Titanium group powder metallurgy

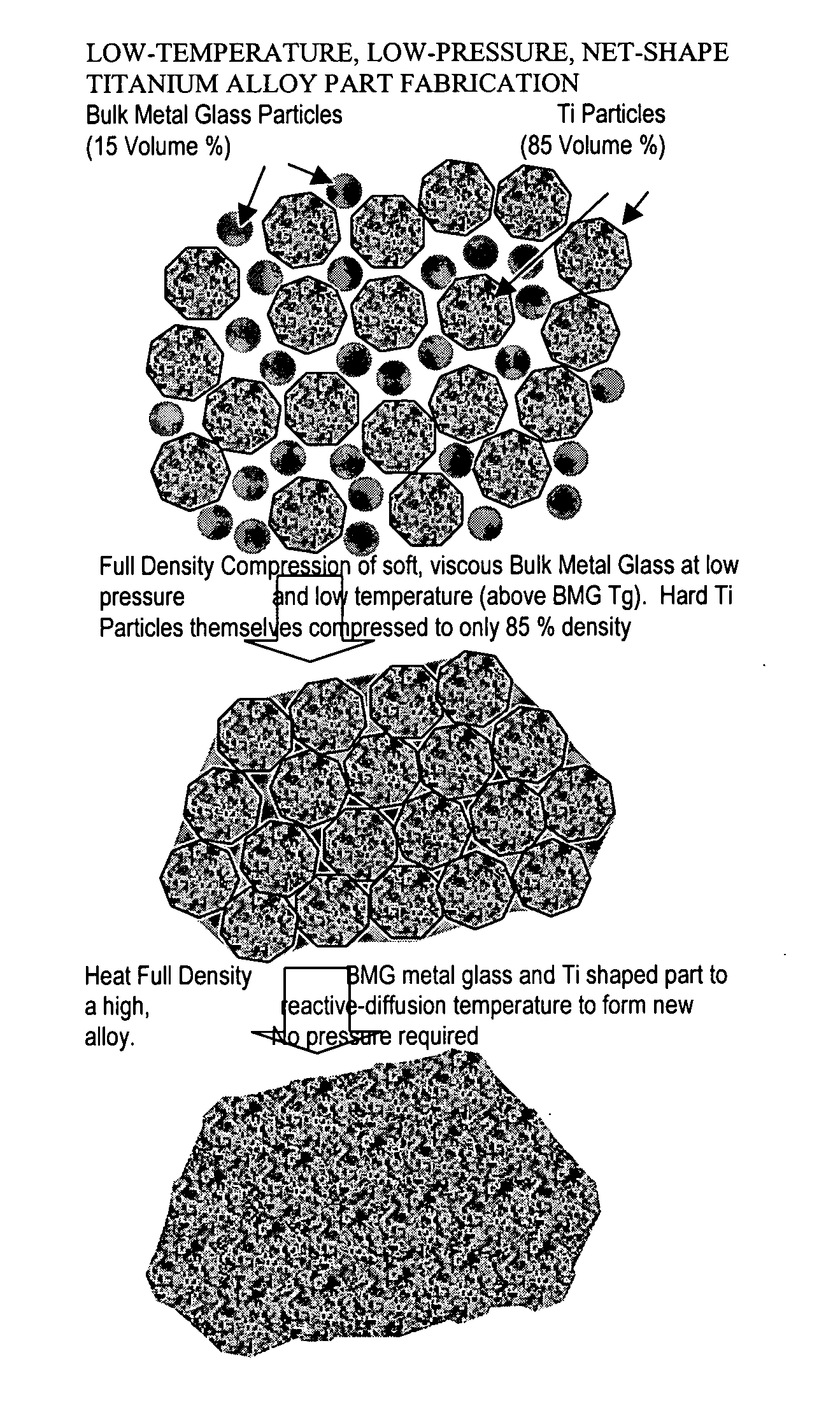

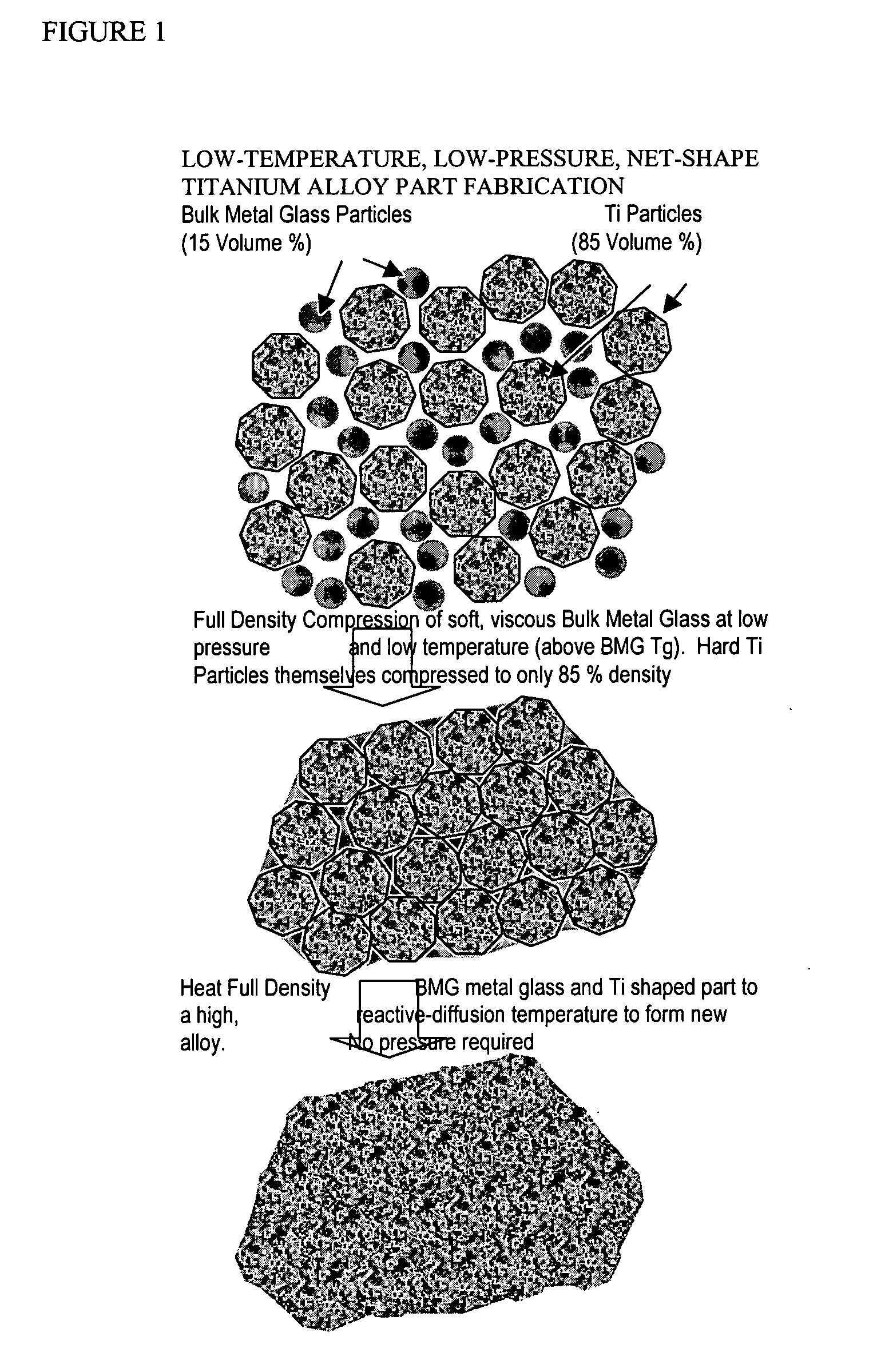

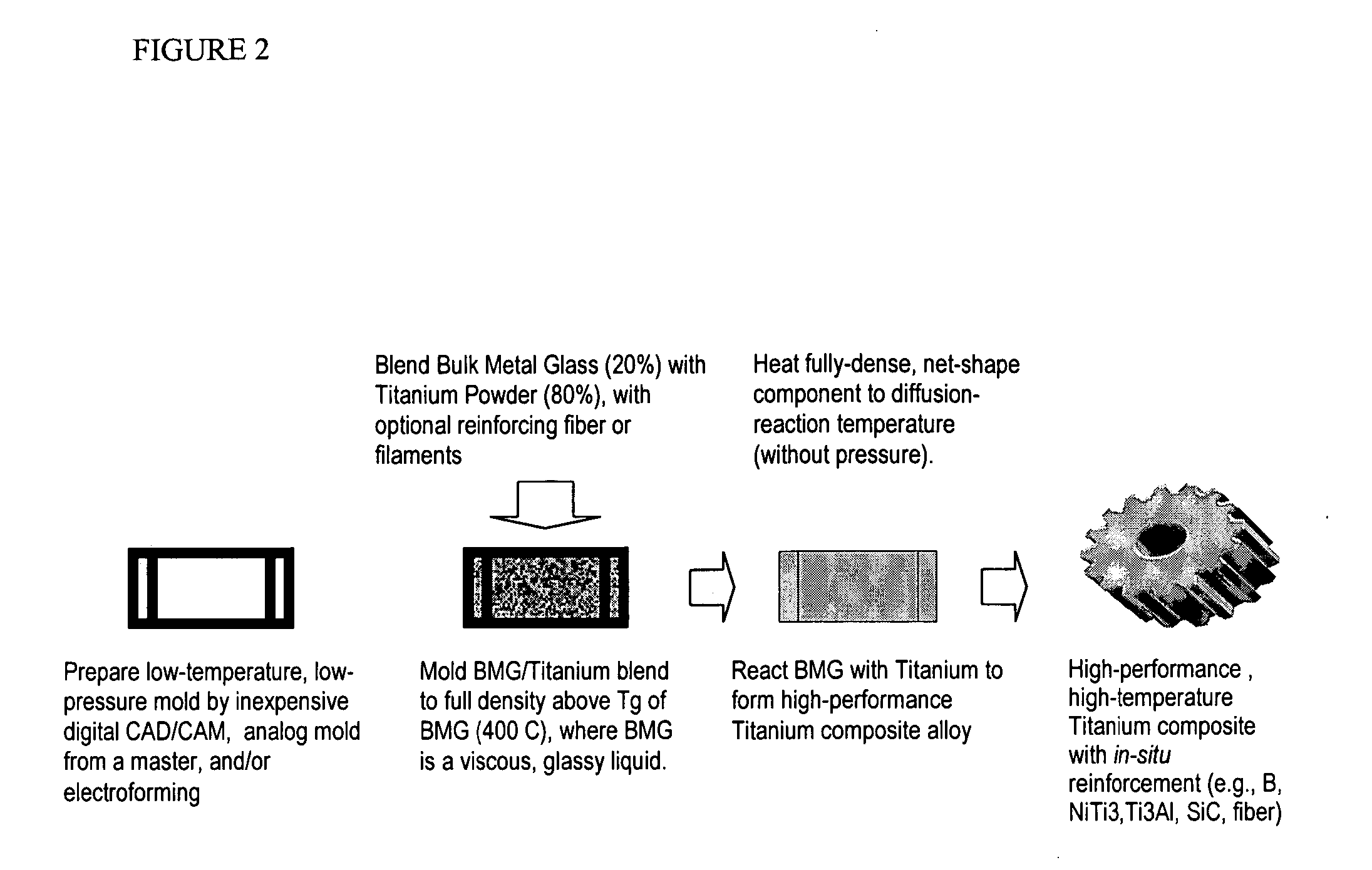

a titanium group and powder metallurgy technology, applied in the field of high-performance powder metallurgy for titanium group metal alloys, can solve the problems of difficult economic elimination of porosity, difficult to achieve full density, and relative difficulty in manufacturing, and achieve good hardenability, cold formability, and high strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0111] Al85Ni5Y8Co2 fully amorphous alloy has a glass transition temperature Tg of 538° K., a relatively high strength of 1250 MPa at room temperature and a relatively wide and a 38° K. supercooled liquid region [Y. Kawamura, et al, “Nanocrystalline Aluminum Bulk Alloys With A High Strength Of 1420 Mpa Produced By The Consolidation Of Amorphous Powders”, Scripta mater. 44 (2001) 1599-1604; A. Inoue, et al., Mater. Trans. JIM. 31, 493 (1990).]. Its initial crystallization occurs through the precipitation of fcc-Al particles while retaining viscous flow in the supercooled liquid region [Y. Kawamura, et al, Int. J. Powder Metall. 33, 50 (1997); Y. Kawamura, et al, J. Jpn. Soc. Powder Powder Metall. 38, 948 (1991); Y. Kawamura, et al, Mater. Trans. JIM. 40, 749 (1999)], and accordingly is used as a minor BMG component with a large volume of crystalline titanium powder.

[0112] A one Kg ingot of an Al85Ni5Y8Co2 (at %) alloy is prepared by arc melting a mixture of the pure elements. The in...

example 2

[0114] 200 grams of SiBNC fibers having a tensile strength of 2-4 GPa, a density of 1.8 / cm3, a diameter of 8-14 microns [See e.g., H. P. Balddus, et al., “Properties of Amorphous SiBNC-Ceramic Fibers”, Key Engineering Materials, Vol. 127-131, pp. 177-184 (1977)] are aligned in a blend of 900 grams of CP titanium powder and 100 grams of a BMG alloy powder, by weight, based on the total powder weight. The BMG alloy powder is Ti50Cu20Ni24Si4B2 (atomic percent), having a Tg of about 745° K. and a supercooled liquid region of about 65° K. The aligned fibers and powder blend are compressed between sheet platens under vacuum at a temperature of 8000 K, at a compression pressure of 465 MPa to produce a fully dense sheet “tape” with a monolayer of aligned fibers. The sheet is removed from the platen press and subsequently heated in an inert temperature to a temperature of about 1200° C. to form a fiber-reinforced, high-temperature composite, in which the fibers are embedded in a matrix havin...

example 3

[0115] 89 grams of a titanium alloy powder which is 96.4 atomic percent titanium and 3.6 atomic percent vanadium is blended with 11 grams of a bulk metal glass powder having a composition of A194V4Fe2 atomic percent. The 100 grams of the powder blend is compressed in a gear-shaped mold under vacuum at a compression pressure of 25 kSI, at a temperature 25° above the glass transition temperature Tg of the amorphous alloy to form a substantially fully dense gear component. The gear is removed from the mold, and heated in a vacuum furnace to a temperature of 1000° C. to first crystallize the BMG and then reactively diffuse it with the Ti alloy powder, to form an alloy with a nominal composition in weight percent of 89.6Ti, 6.09Al, 4.04V and 0.27Fe.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Percent by volume | aaaaa | aaaaa |

| Percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com