Patents

Literature

74805results about How to "Good dispersion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aqueous emulsion polymerization of fluorinated monomers using a perfluoropolyether surfactant

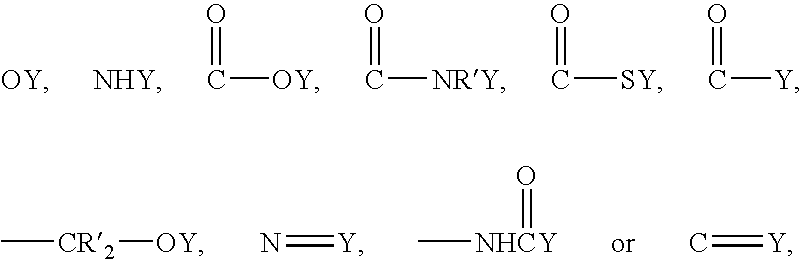

The invention relates to an aqueous emulsion polymerization of fluorinated monomers using perfluoropolyethers of the following formula (I) or (II). In particular, the perfluoropolyether surfactants correspond to formula (I) or (II) CF3—(OCF2)m—O—CF2—X (I) wherein m has a value of 1 to 6 and X represents a carboxylic acid group or salt thereof, CF3—O—(CF2)3—(OCF(CF3)—CF2)z—O-L-Y (II) wherein z has a value of 0, 1, 2 or 3, L represents a divalent linking group selected from —CF(CF3)—, —CF2— and —CF2CF2— and Y represents a carboxylic acid group or salt thereof. The invention further relates to an aqueous dispersion of a fluoropolymer having the aforementioned perfluoropolyether surfactant(s).

Owner:3M INNOVATIVE PROPERTIES CO

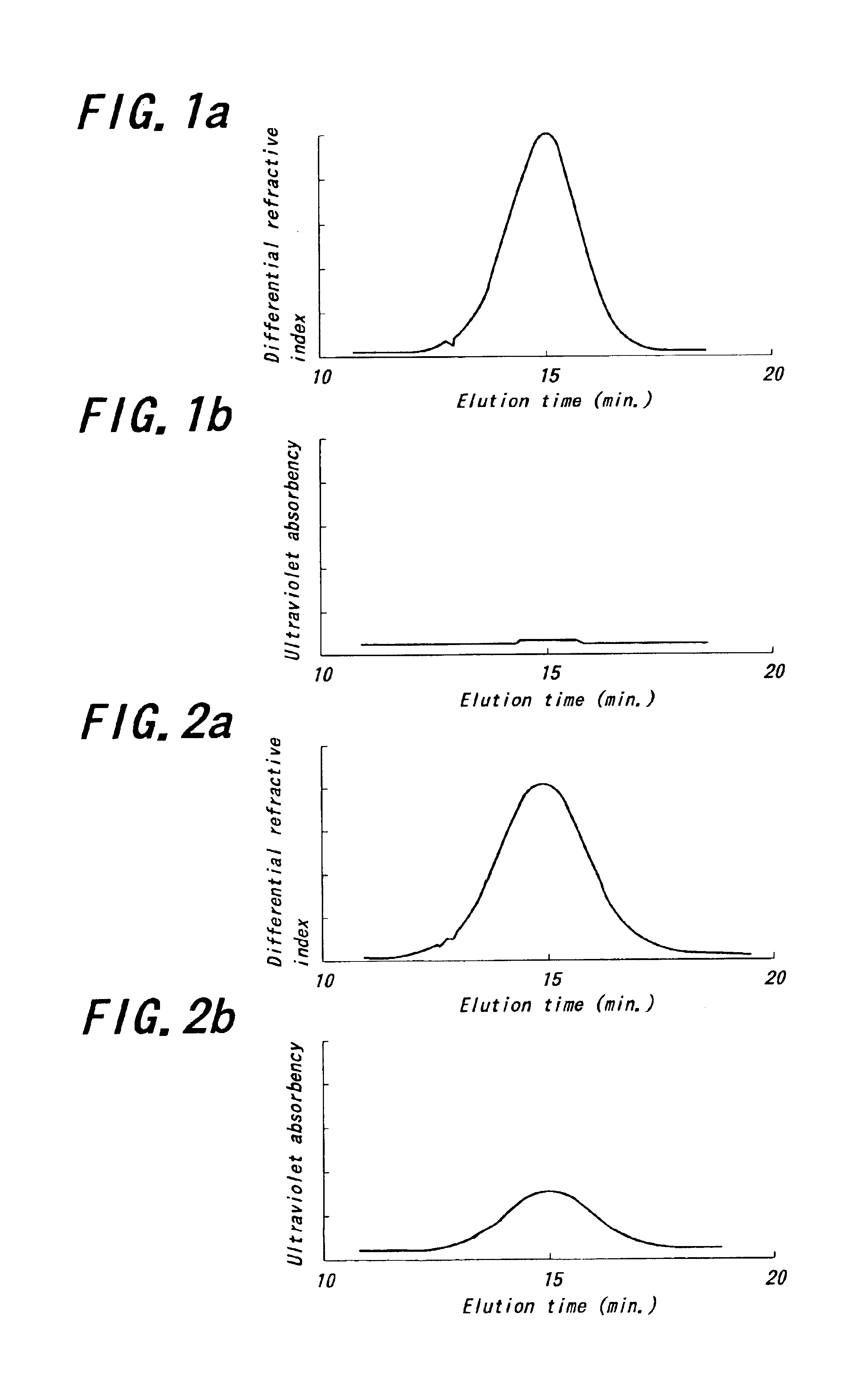

Water-dispersable materials

InactiveUS6211309B1Increase flexibilityGood dispersionMonocomponent polyesters artificial filamentMonocomponent polyamides artificial filamentThermoplasticFiber

The present invention relates to water-dispersible materials (e.g. fibers or films) and to a method of producing same. The materials of the invention comprise a water soluble component, for example, a sulfonated polycondensate thermoplastic, and a modifying auxiliary component, for example, a low melt temperature thermoplastic.

Owner:BASF CORP

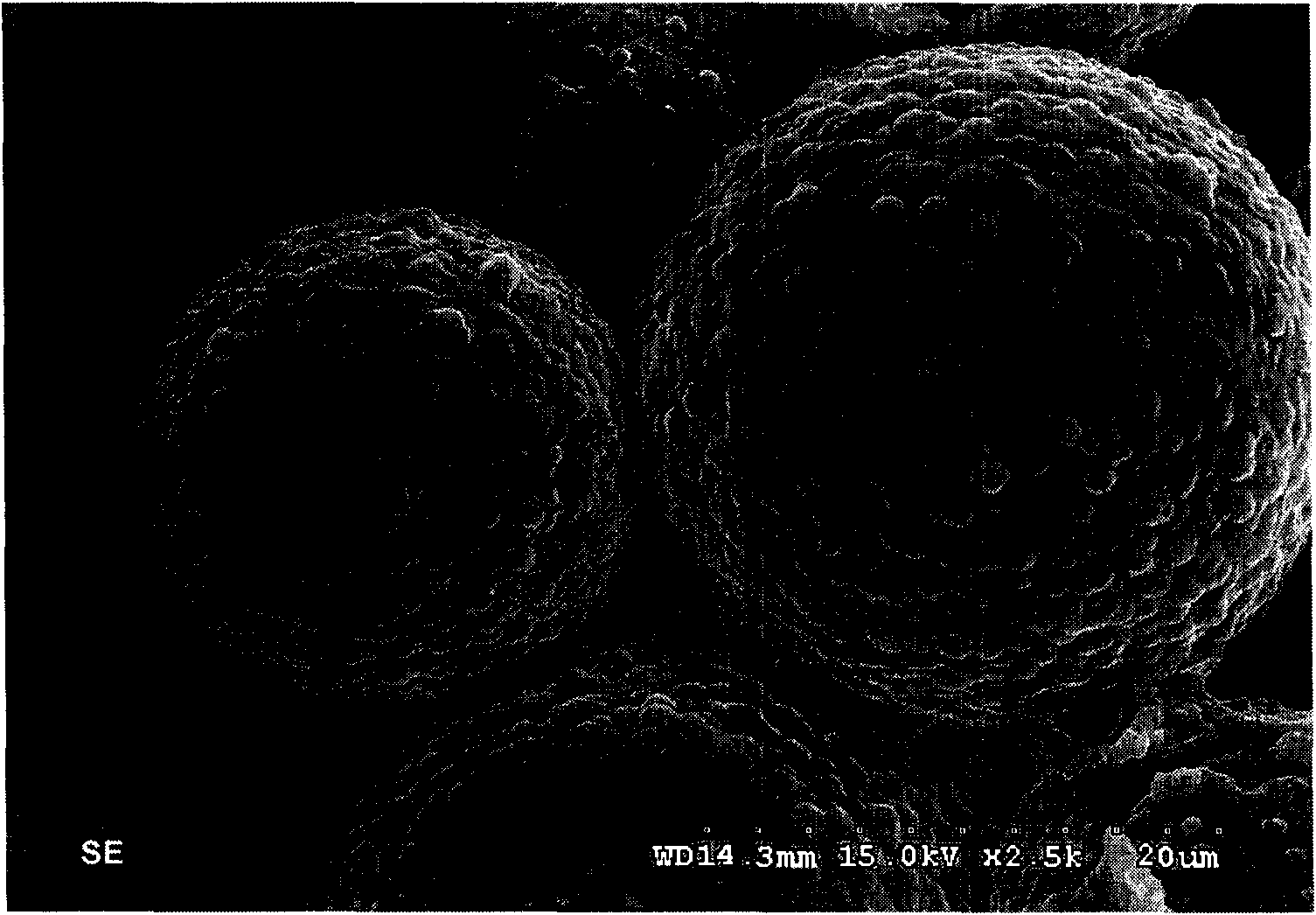

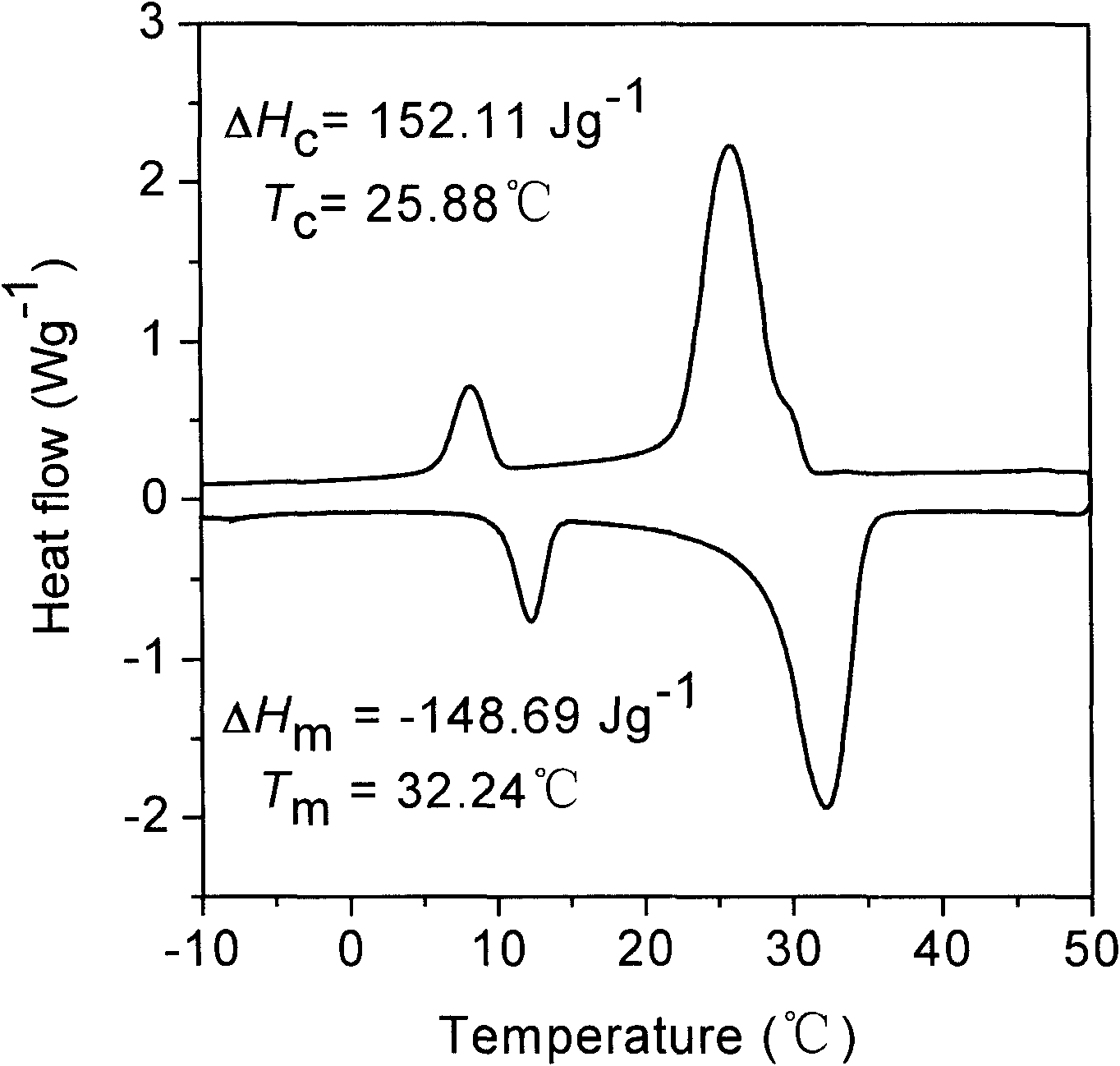

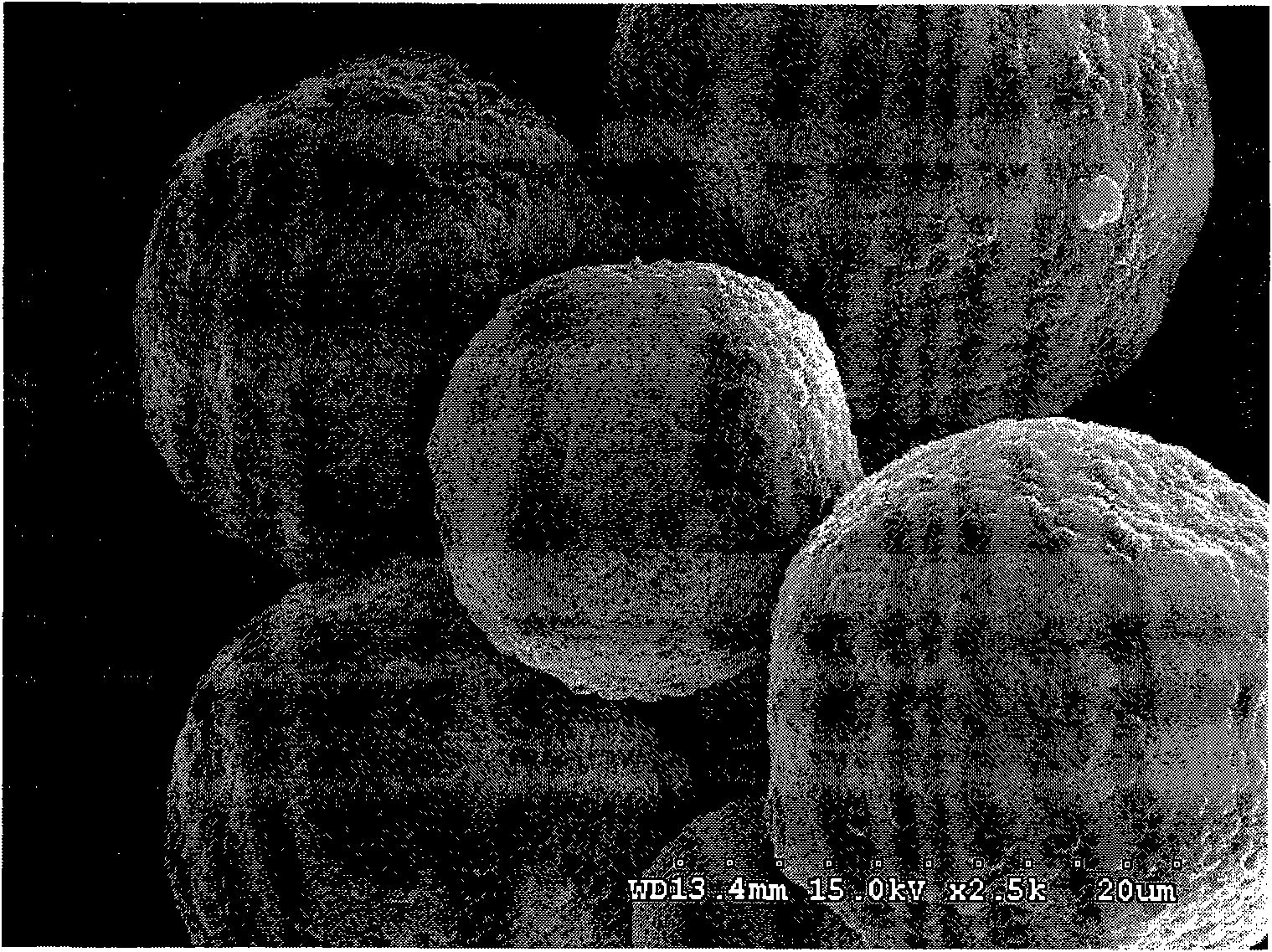

Microcapsule of organic phase change energy storage material and preparation method thereof

ActiveCN101555401AHas infrared reflective propertiesHas infrared absorption propertiesEnergy storageHeat-exchange elementsChemistryIn situ polymerization

The invention discloses a microcapsule of an organic phase change energy storage material and a preparation method thereof. The microcapsule of an organic phase change energy storage material comprises a core and a nucleocapsid, wherein the material of the core comprises the organic phase change energy storage material; the nucleocapsid at least comprises an inner layer and an outer layer, the inner layer is packaged by any one of an in situ polymerization method, an interface polymerization method, a reaction phase separating method, a double agglomeration method and a sol-gal process, and the outer layer is packaged by any one of an in situ polymerization method, a reaction phase separating method, a sol-gal process and a double agglomeration method. The microcapsule has adjustable size, nucleocapsid composition and shell thickness, favorable flexibility, mechanical strength, penetrability resistance and dispersibility and can be widely applied to the fields of energy sources, materials, aero-space, textile, electric power, medical apparatus, architecture, and the like, such as solar utilization, industrial afterheat and waste heat recovery, architecture energy storage, dress with constant temperature, air conditioners for cool and heat accumulation, constant temperature of electric appliances, and the like.

Owner:BEIJING NEW BUILDING MATERIAL

Modified conjugated diene polymer and method of producing the same and rubber composition

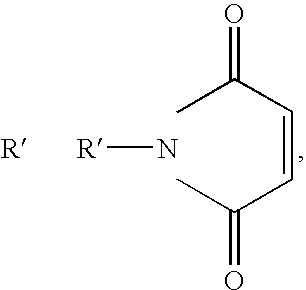

A novel modified conjugated diene polymer is obtained by polymerizing a conjugated diene compound with a specified catalyst consisting of components (a)-(c) and then reacting with at least one specified compound selected from the group consisting of components (d)-(l), and has a content of cis-1,4-bond of not less than 85% and a ratio of weight average molecular weight to number average molecular weight of not more than 4. And also, a rubber composition comprises the modified conjugated diene polymer a rubber ingredient.

Owner:JSR CORPORATIOON +1

Precursor compositions for the deposition of electrically conductive features

InactiveUS6951666B2Reduce settlementGood dispersionRadiation applicationsConductive materialElectrically conductiveCopper metal

A precursor composition for the deposition and formation of an electrical feature such as a conductive feature. The precursor composition advantageously has a viscosity of at least about 1000 centipoise and can be deposited by screen printing. The precursor composition also has a low conversion temperature, enabling the deposition and conversion to an electrical feature on low temperature substrates. A particularly preferred precursor composition includes silver and / or copper metal for the formation of highly conductive features.

Owner:CABOT CORP

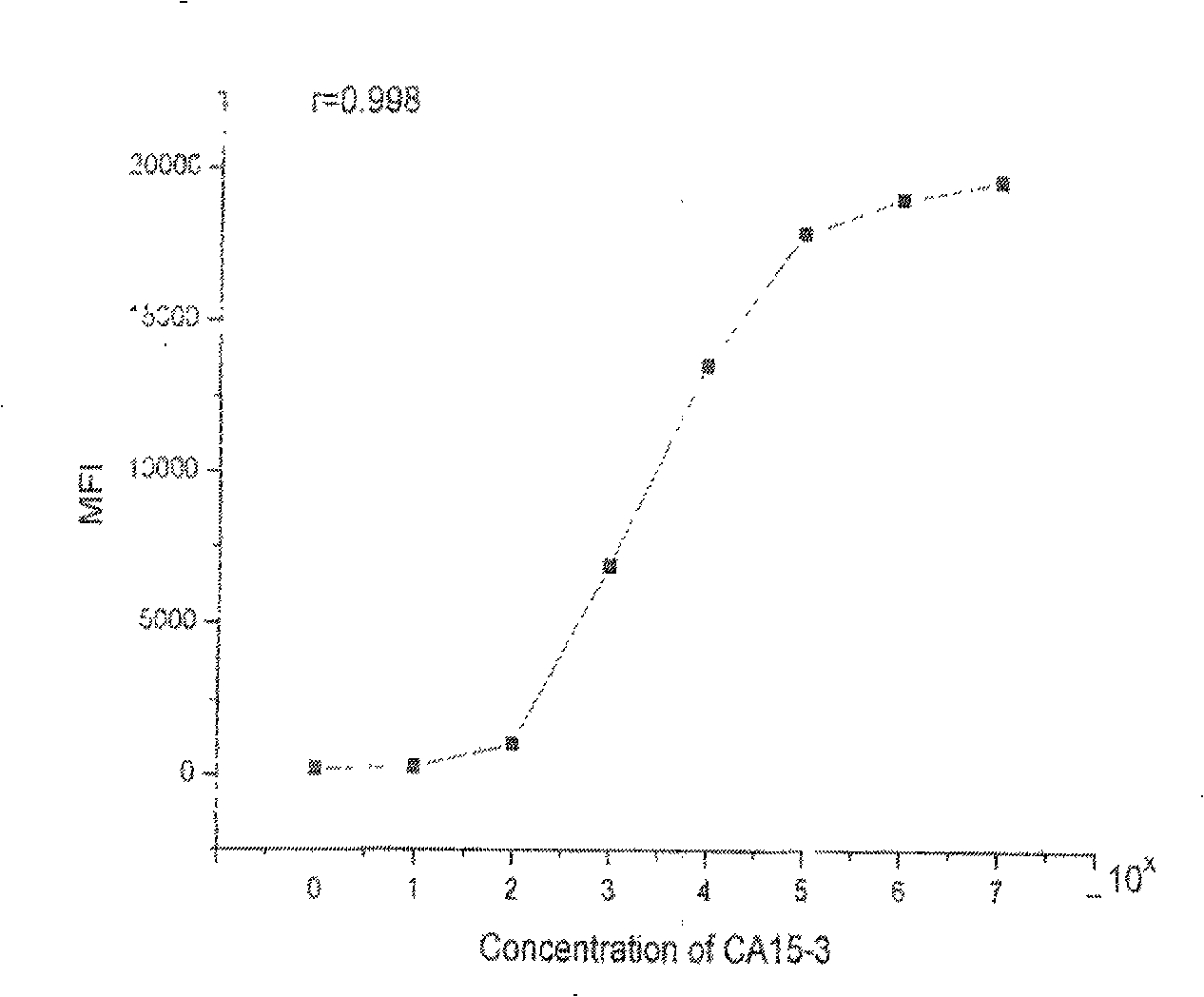

Liquid phase chip for joint detection of multiple tumor markers and preparation method thereof

The invention relates to a liquid phase chip for joint detection of multiple tumor markers and a preparation method thereof. The liquid phase chip comprises micro-balloons of a coupled antibody (at least two of the followings: AFP, CEA, CA125, CA153, CA19-9, CA242, CA72-4, PSA, HGH, Beta-HCG), corresponding biotin-labeled detection antibodies, streptavidin phycoerythrin and vegetable hydrosol or polysaccharide hydrosol which has a solute content of 1-10 wt per thousand and does not contain protein. The preparation of the liquid phase chip comprises refining and purification of hydrosol, coupling between captured antibodies and micro-balloons, preparation of biotin-labeled antibodies, dispersing the coupled micro-balloons into the vegetable hydrosol or the polysaccharide hydrosol, and the like. The liquid phase chip has the advantages of stable performance, good micro-balloon dispersivity, long preservation time, fast and convenient use and operation, small amount of samples in use, high detection sensitivity, wide linear scope and low detection cost, can detect ten tumor markers at most at one time, and requires a cost which is a quarter of the total fee of conventional methods.

Owner:HENAN YUKANG BIOTECH

Stable glassy state powder formulations

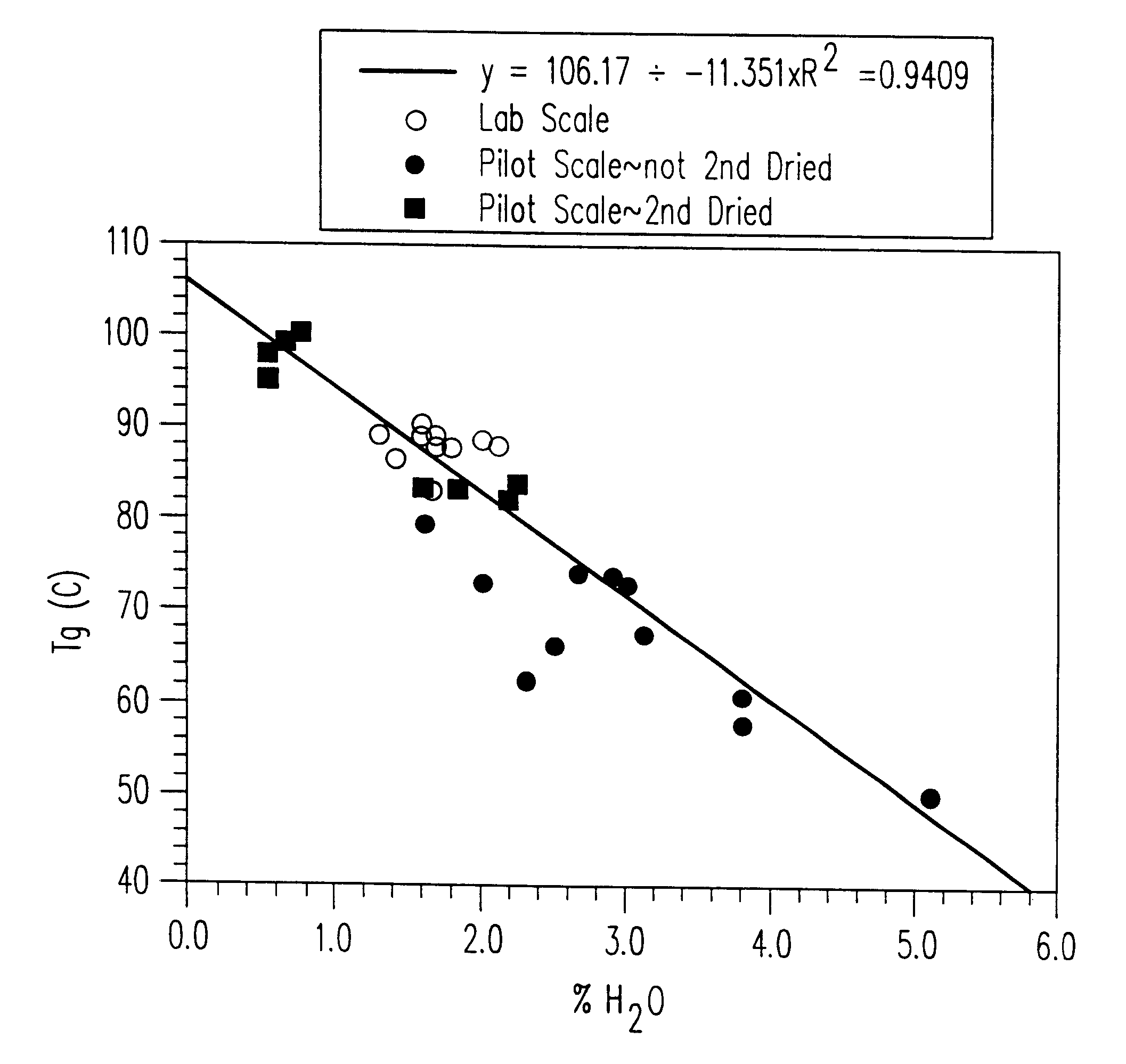

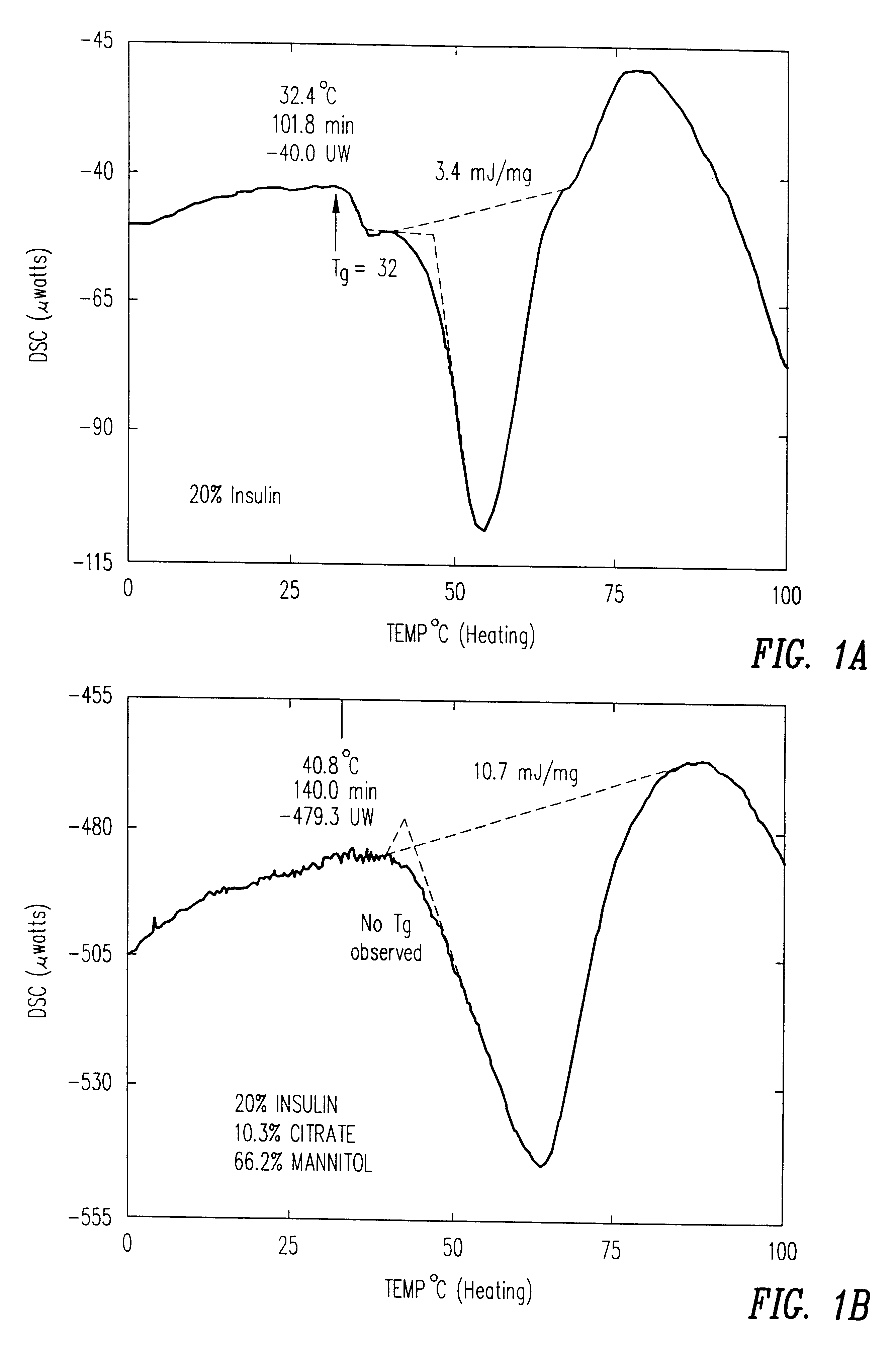

InactiveUS6309671B1Good dispersionGood dispersibilityPowder deliveryPeptide/protein ingredientsSolventChemistry

A powdered, dispersible composition having stable dispersibility over time is provided. The composition exhibits a characteristic glass transition temperature (Tg) and a recommended storage temperature (Ts), wherein the difference between Tg and Ts is at least about 10° C. (i.e. Tg-Ts is greater than 10° C.). The composition comprises a mixture of a pharmaceutically-acceptable glassy matrix and at least one pharmacologically active material within the glassy matrix. It may be further mixed with a powdered, pharmaceutically-acceptable carrier. It is particularly valuable in unit dosage form having a moisture barrier, in combination with appropriate labelling instructions. A process for producing a powdered dispersible composition is also provided, wherein the process comprises removing the solvent from a solution comprising a solvent, a glass former and a pharmacologically active material under conditions sufficient to form a glassy matrix having the pharmacologically active material within the matrix.

Owner:NOVARTIS FARMA

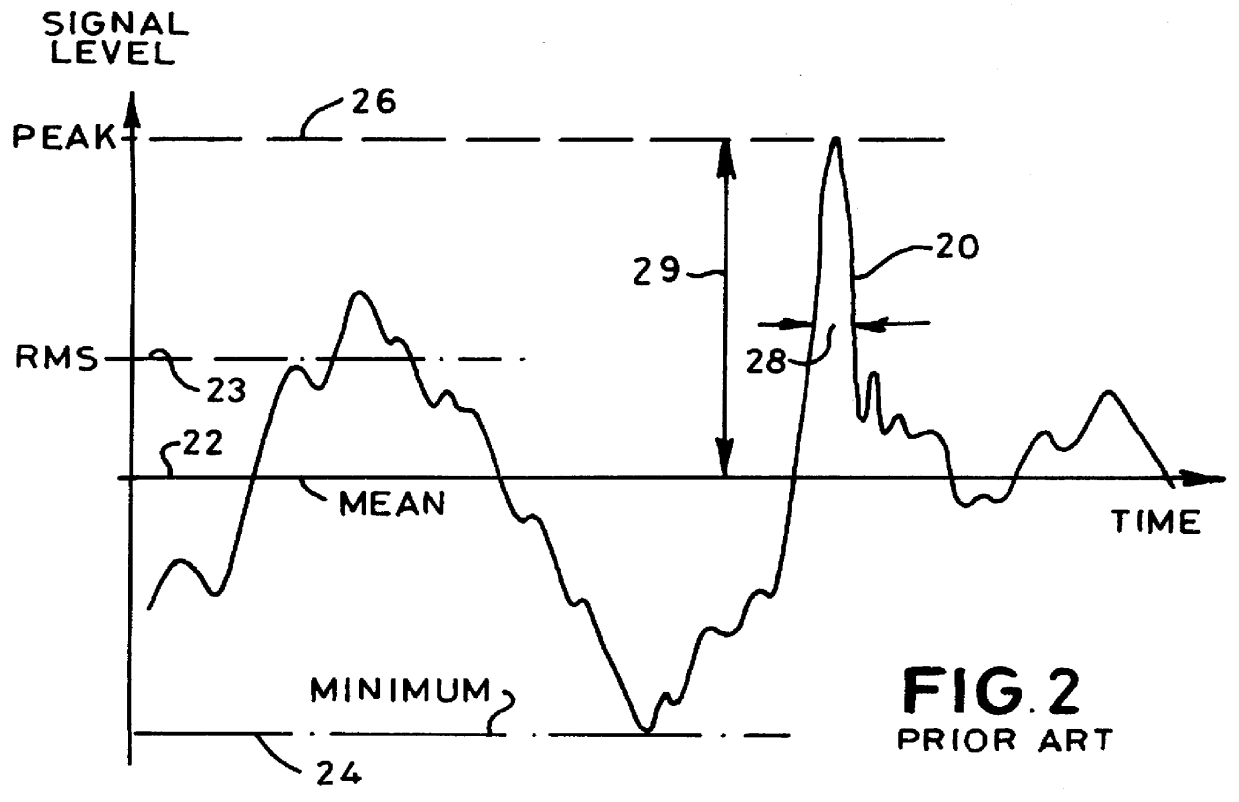

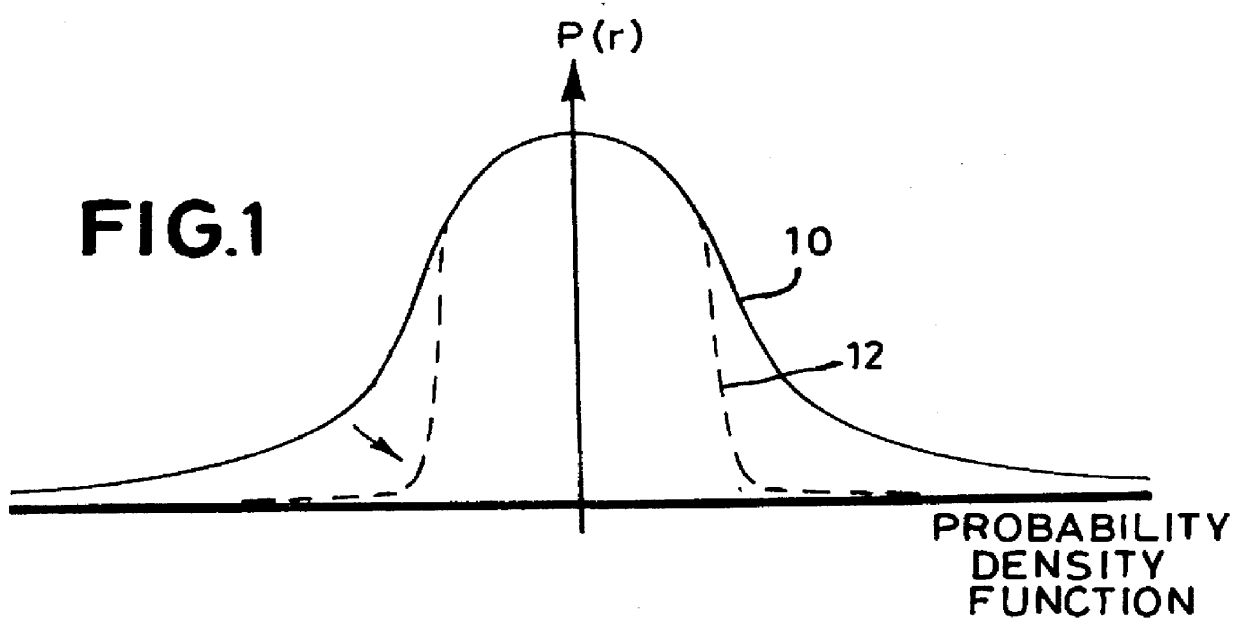

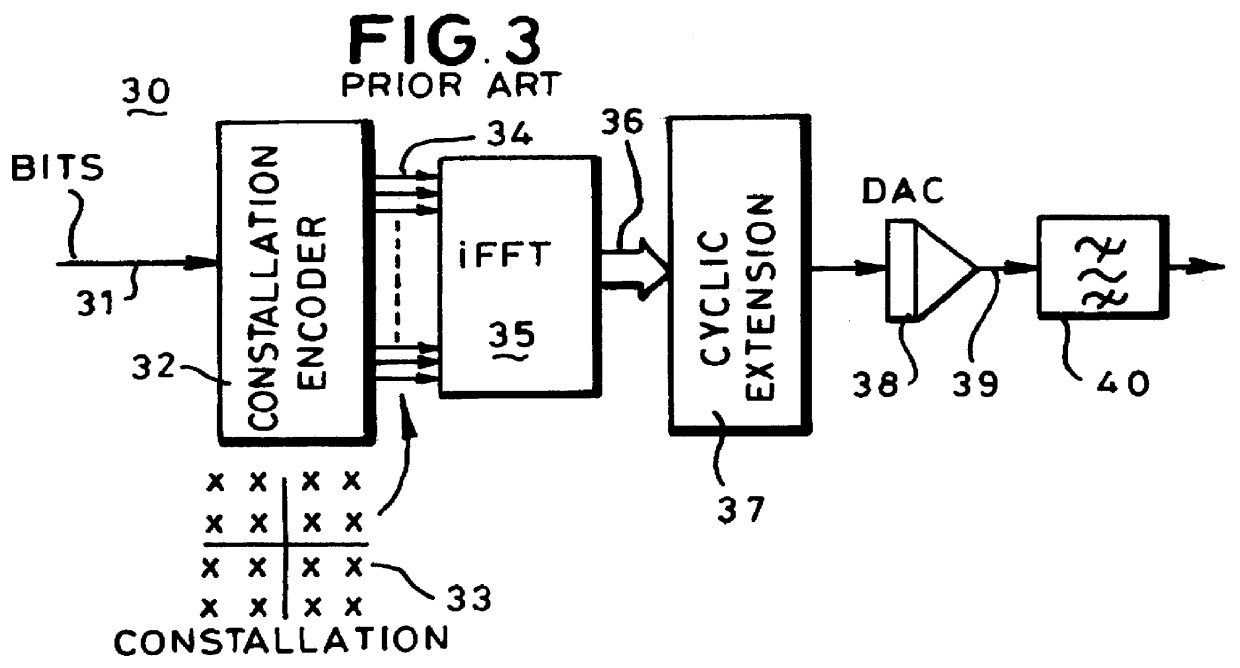

Method and apparatus for reducing the peak-to-average ratio in a multicarrier communication system

InactiveUS6130918AReduce impactGood dispersionAmplitude-modulated carrier systemsMulti-frequency code systemsTime domainData set

A reduction in a peak-to-mean envelope power ratio of a multicarrier signal, represented as a time domain signal, is achieved by applying (76) an offset, indicative of a difference (74) between a mean signal level and a midpoint level of the time domain signal, to the time domain signal. Alternatively, constellation values of positive and negative frequency components are modified by differing functions to produce a modified data set. Preferably, the negative frequency components are set to a predetermined value (namely zero (124)) to provide an alternate coding scheme Once the multicarrier signal has been converted into a time domain representation, real and imaginary parts (126-128) of the modified data set that consequently only contain positive frequency components and zeros are compared with one another to identify (130) which of the real and imaginary parts has a lower peak-to-average signal ratio (134) for the time domain representation. Then, based upon which of the peak-to-average signal ratios is lowest (136), either the real and imaginary part of the time domain signal is selected for subsequent transmission (138).

Owner:RPX CLEARINGHOUSE

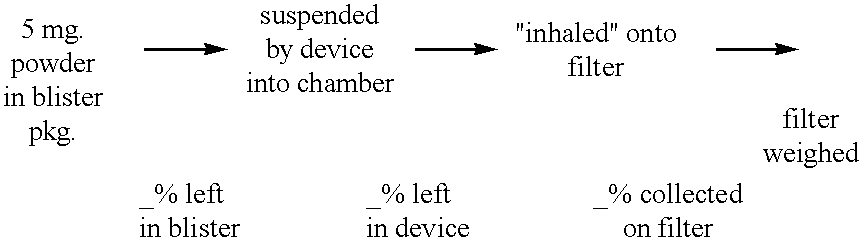

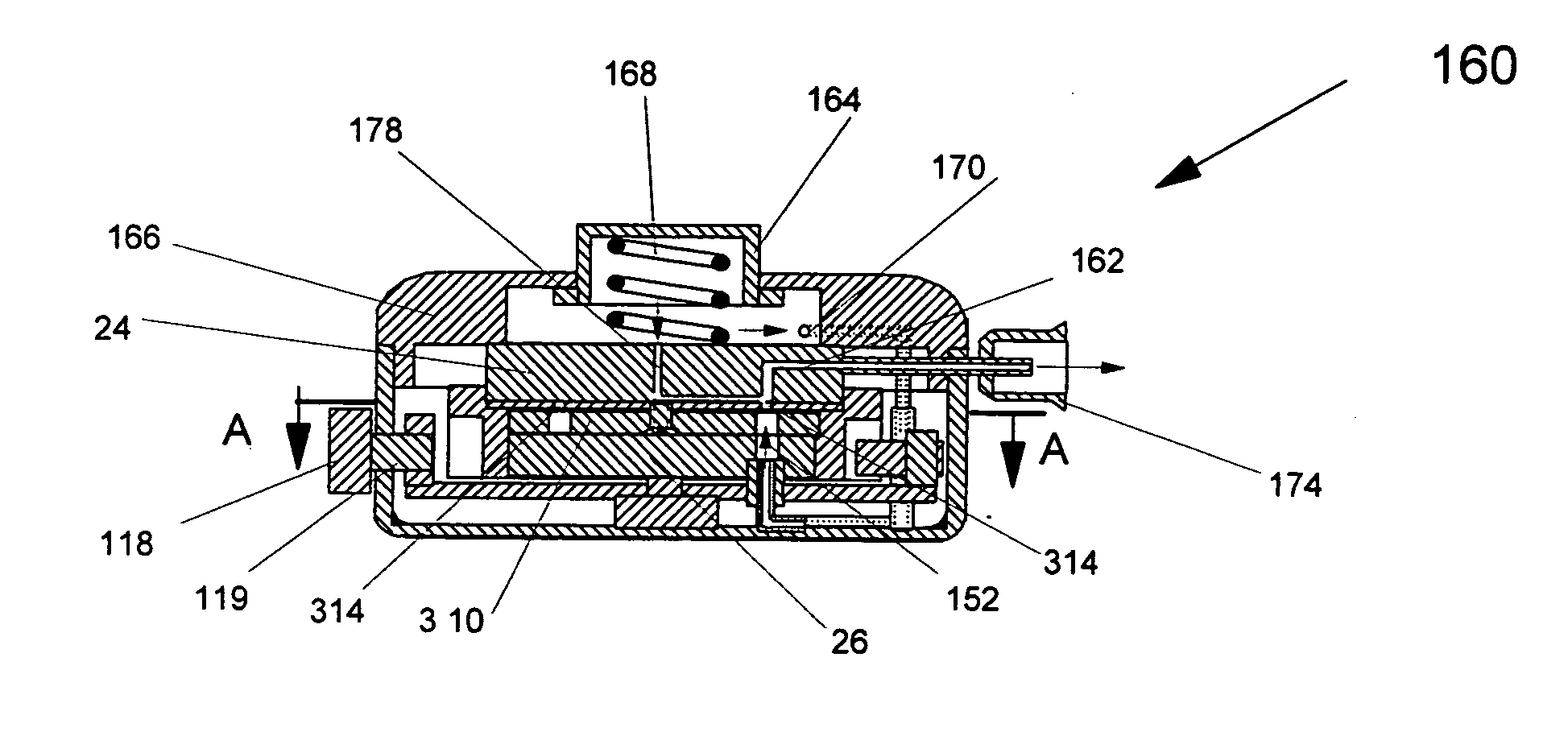

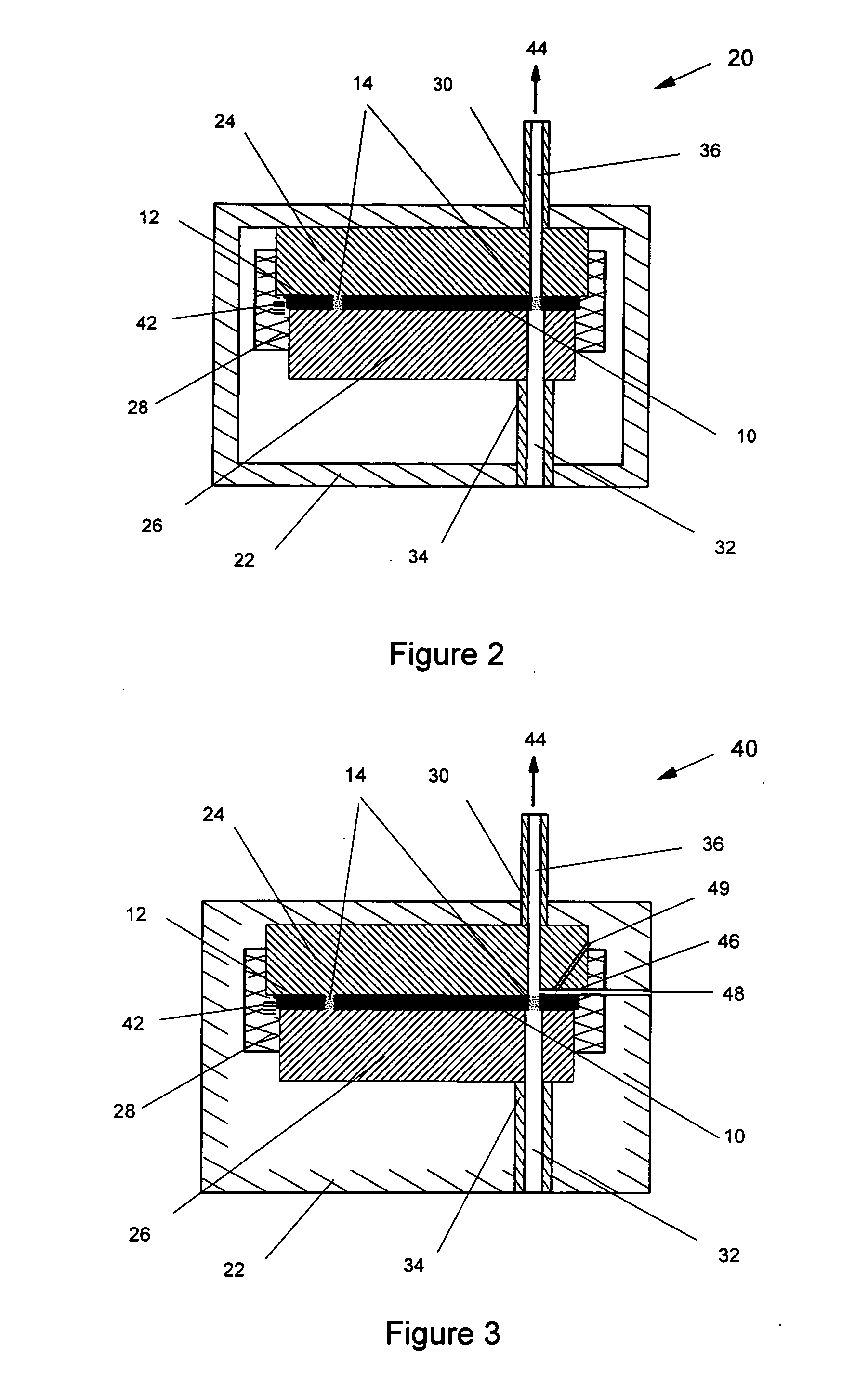

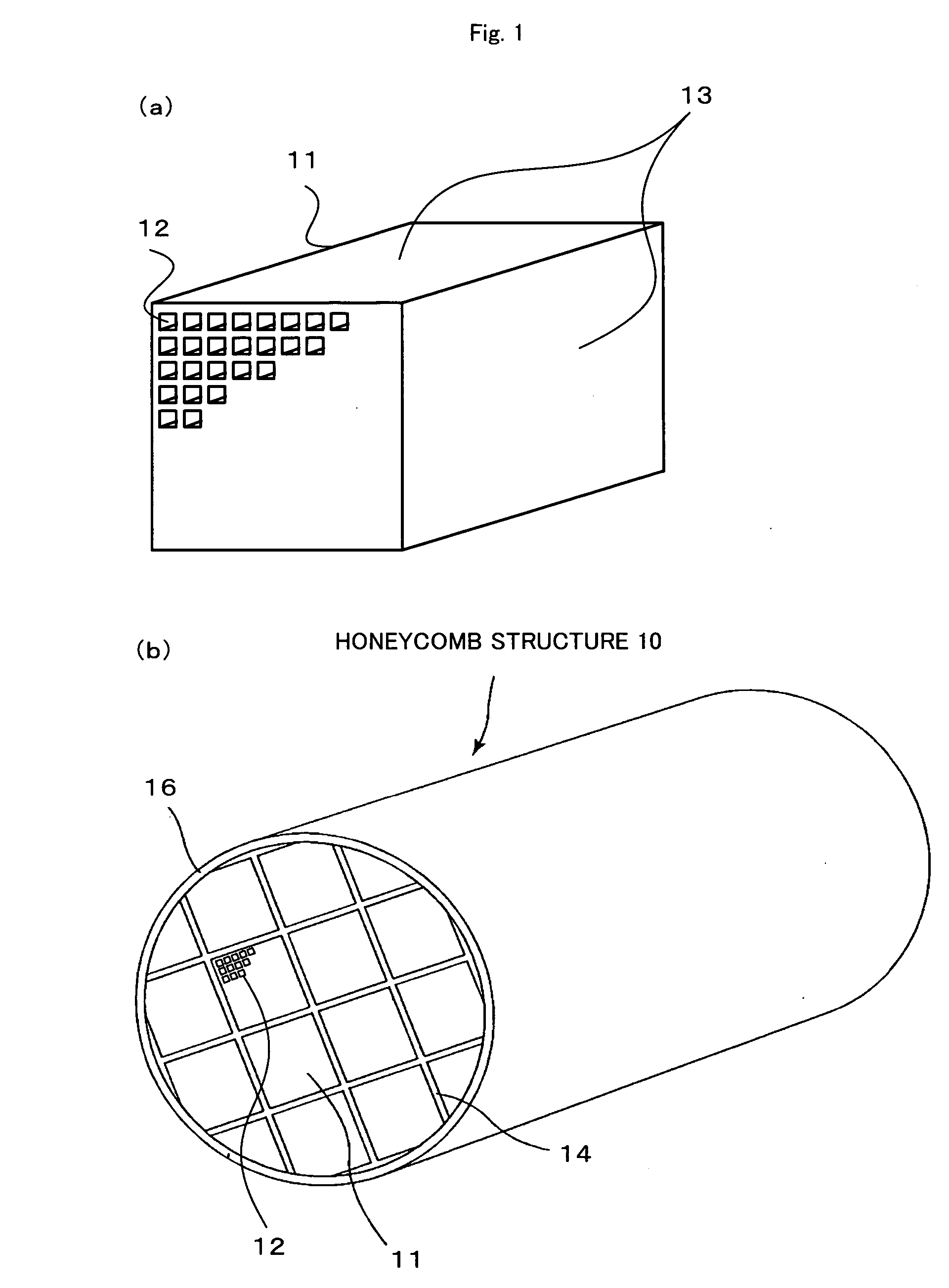

Dry powder inhaler

ActiveUS20070235029A1Small accurate volumePrecise deliveryRespiratorsLiquid surface applicatorsMicroDoseAerosolize

A new dry powder inhaler is developed as a pulmonary medicine delivery device for dispersing precise tiny dosages (10 μg-50 mg) of pure carrier-free ultra-fine powdered medicament (<5 μm aerodynamics particle size) into a patient's lung. The powder is drawn from the blister cell and dispersed through an outlet tube assisted by two air streams. The first air stream goes through a the blister cell from its upstream side, to significantly fluidize the medicament in the dose to flow upward. The second one extracts the fluidized powder from downstream of the blister cell for further deagglomeration and dispersion of the medicament powder by shear force. The rotating multi-dose blister can hold up to 60 doses, which are pre-metered with pure ultra-fine powdered medicament. So that it has higher drug loading capability in small volumes, compared to most current dry powder inhalers, which usually use some excipient. The inhaler efficiently disperse the aerosolized medicament in the air stream to the deep interior of patient's lung. The fine particle fraction (<4.7 μm) is reported to reach as high as 80% using this inhaler.

Owner:NINGBO INHAL PHARMA CO LTD

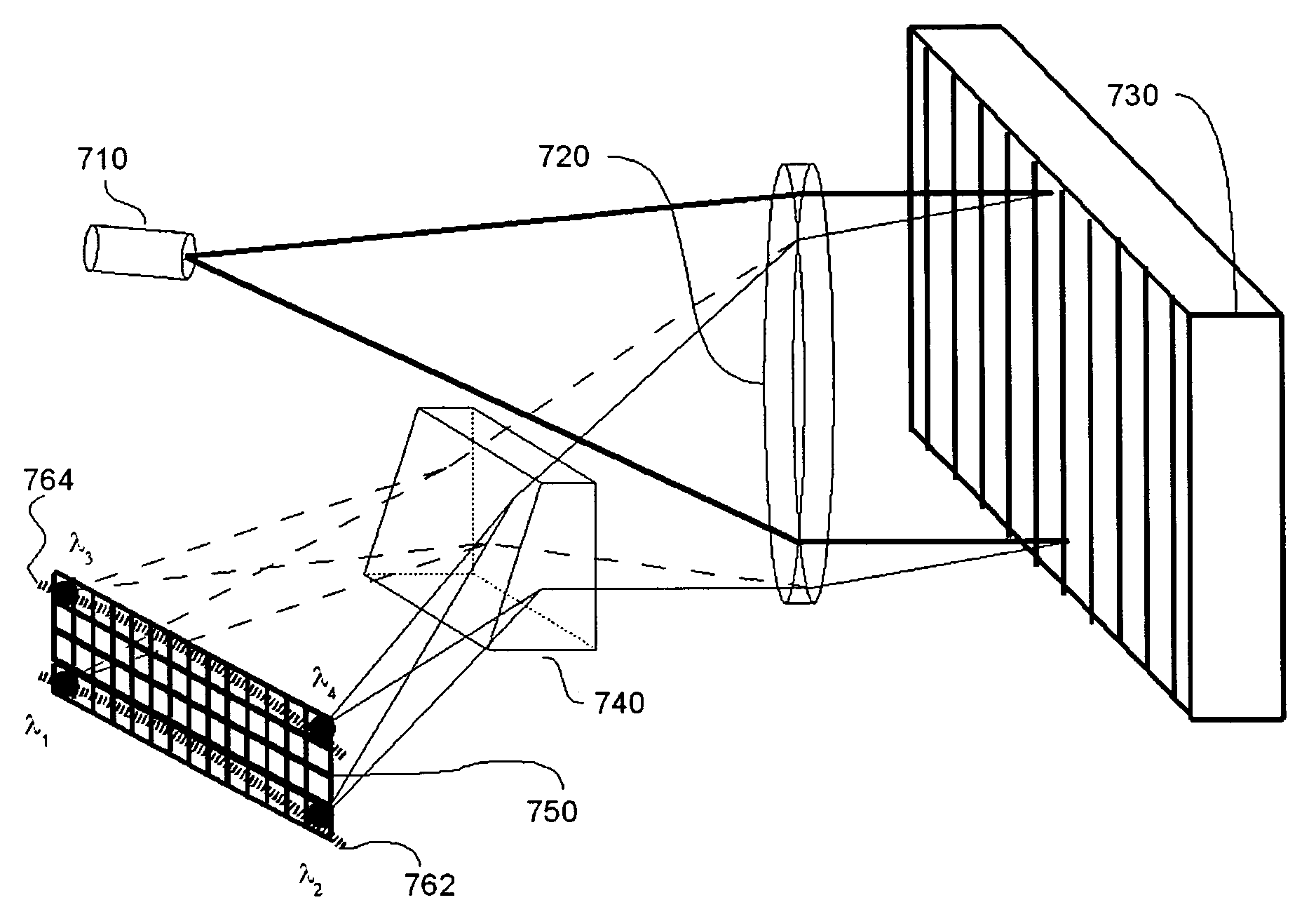

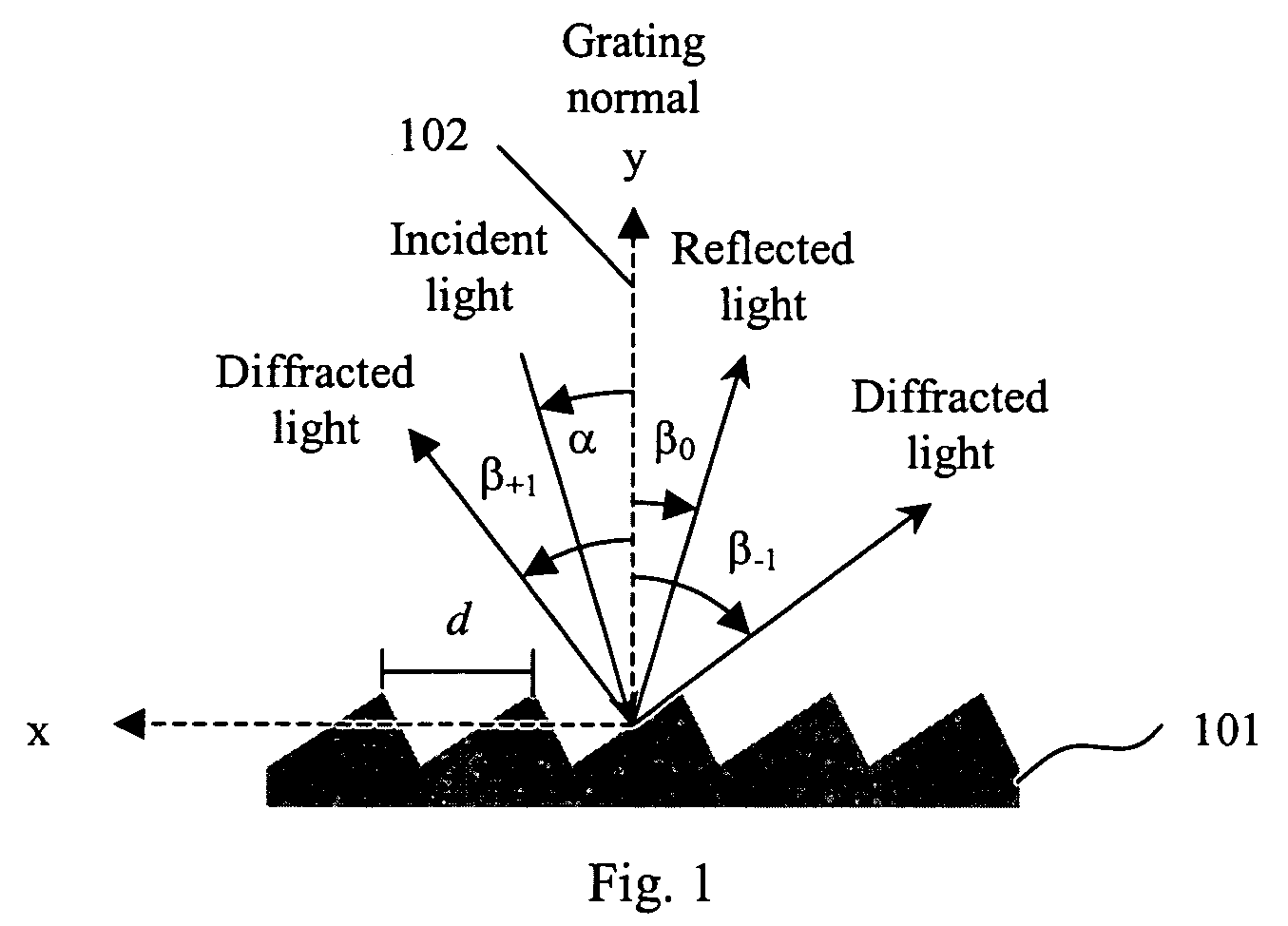

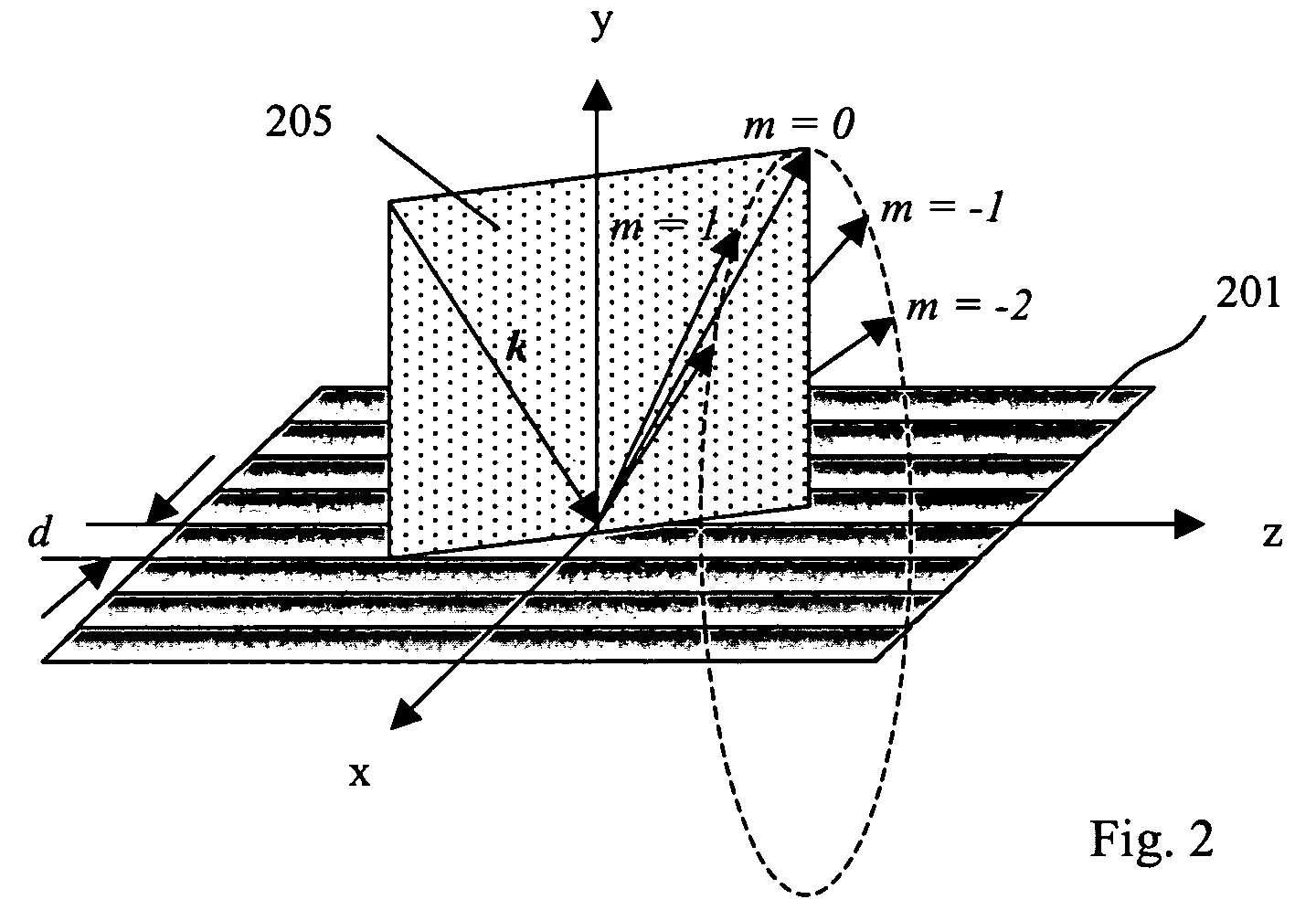

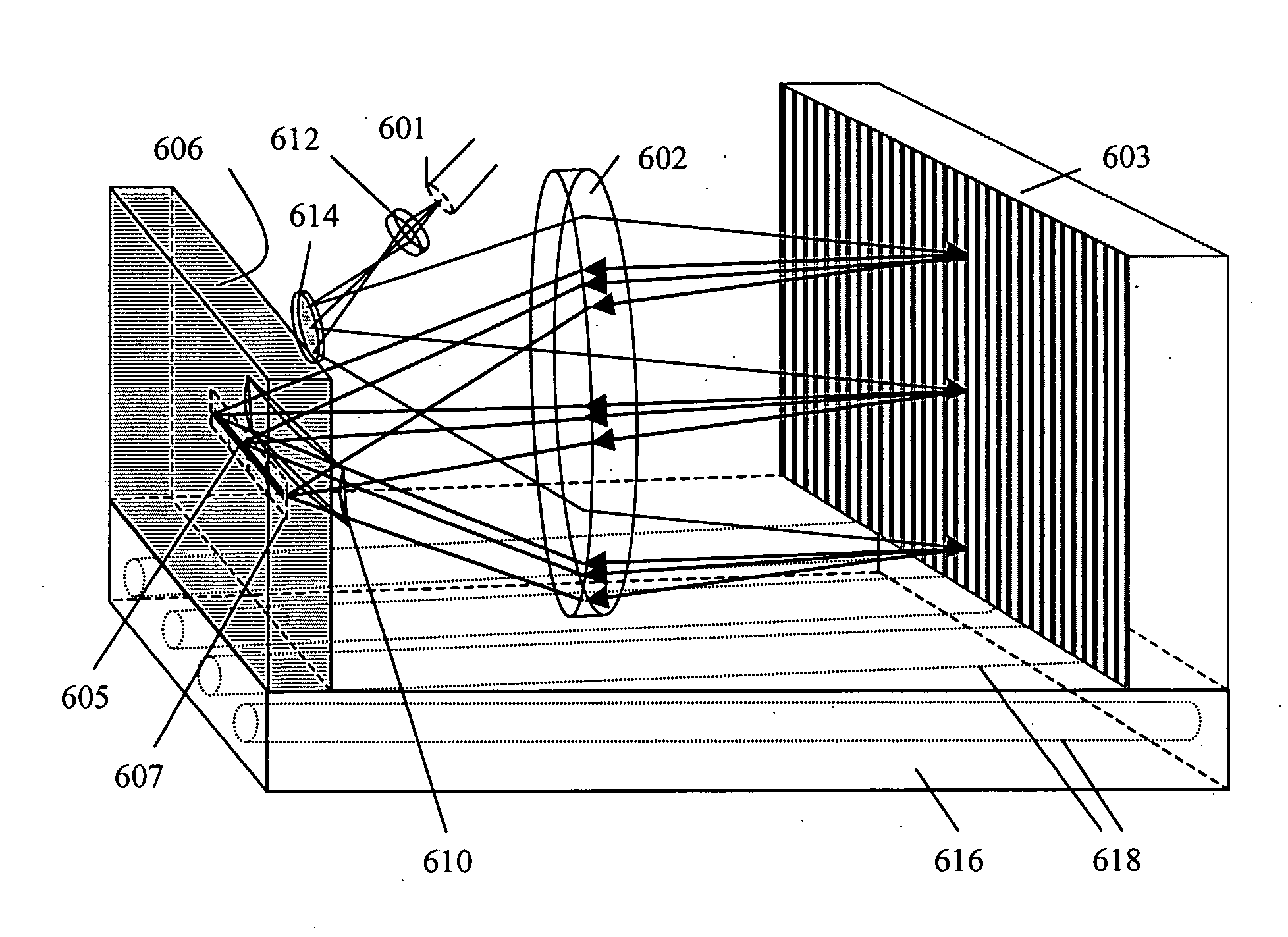

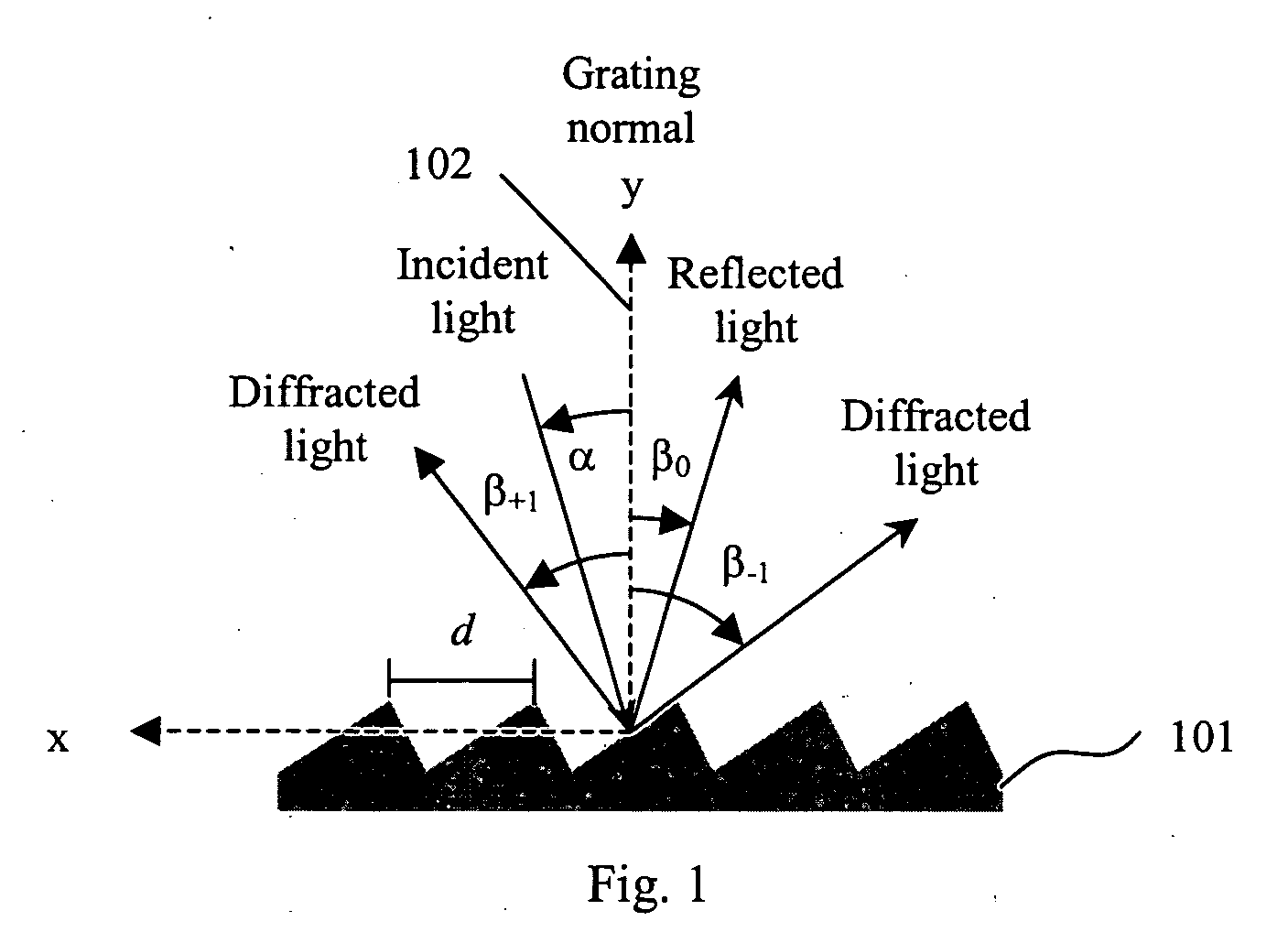

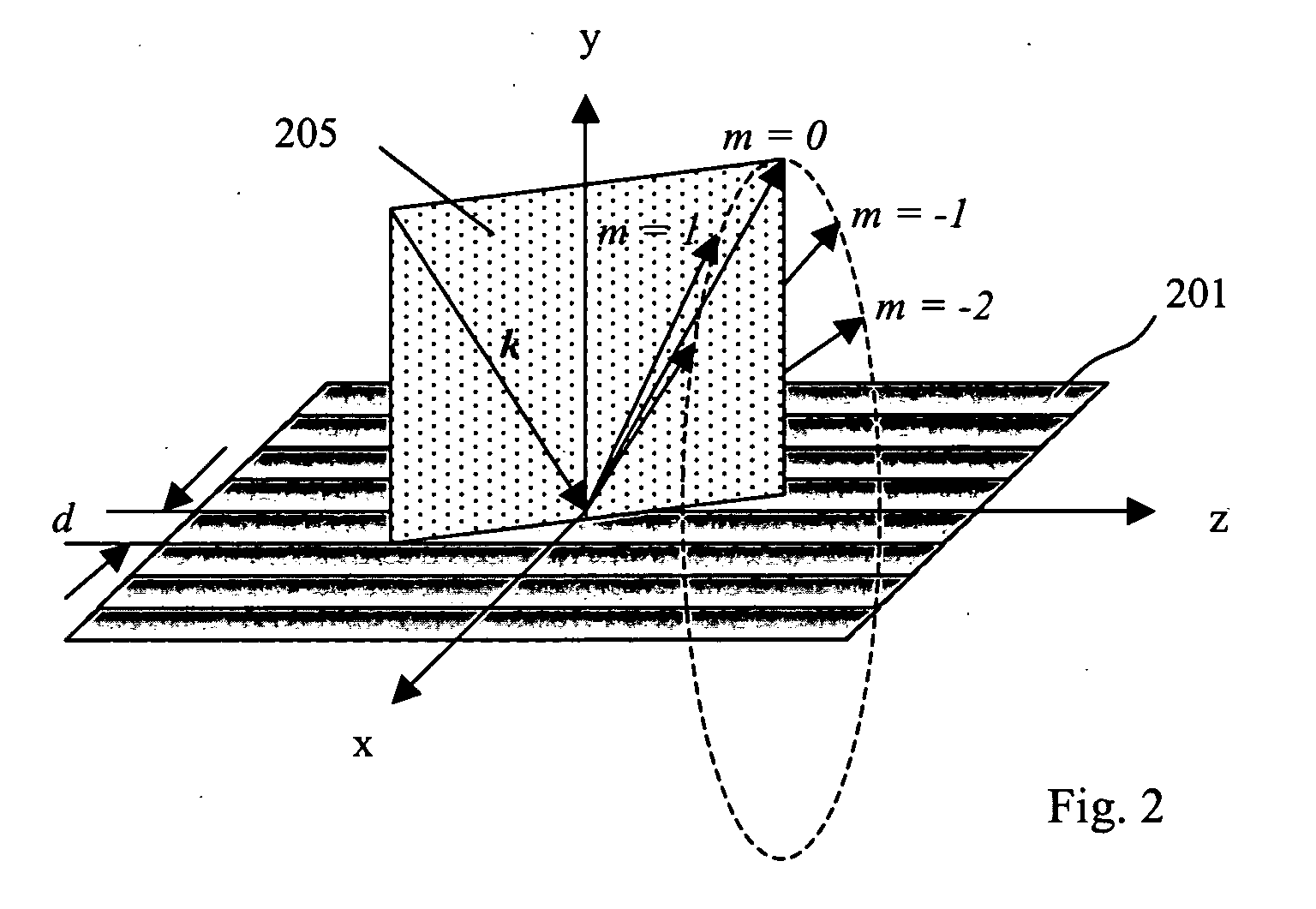

Cross-dispersed spectrometer in a spectral domain optical coherence tomography system

InactiveUS7342659B2Eliminating spatial order overlapReduce non-linearityRadiation pyrometrySpectrum investigationTwo dimensional detectorGrating

Owner:CARL ZEISS MEDITEC INC

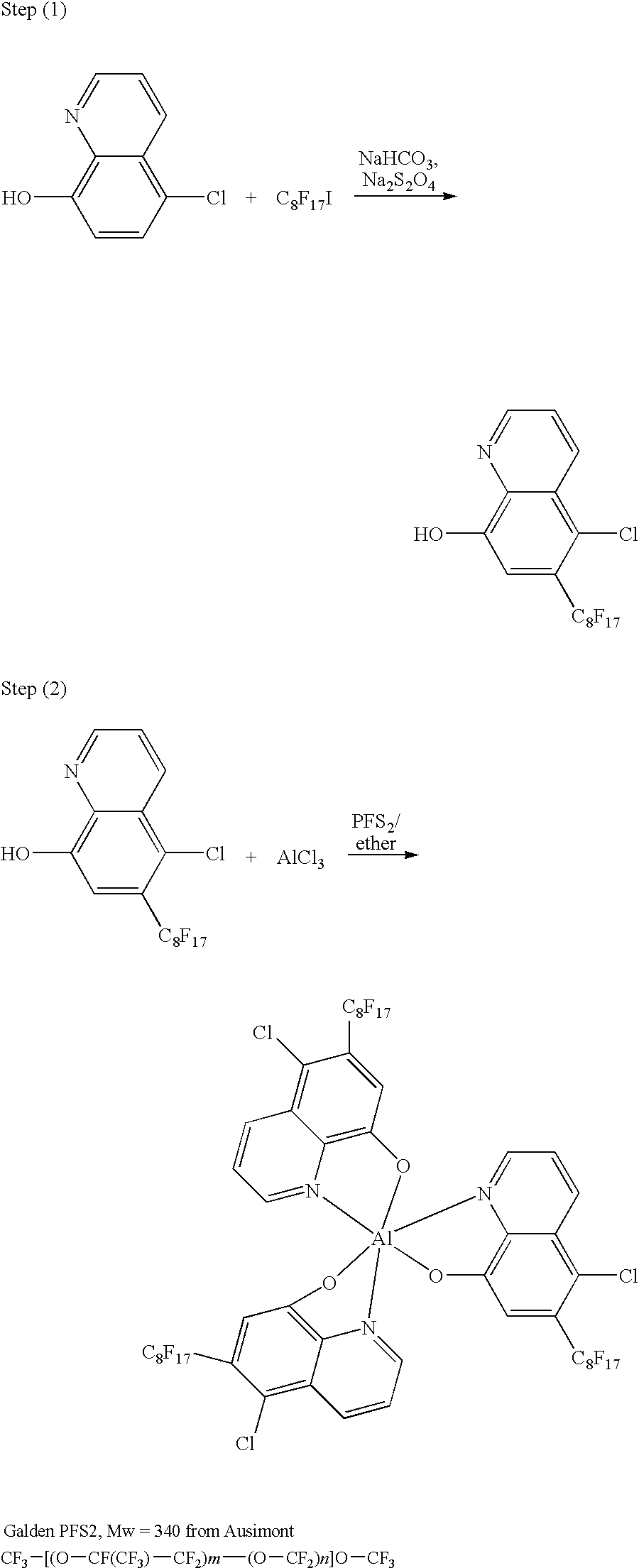

Electrophoretic dispersion with a fluorinated solvent and a charge controlling agent

ActiveUS7110162B2Improve adsorption capacityImprove surface activityStatic indicating devicesAzo dyesElectrophoresisCharge control

The invention relates to a novel electrophoretic dispersion comprising a fluorinated solvent as the continuous phase, charged pigment particles or pigment containing microcapsules as the dispersed phase, and the charge of the pigment particles is provided by a charge controlling agent comprising:(i) a soluble fluorinated electron accepting or proton donating compound or polymer in the continuous phase and an electron donating or proton accepting compound or polymer in the dispersed phase; or(ii) a soluble fluorinated electron donating or proton accepting compound or polymer in the continuous phase and an electron accepting or proton donating compound or polymer in the dispersed phase.

Owner:E INK CALIFORNIA

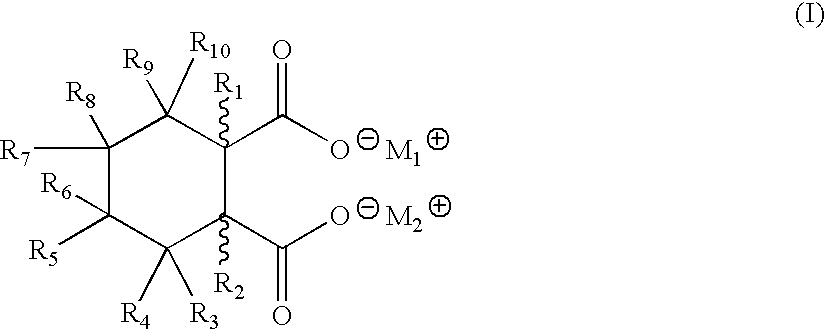

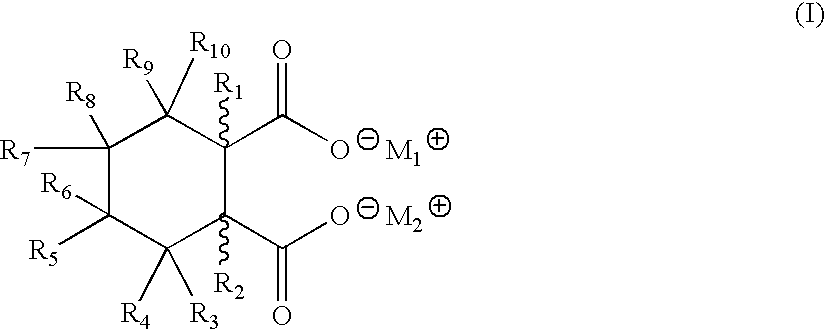

Metal salts of hexahydrophthalic acid as nucleating additives for crystalline thermoplastics

InactiveUS6599971B2Excellent calcium stearate compatibilityExcellent high peak crystallization temperatureOrganic compound preparationFibre treatmentThermoplasticScavenger

Compounds and compositions comprising specific metal salts of hexahydrophthalic acid (HHPA) in order to provide highly desirable properties within thermoplastic articles are provided. The inventive HHPA derivatives are useful as nucleating and / or clarifying agents for such thermoplastics, are practical and easy to handle. Such compounds provide excellent crystallization temperatures, stiffness, and acid scavenger compatibility within target polyolefins. Also, such compounds exhibit very low hygroscopicity and therefore excellent shelf stability as powdered or granular formulations. Thermoplastic additive compositions and methods of producing polymers with such compounds are also contemplated within this invention.

Owner:MILLIKEN & CO

Elastic blends comprising crystalline polymer and crystallizable polymers of propylene

Improved thermoplastic polymer blend compositions comprising an isotactic polypropylene component and an alpha-olefin and propylene copolymer component, said copolymer comprising crystallizable alpha-olefin sequences. In a preferred embodiment, improved thermoplastic polymer blends are provided comprising from about 35% to about 85% isotactic polypropylene and from about 30% to about 70% of an ethylene and propylene copolymer, wherein said copolymer comprises isotactically crystallizable propylene sequences and is predominately propylene. The resultant blends manifest unexpected compatibility characteristics, increased tensile strength, and improved process characteristics, e.g., a single melting point.

Owner:EXXONMOBIL CHEM PAT INC

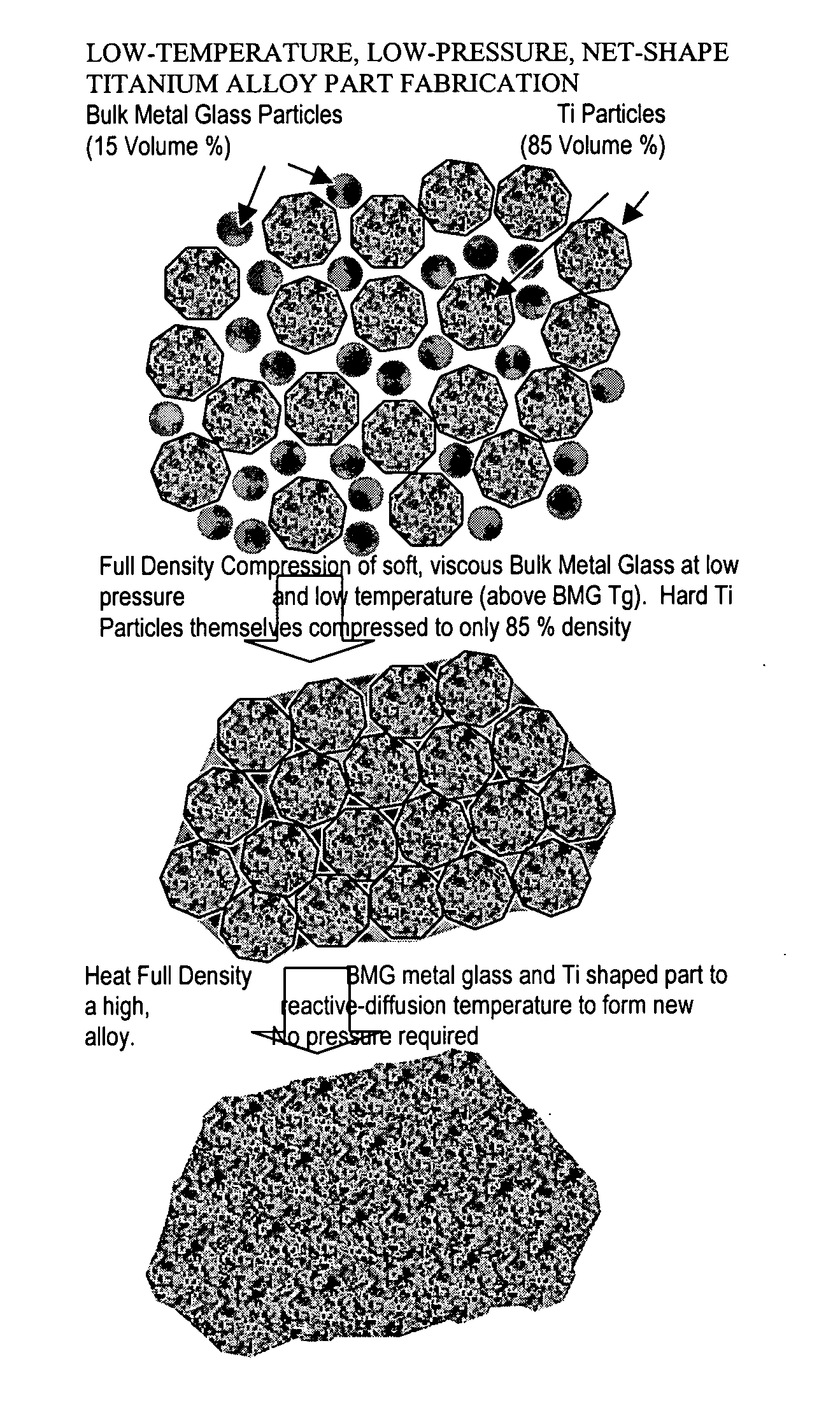

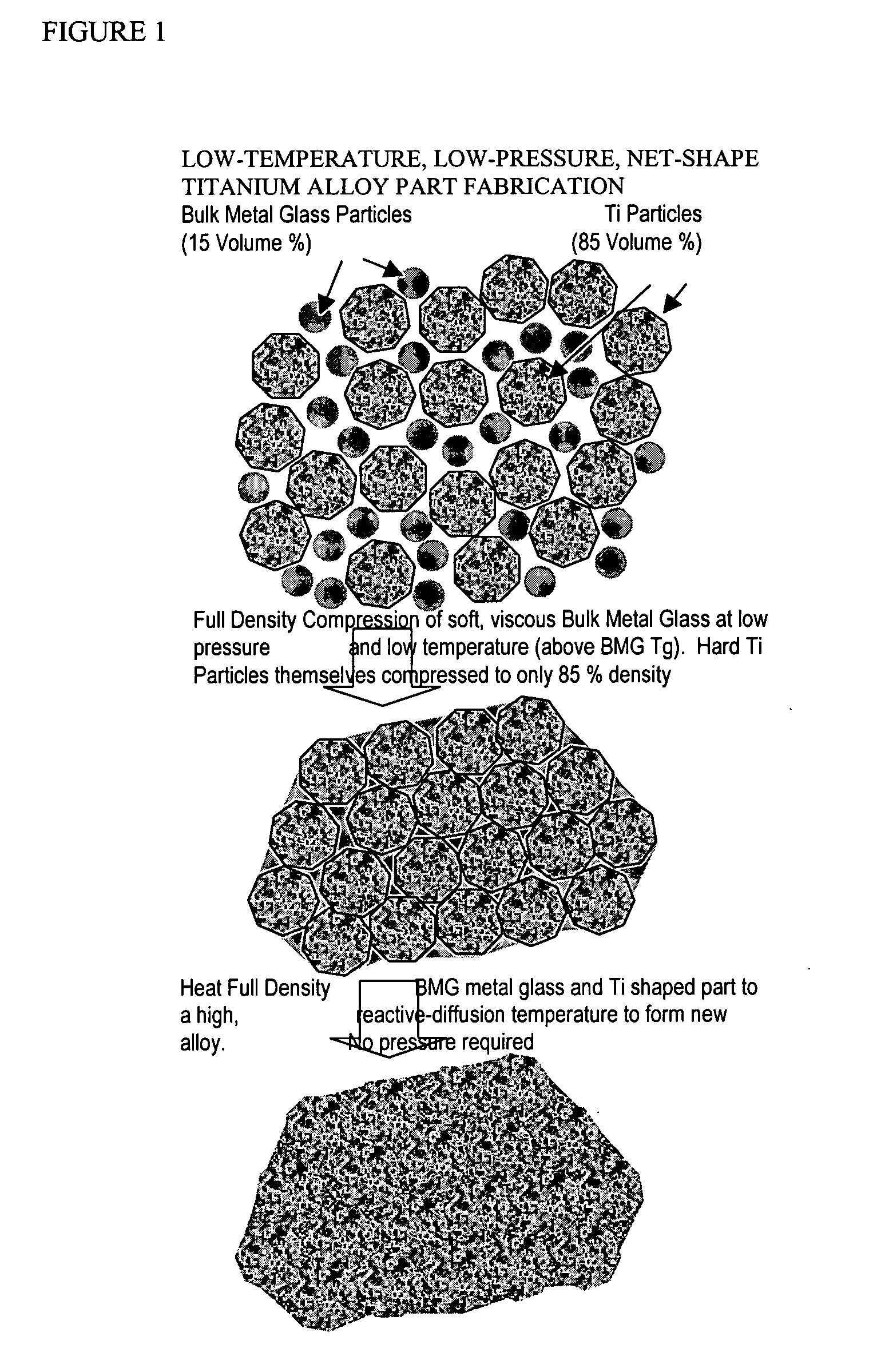

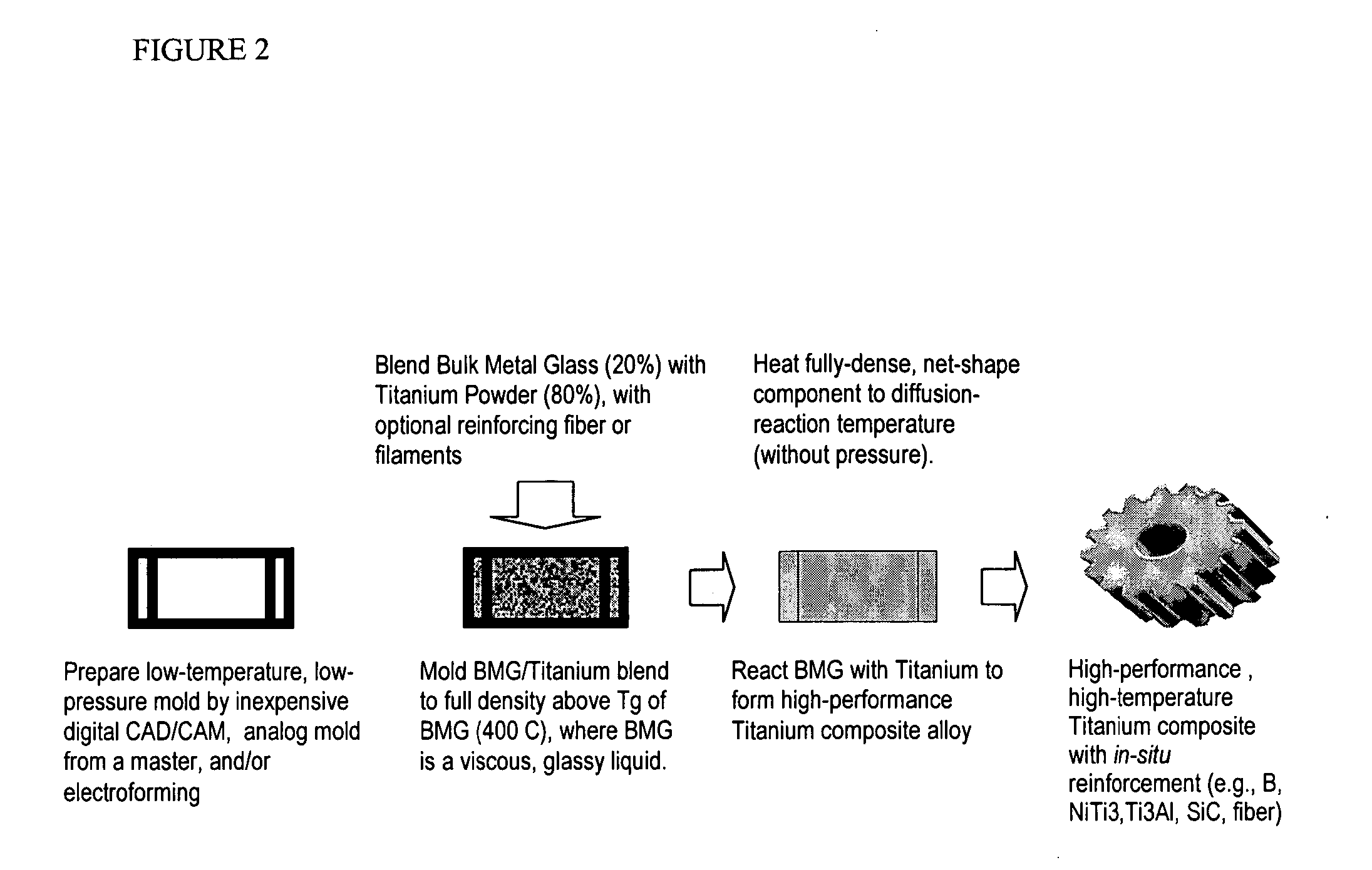

Titanium group powder metallurgy

InactiveUS20050084407A1Excellent cold formabilityImprove hardenabilityVitrificationVolumetric Mass Density

Methods and compositions relating to powder metallurgy in which an amorphous-titanium-based metal glass alloy is compressed above its glass transition temperature Tg with a titanium alloy powder which is a solid at the compression temperature, to produce a compact with a relative density of at least 98%.

Owner:MYRICK JAMES J

Wood-plastic composite material and prepration method thereof

The invention discloses a wood-plastic composite material and a preparation method thereof, and the wood-plastic composite material comprises the following raw materials according to the mixing ratio by parts by weight: 30-80 parts of modified fiber powder; 15-80 parts of plastics; 2-10 parts of phase solvent; 2-10 parts of lubricant; 0-10 parts of stabilizer; 0.2-1.0 part of antioxidant; 5-15 parts of filler; and 2-20 parts of flame retardant. Lignin is utilized for modifying fiber powder, then composition with the plastics is carried out, and a finished-product material is formed by extrusion. The preparation method can solve the problems of the compatibility of wood fibers with the thermoplastic plastics, the surface treatment technology of the raw materials by utilizing the lignin and the like, realize the comprehensive utilization of the lignin and the waste plastics, be capable of replacing wood, increase the additional value of the lignin and solve the utilization problem of the lignin wastes. The manufactured wood-plastic composite material can significantly improve the mechanical performance, the tensile strength, the flexural strength and the impact resistance, and realize the industrial production of high-performance products, such as construction materials.

Owner:BEIJING FORESTRY UNIVERSITY

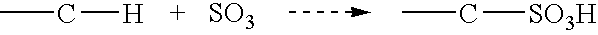

Process for preparing nanostructured materials of controlled surface chemistry

InactiveUS6669823B1Good dispersionReduce hydrolysis rateMaterial nanotechnologyMolten spray coatingCharge carrierNanostructured materials

A process to prepare stoichiometric-nanostructured materials comprising generating a plasma, forming an "active volume" through introduction of an oxidizing gas into the plasma, before the plasma is expanded into a field-free zone, either (1) in a region in close proximity to a zone of charge carrier generation, or (2) in a region of current conduction between field generating elements, including the surface of the field generation elements, and transferring energy from the plasma to a precursor material to form in the "active volume" at least one stoichiometric-nanostructured material and a vapor that may be condensed to form a stoichiometric-nanostructured material. The surface chemistry of the resulting nanostructured materials is substantially enhanced to yield dispersion stable materials with large zeta-potentials.

Owner:NANOPHASE TECH CORP

Cross-dispersed spectrometer in a spectral domain optical coherence tomography system

InactiveUS20060164639A1Eliminating spatial order overlapReduce non-linearityRadiation pyrometrySpectrum investigationTwo dimensional detectorGrating

A spectral-domain optical coherence tomography system using a cross-dispersed spectrometer is disclosed. The interfered optical signal is dispersed by a grating into several orders of diffraction, and these orders of diffraction are separated by an additional dispersive optical element. The spectral interferogram is recorded by a set of linear detector arrays, or by a two-dimensional detector array.

Owner:CARL ZEISS MEDITEC INC

Functionalized nanotubes

InactiveUS20040202603A1Good dispersionImprove adhesionPigmenting treatmentMaterial nanotechnologyChemical MoietyFiber

Owner:HYPERION CATALYSIS INT

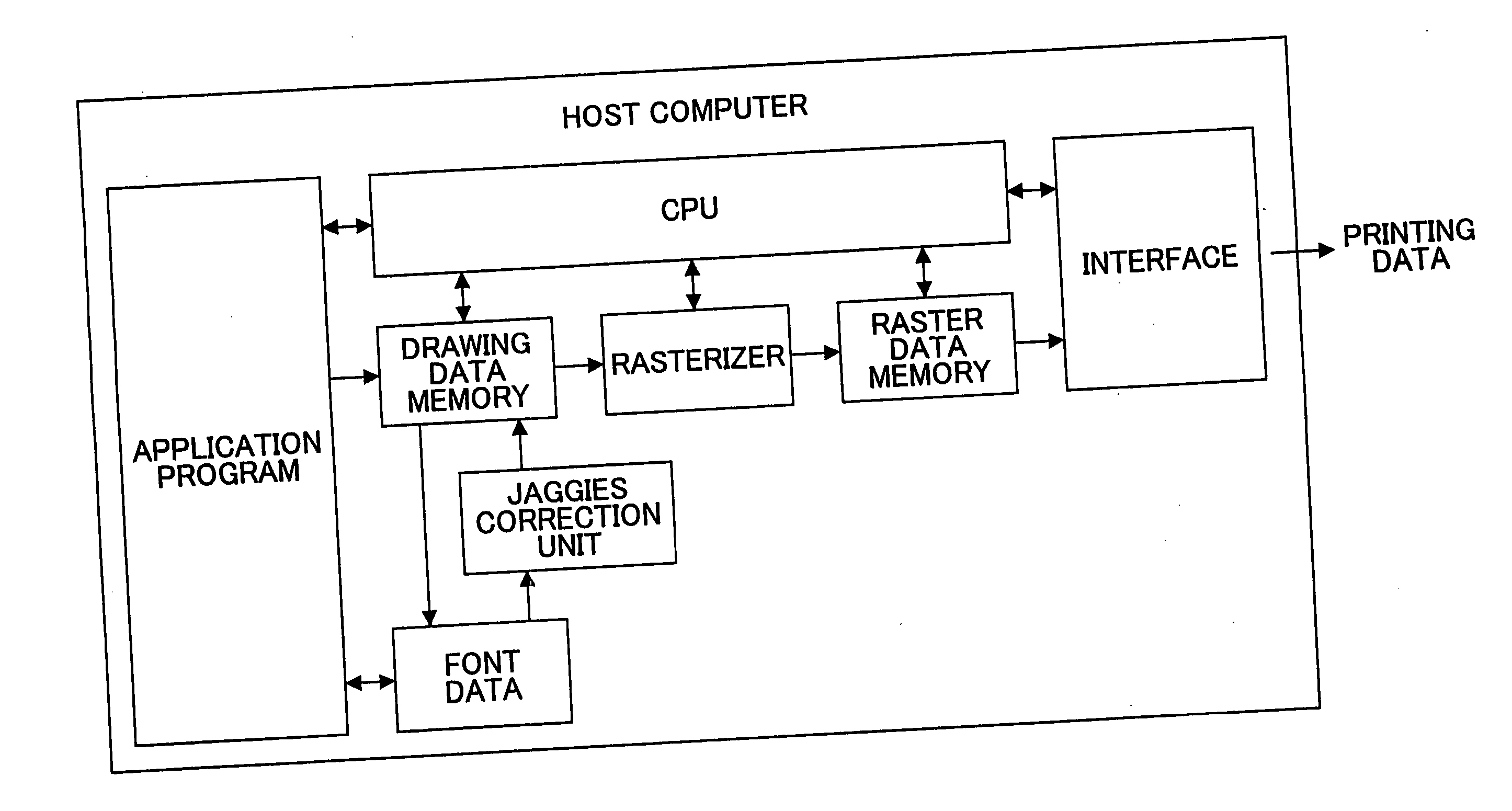

Image-processing method and apparatus, and image-forming apparatus

InactiveUS20060098232A1Reduce step change partImprove image qualityImage enhancementDigitally marking record carriersHueGraphics

In an image-processing method and apparatus, dots forming a step-change part of an outline of an image of characters and / or graphics which image is subjected to half-tone processing are detected, and dots surrounding the detected dots forming the step-change part are transformed into respective dot data each having a size that is smaller than a size of the detected dots forming the step-change part. In the image-processing method and apparatus, one of different transformation methods is selected according to an inclination of the outline in order to produce the dot data in the transforming.

Owner:RICOH KK

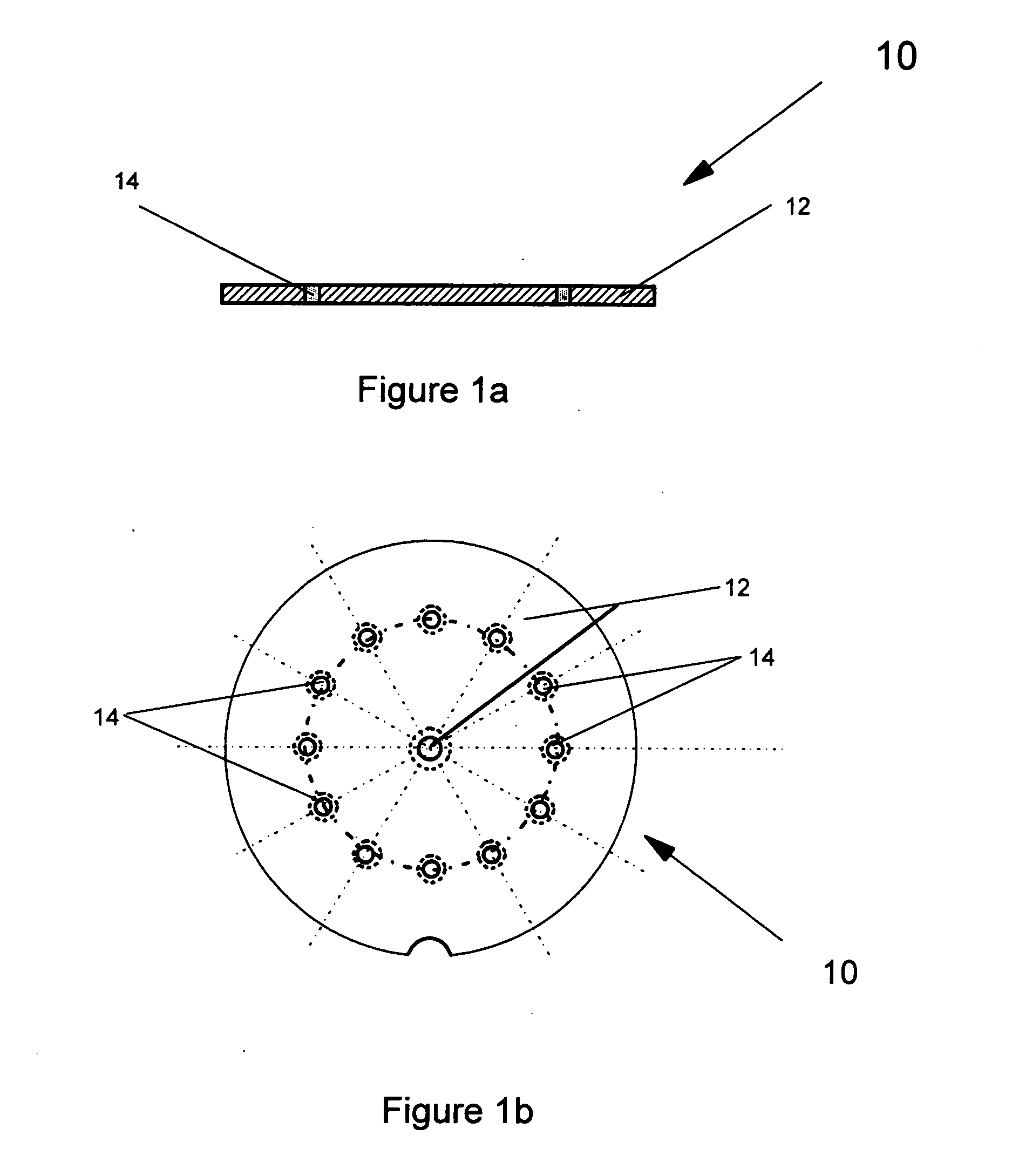

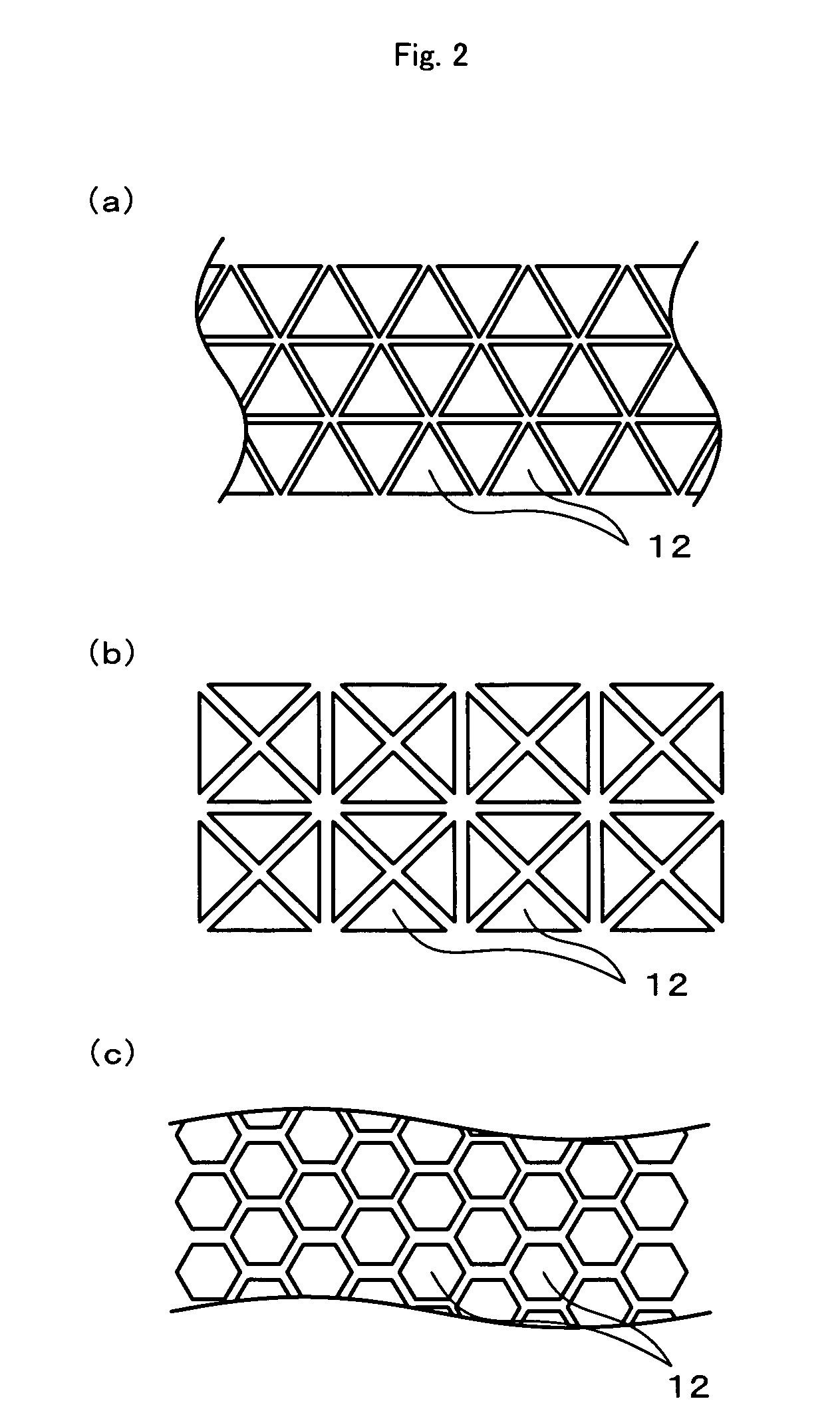

Honeycomb structure

InactiveUS20050266992A1High strengthGood dispersionDispersed particle filtrationExhaust apparatusFiberHoneycomb structure

A honeycomb structure 10 of the present invention comprises: porous honeycomb units 11 having multiple through-holes, including the first form of an inorganic material (for example, ceramic particles), the second form of an inorganic material (for example, inorganic fibers or ceramic particles having large particle sizes), and an inorganic binder; and sealing material layers 14 jointing the porous honeycomb units 11 at outer surfaces 13 where the through-holes are not open. The cross-sectional area perpendicular to the through-holes is about 5 to about 50 cm2. The ratio of the total cross-sectional area of the porous honeycomb units 11 to the cross-sectional area of the honeycomb structure 10 is not less than about 85%. The honeycomb structure 10 reduces thermal stress or vibration applied to each porous honeycomb unit 11, by the sealing material layers 14, and allows for amore effective use of surface on which catalyst components are dispersed.

Owner:IBIDEN CO LTD

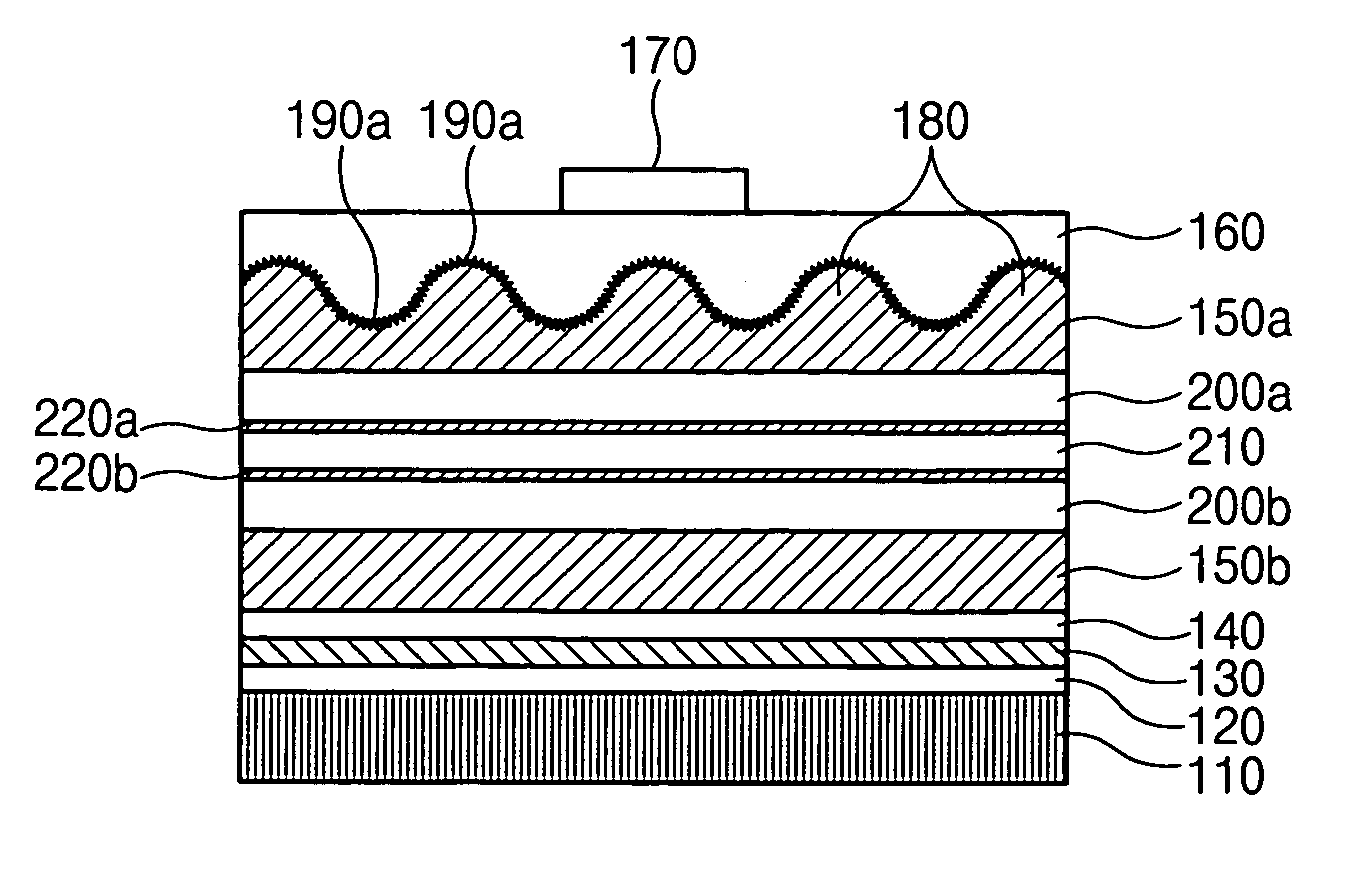

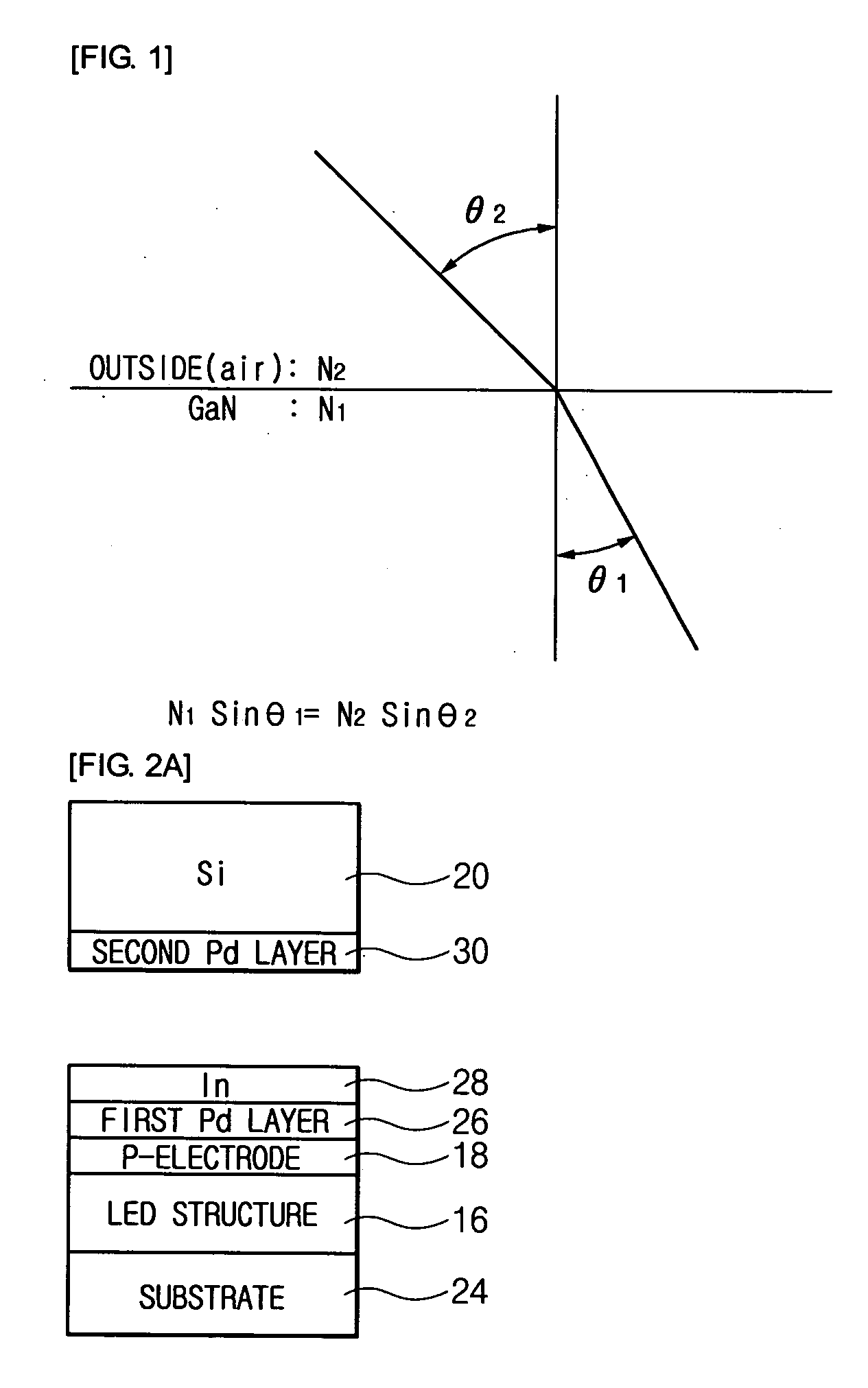

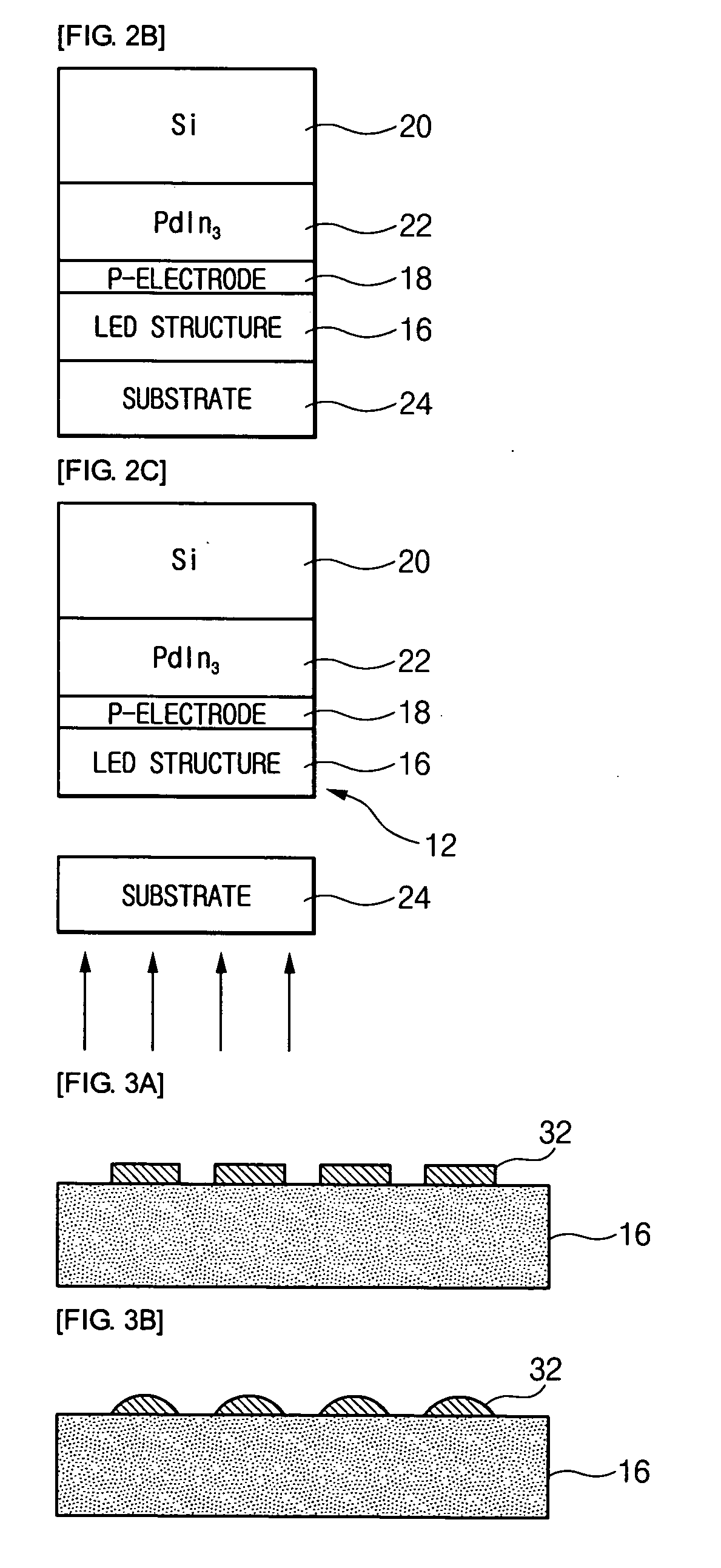

Vertical GaN-based LED and method of manfacturing the same

ActiveUS20070018187A1Maximize improvementImprove power characteristicsSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringActive layer

A vertical GaN-based LED and a method of manufacturing the same are provided. The vertical GaN-based LED includes an n-electrode, a first n-type GaN layer, a first AlGaN layer, a GaN layer, a second AlGaN layer, a second n-type GaN layer, an active layer, a p-type GaN layer, and a structure support layer. The first n-type GaN layer has uneven patterns having a plurality of protuberances. The first AlGaN layer is formed under the first n-type GaN layer, and the GaN layer is formed under the first AlGaN layer. The active layer is formed under the second n-type GaN layer, and the p-type GaN layer is formed under the active layer. A p-electrode is formed under the p-type GaN layer, and the structure support layer is formed under the p-electrode.

Owner:SAMSUNG ELECTRONICS CO LTD

High surface area sol-gel route prepared hydrogenation catalysts

InactiveUS6686310B1Good dispersionImprove uniformityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsRheniumSilicon oxide

This invention concerns novel compositions, useful as hydrogenation catalyst, said compositions comprising metals and metal ions such as ruthenium (Ru) or palladium (Pd) dispersed in and distributed throughout a matrix comprising an inorganic or silicon oxide network. The catalyst may be prepared by the sol-gel method; a solution of at least one catalytic metal compound is added to a solution of at least one metal alkoxide selected from Al, Ti, Nb, Zr, Ta, Si and other inorganic alkoxides, and then gelling the mixture. Promotors such as rhenium (Re), molybdenum (Mo) and tin (Sn) may be added. The catalyst may be used in the reduction of metallic acid or gamma-butyrolactone to tetrahydrofuran (THF) and 1,4-butanediol (BDO).

Owner:EI DU PONT DE NEMOURS & CO

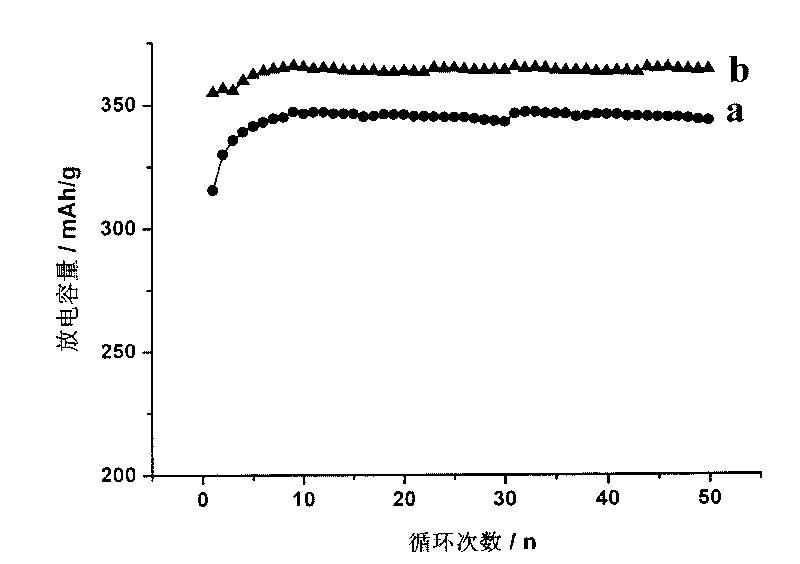

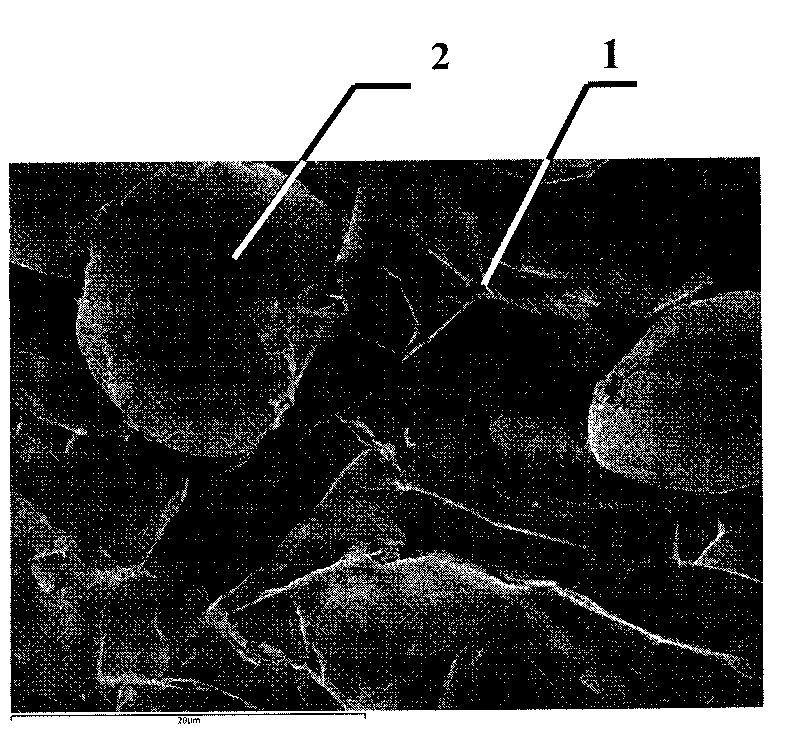

Electrode plate for lithium ion battery and manufacturing method thereof

InactiveCN101710619AChange the conductive contact interfaceImprove conductivityCell electrodesAdhesiveEngineering

The invention discloses an electrode plate for a lithium ion battery and a manufacturing method thereof, and particularly relates to the electrode plate for the lithium ion battery taking multi-layer graphene as a conductive agent and a manufacturing method thereof. The electrode plate of the invention consists of a positive electrode or negative electrode active substance, the conductive agent and an adhesive. The method comprises the steps of: using the positive electrode or negative electrode active substance, the conductive agent and the adhesive as raw materials to obtain electrode slurry through stirring and dispersing, and then obtaining the electrode plate through coating, drying and tabletting. The conductive agent adopted by the invention has the advantages of high dispersivity, high electric conductivity, good filling effect and the like; and the method has the advantages of simplicity, low production cost and convenient popularization and application. The method can remarkably improve the electric conductivity, electrochemical capacity and enhance charge-discharge capability of electrode materials by multiples, so the method can be widely applied to the preparation of electrode plates of lithium ion batteries.

Owner:CHONGQING UNIV

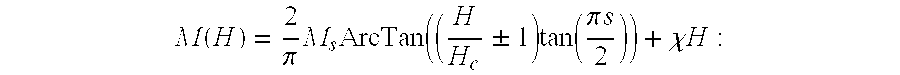

Magnetic nanoparticle composition and methods for using the same

InactiveUS20070264199A1High drug loadingGood dispersionPowder deliveryNanomedicineMagnetite NanoparticlesFatty acid

The present invention is a magnetic nanoparticle composition with enhanced drug delivery characteristics. The magnetic nanoparticle composition is composed of a magnetic particle core surrounded by a fatty acid and surfactant corona. Methods for increasing the efficacy of therapeutic agents and facilitating diagnostic imaging are also provided.

Owner:BOARD OF RGT UNIV OF NEBRASKA

Carbon black composition and usage thereof

InactiveUS20130029183A1Good dispersionInhibition formationPigmenting treatmentMagnetic materials for record carriersCyclohexanoneOrganic solvent

An aspect of the present invention relates to a carbon black composition, which comprises carbon black; an organic tertiary amine selected from the group consisting of an aliphatic tertiary monoamine and an alicyclic tertiary amine; and at least one organic solvent selected from the group consisting of methyl ethyl ketone, cyclohexanone, isophorone, and ethanol.

Owner:SOITEC SA +1

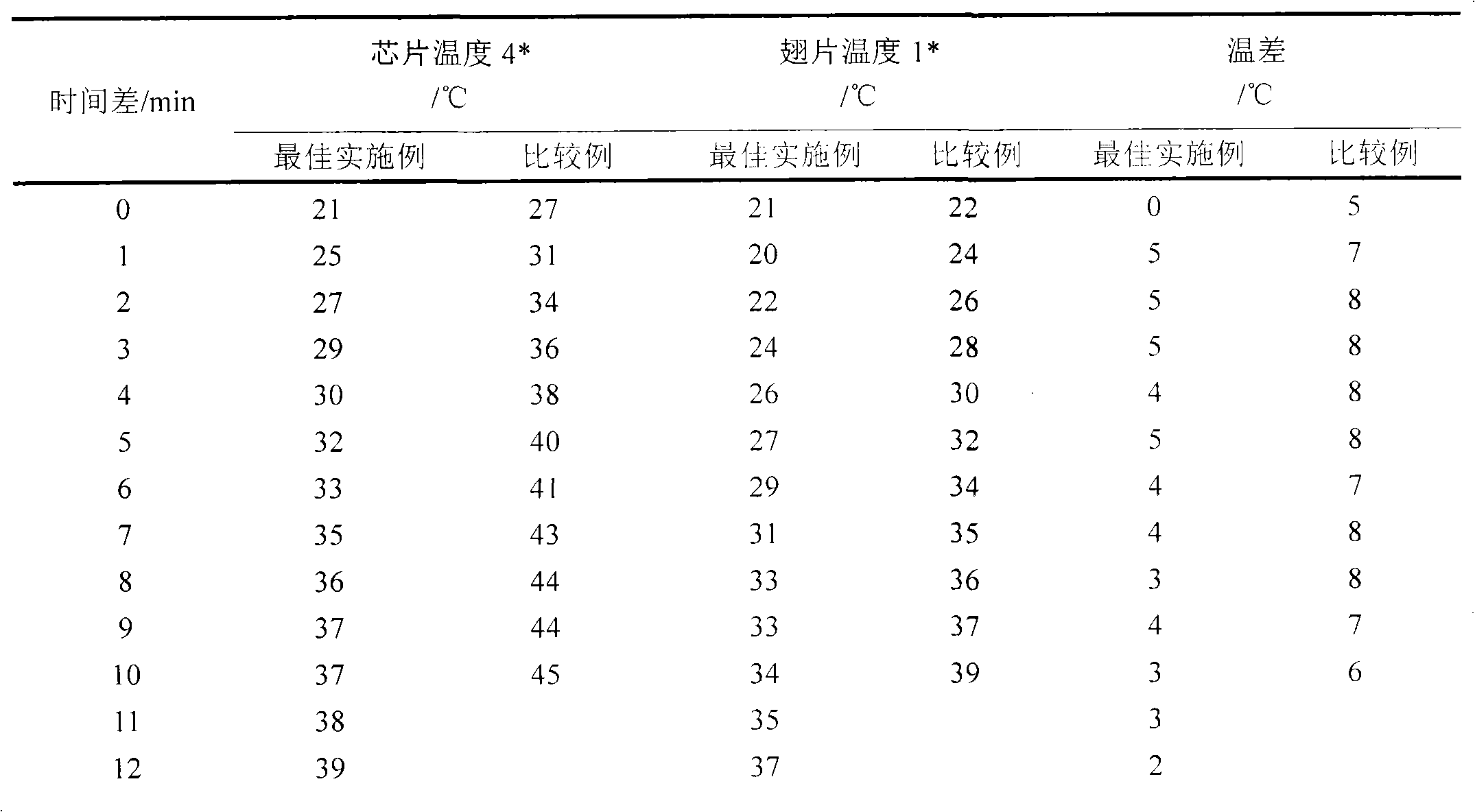

Heat conductive silicone grease composition

ActiveCN102634212AImprove thermal conductivityExtended service lifeHeat-exchange elementsCarbon nanotubeGraphite

The invention discloses a heat conductive silicone grease composition which mainly contains a carbon nano tube, graphite, phase-change capsule particles and silicone oil, wherein the carbon nano tube can speed up the conduction of heat further; the phase-change capsule particles are used for improving the initial temperature absorption velocity of a heat end; the phase-change capsule particles, the carbon nano tube and graphite in a fluid form full-three-dimensional network distribution of particles (phase-change capsule), a line ( the carbon nano tube) and a plane (graphite) in the fluid finally. The heat conductive silicone grease composition provided by the invention has high heat conduction rate and low heat resistivity, the heat radiation efficiency of the heat conductive silicone grease is improved greatly, the service life of the heat conductive silicone grease is prolonged greatly, and the heat conductive silicone grease composition has high practical value.

Owner:HUZHOU MINGSHUO OPTOELECTRONICS TECH CO LTD

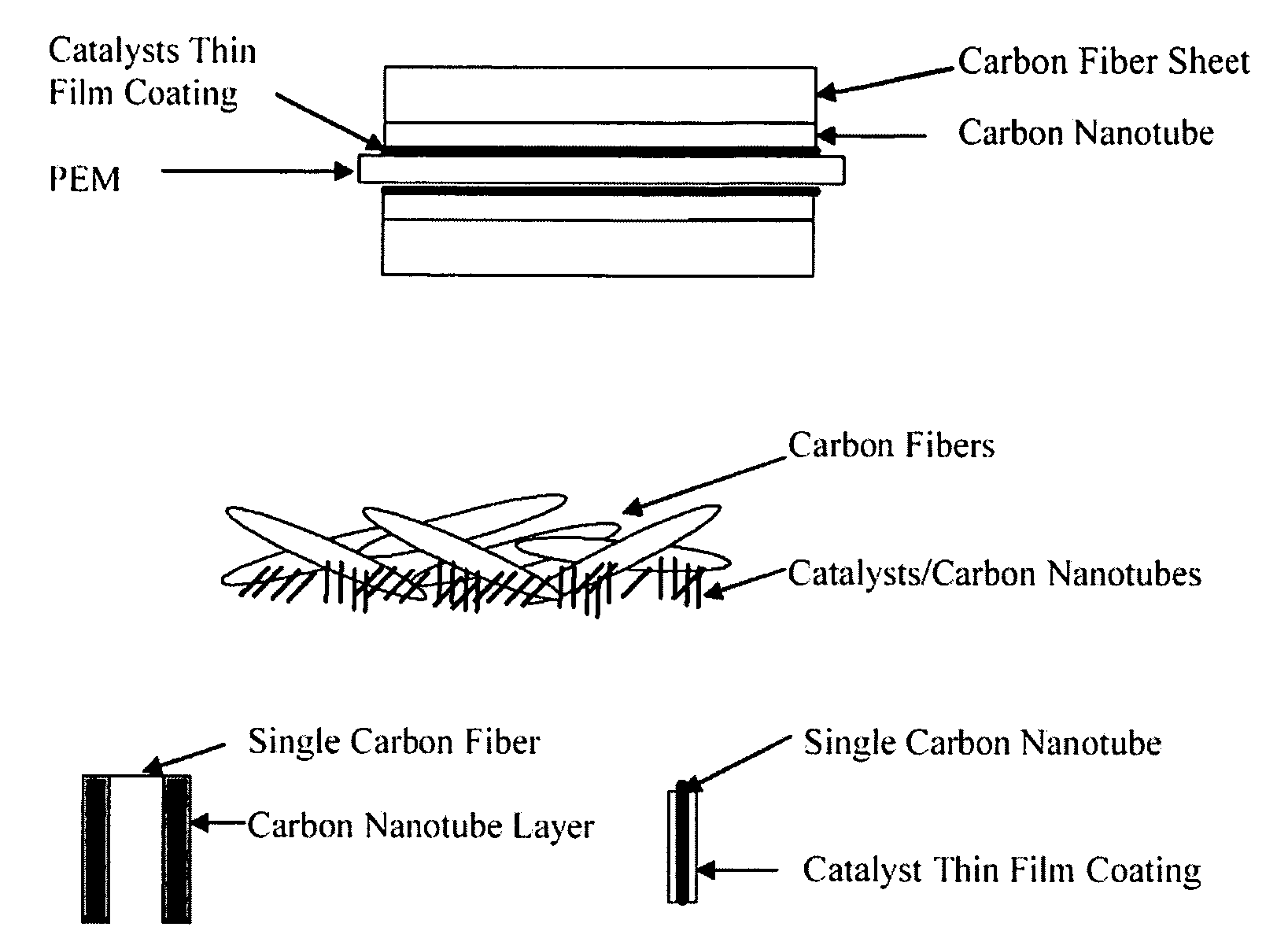

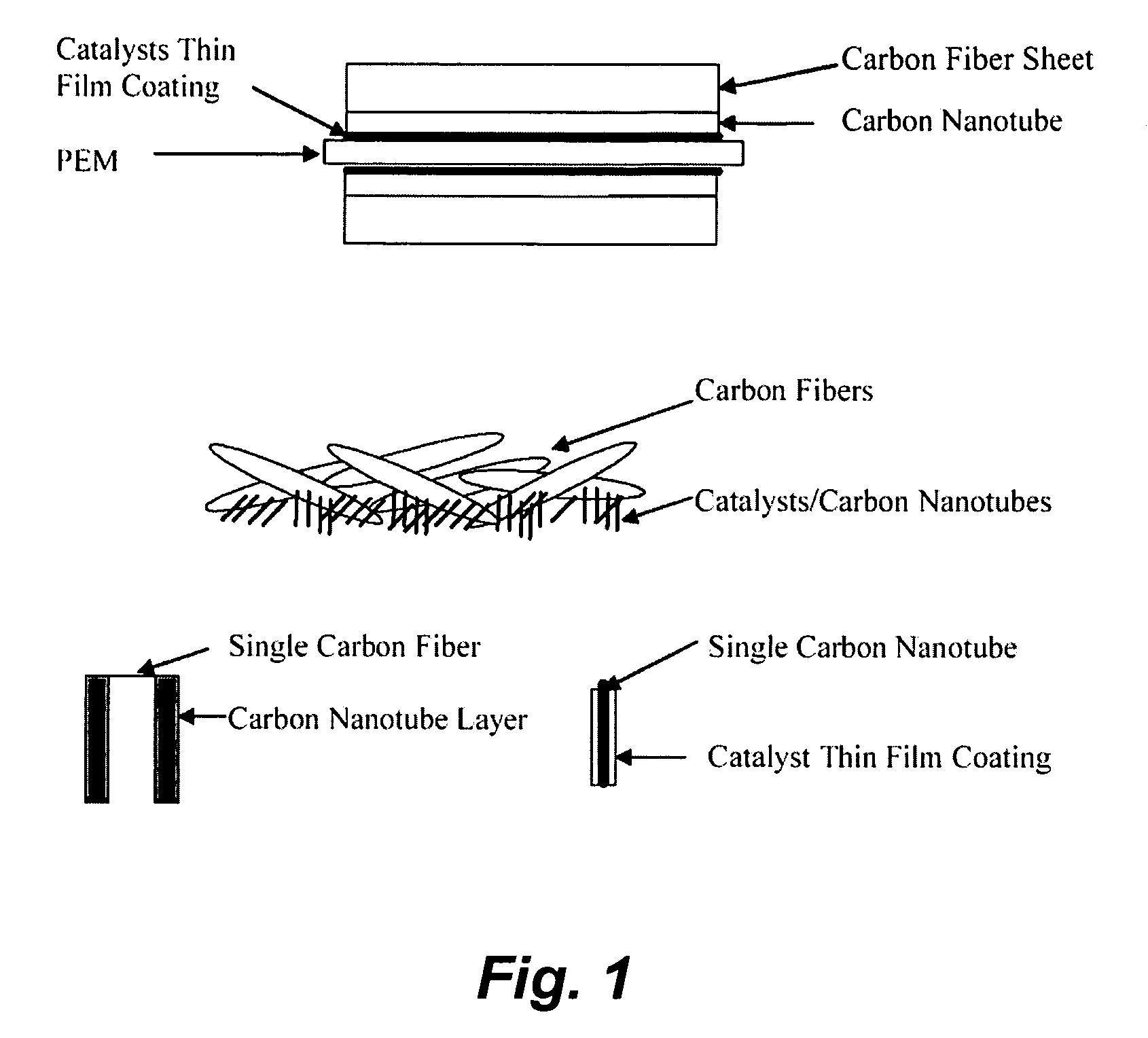

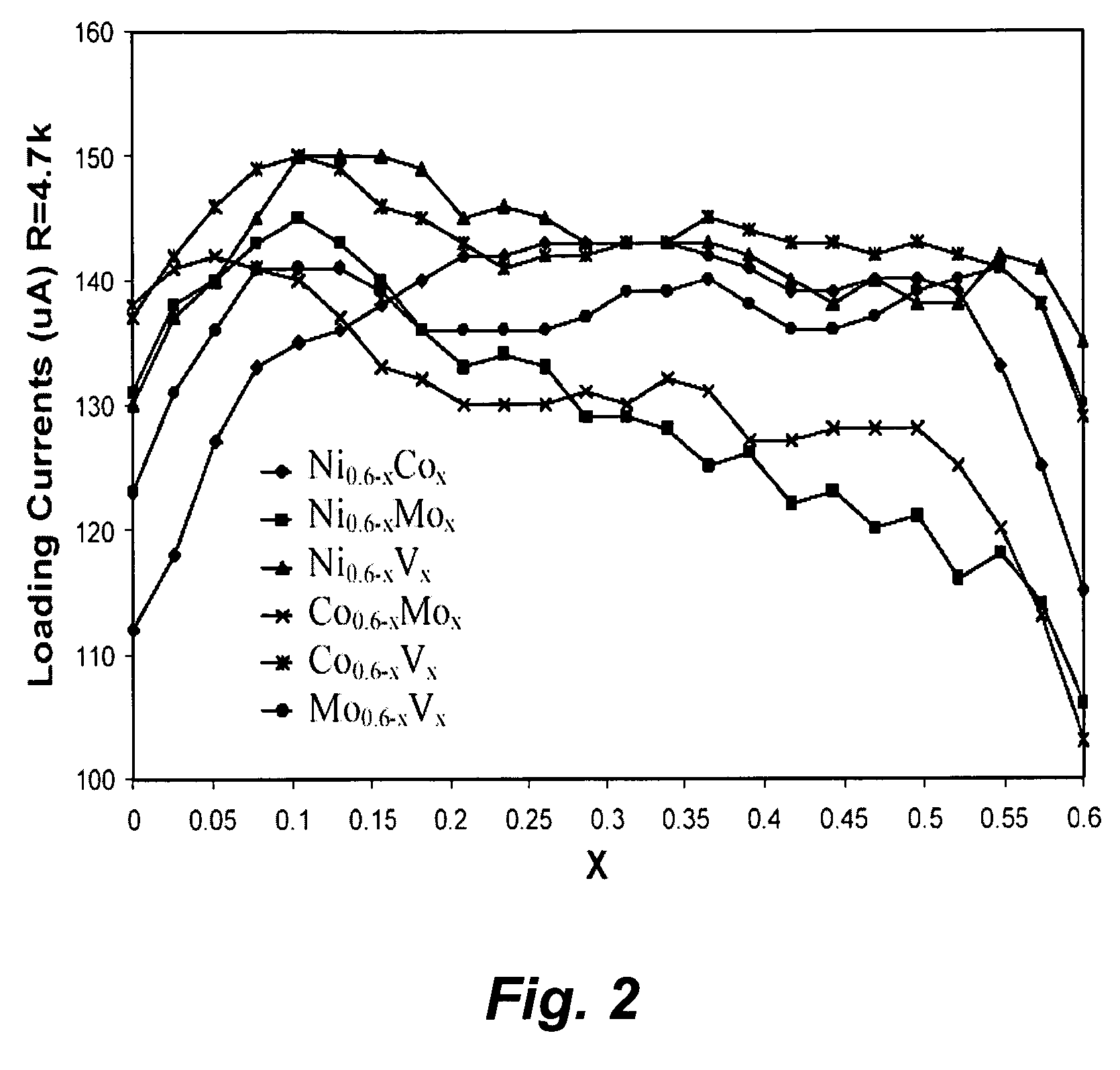

Low platinum fuel cells, catalysts, and method for preparing the same

InactiveUS20060172179A1Efficient processingImprove throughputMaterial nanotechnologyConductive materialFiberCarbon fibers

This invention provides novel fuel cell electrodes and catalysts comprising a series of catalytically active thin-film metal alloys with low platinum concentration supported on nanostructured materials (nanoparticles). Processing of the electrodes and catalysts can include electrodeposition methods, and high-pressure coating techniques. In certain embodiments, an integrated gas-diffusion / electrode / catalyst layer can be prepared by processing catalyst thin films and nanoparticles into gas-diffusion media such as Toray or SGL carbon fiber papers. The catalysts can be placed in contact with an electrolyte membrane for PEM fuel cell applications.

Owner:INTEMATIX

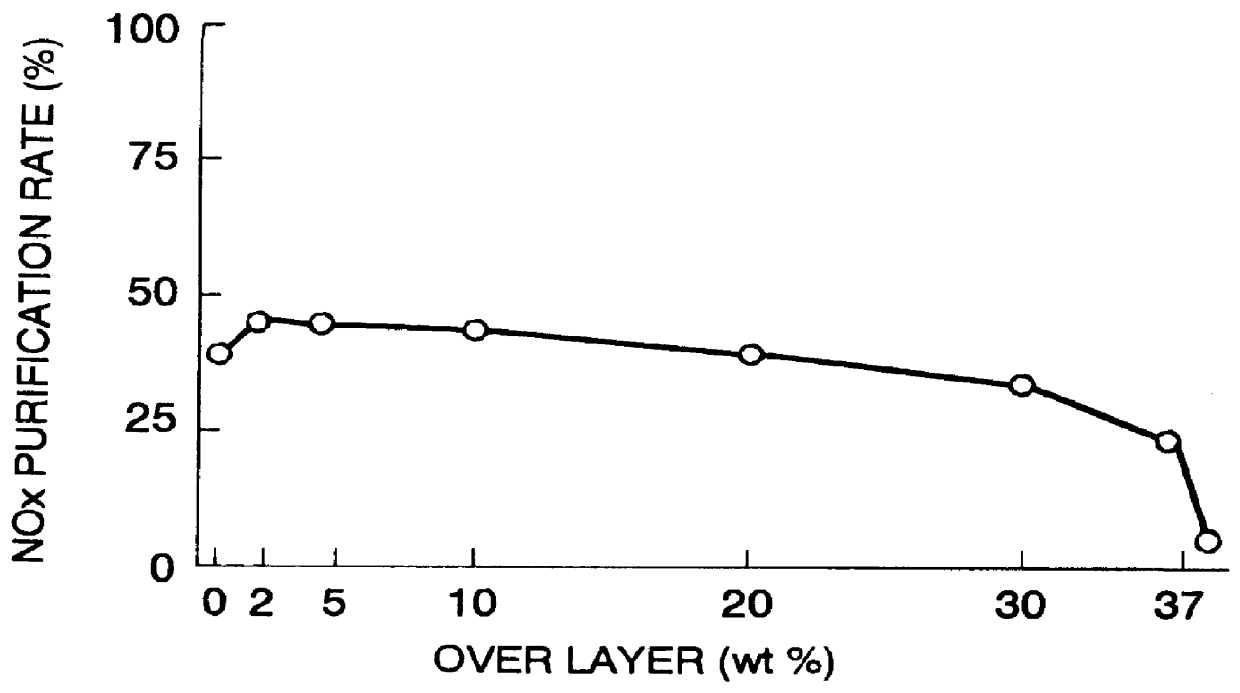

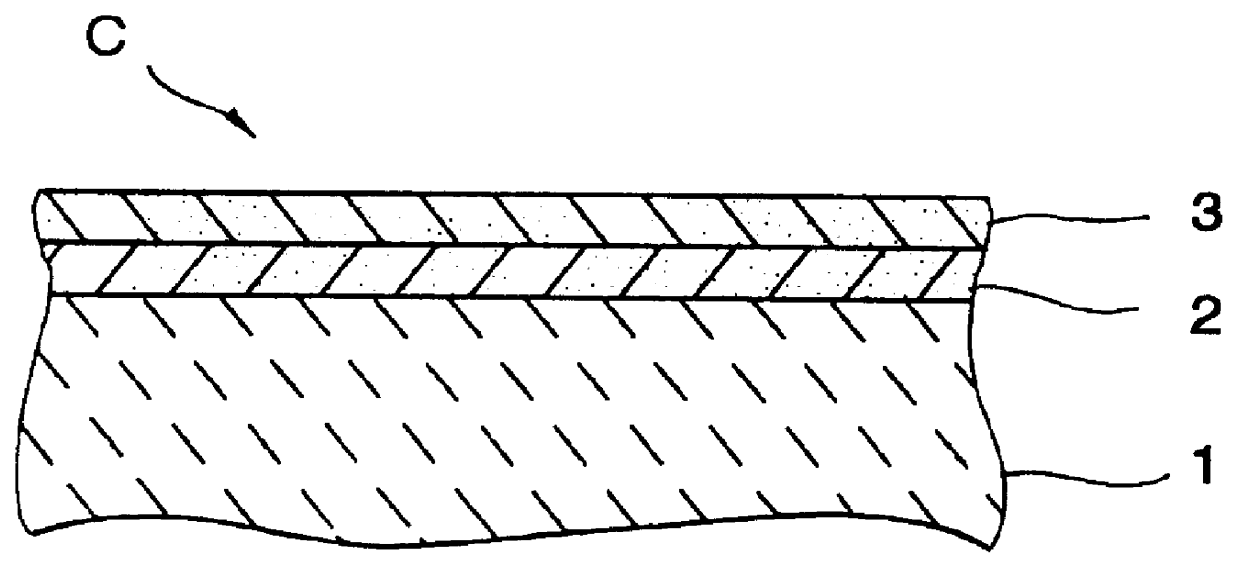

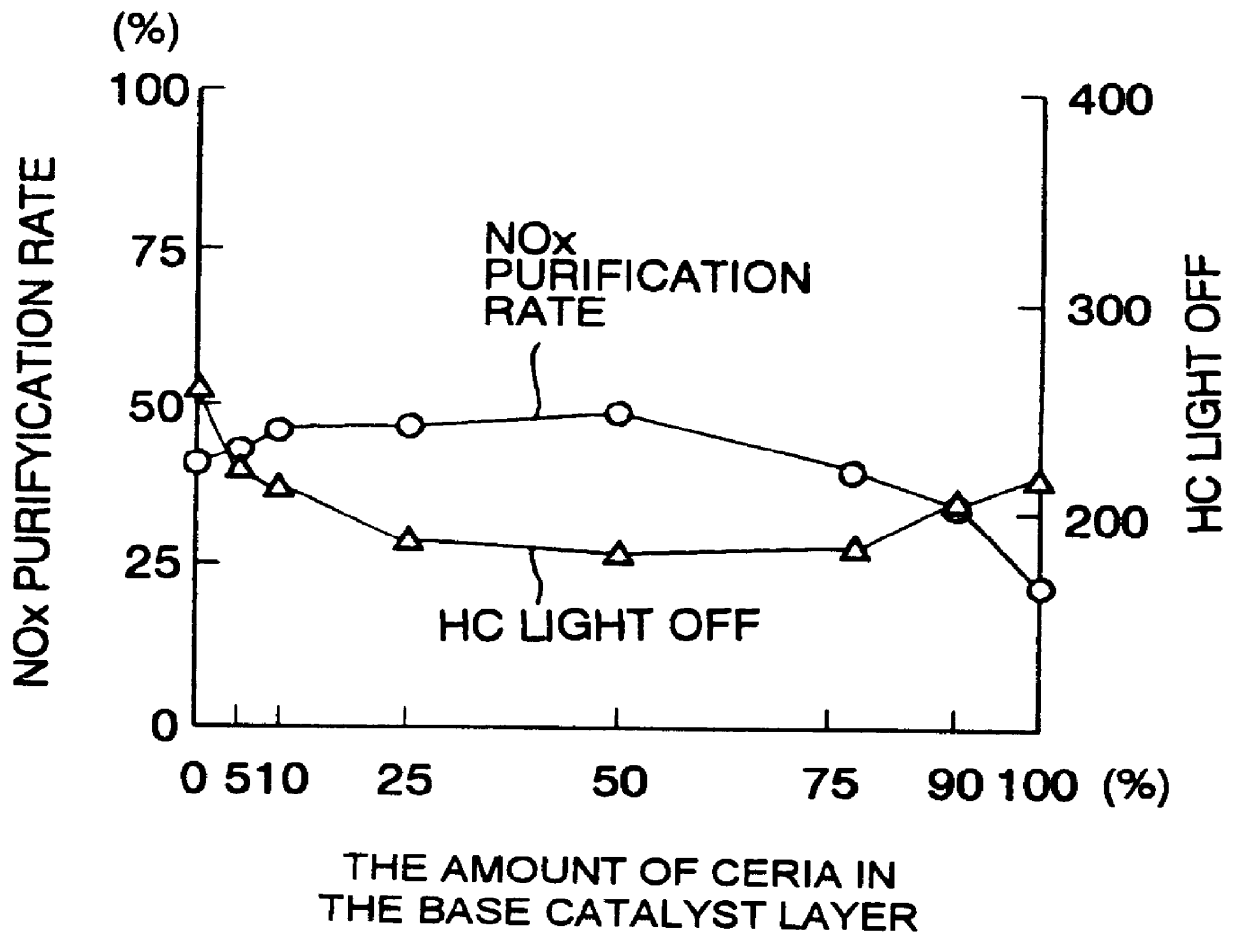

Catalyst for purifying exhaust gas

InactiveUS6066587AImprove responseImprove purification effectMolecular sieve catalystsInternal combustion piston enginesPlatinumPartial oxidation

A catalyst has a base catalyst layer containing platinum and barium as precious metal supported by alumina and an over catalyst layer containing platinum and rhodium as precious metal supported by zeolitr. The platinum and rhodium in the over catalyst layer activate NOx and HC so as to make them more reactive in terms of energy, and the barium in the base catalyst layer makes the platinum be more dispersive in the base catalyst layer. Under the existence of dispersive platinum, NOx in exhaust gas is decomposed and purified by reaction with reactive NO2 and partially oxidized HC generated in the over catalyst layer.

Owner:MAZDA MOTOR CORP

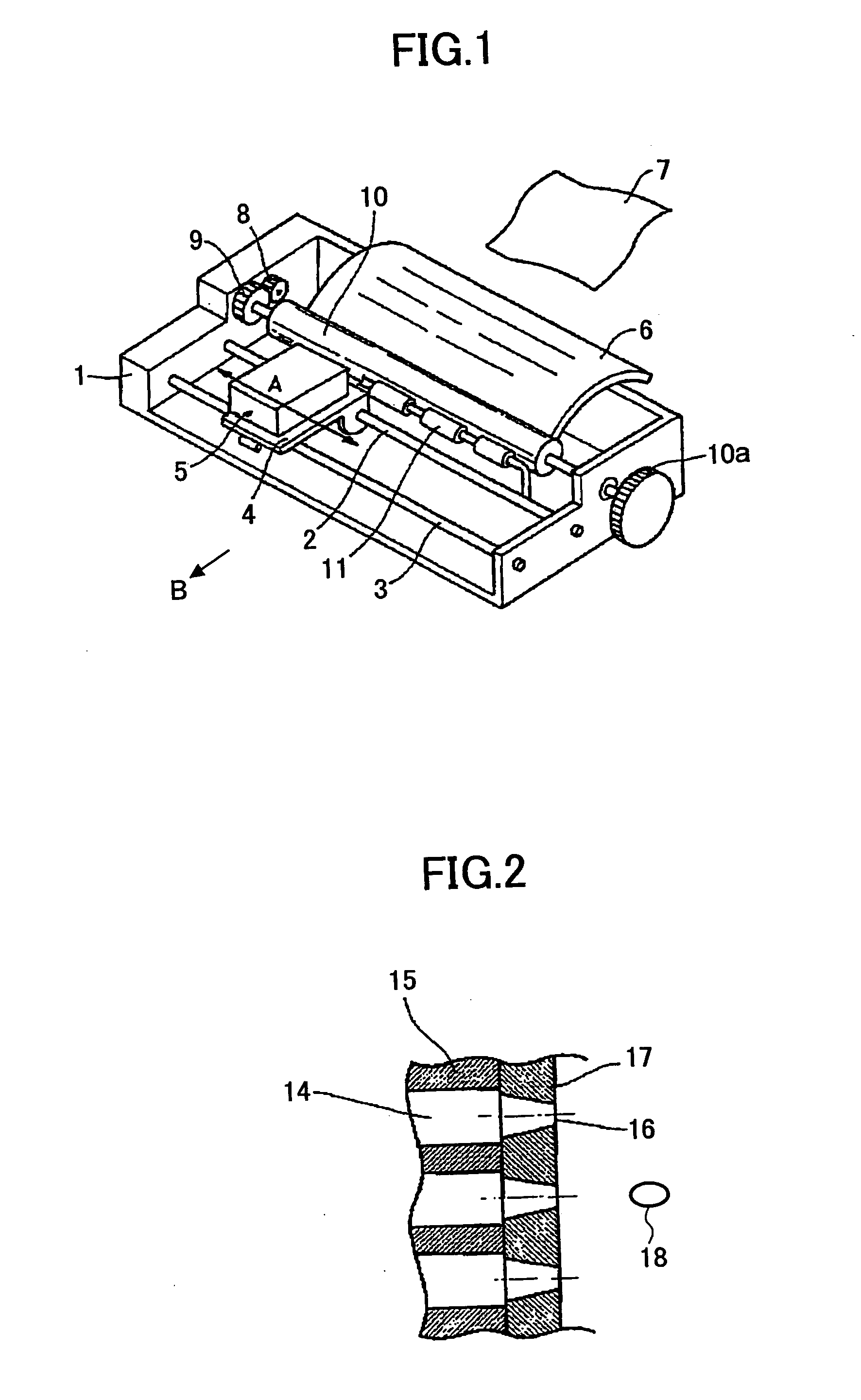

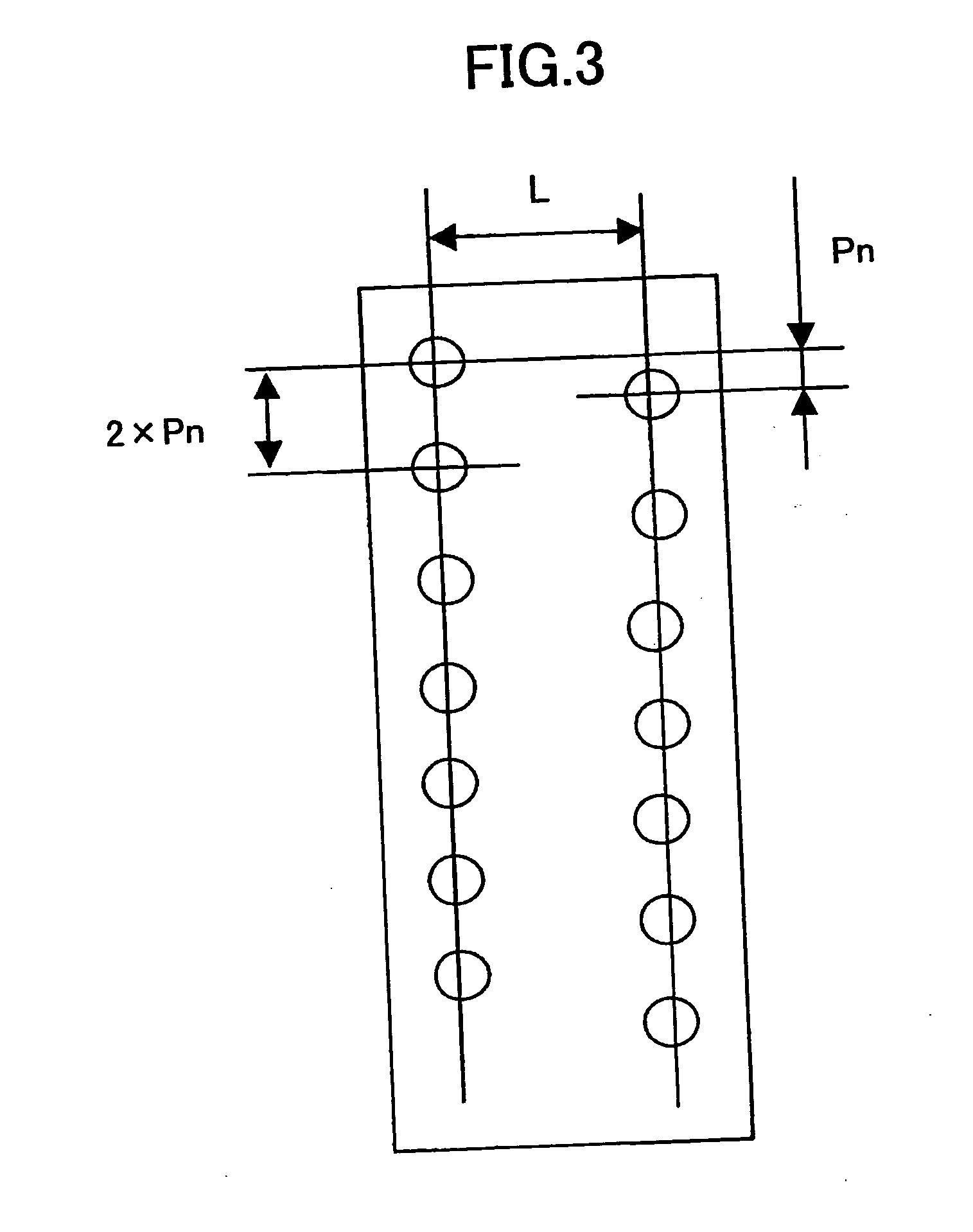

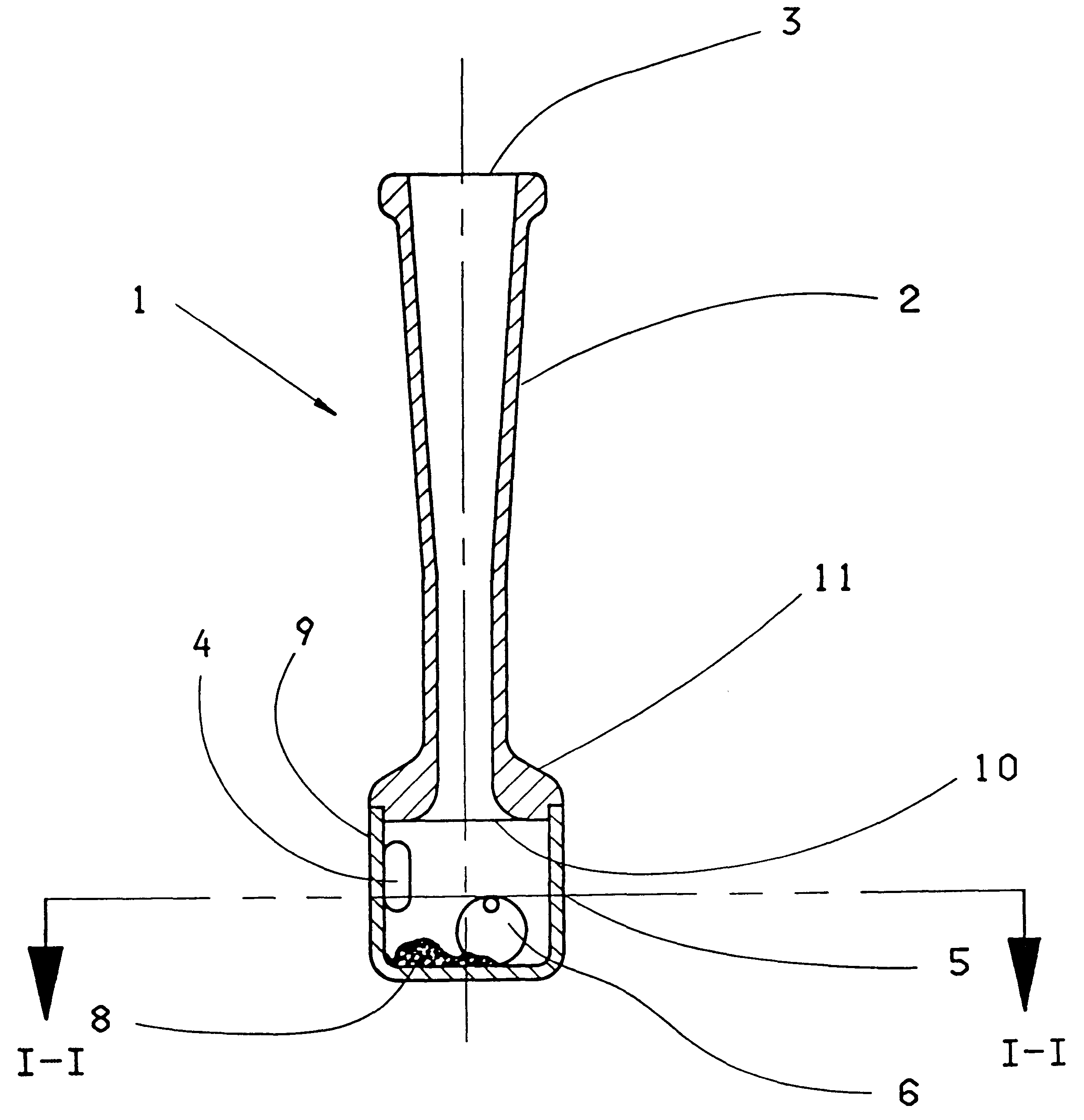

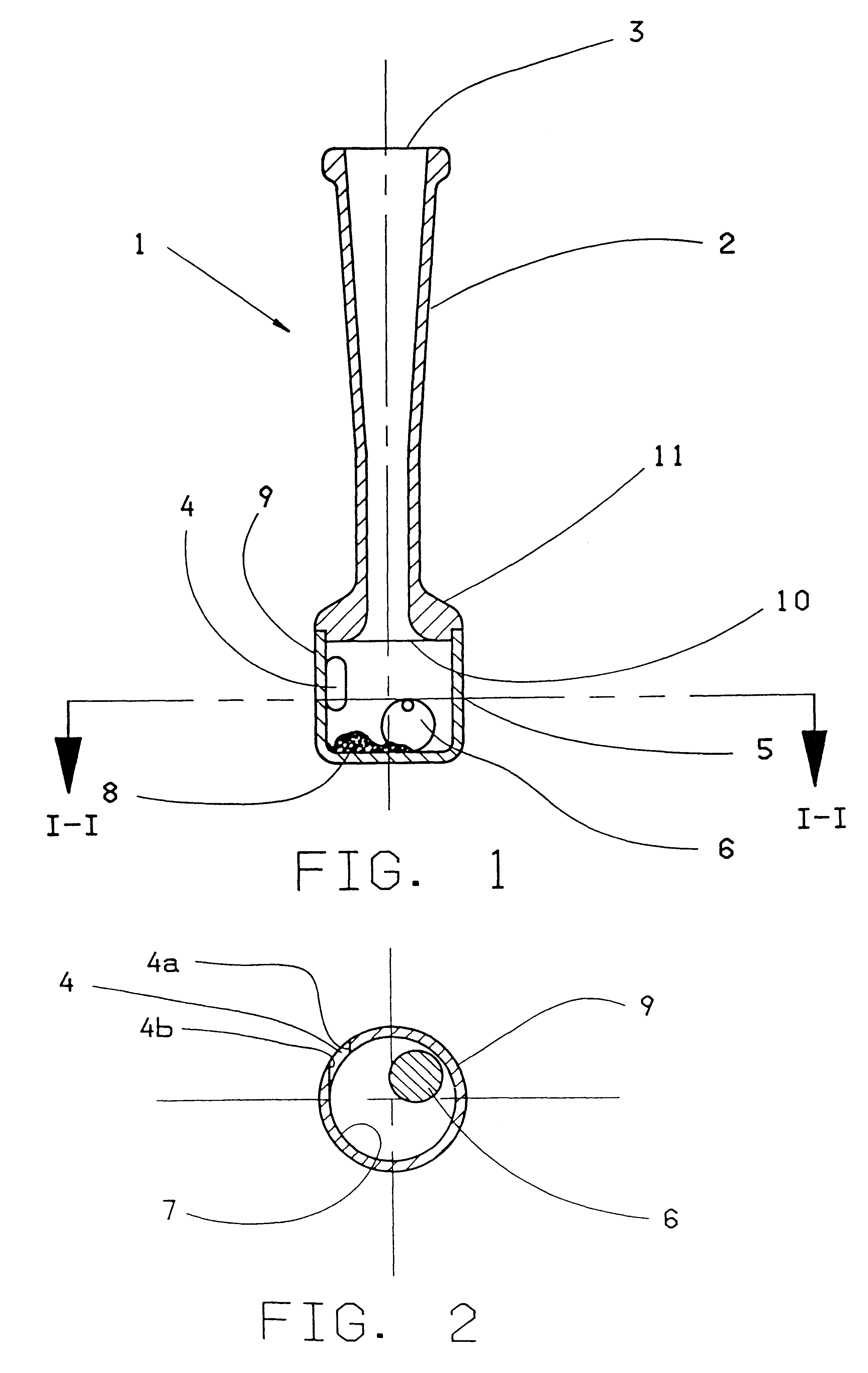

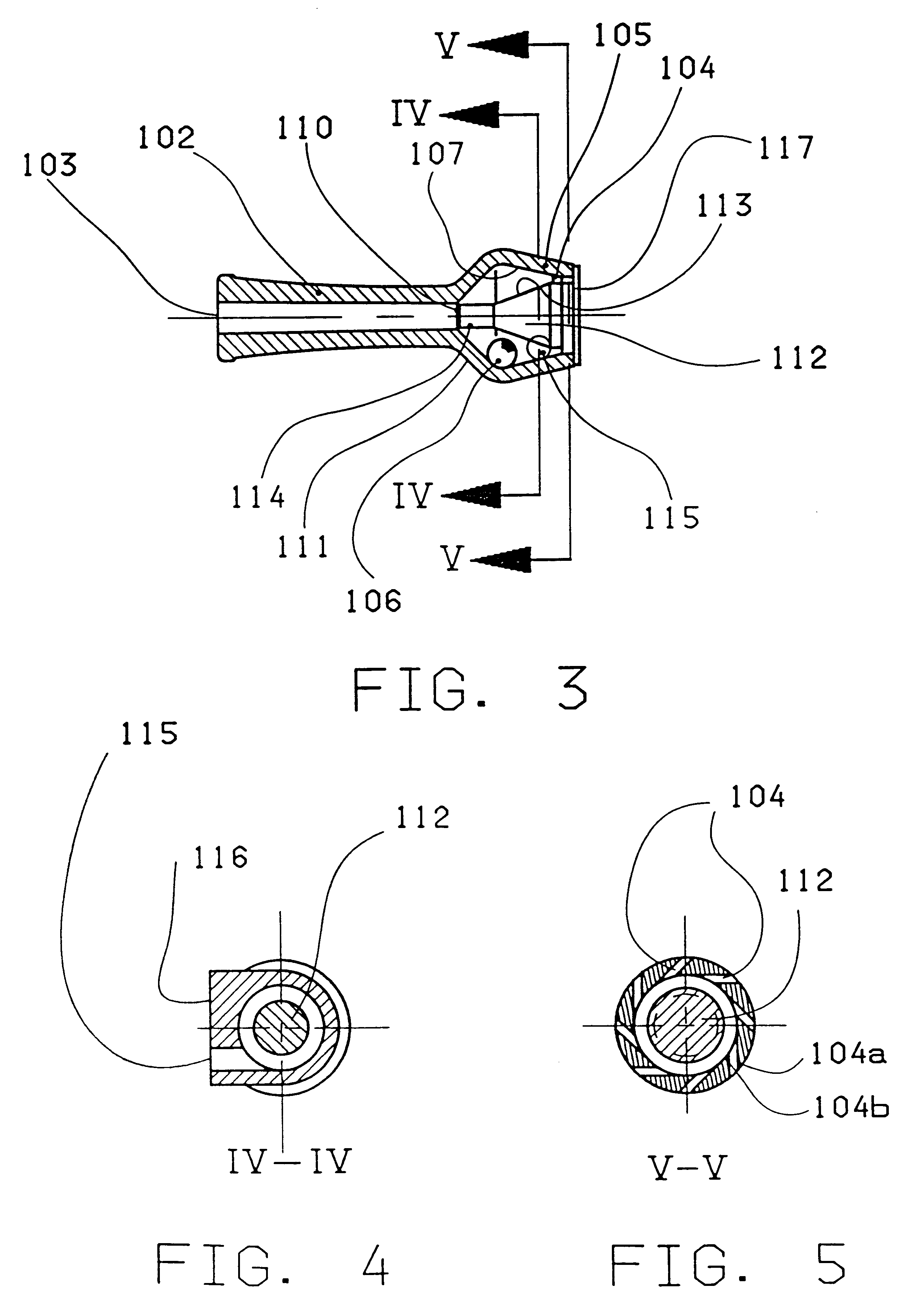

Powder inhaler

InactiveUS6230707B1Good dispersion propertiesEasily reaches lungRespiratorsLiquid surface applicatorsPowder InhalerEngineering

The invention concerns an inhaler device (1) having a hollow tubular member (2, 102, 402) connected to a chamber (5, 105, 405). The tubular member has a first opening (3, 103, 203) at one end through which air can be sucked and the chamber (5, 105, 405) has a hole (4, 104, 204) therein for entry of air. When air is sucked through the first opening, air enters the chamber through the hole swirls and moves towards the first opening (3, 103, 203). To maintain or increase the swirling effect of the air a single restriction (10, 110) is arranged between the opening and the hole (4, 104, 204). A powdered substance (8) within the chamber is picked up by the swirling air within the chamber and is uniformly and finely divided by the swirling effect of the air. The effect can be enhanced by adding a movable element (6) such as a ball inside the chamber (5) and / or by providing a central core element (112, 412) inside the chamber.

Owner:AVENTIS PHARMA LTD

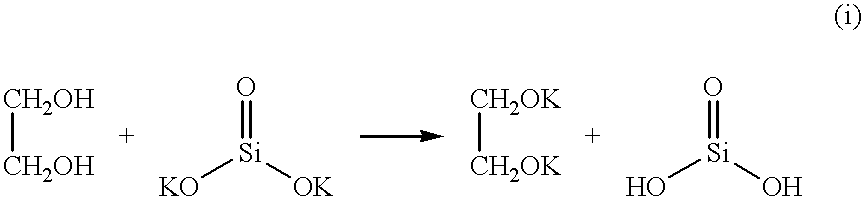

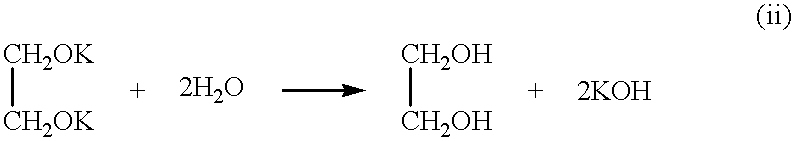

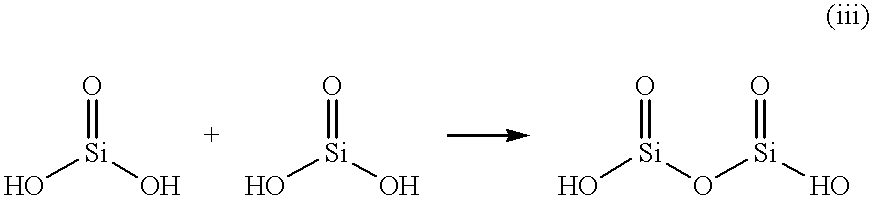

Aqueous compositions, aqueous cutting fluid using the same, method for preparation thereof, and cutting method using the cutting fluid

InactiveUS6221814B1Promote degradationSimple treatmentOther chemical processesWork treatment devicesActivated sludgeLiquid waste

An aqueous cutting fluid which can reduce the impact on working environment and the global environment, and can achieve both preventing precipitates from becoming a hard cake and keeping high dispersibility for abrasive grains is provided. Such an aqueous cutting fluid is obtained by a method comprising dispersing abrasive grains (G) in an aqueous composition comprising a dispersion medium (M) containing a hydrophilic alcohol compound such as ethylene glycol, a lipophilic alcohol compound such as propylene glycol and water, and silica colloid particles dispersed stably in the medium. The dispersion medium (M) is odorless and not flammable. The abrasive grains (G) may settle out after a time, but they do not closely contact with one another, and therefore the resulting precipitates do not become a hard cake, which allows the re-dispersion and reuse of precipitated grains. The instant aqueous cutting fluid is inherently low viscous, and the reduction of viscosity owing to the contamination of water and the increase of viscosity owing to contamination of shavings are both moderate. As a result, the cutting fluid has a long life. And articles which have been cut using the cutting fluid can be washed with water. Further, as the dispersion medium (M) is a biodegradable low molecular weight organic compound, a waste liquid from a process using the cutting fluid can be disposed with an activated sludge.

Owner:SHIN-ETSU HANDOTAI CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com