Patents

Literature

80results about How to "Rich in holes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of carbon aerogel fibers

ActiveCN106012107ASolve difficult to fiber problemsGood flexibilityArtificial filaments from cellulose solutionsWet spinning methodsNitrogenCellulose fiber

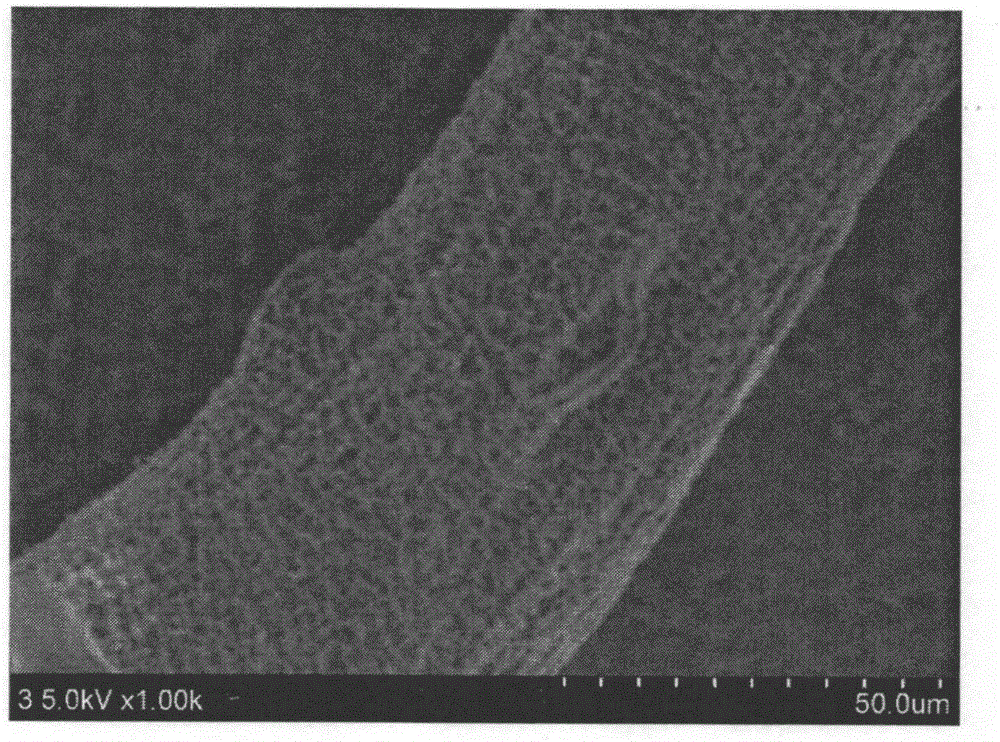

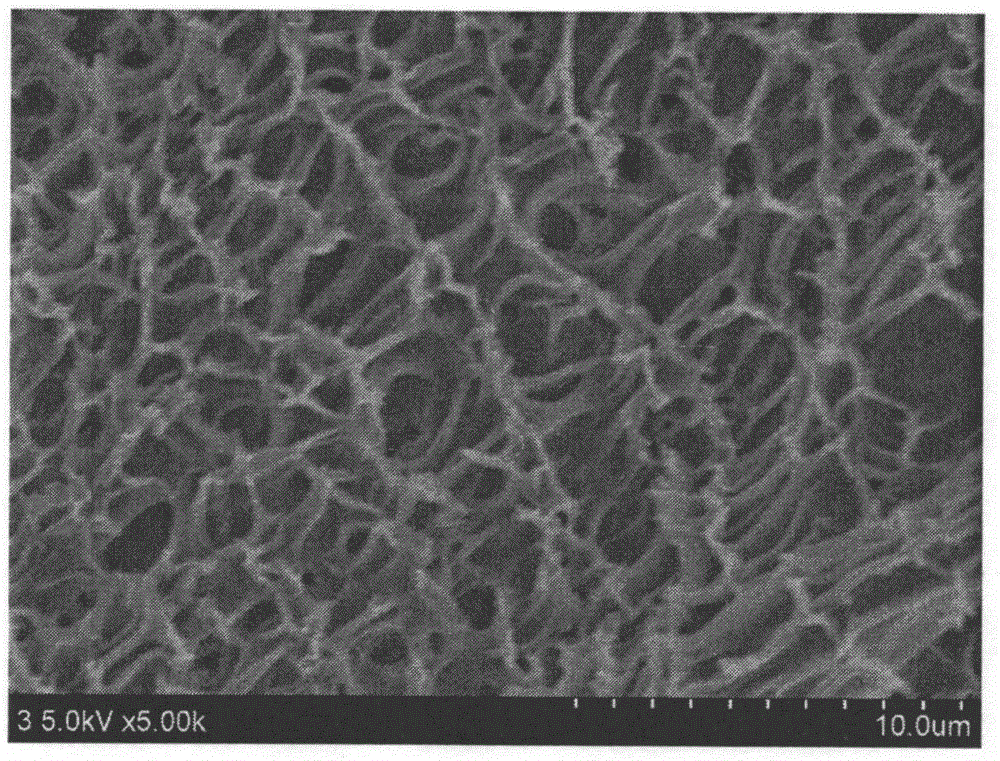

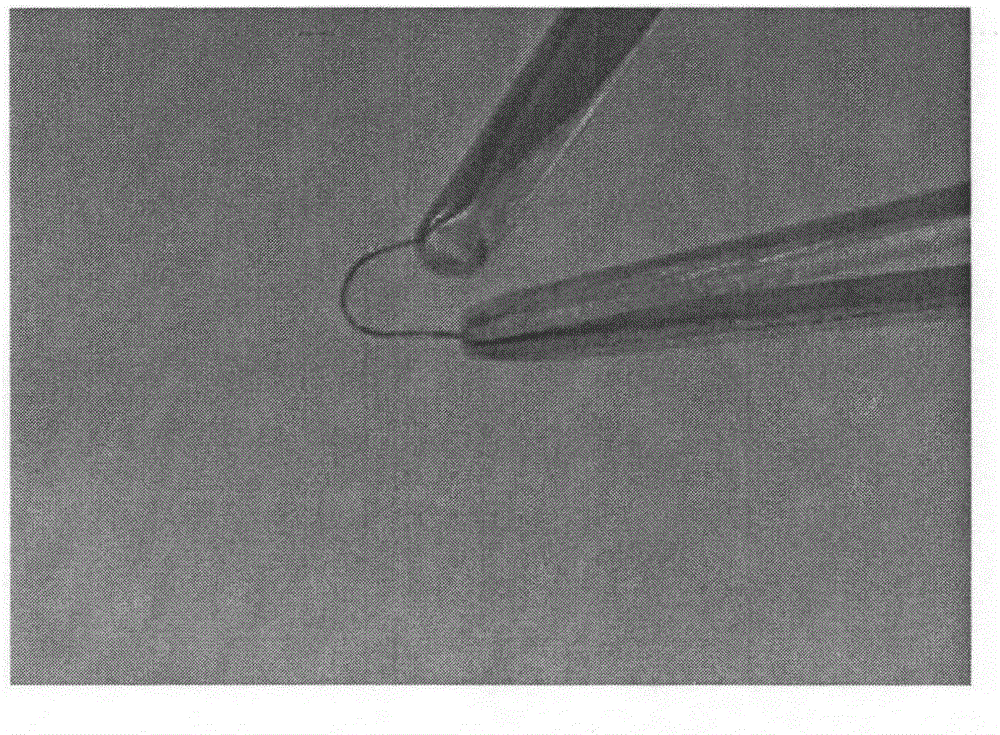

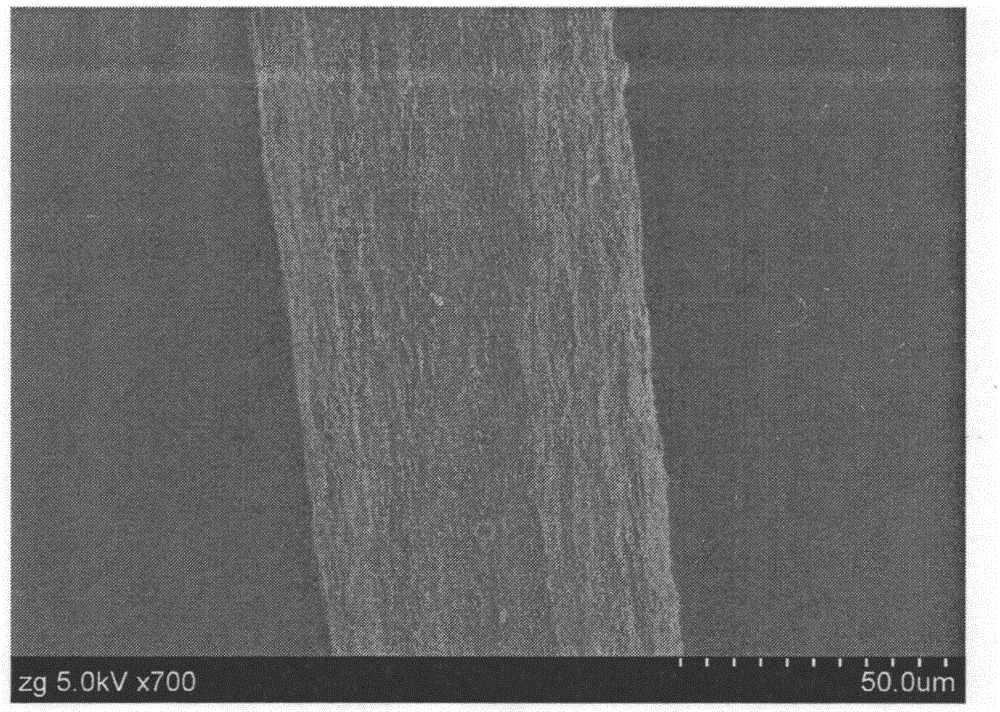

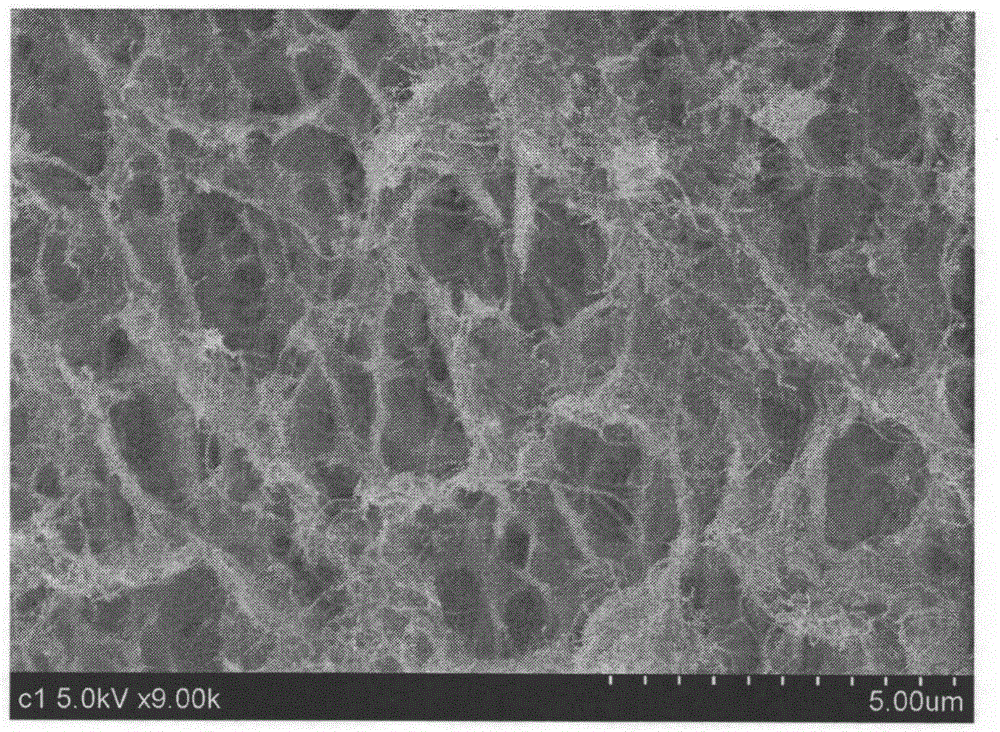

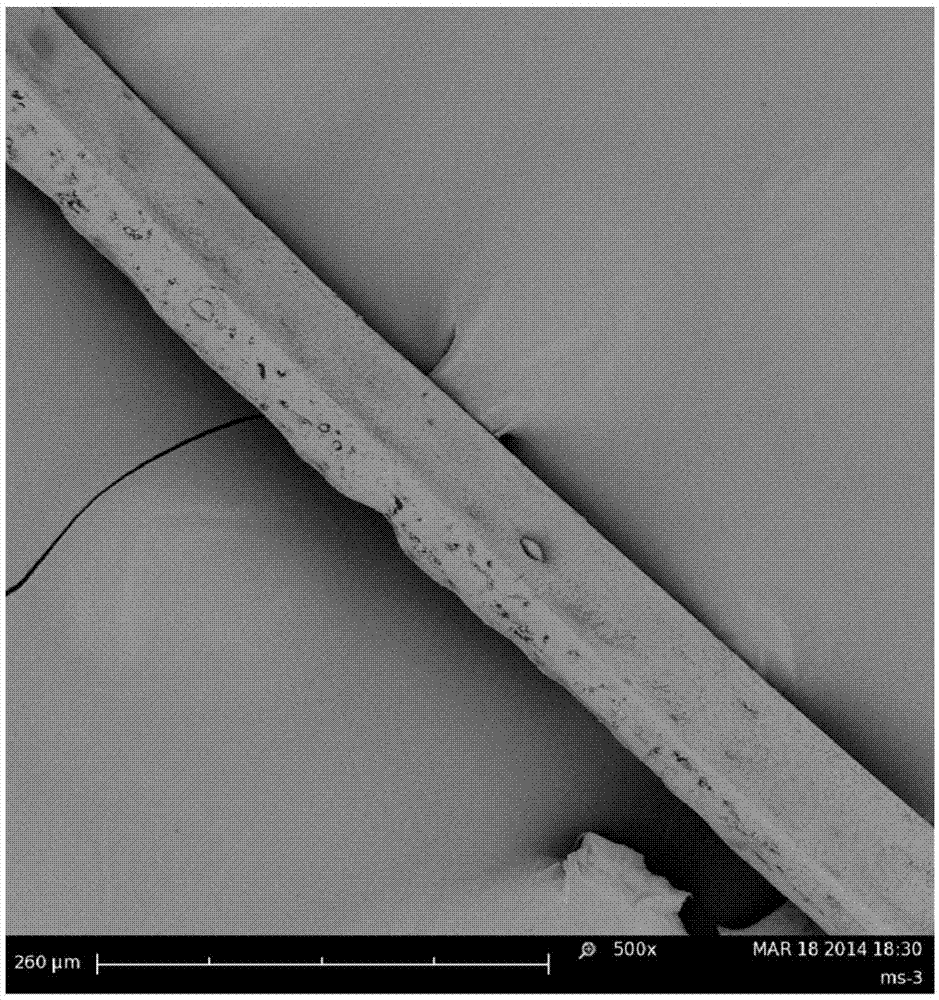

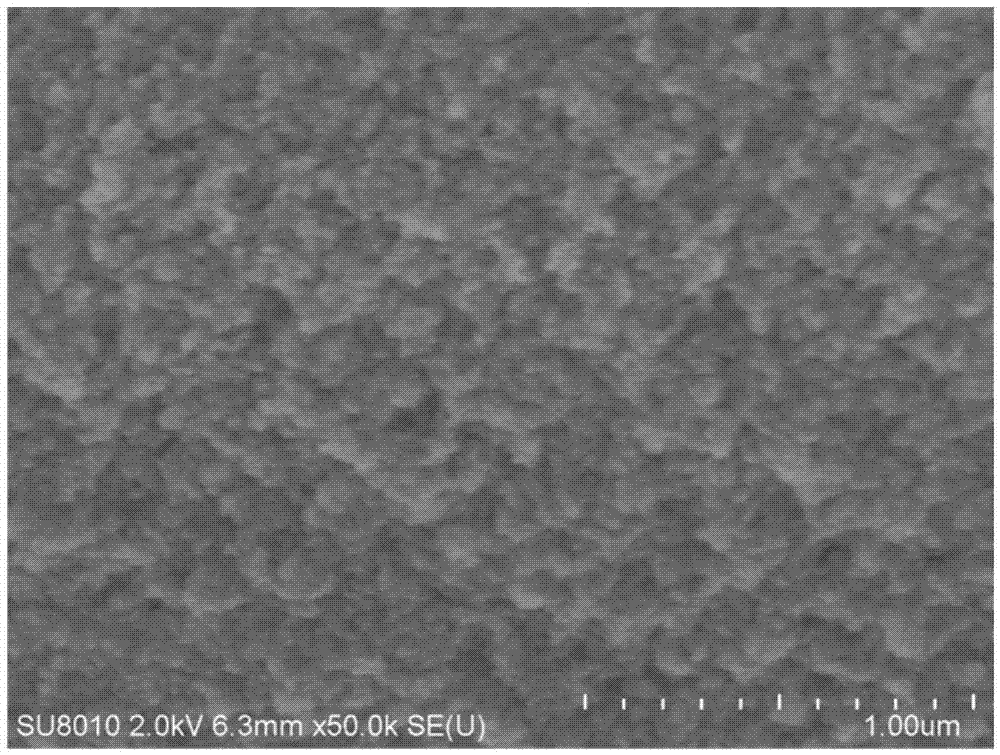

The invention provides a preparation method of carbon aerogel fibers. The method comprises the following steps that a spinning stock solution is prepared; a coagulating bath is prepared; the spinning stock solution is added into the coagulating bath, wet spinning is conducted, and cellulose gel fibers are obtained; the cellulose gel fibers are subjected to winding and immersed into an ageing solution for normal temperature ageing for 15 min to 1 h, the aged cellulose gel fibers are washed to be neutral with deionized water, solvent replacement is conducted with deionized water or ethyl alcohol or tert butyl alcohol, drying is conducted, and cellulose aerogel fibers are obtained; the cellulose aerogel fibers are put into a tubular furnace to be carbonized in a nitrogen environment, and the carbon aerogel fibers are obtained. The preparation method of the carbon aerogel fibers has the advantages that the raw materials are wide in resource, low in price and easy to obtain, the preparation process is simple, the spinnability is good, and the method is green and environmentally friendly, and the problem that a carbon aerogel cannot form fibers easily is solved.

Owner:DONGHUA UNIV

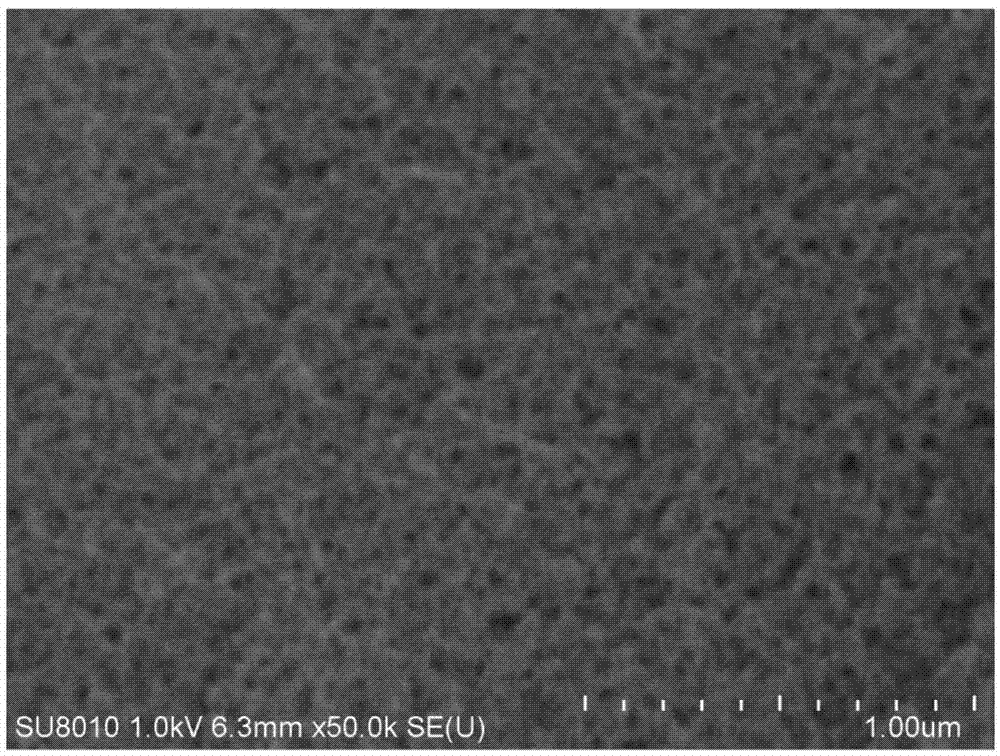

Preparation method of continuous cellulose-carbon nanomaterial composite aerogel fibers

ActiveCN106120007AInnovativePracticalArtificial filaments from viscoseWet spinning methodsCellulose fiberSolvent

The invention provides a preparation method of continuous cellulose-carbon nanomaterial composite aerogel fibers. The method comprises steps as follows: a cellulose dispersion liquid is prepared to serve as a spinning solution, and a carbon nanomaterial is added; an acidic solution, an ethanol solution or an acetone solution is added to a coagulating basin to serve as a coagulating bath; the spinning solution with the carbon nanomaterial added is added to the coagulating bath for wet spinning, and cellulose gel fibers containing the carbon nanomaterial is obtained; the cellulose gel fibers containing the carbon nanomaterial are wound, immersed in an ageing solution to be aged at the normal temperature for 15 min-1 h, washed with deionized water to be neutral, then subjected to solvent replacement with deionized water, ethanol or tertiary butanol and dried, and the continuous cellulose-carbon nanomaterial composite aerogel fibers are obtained. According to the preparation method, the preparation process is simple, the spinnability is good, environmental protection and no pollution are realized, and the prepared continuous cellulose-carbon nanomaterial composite aerogel fibers have good flexibility, rich pores and a large specific surface area.

Owner:DONGHUA UNIV

Method for preparing continuous SiO2/nano-metal aerogel fibers with catalysis performance through finally loading nano-metal

ActiveCN105664933AAdjust the size of the specific surface areaHas catalytic propertiesMetal/metal-oxides/metal-hydroxide catalystsFiberSolvent

The invention relates to a method for preparing continuous SiO2 / nano-metal aerogel fibers with a catalysis performance through finally loading a nano-metal. The method comprises the following steps: processing silicate or silanol sol to prepare a spinning stock solution; adding an acidic solution to a coagulation tank to form a coagulation bath; and injecting the spinning stock solution to the coagulation bath, carrying out reaction wet spinning to obtain orthosilicic acid / silicate fibers, reeling the orthosilicic acid / silicate fibers, ageing the reeled orthosilicic acid / silicate fibers, washing the aged orthosilicic acid / silicate fibers with deionized water until neutrality, immersing the neutral orthosilicic acid / silicate fibers in a metal salt solution, taking out the immersed fibers, removing a solvent on the surface of the orthosilicic acid / silicate fibers, immersing the obtained fibers in a reducing agent, washing the obtained fibers with deionized water until the fibers are neutral, displacing the fibers with deionized water or ethanol, and drying the displaced fibers to obtain the continuous SiO2 / nano-metal aerogel fibers. The method has the advantages of cheap and easily available raw materials, simple reaction process and good spinnability, and the aerogel fibers obtained in the invention have the advantages of abundant holes, high specific surface area, high temperature resistance, chemical corrosion resistance, and adjustable specific surface area and nano-metal load capacity.

Owner:DONGHUA UNIV

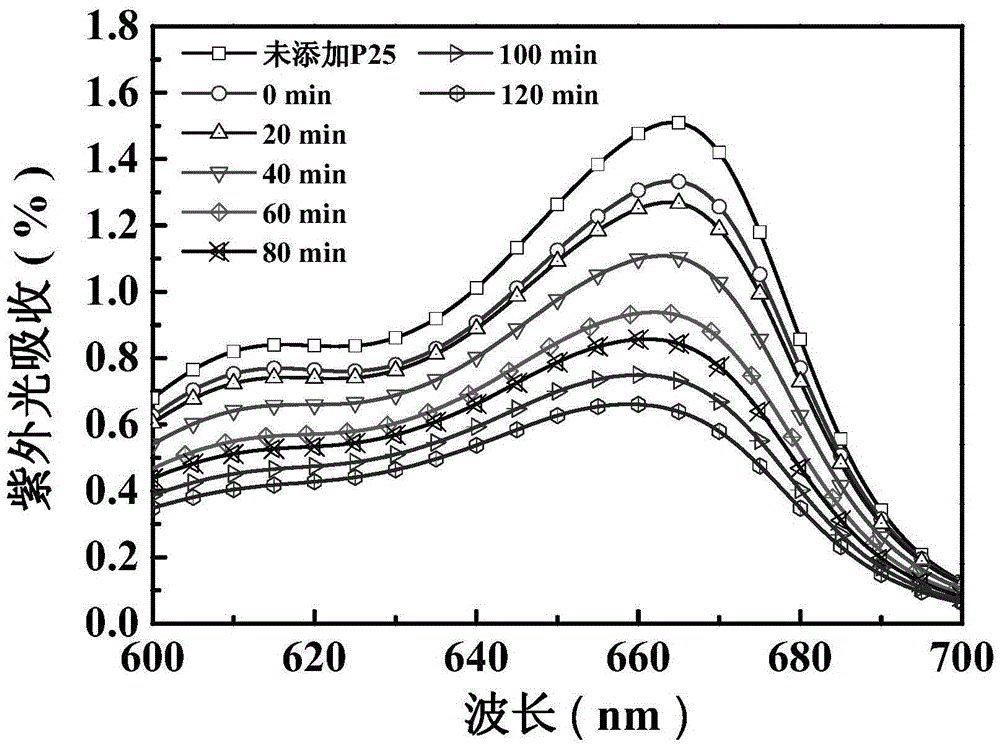

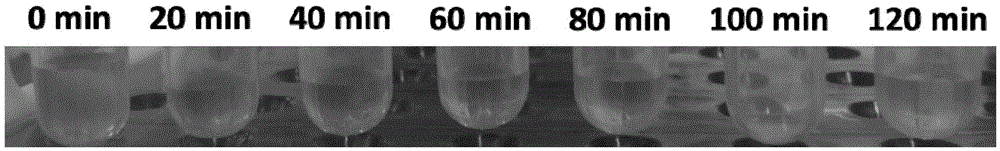

Preparation method of continuous SiO2/TiO2 aerogel fiber with photocatalytic performance

ActiveCN105597720AHas photocatalytic propertiesInnovativePhysical/chemical process catalystsSpinningSilicic acid

The invention relates to a preparation method of continuous SiO2 / TiO2 aerogel fiber with photocatalytic performance. The preparation method includes the steps of preparing a spinning solution from silicate or silanol sol, adding a TiO2 photocatalyst, adding the spinning solution with the TiO2 photocatalyst to an acid solution coagulating bath to conduct reaction wet method spinning to obtain original silicic acid / silicate fiber with the TiO2 photocatalyst, conducting rolling and ageing, washing the fiber with deionized water to neutral, conducting solvent replacement through deionized water or ethyl alcohol, and conducting drying to obtain the SiO2 / TiO2 aerogel fiber. The method has the advantages that raw materials are low in price and easy to obtain, the reaction process is simple, and spinnability is high; the prepared aerogel fiber has abundant pores, a high specific surface area, high temperature resistance and chemical corrosion resistance, the specific surface area and TiO2 content of the fiber can be adjusted, and the method has application prospects in the field of photocatalysis and the like.

Owner:DONGHUA UNIV

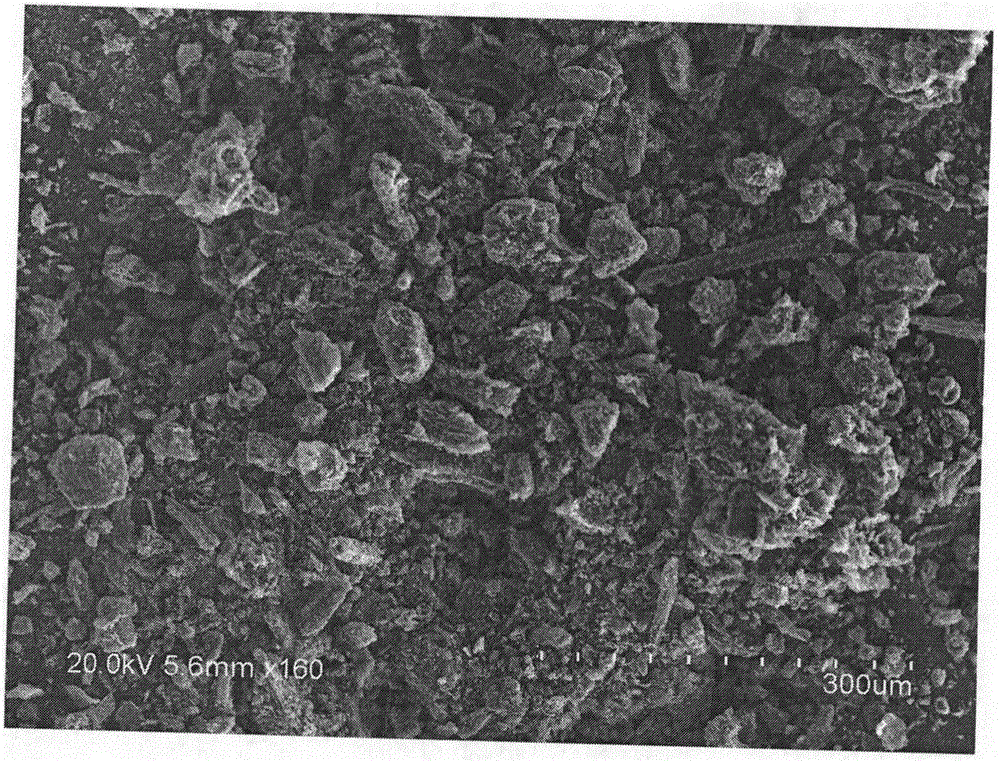

Method for preparing modified water-purifying sludge ammonia nitrogen adsorbent

InactiveCN103331138ARich adsorption effectRich sourcesOther chemical processesWater/sewage treatment by sorptionSorbentSludge

The invention discloses a method for preparing a modified water-purifying sludge ammonia nitrogen adsorbent. The ammonia nitrogen adsorbent is prepared by taking water-purifying sludge from waterworks as a raw material and modifying the water-purifying sludge into a zeolite-like structure which has a loose structure, rich holes and the like. The ammonia nitrogen adsorbent is used for absorbing ammonia nitrogen. By the technical scheme, the ammonia nitrogen absorbing effect of the water-purifying sludge can be obviously improved, the ammonia nitrogen removal rate is greatly improved, and the ammonia nitrogen absorbing effect of the water-purifying sludge is approximate to that of commercial zeolite.

Owner:SUZHOU UNIV OF SCI & TECH

Silicon and graphene composite material, preparing method thereof and lithium ion battery

The invention relates to a method for preparing a silicon and graphene composite material. The silicon and graphene composite material is prepared by a chemical vapour deposition method. The method specifically comprises the following steps: putting substrate nickel foam in an oxygen-free reaction chamber, heating the nickel foam to 500-1300 DEG C, filling a gas carbon source and a gas silicon source, reacting for 30-300 minutes, then putting the nickel foam in a FeC13 solution until the nickel foam is fully dissolved, filtering, washing solid products by deionized water and baking to obtain the silicon and graphene composite material. The invention further relates to a lithium ion battery which is prepared by using the silicon and graphene composite material as a negative electrode material of the lithium ion battery. Compared with the prior art, the prepared silicon and graphene composite material is rich in pores and has excellent energy storage performance and circulating performance when being used as the negative electrode material of the lithium ion battery.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Bamboo charcoal bentonite composite ceramic material and the preparation method of the same

InactiveCN106478069ARich in holesLarge specific surface areaCeramicwareClaywaresPorositySodium Bentonite

The invention belongs to the technical field of bamboo charcoal ceramic processing and particularly relates to a bamboo charcoal bentonite composite ceramic material and the preparation method of the same. The bamboo charcoal bentonite composite ceramic material is prepared from the following parts by weight of raw materials: 1-9 parts of bamboo powder and 1-9 parts of bentonite. The preparation method comprises (1) a step of drying the bamboo powder at temperature between 60 DEG C and 80 DEG C for 1-2 hours and passing through a 200-mesh sieve, (2) a step of drying the bentonite at temperature between 60 DEG C and 80 DEG C for 1-2 hours and passing through a 200-mesh sieve, (3) a step of mixing the bamboo powder and bentonite obtained after screening according to the proportion of 1-9 parts by weight with bentonite according to the proportion of 1-9 parts by weight to obtain the raw material powder, (4) a step of utilizing ball milling after mixing the raw material powder with water to obtain a sizing agent, (5) a step of granulating and molding the sizing agent after stewing for curing, (6) a step of firing a green body and cooling to room temperature. The preparation process of the bamboo charcoal bentonite composite ceramic material has the advantages of being economic and environmental in protection, capable of obtaining the ceramic material of high porosity, large specific surface area and strong adsorption capacity.

Owner:HUZHOU TEACHERS COLLEGE

Transaminase immobilization method

ActiveCN104774830ARich in holesIncrease the areaOn/in organic carrierCross-linkPolyvinyl alcohol sponge

The invention provides a transaminase immobilization method. The method comprises the following steps: oxidizing a hydroxyl group on polyvinyl alcohol sponge, adding transaminase to convert a carbonyl group into an amino group, flocculating, and carrying out cross-linking immobilization by using polyaldehyde to obtain immobilized transaminase. The immobilization method has the advantages of high enzyme activity unit and enzyme purification.

Owner:四川百特芳华医药科技有限公司

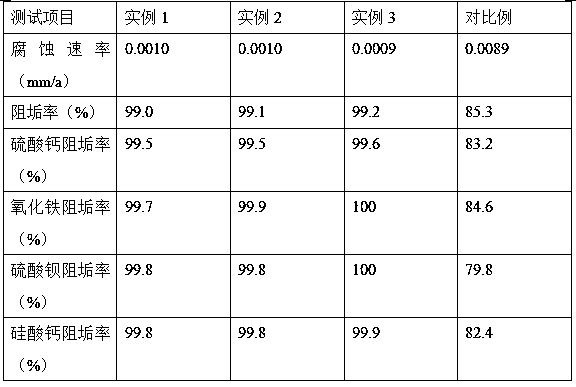

Preparation method of scale and corrosion inhibitor

InactiveCN108911189AImprove hydrophilic abilityChange state of chargeScale removal and water softeningIon exchangeElectronegativity

The invention discloses a preparation method of a scale and corrosion inhibitor, which belongs to the technical field of preparation of water treatment chemicals. Nano cellulose prepared by utilizingneedle wood leaves is used as an adsorption carrier of corrosion inhibitor. The parent corrosion inhibitor prepared by the invention is Mannich base, by virtue of quaternization, the parent corrosioninhibitor adopts nitrogen atoms with larger electronegativity as a center polar group, the polar group is extremely high in hydrophilic performance, the concentration of the metal ions which are easyin forming scales such as calcium and magnesium can be reduced, the surface of a chelated adsorption material is coated with oxidized nano cellulose to form a nano filter membrane, the metal ions canbe efficiently adsorbed, the corrosion of saline-alkaline water for a salt discharging concealed pipe can be reduced, and when the added graphene oxide is oxidized, the graphene lamina is swelled, sothat a gap between two layers can be enlarged, the ion exchange is likely to occur for the metal ions in the saline-alkaline water, and the scale and corrosion inhibitor provided by the invention is high in capability for adsorbing and controlling the metal ions in the saline-alkaline water, and wide in application prospect.

Owner:FOSHAN GAOMING DISTRICT ZHUAHE NEW MATERIAL TECH CO LTD

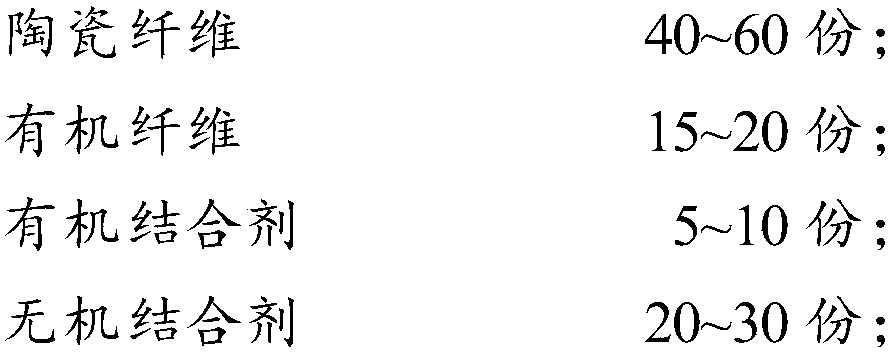

High-temperature-resistant filter material, preparation method thereof and high-temperature-resistant dust-removing filter pipe

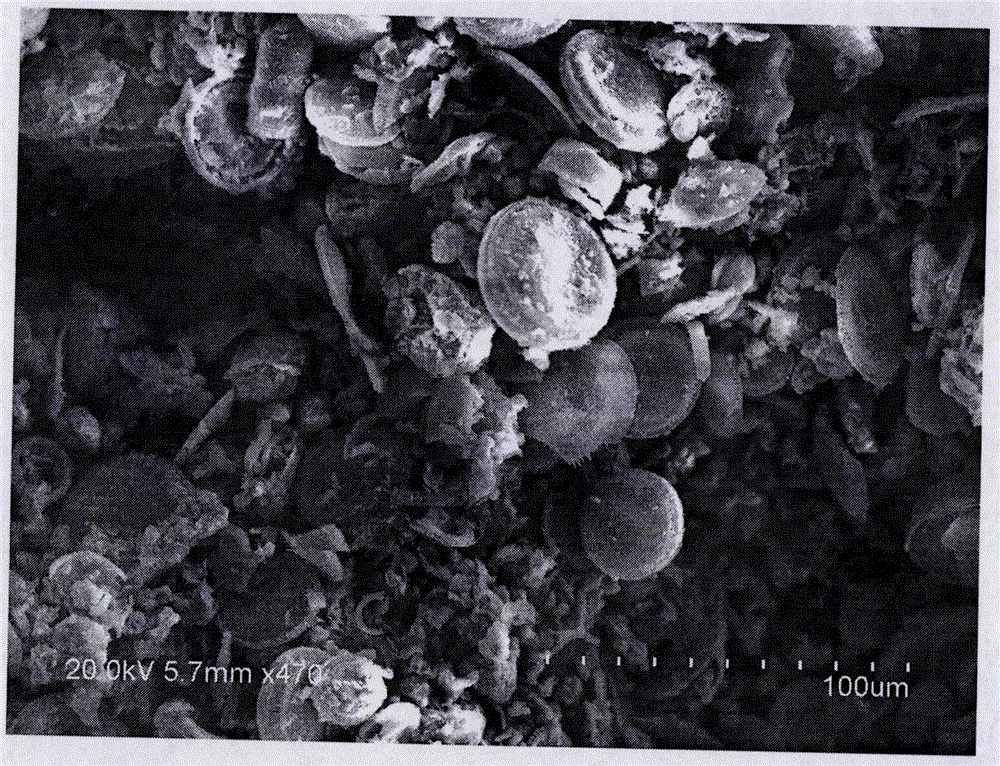

ActiveCN108727003AGood mechanical strength and thermal shock resistanceRich in holesDispersed particle filtrationCeramicwarePolyesterMicrometer

The invention belongs to the field of filter materials and particularly relates to a high-temperature-resistant filter material, a preparation method thereof and a high-temperature-resistant dust-removing filter pipe. The high-temperature-resistant filter material is prepared by mixing, by weight, 40-60 parts of ceramic fibers, 15-20 parts of organic fibers, 5-10 parts of organic binder and 20-30parts of inorganic binder with water and then performing calcining, wherein the dimeter of the ceramic fibers is 2-5 micrometers, the length of the ceramic fibers is 30-100 micrometers, the organic fibers comprise one or more of polypropylene fibers, polyester fibers and viscose fibers, and the length of the organic fibers is 6-10mm. The high-performance high-temperature-resistant filter materialprepared by optimally selecting the raw materials has a fiber interwoven structure inside, is good in mechanical strength and thermal shock resistance and has rich and communicated pores inside, and the dust removing efficiency of the material is increased greatly.

Owner:LUYANG ENERGY SAVING MATERIALS CO LTD

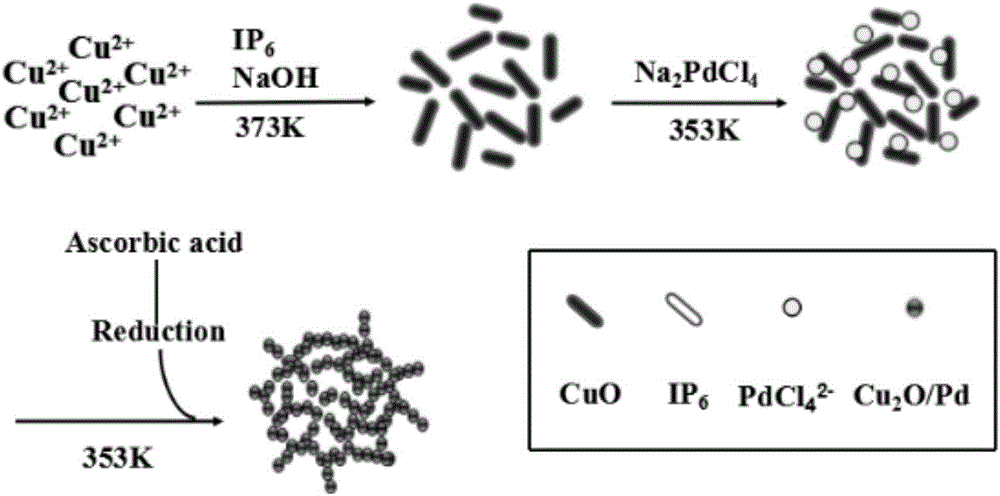

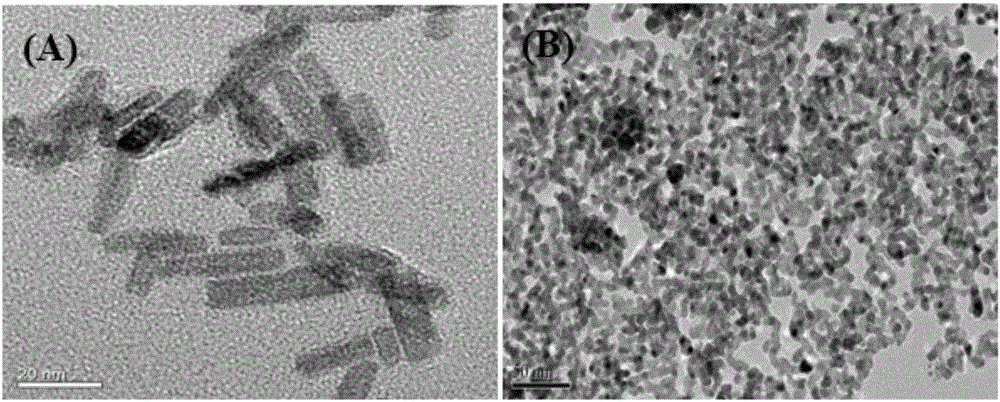

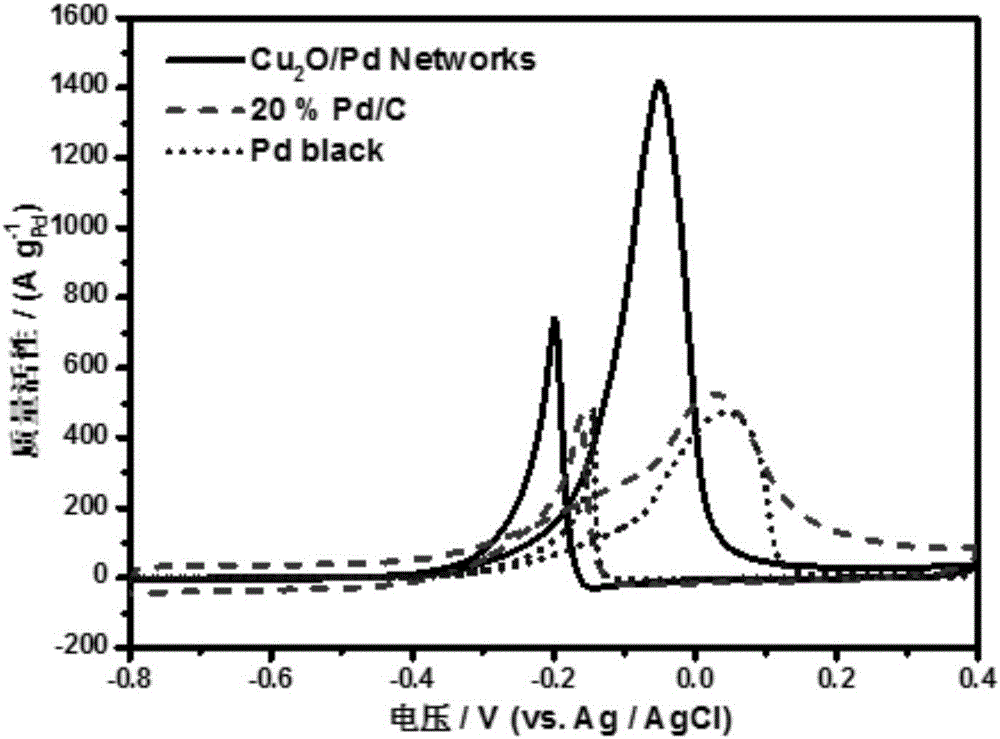

Palladium/cuprous oxide reticular nano catalytic material and preparation and application thereof

InactiveCN106299391AEasy to passFacilitated DiffusionMaterial nanotechnologyCell electrodesCentrifugationCopper oxide

The present invention relates to a palladium / cuprous oxide reticular nano catalytic material and preparation and application thereof. The nano catalytic material is prepared by the following steps: (1) taking a prepared phytate solution, adding deionized water, stirring and heating to boiling, then adding a copper salt solution and an alkali liquor thereto, heating, stirring and reaction, and adding phytate again, to obtain copper oxide nanorod suspension liquid protected by phytate; and (2) taking the copper oxide nanorod suspension liquid in step (1), diluting the suspension liquid by water, then adding a tetrachloropalladate salt solution and an ascorbic acid solution in sequence, performing stirring and heating, centrifugation, and washing, to obtain the palladium / cuprous oxide nano catalytic material. Compared with the prior art, the nano catalytic material of the present invention has higher catalytic activity, anti-poisoning power and stability, the preparation method is environmentally friendly.

Owner:SHANGHAI NORMAL UNIVERSITY

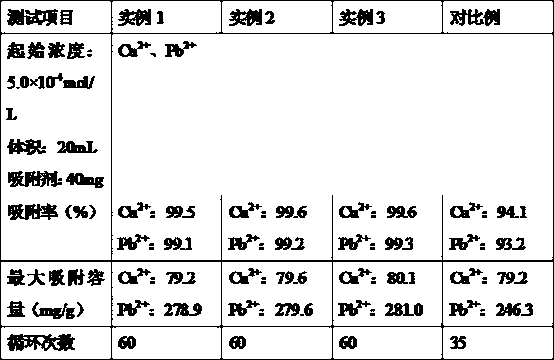

Method for preparing recyclable efficient heavy metal ion adsorbents

InactiveCN107694545ARough surfaceRich in holesOther chemical processesWater contaminantsFiberCellulose

The invention relates to the technical field of sewage treatment, in particular to a method for preparing recyclable efficient heavy metal ion adsorbents. The method has the advantages that mixed reaction is carried out on gamma-chloropropyl trimethoxysilane and activated silica gel which is obtained by means of mixing to obtain chloropropylation silica gel, the chloropropylation silica gel is soaked in polyethylenimine solution, accordingly, strong chelation effects can be realized for metal ions, and the metal ions can be tightly adsorbed on silica gel surfaces to form nanometer filter membranes; hydrogen ions can be ionized by carboxyl groups in oxidized nanometer celluloses, dissociated negative electric groups are hydrocarbon groups, the hydrocarbon groups can be adsorbed and bound with other heavy metal ions in solution, and accordingly the purpose of efficiently adsorbing the heavy metal ions can be achieved; the weakly acidic heavy metal ions are arranged in strongly alkaline environments, accordingly, the heavy metal ions can be desorbed and can be infiltrated from nanometer fibrous filter membranes, the heavy metal ions can be desorbed from the alkaline solution by the heavy metal ion adsorbents, and the purpose of recycling the recyclable efficient heavy metal ion adsorbents can be achieved.

Owner:陈合华

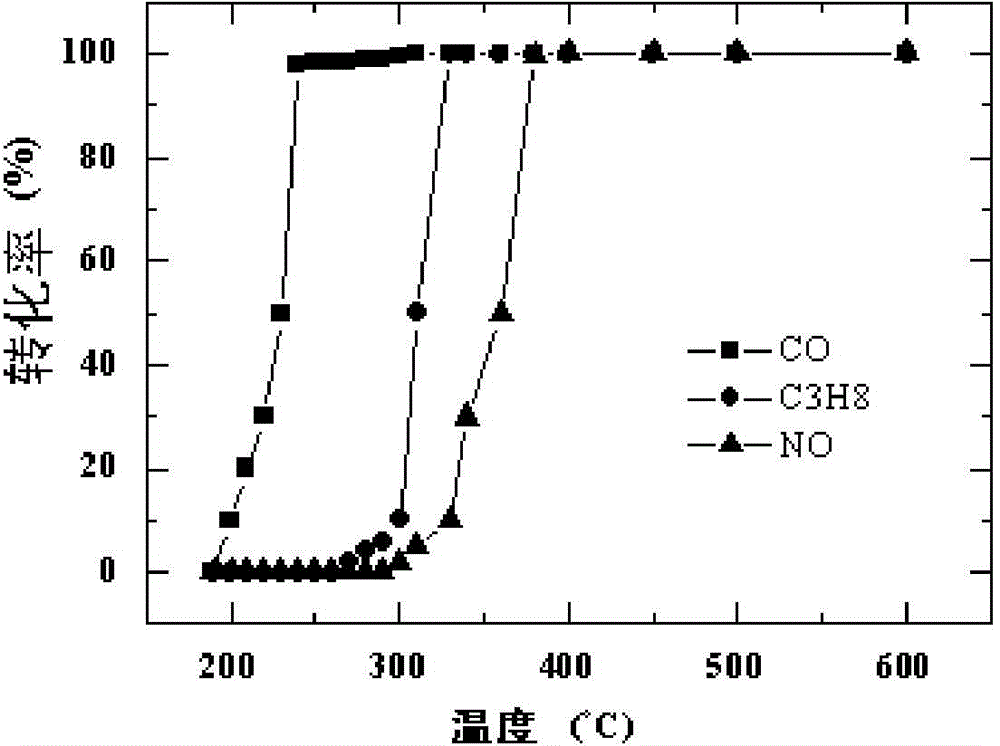

Catalyst and coating material for automobile tail gas purification and preparation methods therefor and application therefor

ActiveCN104959144AAchieve conversionReduce manufacturing costDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsMineral particlesRare earth

The invention discloses a catalyst coating material for automobile tail gas purification. The catalyst coating material comprises an oxygen storage layer and a catalytic active layer, wherein the oxygen storage layer is located at a lower layer, and the catalytic active layer is located at an upper layer; the oxygen storage layer is formed through uniformly loading oxides of one or more of rare-earth metals or transition metals to porous mineral particles; and the catalytic active layer is formed through uniformly loading oxides of one or more of transition metals to porous mineral particles. The invention further discloses a preparation method for the coating material and a catalyst prepared by employing the coating material. The catalyst coating material disclosed by the invention fully consists of rare-earth and transition metal oxides and is completely free of noble metal elements, so that the preparation cost is low; and the load amount of metal elements is large, the number of catalysis sites is large, and the upper and lower layers have a very good synergistic catalysis action, so that the catalytic conversion efficiency is high, and the application prospect is good.

Owner:苏磊

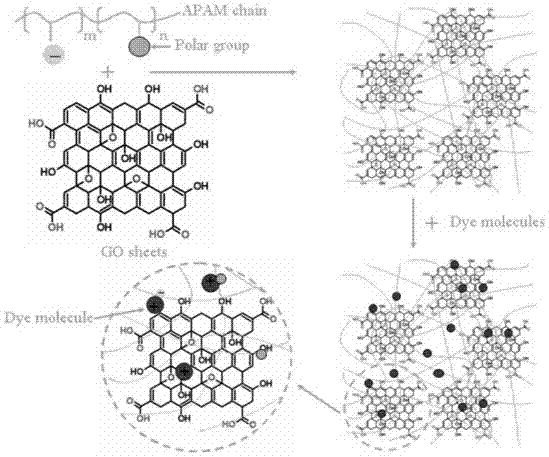

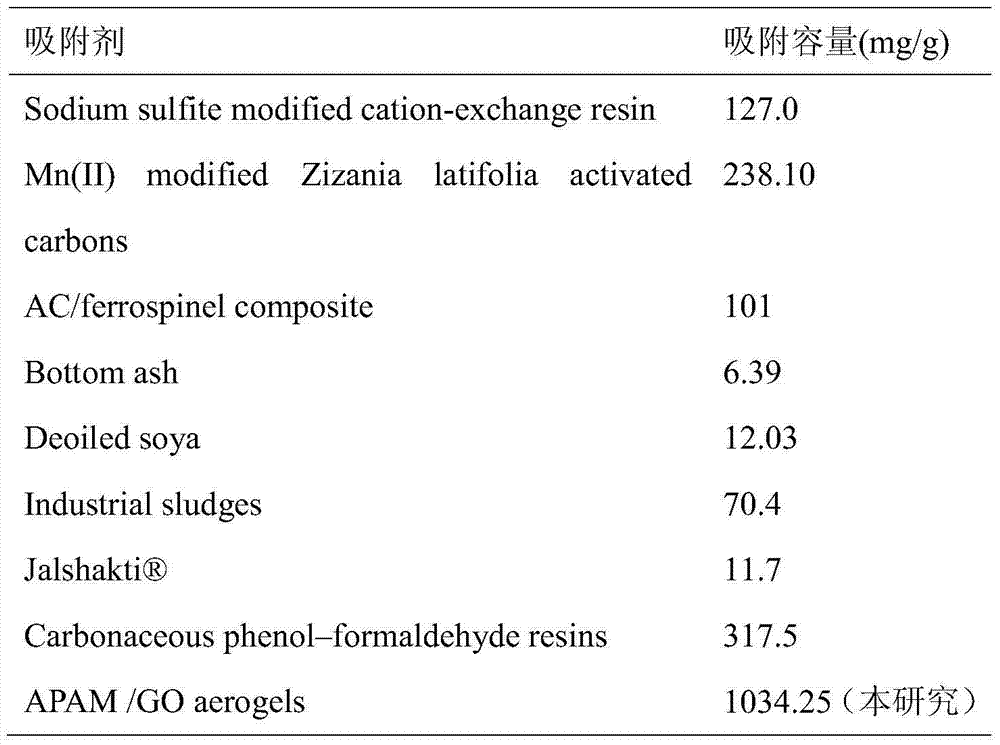

High adsorption performance composite flocculant aerogel and preparation method thereof

ActiveCN104773802AImprove adsorption capacityEasy to makeWater/sewage treatment by flocculation/precipitationPolymer scienceReduction treatment

The invention relates to a high adsorption performance composite flocculant aerogel and a preparation method thereof. An organic high polymer flocculant and a graphene based material are compounded by microwave irradiation and vacuum freeze drying to prepare an organic high polymer flocculant-graphene oxide composite aerogel, and the aerogel is subjected to reduction treatment so as to obtain an organic high polymer flocculant-graphene composite aerogel. The prepared aerogel material has the common advantages of the organic high polymer flocculant, grapheme and aerogel material, presents many surface active groups, large specific surface area, loose structure and rich pore structure, and can reach far more excellent effect than a single high polymer flocculant while it is applied to sewage treatment. The preparation process is simple and is easy to operate.

Owner:QINGDAO UNIV

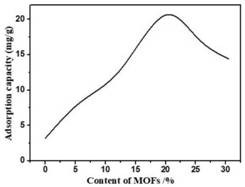

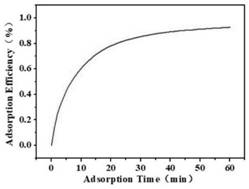

MOFs fiber membrane for adsorbing and intercepting micro-nano plastic in water and preparation method thereof

ActiveCN112755968AImprove adsorption capacityEfficient retentionOther chemical processesSustainable biological treatmentMicro nanoSodium Hypophosphite Monohydrate

The invention belongs to the technical field of processing and application of MOFs fiber membranes, and particularly relates to an MOFs fiber membrane for adsorbing and intercepting micro-nano plastics in water and a preparation method of the MOFs fiber membrane. The preparation method comprises the following steps: putting a fiber fabric, sodium hypophosphite and tetracarboxylic acid into deionized water, stirring for 1 hour, then taking out the fiber fabric, performing rolling twice at 30MPa, baking at 100 DEG C for 5 minutes, performing cleaning with deionized water, and performing drying to obtain a modified fiber fabric; putting the modified fiber fabric into a mixed solution of a long-chain carboxyl organic ligand and protein for 30 minutes, performing fully swelling, taking out the fiber fabric in a swelling state, putting the fiber fabric into a zinc nitrate solution, carrying out in-situ assembly for 5 minutes, taking out the fiber fabric, putting the fiber fabric into a drying oven, treating the fiber fabric at 60 DEG C for 2 hours, cooling the fiber fabric to room temperature, and obtaining the MOFs fiber membrane. The nano MOFs crystalline particles are distributed in swelling holes of cellulose fibers, and the prepared composite membrane material is rich in holes, huge in specific surface area and capable of efficiently adsorbing and intercepting micro-nano plastics in water.

Owner:LANGFANG NORMAL UNIV

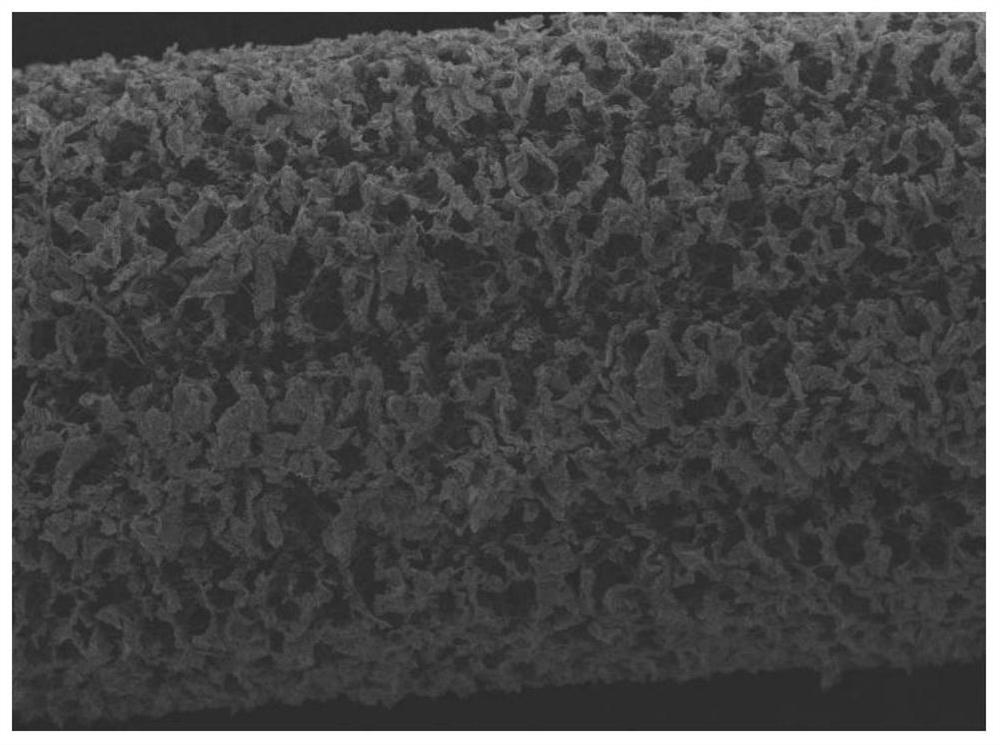

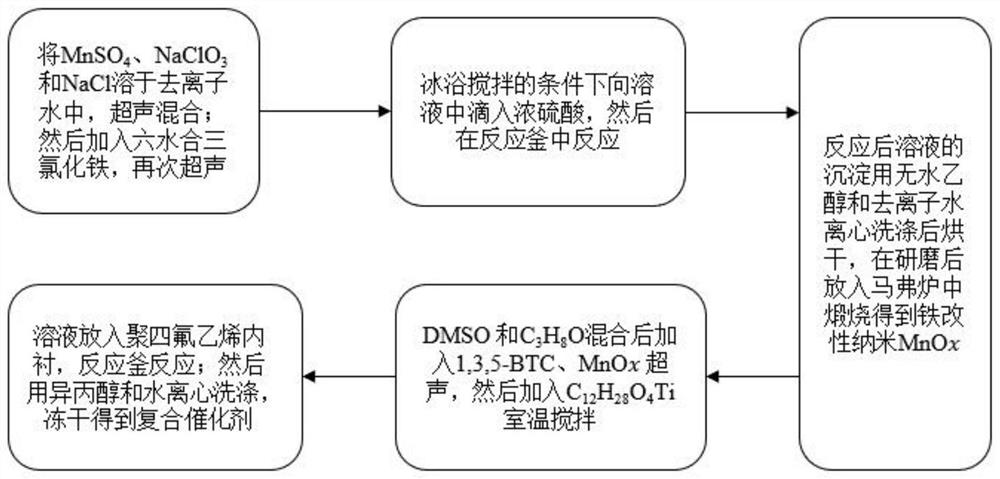

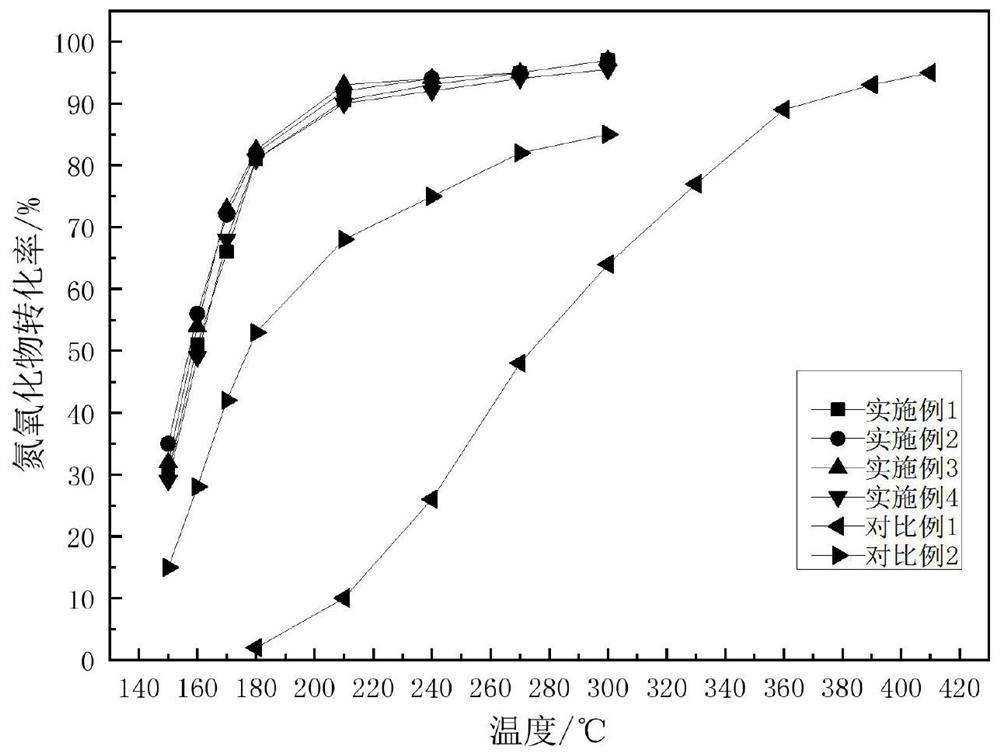

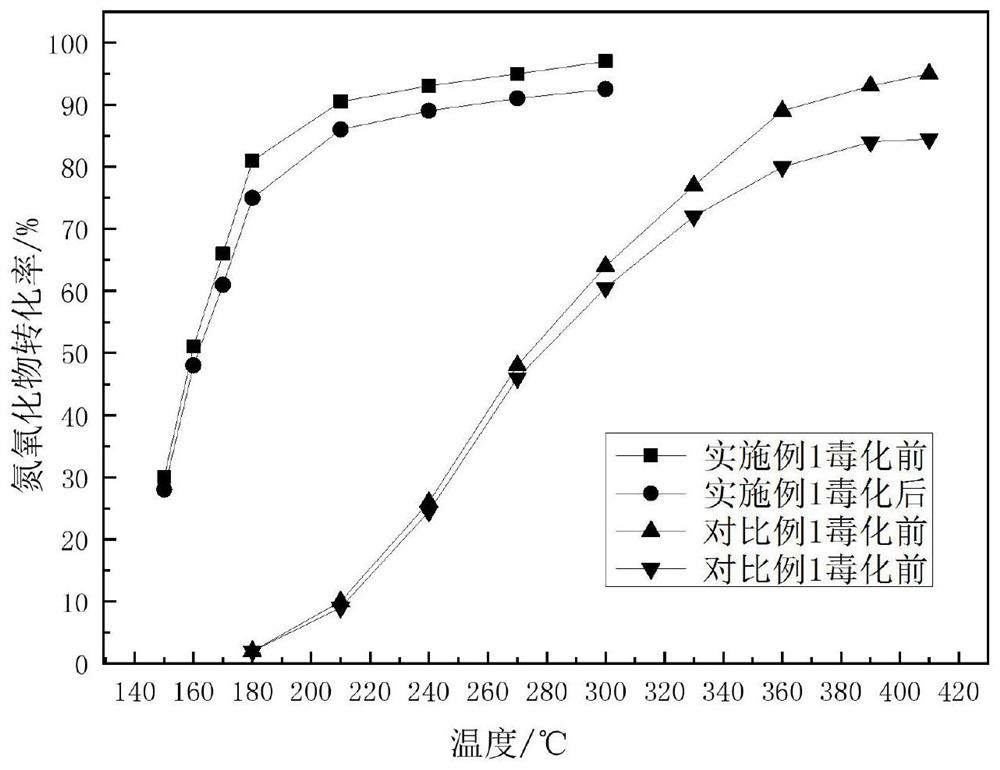

Fe-modified nano manganese oxide/MIL-125 (Ti) catalyst and preparation method thereof

ActiveCN111617807AImprove conversion rateRich variable valenceOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationHydration reactionPtru catalyst

The invention belongs to the technical field of composite material preparation, and particularly relates to a Fe-modified nano manganese oxide / MIL-125 (Ti) catalyst and a preparation method thereof. The preparation method comprises the following steps: A, ultrasonically mixing MnSO4, NaClO3 and NaCl in deionized water; adding ferric trichloride hexahydrate for ultrasonic treatment; then dropwise adding concentrated sulfuric acid into the solution under the condition of ice bath stirring, and reacting in a reaction kettle; B, centrifugally washing the precipitate with absolute ethyl alcohol anddeionized water, drying, grinding, and calcining in a muffle furnace to obtain iron modified nano MnOx; C, after DMSO and C3H8O are mixed, adding 1, 3, 5-BTC and nano MnOx for ultrasonic treatment, and then dropwise adding C12H28O4Ti during stirring at the room temperature; putting the solution into a reaction kettle to react; and finally, centrifugally washing with isopropanol and water, and freeze-drying to obtain the composite catalyst. The composite catalyst provided by the invention can effectively reduce the conversion temperature of nitrogen oxides, improve the toxicity resistance andprolong the service life of the catalyst.

Owner:ZHEJIANG ZHIYUAN ENVIRONMENTAL TECH CO LTD

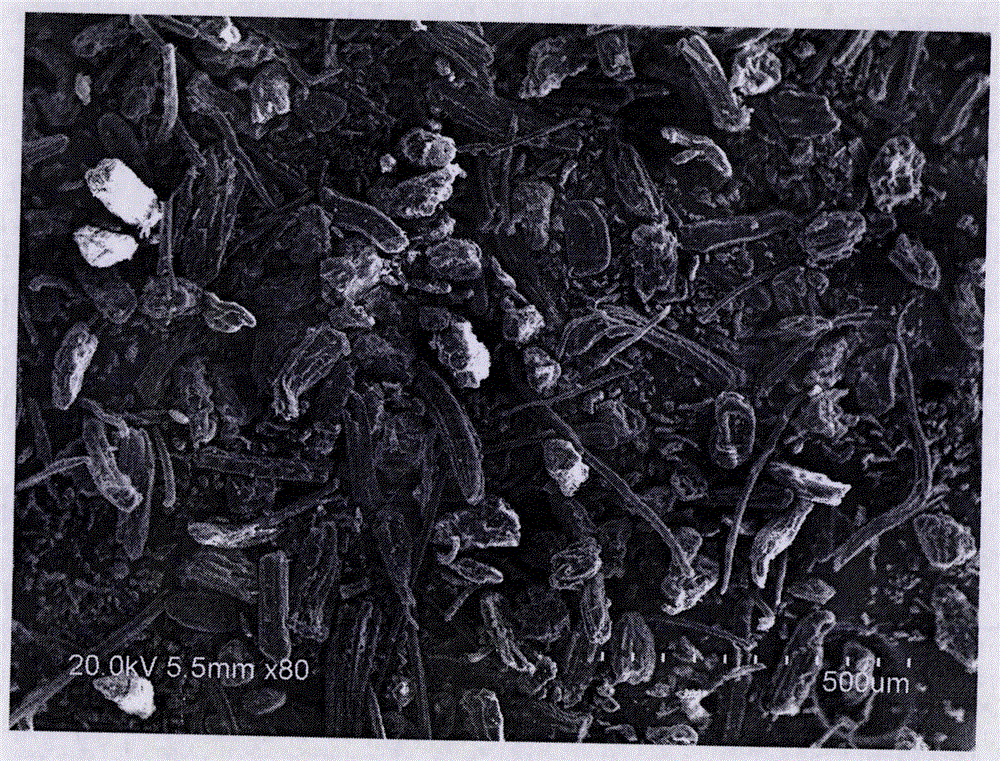

Method for preparing lignin-based hierarchical pore activated carbon fibers

ActiveCN107604479ARich in holesLarge specific surface areaArtifical filament manufactureActivated carbonCarbon fibers

The invention discloses a method for preparing lignin-based hierarchical pore activated carbon fibers. The method comprises the following steps: alternately adding purified lignin and sodium alginateinto a sodium silicate aqueous solution at 60-80 DEG C, uniformly stirring, and adjusting the pH value to 1-2; performing rotary evaporation at reduced pressure to obtain a hybridized material; addingthe hybridized material into a melt spinning machine, and spinning at a temperature of 200-250 DEG C at a speed of 100-6000m / min to obtain hybridized fibers; heating the hybridized fibers in a high-temperature furnace to 280-300 DEG C at a speed of 0.01-3 DEG C, and insulating at a constant temperature for 1-6 hours; and heating to 1000-2000 DEG C at a speed of 1-5 DEG C / min, carbonizing for 0.5-12 hours, and activating and pickling to obtain porous activated carbon fibers. The method has the beneficial effects that the prepared carbon fibers have more pores, large specific surface and controllable pore structure.

Owner:QINGDAO UNIV

Synthetic method for high-performance water-absorbent resin processed by electron beam irradiation

The invention discloses a synthetic method for high-performance water-absorbent resin processed by electron beam irradiation. The synthetic method comprises the following steps: (1) adding 20-80 parts by weight of polymeric monomers, 0.02-5 parts by weight of monomers, 0.001-1 part by weight of a cross-linking agent and 0.01-5 parts by weight of other additives into a reaction kettle and uniformly mixing to obtain a polymeric feed liquid, wherein the polymeric monomers are acrylic acid with the neutralization of 50-90 percent; (2) placing the flowing polymeric feed liquid under radiation of electron beams emitted by an electron accelerator to obtain a water-absorbent gel; (3) cutting, drying, crushing and screening the water-absorbent gel to obtain semi-finished particles; (4) performing surface crosslinking treatment on the semi-finished particles to obtain the high-performance water-absorbent resin finished product. Electron beams produced by the industrial electron accelerator irradiate acrylic acid monomer solutions to enable the feed liquid to finish polymerization reaction at the flowing instant so as to synthesize the high-performance water-absorbent resin.

Owner:CGN DASHENG ELECTRON ACCELERATOR TECH

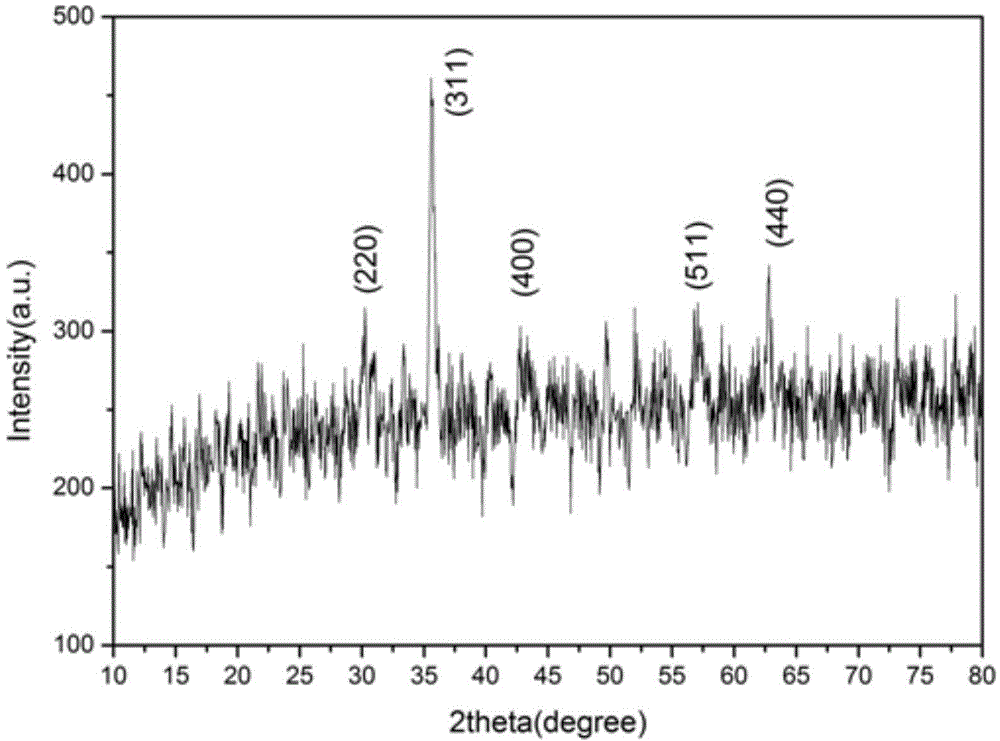

Preparation method of styrene and methyl methacrylate copolymerized magnetic oil absorbing material

InactiveCN104892819AImprove responseGuaranteed stabilityOther chemical processesCross-linkBenzoyl peroxide

The invention discloses a preparation method of a styrene and methyl methacrylate copolymerized magnetic oil absorbing material. During preparation of the styrene and methyl methacrylate copolymerized magnetic oil absorbing material, surfactant PEG (polyethylene glycol) 1000 serves as emulsifier and stabilizer, magnetic Fe3O4 serves as co-stabilizer, styrene and methyl methacrylate serve as monomer, divinylbenzene serves as cross-linking agent, and benzoyl peroxide serves as initiator. The method has the advantages that ferroferric oxide is modified by oleic acid and can be mixed with the oily monomer styrene and the methyl methacrylate well, oil and water which are not compatible can be converted into emulsion which is hard to layer by the PEG1000 which serves as the emulsifier, surface tension is reduced, and each liquid has certain surface tension; when the emulsifier is added into water, the surface tension of the water is reduced obviously, a system is allowed to be stable, and the styrene and methyl methacrylate copolymerized magnetic oil absorbing material can exist stably at high temperature; the prepared styrene and methyl methacrylate copolymerized magnetic oil absorbing material has a developed pore structure, is excellent lipophilic-hydrophobic property, can float on water surface and is good in absorption effect on most of oil pollutions.

Owner:NANJING UNIV OF SCI & TECH

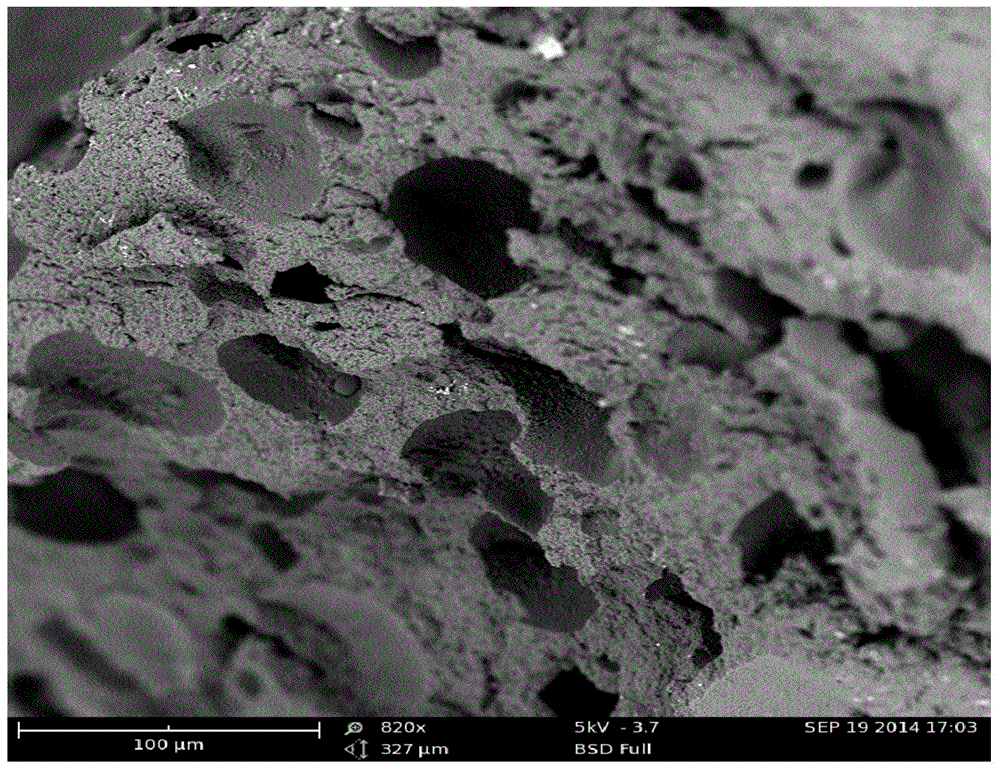

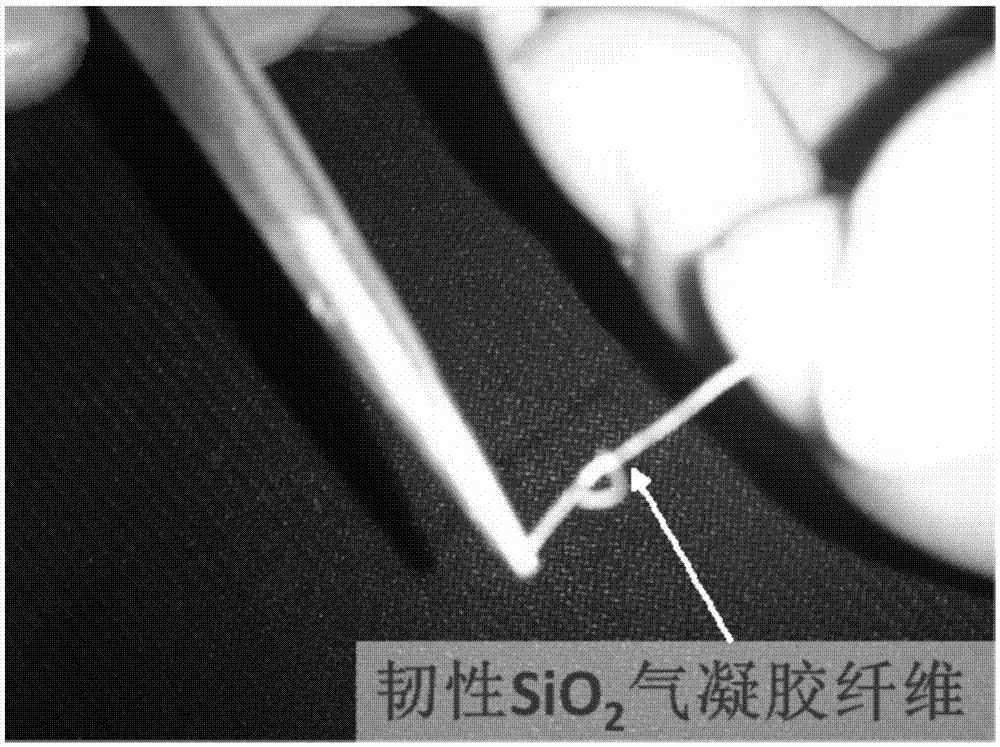

Preparation method of ductile SiO2 aerogel fiber coated with PVP (polyvinylpyrrolidone)

ActiveCN105442098AImprove toughnessToughness hasInorganic material artificial filamentsWet spinning methodsFiberPolymer science

The invention relates to a preparation method of a ductile SiO2 aerogel fiber coated with PVP (polyvinylpyrrolidone). The preparation method comprises the following steps: a spinning solution is prepared from silicate or silanol sol; an acid solution is added to a coagulating basin to serve as a coagulating bath; the spinning solution is added to the coagulating bath for reaction wet spinning, an orthosilicic acid / silicate fiber is obtained and is subjected to winding, aging and washing to be neutral, and solvent exchange and drying performed; the dried fiber is soaked in a PVP aqueous solution, taken out and dried, and a product is obtained. The preparation method has the characteristics of cheap and available raw materials, simple reaction process and good spinnability; the prepared inorganic SiO2 aerogel fiber has rich pores, high specific surface area, high-temperature resistance and chemical corrosion resistance, meanwhile, the specific surface area of the fiber is adjustable, the fiber has certain toughness, the application range of the aerogel fiber can be expanded, and the aerogel fiber has higher practical value.

Owner:DONGHUA UNIV

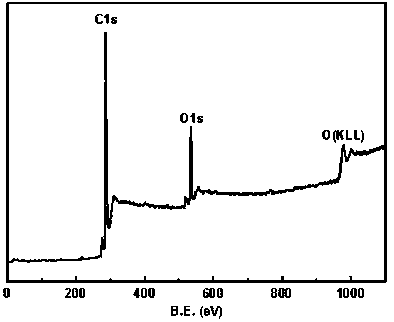

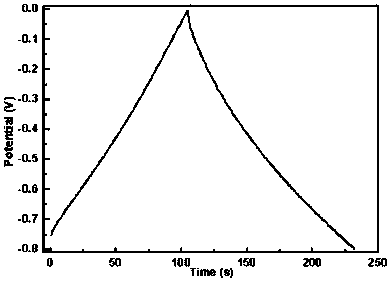

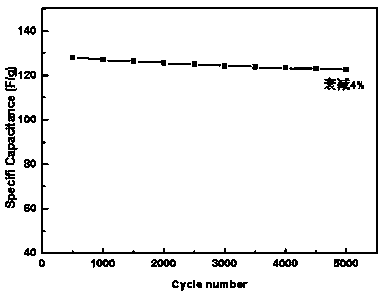

Preparation method and application of oxygen-containing porous carbon aerogel

ActiveCN110143582ARich in holesIncrease the areaHybrid capacitor electrodesCarbon preparation/purificationCellulosePorous carbon

The invention relates to a preparation method of oxygen-containing porous carbon aerogel, comprising the following steps: obtaining porous carbon aerogel through a conventional method, dispersing theporous carbon aerogel material in an aqueous solution of H2O2 and FeCl3 according to the concentration of 0.2-0.3 mg / ml with the molar ratio of H2O2 to FeCl3 being 1:1-1:4, uniformly stirring and mixing, adjusting pH to 2-4 by using a NaOH solution, treating by a plasma technology, carrying out suction filtration by using a mixed cellulose filter membrane after the reaction, washing with lots of deionized water to neutral level, collecting a powder, drying and grinding. The porous carbon aerogel provided by the invention has rich oxygen-containing functional groups, which can enhance wettability of the porous carbon aerogel in an electrolyte and can provide a pseudocapacitor having high capacitance.

Owner:ENERGY RESOURCES INST HEBEI ACADEMY OF SCI

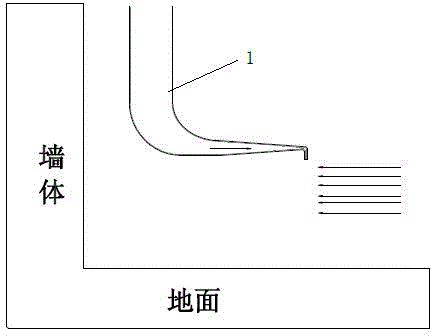

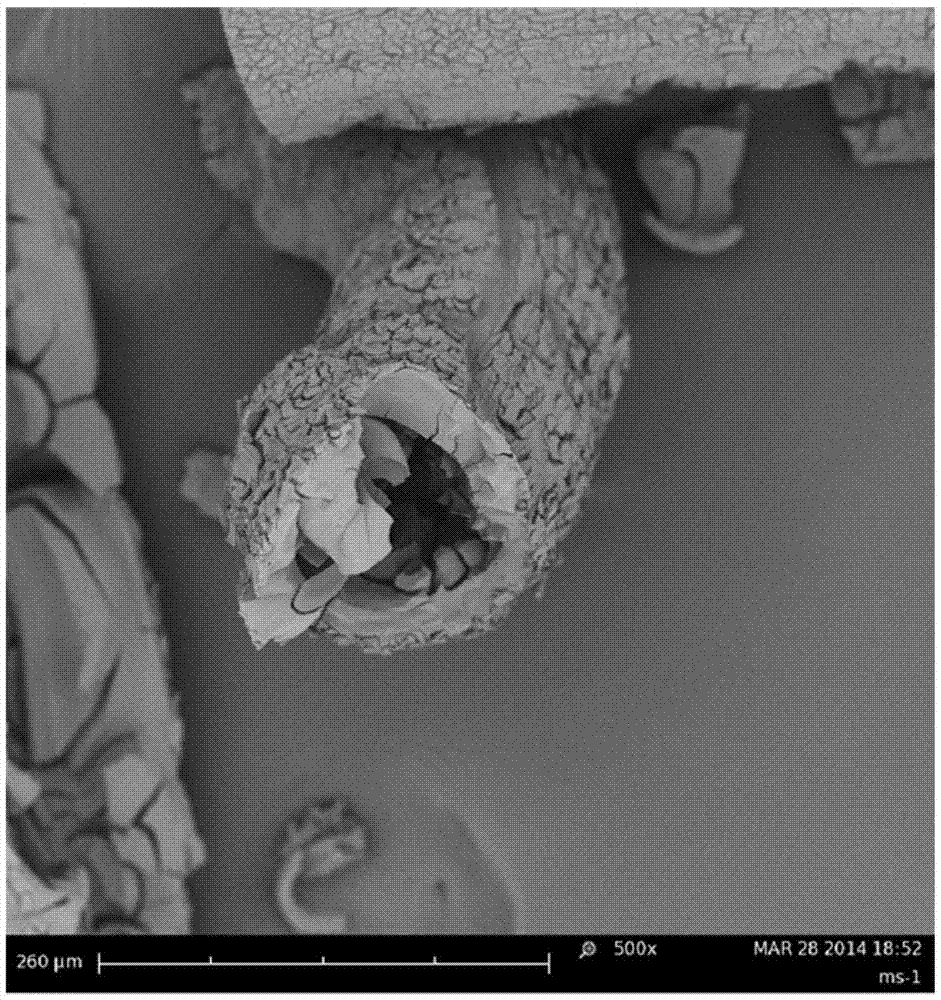

Method for preparing continuous hollow SiO2 porous fibers through coaxial spinning

ActiveCN105442093AAdjust the size of the specific surface areaLarge specific surface areaInorganic material artificial filamentsFiltrationSolvent

The invention relates to a method for preparing continuous hollow SiO2 porous fibers through coaxial spinning. The method comprises steps as follows: a spinning stock solution is prepared from silicate or silanol sol; one acid solution is added to a coagulating tank to be used as a coagulating bath, and the other identical acid solution is used as a coaxial spinning core spinning solution; the spinning stock solution and the coaxial spinning core spinning solution are injected into the coagulating bath through coaxial spinning needles at the same flow rate, reaction wet spinning is performed, hollow orthosilicic acid / silicate fibers are obtained, wound, aged and washed to be neutral with deionized water, solvent displacement is performed, and the continuous hollow SiO2 porous fibers are obtained through drying. The method has the characteristics that equipment is simple, raw materials are cheap and easy to obtain, the reaction process is simple and the spinnability is good. The hollow inorganic SiO2 porous fibers obtained with the method have rich pores and ultra-large specific surface area, are resistant to the high temperature and chemical corrosion, and have more advantages than common porous fibers in fields of catalysis, adsorption, filtration and the like.

Owner:DONGHUA UNIV

Bamboo charcoal-diatomite composite ceramic material and preparation method thereof

The invention relates to a bamboo charcoal-diatomite-bentonite composite ceramic material and a preparation method thereof. A bamboo charcoal-diatomite composite ceramic material is prepared from the following raw materials in parts by weight: 10-90 parts of bamboo powder, 10-90 parts of diatomite and 5-20 parts of a water-soluble macromolecular binder. The preparation method of the bamboo charcoal-diatomite composite ceramic material comprises the following steps: (1), oven-drying the bamboo powder for 1-2 hours at 60-80 DEG C, and making the bamboo powder pass through a 200-mesh sieve; (2), oven-drying the diatomite for 1-2 hours at 60-80 DEG C, and making the diatomite pass through the 200-mesh sieve; (3), mixing the 5-20 parts of water-soluble macromolecular binder with 100-110 parts of water, and sufficiently dissolving the water-soluble macromolecular binder; (4), carrying out mixing in a proportion of the 10-90 parts of bamboo powder to the 10-90 parts of diatomite in a solution obtained in the step (3), and obtaining a mixture; (5), ball-milling the mixture, obtaining slurry, putting the slurry in a vacuum, and removing air bubbles; (6), making the slurry stand and cured, and then granulating and molding the slurry; (7), heating up and calcining a green body, and then cooling the green body to a room temperature. The preparation process of the bamboo charcoal-diatomite composite ceramic material is economical and environment-friendly; a ceramic material with many orifices, a large specific surface area and high adsorption capacity can be prepared and obtained.

Owner:HUZHOU TEACHERS COLLEGE

Method for processing high-performance water-absorbent resin through electron beam irradiation

The invention discloses a method for processing high-performance water-absorbent resin through electron beam irradiation. The method includes the following steps that 1, feed liquid to be polymerized is quickly frozen; 2, the frozen polymerized material is placed under electron beam irradiation of an electron accelerator, and then water-absorbent gel is obtained; 3, the water-absorbent gel is kept for a period of time at high temperature, dried, smashed and screened, and then semi-finished particles are obtained; 4, surface crosslinking treatment is conducted on the semi-finished particles, and then the finished high-performance water-absorbent resin is obtained.

Owner:CGN DASHENG ELECTRON ACCELERATOR TECH

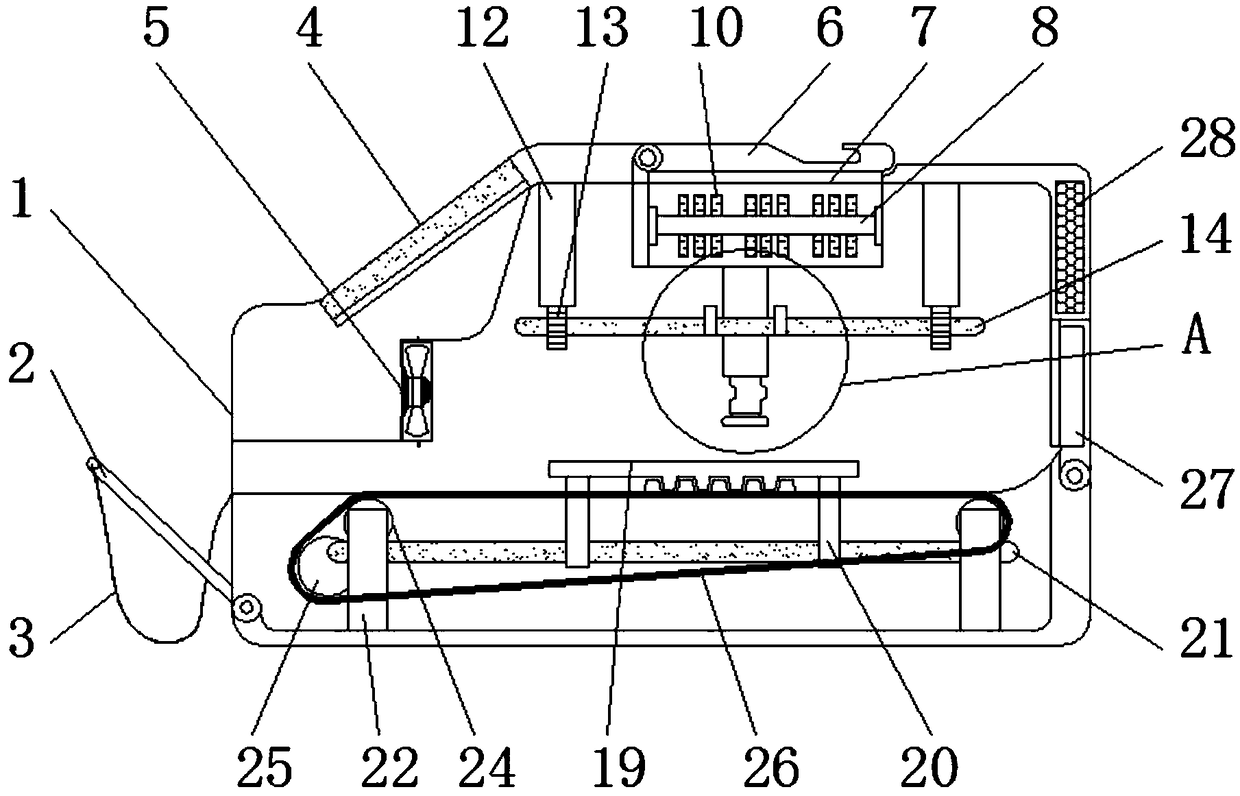

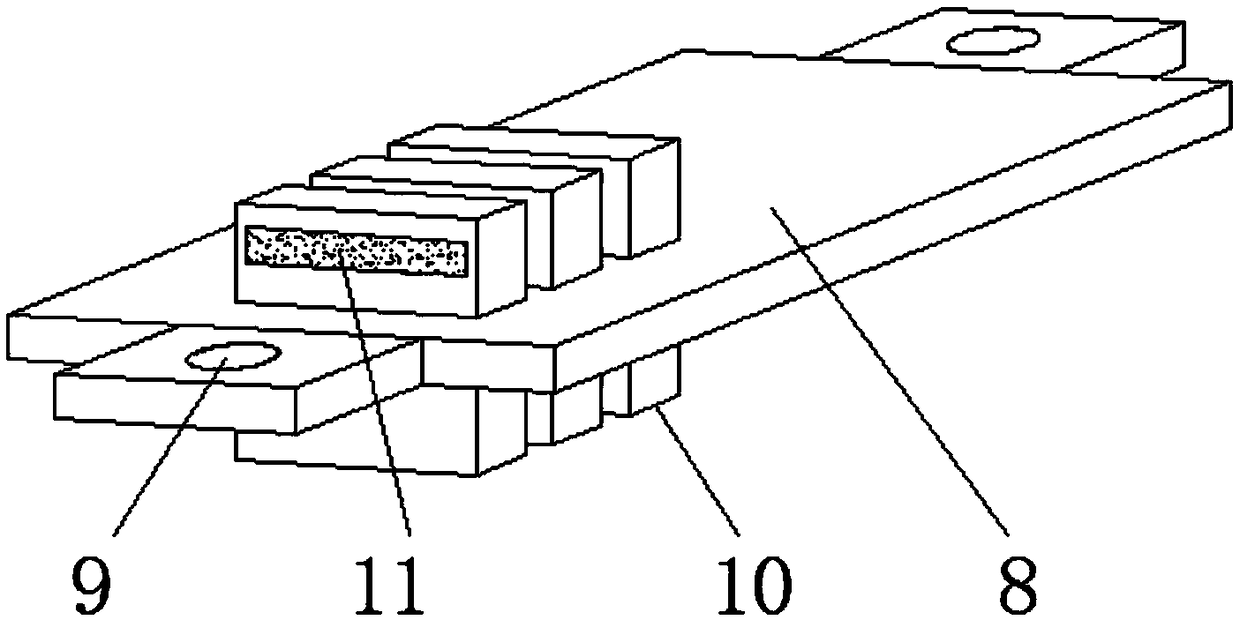

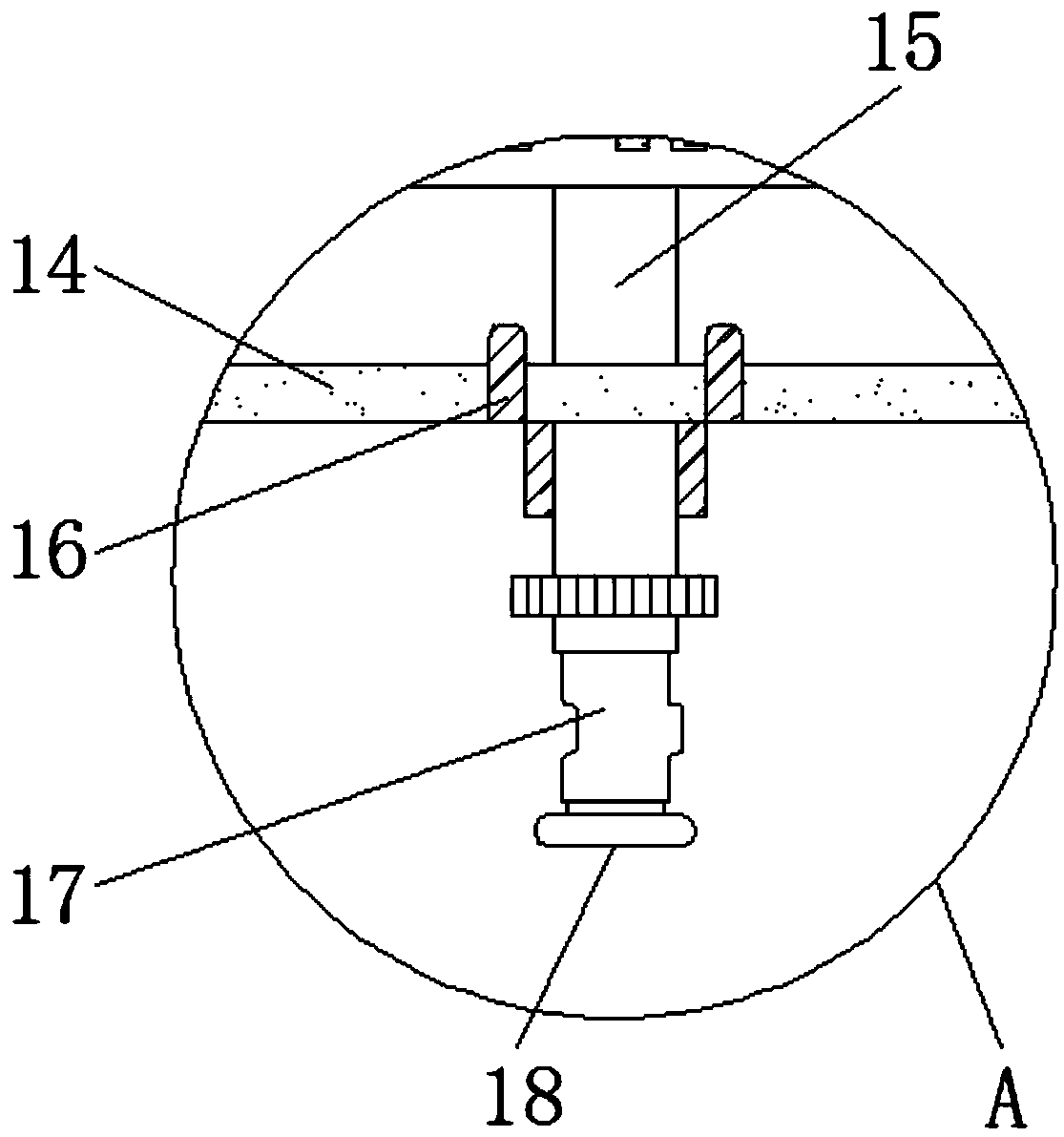

Distance adjustable ink jet type digital printer

InactiveCN108944035APrevent stacking from breakingEasy to stack and breakPrintingSurface mountingEngineering

The invention discloses a distance adjustable ink jet type digital printer. The printer comprises a printer body, an installing plate, an ink-jet material storage box and a first rotating cylinder, amaintenance rod is installed in the outer surface of the left end of the printer body, a display screen is arranged in the left side of the upper surface of the printer body, a cover plate is arrangedin the middle of the upper surface of the printer body, the installing plate is positioned in the middle of the internal of a holding tank, the ink-jet material storage box is positioned in the installing plate, lifting bars are arranged in the two sides of the holding tank respectively, a suspension rod is arranged in a fixed block, a first slide block is fixed to an ink outlet rod, nozzles areinstalled in the lower end of an ink-jet block, a second slide block is fixed to the lower end of a sliding plate, and the two ends of a first fixed rod are connected with pedestal blocks respectively. According to the distance adjustable ink jet type digital printer, a stacking device is arranged for printed materials, the printed materials are uniform and clean, the ink-jet quality is higher, the materials of ink jetting includes abundant colors, and the nozzle distance can be adjusted.

Owner:浙江普崎数码科技有限公司

Preparation method of continuous cellulose-nanometal composite aerogel fibers

ActiveCN106111195AInnovativePracticalArtificial filaments from cellulose solutionsOrganic-compounds/hydrides/coordination-complexes catalystsFiberCellulose

The invention provides a preparation method of continuous cellulose-nanometal composite aerogel fibers. The method comprises steps as follows: a cellulose dispersion liquid is prepared to serve as a spinning solution, and a nanometal catalyst is added; an acidic solution, an ethanol solution or an acetone solution is added to a coagulating basin to serve as a coagulating bath; the spinning solution with the nano catalyst added is added to the coagulating bath for wet spinning, and cellulose gel fibers containing the nanometal catalyst is obtained; the cellulose gel fibers containing the nanometal catalyst are wound, immersed in an ageing solution to be aged at the normal temperature for 15 min-1 h, washed with deionized water to be neutral, then subjected to solvent replacement with deionized water, ethanol or tertiary butanol and dried, and the continuous cellulose-nanometal composite aerogel fibers with catalytic performance are obtained. The preparation method of the continuous cellulose-nanometal composite aerogel fibers has the characteristics that the raw materials are widely sourced, the cost is low, the preparation process is simple, environment-friendly and pollution-free, and the spinnability is good.

Owner:DONGHUA UNIV

Preparation method of light biological filter material

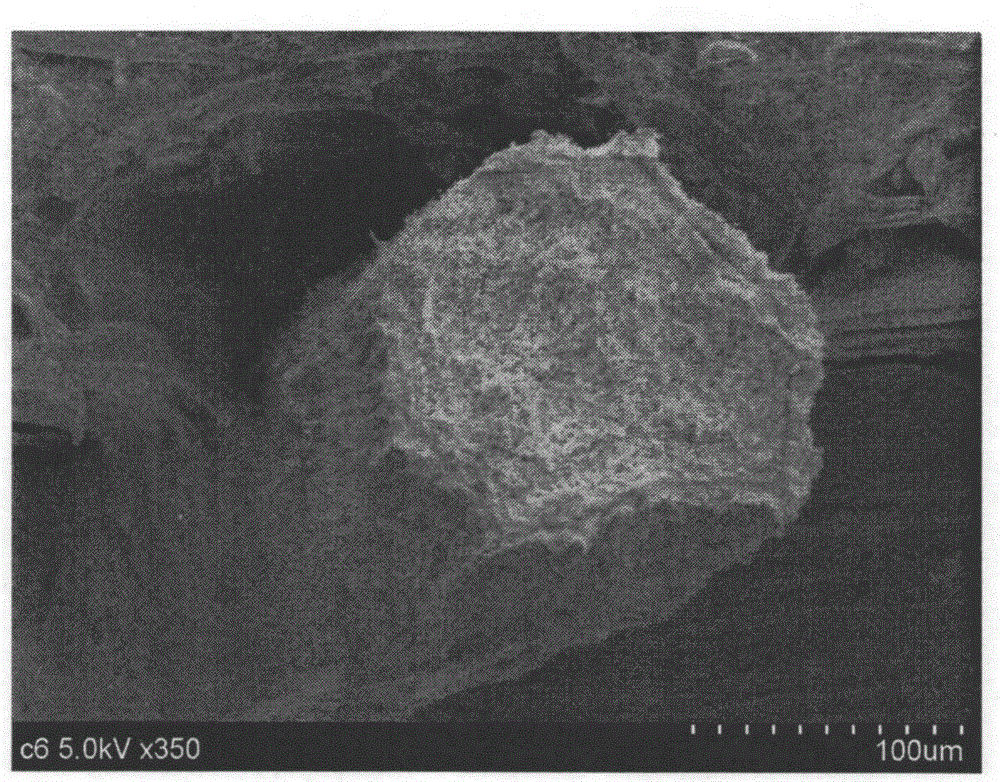

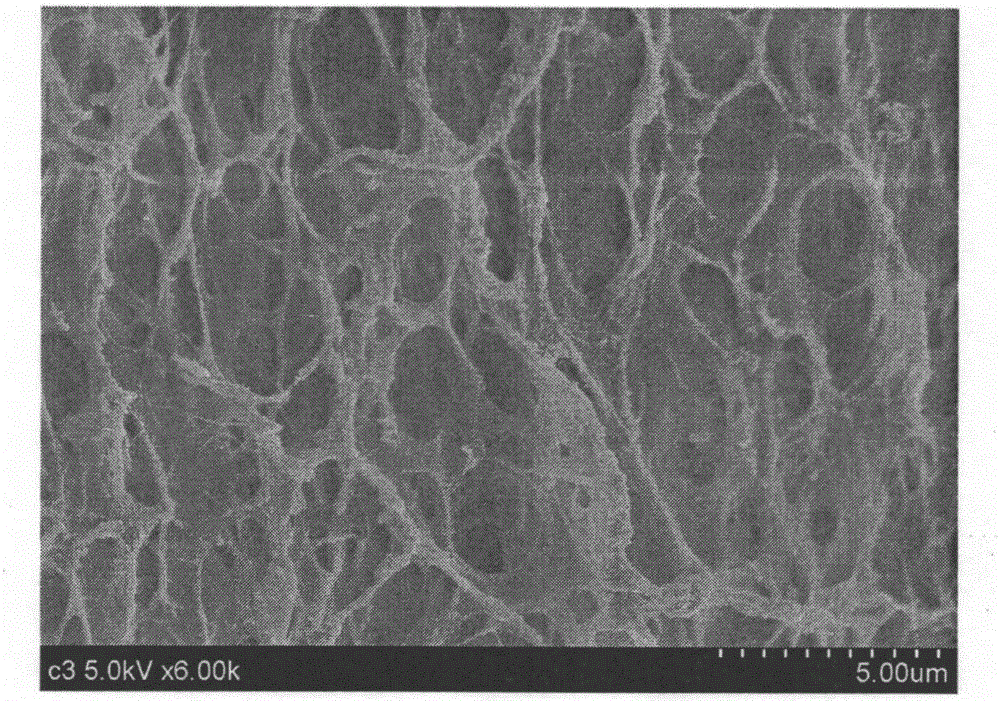

ActiveCN111018094AHigh strengthRich in holesCeramic materials productionTreatment with microorganism supports/carriersMicrobial inoculationBiofilm

The invention relates to the technical field of filter materials, and in particular, relates to a preparation method of a light biological filter material. The biological filter material is prepared from the following components in parts by mass: 60-80 parts of steel slag, 12-18 parts of humic acid, 2-8 parts of ammonium carbonate, 0.6-0.8 part of an adhesive and 10-30 parts of water. The preparation method comprises the following steps: (1) weighing steel slag, humic acid, ammonium carbonate and the adhesive in proportion, adding water, uniformly mixing, preparing into balls in a ball formingmill, transferring into a drying oven, drying, calcining, and cooling to obtain a semi-finished product; (2) soaking the biological filter material semi-finished product obtained in the step (1) in anutrient solution for 30-45 min, and carrying out microbial inoculation for 5-7 d, to obtain the biofilm-culturing biological filter material. According to the prepared light biological filter material, the sewage treatment efficiency per unit volume is improved by 7-8 times compared with that of a conventional filter material, the environment-friendly emission standard can be met, the oxygenating efficiency is high, energy consumption is reduced, and the problem that the treatment efficiency is reduced due to the fact that the material surface is not uniform after an existing filter materialruns for a period of time is solved.

Owner:NANJING GONGCHENG RES INST OF ENERGY CONSERVATION & NEW MATERIALS TECH CO LTD

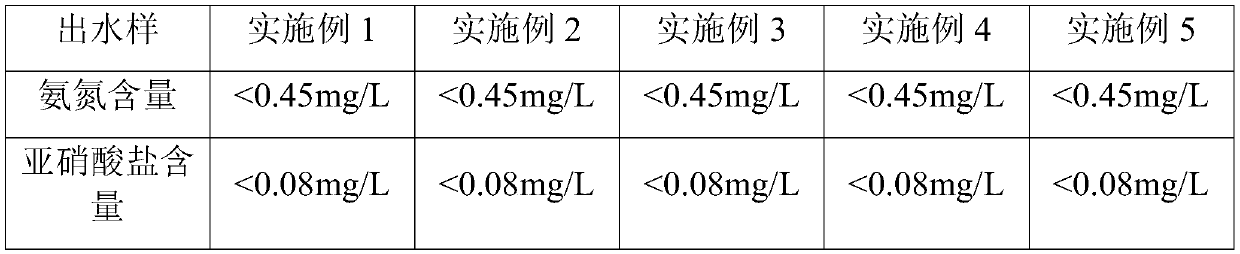

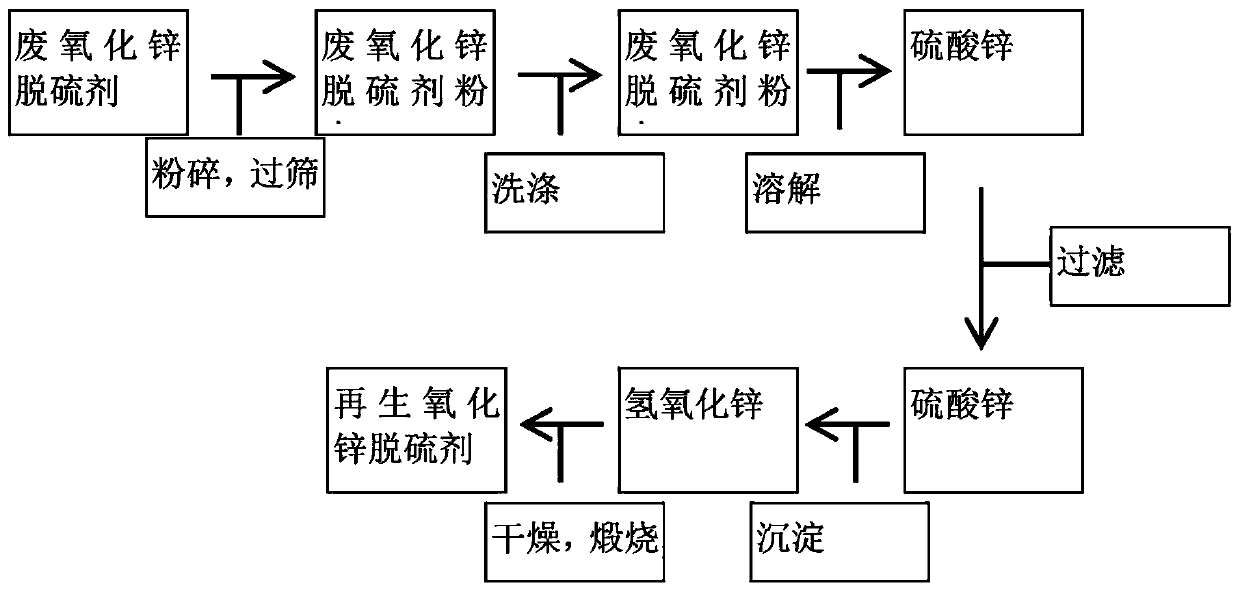

Regeneration method of zinc oxide desulfurizer

ActiveCN110917876AAvoid decompositionMeet environmental protection requirementsDispersed particle separationEthylene diamine tetra aceticEthylene diamine

The invention relates to a regeneration method of a zinc oxide desulfurizer. The method comprises the following steps of pulverizing a zinc oxide desulfurizer to be regenerated to obtain waste desulfurizer powder; washing the waste desulfurizer powder with a mixed aqueous solution of povidone and sodium carbonate, washing with water, mixing the washed waste desulfurizer powder with a sulfuric acidsolution, hydrogen peroxide, a potassium permanganate solution and ethylene diamine tetraacetic acid (EDTA-2Na), reacting for 2-5 hours, and filtering to obtain a filtrate and filter residues; mixingthe filtrate with ammonia water, controlling the pH value to be 7.8-9, stirring for 0.5-3 hours, and filtering to obtain a precipitate; and cleaning, drying and calcining the precipitate to obtain the regenerated zinc oxide desulfurizer. The regeneration method of the zinc oxide desulfurizer is simple and easy to operate, the operation cost is low, the method is free of toxic gas emission and capable of better meeting the environmental protection requirement, the method has wide application range and is suitable for regeneration of the waste zinc oxide desulfurizer, and the regeneration sulfur capacity is high.

Owner:HUNAN HUANDA ENVIRONMENTAL PROTECTION

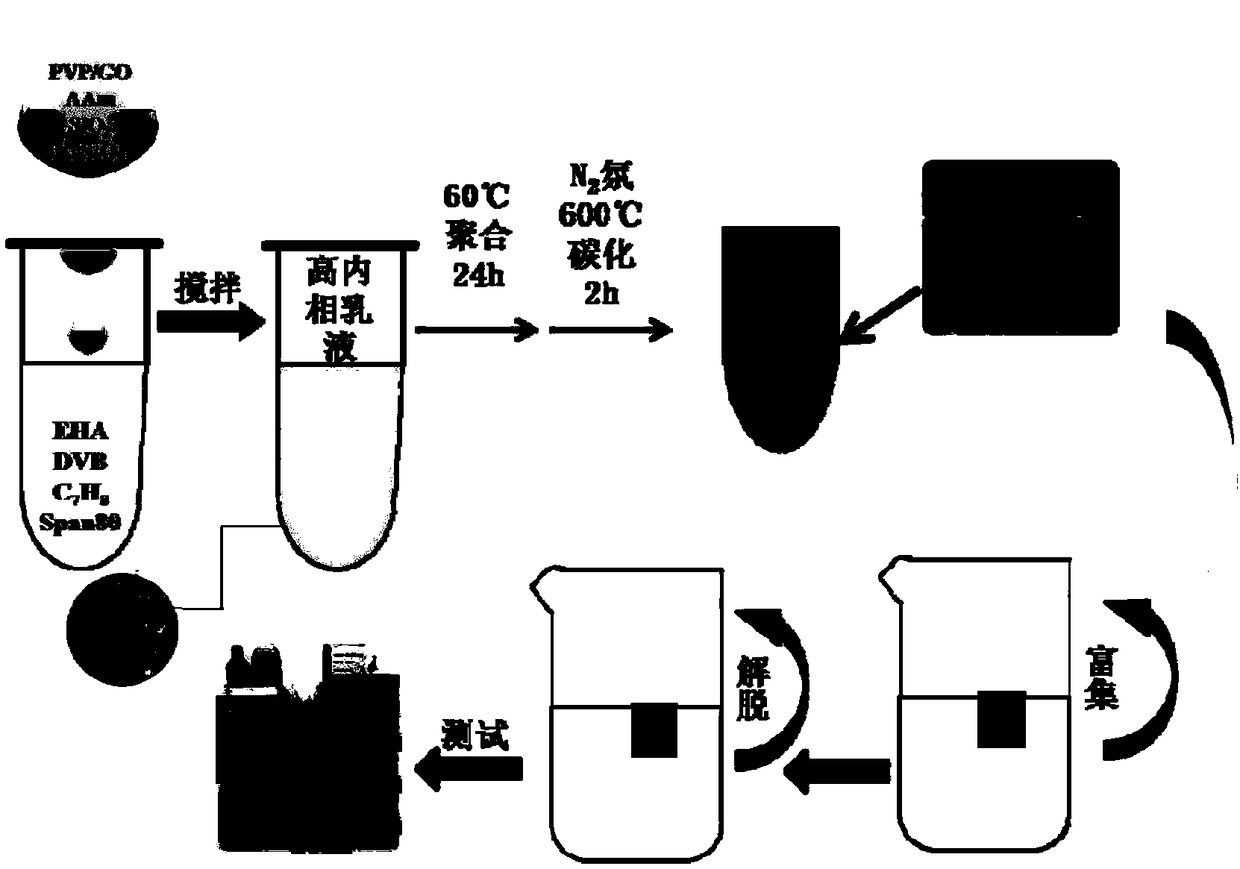

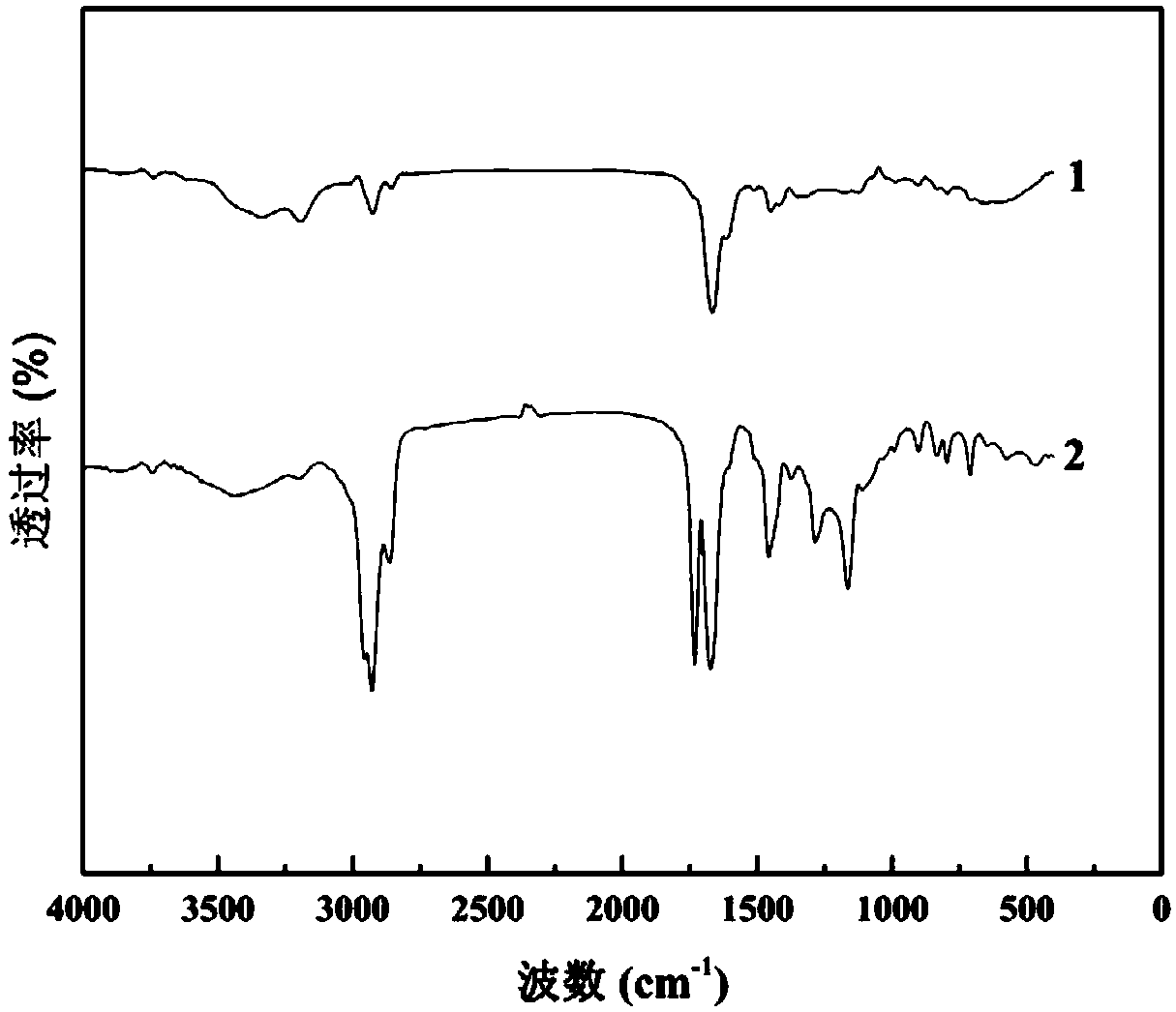

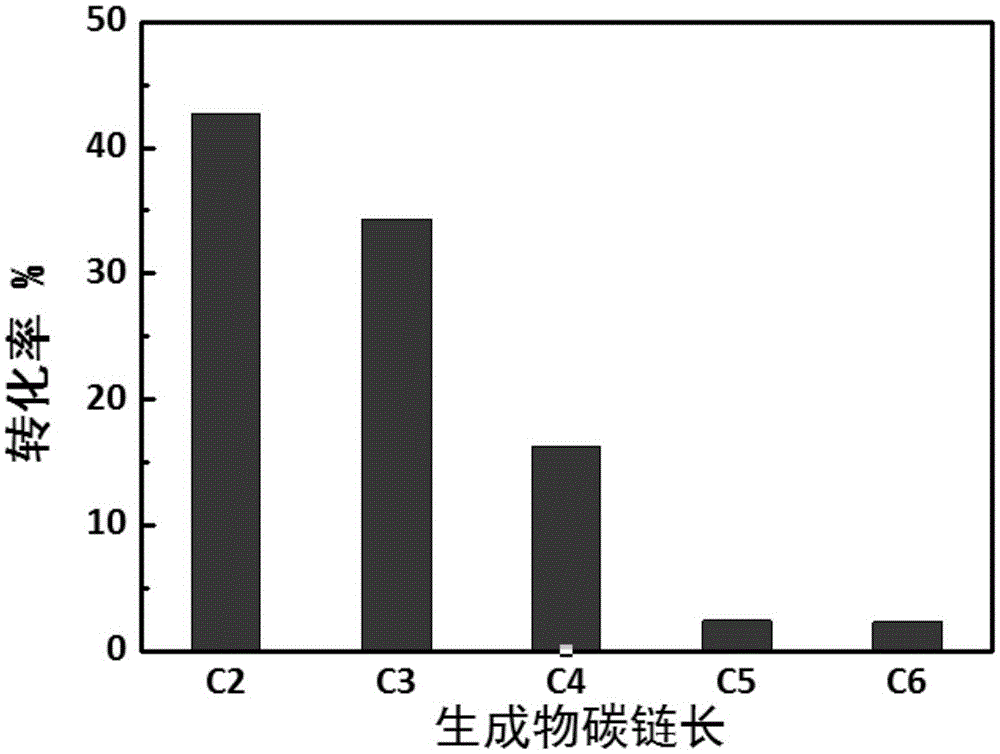

Method for separating and enriching trifluralin herbicide in soil

ActiveCN108956246AImprove adsorption capacityRich in holesPreparing sample for investigationIsooctyl acrylatePolyvinylpyrrolidone

The invention discloses a method for separating and enriching a trifluralin herbicide in soil. The method comprises the steps: mixing isooctyl acrylate, divinylbenzene, Span80 and C7H8, and adding azodiisobutyronitrile to form an organic phase; adding acrylamide into a polyvinylpyrrolidone / graphene oxide aqueous solution, and then adding nano SiO2 to form an aqueous phase; adding the aqueous phaseto the organic phase to form a high internal phase emulsion; drying, thermopolymerizing and washing the high internal phase emulsion, and carbonizing for 2 hours at the temperature of 600 DEG C; drip-washing a carbonized monolithic column with an acetonitrile aqueous solution, eluating the trifluralin herbicide target enriched on the carbonized monolithic column by an acetic acid / acetonitrile solution, and collecting an eluate; and blowing the eluate to dry with liquid nitrogen, redissolving with acetonitrile to obtain a to-be-measured solution, and completing the separation and enrichment ofthe trifluralin herbicide in the soil sample. The method has good extraction and enrichment ability for the trifluralin herbicide, and can be applied to extraction, enrichment and separation analysisof the trace trifluralin herbicide in the soil sample.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Method for preparing continuous SiO2/nanocrystalline metal aerogel fiber with catalytic performance by adding nanocrystalline metal in situ

ActiveCN105603577AHas catalytic propertiesAdjust the size of the specific surface areaInorganic material artificial filamentsWet spinning methodsFiberSolvent

The invention relates to a method for preparing continuous SiO2 / nanocrystalline metal aerogel fiber with catalytic performance by adding nanocrystalline metal in situ. The method comprises the steps that salicate is prepared into a spinning solution, then, a nanocrystalline metal catalyst is added into the spinning solution, the spinning solution is added into coagulating bath, reaction wet spinning is conducted, orthosilicic acid / silicate fiber containing the nanocrystalline metal catalyst is obtained, winding and room temperature ageing are conducted, the orthosilicic acid / silicate fiber is washed to be neutral through deionized water, solvent replacement is conducted through deionized water or ethyl alcohol, drying is conducted, and the continuous SiO2 / nanocrystalline metal aerogel fiber is obtained. The method has the advantages that raw materials are low in price and easy to obtain, the reaction process is simple, and spinnability is good. The continuous SiO2 / nanocrystalline metal aerogel fiber with catalytic performance prepared through the method has abundant holes, and is high in specific surface area, and resistant to high temperature and chemical corrosion; the specific surface area of the fiber and the content of nanocrystalline metal in the fiber are adjustable, and the method has application prospects in catalysis and other fields.

Owner:DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com