Patents

Literature

1604 results about "Reclaimer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A reclaimer is a large machine used in bulk material handling applications. A reclaimer's function is to recover bulk material such as ores and cereals from a stockpile. A stacker is used to stack the material.

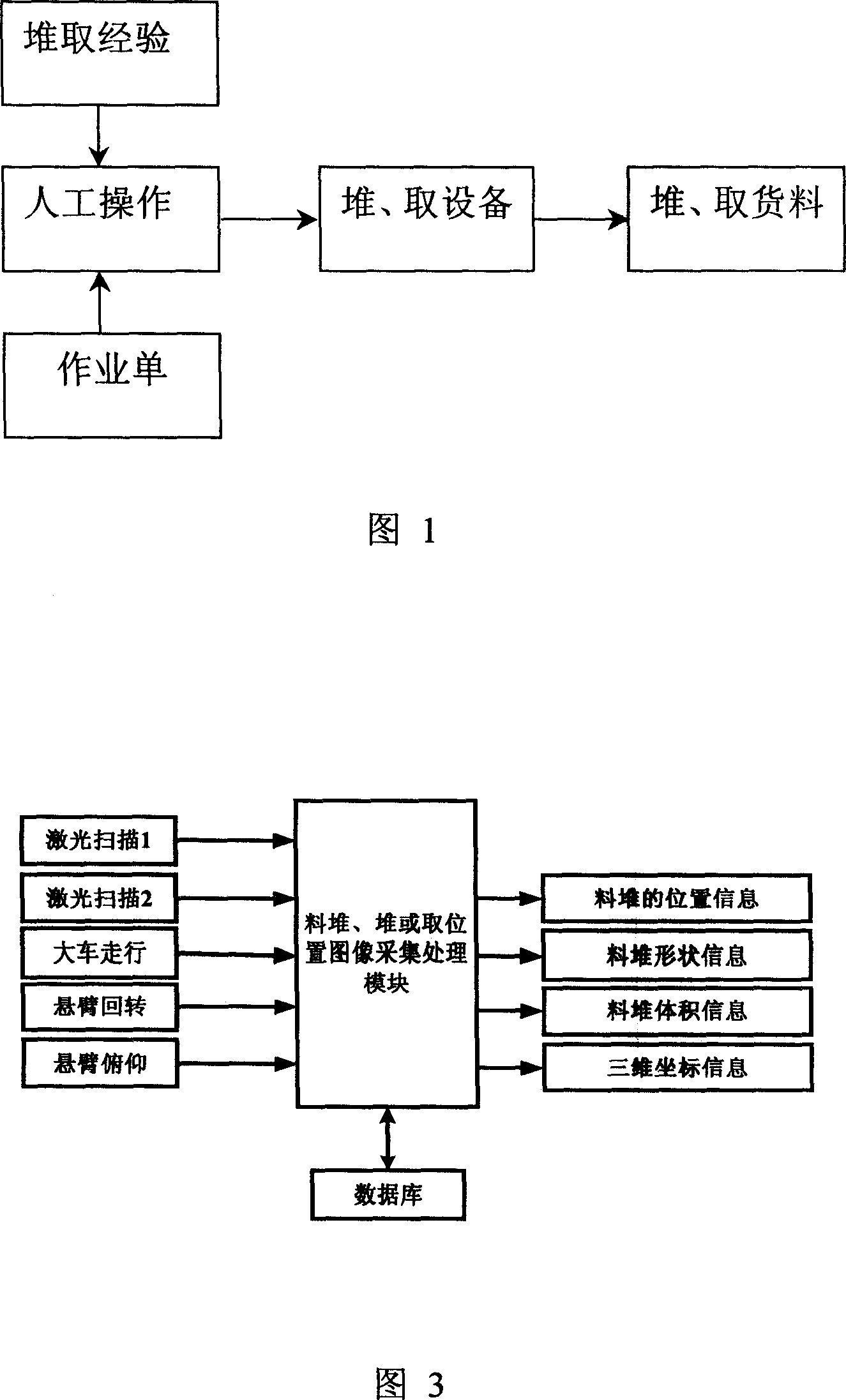

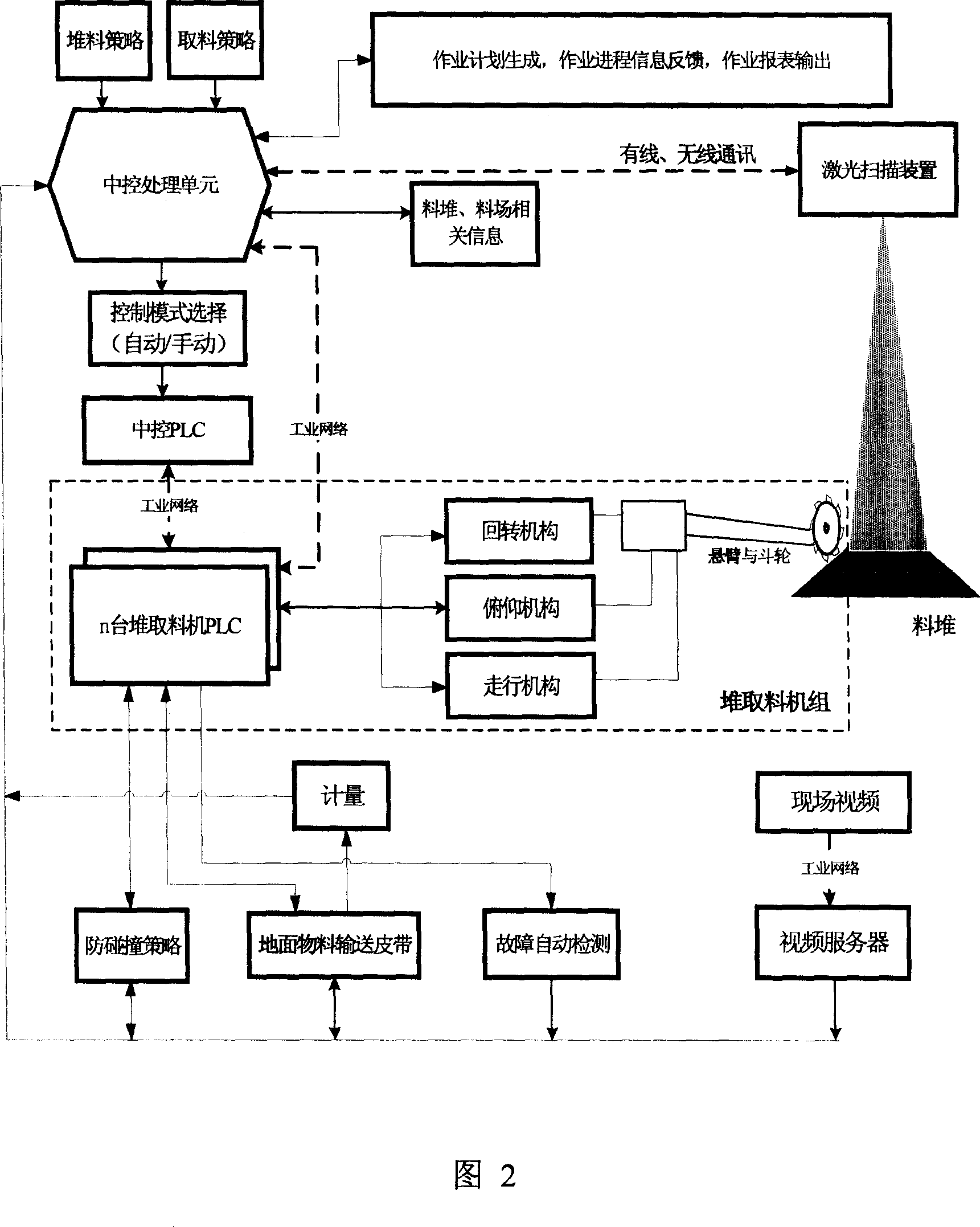

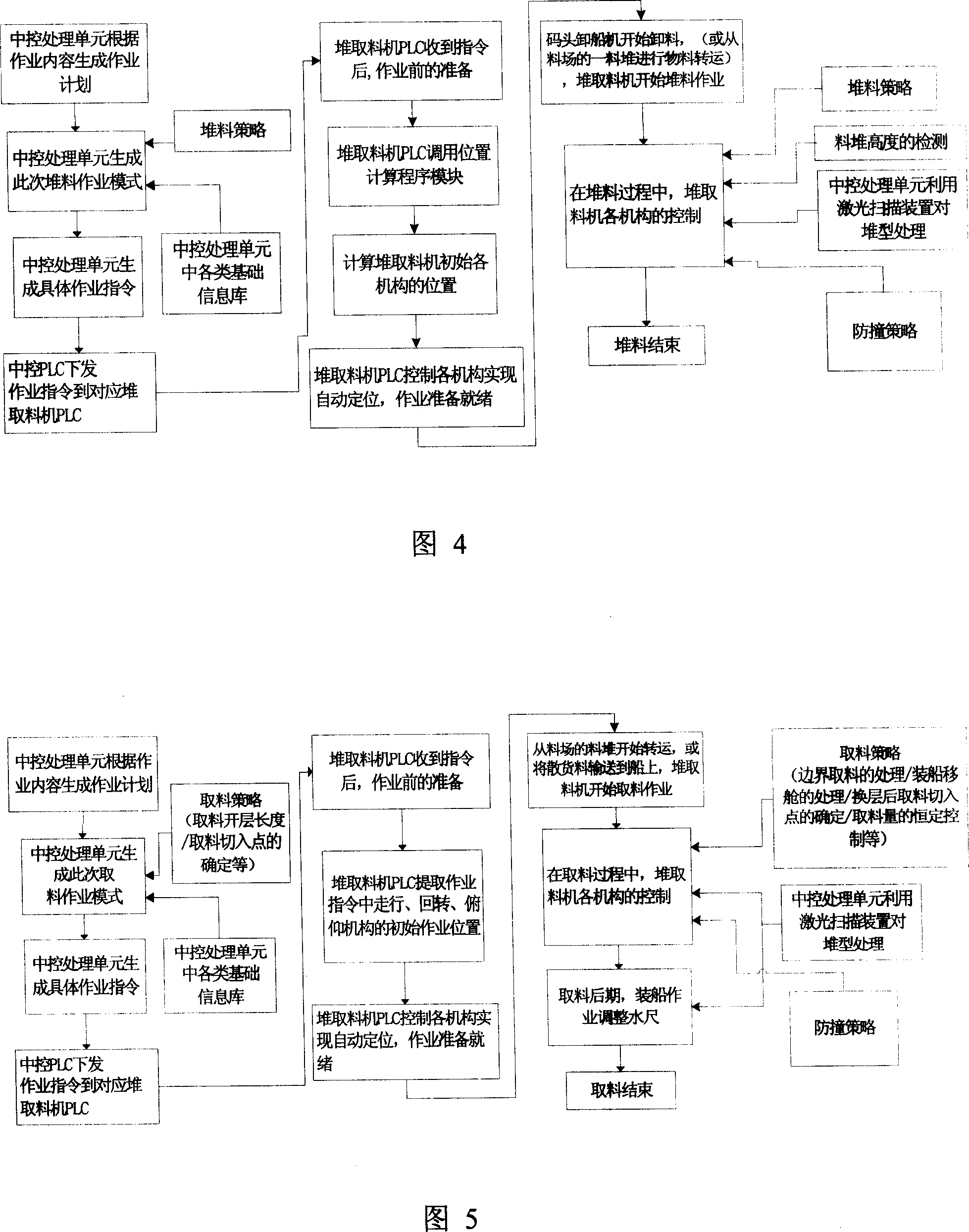

Unmanned piling and taking technique for bulk cargo stock yard

ActiveCN101104480AOvercoming automationOvercome labor intensityElectric programme controlLoading/unloadingBulk cargoLaser scanning

The invention relates to a port warehousing logistics technology, in particular to a bulk material yard unmanned stacking / reclaiming technology. Firstly, a database is established; secondly, operation instructions, automatic stacking / reclaiming operation modes and control instructions for automatic stacking / reclaiming operations are generated through input operation kinds of goods and the planning work amount; thirdly, the relevant instructions are sent to a central control PLC and then transmitted to the corresponding local stacker / reclaimer PLC through the industrial network; fourthly, the local PLC controls the operation of all components of the stacker / reclaimer to complete the local operation control. At the same time, a material stack laser scanning device is used to scan the material yard condition, and the scanned result will then be transferred to a central control processing unit through the industrial network; fifthly, the central control processing unit achieves the stack type scan data processing of the stacker / reclaimer to generate new instructions which will then be sent to the corresponding local stacker / reclaimer PLC; sixthly, a handle operating panel arranged inside a central control room can be taken as a backup means of manual operation under special circumstances. The invention can be applied to large-scale raw material yards, such as ports, wharfs, open warehouses, mine stacking yards, as well as iron and steel enterprises.

Owner:BAOSHAN IRON & STEEL CO LTD +1

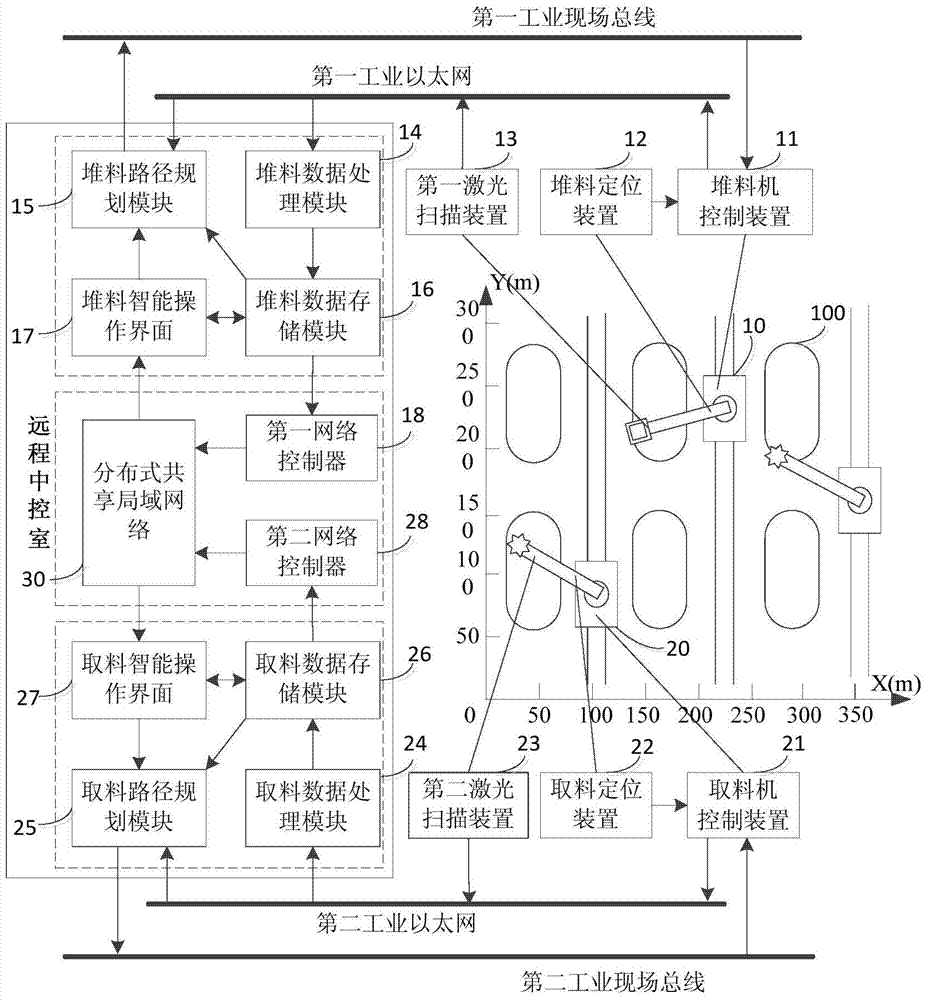

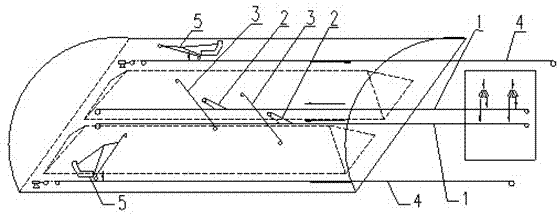

Automatic stacking/reclaiming system for bulk cargo storage yard

InactiveCN104724506ASimplify hardware configurationEasy to installLoading/unloadingBulk cargoControl signal

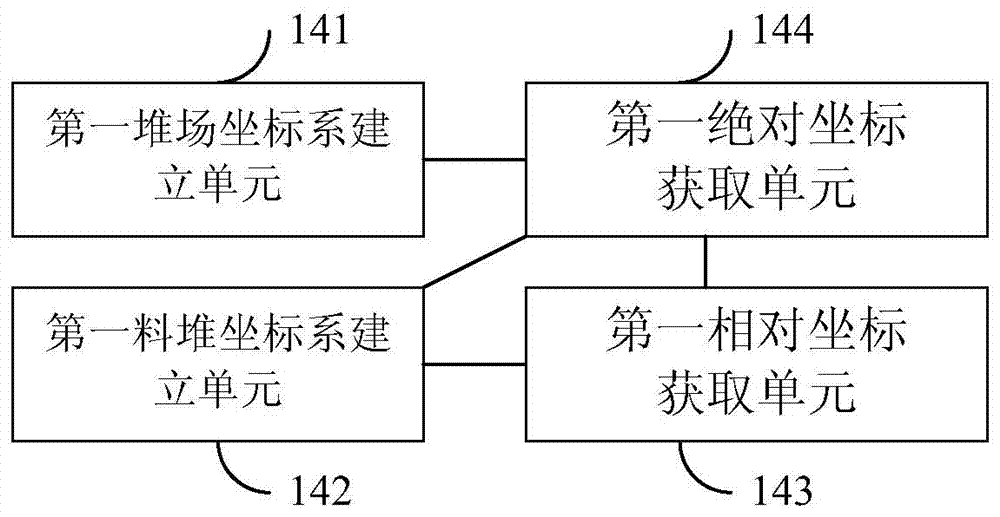

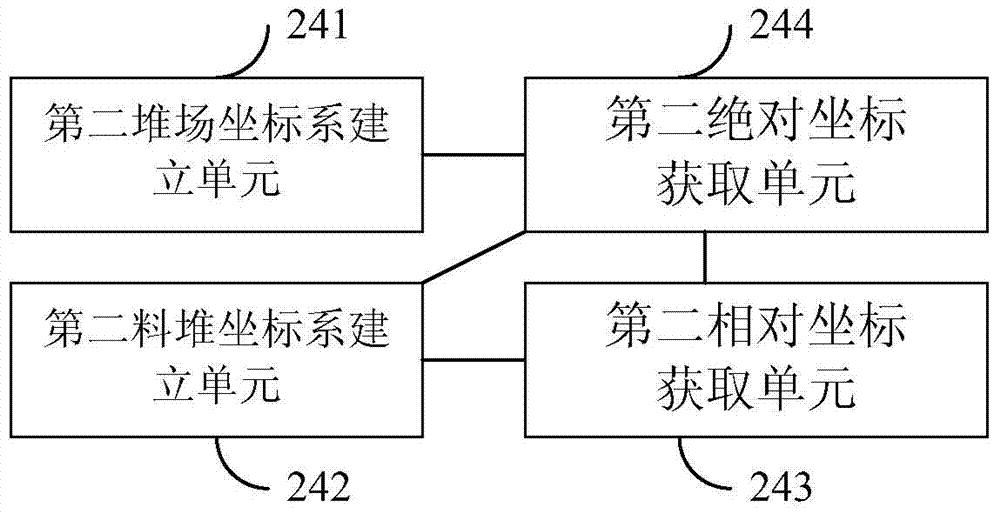

The invention provides an automatic stacking / reclaiming system for a bulk cargo storage yard. The automatic stacking / reclaiming system comprises a stacker distributed in the storage yard and provided with a stacking cantilever, a reclaimer distributed in the storage yard and provided with a reclaiming cantilever, a first laser scanning device installed on the stacking cantilever and used for acquiring scanning data of the storage yard, a second laser scanning device installed on the reclaiming cantilever and used for acquiring the scanning data of the storage yard, a stacking positioning device and a reclaiming positioning device for acquiring GNSS positioning information, a stacker control device, a reclaimer control device, a remote stacking processing device and a remote reclaiming processing device. The stacker control device and the reclaimer control device acquire and output the GNSS positioning information, receive a stacking control signal and a reclaiming control signal, and control the stacker and the reclaimer to execute corresponding stacking / reclaiming actions according to the control signals. The remote stacking processing device and the remote reclaiming processing device receive a stacking instruction and a reclaiming instruction input by a peripheral user, acquire coordinate information of the corresponding storage yard according to the instructions, the scanning data and the GNSS positioning information, and generate stacking / reclaiming path information to serve as the stacking / reclaiming control signals to be output to the stacker control device and the reclaimer control device. The automatic stacking / reclaiming system is based on GNSS positioning, and is high in accuracy and low in cost, data can be shared, and automatic operation of the bulk cargo storage yard is achieved.

Owner:CCCC THIRD HARBOR CONSULTANTS

Coal-fired power plant coal yard refined management system and control method thereof

ActiveCN103455901AFast and accurate deliveryAccurate accessSystems intergating technologiesLogisticsInformatizationData acquisition

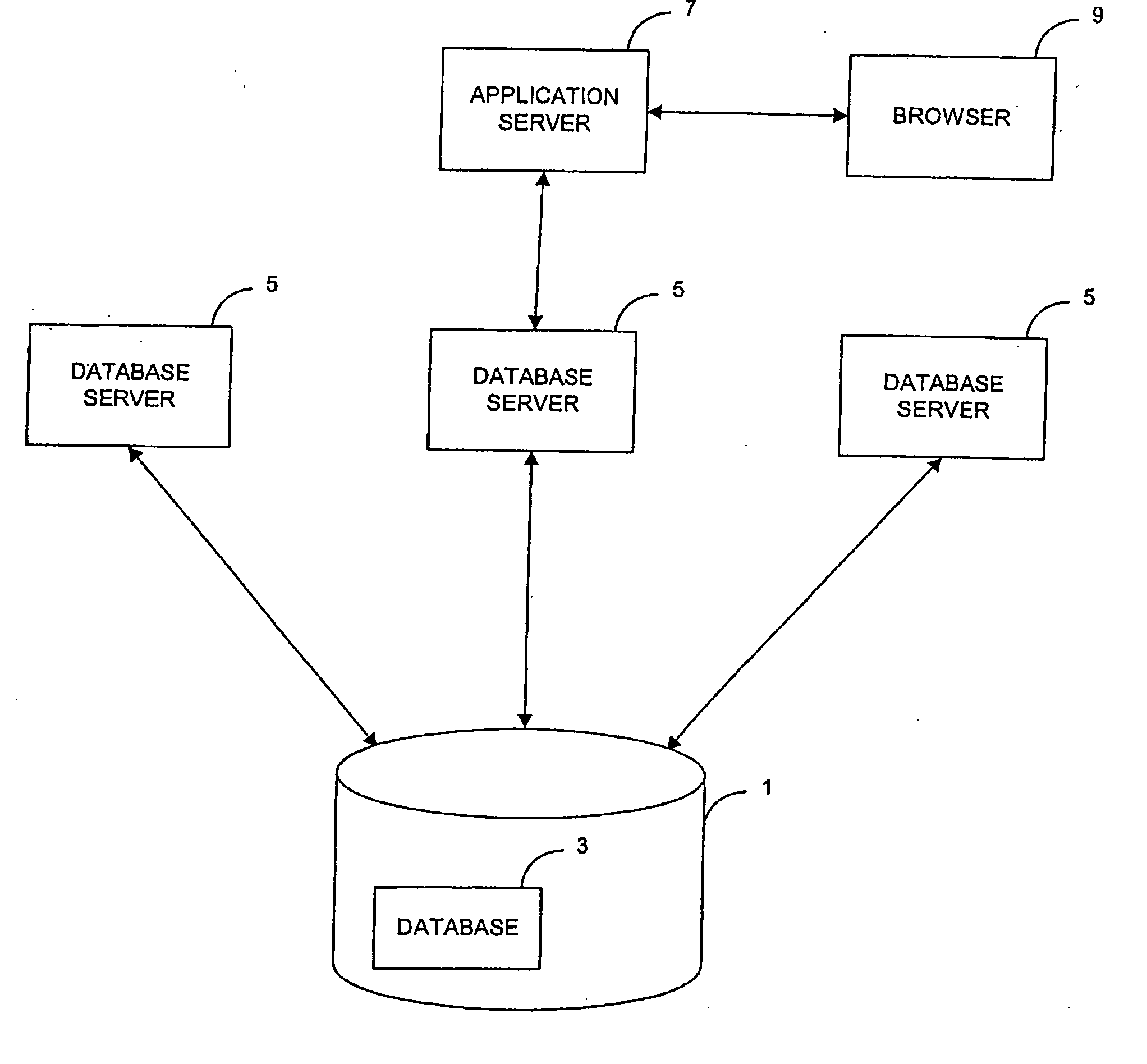

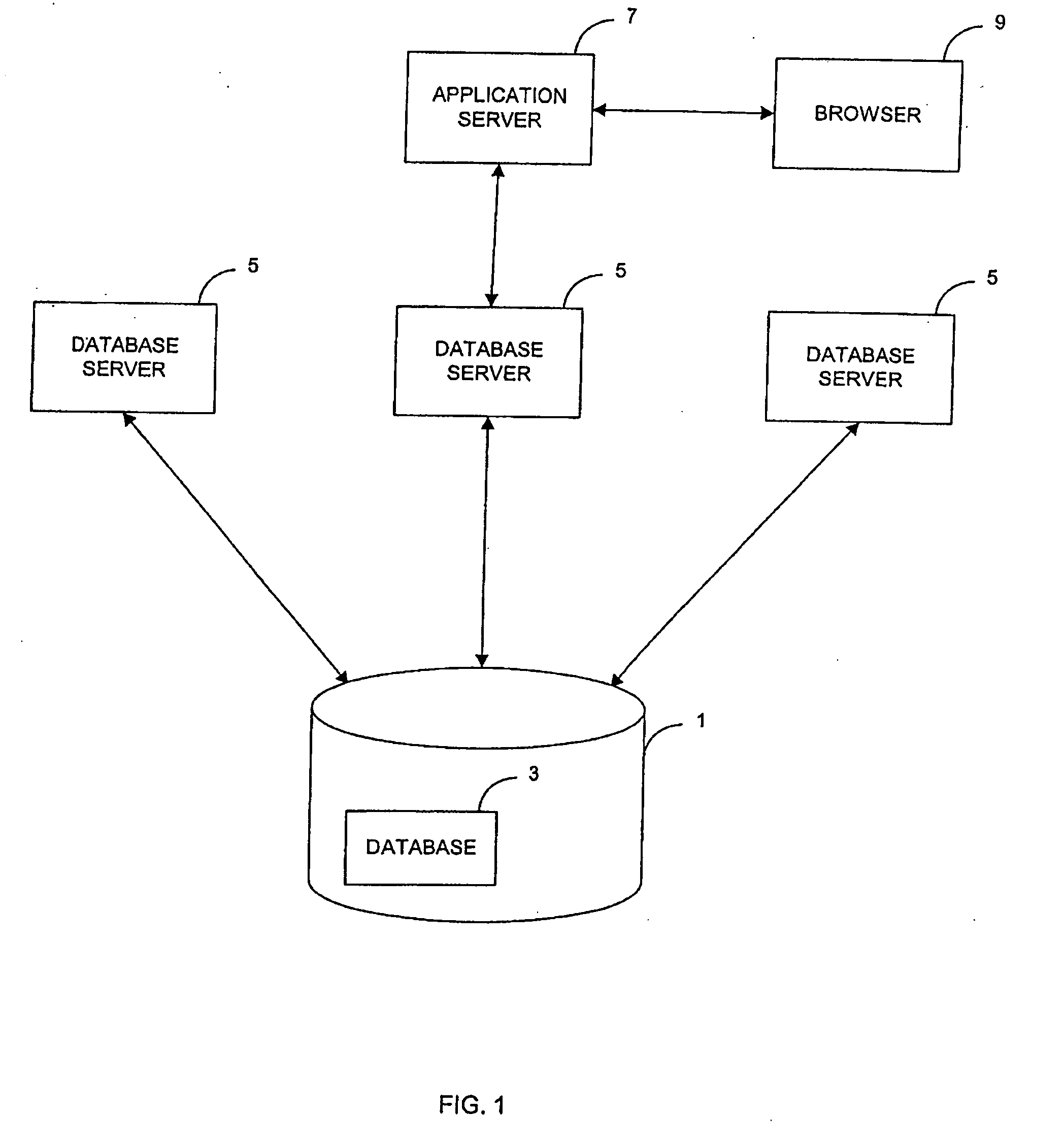

The invention relates to a coal-fired power plant coal yard refined management system and a control method of the coal-fired power plant coal yard refined management system. The coal-fired power plant coal yard refined management system is characterized by comprising a laser disc coal instrument, an intelligent temperature monitoring meter, a metering device, a stacker-reclaimer, a data acquisition unit, a controller, a data server, an application server and a computer client side. The application server comprises a coal database management module, a real-time stock management module, a coal storage management module and a heat loss evaluation and control module. The control method is characterized by including the following steps that coal pile outline data points and digital signs in a coal yard field are acquired according to the laser disc coal instrument, and three-dimensional reconstruction of coal piles is completed based on a VC++ and OpenGL platform; when coal is transported to a factory, information is input to the coal database management module through an input port in the computer client side. According to the coal-fired power plant coal yard refined management system and the control method, the informatization and intelligentization method is adopted, information is quickly and accurately transmitted, and coal heat loss is reduced.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

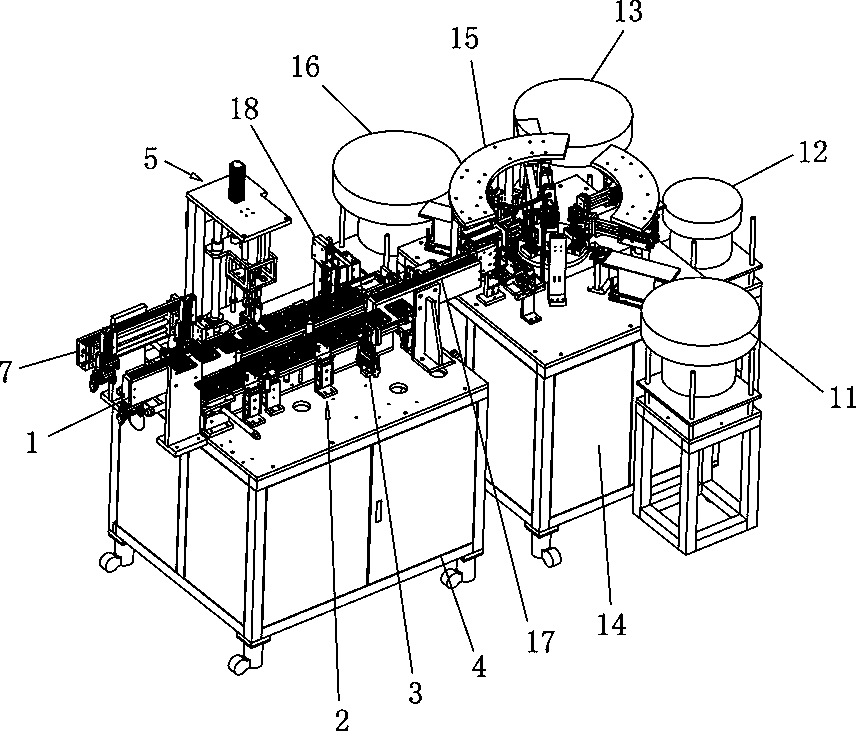

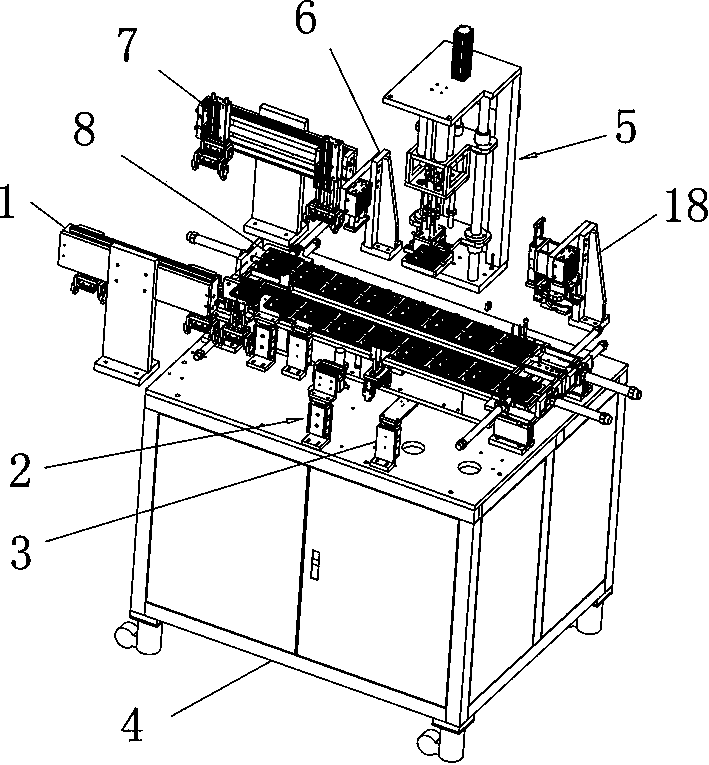

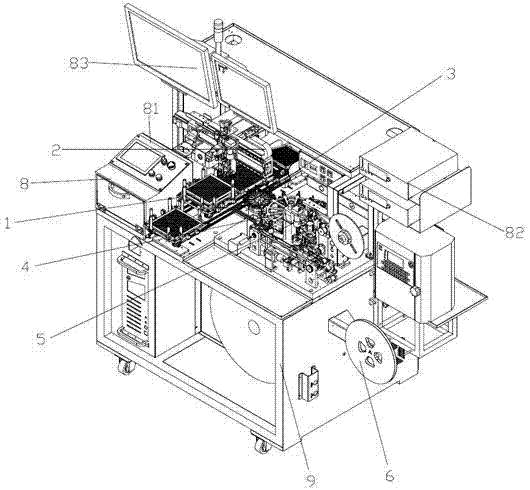

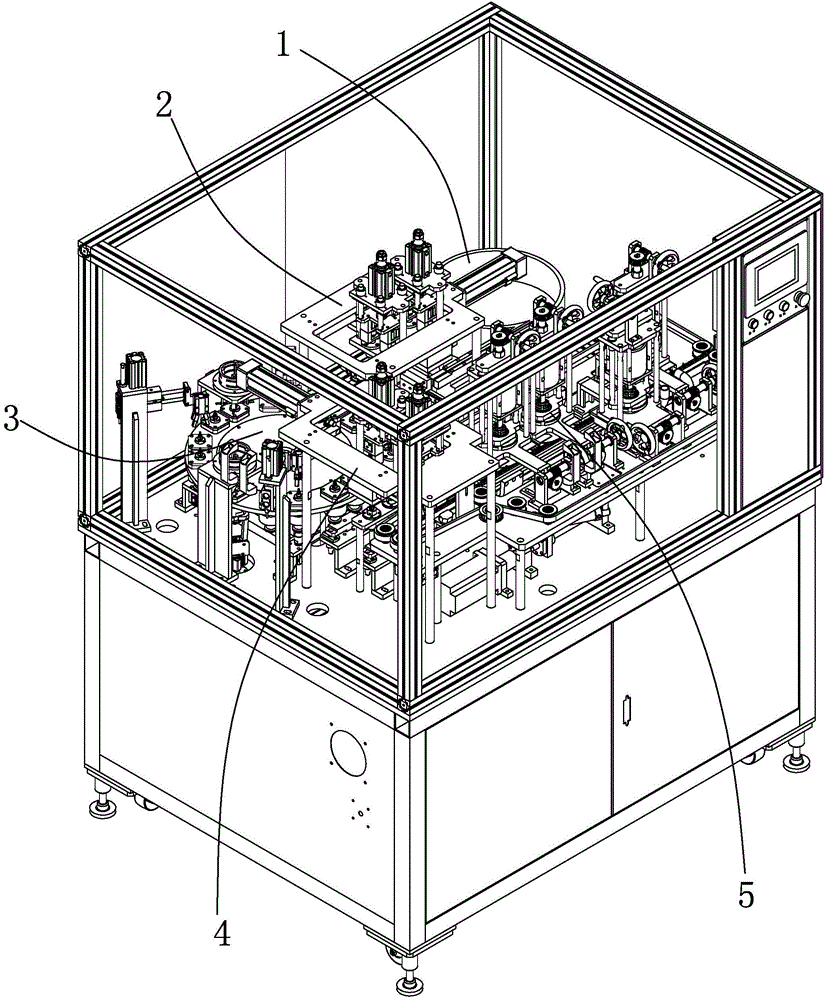

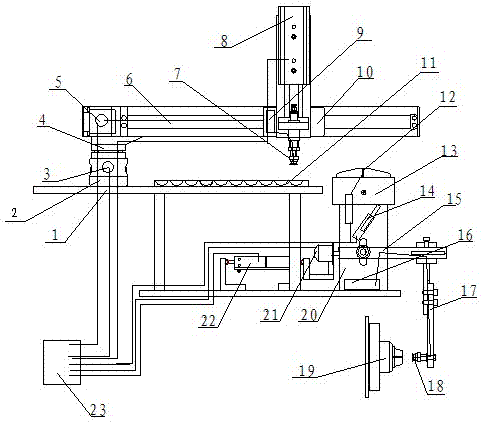

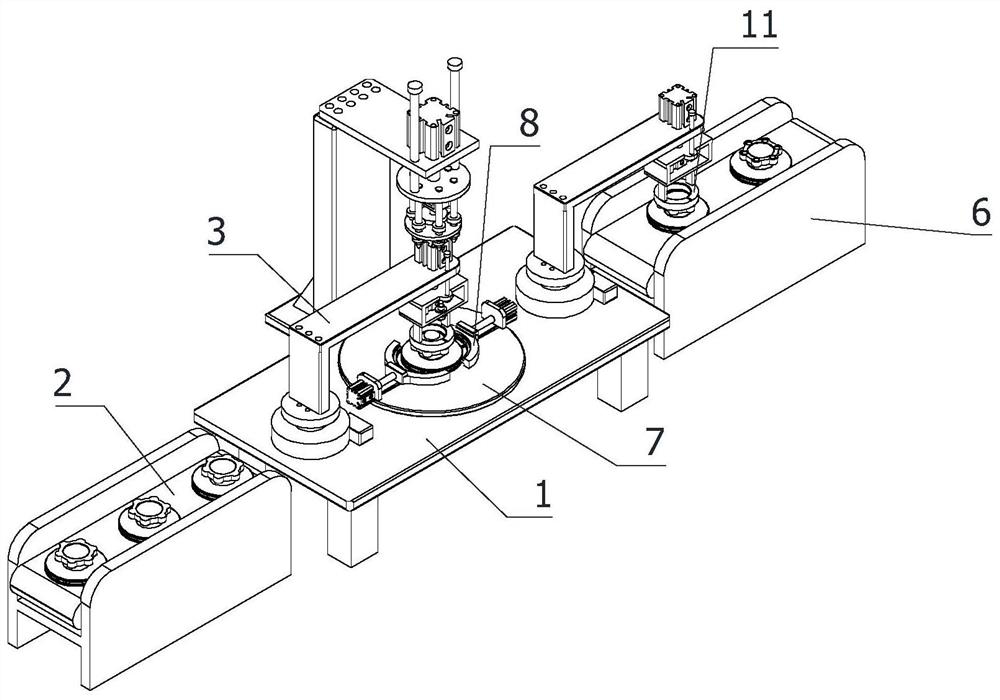

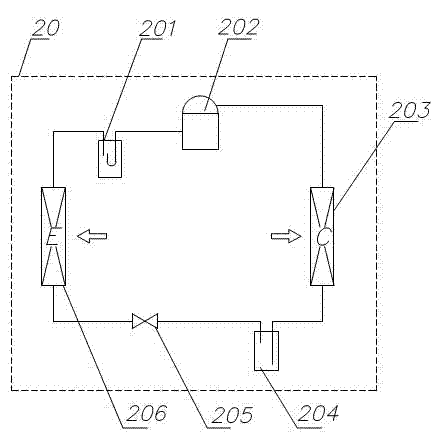

Automatic assembly production line of wall socket

InactiveCN103474862AHigh degree of automationSmall footprintContact member assembly/disassemblyProduction lineRobot hand

The invention discloses an automatic assembly production line of a wall socket. The automatic assembly production line comprises a bottom box automatic assembly part and a panel bottom box automatic assembly part. The bottom box automatic assembly part is of a rotary plate type structure which sequentially arranges multiple processes on the periphery of a rotary plate. A transmission mechanism which integrates transmission and outputting on the same side is adopted by the panel bottom box automatic assembly part, and multiple working positions are respectively arranged in front and in rear of the transmission mechanism. In addition, a bottom box positioning and overturning mechanism between the two parts overturns a bottom box which is assembled by the bottom box automatic assembly part to a preset position, a grabbing mechanical arm in the panel bottom box assembly part is used for moving the bottom box onto a panel, a transmission mechanism of the panel bottom box automatic assembly part transmits the bottom box to a screw feeding mechanism, the socket undergoing screw feeding assembly is moved to a finished product area through a material taking mechanical arm. The automatic assembly production line of the wall socket has the advantages of being high in automation degree, small in occupied space and high in production efficiency.

Owner:惠州市星宝机械设备有限公司

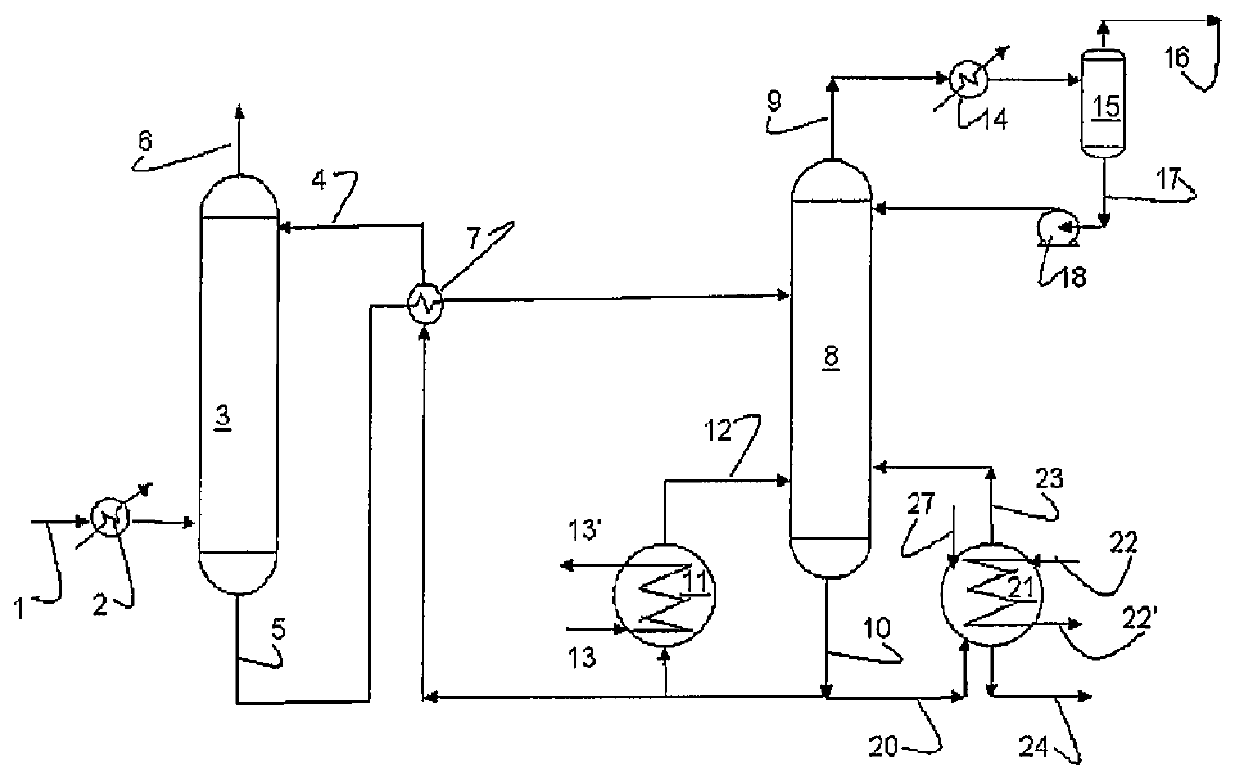

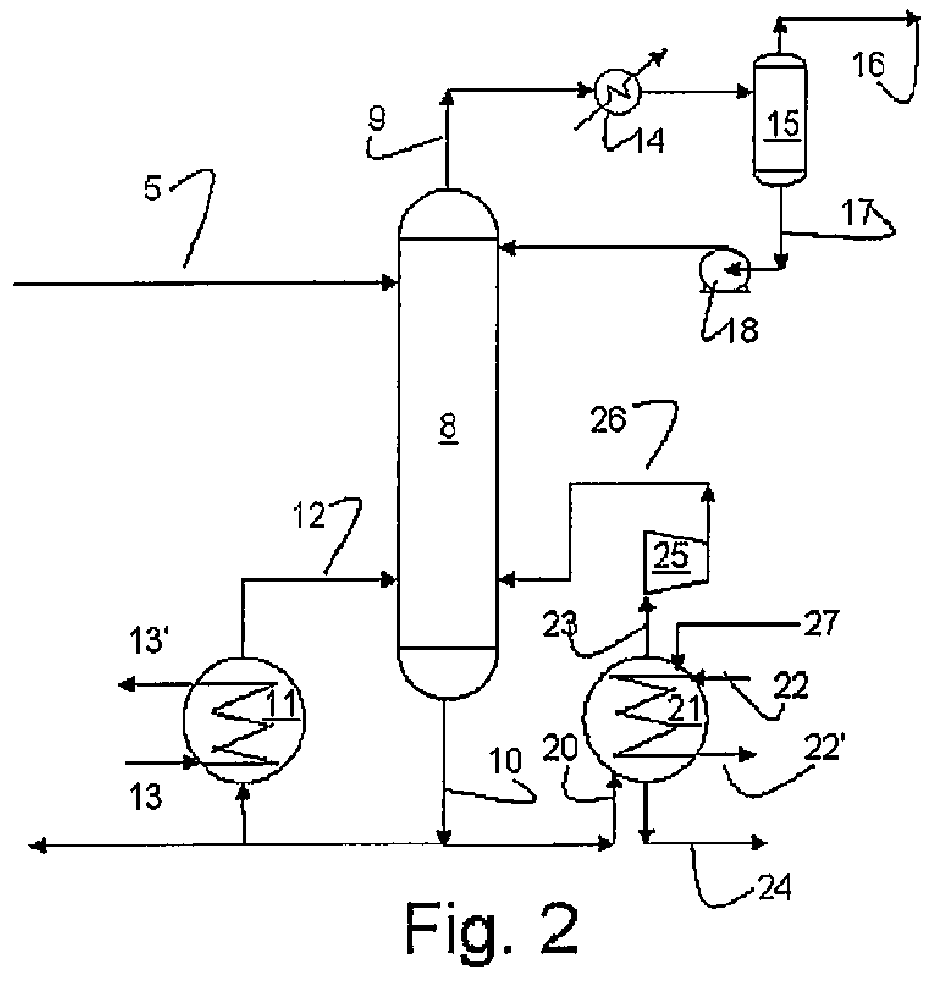

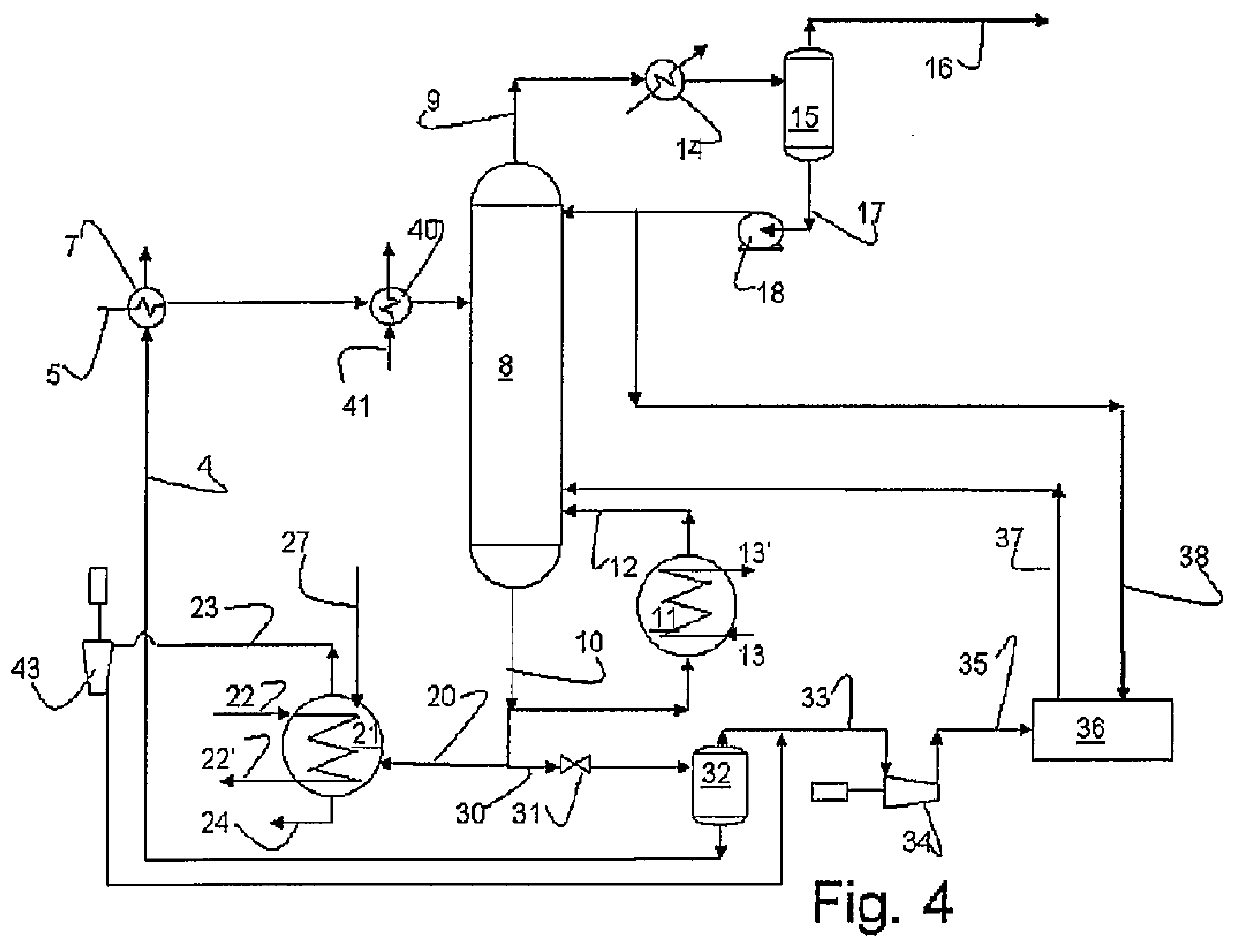

Method for reclaiming of co2 absorbent and a reclaimer

A method for reclaiming CO2 absorbing chemical(s) from a lean aqueous CO2 absorbent leaving a regeneration column (8), where lean absorbent (30) is withdrawn and flashed (31) to generate a vapor that is compressed (34) and returned into the regeneration column as stripper gas (37), where a part of the lean absorbent (20) is withdrawn and introduced into a reclaimer (21) in which the lean absorbent is boiled to generate a gas phase (23) that is withdrawn and returned into the regeneration column as reclaimed absorbent, and a liquid phase containing impurities (24), wherein the gaseous phase that is withdrawn from the reclaimer is compressed (34) together with the vapor part (33) from the flashing of the lean absorbent, to generate a pressure in the reclaimer that is lower than the pressure in the regeneration column, and a reboiler (11) for carrying out the method, are described.

Owner:AKER CARBON CAPTURE NORWAY AS

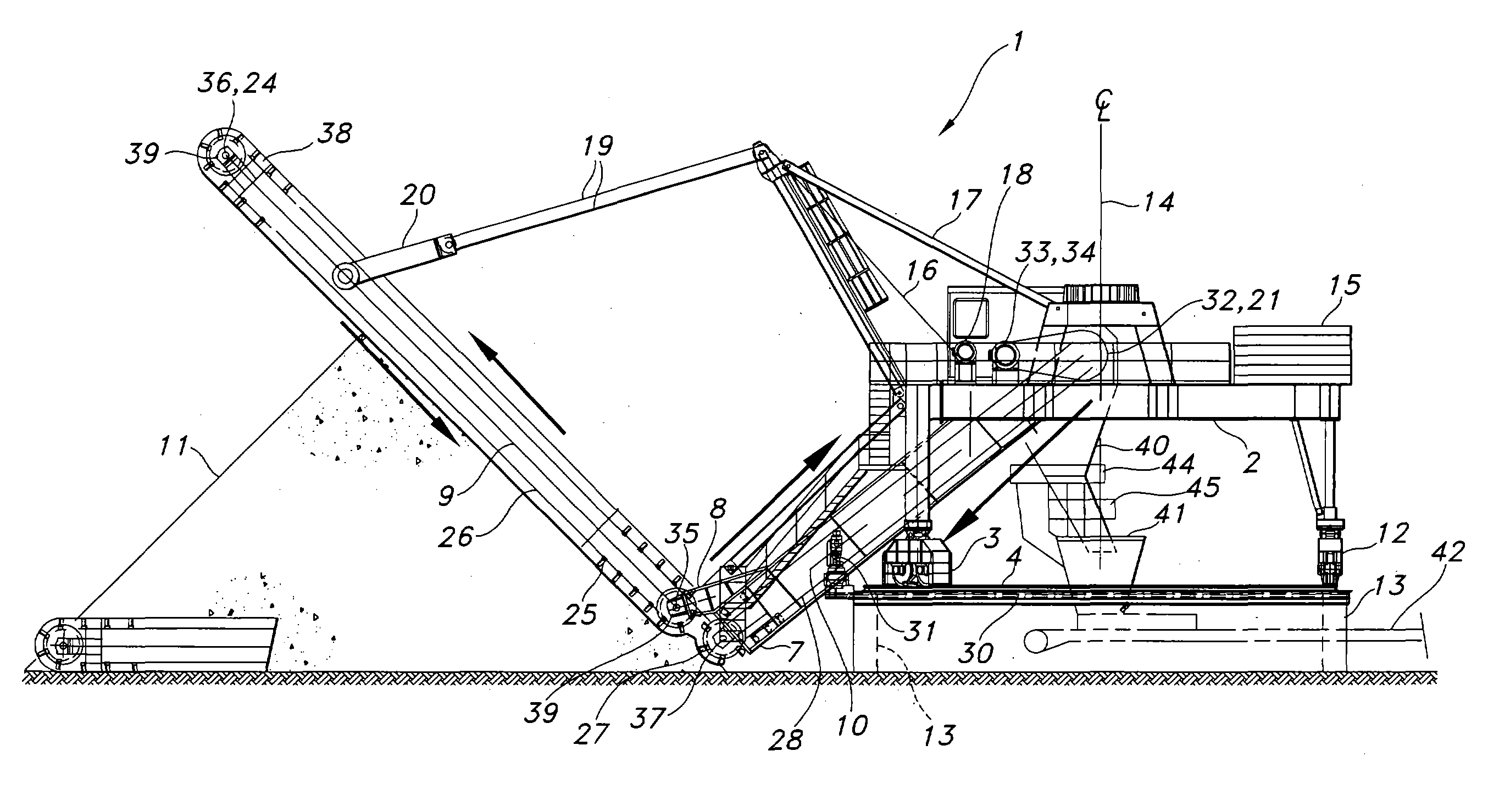

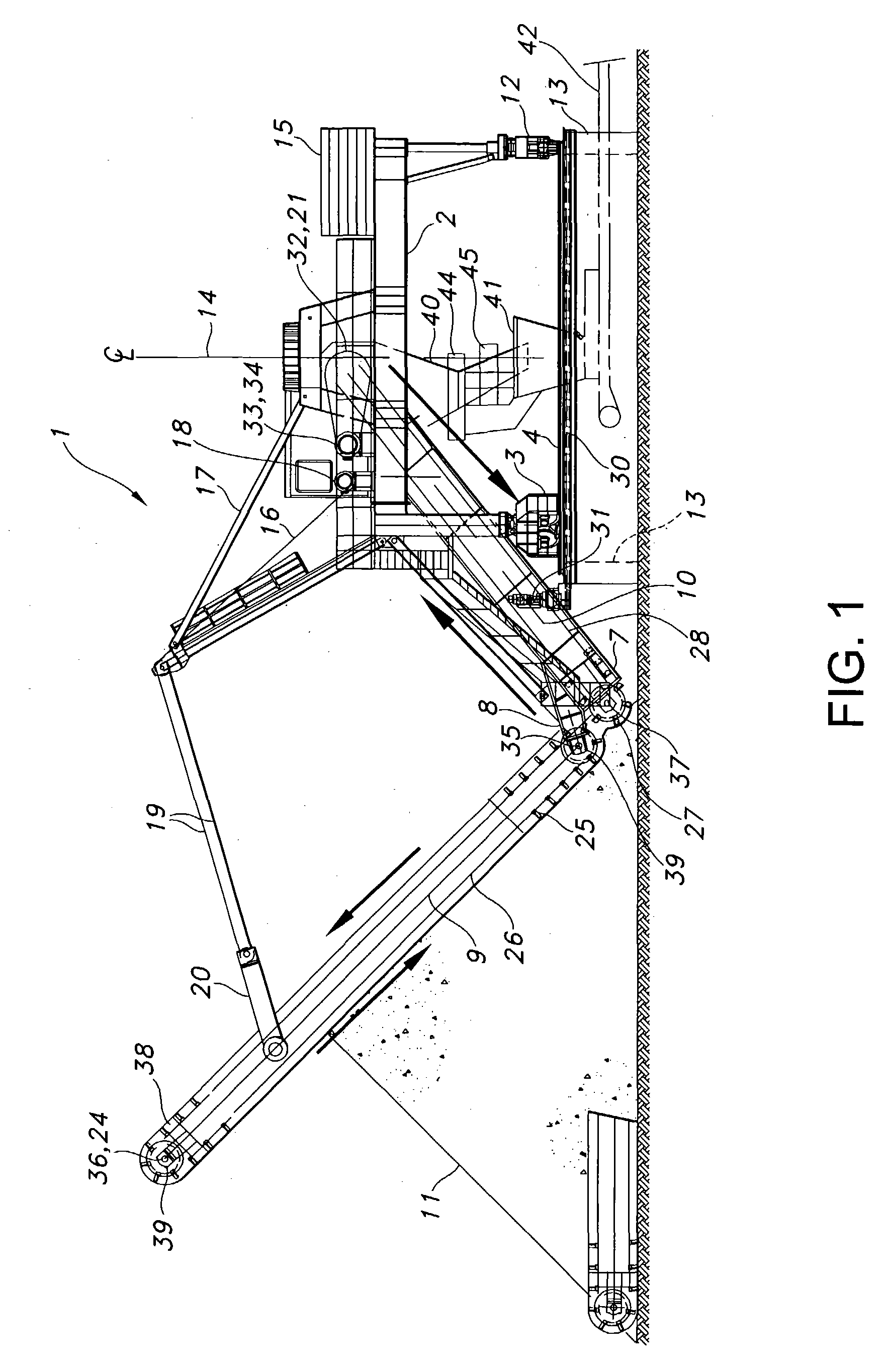

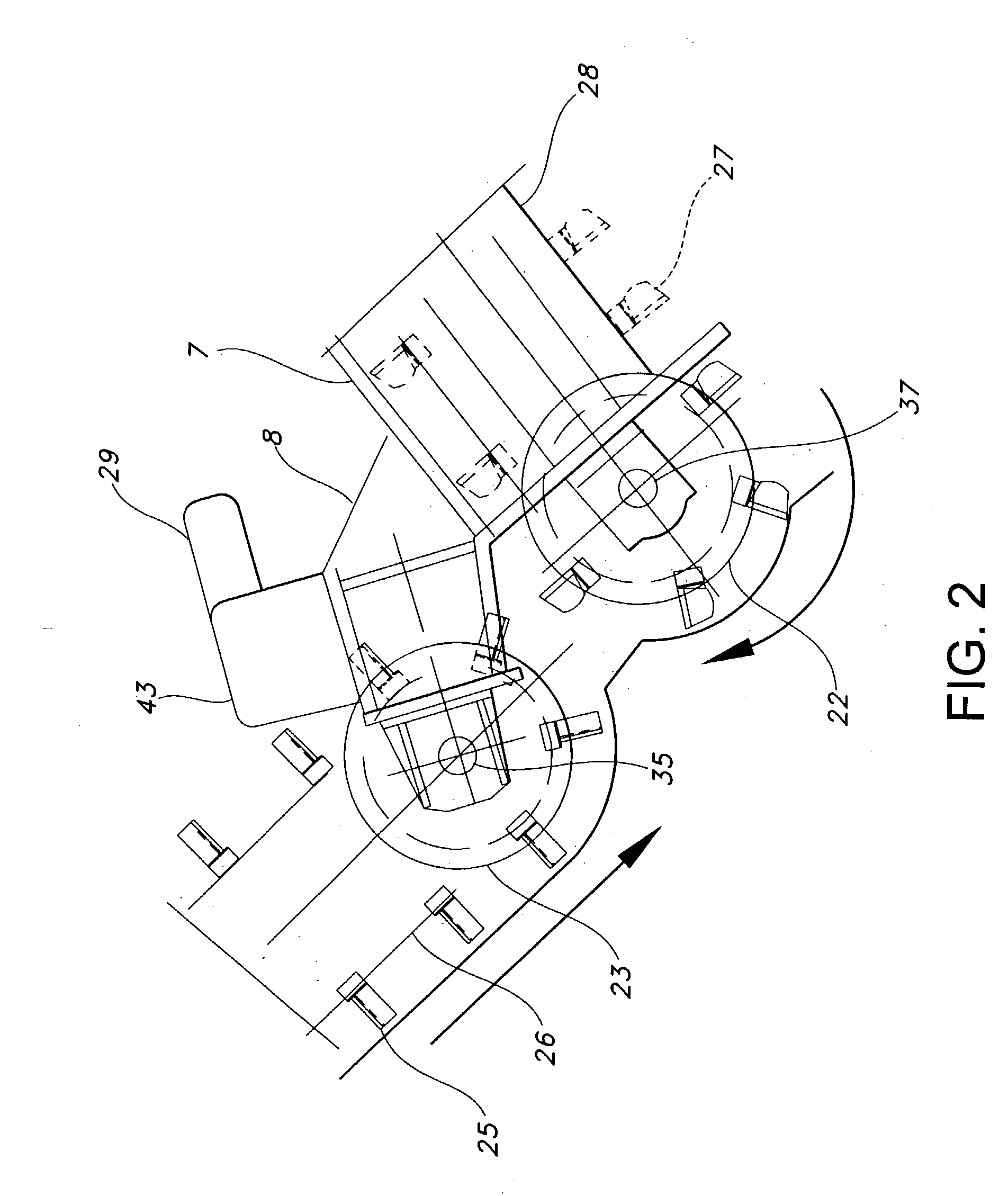

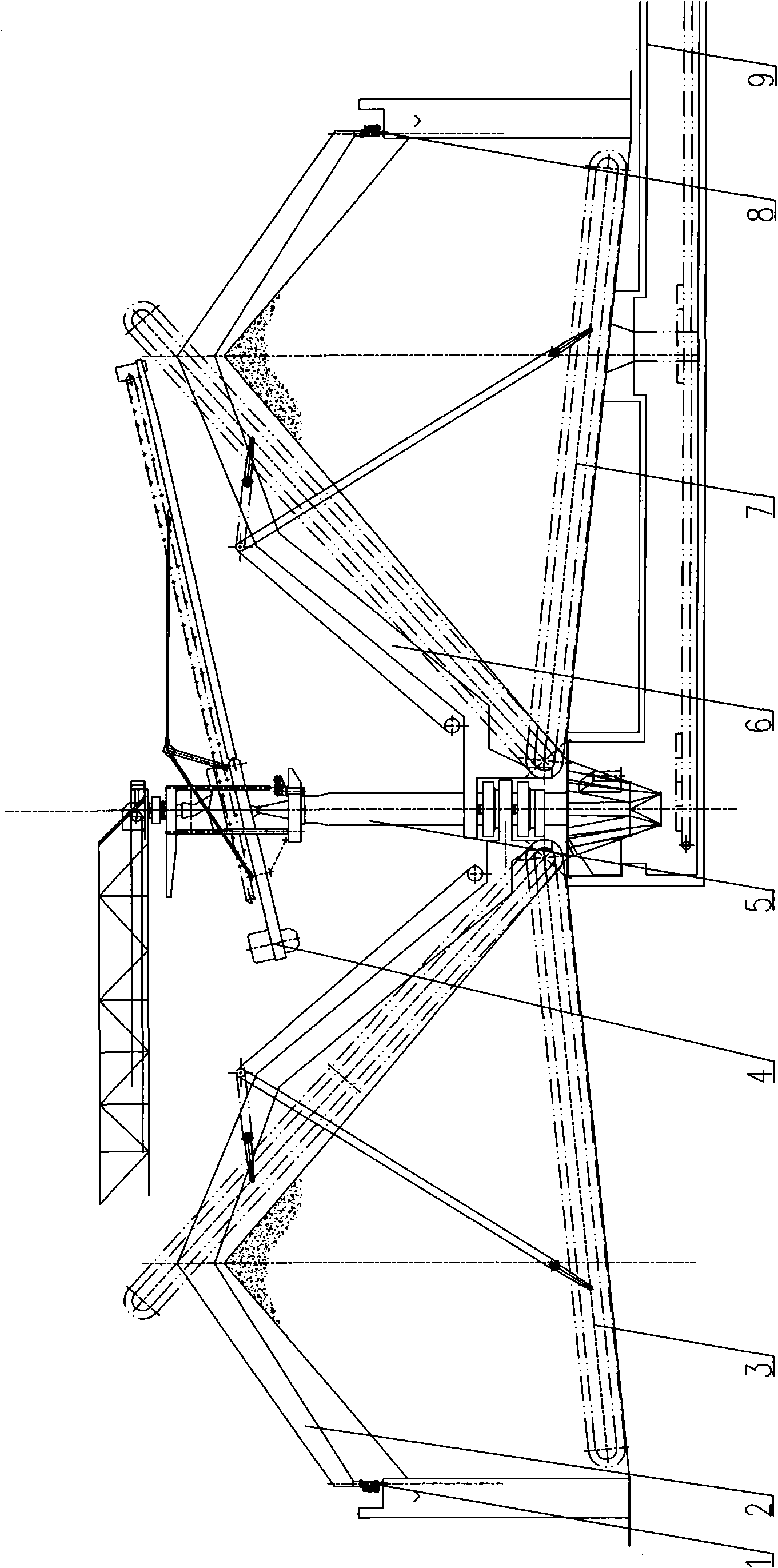

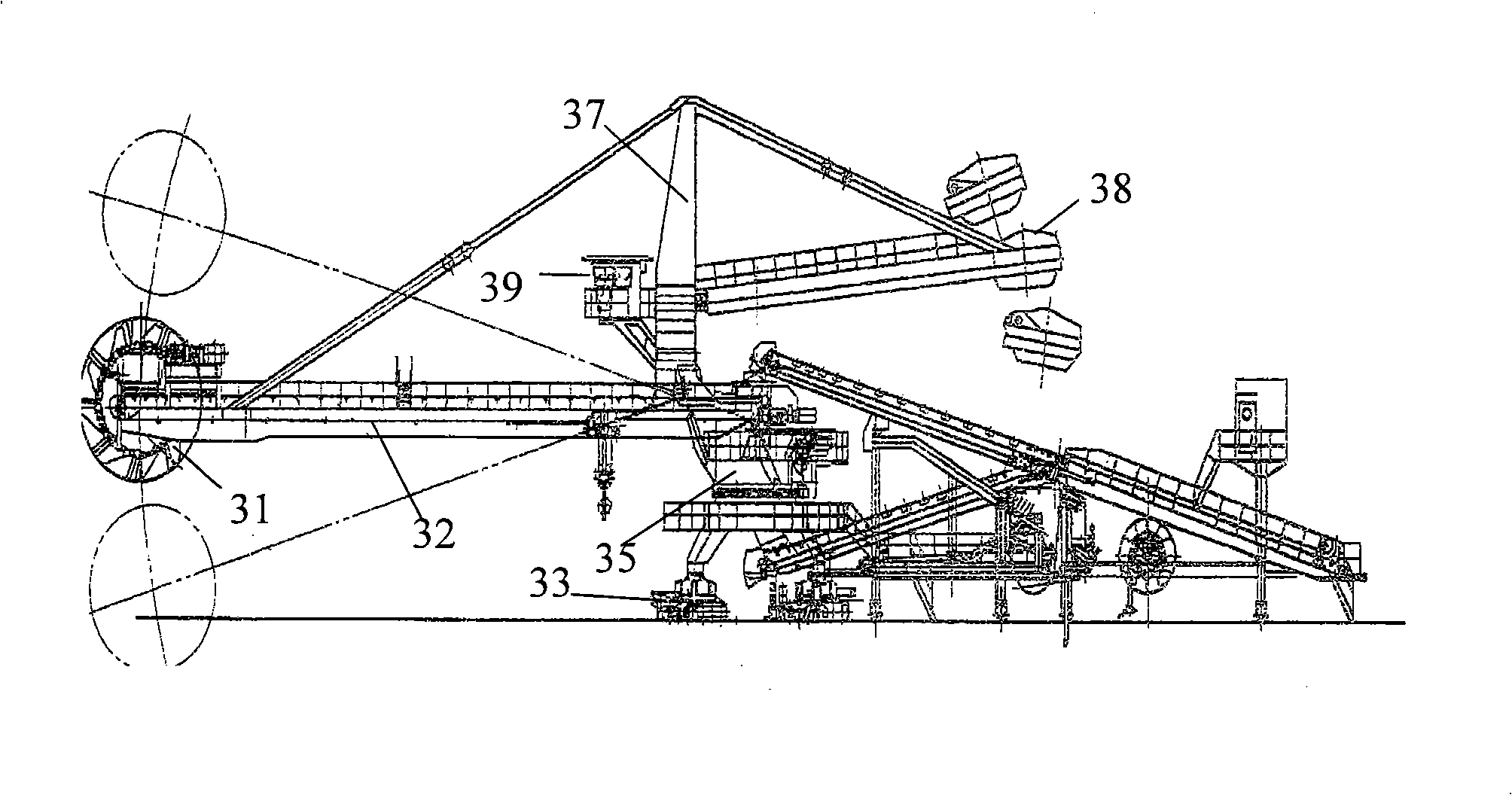

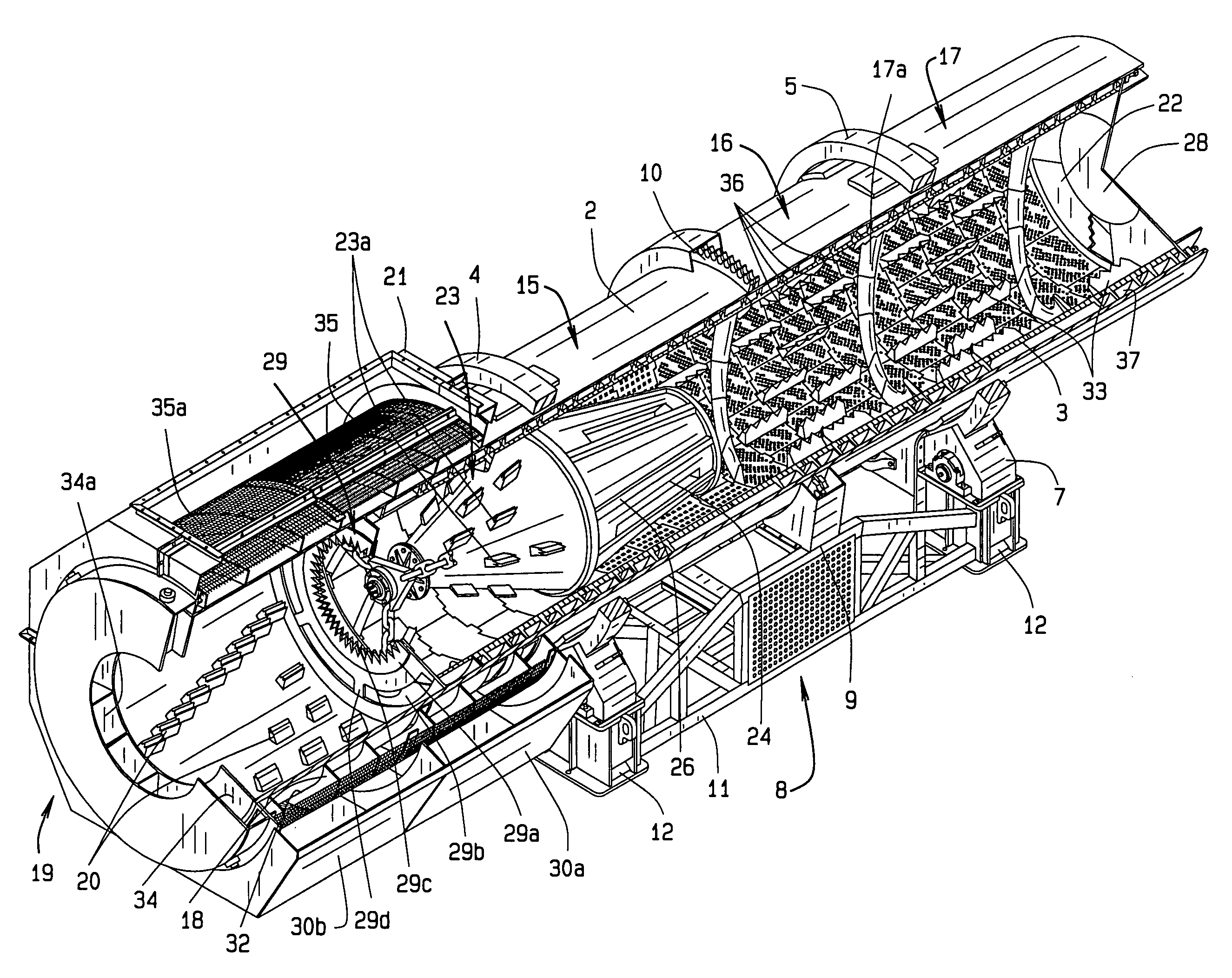

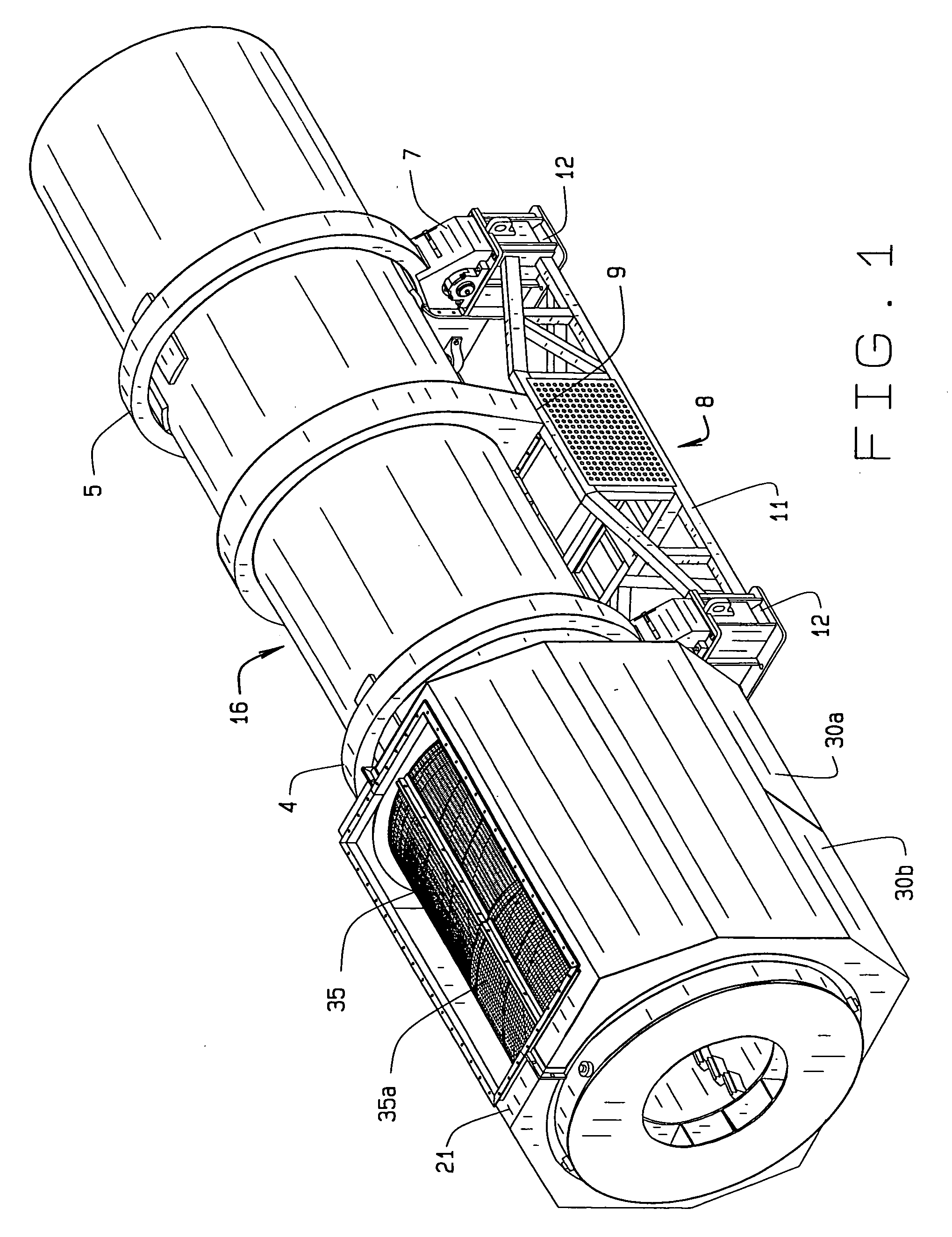

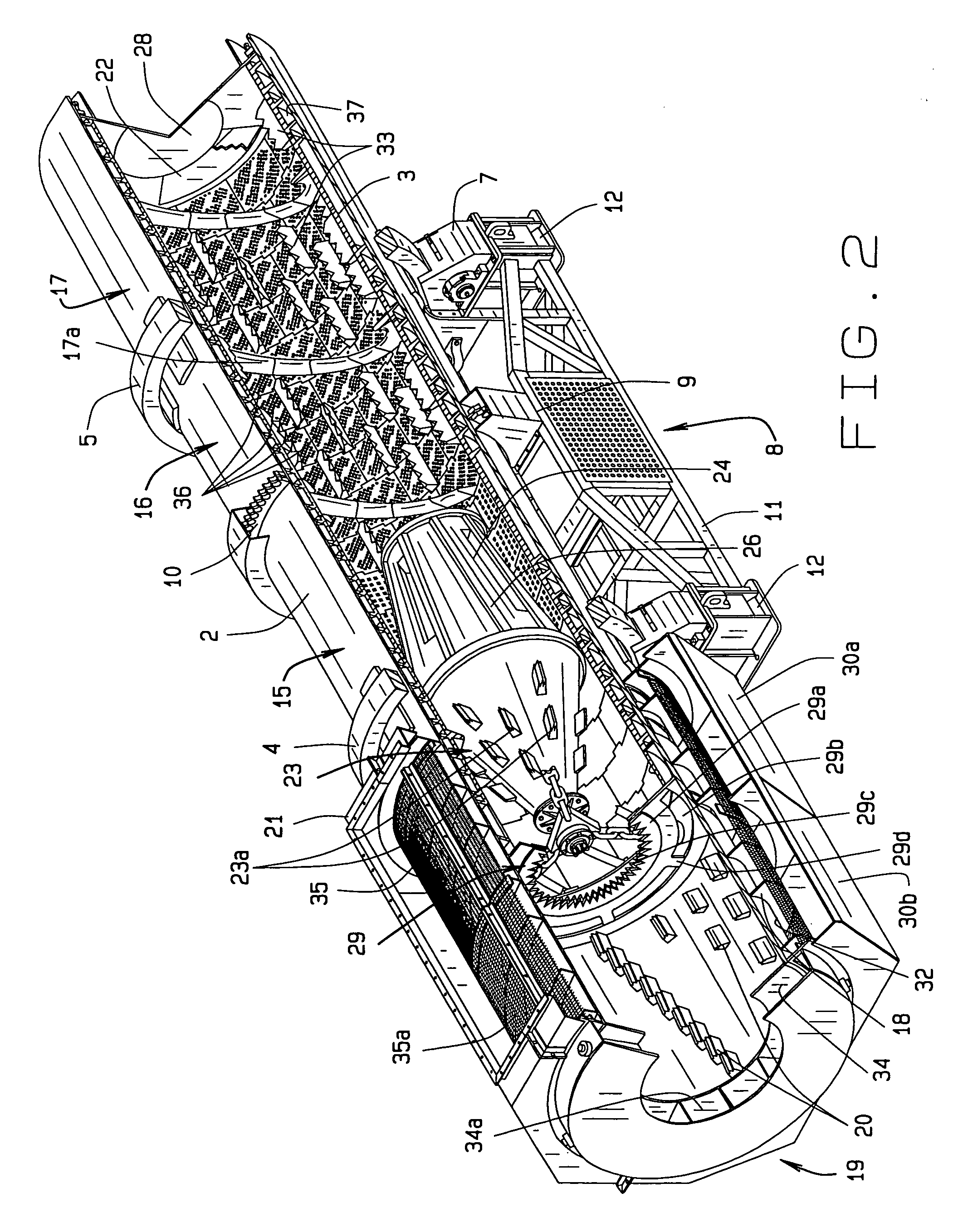

Stacker reclaimer method and apparatus

This invention provides an apparatus for handling bulk material as located at circular or linear storage site. The apparatus can include both a stacker and a reclaimer, wherein the improvement in technology is described in the reclaimer portion of the apparatus. More specifically, a reclaimer apparatus is described having a platform mounted on one or more wheel truck assemblies arranged to roll on at least one rail. The platform having a plurality of means to support a pivotal reclaim conveyor boom and a fixed incline conveyor assembly. A pivotal reclaim conveyor assembly is made of a head shaft and a tail shaft and means to support a plurality of rakes, wherein the plurality of rakes are spaced at intervals in a continuous loop around the pivotal reclaim conveyor assembly. The pivotal reclaim conveyor assembly being driven by a first motor. The fixed incline conveyor assembly having a head shaft and a tail shaft, the incline conveyor assembly having means to support a plurality of buckets, the plurality of buckets being spaced at intervals in a continuous loop around the inclined conveyor assembly, the plurality of buckets being positioned to receive bulk material from the pivotal reclaim conveyor assembly, the incline conveyor assembly being driven by a second motor.

Owner:SCHLEGEL HANS J +1

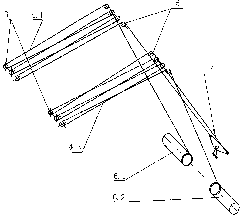

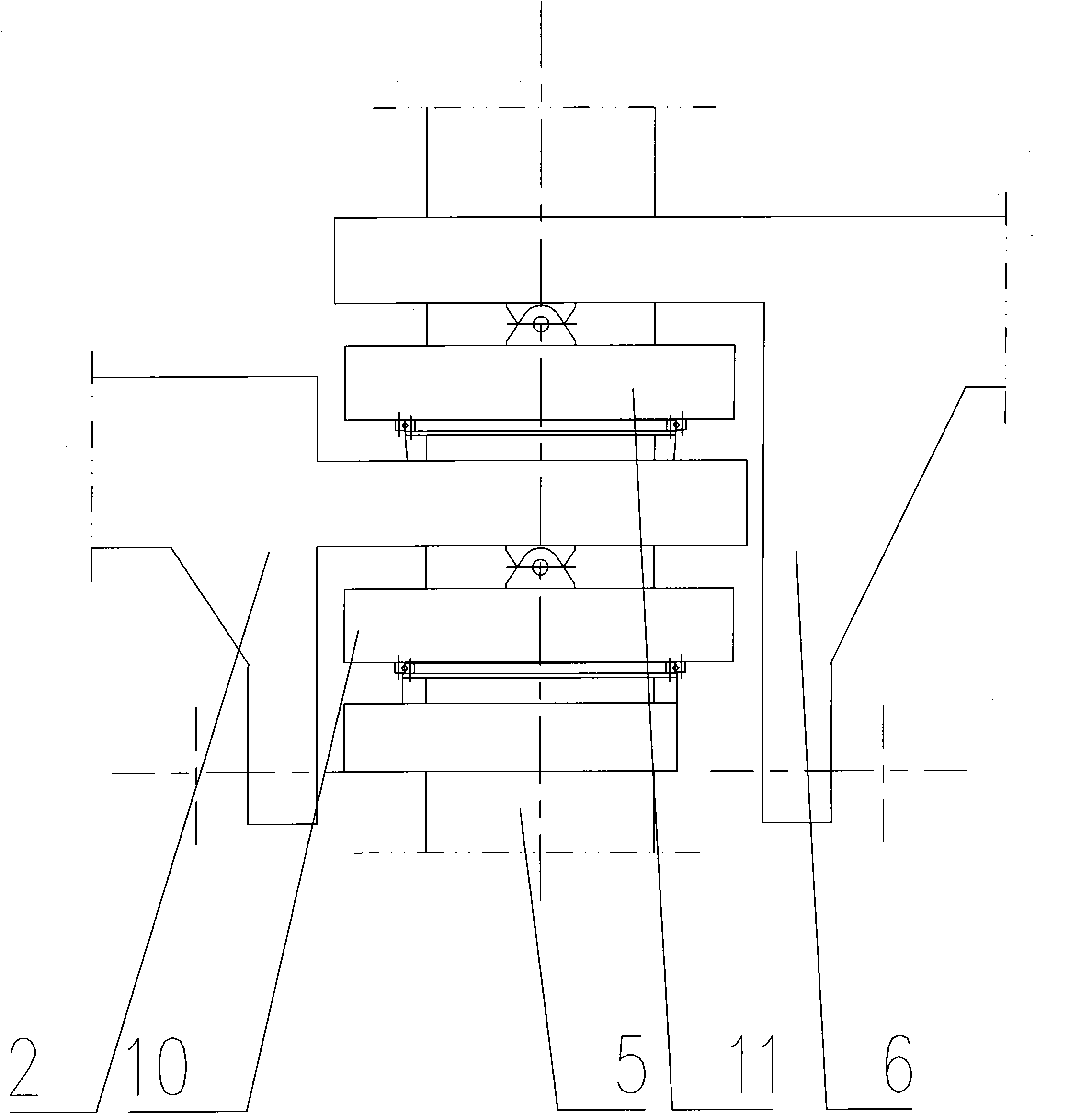

Protective device of elevating mechanism of stacker-reclaimer

InactiveCN101823631ASo as not to damageReduce repair costsLoading/unloadingBlock and tackleEngineering

The invention discloses a protective device of an elevating mechanism of a stacker-reclaimer, which aims at overcoming the shortcomings that a bucket wheel of the traditional stacker-reclaimer makes an elevating motion by using only one wire rope, and the sudden fracture of the wire rope can easily cause safety accidents to people or the device, influence the regular production and increase the repair cost. In the invention, the elevating mechanism is provided with two parallel wire ropes, the top of a stand column and a bucket wheel arm support are respectively provided with two parallel sets of pulley blocks corresponding to the wire ropes, wherein the head ends of the wire ropes are respectively fixed on two coaxial rollers of a hoister, the tail ends of the wire ropes are fixed on a hoister platform, and a balancing device which is connected with the tail ends of the two wire ropes is installed on the hoister platform. When one wire rope suddenly fractures, the other wire rope alone can maintain the balance of the bucket wheel arm support, can not cause damage to the stacker-reclaimer or result in personal safety accidents, and can gain time for the replacement of the wire rope, thereby greatly lowering the repair cost, and ensuring the safe and regular production.

Owner:QINGDAO PORT GRP

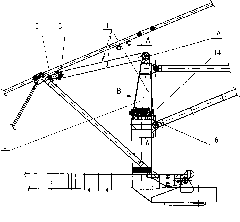

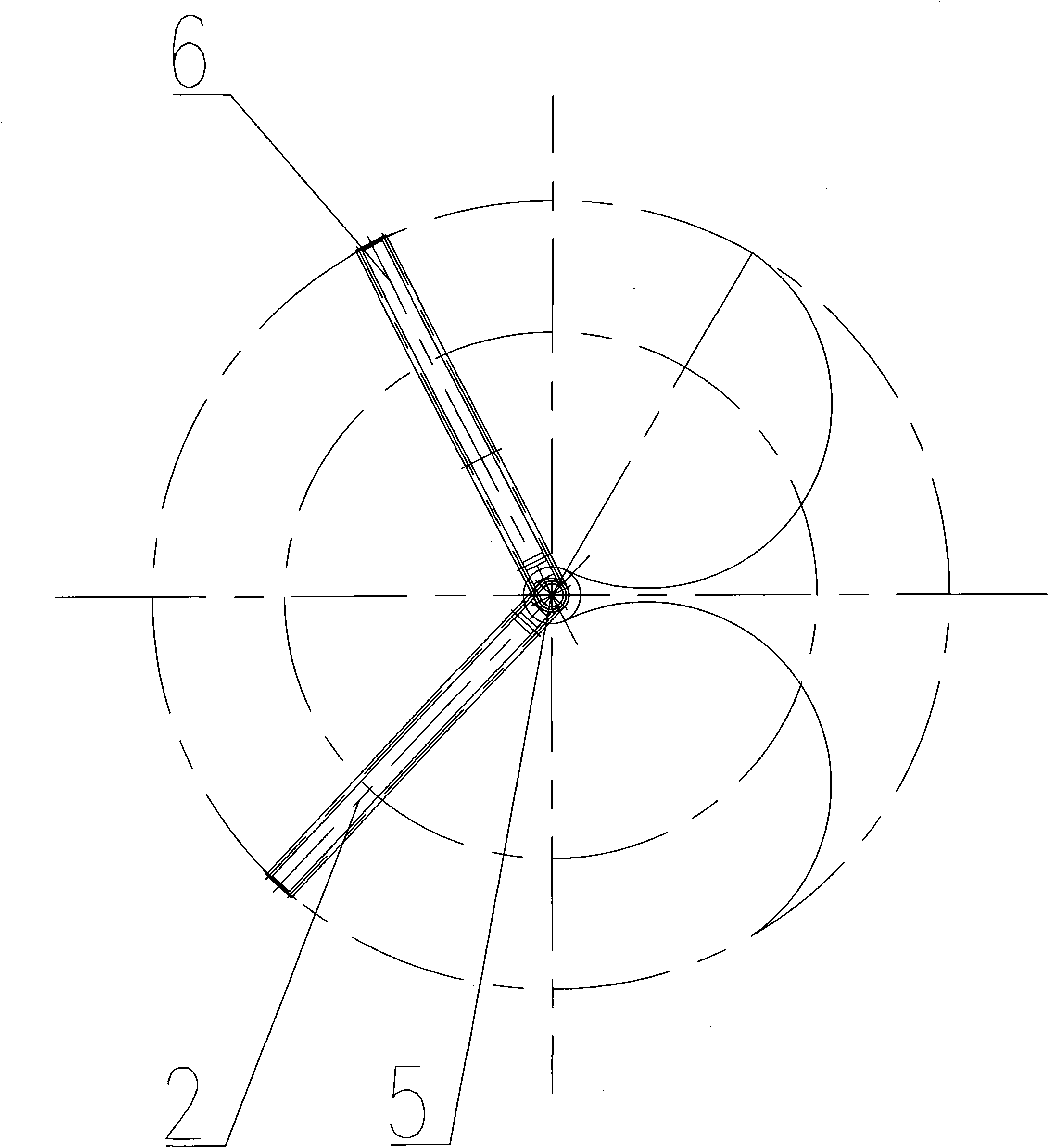

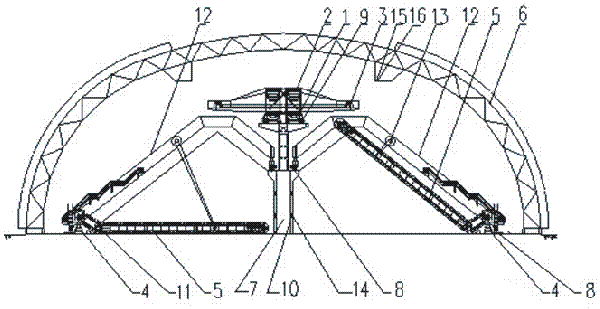

Double-portal type round stock ground scraper stacker-reclaimer

The invention discloses a double-portal type round stock ground scraper stacker-reclaimer, comprising a center stand column, a travelling device I, a portal I, a scraper reclaimer I, a rotary steel structure I, a cantilever stocker, a travelling device II, a portal II, a scraper reclaimer II and a rotary steel structure II, wherein the center stand column is fixed on ground foundation in the center of a stock ground; the cantilever stocker, the portal I and portal II respectively rotate by taking the center stand column as the center of rotation; the rotary steel structure I is connected with the center stand column by a rotary bearing, one end of the portal I is hinged with the rotary steel structure I, the other end is supported on the travelling device I operating on the round orbit on the upper part of a stock stop wall; one end of the scrapper reclaimer I is hinged with the lower part of the portal I, and the other end is hung on the portal I; the rotary steel structure I is positioned below the rotary steel structure II, and the device I and the device II are arranged in the same way. In the invention, two scraper reclaimers arranged on respective portal take two stocks simultaneously, thus realizing the purpose of mixing evenly, and having simple structure and high production efficiency.

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

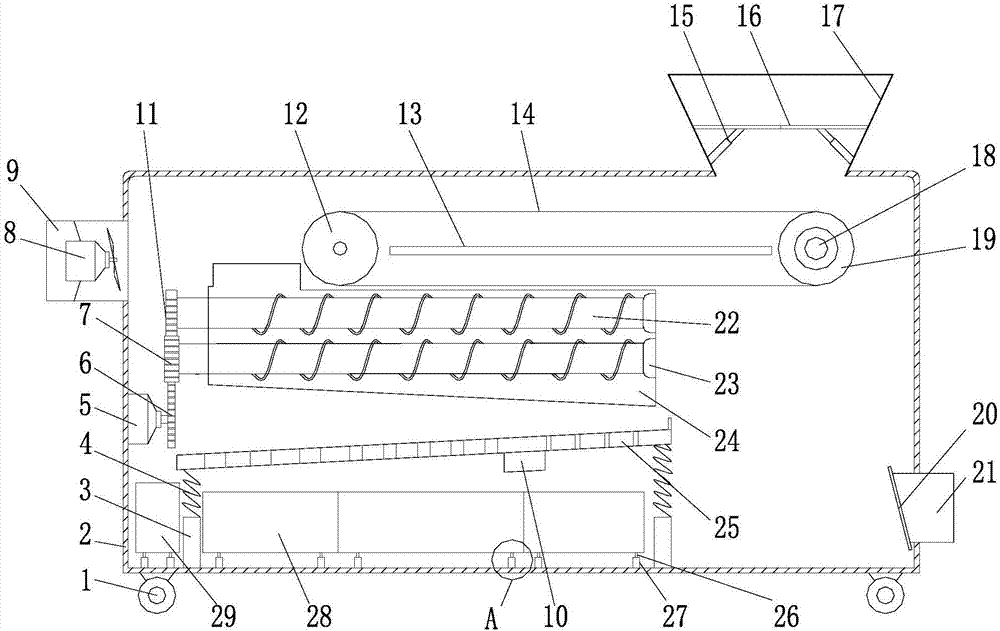

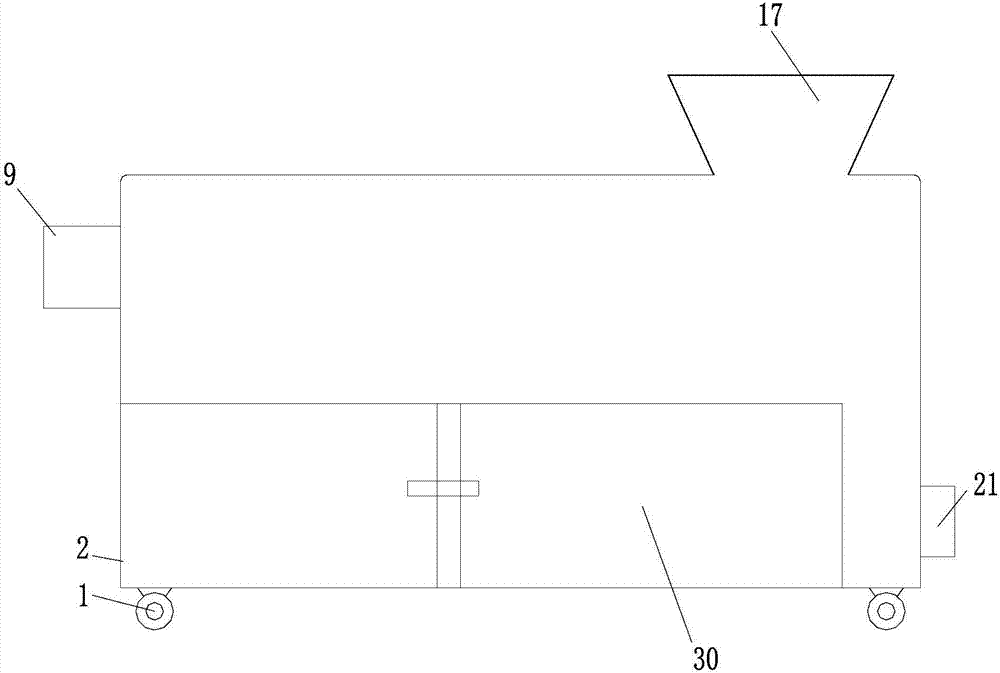

Corn thresher with drying and screening functions

The invention discloses a corn thresher with drying and screening. B. Driven pulley, heating plate, belt, elastic telescopic rod, filling door, filling hopper, motor B, driving pulley, filter screen, air outlet pipe, threshing rod, roller, threshing box, sorting plate, roller , slide rail, corn collection box, cob core collection box, and material retrieving door; the invention adds a heating plate before threshing, which can dry corn cobs, facilitate threshing, and has a sorting board after threshing, which can sort out Corn kernels with different diameters can be used in different categories. There is a shell outside the threshing device, which can effectively reduce dust entering the atmosphere, protect the environment and prevent operators from absorbing a large amount of dust.

Owner:惠安益源信息技术咨询有限公司

Control method and control device for bucket wheel material fetching machine with material measure and calculate

InactiveCN101493676AReduce labor intensityWith automatic reclaiming functionElectric controllersWeighing apparatus for continuous material flowAutomatic controlAC - Alternating current

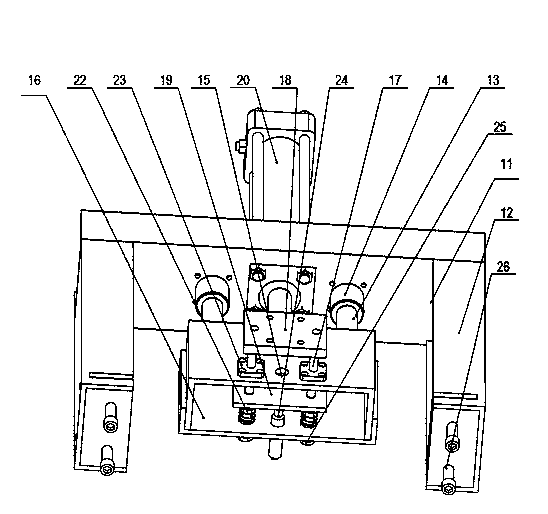

The invention provides a method for controlling a bucket-wheel reclaiming machine with material measurement and calculation, comprising the steps as follows: a current detection module (2) detects corresponding weak alternating current voltage signal from the line current of a bucket-wheel motor current circuit (1); the weak alternating current voltage signal is transmitted to a current / voltage signal conversion module (3) so that the rectification, voltage-stabilization and amplification treatment of the signal is carried out; the voltage signal which is processed by rectification, voltage-stabilization and amplification is input to a reclaiming automatic control module (6) which controls the actions of a revolving mechanism (19) and a truck feeding mechanism (20) according to the change of the voltage signal; and the actions of the revolving mechanism (19) and the truck feeding mechanism (20) cause the bucket-wheel motor current circuit (1) to change. The invention also relates to a reclaiming automatic control device. As the reclaiming automatic control method of the invention is adopted and the reclaiming automatic control device of the invention is installed, the functions of automatic control of reclaiming, flux display and alarming when the flux exceeds the arranged value can be quickly and simply realized at low cost.

Owner:BAOSHAN IRON & STEEL CO LTD

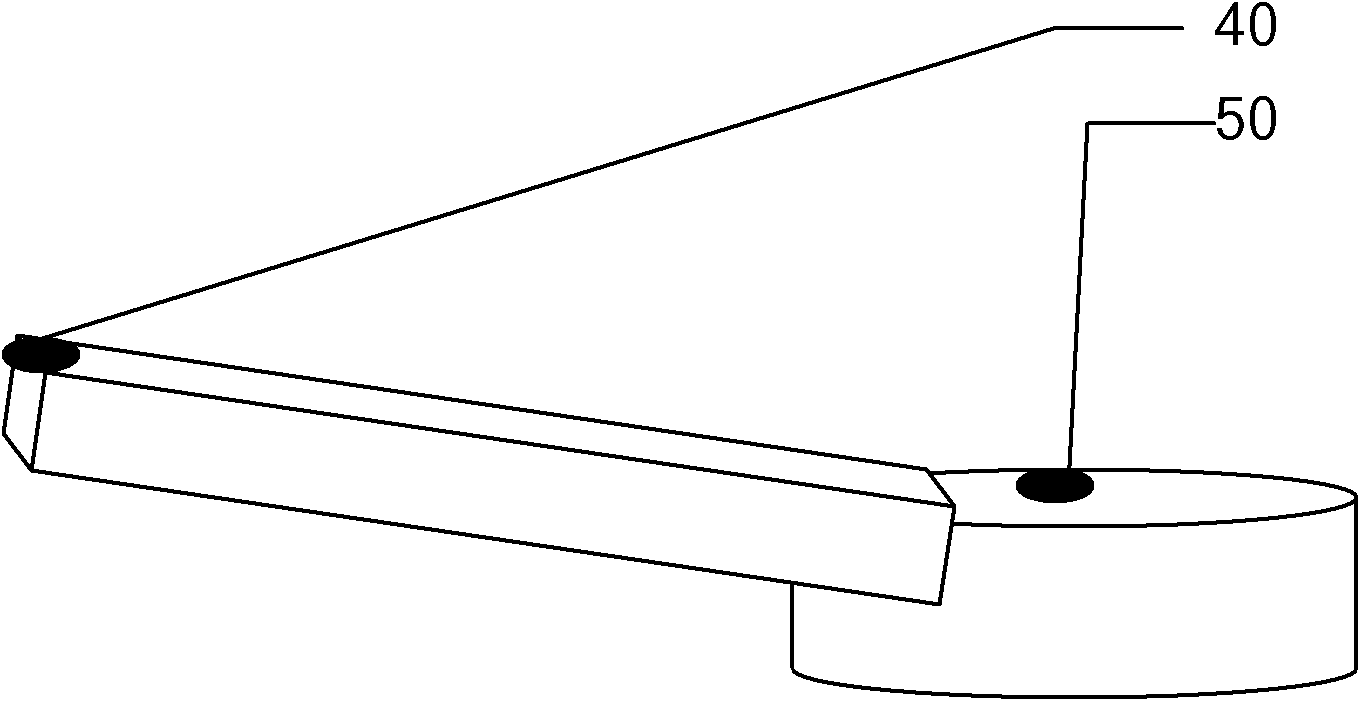

Guide chute and bucket wheel stacker-reclaimer with same

The invention provides a guide chute and a bucket wheel stacker-reclaimer with the same. The guide chute comprises a chute body part, supporting legs for supporting the chute body part and a first rocker part, wherein the supporting legs are arranged on an arm support part of the bucket wheel stacker-reclaimer; a material blocking part is arranged at one end of the chute body part; the first end of the first rocker part is connected with the material blocking part rotationally; and the second end of the first rocker part is connected with a first fixing position outside the chute body part rotationally. The bucket wheel stacker-reclaimer comprises the guide chute. The whole motion of the material blocking part is realized by a rod piece, structure is simple and manufacturing cost is low.

Owner:湖南省吉娃米业有限公司

Multi-time two-sided gas blowing type recycling machine for tobacco shred of waste cigarette

ActiveCN101317694AHigh recovery rateImprove recycling effectCigarette manufactureEngineeringReclaimer

The invention discloses a multi-time double-faced air-blown reclaimer of discarding tobacco shreds consisting of a synchronous pulley, a groove conveyer belt, gas nipple set system for filter tip detection and left and right blowing, a gas nipple set system for uncleaned cigarette detection and blowing, a PLC system, etc., so as to realize the rectilinear and interstitial motion. By adopting the technology of secondary blowing for each end of the discarding cigarette and adding the uncleaned cigarette detection and blowing system, the defects of one-go blowing for a single side or for two sides can be effectively overcome so as to multiply improve the reclaiming effect of the discarding tobacco shreds. Owing to the treatment of the uncleaned cigarettes, the reliable separation of the tobacco shreds and the cigarette paper of the filter tip can be guaranteed. The reclaimer of the invention has reasonable design, simple structure, good applicability and high popularization and application value.

Owner:CHANGDE RUIHUA MFG

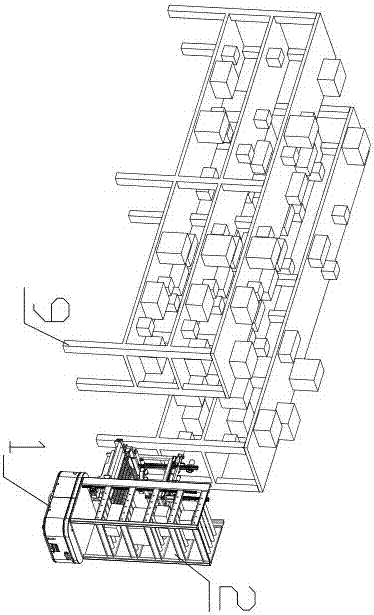

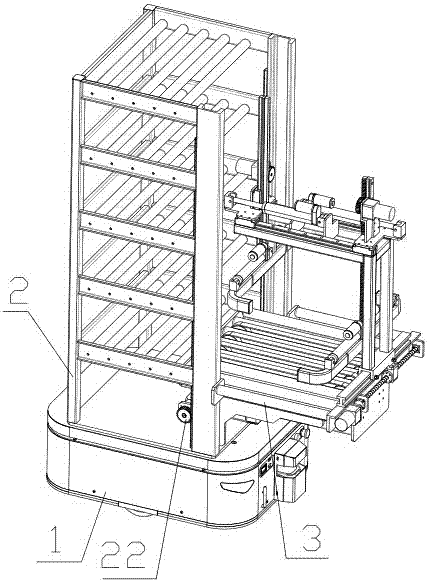

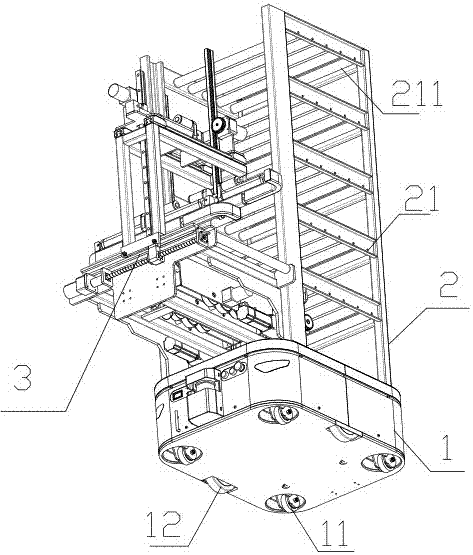

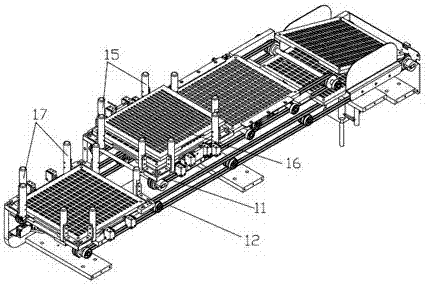

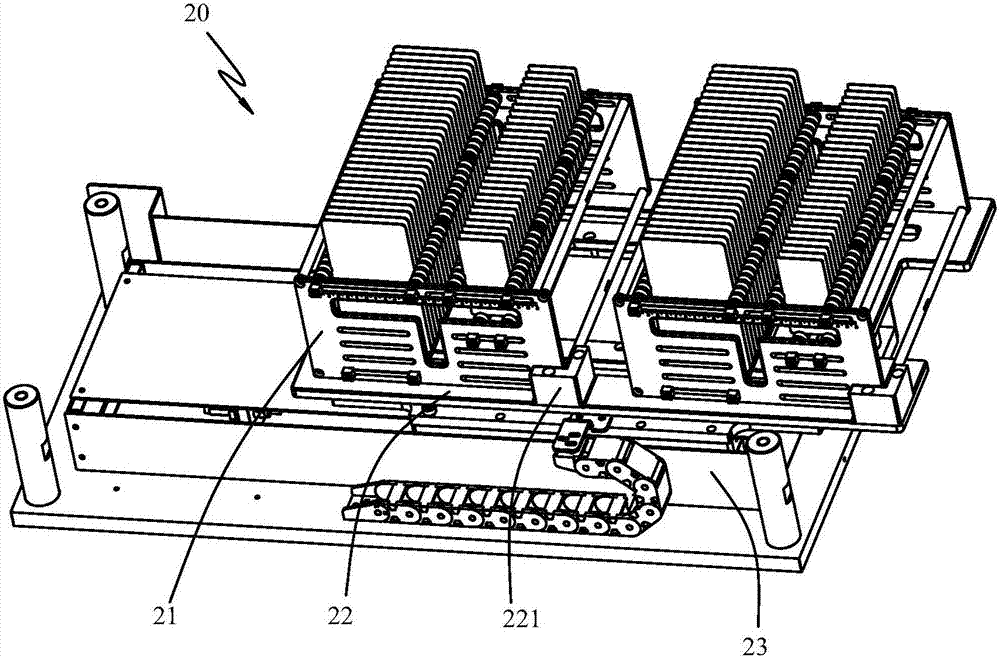

Automatic material taking machine for storage

The invention relates to the field of automation mechanical devices, in particular to an automatic material taking machine for storage. The automatic material taking machine is achieved through the following technical schemes that the automatic material taking machine for storage comprises a travelling device and further comprises a storage device connected with the travelling device, a goods taking device capable of stretching out and drawing back, and a material box transferring assembly used for transferring goods obtained through the goods taking device to the storage device; the storage device comprises at least two layers of storage frames located on the different height positions, and each storage frame comprises a storage transferring device; and the material box transferring assembly is connected with the goods taking device and can rise and fall in the vertical direction. The invention aims to provide the automatic material taking machine for storage, the material taking machine comprises a goods storing device, the goods can be automatically taken and stored, the number of the goods taken through single-time travelling of the material taking machine is increased, and thematerial taking and sorting efficiency is improved.

Owner:上海诺力智能科技有限公司

Rotary tumbler and metal reclaimer

A rotary tumbler metal reclaimer includes an inner cylinder and a concentric outer cylinder that rotate simultaneously. The inner cylinder includes a first compartment that intakes material for breaking by teeth, a second compartment that receives broken material from the first compartment and crushes the material into smaller particles, and a third compartment wherein particulate material enters the space between the inner cylinder and the outer cylinder by attrition through perforated screens. The second compartment includes a crusher having various features for crushing lump material as it rotates. The third compartment provides further breakage and conveyance of particulate material. Particulate material then returns proximate the intake for screening into fine and coarse sizes and then collecting for reuse. Metallics and metallic oxides exit the tumbler through apertures in the rear of the third compartment for collection. The tumbler reclaims metals, metallic oxides, sands, and other materials for reuse.

Owner:DIDION TECHNOLOGIES LLC

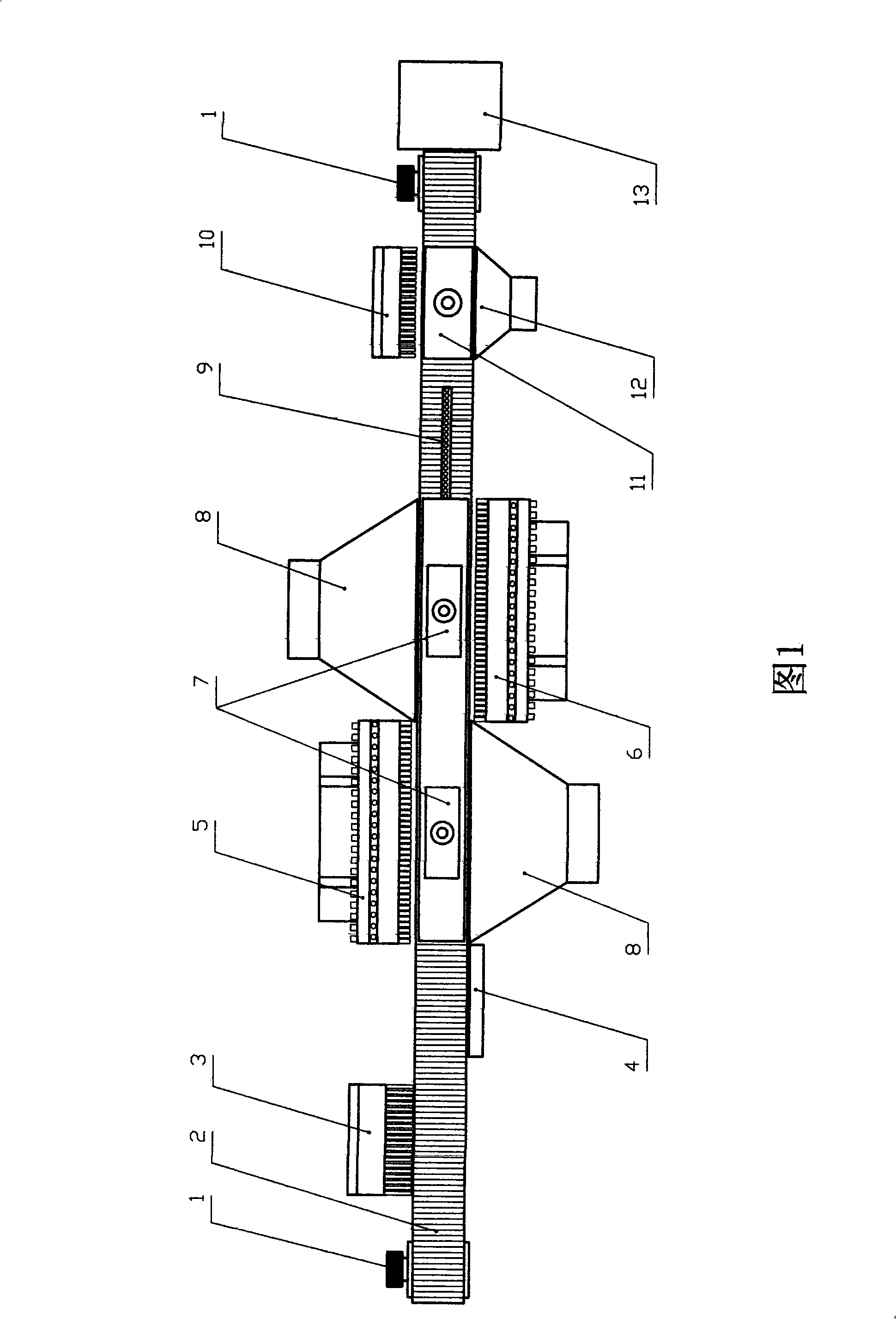

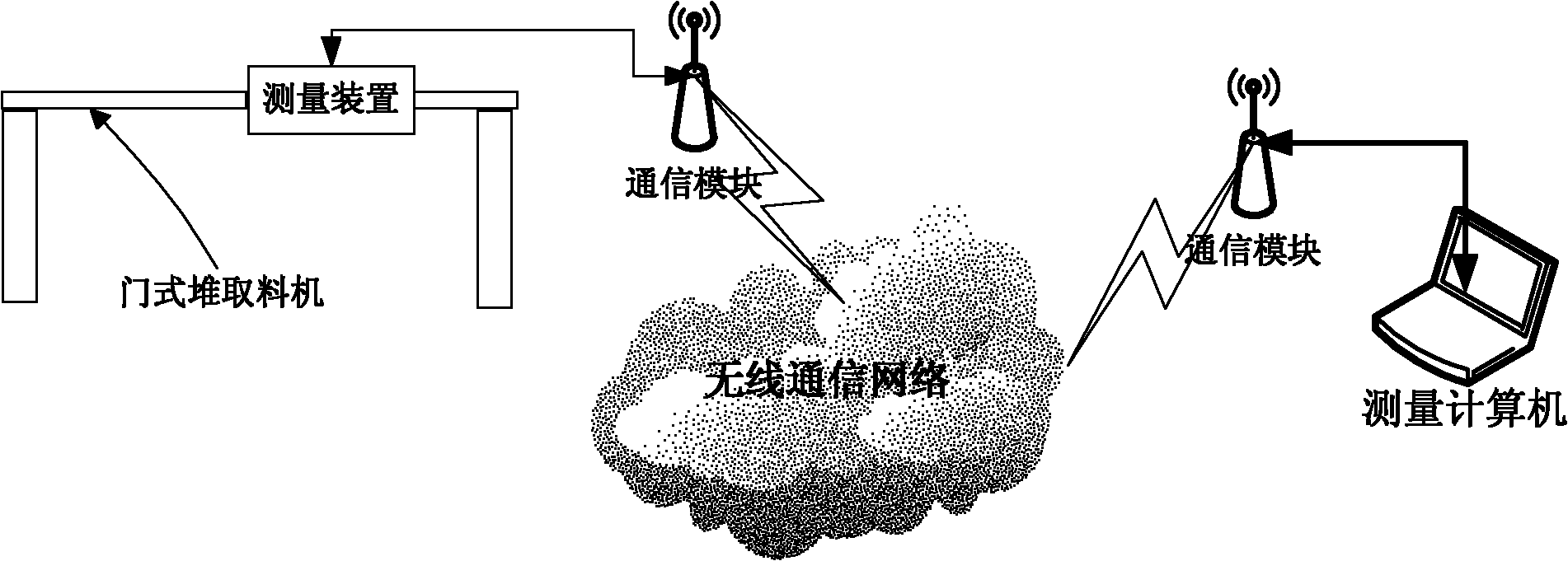

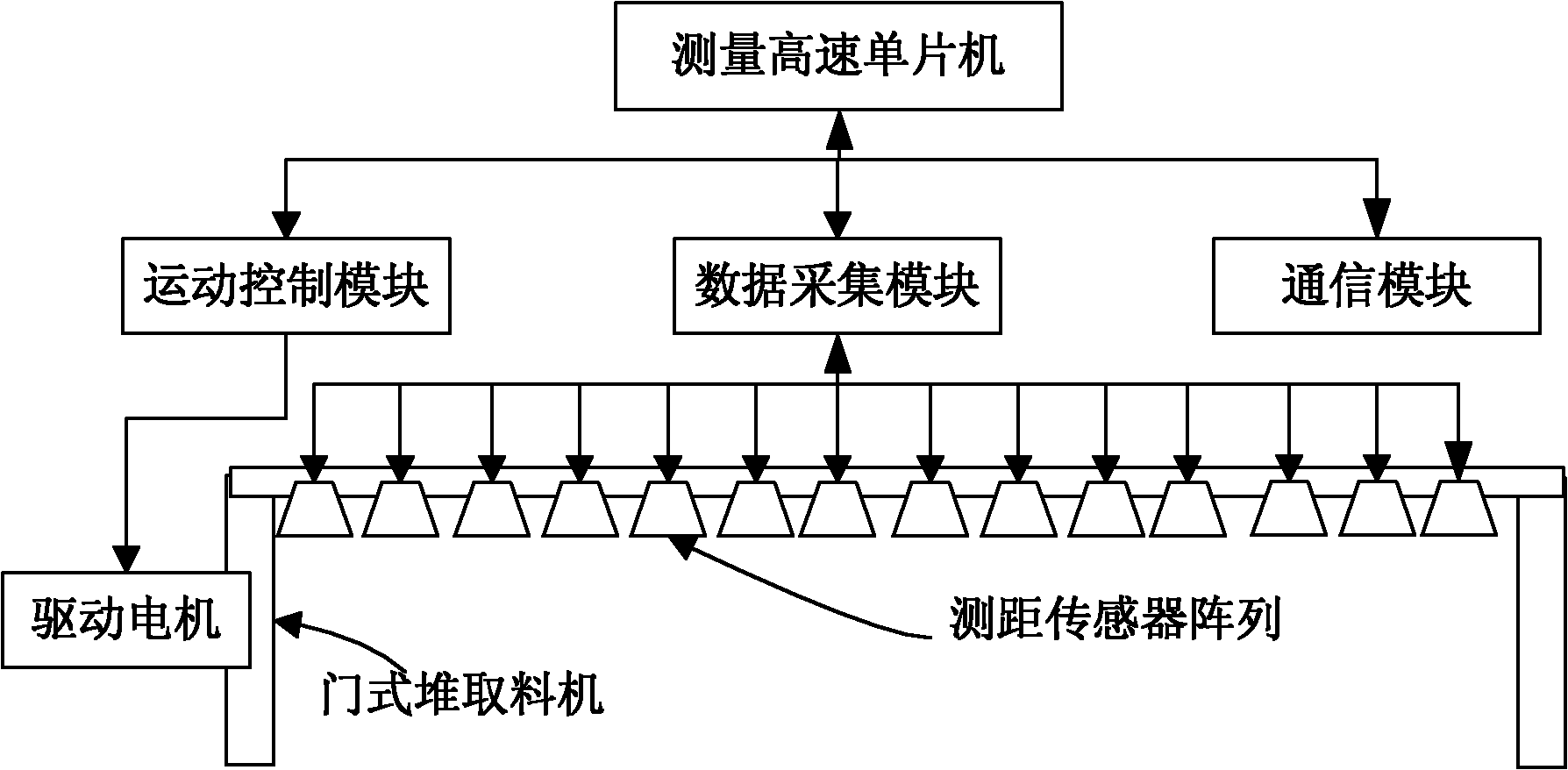

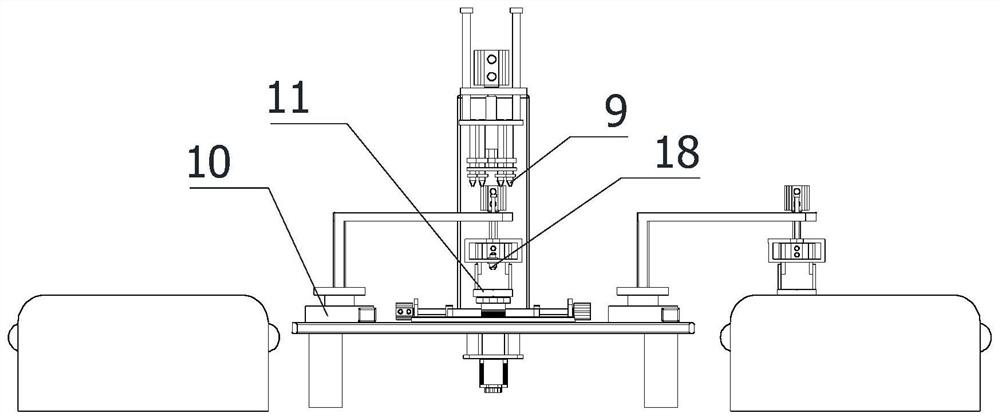

Volume measuring device for large bulk stockpile

InactiveCN102135418AQuick measurementAccurate measurementUsing subsonic/sonic/ultrasonic vibration meansSensor arrayMicrocontroller

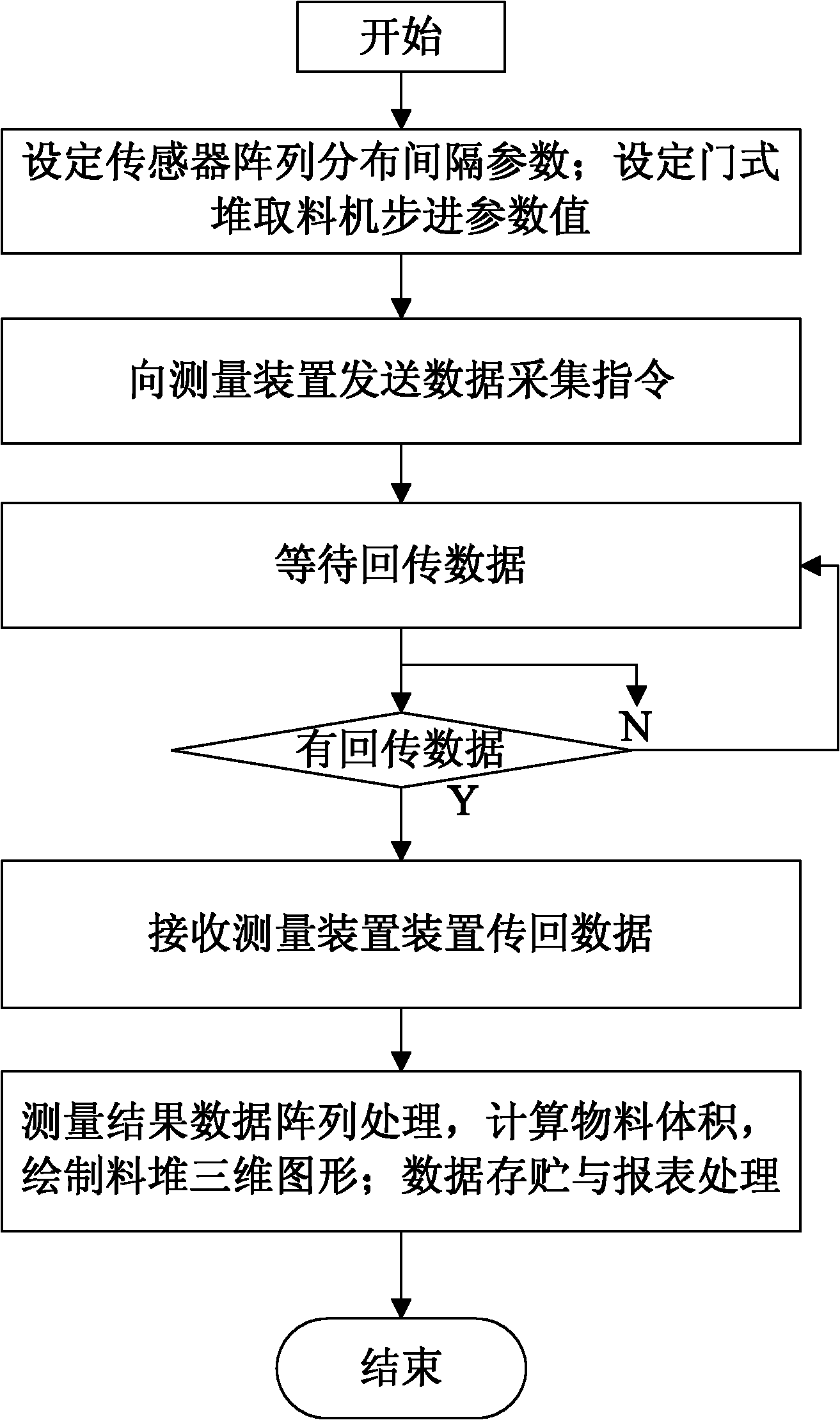

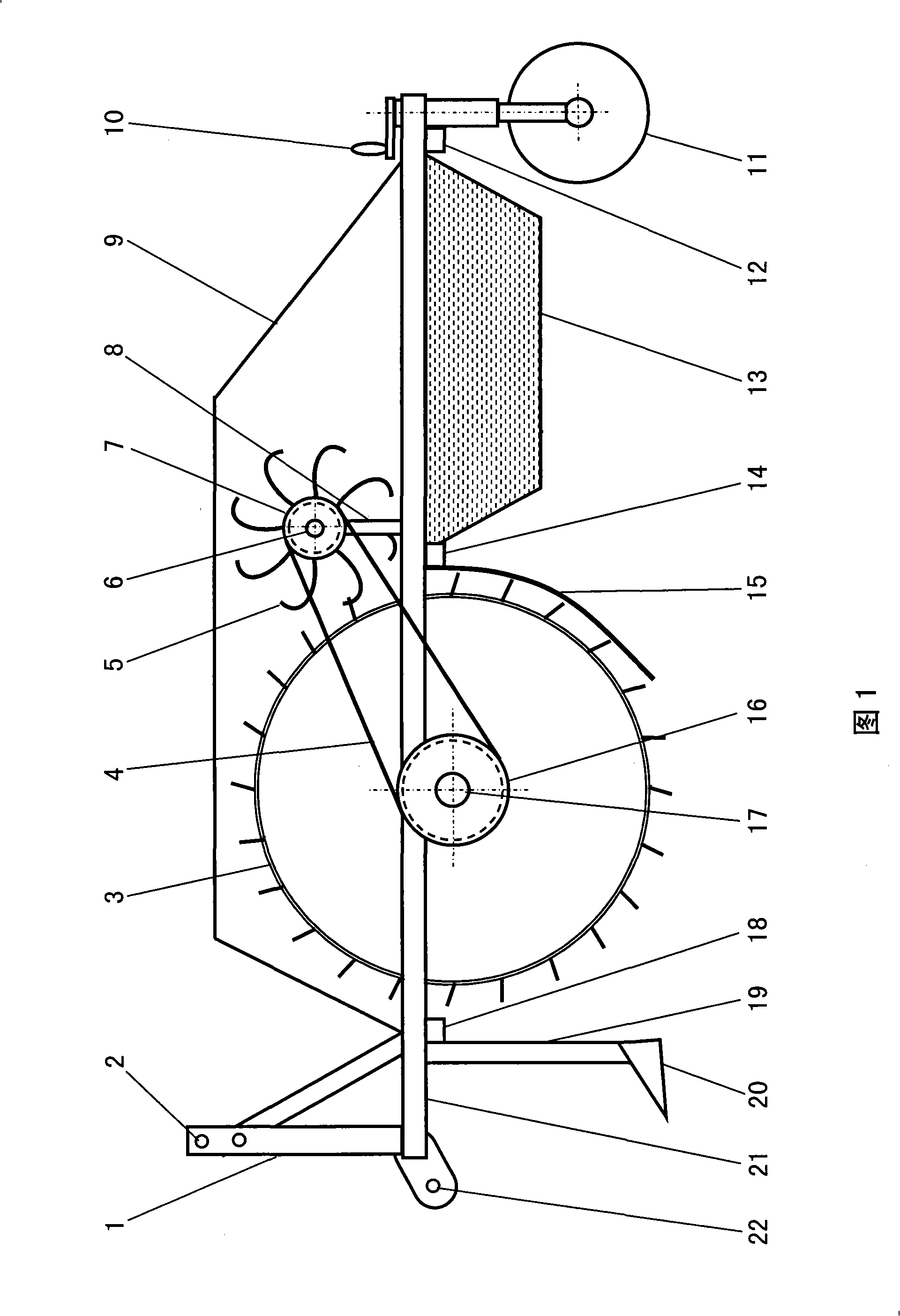

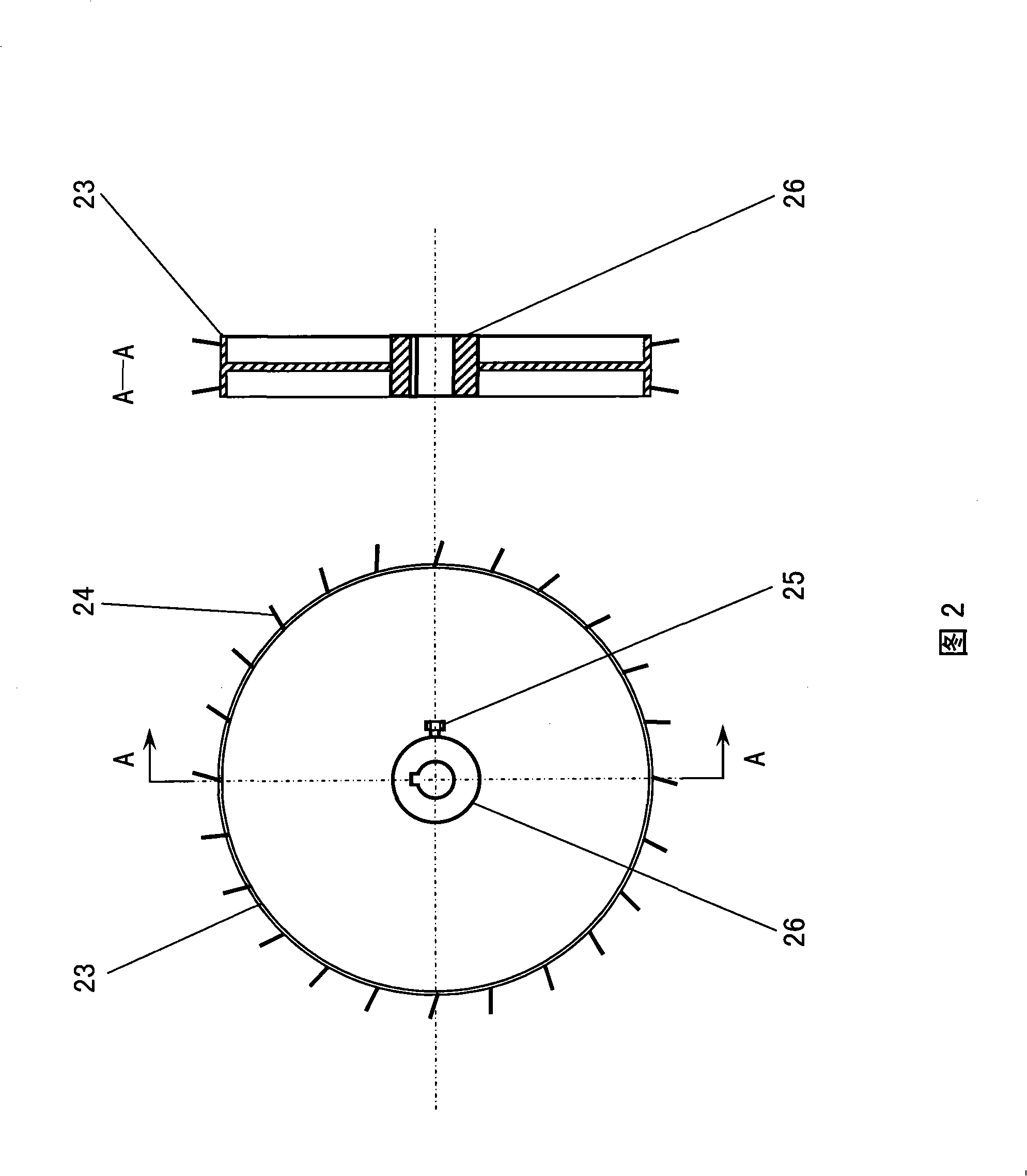

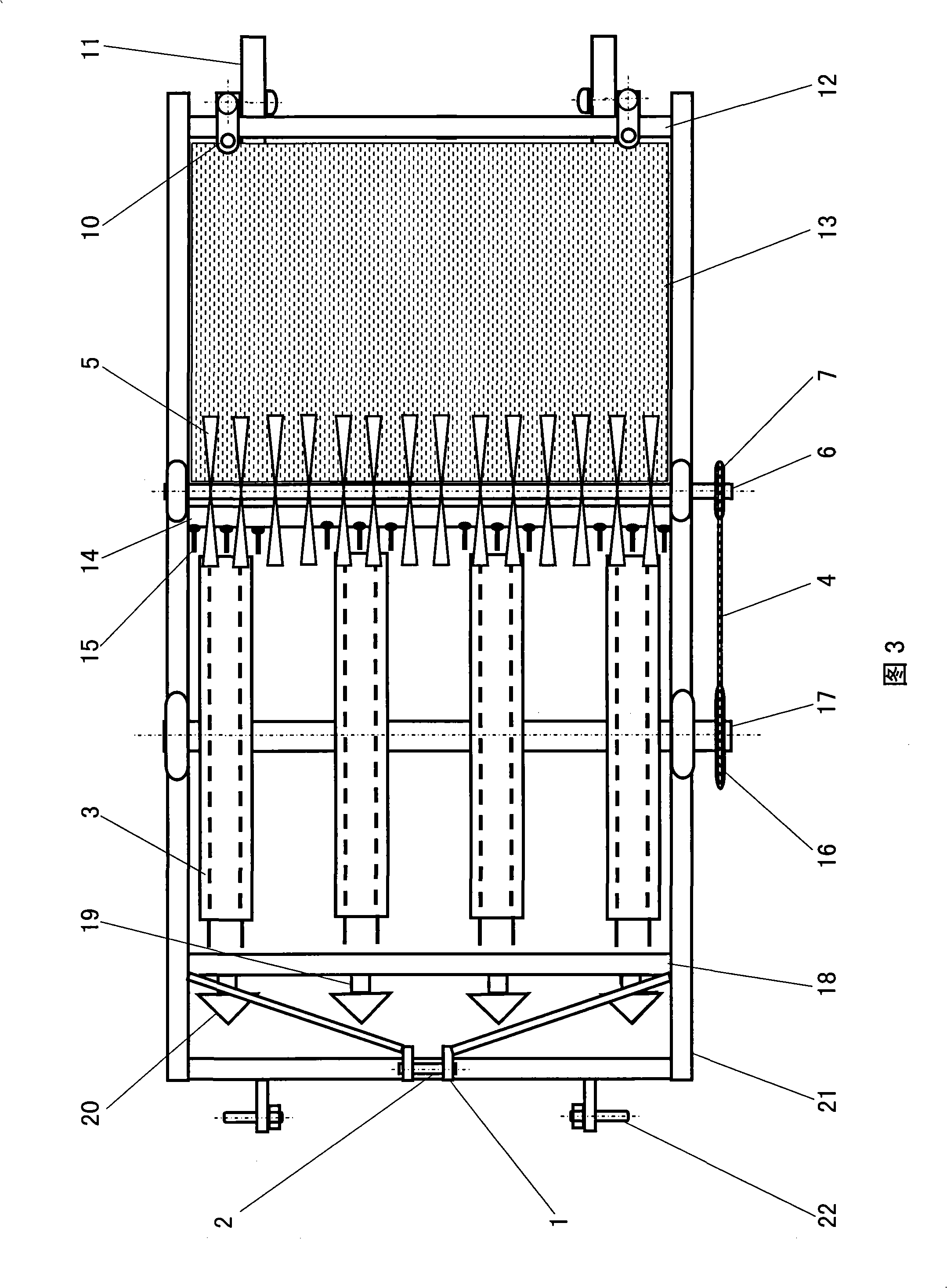

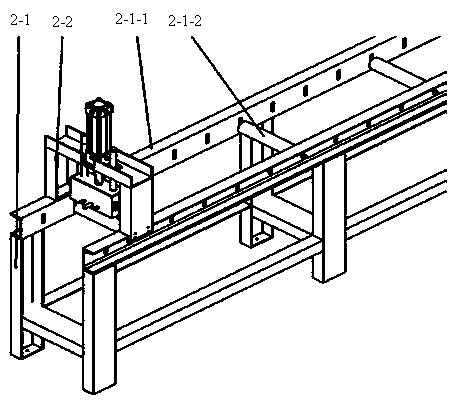

The invention provides a volume measuring device for large bulk stockpiles and a method thereof. The device comprises a measuring device, a measuring computer, and a communication network that is connected with the measuring device and the measuring computer, wherein the measuring device comprises a high-speed singlechip, a portal stacking / reclaiming device, a distance measuring sensor array, a data collecting module, a communication module and a motion control module, wherein the distance measuring sensor array is arranged on a crossbeam of the portal stacking / reclaiming device; and the data collecting module, the communication module and the motion control module are connected with the high-speed singlechip. In the measuring process, the method comprises the steps of firstly setting the spacing parameter and quantity of the distance measuring modules, and the stepping values of the portal stacking / reclaiming machine; subsequently measuring the instructions emitted by the computer; leading the portable stacking / reclaiming machine to advance to the starting position at one end of the stockpiles; scanning the measuring values of each distance measuring module by the singlechip so as to complete scanning data sampling; and finally transmitting the collected data set to the measuring computer by the singlechip; and after receiving the measuring data set by the measuring computer, carrying out the measuring and calculating task and the three-dimension chart drawing tasks. The measuring device is simple, the measuring precision is high, and the measuring device can work reliably for a long time.

Owner:SHAANXI UNIV OF SCI & TECH

Combination type recovering machine for residual-film between seedlings

InactiveCN101258795ASolve the problem of not being able to carry out farmland seedling operationsIncrease the use of functionsSpadesPloughsAgricultural engineeringReclaimer

The invention relates to a combined type furrow residual film reclaimer which can realize the recovery operation of furrow film of a cropland or whole residual film by a machine. The invention is characterized in that: break shovels, spilt spoke disc type film drawing wheels and film collecting harrows with elastic teeth are all designed in a single way, and the quantity of the break shovels, the spilt spoke disc type film drawing wheels and the film collecting harrows with elastic teeth can be determined according to the number of rows and row spacing of crops, and the spaces between the break shovels, the spilt spoke disc type film drawing wheels and the film collecting harrows with elastic teeth are adjusted to realize the furrow residual recovery operation in the cropland. The break shovels, the spilt spoke disc type film drawing wheels and the film collecting harrows with elastic teeth can also be arranged according to the working width of the reclaimer to realize the whole residual film recovery operation by the machine. The combined type furrow residual film reclaimer has the advantages that the use functions of the reclaimer are expanded, multiple operations of scarification, film drawing, film reclaimation, etc. can be finished at one time, thereby effectively promoting the efficiency and working scope of machines. The reclaimer is also characterized by reasonable structure, flexible combination, convenient debugging, simple operation and low consumption, thus having wide application prospect and having important practical significance for the development of agricultural mechanization of China.

Owner:HUAZHONG AGRI UNIV

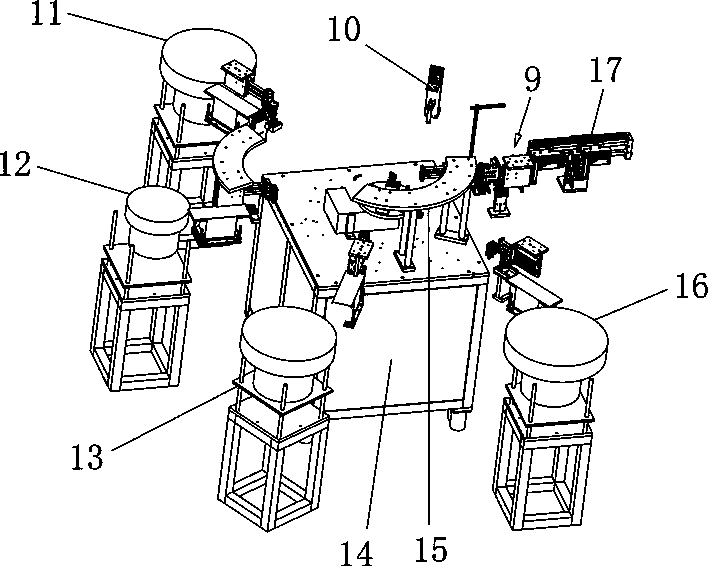

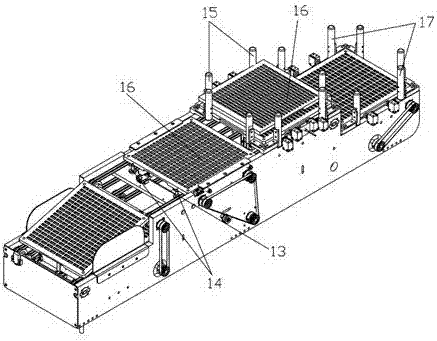

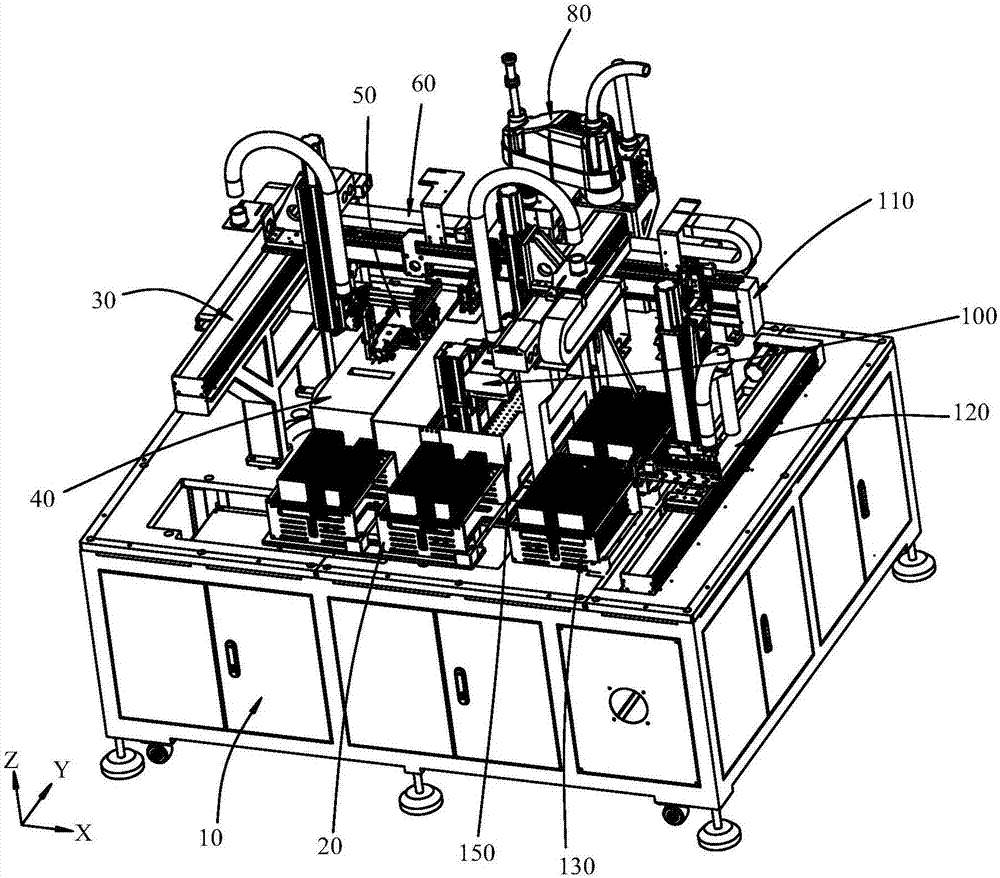

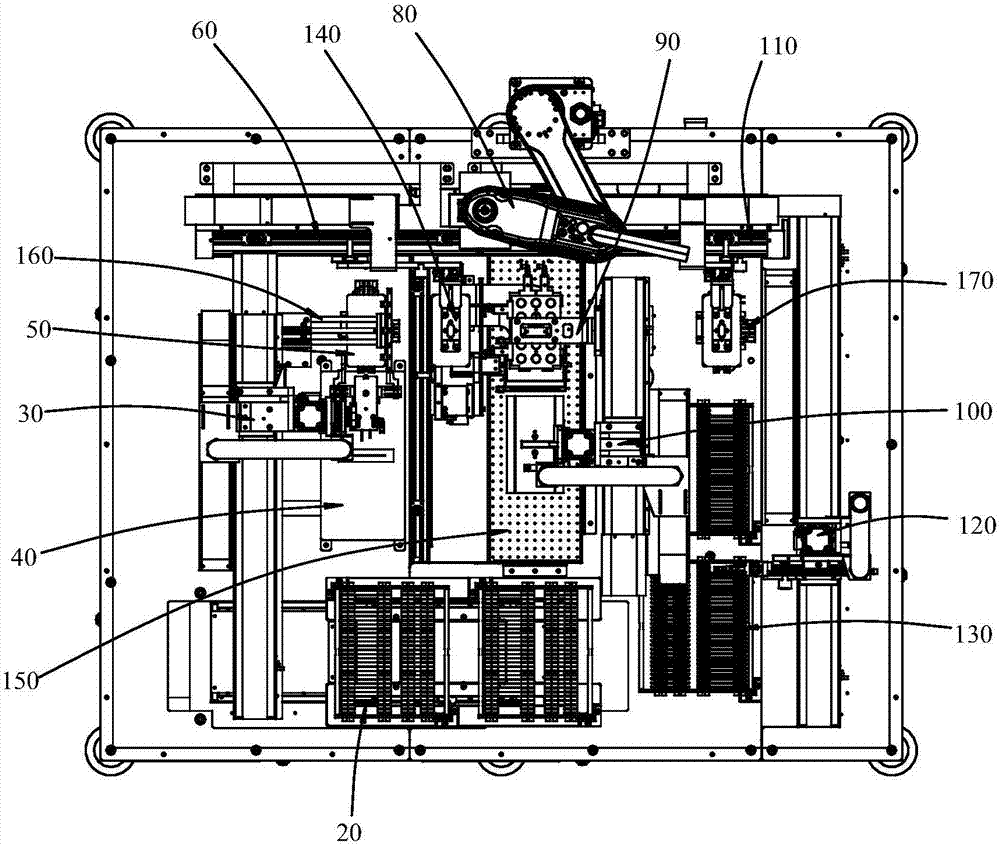

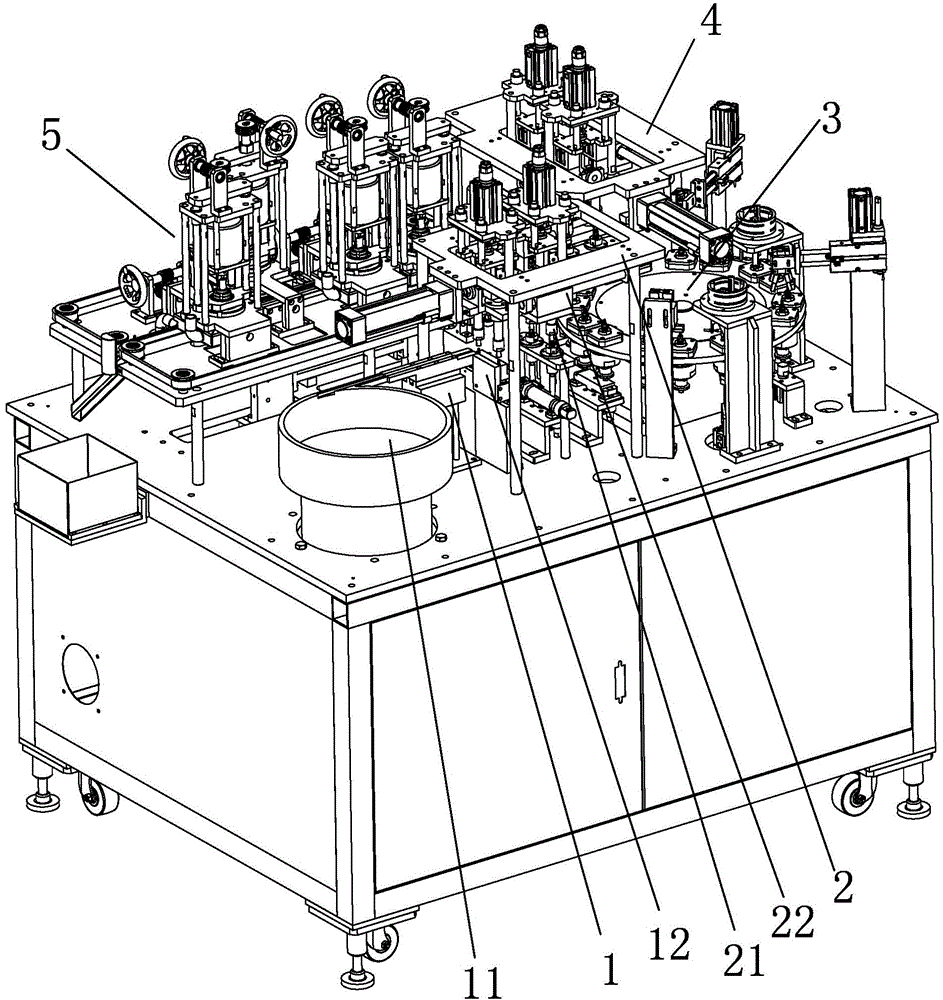

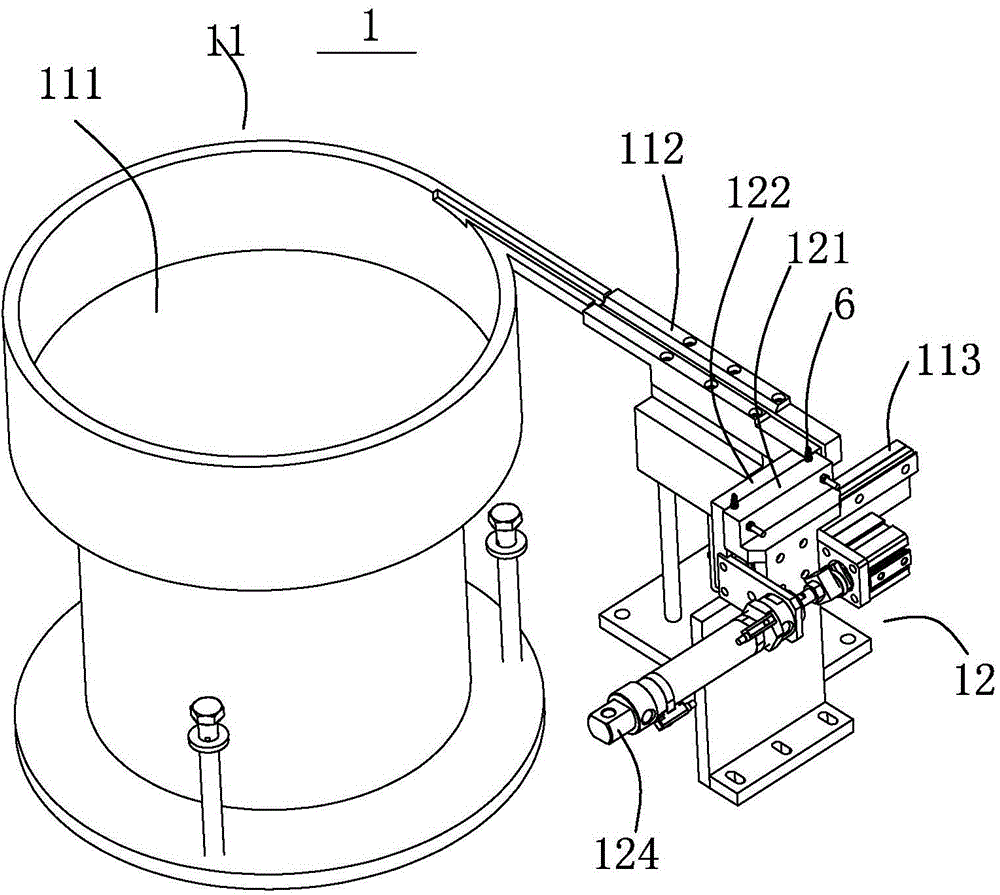

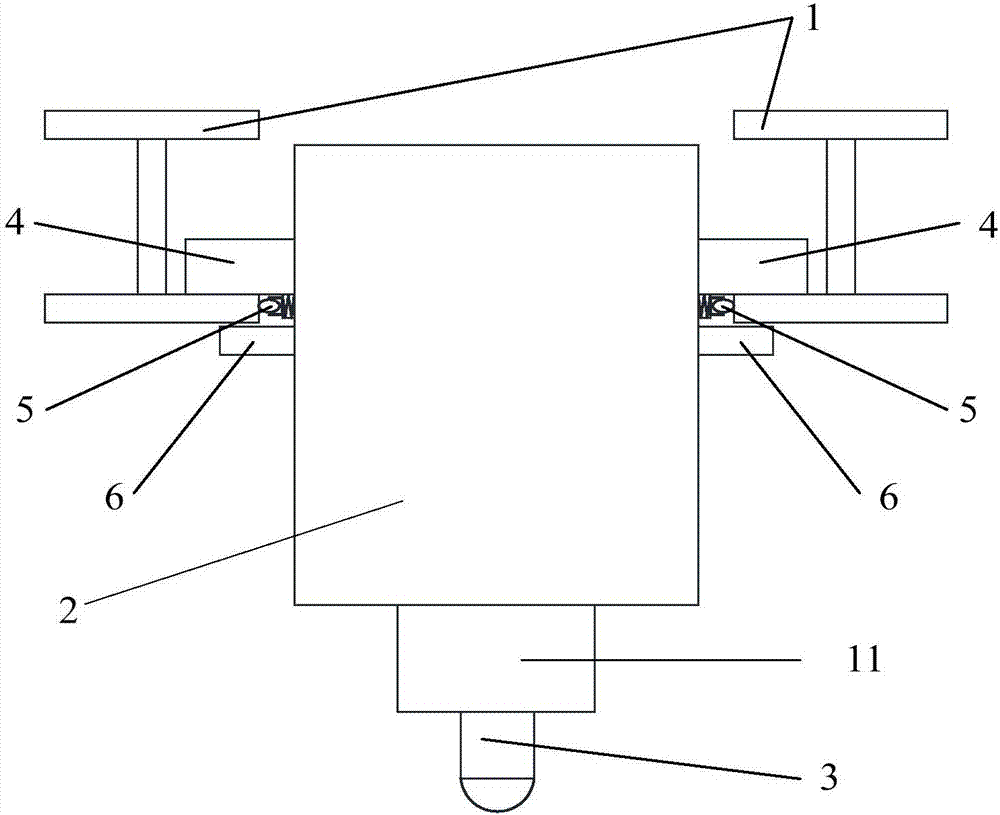

Test packing machine of ID coil and test packing technology of ID coil

ActiveCN107380566ARealize inspection automationFully automatedPackaging automatic controlProduction lineTest sample

The invention relates to the field of electronic product test packing devices, in particular to a test packing machine of an ID coil and a test packing technology of the ID coil. The technology mainly comprises the steps that 1, a feeding mechanism provides materials for inspection; 2, a material taking mechanism takes materials for inspection; 3, a detection mechanism tests samples; 4, a packing mechanism conducts jet printing and packaging; 5, a belt collection mechanism collects a carrier belt. According to the test packing machine, a control device is used for controlling the feeding mechanism, the material taking mechanism, a transition mechanism, the detection mechanism, the packing mechanism and the belt collection mechanism which are electrically connected, the ID coil product to be detected is sequentially subjected to pipelined processing including transmission, testing and packaging, meanwhile the transmission, testing, packaging and collecting processes are automatic, so that high-level integrated automation is achieved, a production line without guard by many persons is achieved, the production cost is lowered, and the detection efficiency and quality are improved.

Owner:DONGGUAN LISU LED MACHINERY TECH

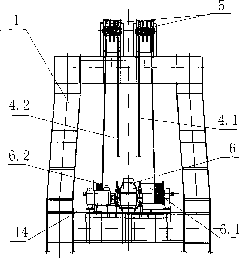

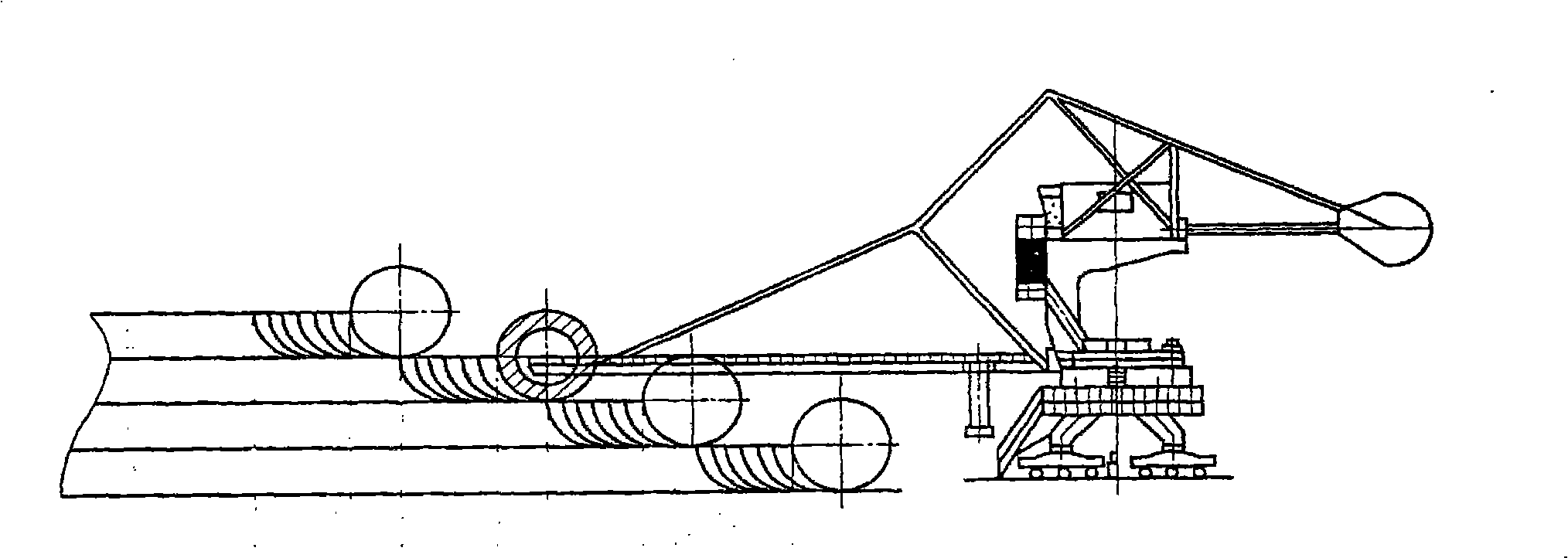

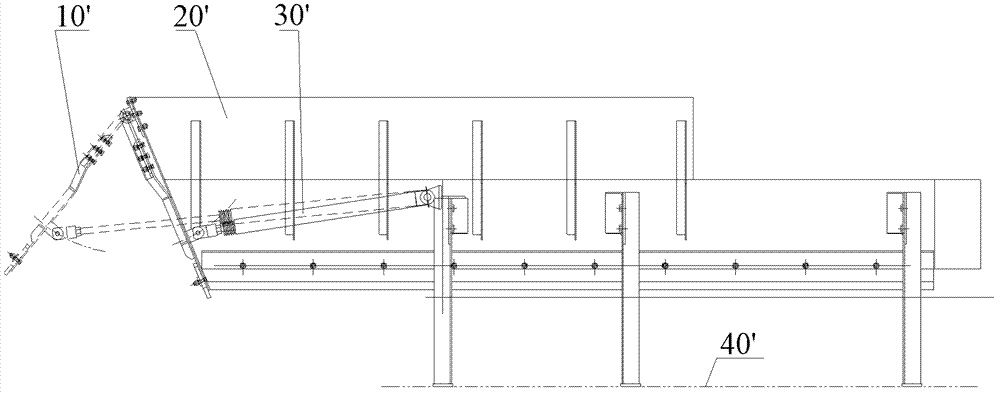

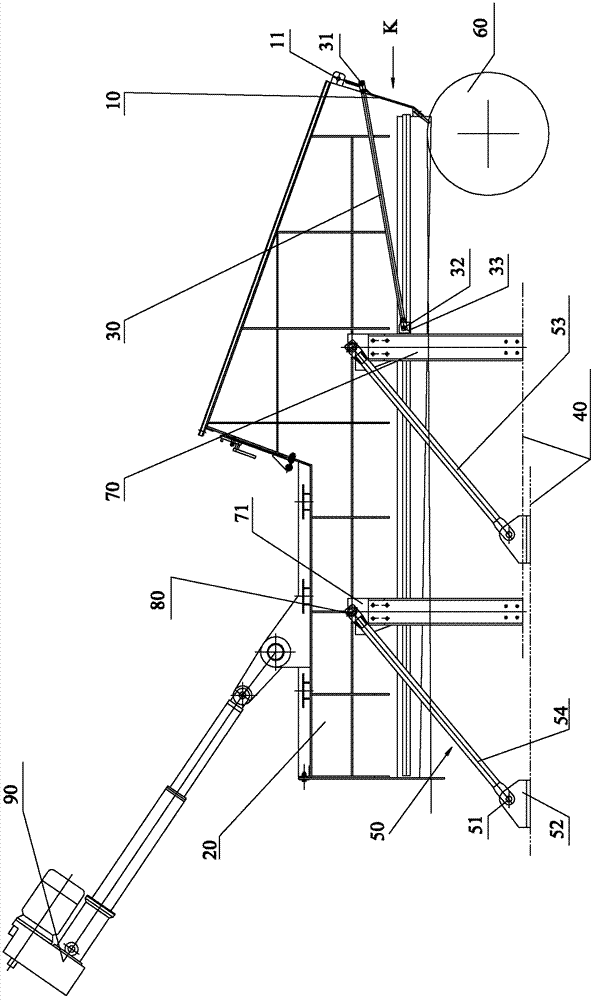

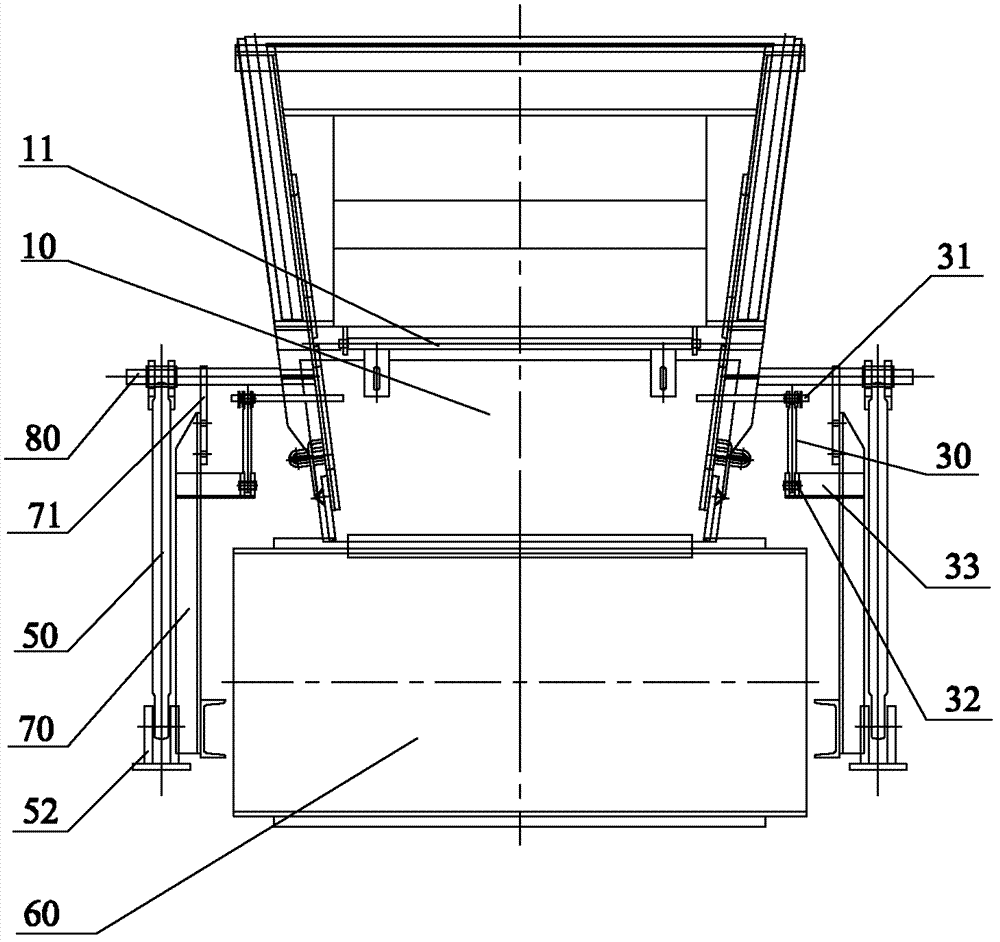

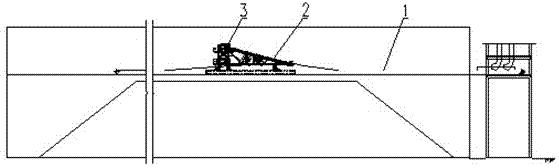

Closed coal yard

ActiveCN103922154ALarge reservesContinuous expansion is convenientLoading/unloadingBulk storage containerEngineeringReclaimer

The invention discloses a closed coal yard comprising a closed net rack, a feed mechanism, a discharge mechanism and a reclaiming mechanism. The feed mechanism comprises a feed belt conveyor. The discharge mechanism comprises a stacker, a cantilever belt conveyor and a column. The reclaiming mechanism comprises a reclaiming belt conveyor and a scraper reclaimer. A feed yard belt conveyor and a stacking travel rail are arranged on the upper portion of the column. A reclaiming travel rail is arranged in the middle of the column. The stacker vertically moving along a coal pile is arranged above the feed belt conveyor; the feed belt conveyor conveys coal to the cantilever belt conveyor of the stacker. The scraper reclaimer regulates pitching angle thereof through a cable hosting mechanism according to the shape of the coal pile. The scraper reclaimer vertically moves along the coal pile through the reclaiming travel rail. The closed coal yard is high in storing capacity, convenient to continuously expand, high in automation level, small in floor area, and economical and energy saving; the closed coal yard is applicable to large storage and distribution coal bases and power plants continuously expanded.

Owner:SOUTHWEST ELECTRIC POWER DESIGN INST OF CHINA POWER ENG CONSULTING GROUP CORP

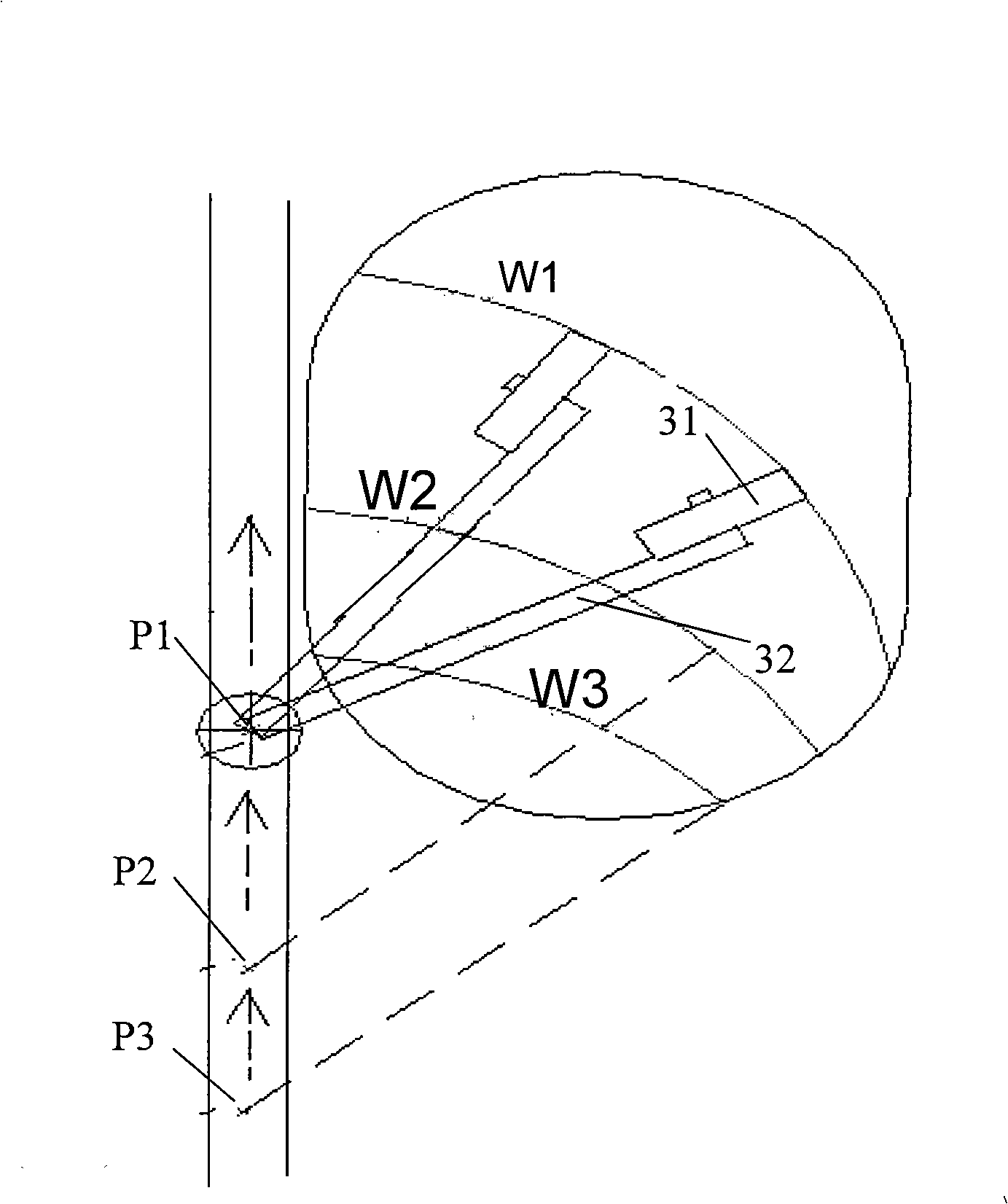

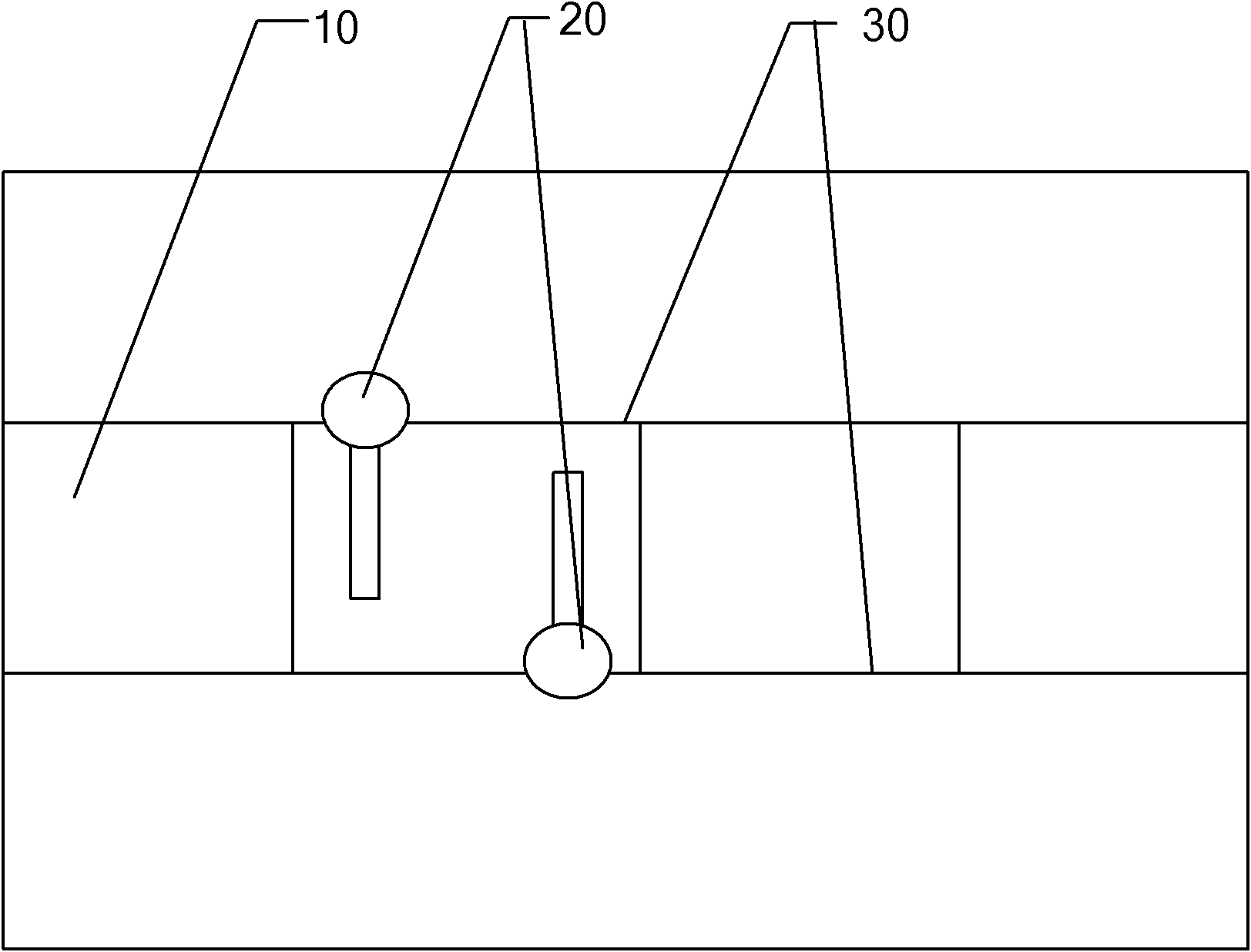

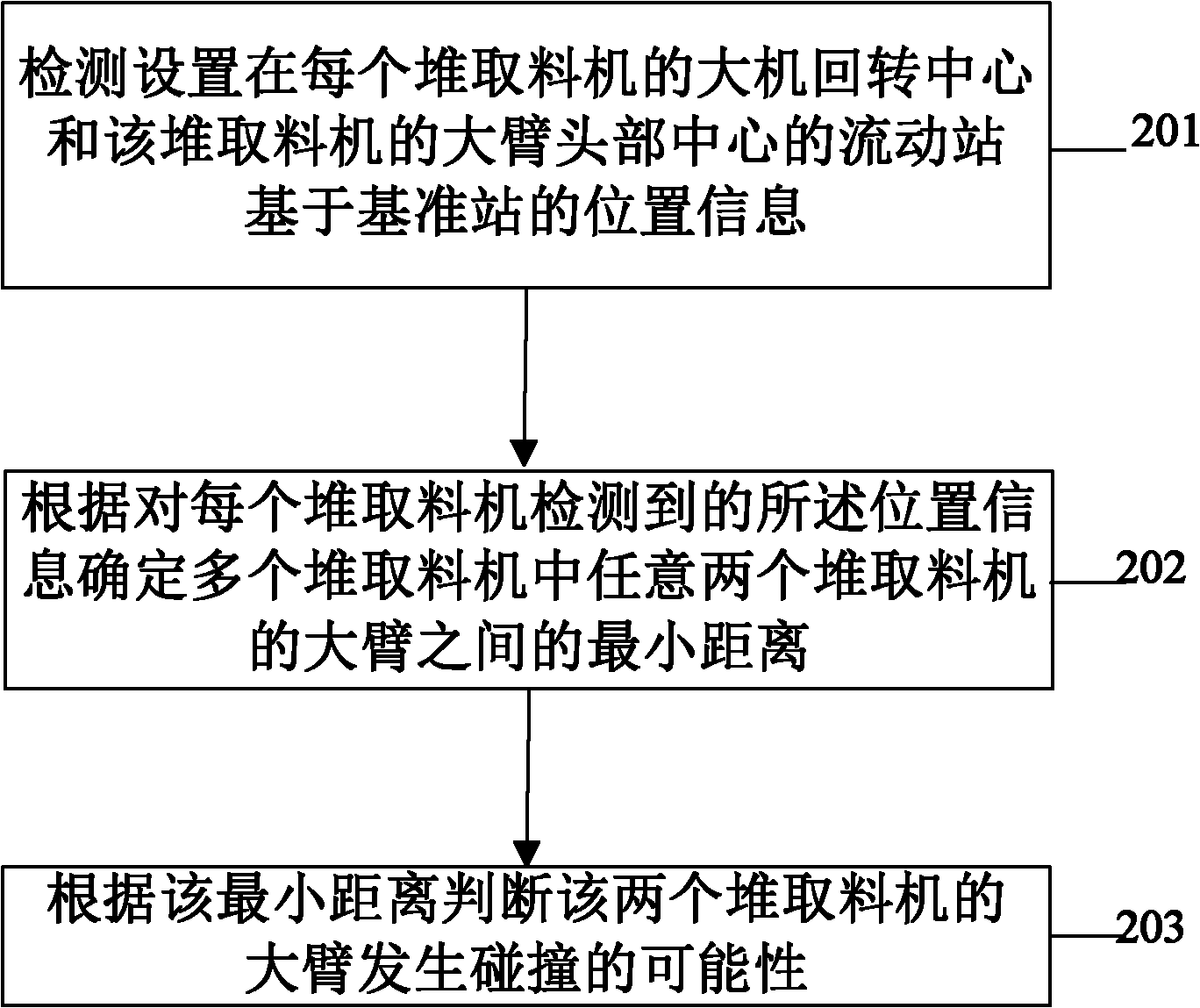

Method and system for predicating collision possibility as well as anti-collision control method and system

ActiveCN102033237ARealize safe operationAvoid collisionSatellite radio beaconingLoading/unloadingMobile stationReclaimer

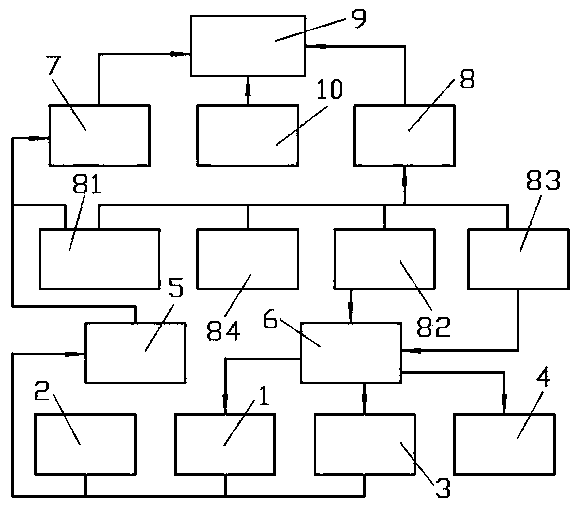

The invention discloses a method and a system for predicating the collision possibility of a plurality of stackers-reclaimers in a stack yard as well as anti-collision control method and system. The method for predicating the collision possibility of the plurality of stackers-reclaimers in the stack yard comprises the following steps of: detecting the position information of a mobile station arranged in the large-machine rotary centre of each stacker-reclaimer and the large-arm head centre of the stacker-reclaimer based on a reference station; determining the minimum distance between the large arms of any two stackers-reclaimers in the plurality of stackers-reclaimers according to the detected position information of each stacker-reclaimer; and judging the collision possibility of the large arms of two stackers-reclaimers according to the minimum distance. Therefore, the invention can judge the collision possibility between the stackers-reclaimers so that operators can further process according to the possibility.

Owner:CHINA SHENHUA ENERGY CO LTD +1

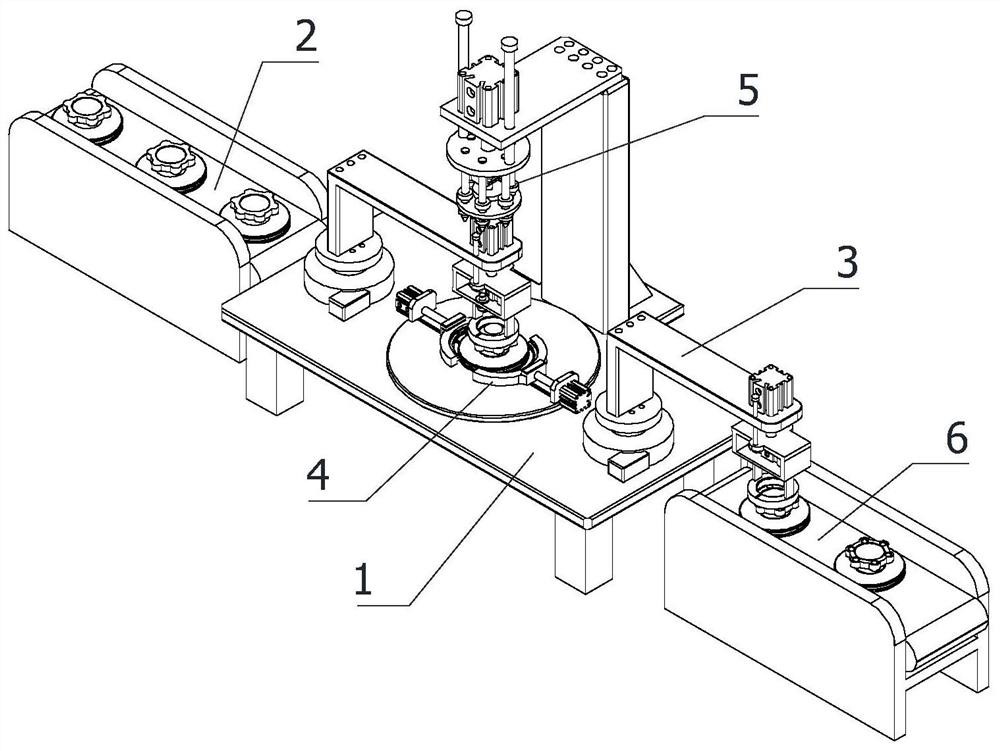

Loading and unloading system for 3D hot bending machine

PendingCN107473575AReduce bumps and other damageImprove yieldGlass reforming apparatusStructural engineeringMachine

The invention relates to a loading and unloading system for a 3D hot bending machine. The loading and unloading system comprises a machine frame, and a 2D glass feeding assembly, a 2D glass reclaiming manipulator, a 2D glass positioning platform, a 2D glass loading manipulator, a mould placing platform, a mould handling manipulator, an upper mould handling manipulator, a 3D glass unloading manipulator, a 3D glass positioning platform, a 3D glass plug-in manipulator and a 3D glass storage assembly which are arranged on the machine frame, wherein the mould handling manipulator is butt-jointed with the 3D hot bending machine and the mould placing platform, the upper mould handling manipulator is butt-jointed with the mould placing platform, the 2D glass reclaiming manipulator is butt-jointed with the 2D glass feeding assembly and the 2D glass positioning platform, the 2D glass loading manipulator is butt-jointed with the 2D glass positioning platform and the mould placing platform, the 3D glass unloading manipulator is butt-jointed with the mould placing platform and the 3D glass positioning platform, and the 3D glass plug-in manipulator is butt-jointed with the 3D glass positioning platform and the 3D glass storage assembly. The loading and unloading system provided by the invention can be combined with the 3D hot bending machine to form an automated assembly line.

Owner:环昱自动化(深圳)有限公司

Automatic insertion pin grinding method and grinding machine

ActiveCN104476360AOptimize machining processes and proceduresImprove versatilityGrinding machinesGrinding feedersMaterial selectionElectric control

The invention discloses an automatic insertion pin automatic grinding machine, which comprises a vibration material selection mechanism, a material grasping mechanism, a positioning detection mechanism, a material taking mechanism, an insertion pin grinding mechanism and an electric control mechanism, wherein the vibration material selection mechanism comprises a vibration material discharging assembly and a moving material collecting assembly, the material grasping mechanism comprises a material grasping assembly and a material grasping position changing assembly, the positioning detection mechanism comprises a divider turntable assembly, an insertion pin detection assembly and a defective product removing assembly, the material taking mechanism comprises a material taking assembly and a material taking replacing assembly, the insertion pin grinding mechanism comprises a belt rolling wheel assembly and a grinding cutter assembly, the electric control mechanism is electrically connected with each mechanism, and controls each mechanism to act in a coordinated way, the material grasping mechanism is arranged between the vibration material selection mechanism and the positioning detection mechanism, and the material taking mechanism is arranged between the positioning detection mechanism and the insertion pin grinding mechanism. The invention also discloses an automatic grinding method adopted by the grinding machine. The automatic grinding machine and the automatic grinding method have the advantage that the high-efficiency and high-quality automatic grinding of earphone insertion pins is realized.

Owner:浦北瀛通智能电子有限公司

Anti-collision control method of bucket-wheel stacker-reclaimers

ActiveCN103964155ASmall amount of calculationImprove reliabilityControl devices for conveyorsLoading/unloadingShortest distanceData information

An anti-collision control method of bucket-wheel stacker-reclaimers comprises the following steps that the respective coordinate position states of the two bucket-wheel stacker-reclaimers are obtained through a positioning system; the revolving angle states of the two bucket-wheel stacker-reclaimers are obtained through a revolving angle encoder; the respective coordinate position state data information and revolving angle state data information of the two bucket-wheel stacker-reclaimers are transmitted to a central control unit PLC; the central control unit PLC calculates the shortest distance of the two bucket-wheel stacker-reclaimers on a horizontal plane projection according to the data information, and compares the worked out shortest distance with a set value; a control instruction on the bucket-wheel stacker-reclaimers is sent to PLCs of the two bucket-wheel stacker-reclaimers through an industrial network according to the comparison result; and the PLCs of the two bucket-wheel stacker-reclaimers determine whether to carry out an alarming operation or stopping operation according to the received control instruction.

Owner:TIDFORE INT ENG

Automatic clamping mechanical hand device for milling machining optical lens

InactiveCN102785144AImprove machining accuracyFully automatedOptical surface grinding machinesManipulatorRobot handMachine

The invention discloses an automatic clamping mechanical hand device for milling machining an optical lens, and the automatic clamping mechanical hand device comprises a blank storage rack, a blank taking mechanism, an intermediate transfusion mechanism, a blank feeding mechanism and a control cabinet, wherein the blank taking mechanism is arranged on the top of the blank storage rack, the intermediate transfusion mechanism is arranged on one side of the blank storage rack, the blank feeding mechanism is connected with the intermediate transfusion mechanism, and the control cabinet is respectively connected with the blank taking mechanism, the intermediate transfusion mechanism and the blank feeding mechanism through a conducting wire. The blank taking mechanism, the intermediate transfusion mechanism and the blank feeding mechanism are controlled by the control cabinet to be coordinated and cooperated with one another, and a work-piece is absorbed by the blank taking mechanism and then is transmitted to the blank feeding mechanism through the intermediate transfusion mechanism. Due to the adoption of the automatic clamping mechanical hand device, automation for clamping the work-piece can be realized, accuracy in positioning, convenience in operation, rapidness and high efficiency can be realized, the machining precision of a milling grinding machine is higher, the labor intensity of workers can be saved, and the production efficiency can be improved.

Owner:南阳中一光学装备有限公司

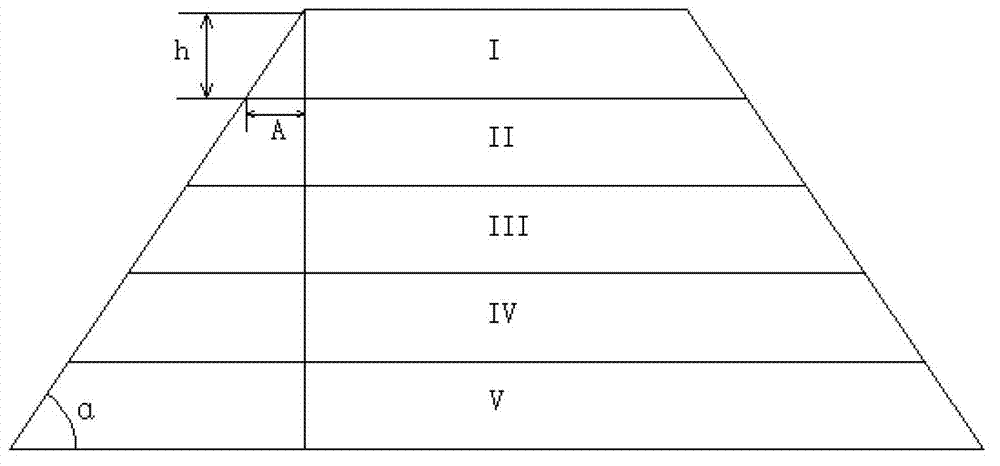

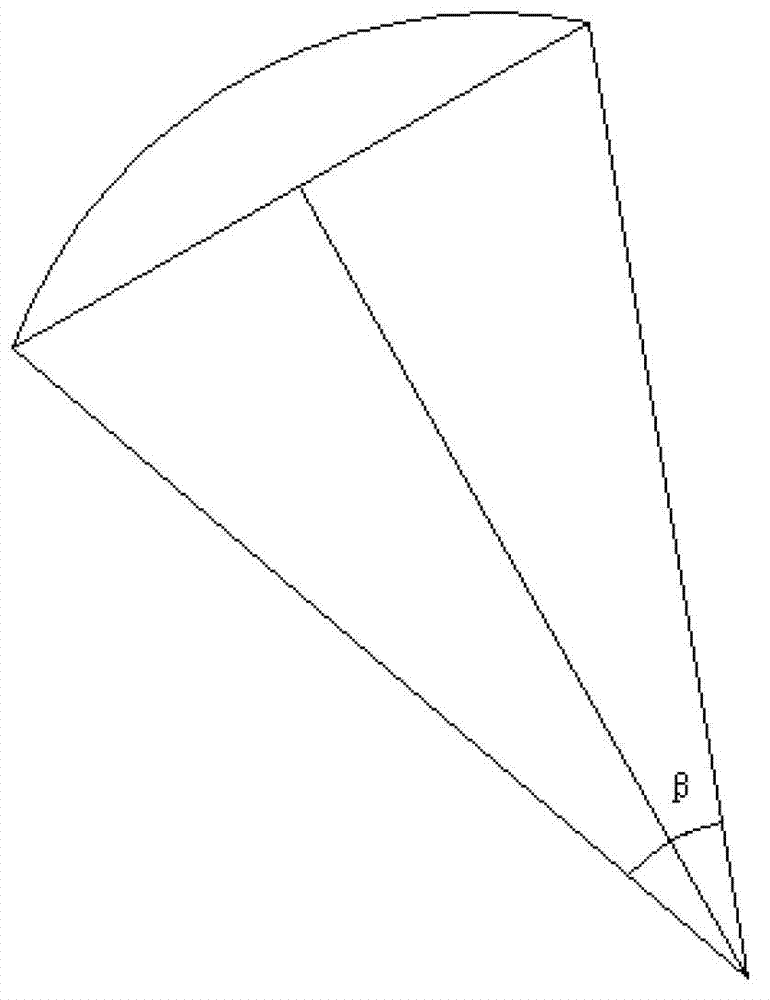

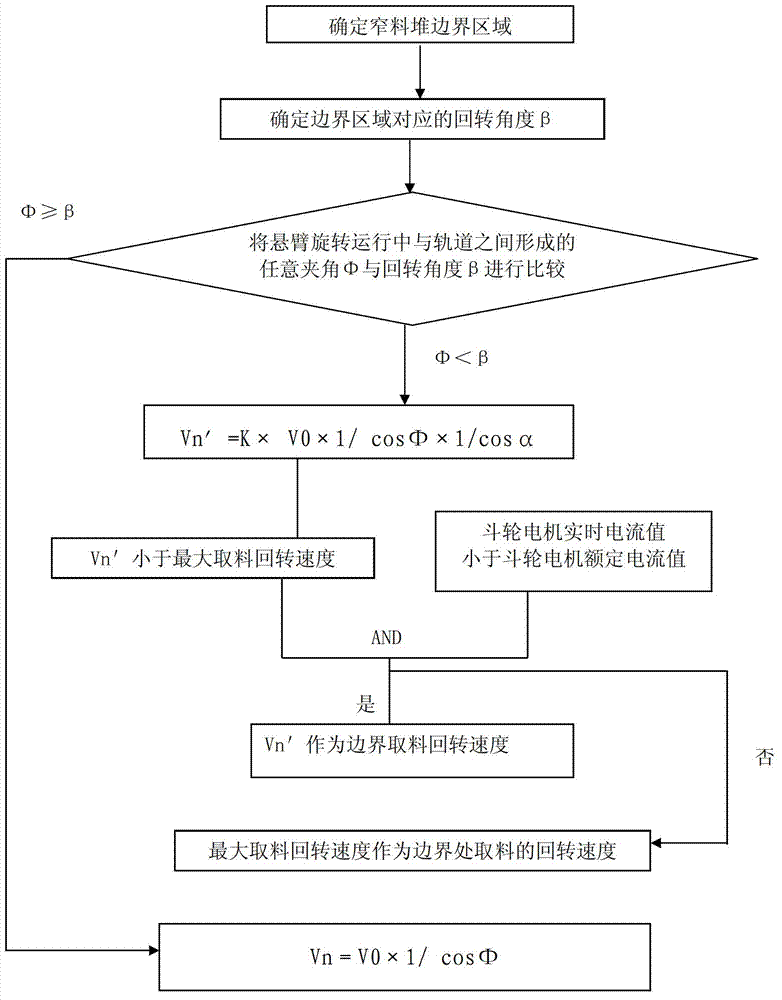

Method for controlling operation speed of cantilever crane rotating mechanism of cantilever type bucket wheel reclaimer

InactiveCN102902284AFast turning speedImprove reclaiming efficiencySpeed/accelaration control using electric meansReclaimerCantilever

The invention discloses a method for controlling operation speed of a cantilever crane rotating mechanism of a cantilever type bucket wheel reclaimer and provides the method capable of increasing material taking efficiency of the cantilever type bucket wheel reclaimer. The method for controlling the operation speed of the cantilever crane rotating mechanism of the cantilever type bucket wheel reclaimer includes: determining a narrow material pile boundary area: setting the length in the horizontal direction corresponding to the boundary area to be A, and determining the rotating angle beta corresponding to the boundary area; comparing an arbitrary included angle phi formed by a cantilever crane during rotating and a rail with the rotating angle beta, wherein if phi is larger than or equal to beta, the rotating speed Vn=V0*1 / cos(phi), and if phi is smaller than beta, the rotating speed Vn'=K*V0*1 / cos(phi)*1 / cos(alpha); if the theoretical rotating speed Vn' of the boundary portion is smaller than the largest material taking rotating speed, and the real-time current value of a bucket wheel motor is smaller than the rated current value of the bucket wheel motor, taking the theoretical rotating speed Vn' on the boundary portion obtained through calculation as the boundary material taking rotating speed; otherwise, taking the largest material taking speed as the material taking rotating speed on the boundary portion.

Owner:天津港中煤华能煤码头有限公司

Method and system for time-based reclamation of objects from a recycle bin in a database

ActiveUS20060074956A1Guaranteed timeData processing applicationsSpecial data processing applicationsObject basedReclaimer

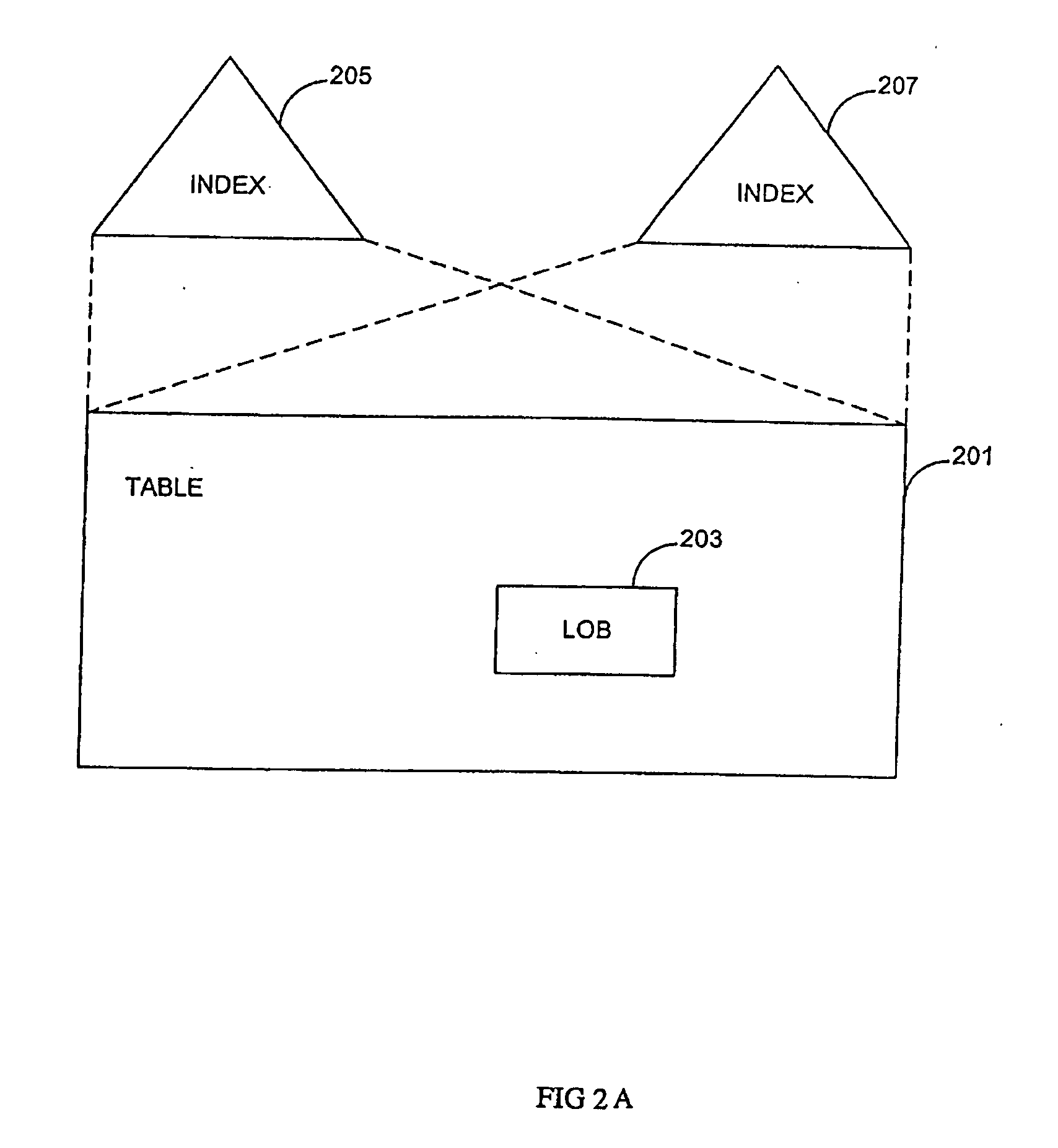

A system for managing dropped objects of a database. The system comprises a finite amount of disk space for temporarily storing the dropped objects. The system further includes an indexer for assigning time stamps to each of the dropped objects and a reclaimer for reclaiming the dropped objects based on their time stamps. These time stamps can also be used to guarantee the amount of time the object remains in the recycle bin.

Owner:ORACLE INT CORP

Automatic loading and drilling equipment of brake disk casting of heavy truck

InactiveCN111715917APrecise positioningReduce manual labor intensityMetal working apparatusBoring/drilling componentsBrakeRobot hand

The invention relates to the field of production and processing of parts and components of heavy trucks and particularly relates to automatic loading and drilling equipment of a brake disk casting ofa heavy truck. The equipment comprises a processing platform, a loading transmission belt, two fetching mechanical hands, a positioning clamping assembly, a drilling processing assembly and an unloading transmission belt, wherein the positioning clamping assembly comprises a rotation mechanism and a clamping mechanism; the rotation mechanism comprises a rotation disk which is disposed horizontallyand can be rotated; the clamping mechanism comprises a clamping claw which can clamp a brake disk; the drilling processing assembly comprises drill bits which can be rotated and liftable; and the drill bits are disposed annularly along the axis of the rotation disk. The automatic loading and drilling equipment of the brake disk casting of the heavy truck disclosed by the invention has the beneficial effects that a to-be-processed brake disk is automatically loaded and positioned; manual labor strength is reduced; working efficiency is increased; processing accuracy is increased; multiple holes with annular distribution are disposed at a time in the brake disk; working efficiency is increased; and a processing error caused by multiple times of adjustment is reduced.

Owner:LIANYUNGANG NORMAL COLLEGE

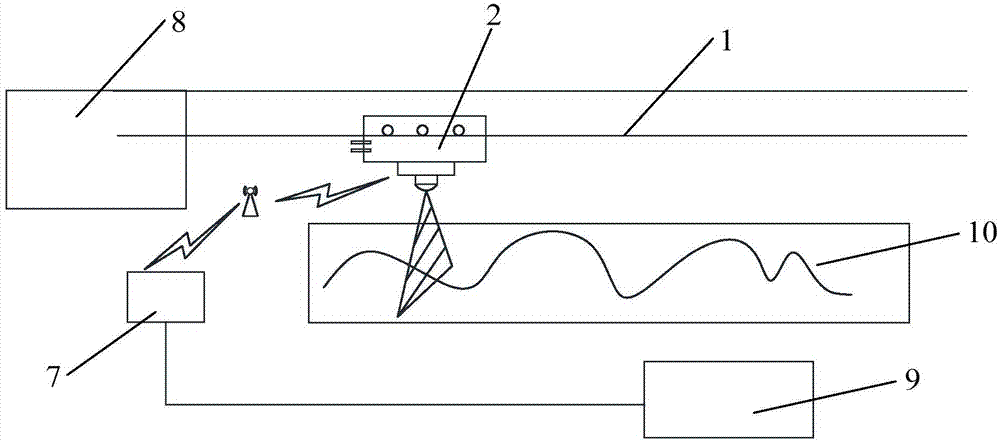

Self-walking intelligent pile body measuring system

InactiveCN107402052ARealize inventory at any timeLow efficiencyVolume measurement apparatus/methodsBody measureControl system

The invention discloses a self-walking intelligent pile body measuring system, a self-walking dolly is installed on a guide rail at the top of a stockyard, under the control of a control system, a driving device works and drives the self-walking dolly to move forward, move backward or stop on the guide rail, and therefore a laser scanner is driven to move in the stock yard and acquire information of coals in a coal yard, and finally a three-dimensional figure and a measuring result of the stock yard are generated in a coal inventory processing system. According to the self-walking intelligent pile body measuring system, according to requirements of stock yard managers at present, the stock yard can be inventoried at any time without a bucket wheel machine or a stacker-reclaimer, and the degree of automation is high. The problems that in the prior art, a laser scanner is installed on a stacking arm or a stacker-reclaimer, and efficiency of measuring work and stacking-reclaiming work is low are overcome, and the efficiency of the measuring and stacking-reclaiming work is improved.

Owner:SAMSINO BEIJING AUTOMATION ENG TECH CO LTD

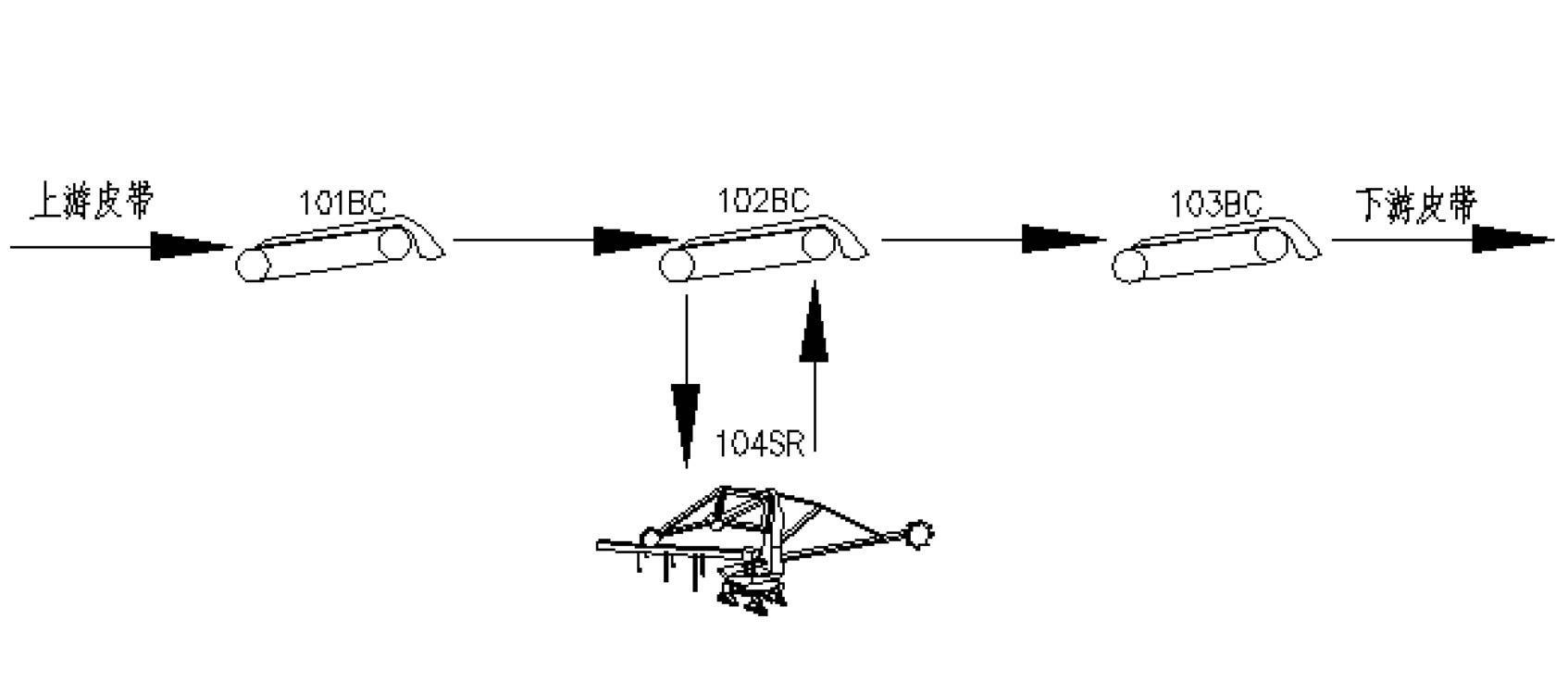

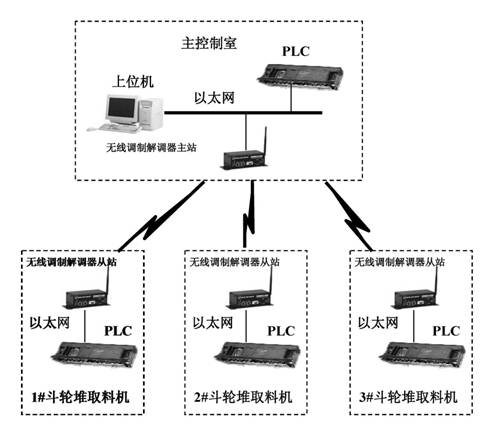

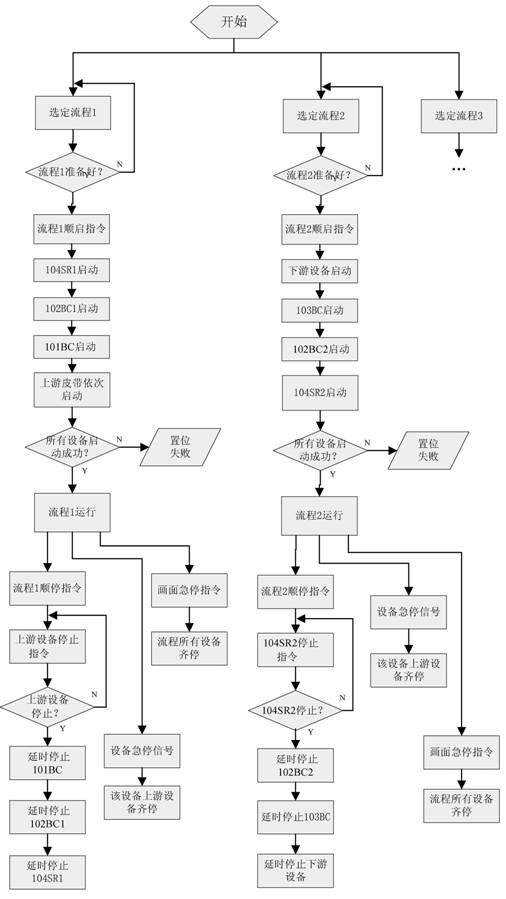

Remote automatic control system and method for bucket wheel stacker reclaimers

InactiveCN102662363ARealize remote automatic stackingRealize automatic stackingTotal factory controlProgramme total factory controlAutomatic controlControl signal

The invention discloses remote automatic control system and method for bucket wheel stacker reclaimers. According to the working mode, the bucket wheel stacker reclaimers are divided into three pieces of independent equipment for participating in interlock control of a stockline in a stock yard; a belt penetrating the stacker reclaimers has three running states for participating in interlock control of the stockline in the stock yard; and corresponding logic processing is performed to state signals and control signals of the divided equipment participating in interlock control. According to the invention, stockline processes comprising the stacker reclaimers are distinguished accurately, when an interlock program of the stockline processes is written in a PLC (Programmable Logic Controller), each equipment formed by dividing the stacker reclaimers serves as an individual in the processes for processing, and is automatically controlled according to the state of upstream and downstream equipment, so that the defect can be solved that in an automatic control system for a stock yard, interlock control can not be performed to the stacker reclaimers and other equipment, full automation of the stacker reclaimers can be realized, and the production efficiency of the stock yard, the product quality and the automation control level of the whole stock yard can be improved greatly.

Owner:WISDRI ENG & RES INC LTD

Automatic pipe cutting machine

ActiveCN103991001APrecise positioningEasy and quick passMetal working apparatusEngineeringStructural engineering

The invention relates to an automatic pipe cutting machine and belongs to the technical field of pipe cutting equipment. The automatic pipe cutting machine mainly solves the problem that an existing pipe cutting machine is not suitable for cutting square pipes. The automatic pipe cutting machine is mainly characterized by comprising an automatic material storage and distribution frame, an automatic material taking mechanism, a material conveying rail, a material pushing system, a cutting system, a sizing and locating mechanism and a discharging frame, wherein the cutting system comprises an automatic clamping mechanism and an automatic cutting mechanism; the sizing and locating mechanism is composed of a sizing and locating box, a large guide rod, an upper girder, uprights, an oil cylinder and a large linear bearing; the sizing and locating box comprises a front panel, a rear panel, a small linear bearing, a small guide rod, a locating striking board, a spring pressing board, a spring clamp, a nut, a spring and a sensor; the uprights at the two sides of the sizing and locating mechanism are fixed to beams at the two sides of the upper end of the discharging frame respectively. The automatic pipe cutting machine has the advantages that the length of a product needing cutting is not limited, automatic material distribution, automation material taking, automatic material conveying and automatic clamping are achieved, and the automatic pipe cutting machine is mainly used for automatically cutting rectangular pipes.

Owner:XIANGYANG YISHUN ELECTROMECHANICAL TECH

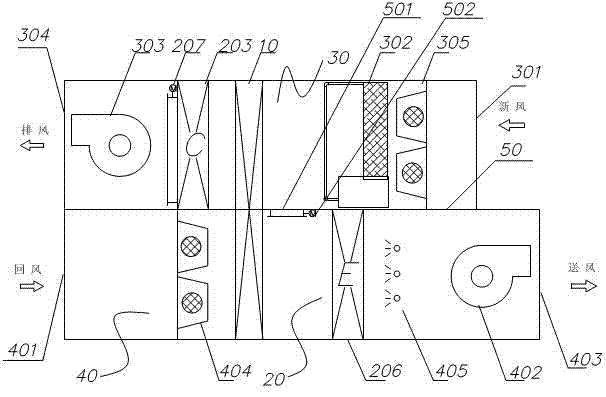

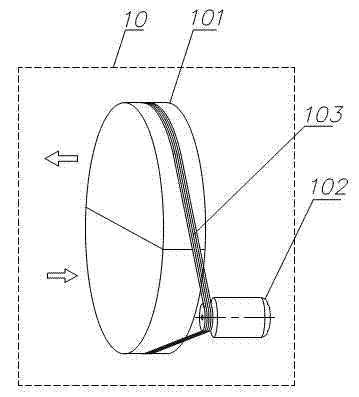

Integral combination type computer room air conditioning unit and control method thereof

ActiveCN102889650AIncrease enthalpyMeet load requirementsEnergy recovery in ventilation and heatingDucting arrangementsCold airVapor–liquid separator

The invention discloses an integral combination type computer room air conditioning unit and a control method thereof. The air conditioning unit comprises a rotating wheel heat reclaimer, a vapour compression refrigerating system, a fresh air current processing channel, a return air current processing channel and a baffle, wherein the fresh air current processing channel is separated from the return air current processing channel by the baffle; part of the rotating wheel heat reclaimer is arranged in the fresh air current processing channel, and the other part of the rotating wheel heat reclaimer is arranged in the return air current processing channel; and the vapour compression refrigerating system comprises a gas-liquid separator, a compressor, a condenser, a liquid storage device, a throttling device and an evaporator which are sequentially connected. The air conditioning unit refrigerates in the three modes of full compressor refrigeration, rotating wheel refrigeration assisted by compressor regulating refrigeration and full rotating wheel refrigeration. The refrigerating system is automatically regulated to run in a matched way according to the load of a computer room and outdoor fresh air conditions. No manual intervention is needed, optimum energy efficiency ratio is achieved, and outdoor fresh air is utilized to an utmost extent for providing an indoor space with cold air.

Owner:GUANGDONG SHENLING ENVIRONMENT SYST CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com