Patents

Literature

414 results about "Regular Production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A Regular Production Option (RPO) is a General Motors standard coding for vehicle configuration options. These codes are a combination of 3 alphanumeric characters and refer to a specific option or modification to the vehicle.

Water soluble effervescence composition and method of making the same

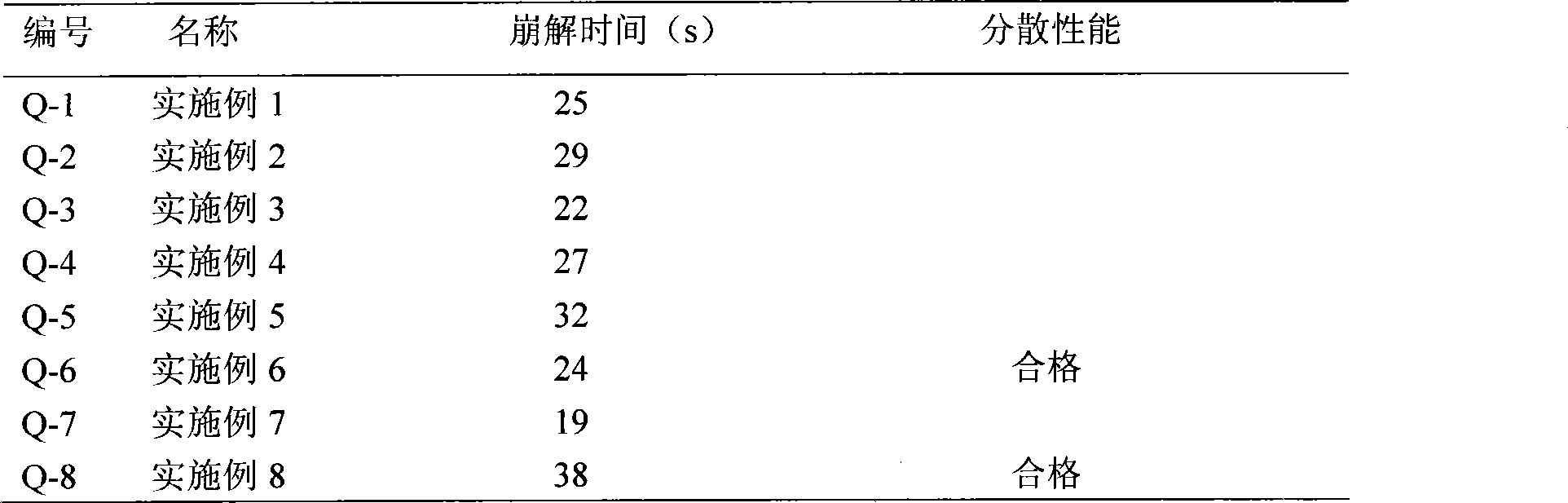

InactiveCN101423443AFast disintegrationQuick Dissolution (Dispersion)Carbon dioxide producing fertilisersMatrix fertilisersAdhesiveAdditive ingredient

The invention relates to an effervescent composition of a water-soluble fertilizer and a preparation method thereof. The effervescent composition contains one or a plurality of plant nutrient substances and one or a plurality of compounds which are contacted with water to generate gas. The effervescent composition comprises an optimized proposal that the plant nutrient substance is monopotassium phosphate. The effervescent composition can be also added with acid, a plant growth conditioner, a surfactant, a filler, a disintegrating agent, an adhesive, dye, a lube and the like. The preparation method comprises the following steps: ingredients are weighed, mixed, pulverized, pelletized and dried to obtain the effervescence composition. The effervescent composition can be manufactured through a routine production process, has rapid disintegrating and dissolving (diffusing) speed in the water, does not block a spray head or drip a pipeline, is uneasy to absorb dampness, has high content of effective compositions, low packaging, storage, metering and using cost and high utilization rate of the effective compositions, reduces waste and pollution to environment, is widely applied to economic crops, gardening, lawns and urban landscaping and has wide market application prospect.

Owner:SHENZHEN LANGTAI BIOTECH

Rapid prototyping and filling commercial pipeline

InactiveUS20050247216A1Cheap and quickFast formingAdditive manufacturing apparatusMechanical working/deformationEngineeringDigital printing

Methods and apparatus provide a means to rapidly develop and modify prototype surface coverings for customer review and approval, and fill the commercial pipeline while more conventional production equipment is obtained, installed and tested. The present apparatus to rapid prototype and fill the commercial pipeline includes a digital printing system to print a film and a press for laminating and embossing the printed film to a substrate. The press uses an embossing plate or roll, which is made from ebonite or by three-dimensional printing equipment. These plates and rolls can be produced within two or three days or less.

Owner:AFI LICENSING

Preparation method and use of carbon molecular sieve

InactiveCN101935032ASolve the problem of difficult and efficient separation of methane-nitrogenNitrogen purification/separationOther chemical processesHigh concentrationLoss rate

The invention relates to a preparation method and use of a carbon molecular sieve. The preparation method comprises the following steps: preparing a conventional carbon molecular sieve; and expanding the pores in the conventional carbon molecular sieve by using a secondary activation technique and modifying the conventional carbon molecular sieve by adjusting the pores. The new carbon molecular sieve is prepared by using coal, coconut shell or phenolic resin, and the like as raw materials, by the conventional production steps of crushing, forming, carbonizing, steam activating, hydrocarbon settling and shrinking and the like and by secondary activation with KOH or CO2 as an activator. The activation temperature is between 550 and 850 DEG C; and the ignition loss rate of the product is kept be between 0.1 and 30 percent. In aspect of use, the carbon molecular sieve can be used for absorbing nitrogen molecules and can also be used for absorbing and separating methane and nitrogen in seam gas under a variable pressure while achieving an adsorption dynamic separation effect and allowing high-concentration methane gas to be collected at the exit of an adsorption tower directly; and thus, the methane in the seam gas can be used efficiently.

Owner:TONGJI UNIV

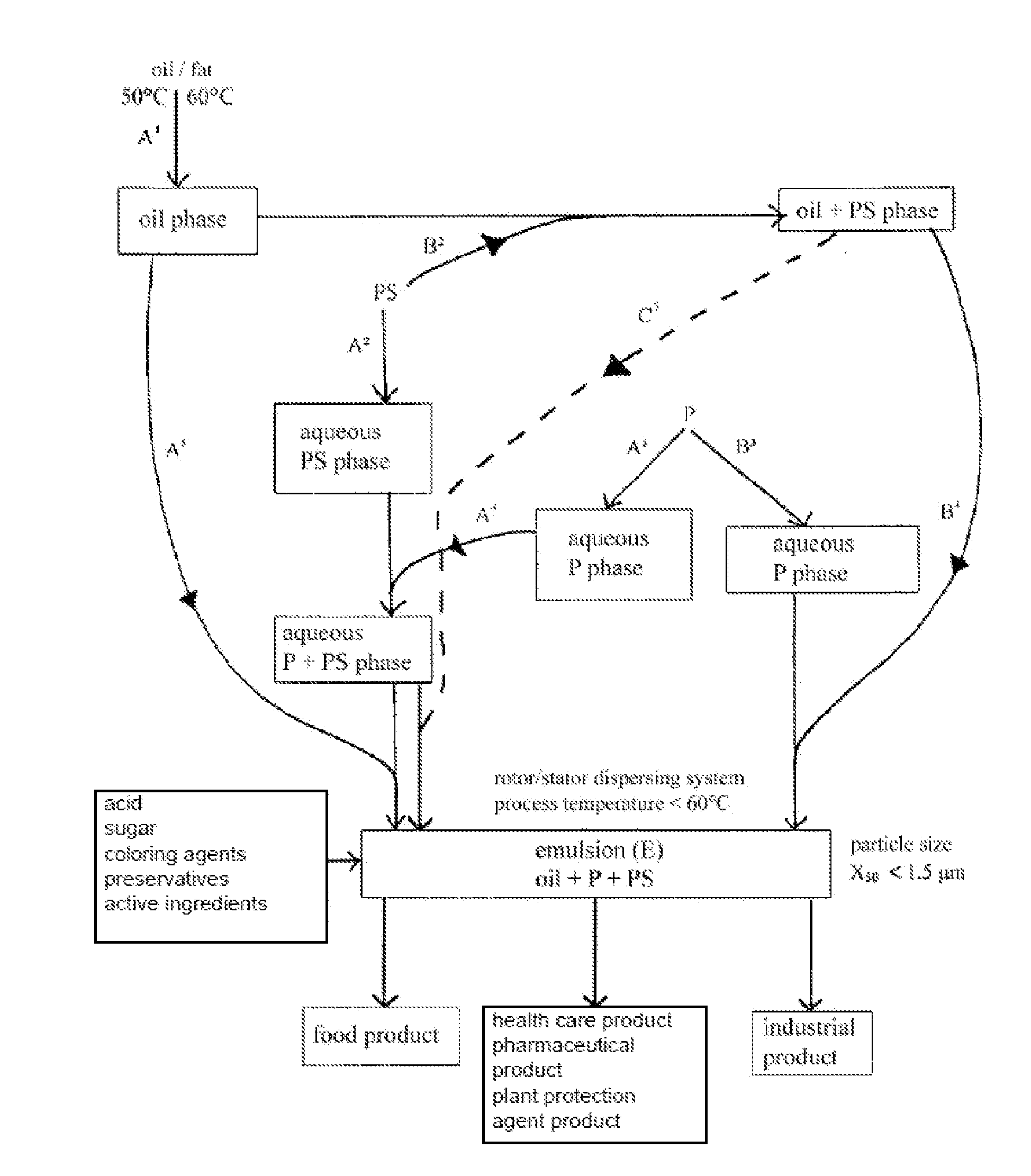

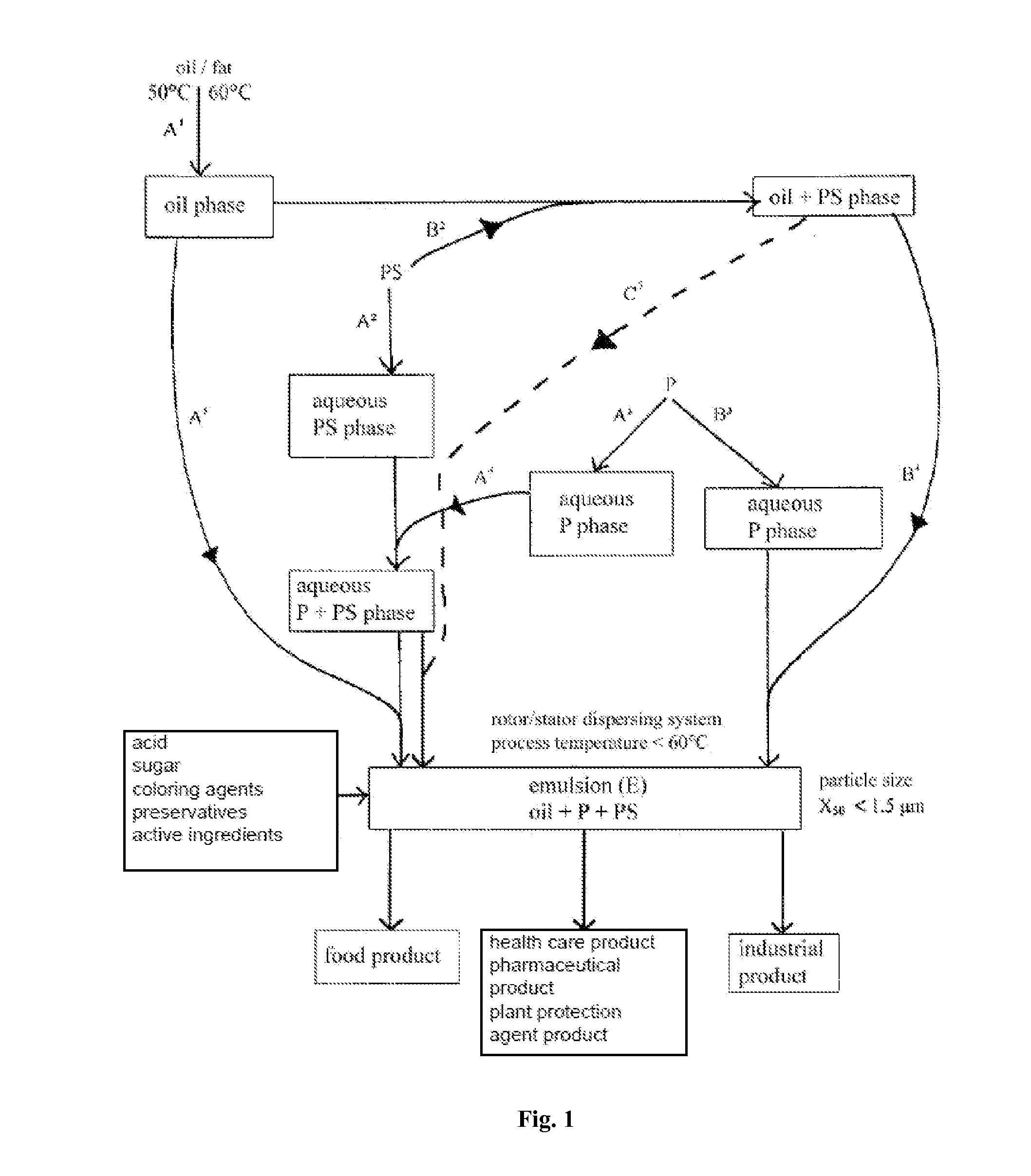

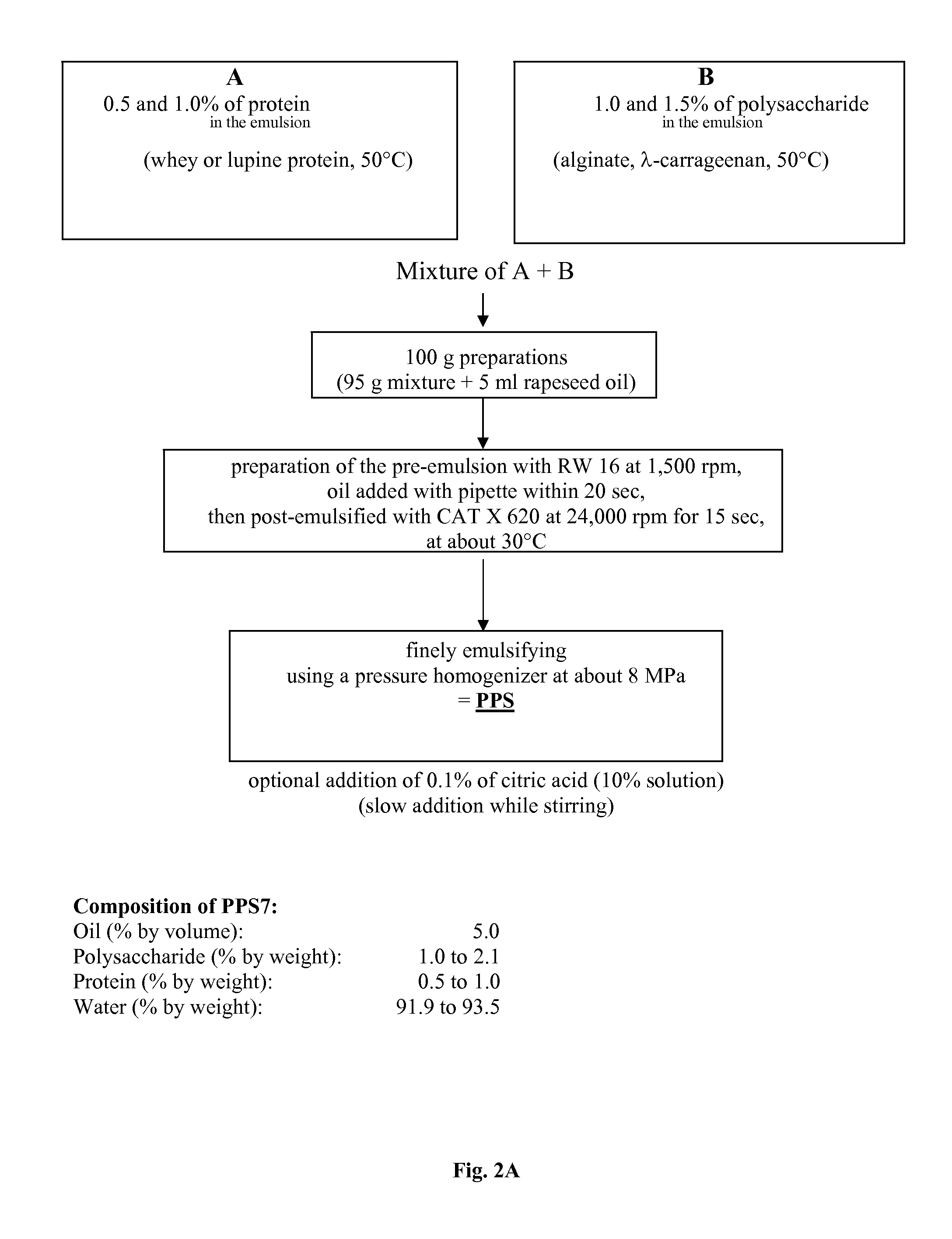

Concentrated, creamy to solid and dry compositions of an oil-in-water emulsion, method for the production thereof and use thereof for producing improved foods in terms of sensory aspects and nutrition physiology

InactiveUS20120135125A1Improve featuresEdible oils/fats ingredientsCosmetic preparationsFood additiveNutrition physiology

The invention relates to an oil-in-water emulsion, substantially comprising protein, polysaccharide and oil or fat having unique stabilizing properties, which is suited for use as a thickener, suspending agent, coating material and as an additive to food in the production of a plurality of products. Furthermore, foods are provided which have improved properties in terms of sensory aspects and nutrition physiology compared to conventionally produced products, and a method for the production thereof is provided. In addition, the emulsion and products produced according to the invention can be dried and subsequently rehydrated in order to obtain compositions that have substantially the same properties as the non-dried compositions.

Owner:OPTISENS

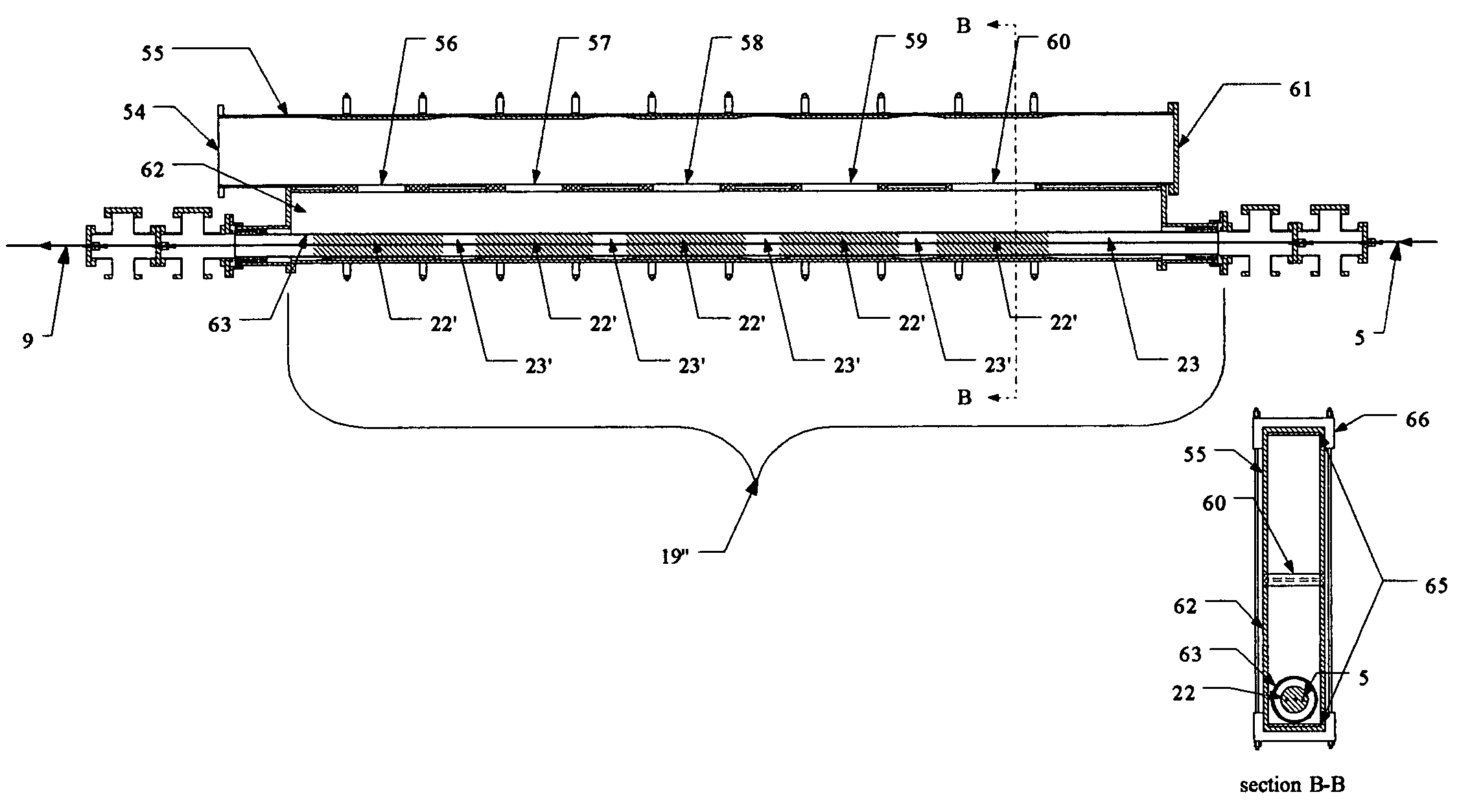

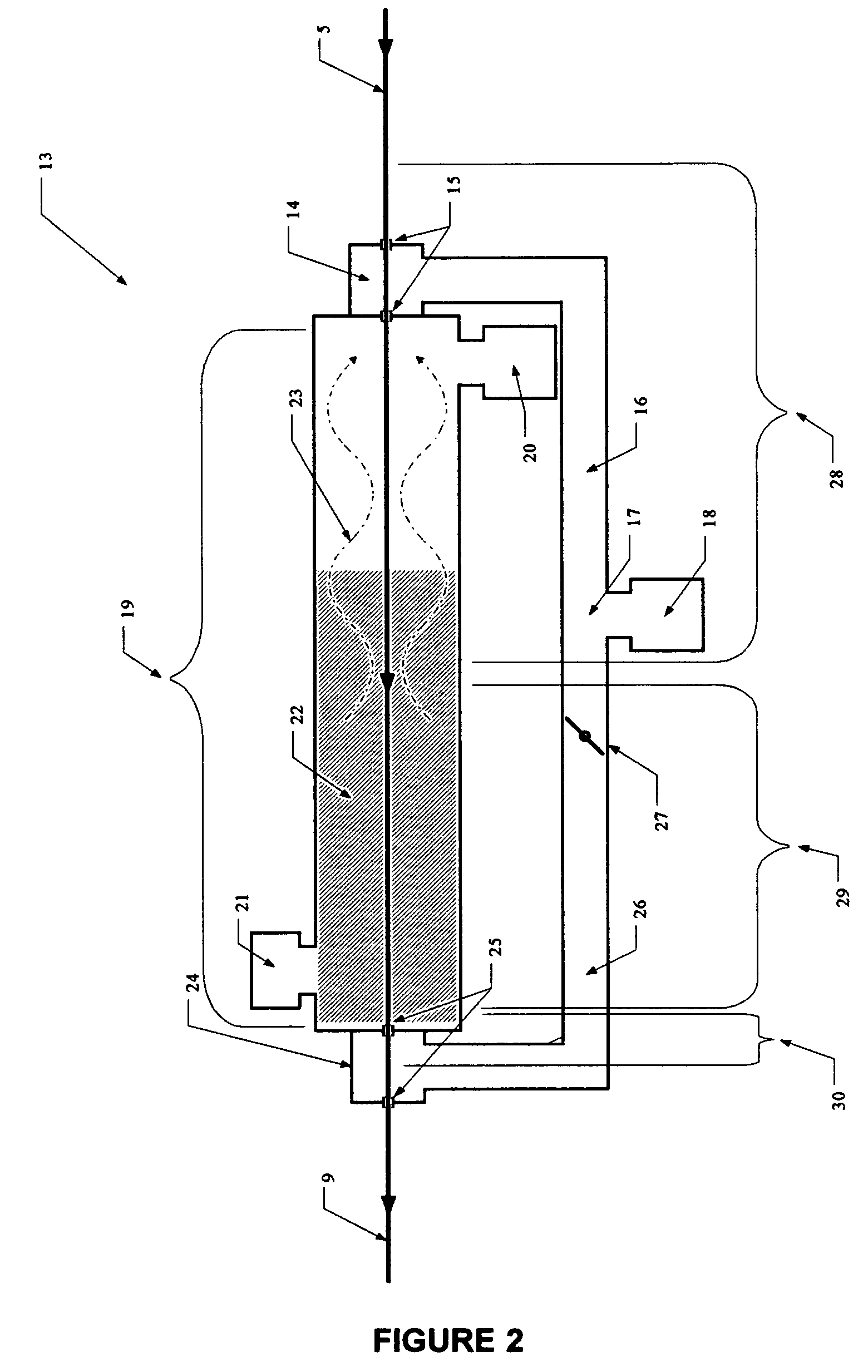

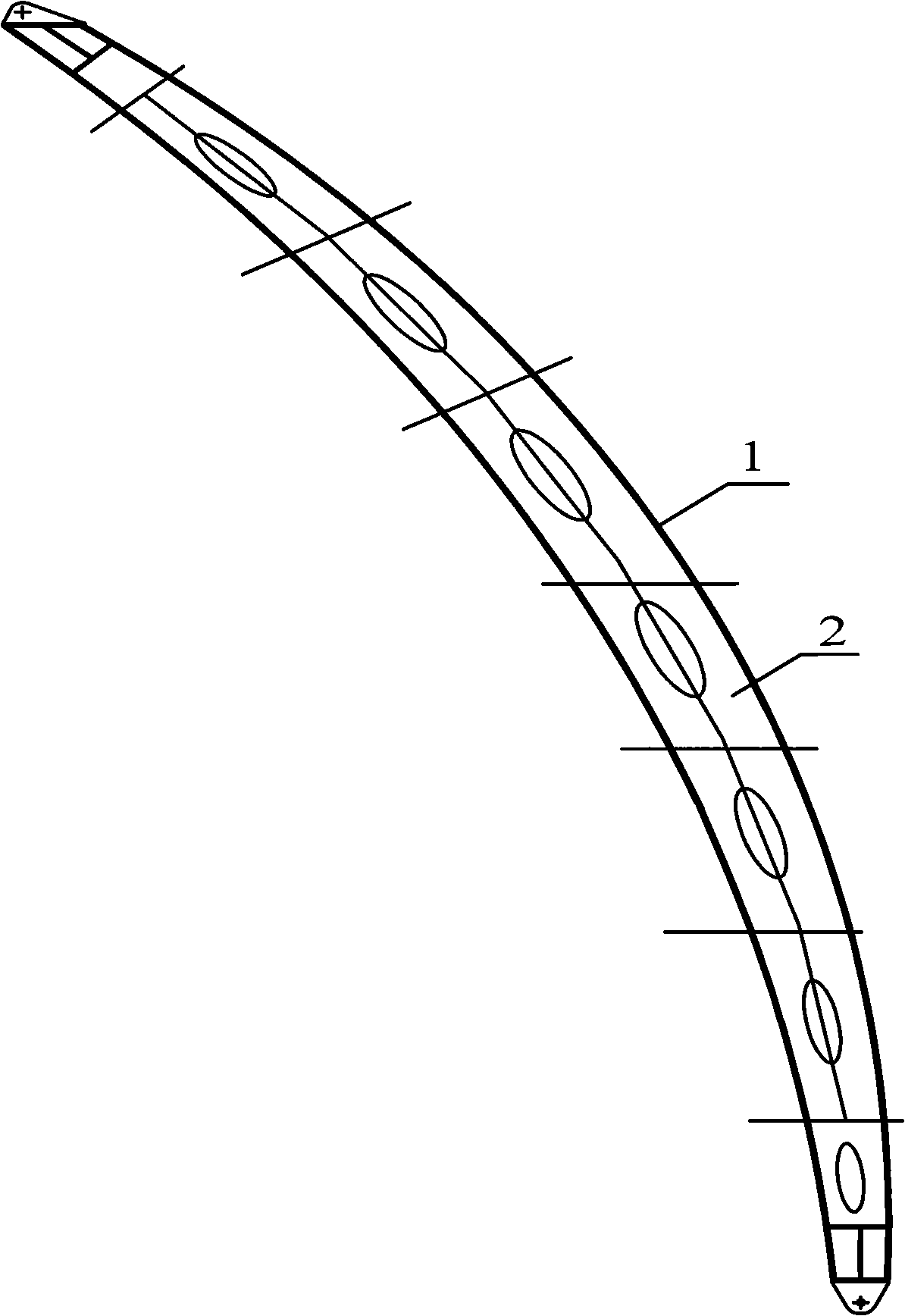

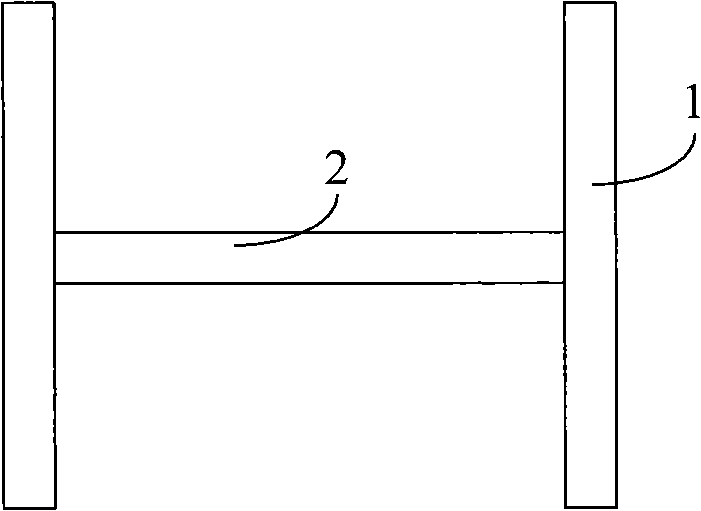

System to continuously produce carbon fiber via microwave assisted plasma processing

ActiveUS7824495B1Low costReduce the amount requiredPhysical treatmentElectric discharge tubesCarbon fibersEngineering

A system to continuously produce fully carbonized or graphitized carbon fibers using microwave-assisted plasma (MAP) processing comprises an elongated chamber in which a microwave plasma is excited in a selected gas atmosphere. Fiber is drawn continuously through the chamber, entering and exiting through openings designed to minimize in-leakage of air. There is a gradient of microwave power within the chamber with generally higher power near where the fiber exits and lower power near where the fiber enters. Polyacrylonitrile (PAN), pitch, or any other suitable organic / polymeric precursor fibers can be used as a feedstock for the inventive system. Oxidized or partially oxidized PAN or pitch or other polymeric fiber precursors are run continuously through a MAP reactor in an inert, non-oxidizing atmosphere to heat the fibers, drive off the unwanted elements such as oxygen, nitrogen, and hydrogen, and produce carbon or graphite fibers faster than conventionally produced carbon fibers.

Owner:UT BATTELLE LLC

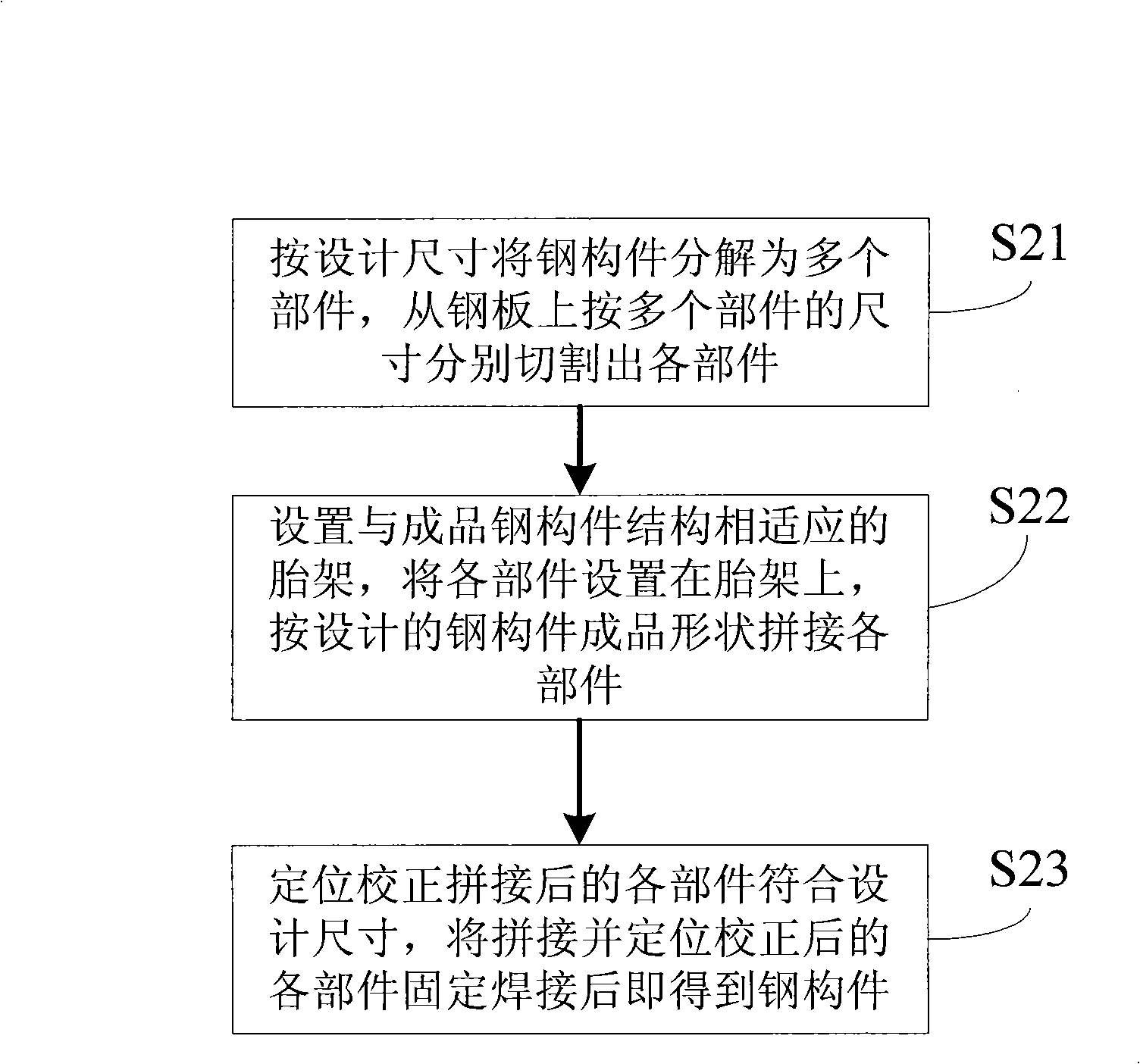

Steel member manufacturing method

ActiveCN101524804ASolve the problem of not being able to produce qualified productsMeet the design requirementsSheet steelRegular Production

The invention discloses a steel member manufacturing method and pertains to the manufacturing field of steel structure members. The manufacturing method includes: decomposing the steel member into multiple components according to the design dimension and respectively cutting out all components from a steel plate according to the dimension of all components; setting an assembly moulding bed corresponding to a finished steel member structure and placing all components on the assembly moulding bed to join all components into the designed steel member shape; positioning and correcting the joined components to be consistent with the designed dimension and fixedly welding all components after joining, positioning and correcting; finally obtaining the steel member. The method is applicable to producing deformed steel members and solves the problem that the conventional production method can not produce qualified products due to the special structure of the anomalous steel members.

Owner:CHINA CONSTR STEEL STRUCTURE ENG CO LTD

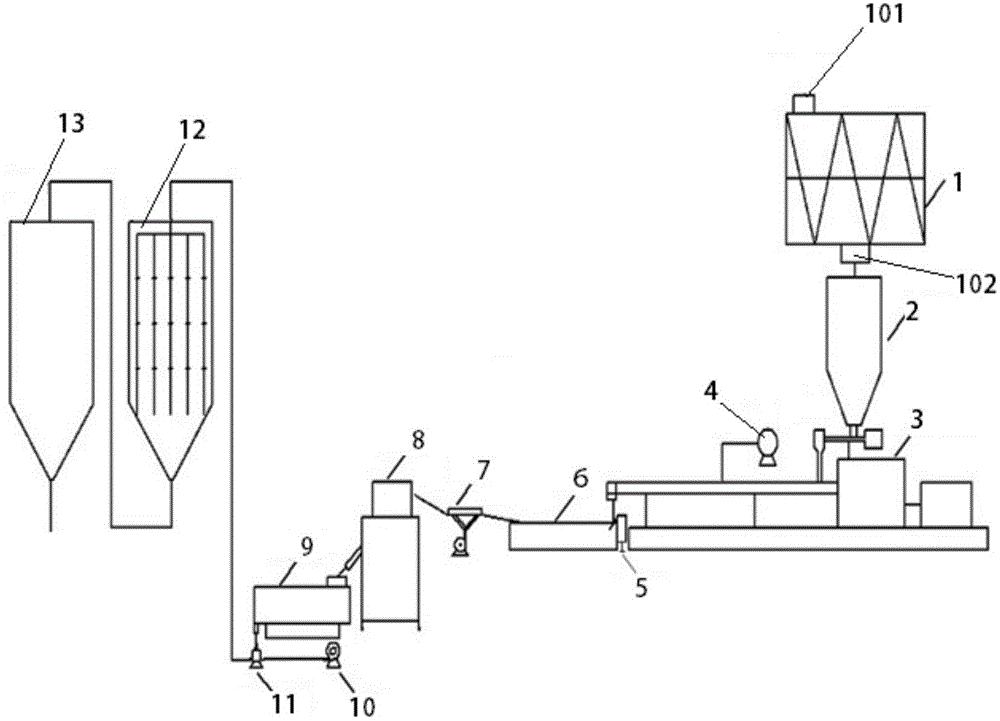

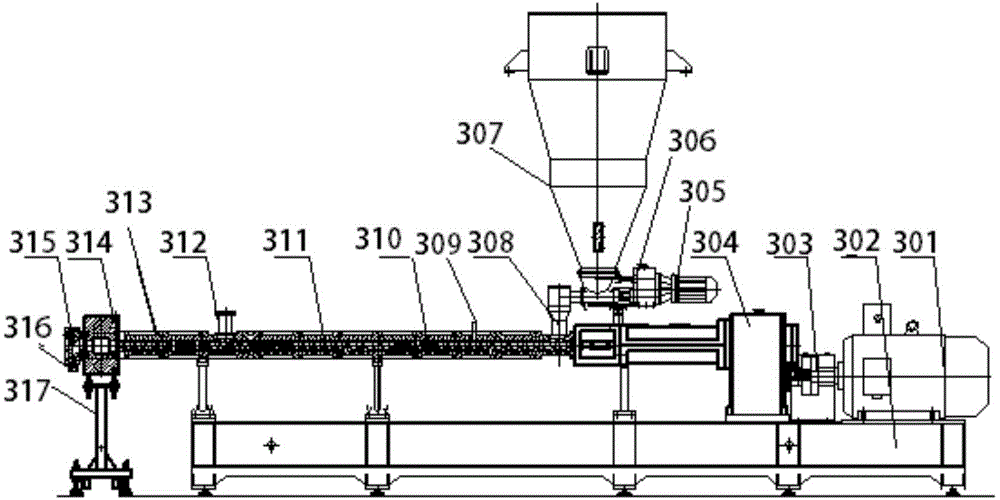

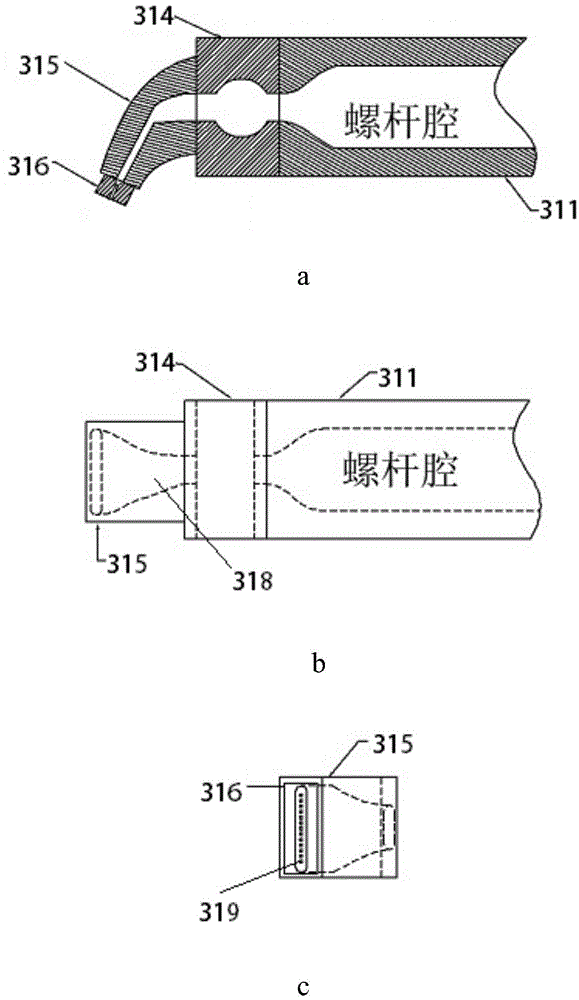

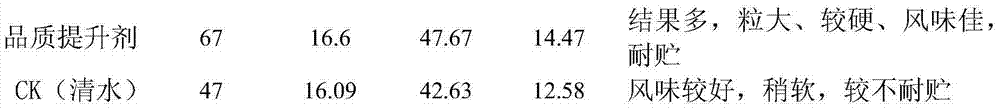

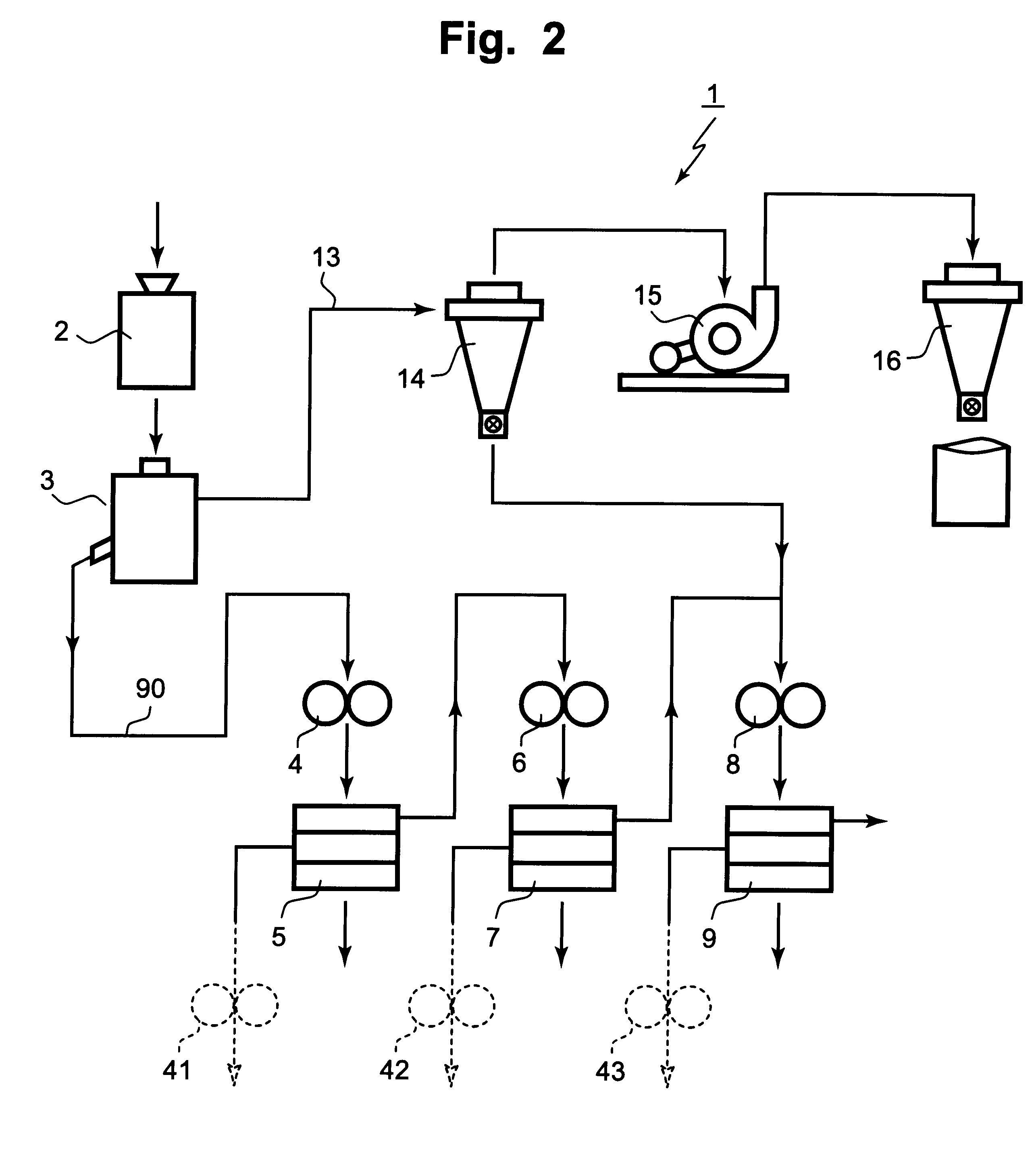

Production method and production equipment of special material for polypropylene melt-blown non-woven fabric

The invention discloses a production method and production equipment of a special material for a polypropylene melt-blown non-woven fabric. The production method comprises the following steps: adding 50-200g of a long-acting stabilizing agent, 25-200g of a short-acting stabilizing agent, 25-160g of a high-temperature-resistant stabilizing agent and 20-100g of a lubricating agent to each 100kg of polypropylene; and mixing by using a mixing machine, and discharging to an extruder, and generating a reaction in a lead-screw reaction section of a double-screw extruder. The production equipment comprises a mixing machine, wherein uniformly mixed raw materials are discharged into an intermediate bunker from a mixed material outlet, an outlet in the bottom of the intermediate bunker is connected with an inlet of the extruder, the extruder is of a dual-screw structure and is used for sending processed materials to a cooling water tank for being cooled by virtue of an inclined water tank, then air-dried by an air dryer, granulated in a granulating machine, screened by a vibrating screen, and sent into a homogenizing and mixing tank by virtue of a rotary discharging device. The production method and the production equipment have the beneficial effects of uniformly mixing the raw materials and solving the difficulty of forming of polypropylene with a high flowing melting index, and are suitable for conventional production.

Owner:HUNAN SHENGJIN NEW MATERIAL

Superfine cobalt powder and its manufacturing technology

The present invention relates to one kind of superfine cobalt powder and its production process. The production process includes the following steps: setting cobalt carbonate or cobalt oxalate powder, grinding dispersant and hard alloy balls in certain weight proportion into high energy ball mill pot; vacuumizing the ball mill pot and introducing protective argon; sealing the ball mill pot, and ball milling at controlled rotation speed to obtain superfine cobalt carbonate or cobalt oxalate powder; and reducing the superfine cobalt carbonate or cobalt oxalate powder in hydrogen atmosphere to obtain superfine cobalt powder in oxygen content not more than 0.5 % and granularity smaller than 0.6 micron. The superfine cobalt powder is applied in producing high quality hard alloy, and has simple production process and low cost.

Owner:GEM CO LTD +1

ZSM-5 structure zeolite, preparation and use thereof

InactiveCN1530322ATroubleshooting FiltrationImprove conversion rateMolecular sieve catalystsPentasil aluminosilicate zeoliteCyclohexeneSilicon oxide

A ZSM-5 zeolite with 15-200 for the mole ration of silicon oxide to aluminium oxide, 0.5-10 microns for diameter, and 25-250 sq.m / g for mesopore surface area is prepared from the large-grain zeolite through treating in alkaline aqueous solution, ammonium ion exchanging, drying, and calcining. Said zeolite can be used to prepare cyclohexanol from cyclohexene by hydrating with high conversion rate, easy separation from liquid phase and easy filter.

Owner:CHINA PETROLEUM & CHEM CORP +1

Processed Cheese Without Emulsifying Salts

ActiveUS20090092730A1Improve the level ofReduce moisture contentMilk preservationCheese manufactureAdditive ingredientRegular Production

The present invention is directed to process cheese type products prepared with calcium-reduced ingredients but without emulsifying salts and methods of producing such process cheese type products without emulsifying salts. The process cheeses of the present invention are advantageously resistant to separation during heating and retain desirable organoleptic properties, such as texture, without using emulsifying salts. The process cheeses of the present invention are also lower in sodium than conventional produces cheese products.

Owner:KRAFT FOODS GRP BRANDS LLC

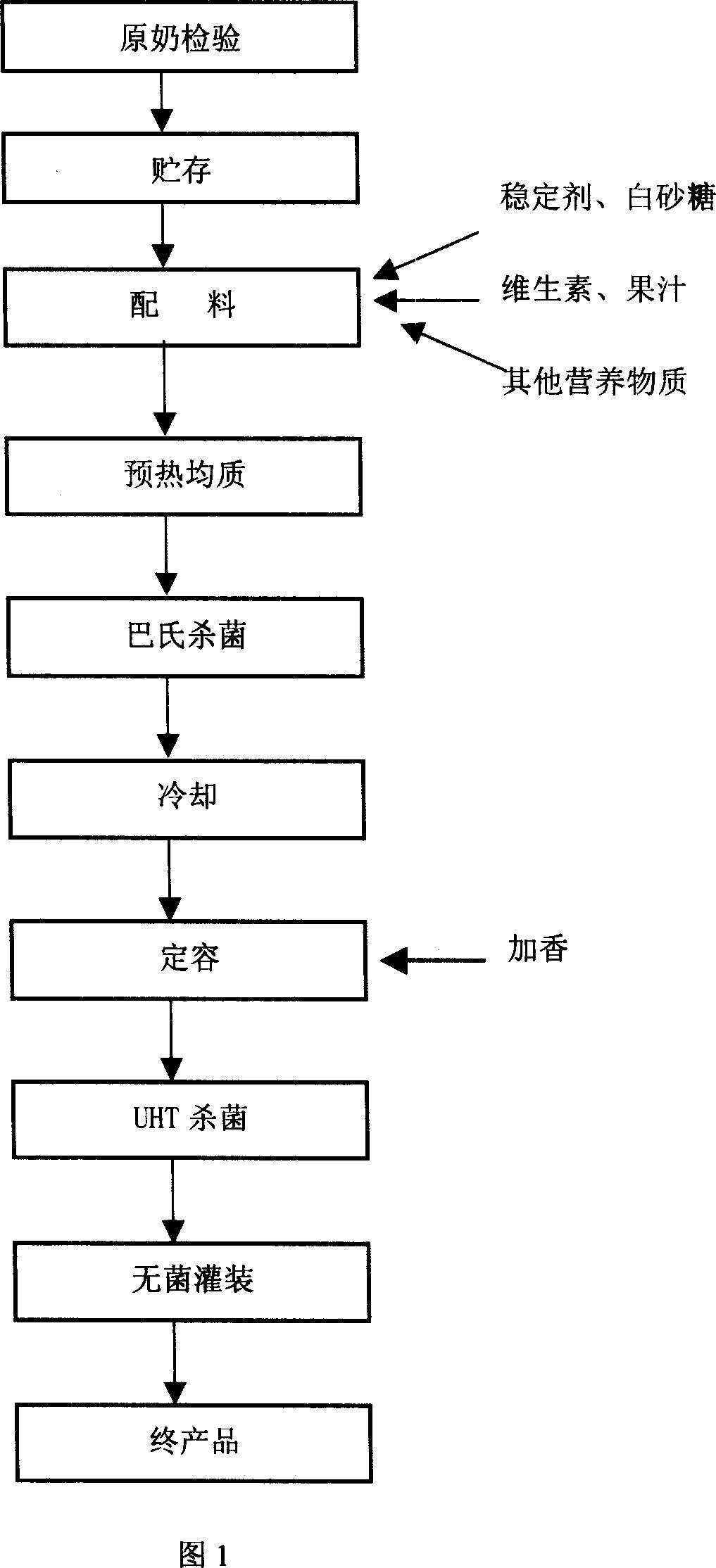

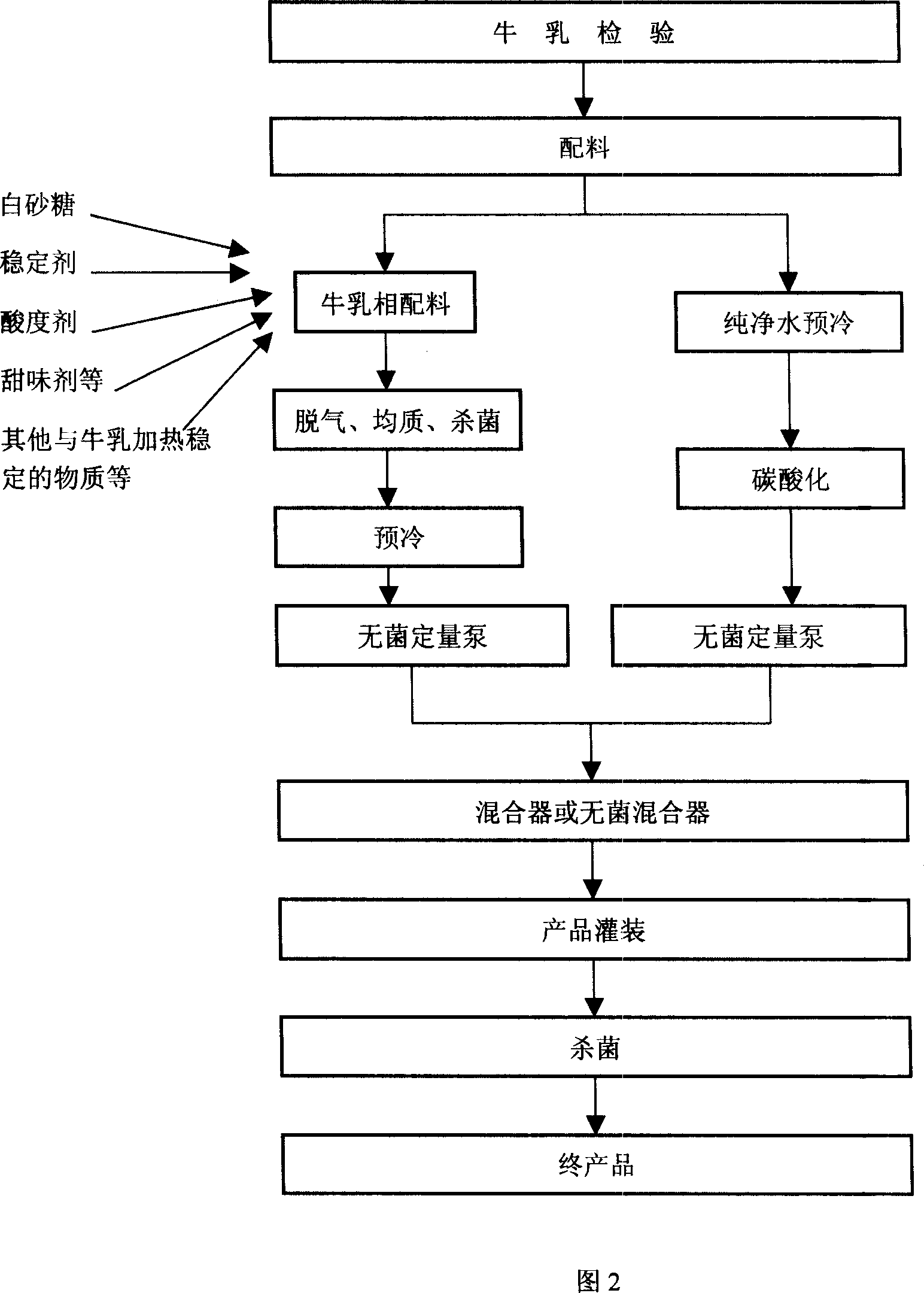

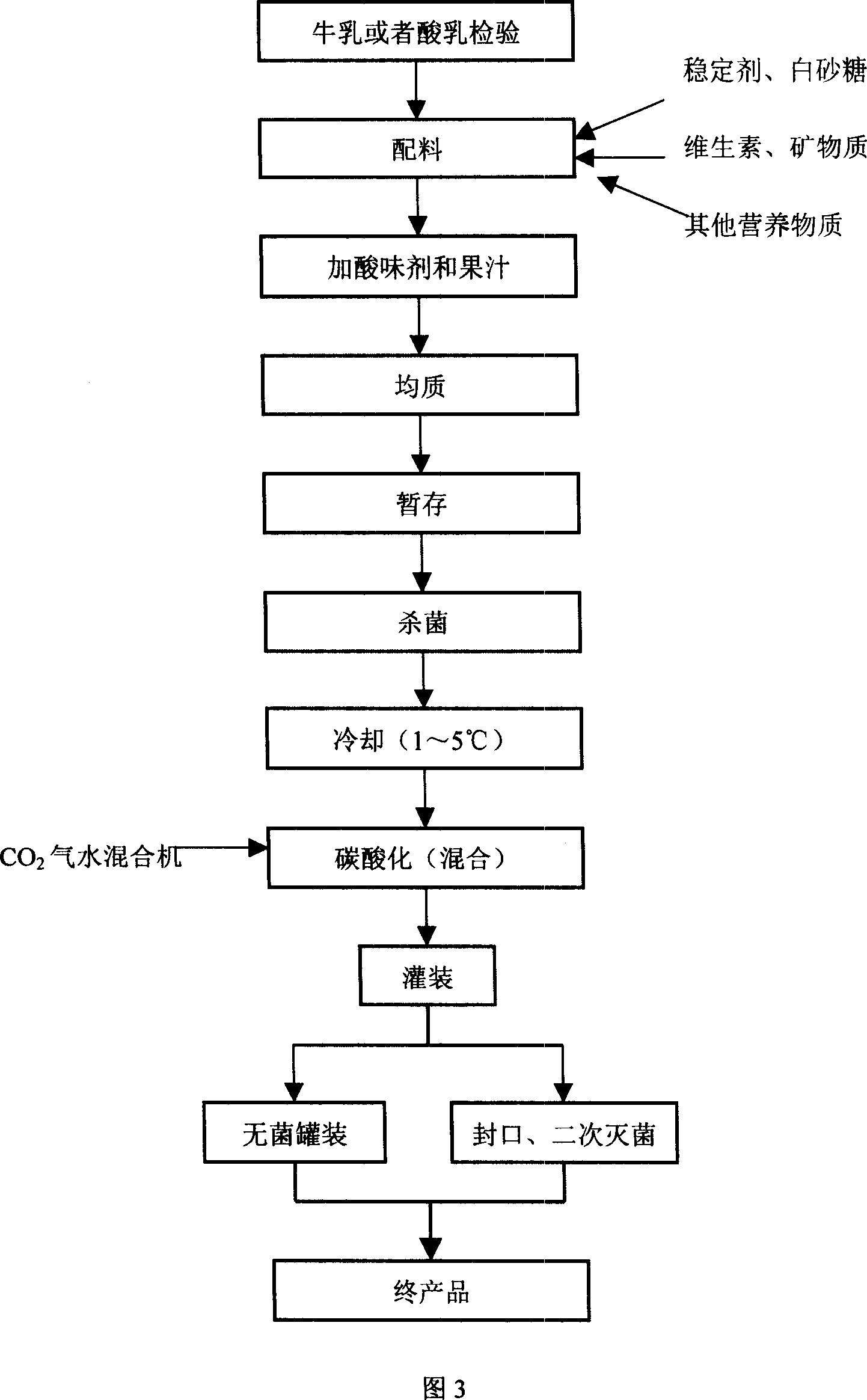

Method for producing air-containing acidic milk-like beverage

InactiveCN101011082AAchieve innovationExpand product rangeMilk preparationFood preparationProduct gasRegular Production

The invention relates to a method for producing lactic acid drink, which comprises that 1, preparing milk phase; 2, adding carbon dioxide gas; 3, packing, disinfecting to obtain the lactic acid drink. Compared with general method, the invention can reduce the pollution of microbe, improve the quality and widen the application.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

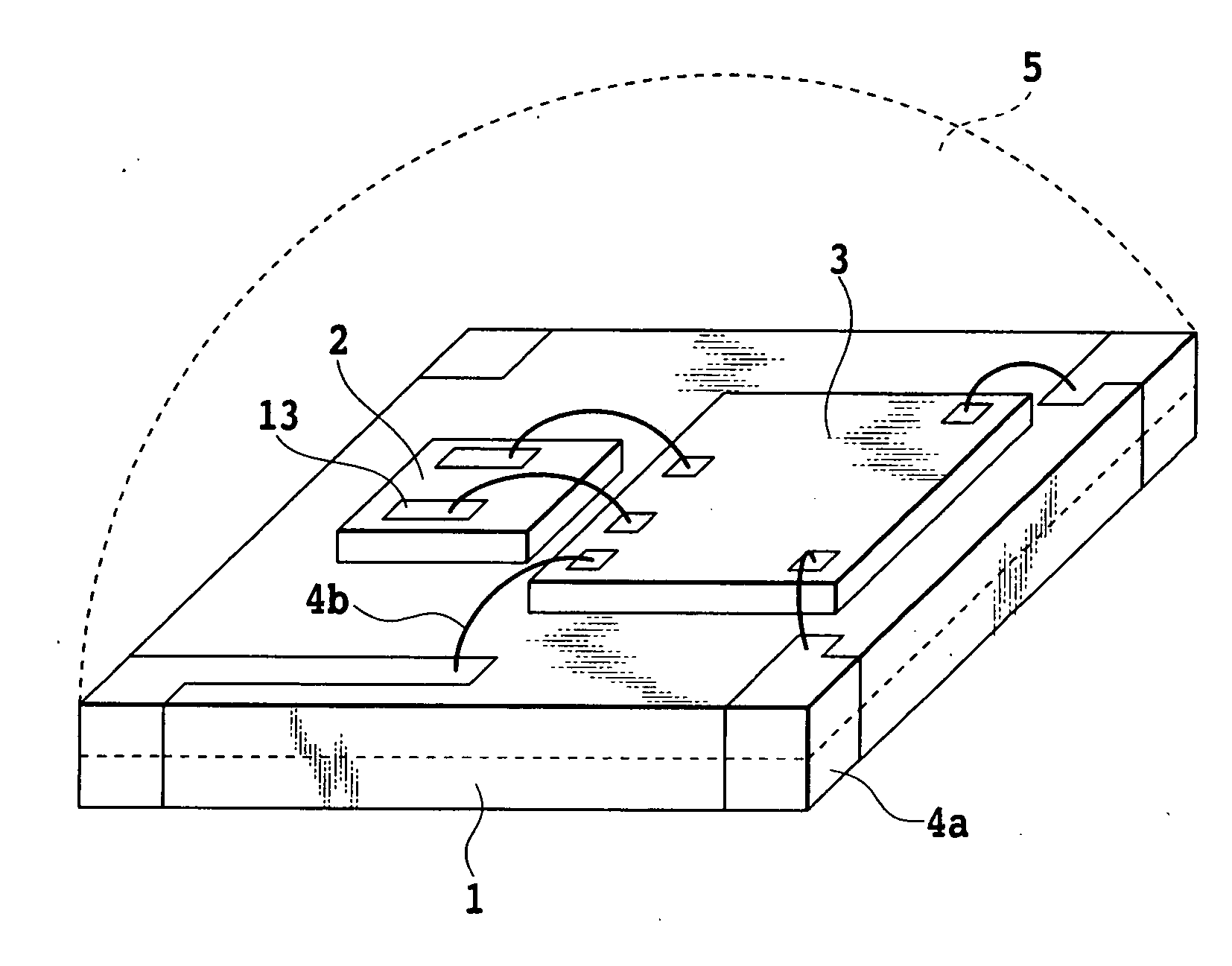

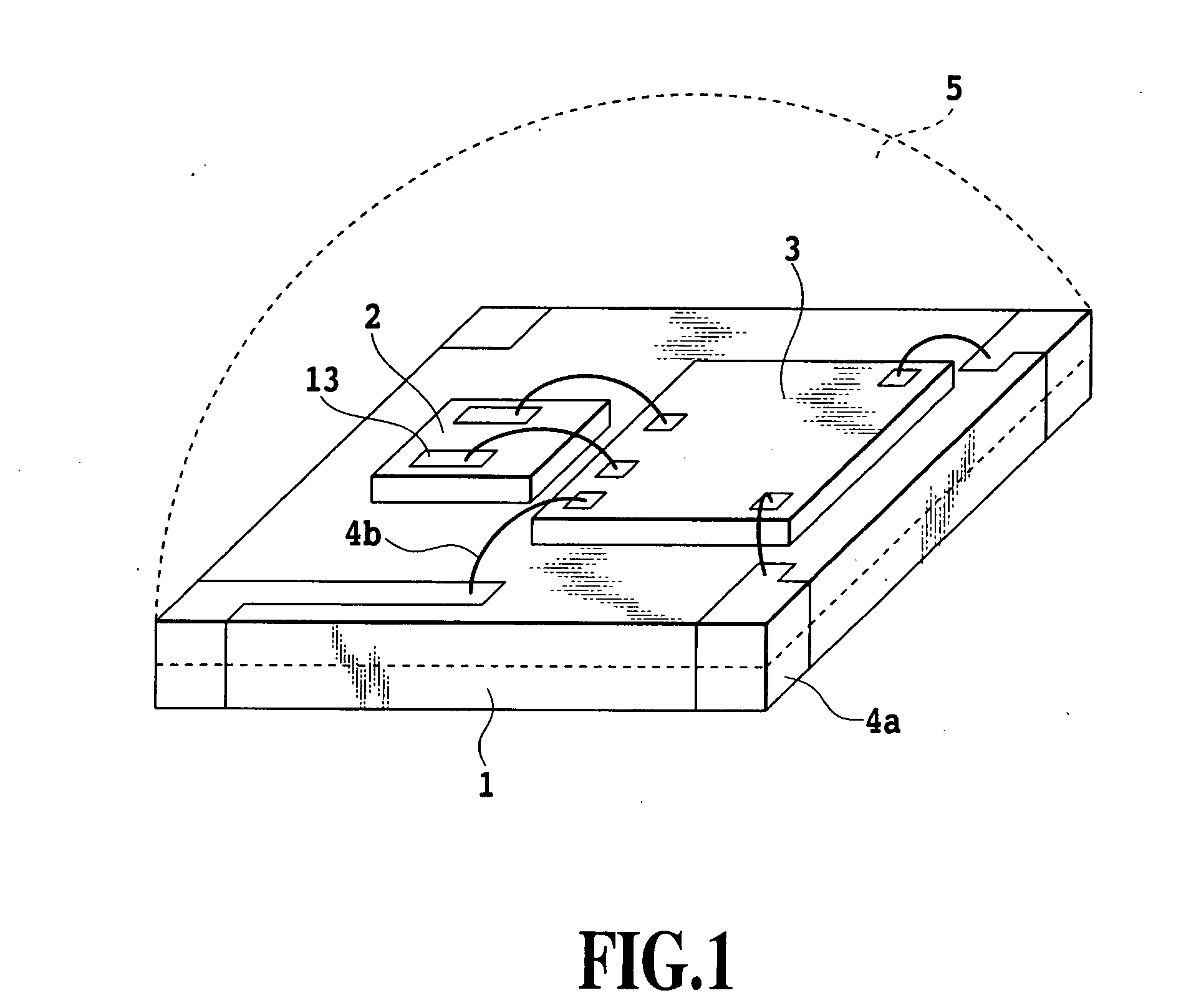

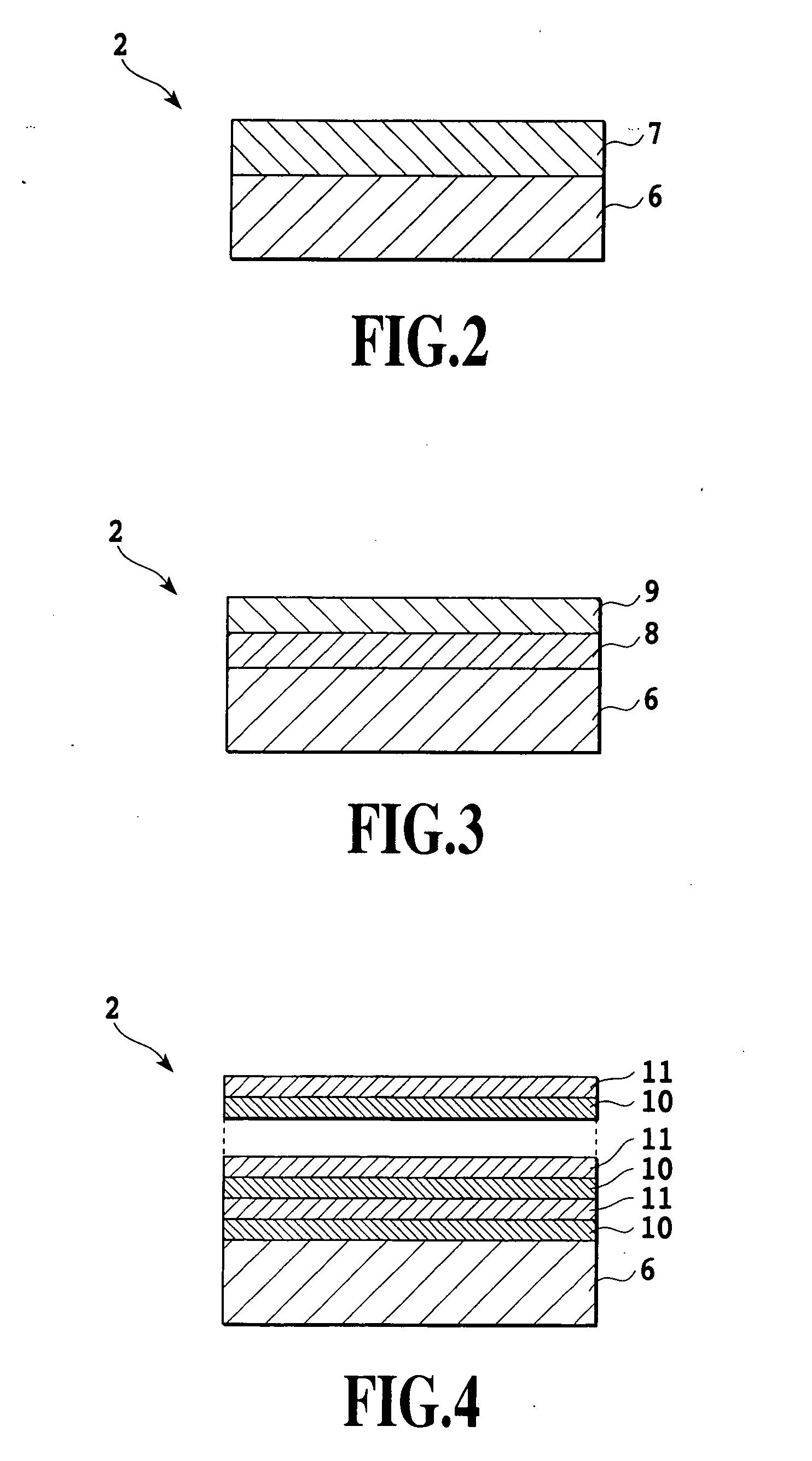

Infrared sensor ic, and infrared sensor and manufacturing method thereof

ActiveUS20070090337A1Easy to installLow device resistancePhotometrySolid-state devicesElectrical resistance and conductanceRoom temperature

An infrared sensor IC and an infrared sensor, which are extremely small and are not easily affected by electromagnetic noise and thermal fluctuation, and a manufacturing method thereof are provided. A compound semiconductor that has a small device resistance and a large electron mobility is used for a sensor (2), and then, the compound semiconductor sensor (2) and an integrated circuit (3), which processes an electrical signal output by the compound semiconductor sensor (2) and performs an operation, are arranged in a single package using hybrid formation. In this manner, an infrared sensor IC that can be operated at room temperature can be provided by a microminiature and simple package that is not conventionally produced.

Owner:ASAHI KASEI ELECTRONICS CO LTD

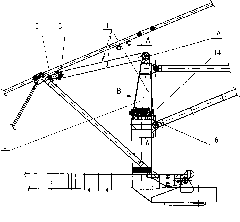

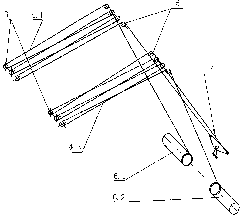

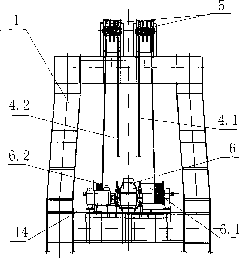

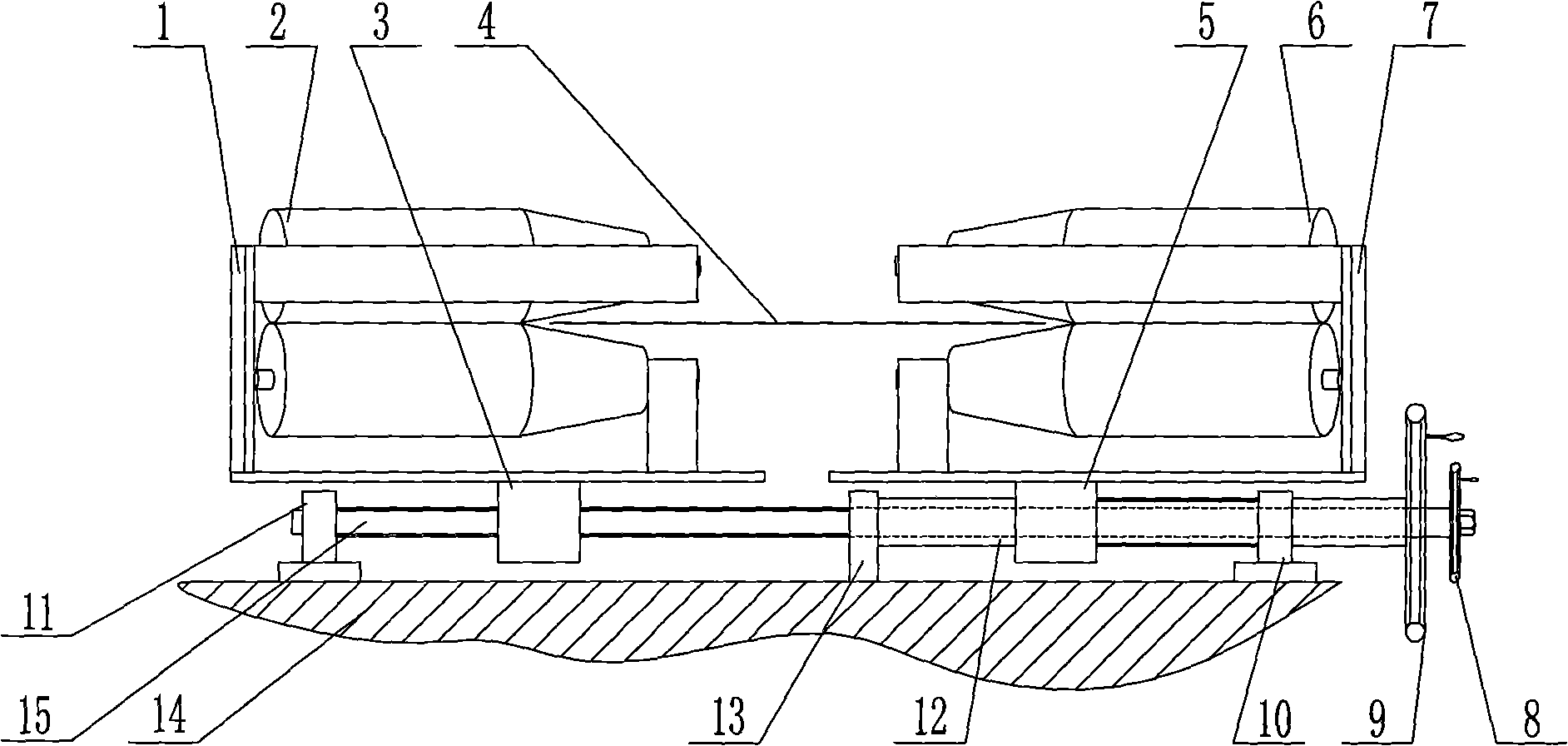

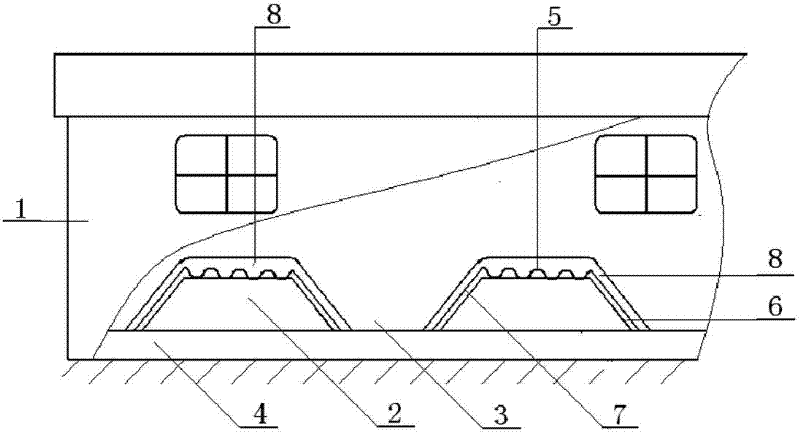

Protective device of elevating mechanism of stacker-reclaimer

InactiveCN101823631ASo as not to damageReduce repair costsLoading/unloadingBlock and tackleEngineering

The invention discloses a protective device of an elevating mechanism of a stacker-reclaimer, which aims at overcoming the shortcomings that a bucket wheel of the traditional stacker-reclaimer makes an elevating motion by using only one wire rope, and the sudden fracture of the wire rope can easily cause safety accidents to people or the device, influence the regular production and increase the repair cost. In the invention, the elevating mechanism is provided with two parallel wire ropes, the top of a stand column and a bucket wheel arm support are respectively provided with two parallel sets of pulley blocks corresponding to the wire ropes, wherein the head ends of the wire ropes are respectively fixed on two coaxial rollers of a hoister, the tail ends of the wire ropes are fixed on a hoister platform, and a balancing device which is connected with the tail ends of the two wire ropes is installed on the hoister platform. When one wire rope suddenly fractures, the other wire rope alone can maintain the balance of the bucket wheel arm support, can not cause damage to the stacker-reclaimer or result in personal safety accidents, and can gain time for the replacement of the wire rope, thereby greatly lowering the repair cost, and ensuring the safe and regular production.

Owner:QINGDAO PORT GRP

Cold rolling working roll with anti-rollar mark and high-wearing resistance and manufacturing method thereof

The invention discloses a cold rolling working roll with roller impression resistance and high wearing resistance and a manufacturing method thereof. The materials of the cold rolling working roll comprises the following chemical compositions in terms of weight percentage: 0.85 percent to 1.10 percent of C, 0.6 percent to 1.0 percent of Si, 0.20t percent to 0.8 percent of Mn, 5.5 percent to 7.5percent of Cr, 0.30 percent to 0.8 percent of Mo, 0.1 percent to 0.3 percent of V, no more than 0.4 percent of Ni, no more than 0.020 percent of P, no more than 0.015 percent of S and the balance of Fe and inevitable impurities. The manufacturing method comprises the following steps: 1. the cold rolling roll billet is manufactured by adopting the conventional production technique according to the chemical compositions and the content thereof; 2. rough turning and tempering are carried out on the roll billet; 3. quenching heat treatment is carried out at the temperature of 950 DEG C to 1010 DEG C; 4. cold treatment is carried out at the temperature of minus 80 DEG C to minus 50 DEG C for 2 hours to 3 hours; and 5. tempering is carried out at the temperature of 120 DEG C to 145 DEG C for 60 hours to 150 hours. The cold rolling working roll has rolling marks resistance and high wearing resistance.

Owner:BAOSTEEL ROLL SCI & TECH

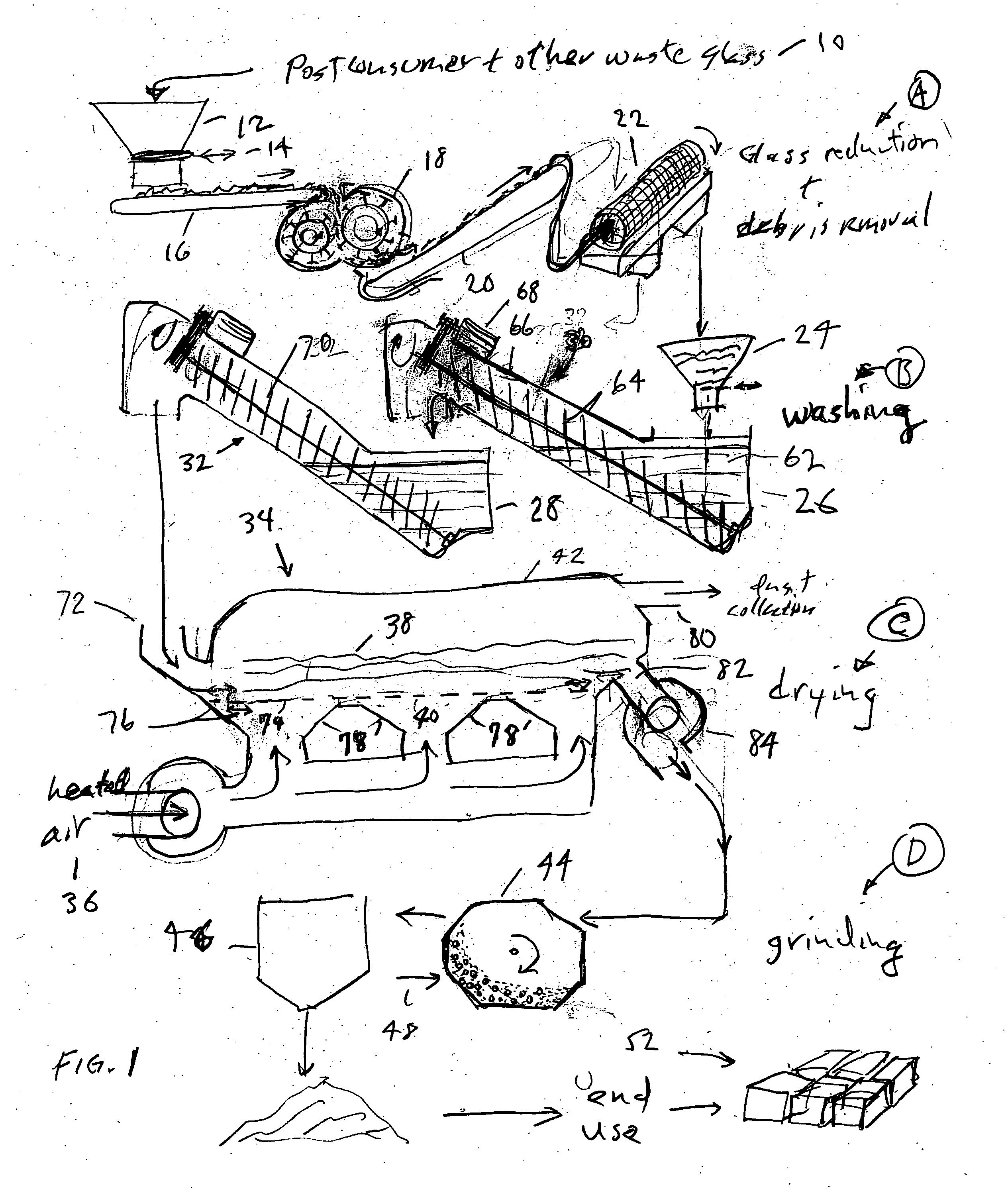

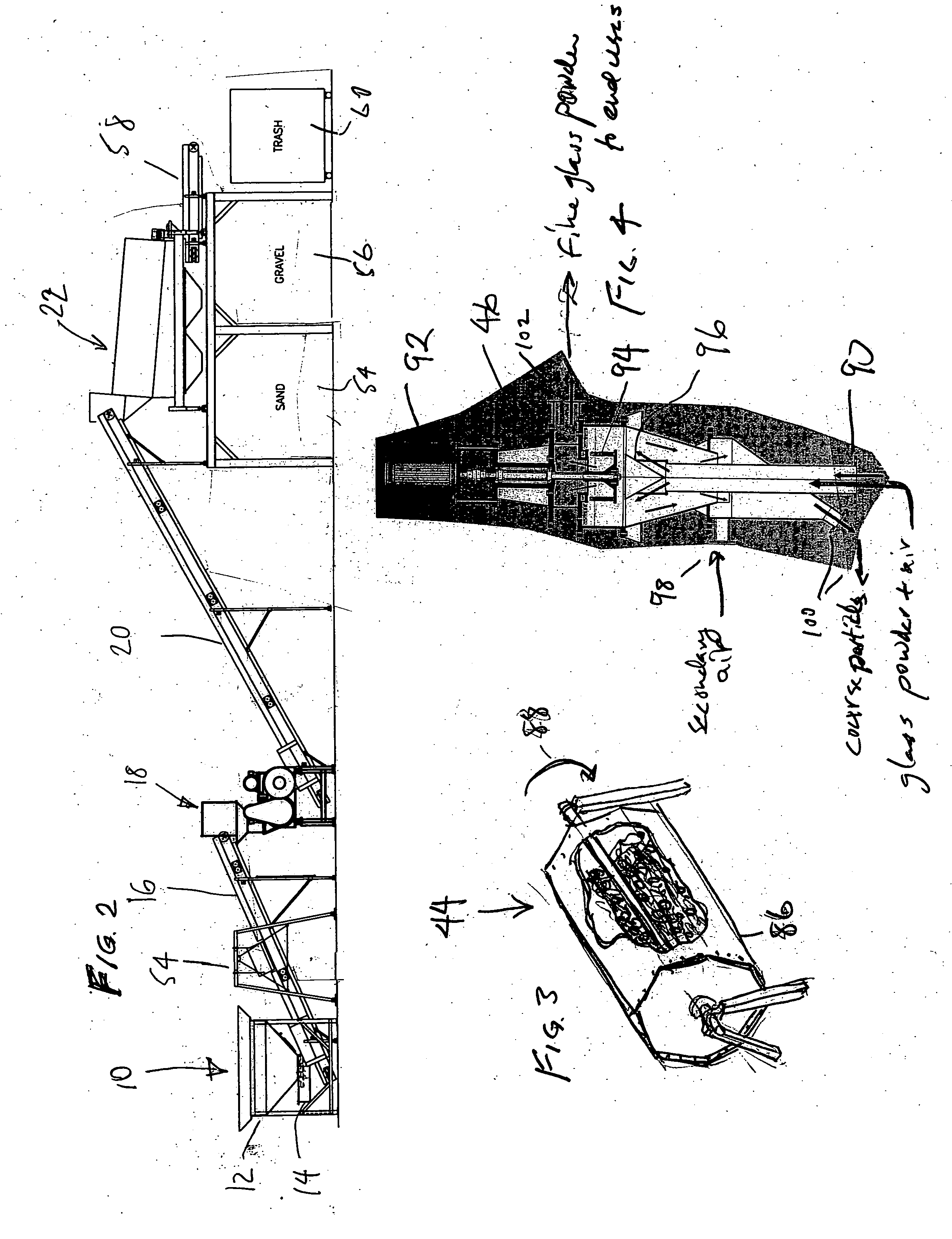

Production of glass powder from waste glass, and products made using the same, especially concrete

ActiveUS20060130707A1Many applicationsSuppress the alkali-silica reactionCocoaGrain treatmentsFluidized bedSmall fragment

A clean dry glass powder useful as a substitute for Portland cement in concrete, in paints, and for other known uses for glass powder produced conventionally can be produced from unsorted post-consumer waste glass, including a subsatantial fraction of non-glass items, by employing glass pulverizing equipment to reduce waste glass to small fragments, allowing removal of trash, employing a multistep washing process to clean the glass fragments, in the preferred embodiment using aggregate cleaning equipment, drying the fragments, preferably using fluidized bed techniques, and grinding the glass to a desired particle size, preferably using a ball mill, in combination with an air classification step to produce a glass powder of uniform particle size.

Owner:URBAN MINING NORTHEAST

Nanometer composite silicon brick and preparation method thereof

The invention relates to a nano-sized composite silica brick and a production method thereof. The invention is characterized in that: raw materials and binder of the silica brick are as follows: silica granules and fine powders, waste silica brick granules, calcium carbonate nanoparticles, iron oxide nanoparticles, silicon dioxide nanoparticles, fluorite powders, lime and sulfite pulp wastes. The production method is based on the existing production process of the silica brick, and introduces compound nanopowders in optimal proportions in the production process of the silica brick after high-efficiency dispersion, to produce nano-sized composite silica bricks. With the addition of nanopowders, the performance of silica brick is significantly improved, and manifested as follows: 1) the particle size fraction is more reasonable, the accumulation is compact and the texture is uniform; 2) the slurry has good plasticity and moldability and the production efficiency is improved; 3) the burning temperature is decreased to 20 DEG C, thus realizing energy conservation and discharge reduction; 4) the tridymite is superior in crystallization conversion and has low content of quartz residues; 5) the number of closed pores is increased, the number of opened pores are reduced, the porosity is reduced, and the strength and refractoriness under load are increased; and 6) the final product has good appearance, smooth end surface and good bonding property, and the rate of qualified products is increased.

Owner:ZHENGZHOU UNIV +1

Intelligent SMT production error-proof tracing method and process

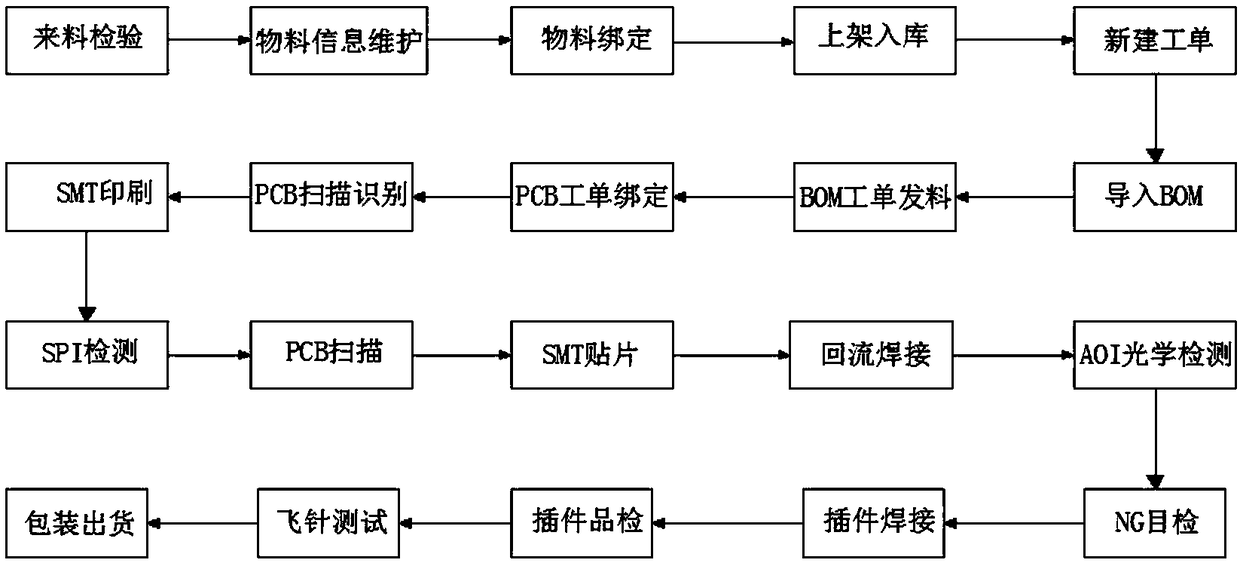

InactiveCN108811365AImprove satisfaction rateGuaranteed traceabilityPrinted circuit assemblingElectrical componentsFunctional testingVisual inspection

The invention discloses an intelligent SMT production error-proof tracing method and process, which comprises the following steps: incoming material inspection, material information maintenance, material binding, putaway and warehousing, work order filling, BOM introduction, material issuance according to BOM work order, PCB work order binding, PCB scanning identification, SMT printing, SPI detection, PCB scanning, SMT patching, reflow soldering, AOI optical inspection, NG visual inspection, insert welding, insert quality inspection, flying probe testing, packaging and shipping. The tracing method and process use the intelligent manufacturing production method on the basis of the conventional production process method to ensure the traceability of the product. After the production of the product, the flying probe test is added to perform the functional test to inspect the product reliability, so that the qualified rate is controlled from the source, the ex factory qualified rate is greatly improved, the customer satisfaction rate is improved, the repair rate is reduced correspondingly, and costs are reduced.

Owner:上海安理创科技有限公司

Functional cigarette paper

InactiveCN1429946AImprove combustion qualityNice appearanceNon-fibrous pulp additionAlkaline earth metalSilicon oxide

A function cigarette paper for reducing tar and improving combustion quality features that it contains the assistant composed of inorganic filler, combustion promoter and flavouring. Said inorganic filler consists of calcium carbonate, alkalimetal algate, nano-class oxide, and silicon oxide or alkali-earth metal silicate or alkali-earth metal carbonate or their mixture. Said combustion promoter is composed of alkali metal (or alkali-earth metal) carboxylate and alkali metal carbonate. Said flavouring contains cylitol or sorbitol or glocose.

Owner:YUNNAN REASCEND TOBACCO TECH GRP +1

Smelting method for low-carbon low-silicon wire-welding steel

ActiveCN104862443AGood welding performanceSolve the problem of nodulation in submerged nozzlesManufacturing convertersOxygen contentRegular Production

The invention discloses a smelting method for low-carbon low-silicon wire-welding steel. The process flow of the smelting method comprises the following procedures: pretreatment and desulphurization of molten iron; treatment in a converter; LF refining; and continuous casting of small square billet with a size of 150 mm * 150 mm. With the smelting method, carbon content is stably controlled to be less than or equal to 0.08%; silicon content is stably controlled to be less than or equal to 0.027%; total oxygen content is no more than 0.0040%; the problem of nozzle clogging is overcome; and surface and internal quality of a casting blank is greatly improved. The process flow of the smelting method is simple and has low cost; and equipment used in the smelting method is conventional production equipment for iron and steel manufacture, is simple to operate, has good versatility and saves energy.

Owner:QINGDAO SPECIAL STEEL CO LTD

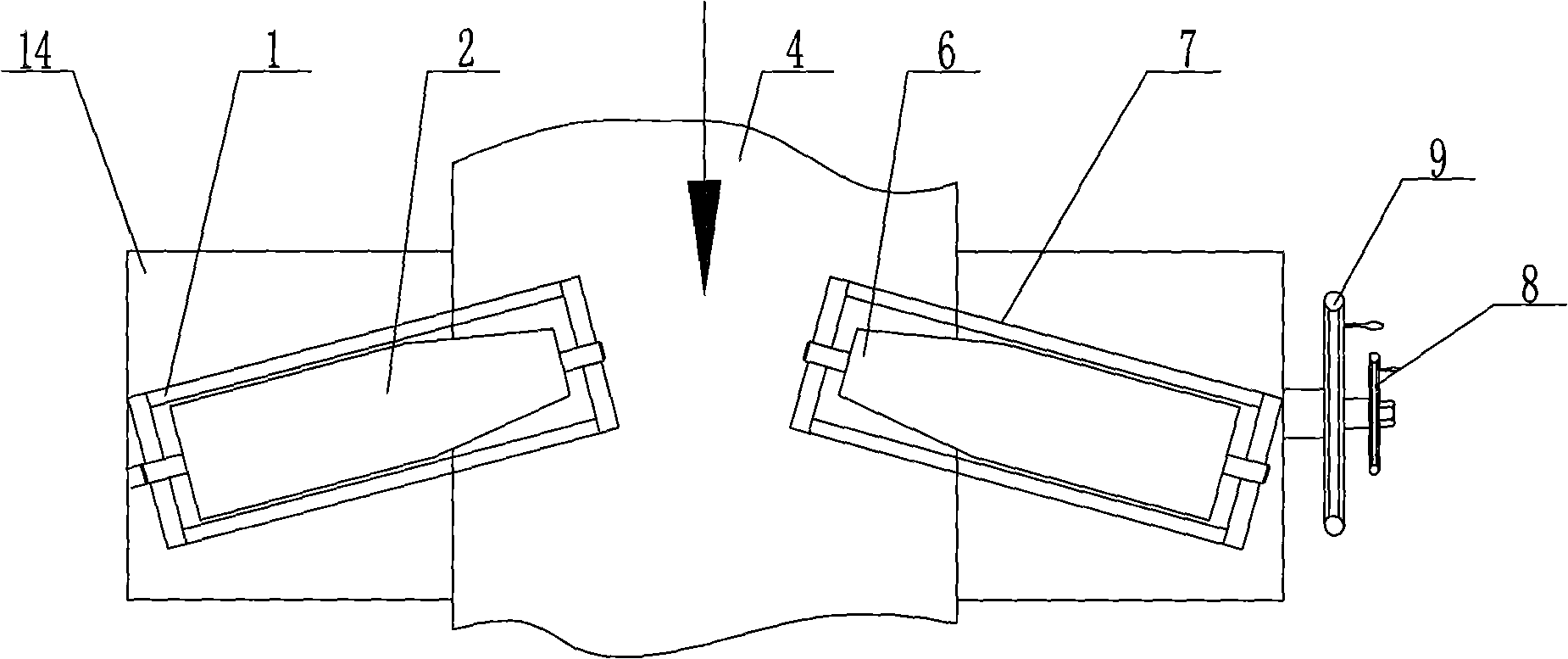

Band steel running deviation control device

InactiveCN101327877ASolve deviationIncrease productivityFurnace typesHeat treatment furnacesStrip steelEngineering

The present invention discloses a device for controlling band steel off-tracking. The device is arranged on a machine unit inlet loop or an annealer outlet, and can effectively solve the problem of the band steel off-tracking, ensure the regular production of the band steel, improve production efficiency and reduce labor cost. The device comprises a bracket, a frame, and a lead screw, wherein the lead screw is connected with a regulating handle. The device is characterized in that the device also comprises two pairs of deviation correcting rollers. The deviation correcting rollers are symmetrically arranged in the vertical direction with a center of the band steel as a borderline. The two pairs of deviation correcting rollers are oppositely arranged at the two sides of the frame and are movably connected with the bracket. The bracket is arranged on the frame through a lead screw structure.

Owner:WUXI SANZHOU COLD ROLLED SILICON STEEL

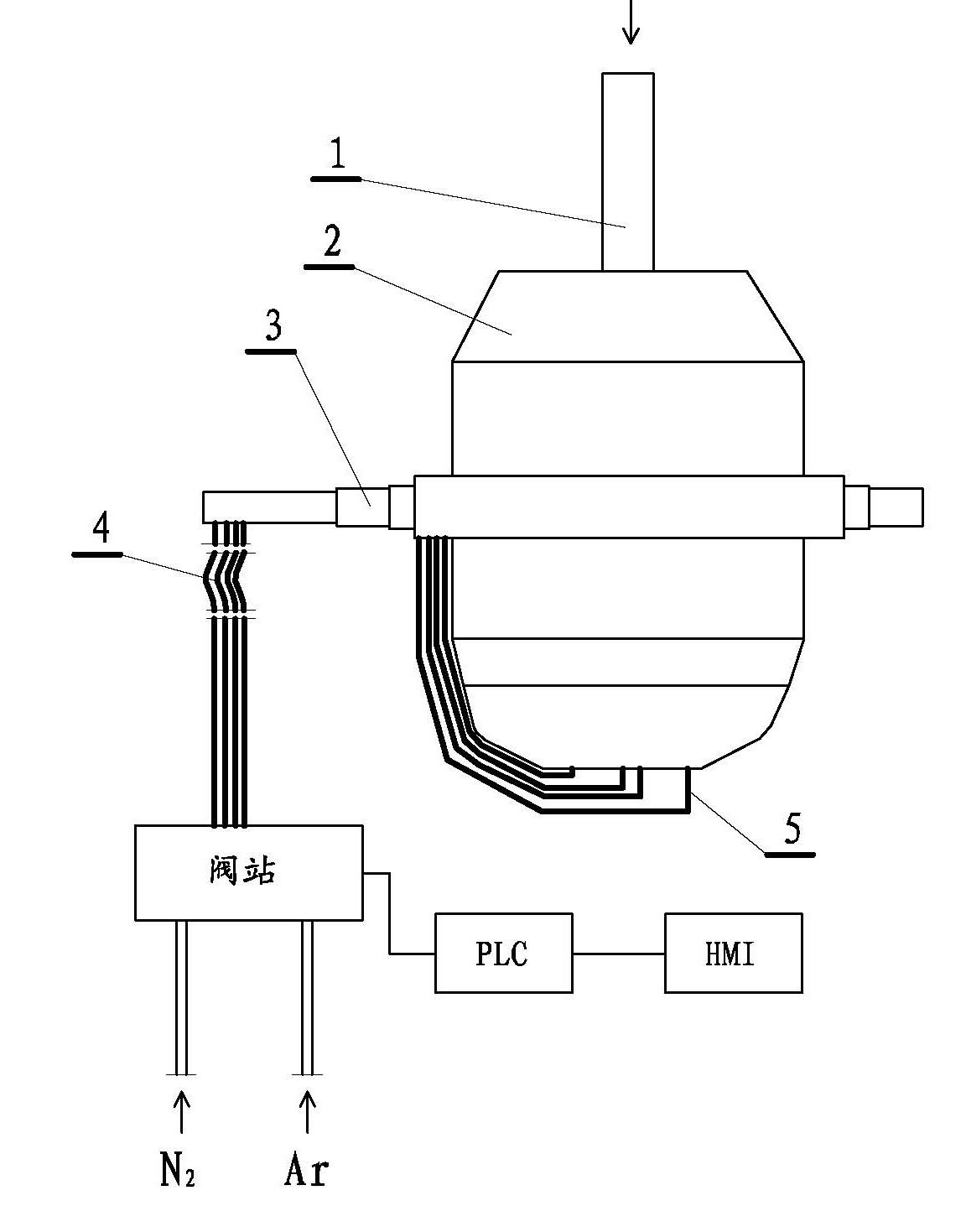

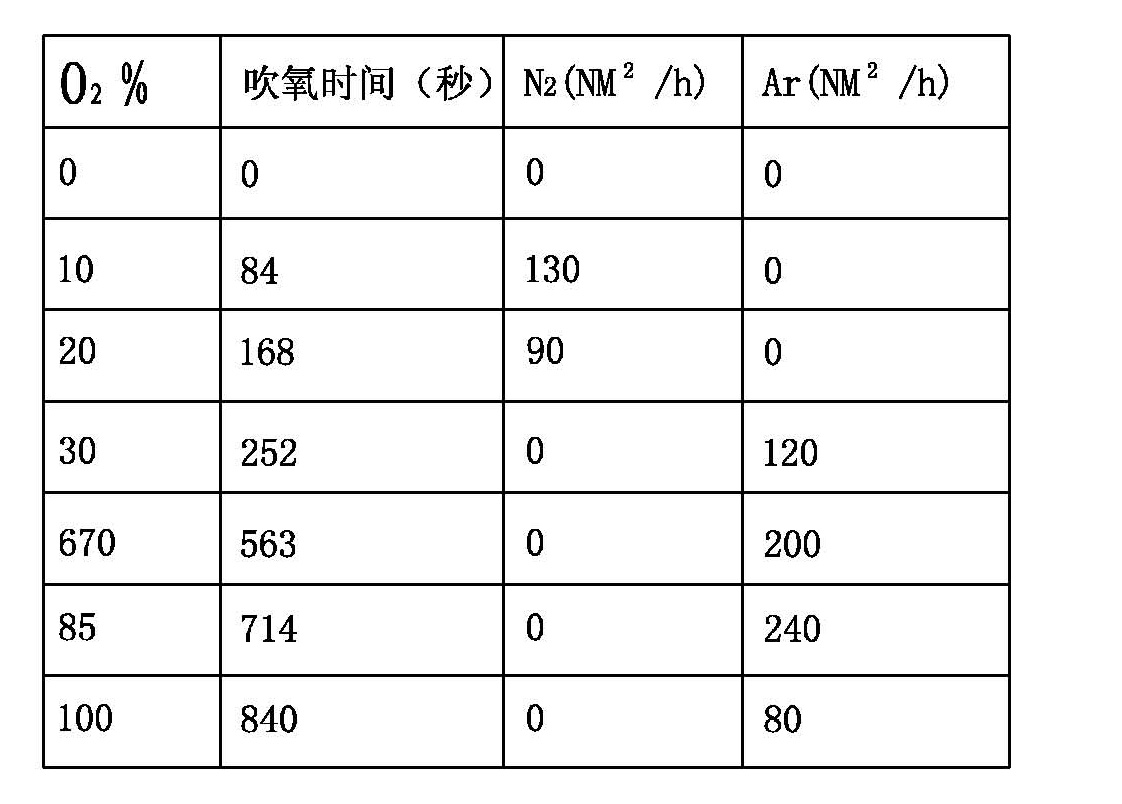

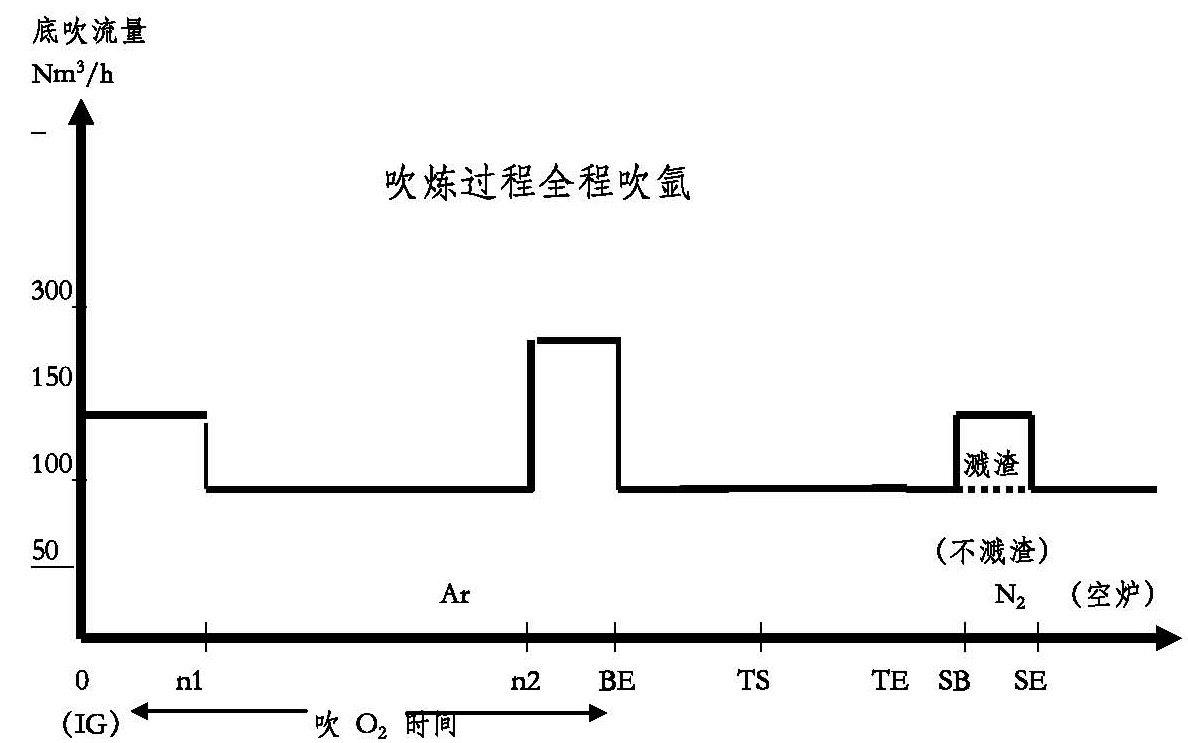

Method for automatic bottom blowing control of converter

InactiveCN102041346AQuality improvementShorten blowing timeManufacturing convertersHuman–machine interfaceSmelting process

The invention relates to a method for the automatic bottom blowing control of a converter. Hardware adopted by the method in the invention comprises a converter with a combined blowing function, a valve station for supplying argon and nitrogen and a PLC (programmable logic controller) with an HMI (human machine interface), wherein the PLC controls the valve station and stores a plurality of bottom blowing models. The method comprises the followings steps: selecting a bottom blowing model; confirming; loading a flow set value; transmitting the flow set value; and monitoring smelting process. According to different nitrogen contents and carbon contents of a target steel type, 9 models are combined in the invention, production operation personnel select a corresponding model code only according to a steel type to be smelted, and the parameter and the curve data of the model are automatically downloaded to the PLC. Thus, in the invention, the phenomenon that production operation personnel continuously and manually adjust valve opening in the conventional production step is reduced, thus the operation intensity is lightened. The PLC automatically switches nitrogen and argon, controls stable intake pressure and adjustable branch pipe flow, has high control precision and strong degree of automation and lowers production cost.

Owner:BEIJING JIANLONG HEAVY IND GROUP

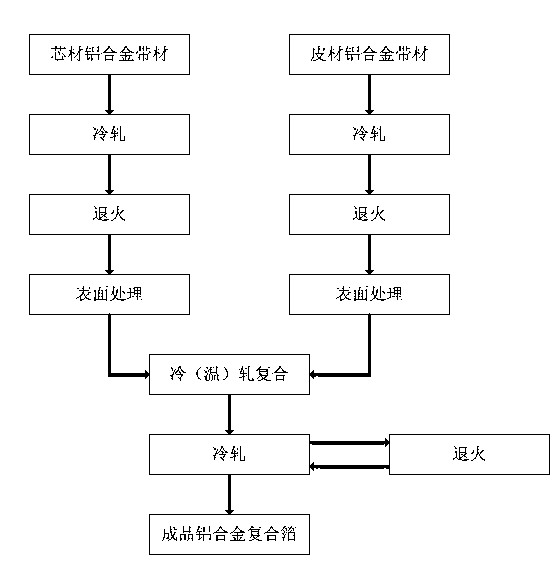

Method for preparing aluminium alloy compound foil by compounding cold rolling and warm rolling

The invention belongs to the technical field of an aluminium alloy and particularly relates to a method for preparing an aluminium alloy compound foil by compounding cold rolling and warm rolling. The method discloses by the invention comprises the following steps: firstly, respectively carrying out cold rolling on an aluminium alloy strip coil and a core aluminium alloy strip coil and annealing the aluminium alloy strip coil and the core aluminium alloy strip coil for 0.5 to 6 hours at a temperature of 300 to 450 DEG C; carrying out rolling compounding on the annealed skin alumium alloy and core aluminium alloy at a temperature of 20 to 250 DEG C to obtain an aluminium alloy composite strip; and carrying out annealing treatment on the aluminium alloy composite strip for 0.5 to 6 hours at a temperature of 300 to 450 DEG C, then carrying out multi-pass cold rolling, controlling the screw-down rate of carrying out cold rolling into the range that epsilon is more than or equal to 90 percent and less than or equal to 96 percent, carrying out annealing treatment for 0.5 to 6 hours in the temperature range of 300 to 450 DEG C after cold rolling, carrying out cold rolling again and controlling the screw-down rate of carrying out cold rolling again into the range that epsilon is more than or equal to 10 percent and less than or equal to 50 percent so as to obtain the finished aluminium alloy compound foil. According to the method disclosed by the invention, complex technical processes of ingot casting, hot-rolling cogging, assembly welding, hot-rolling compounding and the like of a conventional production process are omitted; energy is saved and consumption is reduced; and meanwhile, harmful effects brought to product quality by the hot-rolling compounding process are avoided.

Owner:NORTHEASTERN UNIV

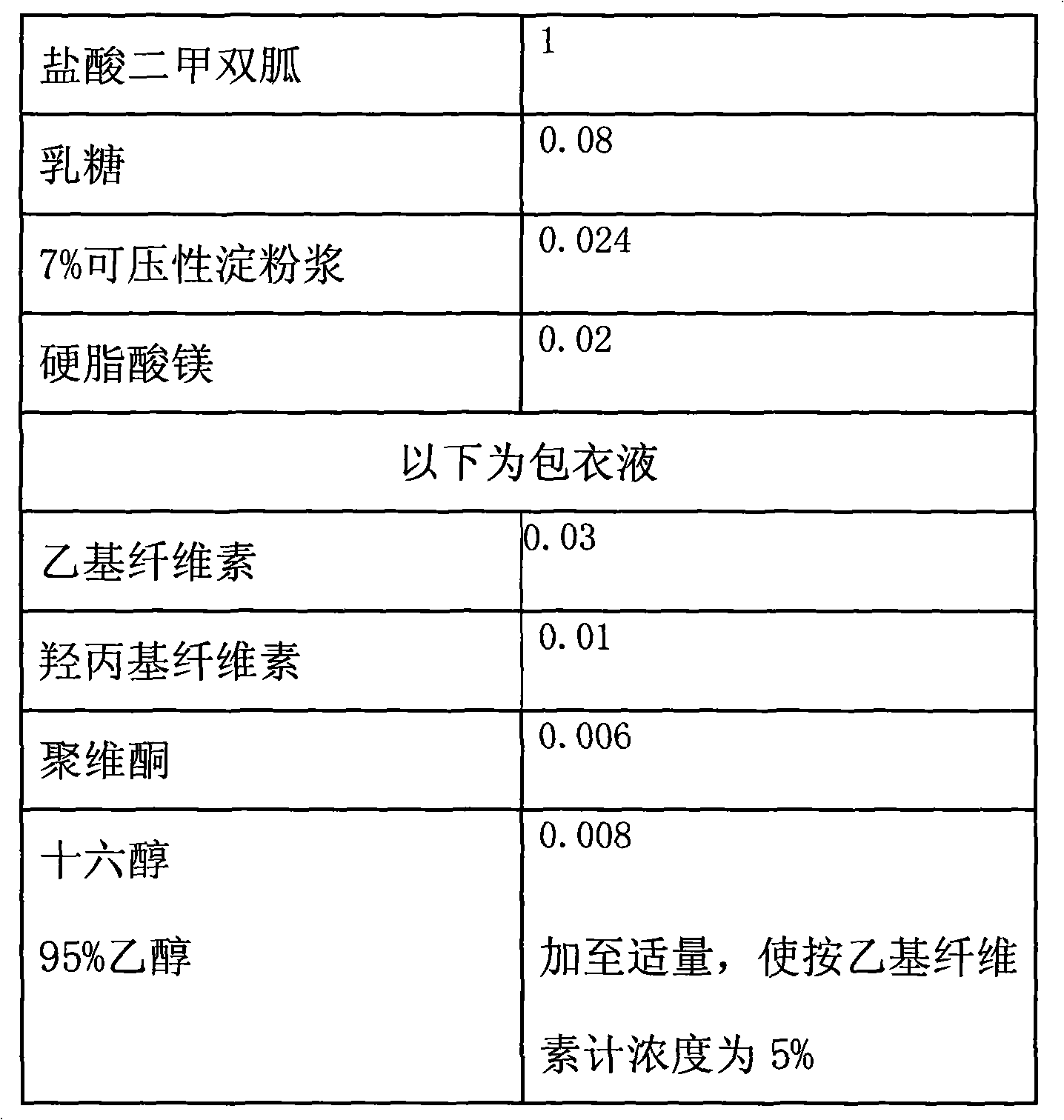

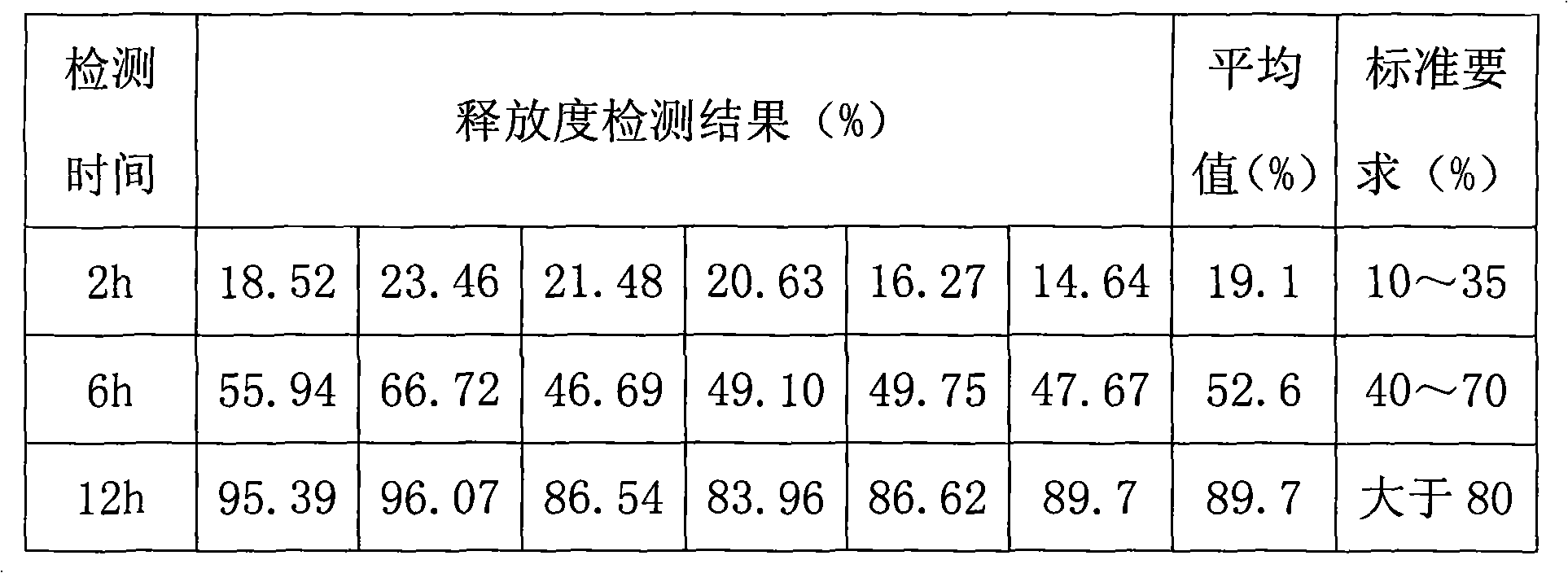

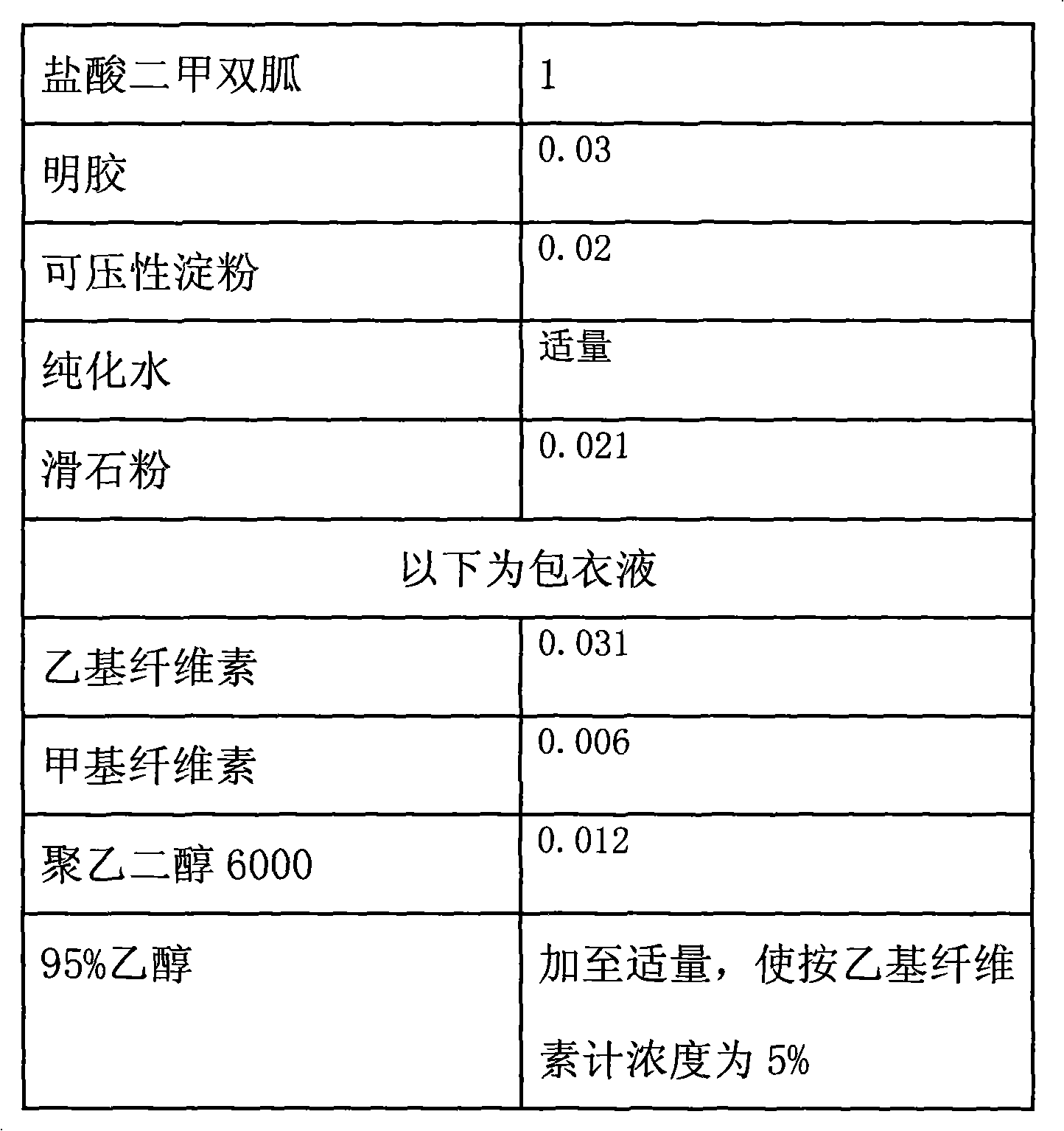

Metformin hydrochloride controlled-release tablet and preparation method thereof

ActiveCN101579325ALess weight gainIncrease production capacityOrganic active ingredientsMetabolism disorderPharmaceutical industryMetformin Hydrochloride

The invention provides a metformin hydrochloride controlled-release tablet, which comprises a metformin hydrochloride controlled-release tablet with effective dose and pharmaceutical accessories and is characterized in that the metformin hydrochloride controlled-release tablet uses the common tabletting, and the controlled-release effect is controlled by totally depending on the film coating technique. The coating adopted by the invention is a releasing system comprising the prescription which can cause the medicine to reach release degree standard in vitro. The preparation method in the invention is simple and convenient; the process conditions are easy to control and suitable for batch production, can use conventional production equipment in pharmaceutical industries for economically and conveniently producing the metformin hydrochloride controlled-release tablet on a large scale, can effectively and stably cause the release degree of the metformin hydrochloride controlled-release tablet in the second hour to be 10% to 35%, the release degree to be 40% to 70% in the sixth hour and the release degree to be more than 80% in the twelfth hour.

Owner:CHONGQING CONQUER PHARML

Low-cost high-yield cultivation method of artificially-cultivated dendrobe

InactiveCN102498860AMeet the requirements of artificial cultivation conditionsIncrease productionHorticultureGreenhouseDitch

The invention provides a low-cost high-yield cultivation method of artificially-cultivated dendrobe, which comprises the steps of building a planting environment, arranging planting ridge-bordered plots, clearing up the planting ridge-bordered plots and planting dendrobe seedlings. The specific steps includes: building a totally-enclosed overshadowing green house with the artificially-affected planting environment and arranging management road ridges and irrigation drainage ditches; arranging the planting ridge-bordered plots in the totally-enclosed overshadowing green house parallelly and arranging border ditches among the planting ridge-bordered plots to be communicated with the irrigation drainage ditches; flattening the surface of the ridge-bordered plots, paving base plates to serve as cultivation seedling bed pad layers, paving flaw-piece plates on the base plates, paving a layer of overshadowing net on the flaw-piece plates and paving cultivation matrix on the overshadowing net; planting the dendrobe seedlings or tissue culture seedlings on seedling beds of cleared planting ridge-bordered plots in sequence according to planting distance of 10*10 cm and performing productionmanagement according to conventional production process. The low-cost high-yield cultivation method adopts the planting ridge-bordered plots with special structures, the cultivation matrix and a soillayer are separated by asbestos tiles, outstanding technological effect is obtained, the requirements of dendrobe to cultivation conditions are met, and dendrobe yield is improved.

Owner:MENGLA QIANSONG DENDROBIUM PLANTING

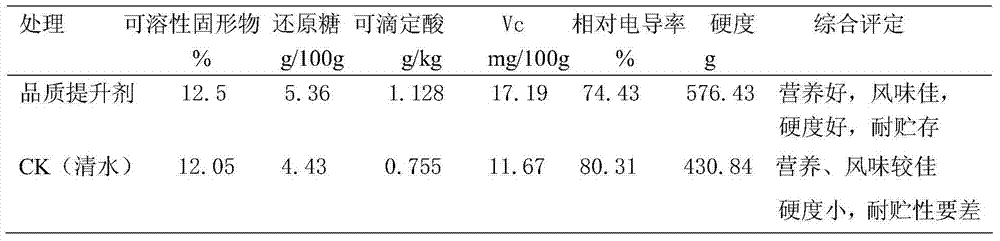

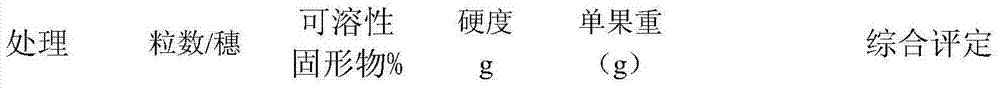

Method for improving quality of southern fruit before picking

ActiveCN103563664AImprove qualityRaise the ratioHorticulture methodsFertilizer mixturesCell divisionPEAR

A method for improving the quality of southern fruit before picking is characterized in that a quality improving agent A, a quality improving agent B and a quality improving agent C are sprayed on the southern fruit during a fruit cell division period, an expanding period and a ripe period respectively; and the southern fruit relates to honey pears, waxberries or grapes. Compared with the prior art, the method has the advantages as follows: before picking, people combine quality improvement with initiative fresh keeping and focus on improving the quality of the southern fruit before storage, so that the nutrition and the storage level of the picked fruit are substantially improved while compared with those of conventionally produced fruit, and the proportion of high-quality storable big fruit is increased.

Owner:YUYAO FORESTRY SPECIALTY TECH PROMOTION GENERAL STATION +2

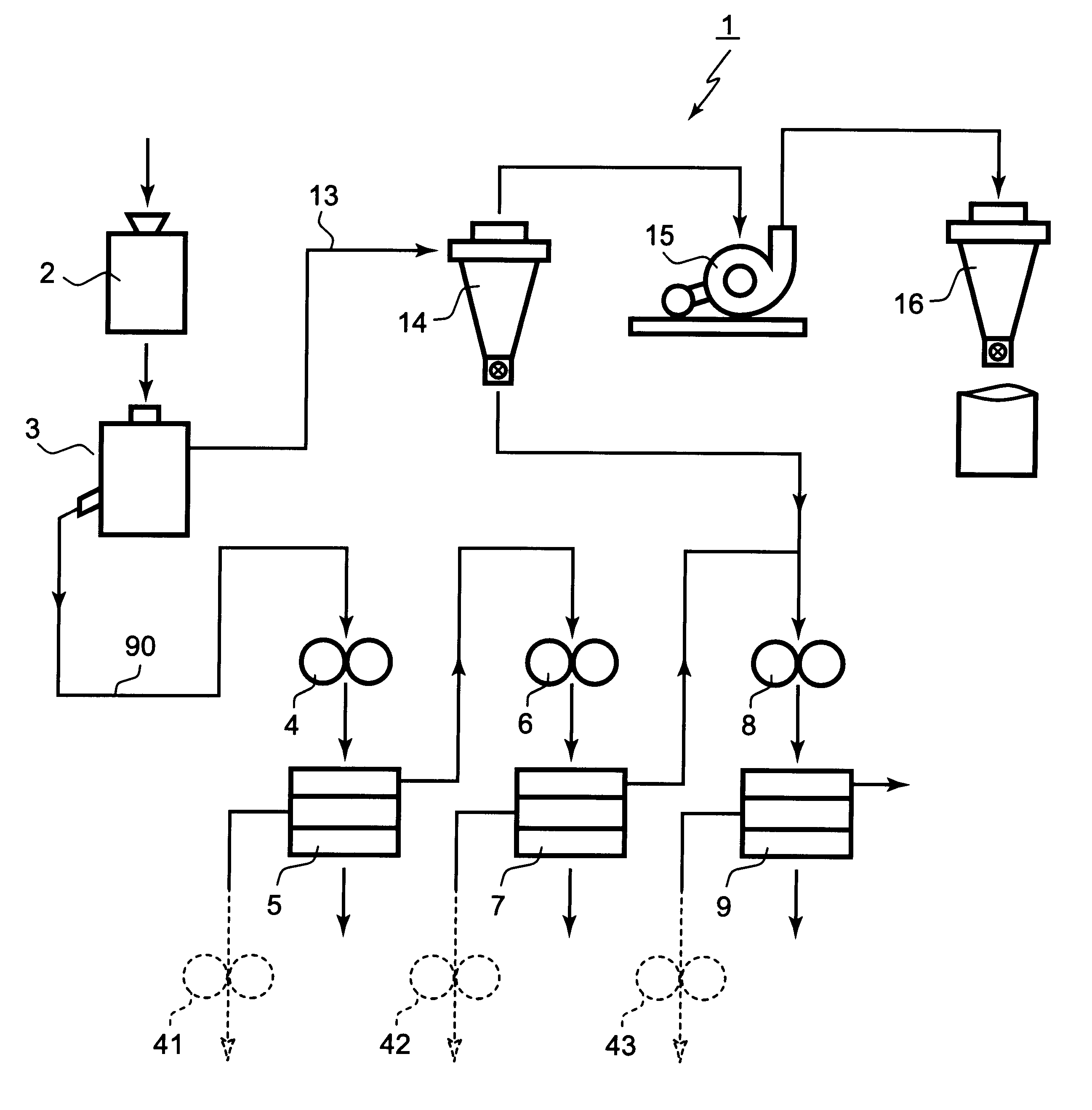

Flour milling method having a sorting step for raw wheat grains and flour milling system adopting the method

InactiveUS6199777B1Enhance advantageous effectHigh yield productionSievingScreeningBiotechnologyRegular Production

A flour milling method and a flour milling system are provided, in which a plurality of milling steps whose milling degrees are different from one another are performed sequentially from an upperstream to a downstream, each of the milling steps including a breaking step and a grading step. The steps are carried out by sorting the raw wheat grains into regular wheat grains and material other than the regular wheat grains, forwarding the sorted regular wheat grains to the uppermost-stream milling step, and forwarding the sorted material other than the regular wheat grains to at least one of downstream milling steps at a downstream of the uppermost-stream milling step. The method and the system enable the production of wheat flour of better quality with better yield than that conventionally produced.

Owner:SATAKE CORP

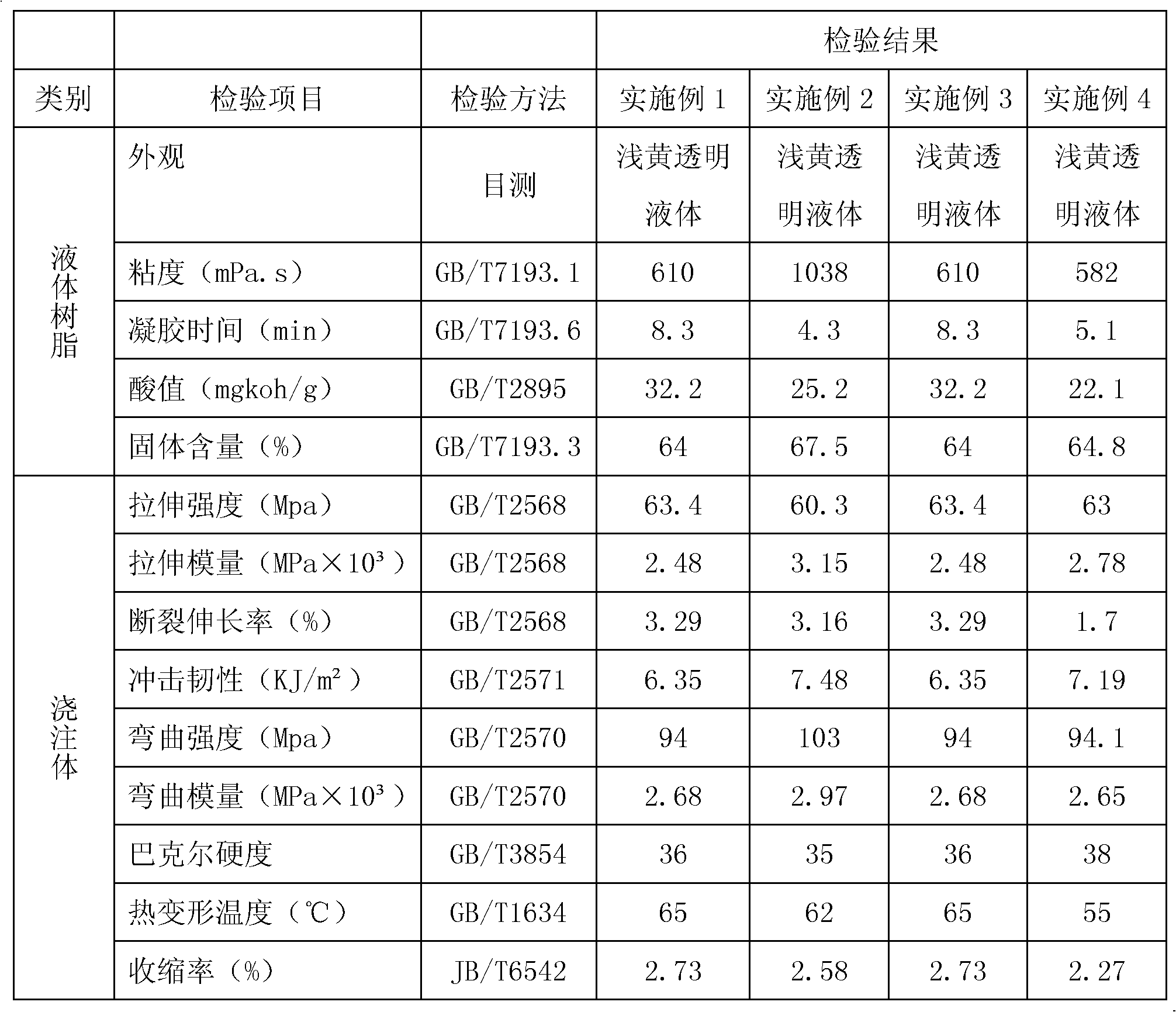

Method for synthesizing unsaturated polyester resin by utilizing glycerol

ActiveCN102219882AExcellent physical and chemical propertiesReduce manufacturing costCross-linkGlycerol

The invention provides a method for synthesizing unsaturated polyester resin by utilizing glycerol. In the method, a weight ratio of synthetic raw materials, namely the glycerol to dihydric alcohol is 1:4-3:2. In addition, the synthetic raw materials also comprise components such as monobasic acid, dibasic acid, a cross-linking agent, a polymerization inhibitor, a defoaming agent and the like. In the method, a part of dihydric alcohol which is used in the conventional production method is replaced by a large amount of glycerol effectively, so the production cost of products is reduced substantially; meanwhile, the produced unsaturated polyester resin has high physical properties such as physical strength, toughness, rigidity and the like.

Owner:ZHAOQING FUTIAN CHEM IND

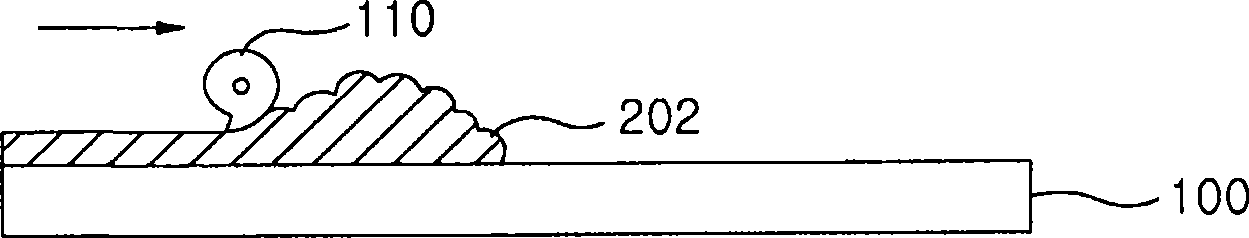

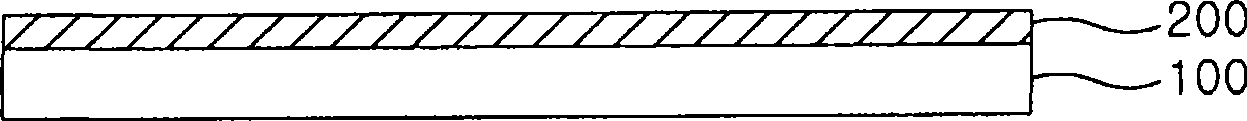

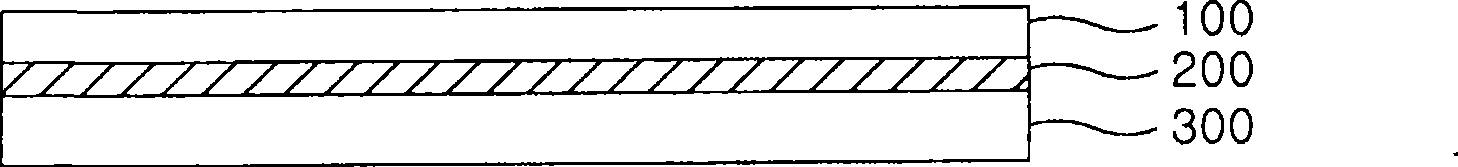

Pressure sensitive adhesive composition for transferring flexible substrate

ActiveCN101443429AHeat resistantChemical resistantTemperatue controlAdhesive articlesAntistatic agentLiquid-crystal display

Disclosed herein is an adhesive composition for transporting a flexible substrate, which is used to manufacture a flexible display device using a flexible substrate such as a plastic substrate by using a conventional line for manufacturing a liquid crystal display device comprising a glass substrate. The present invention provides an adhesive composition for transporting a flexible substrate, which includes 100 parts by weight of an adhesive for transporting a flexible substrate and 0.001 to 5 parts by weight of an antistatic agent, an adhesive sheet containing the composition, and a method of transporting a flexible substrate using the same.

Owner:LG CHEM LTD

Preparation method for moisture-absorbing and heat-radiating polyacrylonitrile yarn

InactiveCN103266381AGood moisture absorption and heating performanceImprove uniformityArtificial thread manufacturing machinesConjugated synthetic polymer artificial filamentsYarnFiltration

The invention relates to a preparation method for moisture-absorbing and heat-radiating polyacrylonitrile yarn. The method comprises the following steps for preparing the yarn: (1) conducting hydrolytic treatment on acrylonitrile copolymer; (2) settling out through solvents, and adjusting pH value after filtration; (3) blending to obtain hydrolysis polyacrylonitrile stock solution; (4) adjusting temperature of the hydrolysis polyacrylonitrile stock solution, and blending the hydrolysis polyacrylonitrile stock solution with conventionally-prepared polyacrylonitrile stock solution evenly and sufficiently to obtain moisture-absorbing and heat-radiating polyacrylonitrile stock solution; (5) placing the stock solution on a polyacrylonitrile wet spinning production line to obtain moisture-absorbing and heat-radiating polyacrylonitrile fiber after the procedures of extrusion and solidification forming, pre-drafting, washing, hydrophilization processing, hot drafting, densifying-crosslinking, coiling and shaping, oiling, and drying; (6) cutting the fiber and spinning. The moisture-absorbing and heat-radiating polyacrylonitrile yarn prepared according to the method is good in moisture-absorbing and heat-radiating performance, good in uniformity and durability, high in production efficiency, and is not restricted by the number and the length of the fiber.

Owner:DONGHUA UNIV

Preparation method of functional regenerated cellulose fiber

ActiveCN106435817AEvenly dispersedStable in natureFlame-proof filament manufactureArtificial thread manufacturing machinesProduction lineCellulose fiber

The invention relates to a preparation method of a functional regenerated cellulose fiber. The method comprises the steps that cellulose with low polymerization degree is dissolved with a cellulose solvent, and a carrier solution of functional powder is obtained; the functional powder is mixed with the carrier solution under the intense shear effects provided by a stirring device, and a functional mother solution is obtained; the functional mother solution is injected into a cellulose spinning solution in a mode of online addition, and the spinning solution is subjected to extrusion and solidification to form the functional regenerated cellulose fiber. According to the preparation method, the problems that by means of a traditional method, the functional powder and the spinning solution are difficult to mix and dispersion is nonuniform are overcome, the used mother solution is solidified and formed with fibers and enters the solvent and the coagulating bath system without any additional auxiliaries. The forming method is simple, flexible and efficient, the production of the functional regenerated cellulose fiber can be achieved based on a conventional production line.

Owner:DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com