Patents

Literature

25105 results about "Petroleum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Petroleum (/pəˈtroʊliəm/) is a naturally occurring, yellowish-black liquid found in geological formations beneath the Earth's surface. It is commonly refined into various types of fuels. Components of petroleum are separated using a technique called fractional distillation, i.e. separation of a liquid mixture into fractions differing in boiling point by means of distillation, typically using a fractionating column.

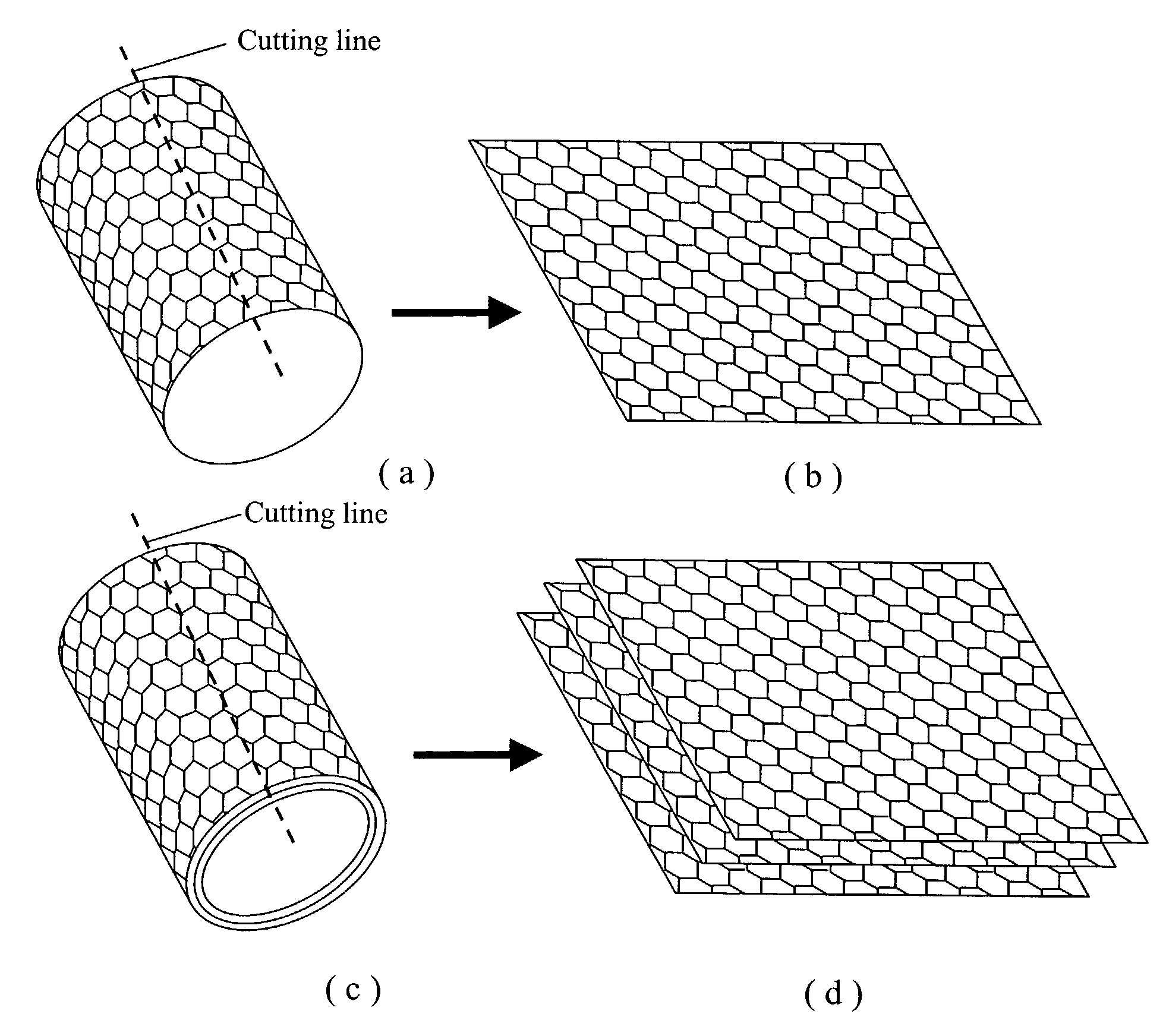

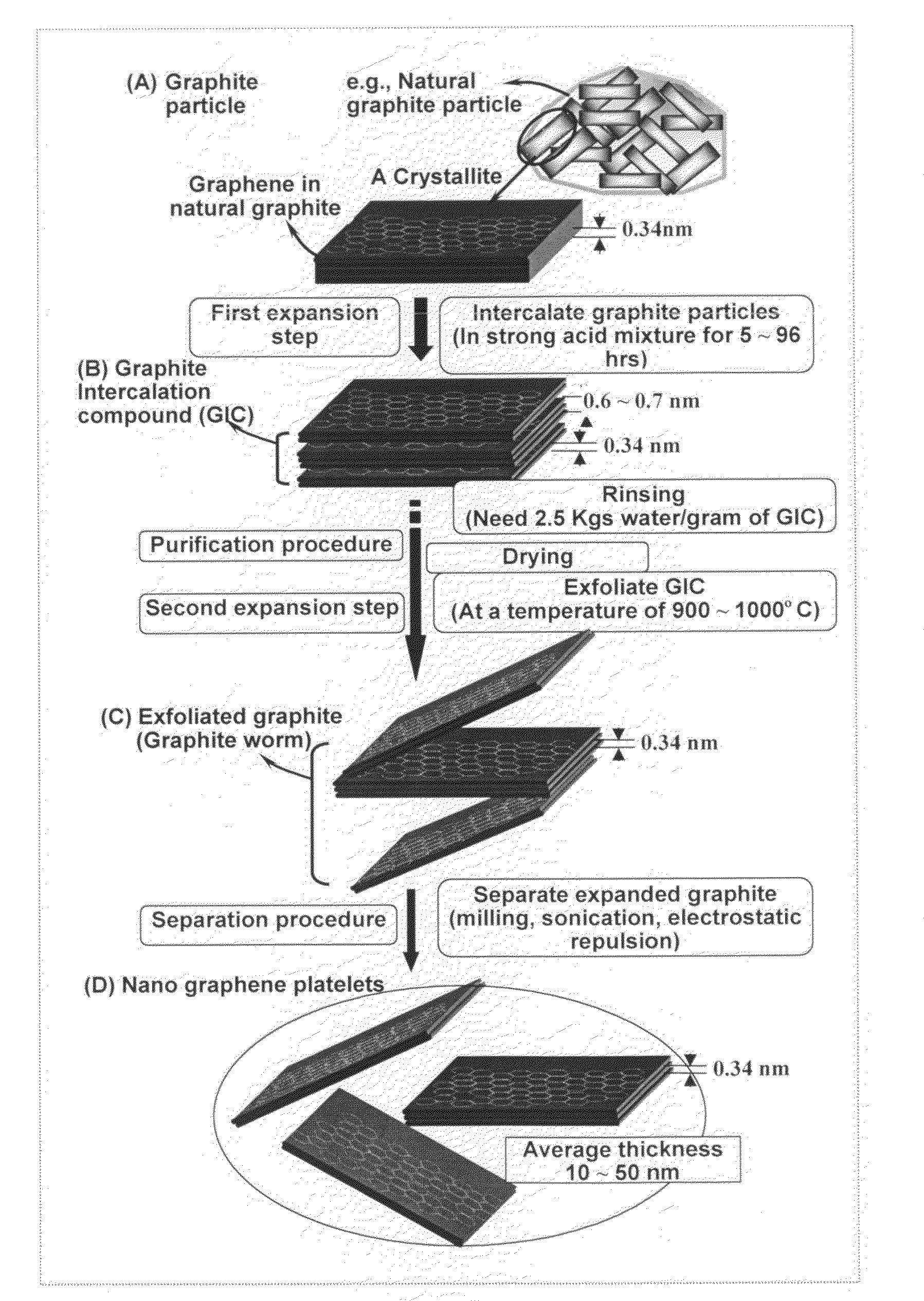

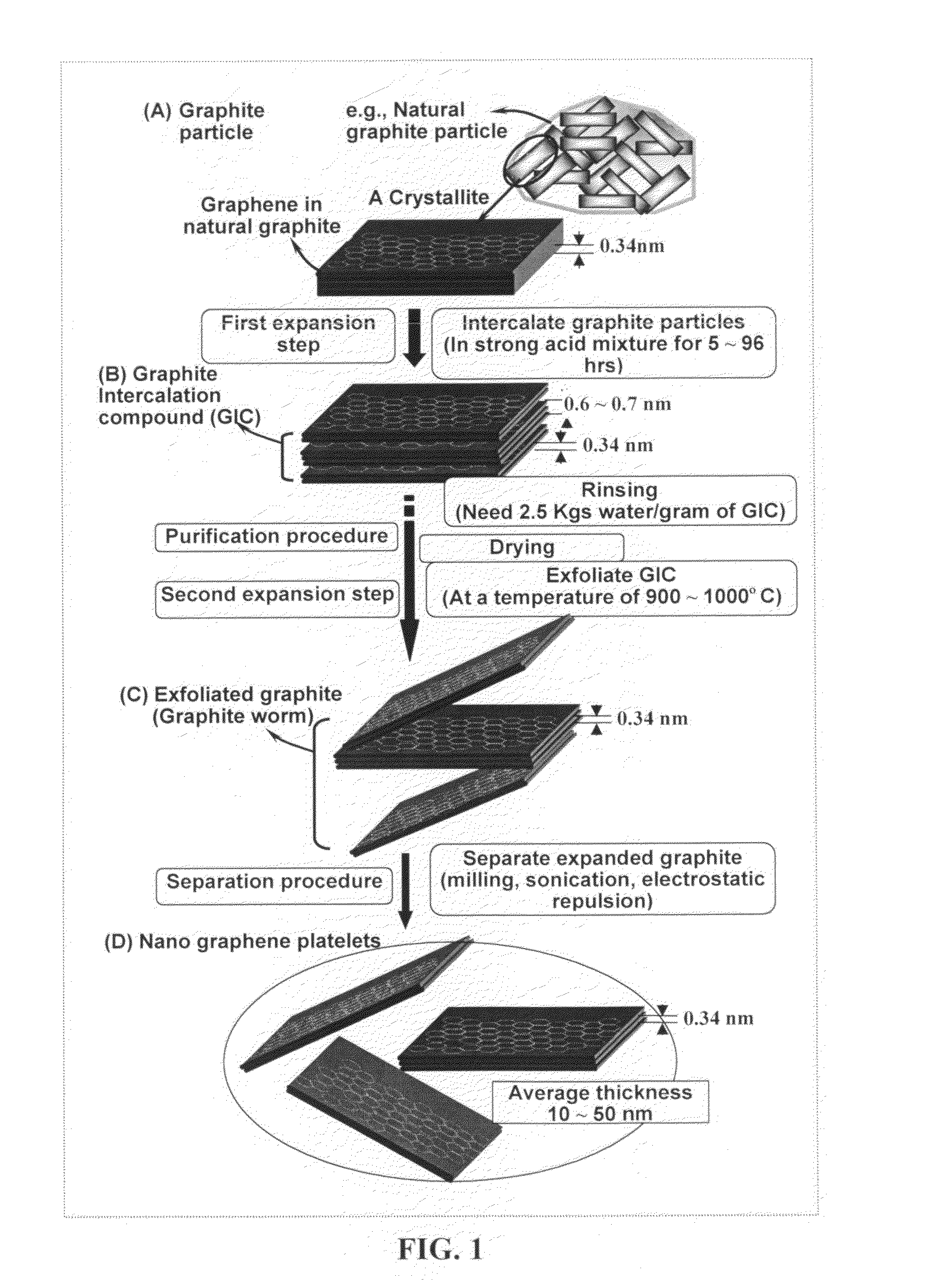

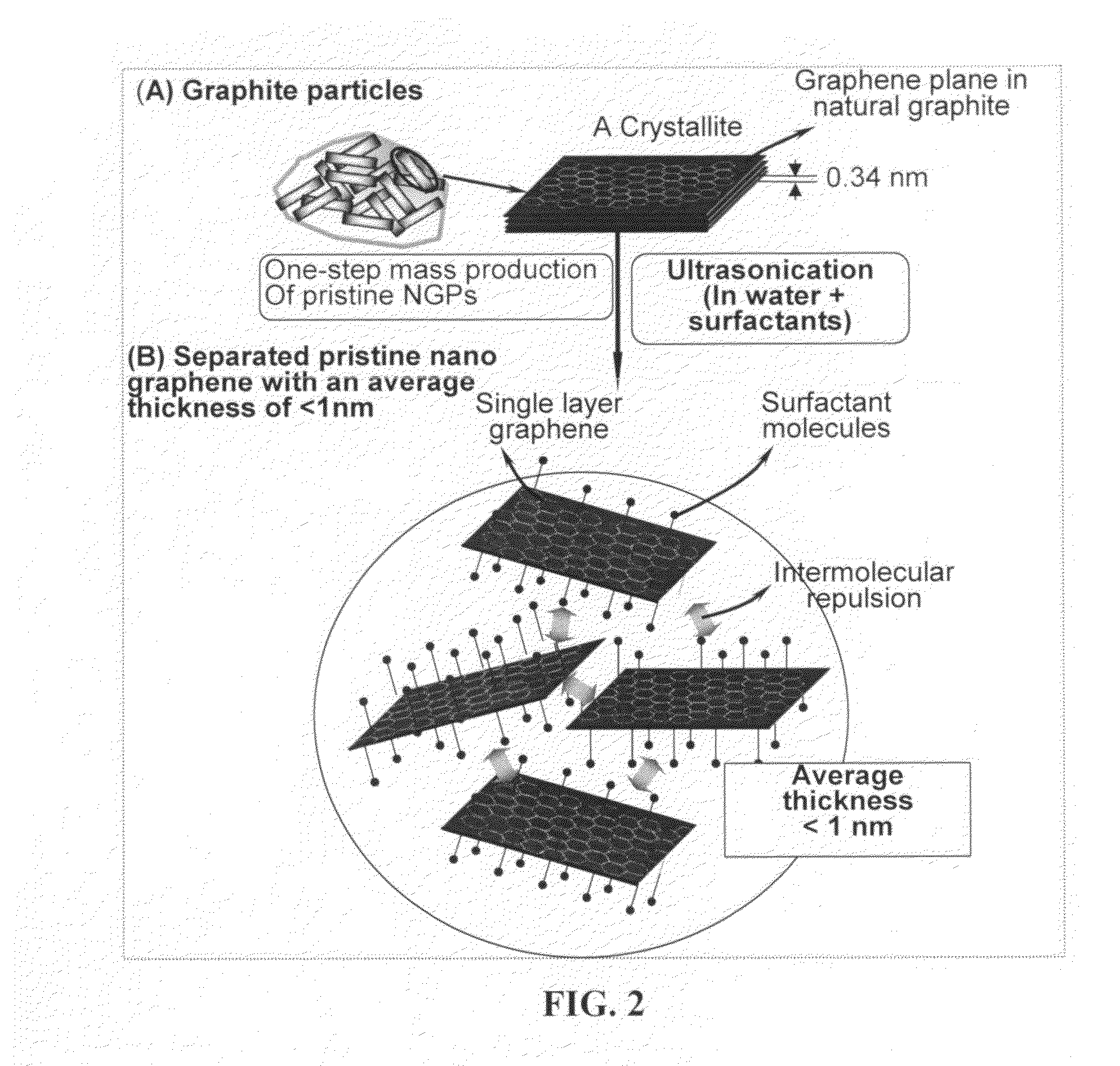

Nano-scaled graphene plates

A nano-scaled graphene plate material and a process for producing this material. The material comprises a sheet of graphite plane or a multiplicity of sheets of graphite plane. The graphite plane is composed of a two-dimensional hexagonal lattice of carbon atoms and the plate has a length and a width parallel to the graphite plane and a thickness orthogonal to the graphite plane with at least one of the length, width, and thickness values being 100 nanometers or smaller. The process for producing nano-scaled graphene plate material comprises the steps of: a). partially or fully carbonizing a precursor polymer or heat-treating petroleum or coal tar pitch to produce a polymeric carbon containing micron- and / or nanometer-scaled graphite crystallites with each crystallite comprising one sheet or a multiplicity of sheets of graphite plane; b). exfoliating the graphite crystallites in the polymeric carbon; and c). subjecting the polymeric carbon containing exfoliated graphite crystallites to a mechanical attrition treatment to produce the nano-scaled graphene plate material.

Owner:GLOBAL GRAPHENE GRP INC

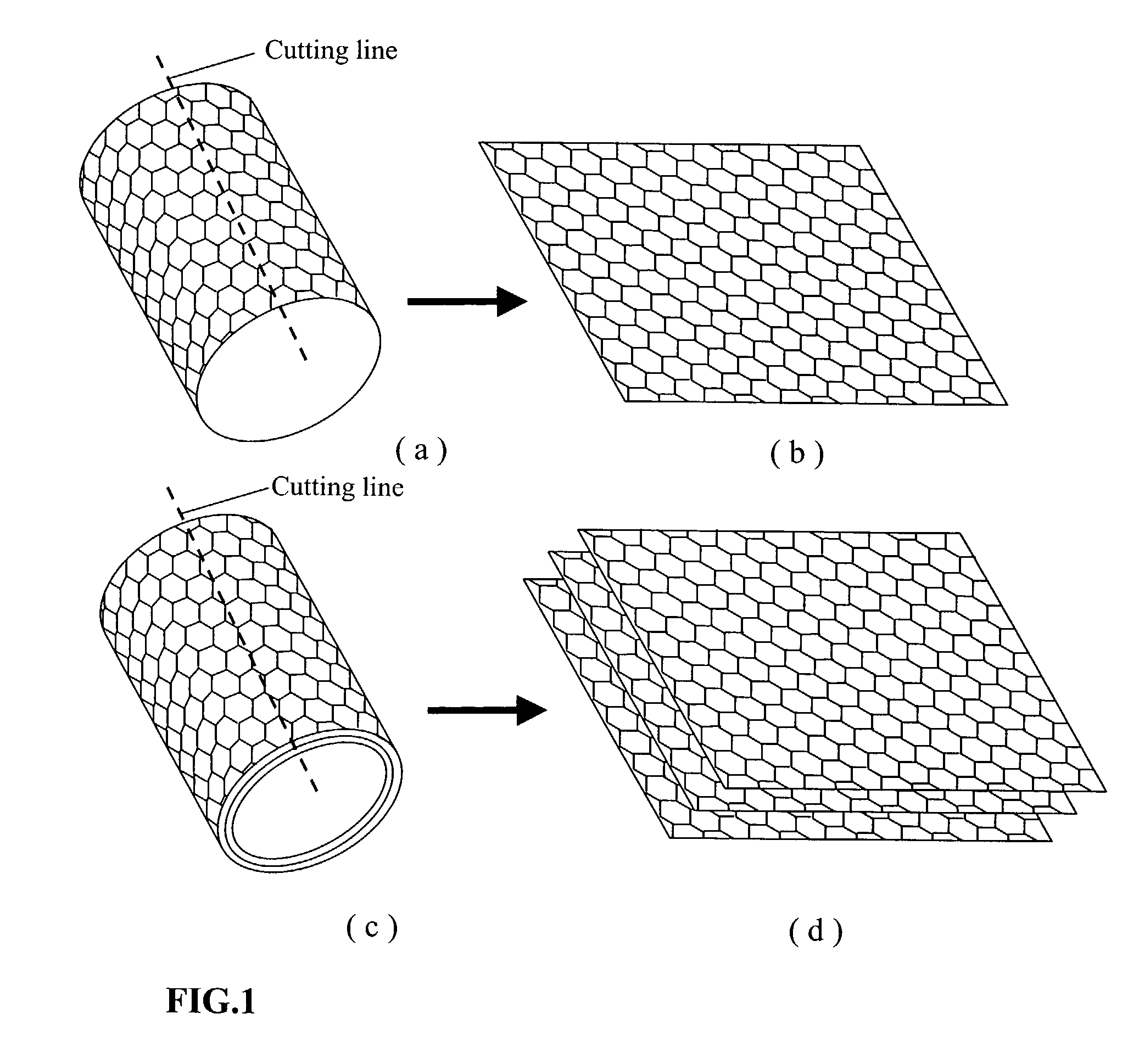

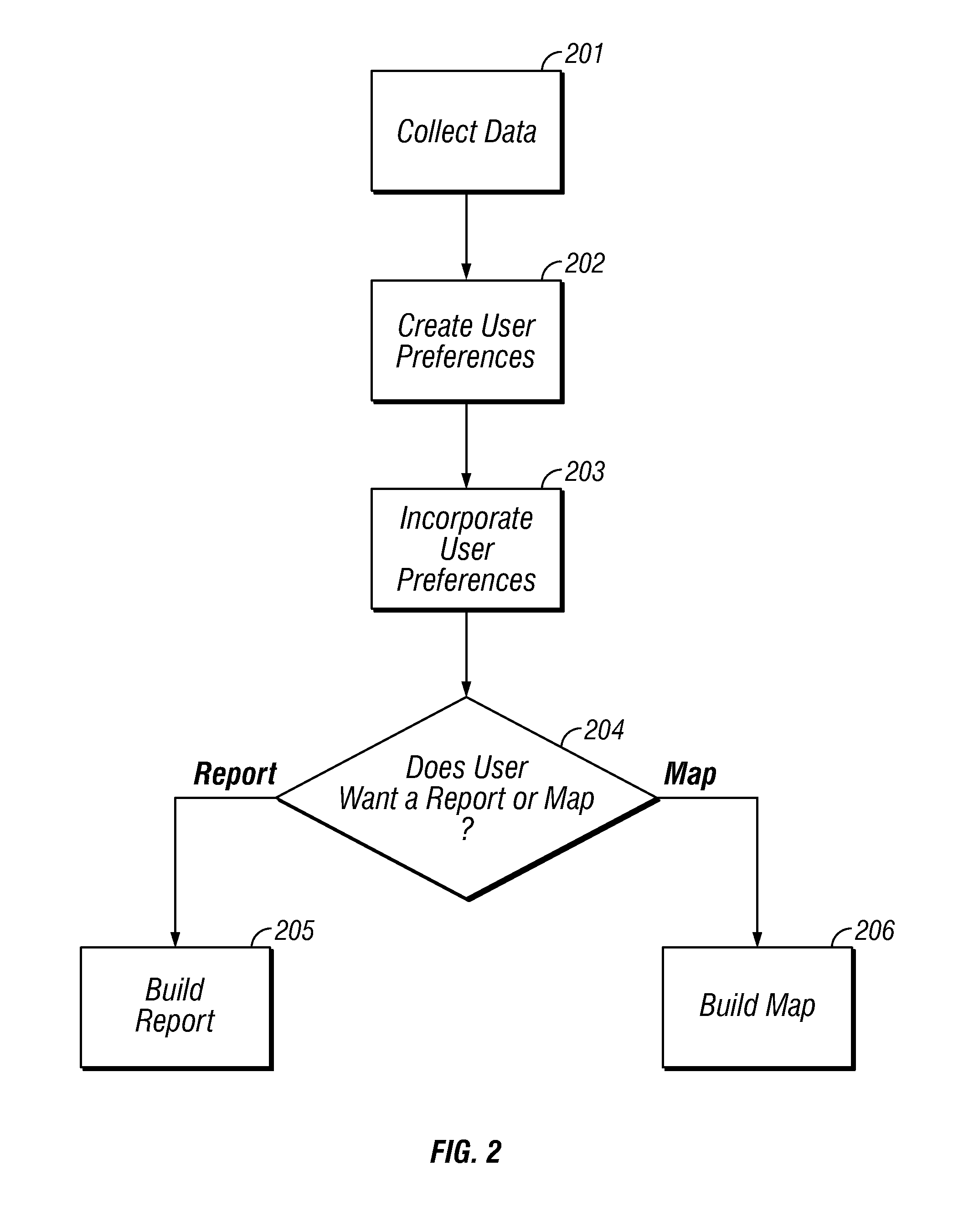

Geographic layout of petroleum drilling data and methods for processing data

InactiveUS20140157172A1Continuous collectionOffice automationInput/output processes for data processingGraphicsGeographic space

The embodiments of the present invention provide systems and methods which update petroleum activity data and allows for geospatial modeling of the data in an interactive fashion or for the creation of a report to display customizable reports in accordance with user-preferred fields. Embodiments of the present invention also provide methods for collection of data from various Internet resources, including Federal Energy Regulatory Commission, and specifically allow user-friendly interaction to select various fields, such as bids, contract information, well production, and produce graphical representation or generate reports that accounts for the organization of the data.

Owner:DRILLMAP

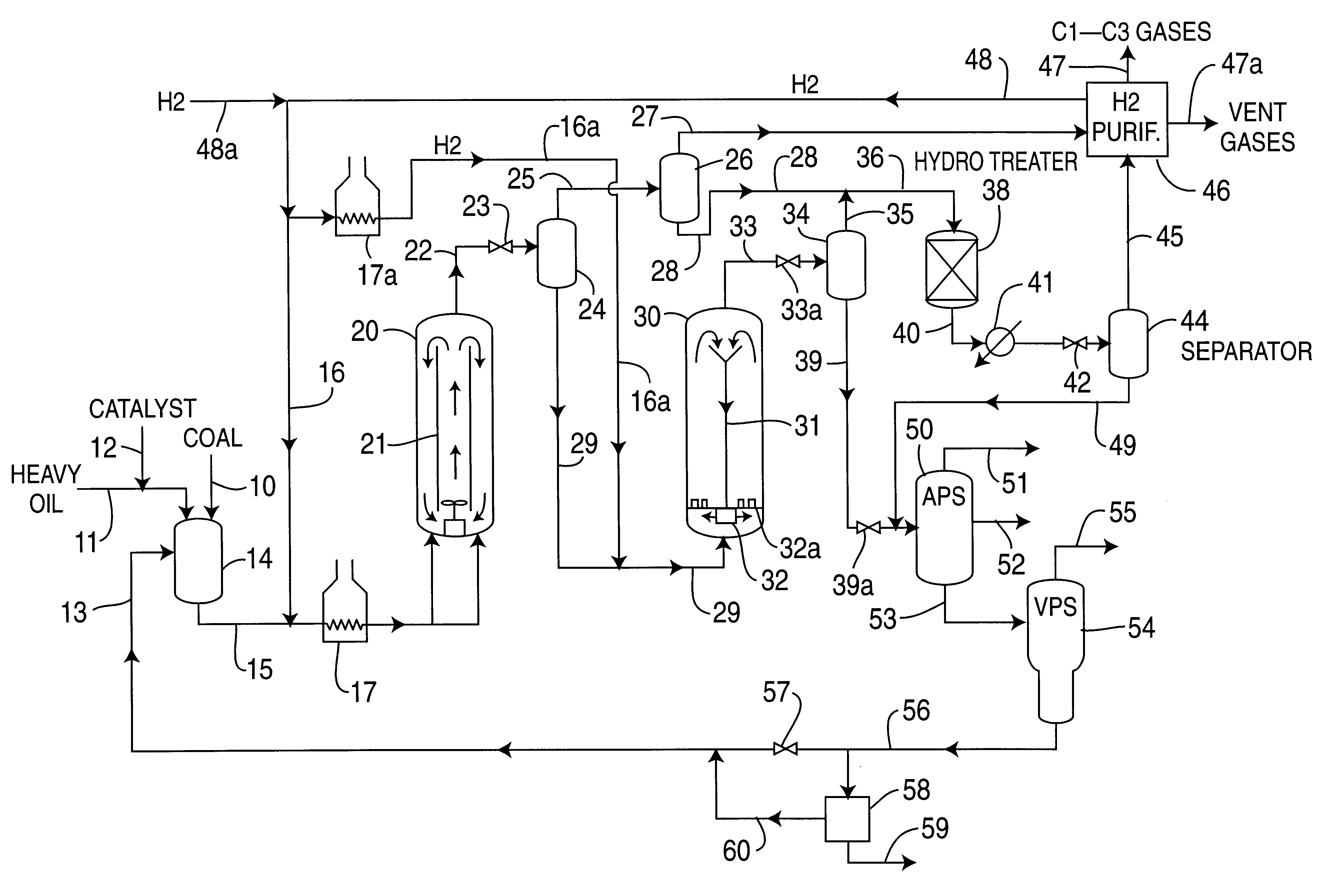

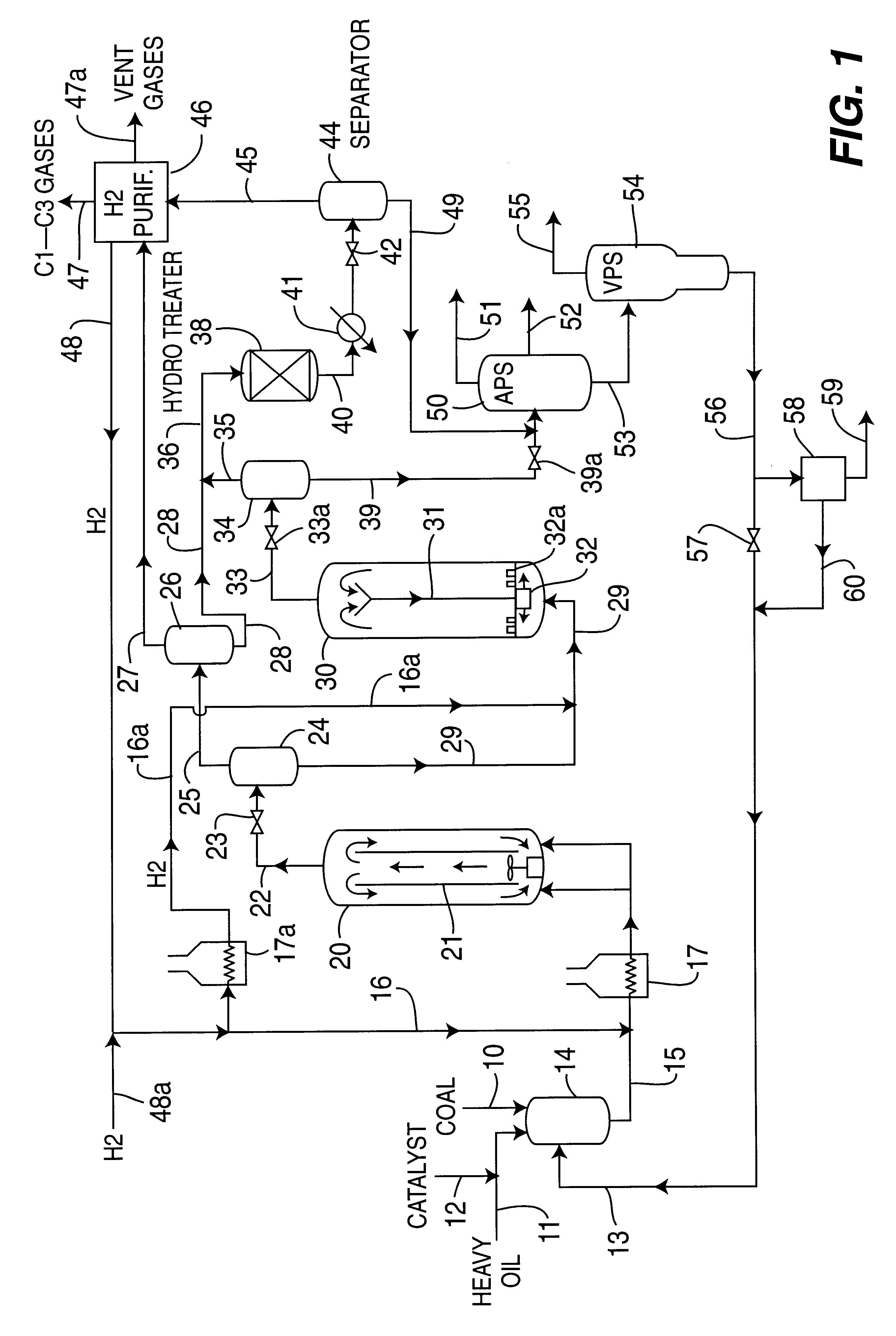

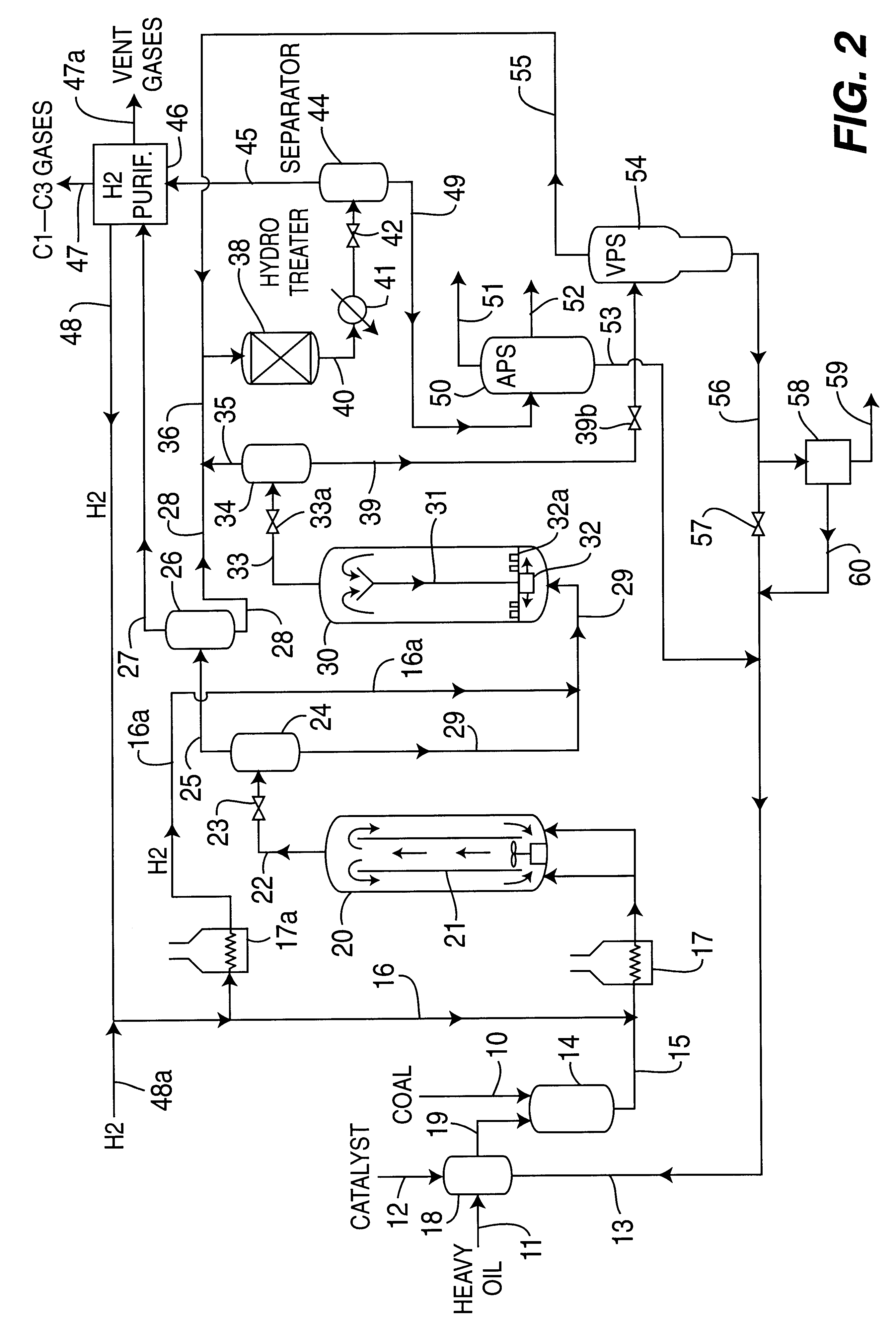

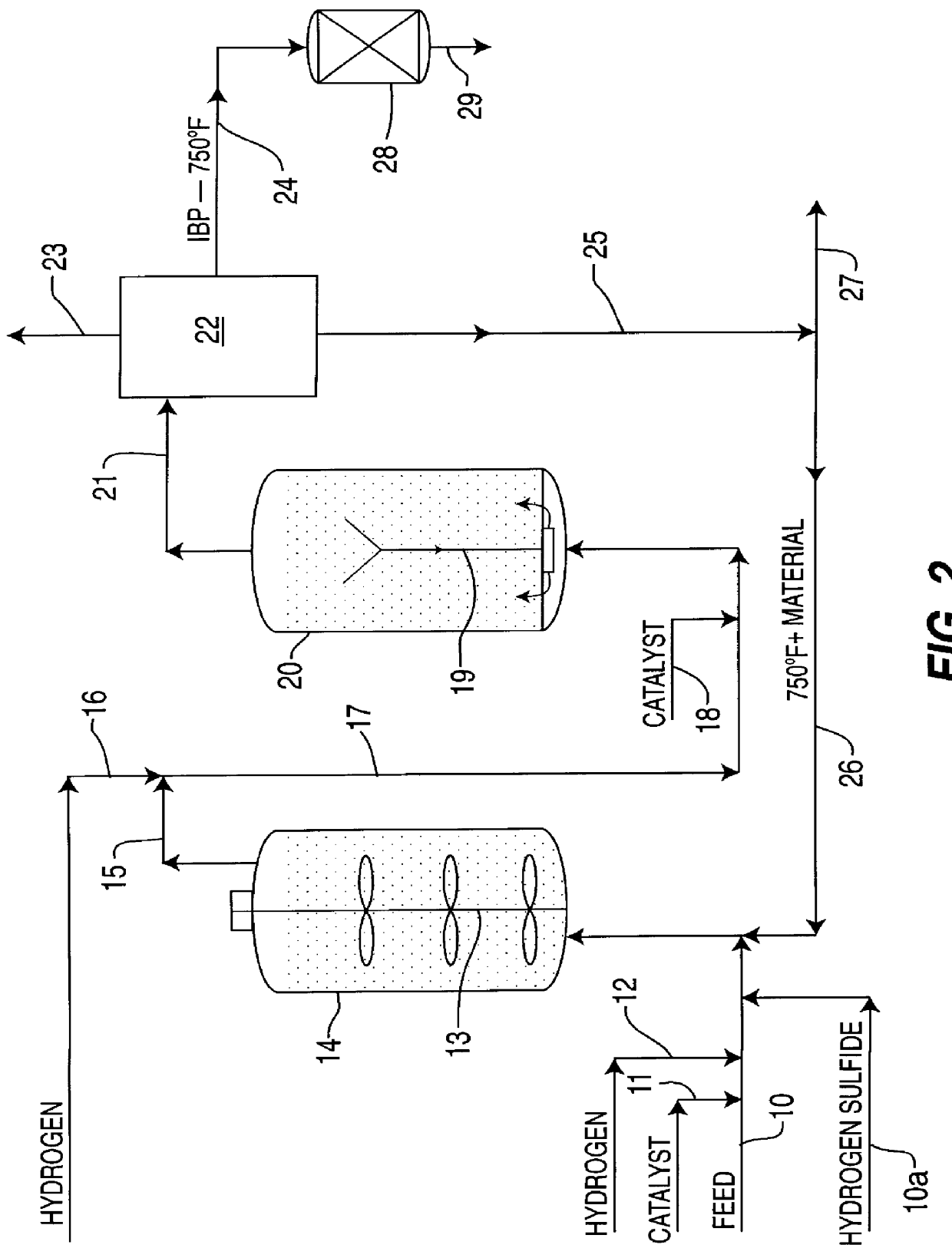

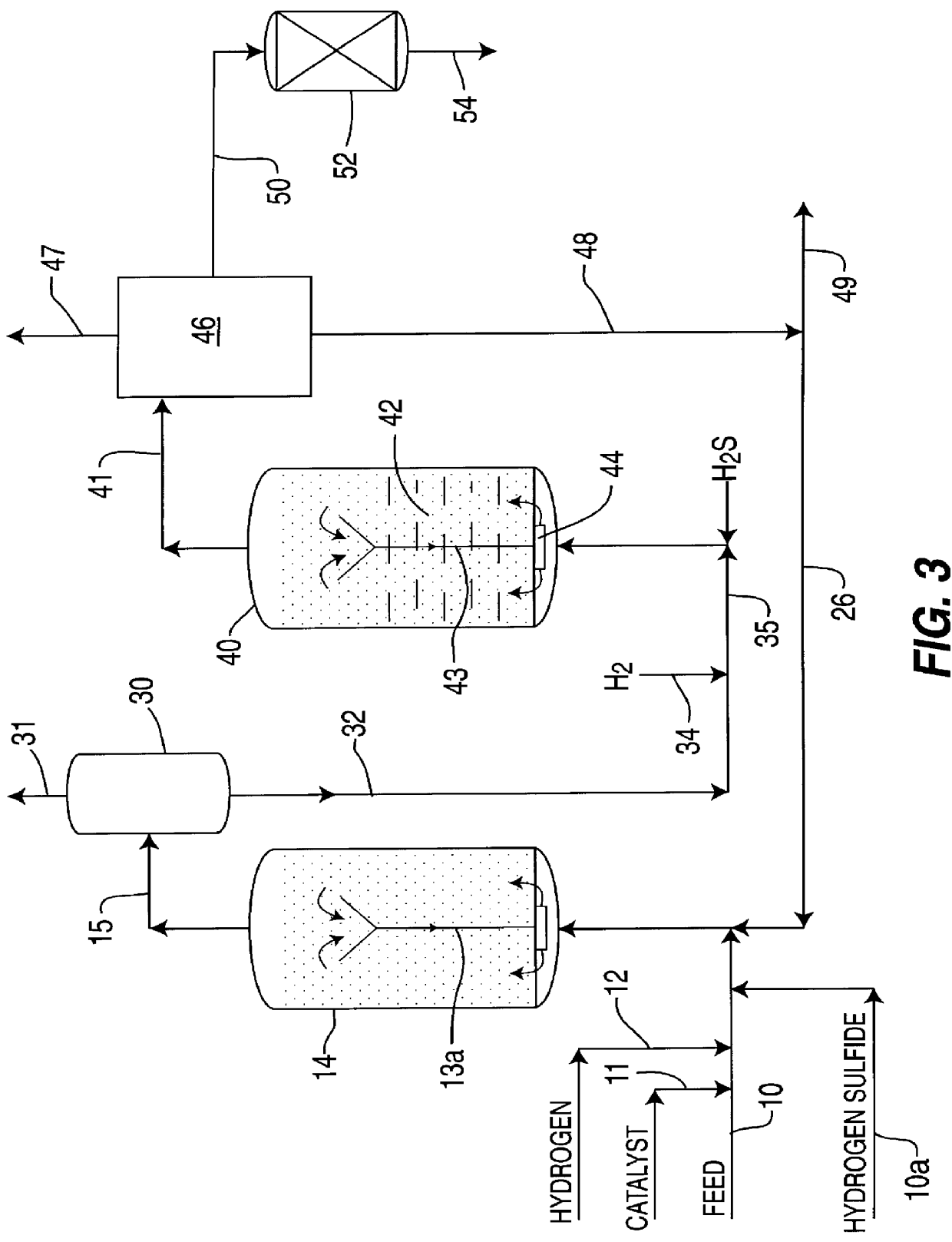

Catalytic multi-stage process for hydroconversion and refining hydrocarbon feeds

InactiveUS6190542B1Improve distillation yieldQuality improvementCatalyst activation/preparationLiquid hydrocarbon mixture productionLiquid productDistillates petroleum

A multi-stage catalytic hydrogenation and hydroconversion process for heavy hydrocarbon feed materials such as coal, heavy petroleum fractions, and plastic waste materials. In the process, the feedstock is reacted in a first-stage, back-mixed catalytic reactor with a highly dispersed iron-based catalyst having a powder, gel or liquid form. The reactor effluent is pressure-reduced, vapors and light distillate fractions are removed overhead, and the heavier liquid fraction is fed to a second stage back-mixed catalytic reactor. The first and second stage catalytic reactors are operated at 700-850.degree. F. temperature, 1000-3500 psig hydrogen partial pressure and 20-80 lb. / hr per ft.sup.3 reactor space velocity. The vapor and light distillates liquid fractions removed from both the first and second stage reactor effluent streams are combined and passed to an in-line, fixed-bed catalytic hydrotreater for heteroatom removal and for producing high quality naphtha and mid-distillate or a full-range distillate product. The remaining separator bottoms liquid fractions are distilled at successive atmospheric and vacuum pressures, low and intermediate-boiling hydrocarbon liquid products are withdrawn, and heavier distillate fractions are recycled and further upgraded to provide additional low-boiling hydrocarbon liquid products. This catalytic multistage hydrogenation process provides improved flexibility for hydroprocessing the various carbonaceous feedstocks and adjusting to desired product structures and for improved economy of operations.

Owner:HEADWATERS CTL

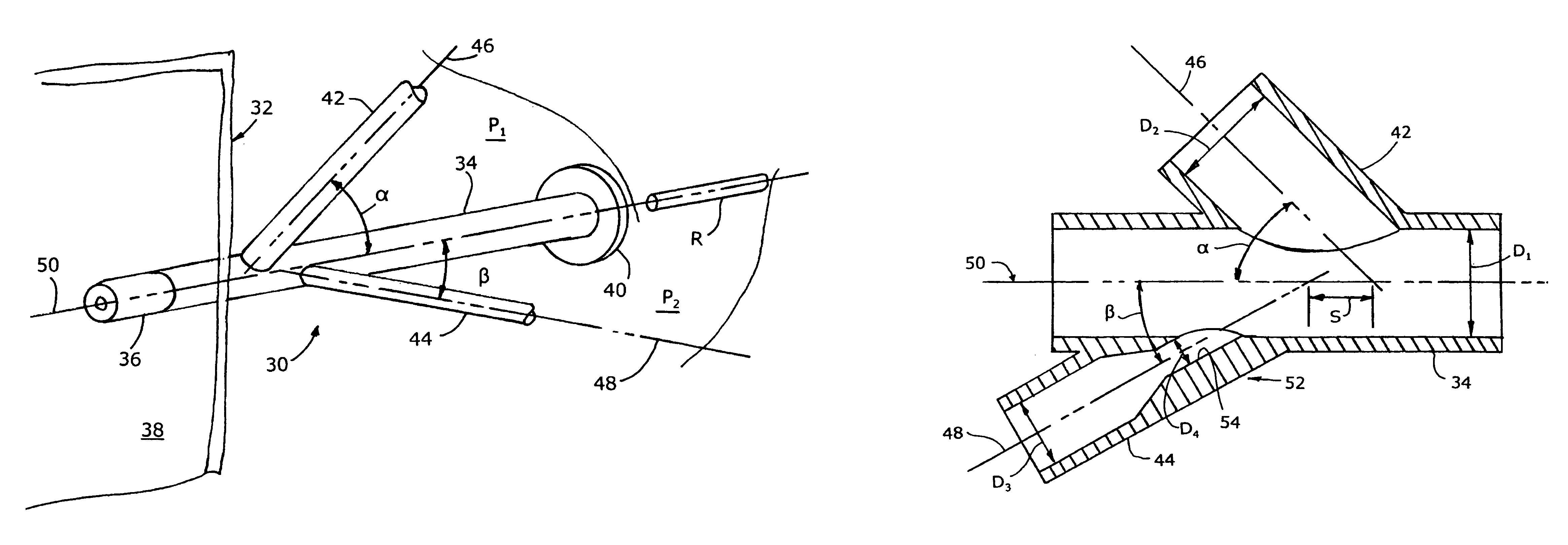

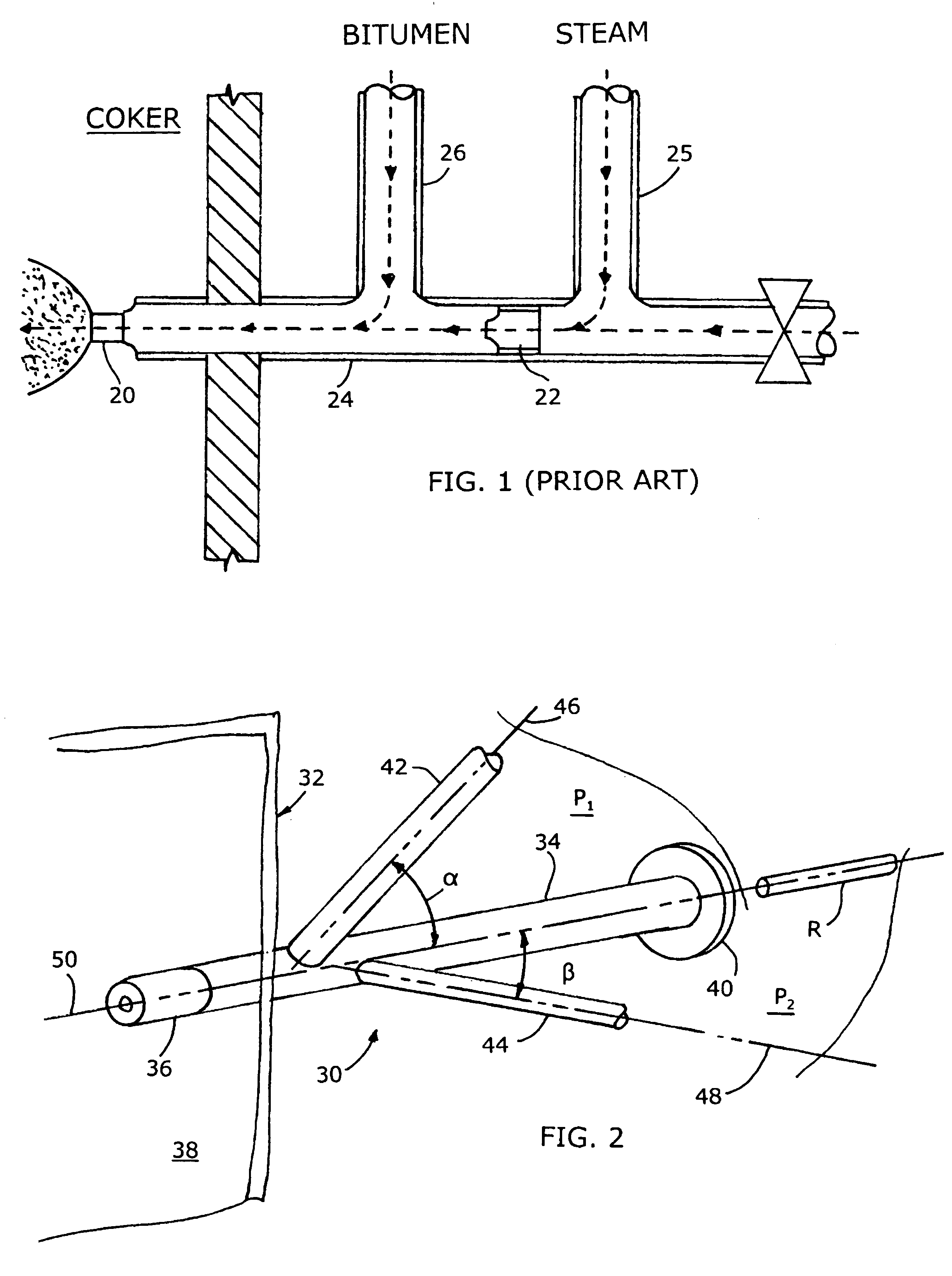

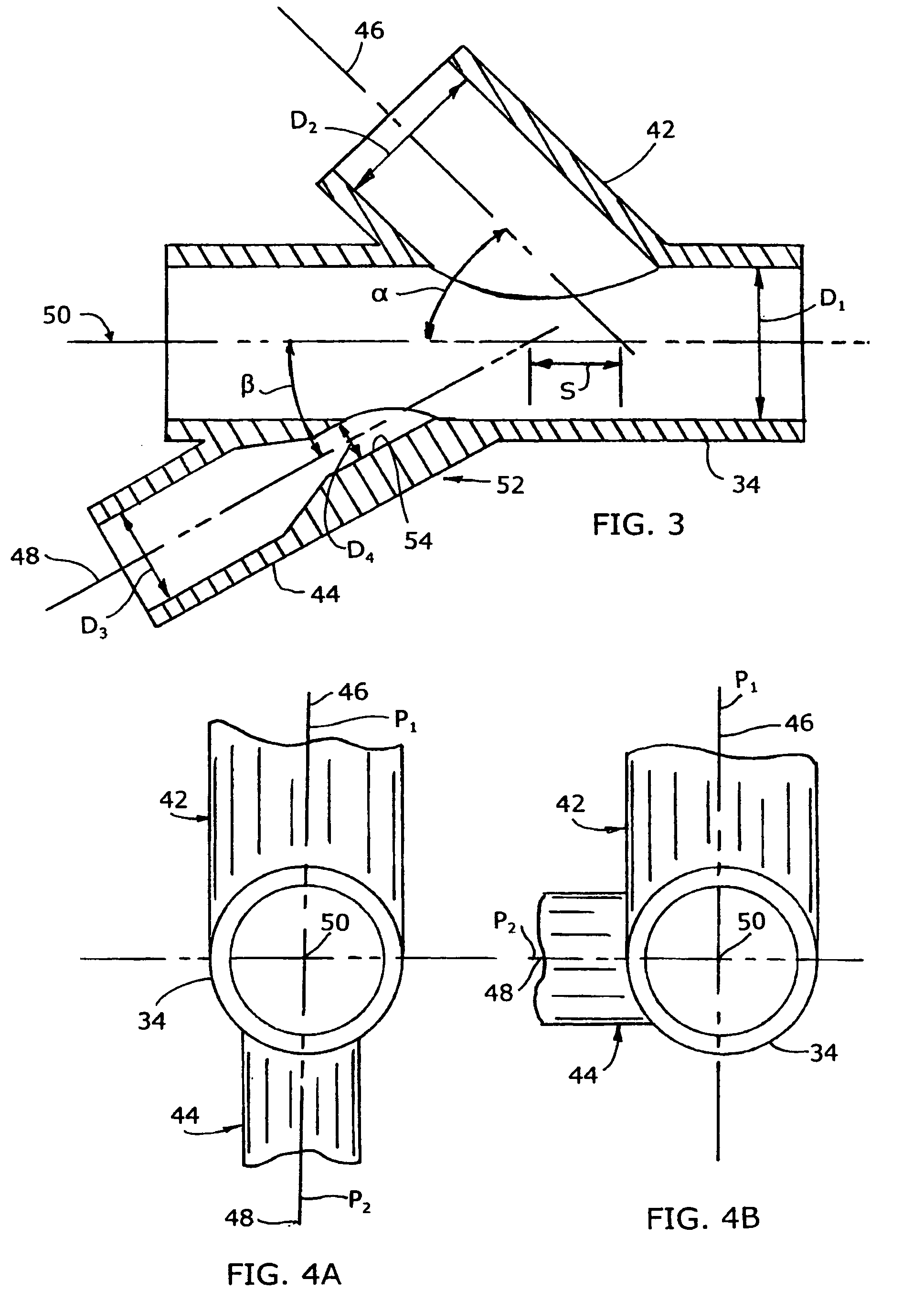

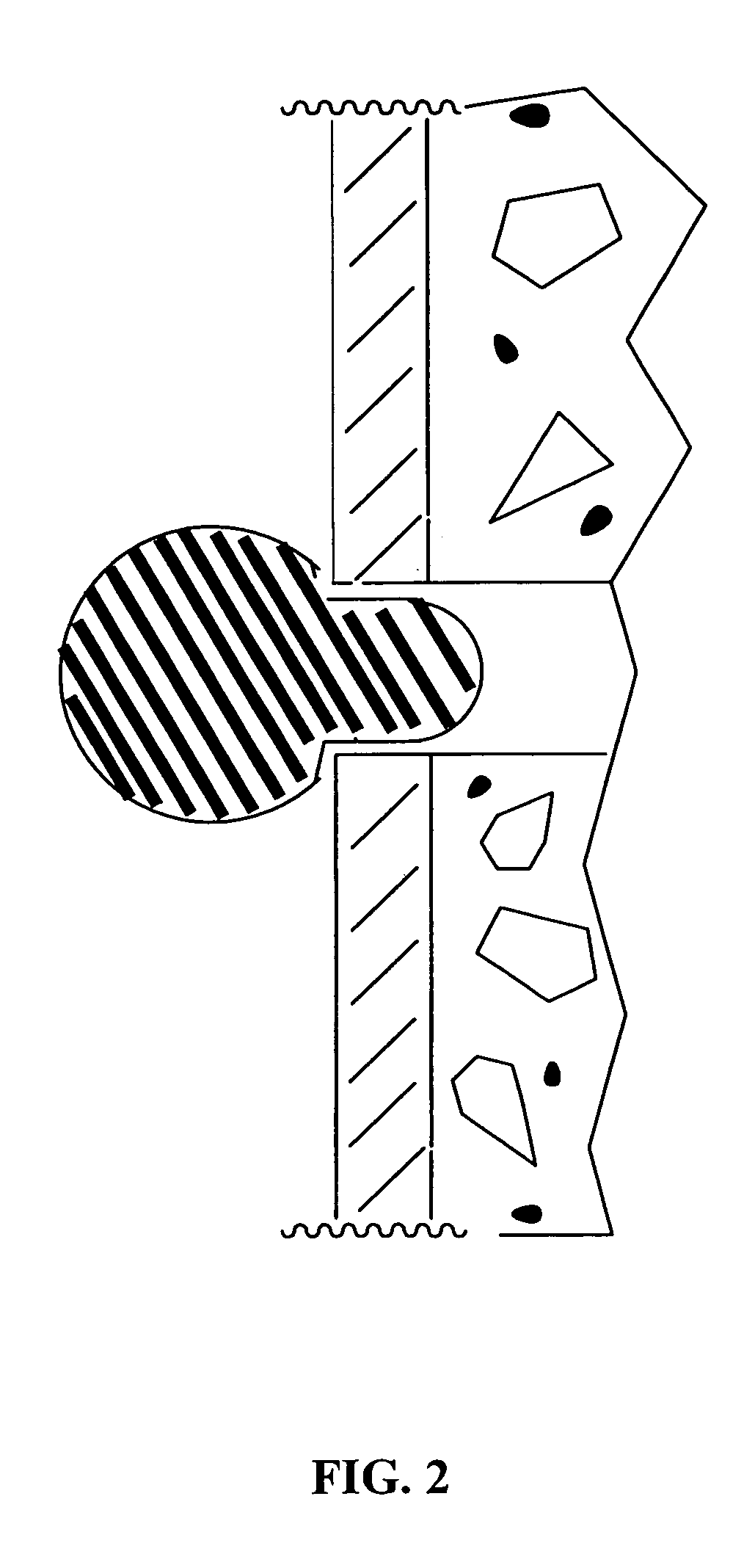

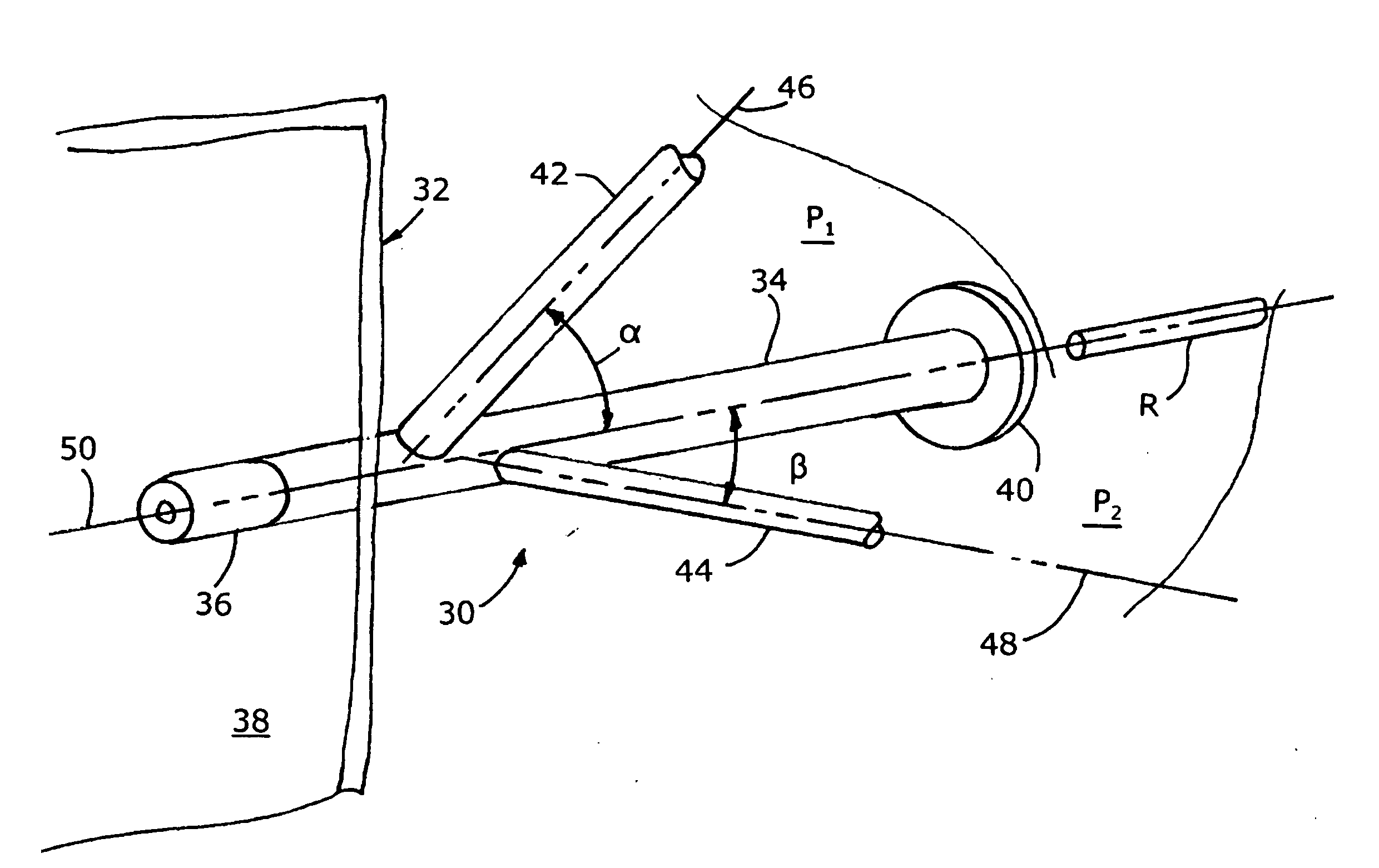

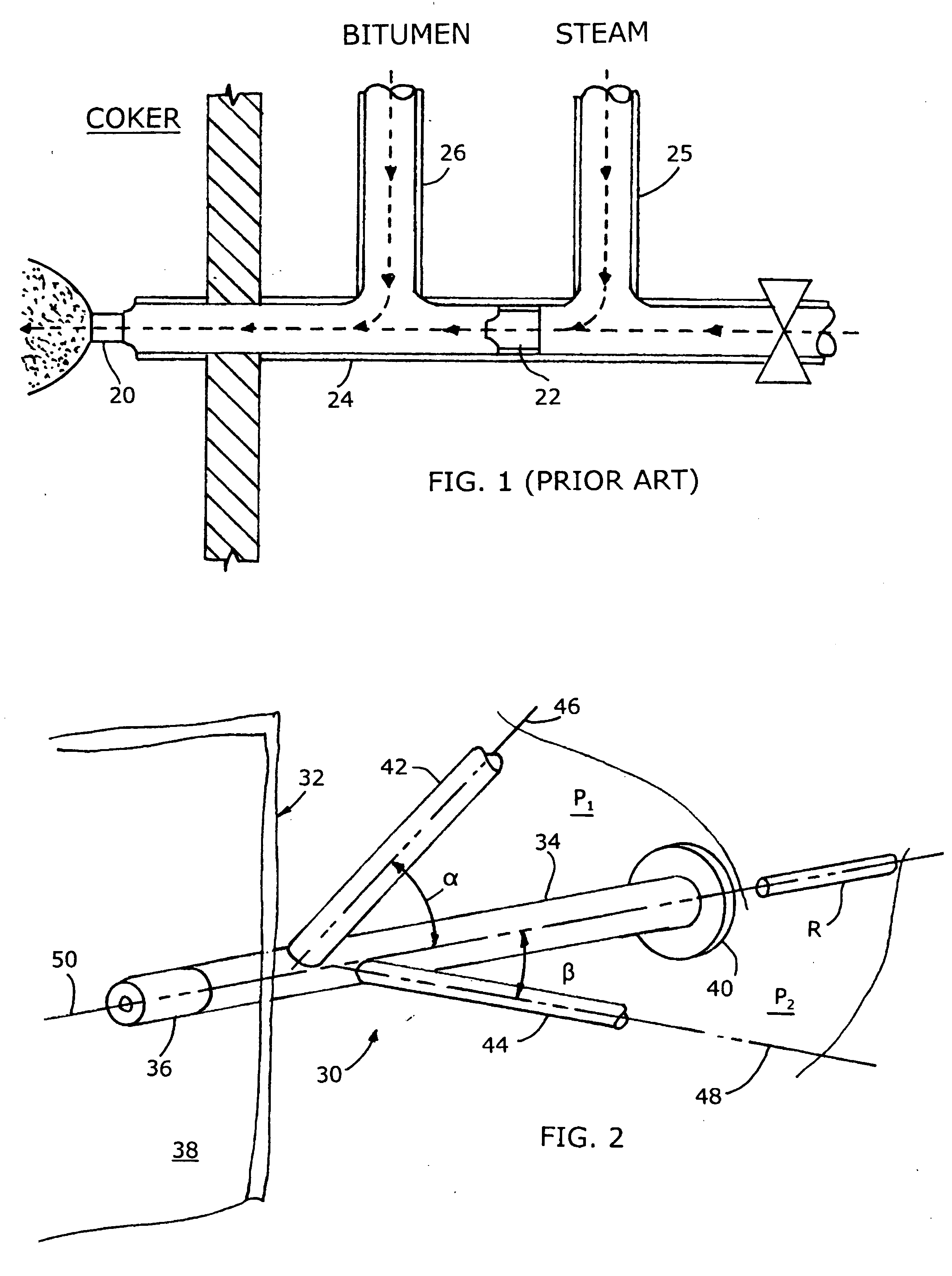

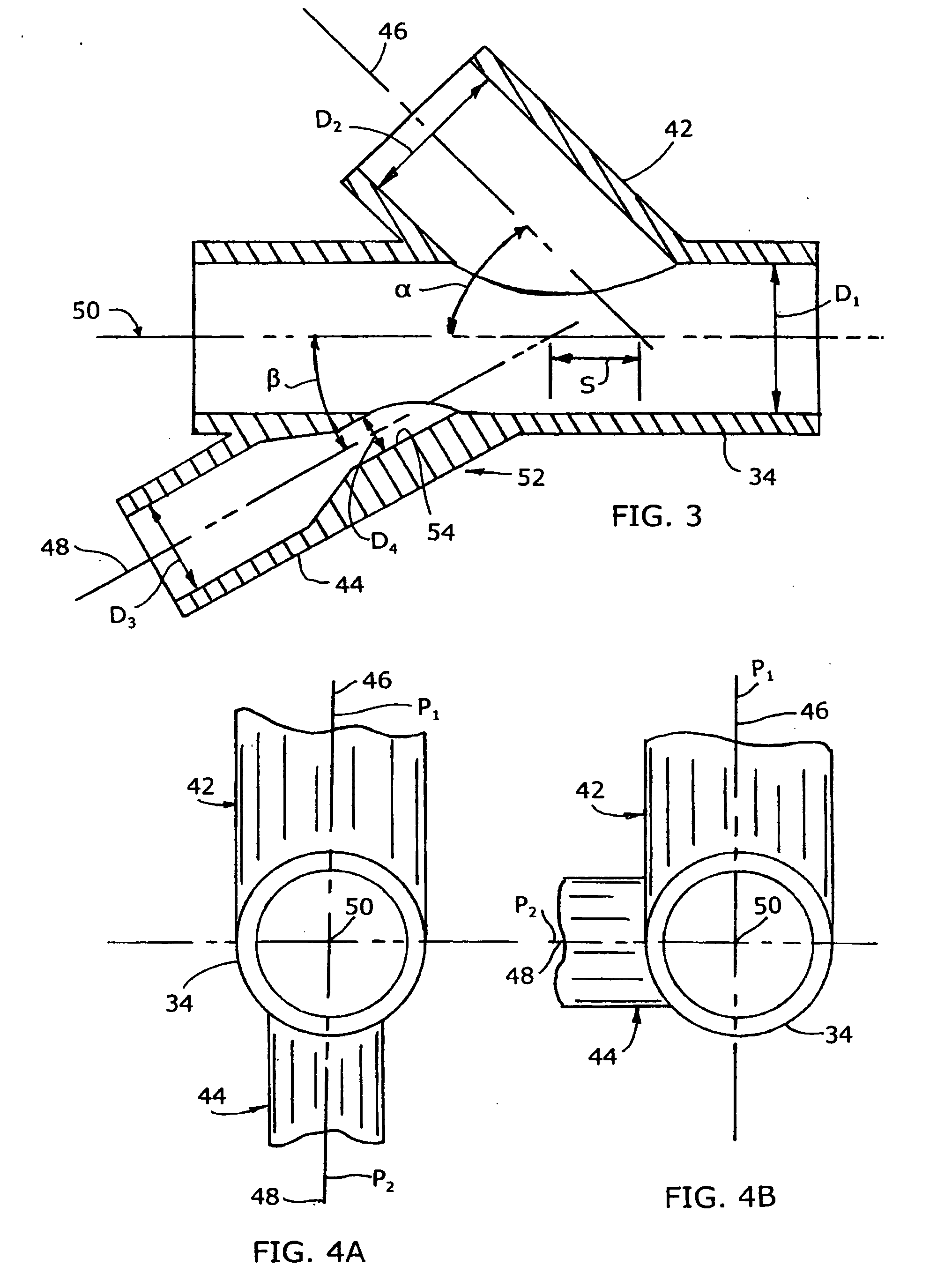

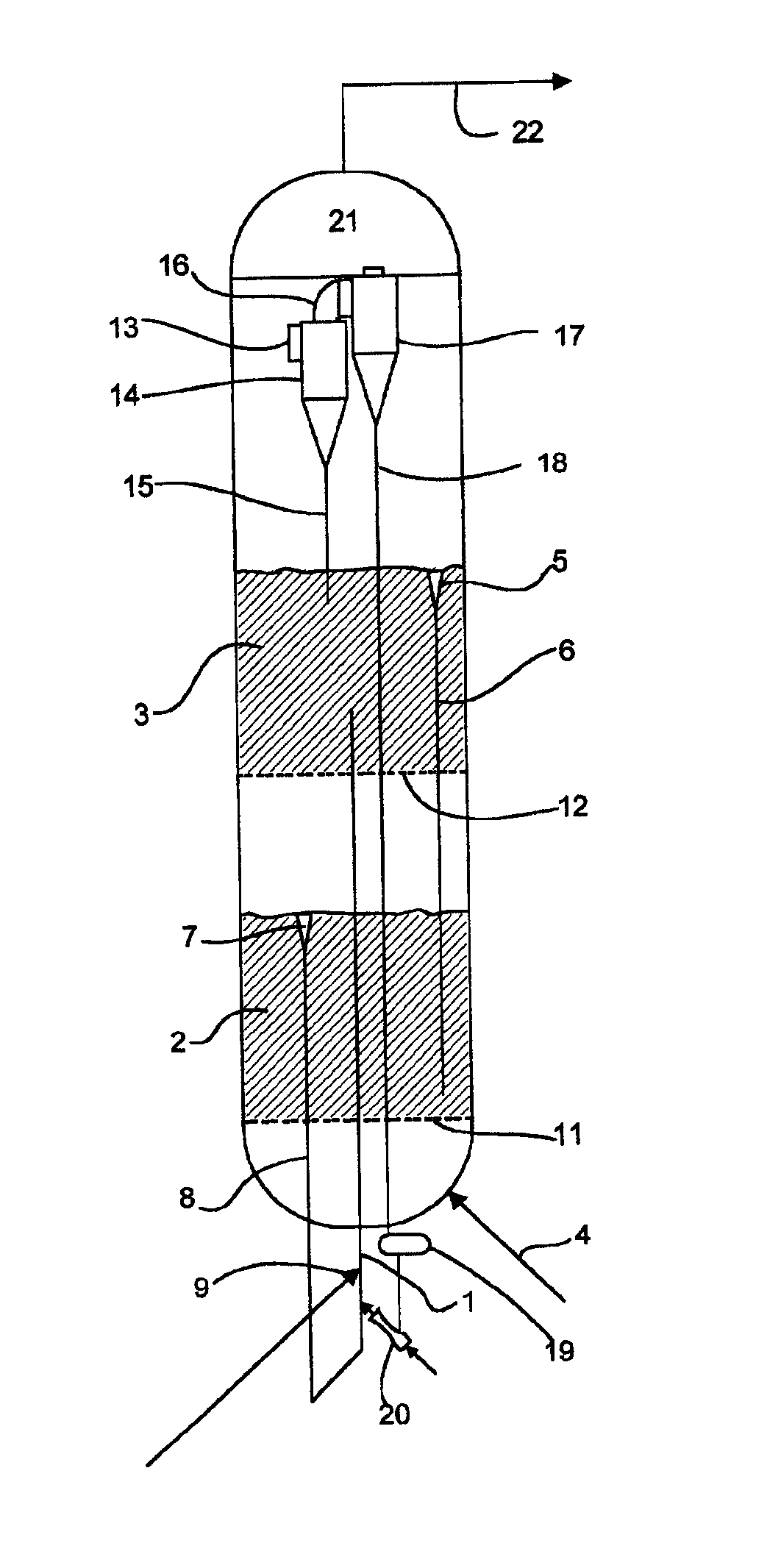

Mixing arrangement for atomizing nozzle in multi-phase flow

ActiveUS7140558B2Smooth transitionEasy to processCharging-discharging device combinationsFlow mixersAcute angleShortest distance

The invention relates to an improved mixing arrangement for, primarily, moving bitumen in steam from sources of such bitumen and steam to a reactor or coker for further processing of the bitumen into petroleum products. The invention provides a main conduit connected to an atomizing nozzle mounted in a wall of the reactor and first and second conduits for flowing bitumen and steam respectively into the main conduit. The first conduit is angled relative to the main conduit at an acute angle of about 45° and the second conduit is angled relative to the main conduit at an acute angle of about 30°. The second conduit is positioned upstream of the first conduit by a short distance of about 23 mm and may be angled radially relative to the first conduit by any angle, although a 90° angle is preferred. A flow accelerating nozzle is located in the second conduit adjacent the entrance therefrom into the main conduit The arrangement of the invention improves the flow characteristics of 2-phase material flowing to the atomizing nozzle, reducing pulsations in the main conduit and improving the resulting atomization of the bitumen in the reactor.

Owner:NAT RES COUNCIL OF CANADA +1

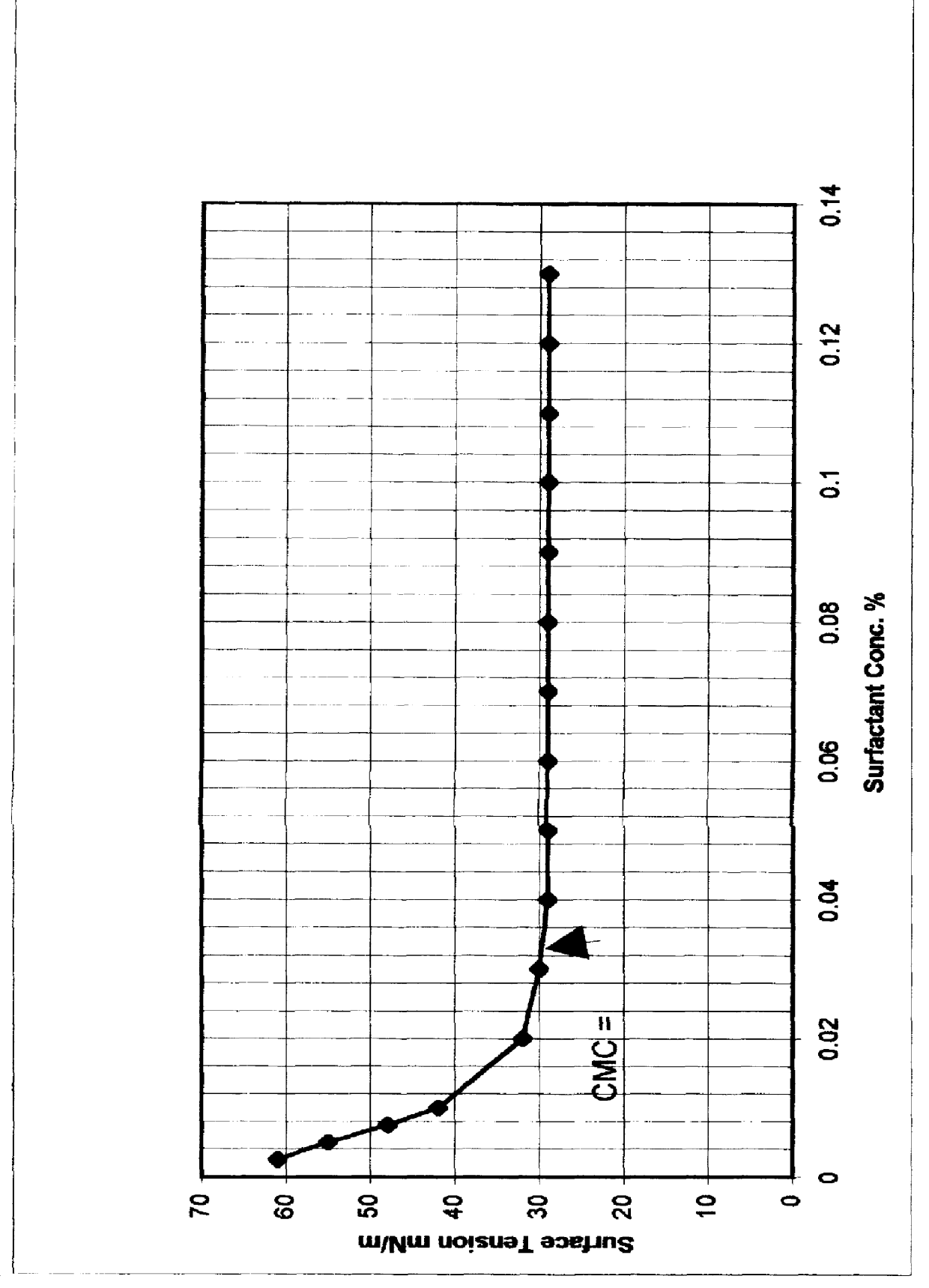

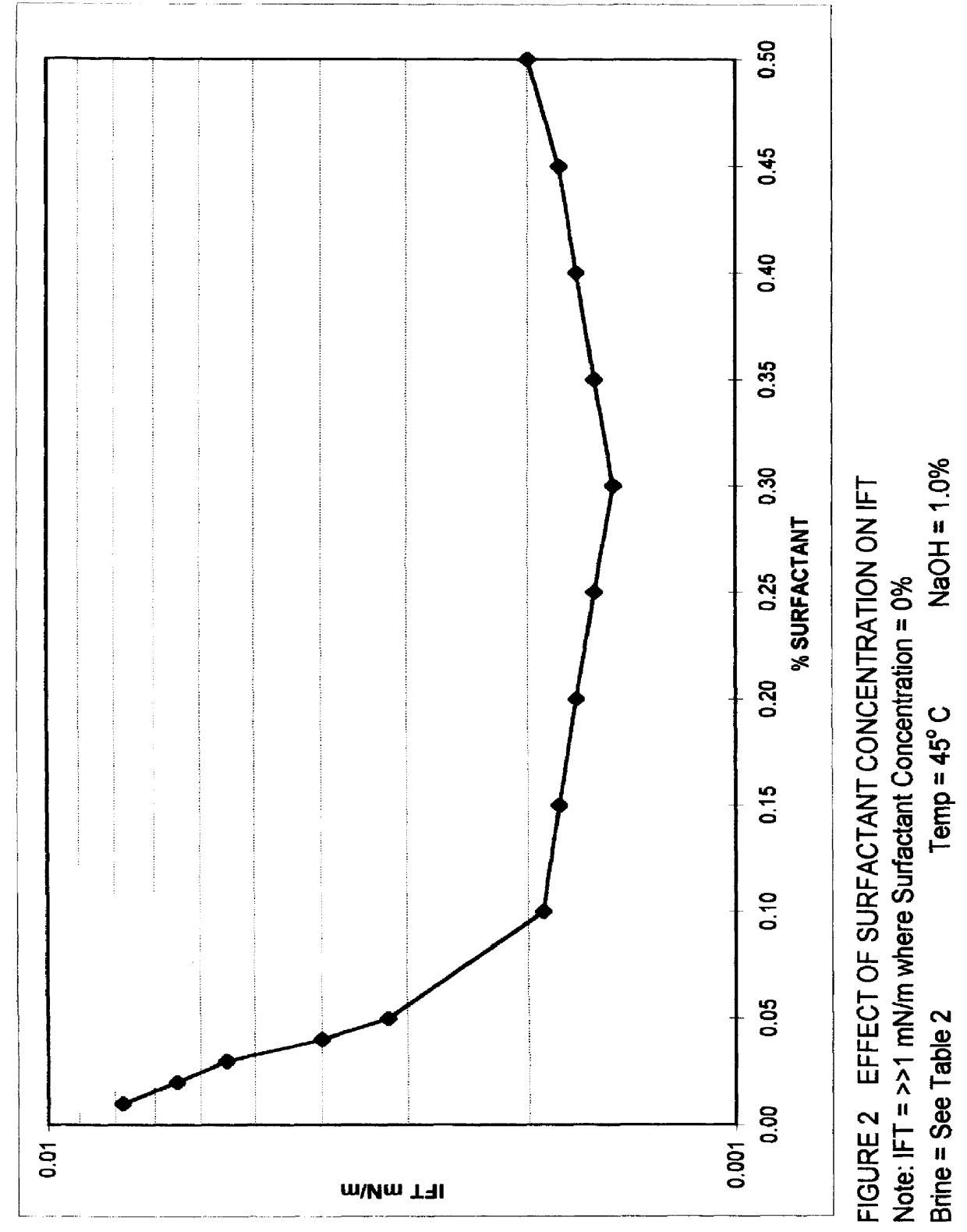

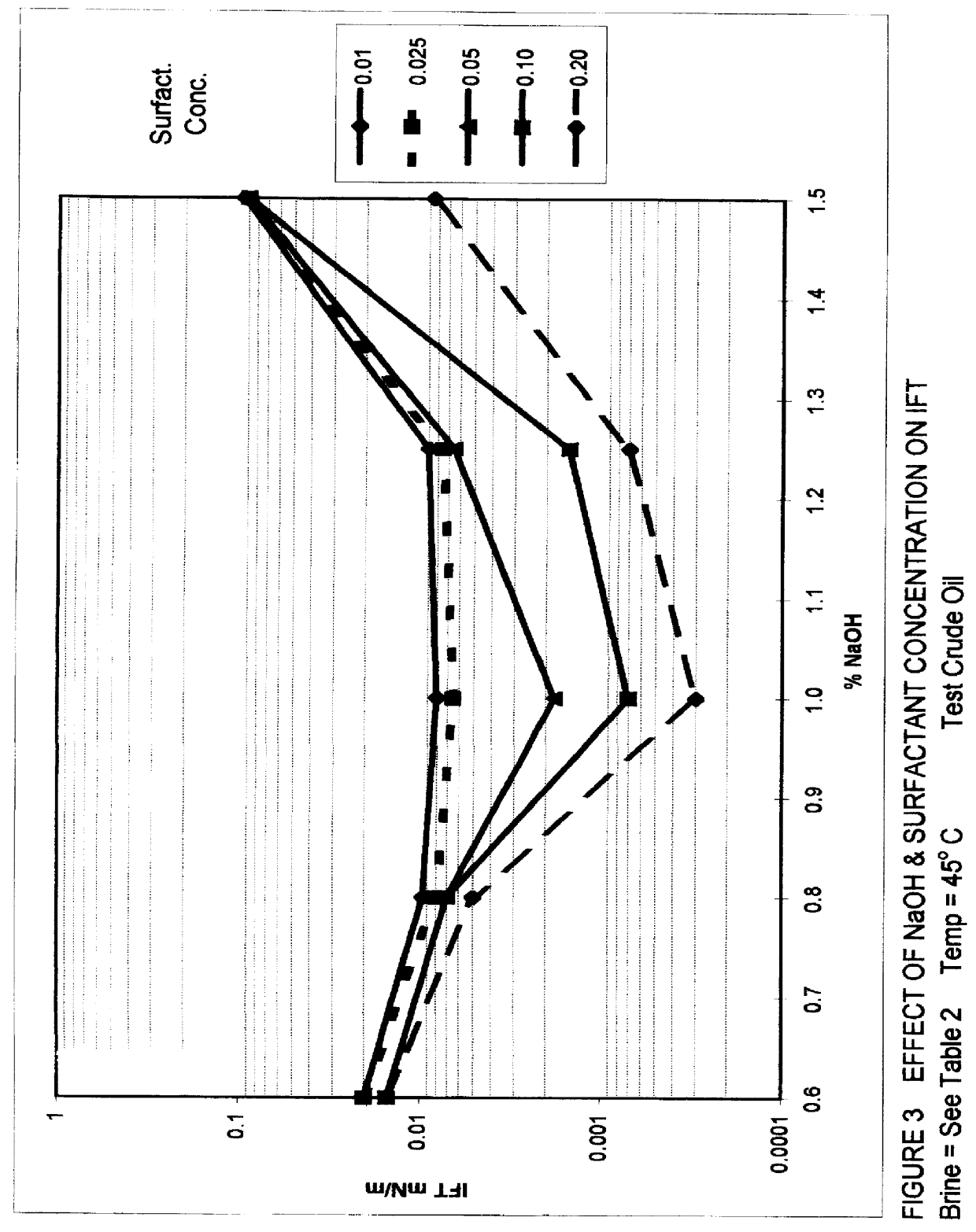

Alkaline surfactant polymer flooding composition and process

An improved concentrated surfactant formulation and process for the recovery of residual oil from subterranean petroleum reservoirs, and more particularly an improved alkali surfactant flooding process which results in ultra-low interfacial tensions between the injected material and the residual oil, wherein the concentrated surfactant formulation is supplied at a concentration above, at, or, below its CMC, also providing in situ formation of surface active material formed from the reaction of naturally occurring organic acidic components with the injected alkali material which serves to increase the efficiency of oil recovery.

Owner:OIL CHEM TECH

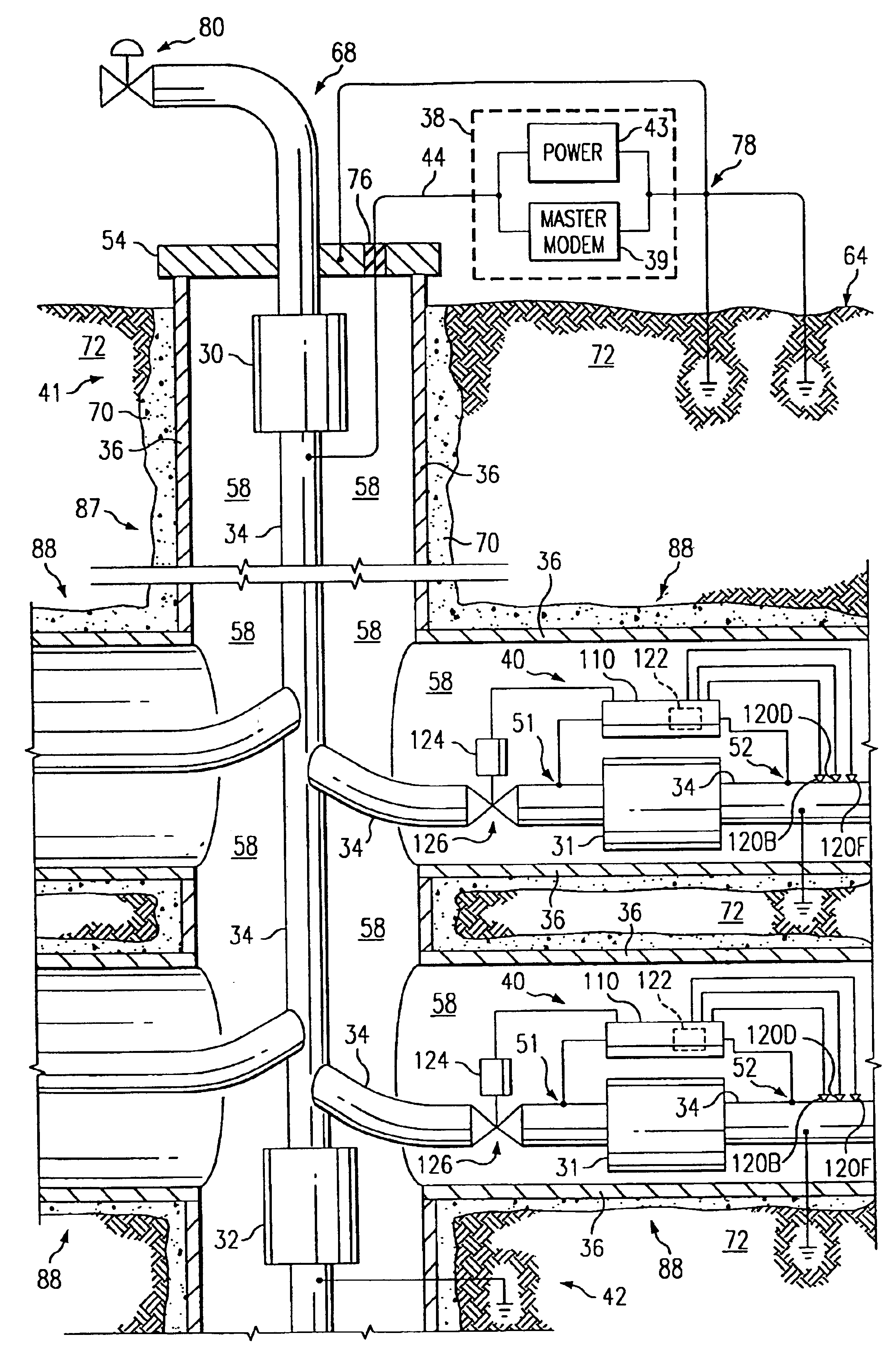

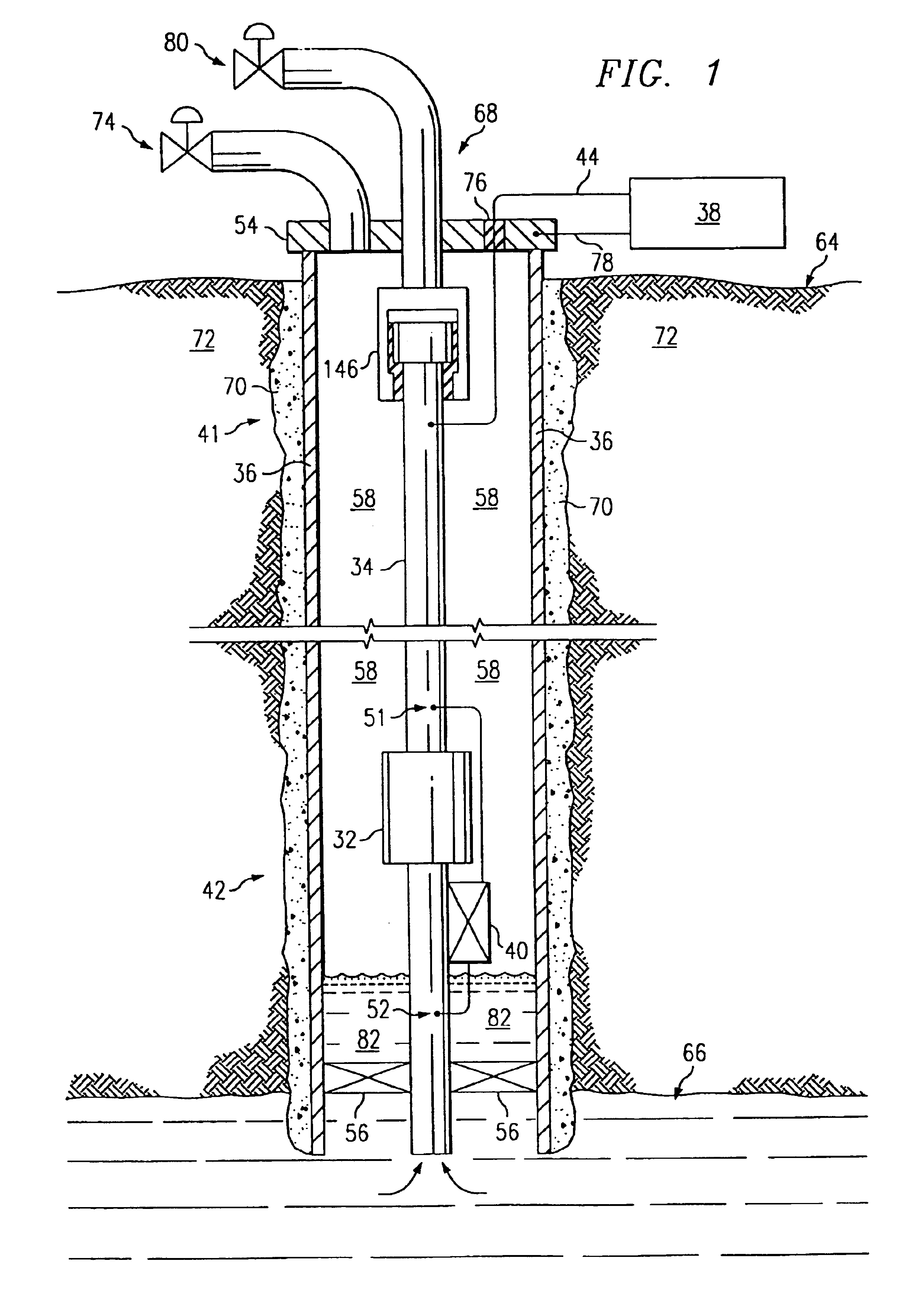

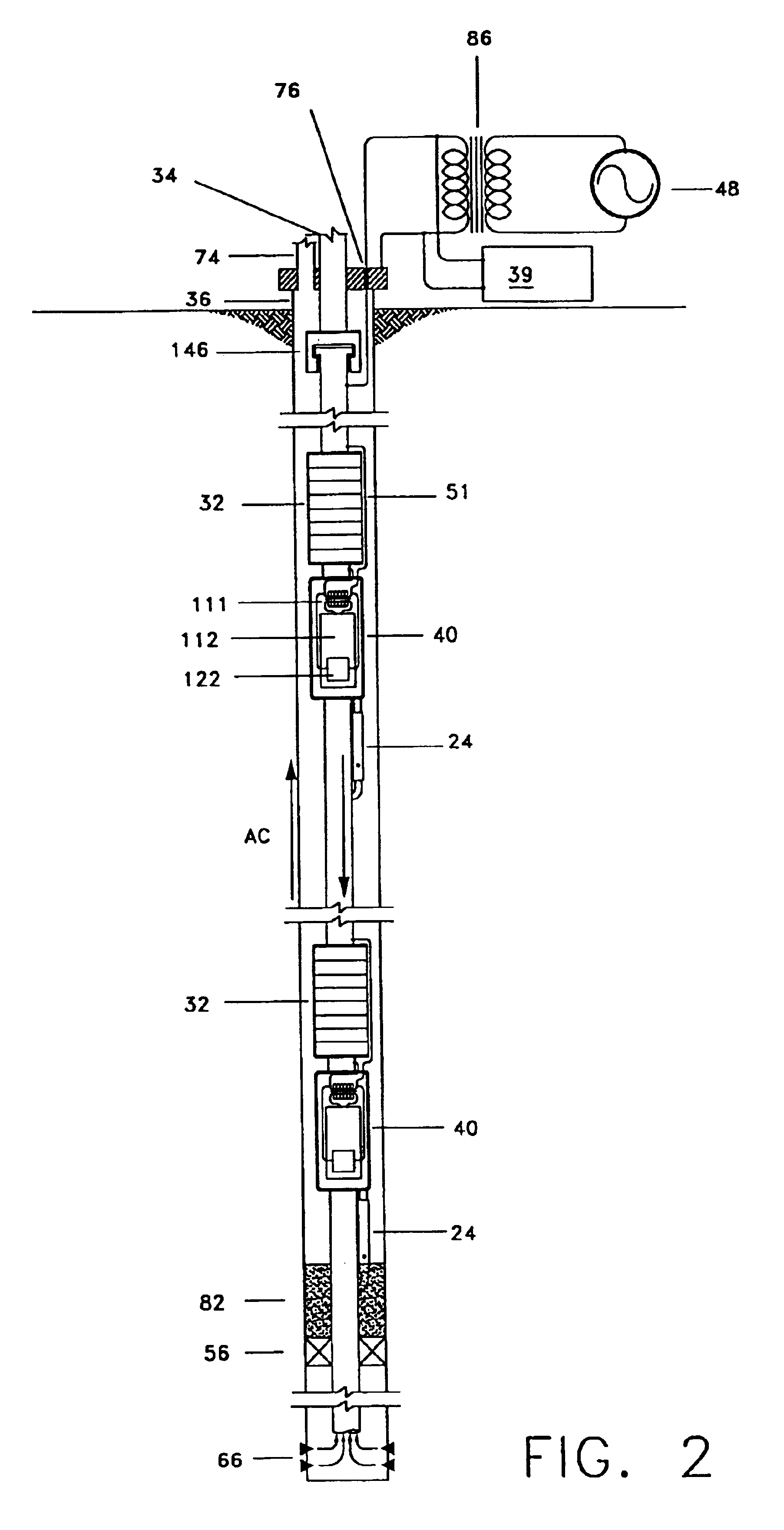

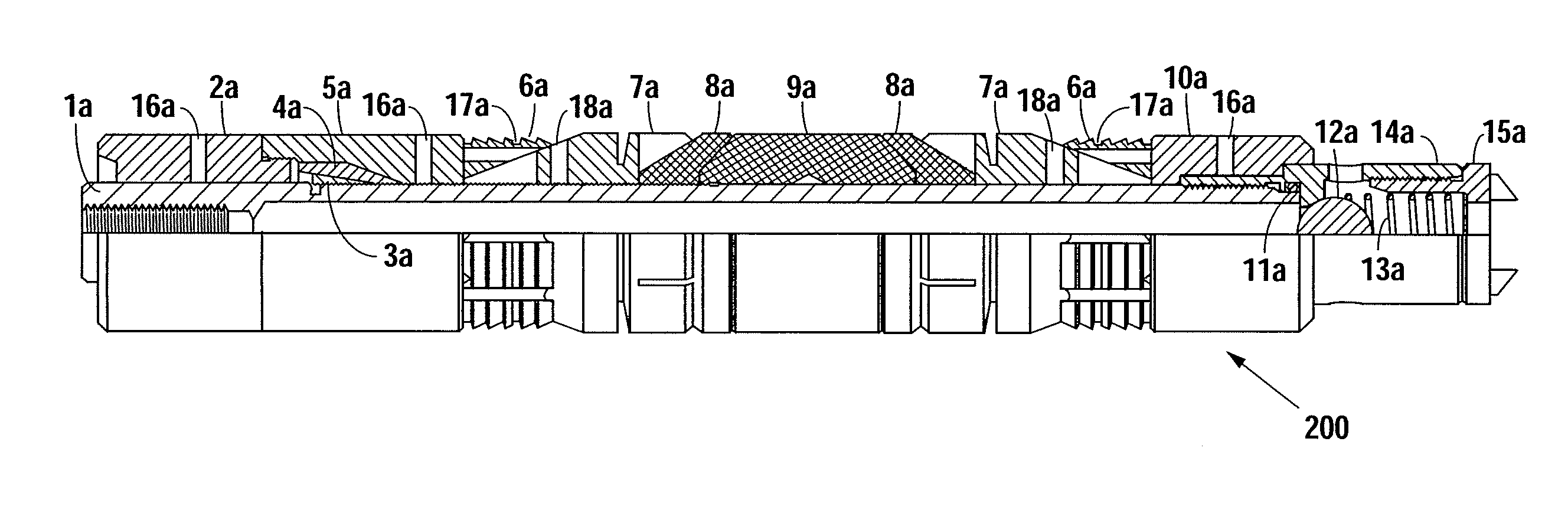

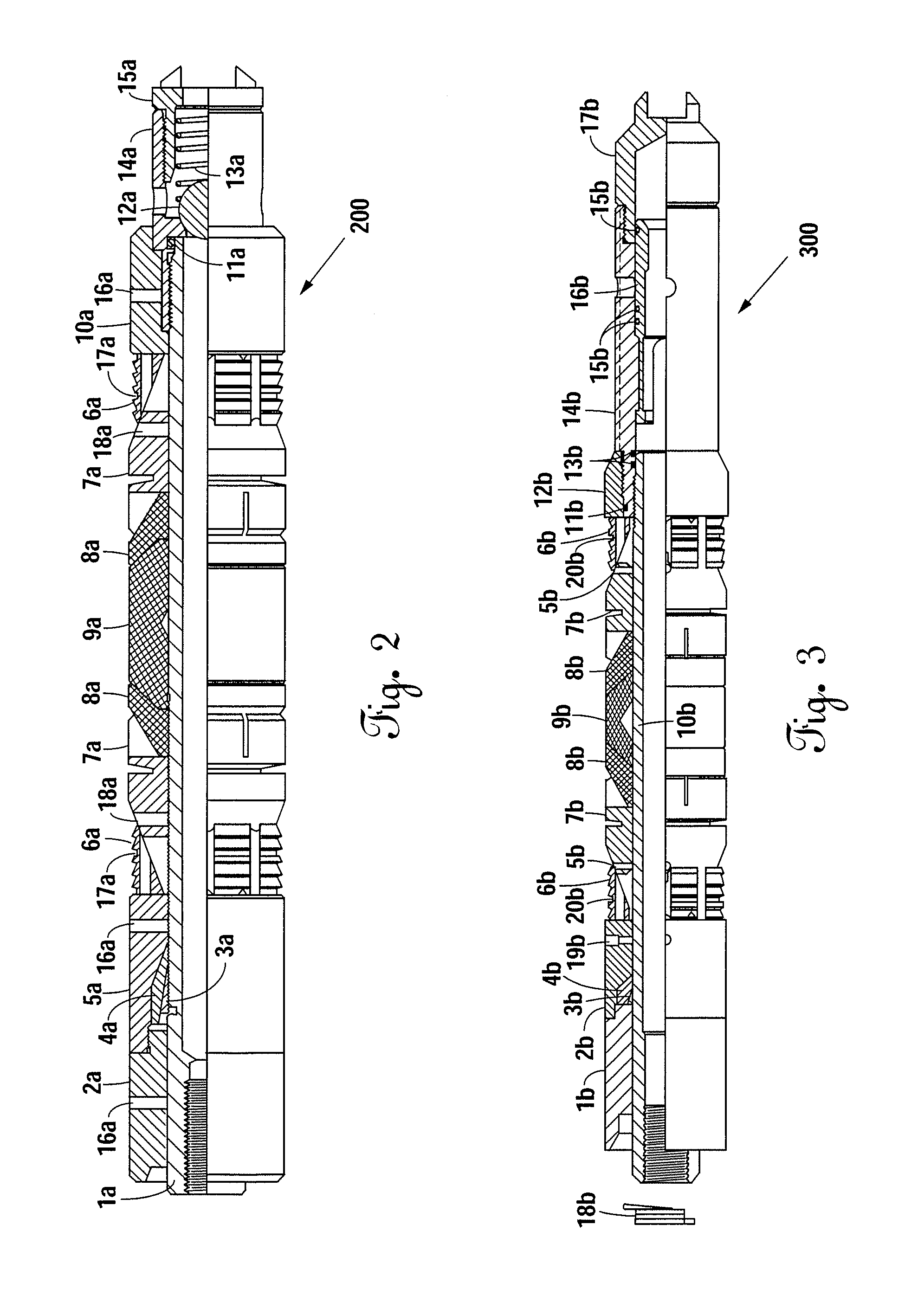

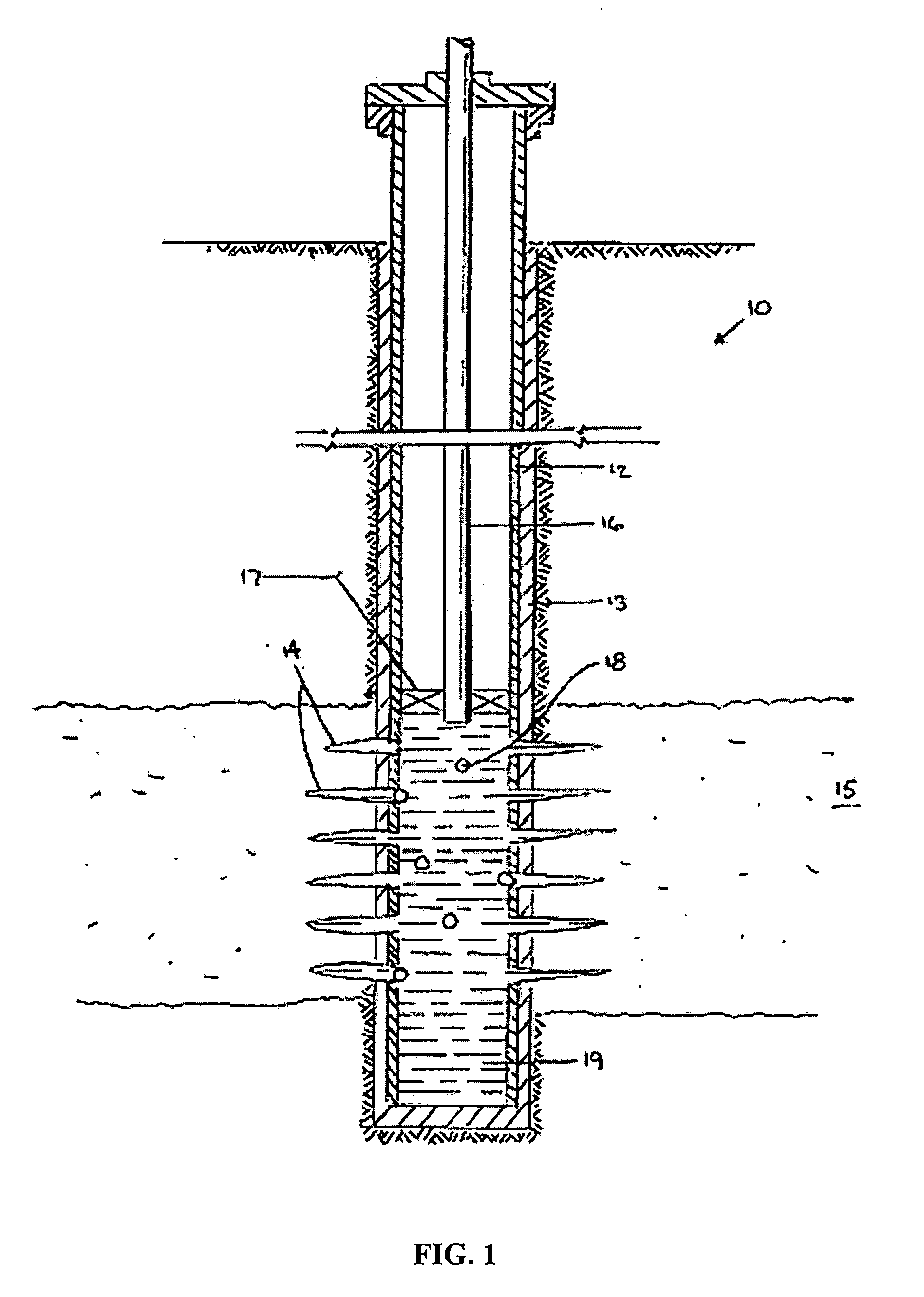

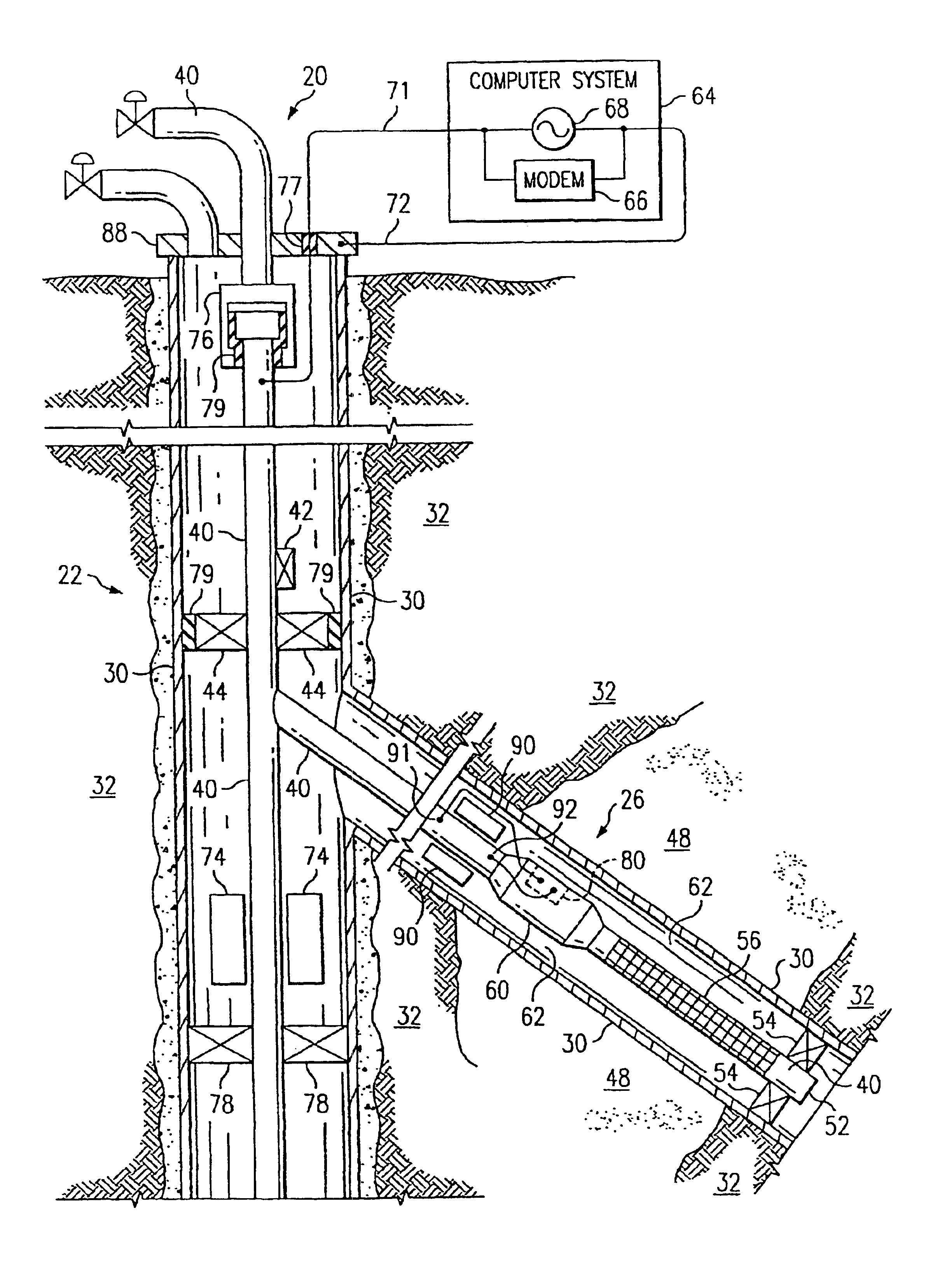

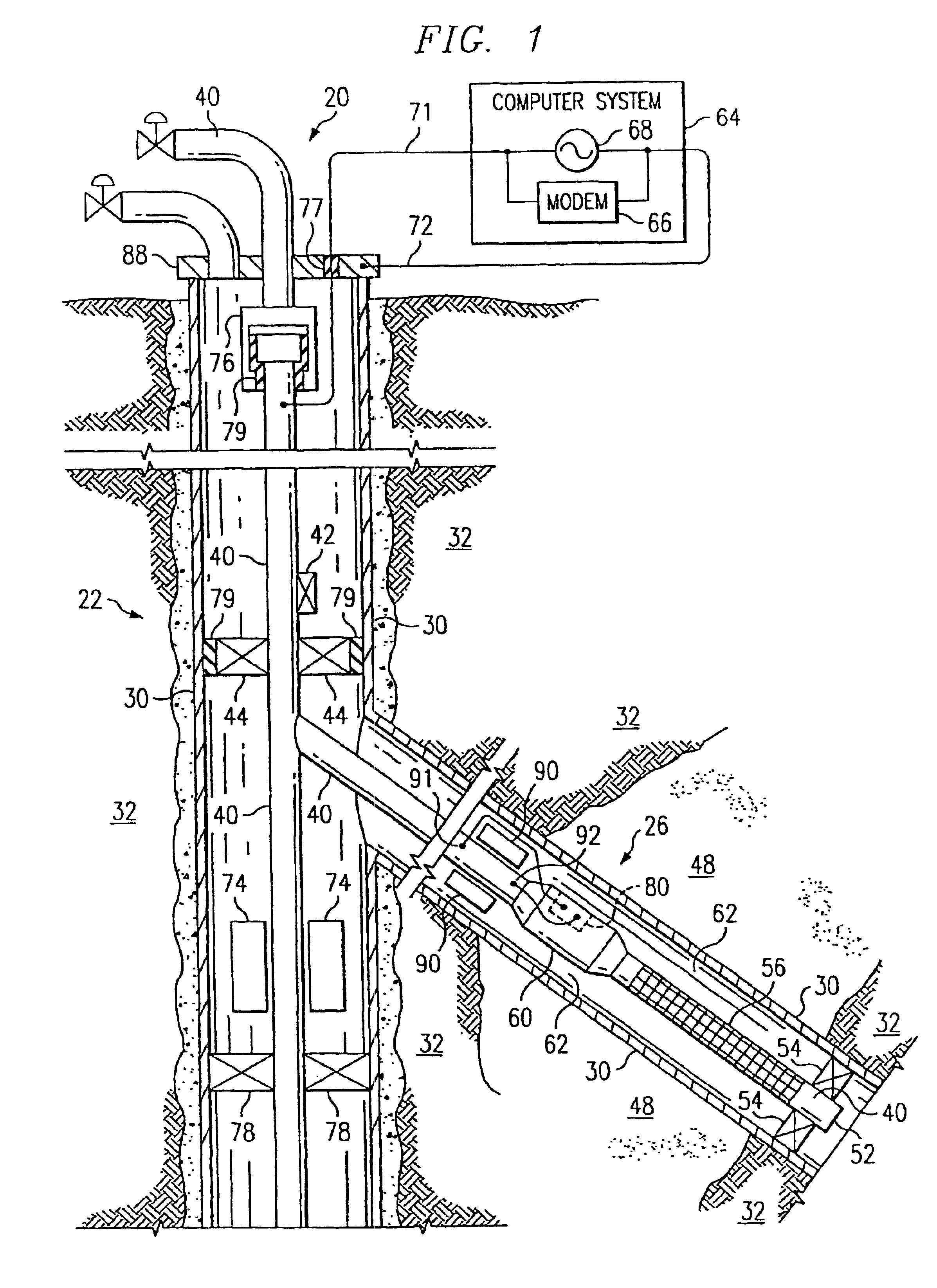

Permanent downhole, wireless, two-way telemetry backbone using redundant repeaters

A system and method of communicating among devices via a piping structure using at least one induction choke about the piping structure to route a time-varying current carrying communication signals between the devices. A communications system comprises a piping structure, a first communication device, a second communication device, and an induction choke. The piping structure comprises a first location, a second location, and an electrically conductive portion extending between the first and second locations. The first and second locations are distally spaced along the piping structure. The first and second communication devices are each electrically connected to the electrically conductive portion of the piping structure along the first location and second location, respectively, and each is adapted to send and receive communication signals via time-varying current. The induction choke is located about an electrically choked portion of the electrically conductive portion of the piping structure, such that the induction choke is adapted to route time-varying current within the piping structure between the electrical connection location for the first communication device and the electrical connection location for the second communication device, and such that the first communication device can communicate with the second communication device via the piping structure. A preferred application of the present invention is a well for producing petroleum products (e.g., oil, natural gas), comprising a communication system as described above.

Owner:SHELL OIL CO

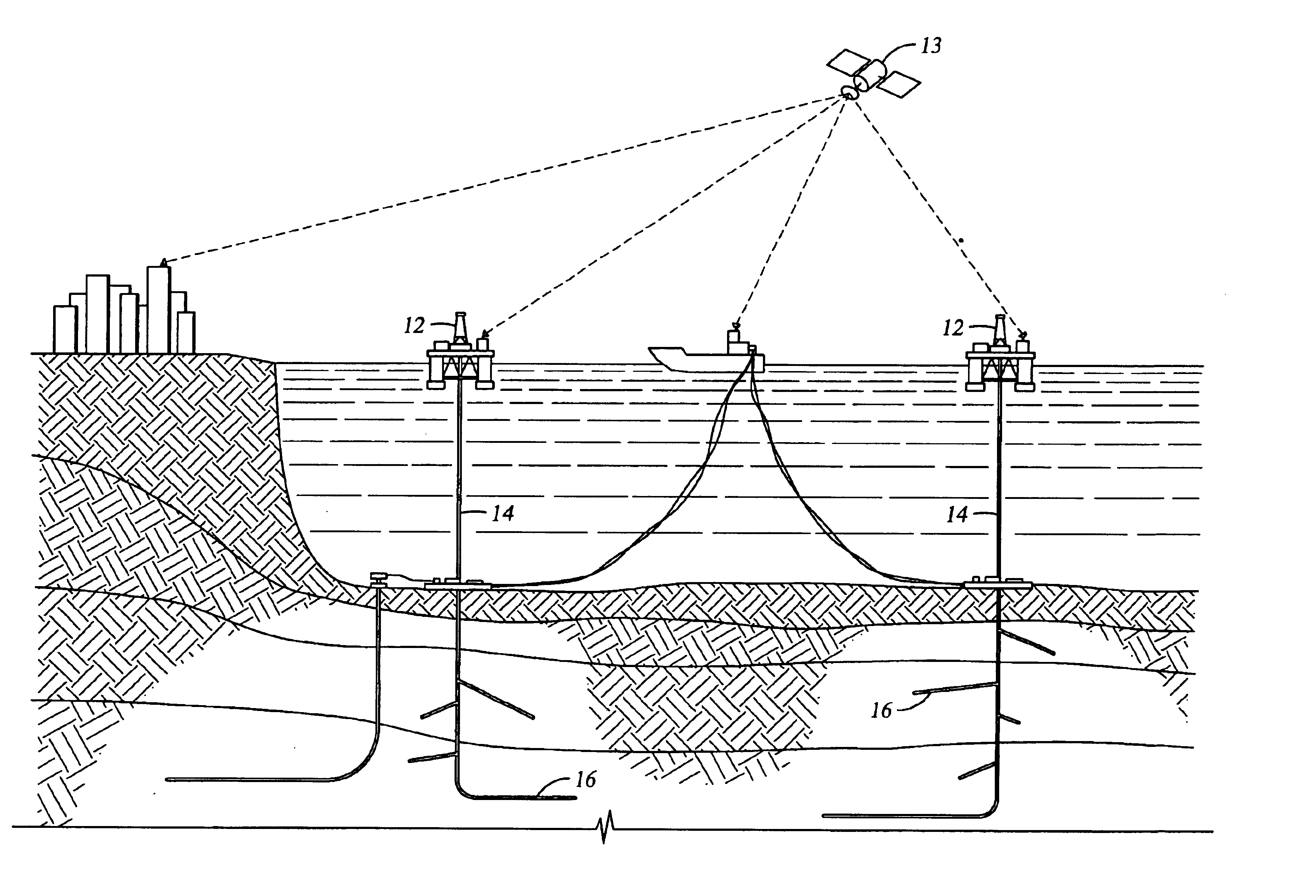

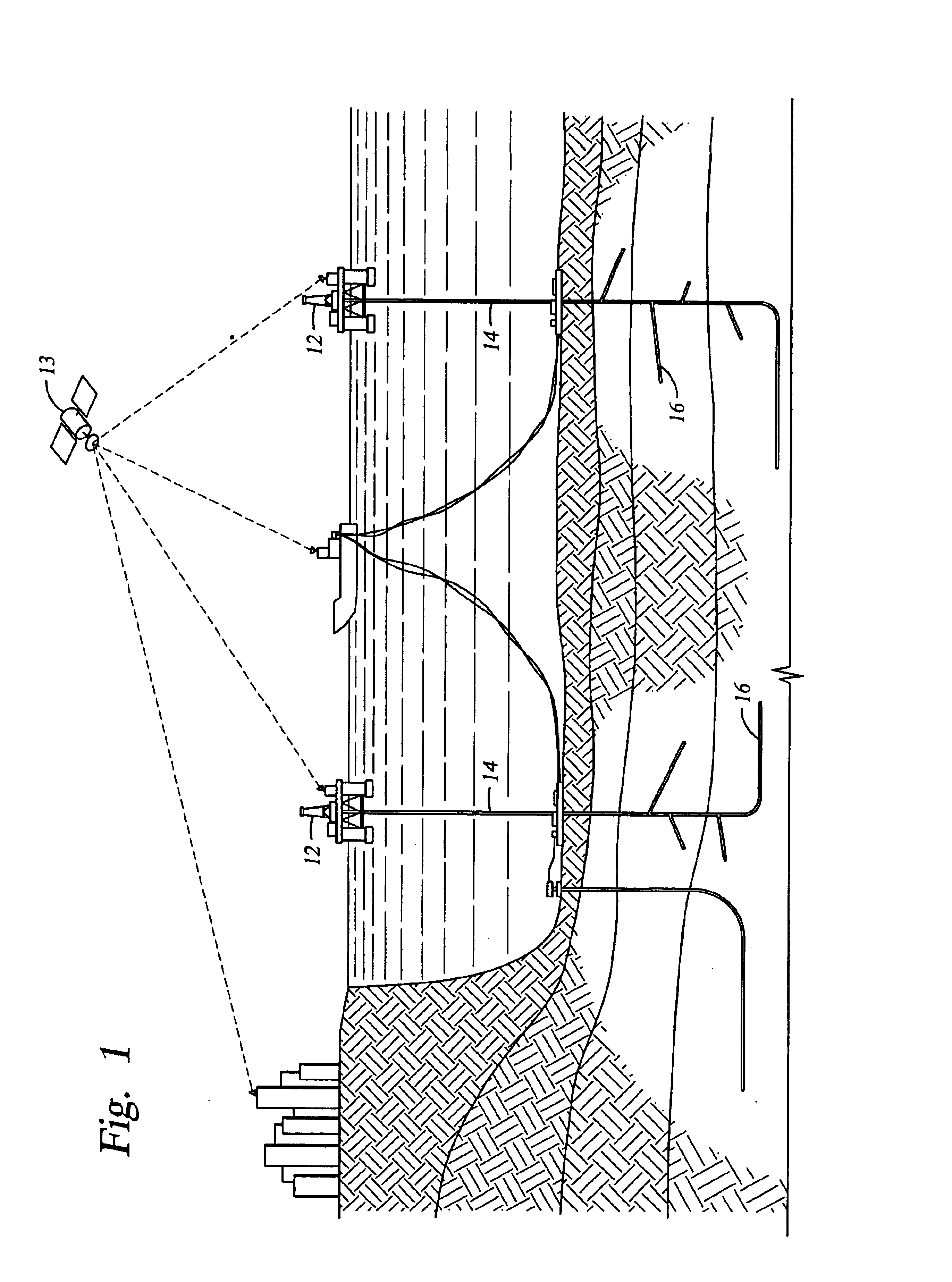

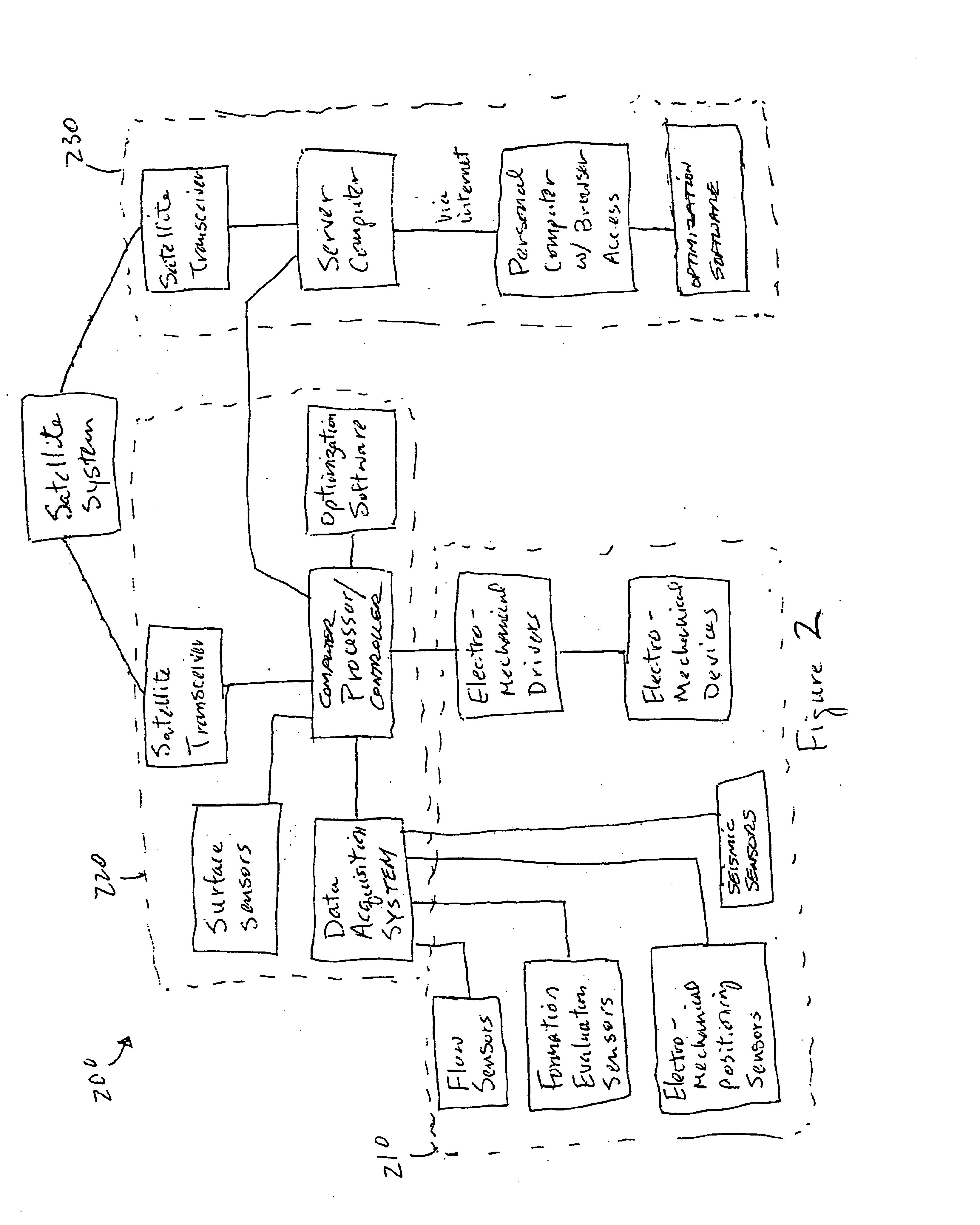

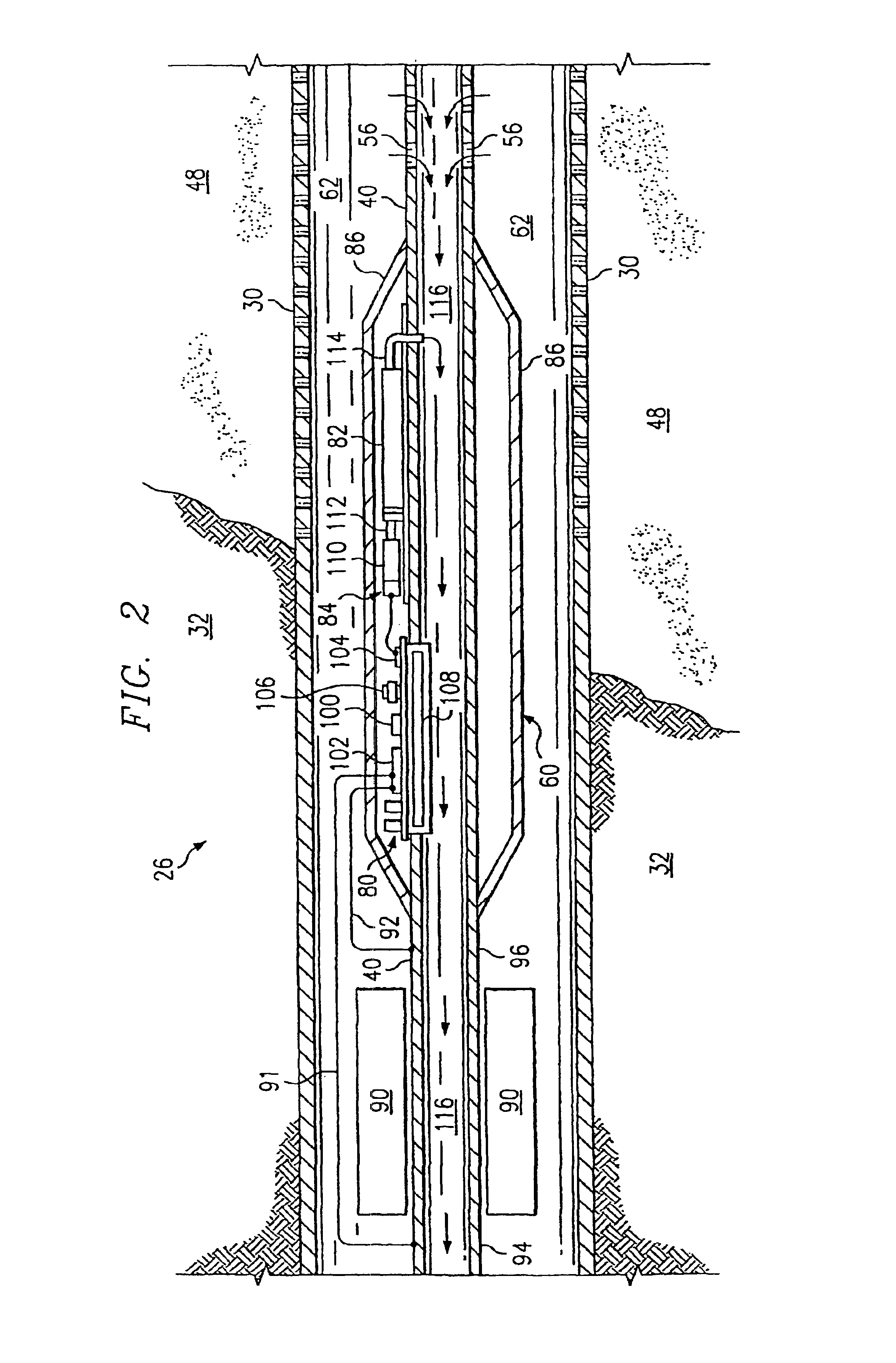

Methods and apparatus for monitoring and controlling oil and gas production wells from a remote location

The invention provides apparatus and methods for monitoring and controlling hydrocarbon production wells and / or injection wells from a remote location. The apparatus for monitoring and controlling one or more hydrocarbon production wells or injection wells from a remote location comprises one or more surface control and data acquisition systems; one or more sensors disposed in communication with the one or more control and data acquisition systems; one or more downhole flow control devices disposed in communication with the one or more control and data acquisition systems; and one or more remote controllers disposed in communication with the one or more control and data acquisition systems. Preferably, the remote controller comprises a computer having an internet access disposed in communication with the one or more control and data acquisition systems through a communication device comprising an internet web site server. The method for monitoring and controlling a downhole hydrocarbon production well or an injection well comprises: transmitting data collected by a downhole sensor module to a control and data acquisition system; evaluating downhole operating conditions and optimizing downhole operating parameters utilizing an optimization software program disposed in communication with the control and data acquisition system; and transmitting signals between the control and data acquisition system system and a remote controller utilizing a satellite communication system, the remote controller comprising a computer and an internet browser control access adapted to display operating conditions and parameters and to accept instructions to change operating parameters.

Owner:WEATHERFORD TECH HLDG LLC

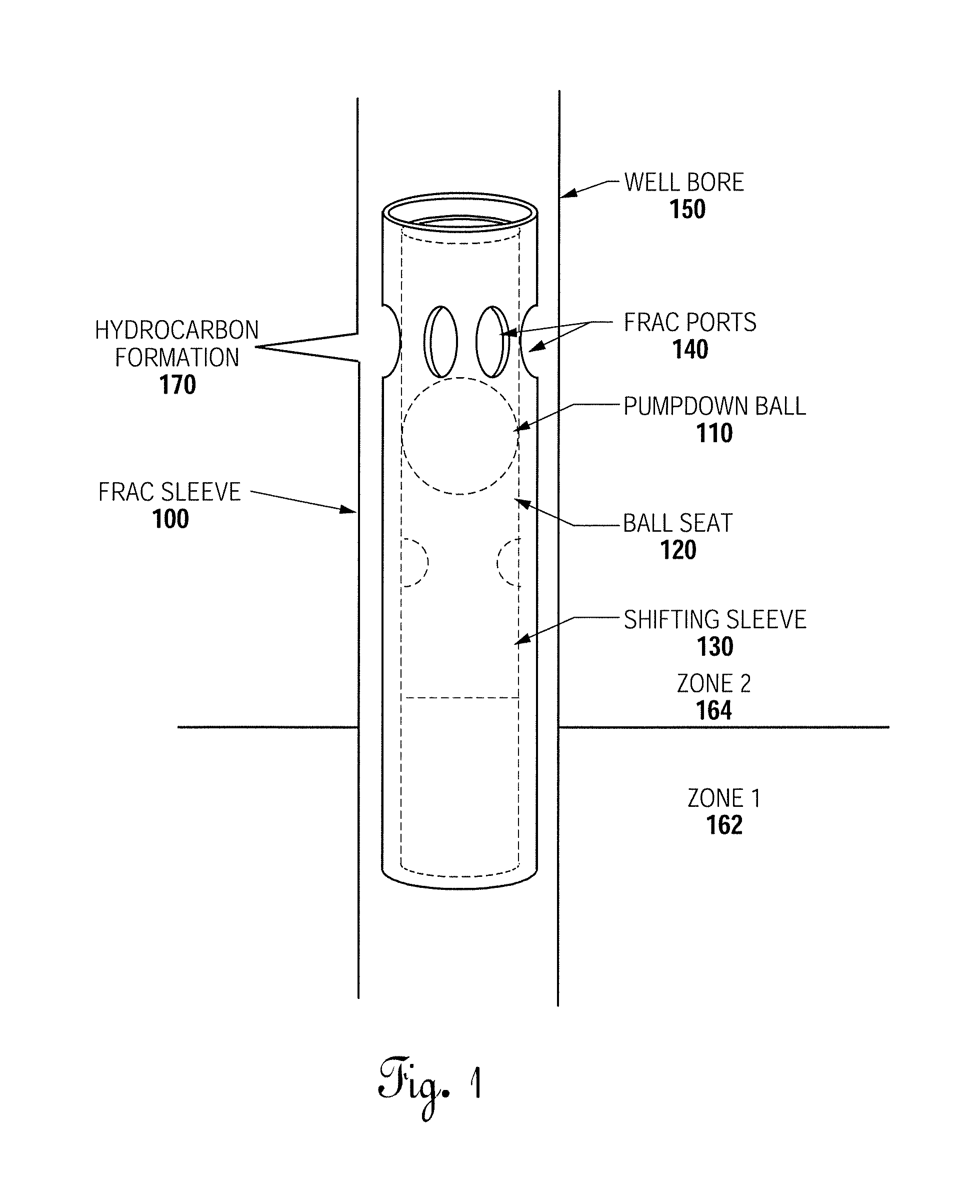

Downhole tools having non-toxic degradable elements and methods of using the same

Downhole tools for use in oil and gas production which degrade into non-toxic materials, a method of making them and methods of using them. A frac ball and a bridge plug comprised of polyglycolic acid which can be used in fracking a well and then left in the well bore to predictably, quickly, and safely disintegrate into environmentally friendly products without needing to be milled out or retrieved.

Owner:NINE DOWNHOLE TECHNOLOLGIES LLC

Degradable ball sealers and methods for use in well treatment

Described is an oil-degradable ball sealer for use in the oil and gas industry. The ball seal comprises a particular composition including ethylene and one or more alpha-olefins, prepared by an injection molding technique to provide a ball sealer which will dissolve in stimulation or wellbore fluids after stimulation operations are complete. The composition, when dissolved into wellbore fluids, does not pose a hazard or problem to aqueous wellbore fluids or further wellbore stimulations.

Owner:FAIRMOUNT SANTROL

Nano graphene-modified lubricant

ActiveUS20110046027A1Modulate viscosityImprove the lubrication effectAdditivesBase-materialsCarbon nanotubeSingle layer graphene

A lubricant composition having improved lubricant properties, comprising:(a) a lubricating fluid; and (b) nano graphene platelets (NGPs) dispersed in the fluid, wherein nano graphene platelets have a proportion of 0.001% to 60% by weight based on the total weight of the fluid and the graphene platelets combined. Preferably, the composition comprises at least a single-layer graphene sheet. Preferably, the lubricating fluid contains a petroleum oil or synthetic oil and a dispersant or surfactant. With the addition of a thickener or a desired amount of NGPs, the lubricant becomes a grease composition. Compared with graphite nano particle- or carbon nanotube-modified lubricants, NGP-modified lubricants have much better thermal conductivity, friction-reducing capability, anti-wear performance, and viscosity stability.

Owner:GLOBAL GRAPHENE GRP INC

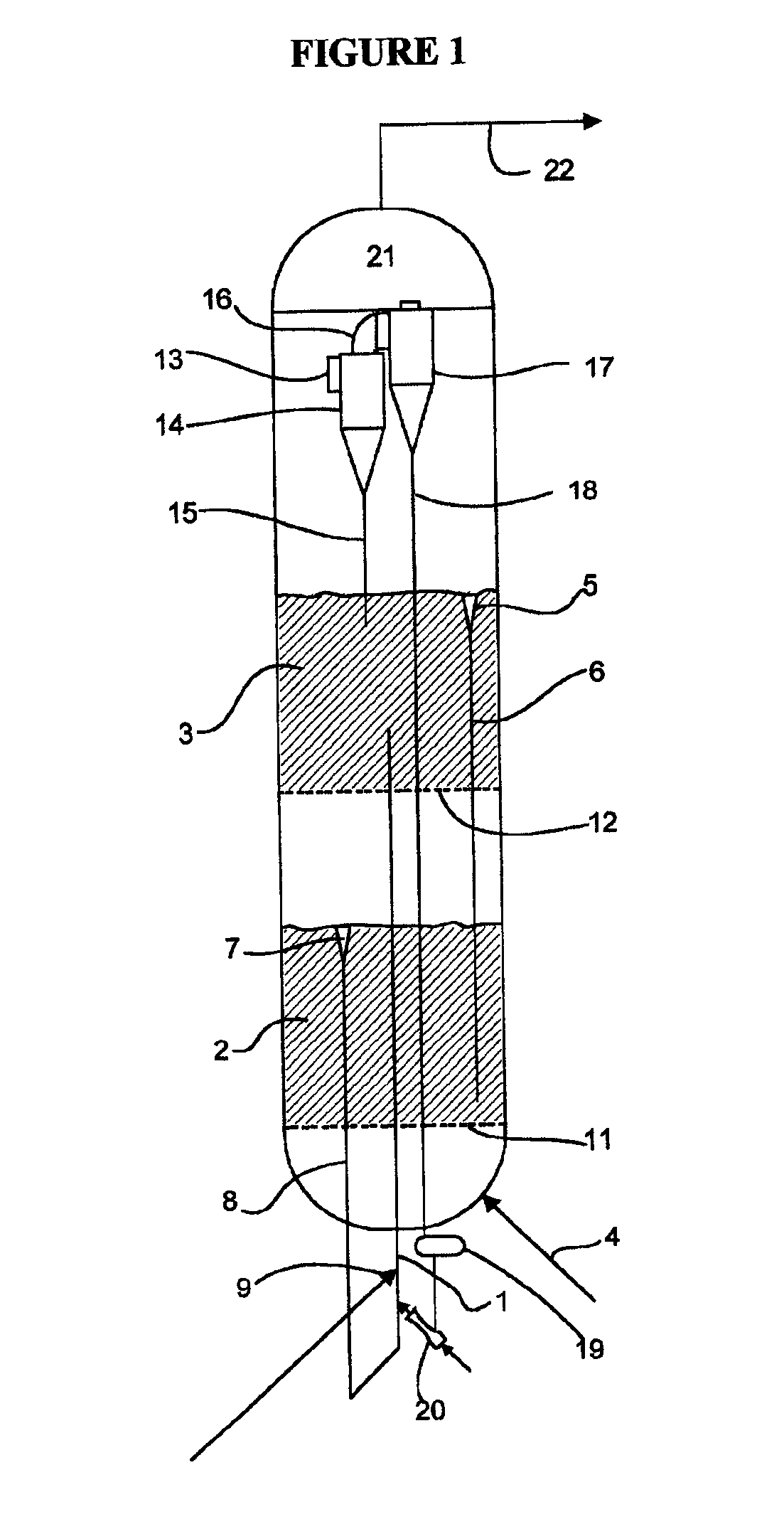

Controlled downhole chemical injection

InactiveUS6981553B2Improve efficiencyImprove flow characteristicsNear-field transmissionSurveyElectrical conductorPetroleum

A petroleum well having a well casing, a production tubing, a source of time-varying current, a downhole chemical injection device, and a downhole induction choke. The casing extends within a wellbore of the well. The tubing extends within the casing. The current source is located at the surface. The current source is electrically connected to, and adapted to output a time-varying current into, the tubing and / or the casing, which act as electrical conductors for providing downhole power and / or communications. The injection device having a communications and control module, a chemical container, and an electrically controllable chemical injector. The communications and control module is electrically connected to the tubing and / or the casing. The chemical injector is electrically connected to the communications and control module, and is in fluid communication with the chemical container. The downhole induction choke is located about a portion of the tubing and / or the casing. The chemical injector is electrically connected to the communications and control module, and is in fluid communication with the chemical container. The downhole induction choke is located about a portion of the tubing and / or the casing. The induction choke is adapted to route part of the electrical current through the communications and control module by creating a voltage potential between one side of the induction choke and another side of the induction choke. The communications and control module is electrically connected across the voltage potential. Also, a method is provided for controllably injecting a chemical into the well downhole, which may be used to: improve lift efficiency with a foaming agent, prevent deposition of solids with a paraffin solvent, improve a flow characteristic of the flow stream with a surfactant, prevent corrosion with a corrosion inhibitor, and / or prevent scaling with scale preventers.

Owner:SHELL OIL CO

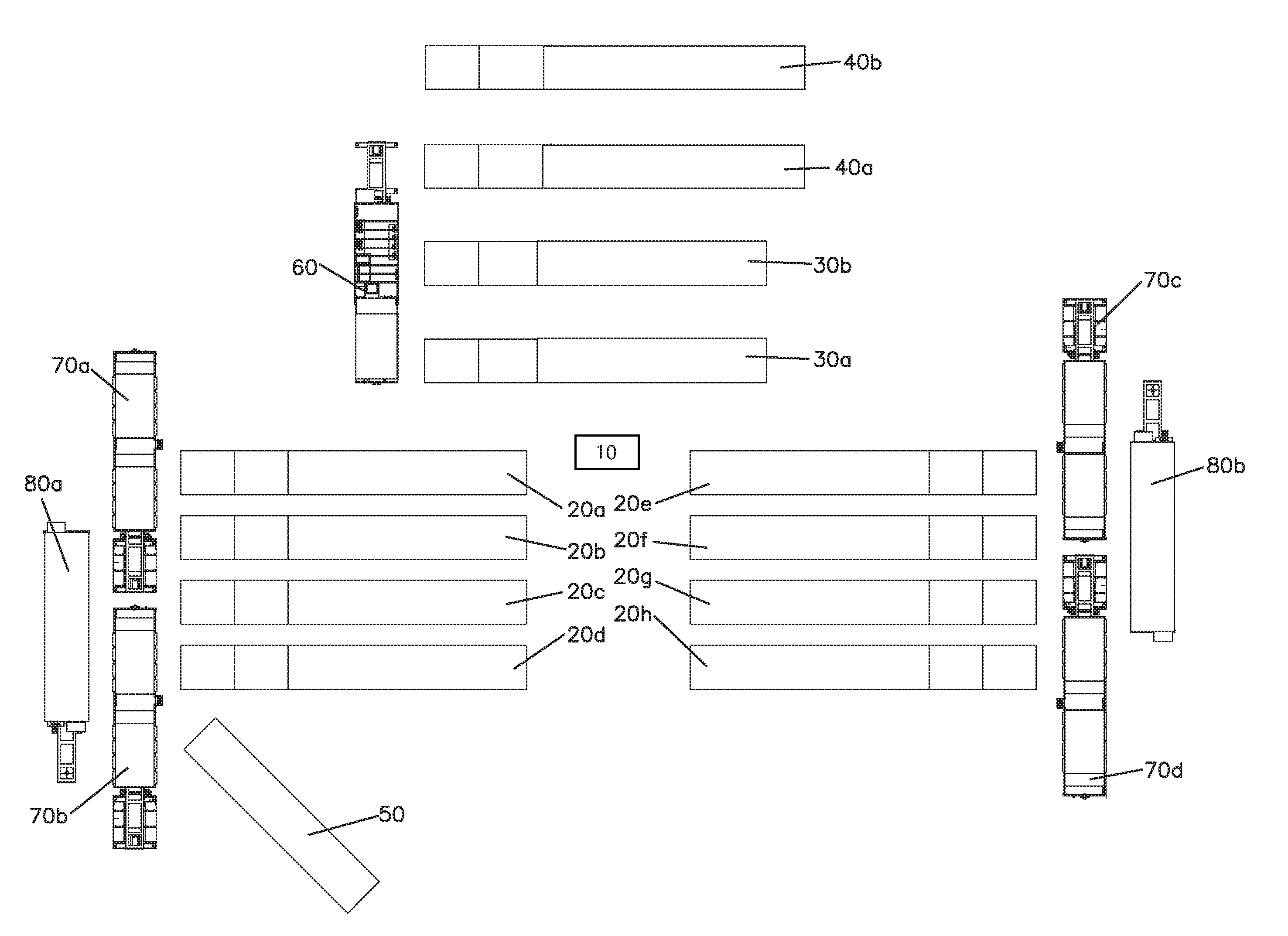

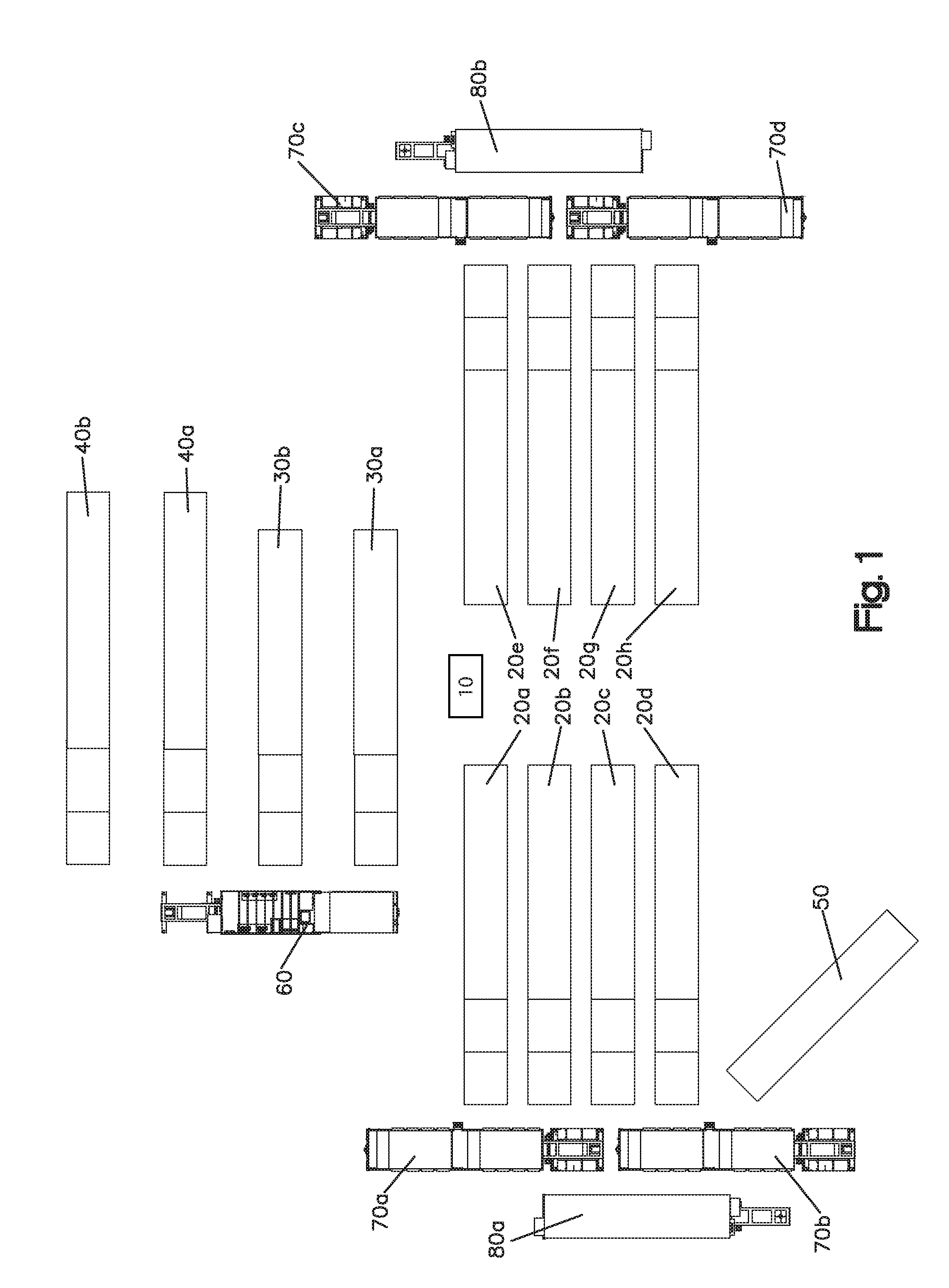

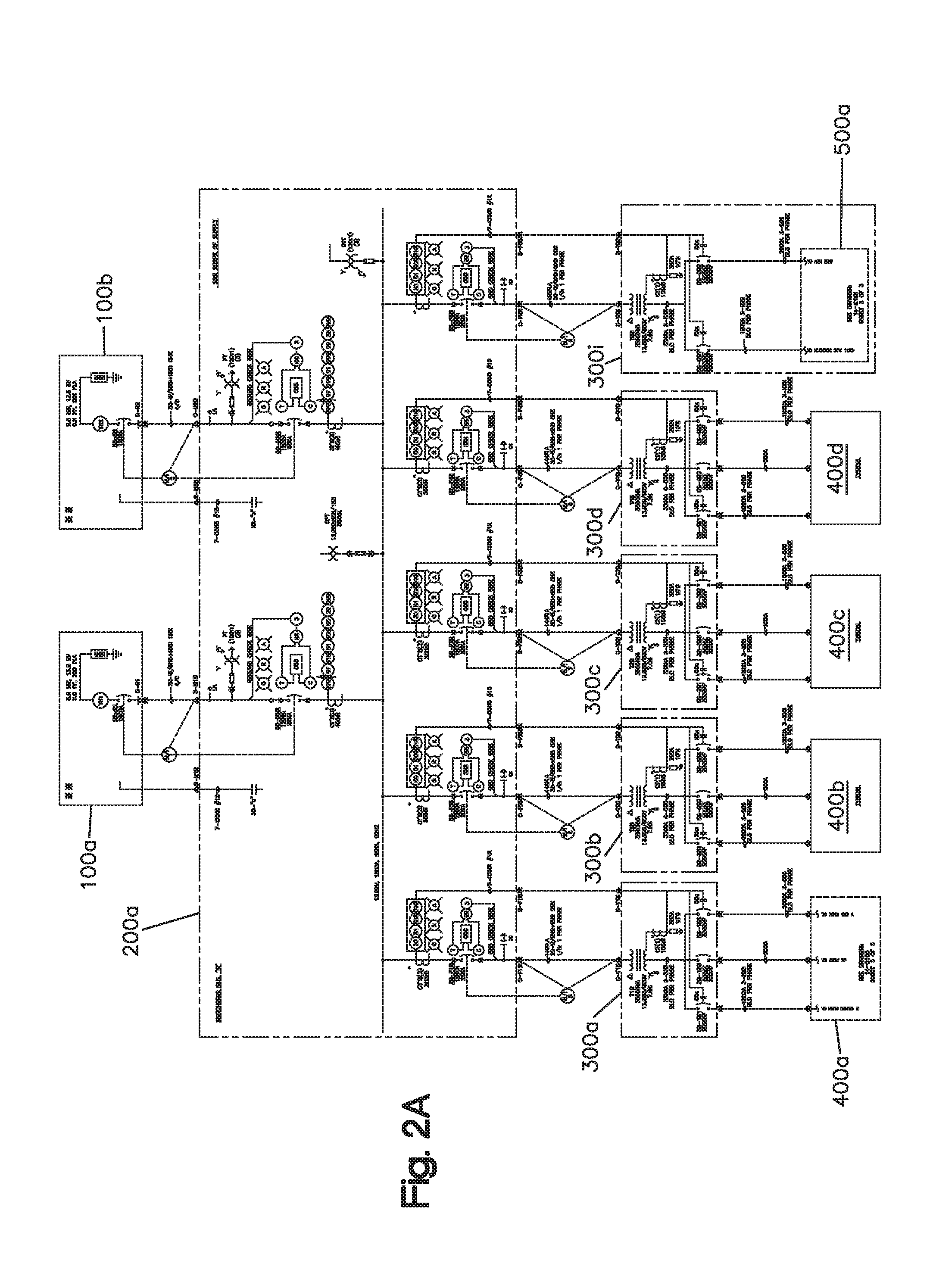

Well fracturing systems with electrical motors and methods of use

A system for stimulating oil or gas production from a wellbore includes a hydraulic fracturing pump unit having one or more hydraulic fracturing pumps driven by one or more electrical fracturing motors, a variable frequency drive (VFD) controlling the electrical fracturing motors, a fracturing pump blower unit driven by a blower motor, and a fracturing pump lubrication unit having a lubrication pump driven by a lubrication motor and a cooling fan driven by a cooling motor. The system may further include a blender unit and a hydration unit. A system control unit may control the operational parameters of the system.

Owner:STEWART & STEVENSON

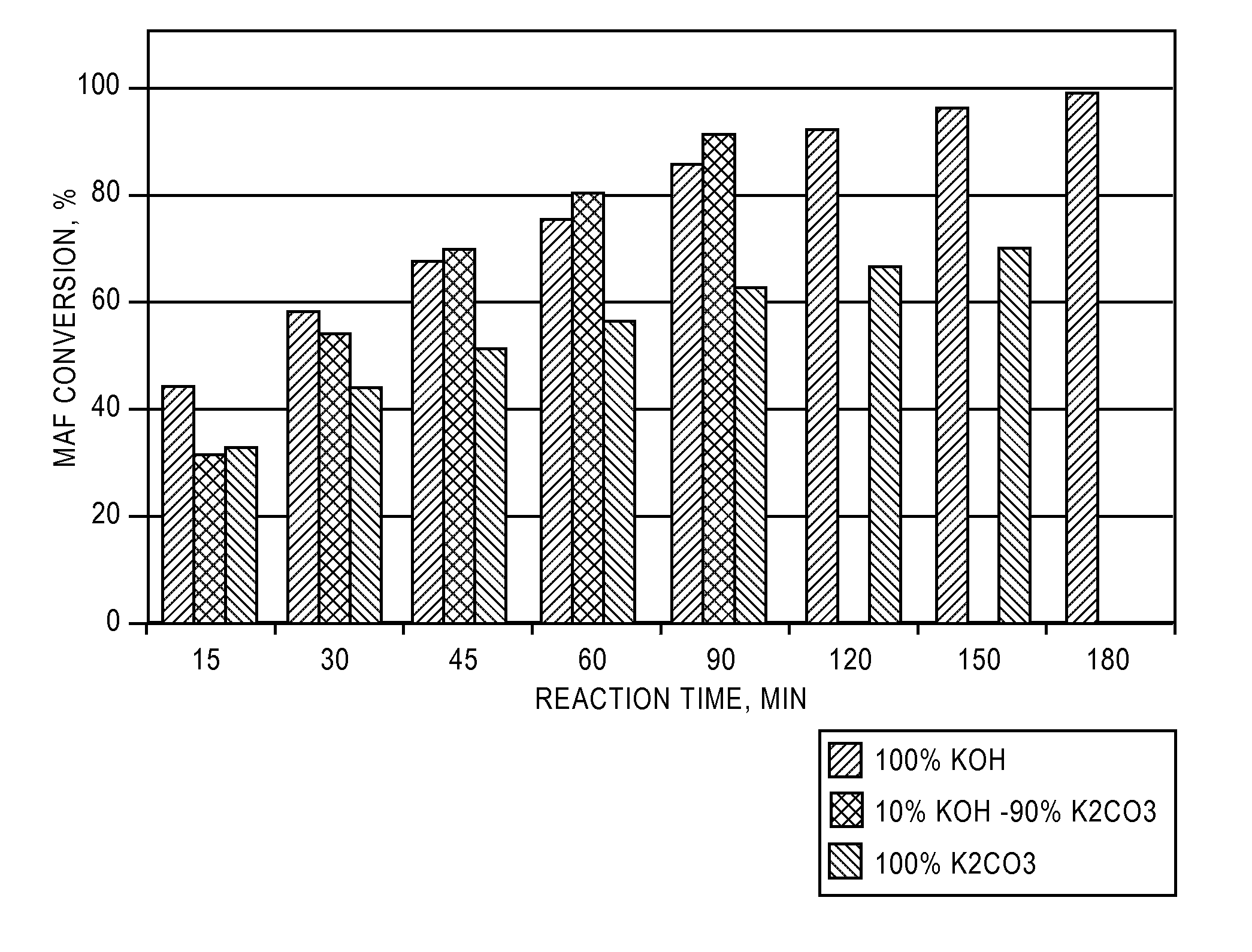

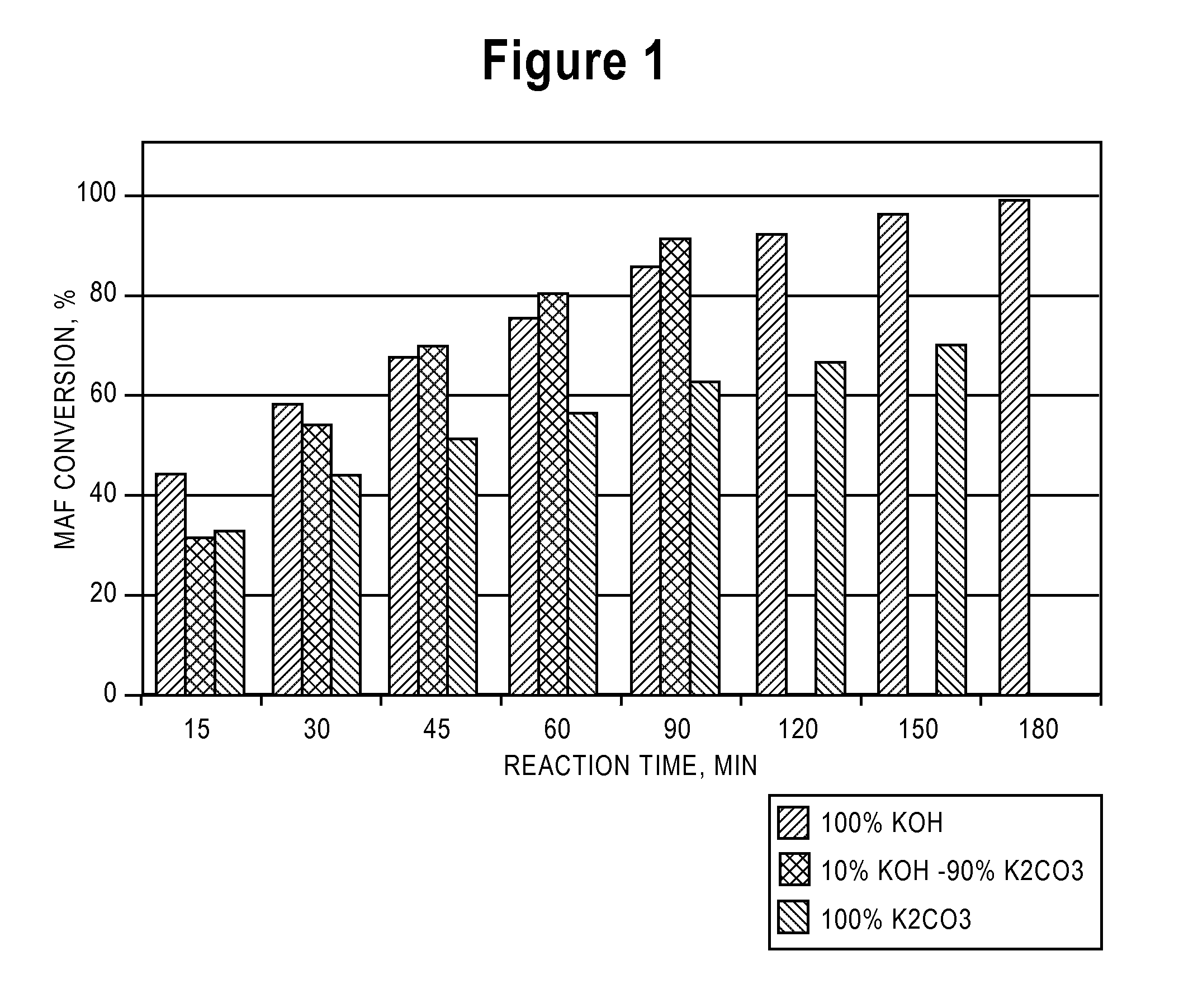

Petroleum Coke Compositions for Catalytic Gasification

Particulate compositions are described comprising an intimate mixture of a petroleum coke and an alkali metal gasification catalyst, where the alkali metal gasification catalyst comprises a combination of an alkali metal hydroxide and one or more other alkali metal compounds are loaded onto coke for gasification in the presence of steam to yield a plurality of gases including methane and at least one or more of hydrogen, carbon monoxide, and other higher hydrocarbons are formed. Processes are also provided for the preparation of the particulate compositions and converting the particulate composition into a plurality of gaseous products.

Owner:SURE CHAMPION INVESTMENT LTD

Mixing arrangement for atomizing nozzle in multi-phase flow

ActiveUS20050001062A1Smooth transitionEasy to processCharging-discharging device combinationsFlow mixersAcute angleShortest distance

The invention relates to an improved mixing arrangement for, primarily, moving bitumen in steam from sources of such bitumen and steam to a reactor or coker for further processing of the bitumen into petroleum products. The invention provides a main conduit connected to an atomizing nozzle mounted in a wall of the reactor and first and second conduits for flowing bitumen and steam respectively into the main conduit. The first conduit is angled relative to the main conduit at an acute angle of about 45° and the second conduit is angled relative to the main conduit at an acute angle of about 30°. The second conduit is positioned downstream of the first conduit by a short distance of about 23 mm and may be angled radially relative to the first conduit by any angle, although a 90° angle is preferred. A flow accelerating nozzle is located in the second conduit adjacent the entrance therefrom into the main conduit. The arrangement of the invention improves the flow characteristics of 2-phase material flowing to the atomizing nozzle, reducing pulsations in the main conduit and improving the resulting atomization of the bitumen in the reactor.

Owner:NAT RES COUNCIL OF CANADA +1

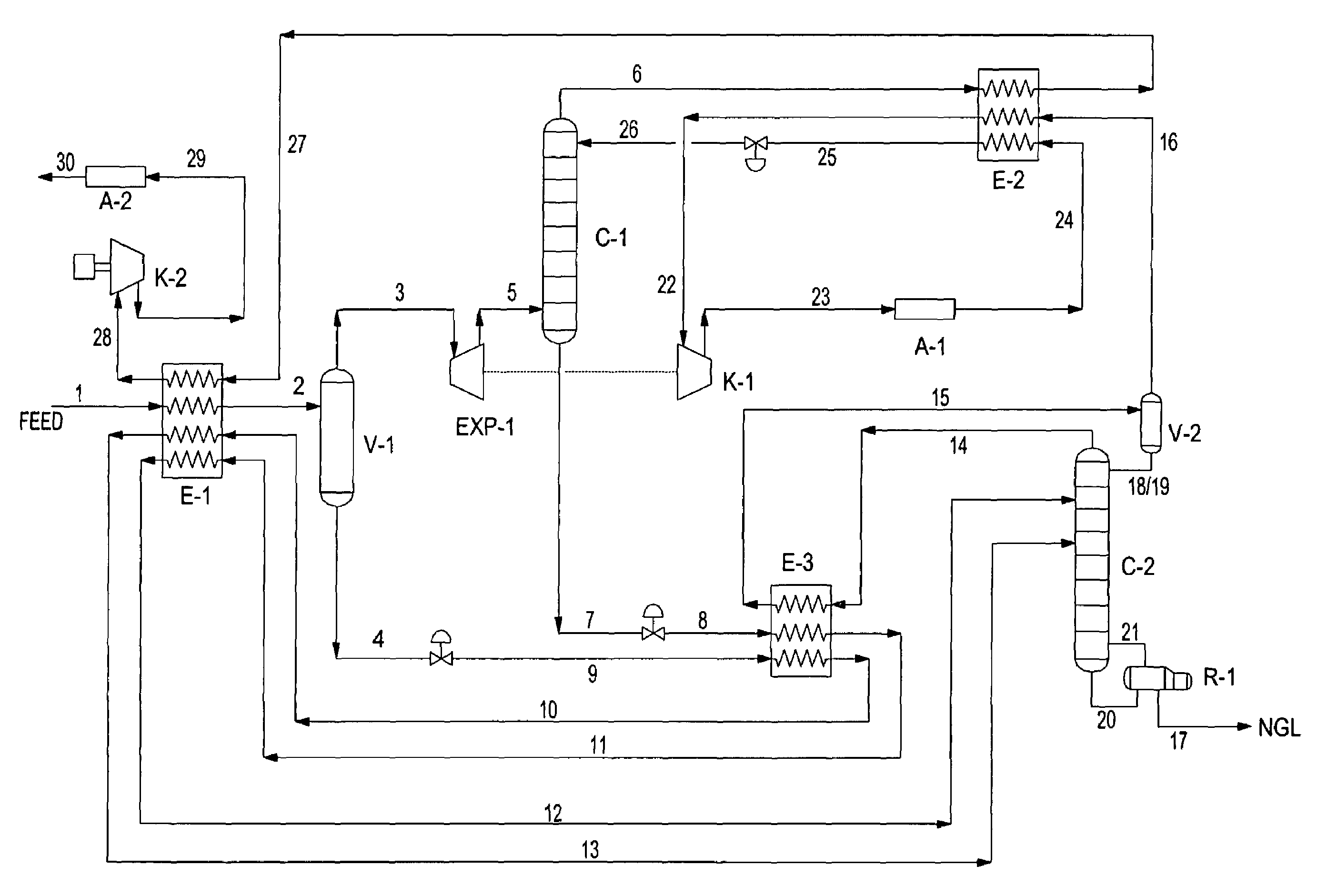

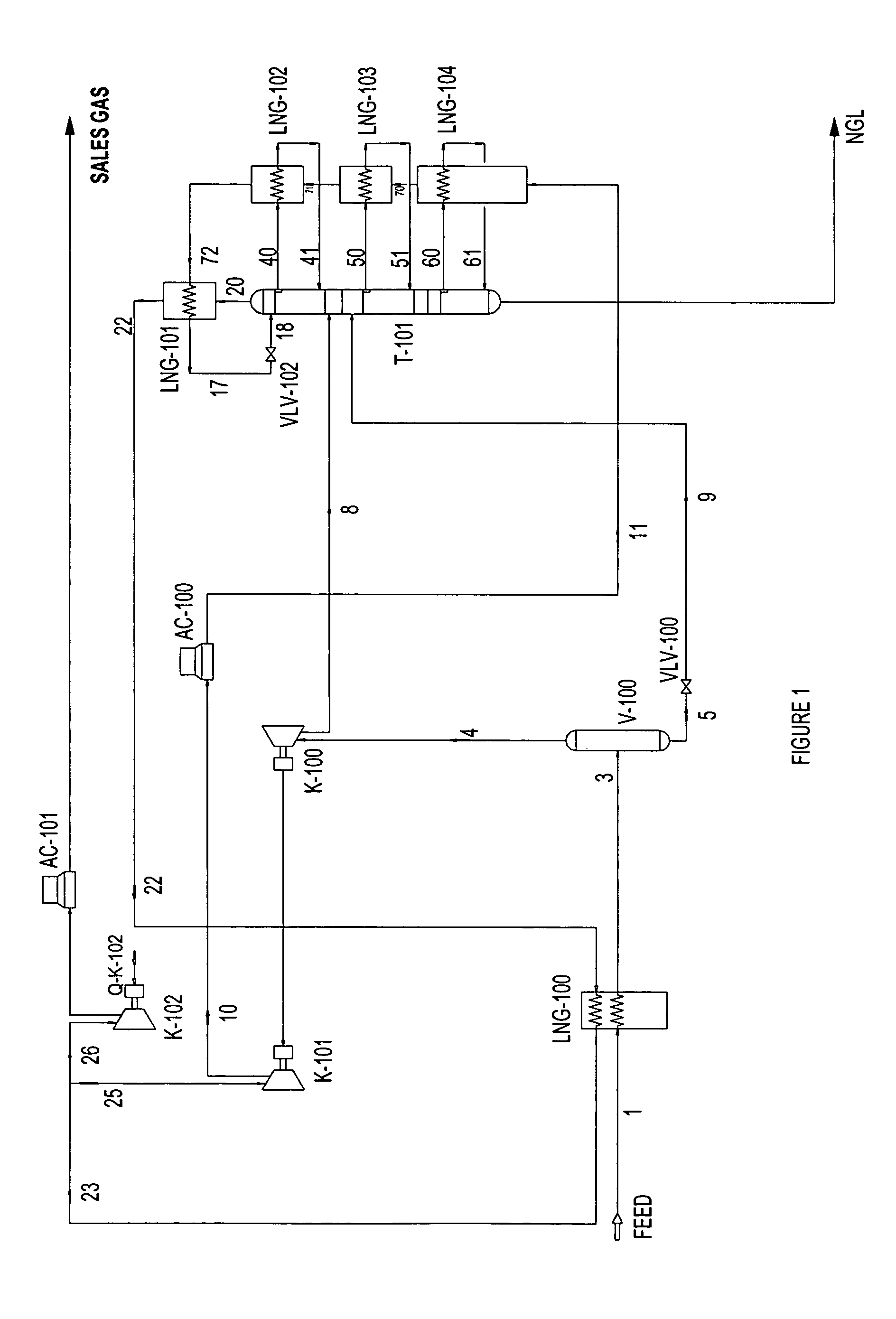

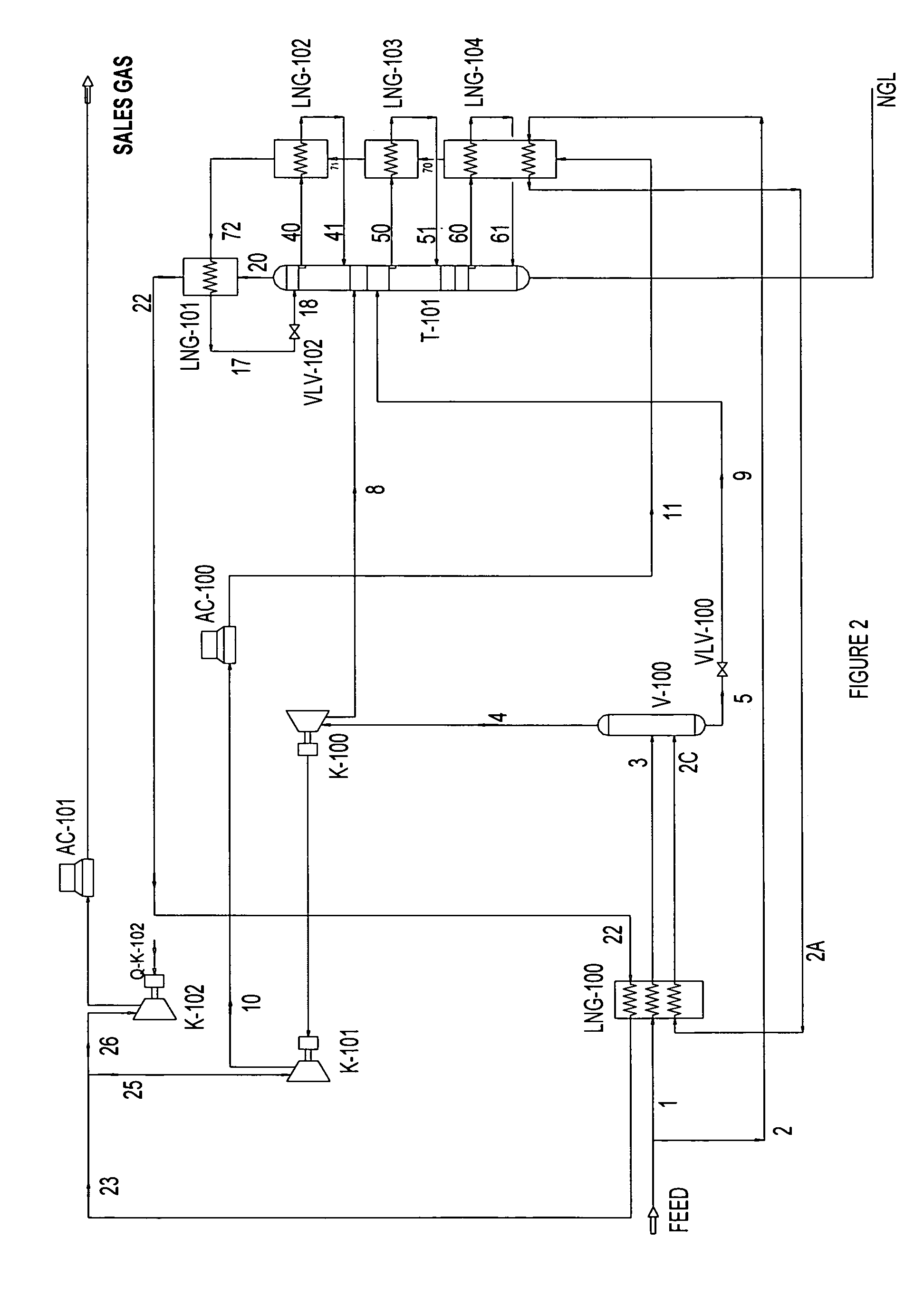

Ethane plus and HHH process for NGL recovery

InactiveUS7219513B1Good fractionation effectHeavy componentSolidificationLiquefactionFractionating columnPetrochemical

The present invention relates to methods for separating and recovering ethane, propane and heavier components from a feed gas, e.g. raw natural gas or a refinery or petroleum plant gas stream or a petrochemical plant gas stream. These methods employ a common new concept which is the use of the turbo-expander shaft compressor to generate the reflux requirement for the cryogenic absorber or distillation columns. The power of the turbo-expander which is absorbed by the shaft compressor is always high enough so that reflux generation by a specific gas compression through the expander shaft compressor and subsequent cooling, condensation and sub-cooling can always be easily maintained. The present invention allows for higher cryogenic absorber pressure and a lower demethanizer / de-ethanizer column pressure thus eliminating the common cryogenic pump at absorber bottom. The present invention ultimately results in a lower residue compression and utilities consumption. The present invention as such allows for a higher 99+% recovery of NGL from the feed gas stream.

Owner:MOSTAFA HUSSEIN MOHAMED ISMAIL

Conversion of petroleum residua to methane

InactiveUS6955695B2Eliminate needReduce usageThermal non-catalytic crackingElectrolysis componentsParticulatesGas phase

This invention discloses improvements on previous inventions for catalytic conversion of coal and steam to methane. The disclosed improvements permit conversion of petroleum residua or heavy crude petroleum to methane and carbon dioxide such that nearly all of the heating value of the converted hydrocarbons is recovered as heating value of the product methane. The liquid feed is distributed over a fluidized solid particulate catalyst containing alkali metal and carbon as petroleum coke at elevated temperature and pressure from the lower stage and transported to the upper stage of a two-stage reactor. Particulate solids containing carbon and alkali metal are circulated between the two stages. Superheated steam and recycled hydrogen and carbon monoxide are fed to the lower stage, fluidizing the particulate solids and gasifying some of the carbon. The gas phase from the lower stage passes through the upper stage, completing the reaction of the gas phase.

Owner:PETRO2020

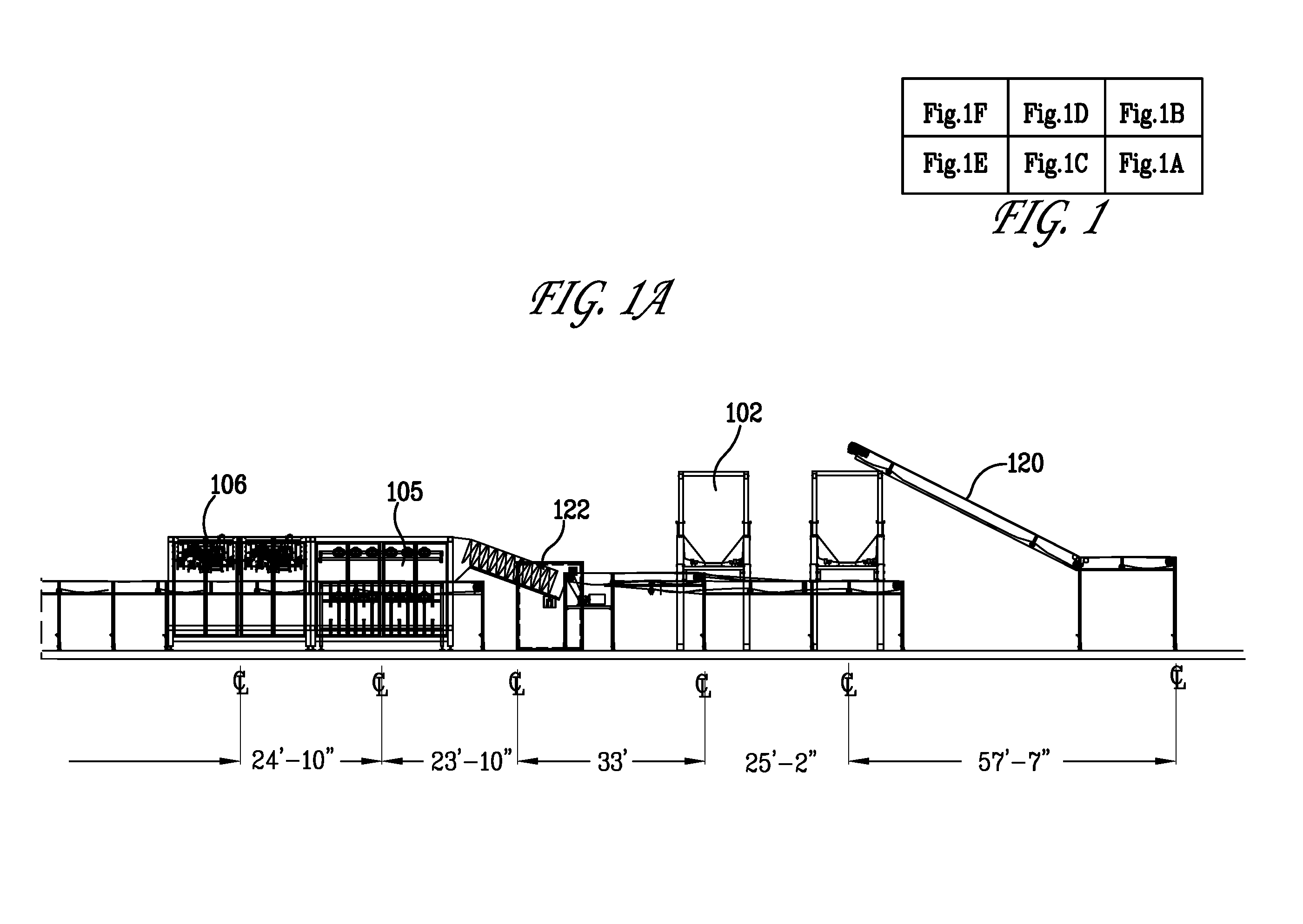

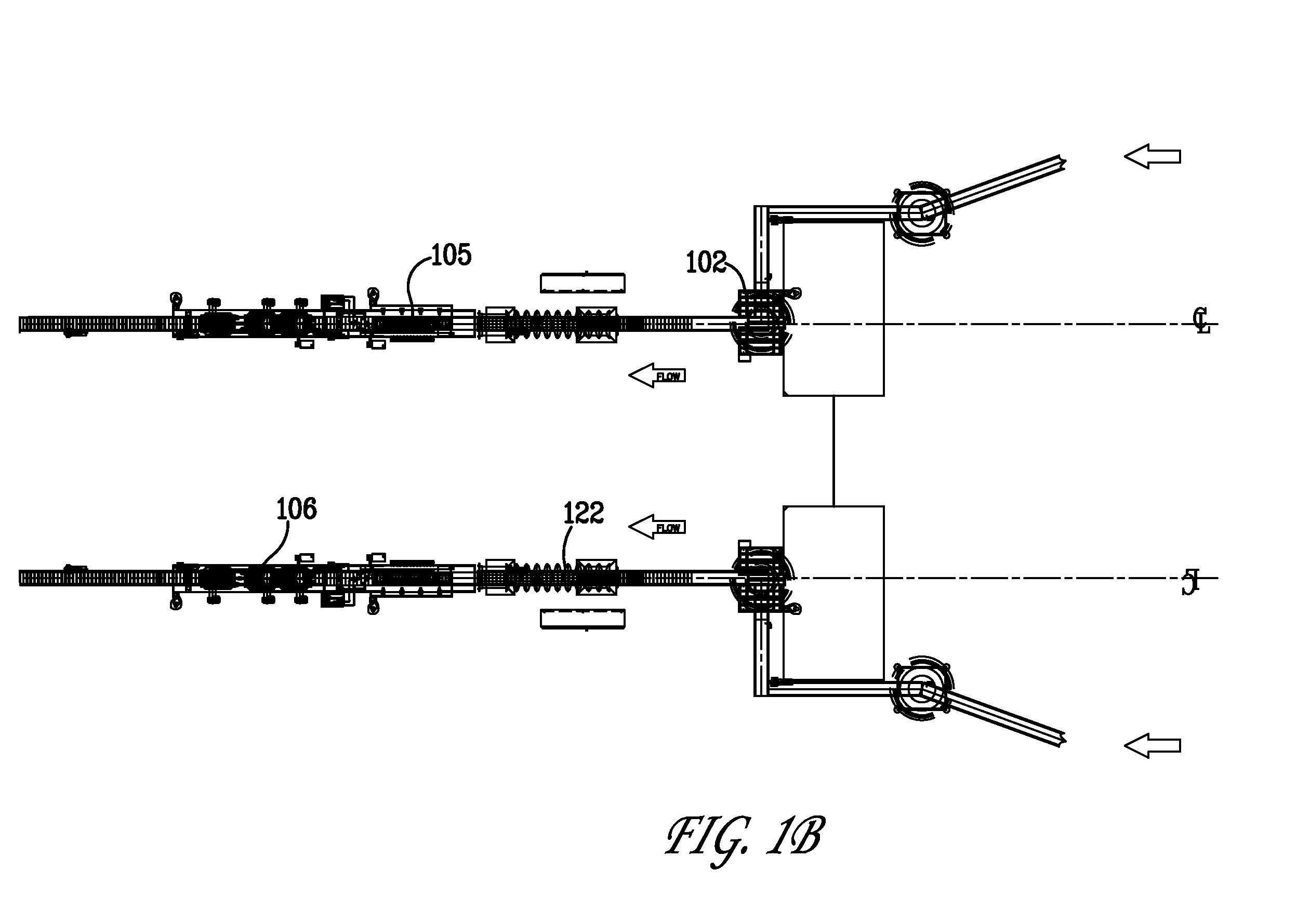

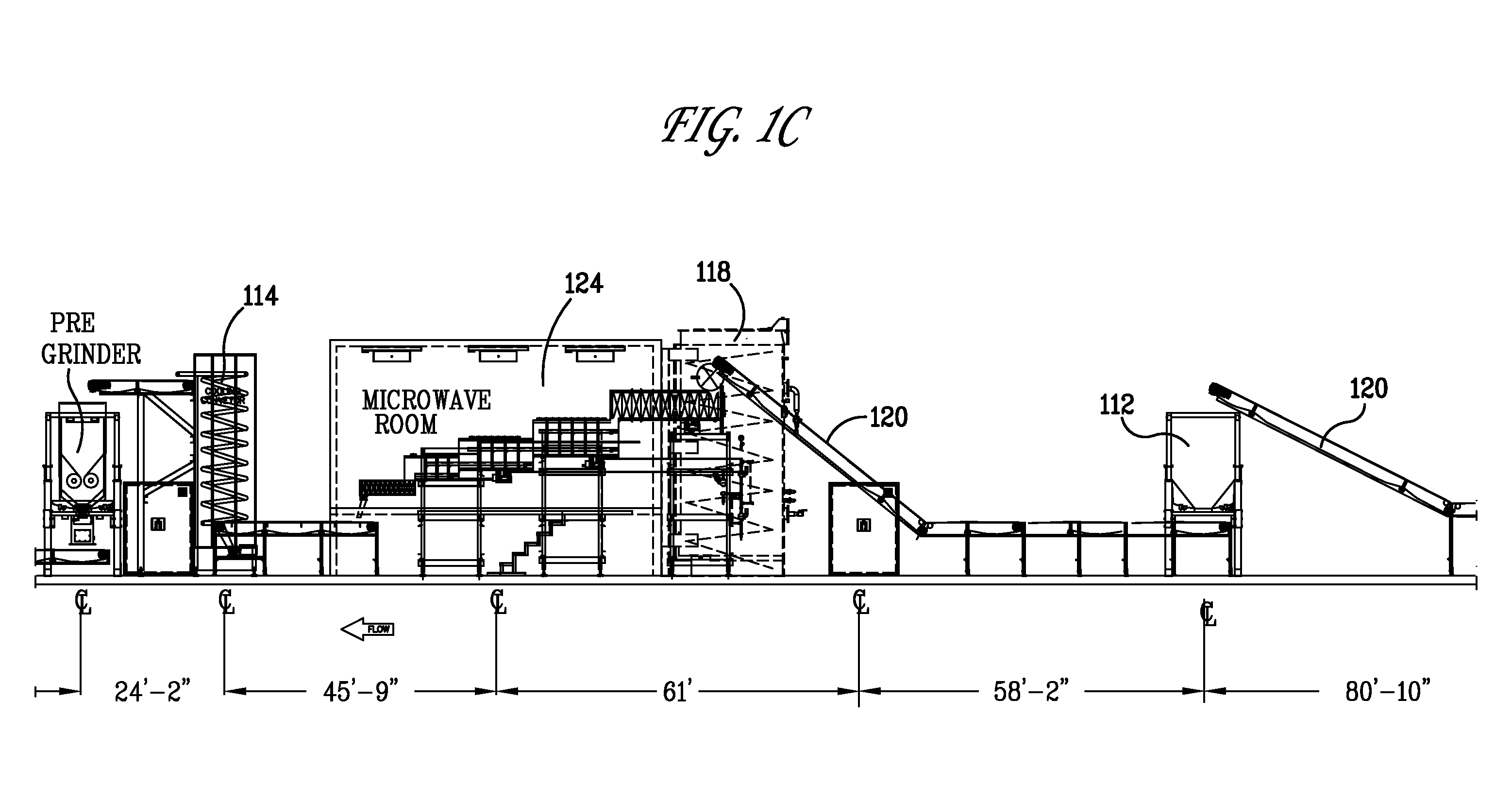

Microwave-based recovery of hydrocarbons and fossil fuels

InactiveUS20070131591A1Organic compounds purification/separation/stabilisationHydrocarbon oil cracking processHydrocotyle bowlesioidesPetroleum

The present invention provides methods for decomposing and extracting compositions for the recovery of petroleum-based materials from composites comprising those petroleum-based materials, comprising subjecting the compositions and / or composites to microwave radiation, wherein the microwave radiation is in the range of from about 4 GHz to about 18 GHz. The present invention also provides for products produced by the methods of the present invention and for apparatuses used to perform the methods of the present invention.

Owner:UNIVERSAL ALTERNATIVE FUELS INC +1

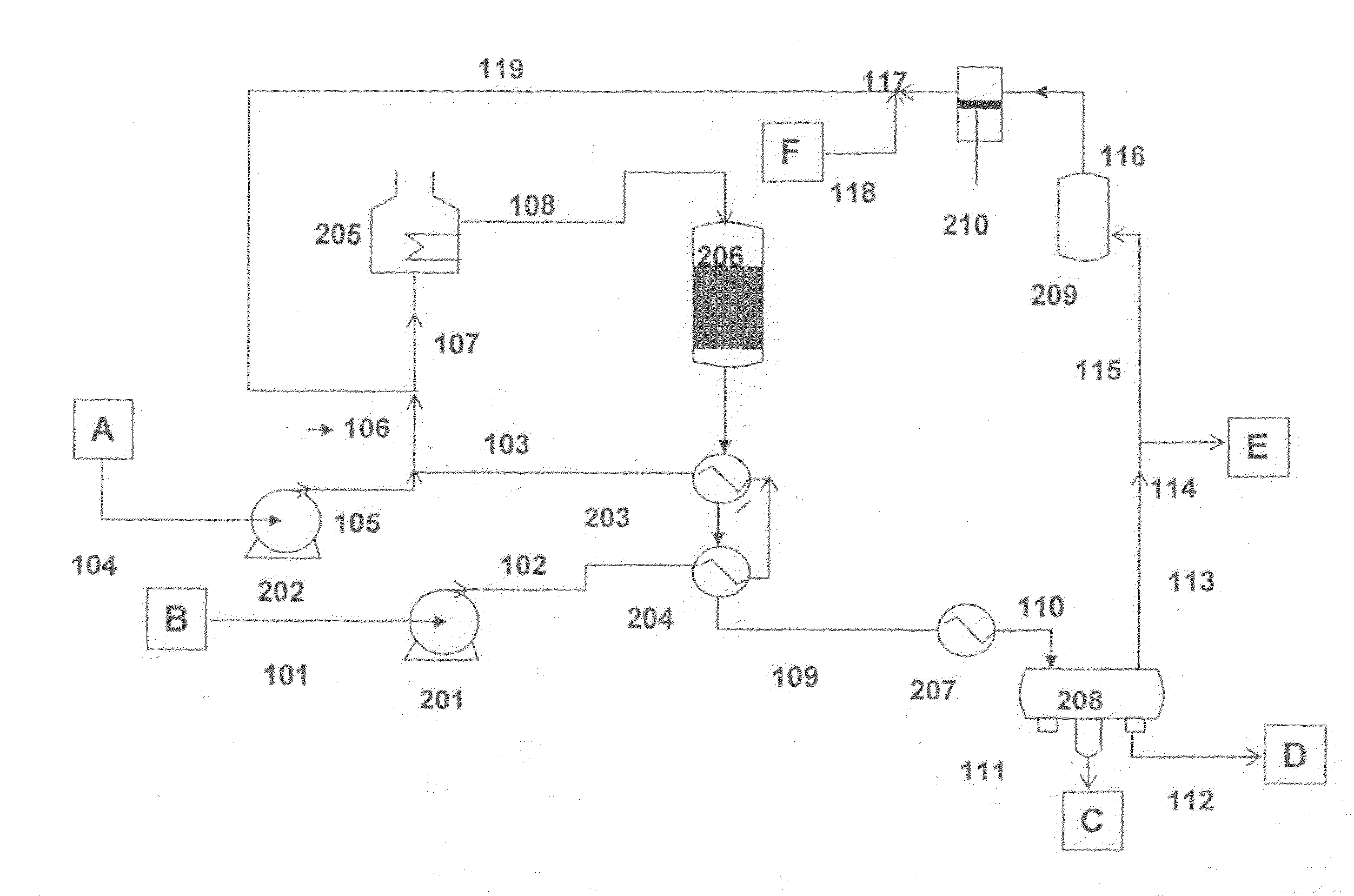

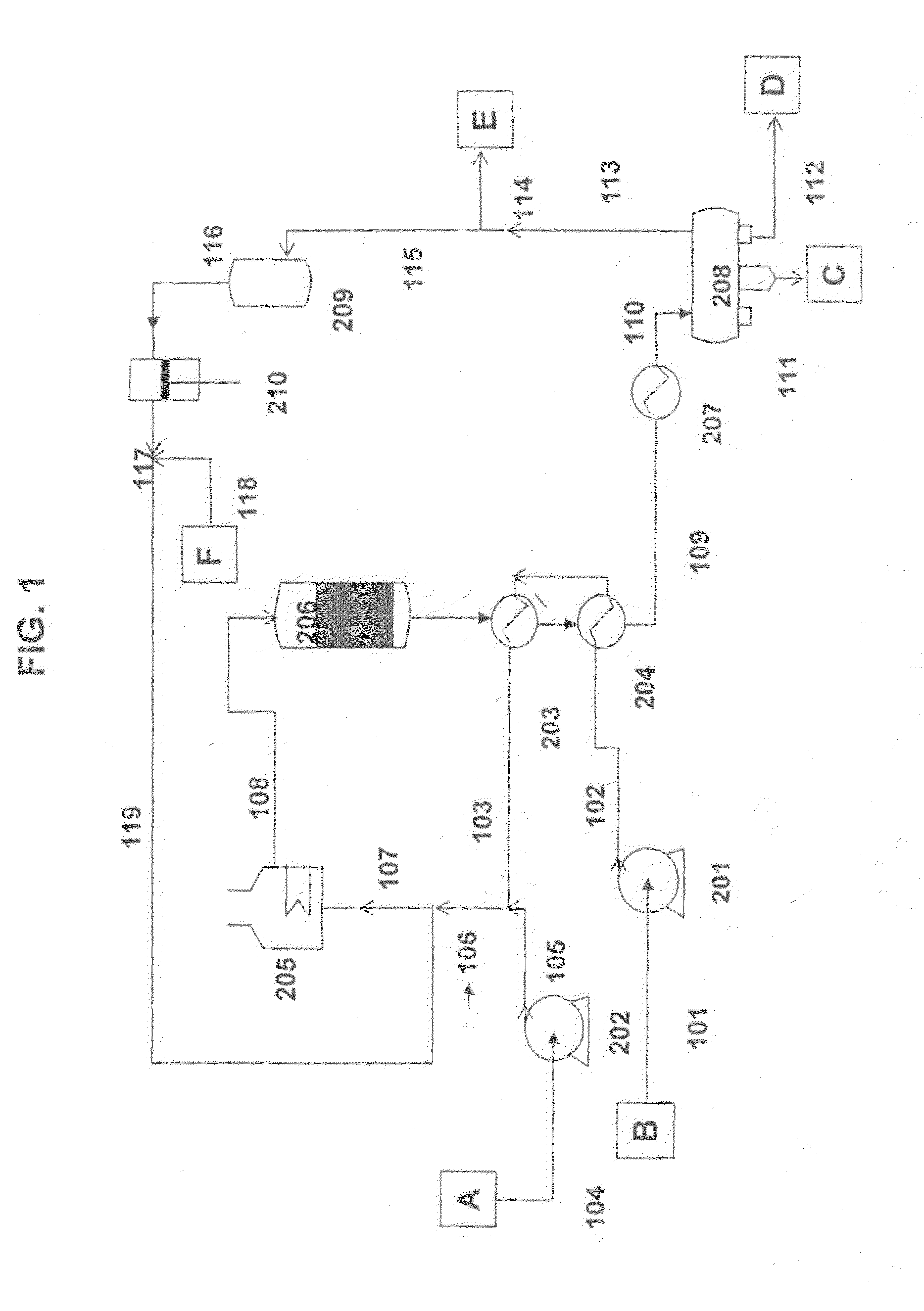

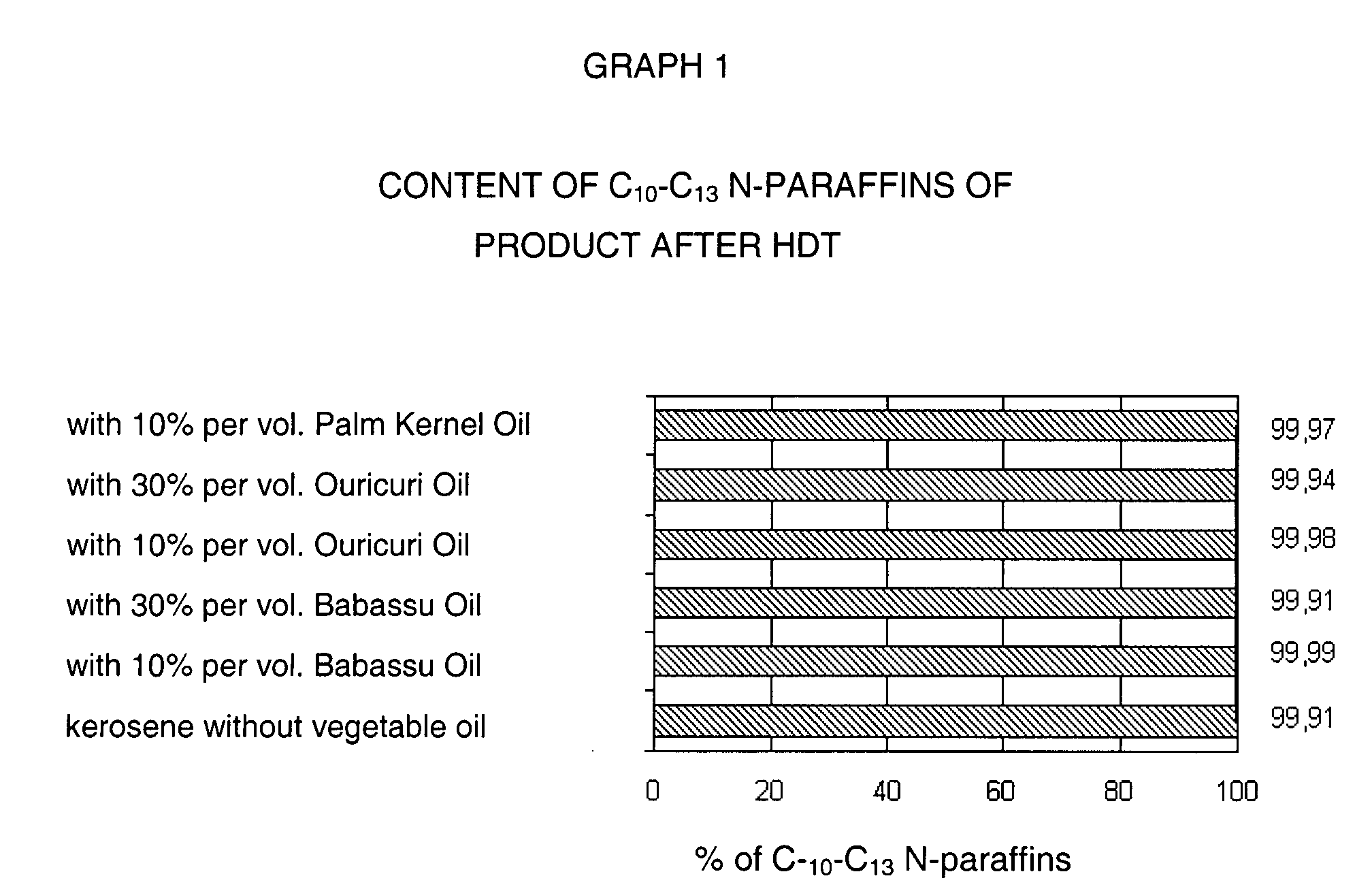

Process to obtain N-paraffins from vegetable oil

The process described by this invention involves the hydroconversion of vegetable oils appropriately selected for the production of N-paraffins, through hydrotreatment of a stream of vegetable hydrocarbon oils in and / or natural fats that may be used in a pure state or in a mixture with mineral hydrocarbon oil. This mixture flow is submitted to the process of hydrotreatment, obtaining as a result, a product flow with an elevated content of N-paraffins in the range of C10-C-13. This process provides an alternative to the usual process that uses a mineral hydrocarbon oil load (petroleum kerosene of paraffin base) to produce C10-C13 N-paraffins that are raw materials for the production of detergents (LAB), being, therefore, especially advantageous for use in situations where kerosene is a limiting factor for producing N-paraffins, resulting in a product of good quality with a reasonable gain in the production of N-paraffins.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

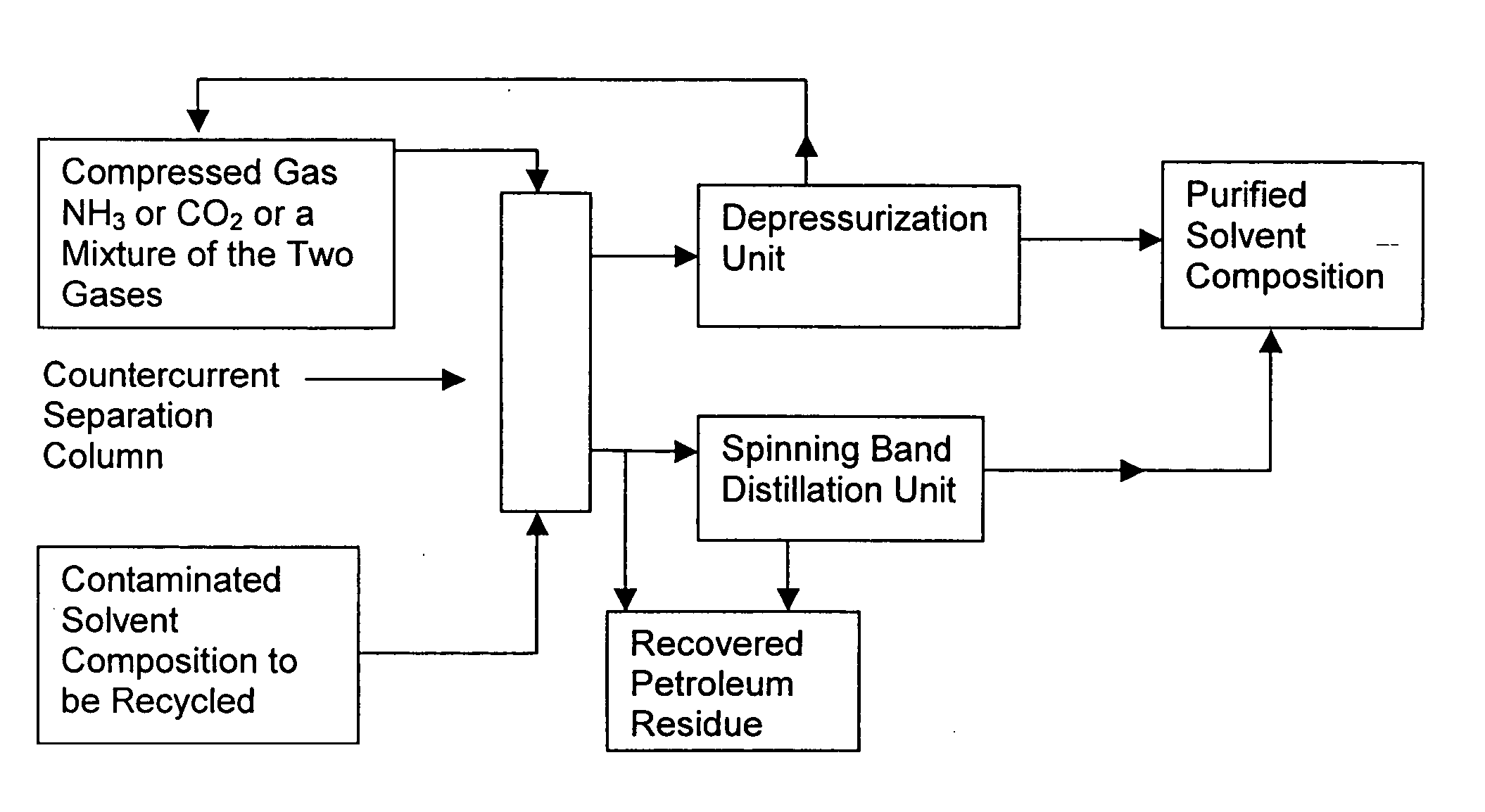

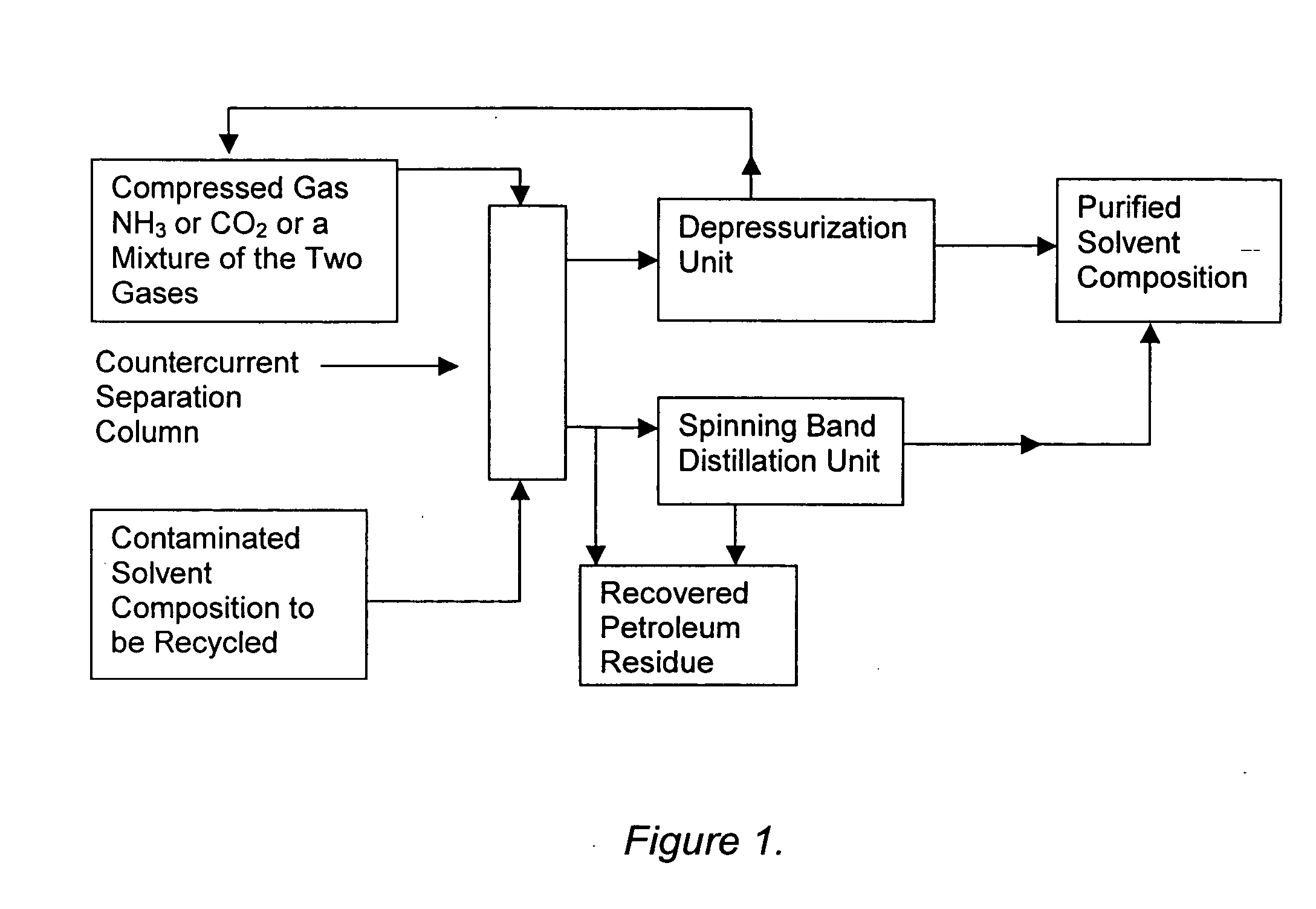

Solvent compositions for removing petroleum residue from a substrate and methods of use thereof

ActiveUS20050197267A1Cationic surface-active compoundsNon-ionic surface-active compoundsSpinning band distillationPetroleum

Water-soluble solvent compositions, including from about 10% to about 60% by weight of an aromatic ester; from about 30% to about 60% by weight of an aliphatic ester; from 0% to about 15% by weight of a co-solvent; from 0% to about 20% of one of a cyclic terpene and a terpenoid; from 0% to about 1% by weight of an odor-masking agent; and from 0% to about 20% by weight of a nonionic surfactant, for removing petroleum residue from a substrate, and methods of use thereof. The composition can further comprise water. The composition also can comprise an aqueous solution. The method for removing petroleum residue from a substrate can further comprise recycling the solvent composition by using a countercurrent separation column charged with compressed ammonia and / or carbon dioxide and a spinning band distillation column to separate the solvent composition from the petroleum residue.

Owner:CRUDE SPILL CLEANING CO INC

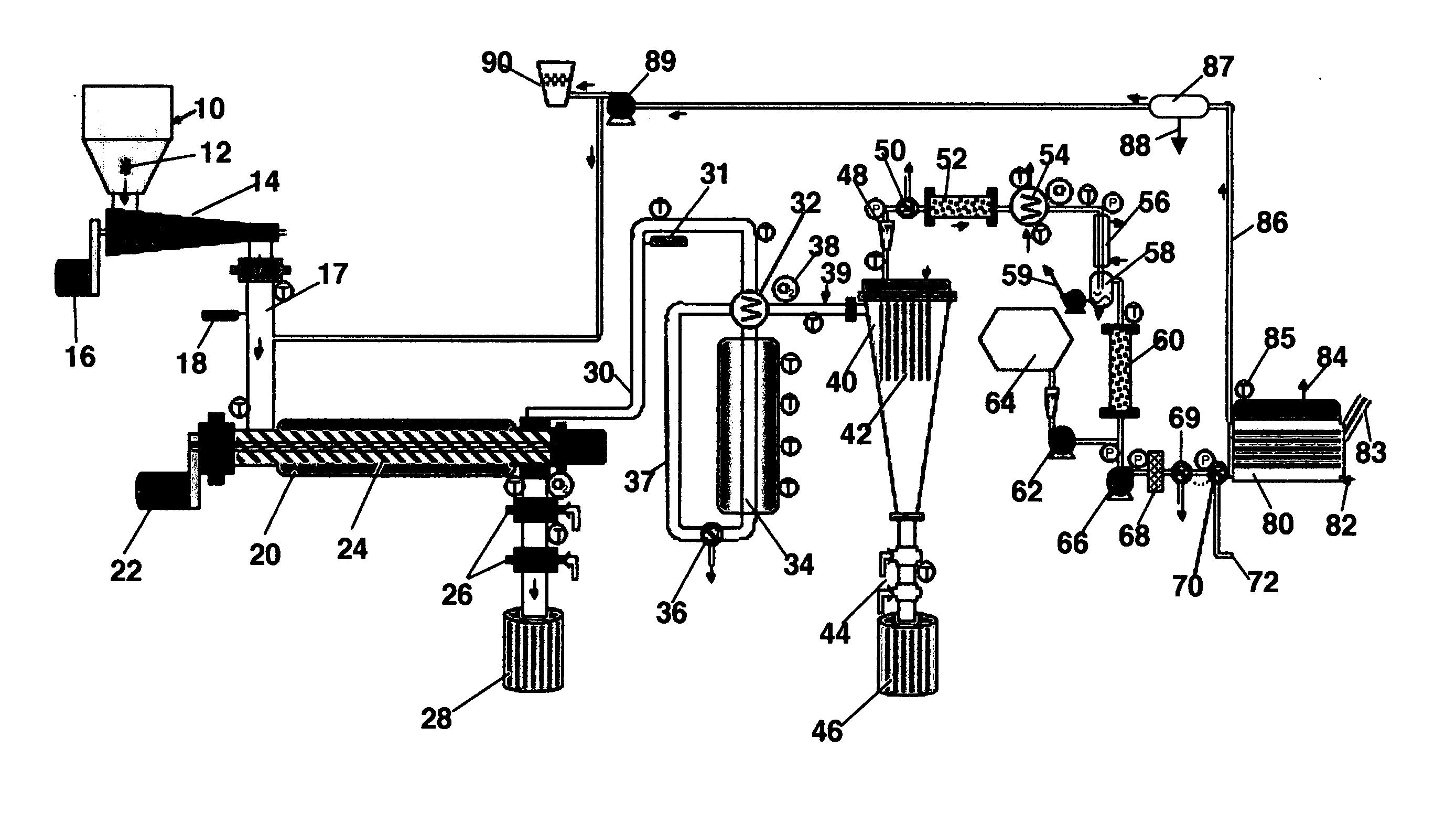

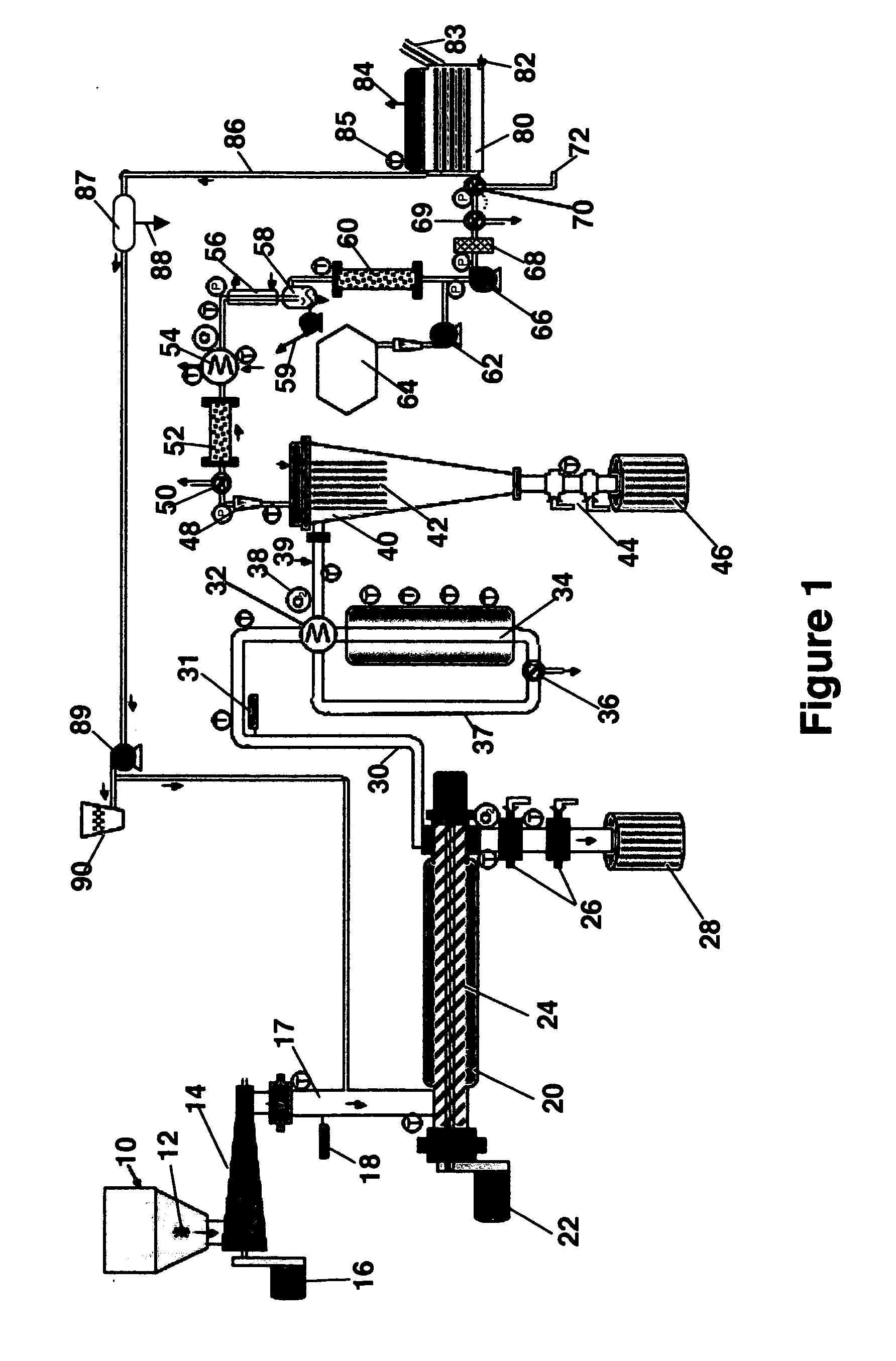

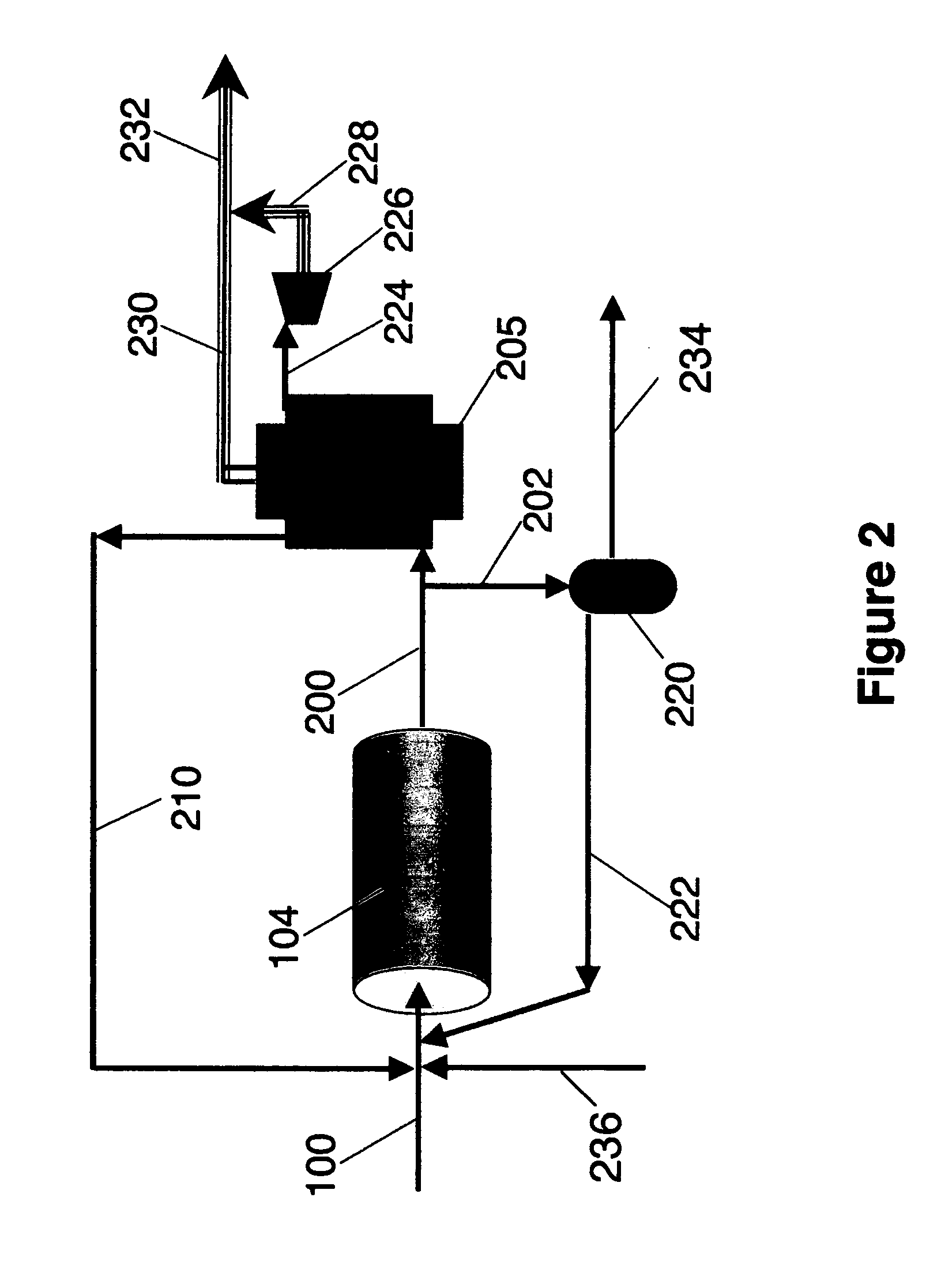

Process and system for converting carbonaceous feedstocks into energy without greenhouse gas emissions

ActiveUS20070099038A1High hydrogen contentFuel cells groupingHydrogen separation using solid contactPetroleum cokePetroleum

The process of the invention converts carbonaceous feedstock such as coal, hydrocarbon oil, natural gas, petroleum coke, oil shale, carbonaceous-containing waste oil, carbonaceous-containing medical waste, carbonaceous-containing military waste, carbonaceous-containing industrial waste, carbonaceous-containing medical waste, carbonaceous-containing sewage sludge and municipal solid waste, carbonaceous-containing agricultural waste, carbonaceous-containing biomass, biological and biochemical waste, and mixtures thereof into electrical energy without the production of unwanted greenhouse emissions. The process uses a steam / CO2 reformer operating in the exit range of at least 700° to about 1600° C. (1300-2900°0 F.) to convert the carbonaceous feedstock and a greenhouse gas stream into a synthesis gas comprising mostly carbon monoxide and hydrogen that contains poisons and the compounds that poison fuel cells. The syngas is sent to an interface zone to remove these poisons and other fouling compounds that are electrochemically oxidized in an electricity-producing fuel cell into an exit gas comprising carbon dioxide and water.

Owner:RAVEN SR INC

Production of biological diesel oil by integrated hydrogenation

InactiveCN101029245AAchieve reliabilityAchieve economyBiofuelsLiquid hydrocarbon mixture productionDistillates petroleumBiodiesel

Production of biological diesel oil by integrated hydrogenation is carried out by mixing straight-run diesel oil with soya-bean, hydrogenation refinery reacting at 3.0-8.0MPa and 250-400degree and under existence of catalyst and converting vegetable oil into biological diesel oil. It's simple and cheap.

Owner:TSINGHUA UNIV

Method for determining the extent of recovery of materials injected into oil wells during oil and gas exploration and production

Disclosed is a method of determining the extent of recovery of materials injected into a oil well comprising the steps of: a) preparing a material to be injected into an oil well; b) admixing therewith a chemical tracer compound at a predetermined concentration; c) injecting the admixture into an oil well; d) recovering from the oil well a production fluid; e) analyzing the production fluid for the concentration of the chemical tracer present in the production fluid; and f) calculating the amount of admixture recovered from the oil well using the concentration of the chemical tracer present in the production fluid as a basis for the calculation. Fluorinated benzoic acids are disclosed as a preferred tracer.

Owner:CORE LAB LP

Polyurethane foams made with alkoxylated vegetable oil hydroxylate

The present invention provides polyurethane foams and elastomers made with an alkoxylated vegetable oil hydroxylate replacing at least a portion of the typically used petroleum-based polyol(s). Also provided are processes for making the inventive foams and elastomers and for making alkoxylated vegetable oil hydroxylates. The alkoxylated vegetable oil hydroxylates are environ mentally-friendly, bio-based polyols which advantageously also offer the potential of improved hydrophobicity in polyurethane foams and elastomers. The inventive polyurethane foams and elastomers may find use in a wide variety of products such as automobile interior parts, polyurethane structural foams, floor coatings and athletic running tracks.

Owner:BAYER MATERIALSCIENCE AG

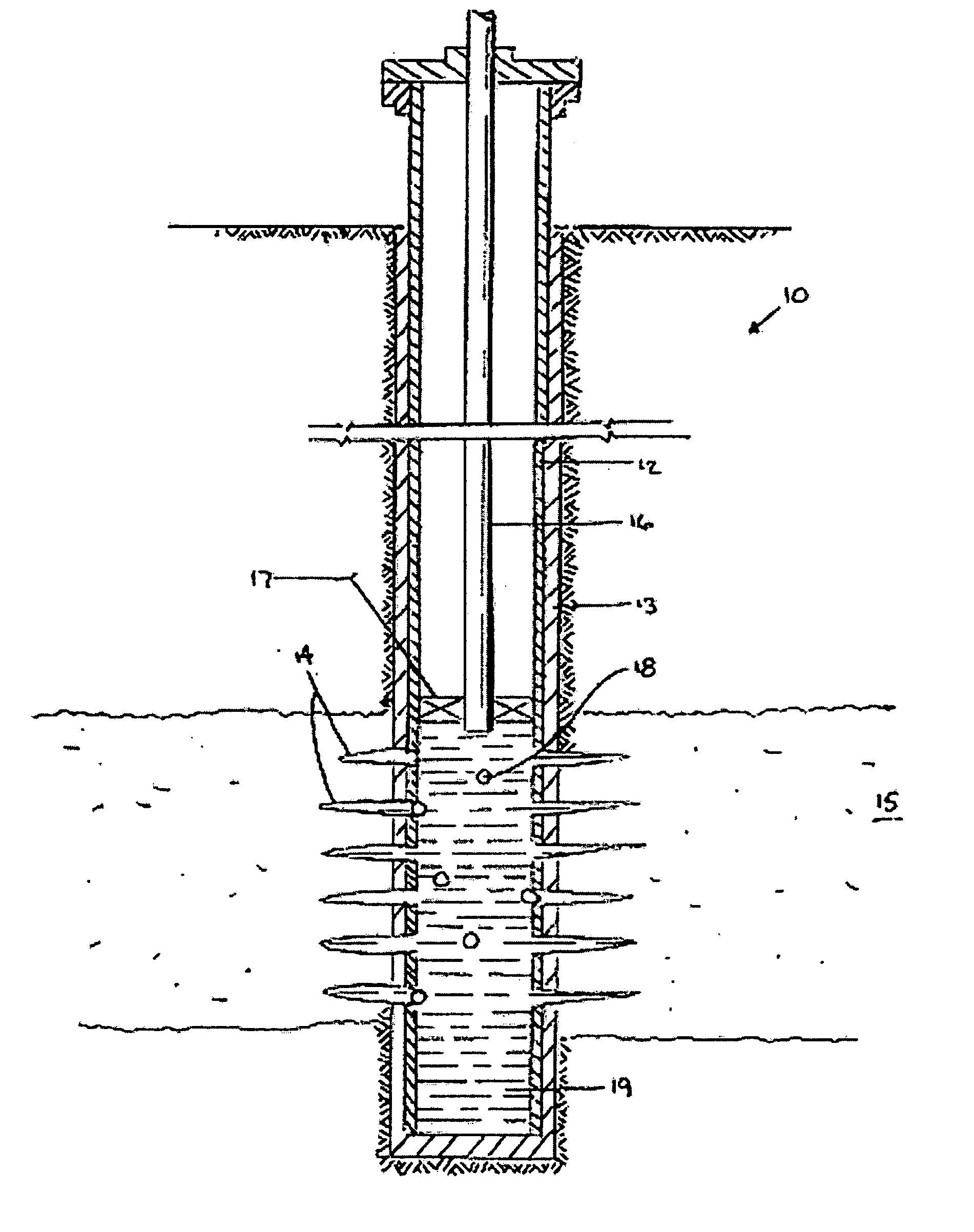

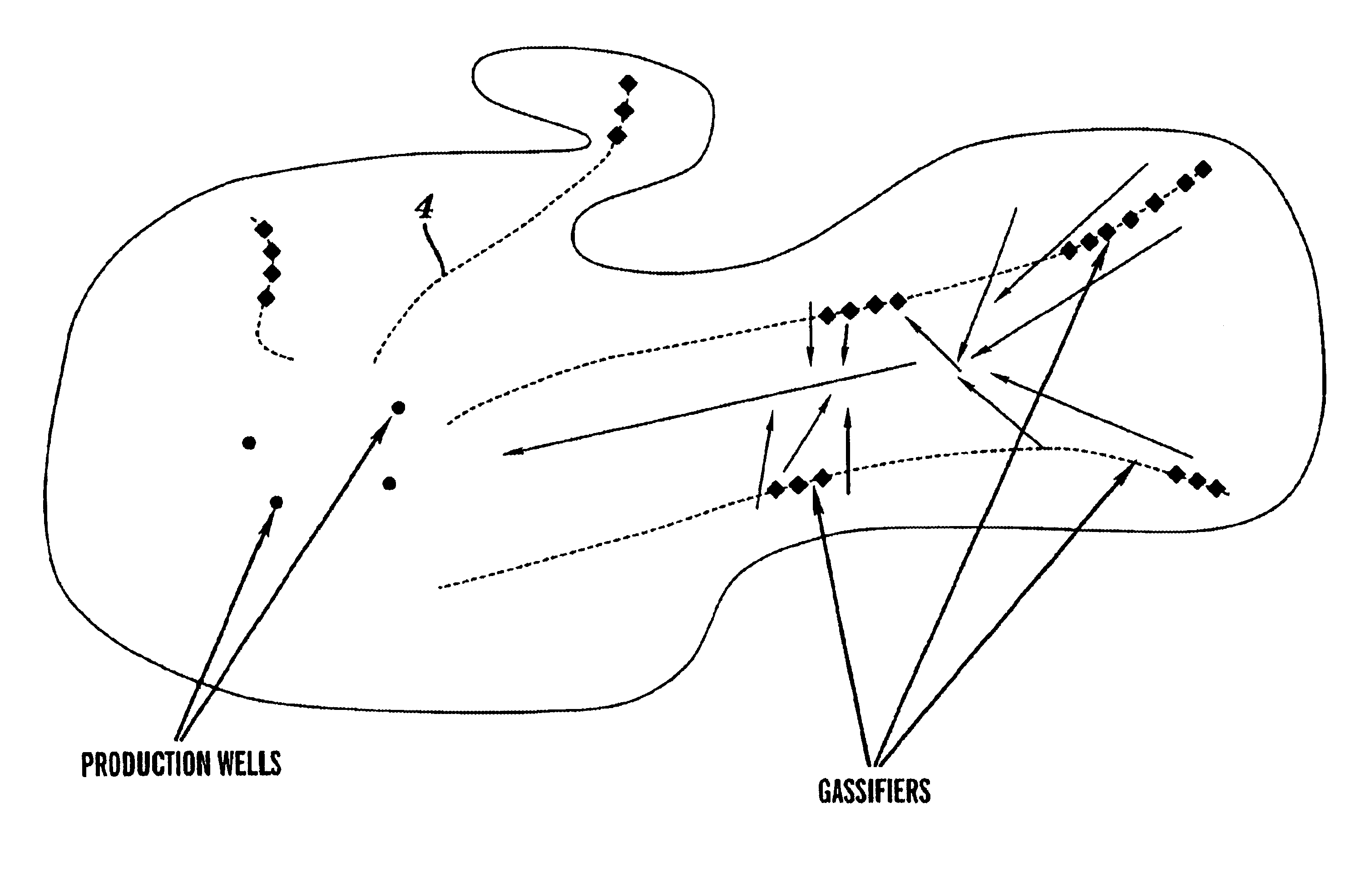

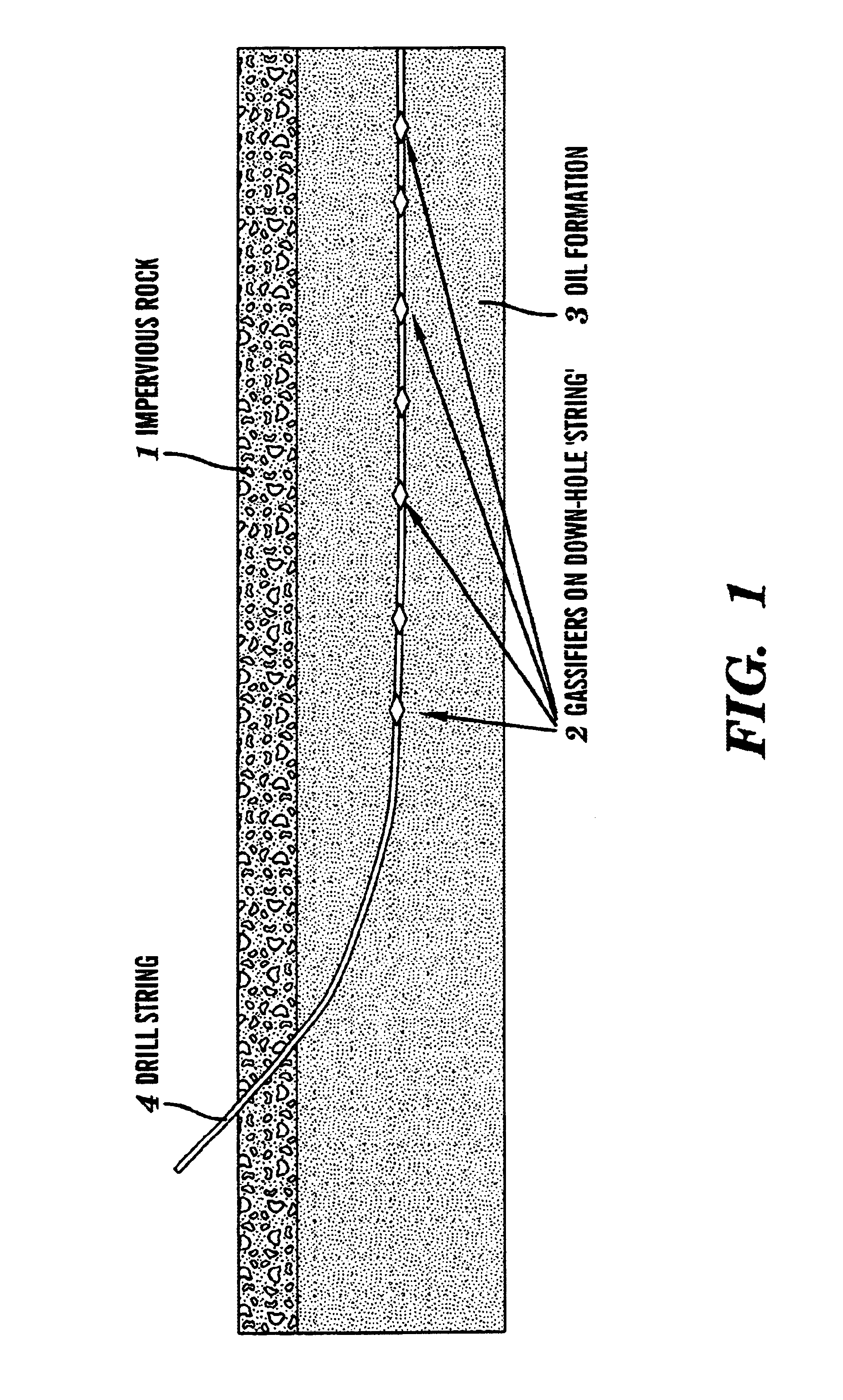

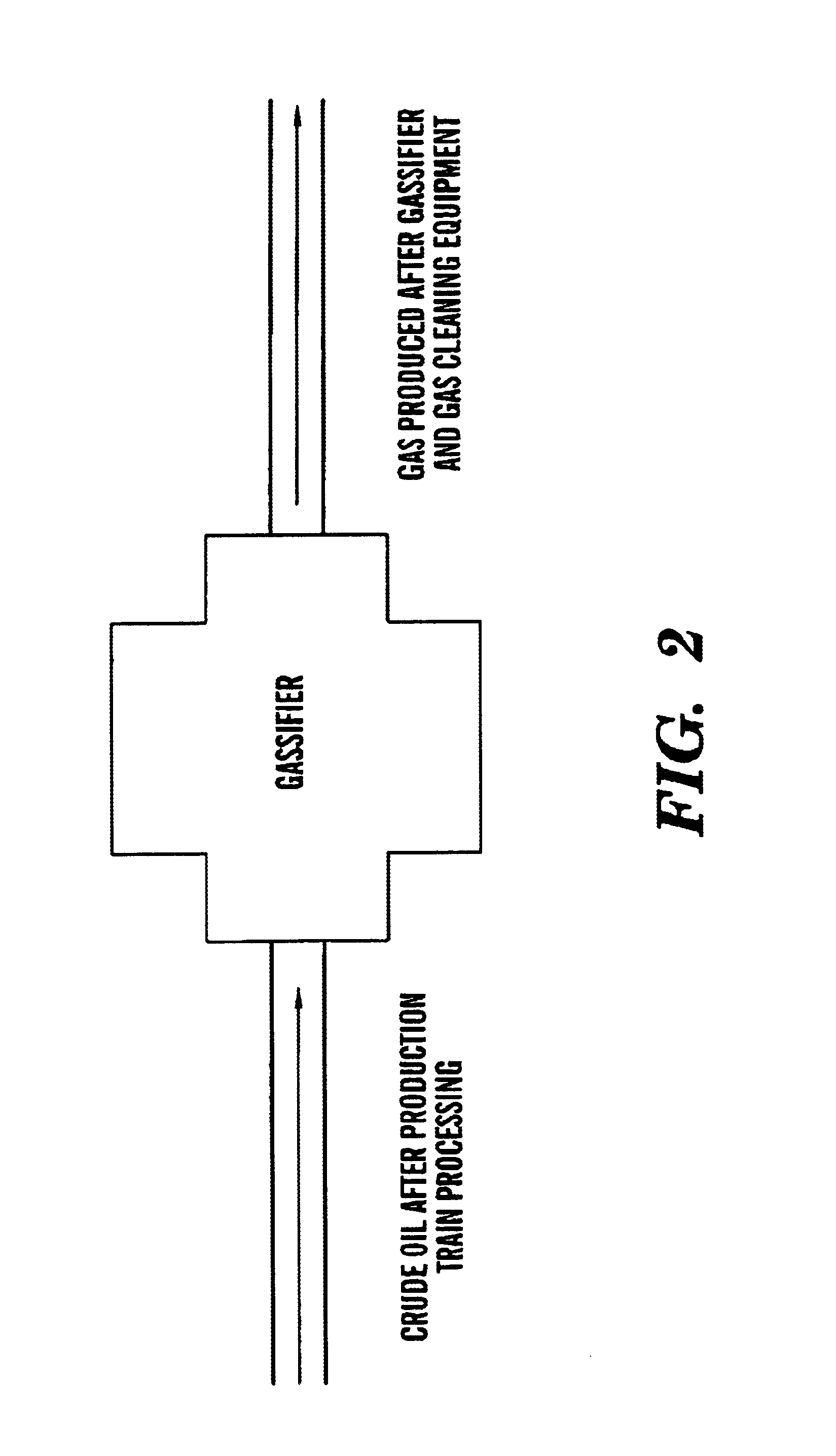

Gas and oil production

A process for in situ gasification of mineral oil in a subterranean formation comprises running a tool having a controllable thermal device therein from a surface production facility down to the subterranean formation, bringing said tool into operational proximity with the mineral oil in said subterranean formation, and activating the tool to operate the thermal device within a predetermined temperature range to generate gases or oily vapours from said mineral oil, which permits either an enhanced oil recovery (EOR) method with reduced water contamination, or a gas production process (GPP) which is useful in reducing environmental risks normally associated with transport of crude oil.

Owner:SCOTOIL SERVICES

Premium synthetic lubricants

InactiveUS6475960B1Refining to change hydrocarbon structural skeletonHydrocarbon purification/separationAntioxidantBoiling point

Premium synthetic lubricants comprise a synthetic isoparaffinic hydrocarbon base stock and an effective amount of at least one, and typically a plurality of lubricant additives such as a detergent, dispersant, antioxidant, antiwear additive, pout point depresant, VI improver and the like. The base stock is derived from a waxy, paraffinic, Fischer-Tropsch synthesized hydrocarbon feed fraction having an initial boiling point in the range of about 650-750° F. and continuously boiling up to at least 1050° F., by a process which comprises hydroisomerizing the feed and dewaxing the isomerate. The waxy feed has a T90-T10 temperature difference of at least 350° F. and is preferably hydroisomerized without any pretreatment, other than optional fractionation. The lubricant may also contain hydrocarbonaceous and synthetic base stock material. Lubricants, such as fully formulated multigrade automotive crankcase and transmission oils formed by adding a suitable additive package to the isoparaffinic base stock have exhibited performance superior to similar fully formulated oils based on both PAO and conventional, petroleum derived base stocks.

Owner:EXXON RES & ENG CO

Cracking catalyst for petroleum hydrocarbon, and preparation method

A cracking catalyst for petroleum hydrocarbon is proportionally prepared from clay, aluminum oxide prepared from alpha-AlO(OH), Y-type molecular sieve containing RE and P and silicon oxide. Its advantages are strong power to convert heavy oil and high output rate of diesel oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

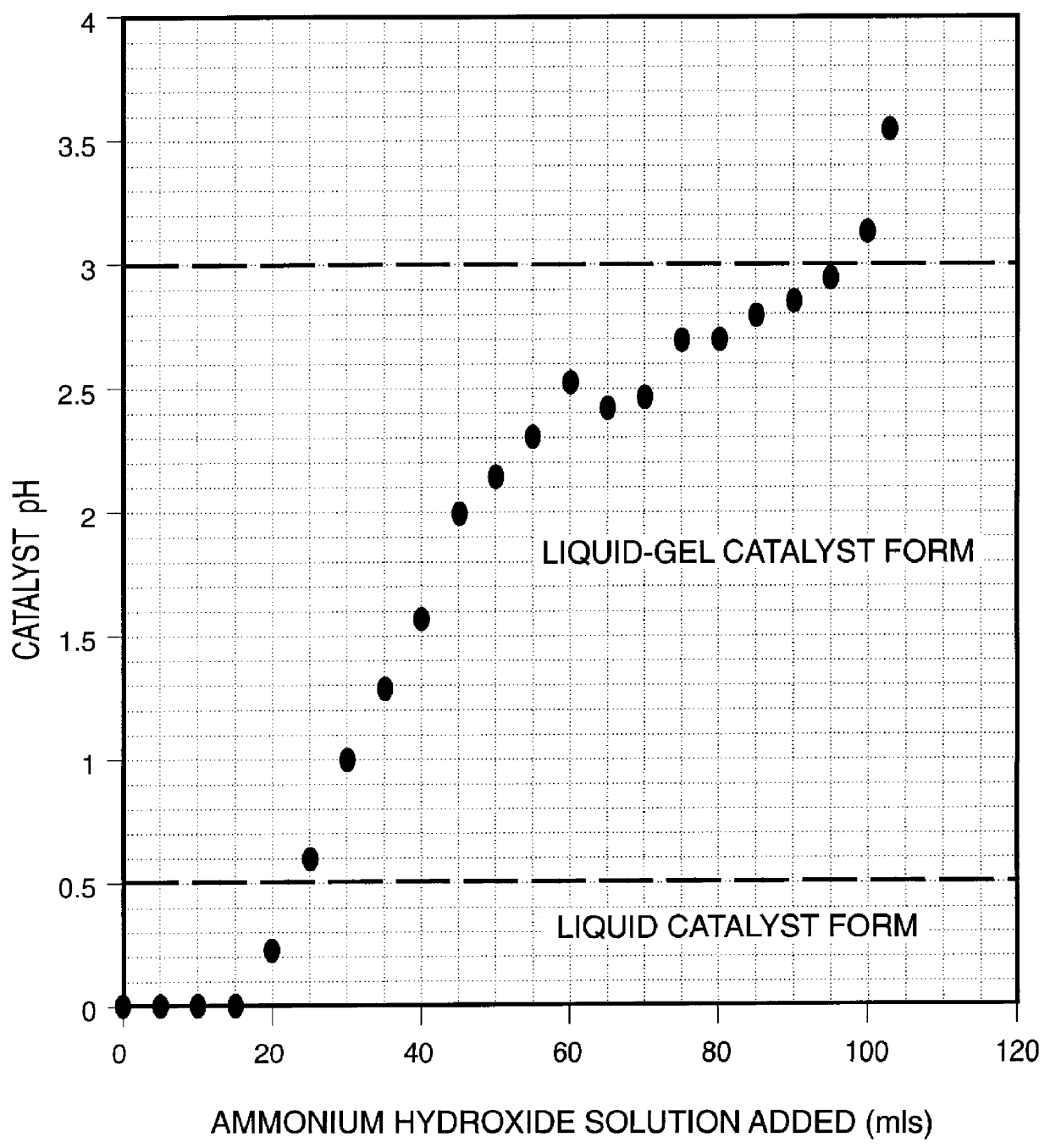

Iron-based ionic liquid catalysts for hydroprocessing carbonaceous feeds

InactiveUS6139723AIncrease hydrocracking ability of catalystIndirect and direct heating destructive distillationCatalyst activation/preparationLiquid productIron salts

A highly dispersed iron-based ionic liquid or liquid-gel catalyst which may be anion-modified and metals-promoted has high catalytic activity, and is useful for hydrocracking / hydrogenation reactions for carbonaceous feed materials. The catalyst is produced by aqueous precipitation from saturated iron salt solutions such as ferric sulfate and ferric alum, and may be modified during preparation with anionic sulfate (SO42-) and promoted with small percentages of at least one active metal such as cobalt, molybdenum, palladium, platinum, nickel, or tungsten or mixtures thereof. The resulting catalyst may be used in a preferred ionic liquid form or in a liquid-gel form, and either fluidic form can be easily mixed and reacted with carbonaceous feed materials such as coal, heavy petroleum fractions, mixed plastic waste, or mixtures thereof. The invention includes methods for making the ionic liquid or liquid-gel catalyst, and processes for using the fluidic catalysts for hydroprocessing the carbonaceous feed materials to produce desirable low-boiling hydrocarbon liquid products.

Owner:HEADWATERS CTL

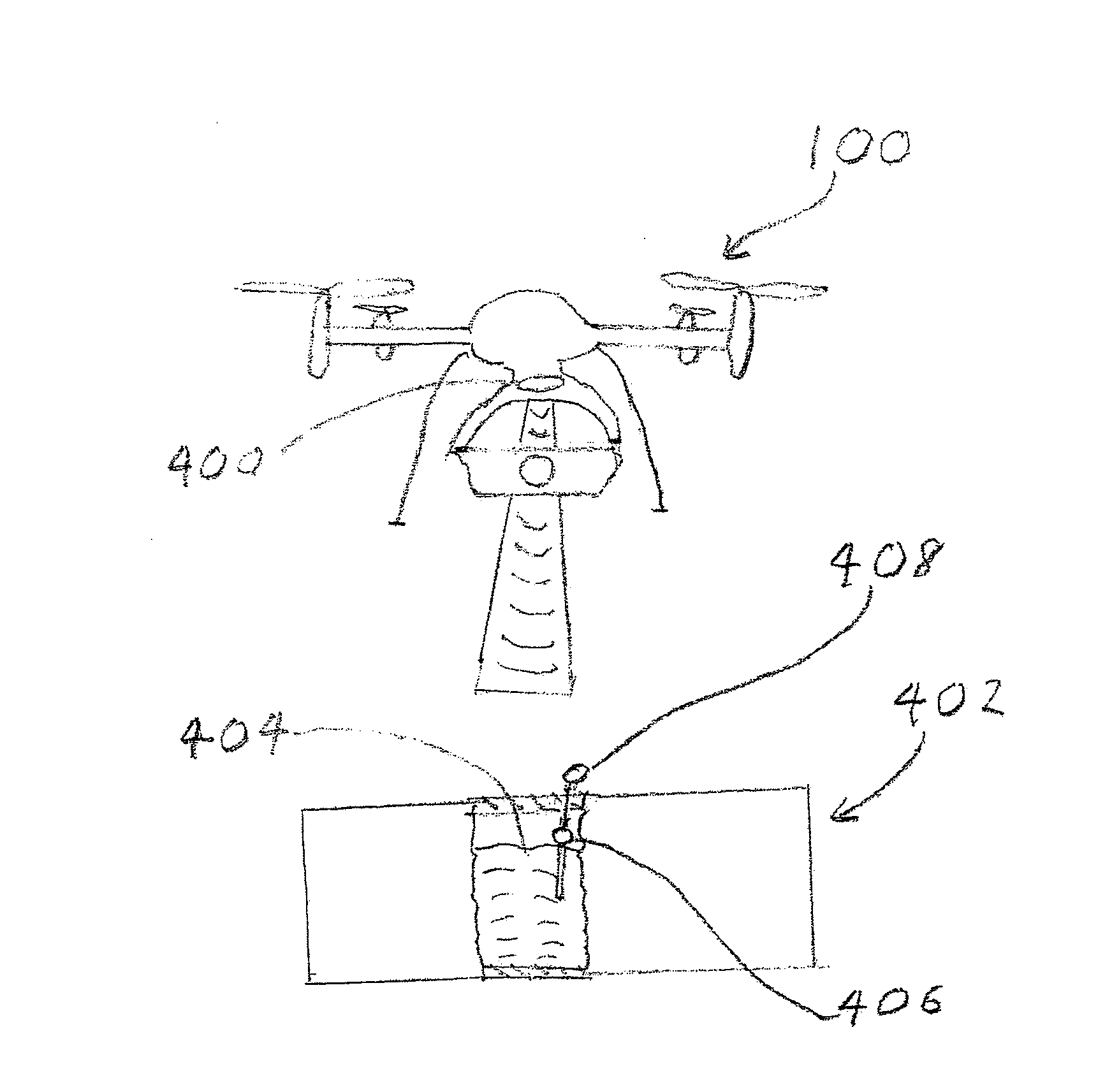

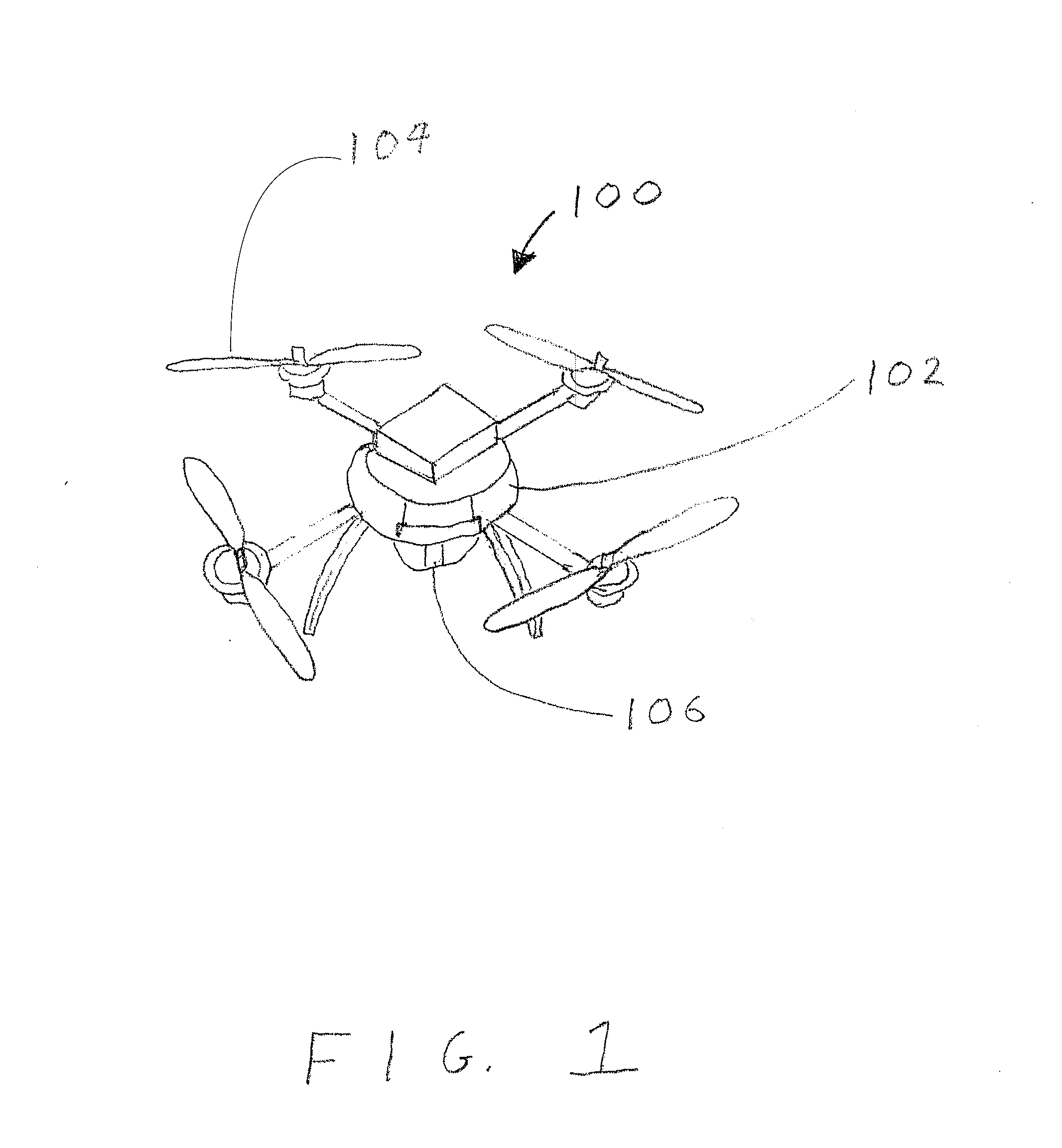

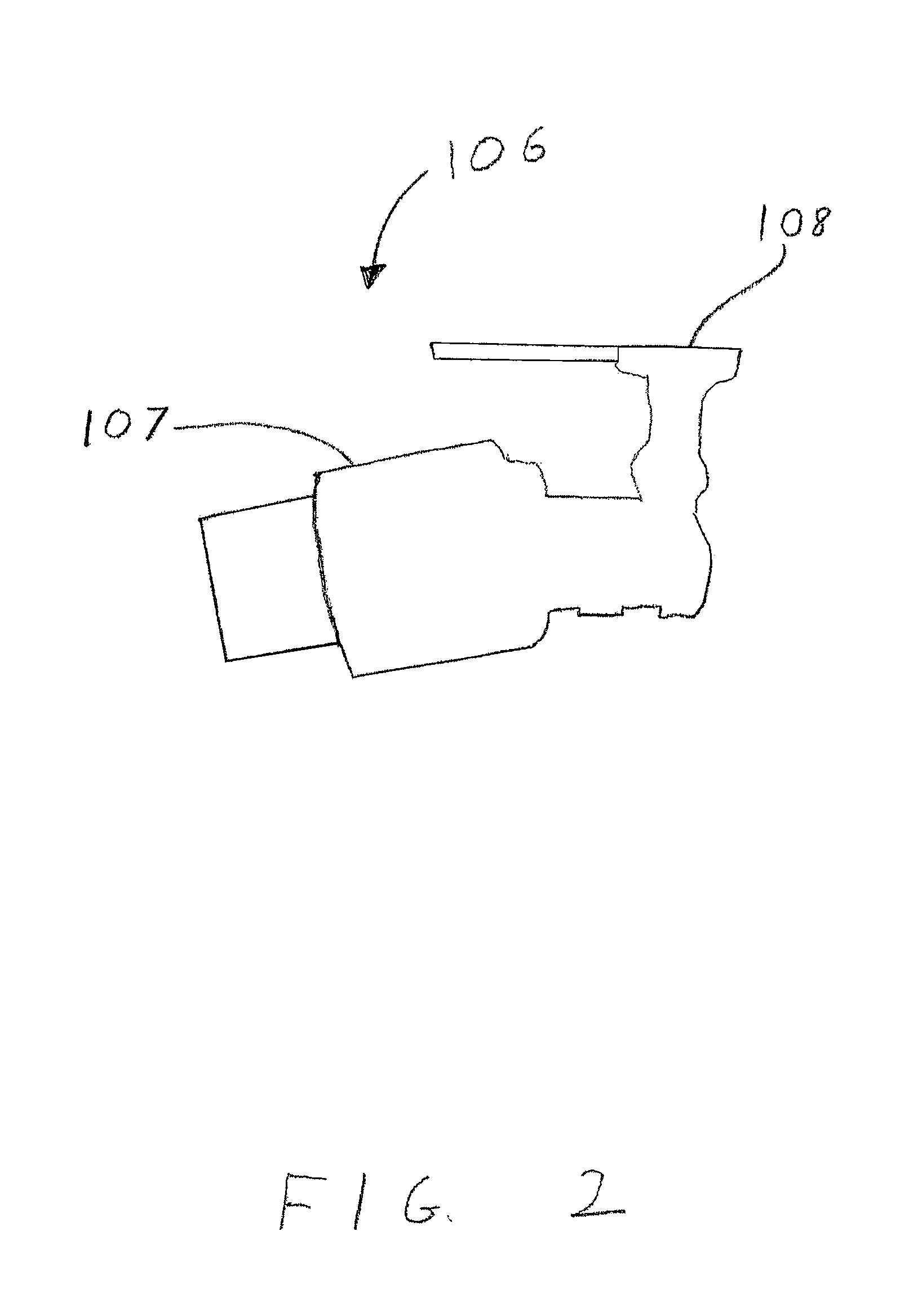

Systems, Methods and Devices for Collecting Data at Remote Oil and Natural Gas Sites

InactiveUS20160214715A1Avoid flyingAccurately determinedAircraft componentsUnmanned aerial vehiclesParticulatesHydrocotyle bowlesioides

Systems, methods and devices are provided for detecting airborne particulates and / or gases at remote oil and natural gas sites, such as wells, and / or processing and refinery plants. One such system comprises an unmanned aerial vehicle (UAV), such as a drone aircraft, configured for aerial dispatch to the remote site and wireless connection to an external processor, cloud apparatus or the like. The UAV includes one or more on-board sensors configured to detect airborne particulates or gases, such as methane gas, hydrogen sulfide, hydrocarbons, weather conditions, ground-based elements or compounds or the like. The on-board sensors may comprise light transmitters, such as lasers, configured for transmitting light or laser pulses into the ambient environment around the remote site and detecting backscatter to detect the concentration and / or velocity vector(s) of the airborne particulates or gases. The UAV is further configured to wirelessly transmit data associated with the airborne particulates or gases to the external processor or cloud apparatus in real-time.

Owner:OIL & GAS IT LLC

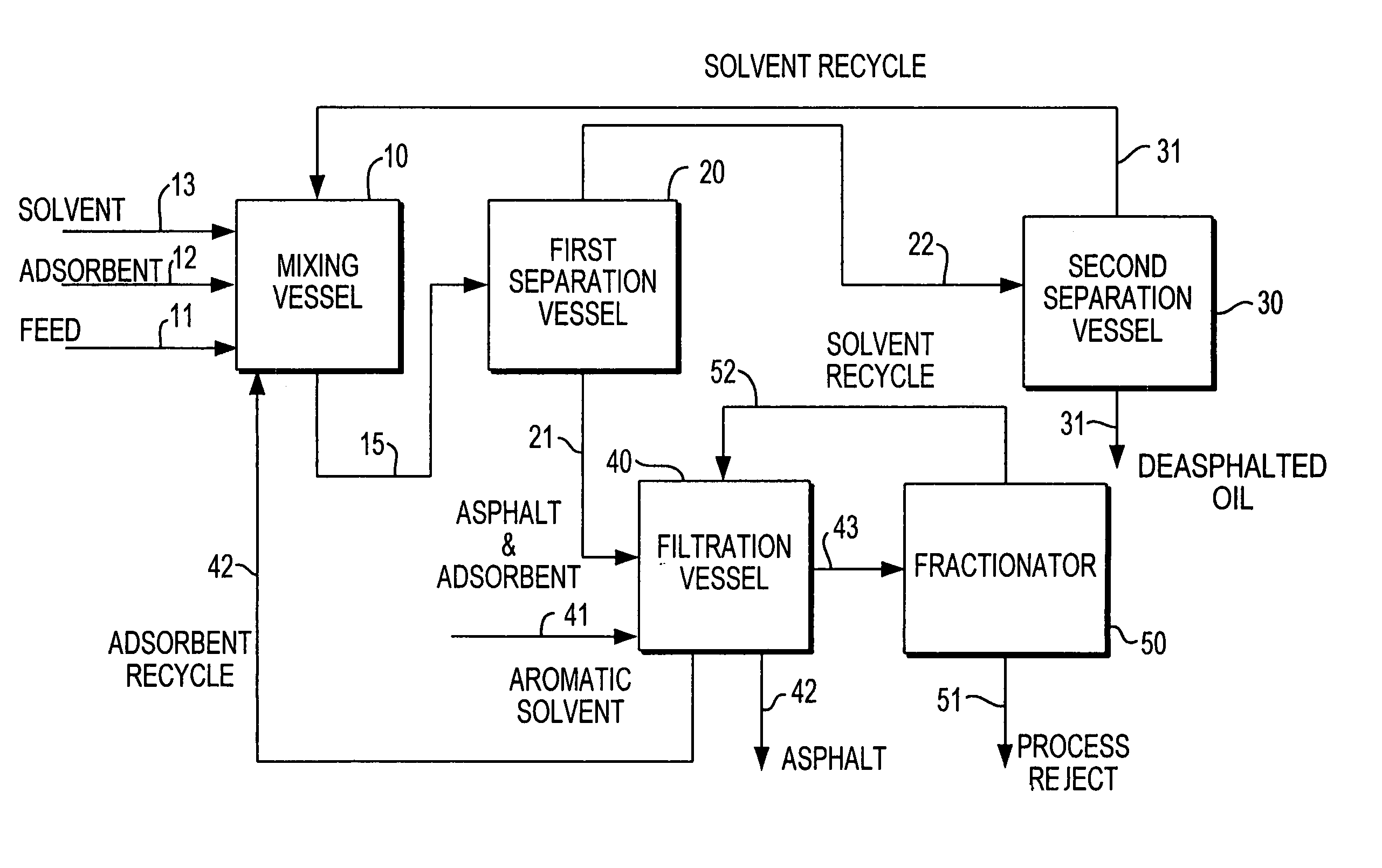

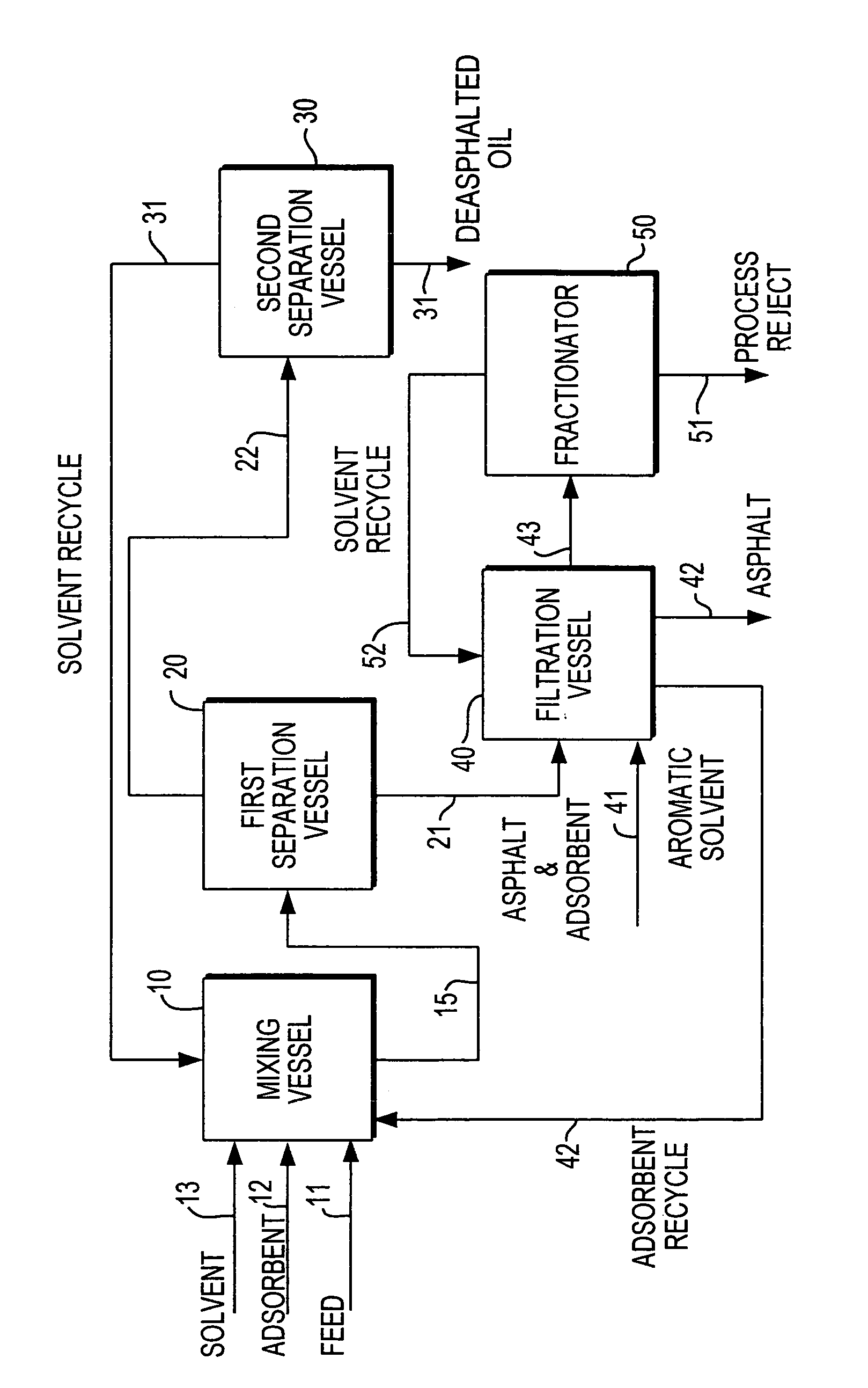

Enhanced solvent deasphalting process for heavy hydrocarbon feedstocks utilizing solid adsorbent

ActiveUS7566394B2Improve performanceImprove current efficiencyWorking-up pitch/asphalt/bitumen by selective extractionHydrocarbon distillationBenzeneActivated carbon

A solvent deasphalting of crude oil or petroleum heavy fractions and residues is carried out in the presence of a solid adsorbent, such as clay, silica, alumina and activated carbon, which adsorbs the contaminants and permits the solvent and oil fraction to be removed as a separate stream from which the solvent is recovered for recycling; the adsorbent with contaminants and the asphalt bottoms is mixed with aromatic and / or polar solvents to desorb the contaminants and washed as necessary, e.g., with benzene, toluene, xylenes and tetrahydrofuran, to clean adsorbant which is recovered and recycled; the solvent-asphalt mixture is sent to a fractionator for recovery and recycling of the aromatic or polar solvent. The bottoms from the fractionator include the concentrated PNA and contaminants and are further processes as appropriate.

Owner:SAUDI ARABIAN OIL CO

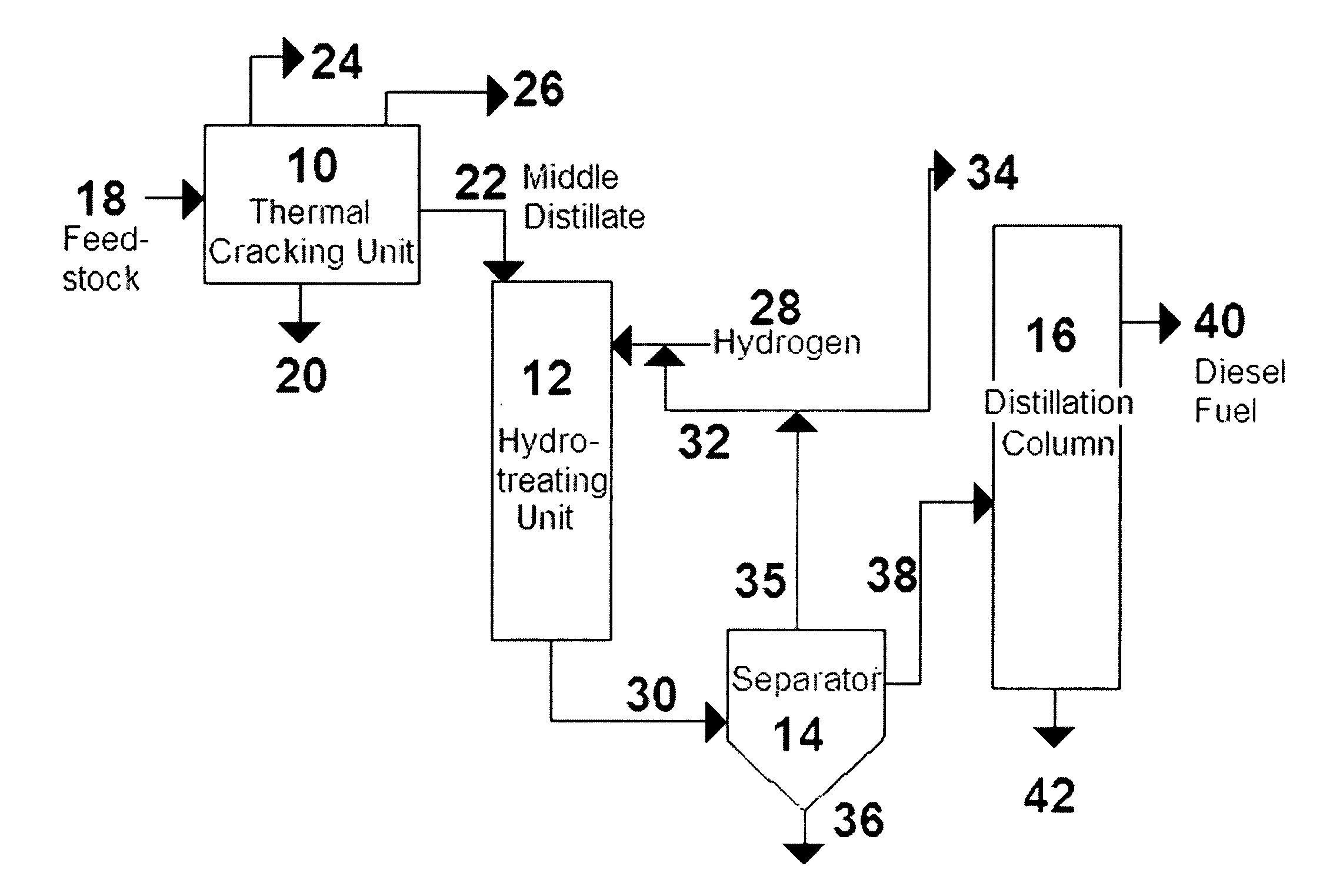

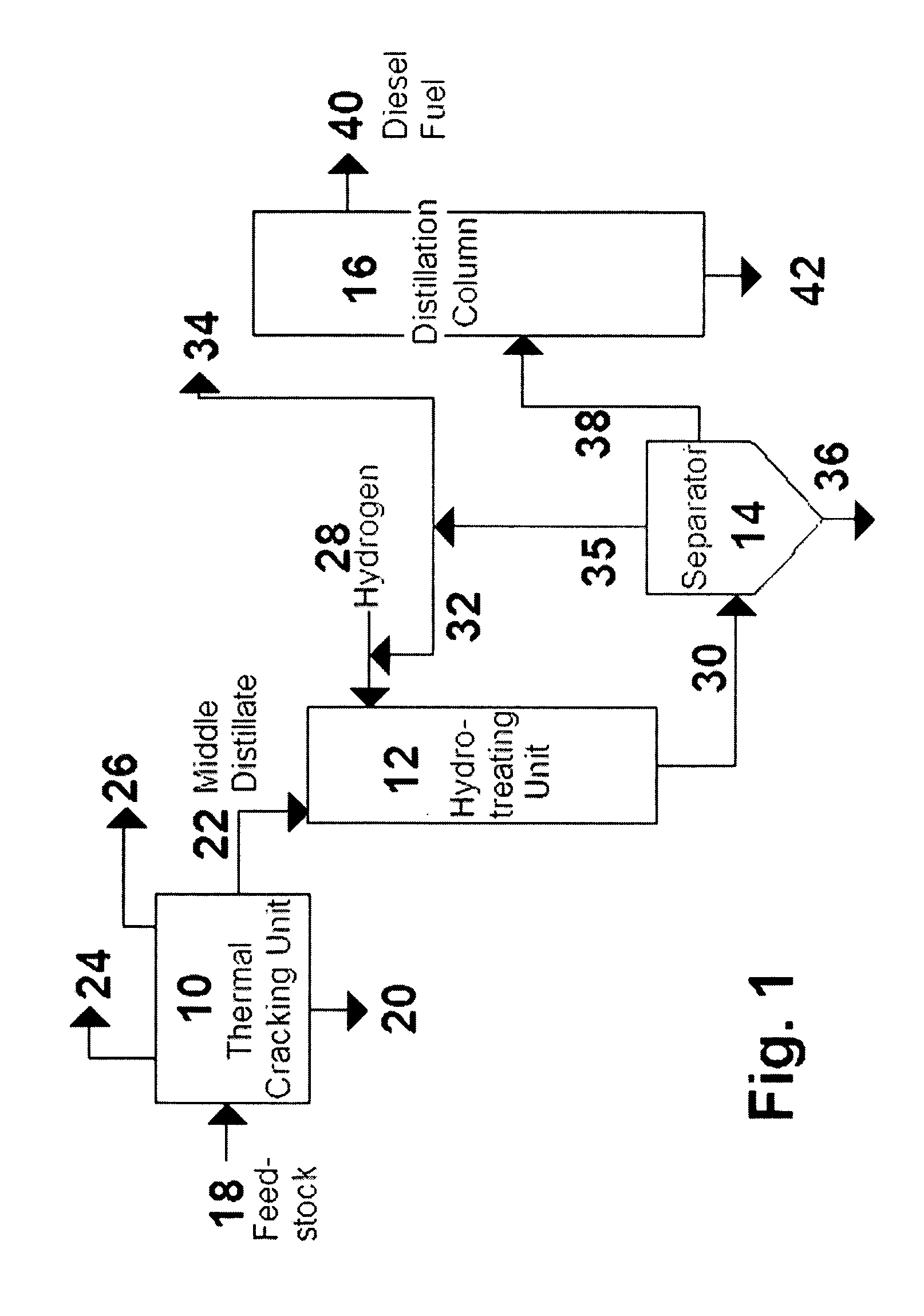

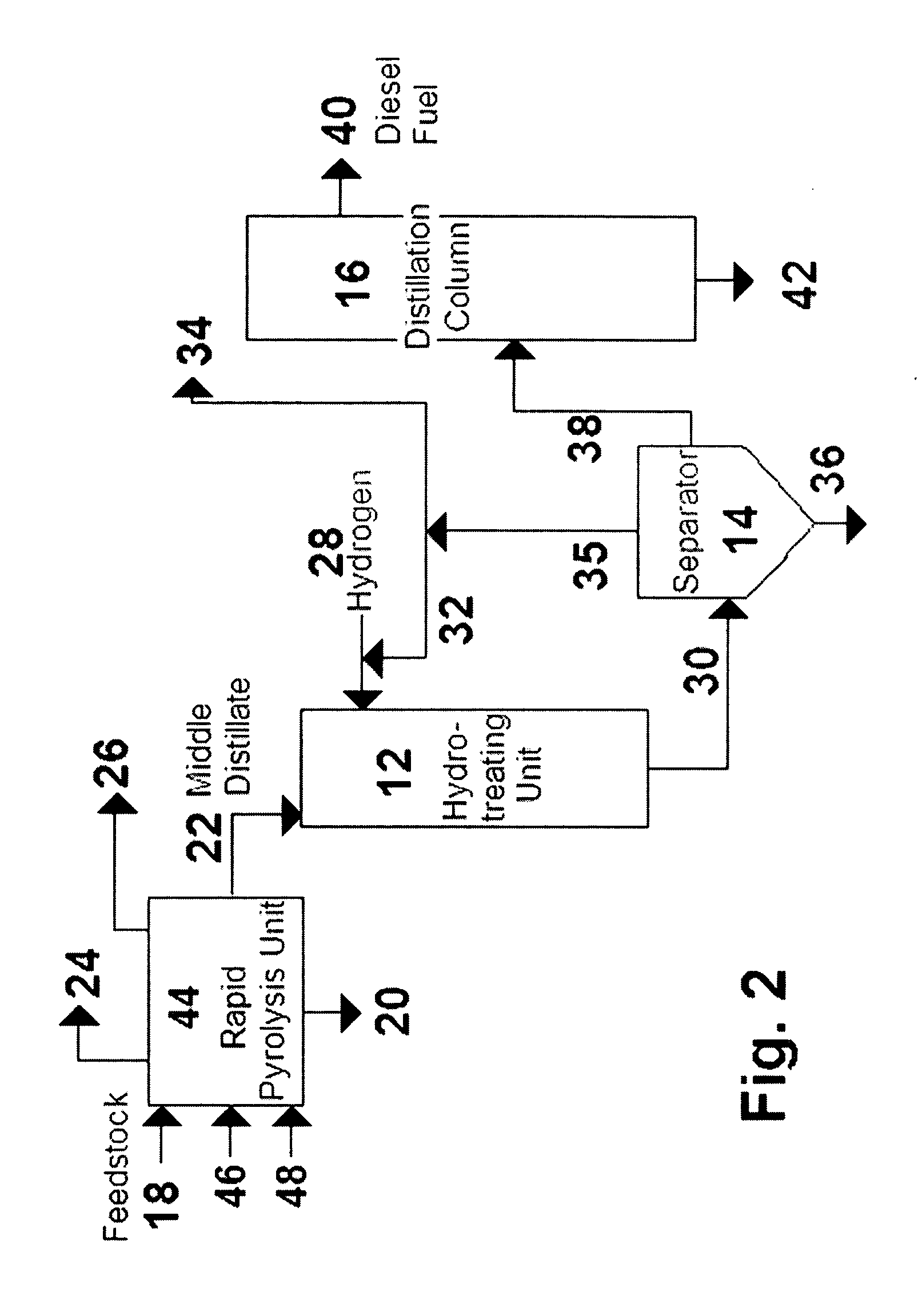

Production of high-cetane diesel fuel from low-quality biomass-derived feedstocks

A method is taught for producing diesel fuels of high cetane value from a triglyceride feedstock, comprising pretreating the triglyceride feedstock by thermal cracking or rapid pyrolysis to partially convert the triglycerides and produce a middle distillates stream, and catalytically hydrotreating the middle distillate fraction to produce high cetane value diesel fuels. A biomass-derived diesel fuel is also taught having sulphur content below 10 ppm, a cetane-value of at least 70, a cloud point below 0° C. and a pour point of less than −4° C. A blended diesel fuel is also taught comprising 5 to 20 vol. % of the biomass-derived diesel fuel of the present invention and 80 to 95 vol. % of a petroleum diesel, based on total volume of the blended diesel fuel.

Owner:HER MAJESTY THE QUEEN & RIGHT OF CANADA REPRESENTED BY THE MIN OF NATURAL RESOURCES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com