Mg-Ni-Gd-Ag serial block amorphous alloy and preparation method thereof

An amorphous alloy, mg75-xni15gd10agx technology, applied in the field of Mg-Ni-Gd-Ag magnesium-based bulk amorphous alloy and its preparation, and metal alloy materials, can solve the problems of low amorphous forming ability, and achieve high Amorphous forming ability, high magnesium content, good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1: Mg with a diameter of 3.0 mm 74 Ni 15 Gd 10 Ag 1 Preparation of Columnar Bulk Amorphous Alloy

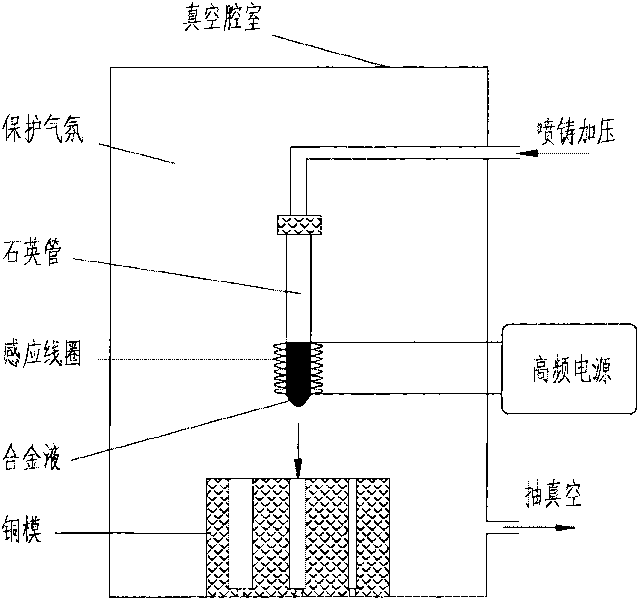

[0018] The magnesium-based bulk amorphous alloy is prepared by using Mg, Ni, Gd and Ag with a raw material purity of 99.9% in a molar mass ratio of 74:15:10:1. First, Ni, Gd, and Ag are melted in an electric arc furnace to obtain a master alloy with uniform composition. Before smelting, the electric arc furnace chamber is vacuumed to 1.2×10 -3 Pa is filled with 0.8 atmospheric pressure of high-purity argon as a protective gas. Ti balls are used to further purify the protective gas during smelting. The master alloy should be turned over before each smelting process. During the smelting process, the metal liquid is stirred by electric arc and electromagnetic to ensure the uniform composition of the alloy ingot. The surface of the intermediate alloy ingot obtained by arc melting is ground and broken, and then put into the crucible together with magnesium in the ...

Embodiment 2-7

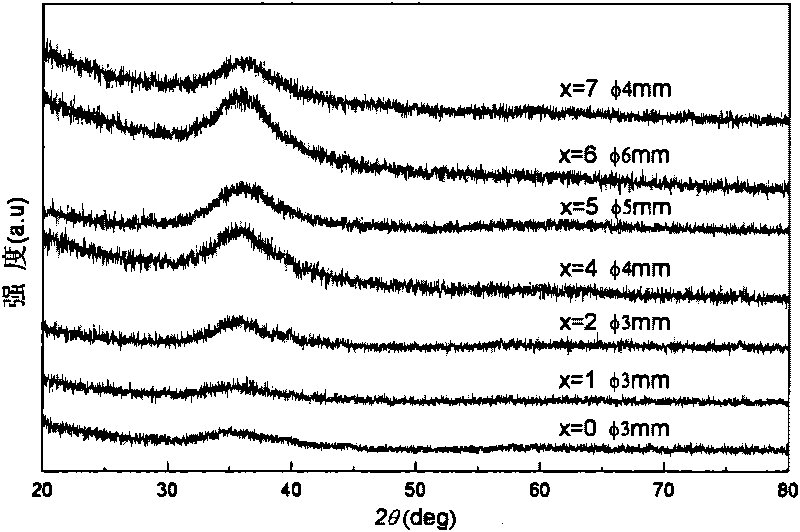

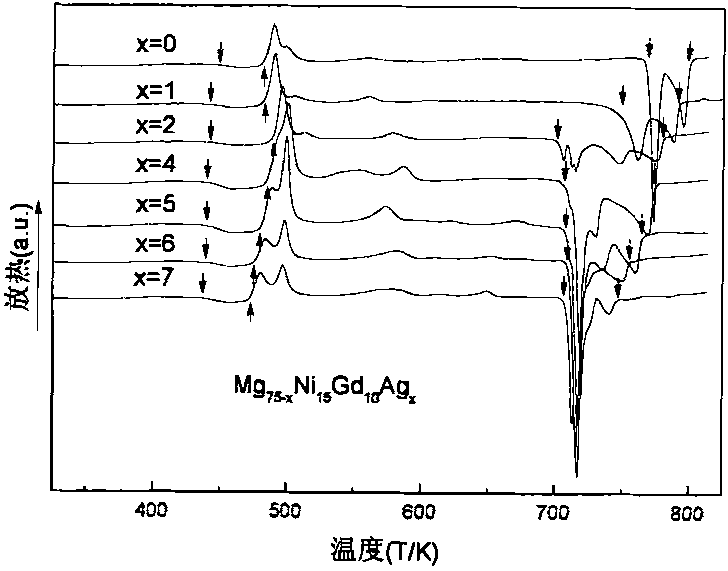

[0024] Magnesium-based bulk amorphous alloys with various compositions were prepared according to the method of Example 1, and their composition and performance parameters are listed in Table 2, where σ is the compressive fracture strength.

[0025] Each magnesium-based bulk amorphous alloy composition and performance parameters in table 2 embodiment 2-7

[0026]

[0027]

[0028] From the data in Table 1 and Table 2, it can be seen that the Mg-based amorphous alloy provided by the present invention has a relatively high width of the supercooled liquid phase region, and the addition of appropriate Ag elements can effectively increase the size of the preparation. In particular, the composition is Mg 69 Ni 15 Gd 10 Ag 6 , it has the largest forming ability, and the preparation size is 6mm. At the same time, the addition of an appropriate amount of Ag elements can improve the fracture strength, especially, Mg 70 Ni 15 Gd 10 Ag 5 It has the maximum compression breaki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com