Patents

Literature

4168 results about "Fine chemical" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fine chemicals are complex, single, pure chemical substances, produced in limited quantities in multipurpose plants by multistep batch chemical or biotechnological processes. They are described by exacting specifications, used for further processing within the chemical industry and sold for more than $10/kg (see the comparison of fine chemicals, commodities and specialties). The class of fine chemicals is subdivided either on the basis of the added value (building blocks, advanced intermediates or active ingredients), or the type of business transaction, namely standard or exclusive products.

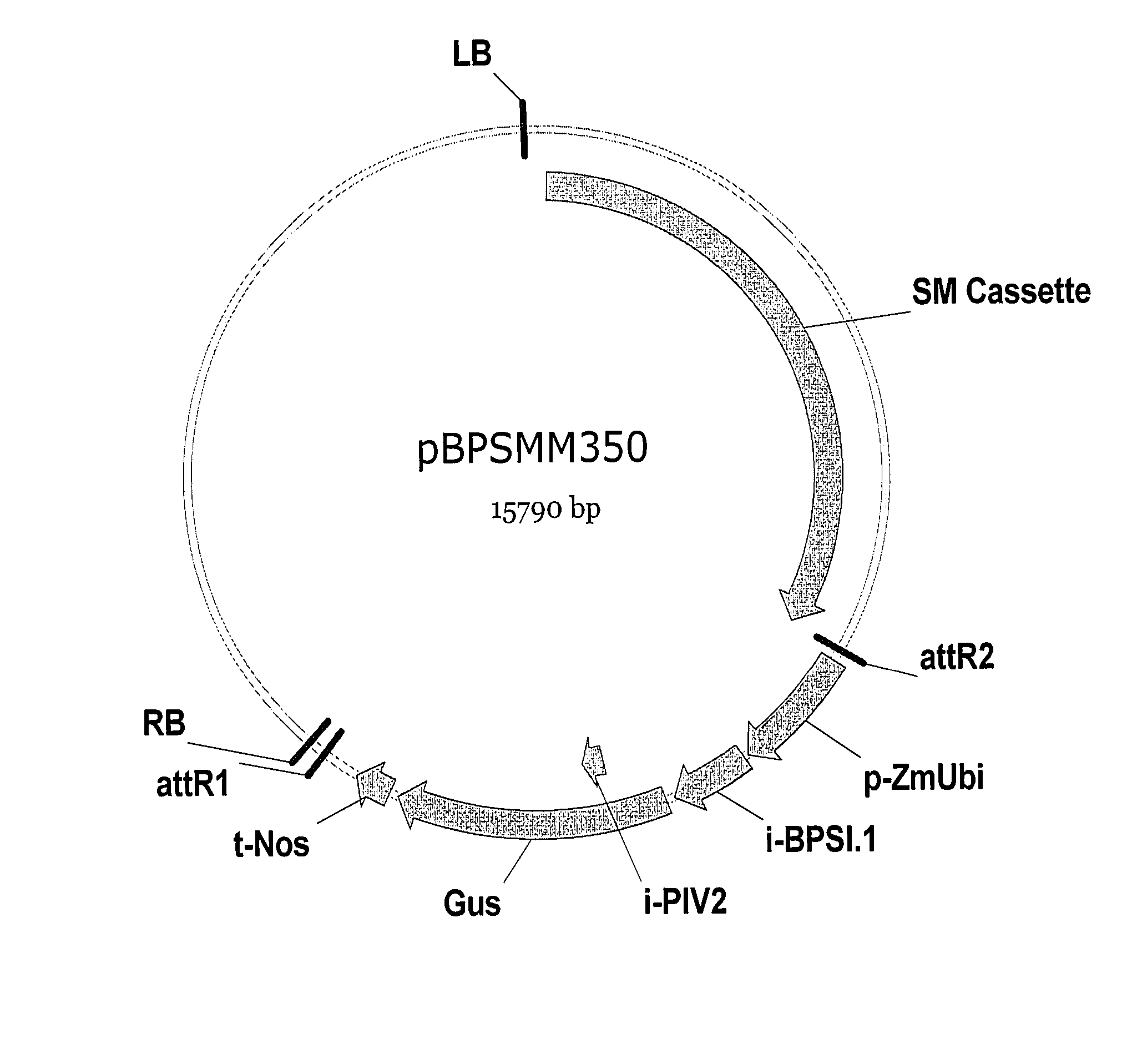

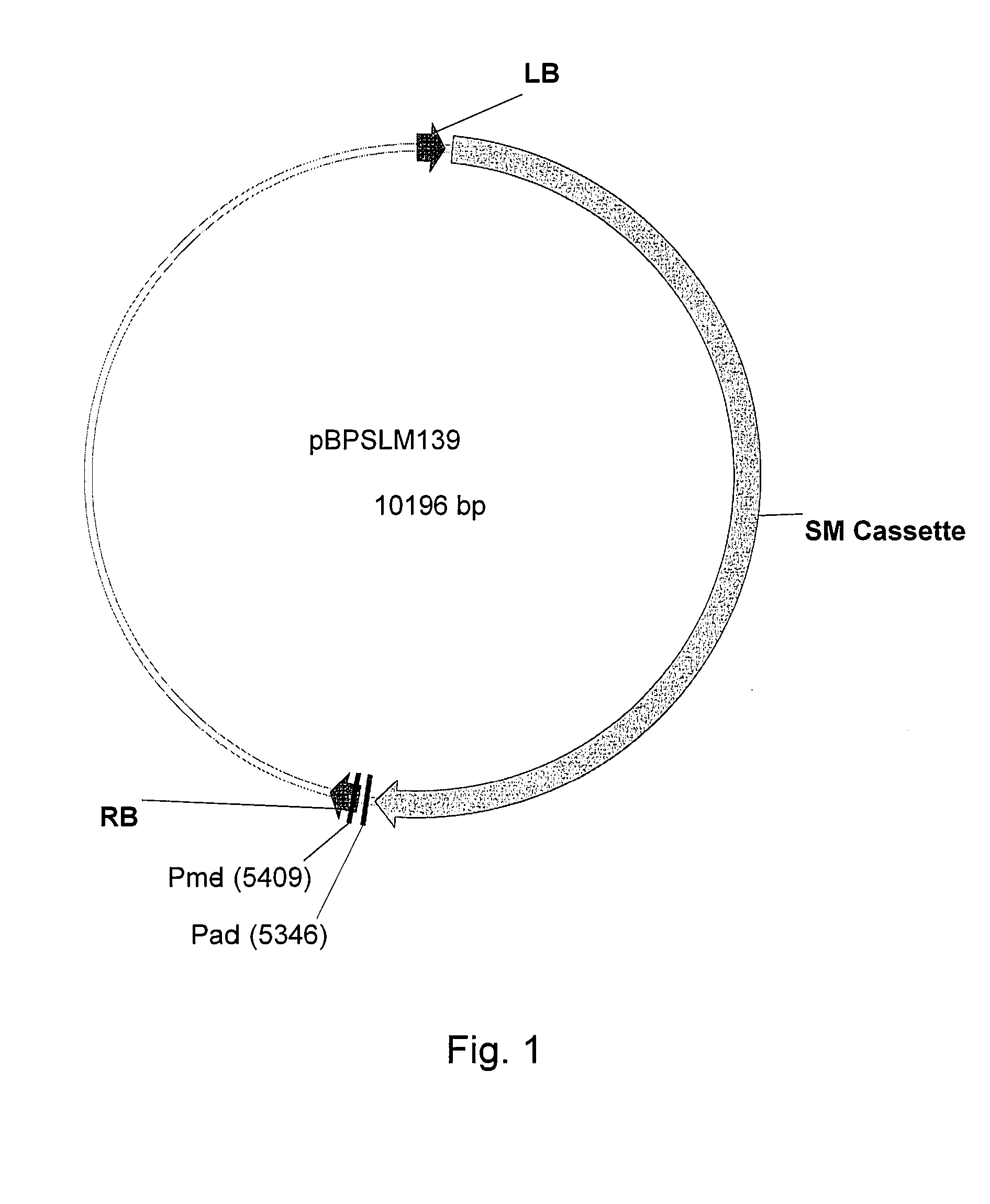

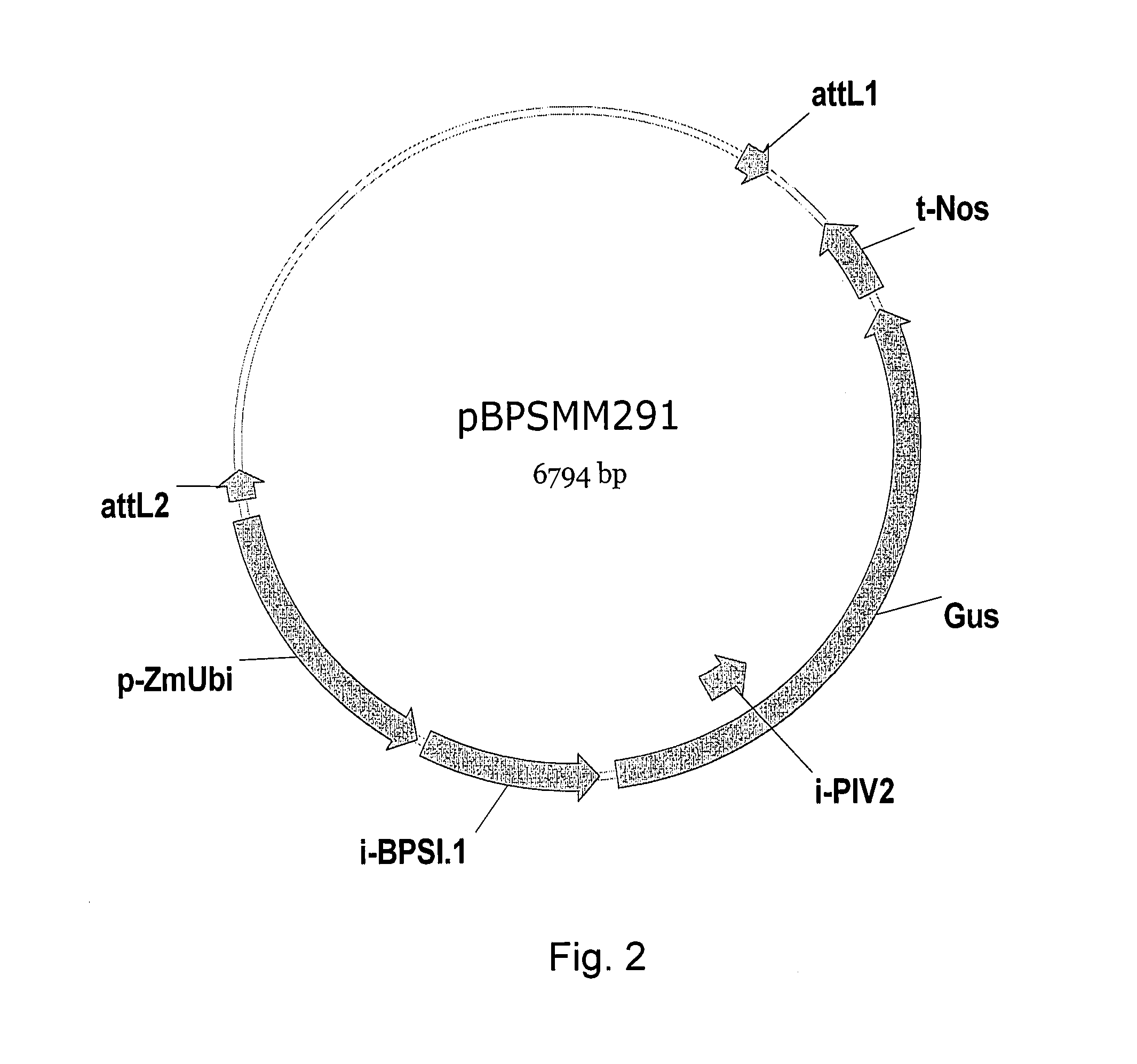

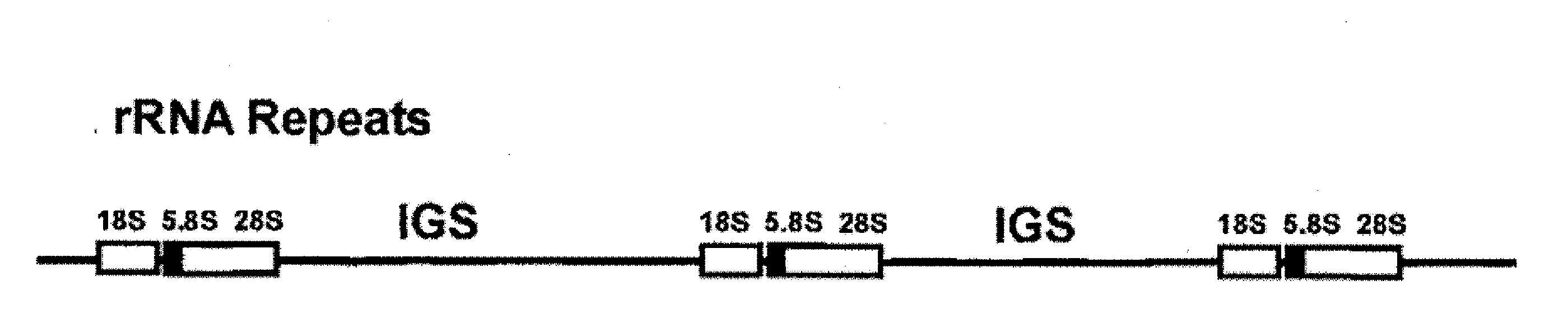

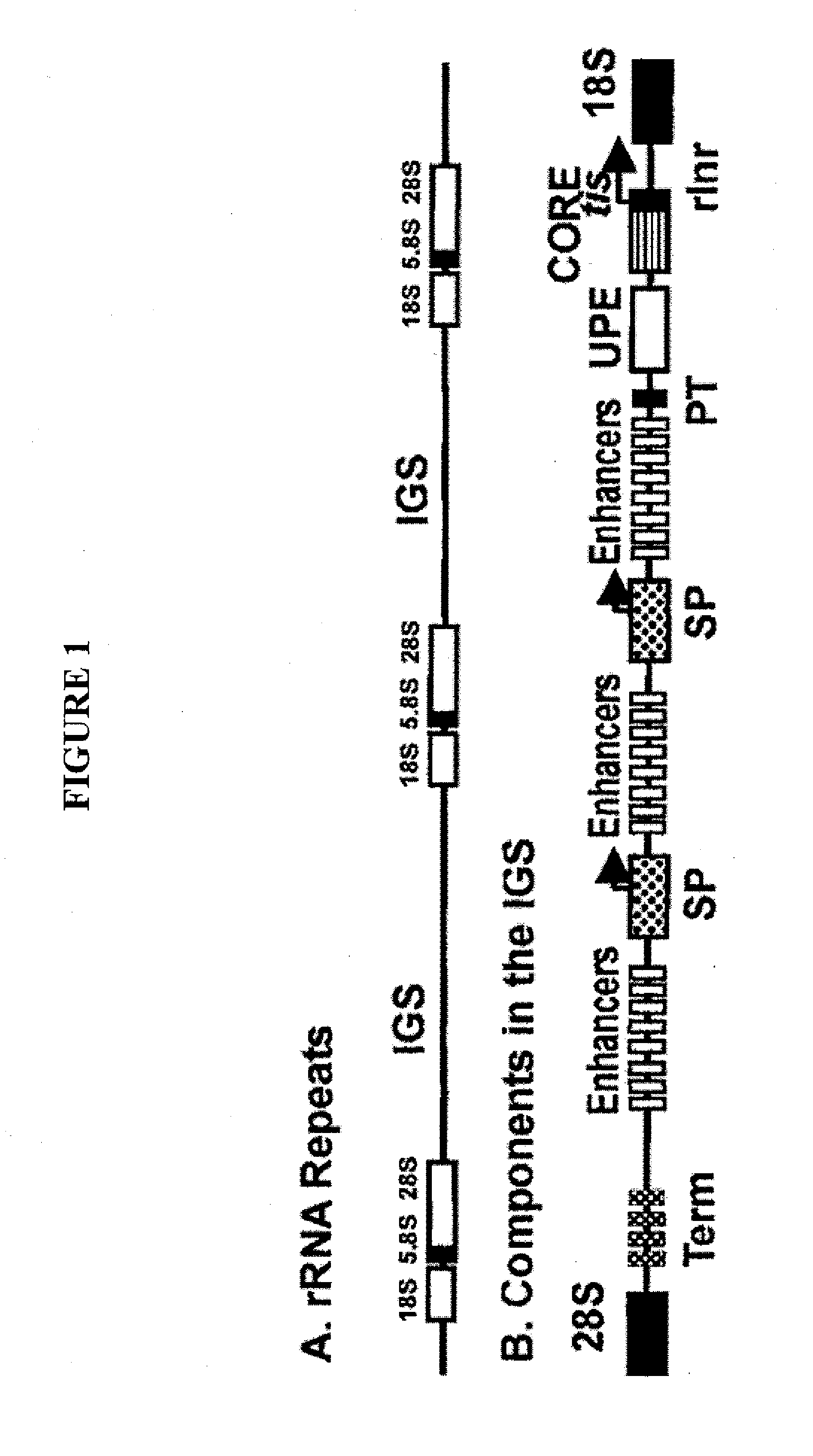

Expression Enhancing Intron Sequences

The invention relates to methods for the identification and use of introns with gene expression enhancing properties. The teaching of this invention enables the identification of introns causing intron-mediated enhancement (IME) of gene expression. The invention furthermore relates to recombinant expression construct and vectors comprising said IME-introns operably linked with a promoter sequence and a nucleic acid sequence. The present invention also relates to transgenic plants and plant cells transformed with these recombinant expression constructs or vectors, to cultures, parts or propagation material derived there from, and to the use of same for the preparation of foodstuffs, animal feeds, seed, pharmaceuticals or fine chemicals, to improve plant biomass, yield, or provide desirable phenotypes.

Owner:BASF PLANT SCI GMBH

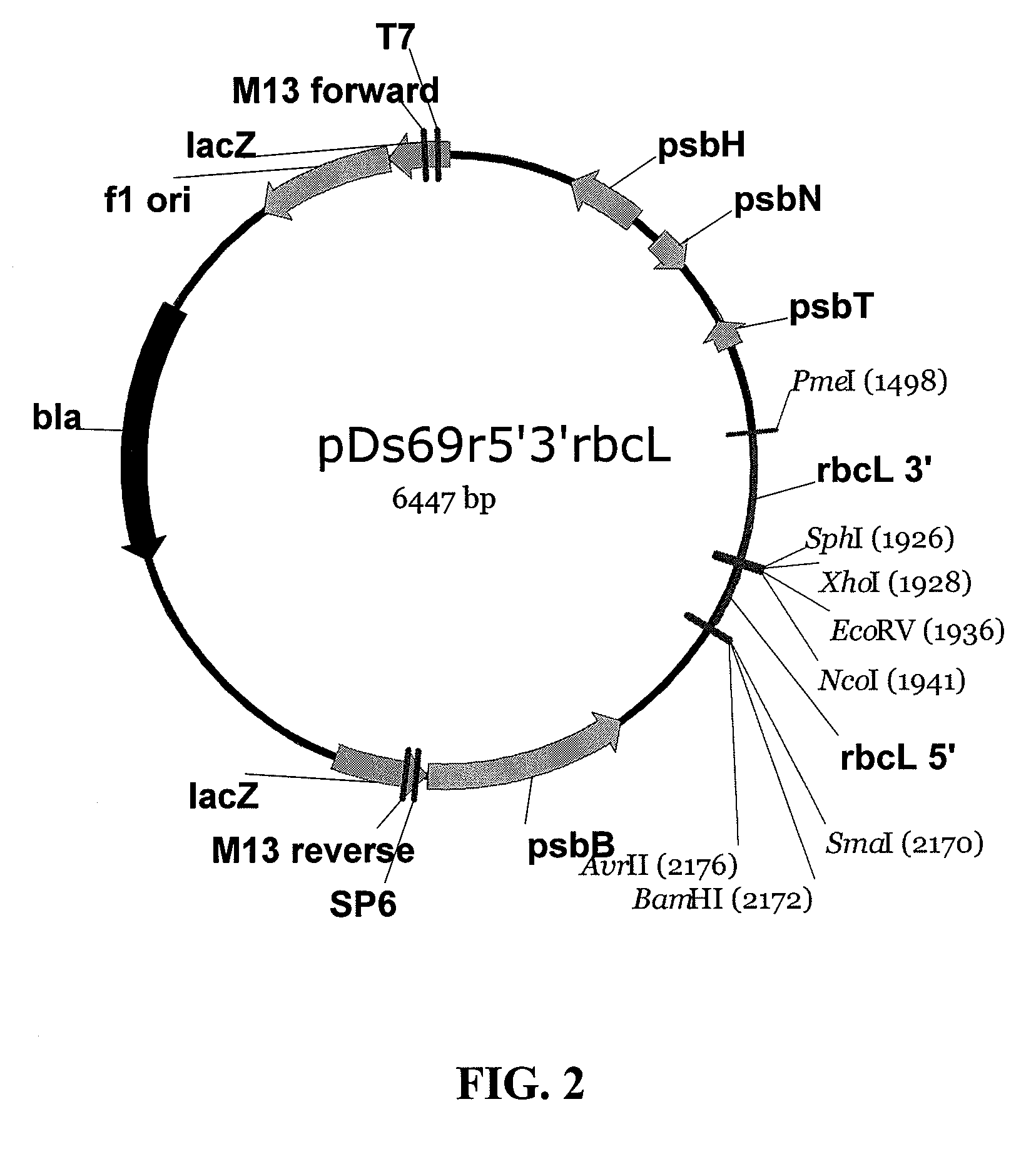

Nuclear based expression of genes for production of biofuels and process co-products in algae

Various embodiments provide, for example, vectors, expression cassettes, and cells useful for transgenic expression of nucleic acid sequences. In various embodiments, vectors can contain nuclear-based sequences of unicellular photosynthetic bioprocess organisms for the production of food- and feed-stuffs, oils, biofuels, starches, raw materials, pharmaceuticals or fine chemicals.

Owner:KUEHNLE AGROSYST

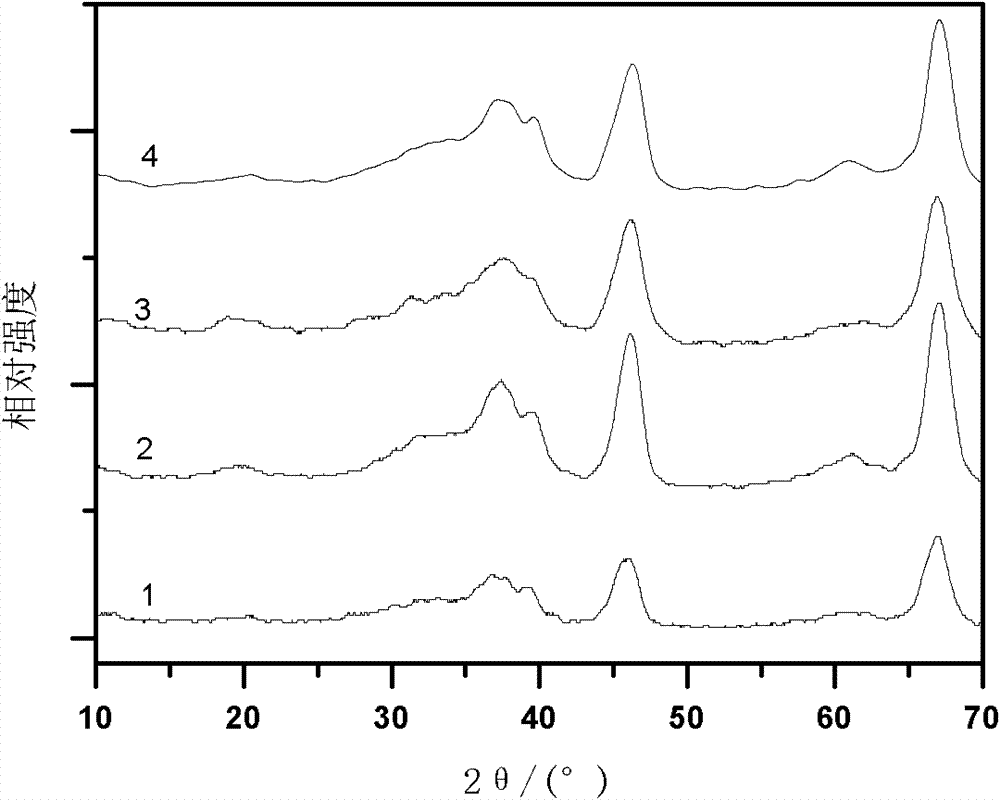

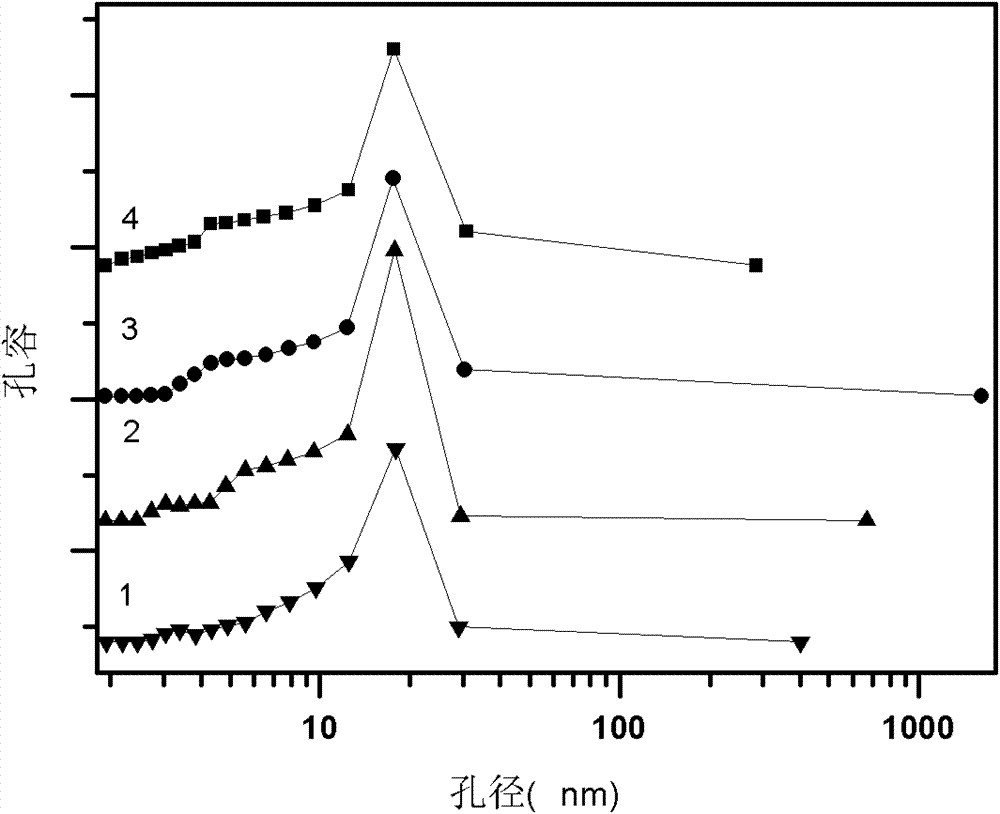

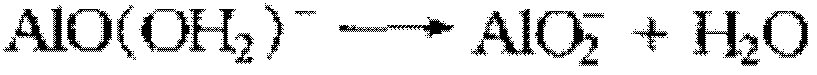

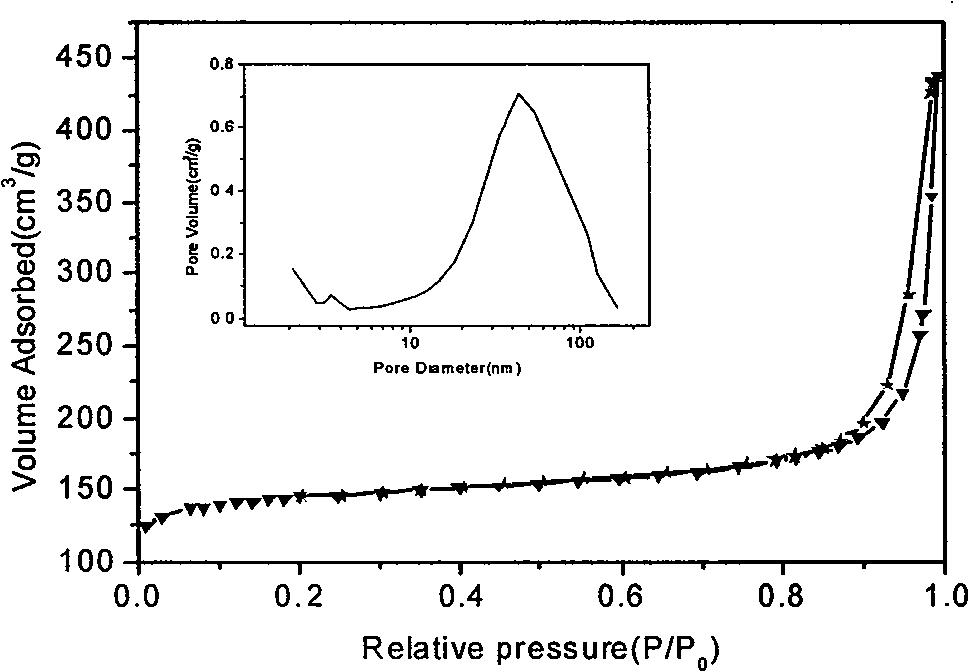

Mesoporous spherical alumina prepared by guiding of template and preparation method thereof

The invention provides mesoporous spherical alumina and a method for preparing the mesoporous spherical alumina by guiding of a template. By the adoption of an oil column forming method, the template with a guiding function is added into aluminum sol during the aluminum sol preparation process; and during the forming and aging processes of the aluminum sol, due to the existence of the template with the guiding function, a large number of meso-structures are prepared in alumina balls. The mesoporous spherical alumina has the following characteristics of: its specific surface is 150-300 m<2> / g; particle diameter is 0.1-5 mm; pore volume is 0.7-1.5 ml / g; holes, hole diameter of which is 2-40 nm, are greater than 97%; bulk density is 0.30-0.80g / cm<3>; and crushing strength is 70-250 N / granule. The mesoporous spherical alumina can be used as a catalyst or a catalyst carrier in the petrochemical industry and the industry of fine chemicals.

Owner:BEIJING UNIV OF CHEM TECH

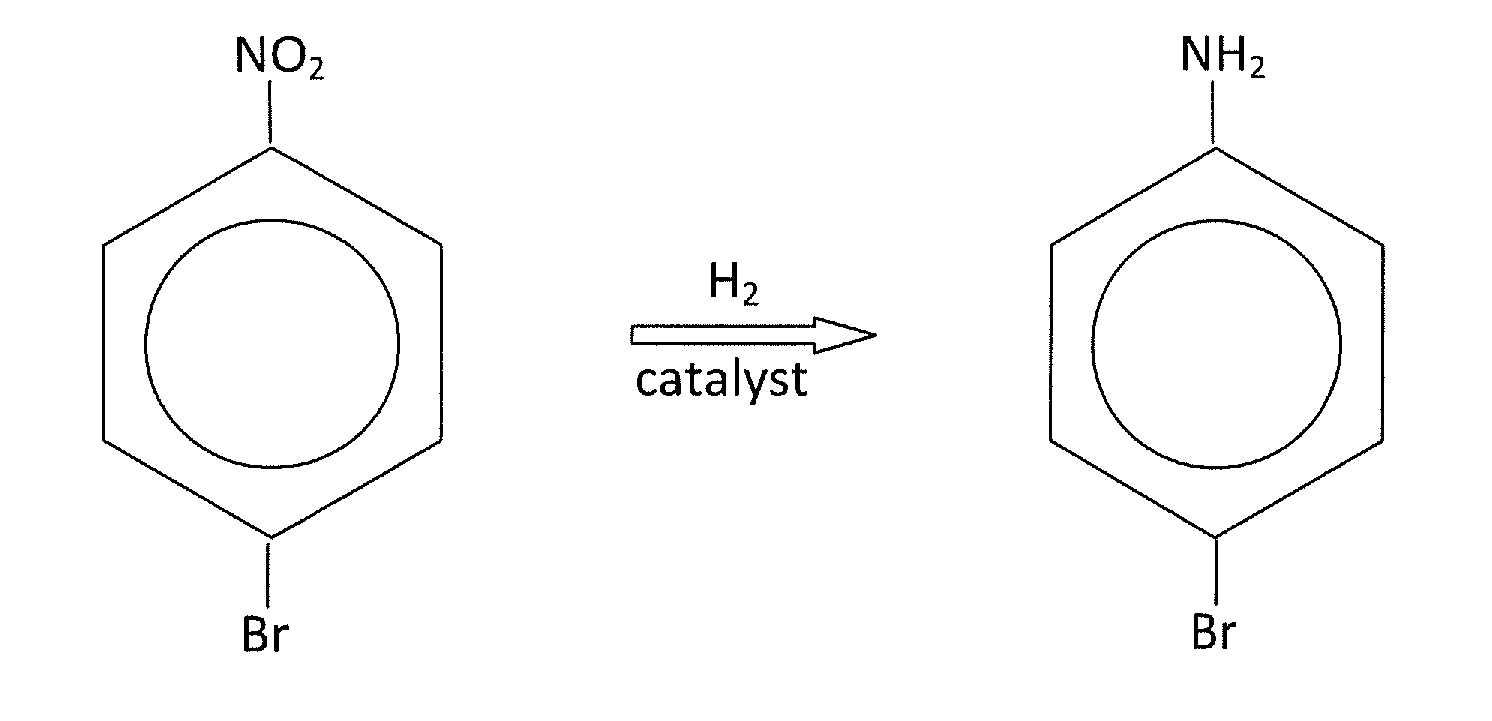

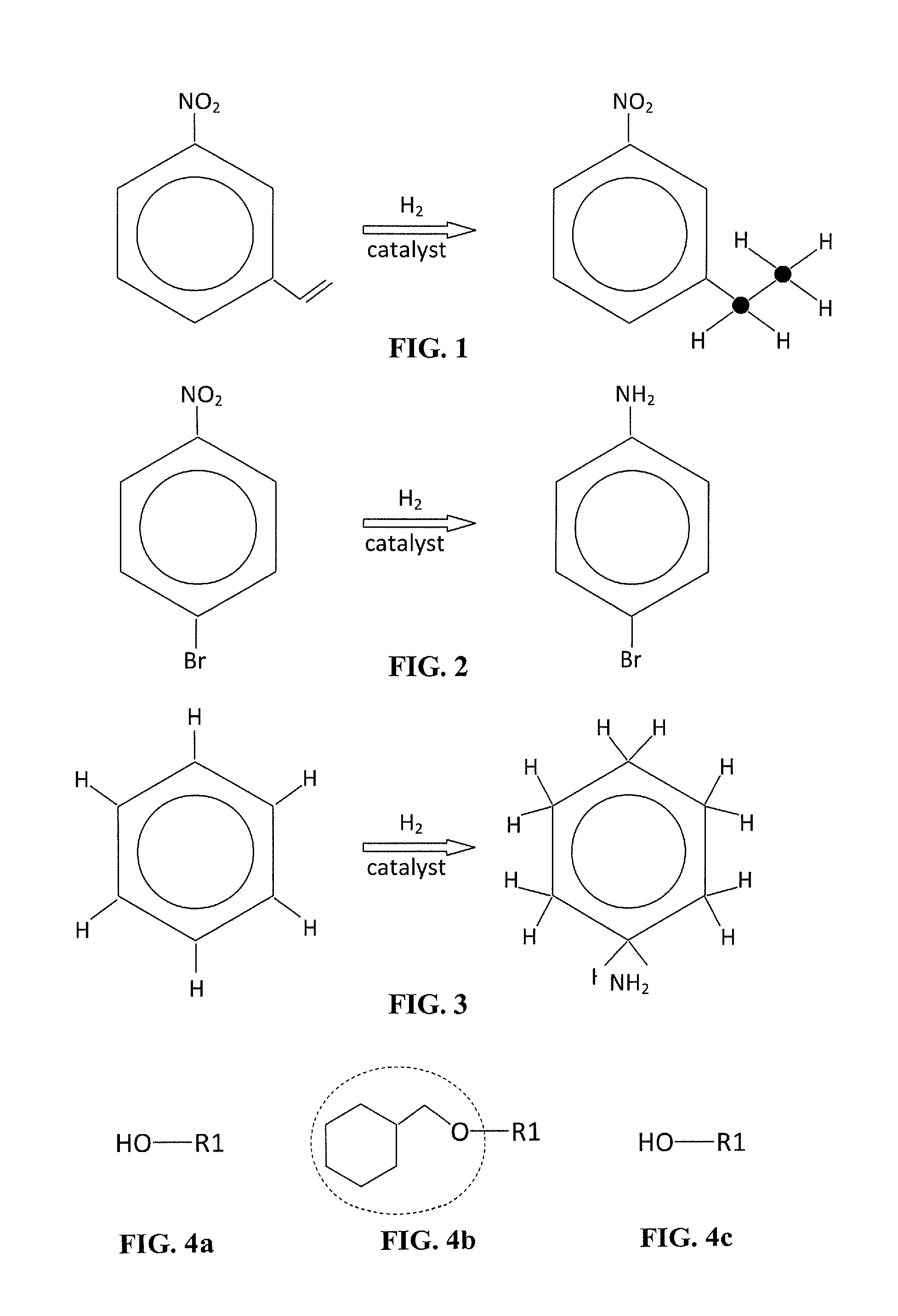

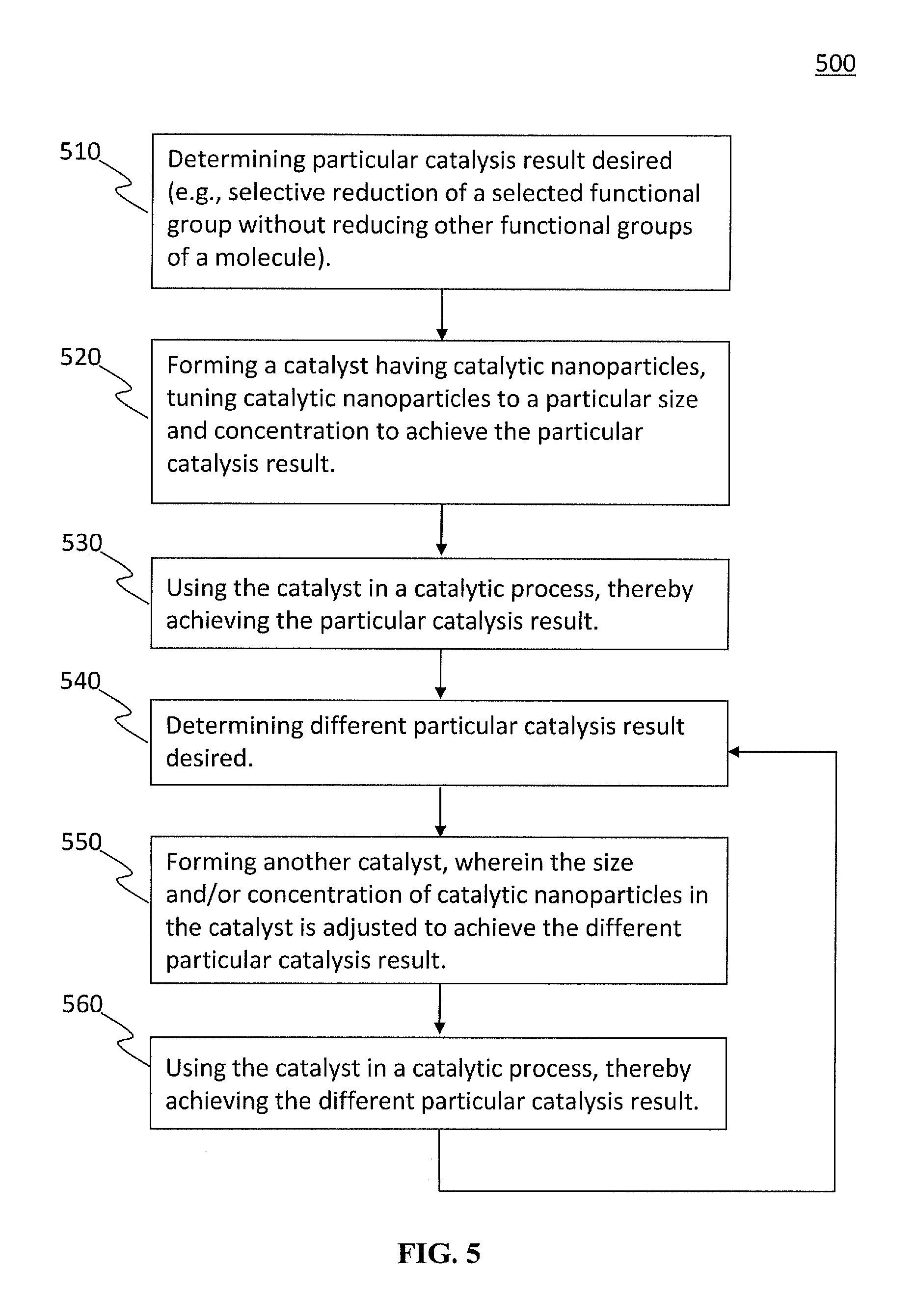

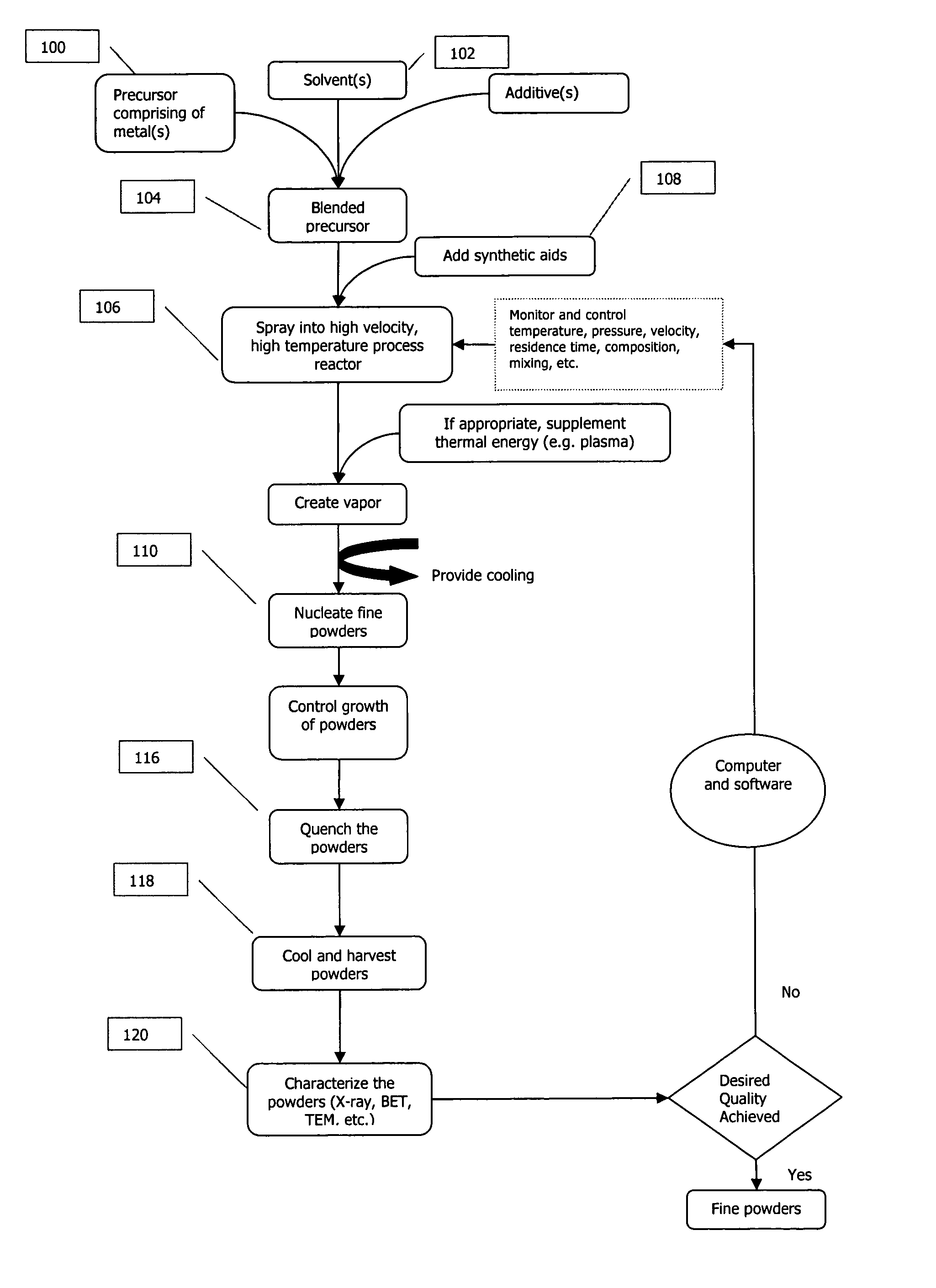

Advanced catalysts for fine chemical and pharmaceutical applications

A catalyst comprising a plurality of support nanoparticles and a plurality of catalytic nanoparticles. At least one catalytic nanoparticle is bonded to each support nanoparticle. The catalytic particles have a size and a concentration, wherein a first configuration of the size and the concentration of the catalytic nanoparticles enables a first catalysis result and a second configuration of the size and the concentration of the catalytic nanoparticles enables a second catalysis result, with the first and second configurations having a different size or concentration, and the first and second catalysis results being different. In some embodiments, the first catalysis result is a selective reduction of a first selected functional group without reducing one or more other functional groups, and the second catalysis result is a selective reduction of a second selected functional group without reducing one or more other functional groups.

Owner:SDC MATERIALS

Zinc comprising nanoparticles and related nanotechnology

InactiveUS20050126338A1Increase volumeLow costPigmenting treatmentMaterial nanotechnologyZincPigment

Nanoparticles comprising zinc, methods of manufacturing nanoparticles comprising zinc, and applications of nanoparticles comprising zinc, such as electrically conducting formulations, reagents for fine chemical synthesis, pigments and catalysts are provided.

Owner:PPG IND OHIO INC

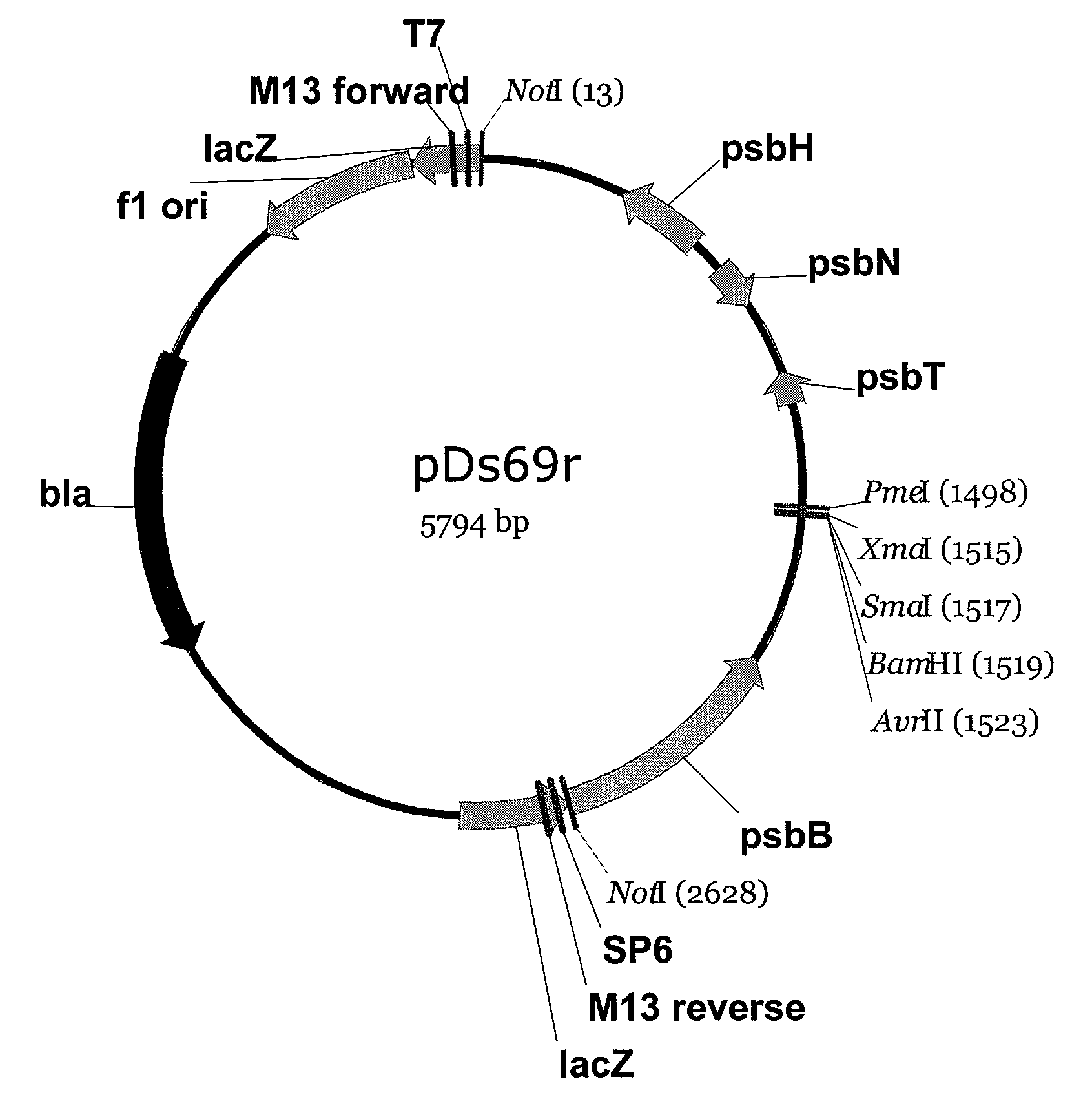

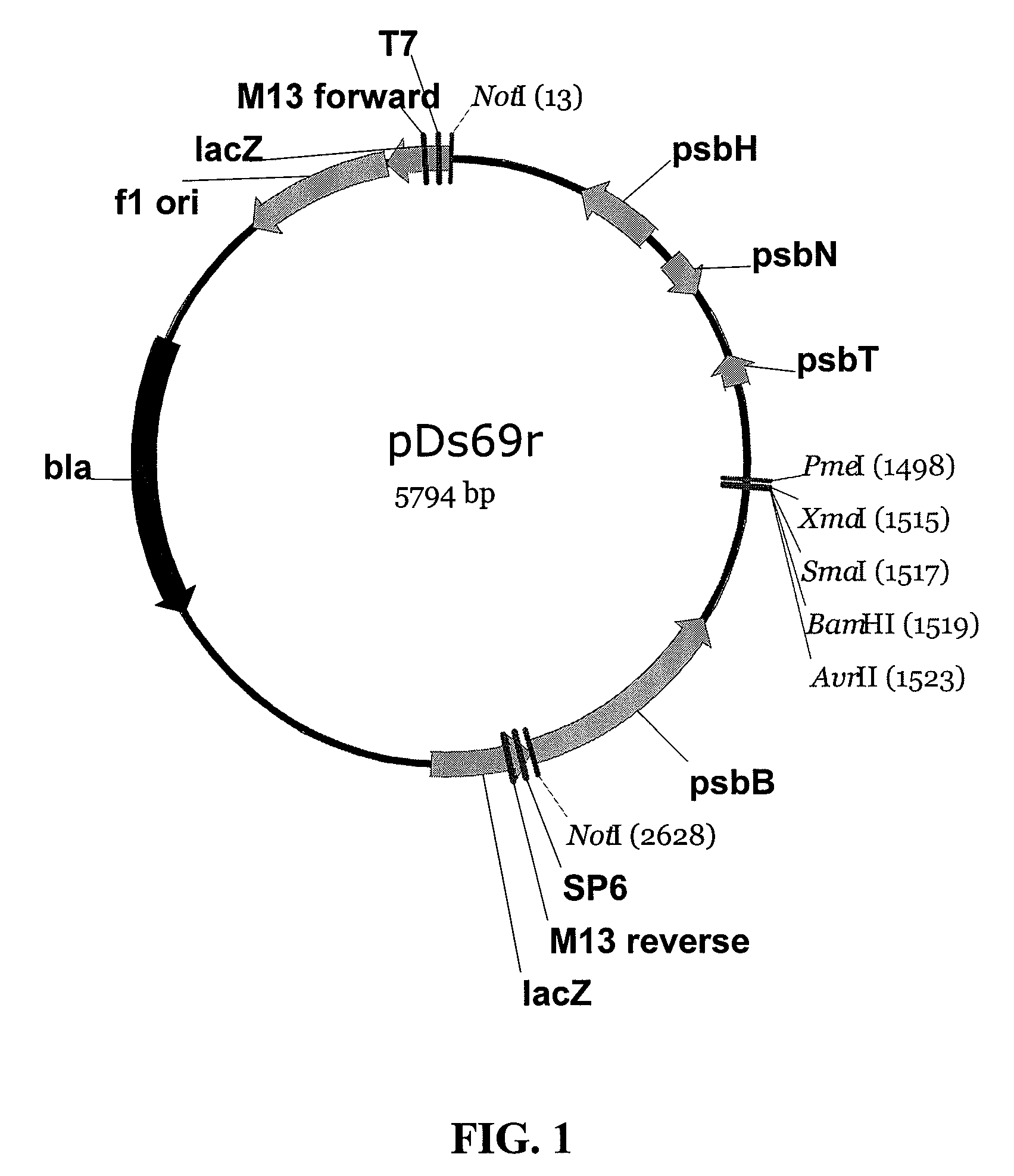

Expression of nucleic acid sequences for production of biofuels and other products in algae and cyanobacteria

Various embodiments provide, for example, vectors, expression cassettes, and cells useful for transgenic expression of nucleic acid sequences. In various embodiments, vectors can contain plastid-based sequences of unicellular photosynthetic bioprocess organisms for the production of food- and feed-stuffs, oils, biofuels, pharmaceuticals or fine chemicals.

Owner:KUEHNLE AGROSYST

Temperature-resistant salt-resistant composite foam oil displacement agent for tertiary oil recovery and preparation method thereof

InactiveCN102086389ARaw materials are easy to getReduce manufacturing costDrilling compositionSulfonateActive agent

The invention relates to a temperature-resistant salt-resistant composite foam oil displacement agent for tertiary oil recovery and a preparation method thereof, belonging to the field of chemical oil displacement for increasing the crude oil recovery ratio of the oil field. The oil displacement agent is compounded by 0.5-1% of alpha-alkene sulfonate as a main surfactant and other auxiliary agents and comprises the following components in percentage by mass:0.1-1.5% of anionic surfactant, 0.2-0.8% of zwitterionic surfactant, 2-10% of organic solvent, 5-12% of stabilizing agent and the balance of a salt solution added to be 100%. Compounds related to the oil displacement agent are industrially produced fine chemical products, the raw materials are easy to obtain, the production cost is low, and the preparation is simple; the oil displacement agent has performances of temperature resistance, salt resistance, ultralow interfacial tension and the like; the persistence of the foam is strong, and the half-life period can be more than 120min at 85 DEG C; the oil displacement age has excellent compatibility with other surfactants, and the comprehensive recovery ratio of the crude oil can be increased by about 10-15%.

Owner:SHANGHAI UNIV

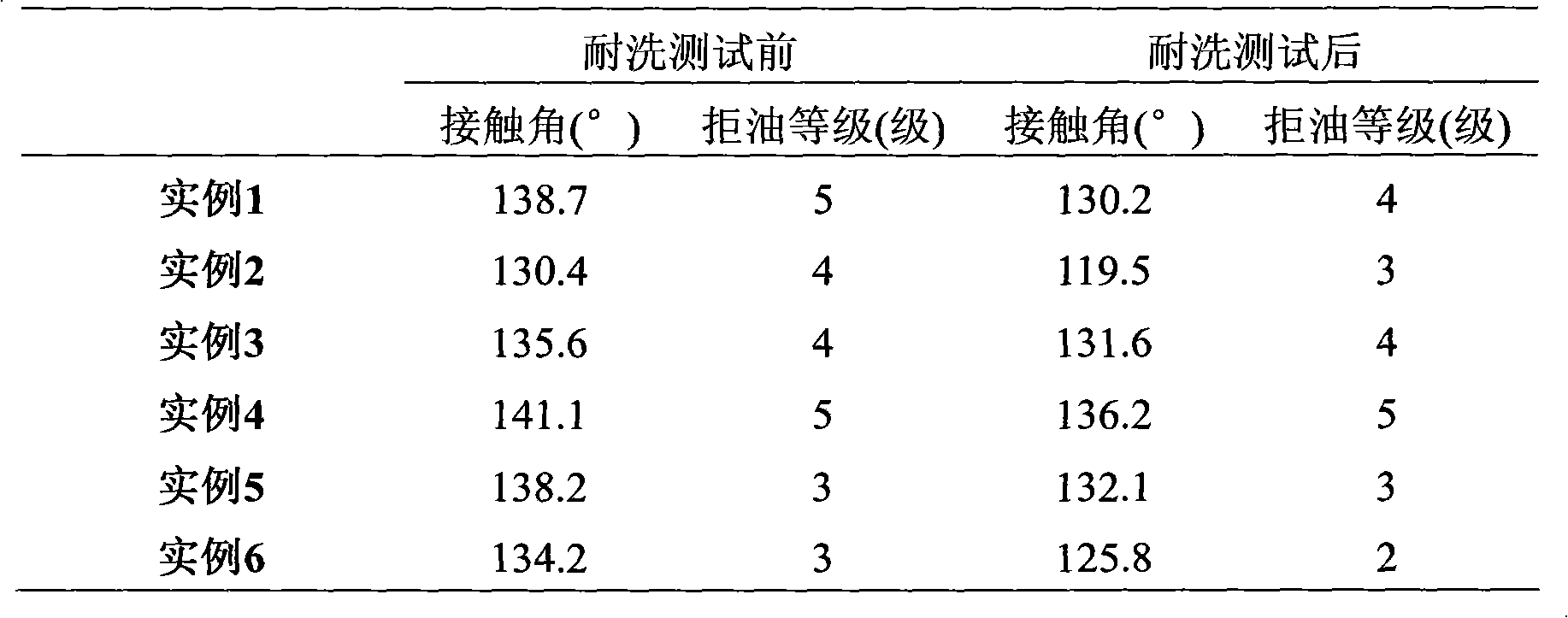

Method for preparing short-chain branch water and oil repellent finishing agent containing modified nano-oxide and fluorine

InactiveCN102041681AImprove securityFeel goodFibre treatmentFunctional monomerEmulsion polymerization

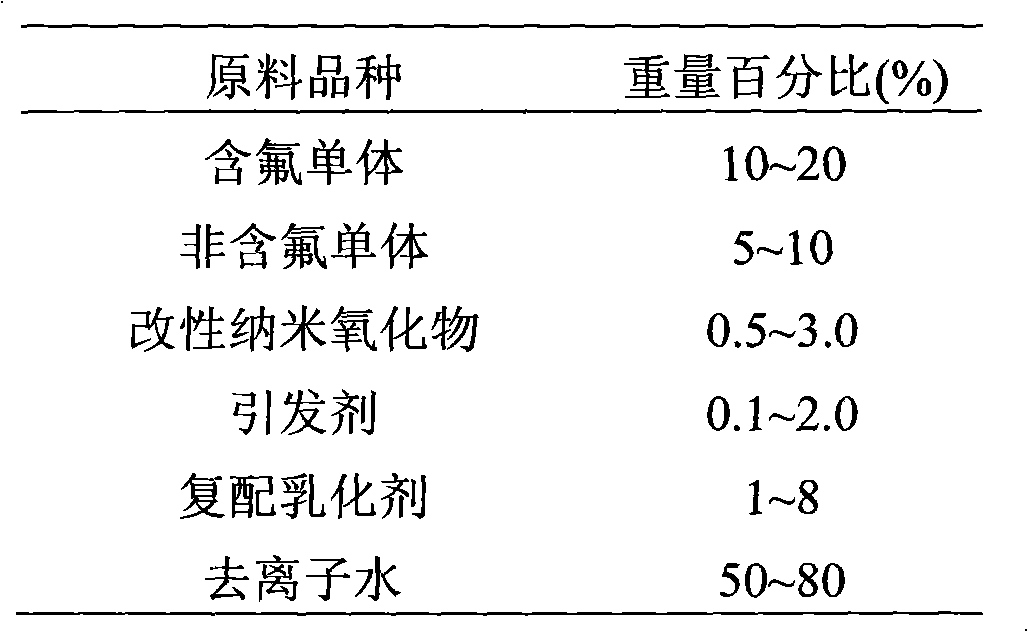

The invention relates to a latex type short-chain branch perfluoroalkyl water and oil repellent finishing agent and a preparation method thereof, belonging to the field of fine chemical industry. The latex type short-chain branch perfluoroalkyl water and oil repellent finishing agent is prepared by the following steps of: pre-emulsifying short-chain branch perfluoroalkyl acrylate monomer (10-20%), fluorine-free functional monomer (5.0-10%), modified nano-oxide (0.5-3.0%), initiator (0.1-2.0%), compound emulsifier (1.0-8.0%) and deioned water (60-80%); and finally heating for emulsion polymerization. The latex type short-chain branch perfluoroalkyl water and oil repellent finishing agent can be used for water and oil repellent finishing of animal and plant natural fiber fabric and chemical fiber fabric and has excellent water and oil repellent performance; fabric finished with the finishing agent has good handfeel and excellent endurance performance. Compared with the traditional fluorine-containing finishing agent , the finishing agent disclosed in the invention does not contain components harmful to human bodies and well accords with environmental protection requirement.

Owner:JIANGNAN UNIV

Preparation method of white paint ink used for textile inkjet printing

ActiveCN102925002ALong term storageImprove dispersion stabilityInksDyeing processDispersion stabilityPolymer science

The invention relates to a preparation method of white paint ink used for textile inkjet printing and belongs to the technical fields of fine chemical industry and material science. The white paint ink used for inkjet printing provided by the invention is formed by the steps of mixing oxide / polymer nano composite particle dispersoid serving as a white colouring agent with a water-soluble cosolvent, a surface active agent and deionized water, stirring and filtering. The white paint ink prepared by adopting the preparation method provided by the invention has good dispersion stability and storage stability, and the preparation method of white pigment ink provided by the invention has the characteristics of low equipment investment, simple production process, stable product quality and the like and is suitable for mass production.

Owner:KUNSHAN YIJIAJU TEXTILE CO LTD

Method for preparing furfural compounds from biomass

The invention relates to a method for preparing furfural compounds from biomass. The method specifically comprises the preparation of a solid acid catalyst and a reaction process of the solid acid catalyst. The method disclosed by the invention can also be applied to biomass derivatives. The method comprises the steps of adding biomass or biomass derivatives and the solid acid catalyst to a reactor, filling with protective gas, and adopting an organic solvent / saturated inorganic salt aqueous-solution two-phase reaction system, thereby obtaining furfural and 5-hydroxymethylfurfural in a high yield manner under mild conditions. The method has the advantages that after the reaction is completed, the produced furfural and 5-hydroxymethylfurfural are efficiently extracted into an upper-layer organic phase, the solid acid catalyst and an unreacted substrate are retained in a bottom-layer water phase, the furfural, the 5-hydroxymethylfurfural or a mixture of the furfural and the 5-hydroxymethylfurfural can be obtained through simple separation, and fine chemicals and liquid fuels can be prepared in a manner that the furfural, the 5-hydroxymethylfurfural or the mixture of the furfural and the 5-hydroxymethylfurfural serves as a reaction intermediate; and the used catalyst is pollution-free and can be recovered and reused, so that the method has good industrial application prospects.

Owner:EAST CHINA UNIV OF SCI & TECH

Human fat mesenchymal stem cell extract and lyophilized powder and application thereof

ActiveCN103784474ABiologically activeEasy to prepareCosmetic preparationsToilet preparationsBiotechnologyChemical products

The invention discloses a human fat mesenchymal stem cell extract and lyophilized powder and applications thereof. The human fat mesenchymal stem cell extract is prepared by the steps: collecting subcultured P3-P30 generations of human fat mesenchymal stem cells, culturing with cell growth liquid until 80% of cells are fused, removing culture liquid, washing the cells with a phosphate buffer solution for three times, adding into a serum-free culture solution, continuously culturing for 72 hours, collecting the serum-free culture solution, digesting uncollected cells with a digestion solution, crushing the cells with an ultrasonic crushing device, centrifuging, and then collecting supernatant; and mixing the collected serum-free culture solution and the collected supernatant, filtering, collecting filtrate, concentrating, and sterilizing. The human fat mesenchymal stem cell extract and the lyophilized powder thereof have multiple biological activities, can be used for preparing wound healing or cell repair medicaments and other biopharmaceutical products, and can also be used for preparing whitening products or skin anti-wrinkle products and other fine chemical products.

Owner:GUANGZHOU SALIAI STEMCELL SCI & TECH CO LTD

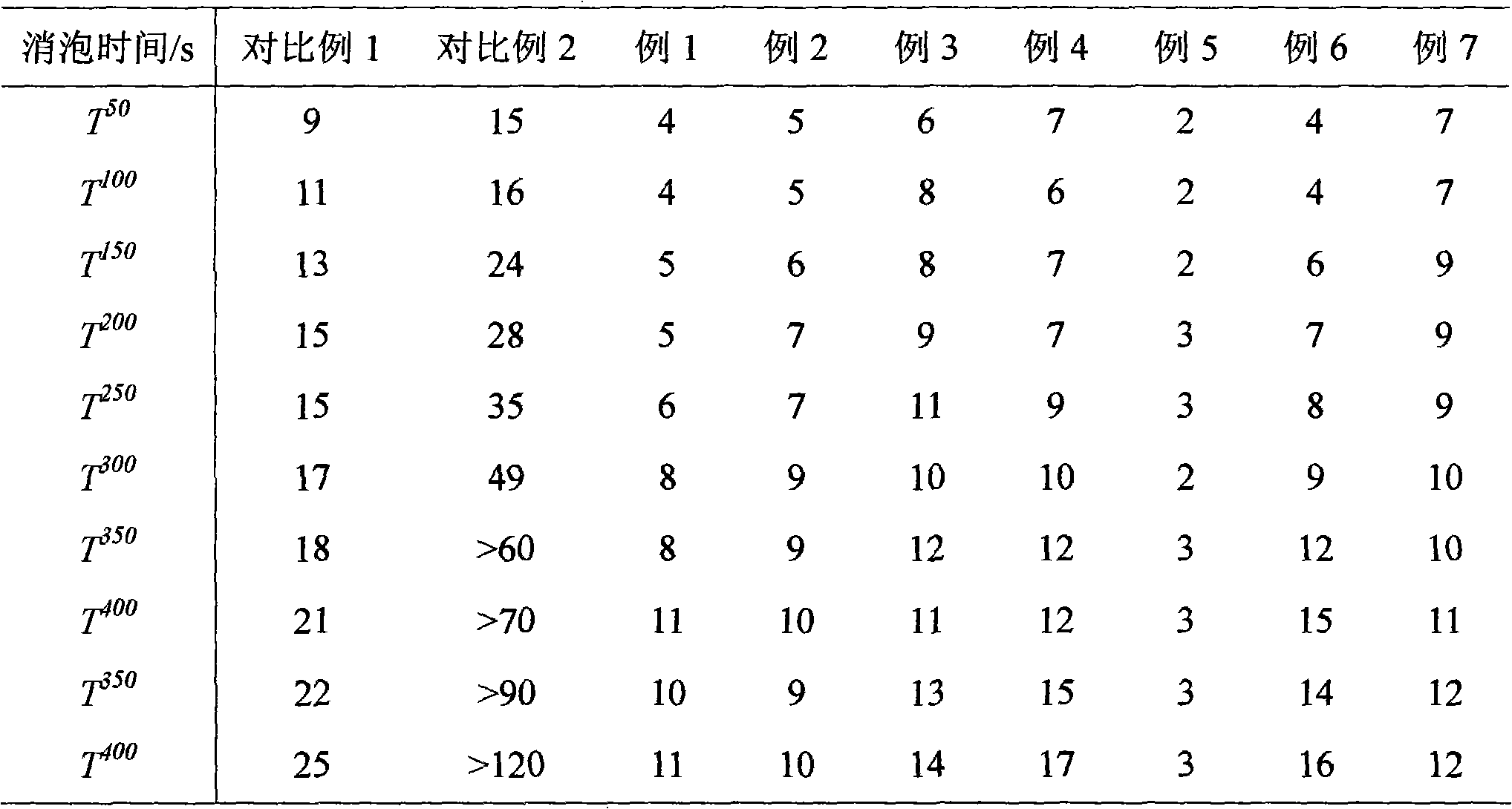

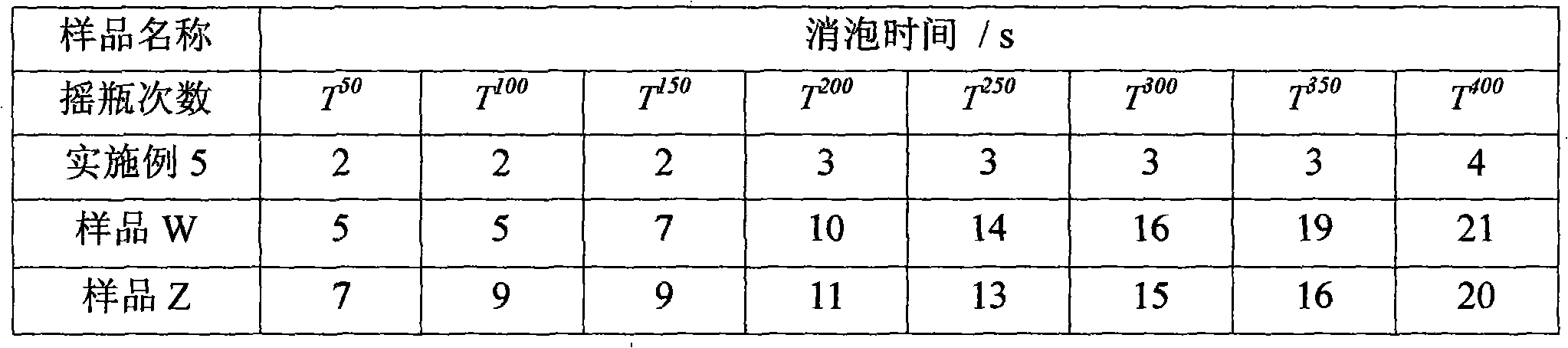

Method for preparing defoaming agent composition

The invention discloses a method for preparing a defoaming agent composition, belonging to the technical field of fine chemical preparation. The invention provides a defoaming agent composition widely used for removing harmful foams in industrial production. The defoaming agent composition comprises the following components: (1) polysiloxane RaSiO(4-a) / 2; (2) a coupling agent; (3) fine filler particles such as silicon dioxide and the like; (4) organic silicon resin; (5) polyether modified polysiloxane MDx(CH3GSiO)yM, wherein M is chain link R'2SiO1 / 2, D is chain link R'2SiO2 / 2, G is polyether radical-(CH2)z(EO)g(PO)hR'' and (6) an alkaline catalyst. The preparation method comprises the following steps: (1) heating the polysiloxane and the coupling agent together in a stirring machine, adding the alkaline catalyst to carry out a polymerization reaction at the temperature of 40-140 DEG C; (2) after crosslinking the mixture, adding the organic silicon resin and the polyether modified polysiloxane, carrying out a reaction again for 1-7 h at the temperature of 80-140 DEG C, and then adding the fine filler particles to mix uniformly, carrying out a reaction for 1-6 h at temperature of 90-180 DEG C; (3) after finishing the reaction, keeping the mixture for 0.1-1.5 h at the vacuum degree of -0.01 to -0.08 MPa, and finally, cooling to the room temperature to obtain white active materials that are defoaming agent compositions.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

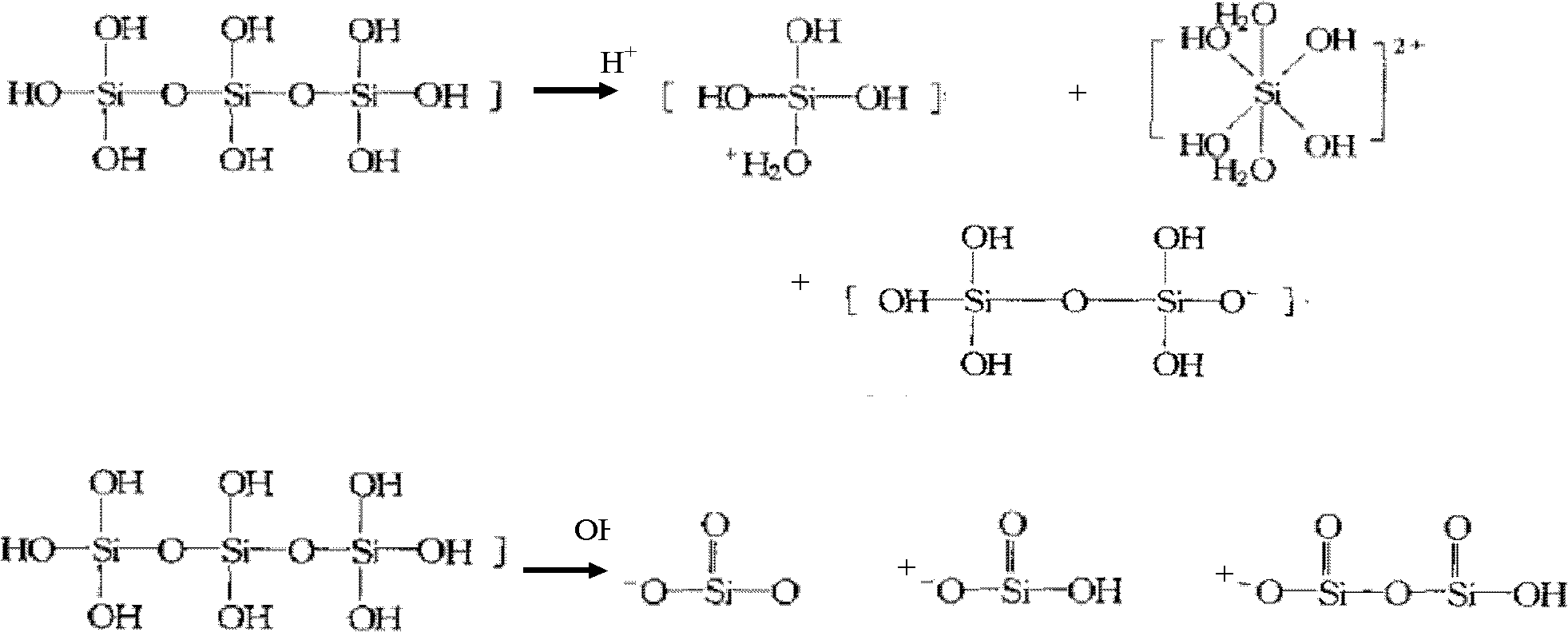

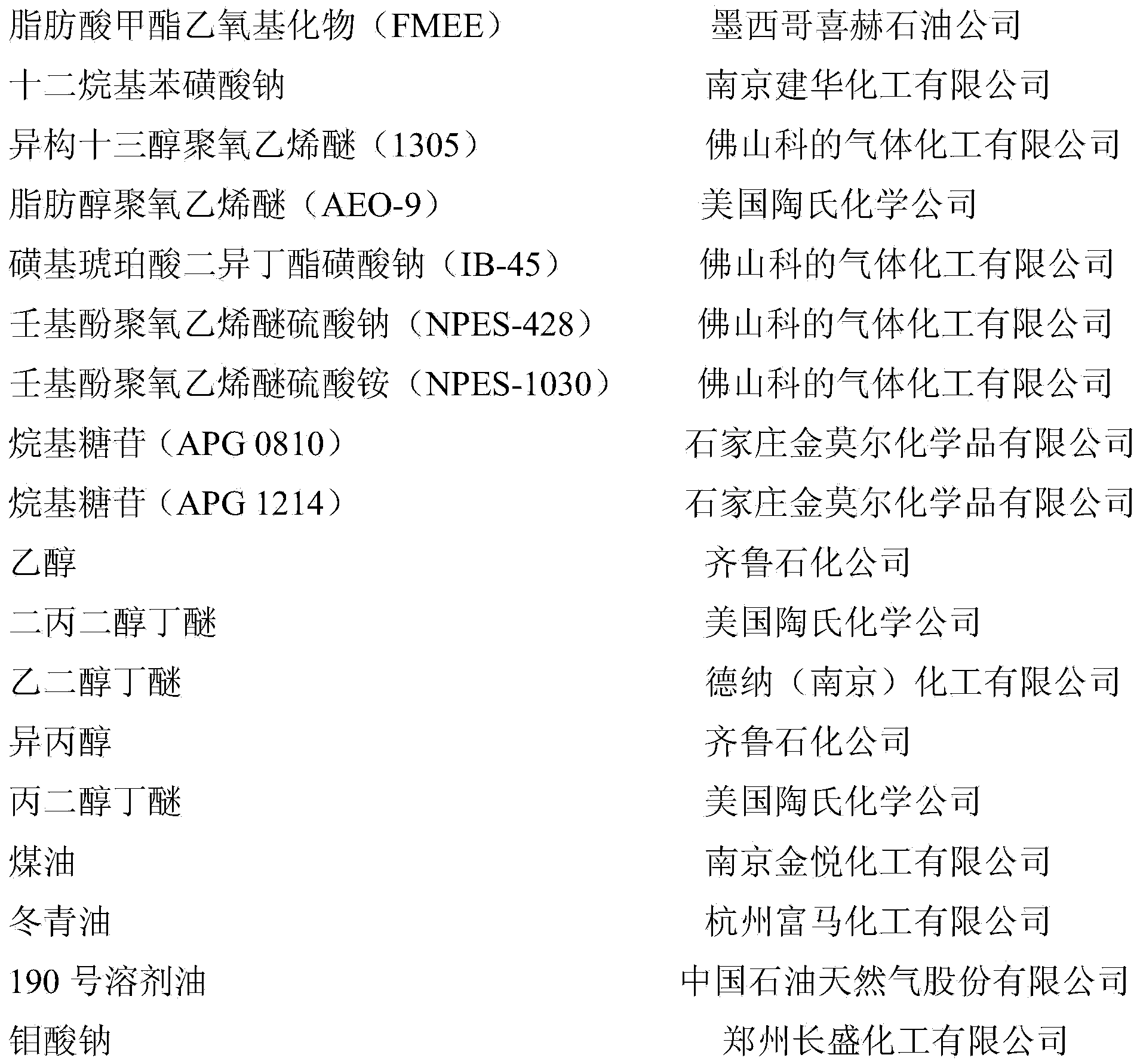

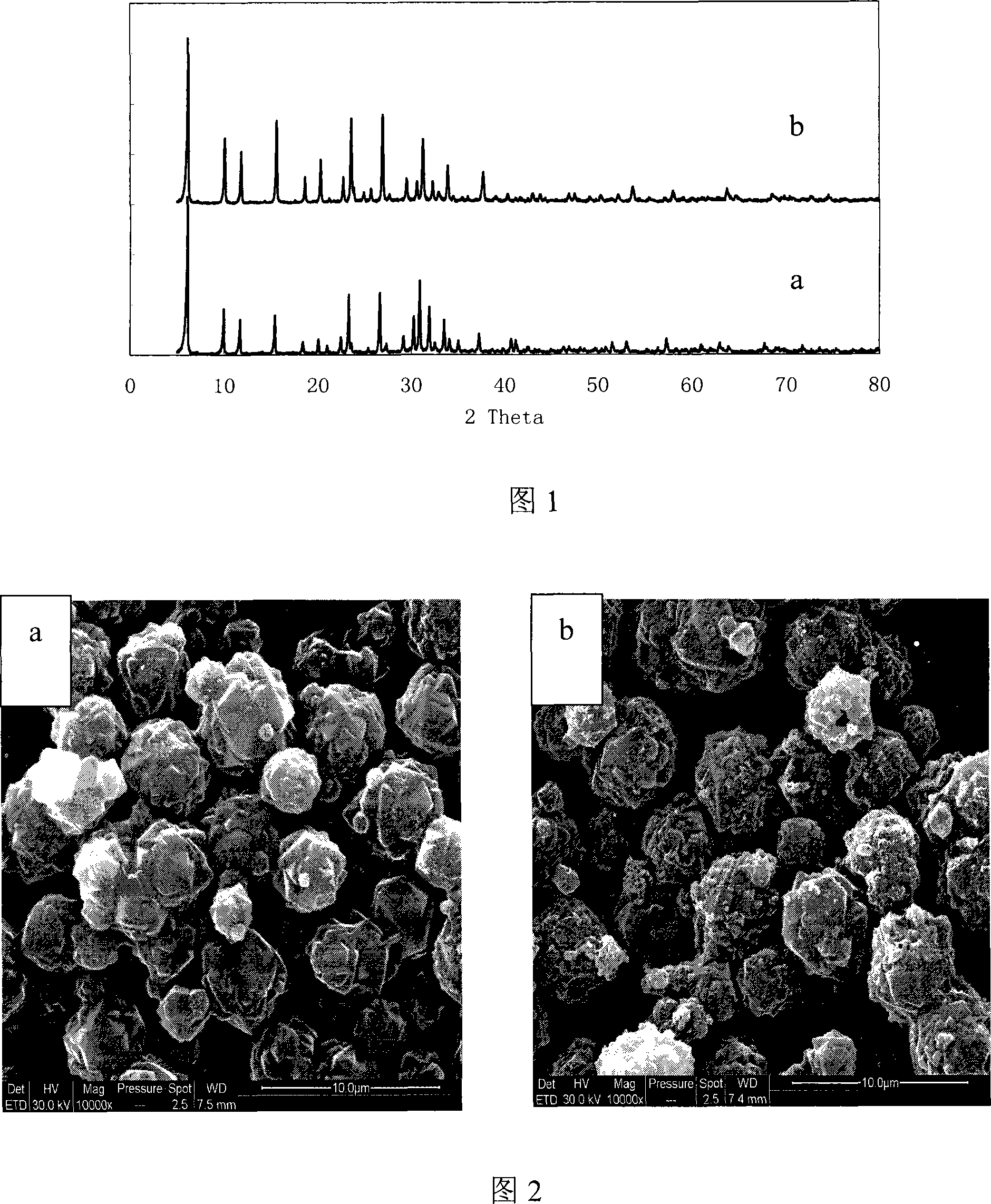

Synthetic method of ZSM-5 zeolites

ActiveCN102502696AReduce the degree of polymerizationHigh activityPentasil aluminosilicate zeolitePetrochemicalCrystallinity

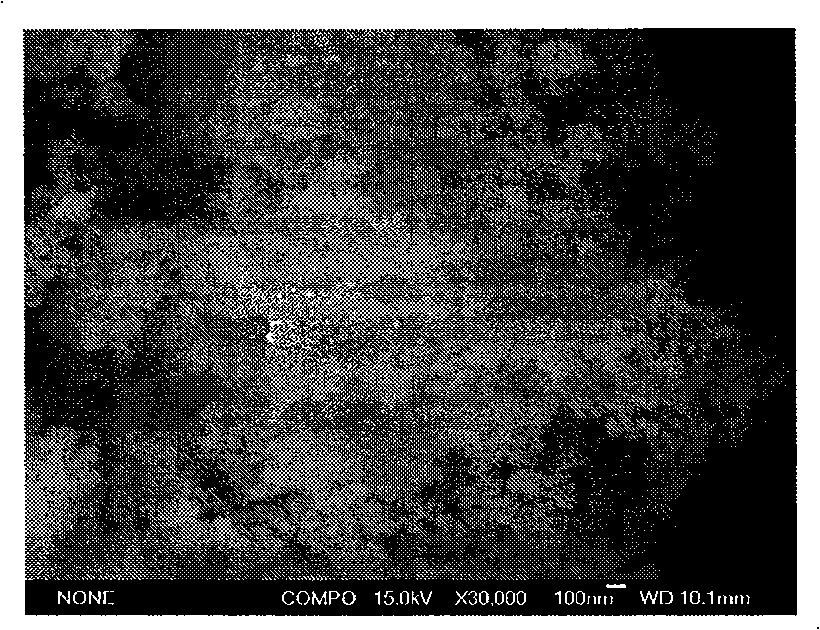

The invention belongs to the synthesis field of aluminosilicate ZMS (Zeolite Molecular Sieve), and relates to a synthetic method of ZSM-5 zeolite molecular sieves. ZSM-5 zeolites are high-silicon micro-porous zeolites with unique three-dimensional ten-membered ring crossing aperture passages, the diameters of the aperture passages are close to the sizes of benzene rings, and the ZSM-5 zeolites can be widely applied to petroleum refining, petrochemical industry and fine chemicals synthesis. Particularly, nano-sized ZSM-5 zeolites achieve larger external surface area and higher intracrystalline diffusion rate, and have higher activity and selectivity as well as strong coking deactivation-resisting capability in hydrocarbons catalysis conversion reactions. The synthetic method regulates the polymerization degrees of silicon sources and aluminum sources respectively by adding acid and alkali so as to obtain highly reactive reactants, and can rapidly achieve nucleus formation in large quantities in a system so as to obtain nano-sized zeolites. The synthetic method is not limited by the types of the silicon sources and the aluminum sources, has strong applicability to raw materials, changes the activity of the raw materials through simple regulation, and can rapidly synthesize products of the nano-sized ZSM-5 zeolites with well crystallinity under the dosage conditions of no template and low-cost templates.

Owner:DALIAN UNIV OF TECH

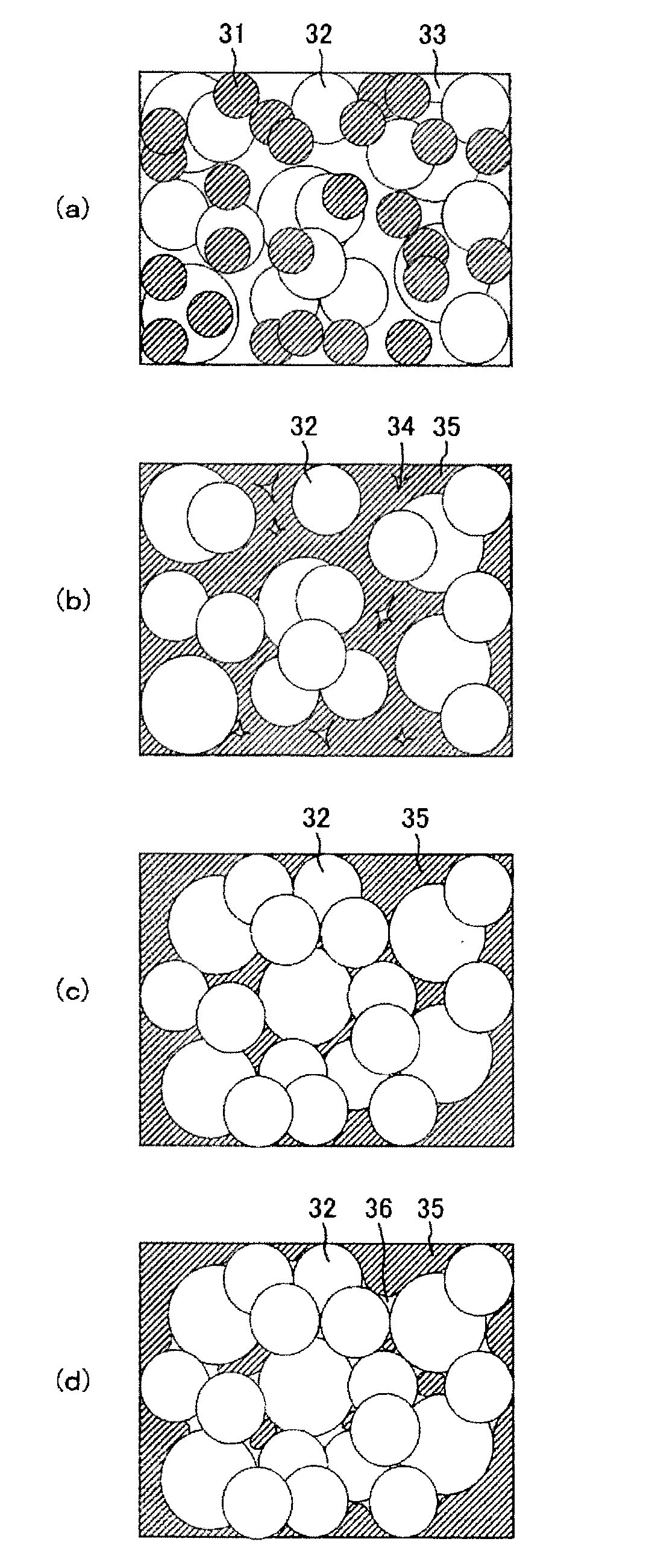

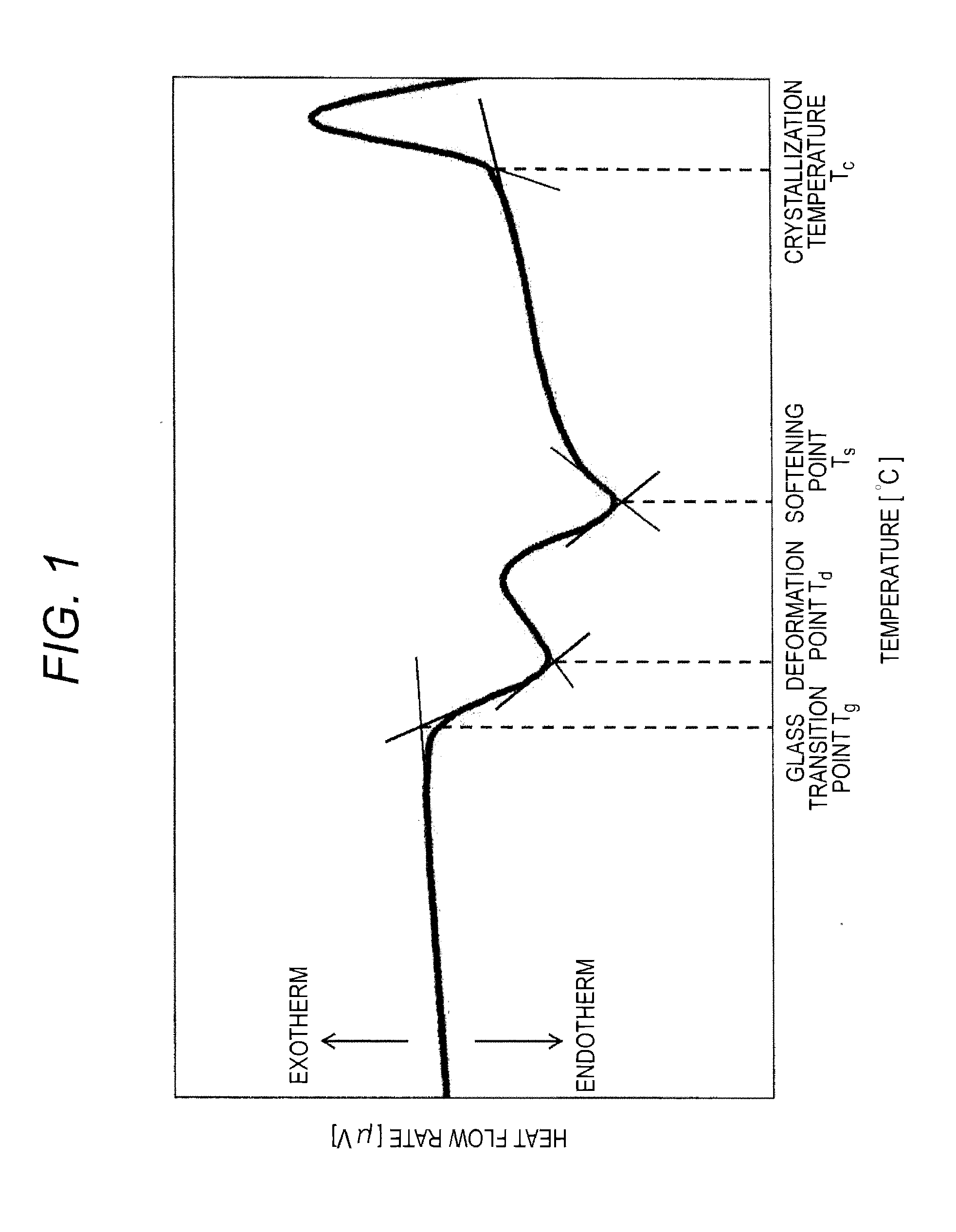

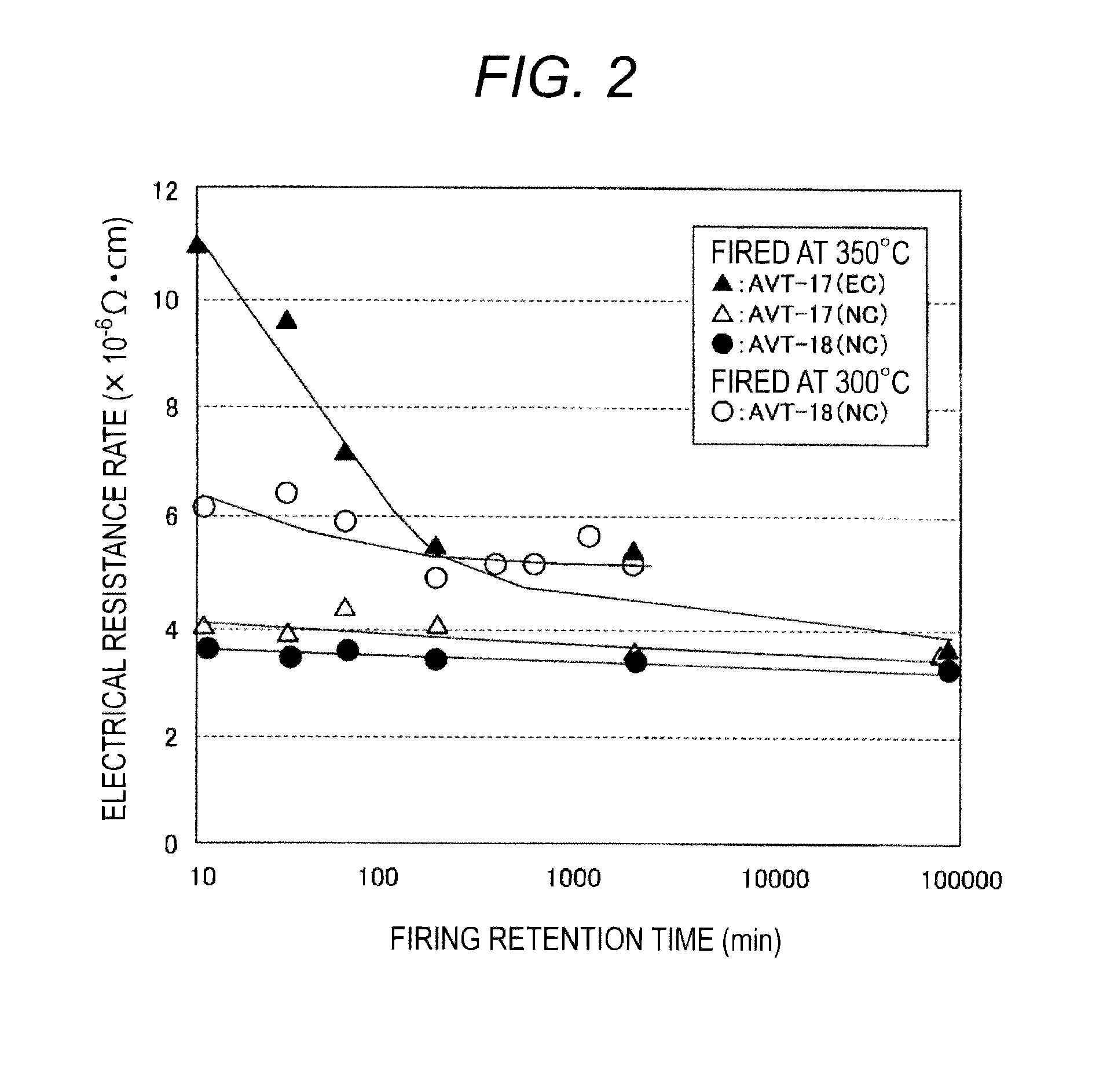

Glass composition, glass frit containing same, glass paste containing same, and electrical/electronic component obtained using same

ActiveUS20140145122A1Improve thermal stabilityGood chemical stabilityCathode-ray/electron-beam tube leading-in arrangementsSemiconductor/solid-state device detailsFritThermal stability

The present invention aims at providing a lead-free glass composition that can be soften and flowed at a firing temperature that is equal to or lower than that of conventional low melting point lead glass. Furthermore, the present invention aims at providing a lead-free glass composition having fine thermal stability and fine chemical stability in addition to that property. The lead-free glass composition according to the present invention is characterized by comprising at least Ag2O, V2O5 and TeO2 when the components are represented by oxides, wherein the total content ratio of Ag2O, V2O5 and TeO2 is 75 mass % or more. Preferably, the lead-free glass composition comprises 10 to 60 mass % of Ag2O, 5 to 65 mass % of V2O5, and 15 to 50 mass % of TeO2.

Owner:HITACHI LTD

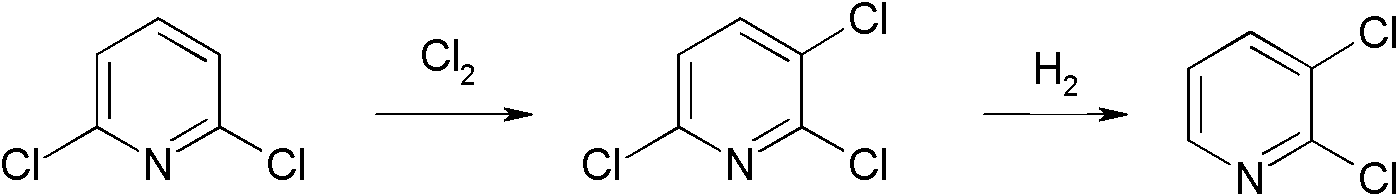

Preparation method of 2,3-dichloropyridine

ActiveCN102153507ANovel process routeReduce manufacturing costOrganic chemistryOrganic solventMetal catalyst

The invention discloses a preparation method of 2,3-dichloropyridine. 2,3-dichloropyridine is an intermediate in fine chemical industry, which is widely used in the fields of medicine and pesticide. The method comprises the following steps: carrying out chlorination reaction on 2,6-dichloropyridine, which is used as a raw material, to obtain 2,3,6-trichloropyridine; adding the 2,3,6-trichloropyridine, an acid binding agent, a metal catalyst and an organic solvent into a reactor, and carrying out hydrogenation reaction, wherein the mol ratio of 2,3,6-trichloropyridine to acid binding agent is 1:(0.1-0.5); and cooling the hydrogenation reaction liquid, adding water to dissolve the acid binding agent hydrochloride, filtering, standing, separating out the water layer, extracting the organic solvent layer with water-containing acid at least three times, merging the water-containing acid layers after extraction, diluting by adding water, precipitating a solid, filtering, and drying to obtain the 2,3-dichloropyridine product. The invention has the advantages of novel process route, short reaction steps, high yield, low production cost and environmental friendliness, is simple to operate, and is suitable for industrial production.

Owner:LIANHE CHEM TECH +1

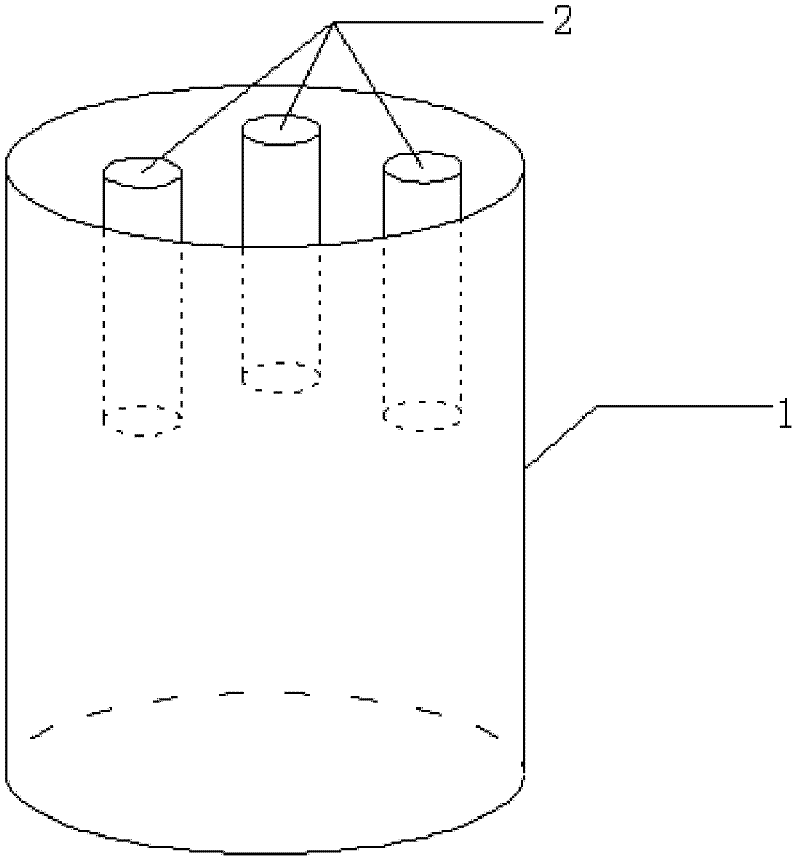

Porous ceramic membrane support with flat structure and preparation method thereof

ActiveCN102688700AReduce frictionAvoid accumulationSemi-permeable membranesPolyvinyl alcoholAdhesive

The invention relates to a porous ceramic membrane support with a flat structure and a preparation method thereof, and belongs to the technical field of ceramic membrane supports. The ceramic membrane support is flat and consists of two flat membrane supports; a certain space is reserved between the two flat membrane supports; at least one supporting column is distributed in the space; and at least one water outlet passage is formed in each flat membrane support, so that flowing resistance of filtrate in the support with the flat structure is reduced. The ceramic aggregate of the support is one or more of alumina, zirconia, silicon dioxide, silicon carbide, titanium oxide, mullite and cordierite; the pore-forming agent is starch, graphite, phenolic resin spheres and the like; and the adhesive is methylcellulose, polyvinyl alcohol and the like. The porosity of the prepared porous ceramic membrane support with the flat structure can reach 30 to 50 percent, the aperture is 20 to 200 nanometers, and the compressive strength can reach 20 to 40MPa; and the support can be used for substituting an organic hollow fiber membrane bioreactor, and has great potential application in the fields of sewage treatment, fine chemical industry and the like.

Owner:TSINGHUA UNIV +1

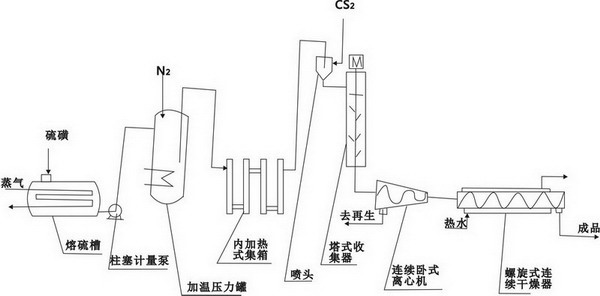

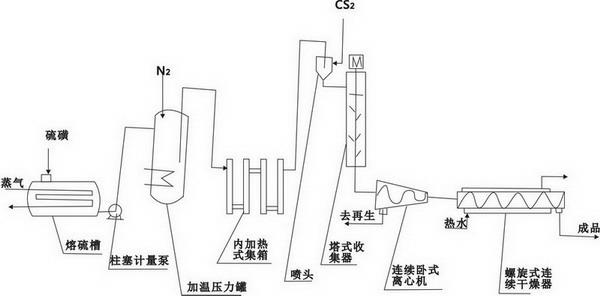

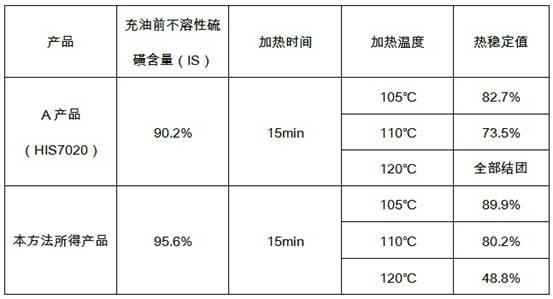

Method for producing insoluble sulfur

The invention discloses a method for producing insoluble sulfur, and belongs to the field of inorganic fine chemical engineering. The production method comprises the following steps of: (1) melting and polymerization; (2) atomization and cold quenching (3) solidification; (4) centrifugal separation; (5) continuous drying; and (6) crushing, screening and charging oil to obtain a finished product. The method is a continuous production method; by the method, the yield of the product is improved; and the product has high purity and stable quality.

Owner:四川中信华诚化工科技有限公司

Method for preparing naphthalene sulphonic acid by sulfonating sulfur trioxide in microreactor

InactiveCN101607925ALarge specific surface areaImprove heat transfer performanceChemical/physical/physico-chemical processesSulfonic acid preparationReaction temperatureNitromethane

The invention relates to a method for preparing naphthalene sulphonic acid by sulfonating sulfur trioxide in a microreactor, belonging to methods for preparing dye intermediates in the field of fine chemical engineering. The method comprises the following steps: taking alkyl halide and nitromethane as an organic solvent, naphthalene and derivative thereof as the raw material and organic solution of liquid sulfur trioxide as a sulfonating agent, preparing a solution according to the mol ratio of the organic solvent, the raw material and the sulfonating agent of 19-74:1:1-3 in the microreactor of with channel with the diameter of 10-50 microns, and sulfonating the reaction solution to prepare the naphthalene sulphonic acid by controlling the sulfonation reaction temperature to be between 17DEG C below zero and90 DEG C. The method adopts a continuous flow reactor, solves the problem of impossible transient mixing in the conventional reactor, prevents secondary reaction caused by local excess, and is especially suitable for strong exothermic reaction, fast reaction and flammable and explosive reaction. Compared with the preparation technology in the traditional batch reactor, the invention has the advantages of no generation of waste water and waste acid, clean and environment-friendly technology, consumption of sulphonic acid close to the theoretical quantity, fast reaction speed, low sulfonation temperature, high product yield, good repeatability, high labor productivity and low equipment cost.

Owner:SPECIAL CHEM CO LTD DALIAN FIRSTAR

Method for preparing multi-level porous channel beta zeolite

InactiveCN101538049ATake advantage ofAdjustable mesoporosityMolecular-sieve and base-exchange compoundsDiffusion resistancePorous carbon

The invention provides a method for preparing multi-level porous channel beta zeolite, and belongs to the technical field of preparation and application of the zeolite. The method is characterized in that: carbon grains which are generated under restriction of the sequent meso-porous channels are taken as a hard mold board, and added with a small molecular organic ammonium soft mold board to convert the meso-porous silicon-aluminum coating the carbon grain into the meso-porous beta zeolite in situ, and the meso-porous beta zeolite is calcined to remove the soft and hard mold boards so as to obtain the multi-level porous channel containing beta zeolite. Compared with the zeolite obtained by directly taking the meso-porous carbon as the mold board, the multi-level porous channel beta zeolite synthesized by the method does not need to remove the meso-porous silicon-aluminum first and then introduce the silicon-aluminum species synthesizing the zeolite, thereby reducing complicated working procedures as well as saving raw materials. The method has the advantages of greatly lowering diffusional resistance, reducing secondary reaction, and having better catalytic property and huge potential application values in fields such as petrochemical industry, fine chemical industry, and the like.

Owner:TAIYUAN UNIV OF TECH

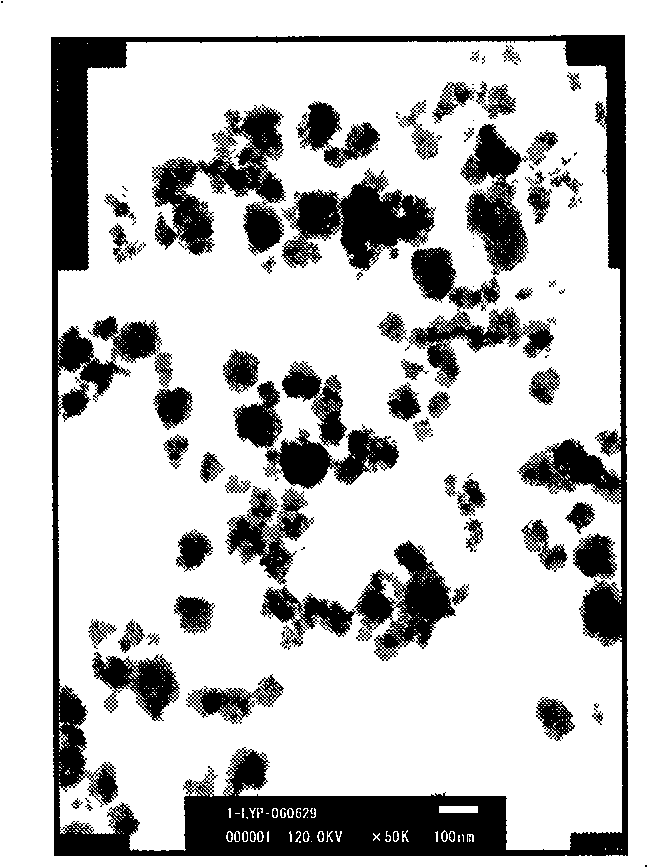

Process for preparing nano gold particle materal

InactiveCN1554503AImproved size distribution rangePrecise size controlPolyvinyl alcoholGold particles

The preparation process of nano gold particle material includes the following steps: preparing mixed water solution of HAuCl4, protecting agent and acetone in the weight ratio of 1 to 10-10000 to 100-1500, with the protecting agent being one of polyglycol, PVA and PVP; and irradiating the mixed water solution with ultraviolet ray of wavelength 254-400 nm to complete the reduction reaction to obtain nano gold particle. The said technological process is simple, and can produce pure nano gold particle with controllable size and narrow size distribution range. The produced nano gold particle may be used in biomedicine, electronic industry and fine chemical industry.

Owner:KUNMING INST OF PRECIOUS METALS

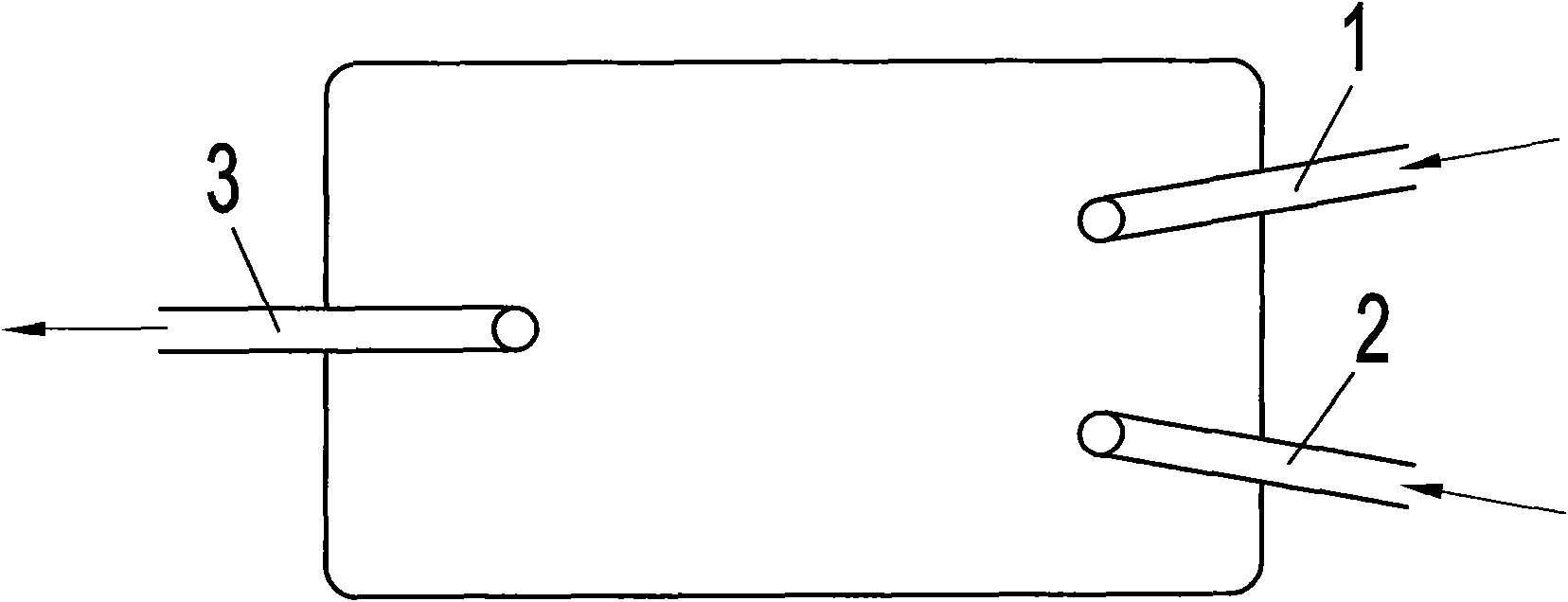

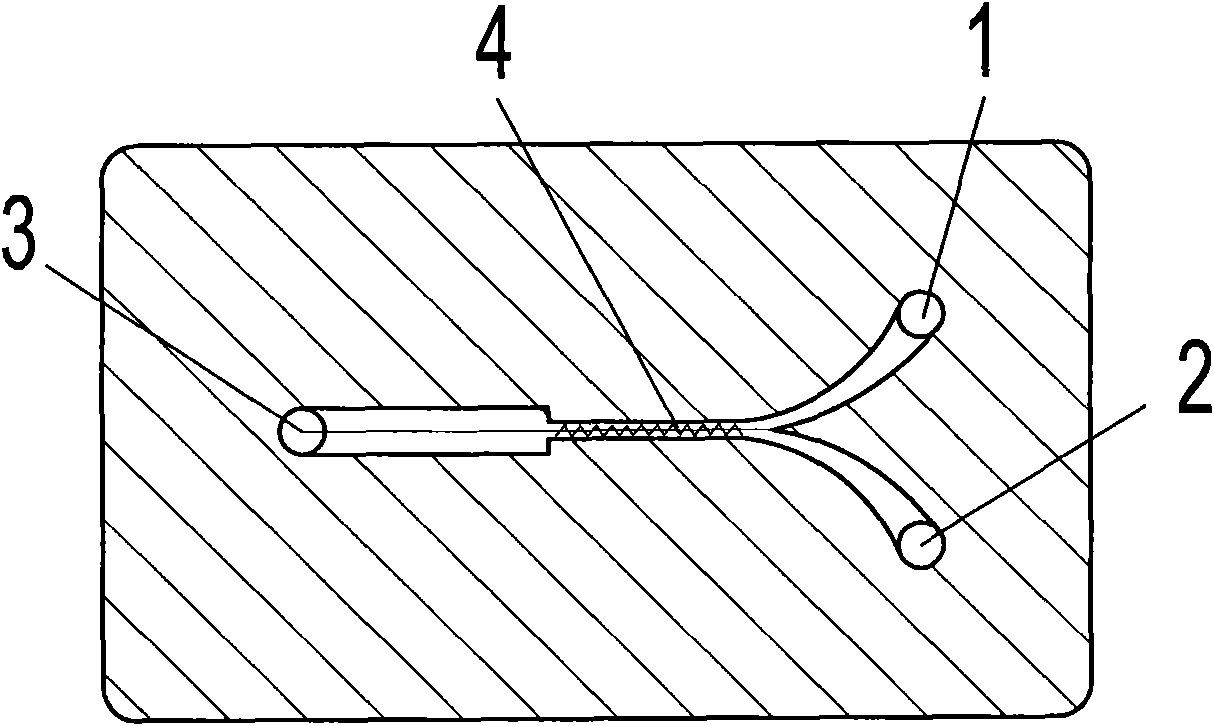

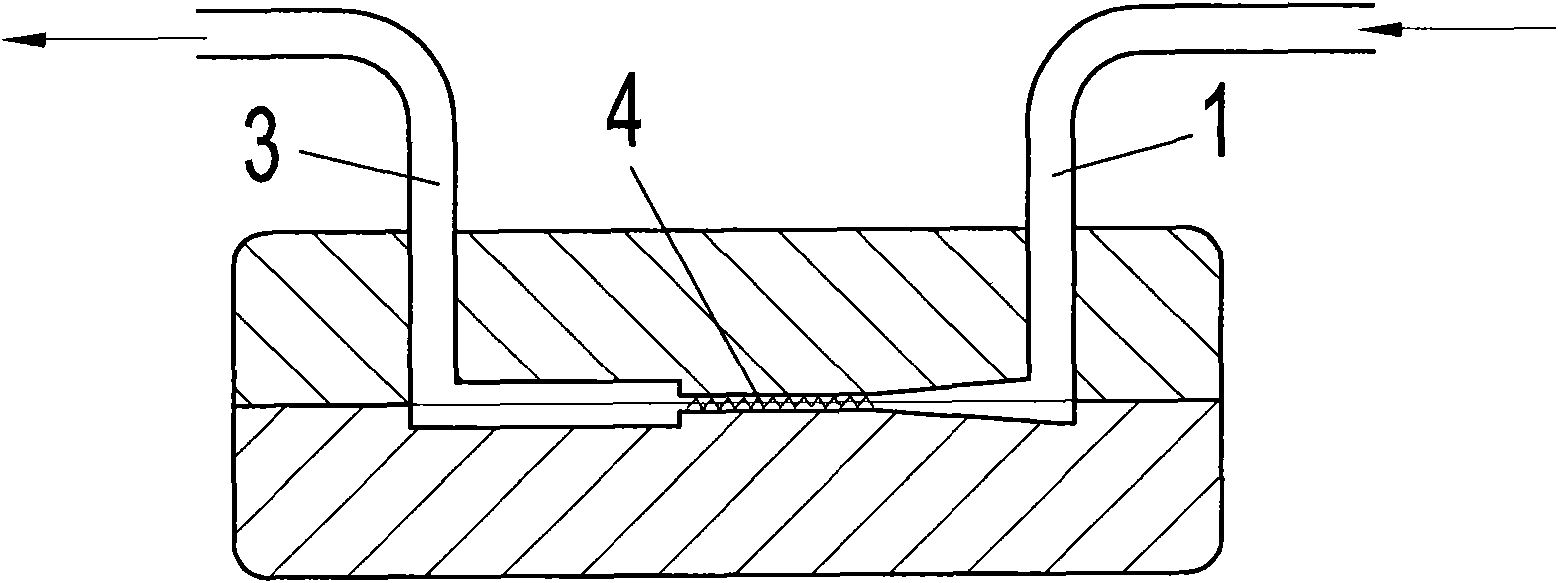

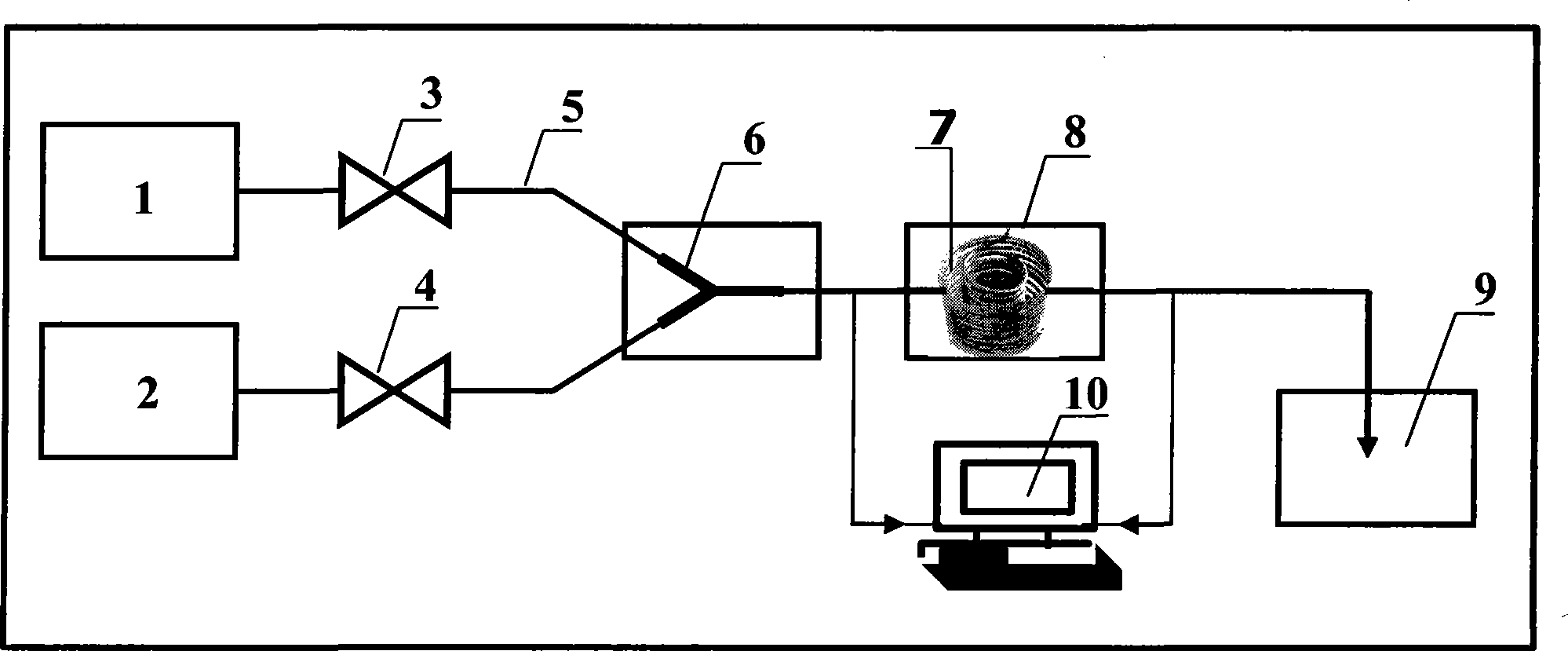

Continuous current micro-reactor and preparation method and use thereof

The invention relates to a continuous flow micro-reactor for medicine and fine chemical production and preparation and application thereof. The invention belongs to the technical field of the micro-reactor and preparation and application thereof. The reactor device consists of a liquor storage tank, a constant flow pump, a micro-mixer, serpentiform double helix capillary reaction pipes, an optical detector, a constant temperature bath and a connecting duct. The continuous flow micro-reactor is capable of making a reactant move back and forth continuously and spirally in the internal and external path coiled reaction pipes, thereby avoiding the phenomenon of local overheating for the reaction in the prior reactor vessel. The invention also provides a preparation method for the reactor and a method for synthesizing chalcone compounds through the reactor. The continuous flow micro-reactor has the advantages of compact structure, simple preparation, convenient use, high reaction efficiency, low power consumption, little pollution, and the like. The continuous flow micro-reactor can carry out continuous production and on-line tracking of the reaction process and has bright market prospect.

Owner:HAINAN UNIVERSITY

Cleaning agent for automobile

ActiveCN103725440AEasy to useSafe storageOrganic detergent compounding agentsNon-ionic surface-active compoundsSide effectAlcohol

The invention relates to a cleaning agent for an automobile, belonging to the field of automobile chemicals of fine chemical engineering. The cleaning agent comprises components of surfactant, alcohol washing aid, oily washing aid, additive and water. The surfactant and the oily washing aid play a role in promoting dissolving, dissolving and cleaning; the alcohol washing aid works together with the surfactant and the oily washing aid so as to form stable microemulsion and has certain role of permeating, moistening and dissolving; the surfactant, the oily washing aid and the alcohol washing aid work together so that the cleaning agent reaches good cleaning effect; the additive is functional additive. The cleaning agent has no side effects on cast iron, cast aluminum, leather, fabric, rubber and plastics, can effectively clean engines or interior trim surfaces, and has no phenomena of corrosion, decoloring, bubbling and falling off.

Owner:中国船舶集团有限公司第七一八研究所

Aqueous polyurethane and preparation thereof

The invention belongs to the technical field of fine chemicals and preparation thereof, and in particular relates to waterborne polyurethane and a preparation method thereof. In order to solve the problems of environmental pollution and non-ideal overall performance of the prior art, the invention adopts a technical proposal that the waterborne polyurethane is prepared by the method sequentially comprising the following: (1) a step of preparing polyurethane prepolymer, which is to take polyglycol and diisocyanate as raw materials for polymerization reaction and form the polyurethane prepolymer; (2) a step of performing chain extension reaction, which is to add hydrophilic chain extender and trimethylolpropane as a crosslinking agent to the polyurethane prepolymer so as to perform chain extension reaction; (3) a step of performing end capping reaction, which is to add organic functional silane to a reactor so as to perform end capping reaction; and (4) a step of emulsifying, which is to add organic base, regulate the pH value between 7.0 and 7.5, add deionized water in a state of stirring and obtain a white emulsion. Compared with the prior art, the preparation method has the advantages of eliminating pollution, and improving the overall performance of the product.

Owner:SHAANXI UNIV OF SCI & TECH

Disinsection mold-proof method with no effect on tobacco mellowing

InactiveCN101416771AThoroughly kills insects and mildewTobacco preparationPackaging under vacuum/special atmosphereNitrogenMildew

The invention belongs to the fine chemical field and especially provides a pest-killing and mildew-resistent method during tobacco leaf without affecting tobacco leaf alcoholization. The invention is characterized by adopting two steps to control the storing environment during tobacco leaf alcoholization process: the first step is sealing and packing tobacco leaves with plastic membranes, decreasing the volume percent of oxygen concentration to 0.01-4% with an oxygen-absorbing material or nitrogen, corbon dioxide or inert gas and sealing for 10-400 days; the second step is supplying oxygen or air into the sealing bag after completely killing pests and mould in the tobacco leaves to increase the volume percent of oxygen concentration in the bag to 4-40%, and storing for 10-700 days. the invention has advantages of completely killing pests and mould in the tobacco leaves without affecting tobacco leaf alcoholization, a good tobacco leaf alcoholization effect and a thorough pest-killing and mould-resistant effect.

Owner:UNIV OF SCI & TECH BEIJING

Ion exchange method for preparing lithium type low silicon aluminum X-shape zeolite molecular sieve

InactiveCN101125664AAvoid wastingOvercome shortcomings such as uneven exchangeFaujasite aluminosilicate zeoliteLithiumMolecular sieve

An ion exchange method for preparing lithium low-silicon low-aluminum X-type zeolite molecule sieve pertains to microporous material technique field. The invention is characterized in that: firstly, a sodium low-silicon low-aluminum X-type zeolite molecule sieve (Na-LSX) is endowed with a certain Li-ion exchange degree through the exchange of Li-ion water solution, then the lithium low-silicon low-aluminum X-type zeolite (Li-LSX) is obtained through a solid phase exchange method, and the Li-ion exchange degree of the final product is larger than 96 percent. Compared with the traditional ion exchange method, the method has the advantages of low cost, simple technique and thorough exchange, etc., and the prepared Li-LSX type zeolite molecule sieve has wide universal application potentials in the field of the fine chemical and absorption exchange, etc.

Owner:BEIJING UNIV OF TECH

Biogas residue humus pot, and preparation method and application of biogas residue humus pot

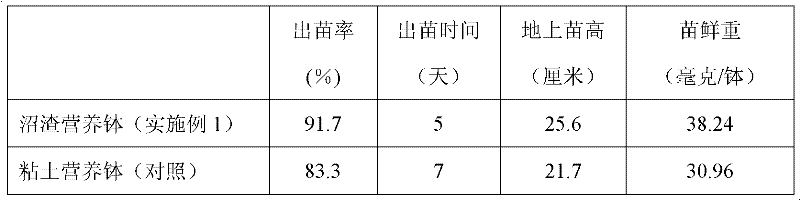

InactiveCN102440158AFull of nutritionComplete ingredientsClimate change adaptationCultivating equipmentsActive enzymeOrganic content

The invention discloses a biogas residue humus pot and a preparation method thereof. The biogas residue humus pot is made of 62.5-186.5 parts of fresh biogas residue, 50-150 parts of clay and 0.5-5 parts of cotton seed hulls or 1-18 parts of wheat straws or corn straws. The fresh biogas residue, the clay and the cotton seed hulls (or wheat / corn straws) are proportionally mixed well to obtain a mixture, the mixture is fed into a mould to be manually or mechanically pressed into an object with a rectangular or disc-shaped seeding hole in the middle, and the object is then stripped and naturally aired for 2-8 days or dried so as to obtain a biogas residue humus pot or seedling raising tray. The biogas residue humus pot is full of nutrients and high in organic content, further contains vitamins B, gibberellin, heteroauxin, amino acid and active enzymes, has fine chemical and biological properties, and meets conditions of compost. The biogas residue humus pot has the advantages of no environmental pollution, natural degradability, no need of stripping, simplicity in preparation, low cost, fastness in seedling raising speed, capability of enhancing seedlings, effectiveness and the like.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI

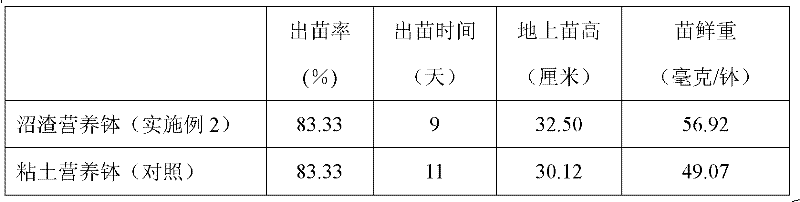

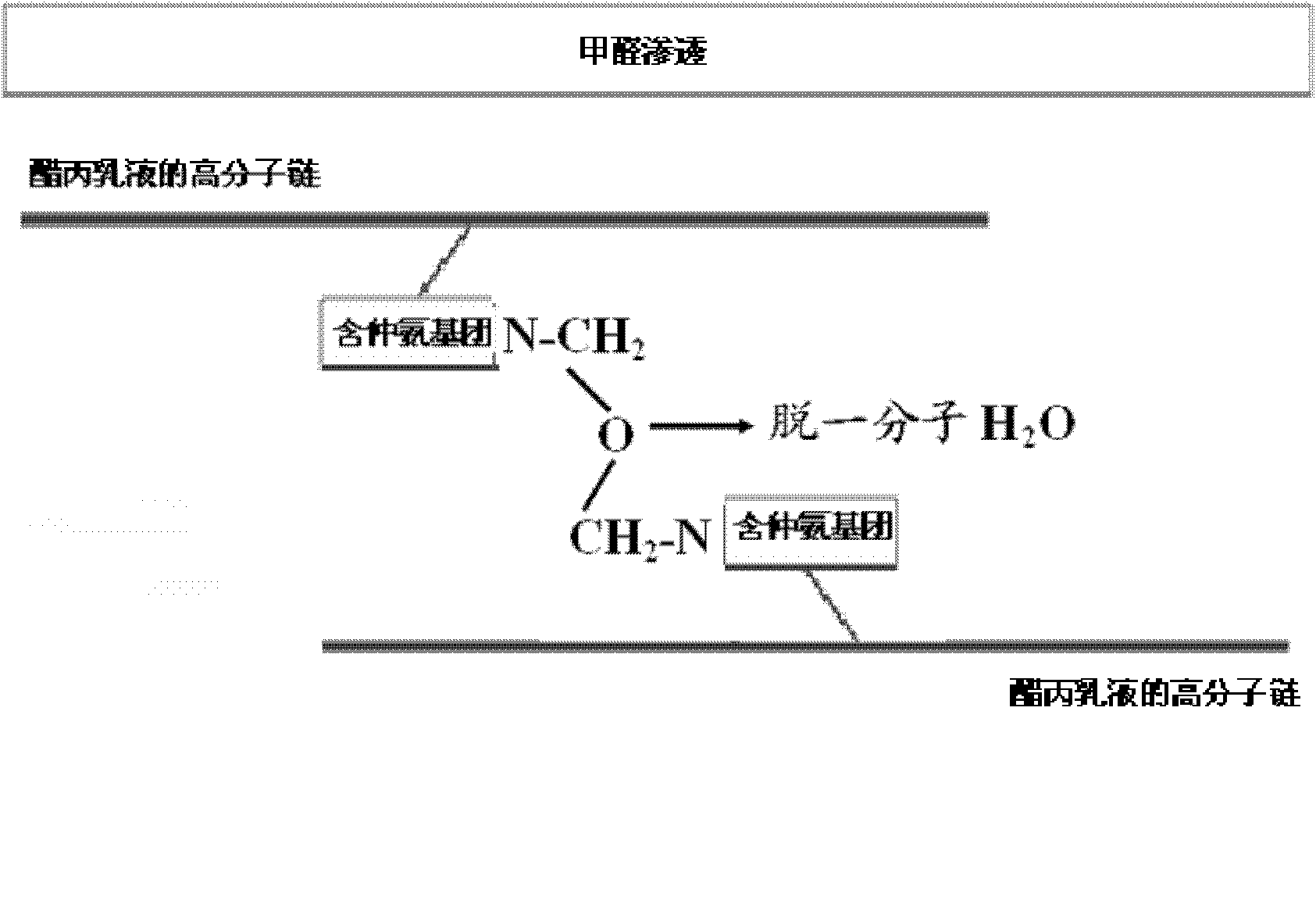

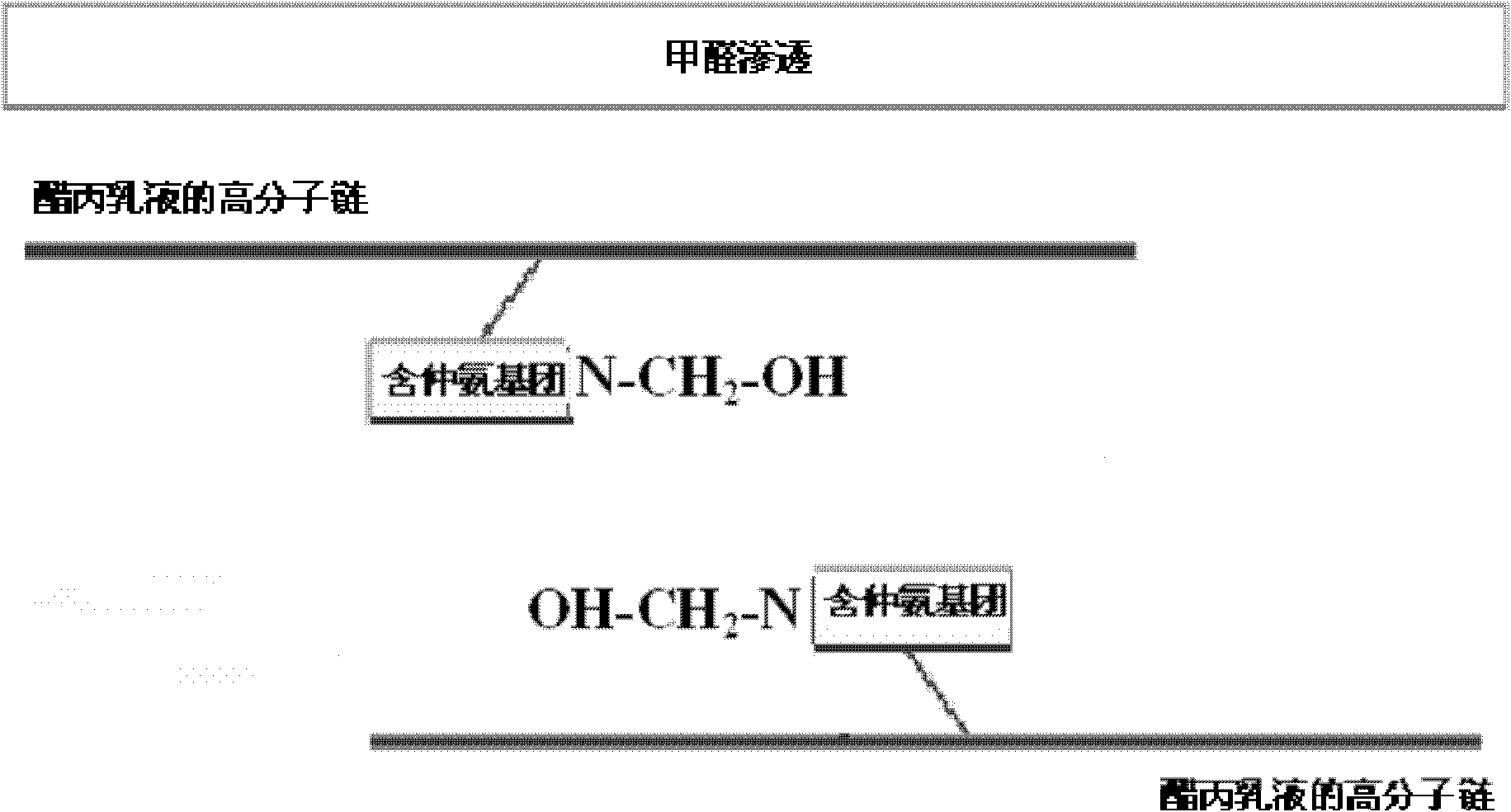

Inner wall latex paint

The invention relates to the field of fine chemical engineering, in particular to an inner wall latex paint. The inner wall latex paint comprises bamboo charcoal powder, photocatalyst, acetate-acrylic emulsion and auxiliary agents acceptable in the coating. The inner wall latex paint provided by the invention releases low formaldehyde and volatile organic compounds (VOC), and the quality of the inner wall latex paint accords with national standards; proved by experiments, the inner wall latex paint can effectively inhibit bacteria, the bacteria inhibiting rate is over 99.99 percent, and the formaldehyde removal rate is 93.05 to 97.06 percent; and the VOC removal rate of the inner wall latex paint is 52.73 to 72.11 percent, the removal rate of benzene is 53.15 to 73.26 percent, and the inner wall latex paint can constantly and effectively remove the formaldehyde and other VOC in the air.

Owner:中山市丽莎涂料有限公司

Preparation method of aqueous self-dispersing nanometer carbon black

ActiveCN106634059AGood dispersionSmall particle sizePigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsDouble bondSolvent

The invention discloses a preparation method of aqueous self-dispersing nanometer carbon black, and belongs to the field of fine chemical engineering. Silane coupling agents containing carbon-carbon double bonds are grafted on the surface of carbon black; polymerizable groups of the silane coupling agents are used for being copolymerized with other aqueous monomers; a layer of polymers with duplex effects of dispersion and stabilization coats the surface of the carbon black particles, so that the goal of self dispersion in an aqueous solvent is achieved.

Owner:JIANGNAN UNIV

Method for producing iron oxide black

This is the producing method of a kind of oxidized iron oxide black including following contents: prepare ferrite watery solution; use sodium hydroxide as neutralizaing agent and react with ferrite watery solution to produce hydroxide ferrous; use oxygenous gas as oxidant, and react with said hydroxide ferrous to produce iron oxide black; make the prepared iron oxide black water washed, sieved, dried and comminuted orderly to get blue oxidized iron oxide black pigment product. The oxidized iron oxide black produced by this method has high purity and thin crystal grain, the grain size of produced pigment is thin and even, and has saturated blue ink light black and stable effect to light and atmosphere. It also has strong pigmentation strength and hiding power, and can be used in such fine chemical industry products as printing ink and carbon powder. The farther project is using waste residue containing ferrous sulfate and vented in titanium oxide powder production, to produce ferrous sulfate watery solution and produce oxidized iron oxide black, which can adequately use industry waste material to produce oxidized iron oxide black products of high quality, and reduce environmental pollution.

Owner:HUBEI WANRUN NEW ENERGY TECH DEV

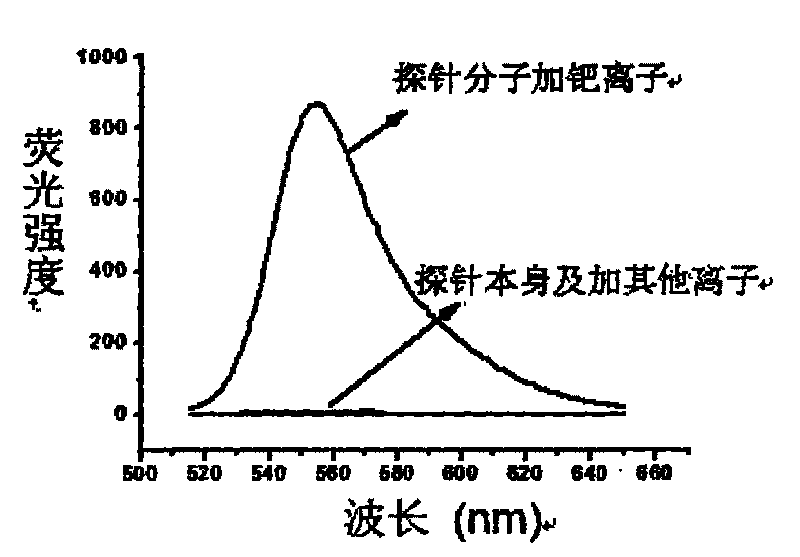

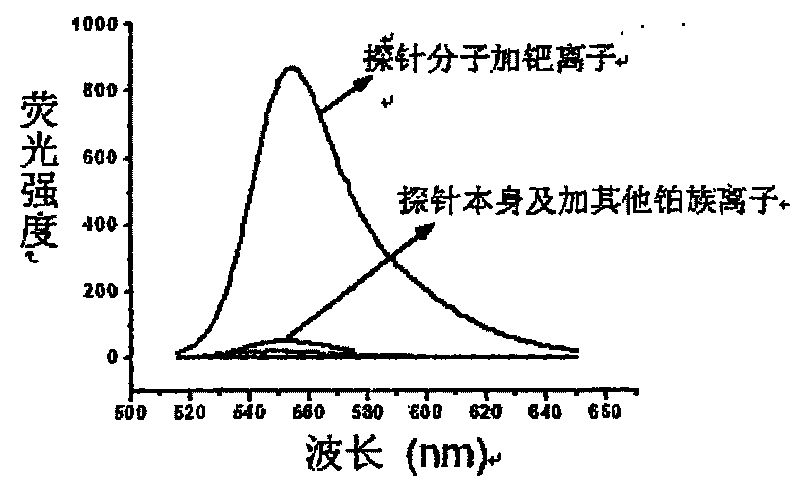

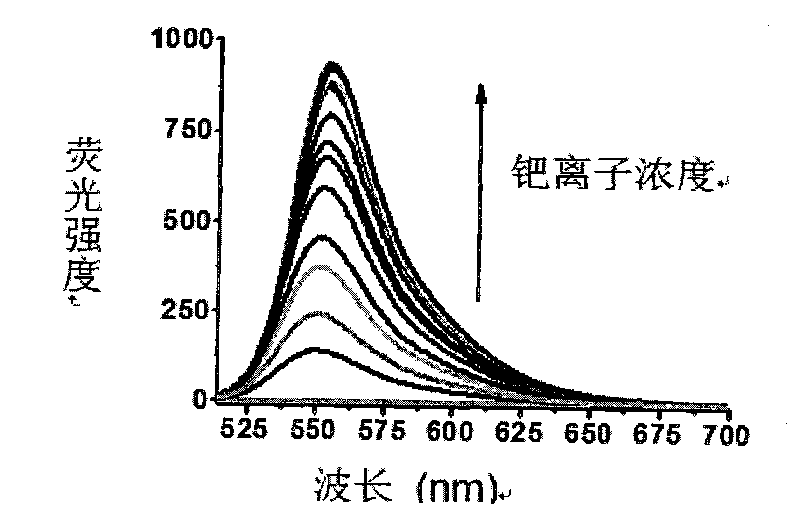

Fluorescent probe compounds, preparation method and use thereof

InactiveCN101735277AHigh detection sensitivityGood choiceGroup 5/15 element organic compoundsAnalysis by subjecting material to chemical reactionLinear relationshipLinearity

The invention provides fluorescent probe compounds, a preparation method and use thereof, belonging to the detection of palladium ions in the field of fine chemical industry. The fluorescent probe compounds designed on the basis of the 'opening-closing' property of the spiral ring in the molecule of a rhodamine luminescent dye well solve the difficult problem that the palladium ions quench fluorescence. The excitation wavelength and the emission wavelength of the probe compounds are both in a visible light region. The compounds have excellent selectivity to the palladium ions in the practical detection range of nearly neutral pH and have excellent sensitivity. The fluorescence is obviously enhanced in the process of detecting the palladium ion concentration of 0-10ppb, an excellent linear relationship between the palladium ion concentration and the fluorescence enhancement is formed, and the palladium ions of 5nm can be detected at lowest. The probe compounds have extremely quick response for distinguishing the palladium ions and are the reported palladium ion probes with the shortest response time so far. The probe compounds can be used for realizing the detection of the palladium ions in the two manners of fluorescent light and color comparison, and has potential application value in the detection of palladium pollution and residual level in medicines, water samples, soils and catalytic reactors.

Owner:DALIAN CHROMAS BIOSCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com