Patents

Literature

2982 results about "Agricultural waste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Agricultural Waste. Agricultural Waste is unwanted or unsalable materials produced wholly from agricultural operations directly related to the growing of crops or raising of animals for the primary purpose of making a profit or for a livelihood. Some examples of agricultural waste include: Grape Vines.

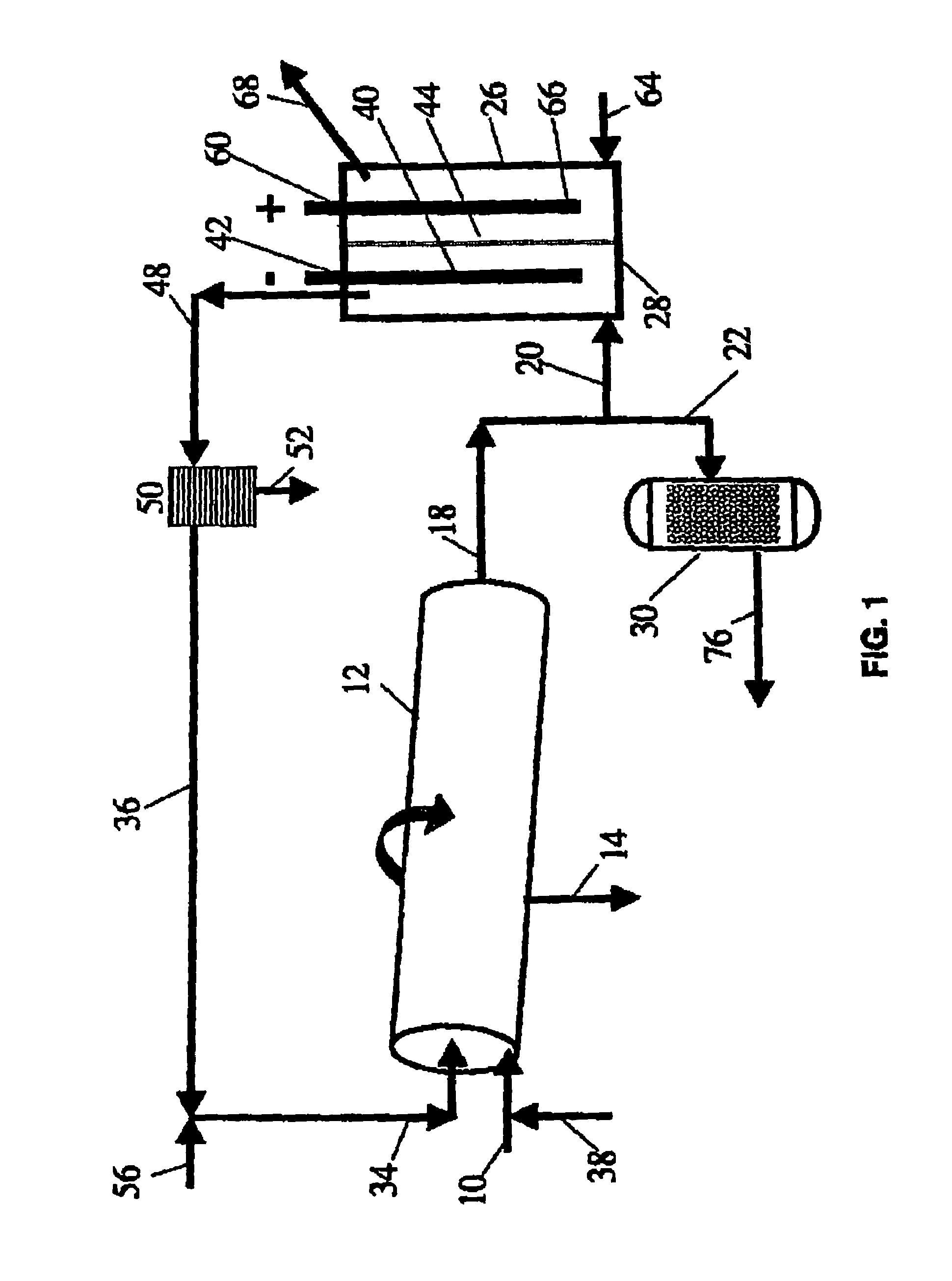

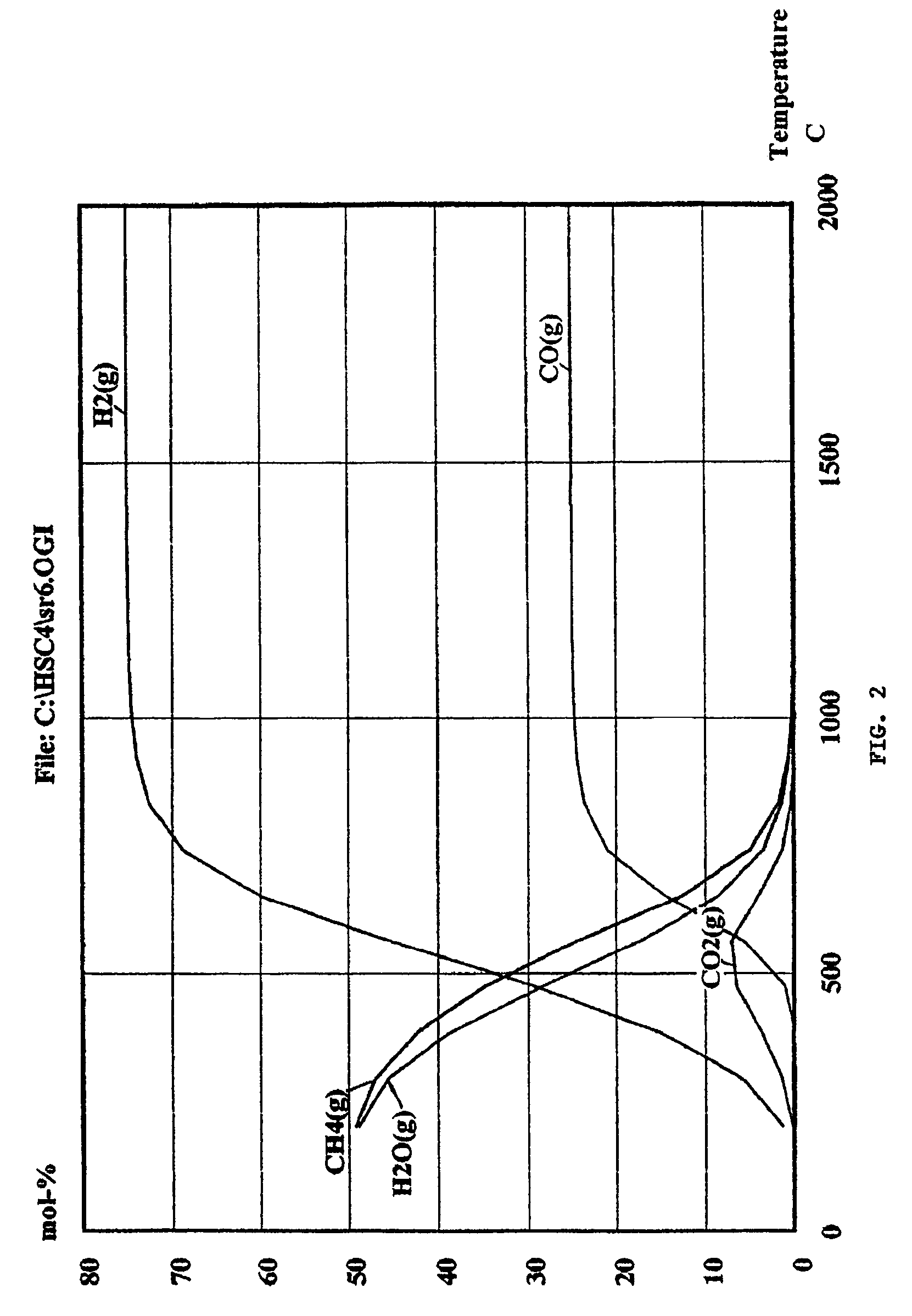

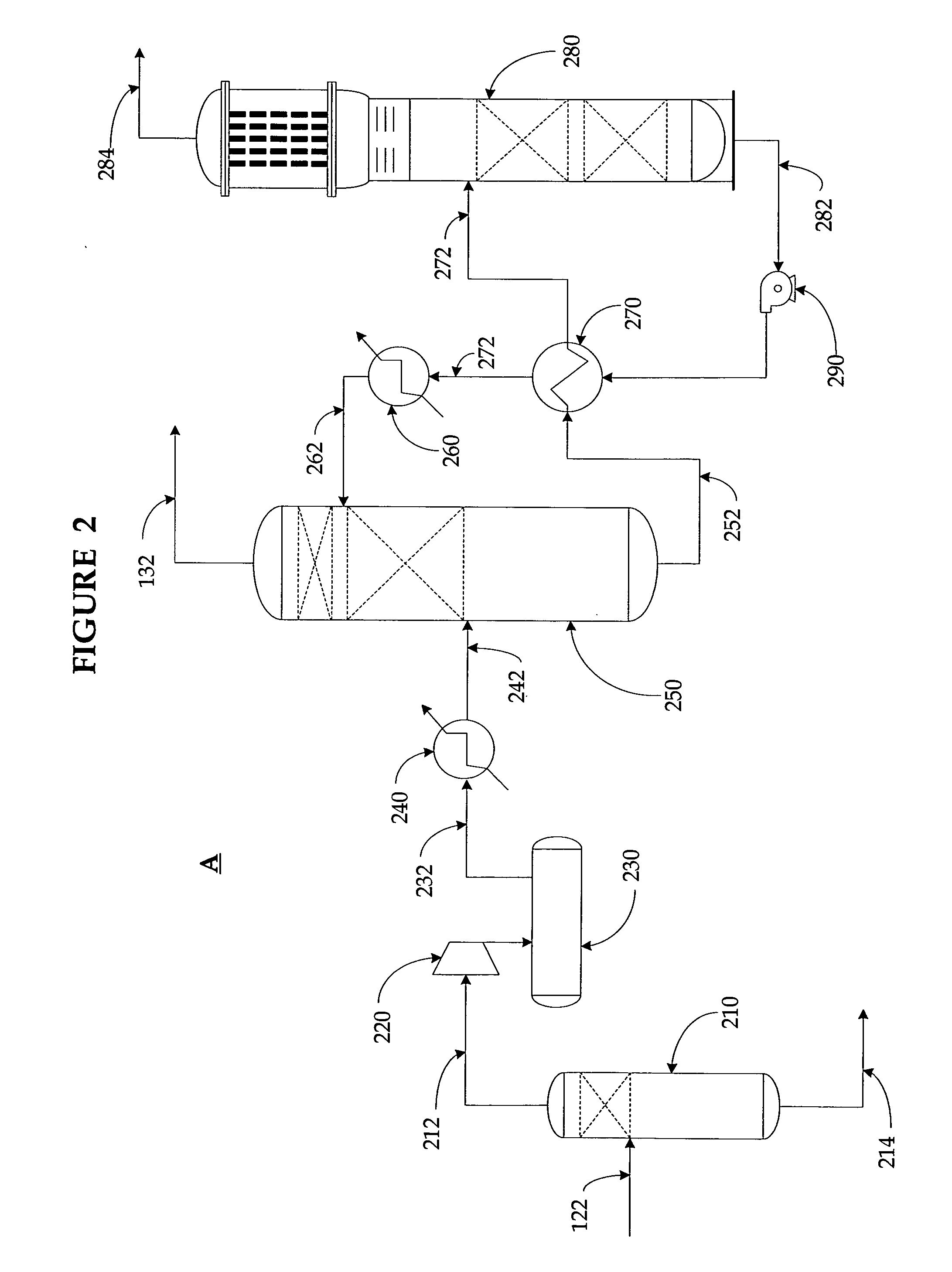

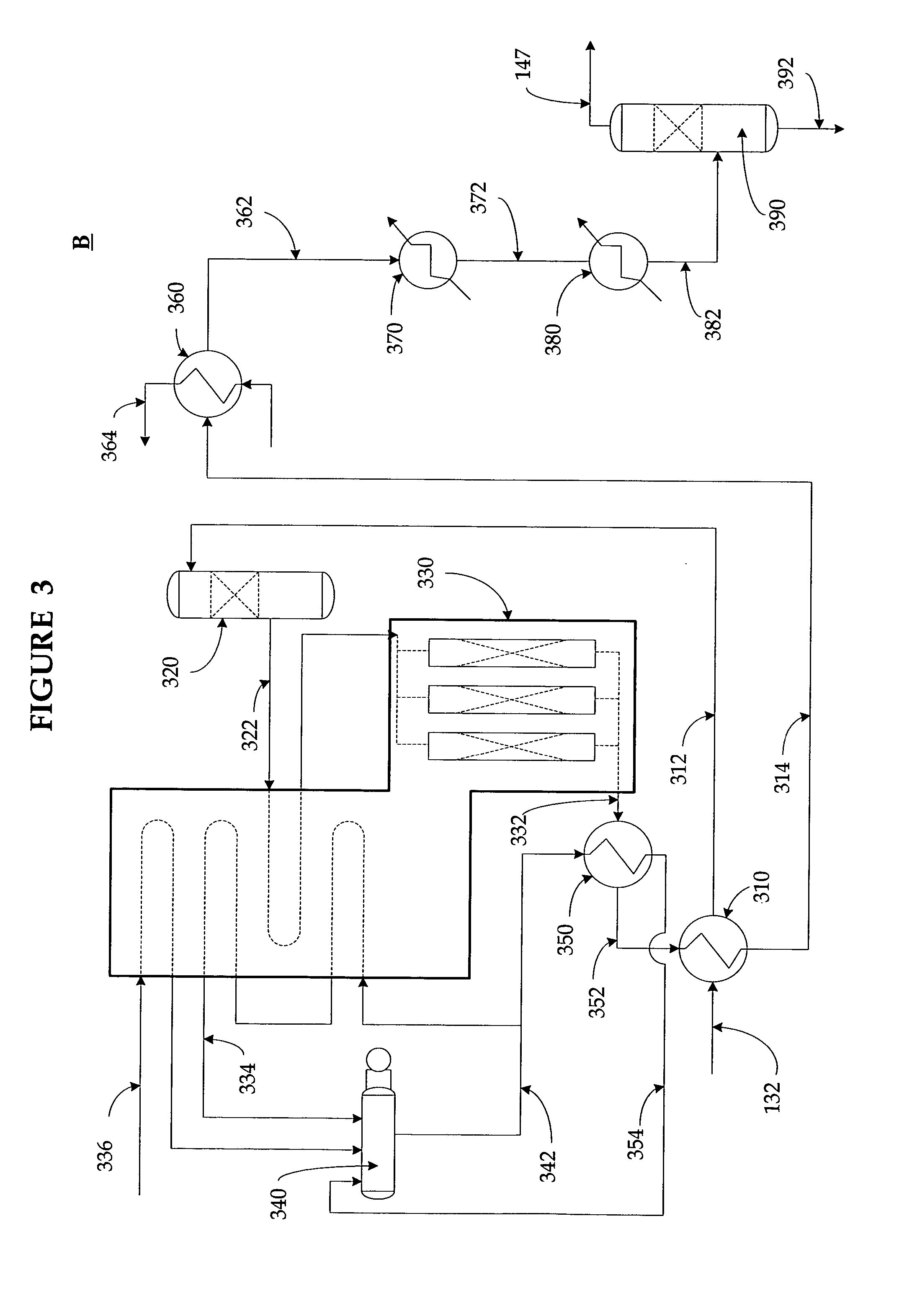

Process and system for converting carbonaceous feedstocks into energy without greenhouse gas emissions

ActiveUS20070099038A1High hydrogen contentFuel cells groupingHydrogen separation using solid contactPetroleum cokePetroleum

The process of the invention converts carbonaceous feedstock such as coal, hydrocarbon oil, natural gas, petroleum coke, oil shale, carbonaceous-containing waste oil, carbonaceous-containing medical waste, carbonaceous-containing military waste, carbonaceous-containing industrial waste, carbonaceous-containing medical waste, carbonaceous-containing sewage sludge and municipal solid waste, carbonaceous-containing agricultural waste, carbonaceous-containing biomass, biological and biochemical waste, and mixtures thereof into electrical energy without the production of unwanted greenhouse emissions. The process uses a steam / CO2 reformer operating in the exit range of at least 700° to about 1600° C. (1300-2900°0 F.) to convert the carbonaceous feedstock and a greenhouse gas stream into a synthesis gas comprising mostly carbon monoxide and hydrogen that contains poisons and the compounds that poison fuel cells. The syngas is sent to an interface zone to remove these poisons and other fouling compounds that are electrochemically oxidized in an electricity-producing fuel cell into an exit gas comprising carbon dioxide and water.

Owner:RAVEN SR INC

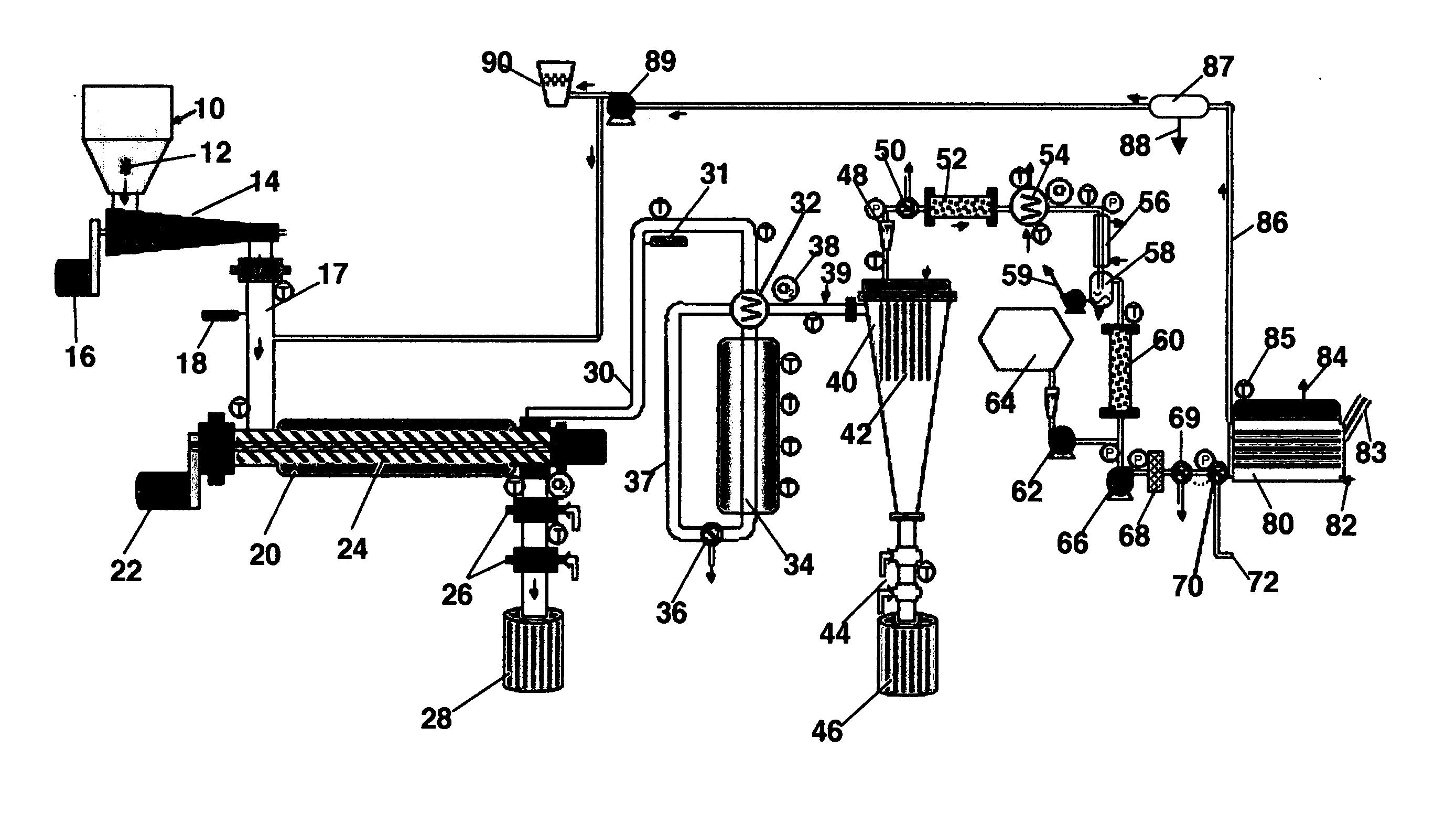

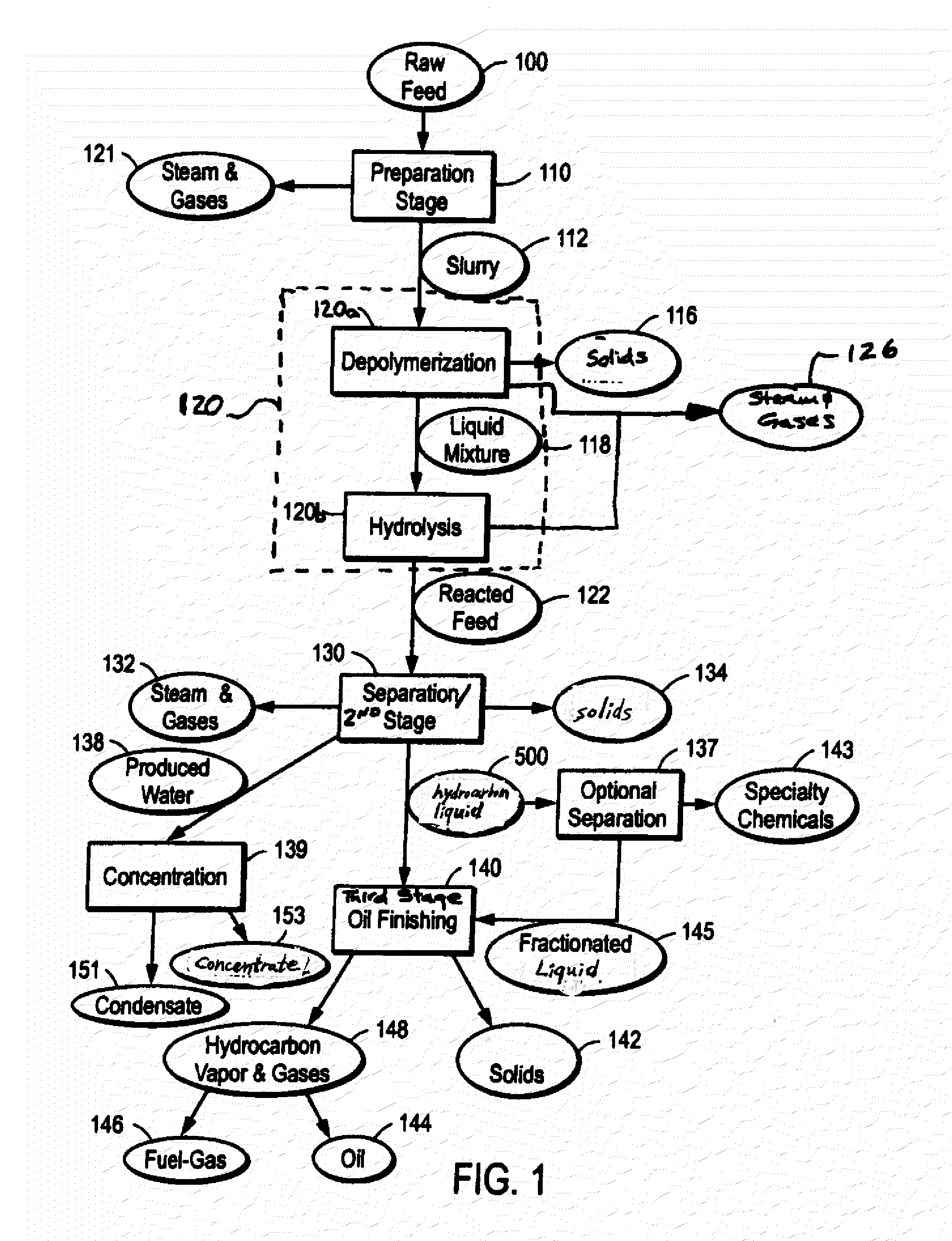

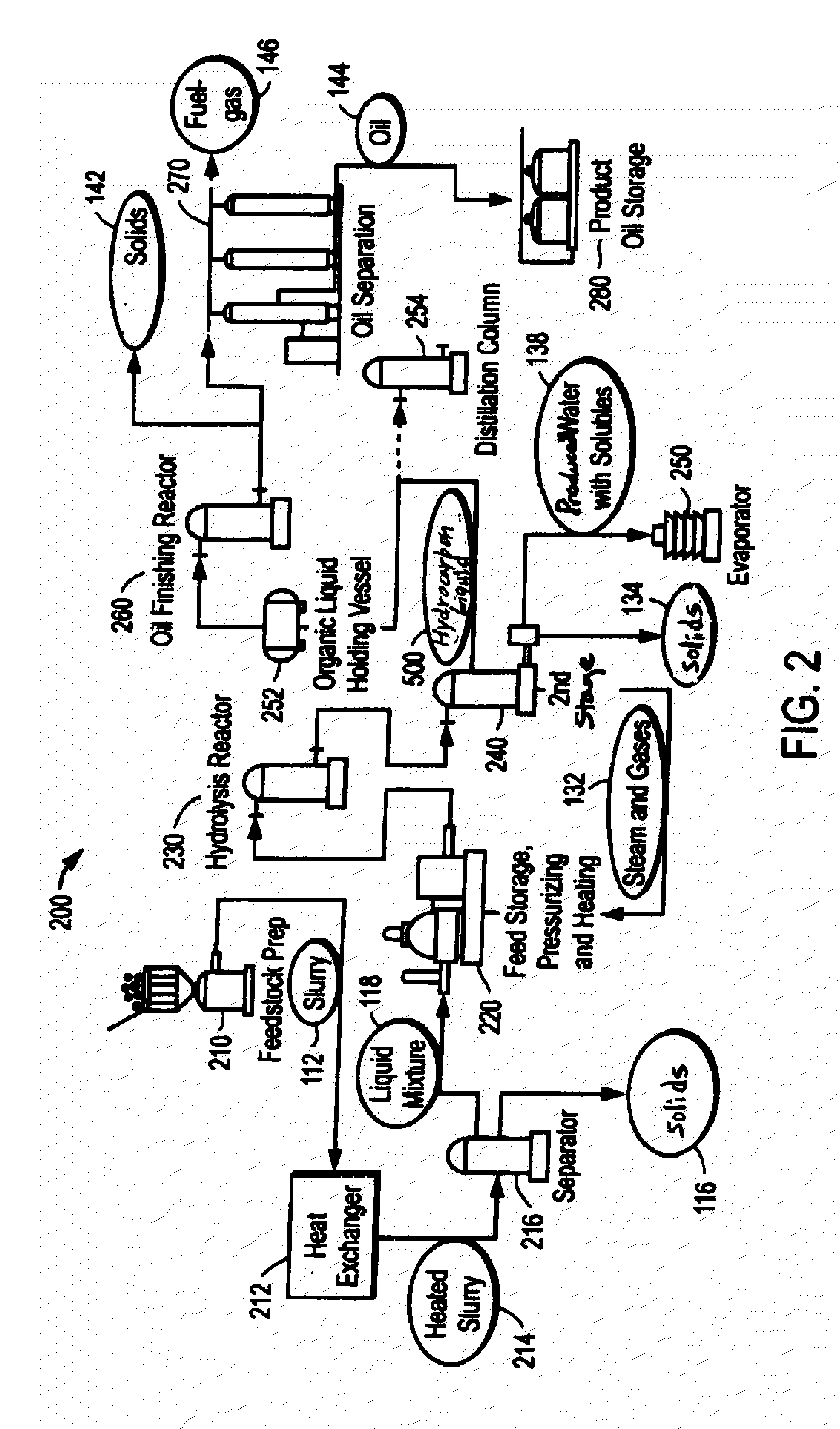

Methods and apparatus for converting waste materials into fuels and other useful products

ActiveUS20090062581A1Effectively handle problematic wasteFree of contaminantsTransportation and packagingSolid waste disposalSpeciality chemicalsBiological waste

Conversion of waste and other organic feedstock into sustainable energy, feed, fertilizer, and other useful products of reliable purities is accomplished using water, heat, and pressure. More specifically, the invention provides methods and apparatus that handle mixed streams of various feedstocks, e.g. agricultural waste, biological waste, municipal solid waste, municipal sewage sludge, and shredder residue, to yield gas, oil, specialty chemicals, and carbon solids that can be used as is or are further processed. Useful products can be diverted at various points of the process or internalized to enhance the efficiency of the system.

Owner:SYNPET TEKNOLOJI GELISTIRME

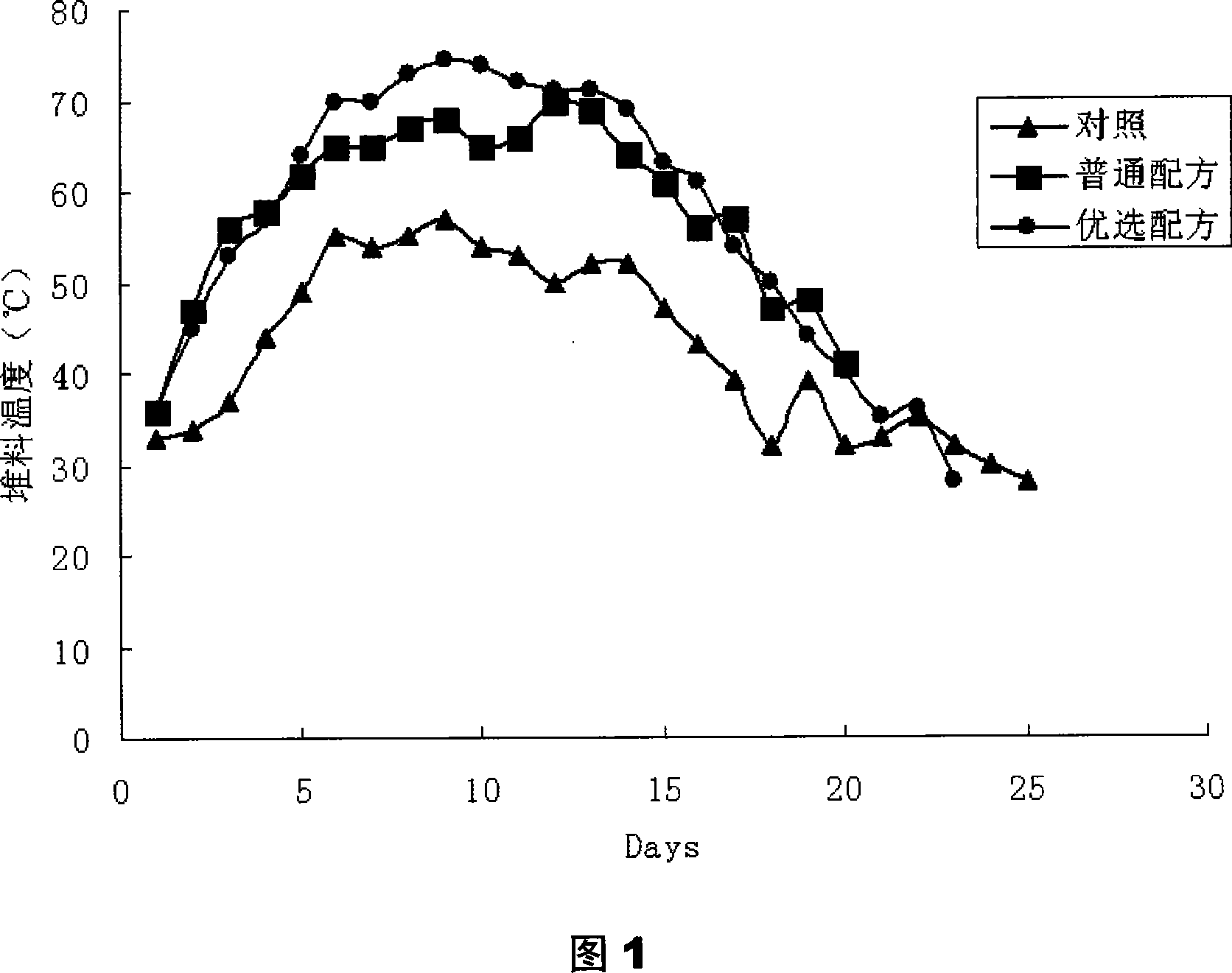

Agriculture castoff compost ternary microorganism composite microbial inoculum

ActiveCN101186879APromote degradationQuick conversionBio-organic fraction processingMicroorganismsMicroorganism resourceCompost

A composite biological agent with ternary microorganism for composting process of agricultural waste is composed of a composite biological agent I, a composite biological agent II, and a composite biological agent III, which is characterized in that the composite biological agent I is composed of bacillus, actinomycetes, microzyme and lactobacillus, the composite biological agent II is composed of trichoderma, ergillus, penicillium and trametes versicolor, and the composite biological agent III is composed of photosynthetic bacterium, azotobacter, phosphorus bacteria, and silicate bacterium. 30-60% composite biological agent I, 30-60% composite biological agent II, 10-20% composite biological agent III are mixed or applied to the process of composting process of agricultural waste in phases. Each component ratio and recruitment of biological agents can be both properly adjusted with different dung materials and dung purpose, thereby achieving purpose of using microorganism resources efficiently and raising fermentation efficiency.

Owner:INST OF SOIL SCI CHINESE ACAD OF SCI

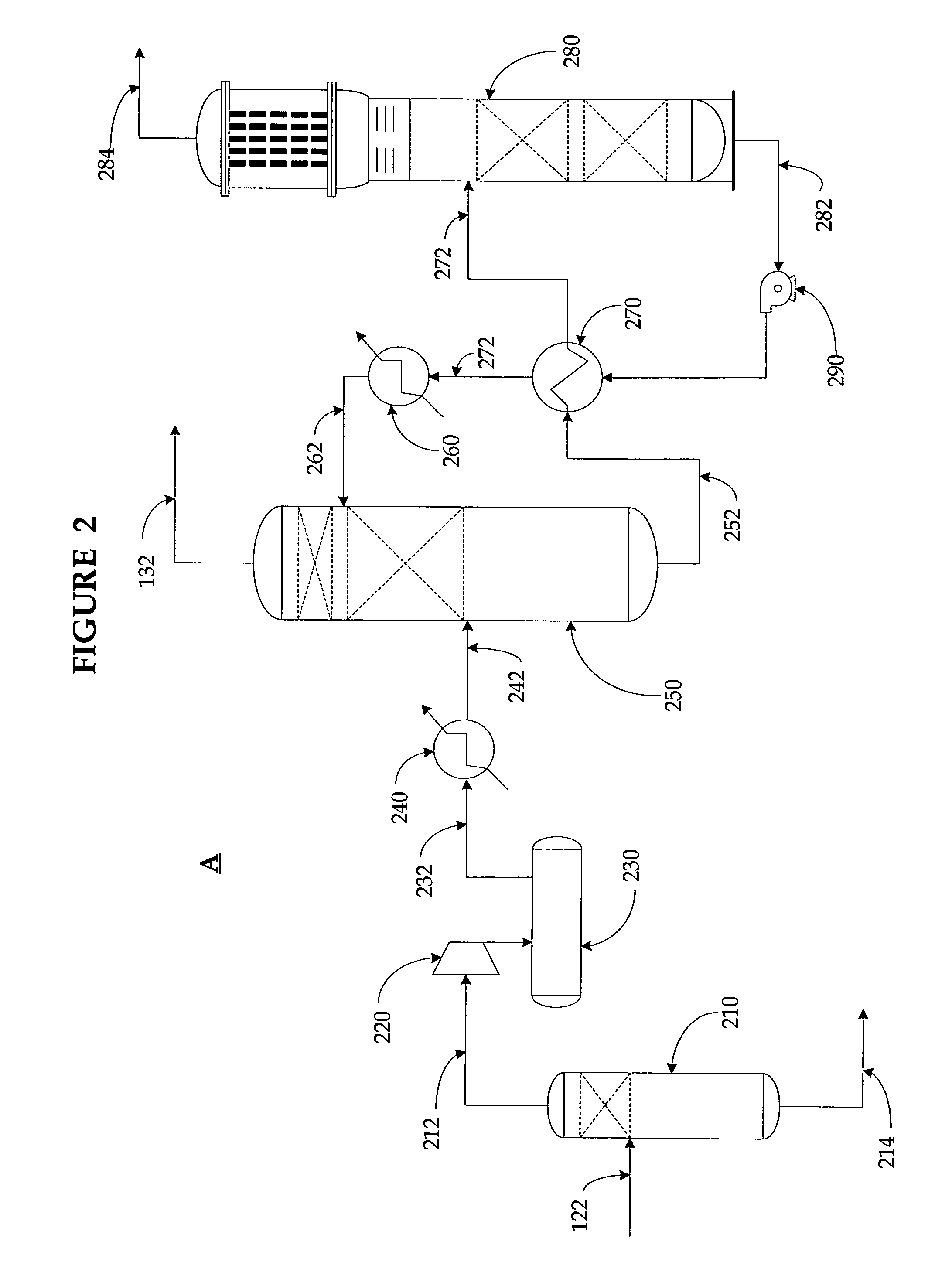

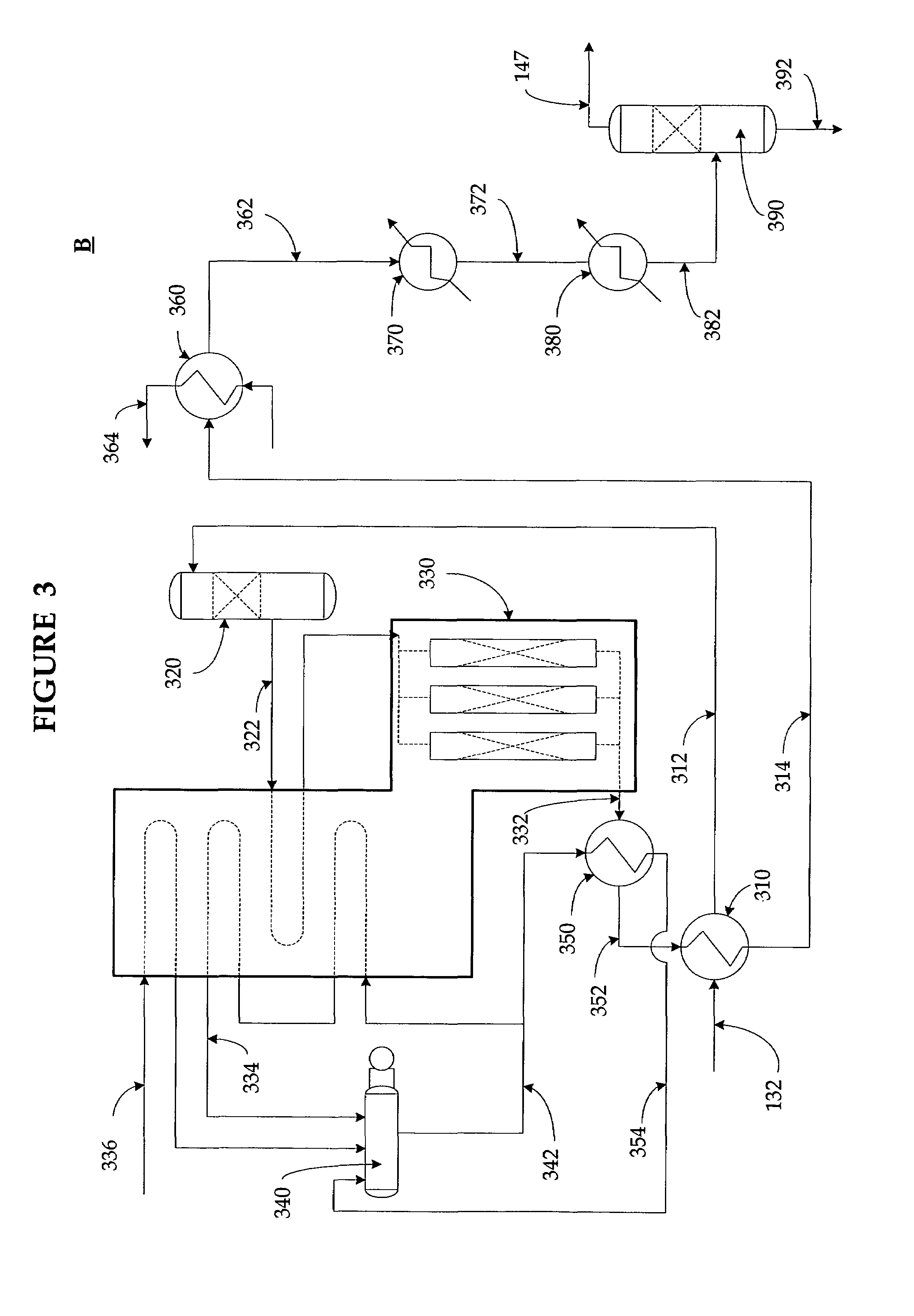

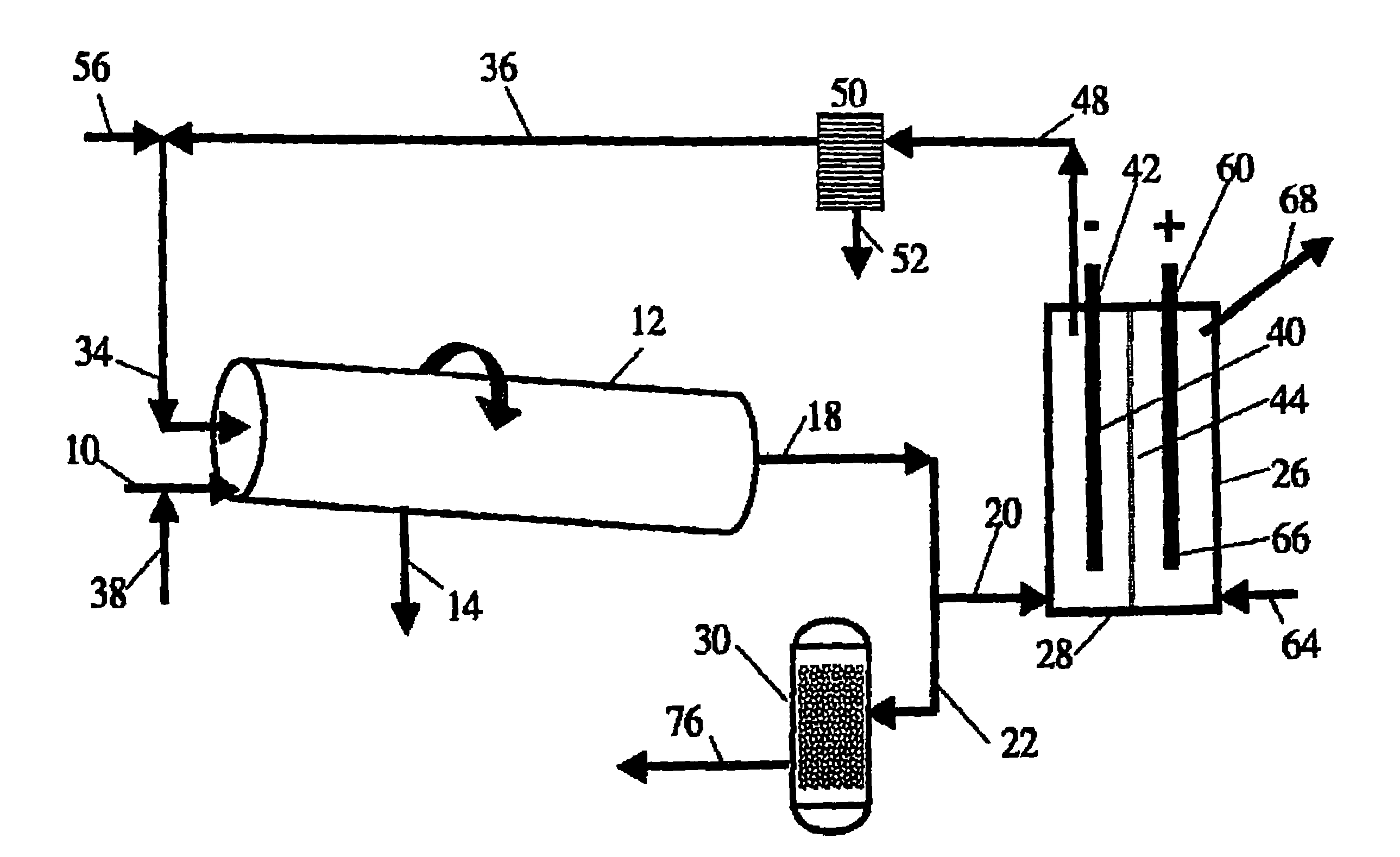

System and method for extracting energy from agricultural waste

InactiveUS7169821B2Reduce decreaseMinimize negative impactBioreactor/fermenter combinationsBio-organic fraction processingSyngasBiodiesel

Owner:BEST BIOFUELS LLC

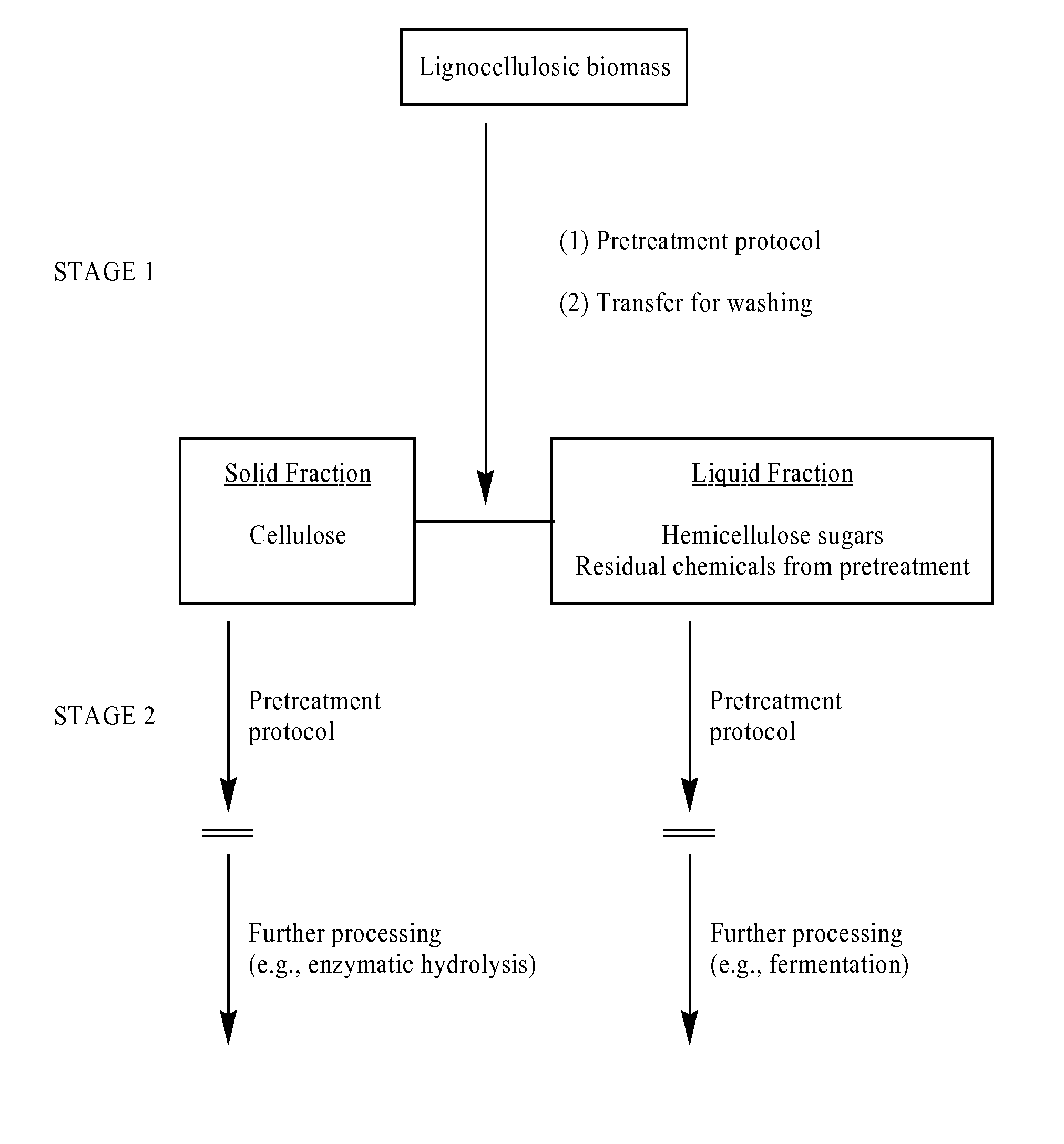

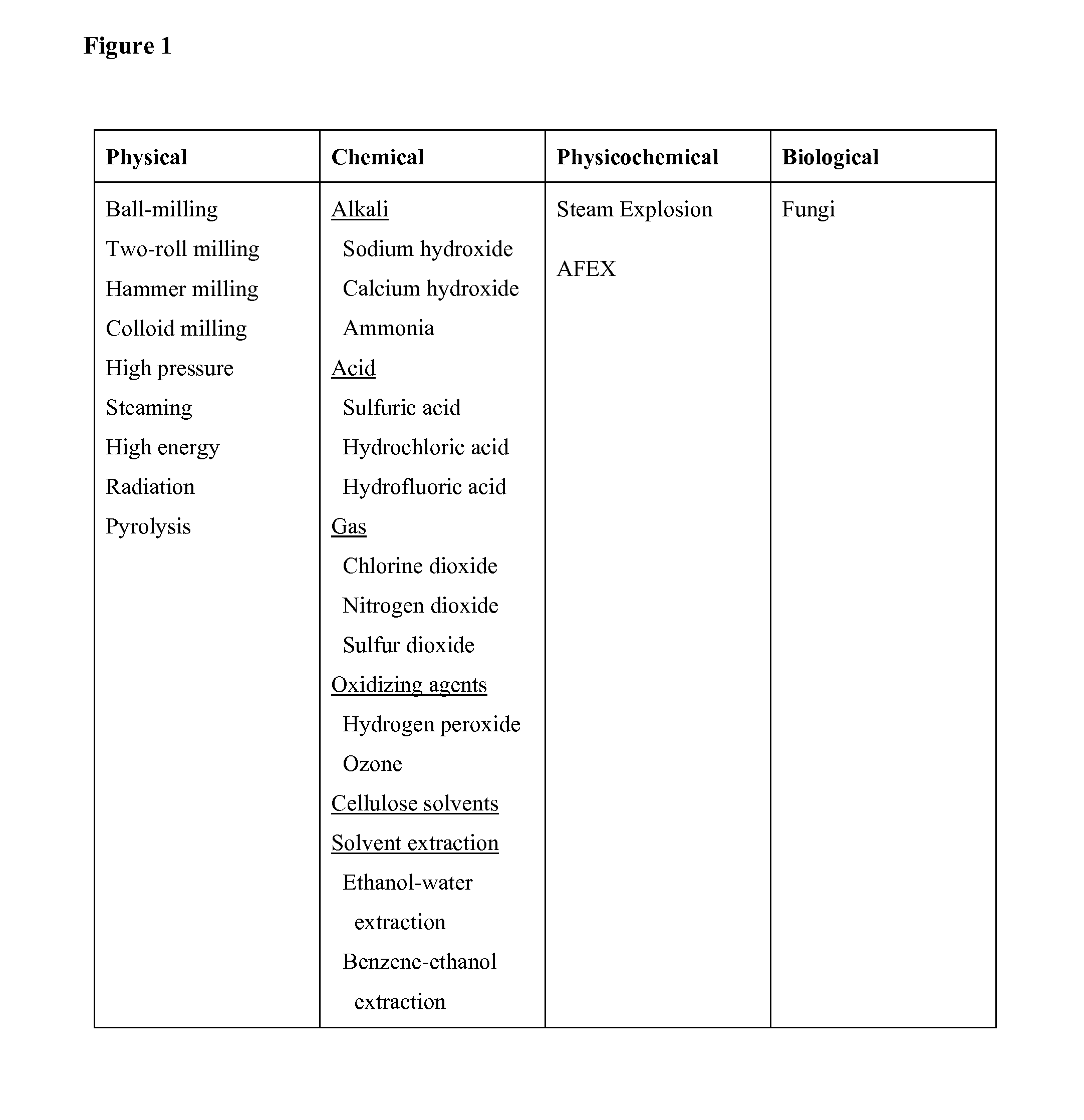

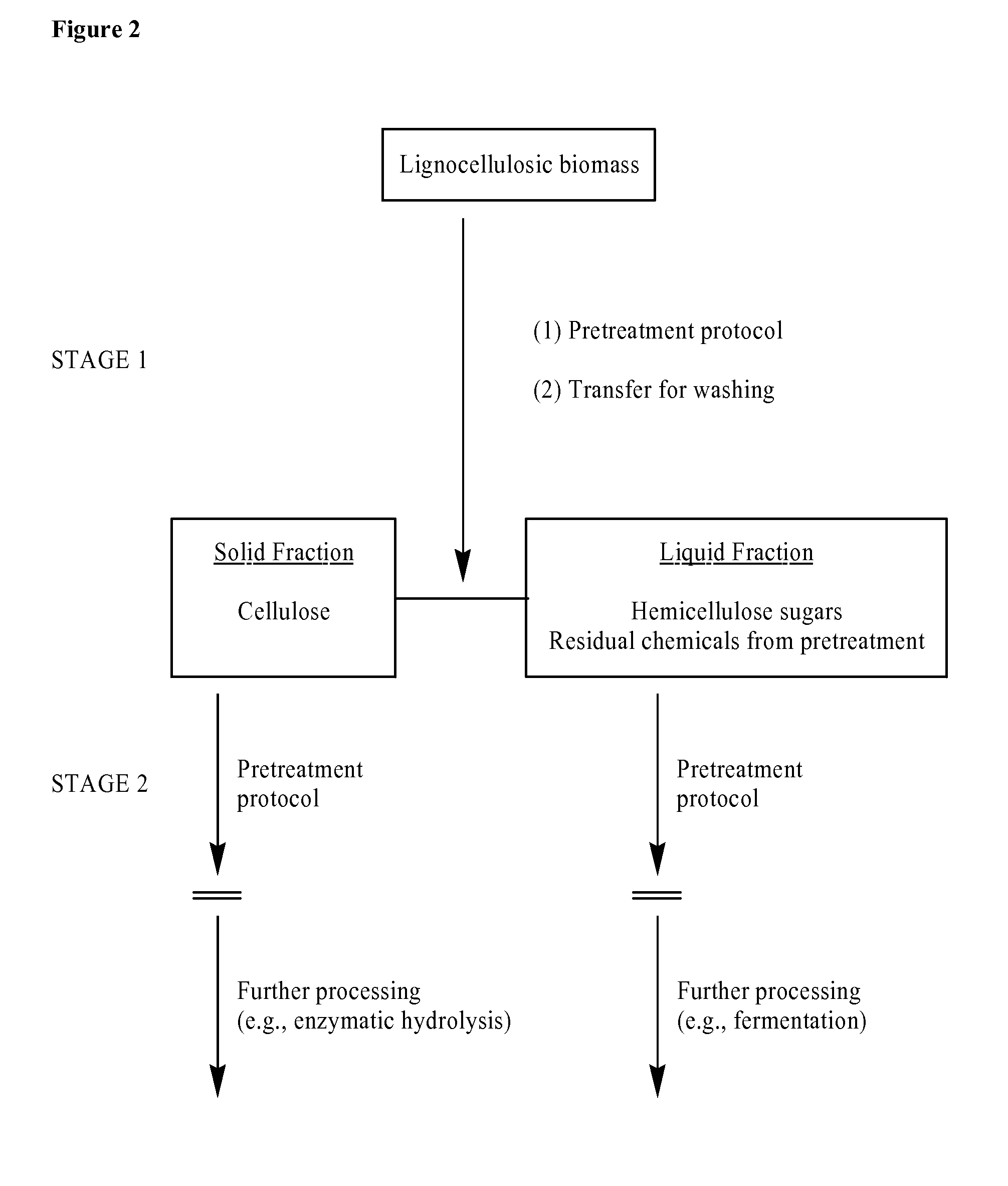

Two-stage method for pretreatment of lignocellulosic biomass

InactiveUS20100279361A1Reduce decreaseMaximize efficiencyOrganic compound preparationFood processingCelluloseFiber

One aspect of the invention relates to a process, comprising treating lignocellulosic biomass according to a first pretreatment protocol, thereby generating a first product mixture; separating the first product mixture into a first plurality of fractions; and treating at least one fraction of said first plurality of fractions according to a second pretreatment protocol, thereby generating a second product mixture. In one embodiment, the lignocellulosic biomass is selected from the group consisting of grass, switch grass, cord grass, rye grass, reed canary grass, miscanthus, sugar-processing residues, sugarcane bagasse, agricultural wastes, rice straw, rice hulls, barley straw, corn cobs, cereal straw, wheat straw, canola straw, oat straw, oat hulls, corn fiber, stover, soybean stover, corn stover, forestry wastes, recycled wood pulp protocol protocol fiber, paper sludge, sawdust, hardwood, softwood, and combinations thereof.

Owner:MASCOMA CORPORATION

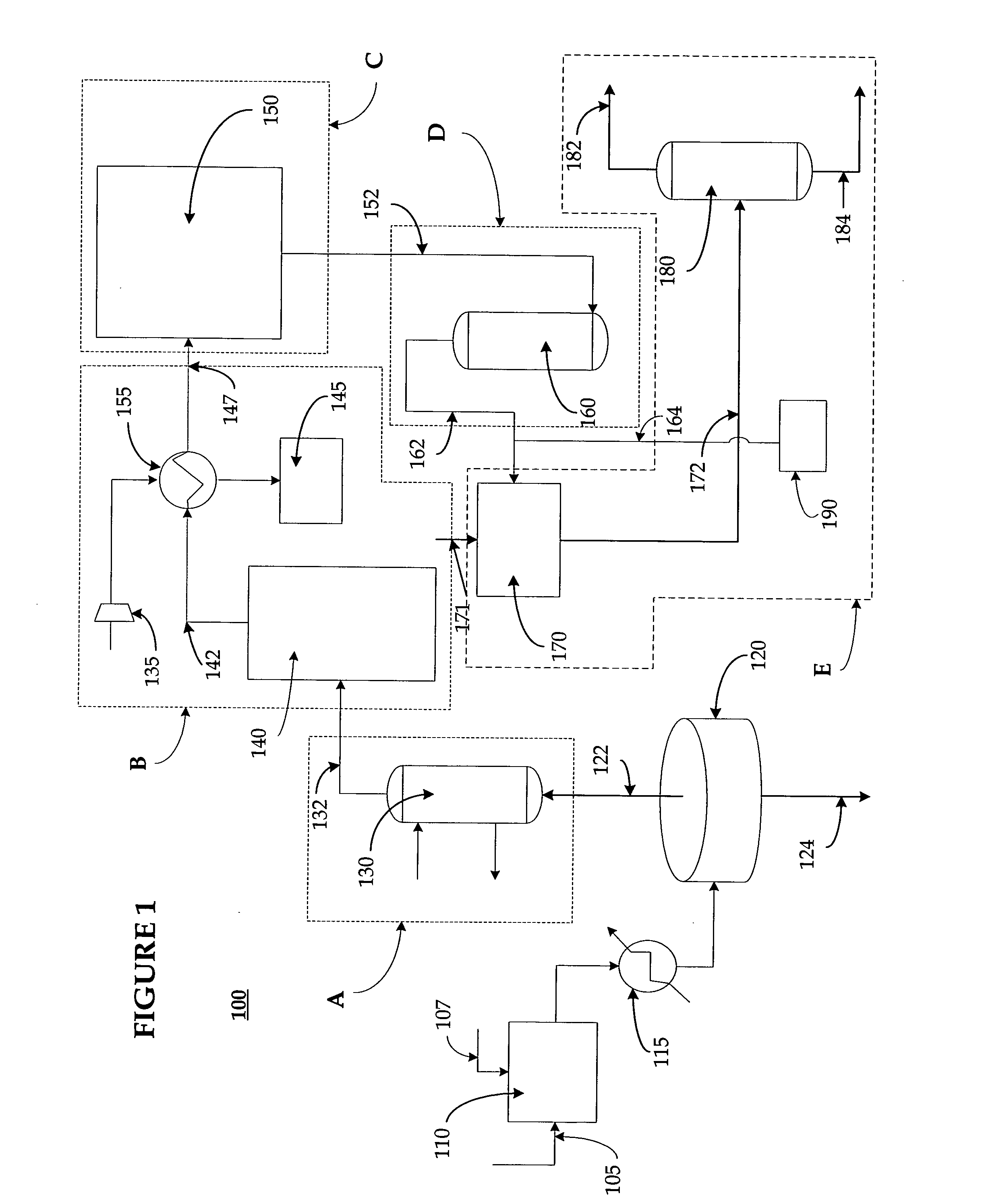

Process and system for converting carbonaceous feedstocks into energy without greenhouse gas emissions

InactiveUS7220502B2Improve efficiencyHigh hydrogen contentFuel cell auxillariesWaste based fuelPetroleum cokeToxic industrial waste

The process and system of the invention converts carbonaceous feedstock such as coal, hydrocarbon oil, natural gas, petroleum coke, oil shale, carbonaceous-containing waste oil, carbonaceous-containing medical waste, carbonaceous-containing military waste, carbonaceous-containing industrial waste, carbonaceous-containing medical waste, carbonaceous-containing sewage sludge and municipal solid waste, carbonaceous-containing agricultural waste, carbonaceous-containing biomass, biological and biochemical waste, and mixtures thereof into electrical energy without the production of unwanted greenhouse emissions. The process and system uses a combination of a gasifier, e.g., a kiln, operating in the exit range of at least 700° to about 1600° C. (1300-2900° F.) to convert the carbonaceous feedstock and a greenhouse gas stream into a synthesis gas comprising mostly carbon monoxide and hydrogen without the need for expensive catalysts and or high pressure operations. One portion of the synthesis gas from the gasifier becomes electrochemically oxidized in an electricity-producing fuel cell into an exit gas comprising carbon dioxide and water. The latter is recycled back to the gasifier after a portion of water is condensed out. The second portion of the synthesis gas from the gasifier is converted into useful hydrocarbon products.

Owner:RAVEN SR INC

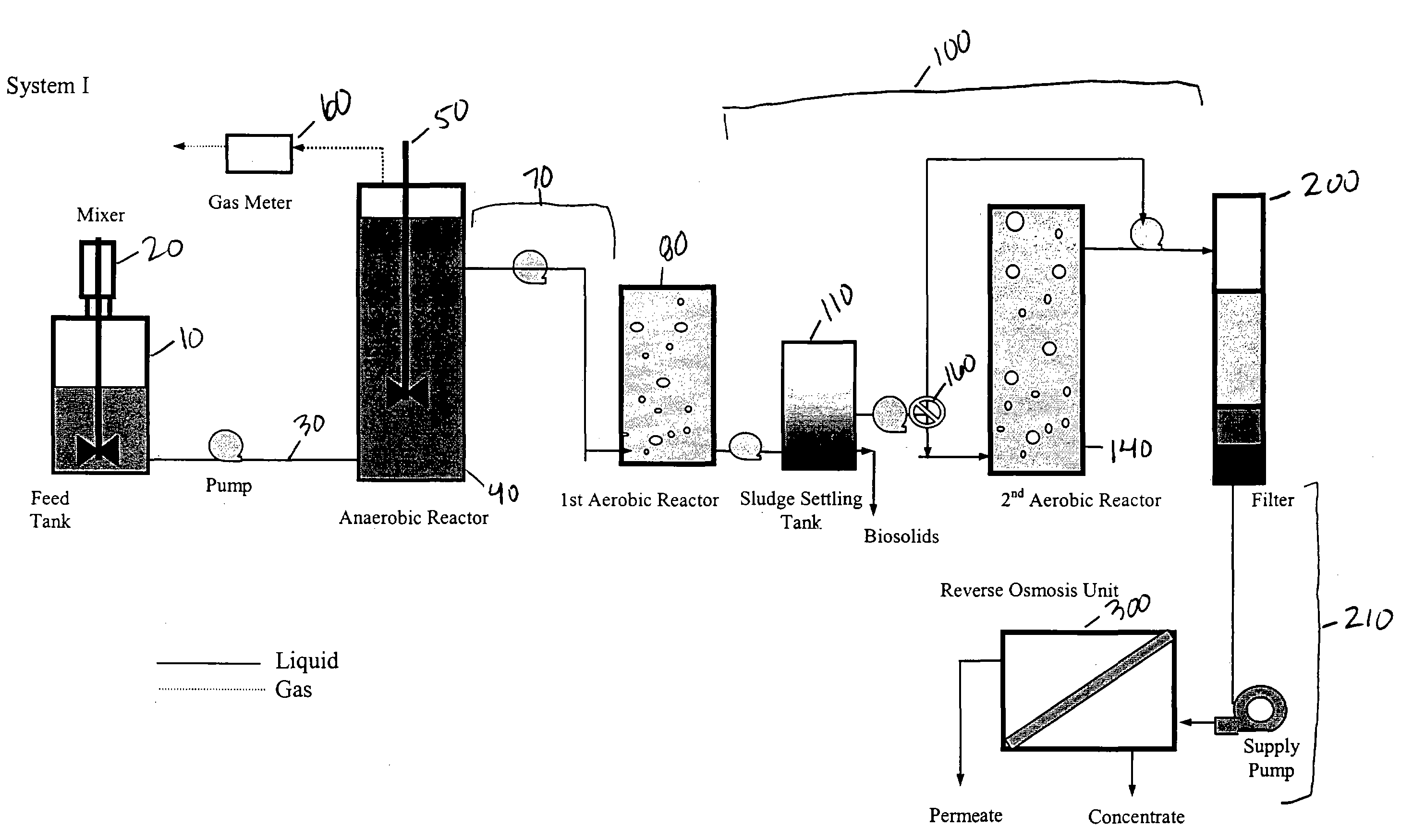

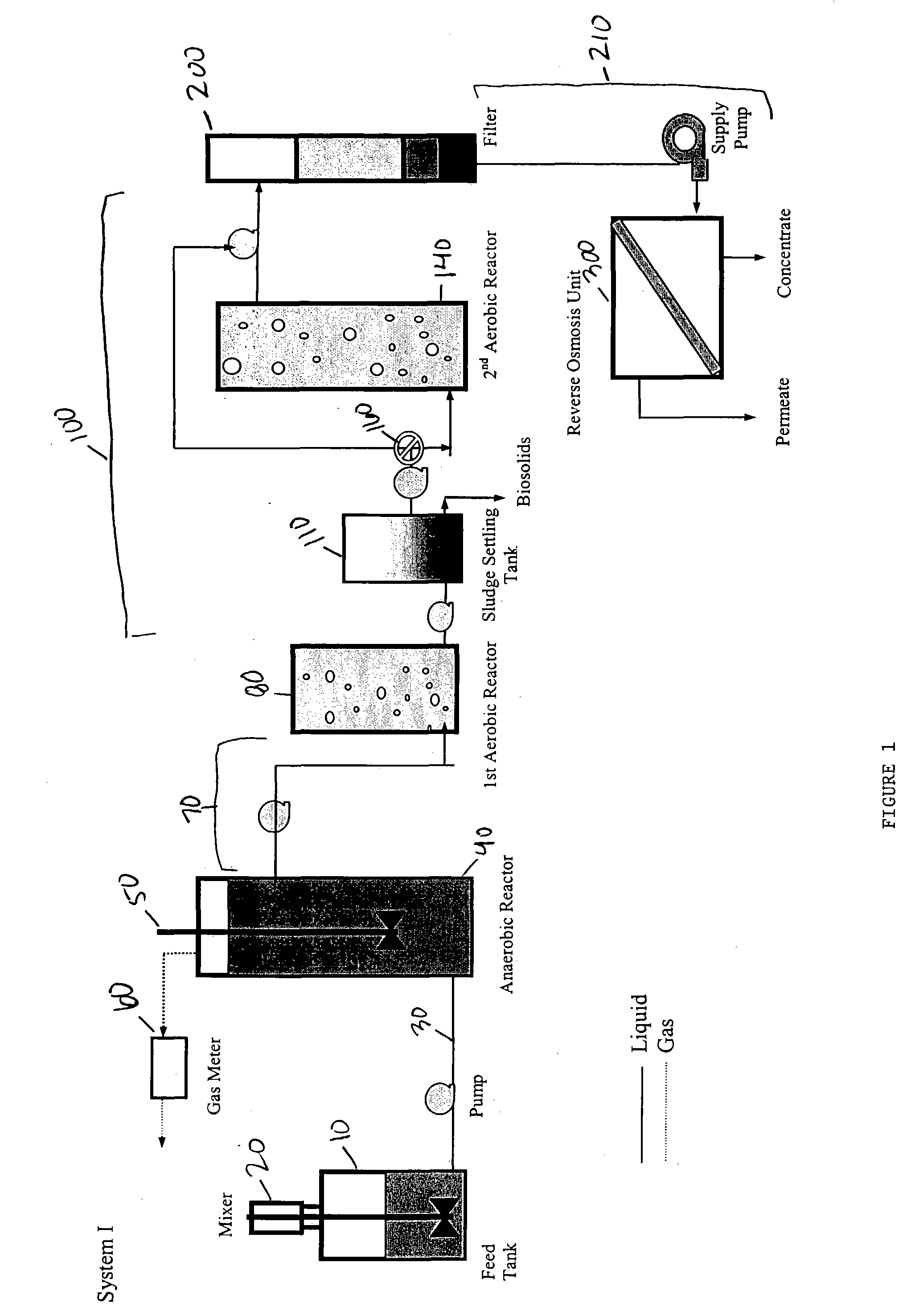

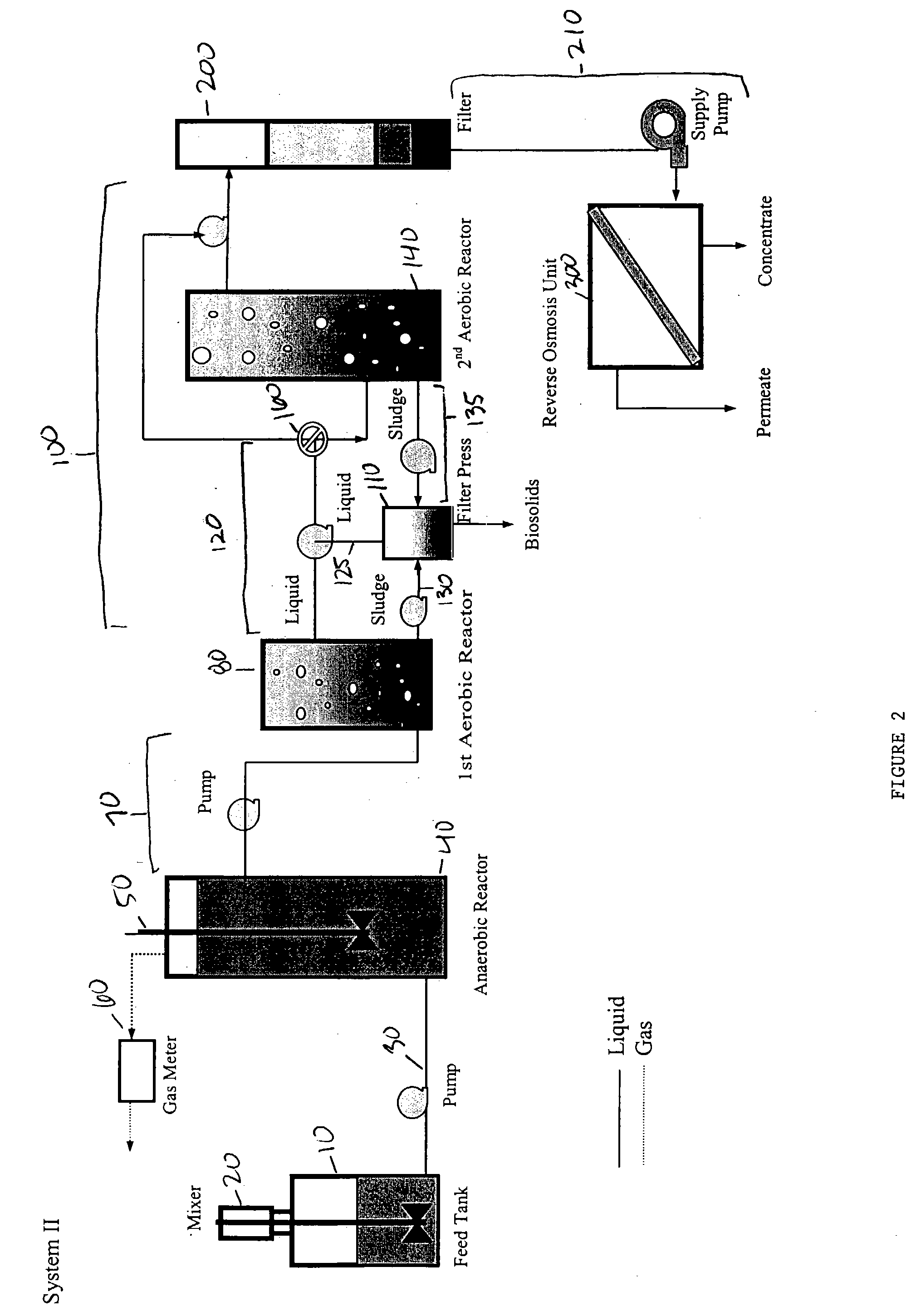

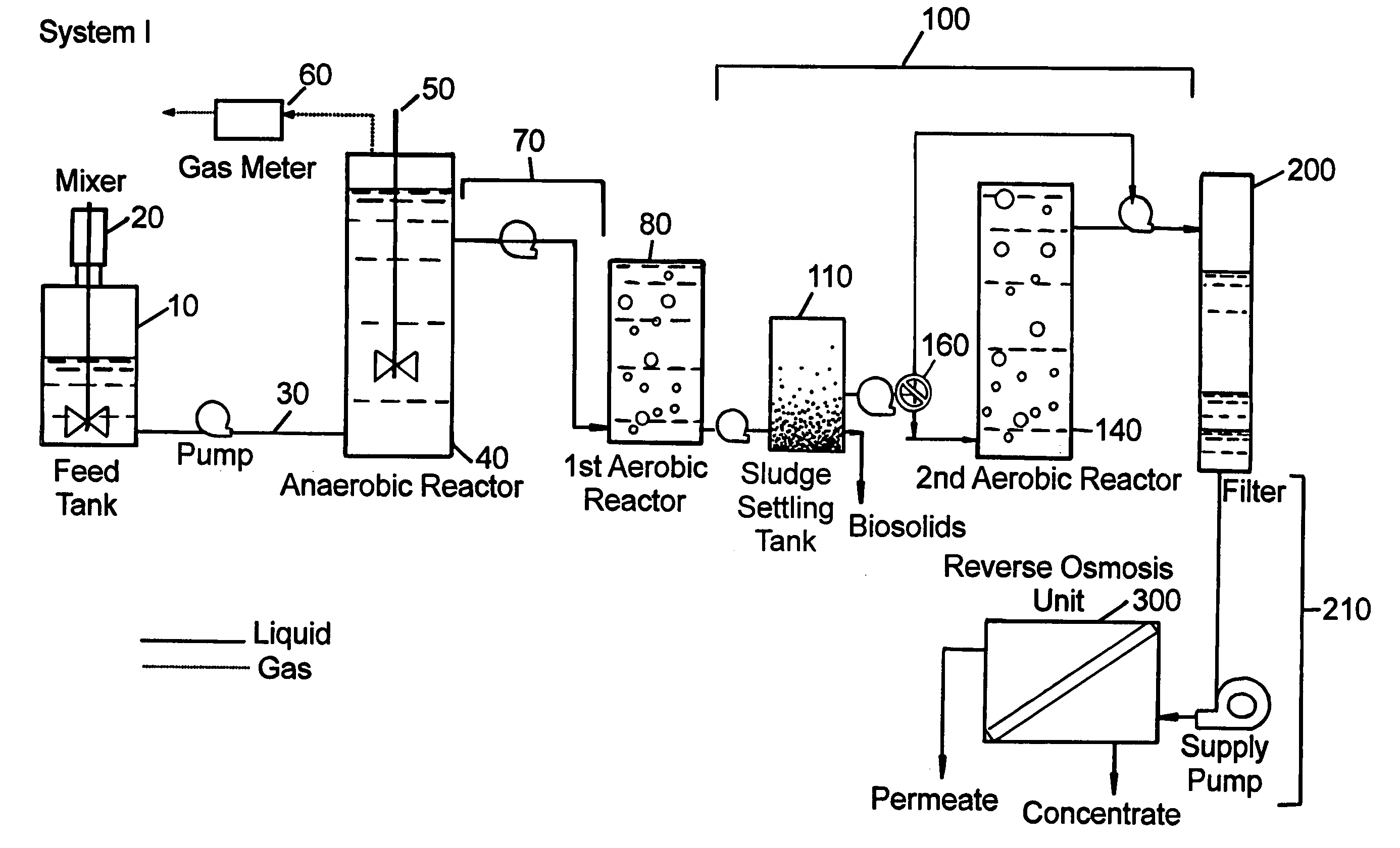

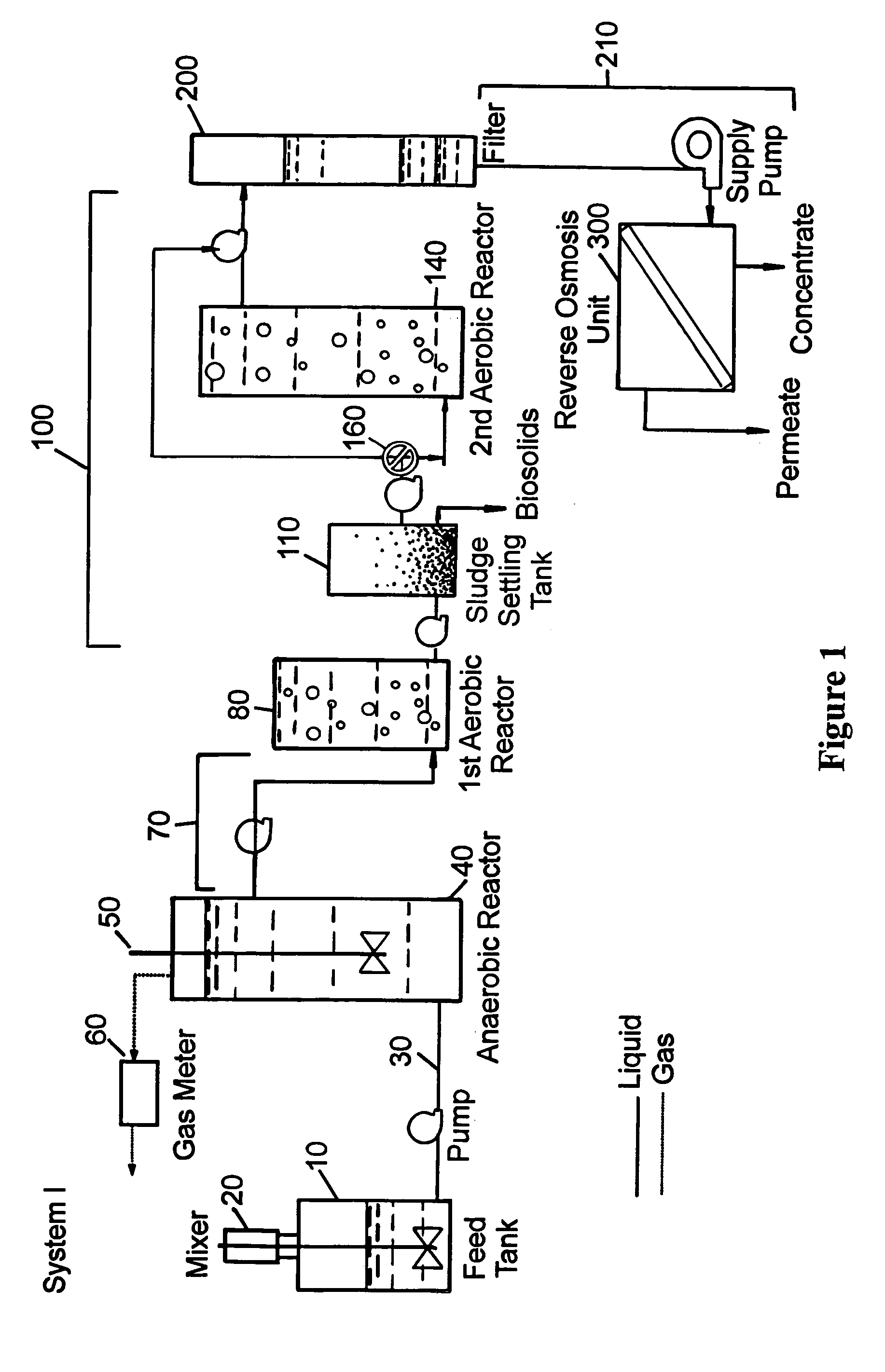

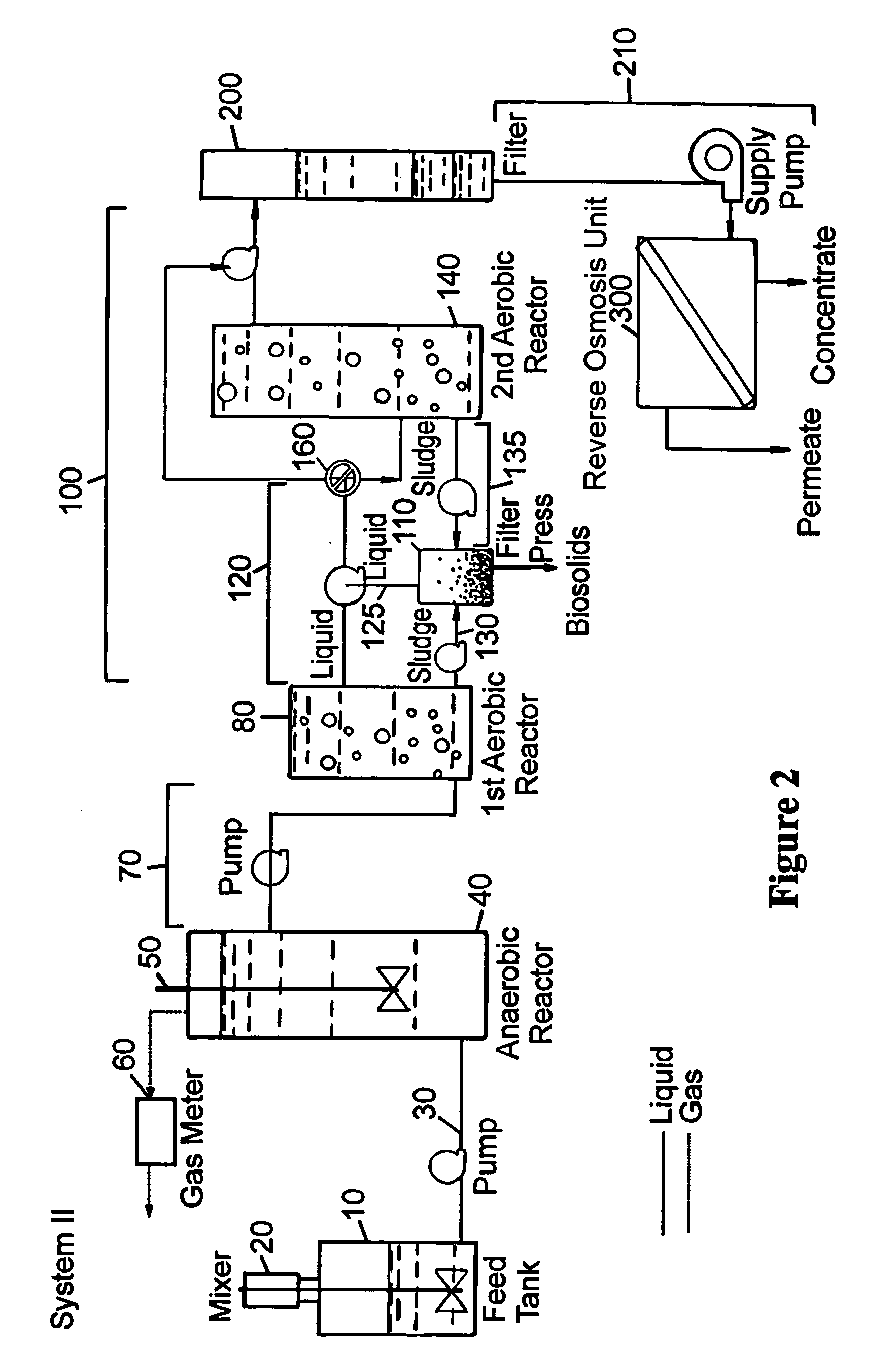

Treatment of swine wastewater by biological and membrane separation technologies

InactiveUS20050035059A1Bio-organic fraction processingWaste water treatment from animal husbandryFiltrationSeparation technology

The present invention provides an integrated system for treatment of biodegradable waste, including sewage sludge, forestry waste, food waste, agricultural waste, municipal waste, and the like. The integrated system comprises an anaerobic reactor, at least one aerobic reactor, a filtration device, and a desalinization device.

Owner:RGT UNIV OF CALIFORNIA

Sludge-based activated carbon and preparation method thereof

The invention relates to a sludge-based activated carbon and a preparation method thereof. In the invention, according to composition of sludge, a certain amount of biomass material (such as corn straw, wheat straw, peanut shell and the like) is appropriately added, mixing to be uniform is carried out, and carbon content of agricultural waste such as crop straw, peanut shell and the like is relatively higher, thus adsorption capacity of the activated carbon is improved (can be improved) when the crop straw and the peanut shell are added into sludge. Activating agent with certain concentration (such as ZnCl2, KOH, KCO3 and the like) is added into the sludge which is mixed to be uniform, impregnating and activating treatment is carried out, and then high temperature activation is carried out, thus the sludge-based activated carbon can be obtained. The sludge-based activated carbon provided by the invention has the advantages of simple process, low cost, and high specific surface area; meanwhile, a way is provided for recycling sludge and treating the agricultural waste, and hazard-free treatment, reduction and reutilization on waste treatment are realized.

Owner:BEIJING UNIV OF TECH

Permeable recycled aggregate and ceramsite concrete doped with industrial and agricultural solid waste and preparation

The invention discloses permeable recycled aggregate and ceramsite concrete doped with industrial and agricultural solid waste and preparation. The permeable recycled aggregate and ceramsite concrete doped with industrial and agricultural solid waste is characterized in that recycled coarse aggregates and ceramsites are taken as coarse aggregates of concrete, an appropriate amount of pretreated industrial and agricultural solid waste such as industrial waste, agricultural waste, household garbage and the like is taken as an admixture, a cementing agent is prepared from cement, water, a superplasticizer and a reinforcement material, and the materials are mixed with a preset stirring process and preparation method, so that ecological concrete with good mechanical property, permeable property and durability is produced. According to the concrete, the waste utilization rate is up to about 80%, the concrete is environment-friendly, locally available materials can be used, the economic benefit is remarkable, ceramist pore is smaller, and sewage can be continuously and stably treated, so that the concrete is commonly used in water environment comprehensive improvement engineering; and besides, the concrete has light weight, high strength and good water permeability and can be also used in permeable pavement engineering such as a sidewalk, a parking lot and the like as well as plant engineering such as ecological riverway slope protection, roof landscape planting and the like.

Owner:YANGZHOU UNIV

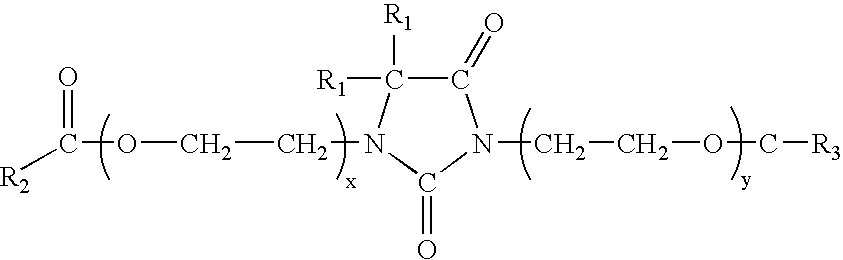

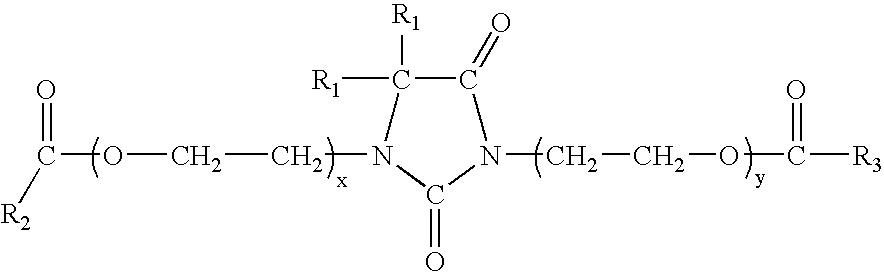

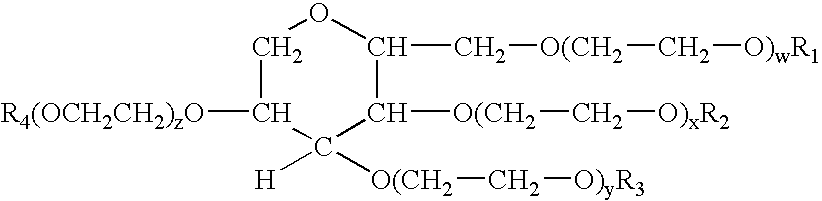

Non-wood fiber plastic composites

This invention is directed to an extrudable compound, an extrusion method using a polymer, a cellulosic fiber, and at least one lubricant selected from the group consisting of ethoxylated esters of hydantoins, ethoxylated esters of sorbitol and sorbitan, and ethylene bisamides made from fatty acids containing 6-10 carbons and composites manufactured through such processes which simulate conventional wood products. Another embodiment of the invention is directed to a composition containing polymer, a cellulosic fiber from an agricultural waste product and a lubricant containing a mixture of an alkylene bisamide derived from a C10-C18 is fatty acid and an alkaline earth salt of a fatty acid.

Owner:ARXADA LLC

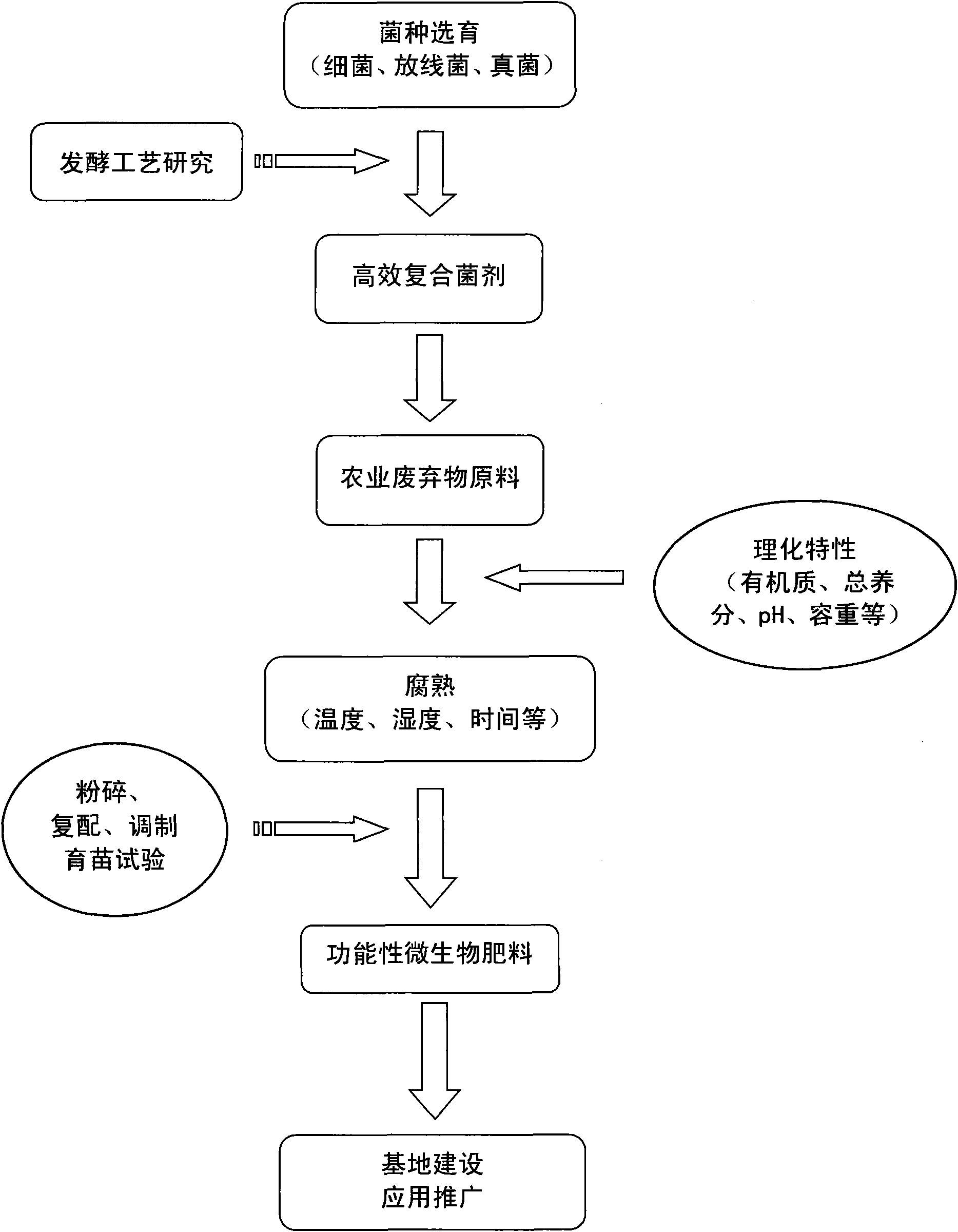

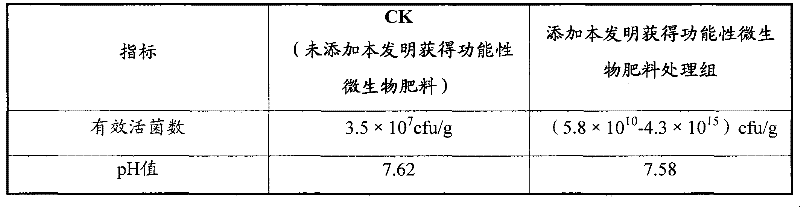

Functional microbial fertilizer production by utilizing agricultural wastes

InactiveCN101665374ASuitable physical and chemical propertiesPromote fermentation and maturityFungiBio-organic fraction processingBacillus licheniformisBiotechnology

The invention discloses a functional microbial fertilizer and a production method thereof. The production method comprises the following steps: grinding 60%-70% of mushroom residue and 15%-25% of livestock manure to 2-3mm to obtain the major material by a grinder, regulating water content to be 60%-65%; adding composite fermenting agent consisting of bacillus subtilis, bacillus licheniformis, trichoderma harzianum and trichoderma viride in accordance with 50g-100g / T; stacking, fermenting and maturing for 15-30d, and turning 5-10 times during the process; evenly mixing the major material prepared from fermentation with auxiliary materials consisting of 6%-10% humic acid and 6%-10% rice hull; adding arbuscular mycorrhiza agent in accordance with 50g-100g / T; and sieving with a 3mm sieve to obtain the fertilizer. The invention provides an economic and effective technological approach for the resource recycling of agricultural wastes in China, and has important application prospect on promoting the development of green agriculture, controlling and reducing rural environmental pollution, improving rural eco-environment and other aspects.

Owner:THE INST OF MICROBIOLOGY XINJIANG ACADEMY OF AGRI SCI

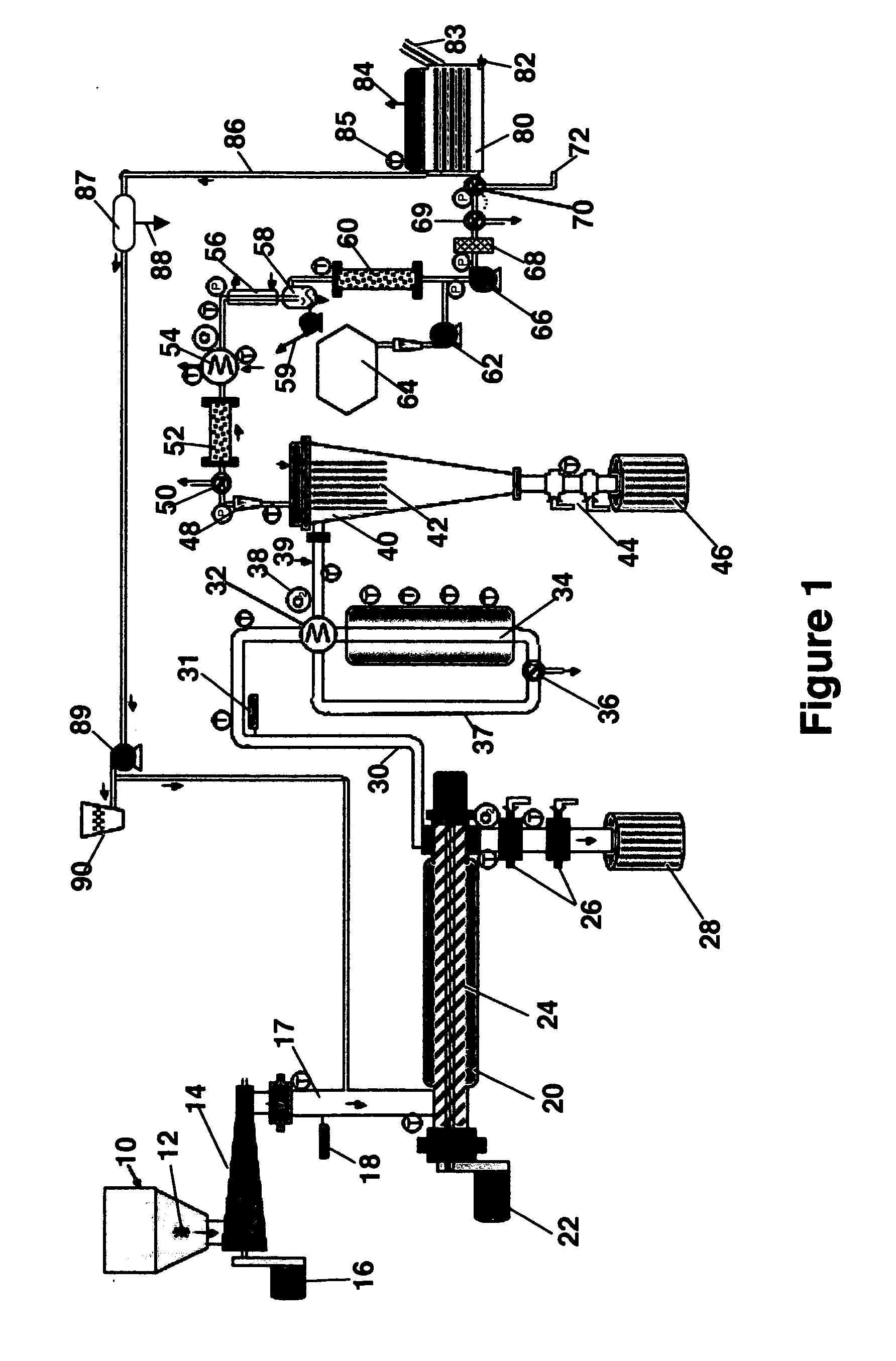

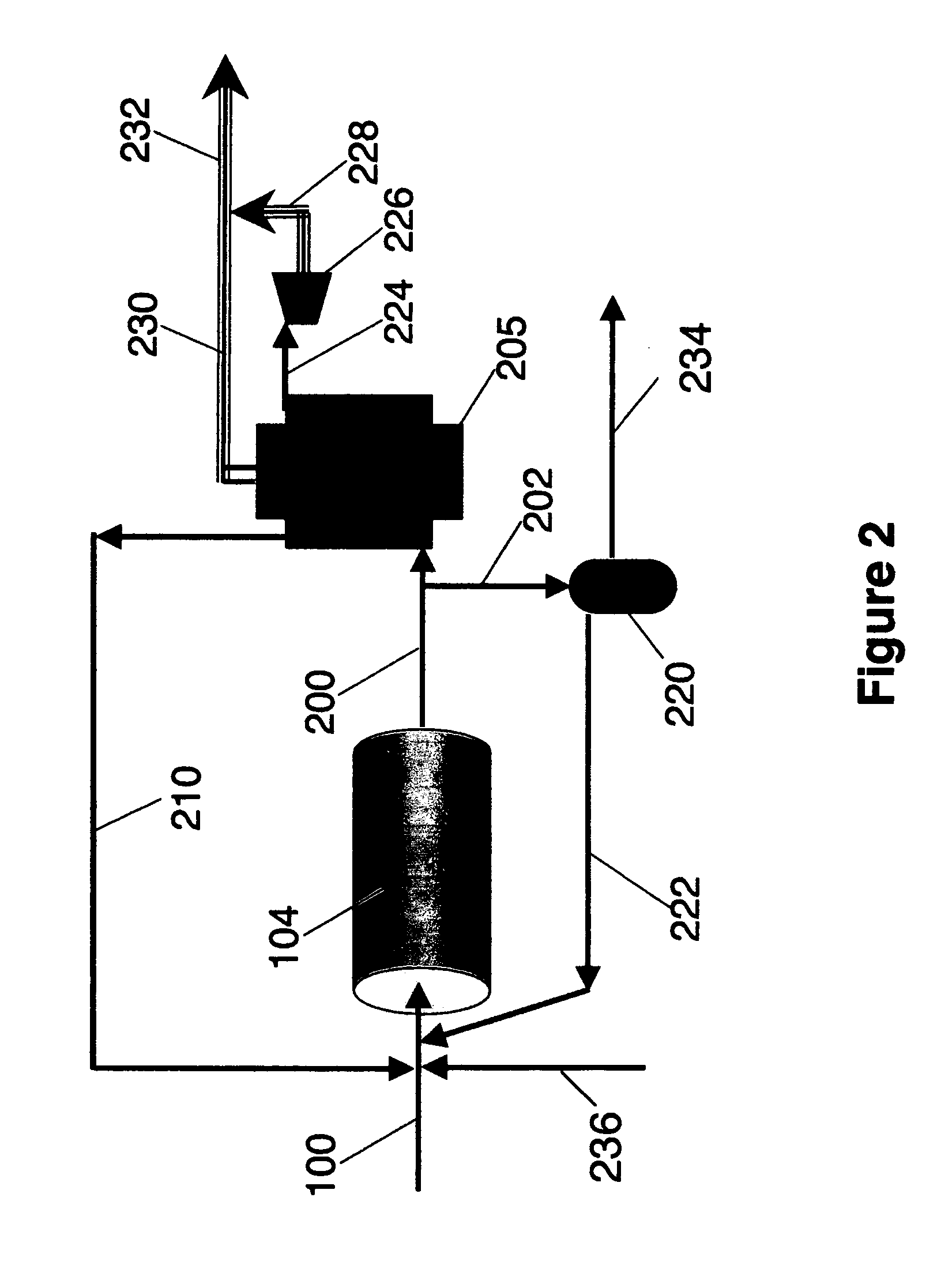

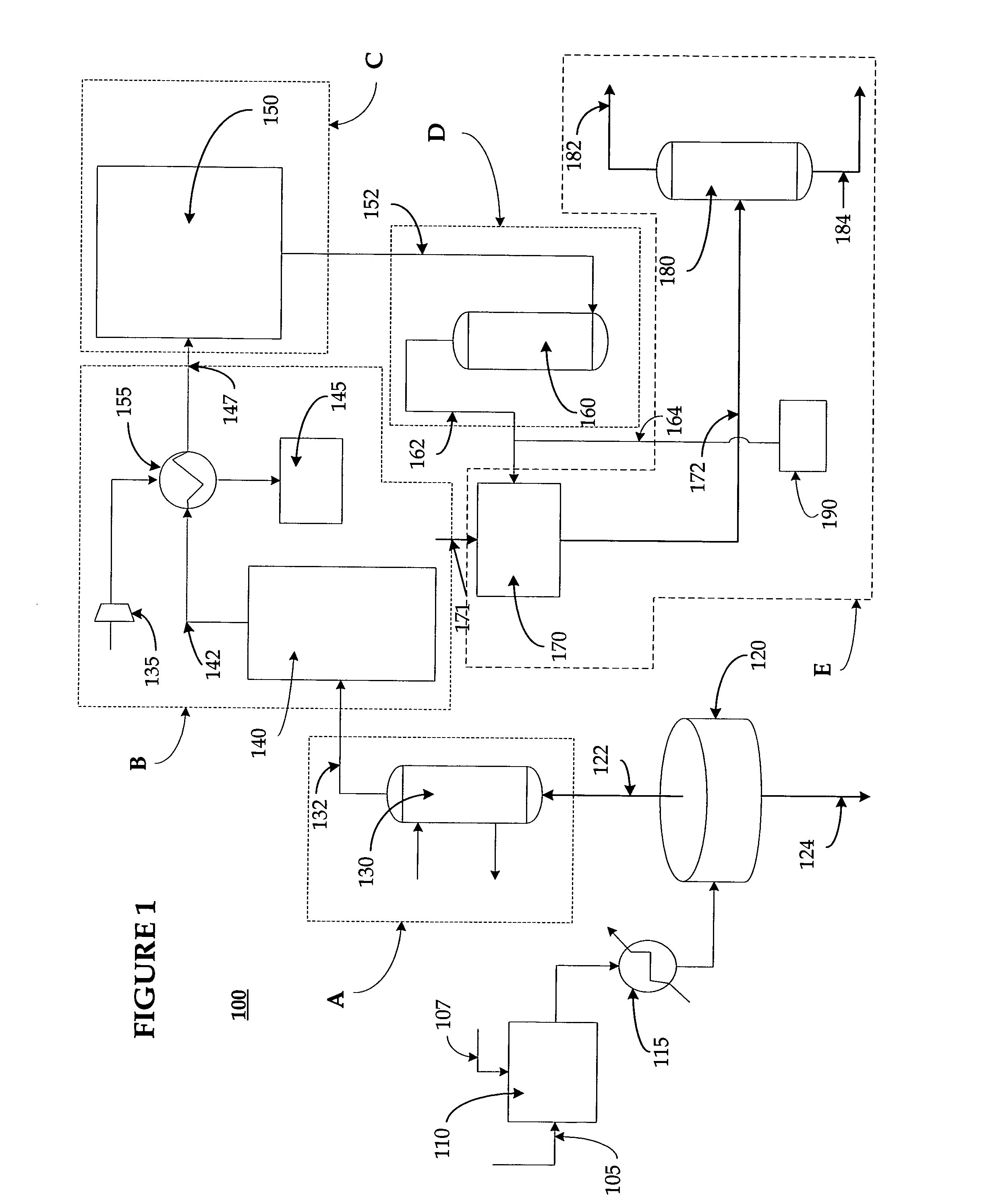

System and method for extracting energy from agricultural waste

InactiveUS20050113467A1Reduce decreaseMinimize negative impactBioreactor/fermenter combinationsBio-organic fraction processingSyngasBiodiesel

The present invention relates to a process and apparatus for processing agricultural waste to make alcohol and / or biodiesel. The agricultural wastes are subjected to anaerobic digestion which produces a biogas stream containing methane, which is subsequently reformed to a syngas containing carbon monoxide and hydrogen. The syngas is converted to an alcohol which may be stored, sold, used, or fed directly to a reactor for production of biodiesel. The solids effluent from the anaerobic digester can be further utilized as slow release, organic certified fertilizer. Additionally, the wastewater from the process is acceptable for immediate reuse in agricultural operations.

Owner:BEST BIOFUELS LLC

Biochar base soil modifier and preparation method thereof

ActiveCN102660291AReduce leaching wasteGood sustained release effectAgriculture tools and machinesOrganic fertilisersDecompositionCarbonization

The invention discloses a biochar base soil modifier and a preparation method thereof. The biochar base soil modifier comprises the following components in percentage by weight: 95.5-98.5% of biomass carbon black and 1.5-4.5% of probiotics agent. Agricultural waste serves as a biomass raw material to carry out low-temperature carbonization to form the porous biomass carbon black; beneficial microorganism is enlarged and cultivated and is fermented into probiotics liquid; after mixing, solid and liquid separation, flash evaporation and drying are carried out to obtain the probiotics agent; the beneficial microorganism is selected from one or more of paenibacillus polymyxa, trichoderma strains, nitrogen-fixing bacteria, rhizobium, phosphate solubilizing bacteria, potassium bacteria, cellulose decomposition bacteria, antibiotic generation bacteria and photosynthetic bacteria. The biochar base soil modifier disclosed by the invention adopts the microporous biomass carbon which has strong adsorption capability and good light absorption and temperature-increasing effect. The probiotics agent has a high survival rate and can be stored for a long time at the normal temperature, the fertilizer synergy action is obvious, and the soil borne disease can be effectively prevented and cured.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI +2

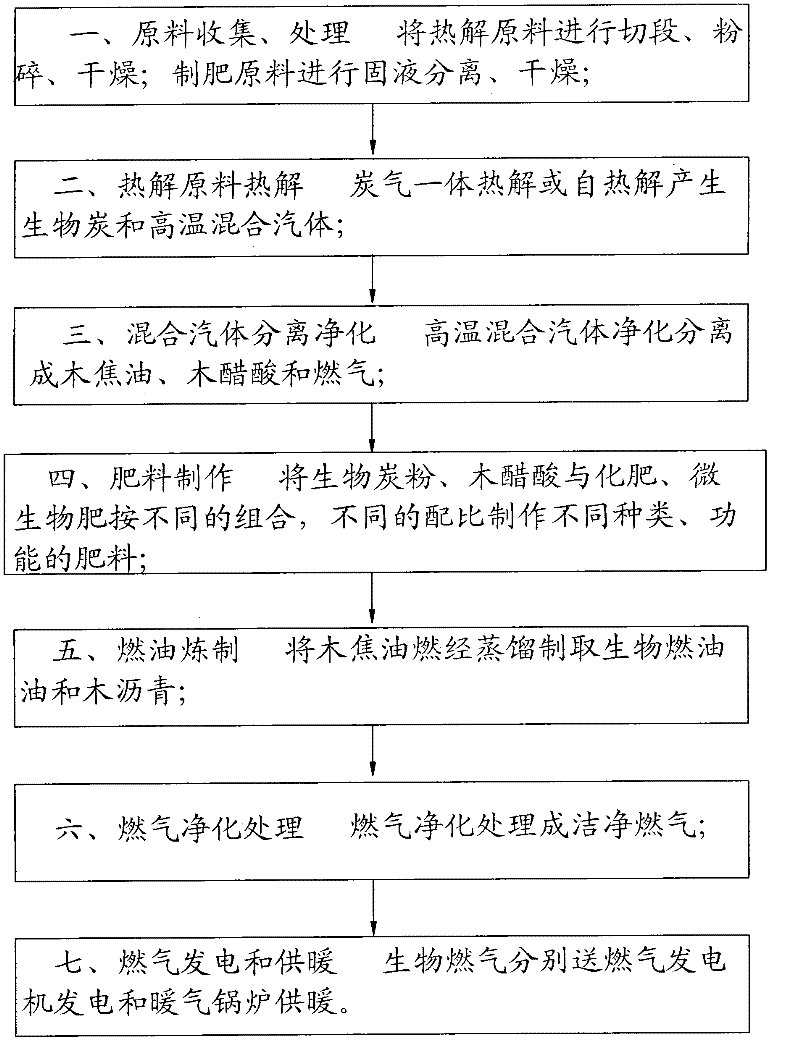

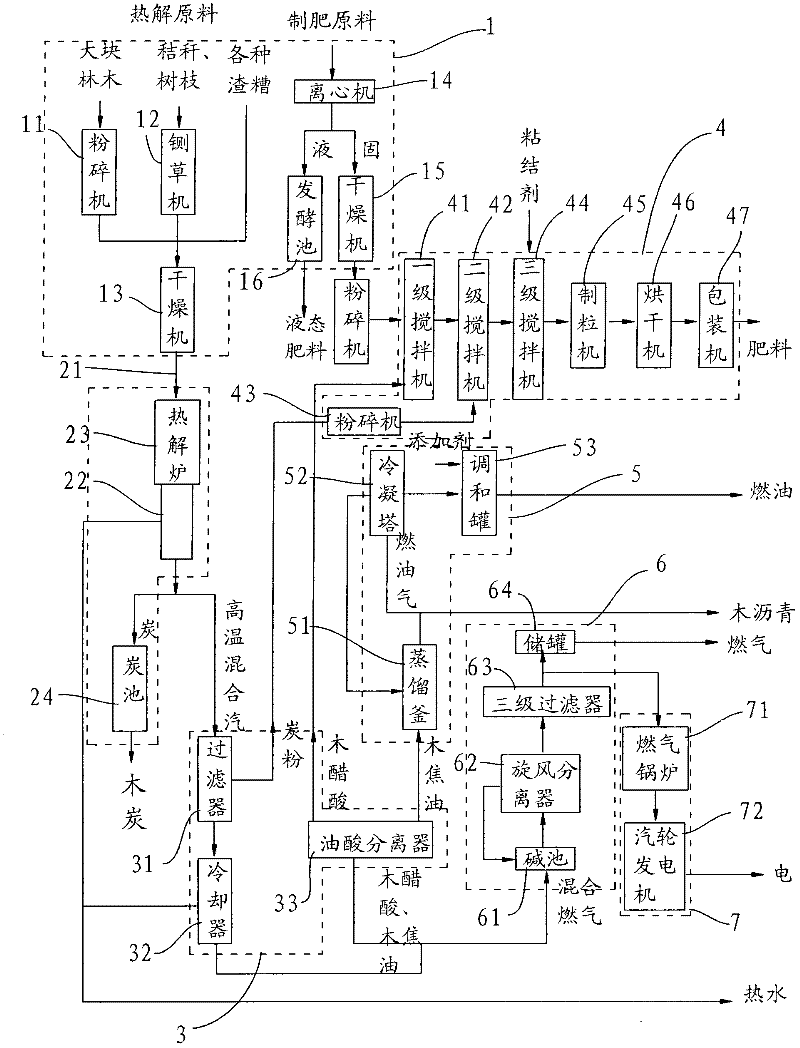

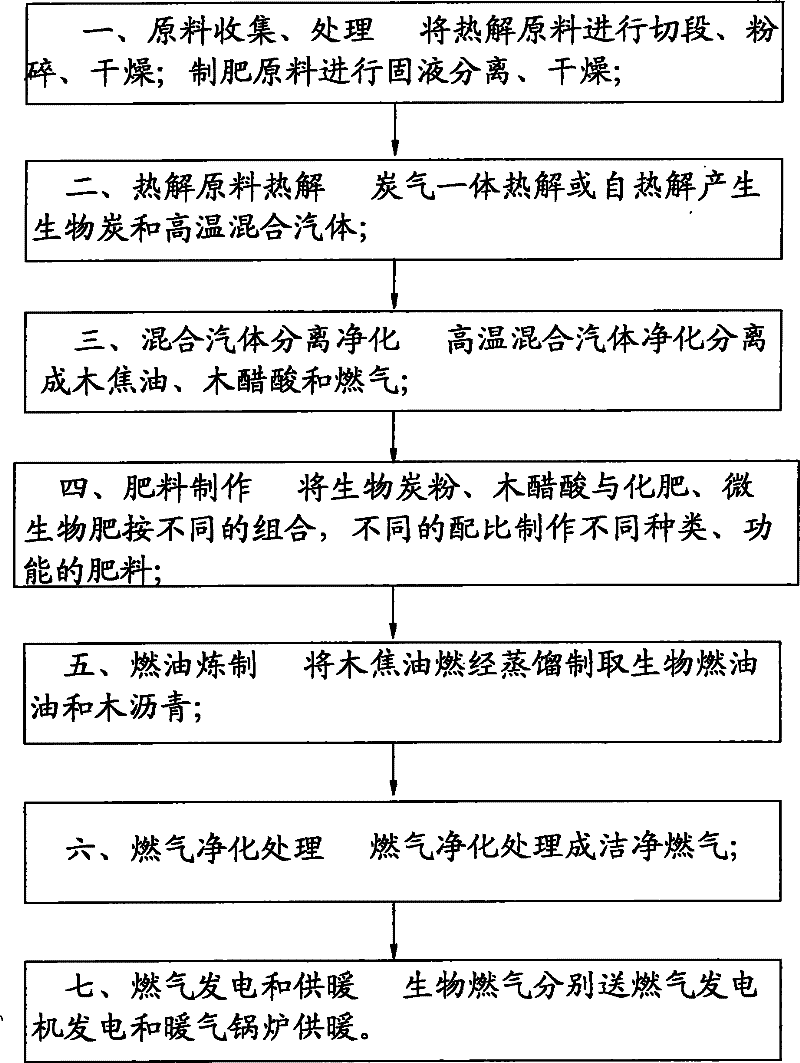

Integrated converting and utilizing co-production method for agricultural waste

InactiveCN102476129AWidely used valueAvoid secondary pollutionSolid waste disposalBiofuelsBiofuelFuel oil

The invention relates to an integrated utilizing technology for agricultural waste and in particular relates to an integrated converting and utilizing co-production method for agricultural waste. The integrated converting and utilizing co-production method comprises the following steps: 1. collecting and processing raw materials; 2. carrying out pyrolysis on the raw materials: generating biochar and high-temperature mixed gas; 3. converting the high-temperature mixed gas: converting the high-temperature mixed gas into wood tar, wood vinegar and fuel gas; 4. manufacturing fertilizers; 5. refining fuel oil: converting the wood tar into biofuel oil and wood pitch; 6. purifying the fuel gas: purifying the fuel gas into clean fuel gas; and 7. converting the fuel gas: respectively sending the biofuel gas into a gas generator, a gas supply pipe network and a heat boiler to covert the biofuel gas into heat energy and electricity energy. The agricultural waste can be converted by multiple levels and are combined to be utilized to obtain straw carbon, fuel gas, heat energy, electricity energy, fertilizers, fuel gas and the like. The use ratio of the agricultural waste reaches 100%. The problem that the agricultural waste is stacked and burnt disorderly can be solved, the pollution problem caused by using chemical fertilizers and pesticides for a long time can be solved, and the problem of utilizing energy, fertilizer and oil in rural areas also can be solved.

Owner:周仁福 +2

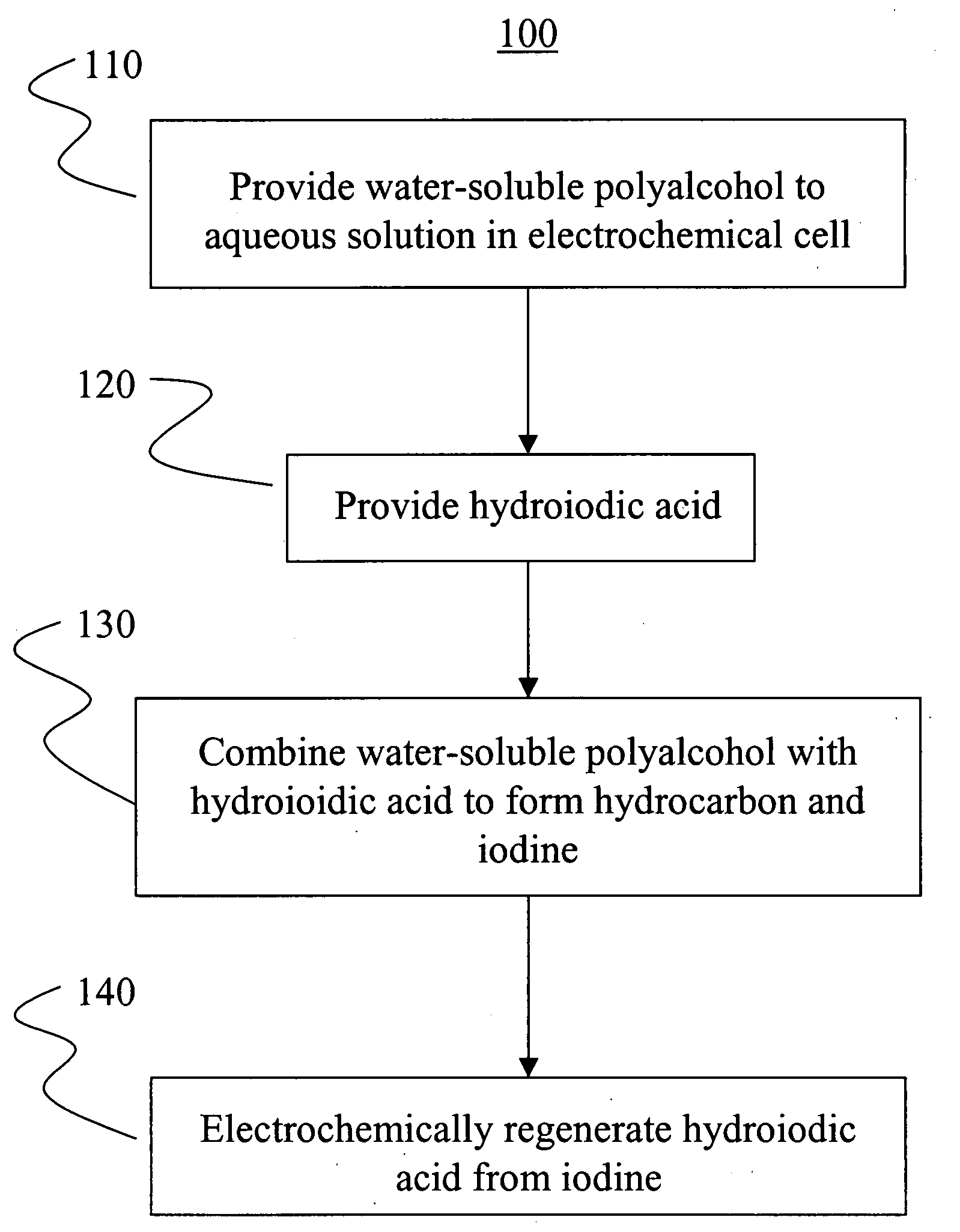

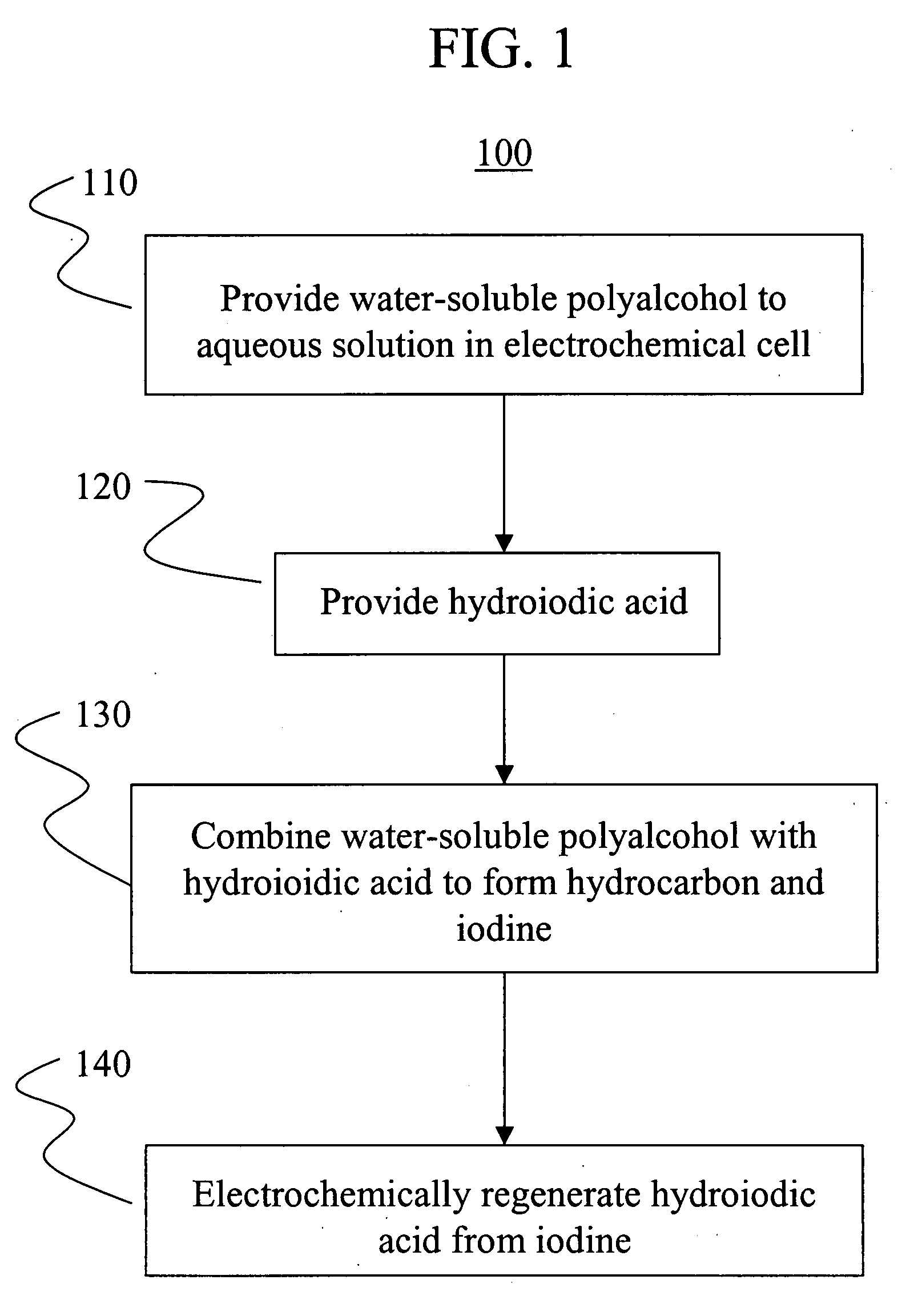

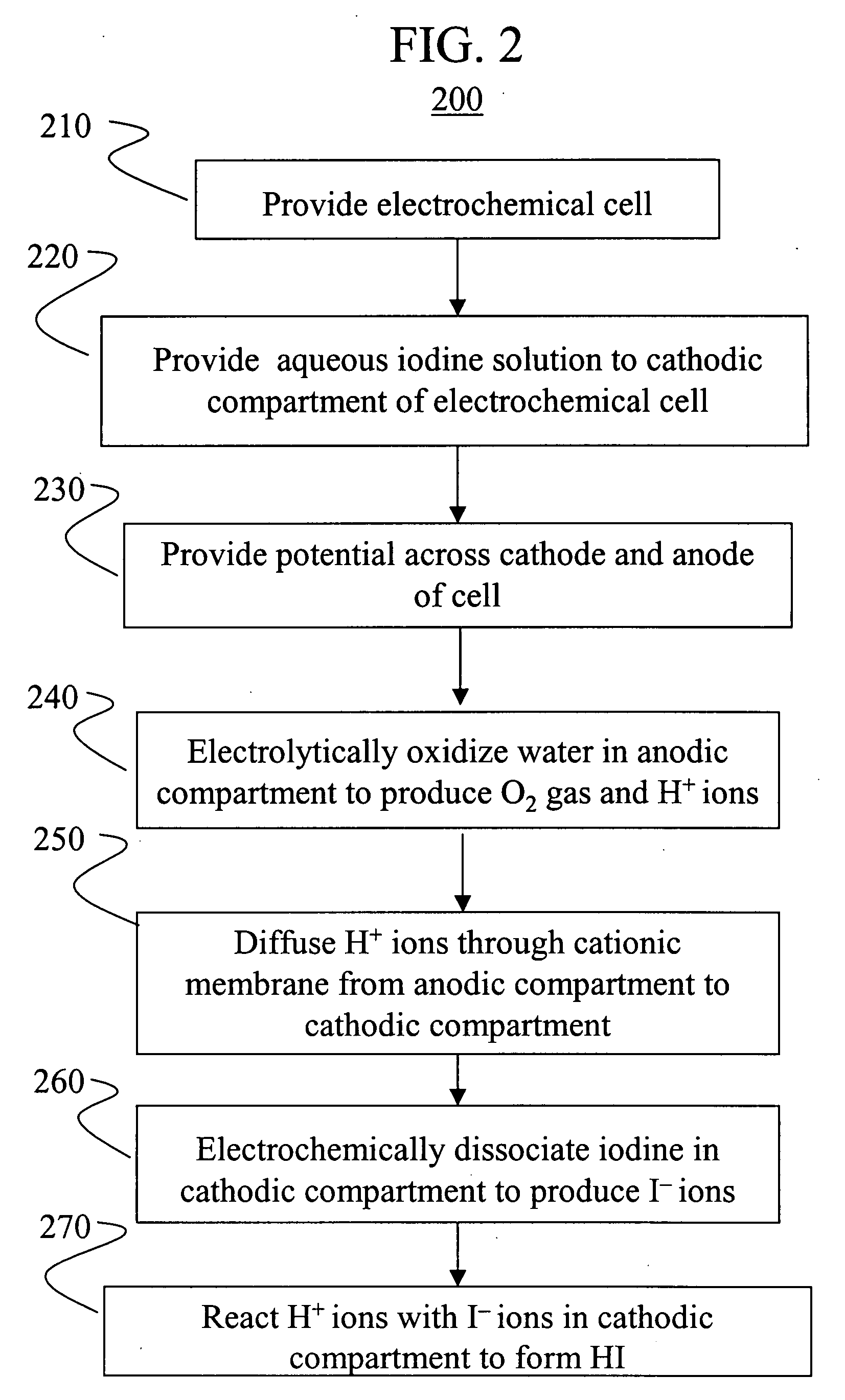

Electrochemical conversion of polyalcohols to hydrocarbons

A method of making hydrocarbons from polyalcohols, such as carbohydrates. The polyalcohols and carbohydrates may be provided from biomass, including paper, cardboard or urban generated paper product waste; wood and wood products, including forest slash and deadfall; agricultural waste; and the like. The polyalcohols and carbohydrates are combined with hydroiodic acid in aqueous solution to form the hydrocarbon and elemental iodine. Hydroiodic acid is then electrochemically regenerated by reducing the elemental iodine in a parallel reaction. A method of electrochemically generating hydroiodic acid from elemental iodine in aqueous solution is also described.

Owner:RGT UNIV OF CALIFORNIA

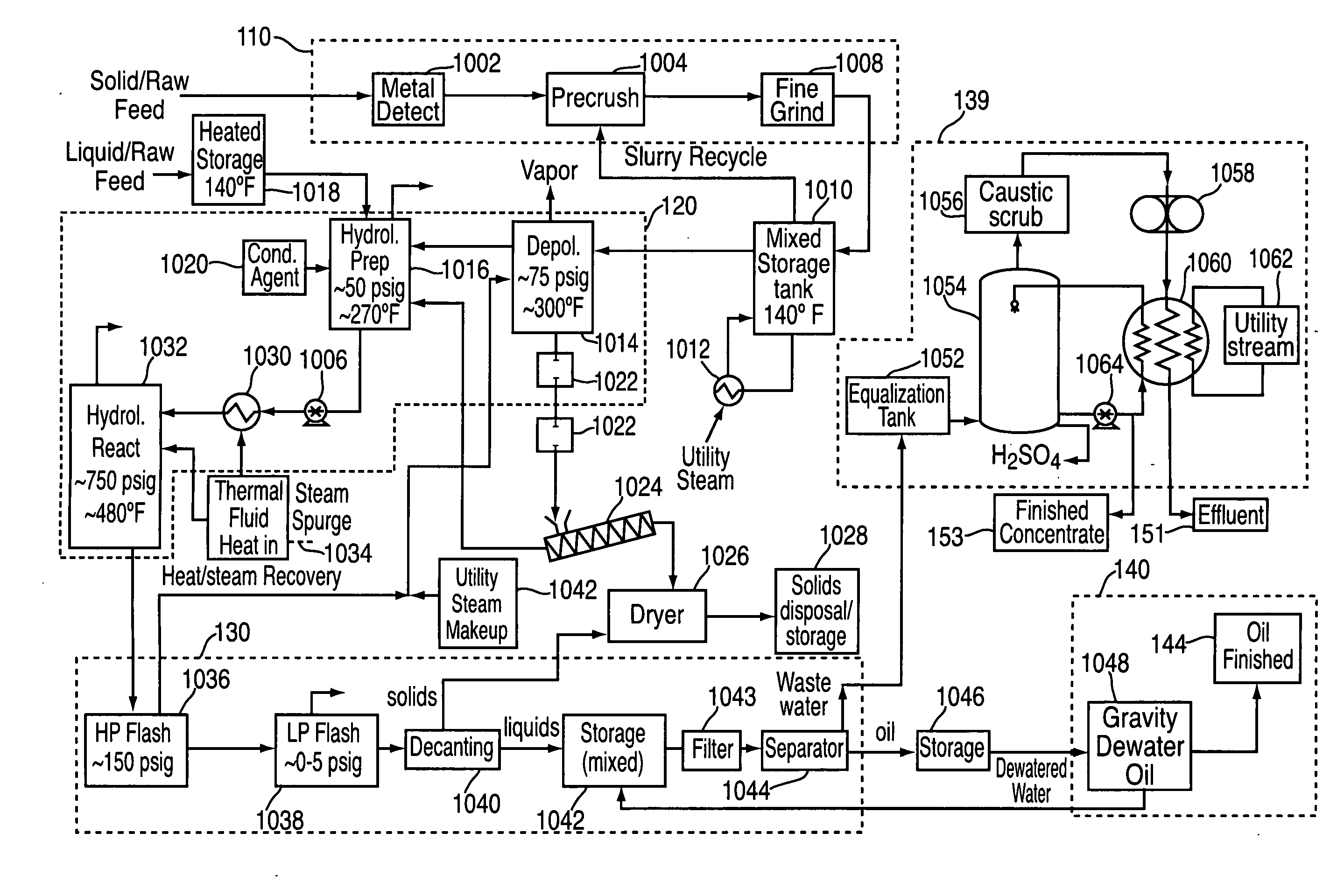

Concentrated sulfuric acid hydrolysis of lignocellulosics

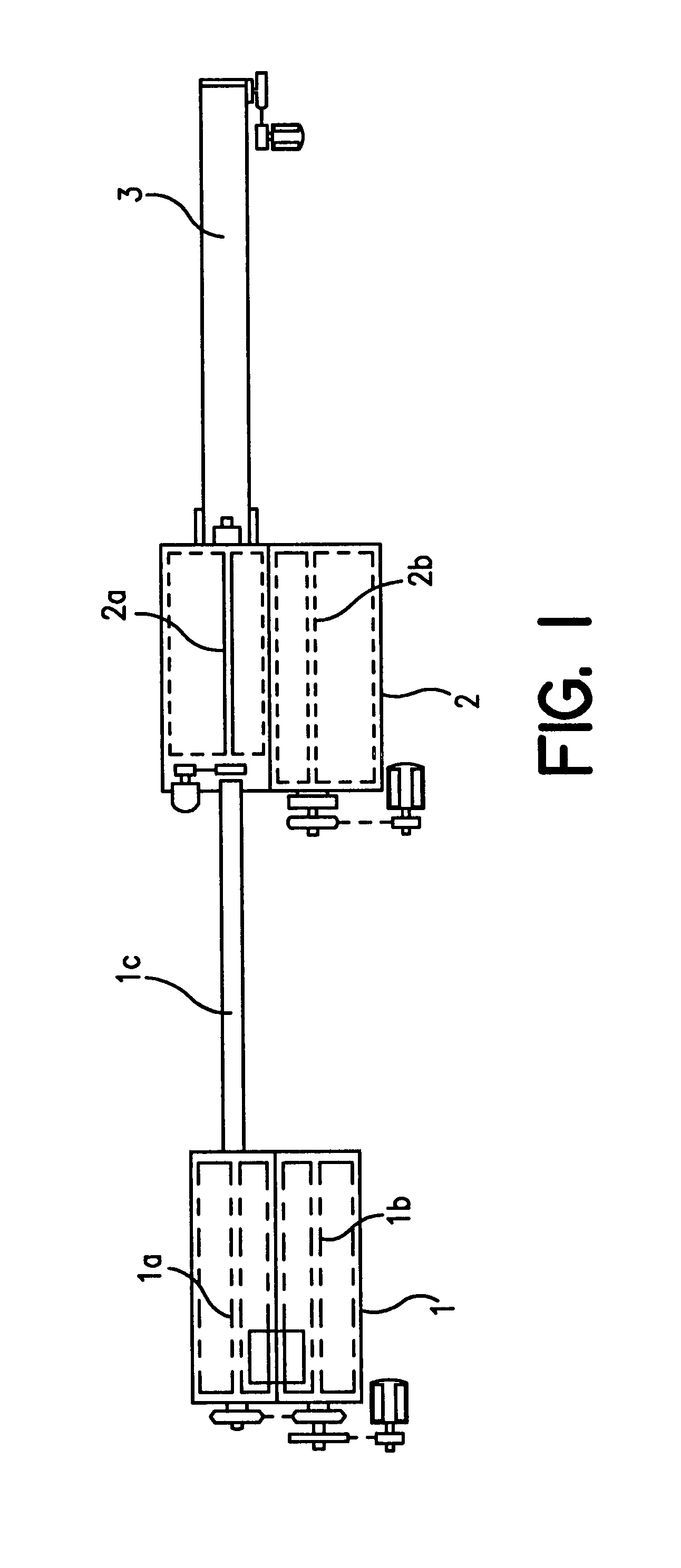

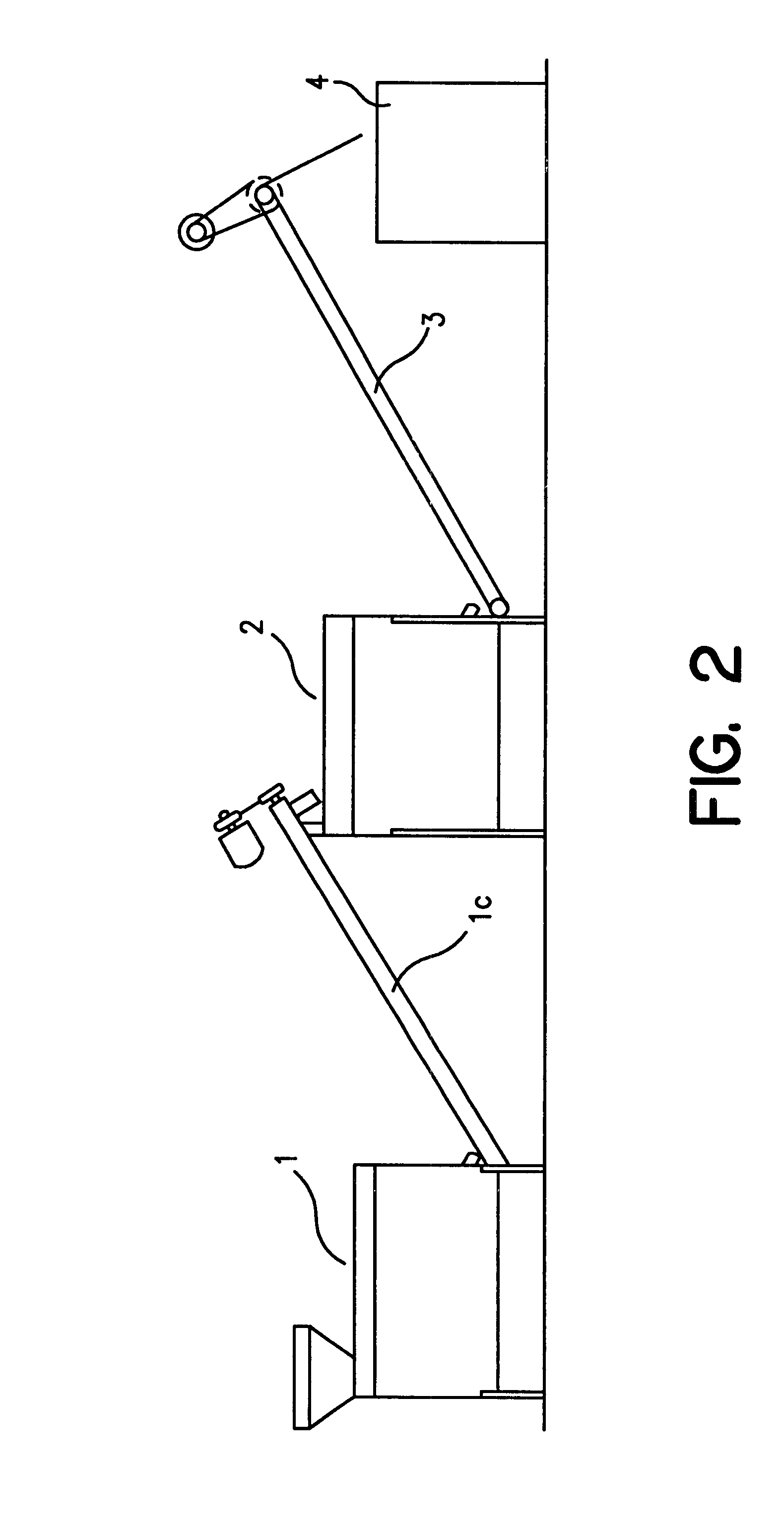

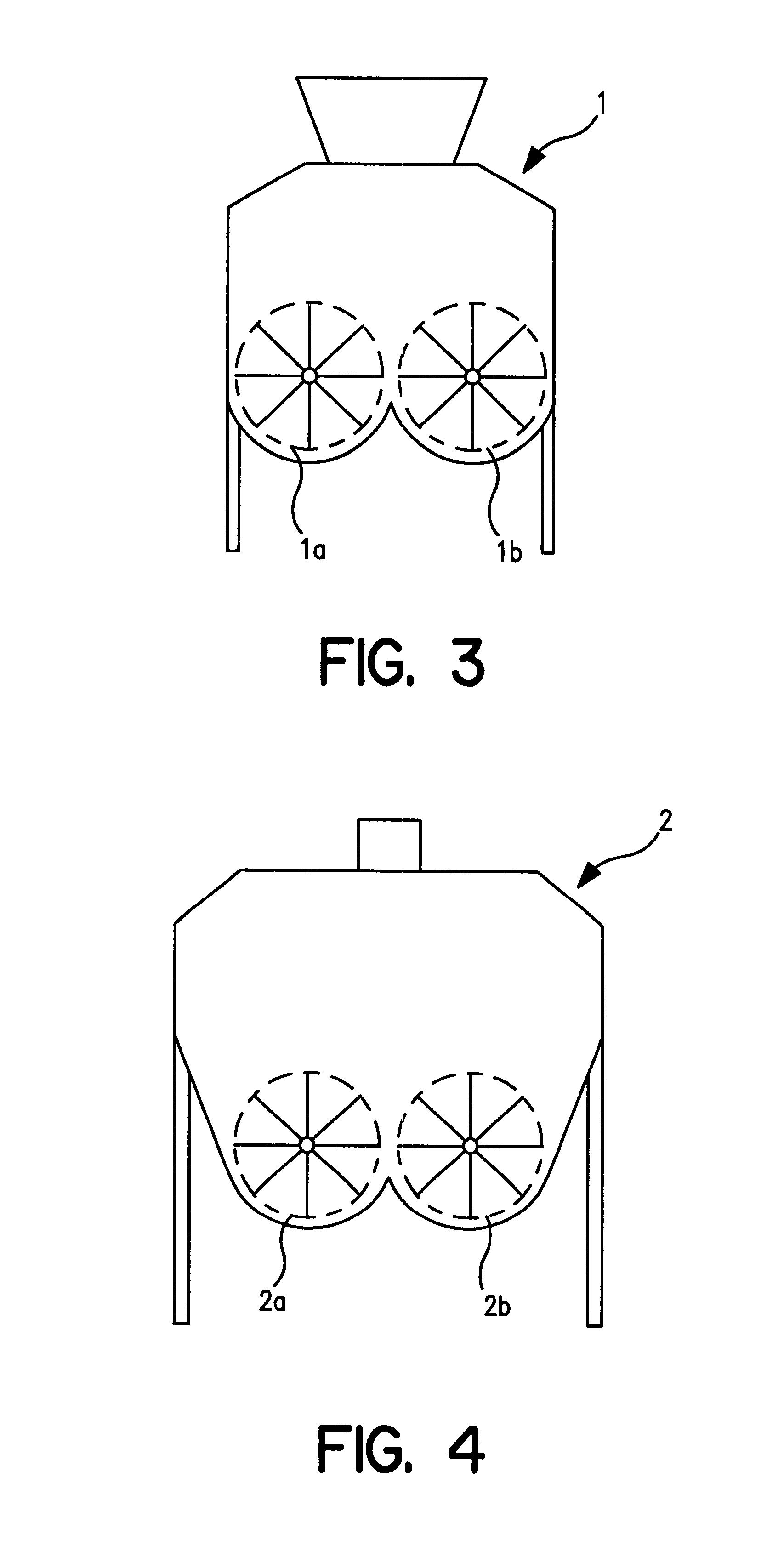

InactiveUS6063204AMinimize and preclude potential backflowEliminate requirementsPressurized chemical processOther chemical processesUnit operationFermentable sugar

A process, system, and apparatus for effectively and economically producing fermentable sugars from cellulosic feedstocks is described. The economic viability of using wood and / or agricultural waste, containing large fractions of cellulose and hemicellulose is highly dependent on the method used for hydrolysis. Underlying the gist of this invention are newly discovered methods, means, and techniques by which both the pentosans and hexosans comprising the hemicellulose fraction of the selected feedstock and the hexosans comprising the cellulose fraction of the selected feedstock can be quickly and efficiently converted in a single pass through a single device to fermentable sugars containing minimal quantities of degradation products known to inhibit fermentation. Successful operation of this new hydrolysis process employing a new reactor design can produce fermentable sugars at rates and efficiencies previously thought unattainable by reducing the number of processing steps, pieces of equipment, and unit operation previously used.

Owner:FARINA GEORGE E

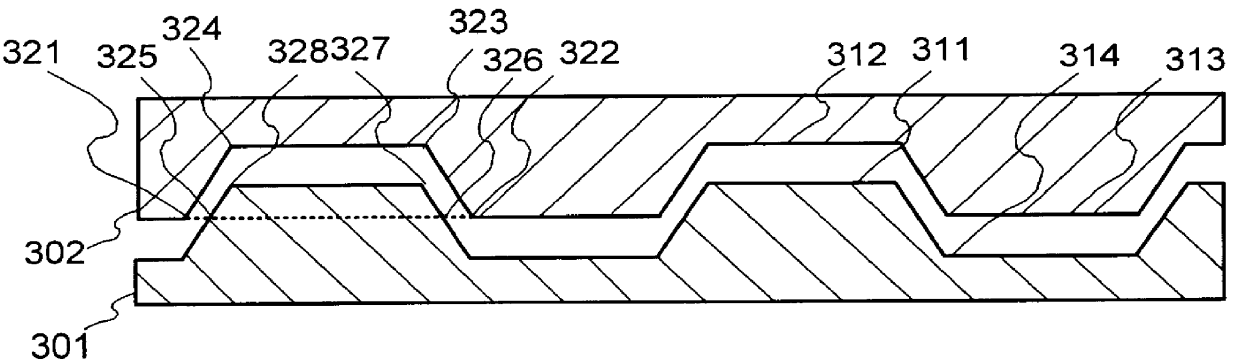

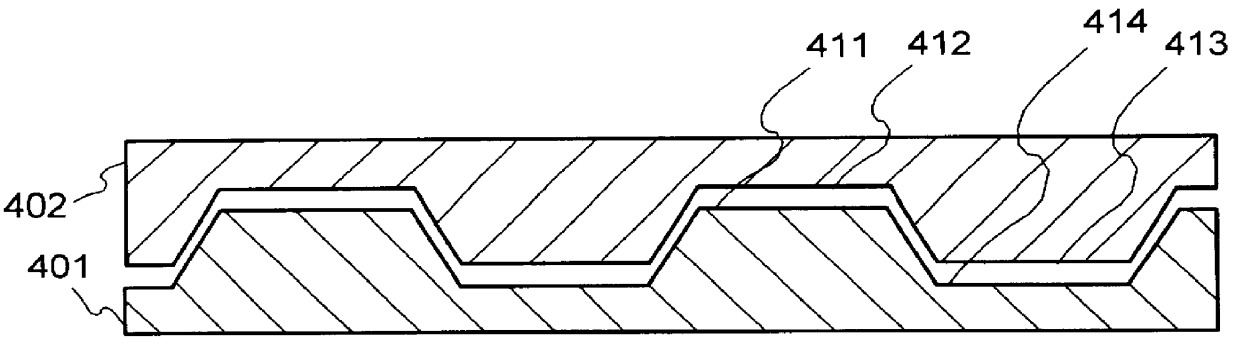

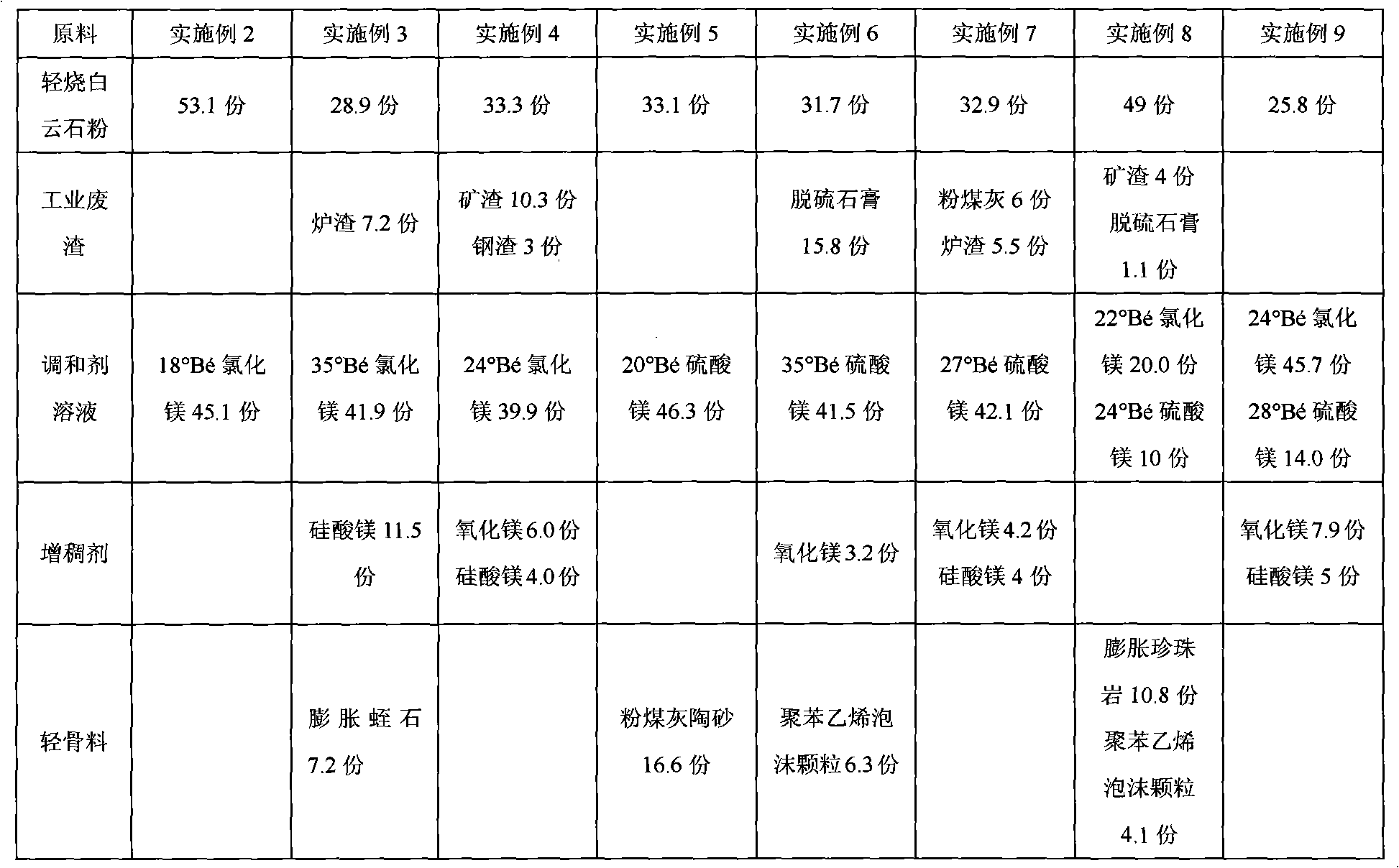

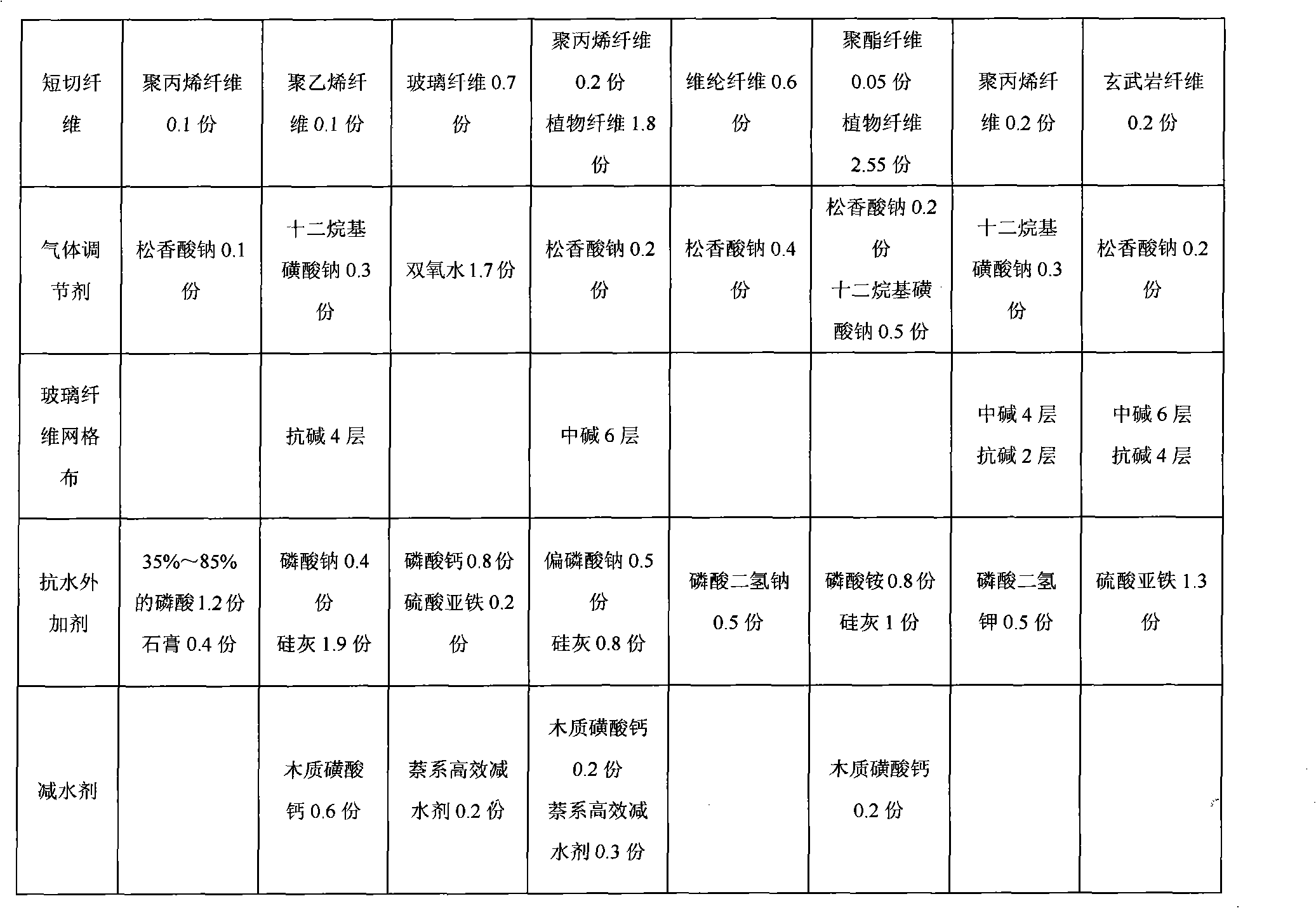

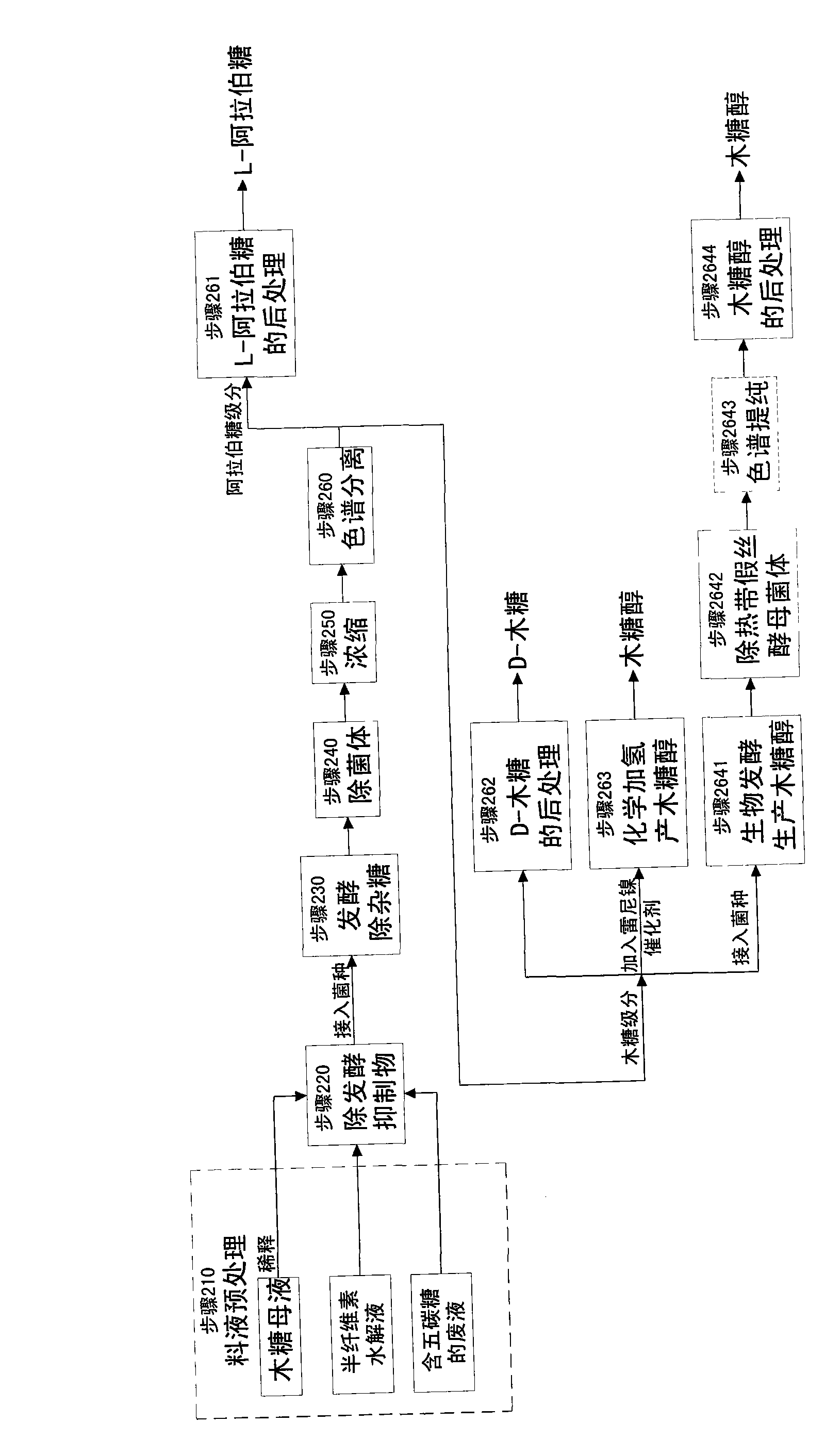

Light-burned dolomite foam light partition board

InactiveCN102070353ACuring reaction at room temperatureHarden fastSolid waste managementCeramicwareFiberMoisture absorption

The invention relates to a light-burned dolomite foam light partition board, which comprises the following components in part by weight: 20 to 55 parts of light-burned dolomite powder, 30 to 85 parts of conditioner solution, 0.1 to 5 parts of chopped fibers, 0.01 to 8 parts of gas regulator, 0.01 to 8 parts of water-resistant admixture, 1 to 60 parts of industrial waste residues, 1 to 30 parts of thickener, 1 to 35 parts of lightweight aggregate, 1 to 16 layers of glass fiber mesh fabrics and 0.1 to 1 part of water reducing agent. The foam light partition board has the advantages of no steam curing or autoclave curing, normal temperature quick reaction and curing, high strength and water resistance, no moisture absorption or halogenation, no scumming, freezing resistance, sound insulation, thermal insulation, heat preservation, flame retardance, utilization of a large number of industrial waste residues and agricultural wastes, resource and energy saving, no emission of waste gas, waste water and waste residues (three wastes), and the like, has low production cost and good social and economic benefits, and is mainly used for a non load bearing partition.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI +2

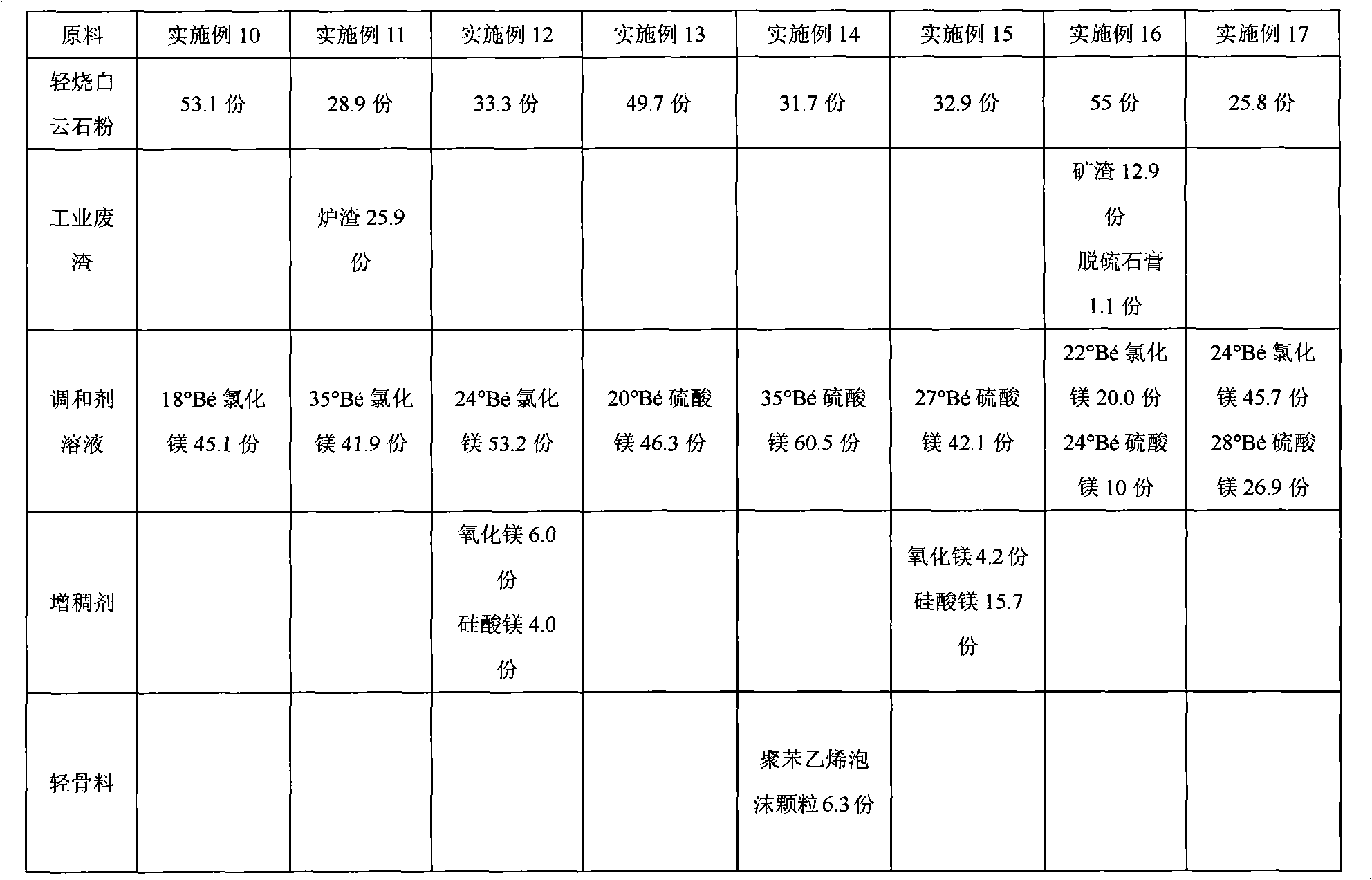

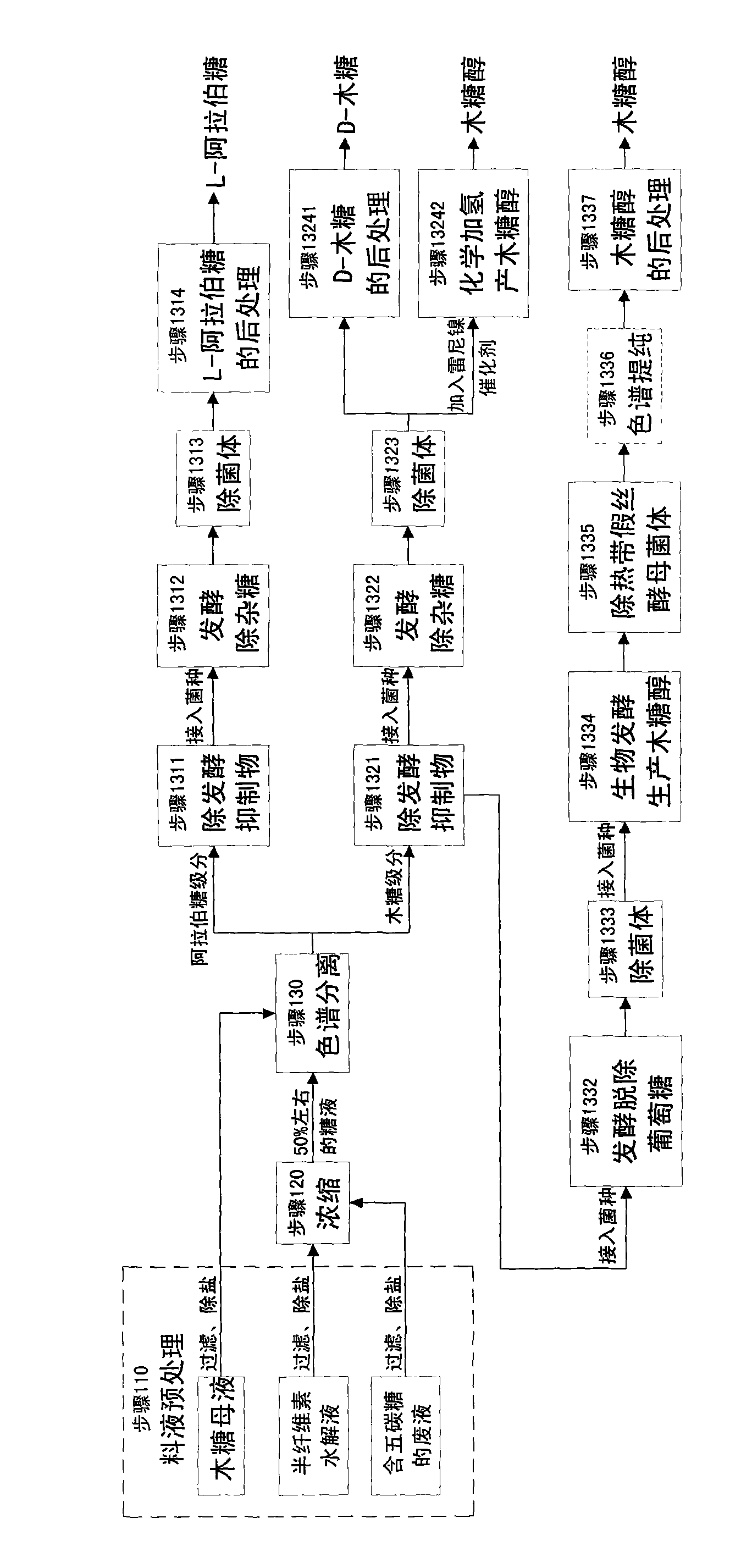

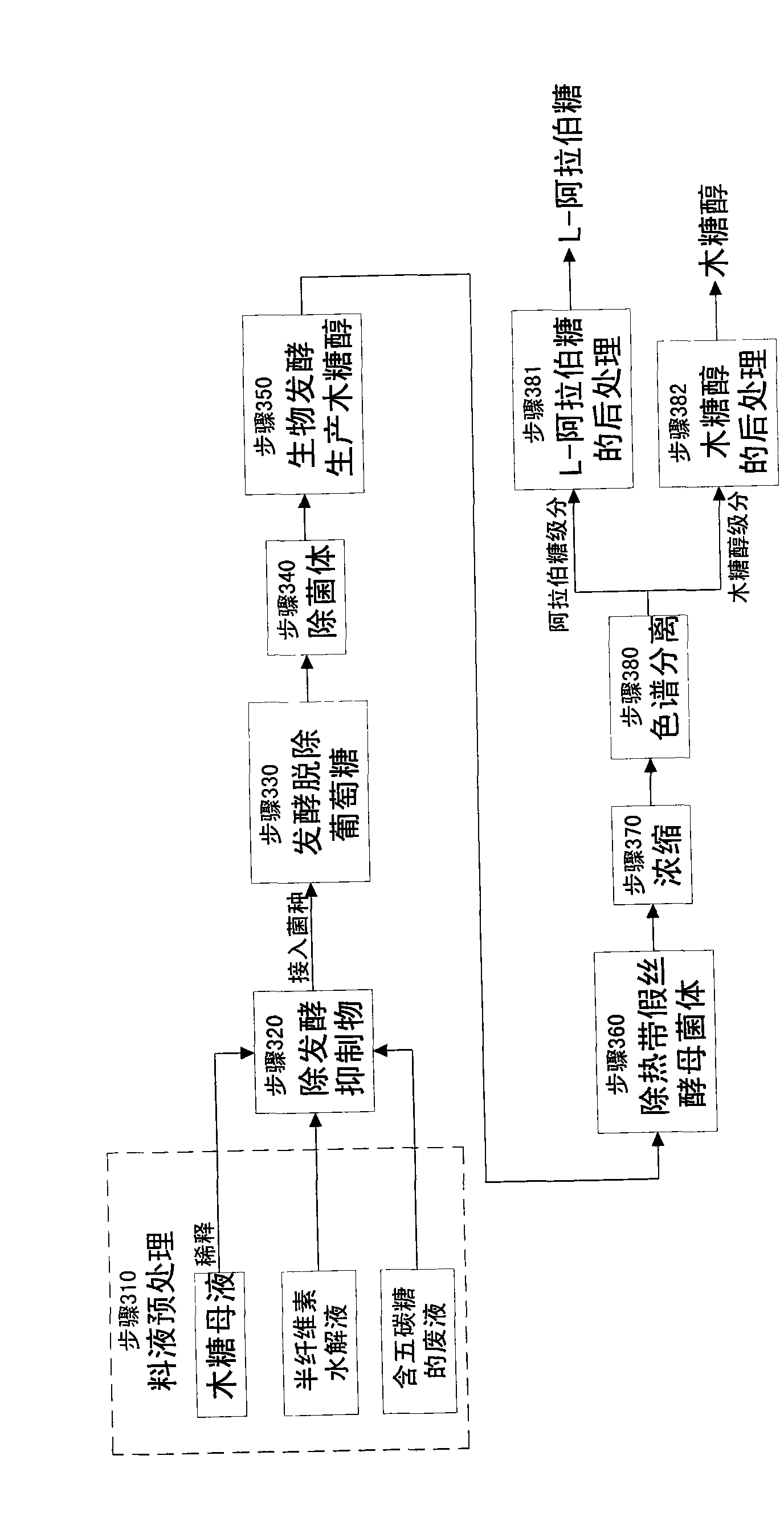

Method for producing L-arabinose and D-xylose

ActiveCN101665523AHigh purityFermentation went wellIon-exchange process apparatusSugar derivativesBiotechnologyChromatographic separation

The invention relates to a method for producing L-arabinose and D-xylose, which can simultaneously produce ethanol or D-ribose or citric acid as a byproduct. The method utilizes a hydrolyzate of agricultural waste, a xylose mother liquor and / or a production waste liquor containing pentose as the raw materials and comprises the following steps: (1) pretreating the raw materials; (b) carrying out the chromatographic resolution to separate the raw materials into an arabinose-stage liquor and a xylose-stage liquor; (c1) removing fermentation inhibitors which are impurities and unwanted bacteria, which have an inhibiting effect on the fermentation; (c2) fermenting to remove unwanted saccharides at least comprising glucose and galactose; (d) and finally, respectively carrying out the post treatment on the arabinose-stage liquor and the xylose-stage liquor to obtain the L-arabinose and the D-xylose. Steps (c1) and (c2) are arranged before the chromatographic resolution in step (b) or after step (b). The method has the advantages of low production cost and high efficiency, and is suitable for large-scale industrial production.

Owner:SHENGQUAN HEALTANG

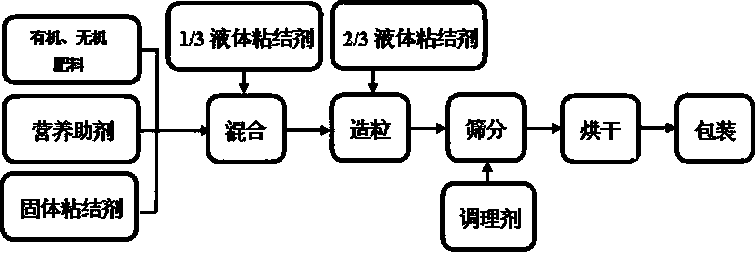

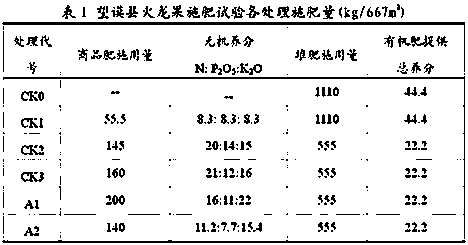

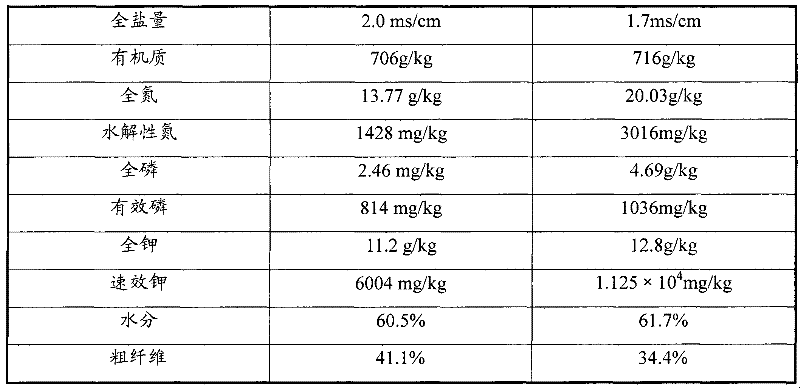

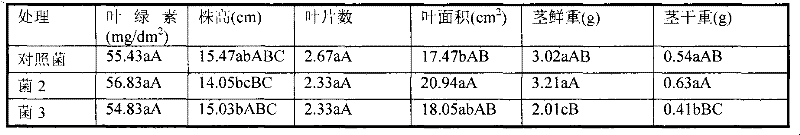

Compound fertilizer special for dragon fruit, and preparation method and application thereof

InactiveCN103819277AImproved physical and chemical propertiesIncrease organic matterFertilizer mixturesNutritionHorticulture

The invention discloses a compound fertilizer special for dragon fruit, and a preparation method and an application thereof, and belongs to the technical field of the fertilizers and the preparation methods thereof. The compound fertilizer special for the dragon fruit is prepared from the following components by weight percent: 40-90% of organic fertilizer, 40-49% of inorganic chemical fertilizer, 4-6% of humic acid, 0.5-1.5% of nutritional additives, 5-7% of composite binder and 0.4-0.7% of conditioner. Due to optimized combination of the organic fertilizer, the inorganic fertilizer, major elements and trace elements, the dragon fruit can be enabled to bloom and bear fruits early, the yield of the dragon fruit can be increased, and the quality of the dragon fruit also can be improved. Due to organic-inorganic combination, complete nutrition is provided for the growth of the dragon fruit, and the soil structure can also be modified easily, the utilization rate of the fertilizer is increased, and the yield and the quality of the dragon fruit can be improved remarkably; in the meantime, the compound fertilizer also has the advantages that the agricultural wastes are recycled and the preparation cost of the fertilizer is low, and therefore, the compound fertilizer is excellent in economic benefit and ecological environmental benefit.

Owner:GUIZHOU UNIV

Bio-organic fertilizer and preparation method thereof

InactiveCN103755404ACause compactionImprove utilizationBio-organic fraction processingOrganic fertiliser preparationPhosphoric acidOrganic fertilizer

The invention discloses a bio-organic fertilizer which is prepared from the following components in parts by weight: 800-820 parts of agricultural wastes, 12-18 parts of calcium superphosphate, 4-6 parts of potassium mineral powder, 4-6 parts of fermenting enzyme agent, 40-60 parts of mineral powder, 90-110 parts of boron soil powder, 8-12 parts of humic acid and 4-6 parts of culture. The preparation method comprises the following steps: uniformly mixing all raw materials, adding water for uniformly stirring, stacking the materials into cubic piles at the temperature of more than or equal to 15 DEG C, and making air holes on the cubic piles; turning for 1-2 times per day when the temperature of the material piles reaches 50 DEG C, turning for 4-5 times per day when the temperature of the material piles is more than or equal to 65 DEG C, controlling the fermentation temperature to be 70 DEG C or below; and preparing the fertilizer when the materials in the material piles are loose and the original odor of the materials is avoided. The bio-organic fertilizer has the advantages that the bio-organic fertilizer is full in nutrient elements and is green and environment-friendly, the soil can be improved, and soil hardening caused by use of the fertilizer is improved.

Owner:SHENYANG SIXIONGDI FERTILIZER

Microbial fertilizer producing by using agricultural wastes and preparation thereof

InactiveCN102515900AEasy to eliminateLight weightBio-organic fraction processingOrganic fertiliser preparationBiotechnologyBacillus licheniformis

The invention discloses a microbial fertilizer producing by using agricultural wastes and preparation thereof. Main materials are obtained by mixing and smashing 20%-40% oil sally bean dregs, 40%-60% crop straw and 15%-25% poultry excrement, moisture content achieves 60-65%, composite leaven is added according to 150g-200g / T to pile to be cone-shaped, yellow mud is used on the outside for sealing, a plastic film is used for covering in a sealing mode, after stacking, fermentation and digesting, and the composite leaven is composed of bacillus subtilis, bacillus licheniformis, trichoderma harzianum and trichoderma viride according to the mass ratio (W / W) of 1.5:1:1:2.5:4. Auxiliary materials made of 5%-10% mushroom dregs and 6%-10% rice husk ash are evenly mixed with fermented and prepared main materials, arbuscular mycorrhizal fungi agent are added according to 600-1000g / T for compounding, and the microbial fertilizer is prepared after passing a 3mm sieve. Good production and efficiency improvement is obtained through application, and the microbial fertilizer has good application value.

Owner:斯华四

Treatment of swine wastewater by biological and membrane separation technologies

InactiveUS7045063B2Bio-organic fraction processingExcrement fertilisersSeparation technologyFiltration

Owner:RGT UNIV OF CALIFORNIA

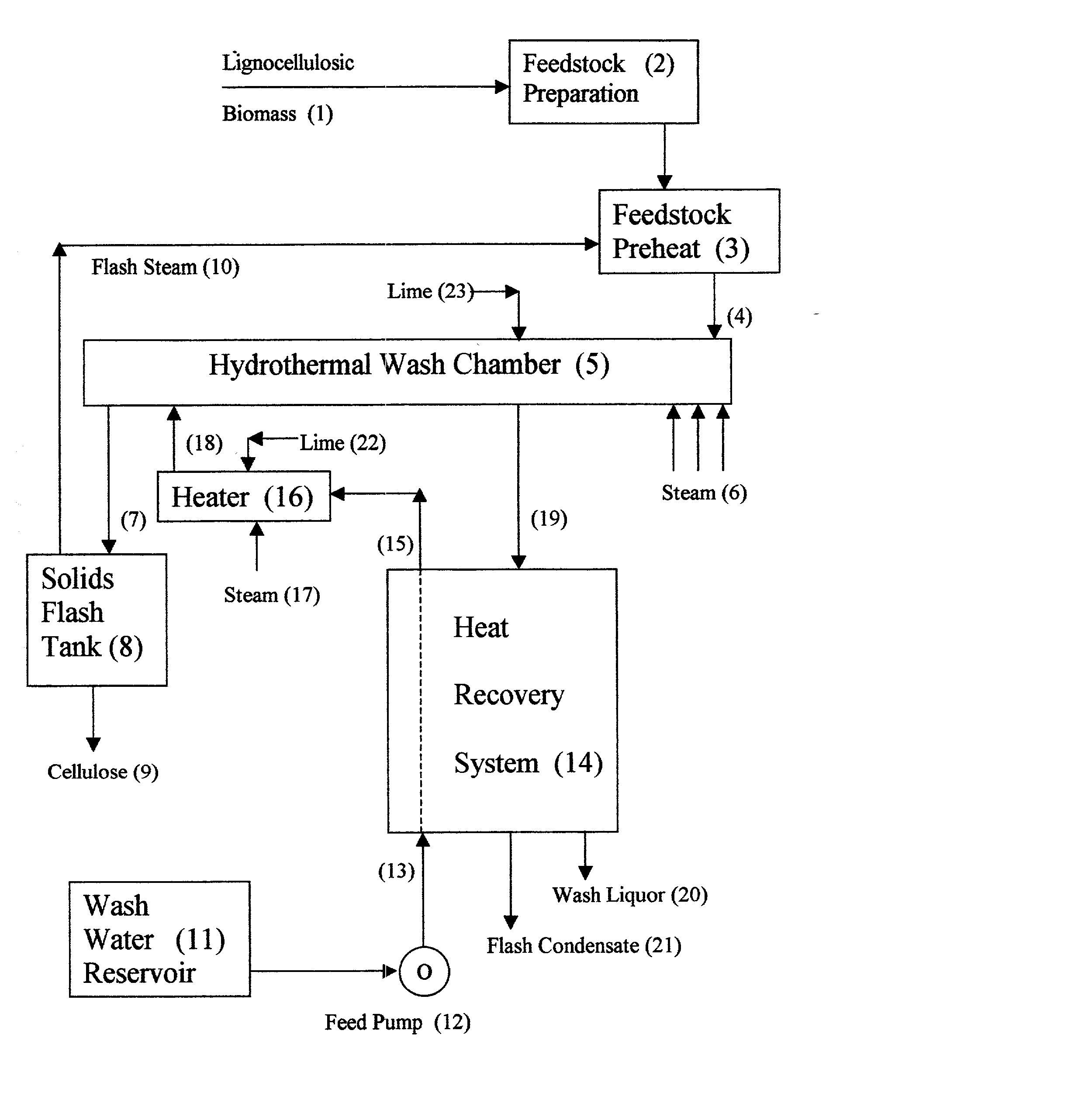

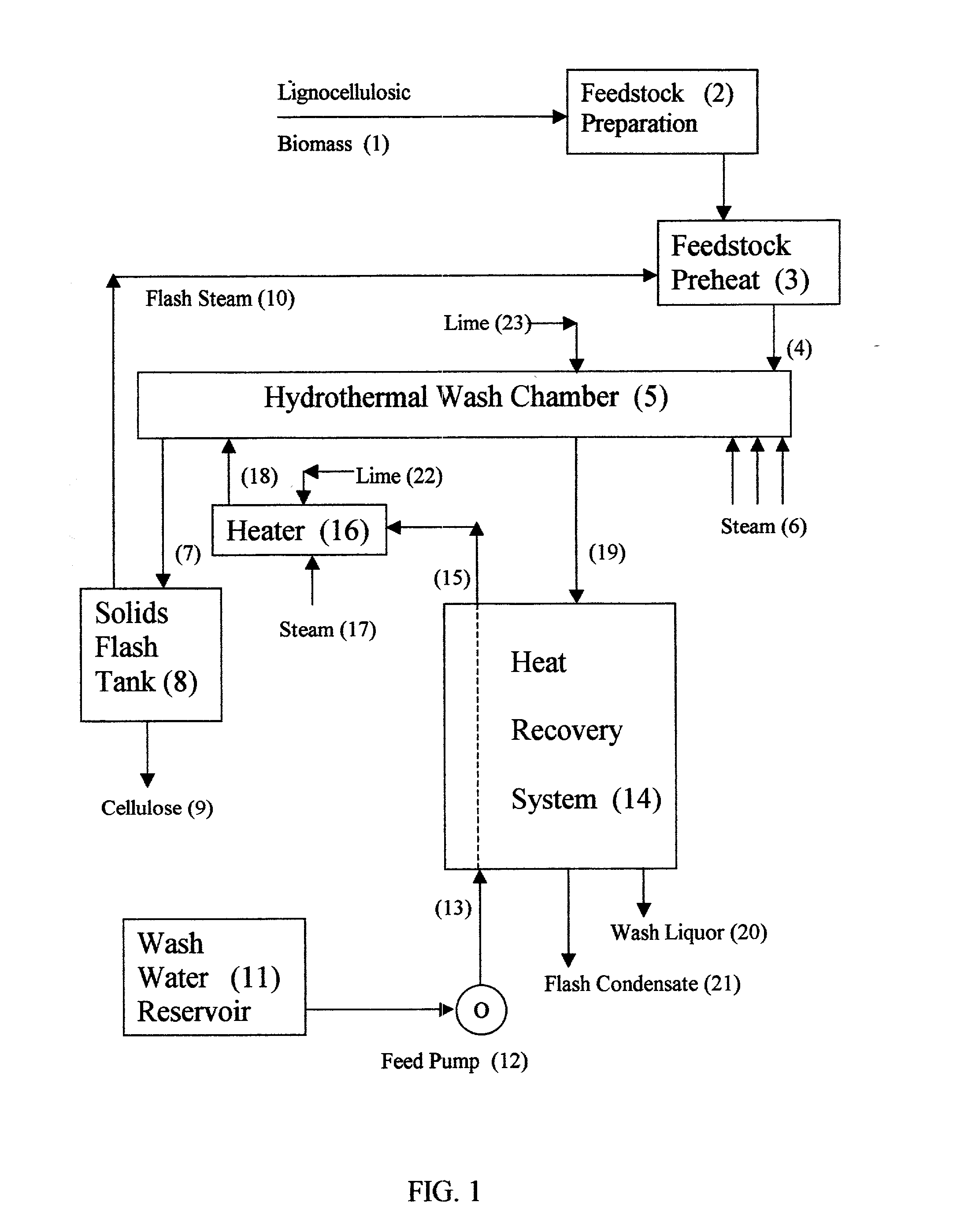

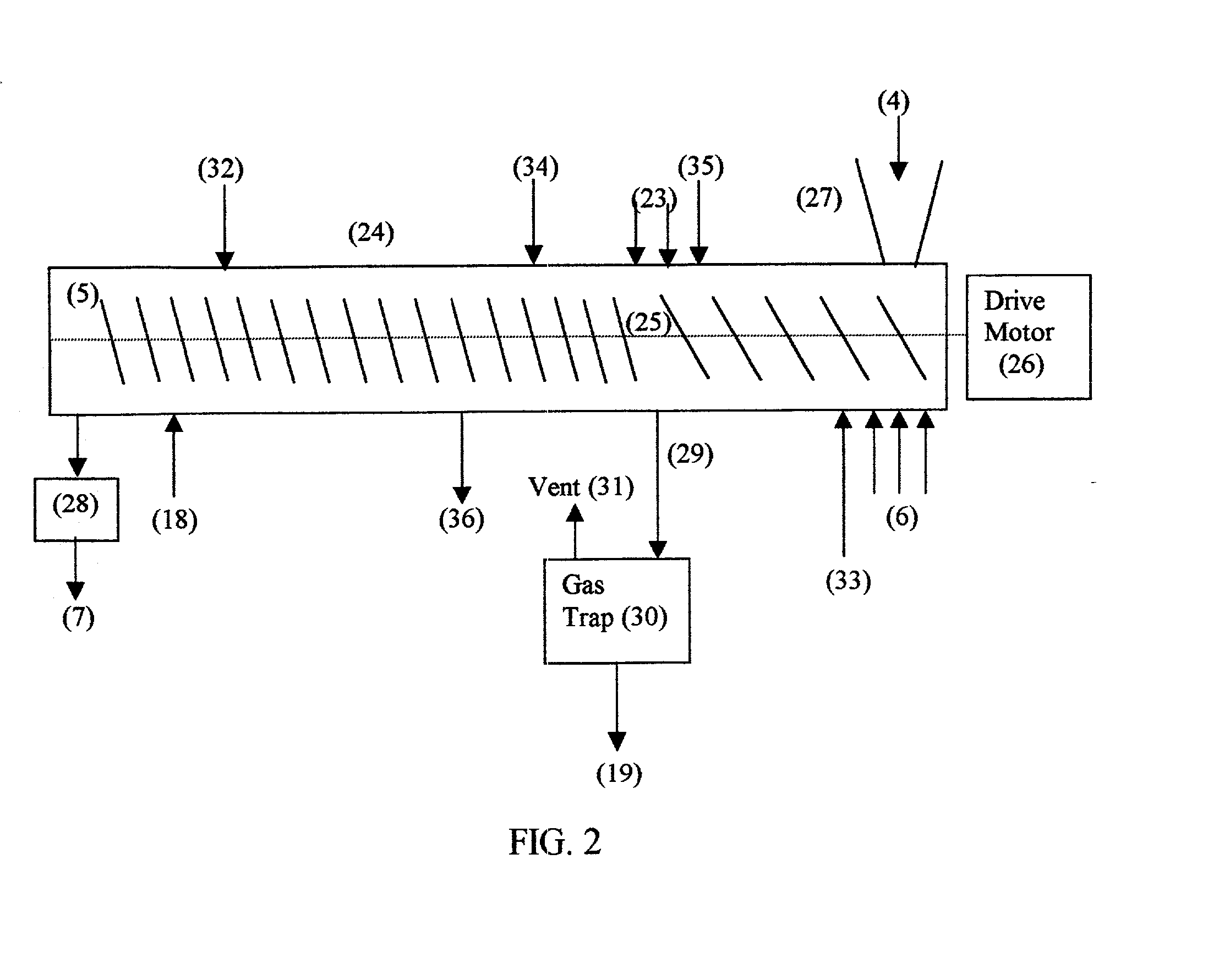

Cellulose production from lignocellulosic biomass

InactiveUS20020148575A1Low costHigh yieldPretreatment with water/steamPulp liquor regenerationEnergy recoveryCellulose fiber

A multi-function process is described for the separation of cellulose fibers from the other constituents of lignocellulosic biomass such as found in trees, grasses, agricultural waste, and waste paper with application in the preparation of feedstocks for use in the manufacture of paper, plastics, ethanol, and other chemicals. This process minimizes waste disposal problems since it uses only steam, water, and oxygen at elevated temperature in the range of 180° C. to 240° C. for 1 to 10 minutes plus a small amount of chemical reagents to maintain pH in the range 8 to 13. An energy recuperation function is important to the economic viability of the process.

Owner:PUREVISION TECH

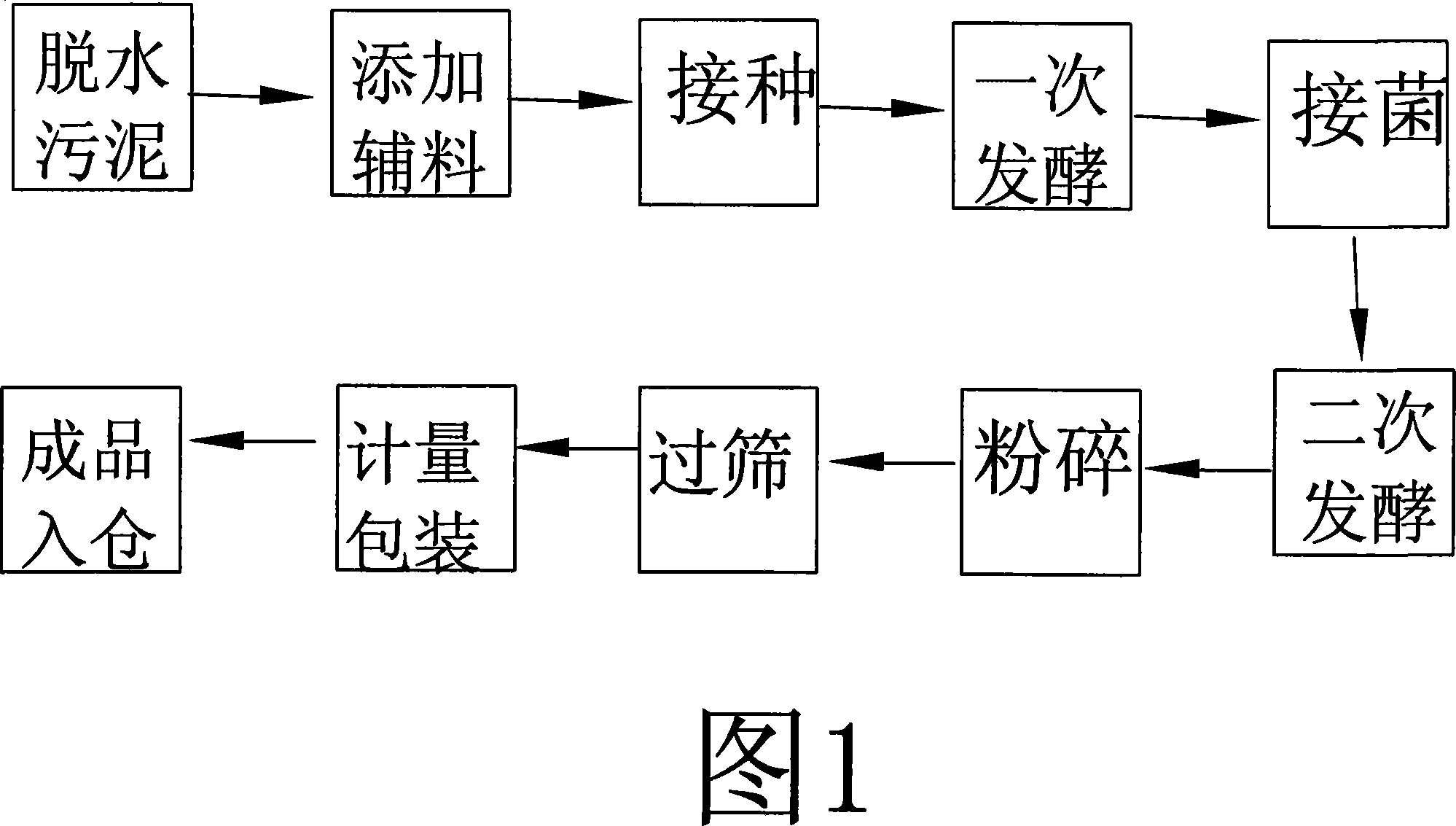

Organic soil conditioner prepared with city sludge and its usage

InactiveCN101066898AIncrease available nutrientsMeet nutrient needsClimate change adaptationBioloigcal waste fertilisersChemical structureSewage

The present invention relates to one kind of organic soil conditioner prepared with city sludge and its production process. The material for the organic soil conditioner consists of dewatered sludge from city domestic sewage 53-72 wt%, organic agricultural waste 4-18 wt%, inorganic supplementary material 2-15 wt%, fertilizer balancing agent 1-5 wt%, and composite microbes 0.5-2 wt%. The production process of the organic soil conditioner includes the following steps: 1. fermenting the dewatered sludge from city domestic sewage, the organic agricultural waste and the inorganic supplementary material with saccharomycetes; 2. inoculating the composite microbes to the first fermented product for secondary decaying; and 3. sieving and packing to produce the organic soil conditioner. The organic soil conditioner has high nutritious component content, and can improve physical and chemical structure of soil, improve agricultural product quality and raise soil fertility.

Owner:刘奋安

Preparation method of biomass-based magnetic biochar

InactiveCN103949212AHigh crystallinity and stabilityEasy to prepareOther chemical processesMagnetite NanoparticlesNitrogen gas

The invention relates to a preparation method of biomass-based magnetic biochar. According to the preparation method, forestry and agricultural waste materials are taken as raw materials; biochar prepared via oxygen-limited pyrolysis or hydrothermal carbonization is taken as a substrate; magnetic nano-material Fe3O4 is obtained via iron precursor pyrolysis, loading of magnetic nano-material Fe3O4 onto the biochar substrate is realized in a polyhydric alcohol solution, and an obtained product is subjected to sintering under nitrogen protection so as to obtain stable magnetic nano particles with high crystallinity. Compared with existing technology, loading of in-situ synthesized Fe3O4 onto the surface of biochar is realized via pyrolysis; reaction selectivity and efficiency are high; size of the Fe3O4 nano particles and loading area on the surface of biochar are controllable; and operation is simple and convenient.

Owner:SHANGHAI JIAO TONG UNIV

Manufacturing method of fertilizer made from organic wastes

InactiveUS6273927B1Neutralize toxicityHigh in magnesiumCalcareous fertilisersProductsHuman wasteChaff

This invention relates to a method of manufacturing the fertilizer made from organic wastes such as food wastes, human excrements, animal excrements, slaugterhouse waste, henhouse waste, fish and shellfish wastes, vegetable wastes and agricultural wastes. Various wastes are mixed and crushed into certain sizes, processes for adjusting the water content, put into the treating tank and digested by mixing a calcined lime. The present invention utilizes a dolomite or mixture of calcined lime and dolomite to provide the first treatment material. This first treatment material is mixed with the supplement material such as charcoal, saw dust, loess, zoelite, chaff, or shell powder to give compost fertilizer. It is also mixed with agricultural products such a watermelons or melons which ferment to provide a special fertilizer for the agricultural product. The treatment material can be added to water and mixed with mugwort, medicinal herb, zeolite, loess, and then extracted to provide a liquid fertilizer. As the various organic wastes are changed to organic fertilizer, the acidified soil is improved, the environmental contamination can be prevented, and the high moisturizing and the fine porous of the soil prevent drought and fertilizer loss so as to raise fertilizing efficiency.

Owner:JMBIO

Microbial composite microorganism inoculant for producing biological organic fertilizer from decomposed organic wastes

InactiveCN101486597AReduce the level of odorPromote growthMicroorganismsOrganic fertilisersBiotechnologyCellulose

The invention relates to the range of microorganism fermentation inoculant, in particular to a microorganism composite fermentation inoculant which is used for digesting the compost of livestock manure, crop straws, mud, mushroom slag, decoction dregs, garden shearing substances, grass peat, castor bean meal, bone meal, and bean pulp meal rich in cellulose and organic matters as well as manufacturing a bio-organic fertilizer. 2 strains screened from a plurality of organic waste materials with high capability for digesting cellulose and high temperature resistance (70 DEG C) are scientifically and reasonably combined with 11 beneficial strains to prepare a microorganism composite fermentation inoculant which can not only digest organic materials, but also enhance the efficiency, quality and biological activity of the compost. The invention can be used in the high efficient and reasonable application of agricultural wastes and in the industry of waste disposal.

Owner:TIANJIN INST OF AGRI RESOURCES & ENVIRONMENTAL

Soil amendment prepared from biogas residue and wormcast as main material and preparation method thereof

ActiveCN102503661AGood effectImprove biotaBio-organic fraction processingClimate change adaptationOrganic manureSoil conditioner

The invention relates to a soil amendment prepared from biogas residue and wormcast as main material and a preparation method of the soil amendment, which belongs to the technical field of recycling of organic fertilizer and agricultural waste resource. The soil amendment is composed of the main material, amine treated lignite, bone meal, bran, soybean meal, and the other additives. The method prepares the soil amendment by biogas residue and wormcast, utilizes waste reasonably and effectively, is low in cost, changes waste into treasure, and protects environment. In addition, the method has simple process, low energy consumption, easy operation, flexible production, and convenient usage, and is easy for large-area promotion and application.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI

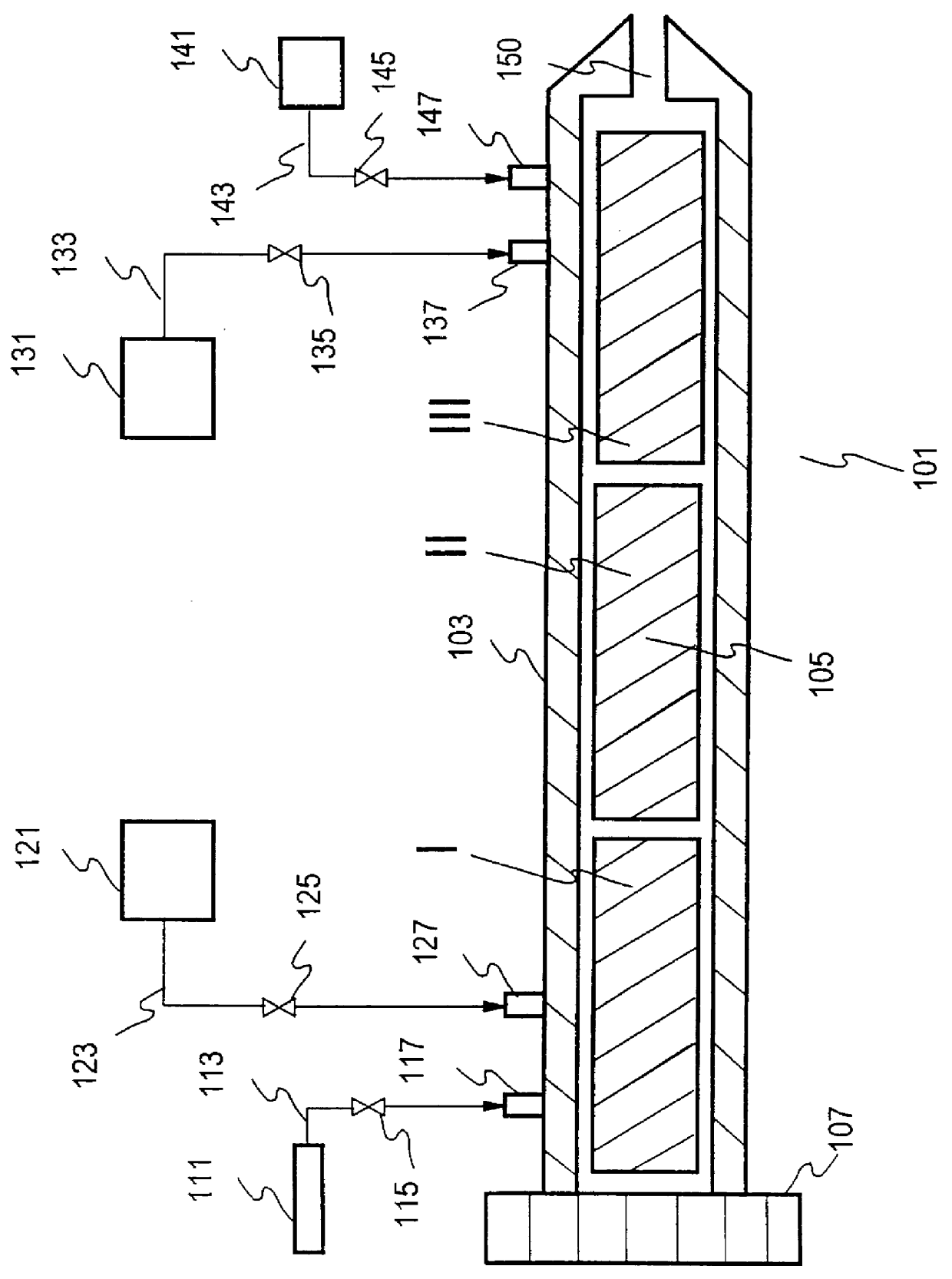

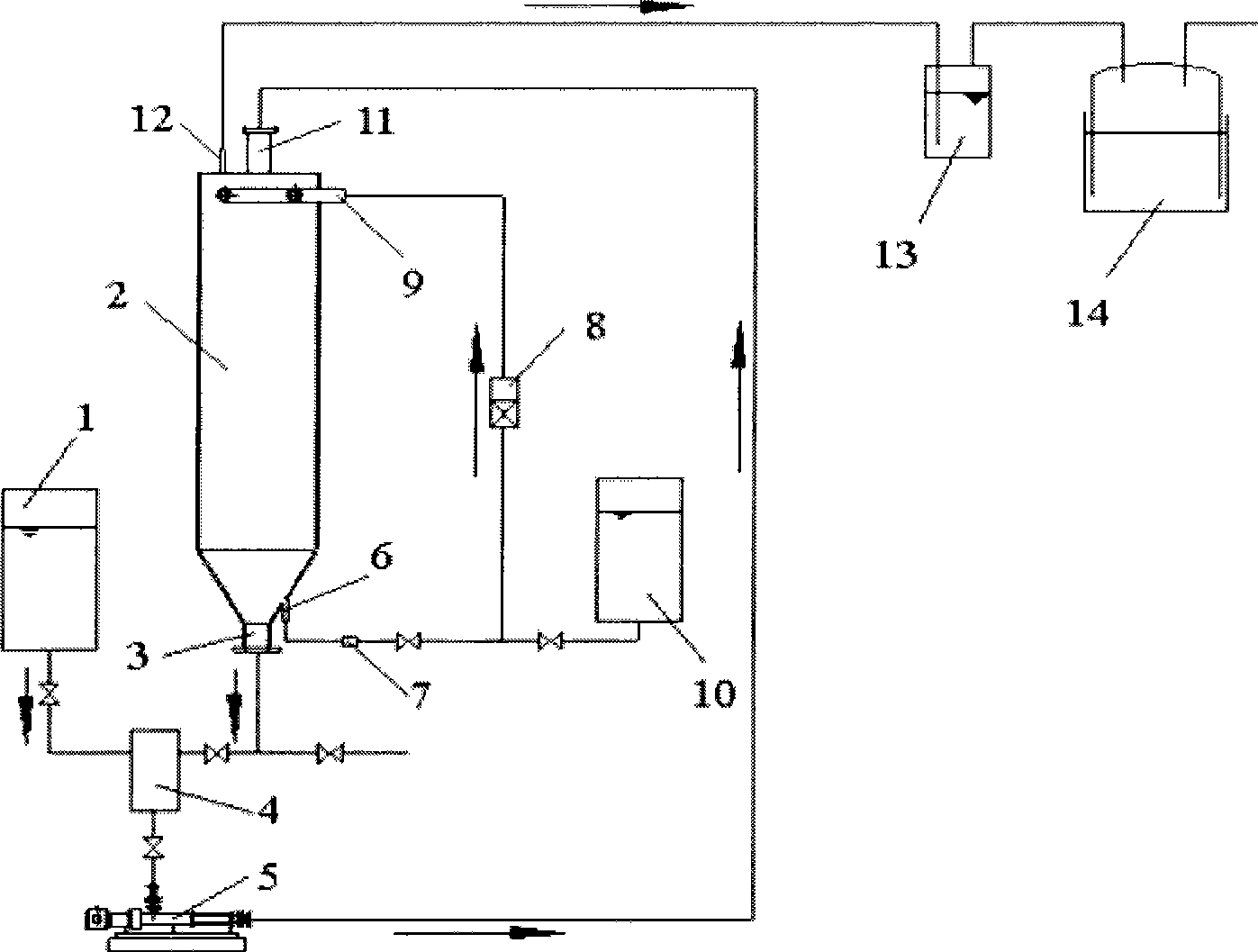

Vertical non-stirred organic waste dry-type anaerobic digestion processing equipment and method

InactiveCN101381674AIncrease volumetric gas production rateOvercome the difficulty of homogeneous mixingBioreactor/fermenter combinationsBiological substance pretreatmentsSlurryEngineering

The invention discloses vertical equipment for treating organic waste by dry anaerobic digestion without stirring and a method thereof. The equipment comprises that a feed port and an air outlet are arranged on the vertical digester; a discharge port is arranged on the bottom of the vertical digester; a feeding storage tank is connected with the discharge port of the vertical digester through a pipeline, an inoculation mixing tank and a delivery pump; the discharge port of the vertical digester is connected with the inoculation mixing tank through a control valve; a biogas slurry discharge pipe is arranged on the lower part of the vertical digester, and is connected with a spraying device arranged on the upper part of the vertical digester through a pH value on-line monitor, a reflux pump sequentially; and an alkali solution storage tank is connected with the reflux pump through the pipeline and the control valve. The vertical equipment for treating organic waste by dry anaerobic digestion without stirring and the method thereof overcome the defects of difficult isotrope mixing, easy isotrope acidification and the like of the prior dry anaerobic digestion system, and is applicable to treatment on household organic garbage, kitchen garbage, excrement of fowls and livestocks, agricultural waste, garden garbage, sewage sludge and other organic waste.

Owner:SOUNDGRP CO LTD

Preparation and application of biological carbon immobilized microbial agent

ActiveCN106148318AImprove removal efficiencyKeep aliveContaminated soil reclamationMicroorganism based processesMicroorganismMicrobial agent

The invention relates to preparation and application of a biological carbon immobilized microbial agent. The method comprises the following steps of: sequentially performing seed solution culture and liquid fermentation culture to microorganisms capable of degrading petroleum to obtain fermentation liquid; performing mixed adsorption to the fermentation liquid and biological carbon to prepare the biological carbon immobilized microbial agent. The invention further provides application of the biological carbon immobilized microbial agent to soil polluted by oily sludge and sand and petroleum. By immobilizing the microorganisms having a function of degrading petroleum and then remedying the soil polluted by oily sludge and sand and petroleum, the petroleum removal efficiency is remarkably improved and the removal rate is improved by 20 to 30 percent as compared with remediation by solely using microorganisms. The invention uses agricultural wastes such as corncobs as precursors to prepare carriers, the cost is low, a great amount of microbial agent is easily obtained and simultaneously the reclamation of wastes is realized.

Owner:山东百科利生态科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com