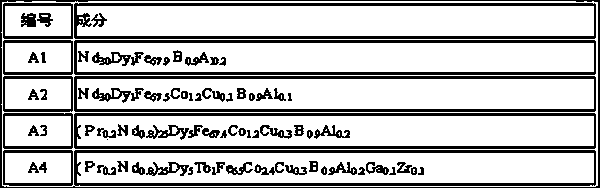

Patents

Literature

157results about How to "Protect natural resources" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

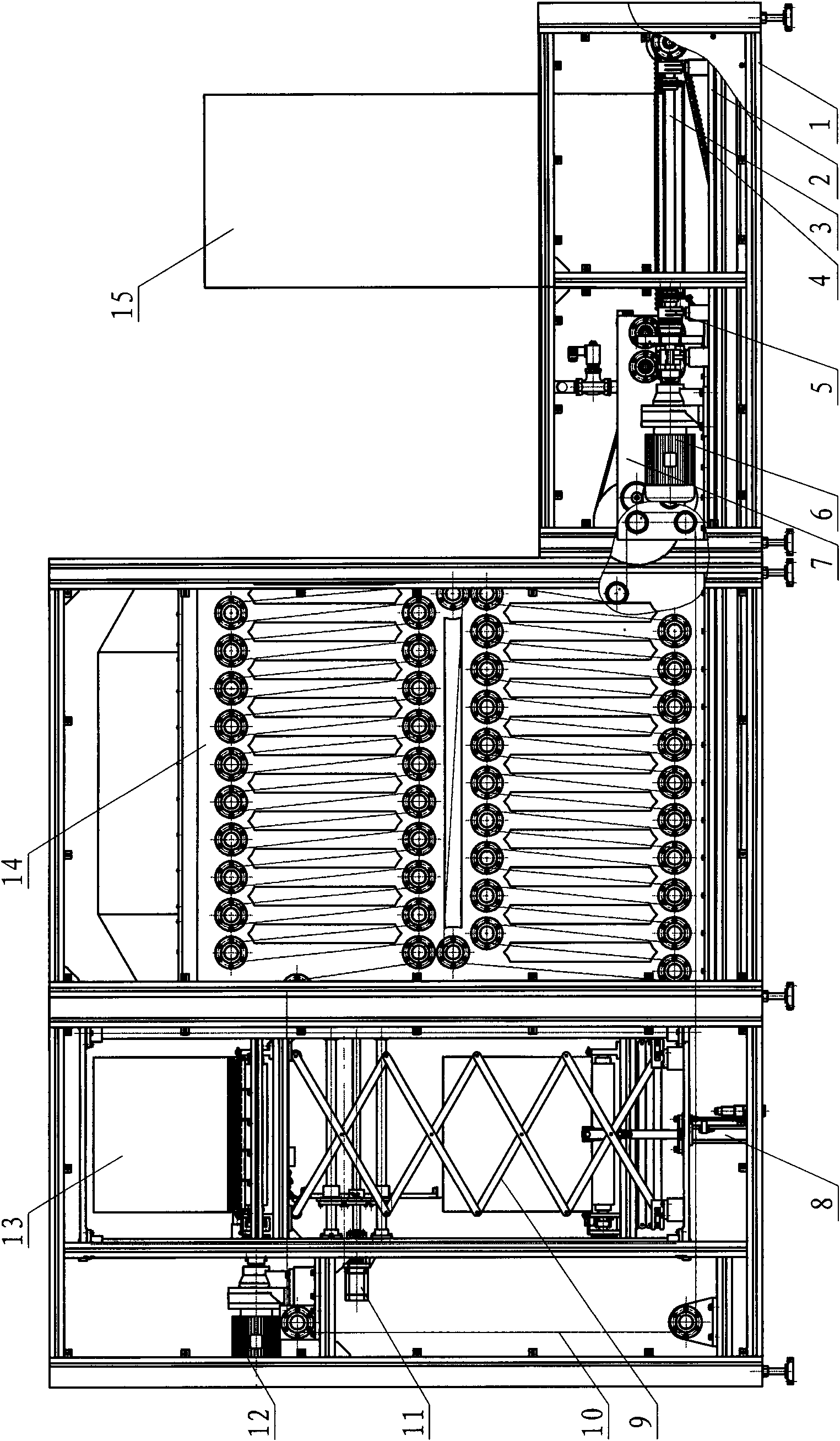

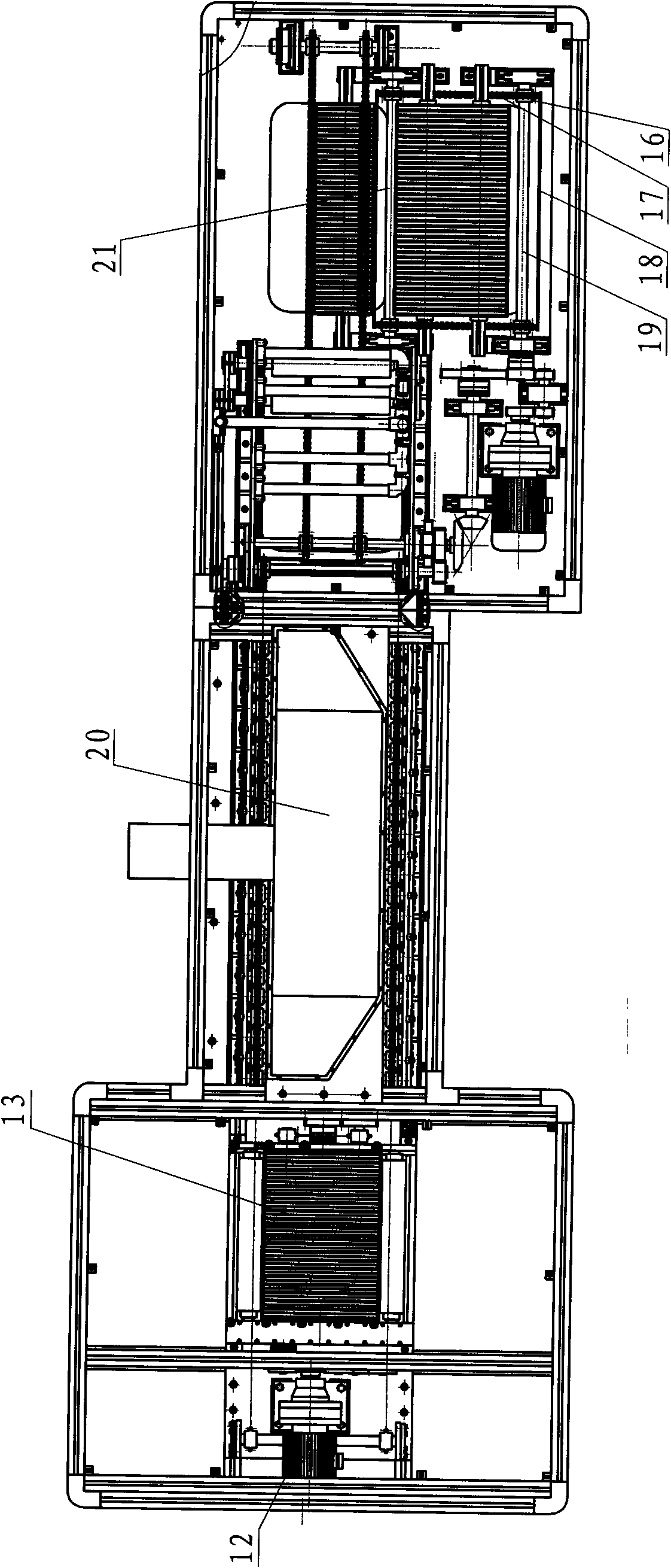

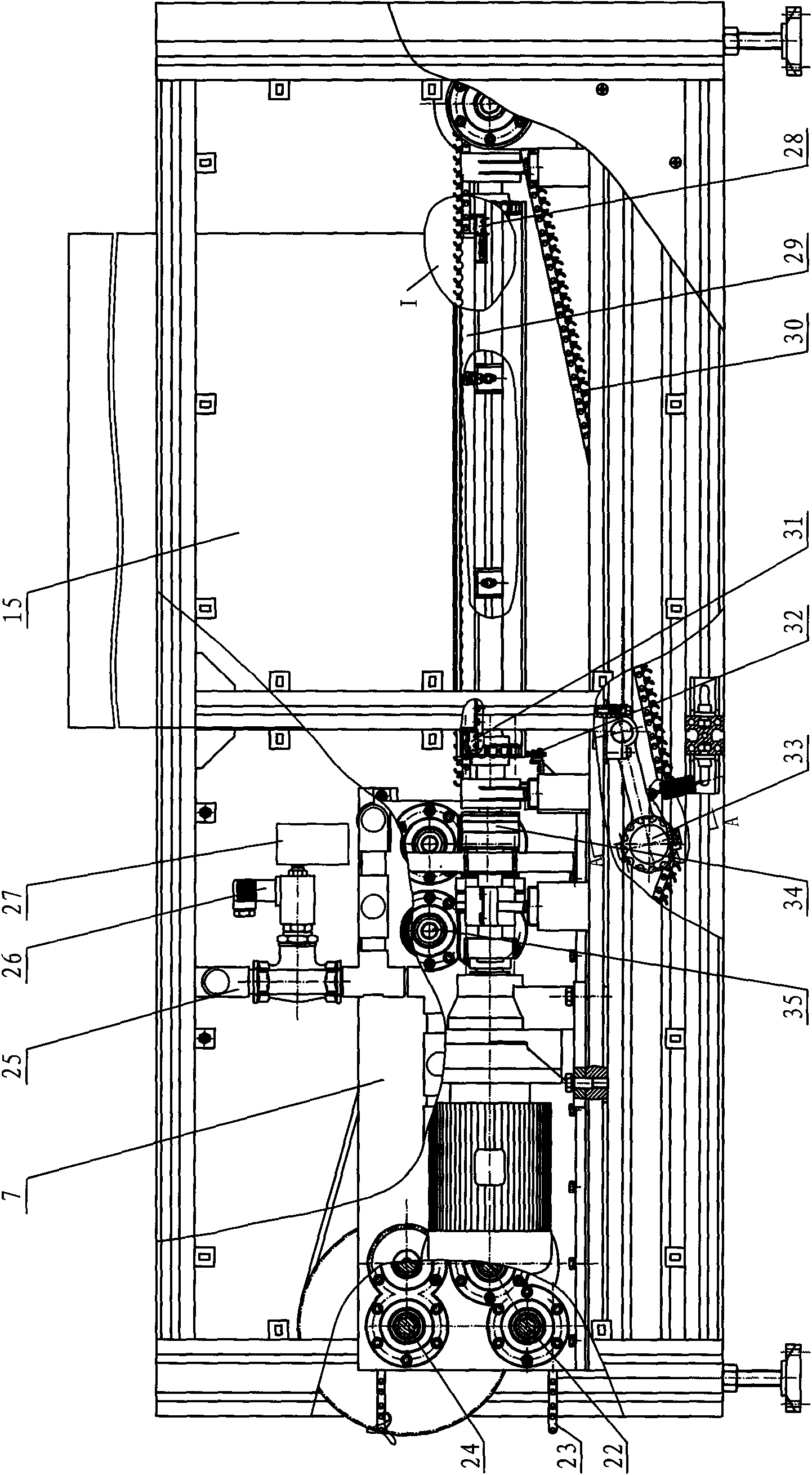

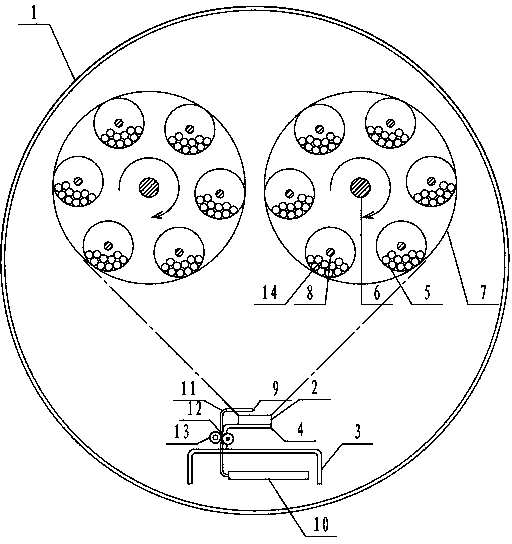

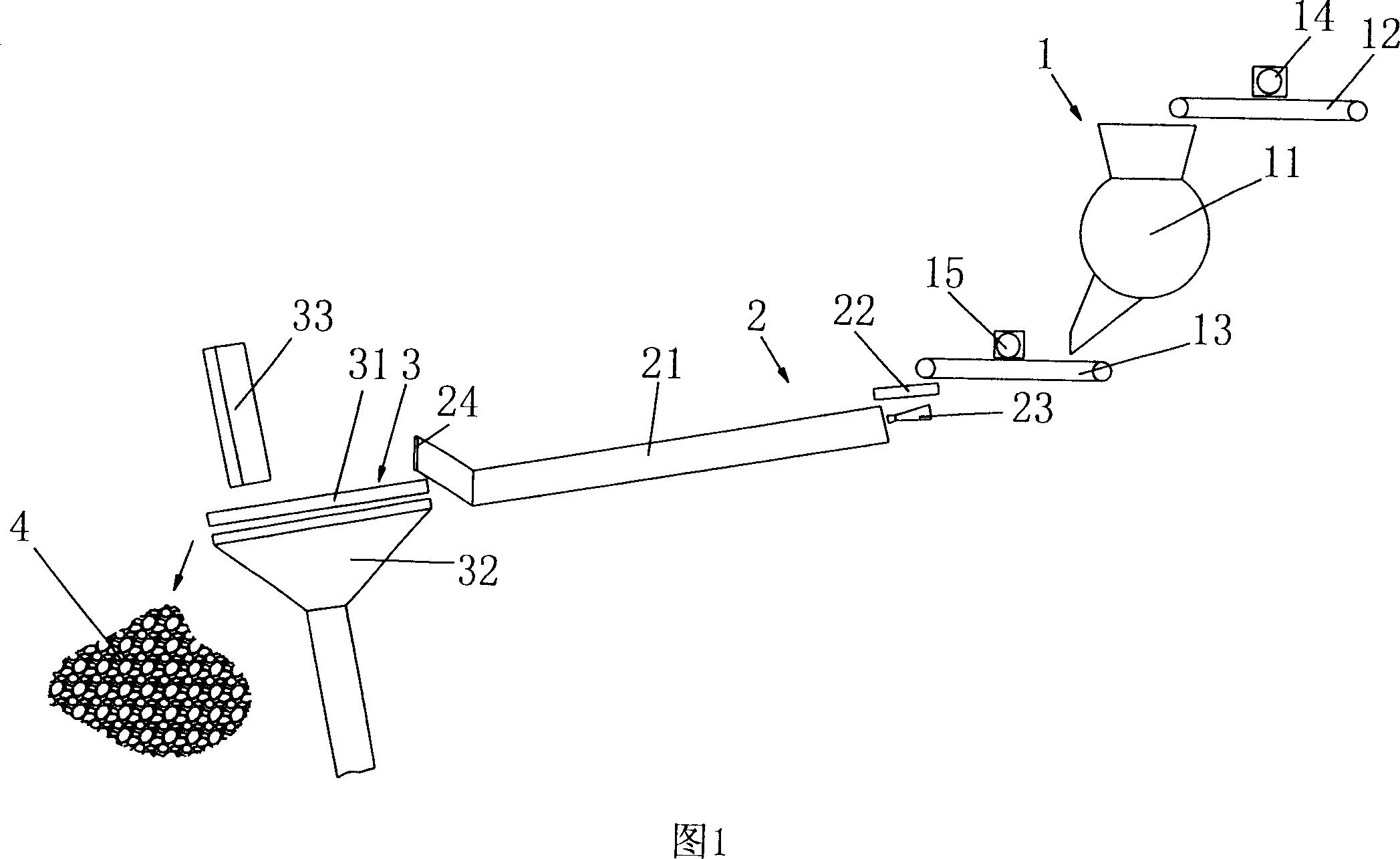

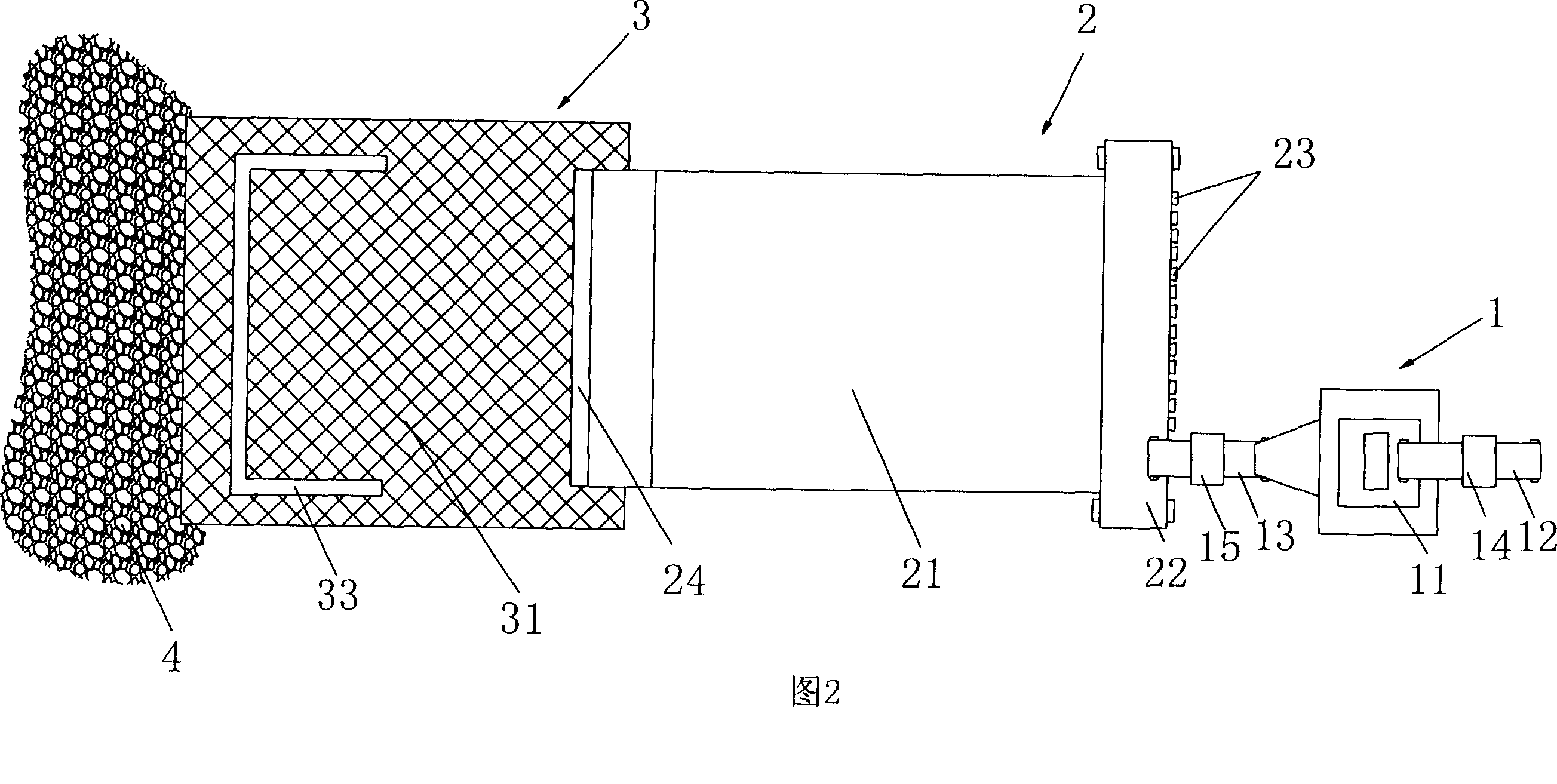

Fully automatic chopstick washing and sterilization integrated machine

InactiveCN101664294ARealize automatic chopsticksReduce energy consumptionTableware washing/rinsing machine detailsRadiationReciprocating motionFully automatic

The invention provides a fully automatic chopstick washing and sterilization integrated machine comprising a stander; the stander is provided with a washing device and a sterilization and neatening device that are arranged thereon from the back to the front; the sterilization and neatening device orderly consists of a drying device, a sterilization device, a neatening and encasement device, a chopstick taking device arranged on a chopstick taking box of the neatening and encasement device and a drying chain transmission mechanism; the neatening and encasement device consists of a stepper motorarranged on the stander, a straight line reciprocator directly connected with the stepper motor, a guide board groove arranged on a reciprocation part of the straight line reciprocator and a chopstick taking box capable of reciprocating; and the drying chain transmission mechanism orderly passes through the washing device, a drying device, a sterilization device and the neatening and encasement device. The machine has the advantages of: being capable of washing and sterilizing the chopsticks, as well as automatically carrying out the processes of neatening, filling into the box, and taking out the chopsticks after sterilization, also realizing the full automation, with excellent washing and sterilization effects and large processing quantity, and being especially adaptable to places usinga plenty of chopsticks.

Owner:李朋

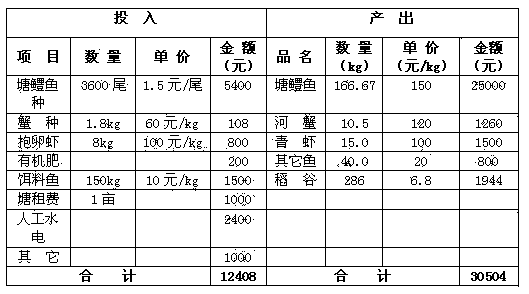

Method for breeding Odontobutis obscura through fish-rice symbiosis in pool

InactiveCN103891659AExtended growing seasonImprove farming outputClimate change adaptationPisciculture and aquariaNutrientFertilizer

The invention relates to a method for aquaculture, in particular to a method for breeding Odontobutis obscura through fish-rice symbiosis in a pool. According to the method, rice is planted in the pool for Odontobutis obscura aquaculture. The fish-rice symbiosis method is adopted for breeding food organisms in water to provide natural baits for fishes, and the rice is used for providing ingestion, shielding and inhabiting space for the fishes, shrimps, crabs and others; the fishes and the crabs prey on insect pests to control ineffective tillering of the rice; original ecology planting mode that no pesticide is sprayed, no fertilizer is applied, and residual baits and excrement are used as nutrients is adopted, , so that while the problem of nutrient enrichment of aquaculture water is effectively solved, shading and cooling are achieved in summer; heat preservation and temperature constancy are achieved in winter, an inhabiting place is provided for the bred variety, the growth period is prolonged, so that the breeding yield and quality and the specification on the market are improved, and the high yield and efficiency are achieved. According to the method, the production problem that wild and natural prey of the Odontobutis obscura is converted into artificial breeding is solved, the environment of breeding water quality, apparent availability and breeding production benefits are improved, and the method is of great importance in protecting natural resources.

Owner:嘉善县净水渔业种苗基地(普通合伙)

Ambergris cigarette and ambergris spices

InactiveCN103584276ALow costProtect natural resourcesTobacco treatmentEssential-oils/perfumesFlavorEngineering

The invention discloses an ambergris cigarette and ambergris spices. The cigarette is composed of a filter tip, an ambergris capsule, cigarette paper and tobacco shreds, the ambergris spices are wrapped by the ambergris capsule, and the ambergris capsule is embedded in the middle of the filter tip. After the tobacco shreds are coiled by the cigarette paper, the cigarette paper and the filter tip are connected to form the cigarette. The ambergris spices are wrapped by the ambergris capsule, then the ambergris capsule is embedded in the filter tip, the capsule is slightly pinched and broken in the use process, it can be guaranteed that the spices are not given out in the transportation and storage process, the persistence of the fragrance is guaranteed, and the original taste of the fragrance of ambergris can be maintained when the cigarette is smoked.

Owner:CHONGQING CHINA TOBACCO IND CO LTD +1

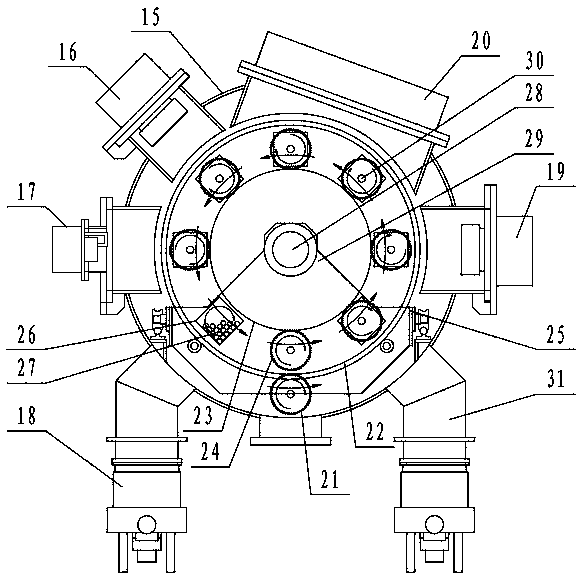

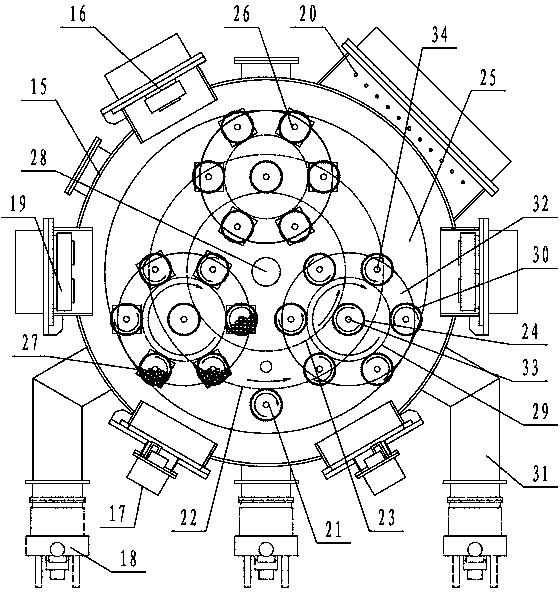

Composite coating equipment and manufacturing method for neodymium iron boron rare-earth permanent magnetic device

InactiveCN103820765AIncrease useImprove corrosion resistanceVacuum evaporation coatingSputtering coatingRare earthPlanar magnetron

The invention discloses composite coating equipment and a manufacturing method for a neodymium iron boron rare-earth permanent magnetic device. The coating equipment comprises a vacuum chamber, a cylindrical rotary cathode magnetron target, a planar cathode magnetron target, a cylindrical or rectangular cathode multi-arc ion target, an anode layer linear ion source, a rotating stand and a charging basket. When the coating equipment works, the rotating stand revolves in the vacuum chamber, and rotating shafts at two ends of the netlike charging basket are arranged on the rotating stand, namely that the rotating stand rotates automatically along with revolution. The cylindrical rotary cathode magnetron target is arranged in the rotating stand in the vacuum chamber; the planar magnetron target, the multi-arc ion target, the anode layer linear ion source and a heating device are arranged around the rotating stand in the vacuum chamber; a composite coating is divided into three layers, wherein the first layer is a magnetron sputtering coating of which the thickness is 0.1-5mu m, the second layer is a magnetron sputtering and multi-arc mixed coating of which the thickness is 1-15mu m, and the third layer is a magnetron sputtering coating of which the thickness is 0.1-5mu m. The composite coating is used for a surface treatment procedure of the rare-earth permanent magnetic device, so that the corrosion resistance of the rare-earth permanent magnetic device is improved, and the magnetic performance of the rare-earth permanent magnetic device is also improved.

Owner:SHENYANG CHINANORTH VACUUM TECH CO LTD

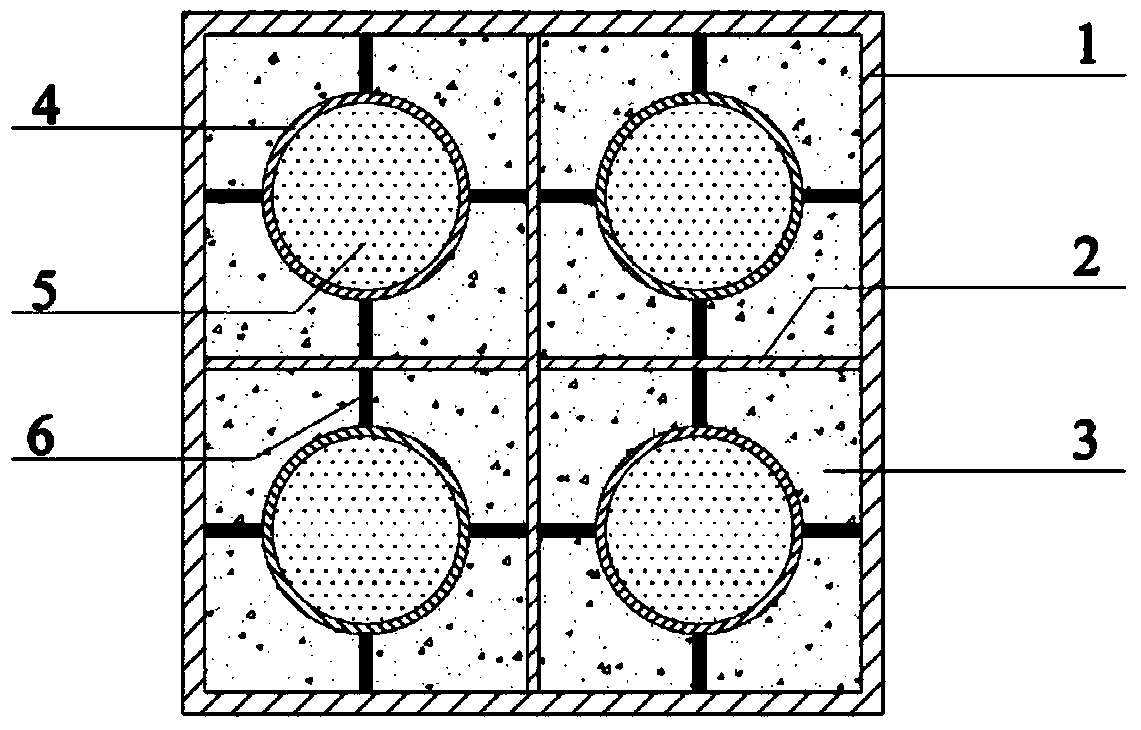

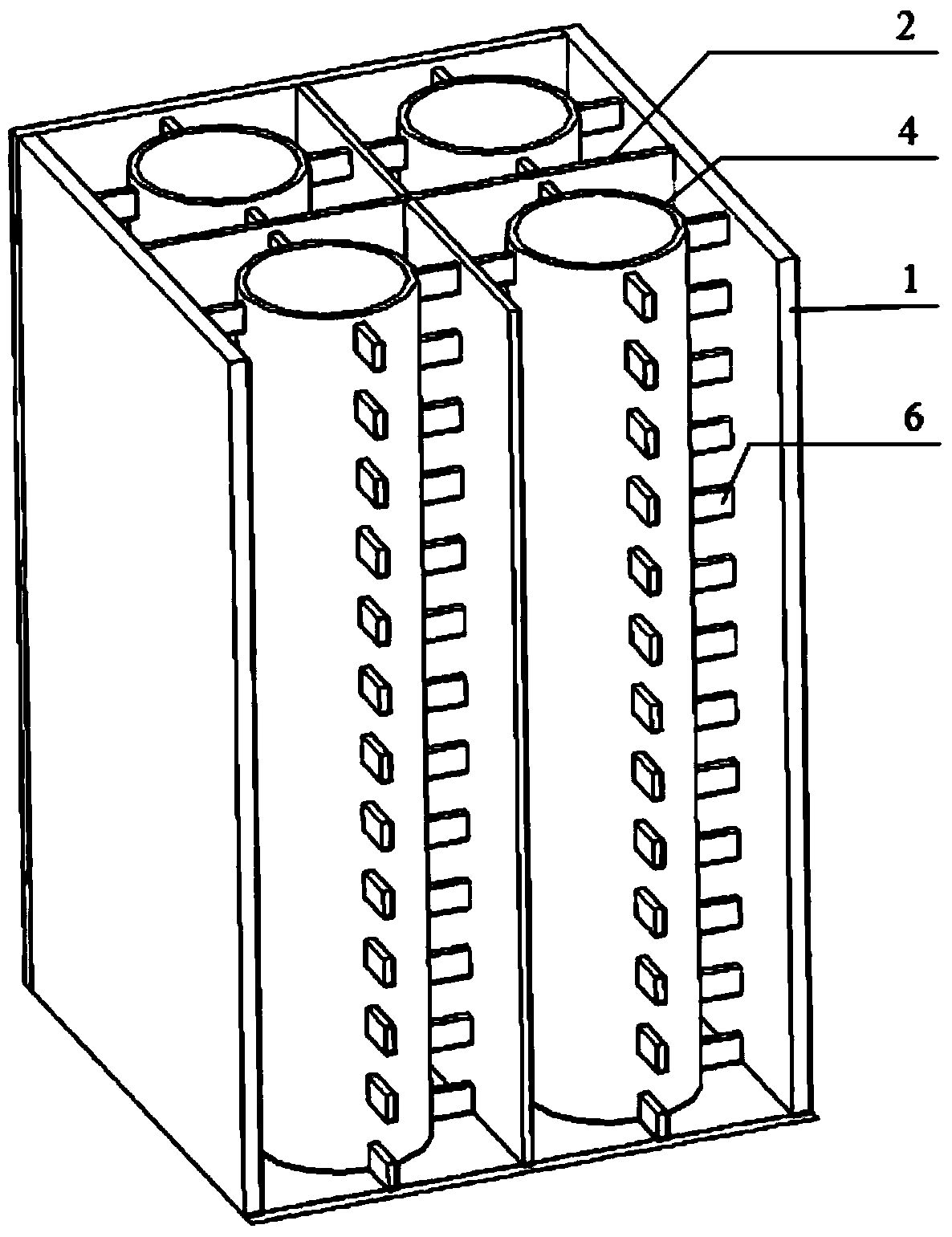

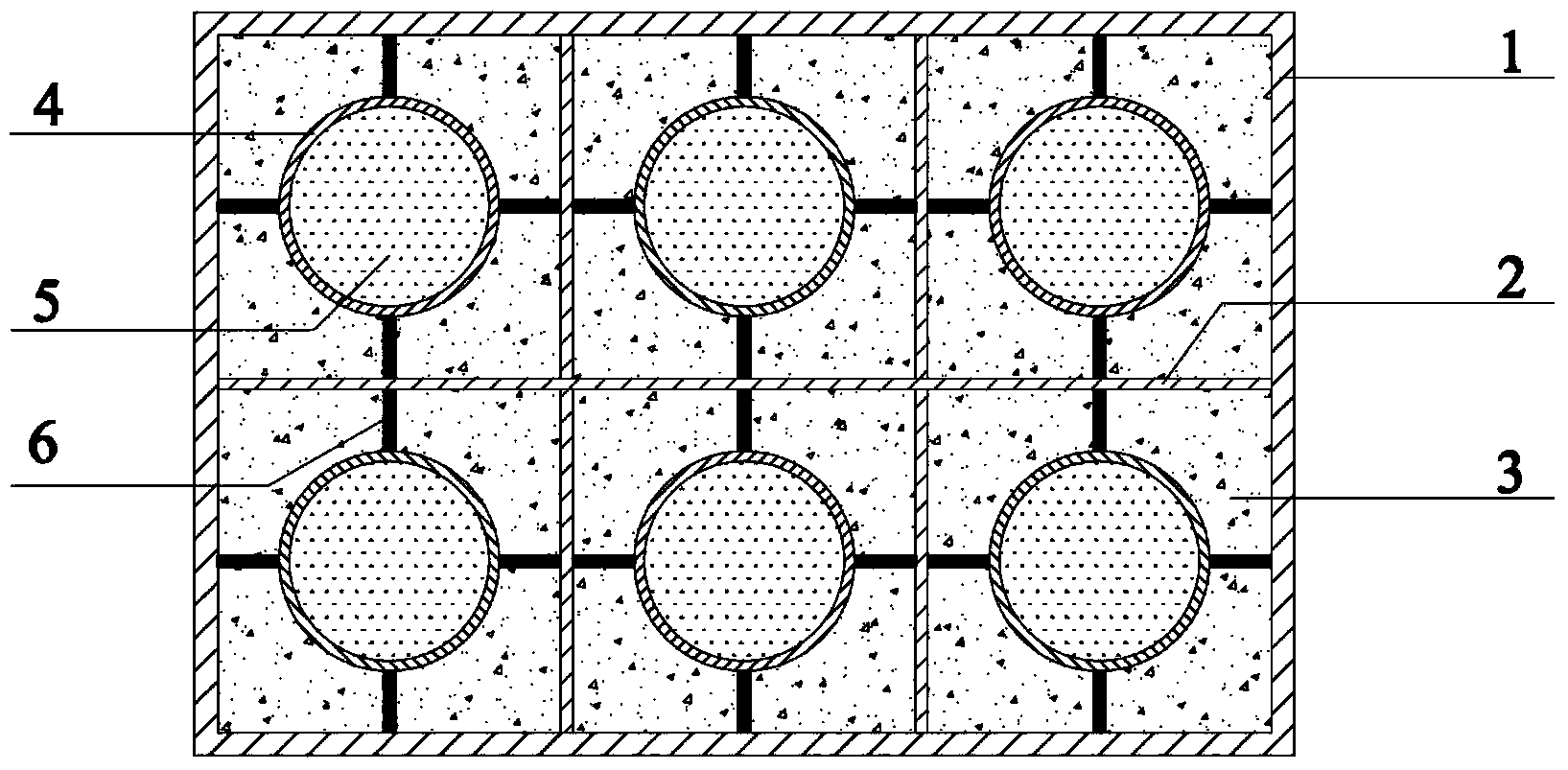

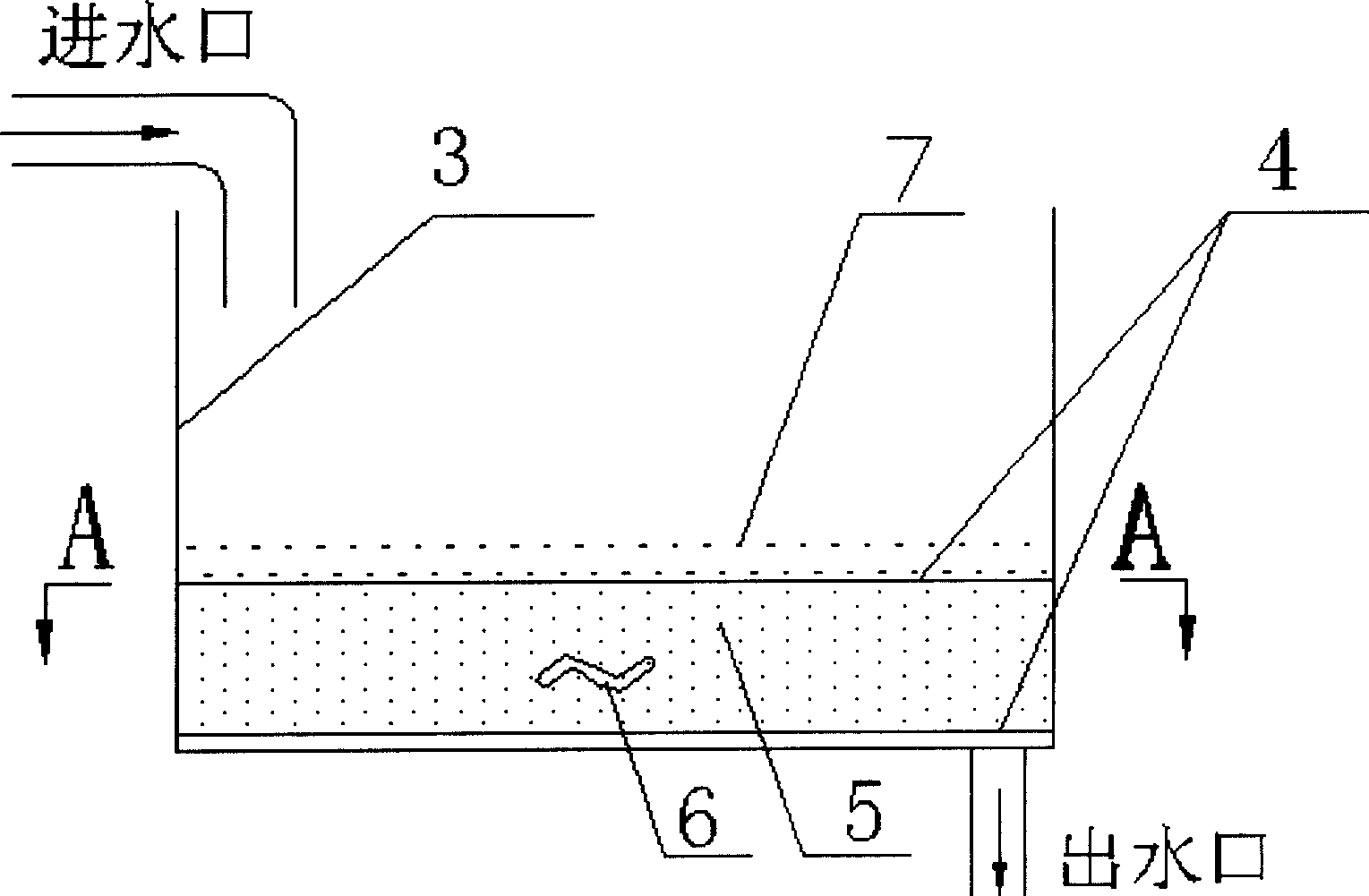

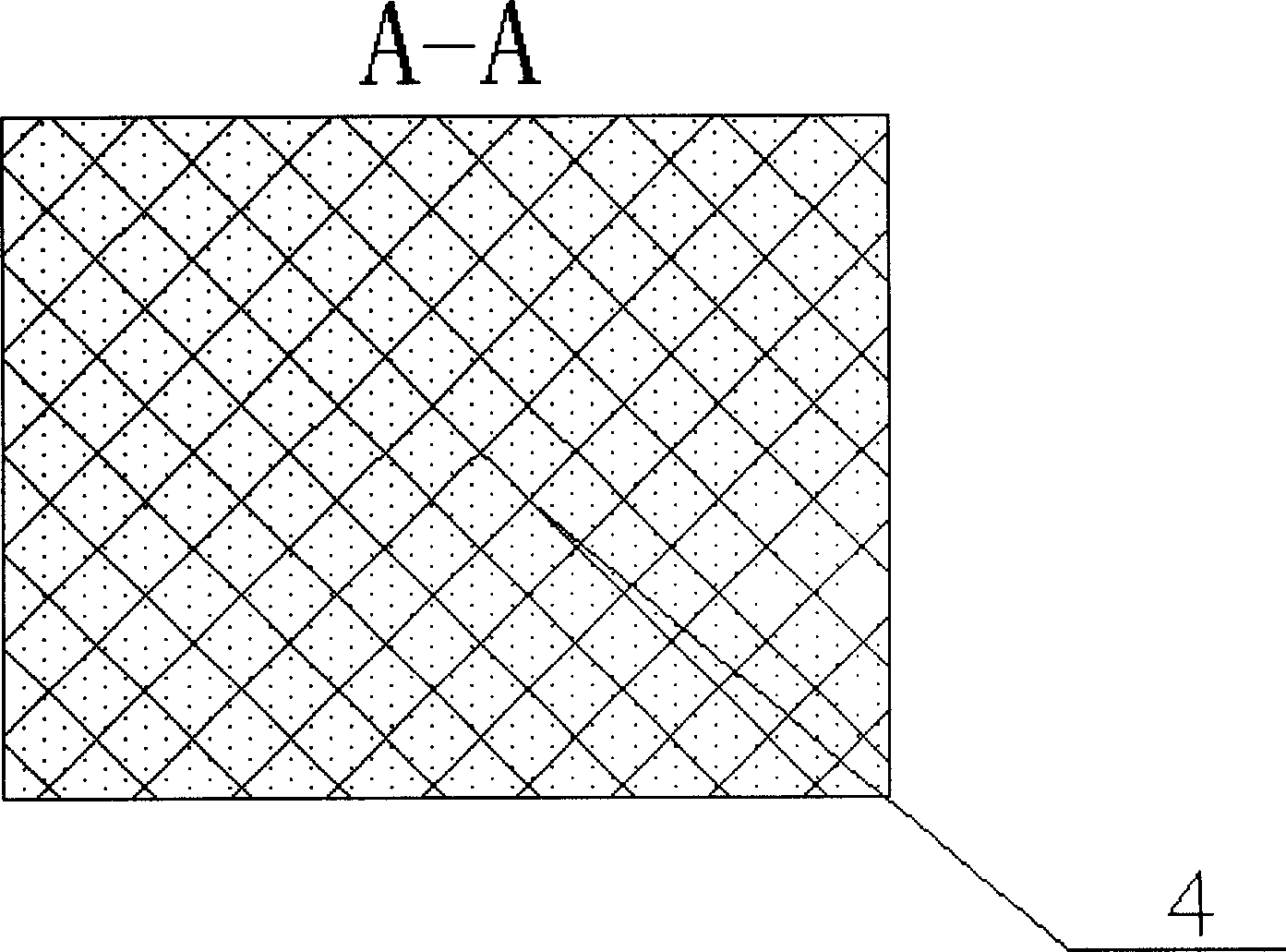

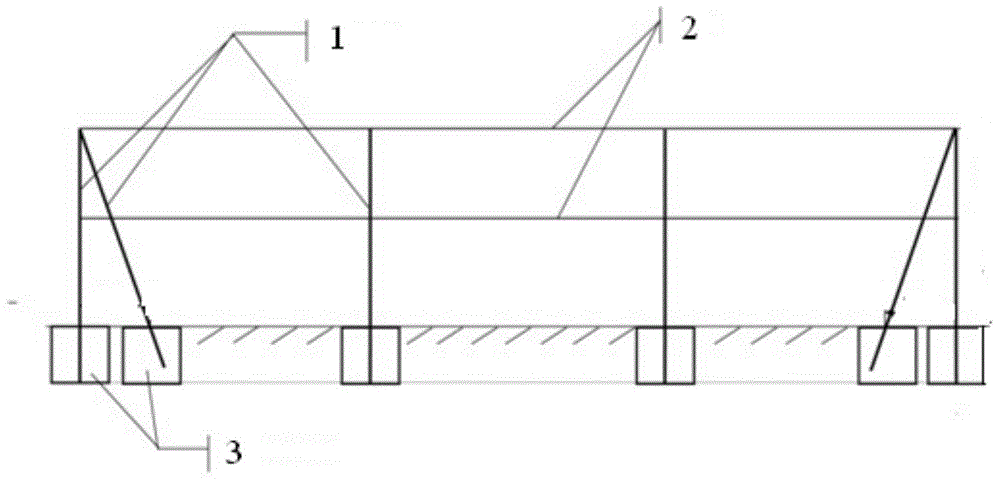

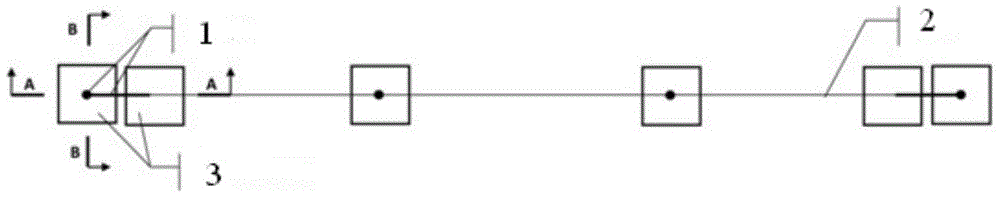

Combined column formed by embedding round steel tubes filled with recycled concrete in multiple-cavity steel pipe filled with concrete and provided with batten plates

ActiveCN103967214AProtect natural resourcesGuaranteed structural performanceStrutsPillarsBattenUltimate tensile strength

The invention provides a combined column formed by embedding round steel tubes filled with recycled concrete in a multiple-cavity steel pipe filled with concrete and provided with batten plates. The combined column comprises a polygonal steel pipe (1), an inner partition board (2), normal concrete (3), the round steel tubes (4), recycled concrete (5) and the batten plates (6), wherein the polygonal steel pipe is divided into multiple small cavities through the inner partition board; the restriction effect of steel plates on the core concrete is improved, so that the concrete is in a three-dimensional pressed state highly, therefore, the concrete strength is improved greatly, and the plasticity and toughness of the concrete are improved remarkably; meanwhile, due to the arrangement of the inner partition board, the stiffness, bearing capacity, ductility and seismic capacity of the whole component are improved to a certain extent; the round steel tubes have the stronger effect of a hoop, so that the influence on stress performance caused by degradation of recycled concrete material performance is reduced even eliminated, the application of the recycled concrete is popularized, and meanwhile, the structural performance is ensured; under the earthquake reciprocating effect, the earthquake energy is consumed through the mutual shearing of the batten plates and the concrete, so that the seismic performance is improved.

Owner:BEIJING UNIV OF TECH

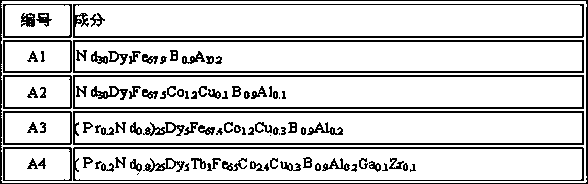

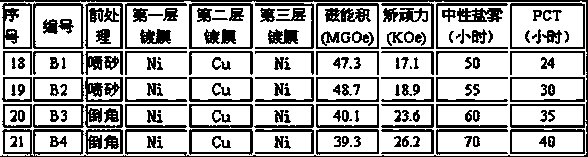

Hybrid film coating method of neodymium iron boron rare earth permanent magnet device

ActiveCN103854819AIncrease useImprove corrosion resistanceVacuum evaporation coatingSputtering coatingMolten stateRare earth

The invention discloses a hybrid film coating method of a neodymium iron boron rare earth permanent magnet device. According to the method, firstly, alloy smelting is carried out, alloy in a molten state is cast onto a rotary copper roller with a water cooling effect for being cooled to be manufactured into an alloy sheet, then, the alloy sheet is subjected to hydrogen decrepitation, material mixing and airflow powder grinding, next, materials are mixed by a material mixing machine and are then sent to a nitrogen gas protection magnetic field orientation pressing machine to be formed, the mixed materials are subjected to isostatic pressing after being encapsulated in a protection box, then, the sintering and the aging are carried out, a neodymium iron boron rare earth permanent magnet blank is prepared, the blank is subjected to machining, a neodymium iron boron rare earth permanent magnet is prepared, next, the neodymium iron boron rare earth permanent magnet is subjected to film coating, the neodymium iron boron rare earth permanent magnet device is formed, the film coating comprises three layers, the first layer and the second layer are magnetron sputtering coatings, and the second layer is a magnetron sputtering and multi-arc ion plating hybrid coating. The hybrid film coating is adopted as a surface treatment work procedure of the rare earth permanent magnet device, the anti-corrosion capability of the rare earth permanent magnet device is improved, and meanwhile, the magnetic performance of the rare earth permanent magnet device is also improved.

Owner:SHENYANG GENERAL MAGNETIC

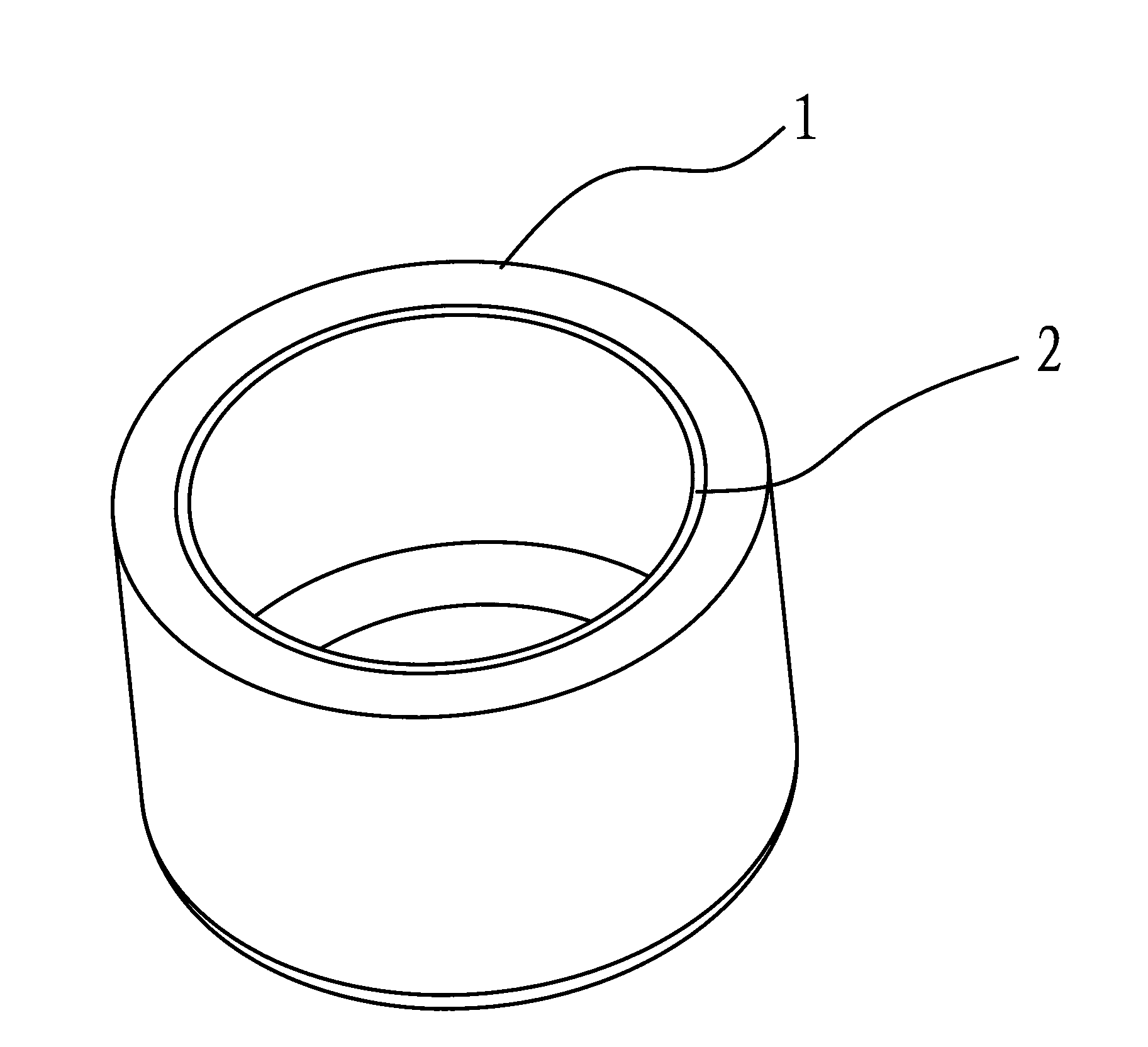

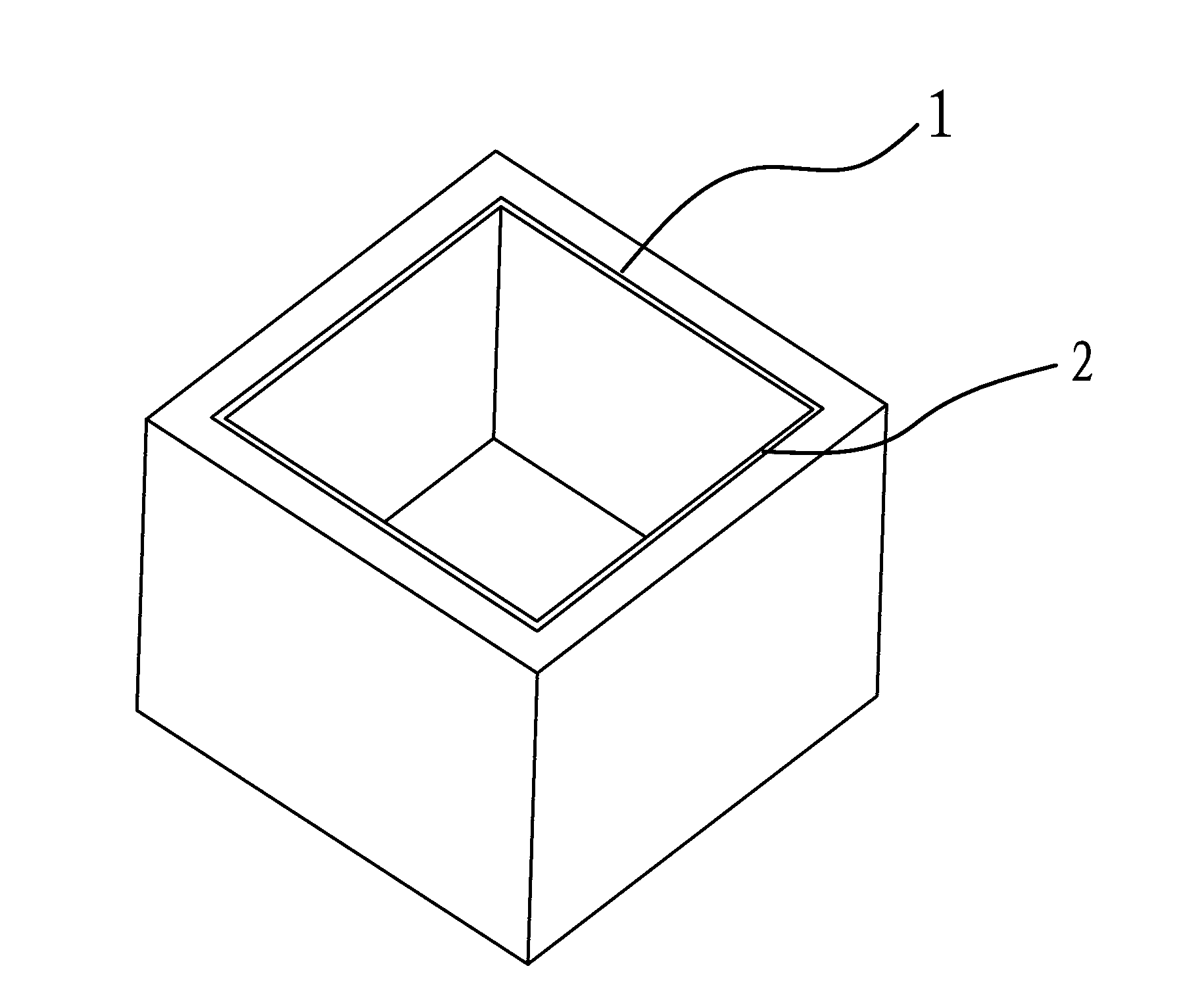

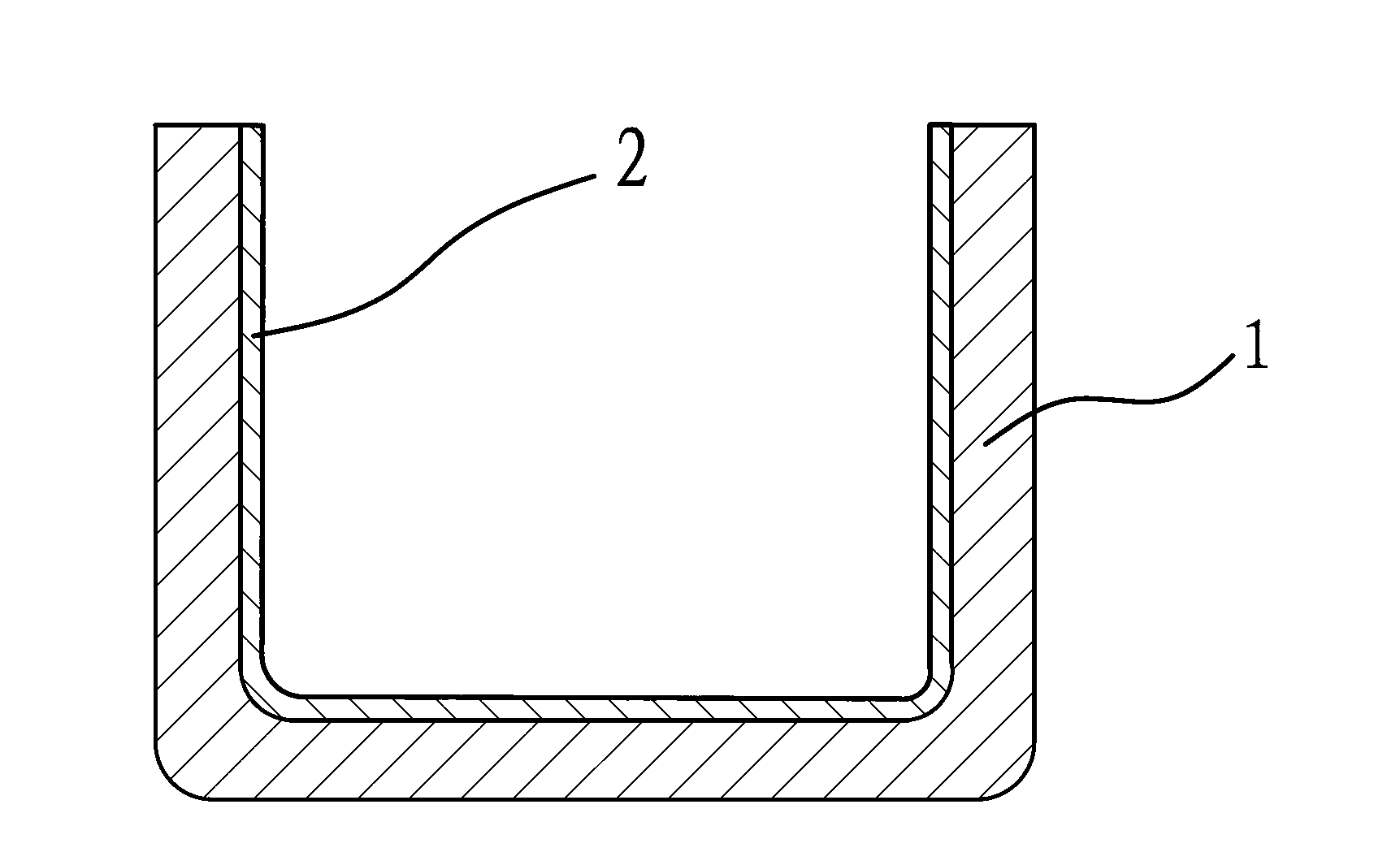

Crucible for melting crystalline silicon, method for producing crucible and spray coating liquid

InactiveCN102797042AIncreased swelling resistanceExtended service lifeAfter-treatment apparatusPolycrystalline material growthCrucibleSpray coating

The invention relates to a crucible for melting crystalline silicon, a method for producing the crucible and a spray coating liquid, belongs to the technical field of crucibles, is used for solving the problem that the coating of the existing crucible is easy to peel off and damage during the use process, so impurities cannot be well prevented from permeating, and aims to provide the spray coating liquid for a coating of a crucible for melting crystalline silicon. The spray coating liquid comprises silicon nitride, a sintering additive, and organic binder, inorganic binder and a sintering binder which can be bonded with a crucible body at normal temperature. The invention further provides the crucible which adopts the spray coating liquid. The crucible comprises a crucible body, the internal surface of the crucible body is coated with a coating, and the coating is formed by spraying the spray coating liquid. The invention also provides the method for producing the crucible, which produces the crucible for melting crystalline silicon through spray coating, drying, burning off and sintering. The crucible can be repeatedly used, the coating is not easy to peel off and damage, so the impurities, particularly oxygen element in the crucible body can be effectively prevented from permeating.

Owner:TAIZHOU BEYOND TECH

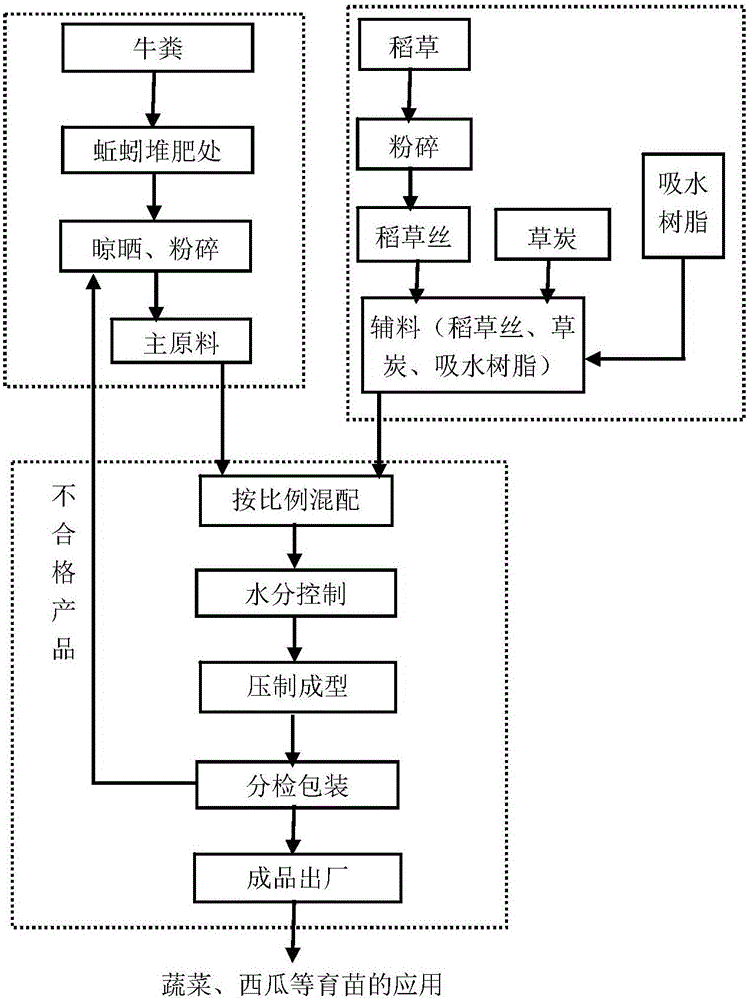

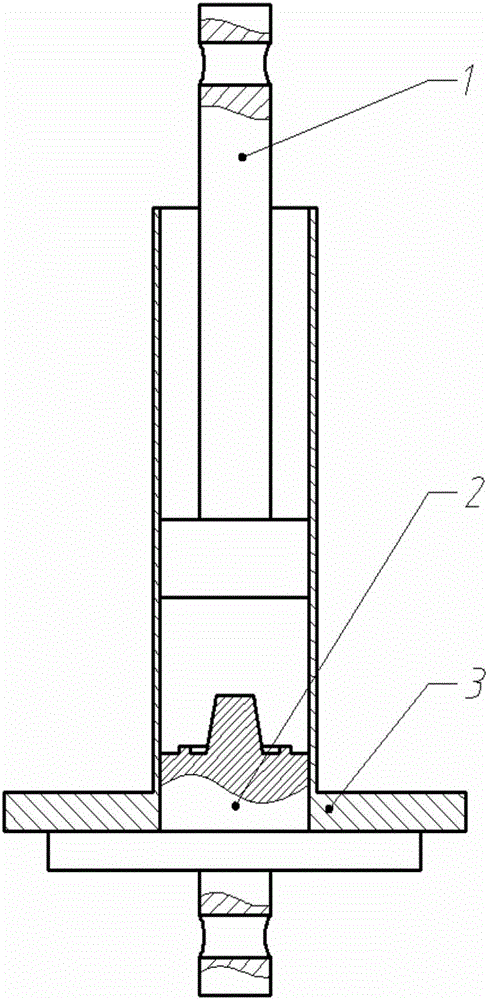

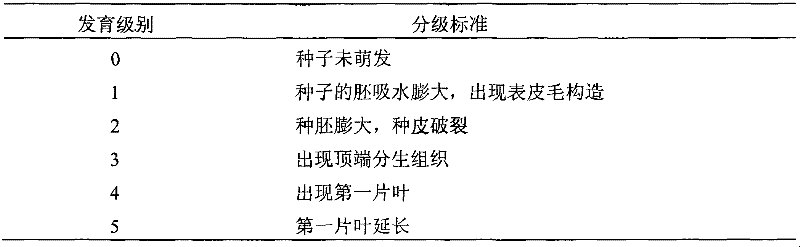

Bovine dung vermicompost seedling culture matrix block and preparation method thereof

InactiveCN105777354AReduce usageReduce pollutionBio-organic fraction processingExcrement fertilisersPeatPollution

The invention belongs to the technical field of agricultural and horticultural fertilities and particularly relates to a bovine dung vermicompost seedling culture matrix block and a preparation method thereof. The preparation method includes steps: properly grinding raw materials including wastes of straws, bovine dung vermicompost materials and the like, adding appropriate peat and water-absorbent resin as an expanding agent and a soil sterilizing agent, adjusting, mixing and using a special forming device to realize primary compression and forming to produce the seedling culture matrix block suitable for agricultural and horticultural plants. The invention further discloses corresponding technical steps. Recycling of wastes is realized, and the prepared seedling culture matrix block is rich in nutrition and meets requirements of seedling growth and development of agricultural crops, melons, fruits, vegetables and the like. In addition, environment pollution caused by plastic cave dishes can be reduced while seedling transplantation integration can be realized. The bovine dung vermicompost seedling culture matrix block and the preparation method thereof have the advantages of freeness of root injuries, seedling injuries and a rejuvenation period, high in survival rate and the like.

Owner:HUAZHONG AGRI UNIV

Two fungi for promoting seeds of Dendrobium to sprout

ActiveCN102127510AIncrease productionSolve the problem of shortage of medicinal resourcesFungiMicroorganism based processesSeedlingDendrobium

The invention discloses two fungi for promoting seeds of Dendrobium to sprout, which have great application value on sexual propagation of Dendrobium, mass production of seedlings and sustainable utilization of resources.

Owner:INST OF MEDICINAL PLANT DEV CHINESE ACADEMY OF MEDICAL SCI

Environment protection baking-free sludge brick and production method thereof

The invention relates to an environment-friendly baking-free sludge brick and a production method thereof. The main compositions of the sludge brick are sludge, sand and cement, and auxiliary chemical raw materials are saturated solvent of potassic salts such as potassium permanganate taken as an oxidant. The invention adopts production processes of waterlogging, oxidation, curing, condensation, moulding and demoulding, fully and effectively utilizes various types of sludge, purifies the environment, does not need to chop hills to unload soil, and protects natural resources; the baking-free technology not only is energy-saving but also reduces the production cost, and has reasonable technological design, simple and convenient operation and no secondary pollution; the brick can be delivered after naturally dried in the air for 15 days, and the quality of the brick completely accords with the national standards; the shaping randomness is strong, and tiles, street bricks and so on can be manufactured only by adoption of different dies; and the environment-friendly baking-free sludge brick has considerable social benefit and economic benefit and obvious promotion value and application value.

Owner:汉寿县永兴砖厂

Steel slag double-layer permeable pavement and production method thereof

InactiveCN101158141AAnti-major blockageImprove aestheticsIn situ pavingsSolid waste managementSlagPortland cement

The invention discloses a steel slag double layer water permeable pavement, which is characterized in that the pavement comprises two layers, wherein, a first layer covers a second layer and comprises the following components according to weight: A. 42.5 ordinary Portland cement: one portion; B. water: 0.25 to 0.35 portions; C. fine steel slag: 4.0 to 7.0 portions, and a diameter of the fine steel slag grain is 1 to 3mm; D. admixture: 1.0 percent to 5.0 percent, and the weight of the cement is taken as the benchmark. The second layer comprises the following components according to weight: a. 42.5 ordinary Portland cement: one portion; b. water: 0.25 to 0.35 portions; c. coarse steel slag: 4.0 to 7.0 portions, and a diameter of the coarse steel slag is 5 to 12mm; d. admixture: 1.0 percent to 5.0 percent, and the weight of the cement is taken as the benchmark. The steel slag double layer water permeable pavement of the invention enjoys a compressive strength in 28 days that is more than or equal to 20 MPa, a bending strength that is more than or equal to 4.5 MPa, and a permeability coefficient that is larger than 1mm / s. In the aspects of bending strength, compressive strength, anti big particle wastes blockage and elegance, the invention is relatively advantageous, compared with a single layer steel slag water permeable concrete pavement.

Owner:MCC BAOSTEEL TECH SERVICE

Plant seed discus basalis and the preparing method and the using method

InactiveCN101080992AImprove the immunityLittle land requirementCultivating equipmentsForestryPlanting seedOrganic matter

The tree planting disc is made with clay and organic matter in the volume ratio of 2 / 3-1 as well as slow released fertilizer and water, and through mixing to form mixture with water content of 40-60 % and forming the mixture into disc. When the tree planting disc is applied, it is set in hole and covered with soil of 1-2 cm thickness before seeding, covering the seed with soil and densifying. The tree planting disc may be used with regenerated material, can ensure good growth condition for tree seedling, and has low cost.

Owner:HENAN AGRICULTURAL UNIVERSITY

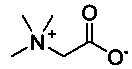

Glycine betaine surfactant composition system and purpose thereof

The invention discloses a glycine betaine surfactant composition system and a purpose thereof. The glycine betaine surfactant composition system comprises one or more mixtures of a glycine betaine surfactant and an anionic surfactant. The glycine betaine surfactant comprises alkyl dimethyl betaine, alkyl amide propyl dimethyl betaine, alkyl sulphobetaine and alkyl hydroxy sulphobetaine. The use concentration ratio of the glycine betaine surfactant and the anionic surfactant, by 100% pure activity, is 1:0.1-10. The glycine betaine surfactant composition system is used for chemical displacement of reservoir oil, and enables the oil deposit of an oil well in which secondary oil-production efficiency in the later period is decreased seriously to be developed by 10-15%, and the economic efficiency is very obvious. Moreover, the use concentration is low, and cost is lowered greatly. Due to the fact that other conventional alkalis are of no need, the select face of polymers is made to be wider, and the significance for protecting natural resources is great.

Owner:SHANGHAI HAIGUI CHEM TECH CO LTD

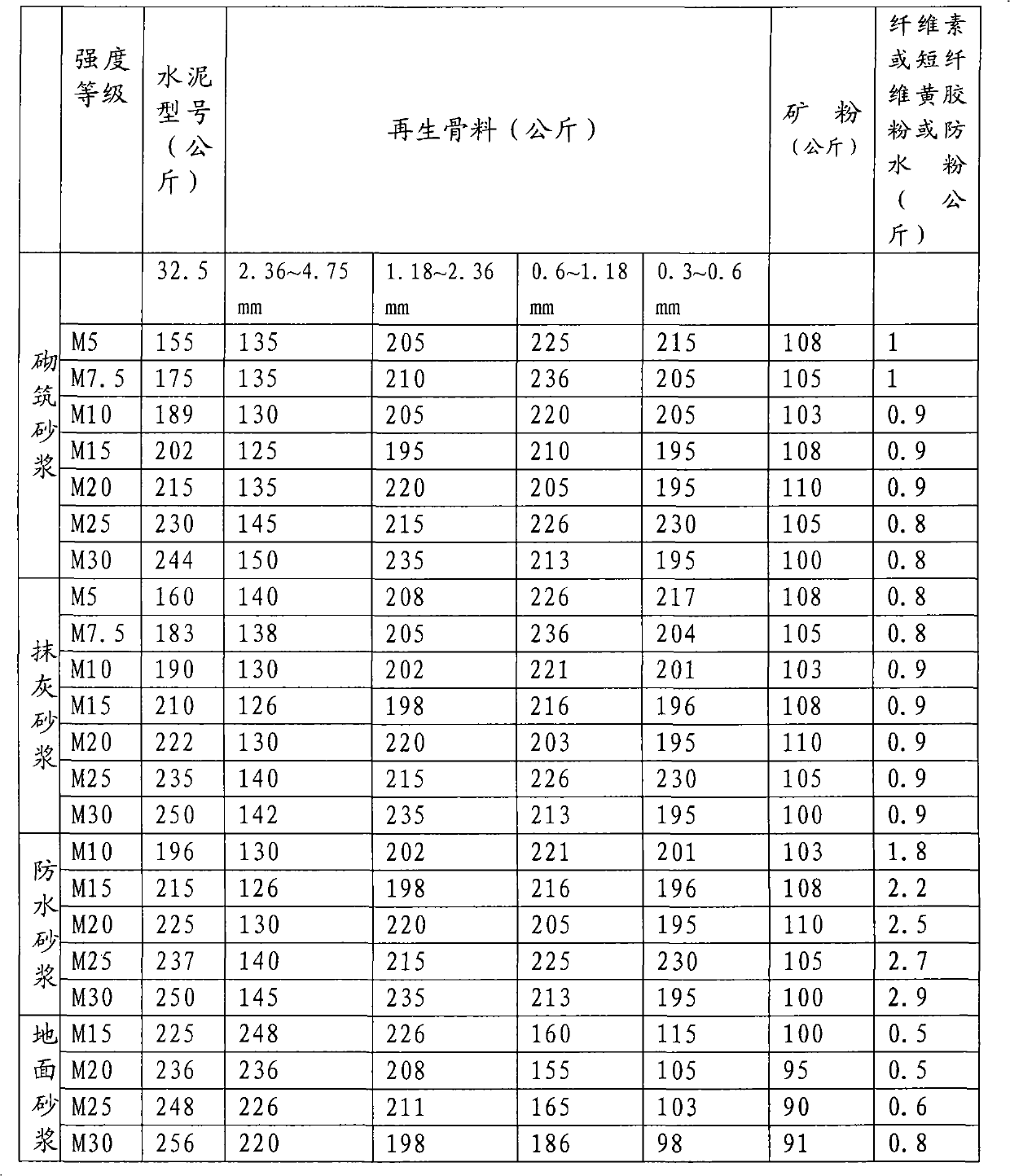

Recycled aggregate special mortar preparation method

InactiveCN102701665AProtect natural resourcesSave labor, save time and effort, and save additional costsSolid waste managementFilling pastesHardnessMoisture

Owner:SHENZHEN WEILUN BUILDING MATERIALS

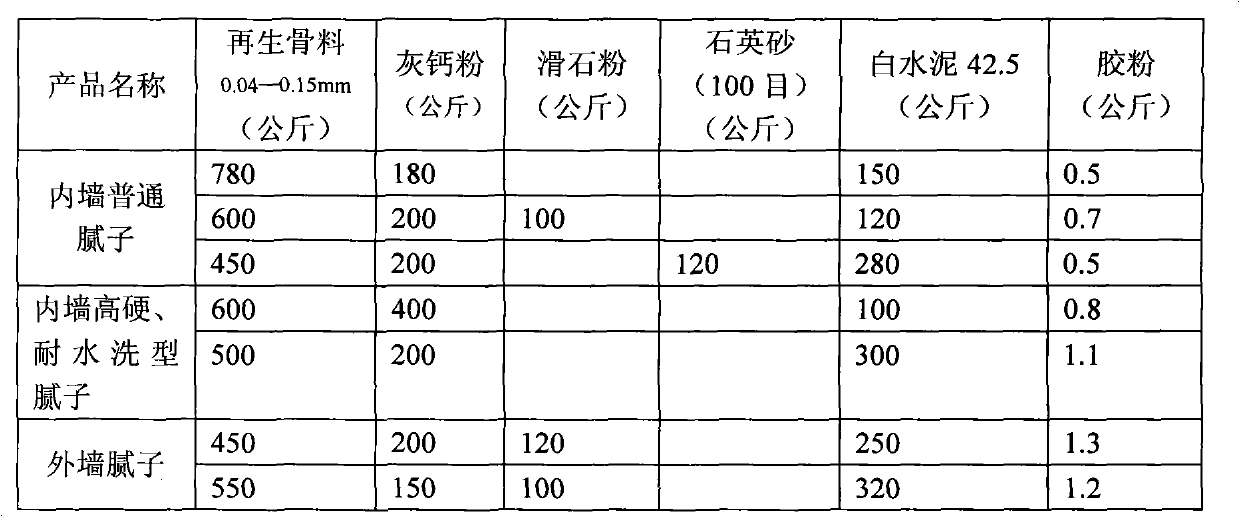

Method for preparing urea ardealite by solution crystallization method taking ardealite as raw material

The invention discloses a method for preparing urea ardealite by a solution crystallization method taking ardealite as raw material. The method comprises the following steps of: (1) preparing a saturated urea aqueous solution, and adding ardealite, soluble phosphate and urea into the saturated urea aqueous solution to form slurry; (2) in the conditions of normal pressure and normal temperature, uniformly mixing the slurry and performing crystallization reaction to obtain urea ardealite slurry; and (3) performing solid-liquid separation on the urea ardealite slurry, and then drying the solid phase to obtain the urea ardealite. According to the invention, on the conditions of normal pressure and normal temperature, ardealite, soluble phosphate and urea are used as raw materials, a solution crystallization method is adopted, the investment is small, and the operation is convenient; and the prepared urea ardealite has the characteristics of regular crystal form, uniform granularity, accurate adjustment of purity and stable quality.

Owner:ZHEJIANG UNIV

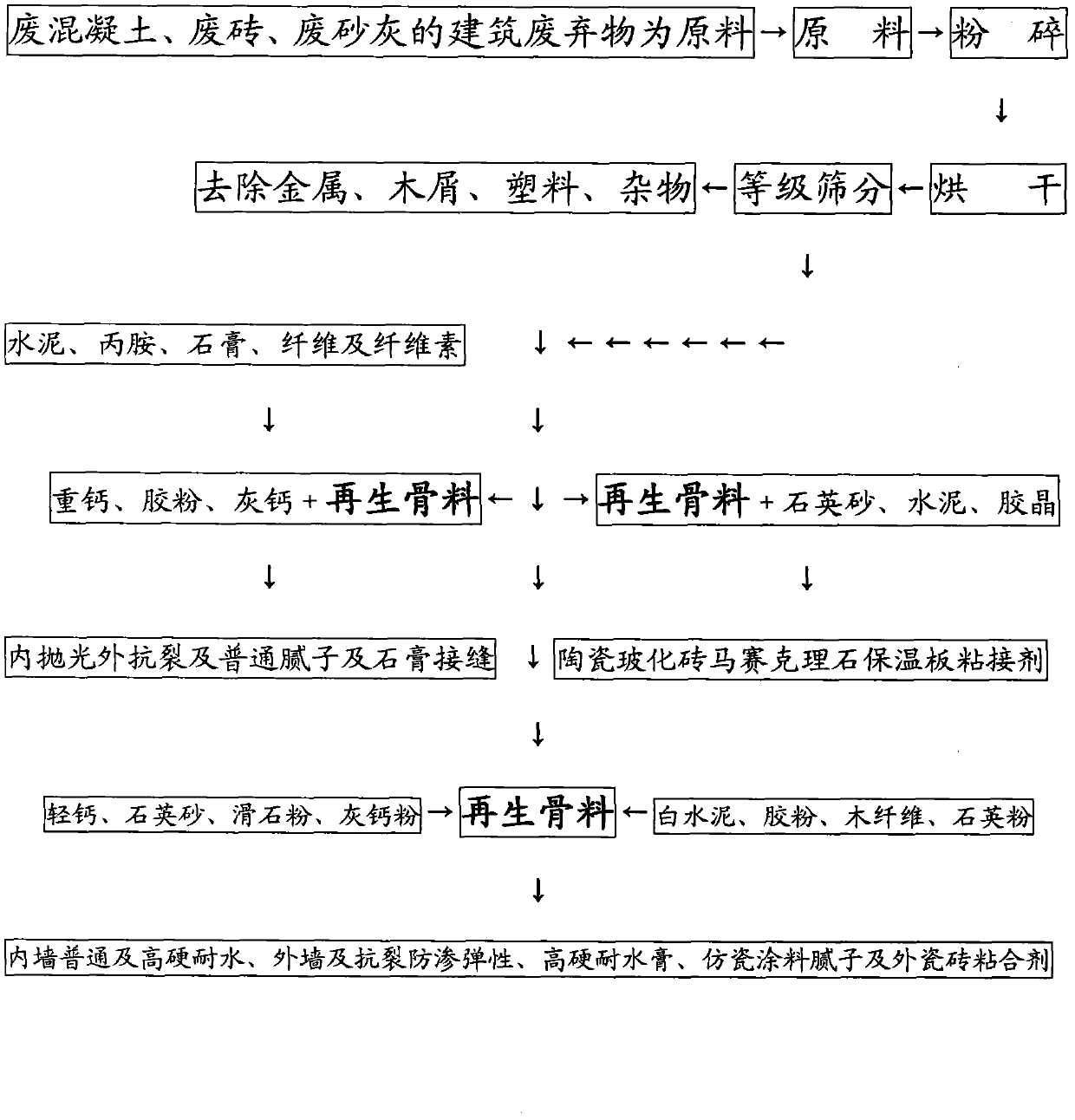

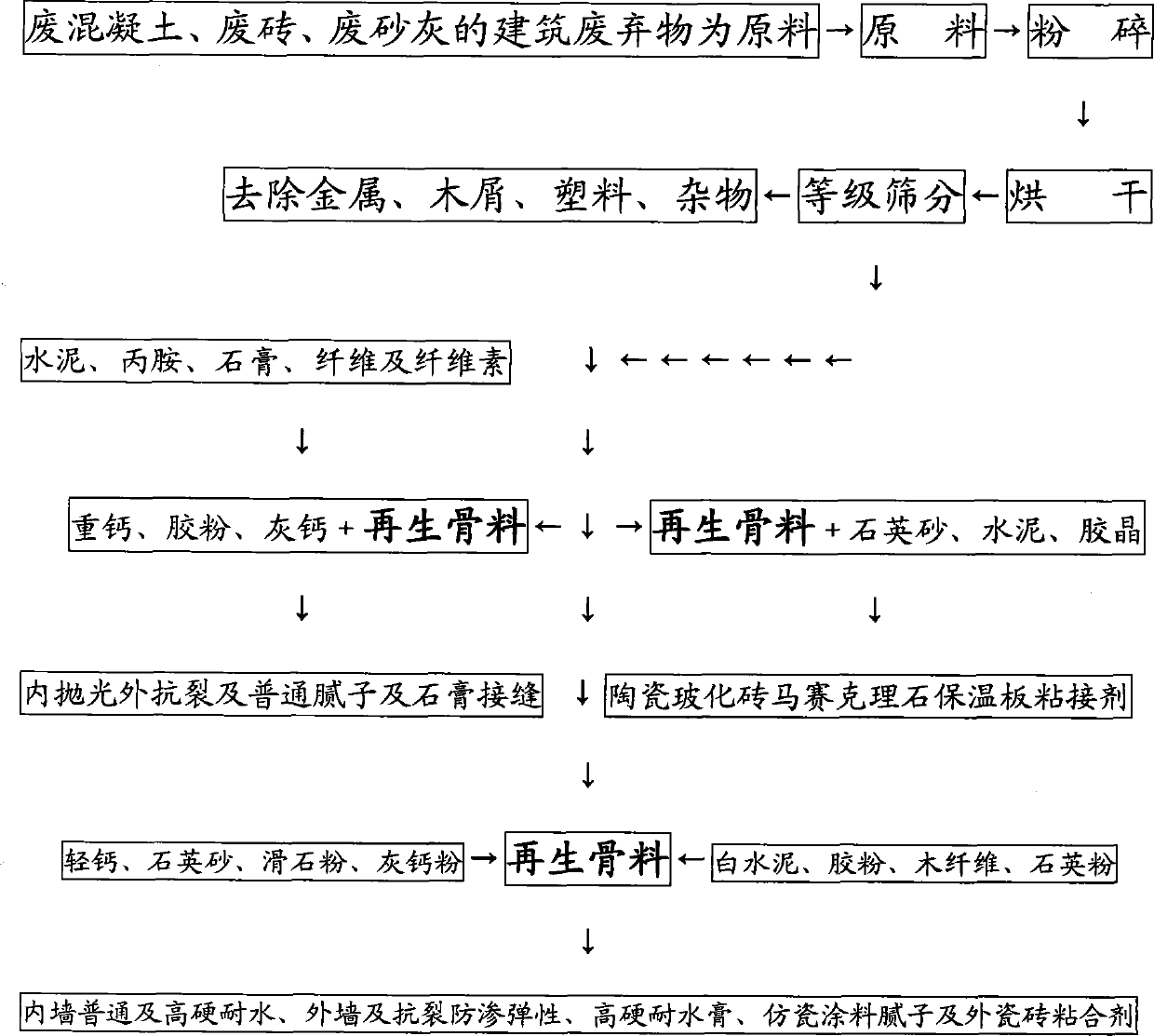

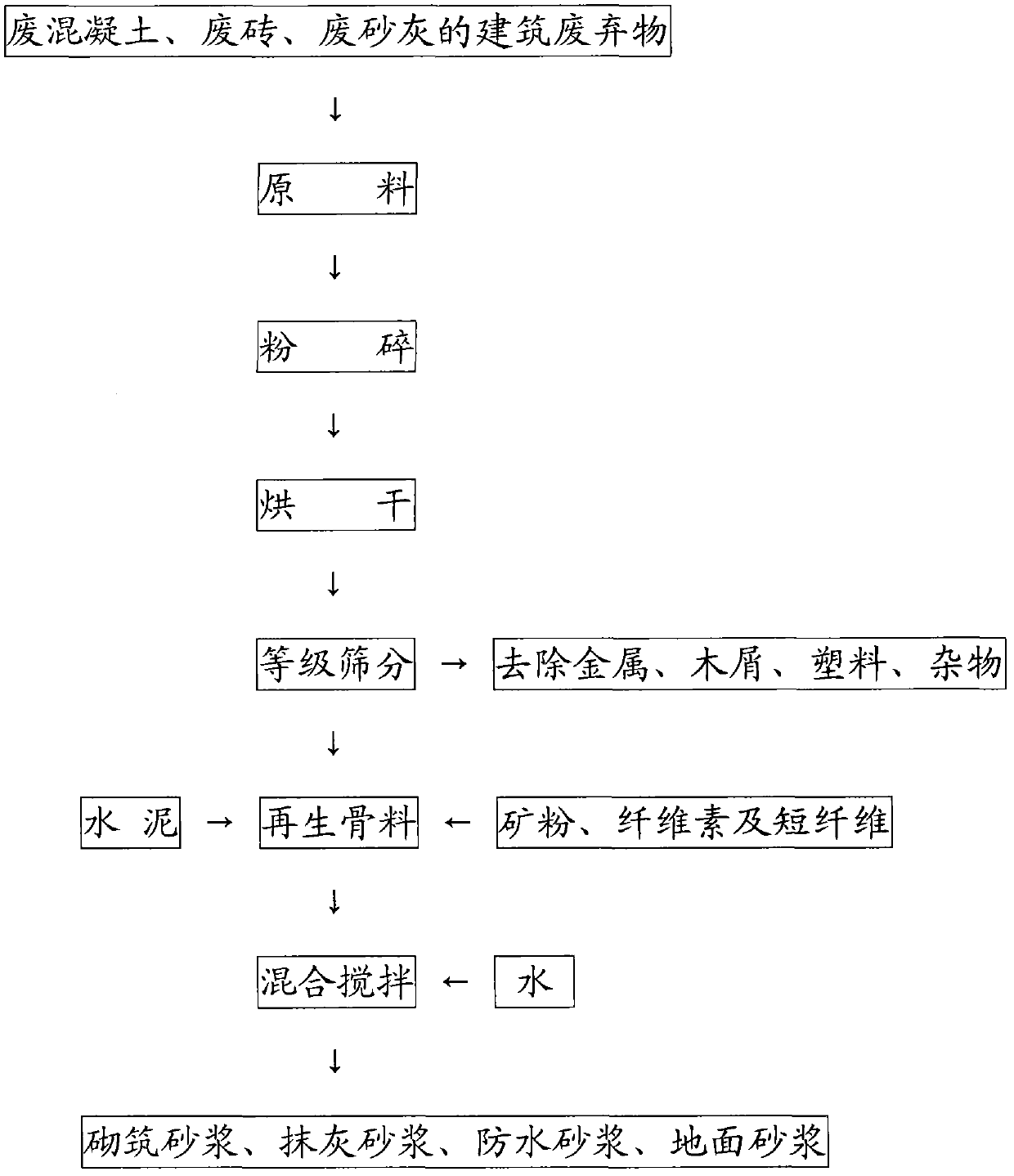

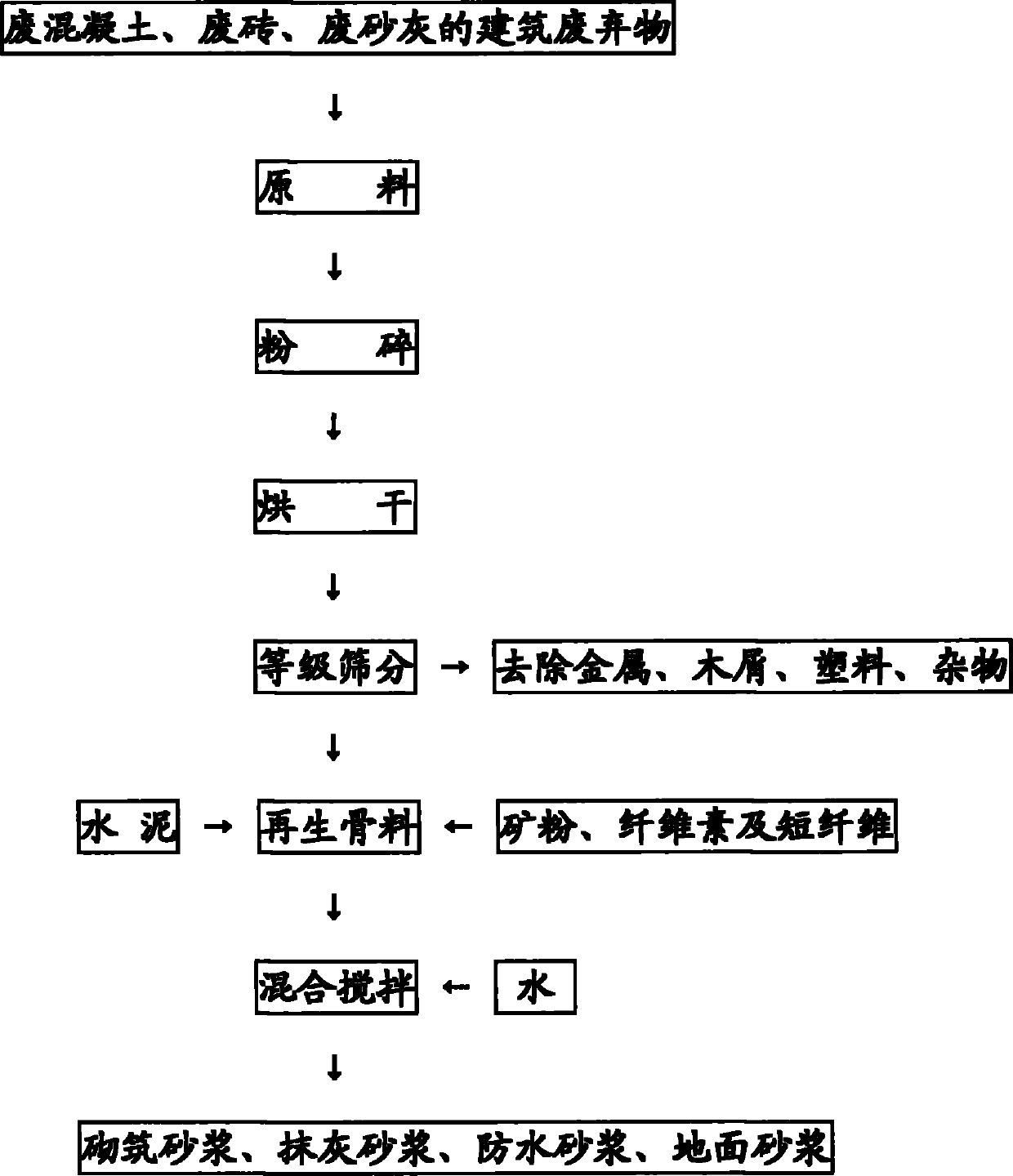

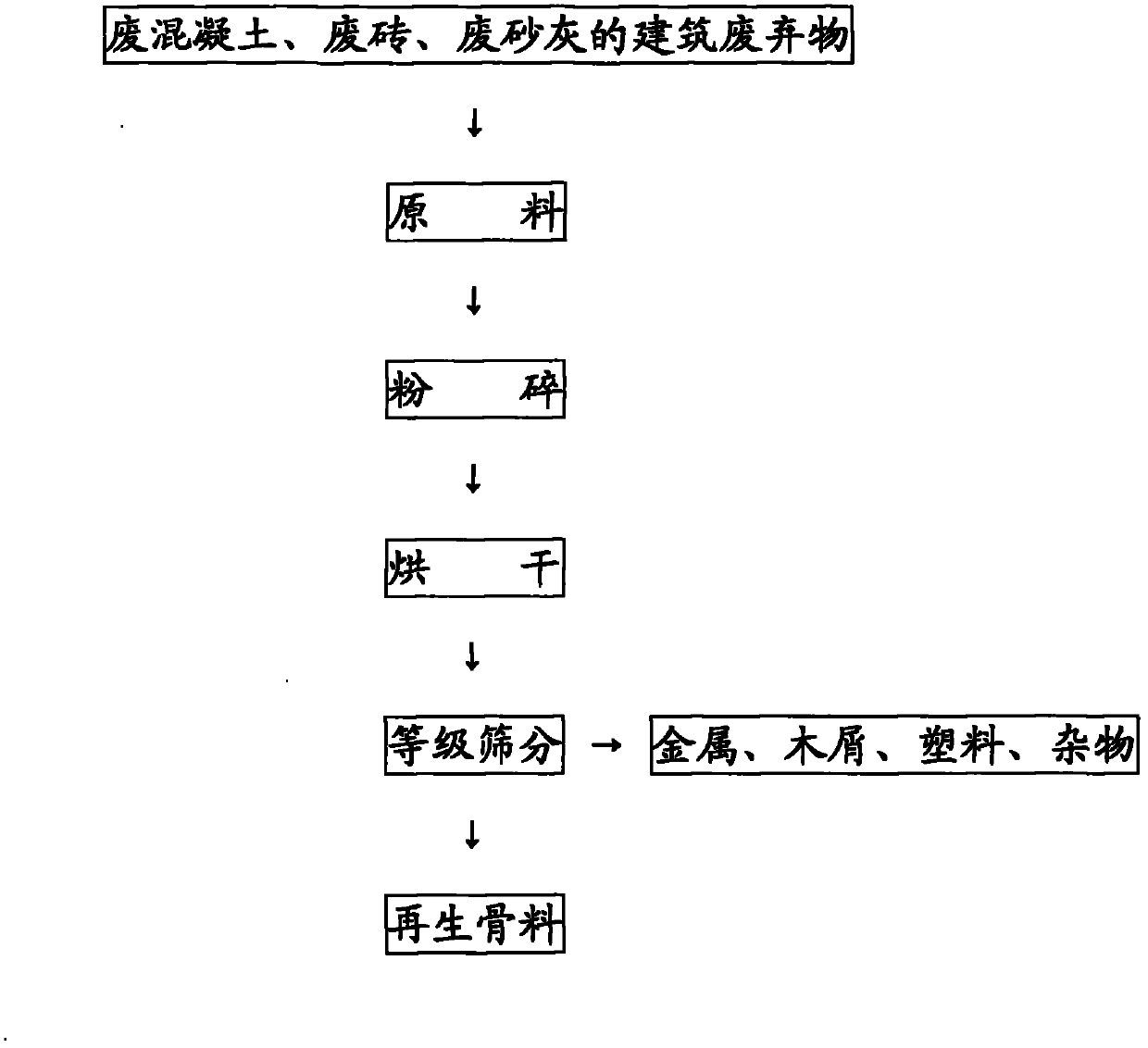

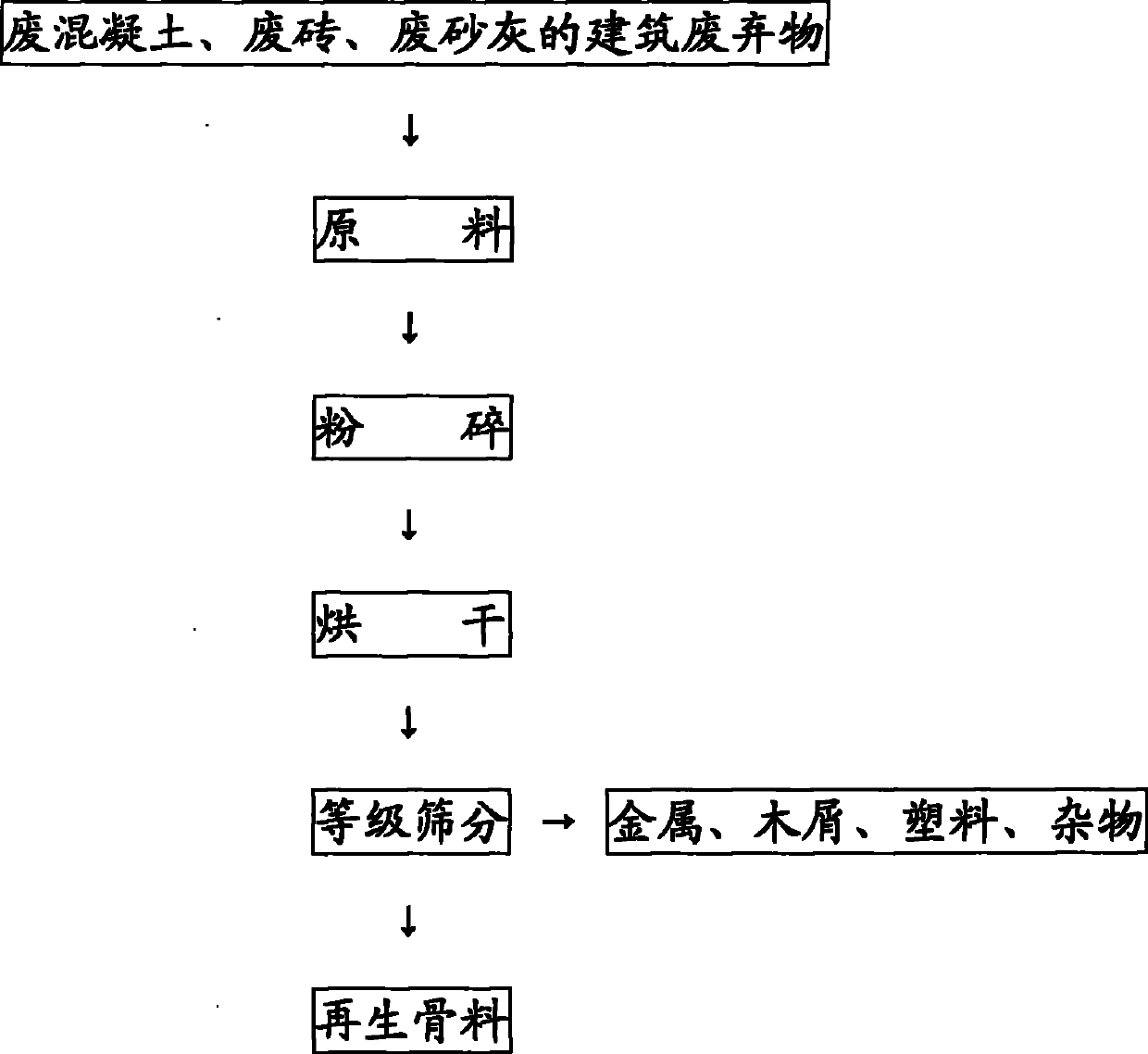

Preparation method of recycled aggregate ready-mixed mortar

InactiveCN102701647AEffective protectionEffective consumptionSolid waste managementFiberNatural resource

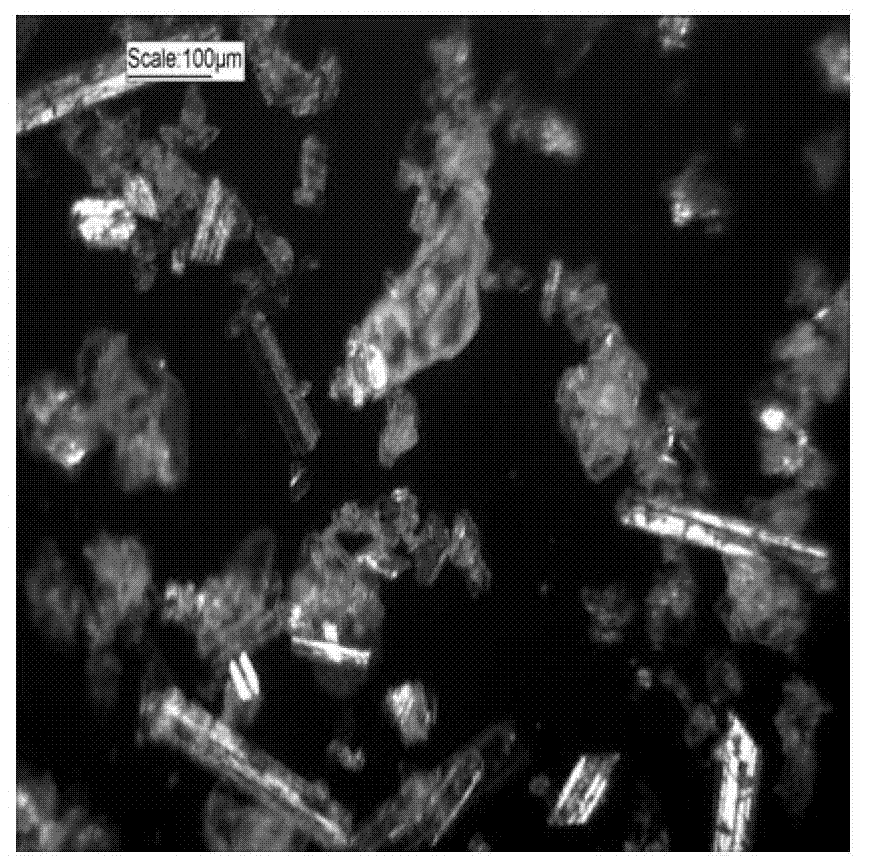

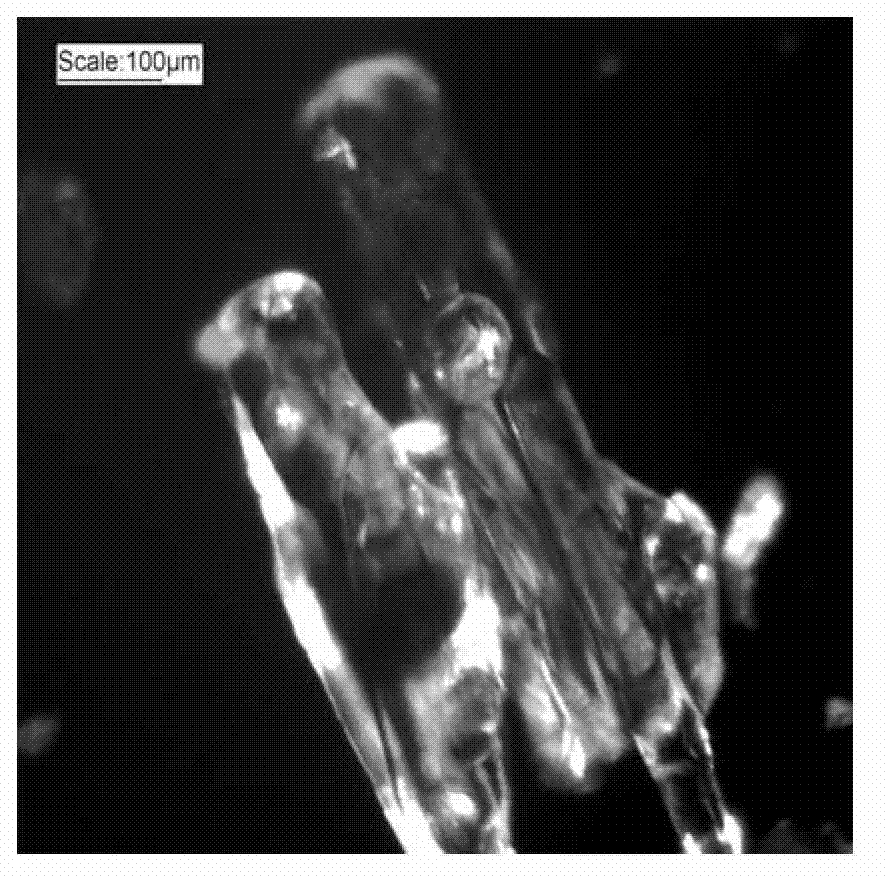

The invention relates to a preparation method of recycled aggregate ready-mixed mortar, belonging to the field of building raw materials. The preparation method comprises the following steps of: taking waste concrete, waste bricks and waste sand-lime building materials, which are smaller than 690mm, as raw materials, determining the quantity according to the needs, crushing and drying till the water content is not more than 0.5%, and then performing graded screening so as to prepare recycled aggregate with the particle sizes of 0.075-0.15 mm, 0.15-0.3 mm, 0.3-0.6 mm, 0.6-1.18 mm, 1.18-2.36 mm, 2.36-4.75 mm, 4.75-10 mm and 10-32 mm, wherein metal, wood chips, plastics and other sundries are removed in the graded screening, and the masonry, plastering, waterproof or ground mortar can be respectively prepared by enabling the proportion of the sum of one of the recycled aggregate, cement, powdered ore and cellulose, and short fiber, xanthan gum powder and waterproof powder to the added water to be 1: 0.18. The recycled aggregate ready-mixed mortar can be used as a building raw material. The preparation method has the advantages of protecting natural resources, saving labor, saving time, saving effort, realizing low cost, changing the wastes into valuable things, and meeting the requirements of low-carbon production and living.

Owner:伏开磊 +1

Preparation method of recycled aggregate from building wastes

The invention discloses a preparation method of recycled aggregate from building wastes, relating to the technical field of building raw materials. The preparation method comprises the following steps of: adopting a waste utilization technology, taking waste concrete, waste bricks and waste sand-lime building materials, which are smaller than 690mm, as raw materials, determining the quantity according to needs, crushing, further drying till the water content is not more than 0.5%, and then performing graded screening so as to prepare the recycled aggregate with the particle sizes of 0.075-0.15 mm, 0.15-0.3 mm, 0.3-0.6 mm, 0.6-1.18 mm, 1.18-2.36 mm, 2.36-4.75 mm, 4.75-10 mm and 10-32 mm and store the recycled aggregate with the different particle sizes respectively, wherein a magnet is applied in the graded screening process for removing metal as well as removing wood chips, plastics and other sundries according to the specific gravity. The recycled aggregate can be used as a building raw material. The preparation method has the advantages of protecting natural resources, saving labor, saving time, saving effort, realizing low cost, changing the wastes into valuable things, and meeting the requirements of low-carbon production and low-carbon living.

Owner:伏开磊 +1

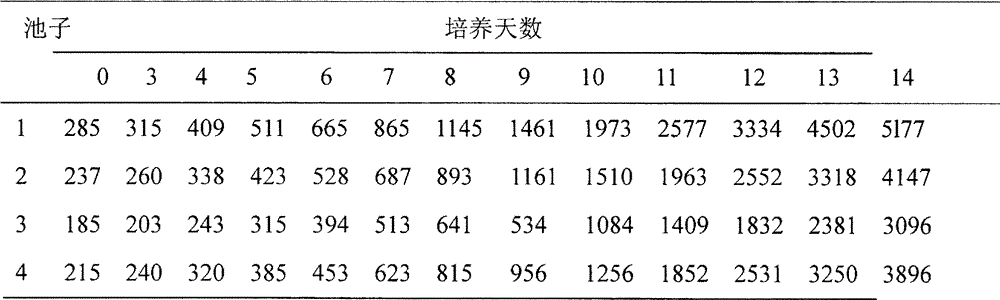

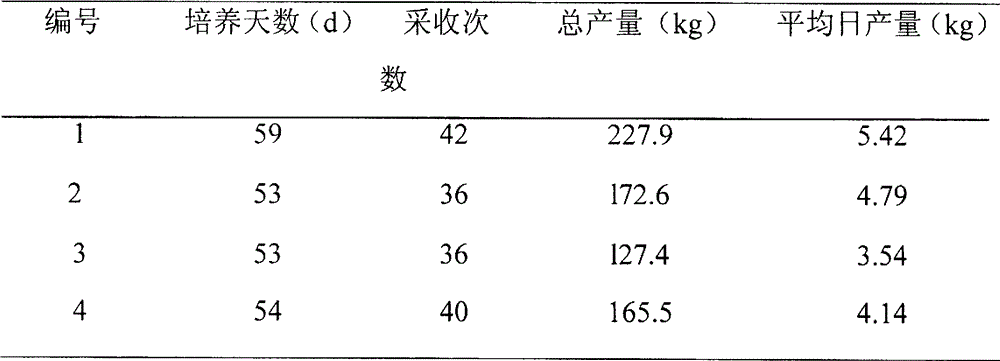

Intensive production method for Mongolian Moina

InactiveCN102972357AImprove reproductive abilityHigh nutritional valueAnimal feeding stuffCultivating equipmentsPhacusAquatic product

The invention relates to the field of aquatic baits and discloses an intensive production method for Mongolian Moina. Characteristics of the Mongolian Moina at all stages are known based on the comprehensive study on aspects of the Mongolian Moina, such as reproduction, development, ingestion, growth and the like. The Mongolian Moina is cultivated to achieve the intensive production by using an indoor cement pool and an outdoor pool, and a scientific and feasible practical technology which can also can utilized fully in production is formed, so that the current situation that a biological bait market is in short supply in the area in seedling production currently is alleviated.

Owner:GUANGXI LANHAO MARINE ORGANISM SCI & TECH

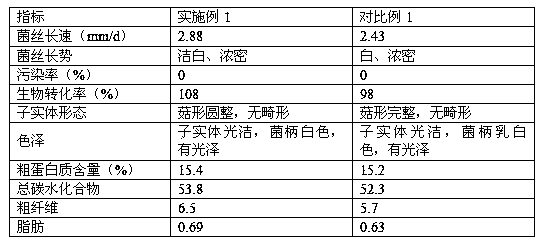

Pleurotus eryngii culture medium containing rubber tree sawdust and preparation method of pleurotus eryngii culture medium

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI

Clam worm culturing metod

A method for raising clam worm includes such steps as choosing health parents, artificial fertilization, putting the fertilized ova in the seawater contained in drum, supplying seaweed (such as spirulina) as feed to culture larvae until the larva has 5-6 pairs of legs, culturing in spool in water flowing mode for 10 days while supplying seaweed and fish powder as feed, culturing in water exchanging mode while supplying fish powder as feed, and culturing in water bath while supplying seaweed and fish powder as feed.

Owner:广东海兴农集团有限公司

Artificial breeding and intensive cultivation method for tylorrhynchus heterochaetus

ActiveCN105994052AImprove farming outputProtect natural resourcesClimate change adaptationAnimal feeding stuffMogulones larvatusArtificial fertilization

The invention provides an artificial breeding and intensive cultivation method for tylorrhynchus heterochaetus. The artificial breeding and intensive cultivation method includes the steps of parent selecting, artificial fertilization, artificial incubation, nursery pond preparing, artificial breeding and intensive cultivation. The technical problems of the tylorrhynchus-heterochaetus breeding male-female proportion, breeding water environment conditions, young tylorrhynchus heterochaetus food intake, tylorrhynchus-heterochaetus pond cultivation and the like are solved, and therefore artificial breeding and intensive cultivation of tylorrhynchus heterochaetus are achieved; seed resources can be provided for large-scale cultivation of tylorrhynchus heterochaetus, the cultivation yield of tylorrhynchus heterochaetus can be increased, and the artificial breeding and intensive cultivation method is of great significance in protecting natural tylorrhynchus heterochaetus resources and meeting the consumption requirement of the market for tylorrhynchus heterochaetus.

Owner:珠海市斗门区河口渔业研究所

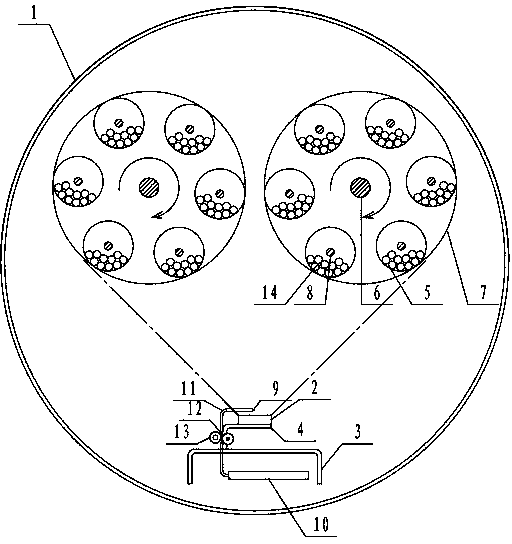

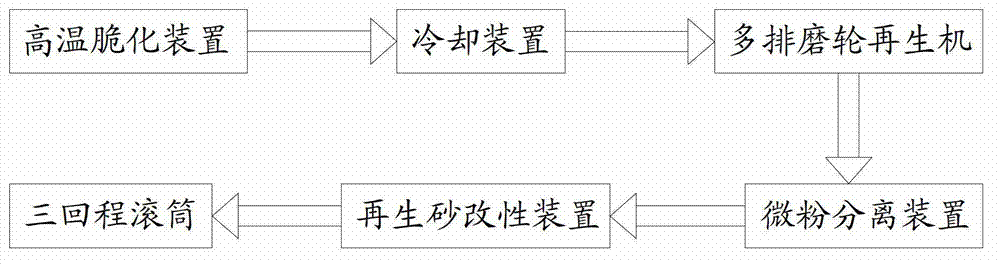

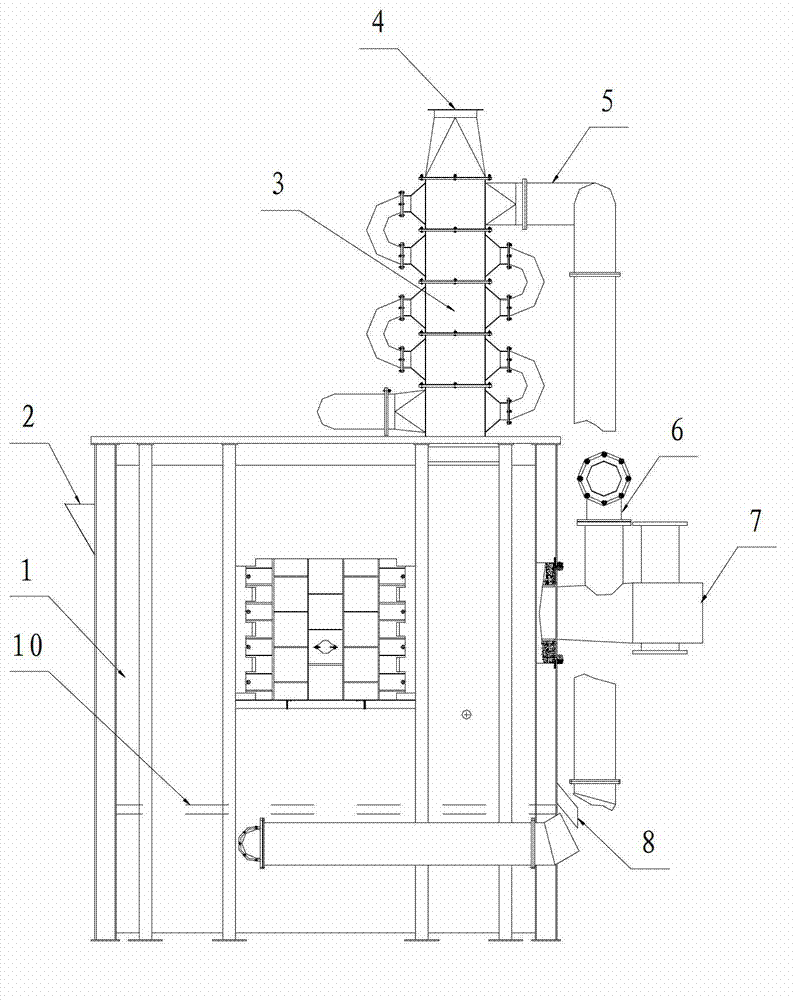

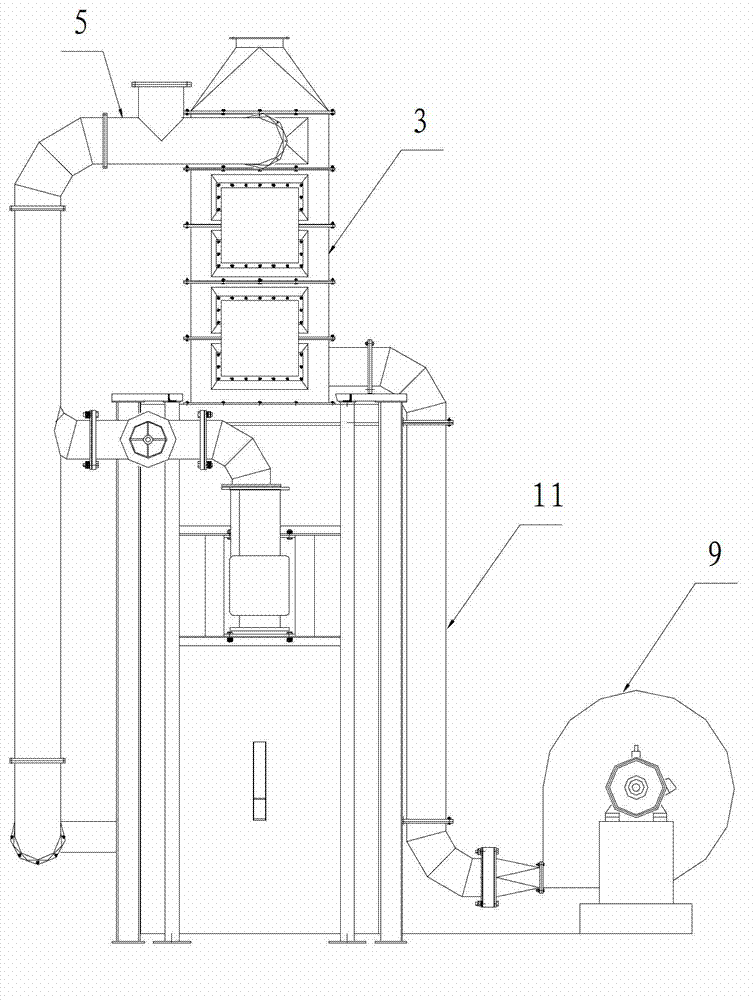

Complete equipment for complete regeneration of used clay sand

ActiveCN103170575AImprove adaptive performanceReduce waste sand dischargeMould handling/dressing devicesNatural resourcePollution

The invention discloses complete equipment for complete regeneration of used clay sand. The complete equipment comprises a high-temperature embrittling device for roasting the used sand at a high temperature, an embrittled used sand cooling device for cooling the high-temperature embrittled used sand, a plurality of rows of grinding wheel regeneration machines for mechanical regeneration of the cooled used sand, a micro powder separating unit for separating micro powder in the regenerated sand, a regenerated sand modifying device for reducing acid consumption of the regenerated sand, and a three-return-stroke rotary drum for drying the modified regenerated sand. The complete equipment has the beneficial effects that the used clay sand can be completely regenerated, and the regenerated sand can be used for core making of various organic binding agents, so that environment pollution caused by discharge of the used sand is alleviated, the environment and natural resources are protected.

Owner:SHANDONG JIANZHU UNIV

Garbage building material regenerating method and device

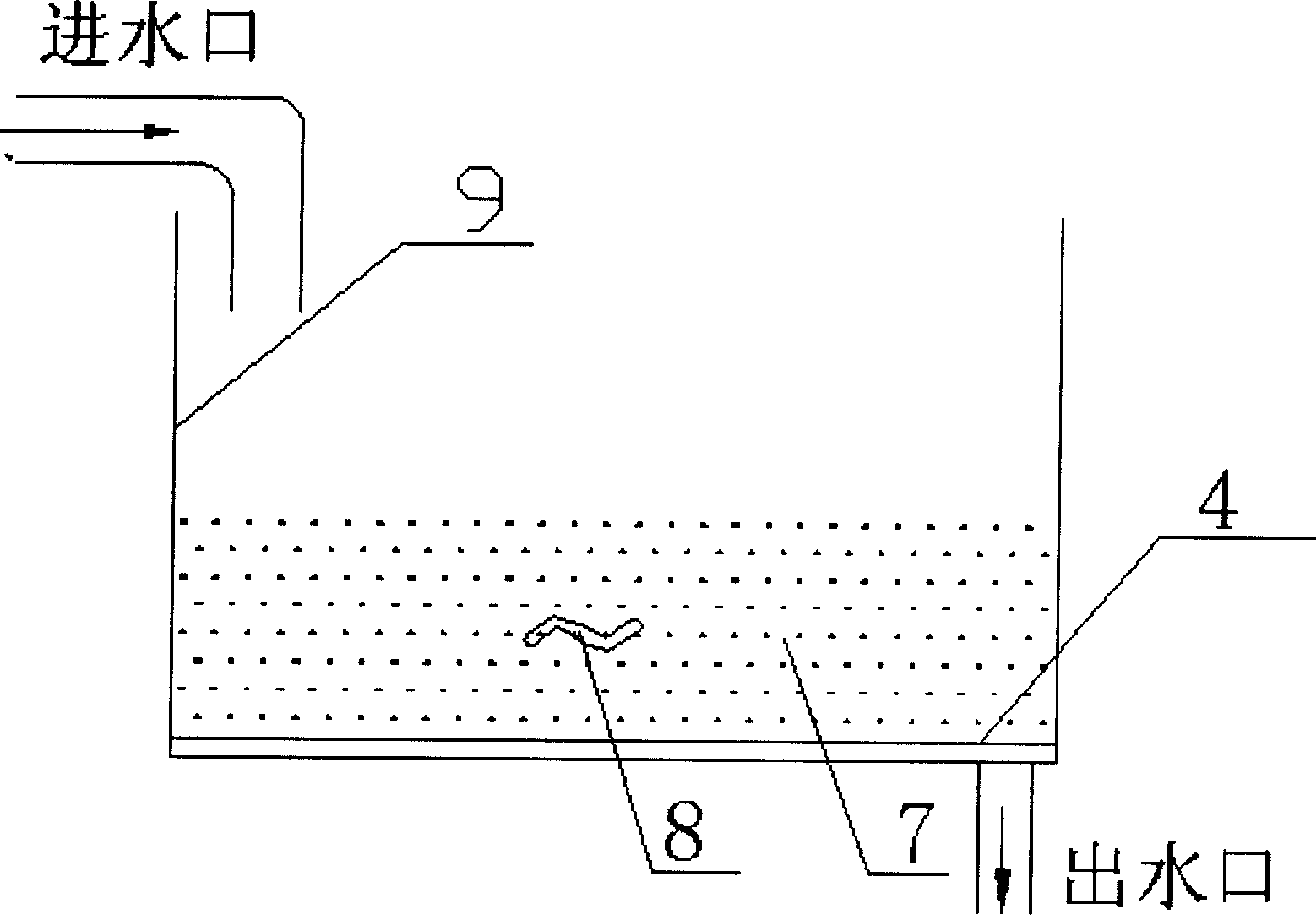

InactiveCN1943868AQuality improvementImprove use valueConstruction waste recoverySolid waste disposalWater flowEngineering

The present invention relates to building refuse regenerating process and apparatus for producing building material. The regenerating process includes the steps of crushing, washing, sieving, conveying, precipitating and water treating to obtain sand of different sizes, stone, etc. The apparatus includes a crushing device, a washing device, a sieving device and a settling tank. The washing device includes washing tank, feeding conveying belt and high pressure water guns.

Owner:郑祥虹

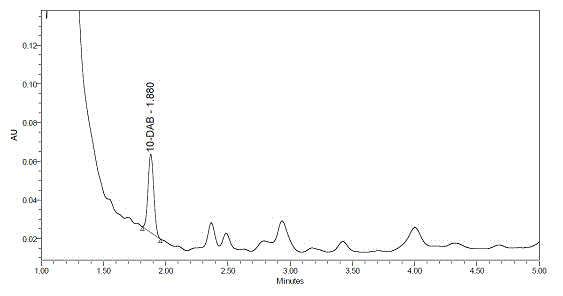

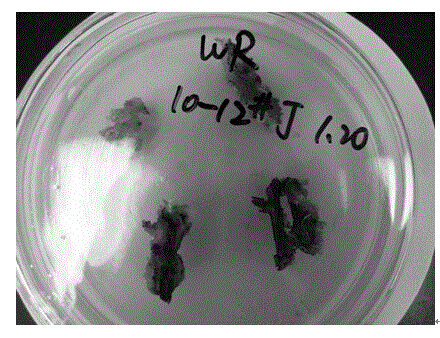

Taxus chinensis cell strain with high yield of 10-DAB and application thereof

ActiveCN104403987AStable growthNot easy to infect bacteriaMicroorganism based processesFermentationMicroorganismDocetaxel-PNP

The invention discloses a taxus chinensis cell strain with high yield of 10-DAB, is named taxuswallichianavar. mairei plant cell line N12#, and is preserved in CGMCC, and the preservation number is CGMCC No.10001. The invention further discloses screening and establishment of a 10-DAB high-yield cell line (10-DeacetylbaccatinIII, CASNO: 32981-86-5). A high-yield 10-DAB cell line is induced and screened from taxuswallichianavar. mairei explant. Experimental results prove that the cell line can highly produce taxane diterpenoids such as secondary metabolites 10-DAB and can be used for production of crude drug precursors of paclitaxel and docetaxel.

Owner:安赛搏(重庆)生物技术有限公司

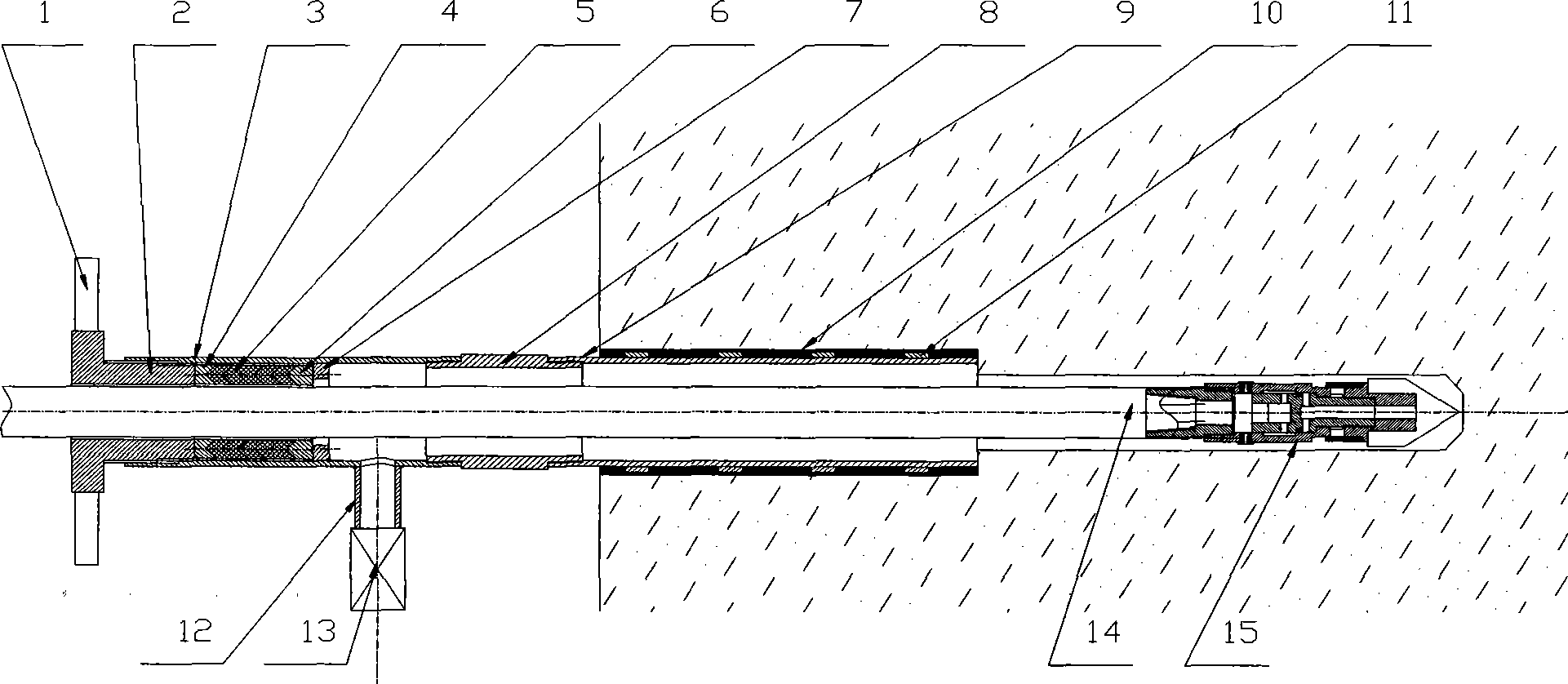

Vertical shaft working surface artesian flow sand layer slurry protecting rotary spraying grouting process

The invention relates to a tunneling and support method for a mine, in particular to a slurry protection, rotary spraying and slurry injection technology for a flowing sand layer of pressure-bearing water of a work surface of a vertical well. When high-pressure and rotary spraying slurry injection is applied to the construction of a sand pebble layer, in particular a flowing sand layer under the condition of the pressure-bearing water of a work surface, the flowing water amount in a drilling hole is high and the pressure is high to cause the injected cement slurry to be flushed away by water, thus, piles can not be formed by rotary spraying. No study on the rotary spraying technology under the condition of pressure-bearing water is reported at home and abroad. In the work surface of a vertical well under the condition of pressure-bearing water, the invention sequentially carries out hole formation in a single-hole mode, pile formation in a slurry protection and single-hole mode and hole sealing and slurry fixation, and the rotary spraying construction of the flowing sand layer under the condition of the pressure-bearing water of integrated pressure and slurry protection is realized. The invention uses the work surface as a main construction field, and has small area of additional occupied land, and the construction machine has simplicity and low energy consumption. The adopted main material is the slurry of the cement series, which has no toxin or harm, and the induration is firm and reliable. The invention can play a positive role in protecting the natural resource and the ecological environment.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

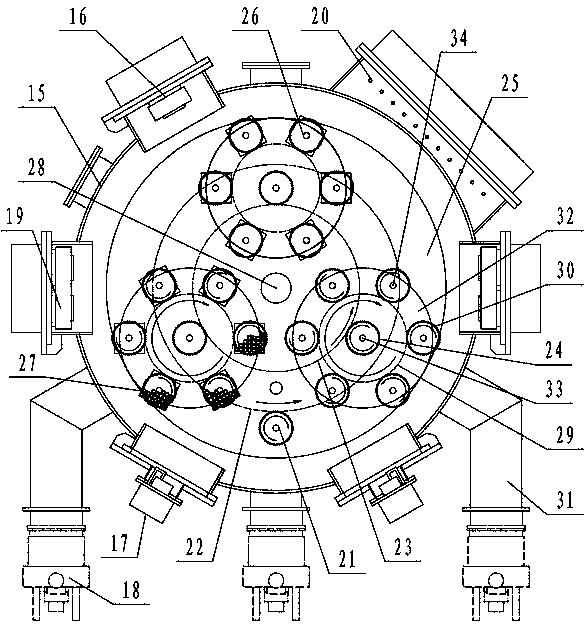

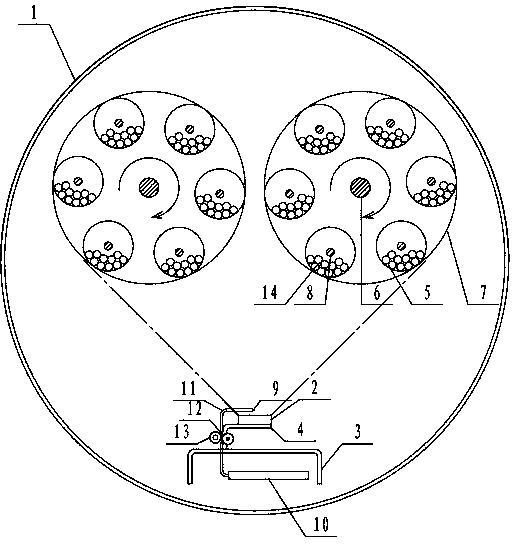

Mixed film coating equipment for neodymium iron boron rare-earth permanent magnet components and manufacturing method thereof

ActiveCN103839641AImprove corrosion resistanceIncrease useVacuum evaporation coatingSputtering coatingMicrometerFilm coating

The invention discloses mixed film coating equipment for neodymium iron boron rare-earth permanent magnet components and a manufacturing method of the mixed film coating equipment. The film coating equipment comprises a vacuum chamber, cylinder rotating cathode magnetic control targets, plane cathode magnetic control targets, multi-arc ion targets, rotating stands and material baskets. In the working process, the rotating stands perform revolution in the vacuum chamber, and the two ends of each net-shaped material basket are installed on the corresponding rotating stand through rotary shafts and not only perform revolution along with the rotating stand, but also perform rotation. The cylinder rotating cathode magnetic control targets are installed in the rotating stands in the vacuum chamber, the plane magnetic control targets, the multi-arc ion targets, anode layer linear ion sources and a heating device are installed around the rotating stands in the vacuum chamber, and vacuum film coating is performed in a three-layer mode. The first layer is a magnetron sputtering coating layer, the thickness of the coating layer is 0.1 micrometer-5 micrometers, the second layer is a mixed coating layer of magnetron sputtering and multiple arcs, the thickness of the mixed coating layer is 1 micrometer-15 micrometers, the third layer is a magnetron sputtering coating layer, and the thickness of the coating layer is 0.1 micrometer-5 micrometers. Mixed film coating is adopted as the surface treatment process of the rare-earth permanent magnet components, so that the anti-corrosion capacity of the rare-earth permanent magnet components is improved, and meanwhile the magnetic performance of the rare-earth permanent magnet components is improved.

Owner:SHENYANG CHINANORTH VACUUM TECH CO LTD

Artificial breeding method of lateolabrax japonicus in northern water areas

InactiveCN110122380AHigh quality broodstockMonitor survival rateClimate change adaptationPisciculture and aquariaNatural resourceSebastes

The invention relates to the technical field of fish culture, in particular to an artificial breeding method of lateolabrax japonicus in northern water areas. The method comprises parent fish selection, parent fish rearing, artificial spawning inducement and insemination and fry rearing. Wild lateolabrax japonicus fries are domesticated and cultured into adult fishes, and high-quality parent fishes are stored by parent fish domestication and screening to become fine breeds for industrialization of the lateolabrax japonicus. Artificially bred fries of the lateolabrax japonicus are provided forthe northern water areas, the limitation of traditional natural conditions is broken through, the natural resources are protected, and the ecological balance is kept.

Owner:利津县双瀛水产苗种有限责任公司

Stringed instrument arch bar compositing lignum and carbon fibre and manufacturing method thereof

The invention discloses a stick of stringed musical instrument and making method, which is made of wood and carbon fiber, wherein the hollow carbon fiber stick is filled with composite material of epoxy resin. The making method comprises the following steps: tailoring the materials; making mandrel; shaping; winding wood layer on the surface; moulding; toasting; solidifying; cooling; stripping; extracting the mandrel; canning the core. The invention simplifies the manufacturing technique with high efficiency, which keeps wood sense of traditional stick with stable stick property and reliable quality.

Owner:朱富良

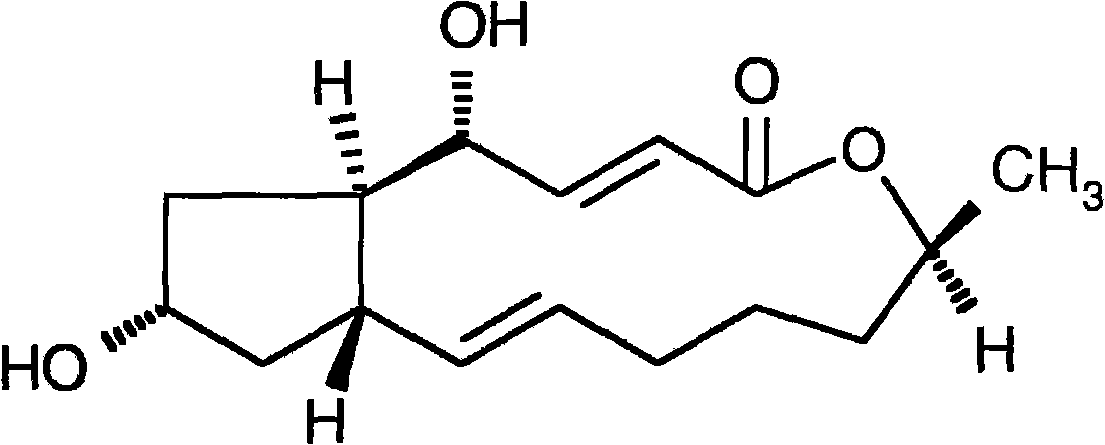

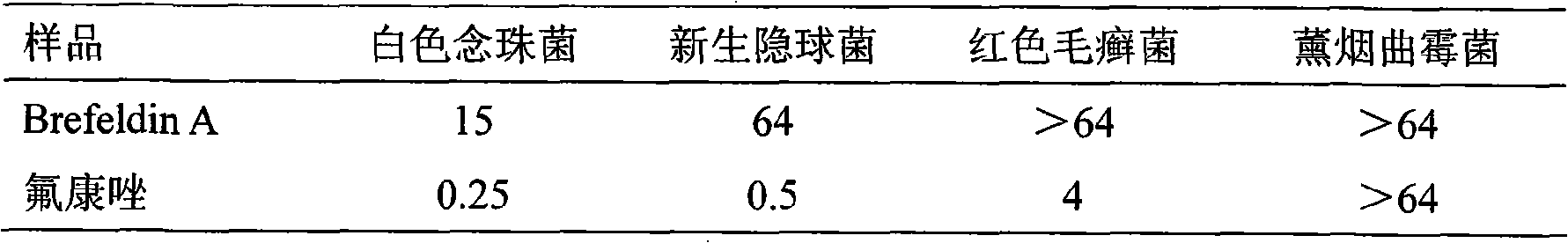

Brefeldin A-producing bacteria and method for preparing brefeldin A by fermentation

The invention relates to Brefeldin A-producing bacteria, a preparation method, a method for preparing the brefeldin A by fermentation and the application thereof. The Brefeldin A-producing bacteria has the advantages of easy selection, cultivation and storage, low cost, simple process, short preparation period, high yield, no usage of toxic raw material, less organic solvent, thorough guarantee of medicine resource, potential of mass production and favorable economic and social benefits, contributes to the maintenance of ecological balance and the protection of natural resources. The fermentation product of the invention, of which the main component is THSG, develops novel medical application, the Brefeldin A has high safety, low toxicity, stable property, stronger pharmacological action, simple preparation process, high yield and considerably wide range of application, is multipurpose, and can provide a novel source for medicines for preventing, diagnosing, detecting, protecting, curing and researching antimycotic, antiviral and antineoplastic diseases and the directly related diseases.

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY

Culture method of zelkova serrata container big seedlings

The invention relates to a culture method of zelkova serrata container big seedlings and belongs to the technical field of plant cultivation. The culture method comprises the steps of garden selection and land preparation, container selection, substrate preparation, seedlings selection, container planting, water and fertilizer management and the like. Zelkova serrata has a slow growing speed, and thus, aiming at the growth characteristics of the zelkova serrata, the culture method adopts a specific culture management, so that the survival rate can be improved, growth of the zelkova serrata is accelerated, the culture period is shortened, the seedlings are enabled to grow into big trees at an early date and natural resources are effectively protected; root control containers used in the culture method have an effect of promoting growth of lateral roots, are unlikely to damage roots in the transplanting process and are beneficial for improving the survival rate of the big seedling transplantation; moreover, in the transplanting process, the crowns of the seedlings do not need to be cut down, full-crown transplantation can be carried out, the transplanting effect is good and the engineering requirements of any construction period can be met.

Owner:WUXI MISHO ECOLOGY LANDSCAPE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com