Patents

Literature

80results about How to "High in magnesium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sputter apparatus for producing multi-component metal alloy films and method for making the same

InactiveUS6709557B1High magnesium contentUniform thicknessCellsElectric discharge tubesIntegrated circuitMetal alloy

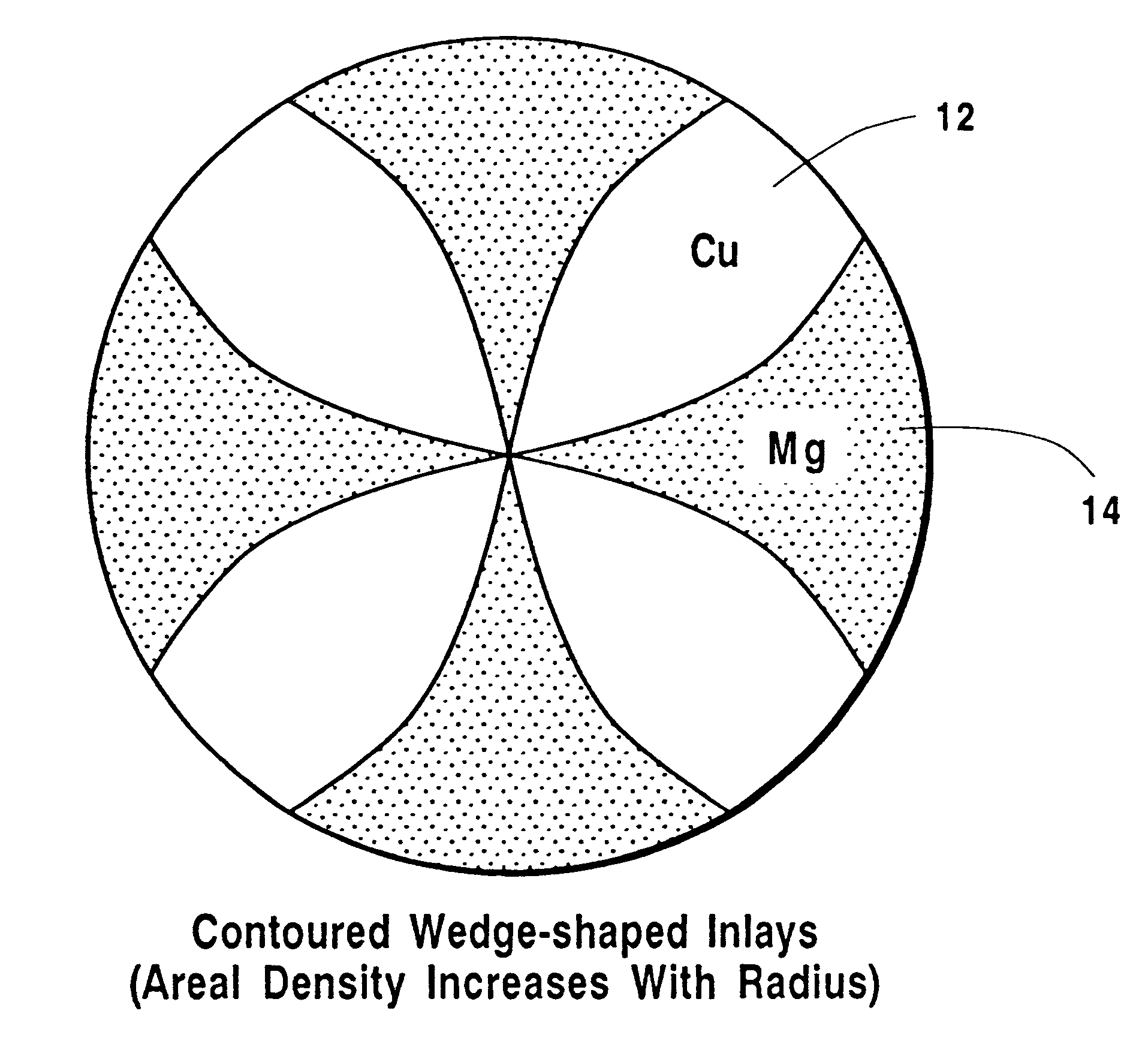

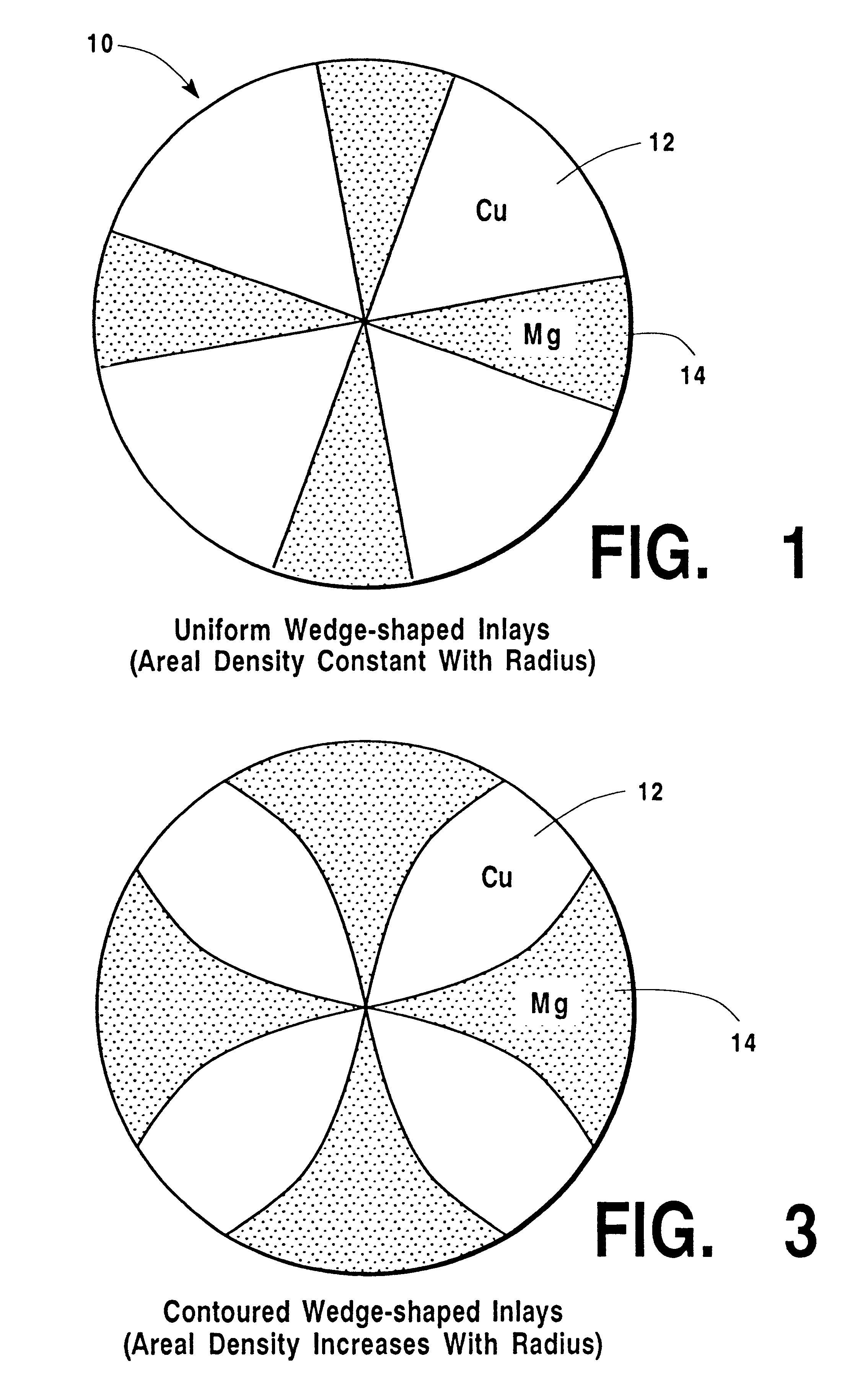

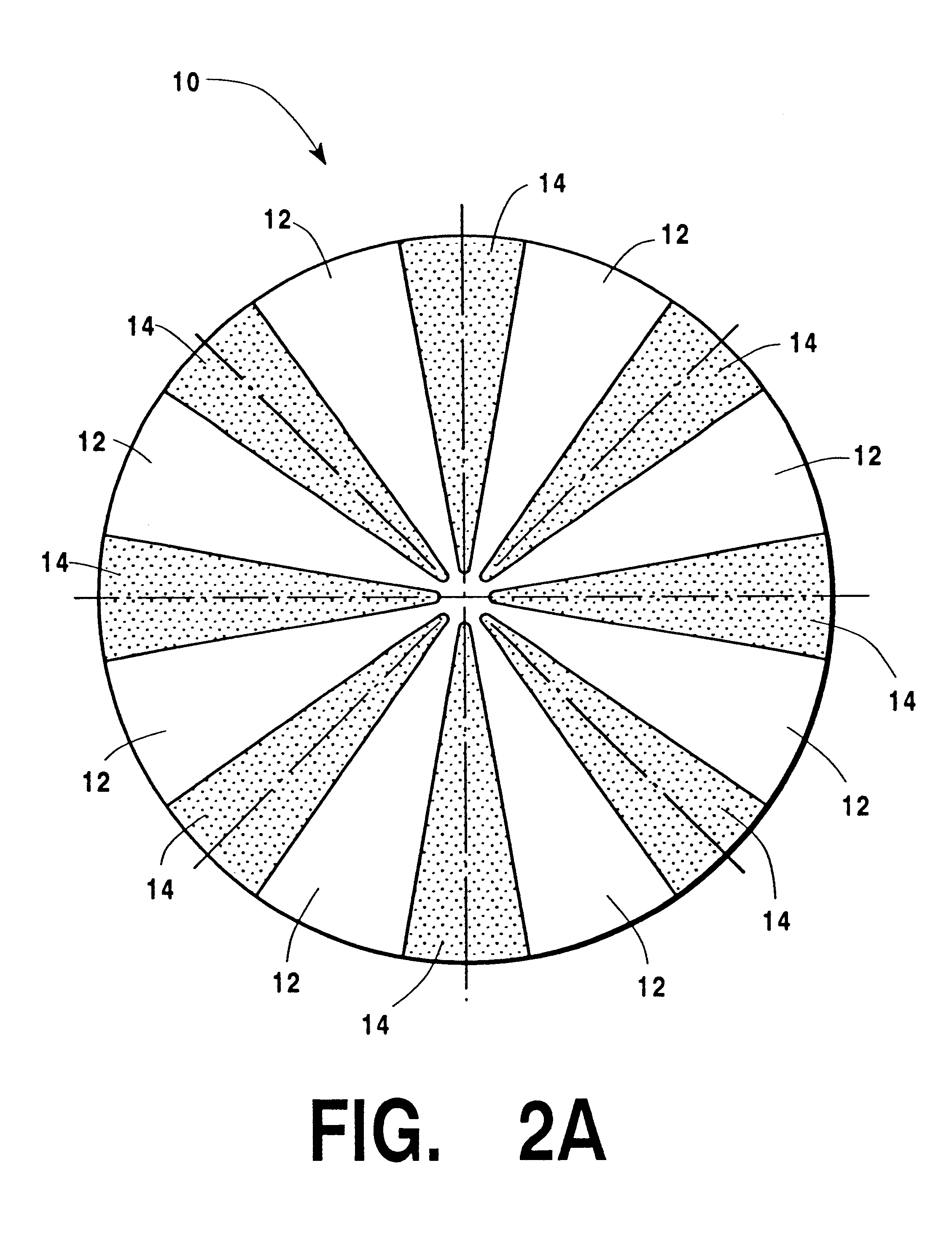

A mosaic or inlaid sputter target design suitable for conventional planar magnetron deposition, RF ionized physical vapor deposition, HCM ionized PVD, ionized metal plasma (IMP) deposition, or self-ionized plasma (SIP) deposition of multi-component alloys for use in integrated circuit metallization. Inlays are inserted within a planar sputter target in the shape of wedges, wires, or buttons to achieve uniform deposition of films on semiconductor substrates during sputtering. Metal alloy strips within a three-dimensional HCM target achieve the same uniform deposition. The deposition leads to the production of CuAl, CuBe, CuB, CuCd, CuCo, CuCr, CuIn, CuPd, CuSn, CuTa, CuTi, CuZr or CuZn alloy films deposited on the wafer. Non-copper films may also be deposited. The inlay-target adjoining surfaces may be machine stepped or tapered to limit wicking from the target backing material.

Owner:NOVELLUS SYSTEMS

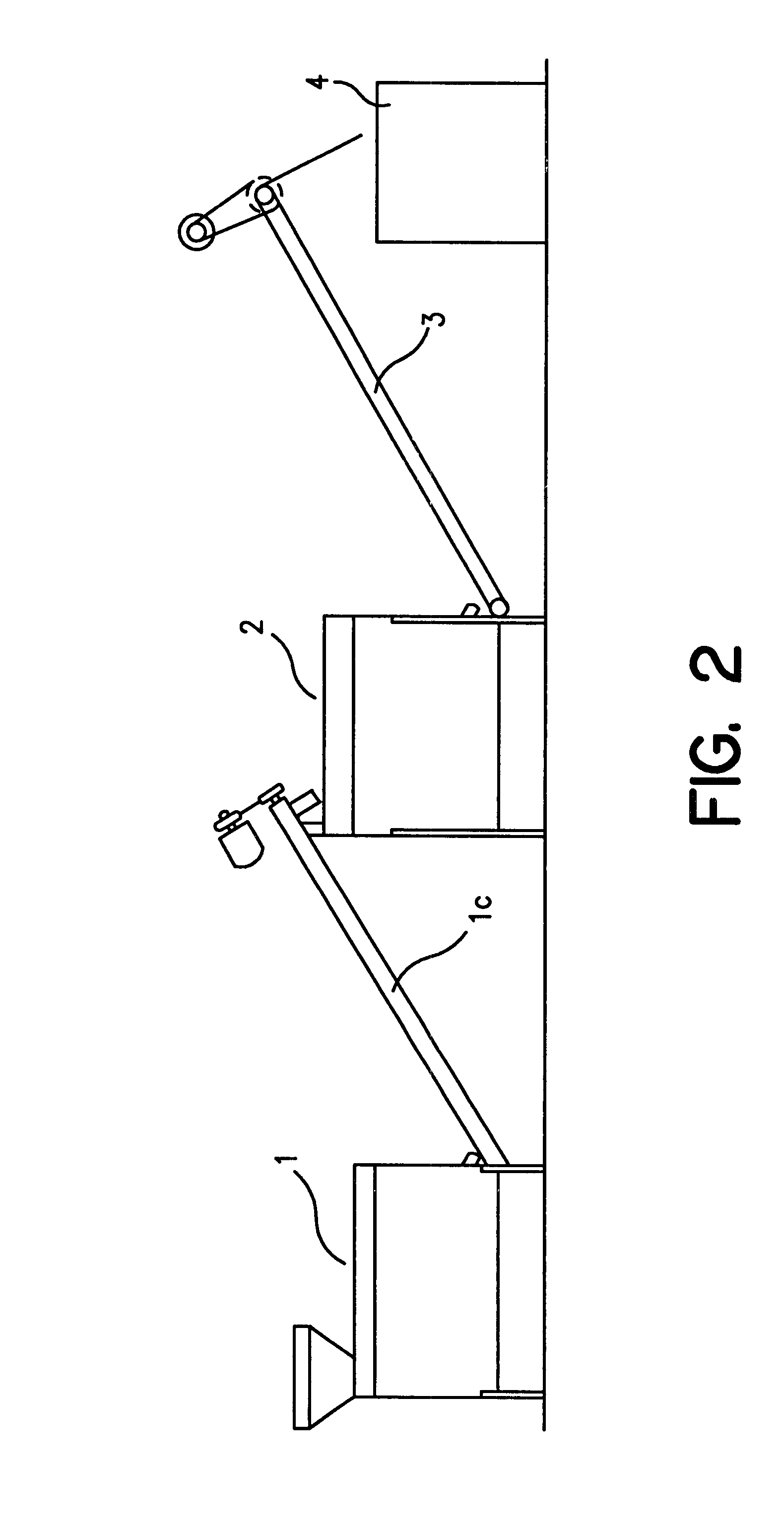

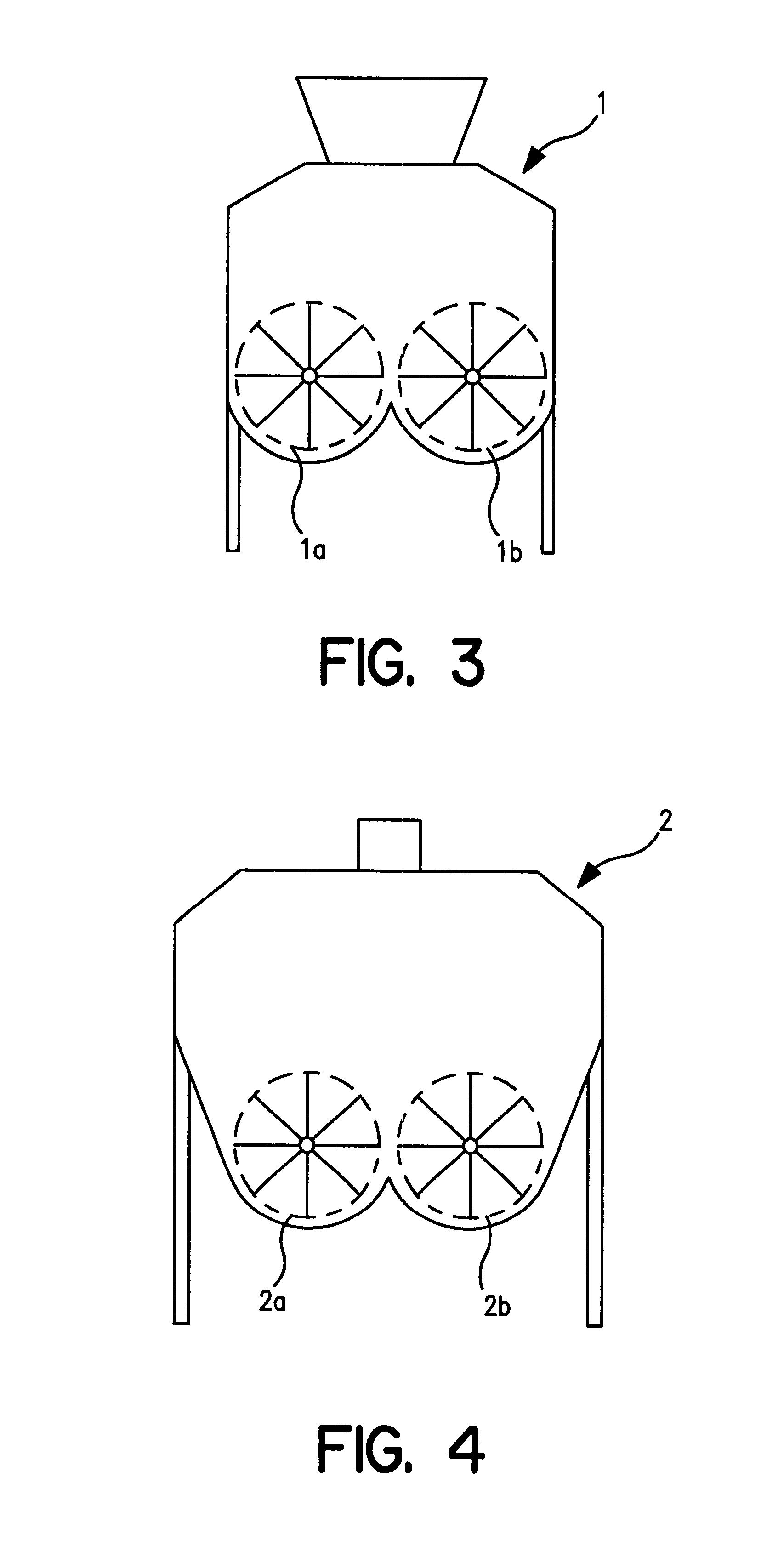

Manufacturing method of fertilizer made from organic wastes

InactiveUS6273927B1Neutralize toxicityHigh in magnesiumCalcareous fertilisersProductsHuman wasteChaff

This invention relates to a method of manufacturing the fertilizer made from organic wastes such as food wastes, human excrements, animal excrements, slaugterhouse waste, henhouse waste, fish and shellfish wastes, vegetable wastes and agricultural wastes. Various wastes are mixed and crushed into certain sizes, processes for adjusting the water content, put into the treating tank and digested by mixing a calcined lime. The present invention utilizes a dolomite or mixture of calcined lime and dolomite to provide the first treatment material. This first treatment material is mixed with the supplement material such as charcoal, saw dust, loess, zoelite, chaff, or shell powder to give compost fertilizer. It is also mixed with agricultural products such a watermelons or melons which ferment to provide a special fertilizer for the agricultural product. The treatment material can be added to water and mixed with mugwort, medicinal herb, zeolite, loess, and then extracted to provide a liquid fertilizer. As the various organic wastes are changed to organic fertilizer, the acidified soil is improved, the environmental contamination can be prevented, and the high moisturizing and the fine porous of the soil prevent drought and fertilizer loss so as to raise fertilizing efficiency.

Owner:JMBIO

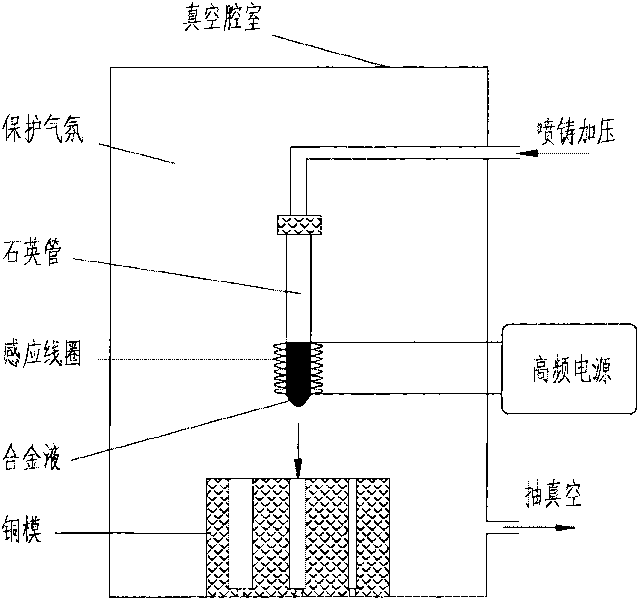

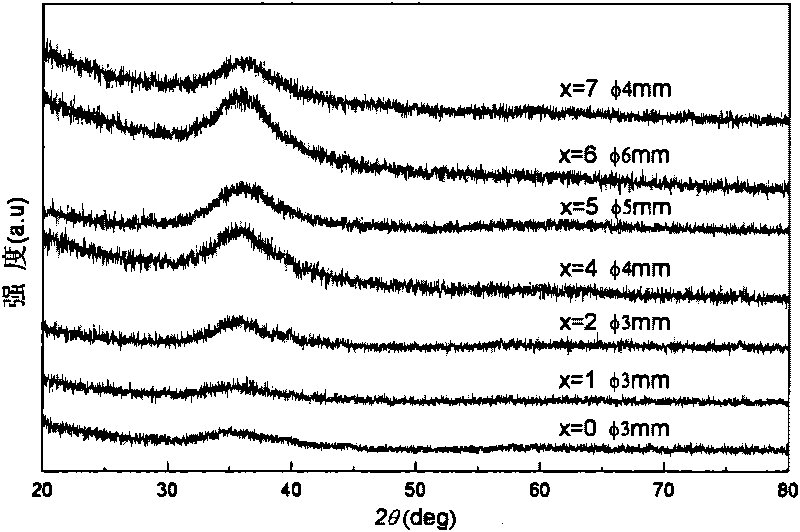

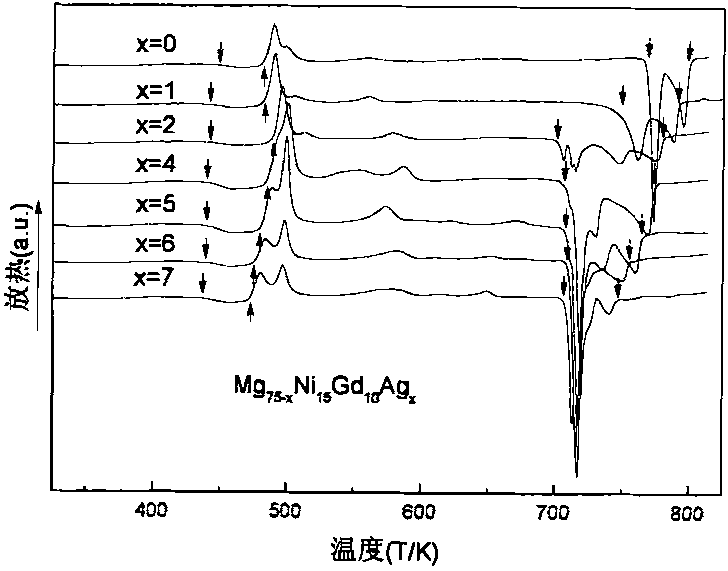

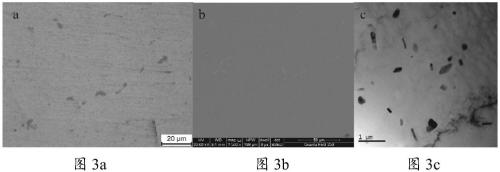

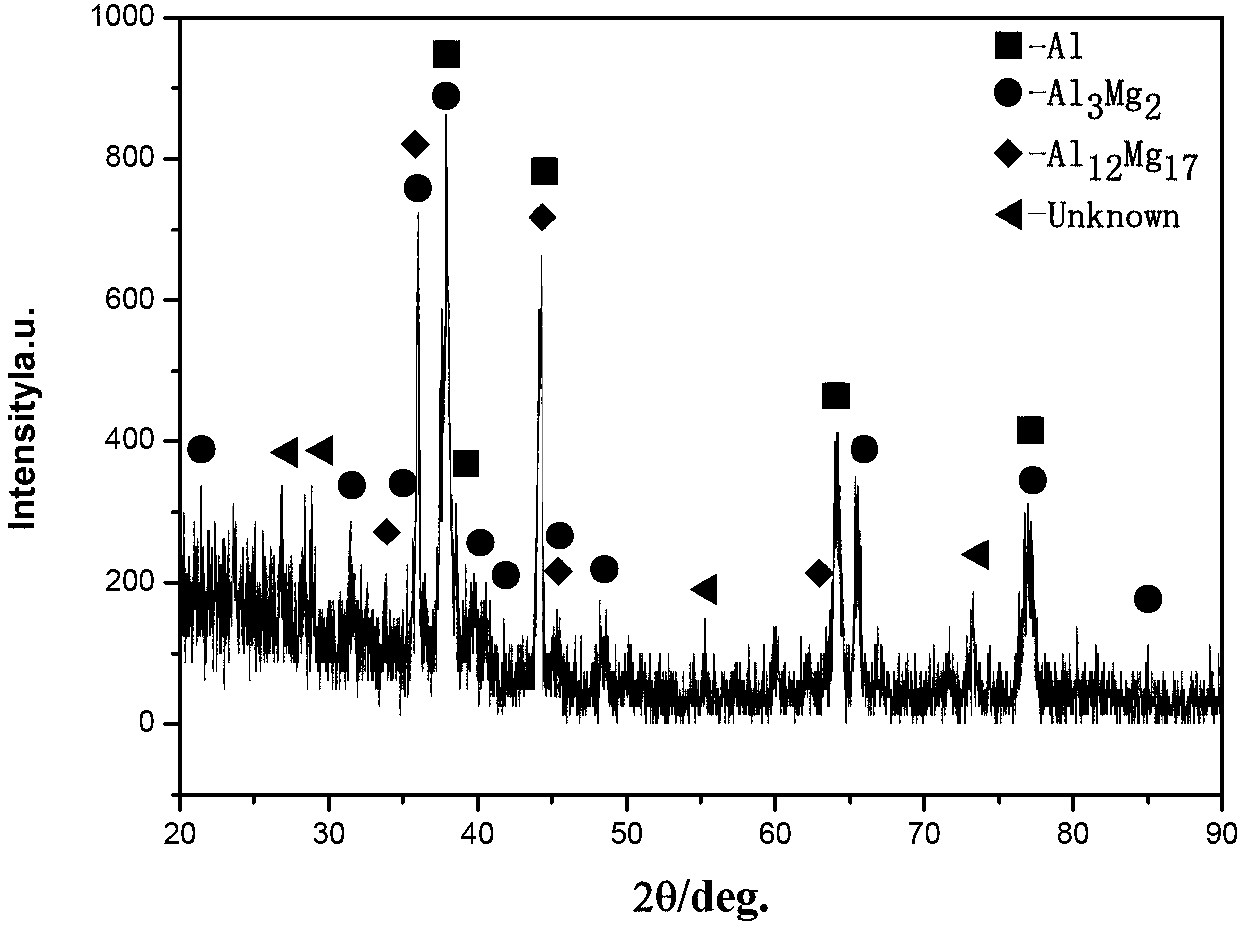

Mg-Ni-Gd-Ag serial block amorphous alloy and preparation method thereof

The invention relates to an Mg-Ni-Gd-Ag serial block amorphous alloy and a preparation method thereof, belonging to the technical field of alloy materials. The alloy uses Mg as a main element, and the formula of the alloy is Mg75-xNi15Gd10Agx(x is not more than 0 and not less than 7), wherein x is the atom percentage of the Ag element, and the purity of all elements is not lower than 99.9 percent. After being weighed according to the atom percentage, the elements of Ni, Gd and Ag are smelted and cooled in an argon atmosphere electric arc furnace; after being broken, the obtained three-element intermediate alloy ingot is smelted in an induction furnace with Mg with corresponding mass; and the product is resmelted and sprayed in a metal cavity to obtain the Mg-based block amorphous alloy Mg75-xNi15Gd10Agx. The Mg-based block amorphous alloy has the advantages of high amorphous formation ability, high Mg content, high strength, good corrosion resistance, and the like. The serial Mg-based block amorphous alloy has wide application prospect in the fields of novel light structure materials, and the like by excellent performance.

Owner:TSINGHUA UNIV

Disintegratable round-granule sulfur magnesium fertilizer and preparation method thereof

InactiveCN102775220AHigh granulation rateHigh in magnesiumFertiliser formsFertilizer mixturesBruciteWater content

The invention belongs to the field of agricultural fertilizers, and relates to a disintegratable round-granule sulfur magnesium fertilizer. Powdery brucite and sulfur powder are used as main raw materials, and a magnesium sulfate heptahydrate solution is used as a binding agent. The disintegratable round-granule sulfur magnesium fertilizer is prepared by granulating the following components in parts by mass: mixture of 90-95 parts of powdery brucite and 5-10 parts of sulfur as the dry material, and magnesium sulfate heptahydrate solution as the binding agent. After drying the round granules, the water content is less than or equal to 3%, the strength is greater than or equal to 2Kg / cm<2>, and the disintegration rate is greater than or equal to 95%. The magnesium sulfate heptahydrate solution is used as the binding agent to enhance the granulation rate; the 60-120 mesh powdery brucite and sulfur powder are mixed as the dry material; and granulation, screening, drying, cooling and packaging are carried out to prepare the spherical granules with the granular size of 2-4mm. The invention has the advantages of low cost, high magnesium content and high disintegration speed. The product is spherical granules, has the advantages of favorable disintegratability, uniform granularity and high strength, and can be conveniently mixed with other nitrogen-phosphorus-potassium fertilizers.

Owner:张浩

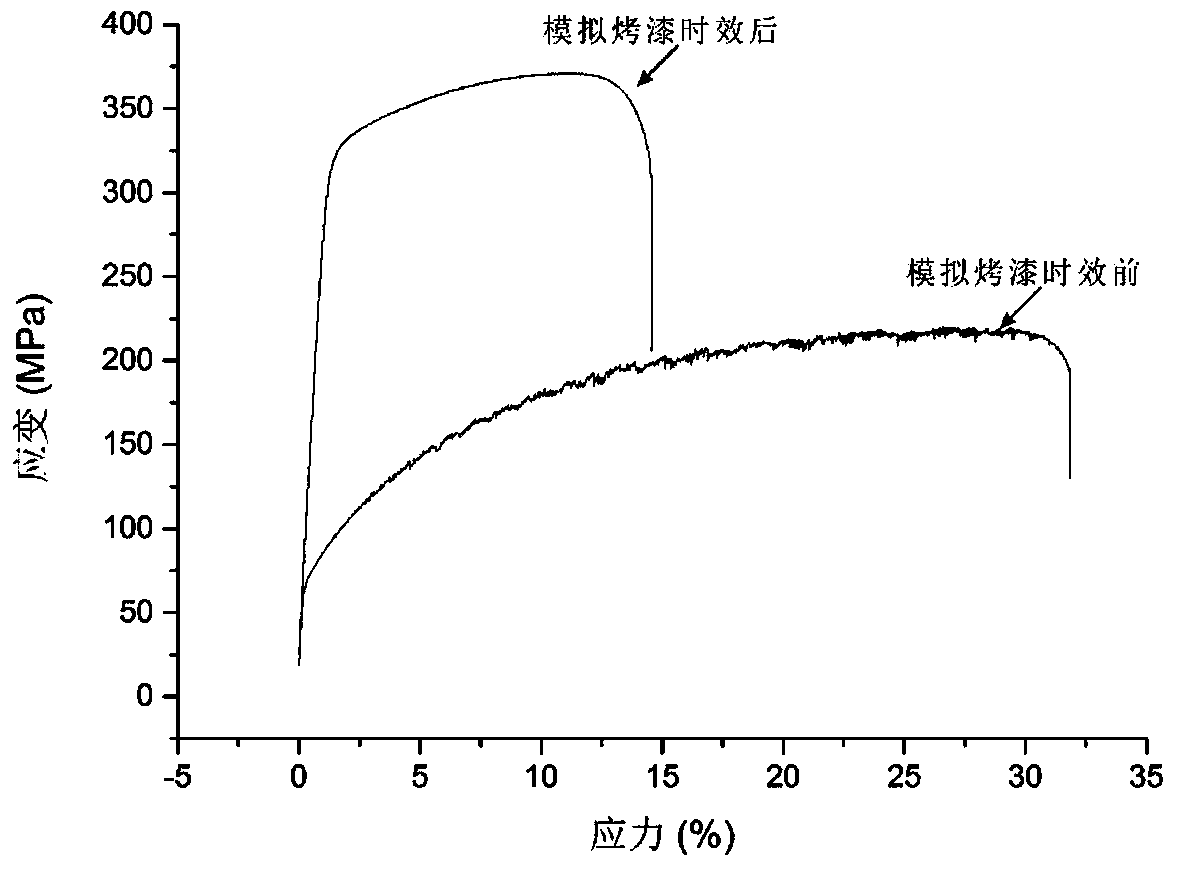

6XXX aluminum alloy suitable for automobile body and preparation process of automobile body plate

ActiveCN109055698AHigh elongationEnhanced precipitation driving forceFurnace typesHeat treatment furnacesManganeseNatural aging

The invention relates a 6XXX aluminum alloy suitable for an automobile body and a preparation process of an automobile body plate. The 6XXX aluminum alloy comprises the following components including,by mass, 0.9%-1.3% of magnesium, 0.70%-1.0% of silicon, 0.45%-0.6% of manganese, 0.15%-0.3% of iron, 0.45%-0.55% of copper and the balance Al and unavoidable impurities, wherein the total amount of the impurities is less than or equal to 0.06%. The preparation process comprises the following steps of melt casting, homogenizing heat treatment, rolling, solution heat treatment, pre-aging heat treatment, natural aging treatment and secondary artificial aging heat treatment. By means of the alloy and the preparation process, by optimizing the alloy composition, the preparation process and the heat treatment method, the strength of the plate after standing at room temperature is reduced, and meanwhile it is guaranteed that the strength of the plate after painting aging is greatly increased. According to the process scheme, melt casting, homogenization and hot and cold rolling are carried out to obtain an alloy plate; and after the plate is subjected to solution treatment, preageing is carried out, and a finished aluminum alloy plate which can be used as an automobile body plate material is obtained. By means of the technical scheme, the aluminum alloy plate which is low in cost, high in quality, capable of achieving room temperature storage and transportation and good in forming property is obtained. After artificial aging is carried out on the plate obtained after deformation treatment, the strength and plasticity are both high.

Owner:CENT SOUTH UNIV

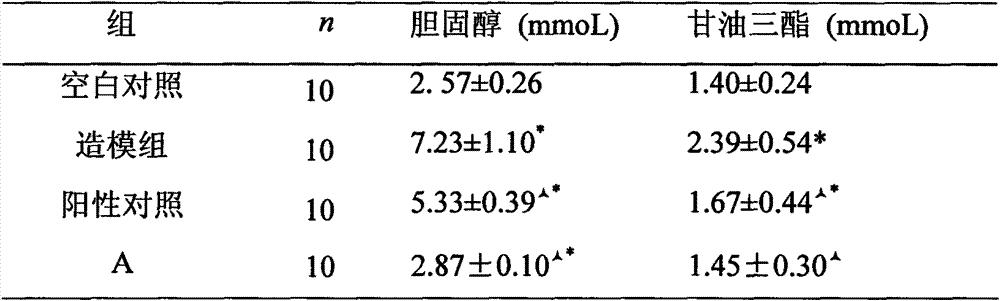

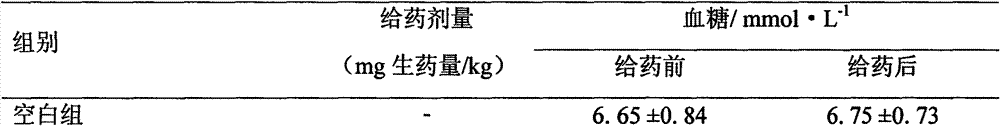

Ampelopsis grossedentata preparation for reducing blood sugar, blood lipid and blood pressure and its preparation method

Belonging to the technical field of traditional Chinese medicine and health care product processing, the invention relates to an Ampelopsis grossedentata preparation for reducing blood sugar, blood lipid and blood pressure and its preparation method. The preparation solves the problem of applying Ampelopsis grossedentata in reducing blood sugar, blood lipid and blood pressure, its effective component utilization rate is high, and the production process is simplified. The preparation method consists of: crushing Ampelopsis grossedentata tender branches and leaves, carrying out water extraction or alcohol extraction one to three times, conducting filtration, combining filtrates, adding an organic solvent for separation or directly conducting concentrating to obtain an extract, performing drying, adding auxiliary materials, mixing the materials, conducting granulation and tabletting, and implementing sugarcoating, thus obtaining tablets or capsules or soluble granules (granules) or other oral preparations.

Owner:GUIZHOU INST OF BIOLOGY

Plant fermentation extract for improving vegetable soil planting and preparation method thereof

PendingCN112251237AIncreased zinc contentImprove absorption and utilizationAgriculture tools and machinesMagnesium fertilisersBiotechnologyTricholoma matsutake

The invention relates to the technical field of vegetable planting, and particularly discloses a plant fermentation extract for improving vegetable soil planting and a preparation method thereof. Theplant fermentation extract for improving vegetable soil planting is prepared from cape jasmine, cyrtomium fortunei, germs, tricholoma matsutake, salicornia europaea, honeysuckle, dried lumbricus, pericarpium citri reticulatae, zinc-rich yeast, hirudin, eucommia ulmoides, selenium yeast, seaweed, red ginseng, monopotassium phosphate, fructus aurantii immaturus, cordyceps sinensis, magnesium sulfate, shredded coconut stuffing, liquorice, adenophora root and pollen through fermentation, extraction and pulverization. Raw materials are easy to obtain, the preparation process is simple, the soil structure is effectively improved, the number and activity of effective microorganisms in soil are increased, the soil magnesium content is increased, vegetable growth, yield increase and quality improvement are facilitated, and the plant fermentation extract is suitable for wide application and popularization.

Owner:山东福鑫寿生物科技有限公司

Overbased magnesium oxide dispersions

ActiveUS20120015853A1High in magnesiumLow viscosityLiquid carbonaceous fuelsAdditivesHigh magnesiumBoiling point

Overbased MgO dispersions with high magnesium content and acceptably low viscosities are reproducibly prepared without gel formation by heating to 280-360° C. a mixture of MgO, selected dispersants, low MW carboxylic acids, water and a combination of high boiling hydrocarbon and organic diluent, wherein water is more than 8%, typically more than 10% of the reaction mixture. No additional solubilizing or dispersing agents, promoters or reactants such as carbon dioxide, amines, alcohols etc are needed to obtain the desired dispersions. Compositions such as lubricating oils and fuels containing the overbased magnesium dispersions as additives are also disclosed.

Owner:LANXESS SOLUTIONS US INC

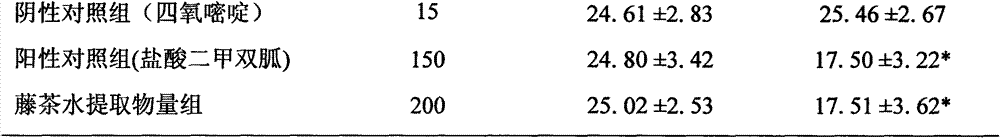

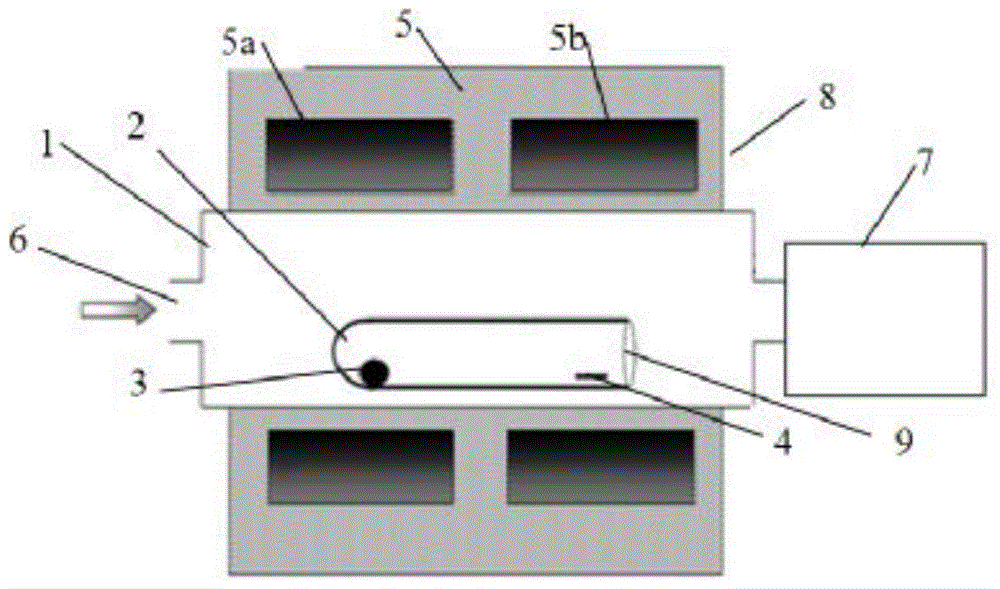

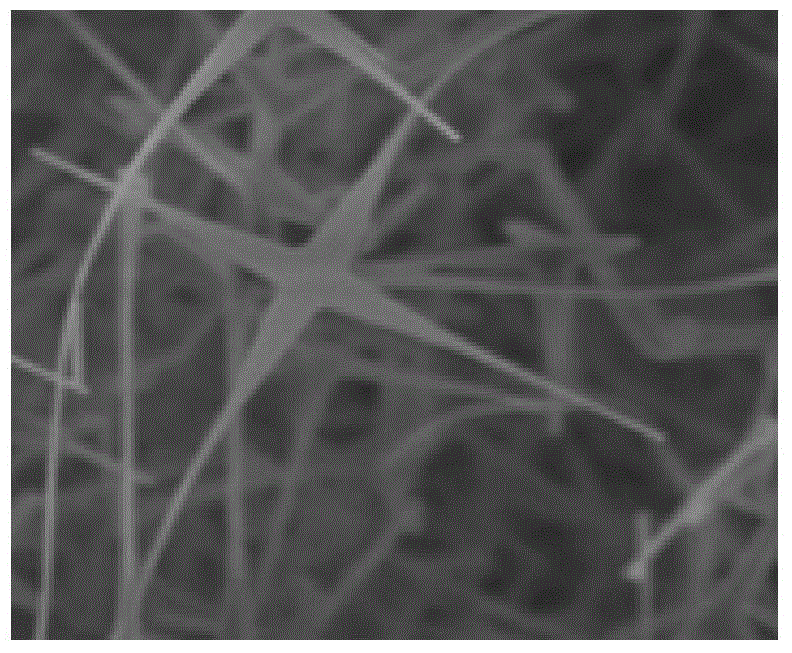

Water chestnut type high-magnesium-content Zn<1-x>Mg<x>O nanometer structure and preparation method thereof

InactiveCN104091844AWell formedIncrease freedomMaterial nanotechnologyVacuum evaporation coatingWater ChestnutsNanostructure

The invention discloses a water chestnut type high-magnesium-content Zn<1-x>Mg<x>O nanometer structure and a preparation method of the water chestnut type high-magnesium-content Zn<1-x>Mg<x>O nanometer structure. A thermal evaporation method is adopted for the preparation method. A two-temperature-zone tube furnace is adopted for the thermal evaporation method. According to the process, pure zinc powder and pure magnesium powder which have a certain stoichiometric ratio are ground and mixed to serve as source material, a certain amount of the mixture is poured into a quartz boat, the quartz boat is placed in the bottom of a quartz tube, a substrate is placed on the opening of the quartz tube, and finally the quartz tube is placed in the tube furnace to allow the mixture to be heated and react under high-purity oxygen and inert gas, so that the water chestnut type high-magnesium-content Zn<1-x>Mg<x>O nanometer structure is obtained. The operation process is simple, the temperature of the source material region and the temperature of the substrate region are independently controlled, process parameters can be flexibly controlled, and nanometer material in the new form can be easily formed. The water chestnut type high-magnesium-content Zn<1-x>Mg<x>O nanometer structure and the preparation method solve the technical problem that phase separation easily happens to Zn<1-x>Mg<x>O nanometer alloy when the content of Mg exceeds 33%, the content of Mg in the Zn<1-x>Mg<x>O three-element alloy obtained through synthesis ranges form 77% to 97%, the Zn<1-x>Mg<x>O three-element alloy is of a water chestnut type nanometer structure, and possibility is provided for ZnMgO-based solar-blind region ultraviolet detector development.

Owner:ZHEJIANG UNIV

Cultivation method of magnesium-enriched red rice

InactiveCN106134875AEfficient killingPrevent pests and diseasesMagnesium fertilisersAnimal corpse fertilisersPaecilomyces lilacinusCrop cultivation

The invention relates to the technical field of crop cultivation, in particular to a cultivation method of magnesium-enriched red rice. The method mainly comprises the following steps of 1 seed soaking and germination accelerating, wherein red rice seeds which are full in granule are taken to be soaked in an aqueous solution containing sodium chloride and paecilomyces lilacinus for 7 h to 16 h; 2 seeding and rice seedling raising, wherein rice seedling raising is conducted in a dry-land rice seedling raising mode or a semi-water rice seedling raising mode; 3 rice field treating, wherein the soil acidity and the soil fertility are improved through rice field treating; 4 field managing, wherein topdressing is conducted twice in the red rice growth process; 5 harvesting, wherein the red rice is harvested when the red rice is ripe. According to the cultivation method of the magnesium-enriched red rice, soil is significantly improved, the yield of the red rice is increased, the quality of the red rice is improved, and then the red rice which is rich in the magnesium element and has a health-care function is obtained.

Owner:包宗辉

Method for producing special multi-element fertilizer for rice from kieselguhr

ActiveCN102775254AHigh content of effective nutrientsReduce usageFertilizer mixturesPorosityDispersity

The invention relates to a method for producing a special multi-element fertilizer for rice from kieselguhr, which belongs to the field of fertilizers and aims to solve the problems of low effective silicon content, poor particle disintegrability, low dispersity and poor water solubility of the existing silicon fertilizer. The method comprises the following steps: evenly mixing kieselguhr and hydroxide, enclosing, and performing hydration reaction in a container at a temperature of 100-1000 DEG C and a pressure of 1.0-1.5 kilograms for 48 hours, wherein the hydroxide includes calcium hydroxide and potassium hydroxide; cooling with more than 3 times of 7 DEG C water until the temperature is below 30 DEG C, precipitating, filtering, baking, and crushing to obtain a mixture; adding magnesium oxide power, wherein the magnesium oxide power accounts for 6% of the mixture; and evenly mixing to obtain the special multi-element fertilizer for rice. The invention is applied to rice planting. The content of silicon, magnesium, calcium and minor elements of the special multi-element fertilizer for rice is about 85%; and the porosity is up to 90%.

Owner:黑龙江华泽农牧发展有限公司

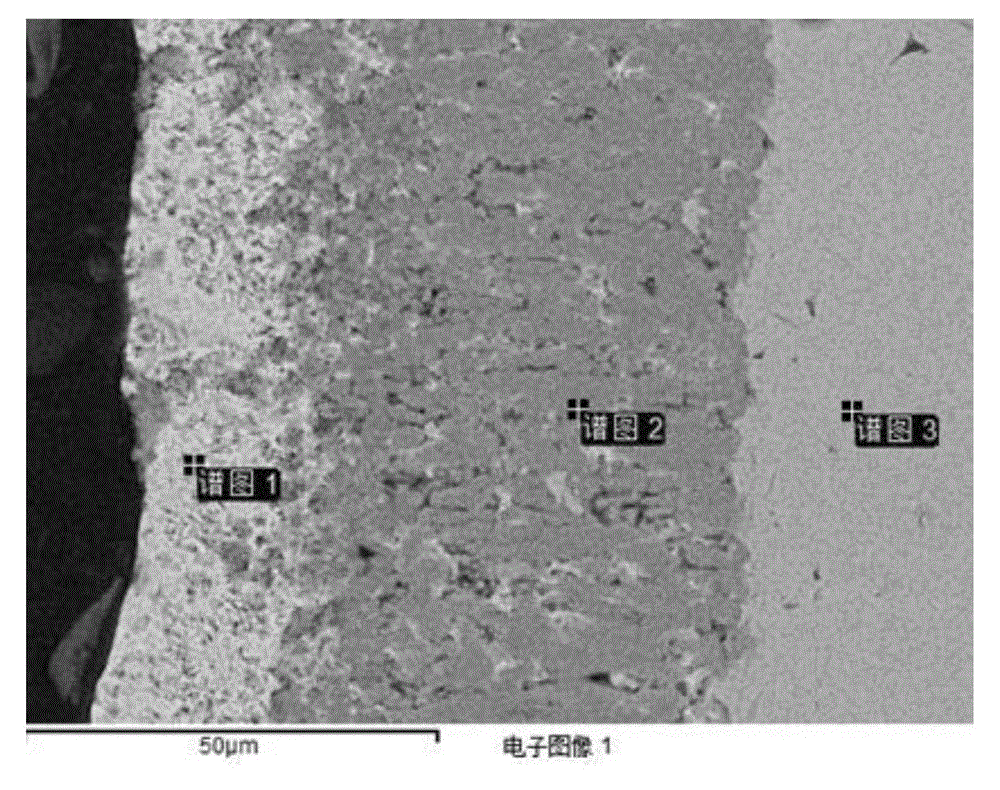

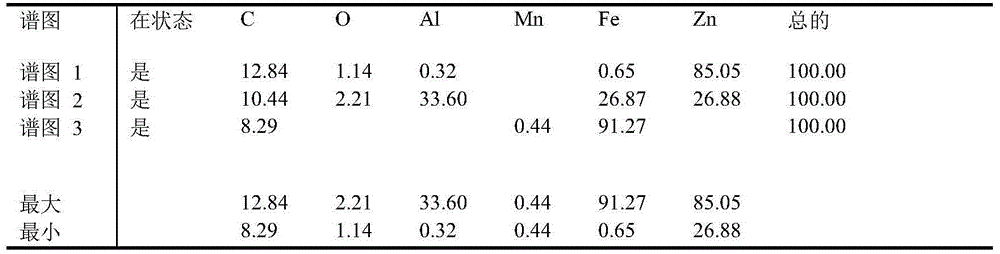

Single plating type zinc-aluminum-magnesium-rare earth protection coating with high corrosion resistance and preparation technology

ActiveCN105063532AGood lookingAchieve surface single platingHot-dipping/immersion processesRare earthAlloy coating

The invention discloses a single plating type zinc-aluminum-magnesium-rare earth protection coating with high corrosion resistance and a preparation technology. According to the single plating type zinc-aluminum-magnesium-rare earth protection coating technology, a zinc-aluminum-magnesium alloy coating can be acquired on a metal surface with a single hot dipping method; respective original performance of the coating and a metal matrix are kept, but the coating and the metal matrix form a metallurgical bonding interface of more than 99.9%, meanwhile, the coating is compact in structure, has stable components and excellent corrosion resisting performance and avoids skip plating, and salt-spray corrosion reaches 2,060 h; the corrosion resistance of the alloy coating is better than that of a common hot dipping pure-zinc coating, and the service life is prolonged. The single plating type technology can be reused and applicable to industrial production, overcomes defects that assistant plating of metal and a zinc-aluminum-magnesium alloy liquid is difficult, an excellent metallurgical bonding interface between the metal and the zinc-aluminum-magnesium alloy liquid is difficult to form, the probability of skip plating is high and the like, and can be widely applicable to preparation of a zinc-aluminum-magnesium alloy plating solution containing 5%-12% of Al and 1%-6% of Mg on the metal surface; a prepared co-penetrated layer forms Zn / Al / MgZn2 ternary eutectic and multiple types of binary eutectic, and the eutectic is the major reason for guaranteeing high corrosion resistance of the co-penetrated layer.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

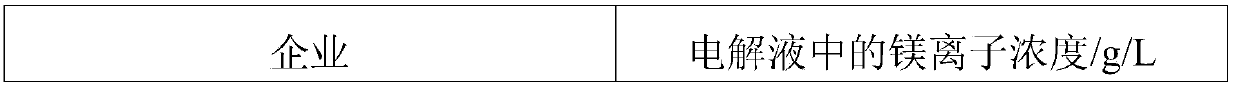

Method for removing magnesium in manganese sulfate solution through double salt crystallization process

ActiveCN109680300AWon't hurtShort processing cyclePhotography auxillary processesElectrolysis componentsElectrolysisSulfate

The invention discloses a method for removing magnesium in a manganese sulfate solution through a double salt crystallization process. According to the method, a crystallization device is additionallyarranged in an electrolytic manganese production system, and the concentration of ammonia sulfate in the manganese sulfate solution is controlled to be 80-140 g / L; the magnesium ion concentration is10-30 g / L; then, the pressure is controlled to be 3-20 Mpa, the initial temperature is 50-90 DEG C, ammonia sulfate magnesium crystals are added, the temperature is reduced to 30-70 DEG C within 45-180 min, the ammonia sulfate magnesium crystals are obtained, the crystals are taken out, and accordingly magnesium removal can be achieved. The method has the advantages that the method is economical and feasible, and no pollution is caused to an electrolytic manganese system.

Owner:GUIZHOU UNIV

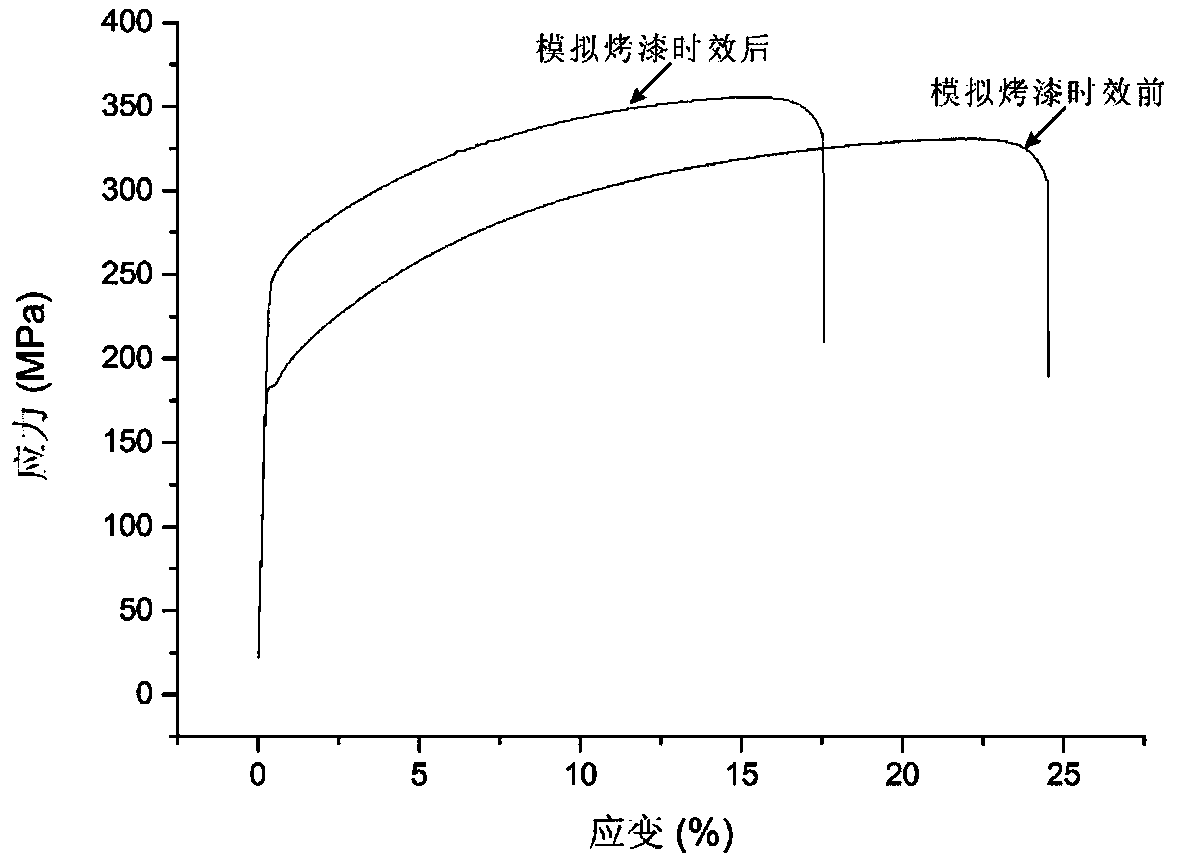

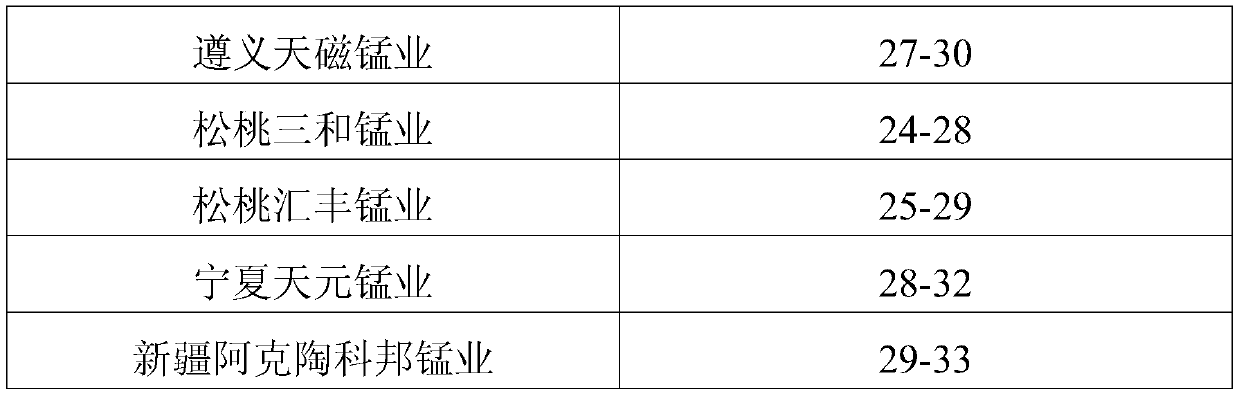

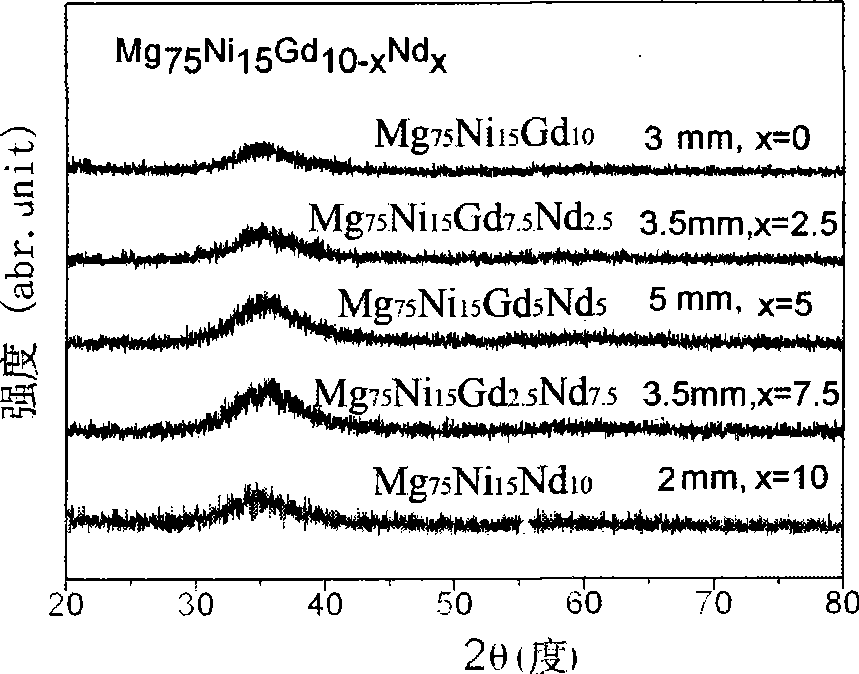

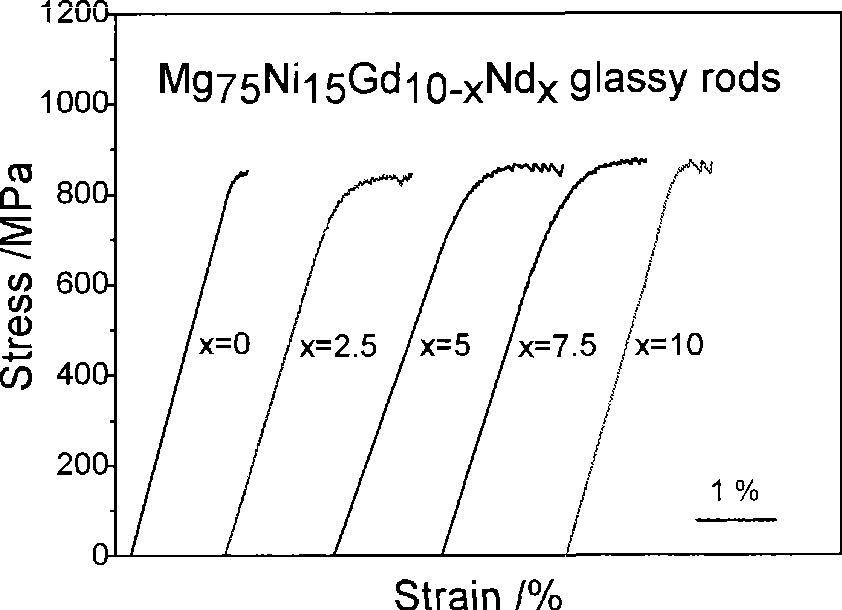

Mg-Ni-(Gd,Nd) bulk amorphous alloy and preparation thereof

InactiveCN101372735AEnhanced Amorphous Formation AbilityImprove plasticityElectric arc furnaceMetallic materials

The invention discloses Mg-Ni-(Gd, Nd) system bulk amorphous alloy and a preparation method thereof in the technical field of metal material. The structural formula of the alloy is Mg75Ni15Gd10-xNdx, wherein, x is the atomic percent of Nd element, and x is more than 1 and less than 10. The method for preparing the alloy comprises the following steps: Ni, Gd and Nd are mixed and smelted evenly in an electric arc furnace in argon atmosphere absorbed with titanium according to the required atomic mixture ratio to obtain a ternary alloy cast ingot; the ternary alloy which is crushed into fine particles and a Mg block are slowly heated for 15 to 20 minutes until being melted evenly by electromagnetic induction by adopting a graphite crucible at an atmosphere to obtain a master alloy ingot; and the bulk amorphous alloy is obtained by adopting the spray cast copper mould cooling method. Mg-based bulk amorphous alloy of Mg-Ni-(Gd, Nd) system is characterized by good amorphous forming capability, low density, high specific tenacity, more than 1 percent of plasticity, as well as excellent thermal stability and corrosion resistance.

Owner:凤阳天镁新材料科技有限公司

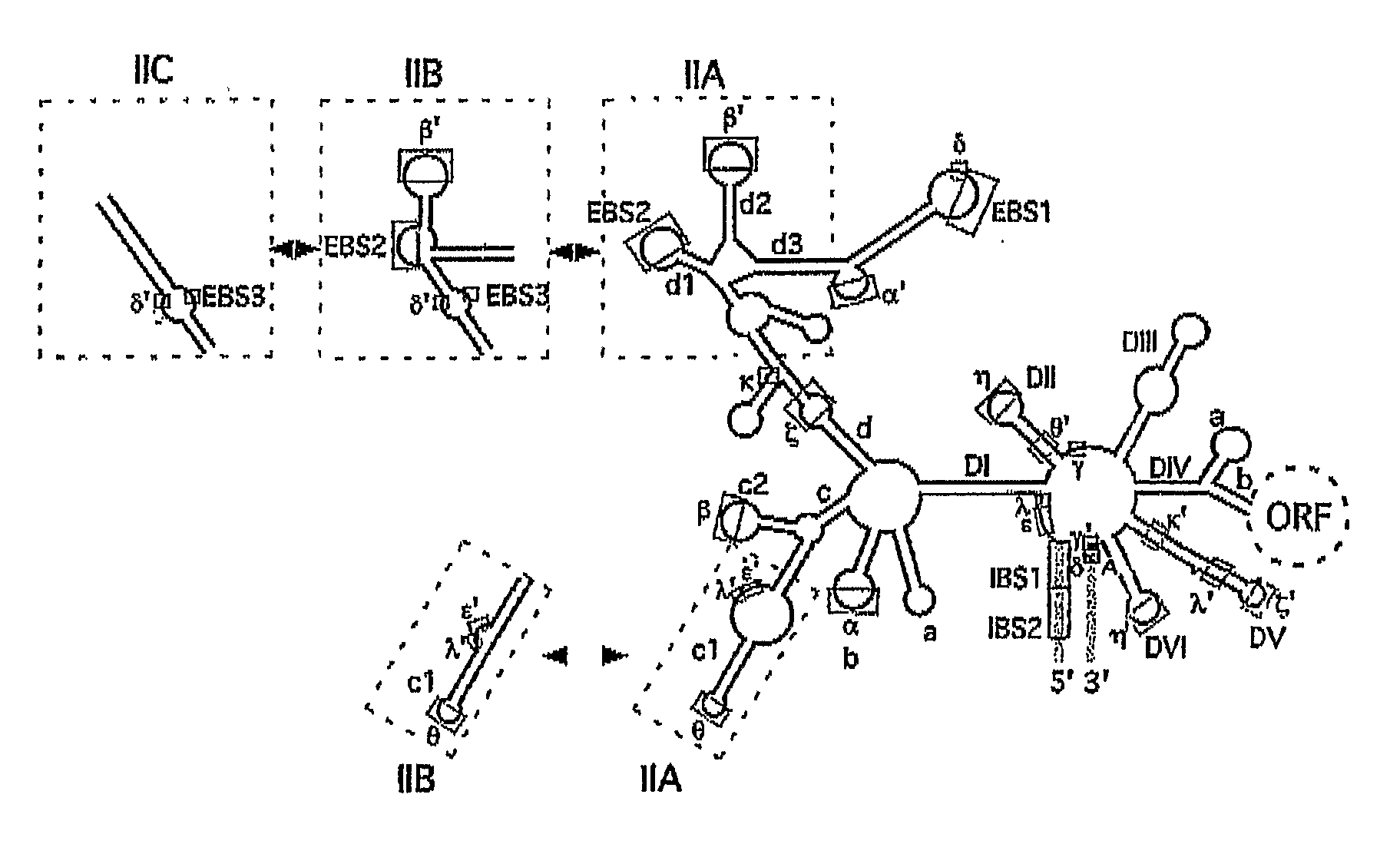

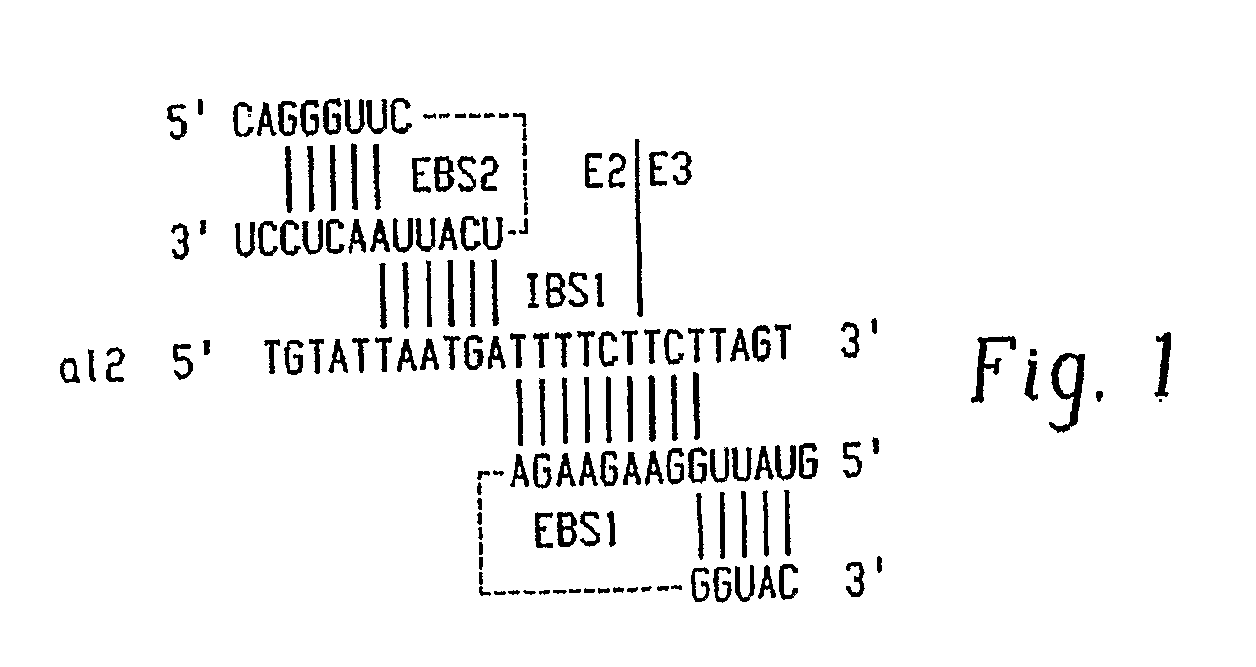

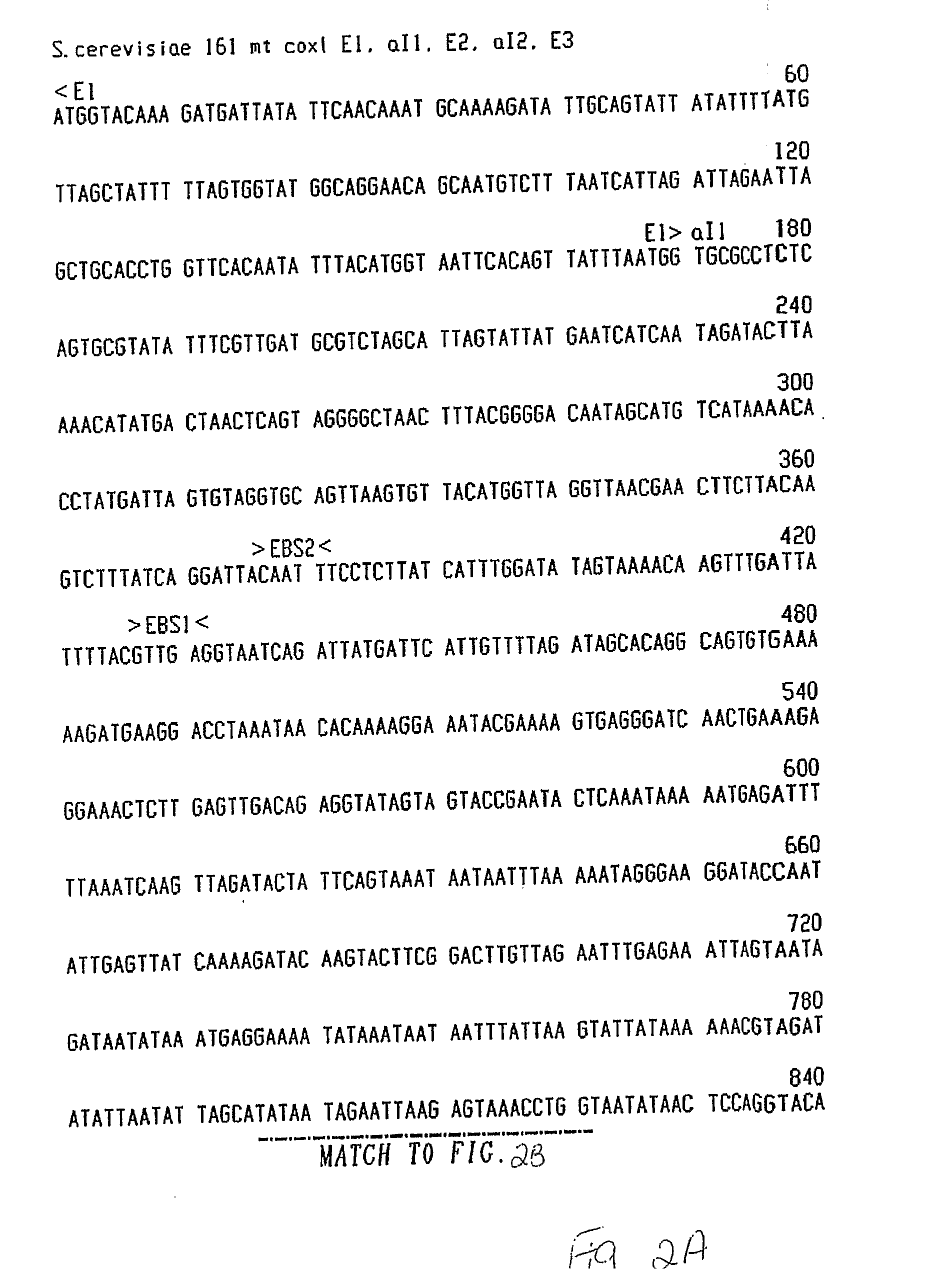

Gene Targeting in Eukaryotic Cells by Group II Intron Ribonucleoprotein Particles

InactiveUS20070254291A1Characteristic changeIncrease contentMicrobiological testing/measurementStable introduction of DNARibonucleoproteinEukaryotic cell

Provided herein are methods of disrupting DNA substrates in eukaryotic cells and methods of introducing exogenous polynucleotides into target sites in the DNA substrates In certain embodiments the methods comprise introducing a purified group II intron ribonucleoprotein (RNP) particle into the host cell. In certain embodiments the method comprises introducing a group II intron RNP particle and a DNA construct comprising an exogenous polynucleotide flanked by sequences that are homologous to sequences that flank the target site in the endogenous DNA substrate. In certain embodiments, the methods also involve introducing magnesium ions into the eukaryotic cells.

Owner:THE UNIV OF TEXAS SYST

Preparation method of cereal lactic acid bacteria beverage with high nutrition value, low heat quantity, excellent flavor and good stability

InactiveCN107156570AImprove eyesightGood conditionFood ingredient as antioxidantFood ultrasonic treatmentMaillard reactionNutritive values

The invention discloses a preparation method of a cereal lactic acid bacteria beverage with high nutrition value, low heat quantity, excellent flavor and good stability. The preparation method comprises the following steps: mixing purple sweet potatoes, corn kernels, taros, Chinese yams, millets, black rice, mung beans and malts to obtain a mixed raw material; performing heating treatment, pectinase enzymatic hydrolysis, cellulase enzymatic hydrolysis, amylase enzymatic hydrolysis, protease enzymatic hydrolysis, Maillard reaction, fermentation, seasoning and homogenization on the mixed raw material to obtain the cereal lactic acid bacteria beverage. The lactic acid bacteria beverage prepared by the preparation method disclosed by the invention contains various nutrient substances, is balanced in nutrition, has a health effect, is sour-sweet and tasty in flavor, has the special flavor of cereals, is good in stability within the shelf life, cannot precipitate, is low in caloric value and cannot bring excessive heat burden.

Owner:湖北省珠穆朗玛食品有限公司

Ductile iron rare earth Mg-Si nodularizer

The invention relates to a ductile iron rare earth Mg-Si nodularizer used in the conventional pour-over process spheroidization treatment of the ductile iron production process. The raw materials contain magnesium ingot, silicon calcium alloy, silicon barium alloy, rare earth ferrosilicon alloy and 75 ferrosilicon and comprise the following components by weight percent: 10-14% of Mg, 1.0-4.0% of Re, 35-50% of Si, 2.0-6.0% of Ca or Ca and Ba and the balance Fe. The nodularizer is produced by the conventional mix-melting method, is irregularly massive and has the grain size between 3-25mm to 5-40mm. By using the nodularizer of the invention, the magnesium content can be increased, the spheroidization treatment cost can be significantly reduced; and the spheroidization quality is stable, the roundness of graphite nodules is good, Re, Ca and Ba are added to realize the functions of purifying molten iron, promoting graphitization, delaying degradated spheroidization, promote nucleation to form fine-grained structure and the like.

Owner:WUXI NOVEL SPECIAL METAL

Slag form system for smelting vanadium-titanium magnetite with electric furnace

ActiveCN110438279ARealize comprehensive utilizationGood acid hydrolysisElectric furnaceElectric arc furnaceMagnetite

The invention discloses a slag form system for smelting vanadium-titanium magnetite with an electric furnace, and belongs to the field of comprehensive utilization of schreyerite. The slag form systemis characterized in that low-silicon vanadium-titanium magnetite concentrate is taken as a raw material; a pre-reduced product of the vanadium-titanium magnetite concentrate is fed into the electricfurnace for smelting; a calcium-containing and magnesium-containing solvent is added in a mass ratio of 0.6 to 1.0 of CaO to SiO2, and a molar ratio of 1.1 to 0.8 of MgO to TiO2 for regulating the slag composition; and a major titanium-containing phase in the slag refers to a magnesium metatitanate phase. Through adoption of the slag form system disclosed by the invention, the inclusion of molteniron in vanadium and the inclusion of slag in vanadium can be effectively controlled during smelting of the electric furnace; vanadium can be recovered from obtained vanadium-containing molten iron through vanadium extraction with a converter; the titanium-containing slag meets the requirement on a sulfate process titanium dioxide raw material; and the comprehensive utilization of iron, vanadium and titanium in the vanadium-titanium magnetite can be realized. in the smelting process, the vanadium-titanium trend is easy to control, and the smelting operation difficulty is low.

Owner:CENT SOUTH UNIV

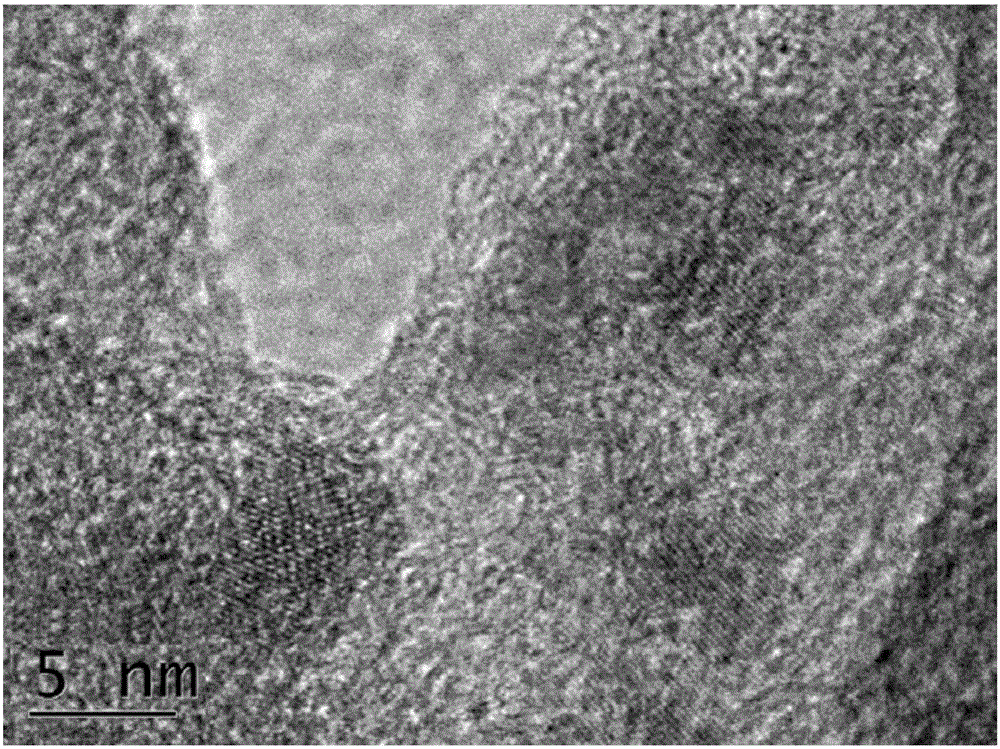

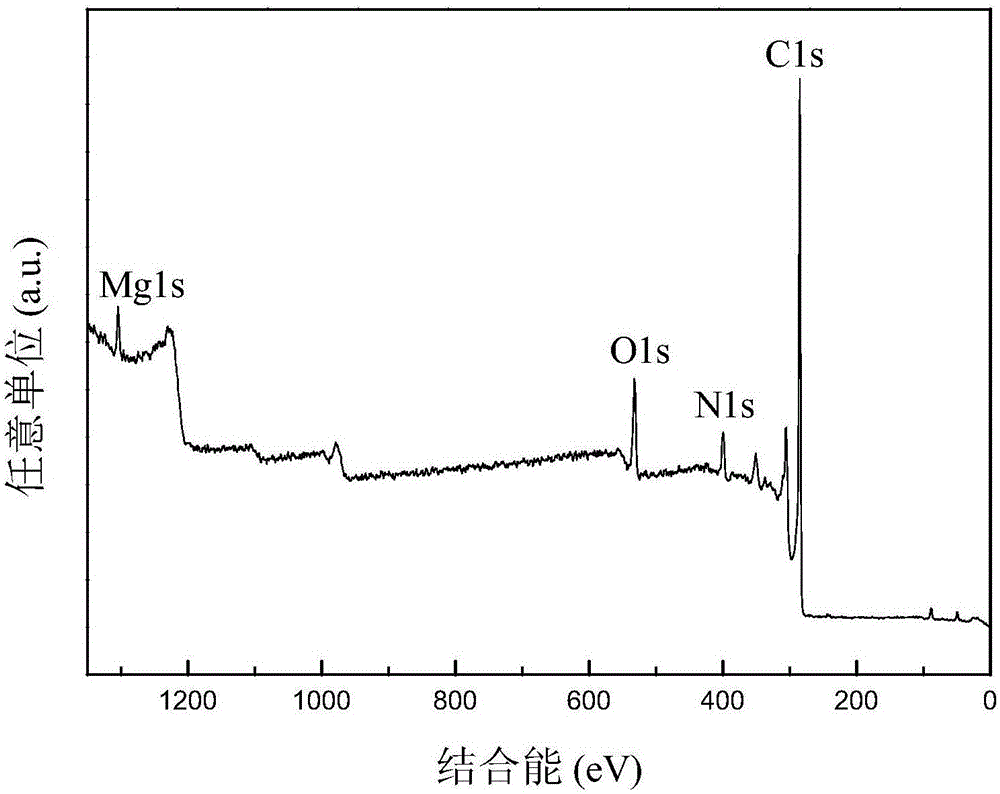

High-performance adsorption material and preparation method thereof

InactiveCN106475051ASimple stepsEvenly dopedGas treatmentOther chemical processesMicrosphereMagnesium salt

The invention discloses a high-performance adsorption material and a preparation method thereof. A hierarchical-pore nitrogen doped carbon / MgO composite microsphere material is prepared by performing a high-temperature thermal treatment carbonization method on polyimide serving as a carbon and nitrogen source, polyurethane foam serving as a macroporous scaffold and metal magnesium salt serving as an additive. According to the high-performance adsorption material and the preparation method thereof, the use of an expensive template agent and a toxic raw material reagent is avoided; the prepared composite microsphere material has an ideal flower-shaped spherical appearance, is of a hierarchical-pore structure with micro holes and macro holes, has controllable surface characteristics, excellent structural stability, high nitrogen content and magnesium content, and shows high adsorption volume and excellent circulating stability when used as a CO2 adsorption material. The preparation method disclosed by the invention is simple and feasible; the process is controllable, and the reaction time is short; furthermore, no complicated experimental equipment and complicated experimental steps are needed; and the industrial large-scale production is facilitated.

Owner:CHONGQING UNIV OF ARTS & SCI

Process for preparing organic magnesium alumen-removing agent

InactiveCN100497550CNot easy to absorbPrevent volatilizationLiquid carbonaceous fuelsTreatment apparatus corrosion/fouling inhibitionDiphenyl etherCyclohexanone oxime

An oil-soluble V-removing agent containing organomagnesium is prepared through preparing water-phase emulsion from magnesium hydroxide (or oxide), preparing oil-phase emulsion from arylhydrocarbon sulfonic acid and petronephthenic acid, adding oil phase to water liquid while stirring, clarifying, removing supernatant, adding two or more of diesel oil, dibenzene, diphenyl ether and arylhydrocarbon, heating for dewatering, ageing and adding butanone (or cyclohexanone) oxime.

Owner:卢箭

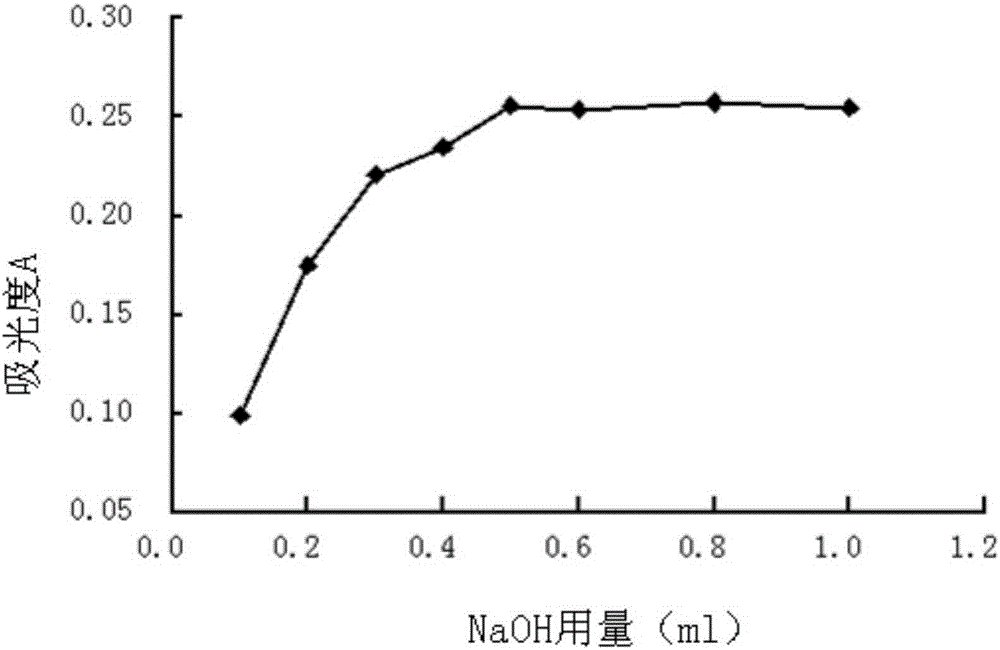

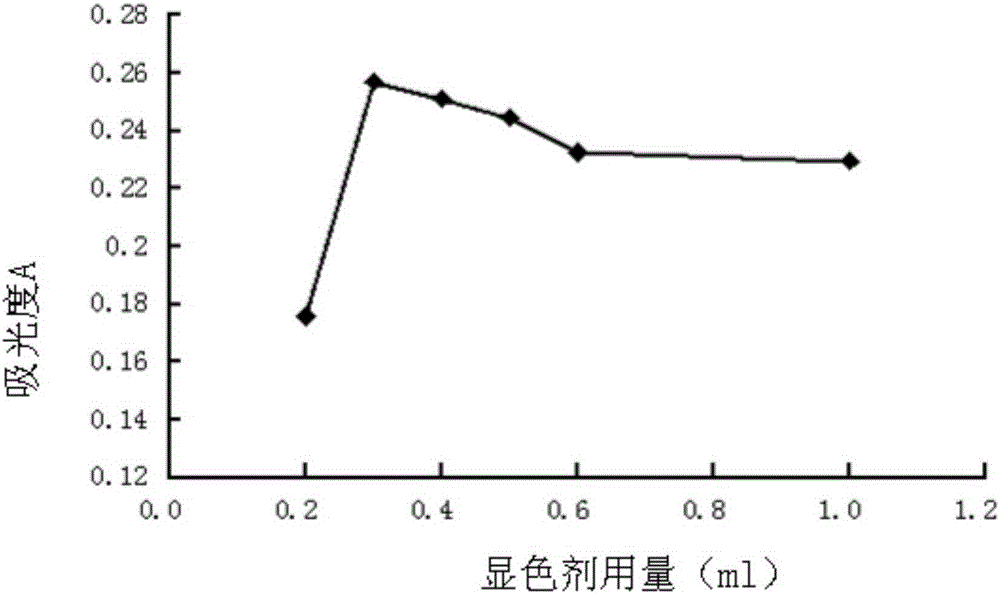

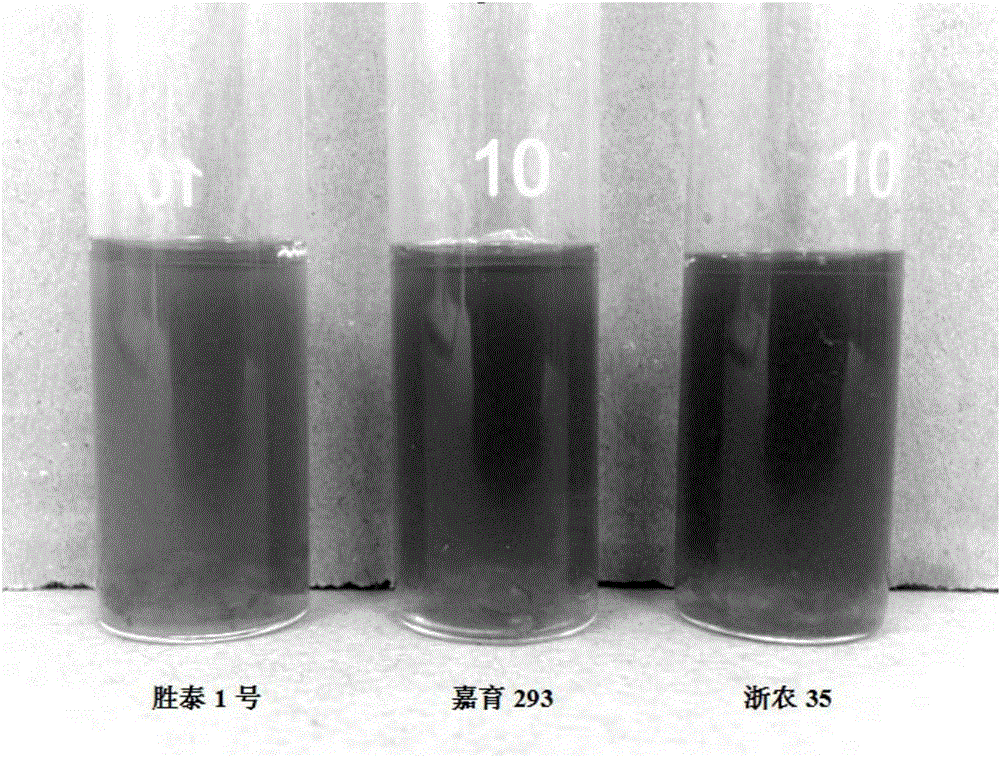

Rapid screening method for magnesium-rich rice

InactiveCN105223142AHigh in magnesiumEasy Breeding ScreeningPreparing sample for investigationColor/spectral properties measurementsBiotechnologyAnimal science

The invention discloses a rapid screening method for magnesium-rich rice. The method includes performing the following steps on to-be-detected brown rice and standard brown rice respectively: conducting brown rice gelatinization; adding hydrochloric acid into the gelatinization product to perform neutralization; then adding a triethanolamine solution, a polyvinyl alcohol solution, a hydroxylamine hydrochloride solution, a Titan yellow staining solution and a sodium hydroxide solution to a constant volume, performing oscillation and shaking the mixture evenly, and then carrying out standing for 8-12min; taking the supernatant so as to obtain the brown rice reactant of the to-be-detected rice and the brown rice reactant of the standard rice; and performing color comparing: when the color of the to-be-detected brown rice reactant is darker than that of the brown rice reactant of the standard rice, the magnesium content of the to-be-detected brown rice is higher than that of standard rice, and the darker the color is, the higher the magnesium content is; otherwise, when the color of the to-be-detected brown rice reactant is lighter than that of the brown rice reactant of the standard rice, the magnesium content of the to-be-detected brown rice is lower than that of standard rice, and the lighter the color is, the lower the magnesium content is.

Owner:ZHEJIANG UNIV

Calcium-magnesium-containing pellet and preparation method thereof

ActiveCN107130070AImproved pyrometallurgical propertiesHigh in magnesiumBlast furnace detailsSodium BentoniteDolomite

The invention discloses a calcium-magnesium-containing pellet and a preparation method of the calcium-magnesium-containing pellet. The calcium-magnesium-containing pellet is composed of magnesium-containing flux-weakening concentrate, magnetic concentrate, dedusting ash of lightly-burnt dolomite, bentonite and water. Through the cooperation of the low-magnesium magnetic concentrate, the magnesium-rich flux-weakening concentrate and the calcium-magnesium-rich lightly-burnt dolomite, the content of calcium and magnesium of the pellet is further increased; the content of magnesium of the prepared calcium-magnesium-containing pellet can reach over 2.0%, the content of calcium can reach over 2.0%, the reduction degree is increased to 74-78%, the softening start temperature is increased to about 30 DEG C, and the soft heat interval is reduced by about 40 DEG C, so that the high-temperature metallurgical performance of the pellet is improved remarkably; meanwhile, the dedusting ash of the lightly-burnt dolomite is added to the pellet, the high-temperature metallurgical performance of the pellet is improved, and the environment protection problem caused by outdoor stockpiling of the dedusting ash is solved; and due to the fact that the dedusting ash of the light-burnt dolomite is fine, the supplying amount of the bentonite is reduced as well, and the content of SiO2 brought into the pellet is reduced.

Owner:JIUQUAN IRON & STEEL GRP

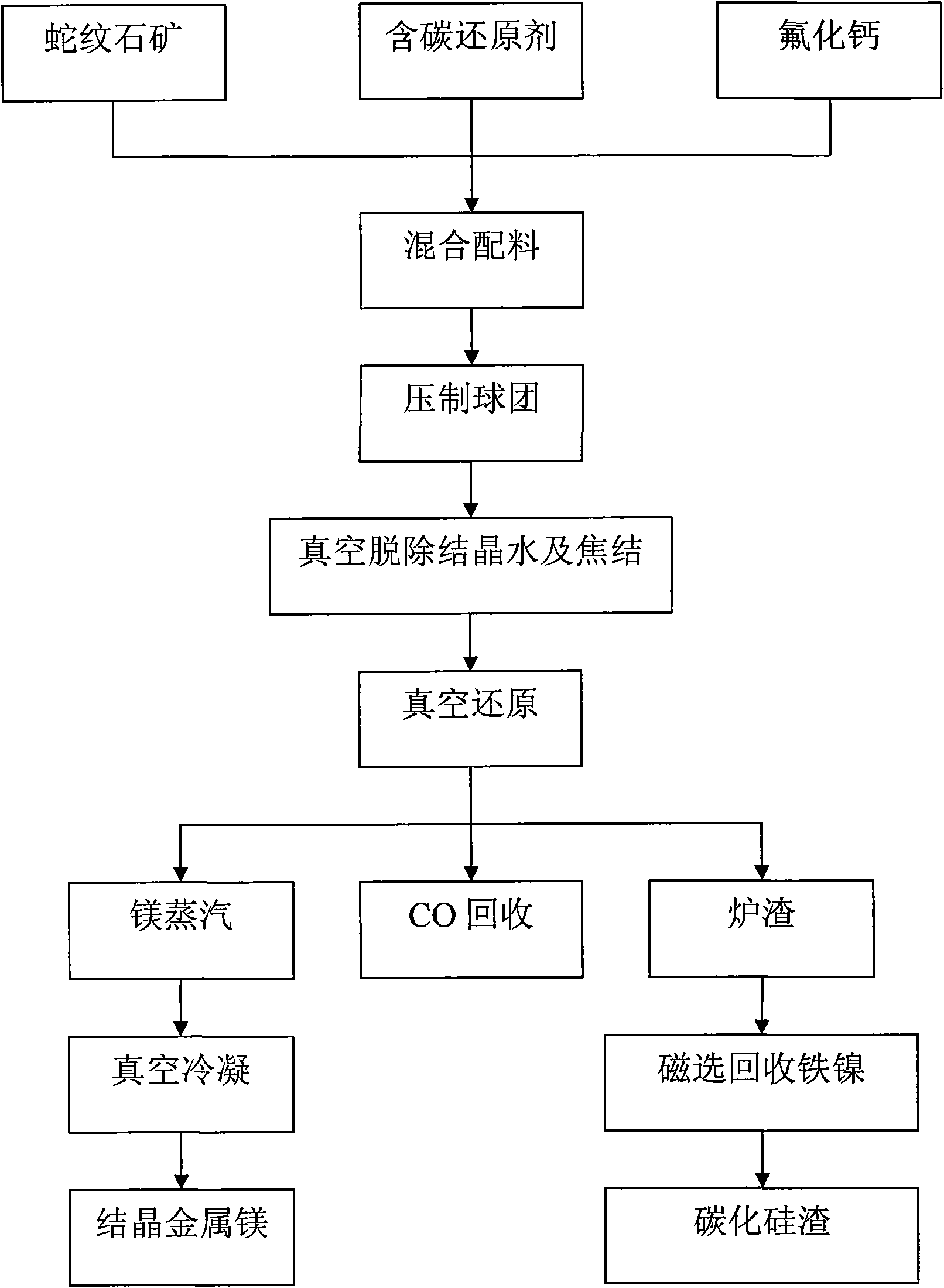

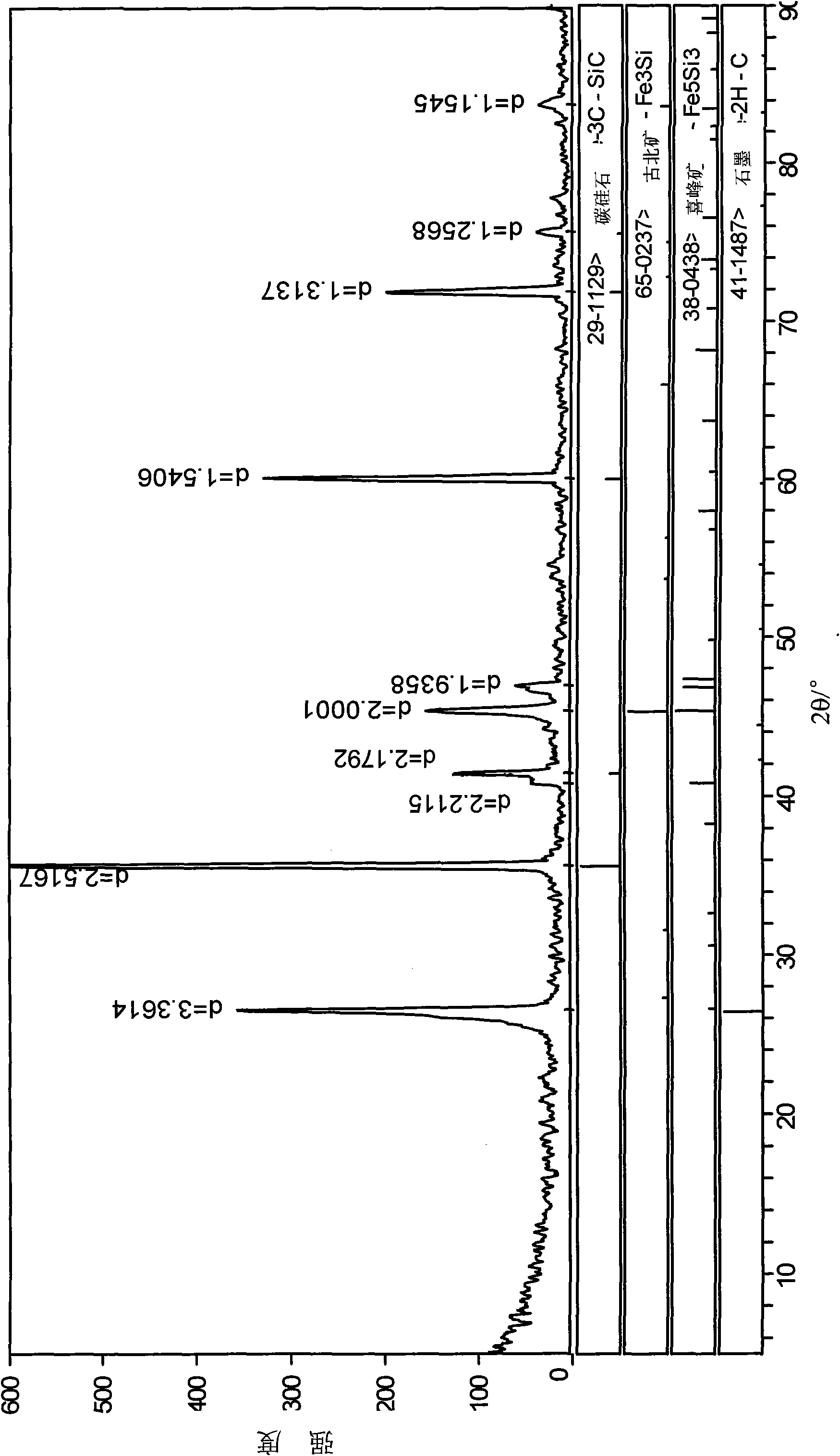

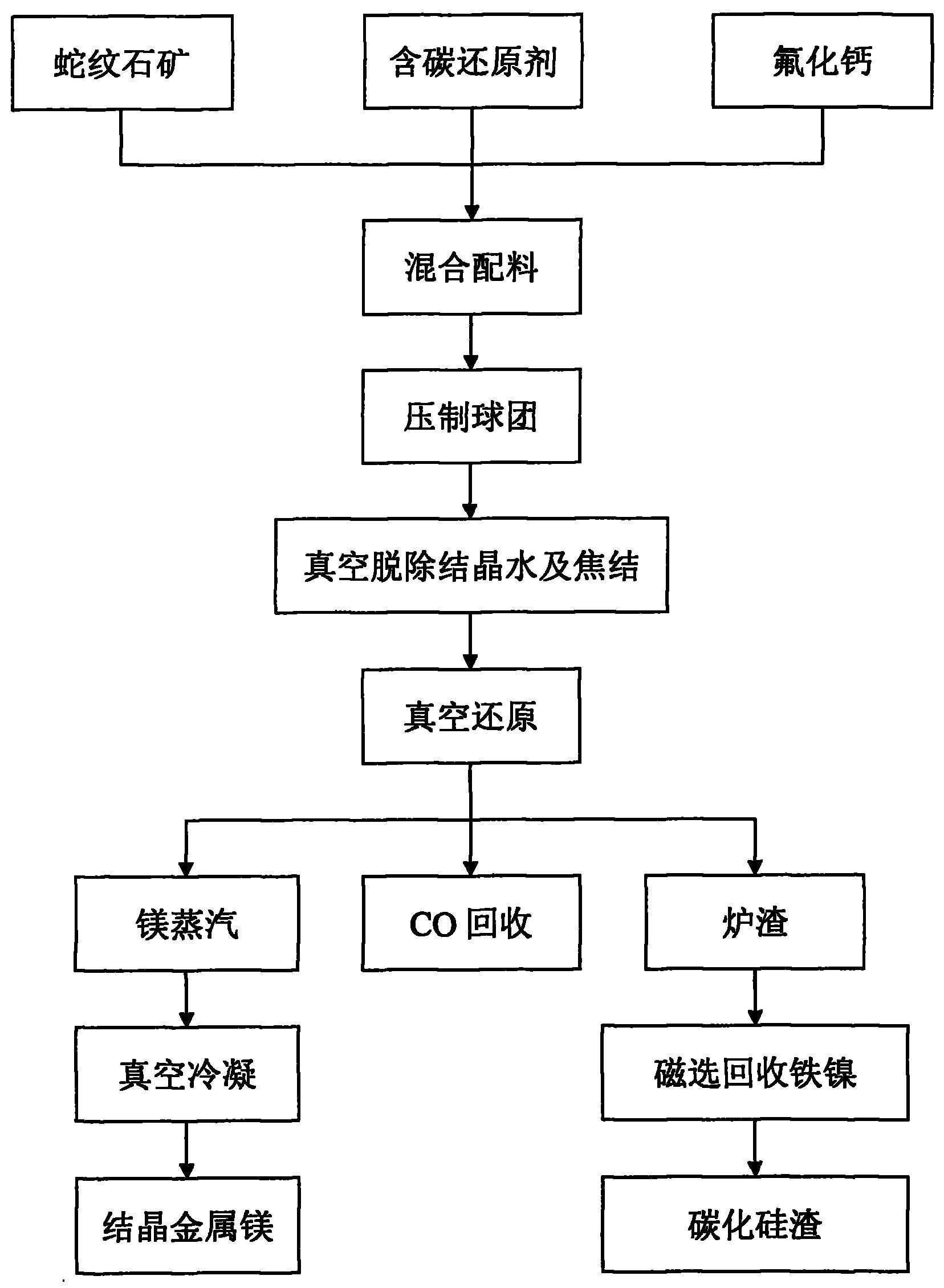

Method for preparing magnesium metal and by-product by vacuum carbothermic reduction with serpentine minerals

InactiveCN101560603BHigh in magnesiumNo need for calcination to remove carbonProcess efficiency improvementMagnetic separationSlagMassicot

The invention discloses a method for preparing a magnesium metal and a by-product by vacuum carbothermic reduction with serpentine minerals. The method comprises the following steps: using serpentine mineral powder as a raw material; adding a carbonaceous reducing agent which is 1 to 2 times of the theoretical quantity of carbon required for completely reducing magnesium silicate in the serpentine; adding a catalyst, and mixing the materials evenly to obtain a mixed raw material; pressing the mixed raw material into spherical or blocky ball agglomerations and drying the ball agglomerations; putting the dried ball agglomerations into a vacuum furnace, controlling the vacuum degree in the furnace to between 10 and 500 Pa, raising the temperature to between 500 and 700 DEG C, and keeping thetemperature for 20 to 60 minutes to remove crystal water and clinker the materials; keeping the vacuum degree in the furnace, raising the temperature to between 1,200 and 1,500 DEG C, and reducing themagnesium silicate and oxides of metallic iron and nickel at a constant temperature for 30 to 60 minutes; and condensing magnesium vapor obtained from the reduction on a magnesium condenser into crystallized magnesium, recycling the metallic iron and the metallic nickel in the slag through magnetic separation, and preparing the slag after the magnetic separation into industrial silicon carbide through decarburization and purification.

Owner:北京华夏建龙矿业科技有限公司

Electrolytic method for manufacturing aluminum-manganese alloy in fluoride-chloride molten salt system

The invention aims to provide an electrolytic method for manufacturing aluminum-manganese alloy in a fluoride-chloride molten salt system. The electrolytic method includes that in an electrolytic bath, inert metal molybdenum is used as a cathode and is placed at a lower portion of the electrolytic bath, and graphite is used as an anode; an electrolyte comprises 39% of NaCl, 50% of KCl and 11% of AlF3, is prepared according to the mass ratio and is heated, so that the temperature of the electrolyte ranges from 680 DEG C to 730 DEG C; MgCl2 is added into the electrolyte after the electrolyte is melted, and the quantity of the added MgCl2 accounts for 40-75% of the mass of the AlF3; direct-current power is switched on for electrolysis, the electrolytic temperature ranges from 680 DEG C to 730 DEG C, the current density of the cathode ranges from 5.2A / cm<2> to 8.7A / cm<2>, the current density of the anode ranges from 0.6A / cm<2> to 1.1A / cm<2>, and the voltage of the bath ranges from 4.7V to 6.1V; and liquid Al-Mg alloy is deposited at a position close to the cathode of the electrolytic bath after electrolysis is carried out for 1.5 to 4 hours, and is cooled down to obtain the solid Al-Mg alloy. The electrolytic method has the advantages that a process of a production technology can be greatly shortened, the technology is simple, energy is saved, and the purity of the product is high.

Owner:HARBIN ENG UNIV

Cultivation method of magnesium-rich 916 heterozygous rice

InactiveCN108370977AEfficient killingPrevent pests and diseasesMagnesium fertilisersExcrement fertilisersPaecilomyces lilacinusCrop cultivation

The invention relates to the technical field of crop cultivation, in particular to a cultivation method of magnesium-rich 916 heterozygous rice. The method mainly comprises the following steps of a, soaking seeds, germinating, taking 916 heterozygous rice seeds with full granules, and soaking the seeds with an aqueous solution containing brassin and paecilomyces lilacinus for 7-16 h; b, sowing, cultivating seedlings, and using a dryland breeding method or semi-water breeding method for the seedling cultivation; c, treating rice fields, and improving soil acidity and fertility through the ricefield treatment; d, managing fields, and conducting topdressing twice during the growth process of the 916 heterozygous rice; e, harvesting, and harvesting the 916 heterozygous rice after mature. Thecultivation method of the magnesium-rich 916 heterozygous rice significantly improves the soil, increases the yield and quality of the 916 heterozygous rice, and obtains the 916 heterozygous rice which is rich in magnesium and has a health care function.

Owner:甘博

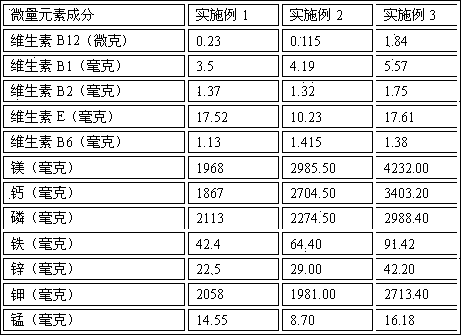

Vegetarian nutrition powder and preparation method thereof

The invention relates to vegetarian nutrition powder which comprises the following components in parts by weight: 50-100 parts of white sesame, 50-100 parts of walnuts, 50-100 parts of corn, 50-100 parts of oats and 200-400 parts of black sesame. By the adoption of pure natural plants serving as raw materials, the vegetarian nutrition powder is green and healthy; the vegetarian nutrition powder is matched with meat analogue prepared from peanuts and soybeans, so that high-quality proteins in the soybeans and the peanuts can be easily absorbed by a human body; most importantly, trace elements such as vitamin B12, vitamin B2, vitamin B6, phosphorus, calcium, manganese, magnesium and iron which are needed by health retaining can be supplied to vegetarians. The components are scientifically and reasonably matched; after the white sesame and the black sesame are mixed, calcium and phosphorus are fully combined to achieve an effect of supplementing the calcium; meanwhile, calcium and phosphorus sediments generated by calcium and phosphorus combination are positioned at a long-bone end, so that increase of the heights of the youths is facilitated.

Owner:吴海元

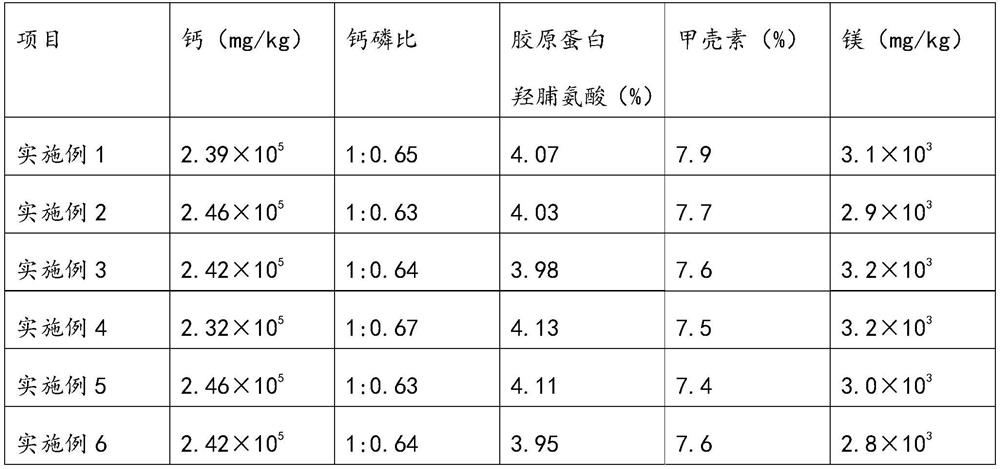

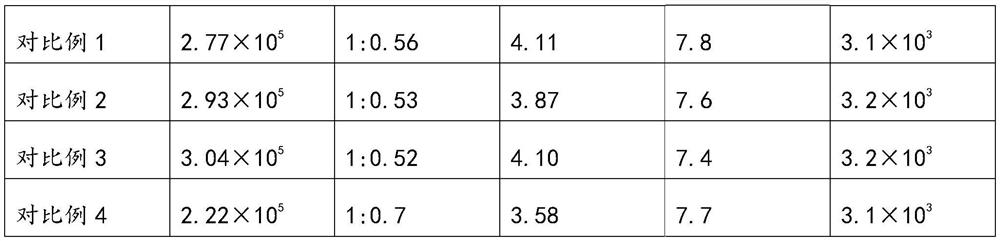

Practical nutritional fish scale biological calcium composite chewable tablet and preparation method thereof

PendingCN112841569ATake advantage ofCalcium-phosphorus ratio is reasonableFood scienceBiotechnologyVitamin C

The invention discloses a practical nutritional fish scale biological calcium compound chewable tablet. The chewable tablet is prepared from the following raw materials: fish scale biological calcium, inulin, trehalose, vitamin C and magnesium stearate. The fish scale biological calcium is obtained by crushing the remaining scales after alkali treatment, acid treatment and partial degumming; a treating agent for alkali treatment is lime milk; a treating agent for acid treatment is a citric acid solution or a malic acid solution. The invention also discloses a preparation method of the practical nutritional fish scale biological calcium composite chewable tablet. According to the method, mucus, pigments, unnecessary impurities and fishy smell on the surfaces of the fish scales are removed at the same time, and collagen, chitin, biological calcium and trace elements of the fish scales are reserved. The fish scale biological calcium compound chewable tablet with reasonable calcium-phosphorus ratio and high magnesium content is obtained by improving the preparation method, and various organic components such as collagen and sclerotin are compounded in the product, so that the synergistic absorption of human intestinal tracts on biological minerals can be promoted.

Owner:青岛蓝色康典海洋生物科技有限公司

A kind of calcium-magnesium-containing pellets and preparation method thereof

ActiveCN107130070BImproved pyrometallurgical propertiesHigh in magnesiumBlast furnace detailsDolomiteCalcium magnesium

The invention discloses a calcium-magnesium-containing pellet and a preparation method of the calcium-magnesium-containing pellet. The calcium-magnesium-containing pellet is composed of magnesium-containing flux-weakening concentrate, magnetic concentrate, dedusting ash of lightly-burnt dolomite, bentonite and water. Through the cooperation of the low-magnesium magnetic concentrate, the magnesium-rich flux-weakening concentrate and the calcium-magnesium-rich lightly-burnt dolomite, the content of calcium and magnesium of the pellet is further increased; the content of magnesium of the prepared calcium-magnesium-containing pellet can reach over 2.0%, the content of calcium can reach over 2.0%, the reduction degree is increased to 74-78%, the softening start temperature is increased to about 30 DEG C, and the soft heat interval is reduced by about 40 DEG C, so that the high-temperature metallurgical performance of the pellet is improved remarkably; meanwhile, the dedusting ash of the lightly-burnt dolomite is added to the pellet, the high-temperature metallurgical performance of the pellet is improved, and the environment protection problem caused by outdoor stockpiling of the dedusting ash is solved; and due to the fact that the dedusting ash of the light-burnt dolomite is fine, the supplying amount of the bentonite is reduced as well, and the content of SiO2 brought into the pellet is reduced.

Owner:JIUQUAN IRON & STEEL GRP

Process for preparing high concentrations of magnesium and boron combination materials

ActiveUS8426347B2High in magnesiumEasy to adjustLiquid carbonaceous fuelsGroup 3/13 element organic compoundsHigh concentrationMagnesium salt

The present invention describes a nanoparticle size composition comprising at least one overbase complex of a magnesium salt and an associated organic boron complex. The present compound is an improvement over previous processes due to less complicated processing requirements and the high concentration of both magnesium and boron that results.

Owner:LIQUID MINERALS GRP LTD

Paddy soil heavy metal passivating improver

PendingCN109913233AReduced activityComposition is stableAgriculture tools and machinesOther chemical processesPhosphatePotassium

The invention discloses a paddy soil heavy metal passivating improver. The paddy soil heavy metal passivating improver comprises a main agent and an auxiliary agent, wherein the main agent comprises natural zeolite, natural limestone and potassium dihydrogen phosphate; the auxiliary agent comprises animal manure, vermiculite, a decomposing agent and a silicon fertilizer. The paddy soil heavy metalpassivating improver can effectively increase the pH value of soil, reduce the change rate thereof, reduce the active cadmium and arsenic contents of the soil and the enrichment amounts of cadmium and arsenic in crops, increase the available phosphorus content of the soil and improve the soil selenium enriching capability of the crops.

Owner:湖南省地球物理地球化学勘查院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com