Patents

Literature

261results about How to "Lower packaging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

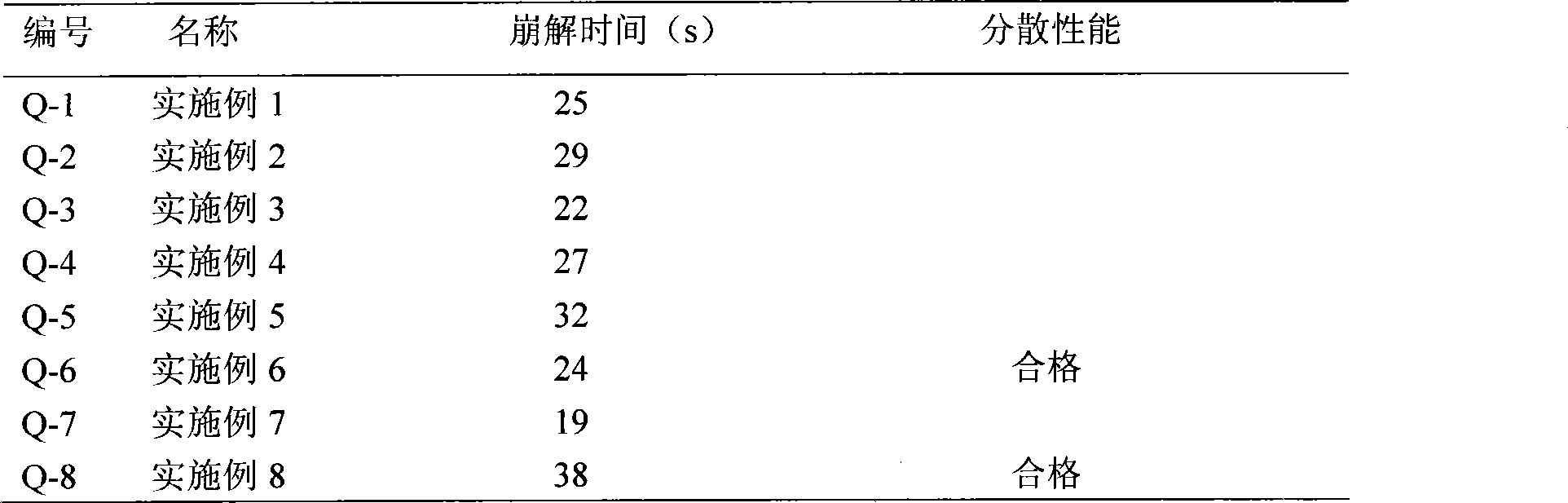

Water soluble effervescence composition and method of making the same

InactiveCN101423443AFast disintegrationQuick Dissolution (Dispersion)Carbon dioxide producing fertilisersMatrix fertilisersAdhesiveAdditive ingredient

The invention relates to an effervescent composition of a water-soluble fertilizer and a preparation method thereof. The effervescent composition contains one or a plurality of plant nutrient substances and one or a plurality of compounds which are contacted with water to generate gas. The effervescent composition comprises an optimized proposal that the plant nutrient substance is monopotassium phosphate. The effervescent composition can be also added with acid, a plant growth conditioner, a surfactant, a filler, a disintegrating agent, an adhesive, dye, a lube and the like. The preparation method comprises the following steps: ingredients are weighed, mixed, pulverized, pelletized and dried to obtain the effervescence composition. The effervescent composition can be manufactured through a routine production process, has rapid disintegrating and dissolving (diffusing) speed in the water, does not block a spray head or drip a pipeline, is uneasy to absorb dampness, has high content of effective compositions, low packaging, storage, metering and using cost and high utilization rate of the effective compositions, reduces waste and pollution to environment, is widely applied to economic crops, gardening, lawns and urban landscaping and has wide market application prospect.

Owner:SHENZHEN LANGTAI BIOTECH

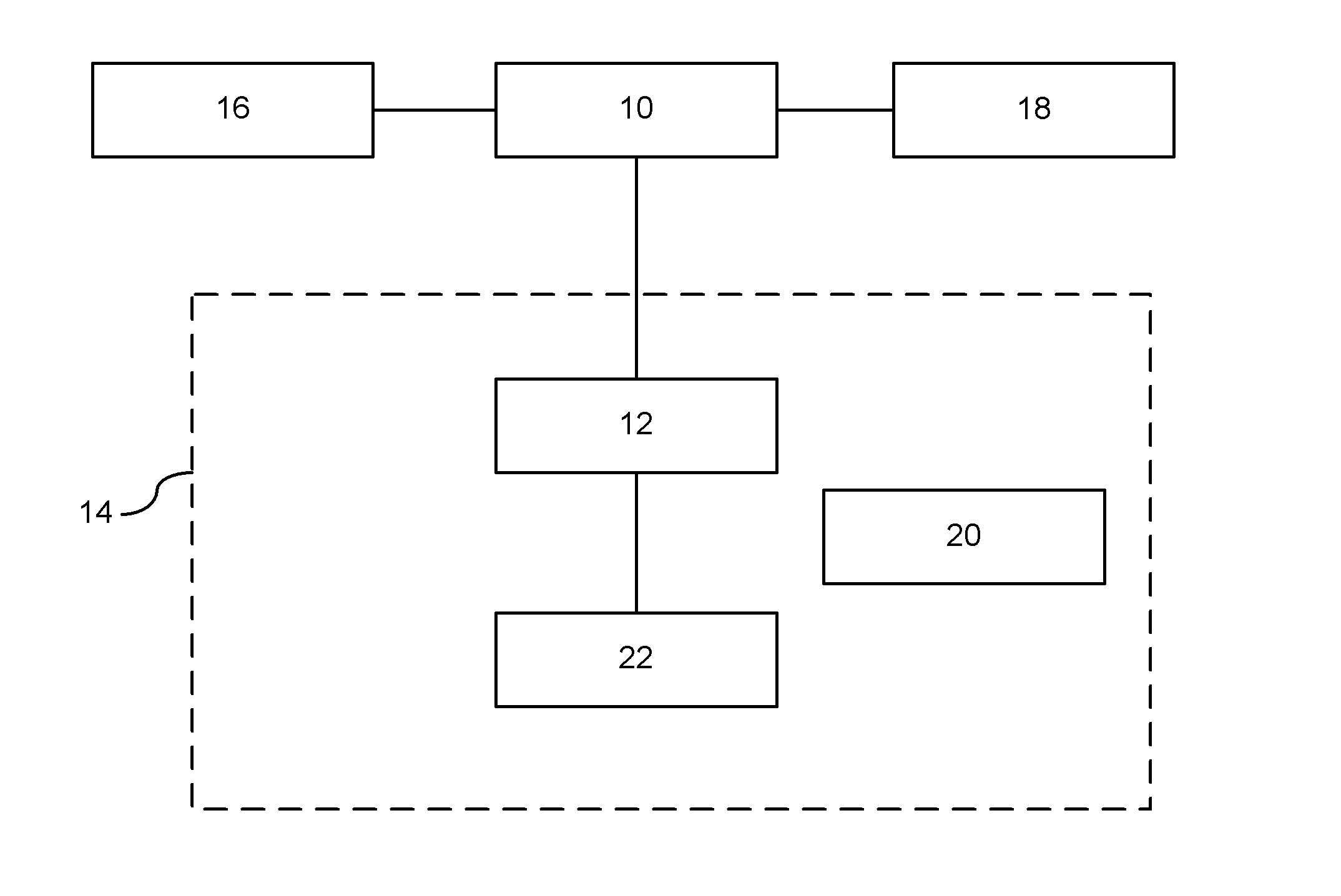

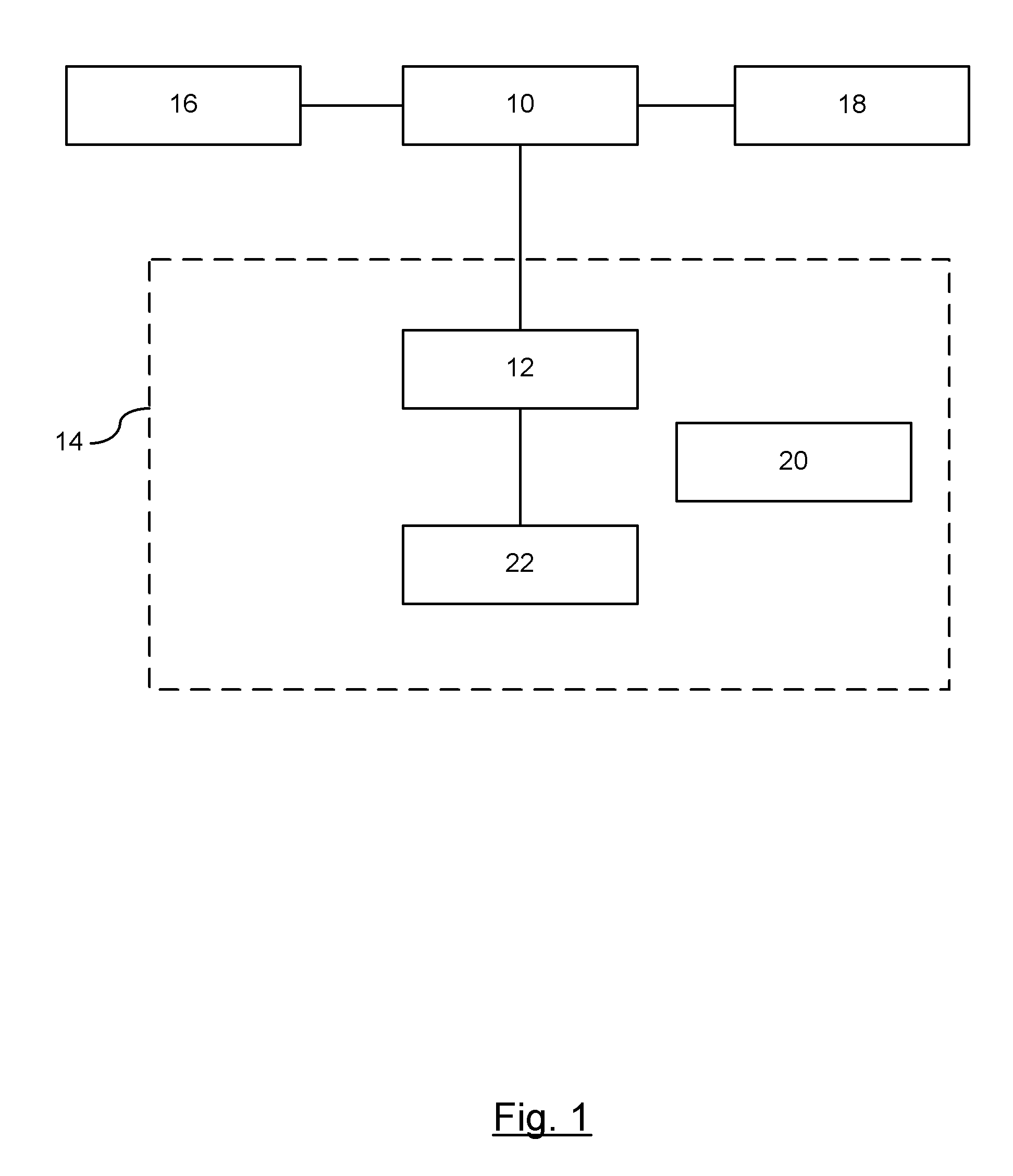

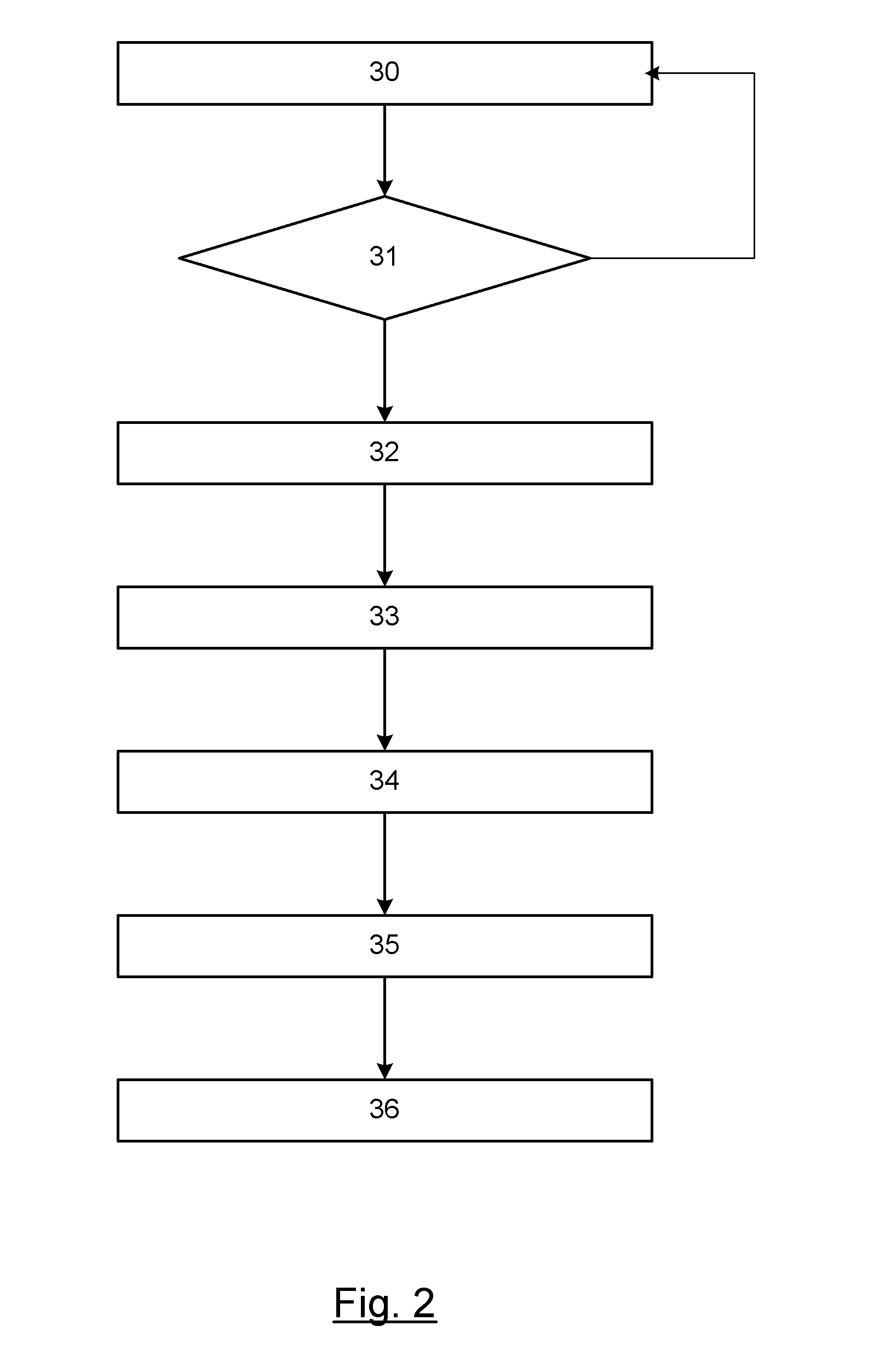

System and apparatus for augmented reality display and controls

InactiveUS20130249942A1Accurate identificationAccurate displayCathode-ray tube indicatorsDigital output to display deviceVirtual controlOutput device

An augmented reality system includes a vision output device for displaying virtual images. A sensing device captures an image within a reference frame. The vision output device is captured within the image. A processing unit identifies the vision output device within the reference frame of the captured image and localizes the vision output device within the reference frame of the captured image for identifying an absolute position and orientation of the vision output device within the reference frame of the captured image. The vision output device generates virtual displays to a user at respective locations based on the absolute position and orientation of the vision output device within reference frame of the captured image. The sensing device captures a user's selection of a virtual control. The processing unit identifies the selection of the virtual control within the captured image and enables a control action of a controllable device.

Owner:GM GLOBAL TECH OPERATIONS LLC

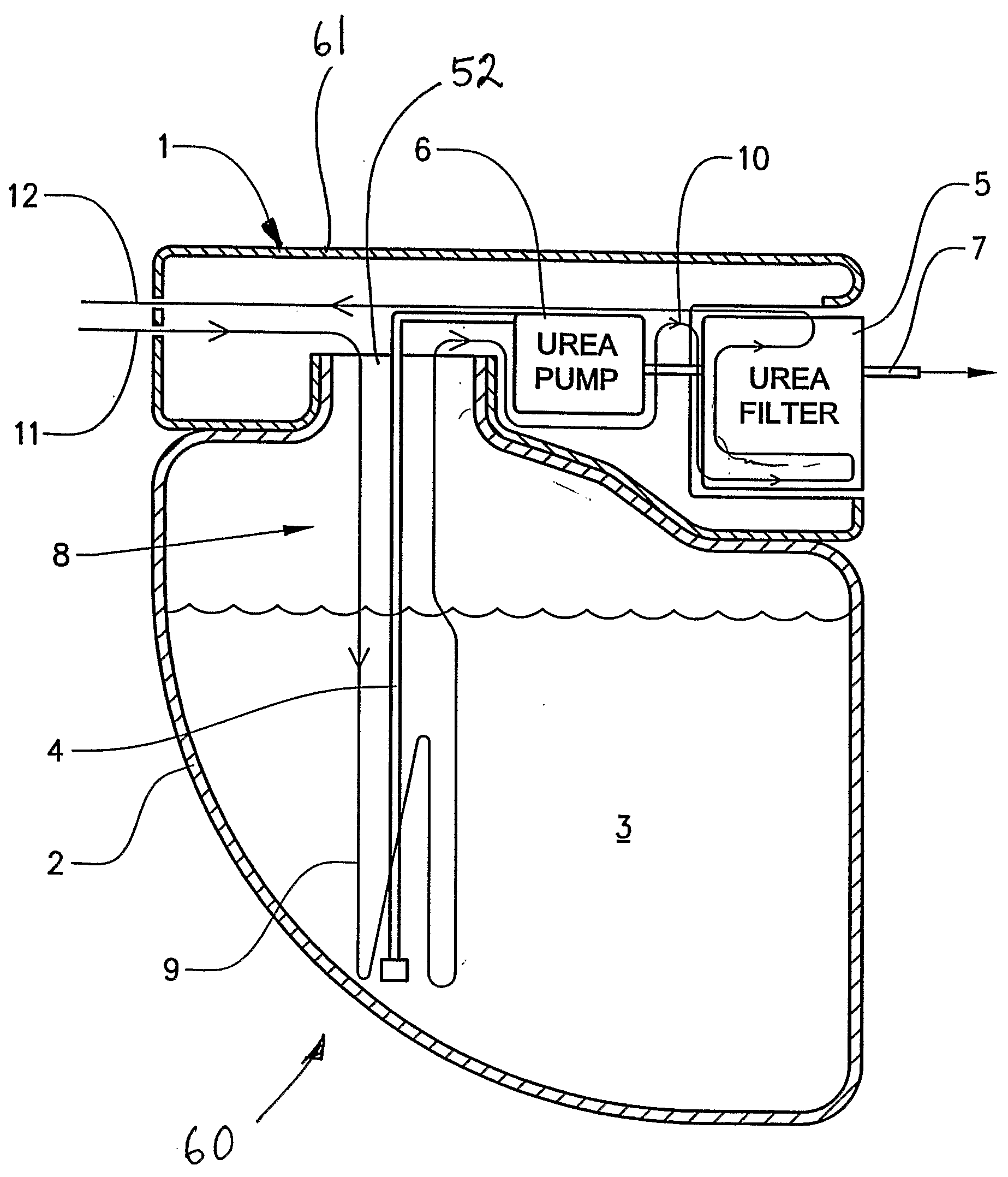

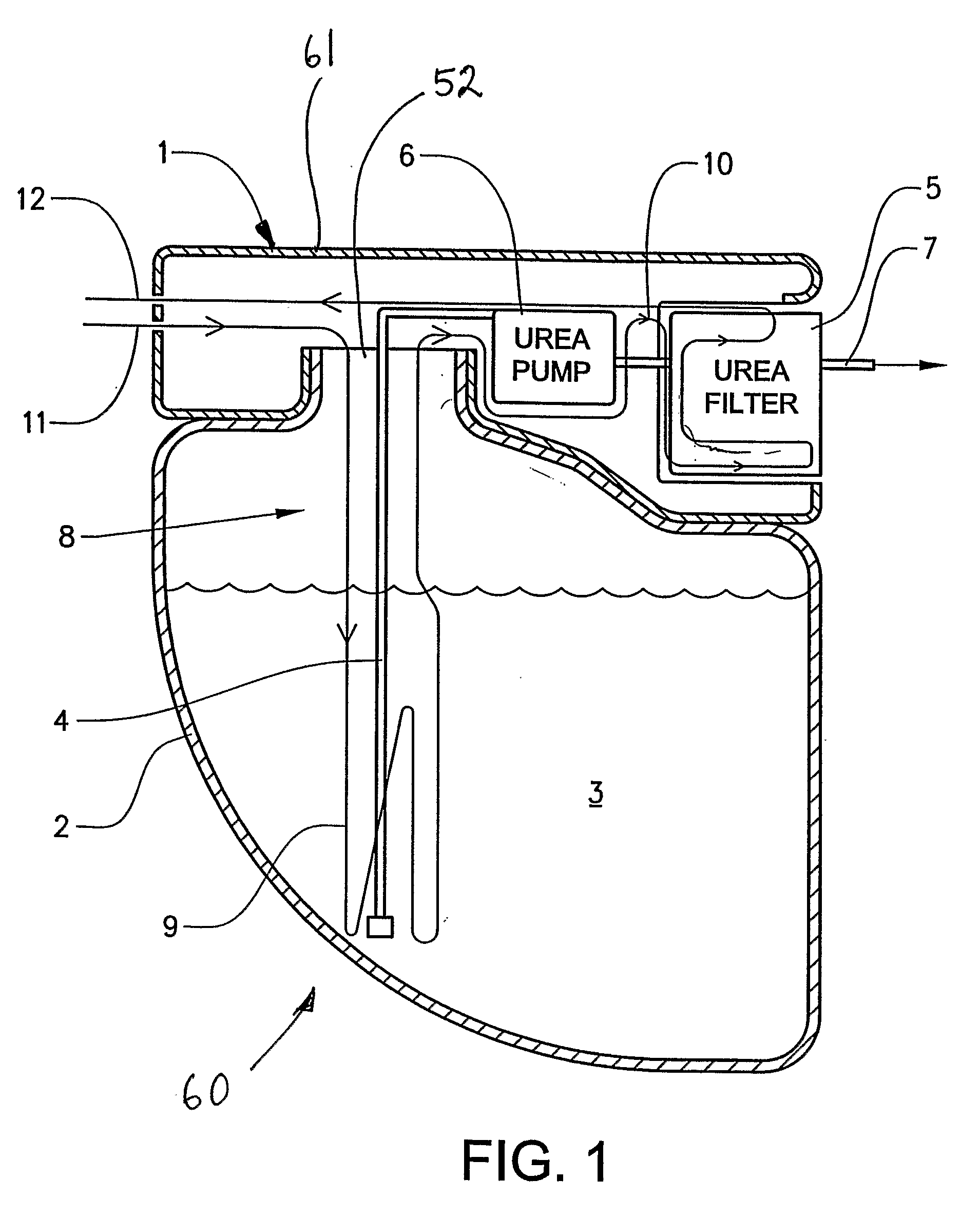

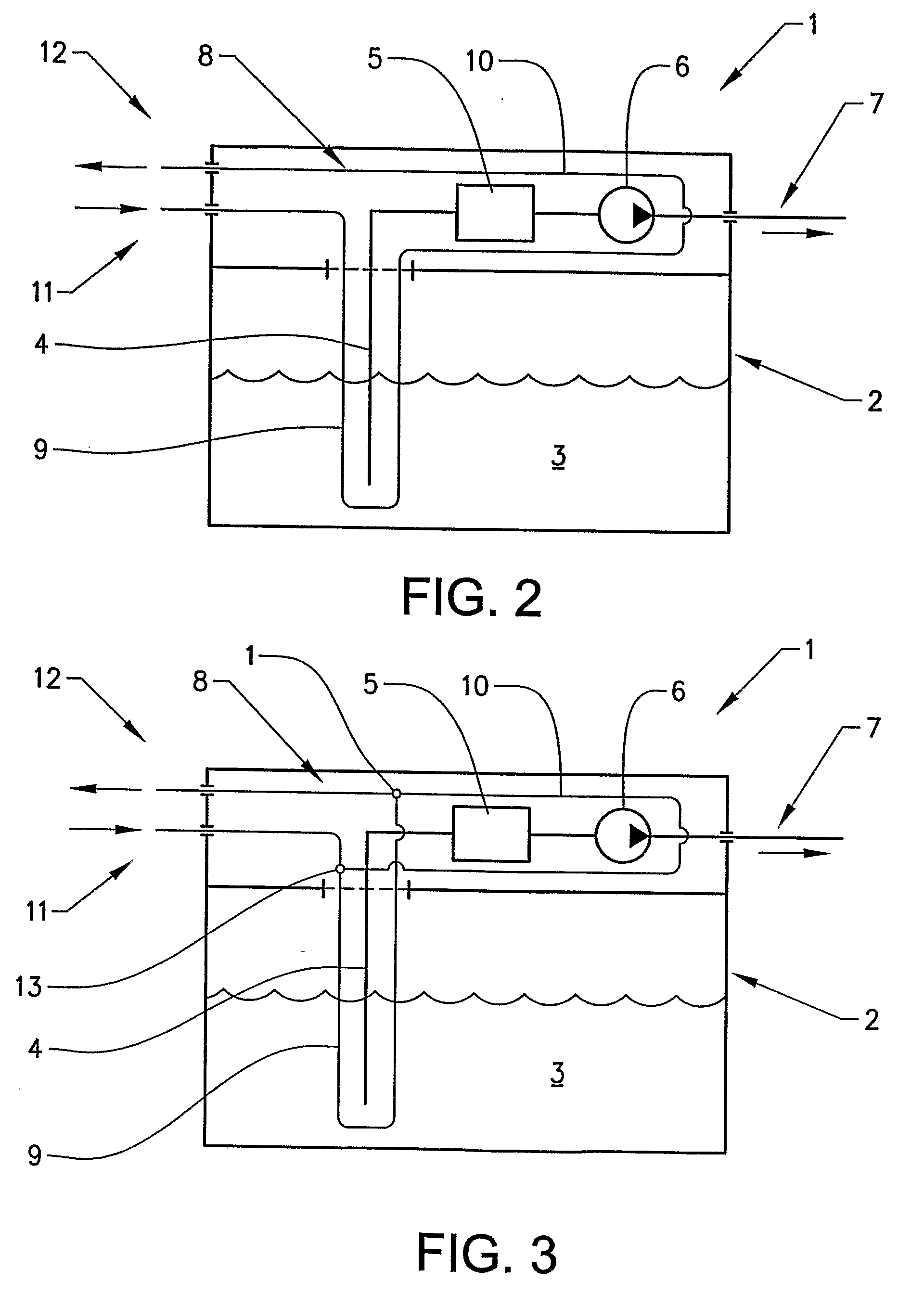

Liquid receptacle for a vehicle

InactiveUS20090127265A1Reduce componentsReduce riskInternal combustion piston enginesExhaust apparatusMechanical engineering

Owner:VOLVO LASTVAGNAR AB

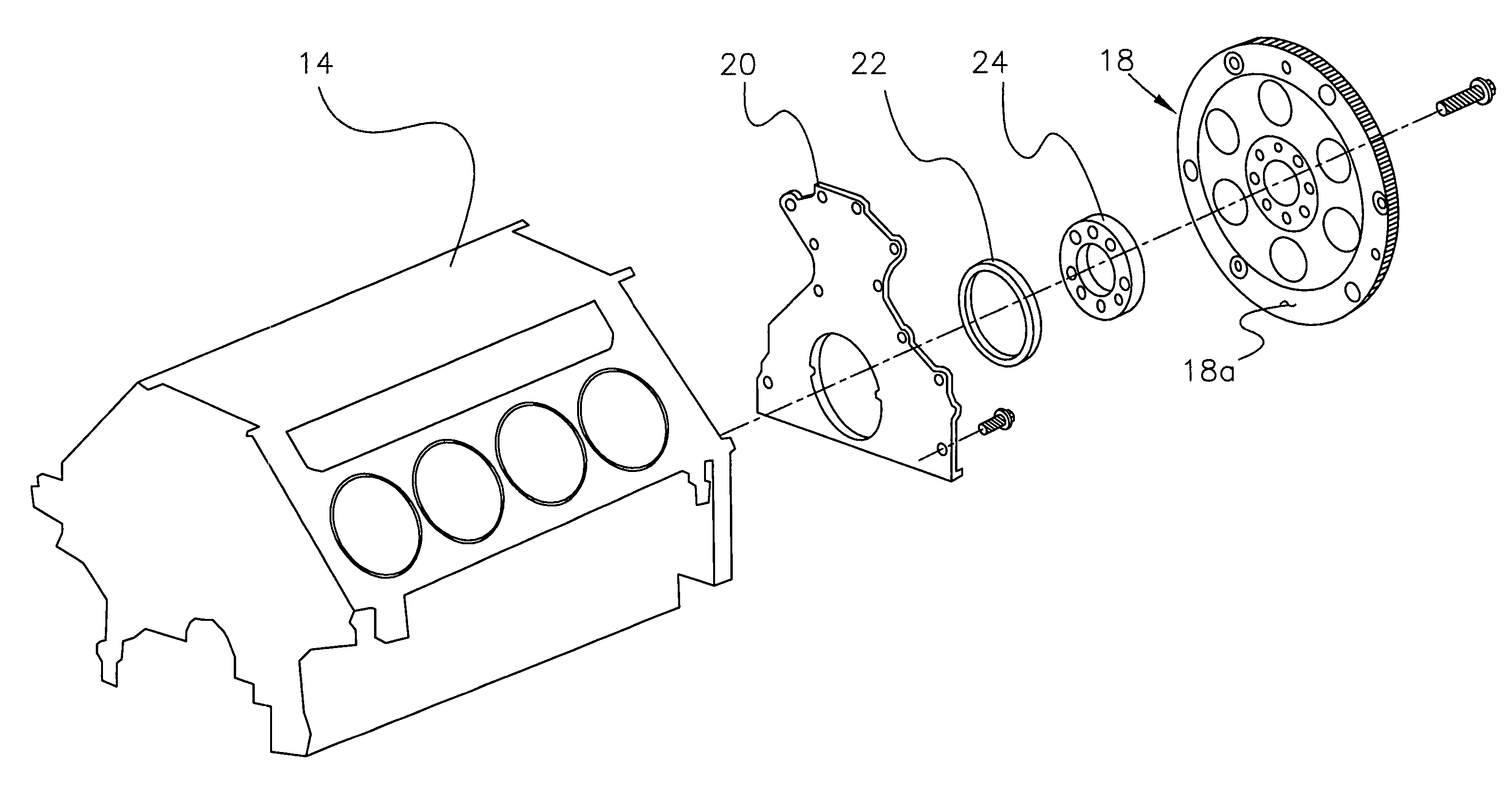

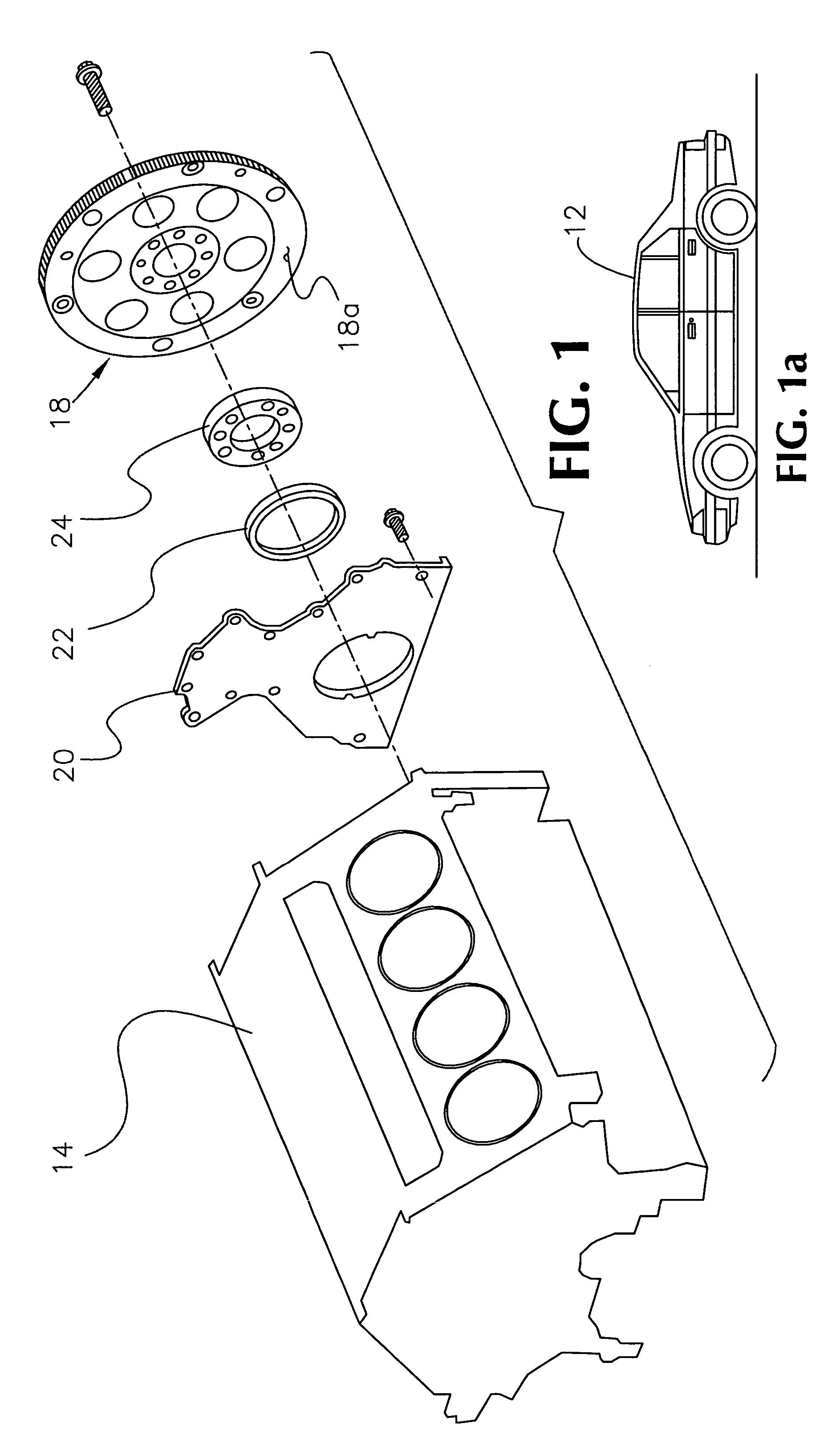

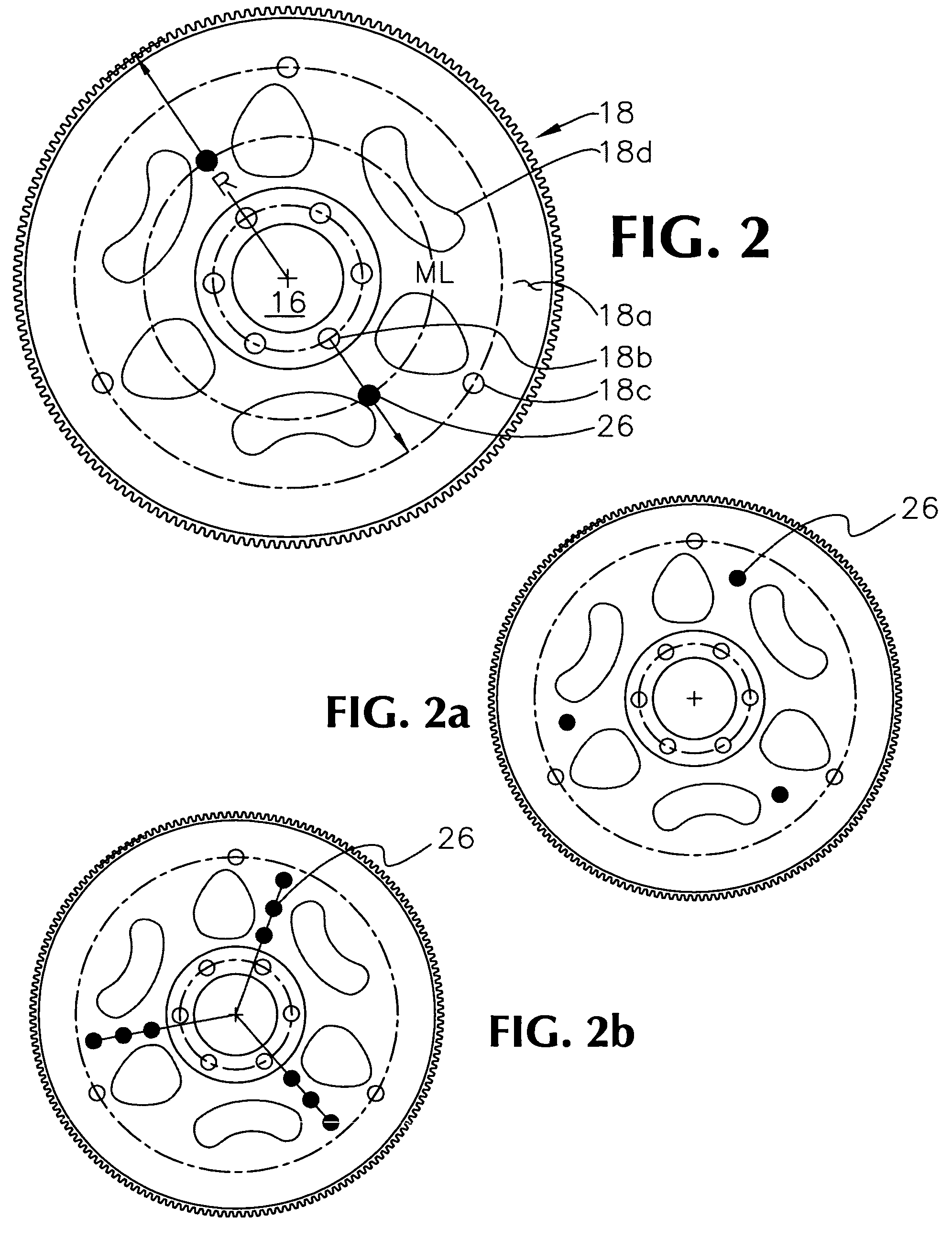

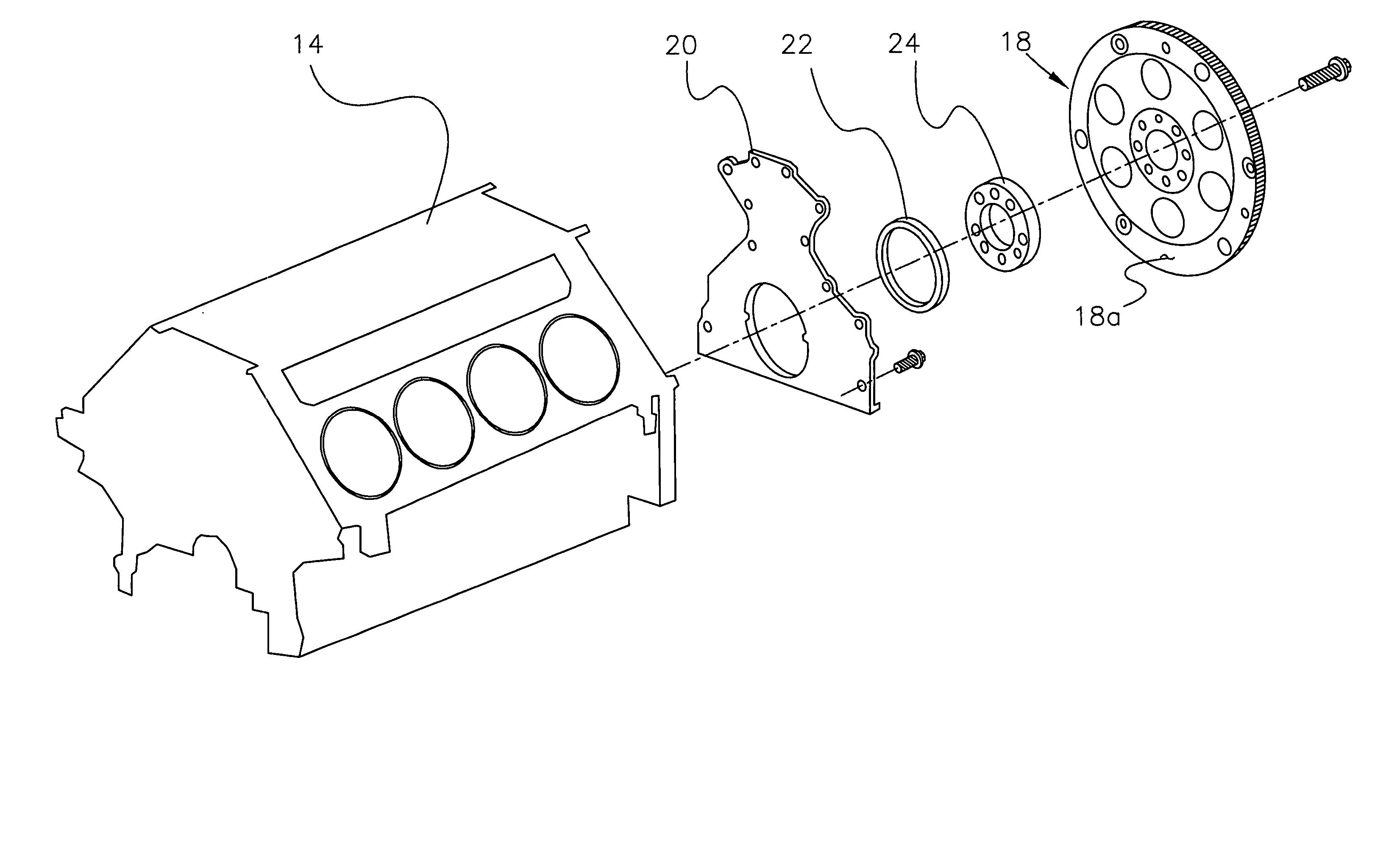

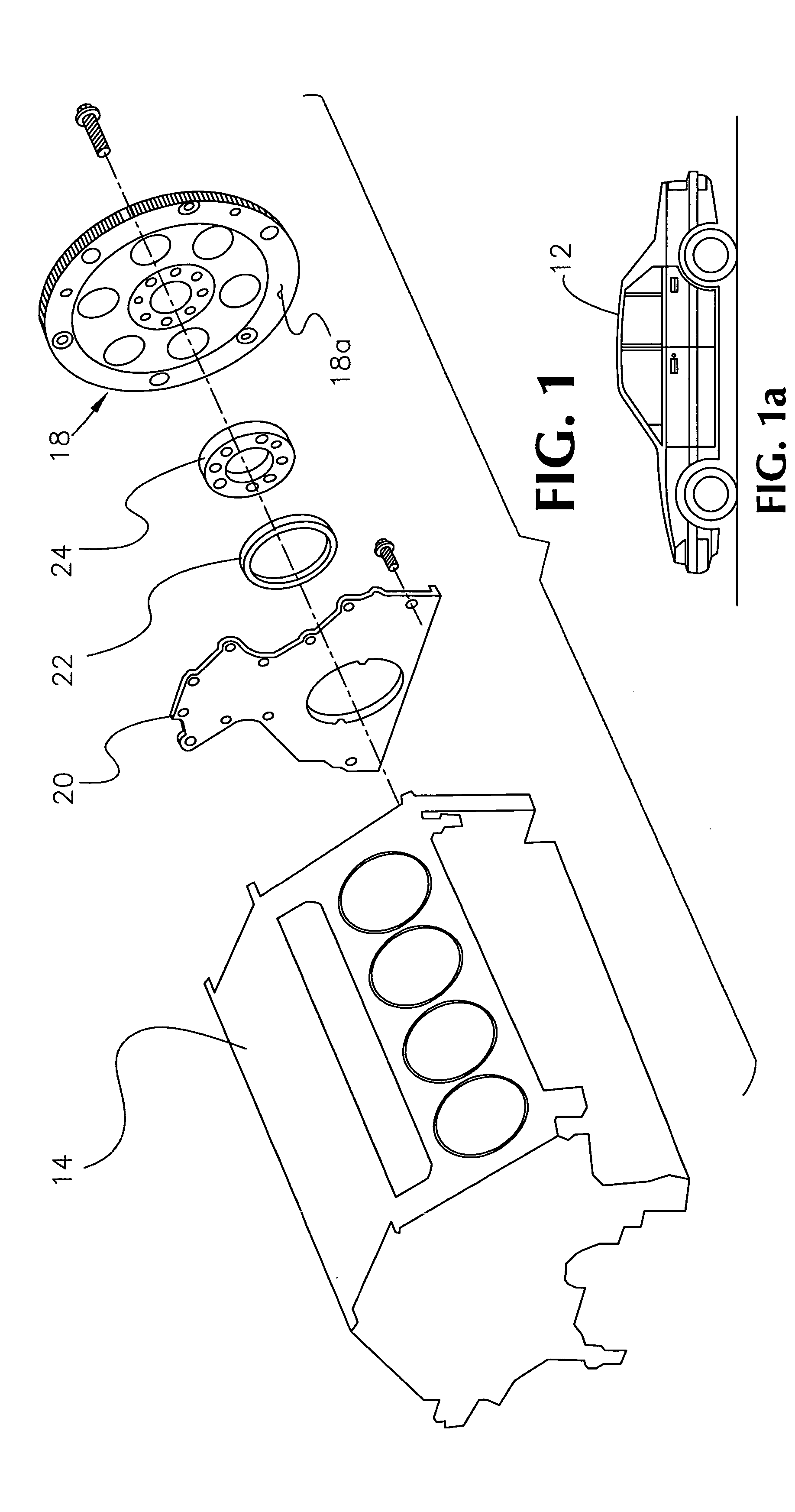

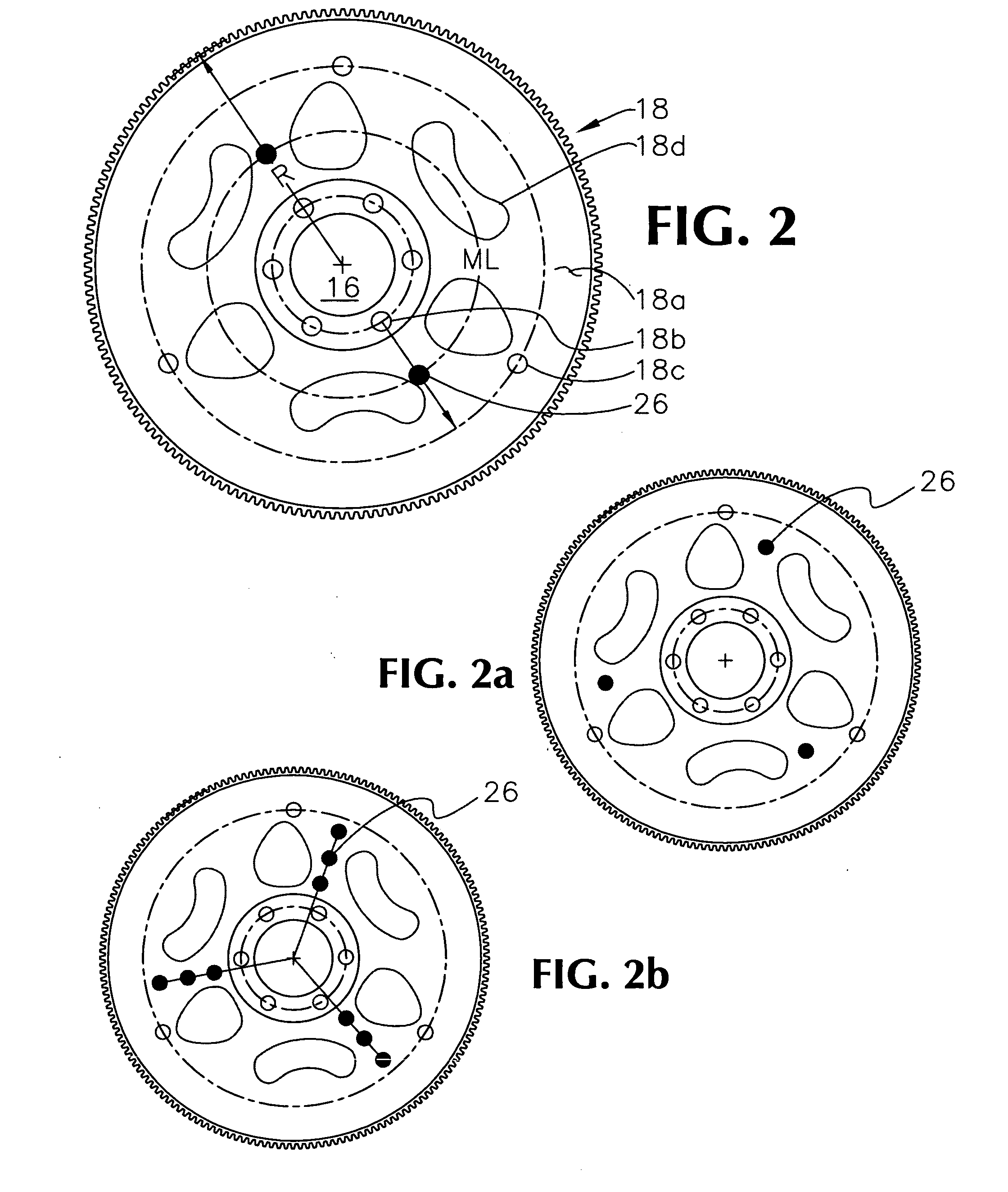

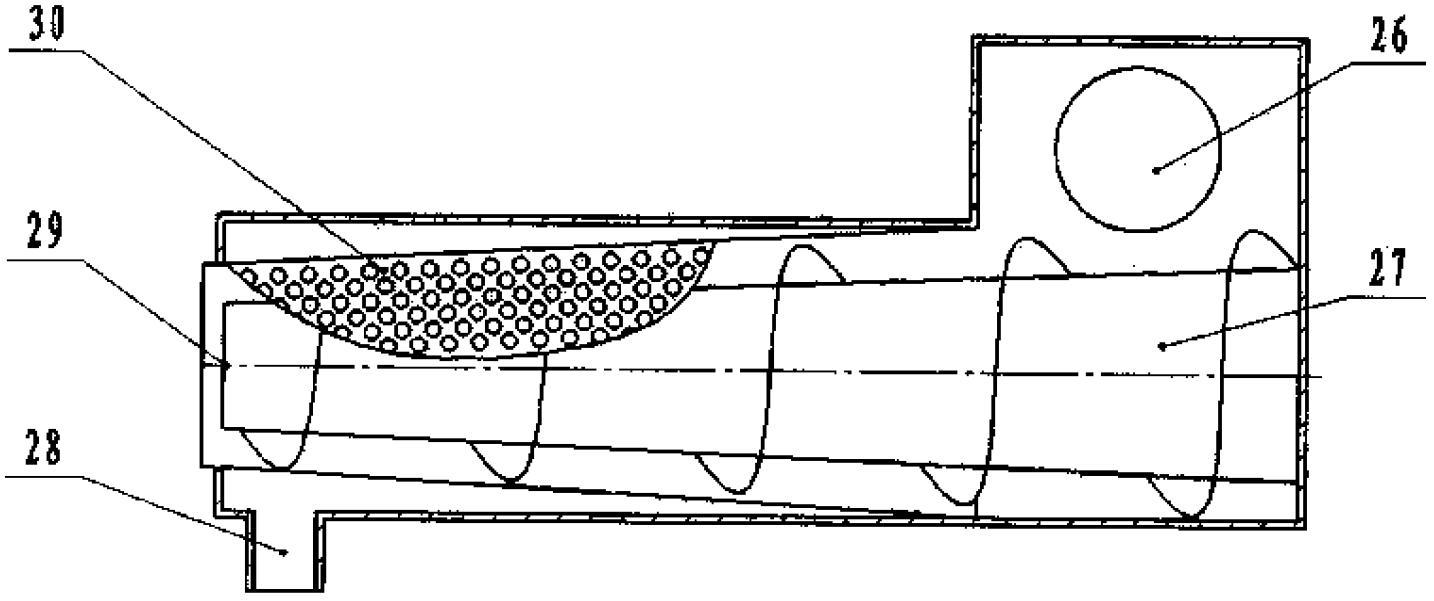

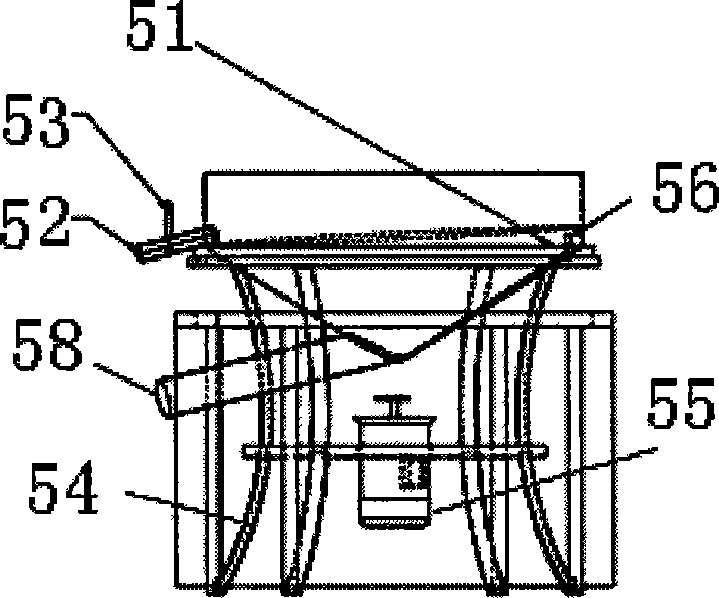

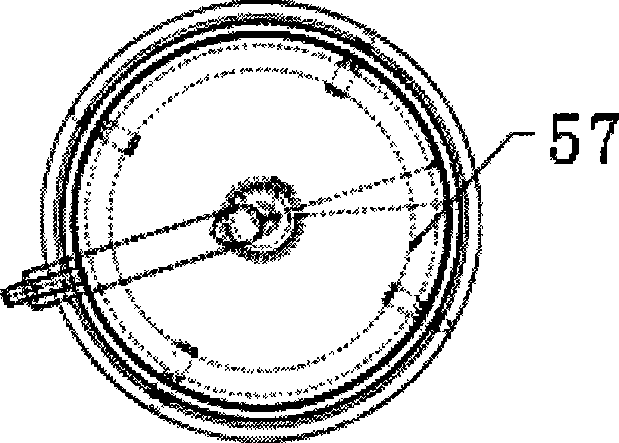

Method and apparatus for engine torque sensing

ActiveUS7389682B2Minimal required modificationLower packagingEngine testingWork measurementEngineering

An engine torque sensory system (10), adapted for use with an engine-driven vehicle (12) having a flexplate (18), including at least one sensor (26) fixedly attached on the surface of the flexplate (18) and operable to detect deformations along the surface of the flexplate (18) caused by the generated engine torque, and further including a receiver (28) communicatively coupled to the sensor (26), spaced from the rotating flexplate (18), and operable to convert sensor readings to correlative engine torque values.

Owner:GM GLOBAL TECH OPERATIONS LLC

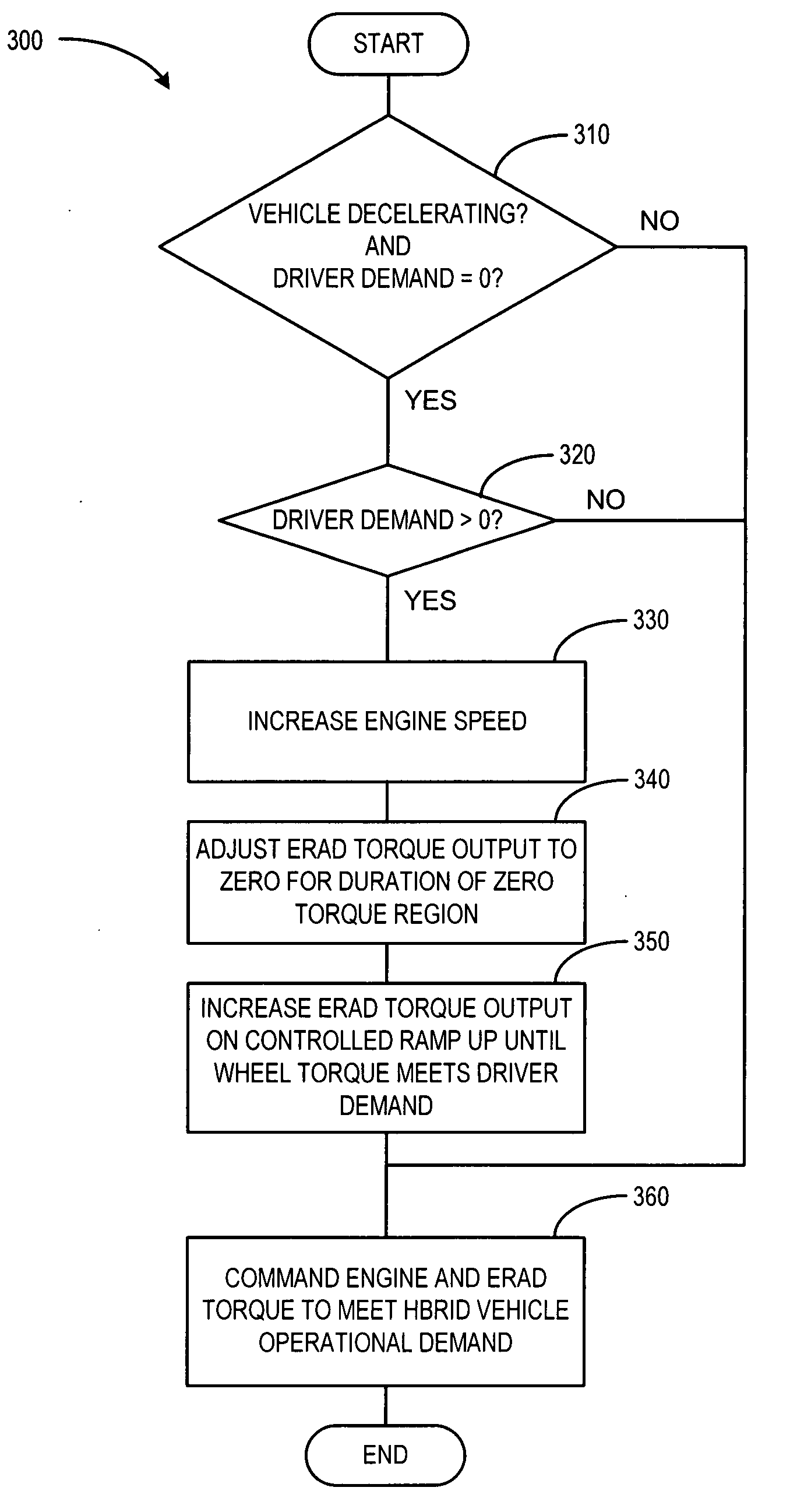

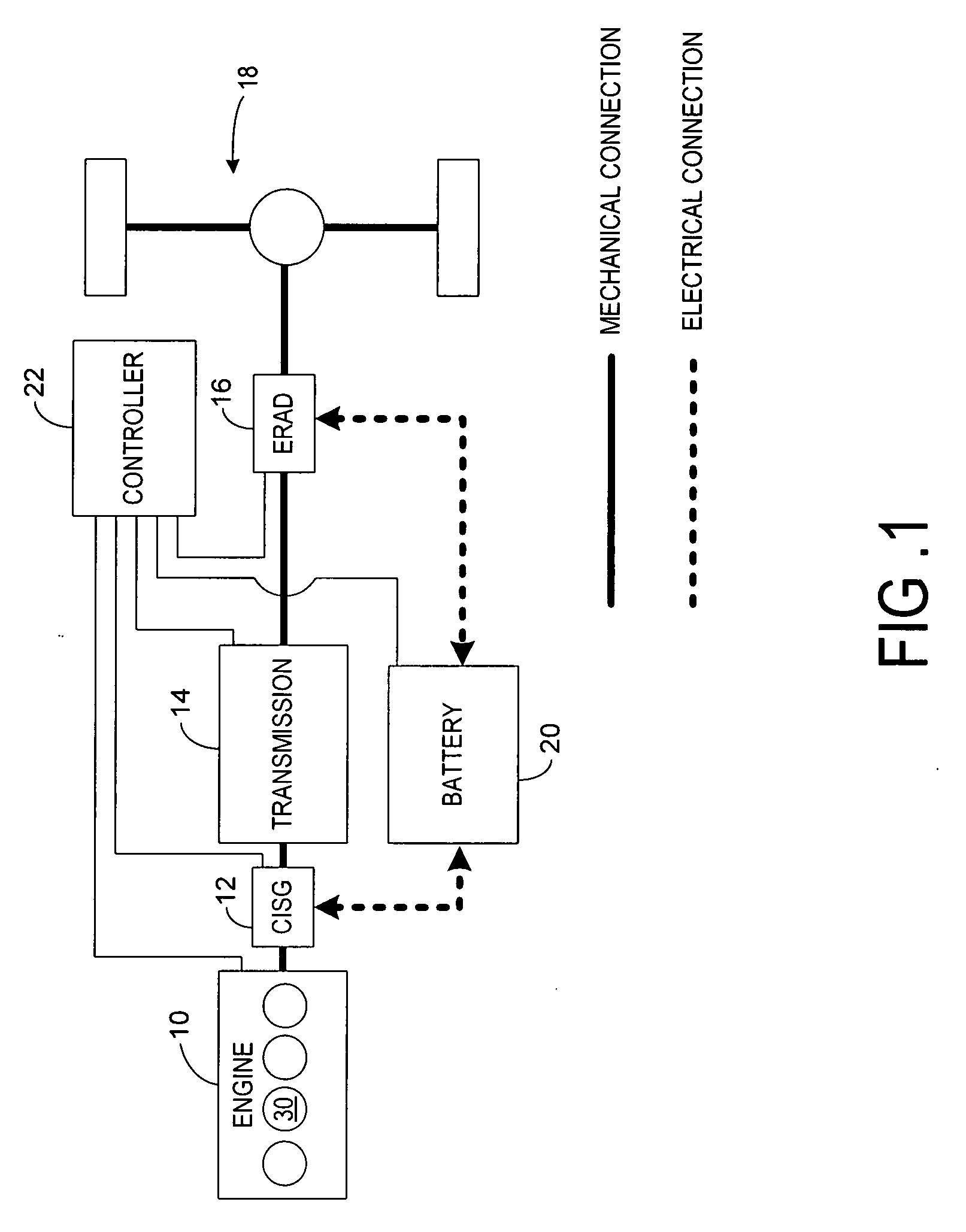

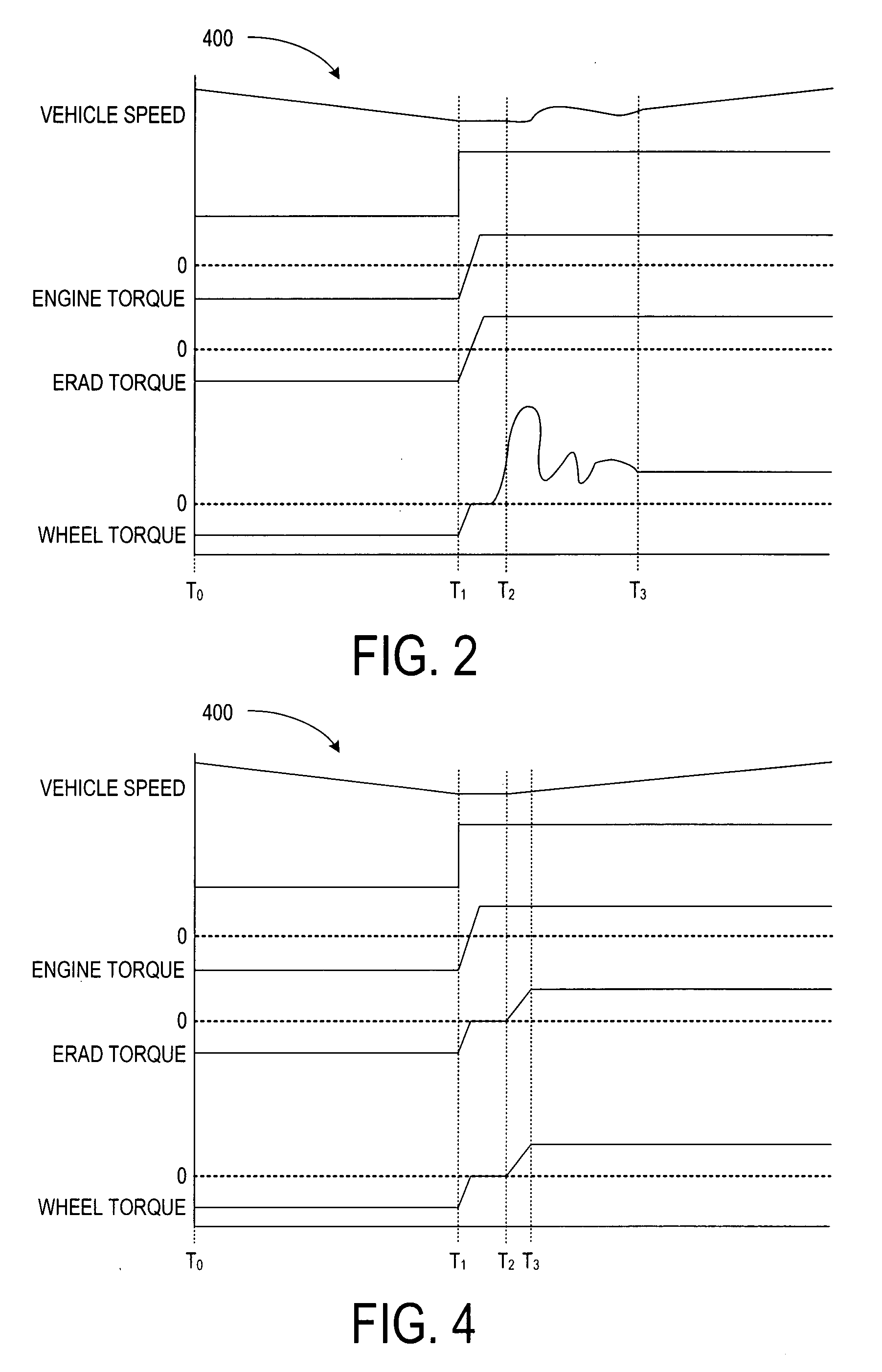

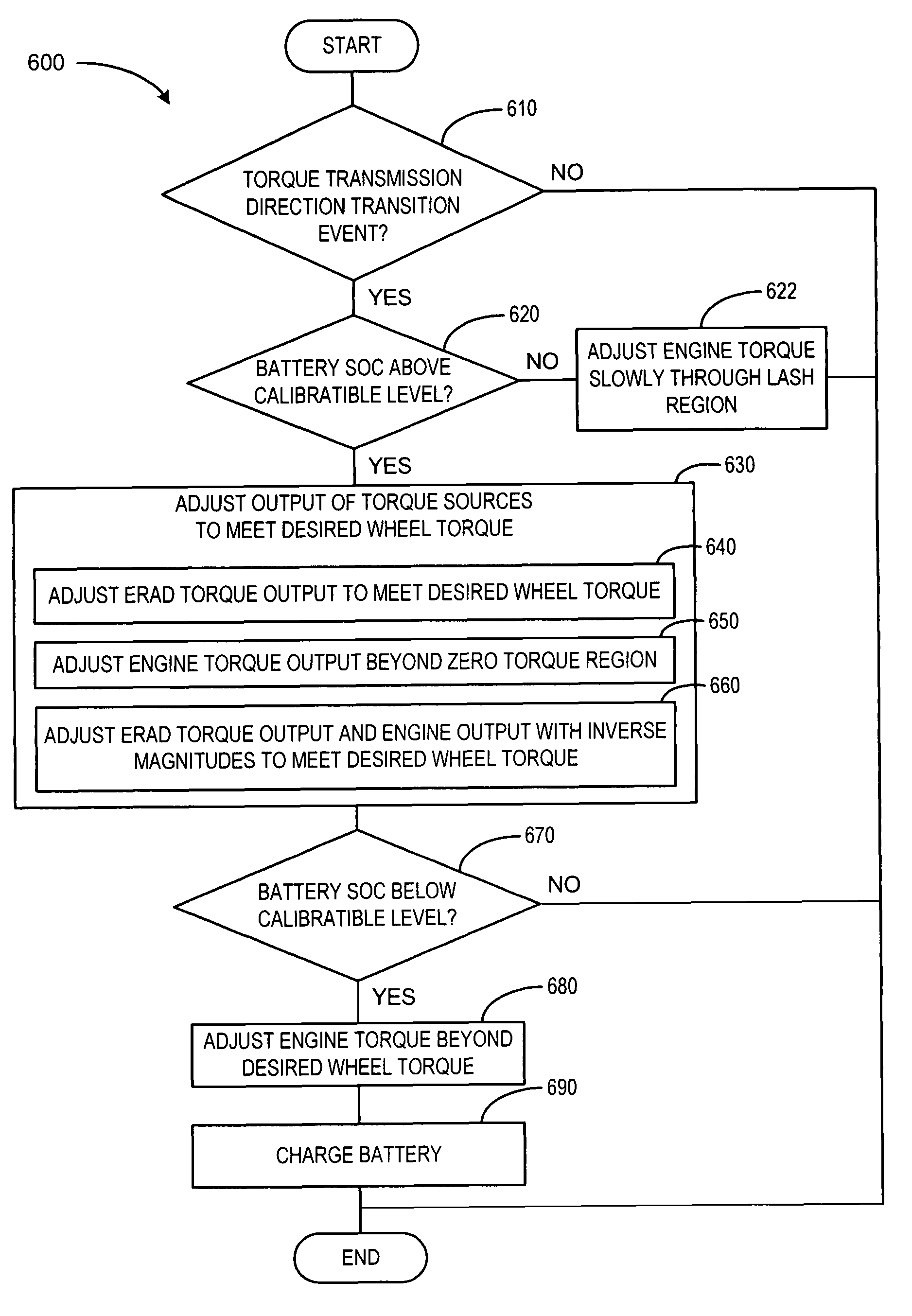

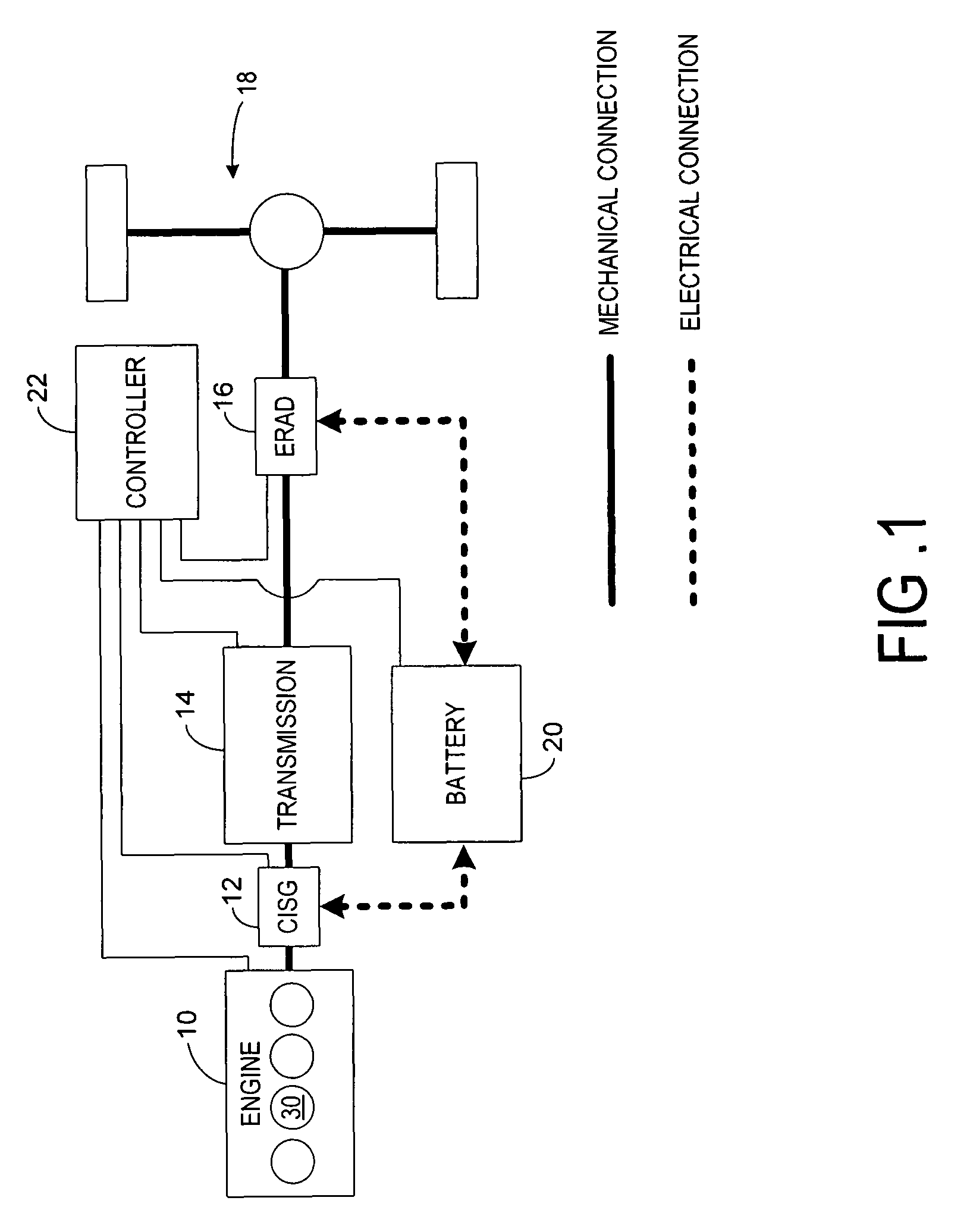

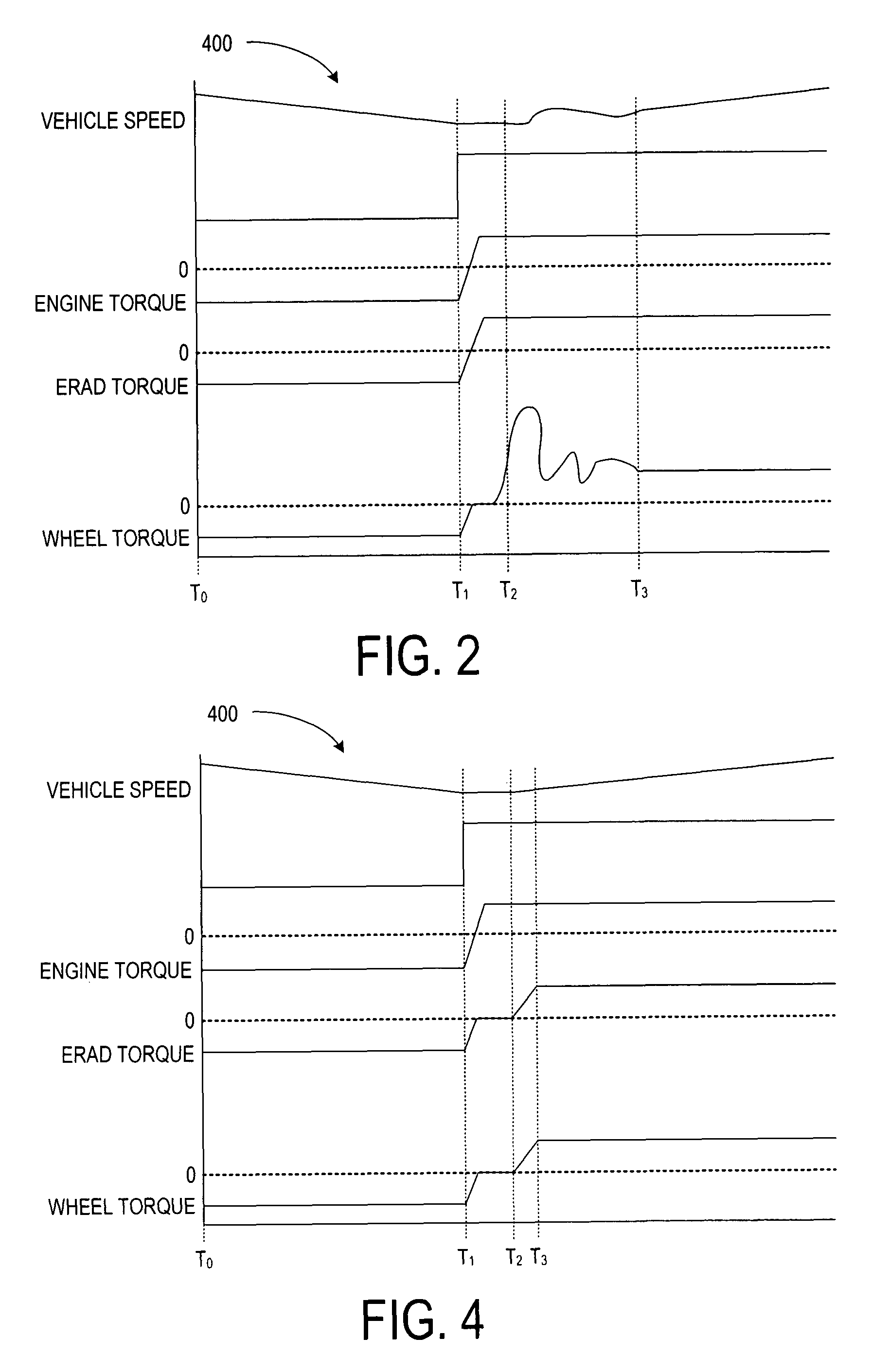

System and method of inhibiting the affects of driveline backlash in a hybrid propulsion system

ActiveUS20080257619A1Fast transient responseReduced energy storageElectric propulsion mountingGas pressure propulsion mountingElectric energyElectric vehicle

A hybrid electric vehicle is provided. The hybrid electric vehicle includes an internal combustion engine, a mechanical torque transmission device for transmitting engine torque to at least one wheel, the mechanical torque transmission device having a lash region, an electric energy conversion device connected downstream of the mechanical torque transmission device, and a control system. The control system, adjusts the electric energy conversion device to meet a desired vehicle response, adjusts the internal combustion engine torque to transition through the lash region, and then adjusts the electric energy conversion device torque and the internal combustion engine torque to meet the desired vehicle response.

Owner:FORD GLOBAL TECH LLC

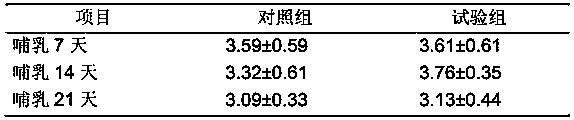

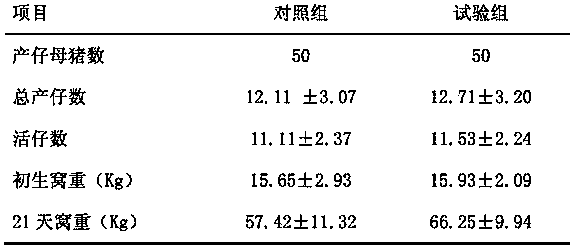

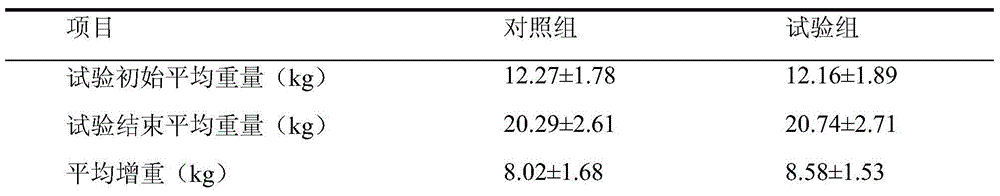

Efficient and environment-friendly compound feed for lactating sow and preparation method thereof

InactiveCN103976194AExtended shelf lifeIncrease in sizeAnimal feeding stuffAccessory food factorsAnimal scienceRoom temperature

The invention discloses an efficient and environment-friendly compound feed for lactating sow and a preparation method thereof. The compound feed is characterized by comprising the following raw materials in parts by weight: 40 to 50 parts of maize, 20 to 30 parts of wheat, 3 to 5 parts of wheat bran, 10 to 15 parts of peeled soybean meal, 1 to 2 parts of fish meal, 3 to 5 parts of biological soybean meal, 1 to 1.2 parts of rock powder, 1.2 to 1.4 parts of calcium hydrophosphate, 0.3 to 0.5 part of table salt, 1.5 to 2.5 parts of soybean oil, 0.4 to 0.45 part of lysine, 0.04 to 0.06 part of methionine, 0.1 to 0.12 part of threonine, 0.01 to 0.02 part of a complex enzyme preparation, 0.06 to 0.1 part of microecologics, 0.03 to 0.06 part of an emulsifier, and 1 to 1.5 parts of a compound premix. The preparation method comprises the following steps: weighing the various raw materials in a predetermined ratio; fine crushing maize, wheat, wheat bran, peeled soybean meal and biological soybean meal; directly adding to a horizontal twin-shaft paddle mixer in a ratio to mix; feeding the mixture to a granulating machine for granulating; processing at a temperature of 85 DEG C until the gelatinization degree is more than 90%; cooling till the temperature is not higher than room temperature by 5 DEG C after granulating; and then weighing, bagging and sealing through an automatic packing machine. The preparation method is mainly used for preparing the compound feed for lactating sow.

Owner:TANGRENSHEN GRP CO LTD

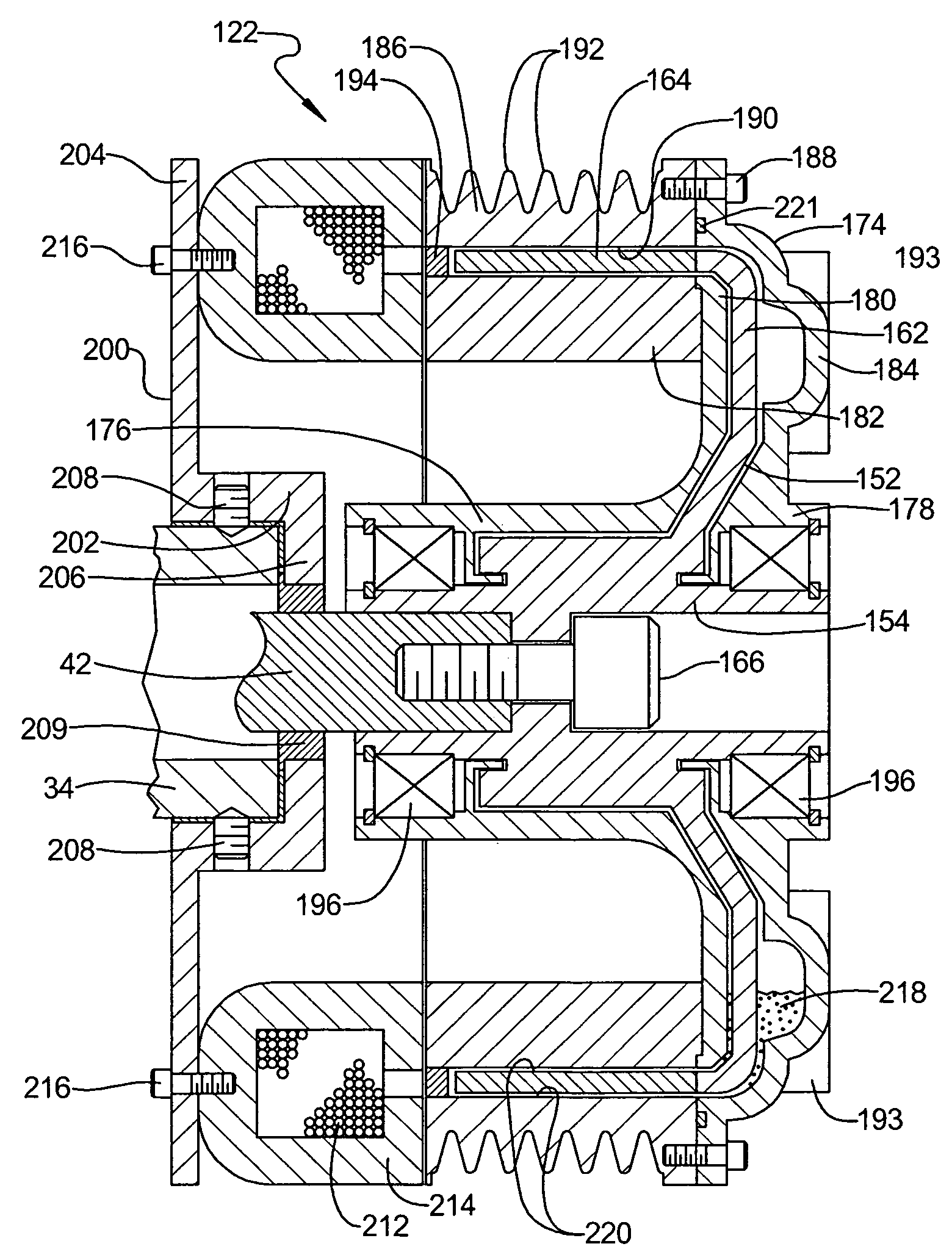

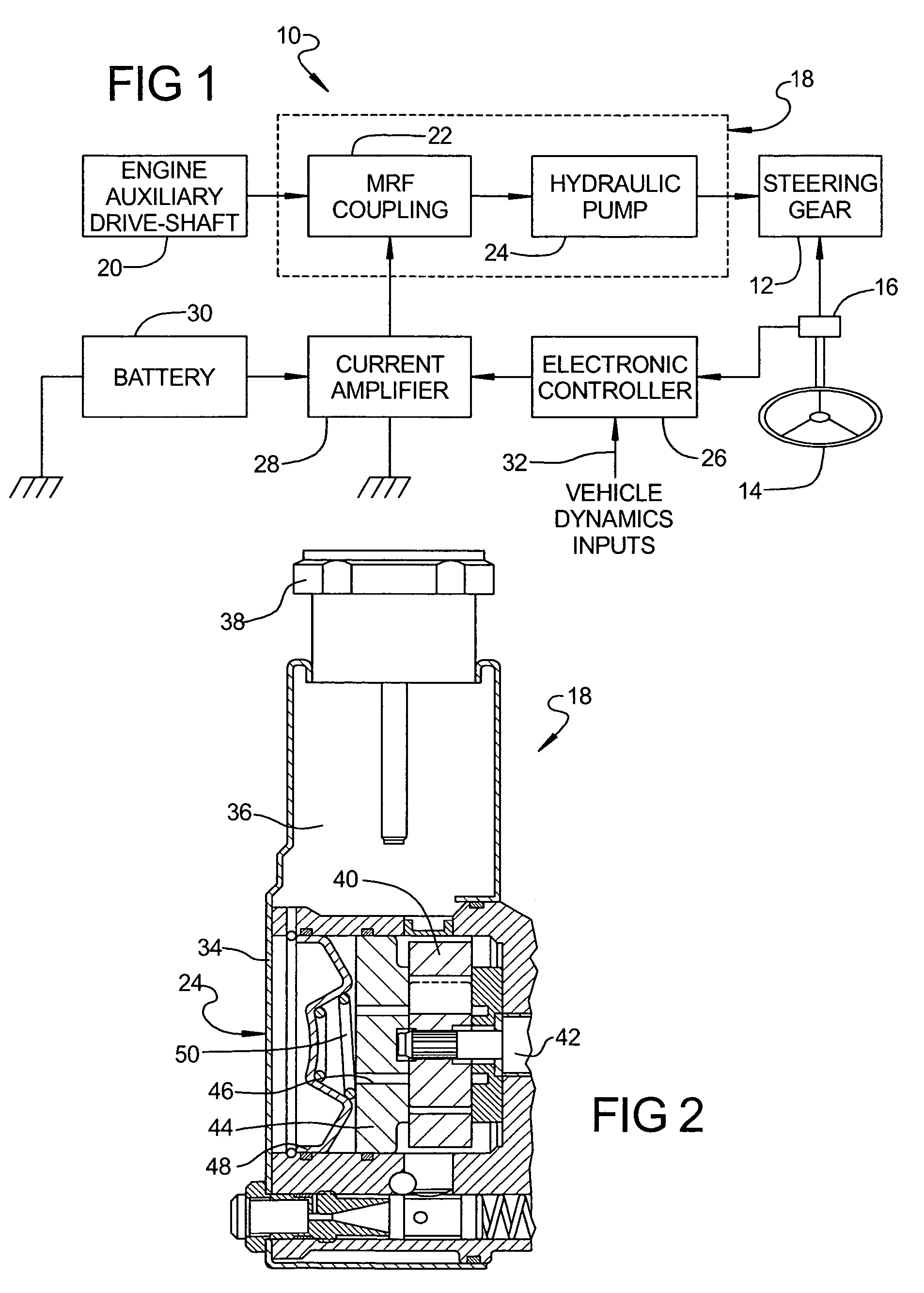

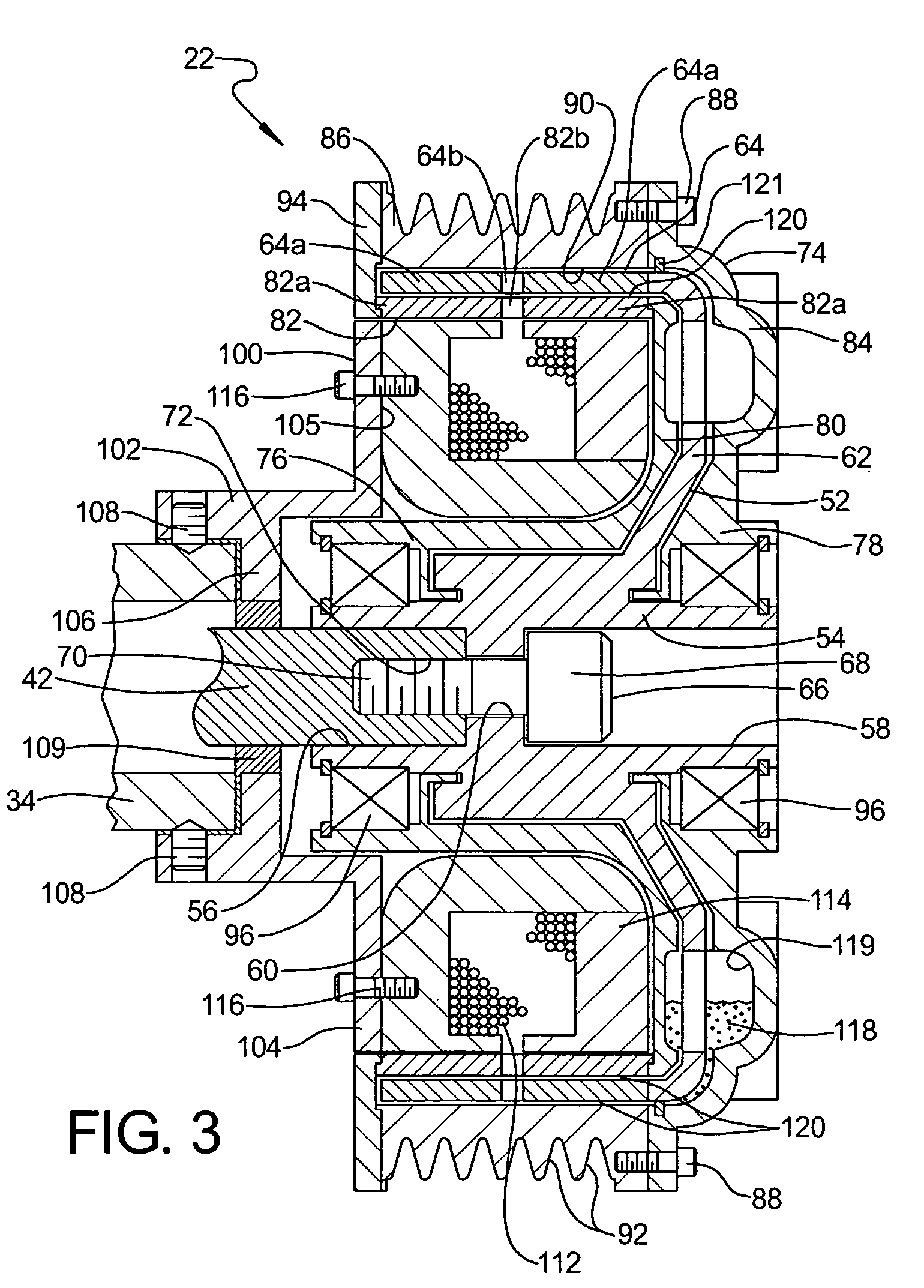

Power steering system

InactiveUS7240485B2Improve fuel efficiencyEliminate lossRotary clutchesFluid steeringAudio power amplifierFluid coupling

A power steering system for a vehicle includes a hydraulic pump connected to a power steering gear of the vehicle and a fluid coupling interconnecting a drive shaft of an engine of the vehicle with the hydraulic pump. The power steering system also includes an electronic controller operable to provide a variable control signal based on received input and an amplifier to receive the variable control signal and energize the fluid coupling in response thereto to vary torque transmitted via the fluid coupling.

Owner:GM GLOBAL TECH OPERATIONS LLC

Polygonal folded type beverage straw

The invention relates to a polygonal folded type beverage straw, which comprises a hollow straw, wherein the hollow straw comprises at least four edges and is made of paper or degradable plastics, and a film layer is arranged on the surface of the inner wall of the papery hollow straw. In manufacturing process, a paper sheet is made firstly; the surface of the paper sheet is compounded or poured with the film, and generally, the inner wall is compounded with the film in actual manufacturing process, but both of the two walls also can be compounded with films; the paper sheet having the film is folded and then spliced into a polygonal hollow straw; and the polygonal hollow straw also can be formed by directly blowing the degradable plastics or the polygonal hollow straw is formed by splicing plastic paper which is made of the degradable plastics. The hollow straw has at least four edges (namely being square or polygonal). After the polygonal hollow straw is flatted and folded, the volume is greatly reduced, thereby saving the package and transportation costs. The polygonal hollow straw can be unfolded when the polygonal hollow straw is used. The paper or degradable plastic straw can be automatically degraded after being used, the environment is free from being polluted, and the economic and social benefits are obvious.

Owner:方毅

Method and apparatus for engine torque sensing

An engine torque sensory system (10), adapted for use with an engine-driven vehicle (12) having a flexplate (18), including at least one sensor (26) fixedly attached on the surface of the flexplate (18) and operable to detect deformations along the surface of the flexplate (18) caused by the generated engine torque, and further including a receiver (28) communicatively coupled to the sensor (26), spaced from the rotating flexplate (18), and operable to convert sensor readings to correlative engine torque values.

Owner:GM GLOBAL TECH OPERATIONS LLC

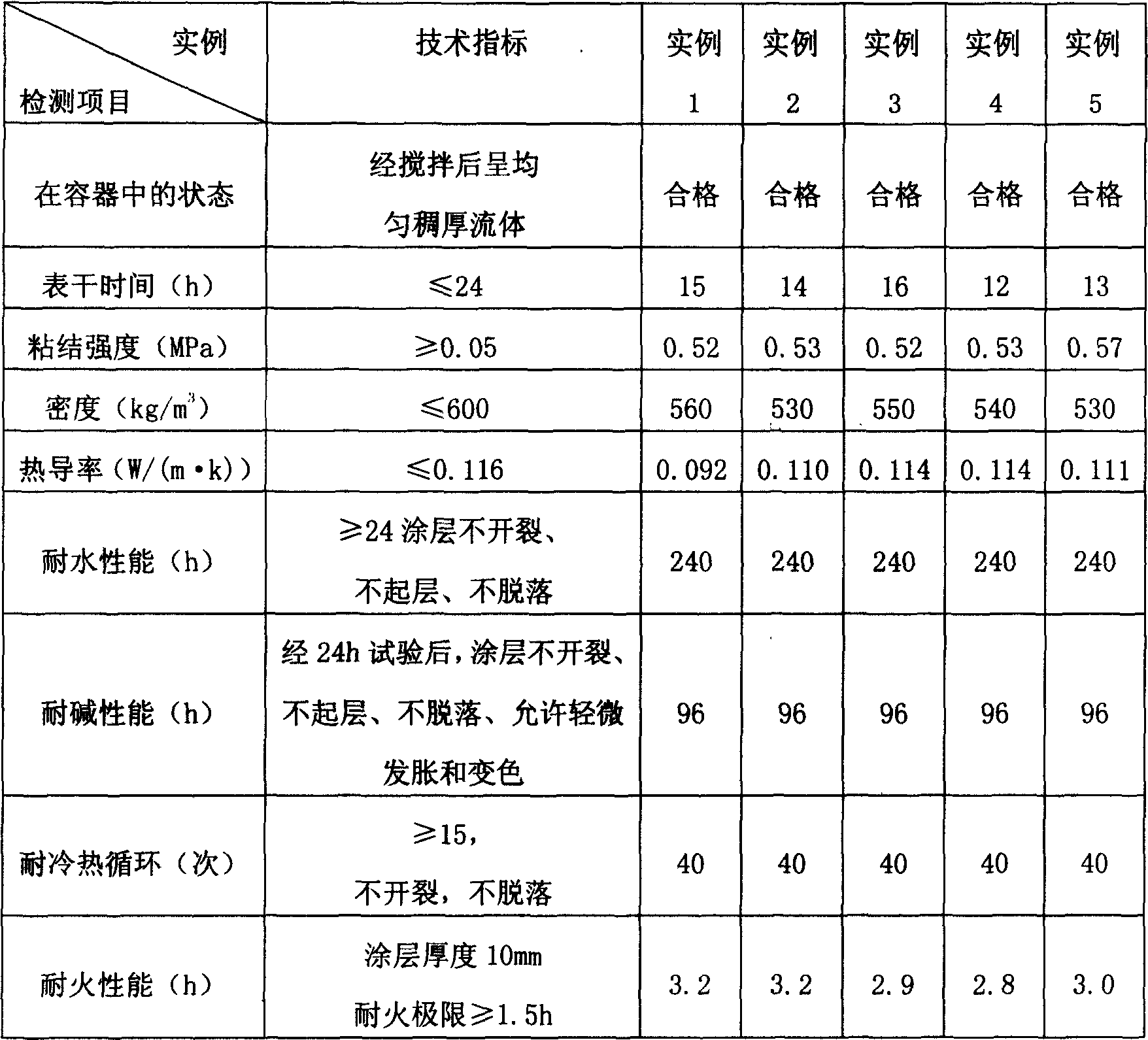

Single system and composite fire retardant coating for tunnel

InactiveCN1687254AAvoid self-strength lossImprove performanceFireproof paintsCement coatingsAdhesiveUltimate tensile strength

The present invention relates to a production method of single system compounded tunnel fire-resisting paint. Its composition includes (by weight portion) 20.0-50.0 portions of adhesive formed from redispersible latex powder and aluminous cement, 55.0-85.0 portions of inorganic heat-insulating filler and 0.1-5.0 portions of adjuvant. Said fire-resisting paint not only has good fire-resisting property, but also has good water-proof and sound-insulating properties.

Owner:SICHUAN UNIV

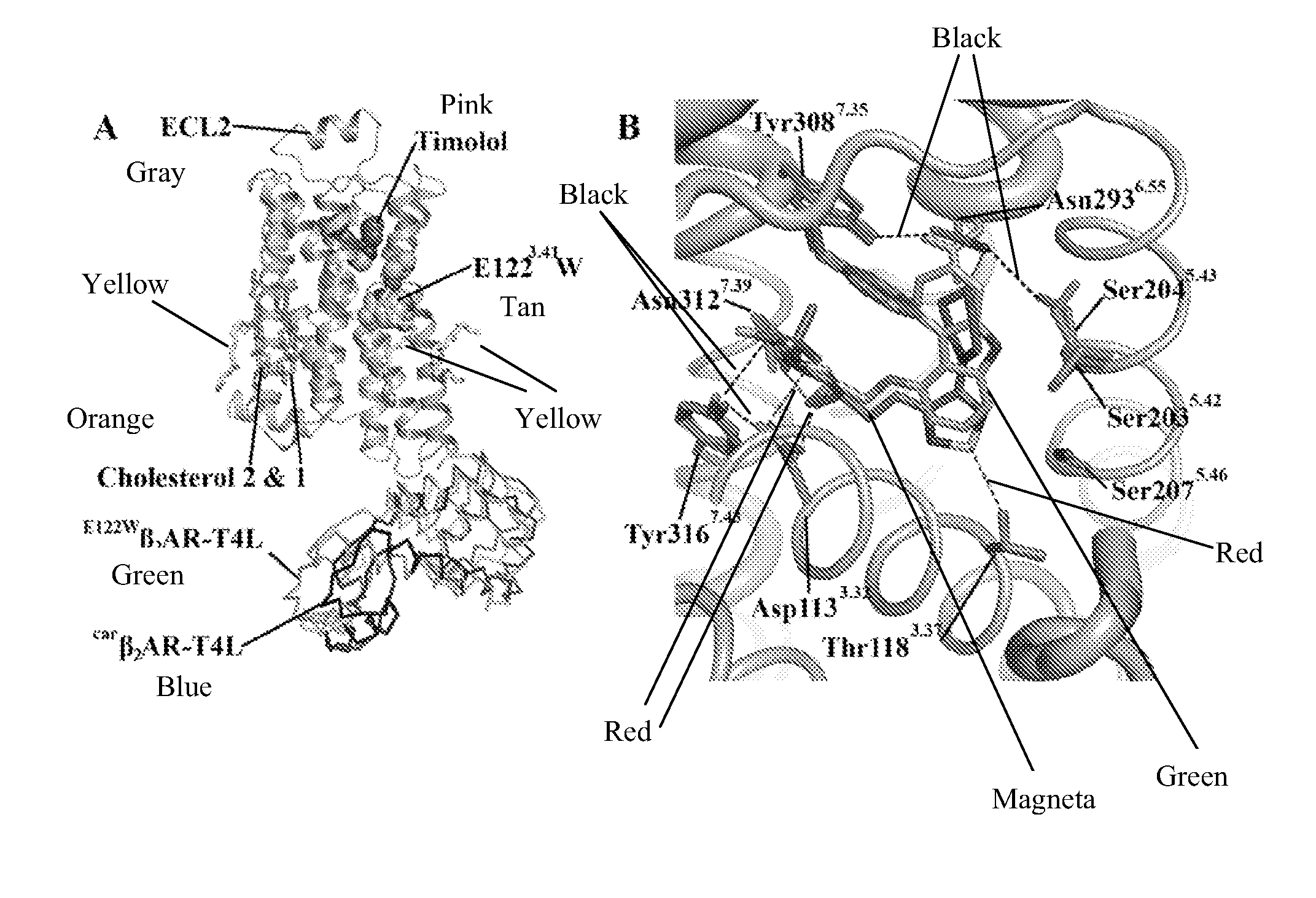

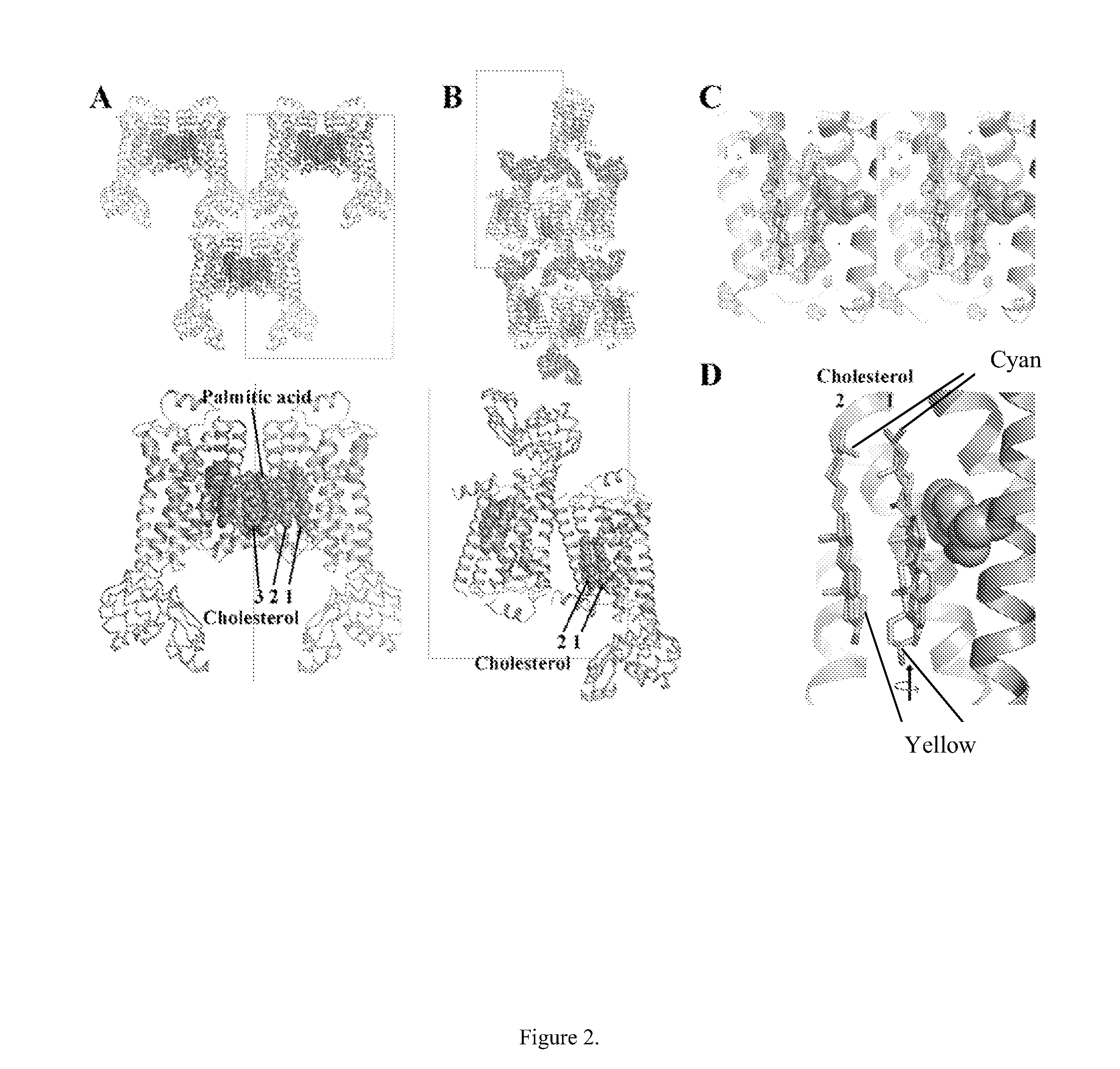

Cholesterol consensus motif of membrane proteins

InactiveUS20110130543A1Improve thermal stabilityIncrease constraintsCell receptors/surface-antigens/surface-determinantsLibrary screeningAdrenergicG protein-coupled receptor

The invention provides the structure of a human β2-adrenergic receptor, a cholesterol consensus motif, and methods of identifying modulators of G-protein coupled receptors (GPCRs). Methods of using the modulators of the receptor, GPCRs, and the cholesterol consensus motif are also provided.

Owner:THE SCRIPPS RES INST

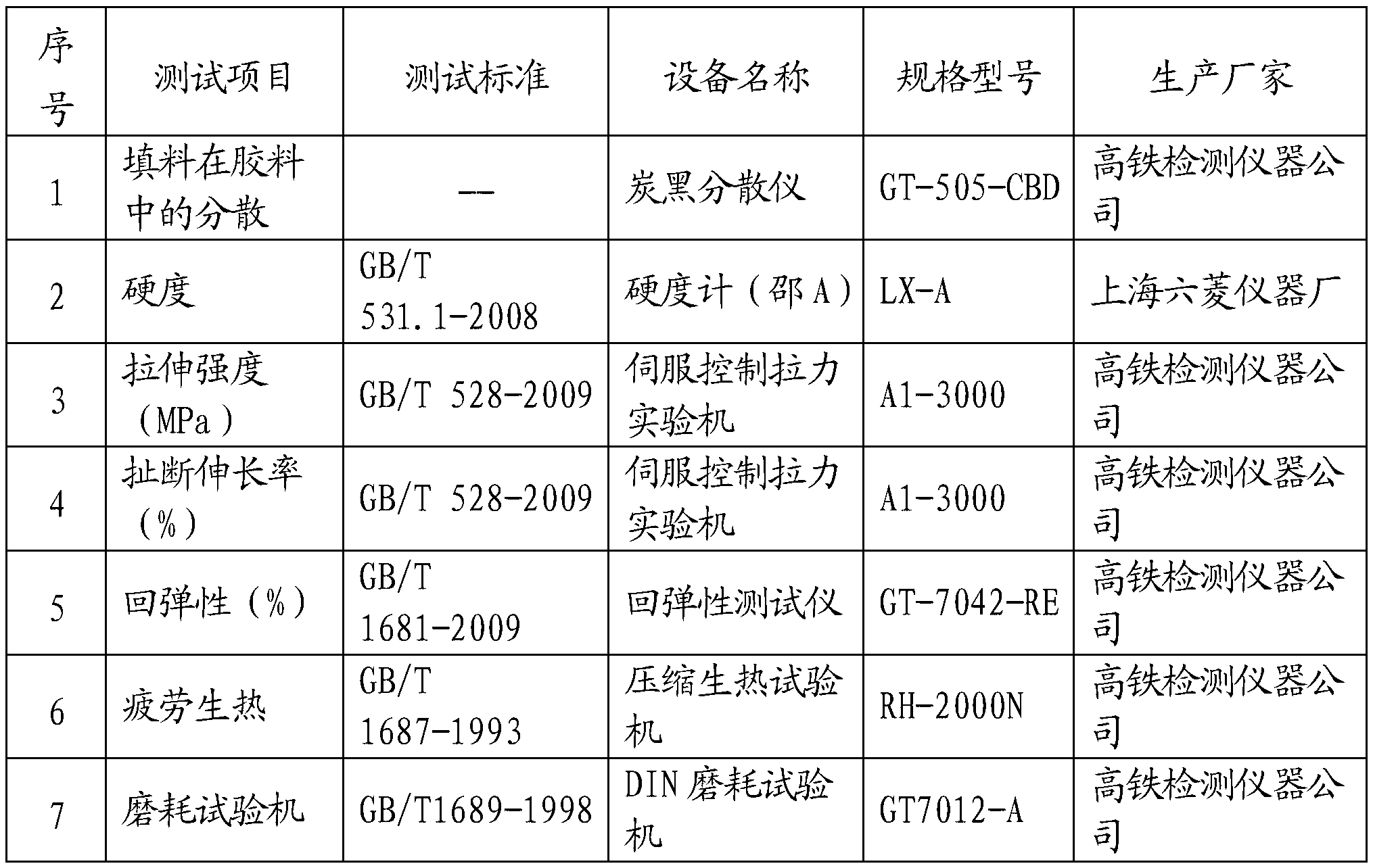

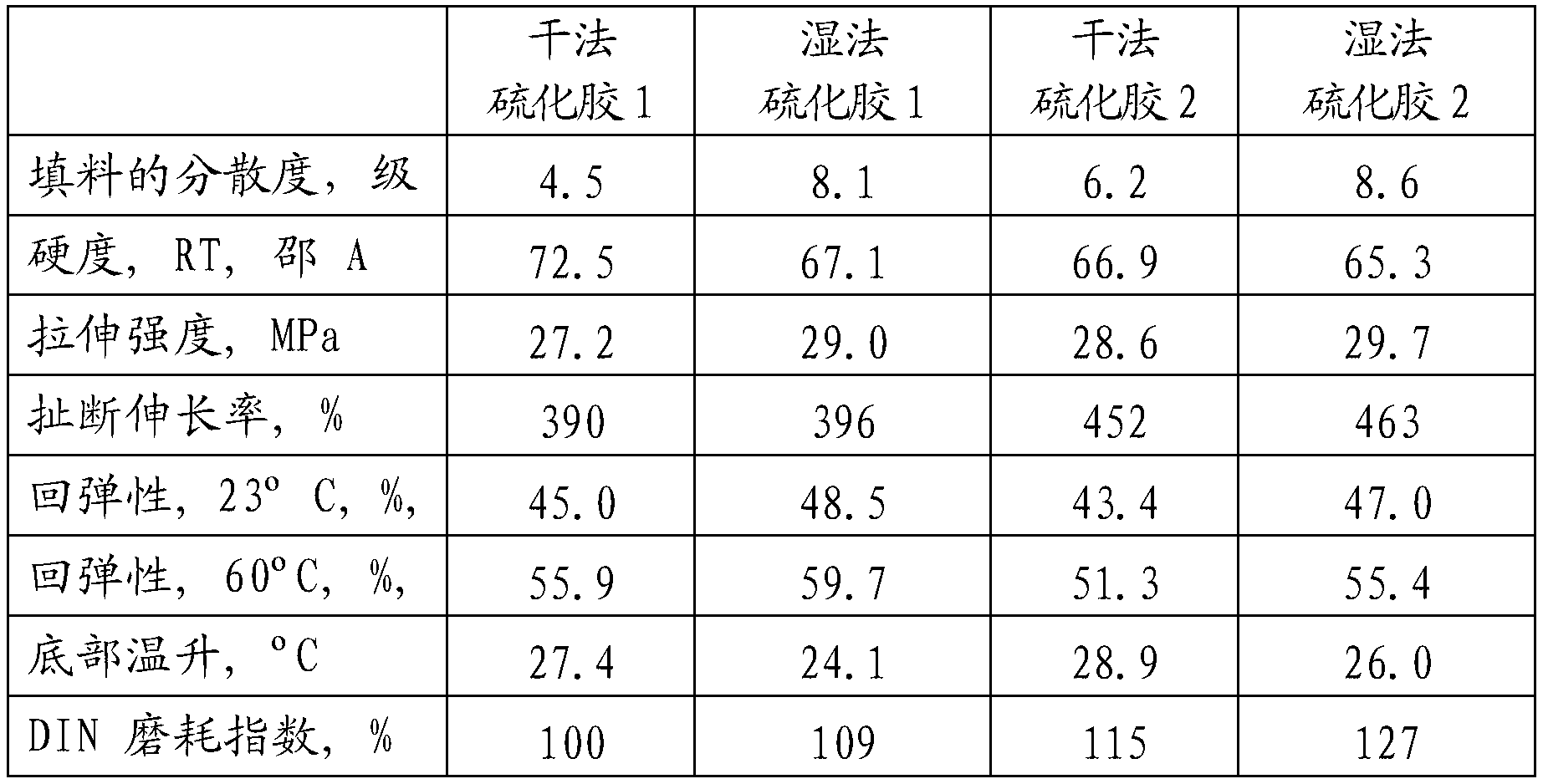

Filler, synthetic rubber and wet rubber compound integrated production method

ActiveCN103224659ABreakthrough applicabilityBreakthrough performancePigmenting treatmentSilicon oxidesSynthetic rubberIntegrated production

The invention discloses a filler, synthetic rubber and wet rubber compound integrated production method. A filler is selected from carbon black, white carbon black or a combination of the carbon black and the white carbon black. Compared with traditional and respective independent technologies, the method disclosed in the invention has the advantages of omitting of the post-treatment technologies of the filler and a synthetic rubber, realization of the cycle of sodium carbonate, and full utilization of carbon dioxide and heat generated in a traditional carbon black production technology. So the method can reduce production equipment and simultaneously realize the low carbon and low pollution discharge through the integrated optimization of the process flow in order to reach the recycle purpose.

Owner:EVE RUBBER RES INST

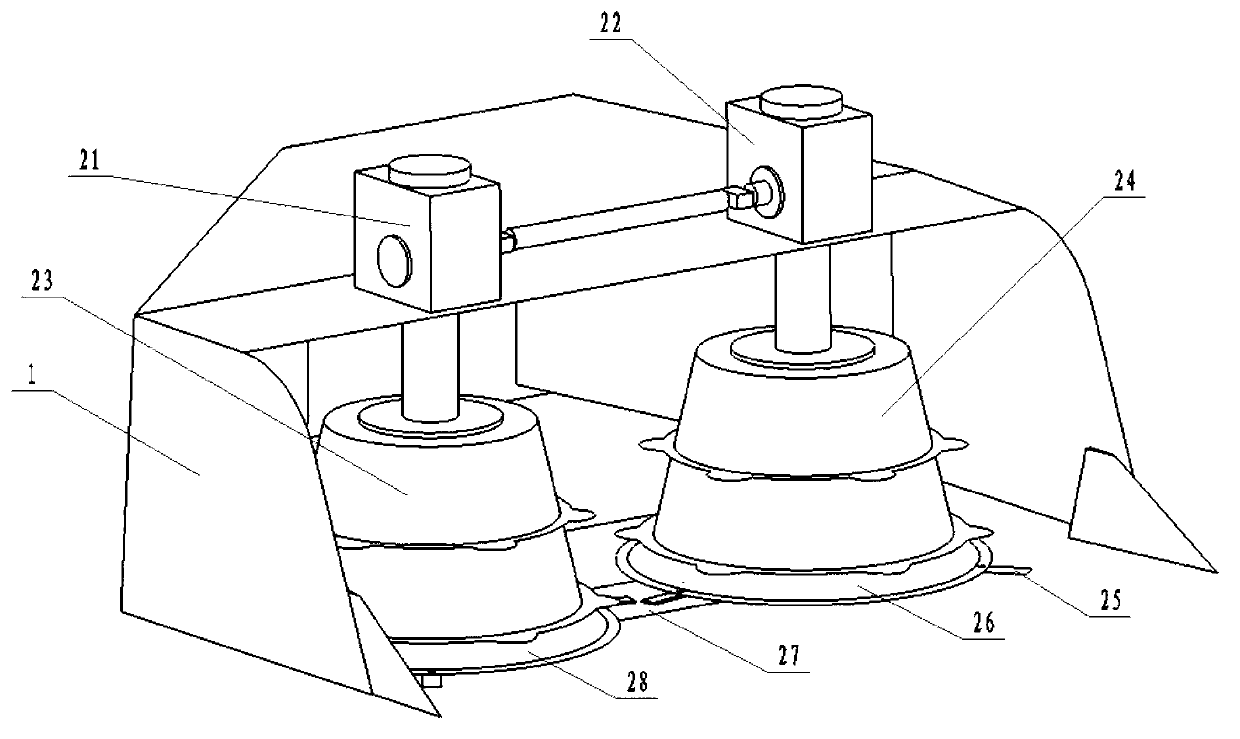

Alfalfa dehydration silage harvesting technology and harvester

InactiveCN102687628ALow input costLower packagingMowersHarvested fruit hanging devicesHerdEngineering

The invention discloses an alfalfa dehydration silage harvesting technology and a harvester, and belongs to stockbreeding machines. Through the harvesting technology and the harvester, the field airing is not required, weather influence is avoided, the harvesting is performed at the best cradling period of alfalfa, multiple operation links of harvesting, dehydrating, cutting up, compacting and bagging and the like are finished at a time, the operation processes are reduced, the harvesting time is shortened, the investment cost on the machine is lowered, and the labor force is saved; and meanwhile, prepared silage alfalfa is small in package and is convenient to carry, and the commercialized production is easy to realize. Squeezed juice can directly flow into the field as liquid fertilizer or can be collected to feed flocks and herds, poultry and the like.

Owner:CHINA AGRI UNIV

Metallic bearing water-based detergent and rinsing agent used together with the same, and method for producing the same

InactiveCN101195790AAvoid corrosionImprove rust resistanceOrganic detergent compounding agentsNon-ionic surface-active compoundsWater basedPhosphoric Acid Esters

The invention relates to metal bearing water-based cleaning agent, rinsing agent matched with the water-based cleaning agent, and the preparation method thereof. Petroleum sodium sulfonate, triethanol amine oleate, fatty alcohol-polyoxyethylene ether, emulgator, and cocoanut oil diethanolamine phosphoric acid ester are mixed with tiethanolamine and ethanolamine according to the weight percentage, are stirred uniformly at room temperature, then are mixed with other raw materials and water, then antibubbling agent AF9020 is added, and therefore the brown yellow and transparent concentrated cleaning agent is formed; nitrous acid dicyclohexylamine, oleic acid triethanolamine and petroleum sodium sulfonate are respectively dissolved into the mixed solvent of tiethanolamine and mono ethanolamine, then benzotriazole is dissolved into water to mix the two solvent, to form the brown yellow and transparent concentrated rinsing agent; the cleaning agent and the rinsing agent are mixed into 5 percent treatment fluid and 1 percent of treatment fluid, then the treatment fluid is cleaned for 30 seconds to 1 minute under ultrasonic wave, rinsed for 30 seconds, and then hot air seasoning, drying and 48 h rust preventing are performed. The invention can replace gasoline cleaning agent, kerosene cleaning agent, and universal water-based cleaning agent, the used raw material is easy to be acquired, the production cost is low, and the invention without parkerizing process can effectively prevent the environmental pollution.

Owner:白马轴承技术(洛阳)有限公司

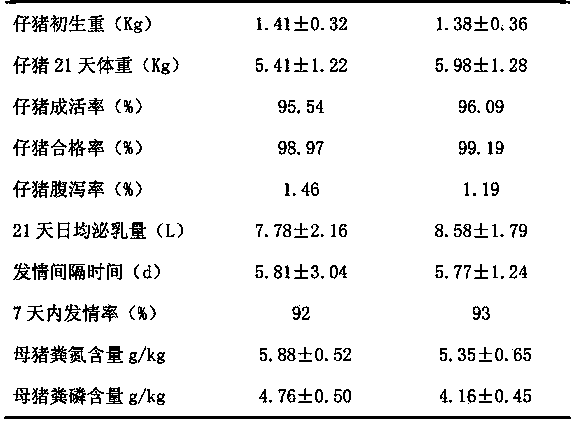

System and method of inhibiting the effects of driveline backlash in a hybrid propulsion system

ActiveUS7971667B2Lower packagingDriveline backlash and clunk may be reducedElectric propulsion mountingPlural diverse prime-mover propulsion mountingHybrid propulsionElectric vehicle

In a hybrid electric vehicle, a motor may be downstream of an engine and transmission. This configuration can be exploited by using the motor to buffer and control torque changes between the engine and the wheels, thereby reducing driveline backlash and clunk.

Owner:FORD GLOBAL TECH LLC

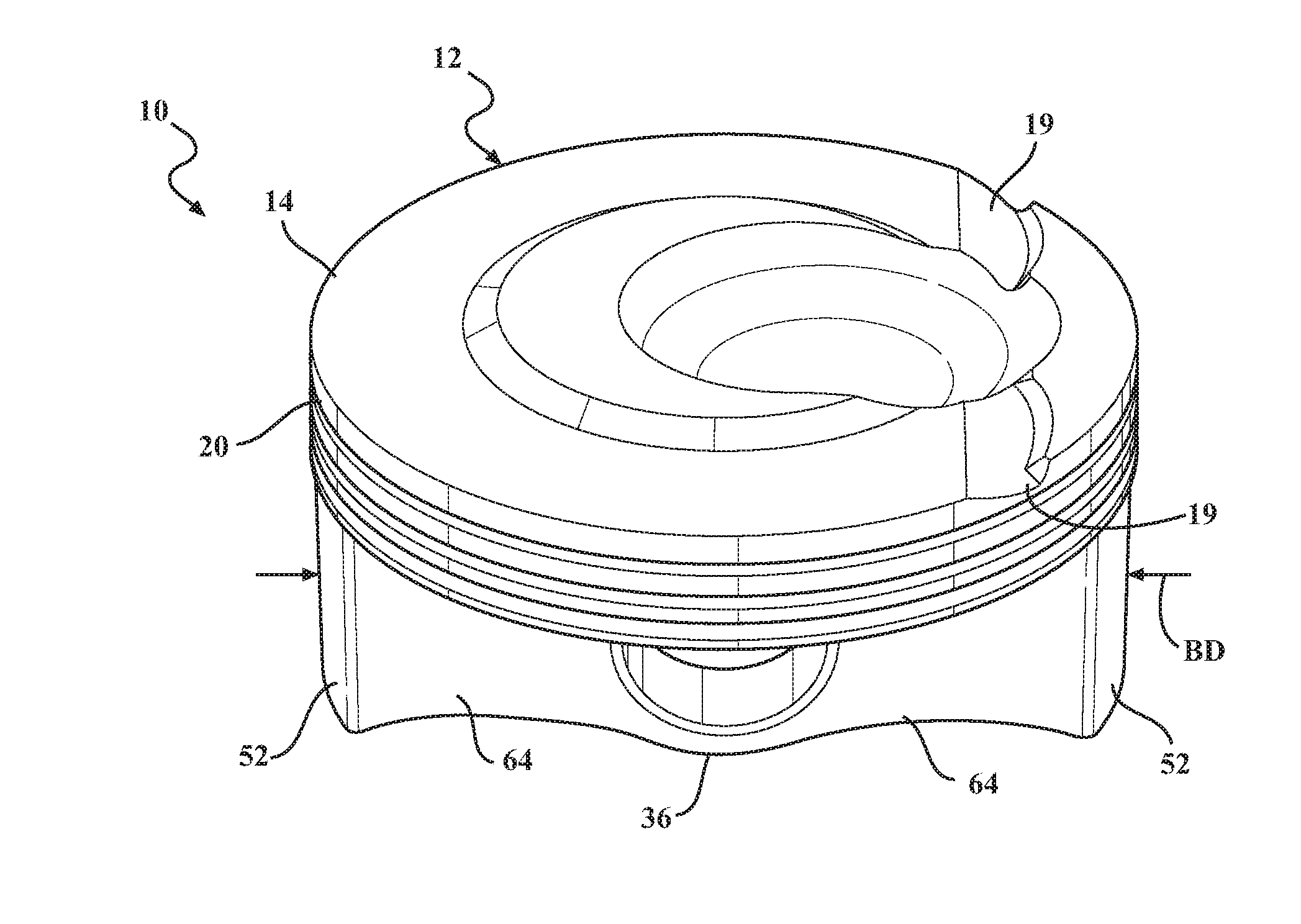

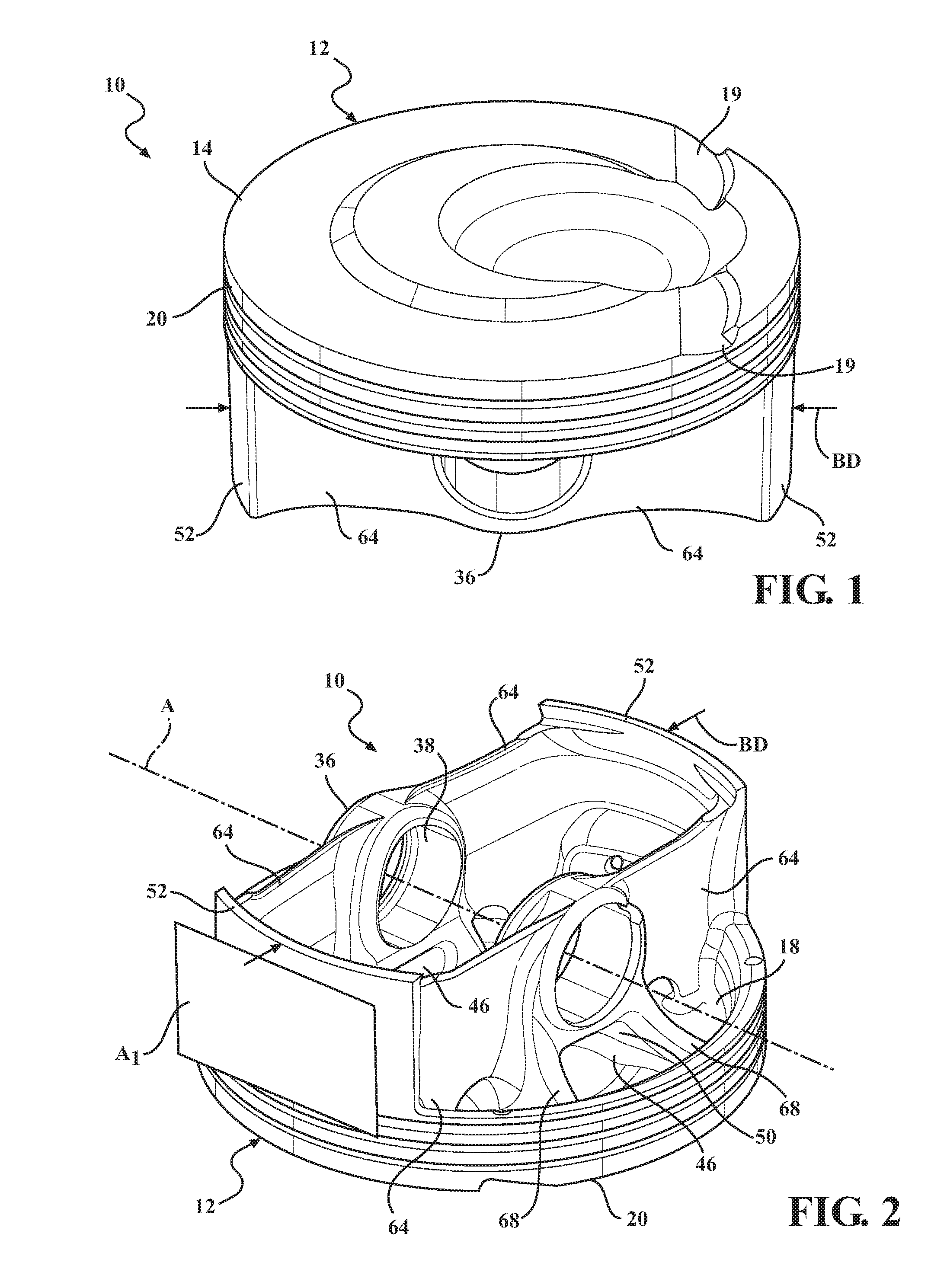

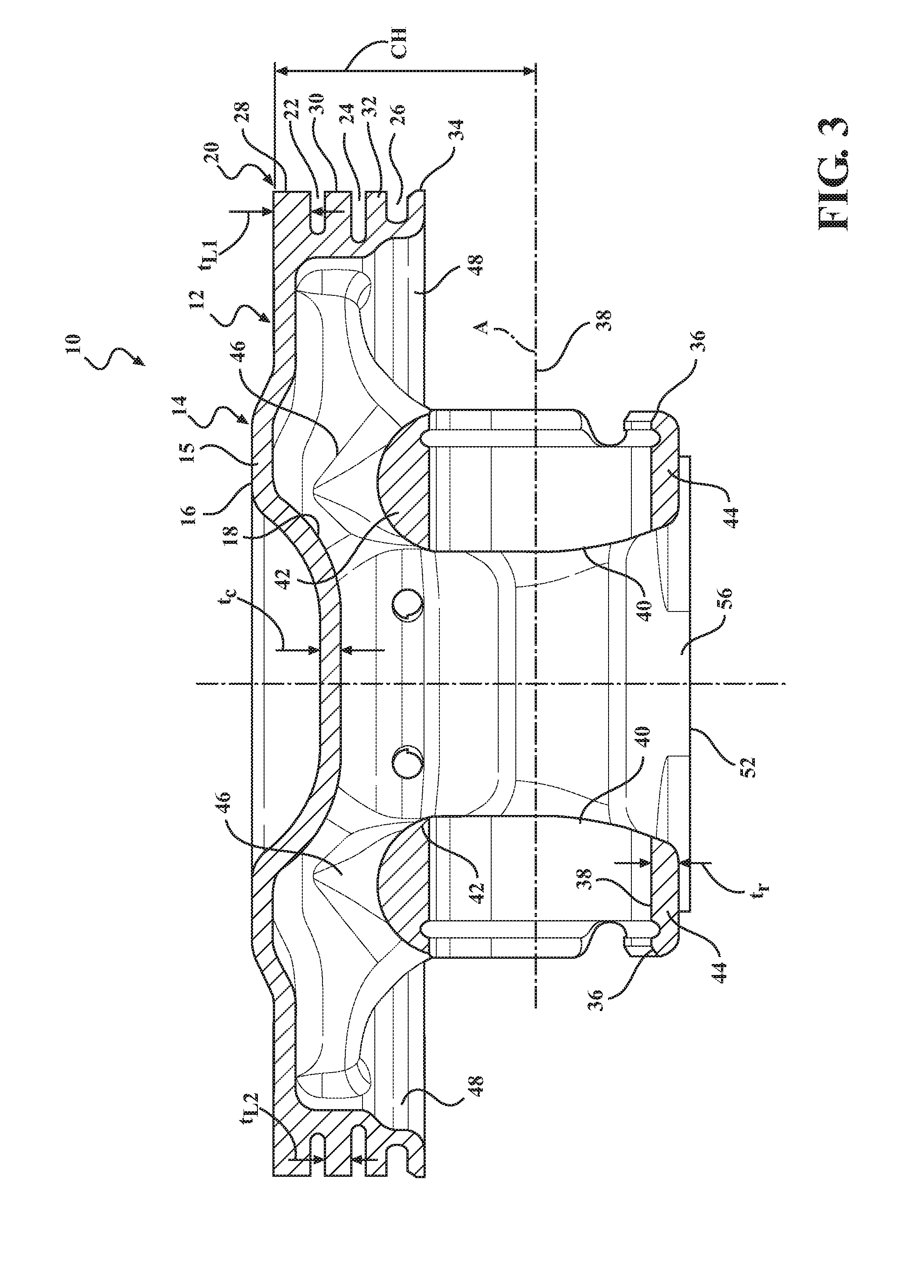

Piston

ActiveUS20160123274A1Small compression heightReduce massLiquid coolingAir coolingPistonProjected area

A ferrous piston for gasoline powered engines having dimensions which achieve reduced mass and improved performance is provided. The piston crown has a thickness of less than 4 mm and includes valve pockets with an axial clearance between the valve pockets and an uppermost ring groove of less than 1.5 mm. The pin bosses have an axial thickness of less than 3.7% of a bore diameter, which is the largest outer diameter of the piston, measured between a pin bore and the crown at 1 mm from an inner face forming the pin bore. Each pin boss has a radial thickness of less than 3% of the bore diameter measured between the pin bore and a lower end of the pin boss. An undercrown surface presents a projected area of less than 45% of a total piston bore area, wherein the total piston bore area is πBD2 / 4, BD being the bore diameter.

Owner:TENNECO

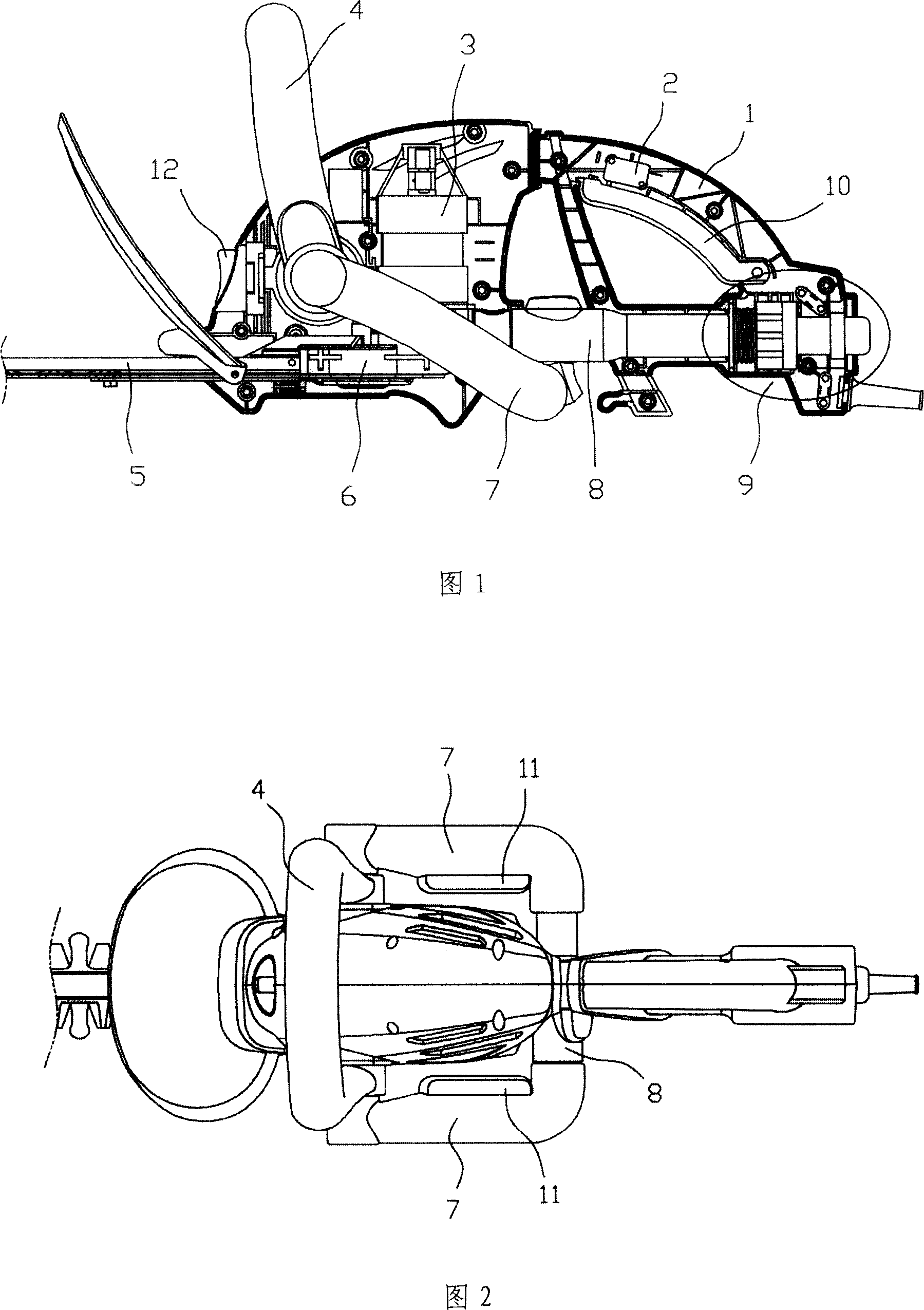

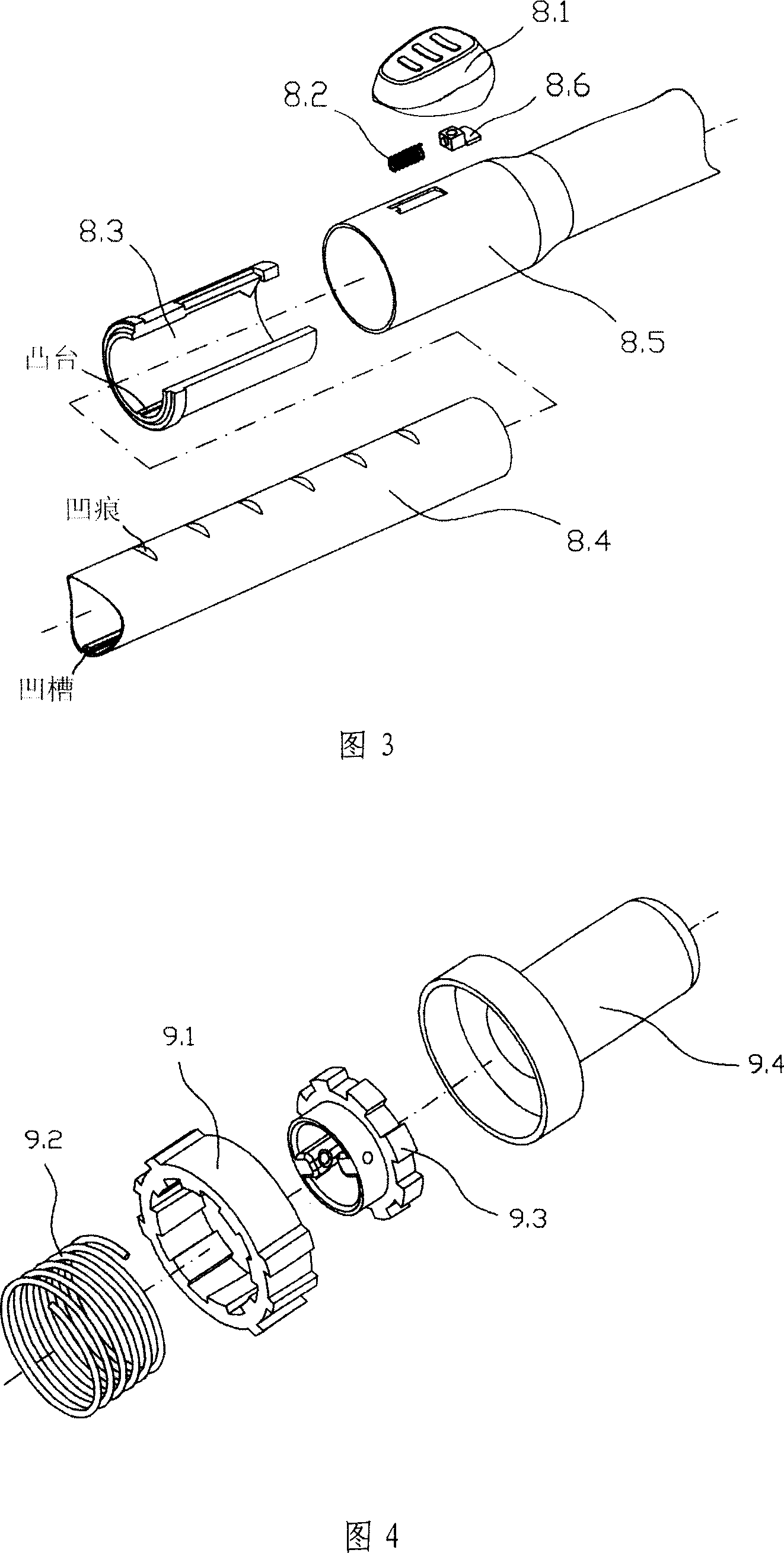

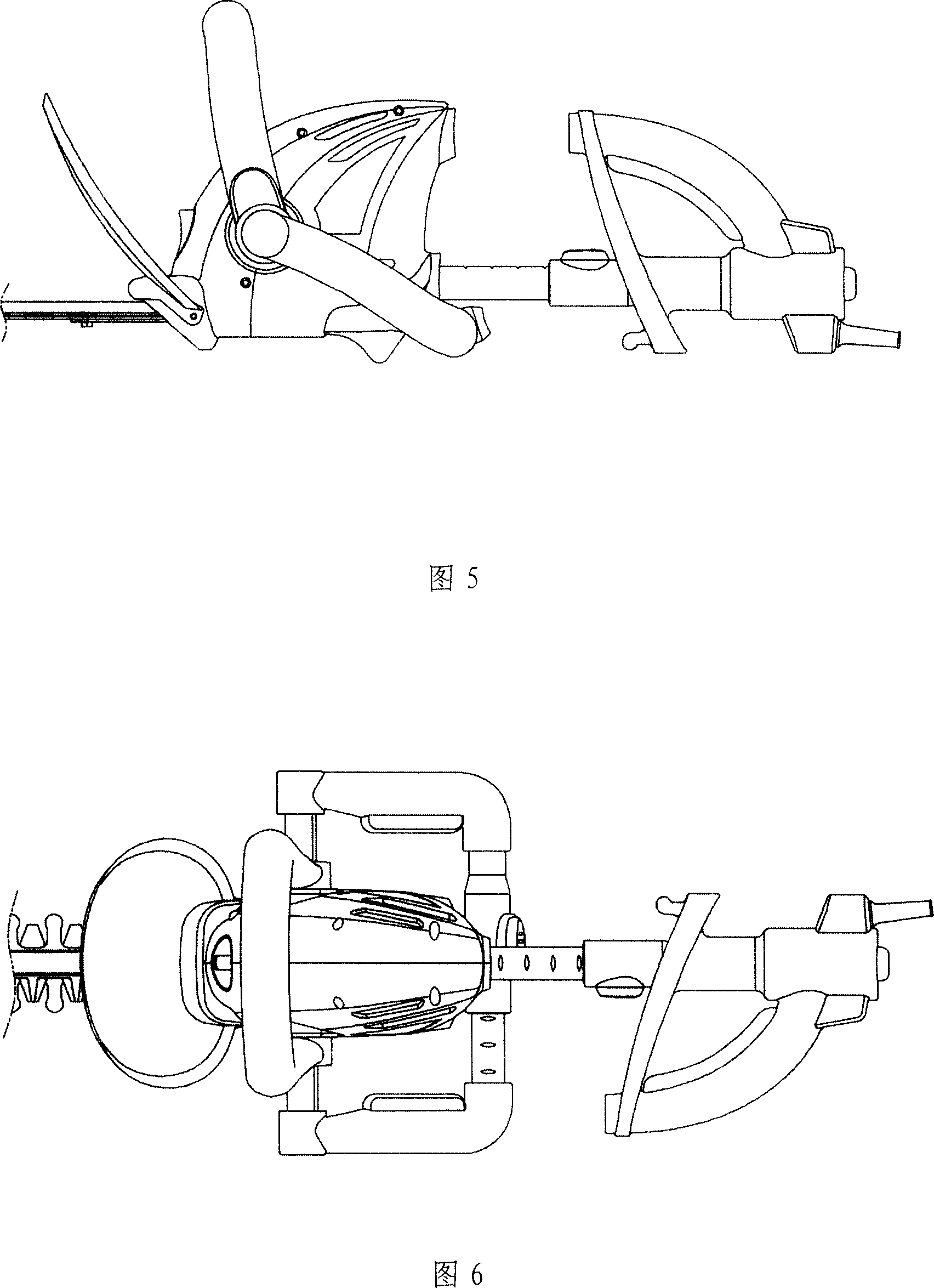

Hedge-trimmer

The invention relates to a kind of hedge machine which comprises a generator, an actuator, a main crank, a fore crank, a switch, a cutter structure and so on. The cutter structure is driven by the generator through the actuator. The main crank is at the back of the machine. The fore crank which can revolve for some angles is assembled at the front of the machine. The machine is characterized in the main crank connecting with the machine main body through a telescoping pole, the telescoping pole connecting with the main crank or the main body through a rotating mechanism. There is a pair of cranks arranged at the two sides of the machine. The cranks are assembled to the machine through telescoping poles mechanisms and rotating mechanism at the junction of the machine. Operators can choose the hold manner, rotation angle and stretching angle of the cranks according to their own requirement and using custom. The machine has the advantages of simple and convenient operation, high working efficiency and small package size.

Owner:JIANGSU GOLDEN HARBOUR ENTERPRISE LTD

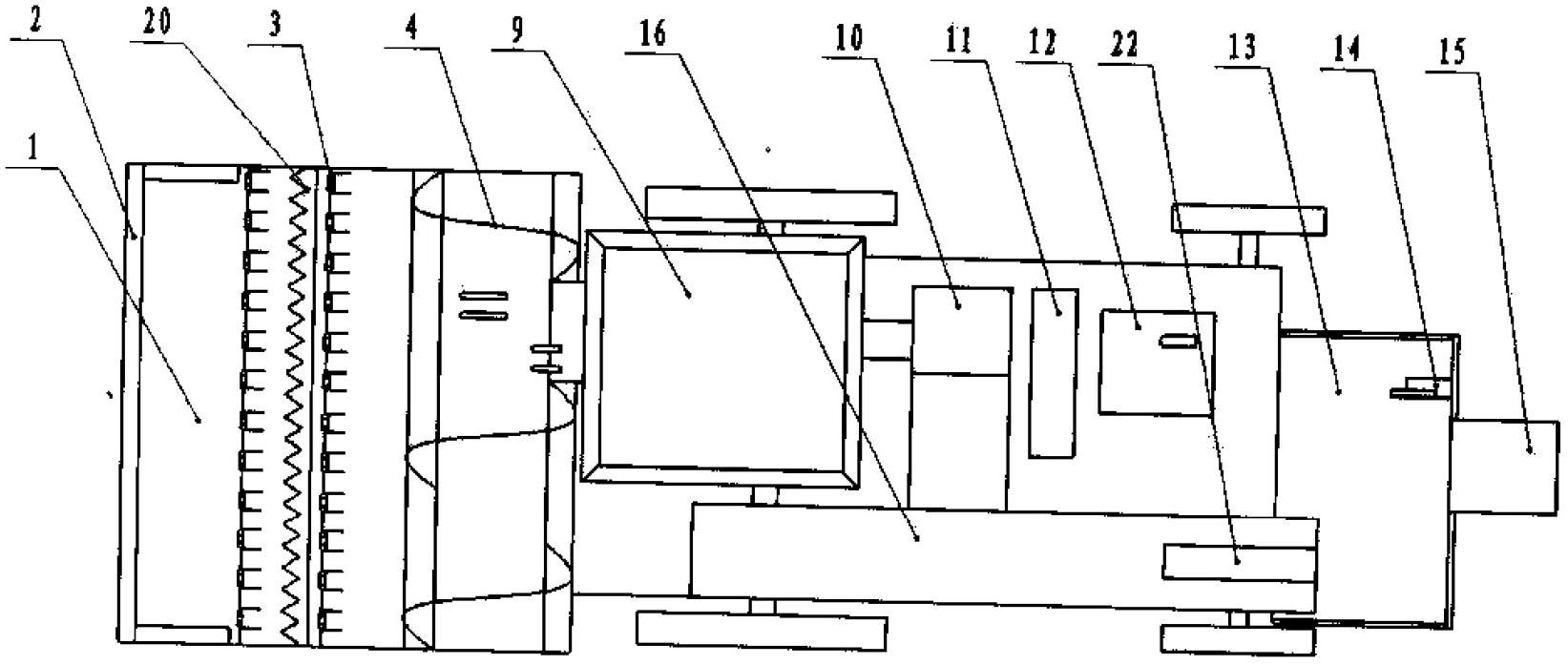

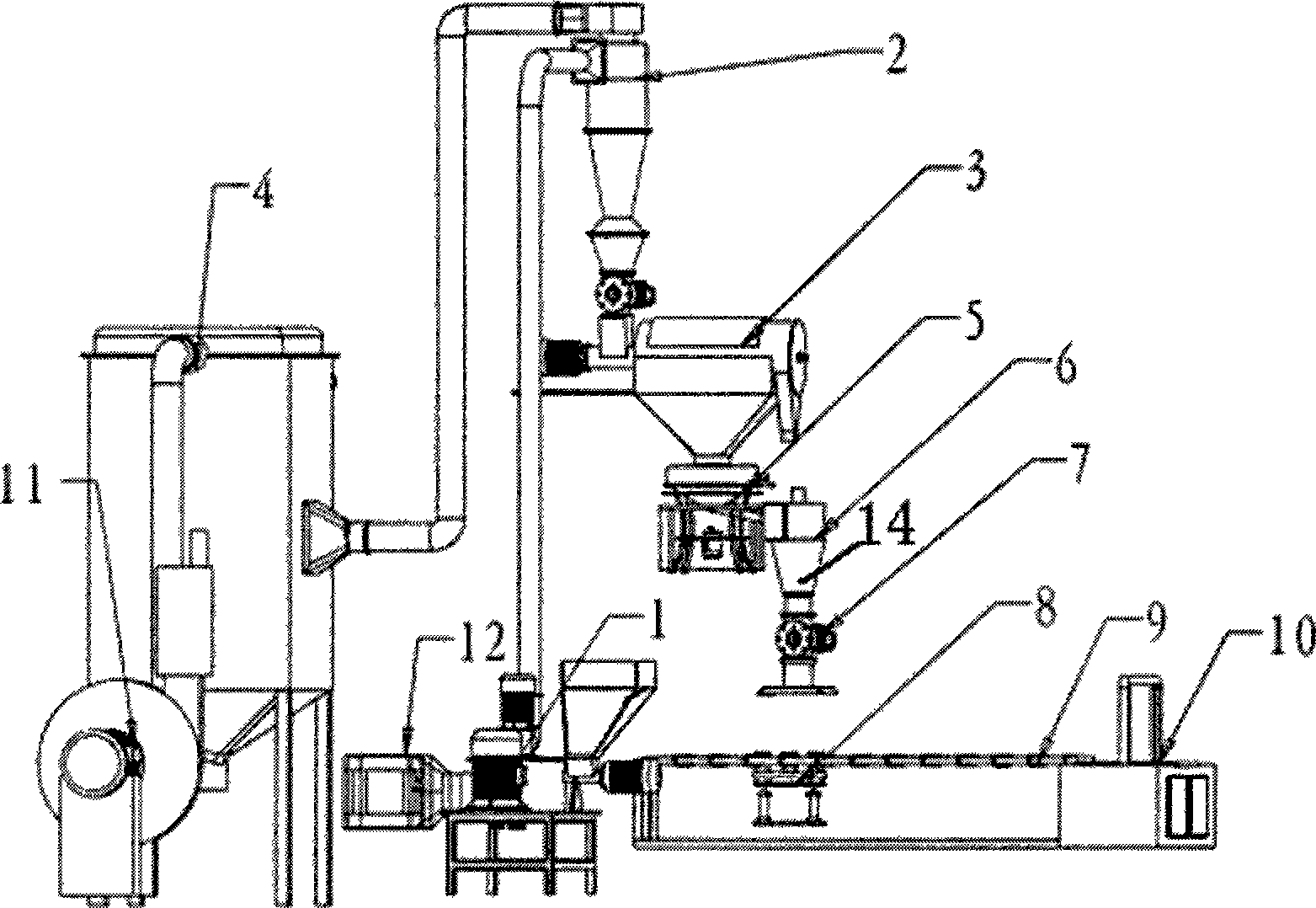

Automatic production apparatus for grinding powder paint

The invention relates to automatic production equipment for powder coating grinding, which belongs to the technical field of the automatic production equipment of power coating grinding. The equipment comprises a grinding head which is arranged inside a feed inlet and forms a grinding device, wherein the grinding head is connected with a cyclone separator through an induced air channel, an outlet of the cyclone separator is connected with a dust collector which is connected with a draught fan, and a lower outlet of the cyclone separator is connected with a gyrating sieve of powder coating with thicker grain diameters. The equipment is characterized in that the lower part of the gyrating sieve is connected with a vibration sieve, the vibration sieve is elastically connected with a small cyclone dust collector at the lower part of the vibration sieve, the lower part of the small cyclone dust collector is connected with a discharge outlet, the lower part of the discharge outlet is provided with a double-valve powder flow controller used to control the evenness and the connection / disconnection of the discharge, and the lower part of the double-valve powder flow controller corresponds to a powder packing case. The equipment can realize noise reduction, automatic sieving and alarming, dust removal, weighing and packing during the production of the powder coating, can realize safety of products and steady continuous production, reduce the leakage amount of dust, and avoid the pollution to the environment.

Owner:刁书才

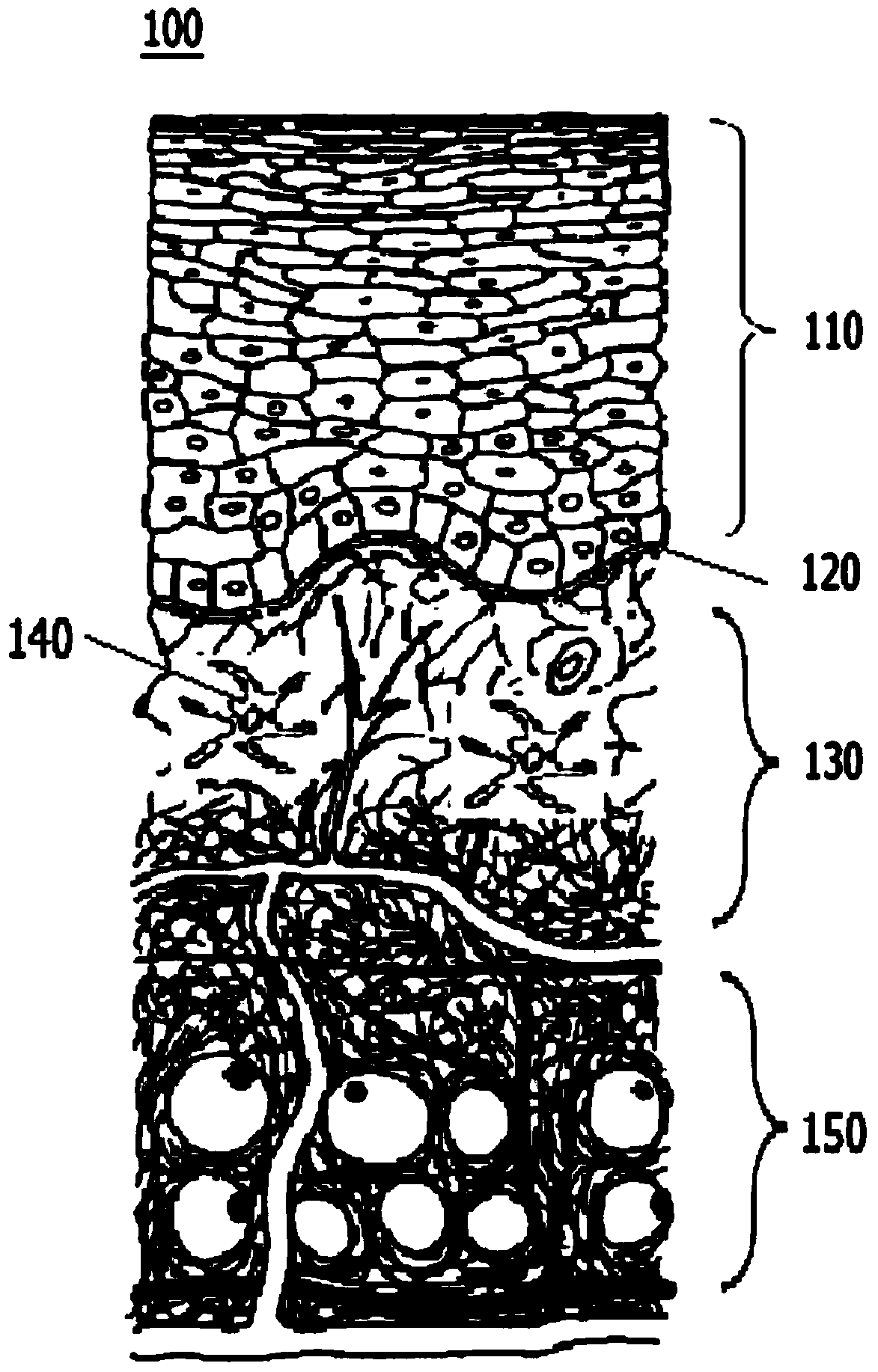

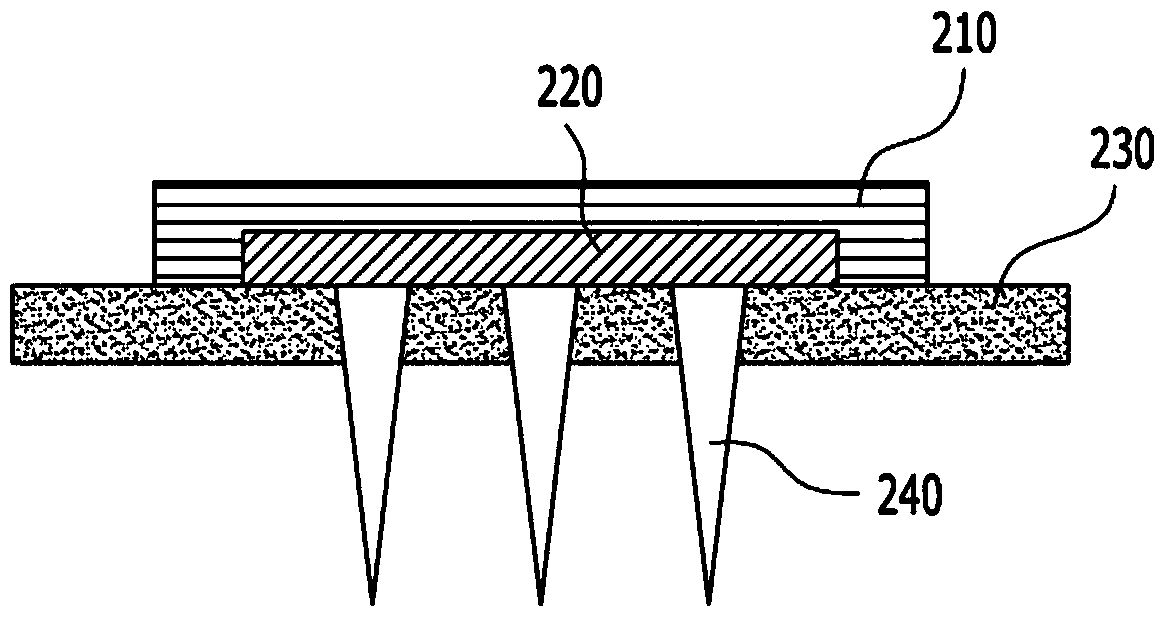

Soluble microneedle arrays for buccal delivery of vaccines

InactiveCN104185475AEasy to administerEasy and economical to makeSurgeryMicroneedlesVaccinationBuccal mucosa

A buccal microneedle patch may be provided for vaccination. The buccal microneedle patch may include at least one of microneedles. The at least one microneedles may be configured to contain a predetermined vaccine and to penetrate an outside layer of a buccal mucosa for promptly delivering the predetermined vaccine.

Owner:THERAJECT INC.

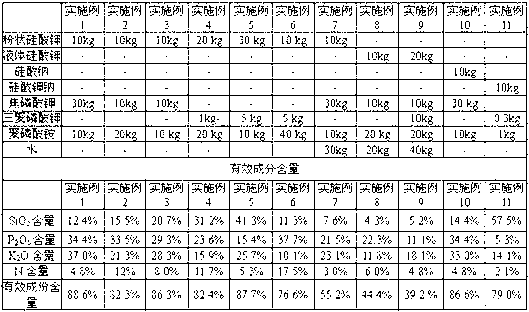

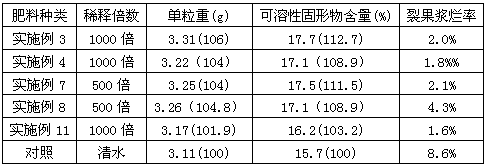

Silicon-containing water-soluble fertilizer

The invention relates to a silicon-containing water-soluble fertilizer. The silicon-containing water-soluble fertilizer is characterized by comprising four main nutrient elements N, P, K and Si, wherein the four main nutrient elements N, P, K and Si are supplied by three substances including water-soluble silicate, poly-condensed potassium phosphate and ammonium polyphosphate. The silicon-containing water-soluble fertilizer can be produced into a solid fertilizer or a liquid fertilizer. The fertilizer with high content of effective elements has a function of obviously increasing the yield, the quality and the stress resistance of plants, and is applicable to food crops, vegetables, fruit trees and the like.

Owner:HEBEI ACAD OF FORESTRY SCI

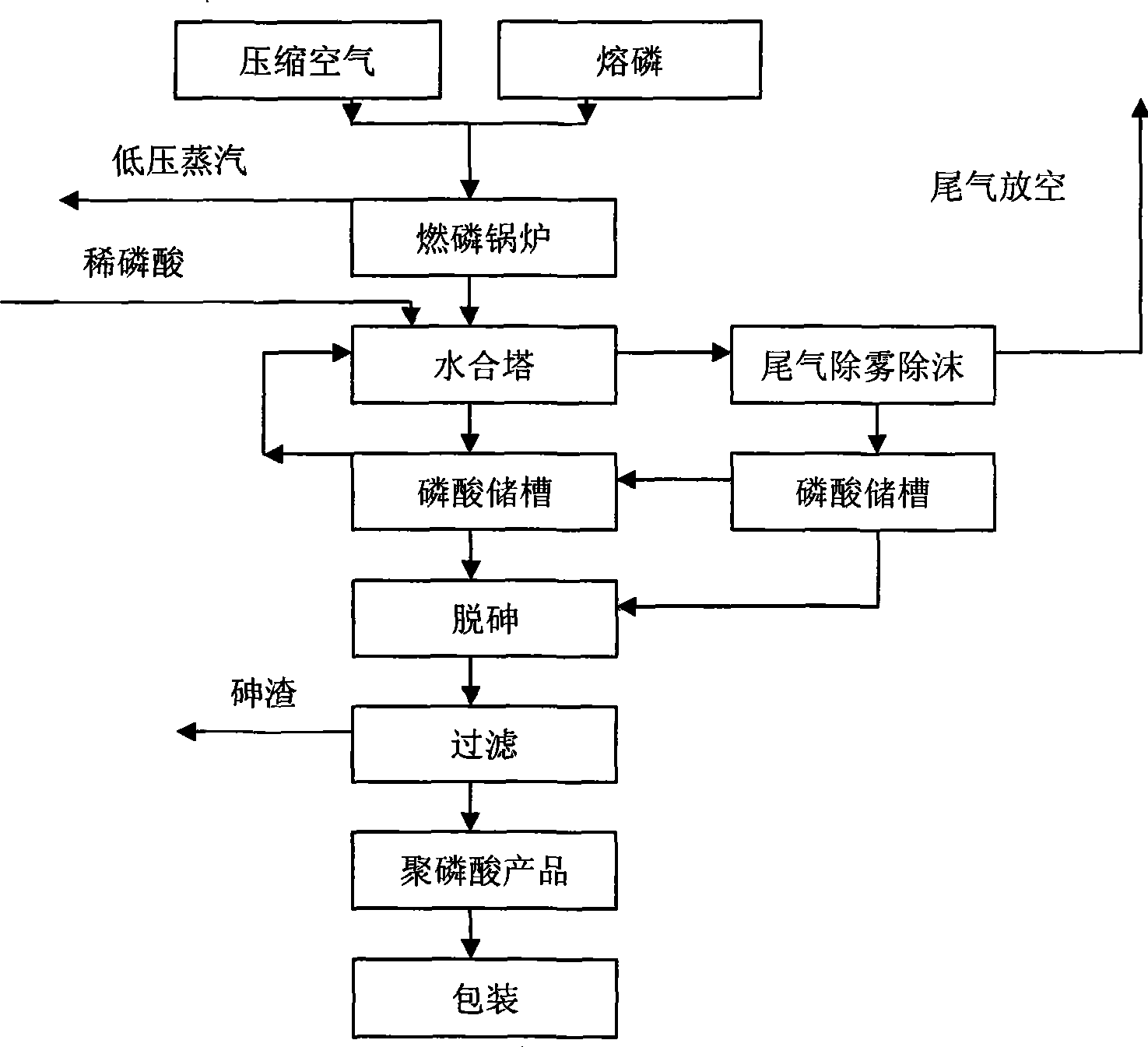

Method for using phosphoric oxide to concentrate diluted phosphoric acid to prepare polyphosphoric acid

ActiveCN101531354ALower packagingReduce logistics costsChemical industryCondensed phosphoric acidsO-Phosphoric AcidEconomic benefits

A method for using phosphoric oxide to concentrate diluted phosphoric acid to prepare polyphosphoric acid, including following steps: mixing yellow phosphorus and air with the proportion of 1kg yellow phosphorus to 6.3-6.6 m3, burning, absorbing the obtained P2O5 by diluted acid; applying the obtained phosphoric acid into a phosphoric acid groove; then using acid pump to send into a condenser to remove the heat; then sending the phosphoric acid into a hydration tower to circularly spray and absorb P2O5 to increase the concentrated phosphoric acid; cycling without stop to obtain the phosphoric acid having 82%-84% P2O5. The recovery coefficient of phosphorus is more than 98%. The obtained product reaches the standard of the food-level phosphoric acid. This invention may greatly reduce the cost of package and distribution of the phosphoric acid production enterprise via using the wet-method phosphoric acid or hot-method phosphoric acid of the concentrated content of the phosphoric acid anhydride of less than 100% obtained by yellow phosphorus burning. This invention does not need to consume the extra energy, and can fully use the burning heat and the hydration heat of the yellow phosphorus; the generated steam can be recycled. So this invention has the advantages of saving energy and greatly reducing the production cost of the polyphosphoric acid, with remarkable social and economic benefits.

Owner:WENGFU (GRP) CO LTD

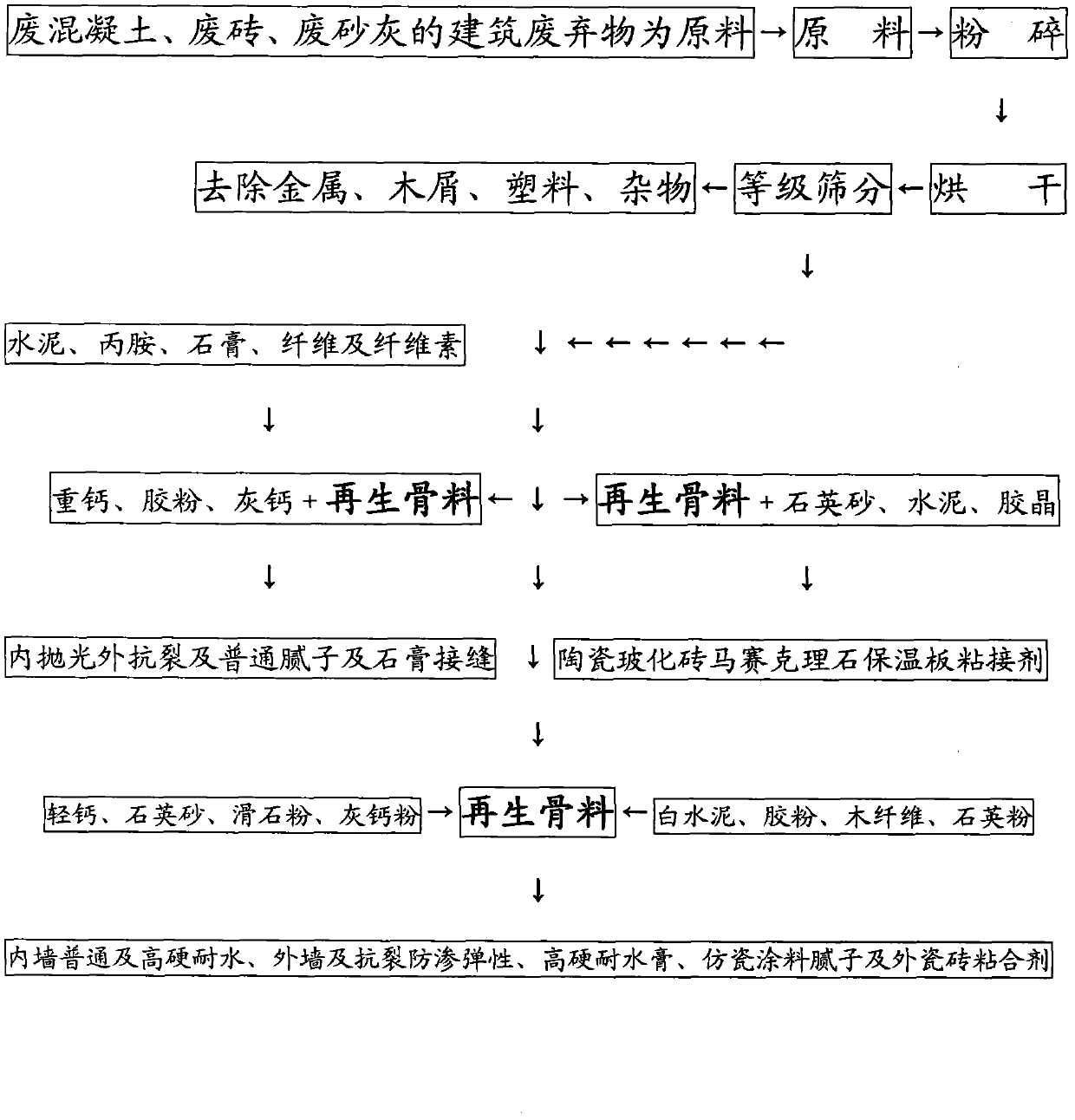

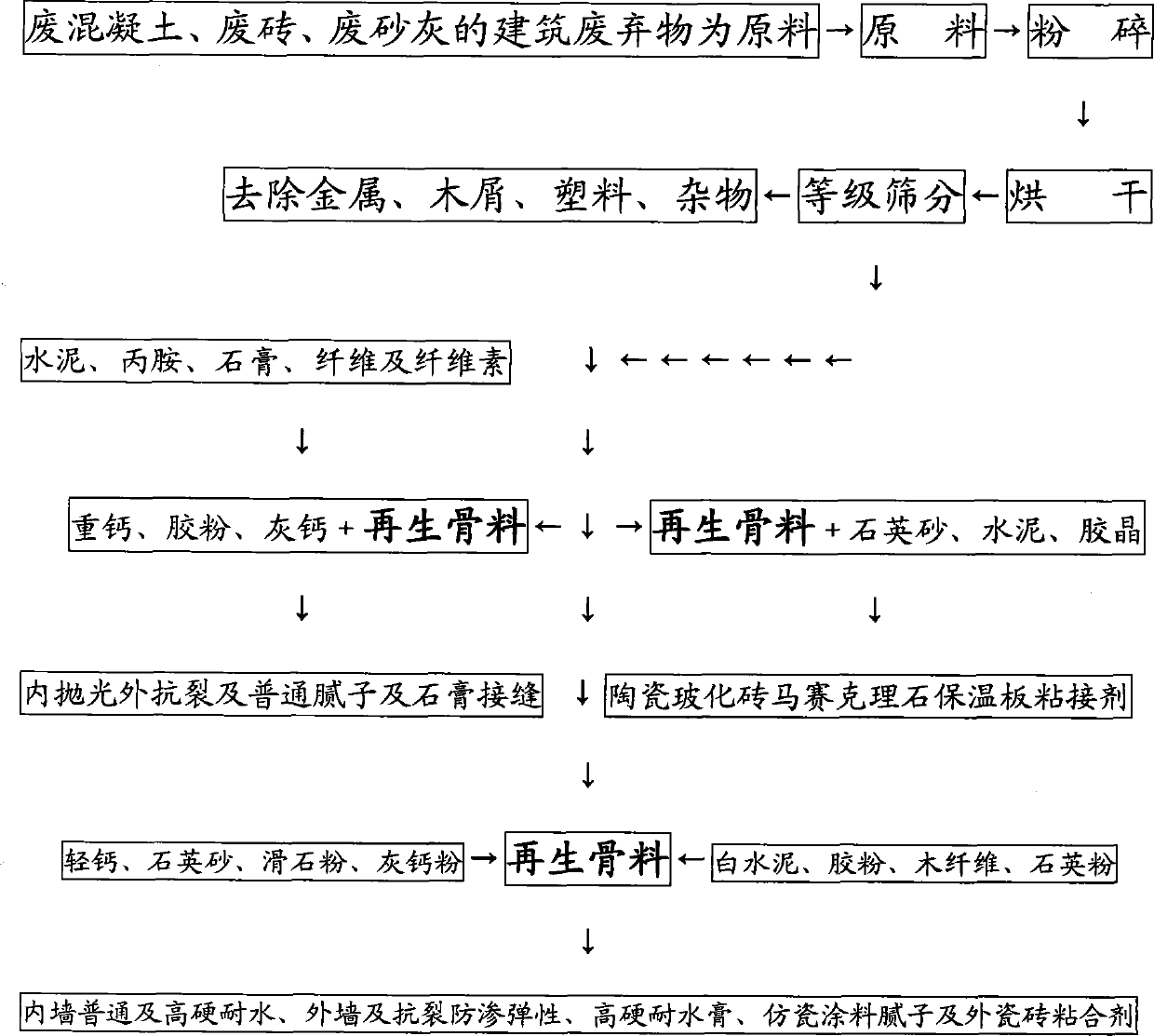

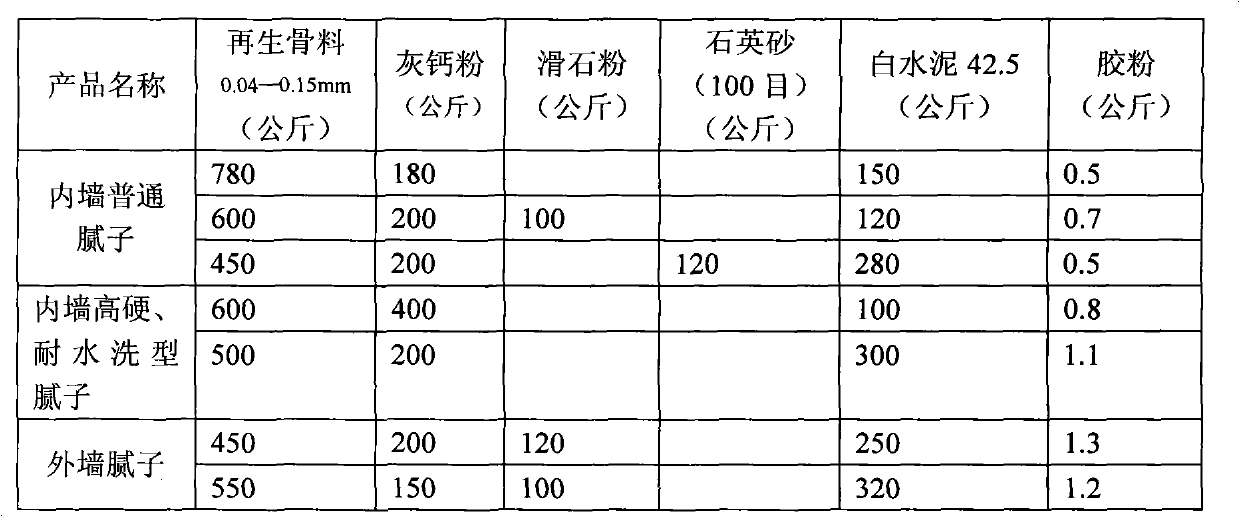

Recycled aggregate special mortar preparation method

InactiveCN102701665AProtect natural resourcesSave labor, save time and effort, and save additional costsSolid waste managementFilling pastesHardnessMoisture

Owner:SHENZHEN WEILUN BUILDING MATERIALS

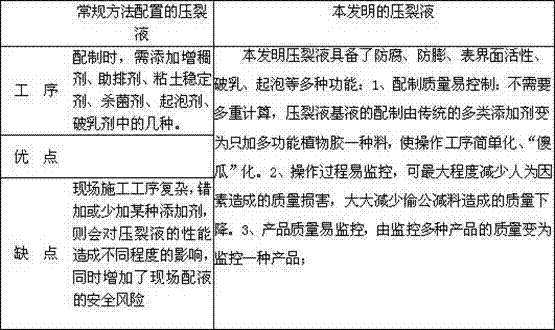

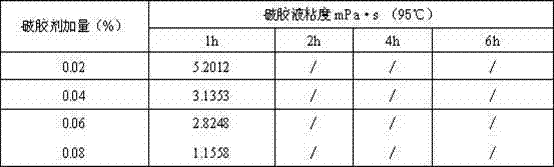

A method for preparing water-based fracturing fluid by using multi-effect thickener

InactiveCN102286276AOptimized formulaQuality improvementDrilling compositionDemulsifierFoaming agent

The invention discloses a method for preparing a water-based fracturing fluid by using a multi-effect thickener, which is characterized in that the fracturing fluid is composed of a base fluid and a cross-linking fluid containing a gel breaker, and is mixed according to the following parts by weight Uniform: 60-99.99 parts of base liquid, 0.01-40.0 parts of cross-linking liquid containing gel breaker; the base liquid is mixed according to the following parts by weight: 99-99.9 parts of water, multi-effect Thickener is 0.1-1.0 parts; the cross-linking liquid containing breaker is mixed according to the following parts by weight: water is 0-99.9 parts, cross-linking agent is 0.1-100.0 parts and breaker is 0.001- 0.1 part. The water-based fracturing fluid formulated with this multi-effect thickener can meet the requirements of use without adding bactericides, clay stabilizers, surfactants, demulsifiers, and foaming agents. Under the condition that the performance indicators of the fracturing fluid are equivalent to those of the traditional fracturing fluid, the operation process is simplified, which is more conducive to improving the quality of the fluid, reducing the conditions required for monitoring, reducing construction procedures and time applications.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD CHANGQING DOWNHOLE TECH CO

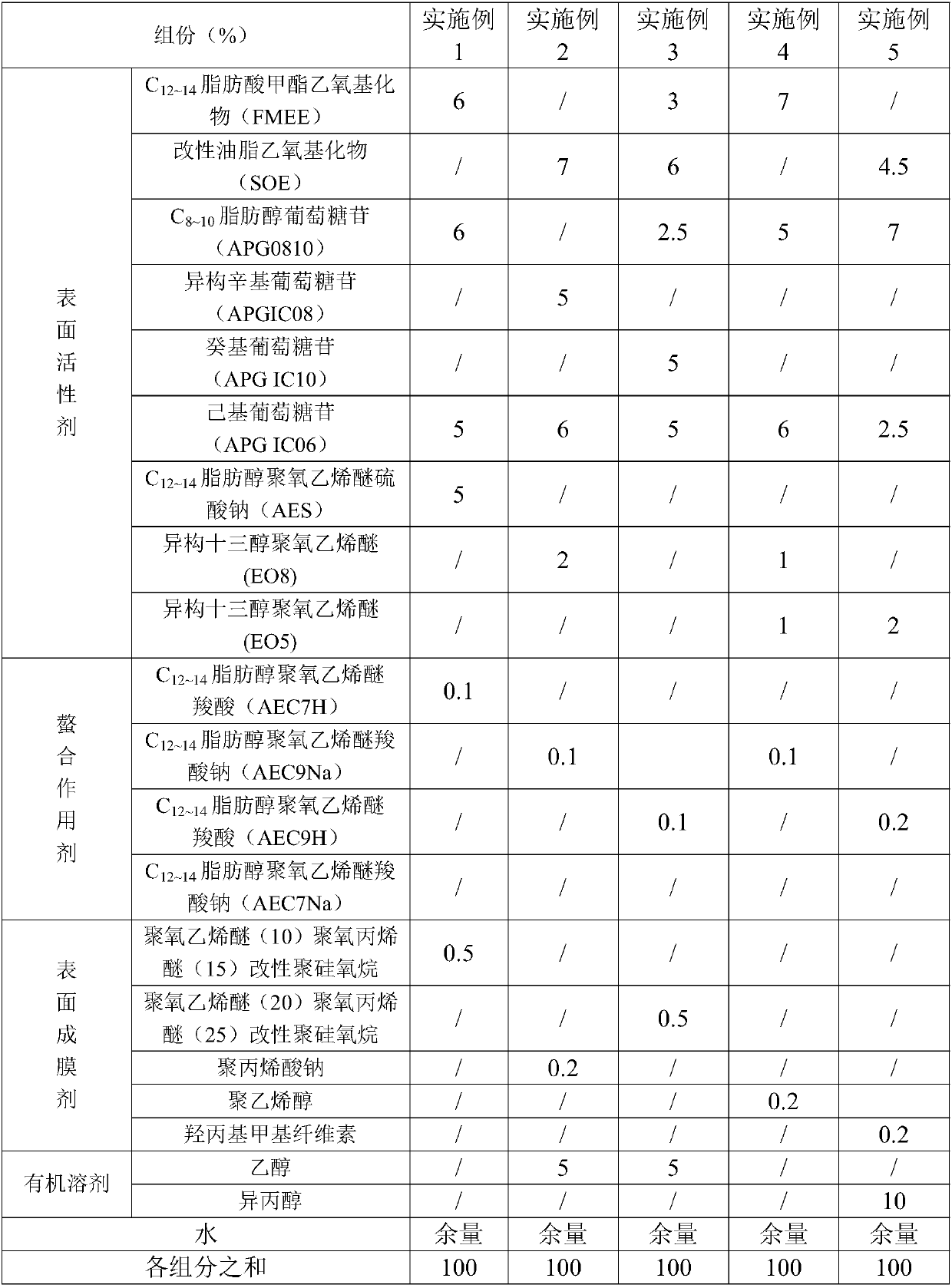

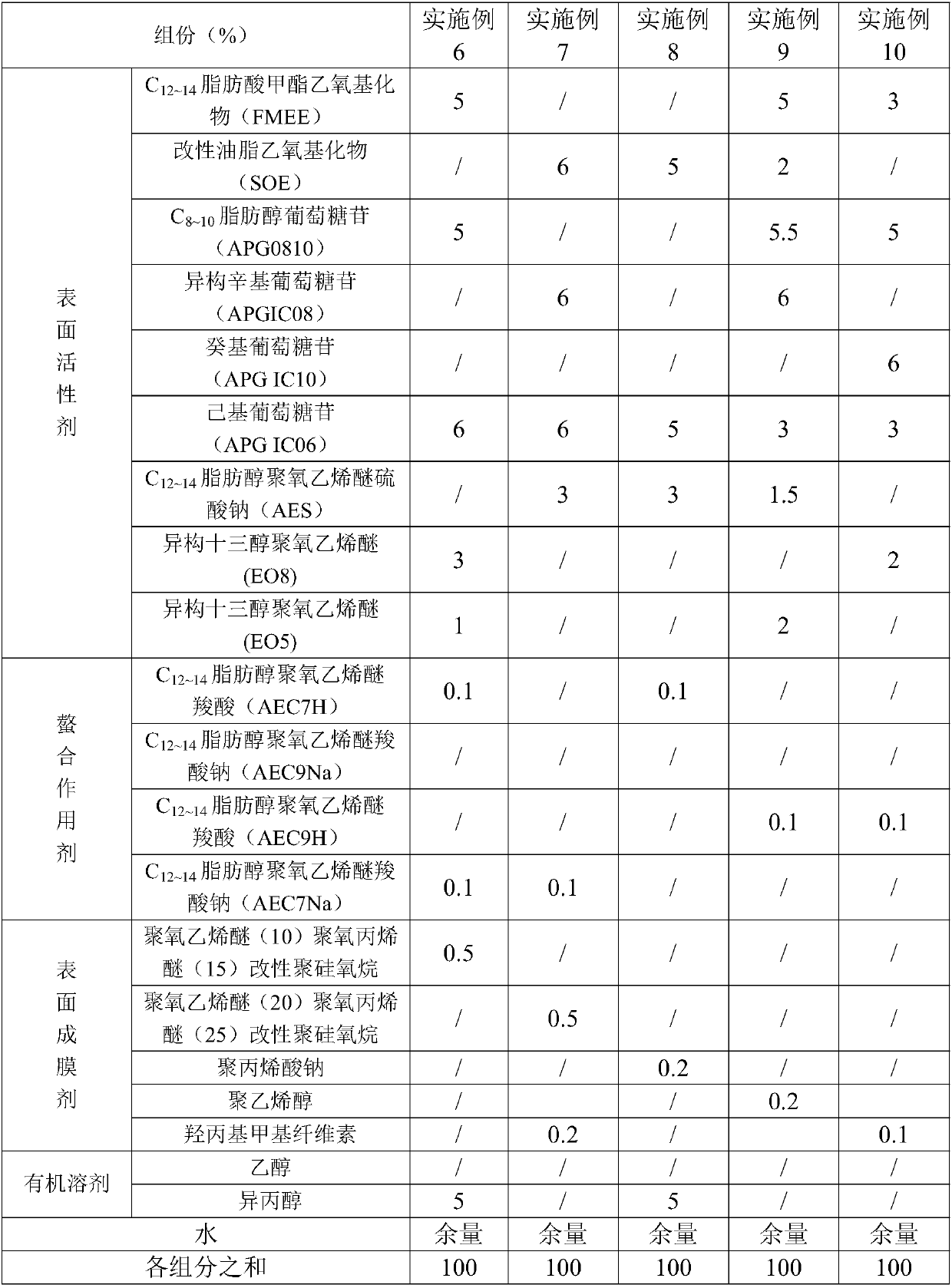

Concentrated antifogging glass cleaning agent

PendingCN107937161AReduce functionEasy to cleanOrganic detergent compounding agentsNon-ionic surface-active compoundsSurface cleaningCleansing Agents

The invention discloses a concentrated antifogging glass cleaning agent. The concentrated antifogging glass cleaning agent comprises the following components in percentages by weight: 10 to 30% of a surfactant, 0.1 to 2% of a chelating agent, 0.1 to 2% of a surface film-forming agent and 0 to 25% of an organic solvent, with the balance being deionized water, wherein the surface film-forming agentis at least one selected from the group consisting of polyvinylether-polypropylene ether block modified polydimethylsiloxane, polyvinylether modified polydimethylsiloxane, polypropylene ether modifiedpolydimethylsiloxane, sodium polyacrylate, polyvinyl alcohol and hydroxypropyl methylcellulose; and the surfactant, the chelating agent and the surface film-forming agent can be coordinatively mixedand dissolved with the need of only a small amount of an organic solvent or without the need of an organic solvent. Thus, the concentrated antifogging glass cleaning agent has good surface cleaning effect and antifogging effect, can greatly reduce the emission of VOC, and is more environment-friendly.

Owner:SHANGHAI FINE CHEM CO LTD

Automatic fixture device of embedded luminaire

ActiveCN101451663AReduce volumeEasy to put inLight fasteningsFixed installationEffect lightLight fixture

The invention provides an automatic fixing device of embedded type lighting fixtures, comprising an elastic structure, furthermore a limiting mechanism and a trigger mechanism; wherein, one end of the elastic mechanism is connected with the lighting fixture and used for fixing the lighting fixtures; the limiting mechanism is used for limiting the other end of the elastic mechanism before the elastic mechanism is installed; the trigger mechanism triggers the elastic mechanism which is arranged on one a side wall of the lighting fixture and which is used for fixing the lighting fixture; one end of the elastic mechanism, which is arranged on the side wall of the lighting fixture is an elastic end while the other end is a swinging installation arm. By adopting the automatic fixing device, the invention can place the embedded type lighting fixtures into an installation opening hole very conveniently and automatically fixes and arranges the lighting fixtures, and the operation is very convenient and saves time; the operation can be carried out with only one hand, and people do not need worry about being wounded by the phenomenon of spring rebounding, which greatly improves the installation efficiency; the volume of the lighting fixture is reduced so as to decrease the package of the lighting fixture and save storage and transportation cost.

Owner:VERTEX LIGHTING & ELECTRICAL CO LTD

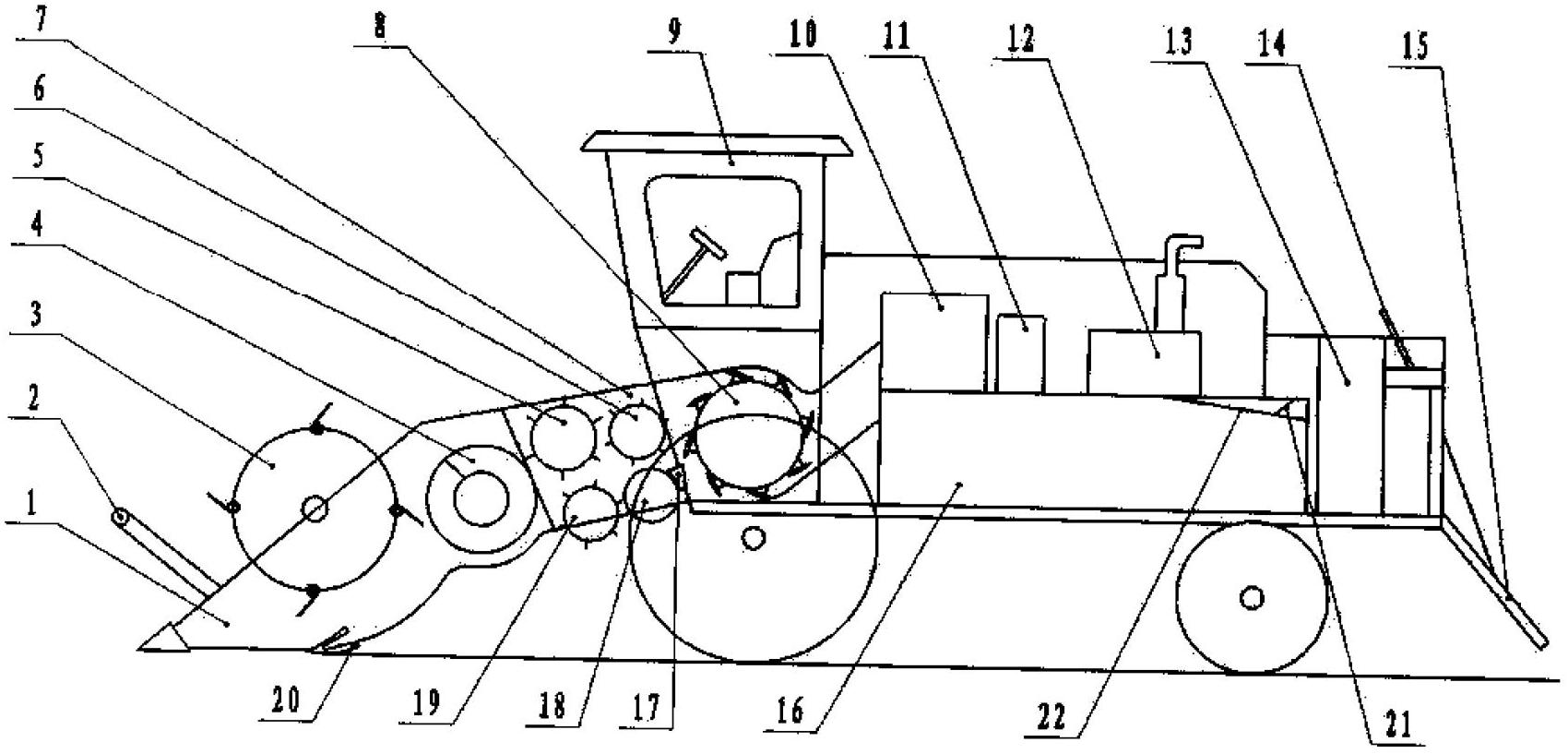

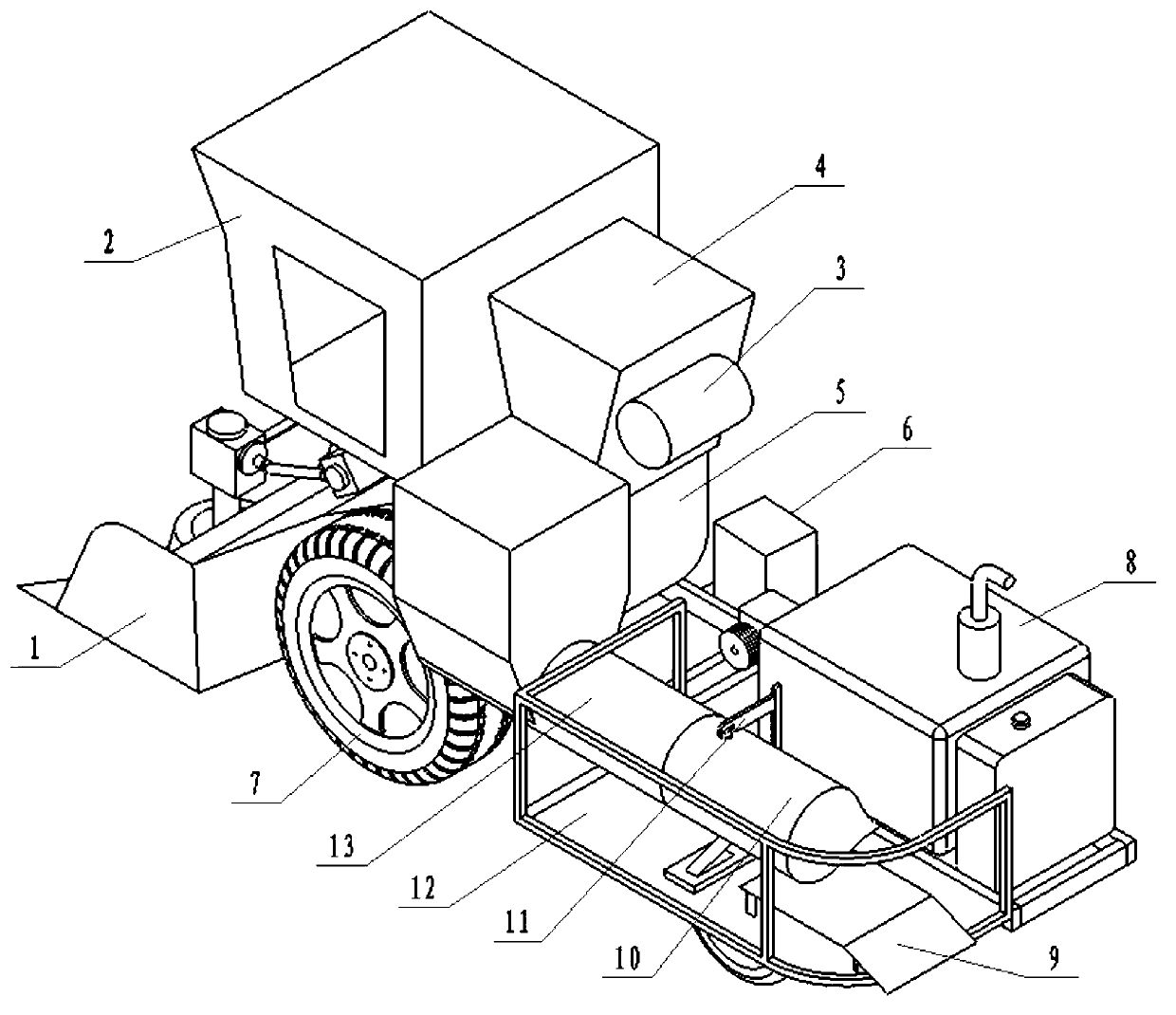

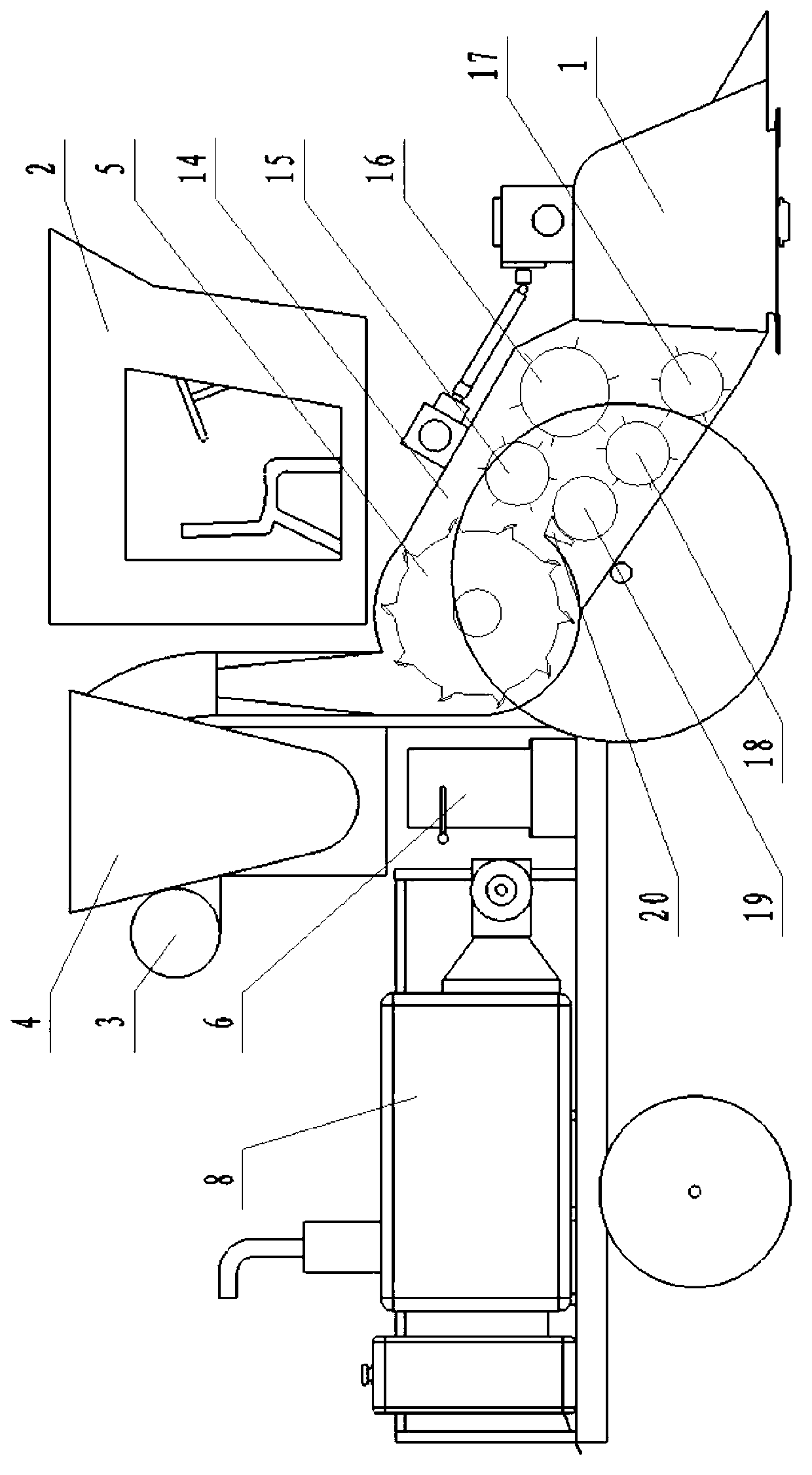

Ensilage harvesting method and ensilage harvester without alfalfa falling to ground

InactiveCN103004383AHigh protein contentGuaranteed qualityAnimal fodder preservationWrapper twisting/gatheringMedicago sativaIndustrial engineering

The invention belongs to the field of stockbreeding machinery and particularly relates to an ensilage harvesting method and an ensilage harvester without alfalfa falling to the ground. The harvester mainly comprises traveling wheels (7), a cab (2), a cutting table (1), a conveyor (14), a chopper (5), a pesticide spaying device (3), a material collector (4), a compressor (13), a sealing device (11), a working table (12) and a discharging table (9). Multiple operation links of cutting, chopping, compacting and bagging can be completed at a time, operation procedures are reduced, harvesting time is shortened, mechanical input cost is lowered, and labor forces are saved. The ensilage harvesting method is unlimited by the weather and can achieve harvesting as long as machines and tools can be operated in fields, so that the problems of difficulty in alfalfa harvesting in rainy seasons, large ensilage loss and the like are solved, prepared alfalfa ensilage is small in package and convenient to transport, and commercial production is achieved easily.

Owner:CHINA AGRI UNIV

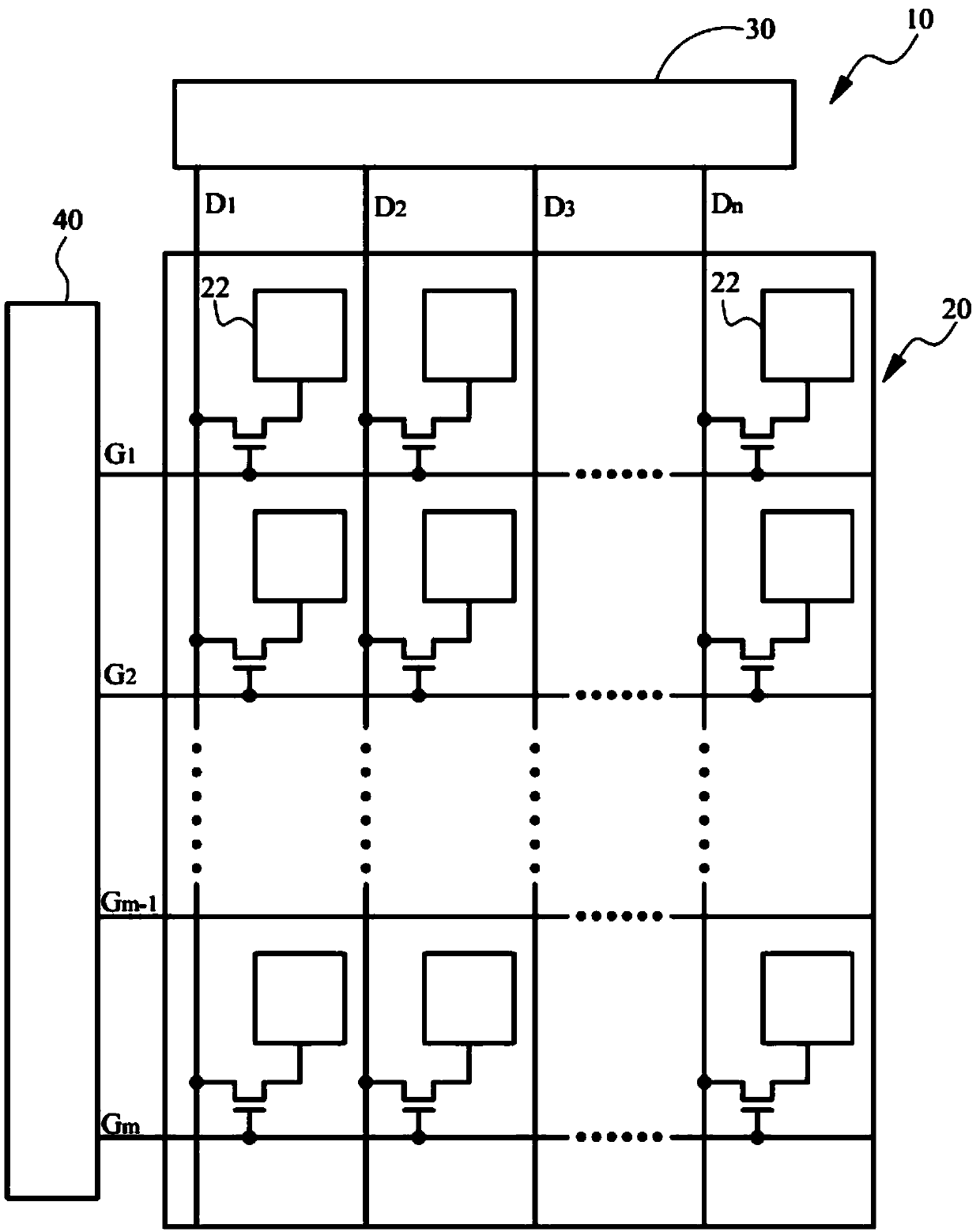

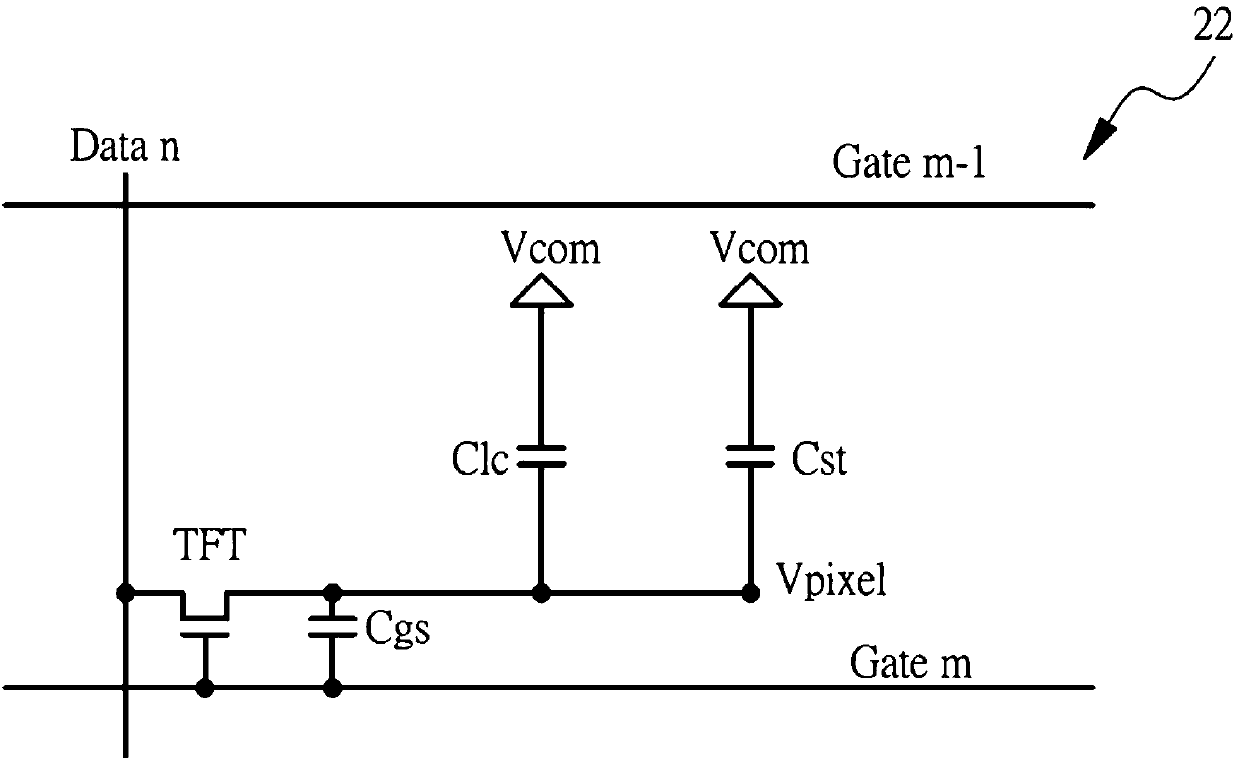

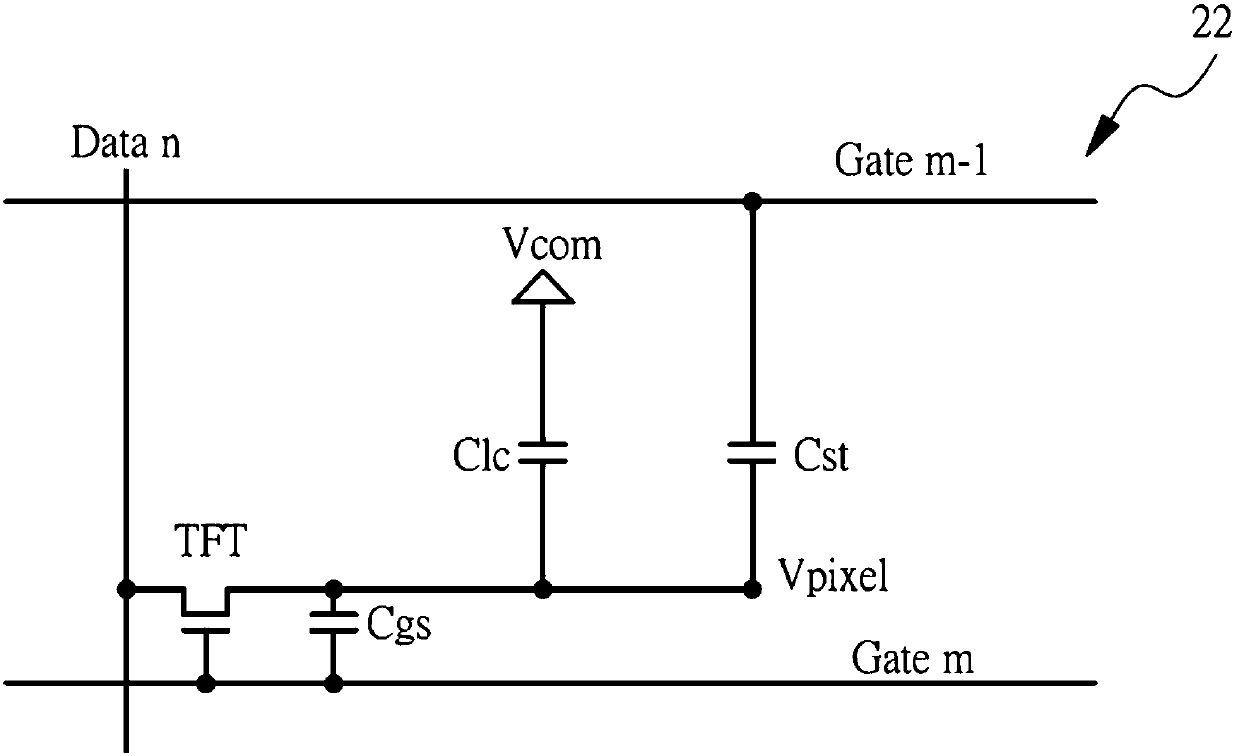

Display device driving unit and driving method thereof

ActiveCN107610661AImprove discrepancies between slicesImprove product qualityStatic indicating devicesComputer moduleDisplay device

The invention relates to a display device driving unit and a driving method thereof; the driving device comprises the following units: a first substrate including a storage unit, the storage unit is electrically connected with a display module and stores display parameters of the display module, and the display parameters comprise a gamma correction code, a common electrode voltage setting code, and a display module uneven brightness distribution compensation module code; a second substrate including a control module electrically coupled to the storage unit, the control module reads the display parameters stored in the storage unit and adjusts the driving parameters of the display module, and the second substrate is electrically coup-led to the first substrate through a serial peripheral equipment interface; an integrated circuit bus electrically respectively coupled to a sequential control unit and a programmable gamma correction buffer circuit unit. The driving device can enable a circuit board and a control panel to separate and can improve the panel inter-chip differences caused by making processes, thus improving the whole product quality without adding extra packaging or operation difficulties.

Owner:HKC CORP LTD

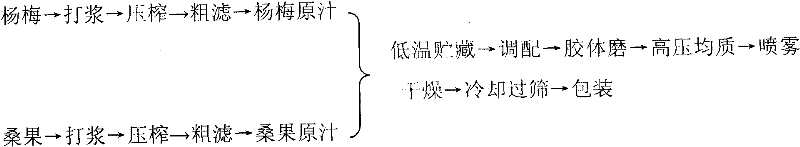

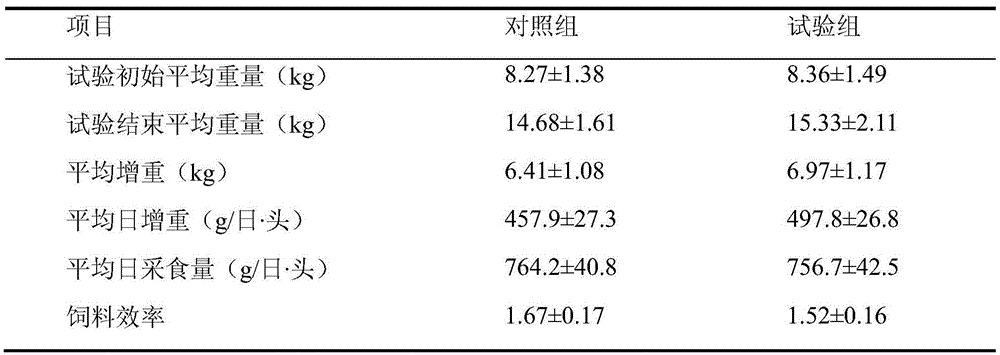

Instant waxberry and mulberry solid drink and preparation method thereof

The invention relates to instant waxberry and mulberry solid drink and a preparation method thereof. The instant waxberry and mulberry solid drink is characterized by comprising the following raw materials in percentage by mass: 10-15% of maltodextrin, 5-7% of sucrose, 0.3-0.4% of aspartame, 1.5-2.5% of citric acid and 0.3-0.4% of isoascorbic acid. The preparation method comprises the following steps: adding the raw materials to raw waxberry and mulberry juice; milling by a colloid mill; homogenizing under high pressure; and spray-drying. The instant waxberry and mulberry solid drink obtainedby the preparation method has the advantages of stable sensory properties such as taste, color, fragrance and the like, long product shelf life, richness in amino acid and mineral substances, good instant solubility and good water-mixing property, and is convenient for package and transportation, thus being worthy of being popularized; and the preparation method has the advantages of simple and easy process and low cost, and can help solve the problems of the waxberry juice drink such as easy degradation and discoloration of anthocyanin and subsequent sedimentation.

Owner:ZHEJIANG WANLI UNIV

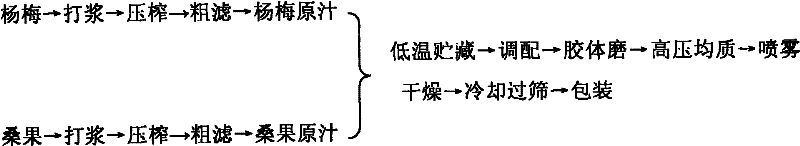

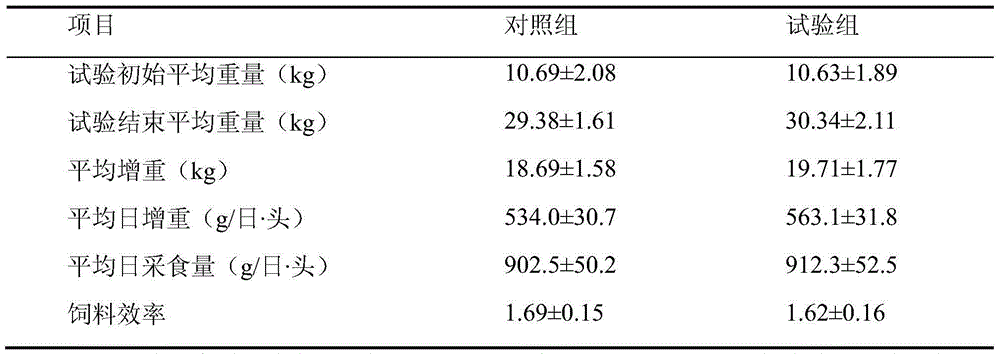

Complete formula feed for piglets and preparation method of complete formula feed

The invention provides a complete formula feed for piglets. The complete formula feed is prepared from the following raw materials: 20-25 parts of corn, 25-35 parts of extruded corn, 10-15 parts of husked soybean meal, 8-12 parts of quick-breaking soybeans, fish meal, biological soya bean meal, whey powder, calcium hydrophosphate, salt, soya-bean oil, lysine, methionine, threonine, a complex enzyme preparation, a microecologic preparation, an emulsifying agent, an acidifier and a compound premix. The invention further provides a preparation method of the complete formula feed. The complete formula feed can meet nutritional requirements of piglets, promote the immunity of the organism and improve the production performance of piglets, the pollution to the environment of excrement is reduced, the cost of the feed and the feeding cost are reduced, and the culturing benefit is improved.

Owner:TANGRENSHEN GRP CO LTD +1

Ammonium glyphosate soluble granule auxiliary and preparation method thereof

ActiveCN103828799APrevent massive decompositionImprove physical stabilityBiocideAnimal repellantsGlyphosateMixed materials

The invention discloses an ammonium glyphosate soluble granule auxiliary, which consists of the following components in parts by weight: 700 to 800 parts of ammonium glyphosate, 50 to 100 parts of ammonium sulfate, 100 to 120 parts of auxiliaries and 6 to 15 parts of water. A preparation method comprises the following technical steps: (1) adding the ammonium glyphosate and the ammonium sulfate into a mixer for mixing in the ratio; (2) crushing the uniformly mixed materials by a crusher, slowly and uniformly adding the auxiliaries into the mixed materials, adding water, and kneading the mixture to form a humid material without obvious blocks; (3) transferring the kneaded material to a granulator for granulation; (4) drying obtained soluble granules at the temperature of not more than 50 DEG C for 2 hours, and sieving the soluble granules by a sieve to obtain glyphosate soluble granule finished products.

Owner:长兴德源环保助剂有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com