Method for processing novel UV (ultraviolet) highlight plate

A processing method and technology of high-gloss sheet, which can be applied to the device for coating liquid on the surface, pretreatment surface, coating and other directions, which can solve the problems of reducing product adhesion, stable performance, high labor intensity of workers, affecting product gloss and other problems , to achieve the effect of high UV stability, strong surface, high impact and abrasion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

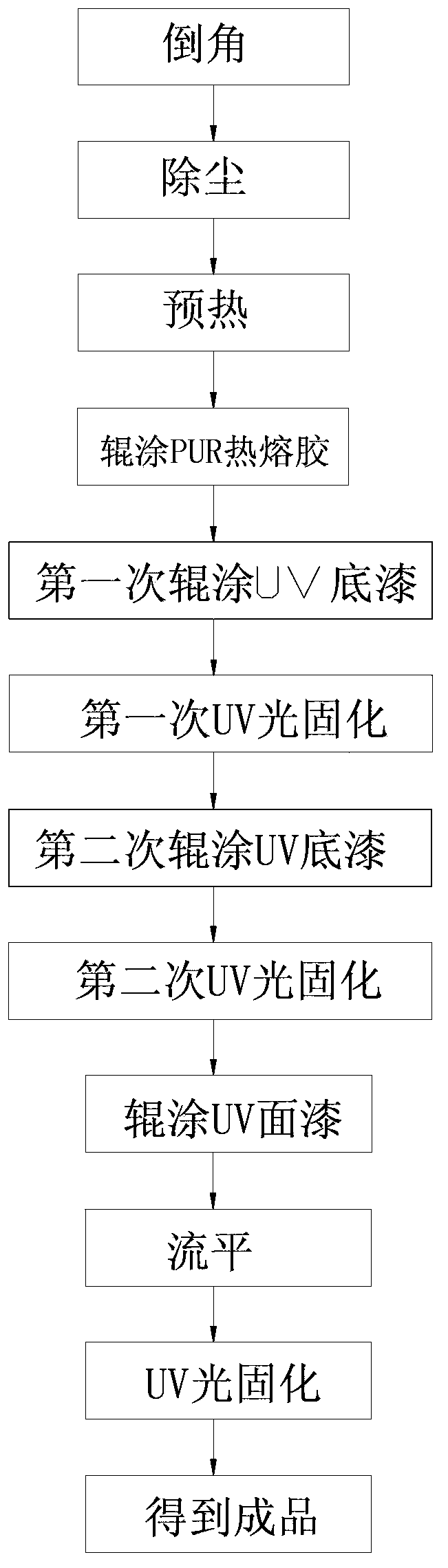

[0022] refer to figure 1 , a new type of UV high-gloss board processing method, followed by the following steps:

[0023] 1) Pre-treatment: first chamfer the edge of the substrate, and then remove dust from the substrate;

[0024] 2) Adhesive base treatment: first preheat the substrate after dedusting, the preheating temperature is 35°C; The tank temperature is 140°C, the roller temperature is 140°C, and the coating weight is 35g / m 2 , the line speed of rolling the PUR hot melt adhesive is 10m / min; the viscosity of the PUR hot melt adhesive is 15000mPa.s. The PUR hot-melt adhesive adopts the PUR hot-melt paint of model 717.1 produced by Klibao Company of Germany.

[0025] 3) Primer treatment: send the substrate after the attached primer treatment into the UV roller coater, and carry out the first roll coating of UV primer, and the coating amount is 15g / m 2 ; Then send it into the UV curing machine for the first UV light curing, using a medium-pressure mercury lamp (120W / cm...

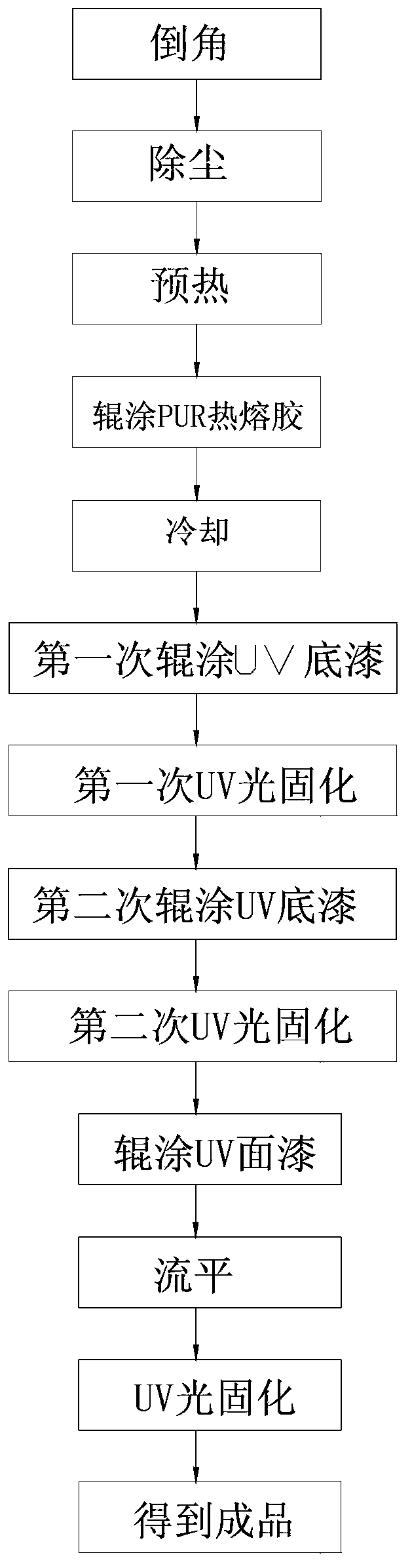

specific Embodiment 2

[0031] refer to figure 2 , The characteristics of this embodiment are: in step 2), the substrate after the PUR hot-melt adhesive is rolled is cooled, and the cooling time is 5-10 minutes until the hot-melt adhesive is completely solidified. Others are the same as in Example 1.

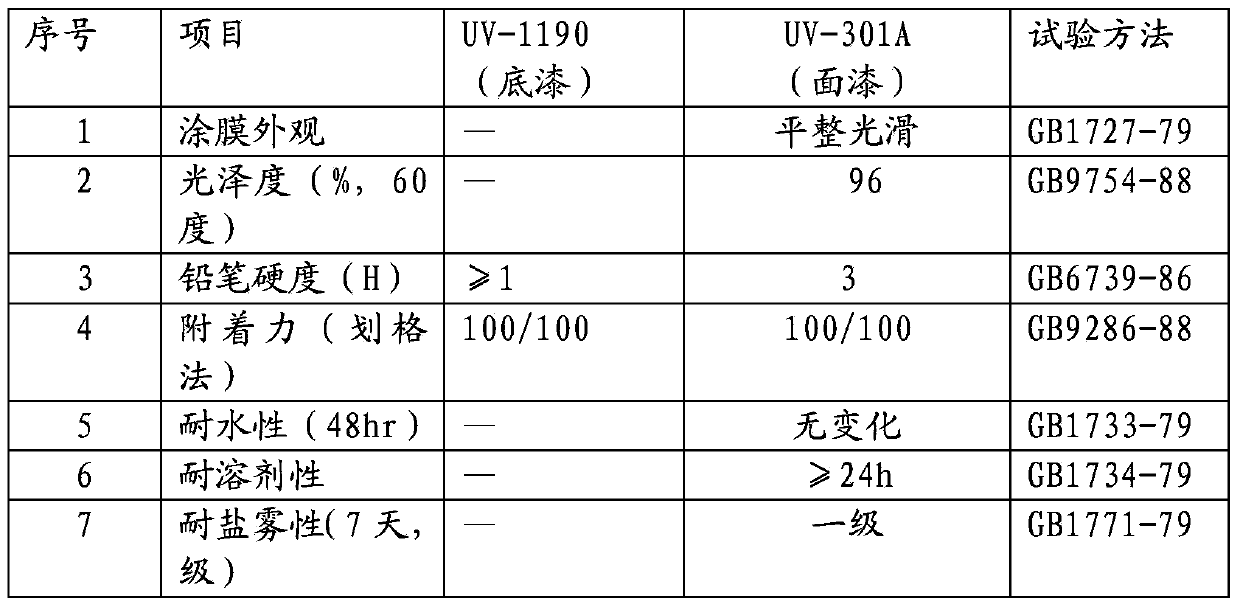

[0032] The specific performance parameters of the UV high-gloss board of this embodiment are shown in Table 2.

[0033] Table 2 Performance indicators of this embodiment

[0034]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com