Water soluble effervescence composition and method of making the same

A composition and effervescent technology, applied in the direction of fertilizer mixture, fertilizer form, inorganic fertilizer, etc., can solve packaging, transportation, storage, metering, inconvenient use, easy to block nozzles and drip irrigation pipelines, low content of active ingredients, etc. Problems, to achieve good liquidity, expand the scope of use, improve the effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

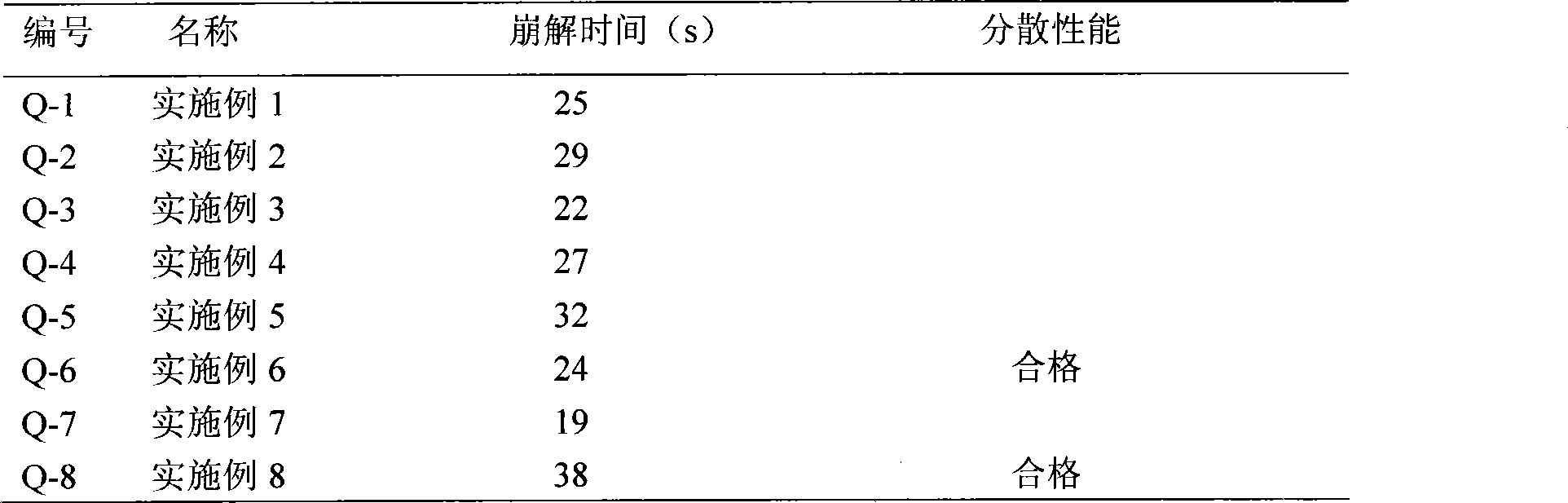

Examples

Embodiment 1

[0040] Weigh each component raw material according to the following ratio

[0043] Gibberellin GA 3 1 g

[0044] KHCO 3 7 grams

[0045] Ascorbic acid 5 g

[0046] Succinic acid half ester sulfonate fatty amide 4 g

[0047] Sodium dodecylbenzene sulfonate 3 g

[0048] Gibberellin GA 3 After ultra-fine pulverization to 250 meshes or more, mix with other components, prepare master powder through coarse pulverization, mix the master powder with an appropriate amount of alcohol solution, and then perform extrusion granulation, drying, sieving, analysis, inspection, and storage Obtain potassium nitrate gibberellin effervescent.

Embodiment 2

[0050] Weigh each component raw material according to the following ratio

[0053] Naphthalene acetic acid 1 g

[0054] NH 4 HCO 3 5 grams

[0055] Fumaric acid 5 g

[0056] NNO 4 g

[0057] Fatty alcohol polyoxyethylene ether 3 g

[0058] Talc 2g

[0059] Arabic gum 1g

[0060] First, the naphthalene acetic acid is superfinely pulverized to more than 250 mesh, mixed with other components, and then coarsely pulverized to prepare a master powder. Mix the master powder with a 3% binder arabinol solution evenly, and then proceed to fluidized bed manufacturing. Granules, dried, compressed, analyzed and tested to obtain potassium nitrate naphthaleneacetic acid effervescent tablets.

Embodiment 3

[0062] Weigh each component raw material according to the following ratio

[0063] Boric acid 65 g

[0064] Microcrystalline cellulose 10g

[0065] KHCO 3 6 grams

[0066] Tartaric acid 4 grams

[0067] Sodium lignosulfonate 5 g

[0068] Sodium dodecylbenzene sulfonate 5g

[0070] Polyvinylpyrrolidone 3g

[0071] Mix the above components and pulverize to prepare a master powder. Mix the master powder with a 3% binder polyvinylpyrrolidone alcohol solution, and then perform roller granulation, drying, tableting, analysis and inspection, and storage to obtain boric acid effervescence tablet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com