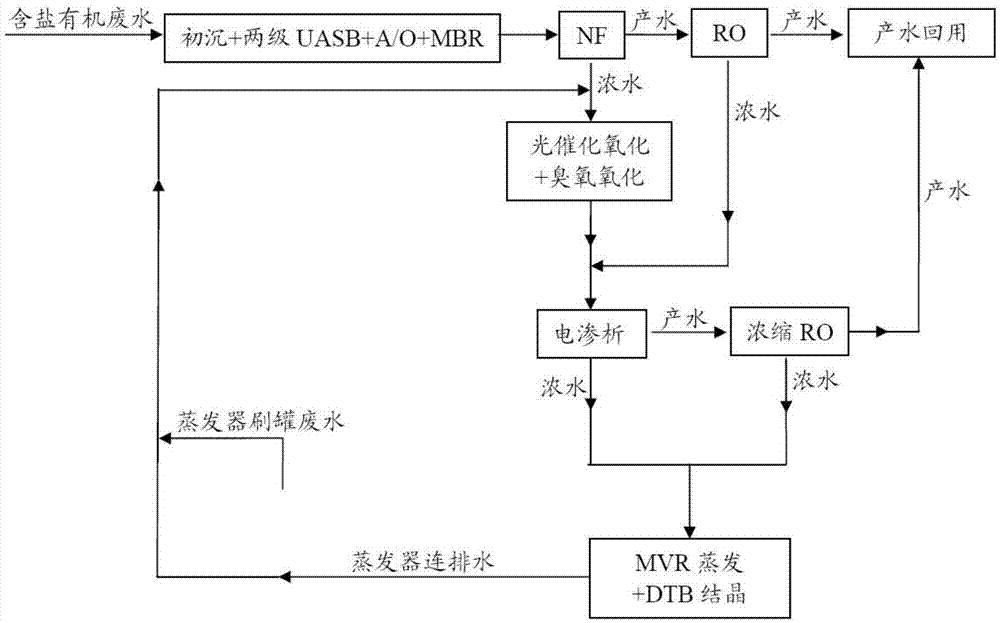

Zero-discharge treatment method of salt-containing organic wastewater

InactiveCN105439395AEasy to handleEfficient reuseTreatment using aerobic processesTreatment involving filtrationEvaporationOrganic matter

The invention provides a zero-discharge treatment method of salt-containing organic wastewater. The method comprises the following steps that biochemical treatment and filtering treatment are performed on wastewater; then, membrane concentration is performed; pure-water-producing high-organic-matter-content membrane concentration concentrated water and optional low-organic-matter-content membrane concentration concentrated water are obtained; the high-organic-matter-content membrane concentration concentrated water is used for high-grade oxidation treatment; high-grade oxidation produced water is used for regulation treatment to obtain high-grade oxidation outlet water; the obtained high-grade oxidation outlet water is subjected to evaporation treatment; or the obtained high-grade oxidation outlet water and the low-organic-matter-content membrane concentration concentrated water are mixed under the condition that the low-organic-matter-content membrane concentration concentrated water exists in the step, and then, the evaporation treatment is carried out; external discharge concentration liquid of an evaporator and / or high-salt-content high-organic-matter-content wastewater discharged during the tank brushing of the evaporator are conveyed back into a high-grade oxidation treatment unit; after the liquid is mixed with the high-organic-matter-content membrane concentration concentrated water, the high-grade oxidation treatment is carried out. The wastewater treatment method is stable and reliable; the long-period and stable operation of an evaporation system can be ensured; the zero discharge of the industrial wastewater is realized.

Owner:DATANG INT CHEM TECH RESINST

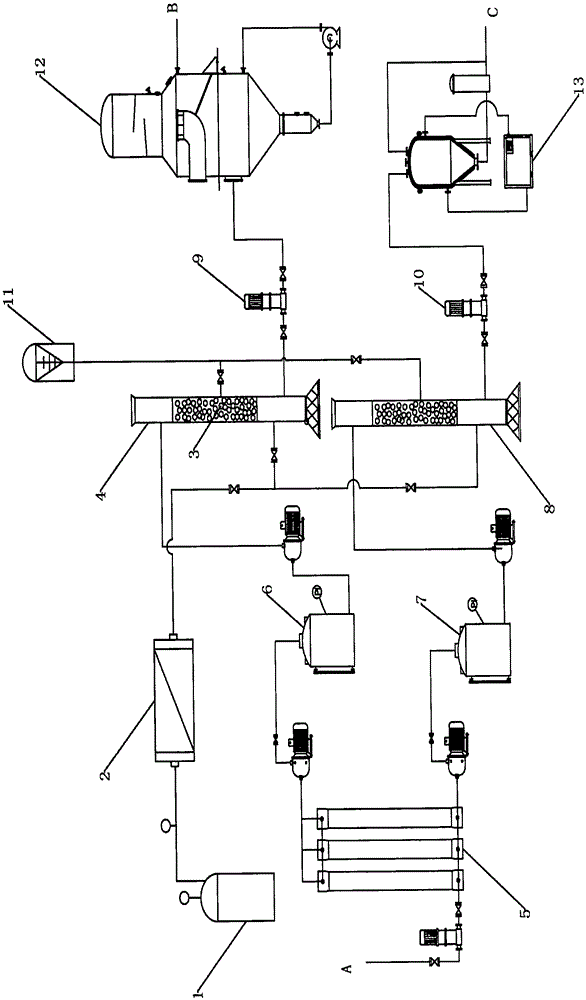

Advanced oxidation-separate salt crystallization combination system of high-salt-salt industrial wastewater

ActiveCN105540980AReduce COD concentrationOvercoming removalTreatment involving filtrationEnergy based wastewater treatmentChemical oxygen demandEvaporation

The invention provides an advanced oxidation-separate salt crystallization combination system and technique of high-salt-salt industrial wastewater, relating to the technical field of water treatment. The technique comprises the following steps: sending high-salt-salt industrial wastewater treated by a pretreatment membrane system into an ozone advanced oxidation device, and standing in the presence of an ozone catalyst at the ozone specific loss of 1.2-3.0 kg O3 / kg COD (chemical oxygen demand) for 2-4 hours, wherein the COD of the treated effluent water is less than 50 mg / L; and sending into a crystallizing system to carry out crystallization treatment, wherein sodium sulfate concentrated water enters a refrigerating crystallizing system, and sodium chloride concentrated water enters a multi-effect evaporation (or MVR (mechanical vapor recompression) evaporation) device. The technique greatly lowers the wastewater COD content, increases the crystal salt purity, has the characteristics of simple operation, low cost, high water treatment quantity, high adaptability and stable water quality, and reduces the blockage problem of the crystallizing equipment.

Owner:INNER MONGOLIA JIUKE KANGRUI ENVIRONMENTAL TECH

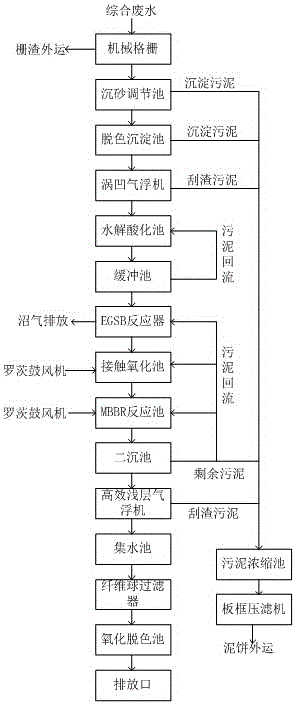

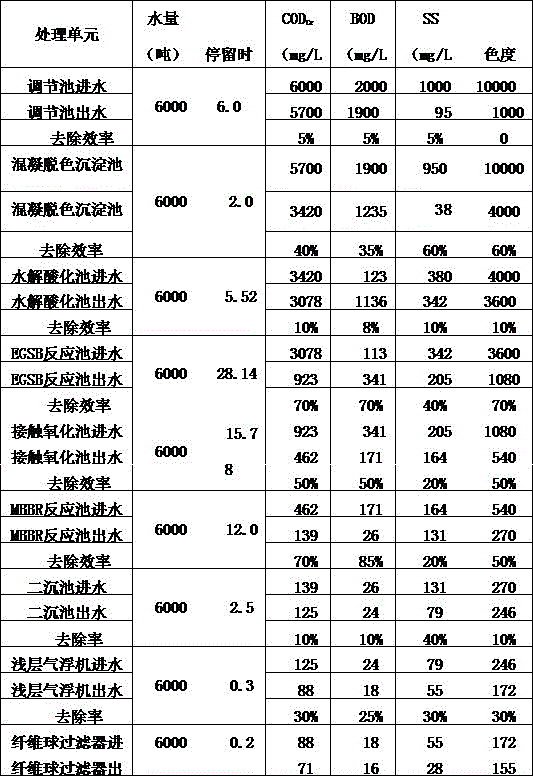

Printing and dyeing waste water treatment process

InactiveCN106630472AEasy to handleEasy to trainSpecific water treatment objectivesWater/sewage treatment by electrochemical methodsExisting TreatmentWastewater

The invention discloses a printing and dyeing waste water treatment process, and solves the problem the existing treatment effects of the printing and dyeing waste water are not good. The printing and dyeing waste water treatment process comprises the steps that 1, in the pretreatment process, impurities in the waste water are removed, and the decoloration process is conducted to a certain degree, and loads of subsequent treating processes are reduced; 2, in the biochemical treatment process, organic pollutants in waste water are degraded; 3, in the advanced treatment process, the impurities, the organic pollutants and chroma in the waste water are further removed. The problems in the prior art are well solved by the above scheme.

Owner:四川亿龙环保工程有限公司

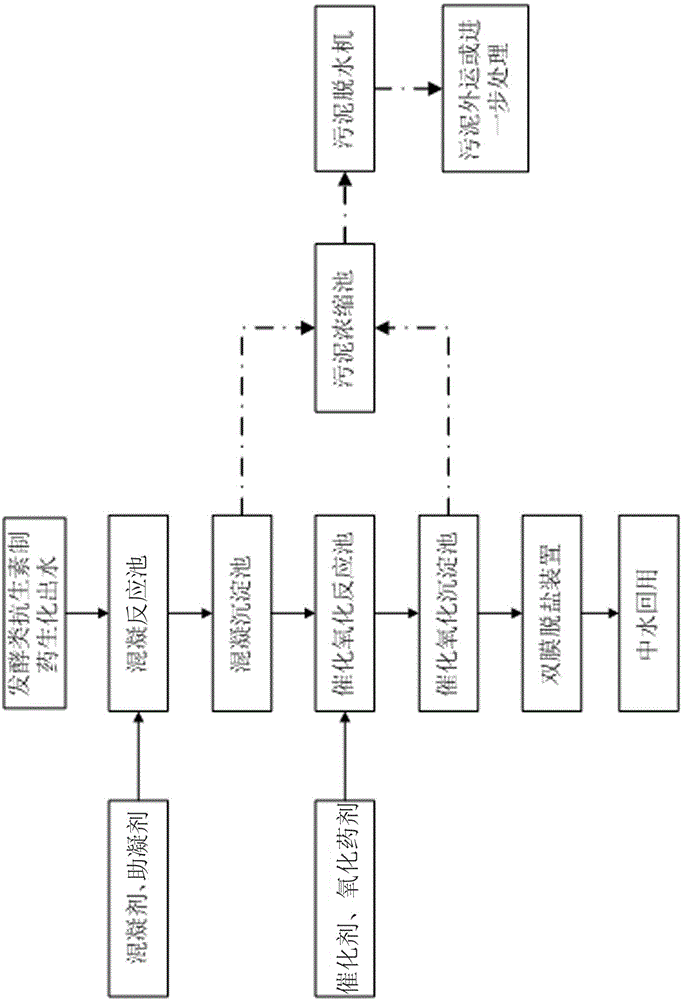

Advanced treatment process for fermentation antibiotic wastewater

InactiveCN106830536AReduce CODReduce COD concentrationSludge treatment by de-watering/drying/thickeningGeneral water supply conservationSludgeReclaimed water

The invention relates to the technical field of wastewater treatment, in particular to an advanced treatment process for fermentation antibiotic wastewater. The advanced treatment process comprises the following steps: the fermentation antibiotic wastewater subjected to biochemical treatment is sent into a coagulation reaction tank, and a coagulant and a coagulant aid are added for a reaction; effluent of the coagulation reaction tank is subjected to precipitation separation treatment in a coagulative precipitation tank, and floc precipitates obtained after precipitation are sent into a sludge thickener; effluent of the coagulative precipitation tank is sent into a catalytic oxidation reaction tank and subjected to a Fenton catalytic oxidation reaction; effluent of the catalytic oxidation reaction tank is sent into a catalytic oxidation precipitation tank for precipitation separation treatment, flocs in the effluent obtained after an oxidation reaction are precipitated in the precipitation tank, and precipitated flocs enter the sludge thickener; effluent of the catalytic oxidation precipitation tank enters a two-membrane process desalter for desalting treatment, and the fermentation antibiotic wastewater treated with the process is high in quality and can meet the requirement for reuse of reclaimed water.

Owner:华夏碧水环保科技股份有限公司

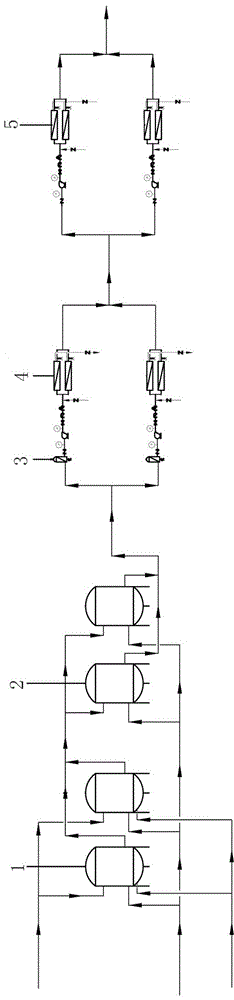

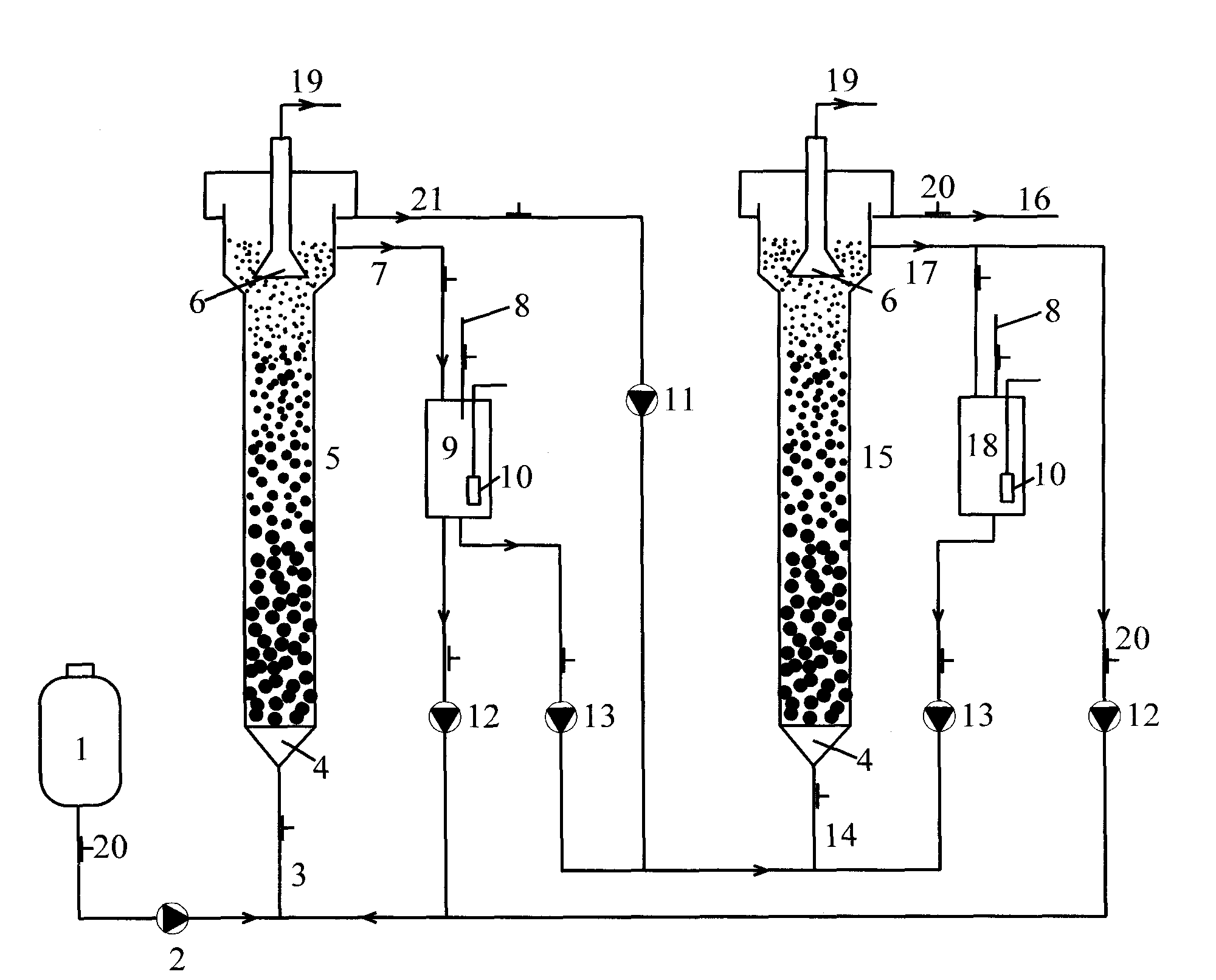

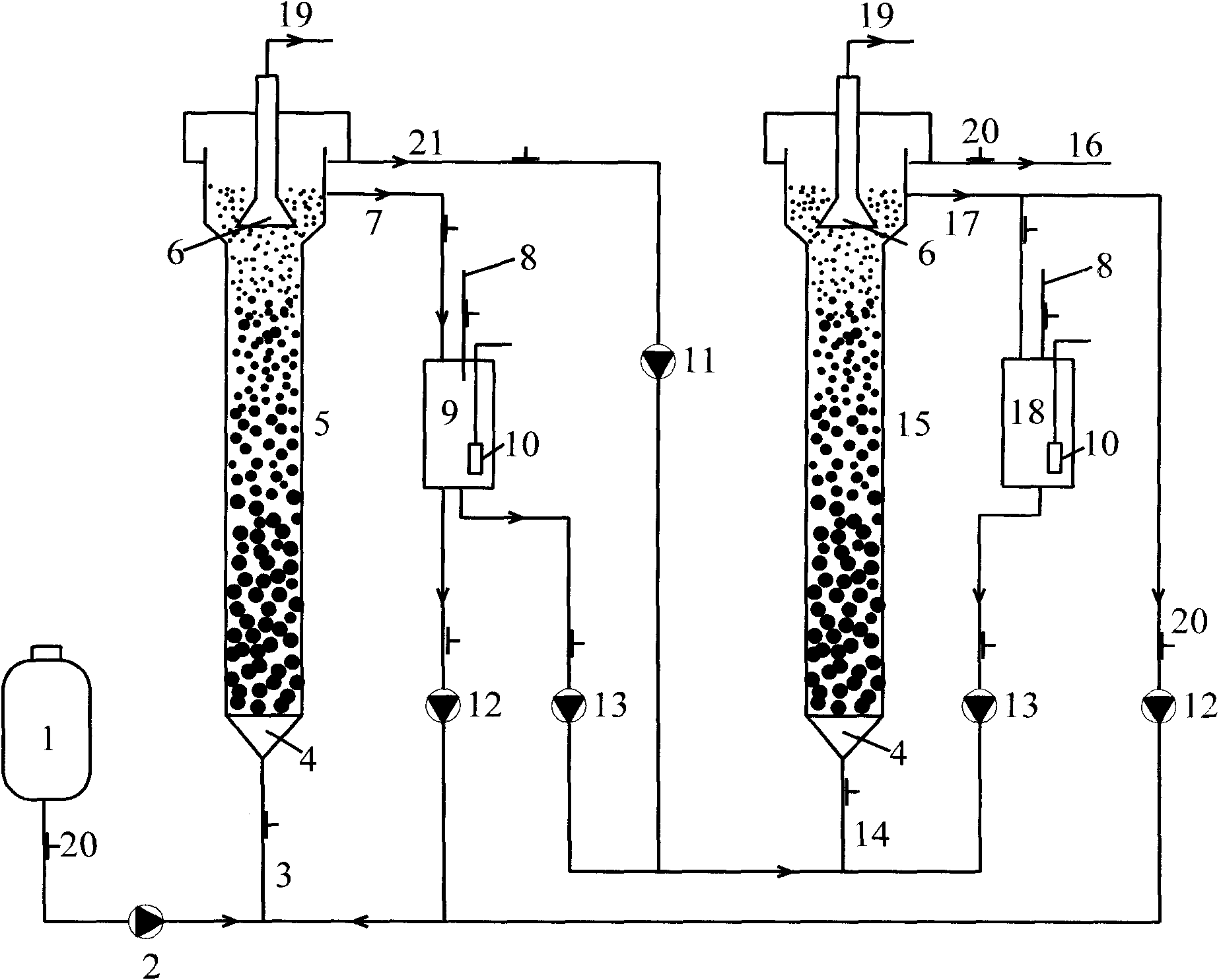

Method and equipment for cross backflow two-stage double-expansion granular sludge treatment of coking wastewater

InactiveCN101786730AClosely arrangedRich varietyWaste water treatment from metallurgical processSustainable biological treatmentAs DirectedSludge

The invention relates to a method and equipment for cross backflow two-stage double-expansion granular sludge treatment of coking wastewater. The method comprises the following steps: introducing the coking wastewater to a first-stage double-expansion granular sludge reactor and degrading the coking wastewater to produce first-stage treated water; delivering a part of the first-stage treated water to a first-stage aeration backflow column and the other part of the first-stage treated water to a second-stage reactor directly; aerating the treated water which enters the first-stage aeration backflow column, allowing a part of the aerated water and return water of second-stage treatment mixed directly and flow to the first-stage reactor, and making the part of the aerated water and the aerated water of the second-stage treatment mixed and flow into the second-stage reactor; degrading the treated water which enters the second-stage reactor to produce water of the second-stage treatment, directly discharging a part of the water of the second-stage treatment, and making the other part of water of the second-stage treatment flow into a second-stage aeration backflow column; and aerating other part of the water of the second-stage treated treatment, and returning part of the aerated water of the second-stage treatment to the second-stage reactor, and returning the other part of the aerated water of the second-stage treatment to the first-stage reactor as direct return water of the second-stage treatment. The treatment method and equipment can realize the simultaneous efficient removal of COD and ammonia nitrogen from the coking wastewater.

Owner:太原大学

Method for blasting plant biomass walls with oxygen

InactiveCN102206928ADecompose thoroughlyBreak down evenlyRaw material divisionProcess engineeringOxygen

The invention discloses a method for blasting plant biomass walls with oxygen, comprising the following steps of: firstly, adding ethanol, hydrogen peroxide with concentration of 30% and water to crushed plant biomass, mixing the materials to oxidize and soak the materials, and conveying the oxidized and soaked materials to an oxygen blasting tank via a feeding port of the oxygen blasting tank; secondly, sealing the feeding port of the oxygen blasting tank, regulating the temperature of the gas in the oxygen blast tank at 80-150 DEG C and the pressure within 1-4 MPa by conveying pressure air to the oxygen blasting tank, preserving heat and keeping pressure for 20-200 seconds to soak the plant biomass into ethanol, hydrogen peroxide with concentration of 30%, steam and water; and finally, completely opening the discharge port of the oxygen blasting tank within 3 seconds to reduce the pressure in the oxygen blasting tank to the normal pressure. The invention aims to provide the method for blasting plant biomass walls with oxygen, which can be used for completely and uniformly decomposing the plant biomass and realizing industrialization production and has high production efficiency.

Owner:BEIJING ZHONGNUO DERUI IND TECH

Multifunctional water treatment agent used for treating refractory wastewater

InactiveCN103241793AExtended reaction timeImprove adsorption capacityOther chemical processesWater/sewage treatment using germicide/oligodynamic-processHazardous substanceEmission standard

The invention relates to a multifunctional water treatment agent used for treating refractory wastewater. The multifunctional water treatment agent is prepared through the following steps of: (1) modifying through bentonite, namely weighing bentonite, pouring the bentonite into an organic modifier solution with mass percent of 3-5%, stirring for 1-3 hours at room temperature, centrifuging, washing, drying and grinding the bentonite to powder so as to obtain modified bentonite; and (2) loading through potassium ferrate: pouring the modified bentonite prepared by step (1) into a potassium ferrate aqueous solution with the pH of 7-9 to be loaded, and air-drying the solution after saturating to obtain the multifunctional water treatment agent. The multifunctional water treatment agent provided by the invention integrates multiple functions, such as oxidation, adsorption, flocculation, sterilization, and the like, thereby greatly reducing the COD concentration and biotoxicity in the wastewater, improving the biodegradability of the wastewater, reducing the treatment cost and improving the emission standard-reaching rate of the refractory wastewater; and the multifunctional water treatment agent has the characteristics of being good in refractory wastewater treatment effect, free of toxic and harmful substance, low in treatment cost, environmentally-friendly, and the like, thereby being suitable for large scale industrial production.

Owner:浙江一清环保工程有限公司

Method for preparing biomass fuel by taking cow dung as raw material

The invention discloses a method for preparing a biomass fuel by taking the cow dung as the raw material, comprising the following steps: (1) treating the fresh cow dung until the water content is decreased to 60-75%; (2) mixing the fresh cow dung with a composite microbial inoculum, and fermenting for 10-20 days until the water content of the product of fermentation is less than 42%; and (3) feeding the product of fermentation into a granulating workshop, grinding, screening, granulating, and airing until water content is less than 30% to obtain the biomass fuel. The stickiness of cow dung is made to decrease by the biological activity of the microbial inoculum so that the solid and the liquid are separated naturally, the COD concentration of the sewage separated out is reduced significantly compared with that of the cow dung liquid mechanically squeezed out and is generally about 500mg / l, and the sewage can enter a sewage treating system of the pasture so as to be treated without generating impact load. The temperature of the cow dunghill rises ceaselessly to about 70 DEG C at most so that various harmful microorganisms in the cow dung can be killed effectively. The content of crude fiber in the product of fermentation enriches gradually, and the calorific value increases correspondingly to more than 2,500kcal.

Owner:太仓东浔生物科技有限公司

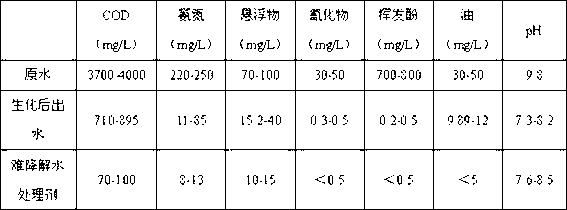

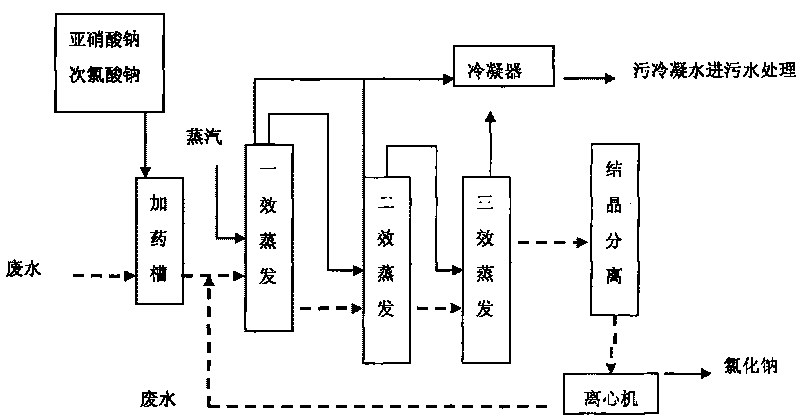

Treatment device and method for simultaneously removing high-concentration SS, fluoride, sulfate, arsenate and COD in desulfurization waste water

ActiveCN105366839AGood processing effectReduced sludge loadWater contaminantsWaste water treatment from gaseous effluentsHigh concentrationFlocculation

The invention relates to a treatment device and method for simultaneously removing high-concentration SS, fluoride, sulfate, arsenate and COD in desulfurization waste water. The treatment device is characterized in that an overflowing port of a settling pond is connected with a first delivery pump through a pipeline, a first-level defecator stirring device is installed on a first-level defecator, and a second delivery pump is connected with a third reaction tank through a pipeline. The treatment method includes the steps that the desulfurization waste water enters the settling pond for primary settling, and then outlet water sequentially enters a first reaction tank and a second reaction tank to be subjected to a chemical-coagulating sedimentation reaction and then enters the first-level defecator for solid-liquid separation; supernate is introduced into the third reaction tank, mixed liquid after the reaction sequentially enters a flocculation tank to be subjected to a flocculation reaction and a second-level defecator to be defecated and concentrated; the supernate is introduced into a filtering device to be filtered, and the pH value of output water is adjusted to be 6-9. The high-concentration SS, fluoride, sulfate, arsenate and COD in the desulfurization waste water are effectively and simultaneously removed.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

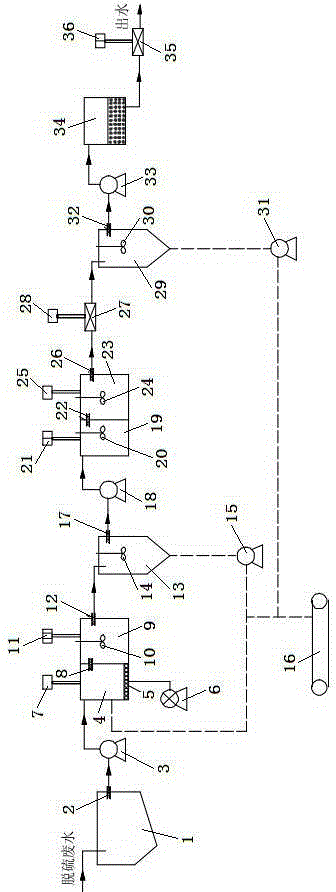

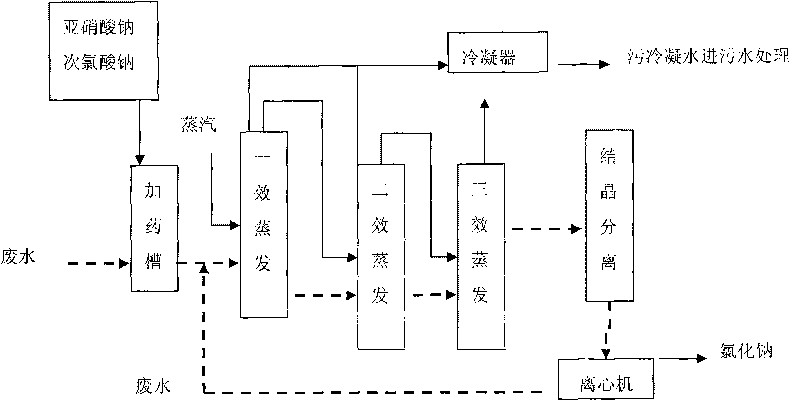

Method for treating N-(phosphonomethyl)iminodiacetic acid wastewater

ActiveCN101717131AReduce CODReduce salt contentNature of treatment waterWater/sewage treatment by heatingEvaporationCatalytic oxidation

The invention relates to a wastewater treatment process, in particular to a method for treating N-(phosphonomethyl)iminodiacetic acid wastewater by a coupling catalytic oxidation technology. The method comprises the following concrete steps of: adding catalytic oxidizers of sodium nitrite and sodium hypochlorite into the N-(phosphonomethyl)iminodiacetic acid wastewater in a mixing tank, filtering after stirring evenly, putting the wastewater into a multi-effect evaporation device, concentrating under the conditions that the temperature is 65-100 DEG C and the vacuum degree is from -0.05MPa to -0.09MPa and crystallizing a concentrate under the condition that the COD concentration of effluent water is below 5000mg / L to precipitate sodium chloride which can reach the standard of industrial salt. The invention has simple and convenient operation, strong controllability, simple equipment, cost reduction, less energy consumption and no secondary pollution; the invention is suitable for treating and reclaiming the N-(phosphonomethyl)iminodiacetic acid wastewater.

Owner:JINGBO AGROCHEM TECH CO LTD

Method for treating degradation-resistant organic pollutants in waste water

InactiveCN103420530AGood dispersionExpand the radiation rangeWater/sewage treatment with mechanical oscillationsWater contaminantsIron nanoparticlePersistent organic pollutant

The invention provides a method for treating degradation-resistant organic pollutants in waste water and overcomes the defect that iron nanoparticles are prone to agglomeration when the iron nanoparticles are subjected to waste water treatment in the prior art. In order to solve the technical problem, the technical scheme includes that the method includes the following steps: under the pneumatic ultrasonic action, adjusting pH to be 1-5, adding ferrous ion salt, casting the iron nanoparticles in, adding hydrogen peroxide, performing solid-liquid separation after the pneumatic ultrasonic action, and discharging the waste water after the waste water reaches the standard. Comparing a pneumatic ultrasonic field with a common electric ultrasonic field, dispersion and radiation range can be widened, and the iron nanoparticles can be dispersed in the waste water more easily; air serves as a medium generating the pneumatic ultrasonic field, functions of an oxidizing agent (O2), stirring and cutting are provided for a waste water treating system, but only an air compressor generating the pneumatic ultrasonic field is energy-consuming equipment, so that energy-saving effect is achieved.

Owner:CHANGSHU CITY YUHENG KNITTING

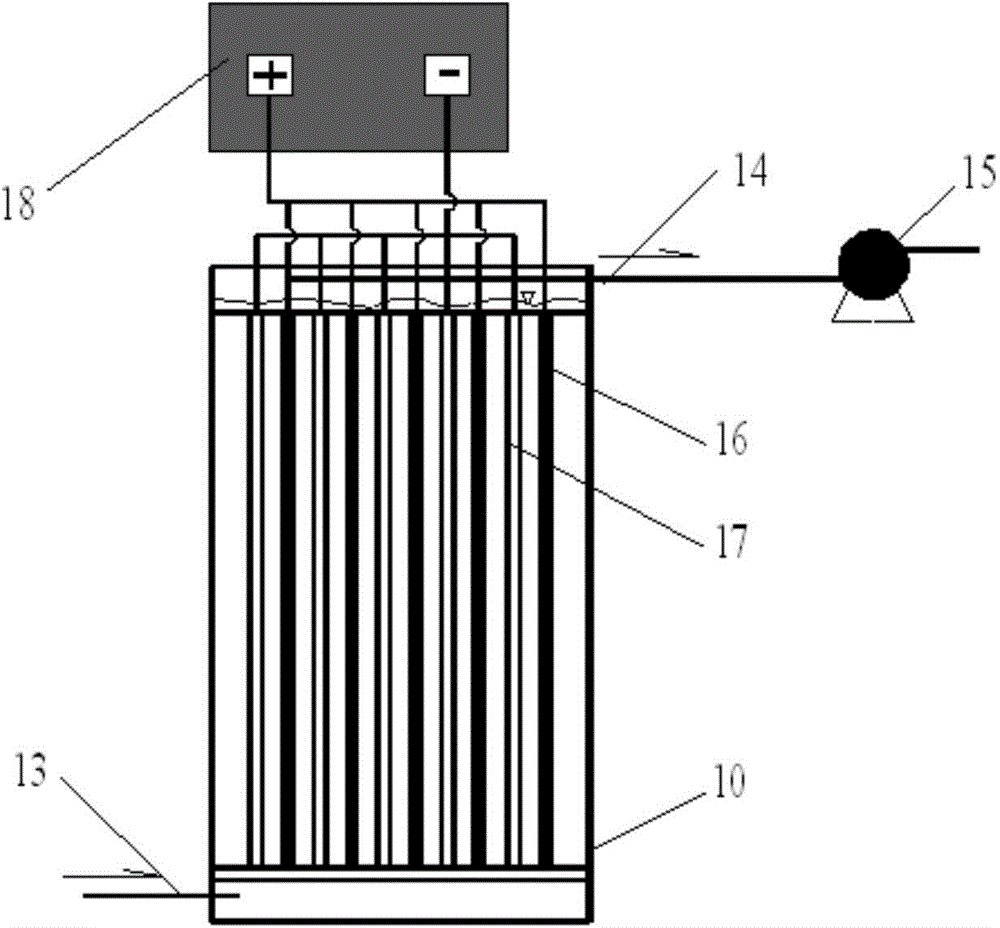

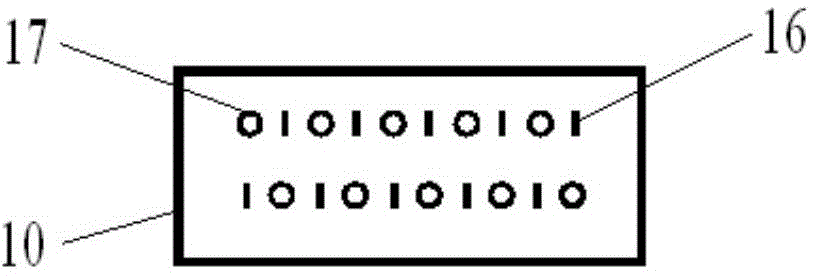

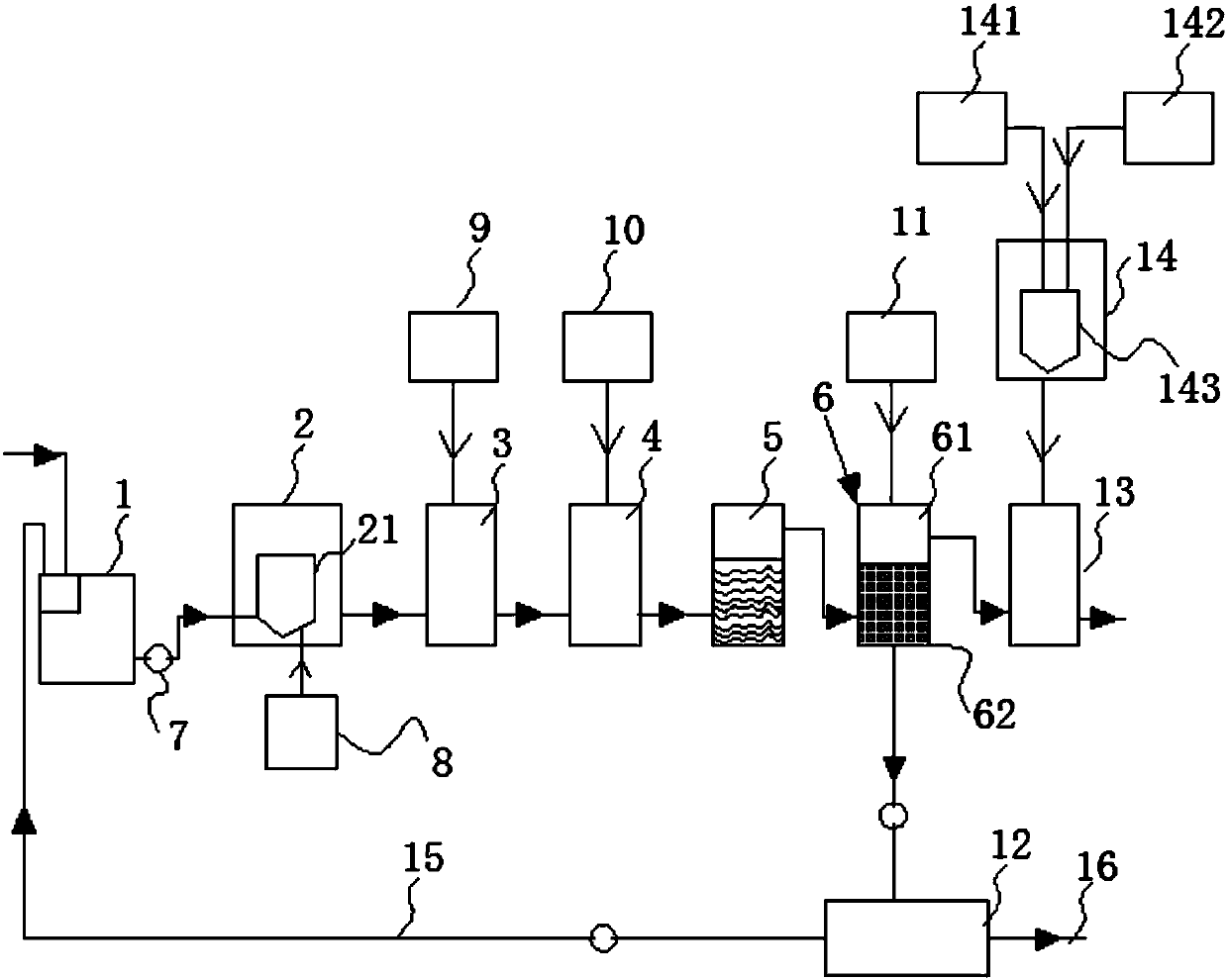

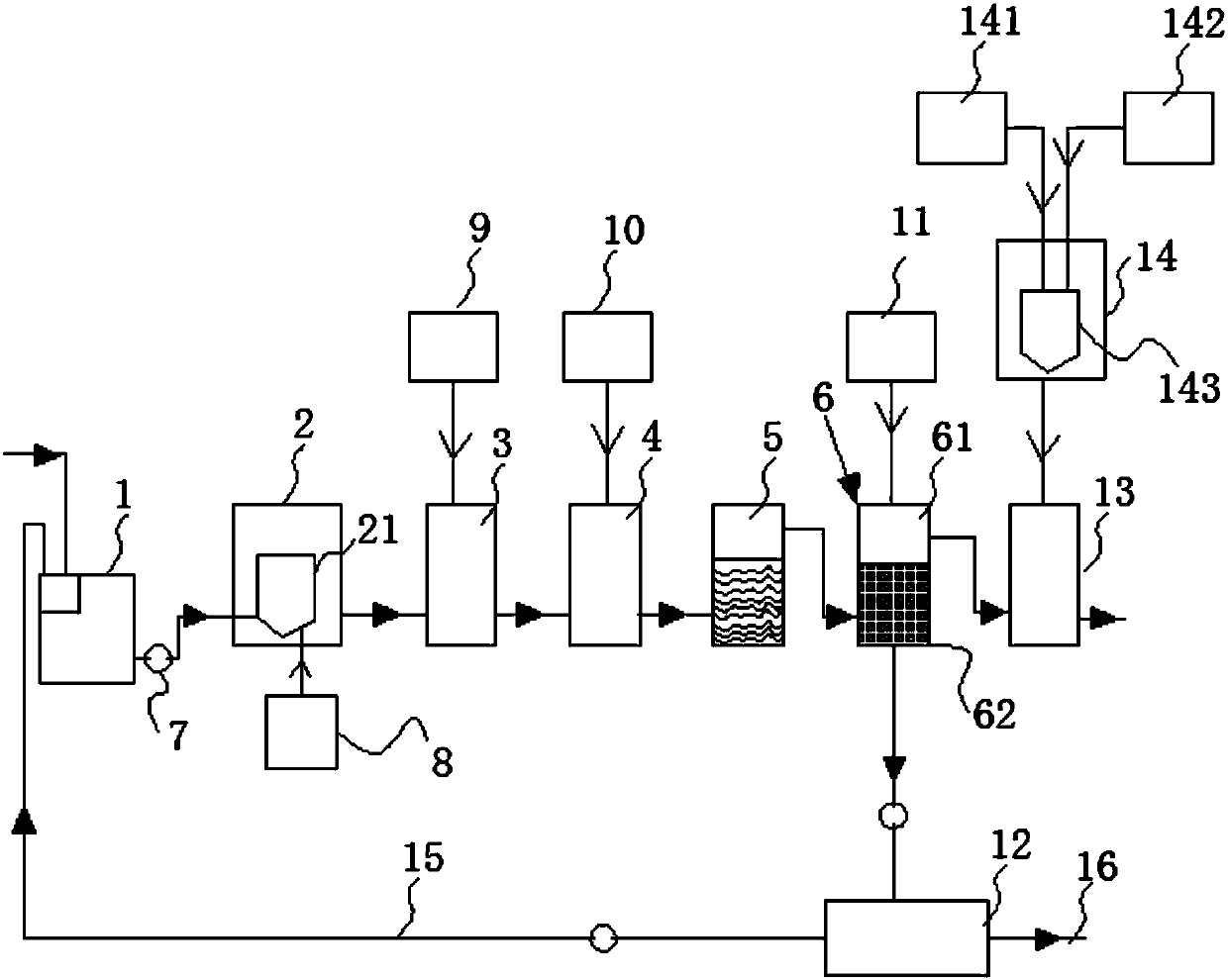

Equipment for treating waste emulsion

ActiveCN104649481AGood removal effectExtended service lifeFatty/oily/floating substances removal devicesMultistage water/sewage treatmentWater treatment systemEmulsion

The invention provides equipment for treating waste emulsion. The equipment is characterized by comprising a floating oil removal device, an oil-water separation device, and an electrochemical treatment device, wherein the floating oil removal device is used for removing floating oil from to-be-treated waste emulsion, and removing the floating oil floating on the level of the waste emulsion; the oil-water separation device is used for performing oil-water separation to the waste emulsion without floating oil, and removing the dispersion oil suspending in the waste emulsion; and the electrochemical treatment device is used for performing electrochemical treatment to the waste emulsion which is subjected to oil-water separation treatment, so that emulsifying oil and dissolved oil are flocculated, wherein an electrified aluminum plate and a nanoceramic membrane are used for performing electrochemical treatment; a disconnected nanoceramic membrane is used for performing ultrafiltration treatment to the stand and precipitated crude emulsion. After being treated through the equipment, the quality of effluent water is good, and the effluent water can completely meet the emission limit requirement of a public sewage treatment system in Beijing Integrated discharge standard of water pollutants DB11 / 307-2013.

Owner:BEIJING SINORICHEN ENVIRONMENTAL PROTECTION

Method for treating waste emulsion

ActiveCN104649482ARelieve pressureExtended service lifeFatty/oily/floating substances removal devicesMultistage water/sewage treatmentUltrafiltrationChemistry

The invention provides a method for treating waste emulsion. The method comprises the following steps: performing oil slick removal treatment on the waste emulsion to be treated to remove oil slick therein; performing oil-water separation treatment on the waste emulsion without oil slick to remove disperse oil therein; performing electrochemical treatment on the waste emulsion after the oil-water separation treatment to obtain roughly treated waste emulsion in which the oil slick and disperse oil are removed and the emulsified oil and dissolved oil are flocculated; and performing static settlement and ultrafiltration treatment on the roughly treated waste emulsion to obtain clear water without oil slick, disperse oil, emulsified oil or dissolved oil, wherein the electrochemical treatment is performed by use of energized aluminum plate and a nano ceramic membrane, and the ultrafiltration treatment is performed by use of the power-off nano ceramic membrane. Through the treatment of the method provided by the invention, the water quality of the yielding water is good, and the yielding water can completely meet the limitation requirements on the discharge into a public sewage treatment system in the Integrated Discharge Standard of Water Pollutants DB11 / 307-2013 of Beijing.

Owner:BEIJING SINORICHEN ENVIRONMENTAL PROTECTION

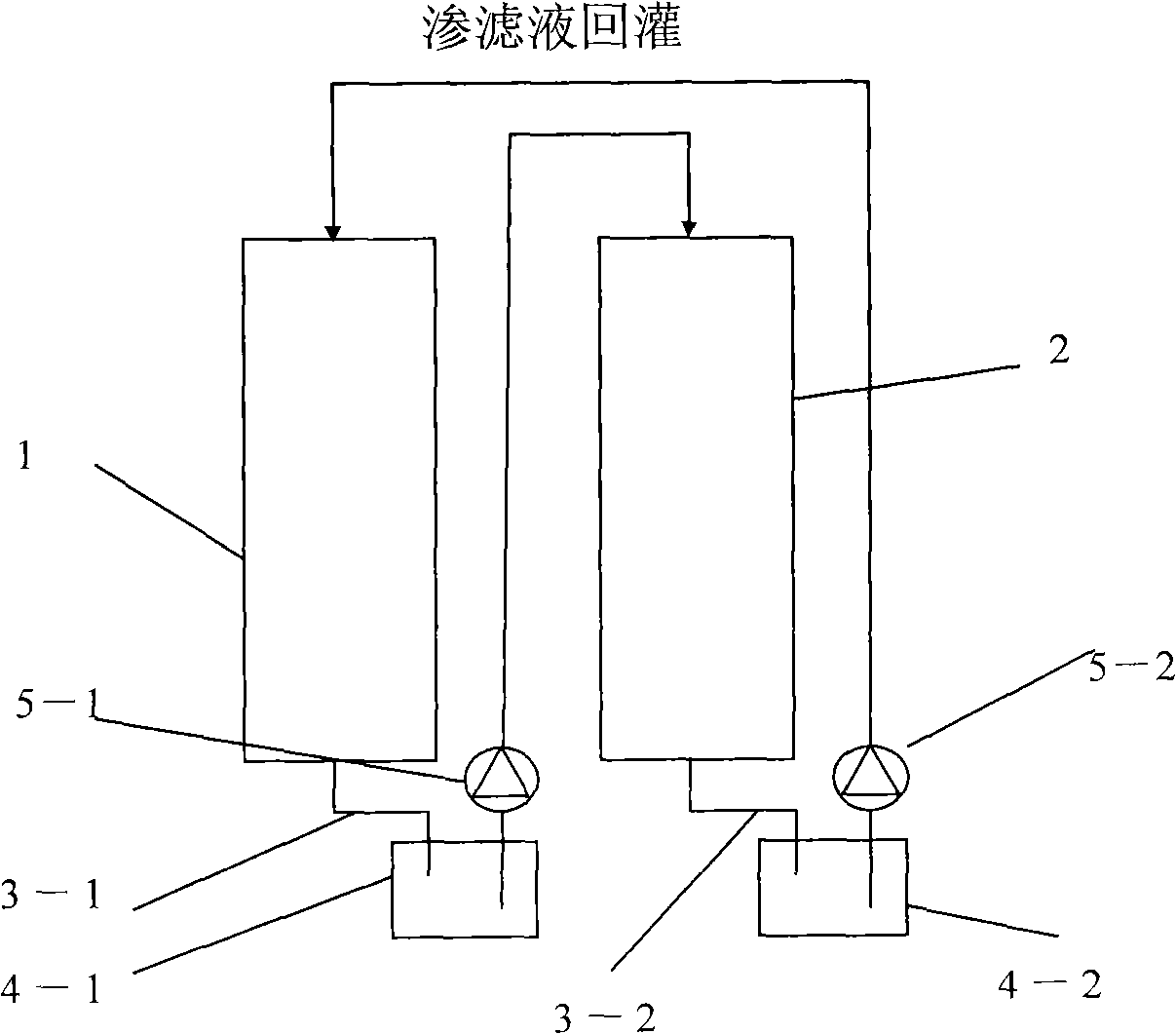

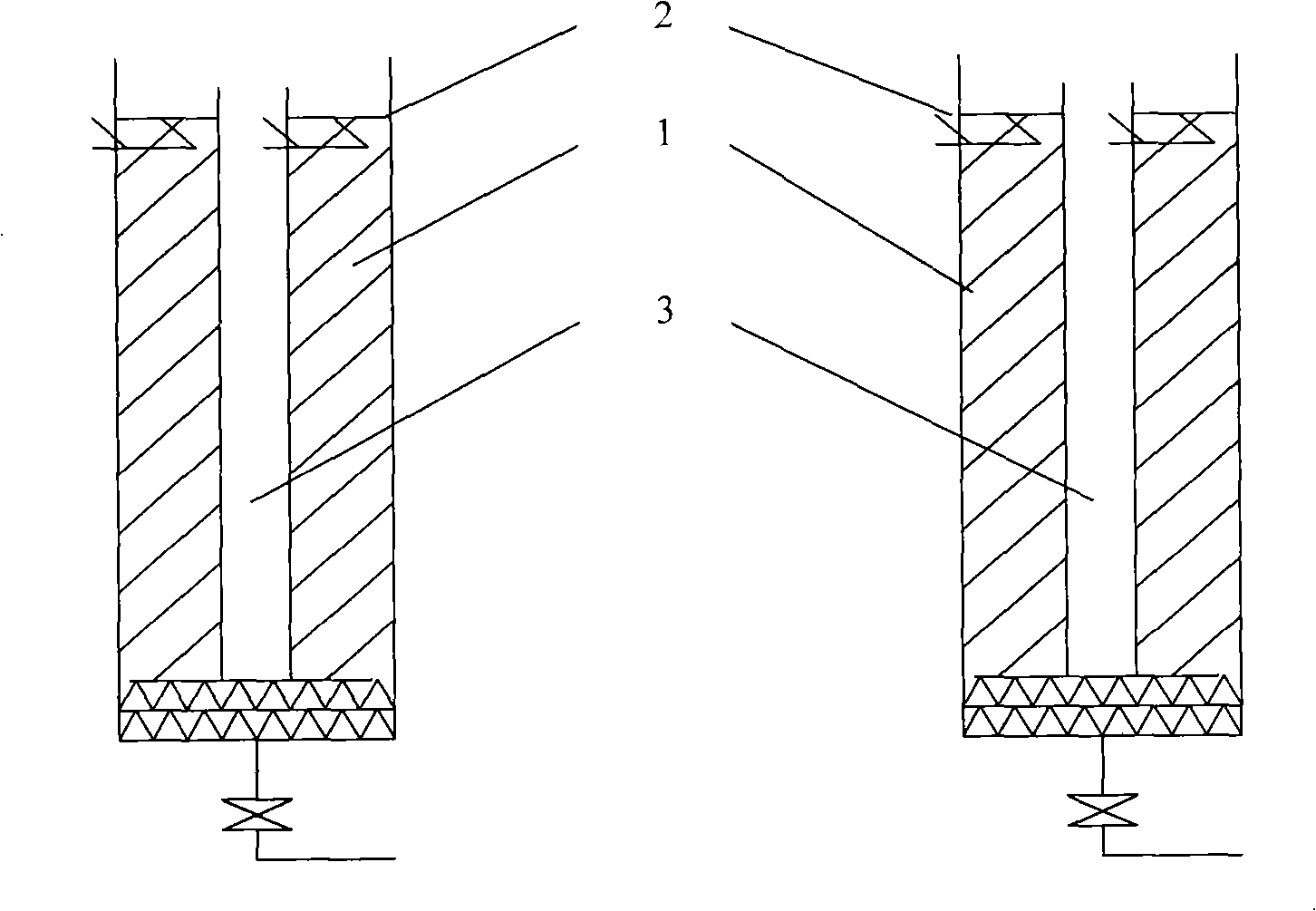

Method and special apparatus for refuse leachate disposal

InactiveCN101269856AShorten landfill cyclePromote degradationWater/sewage treatmentLeachateSustainable yield

The invention discloses a method of treating garbage seeping liquid and a special device thereof. The device of treating the garbage seeping liquid provided by the invention comprises two garbage reactors 1 connected in series and a garbage reactor 2. The garbage reactors 1 and the garbage reactor 2 comprise a pool body, a water distribution device and a vent-pipe. The top part of the pool body is open and the bottom is provided with a through hole. The water distribution device is used for leading the garbage seeping liquid towards the pool body. The vent-pipe is arranged vertically in the tank body to be used for the ventilation. The application of the device of treating the garbage seeping liquid of the invention can realize the sustainable yield of a garbage land fill filed, and achieve the zero draining purpose of the seeping liquid.

Owner:TSINGHUA UNIV

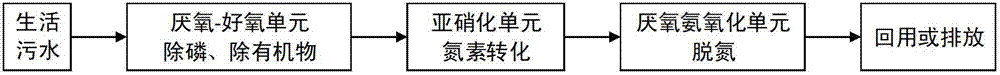

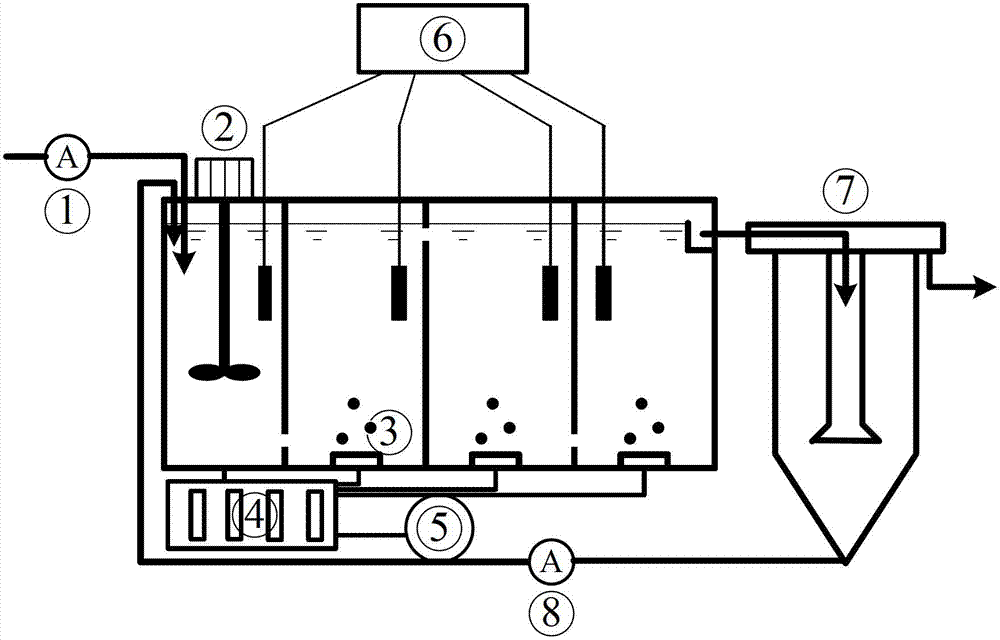

Regeneration method for urban sewage by continuous flow

ActiveCN103112999ASolve denitrificationSolve the contradiction between releasing phosphorus and competing for organic carbon sourceMultistage water/sewage treatmentContinuous flowOxygen

The invention belongs to the technical field of water environment restoration and particularly relates to a regeneration method for urban sewage by continuous flow. In view of the problems existing in a conventional simultaneous nitrogen and phosphorus removal process of serious shortage of carbon sources due to competition for carbon sources in nitrogen and phosphorus removal, big differences in sludge ages of a denitrifier and phosphorus removal bacteria and demand for dissolved oxygen, insufficient alkalinity of sewage, difficulty in giving consideration to nitrogen and phosphorus removal effects concurrently and the like, through overall planning from the process flow and optimization of tasks of all processing units, the regeneration method can be used for removing phosphorus and organic matters by an anaerobic-aerobic process, partially oxidizing ammonia and nitrogen into nitrite nitrogen by a multistage completely hybrid nitrosation process, and realizing autotrophic denitrification by using an upward-flow anaerobic ammonia oxidation biofilter so as to achieve high-efficient low-carbon treatment and regeneration of the sewage, with effluent COD less than 45 mg / L, BOD less than 10 mg / L, TP less than 0.4 mg / L, and TN less than 10 mg / L, so that the treated sewage can reach the national primary standard A.

Owner:BEIJING UNIV OF TECH

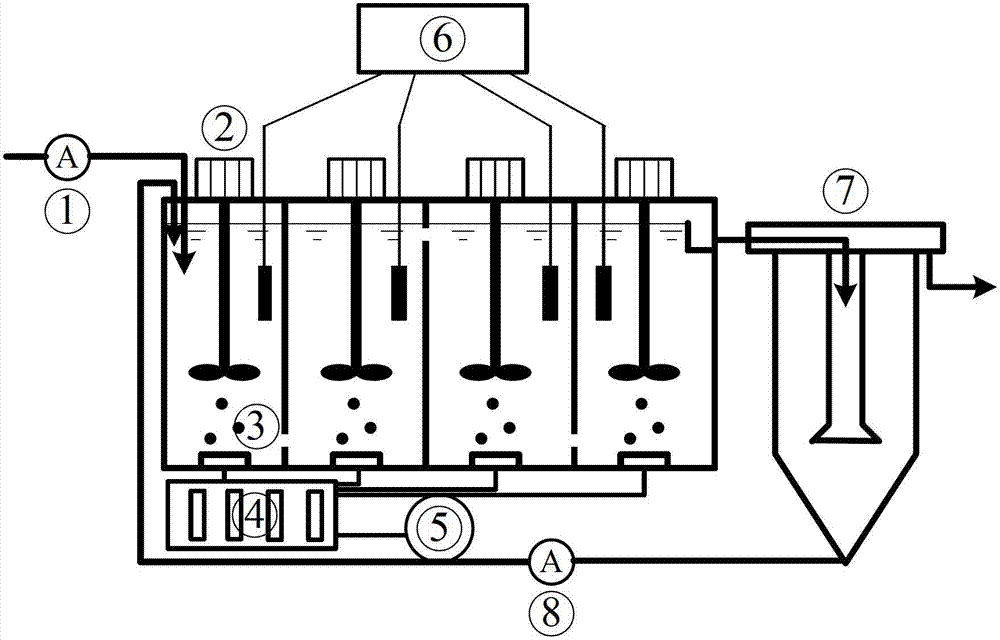

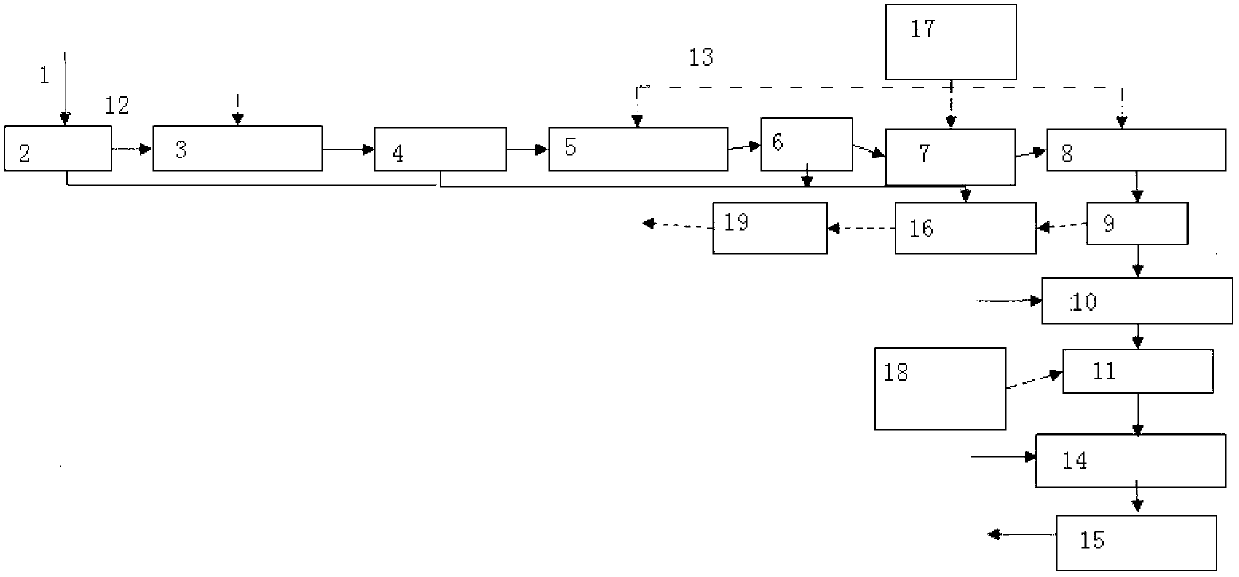

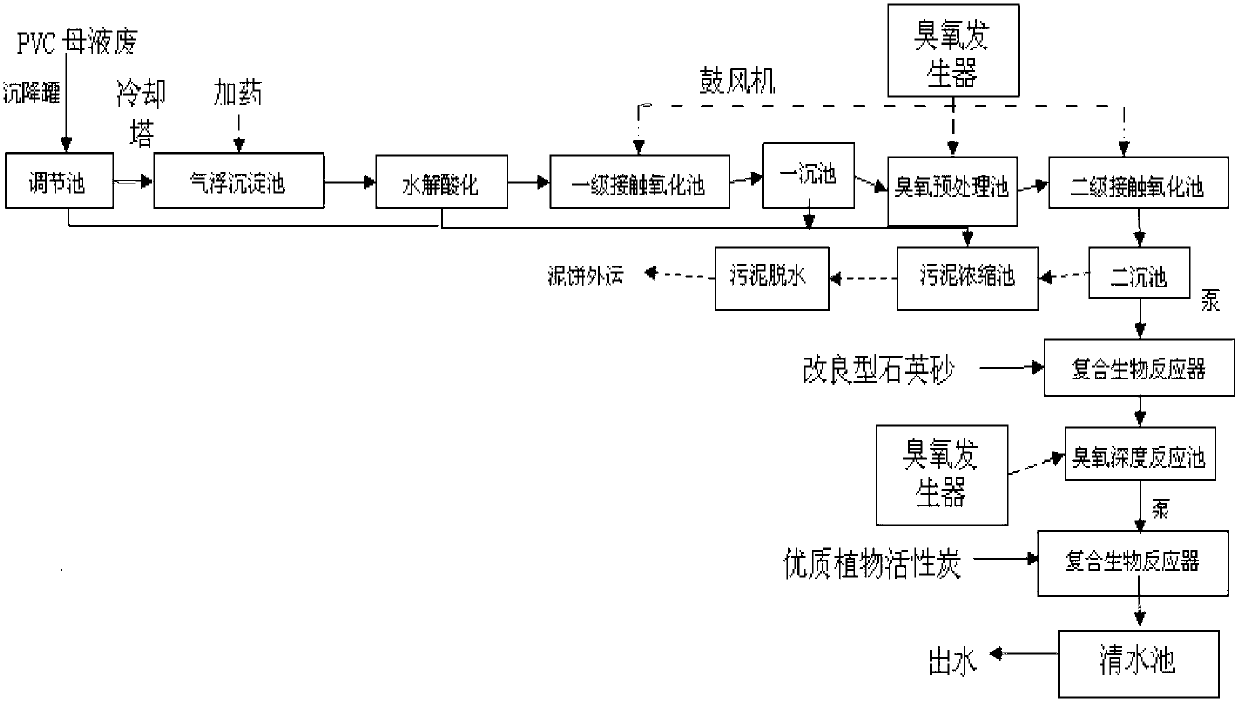

Integrated biotreatment system and method for PVC (poly vinyl chloride) industrial wastewater

InactiveCN103342442AImprove efficiencyReduce energy consumptionMultistage water/sewage treatmentNature of treatment waterHandling systemHydrolysis

The invention discloses an integrated biotreatment system and a method for PVC (poly vinyl chloride) industrial wastewater. The system comprises an air floatation sedimentation unit, a hydrolysis acidification unit, a contact oxidation unit and an advanced treatment unit which are connected sequentially, wherein the air floatation sedimentation unit comprises an air floatation sedimentation pool, the inlet end of the air floatation sedimentation pool is connected with a wastewater pipeline, the hydrolysis acidification unit is a hydrolysis acidification pool, the contact oxidation unit comprises a first grade contact oxidation pool a second grade contact oxidation pool which are in serial connection, the advanced treatment unit comprises a composite membrane bioreactor I connected with the second grade contact pool, and the composite membrane bioreactor I is connected with a clean water basin.

Owner:SHANDONG PACIFIC ENVIRONMENTAL PROTECTION

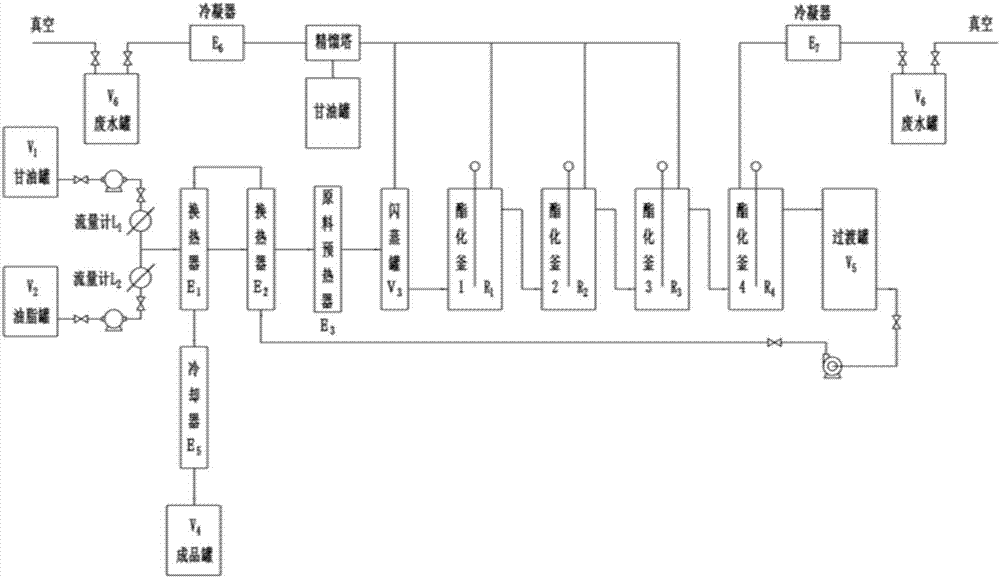

Catalytic-esterification-free acid-degrading process for continuous production of high-acid-value waste oil and fat glycerin

InactiveCN107459997ASolve the problem of meeting the requirements of transesterification for the preparation of biodieselHigh boiling pointBiofuelsLiquid hydrocarbon mixture productionReaction temperatureOil production

A catalytic-esterification-free acid-degrading process for continuous production of high-acid-value waste oil and fat glycerin comprises the steps of raw material mixing and delivery, mixed raw material and finished product heat exchange, mixed raw material preheating after heat exchange, flash evaporation and dehydration of mixed raw materials, continuous esterification reaction and separation of glycerin extracted in the esterification process. The problems of low esterification reaction speed and non-thorough esterification caused by untimely reaction moisture discharging due to low reaction temperature in the process of preparing biodiesel by using high-acid-value waste cooking oil and leftovers in oil production industry and using methyl alcohol as an esterifying agent for pre-esterification and acid decrease are effectively solved, and the problems of device corrosion and environmental pollution brought by a large amount of produced waste acid water due to the fact that sulfuric acid is added to serve as a catalyst in the esterification process is solved. A continuous production process is adopted for esterification reaction, heat exchange of raw materials and finished products is achieved in the continuous process, and the problems of frequent and complicated operation, high labor cost, high production energy consumption, small yield and low efficiency of an intermittent esterification process are solved.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

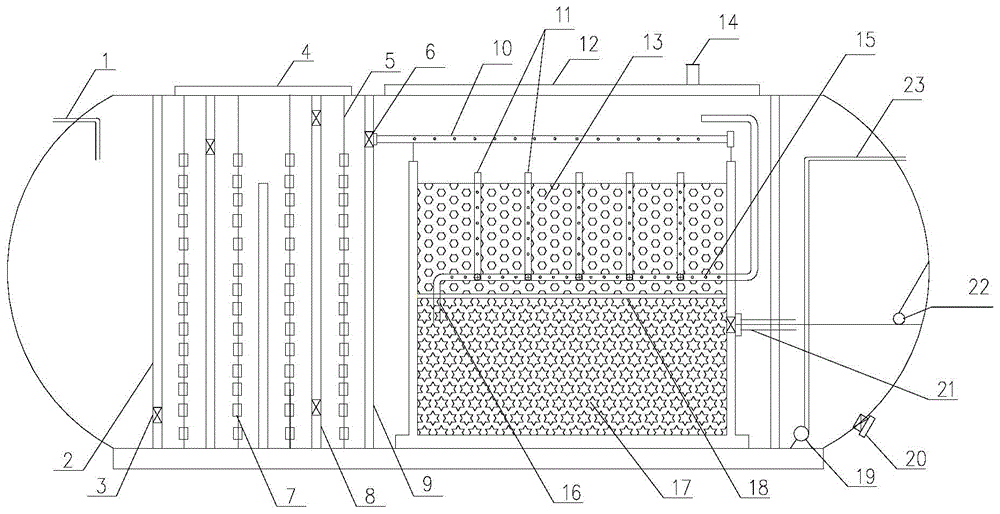

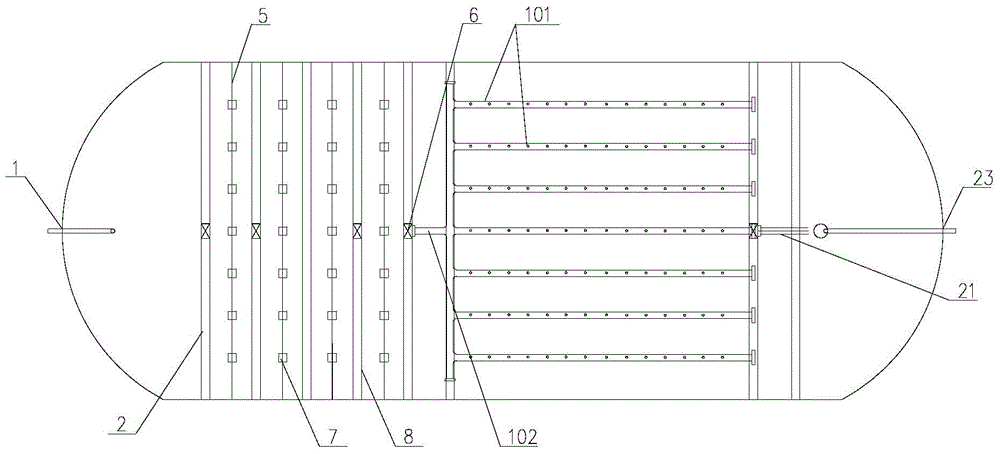

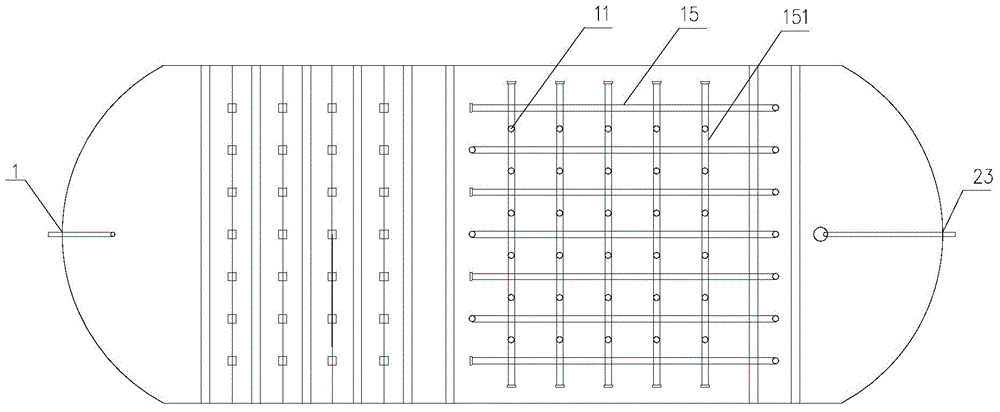

Integrated treatment system for rural domestic sewage and process of system

ActiveCN104556378AEnhanced reoxygenation capacityImprove processing efficiencyBiological treatment apparatusTreatment with aerobic and anaerobic processesOxygenHydrolysis

The invention discloses an integrated treatment system for rural domestic sewage and a process of the system. The integrated treatment system comprises a tank body, and an inlet water adjusting unit, a treating unit and an effluent adjusting unit, which are sequentially communicated with one another in the tank body, wherein the treating unit comprises an anaerobic hydrolysis acidification treating chamber and a stacked ecological filter treating chamber; a zigzag sewage channel is arranged in the anaerobic hydrolysis acidification treating chamber; the inlet of the sewage channel is communicated with the inlet water adjusting unit; a filling material is arranged in the sewage channel; the stacked ecological filter treating chamber comprises an upper ecological filter and a lower ecological filter which are separate from each other; a water distribution pipe communicated with the outlet of the sewage channel is arranged at the top of the upper ecological filter; water collection gas-dispersion pipes with through holes are arranged in the upper ecological filter; the top of the water collection gas-dispersion pipes extend to positions above the upper ecological filter; the bottoms of the water collection gas-dispersion pipes are communicated with the lower ecological filter; the lower ecological filter is communicated with the effluent adjusting unit. According to the integrated treatment system provided by the invention, anaerobic hydrolysis acidification treatment and stacked ecological filter treatment processes are integrated, so that reaeration capacity of a soil seepage system is improved and a favorable condition is created for aerobic / anaerobic reaction.

Owner:ENVIRONMENTAL SCI RES & DESIGN INST OF ZHEJIANG PROVINCE

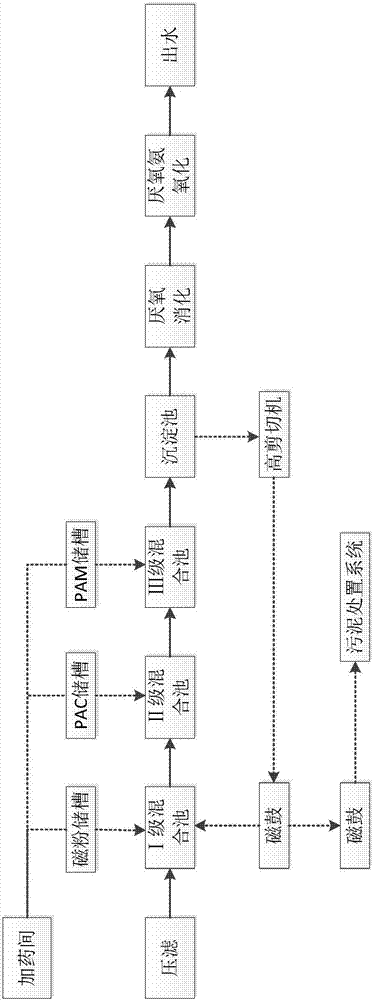

Method for pretreating organic wastewater

InactiveCN107365010ASimple structureHigh densityWater contaminantsWaste water treatment from animal husbandryHigh concentrationPretreatment method

The invention discloses a method for pretreating organic wastewater. The method comprises the following steps: (1) adding a magnetic seed into organic wastewater to be treated, and quickly stirring for 1-2 minutes; (2) adding a flocculating agent, and quickly stirring for 1-2 minutes; (3) adding coagulant aid, quickly stirring for 5-30 seconds, and slowly stirring for 1-2 minutes; (4) standing to precipitate, draining and discharging slurry, wherein the speed of quickly stirring is 150-400r / min, and the speed of slow stirring is 30-80r / min. According to the method, heavy metal, antibiotic and other micropollutants can be removed by adding the magnetic seed to reinforce the coagulating process, so that high solid content, and the suspended solid content, COD concentration and total phosphorous concentration of high-concentration wastewater can be effectively reduced, and load of subsequent treatment units can be reduced.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

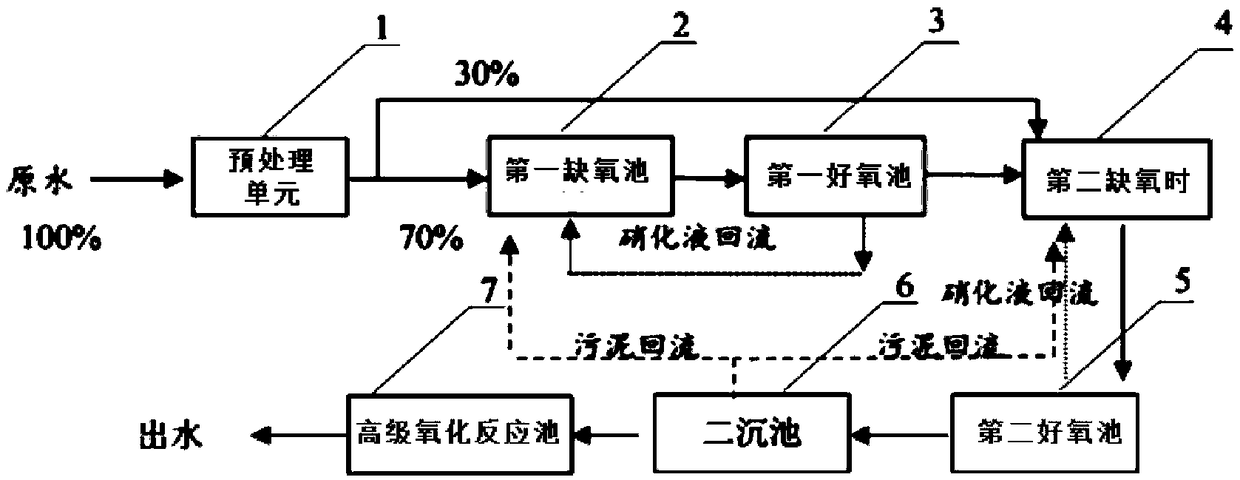

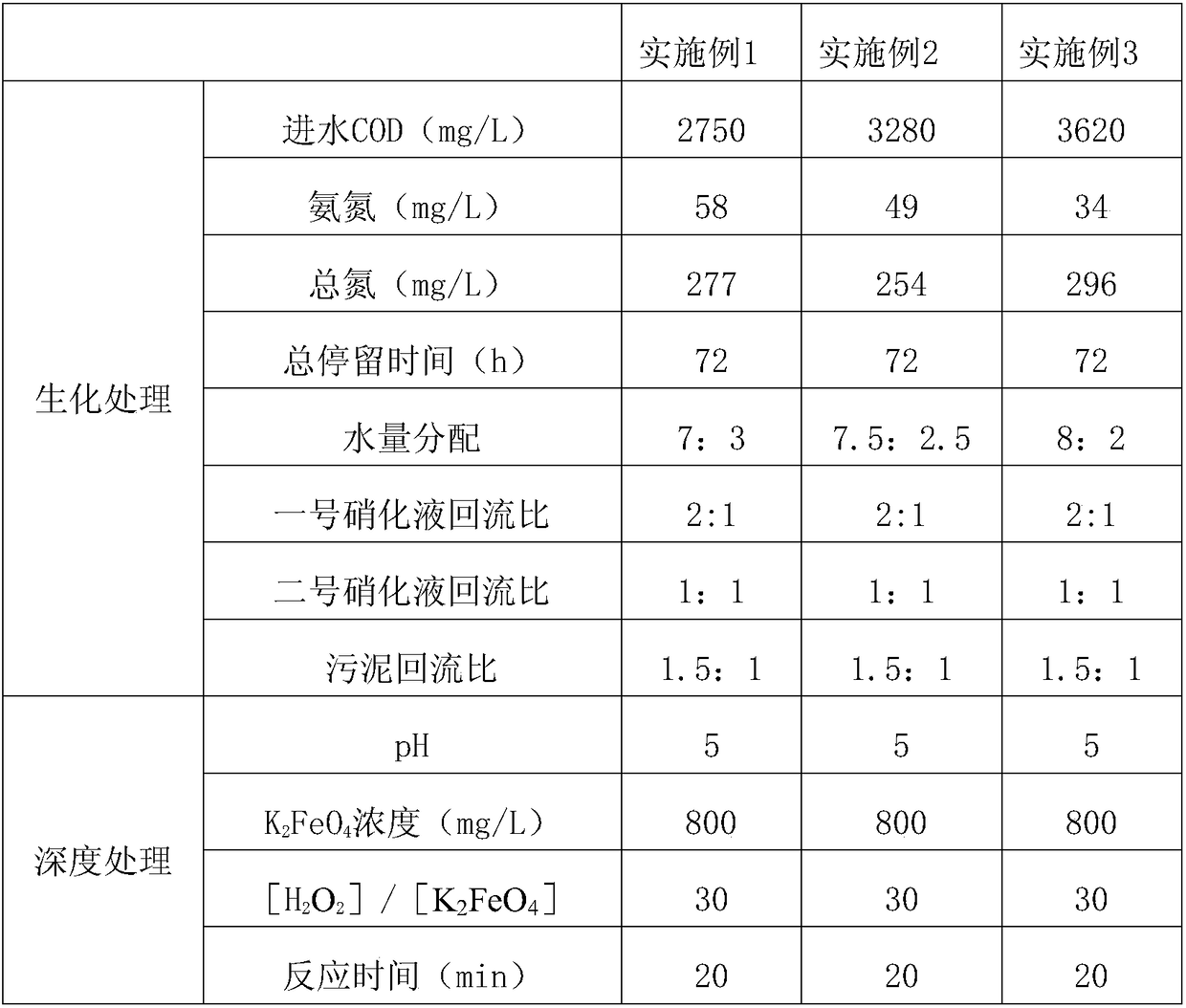

Coking waste water joint-treatment process

InactiveCN109205930AToxic reductionImproved resistance to shock loadsFatty/oily/floating substances removal devicesTreatment using aerobic processesActivated sludgeNitrogen

The invention relates to a coking waste water joint-treatment process, which comprises a biochemical treatment process of coking waste water and an advanced treatment process of coking waste water. The biochemical treatment process of coking waste water adopts two-stage A / O process with segmented water inflow, namely, anoxic, aerobic, anoxic, aerobic biological denitrification process, all using activated sludge method, wherein activated sludge is inoculated from a second sedimentation tank of a coking waste water treatment plant. The advanced treatment process of the coking waste water adoptsthe sequencing batch operation.

Owner:BEIJING JIAOTONG UNIV

Comprehensive treatment method for high-salt high-COD wastewater

InactiveCN110316910AImprove biodegradabilityHigh removal rateWater/sewage treatment with mechanical oscillationsWater/sewage treatment by electrochemical methodsCatalytic oxidationWater quality

The invention relates to a comprehensive treatment method for high-salt high-COD wastewater. The method comprises the following steps that (1) wastewater enters an adjustment tank through a grid, thepH is adjusted, effluent of the adjustment tank enters a coagulating sedimentation tank, and a flocculant is added for coagulating sedimentation; (2) effluent of the coagulating sedimentation tank enters an ultrasonic electrocatalysis oxidation device for treatment; (3) effluent of the ultrasonic electrocatalysis oxidation device enters an electrodialysis device for treatment; (4) through electrodialysis desalination, fresh water enters an ABR anaerobic baffle plate reactor for treatment; (5) effluent of the ABR anaerobic baffle plate reactor enters a BSBR reactor, and a salt-tolerance microorganism reinforcement salt-containing wastewater is added to the BSBR reactor for biochemical treatment; (6) effluent of the BSBR reactor enters an ozone reaction device for treatment; (7) ozone effluent passes through an adsorption filtering device and is reused or discharged at last. The method has the advantages that the technology is reliable and high in stability, the rate of removing pollutants is high, and the water quality of the effluent stably reaches the standard, and the method is suitable for comprehensive treatment of the high-salt high-COD wastewater.

Owner:浙江一清环保工程有限公司

Denitrification and decarbonizing treatment system and method of landfill leachate in late period

ActiveCN109052875AEfficient and low consumption processingEfficient removalWater contaminantsMultistage water/sewage treatmentAmmoniaLeachate

The invention provides a denitrification and decarbonizing treatment system and method of landfill leachate in a late period, and belongs to the field of wastewater treatment. The system comprises a denitrification reactor, a nitrosation reactor, an anaerobic ammonia oxidation reactor, a concentrating pool, an oxidization pool and two return-flow system. According to the system, the concentratingpool is arranged and used for intercepting nondegradable organic substances in water output through the anaerobic ammonia oxidation reactor; the nondegradable organic substances can be oxidized into degradable organic substances through the oxidization pool, so that a carbon source is supplied to the denitrification process; the return-flow system supplies a proper environment to microorganism, and wastewater can be treated with high efficiency and low consumption; with the adoption of the system for treating the landfill leachate in the late period, the high independence of the denitrification process on additional organic substances can be avoided, so that demands on the organic substances can be decreased, and the denitrification cost of the landfill leachate can be decreased.

Owner:SUZHOU UNIV OF SCI & TECH

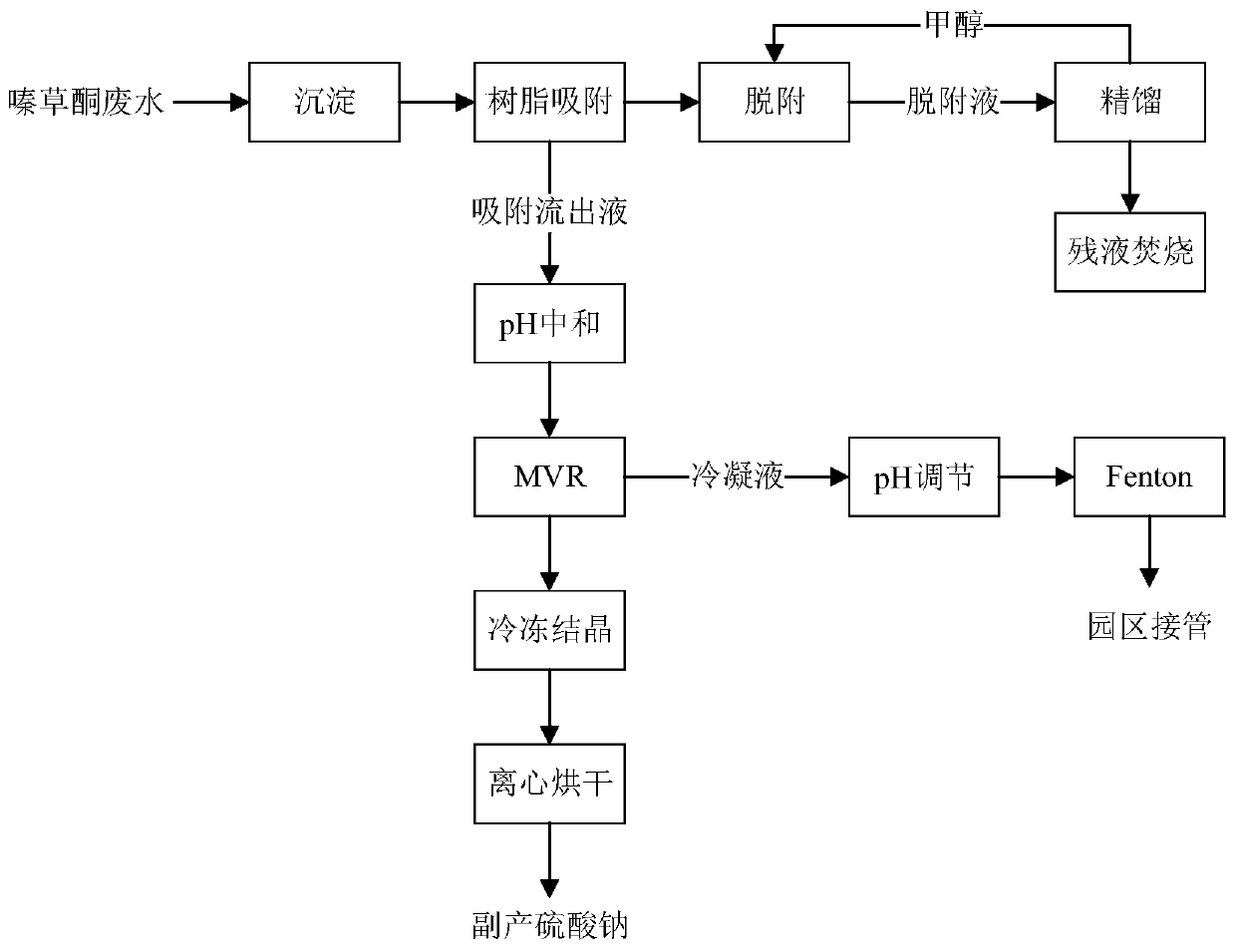

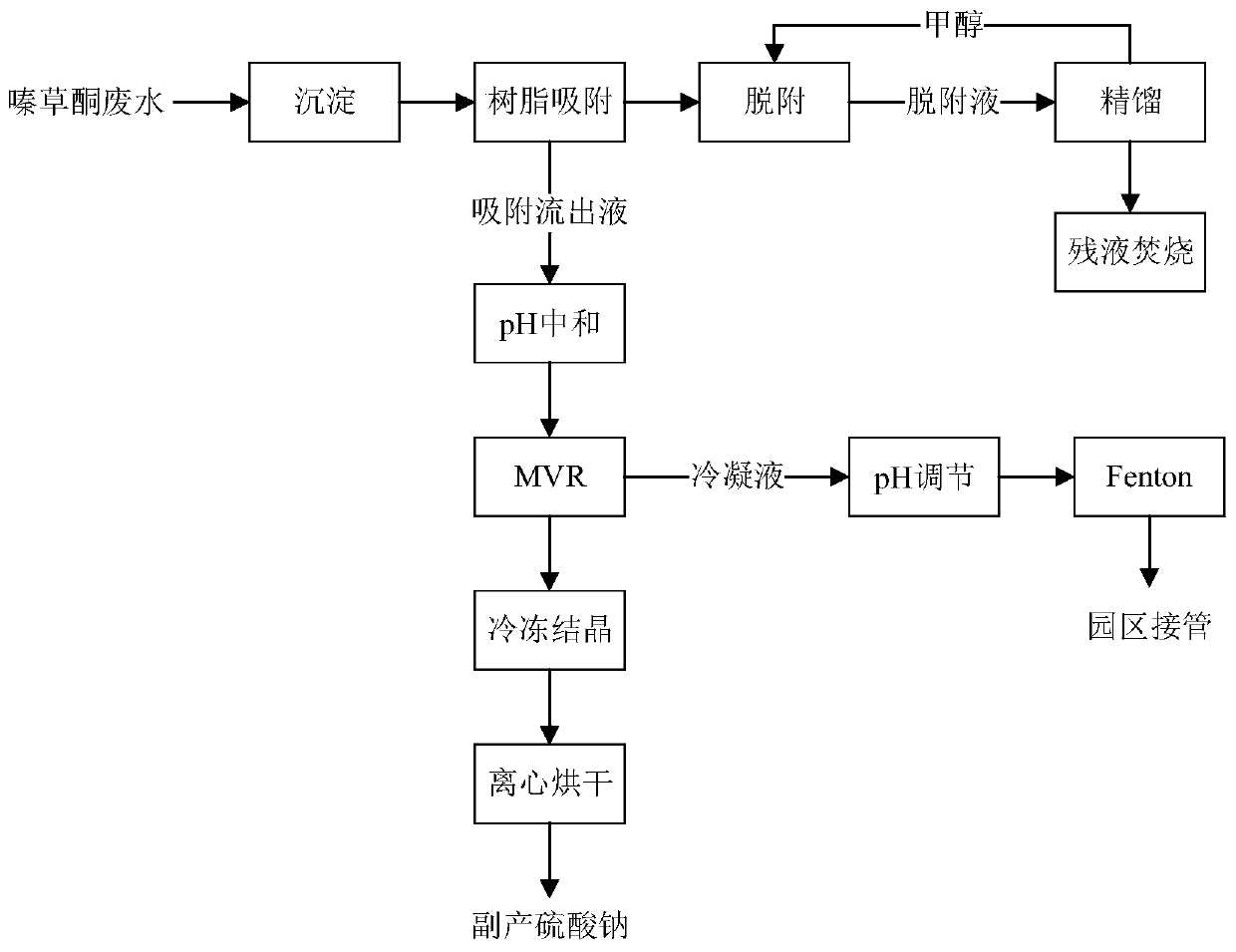

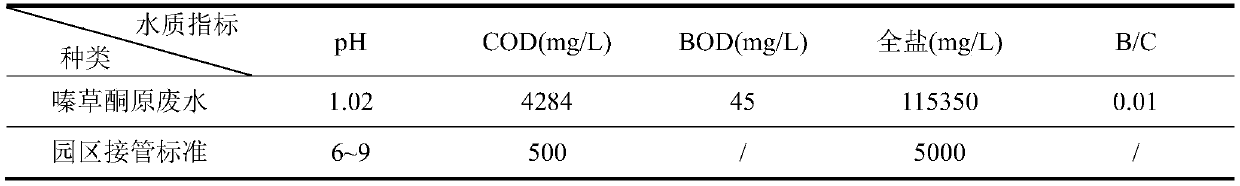

Treatment process for discharging metribuzin wastewater in compliance with standard in coordination with salt recycling and running method of treatment process

InactiveCN109912094AReduce COD concentrationSave resourcesWater contaminantsAlkali metal sulfite/sulfate purificationPh neutralizationFiltration

The invention discloses a treatment process for discharging metribuzin wastewater in compliance with standard in coordination with salt recycling and a running method of the treatment process, and belongs to the technical field of pesticide wastewater treatment. The treatment process mainly comprises the steps of precipitation filtration, resin adsorption, pH neutralization, MVR, pH adjustment andFenton advanced oxidation. Salt recycling is conducted by steps as follows: performing evaporation crystallization and centrifugal drying to obtain refined industrial sodium sulfate. The concentration of COD in the metribuzin wastewater can be greatly reduced by resin adsorption treatment, and salt in wastewater can be further removed by MVR. Finally, Fenton advanced oxidation treatment is adopted, and effluent meets the connection standard of the park pipe network. Efficient and stable treatment of the metribuzin wastewater which contains high COD and high salt and is difficult to biologically degrade is realized, so that the metribuzin wastewater is discharged continuously in compliance with standard, and recycling of sodium sulfate in the wastewater is also realized.

Owner:江苏南大华兴环保科技股份公司

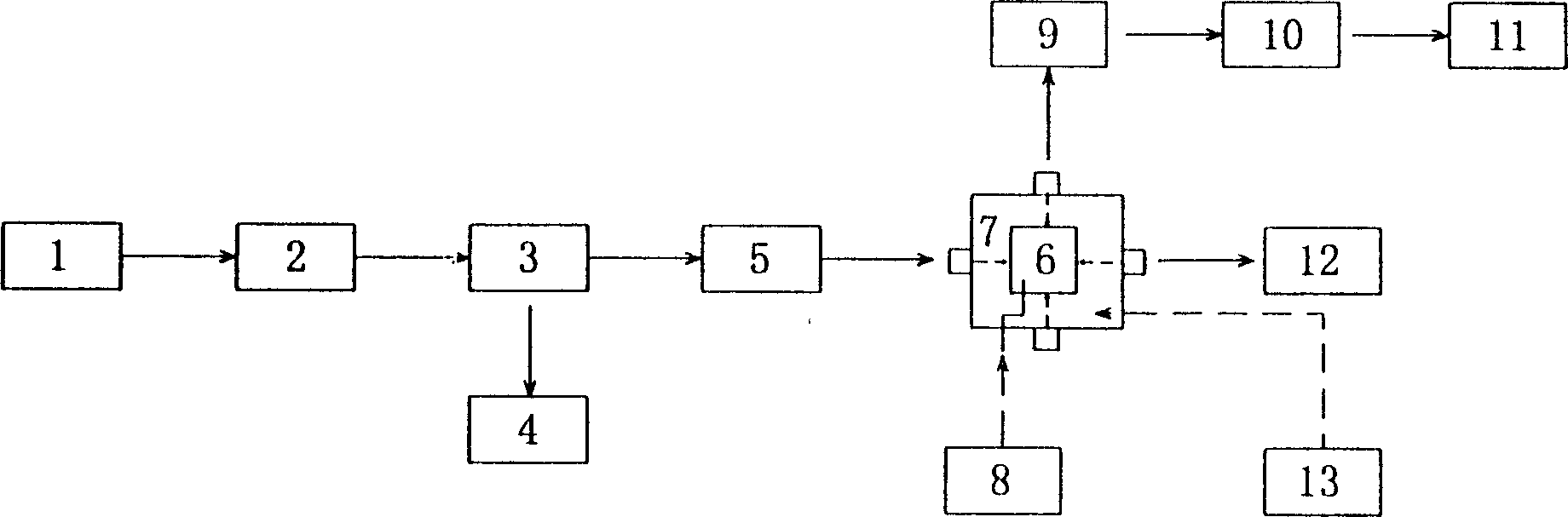

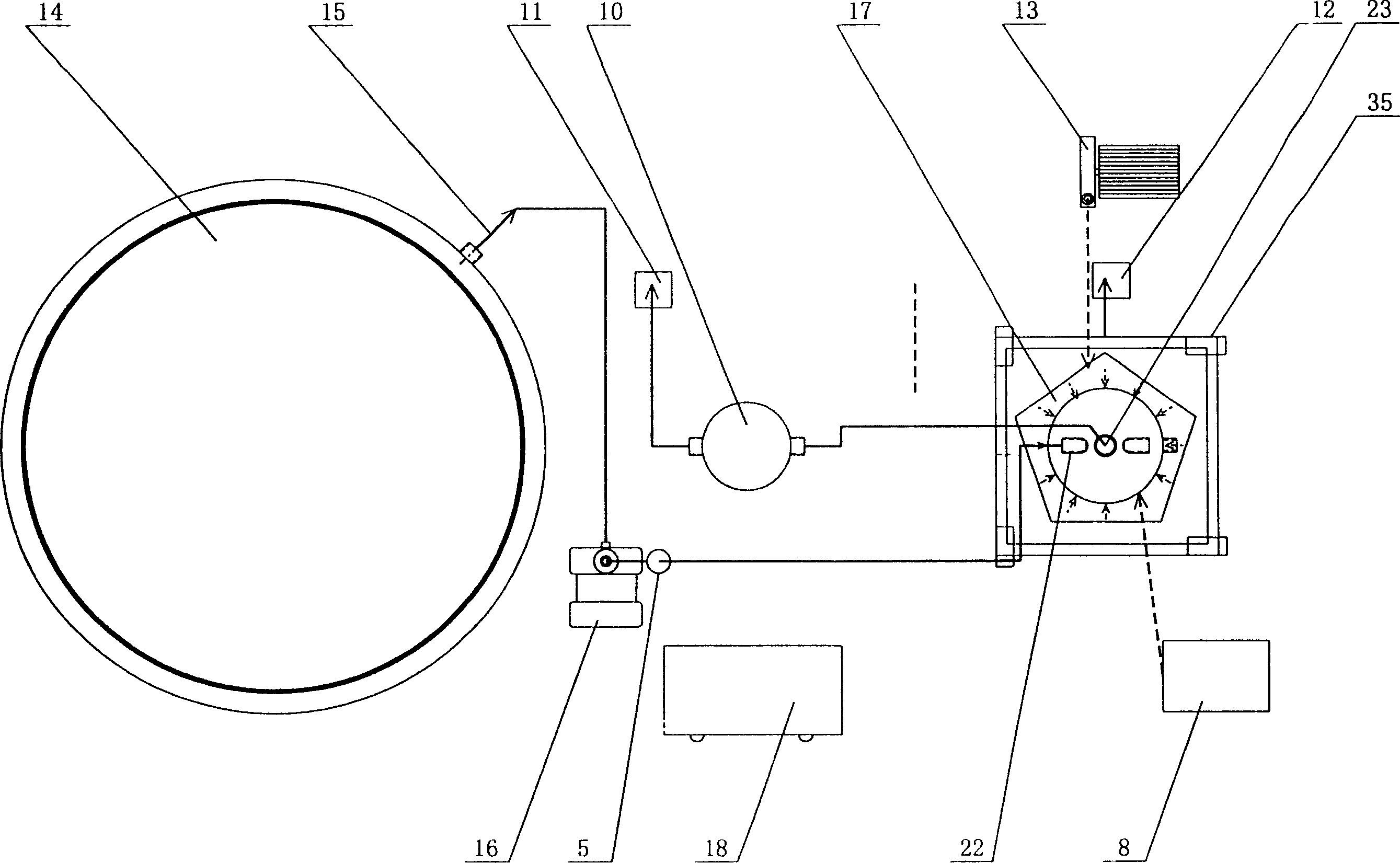

Microwave catalytic oxidation process and apparatus for treating waste water containing hard-to-degrade organic matters

InactiveCN1199887CReduce COD concentrationReduce processing costsMultistage water/sewage treatmentCatalytic oxidationSmall footprint

In the field of water treatment, microwave catalytic oxidation is a process and device for treating refractory organic wastewater. The process includes: grid impurity removal [2], flocculation sedimentation [3], catalytic oxidation and steam [9] condensation, and its characteristics: catalytic oxidation is in It is carried out in a microwave reactor [17], the ratio of oxidant mass to wastewater COD mass is 1.0-20%, the temperature is lower than 100°C, and the residence time is 4-17min. The device includes: a raw water tank [14], a flow meter [5], a gas-liquid mixer [19], a heat exchanger [10], a pump [16] and a fan [13]. Its features: the microwave reactor [17] is composed of an inner reactor [6] and a microwave resonant cavity [7]. Advantages: (1) Low temperature and normal pressure; (2) Small footprint; (3) High degradation efficiency; (4) Simple operation and easy automation.

Owner:DALIAN UNIV OF TECH +1

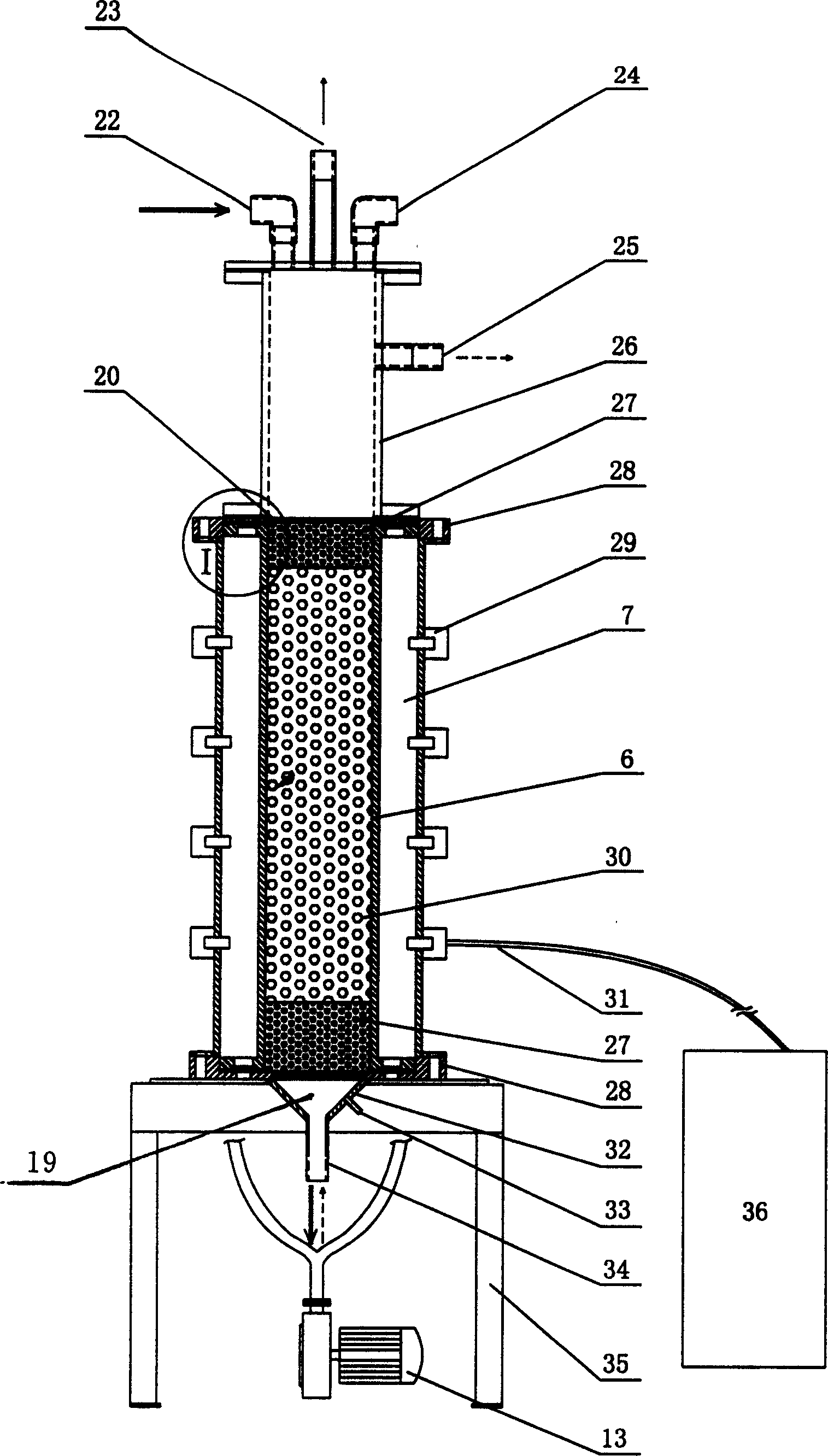

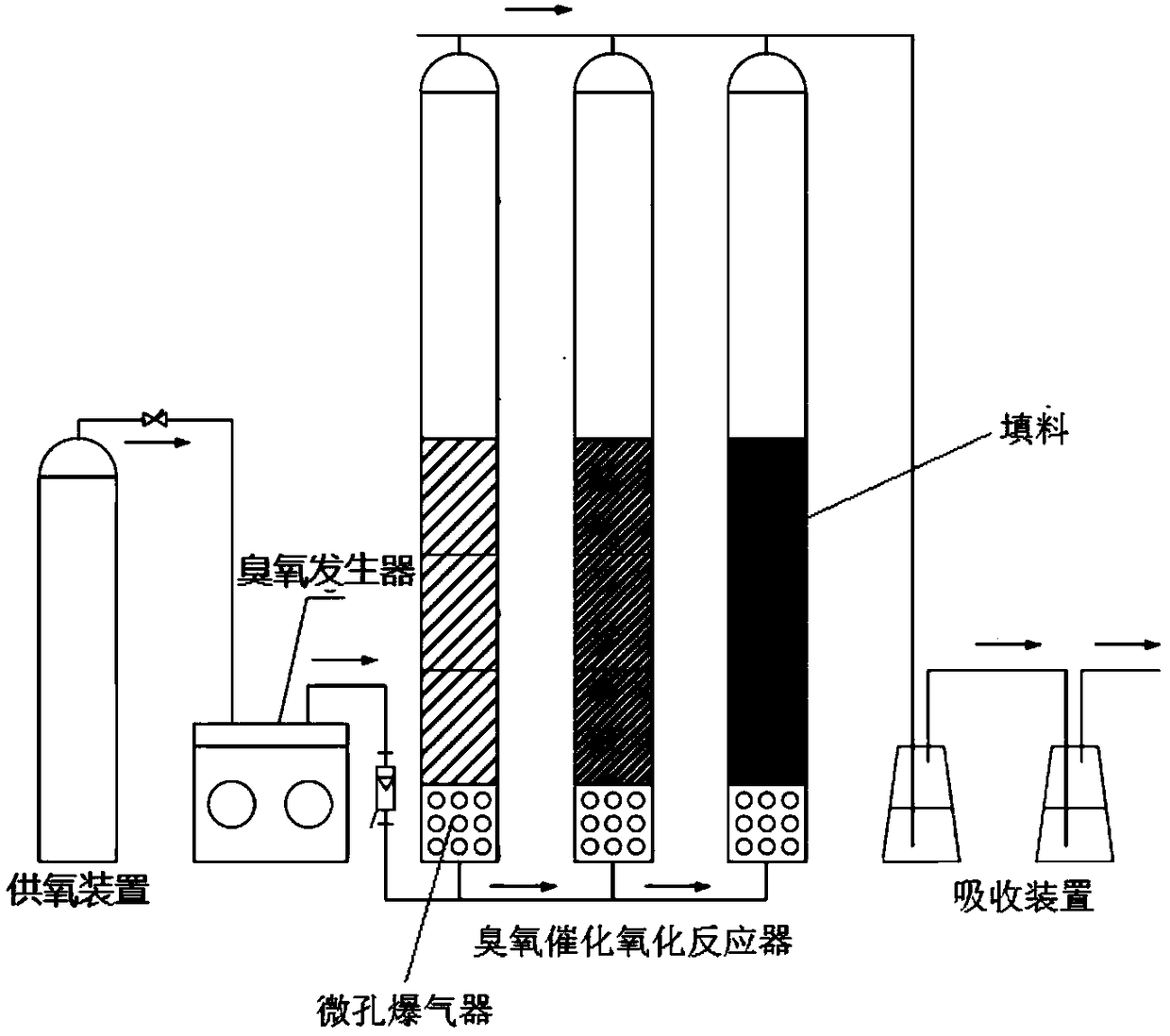

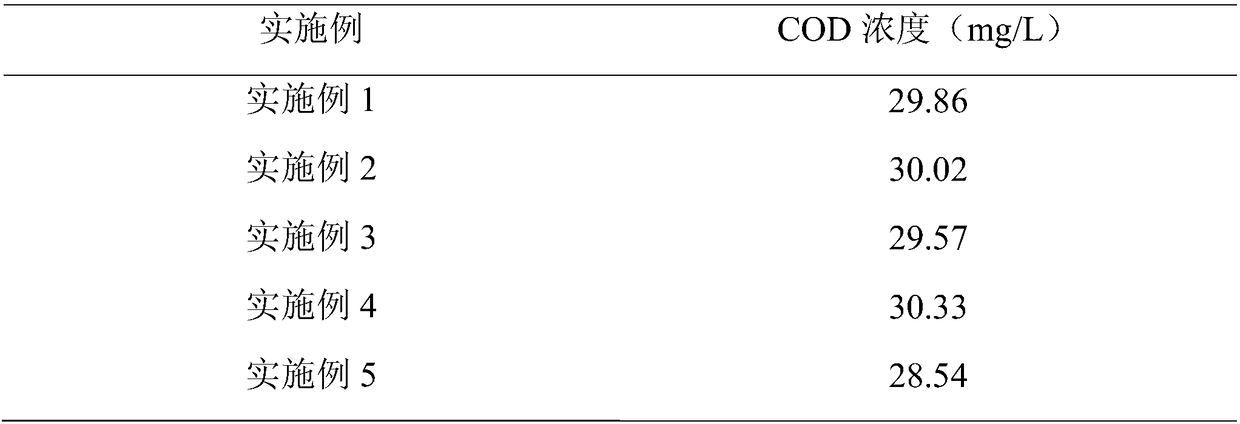

Catalytic ozonization method

InactiveCN109384300AHigh catalytic efficiencyReduce COD concentrationWater/sewage treatment apparatusWater/sewage treatment by oxidationOzone generatorCatalytic oxidation

The invention provides a catalytic ozonization method. The catalytic ozonization method is implemented by using a catalytic ozonization apparatus. The catalytic ozonization apparatus comprises an oxygen supply device, an ozone generator, a catalytic ozonization reactor and an absorption device which are successively connected via pipelines, wherein the catalytic ozonization reactor is a cylindrical pipeline and comprises a microporous aeration device and a packing layer arranged from bottom to top. The effluent of a secondary sedimentation tank is injected into the catalytic ozonization reactor, and catalytic oxidation is carried out under an aeration condition; the COD concentration of the effluent of the secondary sedimentation tank is 60 to 100 mg / L; a packing in the packing layer is acatalytic ozonization catalyst; a volume ratio of the packing to the effluent of the secondary sedimentation tank is (0.5-1): 1; and the aeration efficiency of the microporous aeration device satisfies the condition that a mass concentration ratio of COD in the effluent of the secondary sedimentation tank to ozone is 1: (0.2-1).

Owner:光大水务(深圳)有限公司

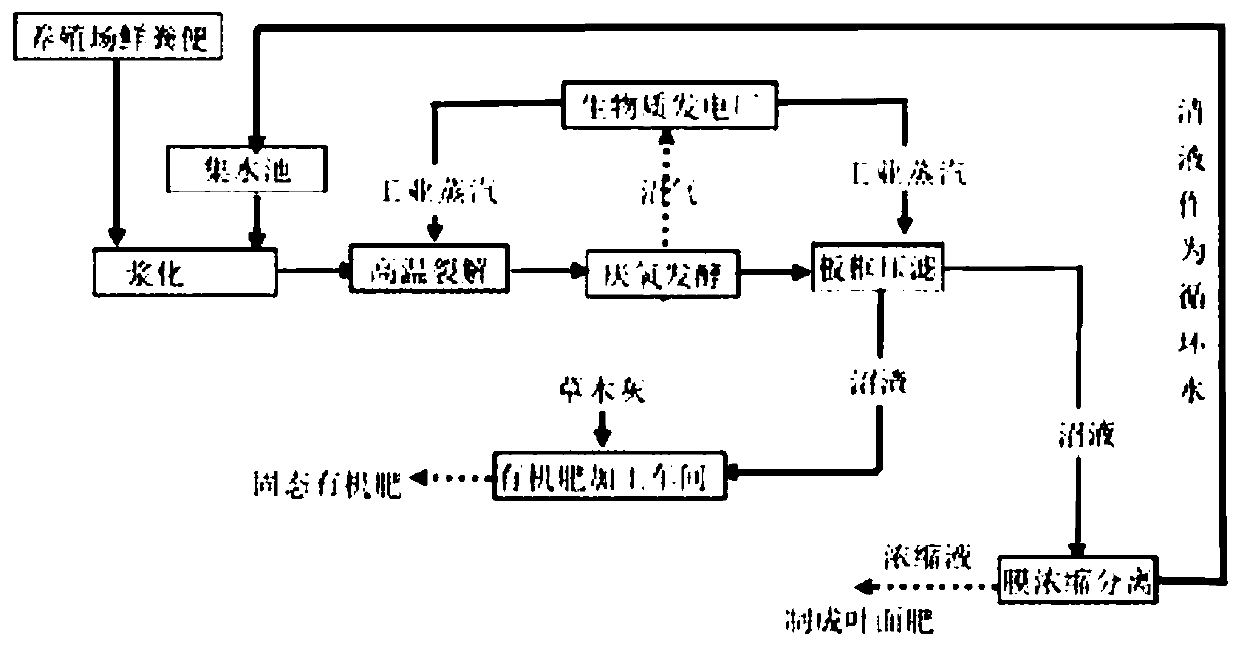

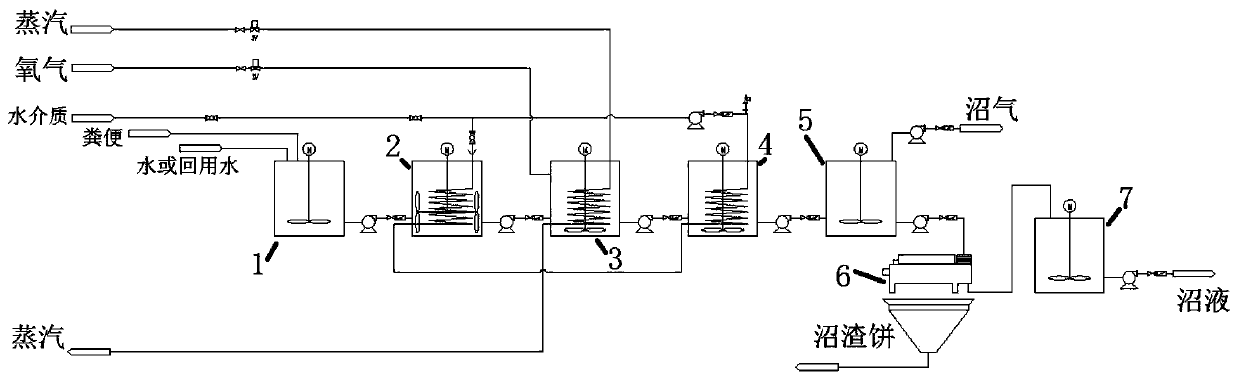

Livestock and poultry excrement disposal system and method taking energy and fertilizer into consideration

InactiveCN110420967AEasy to separateReduce COD concentrationWaste processingSolid waste disposalFecesSlurry

The invention discloses a livestock and poultry excrement disposal method taking energy and fertilizer into consideration. The method comprises the following steps of preparing excrement slurry, specifically, excrement and water are mixed in proportion to prepare the excrement slurry with the input concentration of 10%; carrying out fermentation pretreatment of the excrement slurry, specifically,a critical water oxidation reaction is carried out on the excrement slurry, bacteria is killed to break cell gaps to prepare for deep dehydration, and the reacted slurry is cooled; carrying out anaerobic fermentation, specifically, a medium-temperature anaerobic fermentation reaction is carried out on the cooled slurry to generate biogas; and dehydrating and drying, specifically, after fermentation, the slurry is dehydrated and dried to separate biogas residues from biogas slurry.

Owner:浙江中能环境科技有限公司

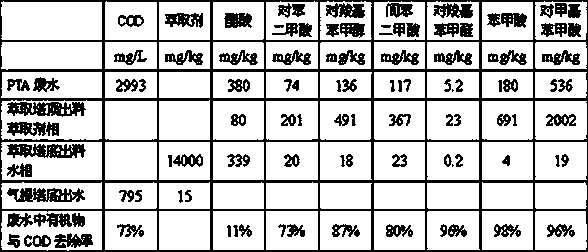

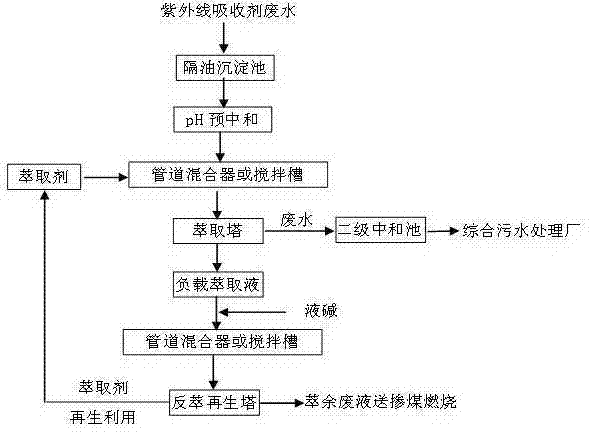

Extraction method for reducing emission of chemical oxygen demand (COD) in pure terephthalic acid (PTA) wastewater

ActiveCN102910761BAchieve emission reductionReduce COD concentrationOrganic compound preparationMultistage water/sewage treatmentBenzoic acidResource utilization

Owner:浙江化安安全技术研究院有限公司

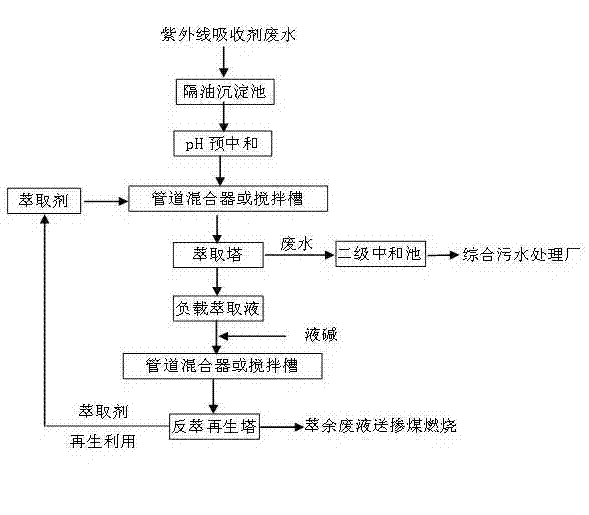

Method for pre-treating wastewater from ultraviolet absorber production

InactiveCN102515391AThe process is simple and reasonableStrong maneuverabilityWater contaminantsMultistage water/sewage treatmentChemistryUv absorber

The invention relates to a method for pre-treating wastewater from ultraviolet absorber production. The method is characterized in that the method mainly comprises the treating processes of settling separated oil, pre-neutralizing, extracting, secondarily neutralizing and regenerating an extracting agent. According to the method, a HLE phenol-containing wastewater extracting agent is used for separating polycyclic phenols which are difficult to be biodegraded in the wastewater; after being regenerated, the extracting agent is reused; after the wastewater of UV-0 production is treated according to the method, the biodegradability is greatly increased; the B / C ratio of the treated discharge water is increased from the original 0.01-0.1 to 0.3-0.5; the total COD (Chemical Oxygen Demand) removing rate is above 40%; the guarantee is supplied to the subsequent biochemical treatment; and the method has the advantages of convenience in operation, and the treating cost is lower than that of the pre-treating technologies, such as evaporation salting, advanced wastewater oxidation, and the like.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

Textile wastewater treatment system<0}

InactiveCN106698867ALow costImprove processing efficiencyFatty/oily/floating substances removal devicesTreatment using aerobic processesAutomatic controlChlorine dioxide

The invention discloses a textile wastewater treatment system. The textile wastewater treatment system comprises a grid oil separator capable of collecting textile wastewater, as well as a decolorizing pretreatment pool, a regulating reservoir, a hydrolysis acidification pool, a contact oxidation pool and a reactive precipitation pool which are sequentially communicated with the grid oil separator through wastewater pipelines, wherein <0}the reactive precipitation pool comprises a top reaction zone and a bottom settling zone; the bottom settling zone is connected with a press filter through a sludge pipeline; the press filter is connected with the grid oil separator through a wastewater pipeline; the press filter discharges sludge through the sludge pipeline; the top reaction zone is connected with a disinfection pool through a wastewater pipeline; the periphery of the disinfection pool is provided with a chlorine dioxide generator; the textile wastewater treatment system further comprises a control system. <0}By virtue of reasonable combination of biochemistry and physical chemistry, a textile wastewater treatment system which is low in cost, high in treatment efficiency and stable in system operation is formed; furthermore, by virtue of a PLC (Programmable Logical Controller), a PH sensor, a flowmeter and the like, the system is automatic in dosage control, high in control process automation degree and accurate in control, and is capable of lowering the labor cost.

Owner:JIANGSU YONGYI ENVIRONMENTAL PROTECTION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com