Patents

Literature

5520 results about "Absorption rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Prosthetic repair device

A prosthetic repair device comprising a nonabsorbable material, a first absorbable material having a first absorption rate and a second absorbable material having a faster absorption rate than the first absorption rate. Alternatively, the nonabsorbable material is encapsulated with a first absorbable component having a first absorption rate.

Owner:ETHICON INC

Absorbent article having improved absorption and retention capacity for proteinaceous or serous body fluids

The present invention relates to absorbent articles for the absorption of proteinaceous or serous body fluids, particularly menses. The absorbent article has a better handling towards such fluids, both in terms of retention capacity and absorption rate, by comprising a selected polyacrylate based material.

Owner:THE PROCTER & GAMBLE COMPANY

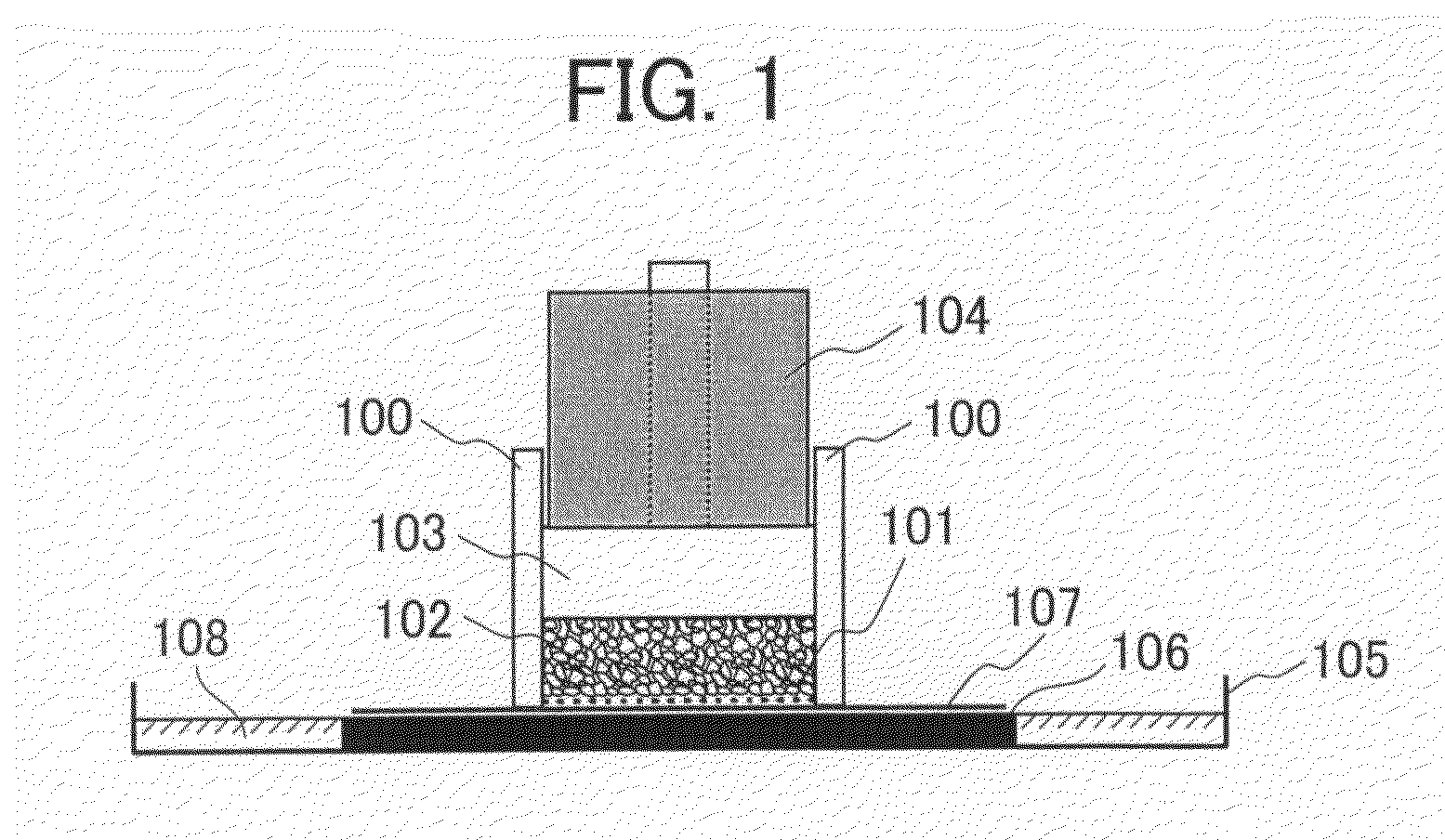

Water-absorbing resin and method for manufacturing the same

The present invention provides a highly productive method for manufacturing a water-absorbing resin, the amounts of fine powder and dust of which are small, the amount of residual monomer of which is small, and whose absorption rate is high. That is, the method for manufacturing the water-absorbing resin of the present invention is a method for crosslinking and polymerizing an aqueous solution of an acid-group containing unsaturated monomer, and is characterized in that stationary polymerization is carried out in such a manner that a solid matter is added to the monomer aqueous solution, and an initiation temperature of the polymerization is adjusted to 40° C. or more or a maximum temperature of the polymerization is adjusted to 100° C. or more.

Owner:NIPPON SHOKUBAI CO LTD

Absorbent article having increased absorption and retention capacity for proteinaceous or serous body fluids

Absorbent articles for the absorption of proteinaceous or serous body fluids, particularly menses. The absorbent article has a better handling towards such fluids, both in terms of retention capacity and absorption rate, by comprising a selected polyacrylate based material.

Owner:PROCTER & GAMBLE CO

Absorbent article having increased absorption and retention capacity for proteinaceous or serous body fluids

Absorbent articles for the absorption of proteinaceous or serous body fluids, particularly menses. The absorbent article has a better handling towards such fluids, both in terms of retention capacity and absorption rate, by comprising a selected polyacrylate based material.

Owner:THE PROCTER & GAMBLE COMPANY

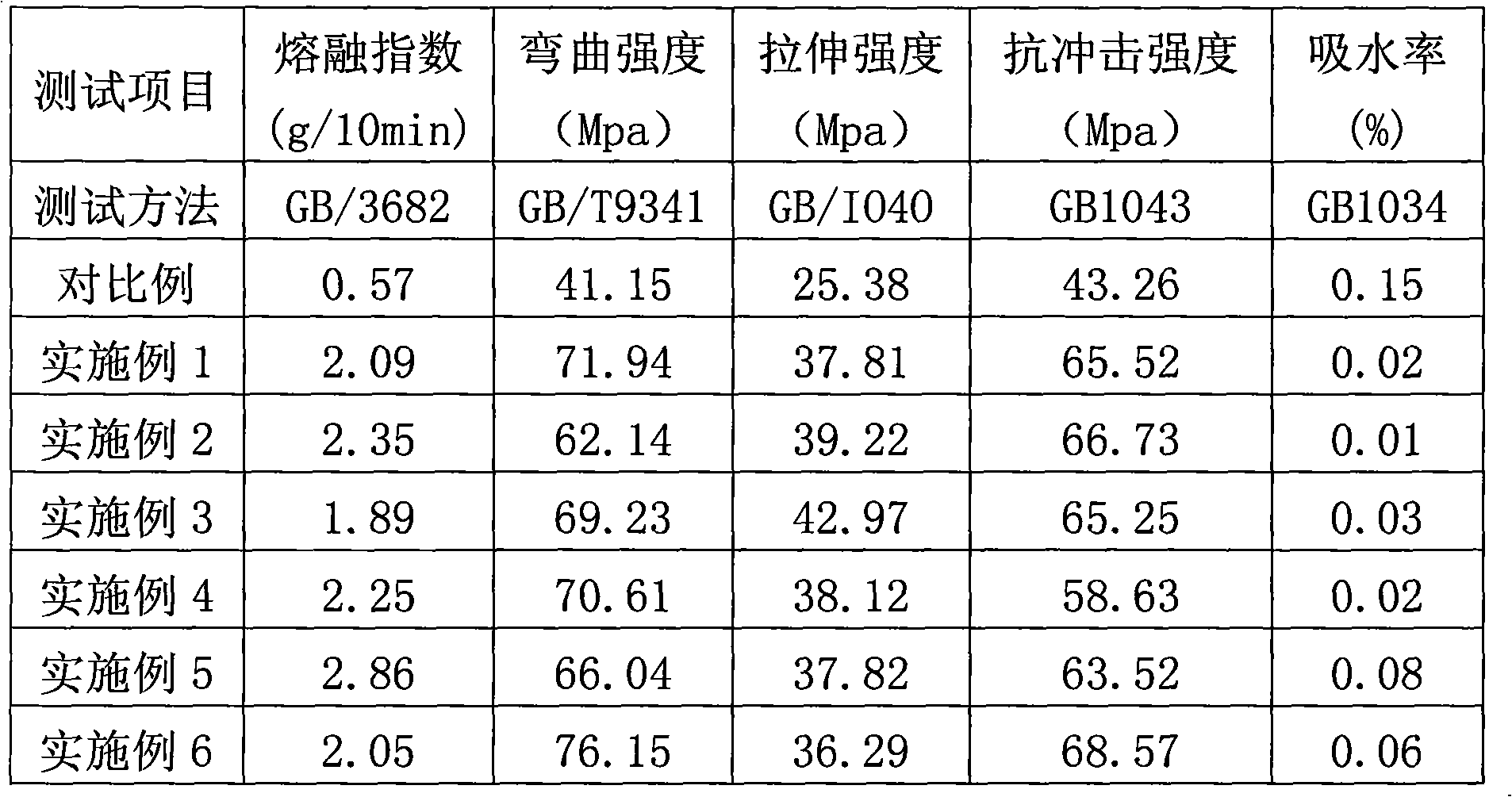

Wood plastic composite material

The invention relates to a wood plastic composite material comprising the following materials in parts by weight: 100 parts of wood meals, 20-80 parts of waste plastics, 5-50 parts of waste rubbers, 10-60 parts of high-melt index thermoplastic resins, 1-12 parts of surface active agents, 2-8 parts of lubricating agents, 0.1-4 parts of cross-linking agents, 0.1-4 parts of antioxygens and 0.05-1.5 parts of processing agents, wherein the grain diameter of the wood meals ranges from 10 meshes to 325 meshes; the flow velocity of the high-melt index thermoplastic resins is higher than 20 g / 10 minutes; the cross-linking agents are peroxides, thus the invention improves the dispersibility and the flowability of the wood meals contained in the composite and the compatibility of plastics by adding the high-melt index thermoplastic resins, can not only better utilize the resources, but also enhances the mechanical strength (such as tensile strength, bending strength, impact strength, and the like) of the composite material by adding the waste rubbers, has the advantages of good processing property, low water absorption rate, good stability of products, and the like and is suitable for injection moulding and beneficial to market promotion.

Owner:东莞市启原实业有限公司

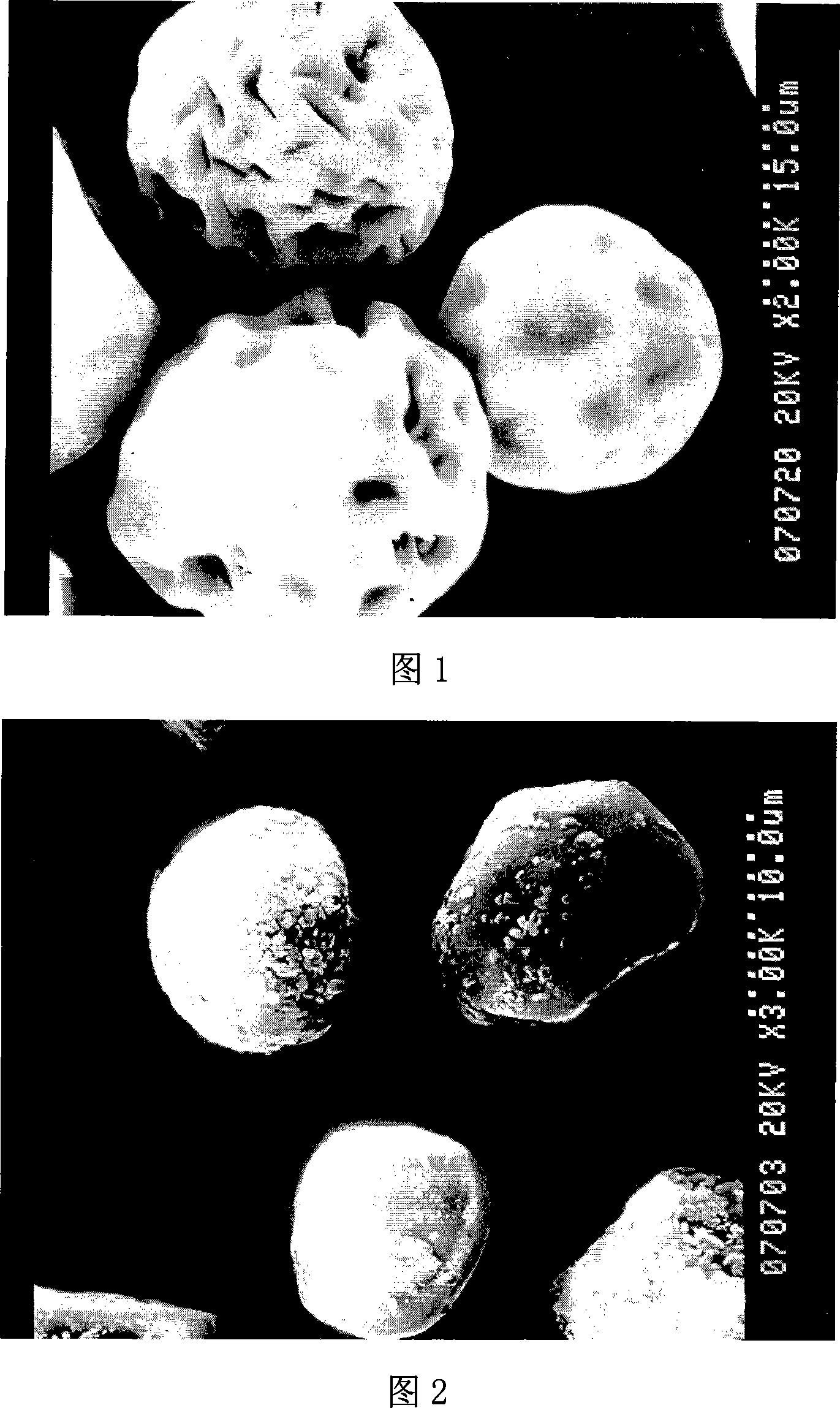

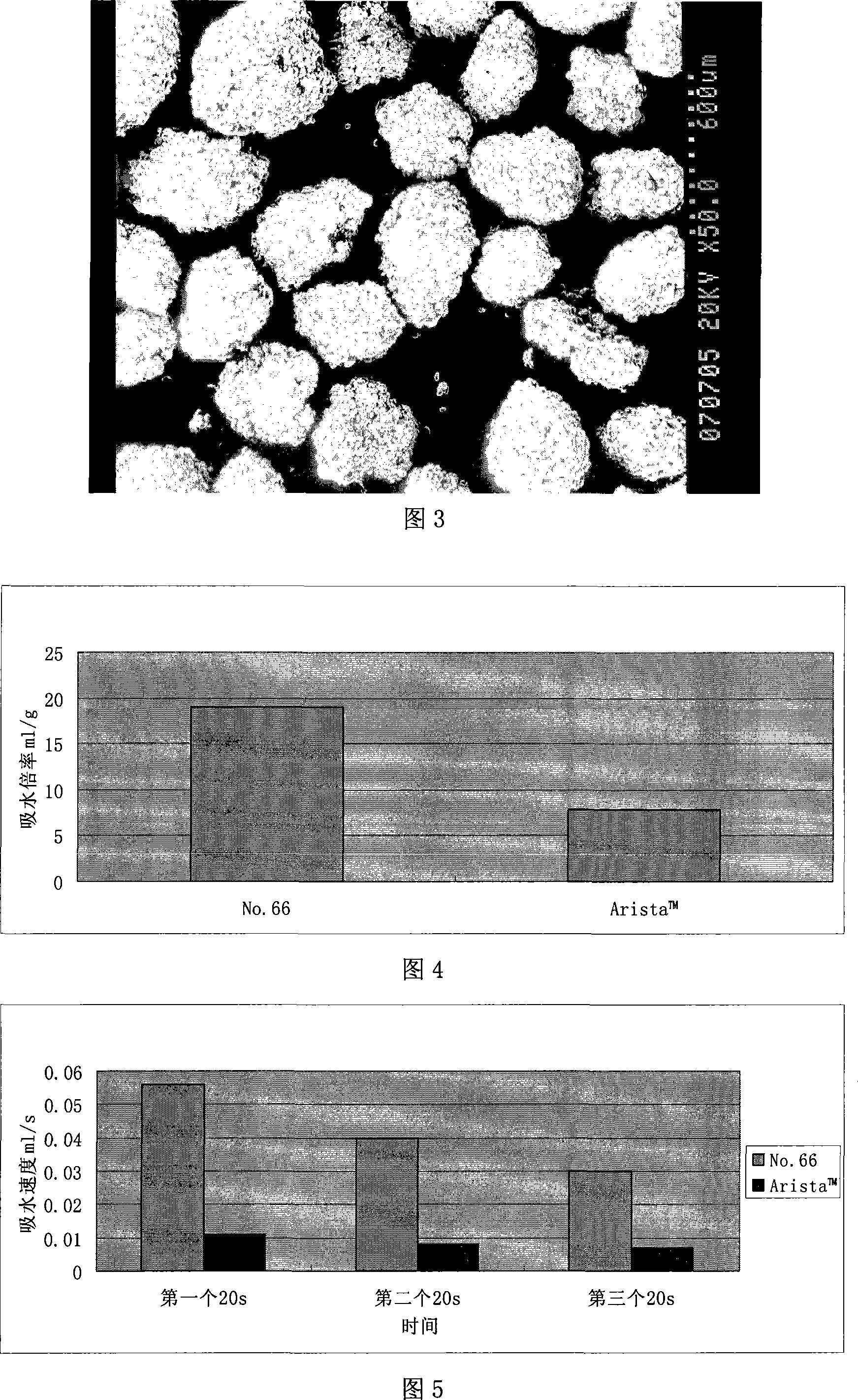

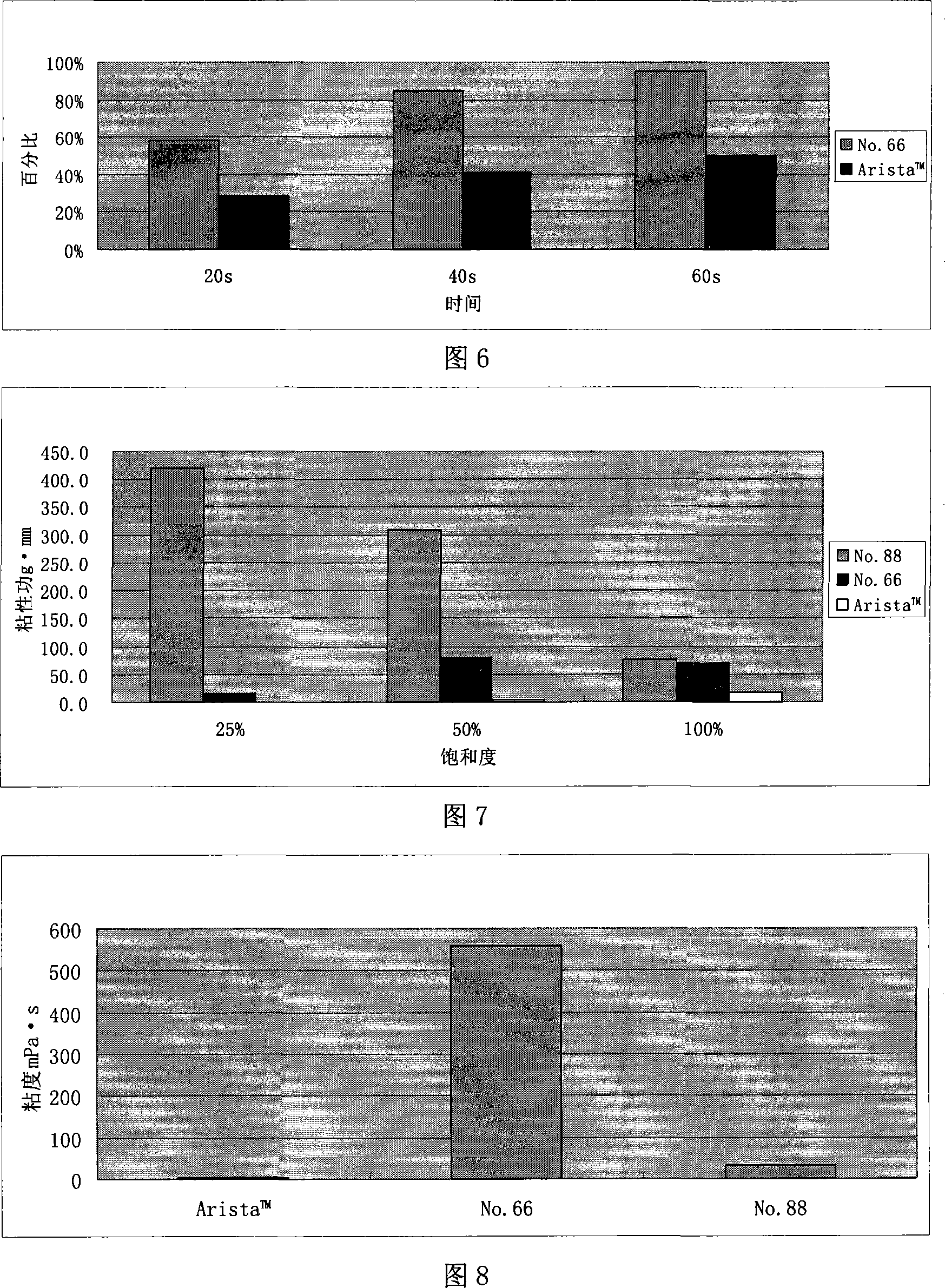

Denaturated starch absorbable hemostatic material and preparation method thereof

InactiveCN101121041AHigh viscosityImprove water absorption speedSurgical adhesivesPharmaceutical delivery mechanismMedicineBlood plasma

An absorbable modified starch hemostatic material and preparation thereof, wherein the hemostatic material is etherified starch, or a mixture of one or more etherified starches, crosslinked starches. The modified starch has a molecular weight of 15,000 - 10,000,000, a particle size of 10 - 1000µm, and a water absorption rate of 1 - 100. The biocompatible hemostatic material can directly effect on the wound with blood, concentrate the blood quickly to congulate blood; moreover, the gelatiniform mixture formed with blood has high viscosity, which can plug damaged tissue and blood vessel. The biocompatible hemostatic material is easy to swell in the water and easy to be washed so that the residue can be reduced; it is stable, not easy to decompose, and has long shelf life and storage advantage. The biocompatible hemostatic material can also be used as absorbable surgical antisticking material, promoting tissue healing material, surgical sealant and wound no-joint tissue adhesive.

Owner:美国淀粉医疗公司

Dosage unit for sublingual, buccal or oral administration of water-insoluble pharmaceutically active substances

ActiveUS20100008985A1Disperse fastEfficient packagingBiocidePowder deliveryWater insolubleProphylactic treatment

One aspect of the invention relates to a pharmaceutical dosage unit for sublingual, buccal, pulmonary or oral administration, said dosage unit having a weight of 20-500 mg and comprising 1-80 Wt. % of a microgranulate that is distributed throughout a solid hydrophilic matrix; said microgranulate being characterised in that it: has a volume weighted average diameter of 5-100 m; contains at least 0.01 wt. %, preferably at least 0.1 wt. % of one or more water-insoluble pharmaceutically active substances; contains at least 10 wt. %, preferably at least 20 wt. % of an emulsifier component; and is capable of forming a micro-emulsion upon contact with saliva or water. The dosage units of the present invention achieve the inherent benefits of oral delivery whilst at the same time realising a high transmucosal absorption rate of the cannabinoids contained therein. Other aspects of the present invention relate to the use of the aforementioned dosage units in the therapeutic or prophylactic treatment and to a process for the manufacture of said dosage units.

Owner:ECHO PHARM BV (NL)

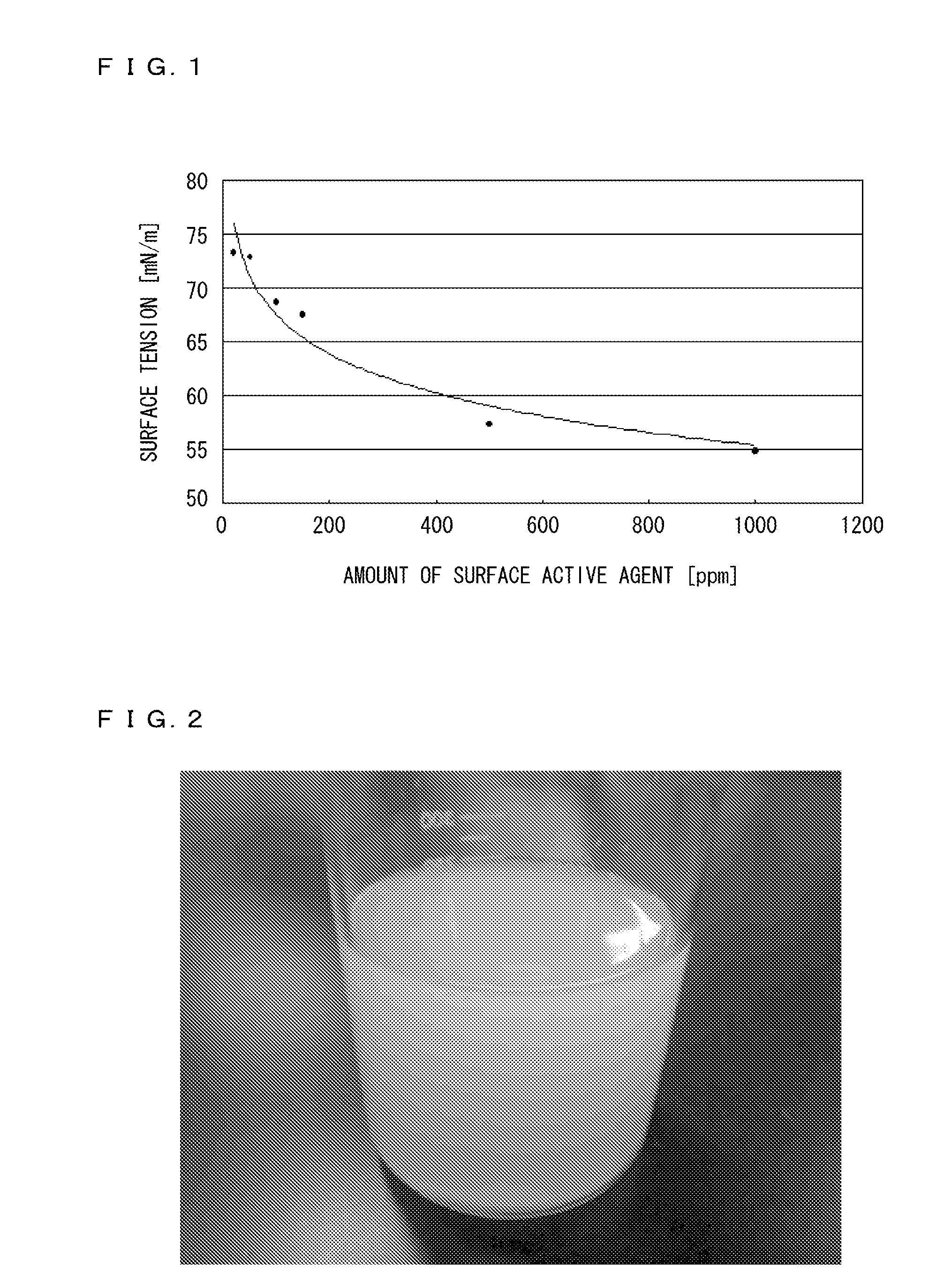

Polyacrylic water-absorbent resin powder and method for producing the same

ActiveUS20110313113A1Improve water absorptionEfficient productionPolymer scienceCrosslinked polymers

A production method of the present invention is a polyacrylic water-absorbent resin powder production method including the steps of: producing an acrylic monomer solution in which gas is dissolved and / or dispersed; polymerizing the acrylic monomer solution in the absence of a surface active agent or in the presence of not more than 300 ppm of a surface active agent; during or after the step of polymerizing, fragmenting a hydrated gel crosslinked polymer obtained by polymerizing the acrylic monomer solution; and drying by heat the hydrated gel crosslinked polymer thus fragmented, the gas being dissolved and / or dispersed in the acrylic monomer solution by at least one of the methods (a) to (c): (a) applying pressure to the acrylic monomer solution and the gas; (b) creating swirling flows of the acrylic monomer solution and the gas; and (c) introducing the gas with the acrylic monomer solution via fine holes. Accordingly, the production method of the present invention makes it possible to efficiently produce a water-absorbent resin having an excellent water-absorption rate without deteriorating a liquid-absorbent property of a sanitary product or the like.

Owner:NIPPON SHOKUBAI CO LTD

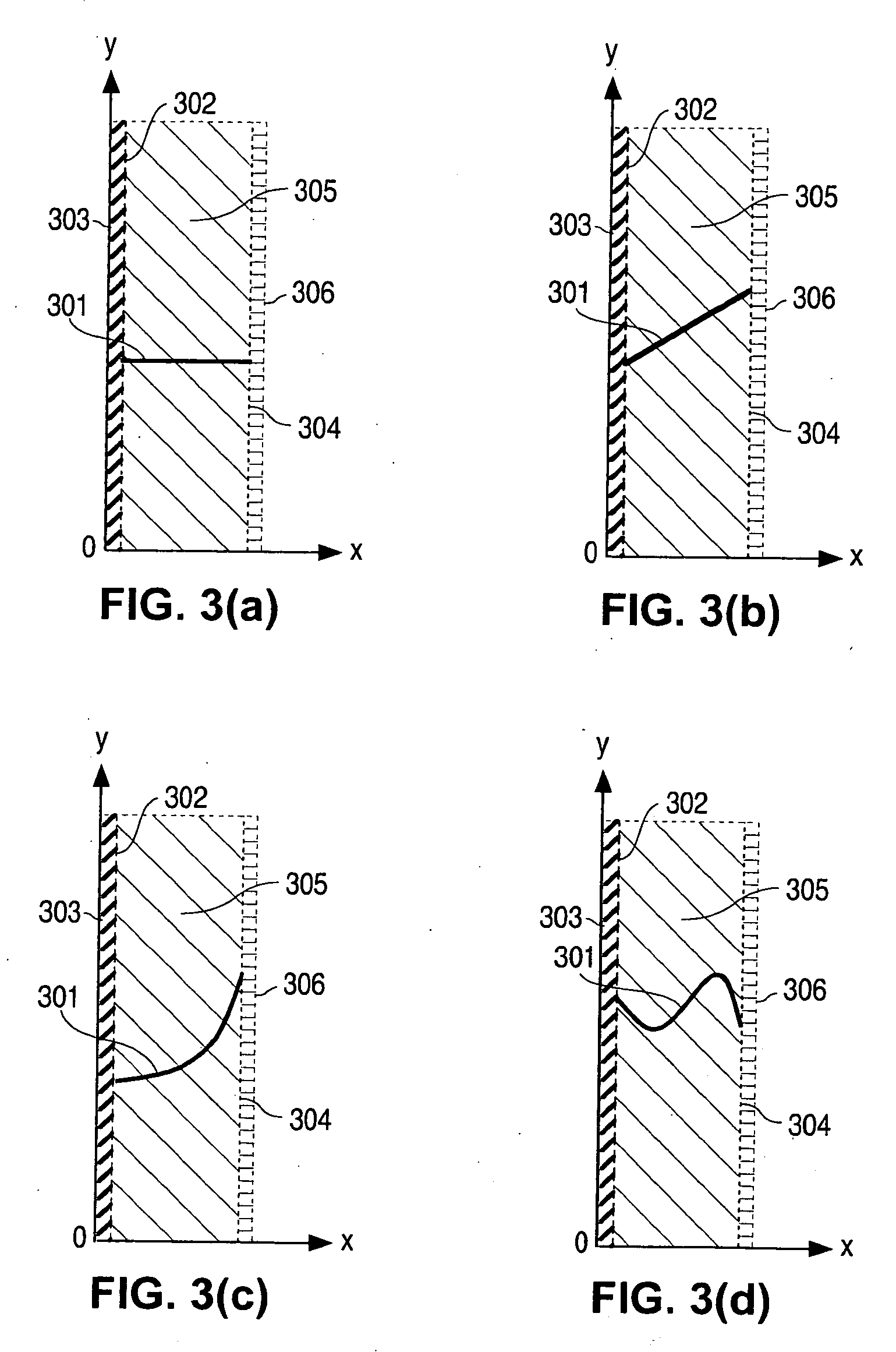

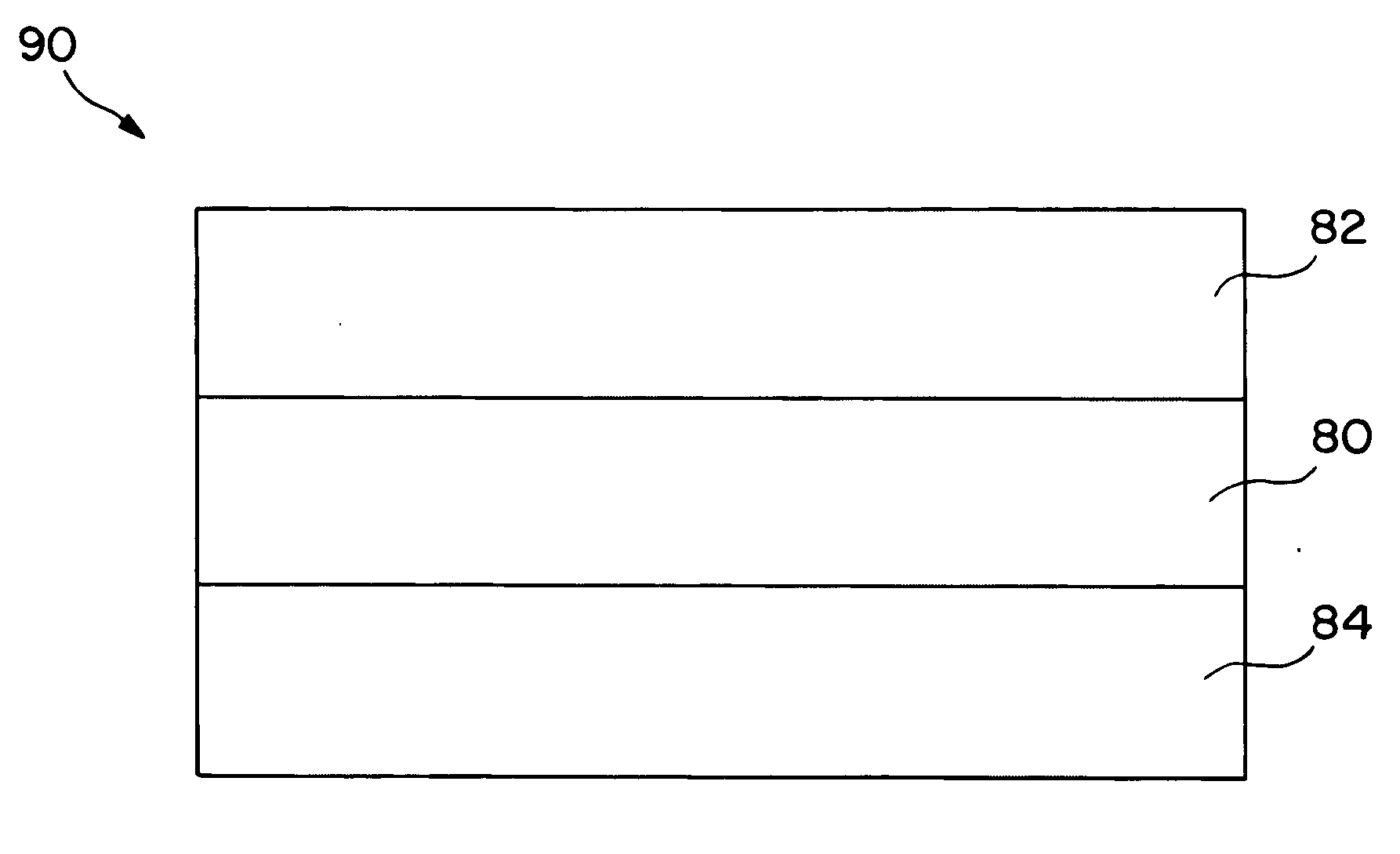

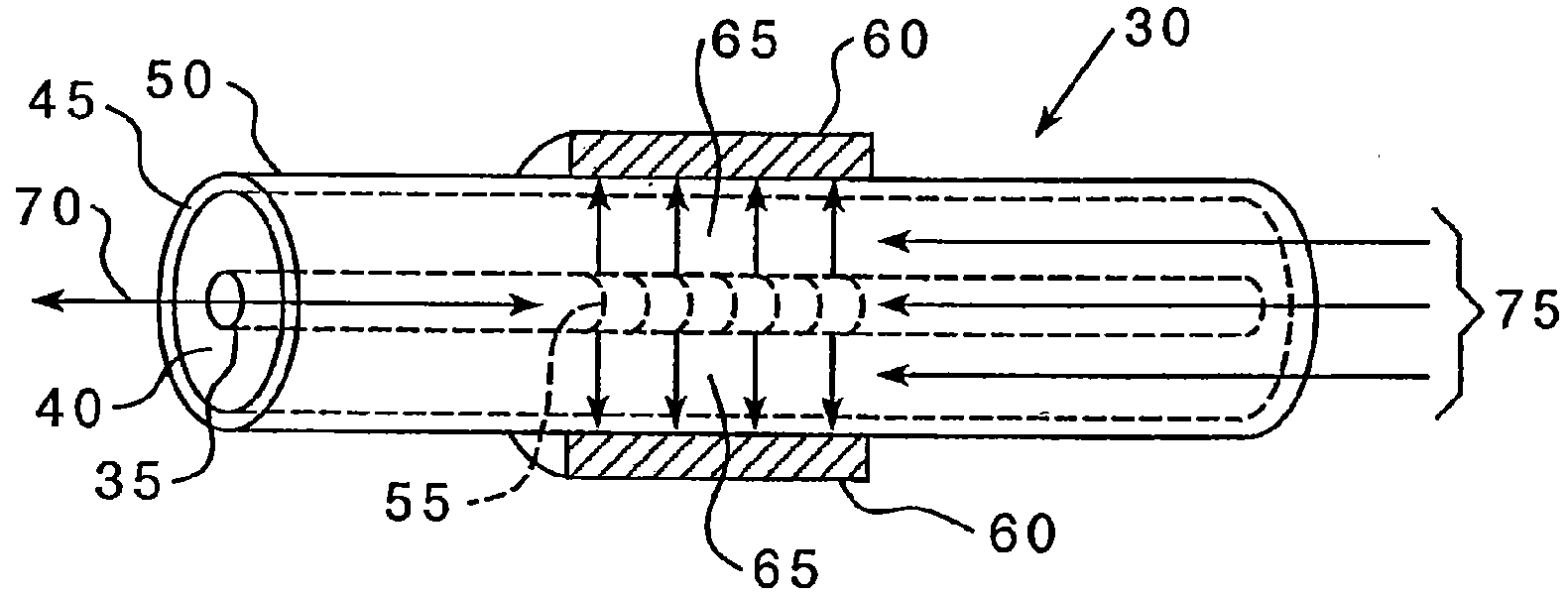

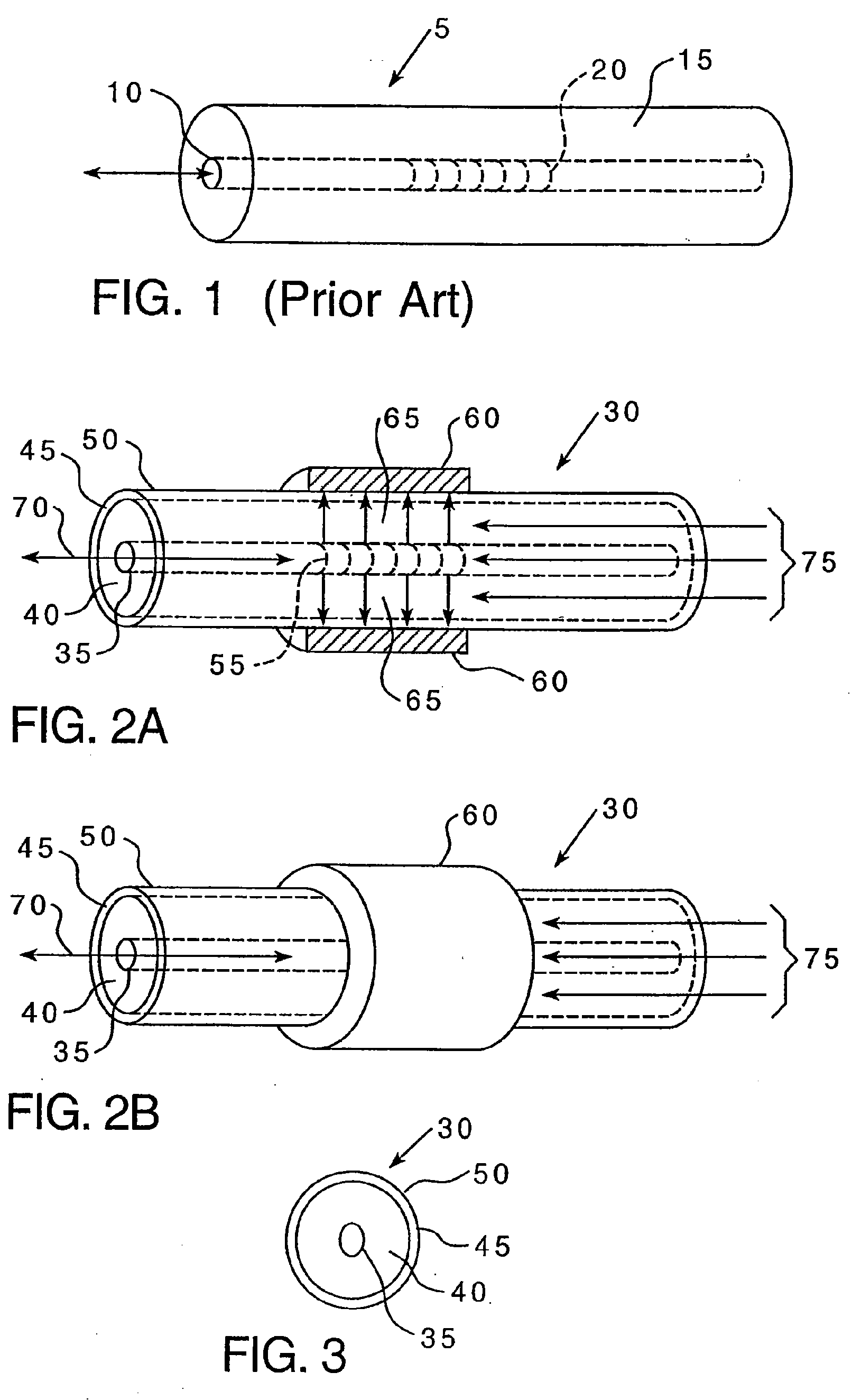

Concentration gradient profiles for control of agent release rates from polymer matrices

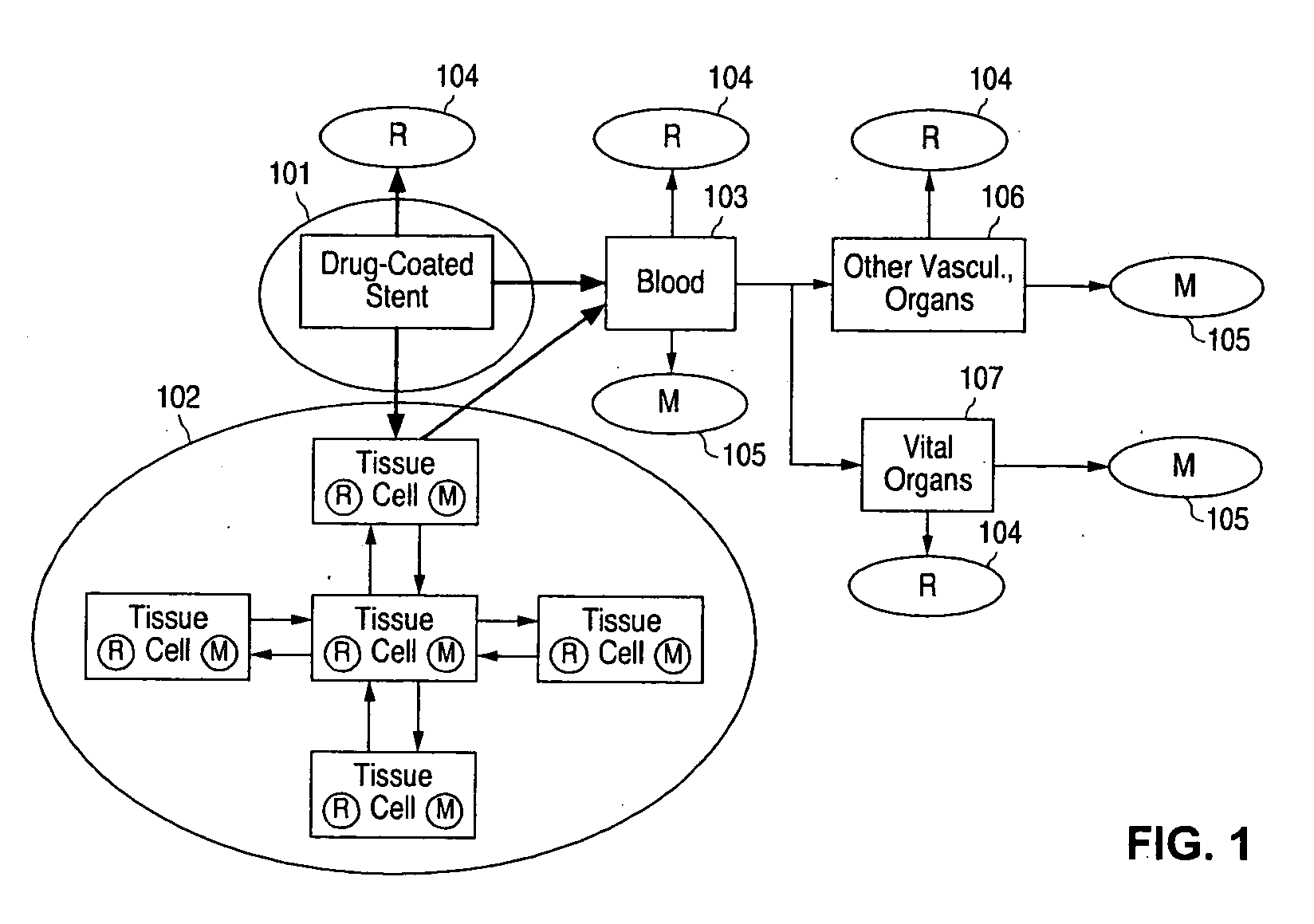

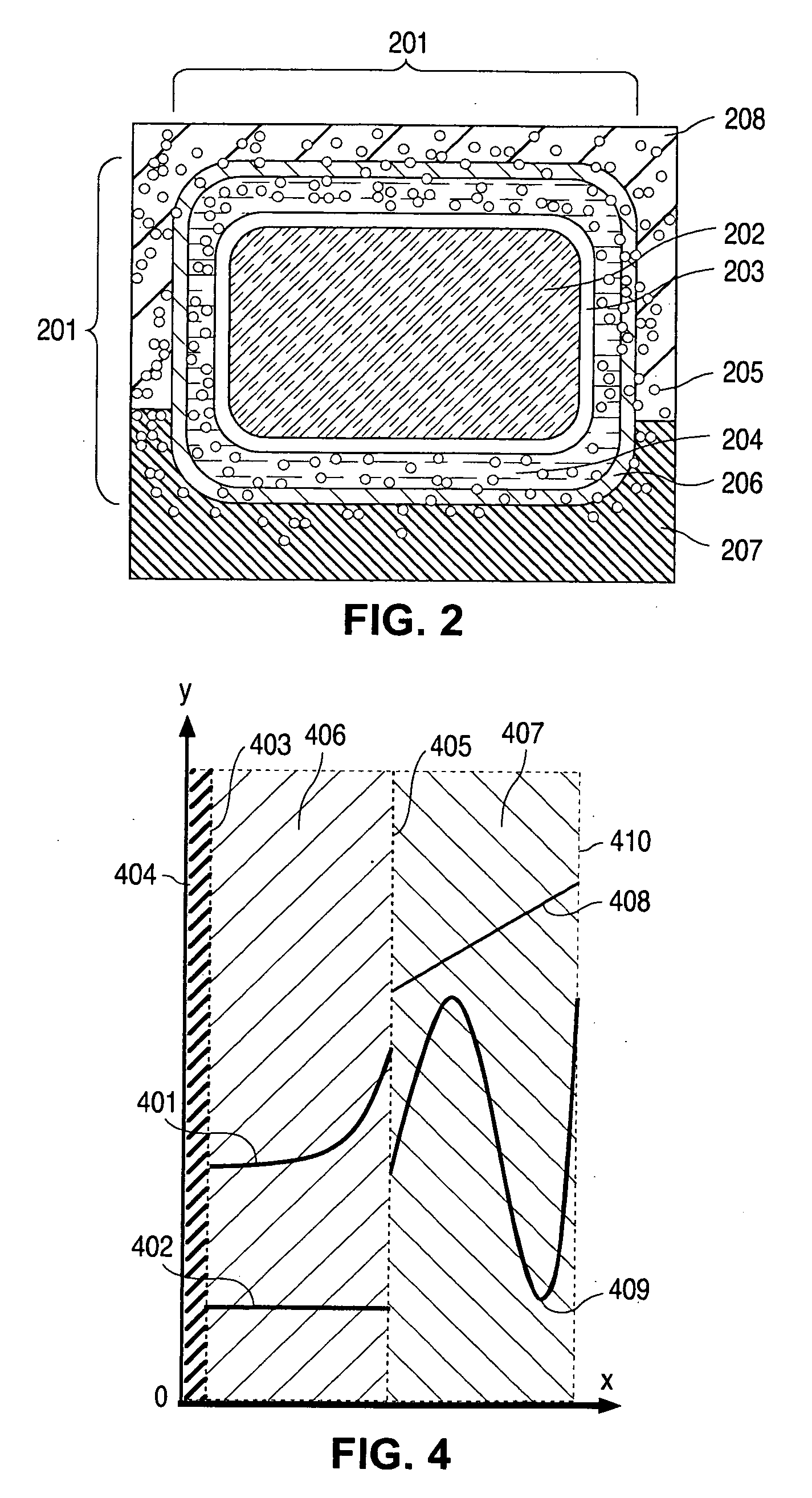

The present invention generally encompasses the control of the release rate of agents from a polymeric matrix. This control over the release rate of agents provides for control over, inter alia, the therapeutic, prophylactic, diagnostic, and ameliorative effects that are realized by a patient in need of such treatment. In addition, the control of the release rate of agents also has an effect upon the mechanical integrity of the polymeric matrix, as well as a relationship to a subject's absorption rate of the absorbable polymers.

Owner:ABBOTT CARDIOVASCULAR

Heat-insulating energy-saving paint for vehicle and method for producing the same

InactiveCN101195725AIncrease reflectionInsulate heat radiationFireproof paintsPolyester coatingsRadiant heatAbsorption rate

The invention relates to heat insulating and energy saving coating used for the vehicle, and the preparation method thereof. The invention takes organic resin film forming material as the main material, the coating at least includes infrared reflection pigment, hollow ceramic micro-spheres and silicon dioxide aerogel, an organic resin film having low sunlight absorption rate is formed in the coating through the organic resin film forming material with high transparency, the visible light and the near infrared ray in the sunlight are reflected through the infrared reflection pigment, the rutile type titanium dioxide and the hollow ceramic micro-spheres, and simultaneously a compact vacuum layer and an inert gas layer are formed on the surface of a coated object through the hollow ceramic micro-spheres and the silicon dioxide aerogel, so as to effectively isolate the radiant heat of the sun, and to reduce the heat conduction of air, and finally the heat insulating and energy saving coating used for the vehicle is formed, which not only can effectively reflect the energy in the sunlight, but also can effectively isolate the radiant heat of the sun and reduce the heat conduction of air, and simultaneously has good weather resistant performance, chemicals resistant performance, mechanical property and decorative property.

Owner:ZHUZHOU FEILU ADVANCED MATERIAL TECH CO LTD

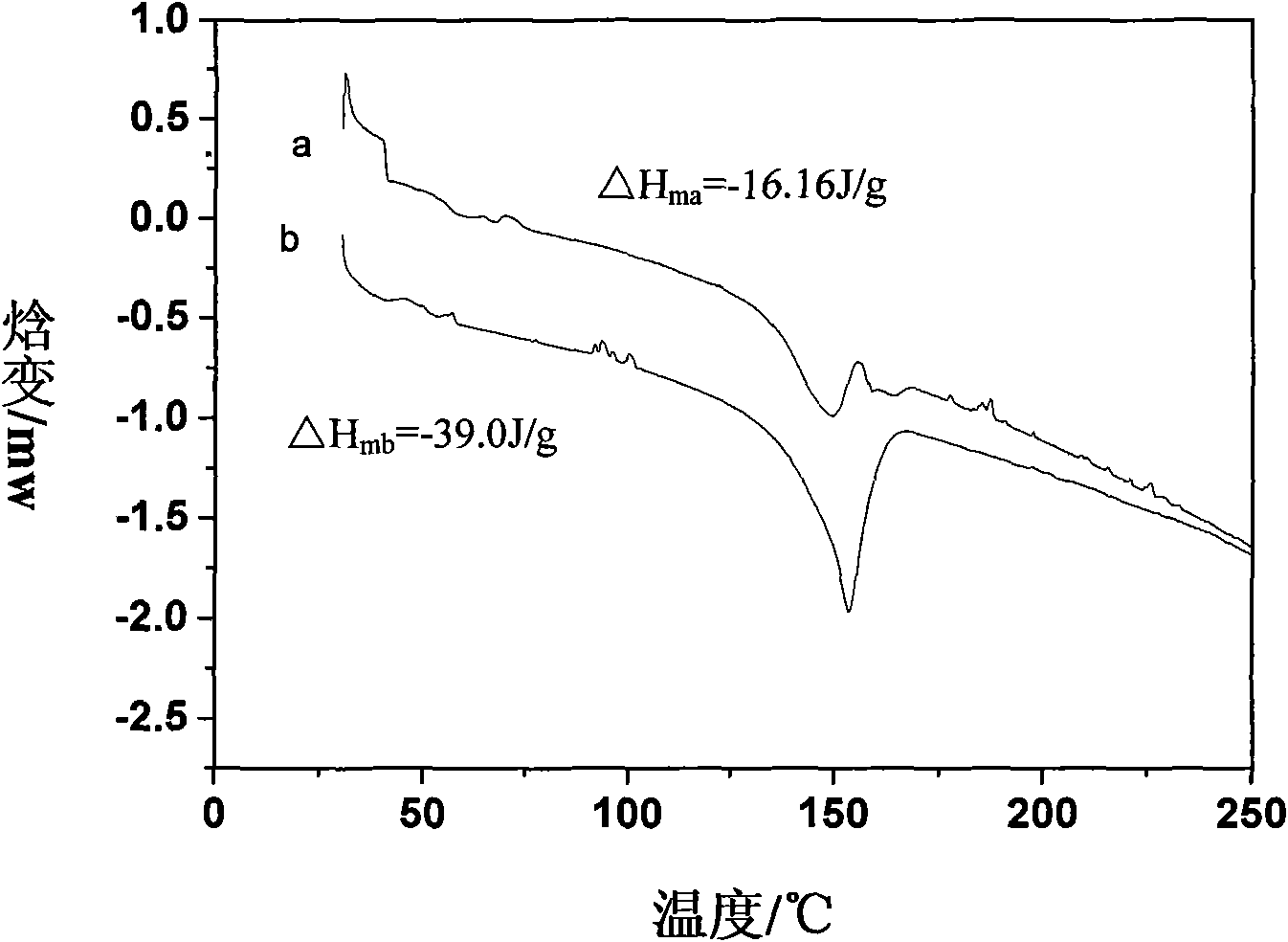

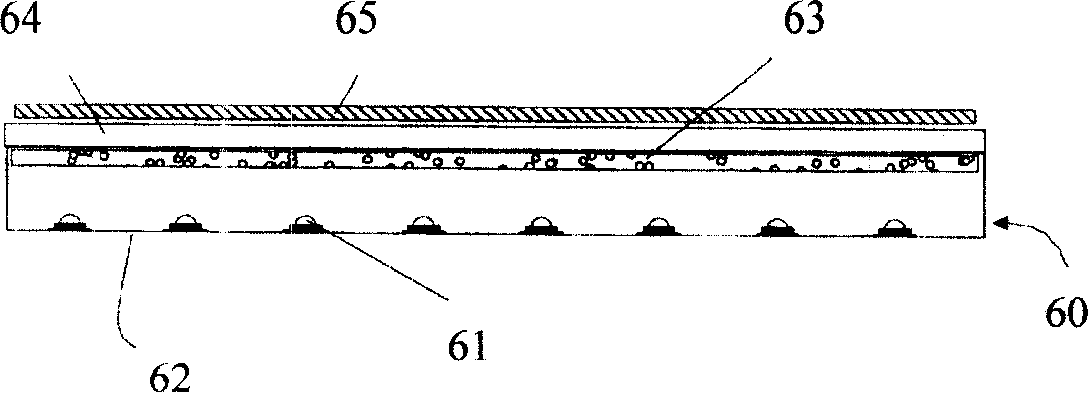

Polymer porous membrane, preparation method thereof, polymer electrolyte, polymer battery and preparation method of battery

ActiveCN102035043AImprove rate discharge performanceImprove cycle performanceFinal product manufactureSynthetic resin layered productsPolymer electrolytesPolymer science

The invention provides a polymer porous membrane, a preparation method of the polymer porous membrane, a polymer electrolyte, a polymer battery and a preparation method of the polymer battery. A carbon material is dispersed in the polymer porous membrane, so that the degree of crystallization of a polymer which constitutes the polymer porous membrane is lowered and the liquid absorption of the polymer porous membrane is increased; the liquid absorption rate, liquid holding capability and ionic conductivity of the polymer porous membrane are increased; interface impedance is reduced, battery magnification discharging performance and the circulating performance of the battery are enhanced; simultaneously, the battery prepared by the method has excellent high temperature circulation and storage performance and low expansion ratio at a high temperature and further meets the development requirement of the polymer battery. Simultaneously, the preparation method is simple and is easy to implement and the prepared battery has high performance.

Owner:SHANGHAI BYD

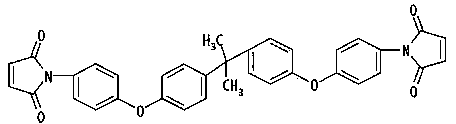

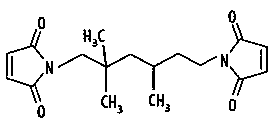

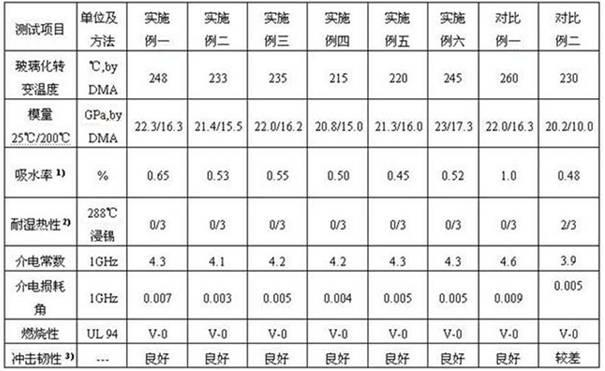

Low dielectric material

InactiveCN103965606ASmall coefficient of thermal expansionLow water absorptionDielectric lossThermal expansion

The invention relates to a low dielectric material. The low dielectric material includes, by weight, 40-80 parts of polyphenyl ether with the number average molecular weight Mn of 1000-4000, the weight average molecular weight Mw of 1000-7000 and the Mw / Mn ratio of 1.0-1.8, 5-30 parts of bimaleimide and 5-30 parts of a polymer additive, and the Dk value and the Df value of the low dielectric material are 3.75-4.0 and 0.0025-0.0045 respectively. The low dielectric material can be applied to semi-cured films or circuit substrate insulating layers, and has the characteristics of high Tg, low thermal expansion coefficient, low water absorption rate, and excellent dielectric properties like dielectric constant (Dk) and dielectric loss (Df).

Owner:ITEQ CORP

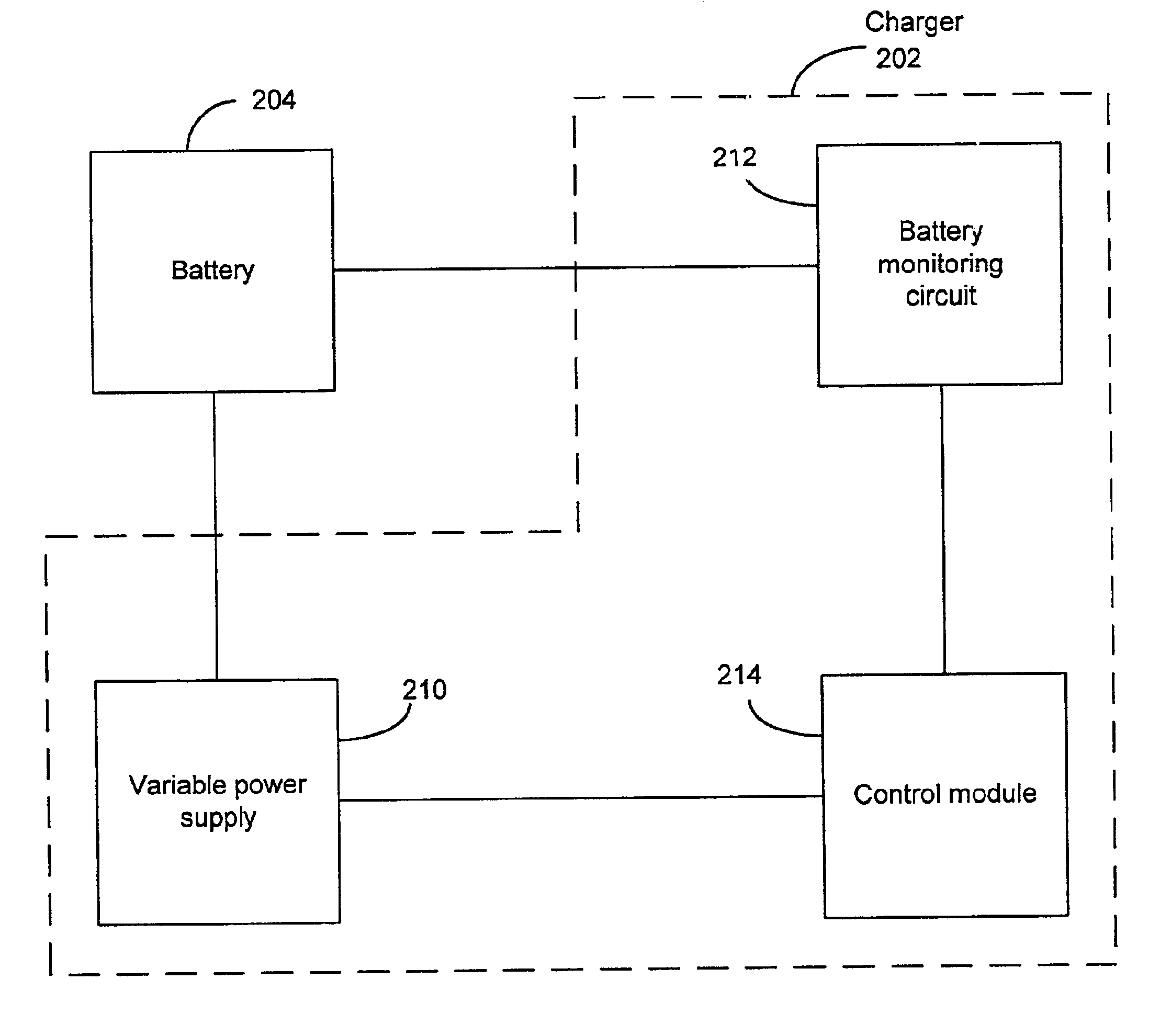

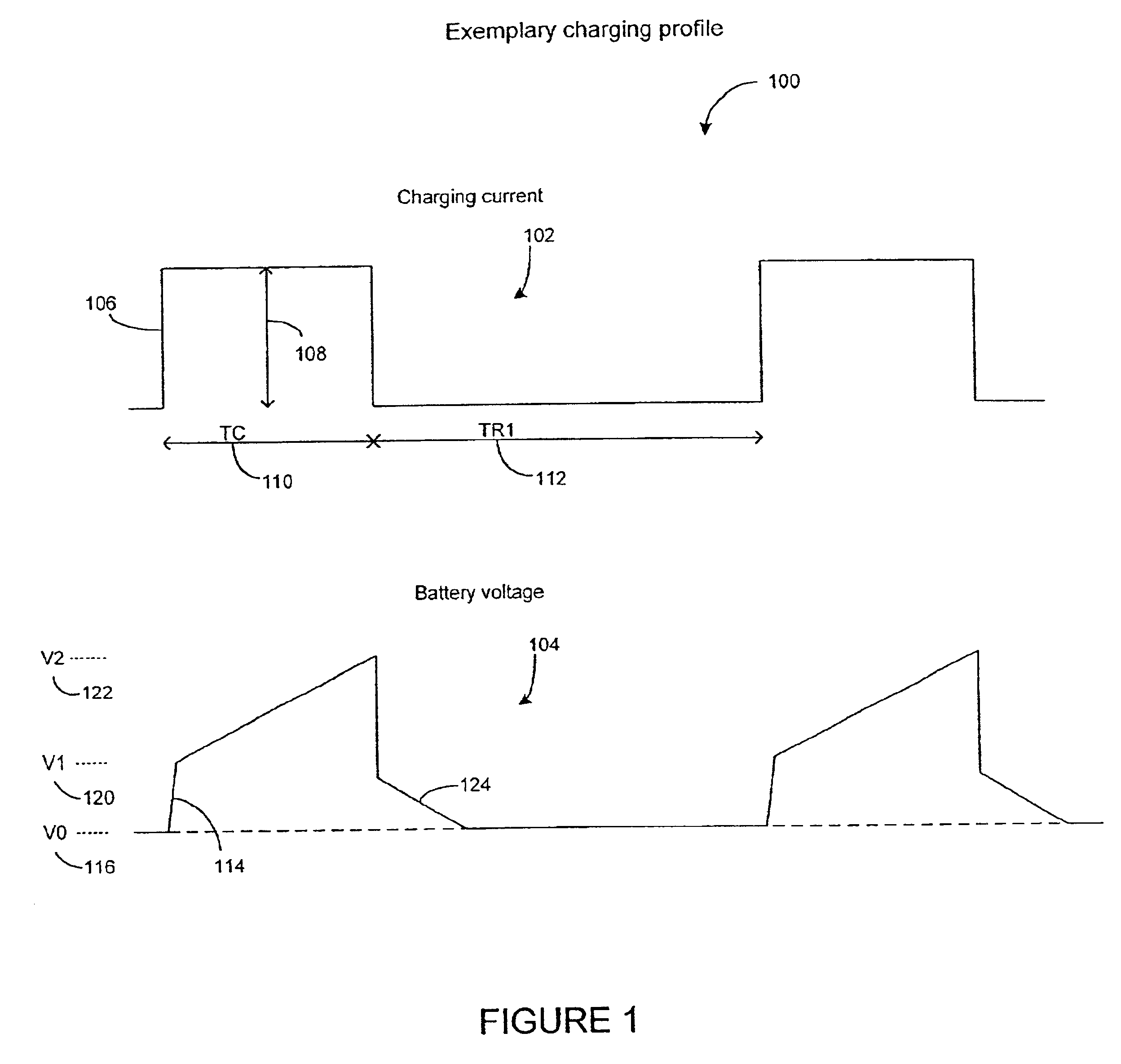

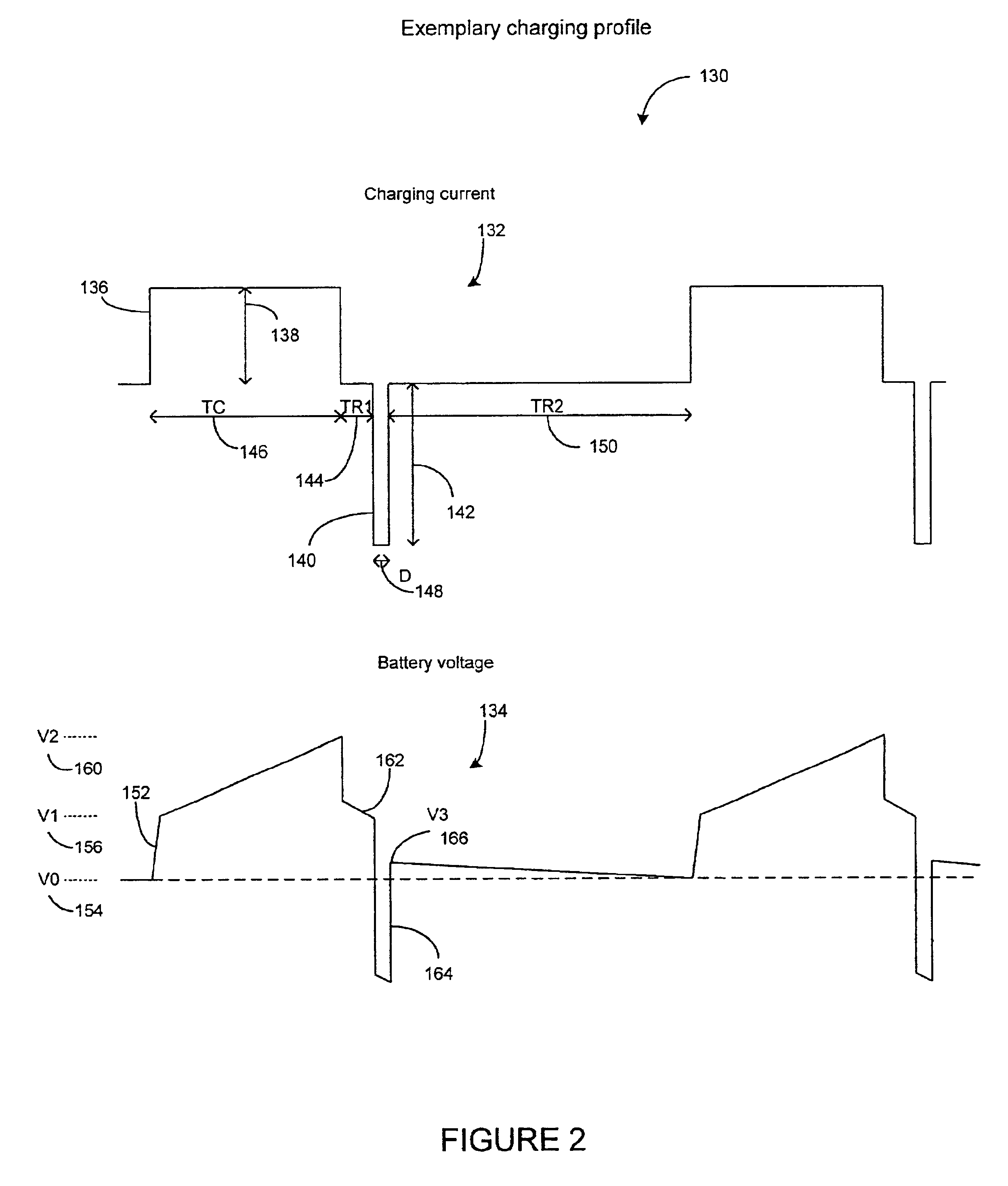

Battery charging method

InactiveUS6841974B2Reduces pulse amplitudeExcellent indicatorsBatteries circuit arrangementsElectric powerHigh rateTerminal voltage

A battery charger that adjusts and applies charging pulses to a battery such that one or more battery parameter is regulated. Terminal voltage of the battery, relative to the battery's quiescent voltage, during the charge application is one such battery parameter indicative of the battery's charge absorption rate. Maintaining the charging voltage at a predetermined value during the charging process is achieved by adjusting the charging pulse both amplitude-wise and temporally. The adjustment of the charging pulse is performed such that a high rate of charge input into the battery is maintained during the charging process.

Owner:HDM SYST

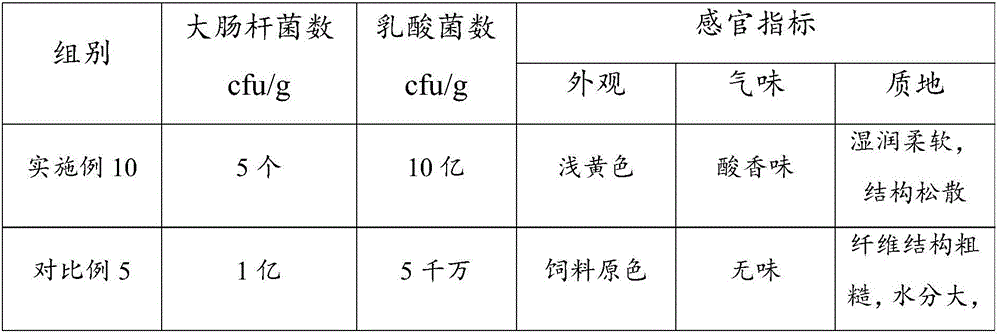

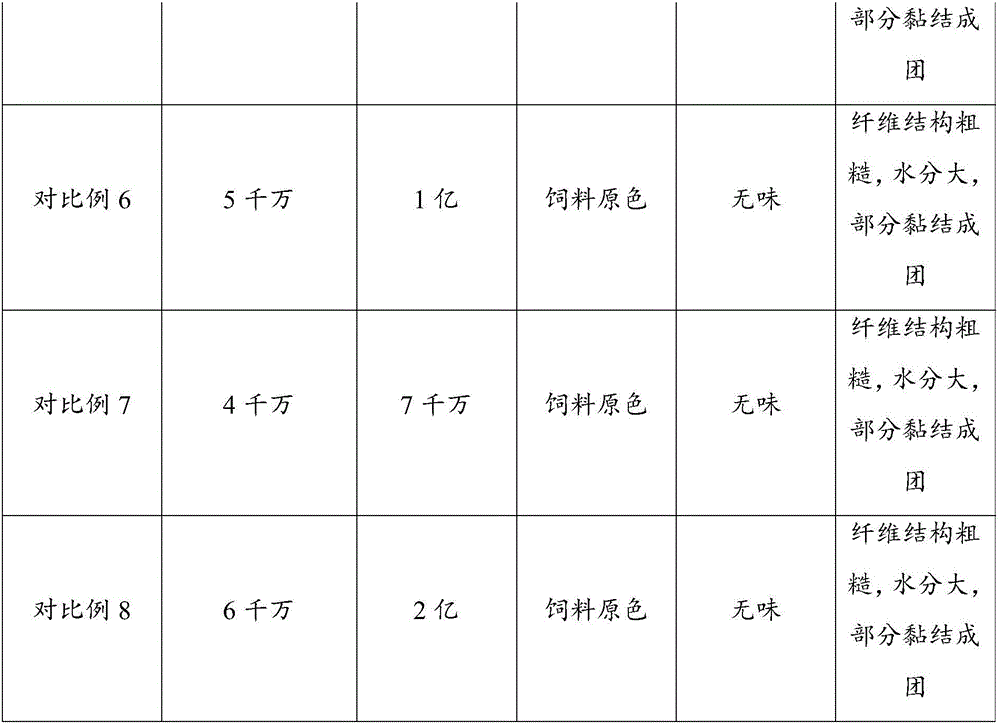

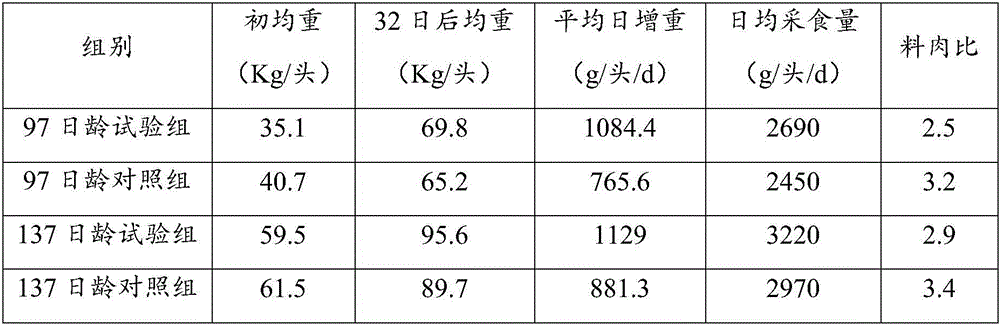

Feed fermenting agent, fermented feed and preparation method thereof

The invention provides a feed fermenting agent, fermented feed and a preparation method thereof, and relates to the technical field of animal product cultivation. The feed fermenting agent is mainly prepared from lactobacillus plantarum, enterococcus faecalis, bacillus subtilis, saccharomyces cerevisiae, lactobacillus cellobiosas, a complex enzyme preparation and the like. The fermented feed is prepared from the feed fermenting agent and fermentation raw materials by using a preparation method of carrying out fermentation in a device which is in one-way exhaust. According to the feed fermenting agent and the fermented feed, disclosed by the invention, the problems of high livestock cultivation cost caused by poor nutritive value, low animal digestion and absorption rate and abuse of antibiotic drugs during cultivation, long fermentation time and slow fermentation starting of existing livestock breeding feed are solved, and high absorption and conversion rate of nutrient contents of the fermented feed are achieved; the fermented feed contains a large amount of probiotics for protecting intestine health of animals, so that the organism immunity of the animals is increased, and the use of antibiotics during livestock cultivation is reduced.

Owner:湖南赛福资源饲料科技有限公司

Thermosetting resin composition, prepreg and laminated board

ActiveCN102115600AExcellent heat and humidity resistanceImprove heat resistanceGlass/slag layered productsMetal layered productsEpoxyDielectric loss

The invention discloses a thermosetting resin composition, which is characterized by comprising the following components in part by weight: 8 to 80 parts of allyl modified bismaleimide resin prepolymer, 15 to 60 parts of cyanate resin and 5 to 40 parts of halogen-free epoxy resin, wherein the allyl modified bismaleimide resin prepolymer is prepared by reacting bismaleimide resin with an allylcompound at the temperature of between 110 and 160DEG C for 20 to 100 minutes, and a weight ratio of the bismaleimide resin to the allylcompound is 100:(30-120). The composition can be used for preparing a prepreg and a laminated board. The composition and the laminated board have excellent humidity resistance, high heat resistance, low water absorption rate, high modulus, lower dielectric constant and dielectric loss, and good processing toughness, and can realize halogen-free flame retardancy.

Owner:SHENGYI TECH SUZHOU

Ceramic imitation cement component, ceramic imitation cement product and preparation method thereof

InactiveCN101891429AExtended service lifeGood compatibilitySolid waste managementCeramic shaping apparatusHigh resistanceFiber

The invention discloses a ceramic imitation cement, a ceramic imitation cement product and a preparation method thereof. The ceramic imitation cement comprises the following components in percentage by mass: 35 to 50 percent of hydraulic adhesive, 15 to 43 percent of aggregate particles, 8 to 28 percent of filler, 0.5 to 8 percent of polymer, 0.3 to 3 percent of fiber, 0.5 to 1.3 percent of water reducing agent, 0.2 to 1.3 percent of additive and the balance of water. The ceramic imitation cement product of the invention has the characteristics of high intensity, toughness, rigidity, non-inflammability, low water absorption rate, high resistance to freezing and thawing, antibiotic property, insect resistance, and mould resistance, looks like ceramic but does not need sintering or glazing, has decorating property of an FC plate but does not have the defects of the FC plate and has more functions; and the ceramic imitation cement product can be taken as inner wall and outer wall decorating plates of buildings, floors, outer wall hung plates, wall plates of subway stations and tunnel wall plates. The preparation method has the advantages of simpleness, convenience, practicability, small investment, quick response and capability of preparing ceramic imitation cement plates, plain concrete plates, and terrazzo slabs and flexible cement plates of various colors.

Owner:SHANGHAI HENGFENG FLUOROCARBON MATERIAL

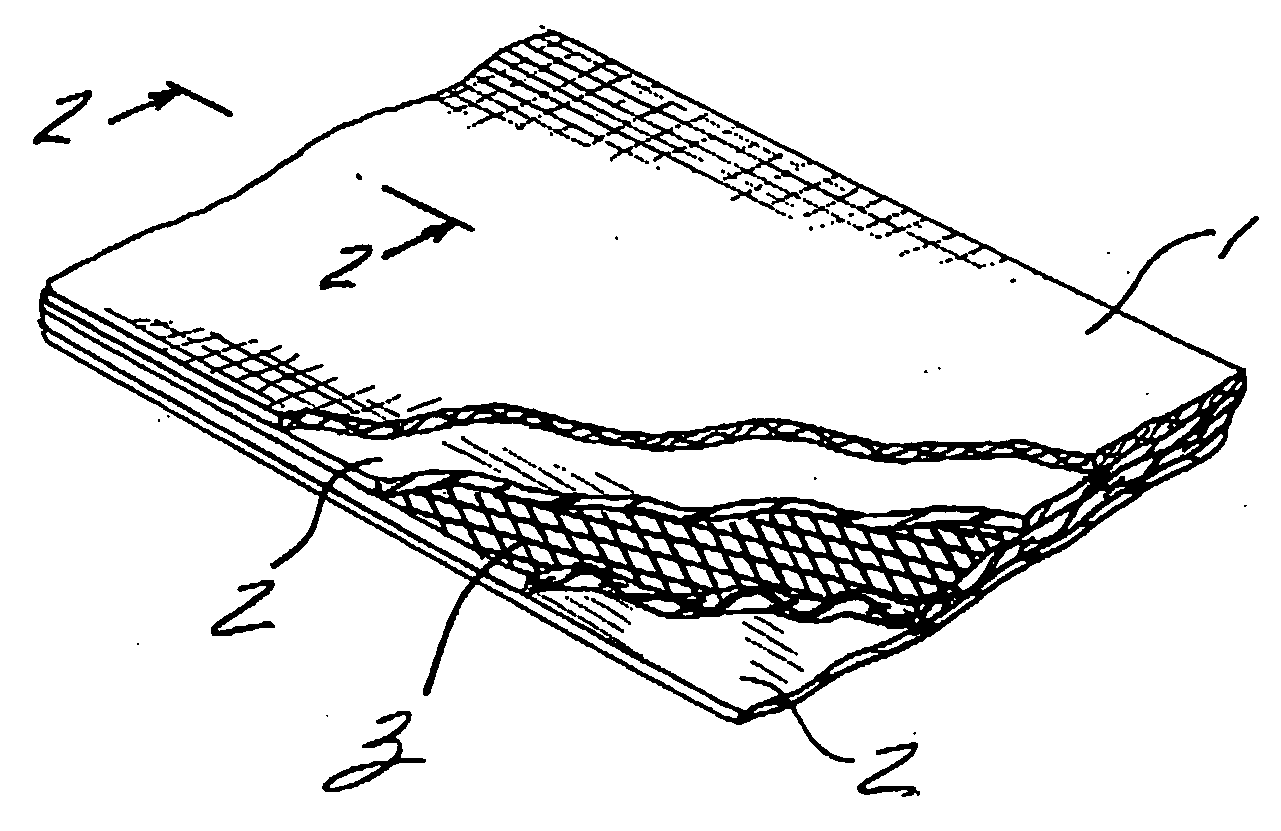

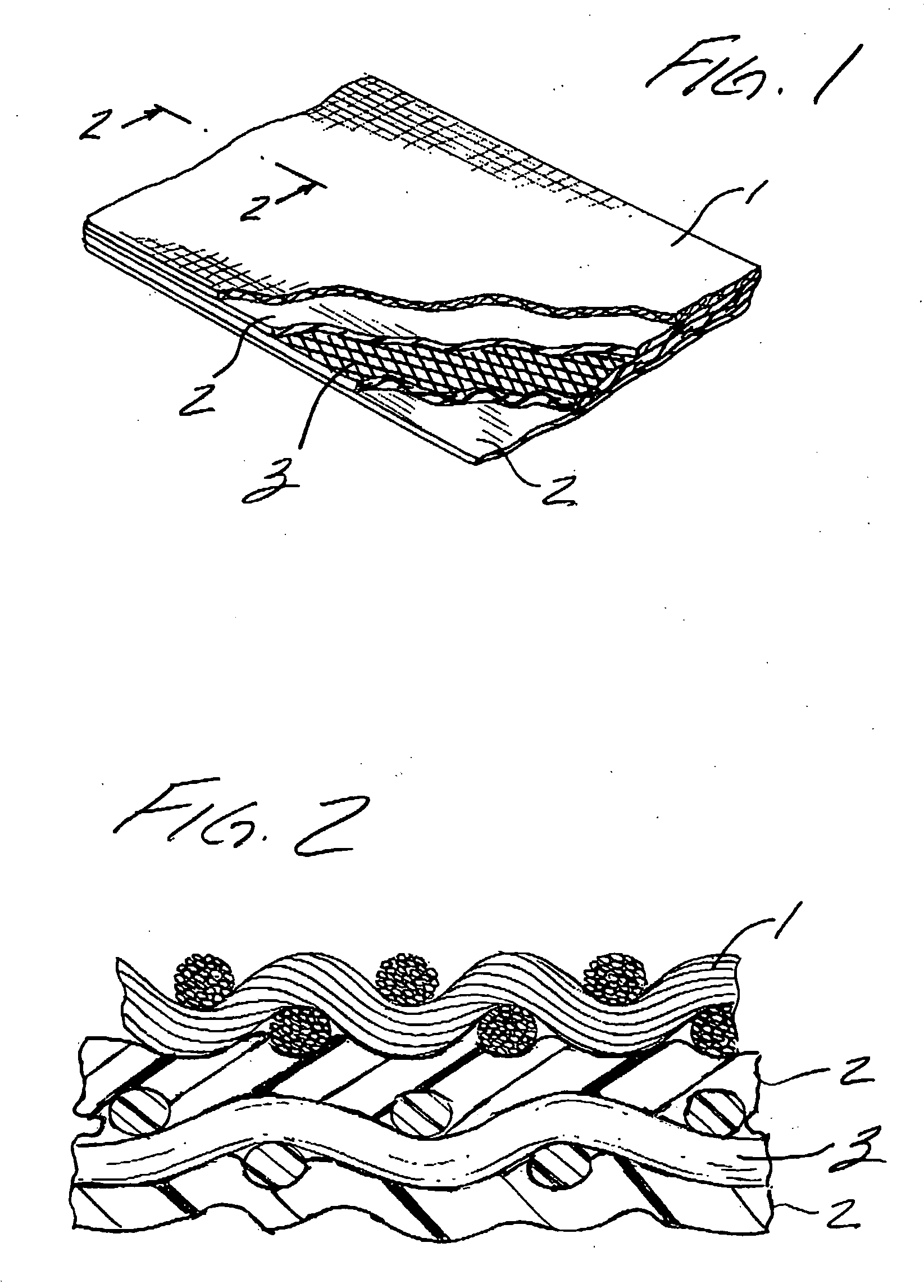

Ultrasonically laminated multi-ply fabrics

A multi-ply fabric is provided that includes an inner ply positioned between two outer plies that contain both thermoplastic fibers and absorbent staple fibers. The plies are ultrasonically bonded together. The material used to form the inner ply may be selectively controlled to optimize certain properties of the fabric for a particular application, such as strength, bulk, absorption capacity, absorption rate, handfeel, etc.

Owner:KIMBERLY-CLARK WORLDWIDE INC

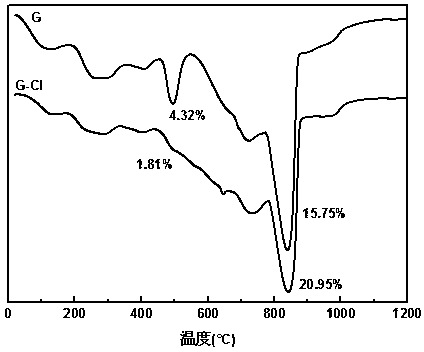

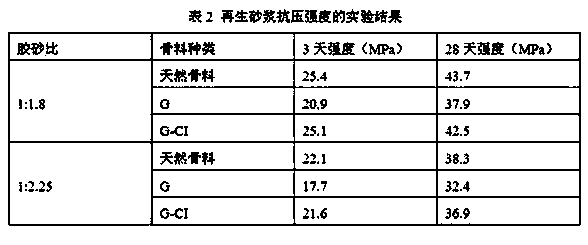

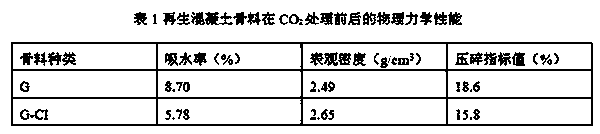

Method for carbon dioxide strengthening of recycled concrete aggregate

ActiveCN104045251AImprove physical and mechanical propertiesImprove early strengthSolid waste managementCarbonizationAbsorption rate

A method for carbon dioxide strengthening of a recycled concrete aggregate comprises the following steps: (1) crushing and sieving waste concrete; (2) placing the sieved recycled concrete aggregate in a sealed container, controlling the relative humidity of 30-90% and the CO2 concentration of 5-90%, and carrying out carbonization treatment; and (3) making the treated recycled concrete aggregate particles into recycled mortar and concrete. Compared with mortar prepared from a recycled concrete aggregate without treatment, the mortar prepared from the obtained recycled concrete aggregate after CO2 strengthening treatment enables the mortar early strength to be improved by 20.1%-22.0% and the later strength to be improved by 12.1%-13.9%; the 28 d drying shrinkage value can be reduced by 7.8%-16.7%; and the 28 d water absorption rate can be reduced by 7.7%-13.3%.

Owner:HUNAN UNIV

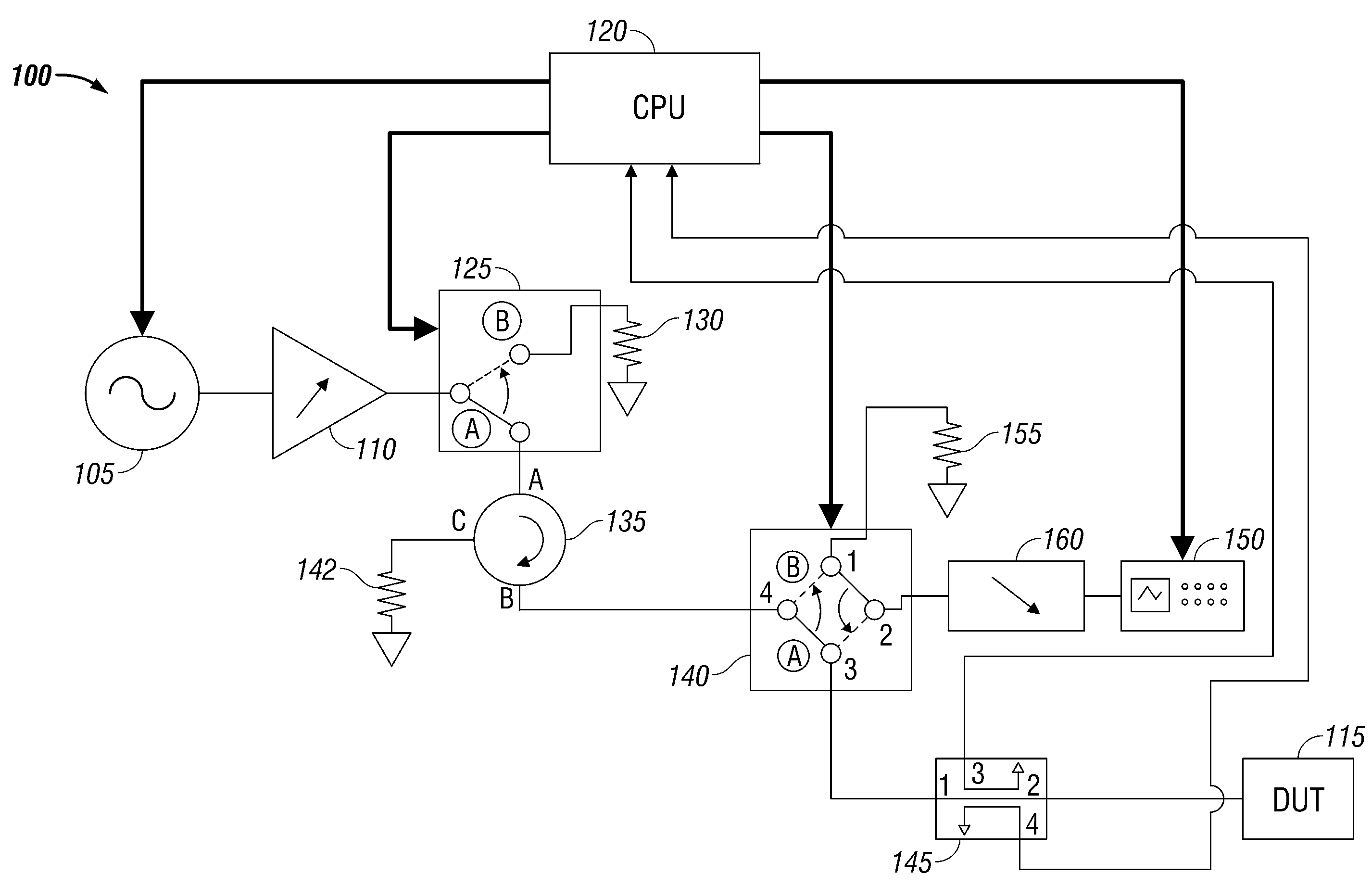

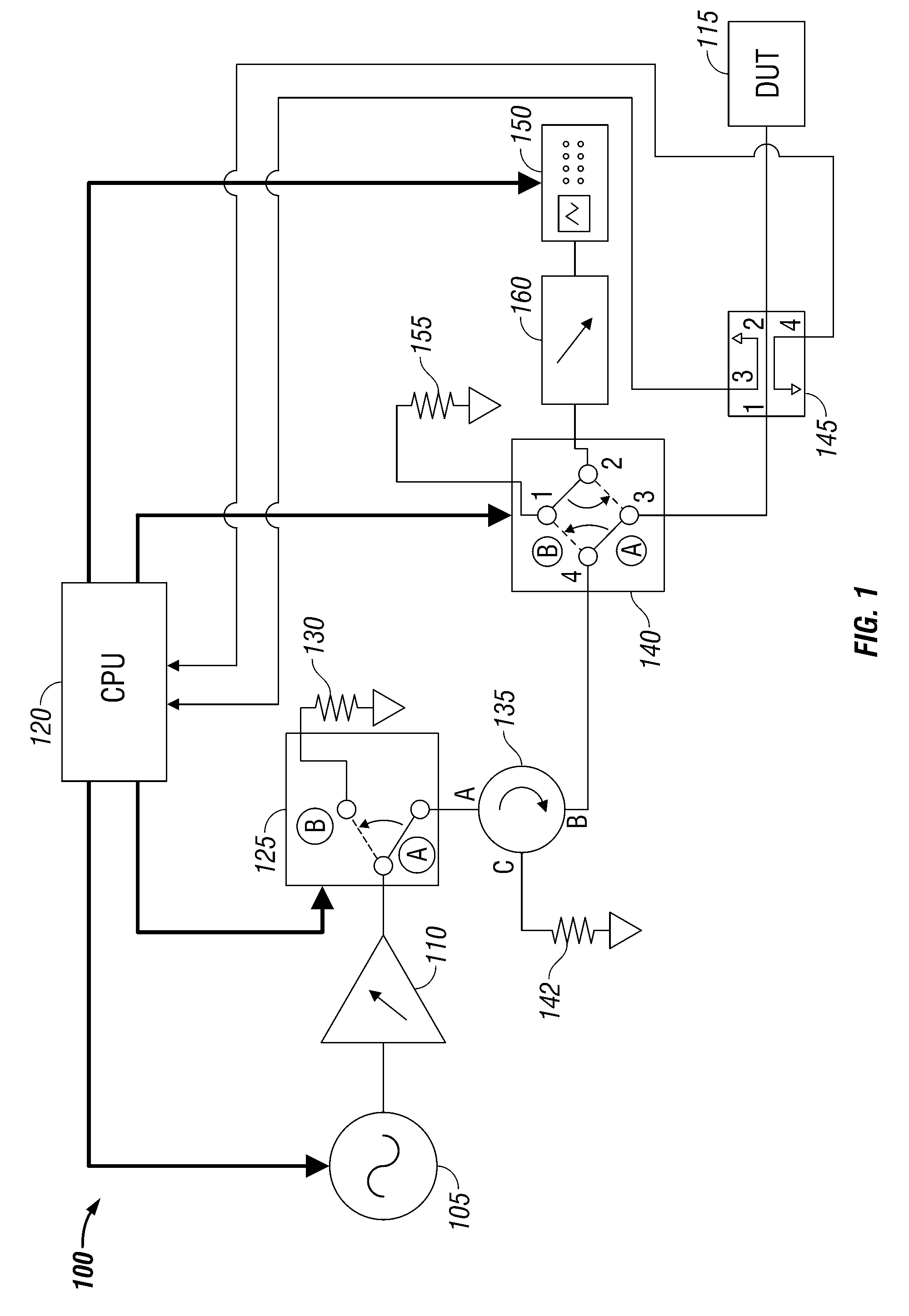

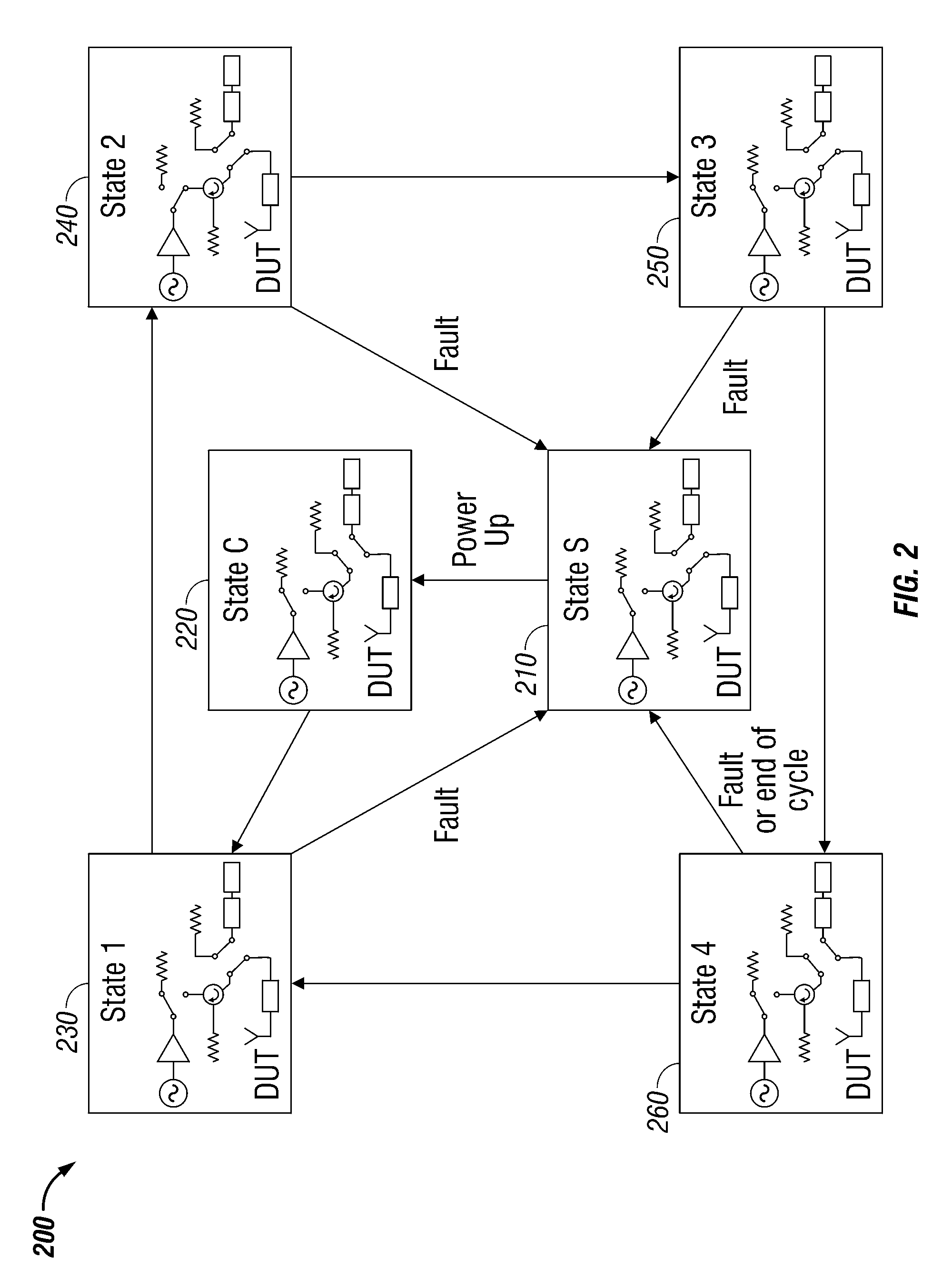

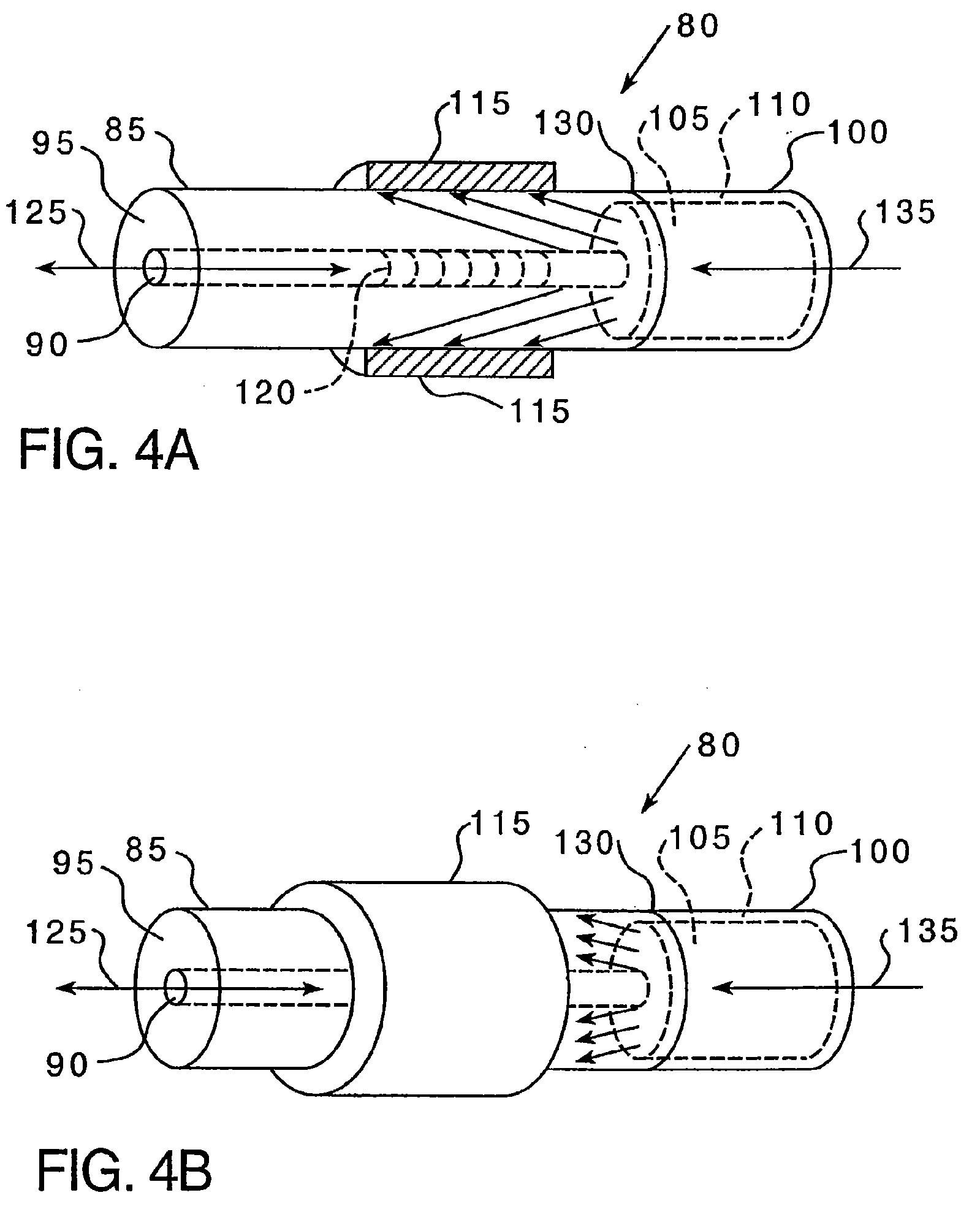

Microwave system calibration apparatus and method of use

An apparatus for calibrating a microwave energy delivery device including a body, the body defining a chamber portion. The chamber portion is configured to receive a portion of a microwave energy delivery device and the body is configured to absorb energy transmitted by the microwave energy delivery device at a predetermined absorption rate.

Owner:TYCO HEALTHCARE GRP LP

Cement-based lightweight porous heat insulating material and preparation method thereof

The invention relates to a cement-based lightweight porous heat insulating material and a preparation method thereof. The material is prepared from portland cement or ordinary portland cement, water reducing agent, foam stabilizer, early strength agent, fiber, emulsion powder, water repellent, foaming agent and water according to a certain ratio. The weight ratio of cement, water reducing agent, foam stabilizer, early strength agent, fiber, emulsion powder, water repellent and foaming agent is 100:0.2-2.4:(0.1-3.)0:(1.0-4.0):(0.3-1.5):(0.1-5.0):(0.1-6.0):(3.0-8.0); and the water cement ratio is 0.45-0.55. The dry density of the LWFC material is 250-300kg / m<3>, the compressive strength is 0.5-1.0MPa, the heat conduction coefficient is 0.05-0.08W / m.k, the water absorption rate is 4-8%; the material can not deform and crack, is used as an inorganic incombustible lightweight heat insulating material and can replace the organic combustible heat insulating material represented by polystyrene foam; and the material can be used in the external wall exterior insulation construction of the building energy-efficient project and can also be used in the roof insulation project, the floor heating project or the occasions for preparing the composite heat insulating board and the like.

Owner:NANJING UNIV OF TECH

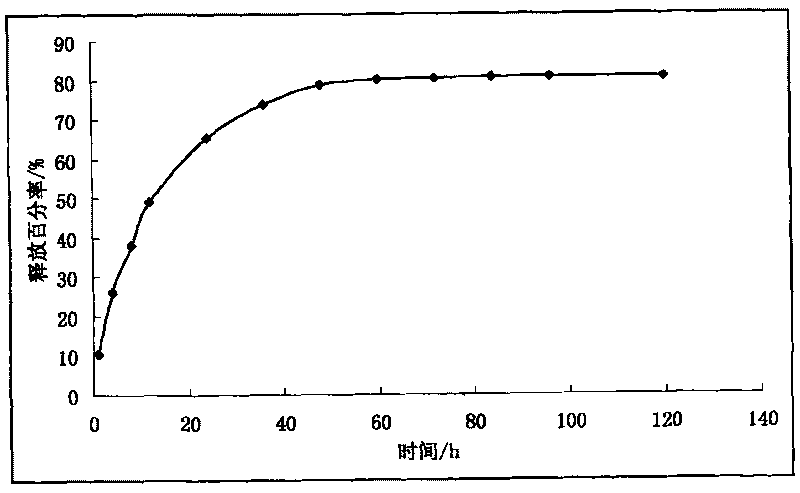

Method for preparing anti-infective agent long-acting injection

ActiveCN101703776AIncrease absorption rateGuaranteed effective concentrationSolution deliveryAntiinfectivesLong actingAbsorption rate

The invention provides a method for preparing anti-infective agent long-acting injection, and relates to an anti-infective agent long-acting injection. Each 1,000 mL of injection comprises the following components: 10 to 500 g of anti-infective agent, 100 to 900 g of cosolvent, 0 to 100 g of blocker, local anesthetic or stabilizer, and the balance of oil solvent. The method method for preparing the injection comprises: 1, dissolving 10 to 500 g of anti-infective agent in 100 to 900 g of cosolvent and mixing the two well; 2, adding 0 to 100 g of blocker and / or local anesthetic or stabilizer; and 3, adding the oil solvent till full volume and mixing thoroughly to form a uniform system. The method has antibacterial medicaments dissolved in the cosolvent first and then uniformly dispersed in the oil solvent capable of dissolving the antibacterial medicaments mutually so as to prolong the absorption rate of organisms to the medicaments, thereby maintaining the effective concentration of the medicaments in the organisms for a long time, achieving the long-acting effects and reducing the toxic effects of the medicaments.

Owner:LUOYANG HUIZHONG ANIMAL MEDICINE +1

High-efficiency fluorescent converted LED light source and backlight module

ActiveCN101162745AIncreased efficiency of fluorescence conversionExpected clean light outputSolid-state devicesSpectral modifiersAngle of incidenceFluorescence

A high efficient fluorescence conversion LED light source and backlight module comprise an LED arranged in a reflecting cup or the bottom of a collimating lens, and a fluorescent powder layer with predetermined thickness which is arranged on the top and is scattered with or coated with fluorescent powders and in particular comprises a first cut-off filter which is arranged between the fluorescent powder layer and the top of the reflecting cup or the collimating lens. Photons from the predetermined wavelength range of the LED penetrate the cut-off filter with an angle of incidence smaller than the predetermined value, while the backward fluorescence photons are reflected by the cut-off filter, thereby improving the fluorescence extraction efficiency. In addition, a second cut-off filter which has the opposite wave property is arranged above the fluorescent powder layer in order that the fluorescence photons can penetrate the second cut-off filter; a chamber structure consisting of two filters has multiple reflections on the incentive photons which are not absorbed by fluorescent powders to fully improve the absorption rate of the incentive photons. With the invention, the product has prominent fluorescence conversion effect and is simple in structure and technique, and convenient in realization of low cost.

Owner:APPOTRONICS CORP LTD

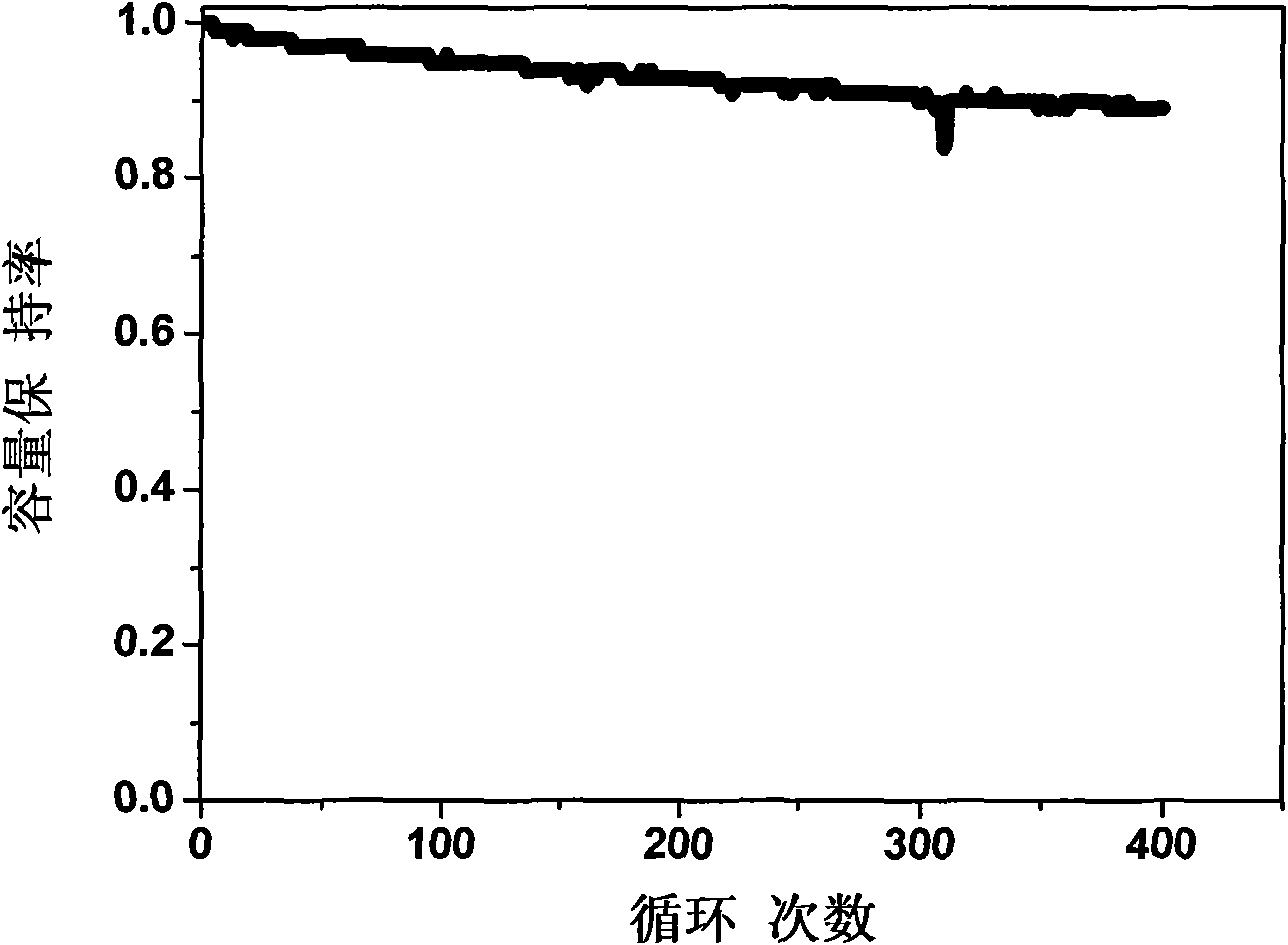

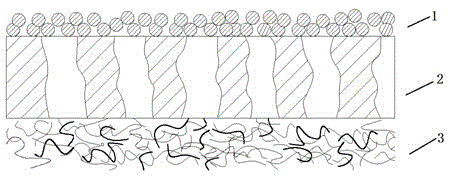

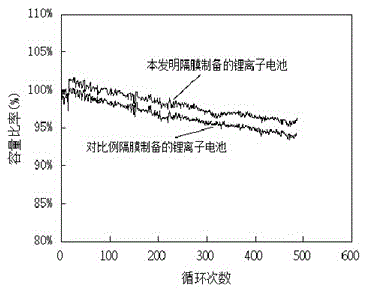

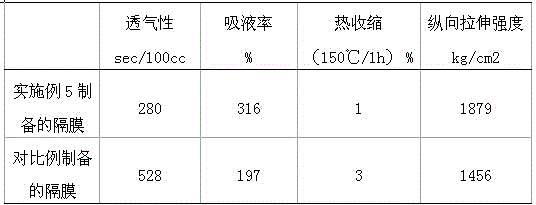

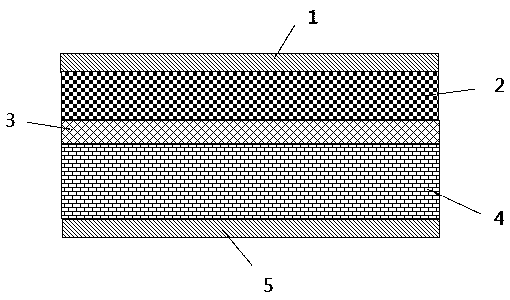

Composite coating lithium-ion battery separator and preparation method thereof

ActiveCN105552284AImprove thermal performanceImprove mechanical propertiesCell component detailsWater basedPole piece

The invention relates to a composite coating lithium-ion battery separator. The composite coating lithium-ion battery separator is composed of a base film, an aramid fiber coating coated on one side of the base film and a PVDF coating coated on the other side of the base film; the aramid fiber coating is obtained by an aramid fiber sizing agent after coating, soaking and drying, and the thickness of the coating is 0.5-4 microns; the PVDF coating is obtained by a water-based PVDF sizing agent after coating and drying, and the thickness of the coating is 0.1-2 microns. The invention also provides a preparation method of the separator. According to the composite coating lithium-ion battery separator and the preparation method thereof, the separator has the characteristics that the aramid fiber coating is good in thermal performance and mechanical performance and the PVDF coating has good wettability and liquid retention property for electrolytes, can effectively adhere batteries and pole pieces and is little in environmental pollution, and is beneficial for preparing lithium-ion batteries with longer cycle life and higher safety. Tests indicate that the separator has good air permeability, liquid absorption rate, thermal contraction and tensile strength, so that the cycle life of the batteries can be obviously prolonged by using the lithium-ion batteries prepared by the separator.

Owner:CANGZHOU MINGZHU SEPARATOR TECH CO LTD

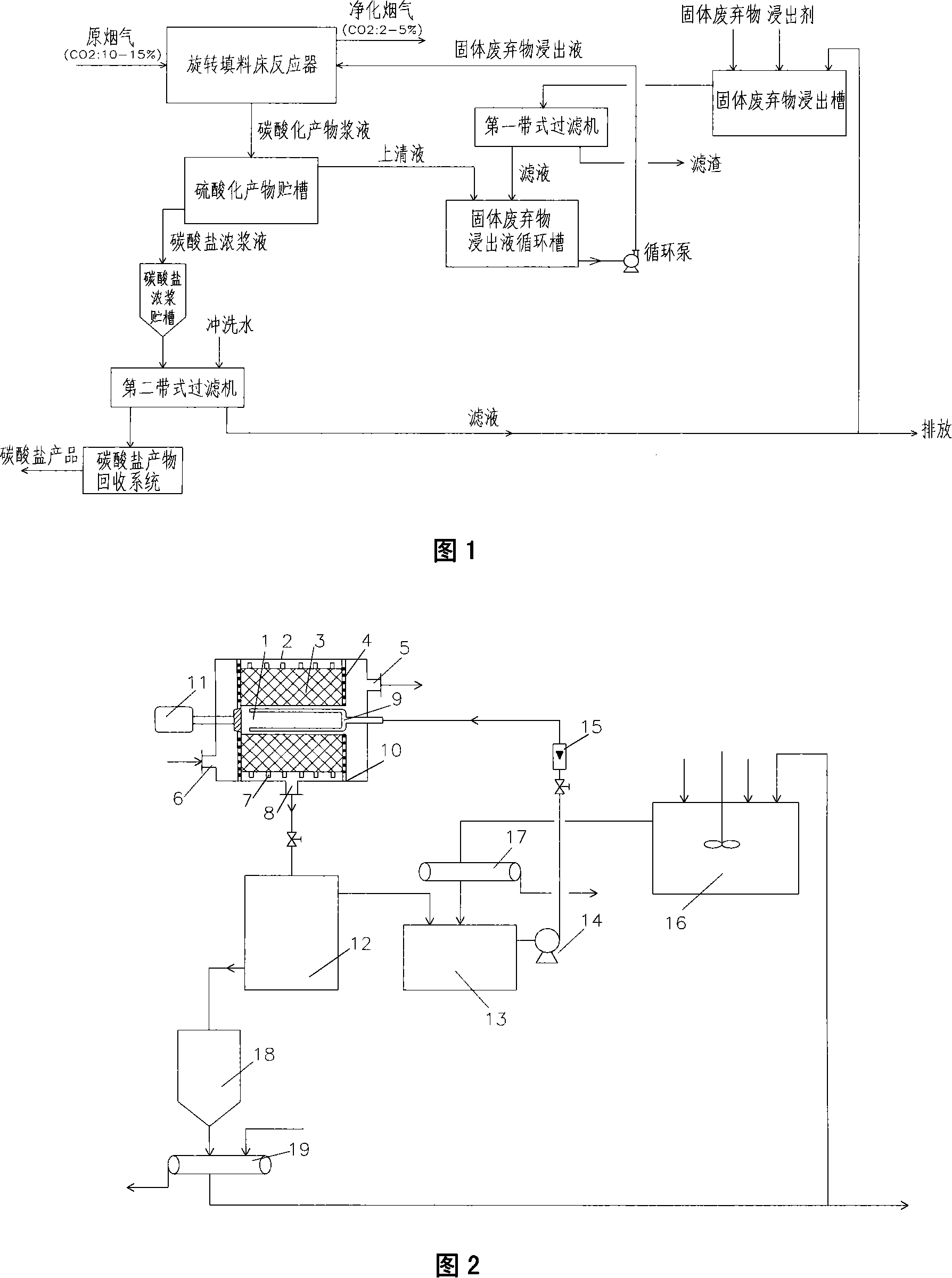

Method and device for fixing CO2 in stack gas by solid castoff carbonatation

InactiveCN101219330AIncrease mass transfer absorption rateIncrease carbon sequestration capacityDispersed particle separationBy chemical separationProcess integrationCentrifugal force

The invention provides a technique method for integrating coupling in-situ CO2 through utilizing a plurality of processes such as CO2 absorbing separation, carbonation fixation and solid wastes recovery in stack gas and a device thereof. A supergravity rotating packing bed reactor is used for intensifying transmission and multi-phase reacting process through utilizing powerful centrifugal force generated by the high-speed rotary packing bed, which is a breakthrough technology and can strengthen order of magnitude to the transmitting process of liquidoid-controlled CO2, etc., thus greatly improving mass transfer absorption rate of the CO2.

Owner:SOUTHEAST UNIV

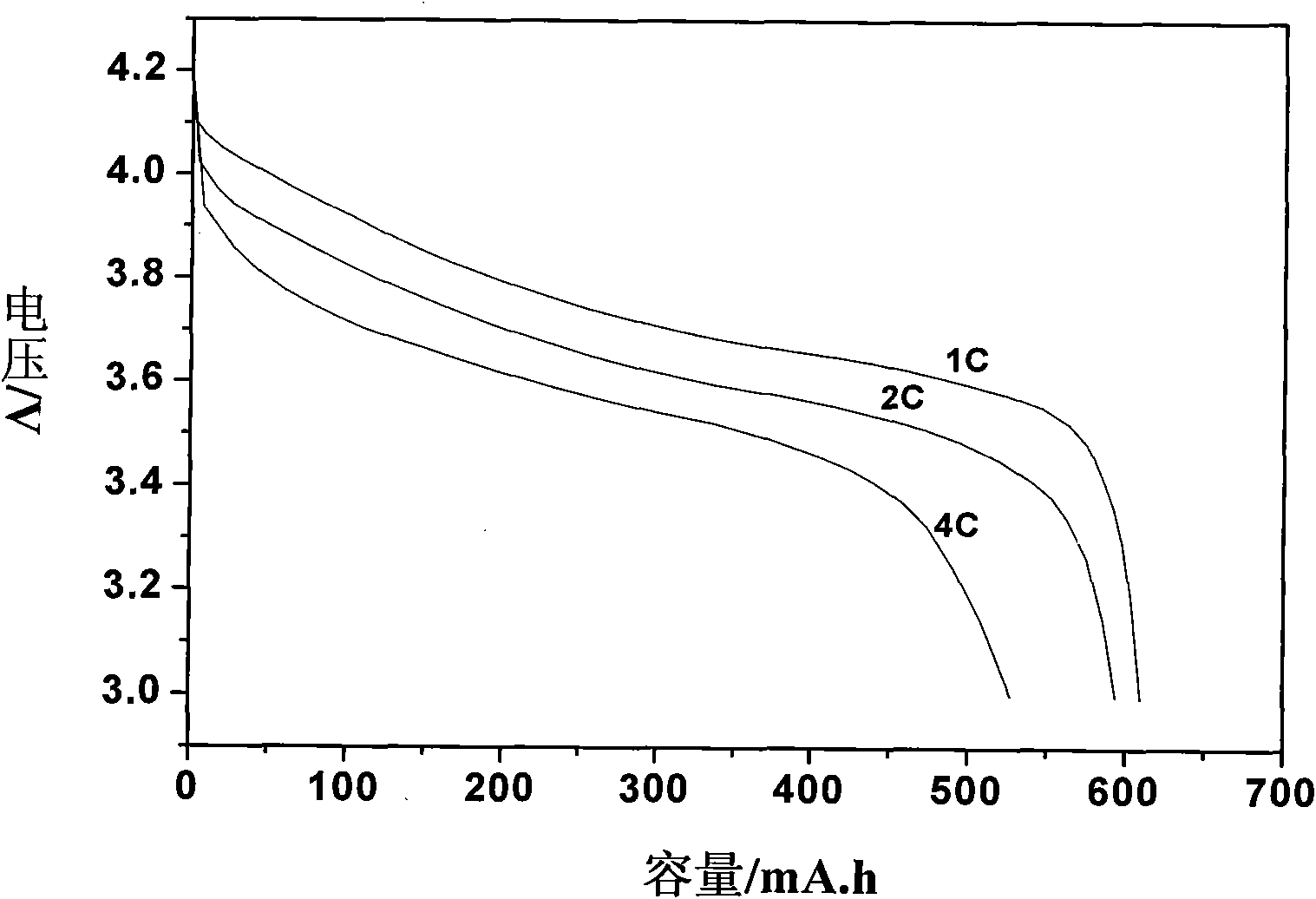

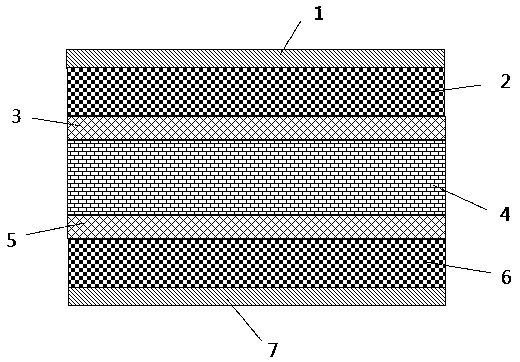

A preparation method of a ceramic coated separator for lithium ion batteries

The invention discloses a preparation method of a ceramic coating separator for lithium ion batteries and belongs to the technical field of lithium ion battery separator production. The method involves a polymer porous base film, a polymer glue applied on one or both sides of the base film surface, a ceramic coating applied on the surface of the polymer glue, and a PVDF and its copolymer glue applied on the other side of the ceramic coating surface and the base film surface, wherein the PVDF and its copolymer glue are coated on the other side of the ceramic coating surface and the base film surface. The inorganic ceramic particles adopted by the invention are non-spherical and multi-particle, which can greatly improve the porosity of the ceramic coating, increase the lithium ion transit property, improve the liquid absorption rate of the diaphragm, and improve the rate performance and cycle life of the lithium ion battery. As the structure design of the ceramic coat diaphragm of the invention can increase the adhesive force of the ceramic coating and the polymer porous base membrane, the adhesive strength of the diaphragm and the positive and negative electrode sheets is improved,the problems of powder dropping and coating peeling off are effectively improved, the high-efficient automatic assembly of the lithium battery is realized, and the heat resistance and electrochemicalstability of the diaphragm are greatly improved.

Owner:HENAN FUSEN NEW ENERGY TECH

Small molecule polypeptide Ca-chelate of fishbone and preparation method

InactiveCN102406176AHigh calcium chelation rateIncreased bioabsorptionFood preparationSolubilitySide effect

The invention discloses small molecule polypeptide Ca-chelate of fishbone, which belongs to the field of functional food or additive. The method for preparing the small molecule polypeptide Ca-chelate of the fishbone comprises the following steps: boiling the fishbone at high temperature and high pressure; pulping to obtain the fishbone paste; utilizing the compound protease to execute enzymolysis; centrifuging to obtain the liquid supernatant and the sediment; filtering the liquid supernatant to obtain the small molecule polypeptide liquid of the fishbone; executing the composite acid acidification through citric acid and lactic acid for the sediment so as to obtain the fishbone calcium liquid; mixing the small molecule polypeptide liquid of the fishbone with the fishbone calcium liquid; executing the chelation at 40-50 degrees centigrade while the pH value is 7.5-8.5; and drying to obtain the small molecule polypeptide Ca-chelate of the fishbone. The invention has high Ca-chelate rate which reaches over 90%, and has high biological absorption rate of the calcium which reaches over 70%. The invention has no side effects, has good flavor, can be directly absorbed from intestinal mucosa after being eaten, solves the problems that the solubility of the traditional calcium source is bad, the absorption rate is low and the side effect is large, and solves the problem of producing calculi. In addition, the invention has a simple preparation method and low cost.

Owner:SHANDONG RONGXIN AQUATIC PROD FOOD GROUP

Fiber optic gas sensor

ActiveUS20090129721A1Induce strainImprove absorption rateMaterial analysis by optical meansCoupling light guidesProduct gasSensor materials

A gas sensor includes an in-fiber resonant wavelength device provided in a fiber core at a first location. The fiber propagates a sensing light and a power light. A layer of a material is attached to the fiber at the first location. The material is able to absorb the gas at a temperature dependent gas absorption rate. The power light is used to heat the material and increases the gas absorption rate, thereby increasing sensor performance, especially at low temperatures. Further, a method is described of flash heating the gas sensor to absorb more of the gas, allowing the sensor to cool, thereby locking in the gas content of the sensor material, and taking the difference between the starting and ending resonant wavelengths as an indication of the concentration of the gas in the ambient atmosphere.

Owner:UNIVERSITY OF PITTSBURGH +1

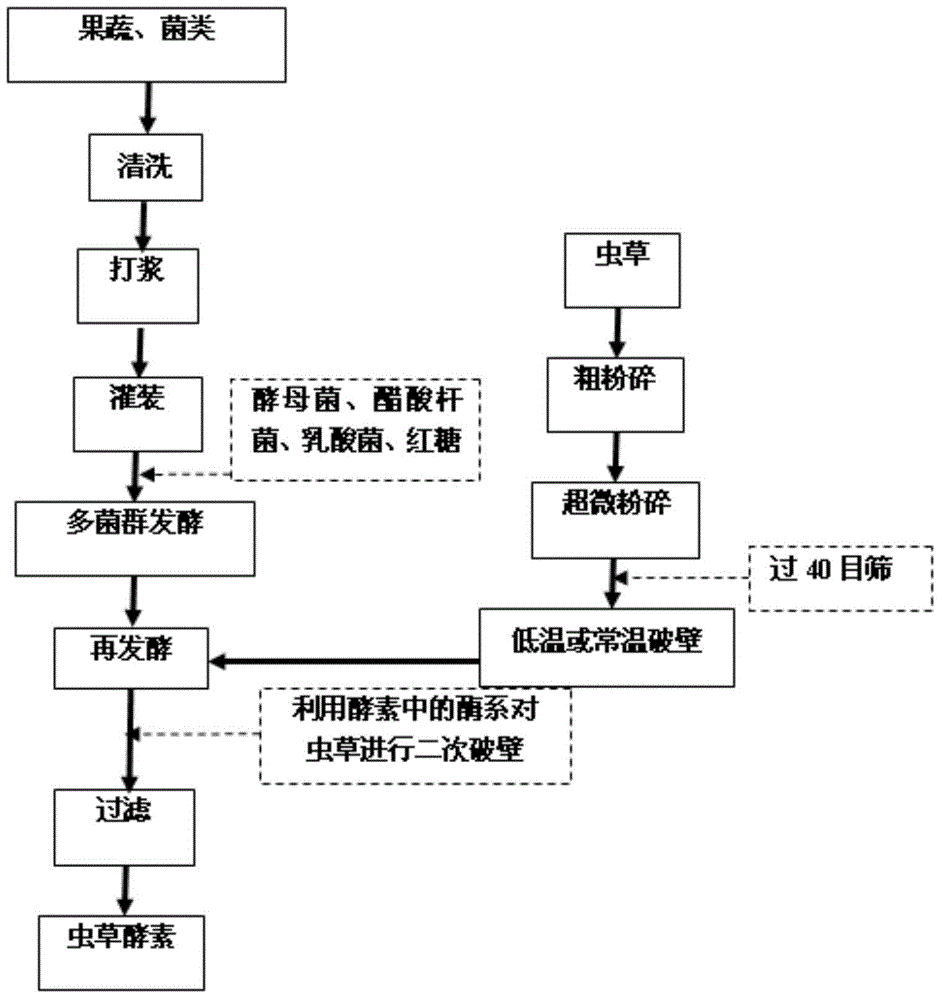

A cordyceps sinensis enzyme and a preparation method thereof

InactiveCN104856015ANo loss of nutritionImprove absorption rateFood preparationEnzyme systemBULK ACTIVE INGREDIENT

The present invention provides a cordyceps sinensis enzyme and a preparation method thereof. The enzyme is prepared by fermenting the following ingredients in parts by weight: fruits and vegetables 55-70 parts, fungi 8-12 parts, cordyceps sinensis 1-2 parts and sugar 15-20 parts with the addition of probiotic 0.2-0.8 part. The preparation method comprises the following steps: preparing cordyceps sinensis sporoderm-broken powder, preparing primary enzyme solution, fermenting the powder and the solution for preparing the cordyceps sinensis enzyme, etc. The enzyme uses ultramicro crushing technology to crush the cordyceps sinensis, and low temperature or room temperature sporoderm-breaking technology to conduct sporoderm-breaking on the cordyceps sinensis so that the nutrition loss of the cordyceps sinensis is prevented and the absorption rate of the cordyceps sinensis is improved; the enzyme utilizes rich enzyme systems of enzymes to conduct additional sporoderm-breaking on the sporoderm-broken powder, which facilitates the release and homogenization of active ingredients in the cordyceps sinensis, and improves the effect of drugs. The prepared enzyme contains proteins, amino acids, vitamins, enzyme substances, etc. essential for human bodies, effectively accumulates functional components of the cordyceps sinensis, and effectively improves various health-care effects of the enzymes.

Owner:西藏月王药诊生态藏药科技有限公司

Preparation method of ceramic granules

InactiveCN102060562ALow water absorptionHigh compressive strengthCeramicwareSpherical granuleDiiron Trioxide

The invention relates to a preparation method of ceramic granules, which comprises the following steps: drying and crushing coal ash, kaolin, ferric oxide and basic magnesium carbonate into powder after wet grinding; carrying out the biscuit firing treatment on the powder to prepare biscuit-firing granules after spherical granules are prepared; preparing microcrystal glass powder by utilizing an Li-Al-Si system; pouring the prepared microcrystal glass powder into a granulator to be stirred; preparing the biscuit-firing granules packaged by the microcrystal glass powder after the surface of the biscuit-firing granules is completely packaged by the microcrystal glass powder; placing the biscuit-firing granules packaged by the microcrystal glass powder into the granulator; adding the powder;preparing the ceramic granules to be treated through the biscuit firing after the biscuit-firing granules packaged by the microcrystal glass powder are completely packaged by the powder; and preparing the ceramic granules after the ceramic granules to be treated through the biscuit firing are placed into a muffle furnace to be sintered and crushed. In the invention, a packaging method is adopted to prepare the ceramic granules, the inner layer of the prepared ceramic granules is completely packaged by the glass powder, and the gas of the inner layer is prevented from discharging in the sintering course so that the inner layer is in a loose porous structure, thereby greatly reducing the water absorption rate of the ceramic granules and decreasing the specific gravity.

Owner:SHAANXI UNIV OF SCI & TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com