A kind of 80mm large-thickness high-toughness low-alloy wear-resistant steel plate and its manufacturing method

A technology of wear-resistant steel plate and manufacturing method, which is applied in the field of wear-resistant steel manufacturing, can solve the problems of low-alloy wear-resistant steel, poor wear-resistant performance, and low impact toughness of low-alloy wear-resistant steel, and achieve improved wear-resistant performance and low temperature Good impact toughness and cold-bending performance, and overall uniform steel temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

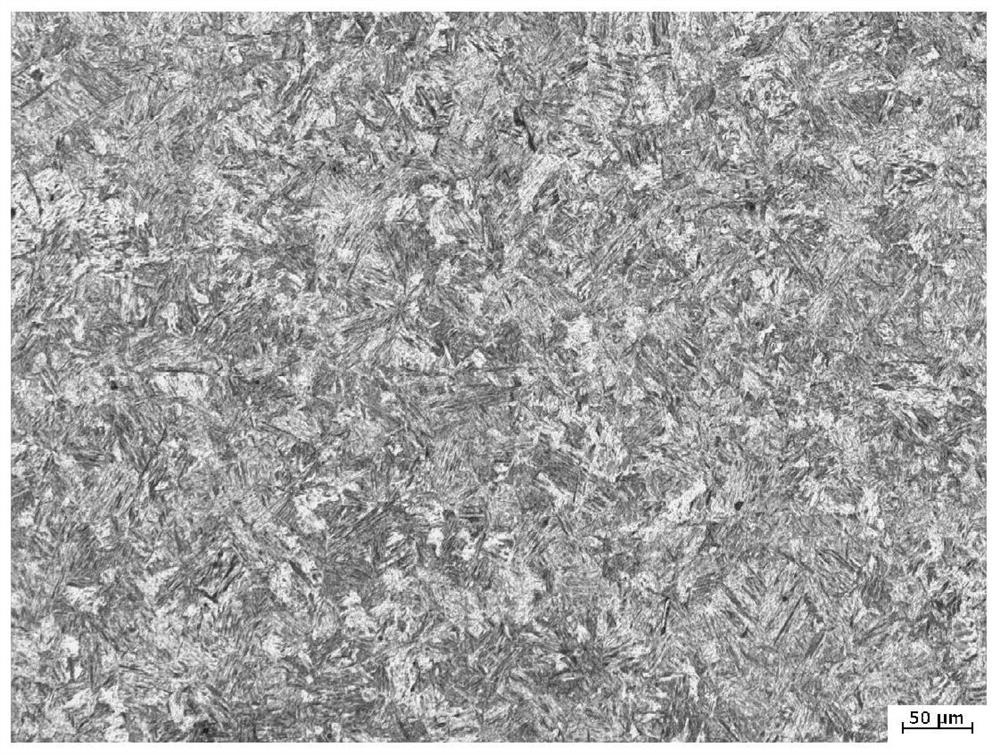

Embodiment 1

[0021] This embodiment is an 80mm large thickness high toughness low alloy wear-resistant steel plate, which includes the following components by weight percentage: C: 0.18%, Si: 0.20%, Mn: 1.20%, P≤0.012%, S≤0.0015 %, Cr: 1.20%, Mo: 0.20%, Ni: 0.50%, Ti: 0.008%, Nb: 0.01%, V≤0.030%, B: 0.0008%, Alt: 0.035%, N≤0.0040%, H≤0.0002 %, the rest is Fe and unavoidable impurities.

[0022] The manufacturing method of the 80mm large thickness, high toughness and low alloy wear-resistant steel plate of this embodiment includes the following process: hot metal desulfurization pretreatment-converter smelting-LF+RH refining-continuous casting-slab stacking slow cooling-slab inspection-casting Billet acceptance - billet heating - dephosphorization - rolling - air cooling - flaw detection - shot blasting - quenching - tempering - straightening - cutting, sampling - printing marks - inspection - storage;

[0023] The steel components are smelted according to the required ratio, and the molte...

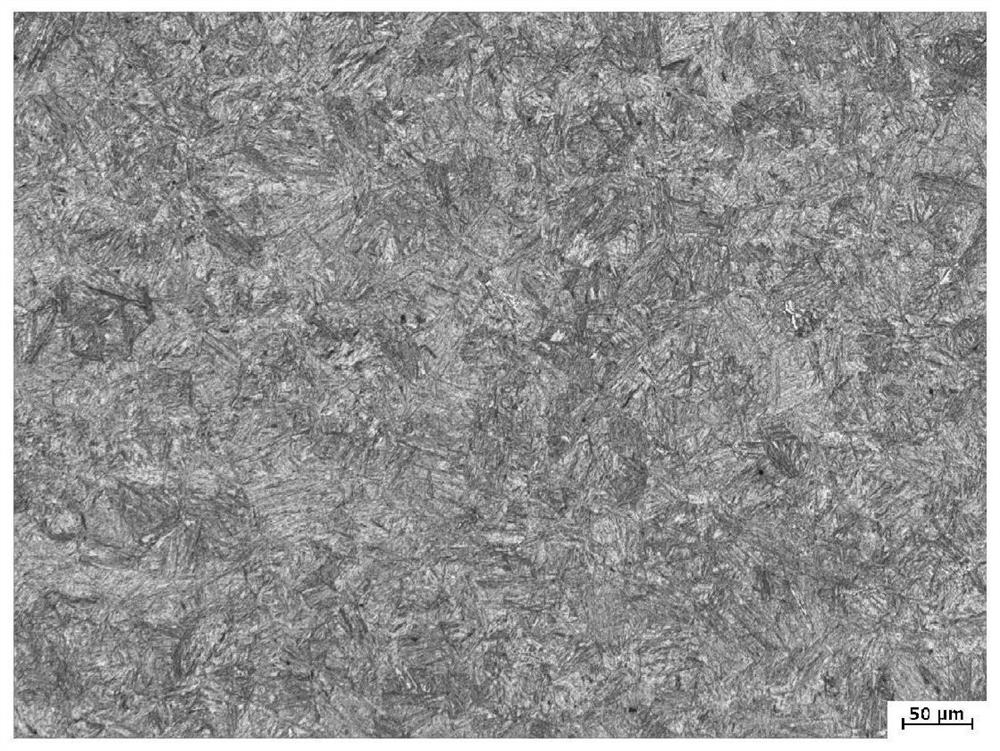

Embodiment 2

[0027] This embodiment is an 80mm large thickness high toughness low alloy wear-resistant steel plate, which includes the following components by weight percentage: C: 0.19%, Si: 0.30%, Mn: 1.10%, P≤0.012%, S≤0.0015 %, Cr: 1.10%, Mo: 0.32%, Ni: 0.70%, Ti: 0.013%, Nb: 0.013%, V≤0.030%, B: 0.0013%, Alt: 0.040%, N≤0.0040%, H≤0.0002 %, the balance is Fe and unavoidable impurities.

[0028] The manufacturing method of the 80mm large thickness, high toughness and low alloy wear-resistant steel plate of this embodiment includes the following process: hot metal desulfurization pretreatment-converter smelting-LF+RH refining-continuous casting-slab stacking slow cooling-slab inspection-casting Billet acceptance - billet heating - dephosphorization - rolling - air cooling - flaw detection - shot blasting - quenching - tempering - straightening - cutting, sampling - printing marks - inspection - storage;

[0029] The steel components are smelted according to the required ratio, and the m...

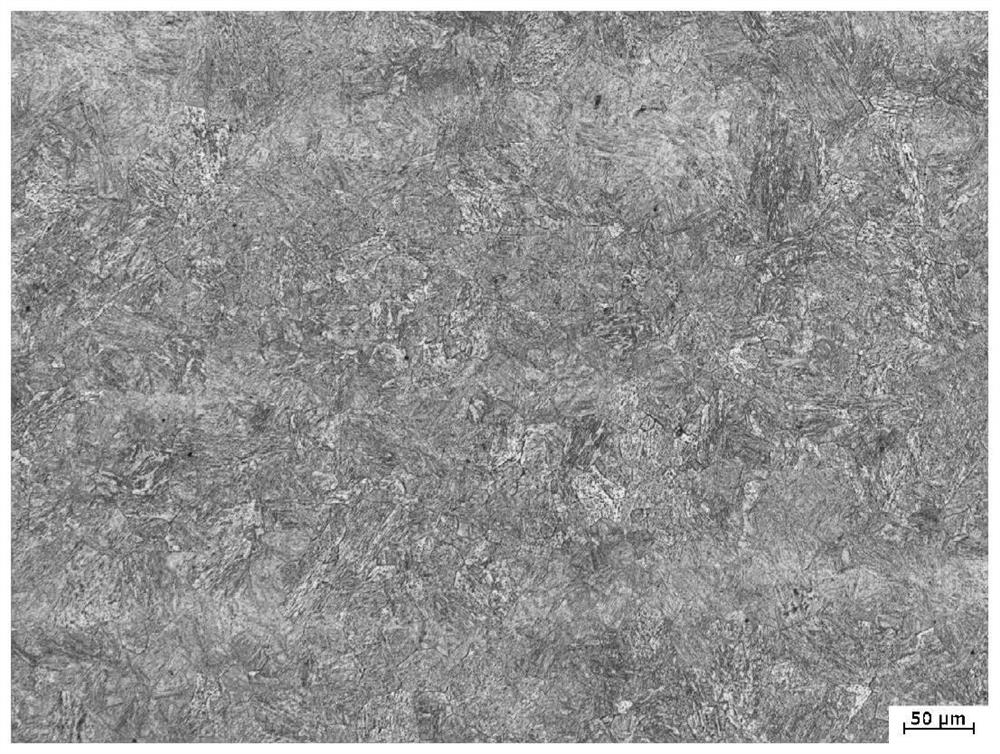

Embodiment 3

[0033]This embodiment is an 80mm large thickness high toughness low alloy wear-resistant steel plate, which includes the following components by weight percentage: C: 0.20%, Si: 0.40%, Mn: 0.90%, P≤0.012%, S≤0.0015 %, Cr: 0.90%, Mo: 0.40%, Ni: 0.80%, Ti: 0.030%, Nb: 0.050%, V≤0.030%, B: 0.0025%, Alt: 0.035%, N≤0.0040%, H≤0.0002 %, the rest is Fe and unavoidable impurities.

[0034] The manufacturing method of the 80mm large thickness, high toughness and low alloy wear-resistant steel plate of this embodiment includes the following process: hot metal desulfurization pretreatment-converter smelting-LF+RH refining-continuous casting-slab stacking slow cooling-slab inspection-casting Billet acceptance - billet heating - dephosphorization - rolling - air cooling - flaw detection - shot blasting - quenching - tempering - straightening - cutting, sampling - printing marks - inspection - storage;

[0035] The steel components are smelted according to the required ratio, and the molte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com