Patents

Literature

172results about How to "Improves UV stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of preparing an aliphatic polyurea spray elastomer system

This invention concerns a method for the preparation of polyurea elastomers, comprising: (a) reacting an amine chain extender with dialkyl maleate to form an aspartic ester, wherein the chain extender has a molar amount of amine groups that is less than the moles of dialkyl maleate; (b) blending the aspartic ester with one or more polyoxyalkyleneamines to prepare a resin blend; (c) contacting the resin blend with an isocyanate under conditions effective to form a polyurea elastomer. This invention also concerns a a polyurea elastomer, comprising the reaction product of (a) a resin blend containing one or more polyoxyalkyleneamine and an aspartic ester and (b) an isocyanate, wherein the aspartic ester in the resin blend comprises a reaction product of an amine chain extender and a dialkyl maleate, wherein the mole ratio of amine functionality in the amine chain extender to dialkyl maleate or fumarate is greater than 1:1.

Owner:JPMORGAN CHASE BANK N A AS COLLATERAL AGENT +1

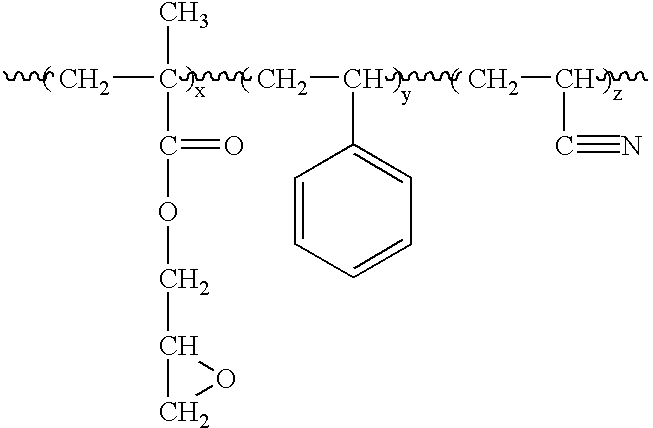

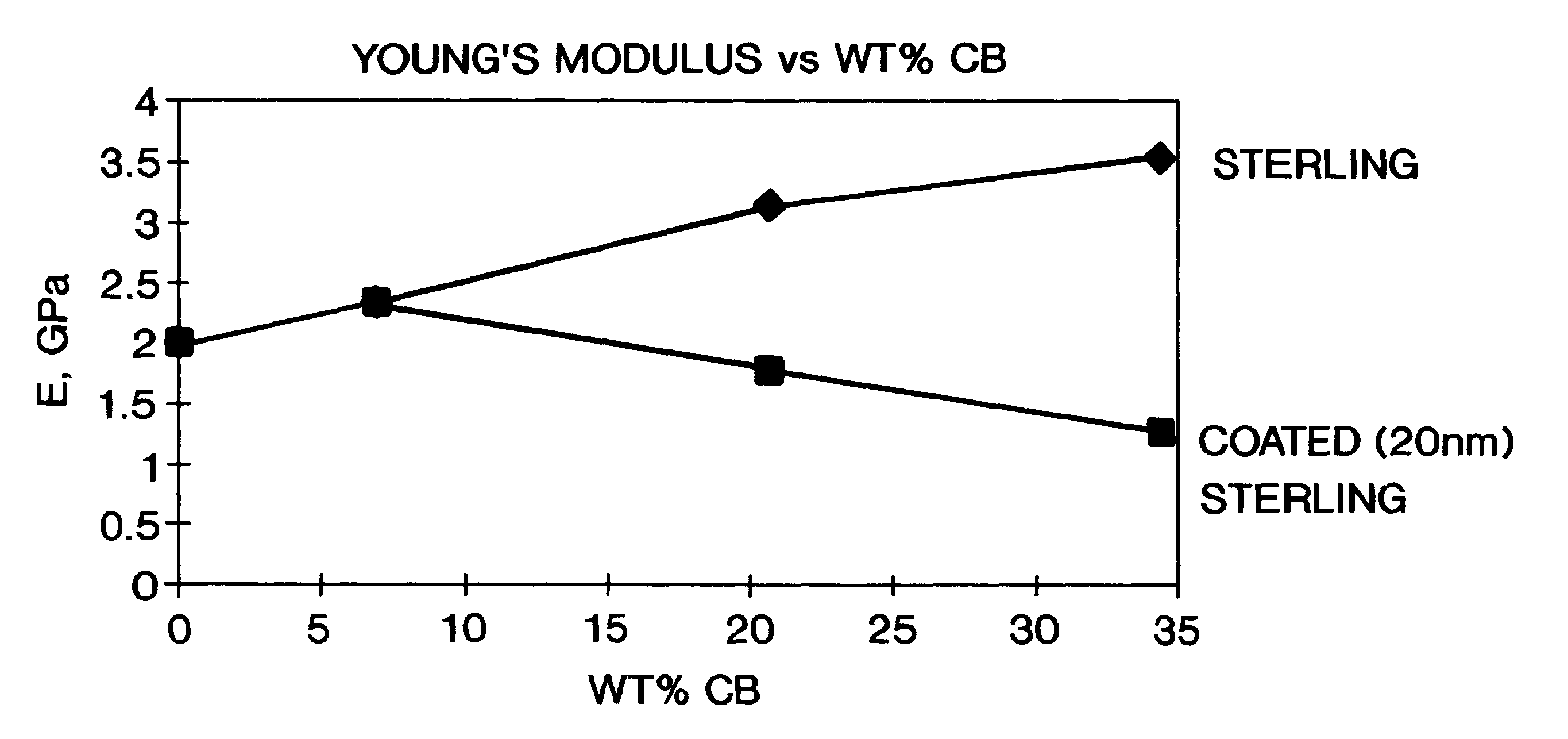

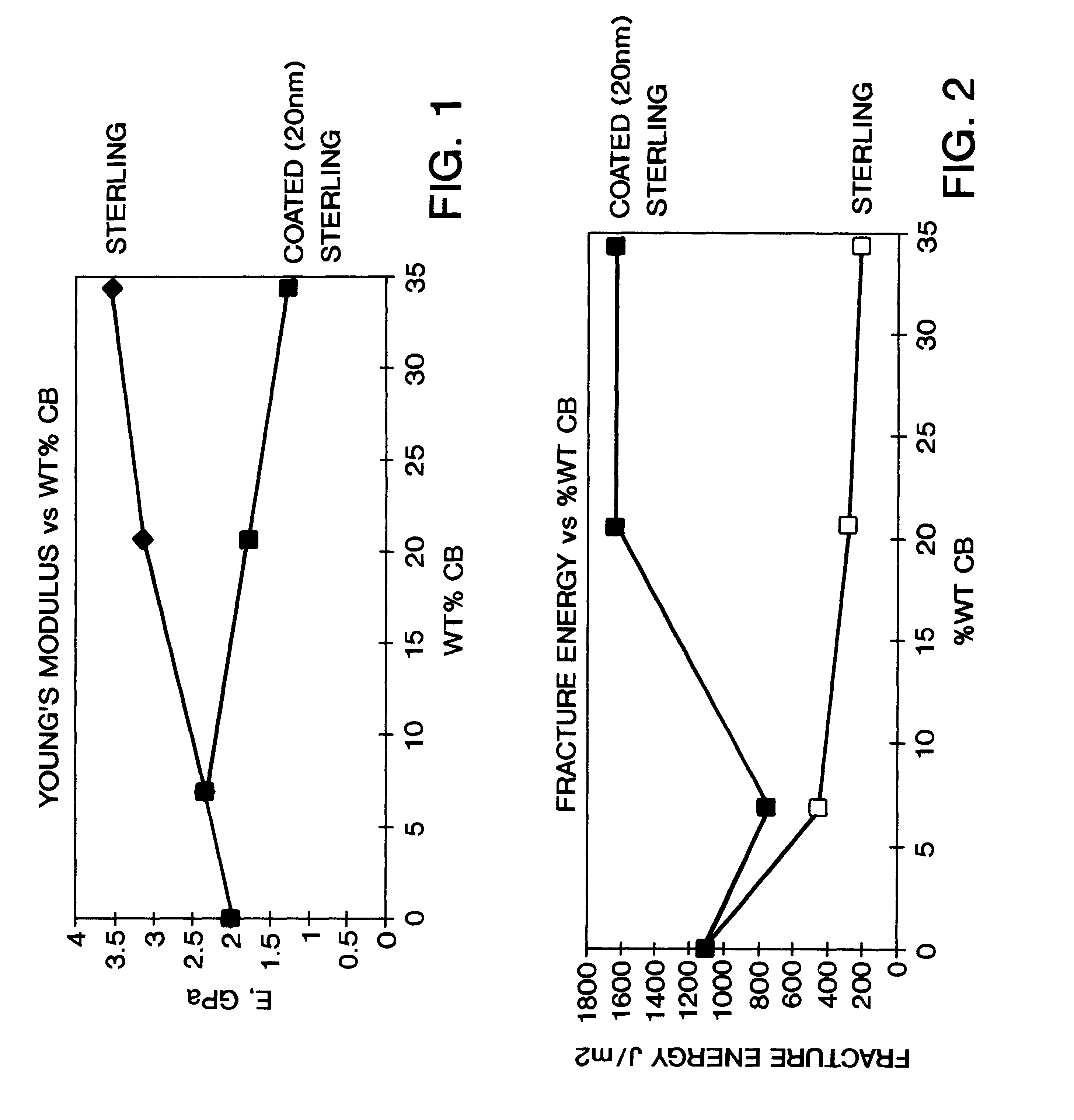

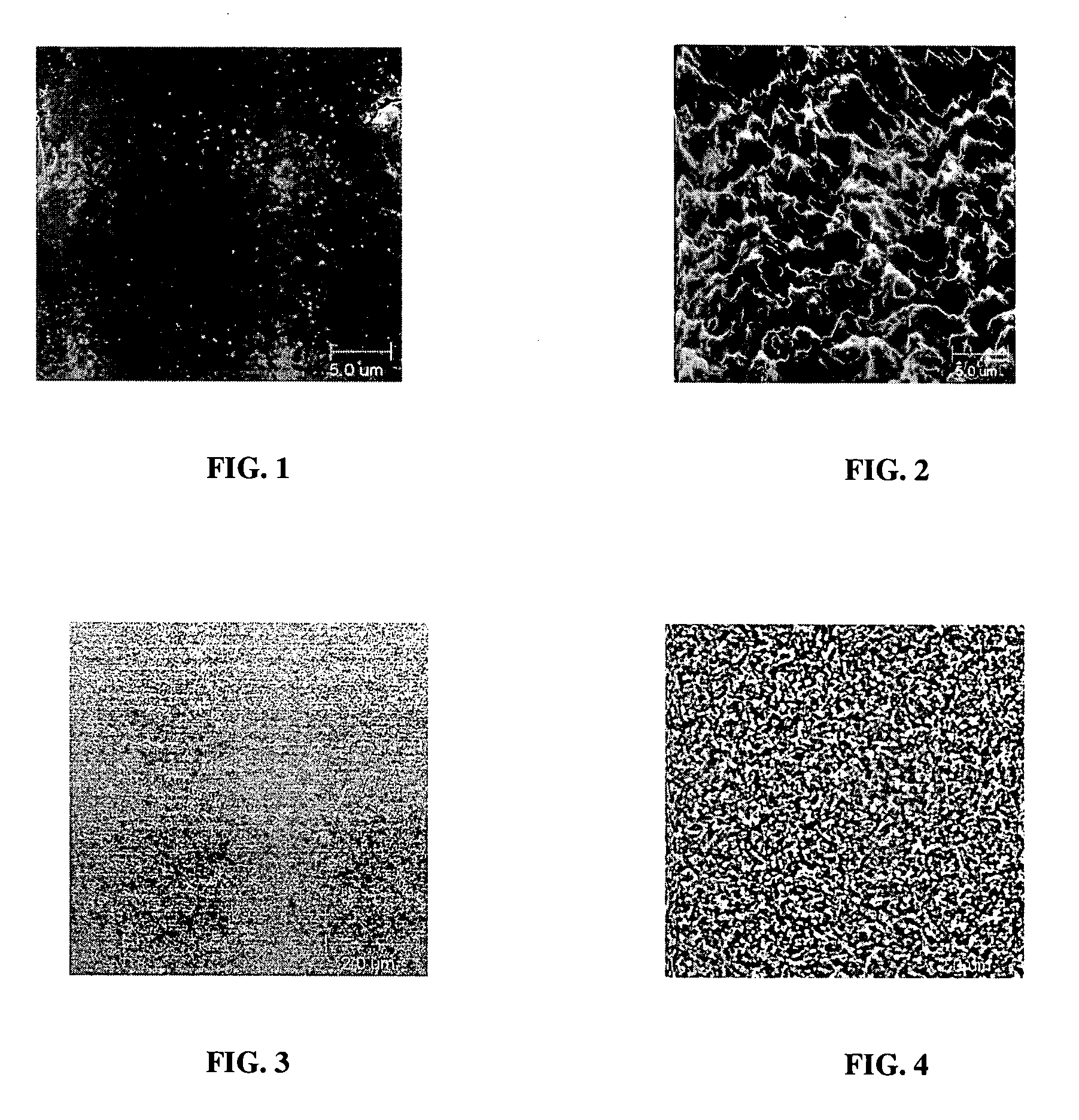

Polymer coated carbon products and other pigments and methods of making same by aqueous media polymerizations or solvent coating methods

InactiveUS6458458B1Improves UV stabilityImproved property to impactSynthetic resin layered productsCellulosic plastic layered productsSolventIon

A polymer coated modified carbon product is described wherein the polymer at least partially coats a modified carbon product. The modified product preferably has at least one organic group attached to the carbon product and the organic group is preferably substituted with an ionic, ionizable, or polar group for preparation in polar or aqueous based media. Methods of making the polymer coated modified carbon product are also described, such as by aqueous-based or solvent free polymerization methods, organic solvent based polymerization methods, or solution coating methods. Polymeric products and masterbatches containing the polymer coated modified carbon products are also described as well as methods to improve properties such as impact properties and tensile properties. Polymer coated modified colored pigments, methods of making the same, and polymeric products and masterbatches containing polymer coated modified colored pigments are also described.

Owner:CABOT CORP

Insulator coating and method for forming same

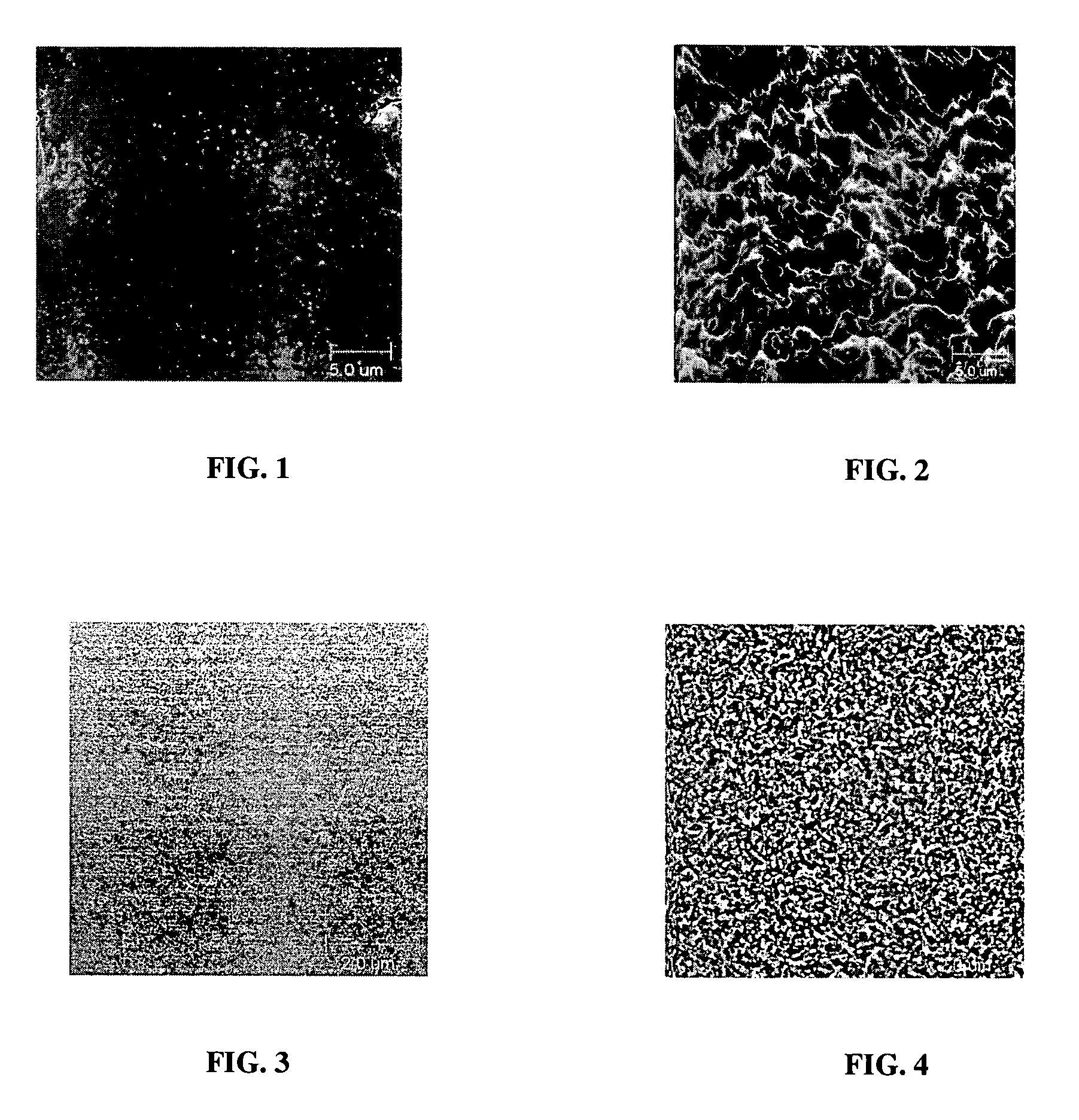

ActiveUS20060081394A1Avoid pollutionImproves UV stabilityPlastic/resin/waxes insulatorsInsulated cablesCoating systemUltraviolet

The present invention is a method of applying Lotus Effect materials as a (superhydrophobicity) protective coating for external electrical insulation system applications, as well as the method of fabricating / preparing Lotus Effect coatings. Selected inorganic or polymeric materials are applied on the insulating material surface, and stable superhydrophobic coatings can be fabricated. Various UV stabilizers and UV absorbers can be incorporated into the coating system to enhance the coating's UV stability.

Owner:GEORGIA TECH RES CORP

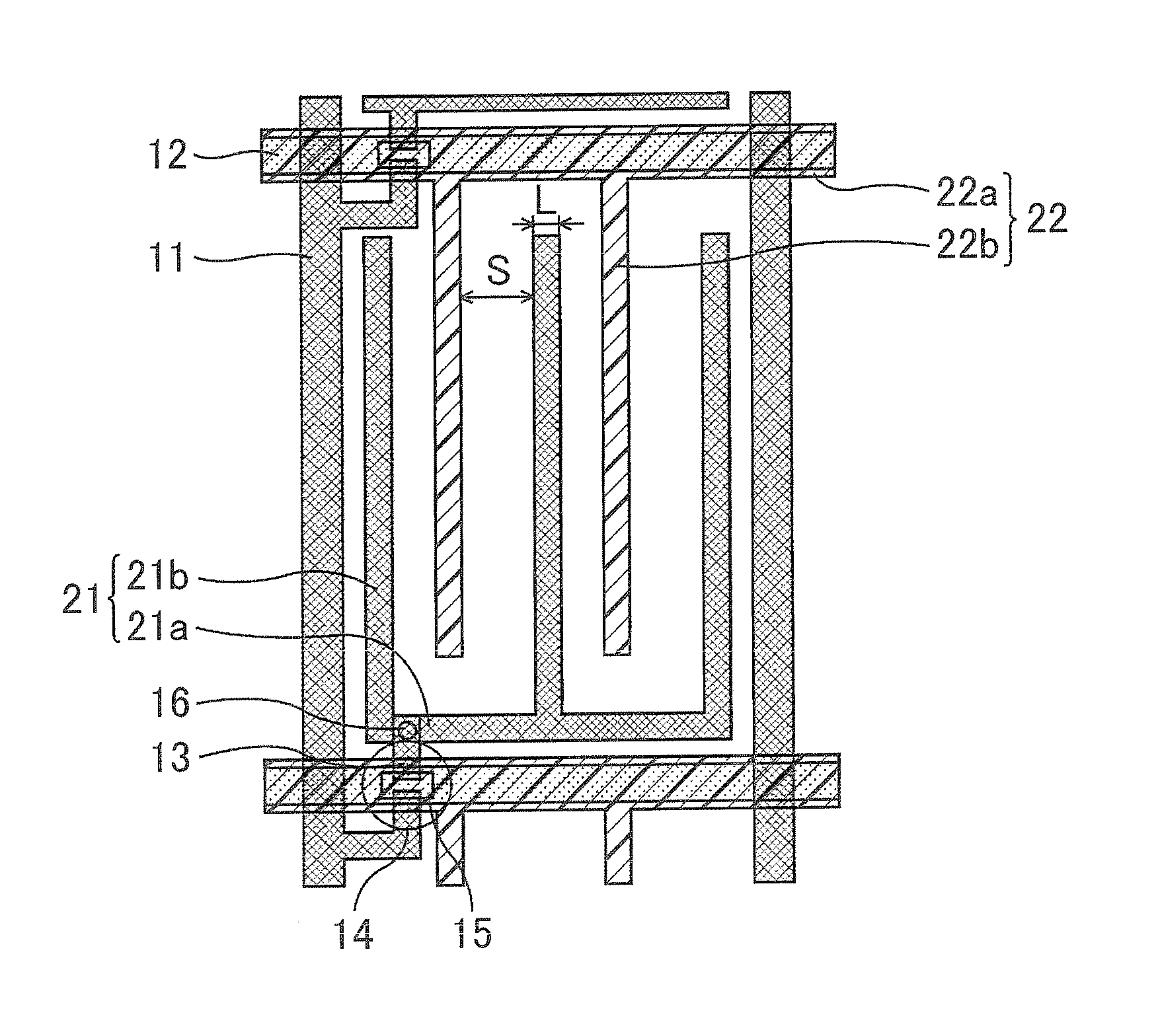

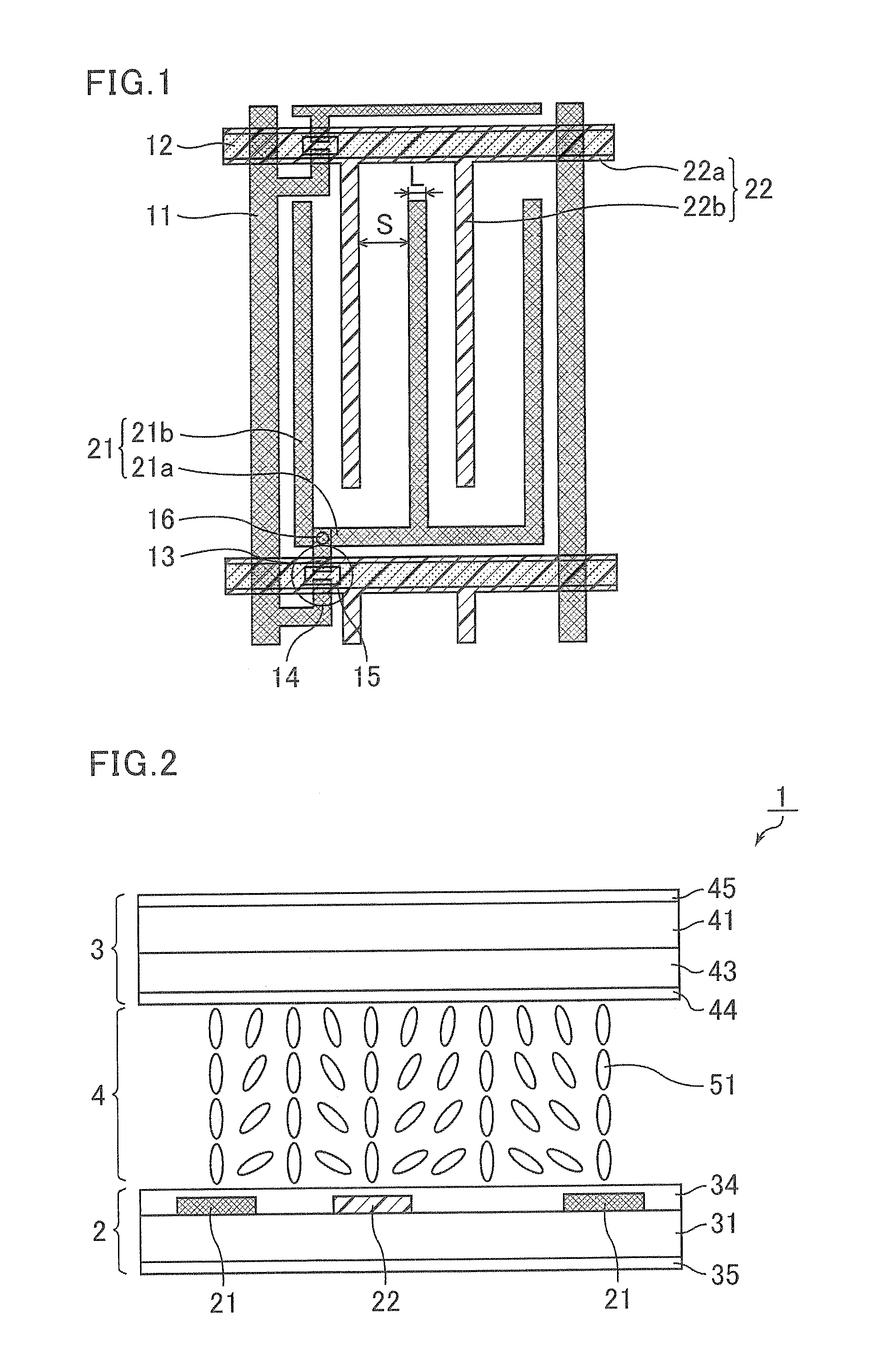

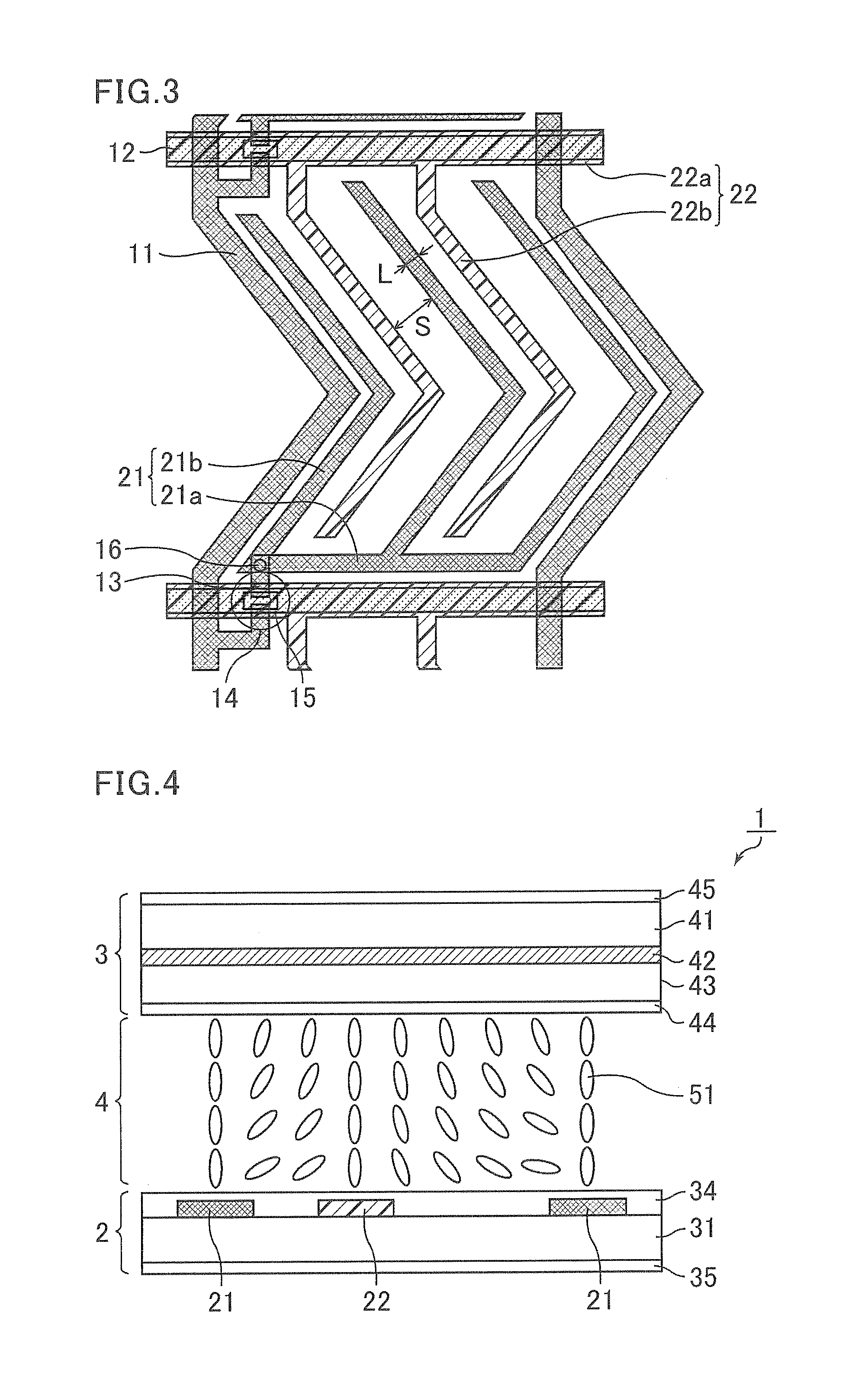

Electrochromic mirrors and other electrooptic devices

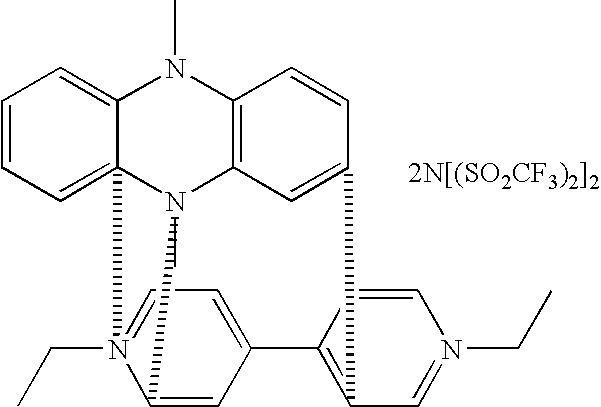

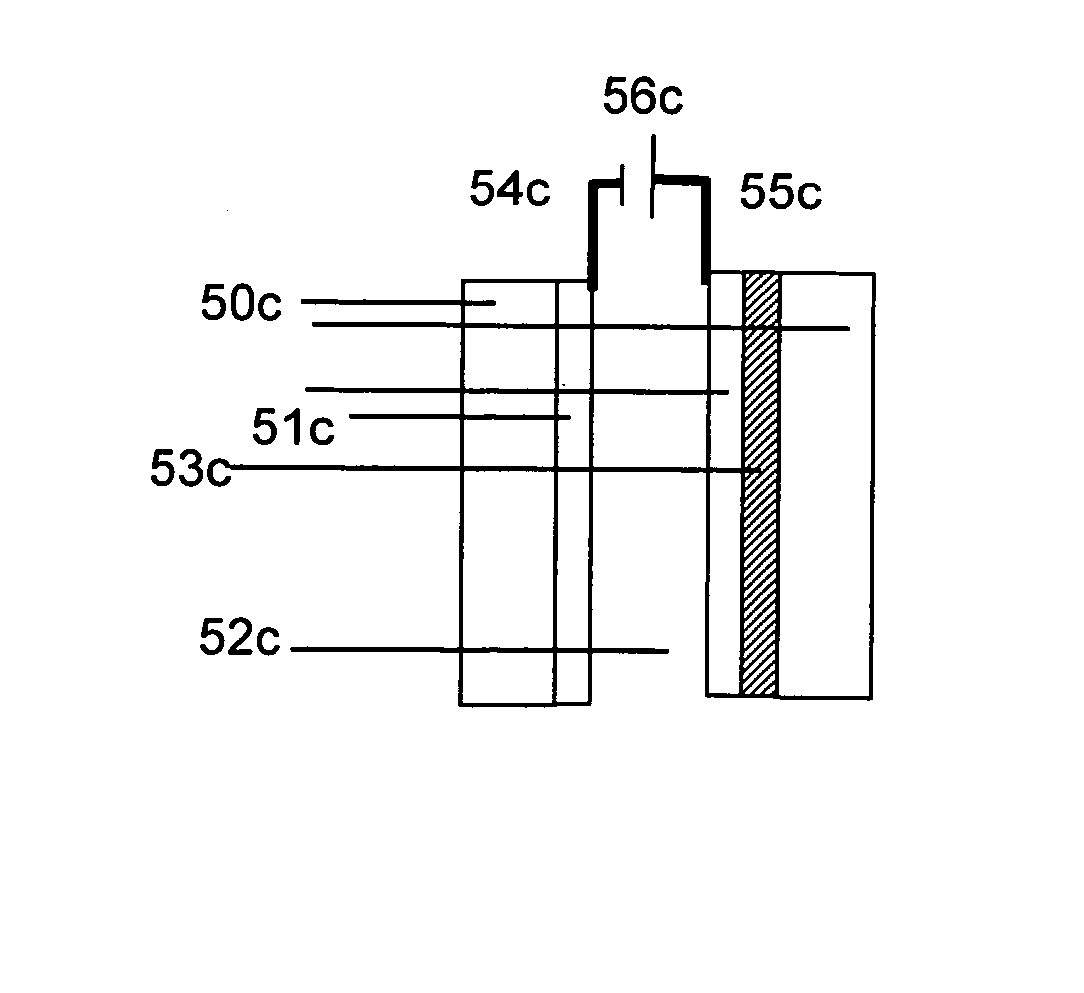

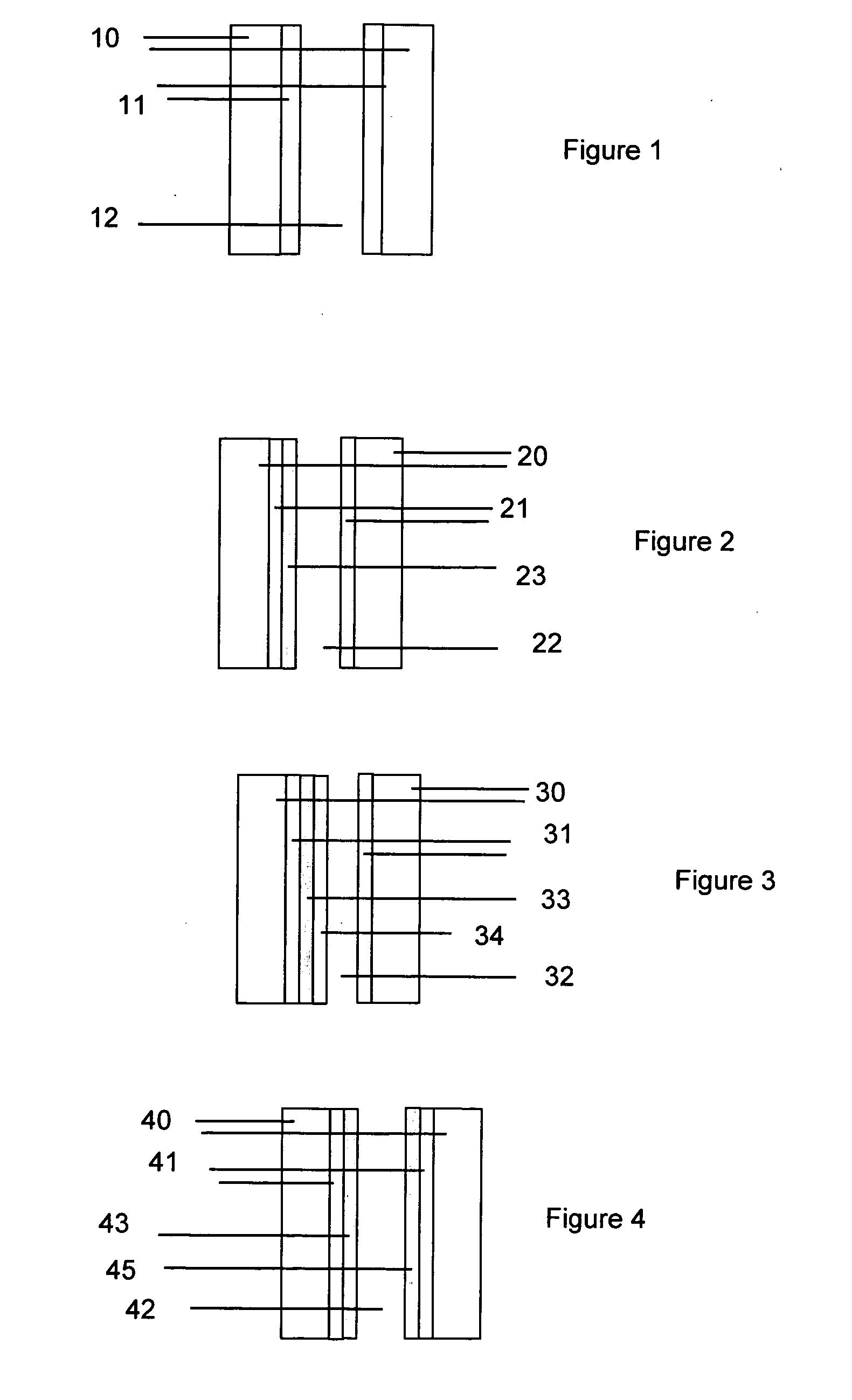

This invention focuses on electrooptic devices and in particular on electrochromic devices with many aspects directed towards automotive EC mirrors. There are several ways to improve these products and their processing using this invention and some of the prominent ones are outlined below. This invention improves on the devices by disclosing new compositions for electrodes and methods of depositing them. It also addresses novel ways to provide busbars to power these devices in order to improve their performance. The device processing attributes and performance are also improved by adhesive compositions and solid electrolytes disclosed herein. In addition sensors are also disclosed which are novel for use in electrochromic mirrors. The invention also discloses how the electrolytes comprising ionic liquids have no adverse effect on attributes of commercial EC mirrors and often result in improved performance and / or feature enhancements.

Owner:AJJER

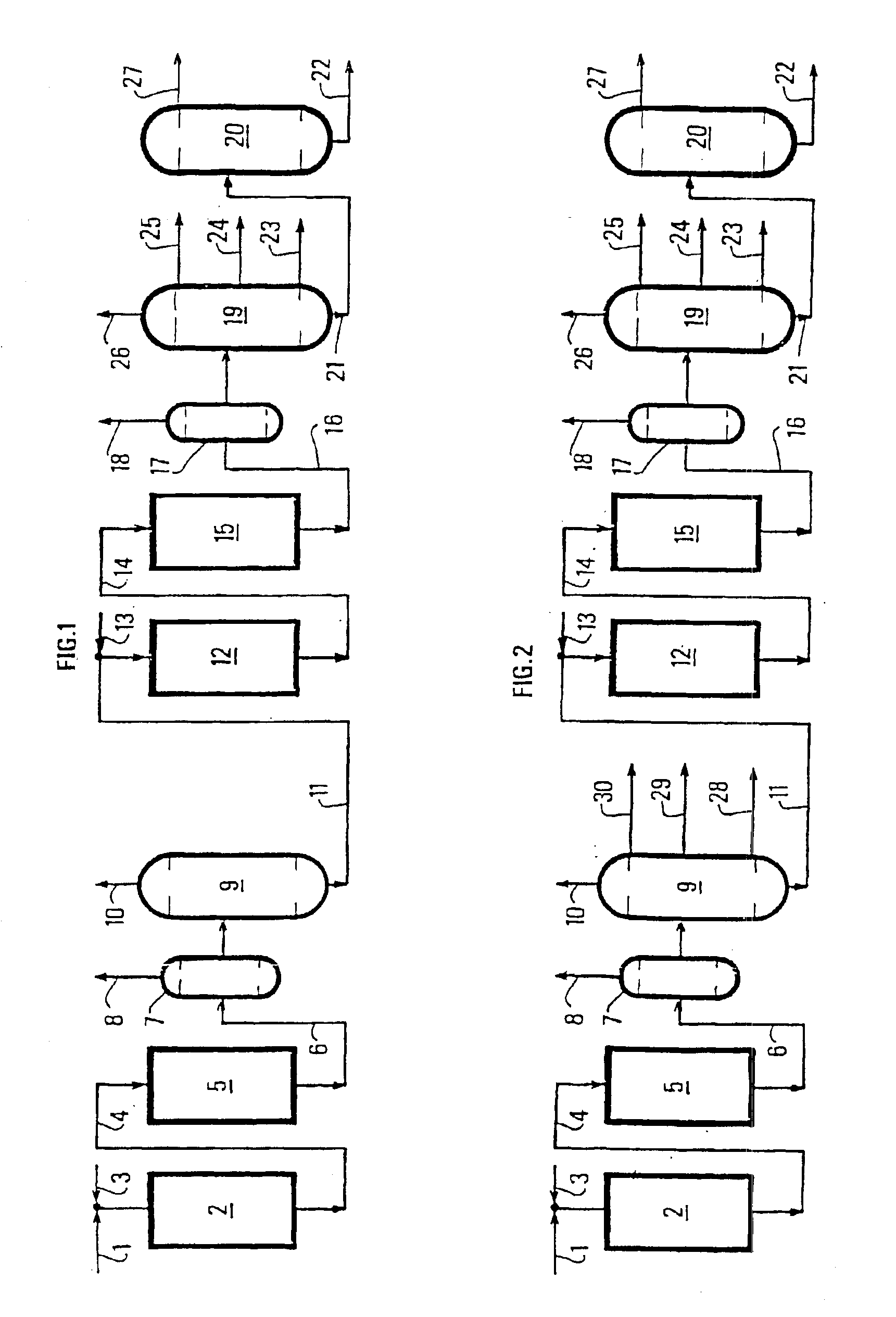

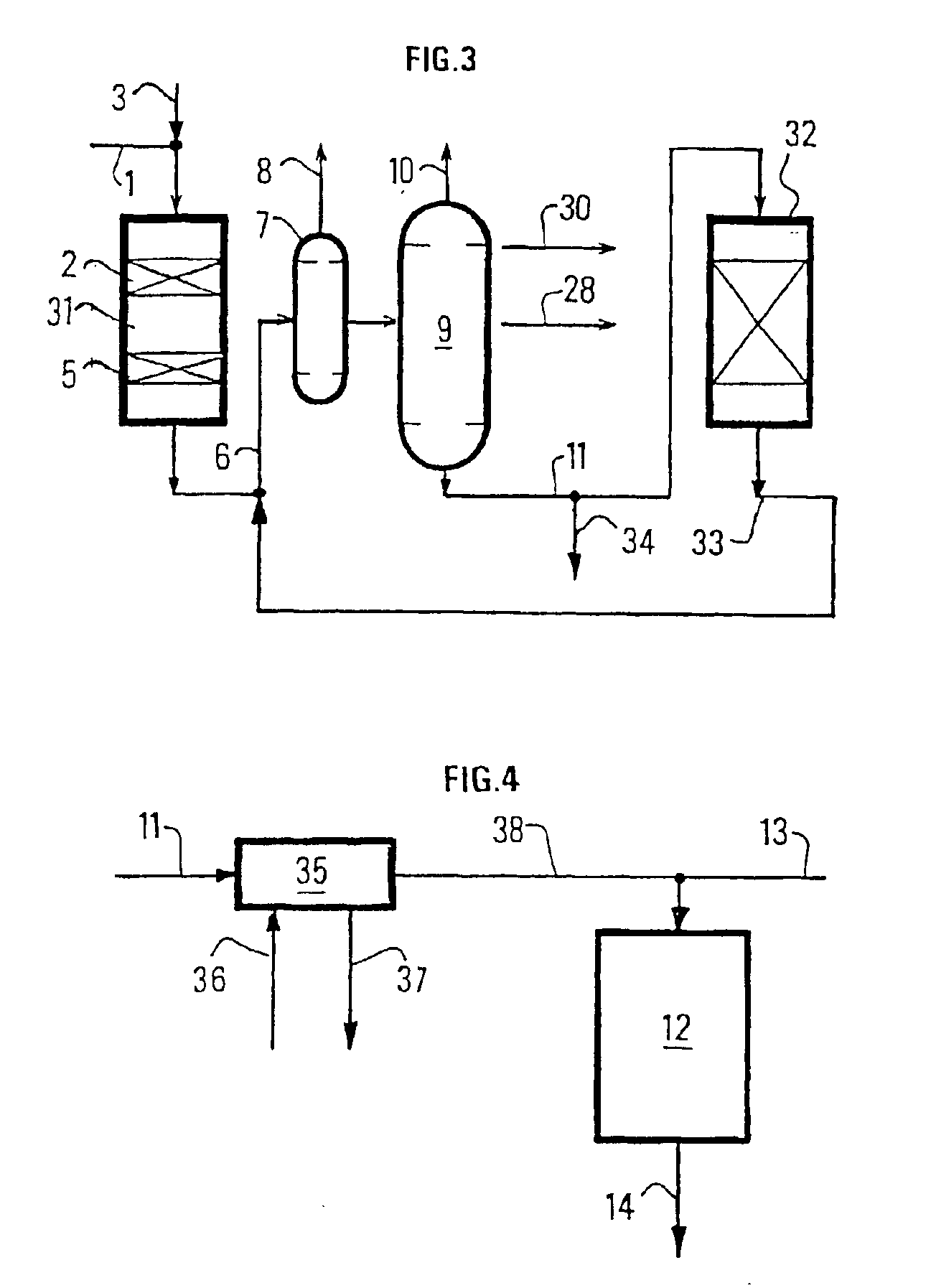

Flexible method for producing oil bases with a ZSM-48 zeolite

InactiveUS6884339B2Reduce contentImproves UV stabilityTreatment with plural serial cracking stages onlyCoke ovensBase oilAzeotropic distillation

A process for the production of very high quality base oils optionally with simultaneous production of high quality middle distillates comprises the stages for hydrotreatment, preferably hydrocracking, on Y or beta zeolite, and atmospheric distillation. The effluent is subjected to a catalytic dewaxing on the ZSM-48 catalyst. The process then comprises a hydrofinishing stage for hydrogenating the aromatic compounds, preferably on a catalyst that comprises at least one noble metal of group VIII, chlorine and fluorine, and the stages of atmospheric and vacuum distillation. The hydrofinishing stage is conducted at a temperature lower by 20-200° C. than the catalytic dewaxing stage.

Owner:INST FR DU PETROLE

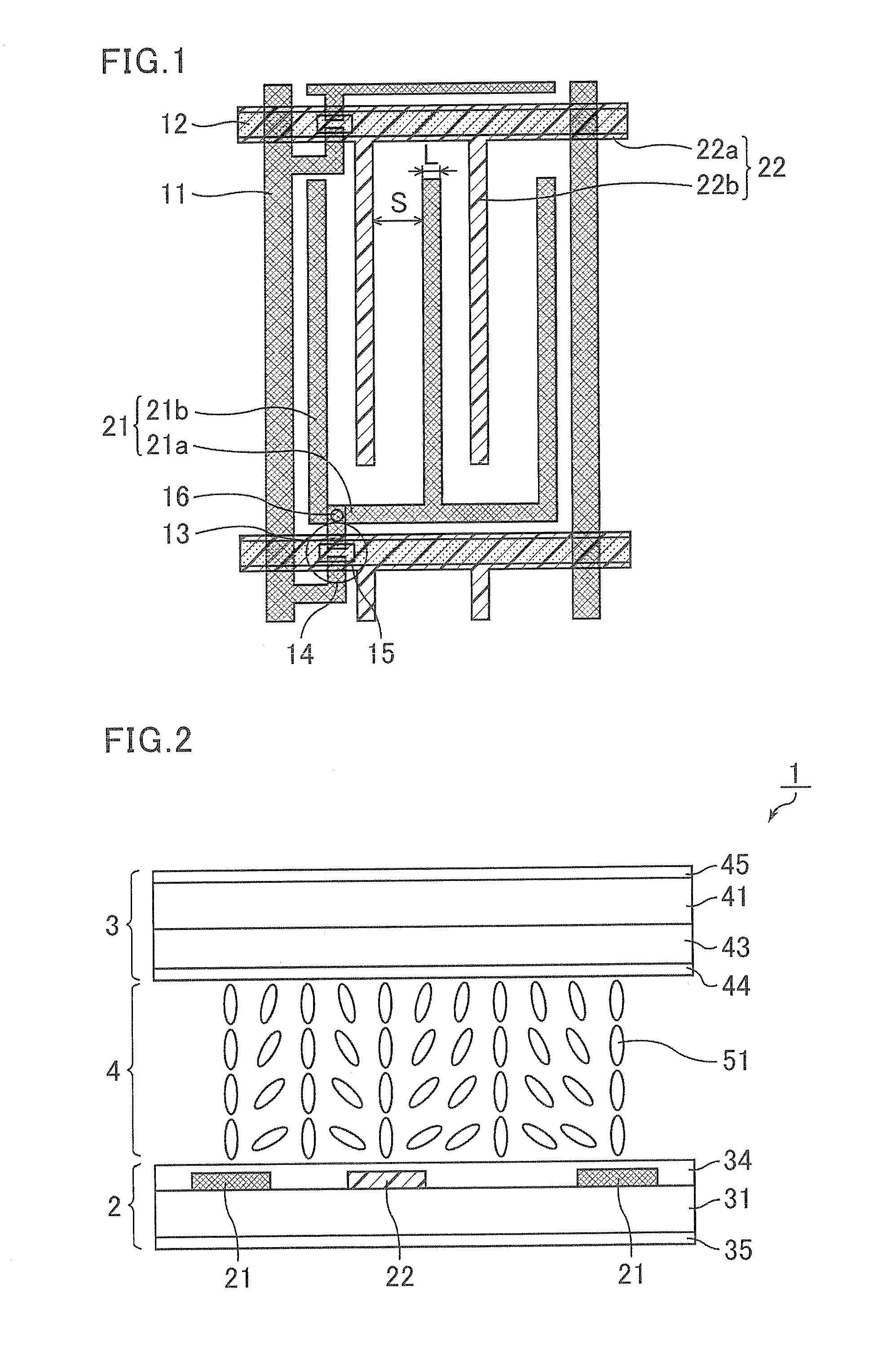

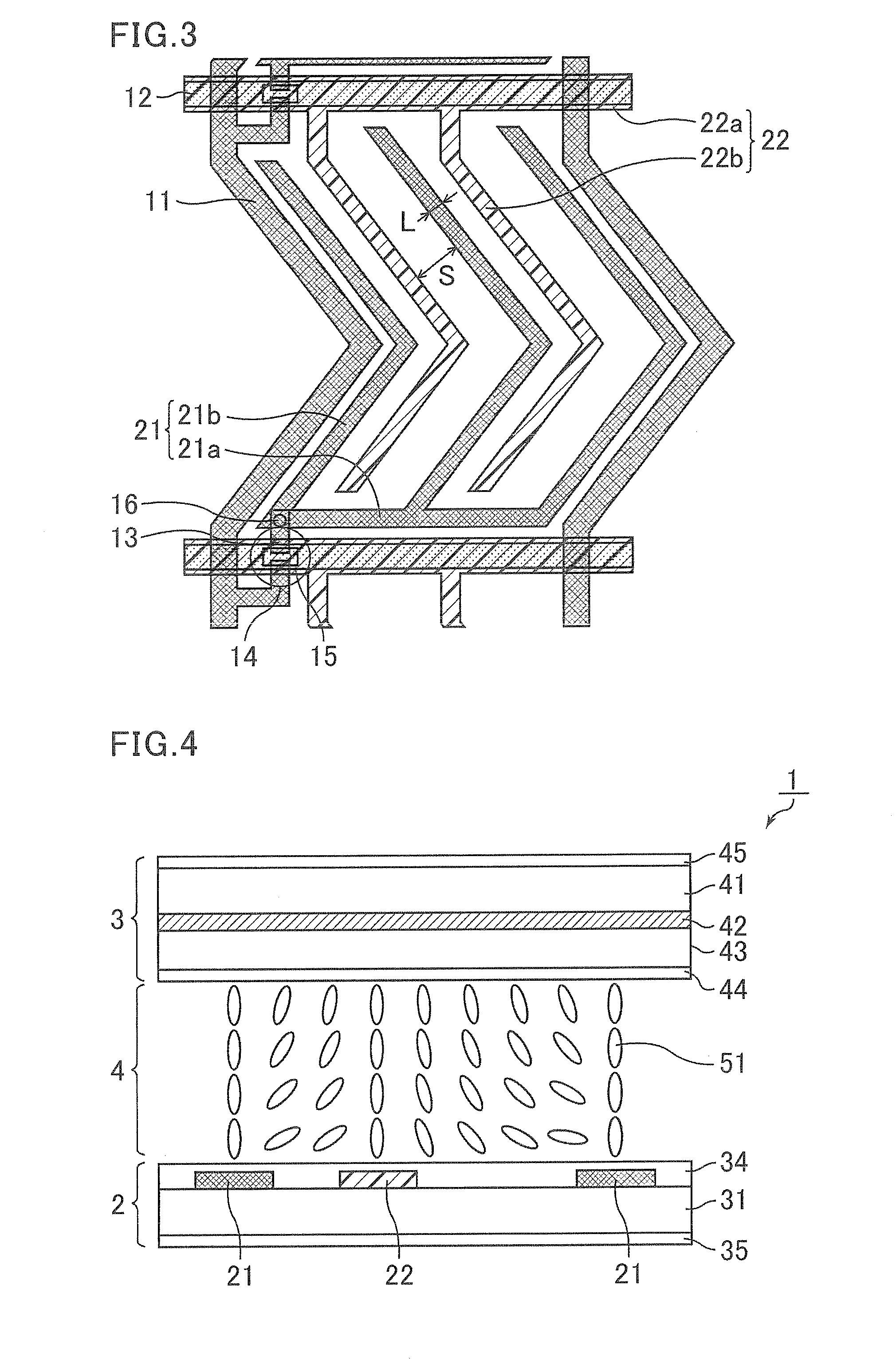

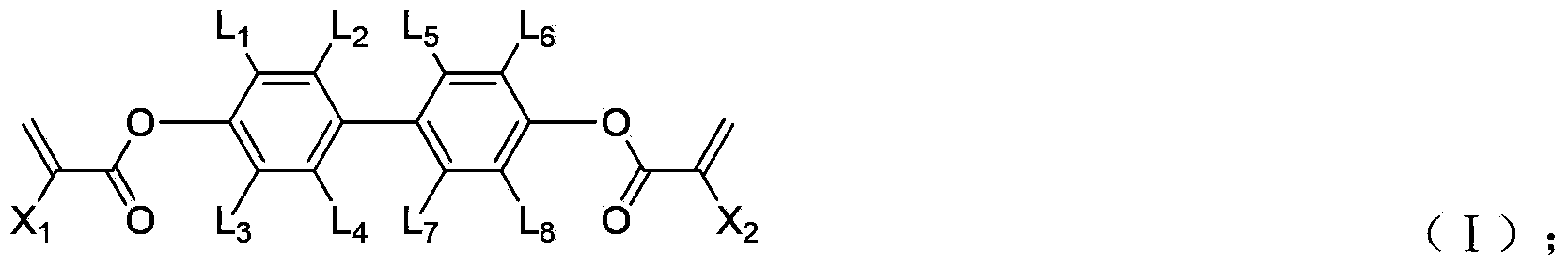

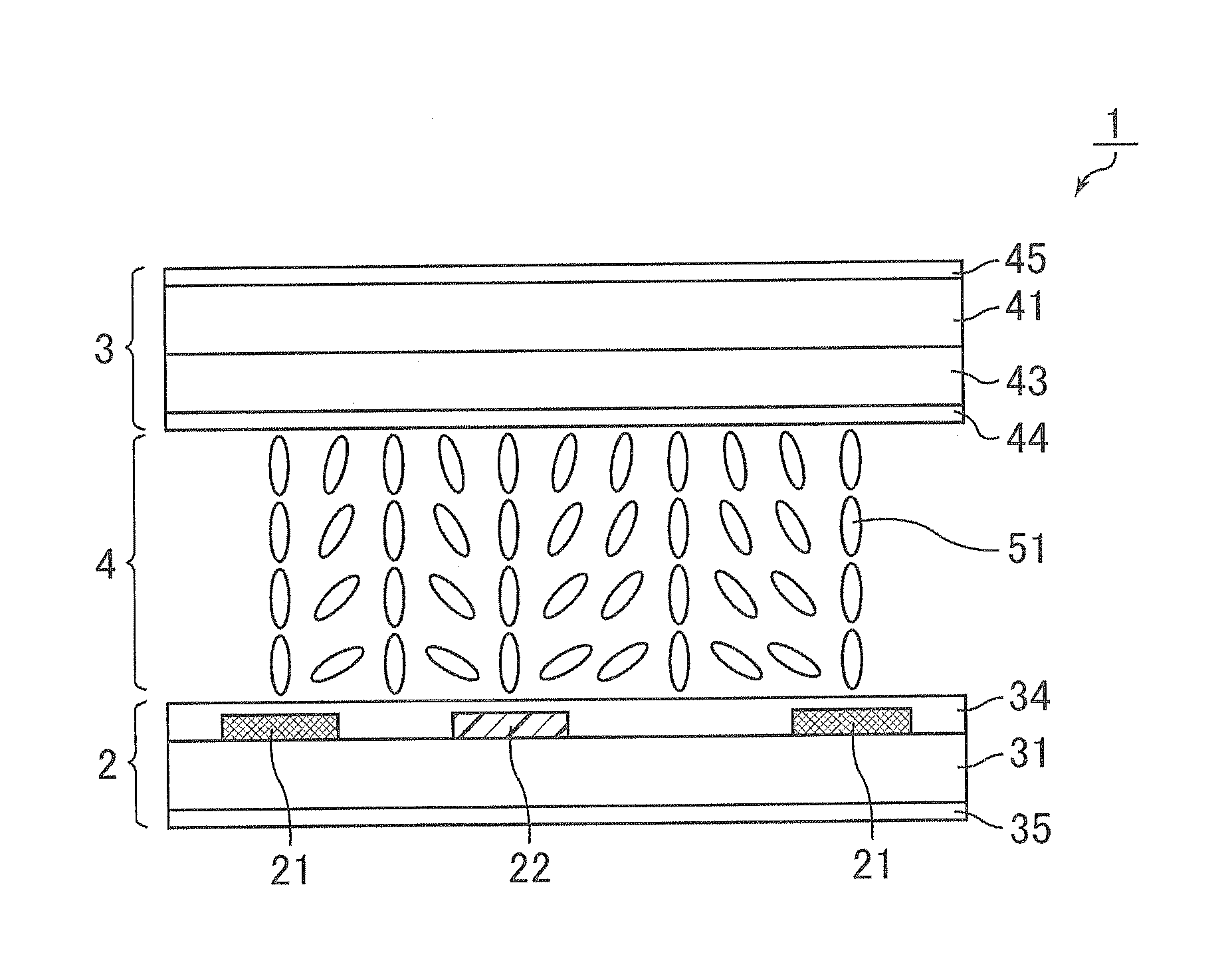

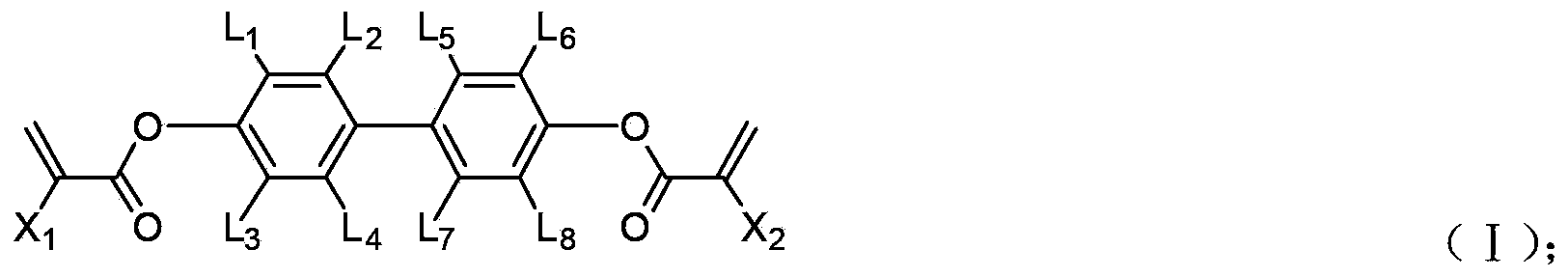

Liquid crystal display panel

ActiveUS20120141694A1Excellent characteristicsImprove the display effectLiquid crystal compositionsThin material handlingDielectric anisotropyChemistry

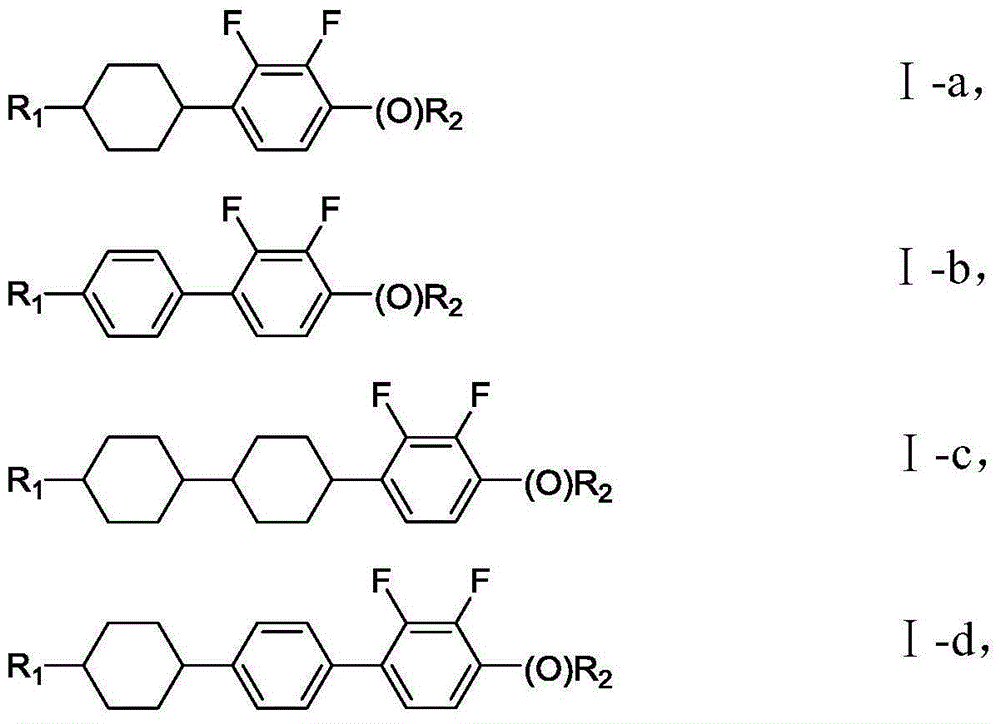

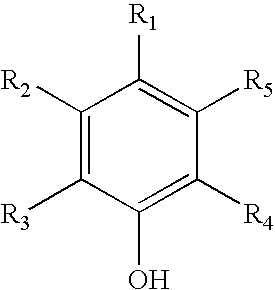

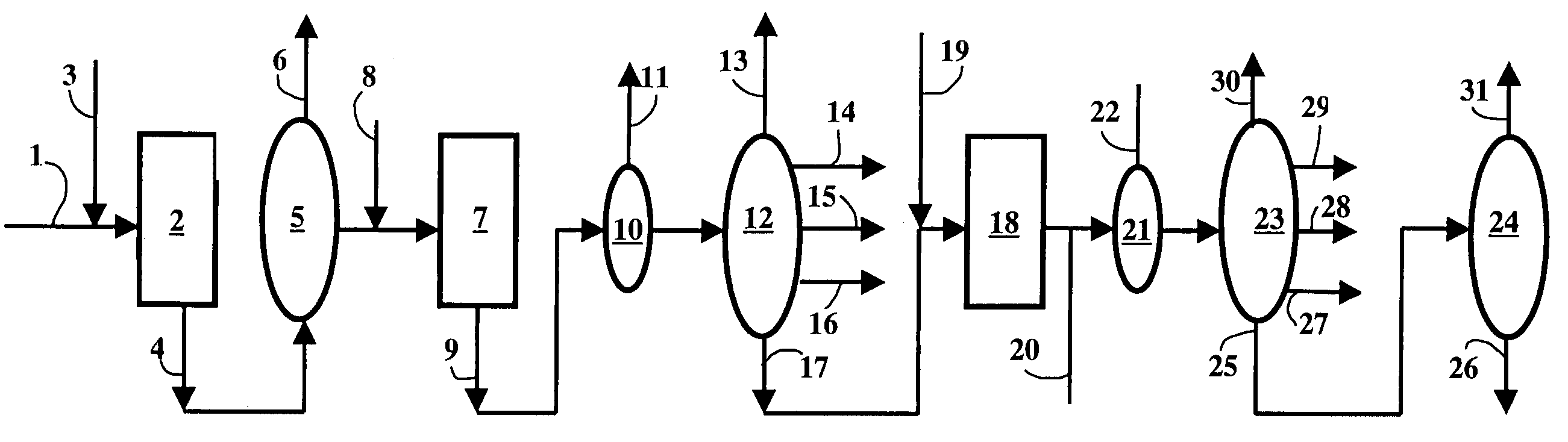

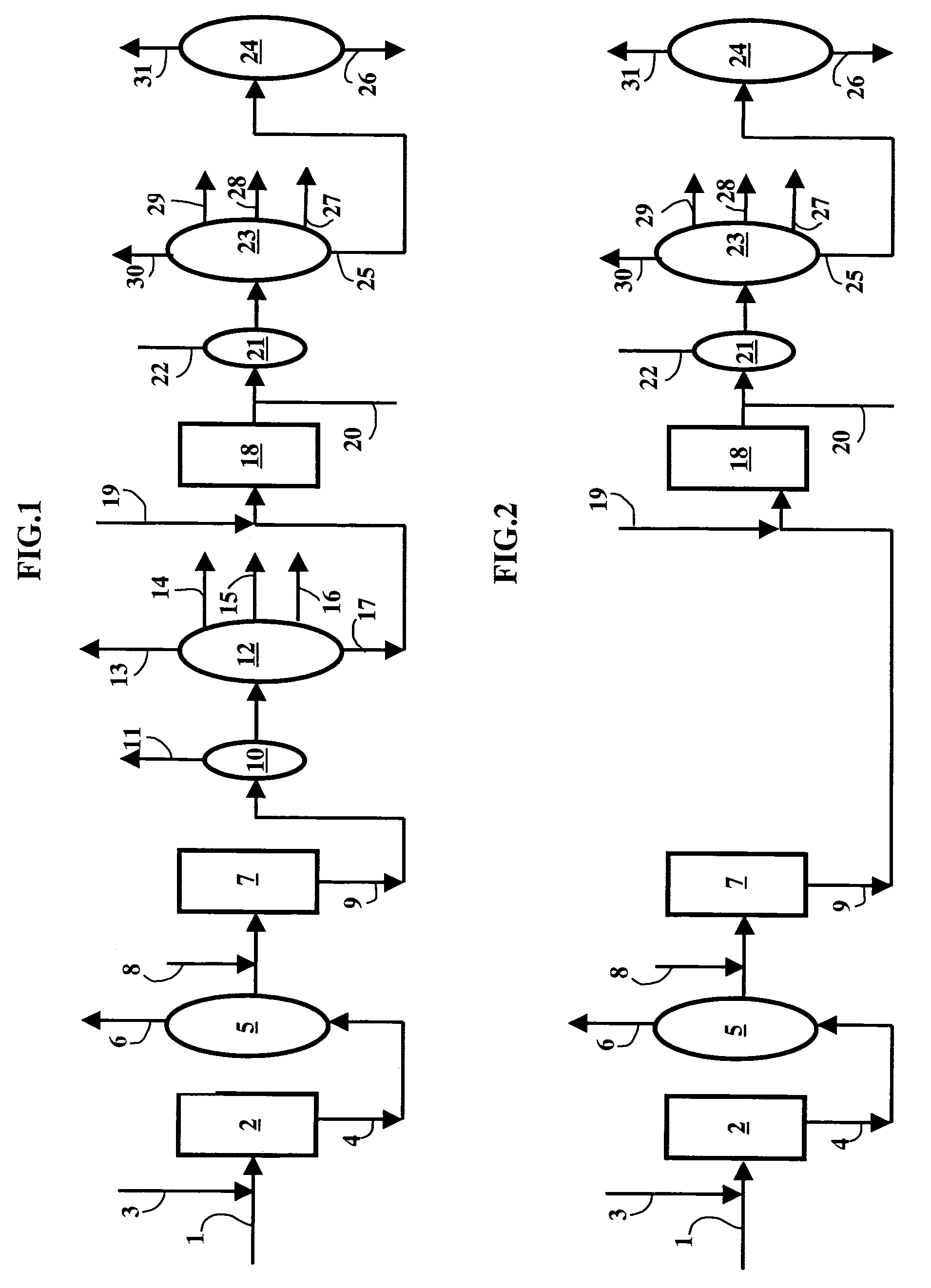

A TBA-liquid crystal display panel including a liquid crystal medium with positive dielectric anisotropy, wherein the liquid crystal medium includes, in 100% by weight of the liquid crystal compounds identified by the compounds recited in formulas I through IX below:wherein,R1, R3, R3*, R5, R6, R7, R8, and R9 independently denote C2-5 linear alkyl, preferably propyl or pentyl,R2 denote C4-6 linear alkyl, preferably butyl or pentyl; andR4 denotes C1-3 linear alkyl, preferably methyl.

Owner:MERCK PATENT GMBH

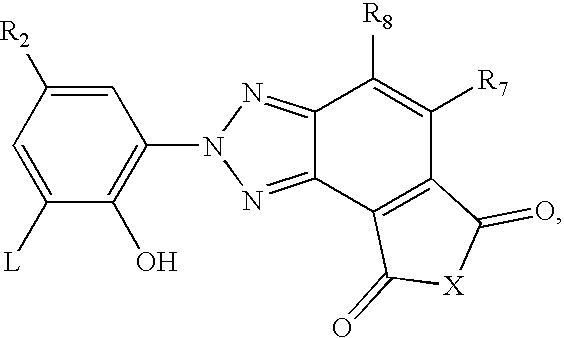

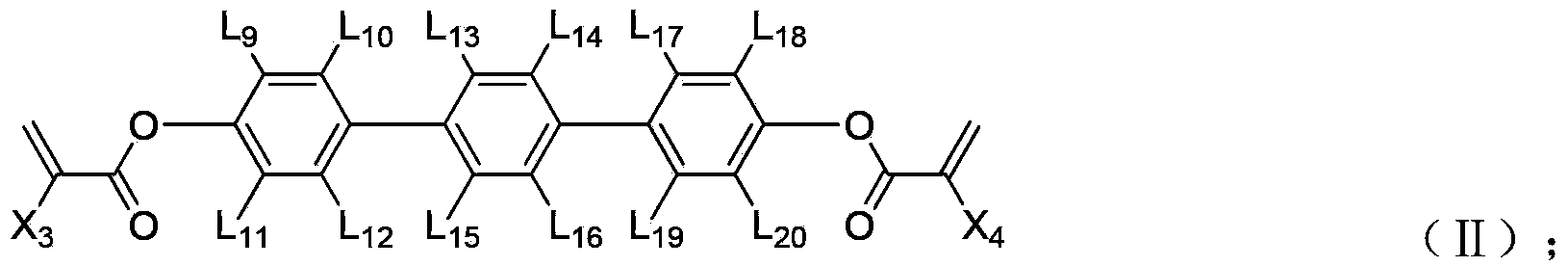

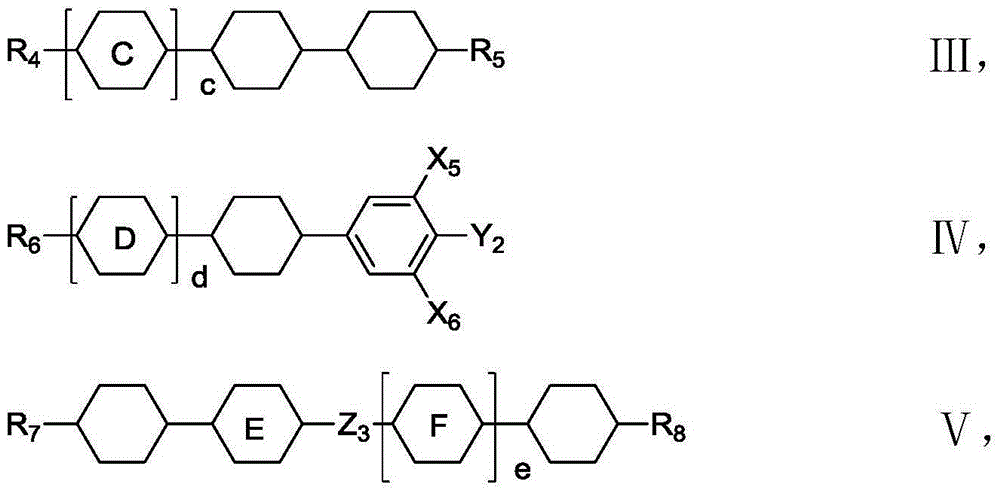

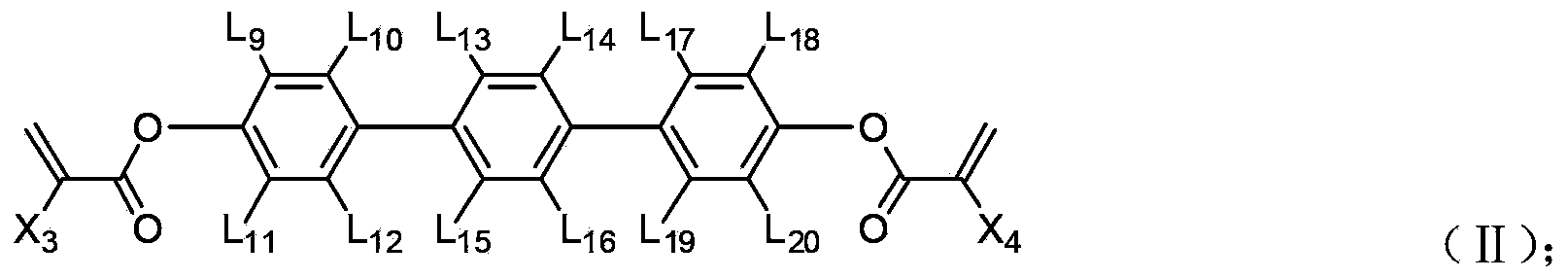

Positive and negative mixed liquid crystal composition

InactiveCN105295955AIncrease ε

<sub>⊥</sub>Improve transmittanceLiquid crystal compositionsNon-linear opticsCrystallographyTransmittance

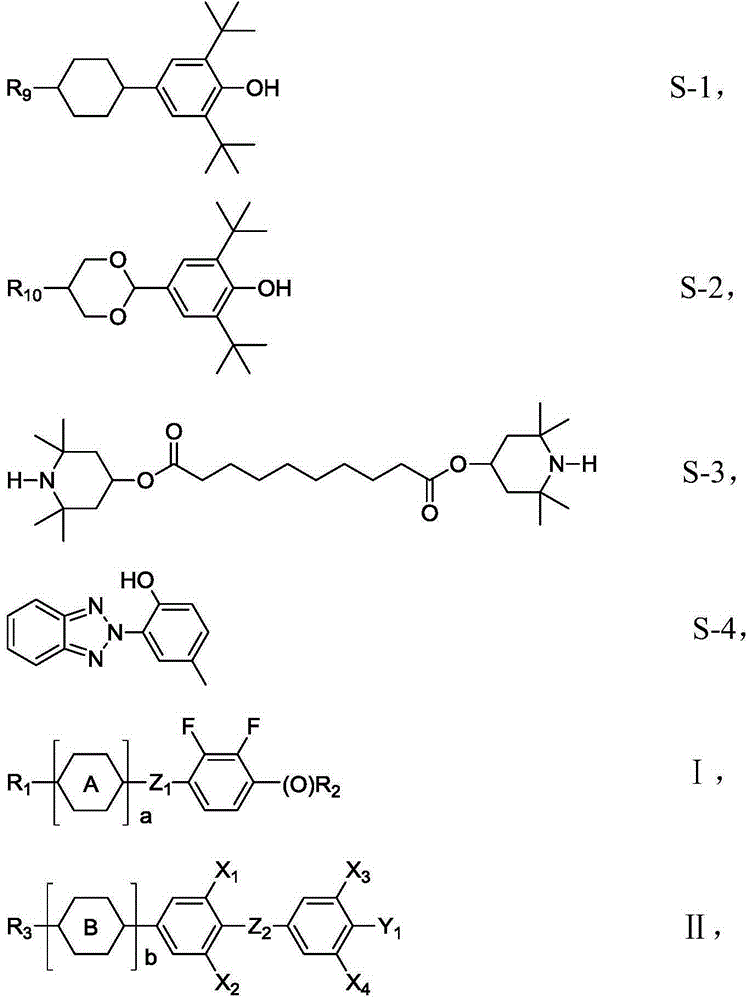

The invention discloses a positive and negative mixed liquid crystal composition. The positive and negative mixed liquid crystal composition is characterized by comprising an additive component A which consists of one or more compounds shown in a general formula S-1, a general formula S-2, a structural formula S-3 and a structural formula S-4, a component B which consists of one or more negative compounds shown in a general formula I and a component C which consists of one or more positive compounds shown in a general formula II. According to the positive and negative mixed liquid crystal composition, the problems of low transmittance, low response speed and especially poor anti-ultraviolet capability of the conventional liquid crystal mixture are solved.

Owner:SHIJIAZHUANG CHENGZHI YONGHUA DISPLAY MATERIALS CO LTD

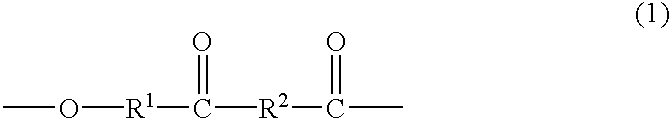

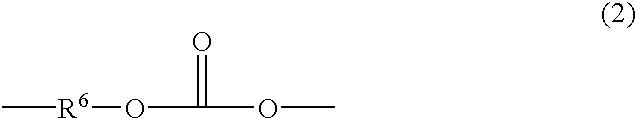

Water-dilutable binder for "soft feel" lacquers

InactiveUS6254937B1Improve scratch resistanceImproves UV stabilityPretreated surfacesPolyurea/polyurethane coatingsCross-linkChemical Linkage

Soft feel lacquers comprising water dilutable binders A which possess functional groups, selected from hydroxyl, amino and carboxyl groups, and of curing agents B which have functional groups capable of reacting with the functional groups of the components A, and forming chemical bonds as cross-linking sites, wherein at least one of the components A and B contains a sufficient quantity of aromatic constituent units to ensure that the mass fraction of the aromatic constituent units in relation to the solid matter in the combination of binder and curing agent is not less than 3%.

Owner:ALLNEX AUSTRIA GMBH

Prepolymer compositions and sealants made therefrom

ActiveUS20050075469A1Improve curing speedImprove weather stabilityOther chemical processesEndcappingAdhesive

Prepolymer compositions for preparing a one-part, moisture-curable sealant, adhesive or coating, and a method of making such prepolymer compositions are provided. The prepolymer compositions comprise a polyurethane prepolymer that is end-capped with silane groups or a combination of silane groups and end capping groups that have been derived from an alcohol and an amount, referred to hereinafter as an “excess”, of unreacted aromatic alcohol having a molecular weight of less than 2000. The excess of unreacted aromatic alcohol in the composition is from greater than 0% to 15% by mole of the level of original NCO groups in the prepolymer. From 50 to 100% of the original NCO groups are end-capped with silane groups, and from 0 to 50% of the original NCO groups are end-capped with a end-capping group that has been derived from an aromatic alcohol, an aliphatic alcohol or both. Sealant compositions and coating compositions comprising the present prepolymer composition are also provided.

Owner:TREMCO CPG INC

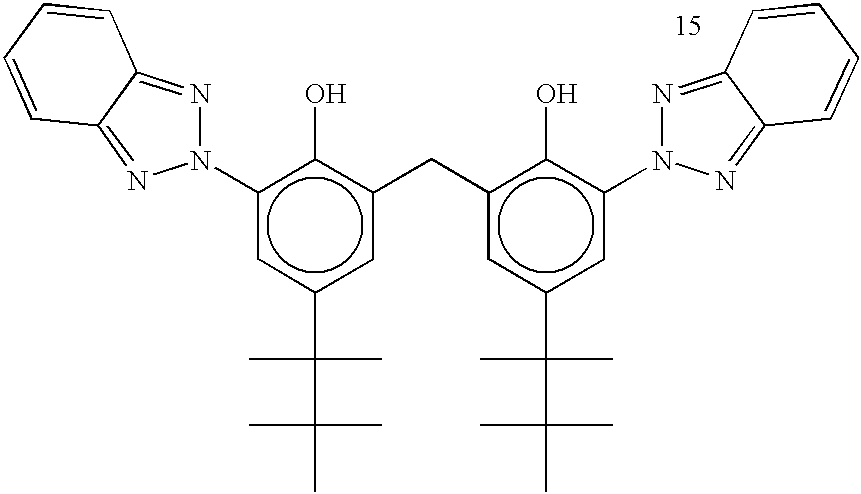

Multicoat paint systems, process for producing them, and their use in automaking

InactiveUS20090317629A1Improves UV stabilityLess influenceSynthetic resin layered productsPretreated surfacesUv absorbanceMoisture exposure

The present disclosure provides multicoat systems exhibiting ultraviolet (UV) stability after ultraviolet exposure and moisture exposure. The systems comprise at least one primer (G), at least one pigmented coating (P) disposed on a surface of the primer, and at least one ultraviolet (UV) absorber which has an absorption maximum of at least 370 nm. The pigmented coating (P) may be comprised of two or more coatings (P1), (P2) to (Pn). The multicoat systems may also comprise a transparent coating material (T) to form a transparent coating (K). The present multicoat systems demonstrate ultraviolet stability, reduced delamination of the pigmented coat from the primer and are available in a variety of shades for use in the finishing, refinishing and coating of component parts.The present disclosure also provides for a process for producing the multicoat system, and provides for the use of the system.

Owner:BASF COATINGS GMBH

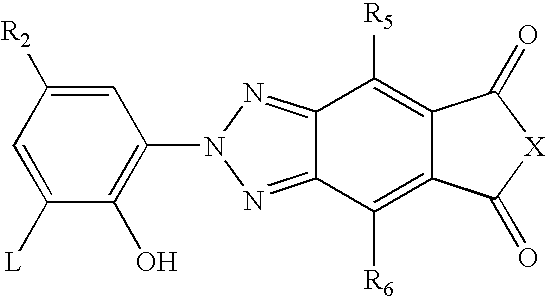

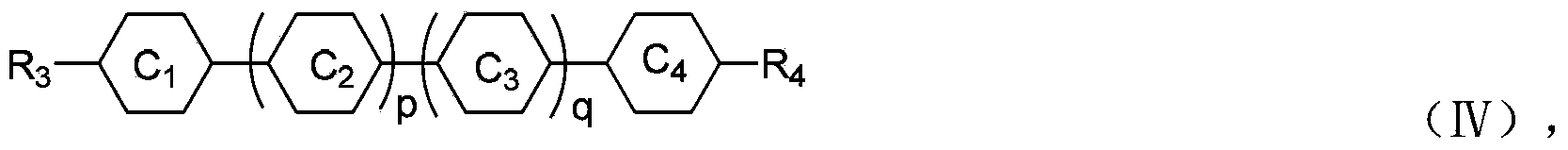

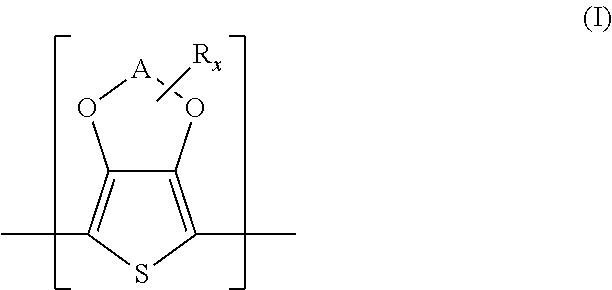

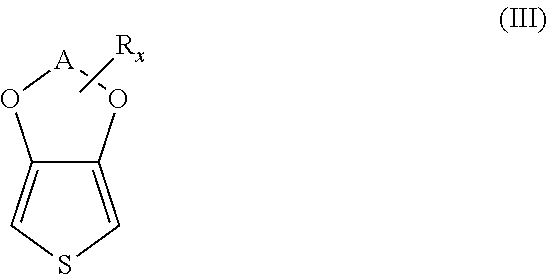

Polymerizable liquid crystal composition and display device

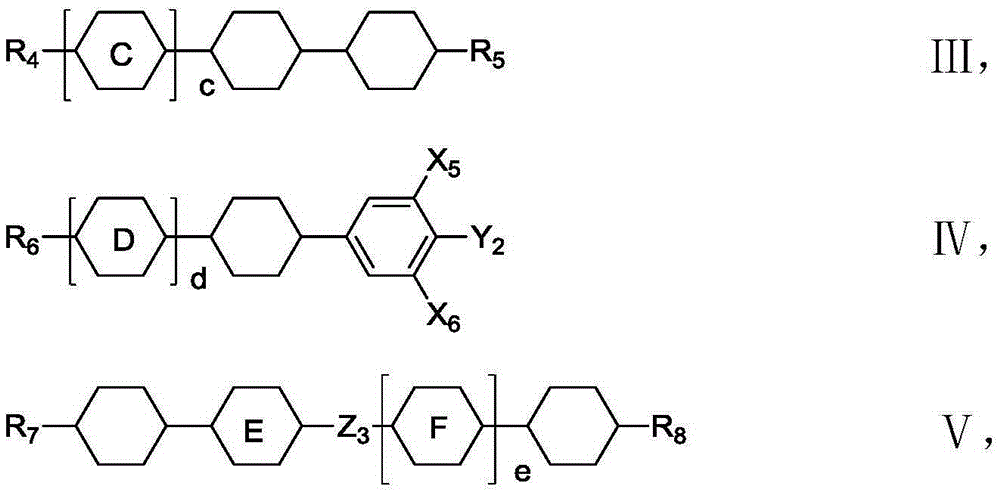

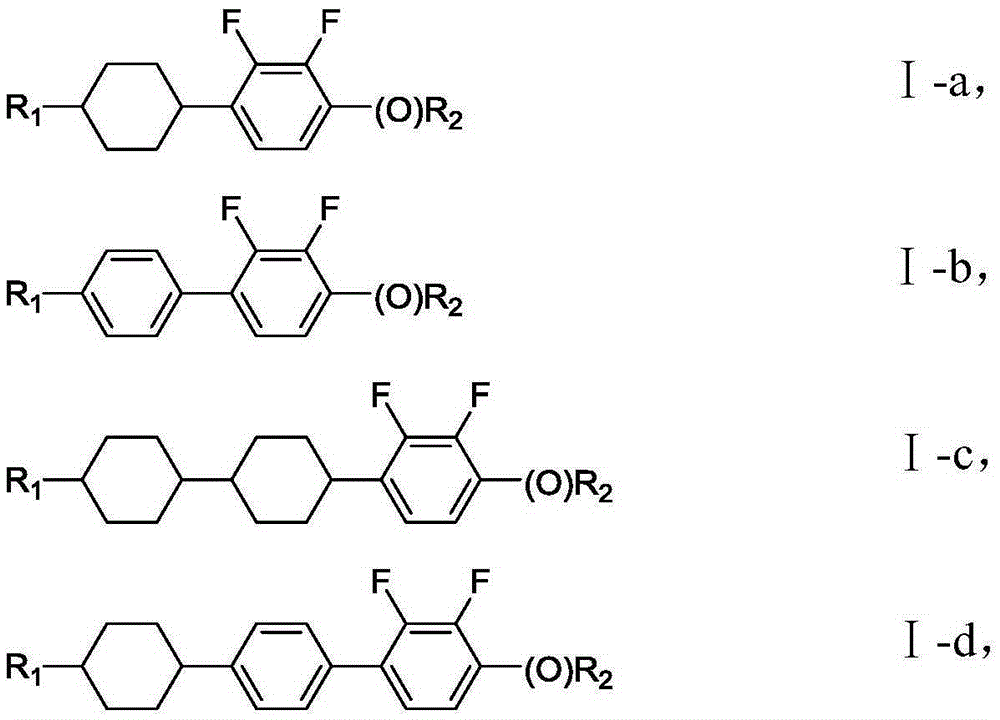

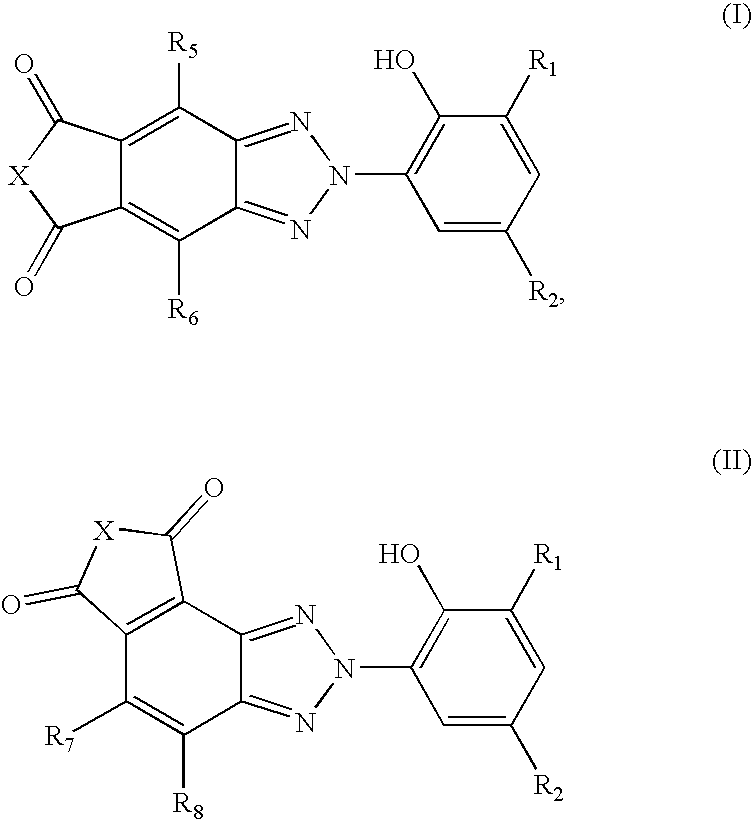

ActiveCN104342167AResidue reductionImproves UV stabilityLiquid crystal compositionsNon-linear opticsDielectric anisotropyDisplay device

The invention provides a novel polymerizable liquid crystal composition comprising a first component of at least one compound represented by the general formula I, a second component of at least one compound represented by the general formula II, a third component of at least one compound represented by the general formula III, and a fourth component of at least one compound represented by the general formula IV. According to the polymerizable liquid crystal composition, polymerization speed can be controlled, polymeric compound residue can be reduced, and problems such as after-image, image display unevenness, low-temperature crystallization, and the like can be greatly reduced. The composition also has good anti-ultraviolet stability, good low-temperature storage performance, relatively high clearing point, appropriate optical anisotropy, and appropriate dielectric anisotropy. The invention also provides a liquid crystal display device comprising the polymerizable liquid crystal composition.

Owner:JIANGSU HECHENG DISPLAY TECHCO

Silicane modified polyurethane cementing sealing glue and method for making same

InactiveCN1594480ANo health hazardNon-hazardous environmentOther chemical processesEpoxy resin adhesivesPlasticizerSolvent

The invention provides a silicane modified polyurethane cementing sealing glue and method for making same, which comprises end hydroxy polyether 20-45, isocyanate 3-10, plasticizer 15-38, mineral filler 15-50, silicane coupling agent 0.01-0.1 catalyst 0.01-0.3, anti-oxidant 0.01-0.2. The invention also discloses the process of preparation.

Owner:ZIBO HITECMEN CHEM

Liquid crystal display panel

ActiveUS8178173B1Excellent characteristicsExcellent contrast ratioLiquid crystal compositionsThin material handlingDielectric anisotropyChemistry

A TBA-liquid crystal display panel including a liquid crystal medium with positive dielectric anisotropy, wherein the liquid crystal medium includes, in 100% by weight of the liquid crystal compounds identified by the compounds recited in formulas I through IX below:wherein,R1, R3, R3*, R5, R6, R7, R8, and R9 independently denote C2-5 linear alkyl, preferably propyl or pentyl,R2 denote C4-6 linear alkyl, preferably butyl or pentyl; andR4 denotes C1-3 linear alkyl, preferably methyl.

Owner:MERCK PATENT GMBH

Insulator coating and method for forming same

ActiveUS7722951B2Avoid pollutionImproves UV stabilityMaintaining distance between parallel conductorsSuspension arrangements for electric cablesCoating systemUv absorber

The present invention is a method of applying Lotus Effect materials as a (superhydrophobicity) protective coating for external electrical insulation system applications, as well as the method of fabricating / preparing Lotus Effect coatings. Selected inorganic or polymeric materials are applied on the insulating material surface, and stable superhydrophobic coatings can be fabricated. Various UV stabilizers and UV absorbers can be incorporated into the coating system to enhance the coating's UV stability.

Owner:GEORGIA TECH RES CORP

Positive-negative-mixed liquid crystal composition

InactiveCN105199745AIncrease ε

<sub>⊥</sub>Improve transmittanceLiquid crystal compositionsNon-linear opticsCrystallographyTransmittance

The invention discloses a positive-negative-mixed liquid crystal composition. The positive-negative-mixed liquid crystal composition comprises an additive component A, a component B and a component C, wherein the additive component A comprises one or more compounds shown in formula S-1, formula S-2, formula S-3 and structural formula S-4, the component B comprises one or more negative compounds shown in formula I, and the component C comprises one or more positive compounds shown in formula II. By the positive-negative-mixed liquid crystal composition, the problems that existing liquid crystal compositions are low in transmittance, slow in response and poor in UV resistance are solved.

Owner:SHIJIAZHUANG CHENGZHI YONGHUA DISPLAY MATERIALS CO LTD

Weatherable glass fiber reinforced polyolefin composition

ActiveUS20070135547A1Improve burst strengthHigh tensile strengthFibre treatmentSynthetic resin layered productsGlass fiberPolymer science

Glass fiber reinforced olefin compositions comprise polypropylene homopolymers, polypropylene copolymers, opacifying pigments, fibrous reinforcers, light stabilizers, lubricants and antioxidants. The opacifying pigments are advantageously ZnO, ZnS or surface treated anatase TiO2

Owner:LYONDELLBASELL ADVANCED POLYMERS INC

Flexible method for producing oil bases and distillates by hydroisomerization-conversion on a weakly dispersed catalyst followed by a catalyctic dewaxing

InactiveUS7371315B2Reduce volatilityImproves UV stabilityHydrocarbon oil crackingTreatment with hydrotreatment processesMolecular sieveBase oil

A process for production of very high-quality base oils, and simultaneous production of high-quality middle distillates, comprises the successive stages of hydroisomerization and catalytic dewaxing. The hydroisomerization takes place in the presence of a catalyst containing at least one noble metal deposited on an amorphous acid support, the metal dispersion being less than 20%. The support is preferably an amorphous silica-alumina. The catalytic dewaxing takes place in the presence of a catalyst containing at least one hydrodehydrogenating element (Group VIII) and at least one molecular sieve chosen from ZBM-30, EU-2, and EU-11.

Owner:INST FR DU PETROLE

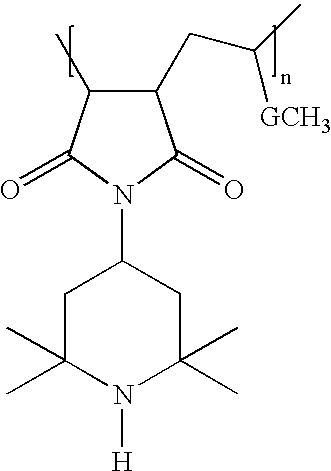

UV stabilized, impact modified polyester/polycarbonate blends, articles, and methods of manufacture thereof

InactiveUS6630527B2Improve stabilityImproves UV stabilityPolymer scienceHindered amine light stabilizers

Owner:SABIC GLOBAL TECH BV

Method for processing novel UV (ultraviolet) highlight plate

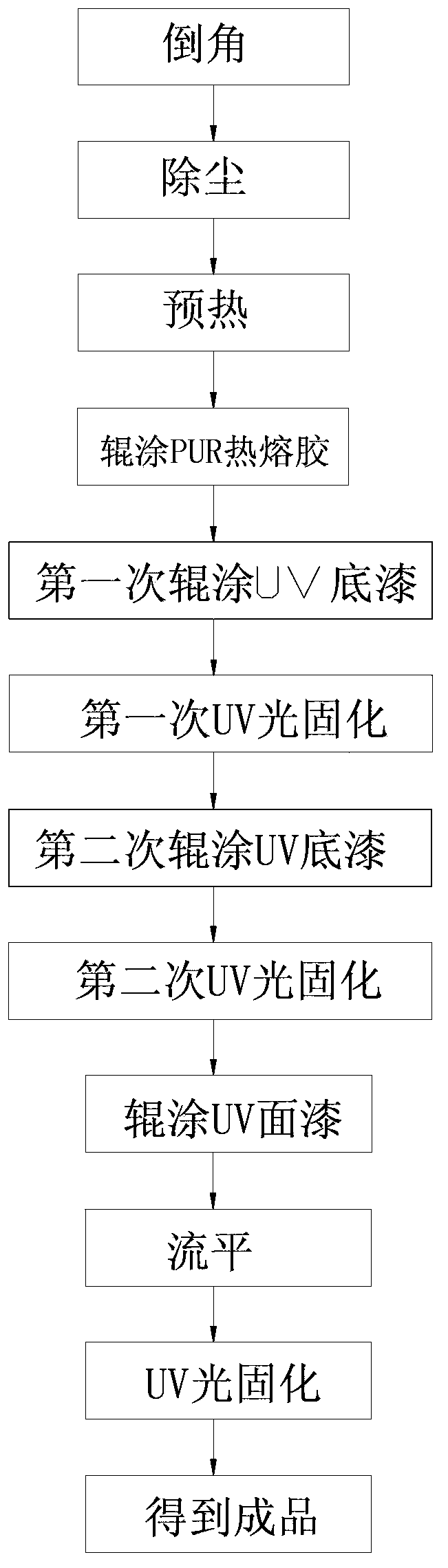

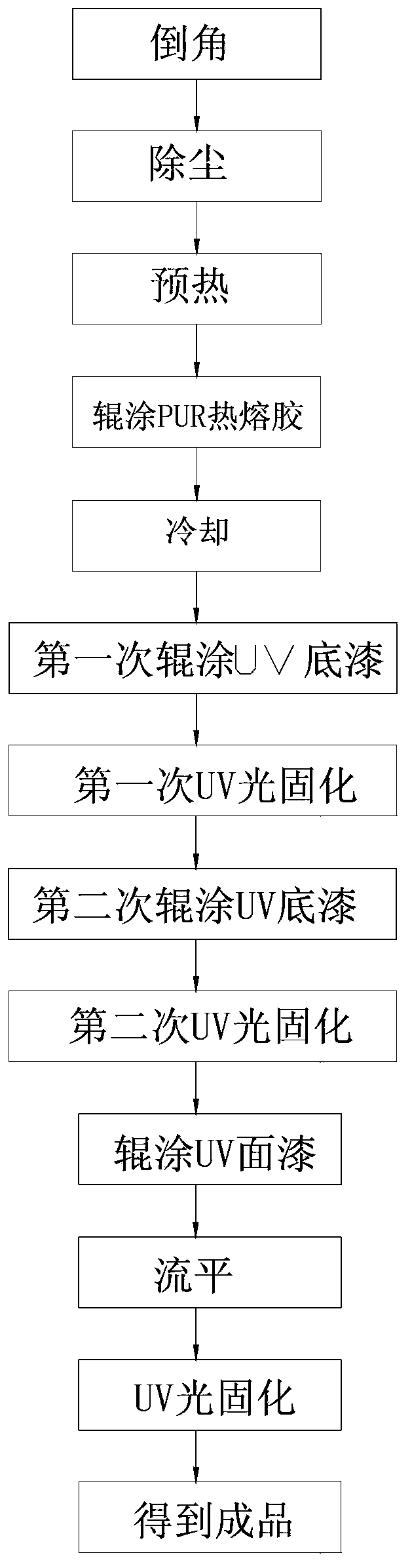

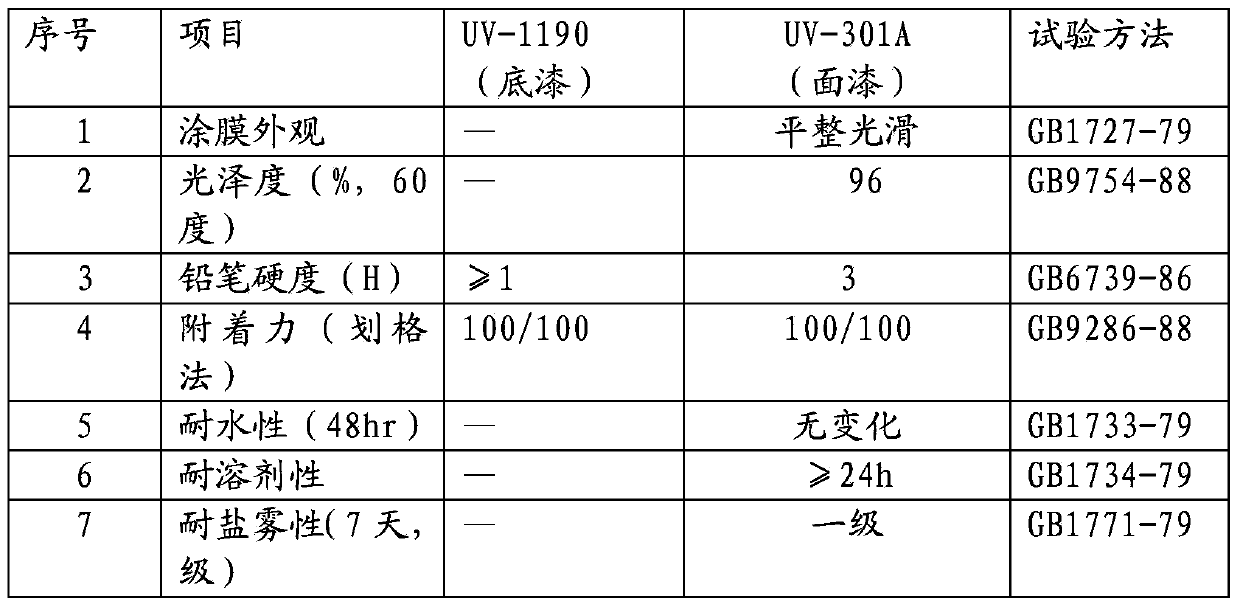

ActiveCN103386394AHigh UV stabilityImproved impact and abrasion resistancePretreated surfacesCoatingsEngineeringHot-melt adhesive

The invention discloses a method for processing a novel UV (ultraviolet) highlight plate, which is carried out sequentially according to the following steps of 1, carrying out preprocessing, i.e. carrying out chamfering on the edge of a substrate and then removing dust; 2, carrying out adhering bottom processing, i.e. firstly, preheating the substrate subjected to dust removal and then feeding the substrate into a hot roller coating machine to carry out roll coating of a PUR (polyurethane) hot melt adhesive; 3, carrying out primer processing, i.e. sequentially carrying out primary roll coating of a UV primer, primary UV photocuring, secondary roll coating of the UV primer and secondary UV photocuring on the substrate subjected to adhering bottom processing; 4, sequentially carrying out sanding processing and dust removal processing on the substrate of which primer processing is completed; and 5, carrying out finish paint processing, i.e. sequentially carrying out roll coating of a UV finish paint, infrared leveling and UV photocuring on the substrate completed in the step 4 so as to obtain a finished product. According to the invention, the surface of the substrate does not need to be sanded, so that production cost is reduced, working efficiency is improved, and labor intensity is reduced; and the UV highlight plate manufactured by adopting the method has the characteristics of good adhesion force, good stability and high glossiness.

Owner:SUOFEIYA HOME COLLECTION

Polymer coatings with improved heat stability

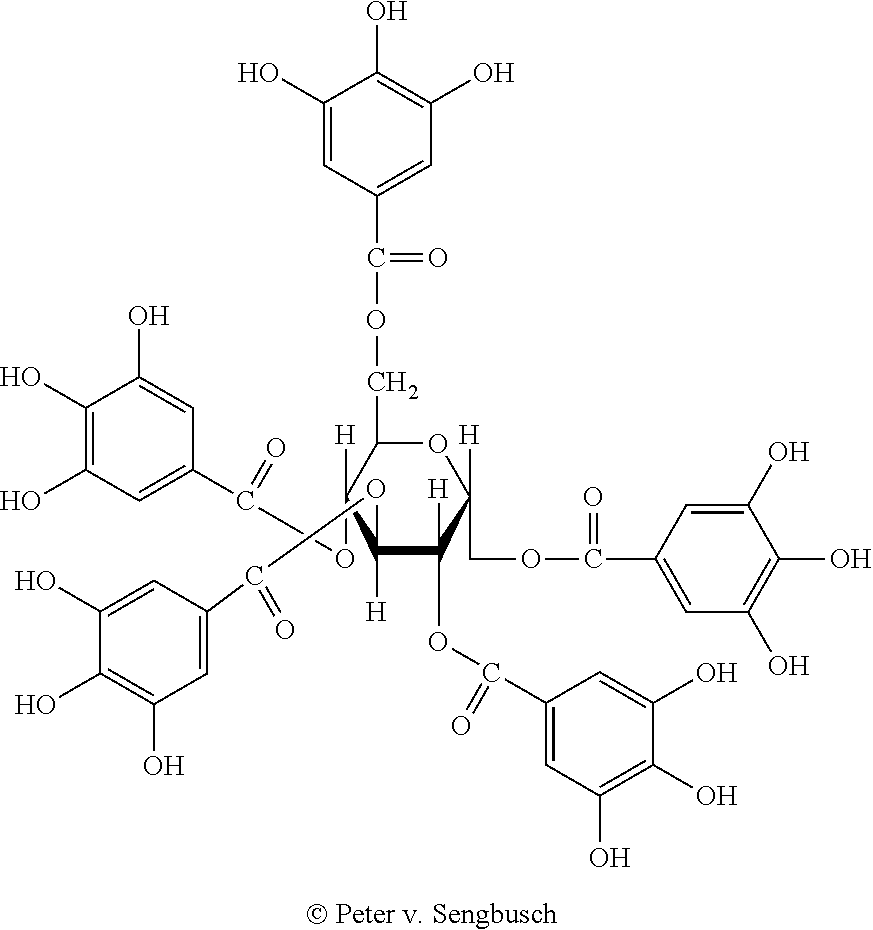

ActiveUS8936735B2Increase heatImproves UV stabilityConductive materialNon-conductive material with dispersed conductive materialGallic acid esterPolymer science

The present invention relates to coatings comprising electrically conductive polymers and esters of gallic acid and sugars, their production and use, and dispersions for the production of such coatings.

Owner:HERAEUS PRECIOUS METALS GMBH & CO KG

Polymerizable liquid crystal composition and display device

ActiveCN104342170AGood UV stabilityHD highlightsLiquid crystal compositionsNon-linear opticsCrystallographyLiquid-crystal display

The invention provides a novel polymerizable liquid crystal composition comprising a first component of at least one compound represented by the general formula I, a second component of at least one compound represented by the general formula II, a third component of at least one compound represented by the general formula III, and a fourth component of at least one compound represented by the general formula IV. According to the polymerizable liquid crystal composition, polymerization speed can be controlled, polymeric compound residues can be reduced, and risks of causing poor display problems such as after-images and image display unevenness can be greatly reduced. The invention also provides a liquid crystal display device comprising the polymerizable liquid crystal composition.

Owner:JIANGSU HECHENG DISPLAY TECHCO

Method for producing poly(pentabromobenzyl acrylate)

ActiveCN102167762ANo physical effectLittle influence on physical propertiesPolymer scienceNitrogen gas

The invention discloses a method for producing poly(pentabromobenzyl acrylate). The method comprises the following steps of: adding ethylene glycol monomethyl ether, acrylic acid, hydroquinone and anhydrous sodium carbonate into a reaction kettle; reacting at the temperature of between 35 DEG C and 45 DEG C until no bubbles are produced; heating to reach the temperature of between 100 DEG C and 120 DEG C; adding pentabromobenzyl bromide to react to obtain pentabromobenzyl acrylate; adding the ethylene glycol monomethyl ether and the prepared pentabromobenzyl acrylate into the reaction kettle; introducing nitrogen gas and stirring; heating to reach the temperature of between 90 DEG C and 110 DEG C; adding a mixed solution of dicumyl peroxide and glycol ether; polymerizing for 1.5 to 2.5 hours and then heating to reach the temperature of between 110 DEG C and 126 DEG C; and continuously reacting for 2 to 5 hours to prepare the poly(pentabromobenzyl acrylate). A product prepared by the method has the advantages of superior performance, no separation, no migration, extremely low influence on properties of materials, capability of increasing productivity, high mechanical property, high anti-ultraviolet stability and high thermal stability.

Owner:SHANDONG RUNKE CHEM

Curable compositions containing isocyanate functional components having improved durability

InactiveUS20140290855A1Improves UV stabilityAdhesive processesSilicon organic compoundsAdhesiveSealant

Owner:DOW GLOBAL TECH LLC

Novel masterbatch thermoplastic delivery system

Clays and organoclays which are treated with resorcinol diphosphate and / or bisphenol diphosphate as general nanoparticle particle dispersants and replacements for quaternary amines. The two compounds are used as self-activating and self-dispersing nanoparticles by localizing themselves on the particle surface in a polymer matrix and acting as a nanoparticle dispersants in general, as well as resulting in exfoliation of clays. The exfoliate clays may be used in polymers in lieu of other organic treatments. When these clays exfoliate poorly in a given thermoplastic, they can be added in high loading rates to polymethylmethacrylate and the PMMA-clay masterbatch added to the plastic where the organoclay performed poorly. The resulting material is a desirable nanocomposite material, with good exfoliation of the organoclay obtained in the final receiving thermoplastic.

Owner:ABECASSIS DAVID +1

White, UV-stabilized film made from a crystallizable thermoplastic

InactiveUS20020176978A1Improves UV stabilityNot to damagePigmenting treatmentSynthetic resin layered productsThermoplasticUltraviolet

A white film whose thickness is in the range from 1 to 500 mum and which comprises, as principal constituent, a crystallizable thermoplastic, wherein the film comprises at least one UV stabilizer as light stabilizer and at least one white pigment, the use of the film, and also a process for its production.

Owner:MITSUBISHI POLYESTER FILM

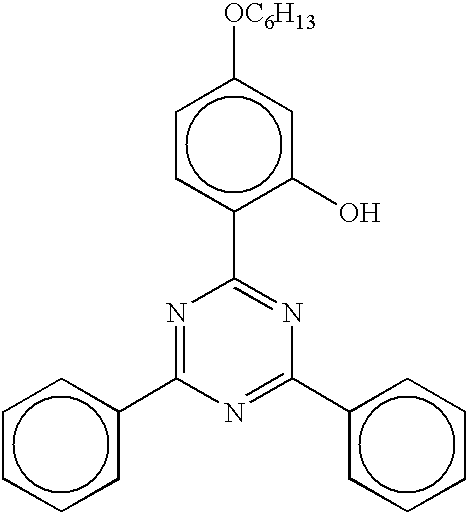

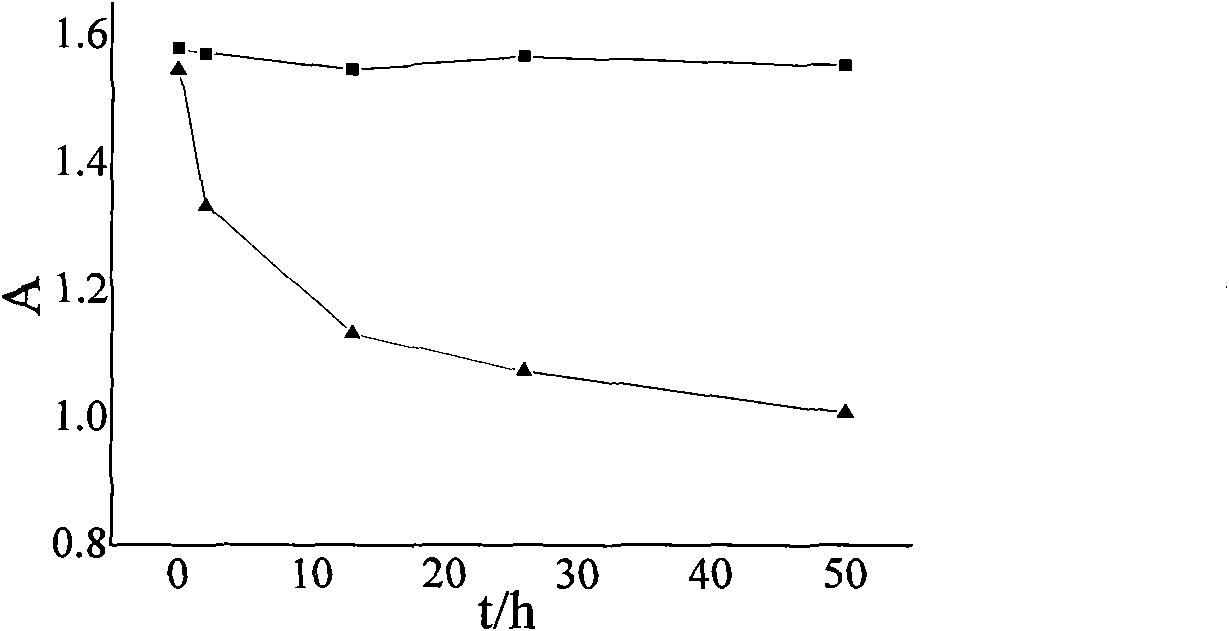

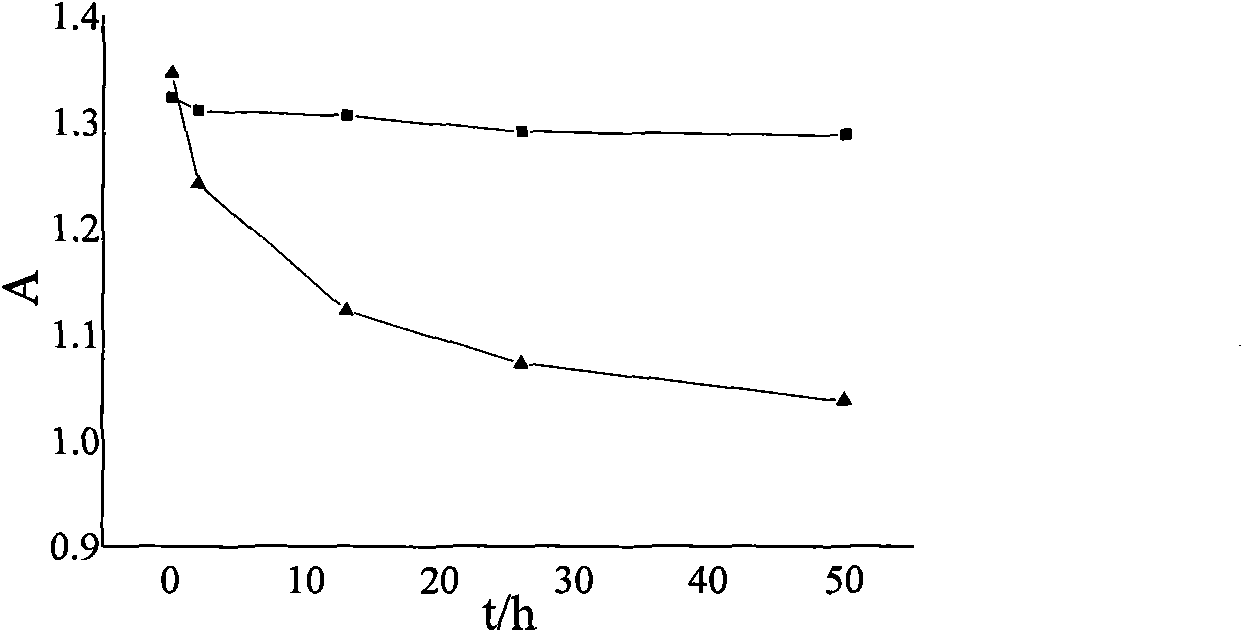

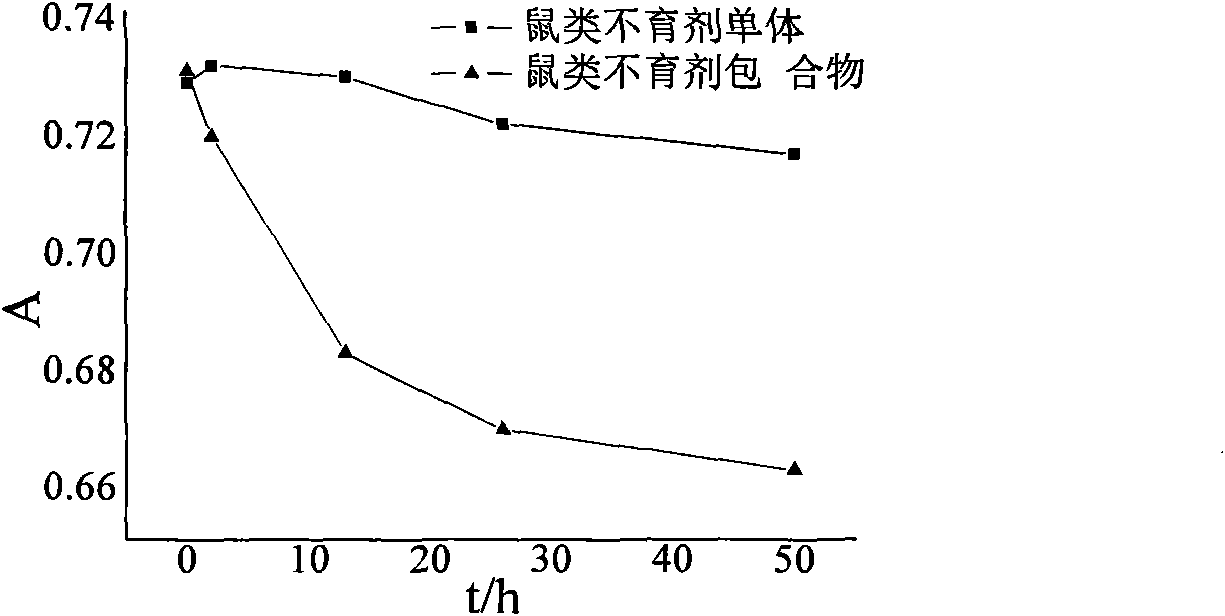

Cyclodextrin inclusion compound of rodents sterilant and preparation method thereof

InactiveCN101869113AGood water solubilityImproves UV stabilityBiocideChemosterilantsSolubilityMass ratio

The invention relates to the field of medicaments, in particular to a cyclodextrin inclusion compound of a rodents sterilant and a preparation method thereof. By the method, the rodents sterilant is mixed with cyclodextrin or a derivative of the cyclodextrin in a mass ratio of 1:1-200 to prepare the inclusion compound. The obtained inclusion compound not only has high water solubility, but also has a high ultraviolet stability. The invention initially provides the cyclodextrin inclusion compound of the rodents sterilant. The cyclodextrin inclusion compound has a tubular structure formed by glucosamine residues to form a unique conformation which is externally hydrophilic and internally hydrophobic, and can form a compound supramolecular system with an indissolvable compound to play a solubilization role and solve the problem of low water solubility of the conventional rodents sterilant; moreover, the inclusion compound has the high ultraviolet stability to meet the requirement of field administration; in addition, the cyclodextrin compound has no toxicity or low toxicity and is a good carrier for performing a medicinal effect research.

Owner:INST OF PLANT PROTECTION CHINESE ACAD OF AGRI SCI

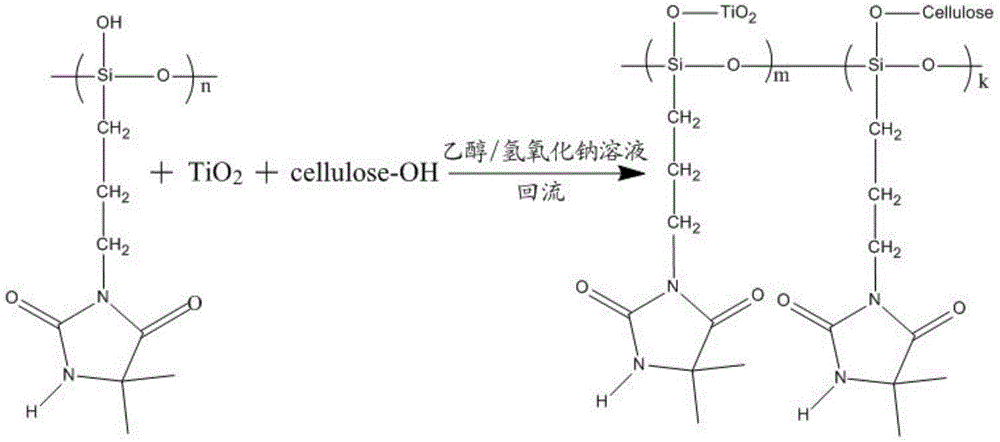

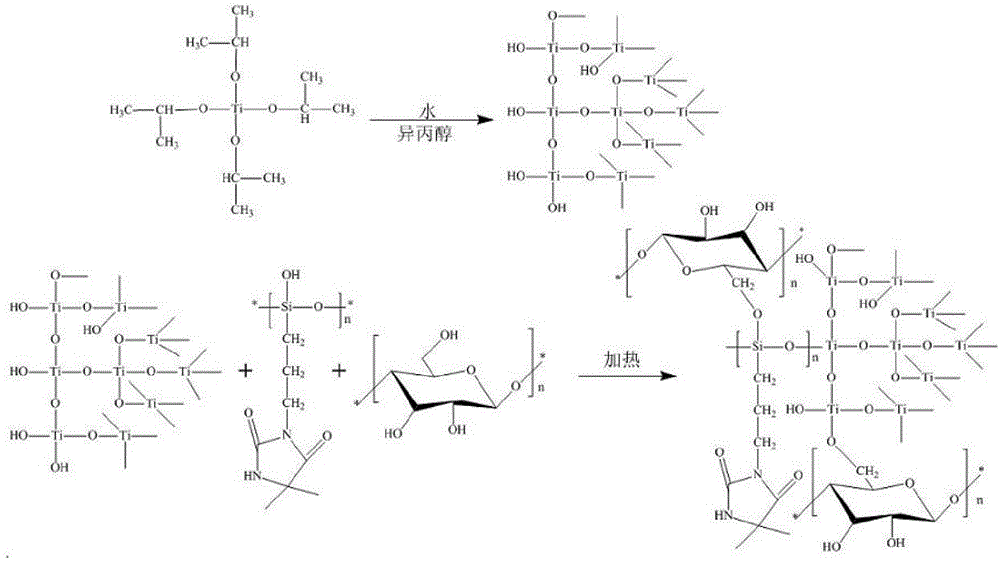

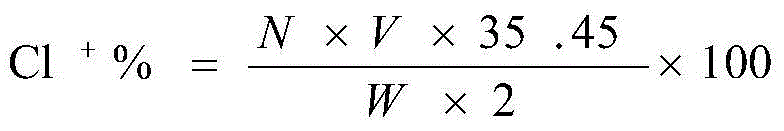

Preparation method of ultraviolet ray resistant antibacterial fabric

ActiveCN104088134ASimple processImproves UV stabilityVegetal fibresAnimal fibresTitanium dioxideFiber

The invention relates to a preparation method of ultraviolet ray resistant antibacterial fabric. The preparation method comprises the following steps of impregnating fiber fabric in finishing liquid for 10-20min, impregnating and padding twice, drying, baking at 90 DEG C -110 DEG C for 30-90min, soaping, washing, airing and chloridizing to obtain the finished product. The process reaction condition is mild, the reaction time is short, the reaction energy consumption is low, the technological process is simple, and synthesized nano-titanium dioxide has high photocatalytic activity.

Owner:JIANGNAN UNIV

Flame-retardant artificial turf and preparation method thereof

ActiveCN103952963AFlame retardantImprove flame retardant performanceGround pavingsFlooring insulationsYarnCombustion

Owner:COCREATION GRASS CO LTD

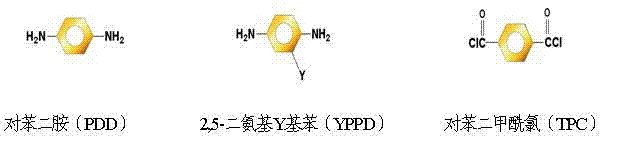

High strength and high modulus para-aramid fiber and preparation method thereof

ActiveCN102383218AGood solvent resistanceHigh tensile strengthArtificial filament washing/dryingFilament/thread formingBenzenePolymer science

The invention discloses a high strength and high modulus para-aramid fiber and a preparation method thereof. The high strength and high modulus para-aramid fiber is characterized by being prepared from steps of: polymerizing 2,5-diamino Y benzene, terephthaloyl chloride or / and p-phenylenediamine monomer according to a molar ratio in a solvent system to prepare a spinning slurry, filtering the slurry, carrying out dry spray wet spinning, drying and reeling. The fiber large molecular chain infrared light spectrum has C-N bond telescoping vibration absorption peaks at wave number of 2230 cm<-1> and 1406 cm <-1> and has amide bond absorption peaks at 1662 cm<-1> and 3500-3300 cm<-1>. Specific indexes of the fiber are as below: tensile strength of 24-28g / d, initial modulus of 700-900g / d, fracture elongation of 2.5-3.5%, filament number of 1-2 D and yarn fineness of 300-3000 D. The invention is easily controlled and environment-friendly and reduces corrosion of apparatus, thereby reducingindustrialization cost and spinning cost relatively.

Owner:南充易安新材料有限公司

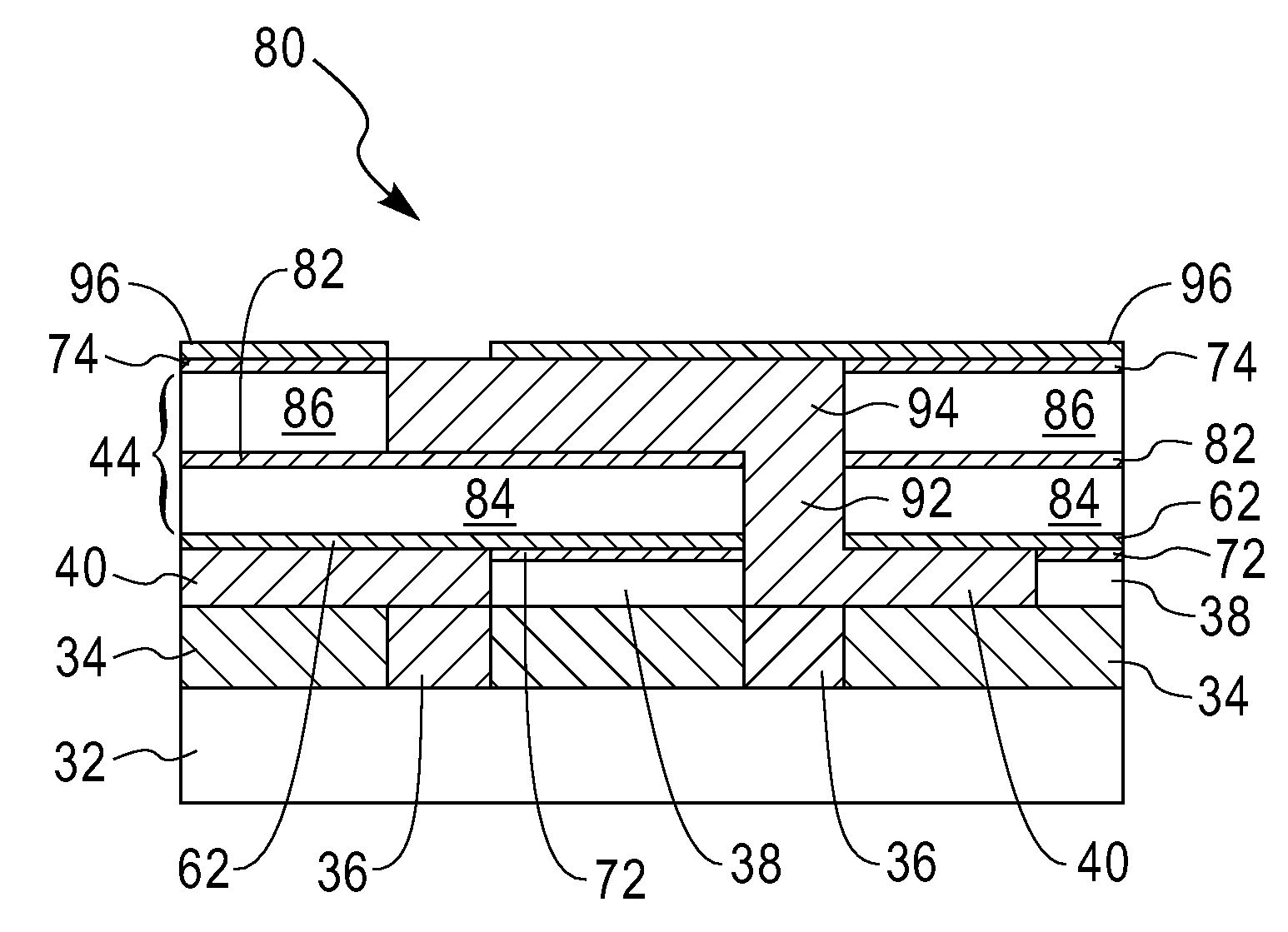

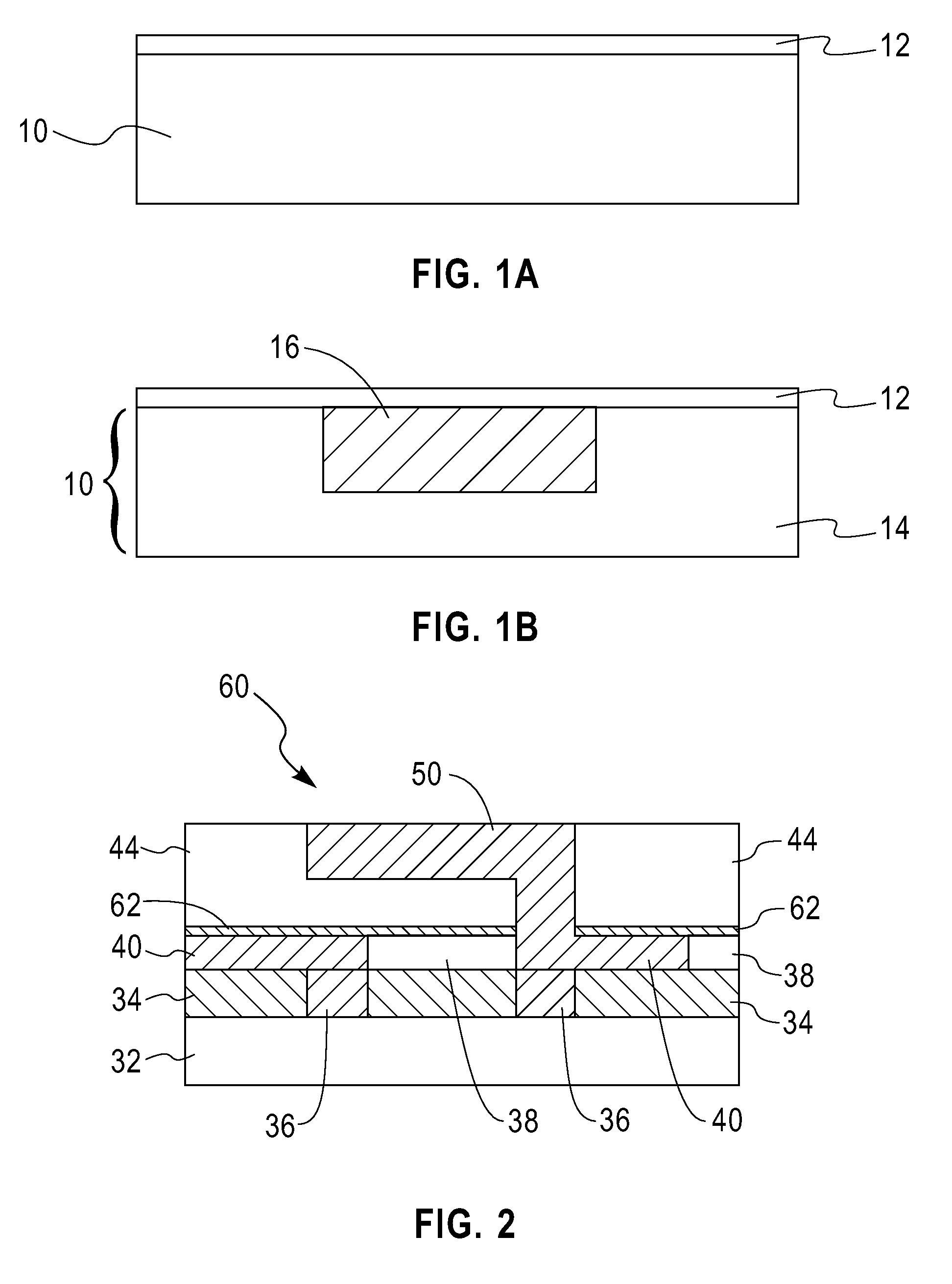

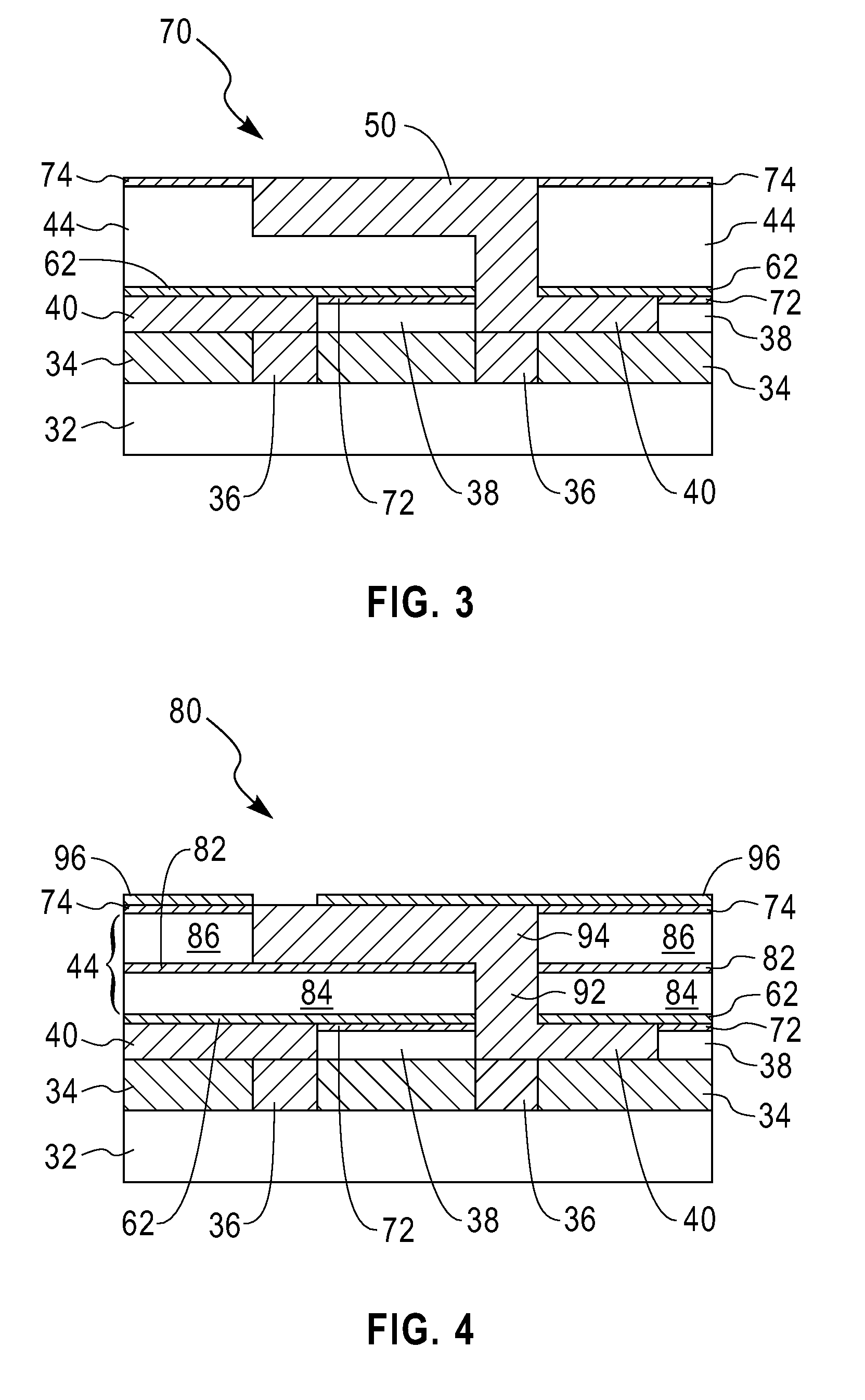

ADVANCED LOW k CAP FILM FORMATION PROCESS FOR NANO ELECTRONIC DEVICES

ActiveUS20090179306A1Low costLow effective capacitanceSemiconductor/solid-state device detailsSolid-state devicesDielectricUV curing

A carbon-rich silicon carbide-like dielectric film having a carbon concentration of greater than, or equal to, about 30 atomic % C and a dielectric constant of less than, or equal to, about 4.5 is provided. In some embodiments, the dielectric film may optionally include nitrogen. When nitrogen is present, the carbon-rich silicon carbide-like dielectric film has a concentration nitrogen that is less than, or equal, to about 5 atomic % nitrogen. The carbon-rich silicon carbide-like dielectric film can be used as a dielectric cap layer in an interconnect structure. The inventive dielectric film is highly robust to UV curing and remains compressively stressed after UV curing. Moreover, the inventive dielectric film has good oxidation resistance and prevents metal diffusion into an interconnect dielectric layer. The present invention also provides an interconnect structure including the inventive dielectric film as a dielectric cap. A method of fabricating the inventive dielectric film is also provided.

Owner:GLOBALFOUNDRIES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com