Patents

Literature

5113 results about "Uv absorber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

UV absorber (UVAs) act by absorbing UV radiation before it reaches the product. These products need to be used in high concentrations to be effective, as otherwise they will not be able to absorb enough light to preserve the product.

Bloom-resistant benzotriazole UV absorbers and compositions stabilized therewith

Benzotriazole UV absorbers substituted with a ultra long ester or amide moiety wherein the ester or amide group is a hydrocarbyl group of 25 to 100 carbon atoms or is a group of alkyl of 25 to 100 carbon atoms interrupted by 5 to 39 oxygen atoms and terminated with an omega-OH or an omega-OR group exhibit excellent stabilization efficacy while they concomitantly do not bloom when incorporated into polyolefin films. These benzotriazole UV absorbers also provide excellent protection to white, dyed, dipped, unscented and / or scented candle wax from discoloration and degradation.

Owner:CIBA SPECIALTY CHEM CORP

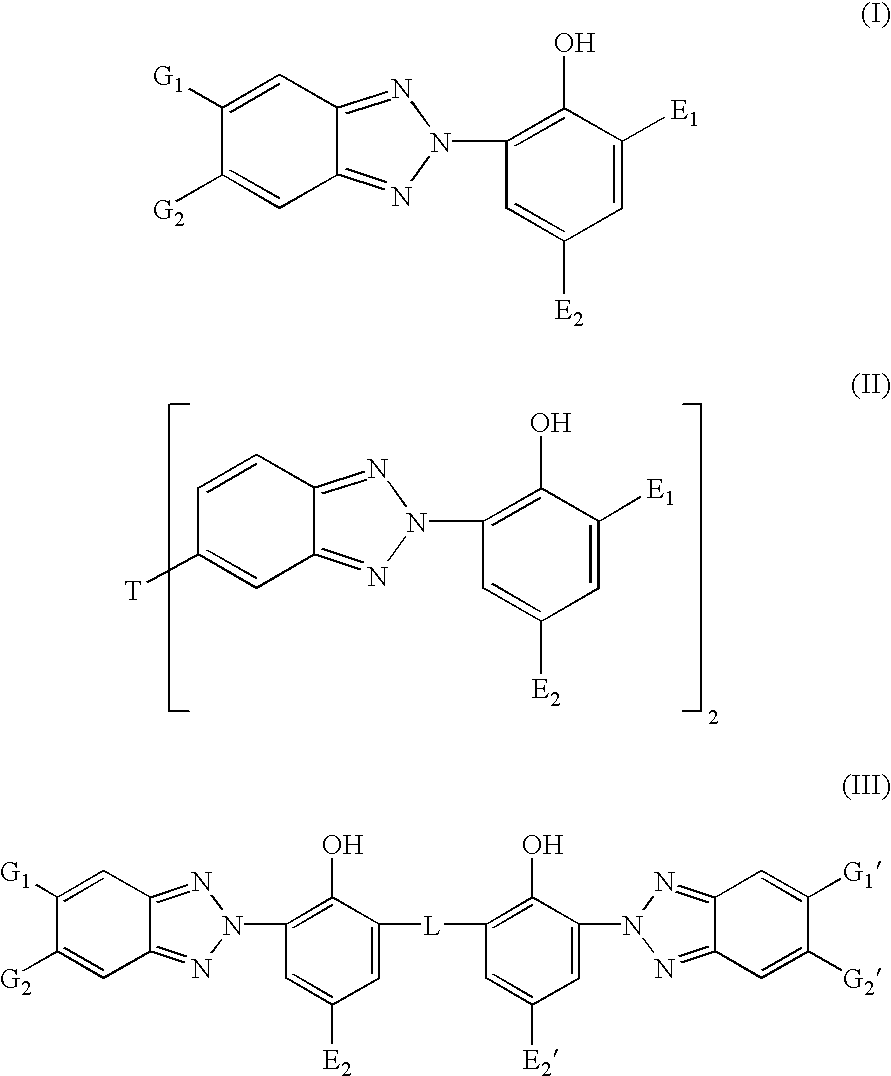

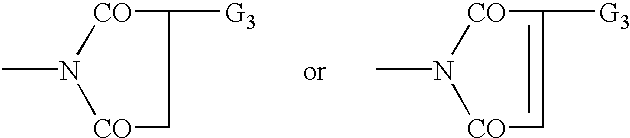

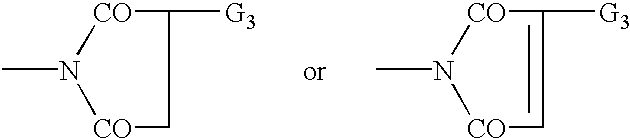

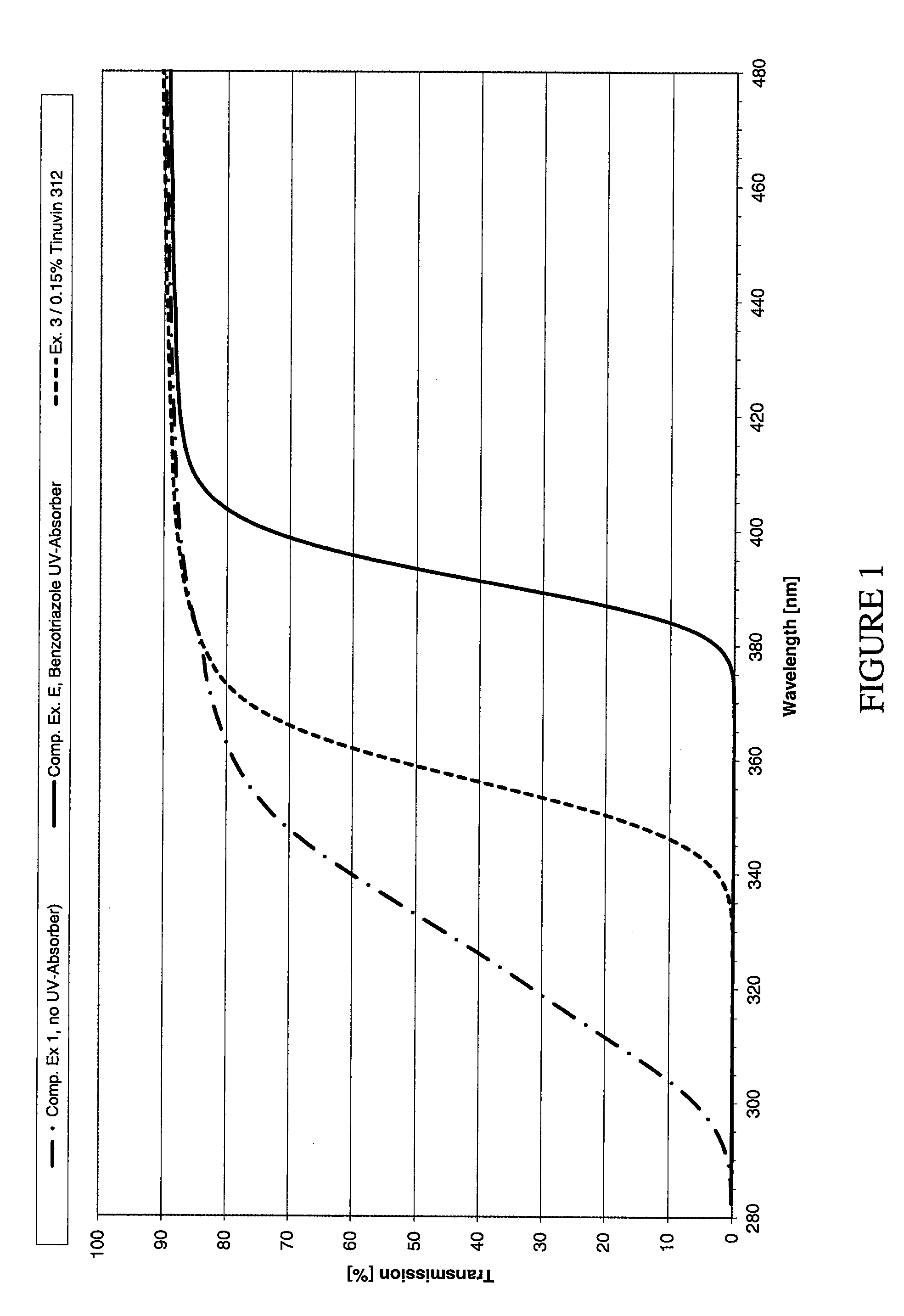

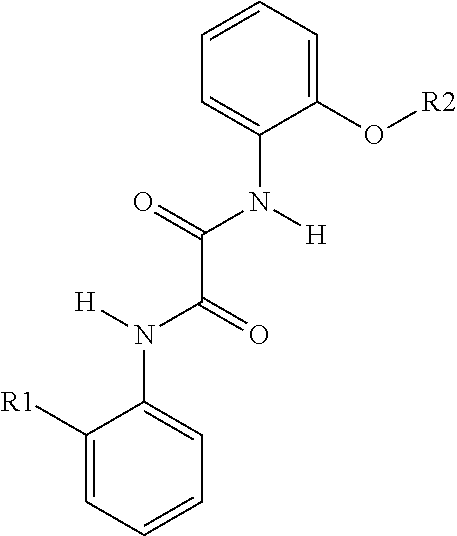

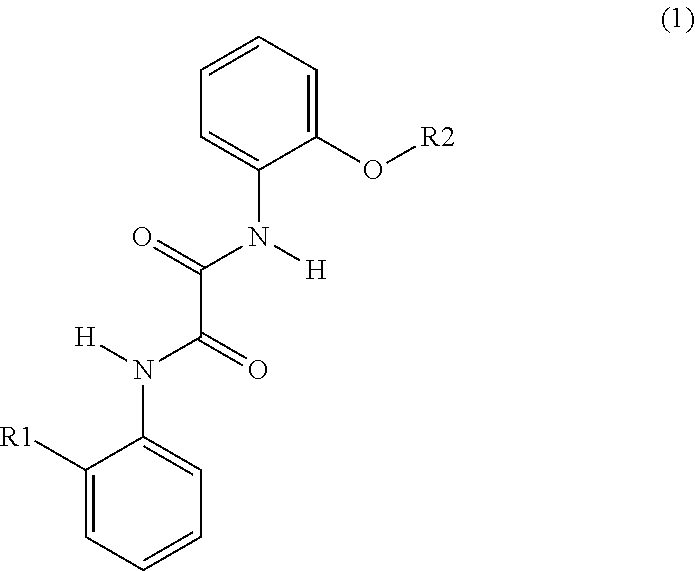

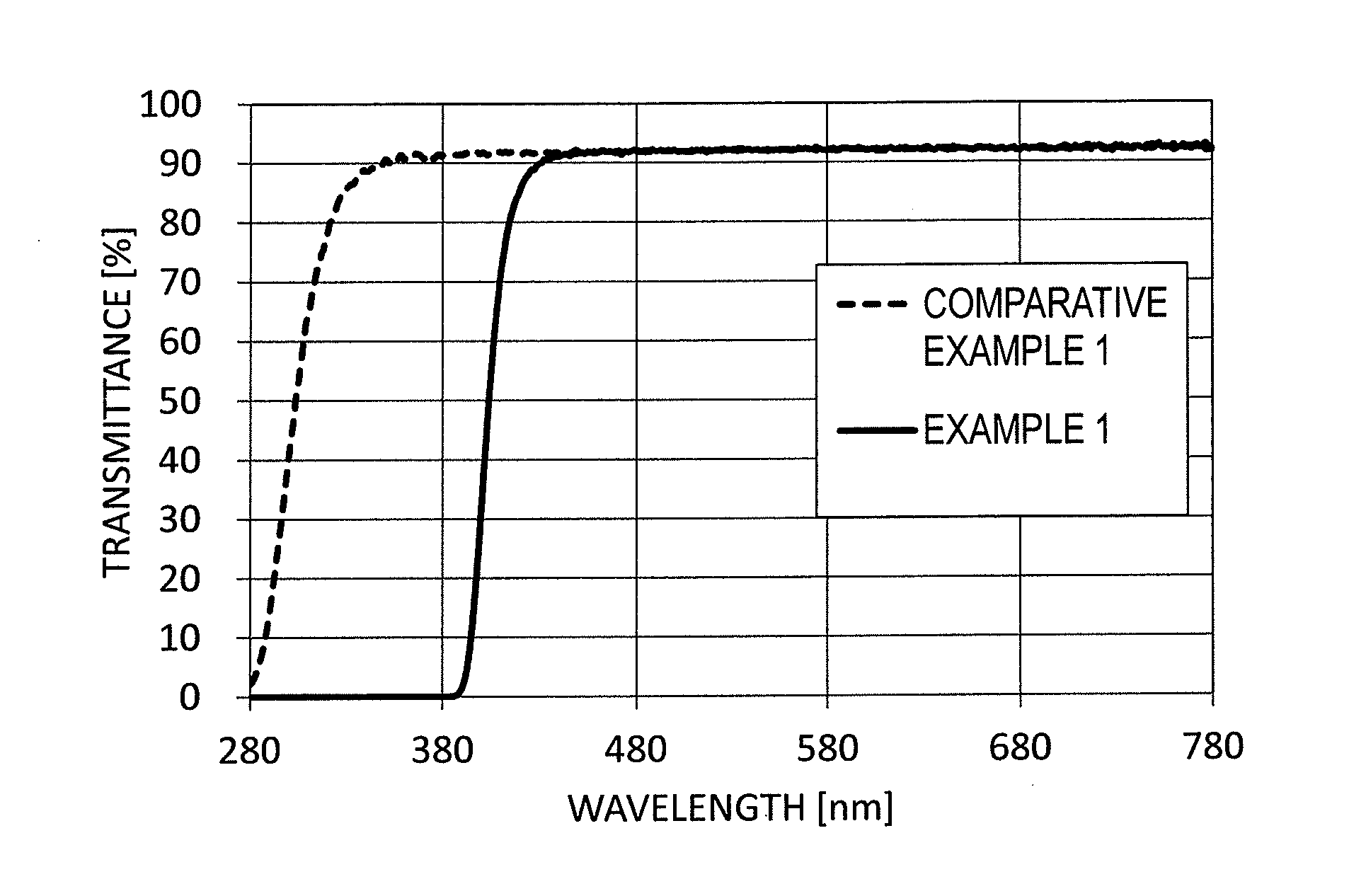

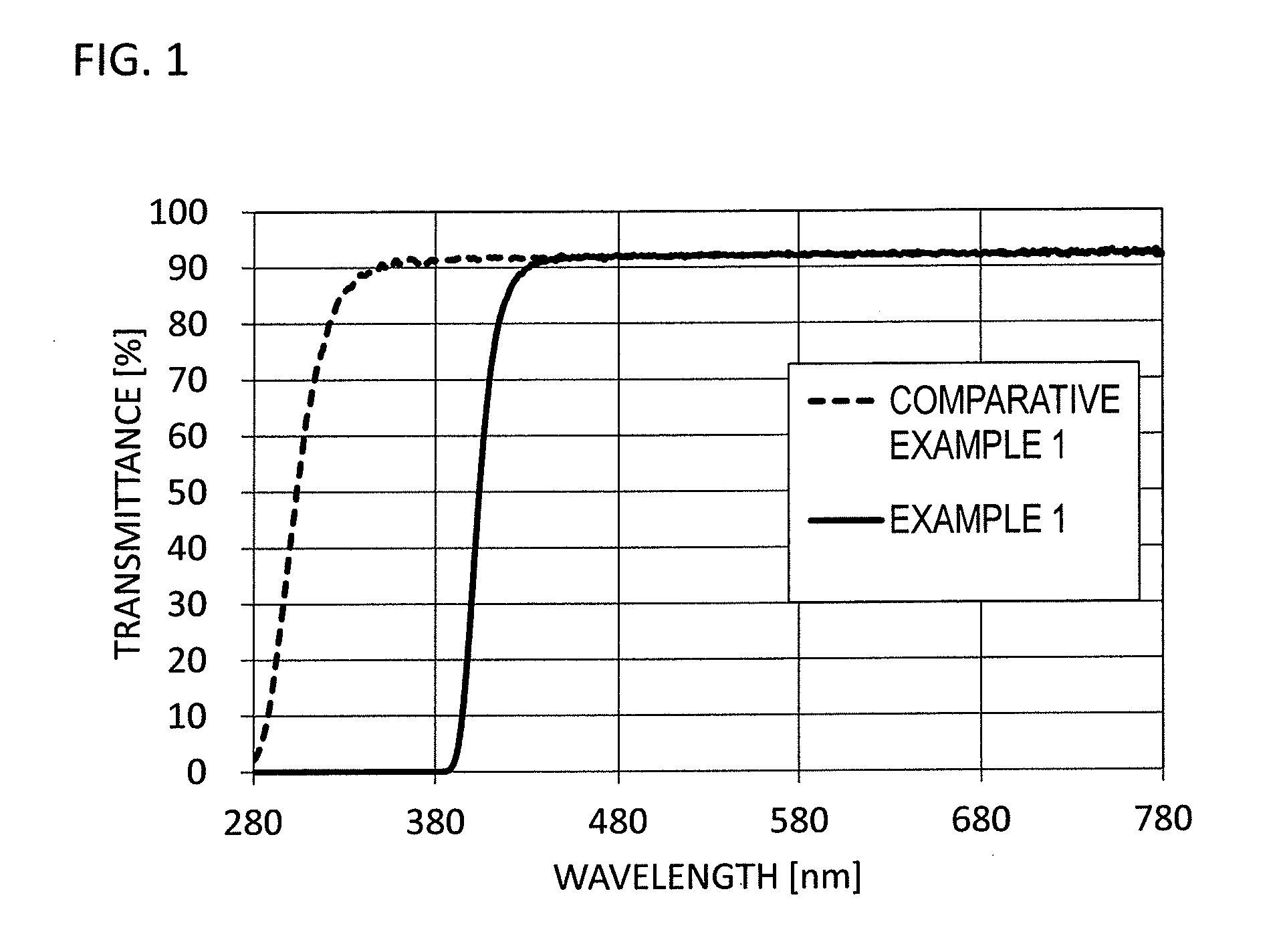

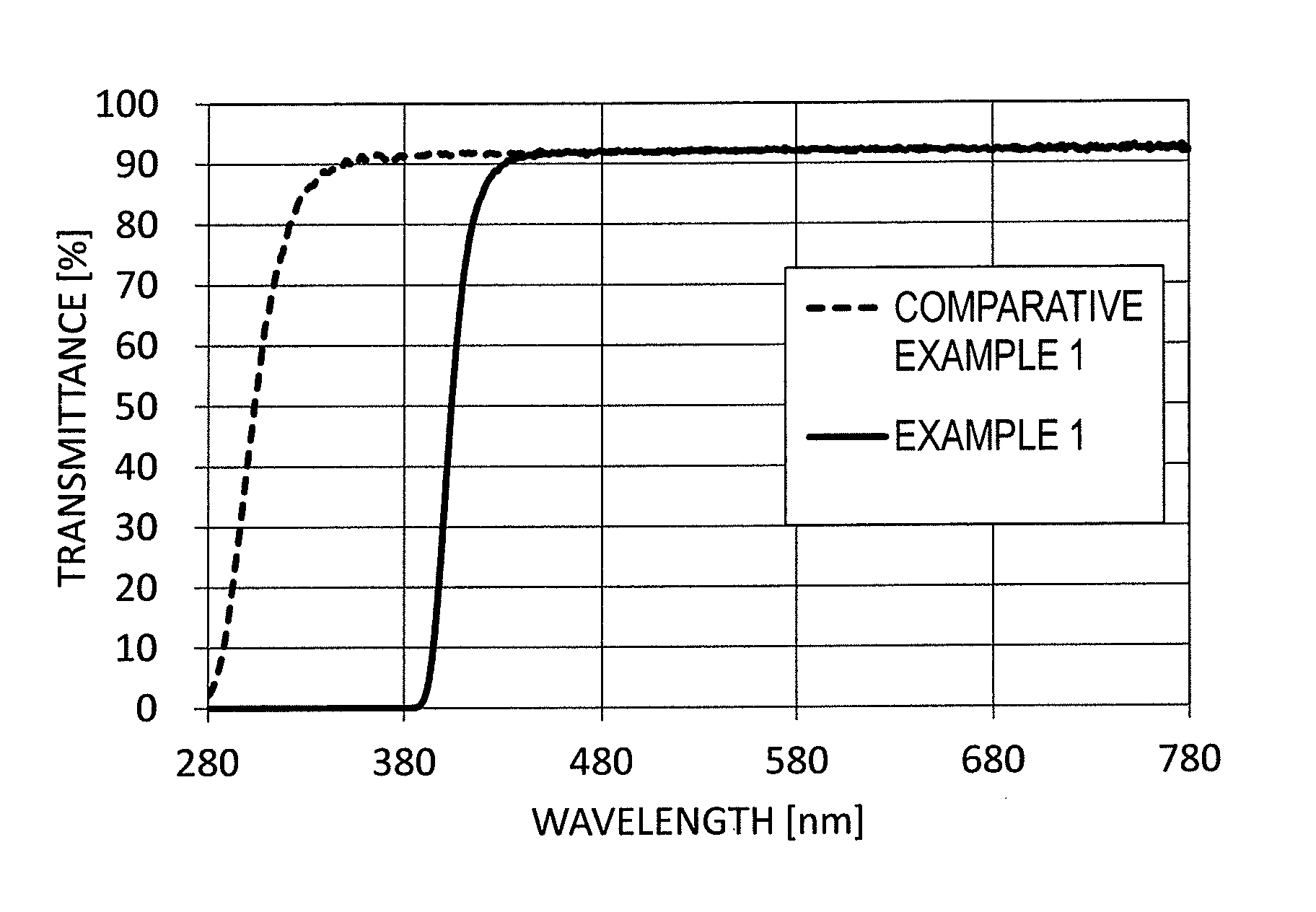

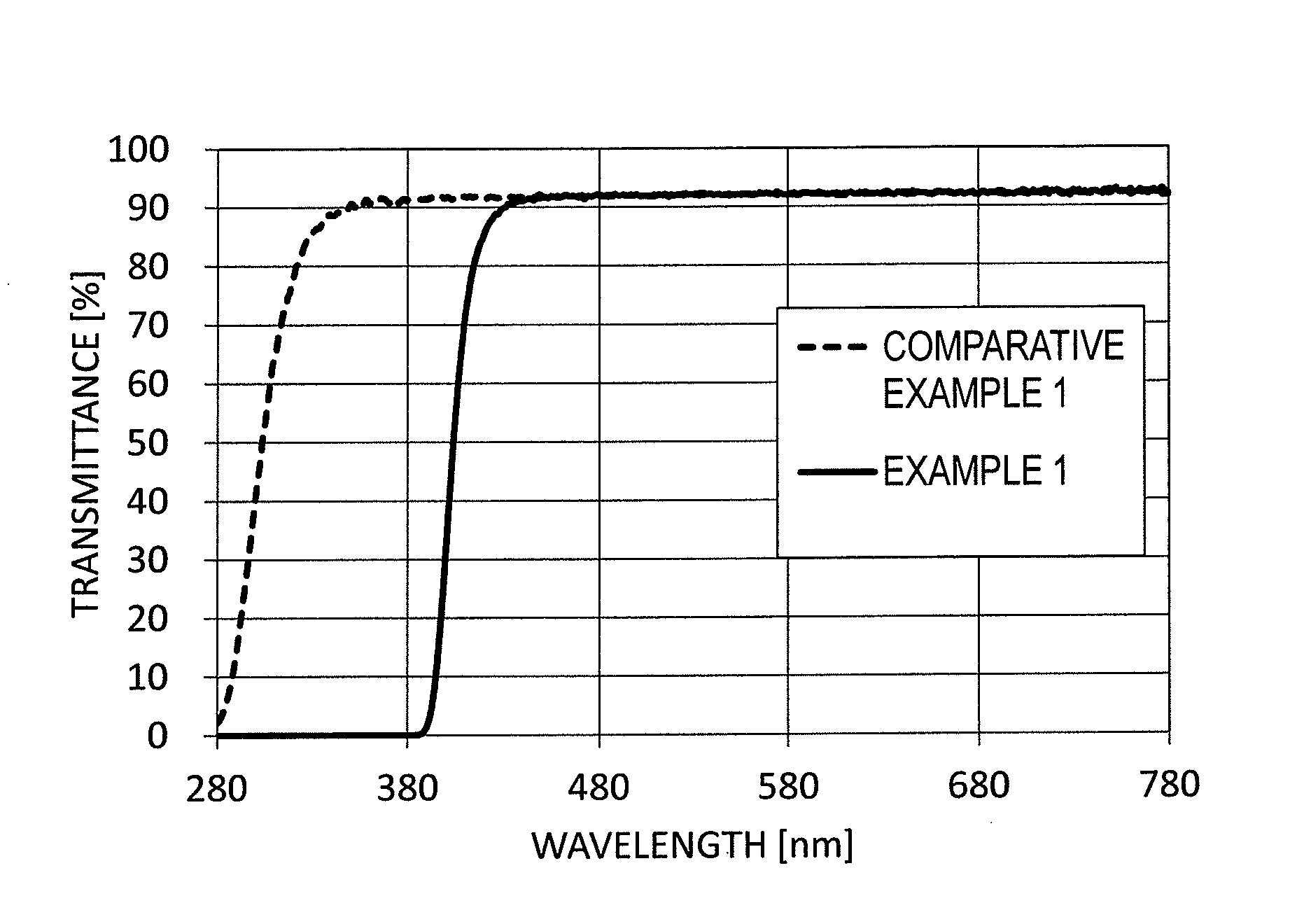

Plasticizer-Containing Films Based On Polyvinyl Acetal Having Selective Permeability For UV Radiation

InactiveUS20120052310A1Climate change adaptationSynthetic resin layered productsPlasticizerUltraviolet

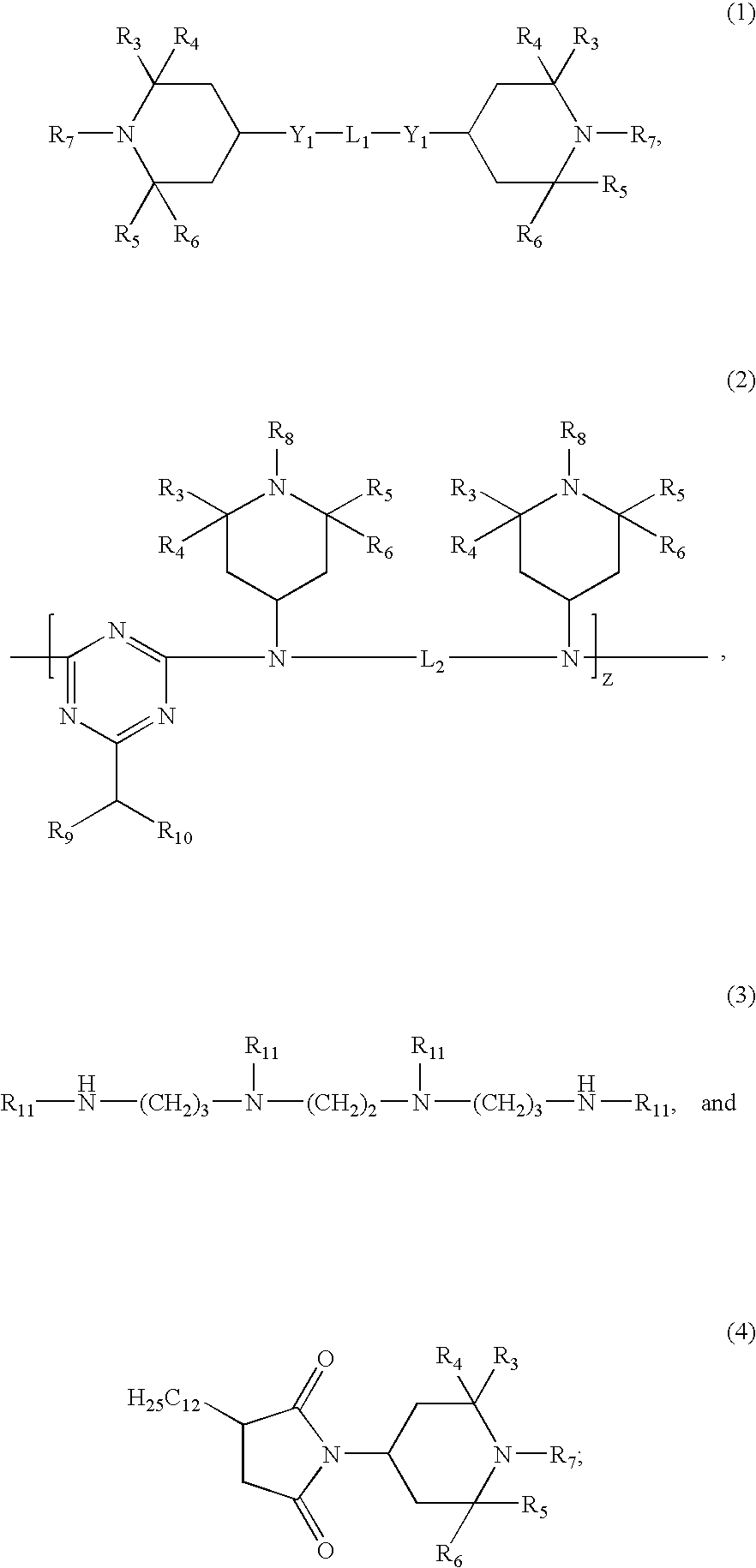

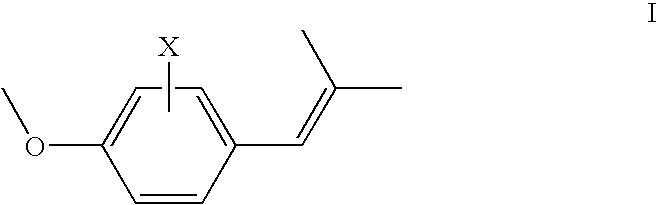

Plasticizer-containing films based on polyvinyl acetal containing a UV absorbers of the oxanilide type of formula (1)exhibit high UVA transmission while also exhibiting low UVB transmission, with reduced tendency to yellow.

Owner:KURARAY EURO GMBH

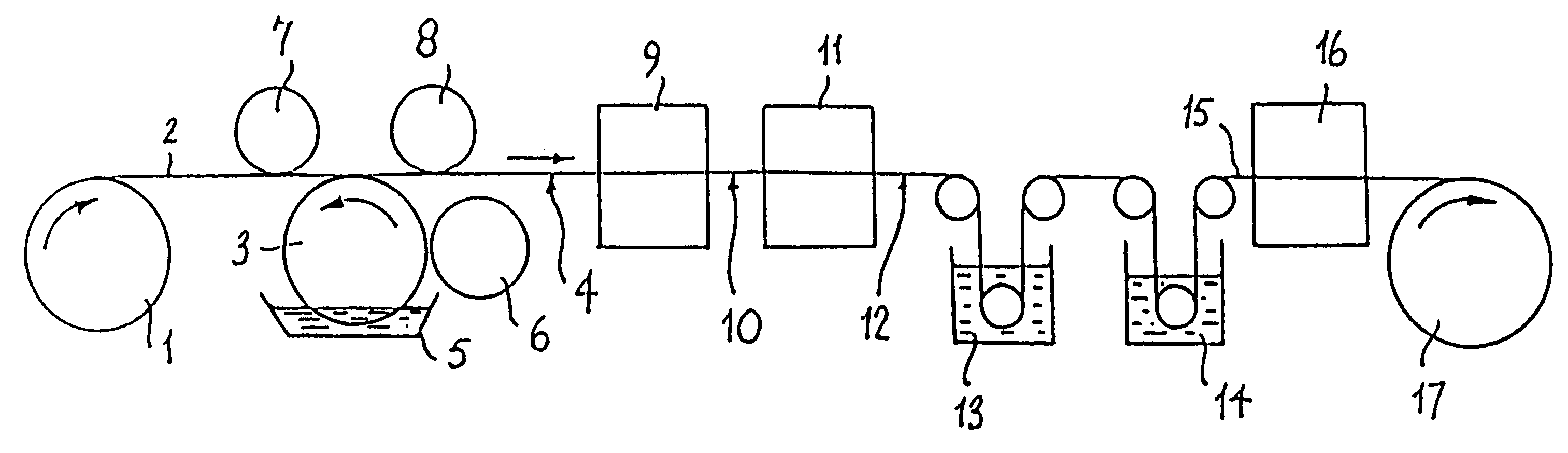

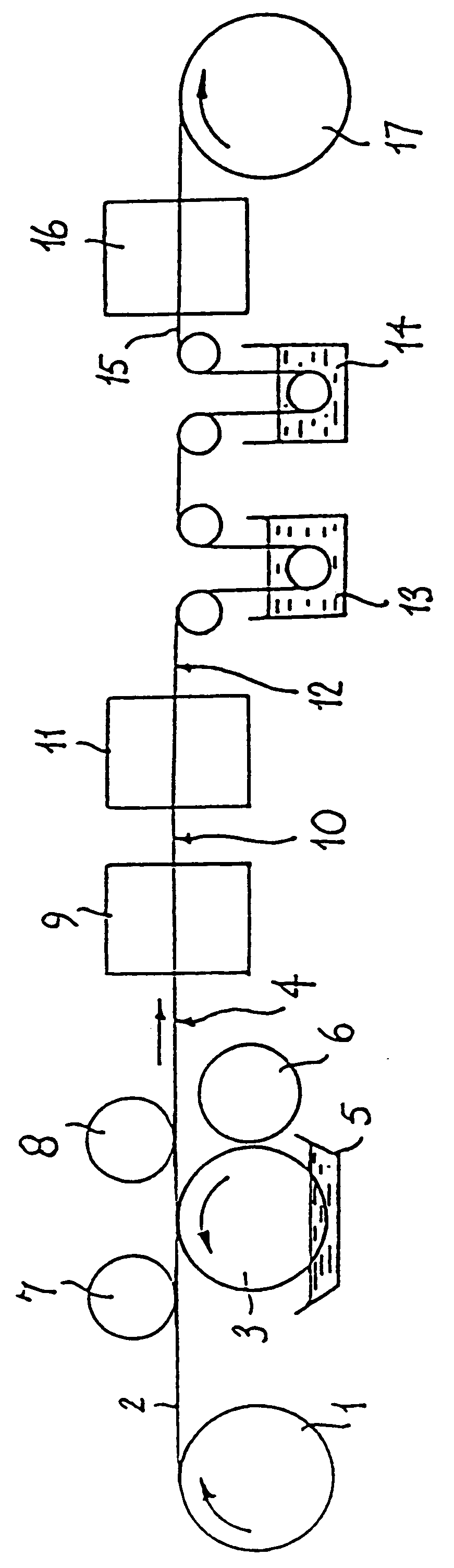

Process for producing a colored polyester film

InactiveUS6221112B1Low viscosityQuality improvementDuplicating/marking methodsFibre treatmentPolyesterUv absorber

A polyester film can be dyed by coating the film with a layer of a dye mixture which is a suspension of at least one disperse dyestuff in a solution of a thickener in water and which has a viscosity of no more than 500 centipoise, preferably 5-50 centipoise, at ambient temperature, followed by heating to cause the dyestuff to migrate from the layer into the film. The coating process is preferably reverse gravure printing. The process can be used to prepare films which contain one or more dyestuffs in one surface region of the film and one or more different dyestuffs, for example an ultraviolet absorber, in the other surface region of the film. The dyed films show good resistance to fading when exposed to light and are useful for example as automobile window films.

Owner:CPFILMS

Stabilized aliphatic polyester compositions

Disclosed are stabilized aliphatic polyester compositions comprising an aliphatic polyester, a HALS, and a tris-aryl-S-triazine UV absorber that show low embrittlement, haze formation, and discoloration during weathering. Also disclosed are aliphatic polyester compositions comprising aliphatic polyester, a hindered amine light stabilizer, a triazine UV absorber, and a phosphite that exhibit low color prior to weathering but retain good clarity, color, and excellent impact strength after exposure to weathering conditions. The aliphatic polyester compositions may be used prepare shaped articles such as, for example, films, sheets, bottles, tubes, profiles, fibers, and molded articles.

Owner:EASTMAN CHEM CO

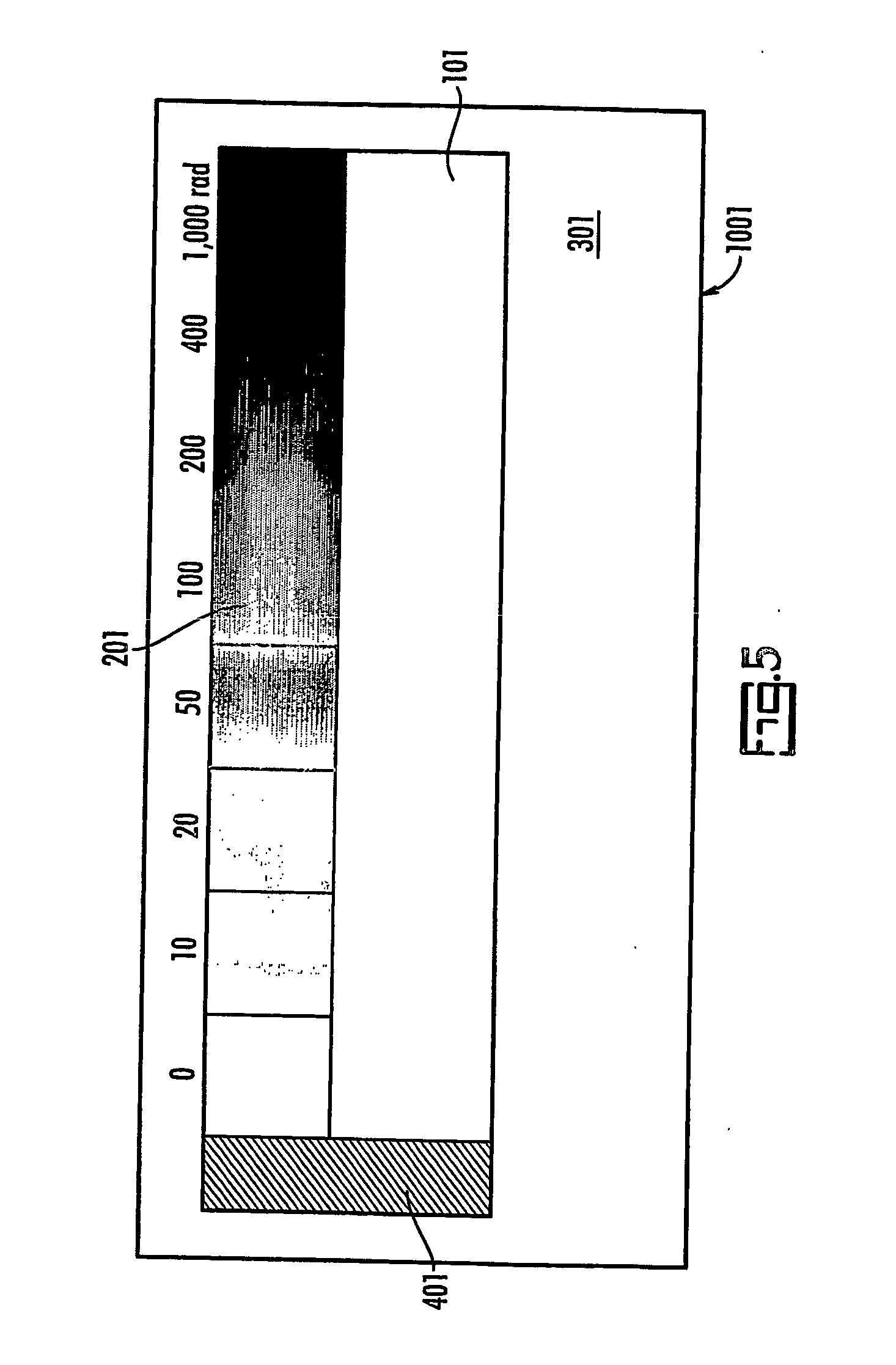

Self indicating radiation alert dosimeter

ActiveUS20060145091A1Suitable for useElectrical apparatusElectroluminescent light sourcesUv absorberPolymer

Described as a self-indicating instant radiation dosimeter (1001) for monitoring high energy radiations, such as X-ray. The dosimeter contains a radiation sensitive, color changing, indicating composition (10), e.g., a diacetylene (R—C═C—C═C—R′, where R and R′ are substituents groups) or a radiochromic dye, a polymeric binder (20) and optionally a shelf life extender (50) or an activator (40). The radiation sensitive composition (10) changes color instantly when exposed to high energy radiation. The dose is estimated by comparing the color with a color reference chart or more accurately with a spectrophotometer or an optical densitometer. The radiation sensitive composition (10) is protected from low energy radiation such as UV light, by a layer of low energy absorbing materials, such as UV absorbers.

Owner:JP LAB INC

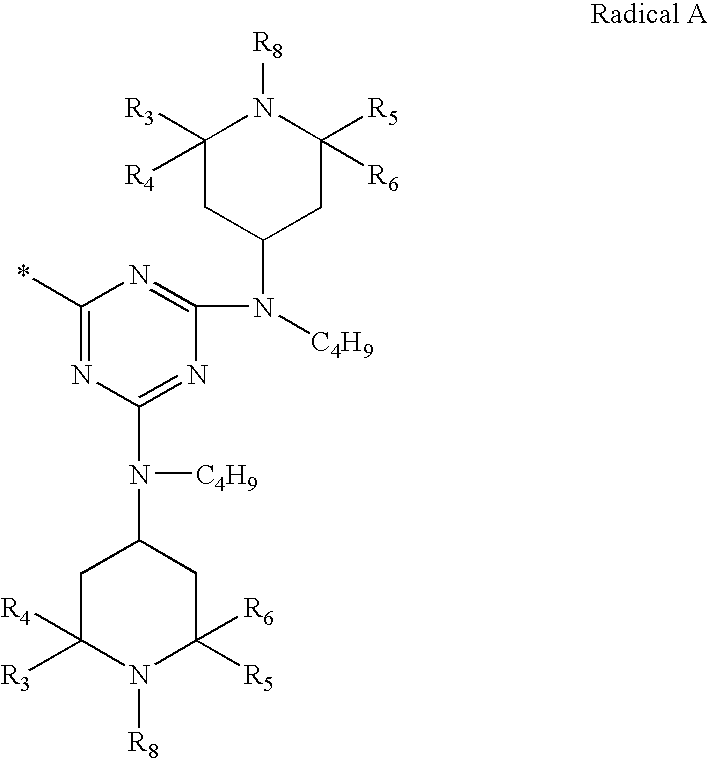

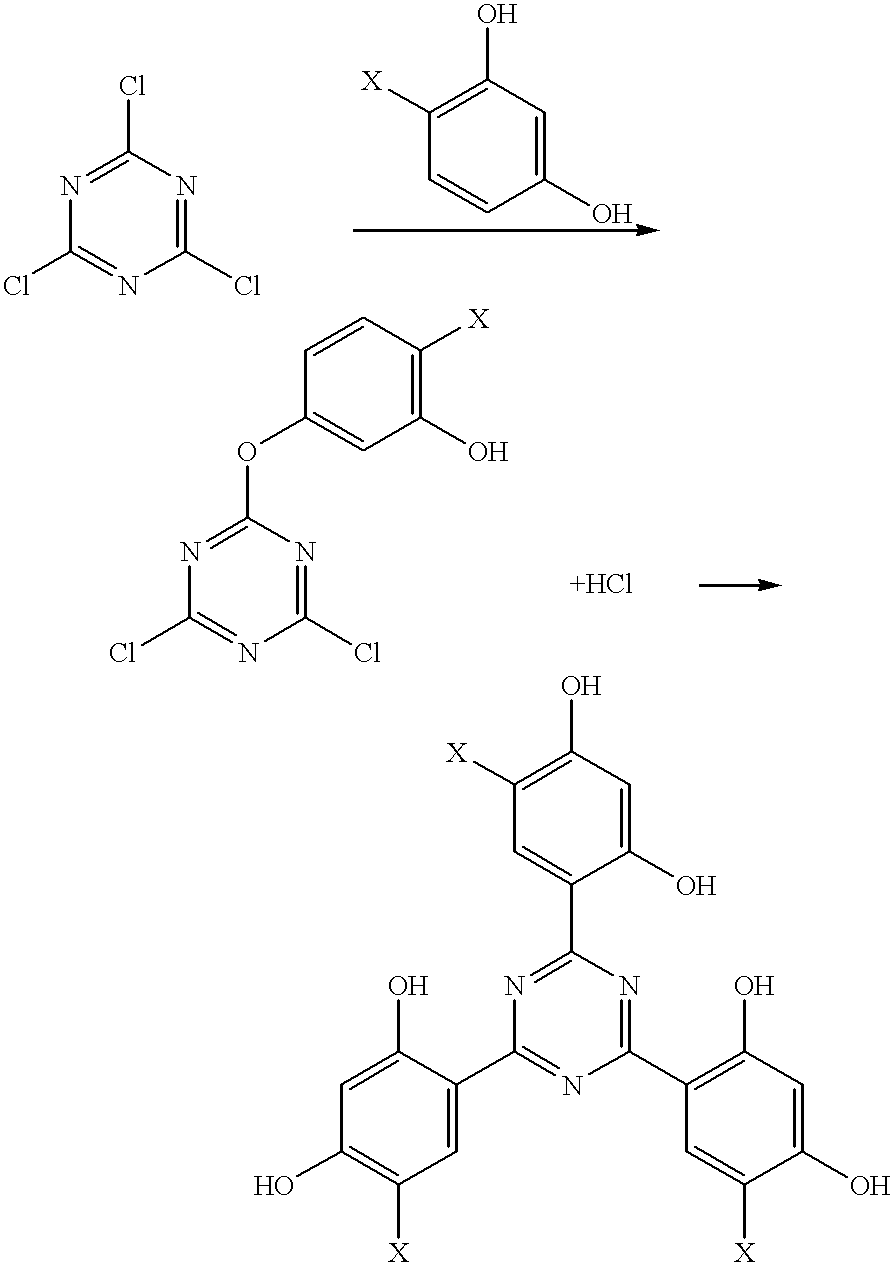

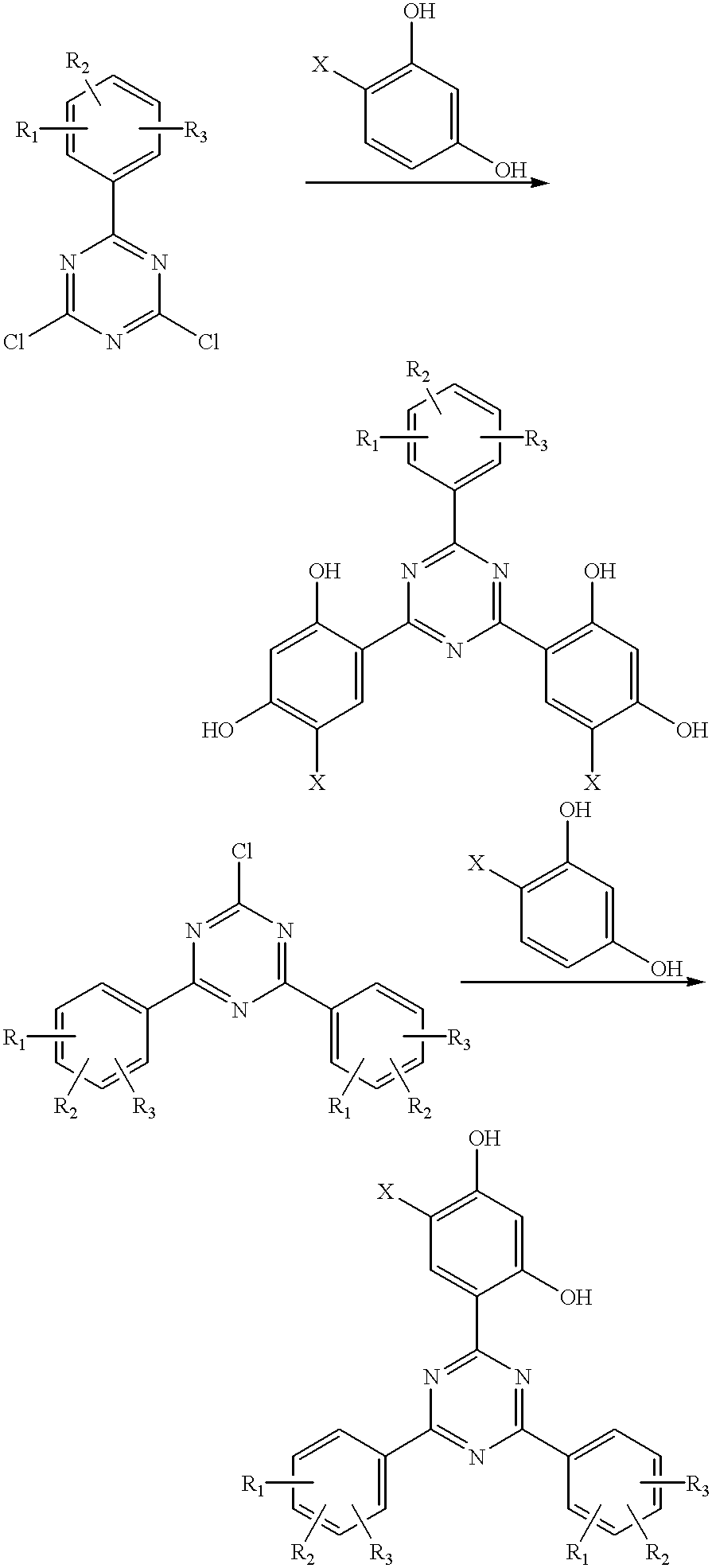

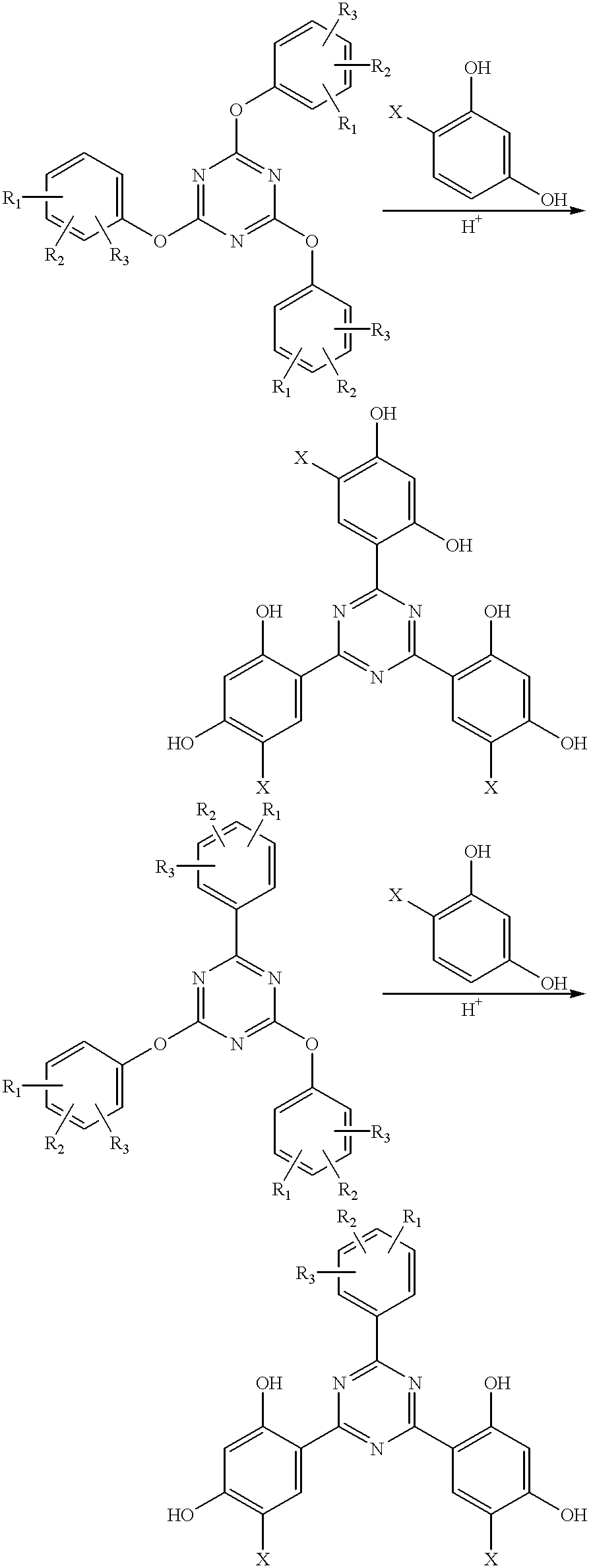

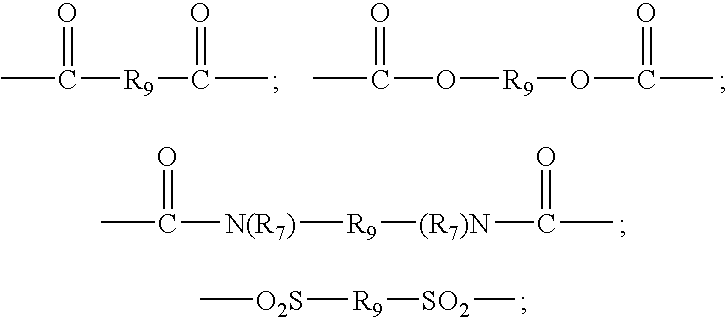

Methods for the preparation of tris-aryl-o-hydroxyphenyl-s-triazines

InactiveUS6242598B1Reduce in quantityPoor leaving groupOrganic chemistryLewis acid catalysisResorcinol

A process for preparing 2-(2,4-dihydroxyphenyl)-4.6-diaryl-s-triazines in three steps starting with cyanuric chloride is described. Step 1 involves the nucleophilic (basic) displacement of one chlorine atom with a phenolic moiety. Step 2 involves a Friedel-Crafts reaction using a Lewis acid catalyst (preferably aluminum chloride) to replace the remaining two chlorine atoms with aryl groups such as xylyl. Finally, step 3 involves replacing the phenolic moiety with resorcinol using either a Lewis acid or protic acid catalyst or combinations thereof. Some additional processes only peripherally related to the three-step process outlined above are also described for the preparation of various s-triazine compounds. The s-triazines prepared are useful as UV absorbers for the stabilization of organic substrates against the adverse effects of actinic light.

Owner:CIBA SPECIALTY CHEM CORP

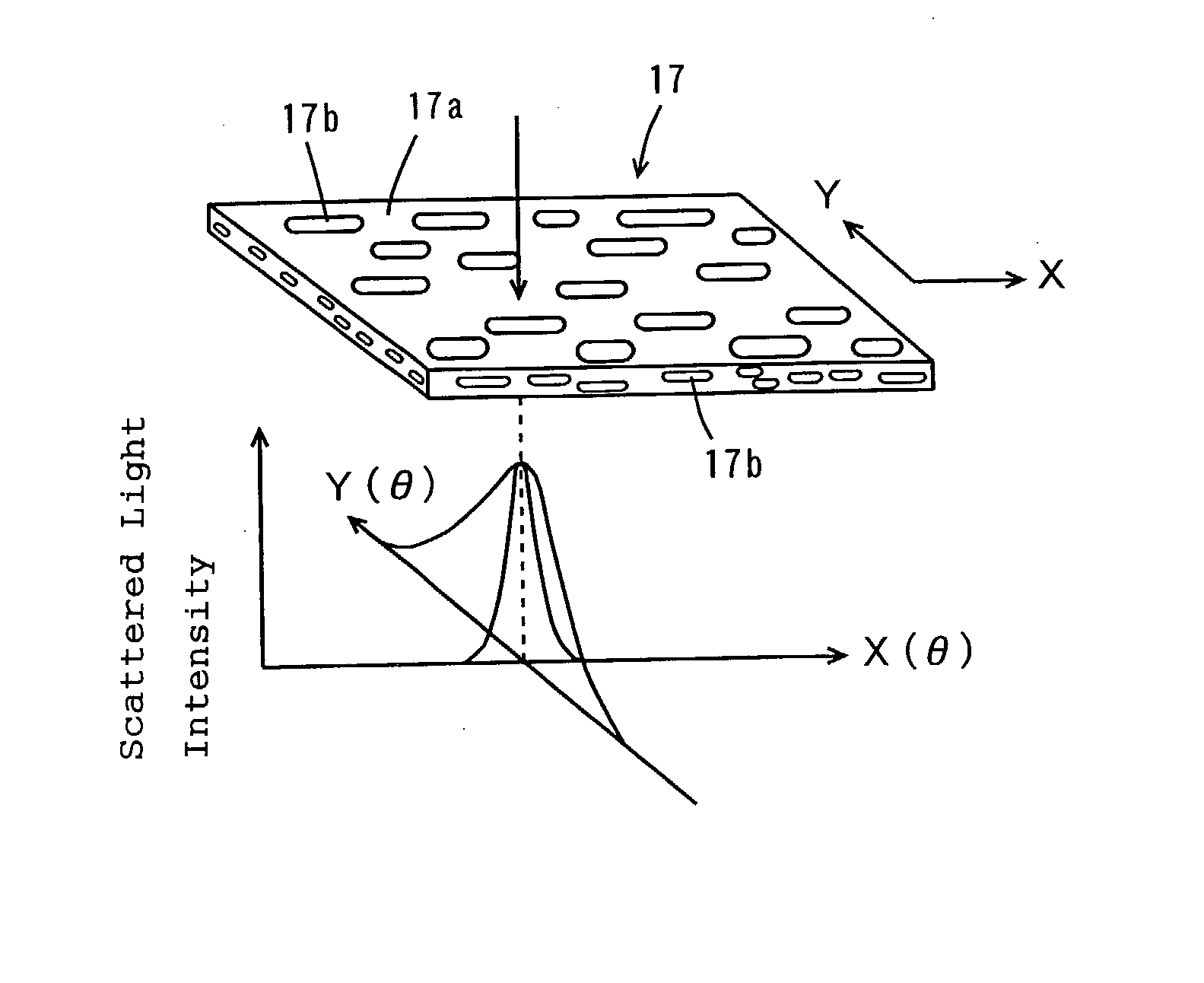

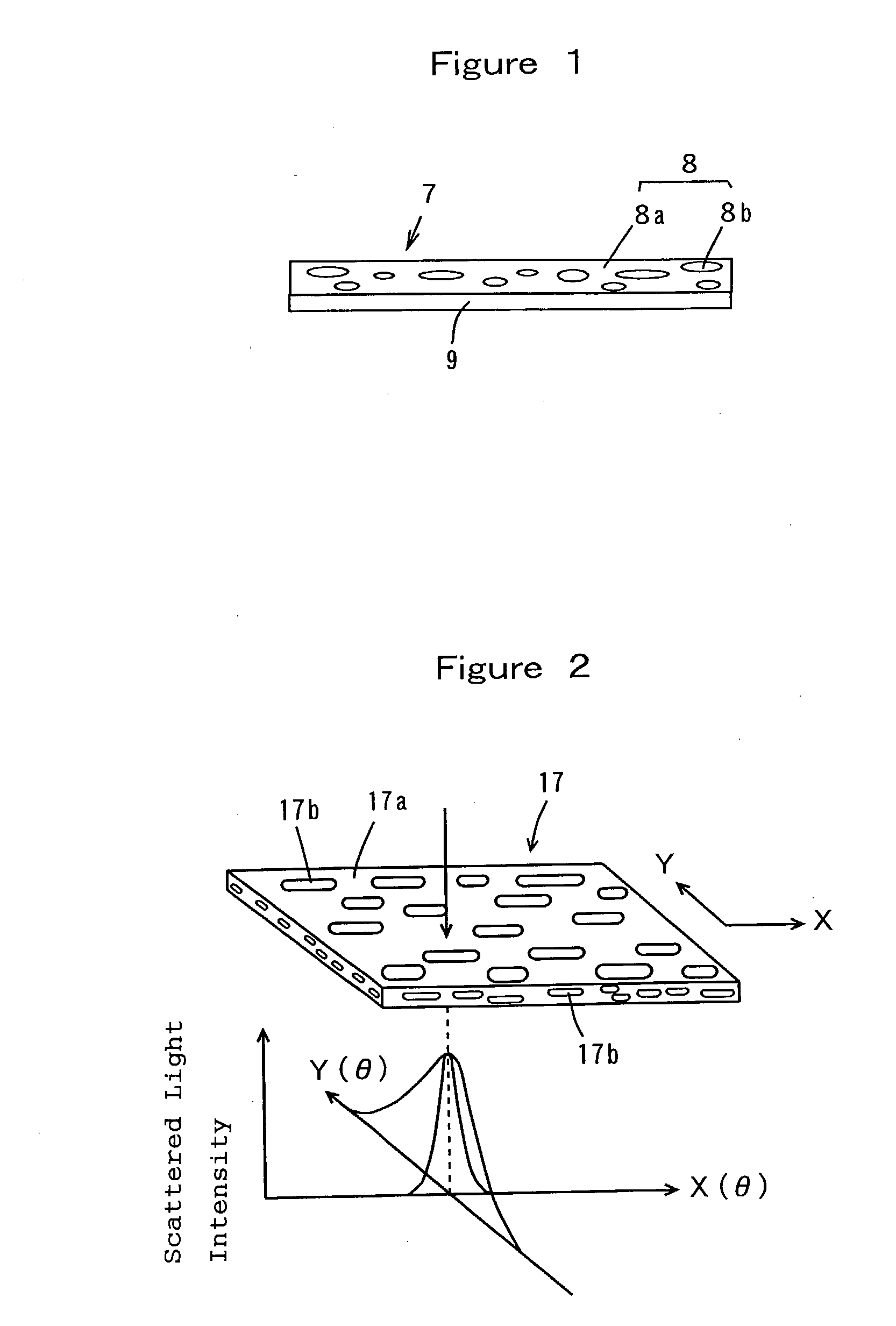

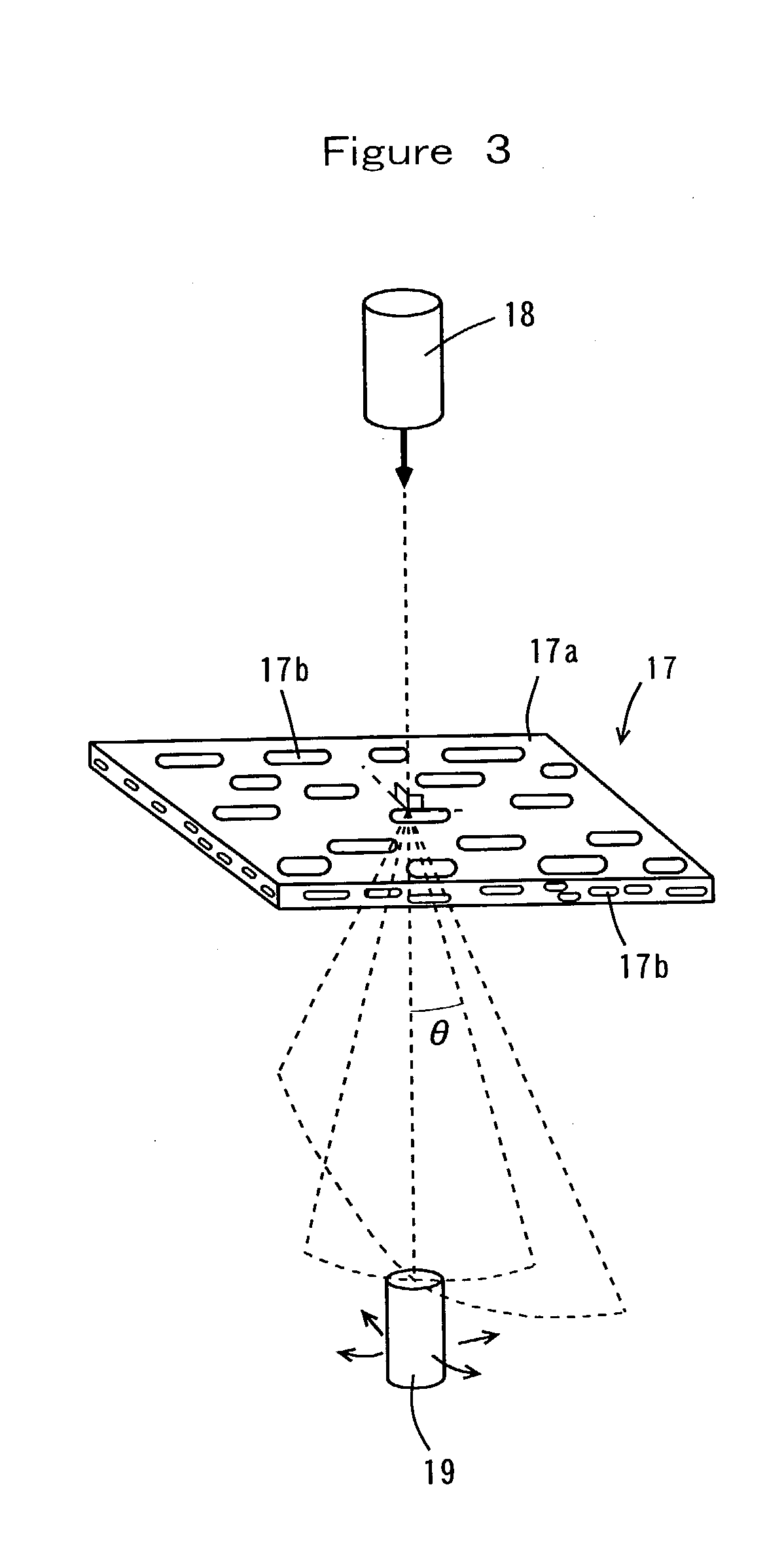

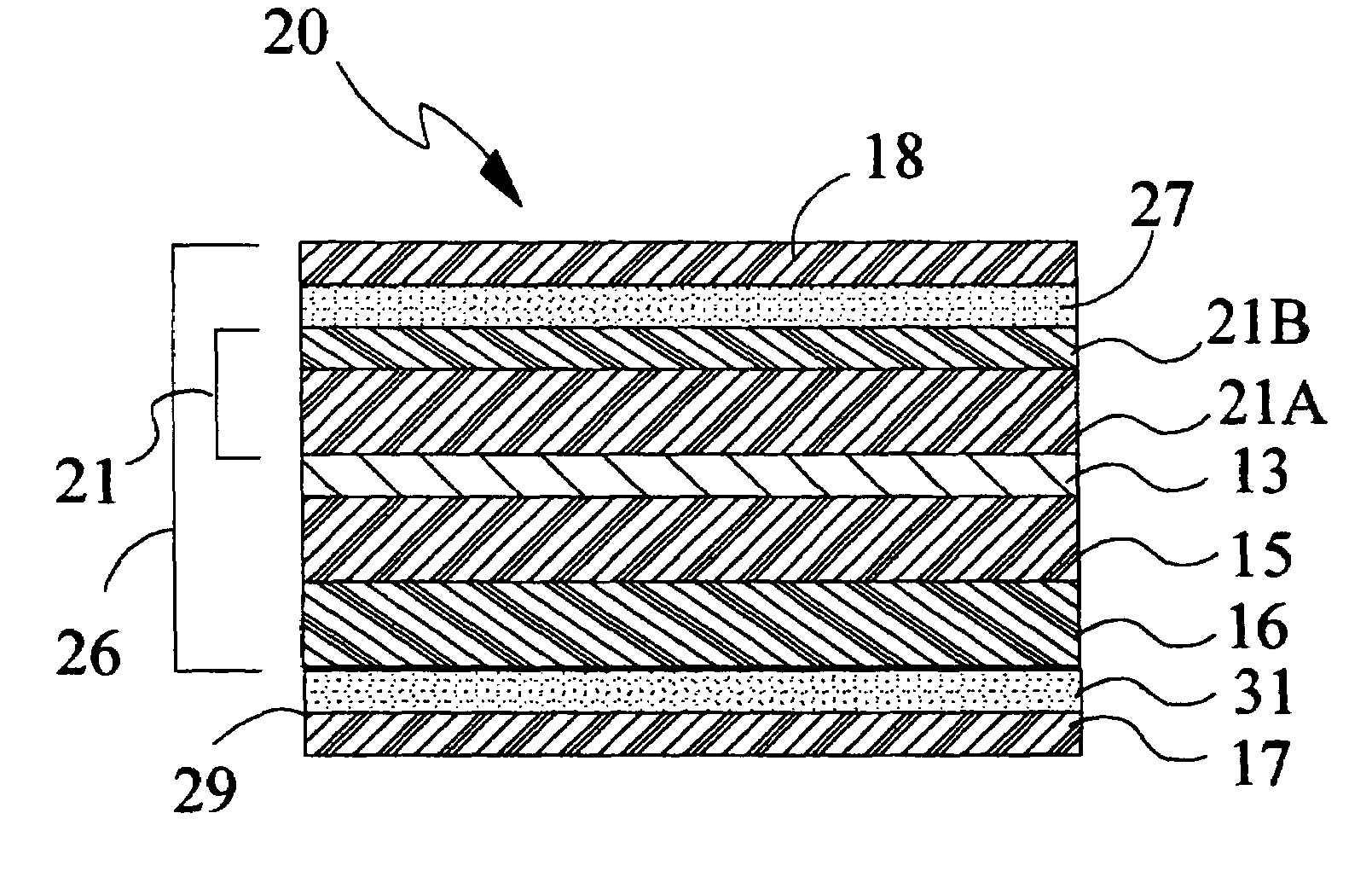

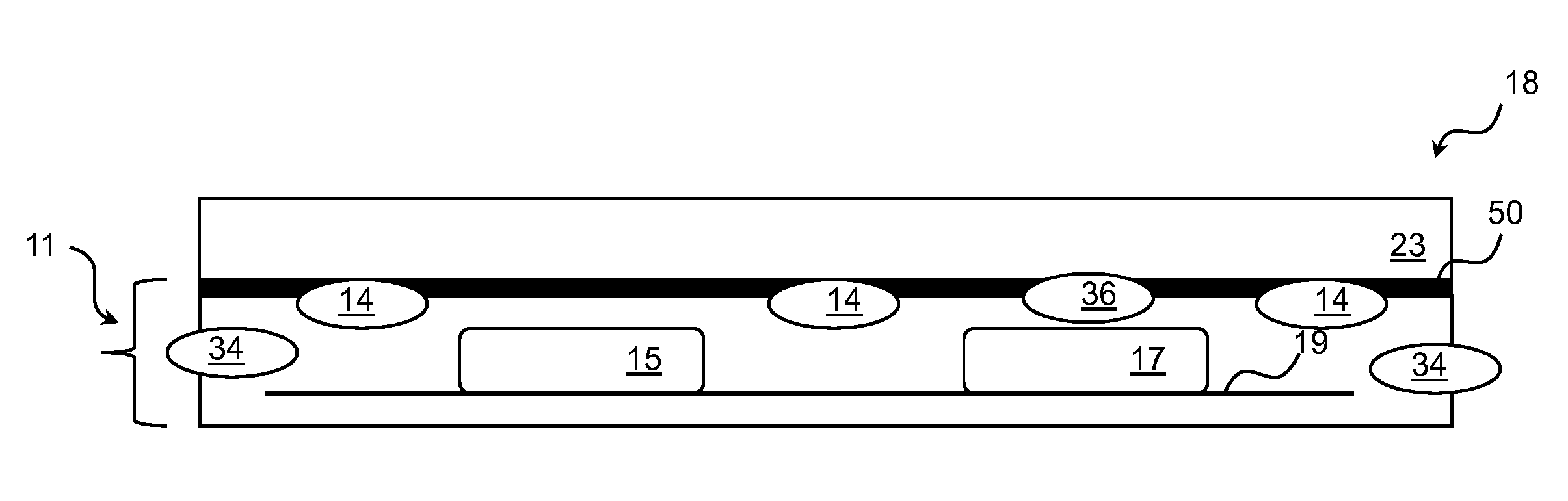

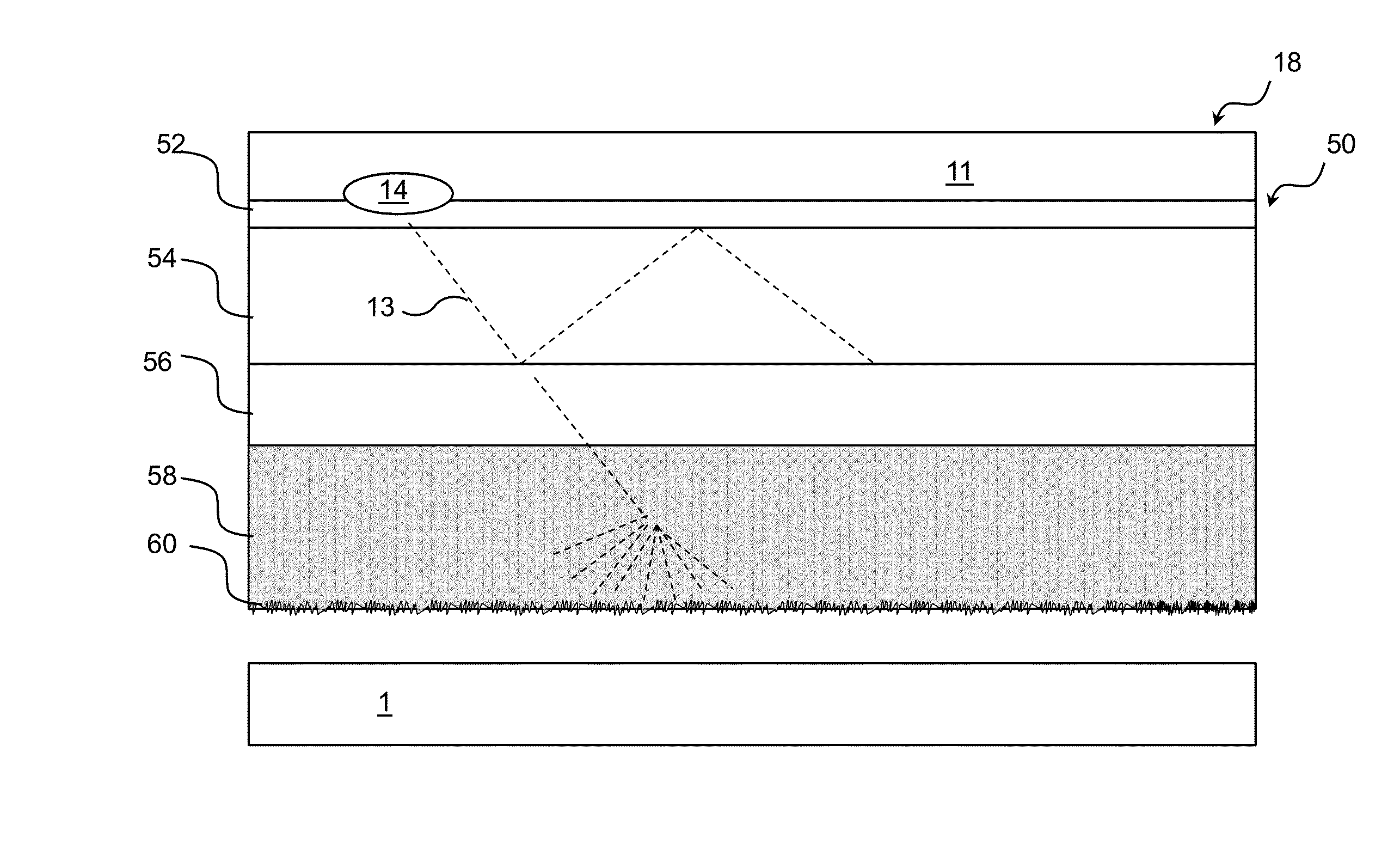

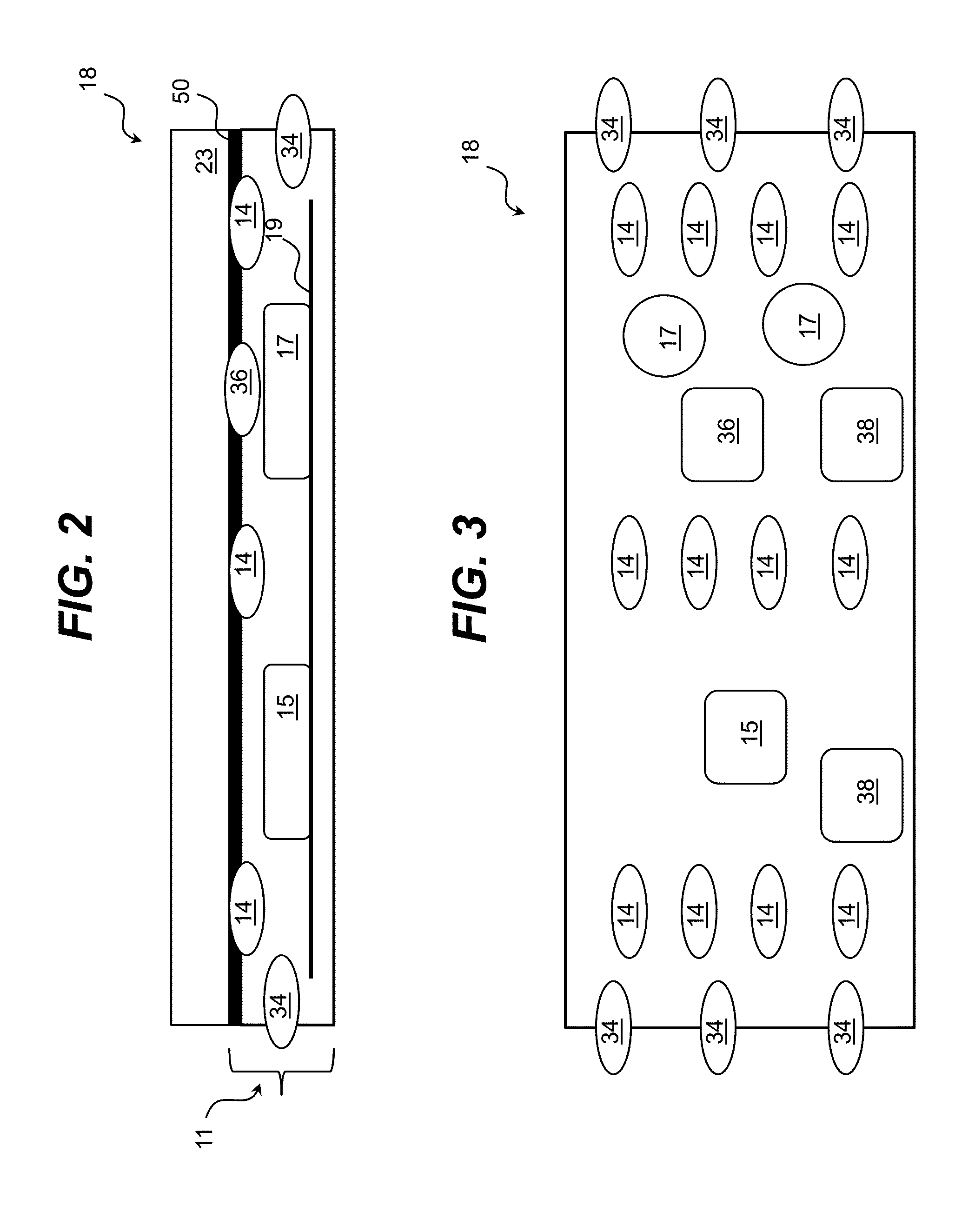

Light diffusion film, surface illuminant device and liquid crystal display device

InactiveUS20030156238A1Low costInhibit deteriorationLiquid crystal compositionsMechanical apparatusLiquid-crystal displayFluorescence

A transmissive display apparatus 21 comprises a liquid crystal display unit 22 and a plane light source unit 23. The unit 23 comprises a tubular light source 24, a light guide 25 having a wedge-shaped reflecting groove formed at the bottom thereof, and a light-diffusing film 27 having anisotropy and / or ultraviolet (UV) absorbability. In the film, a light-scattering characteristic F(theta) representing the relationship between the light-scattering angle theta and a scattered light intensity F fulfills Fy(theta) / Fx(theta)>=1.01 over a range of theta=4 to 30°, wherein Fx(theta) and Fy(theta) represent the light-scattering characteristics in the X-axial direction and the Y-axial direction of the film, respectively. The film comprises a light-diffusing layer composed of a plurality of resins which are different from each other in refractive index, and a transparent layer laminated on at least one side thereof. The transparent layer at least may contain a UV absorber. Such a light-diffusing film ensures simplification of structures of a plane light source device and a liquid crystal display apparatus. When the film has anisotropy, the luminance in the display surface can be uniformized. A UV absorbable light-diffusing film absorbs UV from a light source (fluorescent tube) of the plane light source device (backlight), and can prevent deterioration of a prism sheet and a liquid crystal display cell.

Owner:DAICEL CHEM IND LTD

Pressure-sensitive adhesive sheet

ActiveUS20130085215A1Improves UV protectionRetaining optical characteristicNon-macromolecular adhesive additivesEster polymer adhesivesDisplay deviceEngineering

The present invention realizes a display device or input device having excellent ultraviolet protection property for the touch panel, display element or the like, while retaining optical characteristics, even when a small amount of or no optical film is used. The pressure-sensitive adhesive sheet of the present invention has a total light transmittance of 85% or more, a light transmittance at a wavelength of 380 nm of 5% or less, and a haze of 3% or less. The pressure-sensitive adhesive sheet preferably includes a pressure-sensitive adhesive layer containing an acrylic polymer and a triazine-based ultraviolet absorber.

Owner:NITTO DENKO CORP

Lens Material and Methods of Curing with UV Light

A polymeric material including a UV initiator, a UV absorber, and one or monomers, wherein the polymeric material is cured using UV light.

Owner:POWERVISION

Method of manufacturing composite board

InactiveUS7022756B2Improve flow characteristicsIncreased flexural modulusSynthetic resin layered productsWood working apparatusThermoplasticFiber

A composite board is made from waste medium density fiber (MDF) board or waste particle board that includes solid urea formaldehyde. The waste board is chopped and milled into particles having a size between 20 mesh and 150 mesh, creating a waste flour. After removing moisture from the waste flour, the dried waste flour is mixed with a thermoplastic to bind and encapsulate the waste flour. Internal lubricants are added to improve the flow characteristics of the blended material, and external lubricants are added to present sticking of the mixture to an extruder or mold. Mineral fillers are added to improve the flexural modules of the composite board, and a plasticizer can be added to improve the physical properties or mechanical characteristics of the mixture. An ultraviolet absorber, a biocide, and a pigment can also be added. The blended material is extruded or molded into a desired shape. When cooled, the thermoplastic hardens to form a solid composite board.

Owner:MASCO RETAIL CABINET GROUP

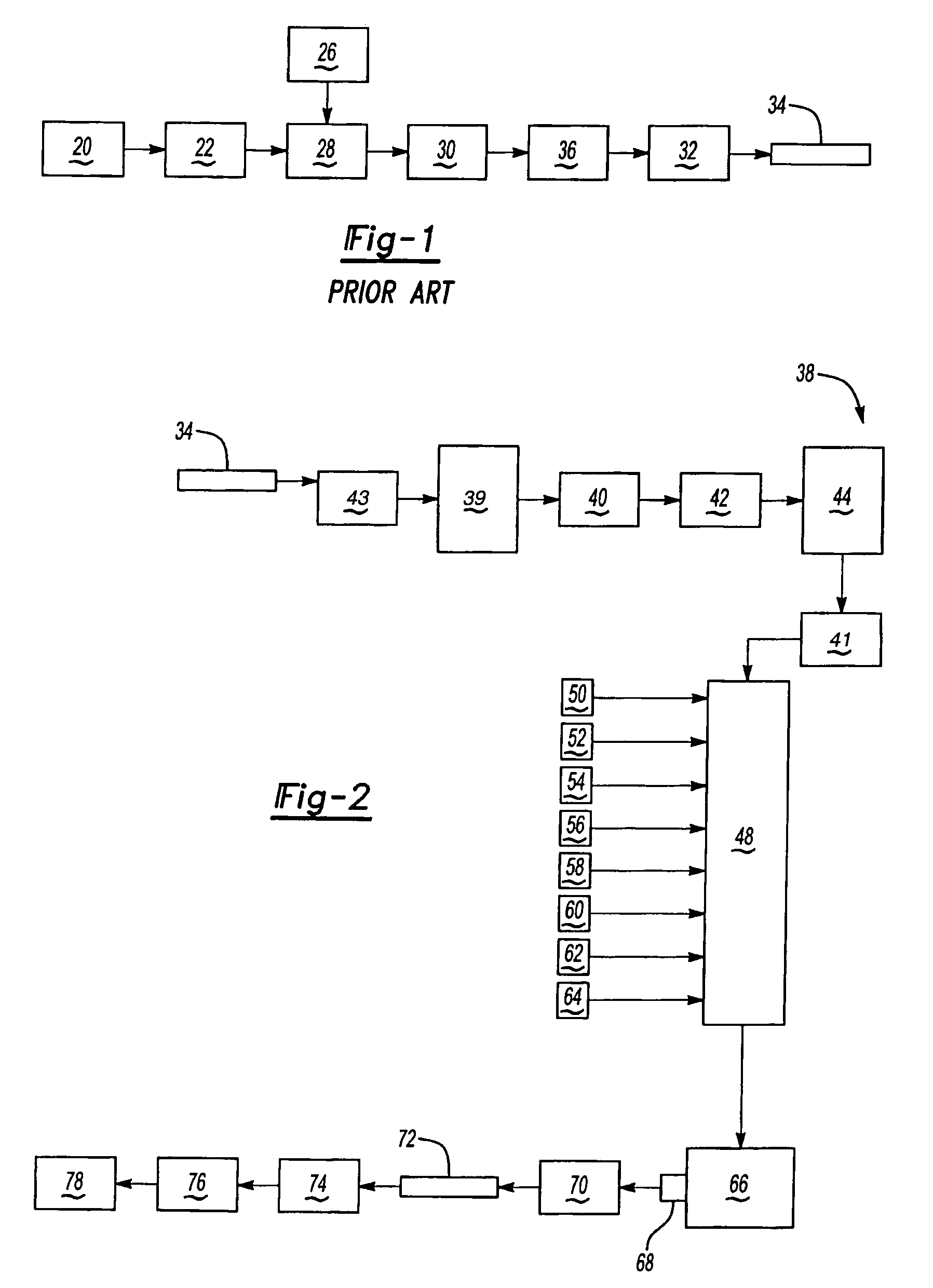

Addition of UV absorbers to PET process for maximum yield

InactiveUS20050008885A1Promote condensation polymerizationSynthetic resin layered productsThin material handlingUltravioletDicarboxylic acid

The present invention is a method for efficiently incorporating a UV absorber into a polyester resin. The method includes forming a reaction mixture comprising a diol component, a diacid component selected from the group consisting of dicarboxylic acids, dicarboxylic acid derivatives, and mixtures thereof, an antimony containing compound, a phosphorus containing compound, a metal containing compound, and a UV absorber. The reaction mixture is polymerized in a polycondensation reaction system. In another embodiment of the present invention, the UV absorber is added while the reaction products from one reactor are transferred to the next reactor in the polycondensation reaction system. A polyester composition having the UV absorber incorporated therein is also disclosed.

Owner:EASTMAN CHEM CO

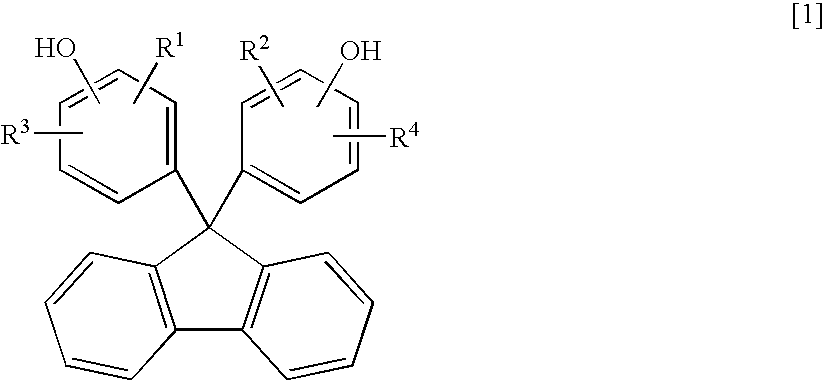

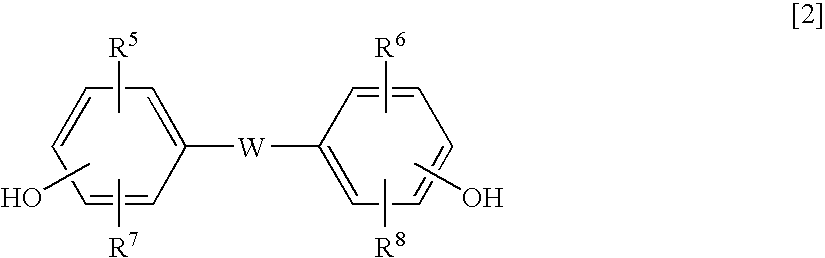

Polycarbonate copolymer, resin composition, and molded article

ActiveUS7244804B2Good colorIncrease resistanceSynthetic resin layered productsCeramic shaping apparatusPolymer scienceUv absorber

There are provided a polycarbonate copolymer (A) which has excellent light resistance and heat resistance and comprises an aromatic dihydroxy component comprising 5 to 95 mol % of fluorene-skeleton-containing dihydroxy compound (1) having a specific structure and 95 to 5 mol % of ordinary bisphenol type dihydroxy compound (2), the content of fluorene-9-one in the copolymer being not higher than 15 ppm; and a polycarbonate composition comprising 0.01 to 5 parts by weight of ultraviolet absorber (B) based on 100 parts by weight of the copolymer (A), and the composition comprising the copolymer.

Owner:TEIJIN KASEK KK

Antioxidant and ultravioresistant polypropylene woven bag raw material

InactiveCN102766918AImprove antioxidant capacityImproves UV resistanceMonocomponent polyolefin artificial filamentArtifical filament manufactureUv absorberStearic acid

The invention discloses an antioxidant and ultravioresistant polypropylene woven bag raw material. The polypropylene woven bag raw material is added with anti-oxidant B215, anti-oxidant 1010, auxiliary anti-oxidant DLTP (dilauryl thiodipropionate) or DSTP (distearyl thiodipropionate), ultraviolet absorber UV531, light stabilizer GW-480, stearic acid, calcium stearate, calcium carbonate, mono-alkoxy titanate coupling agent YDH-101, and zinc stearate in powdered polypropylene, and then subjected to wiredrawing treatment in a drawing machine. Compared with the prior art, the raw material provided by the invention has advantages of good antioxidant and ultravioresistant properties, the raw material is particularly suitable for being used as woven bag raw materials, especially for being used as the raw material for manufacturing container bags.

Owner:尚勇

Stabilization of cosmetic compositions

A composition of matter is used as an ingredient in cosmetics comprising at least 0.5% by weight and preferably 1-30% by weight of highly refined cellulose fiber in a cosmetic composition. Additionally present in the composition are other conventional cosmetic ingredients as known in the art. This composition may include at least colorants (dyes and pigments), lipophilic materials, aqueous materials (water and aqueous solutions), waxes, binding agents (polymers, thickening agents), emollients, emulsifiers, thickening agents, antioxidants, natural and synthetic oils and extracts, clays, ultraviolet radiation absorbers, and the like.

Owner:FIBERSTAR BIO INGREDIENT TECH

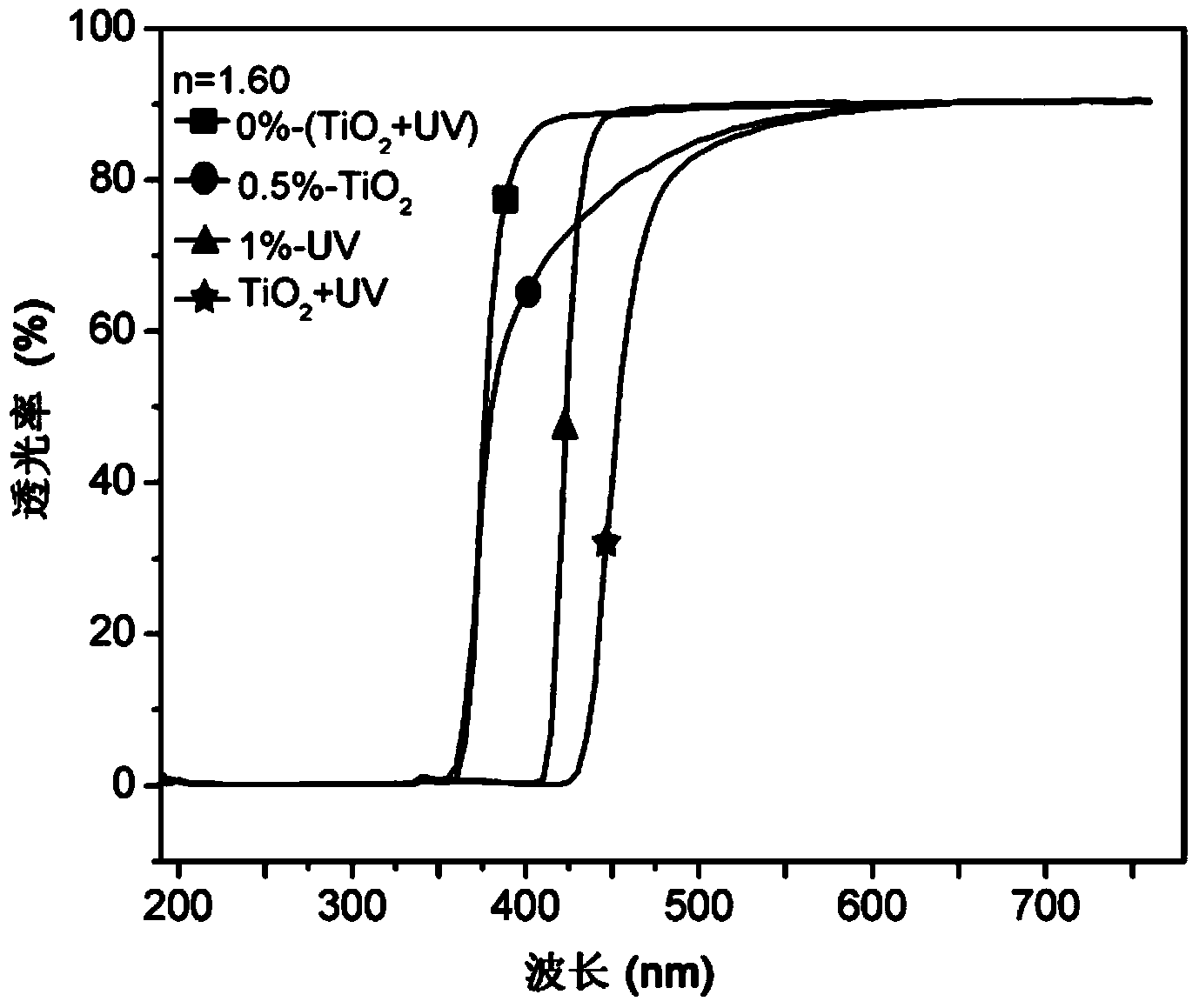

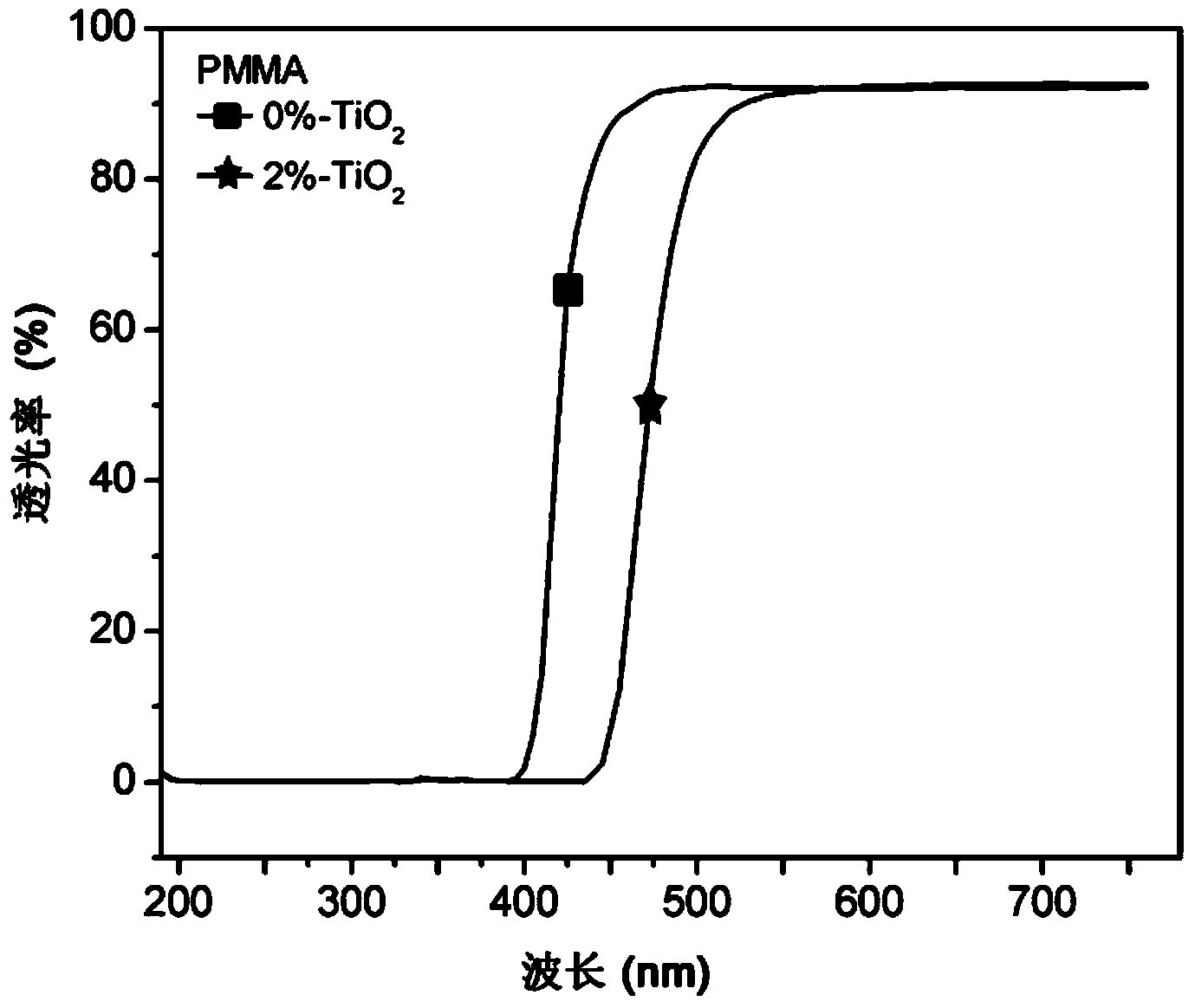

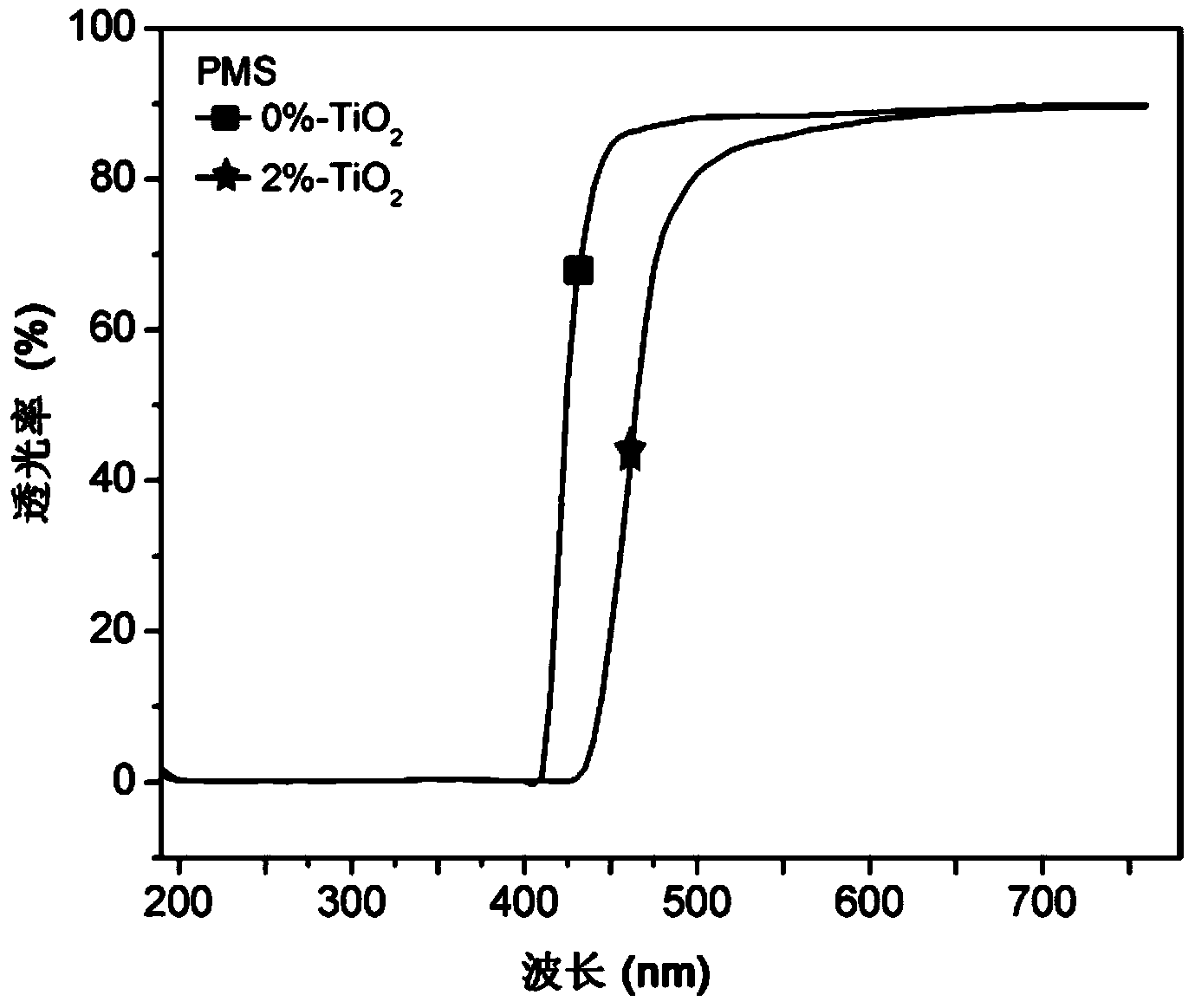

Blue light cut nano compound resin material, lens and preparation method thereof

ActiveCN103980643AEvenly dispersedComprehensive and excellent comprehensive performanceOptical partsHigh energyUltraviolet lights

The invention relates to a blue light cut nano compound resin material and lens and a manufacturing method thereof. The blue light cut nano compound resin material comprises macromolecule resin as well as core-shell type transition metal oxide nano particles and an ultraviolet light absorber which are dispersed in the macromolecule resin, wherein the core-shell type transition metal oxide nano particles account for 0.2-2% of the total weight of the resin, and the ultraviolet light absorber accounts for 0.5-5% of the total weight of the resin; particle size of nano particles is 20-50nm; the shell is a surface active agent, and thickness is 3-10nm; the nano particles and the ultraviolet light absorber are fully dispersed in a macromolecule monomer, and a prepolymerization and secondary polymerization technological process is carried out, so that the blue light cut compound resin material is obtained. The manufacturing method of the blue light cut compound resin material is simple in technology and good in reproducibility, the manufactured resin material and lens can efficiently and permanently shield high energy harmful blue light and ultraviolet light with wavelength within the range of 380-450nm, vision is clear and colour vision is soft under strong and weak light environments respectively, and the blue light cut compound resin material has excellent overall performance.

Owner:JIANGSU SHIKEXINCAI CO LTD

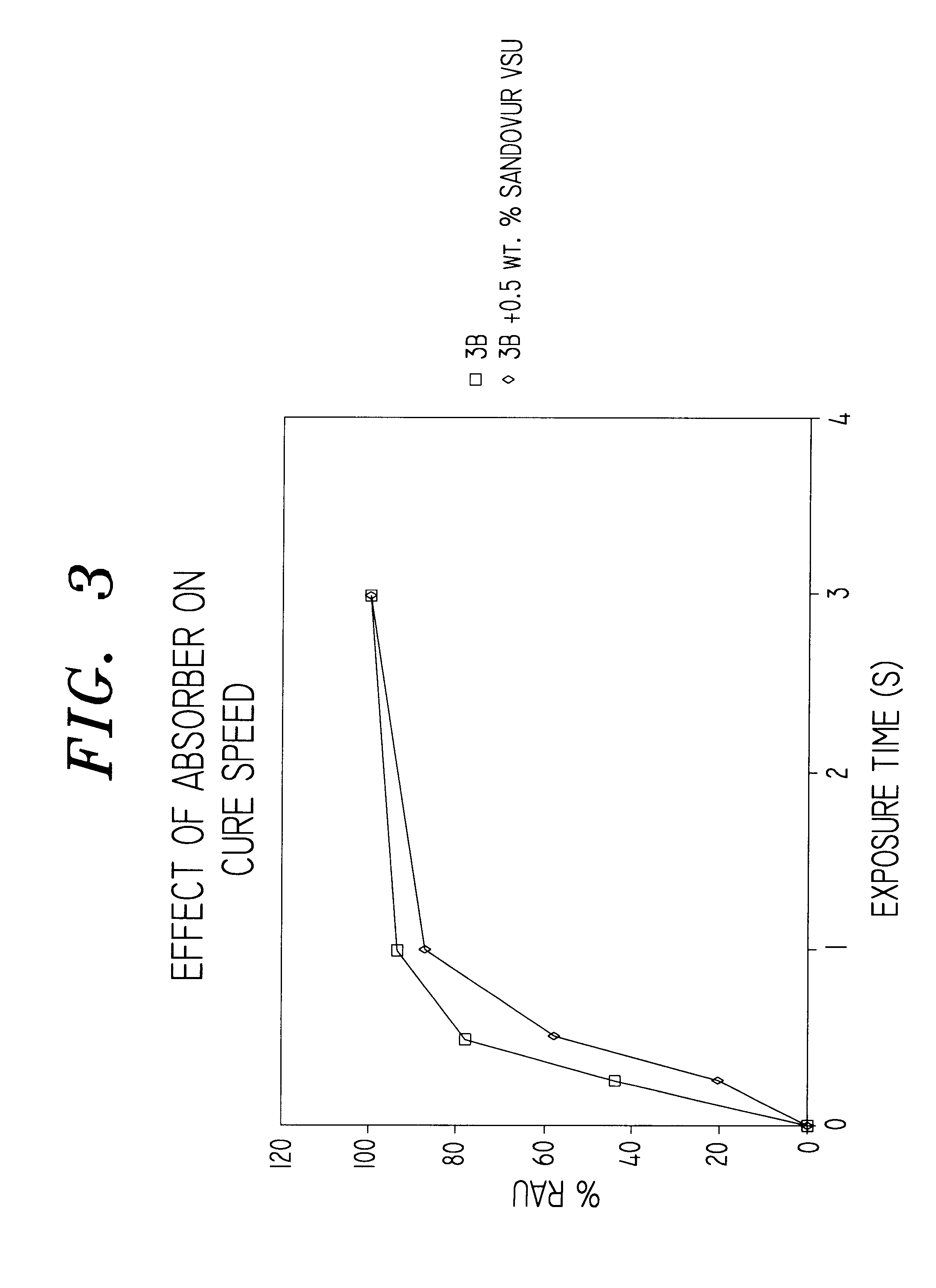

Radiation-curable optical fiber coatings having reduced yellowing and fast cure speed

InactiveUS6187835B1Impair cure speedImprove curing speedLight effect designsLavatory sanitoryUv absorberPhotoinitiator

Radiation-curable inner and outer primary optical fiber coatings are disclosed having both fast cure speed and reduced rates of yellowing. The compositions comprise particular photoinitiators and UV absorbers which are used in amounts to provide the combination of properties. The UV absorber can have ethylenic unsaturation. Outer primary coatings can be formulated to screen inner primary coatings and have fast cure speed.

Owner:DSM IP ASSETS BV

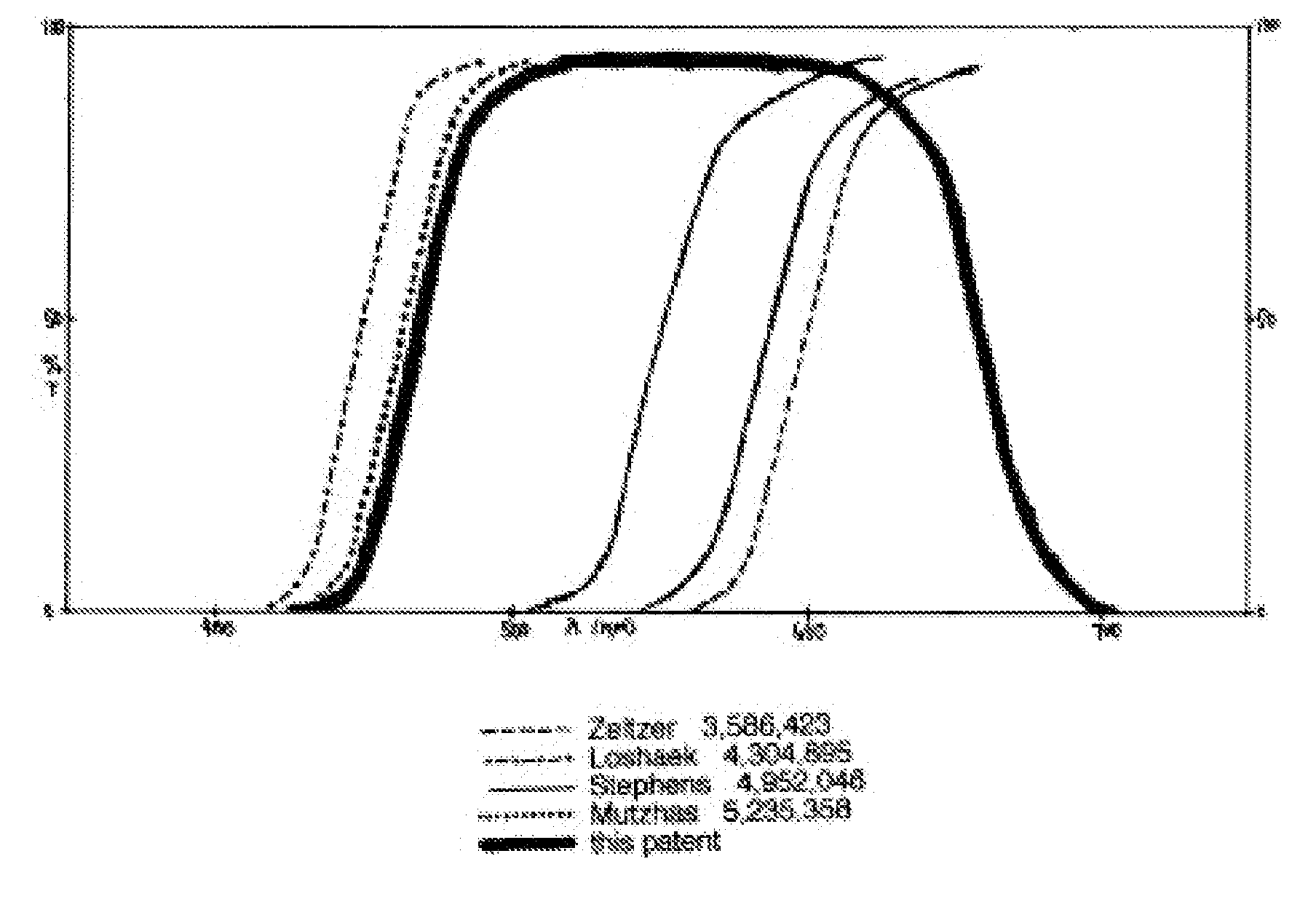

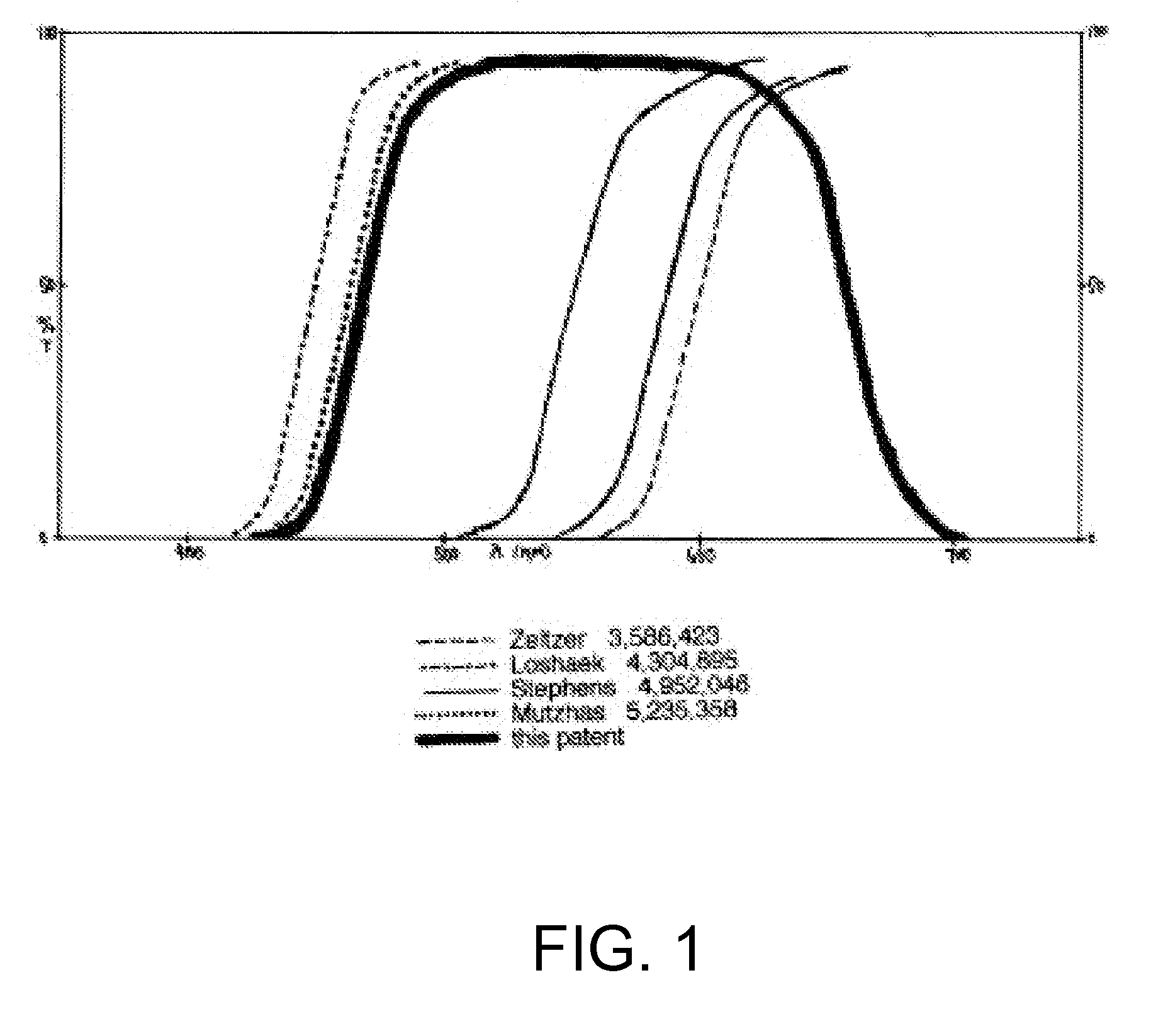

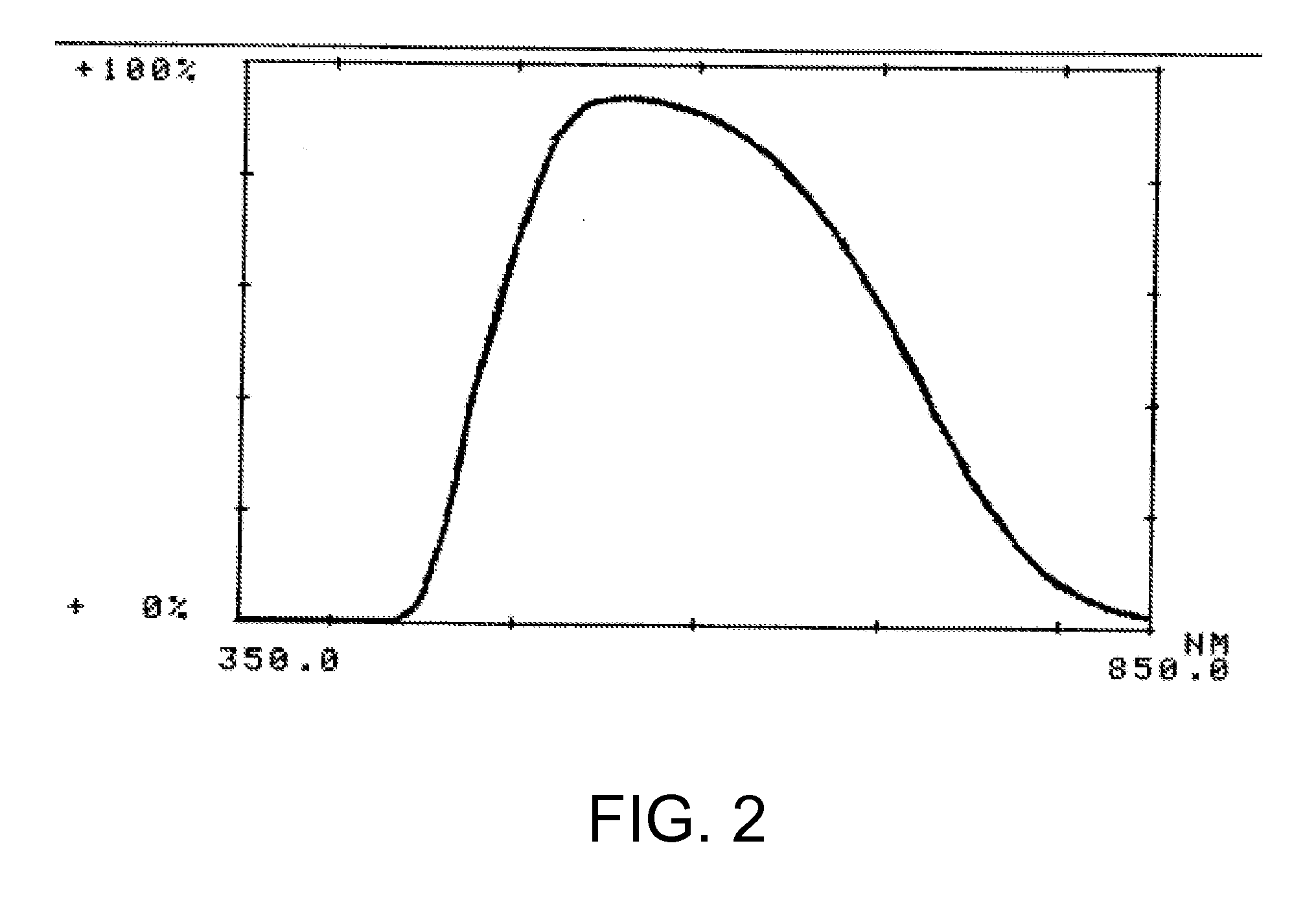

Optical devices with reduced chromatic aberration

InactiveUS20080137030A1Improve stabilityHigh strengthSpectales/gogglesOptical partsUses eyeglassesRigid contact lens

This invention relates to an optical device such as a soft or rigid contact lens, intra ocular lens (IOL), ocular insert, or spectacle lens that improves visual acuity by reducing chromatic aberration. Chromatic aberration is reduced by filtering or blocking ultraviolet and high energy blue / violet light below about 455 nm and red and infrared light above about 655 nm. This is accomplished by including in the polymer formulations blue / violet absorbing colorants and ultraviolet light absorbers to filter or block light below about 455 nm; and red absorbing colorants and infrared absorbers to filter or block light above about 655 nm. When these materials are used for wavefront designed lenses, vision better than 20 / 20 is attainable.

Owner:THE LAGADO CORP

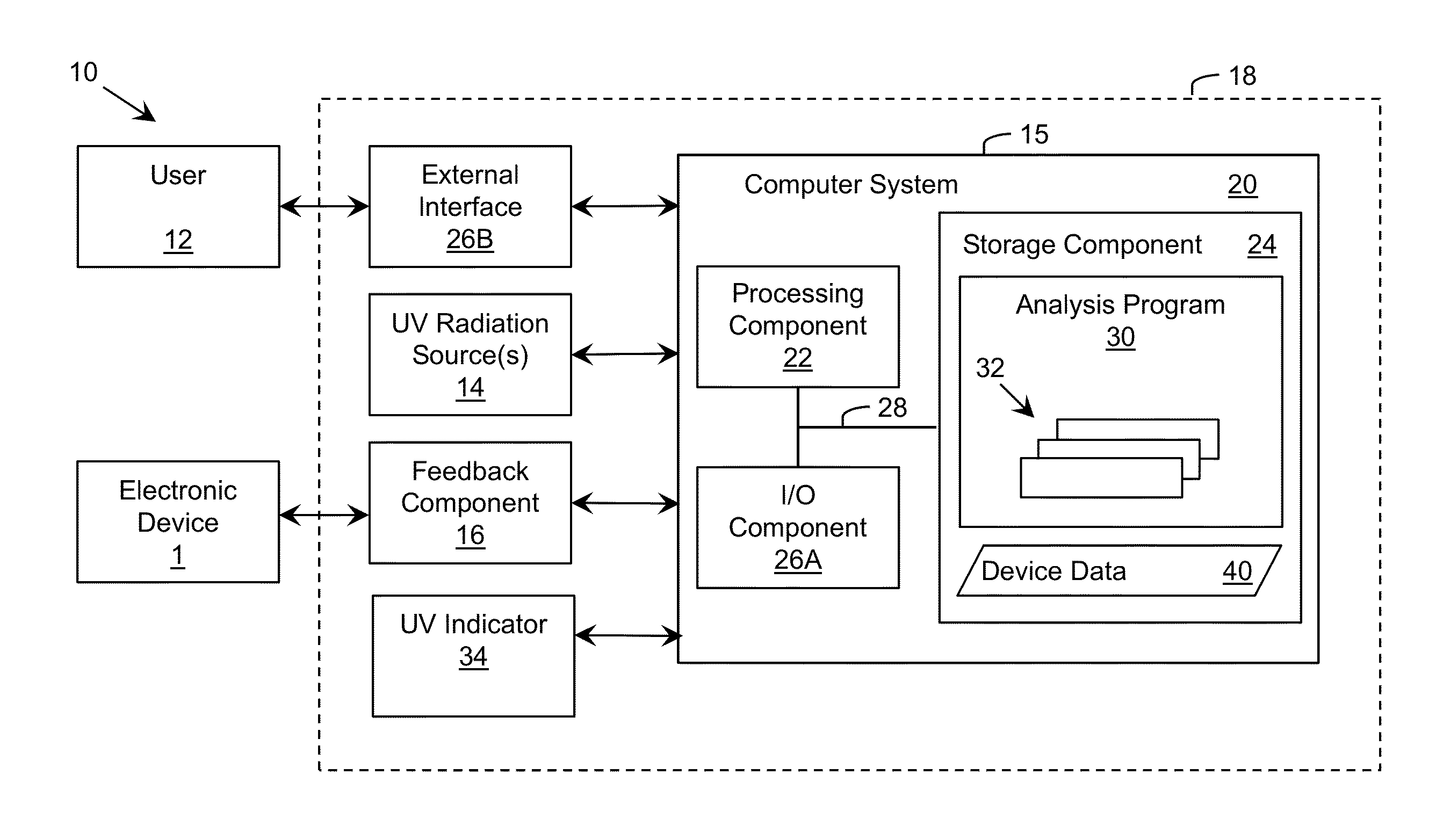

Electronic gadget disinfection

ActiveUS9138499B2Improved UV LED disinfectionEffective disinfectionLavatory sanitoryRadiationControl systemUv absorber

Owner:SENSOR ELECTRONICS TECH

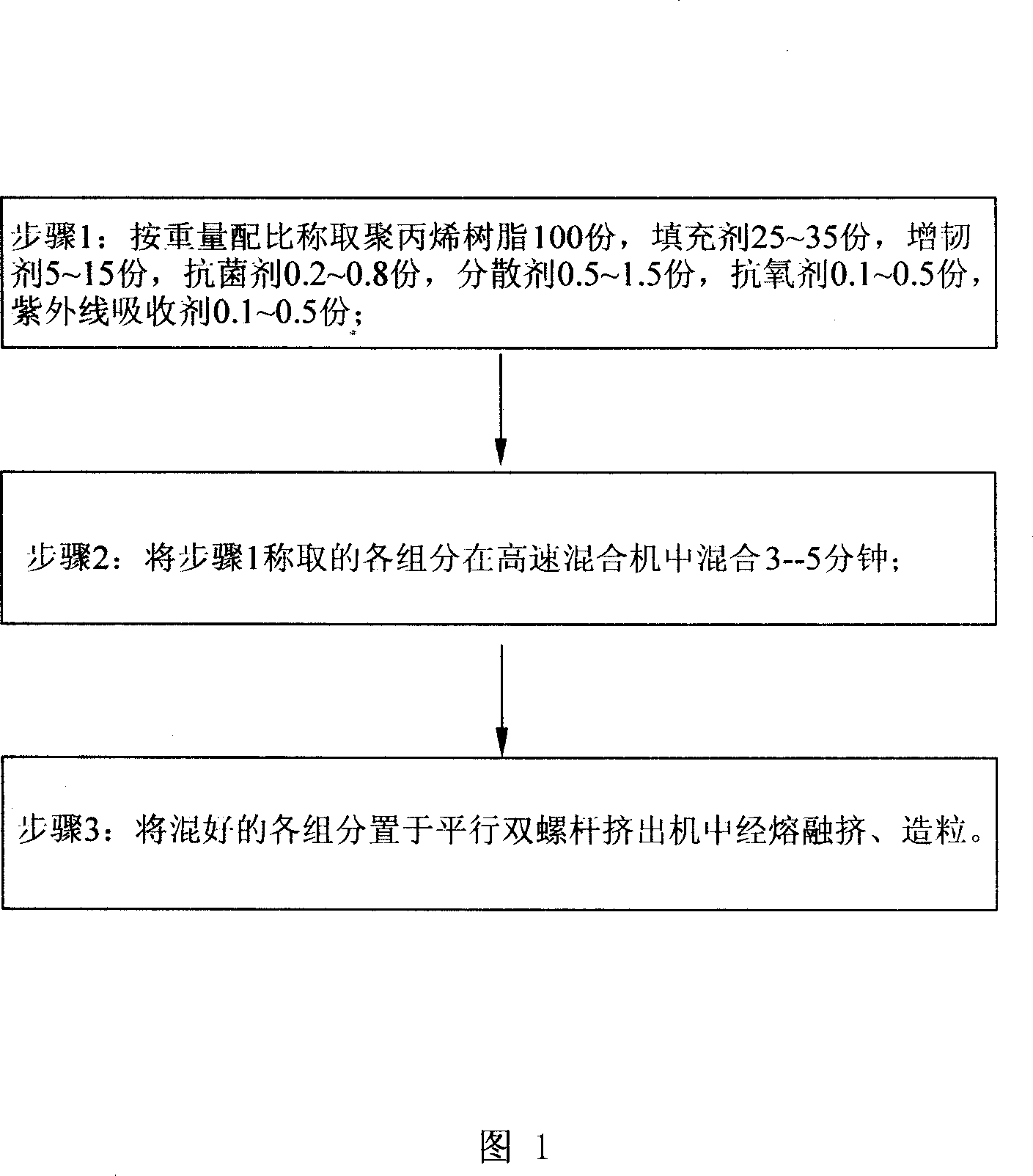

Antibacterial polypropylene material and its prepn process

InactiveCN101089038AReduce manufacturing costHigh surface glossBiocideAnimal repellantsUltravioletPolypropylene

The antibacterial polypropylene material consists of polypropylene resin 100 weight portions, stuffing 25-35 weight portions, toughening agent 5-15 weight portions, antiseptic 0.2-0.8 weight portion, dispersant 0.5-1.5 weight portions, antioxidant 0.1-0.5 weight portion and ultraviolet absorber 0.1-0.5 weight portion. The polypropylene resin is homopolypropylene, and the antiseptic is compounded with nanometer silver and organosilicon antiseptic. The present invention also provides the preparation process of the antibacterial polypropylene material with low production cost, excellent antiseptic performance.

Owner:SHENZHEN KEJU NEW MATERIAL

Filler sheet for solar cell module, and solar cell module using the same

InactiveUS20060201544A1High strengthLow costPV power plantsSynthetic resin layered productsPolyolefinEngineering

A main object of the invention is to provide a filler sheet for a solar cell module which is excellent in various properties such as strength, endurance, weatherability, heat resistance, water resistance, light resistance, wind pressure resistance, hailstorm resistance, and vacuum laminating suitability, and has very good thermal melting / bonding property without being affected by production conditions and others, and which makes it possible to produce a solar cell module, suitable for various use purposes, stably at low costs; and a solar cell module using the same. In order to attain the object, the invention provides, as a filler sheet for solar cell element, a filler sheet made of a resin film produced by a resin composition comprising a copolymer of an α-olefin and an ethylenic unsaturated silane compound, or a modified or condensed body thereof, and one or more selected from the group consisting of a light resisting agent, an ultraviolet absorbent and a thermal stabilizer; and a filler sheet made of a resin film produced by a resin composition comprising a maleic anhydride modified polyolefin.

Owner:DAI NIPPON PRINTING CO LTD

Preparation method of recycled polyester chip microfilaments and usage thereof

InactiveCN101747596ASimple compositionNo smellFilament/thread formingConjugated synthetic polymer artificial filamentsPolyesterLinear low-density polyethylene

The invention relates to a preparation method of recycled polyester chip microfilaments and a usage thereof, belonging to the field of plastic modification and category of composite material / alloy promoter. The polyester chip microfilament is an ideal promoter which has excellent performance, environment-friendliness, high added value, wide application range and broad market prospect and can change the mechanical property of the composite material / alloy. Recycled blow molding polyester (RPET / RPBT) is taken as main raw material, and the following formula and process are adopted for preparing the microfilament according to parts by weight: 100 parts of recycled polyester (RPET / RPBT), 5-30 parts of wire-drawing high-density polyethylene (HDPE) / polypropylene (PP) / linear low-density polyethylene (LLDPE), 0.1-4 parts of crosslinking agent / chain extender / anchoring agent, 0.1-0.8 part of antioxidant, 0.5-6 parts of nucleating agent, and 1-5 parts of nucleate accelerant, and other processing aids (such as lubricant and plasticizer) / functional aids (such as fire retardant and ultraviolet absorber) can be additionally and appropriately added. The microfilament is prepared through extrusion, cooling, drawing and granulating by the reaction under 90-260 DEG C under the action of mechanical shear. The recycled polyester (RPET / RPBT) microfilament prepared in the invention can endow the composite material / alloy with excellent mechanical property.

Owner:王世和

Durable corrosion and ultraviolet-resistant silver mirror

InactiveUS6989924B1Efficient screeningRetains its specular optical efficiency and aesthetic appearanceSolar heating energyMirrorsUltravioletVisible spectral range

A corrosion and ultra violet-resistant silver mirror for use in solar reflectors; the silver layer having a film-forming protective polymer bonded thereto, and a protective shield overlay comprising a transparent multipolymer film that incorporates a UV absorber. The corrosion and ultraviolet resistant silver mirror retains spectral hemispherical reflectance and high optical clarity throughout the UV and visible spectrum when used in solar reflectors.

Owner:ALLIANCE FOR SUSTAINABLE ENERGY

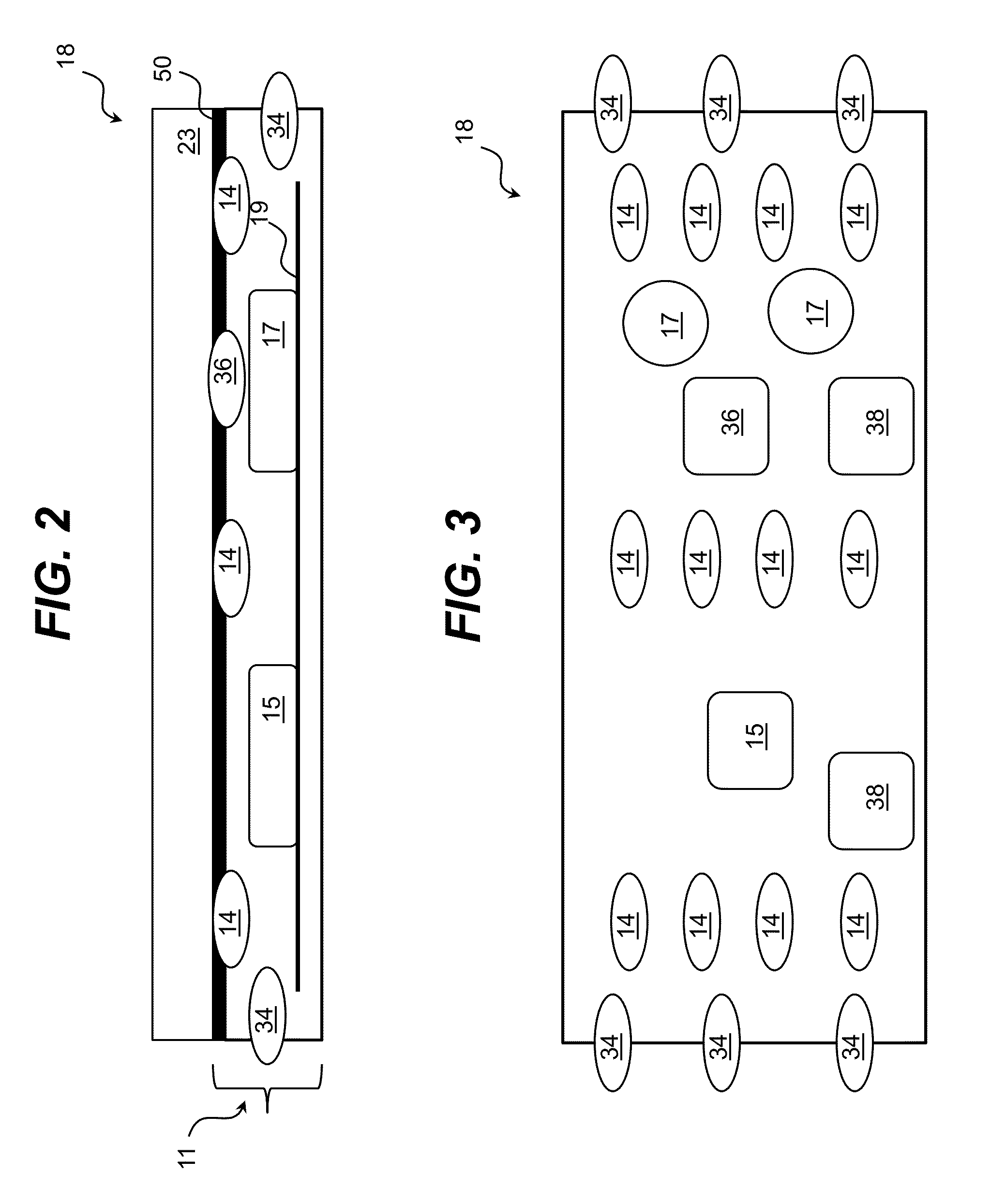

Electronic Gadget Disinfection

ActiveUS20140183377A1Improved UV LED disinfectionEffective disinfectionMaterial analysis using wave/particle radiationElectric discharge tubesUltravioletDrug biological activity

A solution for disinfecting electronic devices is provided. An ultraviolet radiation source is embedded within an ultraviolet absorbent case. While the electronic device is within the ultraviolet absorbent case, ultraviolent radiation is directed at the electronic device. A monitoring and control system monitors a plurality of attributes for the electronic device, which can include: a frequency of usage for the device, a biological activity at a surface of the device, and a disinfection schedule history for the device. Furthermore, the monitoring and control system can detect whether the device is being used. Based on the monitoring, the monitoring and control system controls the ultraviolet radiation directed at the electronic device.

Owner:SENSOR ELECTRONICS TECH

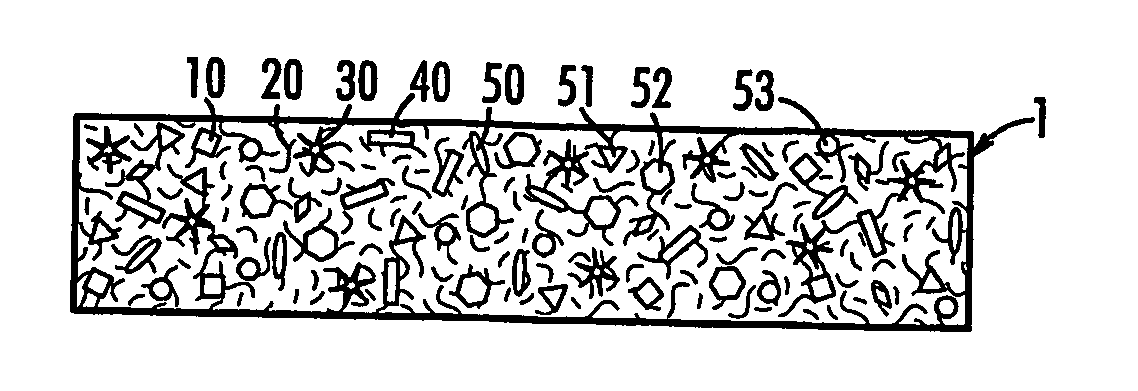

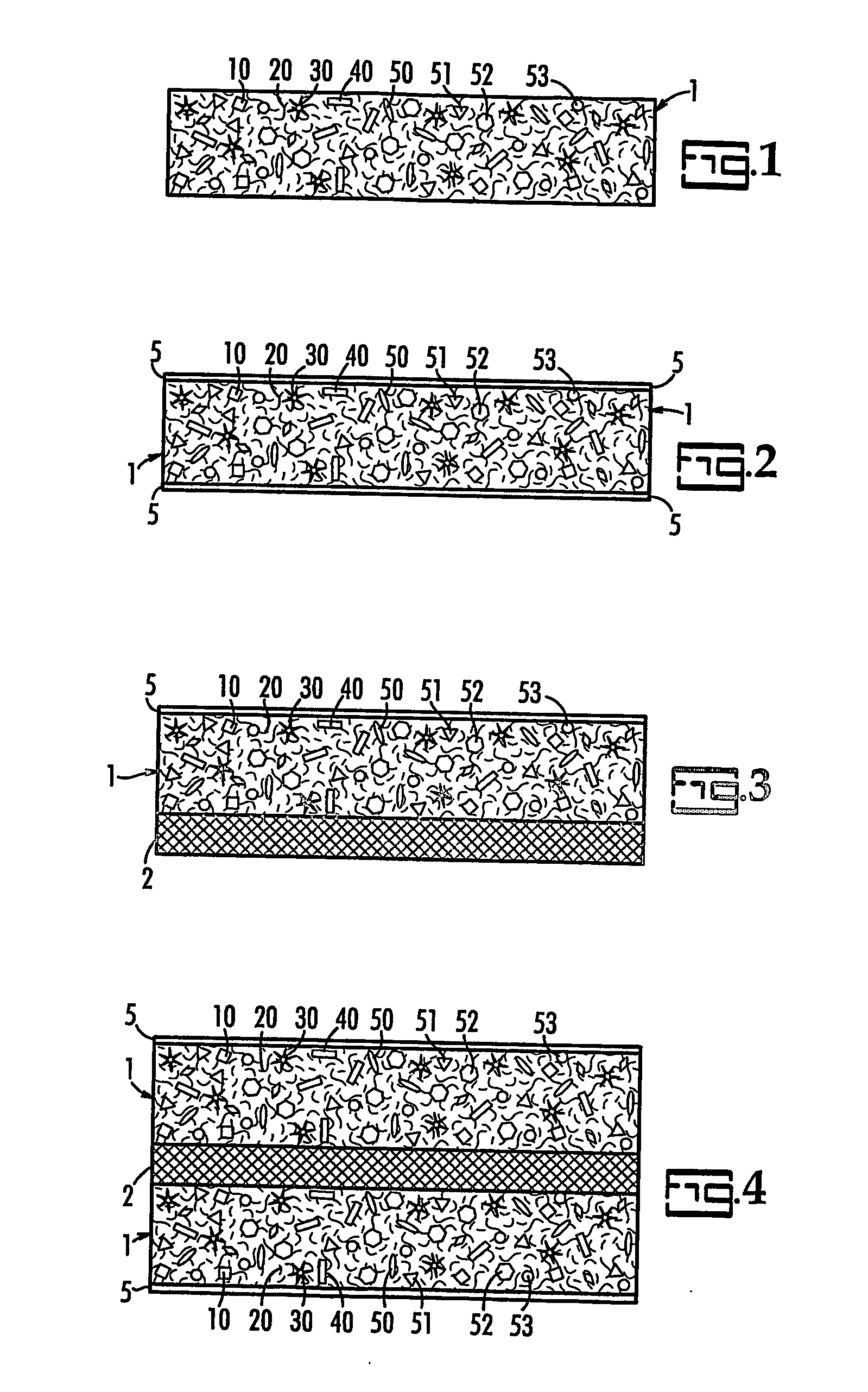

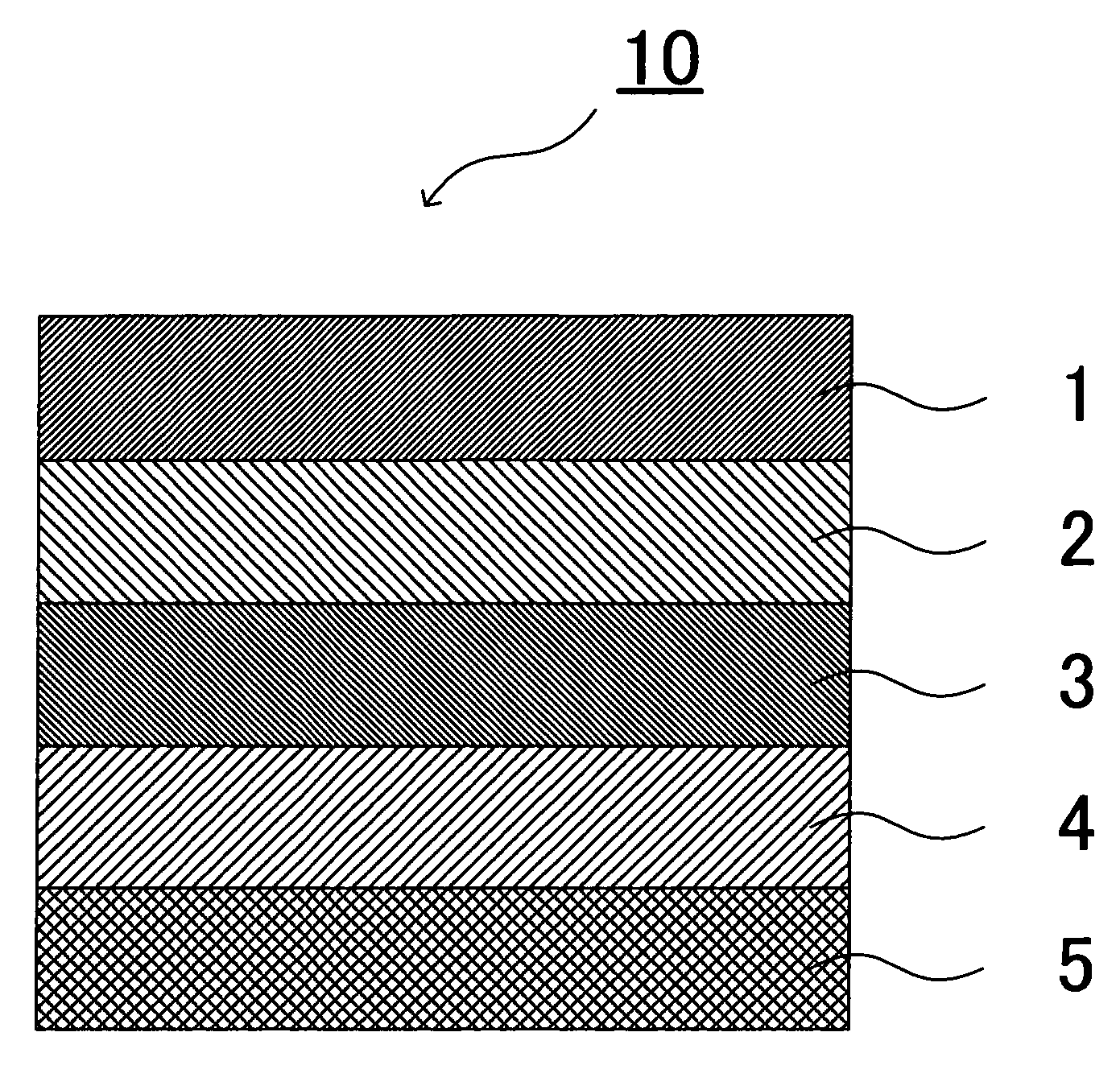

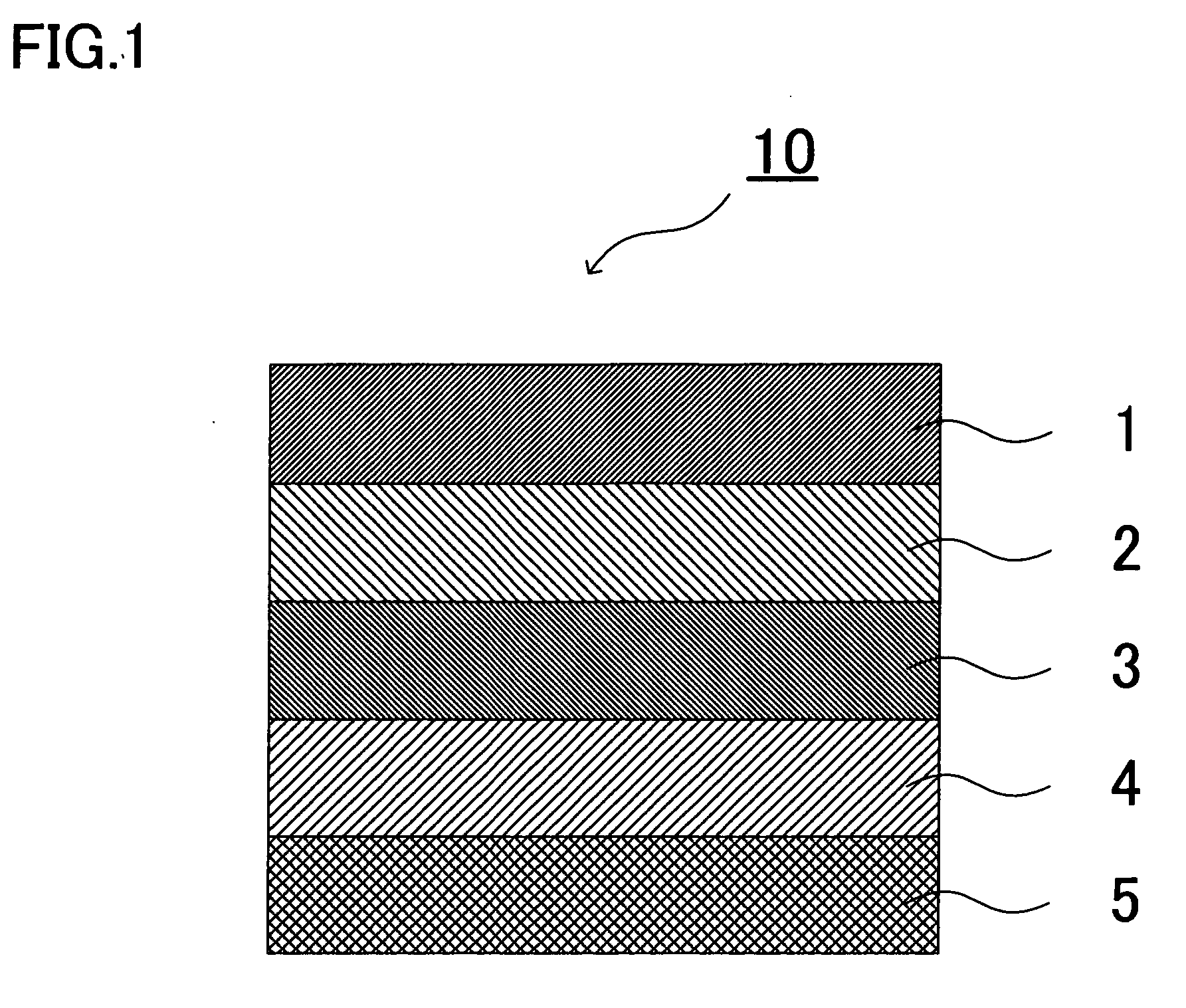

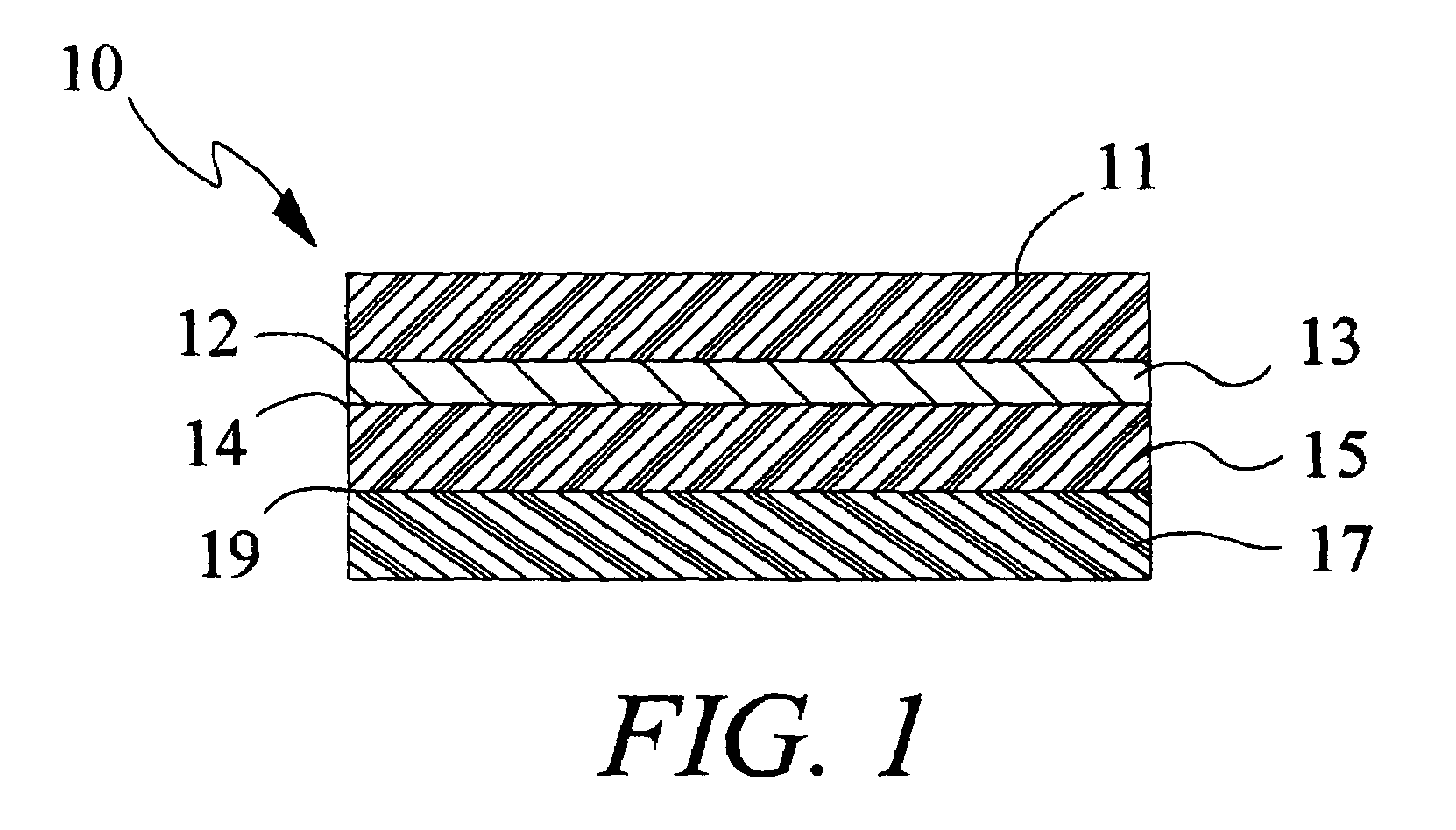

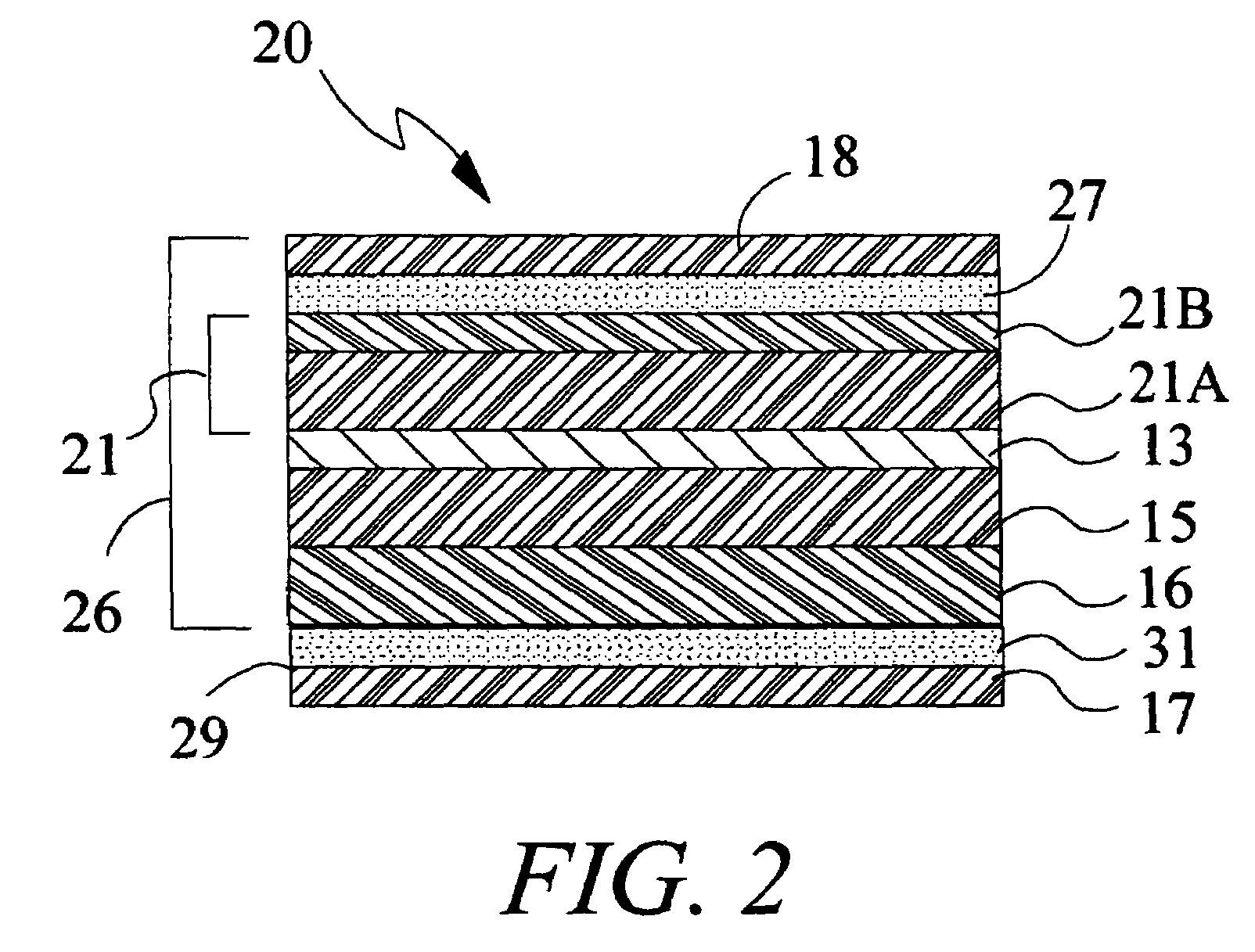

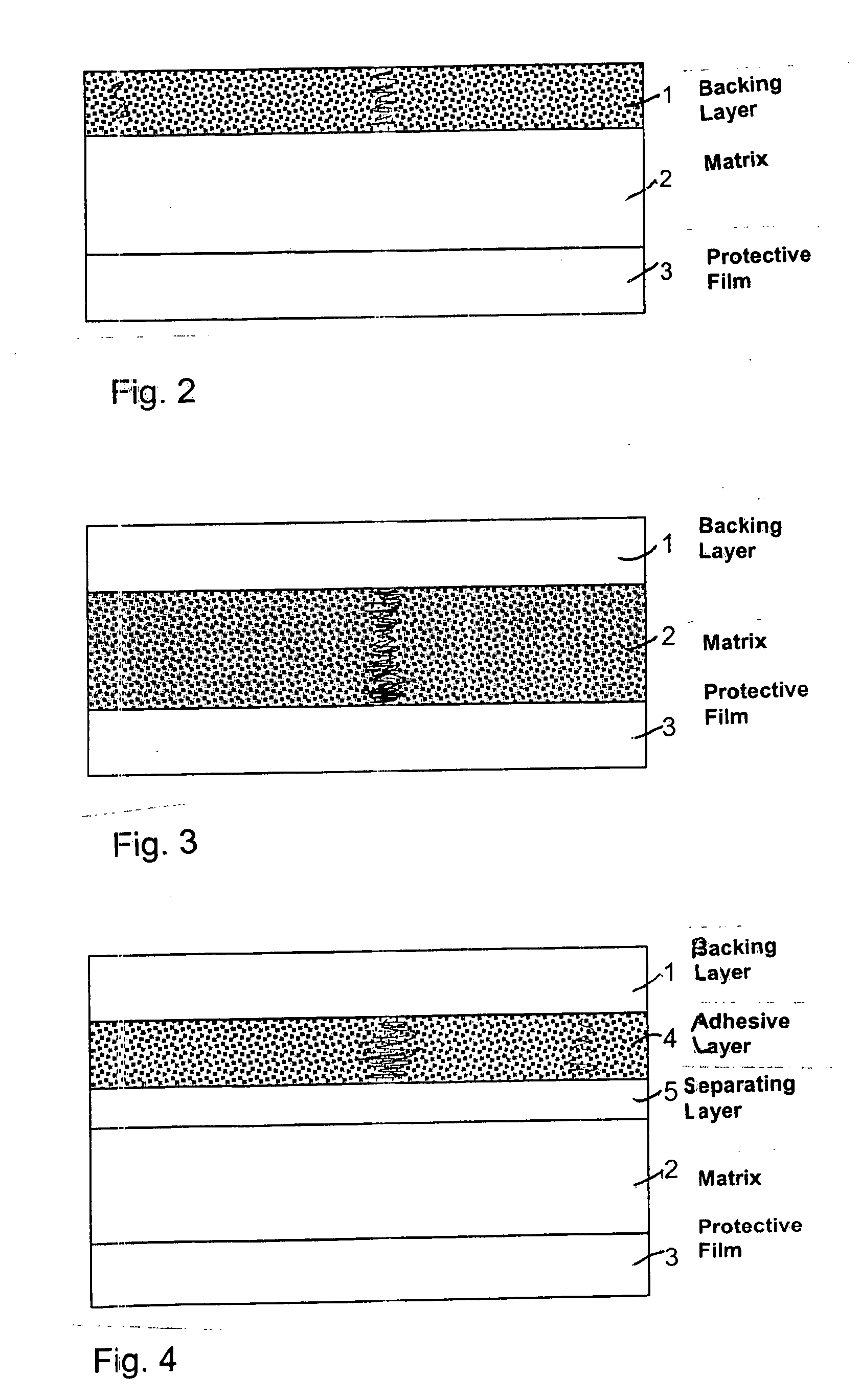

Solid transdermal therapeutic system with UV absorber

ActiveUS20060246122A1Improve the protective effectBiocidePharmaceutical non-active ingredientsTectorial membraneMedicine

The UV-stable solid transdermal therapeutic system (TTS) with UV absorber for photosensitive active pharmaceutical ingredients has a backing layer (1), at least one active ingredient-containing matrix (2), and a detachable protective film (3). Optionally an adhesive layer (4) and a separating layer (5) are introduced between the backing layer (1) and the at least one active ingredient-containing matrix (2). At least one hydroxyphenyltriazine compound acting as UV absorber is embedded in the backing layer (1), in the active ingredient-containing matrix (2), or in the adhesive layer (4). The TTS according to the invention achieves high stability at low concentrations of UV absorber, preferably 0.5 to 3% (m / m), so as to reduce or avoid skin irritation.

Owner:LUYE PHARMA SWITZERLAND AG

Insulator coating and method for forming same

ActiveUS20060081394A1Avoid pollutionImproves UV stabilityPlastic/resin/waxes insulatorsInsulated cablesCoating systemUltraviolet

The present invention is a method of applying Lotus Effect materials as a (superhydrophobicity) protective coating for external electrical insulation system applications, as well as the method of fabricating / preparing Lotus Effect coatings. Selected inorganic or polymeric materials are applied on the insulating material surface, and stable superhydrophobic coatings can be fabricated. Various UV stabilizers and UV absorbers can be incorporated into the coating system to enhance the coating's UV stability.

Owner:GEORGIA TECH RES CORP

Pressure-sensitive adhesive sheet

ActiveUS9045670B2Improves UV protectionRetaining optical characteristicNon-macromolecular adhesive additivesSynthetic resin layered productsDisplay deviceEngineering

The present invention realizes a display device or input device having excellent ultraviolet protection property for the touch panel, display element or the like, while retaining optical characteristics, even when a small amount of or no optical film is used. The pressure-sensitive adhesive sheet of the present invention has a total light transmittance of 85% or more, a light transmittance at a wavelength of 380 nm of 5% or less, and a haze of 3% or less. The pressure-sensitive adhesive sheet preferably includes a pressure-sensitive adhesive layer containing an acrylic polymer and a triazine-based ultraviolet absorber.

Owner:NITTO DENKO CORP

Electronic Gadget Disinfection

ActiveUS20160000953A1Improved UV LED disinfectionEffective disinfectionMaterial analysis using wave/particle radiationElectric discharge tubesControl systemUv absorber

A solution for disinfecting electronic devices is provided. An ultraviolet radiation source is embedded within an ultraviolet absorbent case. While the electronic device is within the ultraviolet absorbent case, ultraviolent radiation is directed at the electronic device. A monitoring and control system monitors a plurality of attributes for the electronic device, which can include: a frequency of usage for the device, a biological activity at a surface of the device, and a disinfection schedule history for the device. Furthermore, the monitoring and control system can detect whether the device is being used. Based on the monitoring, the monitoring and control system controls the ultraviolet radiation directed at the electronic device.

Owner:SENSOR ELECTRONICS TECH

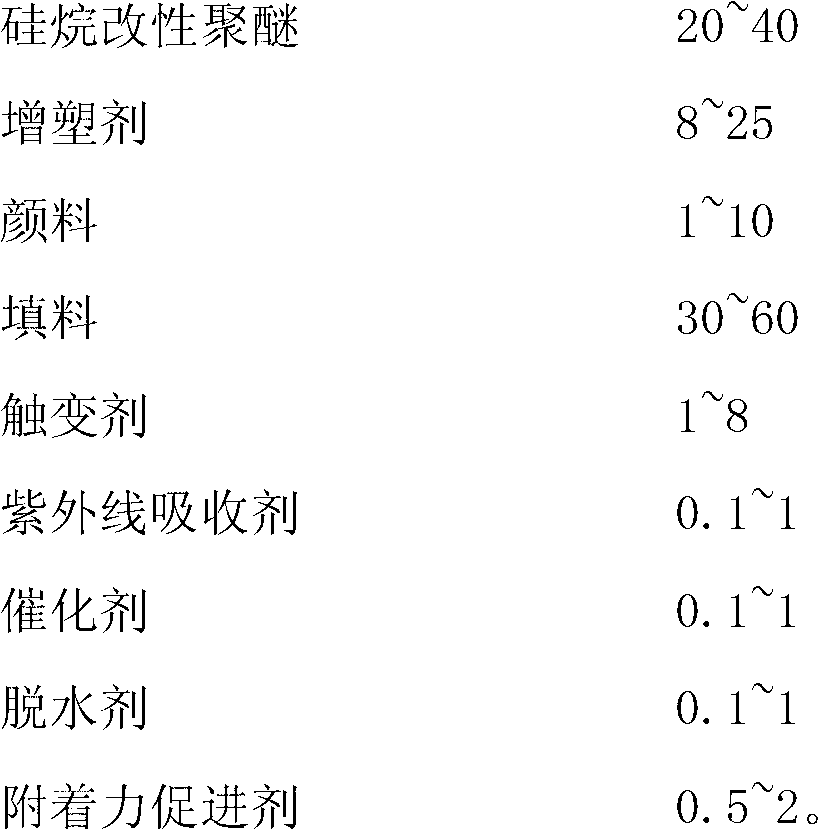

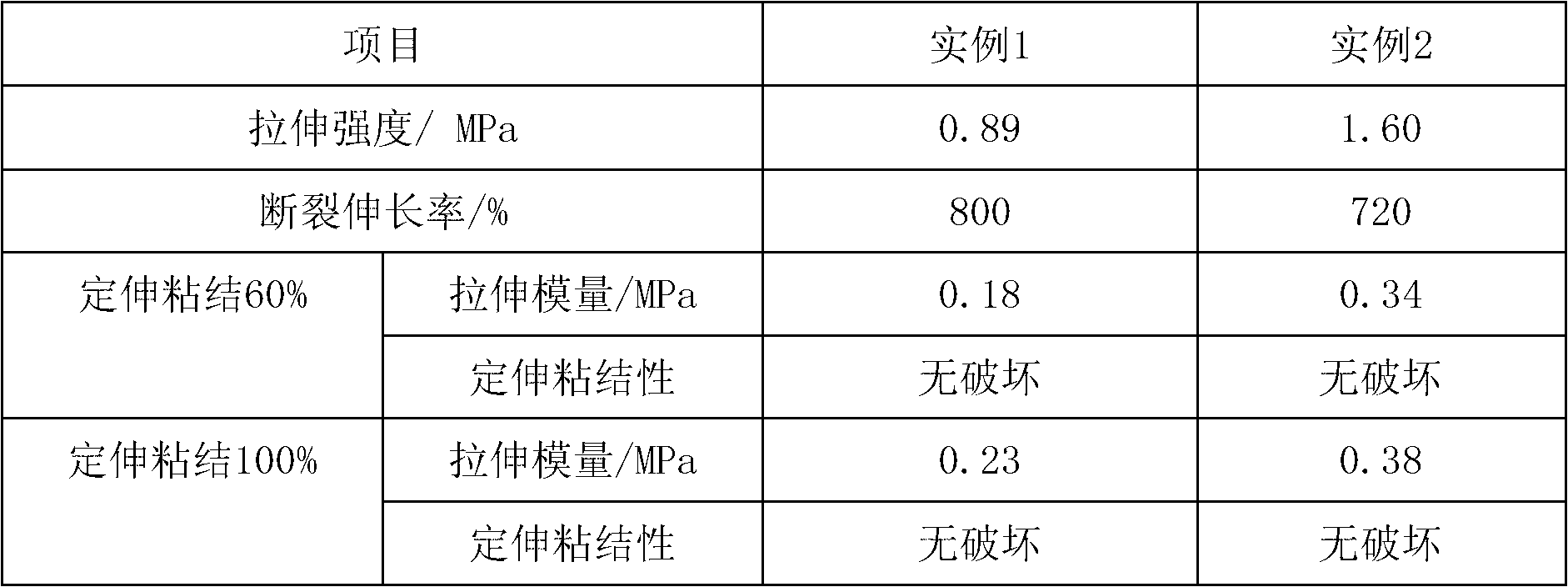

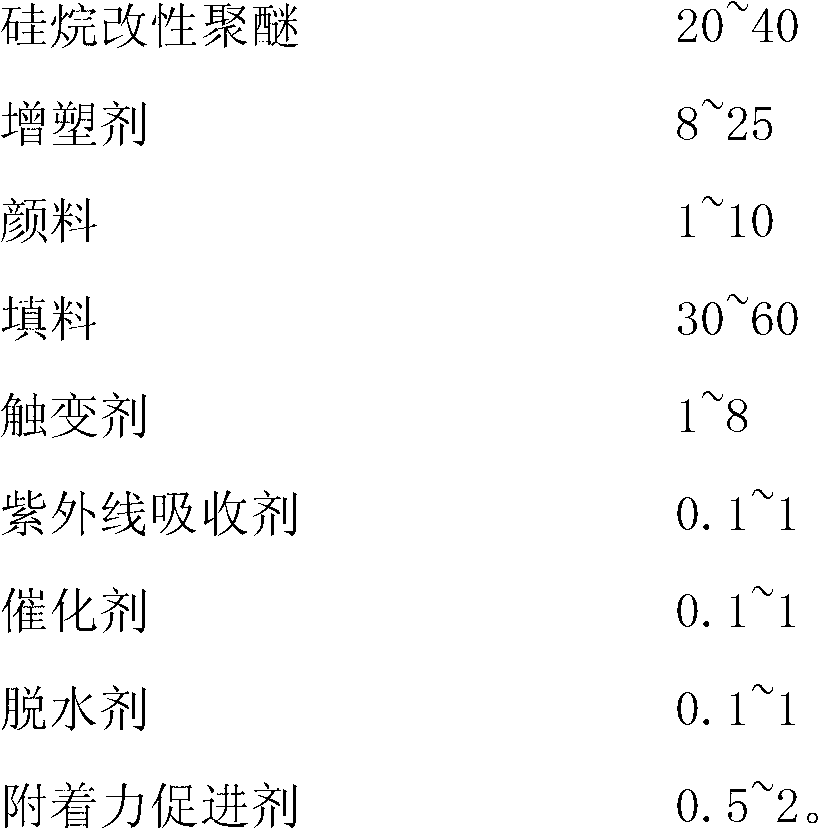

Low-modulus single-component silane modified polyether sealing gum and preparation method thereof

InactiveCN102994034AReduce manufacturing costSimple compositionNon-macromolecular adhesive additivesOther chemical processesSilanesPlasticizer

The invention discloses low-modulus single-component silane modified polyether sealing gum which consists of the following components: silane modified polyether, a plasticizer, pigment, fillers, a thixotropic agent, an ultraviolet light absorber, a catalyst, a dehydrating agent and an adhesion promoter. According to the silane modified polyether sealing gum disclosed by the invention, by controlling the technical parameters such as the types and contents of the fillers, the types and content of the plasticizer, and the types and content of the thixotropic agent, the prepared silane modified polyether sealing gum does not need prime coat, does not contain isocyanate, is economical and environmentally-friendly, low in modulus, can bear dynamic juncture, has good flexibility, cohesiveness and good storage stability, can be firmly adhered with concrete, PVC (Polyvinyl Chloride) materials, aluminum sheets, glass, steel products, ceramic and the like, and can be widely applied to the fields of roads, bridges and buildings.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

Blue ray radiation preventing and achromatism spectacle lens, and method of producing the same

InactiveCN101216611AEffectively filter outReduce harmVacuum evaporation coatingSputtering coatingUltravioletTitanium oxide

The invention relates to a spectacle lens capable of preventing blue light radiation and eliminating the chromatic aberration and a manufacture method thereof, which belongs to the technical field of spectacles and the manufacture method thereof. The spectacle lens is characterized in that a substrate is prepared from an organic polymer, a blue light absorbent and a UV absorbent by mixing; and a coated film layer includes a TiO2 layer, an Al2O3 layer, an ITO layer, a noble metal layer, an MgF2 layer and a SiO2 layer. The manufacture method of the spectacle lens comprises following steps of: preparing materials, mixing, stirring, curing, cleaning the substrate, reinforcing and coating film on the substrate. The spectacle lens capable of preventing blue light radiation and eliminating the chromatic aberration can effectively filter most of UV light and a portion of blue light to reduce the damage to human retina and the irritation of shortwave glare, thus reducing chromatic aberration and improving resolution of human eyes. Accordingly, persons wearing the spectacle lens can view objects clearly in weaker or stronger light environment.

Owner:曾琪 +1

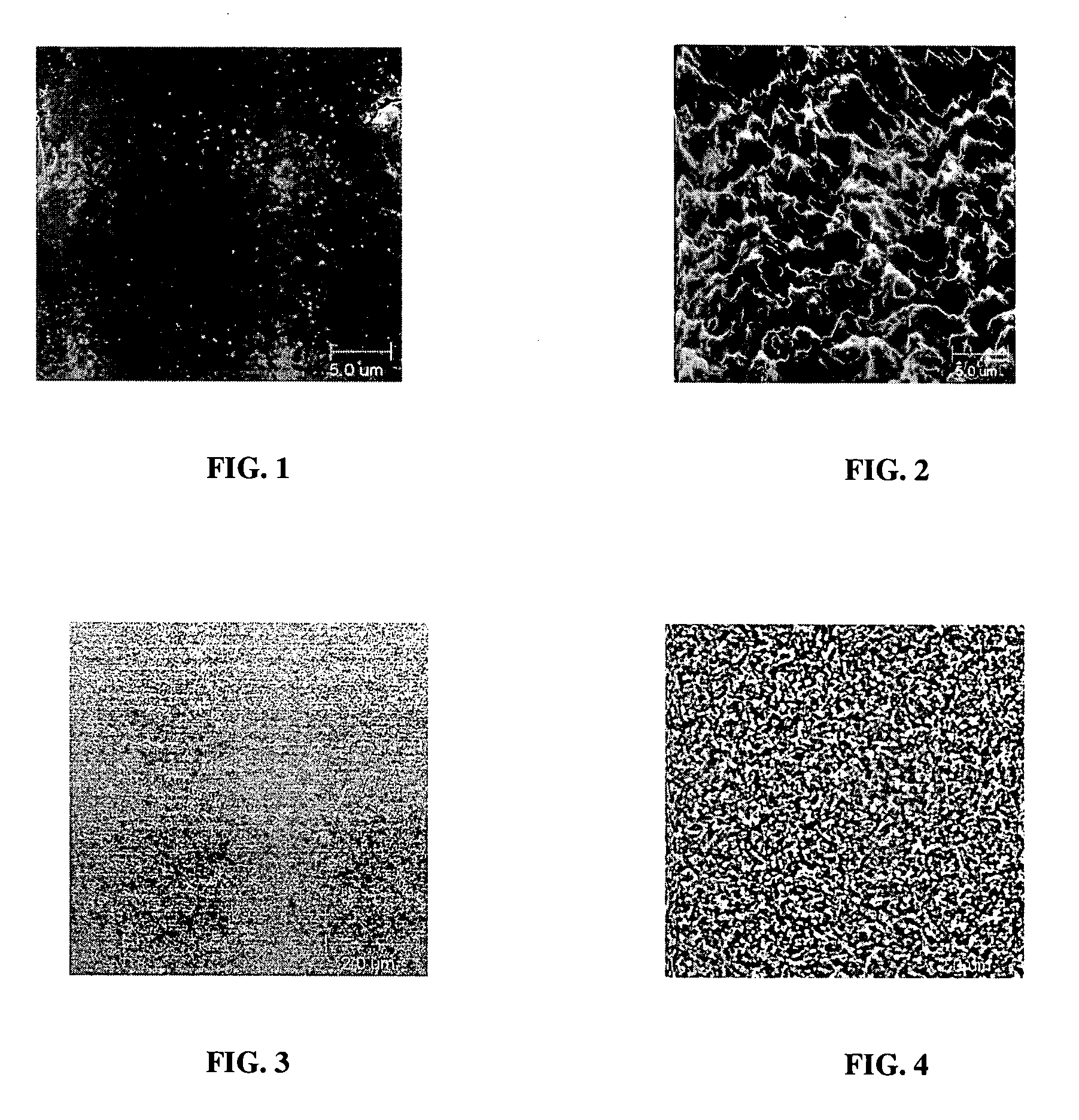

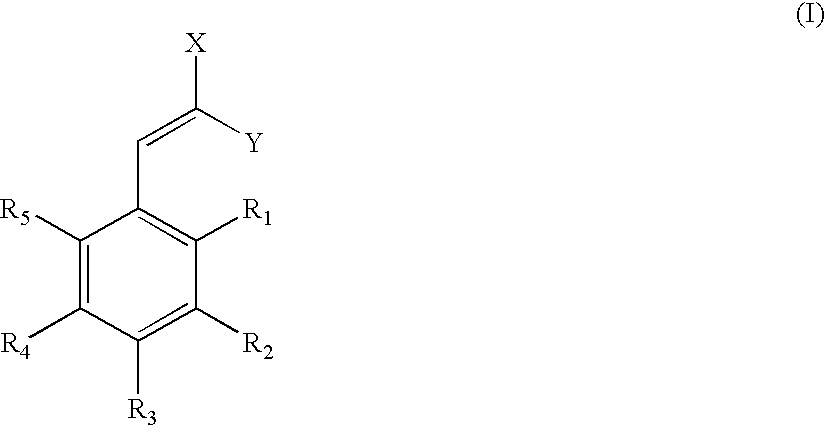

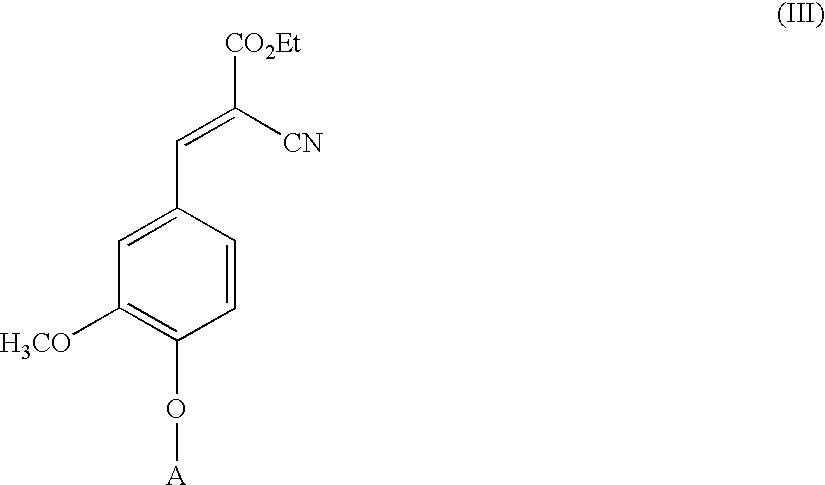

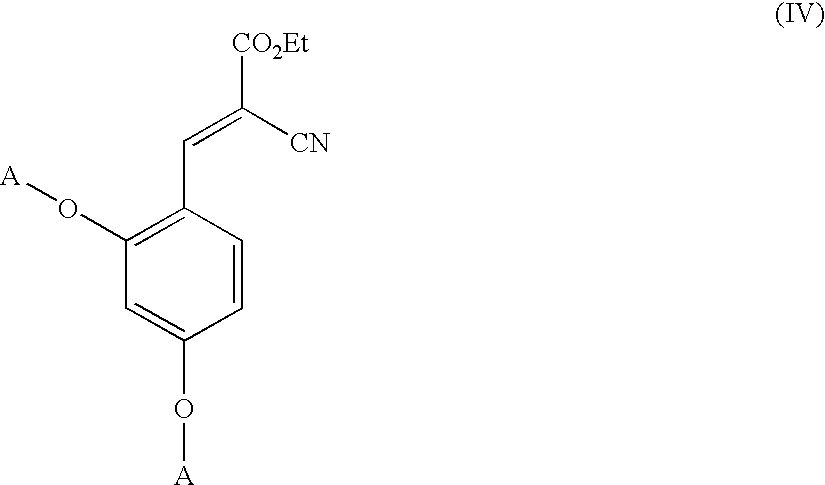

Low-color ultraviolet absorber compounds and compositions thereof

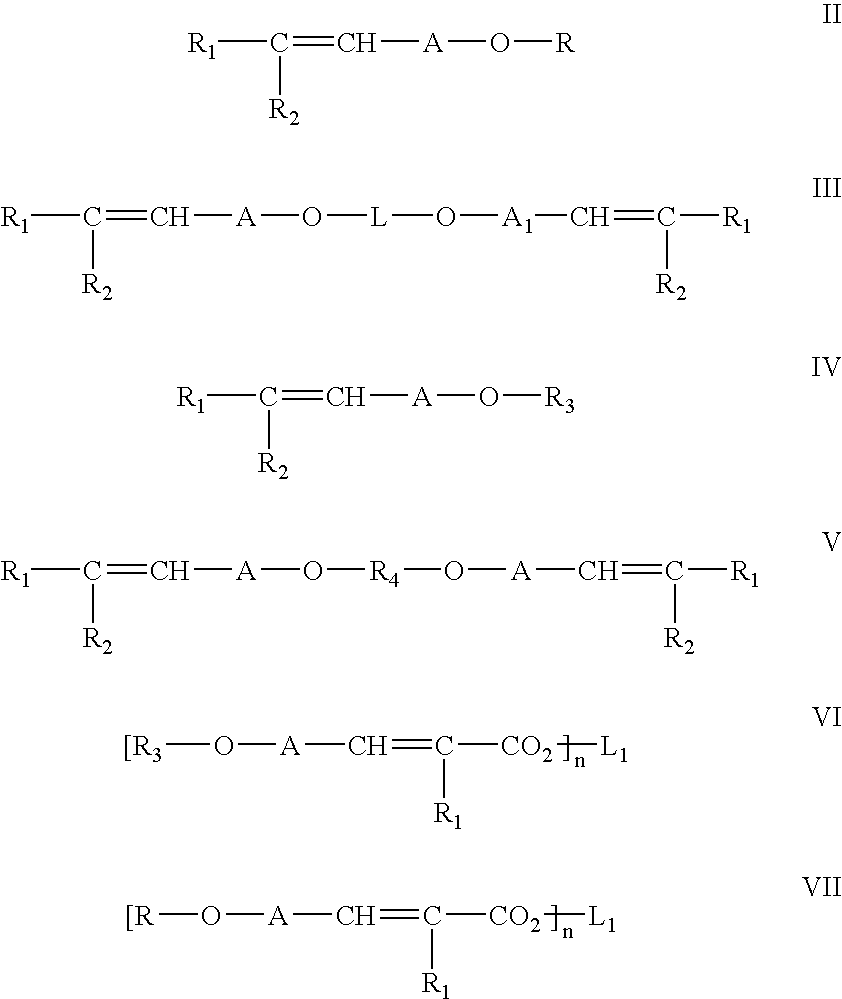

InactiveUS6559216B1Brighter clarityEffective compoundOrganic chemistryOrganic compound preparationThermoplasticChain length

Novel ultraviolet absorbing compounds that are liquid in nature, are extremely low in color (and thus permit use without the concomitant necessity of adding large amounts of other coloring agents to combat such discoloring), and are highly effective in providing protection in wavelength ranges for which previous attempts at low-color ultraviolet absorbers have failed are provided herein. Such compounds provide such excellent, inexpensive, and beneficial protection from ultraviolet exposure within various media, including, but not limited to, clear thermoplastics. The particular compounds are generally polymeric in nature including various chain lengths of polyoxyalkylenes thereon and are liquid in nature to facilitate handling and introduction within the target media. In addition, such ultraviolet absorbers also exhibit extremely low migratory properties thereby providing long-term protective benefits to the target media as well. This invention also concerns the end products, specific broadly defined types of compounds providing such beneficial characteristics, methods of making such low-color compounds, and methods of producing such clear, UV protected end products.

Owner:MILLIKEN & CO

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com