Microwave catalytic oxidation process and apparatus for treating waste water containing hard-to-degrade organic matters

A microwave catalytic oxidation and organic wastewater technology, applied in the field of water treatment, can solve the problems of expensive self-made catalysts, difficulty in technology promotion, high treatment costs, etc., and achieve the effects of easy automatic production, simple process, and high organic degradation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

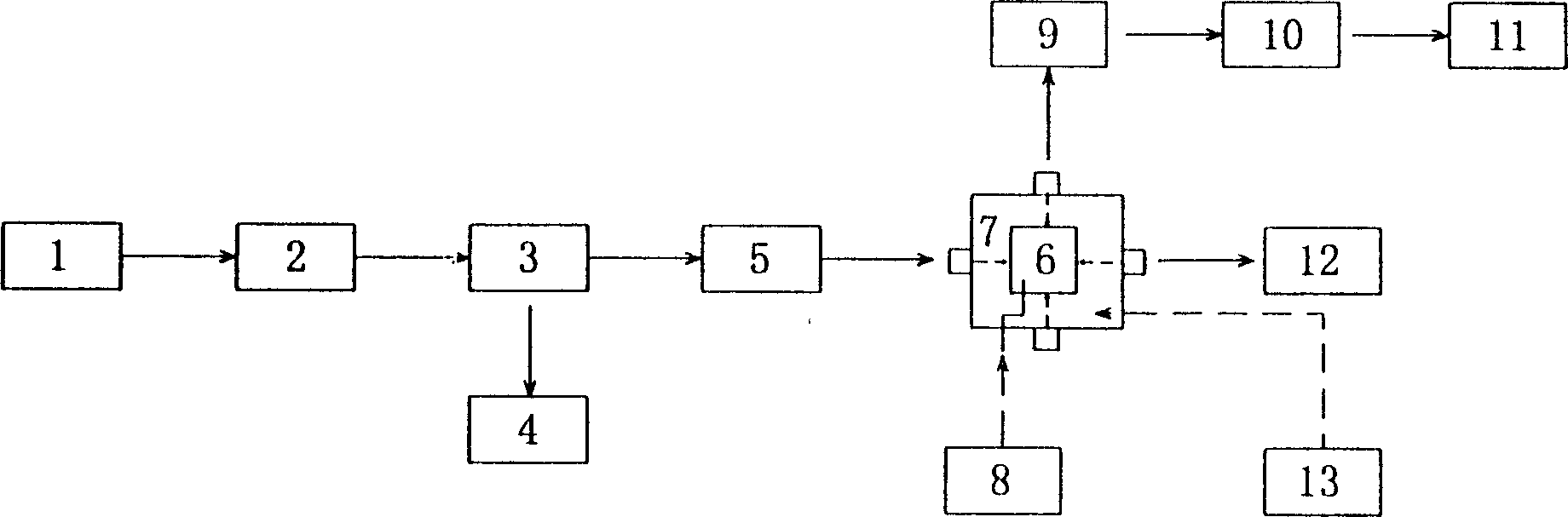

Method used

Image

Examples

Embodiment 1

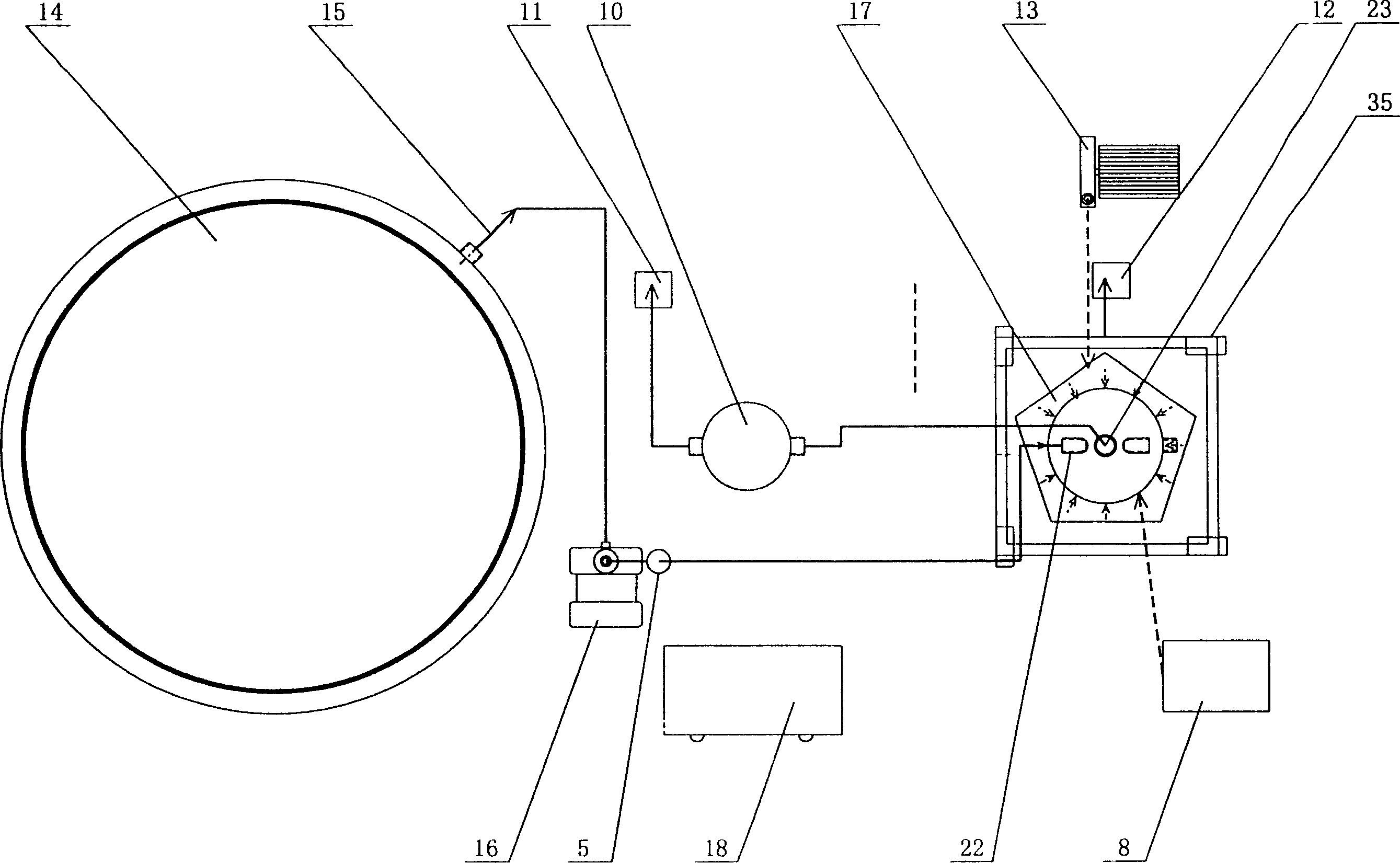

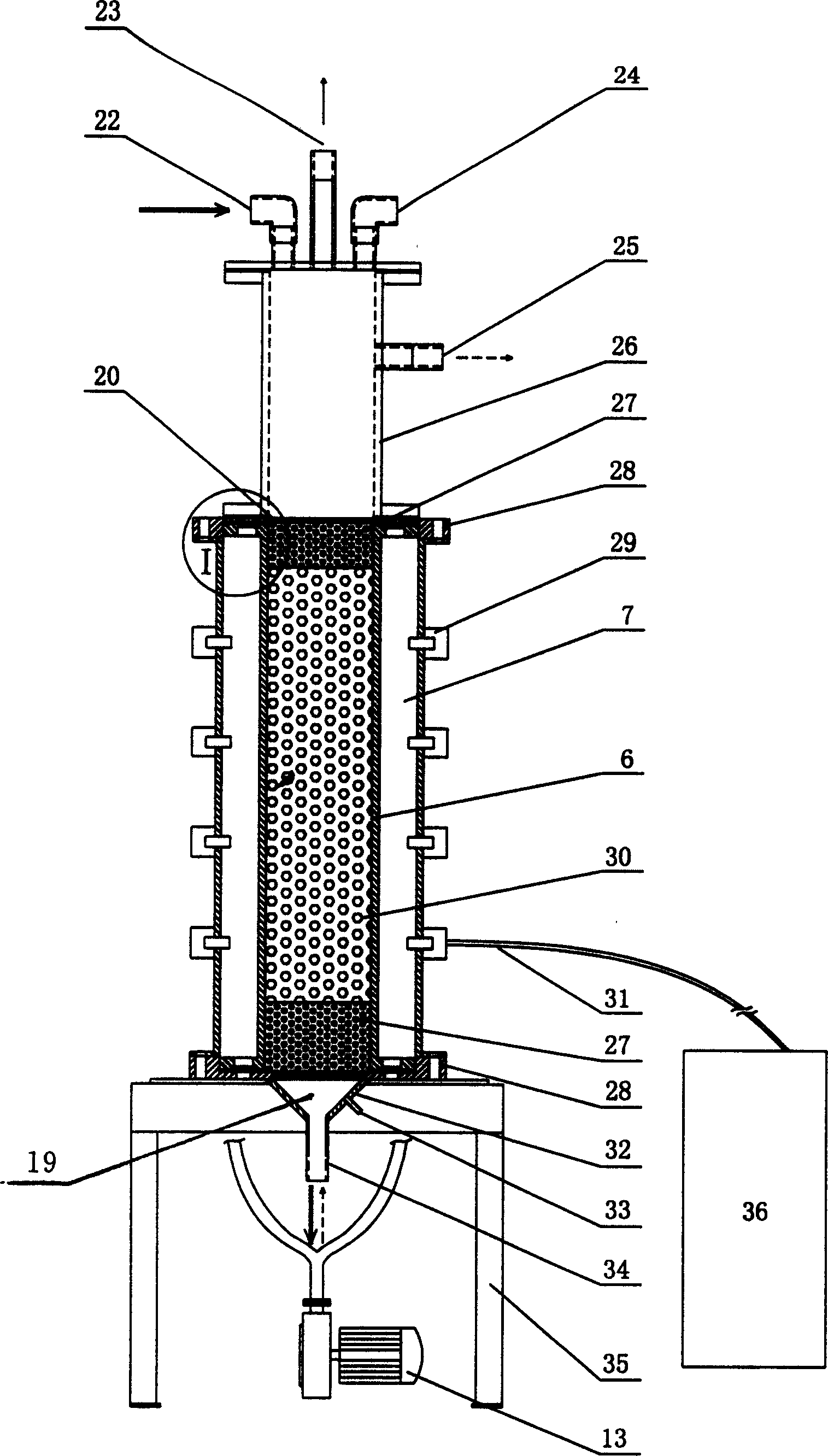

[0051] Dalian ×× Pesticide Factory Production Wastewater Treatment

[0052] This is a ××× pesticide factory with an annual output of ×× 10,000 tons. The amount of pesticide synthesis wastewater is 10 tons / day, and the COD of wastewater is 4000-10000 mg / L. The process and device of the present invention are used to investigate the removal rate of COD in wastewater.

[0053] The wastewater retrieved from Dalian ××× Pesticide Factory has no impurities in the water and is relatively transparent. Therefore, the wastewater [1] is collected in the original water tank [14] and does not need to be treated with grids to remove impurities [2] and flocculation and sedimentation [3]. , directly measured by the pump [16] through the flow meter [5], pumped into the microwave reactor [17] for catalytic oxidation reaction, and the treated water is discharged through the treated water outlet [34] at the lower end of the microwave reactor. The steam [9] generated during the reaction enters the h...

Embodiment 2

[0062] Simulated Dye Wastewater Treatment

[0063] Commercially available acid green dyes are used to prepare simulated dye wastewater with a chromaticity of 6000-7000 times, and the decolorization rate is investigated by using the device of the present invention. The acid green simulated dye wastewater prepared by the experiment is free of impurities and transparent. After passing directly through the flowmeter [5], it is pumped into the microwave reactor [17] for oxidative decomposition reaction. The treated water passes through the treated water outlet at the lower end of the microwave reactor [34] ]Reuse. The steam [9] generated during the reaction enters the heat exchanger [10] through the steam outlet [23] at the upper end of the microwave reactor, and is reused after cooling. Concrete steps are the same as Example 1 (omitted), and its optimum process parameter is as follows: flow rate 100L / h, residence time 12min, temperature 85 ℃, catalyzer Ni-C, oxygenant adopt air, ...

Embodiment 3

[0066] Laboratory organic wastewater treatment

[0067] The laboratory organic wastewater is collected in the original water tank after removing impurities, and water, phenol, acetic acid and other waste organic reagents are added to prepare simulated wastewater with a COD ~ 9000mg / L. The COD removal rate of the wastewater is investigated by using the process and device of the present invention. The simulated organic wastewater prepared by the experiment is translucent and free of impurities. After passing directly through the flowmeter [5], it is pumped into the microwave reactor [17] for oxidation and decomposition reactions. The treated water passes through the treated water outlet at the lower end of the microwave reactor [34] emission. The steam [9] generated during the reaction enters the heat exchanger [10] through the steam outlet [23] at the upper end of the microwave reactor, and is reused after cooling. The specific steps are the same as in Example 1 (omitted), and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com