Patents

Literature

37results about How to "Reduce production conditions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

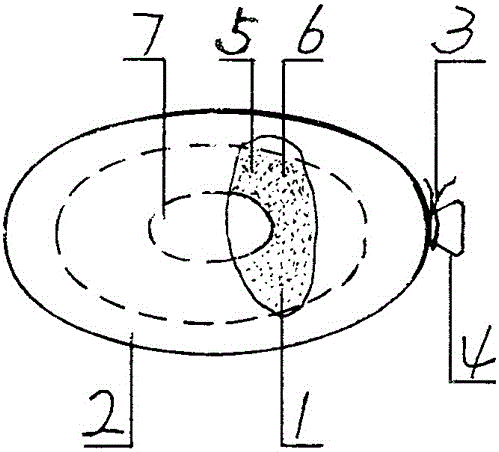

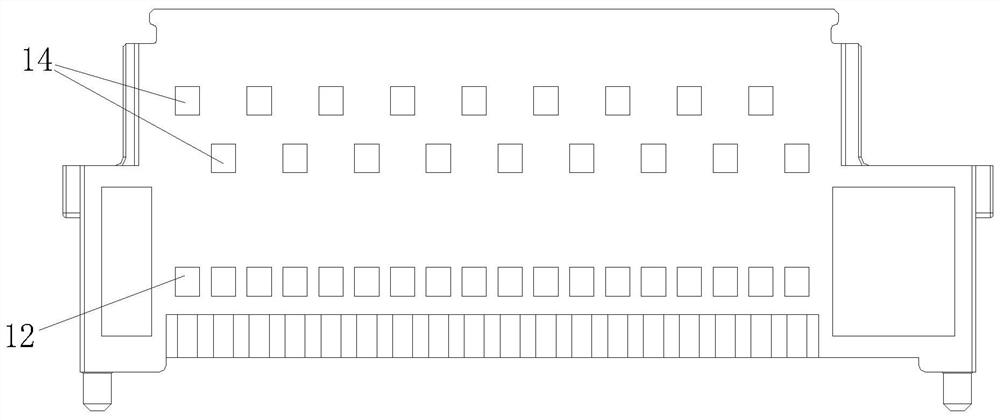

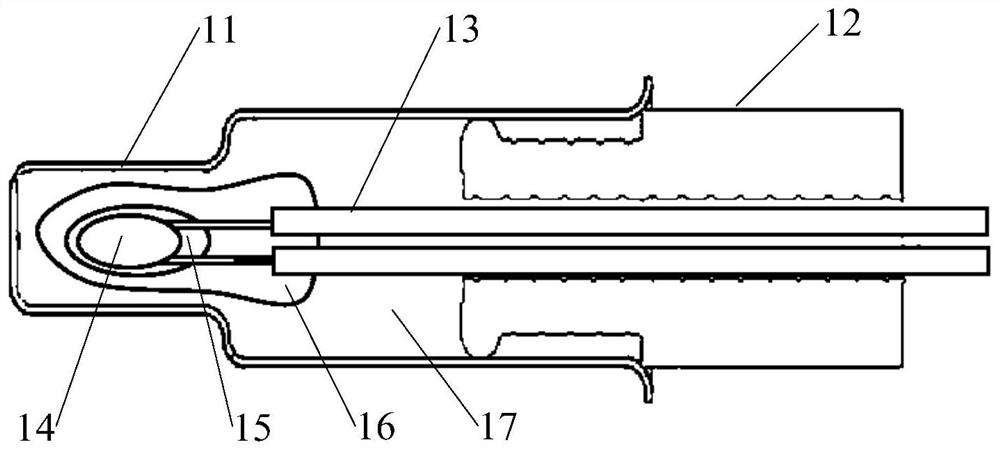

Capacitor MEMS acceleration sensor

ActiveCN1847857AReduce noiseSmall dampingAcceleration measurementFlexible microstructural devicesEngineeringCantilever

The capacitor MEMS acceleration sensor is one sandwich type differential capacitor structure comprising an upper electrode, a middle electrode and a lower electrode, and the movable middle electrode includes one frame with slots, one mass block with one central hole and one cantilever beam. When the mass block moves up and down, the air inside the cavity may pass through the hole and flow out through the slots, and the enhanced air flow can prevent the mass block from moving freely, resulting low damp and less noise.

Owner:WEIHAI SUNFULL GEOPHYSICAL EXPLORATION EQUIP

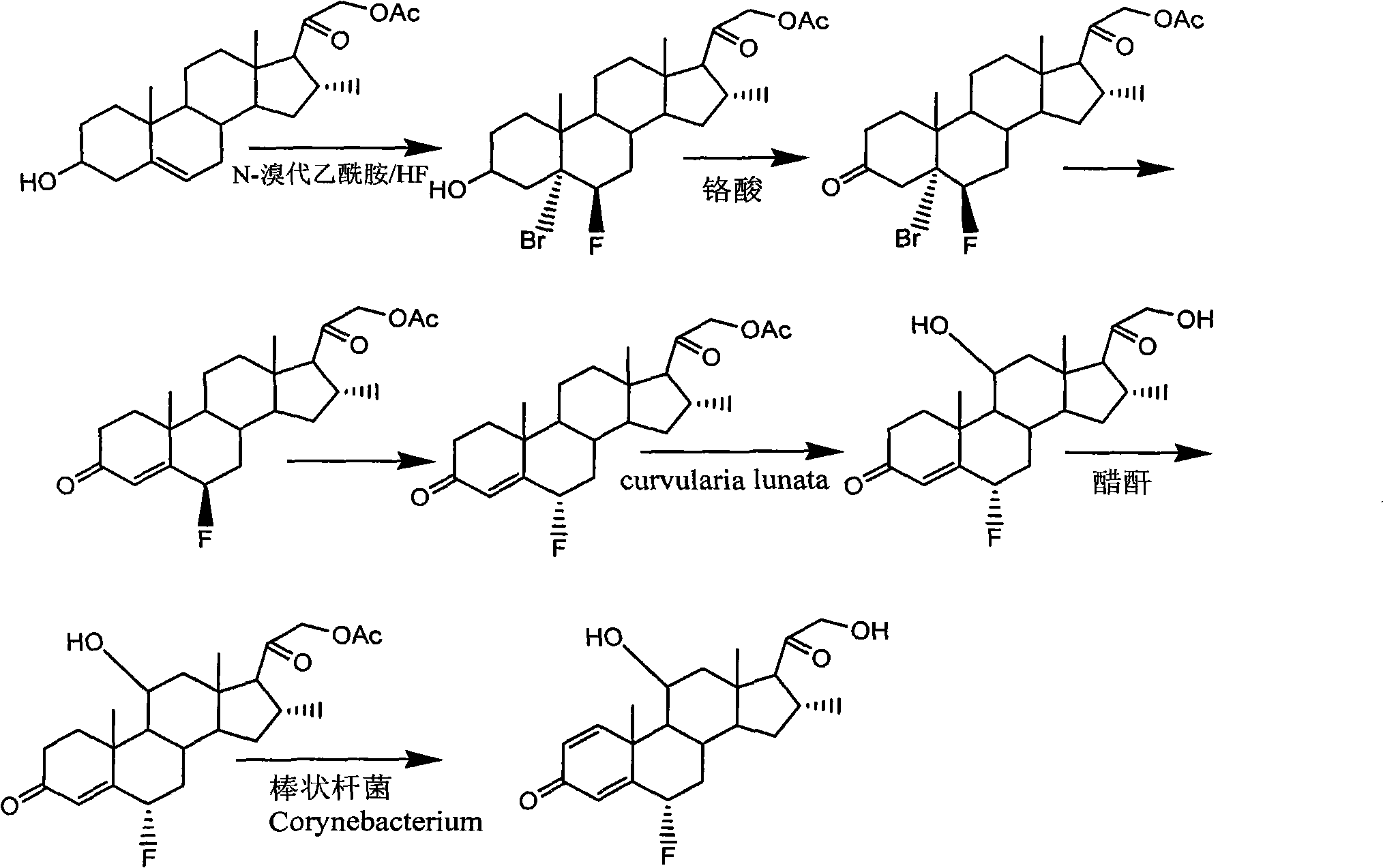

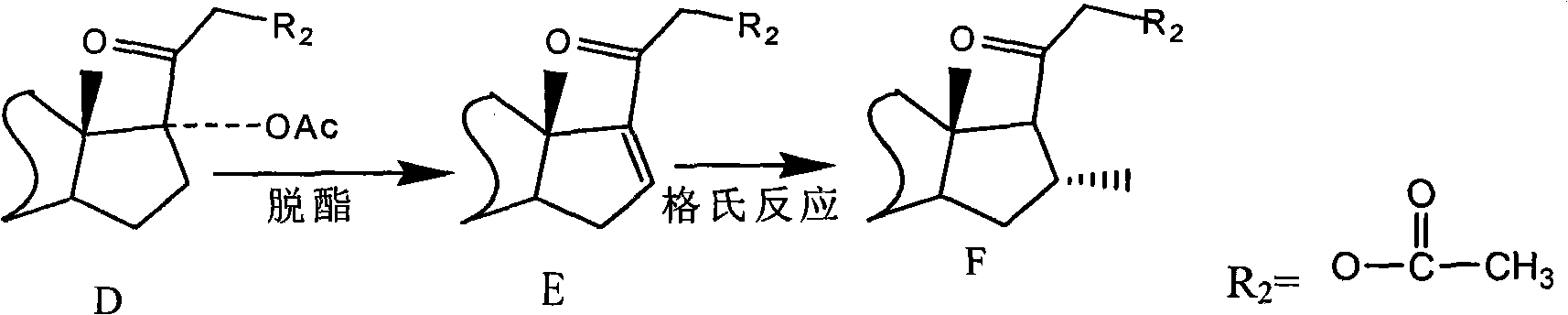

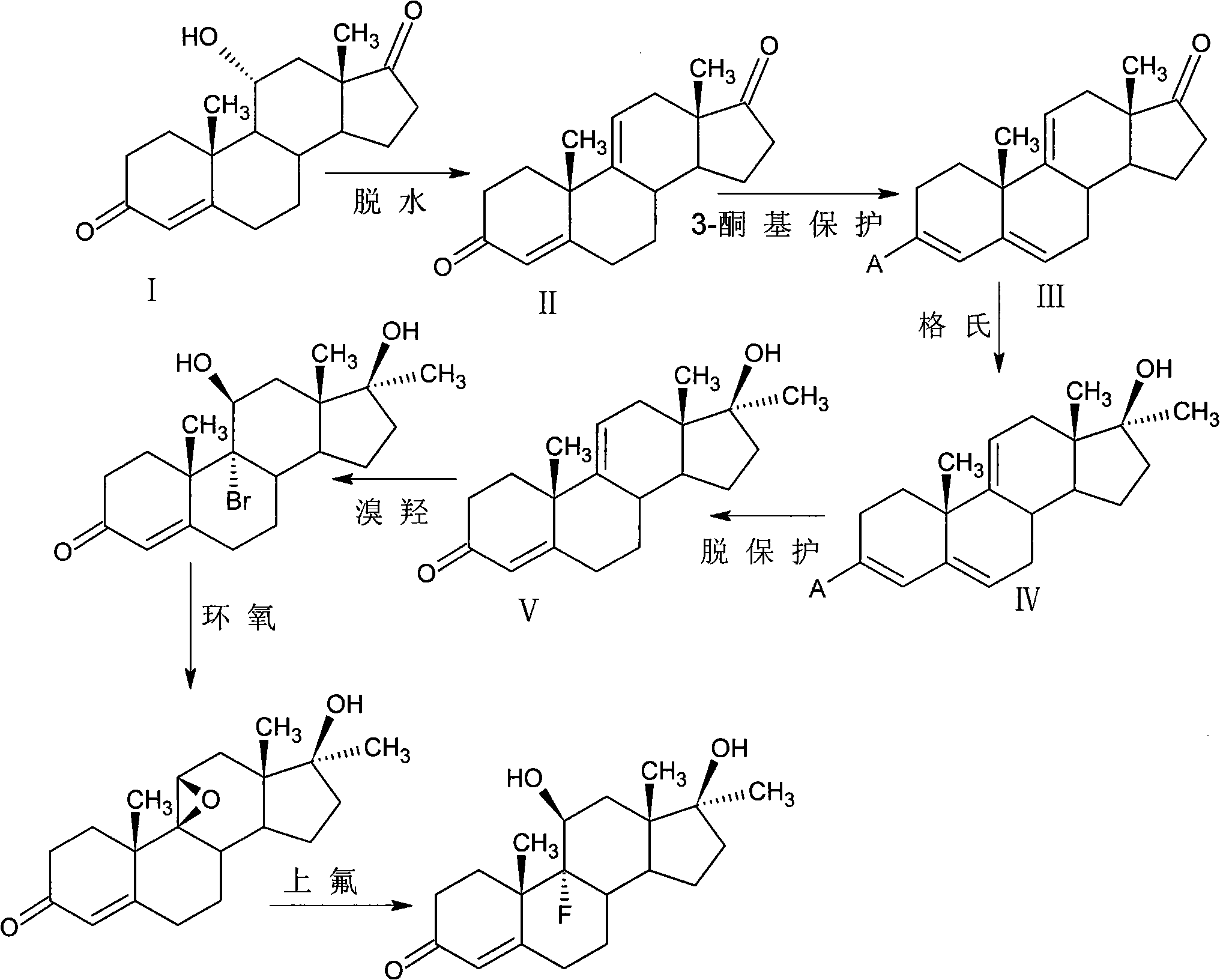

Preparation of fluorine-containing steroid hormone

The invention provides application of compounds(I) of 6 alpha-fluorine-9,11-epoxy-17,21-dihydroxyl-pregnan-1,4-diene-3,20-dione-17,21-diacetate in preparing fluocortolone and 21-bit esters(Z) thereof. By reduction of bromine hydroxides at the 17th and 21st bits, degreasing and grignard reaction at the 16th and 17th bits, modification of methyl at the 16th bit and hydrolysis of acetate and esterification at the 21st bit, the compounds(I) are converted into the fluocortolone and the 21-bit esters(Z) thereof.

Owner:TIANJIN JINYAO GRP

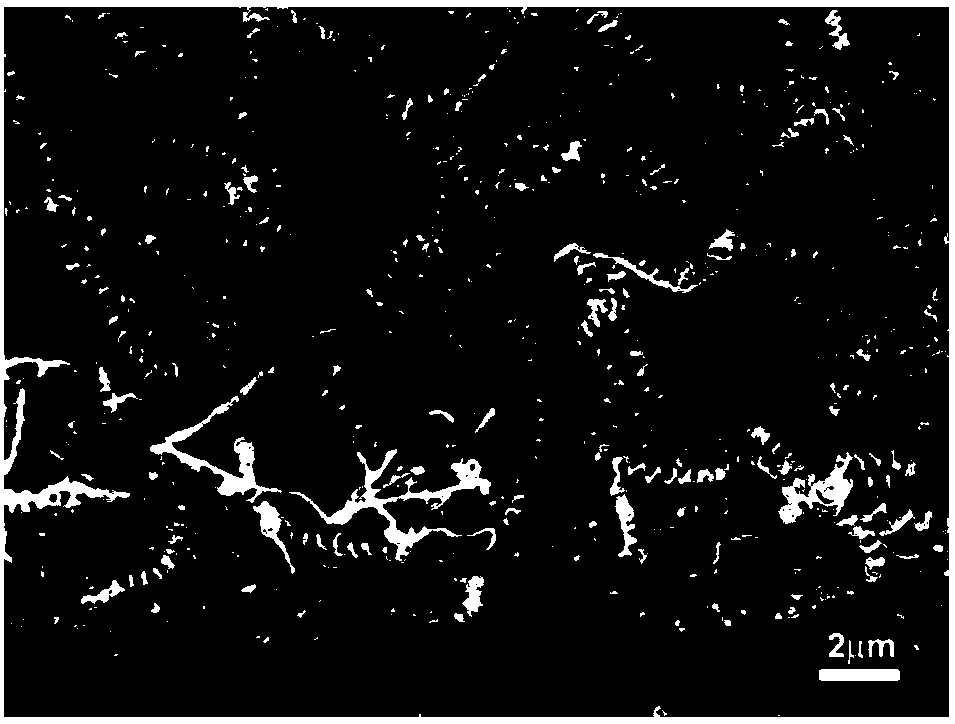

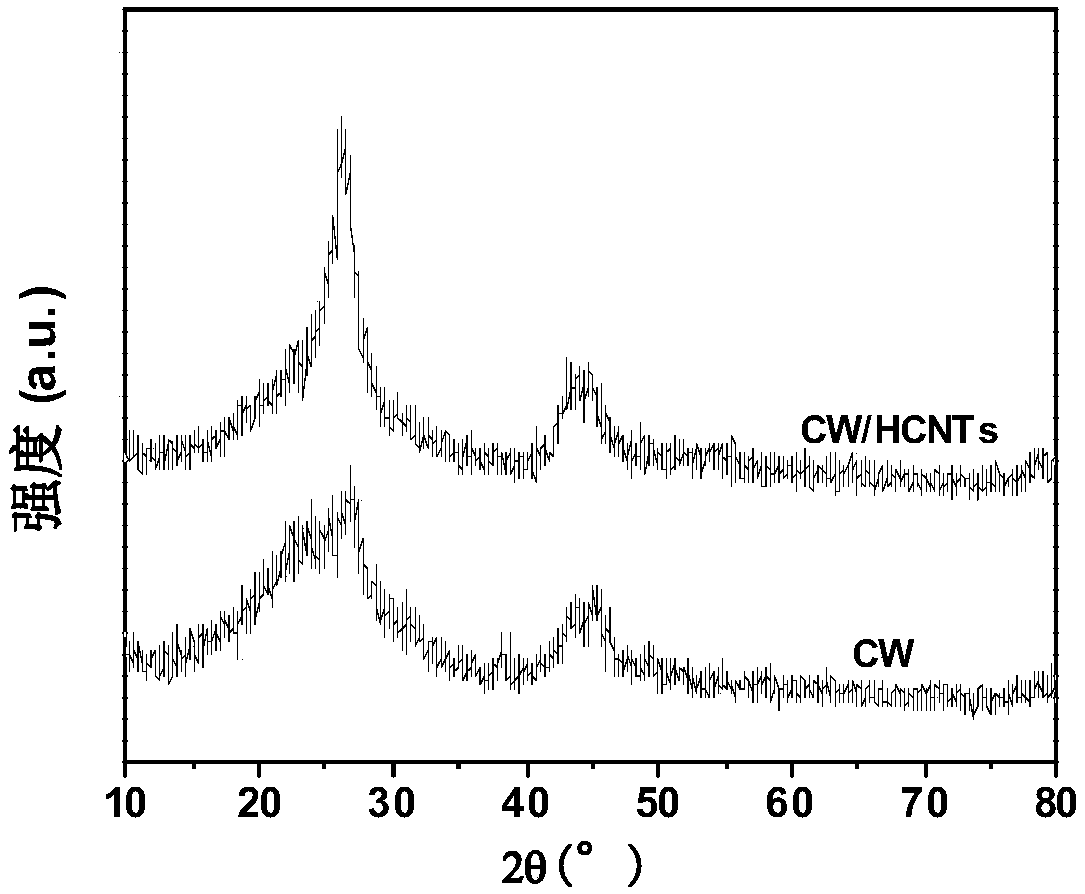

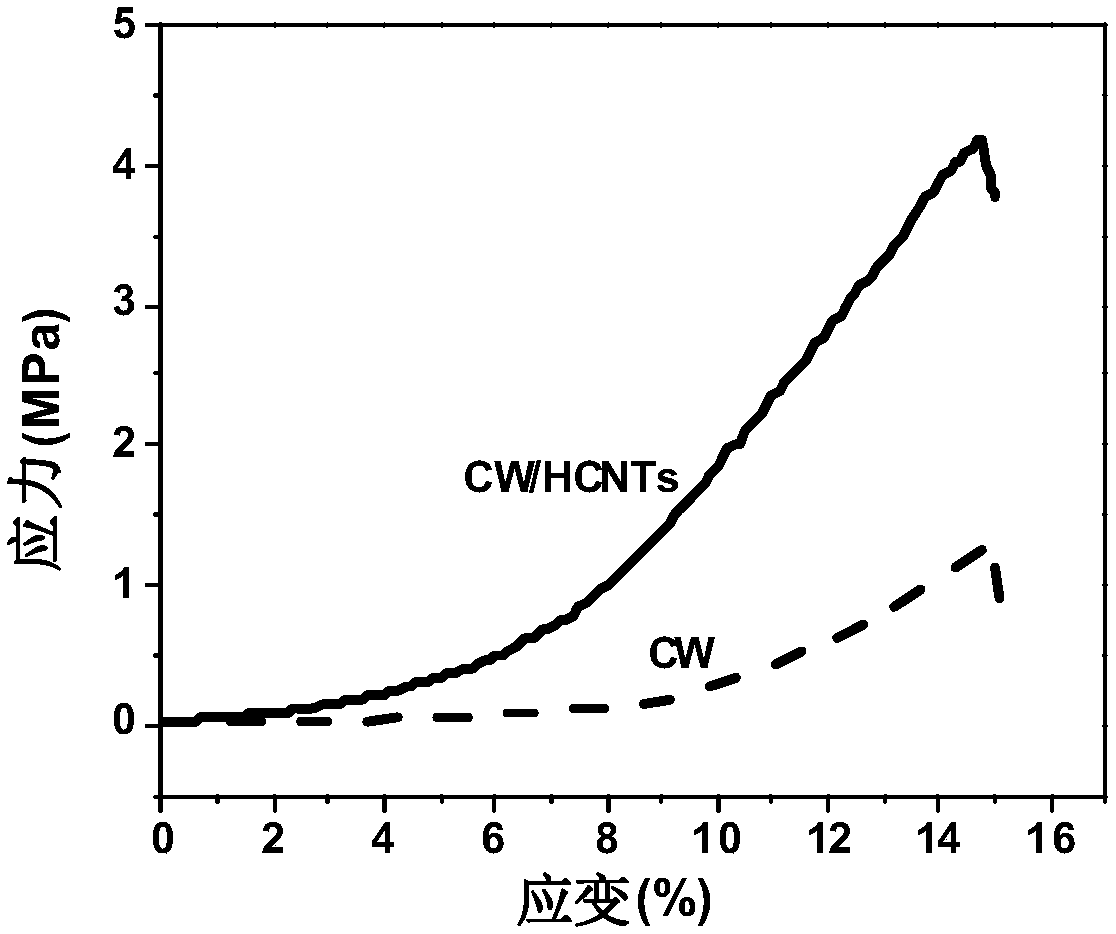

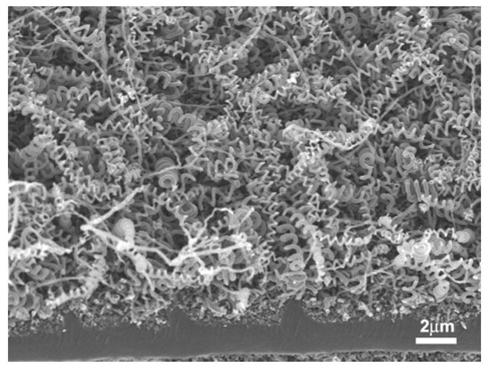

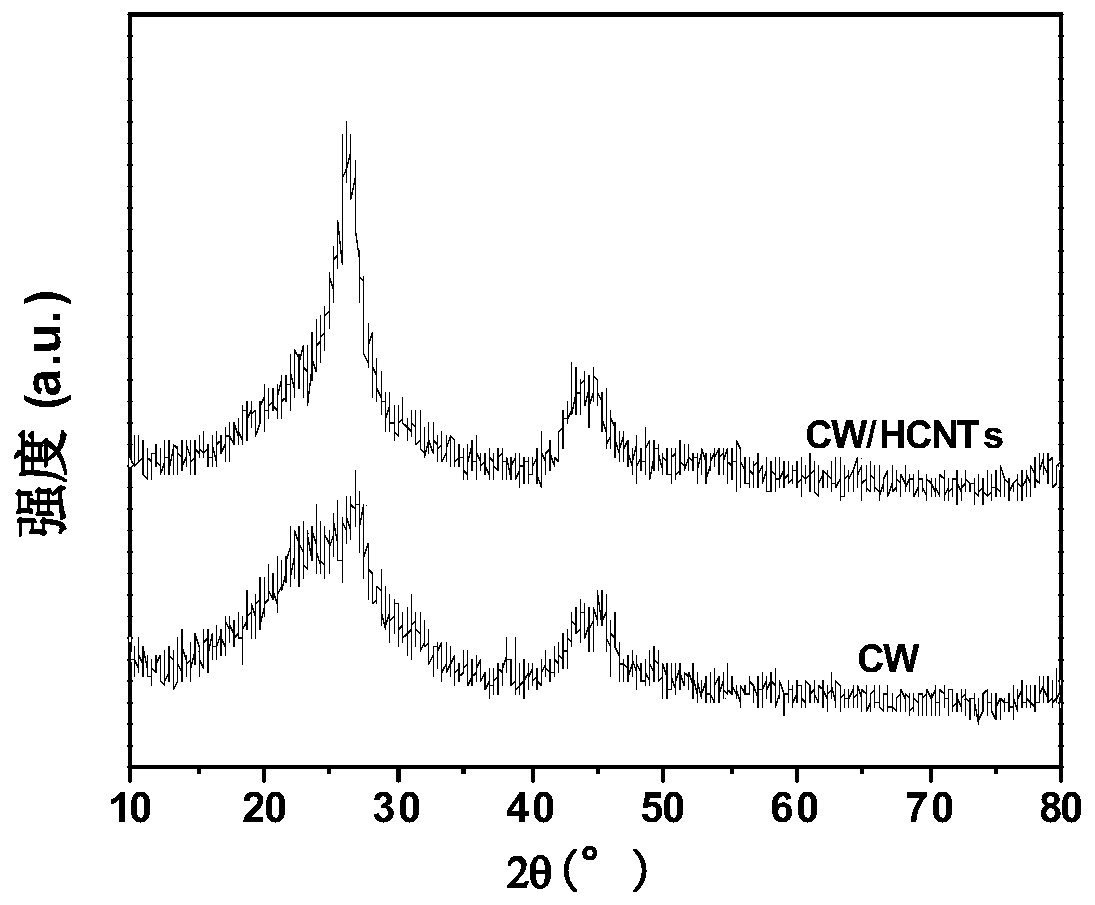

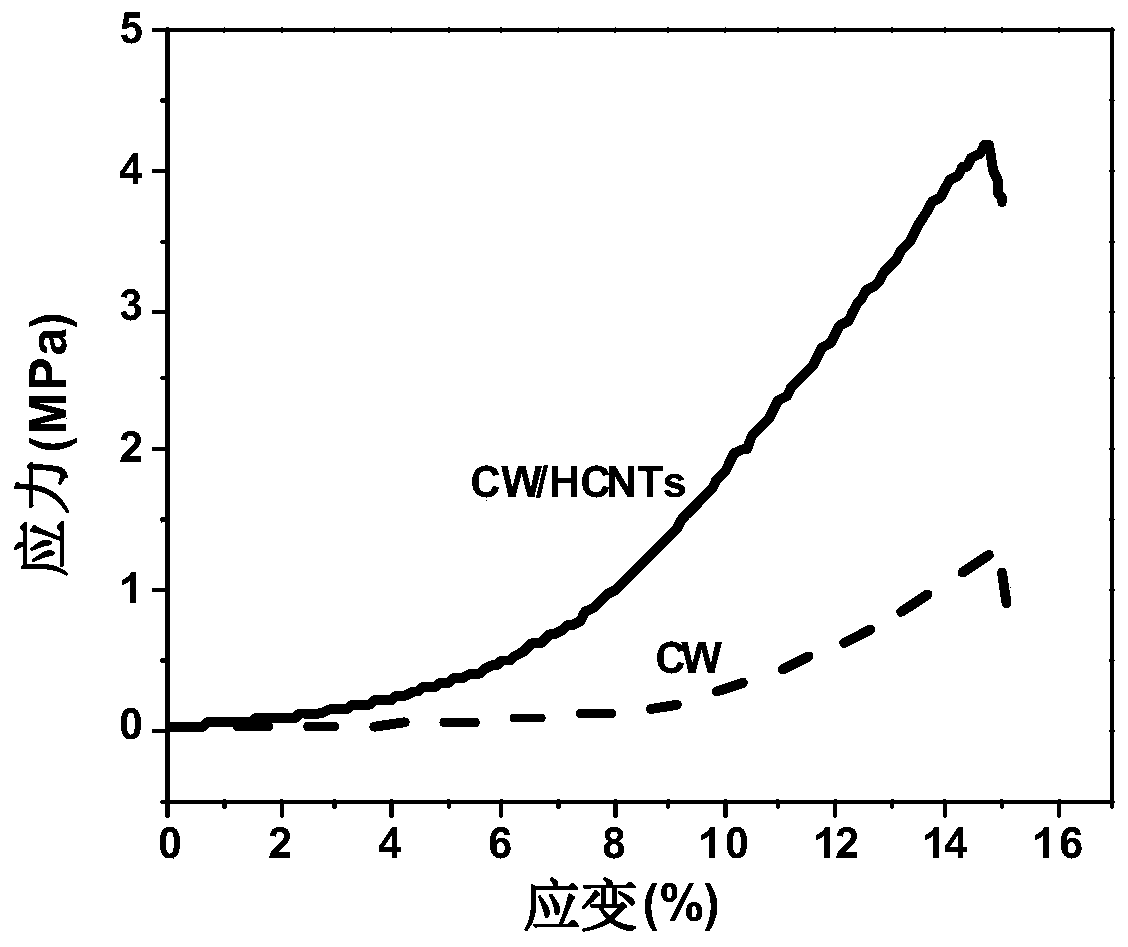

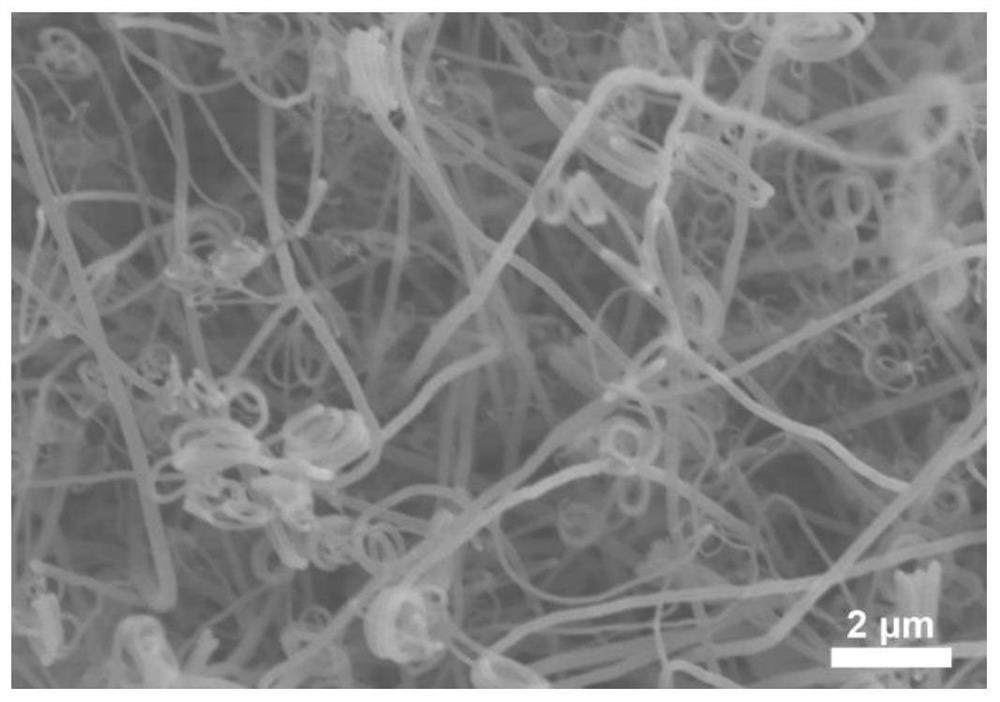

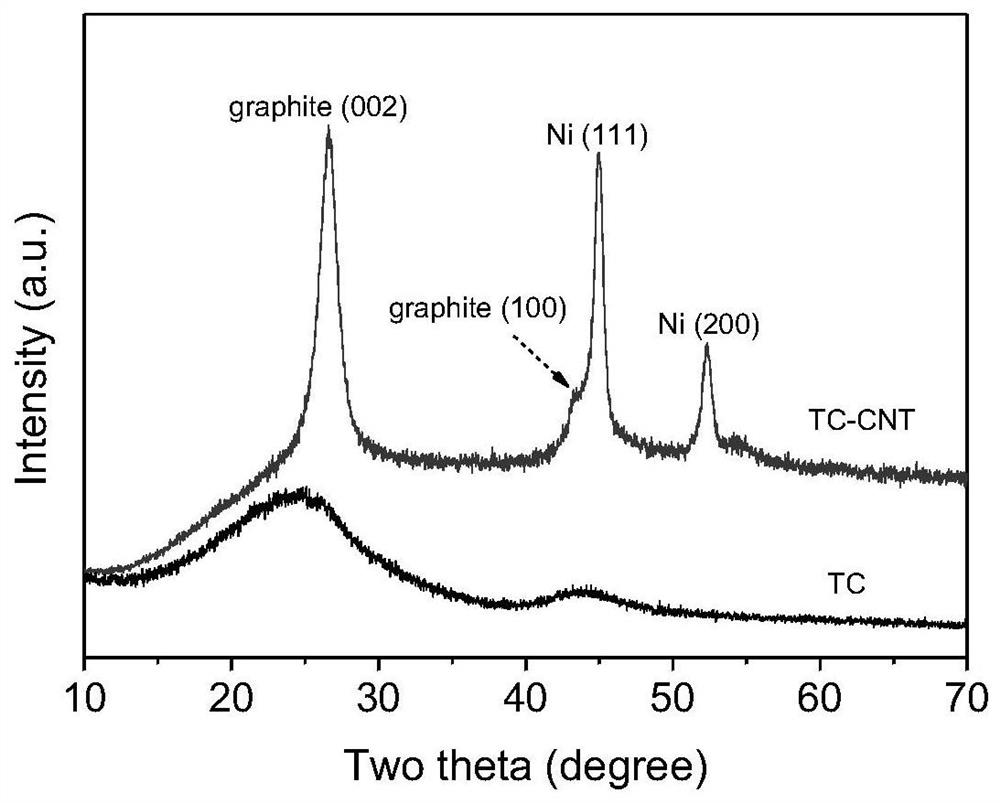

Method for growing spiral carbon nanotube on porous carbon derived from timber

ActiveCN108264034ARich sourcesReduce manufacturing costHybrid capacitor electrodesCarbon preparation/purificationVertical tubeComposite electrode

The invention discloses a method for growing a spiral carbon nanotube on porous carbon derived from timber. The method is characterized in that the carbon nanotube is subjected to chemical vapor deposition on the carbonized wood, space constraint effect of a natural vertical tube of the carbonized wood and the shearing contraction effect of the mixed acid on the carbon nanotube are used, and the spiral carbon nanotube with a uniform morphology height is prepared at the carbonized wood. The spiral carbon nanotube can increase the conductivity of the carbonized wood, and obviously increases themechanical property of a composite material. The composite material can be used as a super capacitor electrode, the natural vertical tube can provide an enough space for introducing other nano-materials, and a composite electrode does not require addition of a binder and a conductive agent. The elastic interleaving network of the spiral carbon nanotube is in favor of transmission of electrolyte ions, and an application of the composite material in the field of energy storage can be widened. The method has the advantages of simple technology, short production period and easy control, and can realize macro-preparation of the spiral carbon nanotube.

Owner:SHAANXI NORMAL UNIV

Preparation method of sodium polyacrylate aqueous solution with high solid content and narrow molecular weight distribution

The invention discloses a preparation method of a sodium polyacrylate aqueous solution with high solid content and narrow molecular weight distribution. The method comprises the following steps: solution preparation: deionized water and sodium hypophosphite are added into a reactor and continuously stirred for dissolving to prepare a solution of sodium hypophosphite, and the solution is heated to 60-110 DEG C at the same time; polymerization: acrylic acid monomer, an initiator and sodium hypophosphite are sequentially dripped into the solution prepared in the step of the solution preparation for 0.5-5h, constant-temperature reaction is carried out for 0.5-5h after the dripping to obtain a mixture, an alkali is added to neutralize the mixture to neutrality after the reaction is completed. The method uses sodium hypophosphite as the chain transfer agent to prepare the aqueous solution of sodium polyacrylate, wherein the solid content of the aqueous solution is greater than or equal to 45.0%, the weight molecular weight of the aqueous solution is 1000-10000, and the molecular weight distribution of the aqueous solution is 1.7-2.5. The aqueous solution of sodium polyacrylate has higher chelating ability, dispersion force and antiredeposition ability, and can partly or completely replace sodium tripolyphosphate to be used in washing products to reduce pollutions of detergents to the environment.

Owner:四川花语精细化工有限公司

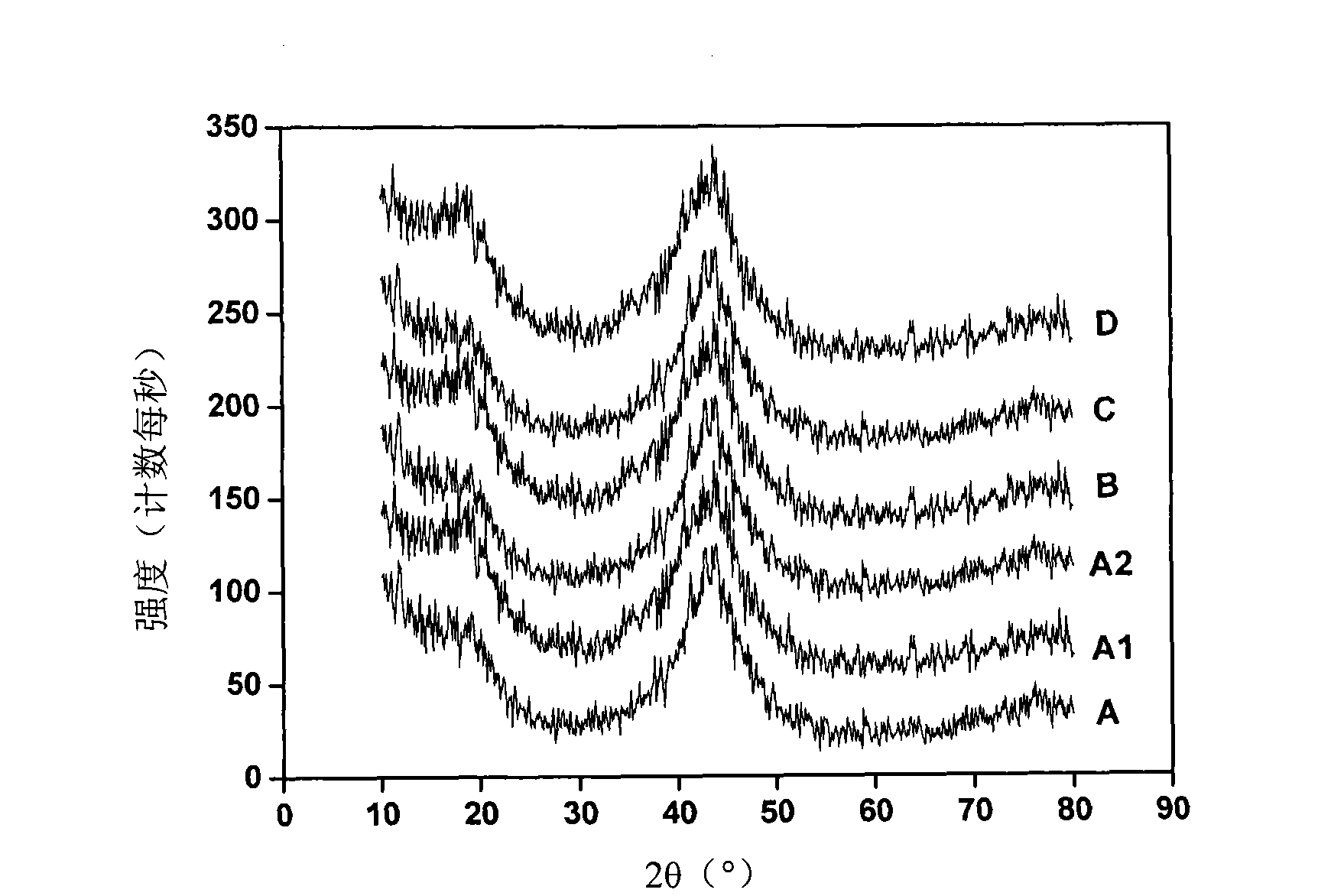

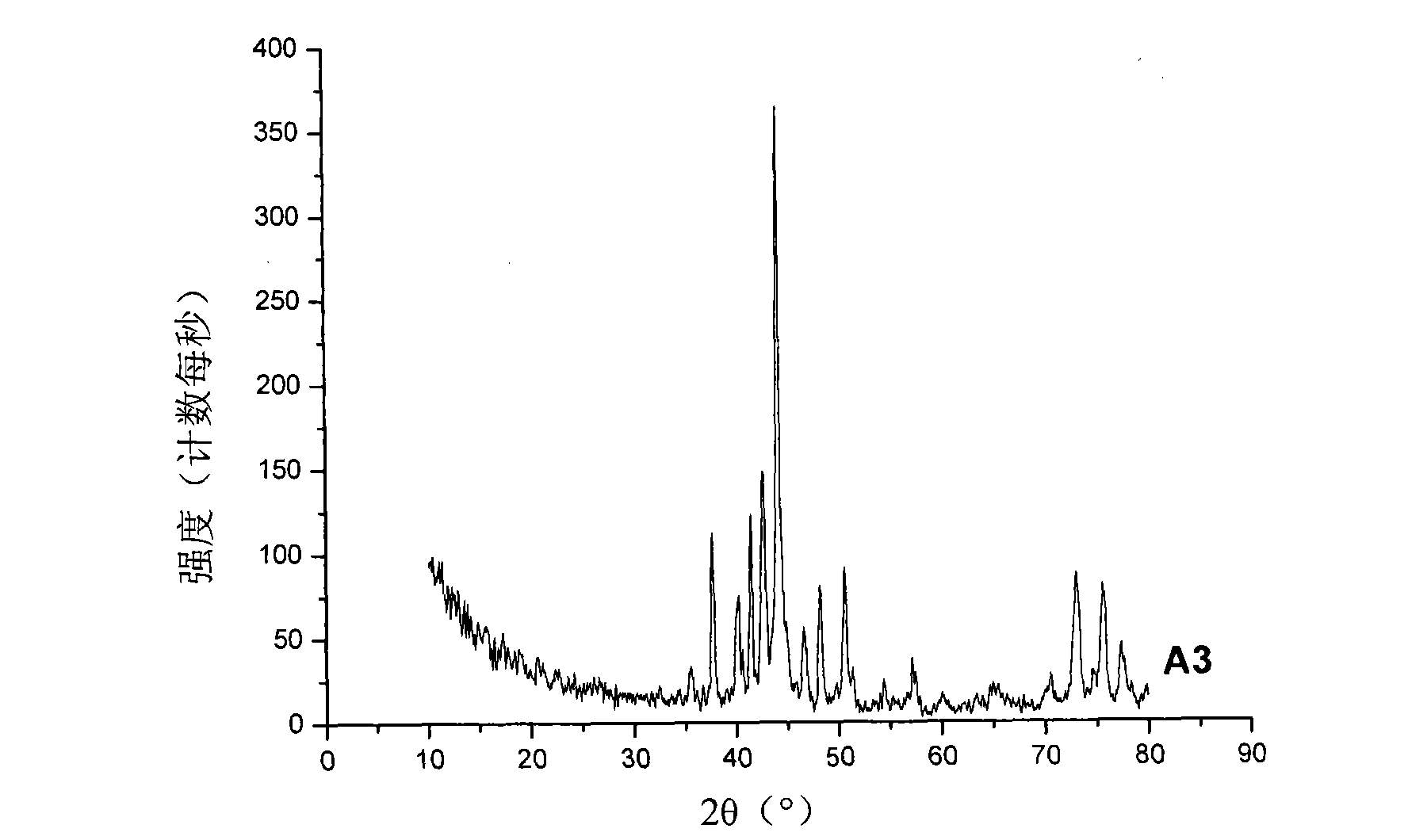

Iron-based amorphous alloy and preparation method thereof

ActiveCN101538693AEnhanced Amorphous Formation AbilityReduce production conditionsRare-earth elementVitrification

The invention provides an iron-based amorphous alloy, which comprises components as the following formula: (FexCo1-x)aETMbCcBdREe, wherein a, b, c, d and e are atomic percent; a is more than or equal to 40 and less than or equal to 60, b is more than 0 and less than or equal to 30, c is more than 0 and less than or equal to 20, d is more than 0 and less than or equal to 10, e is more than 0 and less than or equal to 10, and the sum of the a, the b, the c, the d and the e is equal to 100; x is atomic percent, and x is more than or equal to 0.5 and less than 1; ETM is one or more IVB elements, VB elements and VIB elements; and RE is one or more rare-earth elements. The invention also provides a method for preparing the iron-based amorphous alloy. Compared with the prior iron-based amorphous alloy, the iron-based amorphous alloy forming capability is high, and other properties of the amorphous alloy such as melting point, vitrification temperature, hardness and compressive fracture strength are still high.

Owner:BYD CO LTD

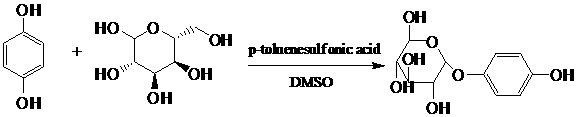

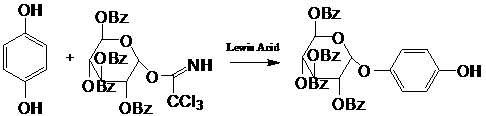

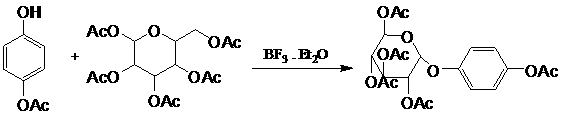

Method for synthesis of alpha-arbutin

InactiveCN103159805ARaise the ratioHigh puritySugar derivativesSugar derivatives preparationGlycosideArbutin

The invention discloses a method for the synthesis of alpha-arbutin. The method comprises: heating a substrate, boron trifluoride etherate and a certain amount of a reaction medium to 30-80 DEG C to react for more than 48h, neutralizing, washing, drying, and concentrating to obtain an alpha-type arbutin intermediate with a relatively high purity, and thus obtaining the alpha-arbutin after hydrolysis and recrystallization. The method of the invention can improve the proportion of alpha / beta-glucoside, or convert a beta-type arbutin intermediate into an alpha- type arbutin intermediate, alpha-type isomer in the obtained intermediate product is high in purity (>=92%), easy to purify, and the obtained alpha-arbutin product has a purity of more than 98%.

Owner:NANJING HUASHI NEW MATERIAL

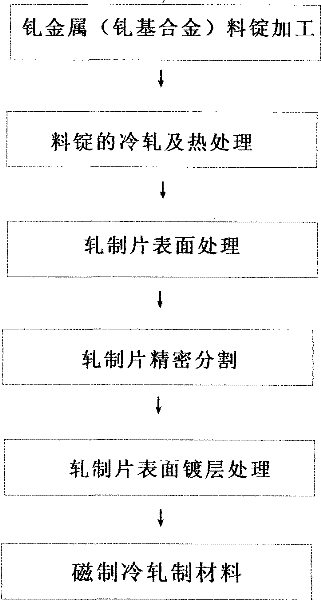

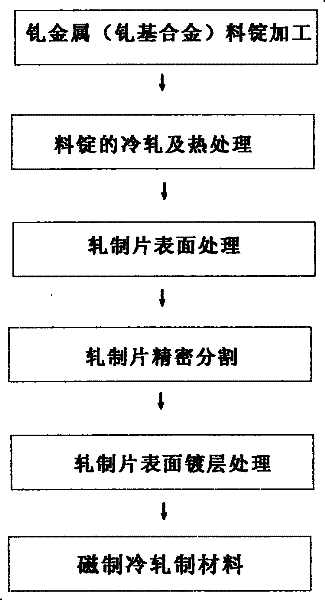

Processing method and anti-corrosion technology for magnetic refrigeration material

InactiveCN102189406AUp to toleranceImprove compactnessMagnetic materialsOther manufacturing equipments/toolsRare earthGadolinium

The invention relates to a method for processing a magnetic refrigeration material by taking rare earth metal Gd and a multicomponent alloy thereof as raw materials. The magnetic refrigeration material taking Gd as a main body mainly comprises a pure Gd piece, pure Gd particles, a rolled Gd piece, a Gd-based alloy and a Gd-based alloy rolled piece. The processing method comprises the following steps of: firstly, processing a Gd metal or Gd-based alloy ingot; secondly, carrying cold rolling and vacuum heat treatment; thirdly, treating the surface of the rolled piece; fourthly, precisely dividing the rolled piece; and fifthly, plating the surface of the rolled piece.

Owner:杨晓峰

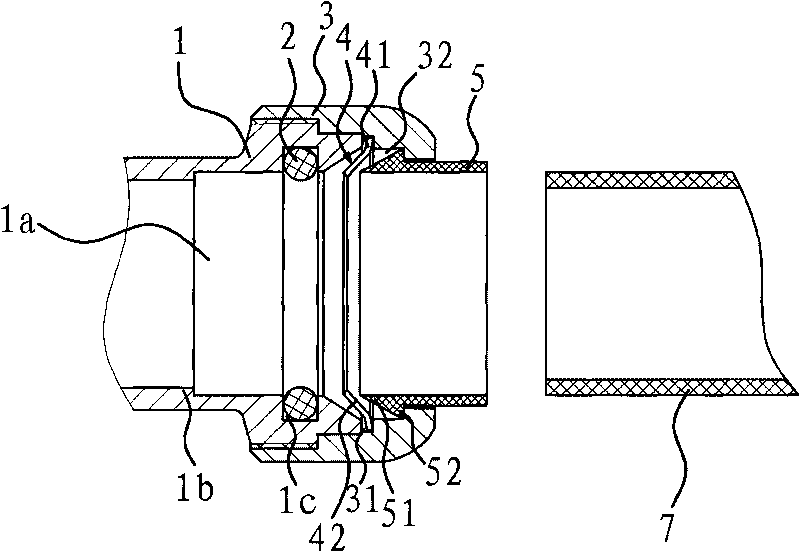

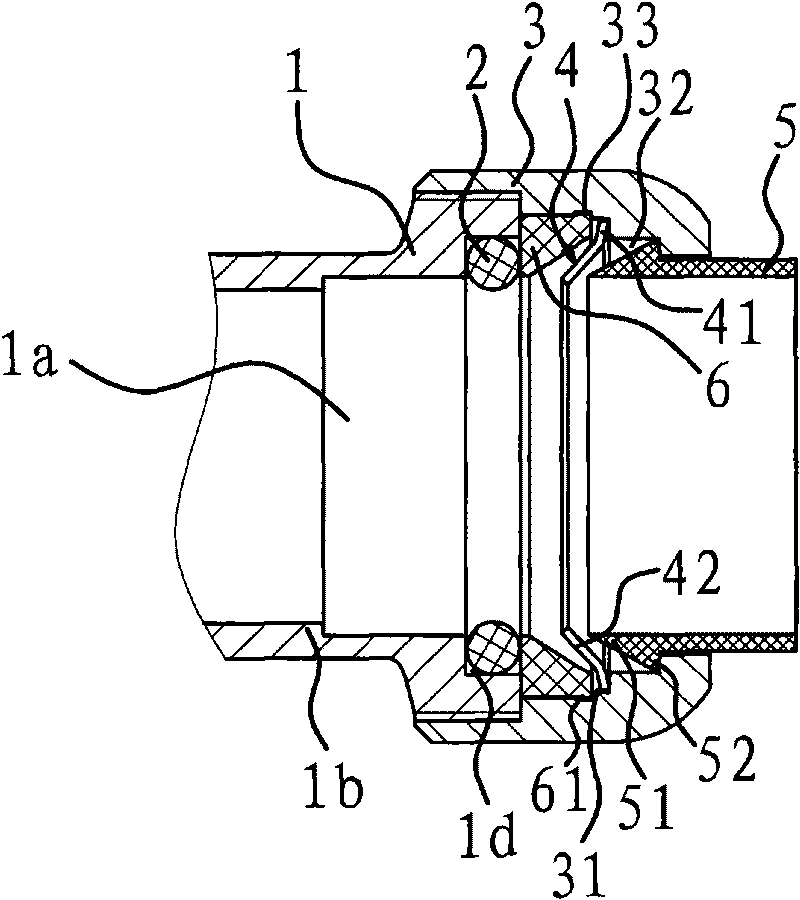

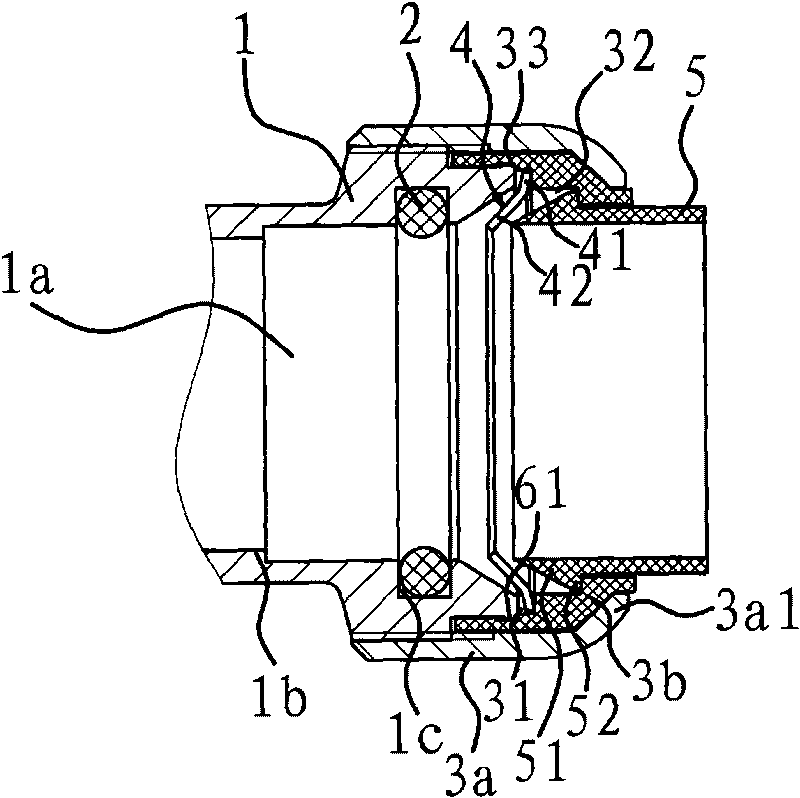

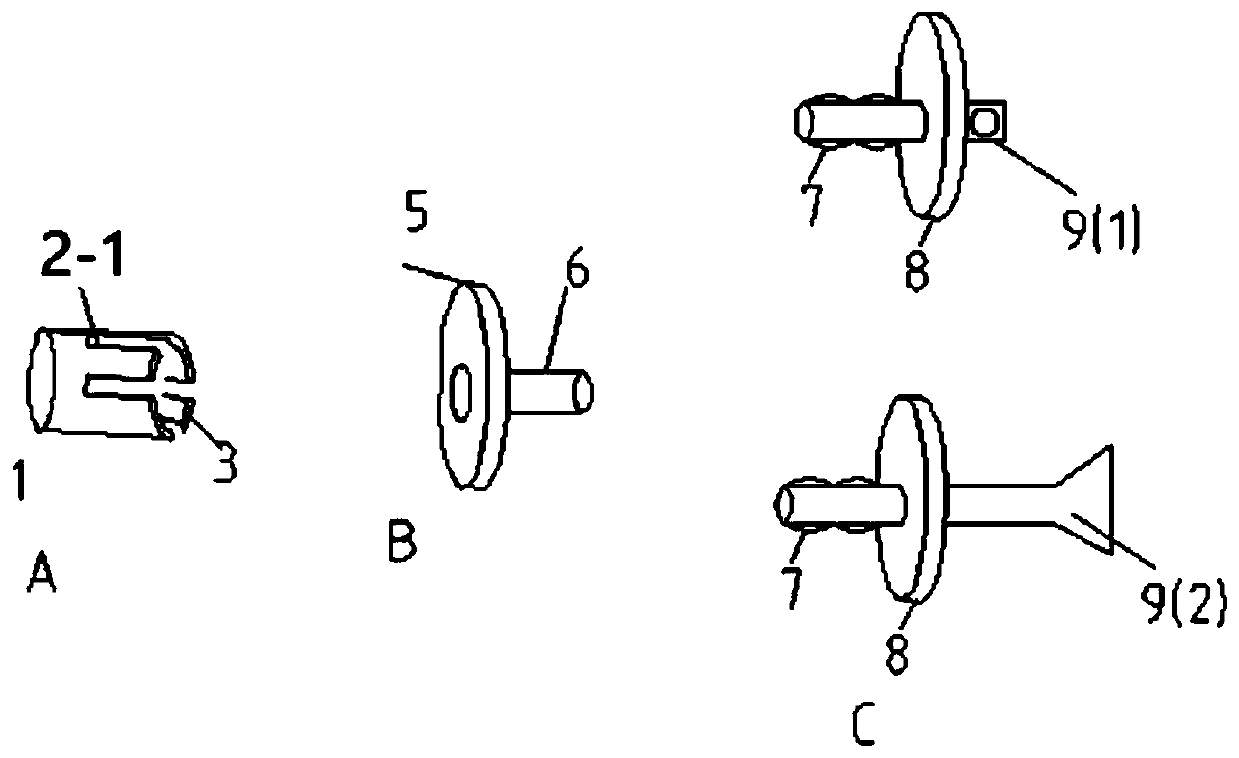

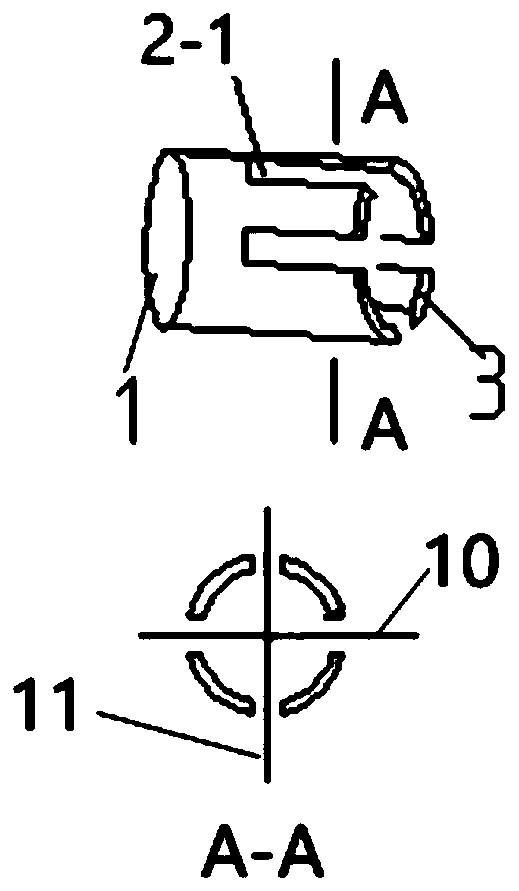

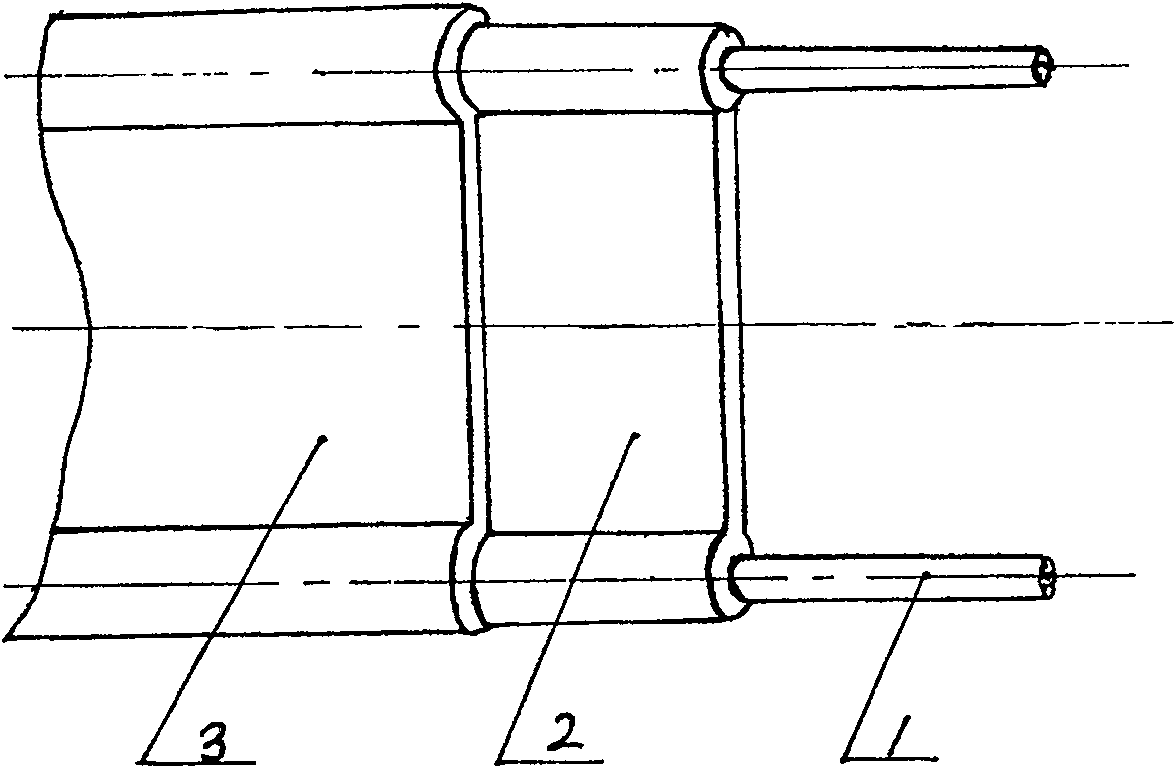

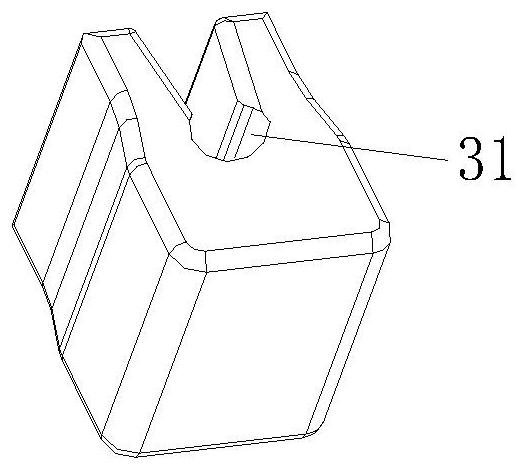

Quick joint

InactiveCN101709815AEasy to processLow production requirementsJoints with sealing surfacesCouplingsEngineeringScrew thread

The invention provides a quick joint belonging to the technical field of pipeline connection and solving the problems of low qualification rate, incapable maintenance, short service life and high cost of the traditional quick joint. The quick joint is provided with a body with a connecting hole which is internally provided with a sealing ring capable of forming the seal with an inserted connecting pipe; and a clamping mechanism capable of clamping or releasing the inserted connecting pipe is arranged at a port of the connecting hole and can be fixed on the body by a fixed cap. The fixed cap is fixedly connected to the body by welding or adopting threads. The quick joint has the advantages of convenient processing, low condition required by the production, convenient and firm connection and convenient maintenance and replacement of the clamping mechanism or the sealing ring.

Owner:玉环县林波铜业制品厂

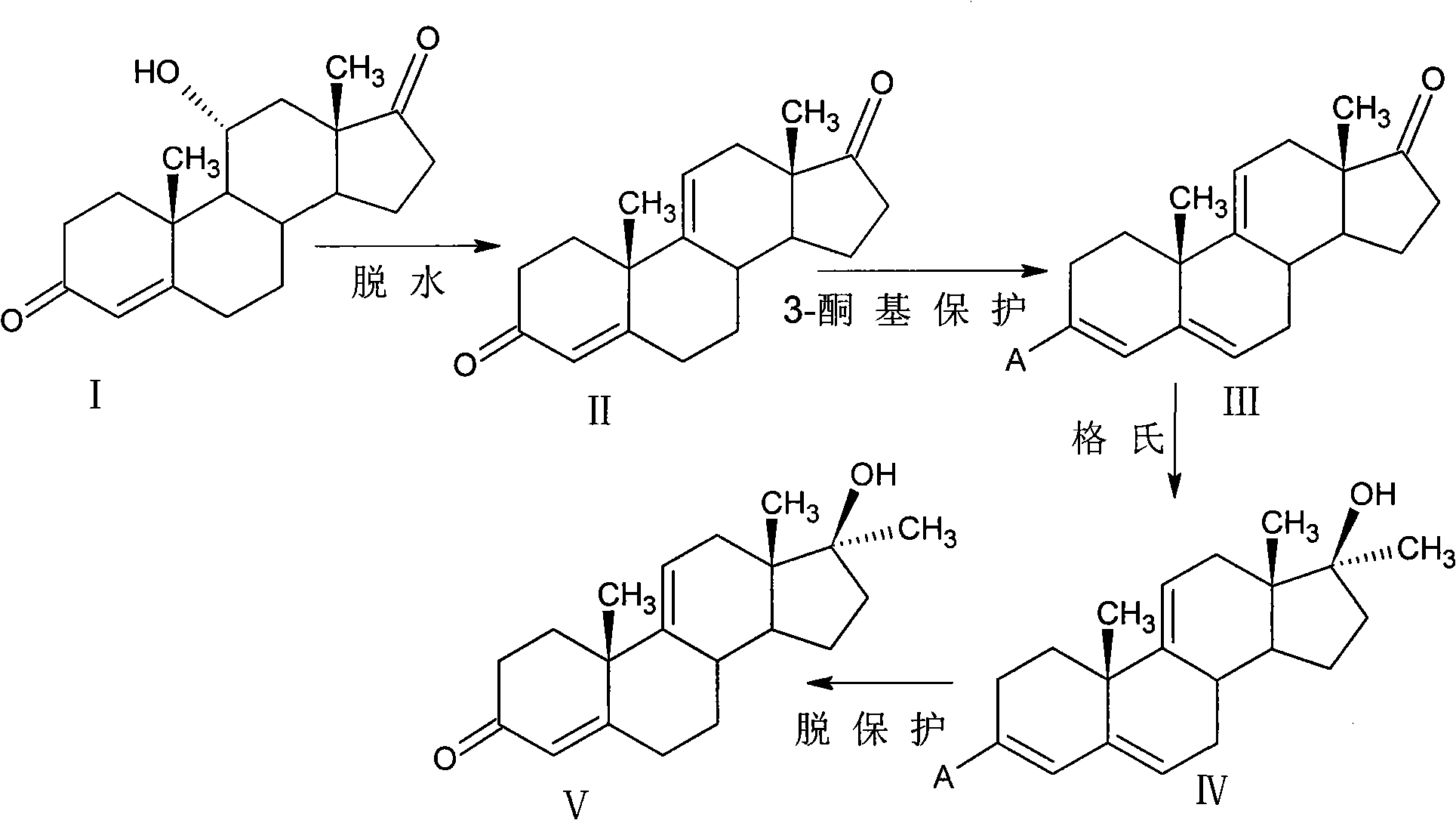

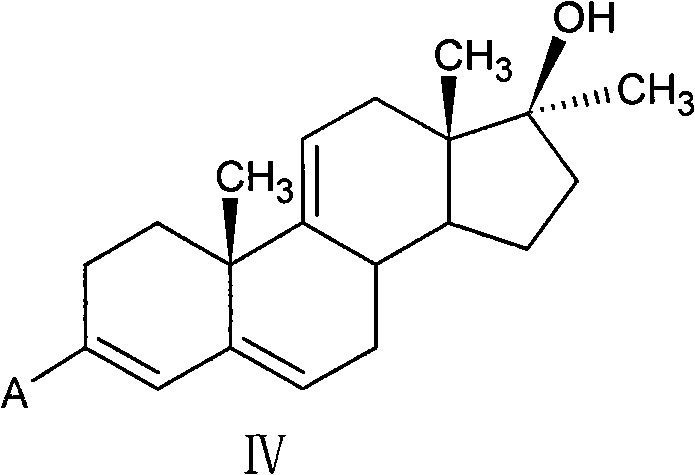

Methods for preparing fluoxymesterone and intermediate thereof

InactiveCN102040639ASimple lineSimple and fast operationSteroidsCombinatorial chemistryFluoxymesterone

The invention relates to methods for preparing fluoxymesterone and an intermediate (V) thereof. The method for preparing the intermediate of the fluoxymesterone comprises the following processes of: with 11alpha hydroxy-4AD (I) as an initial raw material, 9 and 11 position dehydration, 3 position ketonic group protection, 17 position ketonic group Grignard reaction and 3 position hydrolysis protection to obtain the intermediate of the fluoxymesterone.

Owner:TIANJIN JINYAO GRP

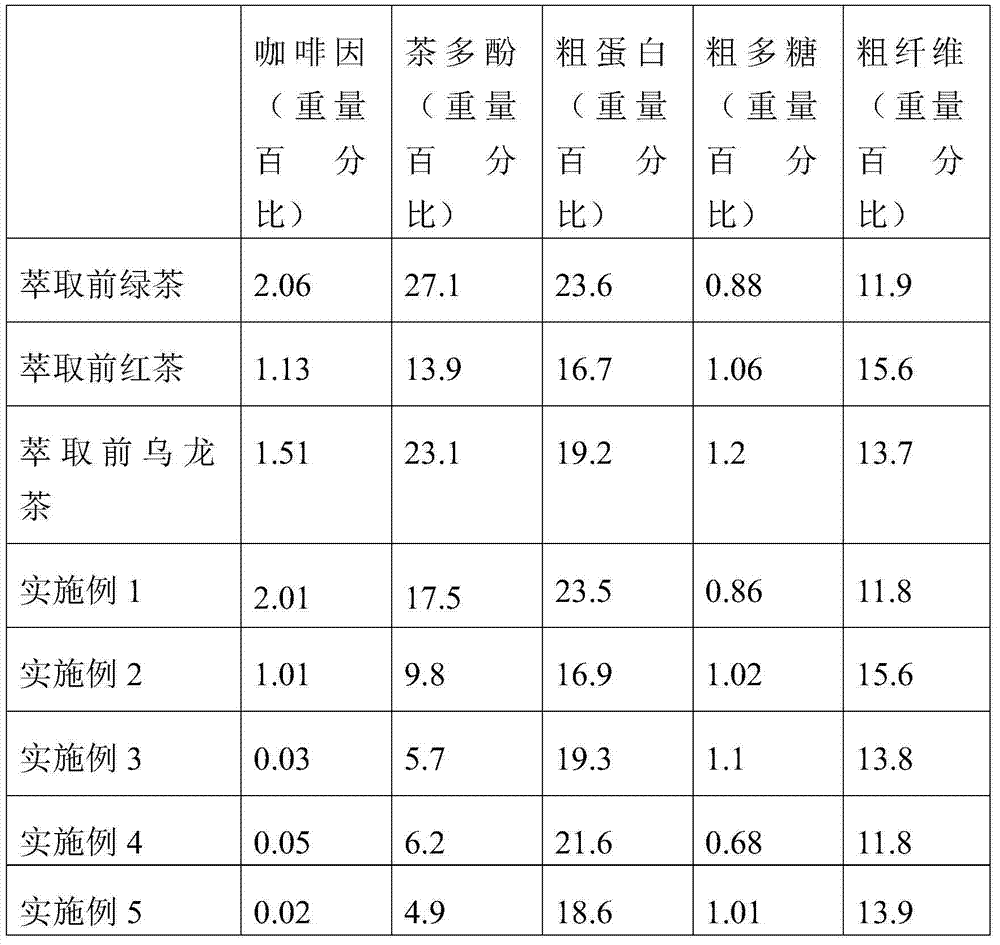

Method for subcritical fluid extraction of tea extract

InactiveCN104738251AReduce production conditionsLow costTea extractionBiologically active substancesWater content

The invention provides a method for subcritical fluid extraction of tea extract. The method comprises the following steps of carrying out dimethyl ether subcritical fluid continuous dynamic extraction on tea at a temperature of 15-60 DEG C under pressure of 0.4-3MPa for 30-270min so that an extract mixture is obtained, removing tea residue from the extract mixture, and carrying out dimethyl ether subcritical fluid gasification at a temperature of 40-60 DEG C under the pressure of -0.08 to 1.2MPa so that the tea extract is obtained. The method needs a low temperature and low pressure in extraction, prevents biologically-active substances in tea from being destroyed, and has a low equipment cost. The tea residue has low water content and a high recycle value. The method can be widely used in the field of tea extract preparation.

Owner:COFCO NUTRITION & HEALTH RES INST +1

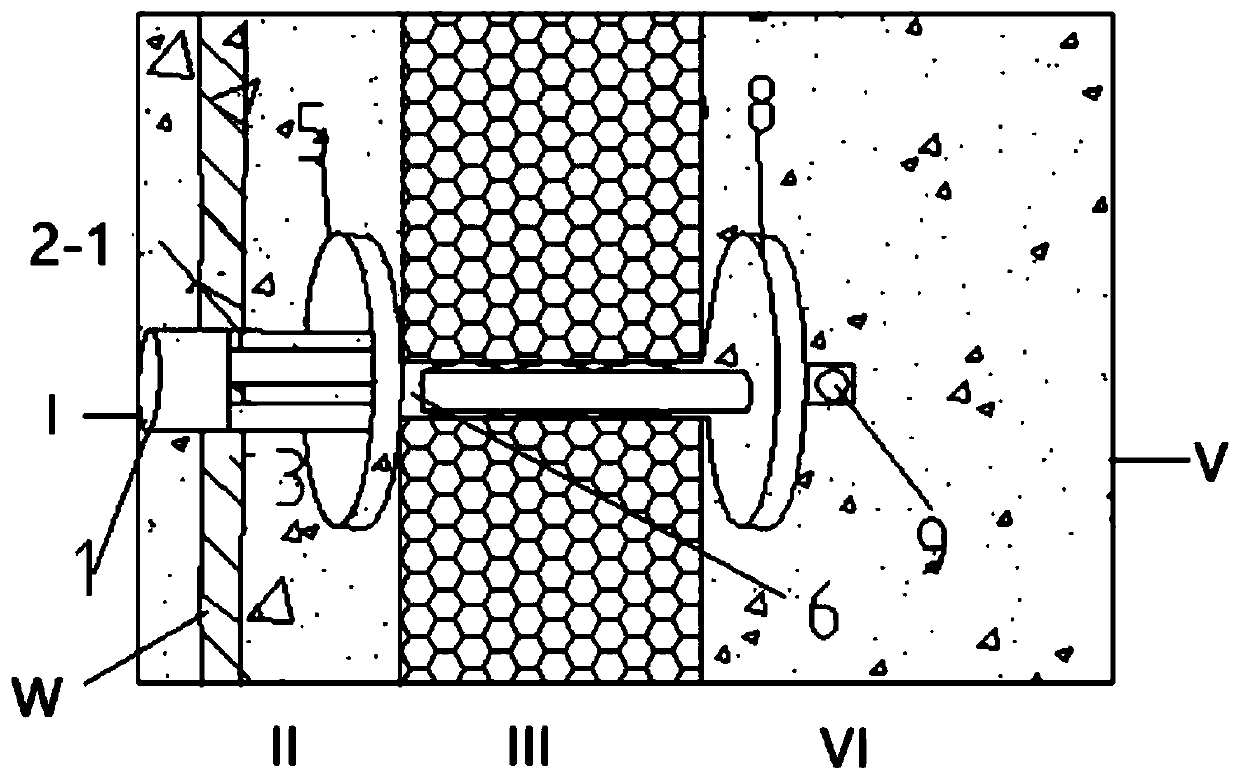

Internally-installed heat-retaining cast-in-place concrete composite shear wall and construction method thereof

PendingCN110029757ALow costSimple production processWallsHeat proofingStructure of the EarthConcrete composites

The invention provides an internally-installed heat-retaining cast-in-place concrete composite shear wall. The internally-installed heat-retaining cast-in-place concrete composite shear wall comprisesa protective layer, a heat-retaining layer and a structure layer, wherein the protective layer, the heat-retaining layer and the structure layer are sequentially arranged between an outer die plate and an inner die plate; and an anti-crack mesh piece, a first connecting piece and a second connecting piece are arranged in the protective layer, the anti-crack mesh piece is arranged between the first connecting piece and the second connecting piece, a third connecting piece is arranged in the structure layer, one end of the second connecting piece is connected with the first connecting piece, and the other end of the second connecting piece penetrates through the heat-retaining layer and is connected with the third connecting piece. The invention further provides a construction method of theinternally-installed heat-retaining cast-in-place concrete composite shear wall. The internally-installed heat-retaining cast-in-place concrete composite shear wall and the construction method thereof have the advantages that compared with other integrated materials, the construction cost is low, the production technology is simple, the production condition is low, the production efficiency is high, and the labor cost is reduced.

Owner:承德建元科技股份有限公司

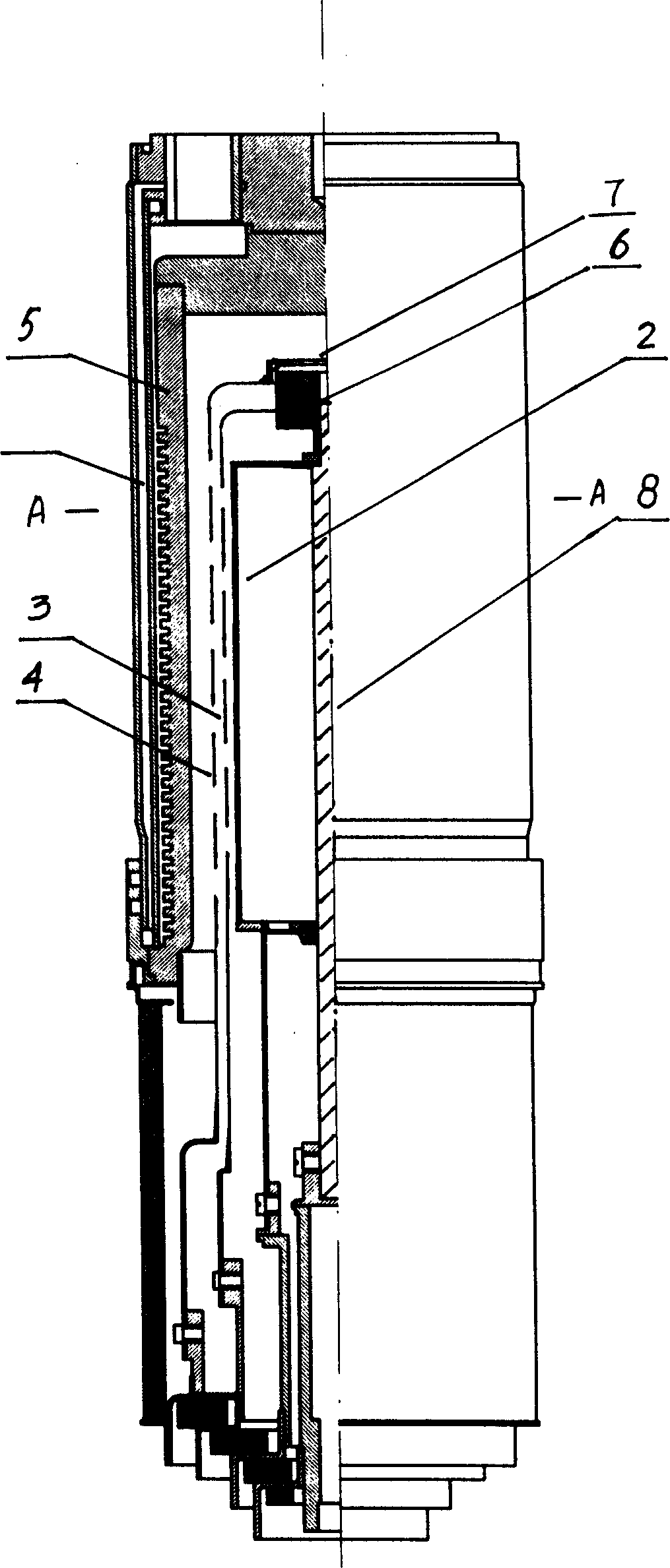

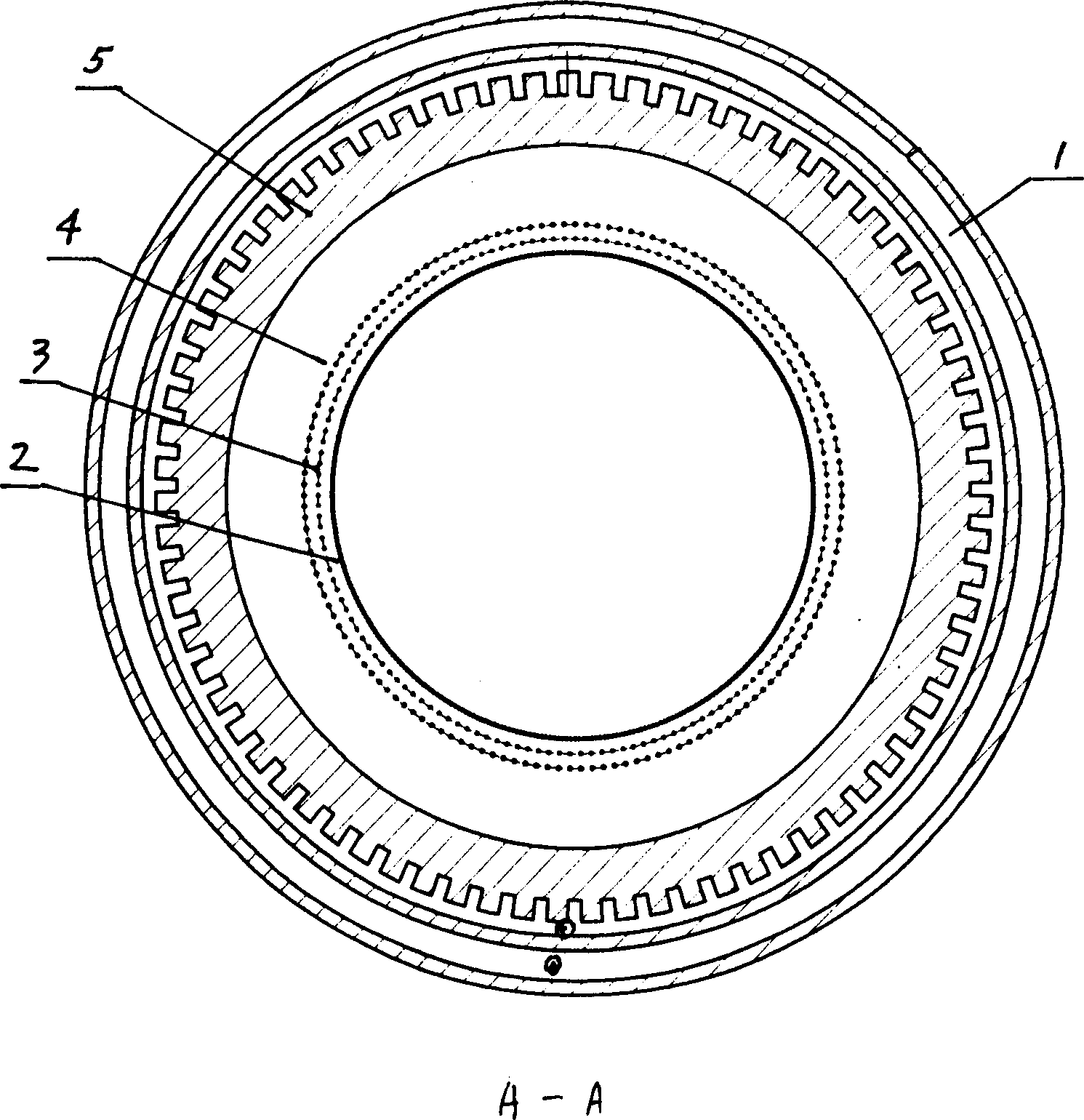

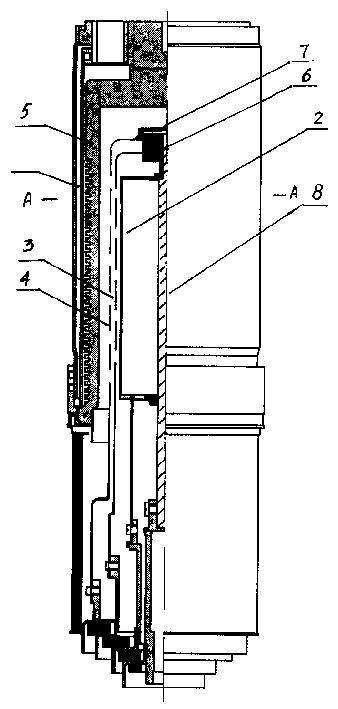

Large power quadrupole delectronic tube and its manufacturing method

InactiveCN1479343ASolve the defect of falling powder and ignitionReduce production conditionsTransit-time tubesNon-electron-emitting electrode materialsRadiation resistantTwo grid

The electron tube consists of cooling water jacket, cathode, first grid, second grid and anode. The improved first grid is made from pyrolytic graphite. The second grid is made from molybdenum filament welded in squirrel cage shape. With surface being sprayed by tungsten carbide, the molybdenum filament is sintered and plated by platinum. The upper parts of two grids are connected to ceramic ring at upper part of cathode. The first grid is made from graphite after dedicated procedure the first grid possesses higher capabilities of high temperature resistant and radiation resistant. The heat dissipation capability of the first grid made from graphite is 5 times of grid made from molybdenum filament so as to reduce size greatly.

Owner:卫军民 +1

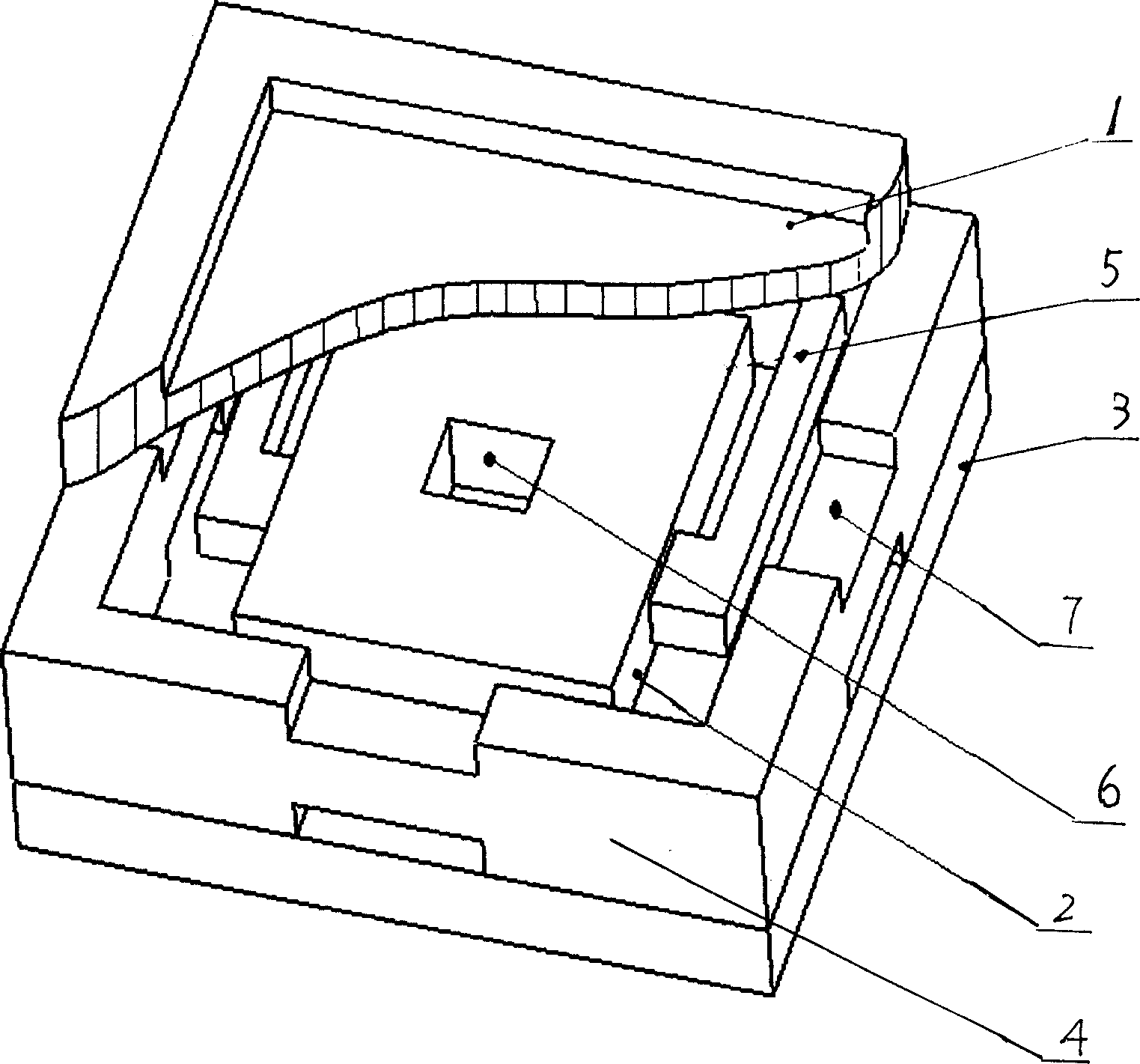

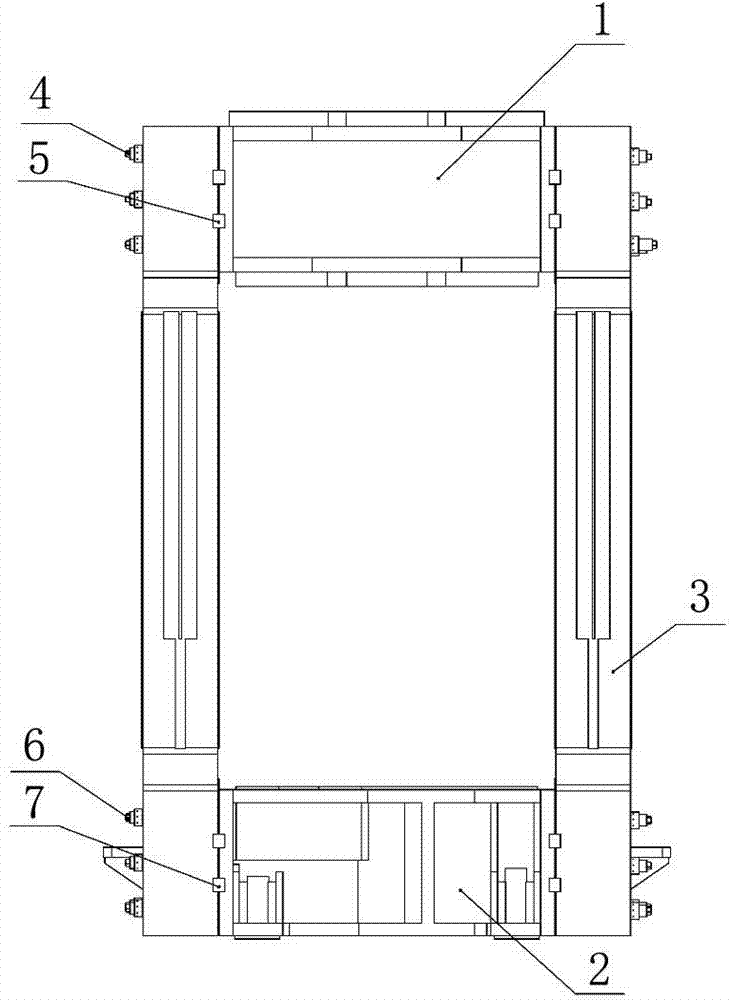

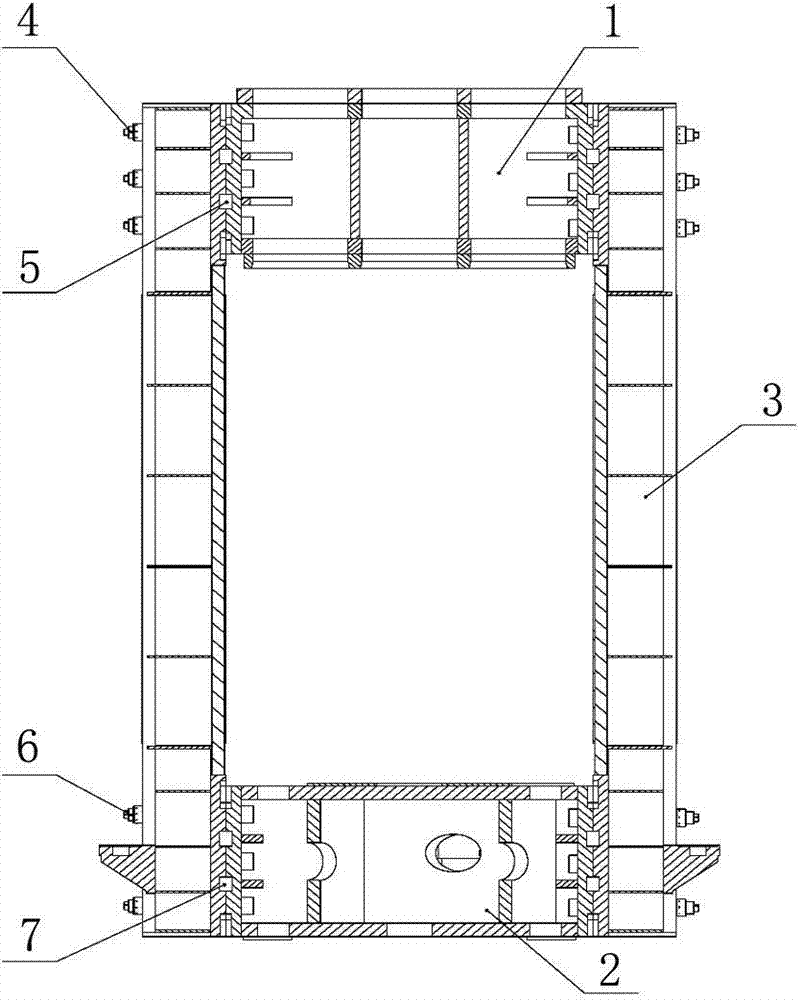

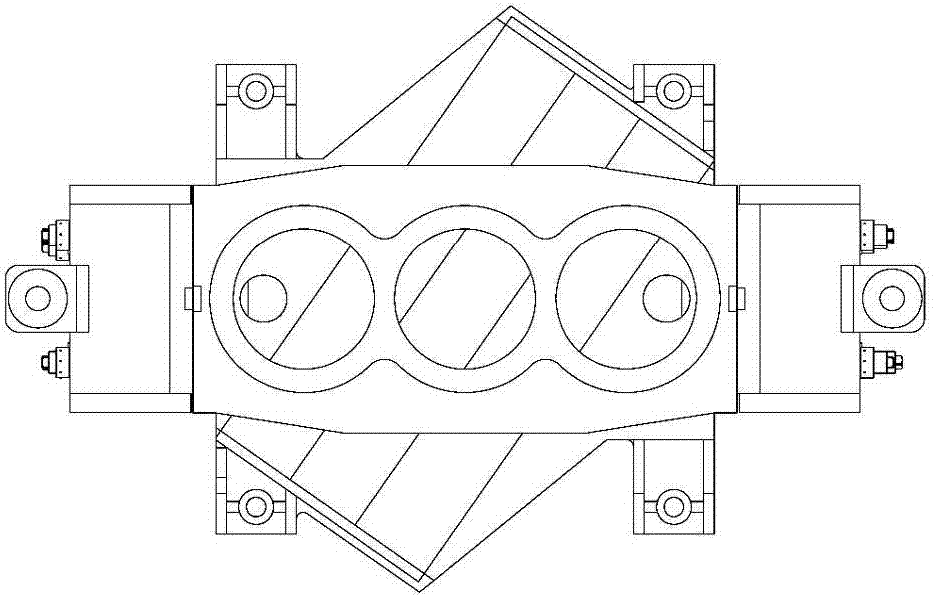

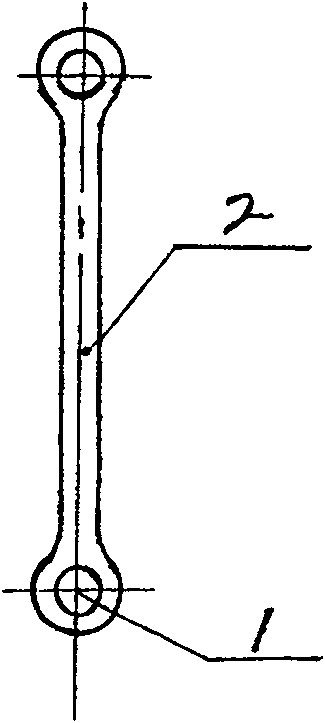

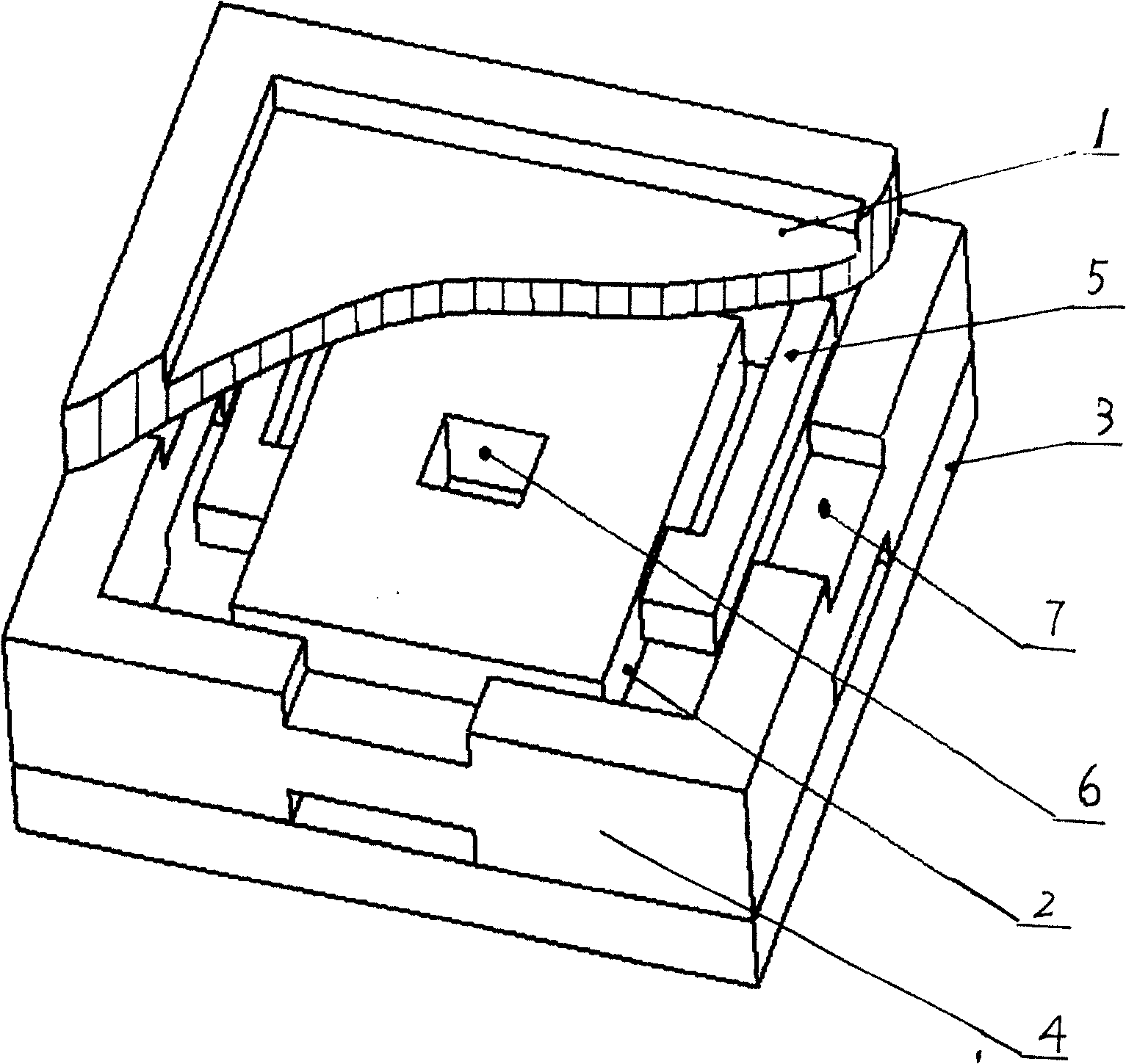

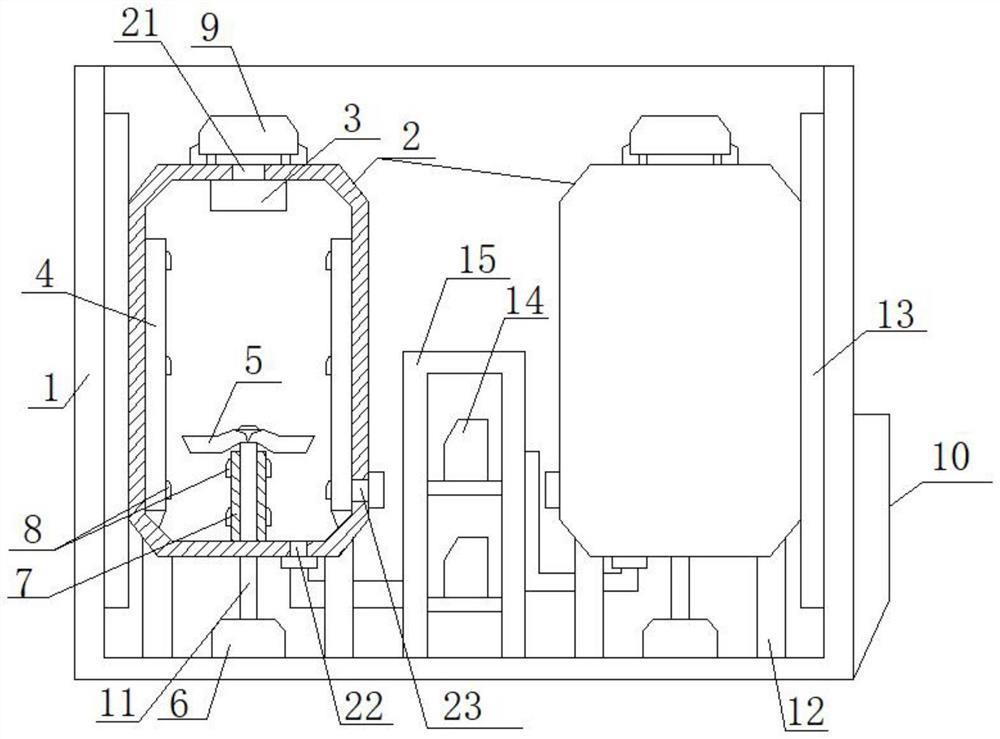

Free forging oil press rack

InactiveCN103691868AShorten the production cycleReduce production conditionsForging/hammering/pressing machinesMachiningWelding process

The invention discloses a free forging oil press rack. The free forging oil press rack comprises an upper cross beam (1), a lower cross beam (2) and two upright columns (3), which are formed by a welding process, wherein the two upright columns (3) are vertically symmetrically arranged at two sides of the free forging oil press rack; the upper cross beam (1) is arranged at the top of the free forging oil press rack, is positioned between the two upright columns (3) and is pre-tightened and assembled together with the two upright columns by upper beam pull rods (4); multiple upper beam rectangular keys (5) are embedded in rectangular key slots reserved in the upper ends of the upper cross beam (1) and the upright columns (3); the lower cross beam (2) is arranged at the bottom of the free forging oil press rack, is positioned between the two upright columns (3) and is pre-tightened and assembled together with the two upright columns by lower beam pull rods (6); multiple lower beam rectangular keys (7) are embedded in rectangular key slots reserved at the lower ends of the lower cross beam (2) and the upright columns (3). The free forging oil press rack has the advantages of simple structure, light weight, low cost, short manufacturing period, easiness in manufacturing and machining and the like.

Owner:SHENYANG CHAOZHONG ENG DESIGN

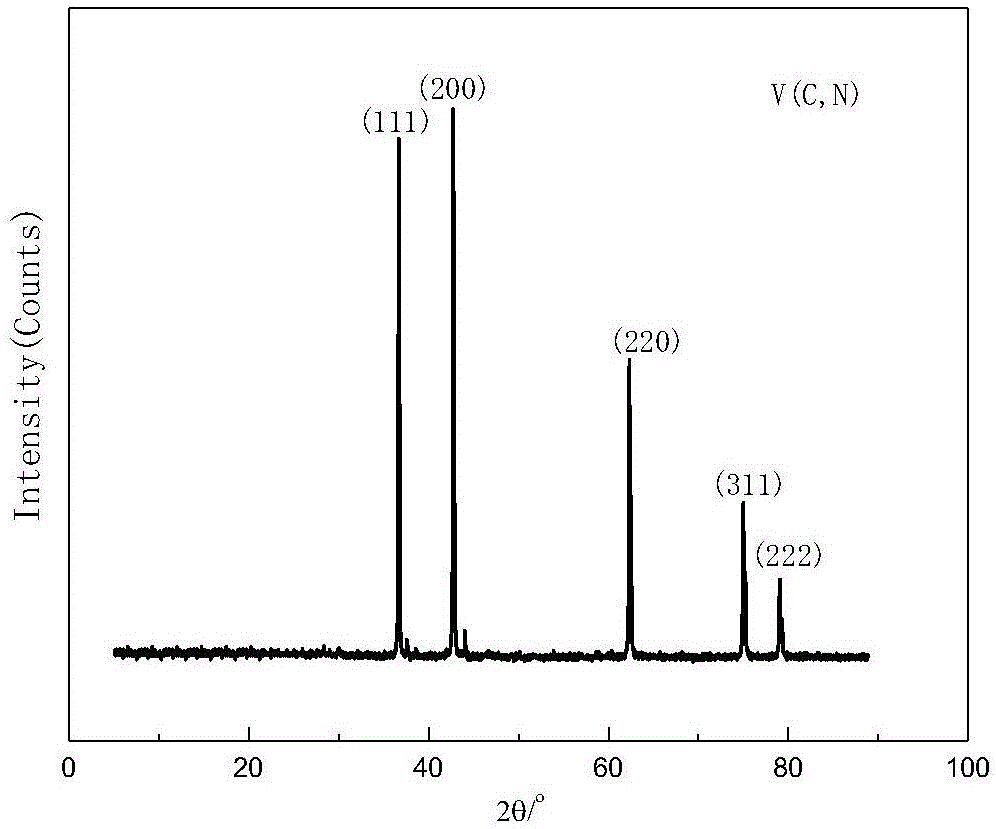

Method for preparing face-centered cubic vanadium nitride nano material and its product

InactiveCN106517110ARich sourcesLow costNitrogen-metal/silicon/boron binary compoundsNanotechnologyReaction temperatureAlloy

The invention belongs to the technical field of preparation of vanadium alloys, and concretely relates to a method for preparing a face-centered cubic vanadium nitride nano material and its product. The method takes ammonium vanadate, hydrazine hydrochloride and sodium as raw materials, the raw materials are heated in a high-temperature reaction apparatus to prepare the product, and the product is naturally cooled to room temperature to the crude product face-centered cubic vanadium nitride nano material. The ammonium vanadate is taken as the raw material, the cost of source of the raw materials is reduced; reaction temperature is obviously reduced, the technology process is simplified, energy is saved, continuous production is convenient, the face-centered cubic vanadium nitride nano material has no pollution on environment, the product purity is high, and the crystallinity is good.

Owner:湖北湖大天沭新能源材料工业研究设计院有限公司

Preparation method of alfalfa extract

The invention discloses a preparation method of alfalfa extract and belongs to the technical field of agricultural product processing. The method comprises the following steps: enzymolysis, centrifugation, precipitation, extraction and the like. The method disclosed by the invention is simple in operation, has relatively low requirements on production equipment, solves the problems of surplus yield of alfalfa and low resource utilization rate, and improves the utilization value and economic added value of the alfalfa.

Owner:QINGYANG DUNBO TECH DEV CO LTD

Methods for making and using three-component weight-reducing pill

InactiveCN106038474AReduce production conditionsReduce storage conditionsMetabolism disorderInorganic non-active ingredientsOrganic acidChemical reaction

A method for manufacturing a three-component slimming pill, which is composed of a medicine and a balloon; after placing the medicine in the balloon, the mouth of the balloon is tied with a silk thread; the medicine is composed of an organic acid, an inorganic base and an initiator; Take the pill out of the chamber and swallow it in the stomach, the heat of the stomach liquefies the initiator, so that the medicine produces a chemical reaction to generate a large amount of gas to inflate the balloon; the balloon occupies part of the space in the stomach, reducing people's eating Quantity and hunger, so as to achieve the purpose of weight loss.

Owner:冯世英

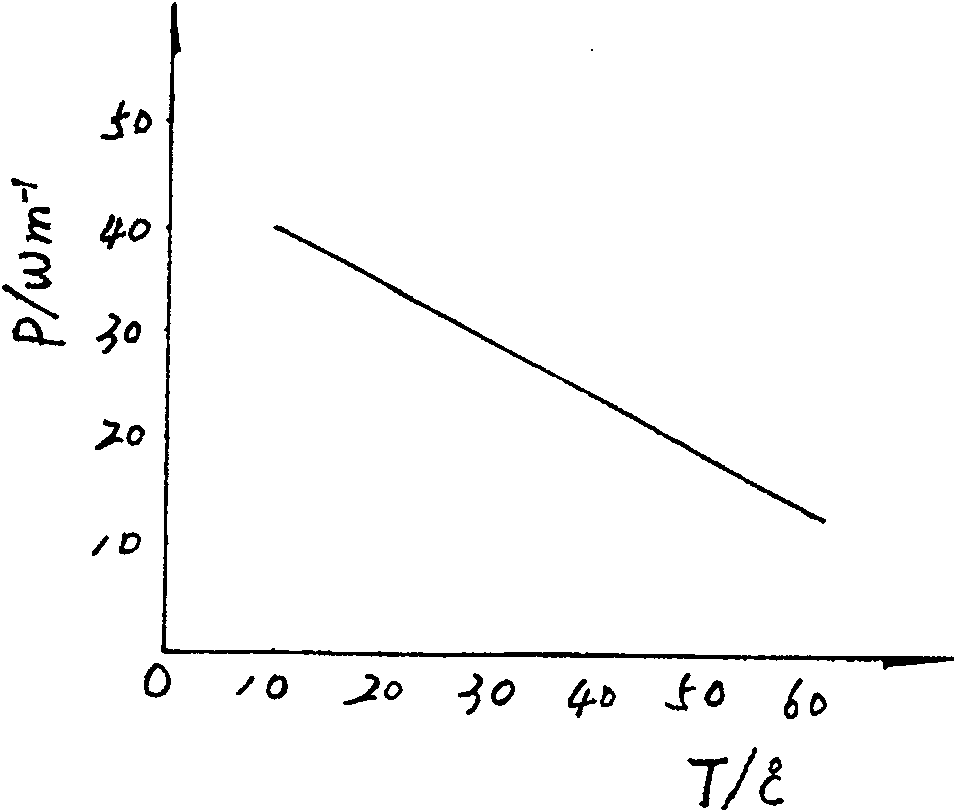

Self-temperature limiting heating belt and producing method thereof

InactiveCN100566475CReduce production conditionsReduce manufacturing costHeating element materialsSelf limitingEngineering

The invention belongs to the technical field of electric heating devices, and discloses a method for manufacturing a self-limiting temperature heating belt. The heating element of the heating belt uses two parallel metal wire cores with a certain distance as electrodes, and continuously lays a kneaded wire core on it. The composite PTC material layer is used as the heating element to form the PTC core of the electric heating element, and then it is prepared by overall chemical cross-linking and then coated with a layer of polymer insulating sheath. The self-limiting temperature is 65±5℃, 85℃ respectively. ±5℃, 105±5℃, the cross-linking degree of the core is 75-95%, and can be widely used in antifreeze, heat preservation, heat tracing and heat preservation projects.

Owner:四平市科学技术研究院

Cyclic preparation method of low-temperature high-strength corrosion-resistant large-density foam glass

ActiveCN102992594BLow strength corrosion resistanceSmall coefficient of thermal expansionGlass shaping apparatusThermal dilatationFoam glass

The invention relates to a cyclic preparation method of low-temperature high-strength corrosion-resistant large-density foam glass. The cyclic preparation method has the advantages that by glassy-state prepared materials, special designing of the steps of preprocessing, pressurization, foaming and demoulding and special optimization of relevant parameter, the defect that the common foam-glass preparation process is difficult to obtain the low-temperature high-strength corrosion-resistant large-density foam glass, the quality of a product is optimized, the toxic and side effects are reduced, the process operation is simple, the yield is higher, the product is high in strength, large in density, high in corrosion resistance, low in water absorption rate, lower thermal expansion coefficient and thermal conductivity coefficient and higher in thermal shock resistance and closed porosity; especially, the mechanical property of the modified low-temperature foam glass is obviously improved; and the preparation method is simple in process and low in cost and is suitable for industrial production.

Owner:ANHUI HUICHANG NEW MATERIAL

Method for growing helical carbon nanotubes on wood-derived porous carbon

ActiveCN108264034BRich sourcesReduce manufacturing costHybrid capacitor electrodesCarbon preparation/purificationVertical tubeComposite electrode

The invention discloses a method for growing a spiral carbon nanotube on porous carbon derived from timber. The method is characterized in that the carbon nanotube is subjected to chemical vapor deposition on the carbonized wood, space constraint effect of a natural vertical tube of the carbonized wood and the shearing contraction effect of the mixed acid on the carbon nanotube are used, and the spiral carbon nanotube with a uniform morphology height is prepared at the carbonized wood. The spiral carbon nanotube can increase the conductivity of the carbonized wood, and obviously increases themechanical property of a composite material. The composite material can be used as a super capacitor electrode, the natural vertical tube can provide an enough space for introducing other nano-materials, and a composite electrode does not require addition of a binder and a conductive agent. The elastic interleaving network of the spiral carbon nanotube is in favor of transmission of electrolyte ions, and an application of the composite material in the field of energy storage can be widened. The method has the advantages of simple technology, short production period and easy control, and can realize macro-preparation of the spiral carbon nanotube.

Owner:SHAANXI NORMAL UNIV

Preparation method for bismuth subsalicylate

ActiveCN103183608AReduce production conditionsEasy to realize industrial productionCarboxylic acid salt preparationChemical reactionSalicylic acid

The invention provides a preparation method for bismuth subsalicylate. The preparation method comprises the steps of smashing bismuth oxide into particles with specified average particle size which is 0.1-1.35 mu m; making an initial excess coefficient of salicylic acid of a salicylic acid aqueous solution 0.05-0.3 according to a chemical reaction equation Bi2O3 + 2C7H6O3 = 2C7H5BiO4 + H2O; preparing the salicylic acid aqueous solution according to mass of the smashed bismuth oxide that to be adopted and the initial excess coefficient; gradually adding the smashed bismuth oxide into the salicylic acid aqueous solution heated to a predetermined temperature; reacting the salicylic acid and the bismuth oxide while keeping the predetermined temperature and a sealed condition away from light; and filtering and drying after the reaction is finished, thus obtaining a bismuth subsalicylate product. The preparation method can reduce production conditions for the raw material metal bismuth, can effectively reduce oxidation of the raw material metal bismuth and can easily realize industrialized production.

Owner:昆明先导新材料科技有限责任公司

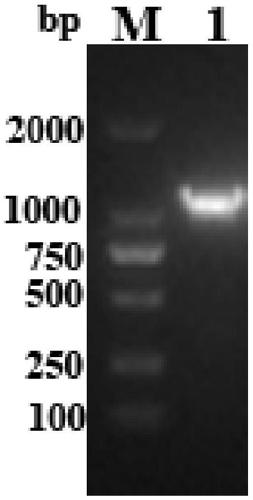

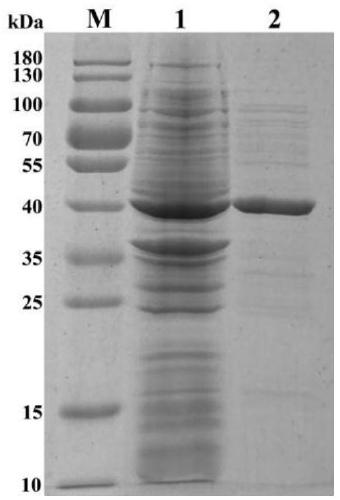

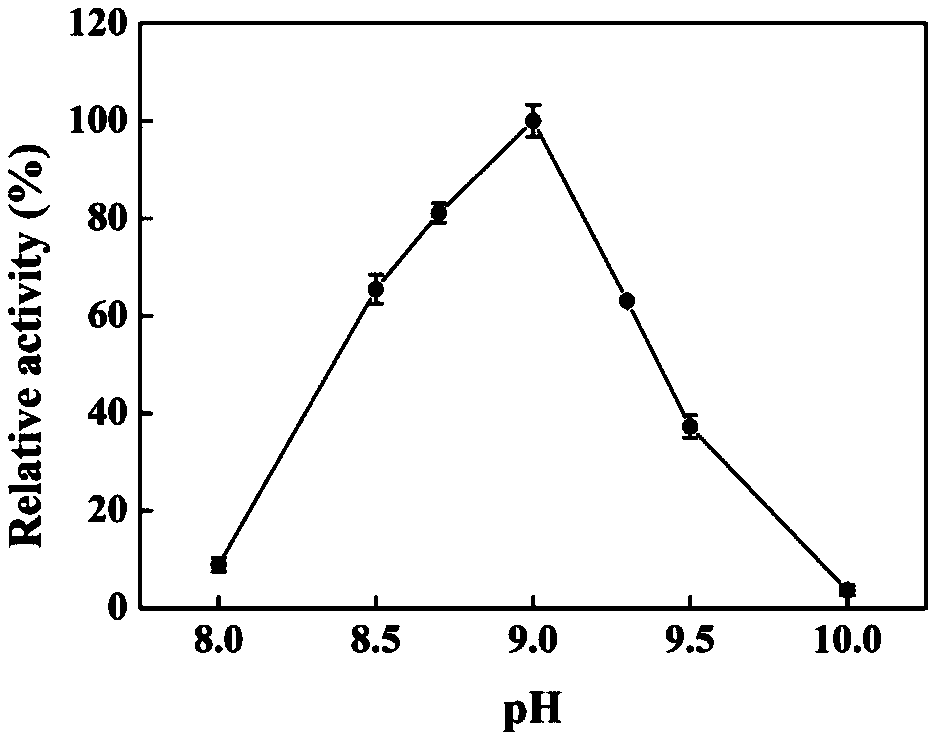

Thermostable citrate synthase gene, engineered bacterium containing gene and expression method thereof

InactiveCN109266665AReduce production conditionsHeat resistantBacteriaFermentationBiotechnologyEscherichia coli

The invention discloses a thermostable citrate synthase gene, engineering bacteria containing the gene and expression method thereof, in accordance with that present invention, the gene of the heat-resistant citrate synthase of the invention takes the genome of Anabaena sp. PCC7120 as a template and is obtained by using PCR amplification technique, the recombinant plasmid containing citrate synthase gene was transformed into Escherichia coli, after kanamycin resistance screening and sequencing, the citrate synthase produced by the genetic engineering bacteria has the characteristics of heat resistance and high enzyme activity, which provides a basis for its better application in the industrial production of citric acid. The characteristics of heat resistance and high enzyme activity enableit to better save production costs.

Owner:ANHUI NORMAL UNIV

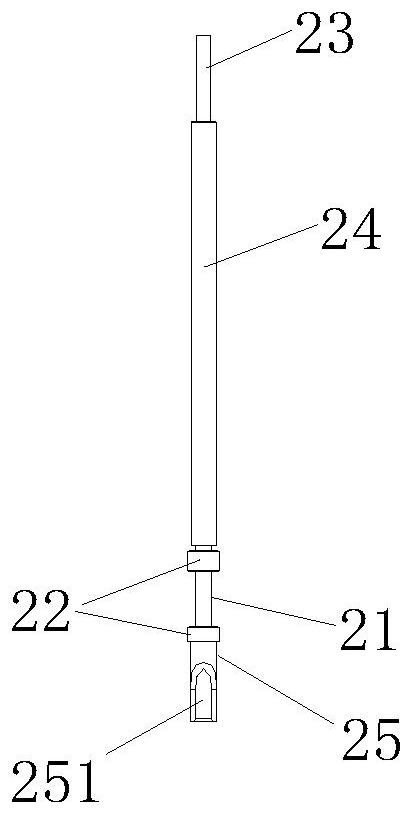

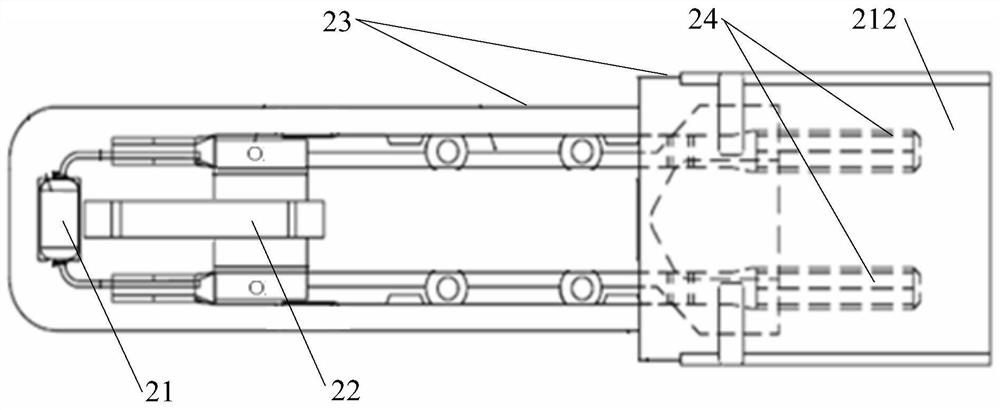

Spring needle mounting and positioning structure for chip testing equipment

PendingCN114814312ASolve the assembly processResolve Assembly DimensionsElectrical measurement instrument detailsElectrical testingTesting equipmentPogo pin

The invention discloses a spring needle mounting and positioning structure for chip testing equipment, and the structure comprises a pedestal which is provided with an assembly hole and a positioning hole, and the assembly hole is communicated with the positioning hole; the spring needle is arranged in the assembly hole in a penetrating manner, a positioning part is arranged on the spring needle, the positioning part is located at the communication position of the assembly hole and the positioning hole, and positioning steps are arranged at the positions, at the two ends of the positioning part, of the spring needle; the positioning piece and the positioning hole are the same in shape and size, a clamping hole is formed in the positioning piece, the cross section of the clamping hole and the cross section of the positioning part are the same in shape and size, the positioning piece is inserted into the positioning hole, and the positioning part is arranged in the clamping hole in a penetrating mode. The two ends of the positioning piece abut against the positioning steps at the external positions of the two ends of the positioning part respectively. According to the invention, the assembling process problem and the size guarantee problem of the spring needle are well solved. The method is simple and reliable, and the problems of welding and positioning of complex equipment are solved. And the production conditions are reduced. And meanwhile, the consistency of finished products is improved, and application and popularization conditions are met.

Owner:SHANGHAI AEROSPACE SCI & IND ELECTRIC APPLIANCE RES INST +1

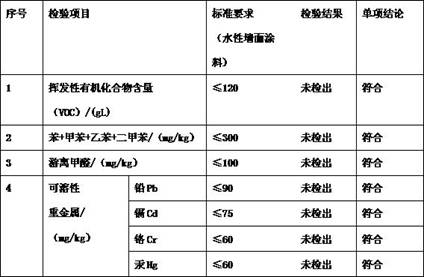

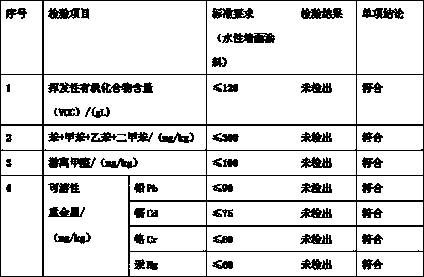

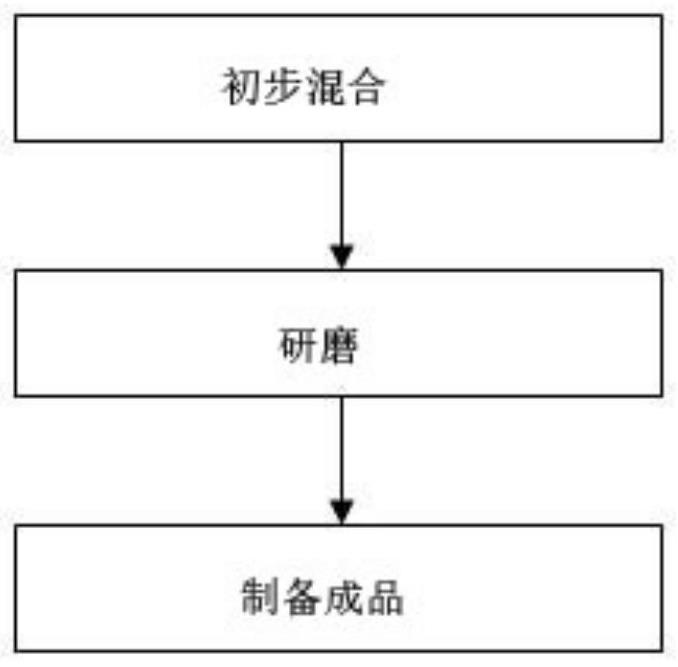

A zero-voc inorganic fire-resistant functional coating suitable for electronic clean workshops and its preparation method

ActiveCN111560178BImprove flame retardant performanceImprove heat resistanceFireproof paintsAntifouling/underwater paintsHazardous substancePhysical chemistry

The invention discloses a zero-VOC inorganic fire-resistant functional coating suitable for electronic clean workshops and a preparation method. The coating consists of the following components in parts by weight: 35-45 parts of filler; 10-20 parts of calcium; tourmaline powder 5‑15 parts; 15‑25 parts of inorganic mineral gel; 5‑25 parts of inorganic mineral pigment; 1‑5 parts of floating beads; 15‑30 parts of clear water. The invention has the advantages of no VOC, formaldehyde, benzene series, heavy metals and other harmful substances, no radioactive hazard, good fire resistance, antibacterial and mildew resistance, no peculiar smell and no reduction in the yield rate of products inside the electronic clean workshop.

Owner:THE IT ELECTRONICS ELEVENTH DESIGN & RES INST SCI & TECHNOLOGICAL ENG

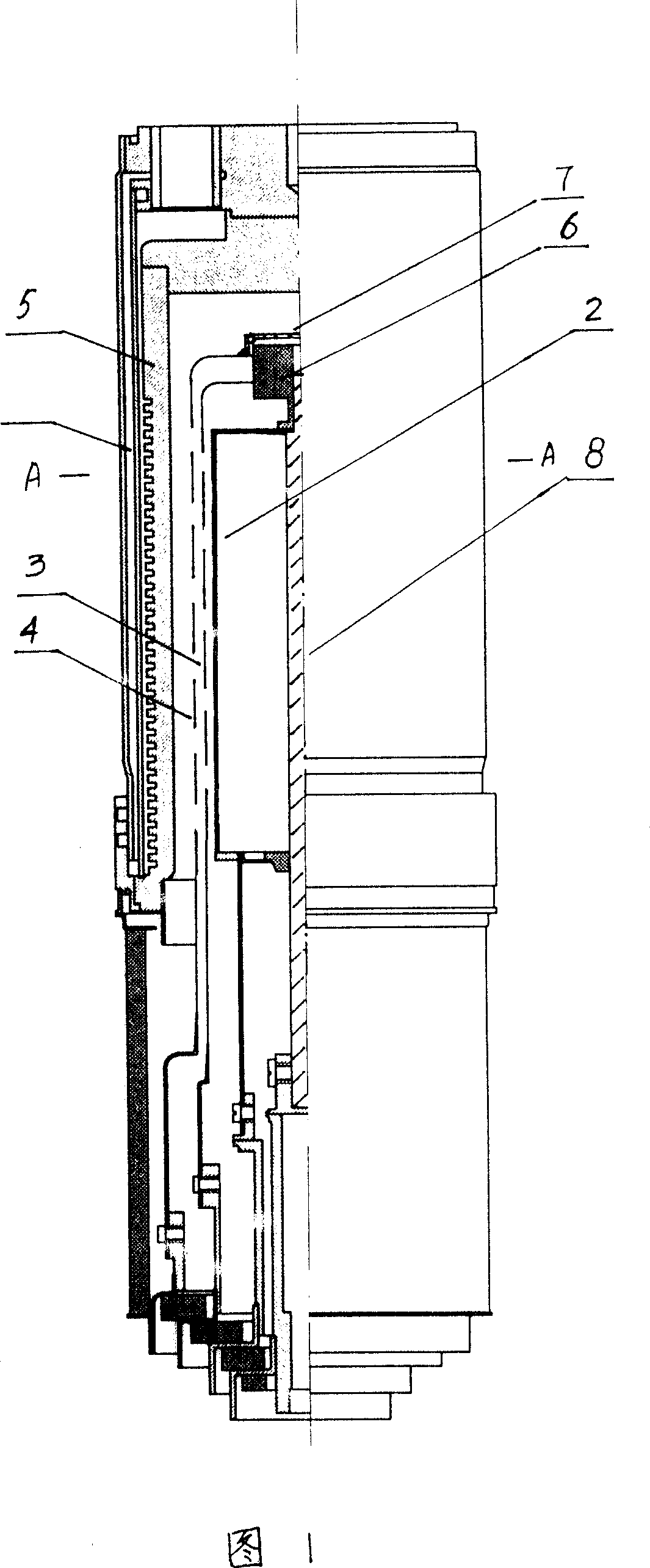

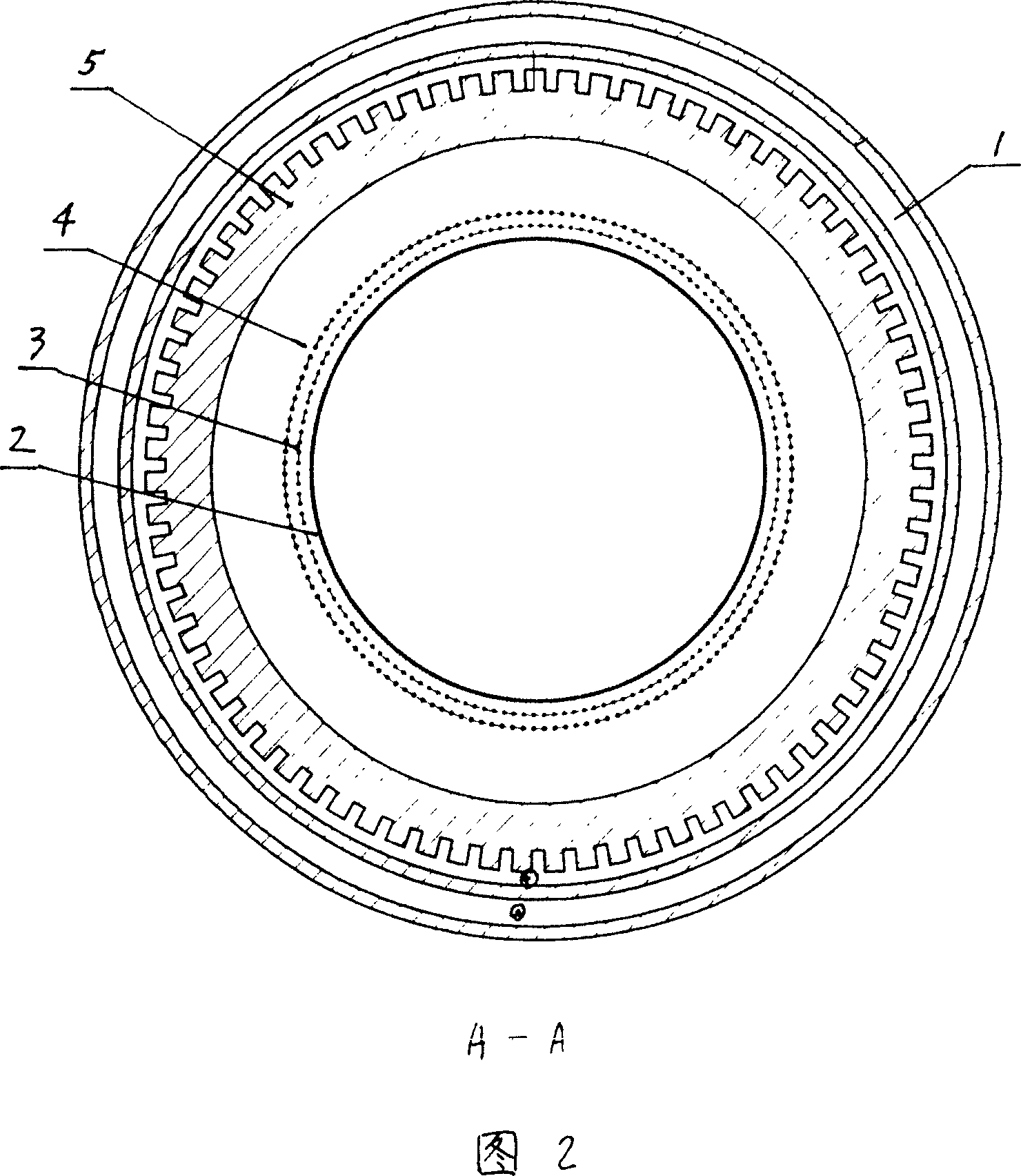

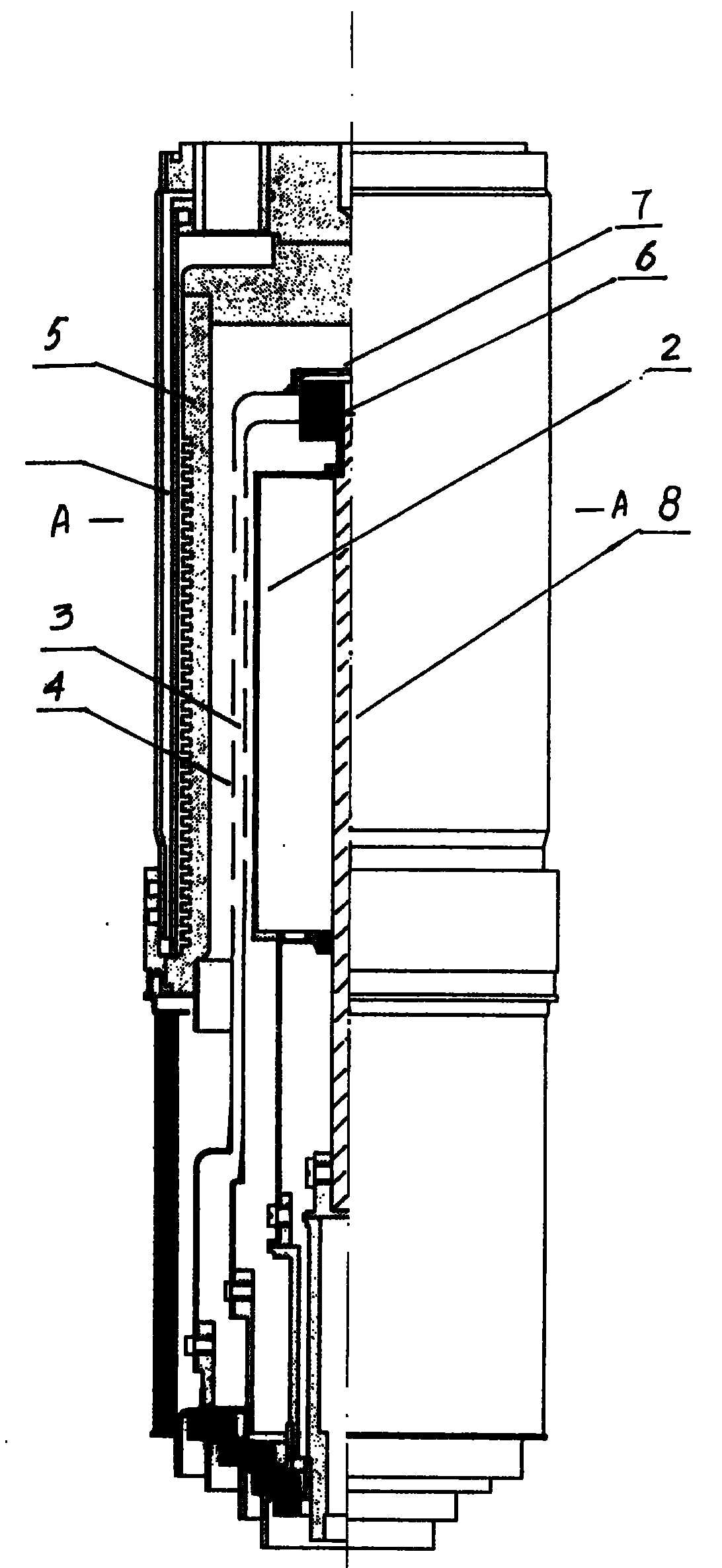

Capacitor MEMS acceleration sensor

ActiveCN100458449CReduce noiseSmall dampingAcceleration measurementFlexible microstructural devicesEngineeringCantilever

The capacitor MEMS acceleration sensor is one sandwich type differential capacitor structure comprising an upper electrode, a middle electrode and a lower electrode, and the movable middle electrode includes one frame with slots, one mass block with one central hole and one cantilever beam. When the mass block moves up and down, the air inside the cavity may pass through the hole and flow out through the slots, and the enhanced air flow can prevent the mass block from moving freely, resulting low damp and less noise.

Owner:WEIHAI SUNFULL GEOPHYSICAL EXPLORATION EQUIP

Zero-VOC inorganic fire-resistant functional coating suitable for electronic clean workshop and preparation method thereof

ActiveCN111560178AImprove flame retardant performanceImprove heat resistanceFireproof paintsAntifouling/underwater paintsHazardous substanceAnti bacteria

The invention discloses a zero-VOC inorganic fire-resistant functional coating suitable for an electronic clean workshop and a preparation method thereof. The coating comprises the following components: 35-45 parts of a filler, 10-20 parts of calcium, 5-15 parts of tourmaline powder, 15-25 parts of inorganic mineral gel, 5-25 parts of inorganic mineral pigment, 1-5 parts of floating beads and 15-30 parts of clear water. The coating has the advantages of no harmful substances such as VOC, formaldehyde, benzene series and heavy metal, no radioactive hazards, good fire resistance, antibacterial performance, mildew resistance, no peculiar smell and no reduction in the yield of products in the electronic clean workshop.

Owner:THE IT ELECTRONICS ELEVENTH DESIGN & RES INST SCI & TECHNOLOGICAL ENG

Inorganic functional coating with contact killing function on new coronavirus and preparation method of same

InactiveCN114015260AImprove breathabilityPromote respirationShaking/oscillating/vibrating mixersAntifouling/underwater paintsToxic gasFire - disasters

The invention relates to an inorganic functional coating with a contact killing function on new coronavirus. The inorganic functional coating is prepared from the following components in parts by weight: 20 to 30 parts of filler, 15 to 25 parts of calcium, 7 to 19 parts of tourmaline powder, 5 to 15 parts of quaternization, 20 to 30 parts of inorganic mineral gel, 5 to 15 parts of inorganic mineral pigment and 20 to 30 parts of deionized water. The inorganic functional coating has good air permeability and breathing performance, cannot burn and emit toxic gas in a fire disaster, is excellent in virus contact killing performance, durable in color, durable, free of color fading, resistant to acid and alkali, durable, resistant to high temperature, and good in capability of effectively preventing ultraviolet radiation.

Owner:朱颖

Large power quadrupole delectronic tube and its manufacturing method

InactiveCN1321431CSolve the defect of falling powder and ignitionReduce production conditionsControl electrodesTransit-time tubesRadiation resistantGraphite

The electron tube consists of cooling water jacket, cathode, first grid, second grid and anode. The improved first grid is made from pyrolytic graphite. The second grid is made from molybdenum filament welded in squirrel cage shape. With surface being sprayed by tungsten carbide, the molybdenum filament is sintered and plated by platinum. The upper parts of two grids are connected to ceramic ring at upper part of cathode. The first grid is made from graphite after dedicated procedure the first grid possesses higher capabilities of high temperature resistant and radiation resistant. The heat dissipation capability of the first grid made from graphite is 5 times of grid made from molybdenum filament so as to reduce size greatly.

Owner:卫军民 +1

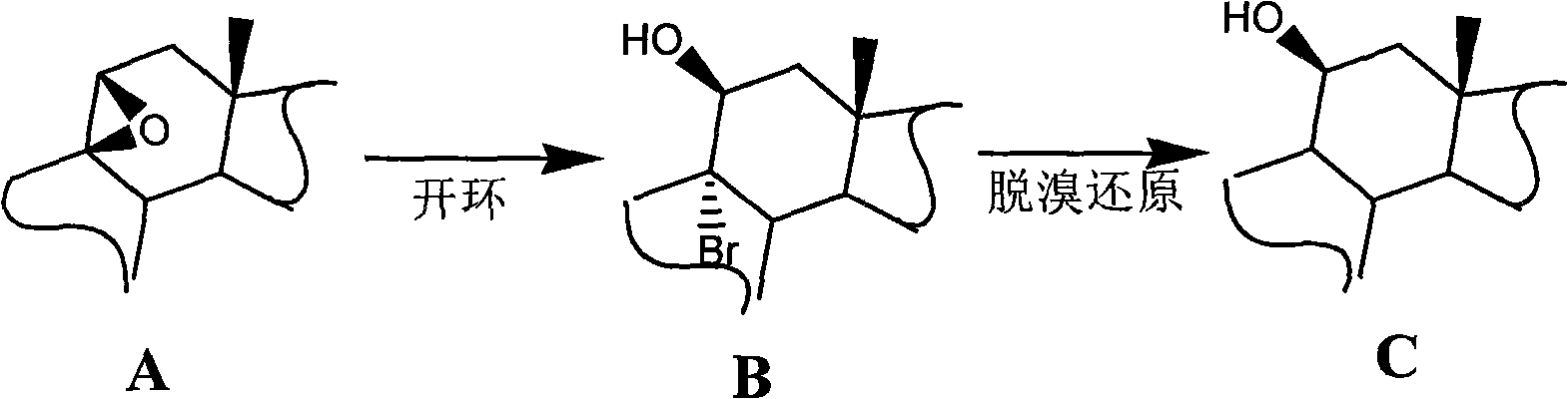

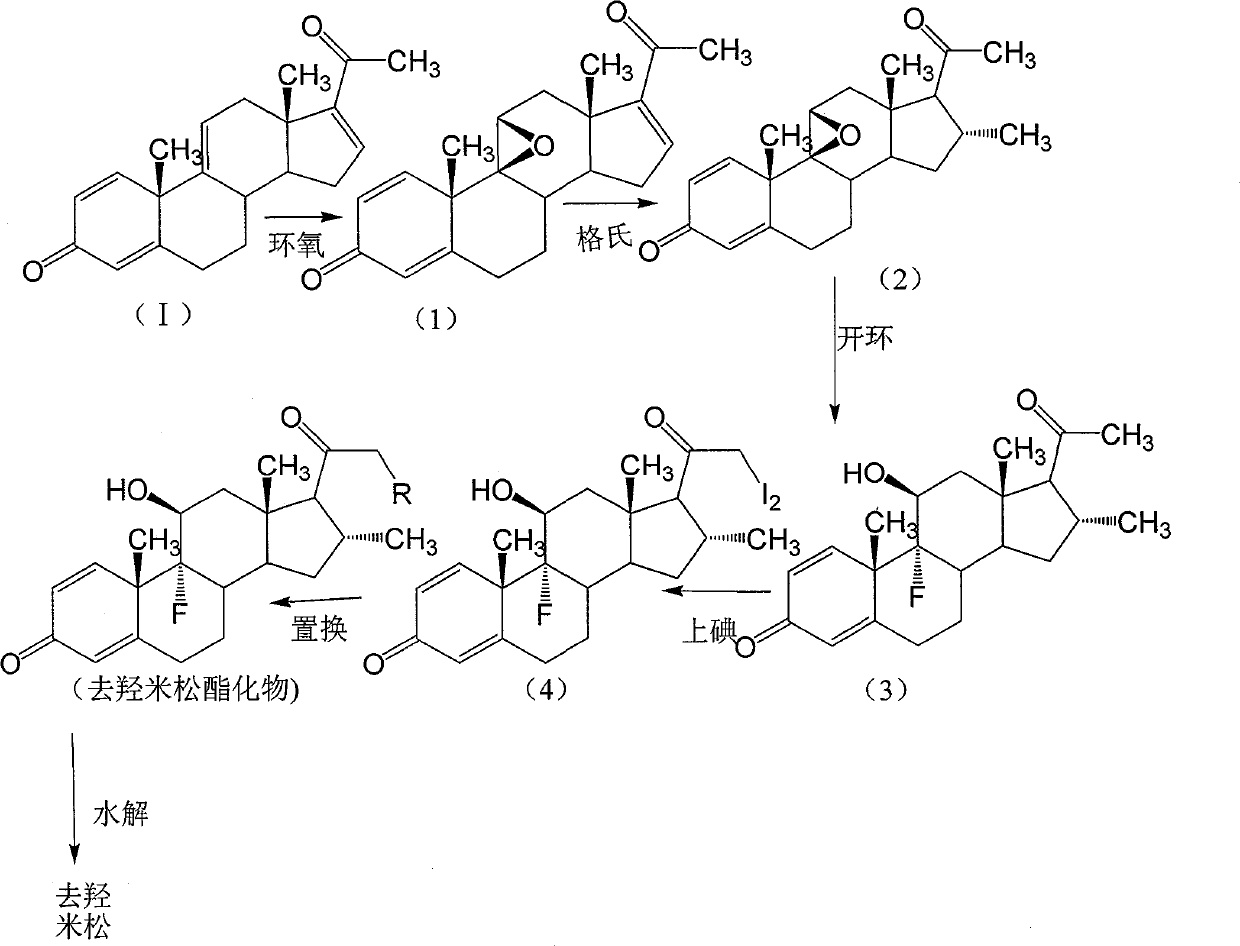

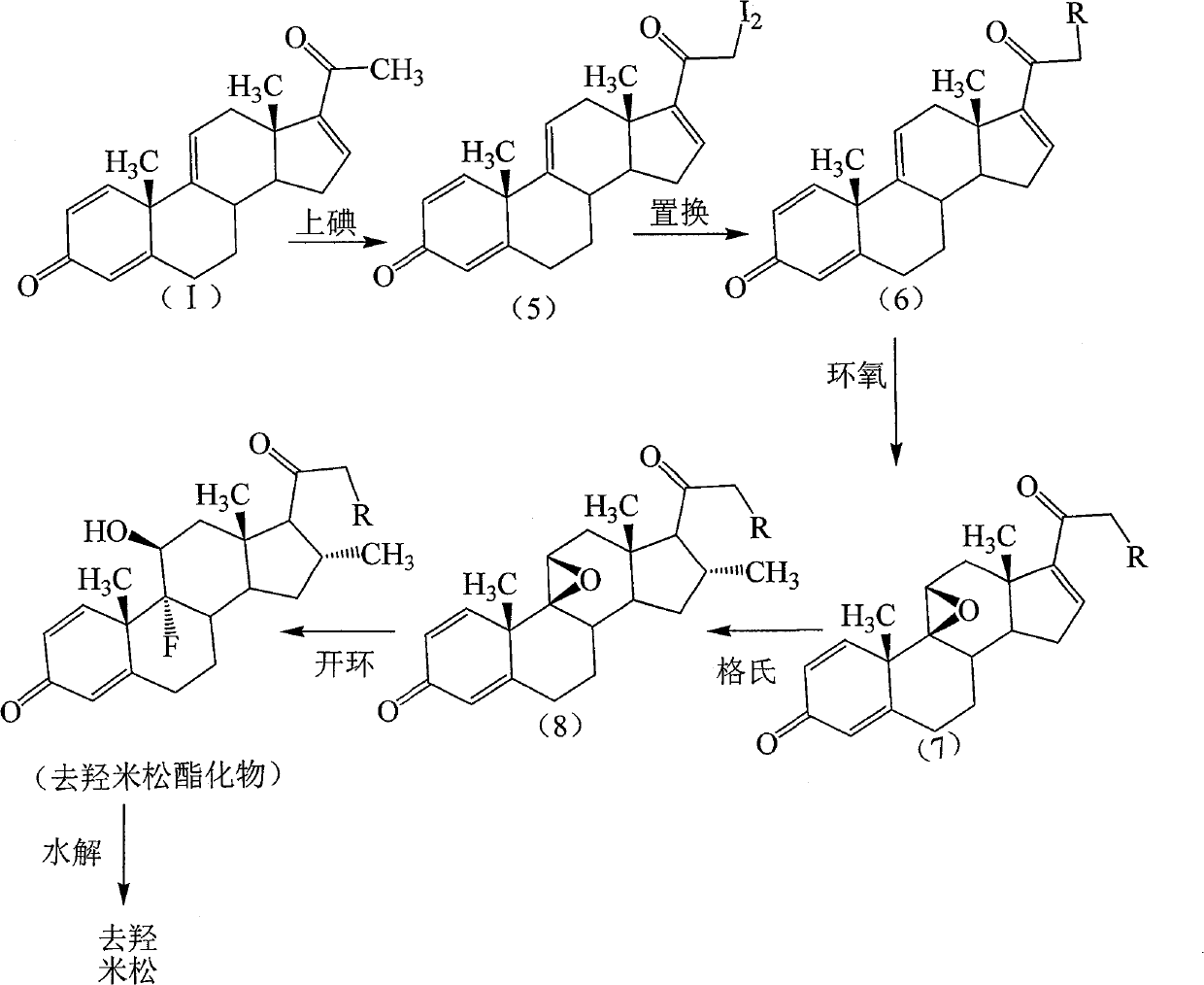

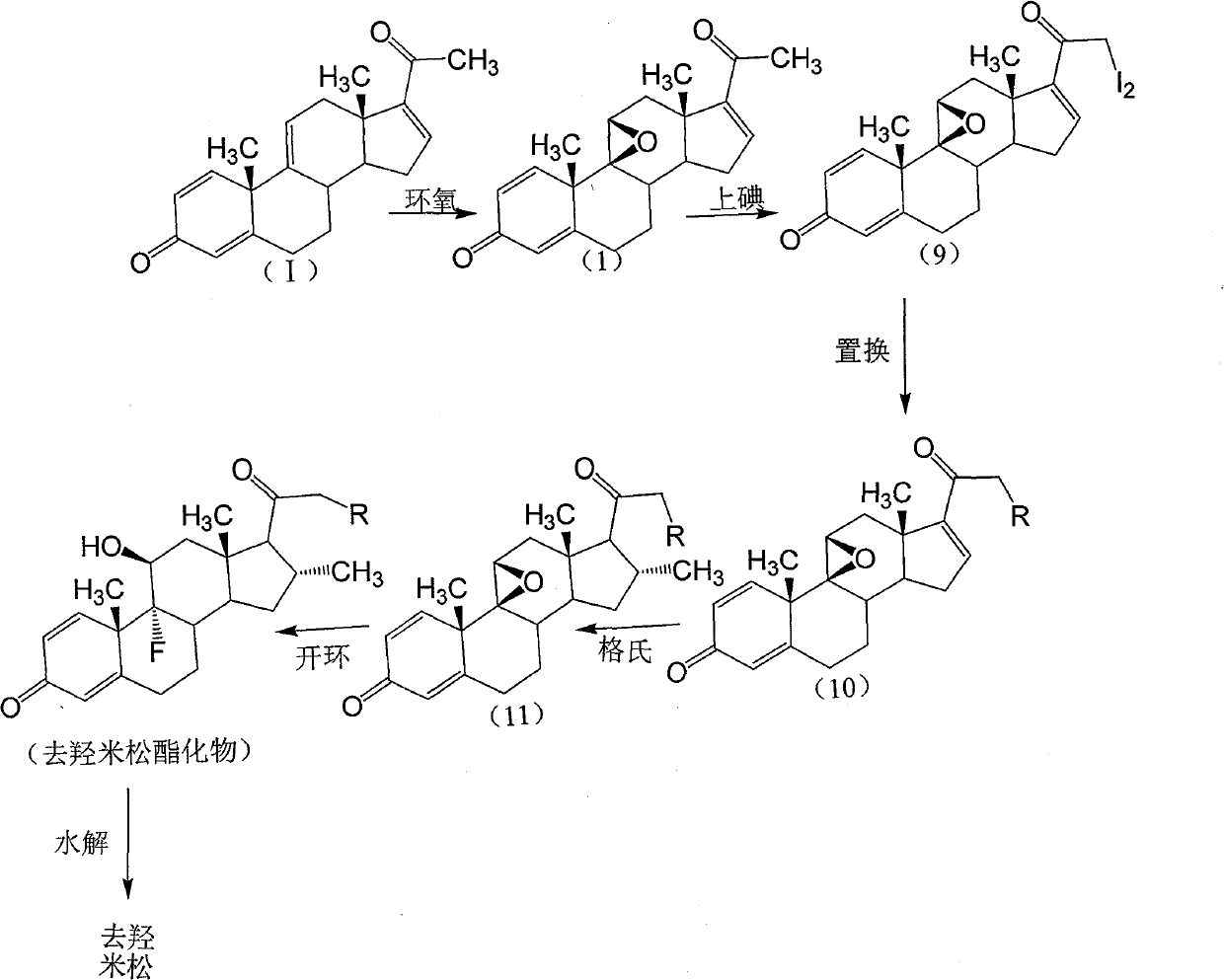

Preparation of desoximetasone

The invention relates to a preparation method of a steroid compound, in particular to the preparation of desoximetasone, which takes 1, 4, 9, 16-arachidonic-pregna-3, 20-diketone (CN1896090) as the initiator and is improved by 16, 17-grignard, 9, 11th and 21st to obtain the desoximetasone and the 21st esterified ester thereof. The process has the advantages that, as the existing intermediate of the company is adopted as the initiator, the line is concise, the material is easy to obtain, expensive auxiliary materials are saved, and the yield and the cost are obviously superior to the historical synthetic method of the desoximetasone; in addition, the adoption of the existing intermediate realizes the doubling production of the dexamethasone products, betamethasone products and the desoximetasone products, thus greatly reducing the production cost and industrial conditions.

Owner:TIANJIN PHARMA GROUP CORP

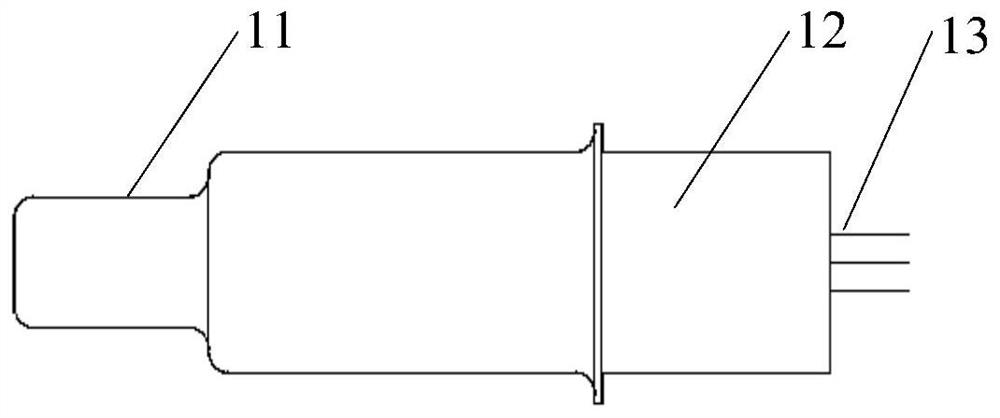

Temperature sensor and washing machine

ActiveCN108018680BIncrease productivityReduce production conditionsOther washing machinesTextiles and paperLaundry washing machineManufacturing technology

The invention discloses a temperature sensor and a washing machine. The temperature sensor is formed through injection-molding sealing. The temperature sensor comprises a resistance core, a draw-forthpart and an injection-molding body, wherein the draw-forth part is connected with terminals of the resistance core, and comprises a first-segment draw-forth part and a second-segment draw-forth partwhich are connected with each other, and the first-segment draw-forth part is connected with terminals of the resistance core; the injection-molding body is subjected to injection-molding sealing outside the resistance core and the first-segment draw-forth part, an avoidance cavity is formed in the injection-molding body, and the second-segment draw-forth part is located in the avoidance cavity. By means of the temperature sensor, through injection-molding sealing forming, the steps of a manufacturing technology are omitted, and thus the manufacturing technology is simplified; meanwhile, the manufacturing technology takes few minutes, and the production efficiency of the temperature sensor is effectively improved; the inject-molding sealing technology does not need high temperature either,the manufacturing condition of the temperature sensor is lowered, and thus the production cost is lowered; bubbles cannot be generated in the injection-molding sealing forming process, and sensing drifting of the resistance core due to the presence of the bubbles is avoided.

Owner:SUZHOU SAMSUNG ELECTRONICS CO LTD +1

A kind of preparation method of textured carbon fiber cloth/carbon nanotube composite material

The invention discloses a method for preparing a textured carbon fiber cloth / carbon nanotube composite material. In the method, cotton cloth impregnated with nickel nitrate is used as a base, nickel nitrate is used as a nickel source, acetonitrile is used as a carbon source, and carbonized in a nitrogen atmosphere Chemical vapor deposition, the morphology of carbon nanotubes is controlled by adjusting the amount of nickel nitrate, chemical vapor deposition time and nitrogen gas flow rate. The growth of carbon nanotubes not only improves the conductivity and mechanical properties of the textured carbon fiber cloth, but also leaves abundant pores on the textured carbon fiber cloth during the reduction process of nickel nitrate, which increases the specific surface area of the electrode. As an electrode of a supercapacitor, it has excellent capacitance characteristics. The interweaving of carbon nanotubes is beneficial to the transmission of ions, which broadens the wide application of the material in the field of energy storage; moreover, the invention has easy-to-obtain raw materials, low cost and simple process, and can realize large-scale production.

Owner:SHAANXI NORMAL UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com