Patents

Literature

970 results about "Sodium Hypophosphite Monohydrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium hypophosphite (NaPO2H2, also known as sodium phosphinate) is the sodium salt of hypophosphorous acid and is often encountered as the monohydrate, NaPO2H2·H2O.

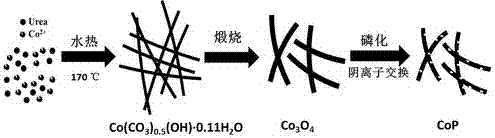

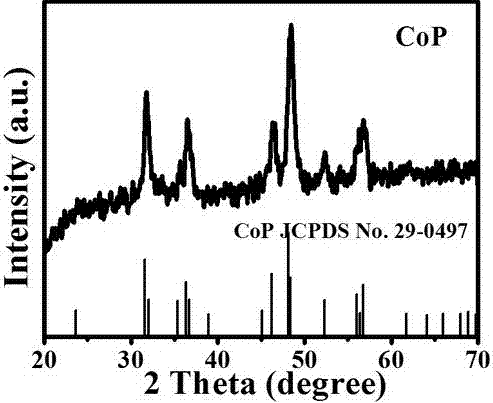

Catalyst for loading cobalt phosphide on activated carbon as well as preparation and application of catalyst

ActiveCN104941674AExcellent hydrogen evolution catalytic performanceRich sourcesCatalyst carriersElectrolysis componentsFiltrationCobalt

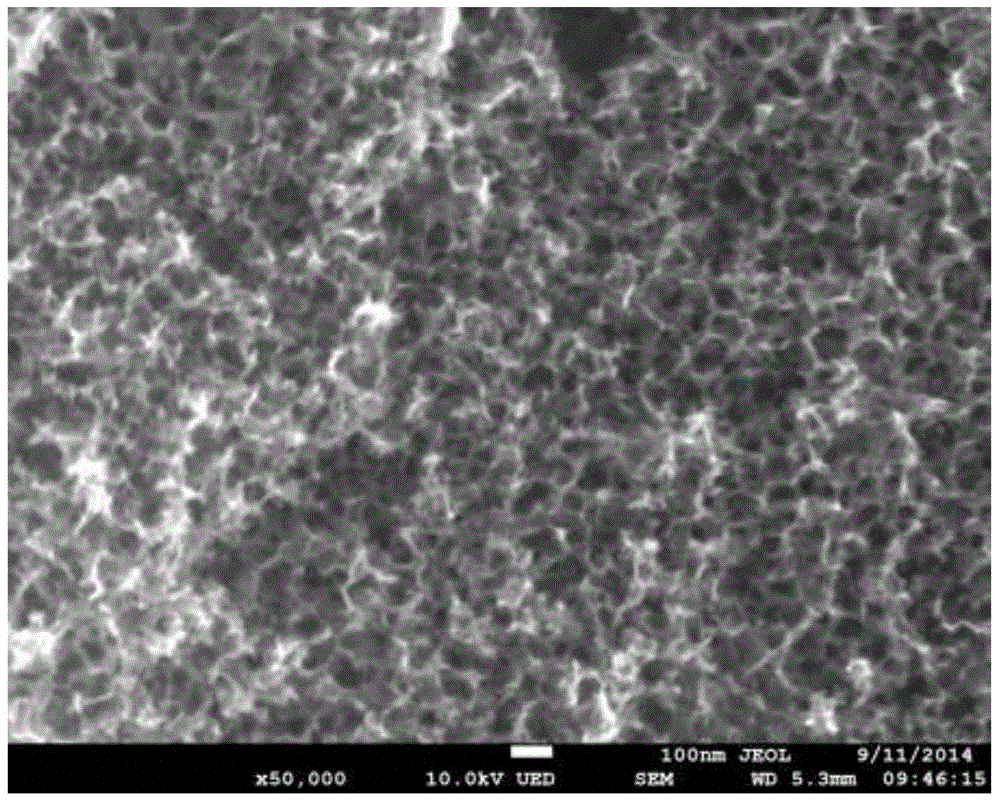

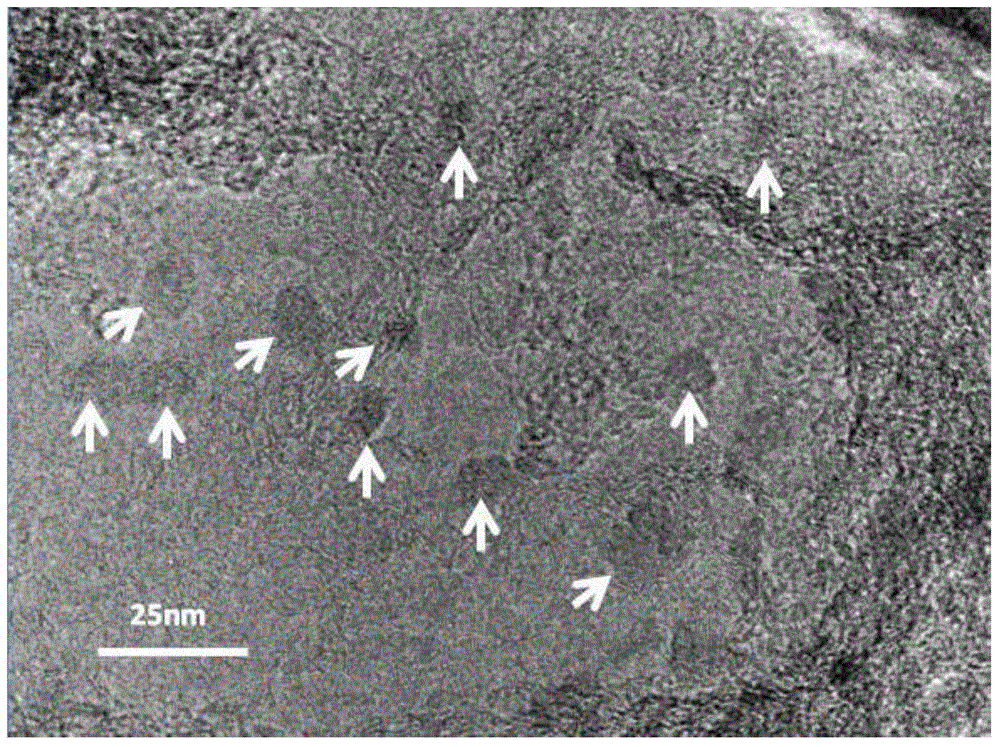

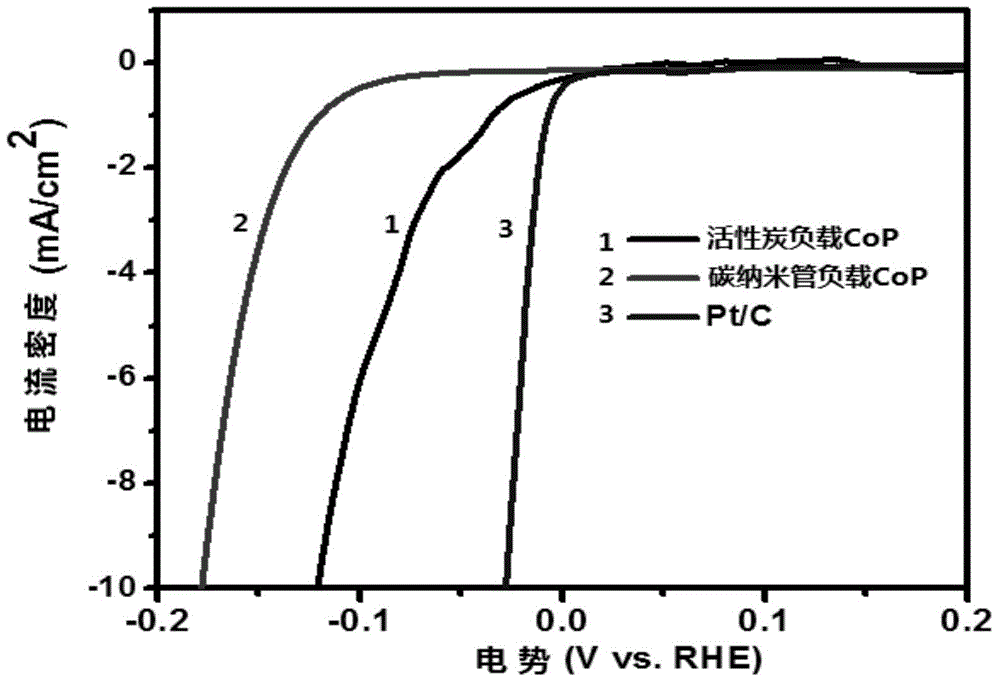

The invention relates to a catalyst for loading cobalt phosphide on activated carbon as well as preparation and application of the catalyst. The catalyst is prepared by taking multilayer nanoporous activated carbon (HNC) as a carrier and loading cobalt phosphide (CoP) on the surface of the activated carbon. The preparation method comprises the following steps: mixing cobalt nitrate hexahydrate (Co(NO3)2.6H2O), urea (CO(NH3)2), ammonium fluoride (NH4F) and deionized water to obtain a reaction mixture raw material; mixing a certain quantity of HNC with the reaction mixture raw material under an ultrasonic condition for hydrothermal reaction; carrying out suction filtration drying to obtain a precursor; conducting annealing on the precursor and sodium hypophosphite under the protecting atmosphere of argon; carrying out cooling. The catalyst prepared according to the preparation method can be used for electrochemical hydrogen evolution, and is excellent in catalytic activity for hydrogen evolution.

Owner:SOUTHWEST UNIV

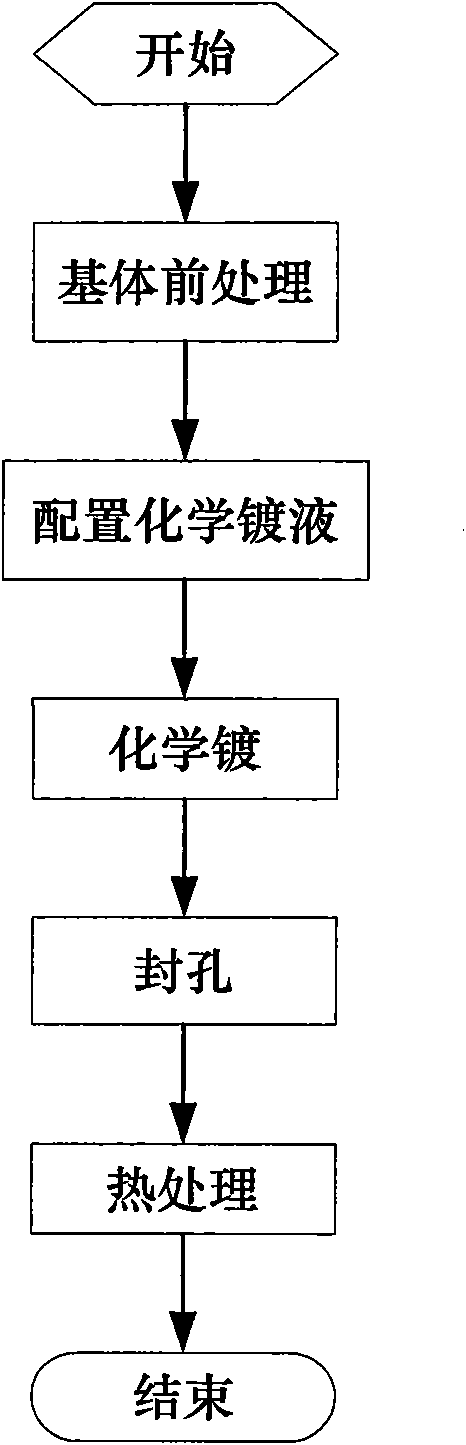

Chemical nickel-plating method for carbon fiber

InactiveCN102086517ALow costEasy to operateLiquid/solution decomposition chemical coatingFiberCarbon fibers

The invention discloses a chemical nickel-plating method for carbon fiber, which is designed for overcoming the disadvantages of high cost, a large number of process steps and poor operability existing in the prior art. In the method, a chemical plating process is adopted; and a pre-treatment is performed on a raw material and chemical plating solution is prepared before the chemical plating. The pre-treatment process comprises the steps of: calcining by using a muffle furnace to remove glue; soaking in solution of absolute ethanol to remove oil; performing surface roughening and activating treatment by using solution of sodium hydroxide and solution of silver ammonia; sensitizing by using a sensitizer, namely stannous chloride; and performing surface reduction by using solution of sodium hypophosphite. The chemical plating solution consists of nickel sulfate hexahydrate, sodium hypophosphite, sodium pyrophosphate and sodium citrate. The chemical nickel-plating on the carbon fiber is finished by placing a pre-treatment product of the chemical plating into the chemical plating solution, and reacting, standing, filtering and drying under a chemical plating condition. The method has the characteristics that: the product has a uniform surface, a compact plating layer and uniform particles.

Owner:沈阳临德陶瓷研发有限公司

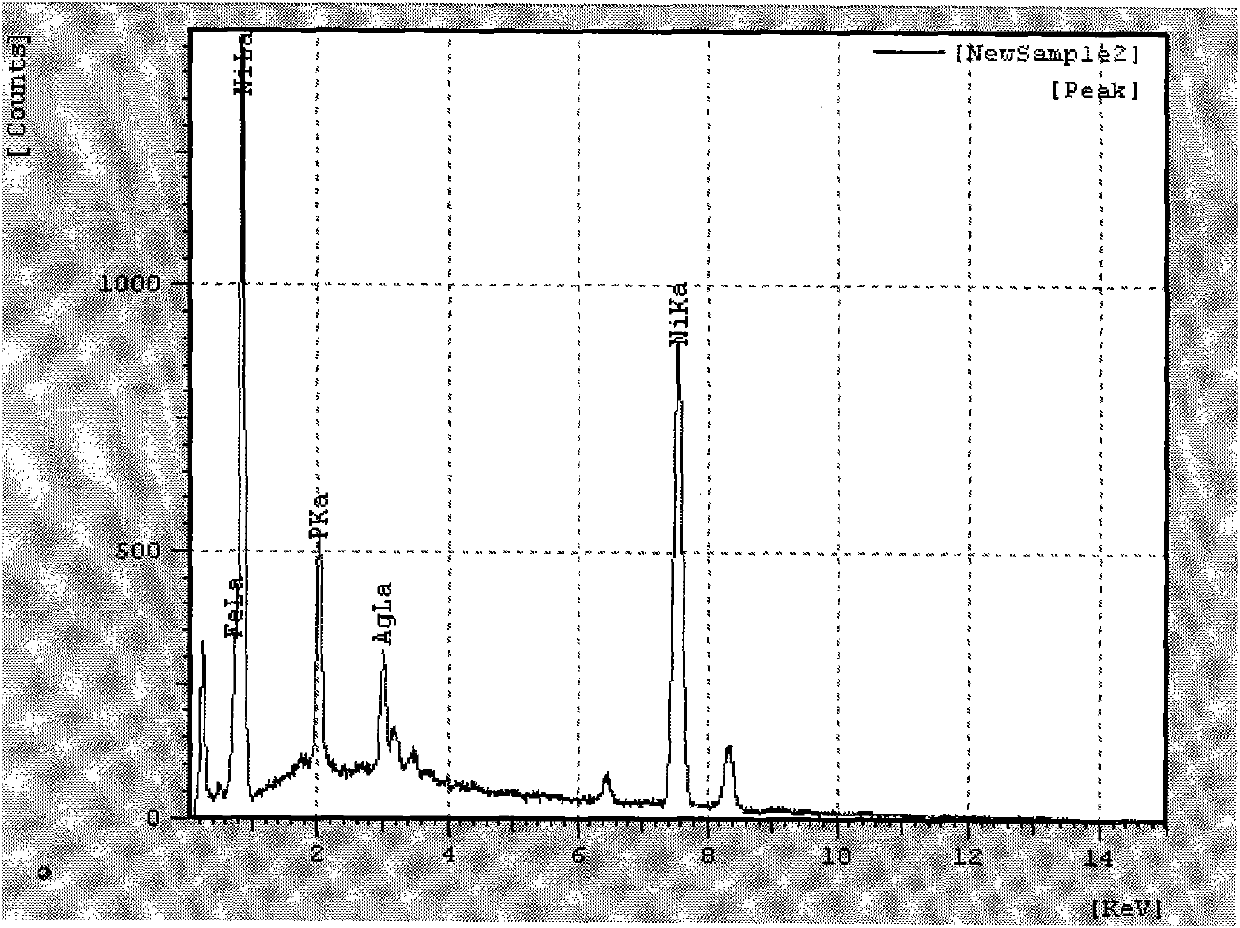

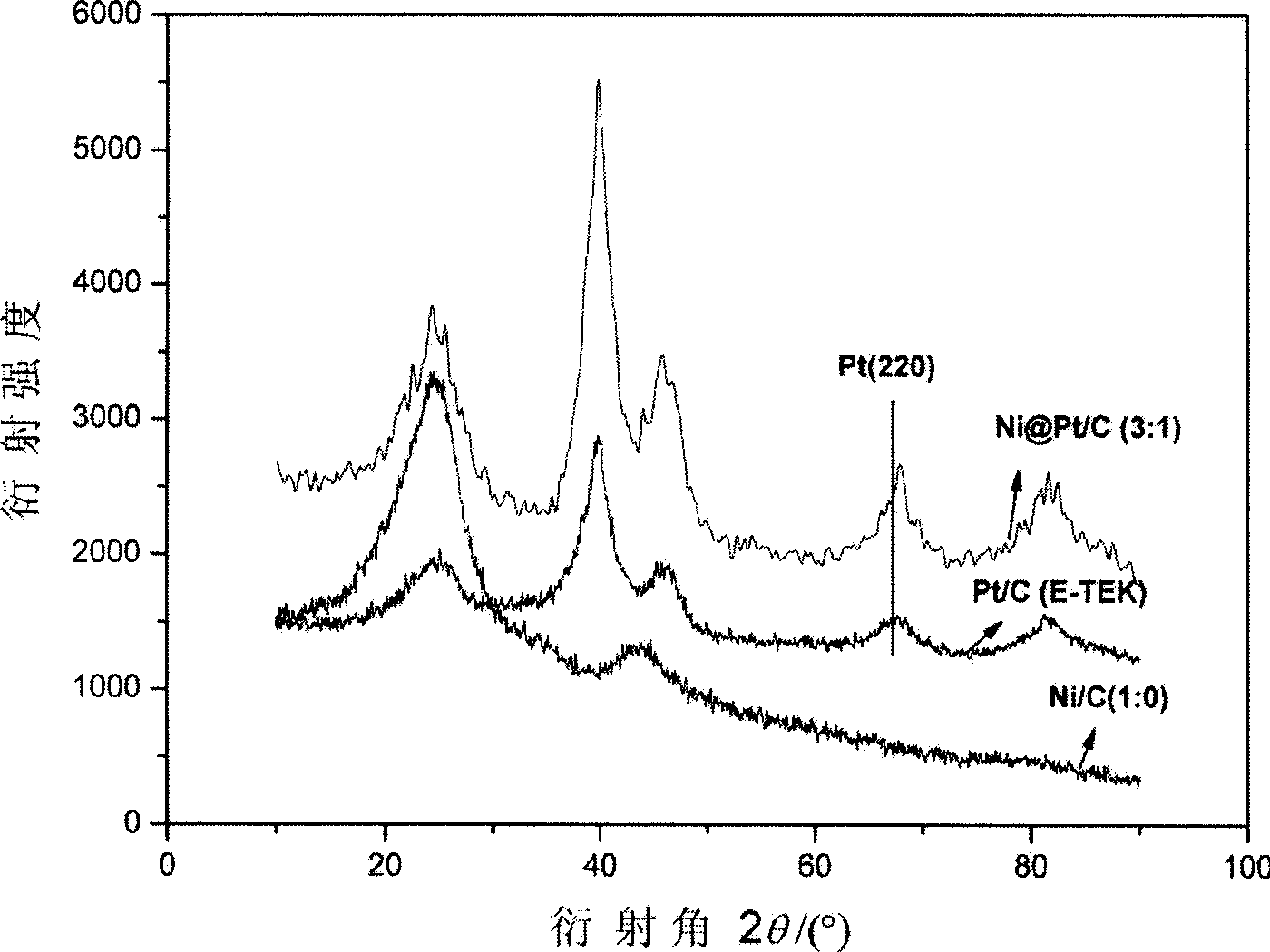

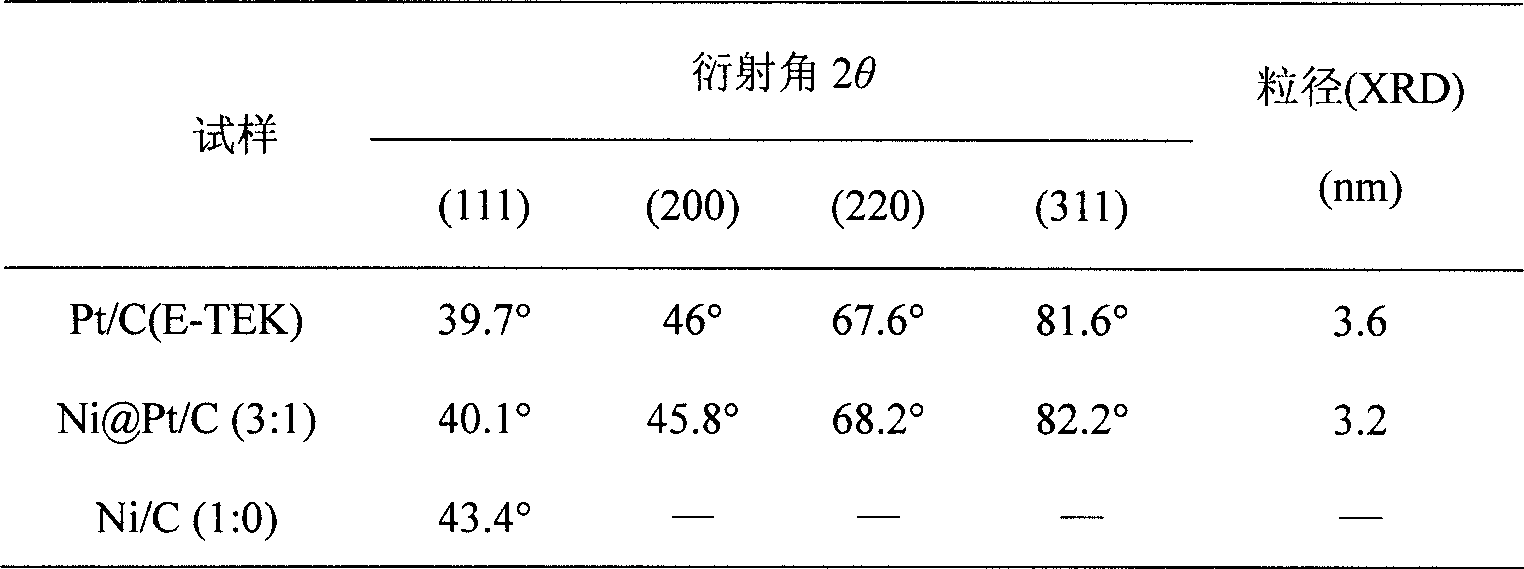

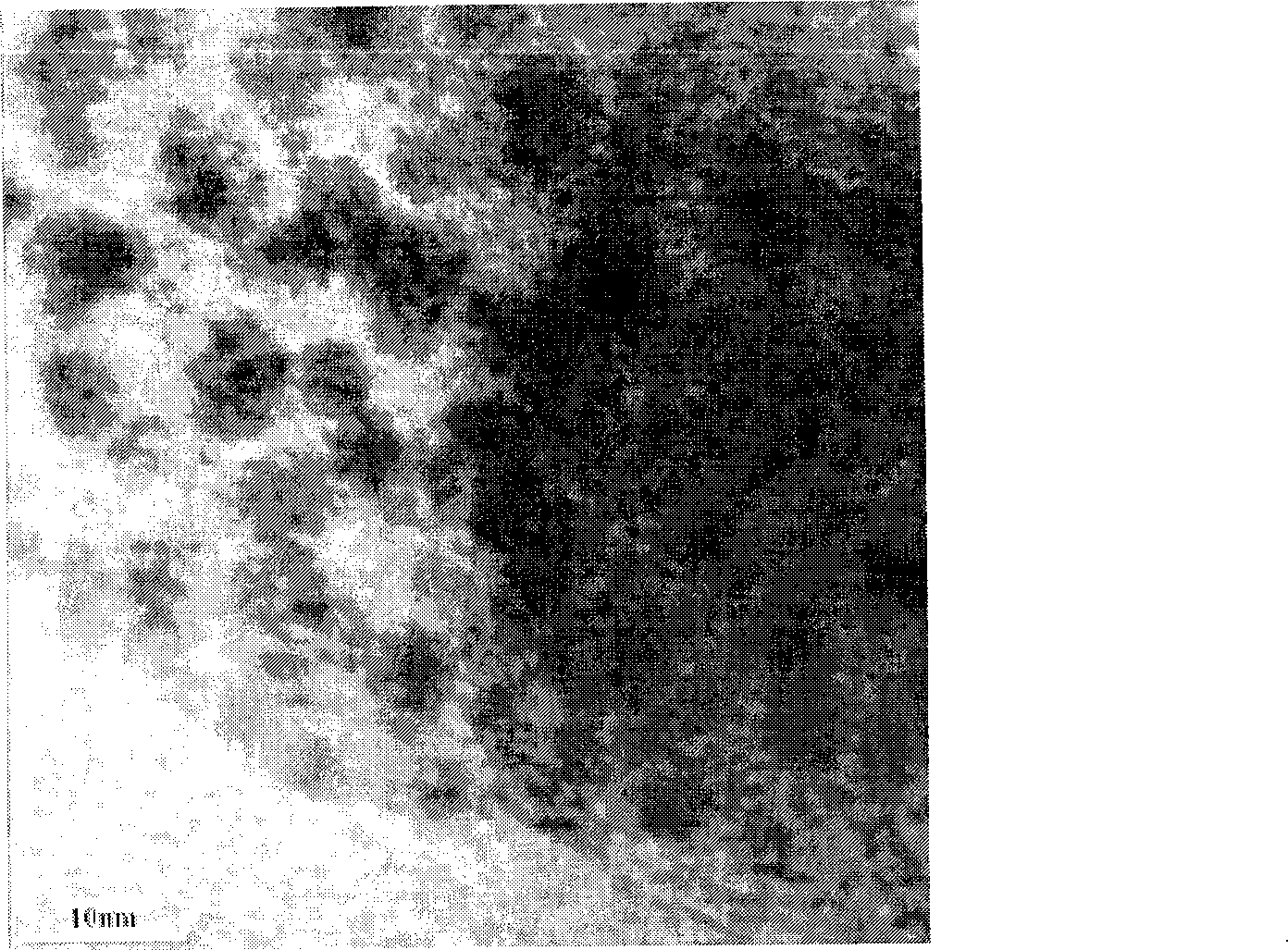

Preparation method of carbon supported core-shell Ni-Pt particles for direct methanol fuel cells

ActiveCN101455970AImprove catalytic performanceLow priceCell electrodesMetal/metal-oxides/metal-hydroxide catalystsChemistryInorganic chemistry

The invention provides a method for preparing carbon-supported nucleocapsid type Ni-Pt particles for direct methanol fuel cell catalysts, which belongs to a preparation process of direct methanol fuel cell catalysts. The method comprises the steps of adopting sodium citrate as a stabilizer, adopting cationic surfactant CTAB as dispersant, using sodium hypophosphite to reduce nickel acetate, generating a Ni kernel on the surface of Vulcan XC-72 or mesoporous carbon treated with sodium borohydride, washing superfluous sodium hypophosphite and generating a Pt shell on the surface of the Ni kernel through chemical replacement. The catalyst has a structure with the Ni kernel and the Pt shell, and has the advantages of low Pt support amount and high catalytic activity.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

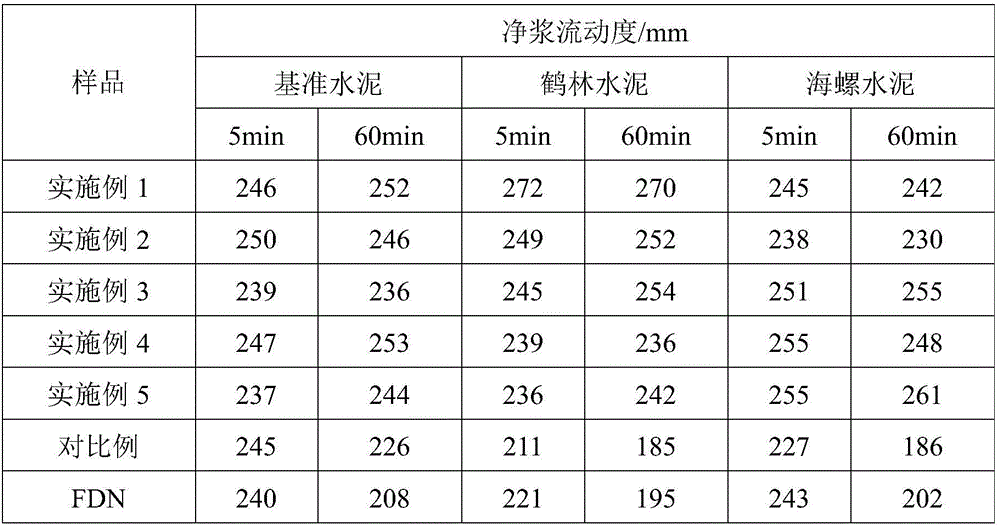

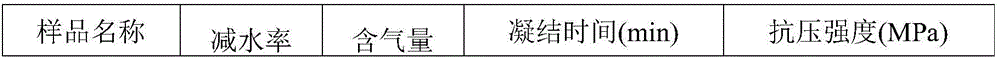

Polycarboxylic acid water reducer and preparation method thereof

ActiveCN104311752AHigh water reduction rateGood slump performanceSodium Hypophosphite MonohydrateAcid water

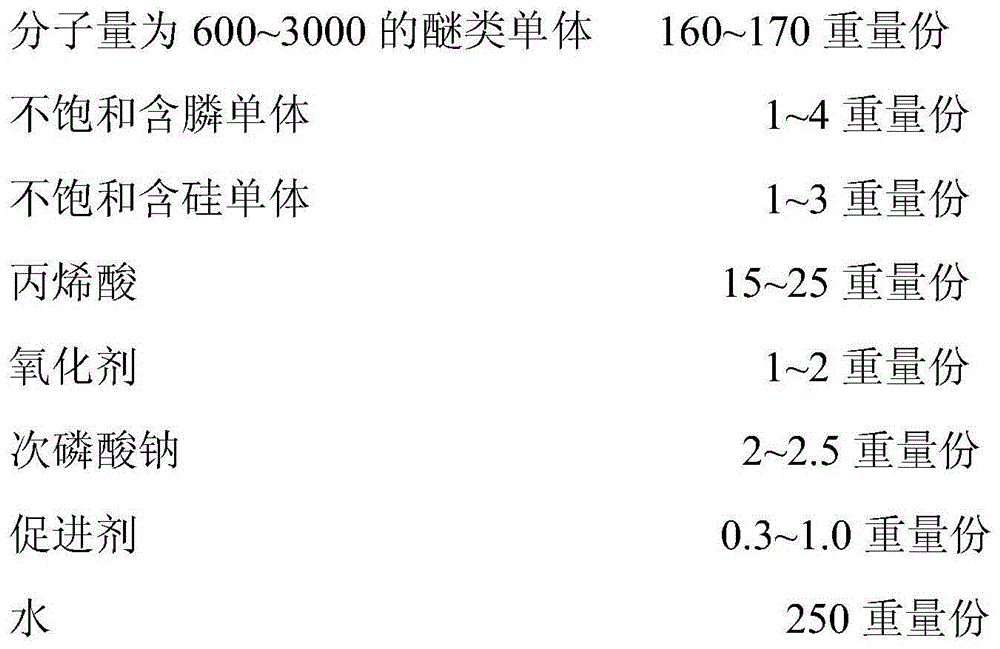

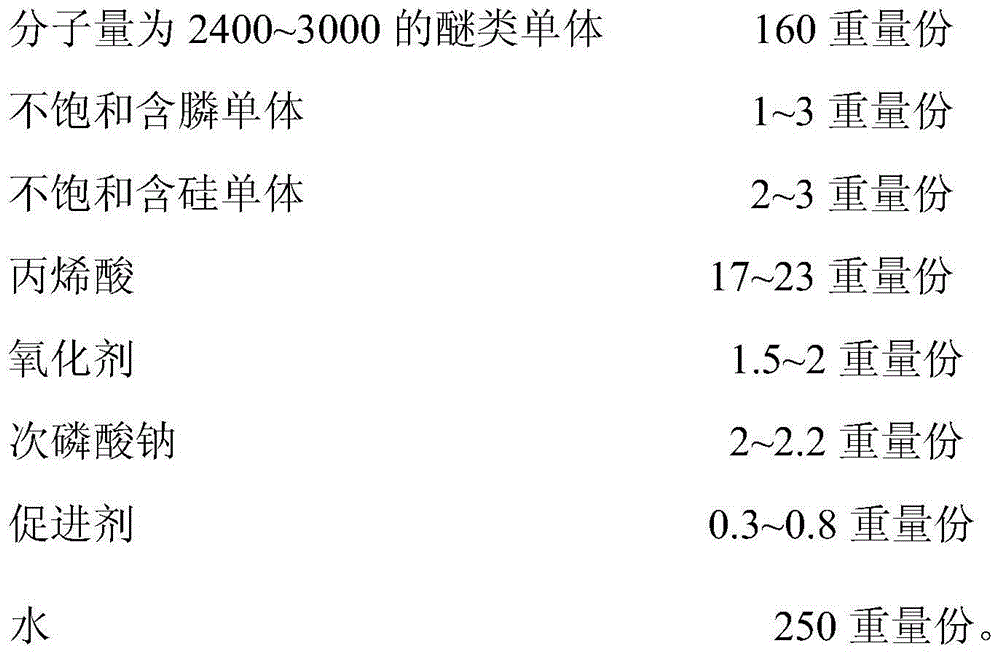

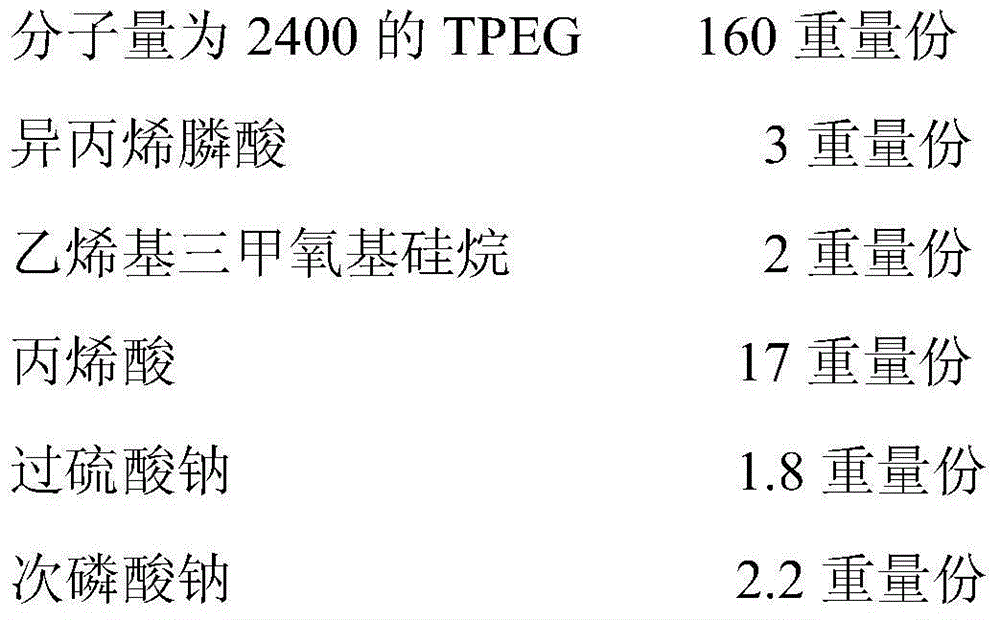

The invention discloses a polycarboxylic acid water reducer and a preparation method thereof. Raw materials of the polycarboxylic acid water reducer comprise the following components in parts by weight: 160-170 parts of an ether-based monomer having a molecular weight of 600-3000, 1-4 parts of an unsaturated phosphorous-containing monomer, 1-3 parts of an unsaturated silicon-containing monomer, 15-25 parts of acrylic acid, 1-2 parts of an oxidant, 2-2.5 parts of sodium hypophosphite, 0.3-1.0 part of promoter and 250 parts of water. Since unsaturated phosphorous-containing and silicon-containing monomers are added into the raw materials of the polycarboxylic acid water reducer, a plurality of phosphorous-containing and silicon-containing groups are introduced into molecular chains of the water reducer, so that the polycarboxylic acid water reducer having the advantages of high water-reducing rate, good slump-retaining property and facilitation in development of early strength of concrete is prepared and the common problems of low water-reducing rate and poor slump-retaining property when the polycarboxylic acid water reducer is applied in machine-made sand are overcome.

Owner:KZJ NEW MATERIALS GROUP CO LTD +2

Magnesium alloy direct chemical plating NI-P-SiC plating solution formula and plating process

InactiveCN101665930AEasy to prepareFormulated stableLiquid/solution decomposition chemical coatingChemical platingSurface-active agents

The invention provides a magnesium alloy direct chemical plating NI-P-SiC plating solution formula and a plating process. The formula consists of chemical plating Ni-P plating solution and SiC dispersing solution, wherein the chemical plating Ni-P plating solution comprises 20-30g / l of nickel sulfate, 20-30g / l of sodium hypophosphite, 15-30g / l of complexing agent, 15-25g / l of sodium acefate, 10-20g / l of fluoride, 1-2mg / l of stablizer, appropriate amount of PH value modifier and the balance of water; the SiC dispersing solution is formed by stirring 10-80mg / l of surface active agent and 1-8g / lof micron SiC by magnetic force; and after pretreatment of the magnesium alloy, a Ni-P-SiC composite plating layer with thickness being 20-50Mum is obtained under the process conditions that the temperature is 80-90 DEG C, the PH value is 4.8-5.6, and the plating time is 60-120 minutes. In the invention, basic nickel carbonate is replaced by nickel sulfate which is introduced as main salt; and themicron SiC is added to conduct plating directly; on the base of keeping the excellent performance of magnesium alloy chemical plating Ni-P alloy, the rigidity and abrasive resistance of the magnesiumalloy chemical plating layer are greatly improved; the problem of lower abrasive resistance of magnesium alloy nickel-plating layer is solved; and the preparation of the plating solution is convenient, the cost is low, the plating solution is stable and the deposition rate is quick.

Owner:CHONGQING UNIV OF TECH

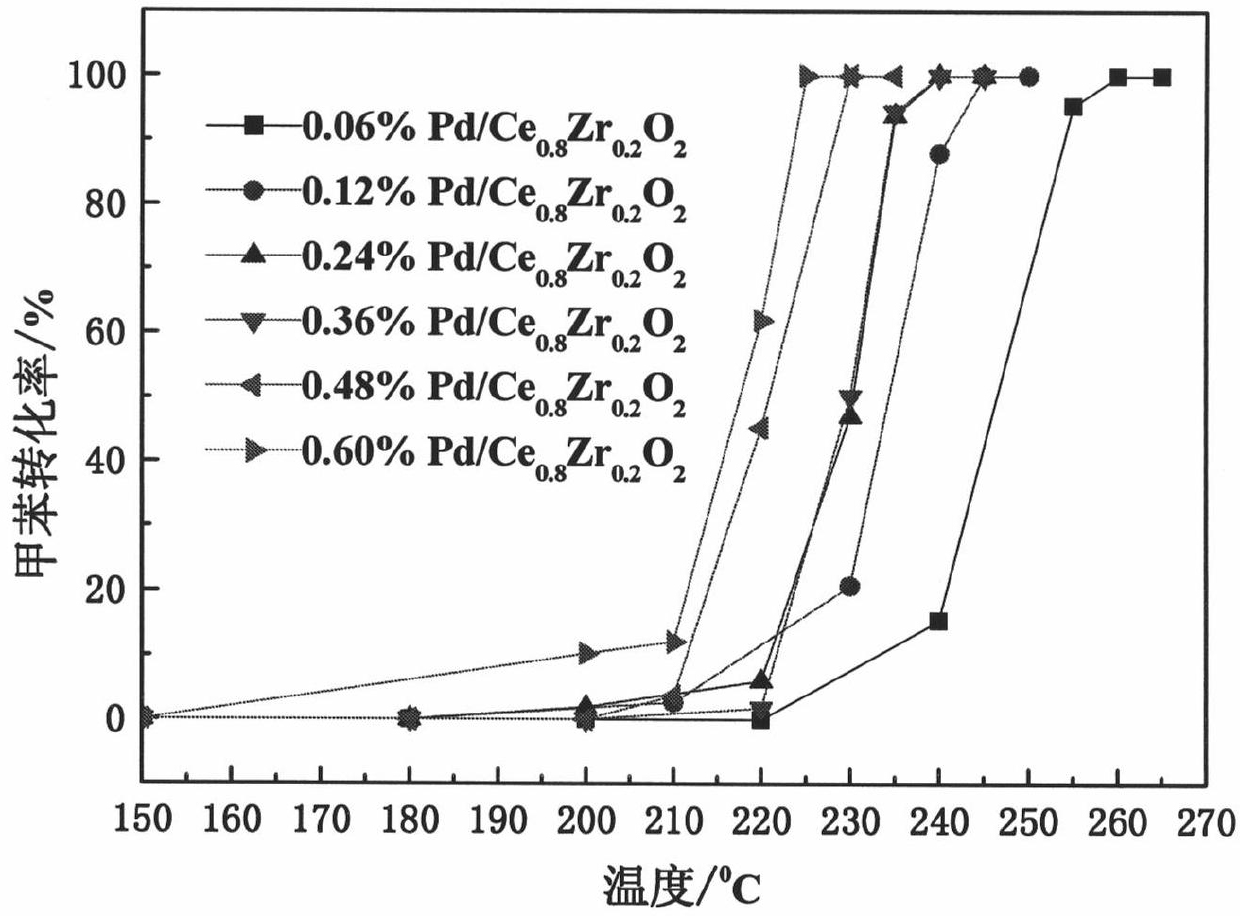

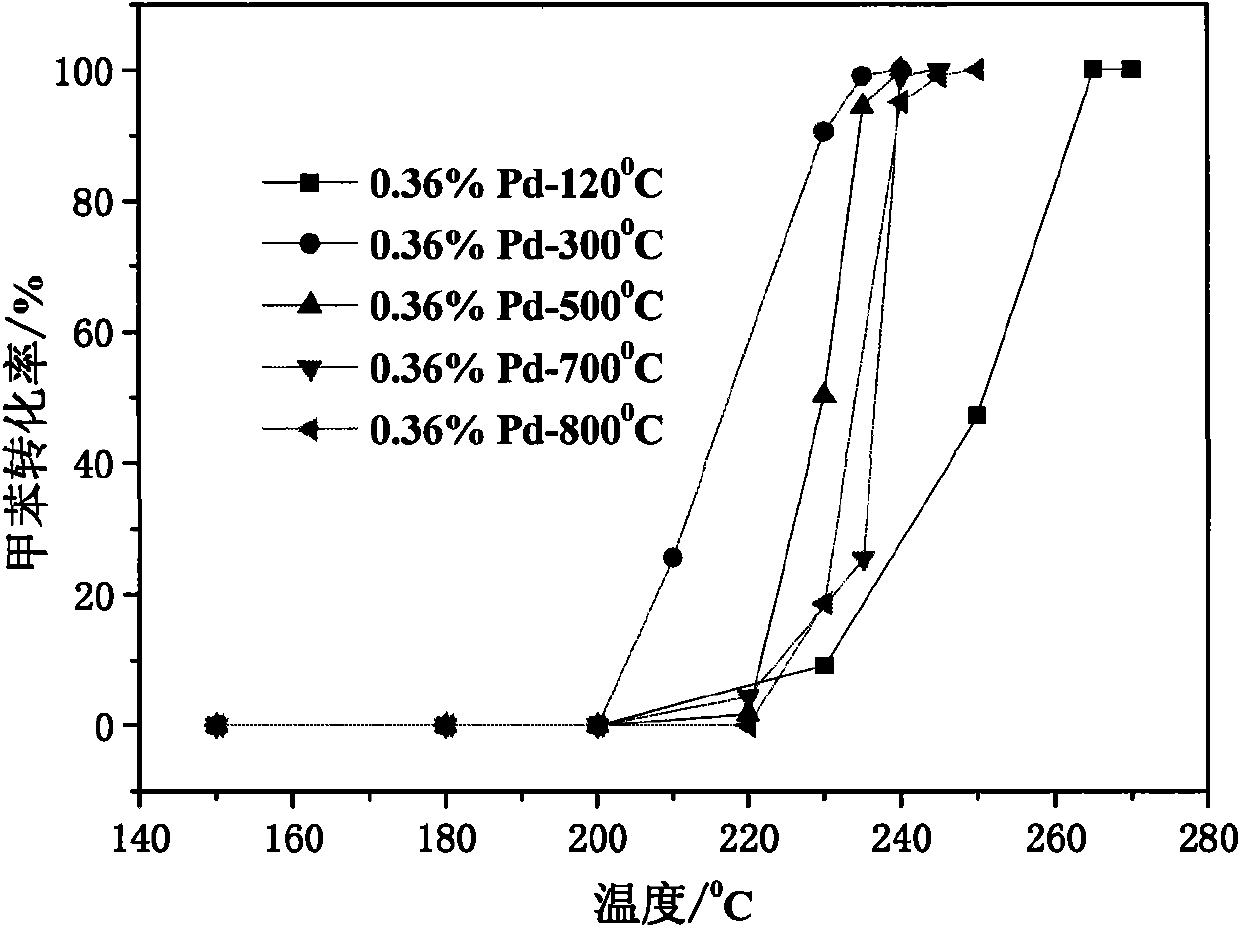

Pd/Ce0.8Zr0.2O2/cordierite honeycomb ceramic monolithic catalyst, preparation method and application thereof

InactiveCN102000570AHigh catalytic activityImprove high temperature resistanceDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystSodium phosphates

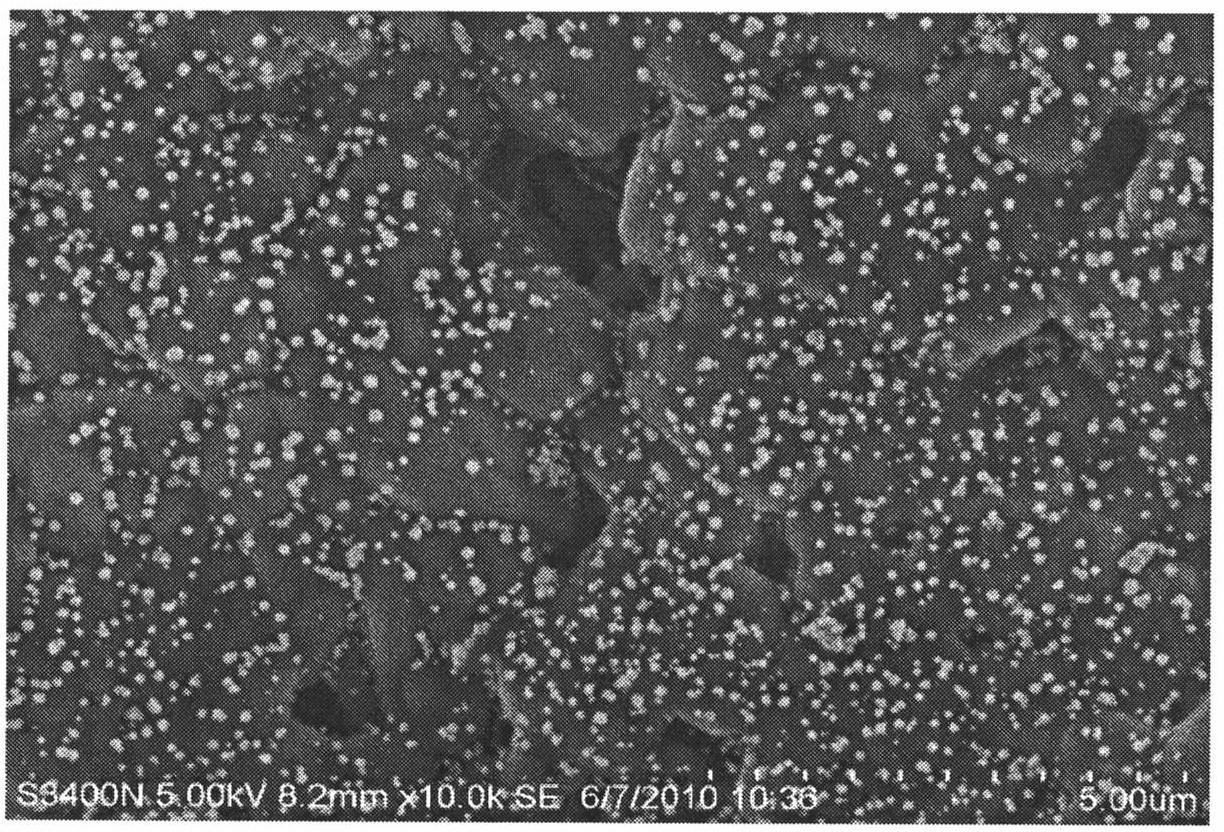

The invention discloses a Pd / Ce0.8Zr0.2O2 / cordierite honeycomb ceramic monolithic catalyst, a preparation method and application thereof. The catalyst is prepared by taking cordierite honeycomb ceramic which is eroded by hydrochloric acid as a first carrier, a cerium-zirconium composite oxide as a second carrier, and a precious metal, namely palladium (Pd) as an active ingredient; preparing a cerium-zirconium composite coating on the cordierite carrier by an immersion method; immersing the carrier into plating solution; and directly reducing palladium onto the cordierite honeycomb ceramic coated with the cerium-zirconium composite coating by the redox reaction of palladium chloride and sodium hypophosphite and the self-catalysis of the palladium. The preparation method improves the oxygen storage performance of the catalyst, improves high-temperature resistance, and realizes uniform load of nano-palladium particles on the carriers without embedding active sites; moreover, the using amount of the palladium is small, the utilization rate of the palladium is improved, the process is simple, the preparation period is short, and the production cost is low. The monolithic catalyst prepared by the method has high activity and high stability; and the methylbenzene can be oxidized into harmless carbon dioxide (CO2) and water (H2O) in the presence of the catalyst at the temperature of 220 to 300 DEG C.

Owner:GUANGDONG UNIV OF TECH

Semi-bright lead-free chemical tinning liquid and using method thereof

InactiveCN101717929AEnables continuous autocatalytic depositionFast depositionLiquid/solution decomposition chemical coatingThioureaBenzaldehyde

The invention discloses new semi-bright lead-free chemical tinning liquid and a using method thereof. A semi-bright silver tin-copper alloy chemical plating layer is obtained on copper and copper alloy matrix. In the chemical plating liquid, tin sulfate is used as a main salt, thiourea is used as a main complexing agent, citric acid is used as an auxiliary complexing agent, sodium hypophosphite is used as a reducing agent, ethylene diamine tetraacetic acid is used as an antioxidant, sulfuric acid is used as a stabilizing agent, gelatin is used as a leveling agent, and benzaldehyde is used as an auxiliary brightening agent. The pH value of the plating liquid is 0.8 to 2.0, the temperature of the plating liquid is between 80 and 90 DEG C, the carrying capacity of the plating liquid is 0.8 to 1.5dm2 / L, and the mechanical stirring speed is 50 to 100 rpm. The continuous self-catalytic deposition of tin is implemented on the copper and copper alloy matrix, plating layers of different thicknesses can be obtained by controlling the chemical plating time, and the deposition speed is high; crystalline grains are obviously refined, the surface flatness of the plating layer is improved, and the plating surface area is large; the plating layer and the matrix are combined firmly; and after passivating treatment, the change resistance of the plating layer is high. The technology has broad application prospect in products such as deep hole pieces, blind hole pieces, small-sized electronic parts and components which are difficult to process, printed circuit boards (PCB) and the like.

Owner:KUNMING UNIV OF SCI & TECH

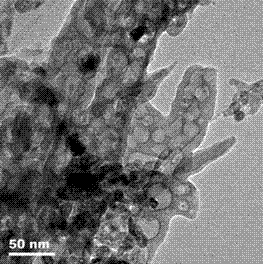

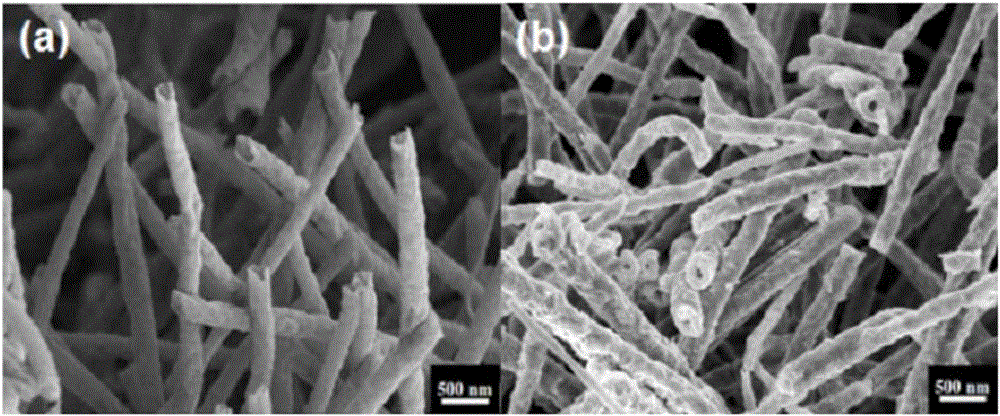

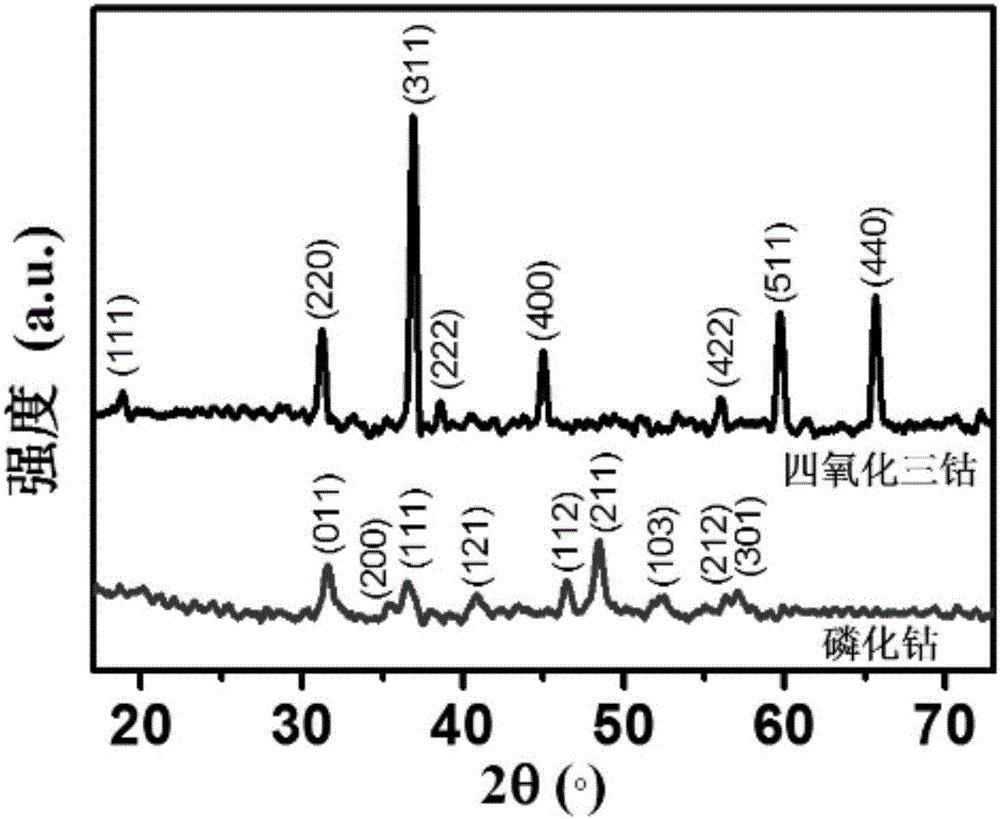

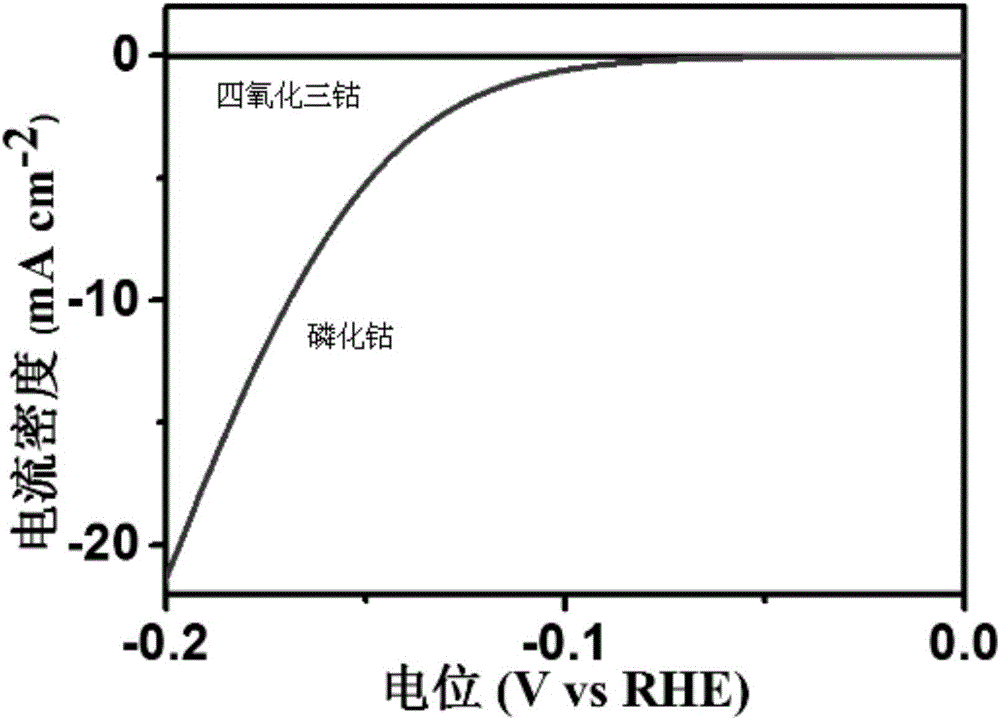

Preparation method of porous cobalt phosphide nanowire catalyst

InactiveCN107245727AImprove electrochemical activityImprove electrochemical stabilityNanotechnologyElectrode shape/formsNanowireFiltration

The invention discloses a preparation method of a porous cobalt phosphide nanowire catalyst. The method comprises the following steps that a solution is prepared by taking urea as a precipitant, taking cobalt sulfate hepathydrate as a cobalt source and taking glycerin and deionized water as solvents; the solution is added into a high pressure reactor for a hydrothermal reaction, after sufficient reaction is achieved, suction filtration and washing are conducted, vacuum drying is conducted, and then linear basic cobalt carbonate is obtained; in a tubular furnace, air burning is conducted on the linear basic cobalt carbonate at certain temperature, and cobaltosic oxide is obtained; and sodium hypophosphite serves as a phosphorus source, a cobaltosic oxide precursor and sodium hypophosphite are placed at the two ends of the same porcelain boat according to a certain proportion, the phosphorus source is placed at the upper stream of airflow, the treated porcelain boat is put into the tubular furnace for lower temperature calcination in an inert atmosphere, and preparation of the porous cobalt phosphide nanowire catalyst is achieved. The preparation method of the porous cobalt phosphide nanowire catalyst has the advantages that the production technology is simple, the cost is low, electrochemical activity and stability of the catalyst can be effectively improved, and the method is wide in application.

Owner:NANCHANG HANGKONG UNIVERSITY

Preparation method of cobalt phosphide hollow nano-fiber material

InactiveCN105803580AIncrease the areaHigh activityInorganic material artificial filamentsNanotechnologyFiberN dimethylformamide

The invention relates to a preparation method of a cobalt phosphide hollow nano-fiber material.The preparation method comprises the steps of adding cobalt salt to N, N-dimethylformamide, after the cobalt salt is dissolved, adding polyvinylpyrrolidone, conducting stirring, so that a precursor spinning solution is obtained, and conducting electrostatic spinning, so that a polyvinylpyrrolidone nanofiber membrane doped with cobalt ions is obtained; conducting pre-oxidation, and then conducting calcination at the temperature of 400-700 DEG C, so that a hollow tubular cobaltosic oxide nano-fiber is obtained; then mixing the hollow tubular cobaltosic oxide nano-fiber with sodium hypophosphite monohydrate, conducting a phosphorization reaction, and conducting cleaning and drying, so that the cobalt phosphide hollow nano-fiber material is obtained.The method is environmentally friendly in process and low in cost; the obtained cobalt phosphide hollow nano-fiber material is stable in chemical property and high in activity of electro-catalysis hydrogen evolution and expected to serve as an ideal high-performance electrochemical hydrogen evolution catalytic material.

Owner:DONGHUA UNIV

Preparation method of thermometal phosphide hydrofining catalyst

ActiveCN103157497AHigh activityAchieving synergyPhysical/chemical process catalystsSodium Hypophosphite MonohydrateNitrogen

The invention provides a preparation method of a thermometal phosphide hydrofining catalyst. The method comprises the following steps of: firstly, preparing a bulk phase WP or a WP loaded by a porous carrier material by adopting a traditional procedure warming reduction method, then soaking the bulk phase WP or the WP loaded by the carrier in a nickel chloride and sodium hypophosphite solution, drying, carrying out thermal treatment in nitrogen, passivating and washing to obtain the bulk phase thermometal phosphide WP-Ni2P catalyst or the catalyst loaded by the carrier, and bulk phase thermometal phosphide MoP-Ni2P catalyst or the catalyst loaded by the carrier can be obtained by adopting the same method. The method provided by the invention has characteristics that the method effectively utilizes temperature difference between the metal phosphide prepared by the procedure warming reduction method and the metal phosphide prepared by a hypophosphite resolving method, a novel preparation technology of the thermometal phosphide hydrofining catalyst is provided, the method realizes the synergy acceleration action of different metal phosphides, and the catalytic activity of the metal phosphide is effectively improved.

Owner:NANKAI UNIV

Polyacrylic acid or copolymer thereof and preparation method of polyacrylate or copolymer salt thereof

ActiveCN101921359AGood production safetyPromote environmental protectionPolymer scienceSodium Hypophosphite Monohydrate

The invention relates to a preparation method of an organic polymer and in particular discloses a preparation method of polyacrylic acid or a copolymer thereof. The method comprises the following steps: firstly preparing 3-62% of acrylic acid or methacrylic acid, 0-48% of comonomers, 0.05-35% of sodium hypophosphite and 30-96% of water; mixing the prepared raw materials all together and stirring the mixture uniformly, placing the mixture in a 60Co gamma ray radiation field to undergo radiation-induced polymerization, with radiation dose of 1.2-30KGy and obtaining the polyacrylic acid or the copolymer thereof after polymerization; and neutralizing the prepared polyacrylic acid or the copolymer thereof in aqueous alkali until the pH value is 6.5-9, thus obtaining polyacrylate or copolymer salt thereof. The invention has the following advantages: the energy consumption is low, the equipment utilization ratio is high, the process is simple and the operation is convenient, chemical initiators are avoided, the product performance is excellent, the production safety and environment-friendliness are better and the product can serve as a dispersing agent, a scale inhibitor, a thickening agent, a flocculating agent, etc.

Owner:湖南葆华环保科技有限公司

Nickel phosphorus chemical plating method of neodymium iron boron permanent magnet material

InactiveCN1410593AUniform thicknessPlay a protective effectLiquid/solution decomposition chemical coatingChemical platingMechanical energy

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Electroplating pretreatment method for acrylonitrile butadiene styrene (ABS) plastic surface

InactiveCN102409320ASimple processEasy to operateLiquid/solution decomposition chemical coatingPretreatment methodSodium phosphates

The invention relates to an electroplating pretreatment method for an acrylonitrile butadiene styrene (ABS) plastic surface. The electroplating pretreatment method comprises the following process steps of: eliminating stress, performing alkali washing for oil removal, pickling, roughening, performing neutralizing treatment, performing chemical activation, and performing the conventional electroplating, wherein in the chemical activation process, plastic base materials are put in to an activation solution and are subjected to hyperthermic treatment in a water bath for a certain period of time, each liter of the activation solution comprises 10 to 12g of nickel sulfate, 20 to 25g of sodium hypophosphite and 5 to 8g of sodium citrate, the pH is 9 to 11, and the temperature is between 70 and 75 DEG C. In the invention, a novel method in which metal palladium activation is not used is provided, can be used for replacing a sodium borohydride and methanol activation process and contributes to environment friendliness; and on the basis of pretreatment, the plastic surface can be directly electroplated, so that the problems of complicated treating processes, high PdCl2 prices, high pollution possibility of a plating solution and the like are solved.

Owner:SHENYANG POLYTECHNIC UNIV

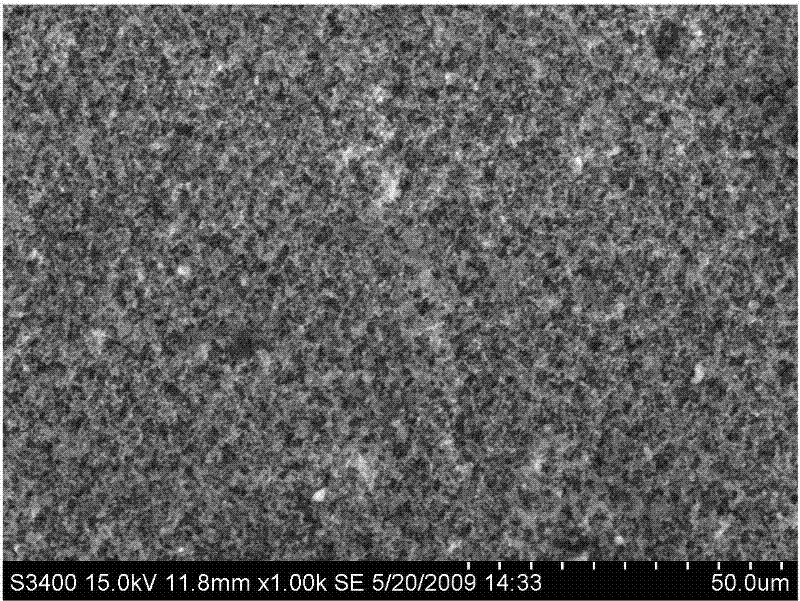

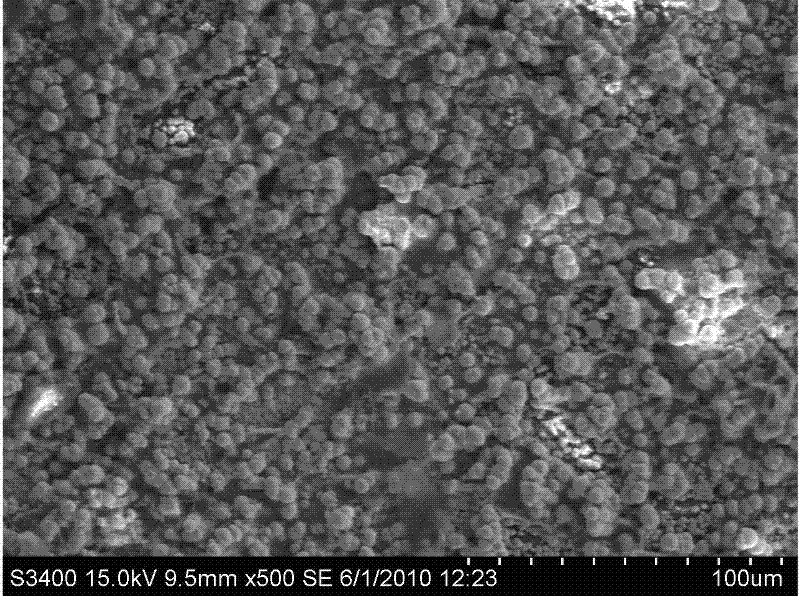

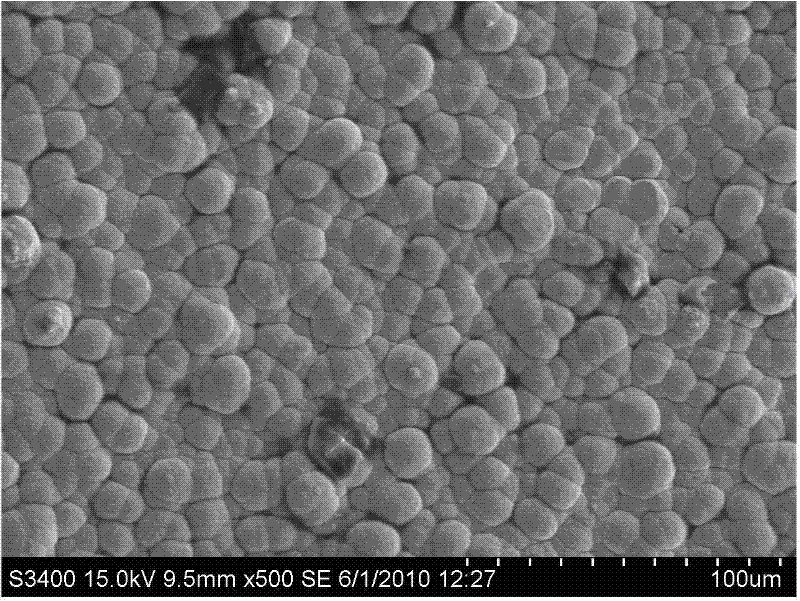

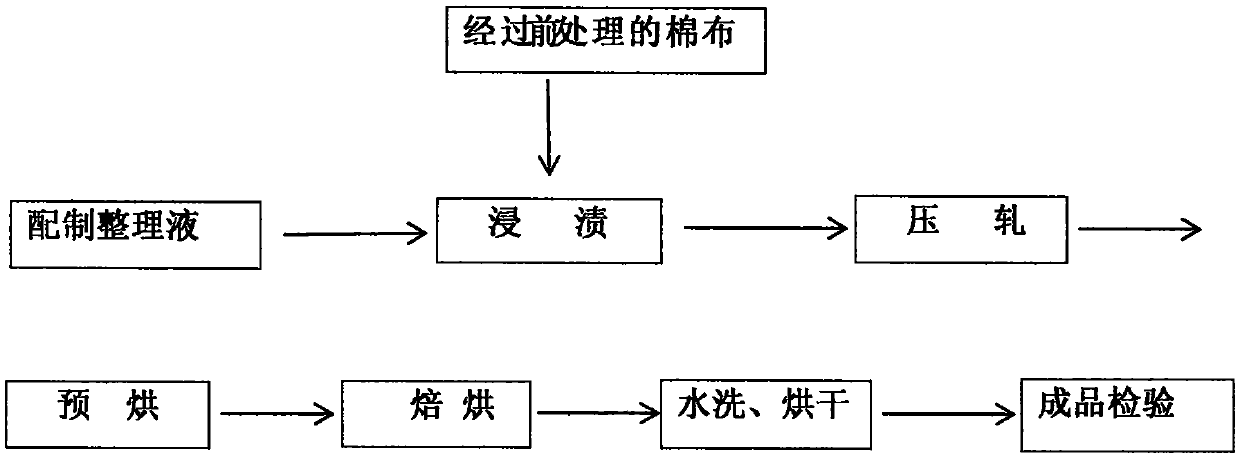

Method for performing antibacterial and antivirus treatment on textiles by utilizing natural biomaterials

The invention discloses a method for performing antibacterial and antivirus treatment on textiles by utilizing natural biomaterials. The method is characterized by comprising the following steps of treatment liquid preparation, impregnation of preprocessed cotton in the treatment liquid, press-rolling, preliminary drying, baking, washing with water, drying, and inspection of finished products. The prepared treatment liquid is prepared from chitosan loaded to cellulose fibers, a plant extract loaded to cellulose fibers, an organic acid cross-linking agent and sodium hypophosphite in the mass ratio of the chitosan to the plant extract to the organic acid cross-linking agent to the sodium hypophosphite being (0.1-2% ) to (0.1-3% ) to (1-10% ) to (1-8% ). According to the method disclosed by the invention, heavy metal antibacterial agents such as nano-silver and chemical synthesis antibacterial agents, generating potential damage to human bodies, are not used, and the natural biological extract is used as an antibacterial antivirus material, has favorable compatibility to the human bodies, is safe and comfortable to use, and is free from toxic or side effects.

Owner:徐新明

Preparation method of graphene/copper composite material

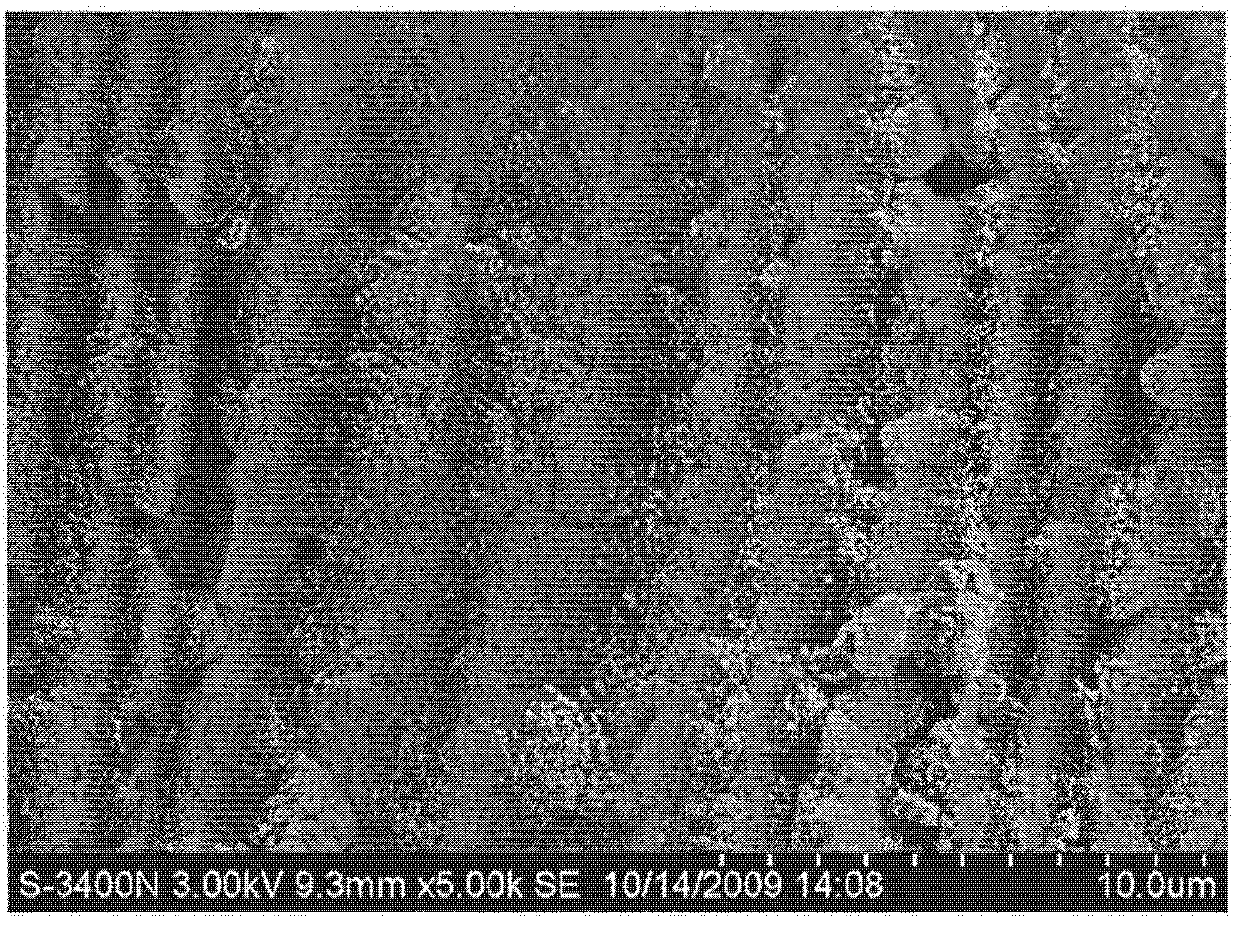

InactiveCN103736993AGood dispersionThe reaction conditions are mild and safeLiquid/solution decomposition chemical coatingWater bathsFiltration

The invention discloses a preparation method of a graphene / copper composite material. The preparation method includes the following steps: step 1, weighing copper sulfate pentahydrate, nickel sulfate, citric acid and boric acid so as to prepare a mixed solution A, and stirring the mixed solution A; step 2, placing the mixed solution A in a magnetic stirring water bath kettle for heating the mixed solution A, then adding graphene oxide solution into the mixed solution A, stirring, and preparing a mixed solution B; step 3, adding sodium hypophosphite solution into the mixed solution B, stirring, and performing an accelerated reaction and ultrasound dispersion treatment so as to obtain a solution of the graphene / copper composite material which is evenly dispersed; step 4, performing repeated suction filtration on the solution by using a microfiltration membrane, repeatedly washing filter residues until PH (potential of hydrogen) value of the filter residues is neutral, performing vacuum drying, and performing reduction so as to obtain the composite graphene / copper composite material. The preparation method of the graphene / copper composite material is simple, convenient to operate, and low in cost, and has good application prospect.

Owner:SHANGHAI JIAO TONG UNIV

Preparation method of integral type catalyst with low content of noble metal and application thereof

ActiveCN101733165AEvenly distributedReunion noCatalyst carriersDispersed particle separationChemical platingHydrazine compound

The invention discloses a preparation method of an integral type catalyst with low content of noble metal and an application thereof. In the invention, the preparation method comprises the following steps of: adopting a chemical plating method, utilizing hydrazine or sodium hypophosphite as a reducer, generating an oxidation-reduction reaction with palladium chloride or chloroplatinic acid in a plating bath and depositing metallic Pd and / or Pt on the surface of a cordierite honeycomb ceramic pore canal directly under the autocatalytic action of Pd or Pt simultaneously so as to obtain a load-type integral type catalyst with low content of the noble metal of the Pt and / or the Pd; the integral type catalyst with the noble metal, which is prepared by the invention, is applied to the purifying treatment of the catalytic combustion of toluene; though the content of the noble metal in the integral type catalyst prepared by the invention is only 0.12-0.60wt%, the conversion rate of the toluene reaches 99% at the lower temperature of 186-244 DEG C when the integral type catalyst is used for the purifying treatment of the catalytic combustion of the toluene, and the concentration of the toluene is lowered below 40mg / m<3>; and the invention is the integral type catalyst for treating VOCs (volatile organic chemicals) by low-temperature catalytic combustion, which has lower cost, simple preparation and obvious purifying effect.

Owner:FOSHAN SHUNDE KINGLEI ENVIRONMENT & TECH CO LTD

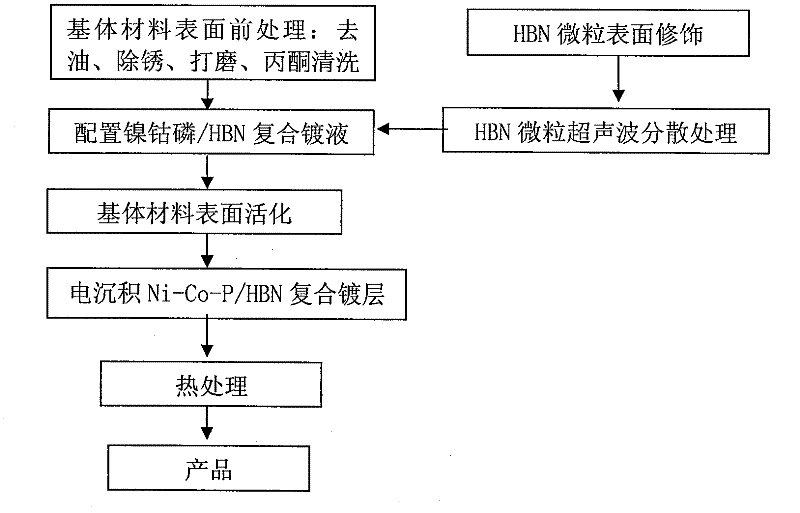

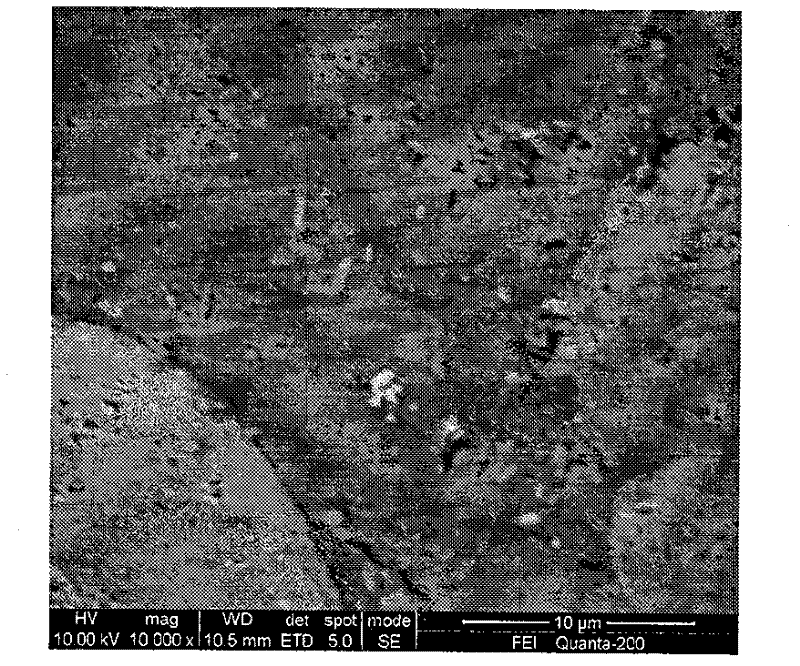

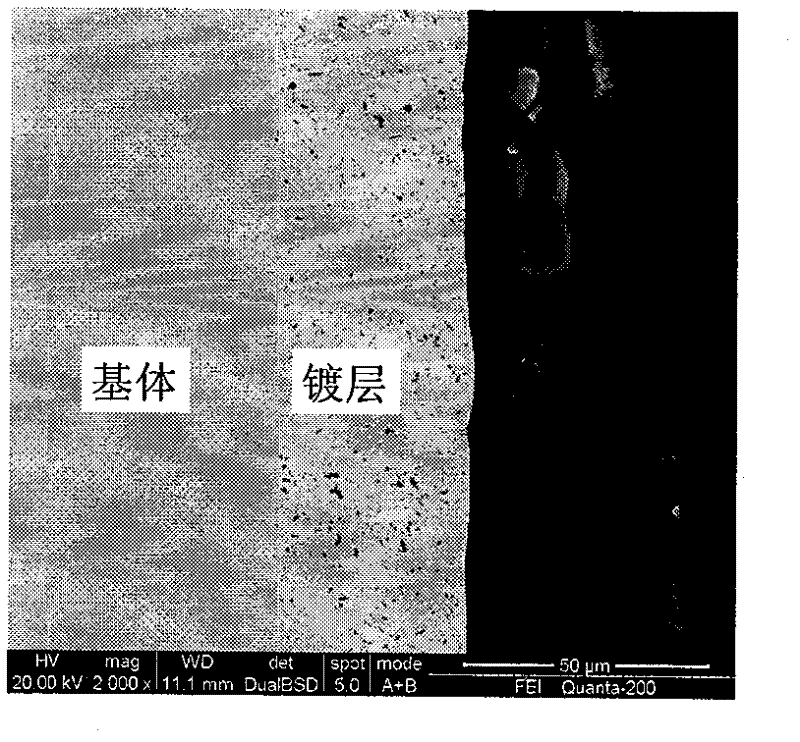

Pulse-electrodeposited Ni-Co-P/HBN composite plating and preparation method thereof

InactiveCN102534732AImprove electrodeposition efficiencyEasy to useElectrolytic coatingsPolyvinyl alcoholHexagonal boron nitride

A pulse-electrodeposited Ni-Co-P / HBN composite plating and a preparation method thereof. The preparation method adopts a metal material as a substrate, and comprises the following steps: firstly pretreating the substrate surface, preparing a composite plating solution with nickel sulfate, cobalt chloride, sodium hypophosphite, citric acid, trisodium citrate, boric acid, and polyvinyl alcohol as main components and hexagonal boron nitride HBN powder as a dispersed phase, performing surface modification and dispersion treatment of the HBN particles by using a surfactant through ultrasonic vibration, allowing the HBN particles to disperse uniformly in the plating solution through reasonable setting of pulse electrodeposition parameters and full stirring, performing codeposition and heat treatment of the HBN particles and the substrate metal nickel cobalt phosphor in a state of applying pulsed current so as to obtain a corrosion-resistant, wear-resistant and antifriction pulse-electrodeposited Ni-Co-P / HBN composite plating. The invention overcomes defects of single component of current composite plating, coarse plating crystal grain, low interface bonding strength with the substrate, non-ideal comprehensive properties of corrosion resistance, wear resistance, and antifriction, and the like; the pulse-electrodeposited Ni-Co-P / HBN composite plating of the invention is applicable to wear-resistant, antifriction and corrosion-resistant surface plating of friction kinematic pair parts in industries of machinery, metallurgy, chemical engineering, and the like.

Owner:HUNAN UNIV OF SCI & TECH

Polycarboxylate superplasticizer with improved workability and encapsulation and preparation method thereof

ActiveCN106116226AImprove workabilitySimple production processSodium Hypophosphite MonohydrateHydrogen

The invention relates to preparation of polycarboxylate superplasticizer, in particular to polycarboxylate superplasticizer with improved workability and encapsulation and a preparation method thereof. An effective dose of monomers, polysaccharide with the molecule side chain containing rhamnose, hydroxide radical and carboxyl, sodium hypophosphite, sodium bisulfoxylate formaldehyde powder, vitamin C, sodium hydrogen sulfite, crylic acid, hydrogen peroxide and sodium hydroxide are dissolved in water and then subjected to blending, fed-batch blending and other steps, and then the polycarboxylate superplasticizer is obtained. The technical problems that in the prior art, during using, the process operation is complex are solved. The polycarboxylate superplasticizer has the advantages that the preparation process and a use method are simple, the polycarboxylate superplasticizer meets national standard requirements, and after being used, the polycarboxylate superplasticizer is good in workability and does not separate or bleed.

Owner:石家庄协耦化学科技有限公司

Electrodeposition preparation method of carbon nanotube/transition metal compound composite material

ActiveCN105251513AThe size is easy to controlAchieve synergyElectrolytic inorganic material coatingCatalyst activation/preparationSupporting electrolytePhotocatalytic water splitting

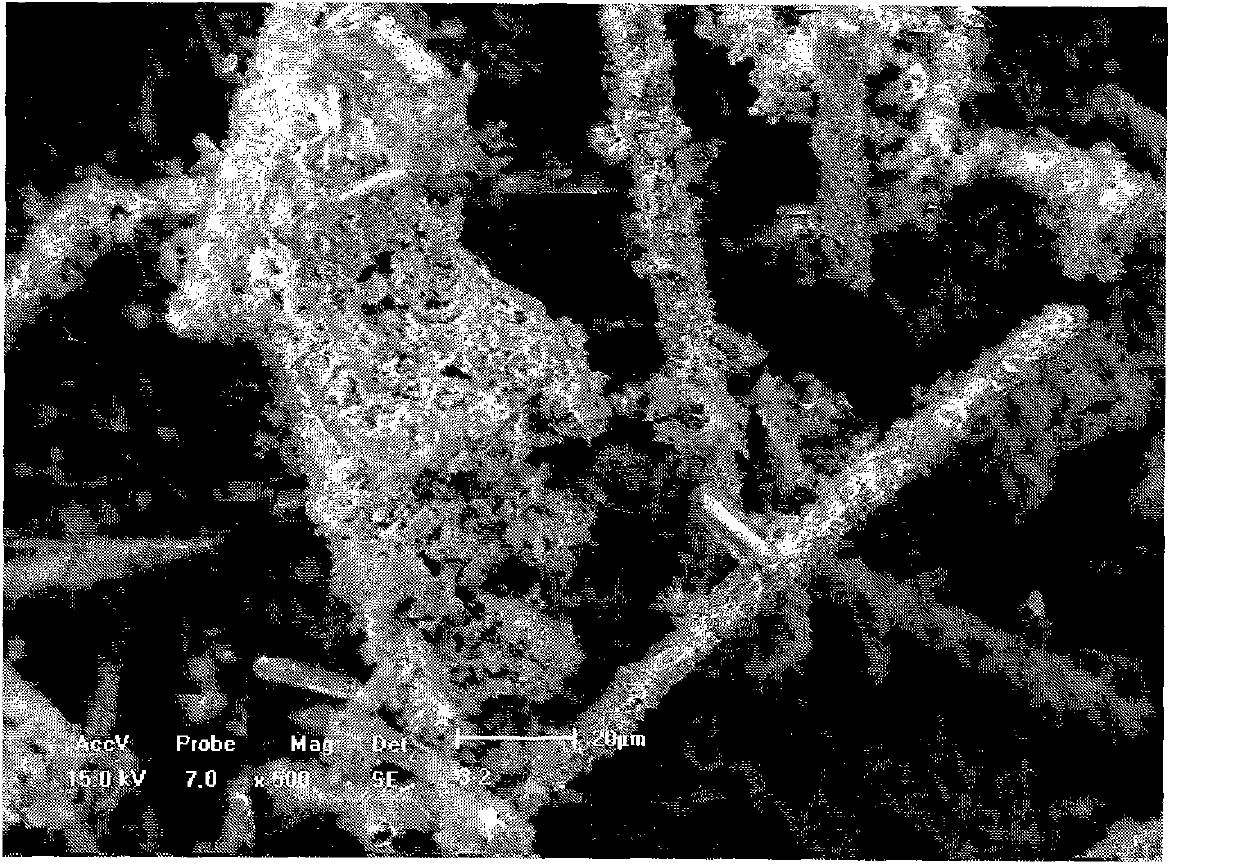

The invention provides an electrodeposition preparation method of a carbon nanotube / transition metal compound composite material. The method comprises the following steps: adding carbon nanotubes into a solvent, carrying out ultrasonic treatment to obtain a suspension, adding the suspension to a preprocessed glassy carbon electrode surface in a dropwise manner, and naturally air-drying to form a uniform carbon nanotube thin layer in order to obtain a carbon nanotube modified glassy carbon electrode; adding a precursor A and a support electrolyte into deionized water, adding a precursor B when necessary, and adjusting the pH value to 0-13 by boric acid and / or sodium hypophosphite to obtain an electroplating solution; and electroplating the carbon nanotube modified glassy carbon electrode in the electroplating solution, cleaning with water, naturally drying at normal temperature, and scrapping a carbon nanotube / transition metal compound composite material off the surface of the glassy carbon electrode by using a blade to obtain the carbon nanotube / transition metal compound composite material. The method has the advantages of simple operation and easy large scale production; and the prepared composite material has great advantages in catalytic hydrogen evolution and energy conversion, and can be applied in the fields of production of hydrogen through photocatalytic water decomposition, and photoelectric conversion.

Owner:WENZHOU UNIVERSITY

Preparation method and application of hydroxypropyl guar gum/nanocellulose cross-linked adsorption film

ActiveCN106345424AGood adsorption/desorption performanceImprove mechanical propertiesSemi-permeable membranesOther chemical processesCross-linkMethyl violet

The invention discloses s preparation method of a hydroxypropyl guar gum / nanocellulose cross-linked adsorption film. The method takes hydroxypropyl guar gum and microcrystalline cellulose as main raw materials, and comprises the steps: thinning the microcrystalline cellulose in a nano grinder and a high-strength ultrasonic wave generator successively to prepare nanocellulose, then respectively dispersing and dissolving the nanocellulose and hydroxypropyl guar gum in maleic acid, then adding maleic anhydride and sodium hypophosphite, stepwise heating to carry out esterification and cross-linking reaction, centrifuging and defoaming the reactant, shaping the reactant in a mold, forming a film by drying, and cleaning and freeze-drying the film to obtain the adsorption film. The film prepared by the method is light yellow and transparent, has good adsorptive capacity on copper ions, zinc ions, led ions, methylene blue and methyl violet, and simultaneously has higher mechanical properties.

Owner:KUNMING UNIV OF SCI & TECH

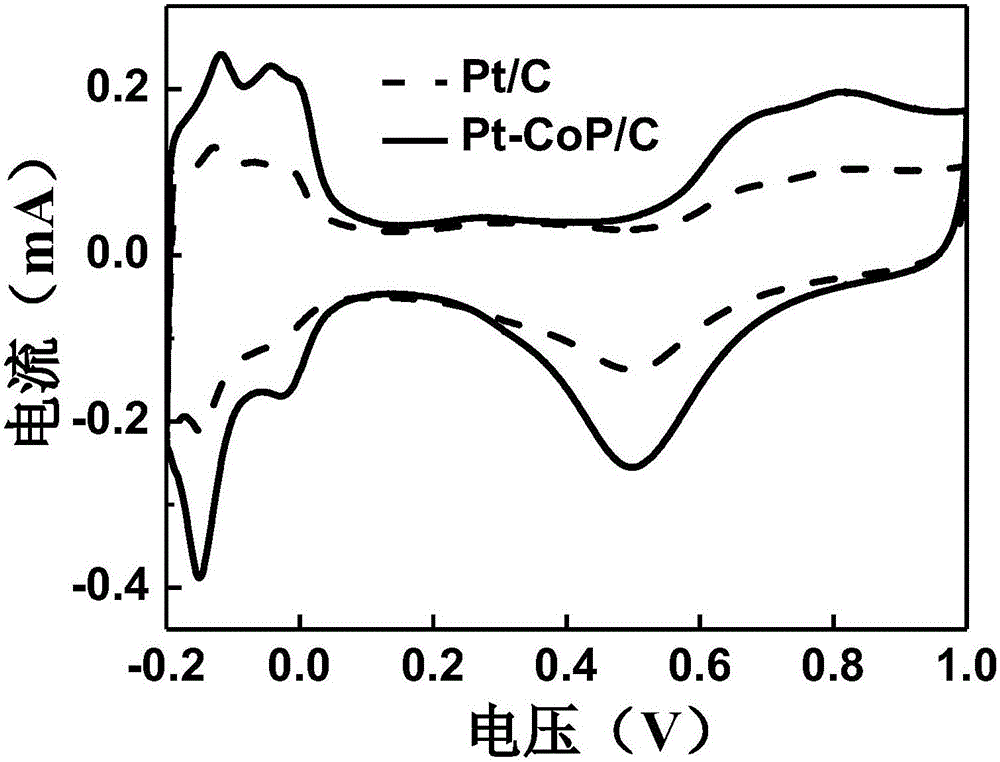

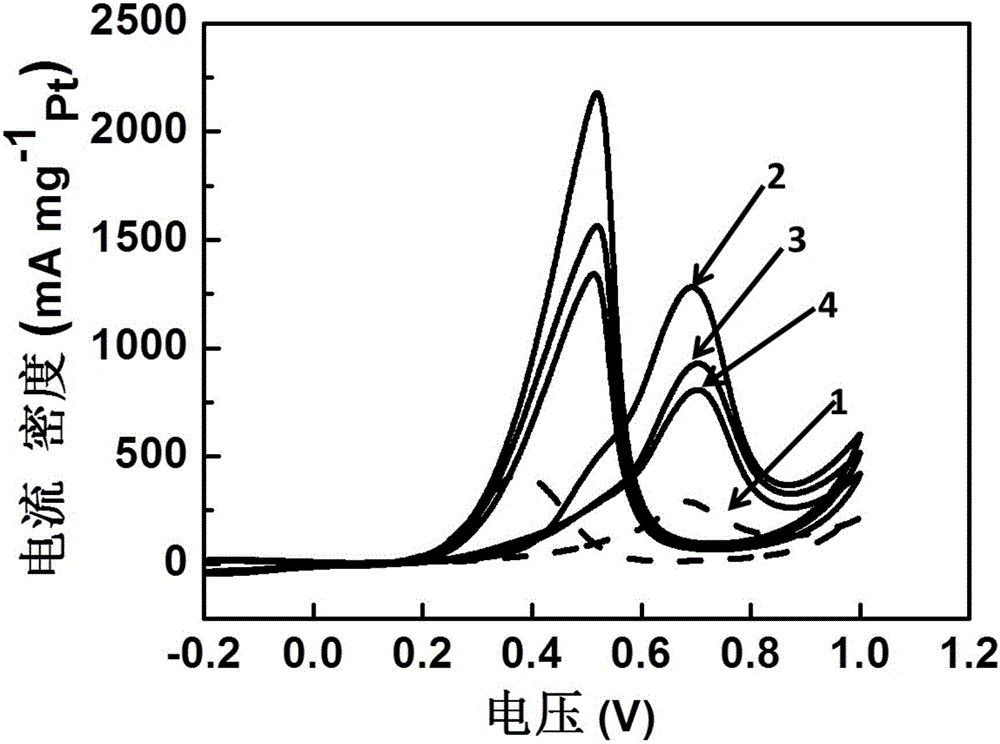

Pt doped phosphatizing cobalt bead catalyst carried by methanol carbon dioxide and preparation method of Pt doped phosphatizing cobalt bead catalyst

InactiveCN105817240AReduce usageHigh activityPhysical/chemical process catalystsCell electrodesShielding gasPolytetrafluoroethylene

The invention discloses Pt doped phosphatizing cobalt bead catalyst carried by methanol carbon dioxide and a preparation method of the Pt doped phosphatizing cobalt bead catalyst. The catalyst is Pt-CoP / C, and the preparation method mainly comprises the following steps: uniformly dispersing a carbon material to a solution of dehydrated alcohol and deionized water, adding cobalt salt and strong ammonia water, and through a heating reflow reaction, generating carbon-carrying cobalt complex compound solution; transmitting the solution into a polytetrafluoroethylene reaction kettle, and performing water heating so as to obtain a carbon-carrying cobaltosic oxide material; mixing the carbon-carrying cobaltosic oxide material with sodium hypophosphite, performing grinding so as to obtain a mixture, and transmitting the mixture to a high-temperature tuber furnace filled with protective gas; preforming heating treatment so as to obtain a CoP / C material, dispersing the CoP / C material to the mixed solution of ethanediol and the deionized water, adding a chloroplatinic acid solution, and then performing a heating reflow reaction so as to obtain a Pt-CoP / C catalyst. Compared with conventional business Pt / C, according to the prepared catalyst disclosed by the invention, the methanol oxidation activity and stability are significantly improved.

Owner:HUAZHONG UNIV OF SCI & TECH

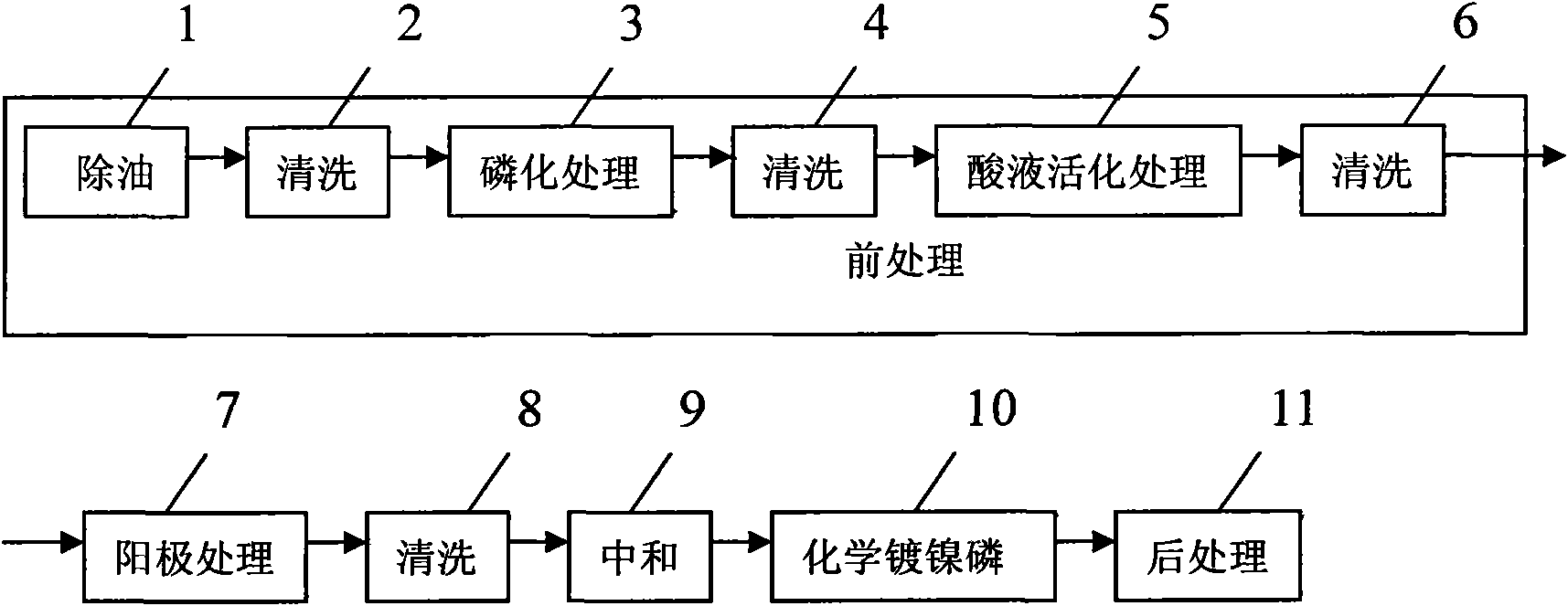

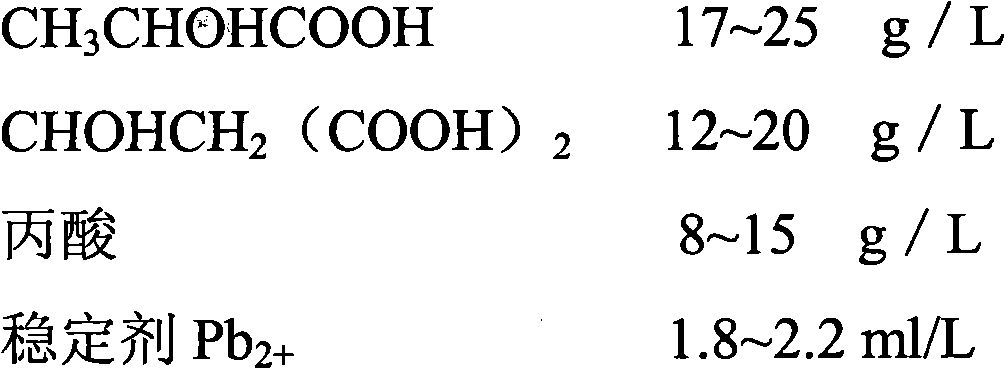

Austenitic stainless steel surface chemical nickel-phosphorus plating method

InactiveCN102051604AImprove acid resistanceGood alkali and salt propertiesLiquid/solution decomposition chemical coatingSalt resistanceNickel salt

The invention relates to an austenitic stainless steel surface chemical nickel-phosphorus plating method, which comprises the following steps of: degreasing: removing greasy dirt from the surface of an austenitic stainless steel; acid liquor activation: putting the austenitic stainless steel into activating solution for erosion; and chemical nickel-phosphorus plating: chemically plating nickel and phosphorus on the austenitic stainless steel in chemical nickel-phosphorus plating solution, wherein the chemical nickel-phosphorus plating solution contains 20 to 30g / L of nickel salt, 20 to 35g / L of sodium hypophosphite and 35 to 60g / L of auxiliary agent. The austenitic stainless steel surface chemical nickel-phosphorus plating method has simple process, can select the phosphorus content of a coating as required, can form a uniform nickel-phosphorus coating with good acid, alkali and salt resistance on the outer surface of the austenitic stainless steel, and enlarges the application field of the austenitic stainless steel.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Method for recovering nickel in chemical nickel-plating ageing liquid

ActiveCN102212842AImprove wettabilityConvenient and quick escapePhotography auxillary processesThioureaPolyethylene glycol

The invention discloses a method for recovering nickel in a chemical nickel-plating ageing liquid, and the method comprises the following steps: (1) adding 1100-1300 parts by weight of the chemical nickel-plating ageing liquid into an electrolytic cell, and regulating the pH value of the ageing liquid to 8-10 by use of solid sodium hydroxide; (2) dissolving 0.01-0.03 part by weight of polyethylene glycol, 0.01-0.02 part by weight of 2-mercapto benzimidazole, 0.03-0.06 part by weight of thiourea, 0.005-0.03 part by weight of hide glue and 0.3-0.5 part by weight of sodium hypophosphite into 40-70 parts by weight of water, adding the mixture into the electrolytic cell, and adding 1-3 parts by weight of 5mol / L hydrochloric acid solution; (3) at normal temperature, on the basis of taking a stainless steel plate as a cathode and a reticular plate plated with iridium oxide titanium alloy as an anode, reacting for 8-10 hours at constant reaction current of 0.6-1.0A, thus obtaining a recoveredmetal nickel on the cathode. The method has the advantages of high recovery rate, simple equipment, low cost and the like, works at normal temperature and is easy to realize.

Owner:WUXI ZHONGTIAN SOLID WASTE DISPOSAL CO LTD

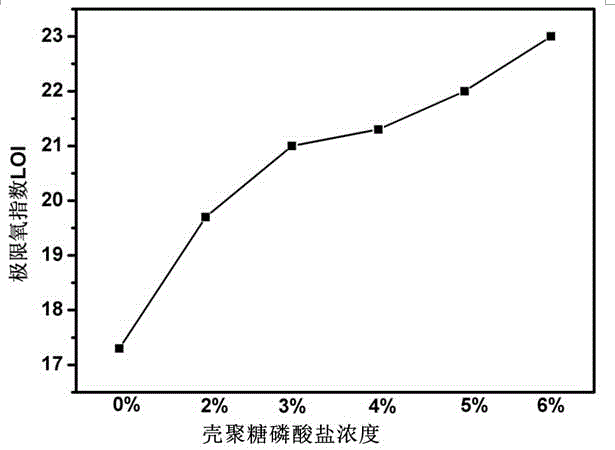

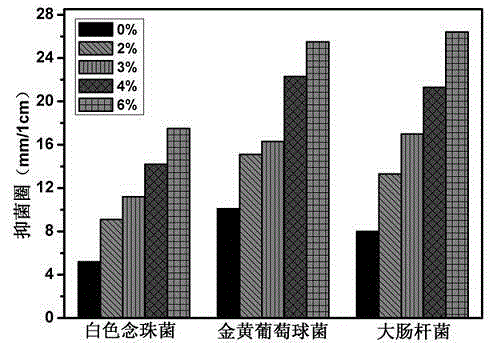

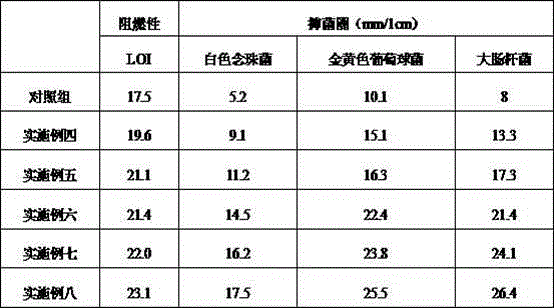

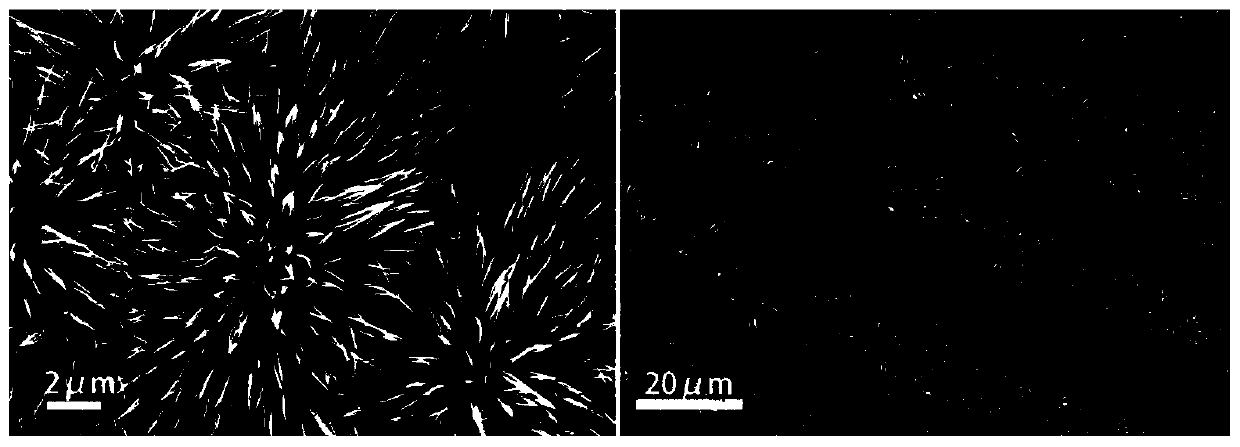

Preparation method of cellulose fabric having antibacterial and inflaming-retarding functions

The invention relates to a preparation method of a cellulose fabric having antibacterial and inflaming-retarding functions, belonging to the field of production of textiles. The preparation method comprises the following steps: dissolving chitosan phosphate into a butanetetracarboxylic acid solution, adding sodium hypophosphite having catalytic amount into the solution to prepare fabric treatment fluid, and dipping the cellulose fabric into the fabric treatment fluid, taking out and rolling for drying the fabric. According to the technical scheme, sodium hypophosphite is used as a catalyst, chitosan phosphate is dissolved into butanetetracarboxylic acid to be prepared into the fabric treatment fluid, and the cellulose fabric is dipped into the fabric treatment fluid, is taken out and is rolled to be dried, thus, the cellulose fabric has antibacterial and inflaming-retarding functions and has remarkable beneficial effects.

Owner:ANHUI AGRICULTURAL UNIVERSITY +2

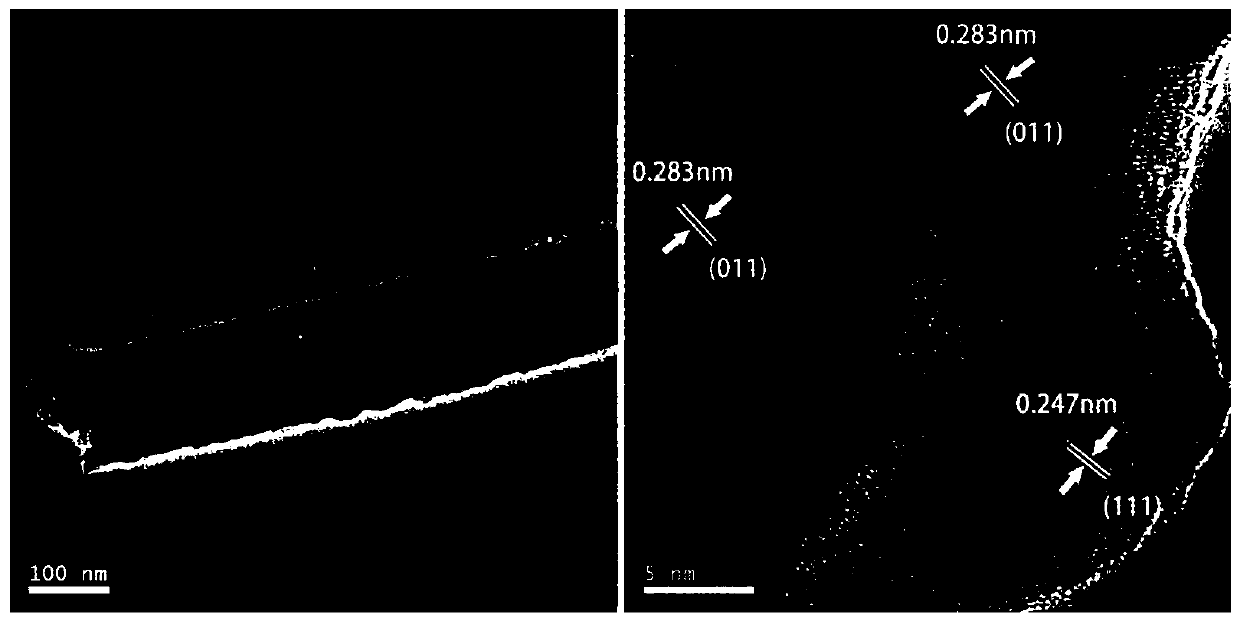

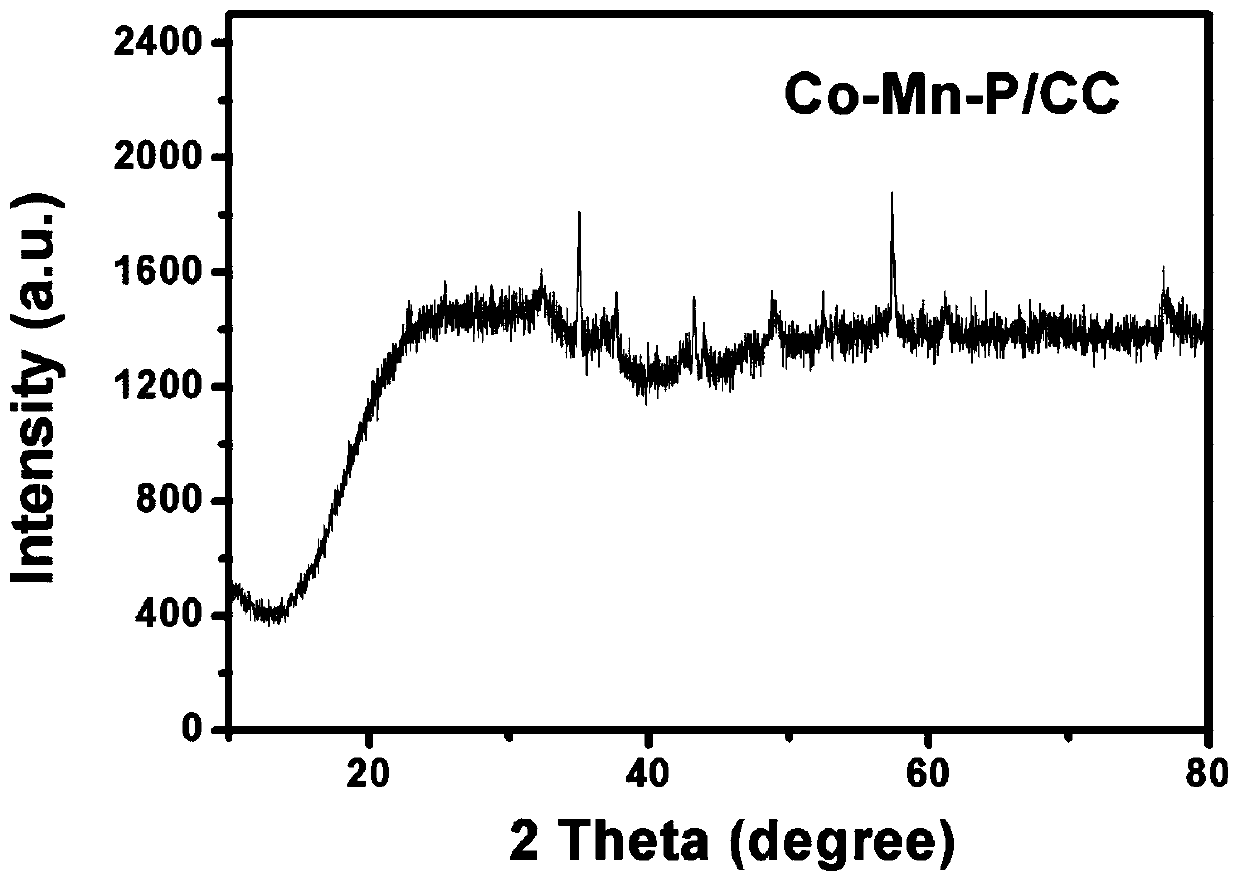

Cobalt-manganese-phosphorus urchin-like nano wire hydrogen evolution catalytic material growing on carbon cloth

InactiveCN110252360AUnique structureLarge specific surface areaPhysical/chemical process catalystsElectrodesNanowireSodium phosphates

The invention discloses a cobalt-manganese-phosphorus urchin-like nano wire hydrogen evolution catalytic material growing on carbon cloth. The preparation method comprises following steps: step one, hydrothermally synthesizing a precursor: weighing urea, ammonium fluoride, manganese sulfate monohydrate, and cobalt nitrate hexahydrate into deionized water, fully and evenly stirring to obtain a mixed solution, adding the mixed solution and preprocessed carbon cloth into a reactor, and carrying out hydrothermal reactions to obtain a precursor; and step two, generating the cobalt-manganese-phosphorus urchin-like nano wire hydrogen evolution catalytic material through phosphorization: preparing a porcelain boat, arranging sodium phosphate on the upstream of the porcelain boat, arranging the precursor on the downstream of the porcelain boat, finally, placing the porcelain boat in a tube furnace, introducing protective gas into the tube furnace, setting the program, and carrying out phosphorization to obtain the product. The provided material has a unique urchin-like nano wire structure, excellent hydrogen evolution catalytic activity, and extremely high stability, moreover, the raw materials are abundant, no precious metal is used, the repeatability is good, and the preparation method is simple.

Owner:ZHEJIANG SCI-TECH UNIV

Corrosion-resistant iron-based powder metallurgy valve and preparation method thereof

The invention discloses a corrosion-resistant iron-based powder metallurgy valve. The corrosion-resistant iron-based powder metallurgy valve is prepared from the following raw materials in parts by weight: 3-5 parts of hafnium boride, 4-6 parts of tantalum nitride, 1-2 parts of polymerization ferrophosphorus powder, 2-3 parts of copper powder, 0.4-0.8 part of boron stearate, 0.5-0.7 part of graphite, 6-9 parts of polycarbosilane, 10-15 parts of titanium powder, 3-5 parts of silicon-calcium-barium ally powder, 0.3-0.5 part of a silane coupling agent kh-550, 2-2.5 parts of ferrozirconium, a proper amount of 1% sodium carbonate solution, a proper amount of water, 0.4-0.6 part of zinc stearate, 2-3 parts of sodium hypophosphite, 0.3-0.4 part of polyethylene glycol, 20-25 parts of 2Mol / L copper sulfate solution, 2-3 parts of a wetting additive and 81-83 parts of iron powder. The valve material is uniform in structure, high in strength and high in tenacity; by adding hafnium boride, tantalum nitride and polymerization ferrophosphorus powder, the heat resistance, the abrasion resistance and the corrosion resistance of the valve are improved.

Owner:TONGLING JINGWEI FLUID SCI & TECH

Method for preparing Ni2P by reducing nickel oxide precursor through thermal treatment at low temperature

InactiveCN101671009ALow preparation temperatureShorten the production cycleMolecular sieve catalystsCatalyst activation/preparationNitrateSodium Hypophosphite Monohydrate

The invention provides a novel method for preparing nickel phosphide (Ni2P) by utilizing phosphine produced by thermal decomposition of sodium hypophosphite to reduce nickel oxide precursor. In the method, nickel nitrate is adopted as a nickel source and then roasted to obtain nickel oxide, and the obtained nickel oxide is dipped into sodium hypophosphite solution to obtain the nickel oxide precursor, and simple low temperature thermal treatment of the nickel oxide precursor is carried out so as to synthesize supported and unsupported Ni2P. The invention has the characteristics of simple process, low Ni2P preparation temperature, short production period, without the complex steps of temperature programming, and the like as well as just simple thermal treatment at normal temperature. Raw materials used in the method are low in price and safety, and devices used in the method are low in cost. The catalyst can be widely used for hydrogenation treatment of oils due to higher hydrodesulfurization and hydrodenitrogenation activities.

Owner:NANKAI UNIV

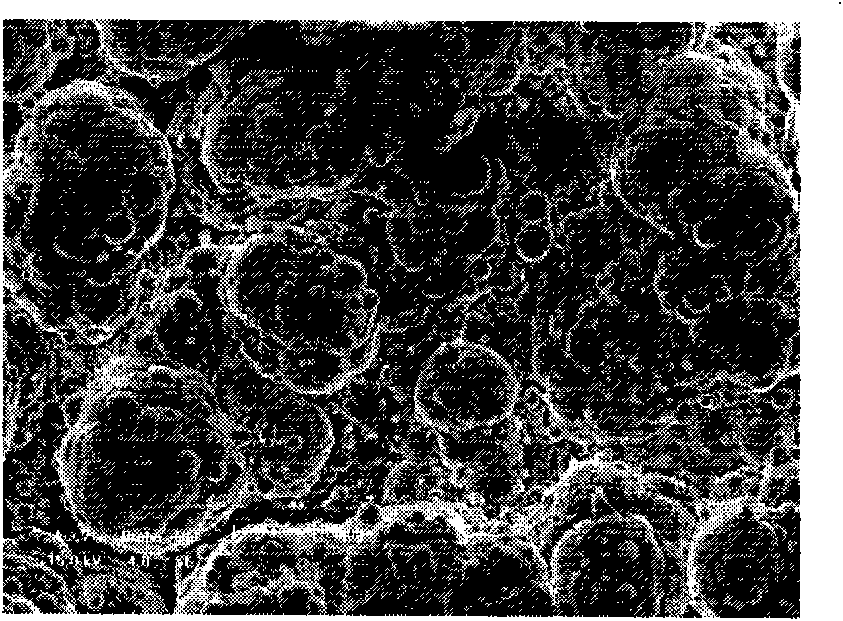

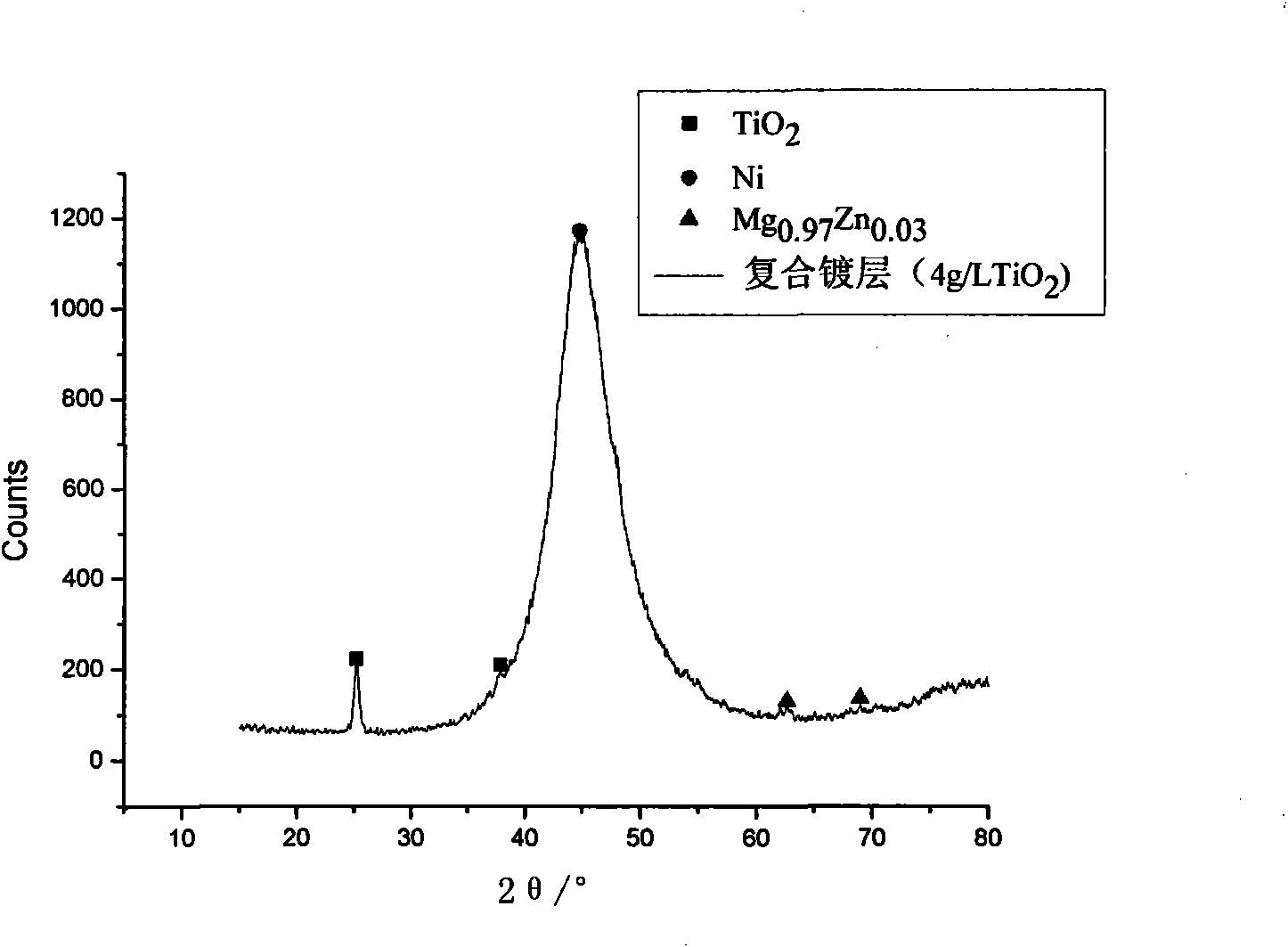

Preparation method of Ni-Cu-P/nano TiO2 chemical composite coating on surface of magnesium alloy

InactiveCN101886256AImprove wear resistanceImprove corrosion resistanceLiquid/solution decomposition chemical coatingChemical platingThiourea

The invention discloses a preparation method of a Ni-Cu-P / nano TiO2 chemical composite coating on the surface of a magnesium alloy. In the method, chemical plating is carried out on the substrate magnesium alloy; the selected plating solution comprises the following components: nickel sulfate, sodium hypophosphite, citric acid, ammonium bifluoride, thiourea, lauryl sodium sulfate, copper sulfate and nano TiO2. The Ni-Cu-P / nano TiO2 chemical composite coating with obvious bacteriostasis is prepared through reasonably setting a chemical plating technology and conditions; the antibacterial rate of the composite coating is up to above 90%; the composite coating has excellent photocatalytic property, corresponds with the catalysis of the TiO2 powders, finds a carrier for the TiO2 powders, can improve repeated use rate of antibacterial property, and is a perfect combination of an antibacterial technology and the chemical plating technology.

Owner:LIAONING TECHNICAL UNIVERSITY

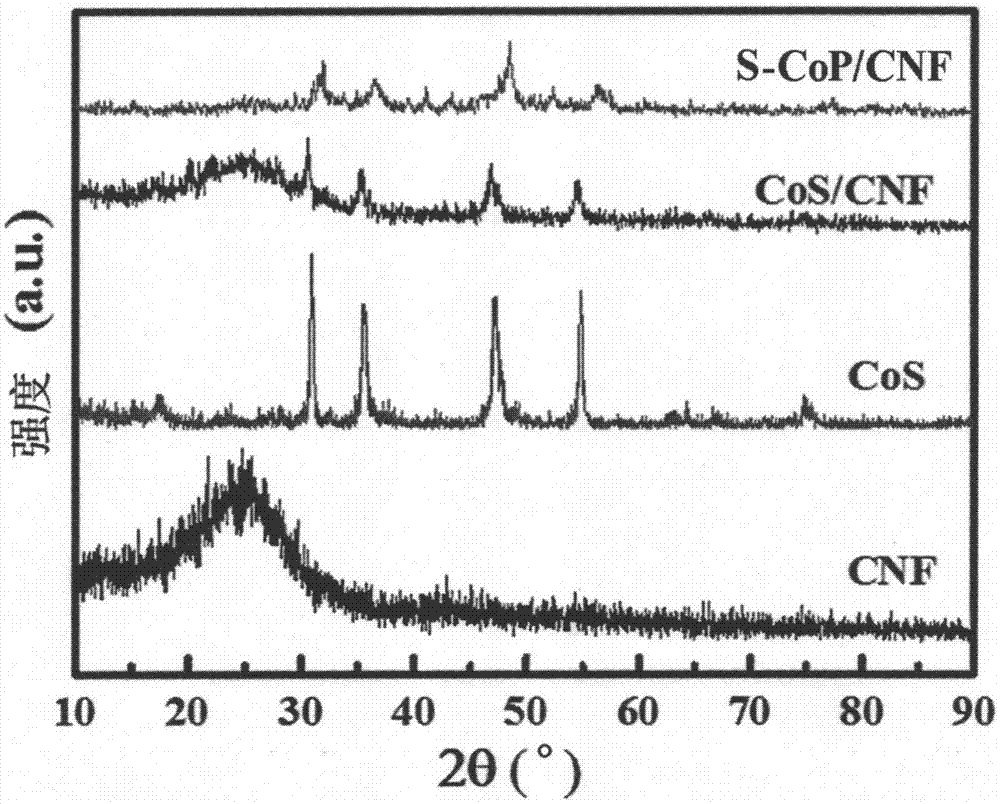

Modified naphthalene water reducer preparation method

ActiveCN106186781AHigh water reduction rateReduce hydrationSodium Hypophosphite MonohydratePhosphate

The invention relates to a modified naphthalene water reducer preparation method, and belongs to the field of concrete admixture. The preparation method includes the steps: (1) preparing copolycondensation monomer from unsaturated dicarboxylic acid, styrene and acrylic acid hydroxyalkyl ester under the action of sodium hypophosphite and initiator; (2) preparing a modified naphthalene water reducer from naphthalene homolog, the copolycondensation monomer, concentrated sulfuric acid, phosphoric acid, formaldehyde and the like by the stages of sulfonation, hydrolysis, condensation and neutralization. A large quantity of carboxyl, hydroxy and phosphate are led into the molecular structure of the water reducer, high water reducing rate of the naphthalene water reducer is kept, hydration of cement can be delayed, the slump retention ability of concrete is improved, the concrete has high flowability after 2 hours, and transportation and construction are facilitated. The preparation method is simple in preparation process, convenient to use, good in effect and high in practicability.

Owner:NANJING RUIDI HIGH TECH

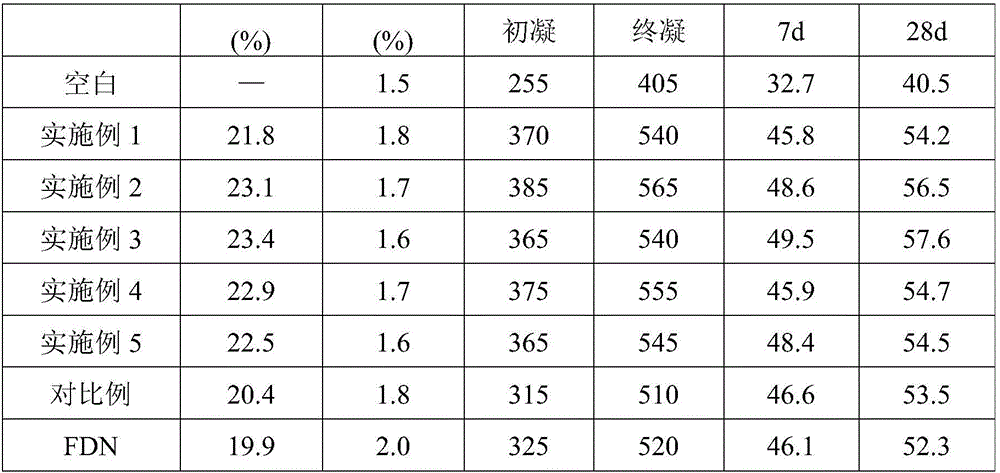

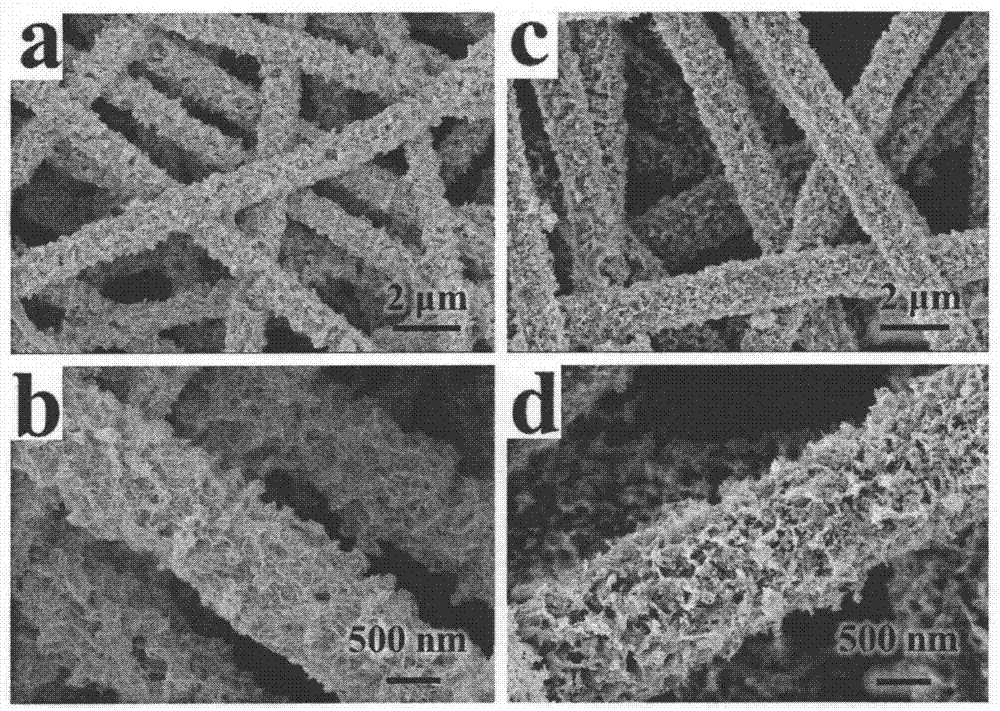

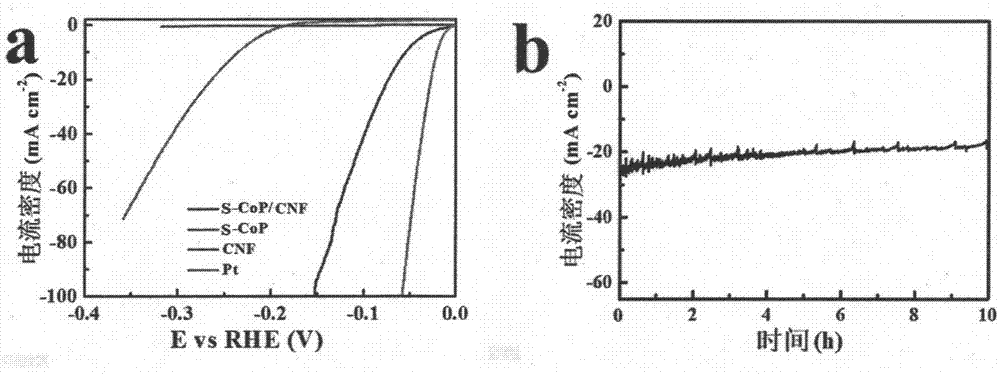

Sulfur-doped cobalt phosphide - carbon nanofiber composite material and preparation method thereof

The invention discloses a sulfur-doped cobalt phosphide - carbon nanofiber composite material and a preparation method thereof. The preparation method comprises the following steps of electrospinning a polyacrylonitrile dispersion liquid to obtain a polyacrylonitrile nanofiber membrane; pre-oxidizing the polyacrylonitrile nanofiber membrane and performing heating and carbonization to obtain a carbon nanofiber membrane, and causing the carbon nanofiber membrane to undergo surface hydrophilic treatment, to obtain a carbon nanofiber pretreatment membrane; proportionally dispersing cobalt salt and thiourea in an organic solvent, and then causing the dispersion liquid and the carbon nanofiber pretreatment membrane to be subjected to a solvothermal reaction to obtain a cobalt sulphide / carbon nanofiber composite material; and causing the cobalt sulphide / carbon nanofiber composite material to undergo phosphorylation reaction with sodium hypophosphite to prepare the sulfur-doped cobalt phosphide - carbon nanofiber composite material. The prepared composite material is controllable in morphology, has high specific surface area and excellent conductivity, and can be used as an ideal high-performance electrocatalytic material as well as an electrode material of new energy devices such as supercapacitors and lithium-ion batteries.

Owner:DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com