Patents

Literature

80results about How to "Improve water absorption speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Denaturated starch absorbable hemostatic material and preparation method thereof

InactiveCN101121041AHigh viscosityImprove water absorption speedSurgical adhesivesPharmaceutical delivery mechanismMedicineBlood plasma

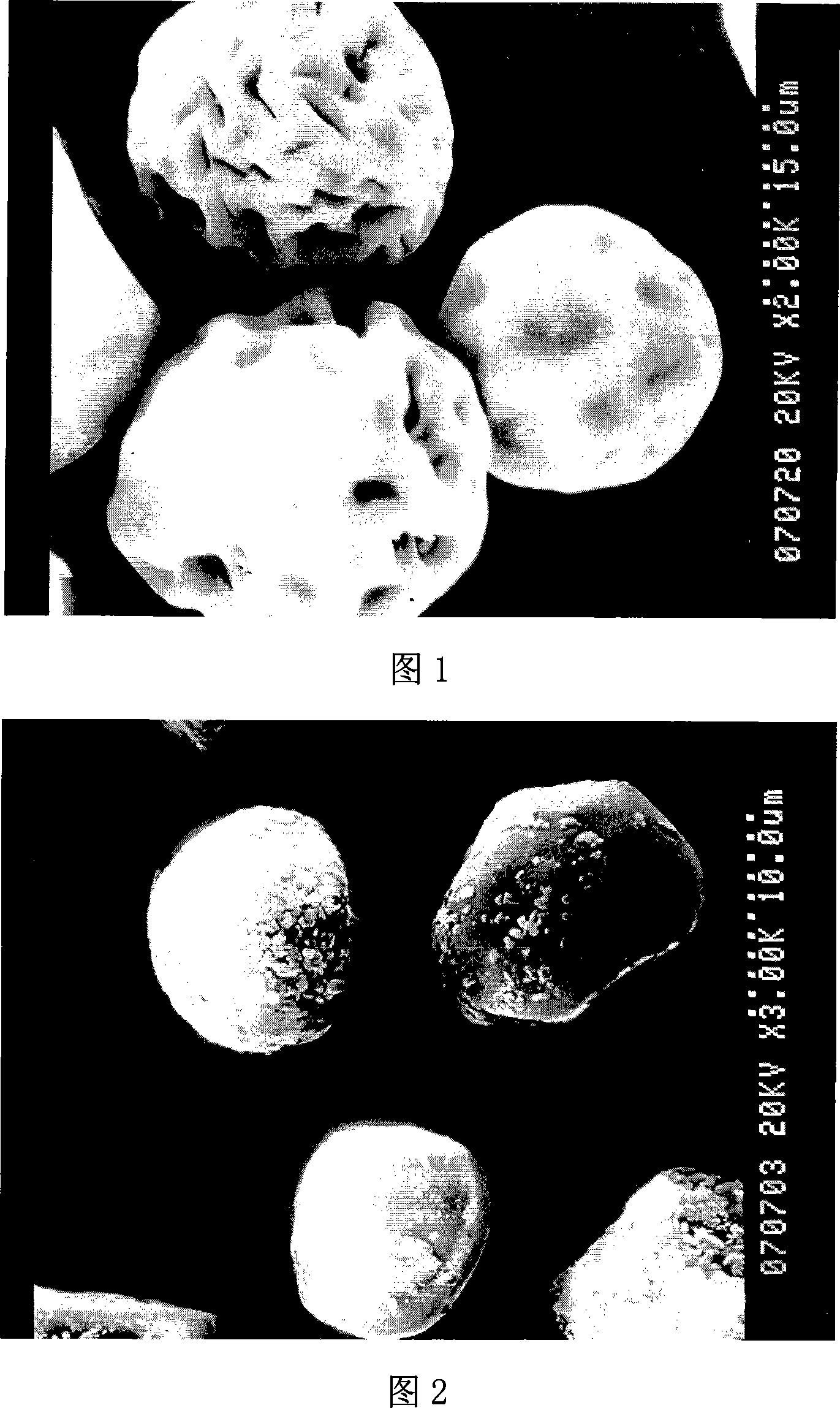

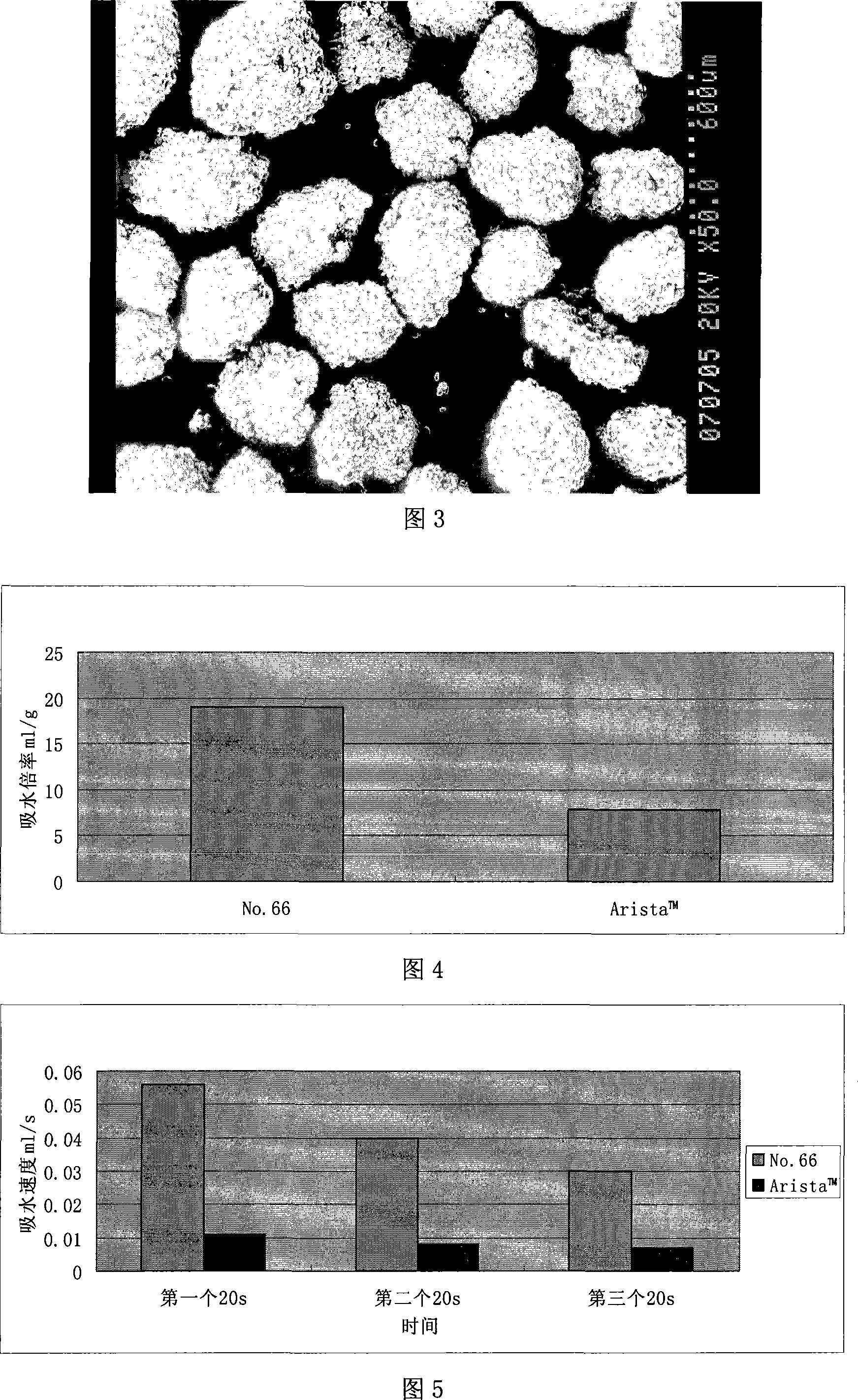

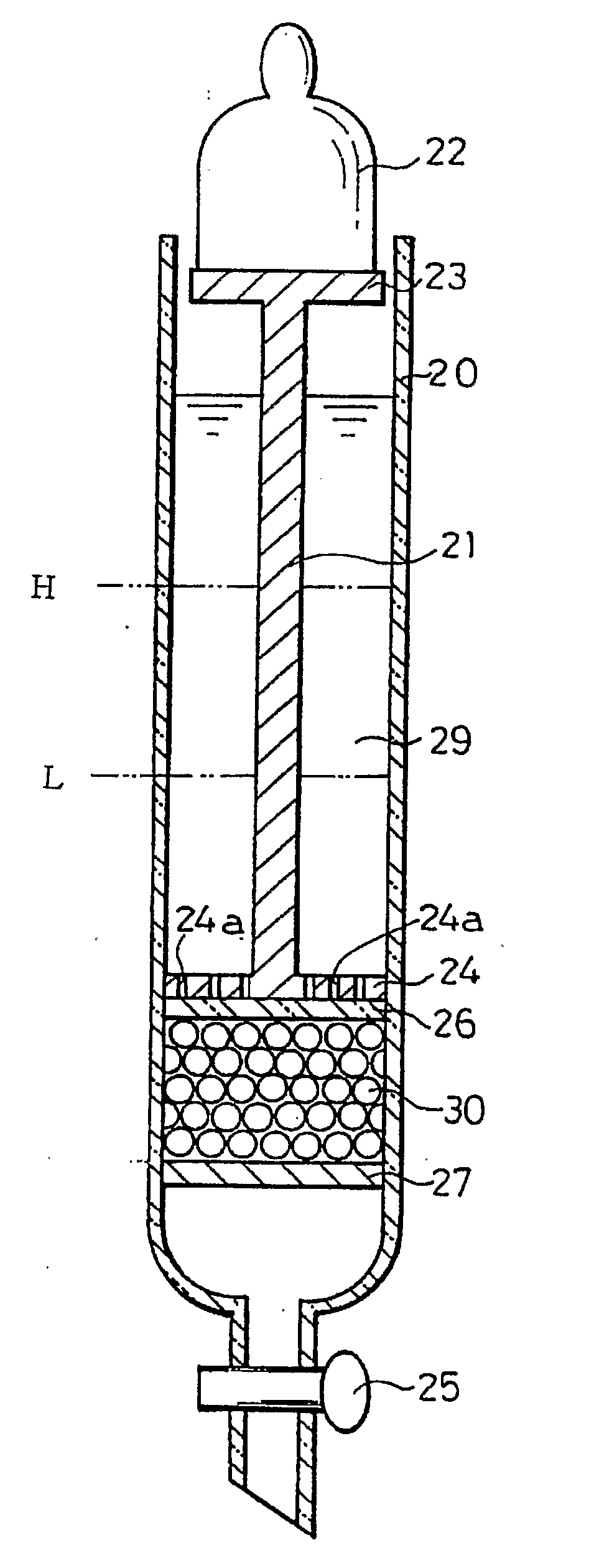

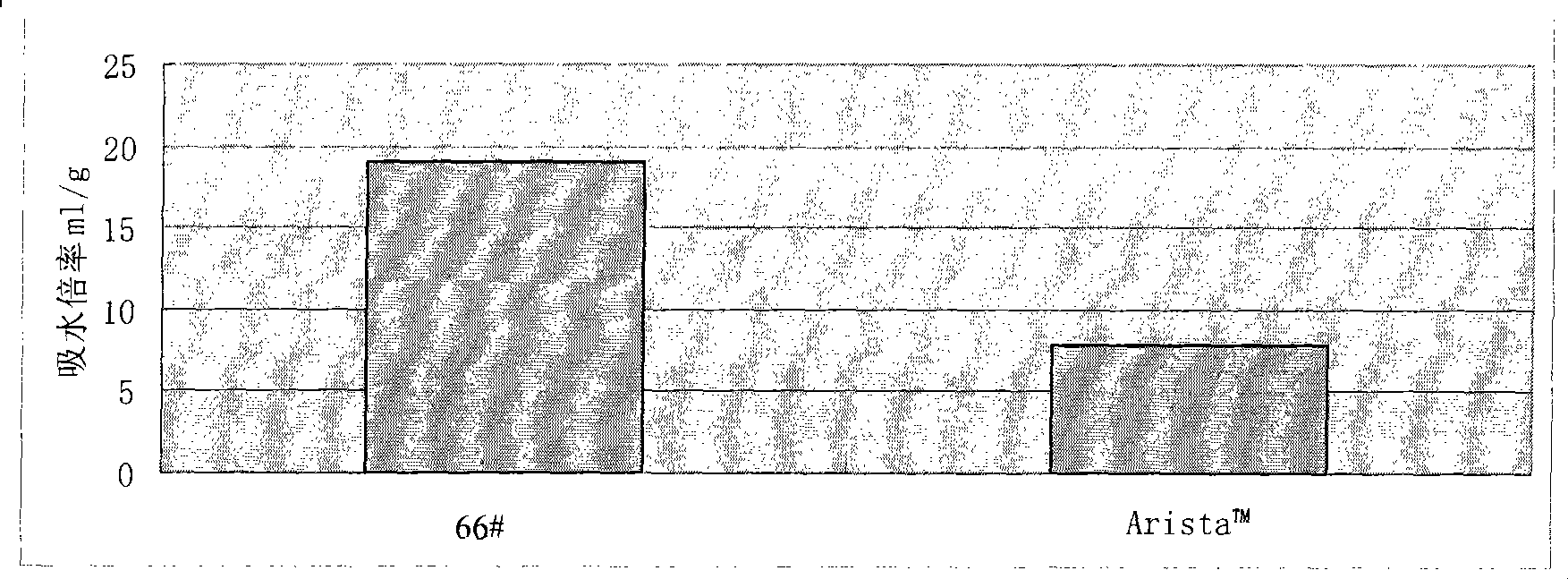

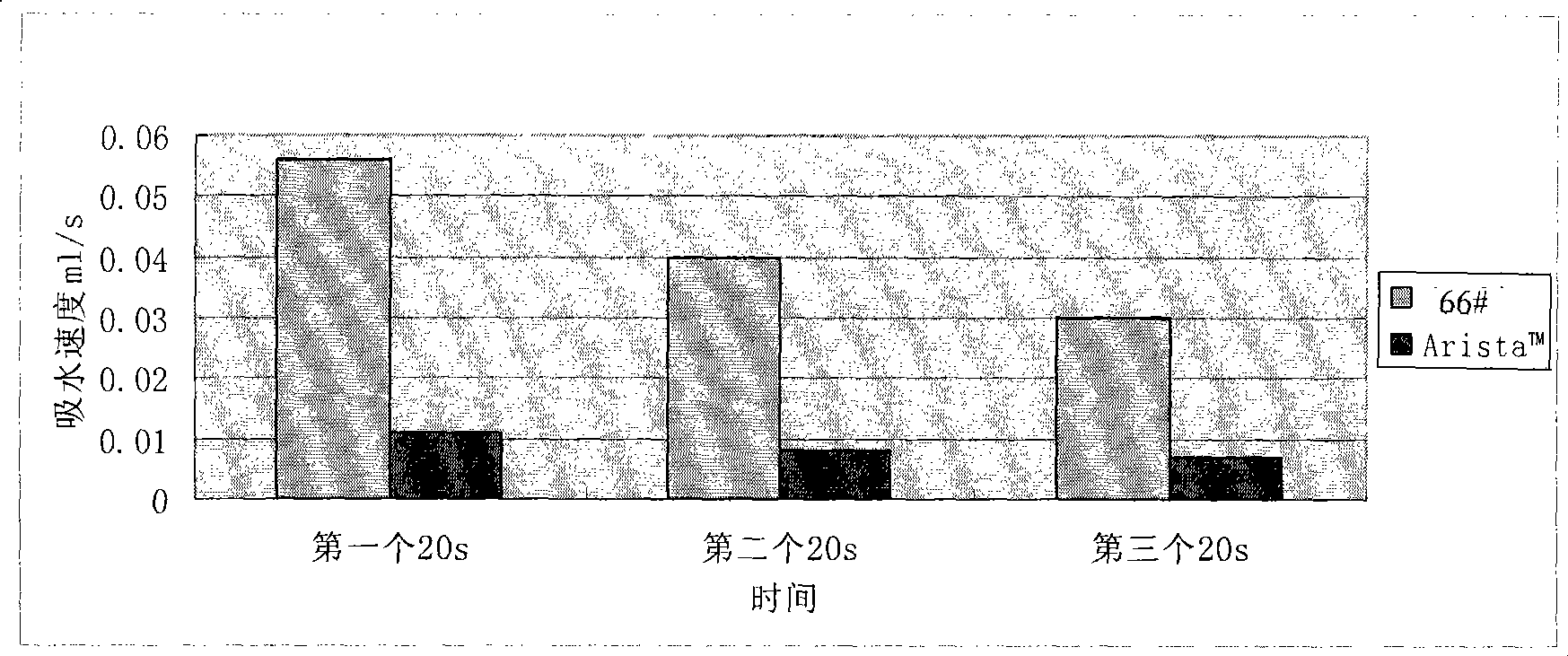

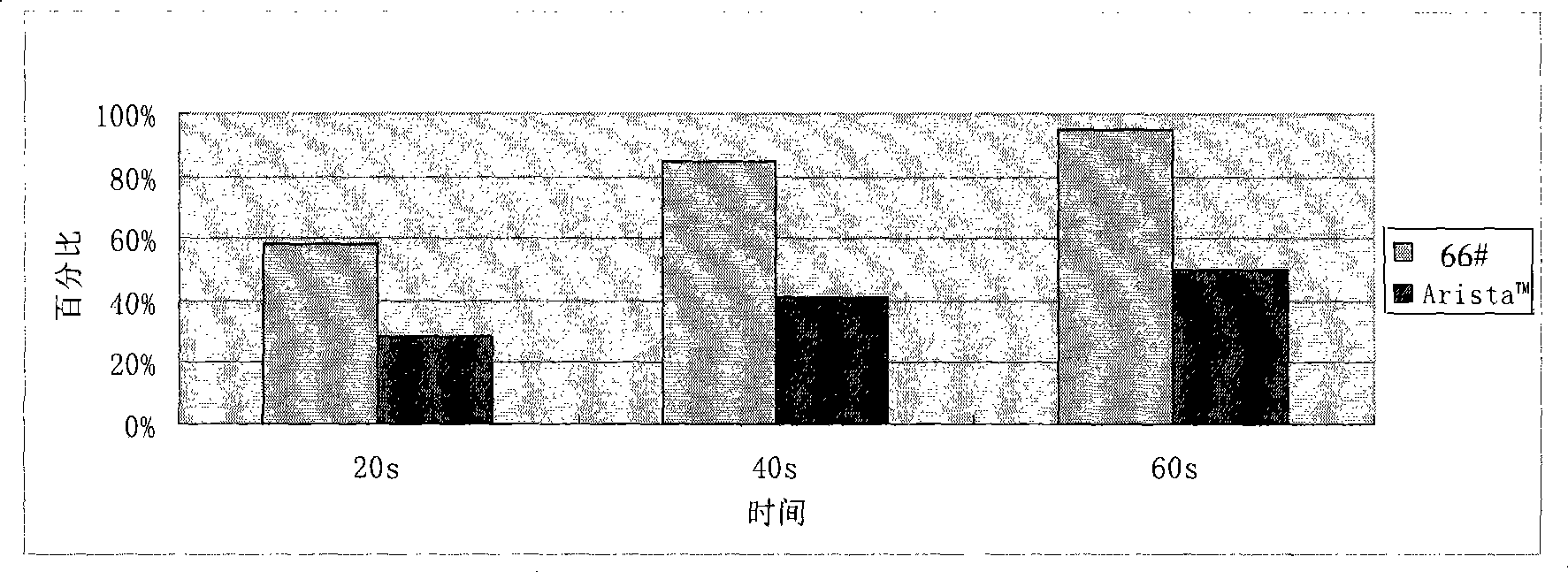

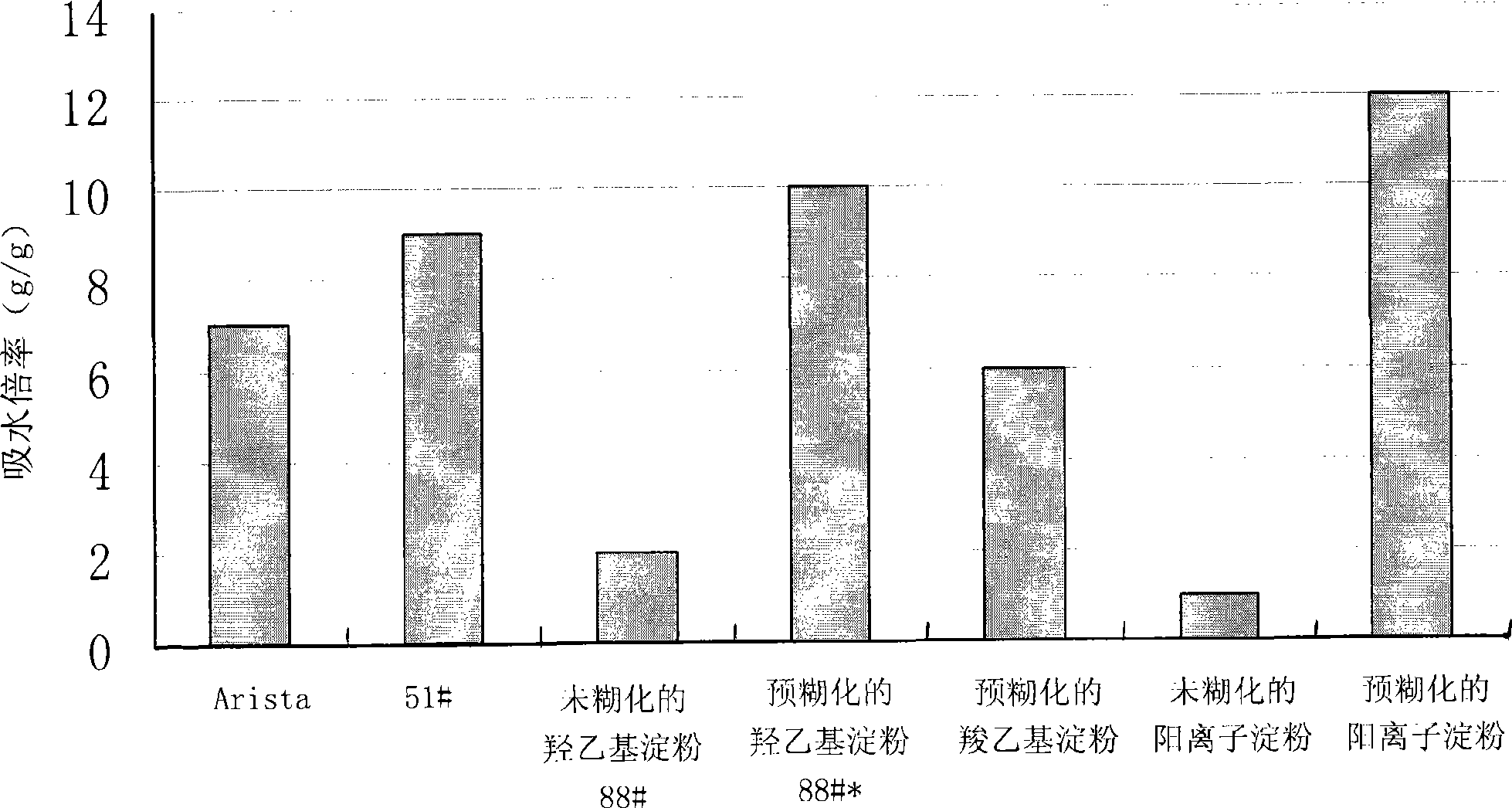

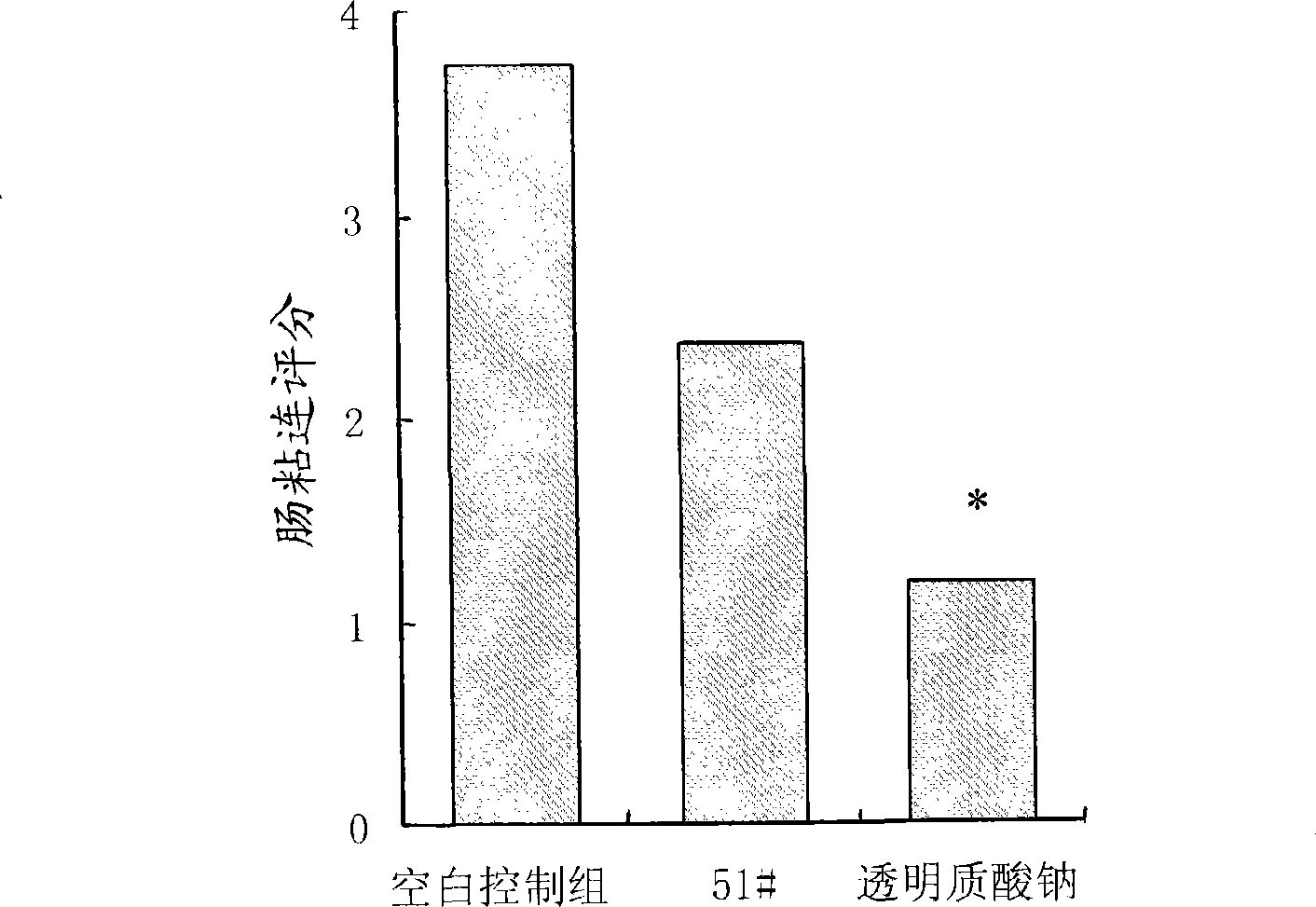

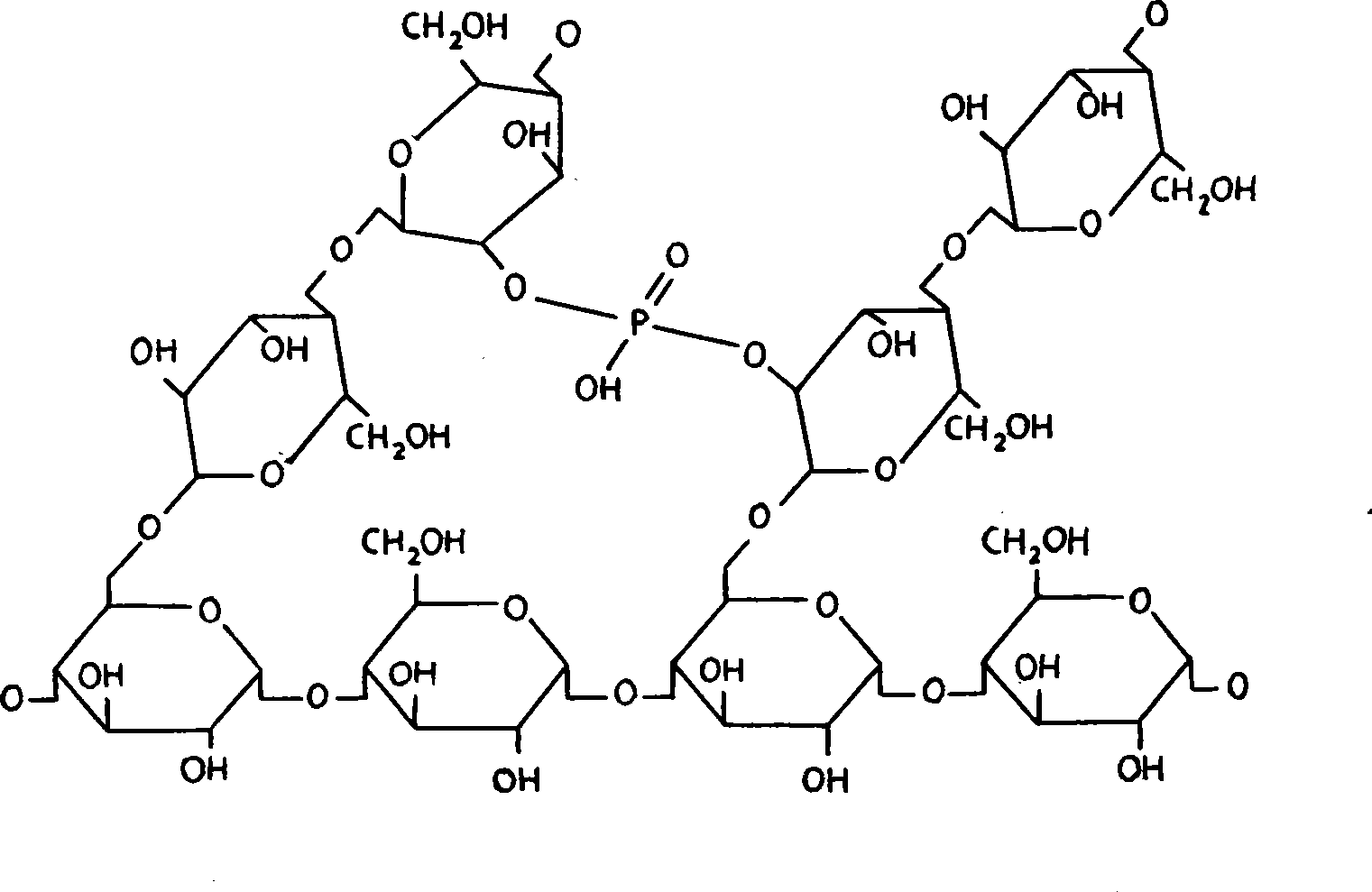

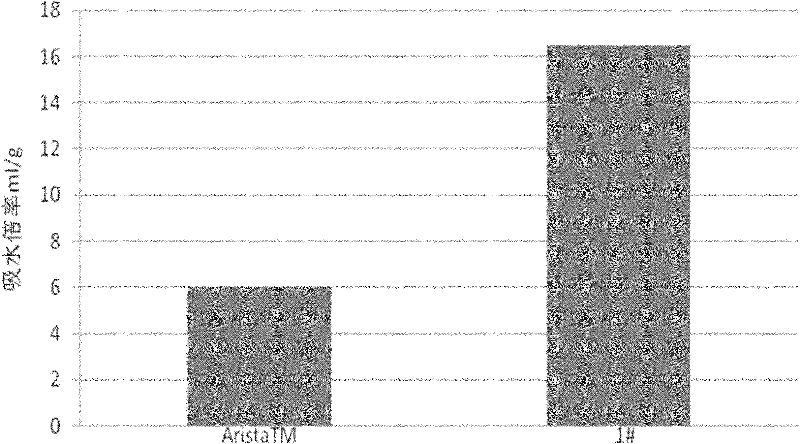

An absorbable modified starch hemostatic material and preparation thereof, wherein the hemostatic material is etherified starch, or a mixture of one or more etherified starches, crosslinked starches. The modified starch has a molecular weight of 15,000 - 10,000,000, a particle size of 10 - 1000µm, and a water absorption rate of 1 - 100. The biocompatible hemostatic material can directly effect on the wound with blood, concentrate the blood quickly to congulate blood; moreover, the gelatiniform mixture formed with blood has high viscosity, which can plug damaged tissue and blood vessel. The biocompatible hemostatic material is easy to swell in the water and easy to be washed so that the residue can be reduced; it is stable, not easy to decompose, and has long shelf life and storage advantage. The biocompatible hemostatic material can also be used as absorbable surgical antisticking material, promoting tissue healing material, surgical sealant and wound no-joint tissue adhesive.

Owner:美国淀粉医疗公司

Particulate water absorbing agent with irregularly pulverized shape

ActiveUS20070141338A1Improve surface drynessUnpleasant feelingOther chemical processesSynthetic resin layered productsParticulatesPermeation

The present invention provides a particulate water absorbing agent for a thin type absorbing substrate suitable for actual use. A particulate water absorbing agent having irregularly pulverized shape, characterized by comprising, a surface crosslinked water-absorbing resin obtained by crosslinking polymerization of an unsaturated monomer with an acid group and / or salts thereof, which absorbing agent contains agglomerated particles therein and further satisfies (i) centrifuge retention capacity (CRC) in a physiological saline solution of not lower than 32 g / g, (ii) mass median particle size (D50) of 200 to 400 μm, and (iii) particles smaller than 600 μm and not smaller than 150 μm of 95 to 100% by weight. By using the particulate water absorbing agent, such absorbing articles can be obtained as have few rugged surface after water absorption, excellent liquid permeation property.

Owner:NIPPON SHOKUBAI CO LTD

Modified starch absorbable hemostasia material and preparation method thereof

ActiveCN101361986AHigh viscosityImprove water absorption speedSurgical adhesivesPharmaceutical delivery mechanismWound healingBiomedical engineering

Owner:BEIJING UNIVERSAL LIKANG TECH CO LTD

Biocompatibility pre-gelatinized modified starch and preparation thereof

InactiveCN101497670AAbsorbentSpeed up absorptionSurgical adhesivesFibre treatmentBiocompatibility TestingHigh pressure

The invention relates to a biocompatible pre-gelatinized modified starch. The water absorbency is not less than one time, and the biocompatible pre-gelatinized modified starch is taken as biocompatible hemostatic material, biocompatible anti-blocking material, biocompatible tissue-healing promoting material, biocompatible surgical sealant or biocompatible wound closure tissue glue. The invention has the advantages that the biocompatible pre-gelatinized modified starch is directly acted on the wounded area with blood for immediately stopping bleeding, has obviously increased water absorbency and speed of water absorption and greater viscosity and stickiness and further plays the role in preventing the tissue and the blood vessel from being damaged during the process of stopping bleeding; the modified starch is easy to swell or dissolve in water, and is washed by normal saline after the bleeding stopping so as to reduce the residual in the body, to be favorable for wound healing and to avoid the pain due to tearing the gauze and the bandage out; the pre-gelatinized modified starch has the actions of bacterial resistance and anti-inflammatory; and the pre-gelatinized modified starch is stable, not easy to decompose, long in guarantee period, convenient for storage, resistant at high pressure and low pressure, resistant at high temperature and low temperature and not easy to change the physicochemical characteristics.

Owner:纪欣

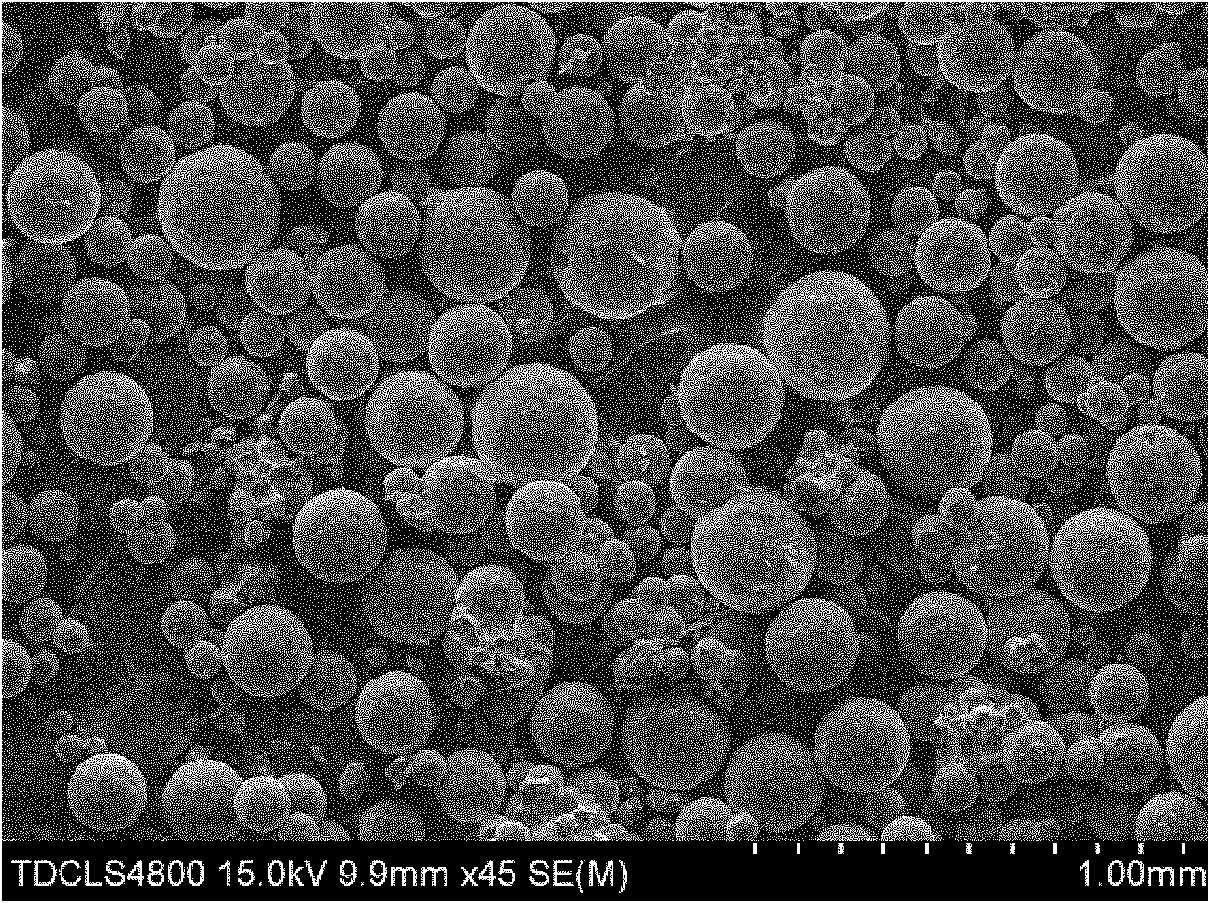

Starch hemostatic microsphere and preparation method thereof

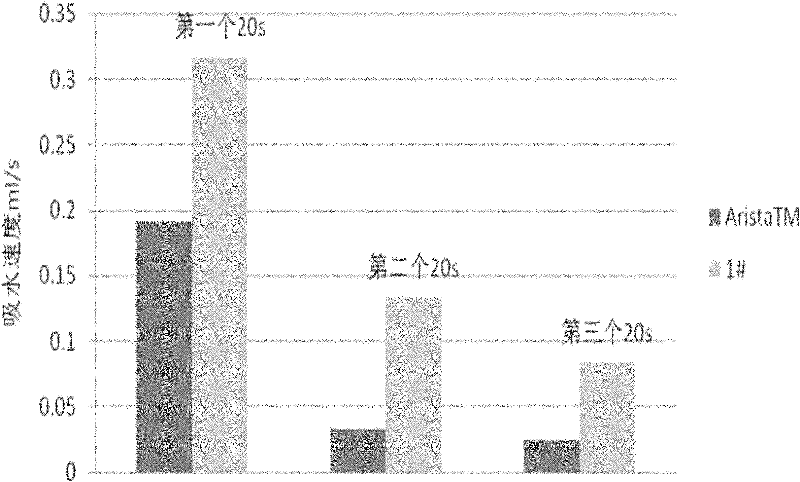

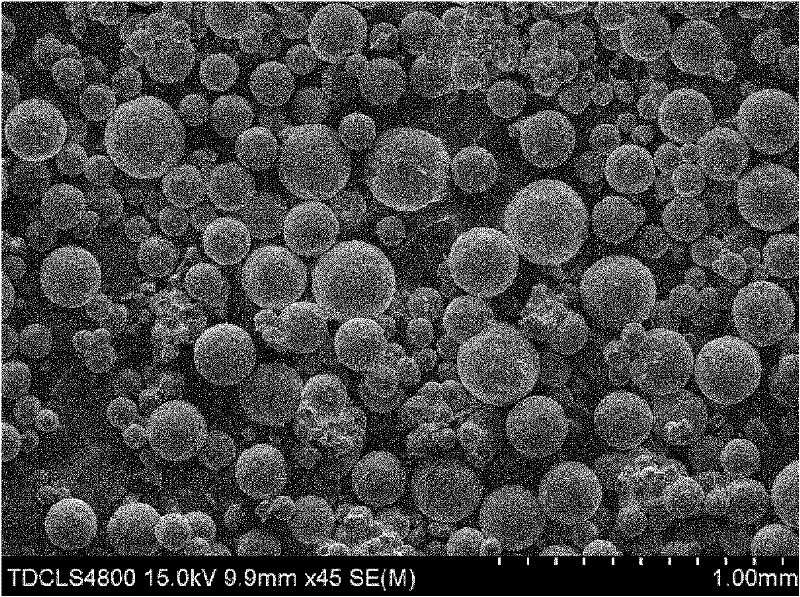

ActiveCN102406956AHigh water absorption rateImprove water absorption speedAbsorbent padsBandagesChemistryActive agent

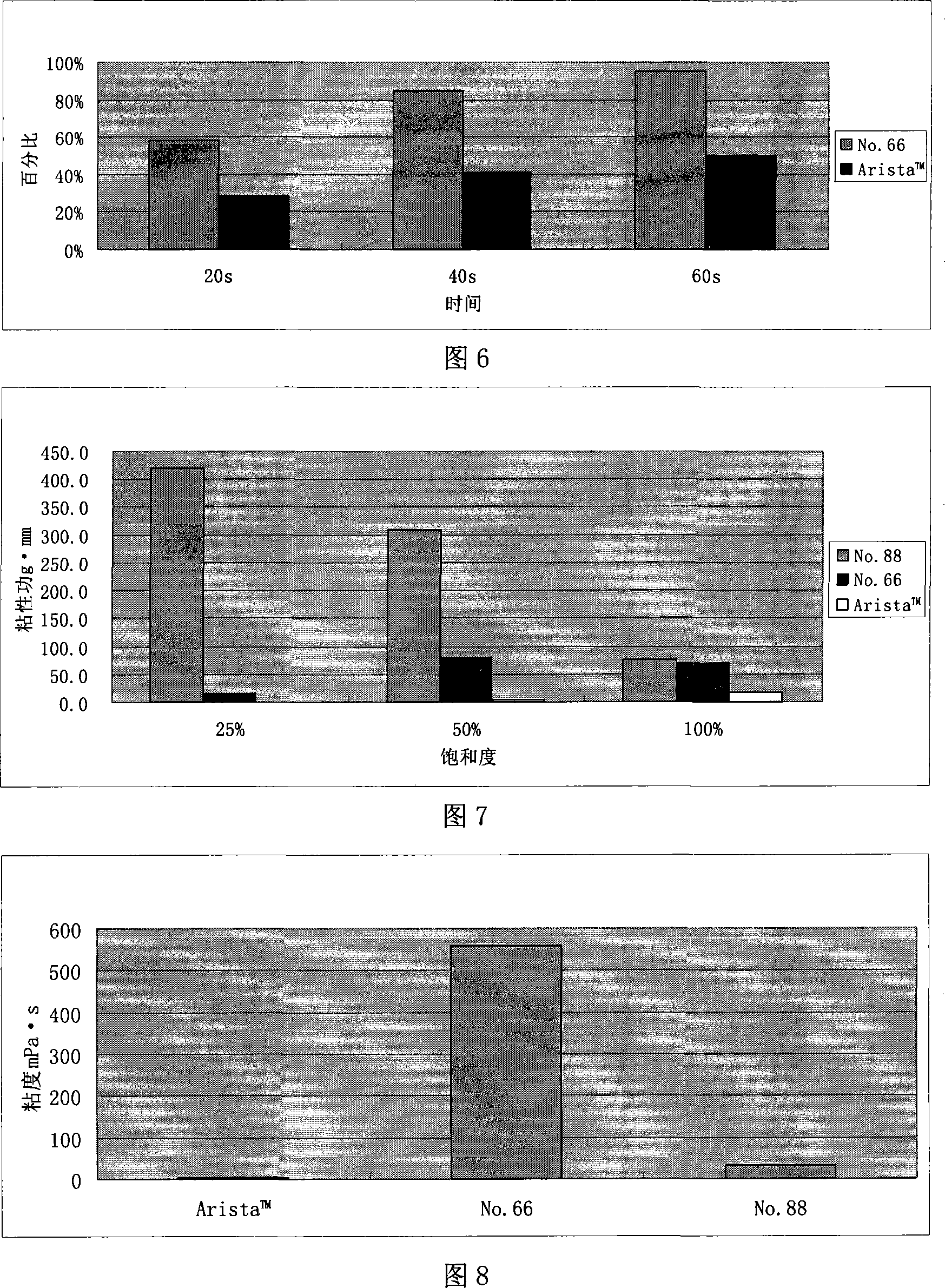

The invention relates to a starch hemostatic microsphere and a preparation method thereof. The starch hemostatic microsphere is prepared from legume starch, potato starch and cereal starch which serve as raw materials by virtue of an inverse suspension polymerization method, and has a molecular weight of between 50000 and 5000000 and the grain diameter of between 0.1 and 1000mu m. The preparationmethod of the starch hemostatic microsphere comprises the following steps: mixing the three types of raw starches, and alkalizing; dispersing with a surfactant and vegetable oil under a condition that the pH is between 8.5 and 10.5; performing crosslinking with a crosslinking agent; cleaning, and performing spray drying; and packaging, and sterilizing with cobalt 60. The starch hemostatic microsphere prepared by using the method has good biocompatibility, and is used for a hemostatic process of a surgical operation; the water absorption rate is multiple times that of a conventional hemostaticmaterial, the water absorption speed is remarkably increased, and the hemostatic effect is reinforced. The starch hemostatic microsphere has easily available raw materials, simple process, low production cost and wide application prospect.

Owner:天津红日爱乐意药用辅料有限公司

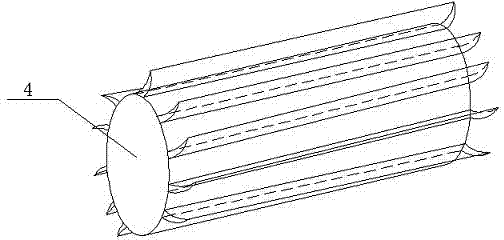

Nonwoven material and its processing method

InactiveCN101457479AImprove water absorptionLarge water absorption (about 8-11 times), high water absorption speedFibre typesMonocomponent polyolefin artificial filamentFiltrationNonwoven fabric

The invention provides a non-woven material and a processing method thereof. The non-woven material is produced by processing 4 layers of materials, melt-blown nonwovens are placed between two layers of spunbond nonwovens to produce SMS compound nonwovens in accordance with SMS compound manufacturing technique, then the laminating technology is adopted to compound waterproof breathable layers on the SMS compound nonwovens to produce four layers of spunmelt hydrophilic anti-infiltration non-woven material, the non-woven material is finally made after going through the steps such as feeding, meltdown, filtration, measurement, spinning, stretching, cooling, web formation, hot air air-thru bonding and winding; the non-woven material is flexible, safe, sanitary and cheap, thus being widely applied in hospitals, nursing rooms, hotels and other hygiene medical systems.

Owner:山东省非织造材料工程技术研究中心

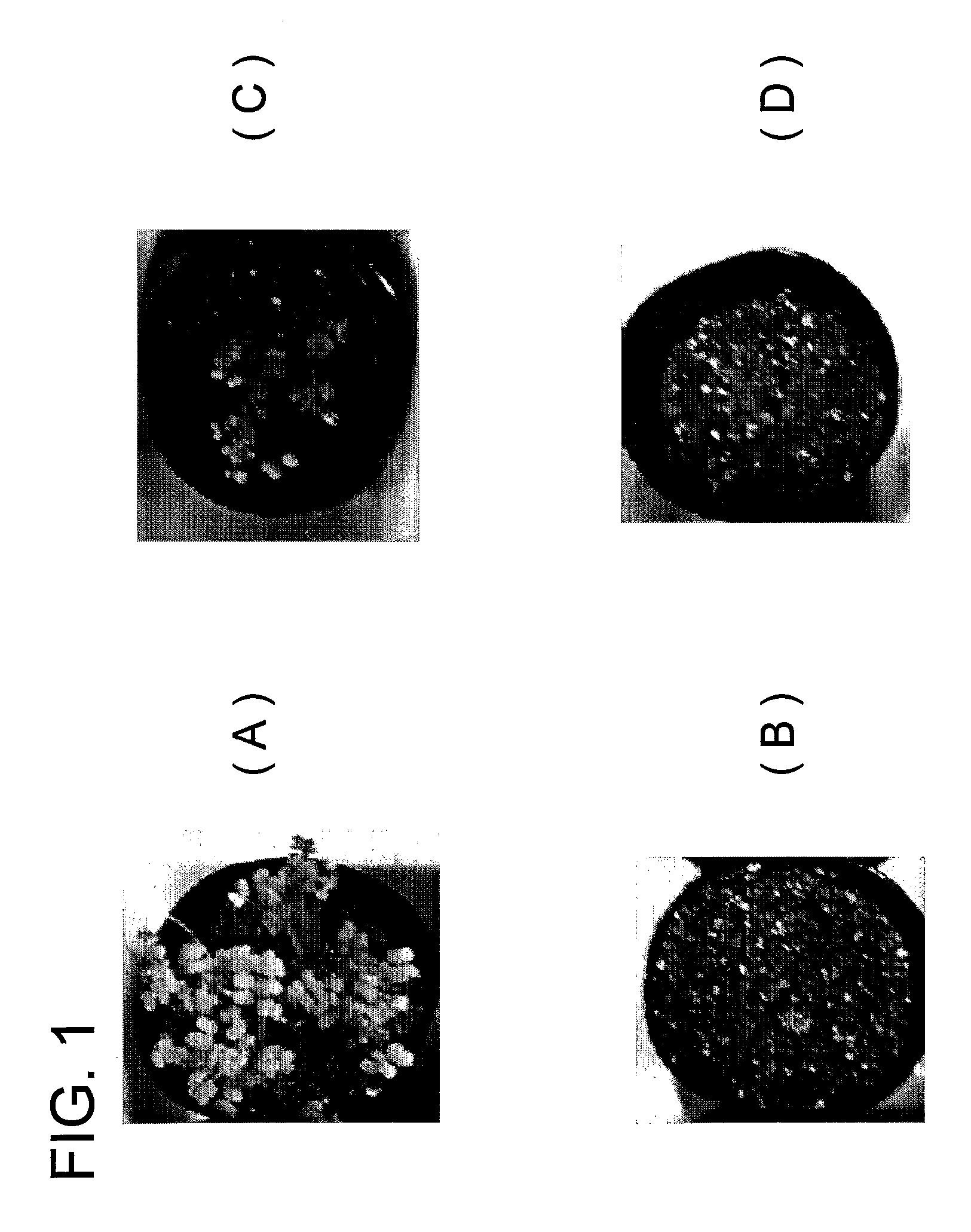

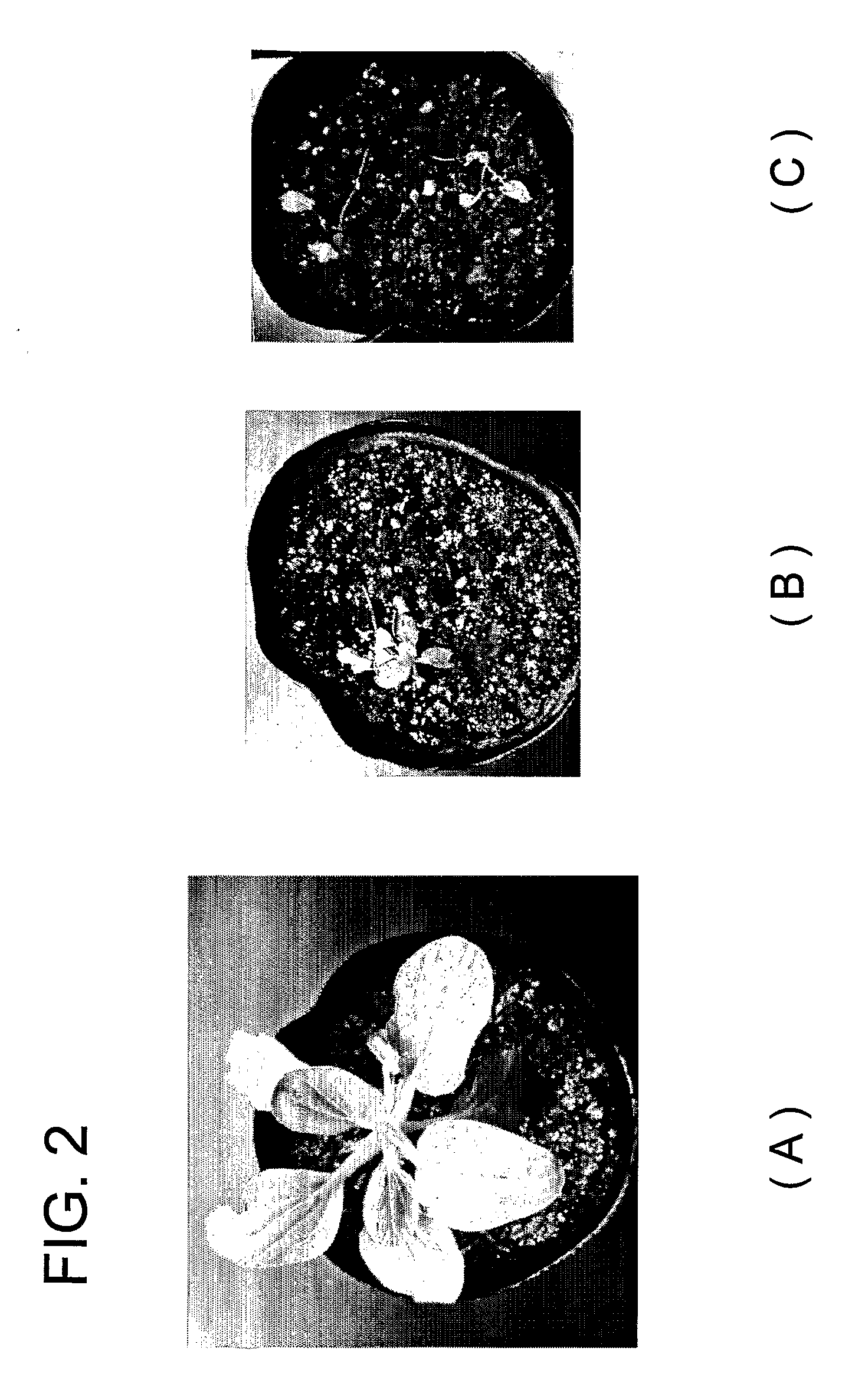

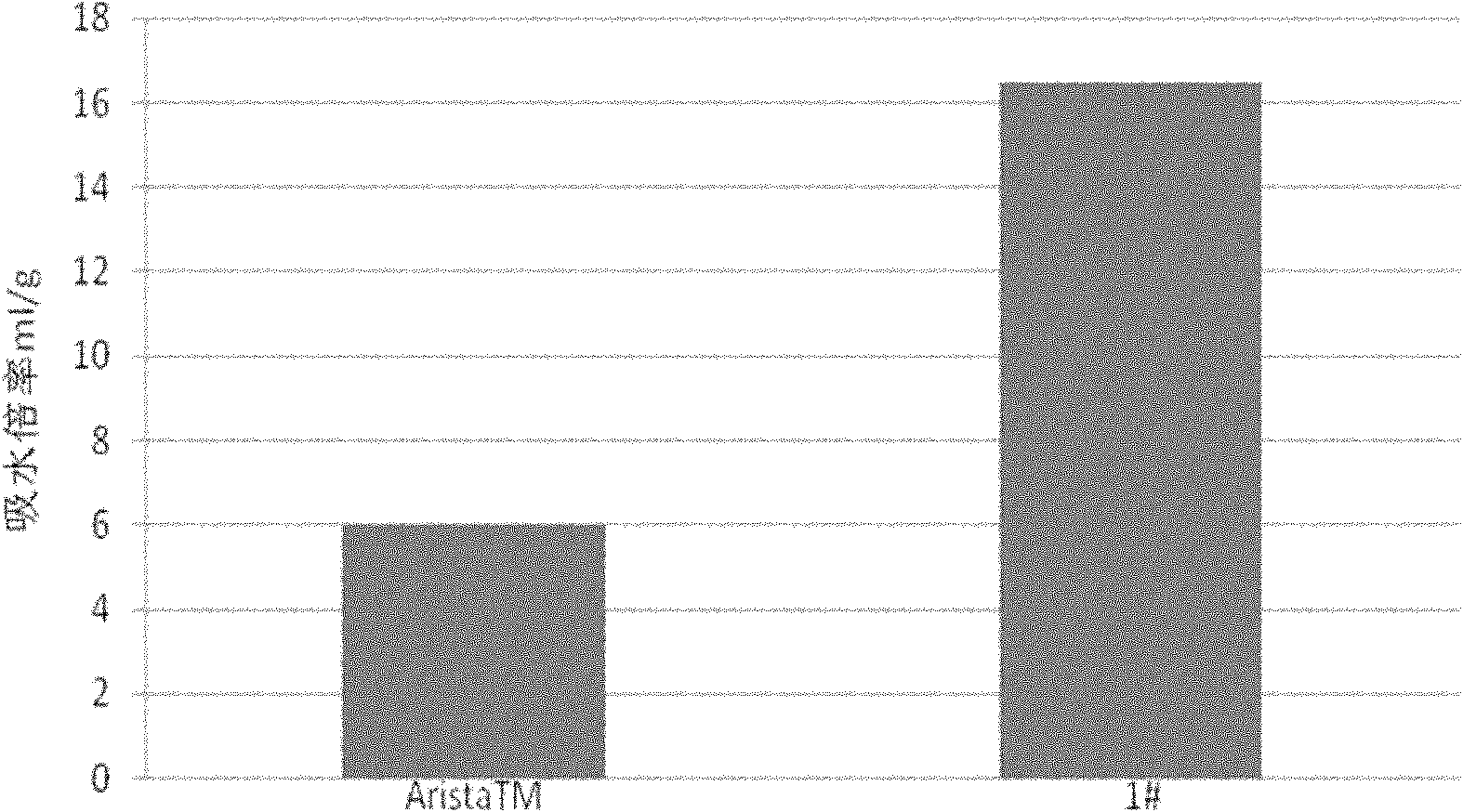

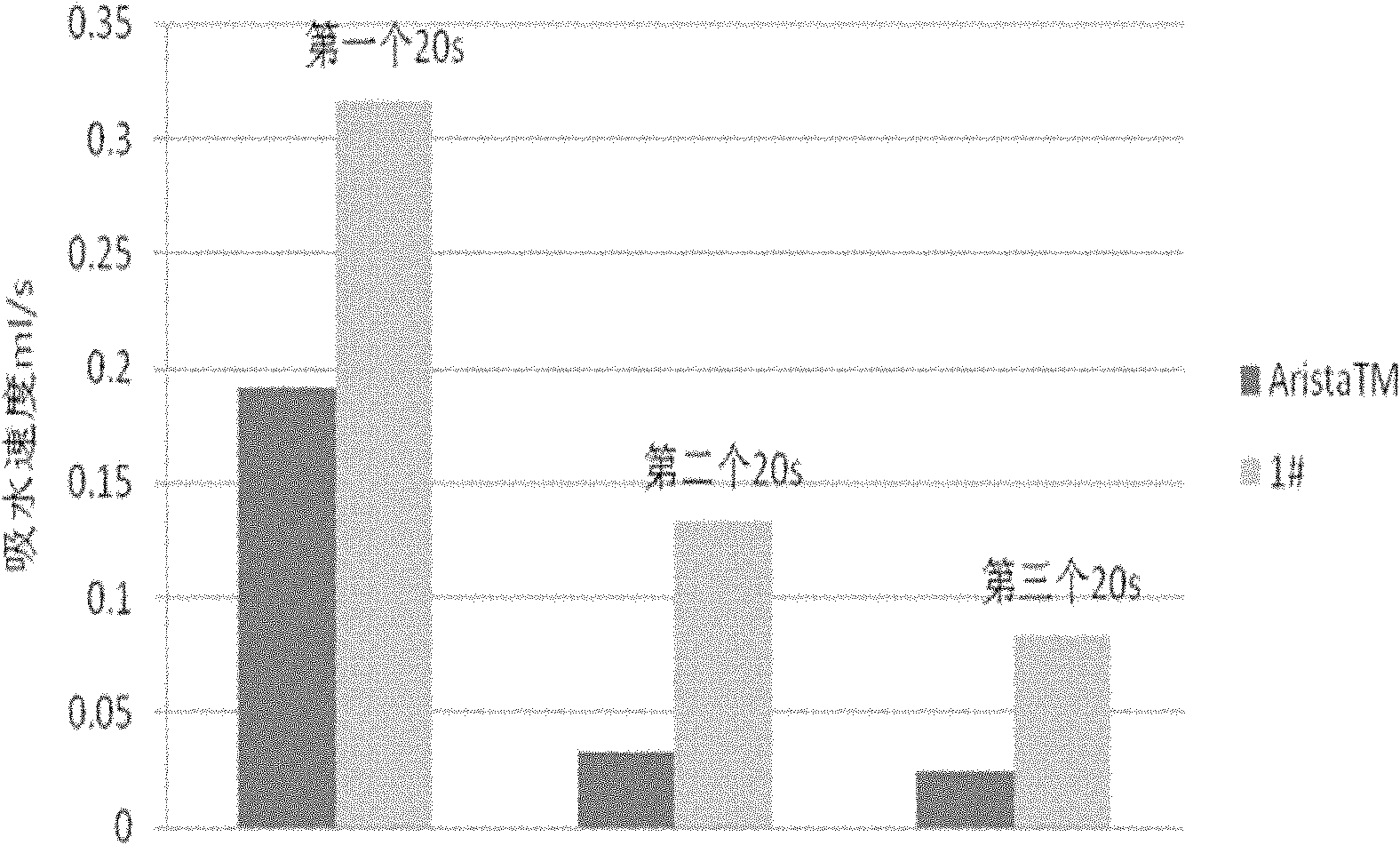

Particulate water retaining material for cultivating plant having water absorbent resin as main component

ActiveUS20070101644A1Promotes rhizogenesisImprove irrigation efficiencyGrowth substratesCulture mediaParticulatesWater insoluble

A particulate water retaining material for cultivating plant comprising (A) a carboxyl group-containing water-insoluble water absorbent resin and (B) a polyvalent metal compound, by having the compound (B) deposited on the the rerin (A), it is made possible to possess an outstanding water absorbing property without impairing the growth of a plant.

Owner:NIPPON SHOKUBAI CO LTD

Method for producing instant noodles

ActiveUS20110129582A1High water absorption speedExcellent flavorDough treatmentBaking mixturesChemistryFlavor

The present invention provides a method for producing instant noodles having fresh noodle-like texture and flavor and having an excellent reconstitution property even if the noodles are thick. In the present invention, superheated steam flow is directly sprayed to raw noodle strings for 5 to 50 seconds such that a temperature of superheated steam to which surfaces of the noodle strings are exposed becomes 125 to 220° C., the noodle strings are supplied with moisture using water or hot water, the noodle strings are further steamed by directly spraying the superheated steam flow to the noodle strings for 5 to 50 seconds and / or steamed by using non-superheated steam, and the noodle strings are dried to produce the instant noodles.

Owner:NISSIN FOODS HLDG CO LTD

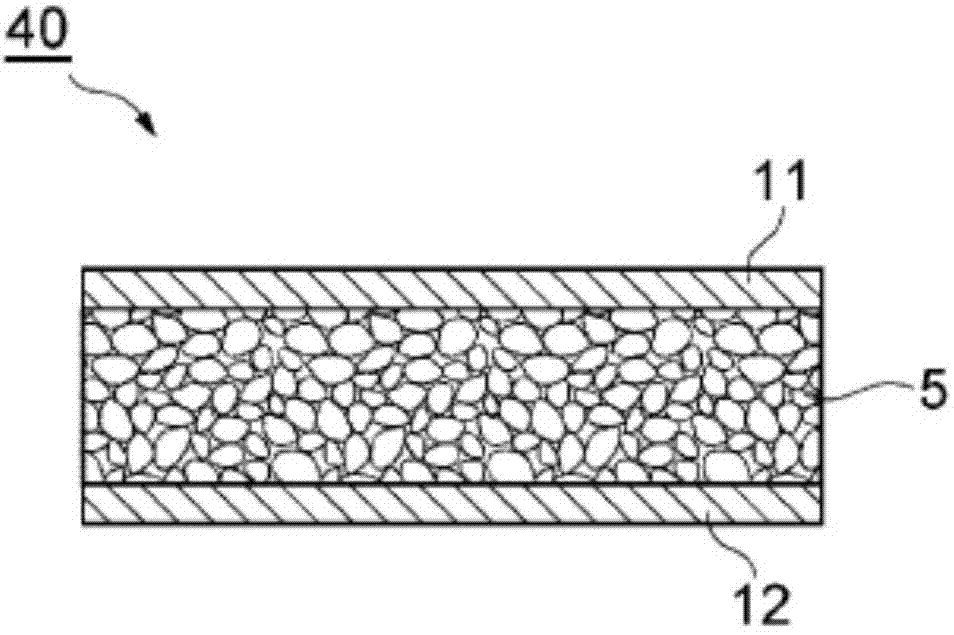

Process for production of water-absorbing resin particles, water-absorbing resin particles, water-stopping material, and absorbent article

ActiveCN102648218ALarge particle sizeEasy to handleAbsorbent padsThin material handlingHydrocarbon solventsPolymer science

Provided are: a process for the production of water-absorbing resin particles which exhibit high equilibrium swelling performance and combine a high speed of water absorption and speedy initial swelling performance and which have moderate particle diameters and exhibit excellent handleability; water-absorbing resin particles obtained by the process; and a water-stopping material and an absorbent article which are made using the water-absorbing resin particles. The process comprises a step of preparing a hydrous gel-like polymer by conducting the inverse suspension polymerization of a water-soluble ethylenically unsaturated monomer in a hydrocarbon solvent in the absence of an internal crosslinking agent in the presence of a surfactant having an HLB of 8 to 12, and a step of adjusting the water content of the hydrous gel-like polymer to 30 to 110% by mass relative to the water-soluble ethylenically unsaturated monomer constituting the hydrous gel-like polymer, and then subjecting the resulting hydrous gel-like polymer to post-crosslinking.

Owner:SUMITOMO SEIKA CHEM CO LTD

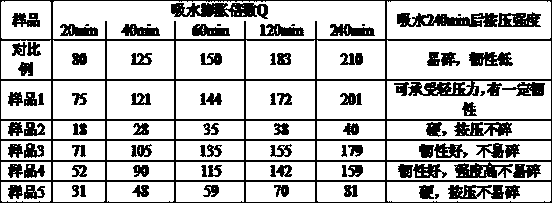

High-strength interpenetrating-polymer-network type water-absorbent resin, and preparation method thereof

The invention relates to a high-strength interpenetrating-polymer-network type water-absorbent resin, and a preparation method thereof, belonging to the field of preparation of high polymer materials.The high-strength interpenetrating-polymer-network type water-absorbent resin comprises the following raw materials: 10 to 20 parts of acrylamide monomers, 2 to 10 parts of acrylic acid monomers, 1 to 5 parts of other polymerizable monomers, 0.01 to 0.05 part of a cross-linking agent A, 0.2 to 0.8 part of a cross-linking agent B, 2 to 5 parts of a reactive water-soluble polymer and 0.01 to 0.05 part of an initiator, with the balance being water. The interpenetrating-polymer-network type water-absorbent resin substantially improves the toughness and strength of gel after water absorption on the premise of maintaining water absorption ability; the raw materials are simple and easily available; and a conventional solution polymerization process is employed, which is beneficial for industrialscale-up production of the water-absorbent resin.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method of preparing crosslinking poly(sodium acrylate) and crosslinking carboxymethyl starch complex high water absorption resin

InactiveCN101058660AImprove securityImprove water absorptionCarboxymethyl starchEmulsion polymerization

The invention discloses a making method of crosslinking sodium polyacrylate and crosslinking carboxymethyl starch built high-adosrbing resin in the macromolecular composite material technical domain, which comprises the following steps: building crosslinking sodium polyacrylate and crosslinking carboxymethyl starch; blending; gelatinizing; tabletting; grinding; sieving; obtaining the product with low manufacturing cost and high safety; making the distilled water adsorbing rate by 800-1200 times and physiological saline adsorbing rate by 60-100 times.

Owner:JIANGNAN UNIV

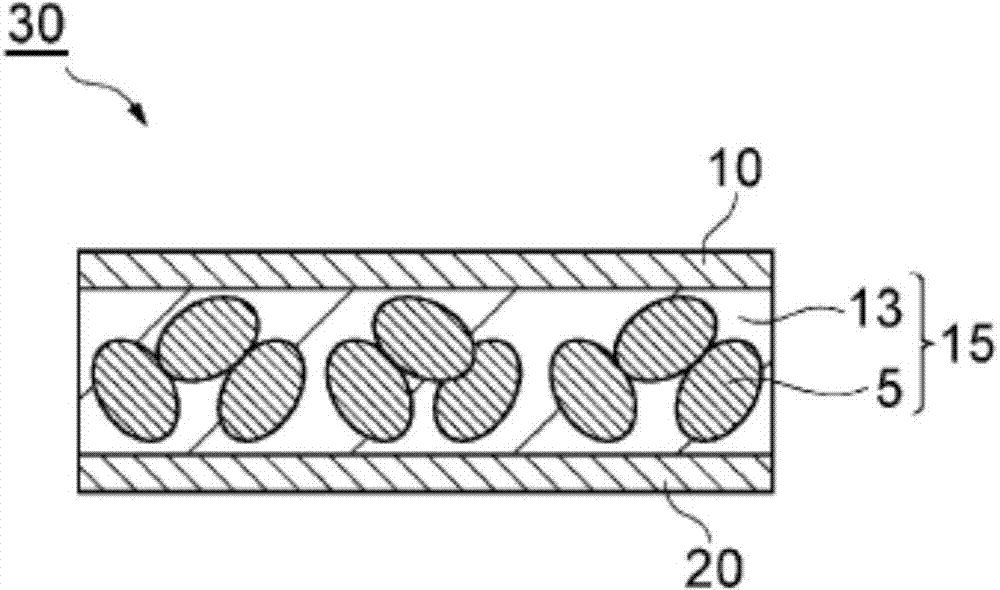

Water absorbing resin particles, method for manufacturing water absorbing resin particles, absorption body, absorptive article, and water-sealing material

ActiveCN103703028AImprove water absorption speedEasy to handleAbsorbent padsThin material handlingSaline waterPhotochemistry

In the present invention, water absorbing resin particles are disclosed in which the speed of absorption of a physiological saline solution is 1-15 seconds, median particle size is 100-600[mu]m, and the amount of residual volatile components is no more than 1.5 by mass percent.

Owner:SUMITOMO SEIKA CHEM CO LTD

Multifunctional shower cap

The invention relates to a multifunctional shower cap which comprises a quadrangular shower cap body, wherein at least one edge of the shower cap body is provided with a lacing which can be tightened; the shower cap body is made of galling ultrafine fiber material; the surface of the shower cap is subjected to velvet cut processing to form a fluff end surface in a cambered surface shape; the front cambered surface of the fluff end surface in a cambered surface shape is a convex cambered surface, and the rear cambered surface is a concave cambered surface; the front cambered surface and the rear cambered surface are mutually connected smoothly; an acute angle is formed between the rear cambered surface and the bus of the rear side surface of fluff; and the front cambered surface and the bus of the front side surface of the fluff are smoothly connected. The multifunctional shower cap can be conveniently fixed on the head, has good water absorption, can be quickly dried and is flexible and comfortable. The shower cap also can be unfolded to serve as a shawl, and therefore the shower cap is economical, convenient and practical.

Owner:BEIJING GUANGHUA TEXTILE GRP +1

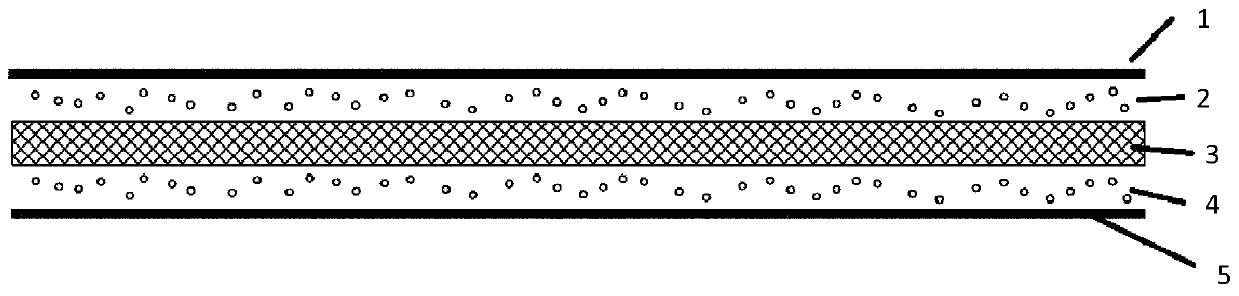

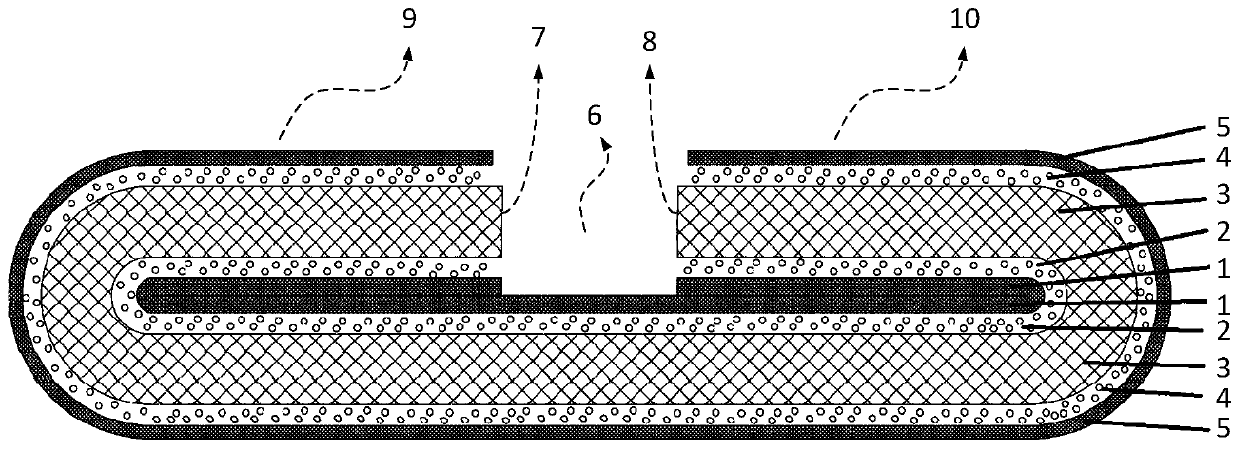

Paper diaper absorption core and preparation method thereof

InactiveCN109758305AAbsorbs quickly and in large quantitiesImprove sleep qualityAbsorbent padsBaby linensLiquid diffusionFluff pulp

The embodiment of the invention discloses a paper diaper absorption core and a preparation method thereof. The absorption core comprises a body, and the body comprises an upper cladding layer, a firstpolymer absorption layer, a fluffy cotton layer, a second polymer absorption layer and a lower cladding layer which are sequentially overlaid from top to bottom. The absorption core is implemented bybending the two side ends of the body towards the cladding layers on the body, the intervals between the two side ends after bending are opposite, so that a groove is formed in the upper surface of the absorption core. The absorption core is improved based on an absorption core in the prior art, the problem of lump formation and fault of a fluff pulp core can be effectively solved, and the liquiddiffusion property of an ultra-thin composite core and the core utilization rate are improved.

Owner:山东爸爸的选择健康科技有限公司

Wolfiporia cocos planting method

ActiveCN104838889AIndividual bigIncrease productionCultivating equipmentsMushroom cultivationPinus thunbergiiFruit tree

The invention discloses a wolfiporia cocos planting method and belongs to the technical field of planting of polyporaceae. The wolfiporia cocos planting method specifically includes steps of selecting a culture medium for wolfiporia cocos pulp in the size same as wheat kernels into PDA, culturing to obtain wolfiporia cocos mycelium and inoculating wolfiporia cocos mycelium into a stock culture medium to obtain wolfiporia cocos mycelium leads; cultivating plump and strong wolfiporia cocos strains by preparing niblet and fruit branch cultivating compost, annularly excavating grooves in pine stems, and inoculating the wolfiporia cocos strains into the peripheries of the grooves, fixing a bacterium bag by kelp, culturing by earth, reasonably sterilizing, killing insects, adjusting soil temperature and humidity, checking strain conditions periodically, and harvesting wolfiporia cocos in time. The wolfiporia cocos planting method is simple in operation, and biological efficiency is improved by using high salt of the kelp. Meanwhile, more sufficient nutrition is provided for growth of wolfiporia cocos, and large, high-yield and good-quality wolfiporia cocos are obtained.

Owner:黄胜

Preparation method of super absorbent resin for sanitary material

The invention discloses a preparation method of super absorbent resin for a sanitary material. The preparation method comprises the following steps: (1) adding 20-80 parts by weight of a polymerized monomer, 0.02-5 parts by weight of a secondary monomer, 0.001-1 part by weight of a crosslinking agent and 0.01-5 parts by weight of other auxiliaries into a container to obtain to-be-polymerized feed liquid, mixing uniformly the feed liquid and filling in a sealed plastic bag, exhausting gas out of the plastic bag, putting the plastic bag on a tray, enabling the plastic bag to pass through electron beams for irradiation at a constant speed, wherein the feed liquid quickly expands to form gel; (2) cutting the gel cooled in the step (1) into gel particles with the diameter being less than 3mm; (3) drying the gel particles obtained in the step (2) to small solid particles at 50-180 DEG C; (4) screening the solid particles obtained in the step (3) and selecting 20-150-mesh semiproduct solid particles; (5) adding 100 parts by weight of semiproduct solid particles obtained in the step (4) as a base material into surface crosslinking liquid to react; and (6) reducing the temperature of the material after surface treatment to less than 60 DEG C, spraying, adding 1-5 parts by weight of a water agent and uniformly mixing to obtain the super absorbent resin for the sanitary material.

Owner:CGN DASHENG ELECTRON ACCELERATOR TECH

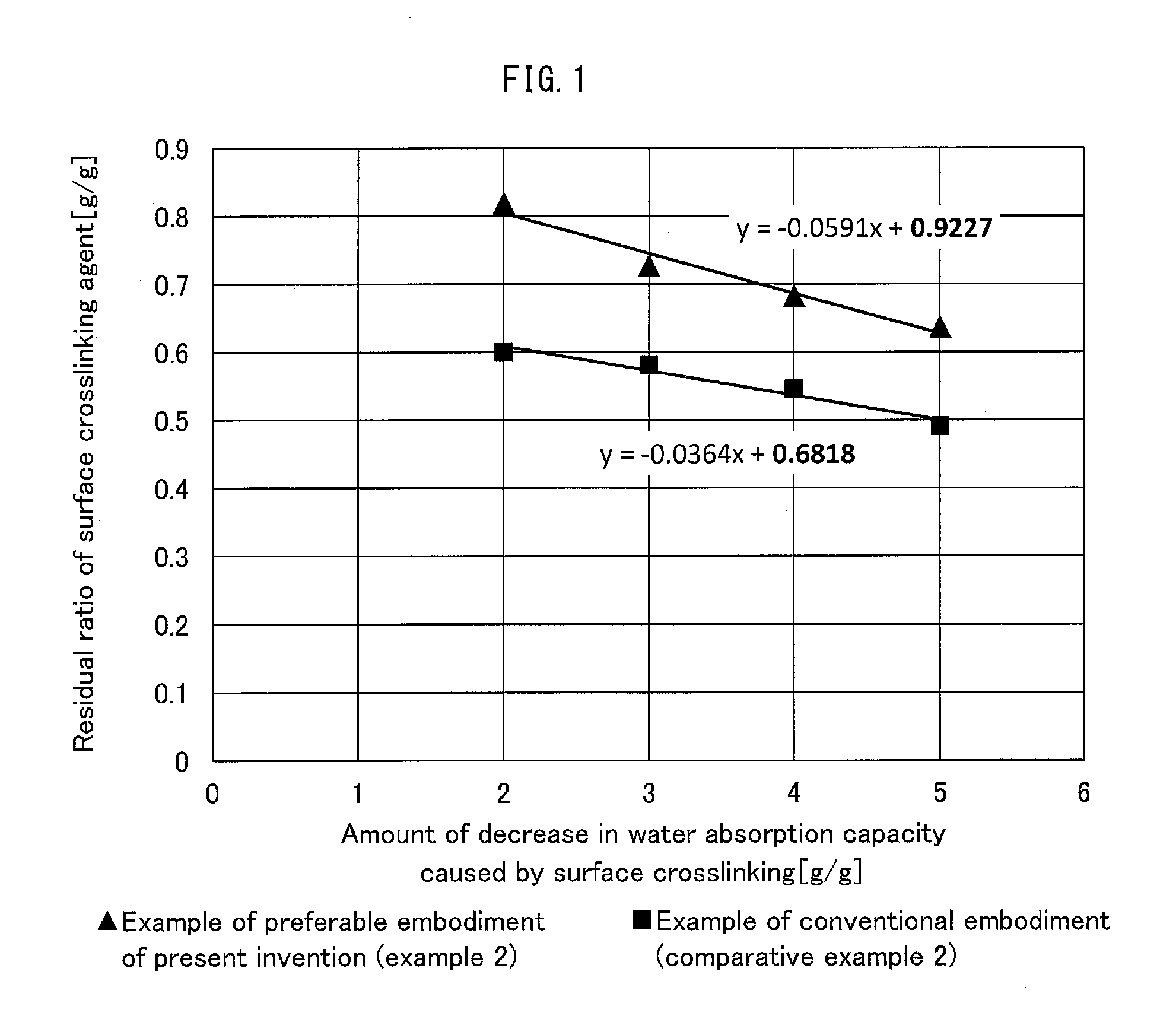

Polyacrylic acid (SALT) water absorbent, and method for producing same

ActiveUS20160375171A1Improve liquid permeabilityImprove retentionOther chemical processesAbsorbent padsALLYL SUCROSEPhysical property

Provided is a water-absorbing agent which is less likely to cause gel blocking and is suitable for a sanitary product and an absorbent article each being thin and containing a large amount of a water-absorbing agent, and which, while maintaining or hardly losing the other physical properties (a fluid retention capacity and a bulk specific gravity) of the water-absorbing agent, simultaneously achieves a high water absorbing speed (e.g., FSR), a high fluid retention capacity under load, high liquid permeability, and salt tolerance. The water-absorbing agent is a polyacrylic acid (salt)-based water-absorbing agent whose surface and its vicinity are crosslinked by an organic surface crosslinking agent, characterized by satisfying the following (A)-(D): (A) Free Swell Rate (FSR) of at least 0.28 g / g / s, or Absorption Time (Vortex) of 42 seconds or less; (B) Absorption Against Pressure (AAP) of at least 20 g / g; (C) Salt Tolerance Index represented by “Salt Tolerance Index=(CRCdw) / (CRCs)” where CRCdw is a centrifuge retention capacity (unit; g / g) for deionized water (dw), and CRCs is a centrifuge retention capacity (unit; g / g) for a 0.9 weight % saline, satisfying “Salt Tolerance Index≦0.49×CRCs−7.47”; and (D) Bulk Specific Gravity of 0.55 to 0.70 g / cm3.

Owner:NIPPON SHOKUBAI CO LTD

Method for producing instant noodles

ActiveUS8236363B2Improve water absorption speedGreat tasteDough treatmentBaking mixturesFlavorInstant noodle

The present invention provides a method for producing instant noodles having fresh noodle-like texture and flavor and having an excellent reconstitution property even if the noodles are thick. In the present invention, superheated steam flow is directly sprayed to raw noodle strings for 5 to 50 seconds such that a temperature of superheated steam to which surfaces of the noodle strings are exposed becomes 125 to 220° C., the noodle strings are supplied with moisture using water or hot water, the noodle strings are further steamed by directly spraying the superheated steam flow to the noodle strings for 5 to 50 seconds and / or steamed by using non-superheated steam, and the noodle strings are dried to produce the instant noodles.

Owner:NISSIN YORK

Pea planting method

InactiveCN107593351AThe planting method is scientific and reasonableImprove disease resistanceBiocidePlant growth regulatorsRoot noduleDisease

The invention discloses a pea planting method. The method comprises the following steps of 1, seed selection and preprocessing; 2, seed sprouting; 3, land selection and preparation; 4, seed sowing, wherein seeds obtained after sprouting in the step 2 and nodule bacteria are mixed evenly planting pits are dug in rectangular pieces of land, and 3-5 seeds are sown in each planting pit; 5, field management; 6, harvesting, wherein after the seeds are ripened, timely harvesting is performed, and ventilation and low-temperature storage are performed. The pea planting method is scientific and reasonable, the pea disease resistance is enhanced, growth is promoted, the pea yield and quality are improved, the cultivated peas have abundant nutrients, and are tender and delicious in taste, and the farmers' income is increased.

Owner:ANHUI HUIDA AGRO

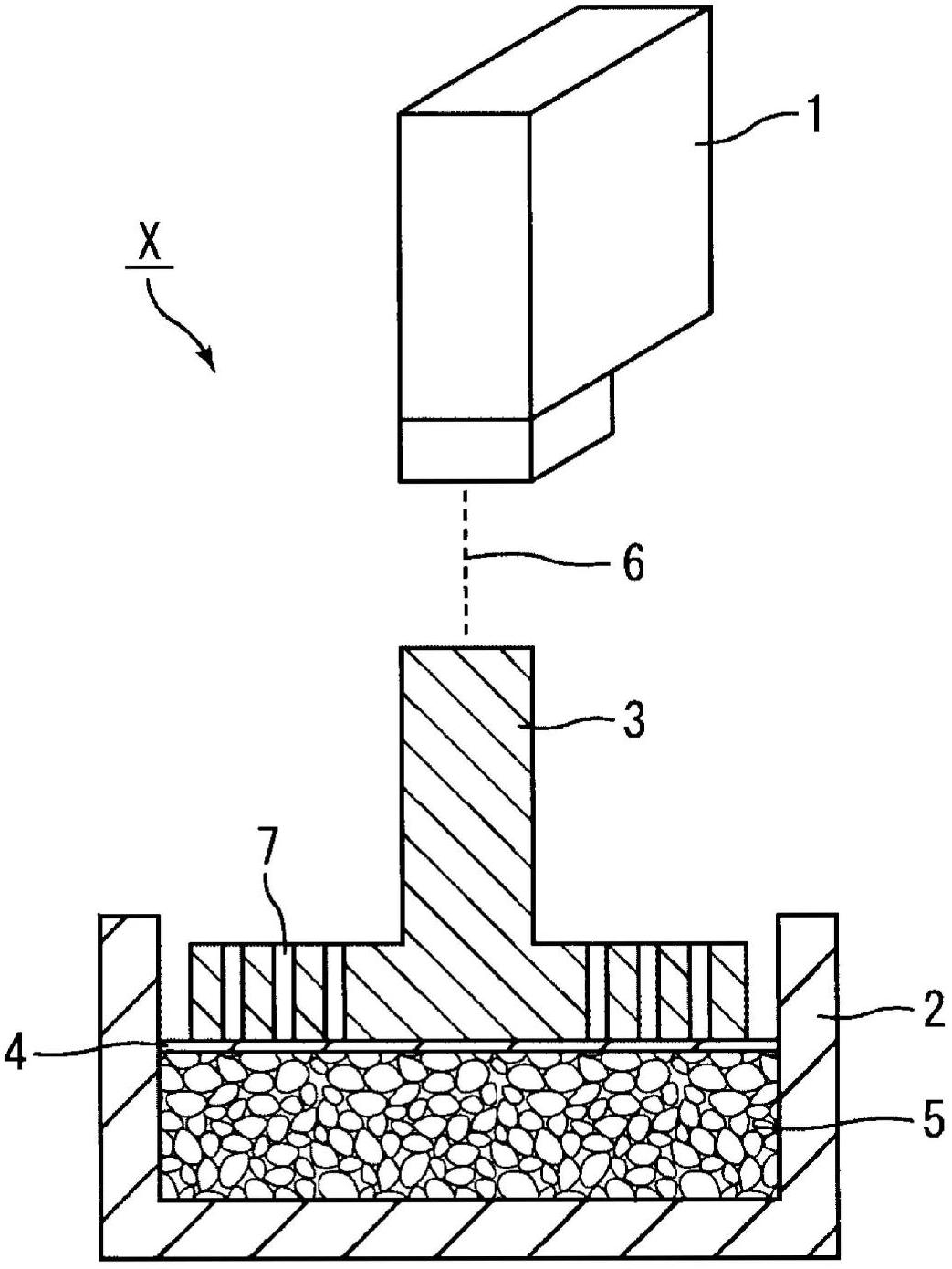

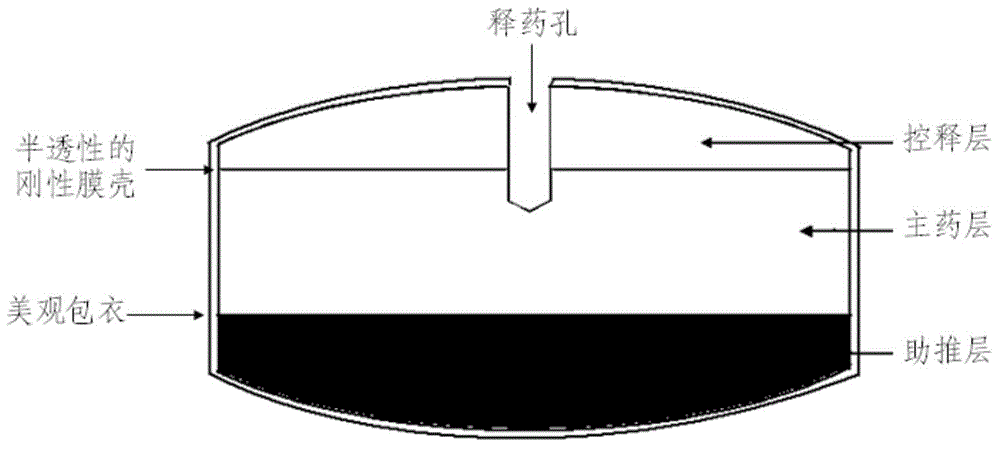

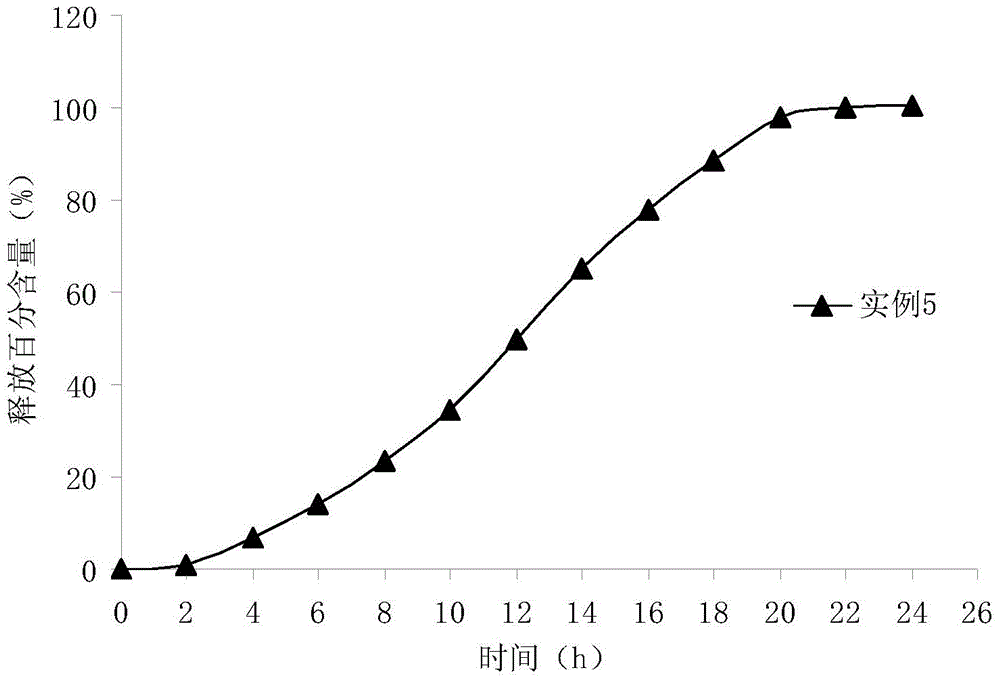

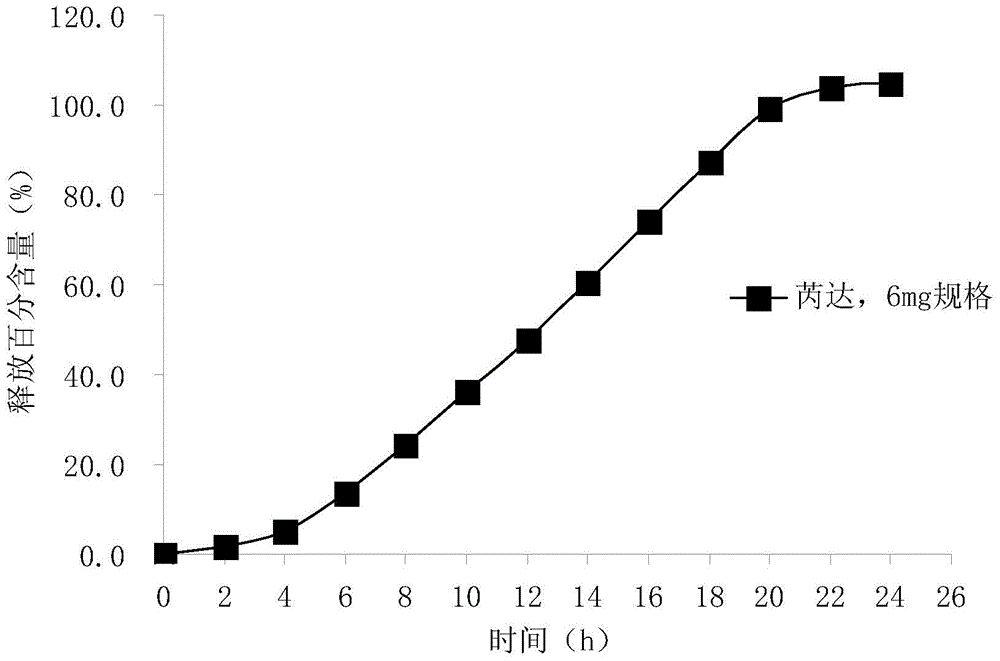

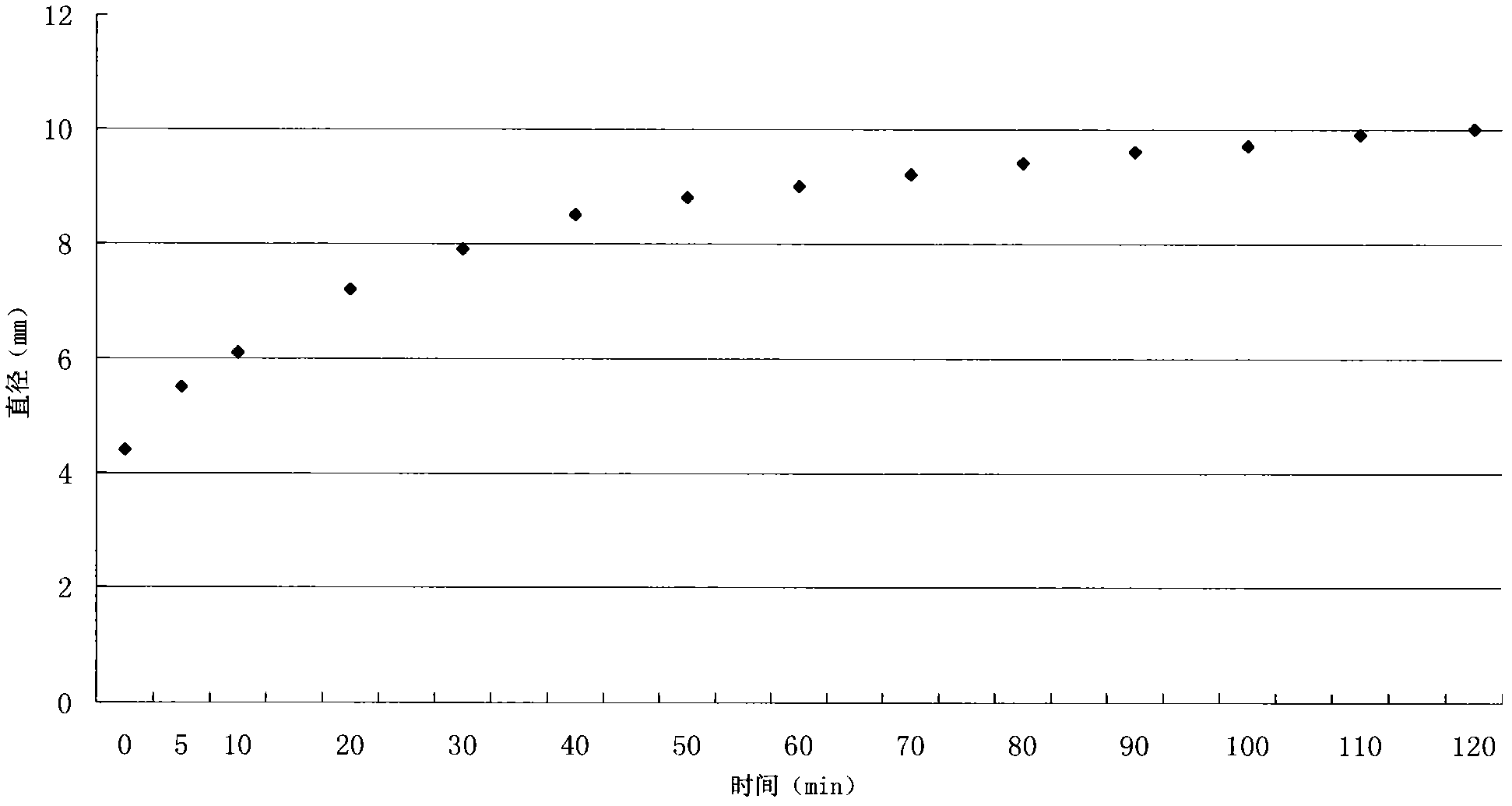

Paliperidone release rate progressive increasing preparation and preparation method thereof

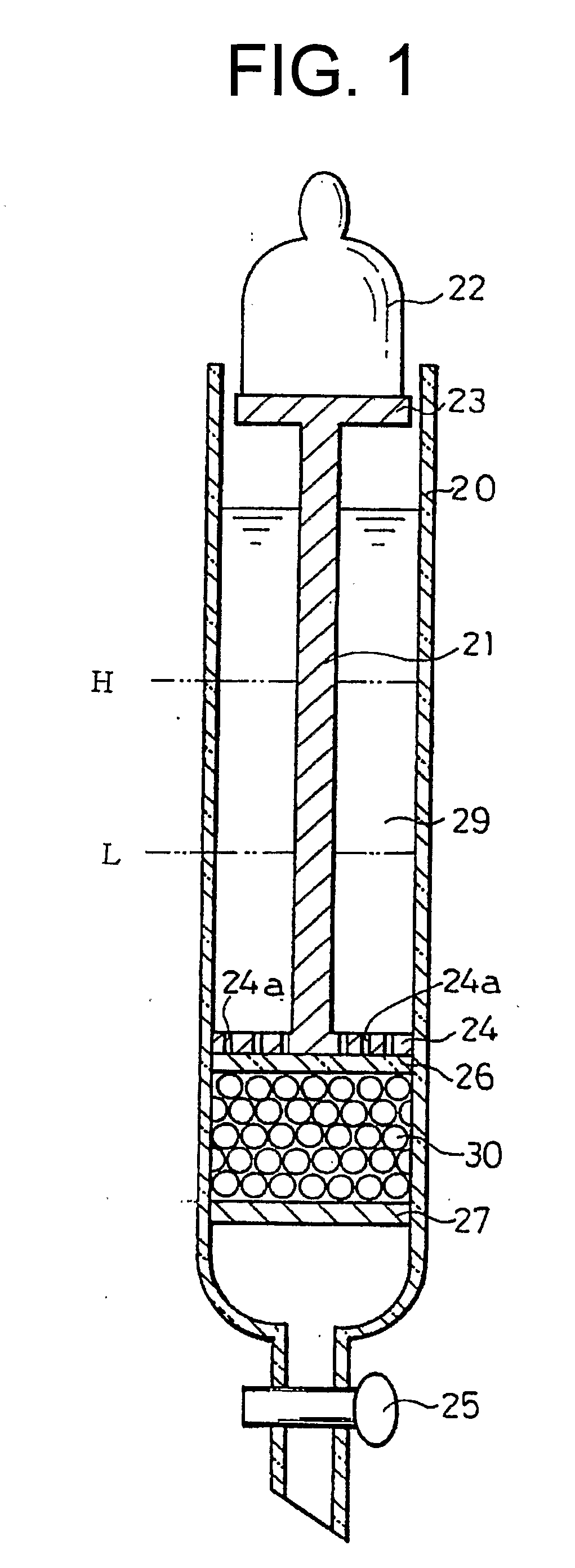

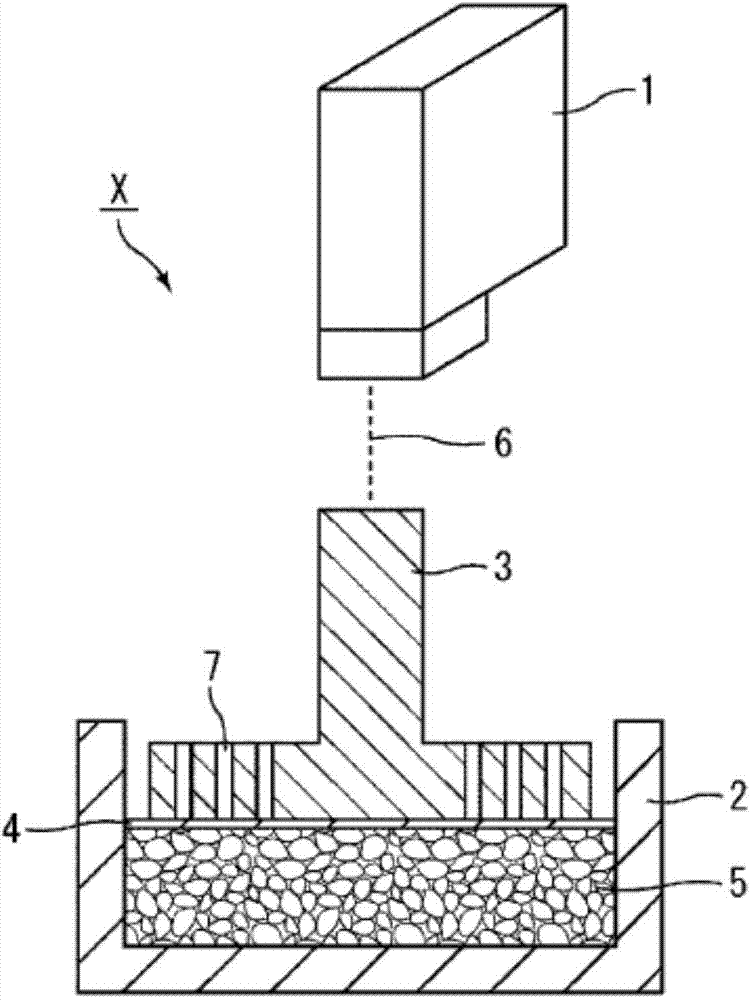

ActiveCN106265583AControlled release rateThe blood concentration curve is stableOrganic active ingredientsNervous disorderPaliperidoneOsmotic pump

The invention discloses a paliperidone release rate progressive increasing preparation and a preparation method thereof. The paliperidone release rate progressive increasing preparation provided by the invention, from outside to inside, comprises a non-essential damp-proof beautiful coating, a semipermeable rigid film shell which plays a vital role, and an osmotic pump tablet core provided with one or more holes. The osmotic pump tablet core, from top to bottom, is composed of a controlled-release layer, a drug-containing layer and a push promoting layer; and penetration enhancers in the push promoting layer, in accordance with different coating weight increasing degrees, include a coating penetration enhancer I, a coating penetration enhancer II and a coating penetration enhancer III. The various coating penetration enhancers, which are different in coating weight increasing degree, differ in osmotic pressure in water. With the application of the paliperidone release rate progressive increasing preparation disclosed by the invention, when water enters the tablet core along with an osmotic pressure difference, the push promoting layer absorbs water to be swelled so as to push the outward release of the drug-containing layer and the controlled-release layer, and as time varies, the isolating coating penetration enhancers are exposed in the water, so that the osmotic pressure is continuously increased, a water-absorbing rate is increased and a drug-release rate is increased as well, thus progressive increasing drug release is achieved; therefore, the drug-release rate is effectively controlled, a blood drug concentration curve is kept stable and the fluctuation of blood drug concentration is relieved.

Owner:ZHEJIANG JINGXIN PHARMA

Synthetic method for high-performance water-absorbent resin processed by electron beam irradiation

The invention discloses a synthetic method for high-performance water-absorbent resin processed by electron beam irradiation. The synthetic method comprises the following steps: (1) adding 20-80 parts by weight of polymeric monomers, 0.02-5 parts by weight of monomers, 0.001-1 part by weight of a cross-linking agent and 0.01-5 parts by weight of other additives into a reaction kettle and uniformly mixing to obtain a polymeric feed liquid, wherein the polymeric monomers are acrylic acid with the neutralization of 50-90 percent; (2) placing the flowing polymeric feed liquid under radiation of electron beams emitted by an electron accelerator to obtain a water-absorbent gel; (3) cutting, drying, crushing and screening the water-absorbent gel to obtain semi-finished particles; (4) performing surface crosslinking treatment on the semi-finished particles to obtain the high-performance water-absorbent resin finished product. Electron beams produced by the industrial electron accelerator irradiate acrylic acid monomer solutions to enable the feed liquid to finish polymerization reaction at the flowing instant so as to synthesize the high-performance water-absorbent resin.

Owner:CGN DASHENG ELECTRON ACCELERATOR TECH

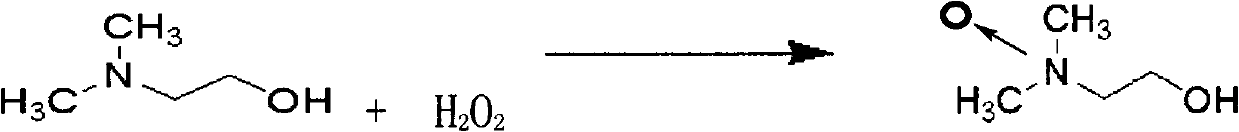

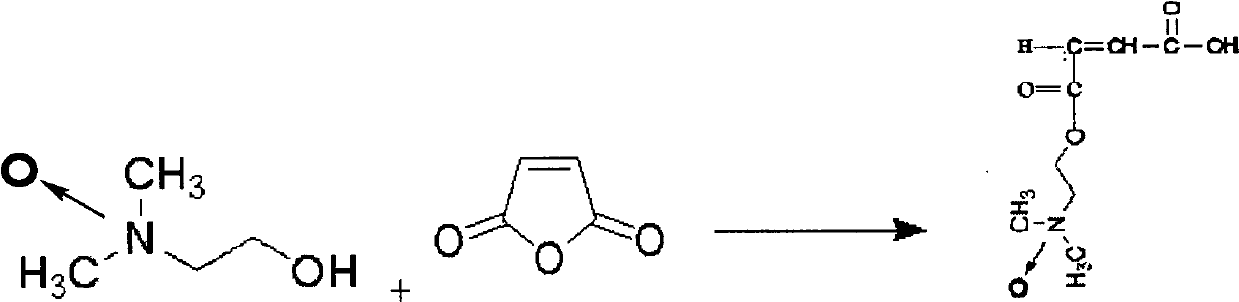

Amine oxide antibacterial super absorbent polymer (SAP)

The invention relates to an antibacterial super absorbent polymer (SAP) and a preparation method thereof. The SAP belongs to a functional polymer material. The product is prepared by copolymerizing and crosslinking an unsaturated amine oxide amphoteric ion monomer, an anionic monomer acrylic acid neutralized by alkali parts and an acrylamide non-ionic monomer in a redox initiation system by adopting N,N'-methylene bisacrylamide as a crosslinking agent. The SAP not only has excellent water absorption and retention properties and substantially improved saline water absorbing capacity but also has good antibacterial and bacteriostatic effects. The SAP is researched and developed specially for female hygienic products and cosmetics.

Owner:连宗旭

Particulate water retaining material for cultivating plant having water absorbent resin as main component

ActiveUS8765857B2Promotes rhizogenesisImprove irrigation efficiencyAlkaline-earth metal silicatesGrowth substratesParticulatesChemical compound

A particulate water retaining material for cultivating plant comprising (A) a carboxyl group-containing water-insoluble water absorbent resin and (B) a polyvalent metal compound, by having the compound (B) deposited on the rerin (A), it is made possible to possess an outstanding water absorbing property without impairing the growth of a plant.

Owner:NIPPON SHOKUBAI CO LTD

Graphene absorbing object and preparation method thereof

InactiveCN106890354AIncrease surface areaReduce contentAbsorbent padsBaby linensSurface layerFluff pulp

The invention relates to the field of sanitation supplies, and provides a graphene absorbing object and a preparation method thereof with an aim to solve problems about poor liquid absorption effect, slow liquid absorption speed and no antibacterial efficacy in the prior art. The graphene absorbing object comprises a permeable surface layer, an absorber and an impermeable bottom layer which are laminated sequentially from top to bottom, the absorber is formed by wrapping an absorbing core with non-woven fabric, and the absorbing core is formed by mixing fluff pulp, super absorbent polymer and graphene powder.

Owner:泉州信和石墨烯研究院有限公司

Drought-resistant and water-retaining fertilizer and preparation method thereof

InactiveCN110776369AImprove water retentionImprove water absorptionBio-organic fraction processingOrganic fertiliser preparationChaffAnimal waste

The invention discloses a drought-resistant and water-retaining fertilizer and a preparation method thereof. The drought-resistant and water-retaining fertilizer is prepared from the following raw materials by weight: 20-35 parts of crop straw, 9-16 parts of animal waste, 15-25 parts of chaff powder, 5-9 parts of bagasse, 17-24 parts of urea, 11-15 parts of potassium nitrate, 7-9 parts of an organic acid agent, 8-13 parts of microbial powder and 4-7 parts of starch grafted acrylate. According to the invention, the starch grafted acrylate is added into the drought-resistant and water-retainingfertilizer, the starch grafted acrylate has ultrahigh water absorption rate and water absorption speed, is non-toxic and harmless, can release and absorb water repeatedly, and endows the drought-resistant and water-retaining fertilizer with good water-retaining properties, by adding the organic acid agent composed of alginic acid, oxalic acid and salicylic acid, the organic acid agent can bind soil into a stable aggregate structure to loosen the soil, and the drought-resistant and water-retaining fertilizer added with the organic acid agent can activate phosphorus, potassium and trace elementssolidified in the soil out for crops to absorb and utilize, and the soil is effectively improved.

Owner:JILIN ACAD OF AGRI SCI

Long-shelf-life fermented soybean and preparation method thereof

InactiveCN105852051AReduced nutritional valueHigh nutritional valueFood ingredient functionsFlavorPurified water

The invention discloses long-shelf-life fermented soybean. The long-shelf-life fermented soybean is prepared from black soybeans, salt, peppers, Fructus Litseae, Fructus Zanthoxyli, borneol, Radix Scutellariae, Cortex Pseudolaricis and purified water. The long-shelf-life fermented soybean is free of colorants, additives and the like and low in harmful substance content and belongs to purely natural fermented green safe food; a finished production of the long-shelf-life fermented soybean is black brown, oily, glossy, tasty, tender, free of astringent taste, refreshing and rich in flavor and imperishable in aroma after long-time storage; by addition of the Chinese herbal medicines, the shelf life of the fermented soybean is remarkably prolonged while the fermented soybean has dietary therapy efficacies of Qi regulating, stasis removing, liver protection, diuresis promoting, antibacterial and anticancer efficacies and the like, and high edible and healthcare values are achieved. In addition, the preparation method is scientific and reasonable in process, preparation time is shortened by 60-80% as compared with that of a traditional preparation method, and the preparation method is suitable for large-scale factory production and high in promotion value.

Owner:ANHUI HONGHUA FOOD

Concrete foaming agent and foamed concrete

The invention relates to a concrete foaming agent and foamed concrete. The concrete foaming agent comprises the following components in parts by weight: 1-5 parts of hydrophobic rubber powder, 1-10 parts of gelatin, 5-15 parts of modified diatomite, 10-20 parts of water-absorbent resin, 5-10 parts of rosin resin, 5-15 parts of an anionic surfactant, 15-20 parts of a plant protein foaming agent and1-15 parts of cellulose. The foaming agent is used for foaming concrete, the frosting degree of the obtained foamed concrete is small, the foaming height of the foaming agent is high, and the foam stability is good.

Owner:TAICANG YUNTONG BIOCHEM ENG

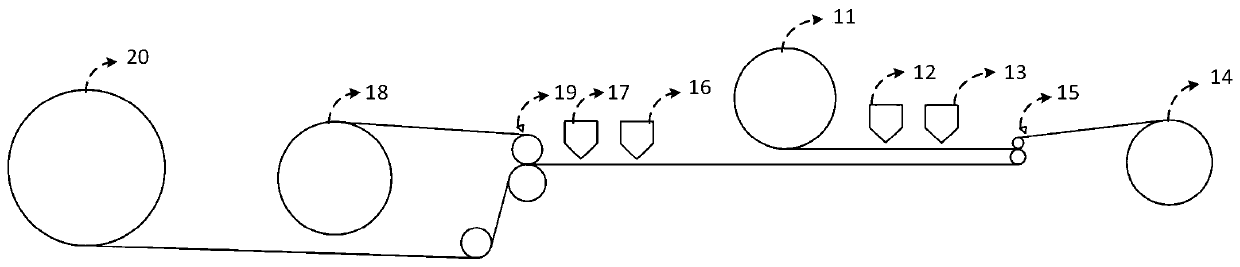

Production technology of pure silk non-woven fabric with rapid water-absorbing effect

InactiveCN110230150AImprove water absorption speedImprove water absorptionBiochemical treatment with enzymes/microorganismsAnimal materialPolyesterAntistatic agent

The invention provides a production technology of pure silk non-woven fabric with a rapid water-absorbing effect. The production technology comprises the following steps: 1, putting silk into a treating solution A, soaking for 1-10 minutes, and then taking out and spin-drying the silk; 2, putting the silk into a cotton opener for opening silk staple; 3, sending the silk staple into a spunlacing line, and carding into a silk staple fiber cotton mesh; 4, lapping the silk staple cotton mesh in a crossing manner by a lapping machine, and then sending into the spunlacing line for high-pressure spunlacing shaping to obtain silk fabric; 5, soaking the silk fabric in a treating solution B for 5-10 s, and squeezing out the excess treating solution; 6, drying the silk fabric treated in the step 5, wherein the treating solution A comprises water, protease and an antistatic agent; the treating solution B comprises water, monomeric polyester polyether, an aqueous adhesive, an emulsifying agent, a pH regulator and a high temperature-resistant long-acting antibacterial agent. The pure silk non-woven fabric produced by the production technology provided by the invention has greatly increased water-absorbing speed and water-absorbing amount and is safe to use.

Owner:江苏蓝丝雨生物科技有限公司

Starch hemostatic microsphere and preparation method thereof

ActiveCN102406956BImprove water absorptionGood hemostatic effectAbsorbent padsBandagesSurgical operationVegetable oil

The invention relates to a starch hemostatic microsphere and a preparation method thereof. The starch hemostatic microsphere is prepared from legume starch, potato starch and cereal starch which serve as raw materials by virtue of an inverse suspension polymerization method, and has a molecular weight of between 50000 and 5000000 and the grain diameter of between 0.1 and 1000mu m. The preparation method of the starch hemostatic microsphere comprises the following steps: mixing the three types of raw starches, and alkalizing; dispersing with a surfactant and vegetable oil under a condition that the pH is between 8.5 and 10.5; performing crosslinking with a crosslinking agent; cleaning, and performing spray drying; and packaging, and sterilizing with cobalt 60. The starch hemostatic microsphere prepared by using the method has good biocompatibility, and is used for a hemostatic process of a surgical operation; the water absorption rate is multiple times that of a conventional hemostatic material, the water absorption speed is remarkably increased, and the hemostatic effect is reinforced. The starch hemostatic microsphere has easily available raw materials, simple process, low production cost and wide application prospect.

Owner:天津红日爱乐意药用辅料有限公司

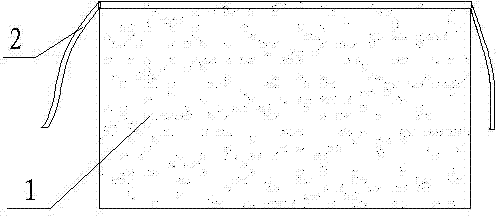

Application of water absorbing material to medical tract dilator

InactiveCN102921098AImprove water absorptionImprove water absorption speedSurgeryDilatorsDilatorWaiting time

The invention provides a medical tract dilator which is prepared from water absorbing resin. The water absorbing capacity and speed of the tract dilator are greatly improved; specifically, the water absorbing speed is improved so much that the waiting time of a patient can be greatly reduced; and the tract dilator is suitable for dilation during tract operation. After the tract dilator absorbs water, the surface of the tract dilator has the super-lubricity effect, so that lubricant is not needed to be coated on the tract dilator, and the tract dilator can smoothly enter a tract.

Owner:LIAONING AIMU MEDICAL SCI&TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com