Stringed instrument arch bar compositing lignum and carbon fibre and manufacturing method thereof

A production method and carbon fiber technology, applied in stringed instruments, musical instruments, instruments, etc., can solve the problems of different effects, difficult product quality, and high cost of stringed instrument bows, achieving easy operation, reliable quality, and saving high-grade wood. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

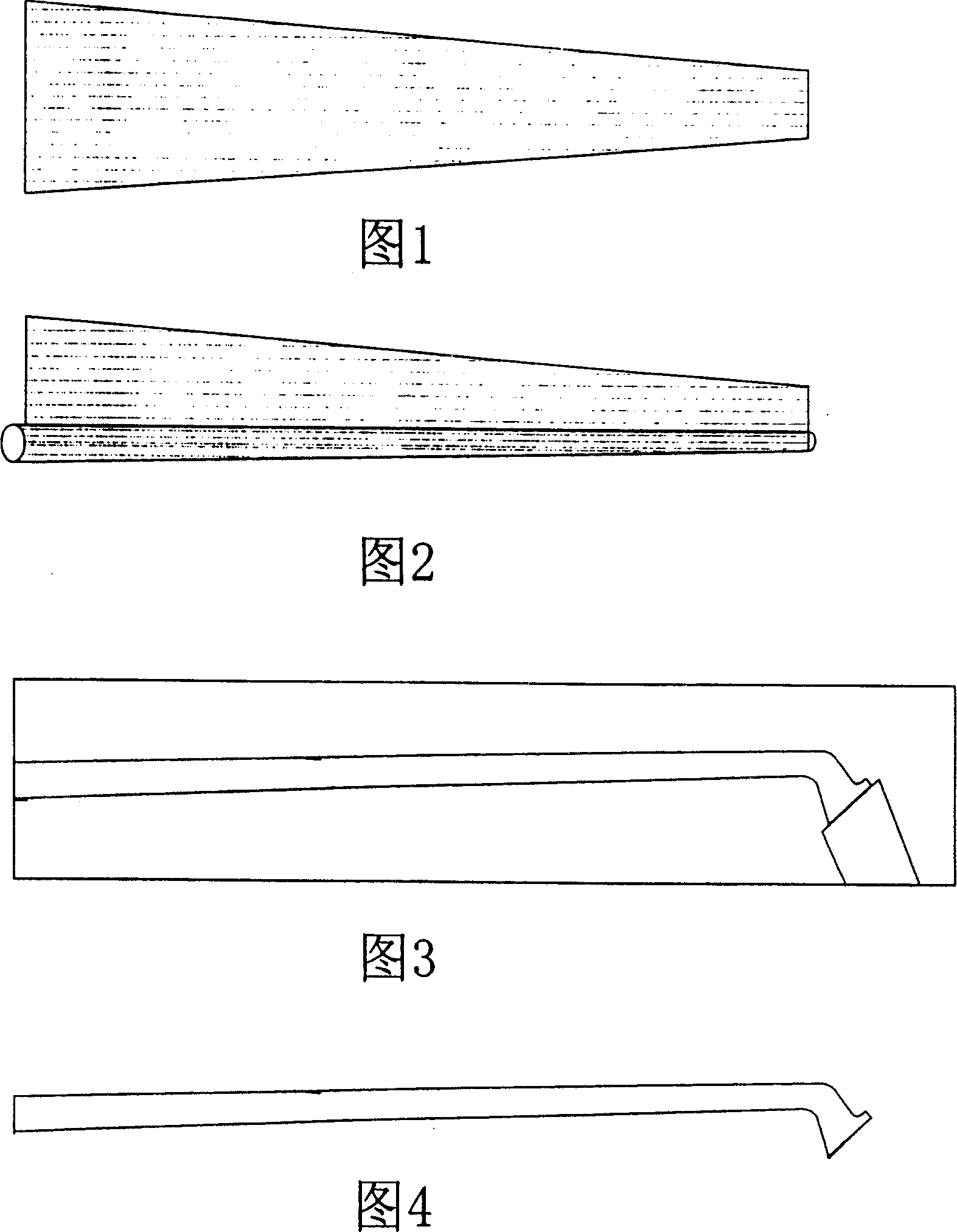

[0028] Embodiment 1. The violin bow of the present invention comprises a hollow carbon fiber bow and a wood layer wrapped outside the bow, and the hollow carbon fiber bow is filled with epoxy resin mixture. The method for making a violin bow comprises the following steps: cutting materials, cutting carbon fiber fabrics of a certain specification according to the needs of the violin bow made, as shown in Figure 1; making mandrels, processing plastic mandrels according to the wooden shape of the bow shape and specifications; forming, the cut carbon fiber cloth is rolled on the processed plastic mandrel, and the surface of the carbon fiber bow is wrapped with a wooden layer, and the wooden layer is made of wood into a sheet with a thickness of 2mm. The sheet-like wood layer is wound around the bow shaft at 360 degrees and fixed by adhesion. See Figure 2; Molding, put the rolled carbon fiber rod together with the mandrel into the mold, see Figure 3, then cover the upper mold, and ...

Embodiment 2

[0029] Embodiment 2 The cello bow of the present invention includes a hollow carbon fiber bow and a wooden layer wrapped around the bow, and the hollow carbon fiber bow is filled with epoxy resin mixture. The manufacturing method of the cello bow includes the following steps: cutting materials, cutting carbon fiber cloth according to the requirements for making the cello bow. Make the plastic mandrel, process it into the shape and specification of the corresponding plastic mandrel according to the shape and specification of the bow rod; form it, roll the cut carbon fiber cloth on the formed plastic mandrel by hand, and roll it on the carbon fiber bow The surface of the rod is wrapped with a wooden layer, and the wooden layer is made of wood into a sheet with a thickness of 2.5mm. The sheet-shaped wooden layer is wound around the bow rod at 360 degrees, and glued and fixed, so that the cello bow is completed. Molding, put the rolled carbon fiber rod together with the mandrel in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com