Toluene liquid-phase selective oxidation catalyst and preparation method thereof

A selective oxidation and catalyst technology, which is applied in catalyst activation/preparation, physical/chemical process catalysts, hydrocarbon oxidation to prepare oxygenated compounds, etc., can solve the problems of low toluene conversion, decomposition at elevated reaction temperature, and low toluene concentration, etc. To achieve the effect of rational utilization of resources and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

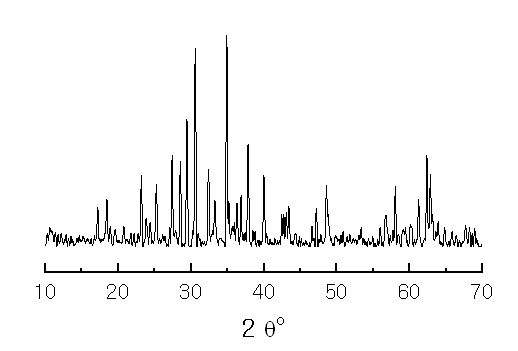

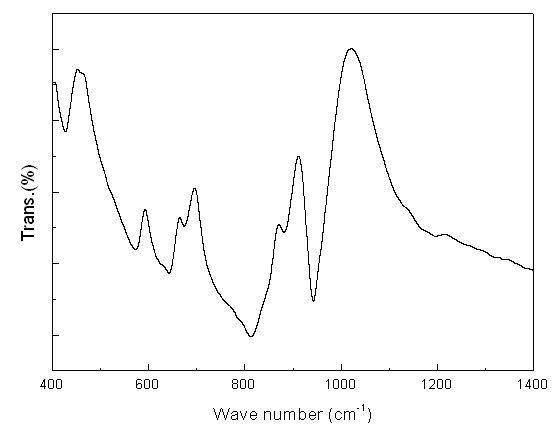

[0049] Embodiment 1-6 illustrates, selects different transition metal element Me, adopts co-precipitation method, the transition metal vanadate catalyst (Me) prepared under different conditions x V y O) and its catalytic performance for liquid-phase selective oxidation of toluene. The preparation method of each catalyst is as follows: (1) determine Me x V y The molar ratio of Me / V in the O catalyst is 1 / 1; accordingly, the corresponding soluble metal salt is weighed; and it is just dissolved with an appropriate amount of deionized water to obtain a clear solution. (2) Under the condition of rapid stirring, mix the above-mentioned aqueous solutions of Me and V, and use nitric acid solution (concentration: 1 mol / liter) to adjust the pH value of the mixed solution to keep the mixed solution in a clear state. (3) Slowly add 25% (mass) ammonia solution dropwise to the rapidly stirred above mixture, and stir while adding until the precipitation is complete. Then, under the condi...

Embodiment 7-9

[0054] Examples 7-9 illustrate the preparation of Ni-V-O catalysts under different conditions by co-precipitation method and their catalytic performance when used in the liquid-phase selective oxidation of toluene. The preparation method of each catalyst is as follows: (1) determine Me x V y The molar ratio of Me / V in the O catalyst is 1 / 2, 1 / 1 and 2 / 1; accordingly, the corresponding soluble metal salt is weighed; and it is just dissolved with an appropriate amount of deionized water to obtain a clear solution. (2) Under the condition of rapid stirring, mix the above-mentioned aqueous solutions of Me and V, and use nitric acid solution (concentration: 1 mol / liter) to adjust the pH value of the mixed solution to keep the mixed solution in a clear state. (3) Slowly add 25% (mass) ammonia solution dropwise to the rapidly stirred above mixture, and stir while adding until the precipitation is complete. Then, under the conditions of pH value of 11 and room temperature, static agi...

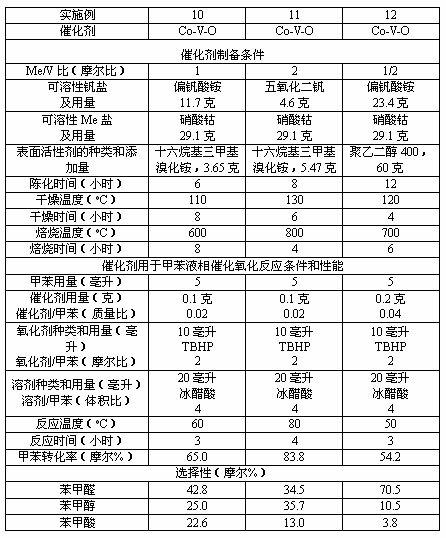

Embodiment 10-12

[0059] Examples 10-12 illustrate the Co-V-O catalysts prepared under different conditions by using the sol-gel method and their catalytic performance when used in the liquid-phase selective oxidation of toluene. The preparation method of the catalyst is as follows: under the condition of rapid stirring, according to the distribution ratio of the catalyst components, a certain amount of soluble vanadium salt aqueous solution and soluble Me metal salt aqueous solution are mixed, and the pH value is adjusted so that the mixed solution remains in a solution state. Next, under the condition of rapid stirring, an appropriate amount of surfactant or organic high polymer is added to the above mixed liquid, and stirred while adding, until a viscous colloid is formed. Then, the colloid is statically aged for 4-12 hours. Finally, the colloid was filtered and washed to obtain a solid product. Solid product at 110-150 o C dry for 4-8 hours at 550-850 o C is calcined for 4-8 hours to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com