Patents

Literature

114results about How to "Change the ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

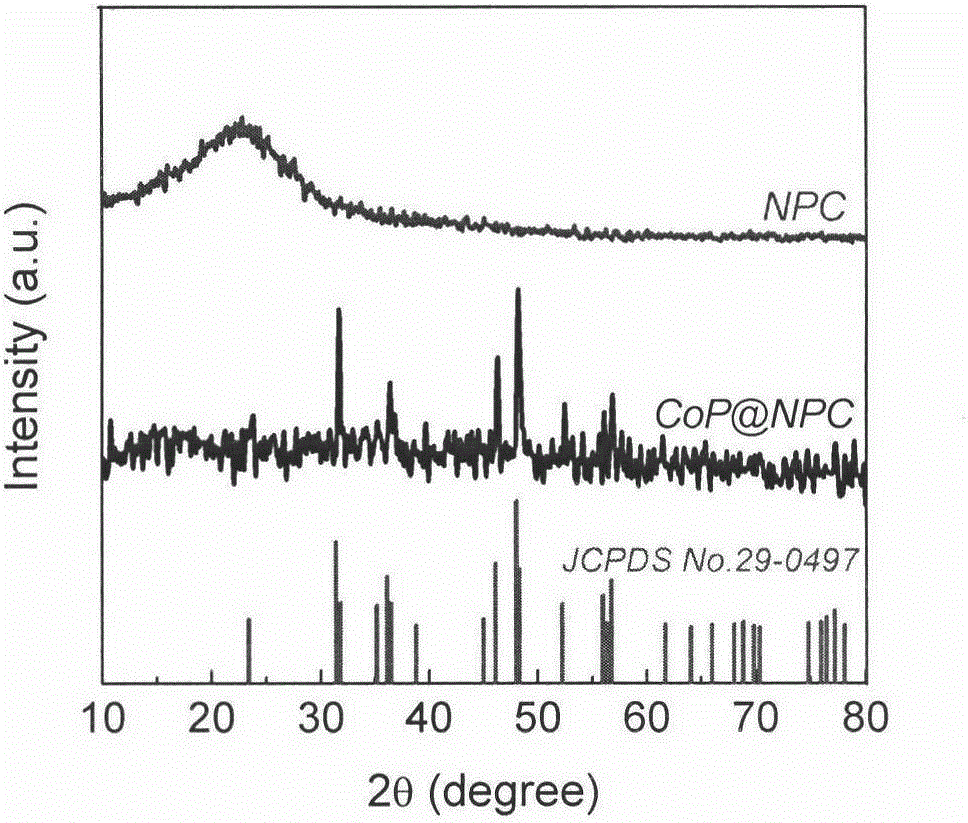

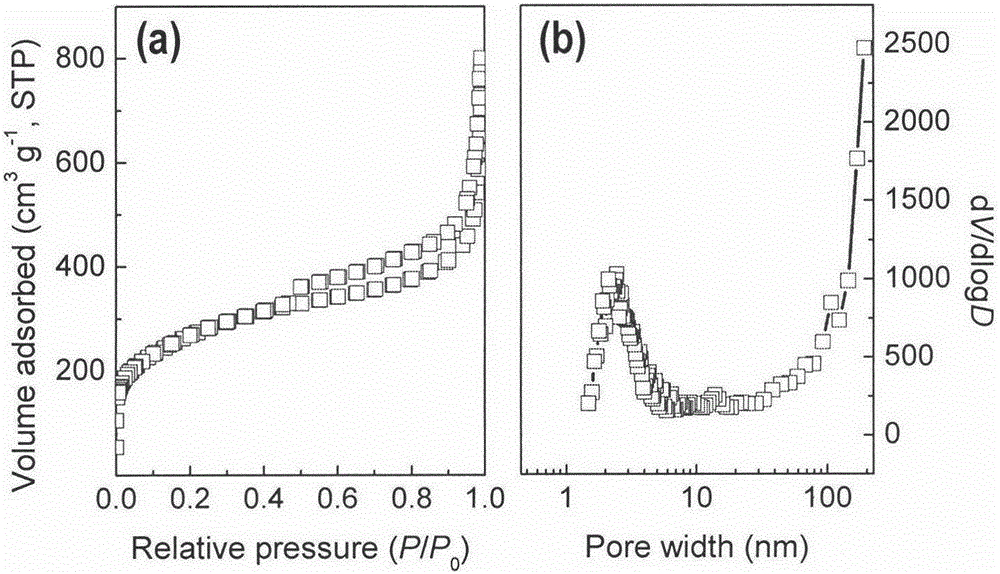

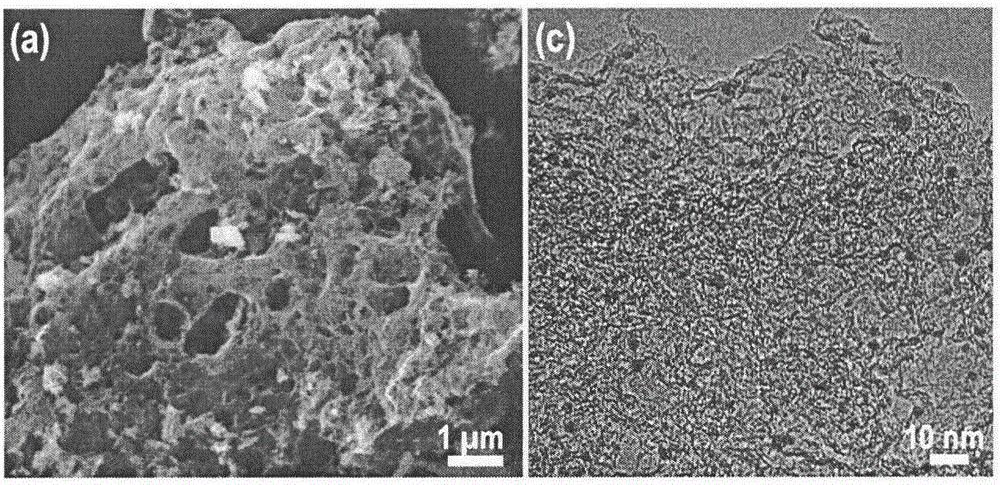

Preparation method of porous carbon-doped high-dispersion cobalt-phosphide-loaded material and application of porous carbon-doped high-dispersion cobalt-phosphide-loaded material in electro-catalysis hydrogen evolution

InactiveCN105214699AImprove protectionChange the ratioPhysical/chemical process catalystsElectrodesPorous carbonCarbonization

The invention belongs to preparation of a porous nano catalytic material, and particularly relates to a preparation method and application of a porous carbon-doped high-dispersion cobalt-phosphide-loaded material. The material is a carbon-based composite material which is of a mesoporous-macropore hierarchical porous structure and in which nitrogen atoms and phosphorus atoms are chemically doped in carbon skeletons and cobalt phosphide nanoparticles are loaded in a high-dispersion mode, and the specific surface area reaches up to 867 m<2> / g. The material is synthesized through the method comprising the steps that prepolymerization is firstly performed on organic phosphonic acid and melamine, and then high-temperature carbonization is performed. The material is applied to electro-catalysis hydrolysis hydrogen production and has the good effect. Used equipment is simple, the synthesis conditions are mild, the raw materials are easy to obtain, and the material is suitable for industrialized mass production.

Owner:NANKAI UNIV

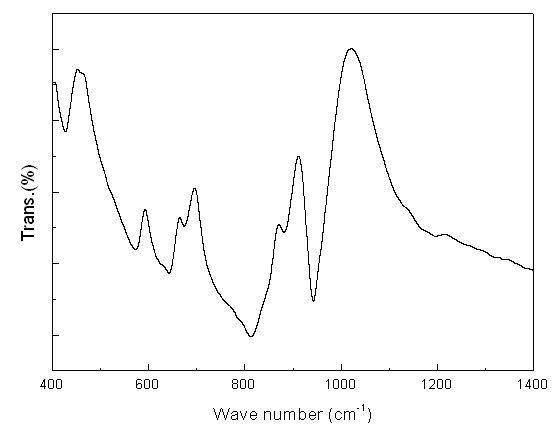

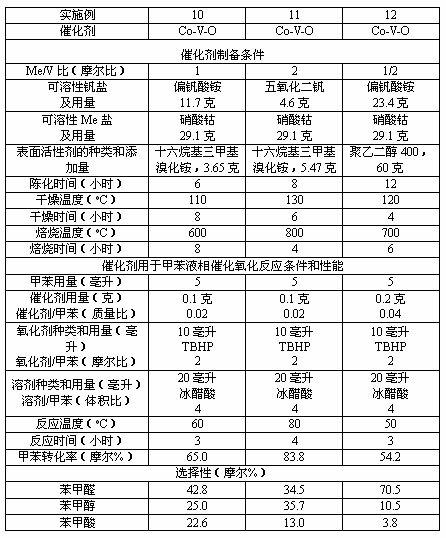

Toluene liquid-phase selective oxidation catalyst and preparation method thereof

InactiveCN101972646AImprove conversion rateRealize rational utilization of resourcesOxygen compounds preparation by hydrocarbon oxidationCatalyst activation/preparationSolventBenzaldehyde

The invention discloses a toluene liquid-phase selective oxidation catalyst and a preparation method thereof. The catalyst is transition metal or rare earth vanadate which has the composition shown by MexVyO, wherein Me is one of transition metals of VIB, VIIB or VIIIB group; V is vanadium; and the molar ratio x / y of Me to V is 0.1 to 10. The catalyst provided by the invention can be used for toluene liquid-phase oxidation reaction, the conversion rate of the toluene is high and the main product is benzaldehyde; by changing the composition and modulating reaction conditions of the catalyst, the proportion of the benzaldehyde to benzoic acid in the product can be changed; the catalyst does not pollute equipment and environment; and a solved used in the reaction can be recovered and rational resource utilization is basically realized.

Owner:NORTHWEST UNIV

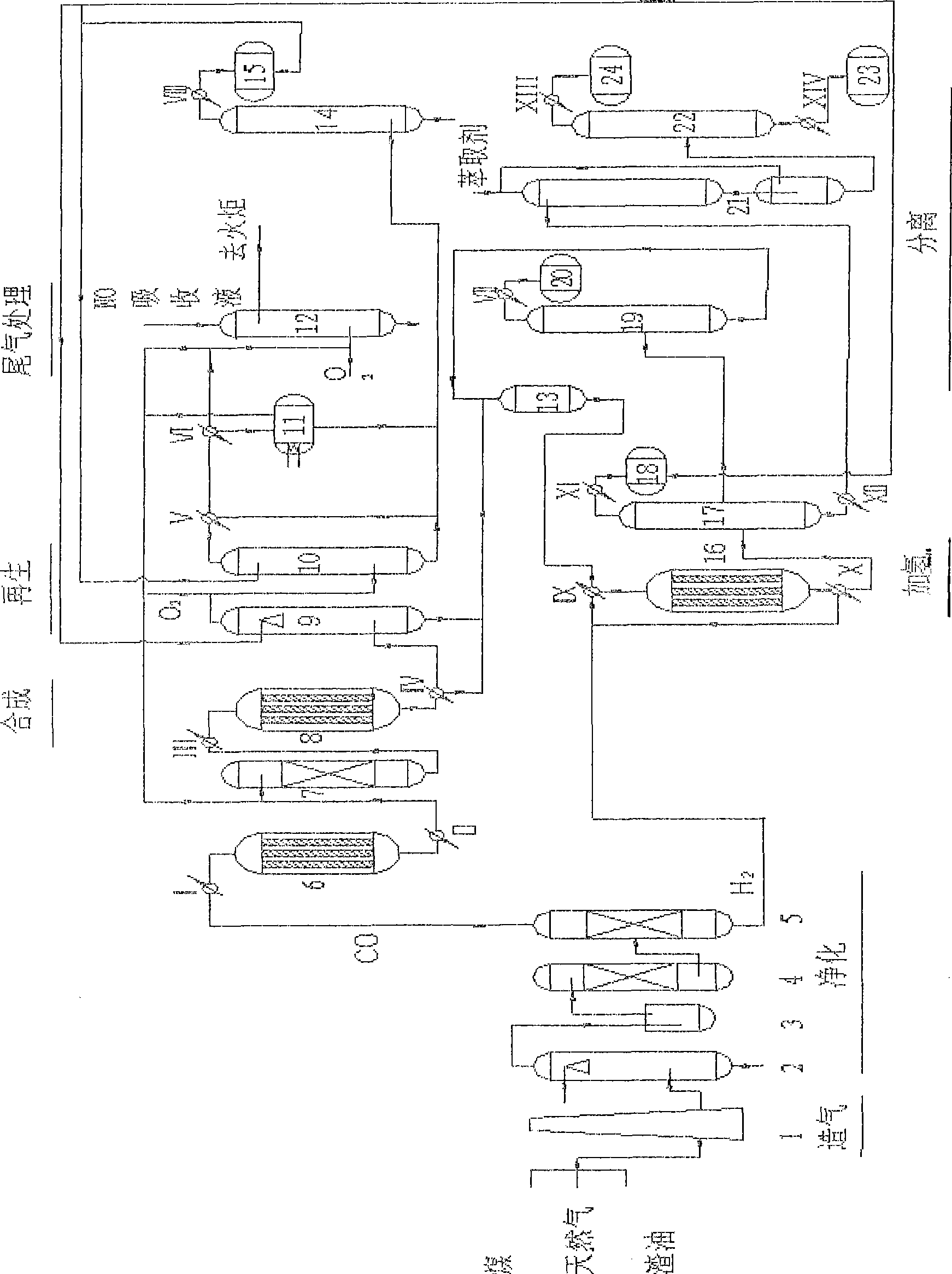

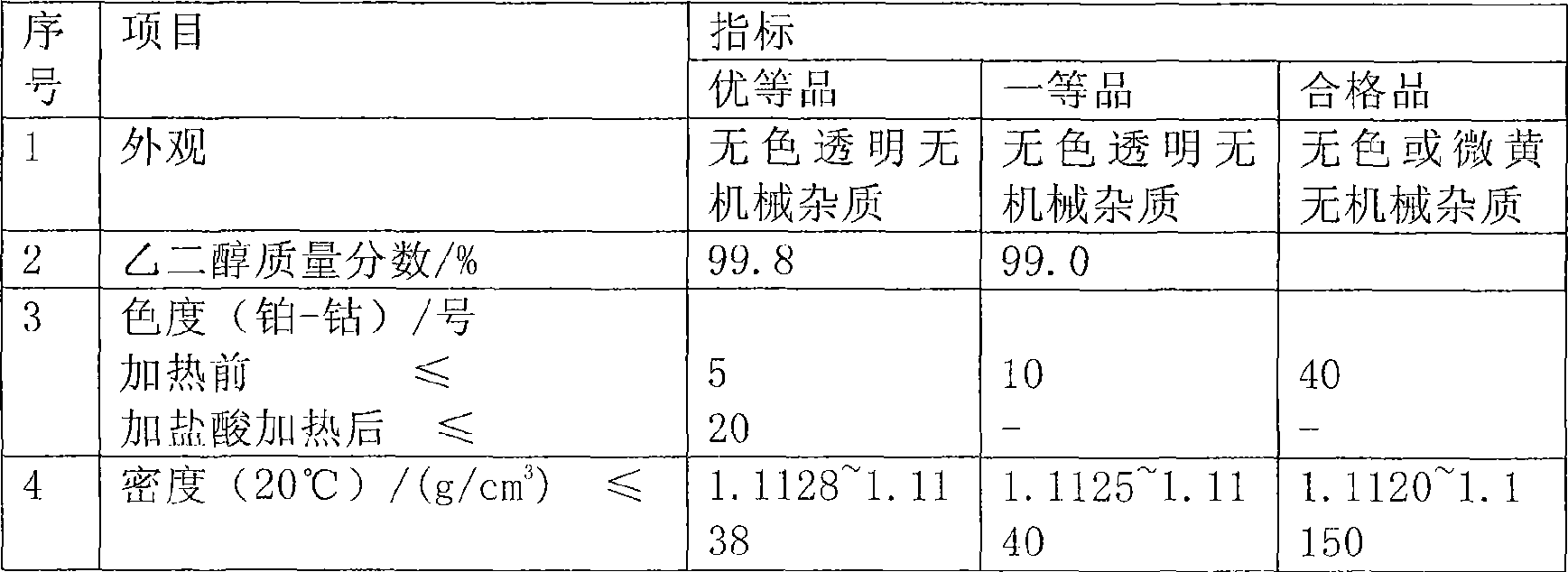

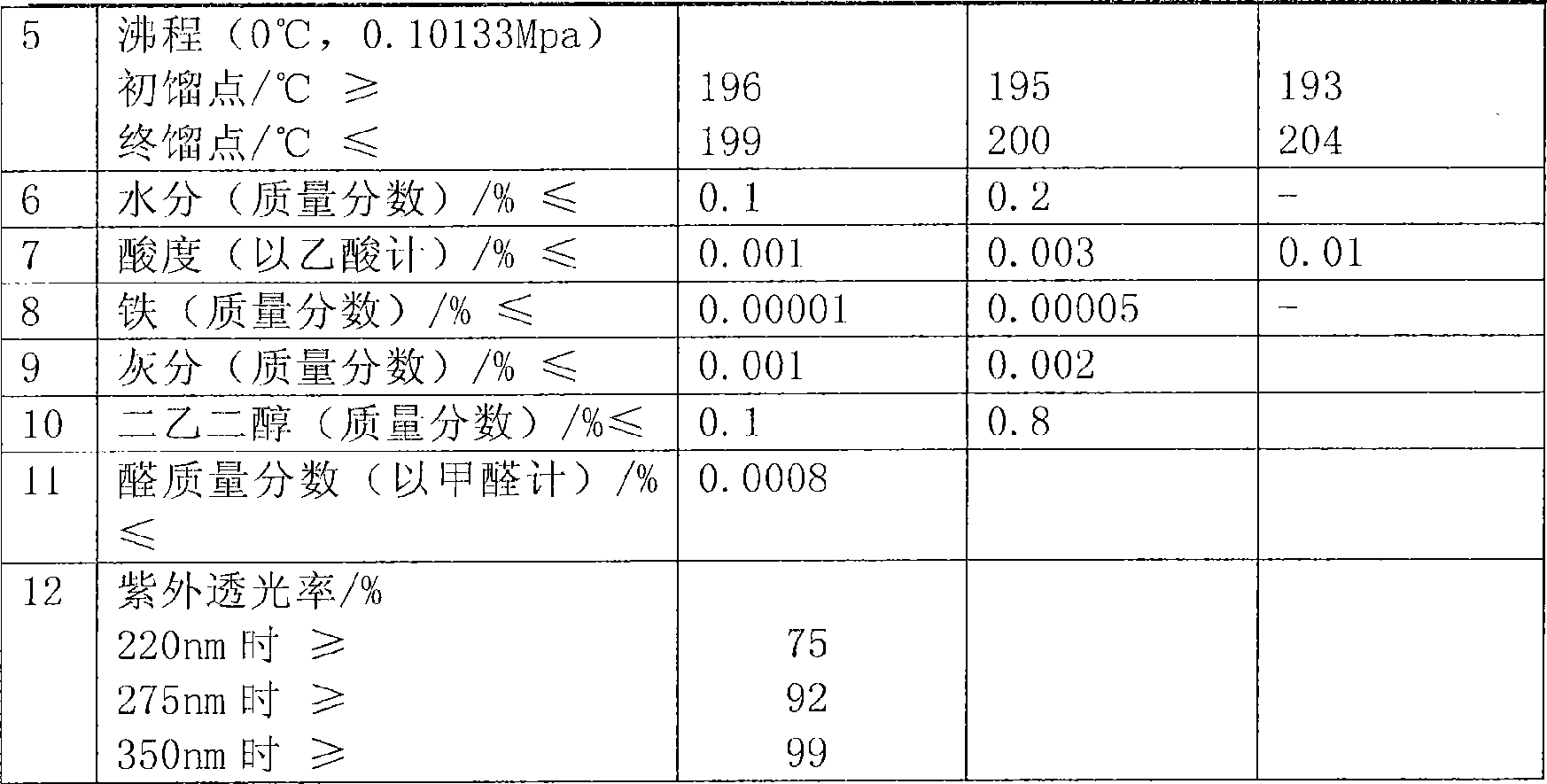

Method for producing polymer grade ethylene glycol and co-producing methyl glycolate

ActiveCN101544539AChange the ratioReduce energy consumptionOrganic compound preparationCarboxylic acid esters preparationNitric oxideOxygen

The invention discloses a method for producing polymer grade ethylene glycol and co-producing methyl glycolate, which comprises the following steps that: feed gas produced by taking coal, natural gas or residual oil as a raw material is subjected to purification treatment to obtain carbon monoxide and hydrogen through pressure varying absorption; the carbon monoxide, the hydrogen and auxiliary raw materials, namely industrial methanol, oxygen and nitrogen oxide are subjected to processes such as nitrosation reaction, carbonylation reaction, hydrogenation reaction, rectification separation, tail gas purification treatment and the like to obtain the ethylene glycol and the methyl glycolate; and the yield proportion of the ethylene glycol and the glycollic acid can be adjusted by controlling the hydrogenation reaction and the rectification process. In the method, the carbonylation reaction is performed on a Pd / alpha-Al2O3 catalyst added with two additives, and the carbonylation reaction is performed on a Cu-SiO2 or Cu-Cr2O3 or Cu-Zn-Al methanol catalyst, wherein the conversion ratio of the CO and the H2 is over 99.9 percent; and the selectivity is over 98 percent. Compared with the prior method for producing the ethylene glycol and the methyl glycolate, the method has the characteristics of low cost and high benefit.

Owner:HAISO TECH +2

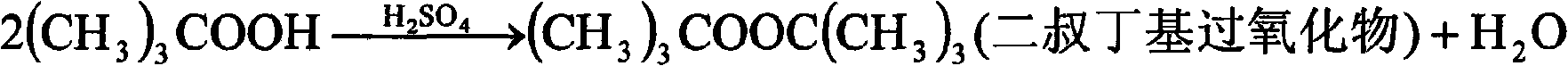

Preparation of tert-butyl hydrogen peroxide and di-tert-butyl peroxide

ActiveCN101298429AMild reaction conditionsHigh yieldOrganic chemistryDi-tert-butyl peroxideOil phase

The invention discloses a preparation method of tert-butyl hydroperoxide and di-t-butyl peroxide which includes the following steps: after mixing vitriol, oxyful and phosphotungstic acid with certain concentration, adding tertiary butyl alcohol into a mixed liquor or adding the mixed liquor into the tertiary butyl alcohol; reacting for 0.5 to 5 hours under 20 to 60 DEG C; obtaining an oil phase after carrying out liquid separation on the crude product of the reaction; obtaining the tert-butyl hydroperoxide and di-t-butyl peroxide products by carrying out decompressing and rectifying on the oil phase; the method has the advantages of simple and convenient operation, low manufacture cost, safety, high efficiency and high yield; in addition, the method of the invention can adjust the relative content of the two reaction products by changing the reaction conditions. The reaction products of tert-butyl hydroperoxide and di-t-butyl peroxide are separated by decompressing and rectifying, thus avoiding the working procedures of acid cleaning and caustic wash in the traditional technique, solving the defect of overlarge waste water amount in the traditional technique, being beneficial to protecting the environment, reducing the manufacture cost and being capable of greatly increasing the enterprise benefits.

Owner:ZHEJIANG JINKE CHEM

Method for adding carbon nano tube into metal bath

The invention relates to a method for adding carbon nano tube into metal bath, which is characterized in mixing carbon nano tube, metal powder and stearic acid according to a weight ratio between the carbon nano tube and metal powder of 1:10-2, and a weight ratio between stearic acid, carbon nano tube and metal powder of 1:15-20, putting into a ball mill for ball milling, sieving with a 50-80 mesh stainless steel sieve to obtain a uniform mixture, adding the mixture into the mold, pressing for molding to obtain carbon nano tube / metal composite press block; adding the carbon nano tube / metal composite press block into a metallic or alloy solution, regulating temperature of fused mass to a casting temperature, casting the article.

Owner:NANCHANG UNIV

Low-temperature conductive silver paste and preparation method thereof

ActiveCN102157222AGood shrinkage propertiesGood strengthConductive layers on insulating-supportsNon-conductive material with dispersed conductive materialIsophoronePolyester

The invention discloses a low-temperature conductive silver paste and a preparation method thereof, relating to conductive silver paste materials and aiming at solving the problems of high cost and large resistance of conductive silver pastes used for a printing industry. The low-temperature conductive silver paste comprises the following components in percentage by weight: 45% of silver powder, 6% of additive bismuth oxide, 6.2% of macromolecule resin vinyl chloride-acetate, 6.2% of macromolecule resin polyester, 34% of solvent DBE and 2.6% of solvent isophorone. The preparation method comprises the following steps of: a, weighing and mixing the solvent DBE, the solvent isophorone and macromolecule resins according to weight percentage to obtain an organic carrier; b, weighing the silver powder and the additives according to the weight percentage, and then mixing with the organic carrier obtained from the step a in a stirring way to obtain a uniform paste; and c, grinding and rolling the paste obtained from the step b to obtain the low-temperature conductive silver paste.

Owner:CHENGDU BANKNOTE PRINTING

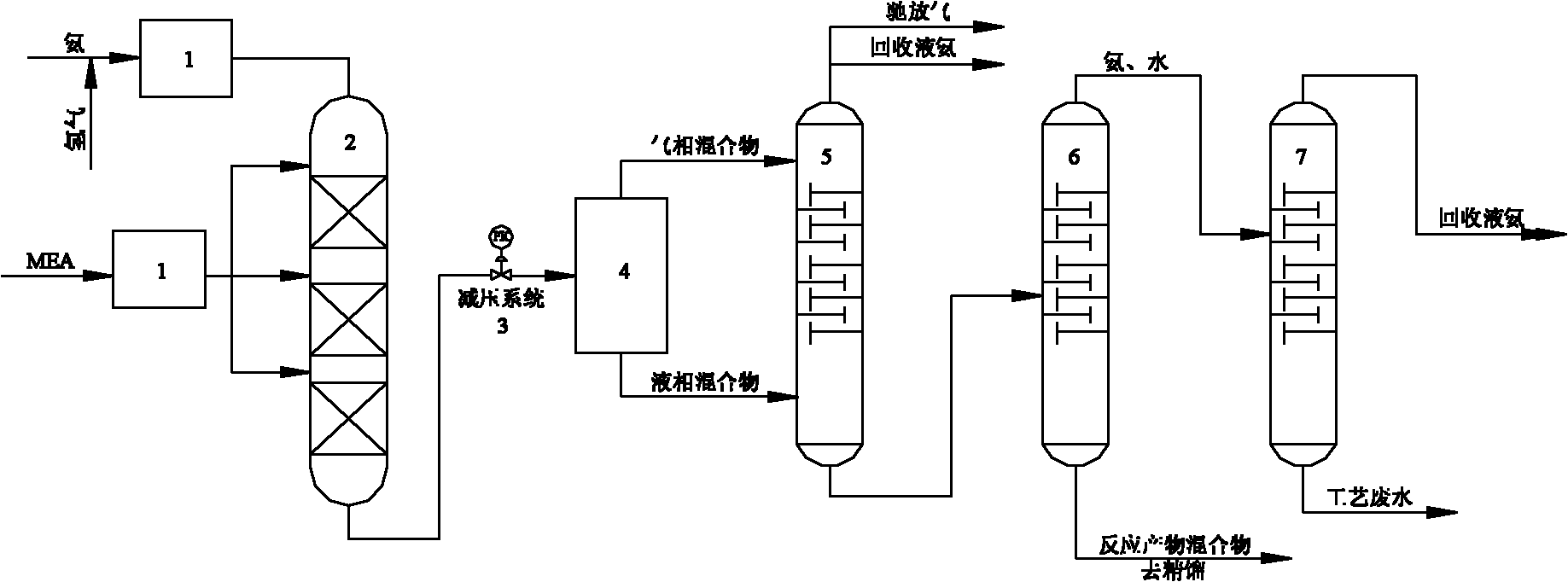

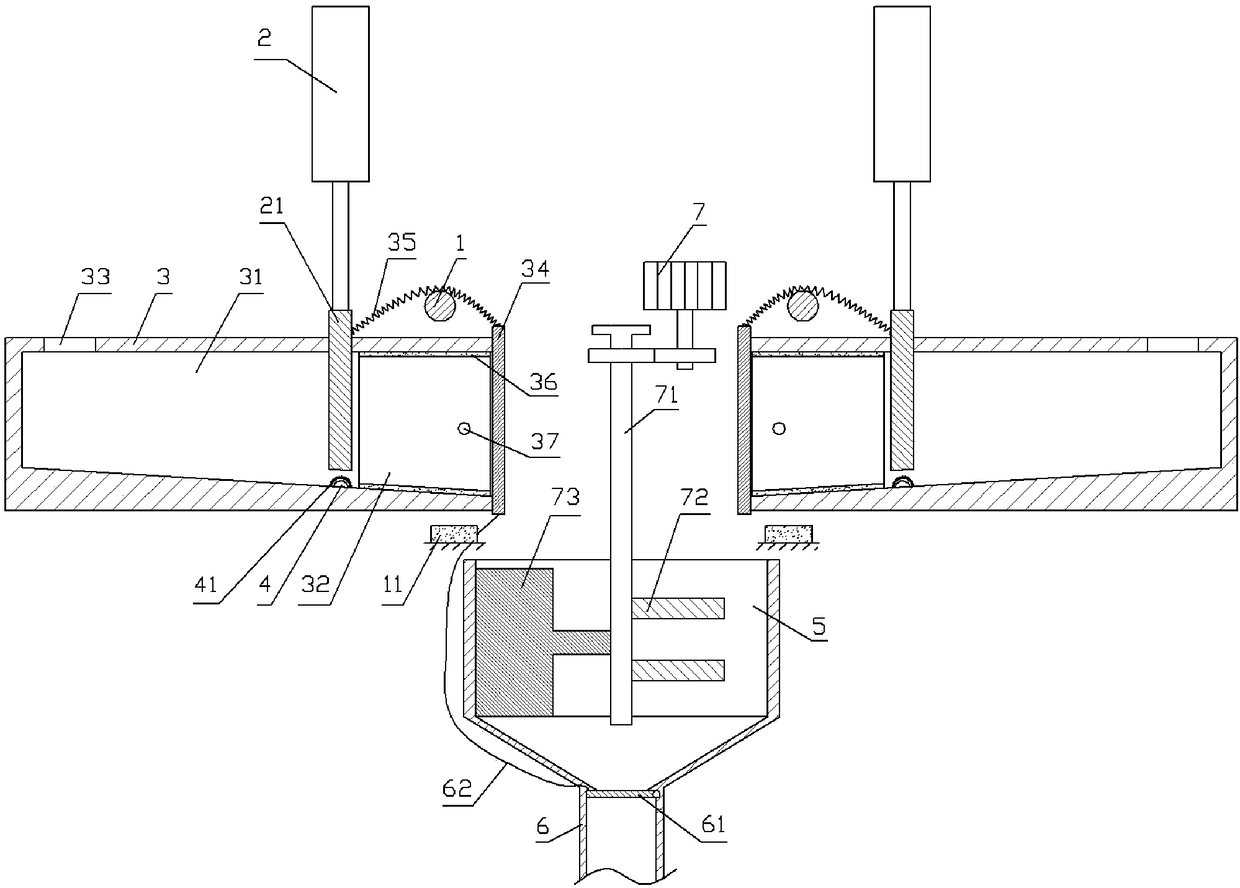

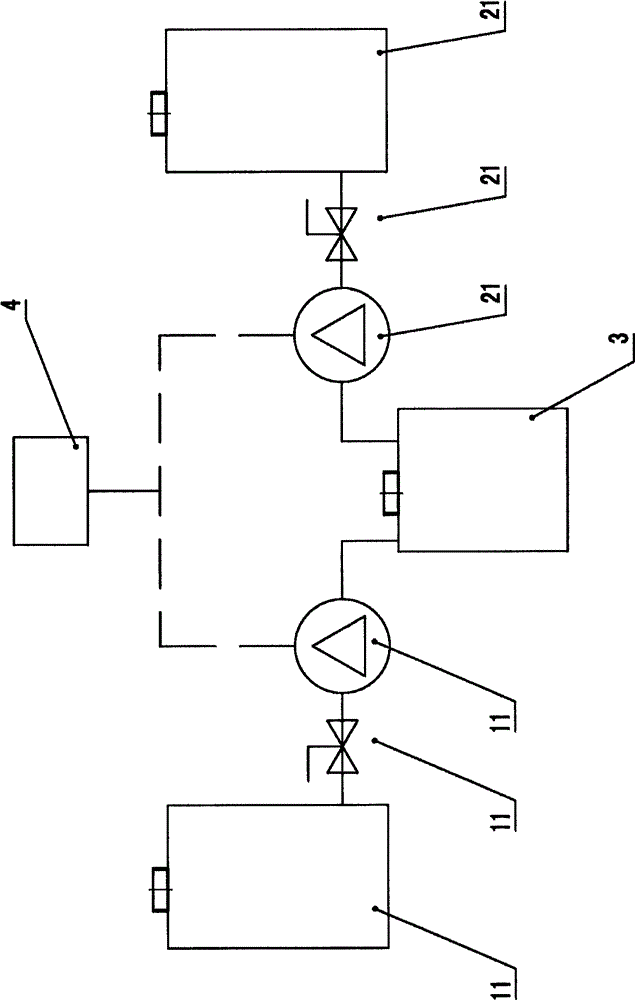

A method for preparing ethylenediamine by using ethanolamine and ammonia as raw materials

ActiveCN103159630AReduce reaction pressure and energy consumptionHigh selectivityOrganic compound preparationAmino compound preparationChemistryEthylenediamine

A method for preparing ethylenediamine by using ethanolamine and ammonia as raw materials. Apparatuses adopted in the method comprise a material heater, a reactor for ammonification reactions, a pressure reduction control valve, a gas-liquid separator, a distillation column for removal of the ammonia, a distillation column for ammonia stripping and a rectification column for ammonia recycling. Raw materials reacts in the presence of hydrogen, the reaction product mixture is subjected to the recovery of ammonia after pressure reduction, and separated aqueous ammonia and liquid ammonia are recycled as a raw material.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

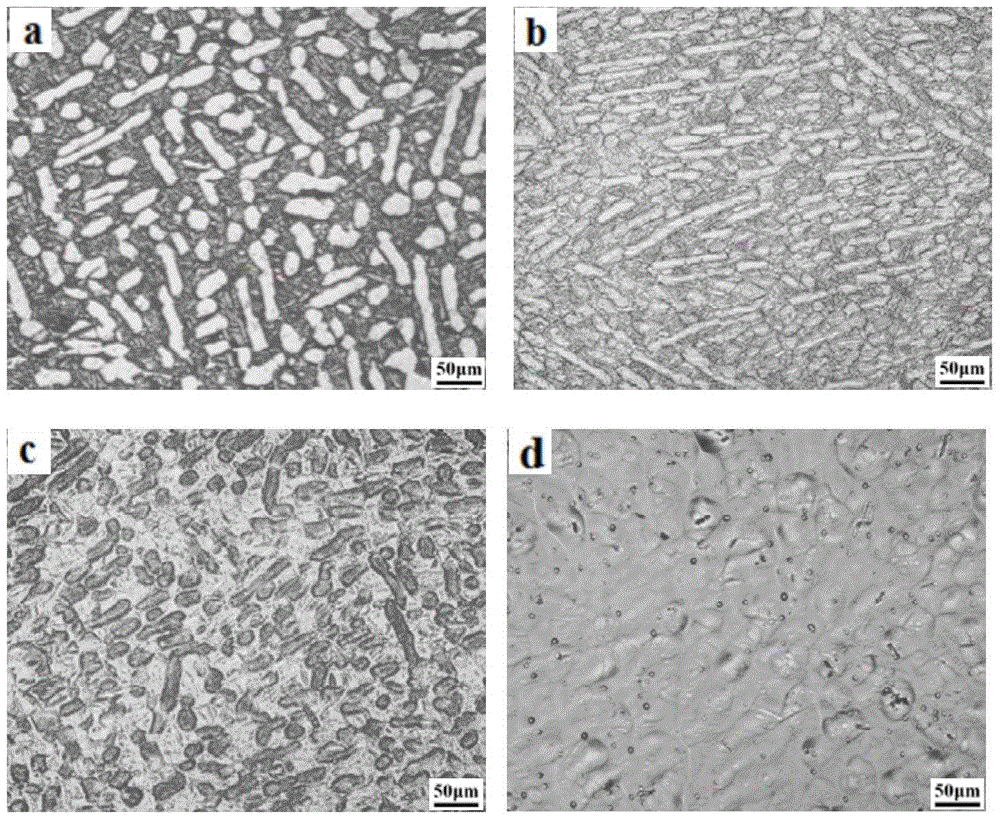

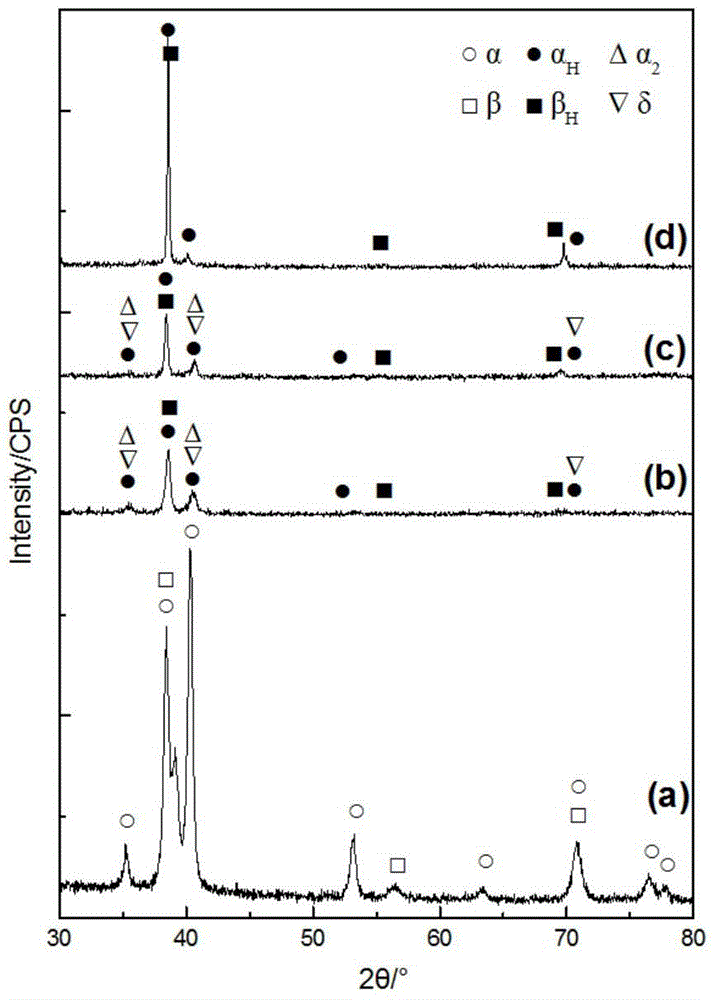

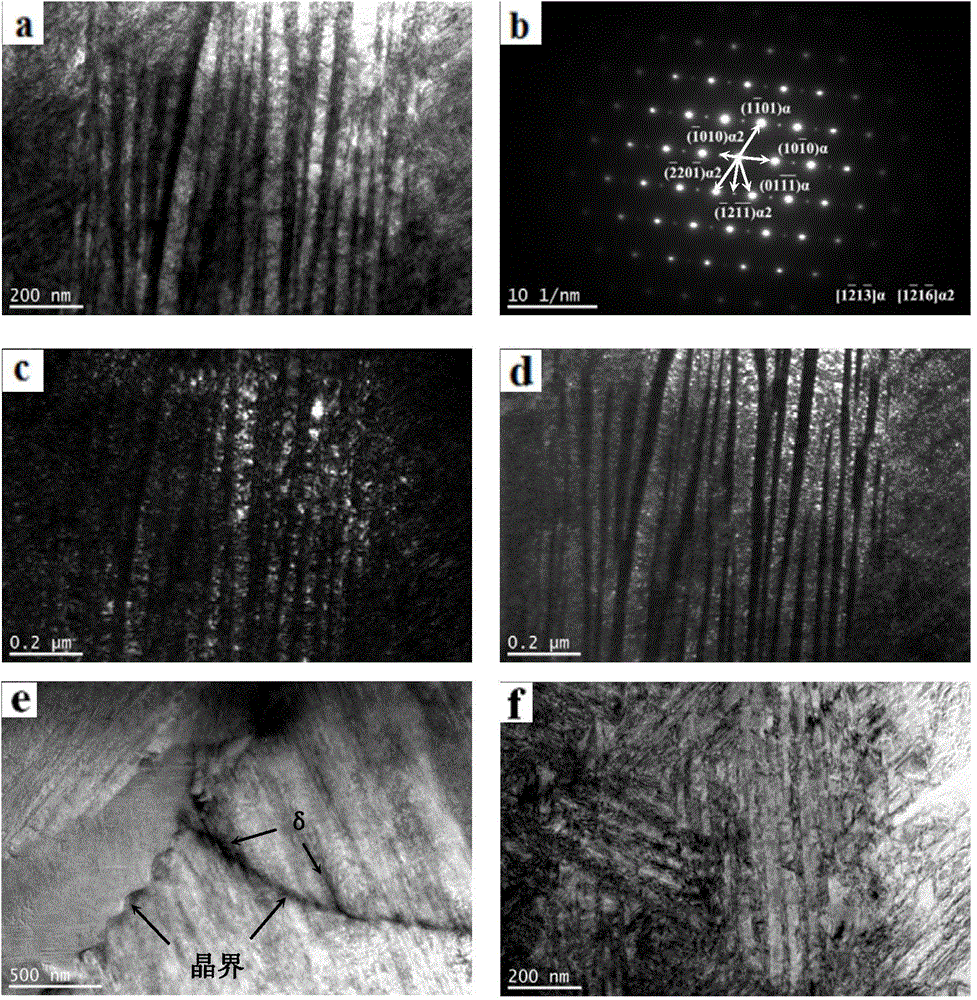

Thermo-hydrogen processing technology for improving room temperature plasticity of TC21 titanium alloy

The invention discloses a thermo-hydrogen processing technology for improving room temperature plasticity of TC21 titanium alloy. The thermo-hydrogen processing technology is characterized in that a TC21 sample is put into a furnace tube of a tubular furnace, the surface of the TC21 sample is covered by a layer of titanium scraps to prevent the TC21 sample from being oxidized, vacuum pumping is conducted, when the vacuum degree in the furnace tube is lower than 1*10-3 Pa, the furnace tube is heated, the temperature is increased to 750 DEG C, nitrogen is led into the furnace tube, the nitrogen pressure in the furnace tube is stabilized to 15-25 kPa, the temperature is preserved for 1-2 hours, the furnace tube is pulled out from the furnace and naturally cooled to the room temperature, and the TC21 sample in the furnace tube is taken out.

Owner:HEFEI UNIV OF TECH

Automatic proportioning type cement hopper

InactiveCN108312356ARealize automatic batchingChange the ratioDischarging apparatusMixing operation control apparatusAgricultural engineeringAirbag

The invention relates to the field of buildings and in particular discloses an automatic proportioning type cement hopper. The automatic proportioning type cement hopper comprises a rack, a stirring mechanism, a feeding hopper and a proportioning mechanism, wherein the feeding holler comprises a feeding part and a discharging pipe; a sealing plate is hinged to the upper part of the discharging pipe; a pull rope is fixed on the sealing plate; the stirring mechanism comprises a motor, a stirring shaft and stirring blades; one end of the stirring shaft and the stirring blades are arranged in thefeeding part; the proportioning mechanism comprises an extension spring, a separating plate, a hydraulic jacking device, an electromagnet, a proportioning box and a baffle plate; the pull rope is fixedly arranged on the baffle plate; the proportioning box is divided into a proportioning cabin and a feeding cabin by the separating plate; two ends of the extension spring are fixedly arranged on thebaffle plate and the separating plate respectively; the bottom of the proportioning box is an inclined surface; the electromagnet can adsorb the baffle plate; a switch is arranged on an inner wall ofthe proportioning box; the separating plate can press the switch; an airbag is fixedly arranged at the bottom of the proportioning cabin; an air inlet is formed in the airbag; a feeding opening is formed in a lateral wall of the feeding cabin. By adopting the automatic proportioning type cement hopper provided by the invention, the quantity of entered raw materials can be controlled.

Owner:苏州相城埭辰科技产业发展有限公司

Method for purifying montmorillonite, purified montmorillonite and combination thereof

ActiveCN101340979BReduce moisture contentAvoid cakingWet separationClaywaresPhysical chemistryMontmorillonite

A method for purification and separation of inorganic mineral, especially for purification and separation of montmorillonite from natural bentonite is provided. The said method is simple, and uses high-speed centrifugal device to well solve the problems present in purification of montmorillonite that a-quartz and cristobalite are difficult to be separated and removed and purified slurry is difficult to be concentrated and dehydrated. The purity of montmorillonite thus obtained is not less than 95%.

Owner:ZHEJIANG HAILISHENG PHARM CO LTD

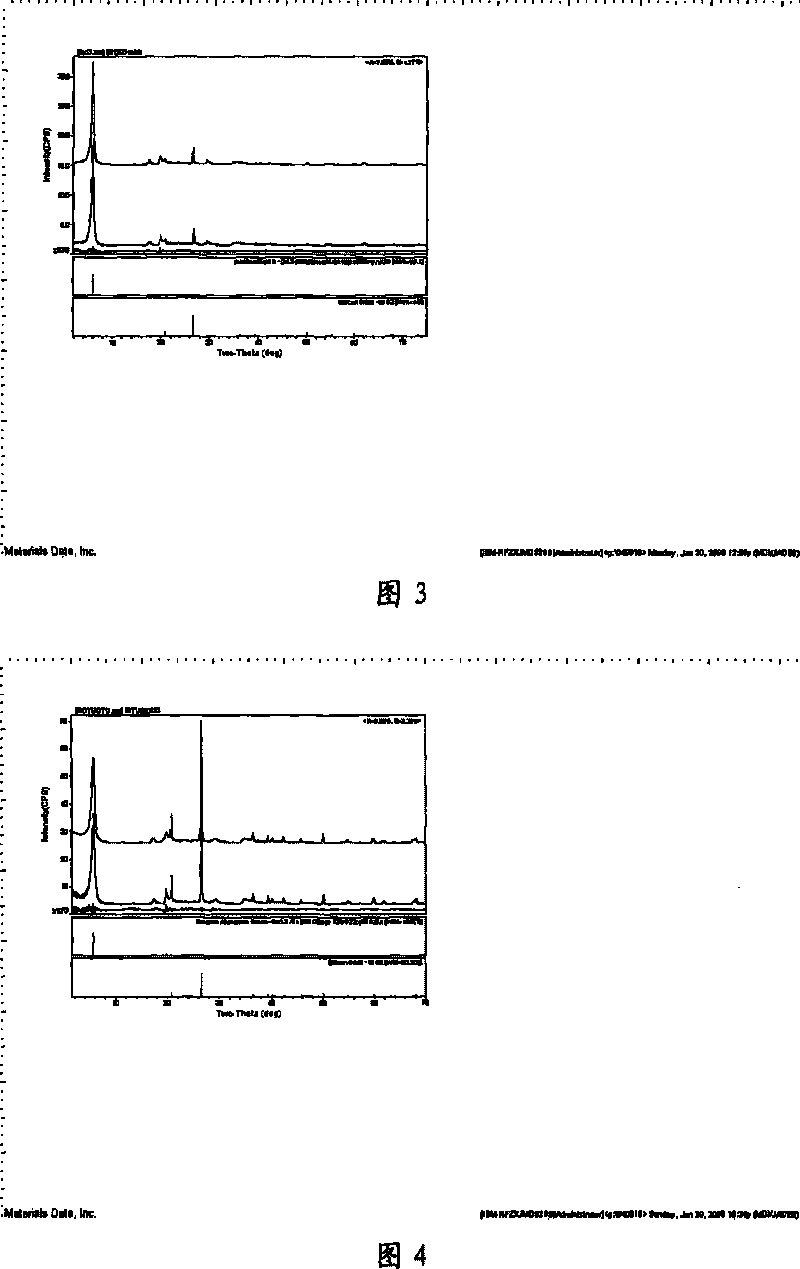

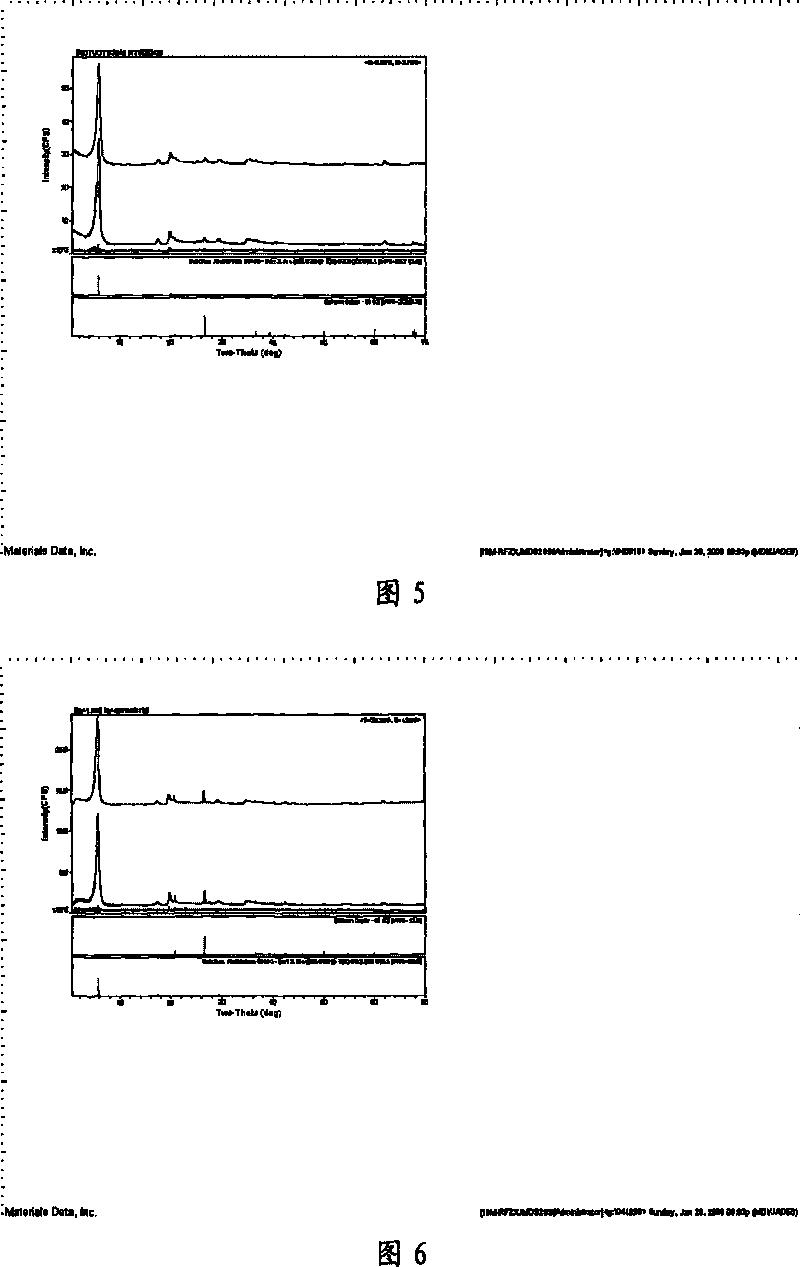

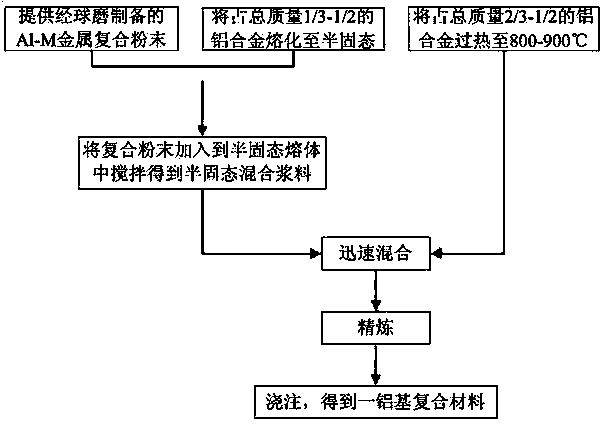

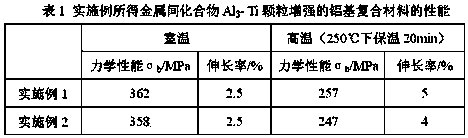

Preparation method of intermetallic compound Al3-M particle reinforced aluminum matrix composite

The invention relates to a preparation method of an intermetallic compound Al3-M particle reinforced aluminum matrix composite and belongs to the technical field of aluminum matrix composite preparation and metal smelting. The invention aims at providing the preparation method of the intermetallic compound Al3-M particle reinforced aluminum matrix composite, and provides the intermetallic compound Al3-M particle reinforced aluminum matrix composite prepared by the method at the same time. The invention adopts the technical scheme that the preparation method of the intermetallic compound Al3-M particle reinforced aluminum matrix composite well solves the problem of no infiltration between an intermetallic compound reinforced particle and molten metal by a stepped method of firstly increasing the magnesium concentration in aluminum melt and adding the intermetallic compound particle.

Owner:ZHONGBEI UNIV

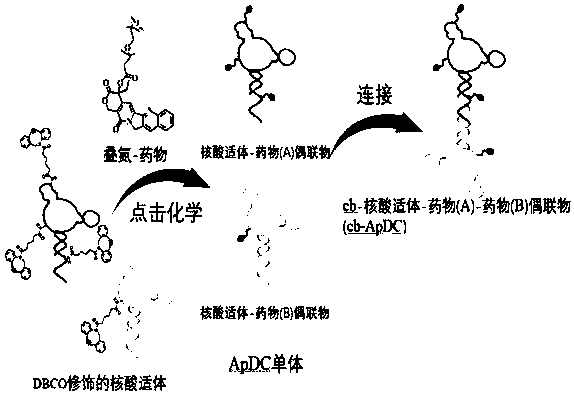

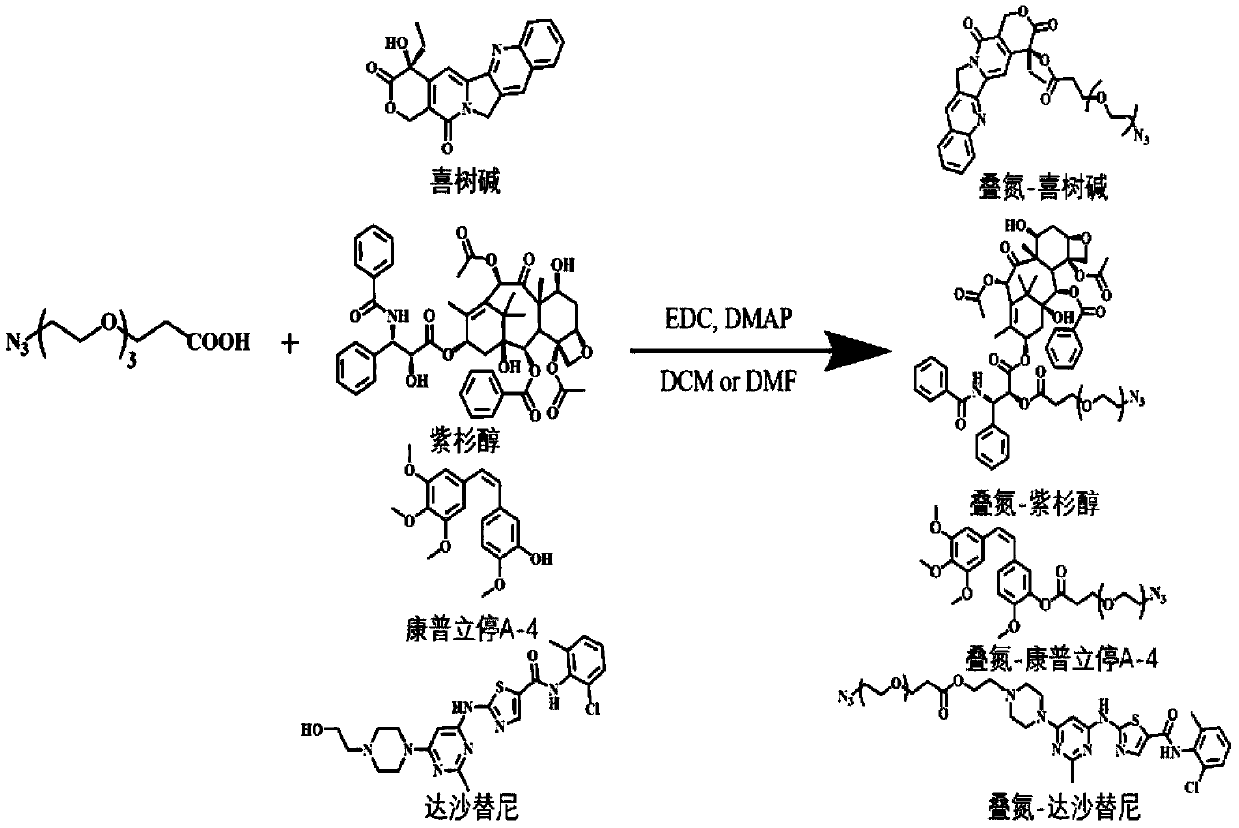

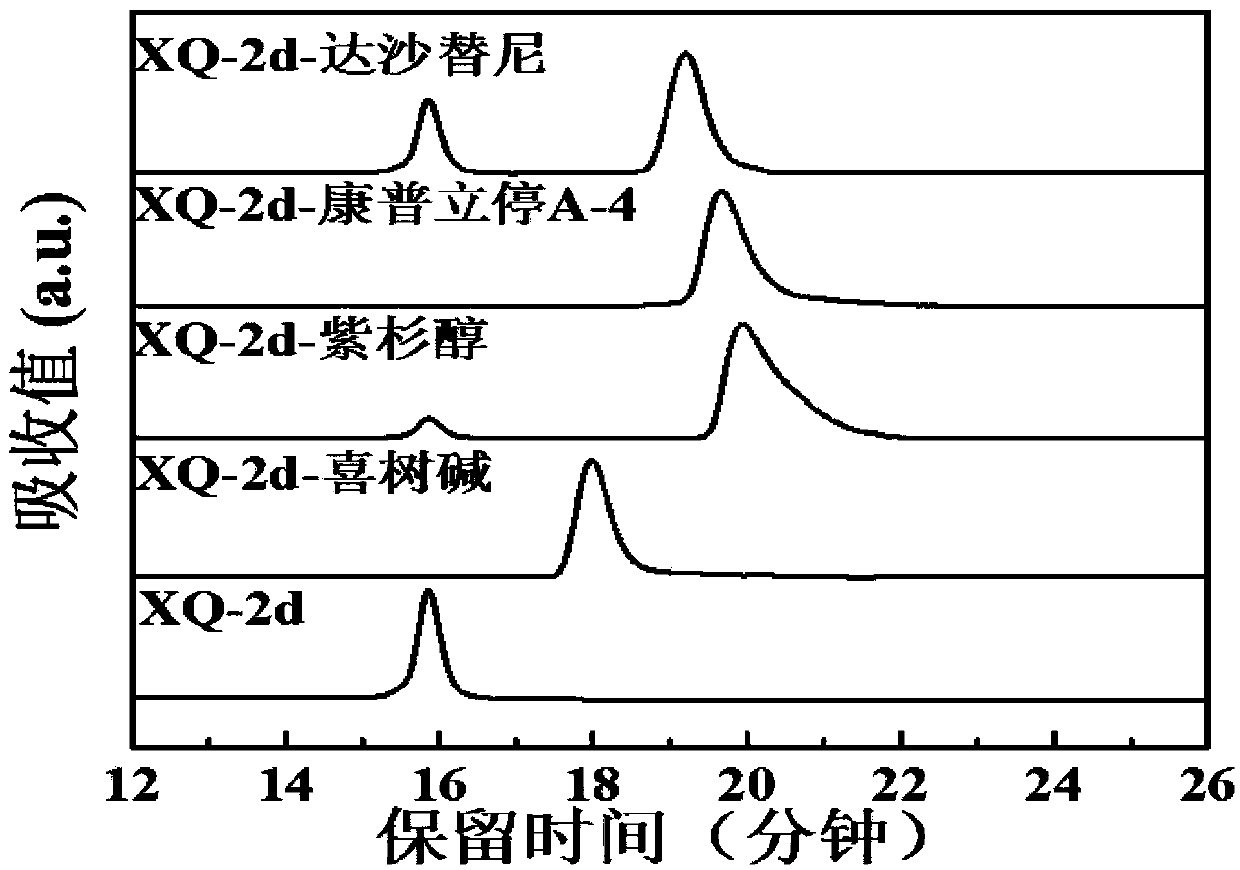

Nucleic acid aptamer and its circular bivalent nucleic acid aptamer-drug coupling system and application thereof

ActiveCN110354268AHigh affinityImprove stabilityPharmaceutical non-active ingredientsAntineoplastic agentsAptamerCancer cell

The present invention discloses a nucleic acid aptamer and its circular bivalent nucleic acid aptamer-drug coupling system and an application thereof. The system comprises a nucleotide sequence of X-GCTCATAGGGTTAGGGGCTGCTGGCCAGATACTCAGATGGTAGGGTTACTATGAGC, wherein: X is absent (SEQ ID NO: 1), or is one of the TGACTGATTTACG (SEQ ID NO: 2) and CGTAAATCAGTCA (SEQ ID NO: 3) sequences. The nucleic acidaptamer of the invention has good affinity for various cancer cells, and after modification, the nucleic acid aptamer can be combined with various anticancer drugs to make the drug targeted, and theutilization rate of the drug is increased, a monomer linked to the drug after modification can also be prepared into the nucleic acid aptamer-drug coupling system, which is loaded with a plurality ofdrugs, and synergistic effect of drugs is achieved. The drug effect is improved, the circular divalent nucleic acid aptamer-drug coupling system is simple and efficient in synthesis, and does not require complicated reactions, and provides a new method for multi-drug combination therapy.

Owner:HUNAN UNIV

Liquid blending apparatus and cleaning equipment possessing same

InactiveCN104437225AChange the ratioSimple structureMixer accessoriesCleaning processes and apparatusEngineering

Owner:SHENZHEN UNICOMP TECH CO LTD

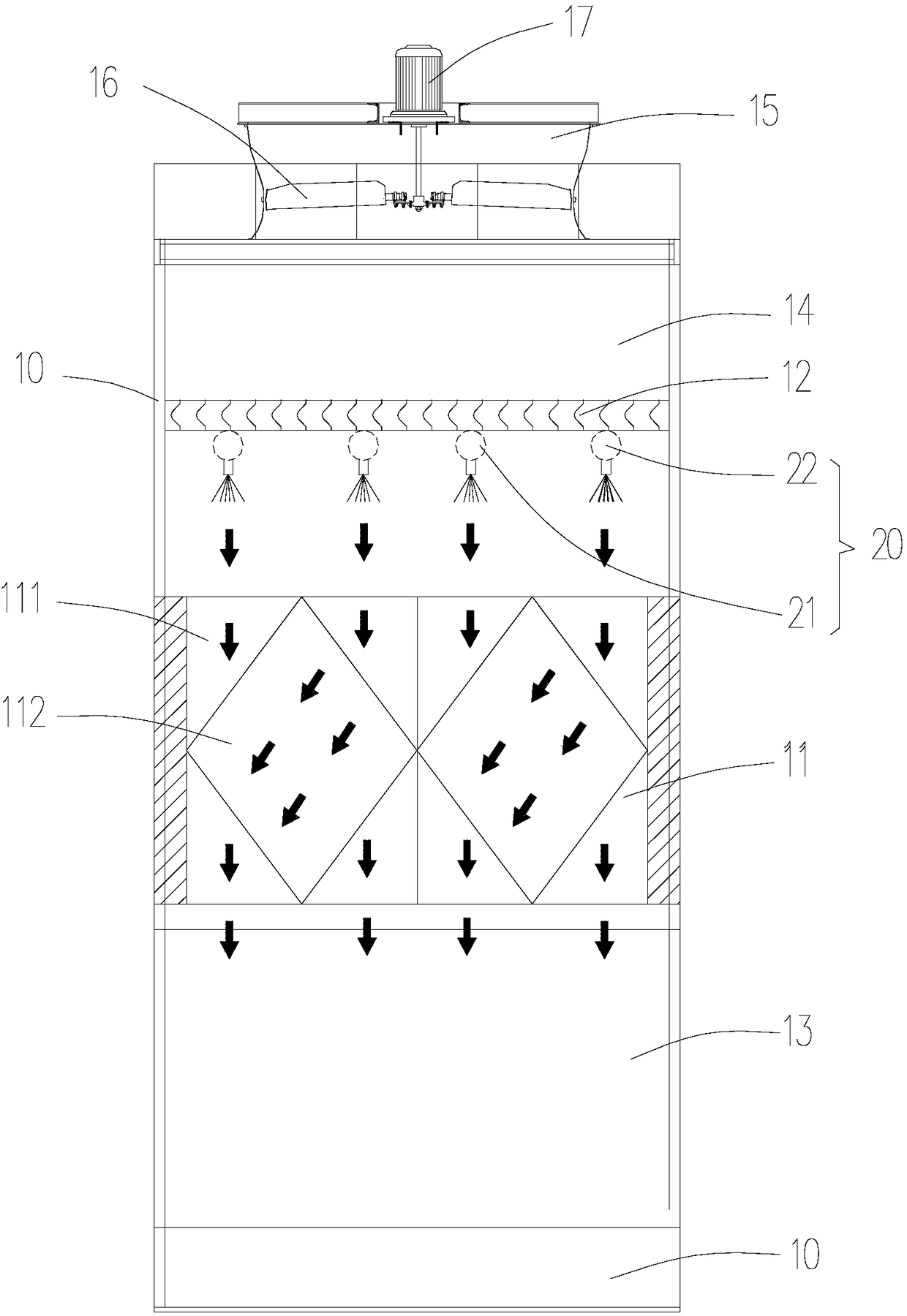

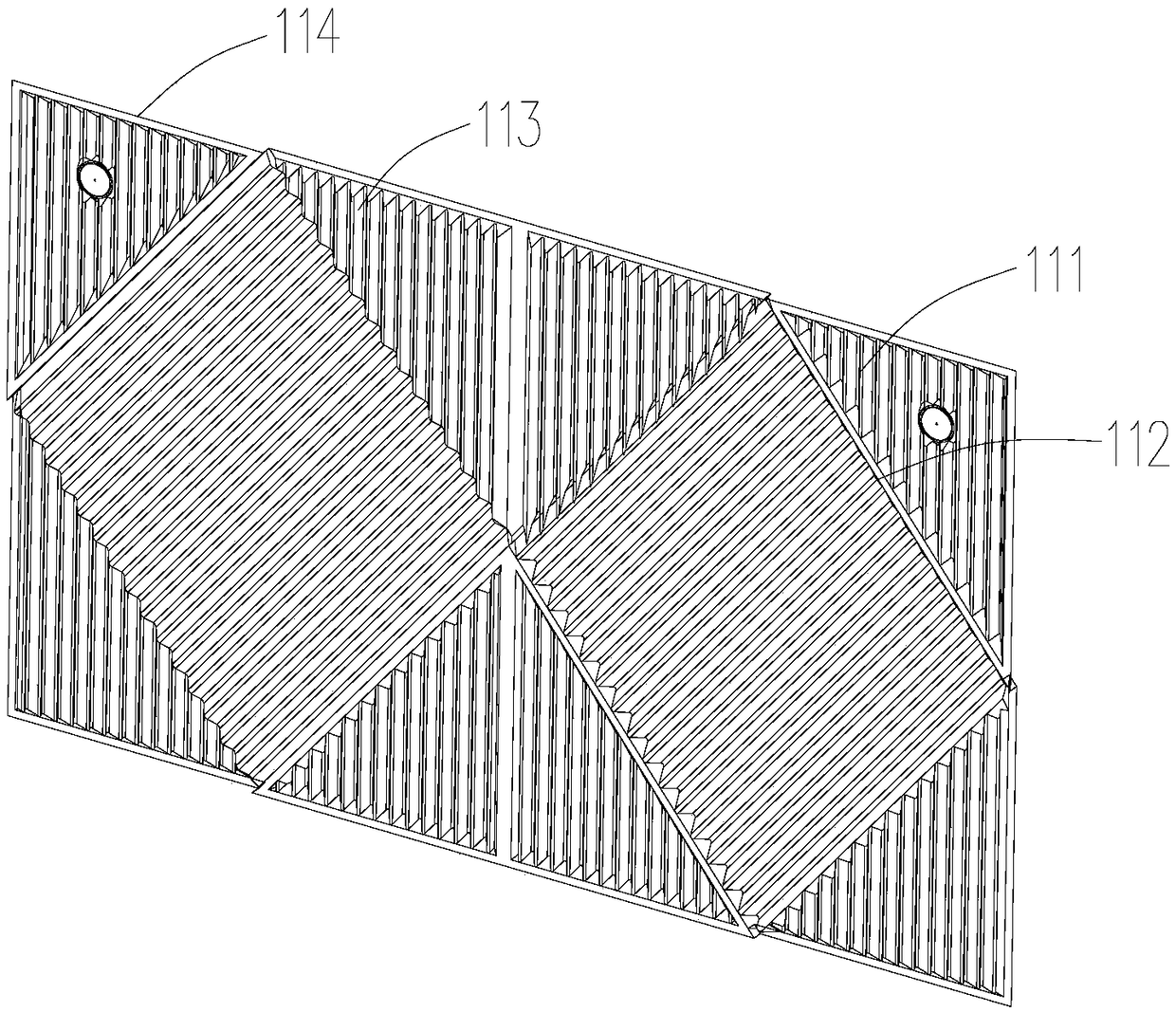

Plate-heat-exchanger mist elimination module and cooling tower with same

PendingCN108344310AGood dispersionChange the ratioTrickle coolersCompression moldingPlate heat exchanger

The invention provides a mist elimination cooling tower with a mist elimination module. The mist elimination cooling tower comprises a tower body, wherein the mist elimination module is arranged in the tower body; the mist elimination module comprises first packing sheets and second packing sheets; the first packing sheets and the second packing sheets are both corrugated plates; the section of each first packing sheet is Z-shaped; a connection sheet is arranged at the middle of each first packing sheet; the two sides of each connection sheet are concave surfaces; and each second packing sheetis arranged on the two concave surfaces of the corresponding first packing sheet, and the corrugation of the second packing sheets and the corrugation of the first packing sheets are formed slantwise. According to the mist elimination module provided by the invention, the Z-shaped first packing sheets are formed through compression molding, the second packing sheets are arranged on the first packing sheets, and the corrugation of the first packing sheets and the corrugation of the second packing sheets are mutually intersected to form staggered channels, so that water flow can be better dispersed, and the heat exchange efficiency is increased.

Owner:江苏海鸥冷却塔股份有限公司

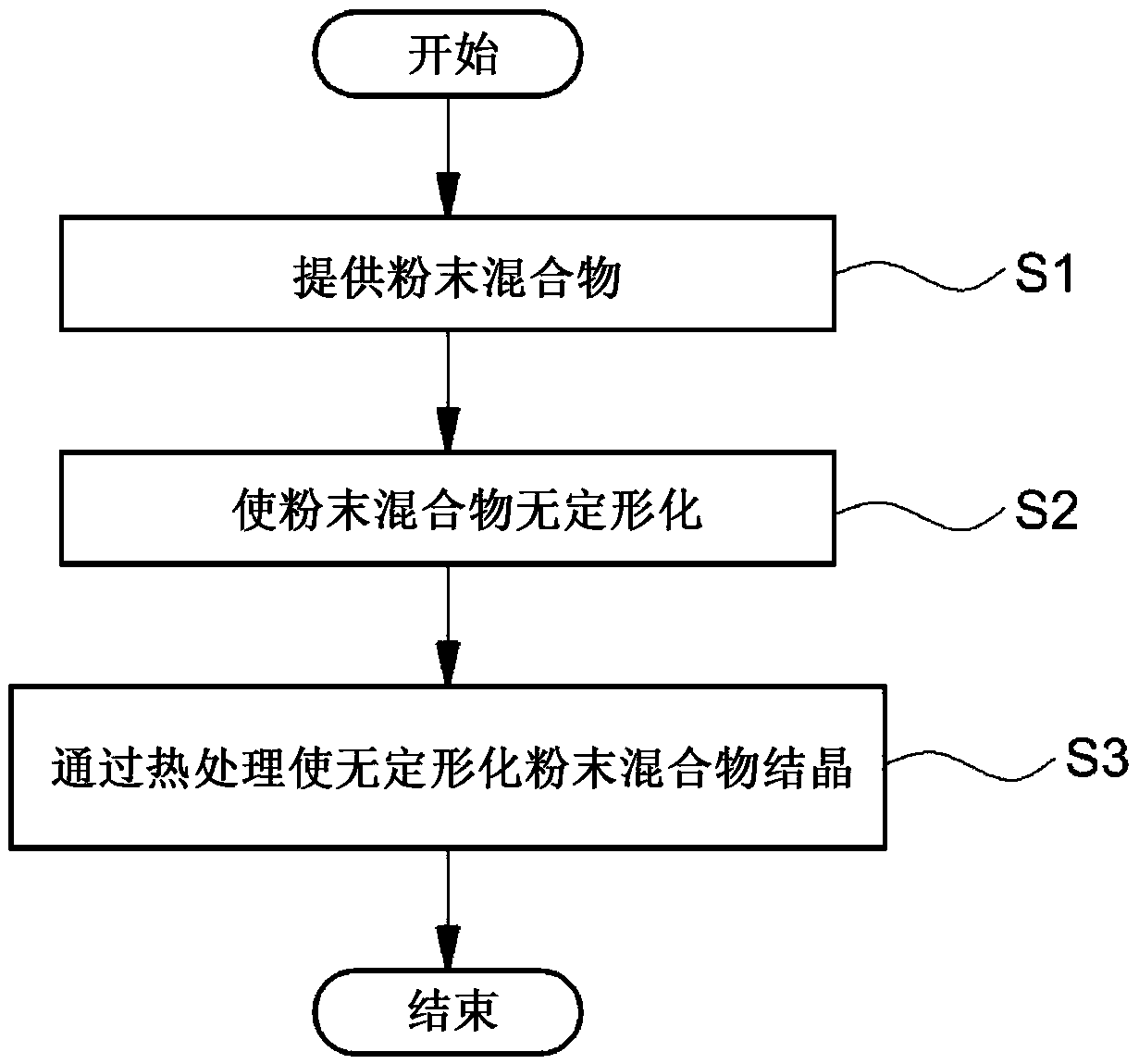

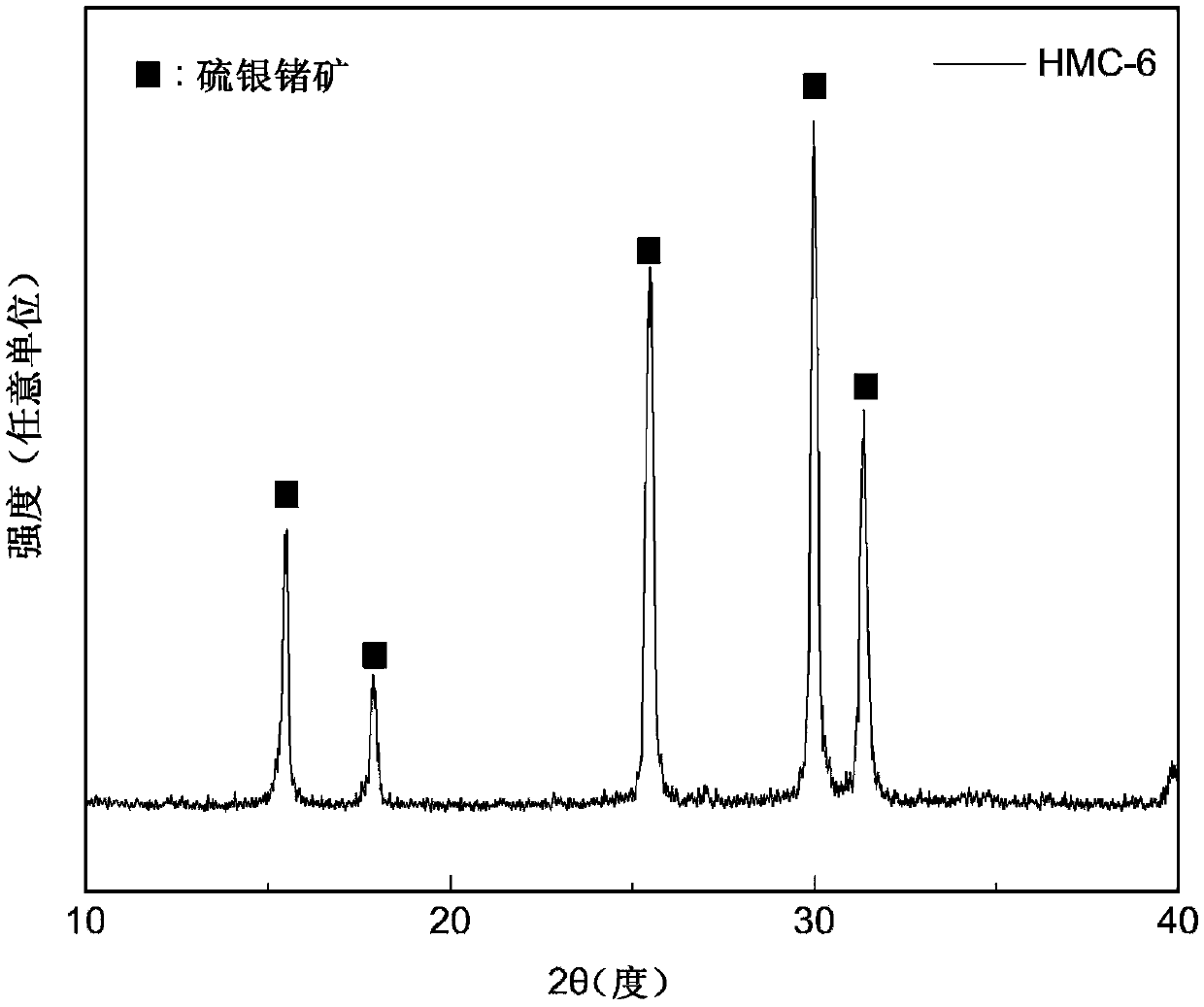

Solid electrolyte for all-solid battery and method of preparing same

ActiveCN109942008ALow costChange the ratioSolid electrolytesElectrode thermal treatmentCrystal structureElectrolyte

Disclosed is a solid electrolyte for an all-solid battery and a method of preparing the same. Particularly, the solid electrolyte may have an argyrodite-type crystal structure.

Owner:HYUNDAI MOTOR CO LTD +1

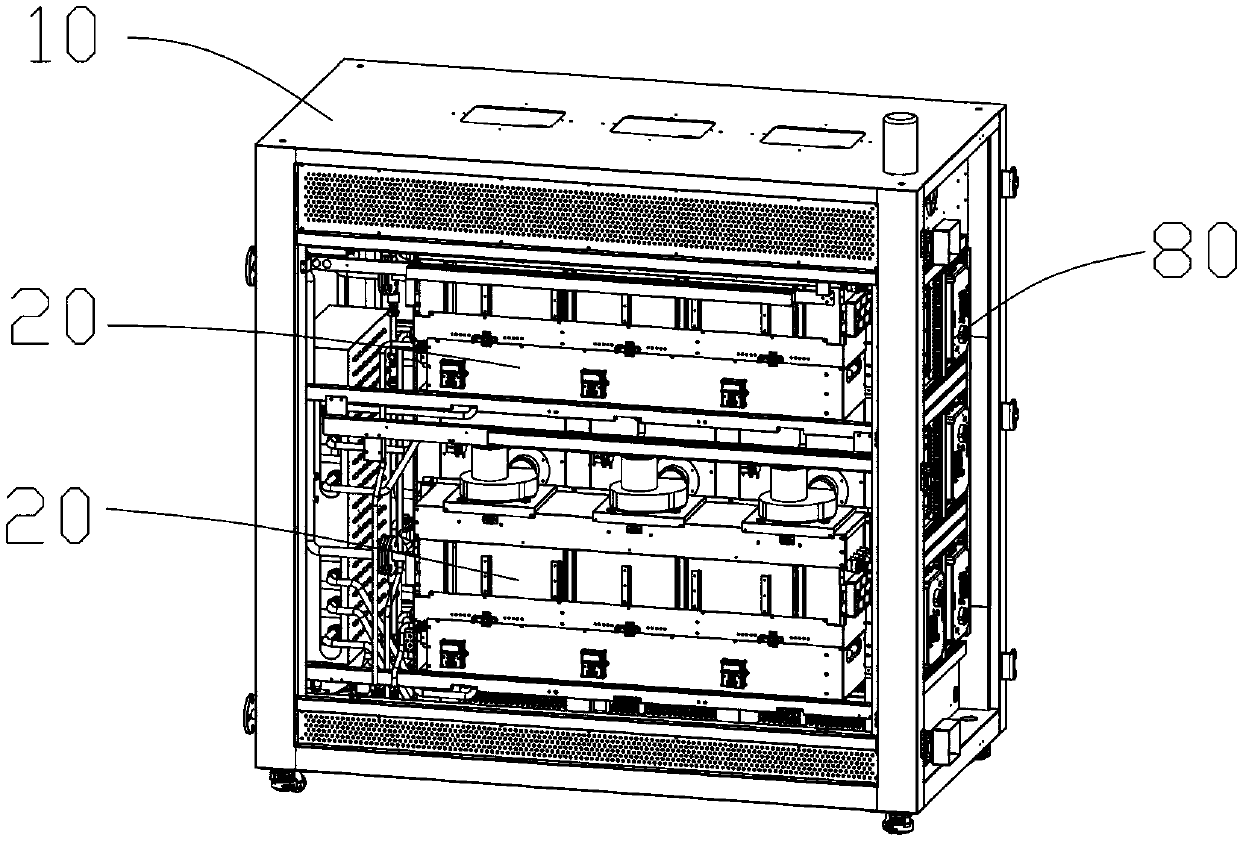

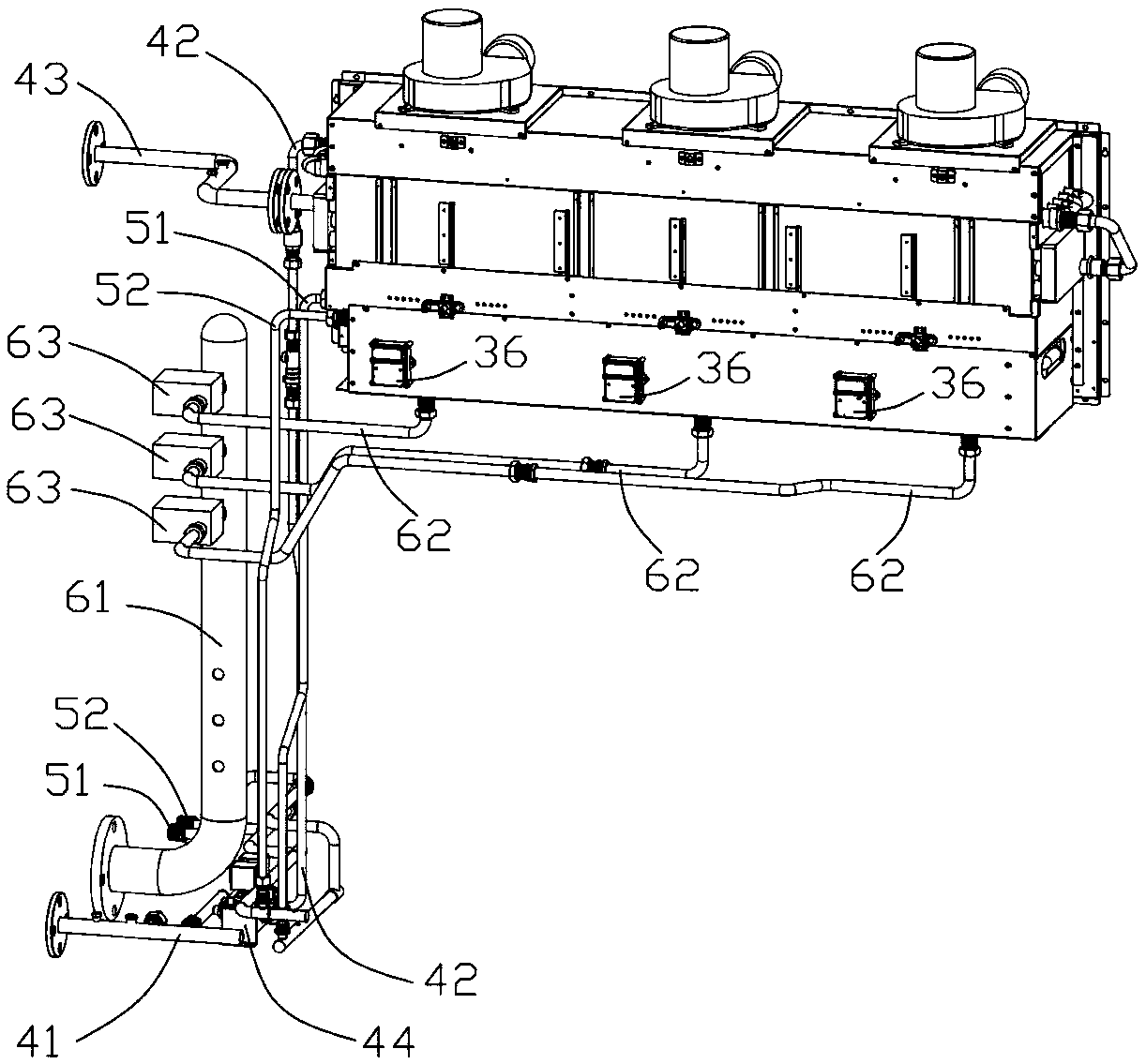

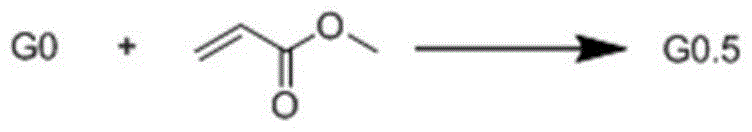

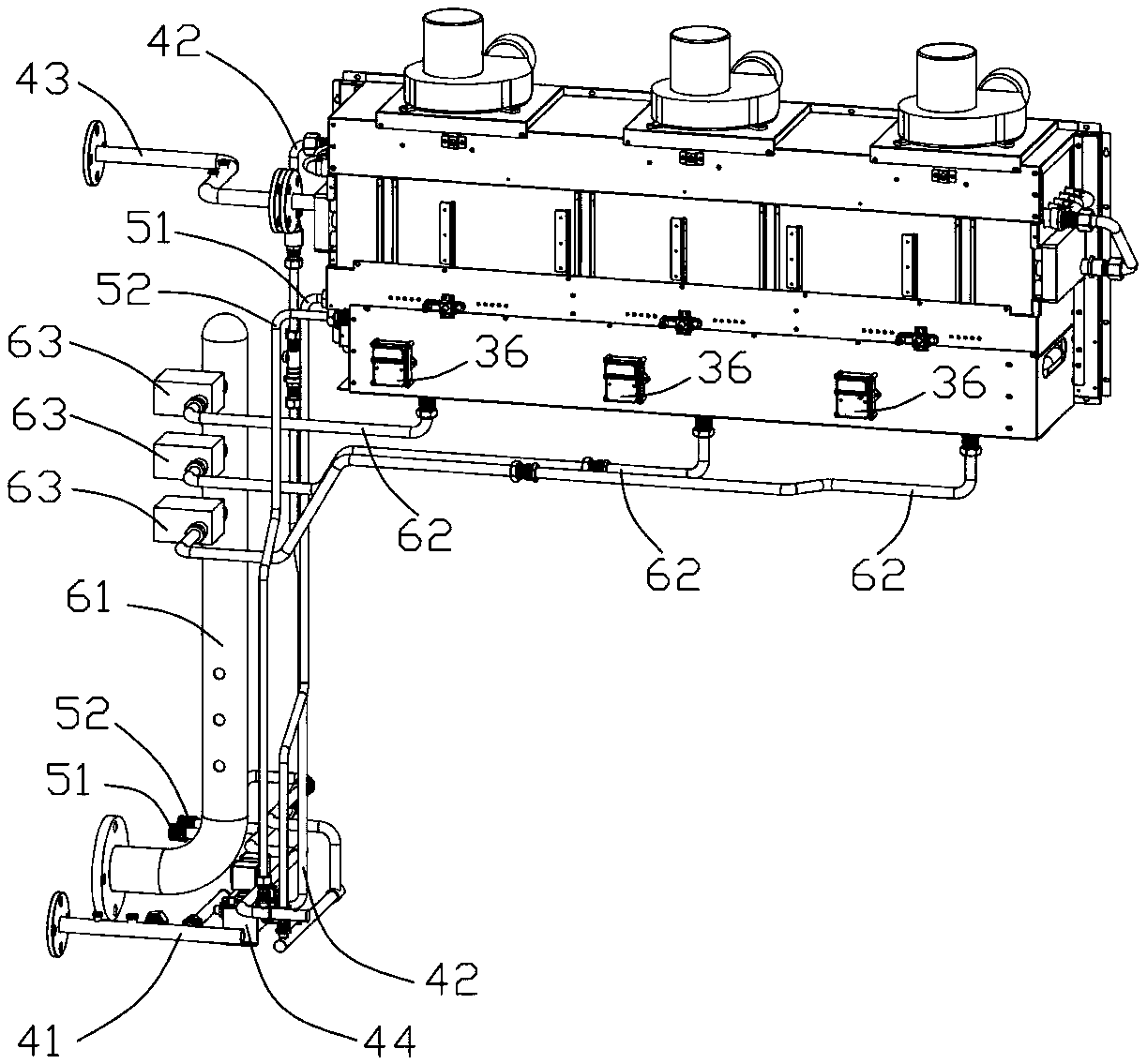

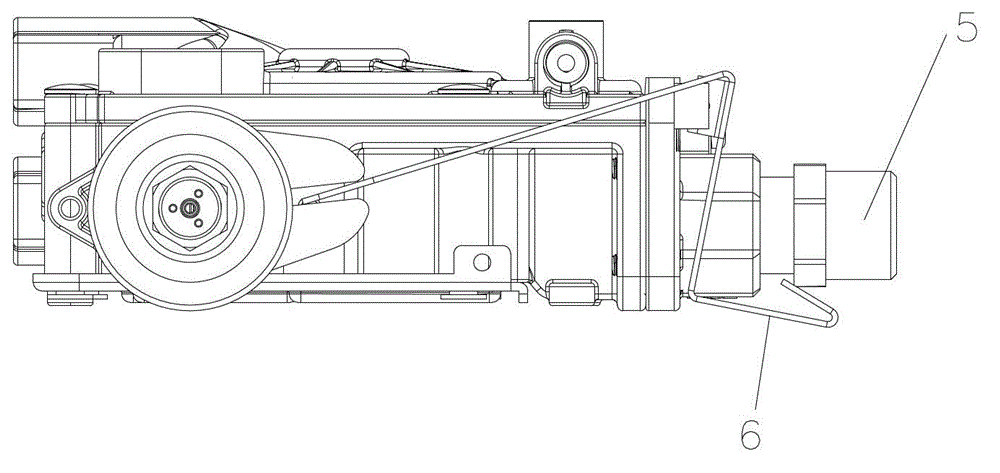

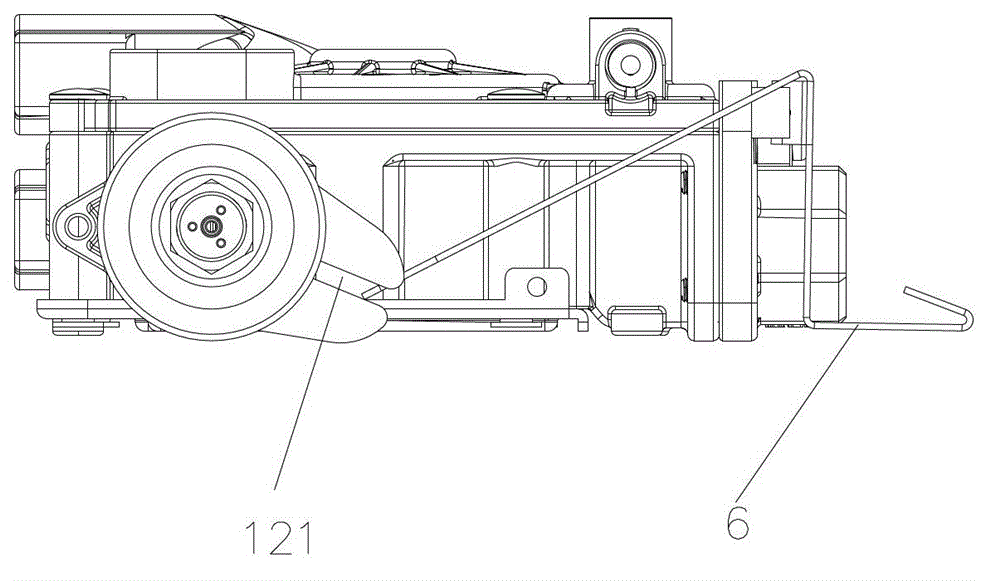

Gas steam generating equipment

PendingCN109654467AImprove qualityExtended pathStationary tubular conduit assembliesSteam boilersCombustion chamberCombustor

The invention discloses gas steam generating equipment. The gas steam generating equipment comprises a machine frame and more than one set of steam generating modules arranged in the machine frame, and each steam generating module comprises a combustion chamber, a finned heat exchanger, a tube type light tube heat exchanger and a low-nitrogen fire grate burner which are sequentially arranged in the combustion chamber from top to bottom; a cold water inlet and a hot water outlet are formed in each finned heat exchanger; each tube type light tube heat exchanger is provided with a hot water inletand a steam outlet; and the hot water outlets communicate with the hot water inlets. According to the steam generating equipment, the tube type light tube heat exchanges are adopted to be arranged inthe middle layers of the combustion chambers and serve as vaporization layers, so that heat absorbed by cold water is more sufficient, and higher-quality steam can be produced. The bottom layers of the combustion chambers adopt the brand-new low-nitrogen fire grate combustors, so that the heat exchange amount is improved, and meanwhile, the generation of nitrogen oxide is reduced, and the gas steam generating equipment is energy-saving and environment-friendly.

Owner:广东念智节能科技有限公司

Mulberry enzyme powder and preparation method thereof

The invention relates to the technical field of foods, in particular to mulberry enzyme powder and a preparation method of the mulberry enzyme powder. The mulberry enzyme powder is characterized by mainly comprising the following raw materials in parts by weight: 70-85 parts of mulberry enzyme protoplasm and 15.0-30 parts of resistant dextrin. The mulberry enzyme powder is prepared by subjecting the mulberry enzyme protoplasm to powder spraying, is easier for people to eat; a proper amount of L-arabinose and xylitol are added to promote the absorption of minerals in the mulberry enzyme powder,so that nutrient elements in the mulberry enzyme powder can be absorbed and utilized by a human body to the maximum extent; and meanwhile, the raw materials are granulated through a boiling granulator, so that a finished mulberry enzyme powder product is not easy to agglomerate, and the shelf life of the mulberry enzyme powder is prolonged.

Owner:FUTASTE PHARM CO LTD

Composite phase change material for microwave heating energy storage, as well as preparation method and application thereof

InactiveCN110283573ASafe and non-toxicIncentivize cross-developmentHeat-exchange elementsDrinking vesselsMicrowaveMass ratio

The invention discloses a composite phase change material for microwave heating energy storage, as well as a preparation method and application thereof. The composite phase change material comprises a phase change material and graphene, wherein the mass ratio of the phase change material to the graphene is 1:(0.01-0.05); the phase change temperature of the composite phase change material is 54-62 DEG C; the heat of fusion is 200-220 J / g; the density is 0.9 g / cm<3>. According to the composite phase change material for the microwave heating energy storage, as well as the preparation method and application thereof, the design is simple; no harsh environment such as vacuum in the production process is needed; the cost can be reduced; a safer effect is realized; mass production on a large scale can be realized; microwaves are utilized to rapidly heat a vacuum cup and a large amount of heat energy is stored; the daily heat preservation demand for beverages is met; the heat preservation time is long; the cost is saved; no additional device is used.

Owner:XI AN JIAOTONG UNIV

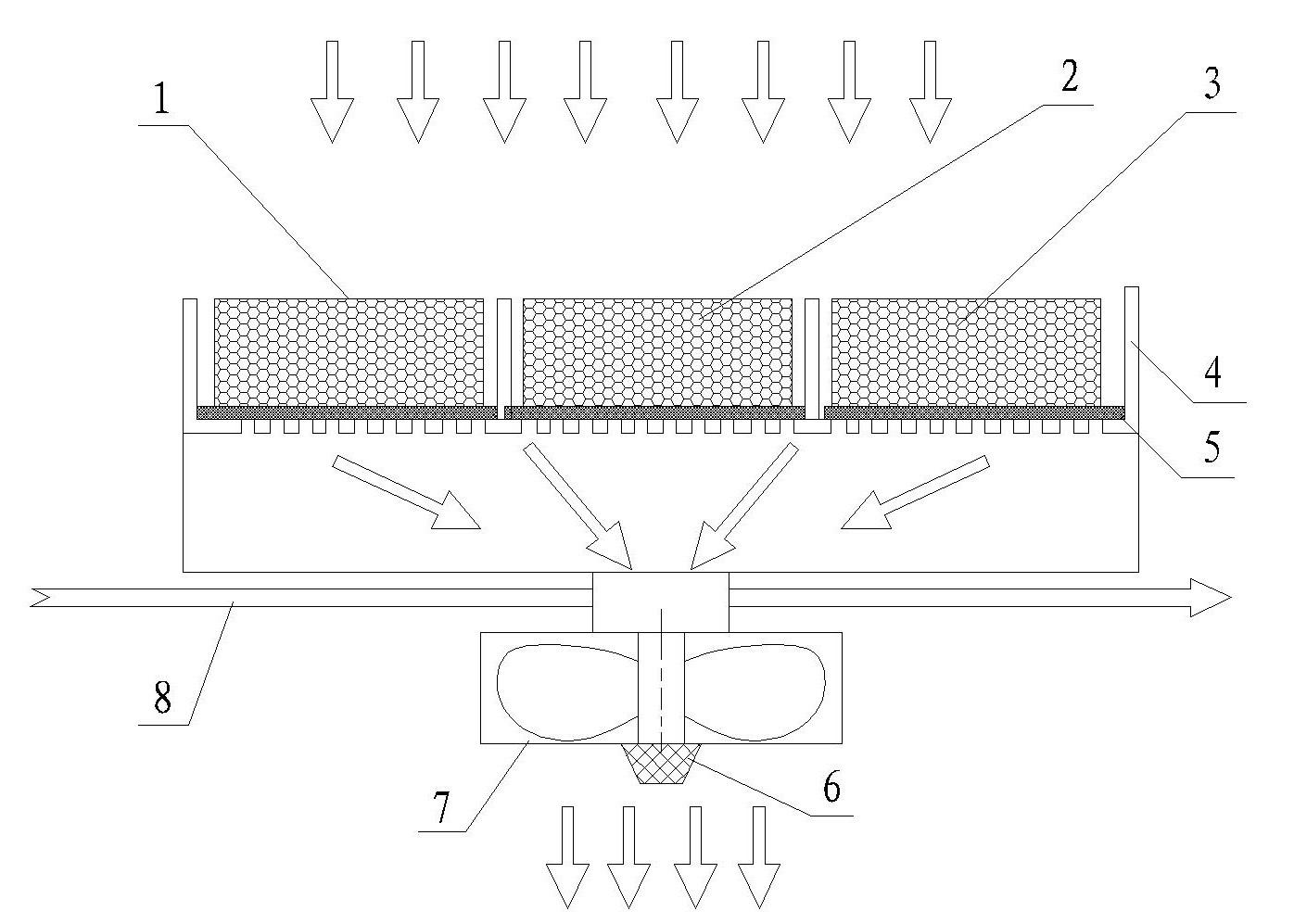

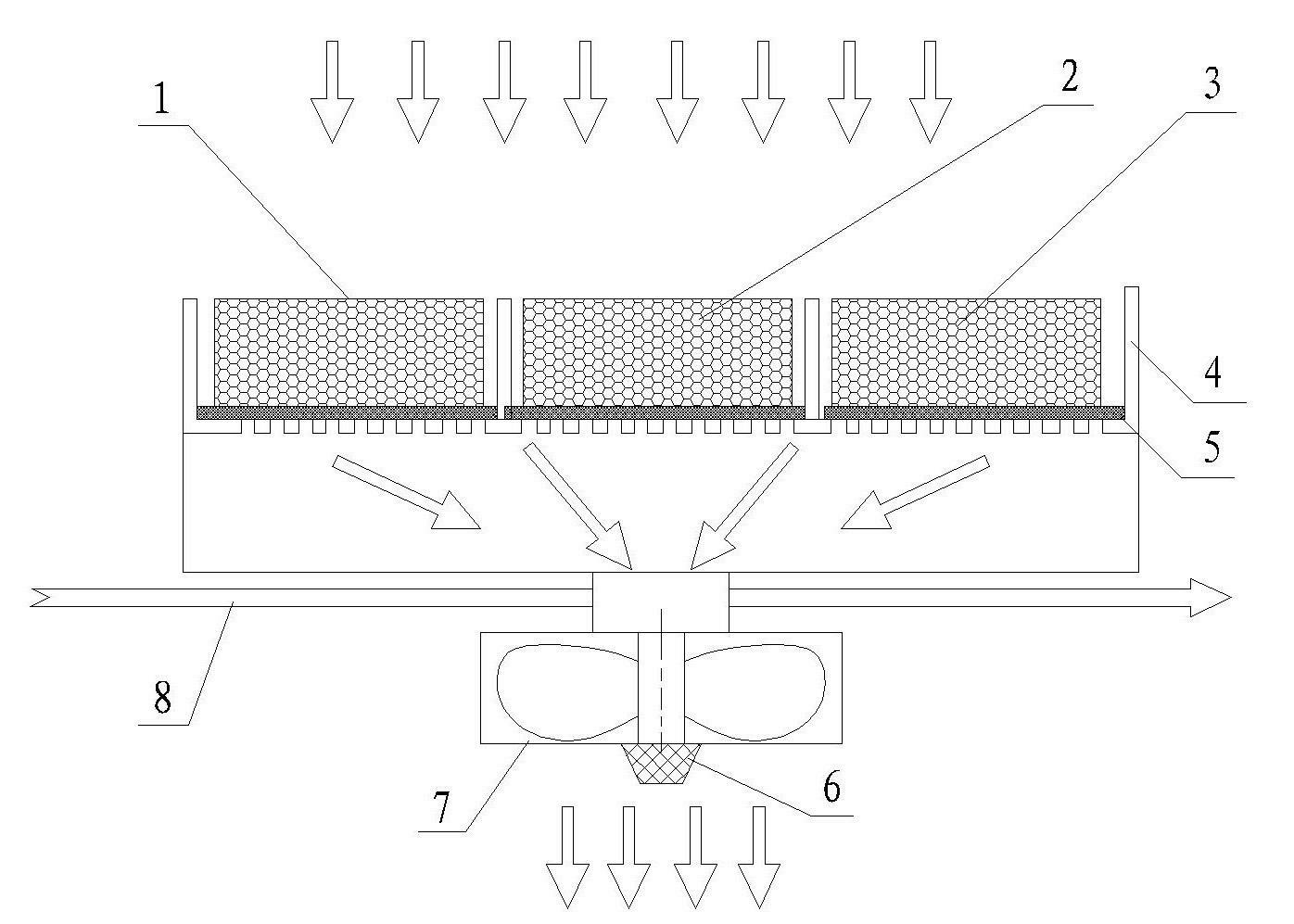

Air purification device of underground refuge chamber

InactiveCN102116172AImprove reliabilityEasy to change medicineDispersed particle filtrationBy adsorptionCarbon dioxideEngineering

The invention provides an air purification device of an underground refuge chamber, and aims to solve the problems of adopting lithium hydroxide to manufacture an absorbing curtain and hanging the absorbing curtain in the chamber to absorb or remove poisonous and harmful gases, such as CO2, and the like. The prior equipment needs to occupy a large amount of space when in use and has a poor adsorption effect. The key points of the air purification device lie in that a filter screen is arranged on a support frame; an adsorption material capable of adsorbing gases of CO and CO2 is arranged on the upper surface of the filter screen; a pneumatic fan is mounted below the support frame; and a power input end of the pneumatic fan is connected with a mine pressure ventilation system or a carbon dioxide refrigerating air-conditioning system. The air purification device is used in the refuge underground chamber for purifying air of the refuge underground chamber.

Owner:LIAONING ZHUOYI TECH

Production method of aluminum-silicon-titanium alloy

The invention provides a production method of aluminum-silicon-titanium alloy. The production method comprises the following steps: evenly mixing the following raw materials in parts by weight: 55-75 parts of pulverized fuel ash, 15-35 parts of carbonaceous reducing agent, 5-7 parts of binder, and 4-6 parts of water, then pressing into pellets, and drying; adding the dried pellets into an ore-smelting heating arc furnace for smelting, and controlling the temperature inside the furnace to be 1,800-1,950 DEG C; after the reaction is entirely finished, filling cold-state high-titanium blast furnace slag powder into the ore-smelting arc furnace for smelting, and controlling the temperature inside the furnace to be 1,600 DEG C-1,700 DEG C; after the reaction is completely finished, discharging from the furnace and refining in a refining furnace; filtering to remove slag, and pouring to obtain the aluminum-silicon-titanium alloy. By adopting the production method for aluminum-silicon-titanium alloy, the application difficulty of two industrial solid wastes namely high-titanium blast furnace slag and pulverized ash can be solved, beneficial elements of aluminum, silicon and the like in the pulverized ash can be comprehensively utilized while the high-titanium blast furnace slag is dug, the method is short in production flow, low in cost and higher in economic additional value, and the slag can also be used as building materials and the like.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Welding wire commonly used for high strength-toughness magnesium alloy and preparation method of welding wire

ActiveCN107335941AChange the ratioHigh strengthWelding/cutting media/materialsSoldering mediaGrain structureUltimate tensile strength

The invention relates to a welding wire commonly used for high strength-toughness magnesium alloy and a preparation method of the welding wire. The chemical components in the welding wire comprise, by weight, 1.4-2.7% of Al, 0.53-0.72% of Zn, less than 0.1% of Si, less than 0.05% of Fe, less than 0.1% of Ca, less than 0.1% of Cu, 0.04-0.1% of Be, less than 0.2% of Mn, 0.05-0.35% of Sr, and the balance magnesium and unavoidable impurity elements. A proper amount of Be and Sr are contained in the welding wire, the crystal grain structure of the welding wire is changed, so that the strength and the toughness of the magnesium alloy on the welding part are improved while crystal grains are finer, and meanwhile, the welding wire is suitable for the welding work of the magnesium alloy of multiple types.

Owner:河南明镁镁业科技有限公司

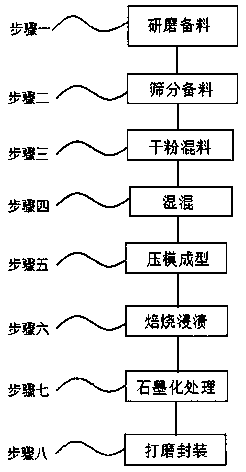

Ultrahigh-power graphite electrode and preparation method thereof

InactiveCN110330337AIncrease needle coke contentImprove conductivityElectric heating for furnacesFiberHigh pressure

The invention discloses an ultrahigh-power graphite electrode and a preparation method thereof. The ultrahigh-power graphite electrode comprises graphite powder, modified asphalt, iron trioxide, carbon fiber and needle coke. The preparation method of the graphite electrode comprises the following steps: grinding materials, sieving the materials, mixing with dry powder, performing wet mixing, performing compression molding, roasting and impregnating, performing graphitizing treatment as well as grinding and packaging. The content of the needle coke in the graphite electrode is increased, so that the electric conductivity of the graphite electrode is improved and the proportion of the graphite electrode is changed; along with increment of the needle coke quantity, the resistivity can be greatly reduced, the electric conductivity of the graphite electrode can be improved, loss of electric energy can be reduced and the conductive efficiency can be improved; through change of a mixing process, the uniformity of the mixed material can be improved, the intensity of the graphite electrode can be improved and the conductive efficiency of the graphite electrode can be improved; and through high-pressure impregnation, the compactness of the graphite electrode can be greatly improved, the hardness of the graphite electrode can be improved and the graphite electrode is not liable to damage.

Owner:CHENGDU CHENGXIN TECH CO LTD

Loss-control fertilizer additive and preparation method thereof

InactiveCN103964976AGood flocculationStrong environmental protectionFertilizer mixturesNutrientFertilizer

The invention relates to a loss-control fertilizer additive and a preparation method thereof, belonging to the technical field of agricultural fertilizers. The additive is prepared from the following raw materials in parts by weight: 30.00-49.50 parts of bentonite, 30.00-49.50 parts of smectite, 1.00-37.00 parts of polyacrylamide, 0-0.50 part of chitosan, 0-1.00 part of compound sodium nitrophenolate, 0-0.50 part of DMPP (dimethyl-phenyl-piperazinium) and 0-1.00 part of DA-6. The loss-control fertilizer additive has the advantages of high environment friendliness and favorable flocculability, can effectively prevent the nutrients in the fertilizer from loss, and does not influence the fertilizer absorption of crops, thereby achieving the goal of long lasting. Meanwhile, the loss-control fertilizer additive has the effect of improving the soil; after being applied into soil, the loss-control fertilizer additive can loosen the soil structure and improve the physical behaviors of the soil; and thus, the loss-control fertilizer additive has multiple functions and is very effective.

Owner:YUNNAN YUNYE FERTILIZER

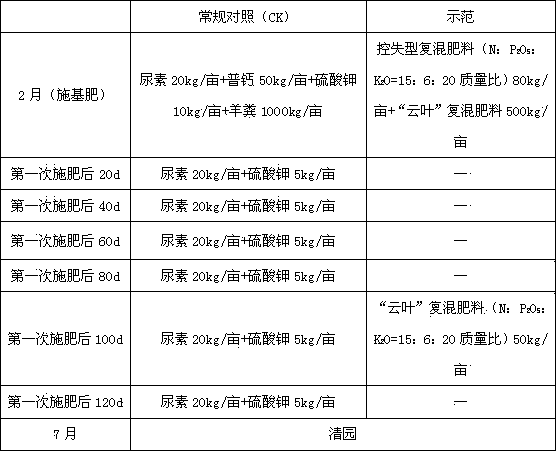

Multifunctional nano titanium dioxide composite foliar fertilizer

InactiveCN108558524AImprove hydrophilicityImprove photocatalytic activityAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPesticide residuePhosphoric acid

The invention relates to multifunctional nano titanium dioxide composite foliar fertilizer, belonging to the technical field of fertilizer. The multifunctional nano titanium dioxide composite foliar fertilizer is prepared from the following components by mass percent: 5-15% of nano titanium dioxide, 40-50% of nitrogen phosphorus potassium fertilizer, 30-40% of micronutrient fertilizer, 0.5-1% of dispersant, 5-10% of complexing agent and 0.1-0.5% of surfactant, wherein the nitrogen phosphorus potassium fertilizer is prepared from the following components by mass percent: 40-50% of urea, 10-20%of ammonium chloride and 35-45% of dipotassium phosphate; the micronutrient fertilizer is prepared from the following components by mass percent: 30-40% of ferrous sulfate, 10-20% of zinc sulfate, 10-20% of copper sulfate, 15-25% of magnesium nitrate and 10-15% of calcium nitrate. The multifunctional nano titanium dioxide composite foliar fertilizer is prepared by utilizing the special photocatalytic function of the nano titanium dioxide and then compounding other foliar fertilizer components; the composite foliar fertilizer can promote the photosynthesis of green crops, can also promote the rapid absorption of other nutrient components by leaf surfaces, can also degrade the pesticide residue and other organic residues on the leaf surfaces, also has antibacterial, insect-resistant and leafsurface self-cleaning effects, and achieves the effects of strengthening seedlings, resisting diseases, sterilizing, increasing yield, improving quality, and the like.

Owner:HEBEI MILSON TITANIUM DIOXIDE

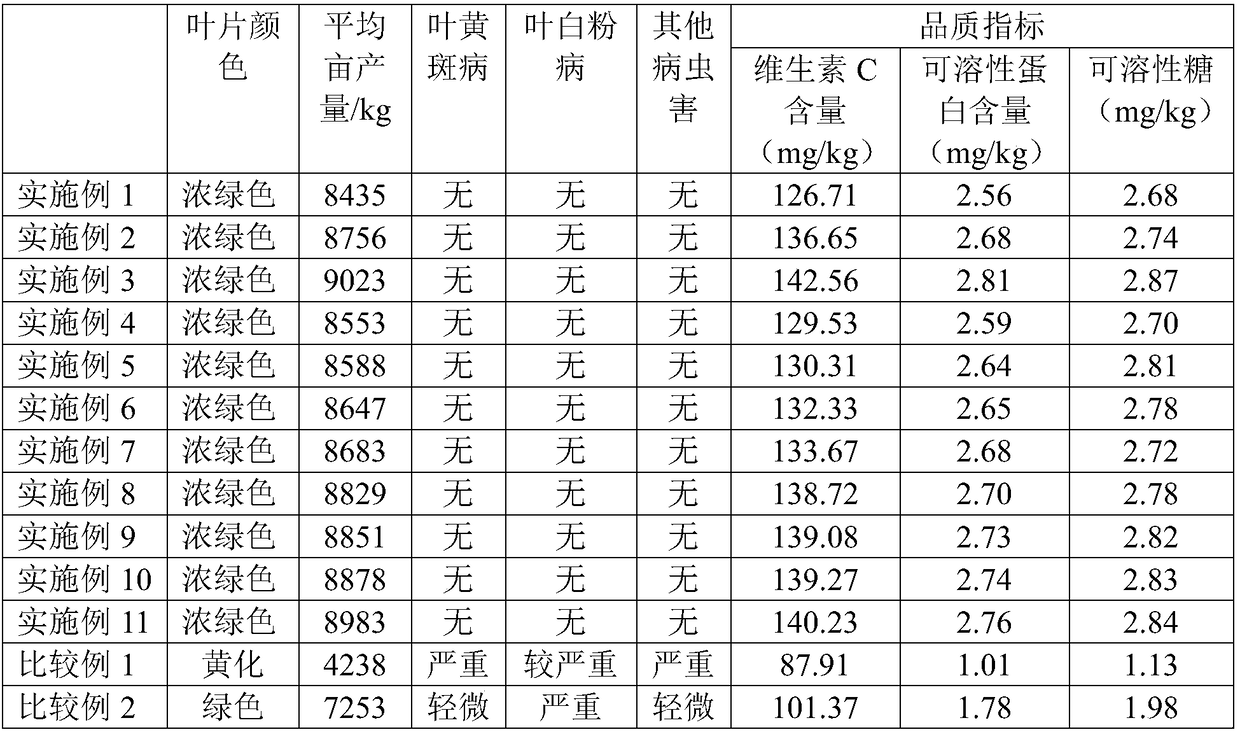

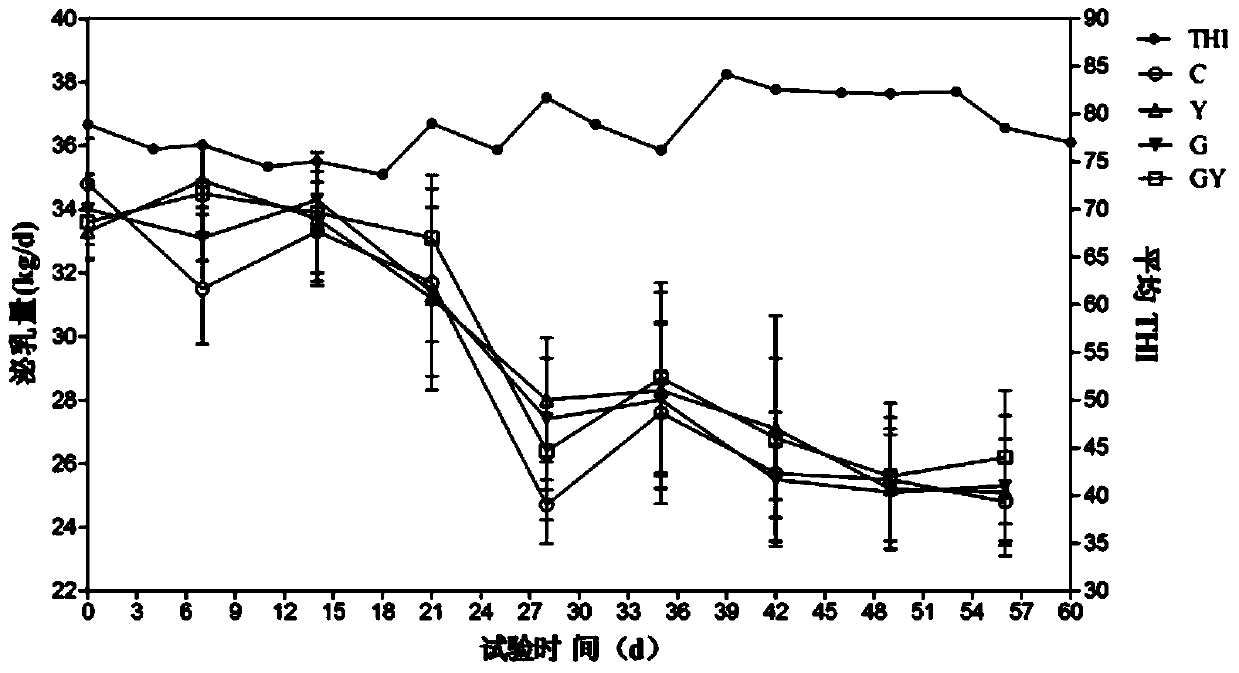

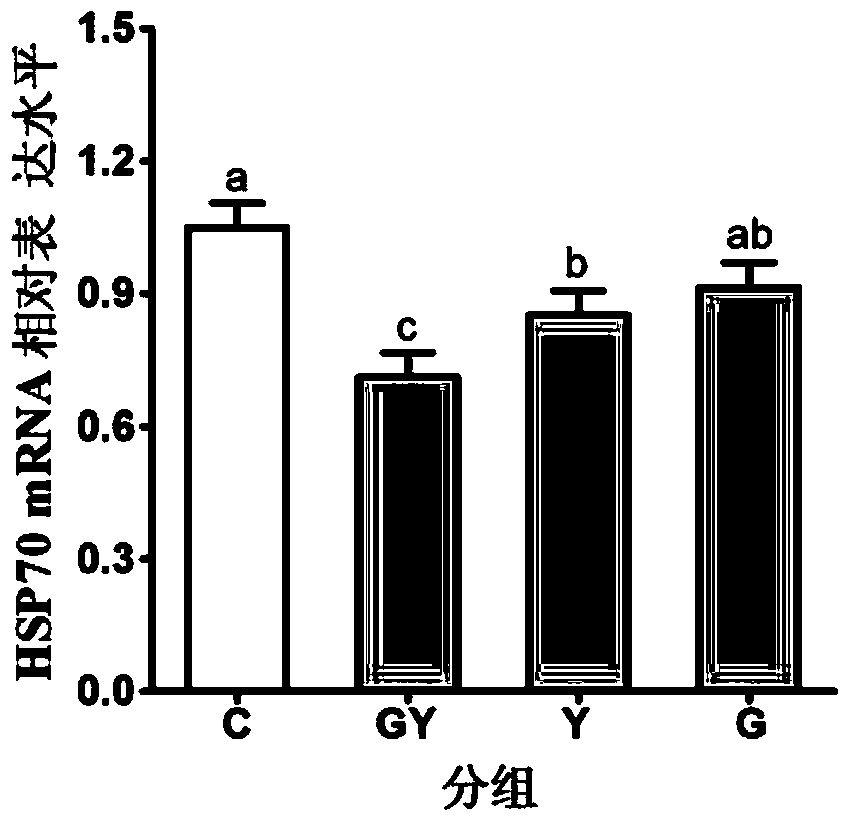

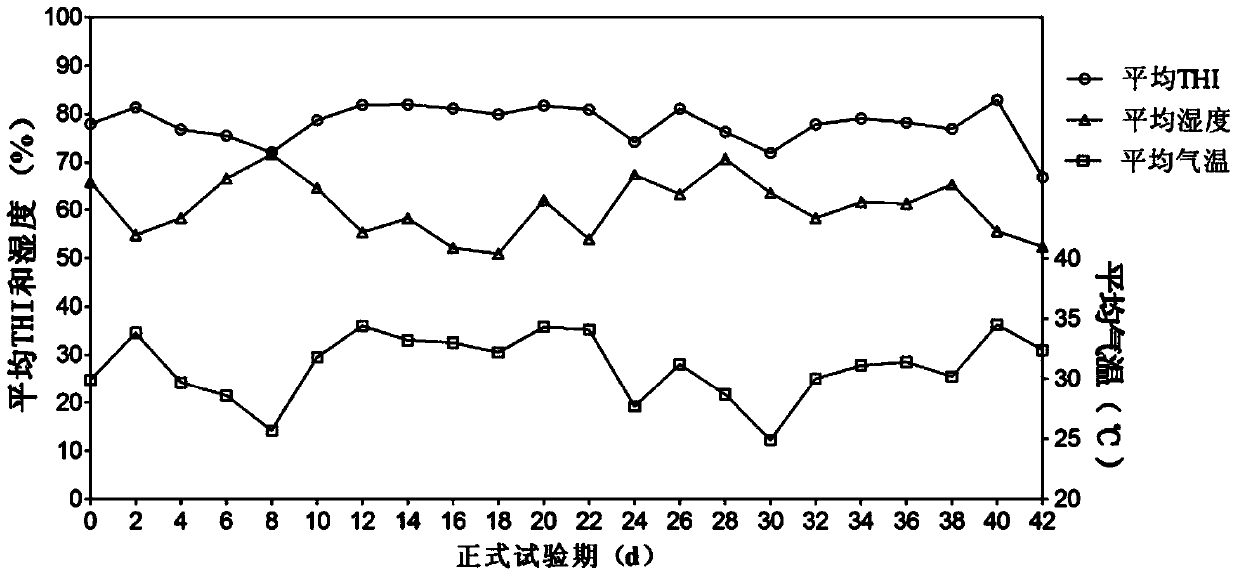

Cow heat-stress resistant feed additive

The invention discloses a cow heat-stress resistant feed additive. Saccharomyces cerevisiae (Sc) NAU-ZH-GY1 is applicable to prepare the cow heat-stress-resistant feed additive. The cow heat-stress-resistant feed additive, which is rich in glycerin, yeast live bacteria and microbial metabolites such as amino acids, vitamins and the like, is produced under the high-permeability condition by employing a continuously feeding manner for fermentation; and the cow heat-stress resistant feed additive is capable of cooperatively perform dual efficacy of glycerin and yeast, and is capable of substantially improving lactation yield, 4% fat corrected milk yield and milk fat percentage of cow under heat-stress condition, improving blood sugar concentration, reducing somatic cell number, concentration of non-esterified fatty acid and concentration of urea nitrogen in milk, supplementing energy for cows, alleviating body weight reduction, enhancing antioxidation capability, reducing HSP70mRNA level and effectively alleviating heat stress of cows.

Owner:NANJING AGRICULTURAL UNIVERSITY

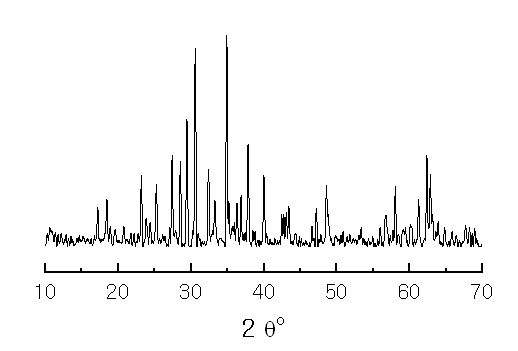

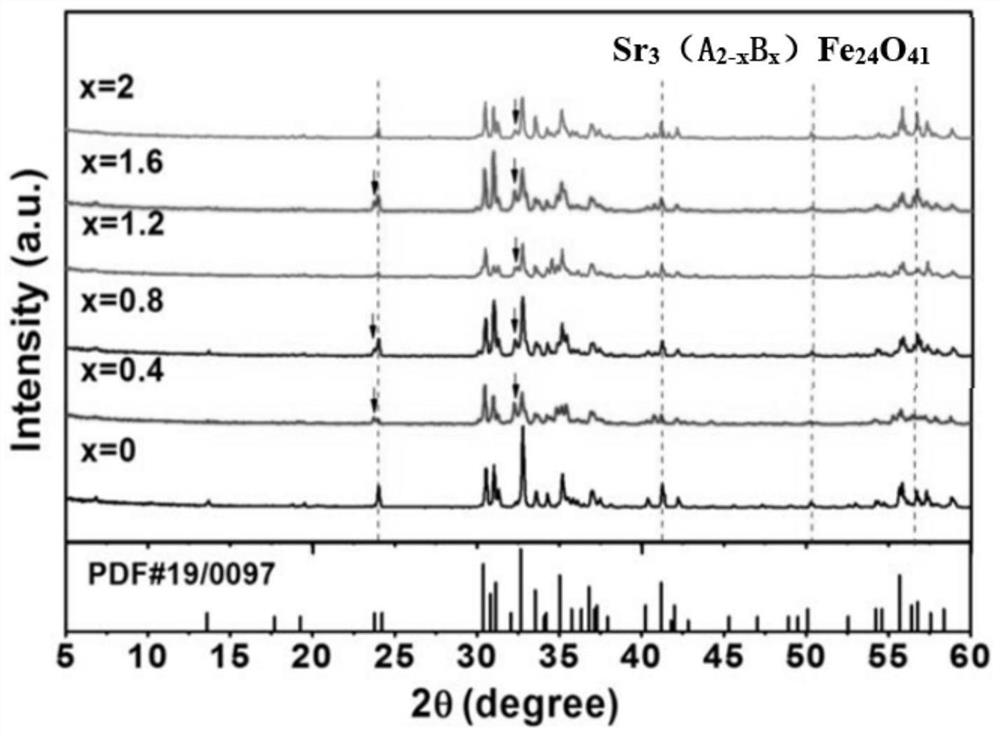

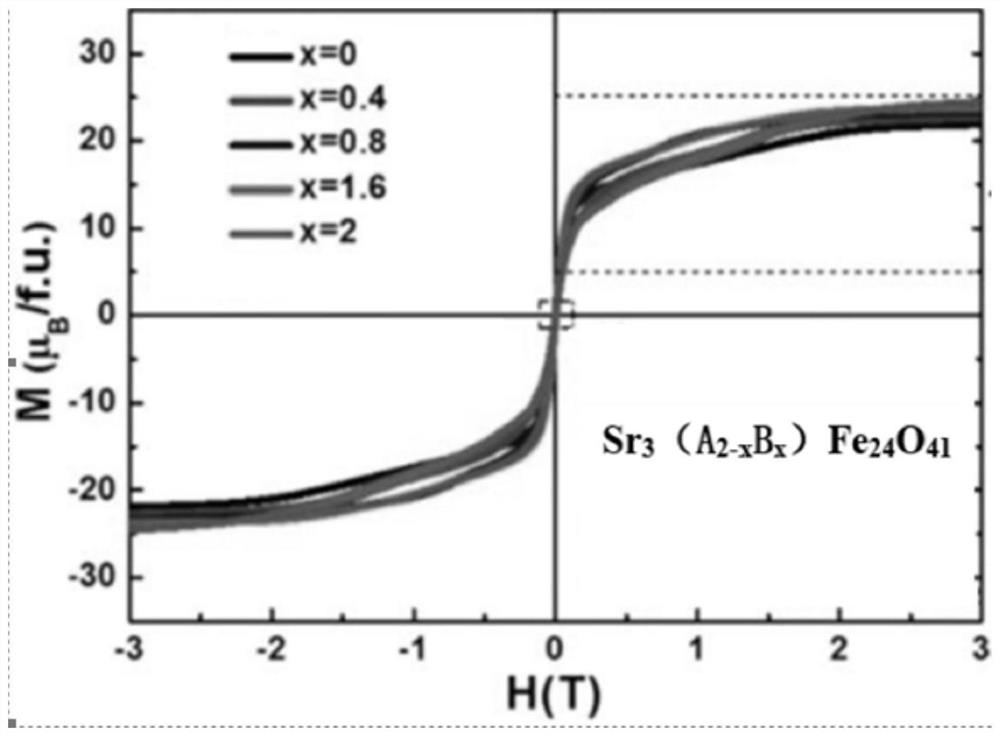

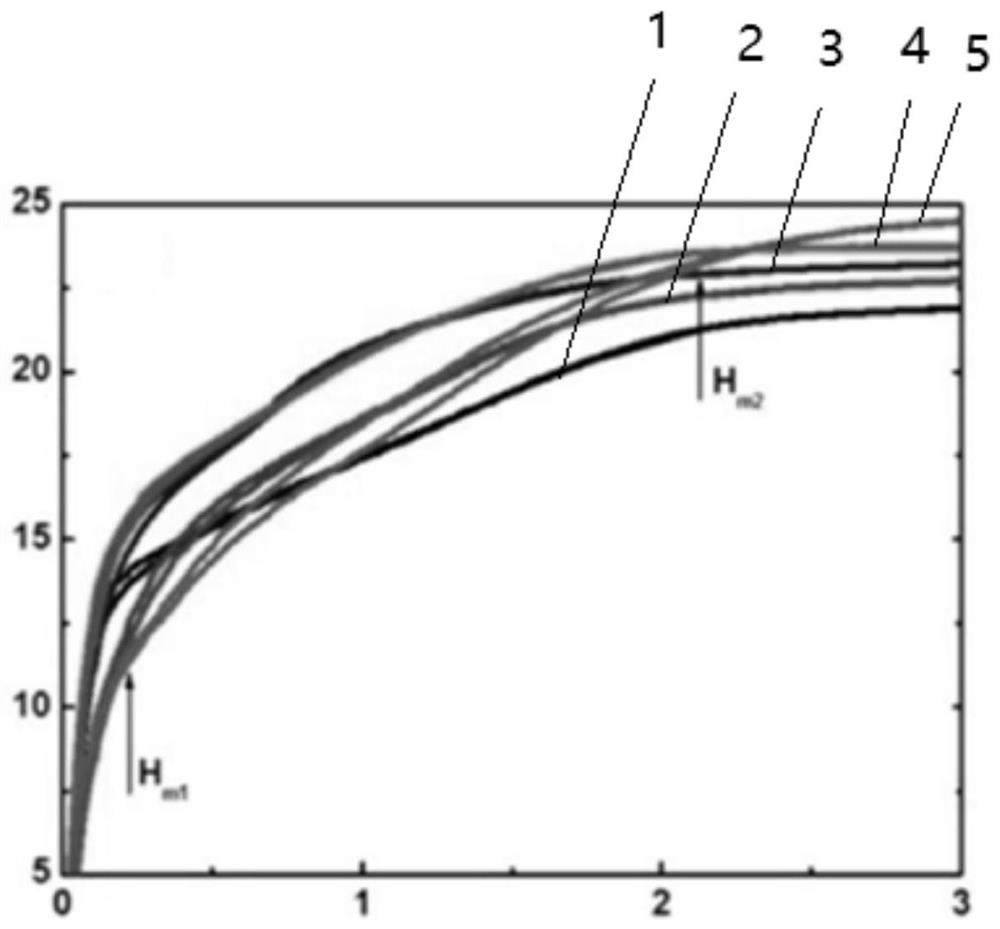

High-saturation magnetization Z-type hexagonal ferrite powder and preparation method thereof

ActiveCN112851325AHigh local average magnetic momentChange the ratioInorganic material magnetismInductances/transformers/magnets manufactureHigh saturation magnetizationMaterials science

The invention provides high-saturation magnetization Z-type hexagonal ferrite powder. The structure of the Z-type hexagonal ferrite powder with high saturation magnetization intensity is Sr<3>(A<2-x>B<x>)Fe<24>O<41>, A and B are one of Co element, Mg element, Zn element and Cr element, A and B are different, x is the atomic ratio content of B, and x is greater than or equal to 0 and less than or equal to 2. According to the Z-type hexagonal ferrite powder with high saturation magnetization and the preparation method thereof disclosed by the invention, the electronic environment around Fe ions is changed by adding A and B ions, so that the proportion of adjacent forward and reverse orientation Fe ions is changed, and the exchange action between the adjacent forward and reverse orientation Fe ions is further changed, and thus a higher local average magnetic moment is generated, and the saturation magnetization intensity is improved.

Owner:WUXI JIEFU ELECTROACOUSTIC

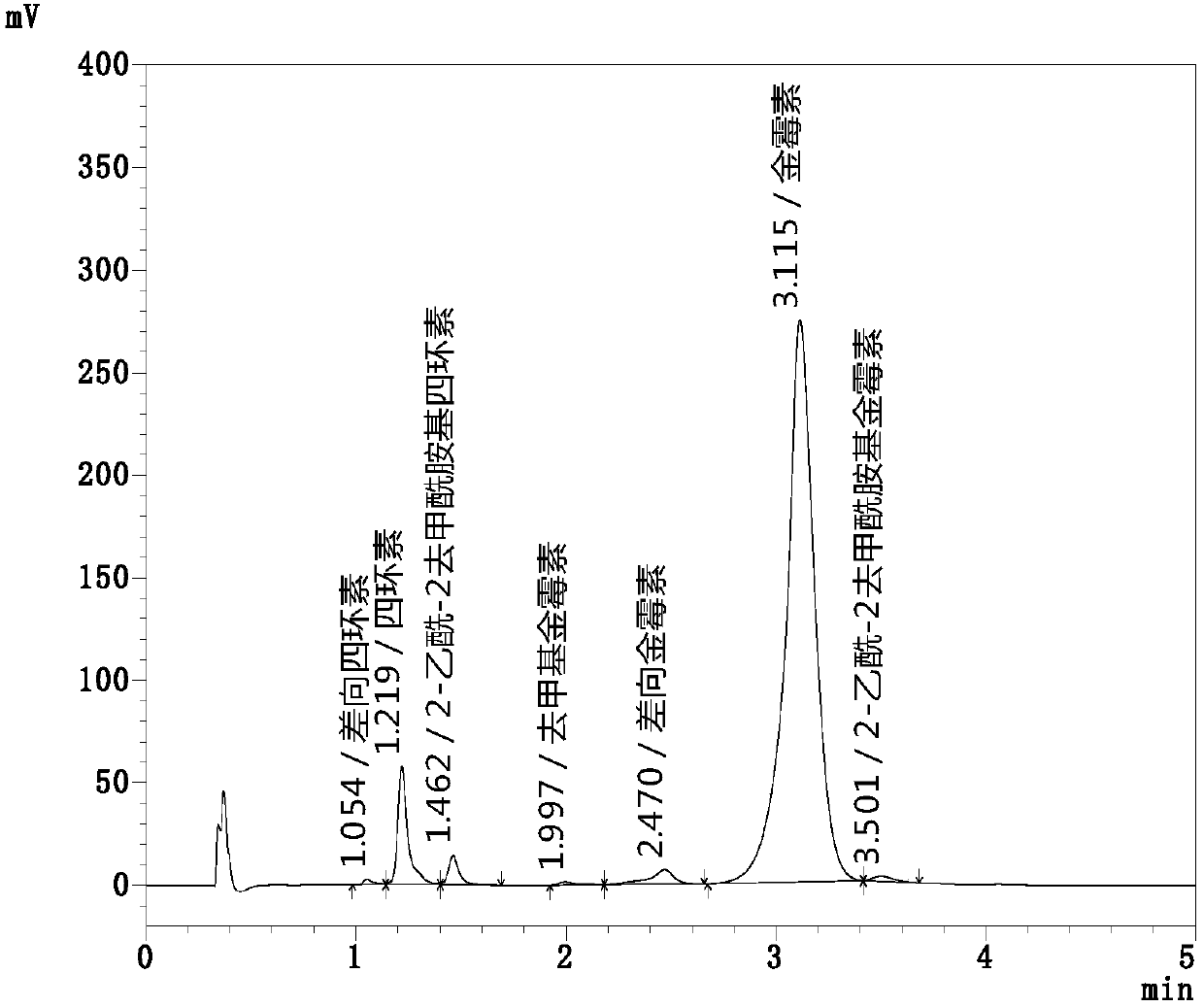

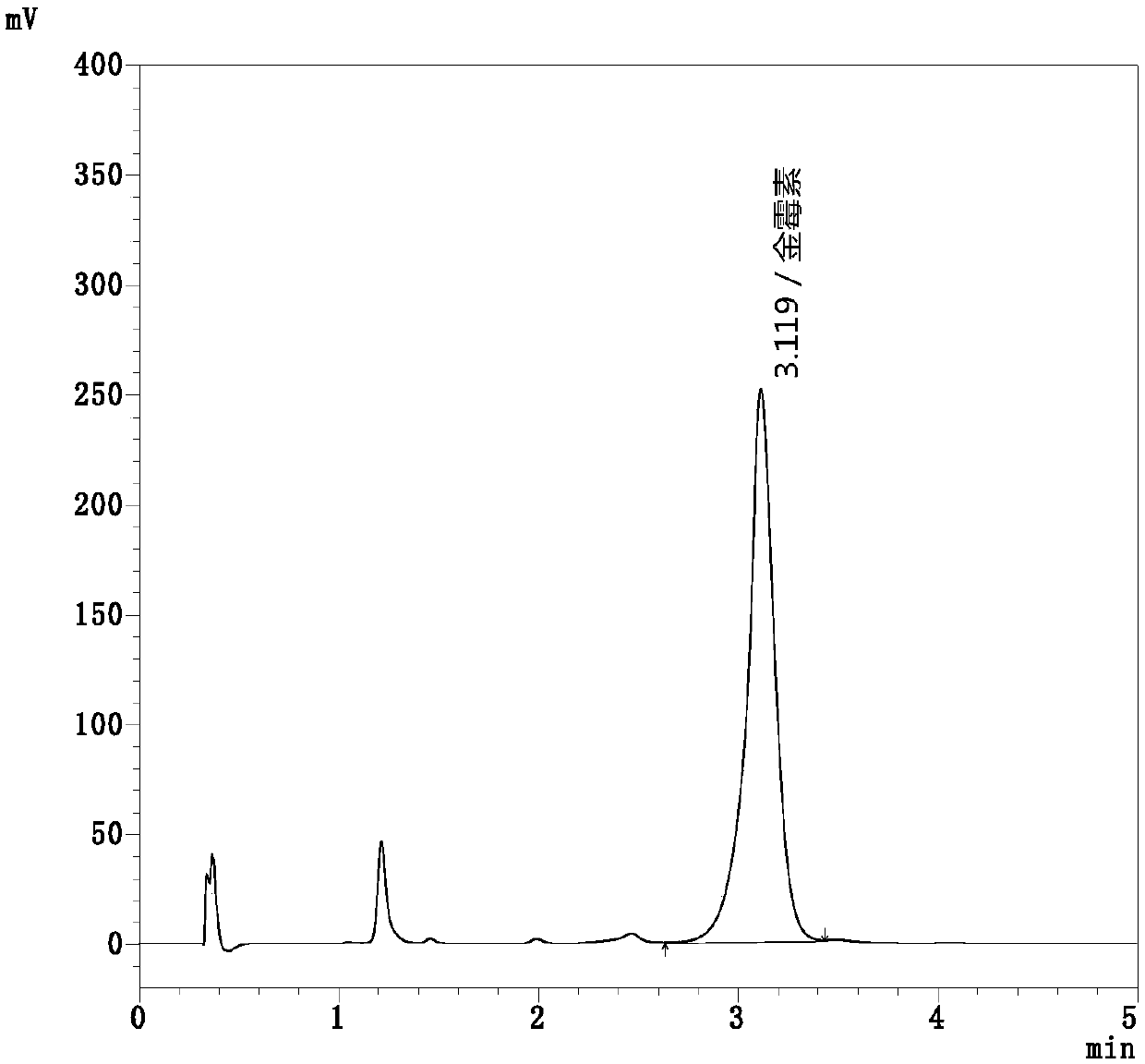

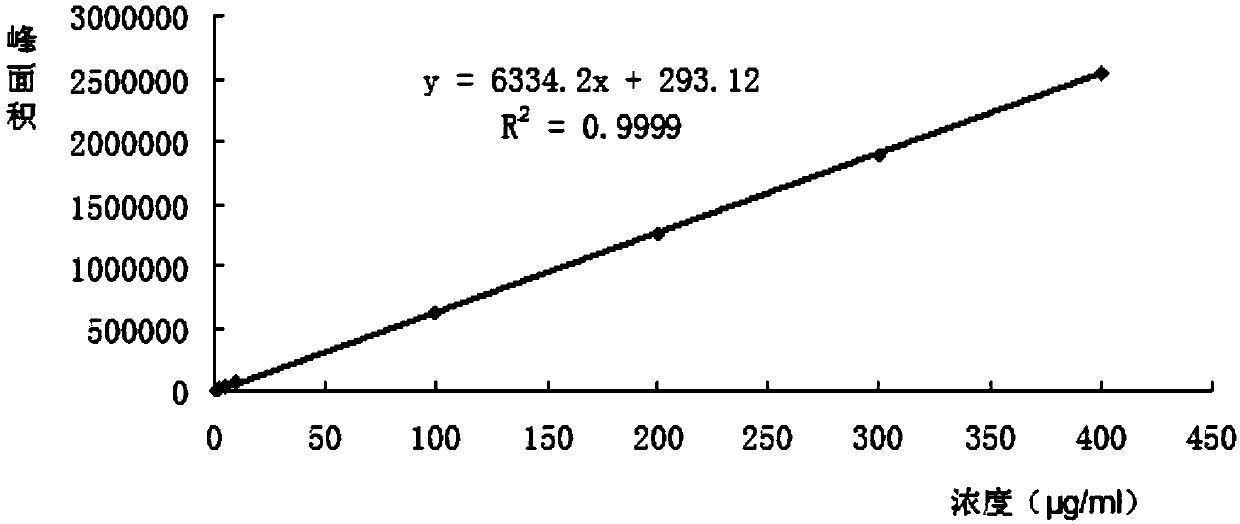

Method for determining content of chlortetracycline premix and related substances

InactiveCN107727766AReduce dosageSolve the detection speed is slowComponent separationInjection volumeN dimethylformamide

The invention relates to a method for determining the content of a chlortetracycline premix and related substances and belongs to the technical field of analysis and testing. The method adopts the following chromatographic conditions: a C18 chromatographic column, a column temperature of 45 DEG C, detection wavelength of 280 nm, a mobile phase which is a mixed solution of water, a phosphoric acidsolution and N, N-dimethylformamide in a volume ratio of 220: 80: 100, the concentration of the phosphoric acid solution of 2 mol / L, a pump flow rate of 0.4 mL / min, an injection volume of 4 microliters and running time of 5min. The method comprises preparing a chlortetracycline standard stock solution, a chlortetracycline work standard solution and a chlortetracycline test solution and carrying out high performance liquid chromatography analysis so that relevant substance content contents are calculated through a main component self-control method through a peak area external standard method.The method has good repeatability, good reproducibility, high accuracy, a wide linear test range and good durability, saves the use amounts of all solutions and improves the detection speed and precision.

Owner:金河生物科技股份有限公司

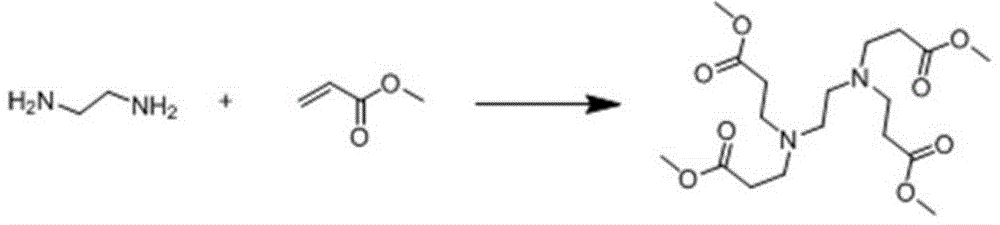

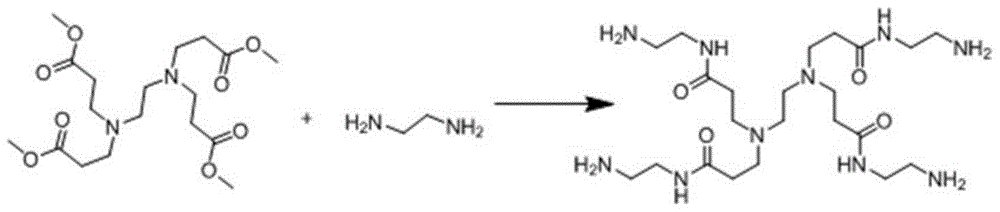

Production process of dendritic polyamidoamine

The invention belongs to a production process of a dendritic polymer, in particular to a production process of a dendritic polyamidoamine. The reaction temperature is precisely controlled by a low-temperature circulator. The initial reaction temperature is controlled at about -5±2°C, and after the addition of materials, the reaction temperature is controlled at 20±2°C to make the reaction more stable, and the appropriate excess monomer ratio can be adjusted to reduce the generation of by-products. , cooperate with ton-scale industrial synthesis reactor to realize industrial production scale; for the first time, continuous feeding and discharging rotary evaporation equipment is used to purify dendrimeric polyamidoamine to improve purification efficiency; The raw materials are recovered and purified to obtain reusable raw materials, which further reduces the cost of raw materials in industrial production.

Owner:WEIHAI CY DENDRIMER TECH

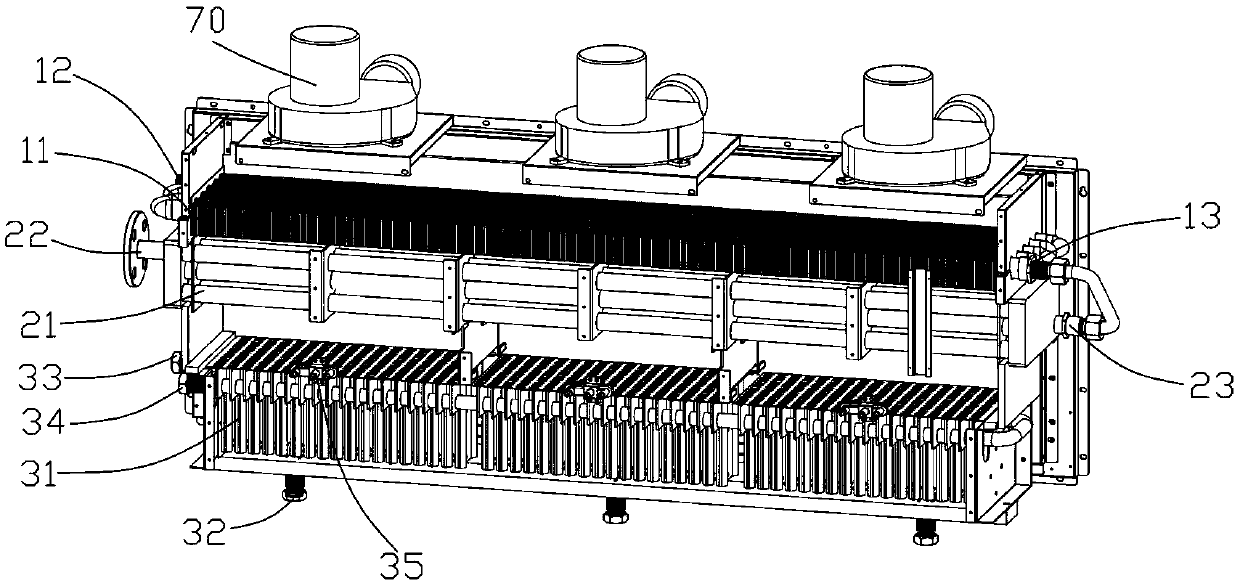

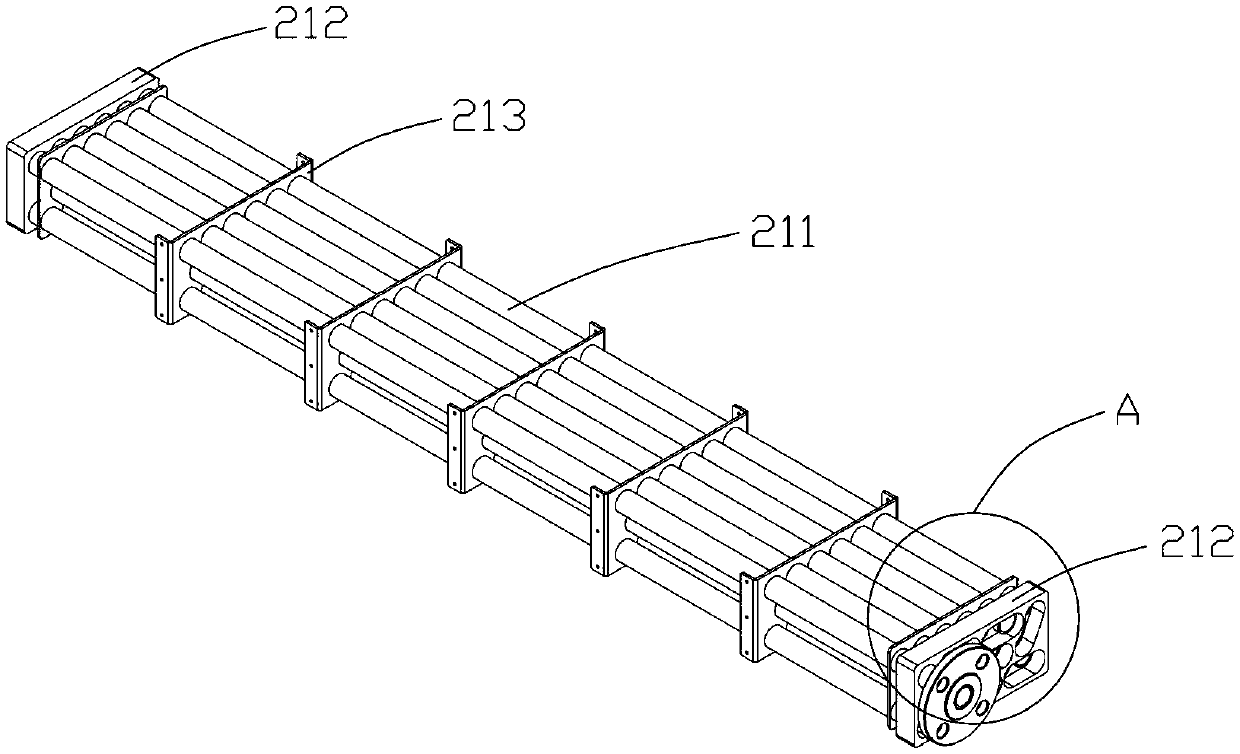

Steam generation module

PendingCN109654468AImprove qualityExtended pathStationary tubular conduit assembliesSteam boilersCombustion chamberEngineering

The invention discloses a steam generation module. The steam generation module comprises a combustion chamber, a finned heat exchanger, a tube type light tube heat exchanger and a low-nitrogen fire grate burner, wherein the finned heat exchanger, the tube type light tube heat exchanger and the low-nitrogen fire grate burner are sequentially arranged in the combustion chamber from top to bottom; acold water inlet and a hot water outlet are formed in the finned heat exchanger; the tube type light tube heat exchanger is provided with a hot water inlet and a steam outlet; and the hot water outletcommunicates with the hot water inlet. The steam generation module is novel in structure, the improved tube type light tube heat exchanger is adopted to replace a traditional fin type heat exchangerto be placed in the middle layer of the combustion chamber, heat absorbed by the cold water is more sufficient, and higher-quality steam can be produced. A brand-new low-nitrogen fire grate combustoris adopted by the bottom layer of the combustion chamber, so that the heat exchange amount is improved while the generation of nitric oxide is reduced, and the steam generation module is energy-savingand environment-friendly.

Owner:广东念智节能科技有限公司

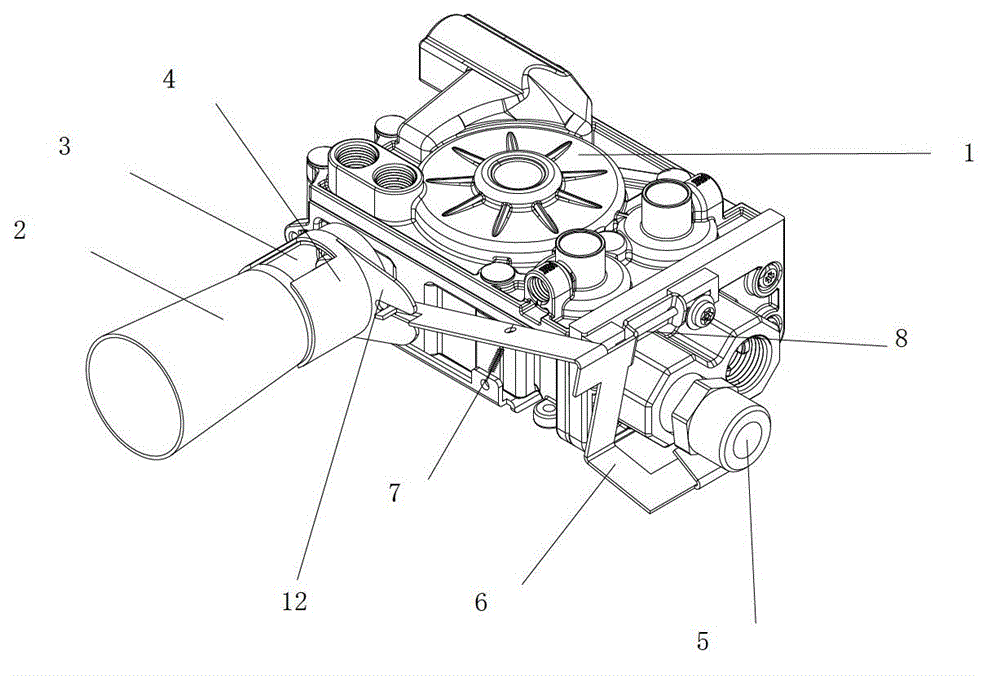

Double-gas source valve with adjustable gas door

ActiveCN102913673AChange sizeChange the ratioOperating means/releasing devices for valvesSpray nozzleEngineering

The invention relates to a double-gas source valve with an adjustable gas door. The double-gas source valve is connected with a gas interface through a joint and comprises a gas valve body, a nozzle, the gas interface, a venturi tube, an air window and the gas door, wherein the nozzle and the gas interface are arranged on the gas valve body, the venturi tube is sheathed on the nozzle, the air window is arranged on the venturi tube, and the gas door is arranged at the air window and can be used for rotatably adjusting the size of the air window; the double-gas source valve also comprises an air door adjustment device, a supporting point and a linkage device; the air door adjustment device is connected with the air door, the supporting point is arranged on the gas valve body, the linkage device is connected with the supporting point and can rotate around the supporting point, one end of the linkage device is movably connected with the air door adjustment device, and the other end of the linkage device is arranged at the side part of the gas interface of the gas valve; the gas interface is connected with the joint in a matching manner; and when the joint is connected into the gas interface, the side part of the joint props against the linkage device to drive the linkage device to rotate, thereby driving the air door adjustment device to drive the air door to rotate. When different joints are connected into the double-gas source valve, a linkage rod is touched, so that the size of the primary air door and the proportion of gas to air are changed and the best burning effect is achieved.

Owner:PROCOM ELECTRIC APPLIANCES SHANGHAI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com