MOFs fiber membrane for adsorbing and intercepting micro-nano plastic in water and preparation method thereof

A medium, micro, nano, and fiber membrane technology, applied in the direction of adsorption water/sewage treatment, chemical instruments and methods, and other chemical processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

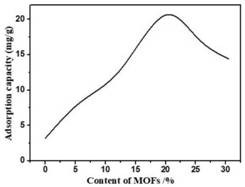

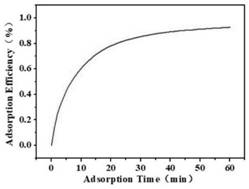

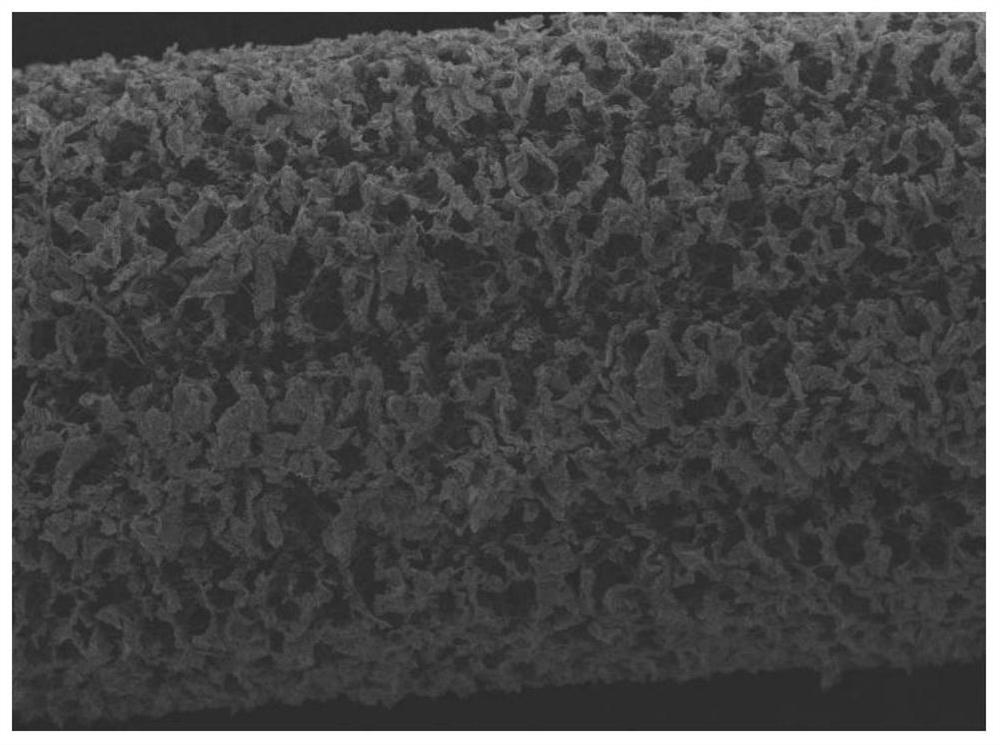

[0026] Example 1, MOFs cotton fabric composite crystalline membrane material

[0027] (1) First place the 5cm 2 Cotton fabrics of different sizes, 1g of sodium hypophosphite and 1g of pyromellitic acid (can be replaced with other kinds of tetracarboxylic acids) were placed in deionized water, stirred for 1 hour, and then the cotton fabric was rolled out twice at 30MPa, 100 Bake at ℃ for 5 minutes, wash with deionized water, and dry to obtain a cotton fabric modified with pyromellitic acid;

[0028] (2) Step (1) can be repeated 2 to 5 times;

[0029] (3) Immerse the cotton fabric modified by pyromellitic acid in the mixed solution of butenedioic acid (can be replaced by other flexible long-chain carboxylic acid ligands) and bovine serum albumin (can be replaced by other various proteins) for 30min , fully swelled, taken out in the swollen state and placed in zinc nitrate solution, assembled in situ for 5 minutes (this method is mainly protein-induced biomimetic mineralization...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com