Patents

Literature

108 results about "Time temperature indicator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A time temperature indicator (TTI) is a device or smart label that shows the accumulated time-temperature history of a product. Time temperature indicators are commonly used on food, pharmaceutical, and medical products to indicate exposure to excessive temperature (and time at temperature).

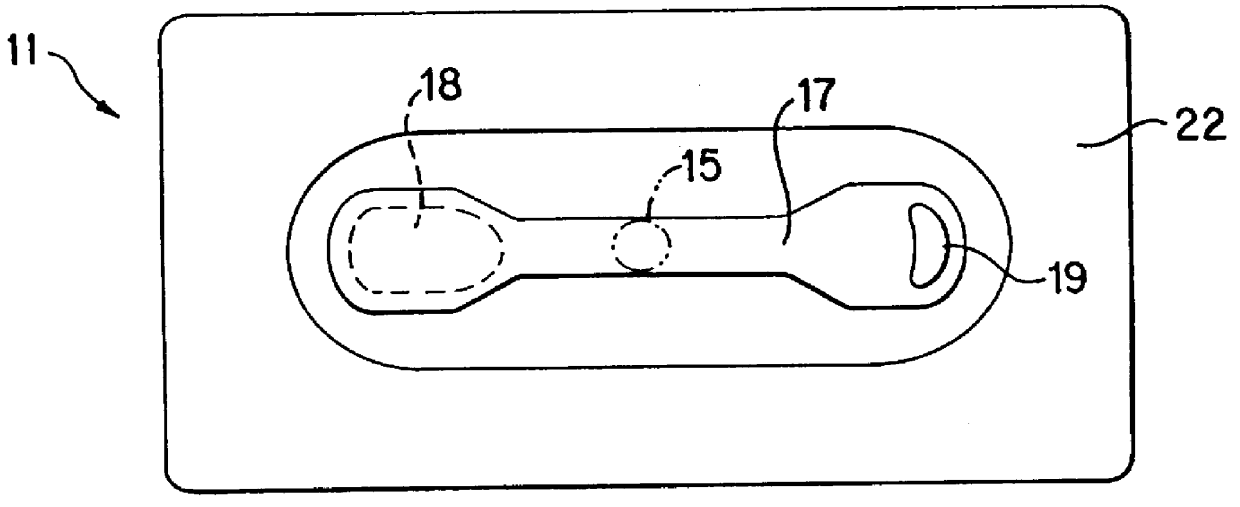

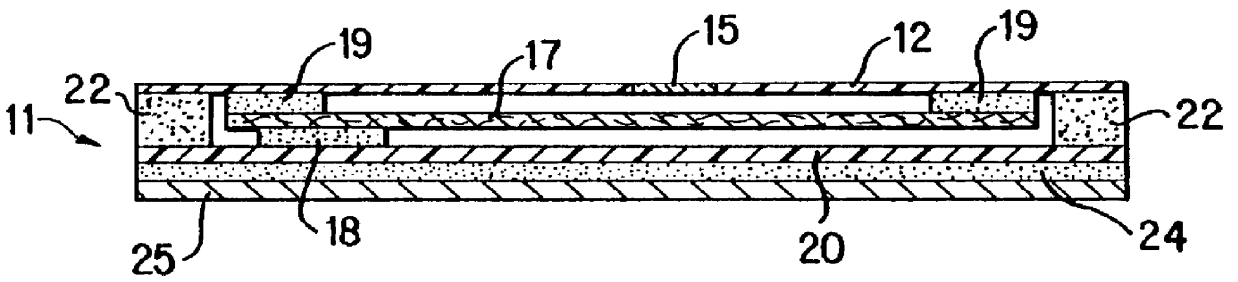

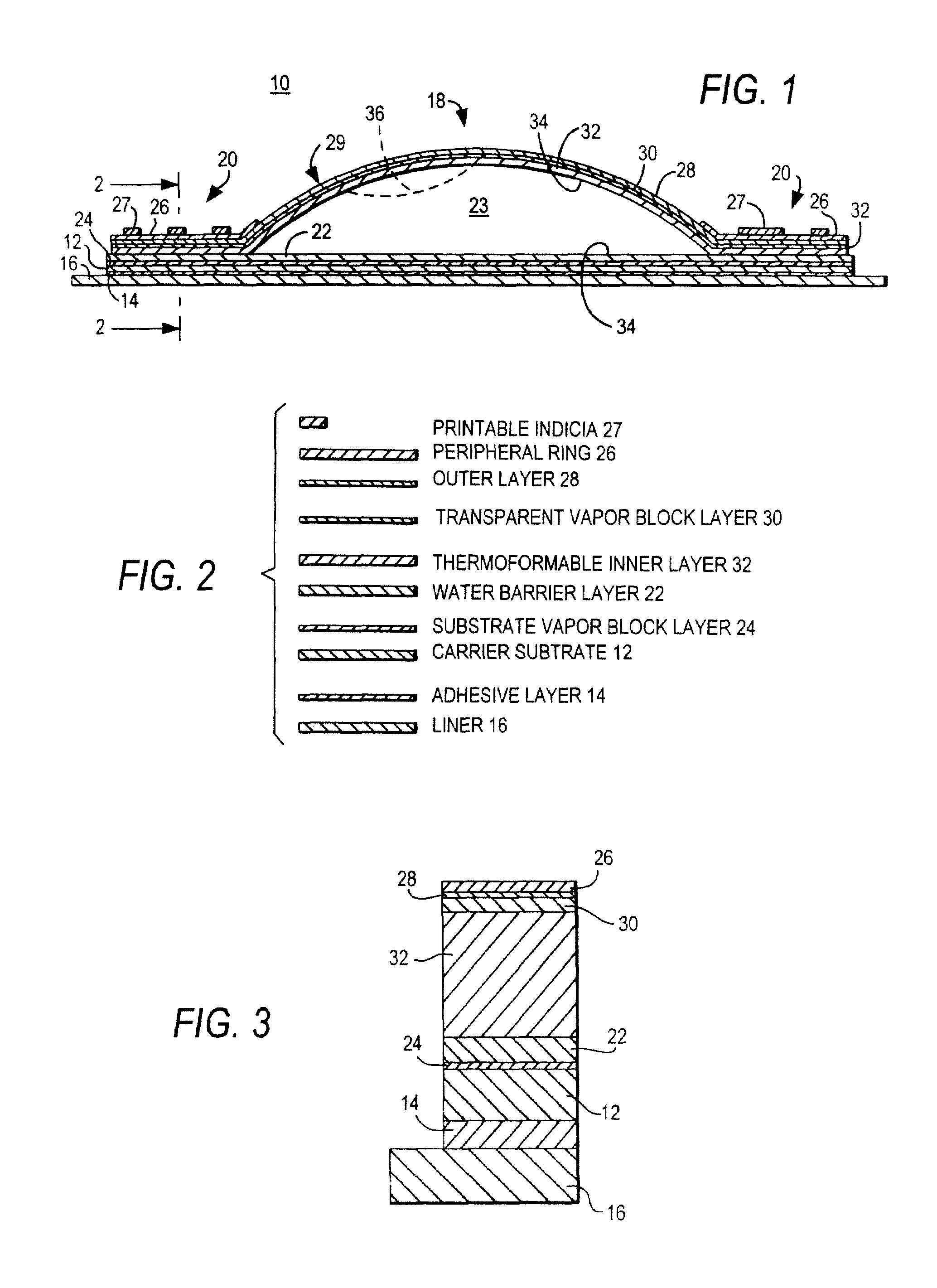

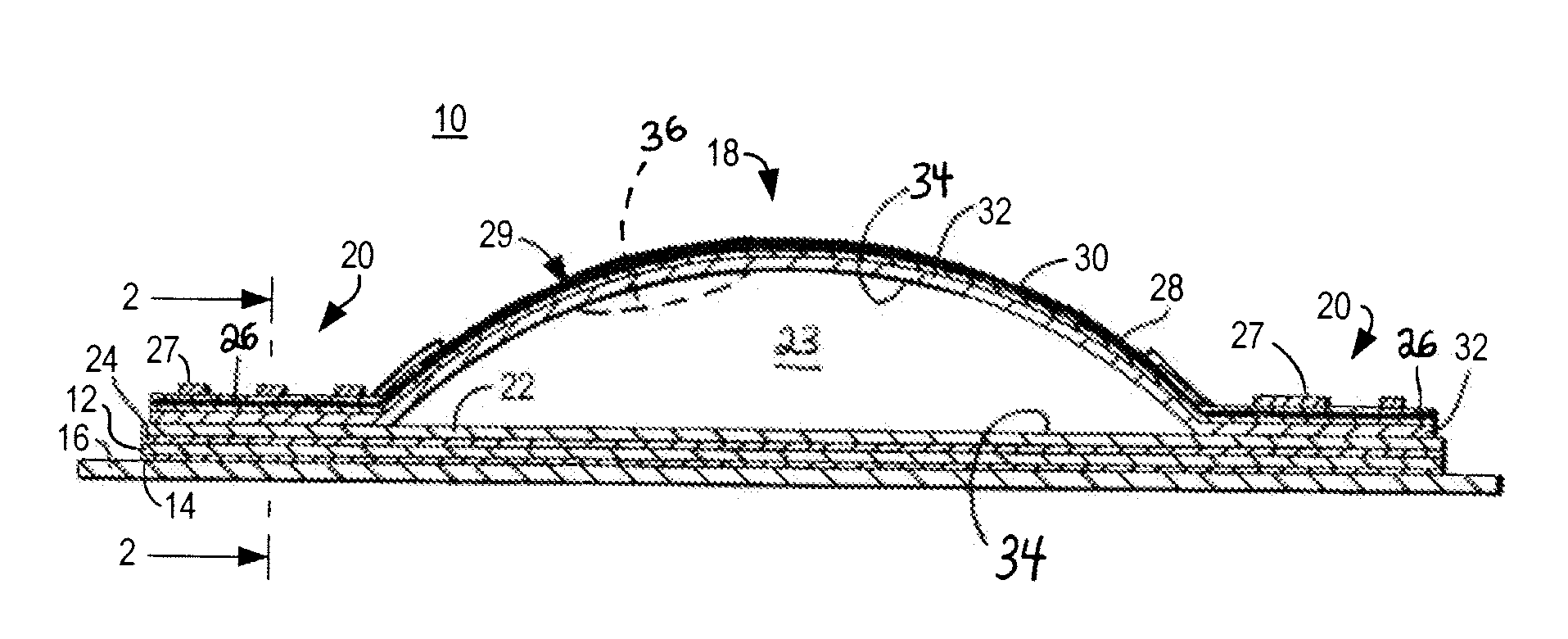

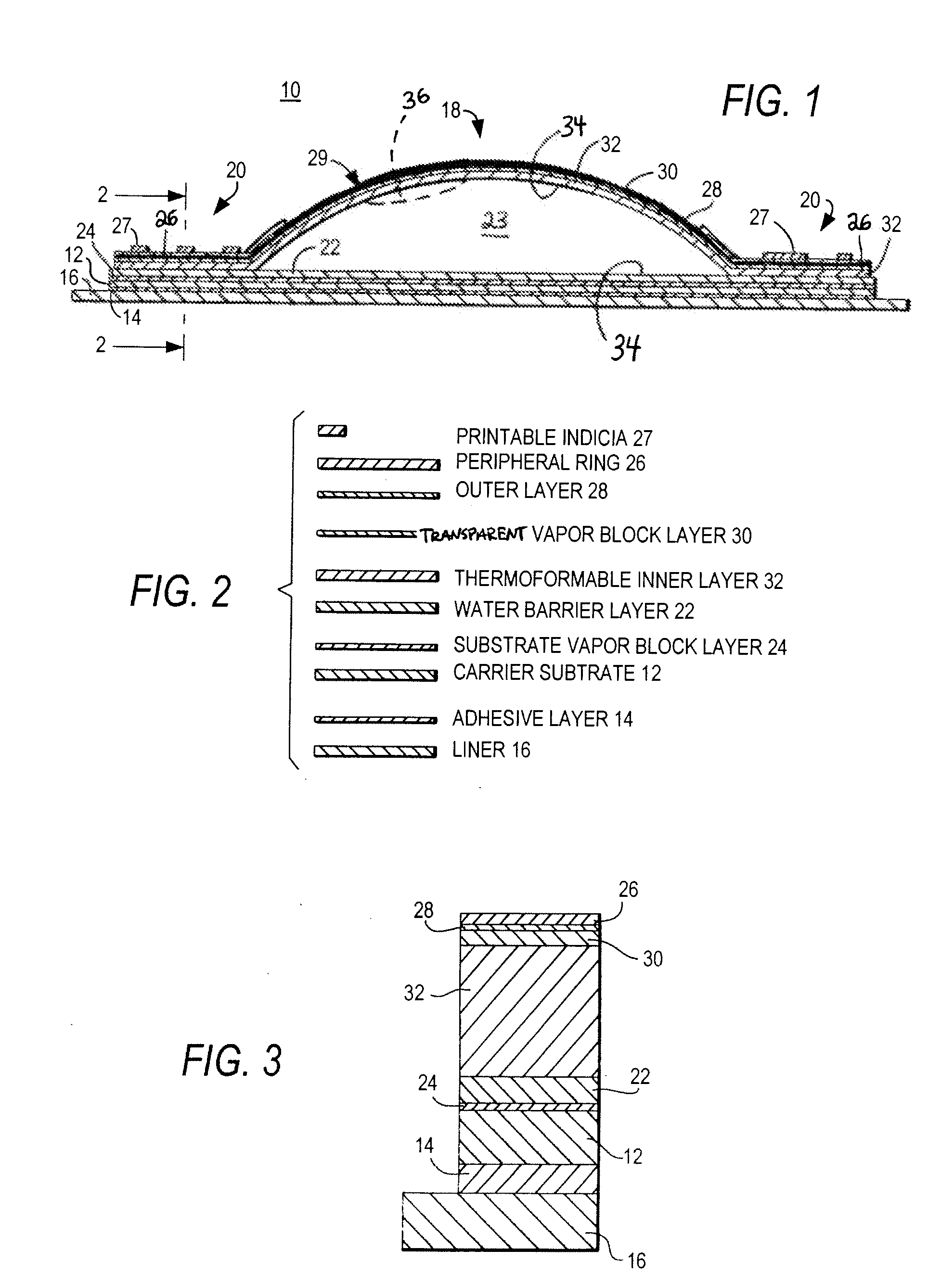

Time-temperature indicator device and method of manufacture

InactiveUS6042264AExtensive exposureSufficient supplenessThermometer detailsThermometers using mean/integrated valuesSurface layerHot melt

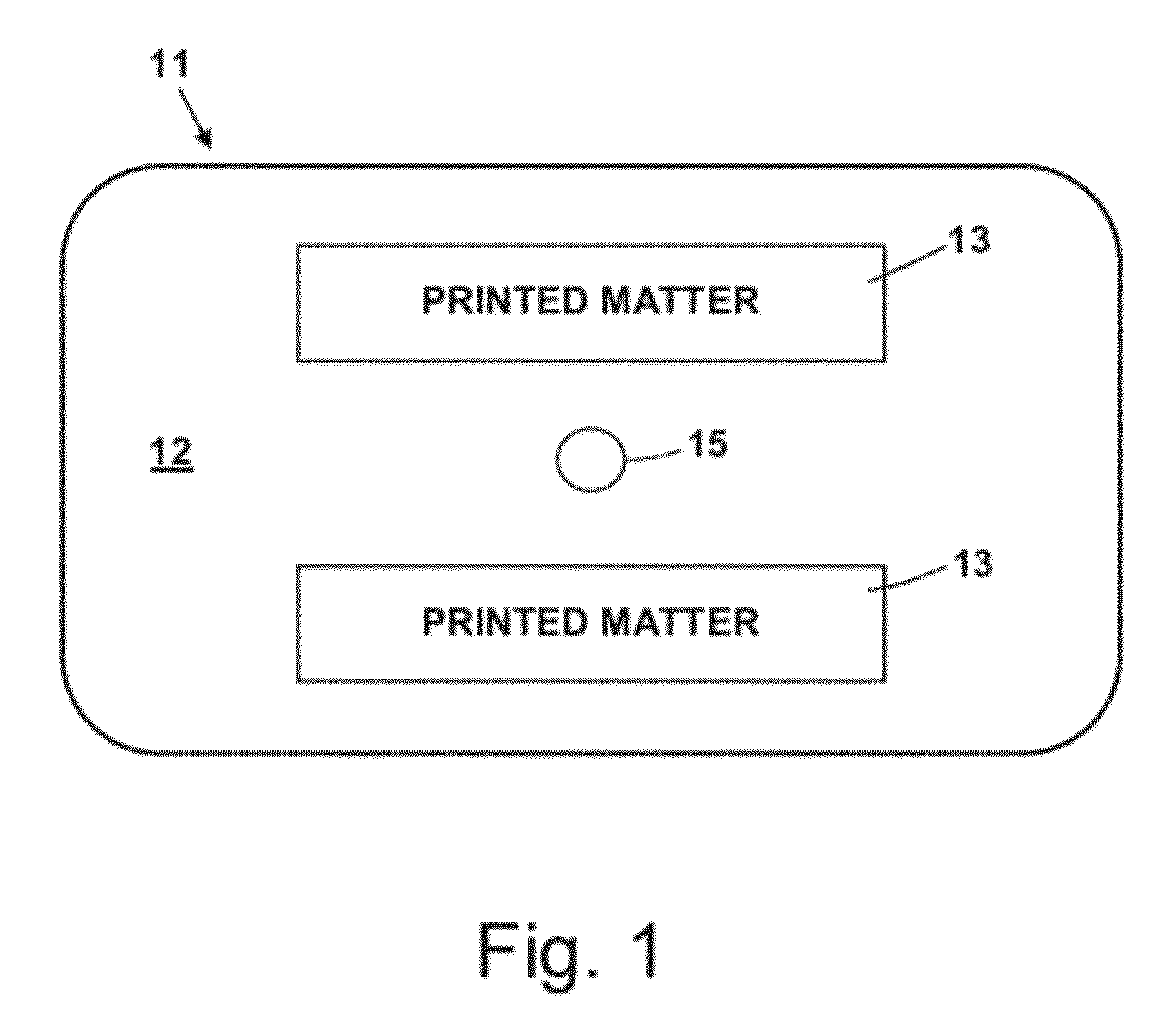

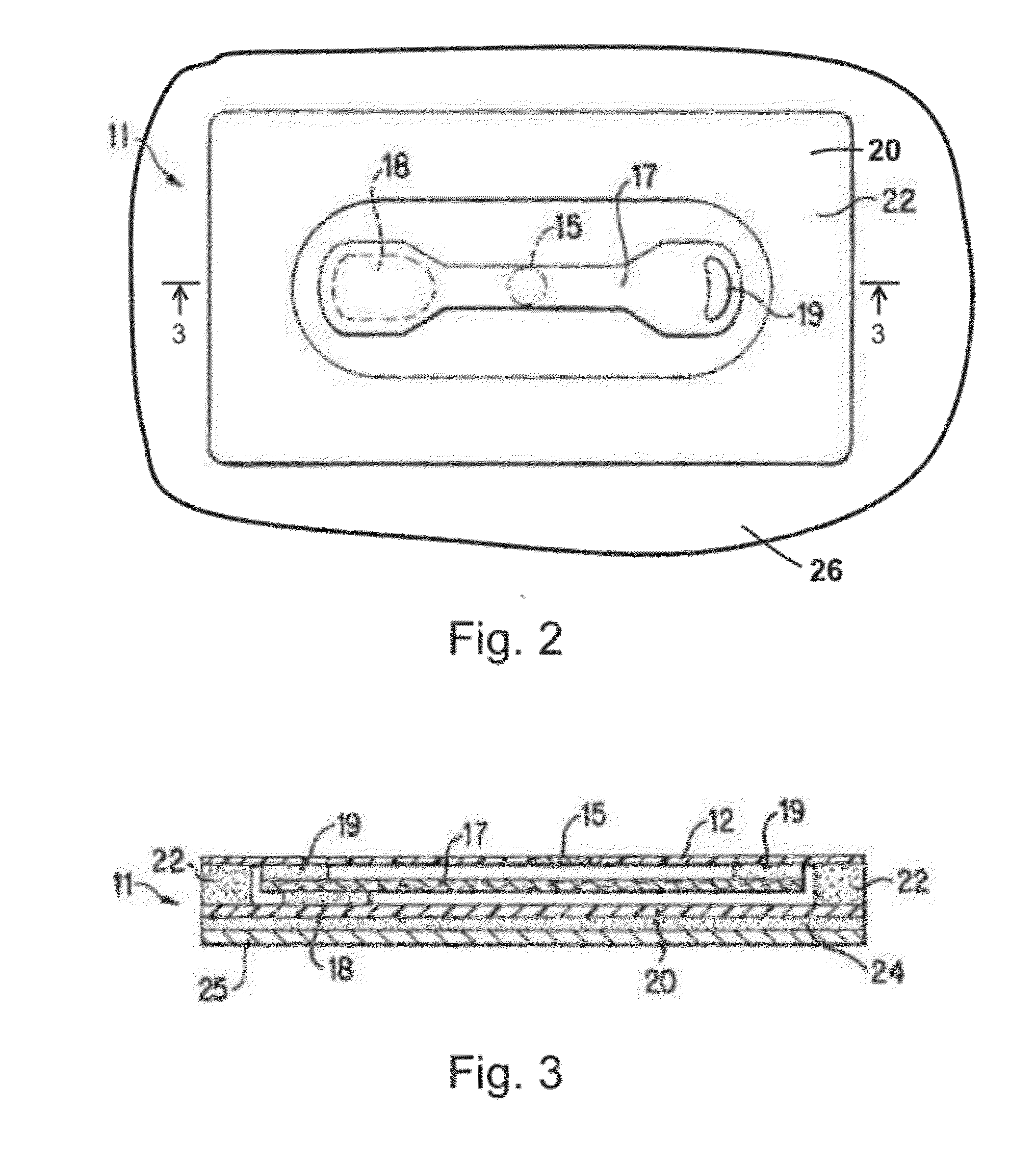

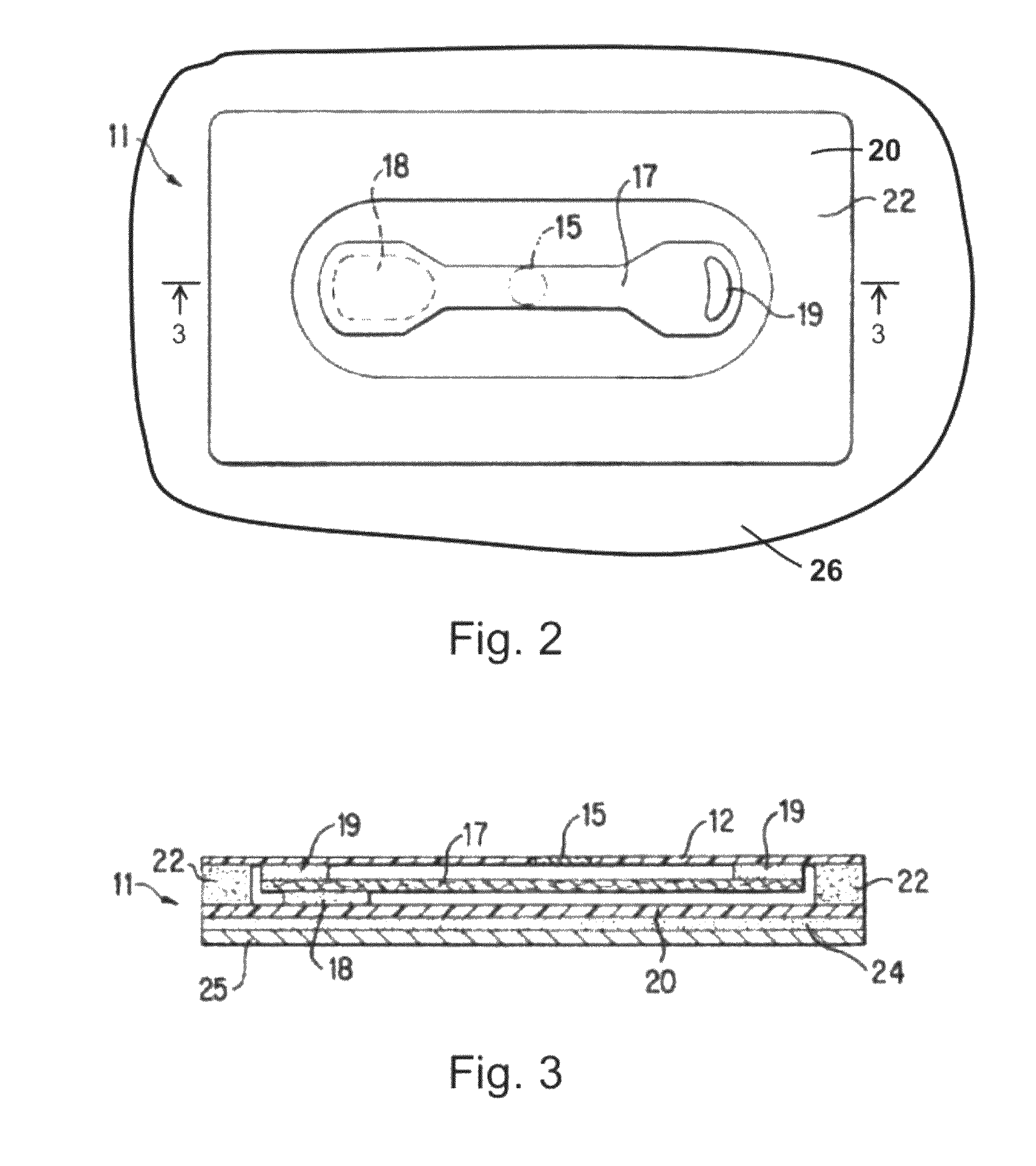

A time-temperature indicator label for measuring the length of time to which a product has been exposed to a temperature above a pre-determined temperature is provided. The period of time of exposure is integrated with the temperature to which the indicator is exposed. The label is a composite of a plurality of layers adapted to be adhered at its underside to a product container. The label includes a printable surface layer, a longitudinal wicking strip that is adhered underneath the surface layer substantially at the opposite extremities only of the wicking strip and a lower substrate layer forming an envelope with said surface layer. A heat-fusible substance, which melts and flows above a pre-determined temperature, is applied on the surface of the wicking strip contiguous to at least one of the ends of the wicking member. When the heat-fusible substance is exposed to a temperature above the pre-determined temperature, the heat-fusible substance flows along the length of the wicking member. The label has a printable surface layer and is sealed at its peripheral edge to the peripheral edge of the substrate layer. These layers encapsulate the wicking member and the heat-fusible substance. The surface layer is provided with a sight window at an intermediate location over the wicking member through which the progress of flow on the wicking member is observed.

Owner:TEMPTIME CORP

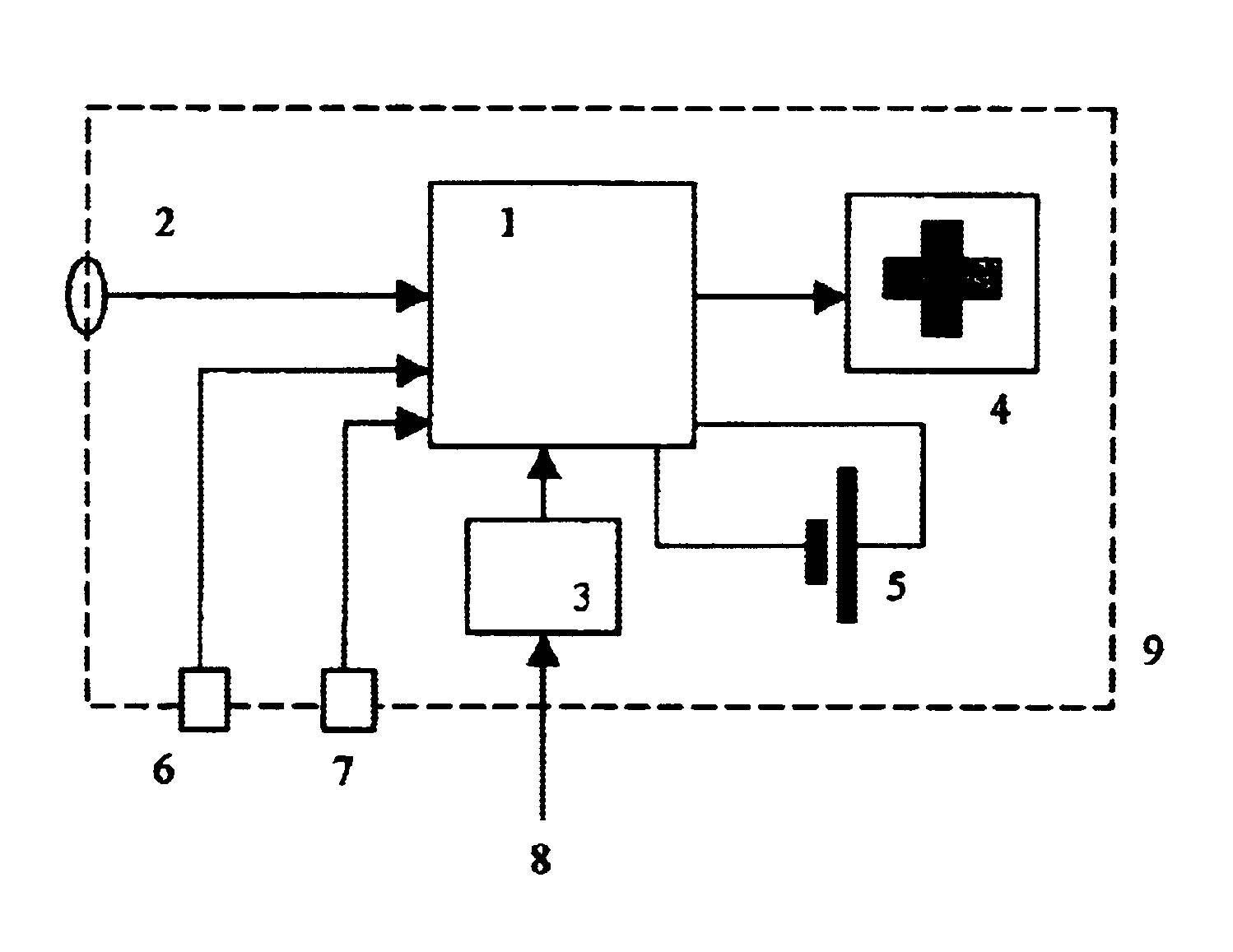

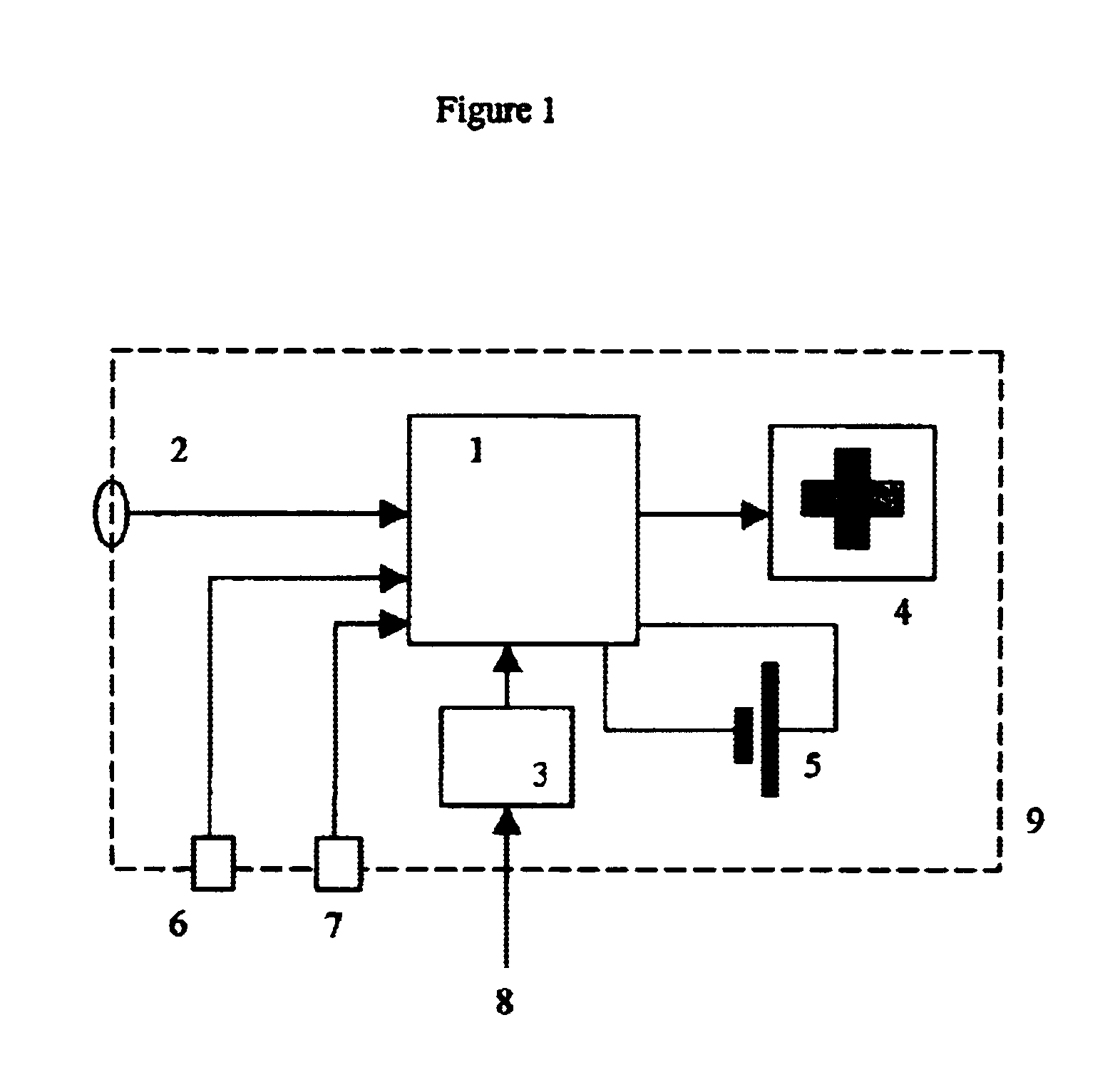

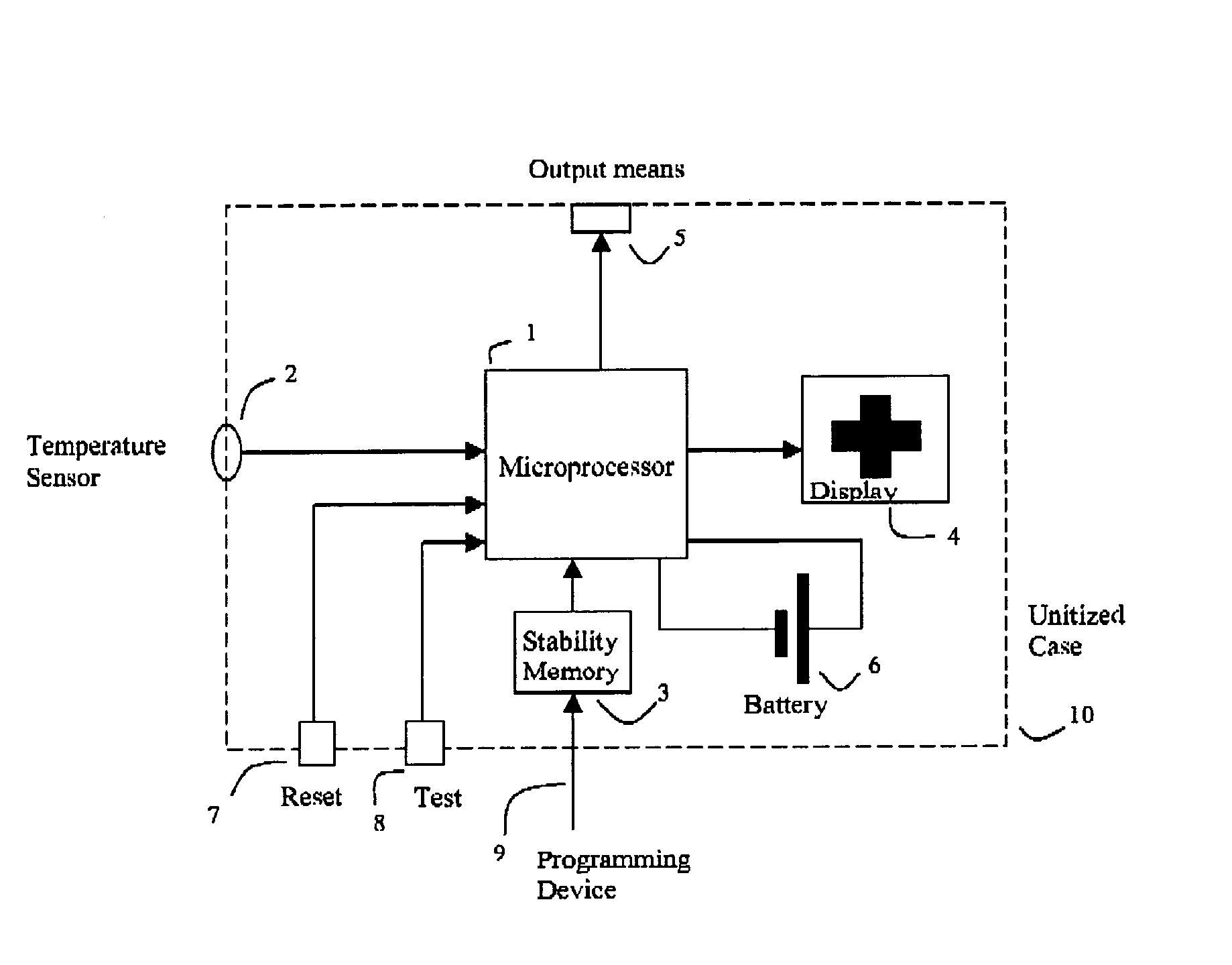

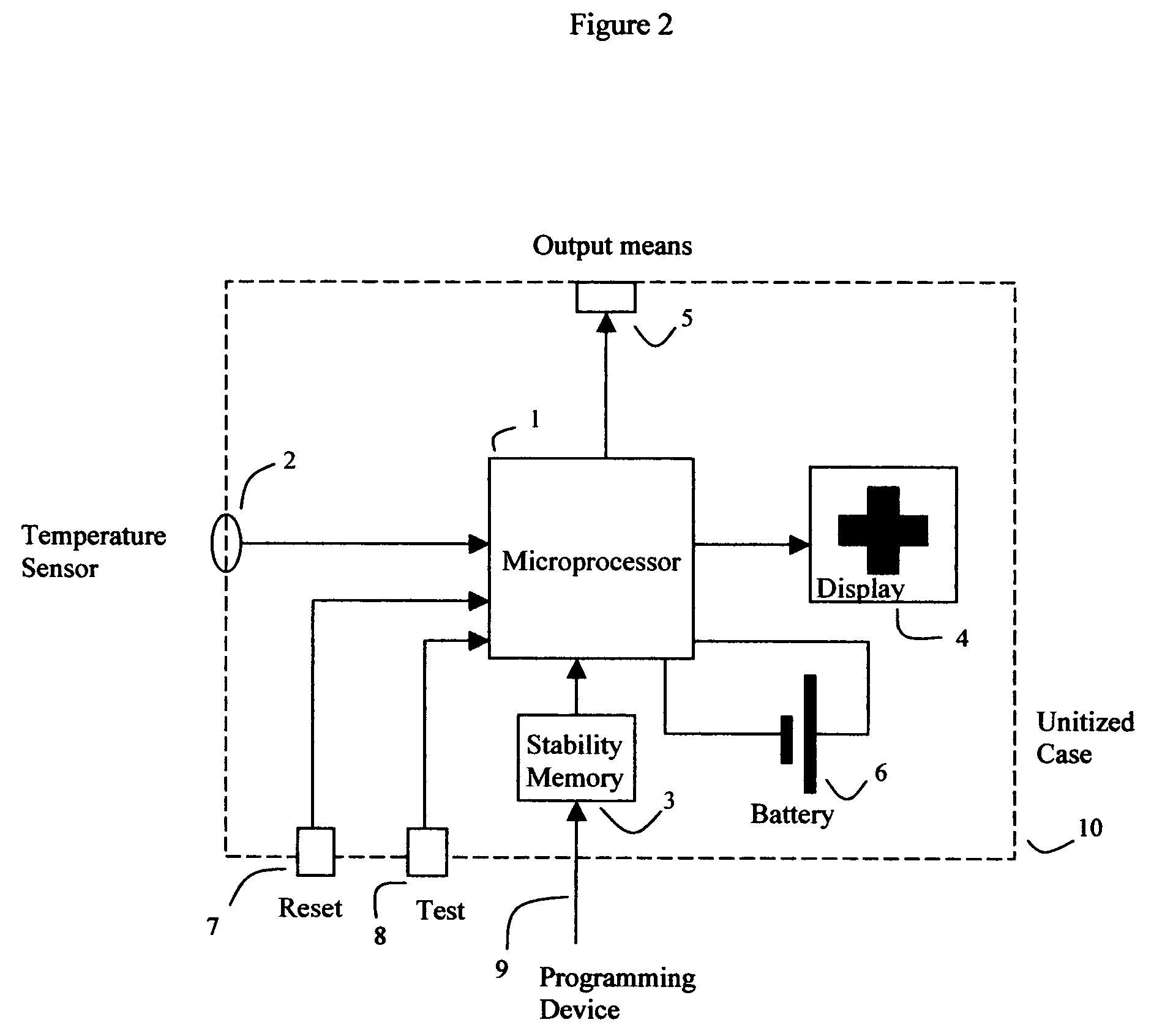

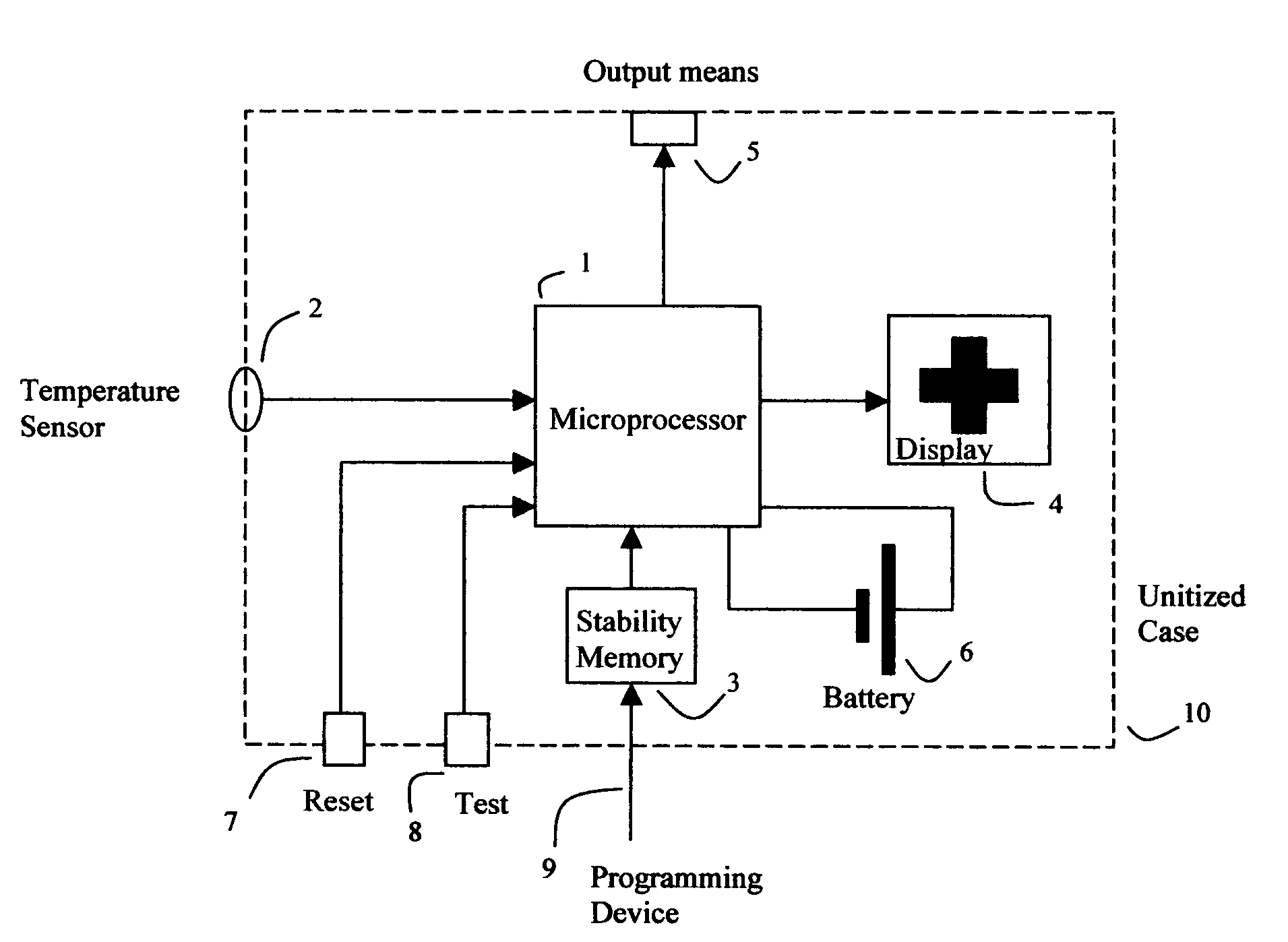

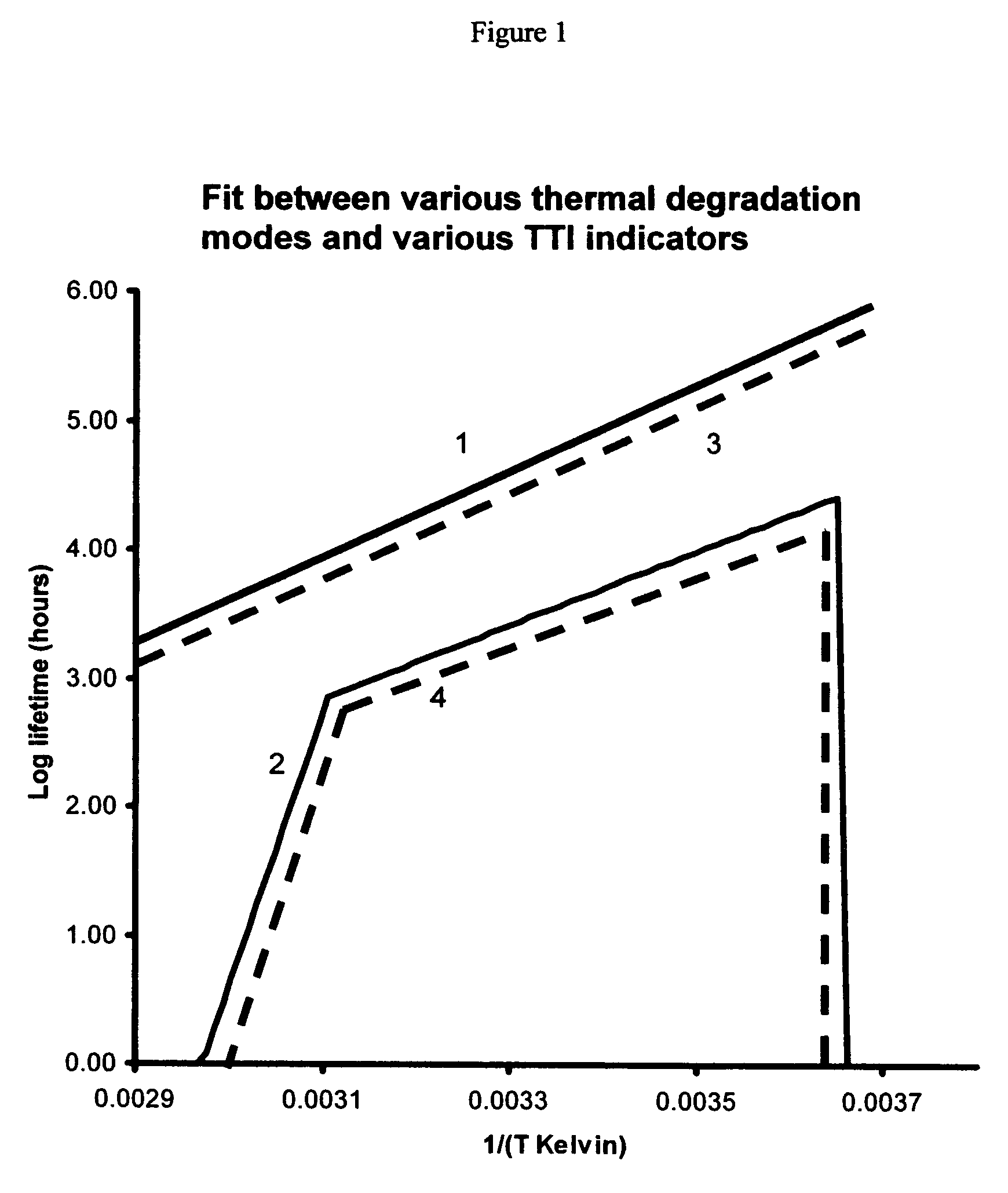

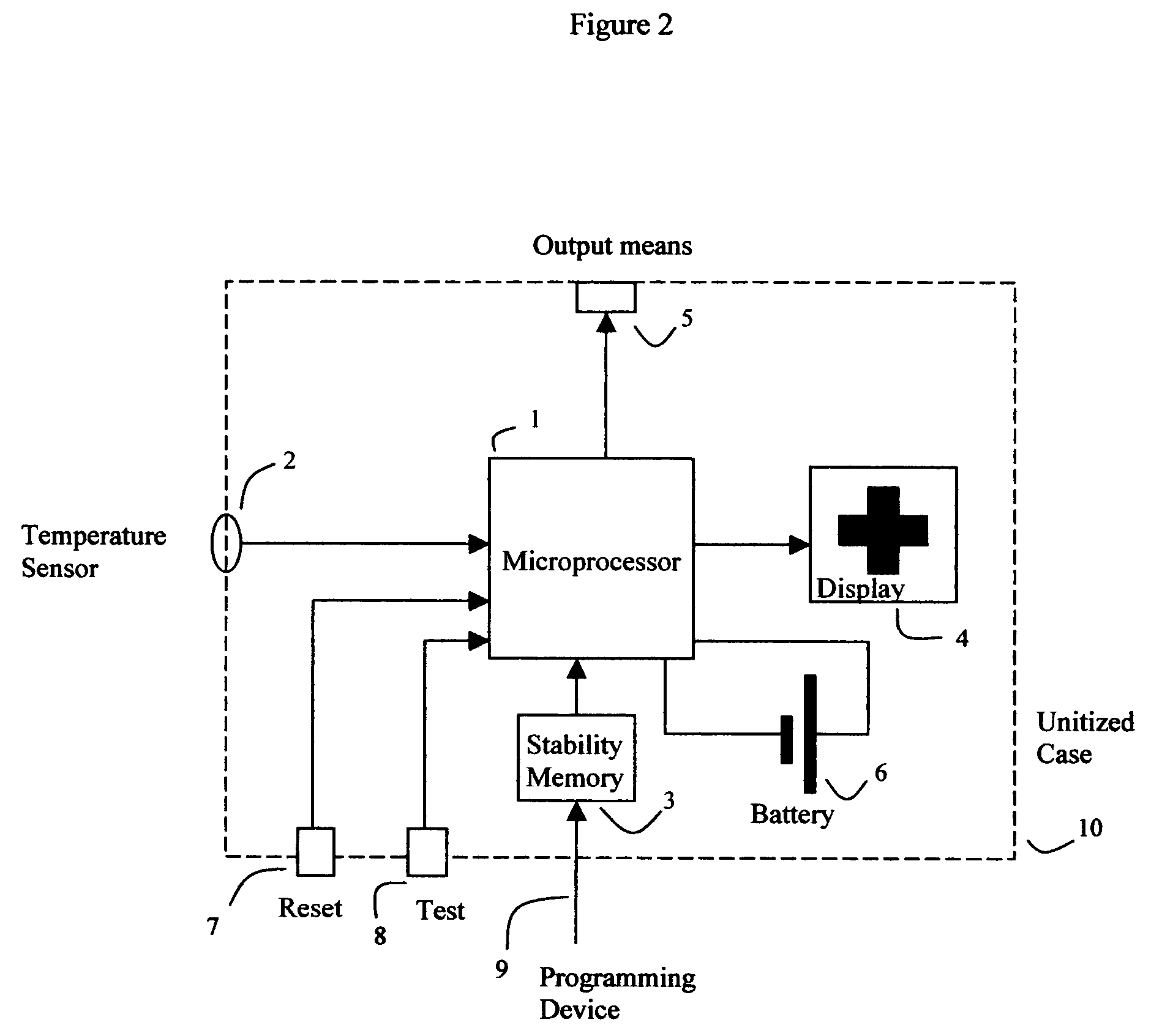

Electronic time-temperature indicator

InactiveUS6950028B2Easily and precisely customizedHigh outputThermometer detailsThermometers using mean/integrated valuesData transmissionComputer science

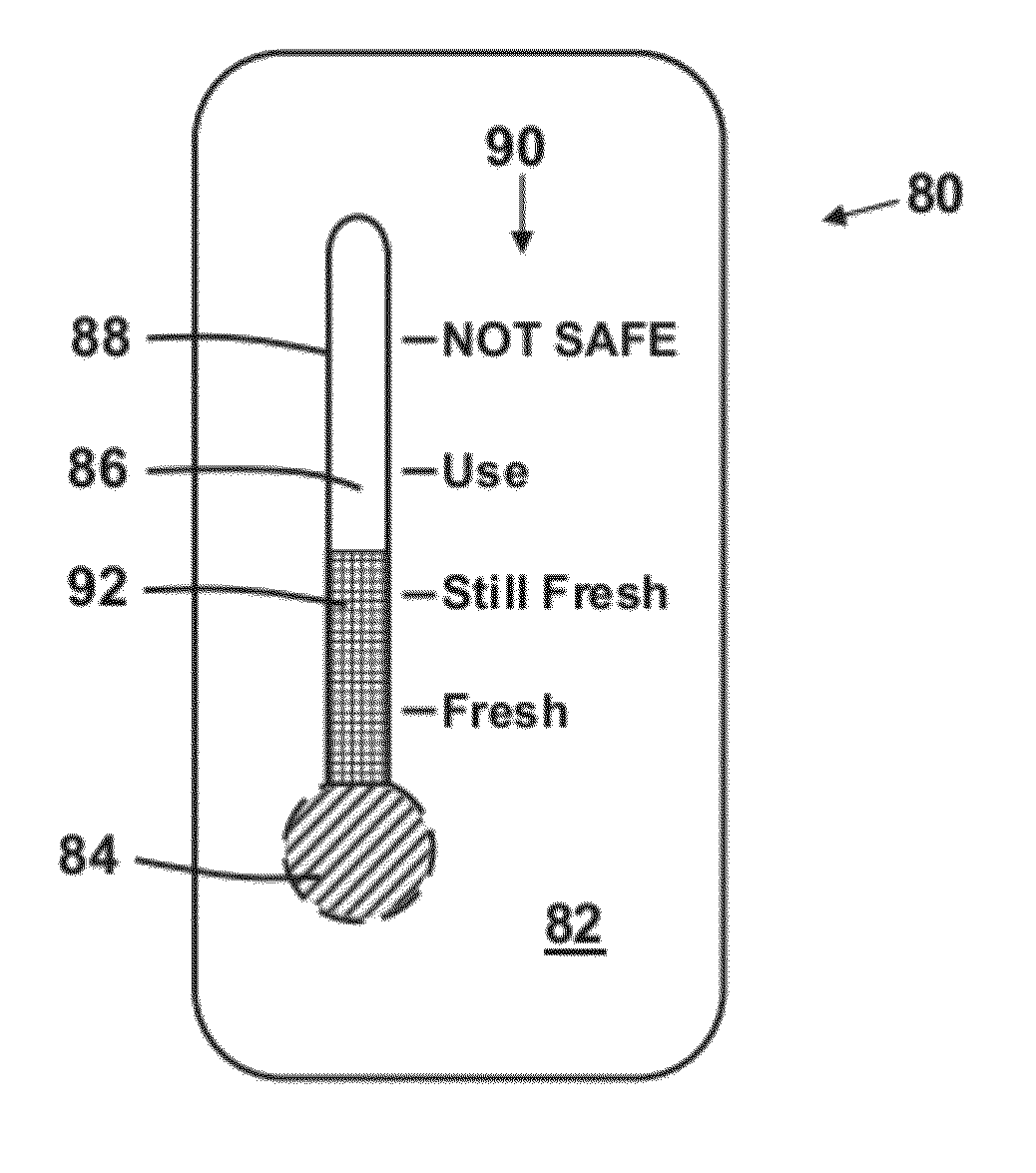

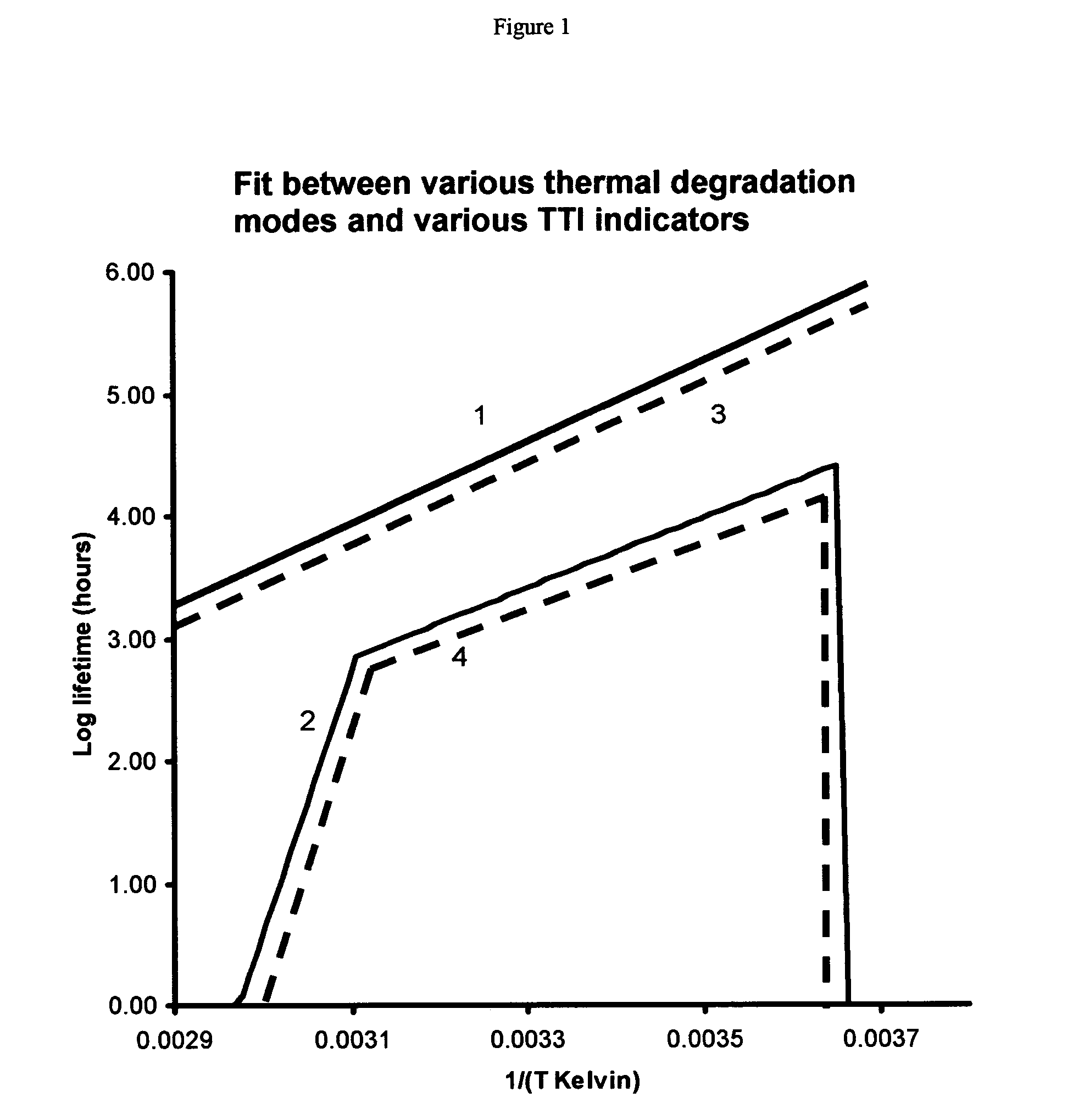

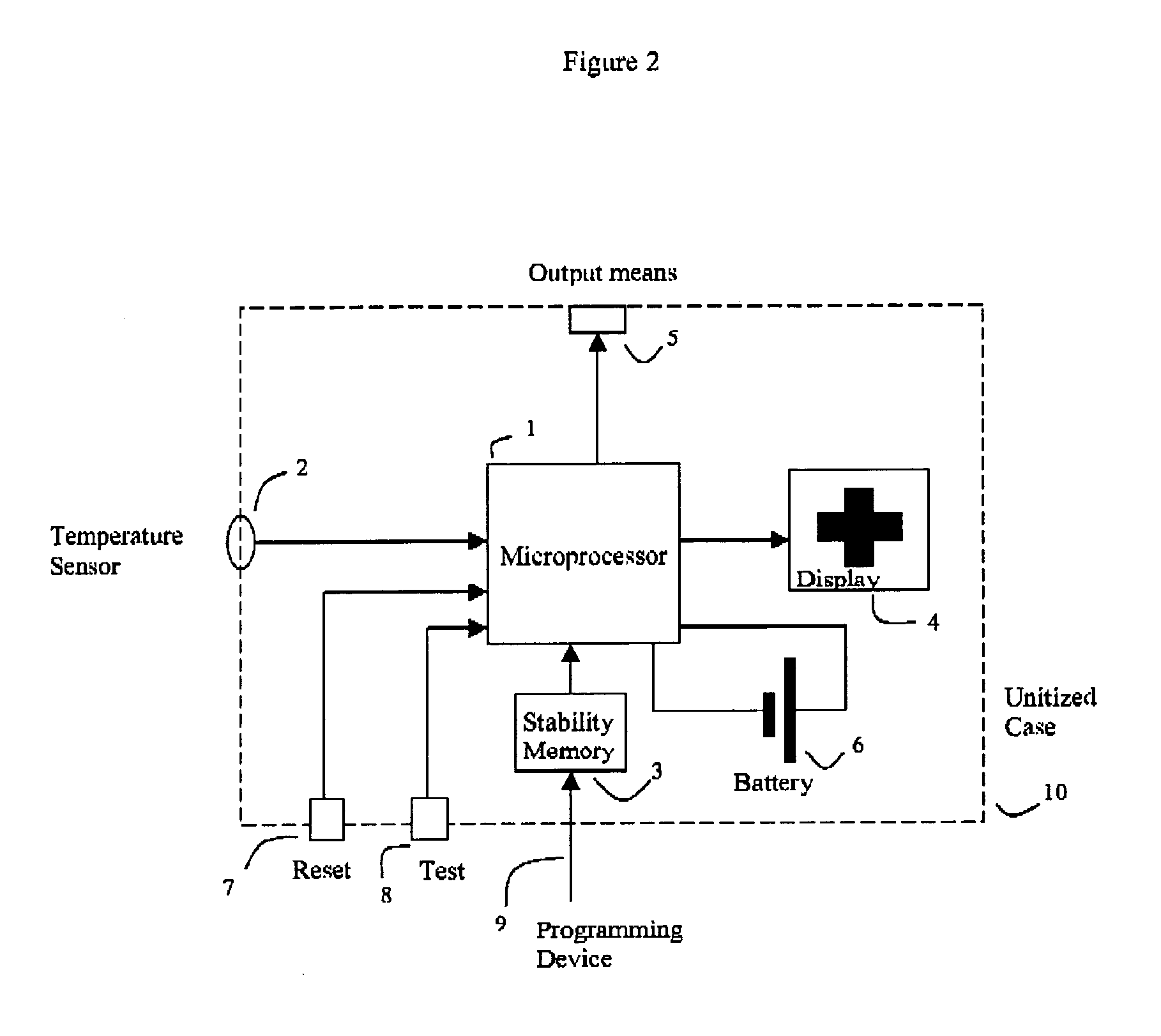

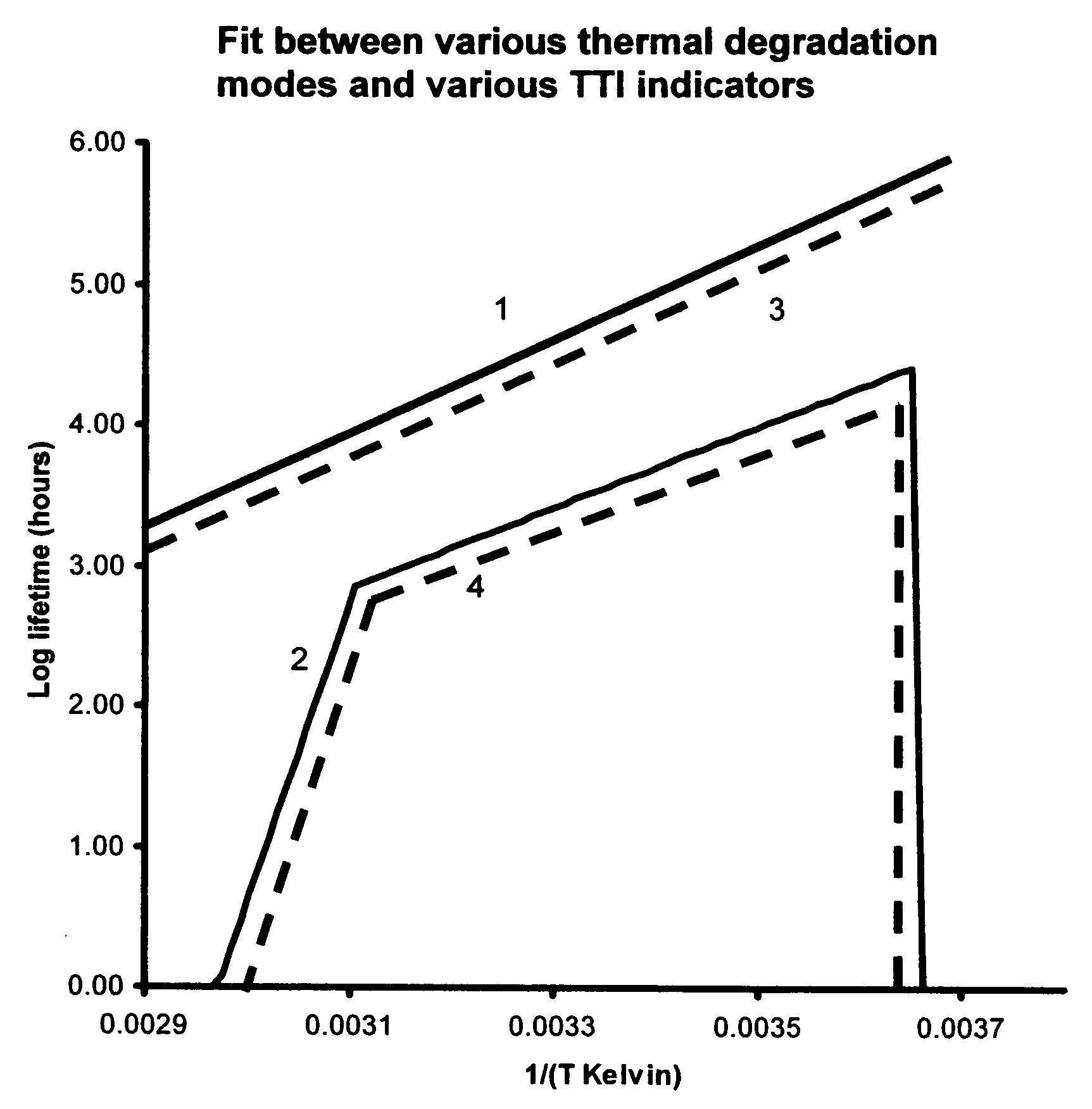

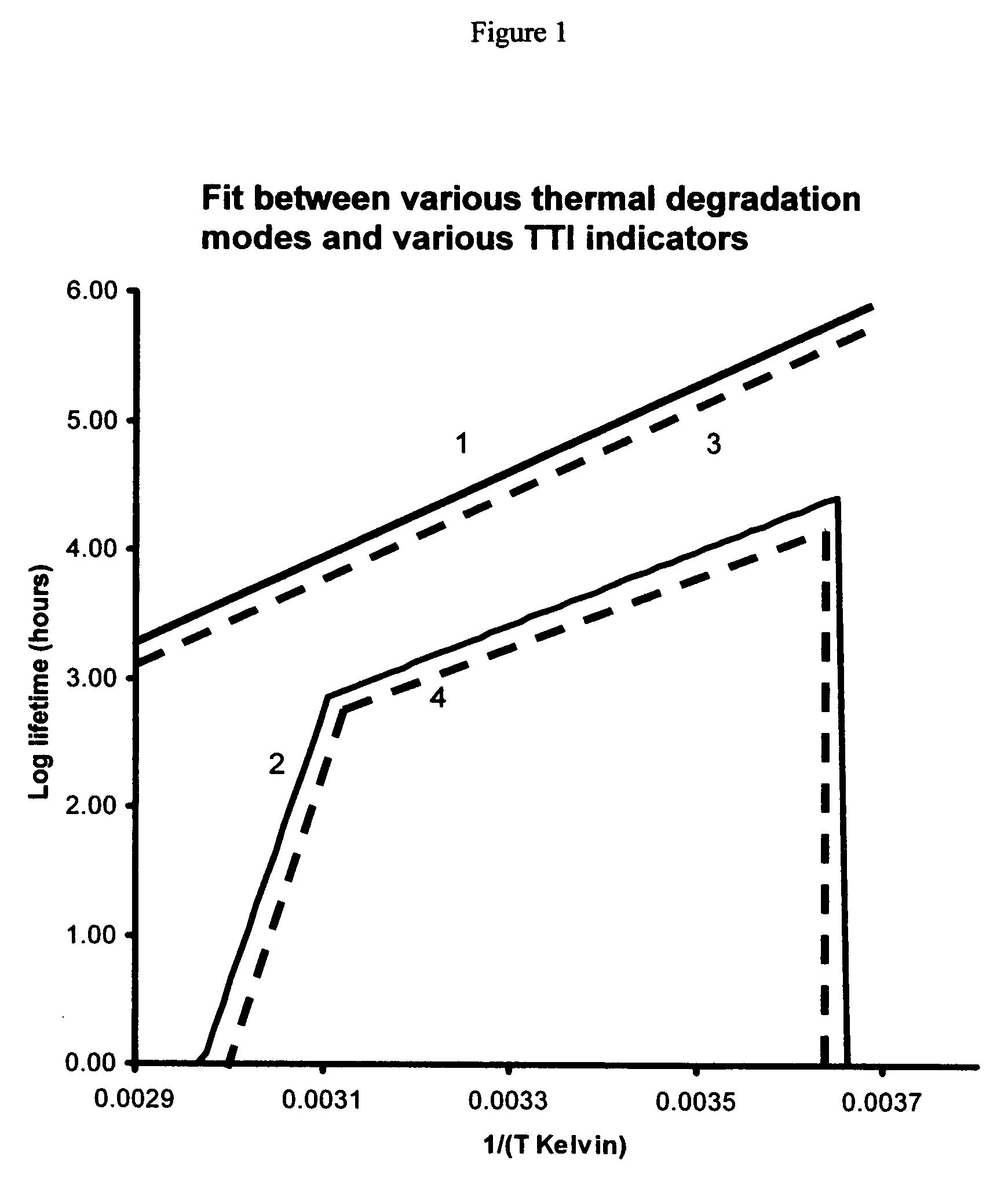

This invention covers electronic time-temperature indicators with a visual output, and other devices and methods by which the thermal history of a material may be monitored, and the subsequent fitness for use of the tracked material may be quickly ascertained. In particular, the invention discloses a rapidly reprogrammable electronic time-temperature tag that may be easily customized with the thermal time-temperature stability profile of an arbitrary material, using electronic data transfer methods. Using this device, a single, low-cost, generic time-temperature tag may be mass-produced, and then subsequently programmed to mimic the stability characteristics of nearly any material of interest.

Owner:ZWEIG STEPHEN ELIOT

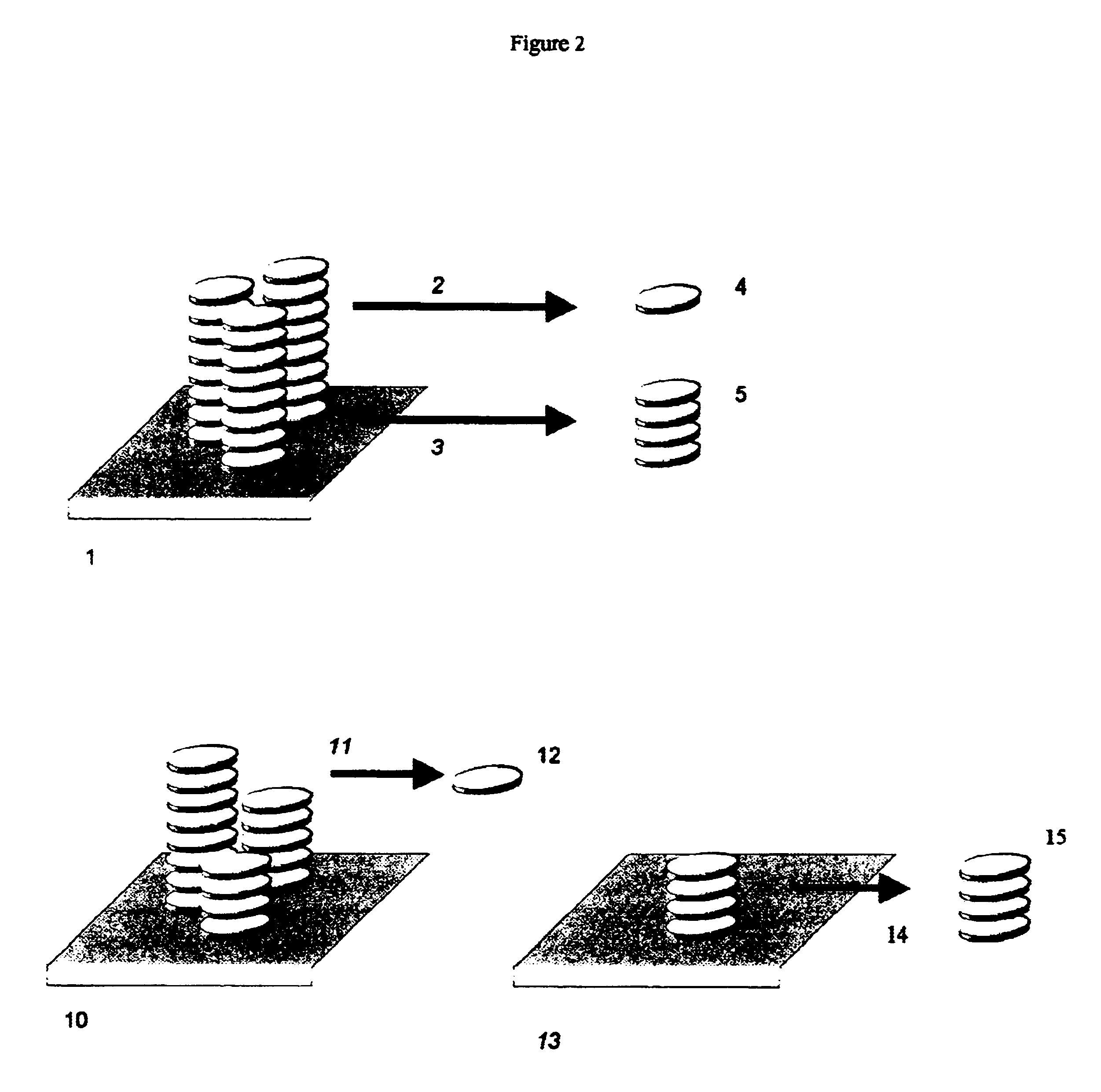

Combination freeze indicators

ActiveUS7490575B2Simple and reliable and inexpensiveThermometer detailsThermometers using mean/integrated valuesEngineeringThreshold temperature

Owner:TEMPTIME CORP

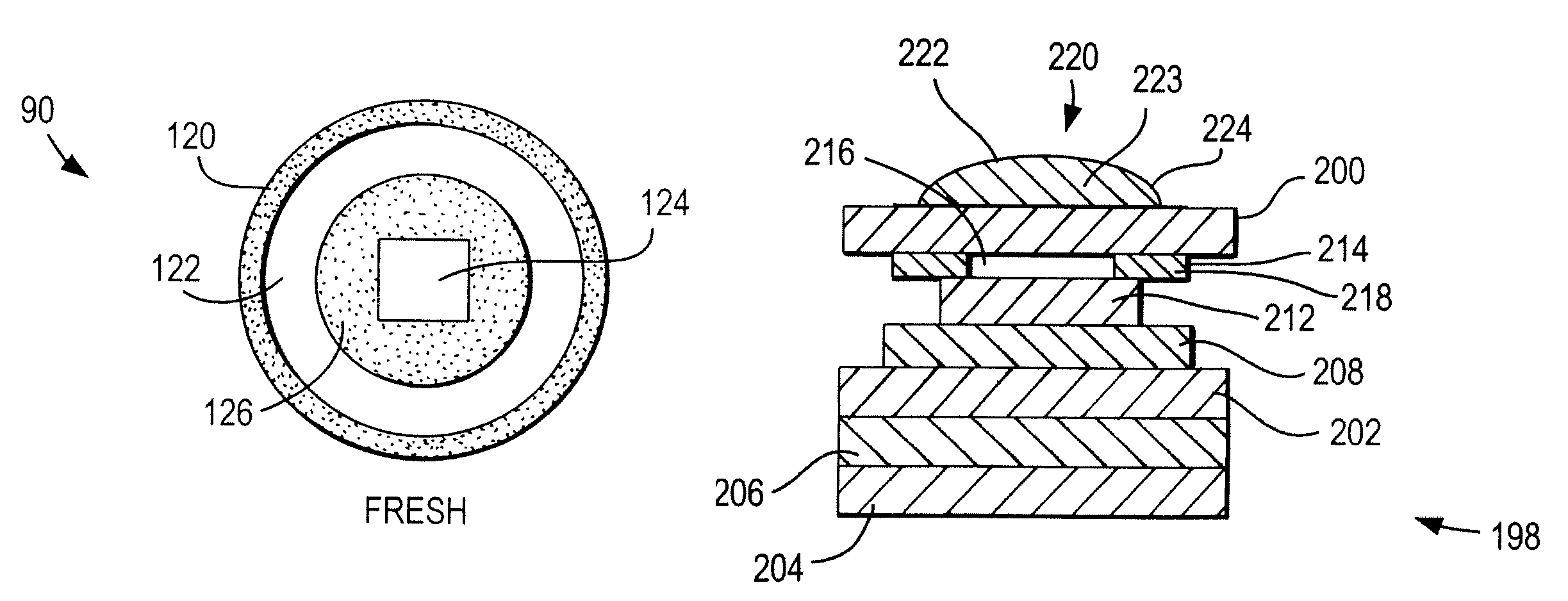

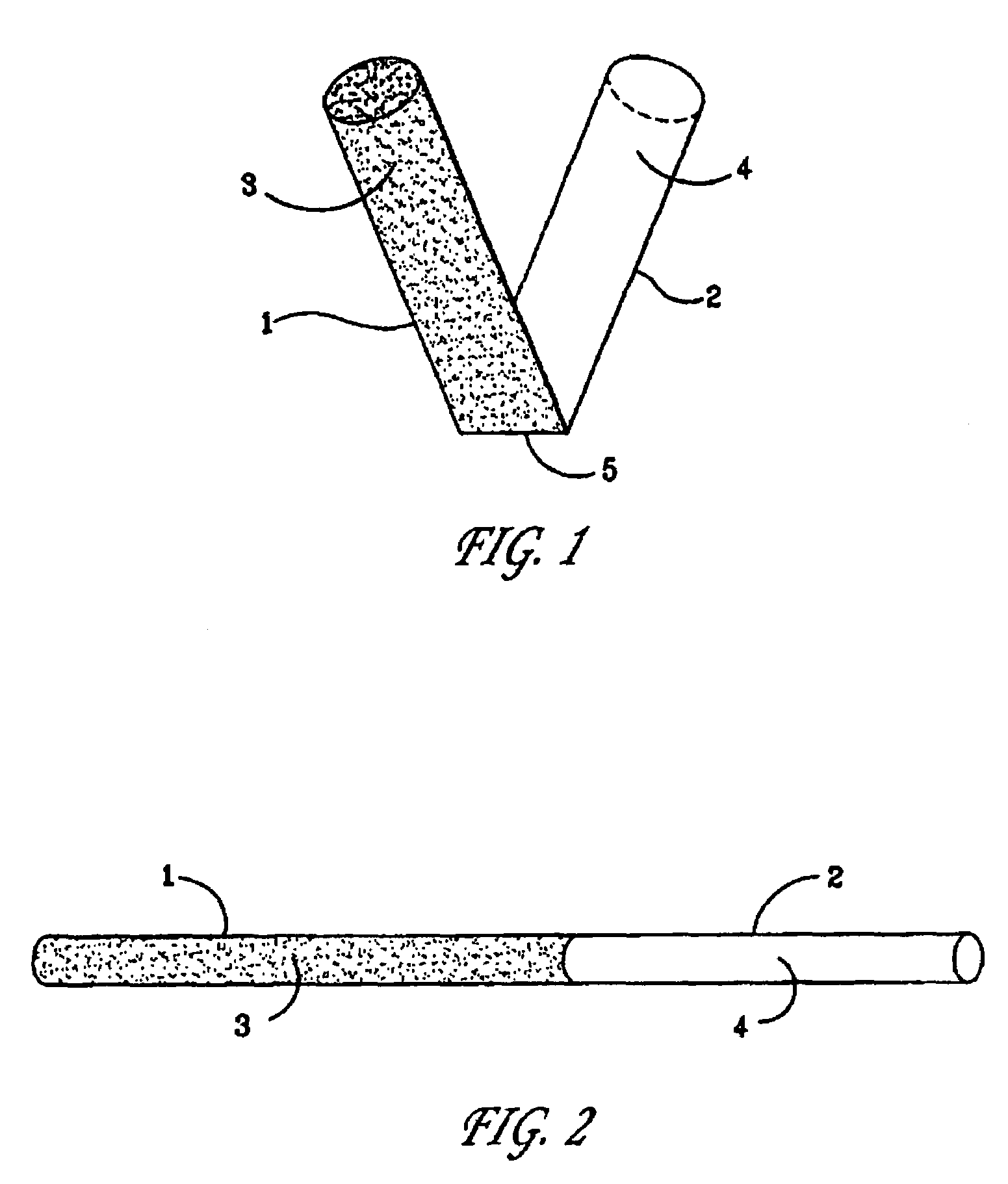

Temperature-activated time-temperature indicator

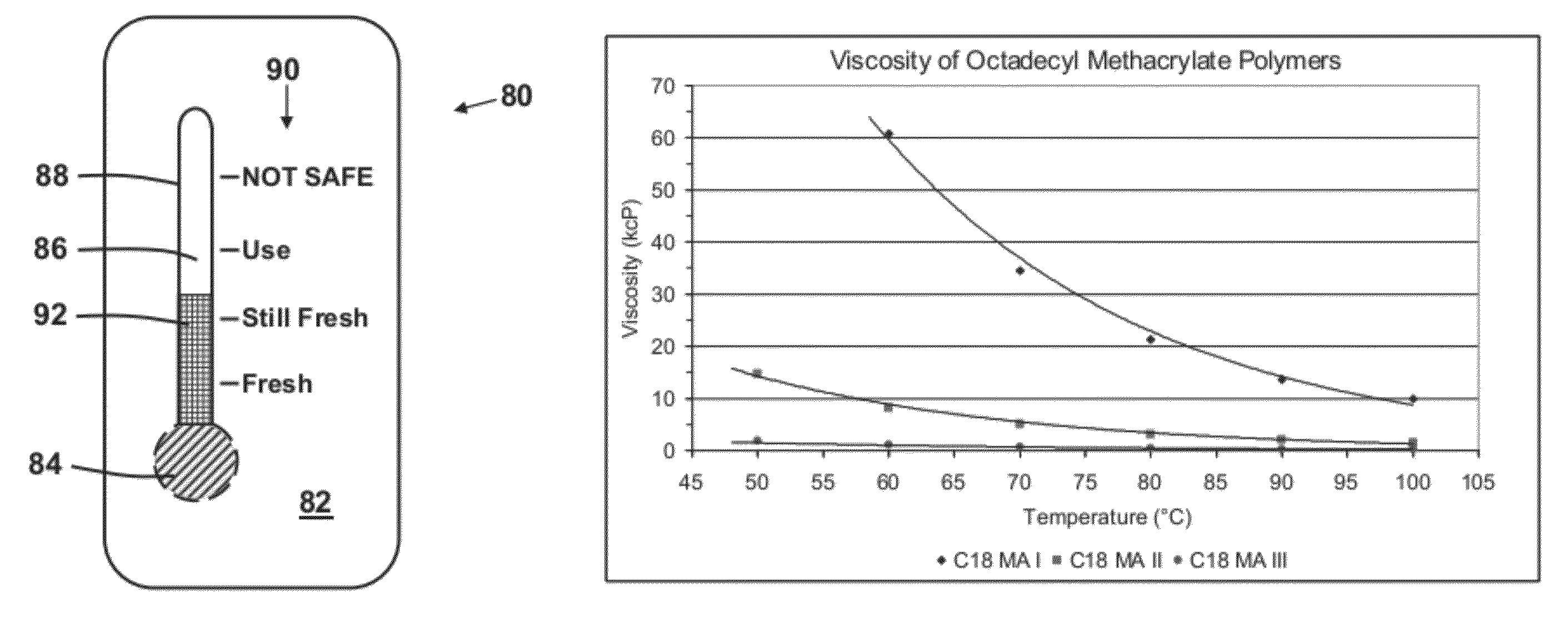

ActiveUS20120079981A1Intense colorSharp contrastThermometer detailsThermometers using mean/integrated valuesViscous liquidSide chain

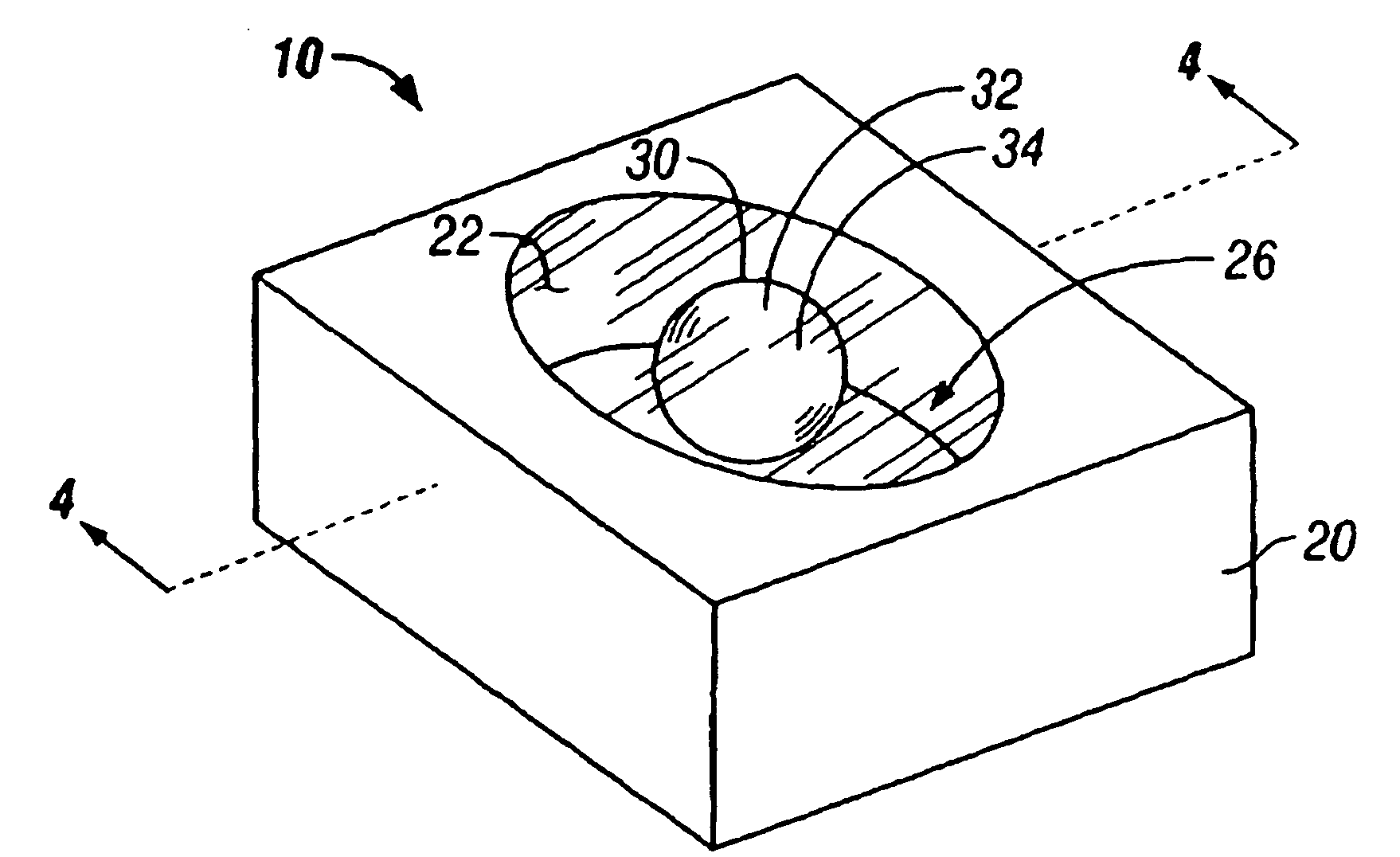

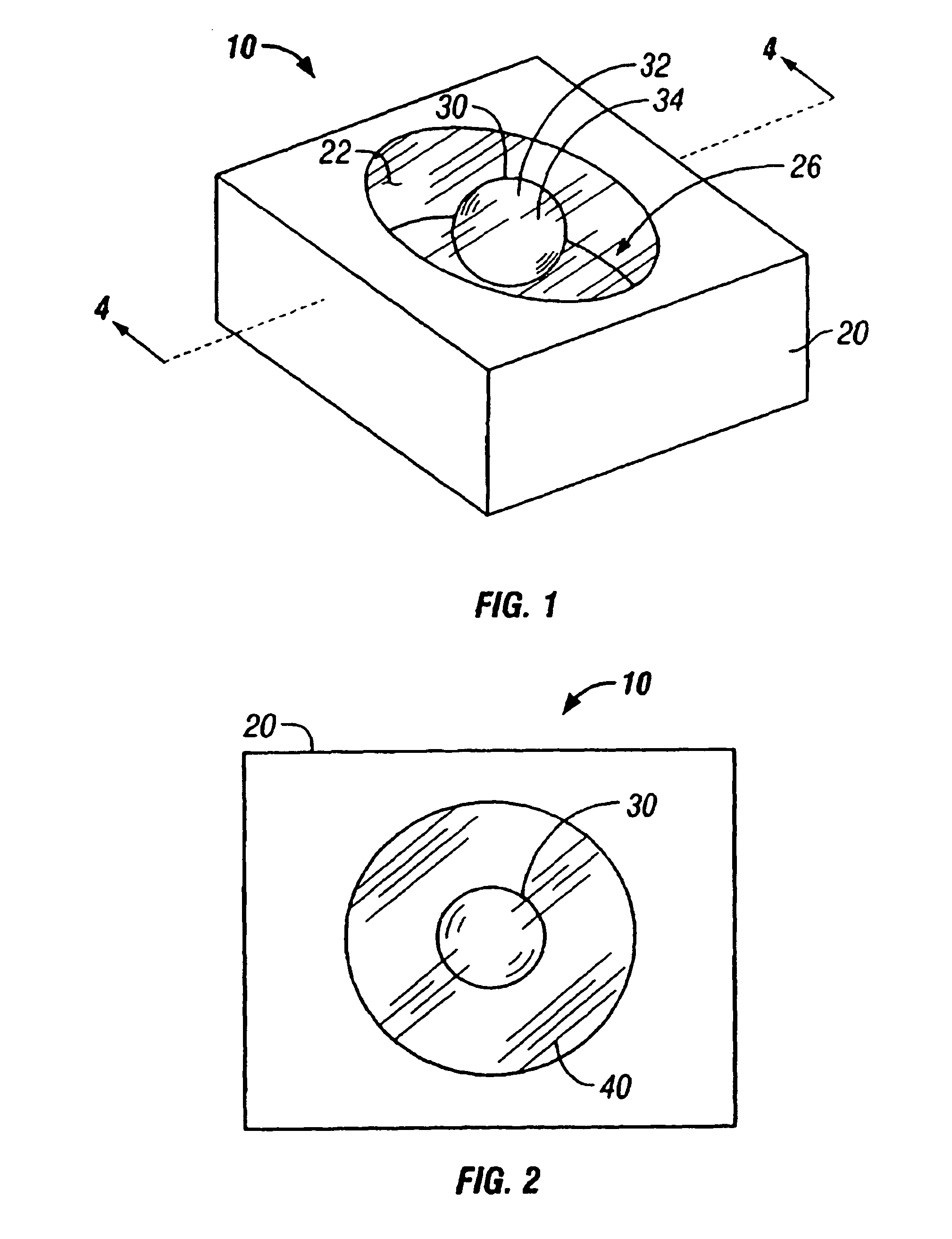

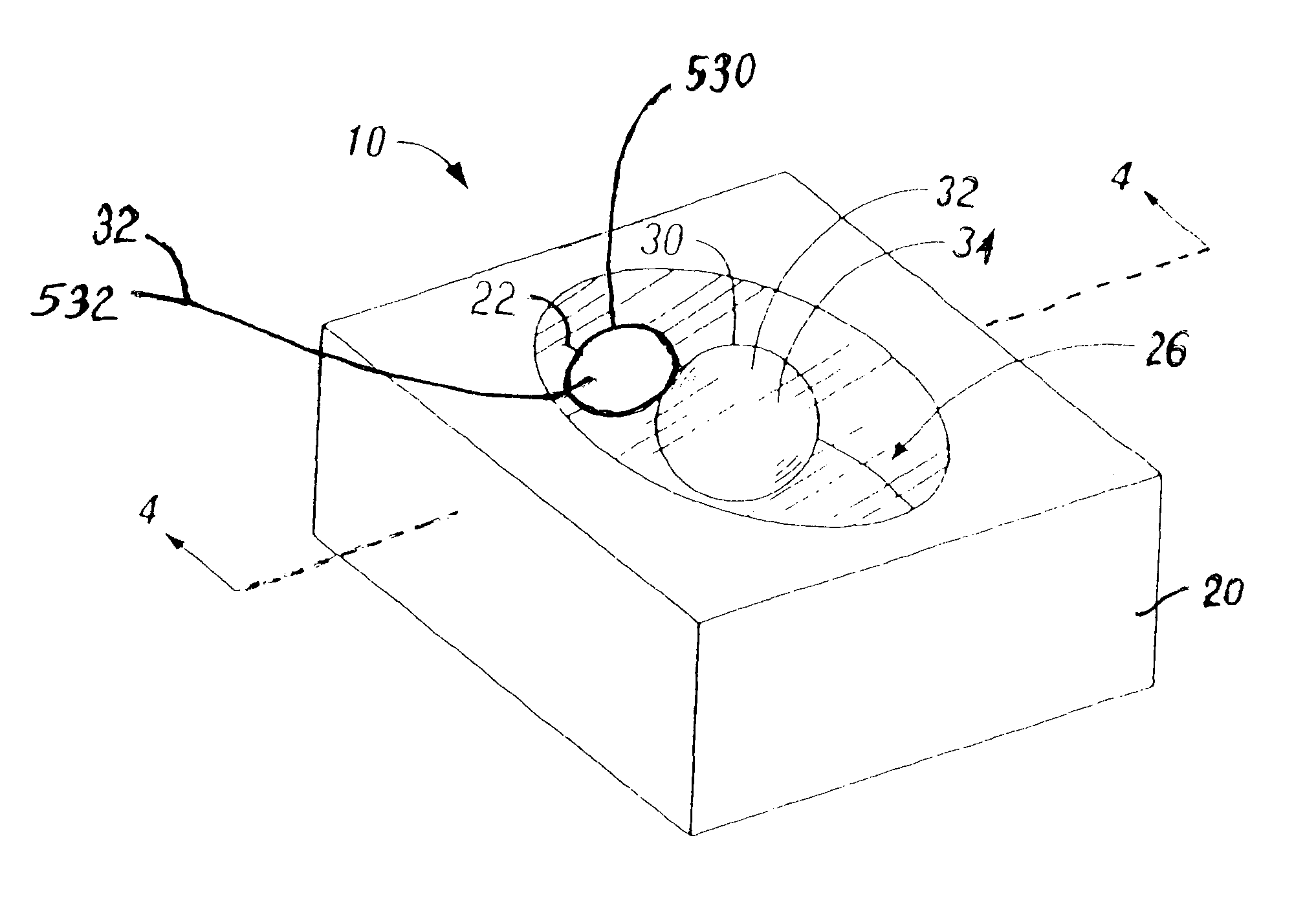

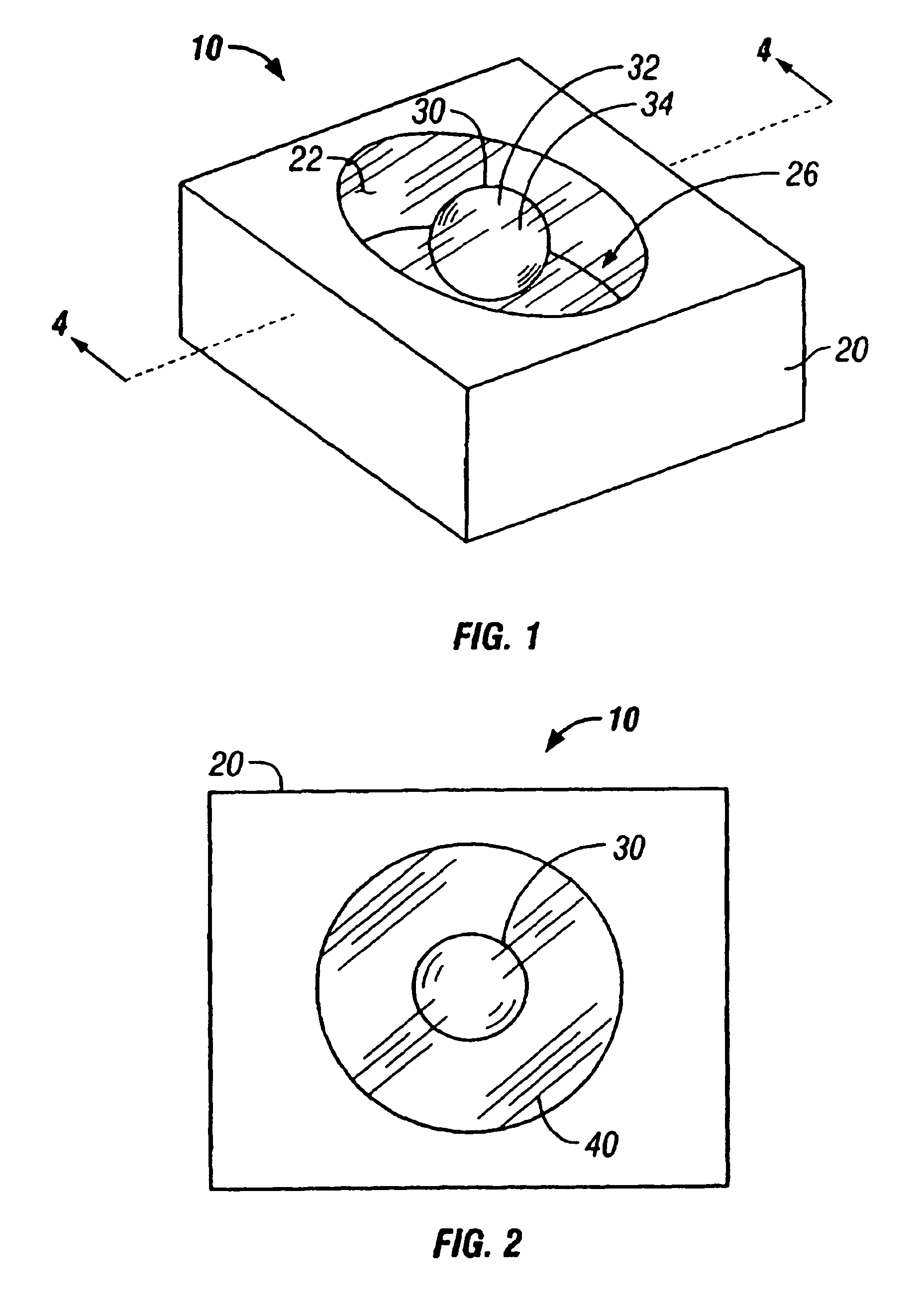

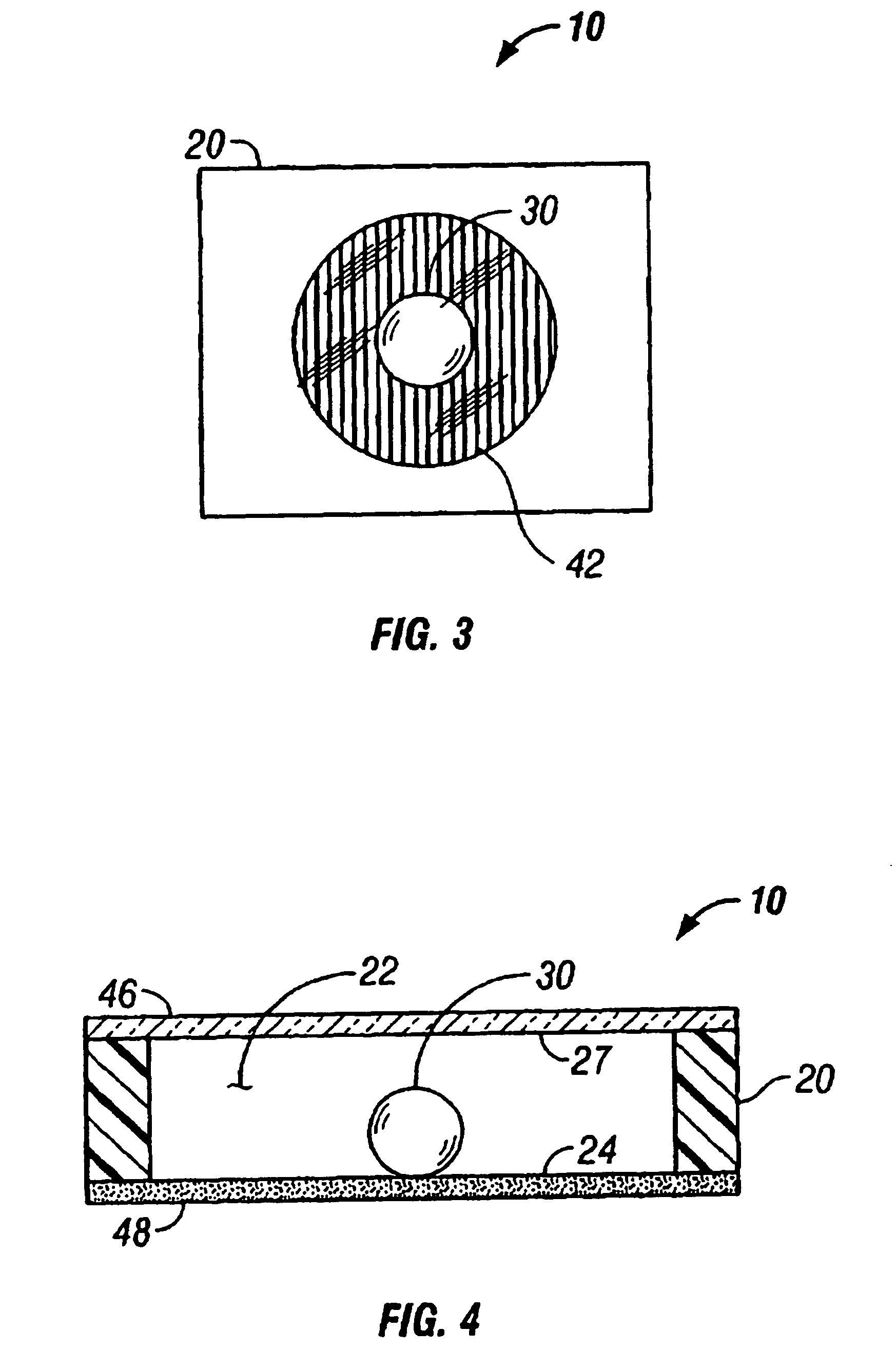

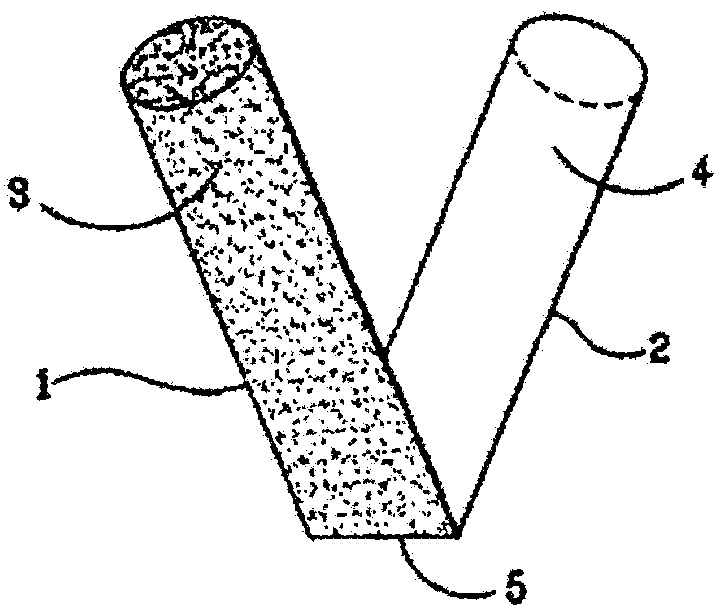

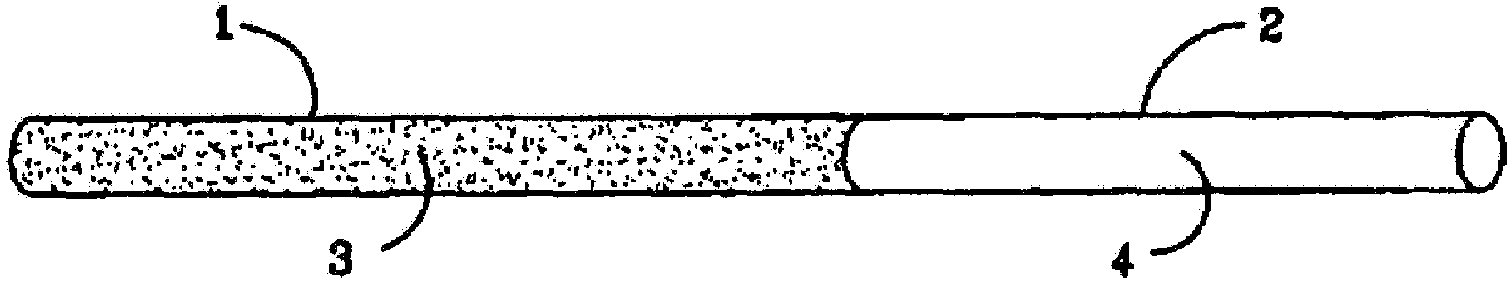

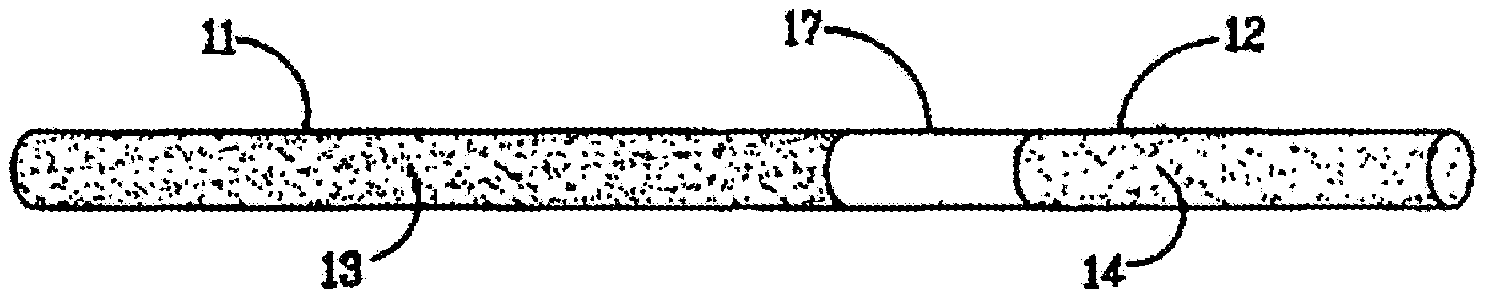

A temperature-activatable time-temperature indicator that can be used to monitor the historical exposure of a host product to ambient temperatures includes an optically readable, thermally sensitive indicator element. The indicator element can be inactive below a base temperature and is intrinsically thermally responsive at or above an activation temperature which is equal to or greater than the base temperature. The indicator can record cumulative ambient temperature exposure above the activation temperature irreversibly with respect to time. The indicator element can include a synthetic polymeric material, and optionally, a dye. A side-chain crystallizable polymer such as poly(hexadecylmethacrylate), that is solid below the base temperature and is a viscous liquid above the activation temperature can be employed. Intense indicator element colors can be obtained using an appropriate dye or dyes. Various structural configurations of indicator are described and illustrated.

Owner:TEMPTIME CORP

Full history time-temperature indicator system

InactiveUS7290925B1Avoid contactThermometer detailsThermometers using mean/integrated valuesChemical reactionDependent manner

A full-history time-temperature indicator system which is capable of exhibiting a time-temperature dependent and visually detectable chemical reaction, useful for monitoring the time and temperature exposure of food products. The system comprises an immobilized reactant, such as Fe3+, and a mobile reactant, such as Fe(CN)64-, initially contained in separate compartments, and separated by a sealing. The system is activated by removing a sealing between the compartments whereby the mobile reactant in a time-temperature dependent manner is brought into contact with the immobilized reactant resulting in a visually detectable reaction signal.

Owner:TIMETEMP

Electronic time-temperature indicator and logger

InactiveUS7102526B2Improve protectionEasily and precisely customizedThermometer detailsThermometers using mean/integrated valuesData transmissionComputer science

This invention covers improved electronic time-temperature indicators with a visual output, and other devices and methods by which the thermal history of a complex material, which may not obey a simple exponential Arrhenius law degradation equation, may be monitored, and the subsequent fitness for use of the tracked material may be quickly ascertained. In particular, the invention discloses a rapidly reprogrammable electronic time-temperature tag that may be easily customized with the thermal time-temperature stability profile of an arbitrary material, using electronic data transfer methods. Using this device, a single, low-cost, generic time-temperature tag may be mass-produced, and then subsequently programmed to mimic the stability characteristics of nearly any material of interest.

Owner:ZWEIG STEPHEN ELIOT

Material lifetime data abstraction device and method

InactiveUS20070001862A1Improve protectionQuick configurationThermometer detailsThermometers using mean/integrated valuesData compressionData abstraction

This invention covers improved electronic time-temperature indicators with an RFID output, and other devices and methods by which the thermal history of a complex material, which may not obey a simple exponential Arrhenius law degradation equation, may be monitored, and the subsequent fitness for use of the tracked material may be quickly ascertained. In particular, the invention discloses a rapidly reprogrammable electronic time-temperature RFID tag that may be easily customized with the thermal time-temperature stability profile of an arbitrary material, using electronic data transfer methods. Using this device, a single, low-cost, generic time-temperature tag may be mass-produced, and then subsequently programmed to mimic the stability characteristics of nearly any material of interest. By utilizing data compression to compress a material's extensive thermal history into the small user data field transmitted by modern RFID tags, a considerable amount of information relating to product status and cause of failure may be rapidly transmitted within the small memory confines of standard RFID tag protocols.

Owner:ZWEIG STEPHEN ELIOT

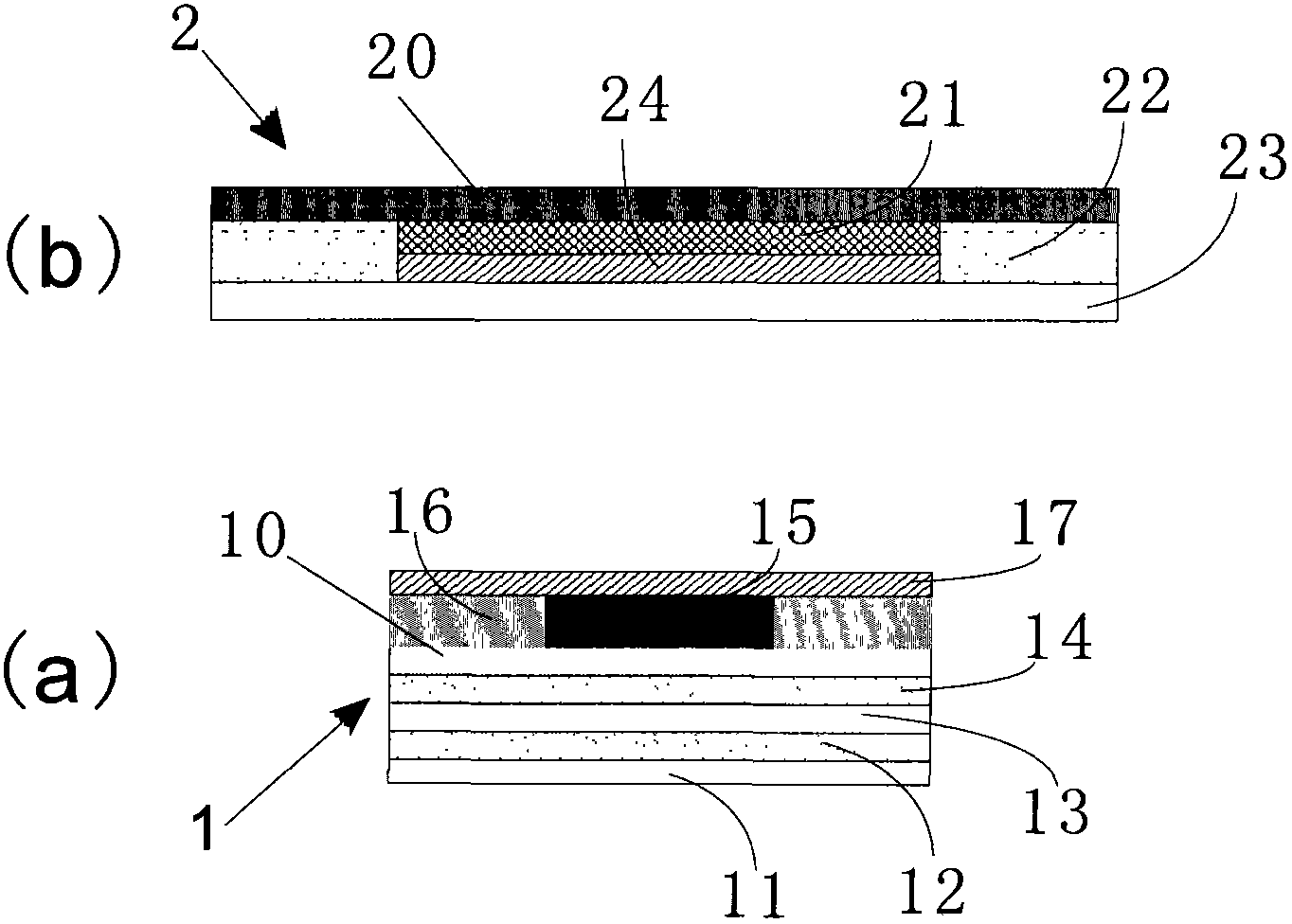

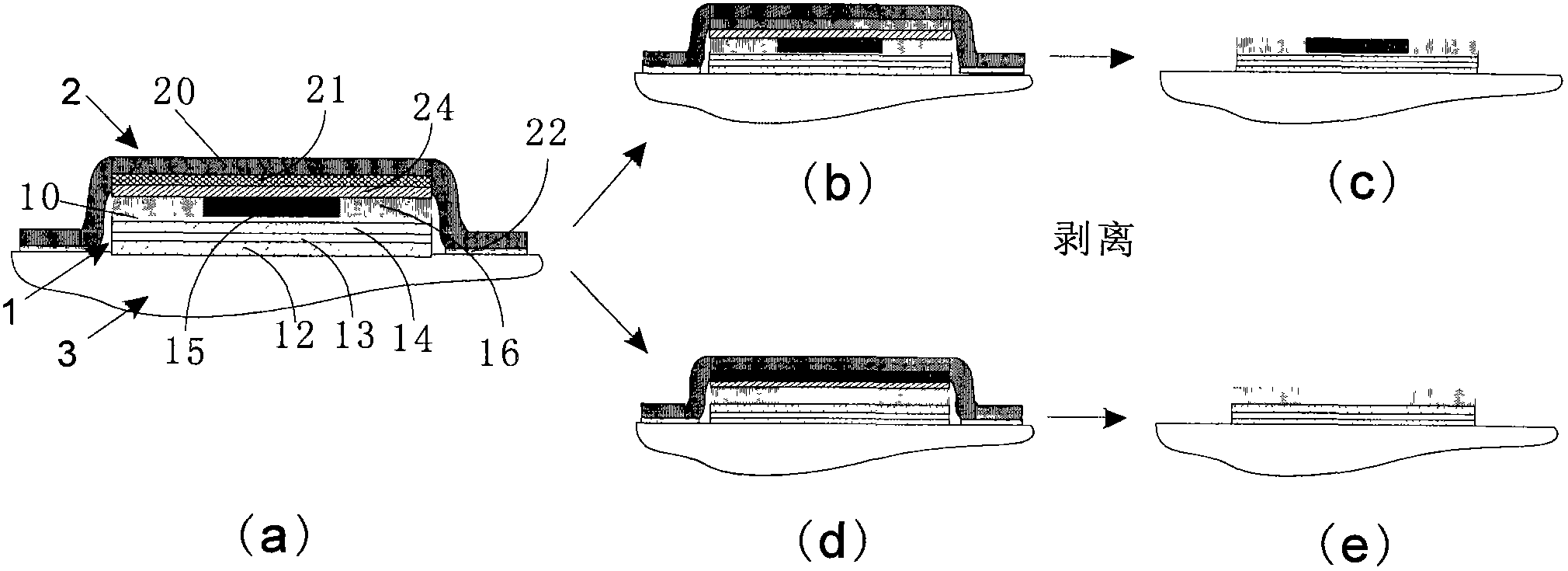

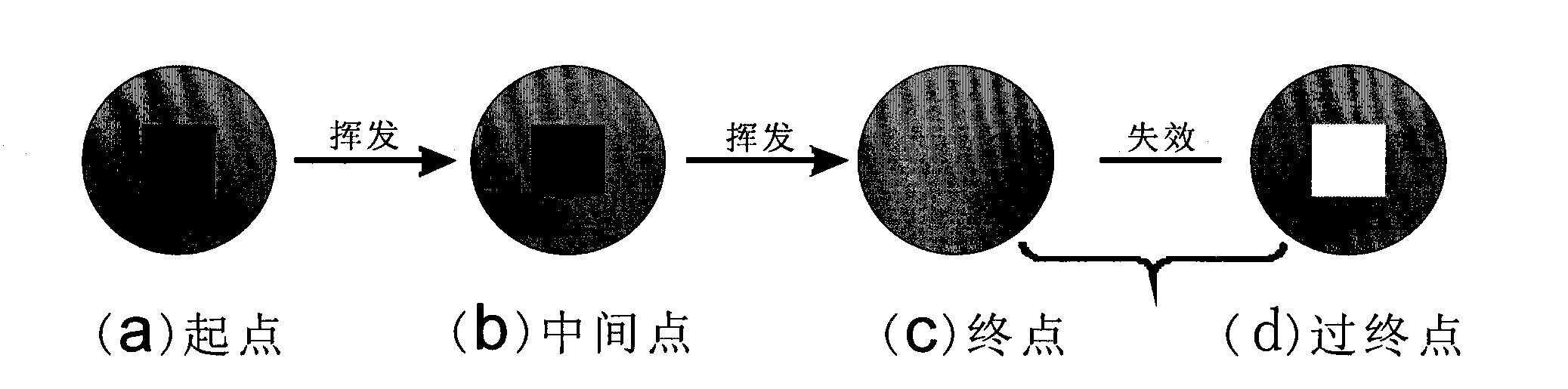

Method for monitoring accumulative heating quantity of heat reactive articles and indicator used by method

ActiveCN102853946ASure easyThermometers using mean/integrated valuesSynthetic resin layered productsEngineeringMaterials science

The invention relates to a method for monitoring accumulative heating quantity of heat reactive articles and an indicator used by the method. The method for monitoring accumulative heating quantity of heat reactive articles comprises the following steps: (a) providing a heat reactive article; (b) adhering a layer of volatile dye to certain areas of the heat reactive article; (c) adhering a layer of adsorbing materials to the volatile dye; and (d) adhering sealing film to the certain areas and the peripheries of the certain areas, wherein the sealing film enables the adsorbing materials layer and the volatile dye layer to adhere on the heat reactive article in sealing mode, the volatile dye can volatilize under the condition of being heated, the adsorbing materials are adhered on the volatilized dye in irreversible mode, the color fading quantity of the volatile dye layer is in positive correlation with volatilizing quantity of dye, and the volatilizing quantity of dye is in positive correlation with heat absorbed by the heat reactive article. By means of the method for monitoring accumulative heating quantity of heat reactive articles and the time-temperature indicator provided according to the method, heating condition and quality state of the heat reactive articles can be effectively indicated.

Owner:SUZHOU HUASHI MATERIAL TECH

Temperature-activated time-temperature indicator

ActiveUS8671871B2Sharp contrastIntense colorThermometer detailsThermometers using mean/integrated valuesViscous liquidSide chain

A temperature-activatable time-temperature indicator that can be used to monitor the historical exposure of a host product to ambient temperatures includes an optically readable, thermally sensitive indicator element. The indicator element can be inactive below a base temperature and is intrinsically thermally responsive at or above an activation temperature which is equal to or greater than the base temperature. The indicator can record cumulative ambient temperature exposure above the activation temperature irreversibly with respect to time. The indicator element can include a synthetic polymeric material, and optionally, a dye. A side-chain crystallizable polymer such as poly(hexadecylmethacrylate), that is solid below the base temperature and is a viscous liquid above the activation temperature can be employed. Intense indicator element colors can be obtained using an appropriate dye or dyes. Various structural configurations of indicator are described and illustrated.

Owner:TEMPTIME CORP

Particle size control for acetylenic agents useful in condition monitoring systems

ActiveUS7019171B1Improving quality performanceUrea derivatives preparationOrganic compound preparationNitrocelluloseRadiation Exposure Monitoring

Precipitation of polyacetylenic agents can be effected with control of a particle size parameter such as mean size or spread, by mixing a warm solution of the acetylenic agent with a cold precipitation fluid and appropriate selection of a constituent of the cold precipitation fluid and / or of the temperature conditions and collecting the precipitated acetylenic agent. Precipitation additives such as nitrocellulose or gelatin can usefully be employed. Solvents such as aqueous methanol and ethyl 3-ethoxypropionate can be useful. Polyacetylenic agents, e.g. substituted diacetylenics are useful to provide visual changes in condition-monitoring indicators such as time-temperature indicators, “TTIs”, useful as freshness indicators for radiation exposure monitoring and for other purposes. Controlled, small and / or consistent particle sizes of such polyacetylenic agents are helpful in providing consistent commercial properties, especially in inks in which they may be formulated.

Owner:TEMPTIME CORP

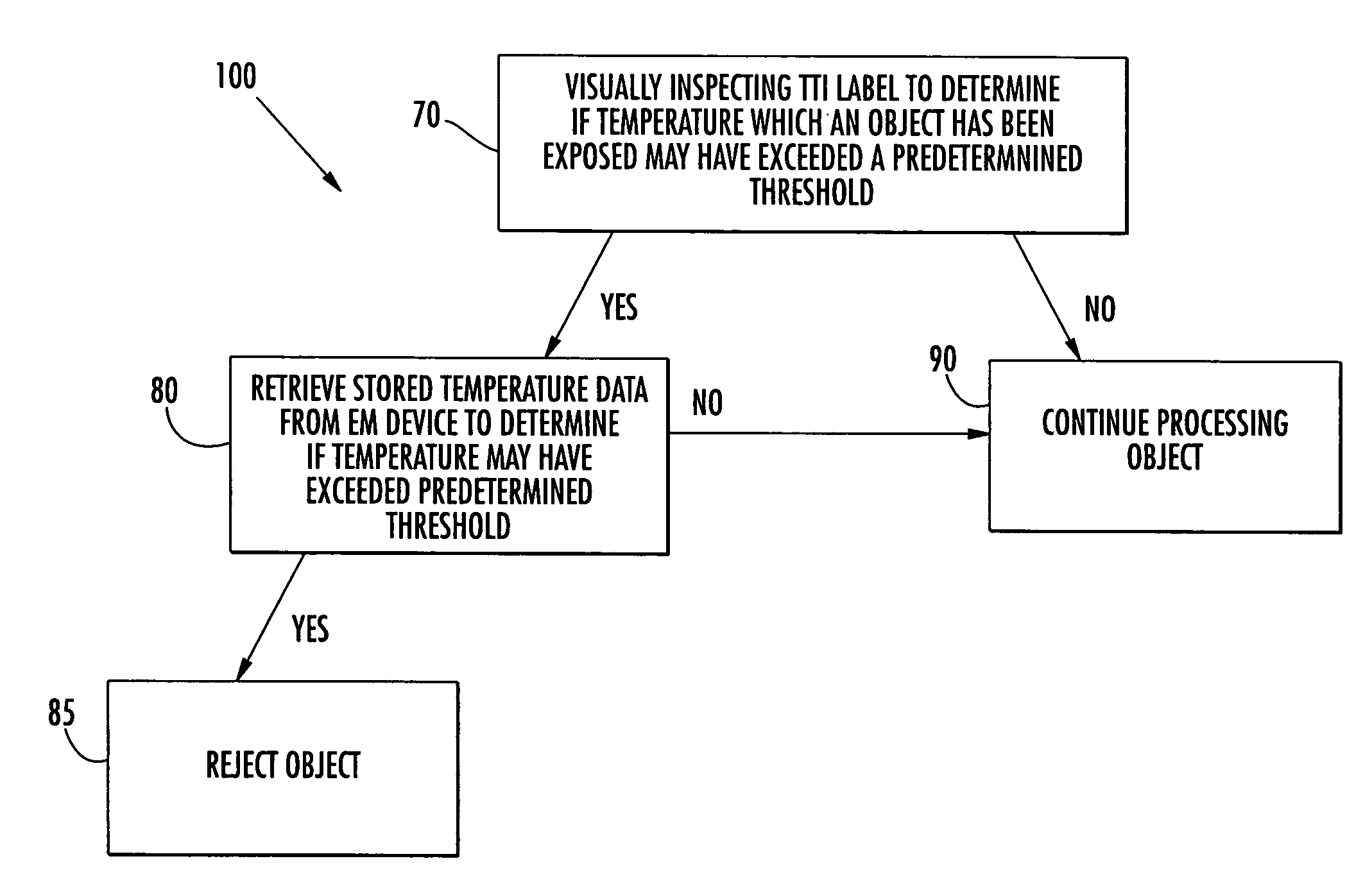

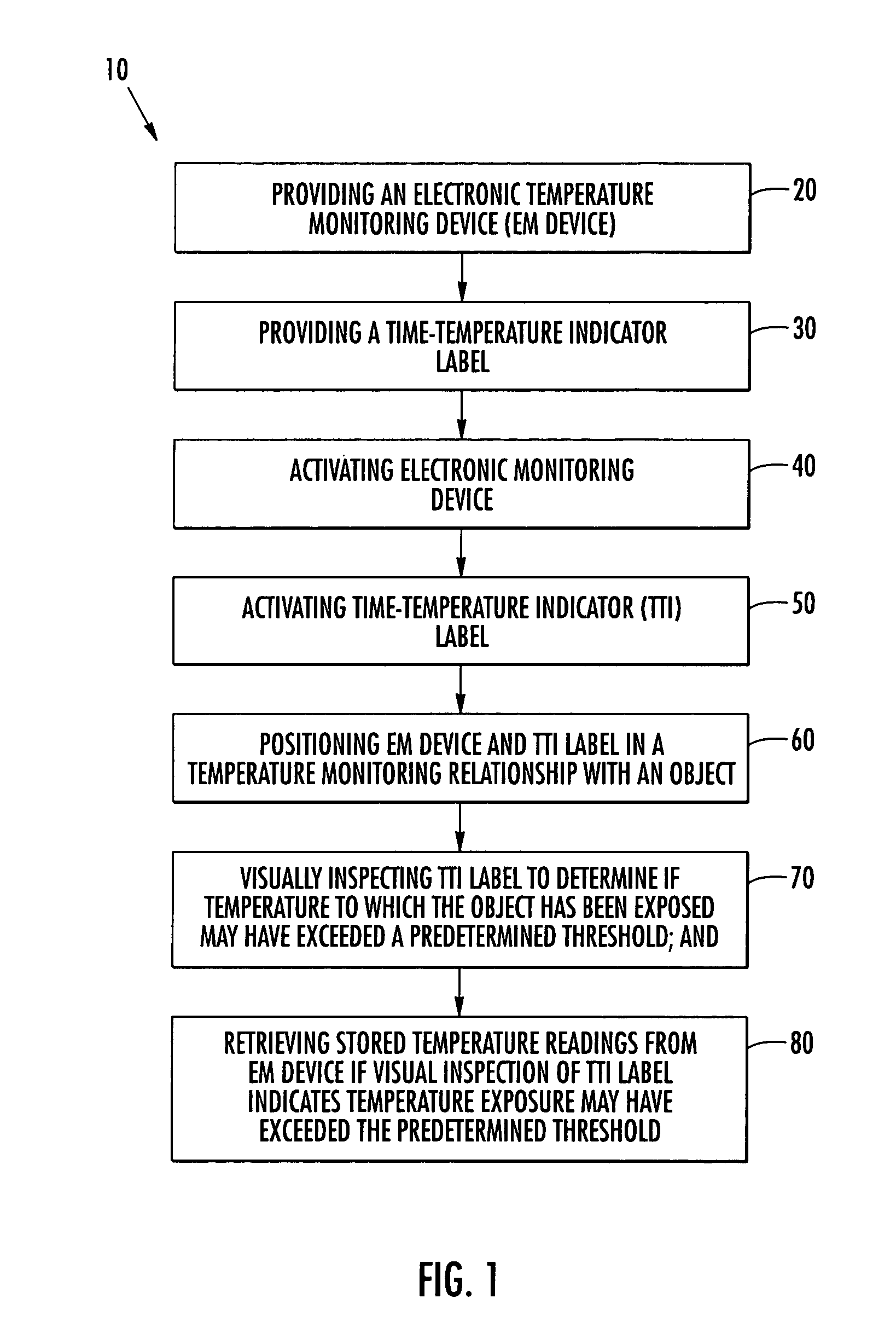

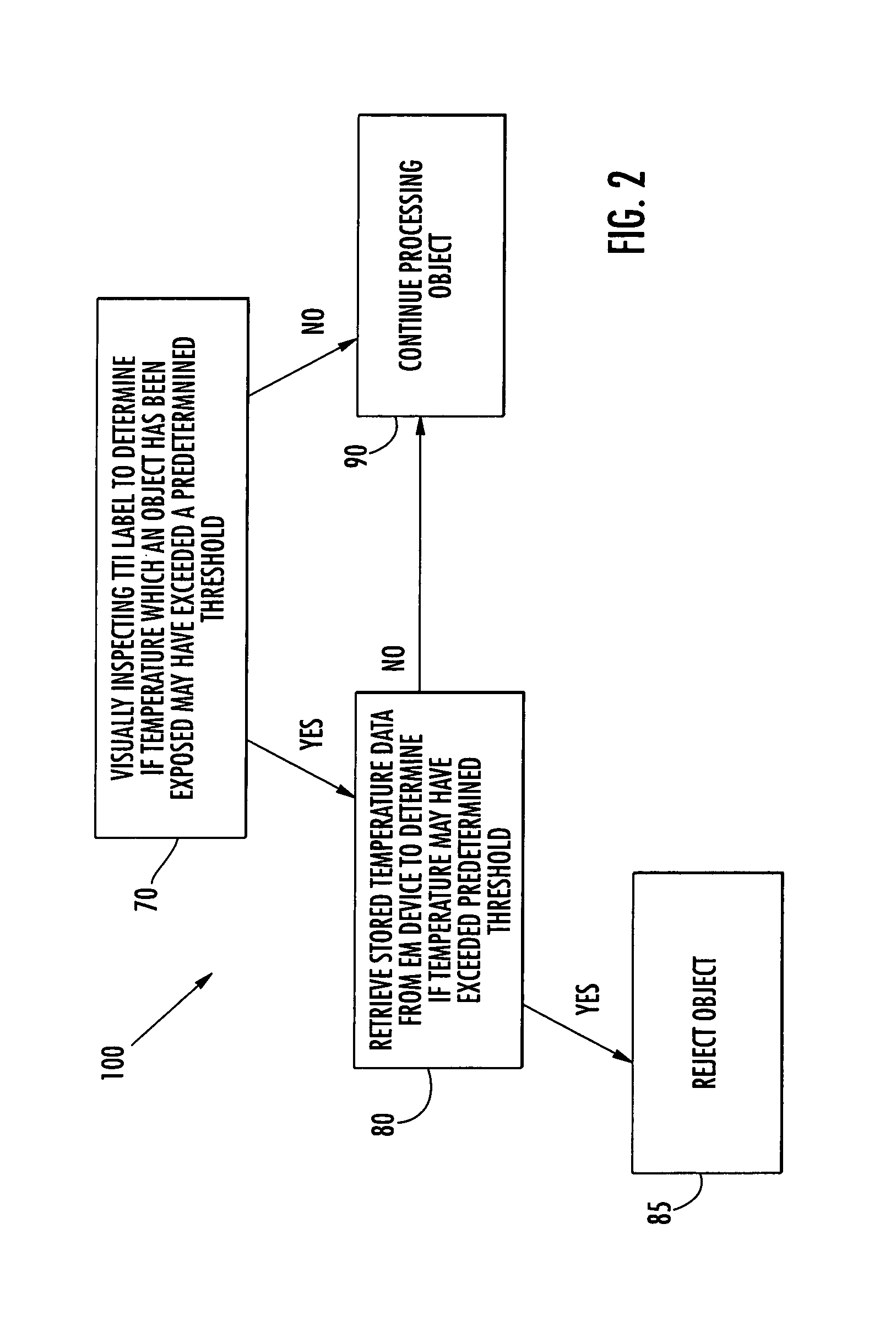

Method of monitoring temperature exposure

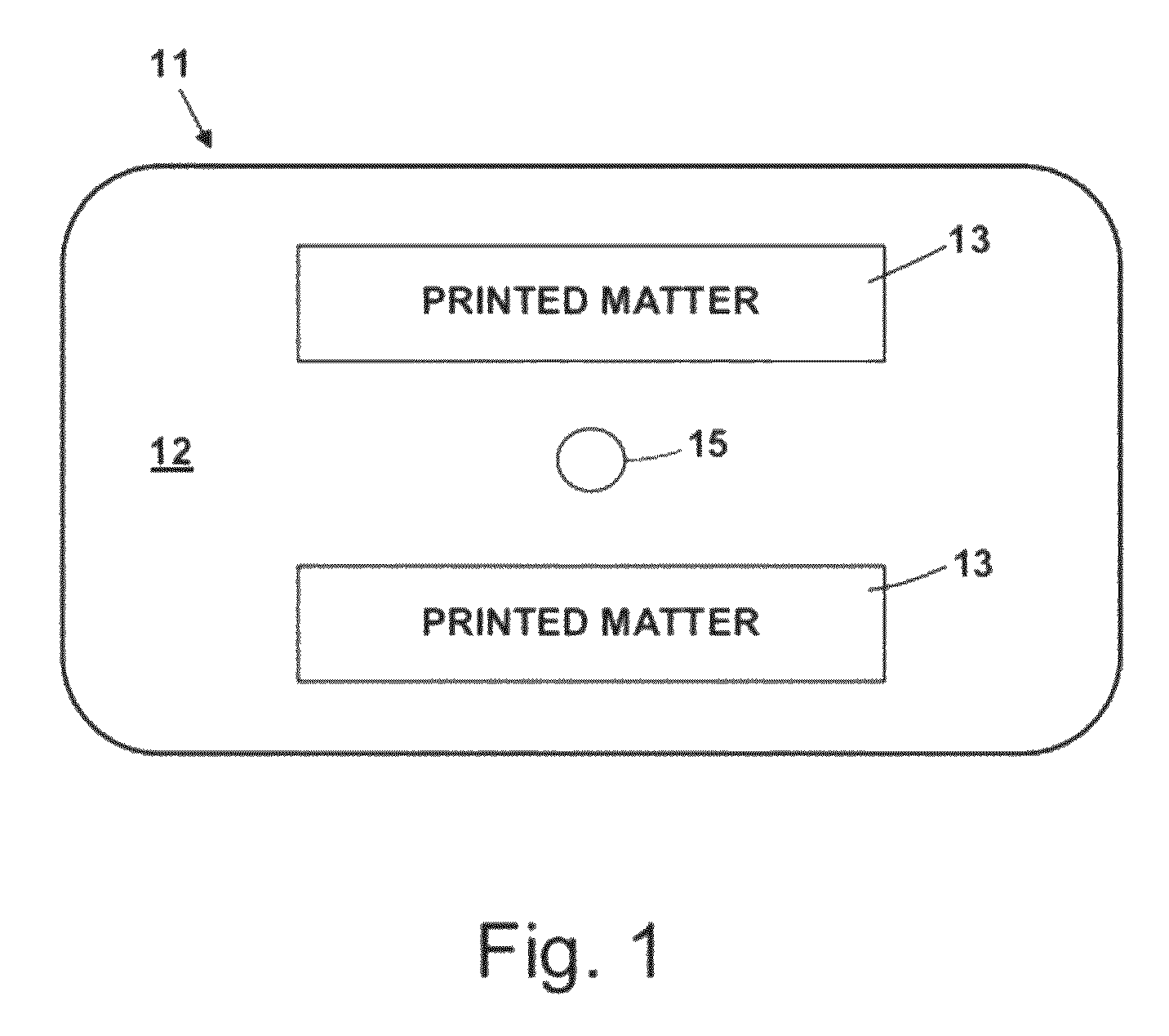

ActiveUS7004621B2Rapidly and efficiently inspectedGuaranteed accuracyThermometer detailsThermometers using mean/integrated valuesMonitoring temperatureVisual inspection

Owner:CRYOVAC ILLC

Material lifetime data abstraction device and method

InactiveUS7564364B2Easily and precisely customizedHigh outputThermometer detailsThermometers using mean/integrated valuesData compressionData abstraction

This invention covers improved electronic time-temperature indicators with an RFID output, and other devices and methods by which the thermal history of a complex material, which may not obey a simple exponential Arrhenius law degradation equation, may be monitored, and the subsequent fitness for use of the tracked material may be quickly ascertained. In particular, the invention discloses a rapidly reprogrammable electronic time-temperature RFID tag that may be easily customized with the thermal time-temperature stability profile of an arbitrary material, using electronic data transfer methods. Using this device, a single, low-cost, generic time-temperature tag may be mass-produced, and then subsequently programmed to mimic the stability characteristics of nearly any material of interest. By utilizing data compression to compress a material's extensive thermal history into the small user data field transmitted by modern RFID tags, a considerable amount of information relating to product status and cause of failure may be rapidly transmitted within the small memory confines of standard RFID tag protocols.

Owner:ZWEIG STEPHEN ELIOT

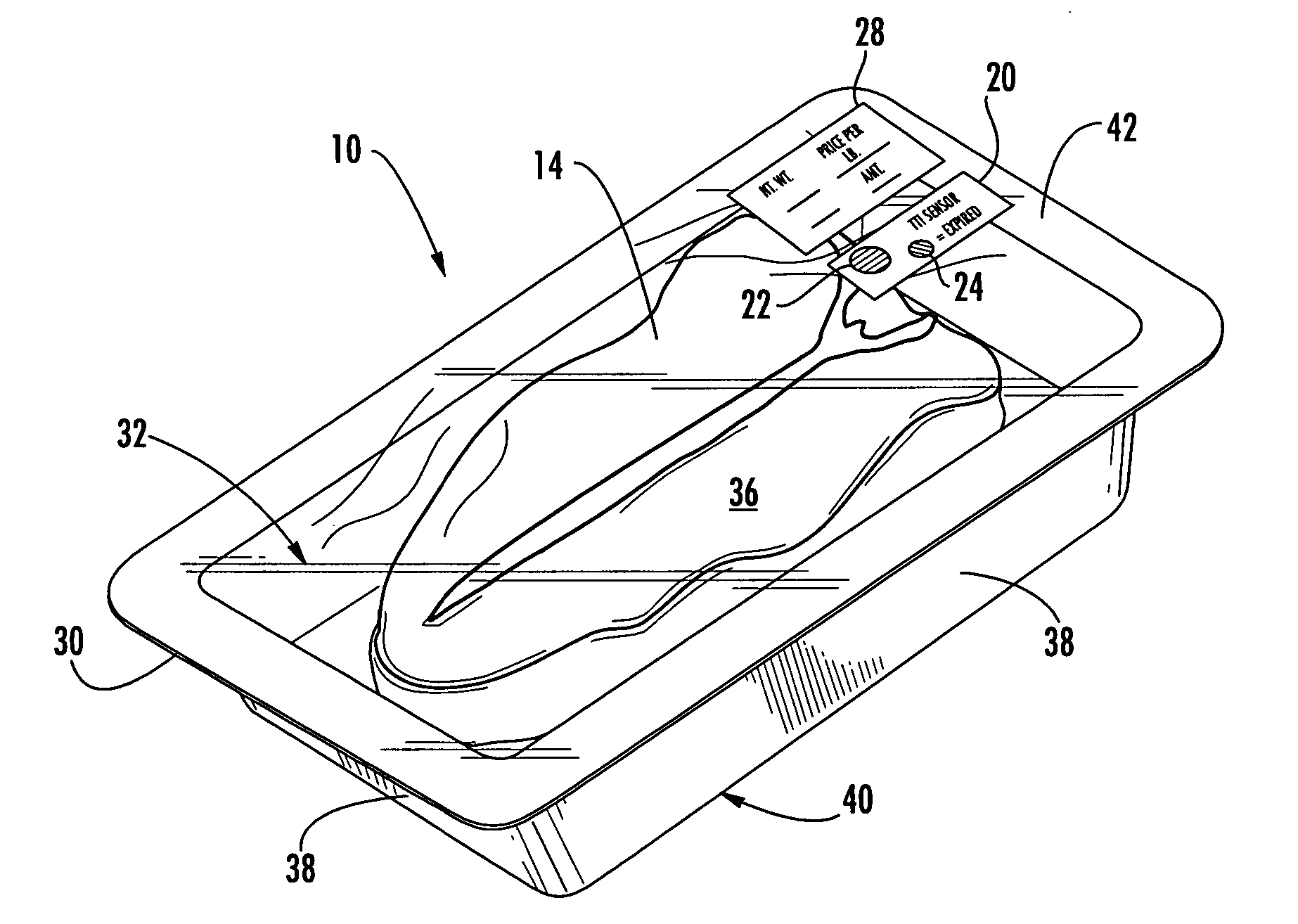

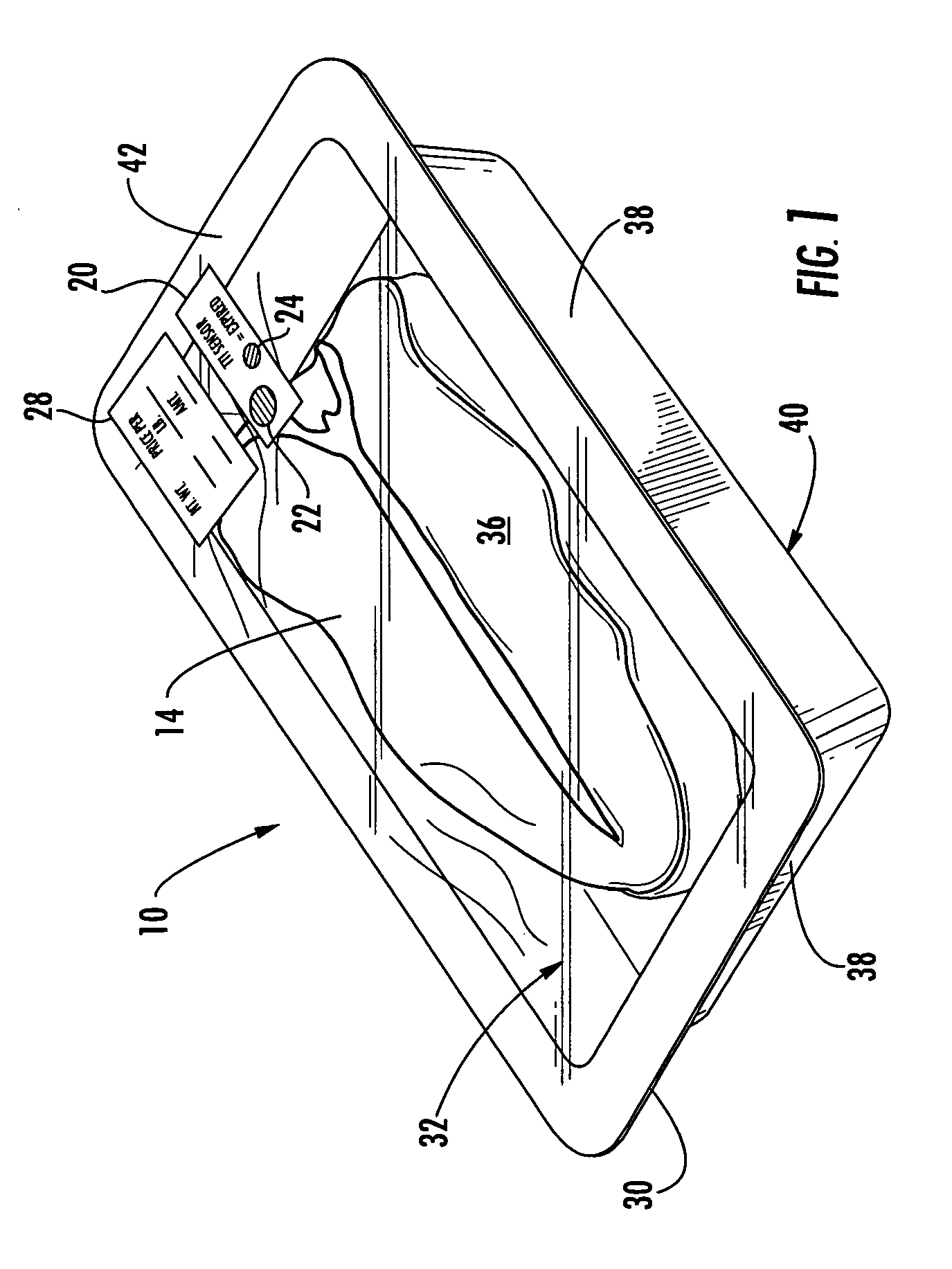

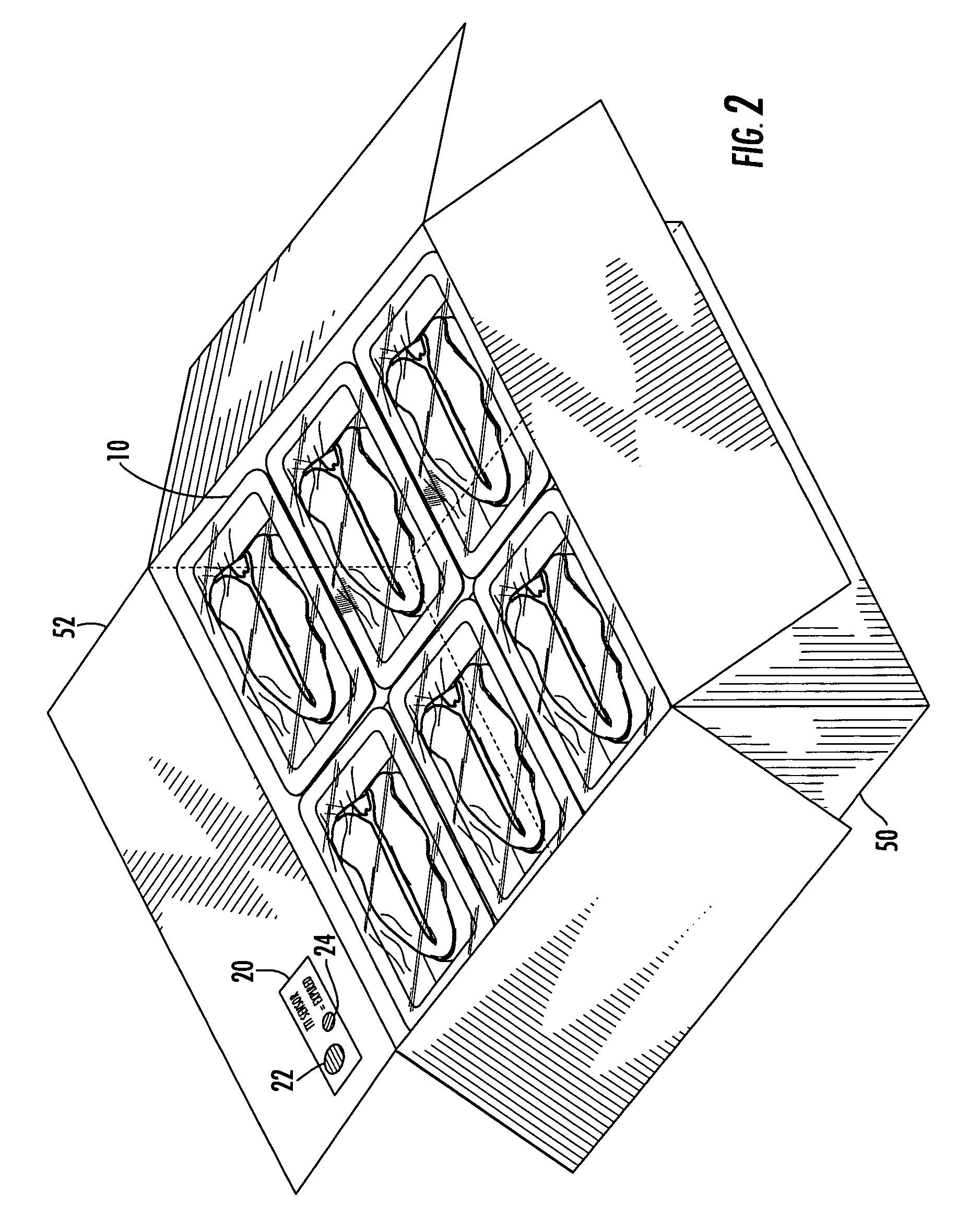

Carbon monoxide modified atmosphere packaging having a time temperature indicator

InactiveUS20070059402A1Reduce the possibilityMeat/sausages markingSausage casingsEngineeringTemperature monitoring

The invention is a modified atmosphere package comprising about 0.1 to 5 vol. % carbon monoxide and that includes a time-temperature indicator that is disposed in a temperature monitoring relationship with the package and that is configured to indicate whether a perishable product disposed in the package has been exposed to a time-temperature exposure that may have caused spoilage of the product. The time-temperature indicator may be used to alert a person that a red meat product disposed in the package has potentially spoiled even though the meat product may have a fresh “bloomed” appearance. As a result, the possibility of a consumer purchasing a spoiled product may be reduced. The invention is also directed to a method of using the time-temperature indicator to indicate the likelihood of spoilage in the packaged product. In one embodiment, the time-temperature indicator changes visual appearance based on a combination of predetermined times and temperatures.

Owner:CRYOVAC ILLC

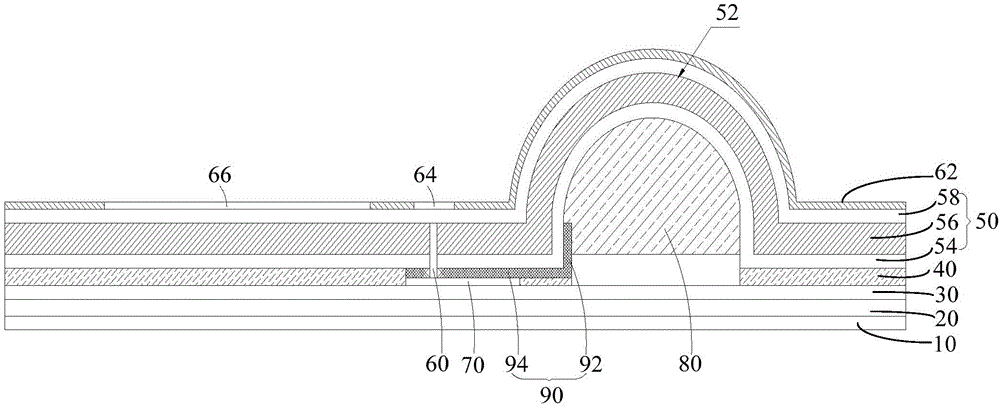

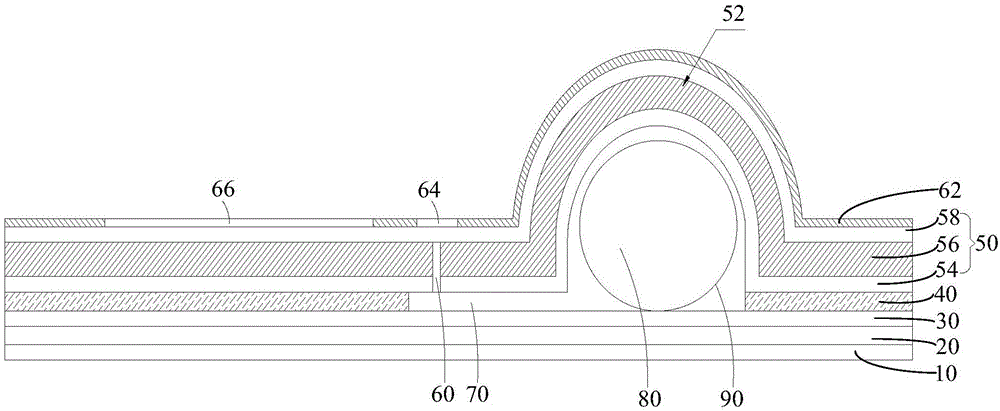

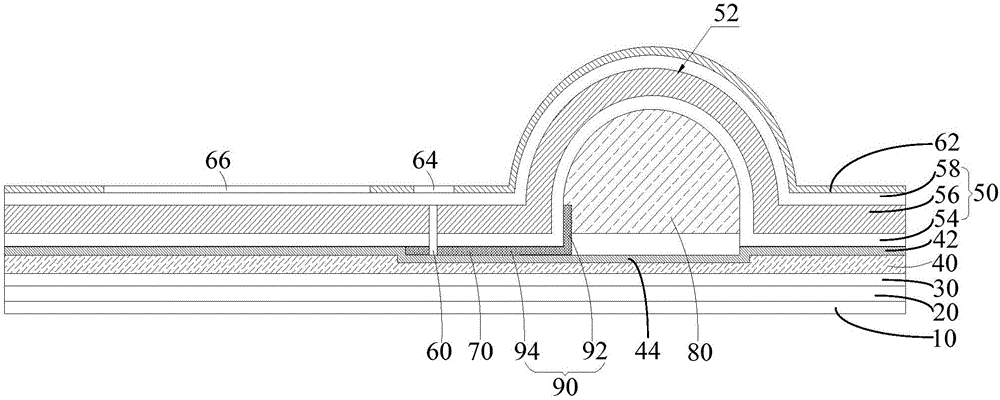

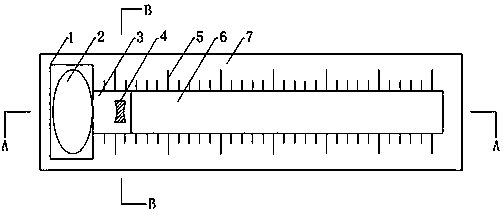

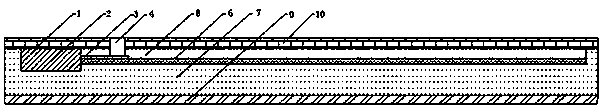

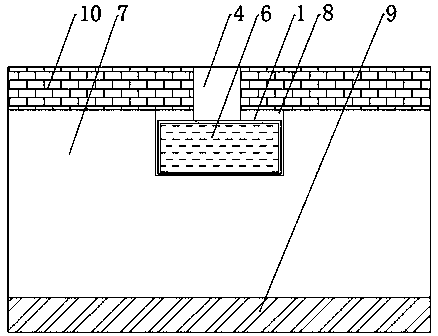

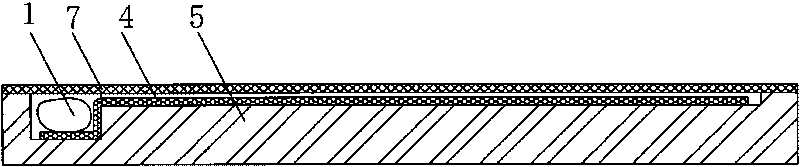

Time temperature indicator and manufacturing method thereof

ActiveCN105136330AMicroporous features are obviousHigh affinityThermometers using physical/chemical changesLiquid statePhase-change material

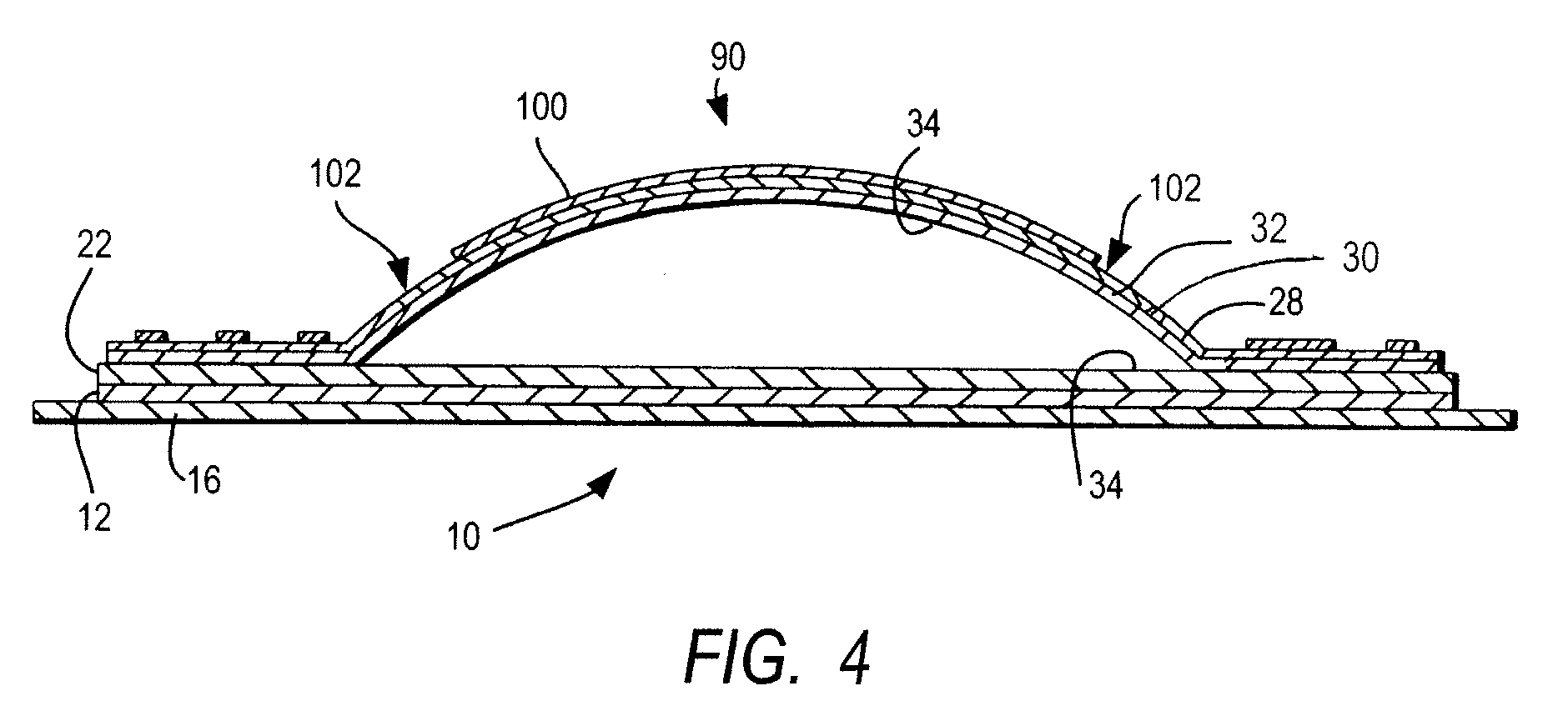

The invention discloses a time temperature indicator and a manufacturing method thereof. The time temperature indicator comprises a substrate layer, a bonding layer, an indication layer, a phase-change material and a blocking layer, wherein part of the indication layer forms a convex hull, and the convex hull is provided with a storage room; the indication layer comprises at least two interlayers and a sandwich layer arranged between the two interlayers, the interlayer between the sandwich layer and the bonding layer is a dense film layer, a notch passing through the sandwich layer is arranged on the dense film layer, and a liquid channel is communicated between the storage room and the notch; the phase-change material is located in the storage room, and the blocking layer is arranged between the phase-change material and the notch; and the liquid phase-change material can press the blocking layer broken under effects of an external force to enter the liquid channel and be penetrated in the sandwich layer through the notch, and the penetration length to the time length of the liquid phase-change material on the sandwich layer is in direct proportion. Due to the time temperature indicator of the invention, the liquid phase-change material can be prevented from passing through the interlayers to be penetrated in the sandwich layer.

Owner:SHENZHEN NINE STARS PRINTING & PACKAGING GRP

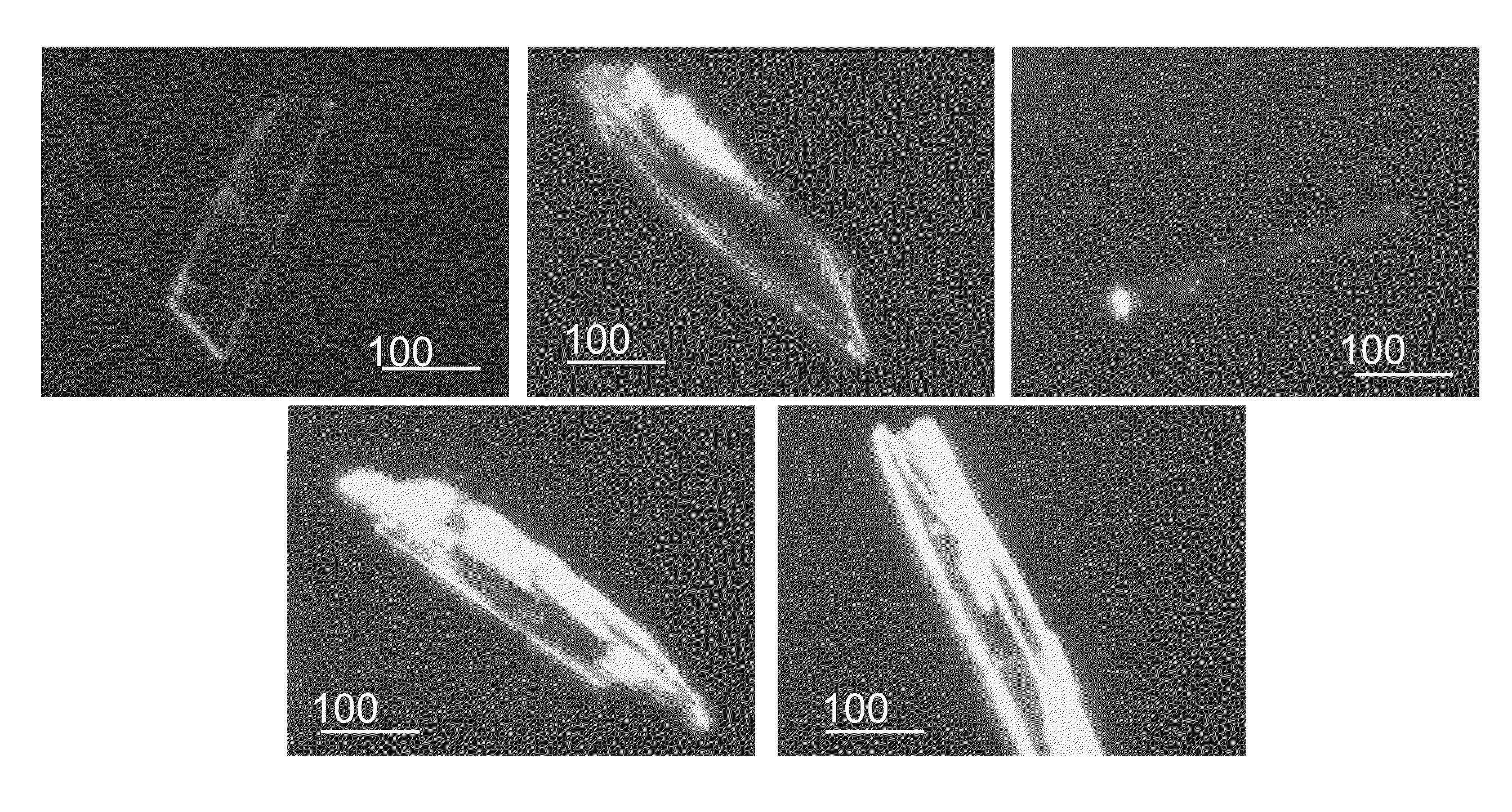

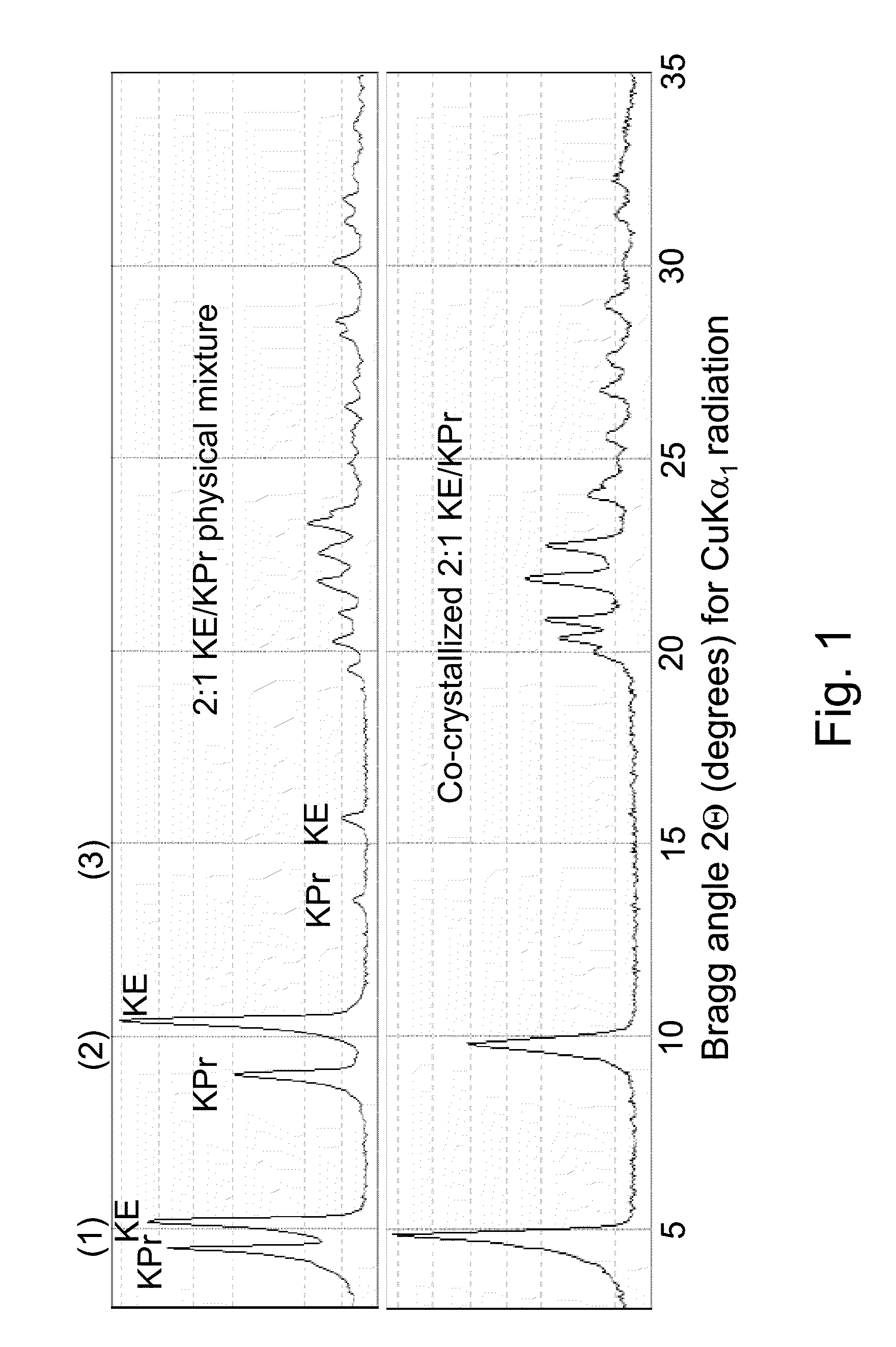

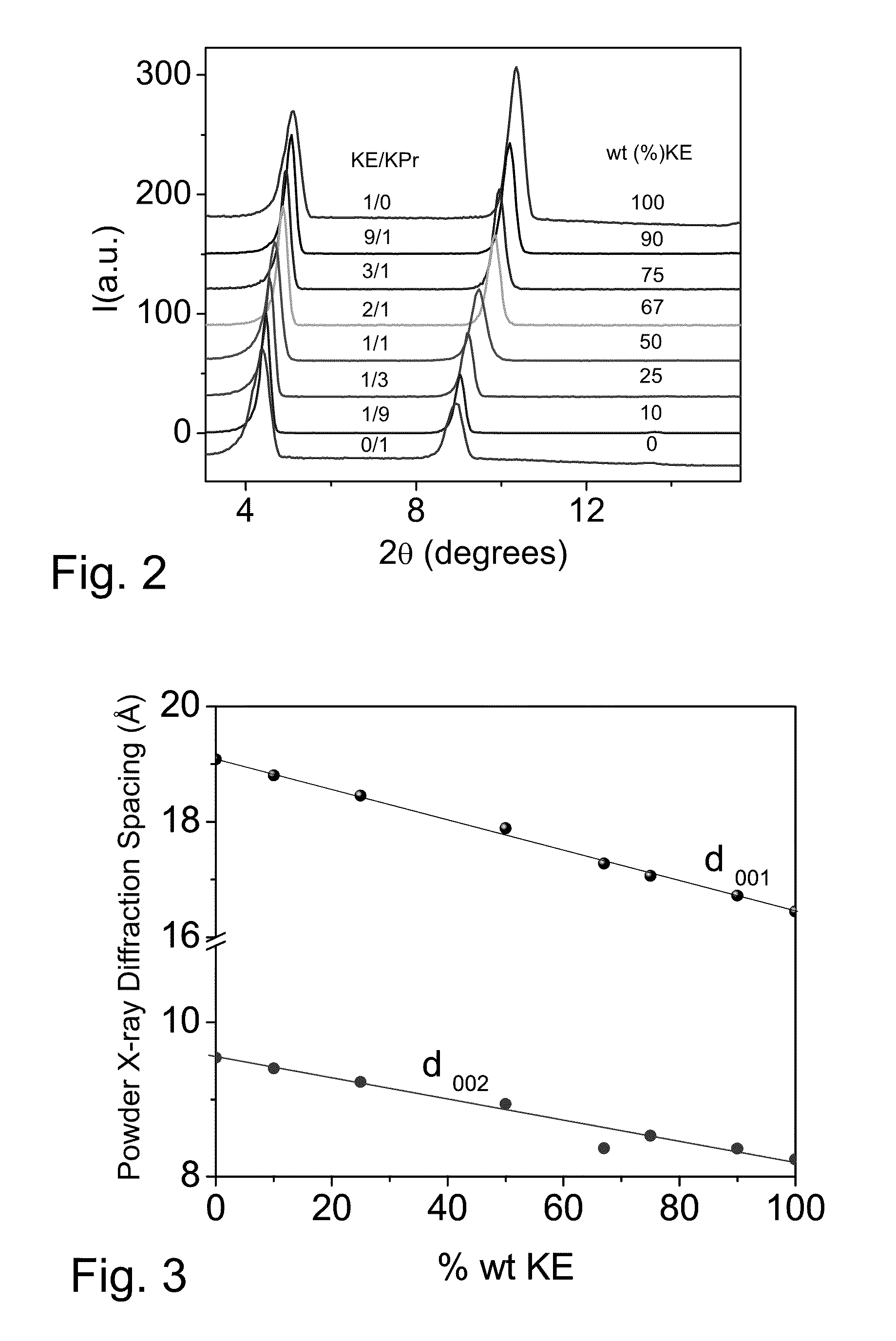

Co-crystallizable diacetylenic monomer compositions, crystal phases and mixtures, and related methods

ActiveUS20110086995A1Thermometer detailsOrganic chemistryMonomer compositionNMR - Nuclear magnetic resonance

Solid polymerizable diacetylenic monomer compositions, including compositions co-crystallized from a diversity of solvent systems under diverse cooling conditions, can exhibit diffraction patterns associated with the color development reactivities of the compositions. High reactivity compositions are disclosed and high reactivity and low reactivity phases can be identified. A low angle powder X-ray diffraction peak can indicate the presence of one or more crystal phases in a composition. A fingerprint region can exhibit fingerprint patterns of diffraction peaks associated with different reactivities. Information about polymerization of the diacetylenic monomers is disclosed using 13C nuclear magnetic resonance (“NMR”) characterization. Diacetylenic monomer compositions useful in ambient condition indicators, for example time-temperature indicators are disclosed.

Owner:TEMPTIME CORP

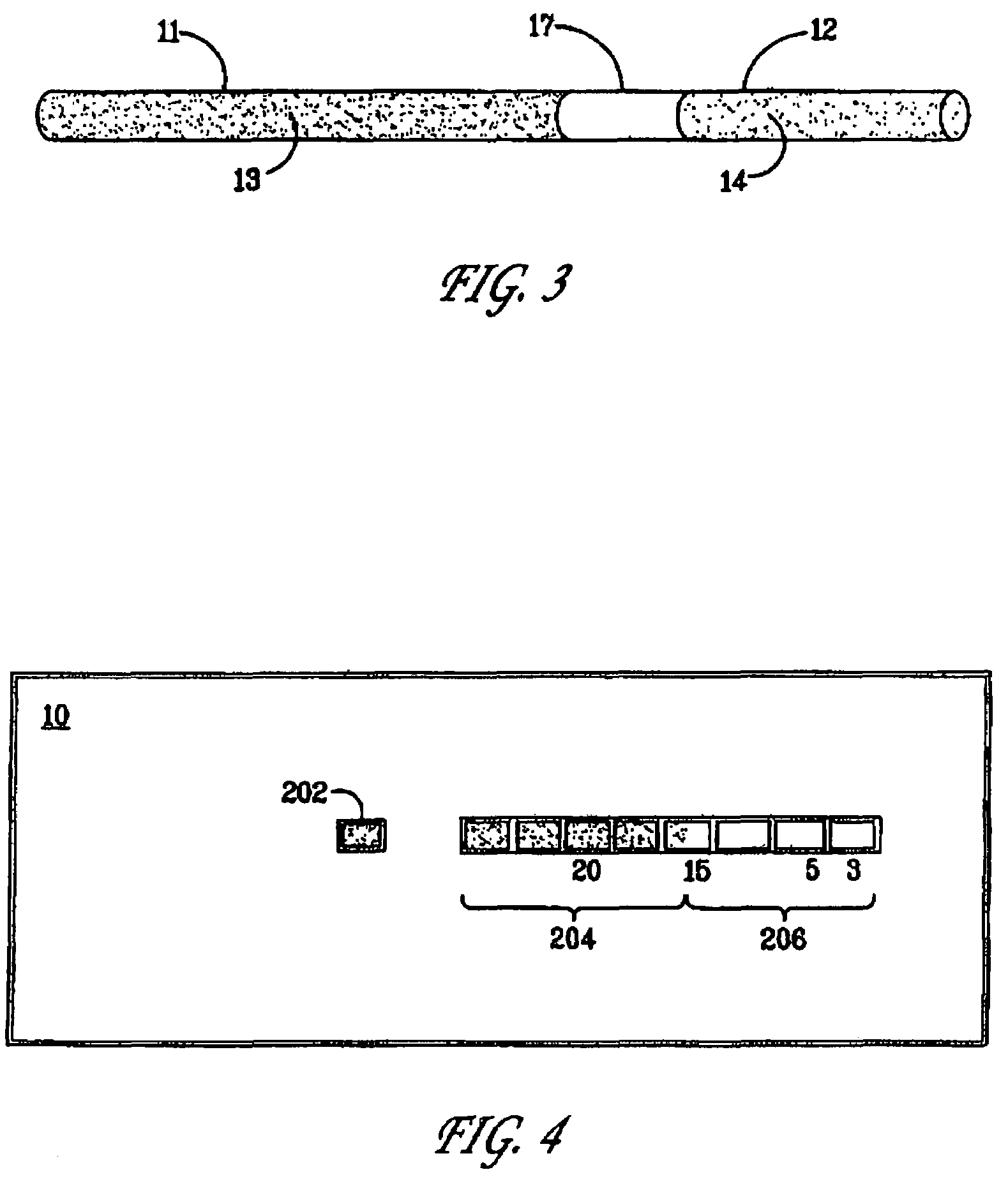

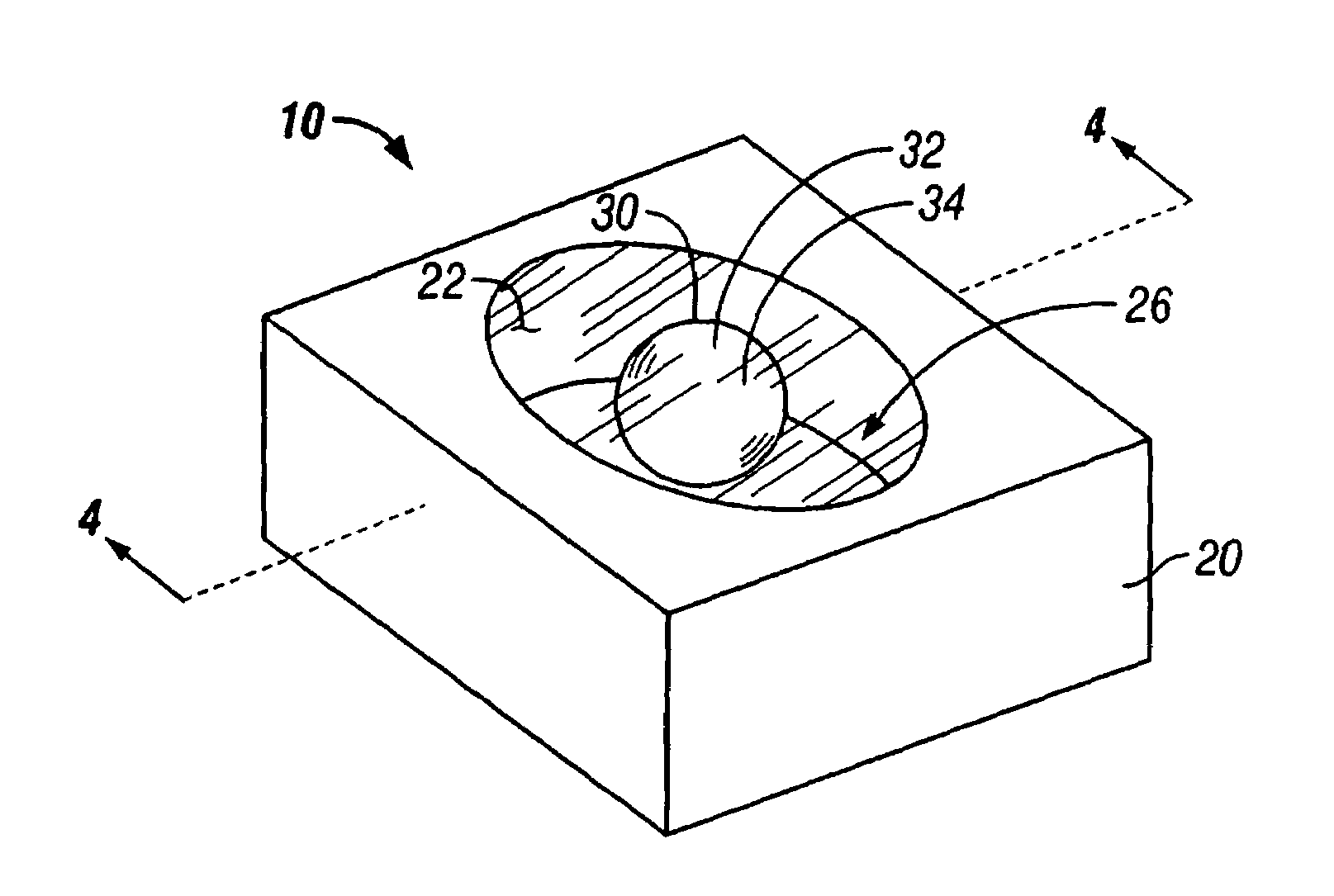

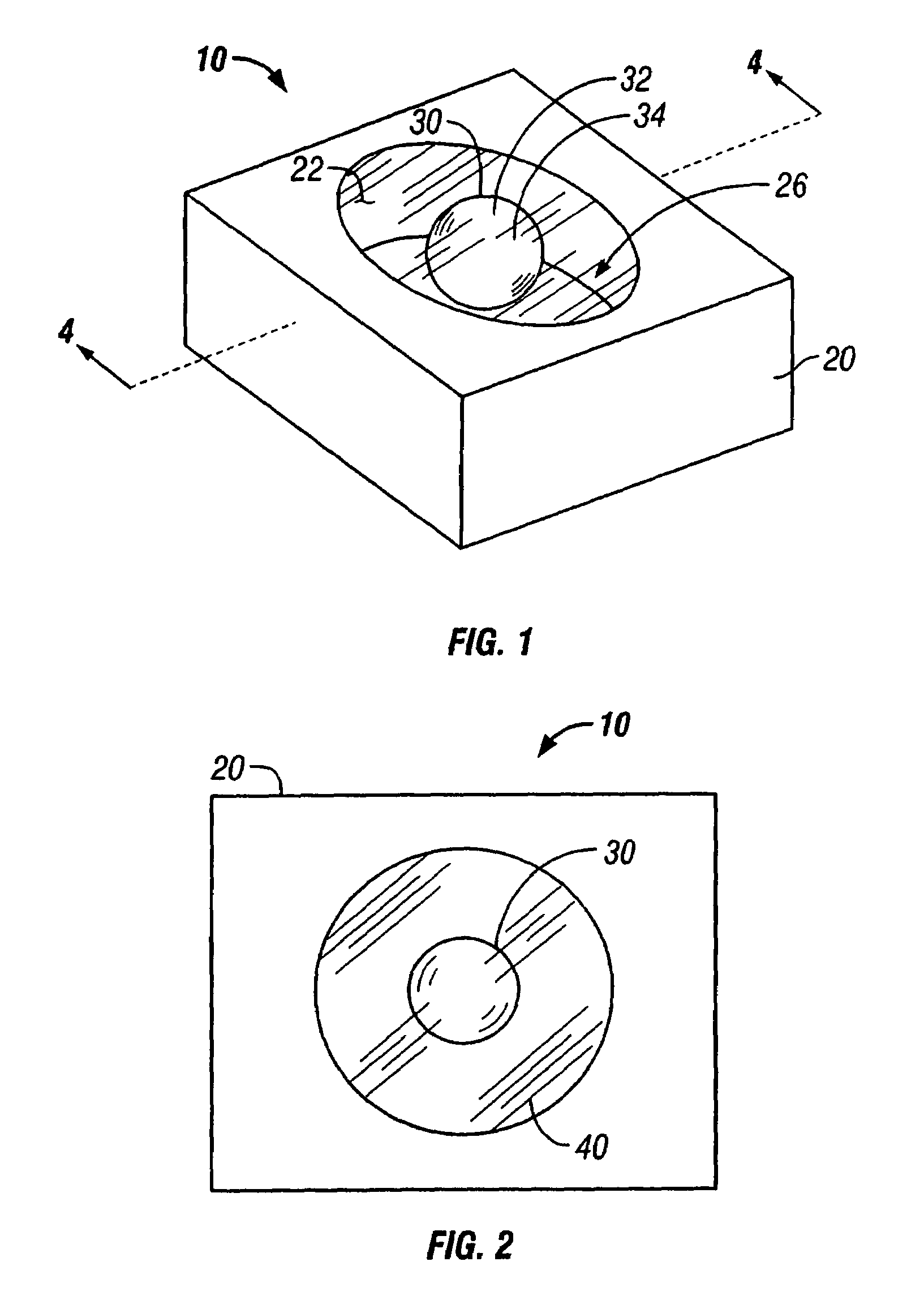

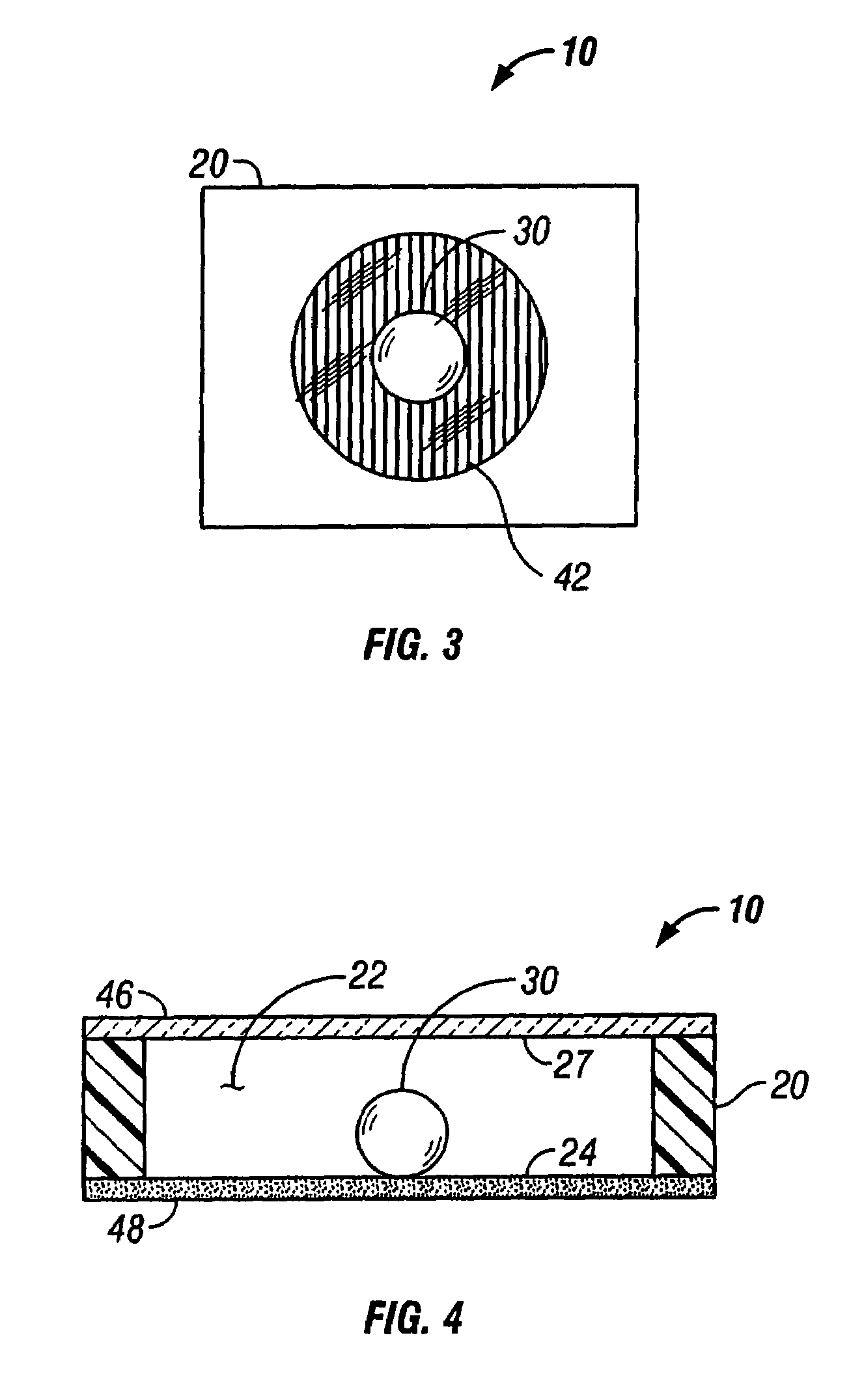

Combination freeze indicators

ActiveUS20070125296A1Simple and reliable and inexpensiveThermometer detailsThermometers using mean/integrated valuesEngineeringThreshold temperature

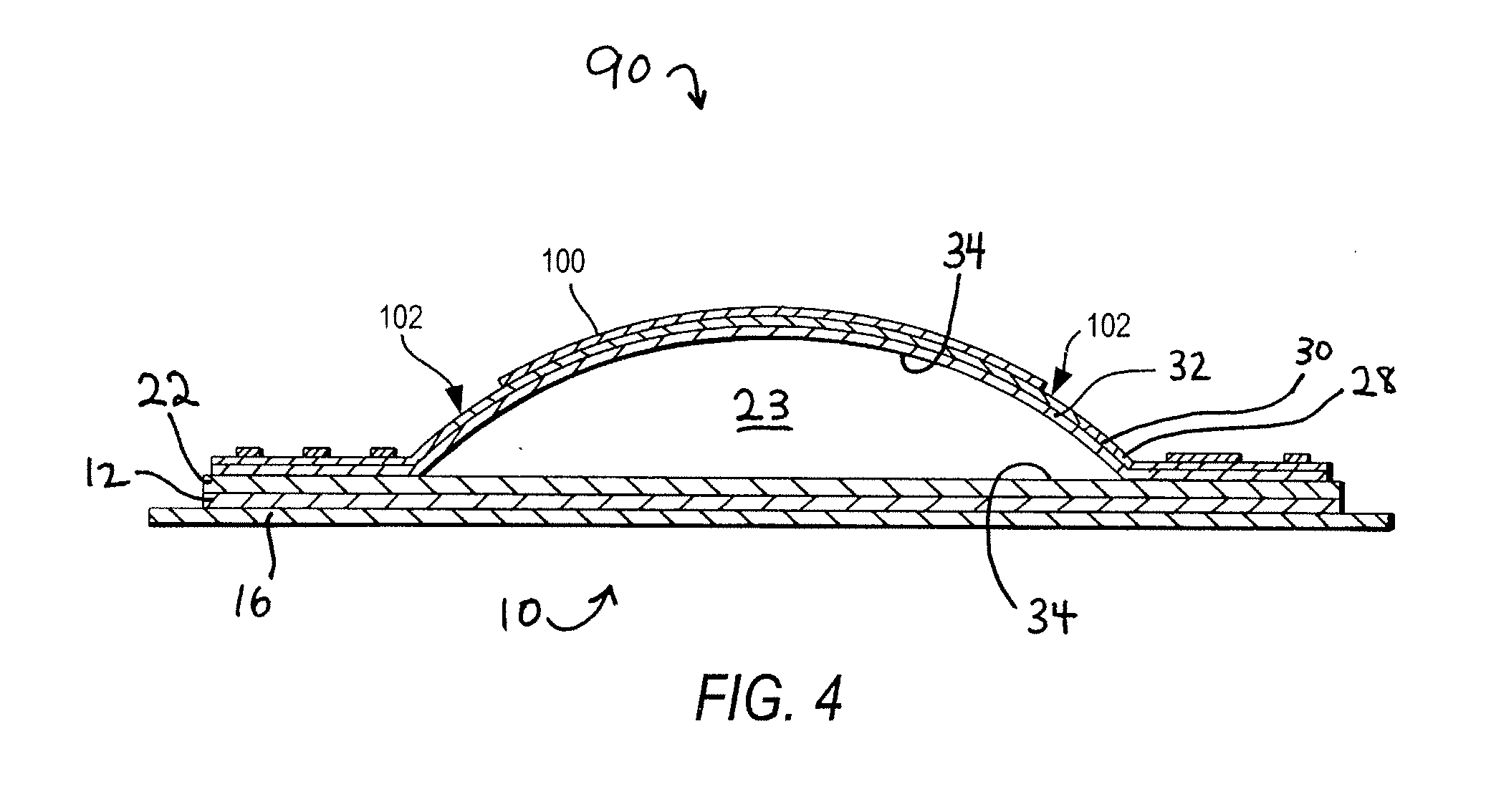

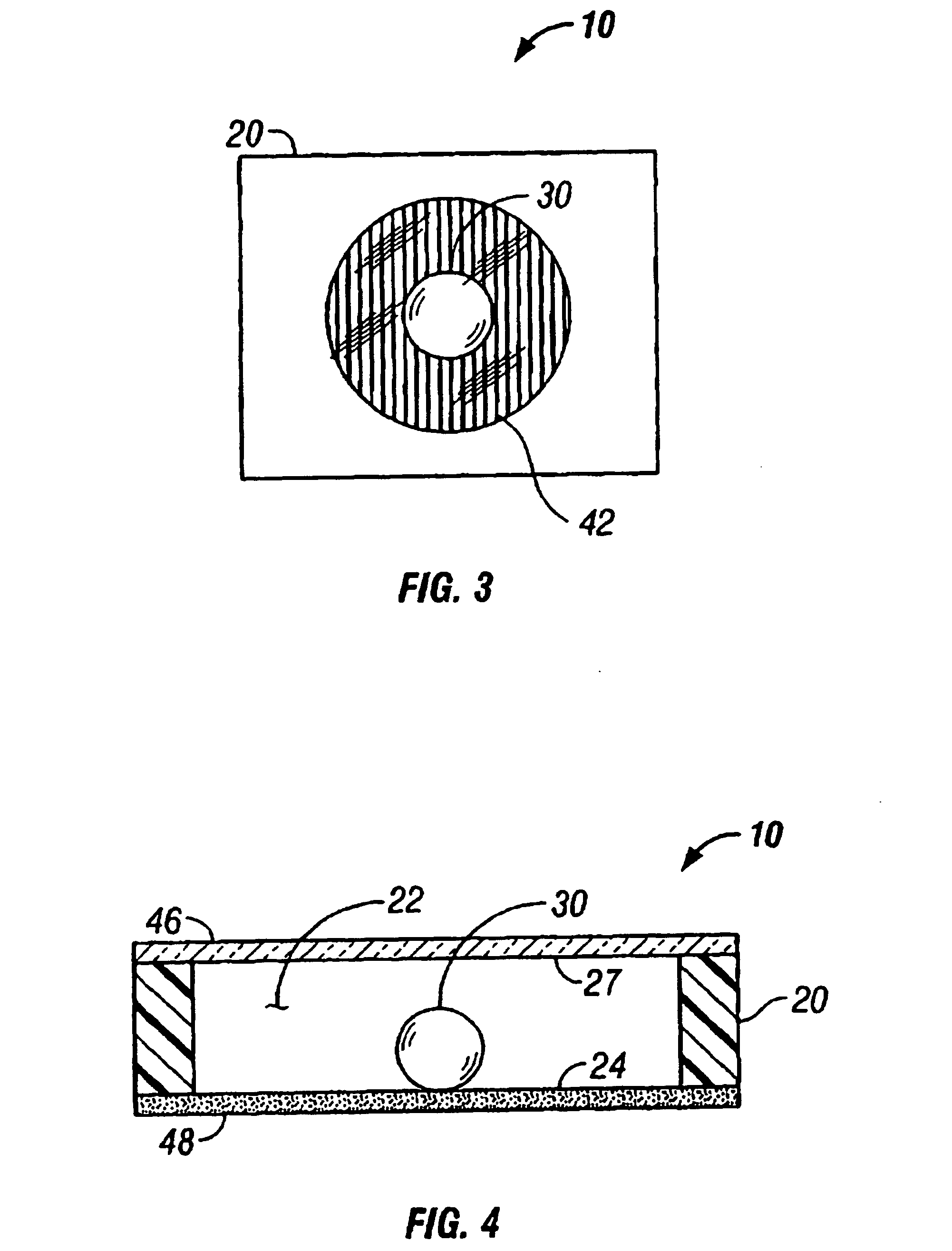

A combination temperature exposure indicator suitable for attachment to, or association with, a host product has a substrate, a freeze indicator supported by the substrate and a cumulative ambient time-temperature indicator also supported by the substrate. The freeze indicator can provide a visual indication of exposure of the freeze indicator to a freezing or near-freezing temperature and the cumulative time-temperature indicator can provide a visual indication of exposure of the cumulative time-temperature indicator to a predetermined cumulative time-temperature value. Also disclosed are: a combination freeze indicator and threshold temperature indicator; a combination threshold indicator and cumulative temperature indicator; and three-way combination indicators that can provide indications of cumulative past temperature exposure, exposure to freezing temperatures and exposure to a temperature above a threshold.

Owner:TEMPTIME CORP

Changed condition indicator

InactiveUS20070151502A1Thermometer detailsThermometers using mean/integrated valuesStrong acidsThreshold temperature

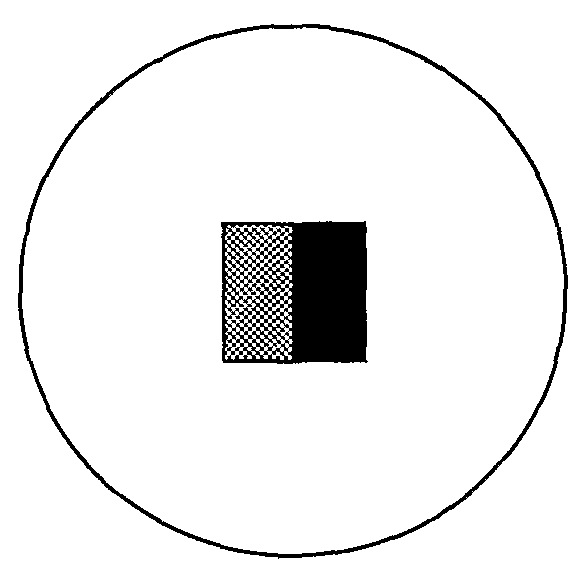

A system and method for indication of temperature exposures beyond a set of predetermined limits employs the salts of weak acid-strong base or of a strong acid-weak base compound as reactants. A device includes a housing and capsule. A first reactant and a liquid are included within the capsule. The liquid is chosen such that it expands upon freezing. The capsule is sized such that when the liquid freezes and expands, the capsule fractures. A second reactant is provided within the housing. The location of the second reactant and the method of attaching (if any) the second reactant to the housing may take various forms. When the liquid within the capsule freezes, it expands and fractures the capsule. Upon thawing, the reactant within the capsule escapes and mixes with the reactant located outside the capsule. A second embodiment is a time-temperature indicator. A flexible housing is used, allowing the user to manually deform the housing to fracture a capsule enclosed therein. The reactants combine to produce a color. The color is chosen to be a different color than the housing, allowing a person viewing the indicator device to quickly and easily determine the status of the object being monitored. The threshold temperature at which the device will indicate a changed condition may be varied. Exemplary temperatures include below the freezing temperature, at the freezing temperature, and above the freezing temperature. The capsule composition may be varied such that it melts at a predetermined temperature. Thus, the device may also be used to indicate whether a high temperature has been met or exceeded.

Owner:THERMOPROX

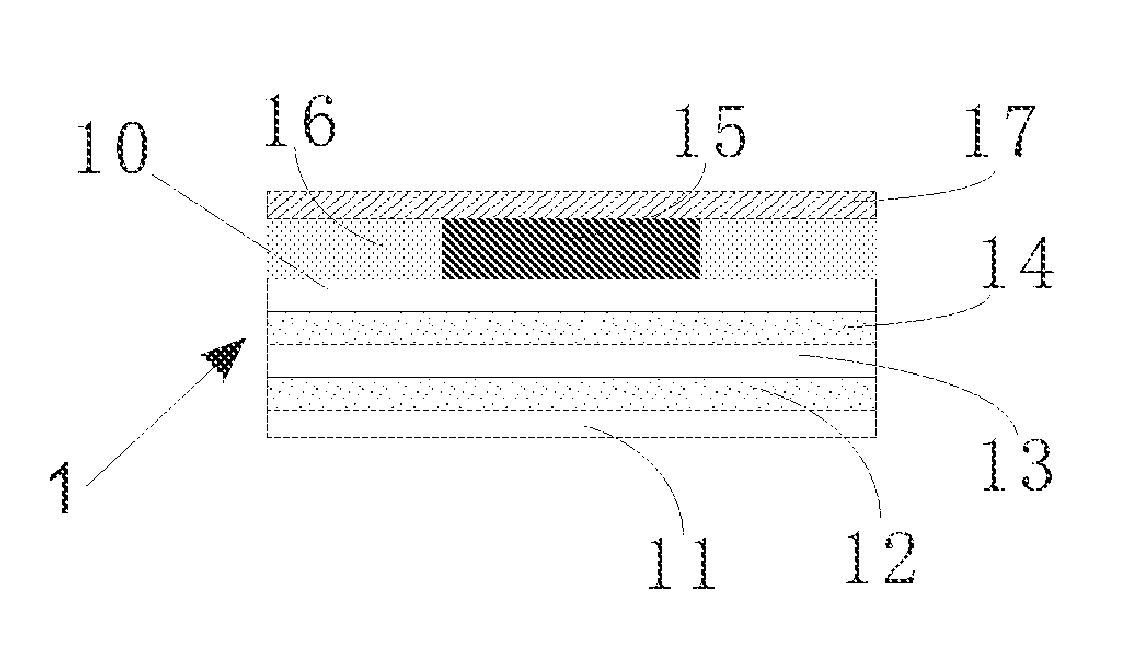

A kind of time-temperature indicator and preparation method thereof

InactiveCN102279056ASynchronization of mass changesReal-time monitoring of quality changesNon-fibrous pulp additionAnalysis using chemical indicatorsPulp and paper industryTime temperature indicator

The invention discloses a time-temperature indicator. The time-temperature indicator disclosed by the invention comprises a back coating, a paper base, a bottoming layer, an indicating layer and a protective layer, wherein the back coating is arranged at one side of the paper base; and the bottoming layer, the indicating layer and the protective layer are sequentially arranged at the other side of the paper base. The invention also discloses a preparation method of the time-temperature indicator. The time-temperature indicator disclosed by the invention can be better applied to monitoring thequality change of storage-resistant food.

Owner:王斌

Time-temperature indicators

InactiveCN101258388AThermometer detailsThermometers using mean/integrated valuesWaxVisual appearance

The present invention provides a visual thermal history indicator comprising a pattern produced from at least two waxes wherein one wax has a melting point that differs from the other wax, or where the waxes have the same melting point but different melt flow behaviour, and wherein the pattern is adapted so that when the lower melting point wax melts or the wax with greater melt flow behaviour flows, the visual appearance of the pattern changes, and wherein when the second and subsequent higher melting waxes melt, or when the lower melt flow behaviour waxes flow, the visual appearance of the pattern changes as each wax melts or flows.

Owner:AUSTRALIEN NAT UNIV

Time-temperature indicator and preparation method thereof

ActiveCN103630503APrecise prediction of shelf lifeEarly warning of food safety issuesColor/spectral properties measurementsDiffusionBiochemical engineering

The invention belongs to the technical field of cold storage and refrigeration, and particularly relates to a time-temperature indicator and a preparation method thereof. The time-temperature indictor comprises an indicator fixing plate and a sealing thin film, wherein a fixing clamping slot is formed in the other end of the indicator fixing plate, the end part of one end of the fixing clamping slot is close to a thin film liquid storage bag, a diffusion medium belt matched with the fixing clamping slot in length is fixed in the fixing clamping slot, a thorn sheet is embedded in one end, close to the thin film liquid storage bag, of the diffusion medium belt, and scale marks are marked on the front side of the indicator fixing plate. The time-temperature indicator can reflect the change of the quality of a frozen food and indicate the remaining shelf life of the frozen food, and the critical temperature is freely regulated within the scope of 0-12 DEG C, so that the scope of application of the indicator is greatly expanded.

Owner:SHANDONG INST OF COMMERCE & TECH

Changed condition indicator

InactiveUS7770534B2Thermometer detailsThermometers using mean/integrated valuesStrong acidsThreshold temperature

A system and method for indication of temperature exposures beyond a set of predetermined limits employs the salts of weak acid-strong base or of a strong acid-weak base compound as reactants. A device includes a housing and capsule. A first reactant and a liquid are included within the capsule. The liquid is chosen such that it expands upon freezing. The capsule is sized such that when the liquid freezes and expands, the capsule fractures. A second reactant is provided within the housing. The location of the second reactant and the method of attaching (if any) the second reactant to the housing may take various forms. When the liquid within the capsule freezes, it expands and fractures the capsule. Upon thawing, the reactant within the capsule escapes and mixes with the reactant located outside the capsule. A second embodiment is a time-temperature indicator. A flexible housing is used, allowing the user to manually deform the housing to fracture a capsule enclosed therein. The reactants combine to produce a color. The color is chosen to be a different color than the housing, allowing a person viewing the indicator device to quickly and easily determine the status of the object being monitored. The threshold temperature at which the device will indicate a changed condition may be varied. Exemplary temperatures include below the freezing temperature, at the freezing temperature, and above the freezing temperature. The capsule composition may be varied such that it melts at a predetermined temperature. Thus, the device may also be used to indicate whether a high temperature has been met or exceeded.

Owner:THERMOPROX

Time-temperature indicators

InactiveUS20090050049A1Change in visual appearanceThermometer detailsThermometers using mean/integrated valuesWaxVisual appearance

A visual thermal history indicator comprising a pattern produced from at least two waxes wherein one wax has a melting point that differs from the other wax, or where the waxes have the same melting point but different melt flow behaviour, and wherein the pattern is adapted so that when the lower melting point wax melts or the wax with greater melt flow behaviour flows, the visual appearance of the pattern changes, and wherein when the second and subsequent higher melting waxes melt, or when the lower melt flow behaviour waxes flow, the visual appearance of the pattern changes as each wax melts or flows.

Owner:AUSTRALIEN NAT UNIV

Time-temperature indicators

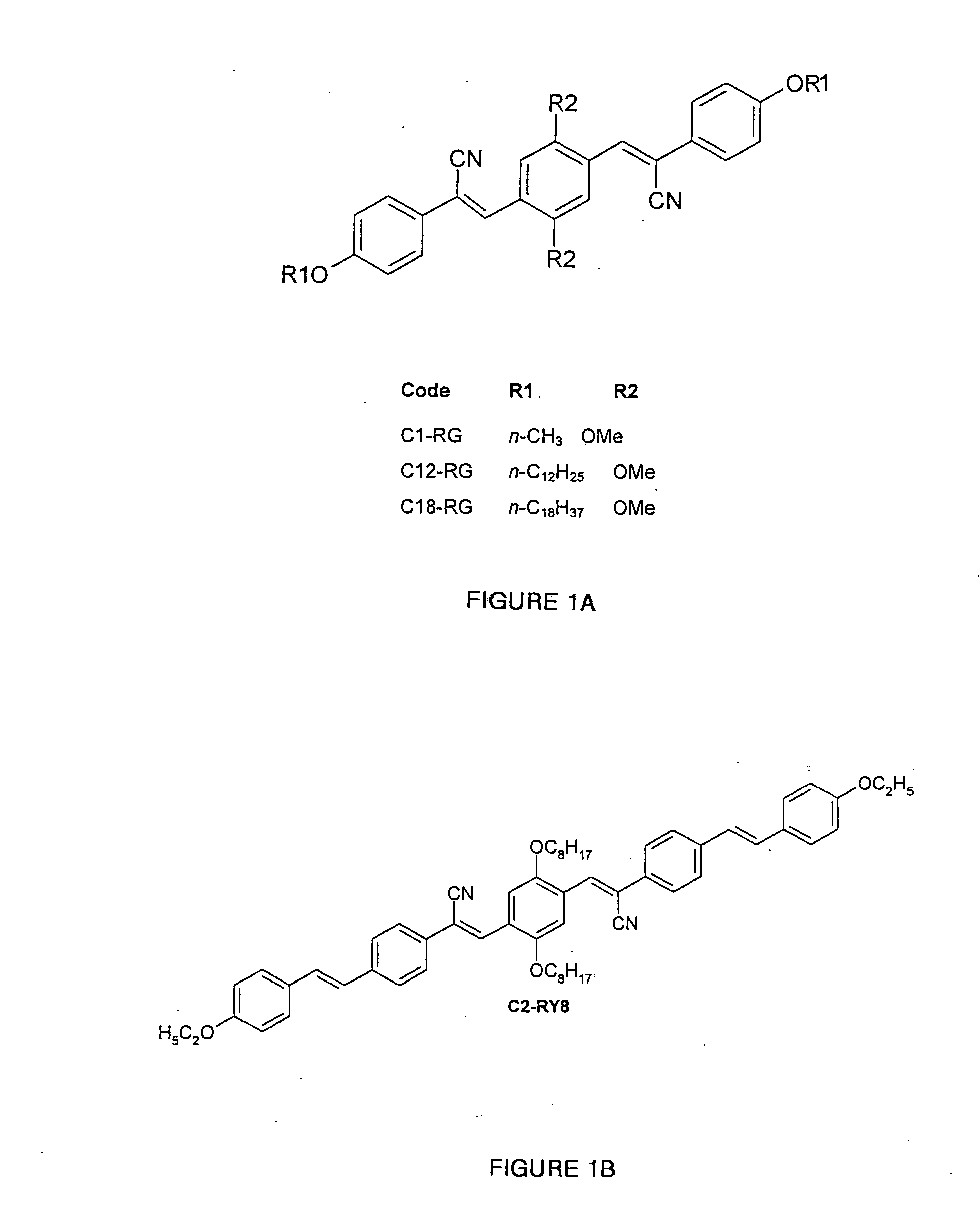

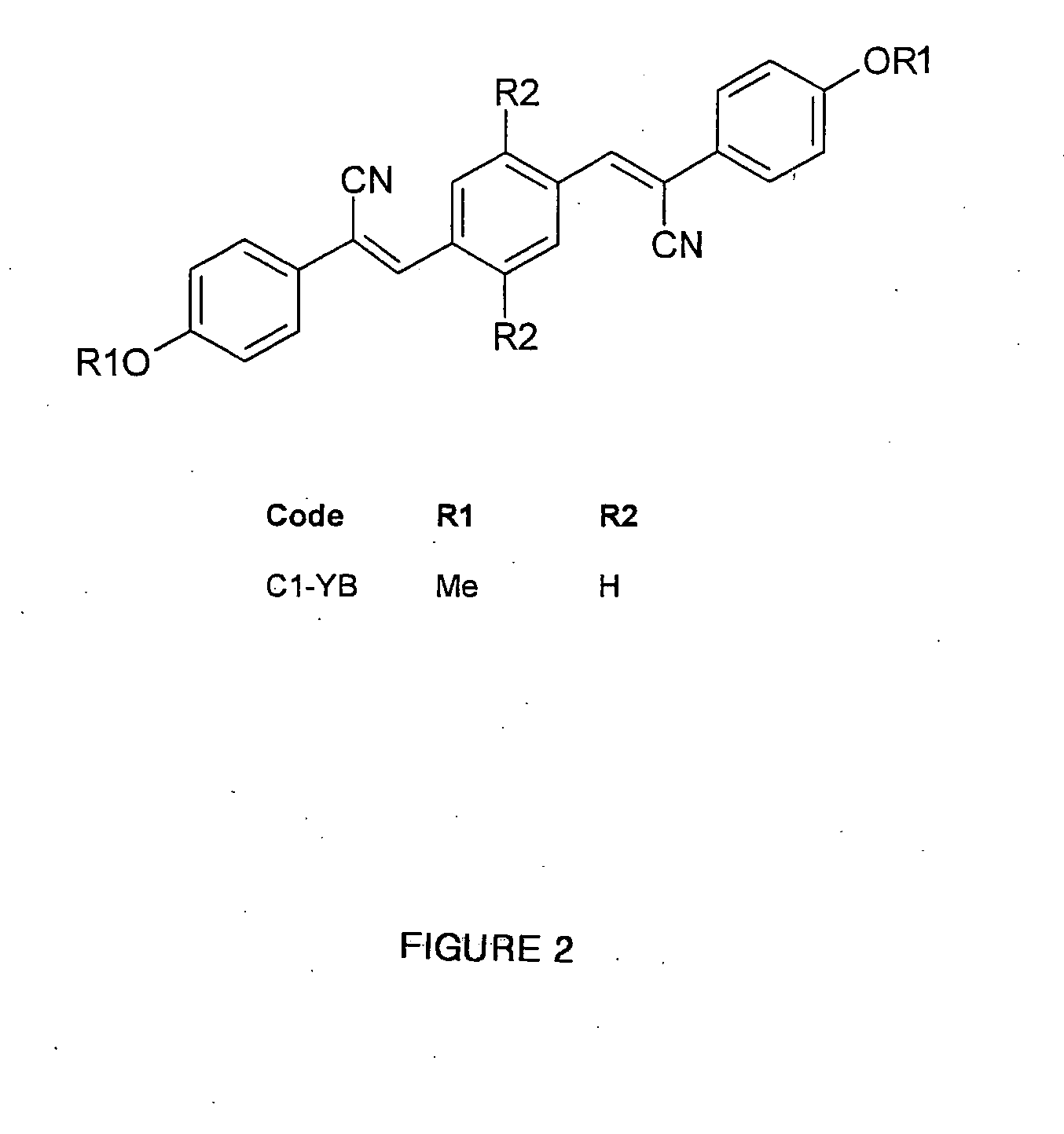

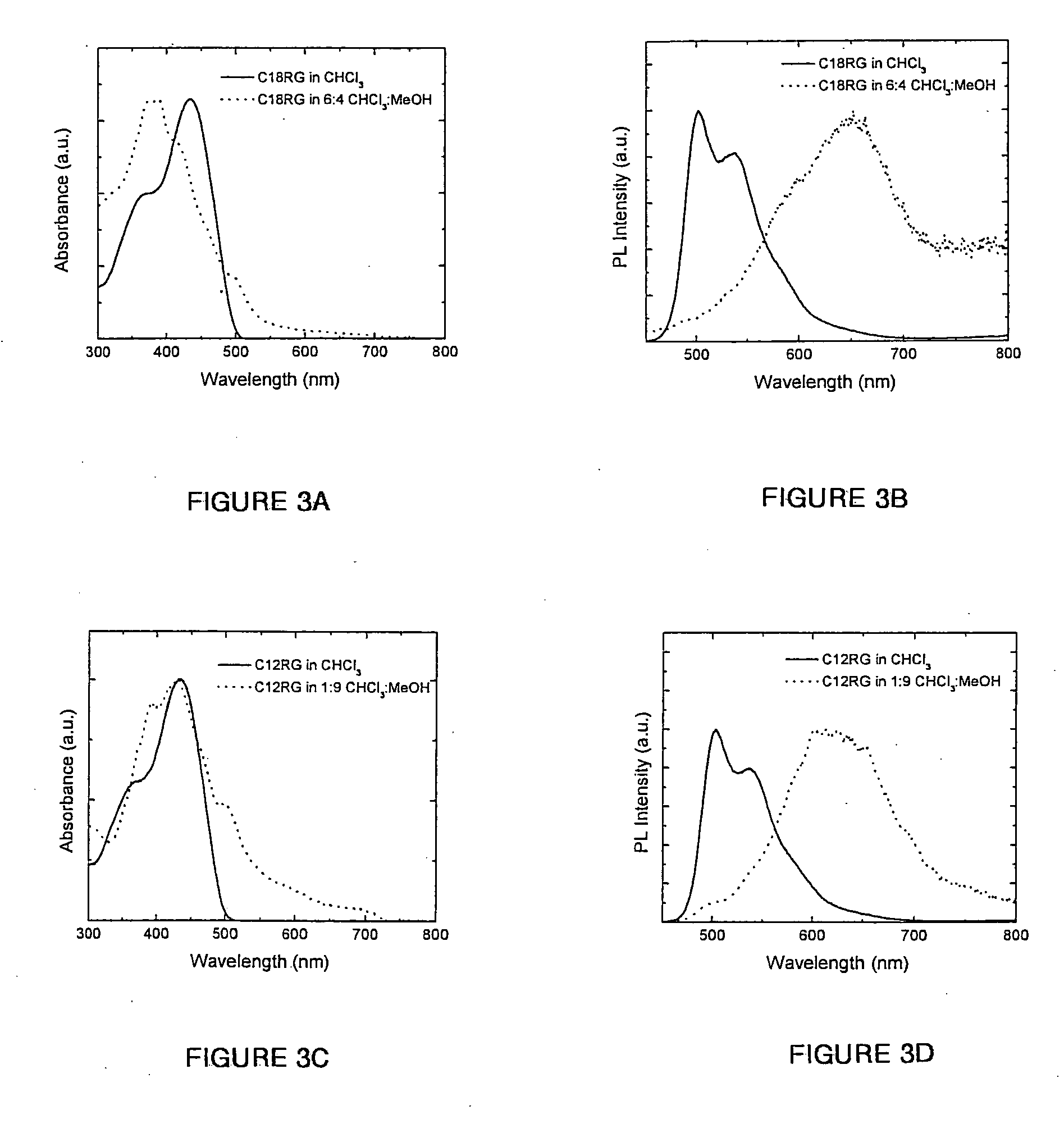

InactiveUS20070158624A1Reduce manufacturing costEasy to measureDiffusing elementsCamera filtersEngineeringColor changes

Time temperature indicators are disclosed which comprise at least one carrier material and one aggregachromic indicator dye and which respond to the combined effects of temperature and time with an easily measurable, time-temperature dependent, irreversible, color change. The invention also discloses to methods to produce such time-temperature indicators and materials therefore. Also, the devices disclose methods for determining the time / temperature history.

Owner:CASE WESTERN RESERVE UNIV

Full history time-temperature indicator system

InactiveCN1390303AThermometers using mean/integrated valuesInvestigating time/temperature historyChemical reactionEngineering

A full-history time-temperature indicator system which is capable of exhibiting a time-temperature dependent and visually detectable chemical reaction, useful for monitoring the time and temperature exposure of food products. The system comprises an immobilised reactant, such as Fe<3+>, and a mobile reactant, such as Fe(CN)6<4->, initially contained in separate compartments, and separated by a sealing. The system is activated by removing a sealing between the compartments whereby the mobile reactant in a time-temperature dependent manner is brought into contact with the immobilised reactant resulting in a visually detectable reaction signal.

Owner:TIMETEMP

Changed condition indicator

InactiveUS7011037B2Easy to useQuickly and easily knowThermometer detailsThermometers using mean/integrated valuesEngineeringThreshold temperature

A device and method of making a device for indicating a change in condition is disclosed. A first embodiment is a device for indicating a transition from a frozen condition to a thawed condition is disclosed. The device includes a housing and a capsule. A first reactant and a liquid are included within the capsule. The liquid is chosen such that it expands upon freezing. The capsule is sized such that when the liquid freezes and expands, the capsule fractures. A second reactant is provided within the housing. The location of the second reactant and the method of attaching (if any) the second reactant to the housing may take various forms. When the liquid within the capsule freezes, it expands and fractures the capsule. Upon thawing, the reactant within the capsule escapes and mixes with the reactant located outside the capsule. A second embodiment is a time-temperature indicator. A flexible housing is used, allowing the user to manually deform the housing to fracture a capsule enclosed therein. The reactants combine to produce a color. The color is chosen to be a different color than the housing, allowing a person viewing the indicator device to quickly and easily determine the status of the object being monitored. The threshold temperature at which the device will indicate a changed condition may be varied. Exemplary temperatures include below the freezing temperature, at the freezing temperature, and above the freezing temperature. The capsule composition may be varied such that it melts at a predetermined temperature. Thus, the device may also be used to indicated whether a high temperature has been met or exceeded.

Owner:THERMOPROX

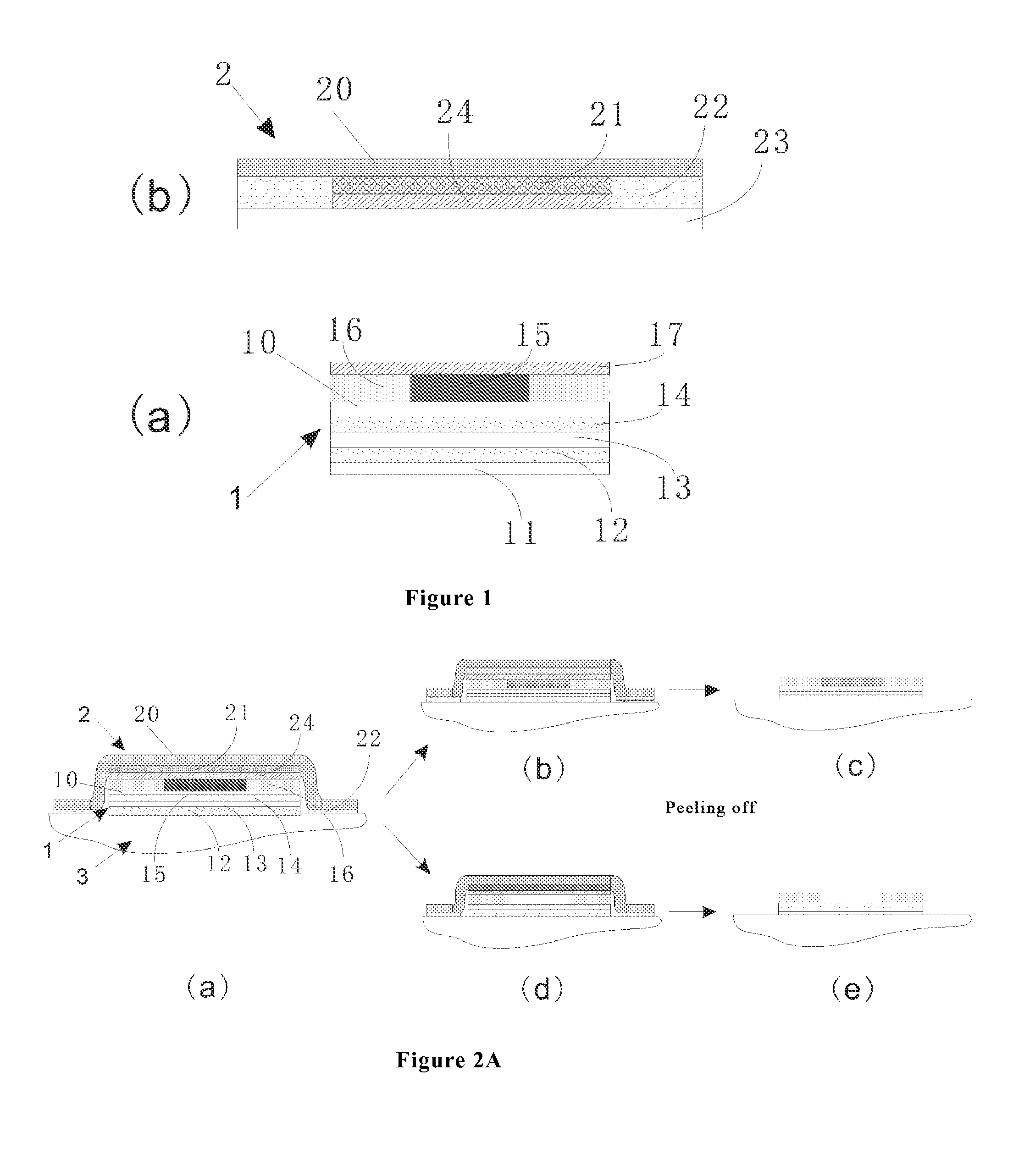

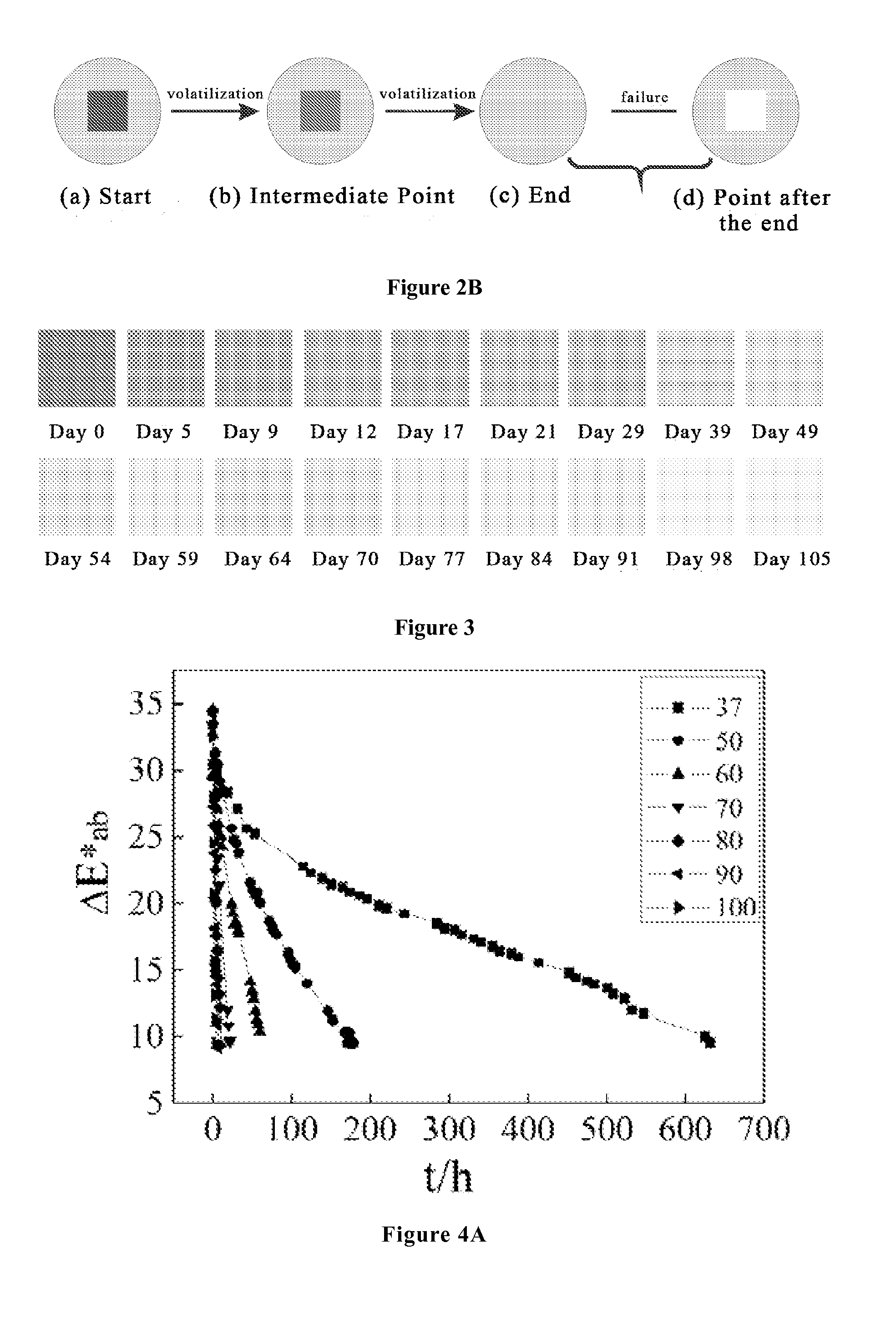

Time-temperature indicator and monitoring method for monitoring quality state of thermally sensitive article

ActiveUS20140119402A1Sure easyIncrease relative volatilityThermometers using mean/integrated valuesSynthetic resin layered productsRoom temperaturePhysical separation

The present invention relates to a time-temperature indicator for monitoring the quality state of a thermally sensitive article and a monitoring method. The present invention also relates to a preparation method of the time-temperature indicator and a thermally sensitive article using the time-temperature indicator. The time-temperature indicator according to the present invention comprises two laminated layers which are physically separated, i.e. a function indication layer and an adsorption function layer. The two laminated layers are stored and transported separately, and combined together in use. Therefore, the time-temperature indicator of the present invention can be stored and transported at room temperature, which reduces the usage costs of the time-temperature indicator.

Owner:SUZHOU HUASHI MATERIAL TECH

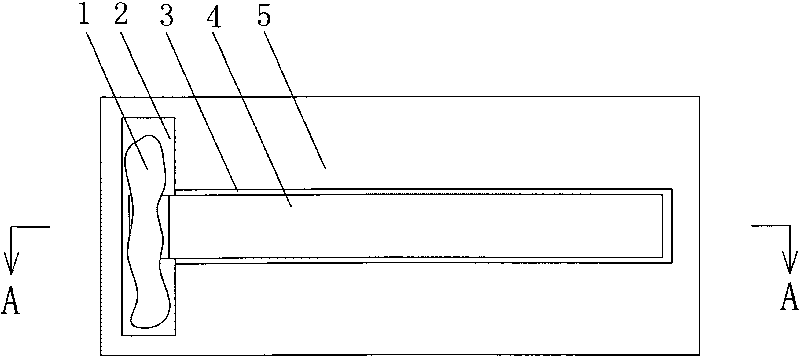

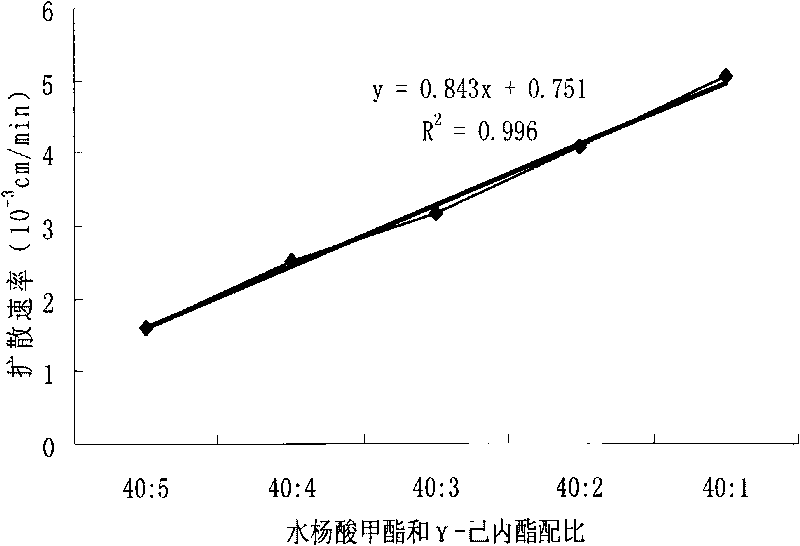

Diffusible time-temperature indicator, indicator card and preparation method of the indicator card

InactiveCN101718597AChange the ratioRealize regulation of critical temperatureThermometers using physical/chemical changesMethyl salicylateCryogenic treatment

The invention discloses a diffusible time-temperature indicator, an indicator card and a preparation method thereof, wherein the time-temperature indicator consists of methyl salicylate, gamma-caprolactone and a coloring agent, and the volume ratio of the methyl salicylate to the gamma-caprolactone is 40: (1-5). The time-temperature indicator card adopts the mixture of the methyl salicylate and the gamma-caprolactone as a diffusible substance, the coloring agent is further added, the indicator is prepared by fully mixing, then the solidified state is formed by ultra-low temperature processing, and the solidified indicator is in contact with the diffusible medium for preparing the indicator card. The time-temperature indicator card can change the mixing ratio of the methyl salicylate and the gamma-caprolactone, realize the regulation of the critical temperature of the indicator, be applicable to the needs of different frozen foods and have a wide range of applications.

Owner:HENAN AGRICULTURAL UNIVERSITY

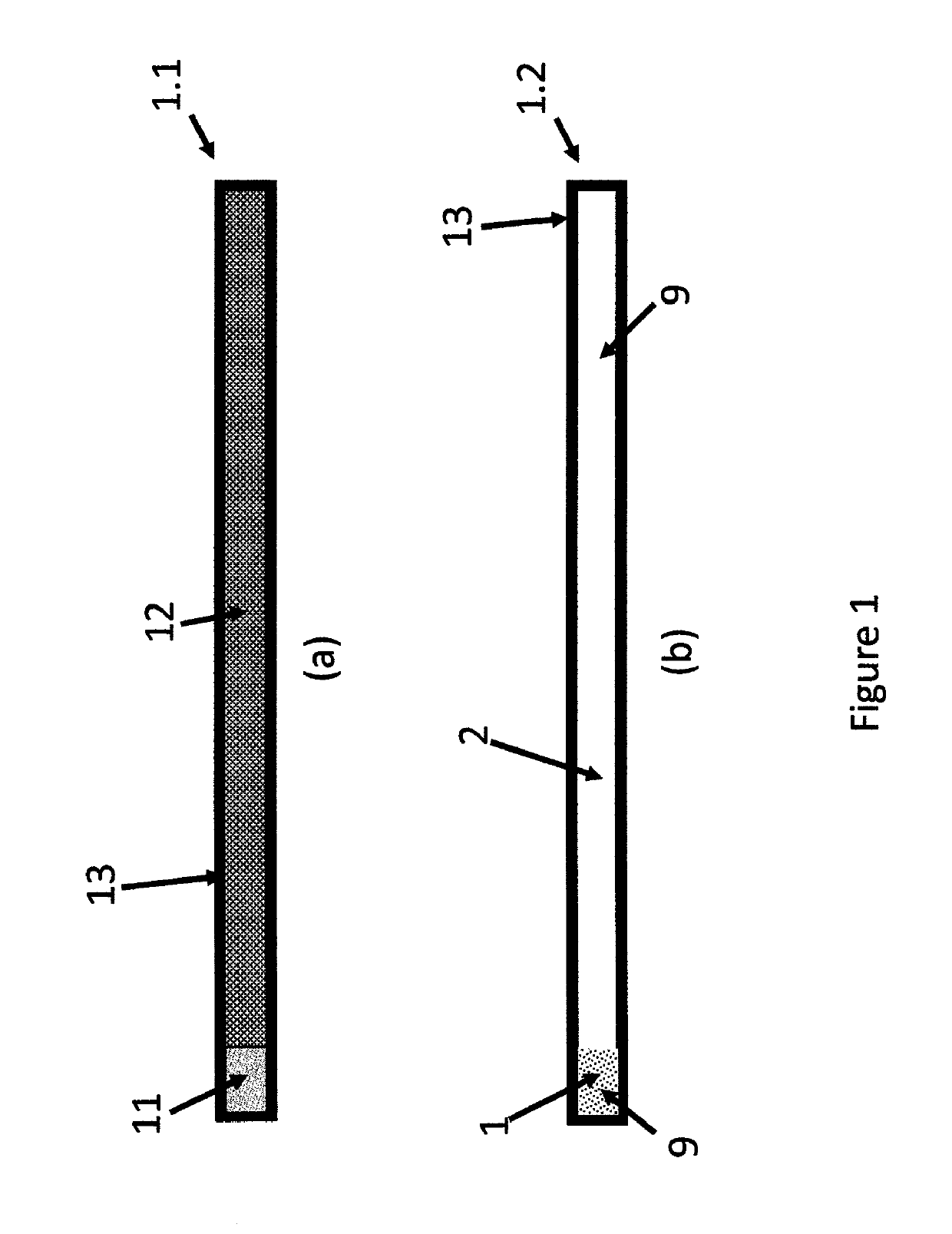

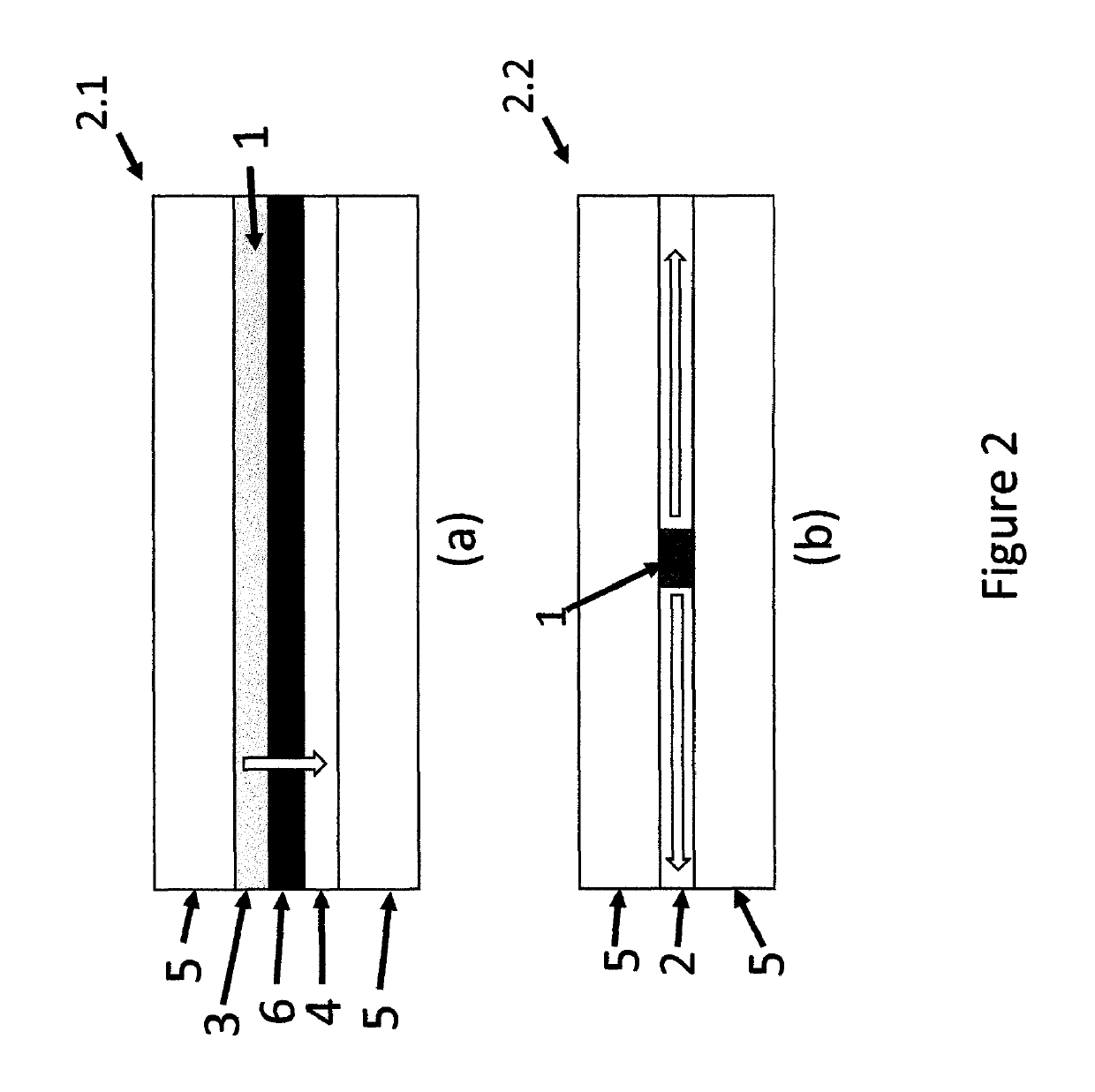

Indicating devices based on lateral diffusion of a mobile phase through a non-porous stationary phase

ActiveUS10451595B2Registering/indicating time of eventsThermometers using mean/integrated valuesStationary phaseEngineering

This invention relates to indicating devices, such as time-temperature indicators based on lateral diffusion of a vapor of a solid and / or liquid mobile phase (e.g., a sublimeable dye or an activator) through a non-porous stationary phase, such as a thin layer of a polymeric material. The lateral diffusion of the mobile phase creates a noticeable boundary in the stationary phase whose movement depends upon processes, such as time and temperature.

Owner:JP LAB INC

Electronic tag combining time-temperature indicator and radio frequency identification

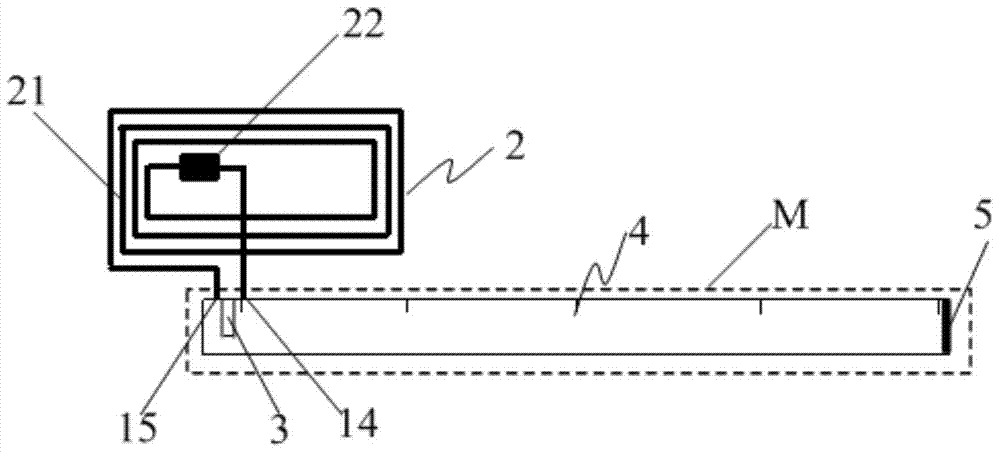

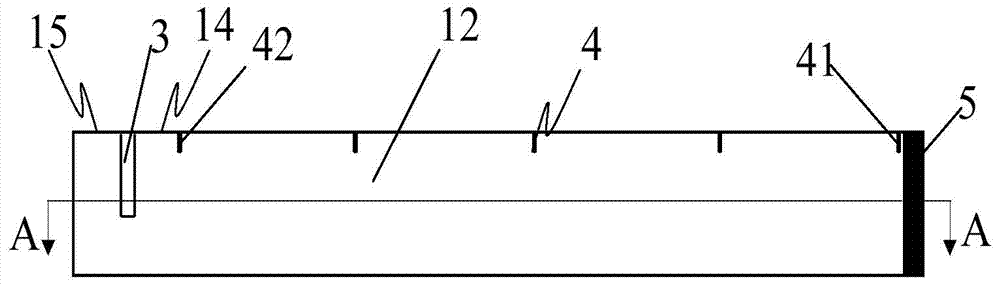

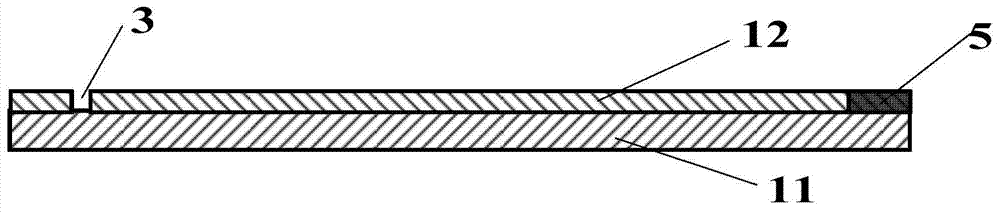

InactiveCN103543146AEffective monitoringEasy to prepareThermometers using mean/integrated valuesMaterial analysis by observing effect on chemical indicatorReaction layerContinuous use

The invention discloses an electronic tag combining a time-temperature indicator and radio frequency identification. The electronic tag comprises a substrate layer, a reaction layer which is adhered to the substrate layer, an RFID (Radio Frequency Identification) transponder which is connected with the reaction layer, and an activator which is used for activating the reaction layer, wherein the substrate layer is made of transparent material; the reaction layer is a conductive polymer film; the activator is an electrolyte solution. The electronic tag prepared by the invention is capable of recording the time-temperature changing process of the products to be indicated through the time-temperature indicator, tracking and recording various information of the products to be indicated through the RFID transponder, and automatically closing the RFID transponder after the products to be indicated exceed the expiration date, thus effectively preventing the continuous use of the expired or invalid products.

Owner:ANHUI UNIV OF SCI & TECH

Time-temperature indicator system I

InactiveCN103649700AThermometers using mean/integrated valuesThermometers using physical/chemical changesEngineeringTime temperature indicator

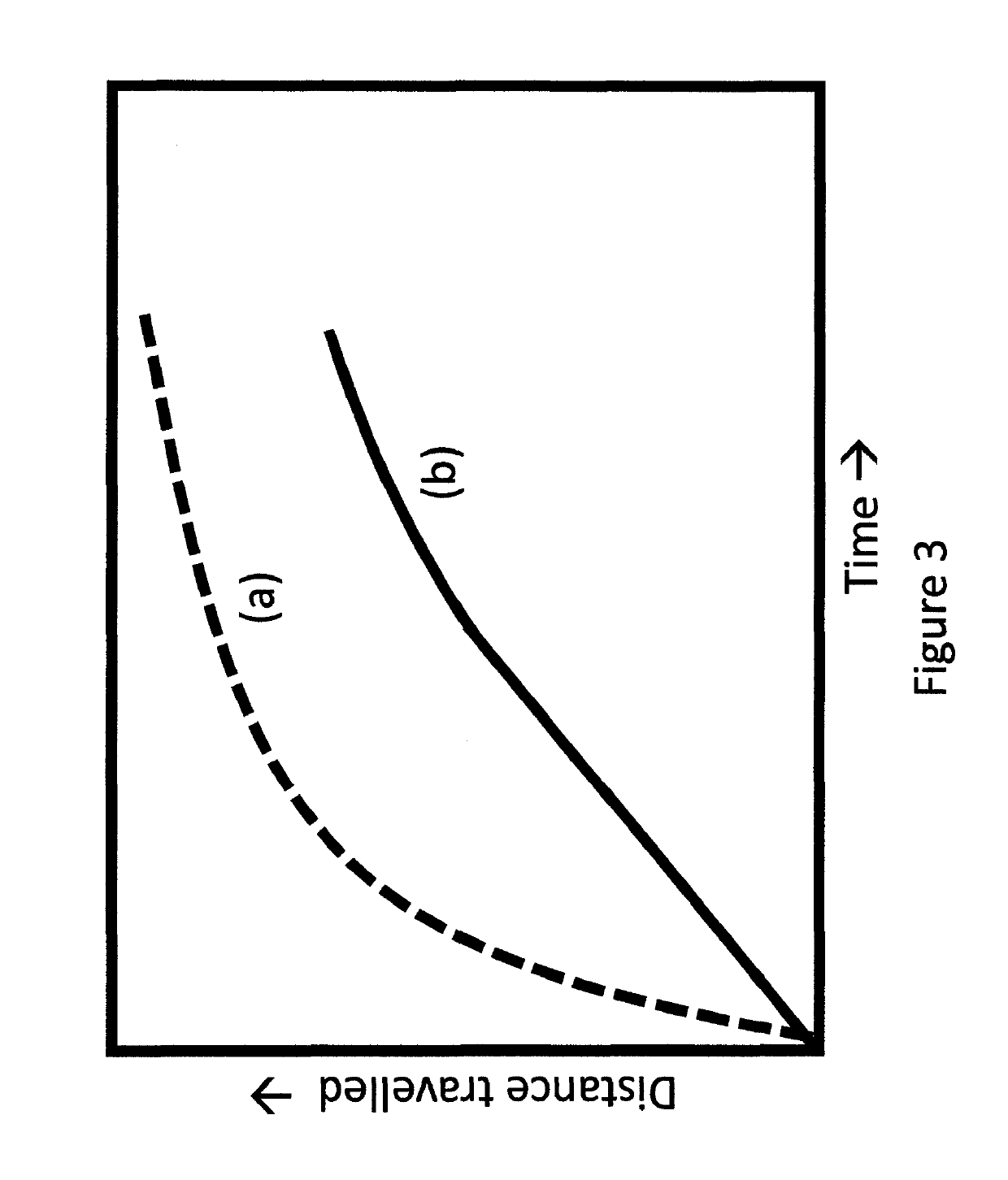

The present invention relates to a time-temperature indicator system useful for monitoring the time and temperature exposure of foods, nutraceuticals, pharmaceuticals, cosmetics, chemicals and other products. The system provides improved time-temperature sensitivity, time-temperature sensitivity control and a response which better reflects that of the reactions leading to quality loss of the monitored product. Further, the invention also relates to a combination comprising a time-temperature indicator system and a product storage container or a bag closure device. A method for producing said time-temperature indicator system is also part of the present invention.

Owner:KEEP-IT TECHNOLOGIES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com