Catalyst for loading cobalt phosphide on activated carbon as well as preparation and application of catalyst

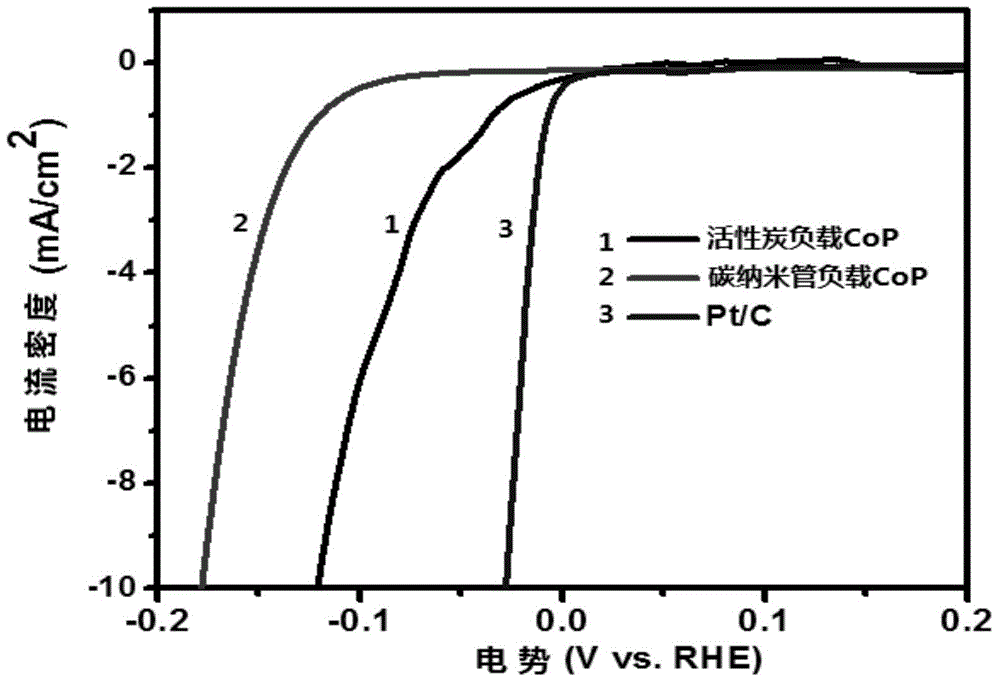

A technology of activated carbon and cobalt phosphide, which is applied to a catalyst supporting cobalt phosphide on activated carbon and its preparation field, can solve problems such as being in the initial stage, and achieve the effects of simple operation, good catalytic performance, and excellent hydrogen evolution catalytic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

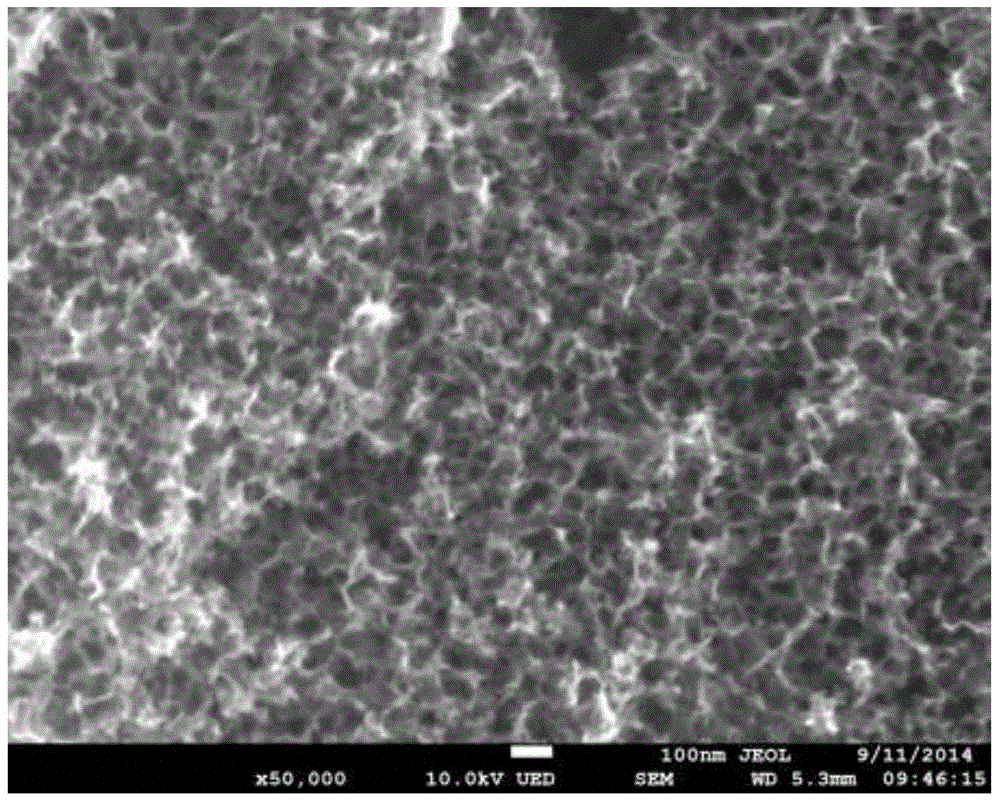

[0031] The preparation method of activated carbon is as follows:

[0032] 1) Wash and cut the harvested camphor leaves with deionized water, mix the chopped camphor leaves with CaCO 3 Mix the nanoparticles, add an ethanol solution with a mass fraction of 50% to fully grind, and then microwave for 2 minutes at a power of 300W-500W;

[0033] 2) Filter with a filter membrane with a pore size of 0.2 μm, and the resulting filtrate is dried at 70°C to obtain a viscous product. 3g of the above product and 3g of CaCO3 nanoparticles are mixed with ethanol and fully ground evenly and placed in a blast drying oven at 60°C Bake for 2 hours, then anneal for 2 hours at 800°C under the protection of argon atmosphere;

[0034] 3) The product obtained above was washed successively with 1M HCl and deionized water, repeated three times, and dried at 60° C. to obtain activated carbon.

Embodiment 1

[0036] In this embodiment, the preparation method of a hydrogen evolution catalyst with activated carbon (HNC) as a carrier comprises the following steps:

[0037] 1) Weigh 1mol Co(NO 3 )2·6H 2 O, 2.5mol CO(NH 3 )2 and 5mol NH4F were dissolved in 40ml deionized water, stirred for 10min to form a mixed solution;

[0038] 2) Transfer 0.5ml of the mixed solution prepared in step 1) to a polytetrafluoroethylene-lined stainless steel reaction kettle with 29.5ml of deionized water, and weigh 10mg of HNC in the reaction kettle for 30min sonication;

[0039] 3) The mixed solution in step 2) was subjected to a hydrothermal reaction at 120° C. for 12 hours;

[0040] 4) Washing, suction filtering and drying the solution in step 3) to obtain the precursor;

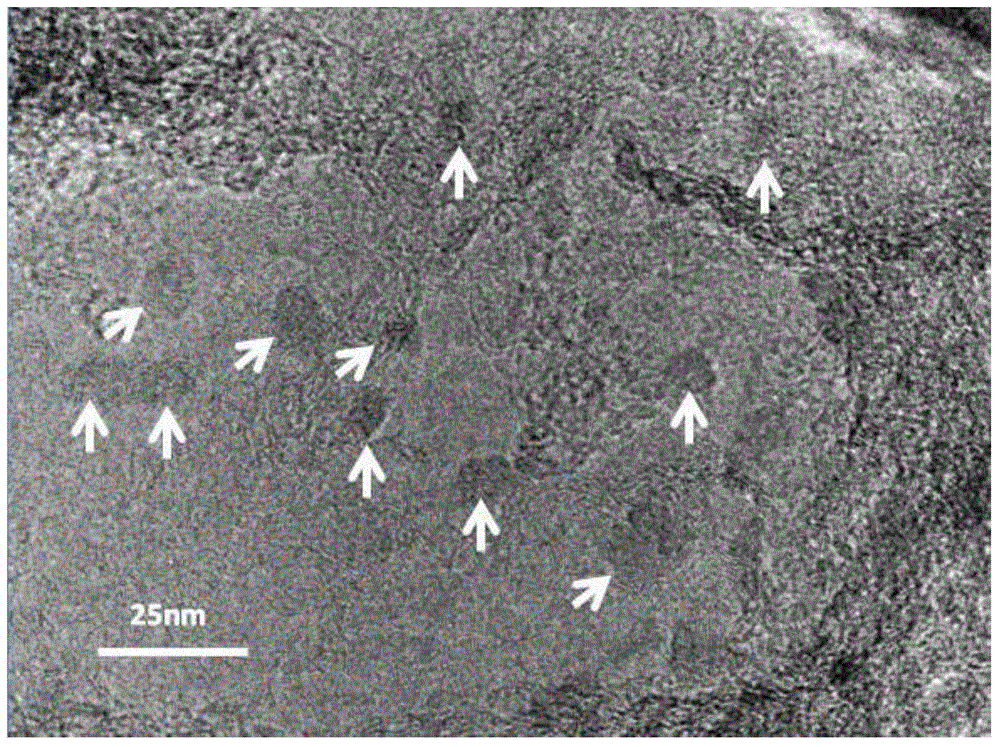

[0041] 5) Rapidly raise the temperature of the precursor and sodium hypophosphite obtained in step 4) to 300°C at a rate of 2°C / s under the protection of argon and keep it for 2h, and the product obtained after cooling is the targ...

Embodiment 2

[0048] The preparation method of the hydrogen evolution catalyst with HNC as the carrier of the present embodiment comprises the following steps:

[0049] 1) Weigh 1mol Co(NO 3 )2·6H 2 O, 2.5mol CO(NH 3 )2 and 3mol NH4F were dissolved in 40ml deionized water, stirred for 10min to form a mixed solution;

[0050] 2) Take 0.25ml of the mixed solution prepared in step 1) and transfer it to a polytetrafluoroethylene-lined stainless steel reaction kettle with 29.75ml of deionized water, and weigh 10mg of HNC in the reaction kettle for 30min sonication;

[0051] 3) The mixed solution in step 2) was subjected to a hydrothermal reaction at 120° C. for 12 hours;

[0052] 4) Washing, suction filtering and drying the solution in step 3) to obtain the precursor;

[0053] 5) The precursor and sodium hypophosphite obtained in step 4) were rapidly heated to 300°C at a rate of 2°C / s under the protection of argon and kept for 2h, and the product obtained by cooling was the hydrogen evolution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com