Patents

Literature

12461 results about "Hot melt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

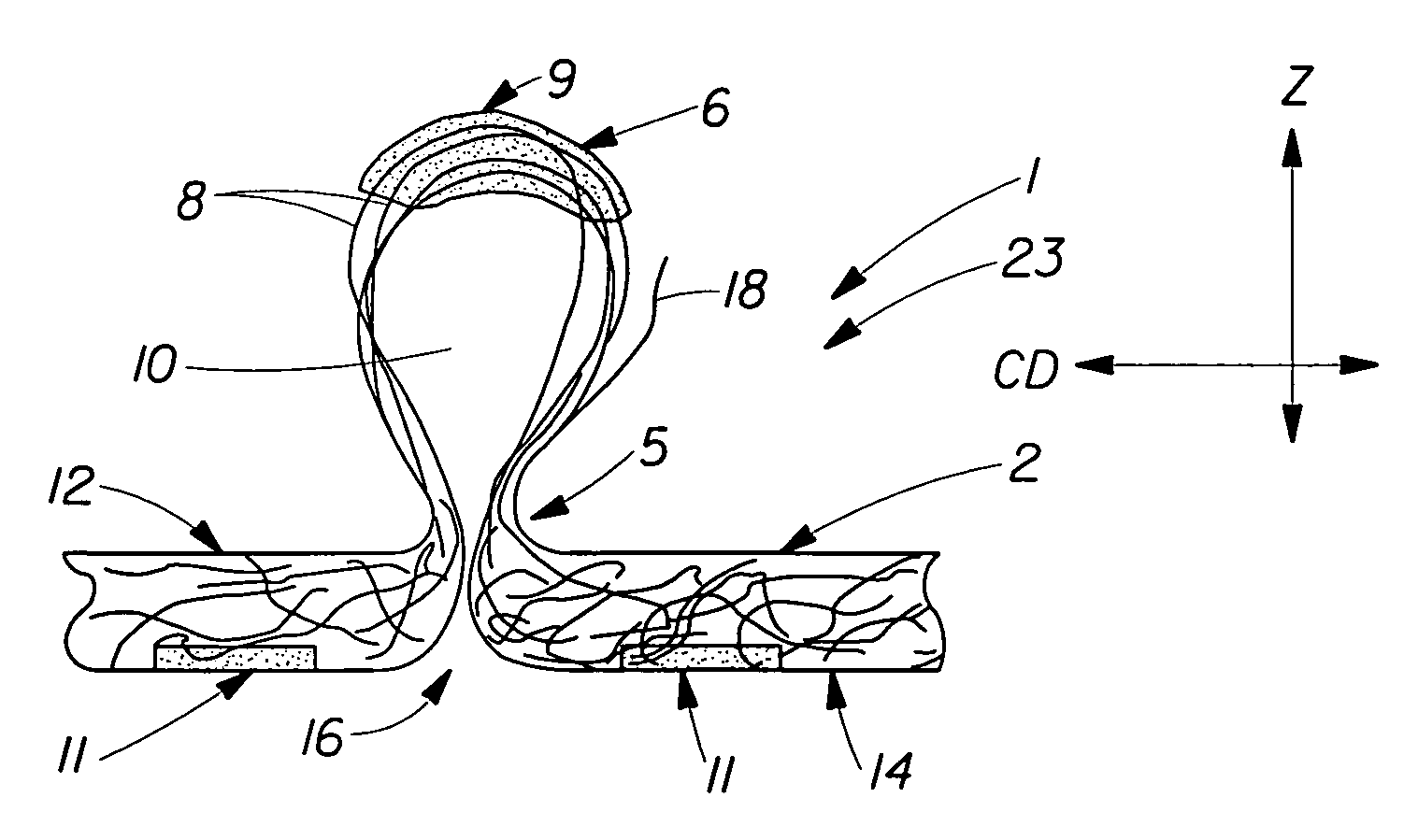

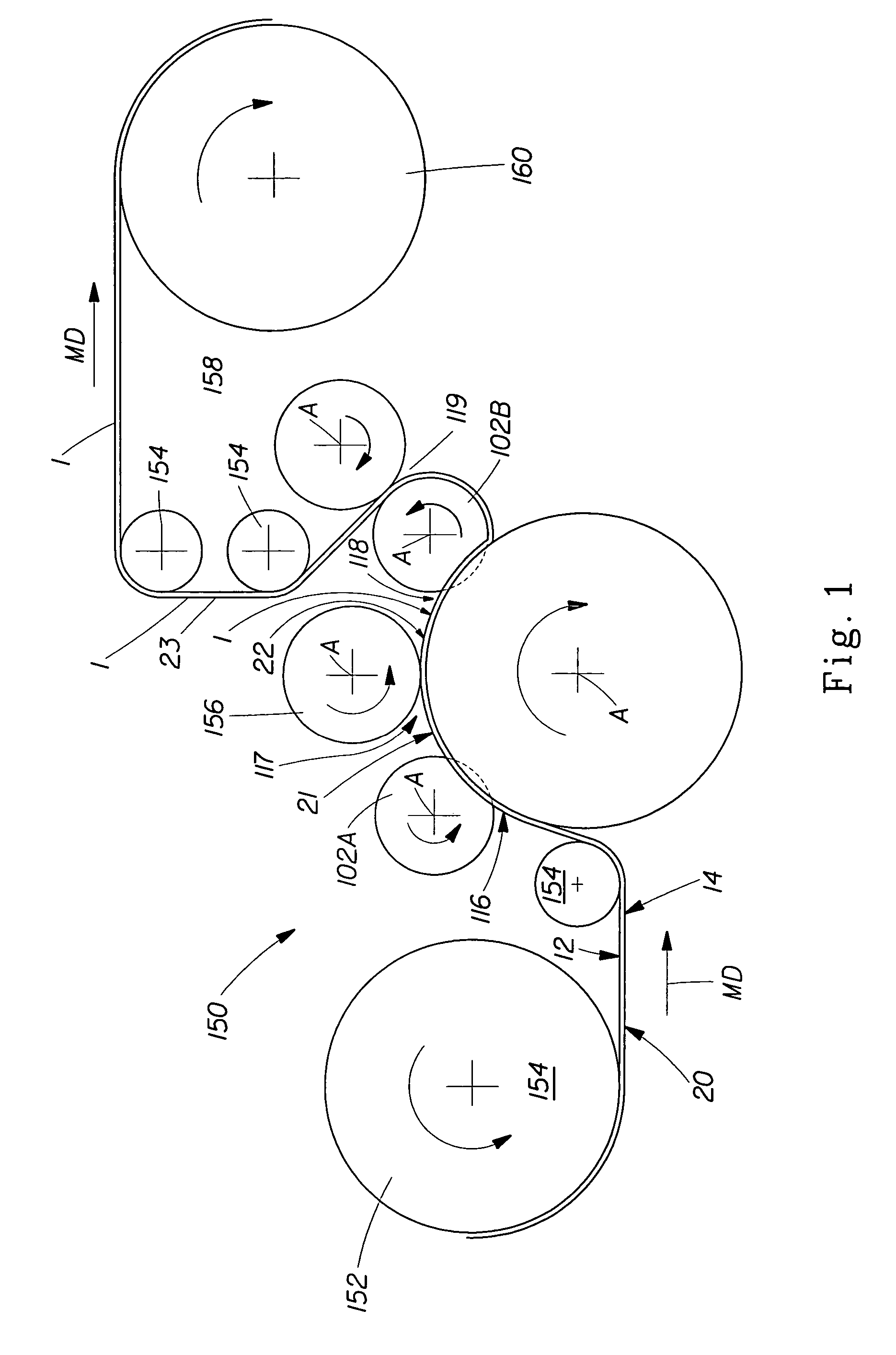

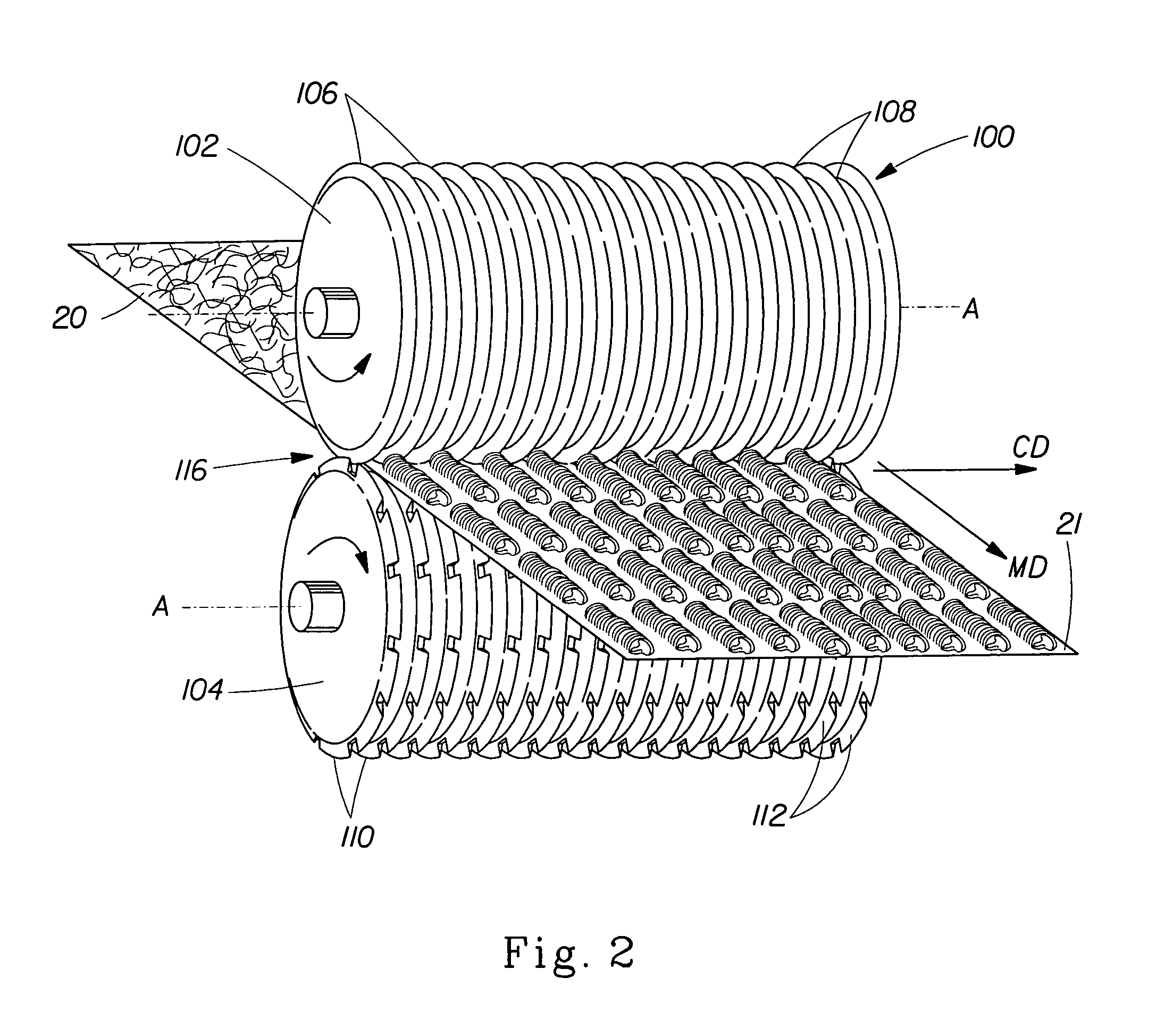

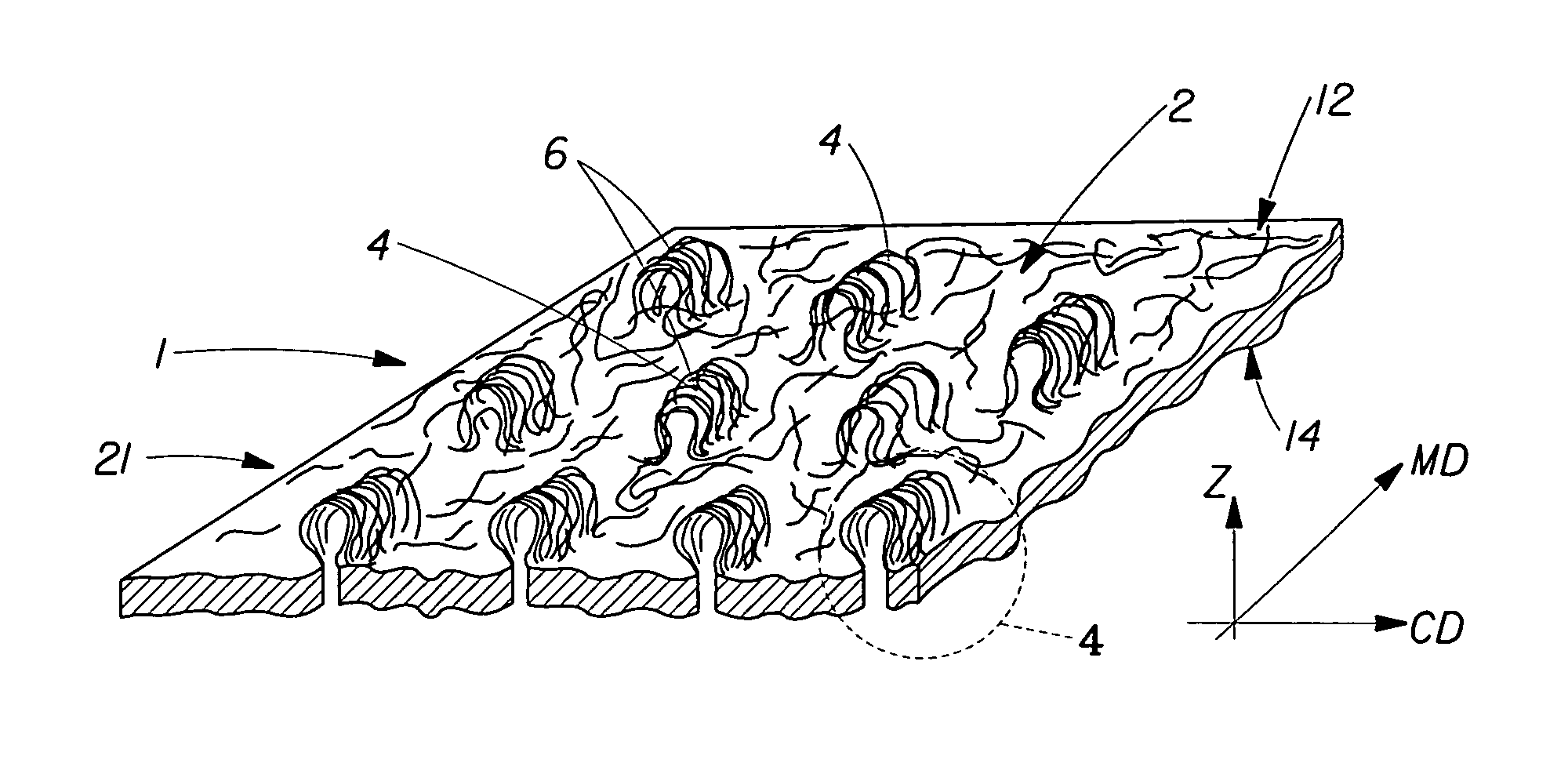

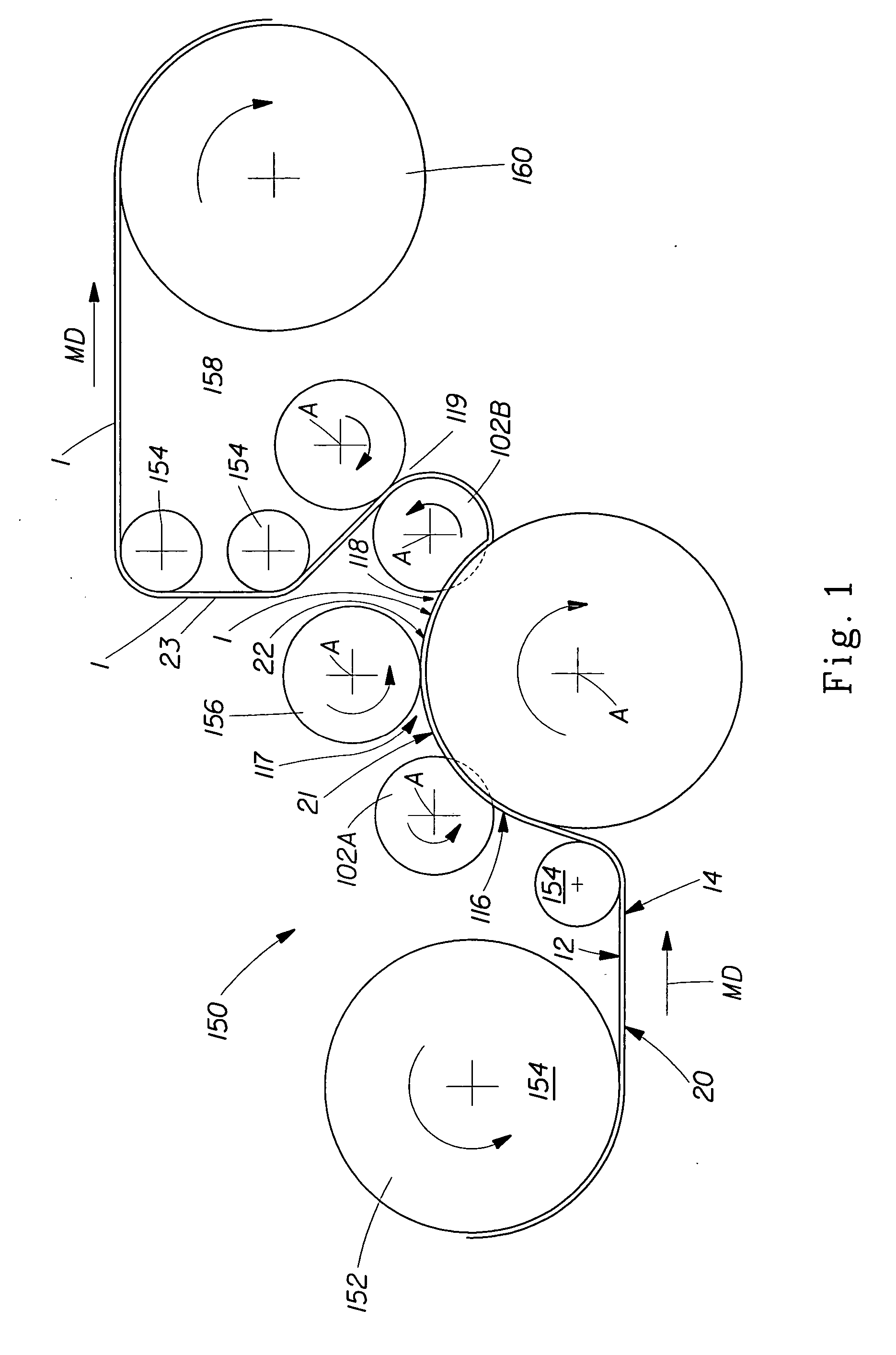

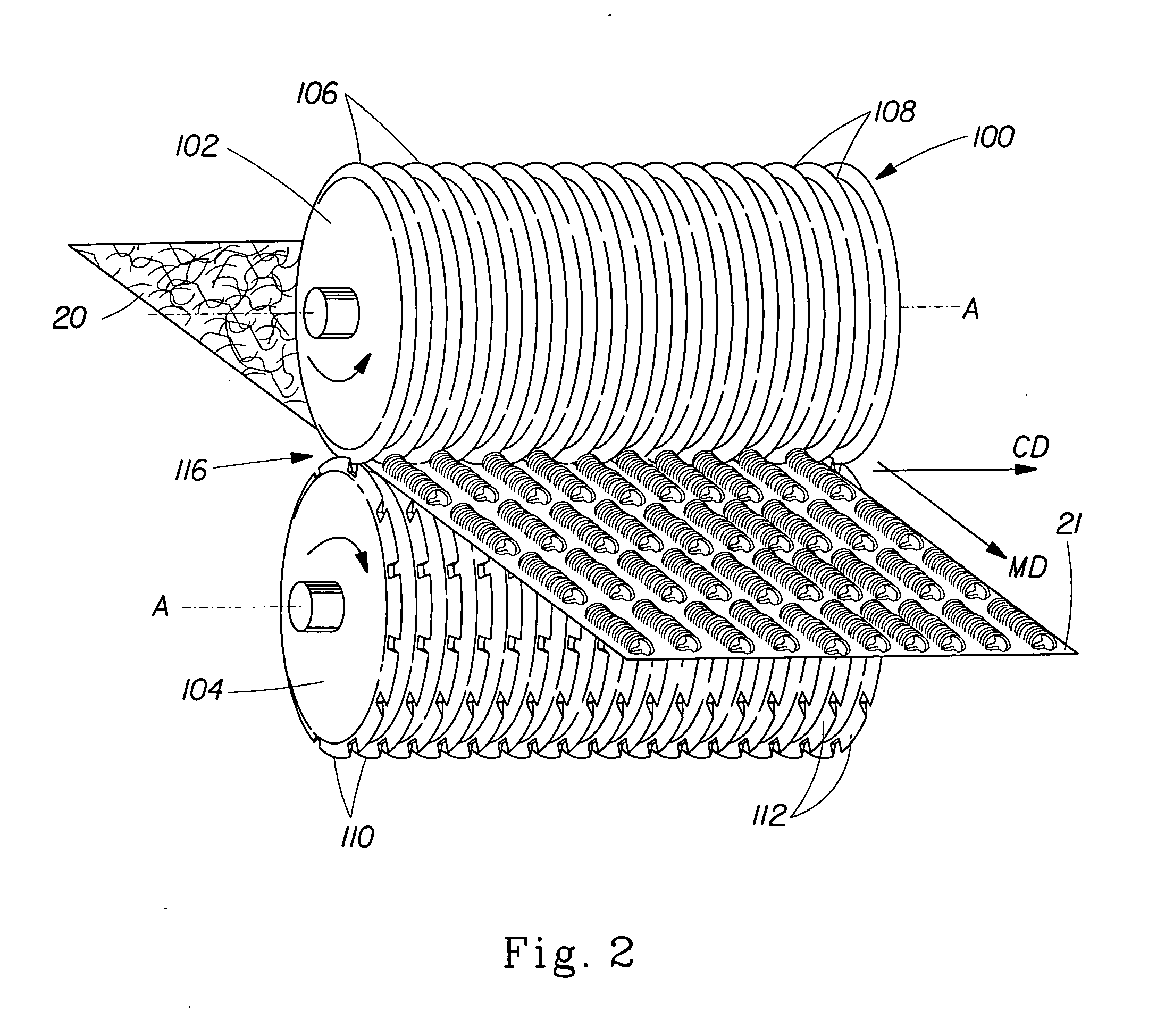

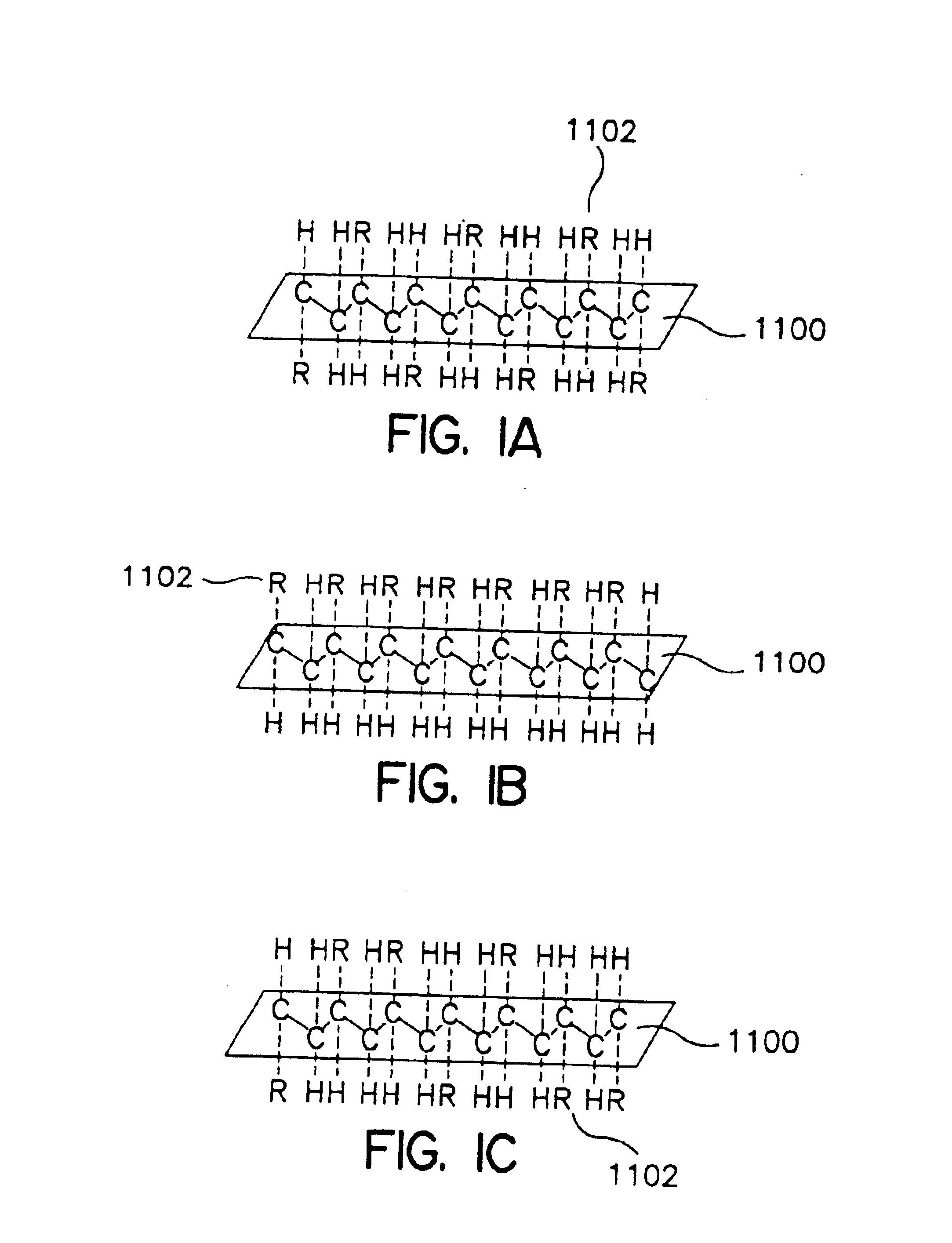

Tufted fibrous web

A fibrous web having a first surface and a second surface. The fibrous web has a first region and at least one discrete second region, the second region being a discontinuity on the second surface and being a tuft comprising a plurality of tufted fibers extending from the first surface. The tufted fibers define a distal portion, the distal portion comprising portions of the tufted fibers being bonded together. Bonding can be thermal melt-bonding. In another embodiment the second surface of the web can have non-intersecting or substantially continuous bonded regions, which also can be thermal melt-bonding.

Owner:PROCTER & GAMBLE CO

Tufted fibrous web

A fibrous web having a first surface and a second surface. The fibrous web has a first region and at least one discrete second region, the second region being a discontinuity on the second surface and being a tuft comprising a plurality of tufted fibers extending from the first surface. The tufted fibers define a distal portion, the distal portion comprising portions of the tufted fibers being bonded together. Bonding can be thermal melt-bonding. In another embodiment the second surface of the web can have non-intersecting or substantially continuous bonded regions, which also can be thermal melt-bonding.

Owner:THE PROCTER & GAMBLE COMPANY

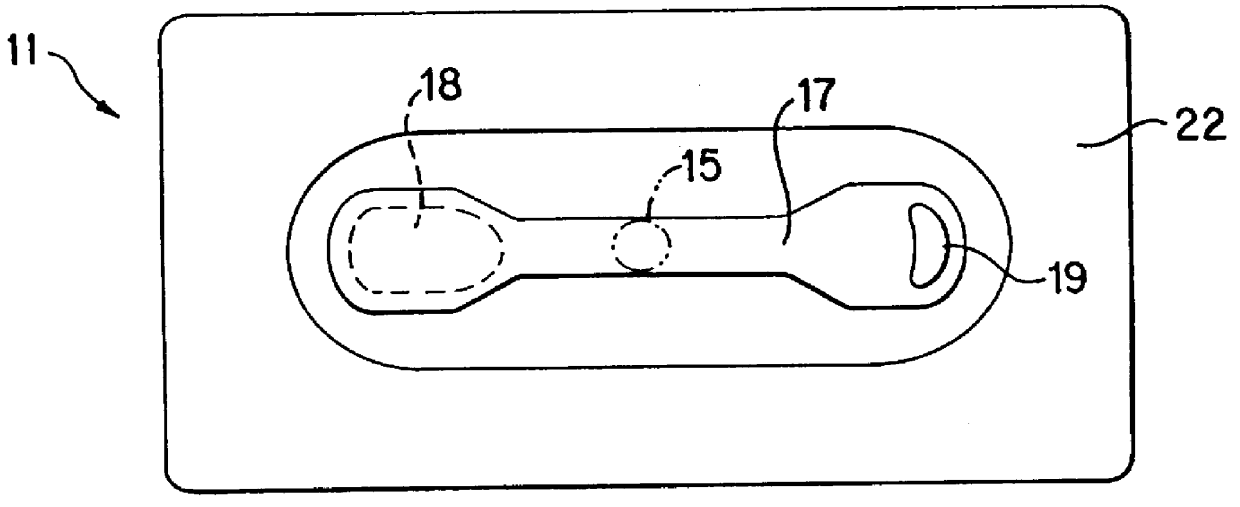

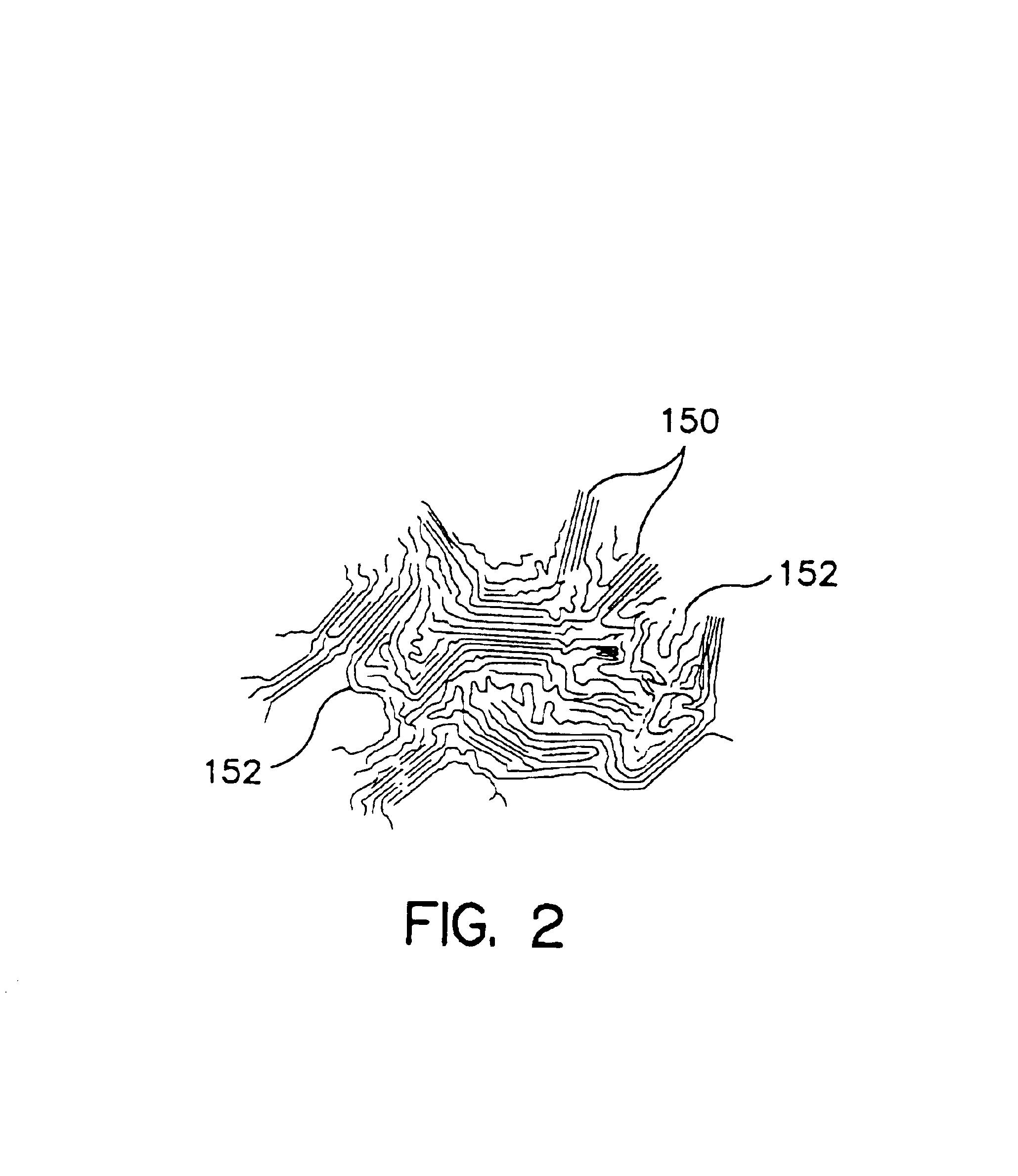

Time-temperature indicator device and method of manufacture

InactiveUS6042264AExtensive exposureSufficient supplenessThermometer detailsThermometers using mean/integrated valuesSurface layerHot melt

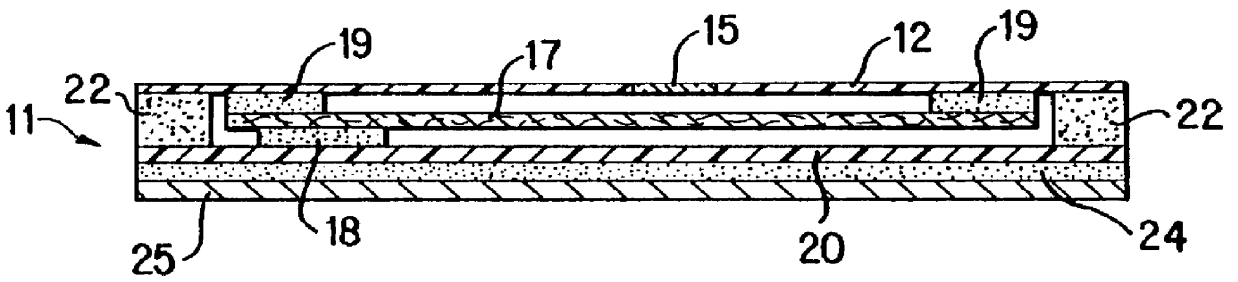

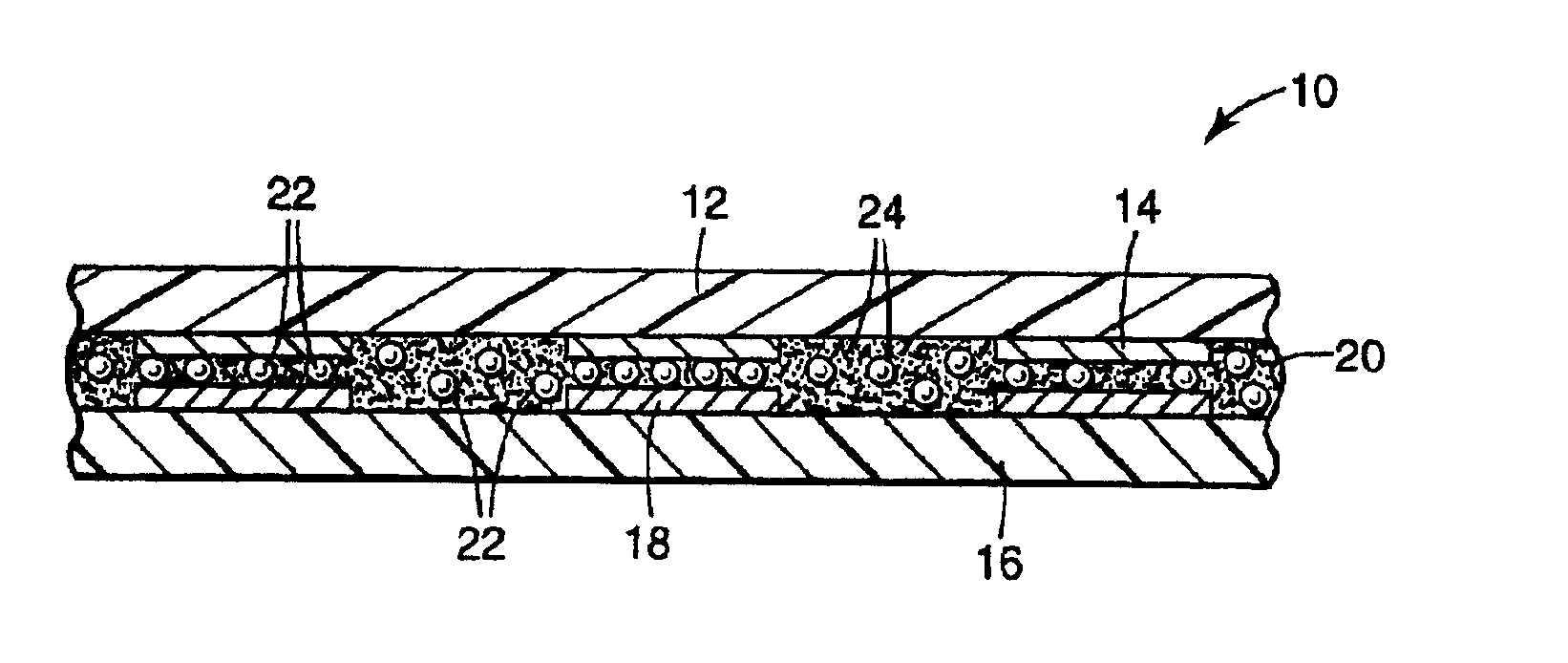

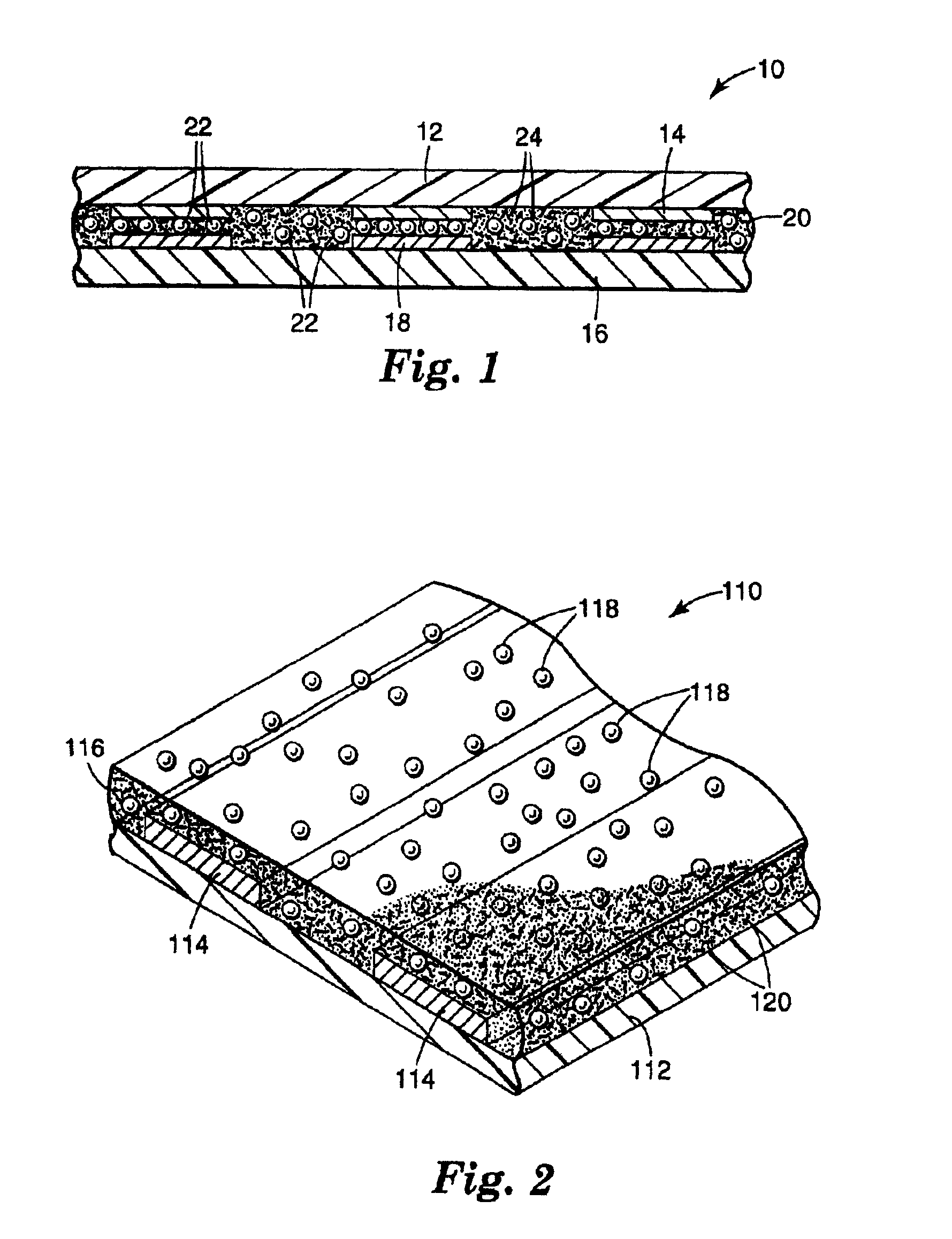

A time-temperature indicator label for measuring the length of time to which a product has been exposed to a temperature above a pre-determined temperature is provided. The period of time of exposure is integrated with the temperature to which the indicator is exposed. The label is a composite of a plurality of layers adapted to be adhered at its underside to a product container. The label includes a printable surface layer, a longitudinal wicking strip that is adhered underneath the surface layer substantially at the opposite extremities only of the wicking strip and a lower substrate layer forming an envelope with said surface layer. A heat-fusible substance, which melts and flows above a pre-determined temperature, is applied on the surface of the wicking strip contiguous to at least one of the ends of the wicking member. When the heat-fusible substance is exposed to a temperature above the pre-determined temperature, the heat-fusible substance flows along the length of the wicking member. The label has a printable surface layer and is sealed at its peripheral edge to the peripheral edge of the substrate layer. These layers encapsulate the wicking member and the heat-fusible substance. The surface layer is provided with a sight window at an intermediate location over the wicking member through which the progress of flow on the wicking member is observed.

Owner:TEMPTIME CORP

High dose solid unit oral pharmaceutical dosage form of amorphous nelfinavir mesylate and process for making same

InactiveUS7014866B2Satisfactory bioavailabilitySatisfactory dissolutionPowder deliveryBiocideHigh dosesNelfinavir mesylate

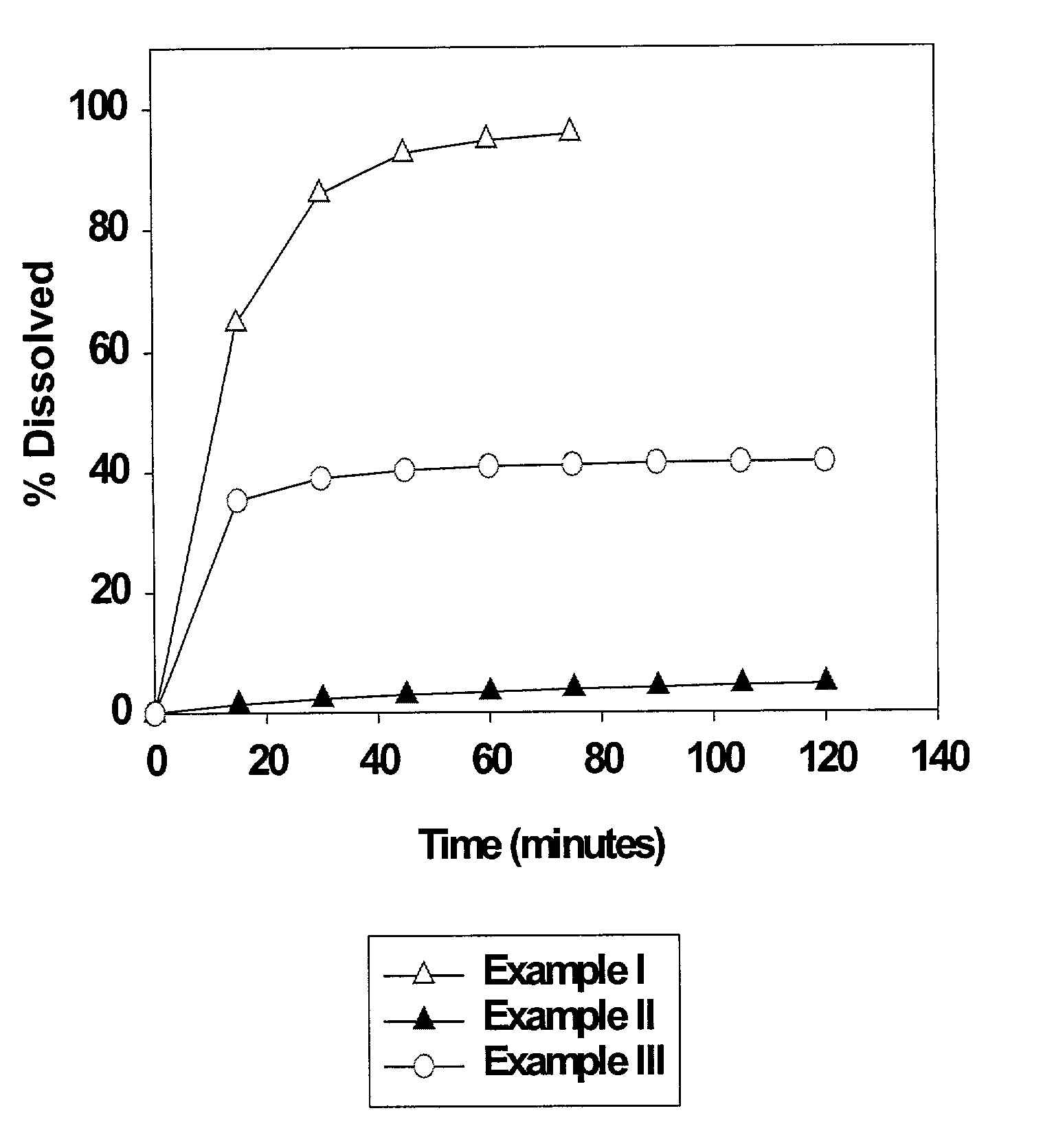

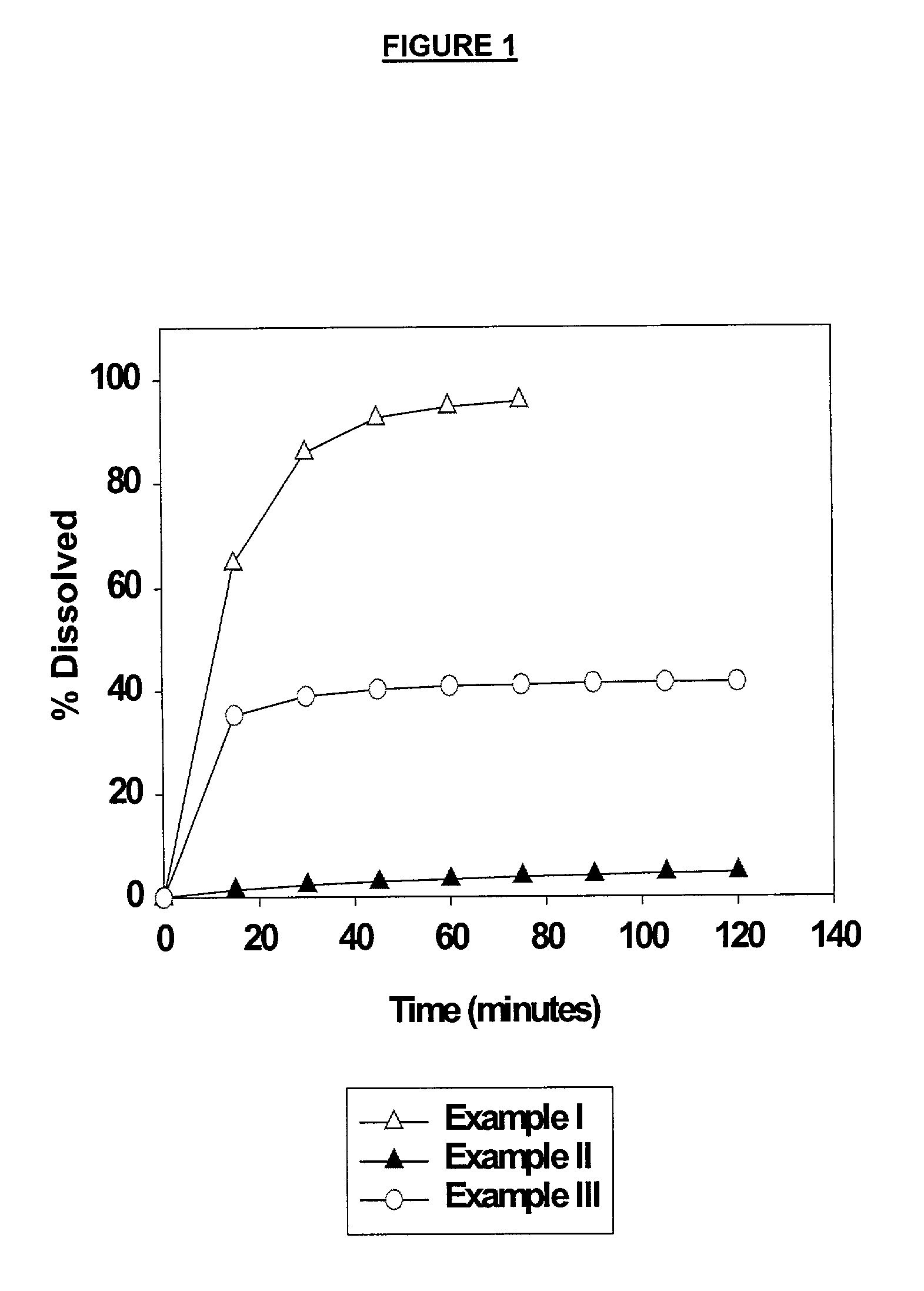

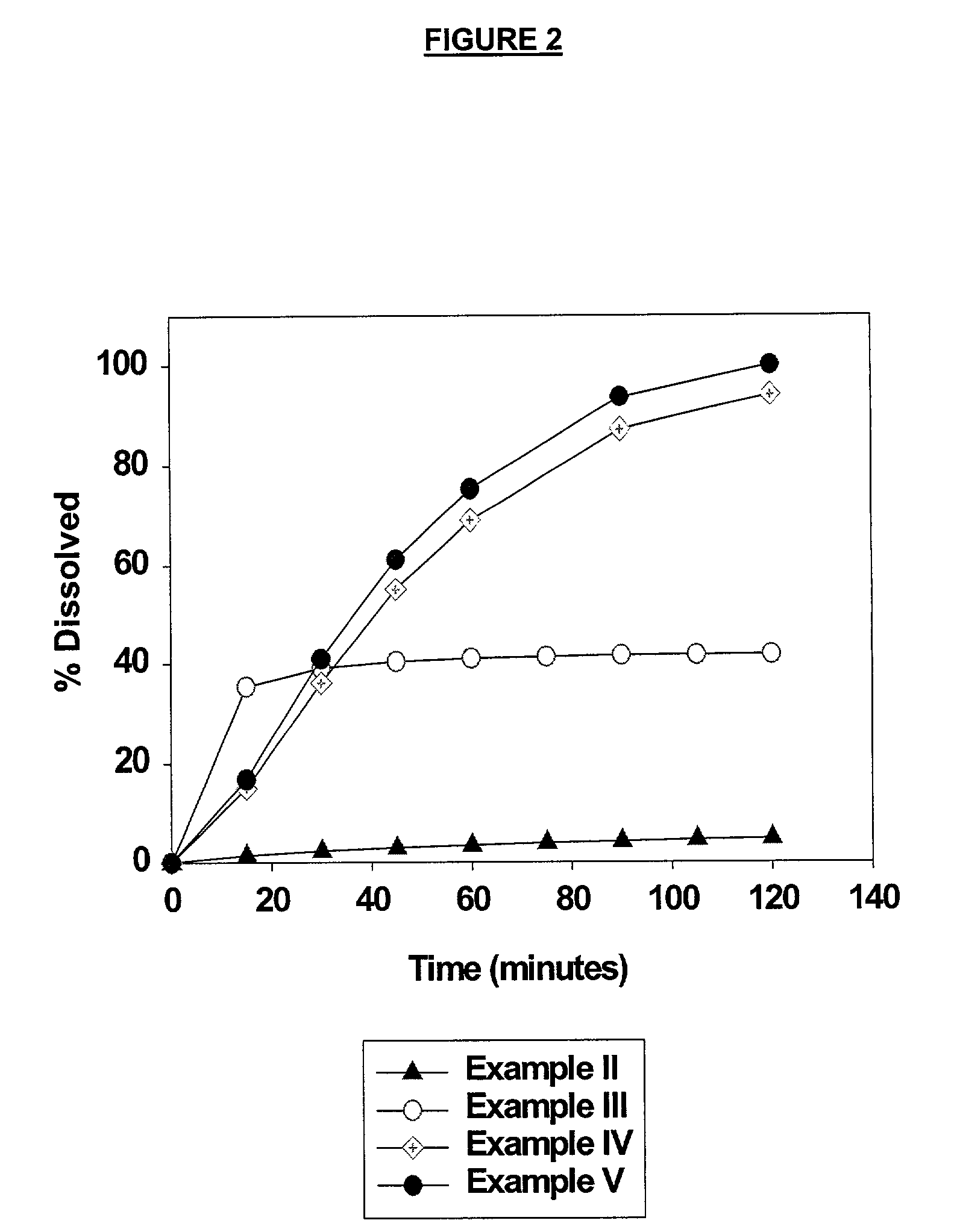

A solid unit oral pharmaceutical dosage form of amorphous nelfinavir mesylate is provided comprising amorphous nelfinavir mesylate in an amount of from about 400 mg to about 700 mg calculated as nelfinavir base, and a pharmaceutically acceptable water soluble, non-ionic synthetic block copolymer of ethylene oxide and propylene oxide, the copolymer having a melting point of at least about 45° C. and an HLB value at 25° C. of from about 18 to about 29, wherein the copolymer is present from about 40% to about 65% by weight of the nelfinavir mesylate. A hot melt granulation process for making the dosage form is provided.

Owner:F HOFFMANN LA ROCHE & CO AG

Effervescent granules and methods for their preparation

InactiveUS6071539AMinimize degradationMelt and soften binderPowder deliveryPill deliveryPlasticizerHot melt

According to the present invent, effervescent granules having a controllable rate of effervescence are provided. Such granules comprise an acidic agent, an alkaline agent, a hot-melt extrudable binder capable of forming a eutectic mixture with the acidic agent and, optionally, a plasticizer. The effervescent granules are made by a hot-melt extrusion process.

Owner:ETHYPHARM SA

Dust filter bag including a highly porous backing material ply

InactiveUS6706086B2Simple and cost-effective productionCleaning filter meansCombination devicesBursting strengthCellulose fiber

A dust filter bag having a highly porous backing material ply and a method for producing the dust filter bag. The dust filter bag includes at least one filter material ply and at least one backing material ply, the backing material ply possessing an air permeability of at least 900 l / m<2 >x s, a burst strength of at least 70 kPa, a rupture strength longitudinally better than 10 and transversely better than 3 N, a flexural rigidity longitudinally better than 0.5 cN cm<2 >and transversely better than 0.25 cN cm<2>, a basis weight of 30-80 g / m<2 >and a droplet sink-in time of less than 10 minimum. The dust filter bag can be produced by the following steps: mixing fibers including cellulose fibers and fusible fibers into a homogenous fiber mix, processing the fiber mix into a fiber web by wet laying, drying the fiber web, curing the dried fiber web by thermofusion into a backing material ply, processing the backing material ply with a filter material ply into a raw bag, and finishing the raw bag into a dust filter bag.

Owner:NEENAH GESSNER GMBH

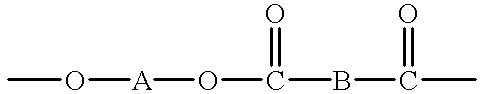

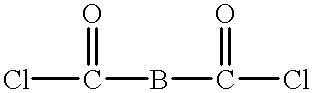

Blend material including macrocyclic polyester oligomers and processes for polymerizing the same

A blend of a macrocyclic polyester oligomer and a polymerization catalyst as a one component ready-to-use material with a long shelf life enables production of parts from macrocyclic polyester oligomers without the modification of existing equipment, thereby reducing time and cost of manufacture while expanding the application of macrocyclic polyester oligomers. In this blend material, the macrocyclic polyester oligomer remains intact in solid state at ambient conditions. Upon melting, the blend material initially forms low viscosity fluid, and then rapidly polymerizes to form high molecular weight polyesters which subsequently solidify to form crystalline polymers. In the case of certain macrocyclic polyester oligomers, for example, poly(1,4-butylene terephthalate), demolding can take place at the polymerization temperature, e.g., at about 180° C. to 200° C., because the resulting polyester polymer solidifies fairly rapidly at that temperature without cooling. In one aspect, the invention generally features a blend material that includes a macrocyclic polyester oligomer, a polymerization catalyst, and optionally, a filler. In another aspect, the invention generally features a process for preparing a blend material. In yet another aspect, the invention features processes such as rotational molding, resin film infusion, pultrusion, resin transfer molding, filament winding, making and using powder-coated or hot melt prepreg, compression molding, and roll wrapping, which use the blend material.

Owner:CYCLICS CORP

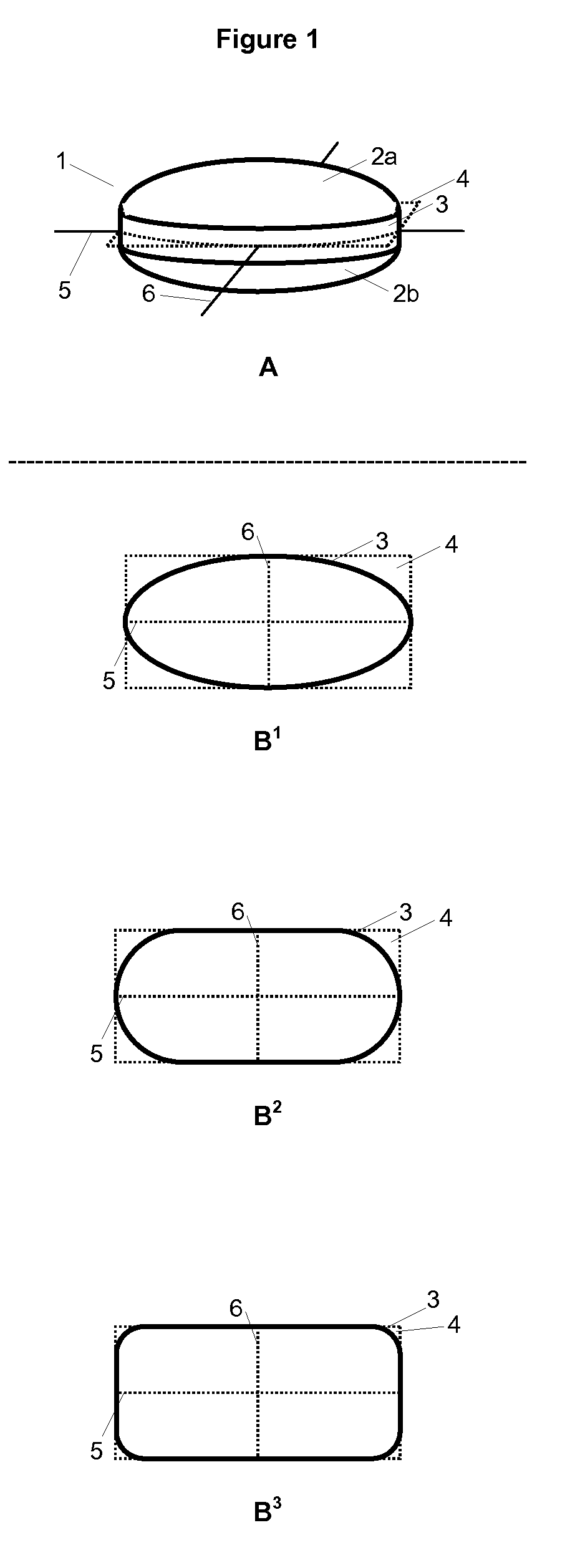

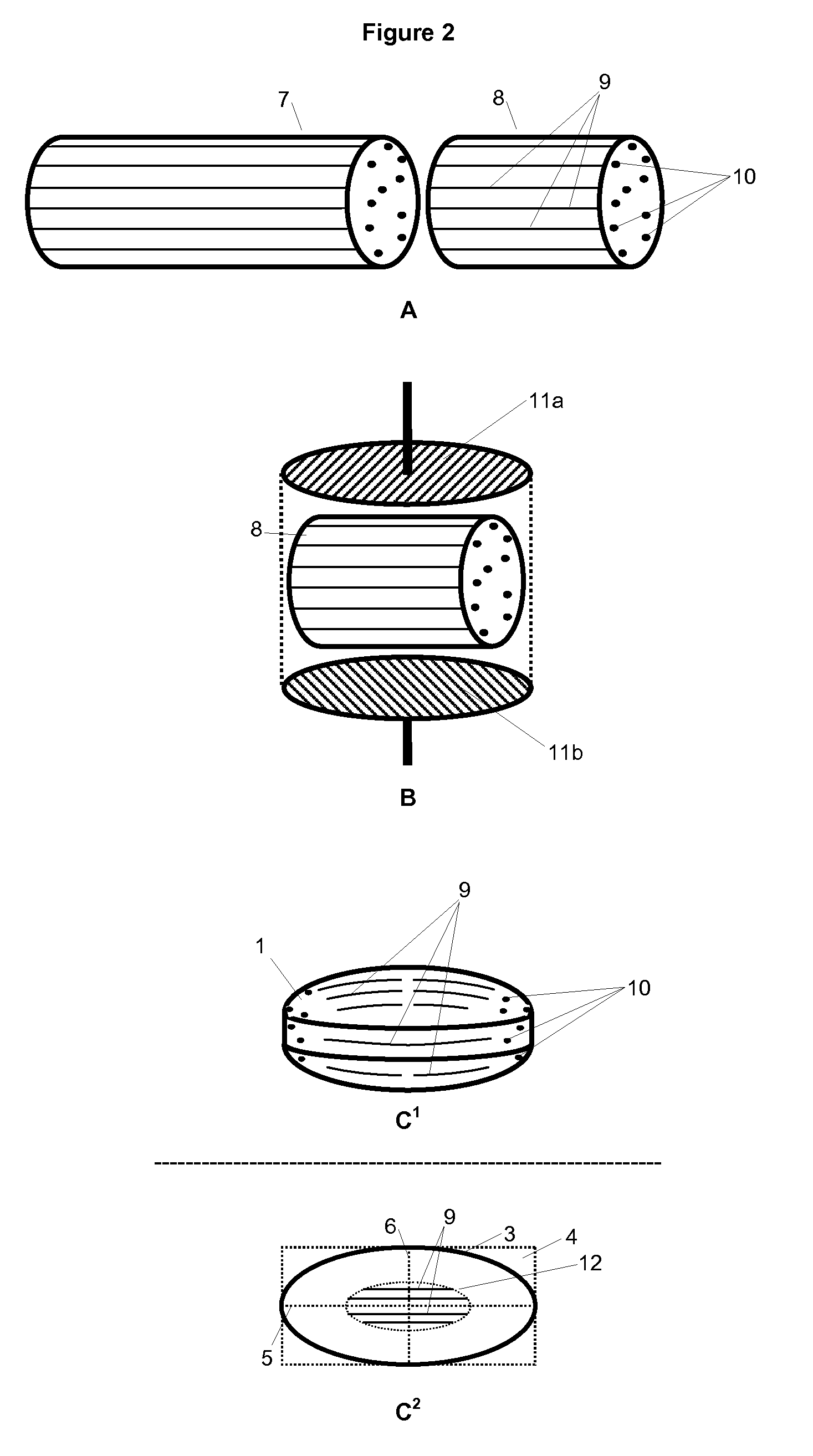

Hot-melt extruded pharmaceutical dosage form

ActiveUS20110038930A1Quick releaseRate of releaseBiocideNervous disorderBreaking strengthControlled release

The invention relates to a hot-melt extruded pharmaceutical dosage form with controlled release of a pharmacologically active ingredient (A) embedded in a matrix comprising a polymer (C), the dosage form exhibiting a breaking strength of at least 300 N and having an oblong shape comprising a longitudinal direction of extension, a transversal direction of extension orthogonal to the longitudinal direction of extension, a front side, an opposite back side and a circumferential rim between said front and back side;whereinthe core of the pharmaceutical dosage form has a morphological orientation caused by hot-melt extrusion that is substantially orthogonal to the longitudinal direction of extension of the dosage form; and / orthe release per area of the pharmacologically active ingredient (A) through the front side and the opposite back side is faster than the release through the circumferential rim.

Owner:GRUNENTHAL GMBH

Effervescent granules and methods for their preparation

InactiveUS6649186B1Improve stabilityParticular regionPowder deliveryNervous disorderHYDROMORPHONE HYDROCHLORIDEAlpha adrenergic blockade

Disclosed here are effervescent granules having a controllable rate of effervescence. In some embodiments, the such granules comprise an acidic agent, an alkaline agent, a pharmacologically active agent, hot-melt extrudable binder capable of forming a eutectic mixture with the acidic agent and, optionally, a plasticizer. The effervescent granules are made by a hot-melt extrusion process. The present invention also provides a thermal heat process for preparing a pharmacologically active agent containing effervescent granule. In certain aspects, the granules contain pharmacologically active agents such as narcotics, antidiarrheal agents, antiviral agents, anxiolytic agents, a cholesterol lowering agent, an alpha adrenergic blocking agent, a phenanthrene derivative. By way of example, some of the narcotics that may be included in the granules and in the process of preparing the granules include, by way of example: phenanthrene derivatives (e.g., morphine sulfate), and morphine derivatives (e.g., hydromorphone hydrochloride).

Owner:ETHYPHARM SA

Effervescent granules and methods for their preparation

InactiveUS6488961B1Improve stabilityParticular regionPowder deliveryBiocideAnesthetic AgentHYDROMORPHONE HYDROCHLORIDE

Disclosed here are effervescent granules having a controllable rate of effervescence. In some embodiments, the such granules comprise an acidic agent, an alkaline agent, a pharmacologically active agent, hot-melt extrudable binder capable of forming a eutectic mixture with the acidic agent and, optionally, a plasticizer. The effervescent granules are made by a hot-melt extrusion process. The present invention also provides a thermal heat process for preparing a pharmacologically active agent containing effervescent granule. In certain aspects, the granules contain pharmacologically active agents such as narcotics, antidiarrheal agents, antiviral agents, anxiolytic agents, a cholesterol lowering agent, an alpha adrenergic blocking agent, a phenanthrene derivative. By way of example, some of the narcotics that may be included in the granules and in the process of preparing the granules include, by way of example: phenanthrene derivatives (e.g., morphine sulfate), and morphine derivatives (e.g., hydromorphone hydrochloride).

Owner:ETHYPHARM SA

Method of forming a photoresist element

InactiveUS20060257785A1Nanostructure manufacturePhotosensitive material auxillary/base layersCoating systemMetallurgy

A method of forming a photoresist element comprising the steps of: preparing a hot melt photoresist mixture; applying the photoimageable hot melt composition to a film substrate using a slot die coating system; cooling the hot melt sufficiently to prevent flow; and applying a protective cover film to the opposite surface of the partially cooled composition, thereby forming a photoresist element.

Owner:MICROCHEM CORP

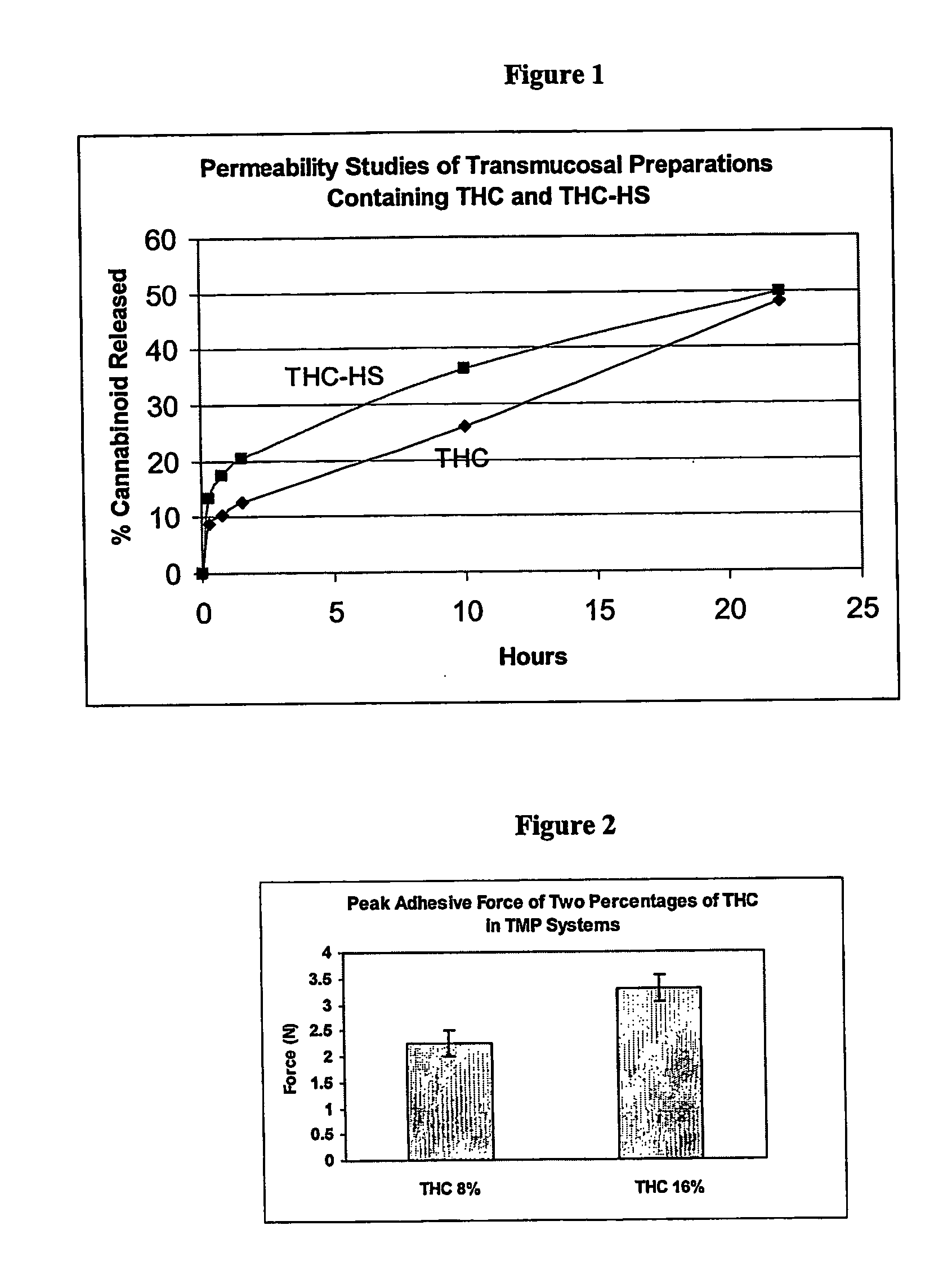

Transmucosal delivery of cannabinoids

InactiveUS20060257463A1Strong tendencyReduced bioavailabilityBiocidePharmaceutical non-active ingredientsCannabisCannabinoid

A method of transmucosally delivering a cannabinoid to a subject in need of such treatment comprising the steps of: administering to the subject a transmucosal preparation containing the cannabinoid wherein said transmucosal preparation is made by incorporating an effective amount of the cannabinoid via hot-melt extrusion technology, hot-melt molding, admixing or a solvent cast technique into a film matrix or a reservoir containing the cannabinoid, and attaching said transmucosal preparation to the mucosa of the subject.

Owner:UNIVERSITY OF MISSISSIPPI

Laminated structures

InactiveUS6887941B2High bonding strengthImproved performance characteristicsControlling laminationSynthetic resin layered productsHot meltAlpha-olefin

Hot-melt, pressure-sensitive adhesive compositions of amorphous polyalphaolefin and crystalline polypropylene have improved bond strength over the amorphous polyalphaolefin alone. The adhesive compositions improve dynamic shear strength, dynamic peel strength, as well as static peel strength. The adhesive compositions are particularly suitable for use in absorbent articles.

Owner:KIMBERLY-CLARK WORLDWIDE INC

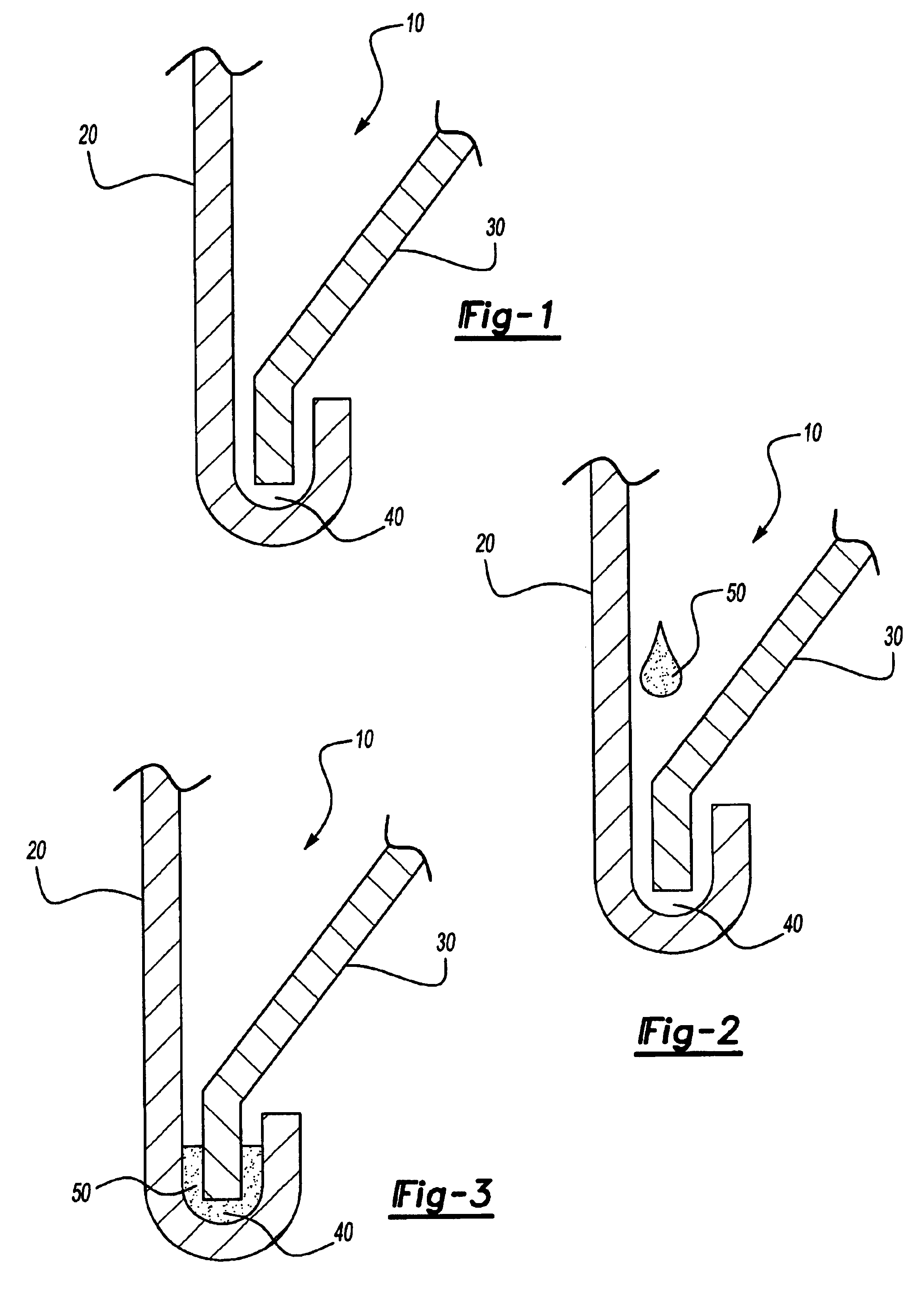

Structural hot melt material and methods

InactiveUS6887914B2Reduce and eliminate stepAvoid corrosionAdhesive processesNon-macromolecular adhesive additivesEpoxyHot melt

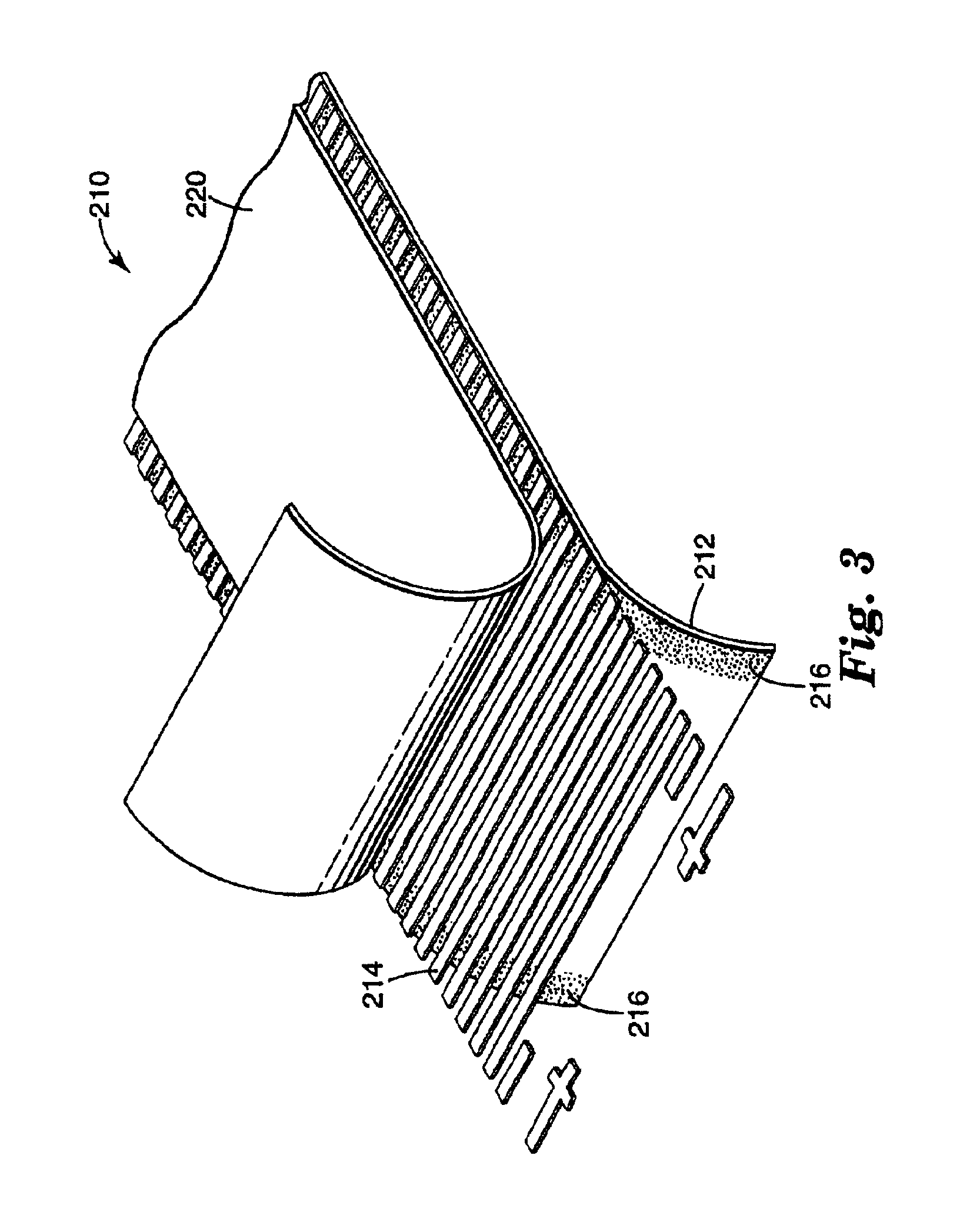

The present invention relates to a material, method, and application for reinforcement of structural members, especially joints such as a hem flange joint of an automobile. The method and material of the present invention comprises of combining, in parts by weight: less than about twenty percent (<20%) ethylene copolymer, less than about forty percent (<40%) epoxy, less than about thirty percent (<45%) epoxy-based resin, less than about two percent (<2%) blowing agent and from about one percent (1%) to about five percent (5%) curing agent (and optionally add any of the following components: less than about two percent (<2%) curing agent accelerator, from about twenty-five percent (25%) to fifty-five percent (55%) filler, and less than about one percent (<1%) of coloring agent). The application of the present invention comprises of: (1) providing a structural member having two substrates forming a space to be joined; (2) placing the material of the present invention in proximity of the space to be joined; (3) exposing the material to a heat source causing it to flow, fill, and cure in the defined area or space to be joined.

Owner:ZEPHYROS INC

Devices, compositions, and methods incorporating adhesives whose performance is enhanced by organophilic clay constituents

InactiveUS6884833B2Faster build-upImprove adhesionPrinted circuit assemblingNon-insulated conductorsOrganoclayHot melt

Incorporating organophilic clay into hot melt adhesive compositions, particularly those comprising semi-crystalline, thermoplastic polymers, greatly improves the adhesive properties in many respects. Some of these improvements are particularly beneficial to the specific use of hot melt adhesives filled with electrically conductive particles for use as electrically conductive adhesives.

Owner:3M INNOVATIVE PROPERTIES CO

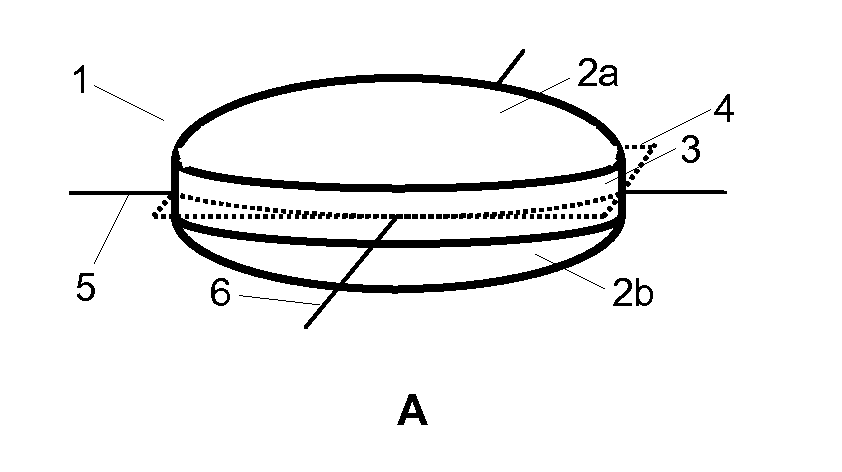

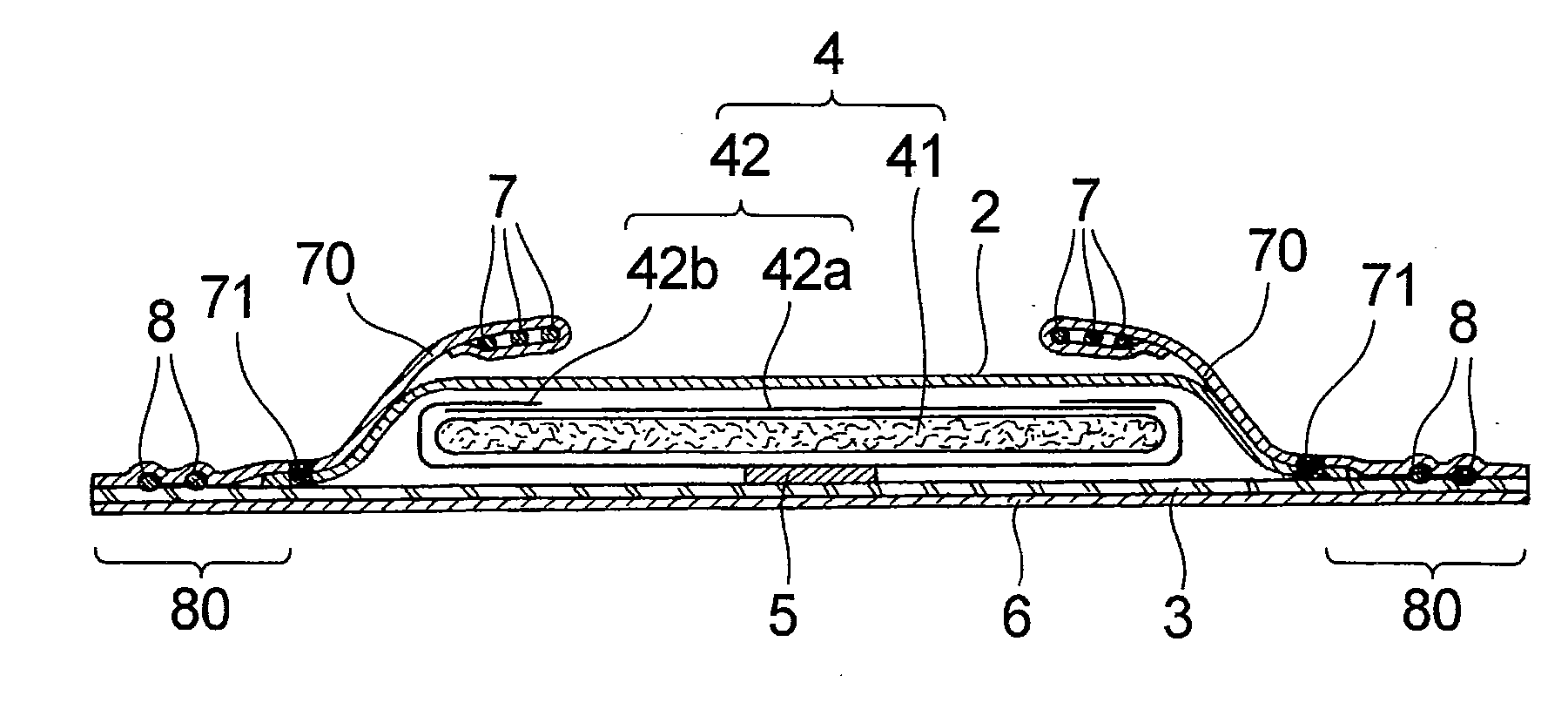

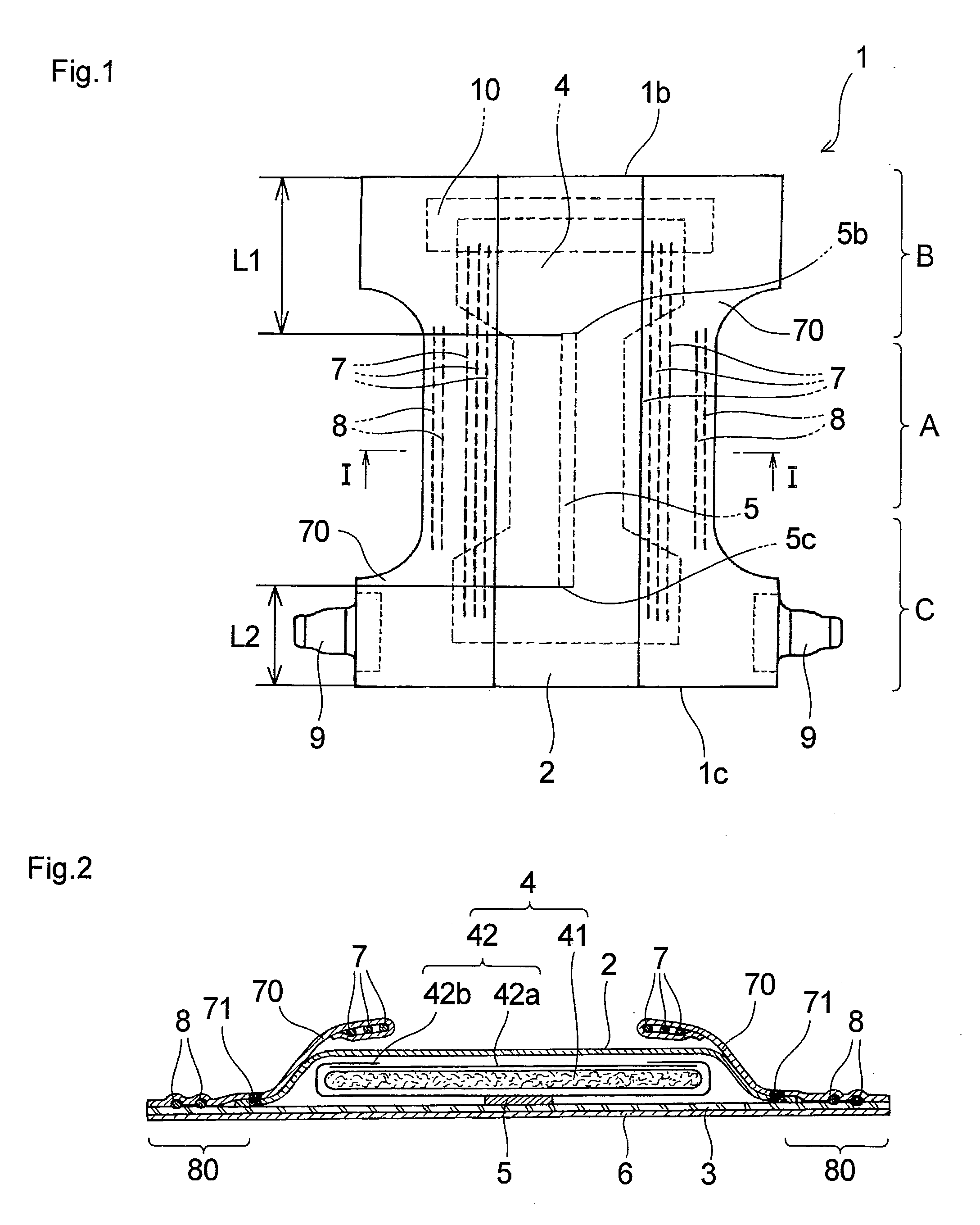

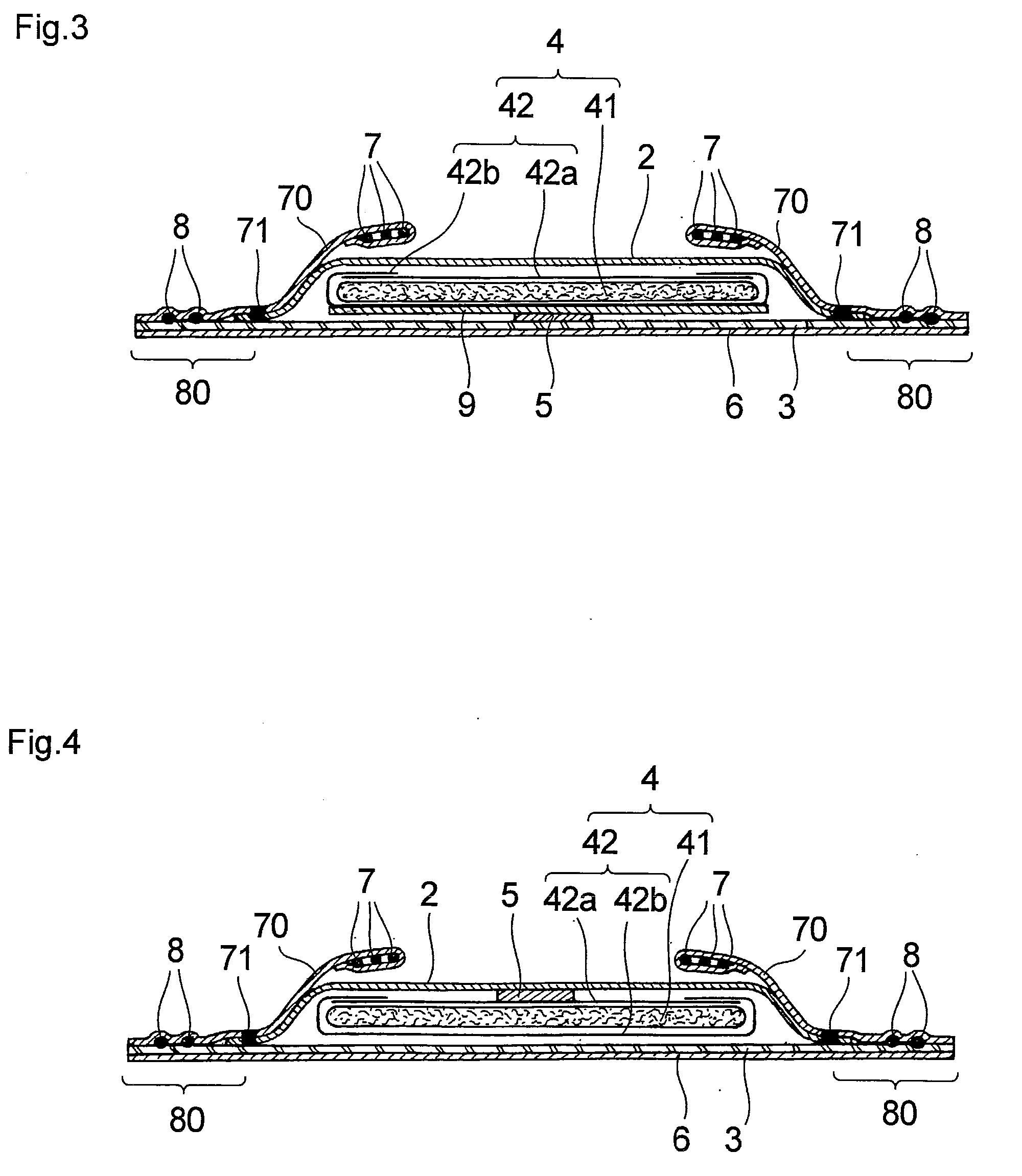

Absorbent article

A wetness indicator composition contains (a) 0.1% to 5% by weight of a pH indicator that is substantially colorless at pH 7 and develops a color in an acidic environment, (b) 20% to 90% by weight of a surfactant, (c) 5% to 55% by weight of a polyalkylene glycol, (d) 0% to 70% by weight of a polymer having a carboxyl group, and (e) 0.1% to 5% by weight of an acidic substance other than components (b) and (d). In an absorbent article including a topsheet 2, a backsheet 3, and an absorbent member 4 interposed between the topsheet 2 and the backsheet 3 and having applied thereon a hot-melt composition that changes color on contact with a body fluid, the wetness indicator composition is used as the hot melt composition.

Owner:KAO CORP

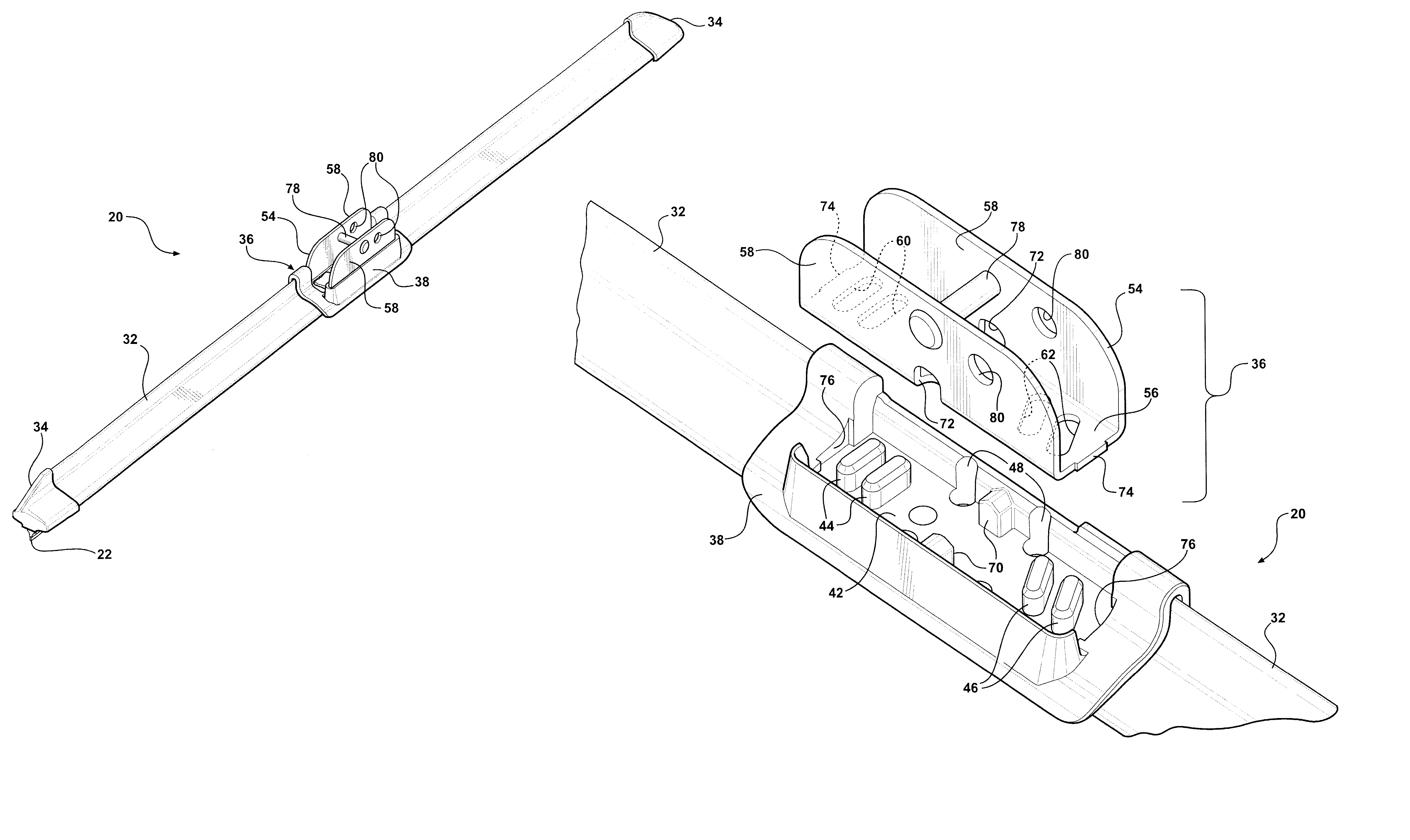

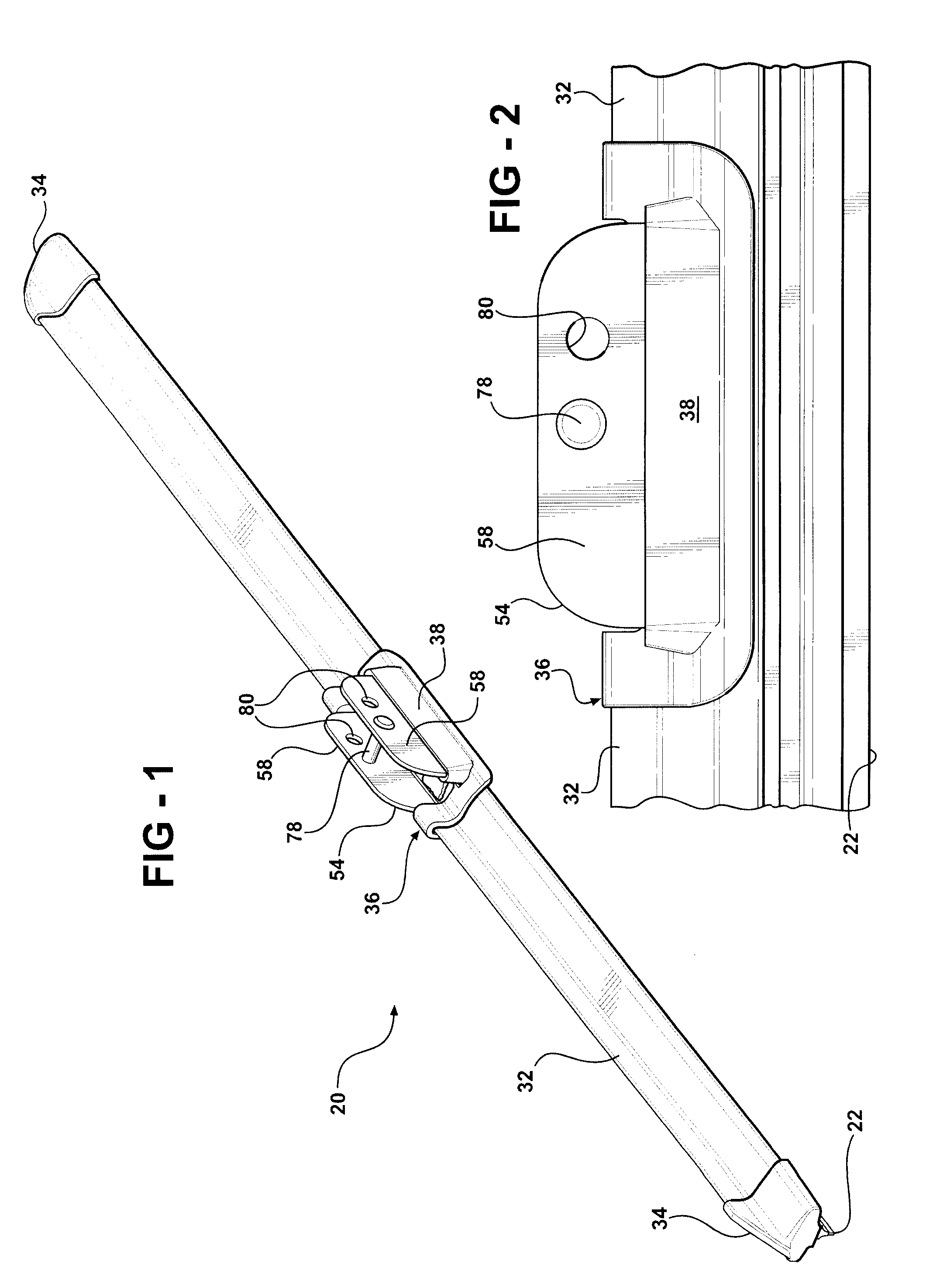

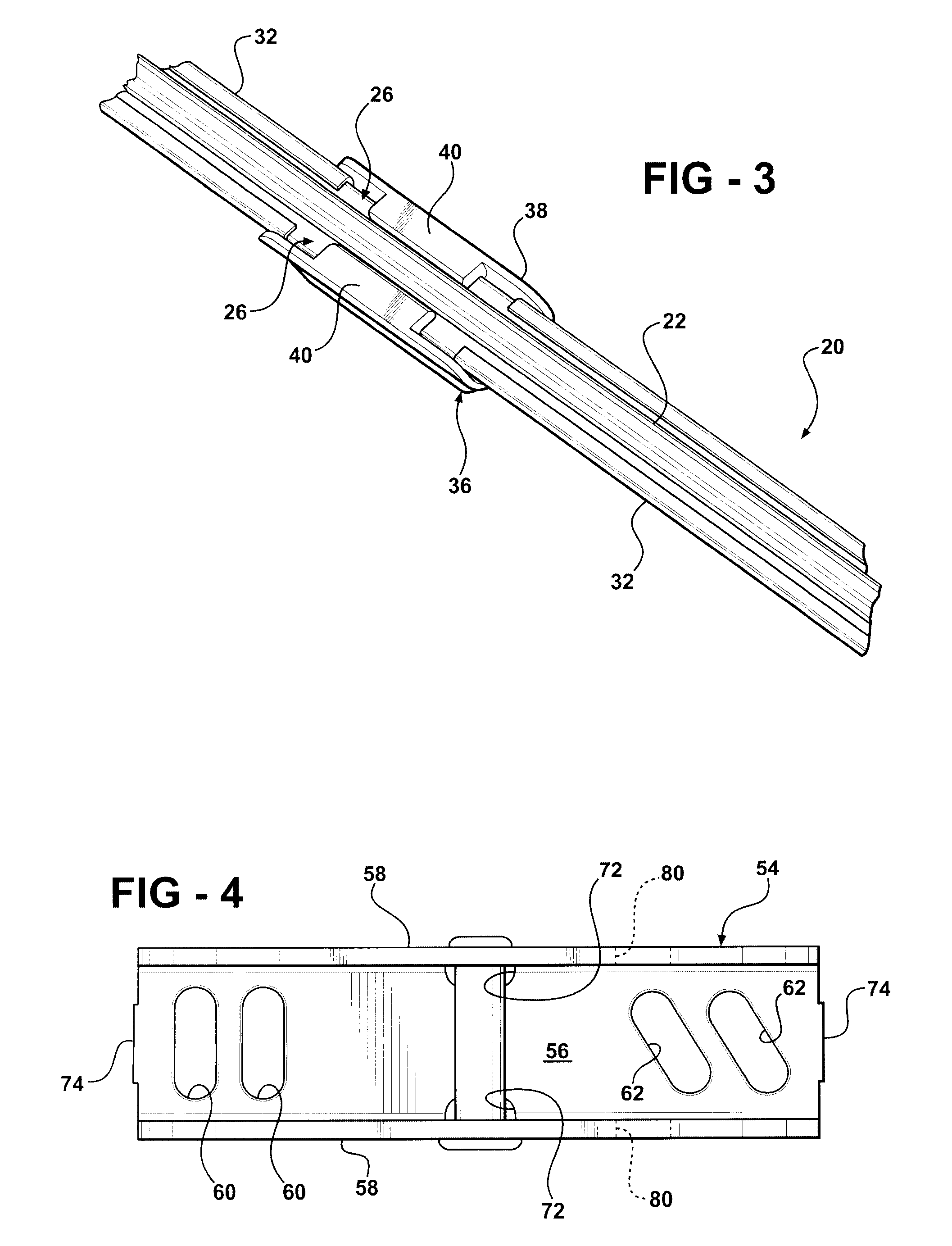

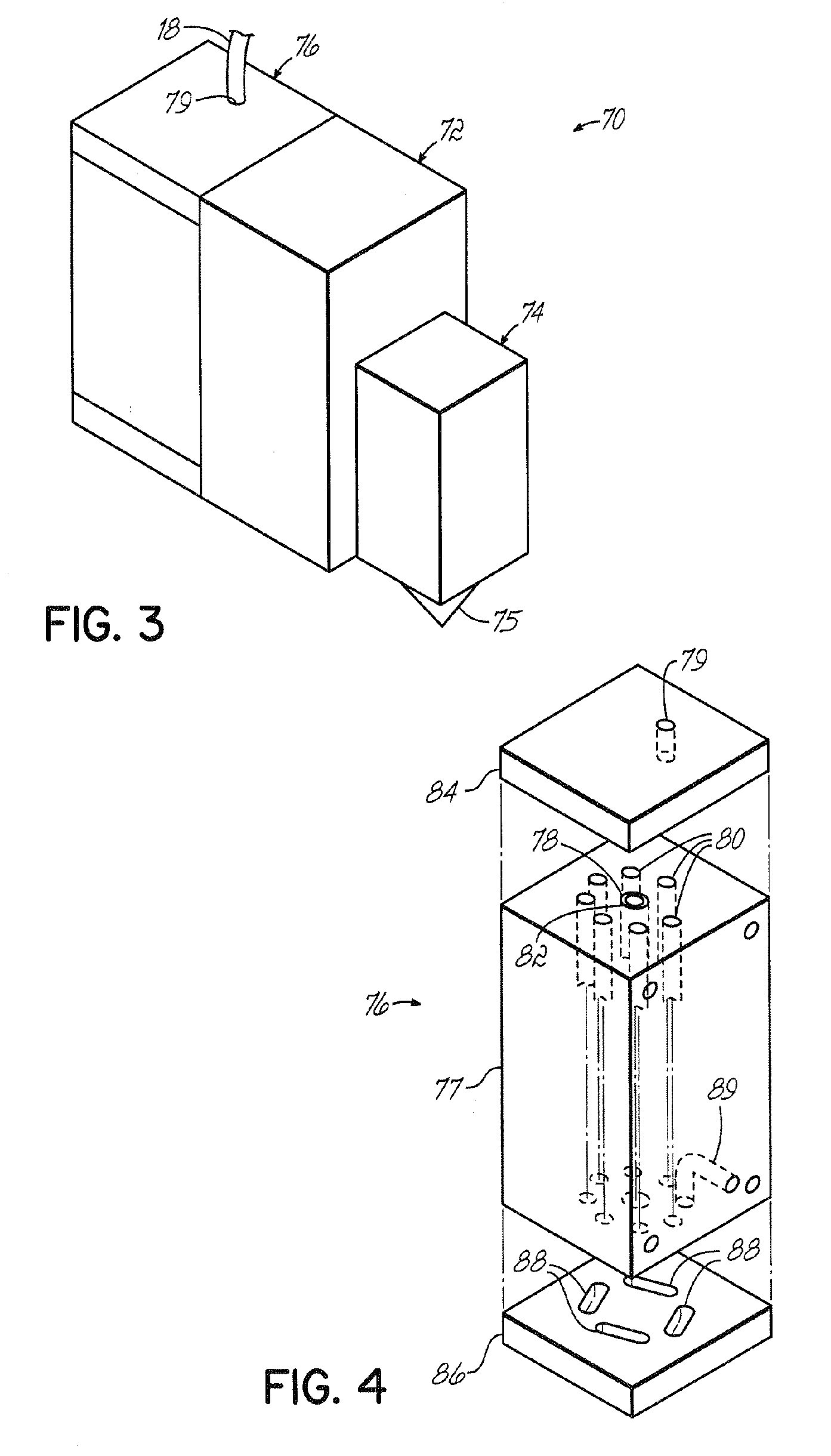

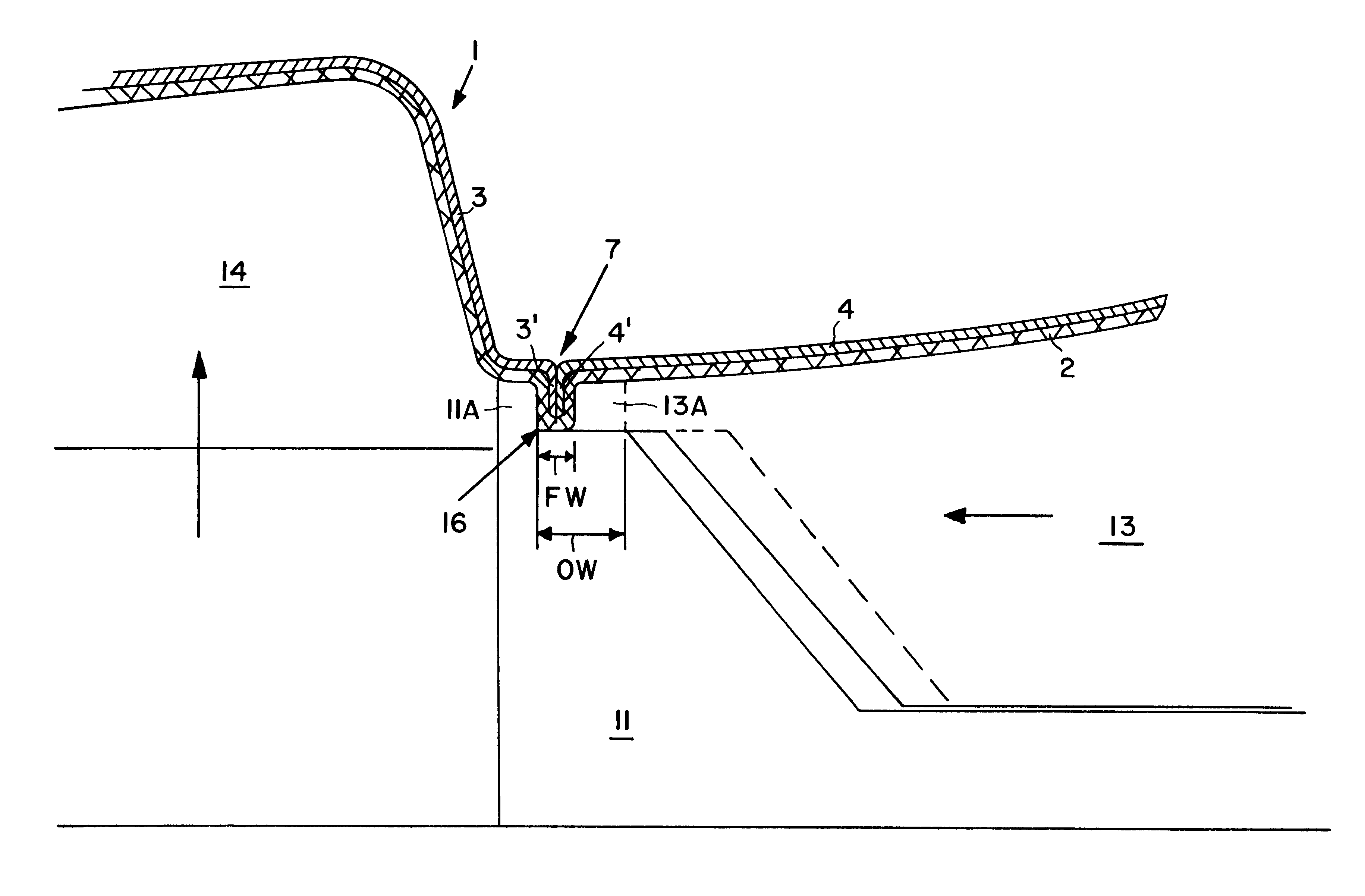

Two-piece connector for flat blade windshield wiper

ActiveUS7523522B2Easy to manufactureEasy to assembleWindow cleanersVehicle cleaningUltrasonic weldingHot melt

A central connecting device (36) for a flat blade style wiper blade assembly (20) includes a plastic intermediate base (38) that is fixed, such as by ultrasonic welding, to a pair of flexors (26) extending the length of the wiper blade assembly (20). The intermediate base (38) includes a recessed deck section (42) for receiving a metallic housing (54). The housing (54) is heat-staked in position to the intermediate base (38) to secure the two elements together as an integral unit. A rivet (78) extends transversely across the sidewalls (58) of the housing (54) for adjoining to a universal connector (82) or other suitable adaptor or by direction connection to the end of a wiper arm.

Owner:TRICO PROD CORP

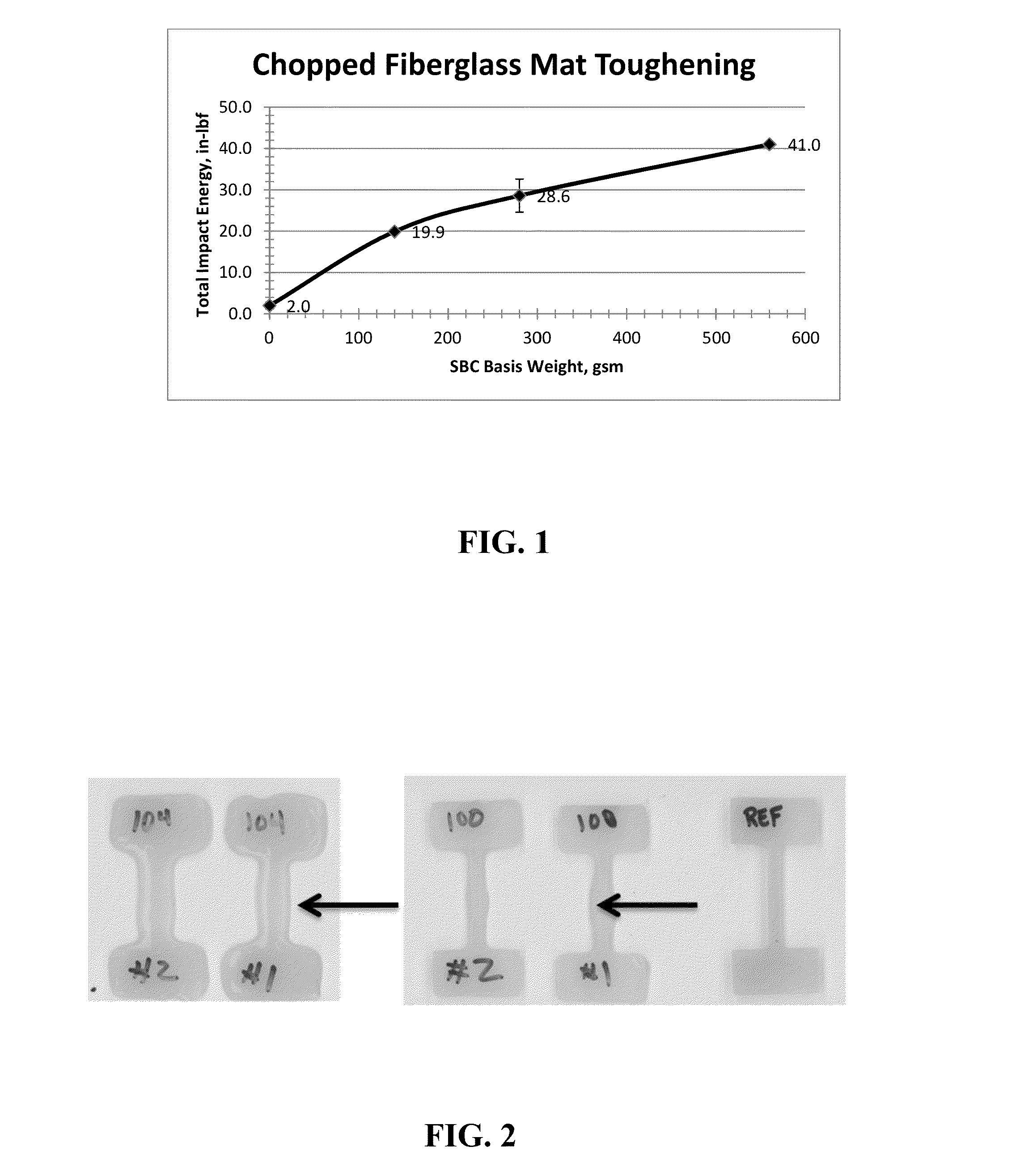

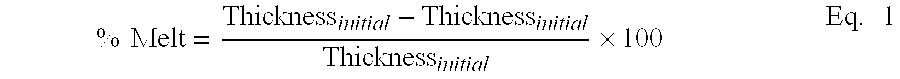

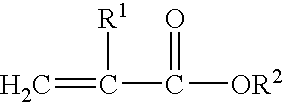

High flow, hydrogenated styrene-butadiene-styrene block copolymer and applications

The invention relates to unique applications for the novel high melt flow, low viscosity, selectively hydrogenated styrene-butadiene-styrene (hSBS) or selectively hydrogenated controlled distribution styrene-butadiene / styrene-styrene (hSBSS) block copolymers, wherein the melt flow rate of said block copolymer is at least 100 g / 10 min at 230° C. under 2.16 kg mass according to ASTM D1238. These block copolymers are novel and have the highest melt flow rate of any styrenic block copolymer also possessing high strength and elasticity. It has applications that prior to the present invention were not normally possible due to the normal low melt flow rate of styrenic block copolymers. The present invention also encompasses various fields of use such as a fiberglass hSBS or hSBSS reinforced mat, low viscosity hSBS or hSBSS coatings for industrial uses, hot melt adhesives prepared from hSBS or hSBSS blended with polyalpha-olefins, and elastic film, fiber, and nonwoven constructions using hSBS or hSBSS.

Owner:KRATON POLYMERS US LLC

Hot melt sealant and foam-in-place gasketing material

ActiveUS20070042193A1Good balance of propertyImprove adhesionSynthetic resin layered productsOrganic dyesPolymer scienceSealant

A hot melt sealant and foam-in-place gasket composition based on a rubber such as ethylene propylene rubber (EPR) and / or ethylene propylene diene rubber (EPDM) and at least one semicrystalline olefinic polymer. The hot melt composition includes the rubber or a blend of rubbers in an amount of 5% to 50% by weight, at least one semicrystalline olefinic polymer in an amount of 5% to 40% by weight, at least one amorphous poly-α-olefin (APAO) polymer in an amount of 0% to 70% by weight, a compatible tackifier in an amount of 0% to 50% by weight, and a plasticizer in an amount of at least 30% by weight. The composition is particularly useful for foamed gasket applications as a replacement for pressure sensitive adhesive (PSA) coated foam tape.

Owner:BOSTIK INC

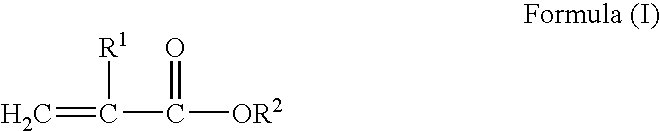

Block copolymer hot-melt processable adhesives, methods of their preparation, and articles therefrom

Hot-melt processable adhesive, such as pressure-sensitive-adhesive (PSA) or heat-activatable adhesive, compositions of the present invention possess a broad formulation latitude and adequate cohesive strength after application for use in high performance applications. Hot-melt processable adhesives of the invention comprise at least one block copolymer comprising at least two A blocks and at least one B block. The A and B blocks are derived from monoethylenically unsaturated monomers, which monomers result in saturated polymer backbones without the need for subsequent hydrogenation upon their polymerization. Preferably, the block copolymer is a (meth)acrylate block copolymer.

Owner:3M INNOVATIVE PROPERTIES CO

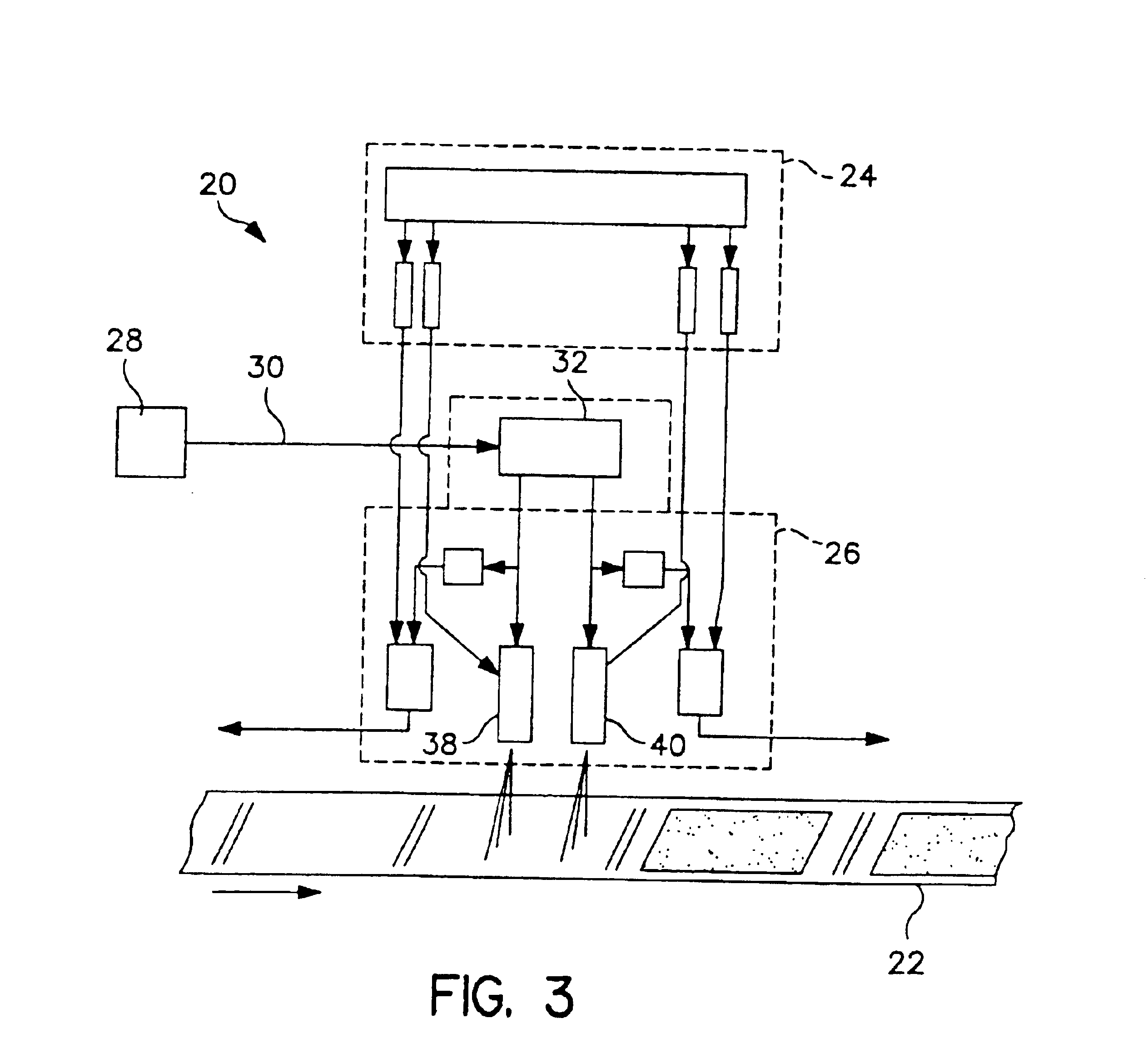

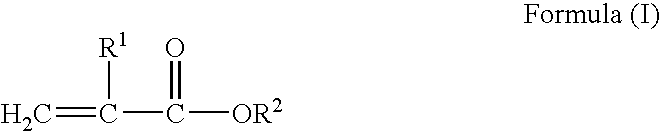

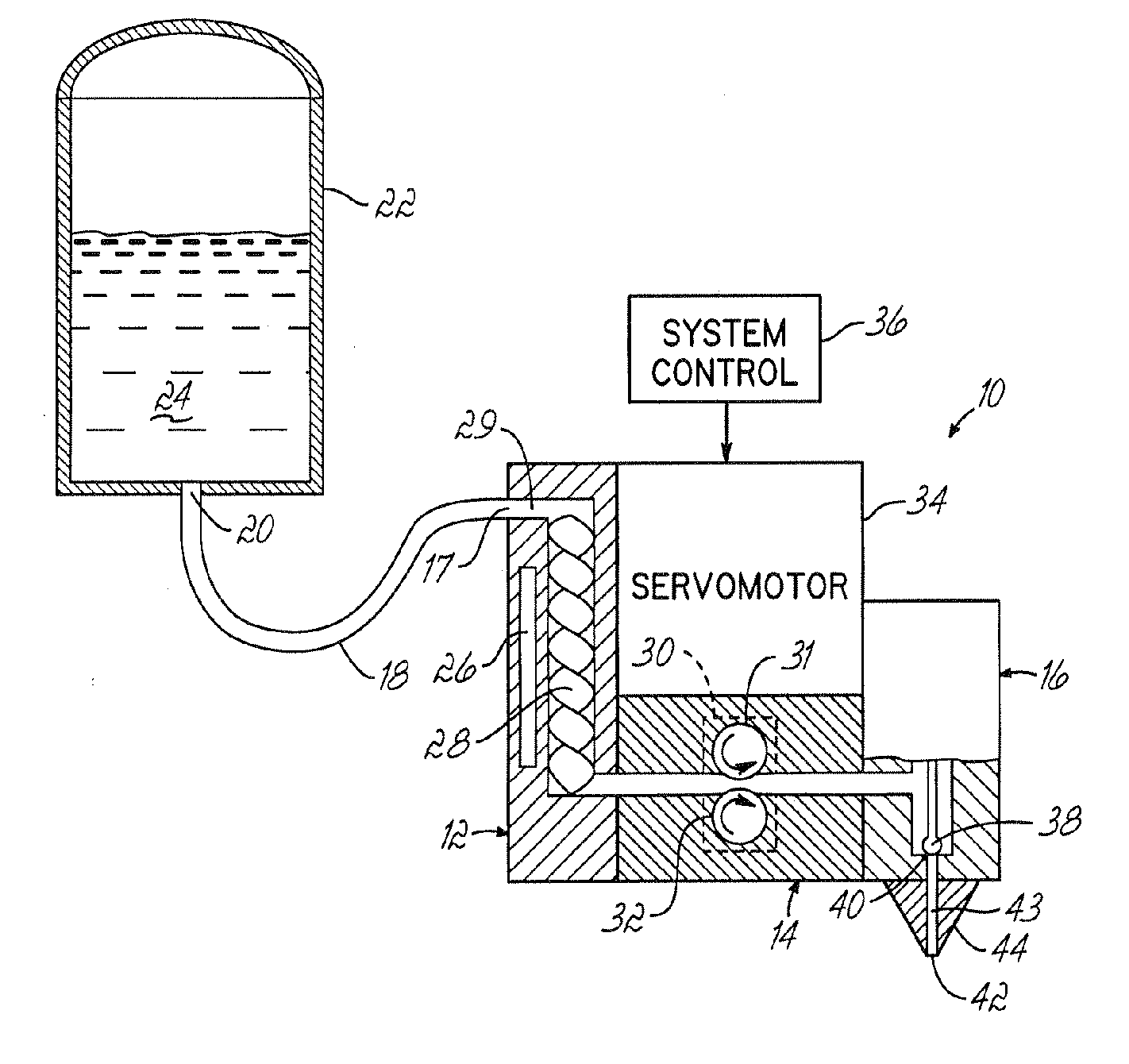

Applicators for liquid hot melt adhesive and methods of applying liquid hot melt adhesive

InactiveUS20050230423A1First viscosity is relatively lowLiquid surface applicatorsManual label dispensersPressure dependenceHot melt

Applicators and dispensing systems for dispensing liquid hot melt adhesives and methods of dispensing liquid hot melt adhesives. The dispensing system supplies the liquid hot melt adhesive in a non-activated state to the applicator. The liquid hot melt adhesive is processed to modify at least one activation-sensitive property before dispensing onto a substrate. The property may exhibit a temperature dependence, in which case the applicator or other structure near the applicator heats the liquid hot melt adhesive immediately before application. The property may exhibit a pressure dependence, in which case the applicator or other structure near the application applies pressure and / or shear forces to the liquid hot melt adhesive shortly before dispensing. Alternatively, a property that is both temperature and pressure dependent may be modified.

Owner:RINEY JOHN M +2

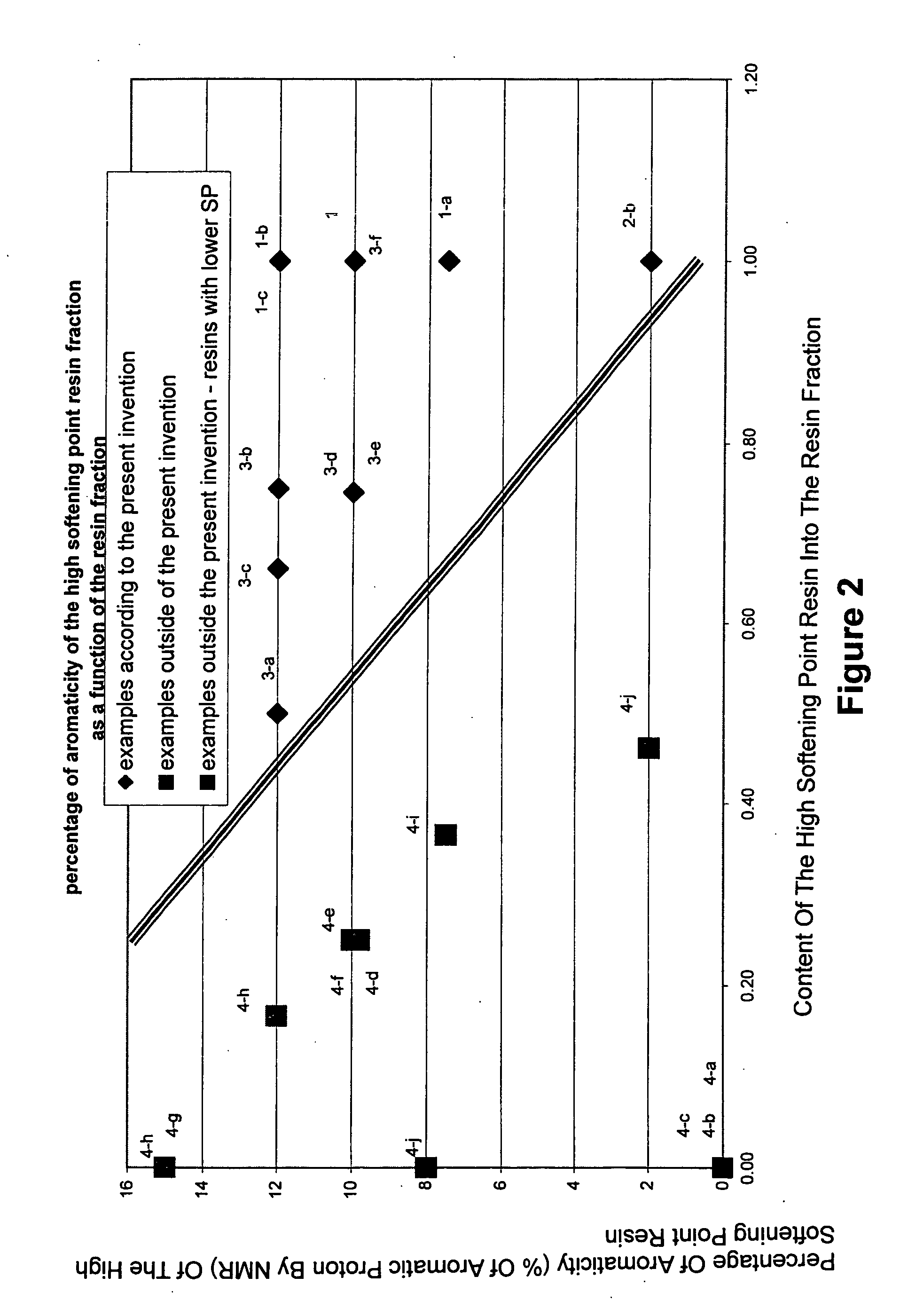

Low application temperature hot melt adhesive

InactiveUS20070088116A1High bond strength levelSame level of performanceAbsorbent padsAdhesivesElastomerCardboard

A hot melt adhesive composition, comprising a blend of components including about 10% to about 40% by weight of an elastomeric block copolymer, preferably styrene-isoprene-styrene (SIS) or styrene-butadiene-styrene (SBS), about 15% to about 70% by weight of a first midblock tackifying resin having a softening point of at least about 110° C. and having an aromatic content of at least about 1.5% by weight; about 0 to 55% of second midblock tackifying resin, about 5% to about 35% by weight of a plasticizer; and about 0% to about 20% by weight of an end block resin having a softening point lower than 125° C.; wherein the components total 100% by weight of the composition, the viscosity of the composition is equal to or less than about 20,000 mPa.s at 120° C., and is applied at a temperature lower that 150° C. and initial bond retention of the composition on elastic strands is at least about 60%. Also, the elastic modulus G′ of the composition is higher than about 5000 Pa, the vicous modules G″ is higher than about 50 Pa, and the tan delta value is between about 0.5 and about 60. Laminates, especially those used in disposable soft goods, and methods of making such laminates are also described. The adhesive composition and / or laminate may be used in making a variety of end products such as a disposable diaper, a sanitary napkin, a bed pad, a bandage, a surgical drape, a tape, a label, a plastic sheet, a nonwoven sheet, a paper sheet, a cardboard, a book, a filter, or a package.

Owner:BOSTIK INC

Hot melt pressure sensitive adhesives based on blends of styrene/butadiene copolymers

Hot melt pressure sensitive adhesives useful in a wide range of end-use applications may be formulated without the use of isoprene-containing polymers using combinations of different styrene / butadiene copolymers including at least one S-B-S triblock copolymer.

Owner:HENKEL CORP

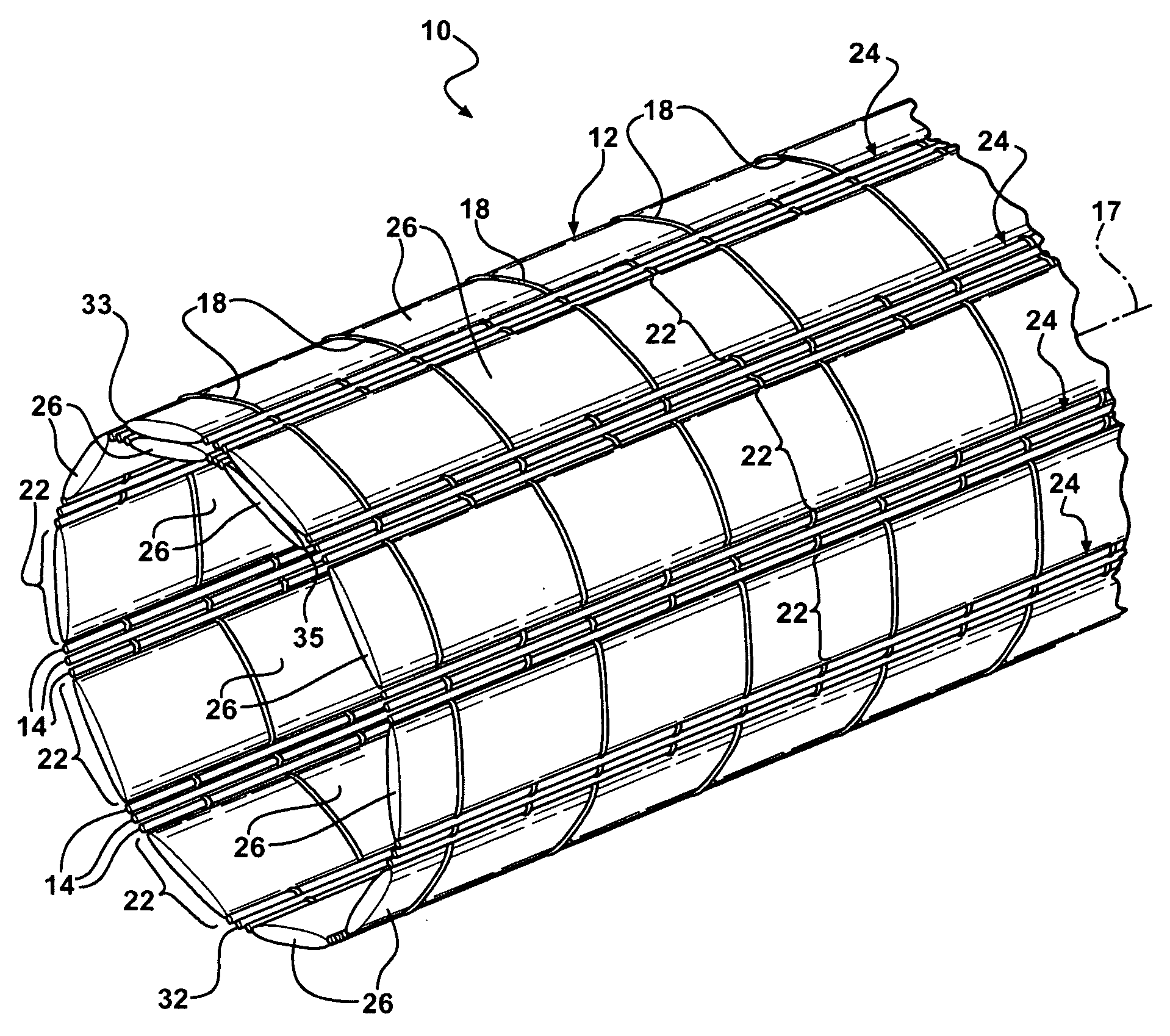

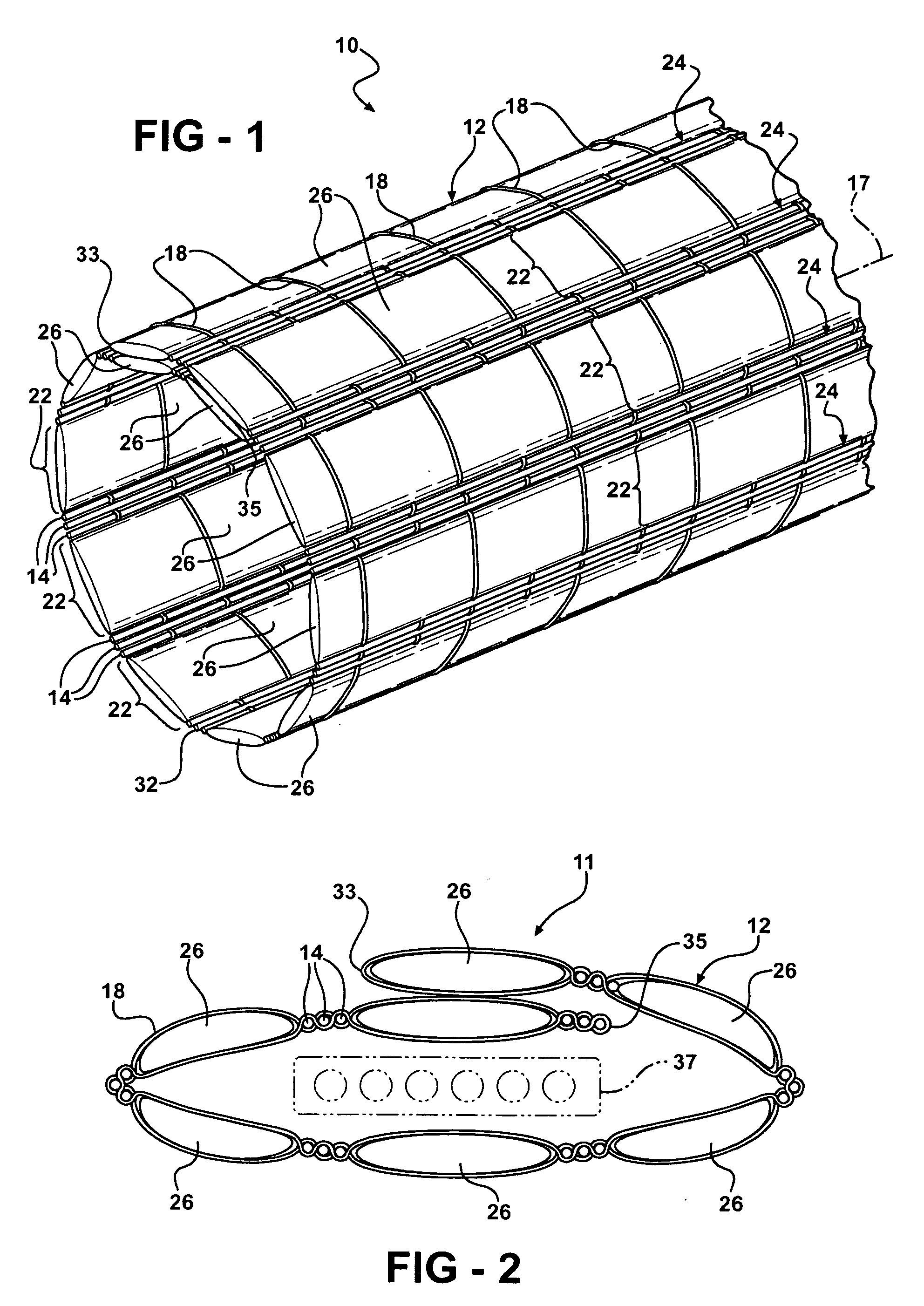

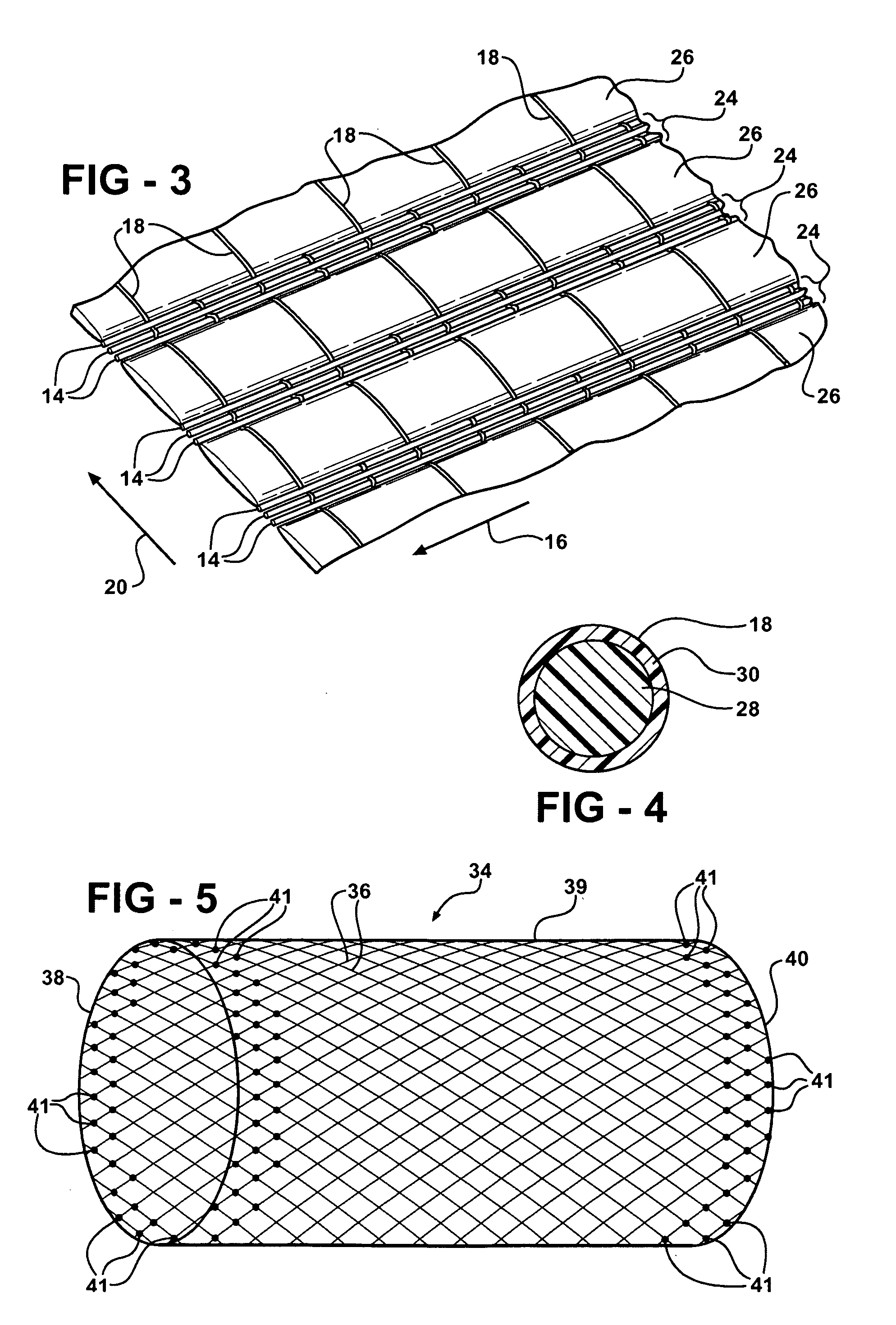

Fabric for end fray resistance and protective sleeves formed therewith and methods of construction

ActiveUS20070166495A1Prevent the sleeve from frayingElectrical apparatusPedestrian/occupant safety arrangementHot meltEngineering

An elongated protective textile sleeve for protecting elongate members and methods of constructing a fabric substrate therefore. The fabric substrate has a plurality of filamentary members either woven, knitted or braided with one another. At least some of the filamentary members of the substrate extend to cut edges and are fabricated of a multi-component material that includes a core of a first polymeric material and an outer sheath of a second polymeric material. The outer sheath is heat-fusible and the inner core is heat-settable. The outer sheaths of the filamentary members are heat fused at least in the regions near the cut edges to keep the cut edges from fraying or the filamentary members from pulling out of the substrate. The core is heat set to form the desired shape of the protective sleeve.

Owner:FEDERAL MOGUL WORLD WIDE LLC

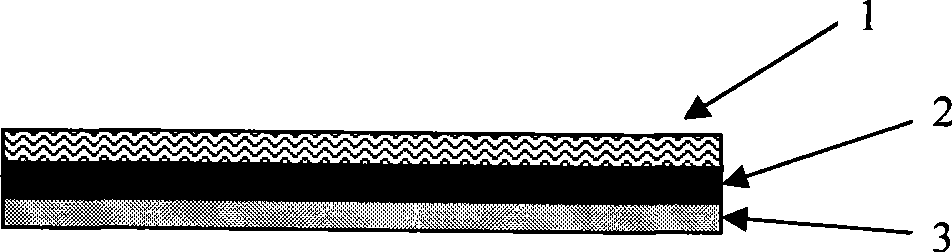

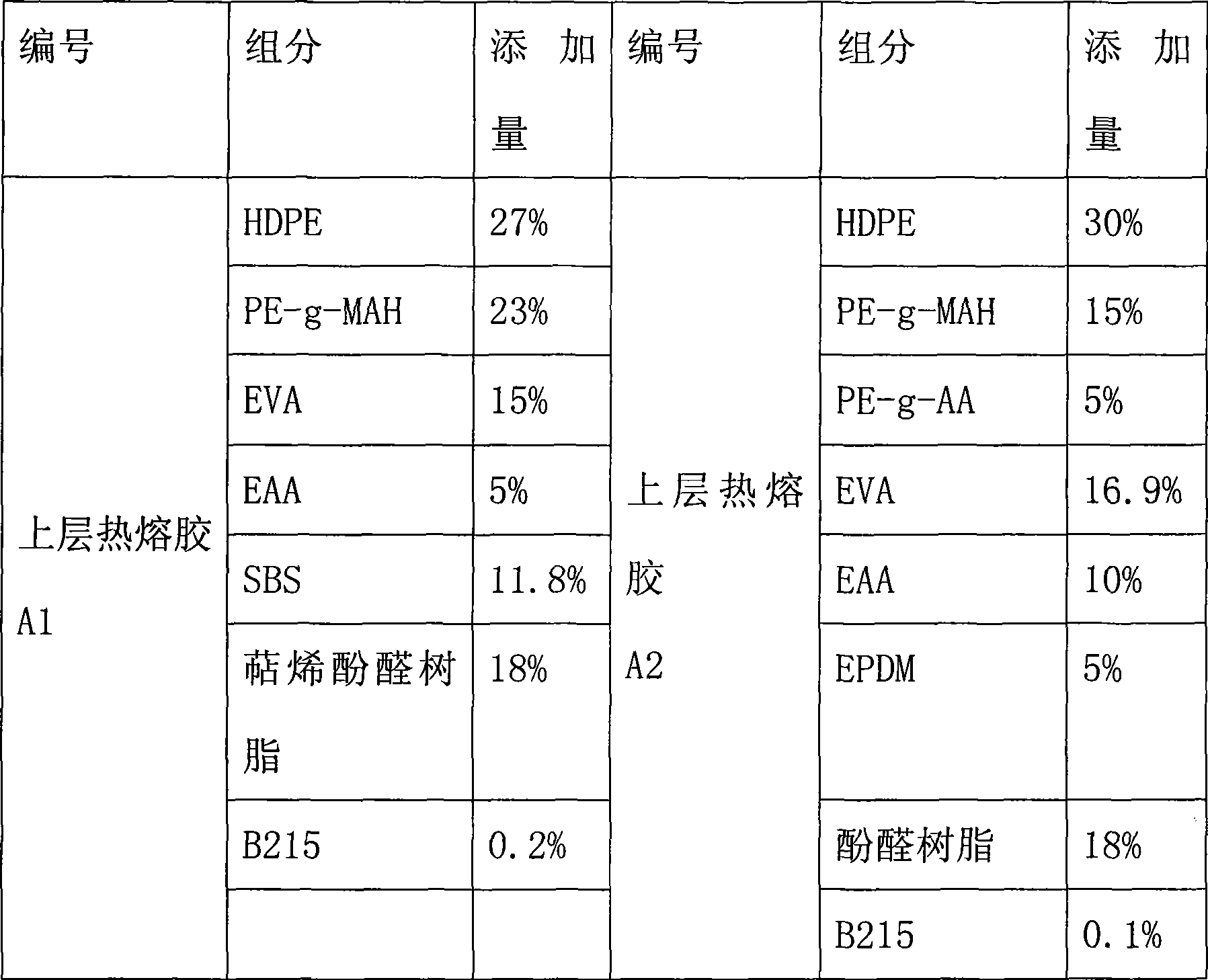

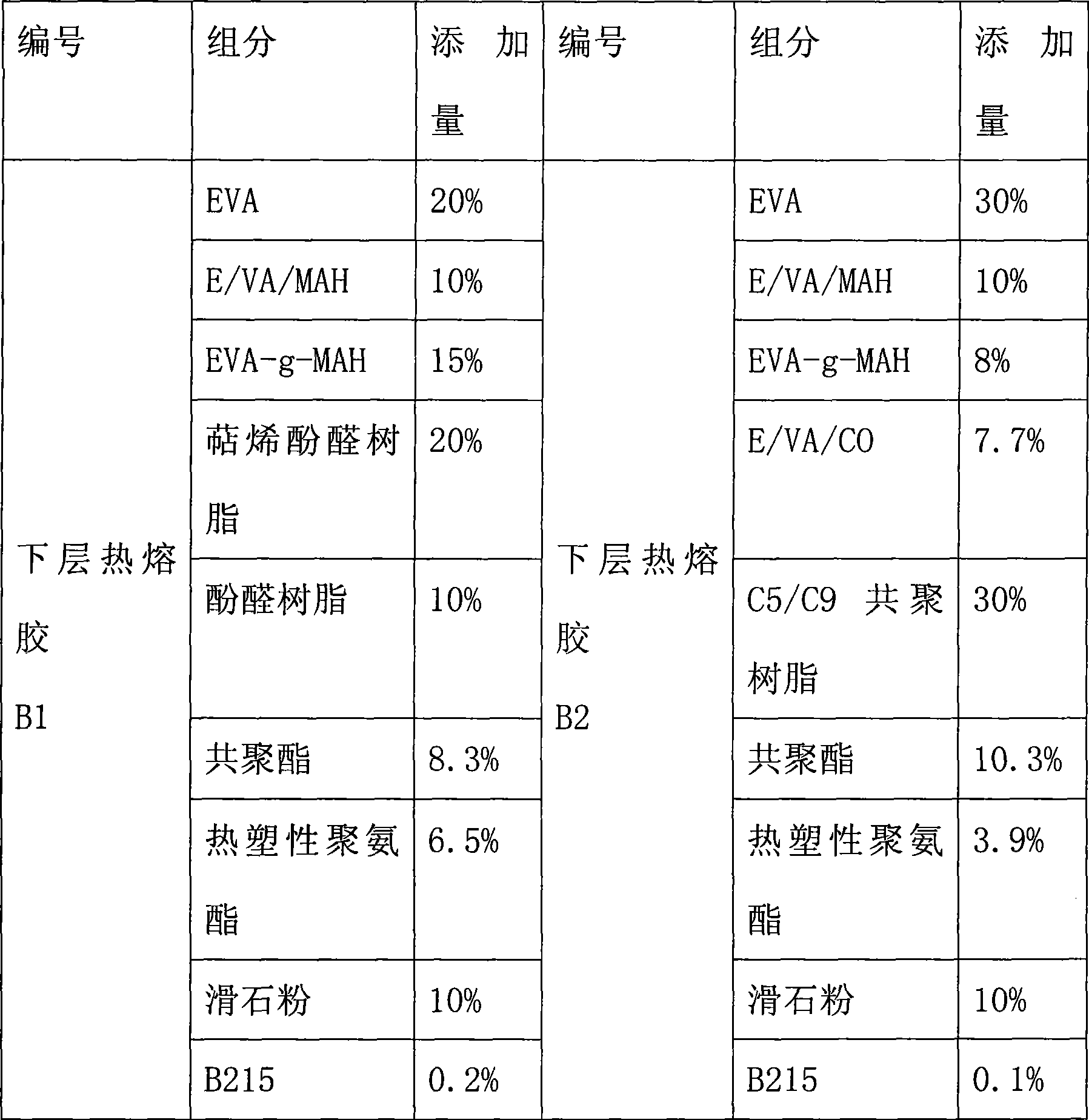

Double-layer composite hot melt adhesive film for bonding metal and plastic

The invention discloses a double-layer composite hot melt adhesive film adhering metal and plastic, which is formed by compounding an upper adhesive film layer and a lower adhesive film layer, wherein the lower adhesive film layer is attached to a piece of release paper, the thickness of the composite adhesive film is 0.05 to 0.20 millimeter, the upper adhesive film layer is a hot melt adhesive layer adhered with the metal, the thickness of the upper adhesive film layer is 30 to 60 percent of the thickness of the composite film, the lower adhesive film layer is a hot melt adhesive layer adhered with the plastic, the thickness of the lower adhesive film layer is 40 to 70 percent of the thickness of the composite film, and the lower adhesive film layer is attached to a piece of glassine release paper. The double-layer composite hot melt adhesive film directly compounds two modified hot melt adhesives with different adhesive properties, is adhered with the release paper to prevent rolling from adhering and the adhesive film from being damaged, reduces application of a middle isolating layer, reduces the thickness of the composite adhesive film, and is prepared by once casting through coextrusion casting equipment or twice casting through common coextrusion casting equipment. The double-layer composite hot melt adhesive film can be used for composite adhesion of metallic materials such as aluminum, stainless steel and the like and plastic such as ABS, PVC, PET and the like, is particularly suitable for mutual adhesion between sheets, plates and films of the metal and the plastic, and has simple and convenient operation and no pollution.

Owner:GUANGZHOU LUSHAN NEW MATERIALS

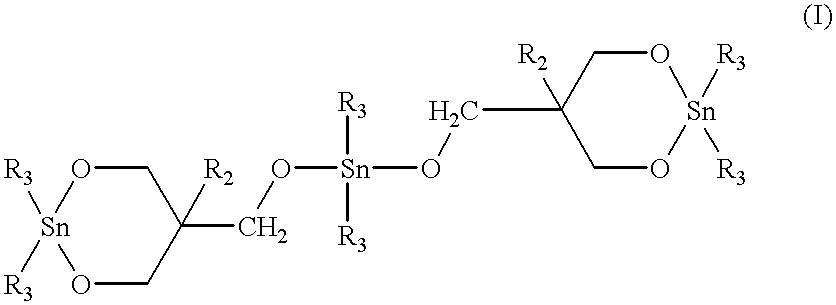

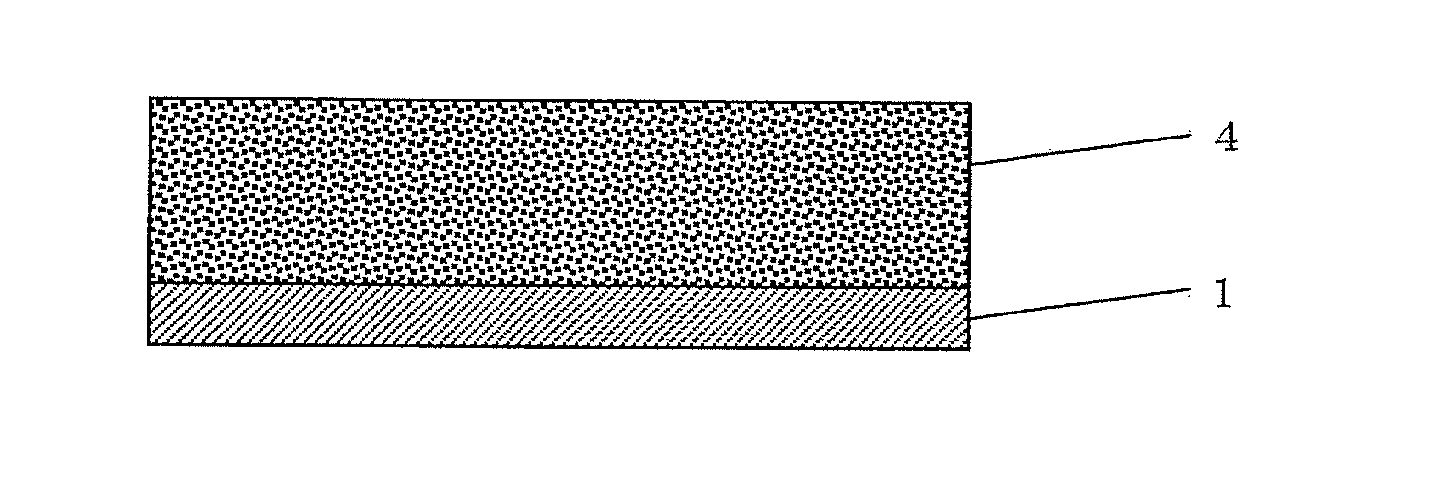

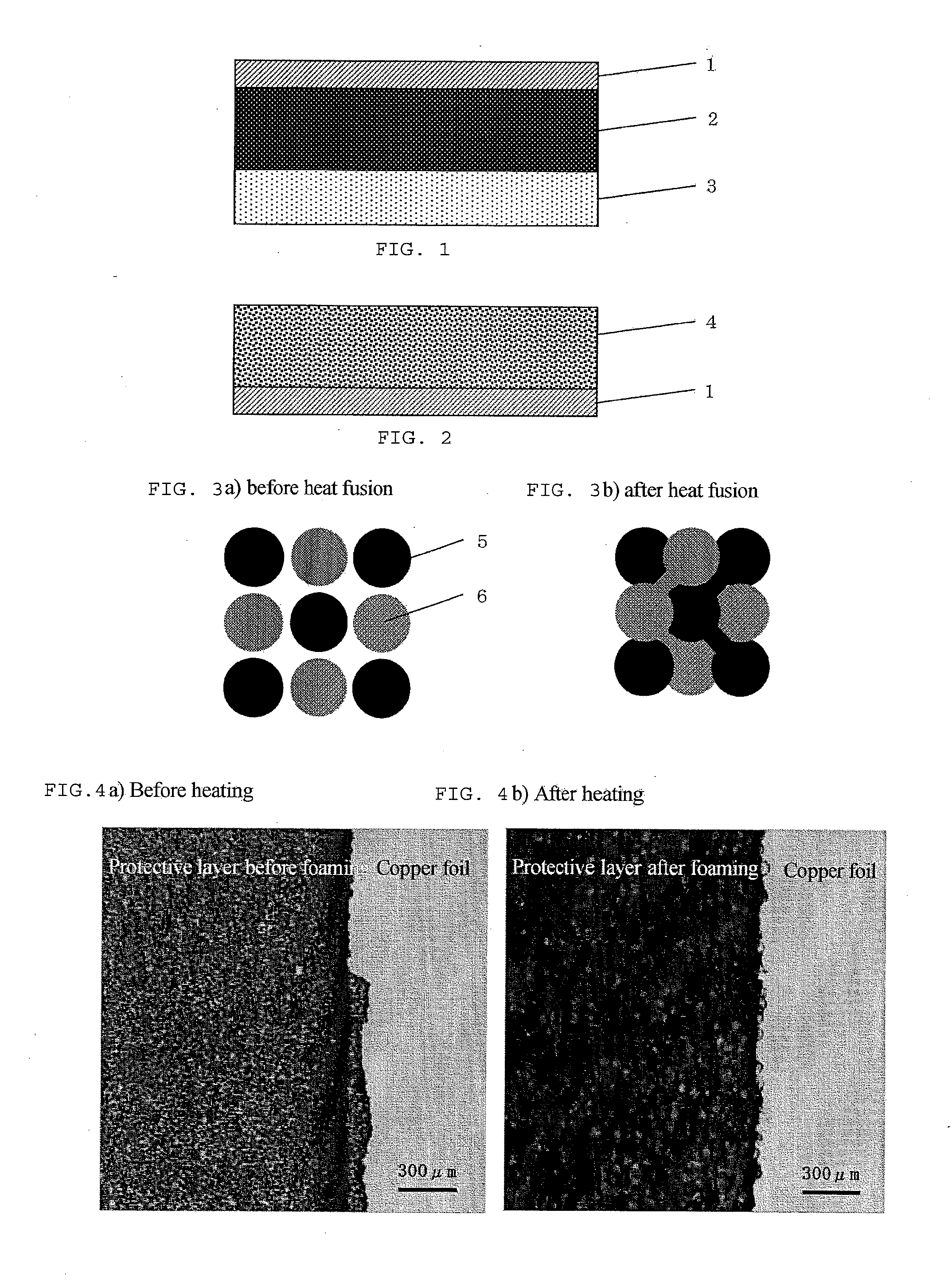

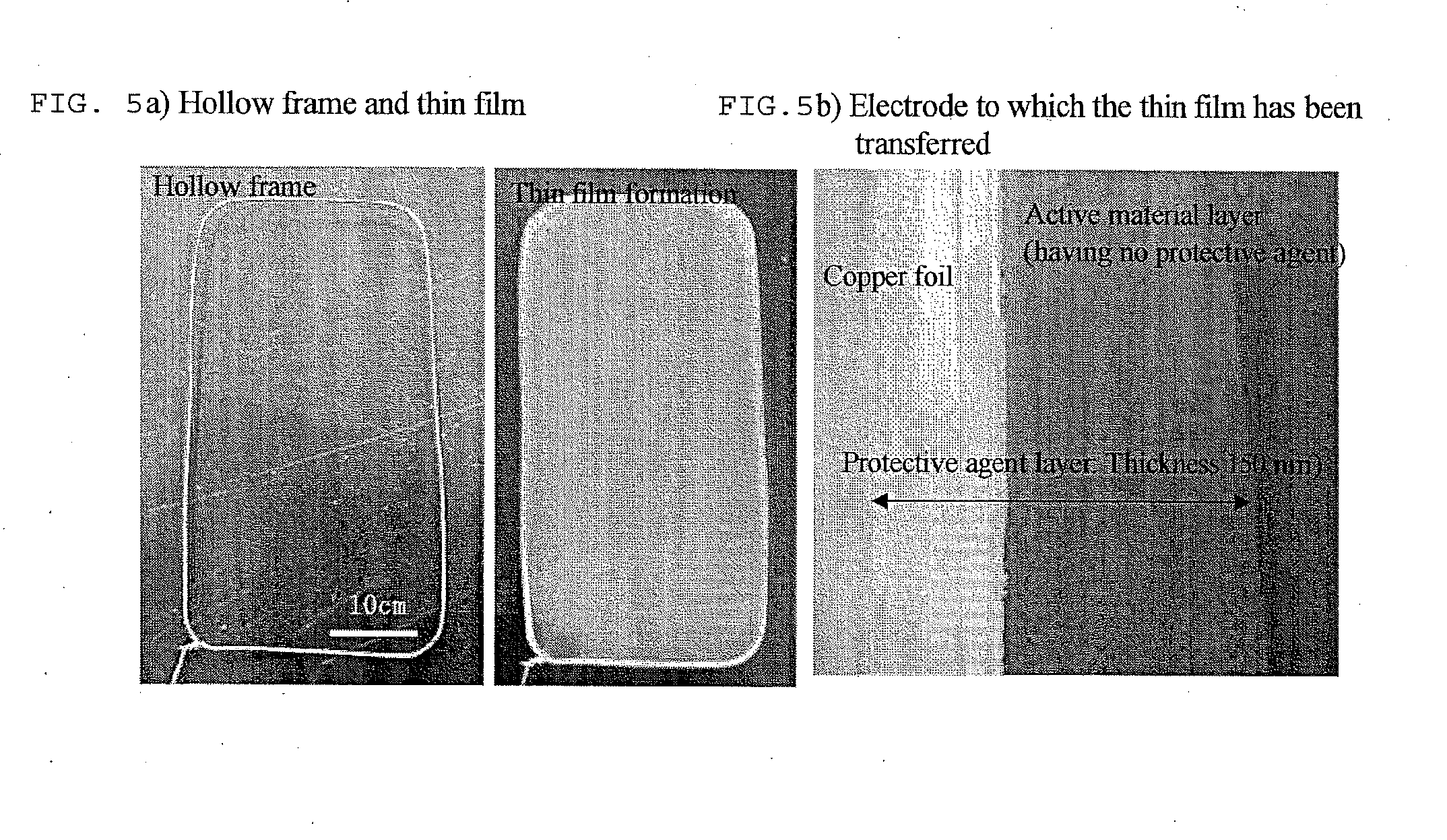

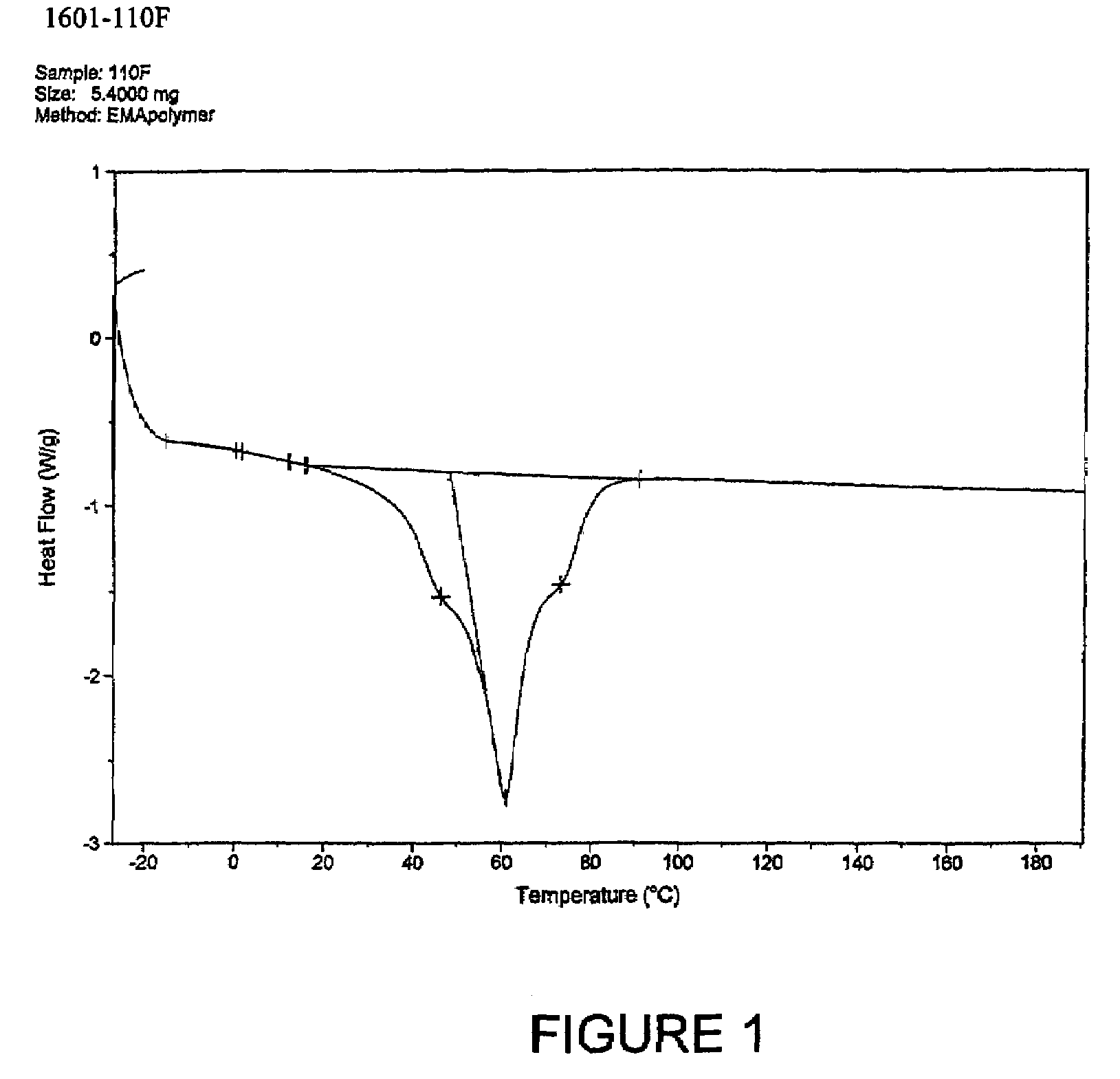

Battery electrode or separator surface protective agent composition, battery electrode or separator protected by the composition, and battery having the battery electrode or separator

ActiveUS20130260207A1Excellent electrolytic solution impregnation propertyImprove heat resistanceCosmetic preparationsNon-fibrous pulp additionHot meltEngineering

A battery electrode or separator surface protective agent composition having fluidity and being capable of being solidified by hot melt, and comprising at least two types of organic particles comprising organic materials, wherein the organic particles of types different from each other are substantially incompatible with each other, wherein when the composition is solidified by hot melt, the organic particles of the same type thermally fuse with one another to form a continuous phase.

Owner:KYORITSU KAGAKU SANGYO KK

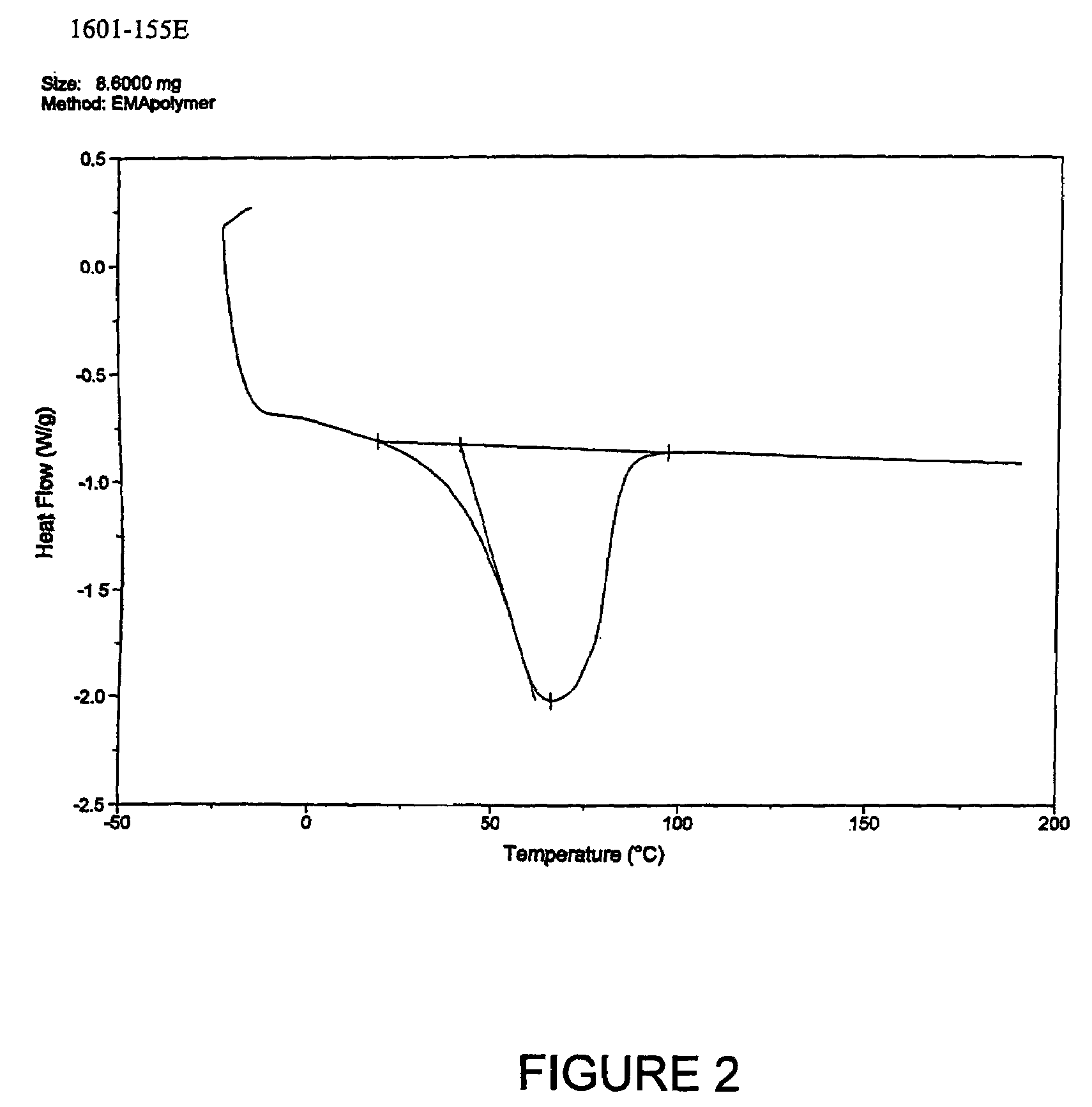

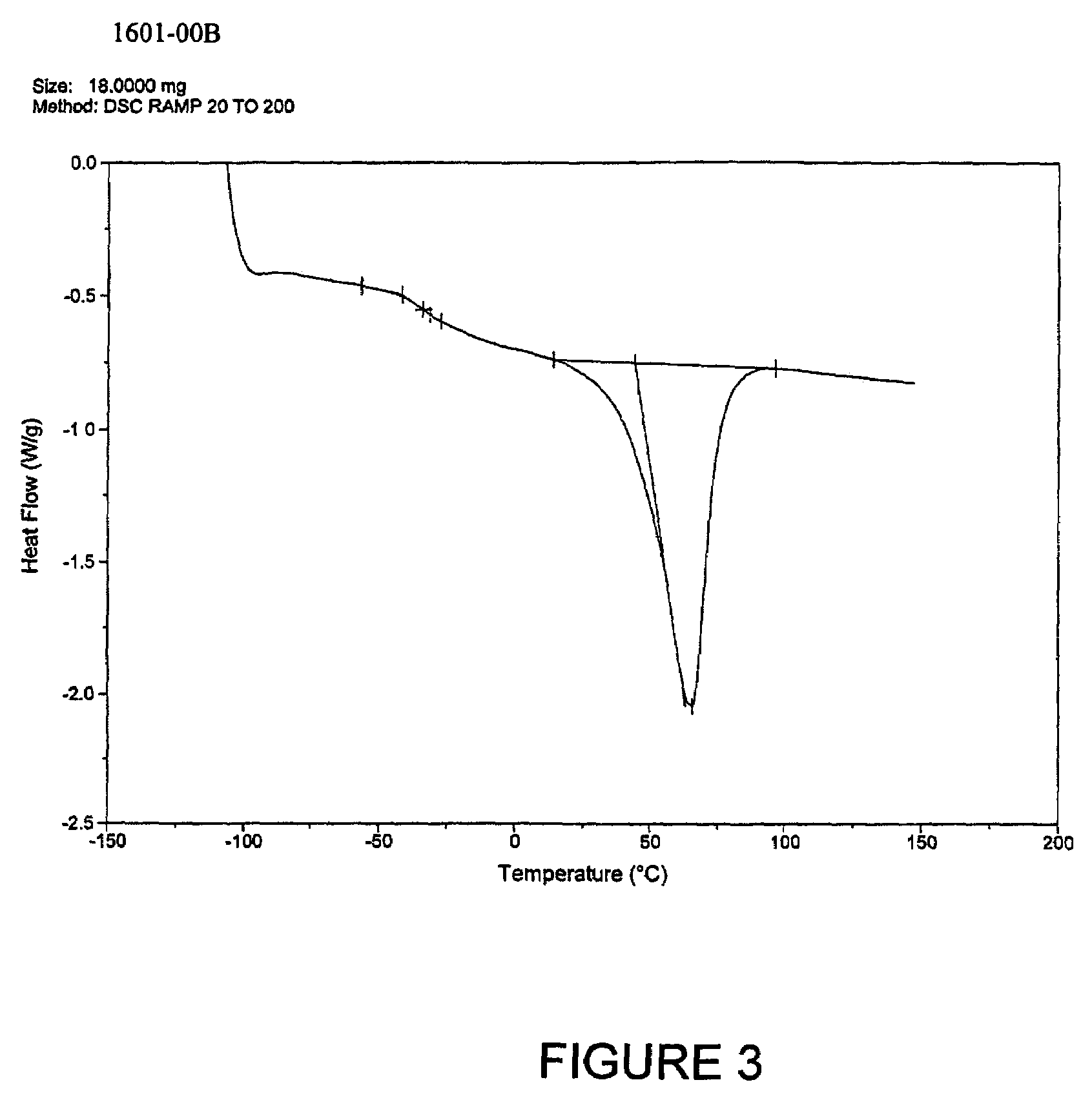

Process for packaging plastic materials like hot melt adhesives

A method for packaging plastic material using a film to surround the material, and more particularly to a method for packaging hot melt adhesives, the resulting package formed thereby, and the film composition used therein. The method is preferably a coextrusion process for packaging a pressure sensitive hot melt adhesive by extruding a hot melt adhesive through a die orifice, and coextruding a wax-based polymeric film to surround the hot melt adhesive. The coated adhesive may then be formed into individual packaged units having a finite size and shape. The polymeric film comprises a composition having at least 25% by weight of a wax material, an enthalpy of fusion of at least about 100 J / g, and an elongation value at break of at least about 100%. Any type of hot melt adhesive formulation can be packaged or surrounded by the polymeric film in the process. Also, the specific enthalpy of fusion desired and / or elongation value at break desired for the polymeric film can be obtained by blending an appropriate amount of partially crystalline ethylene-based polymer together with a thermoplastic elastomeric block copolymer and / or an ethylene based or propylene-based elastomer.

Owner:BOSTIK INC

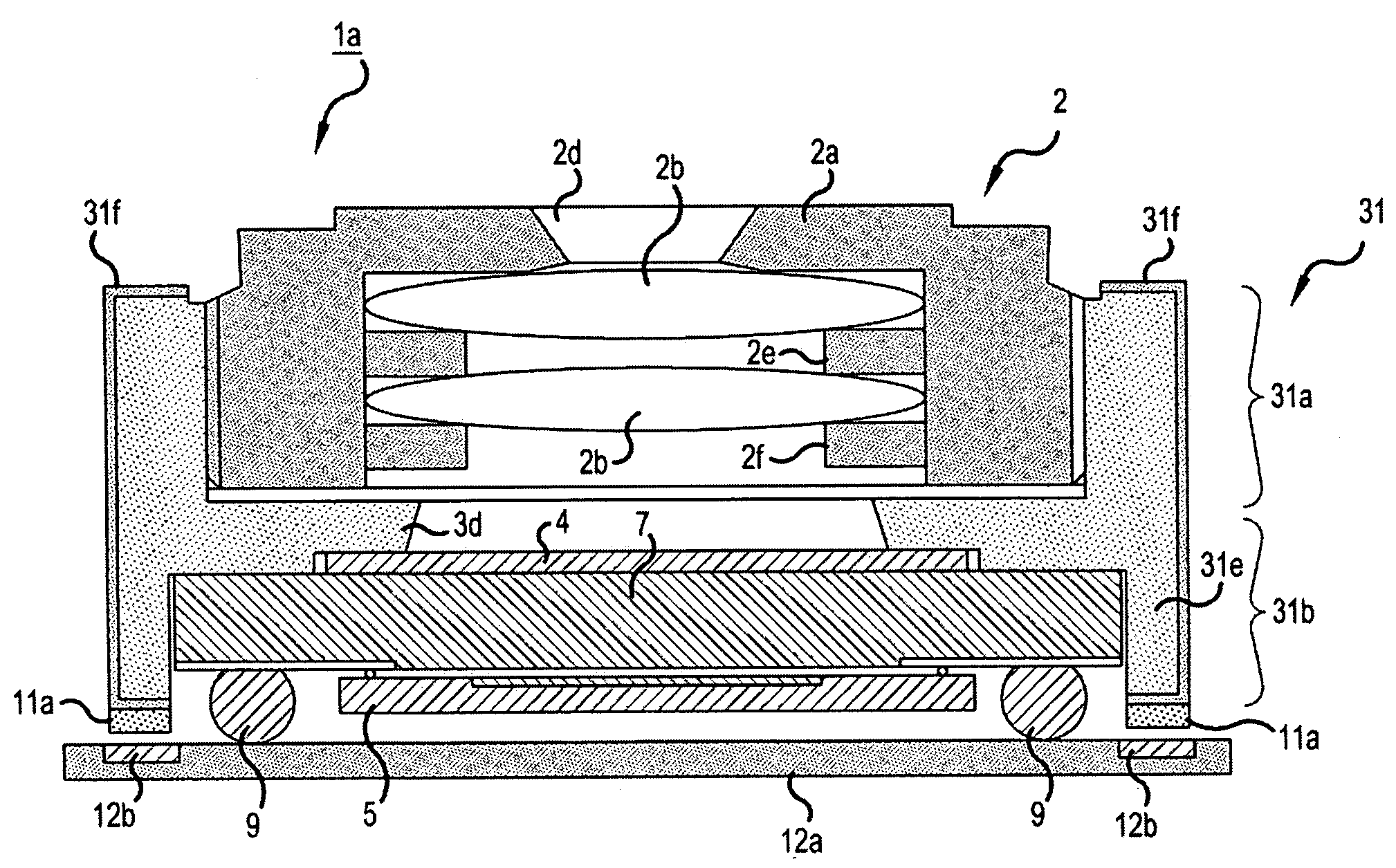

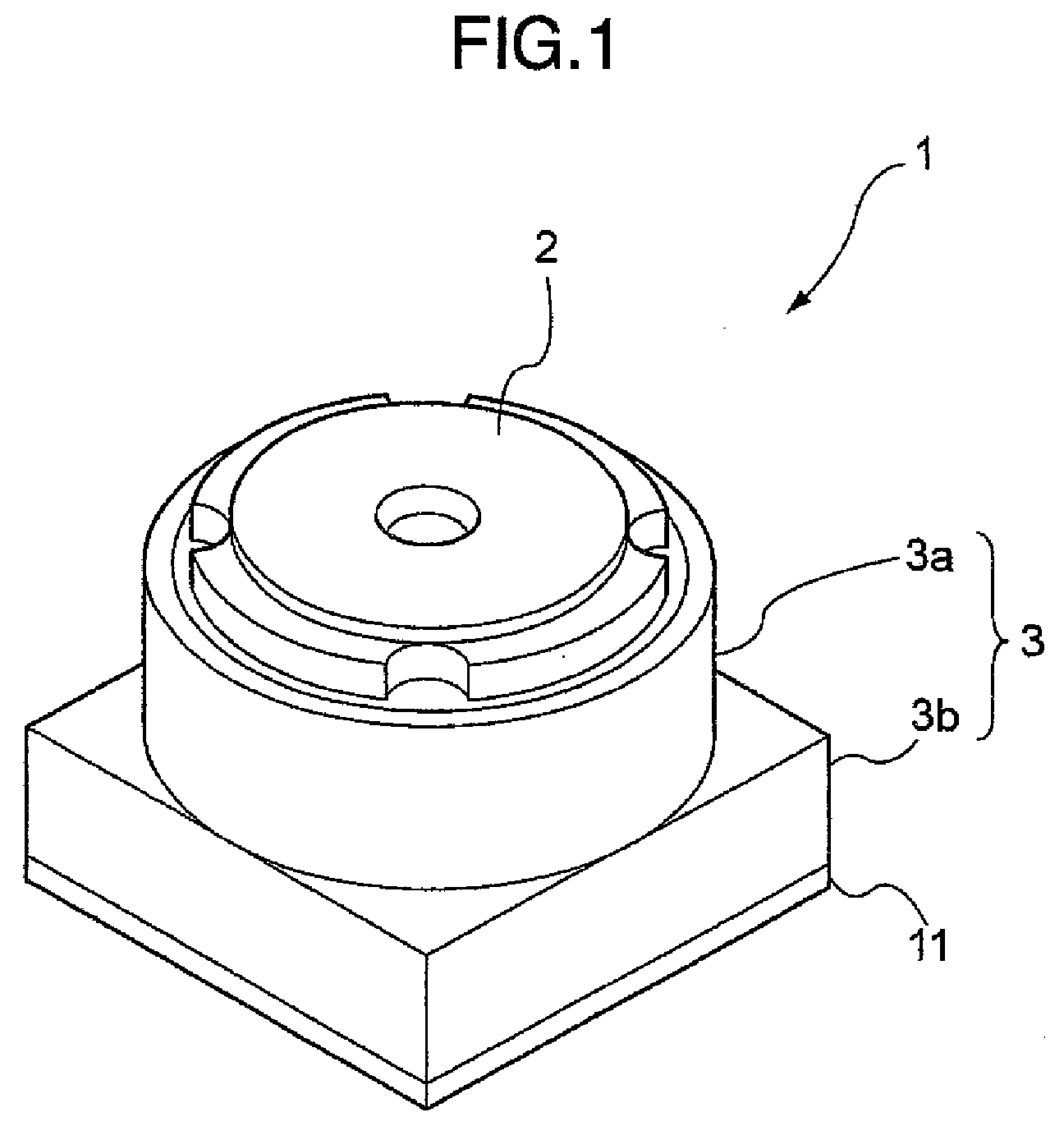

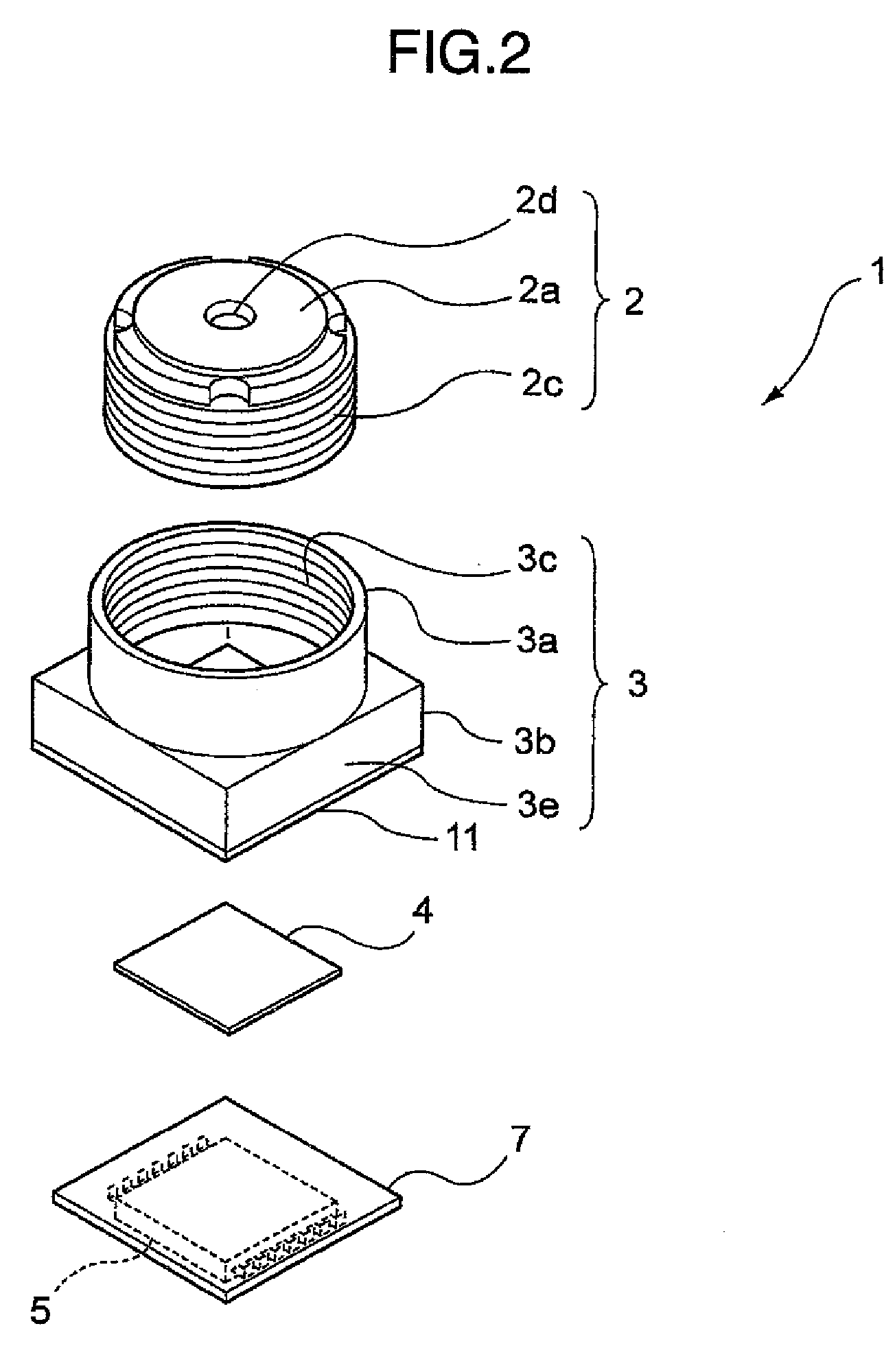

Camera module, manufacturing method of imaging apparatus and hot melt molding method

InactiveUS20090079863A1Improve productivityReduce material costsTelevision system detailsColor television detailsHot meltEngineering

The invention provides a camera module which can make a work for filling up a clearance between a pedestal mount and a circuit board in a post process unnecessary. The invention provides a camera module including a lens unit, an imaging element converting an incoming light formed by the lens unit into an electric signal and a pedestal mount attaching the lens unit thereto and storing the imaging element, in which a lower end portion of a side wall portion of the pedestal mount is provided with a bottom surface portion made of a thermoplastic resin melting at a reflow temperature.

Owner:HITACHT MAXELL LTD

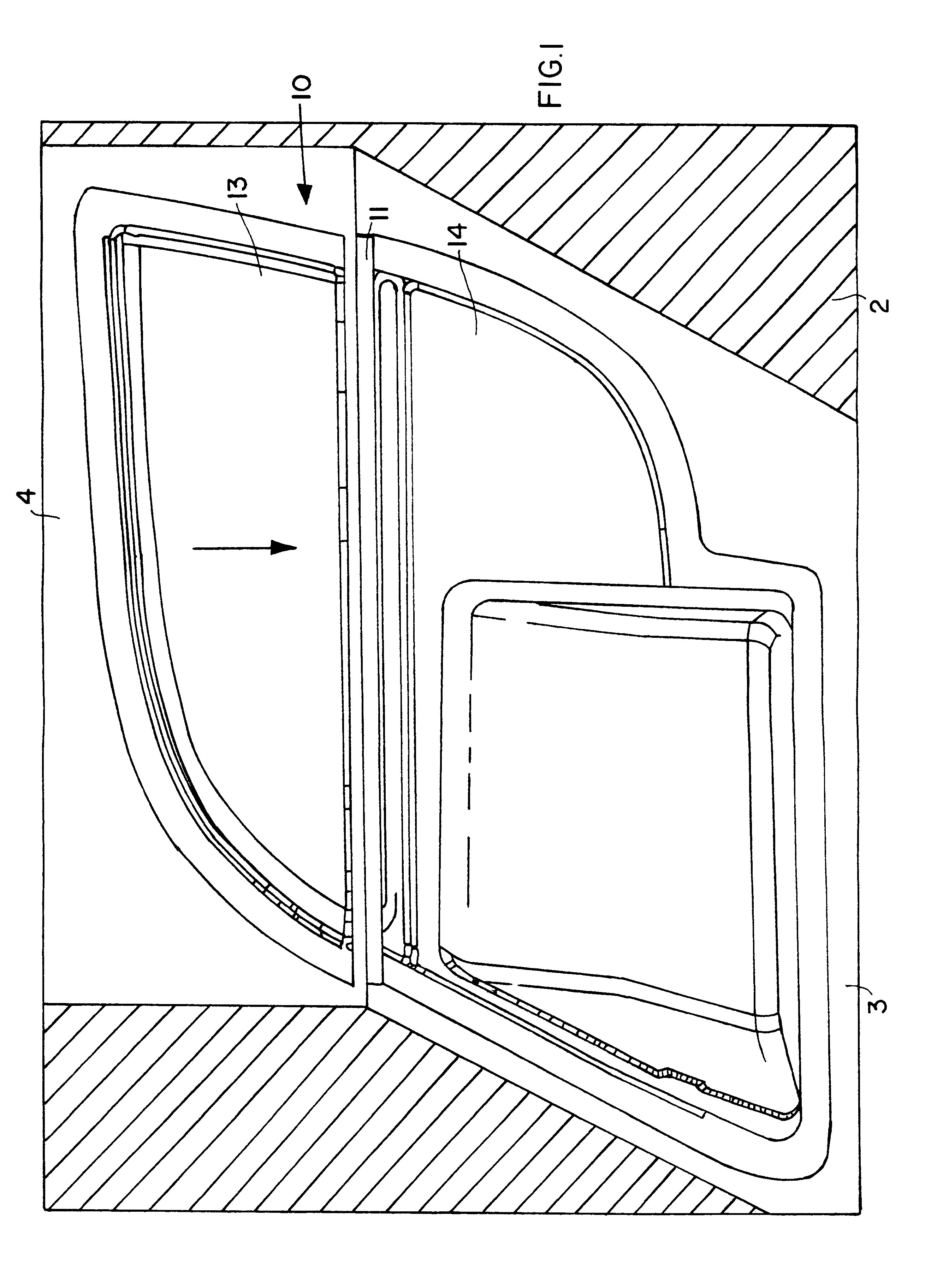

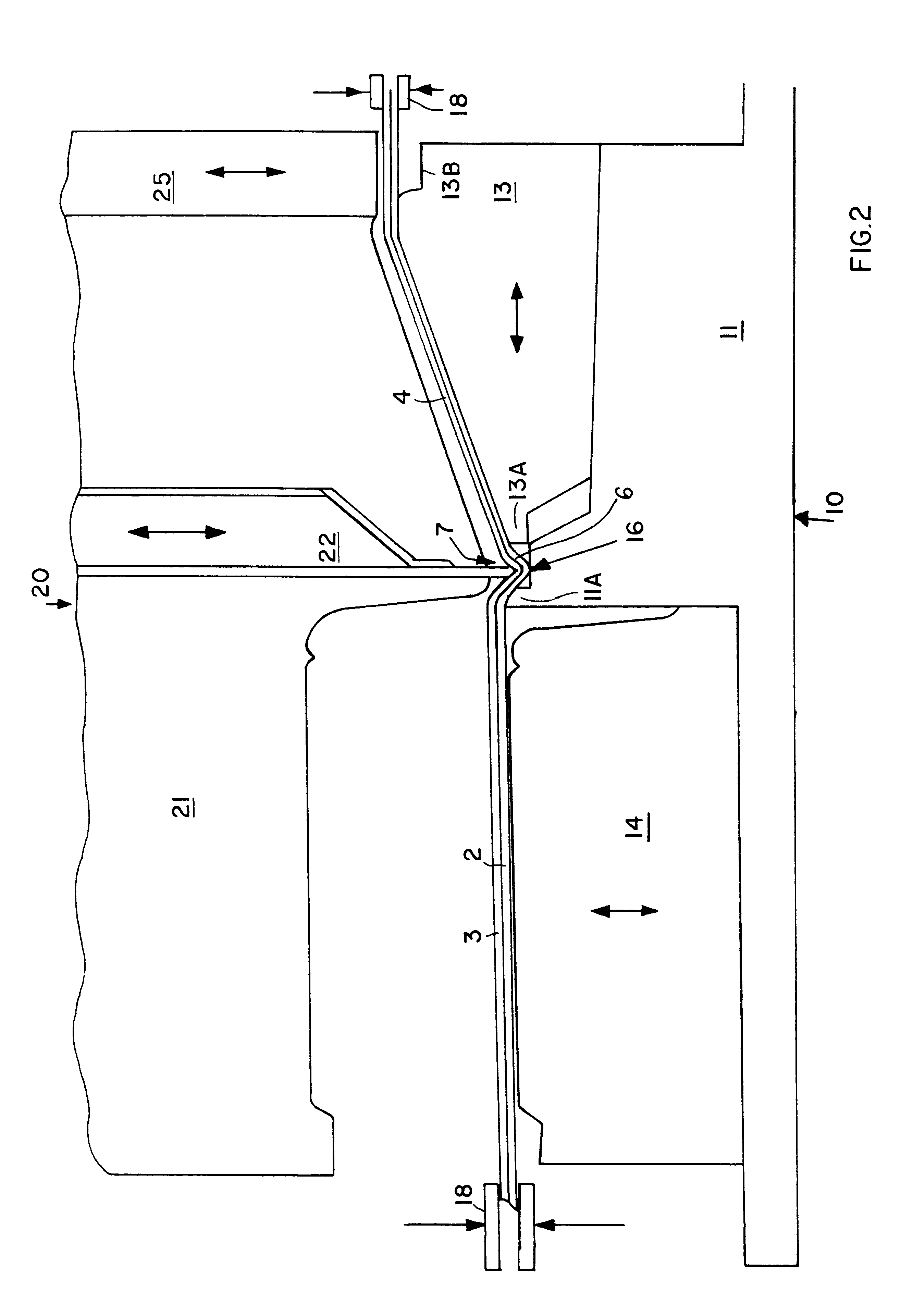

Vehicle trim component having two-part cover material, and method and apparatus for producing the same

InactiveUS6214157B1Large toleranceClean and crisp closed appearanceLayered productsBuilding componentsHot meltEngineering

Owner:HERBERT OLBRICH

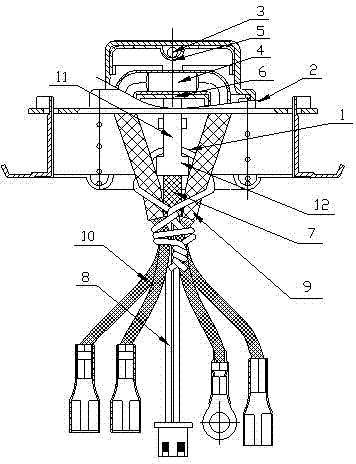

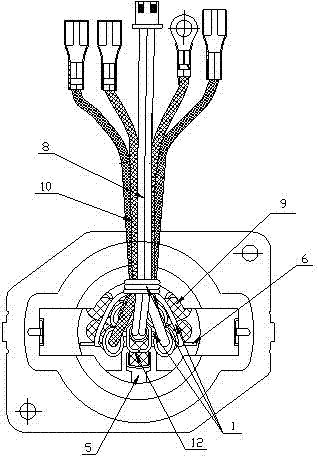

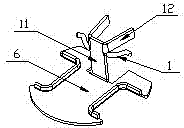

Temperature sensor for electric cooker

InactiveCN103750730AImprove safety and reliabilityReliable folding and fixingThermometers using electric/magnetic elementsCooking vesselsElectrical resistance and conductanceHeat sensitive

The invention aims to provide a temperature sensor for an electric cooker. In the temperature sensor for the electric cooker, an insulating bush and an electric wire can be gathered and bound reliably. Moreover, the temperature sensor is simple in structure and convenient to install, and the safety of the electric cooker can be enhanced greatly. The temperature sensor for the electric cooker comprises a binding wire and an aluminum cover, wherein a thermistor and a thermofuse are arranged in the aluminum cover through a bracket, are sleeved in the insulating bush respectively, and are connected with a lead which is led out of the aluminum cover respectively. Key points are that the bracket is provided with a support claw; the support claw is provided with a U-shaped clamping portion; the U-shaped clamping portion is used for clamping and fixing the insulating bush on which the thermistor and / or thermofuse is positioned; the binding wire passes through a gap between the support claw and the insulating bush, and is meshed crossly after being wrapped around the insulating bush; the two ends of the binding wire are tied together or wound firmly after being wound around the lead by at least one circle.

Owner:GUANGDONG FUER ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com