Patents

Literature

153results about How to "Wide range of ingredients" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-entropy alloy with dispersion nano-sized precipitate strengthening effect and preparing method thereof

ActiveCN104694808AWide range of ingredientsControl mechanical propertiesElectric arc furnaceHigh entropy alloys

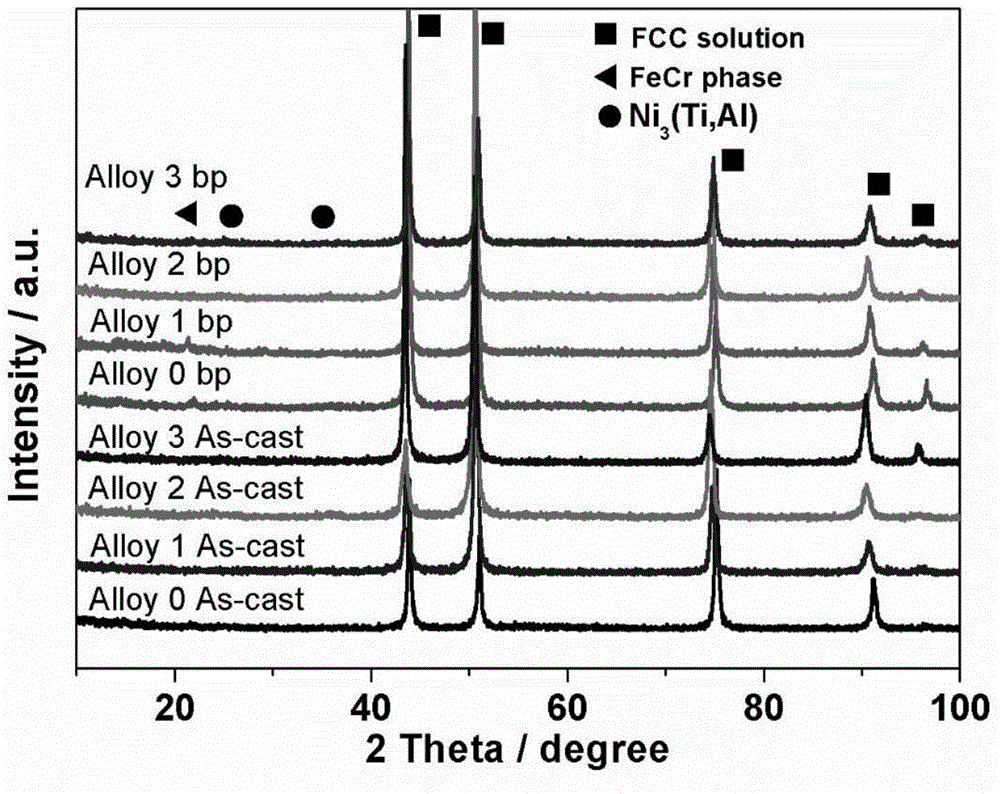

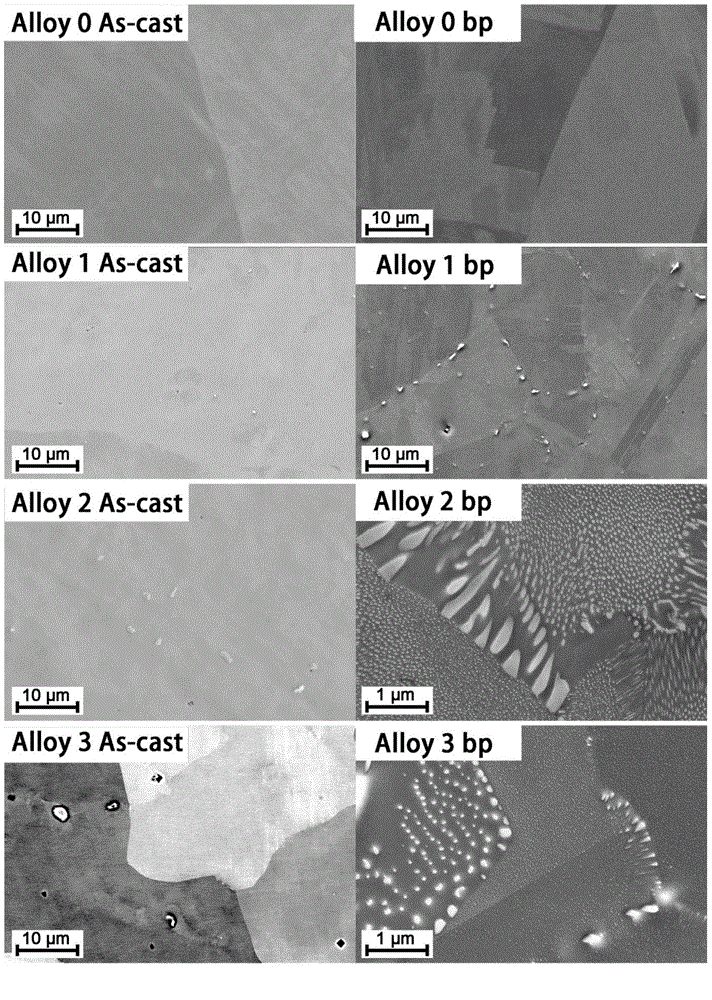

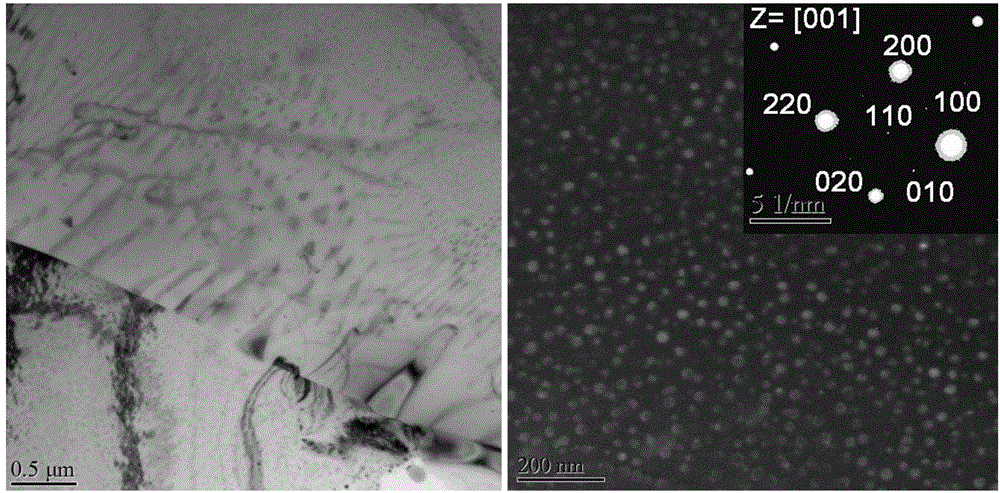

The invention discloses high-entropy alloy with the dispersion nano-sized precipitate strengthening effect and a preparing method thereof. The method comprises the steps of removing oxidized skin of a metal material, and then conducting weighing and burdening accurately according to a ratio; conducing smelting in an electric-arc furnace in an argon shield atmosphere of titanium absorbed oxygen to obtain an initial high-entropy alloy ingot, and conducting cold rolling, wherein rolling reduction is 20-50%; placing the ingot in a heat treatment furnace with a temperature ranging from 900 DEG C to 1000 DEG C for heat preservation for 0.5-2 hours, and conducting quenching; placing the ingot in a heat treatment furnace with a temperature ranging from 700 DEG C to 800 DEG C for heat preservation for 2-18 hours, and conducting quenching. By means of precipitation strength, on the premise that high plasticity is kept, yield strength and tensile strength are improved greatly. The room-temperature tensile strength of (FeCoNiCr)94Ti2Al4 in the final state reaches 1094 MPa, plastic elongation is 35%, work hardening effect is remarkable, comprehensive room-temperature mechanical property is prominent, high-temperature tensile strength can reach 400 MPa at the temperature of 800 DEG C and strain rate of 10<-3>, steady creep rate is smaller than or equal to 10<-8> under the stress of 100 MPa and at the temperature of 750 DEG C, and high-temperature tensile strength and creep mechanical property are excellent.

Owner:UNIV OF SCI & TECH BEIJING

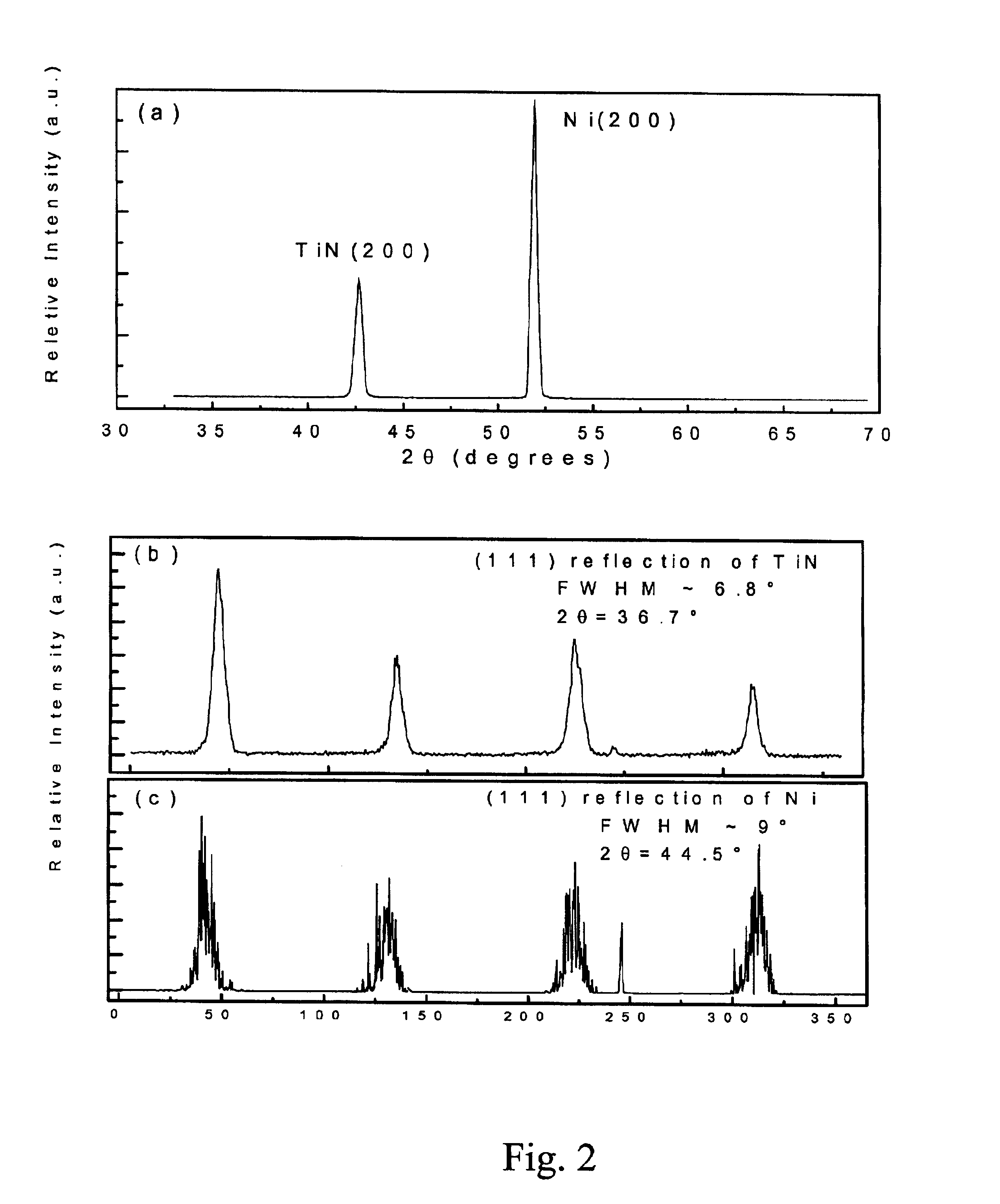

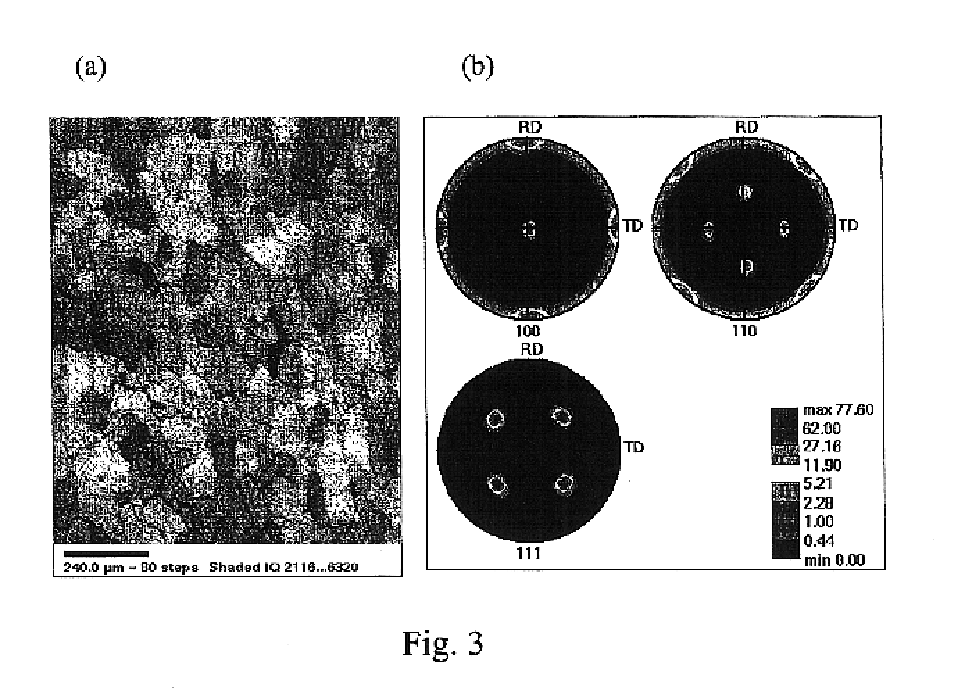

Conductive and robust nitride buffer layers on biaxially textured substrates

InactiveUS6784139B1Wide range of ingredientsReduce interface stressSuperconductors/hyperconductorsSuperconductor device manufacture/treatmentForming gasAlloy

The present invention relates to epitaxial, electrically conducting and mechanically robust, cubic nitride buffer layers deposited epitaxially on biaxially textured substrates such as metals and alloys. The invention comprises of a biaxially textured substrate with epitaxial layers of nitrides. The invention also discloses a method to form such epitaxial layers using a high rate deposition method as well as without the use of forming gases. The invention further comprises epitaxial layers of oxides on the biaxially textured nitride layers. In some embodiments the article further comprises electromagnetic devices which may be super conducting properties.

Owner:APPL THIN FILMS INC +1

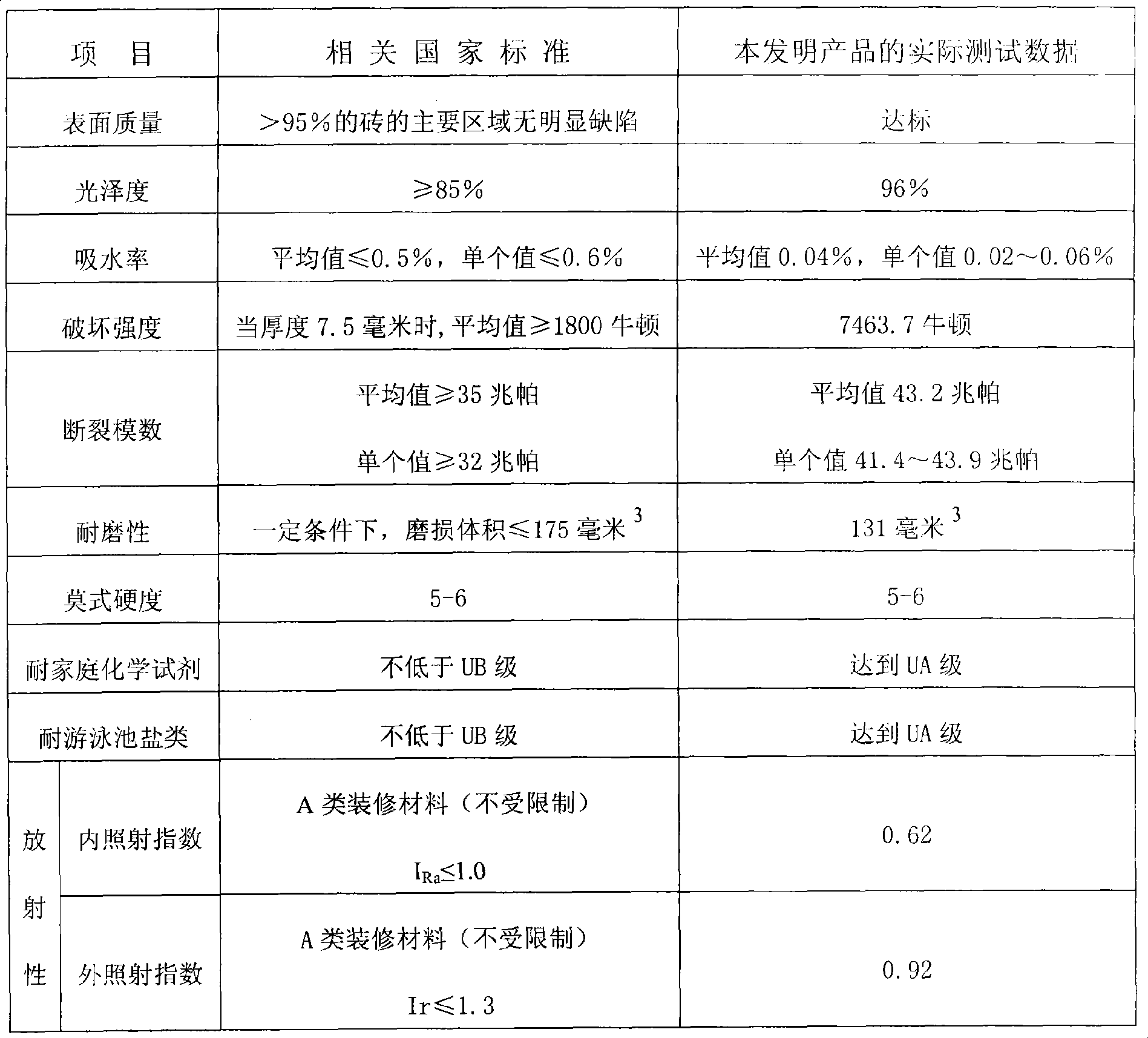

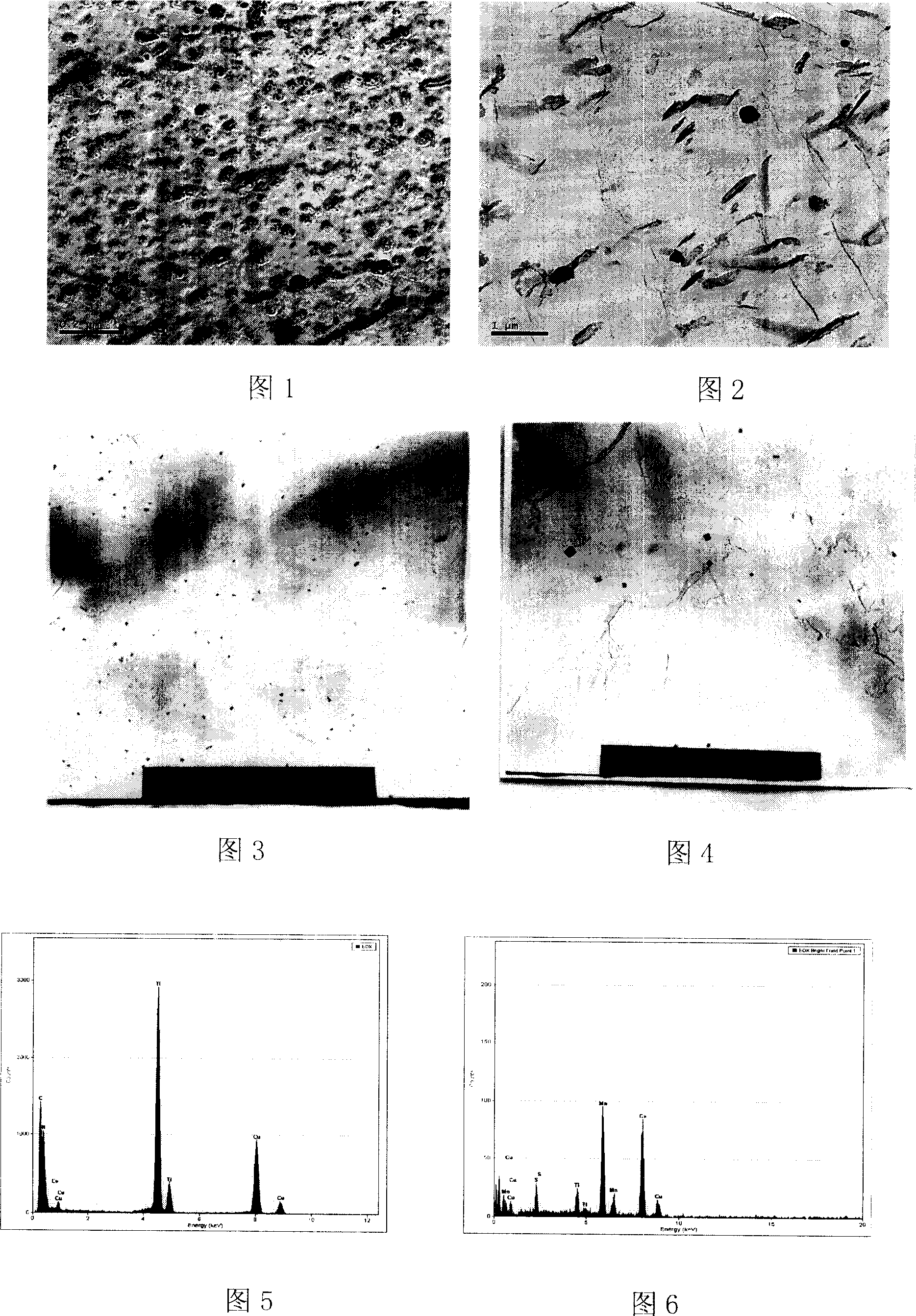

Method for producing microcrystalline glass-ceramics composite board with novel microcrystalline phase

The invention discloses a method for producing a microcrystalline glass-ceramics composite board with novel microcrystalline phase, which is characterized in that the composite board takes diopside-containing pyroxene as microcrystalline phase and the production method thereof comprises the steps as follows: firstly, microcrystalline glass granules are prepared; according to the weight percentage, the microcrystalline glass consist of 50-65% of SiO2, 5-25% of Al2O3, 5-20% OF CaO, 2-10% of MgO, 1-8% of K2O+NaO, 0-1% of Li2O, 0-8% of BaO, 0-8% of B2O3 and the balance of nucleating agent, clarifier and corant with the content ranging from 0 to 20%; secondly, a ceramic palette board is prepared; according to the weight percentage, the ceramic palette board comprises 66-75% of SiO2, 13-23% of Al2O3, 0.3-3% of CaO+MgO, 3-8% of K2O+Na2O and the balance of 0-2% of auxiliary raw material; finally, the raw materials are distributed, sintered and post-processed, thus gaining the finished product of the microcrystalline glass-ceramics composite board. The method has the advantages of low production cost, high product quality, good appearance effect, and the like.

Owner:GUANGDONG BODE FINE IND CONSTR MATERIAL

Nb-Ti microalloying steel suitable for large line energy welding and smelting method therefor

InactiveCN1962916AImprove toughnessSimple production processWelding/cutting media/materialsSoldering mediaSheet steelPre treatment

The invention discloses an Nb-Ti microalloy steel for large line power welding, which comprises the following parts: 0.06%-0.12% C, 0.10%-0.50% Si, 0.40%-1.8% Mn, not more than 0.015% P, not more than 0.010% S, 0.020%-0.050% Nb, 0.006%-0.030% Ti, 0.0030%- 0.0100% N, one or more of not more than 0.40% Mo, not more than 0.06% V, not more than 1.0% Ni, not more than 1.0% Cr, and not more than 0.50% Cu and Fe and inevitable impurity, wherein the Ceq is C+Mn / 6+Si / 24+Ni / 40+Cr / 5+Mo / 4+V / 14<=0.45%; the [Ti%]T is not less than 2.667[N%]T-0.004667%. The smelting method comprises the following steps: predisposing molten iron; smelting through rotary furnace; removing S in the LF furnace; refining in the VD or RH; adding Ti and Nb in the VD or RH. The steel board possesses excellent flexibility in the welding heat influencing region when it is welded at 50-150KJ / cm.

Owner:ANGANG STEEL CO LTD

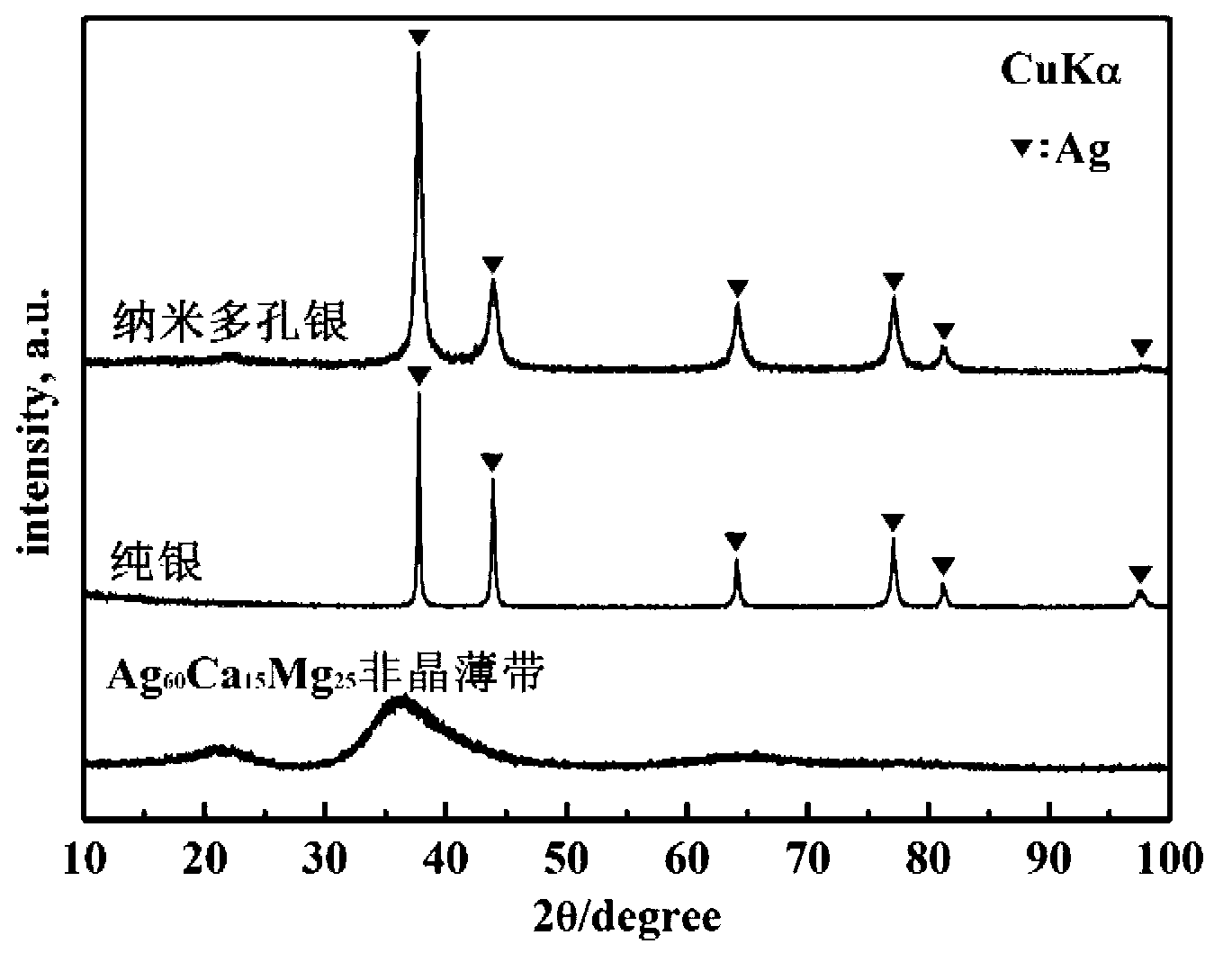

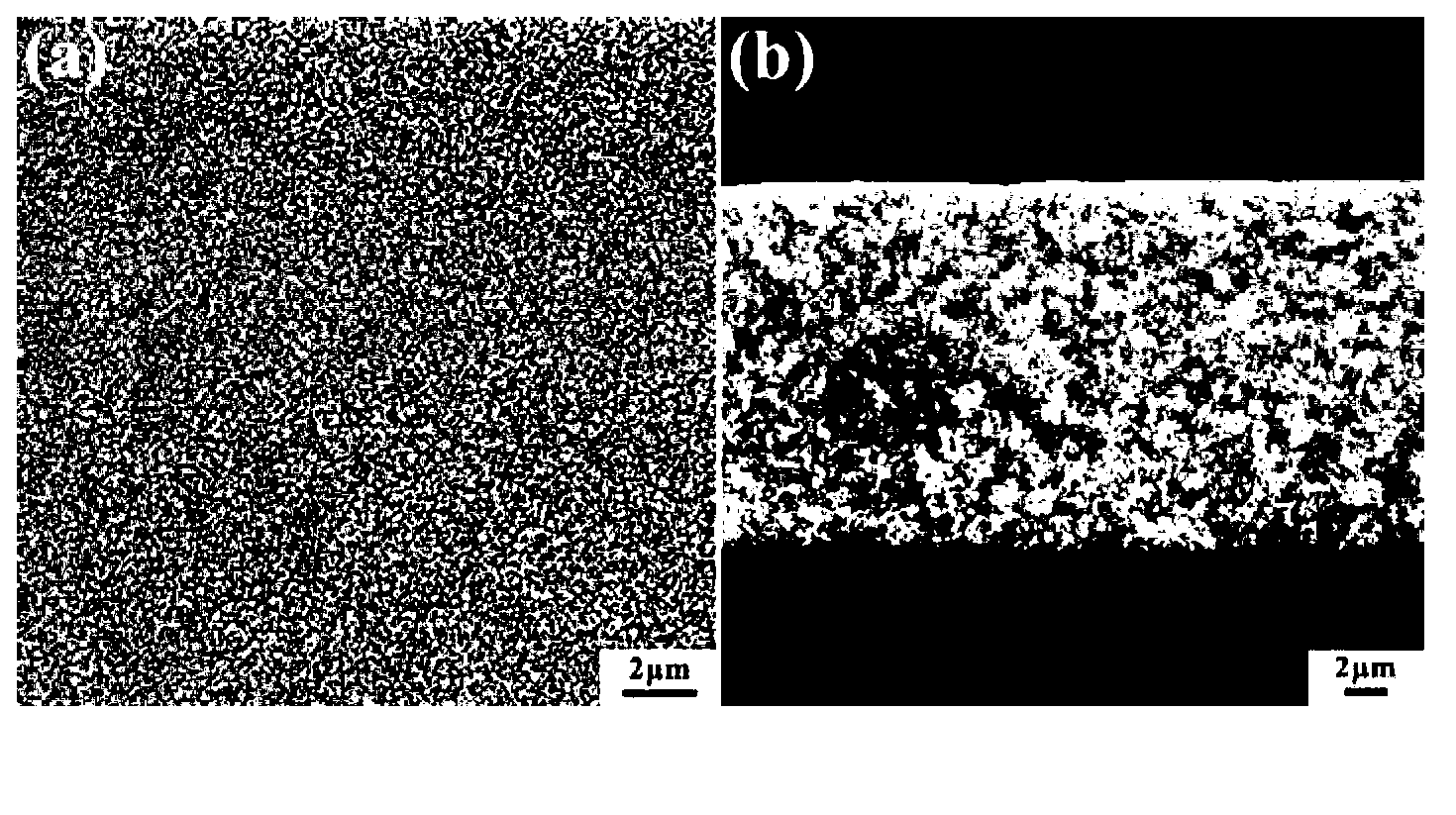

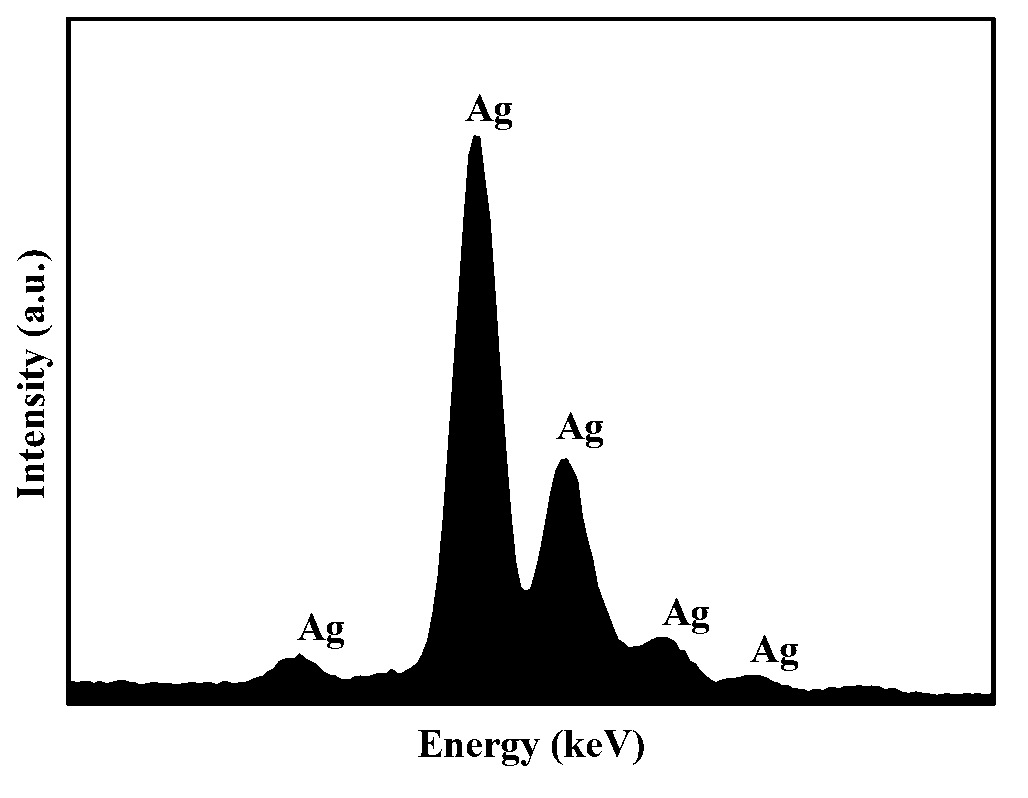

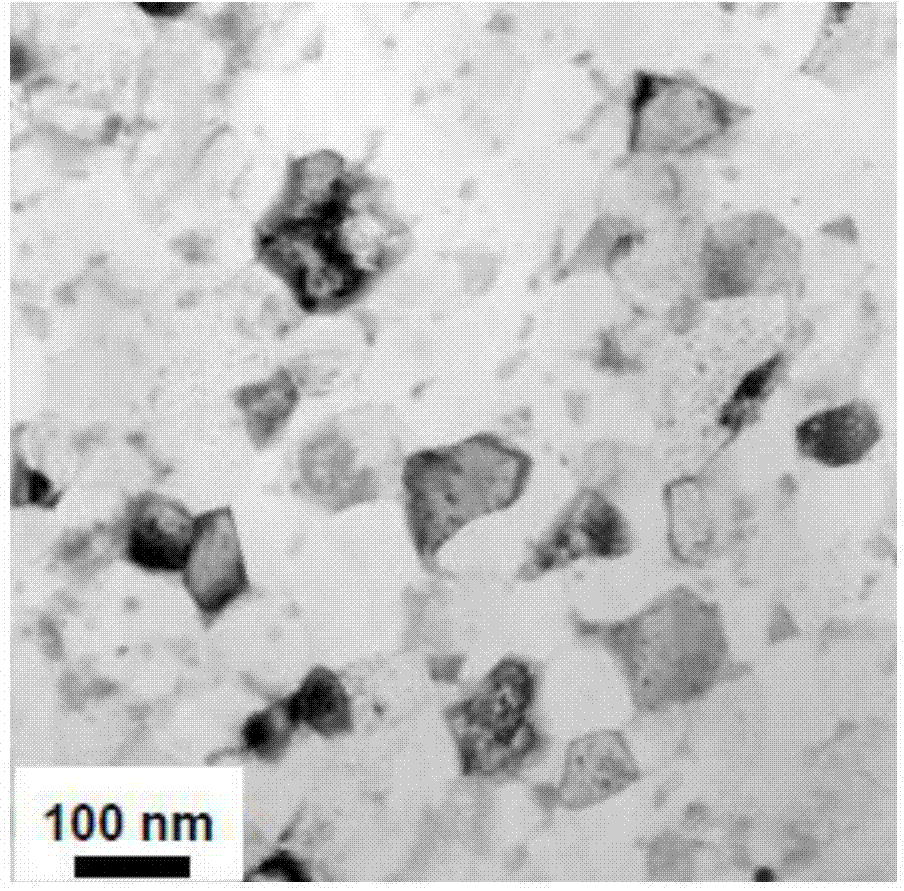

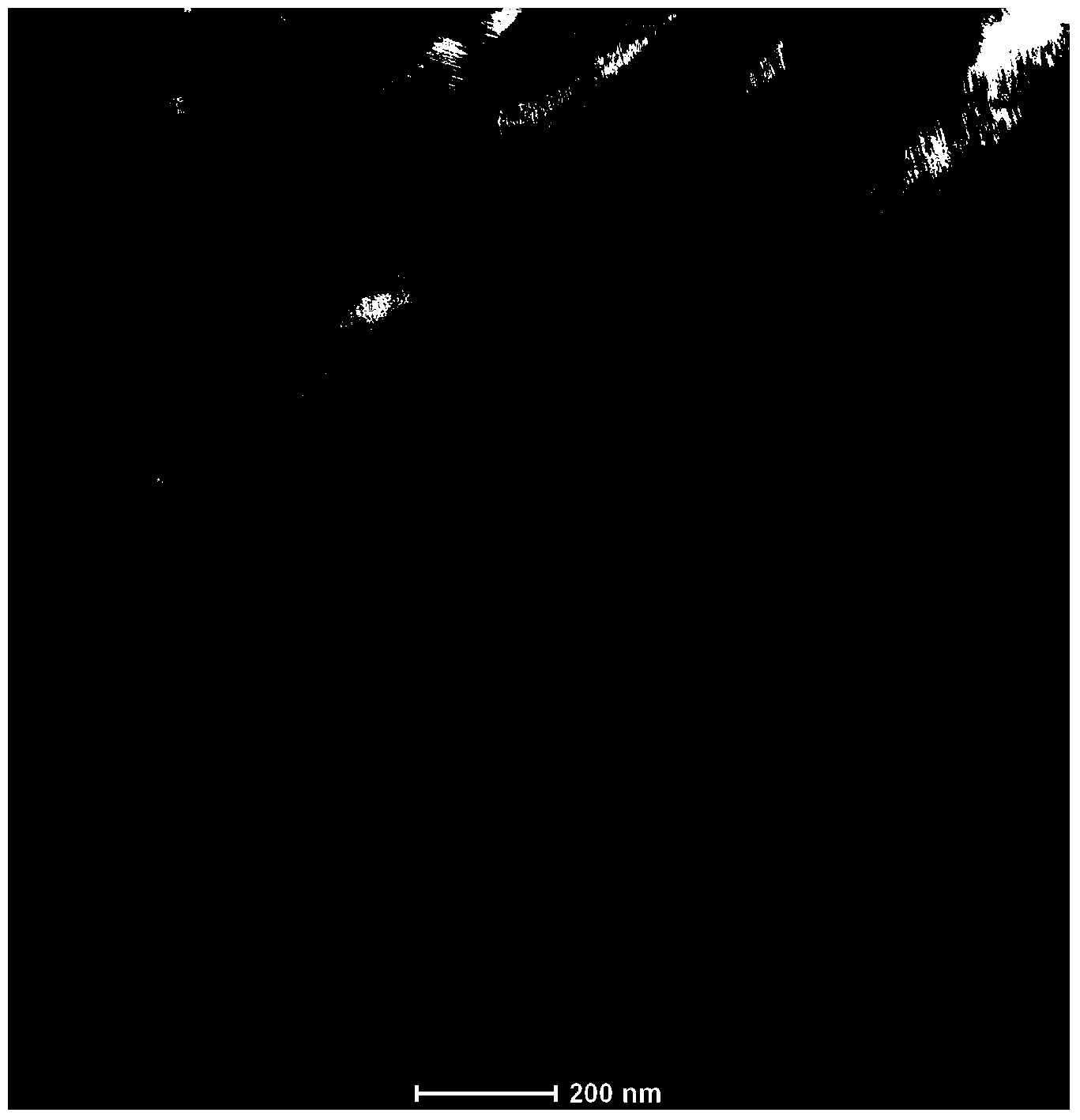

Method for preparing nano porous silver based on Ag-based amorphous alloy

The invention belongs to the field of preparation of nano porous metal materials, and relates to a method for preparing nano porous silver based on an Ag-based amorphous alloy. By the method, the nano porous silver with the aperture of 20-100 nm is finally obtained by preparing a series of Ag-Mg-Ca amorphous alloy thin bands by taking the Ag-based amorphous alloy as a precursor by a solvent quick quenching method and then removing Mg and Ca elements by performing electric chemical alloy component corrosion removal by proper electrolyte. By the method, the structure and the size of the nano porous silver are adjusted and controlled by controlling the amorphous alloy components or electric chemical corrosion temperature; the operation technology is simple; and furthermore, the nano porous silver is extremely high in surface-enhancement raman scattering (SERS) performance and has a wide application prospect in the fields of environment friendliness, catalysis and biological sensors.

Owner:UNIV OF SCI & TECH BEIJING

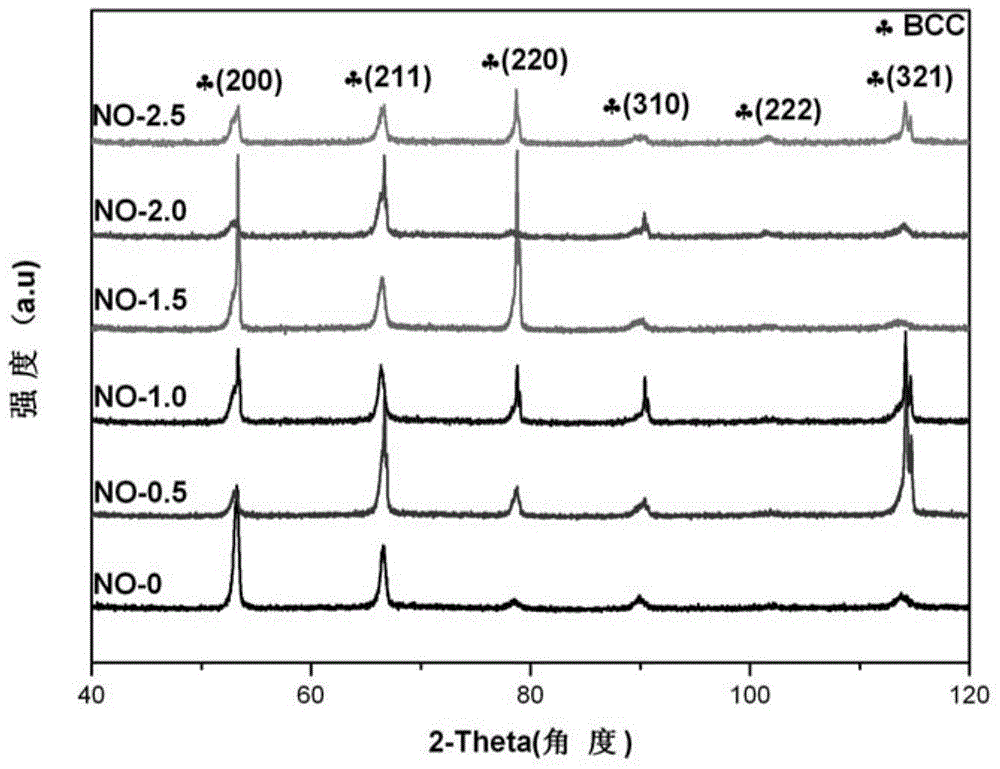

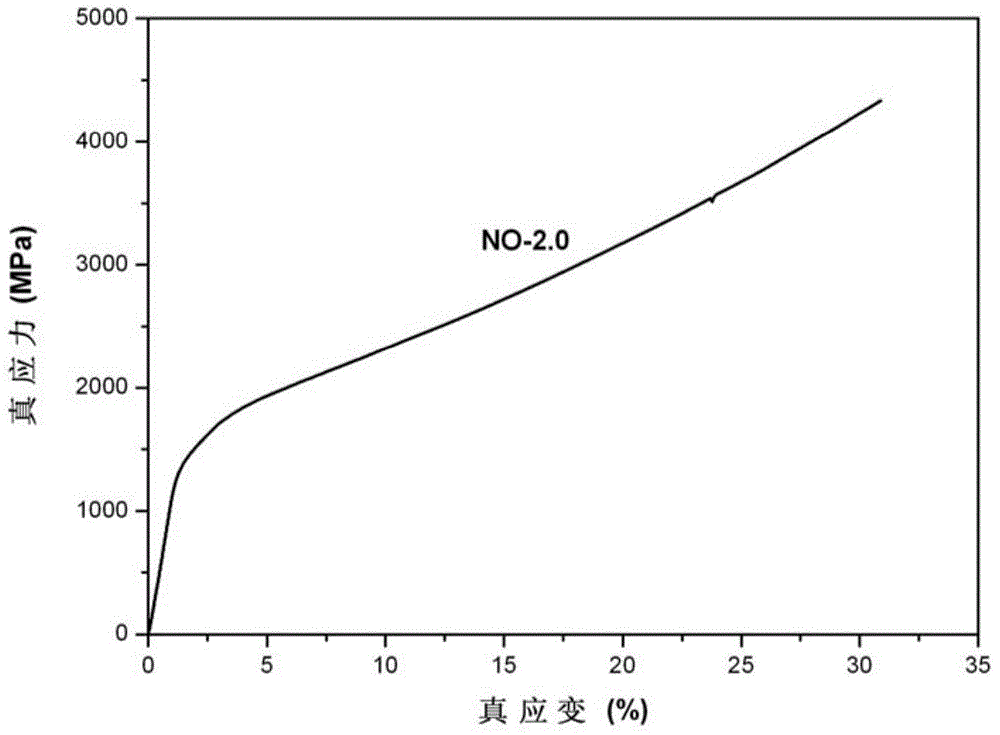

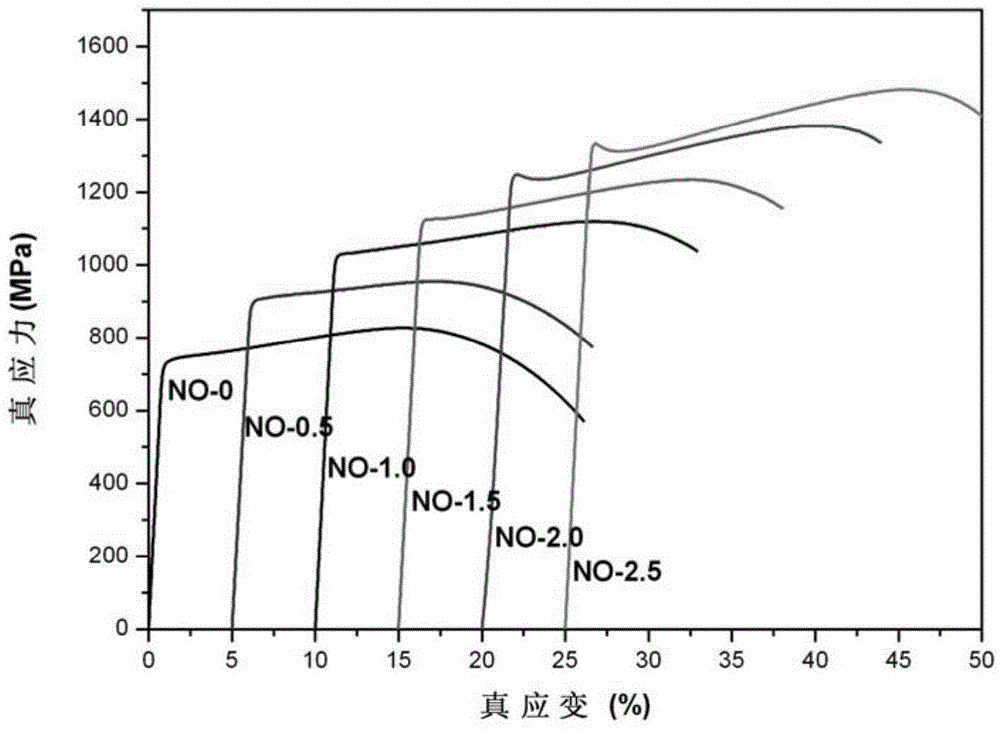

TiZrHfNb based high-entropy alloy with nitrogen and oxygen alloyed together and preparation method thereof

ActiveCN105671404AWide range of ingredientsWide range of preparation conditionsHigh entropy alloysOxygen

The invention relates to TiZrHfNb based high-entropy alloy with nitrogen and oxygen alloyed together and a preparation method thereof. Particularly, the tensile strength and tensile ductility of the alloy are remarkably improved by simultaneously microalloying N and O elements. The preparation method includes the following steps that metal raw materials of Ti, Zr, Hf and Nb are accurately weighed according to the molar ratios after oxide skin is removed; other added elements are accurately weighed according to the molar ratios after oxide skin is removed and the elements are washed with alcohol; the N element is added in the form of nitride, and the O element is added in the form of oxide; and target alloy is smelted in a nonconsumable vacuum arc furnace or cold crucible shower furnace, and the alloy is obtained through vacuum suction casting or casting equipment. The tensile property of the high-entropy alloy is improved remarkably by simultaneously adding the N and O elements, the tensile strength of (TiZrHfNb)97.5(NO)2.5 based high-entropy alloy reaches 1300 MPa, meanwhile, the tensile ductility exceeds 15%, the work-hardening rate is low, and the comprehensive tensile property is excellent.

Owner:UNIV OF SCI & TECH BEIJING

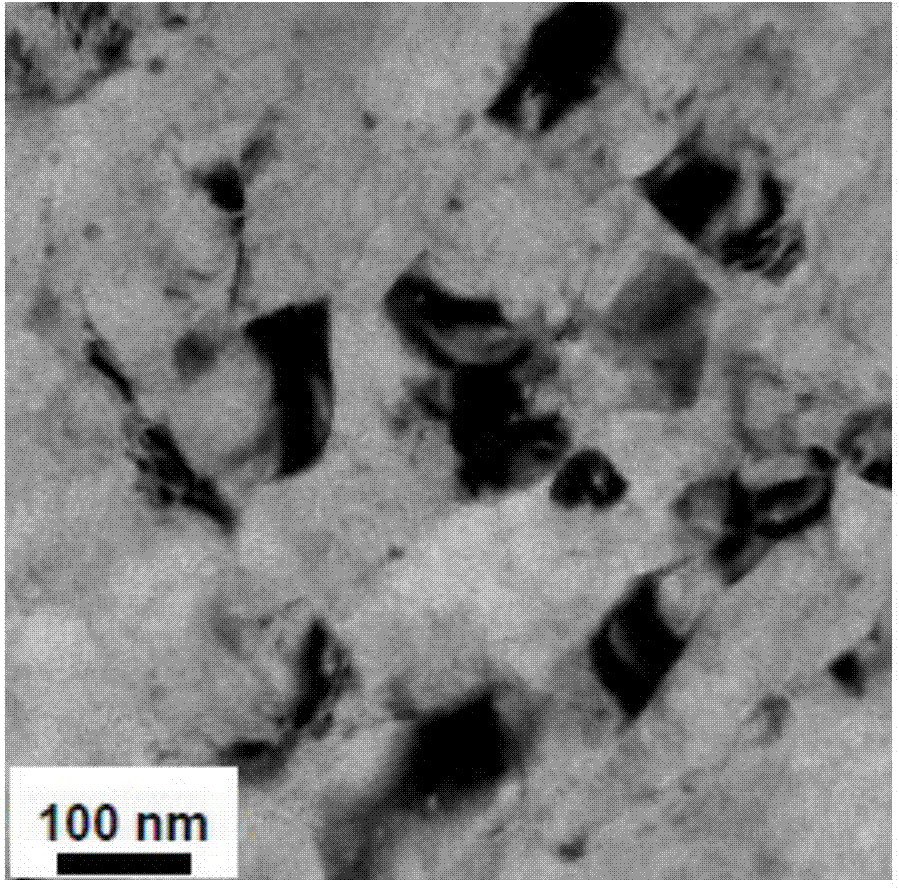

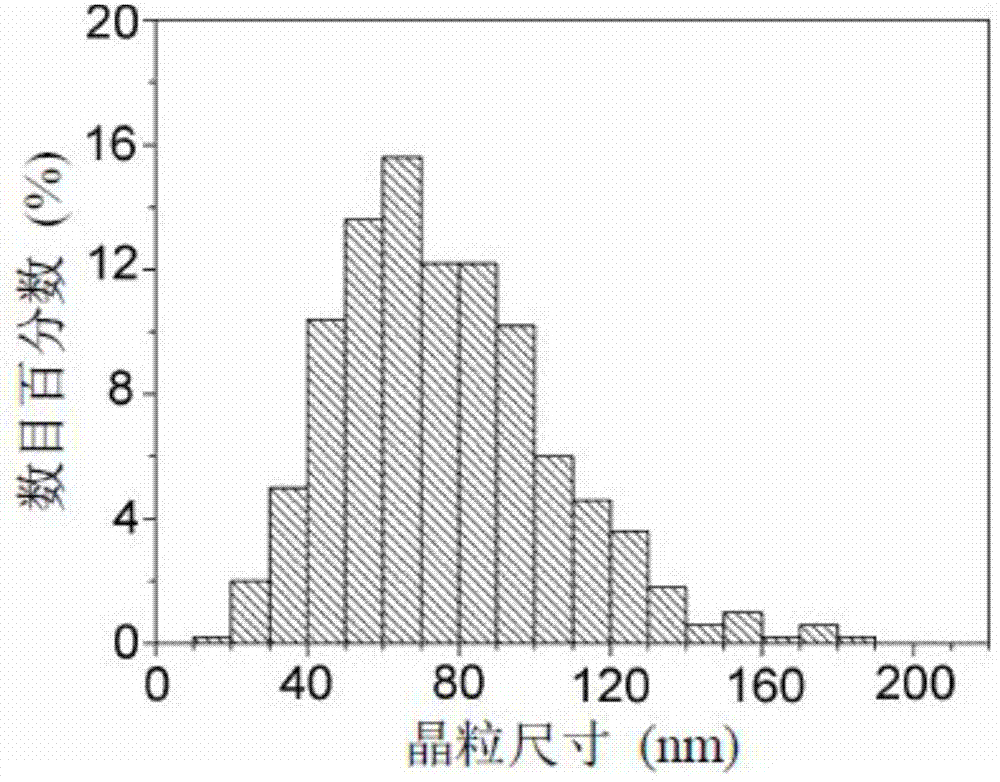

Method for preparing nanocrystalline metal material containing nano-sized precipitates within crystal

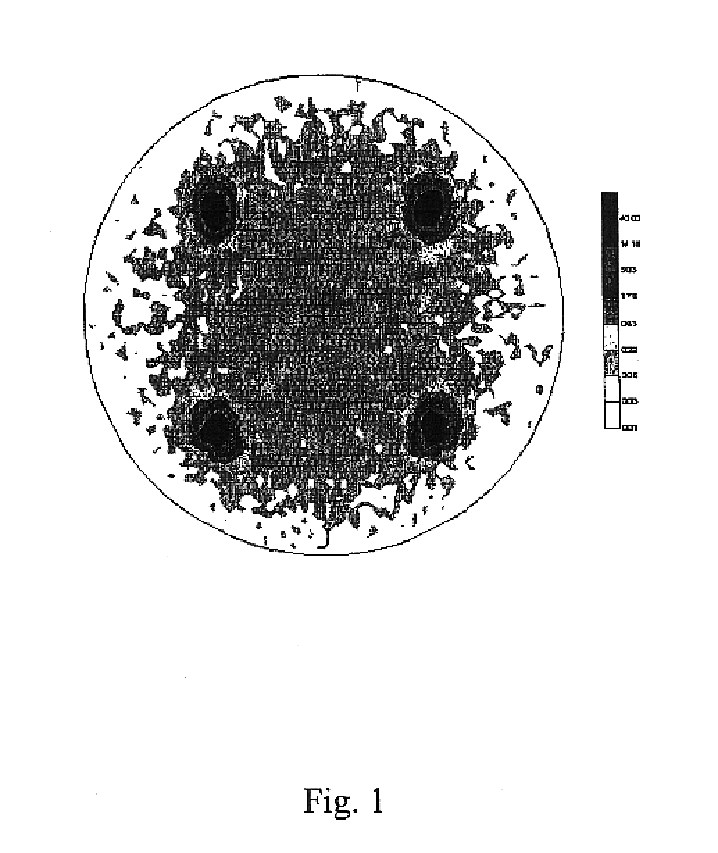

The invention provides a method for preparing a nanocrystalline metal material containing nano-sized precipitates within a crystal. The method comprises the following steps of firstly, performing high-temperature solution treatment on a coarse crystalline metal material, thereby obtaining single phase solid solution with supersaturated and dissolved alloy element, wherein the coarse crystalline metal material contains alloy element in a matrix, and the solid solubility is reduced as the temperature is reduced; then, performing severe plastic deformation and high-pressure reverse processing at or below the room temperature, thereby obtaining single phase solid solution nanocrystalline material composed of nanocrystalline grains with supersaturated and dissolved alloy element; and finally, ageing the obtained nanocrystalline material at a pressure of 3-25 GPa and at a temperature of 100-800 DEG C, and holding the temperature for 5-8 h, thereby obtaining a nanocrystalline metal material containing nano-sized precipitates within a crystal. The method provided by the invention is wide in suitable material component range, and can be used for effectively avoiding severe plastic deformation to produce microcrack in a material, and the prepared nano-sized precipitates in the nanocrystalline material are distributed uniformly.

Owner:YANSHAN UNIV

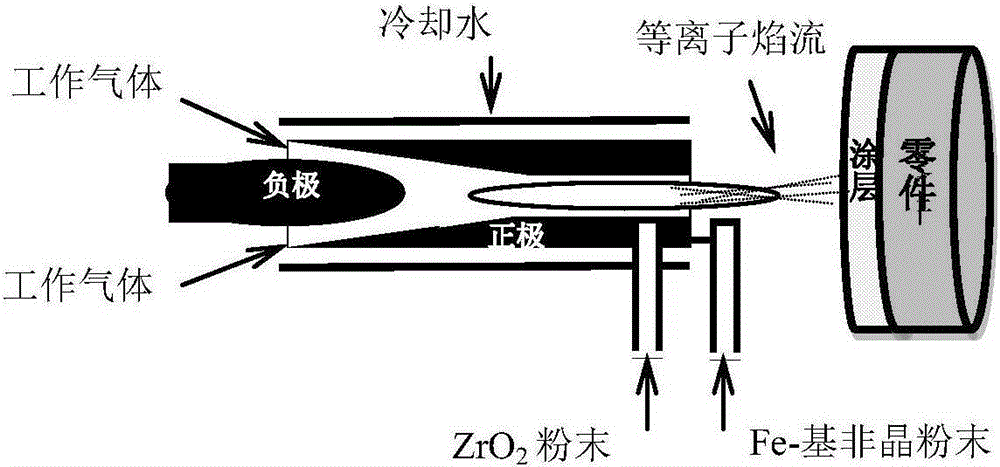

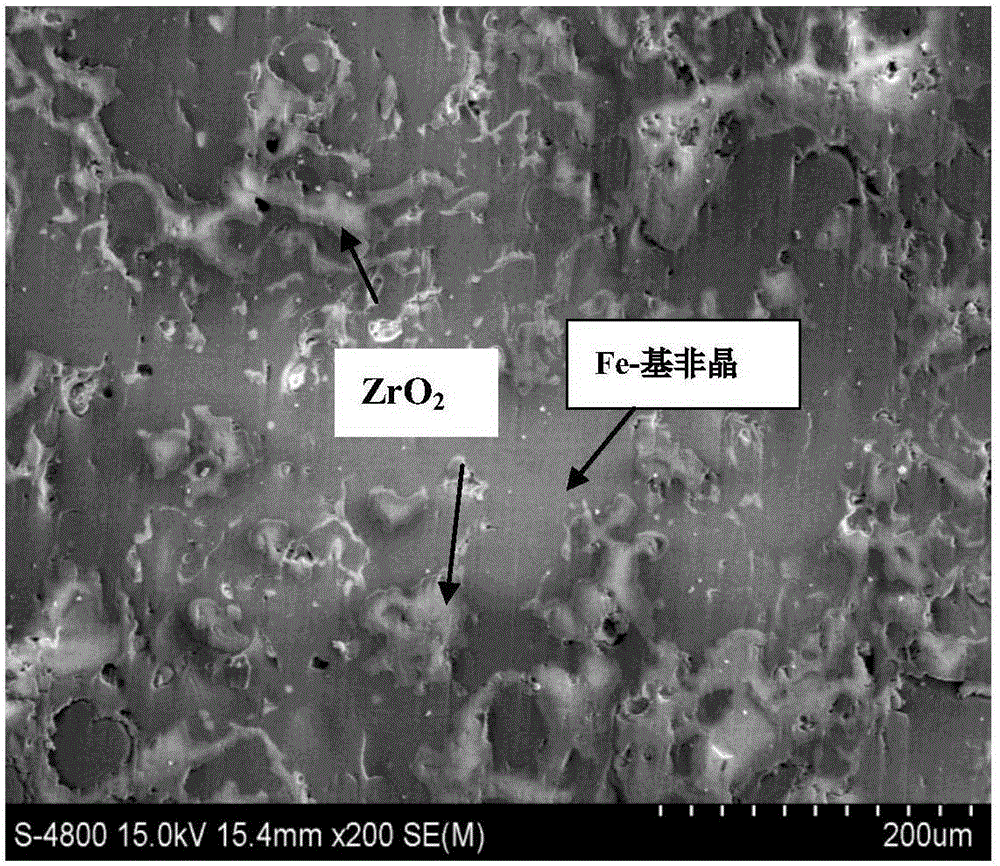

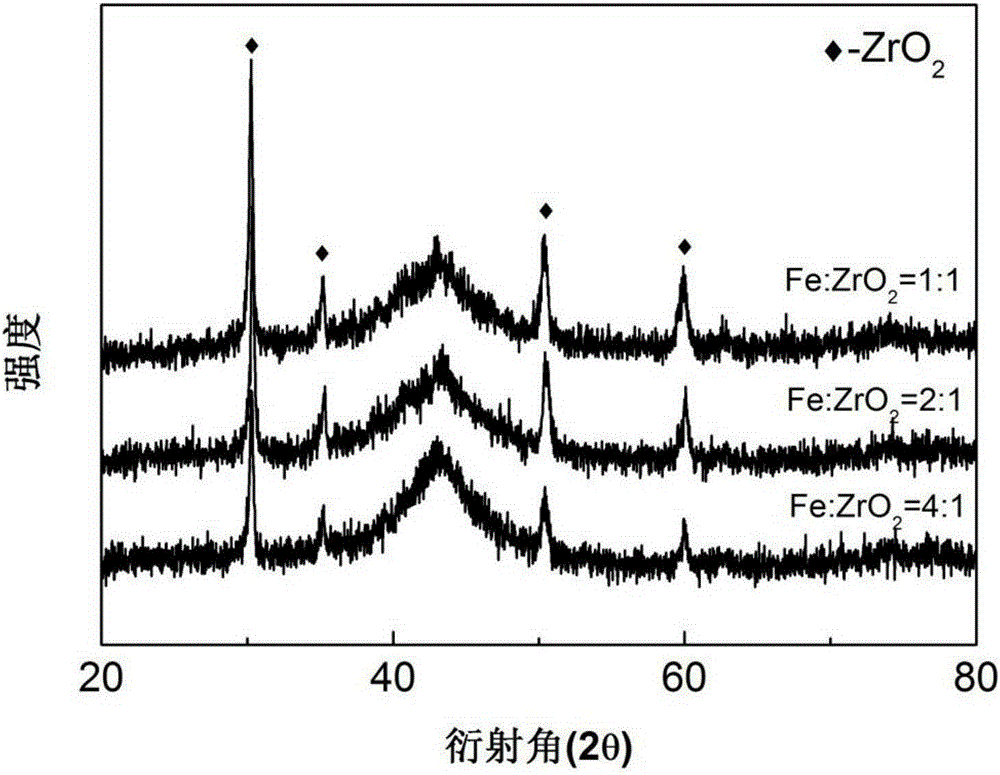

Method for preparing ceramic/iron-based amorphous composite coating

ActiveCN105200363AThe proportion of ingredients can be adjustedWide range of ingredientsMolten spray coatingAbrasive blastingMicrometer

The invention discloses a method for preparing a ceramic / iron-based amorphous composite coating. The method includes the following steps that 1, cleaning pretreatment is carried out on the surface of an alloy workpiece before spraying is carried out; 2, abrasive blasting coarsening activating treatment is carried out; 3, spraying is carried out on the surface of the alloy workpiece with a plasma spraying technology, and a binding bottom layer with the thickness ranging from 80 micrometers to 100 micrometers is obtained; 4, spraying is carried out on the surface of an alloy workpiece base body obtained in the step 3 with a multi-path and different-position plasma spraying powder feeding technology, wherein the powder feeding gas flow for ceramic powder ranges from 18 L / min to 23 L / min, and the powder feeding gas flow for iron-based amorphous powder ranges from 10 L / min to 200 L / min; finally the ceramic / iron-based amorphous composite coating is obtained. According to the method, as the plasma multi-path and different-position powder feeding technology is adopted, amorphous materials and ceramic can be co-deposited on the base body, and the proportion of ingredients of the composite coating can be adjustable and controllable. The obtained ceramic-amorphous composite coating has higher rigidity and higher abrasion resistance compared with a single amorphous coating.

Owner:HEBEI UNIV OF TECH

Neodymium iron boron magnet, preparation method and device applying same

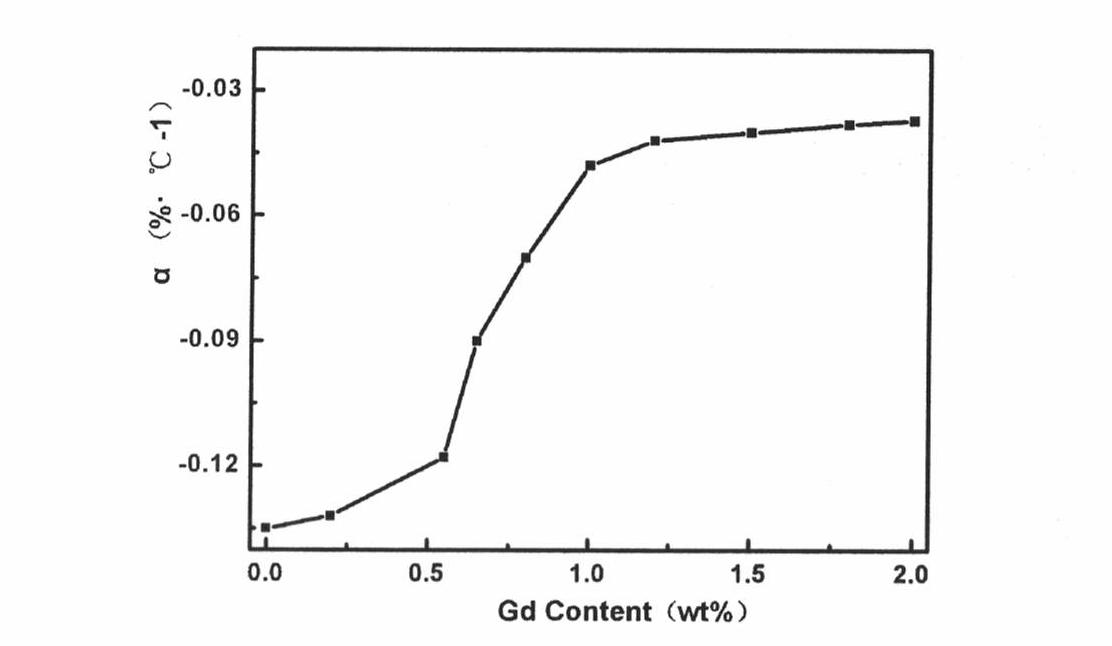

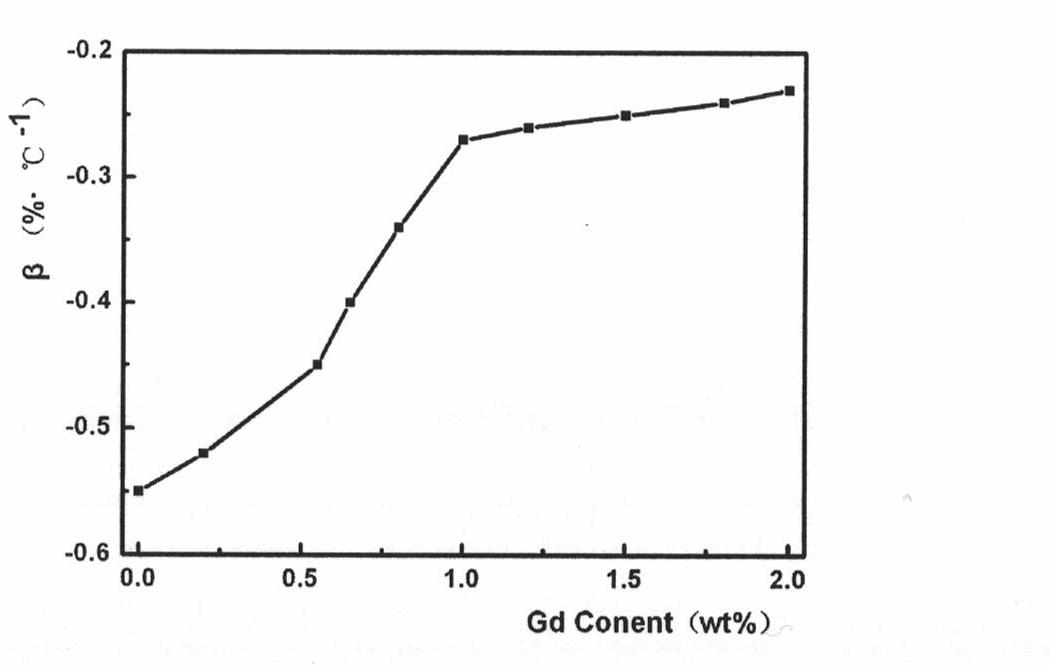

ActiveCN102103917ASmall temperature coefficientImprove coercive forceInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementMetallurgy

The invention discloses a neodymium iron boron magnet, a preparation method and a device applying the same, belonging to the field of magnetic materials. The magnet comprises the following components in percentage by weight according to the general formula: 27 to 35 percent of R representing one or two rare-earth elements except Gd, 0.55 to 2 percent of Gd, 0.5 to 3.5 percent of Co, 0.05 to 0.5 percent of M1 representing one transition metal element such as Cu, Al or Ge, 0 to 0.5 percent of M2 being one or two transition metal elements except Co and M1, 0.9 to 1.2 percent of B (namely boron) and the balance of Fe and unavoidable impurities. The neodymium iron boron magnet disclosed by the invention is compounded with Gd, Co, M1 and M2, thus the reversible magnetic induction temperature coefficient alpha and the coercive force temperature coefficient beta are better improved, the coercive force of the magnet is greatly improved while the magnetic energy product and residual magnetism are guaranteed not to reduce, the heavy rare earth element Gd is effectively utilized, and the performance is improved while the manufacturing cost is well saved.

Owner:GRIREM ADVANCED MATERIALS CO LTD

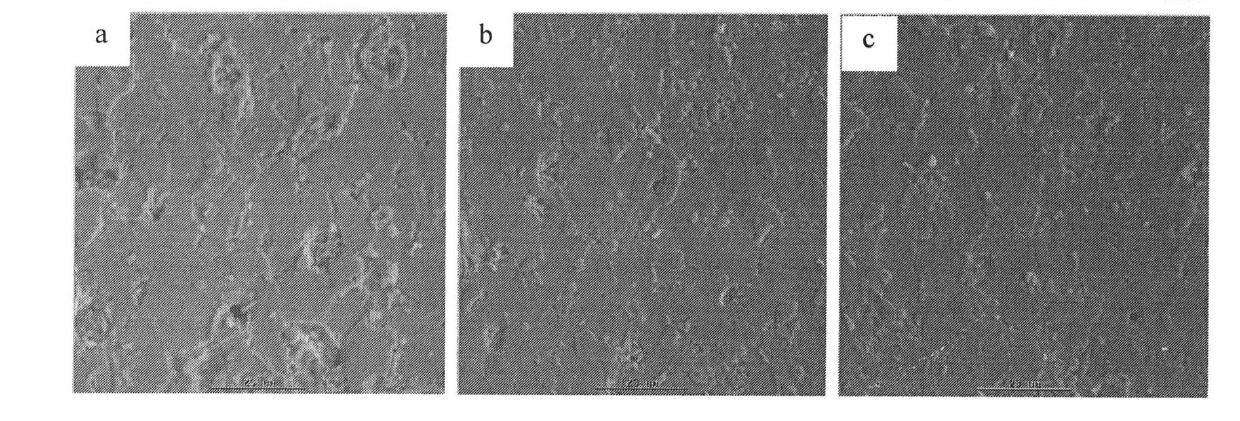

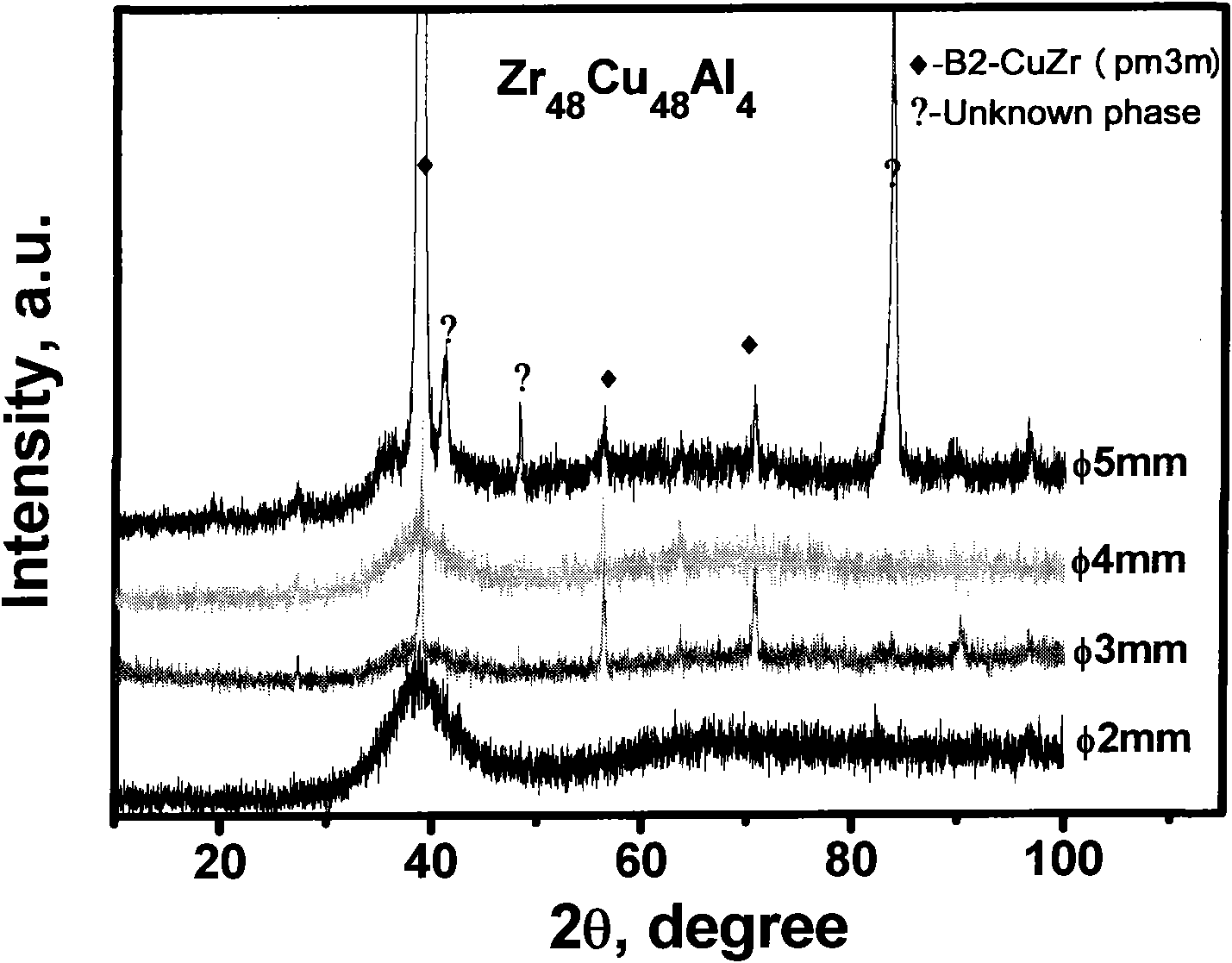

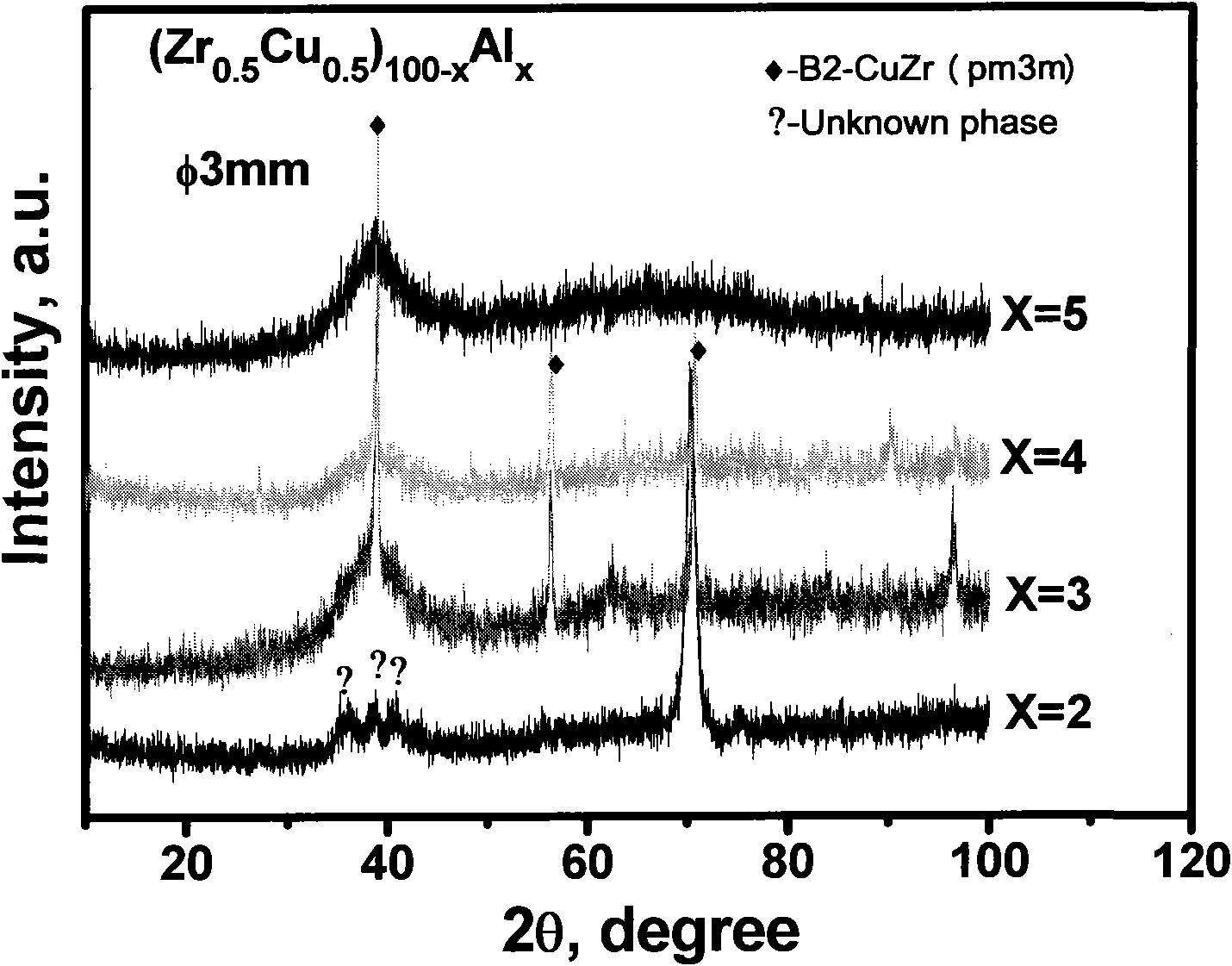

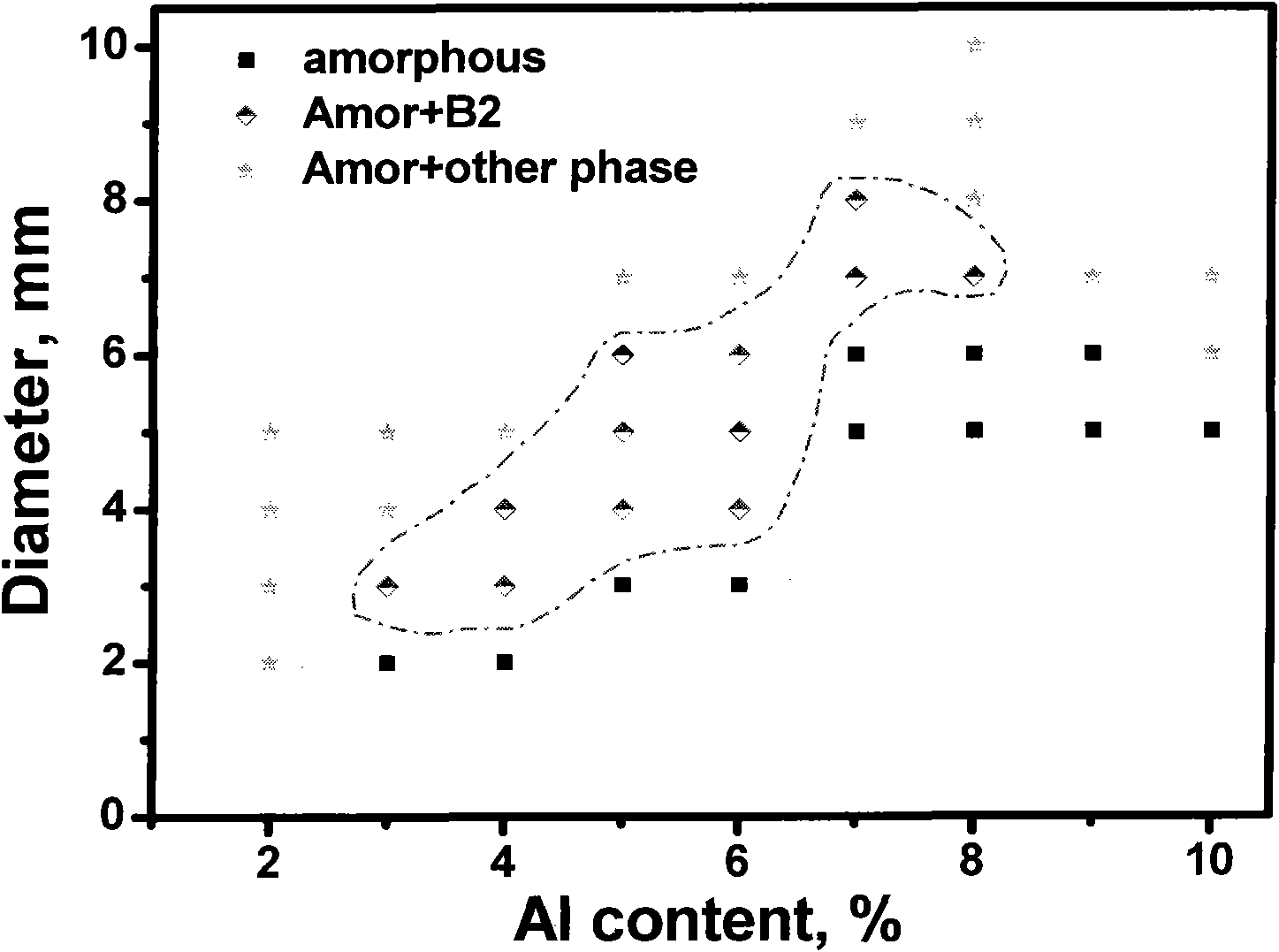

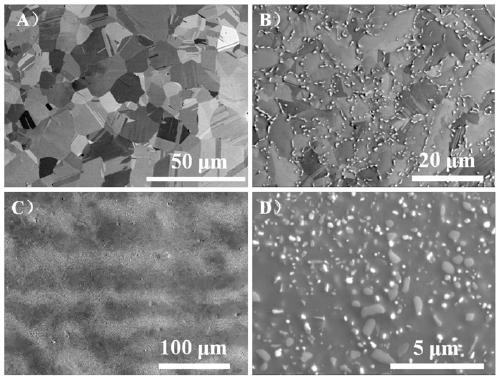

Bulk metal glass composite material with stretching plasticity and work hardening capacity

The invention relates to a bulk metal glass composite material with stretching plasticity and work hardening capacity. A crystal phase capable of producing phase change is generated in the metal glass during deforming by alloy component control and cooling speed adjustment, and the crystal phase is deformed to produce the phase change so as to prepare the composite material. The bulk metal glass composite material with the stretching plasticity and work hardening capacity is prepared by taking common pure metal elements as main components, mixing the materials according to an atomic percentage expressed by an alloy component expression, and smelting and suction casting. The bulk metal glass composite material contains 10 to 60 volume percent of crystals. The bulk metal glass composite material of the invention can undergo the phase change during deforming, has higher strength and compression plasticity, particularly has higher stretching plasticity and work hardening capacity, and can meet the requirement of practical engineering application; therefore, the composite material has quite broad engineering application prospect.

Owner:UNIV OF SCI & TECH BEIJING

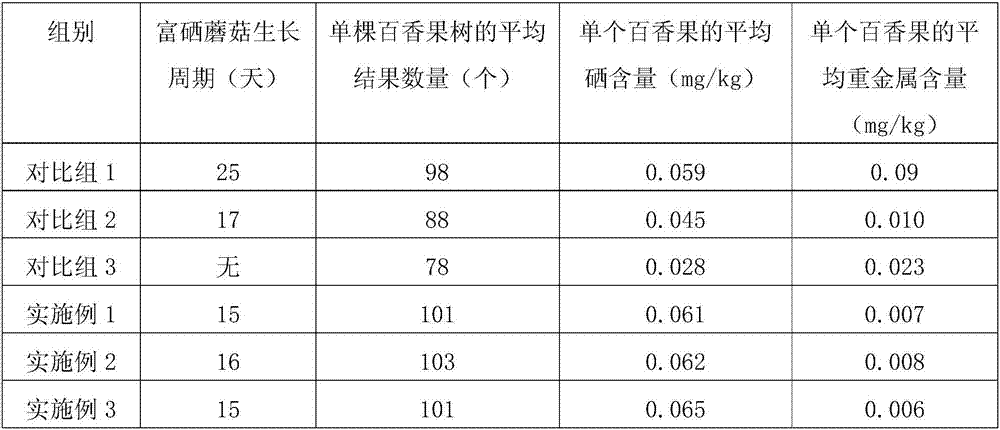

Selenium-enriched passion fruit plantation method

InactiveCN106912272AShorten the growth cycleIncrease contentAnimal corpse fertilisersBioloigcal waste fertilisersSite managementMushroom

The invention relates to the technical field of plantation and concretely relates to a selenium-enriched passion fruit plantation method. The method comprises the following steps of (1) selecting a piece of land, (2) performing transplanting, (3) managing water and fertilizer and (4) performing field management regularly. In the method, selenium-enriched mushrooms are matched with other farmyard manure to replace traditional selenium-enriched chemical fertilizers, so the output of the passion fruits is great and average selenium content of an individual passion fruit is high and average heavy metal is low; and therefore, the selenium-enriched passion fruit plantation method is suitable for promotion.

Owner:陆川县绿丰农业专业合作社

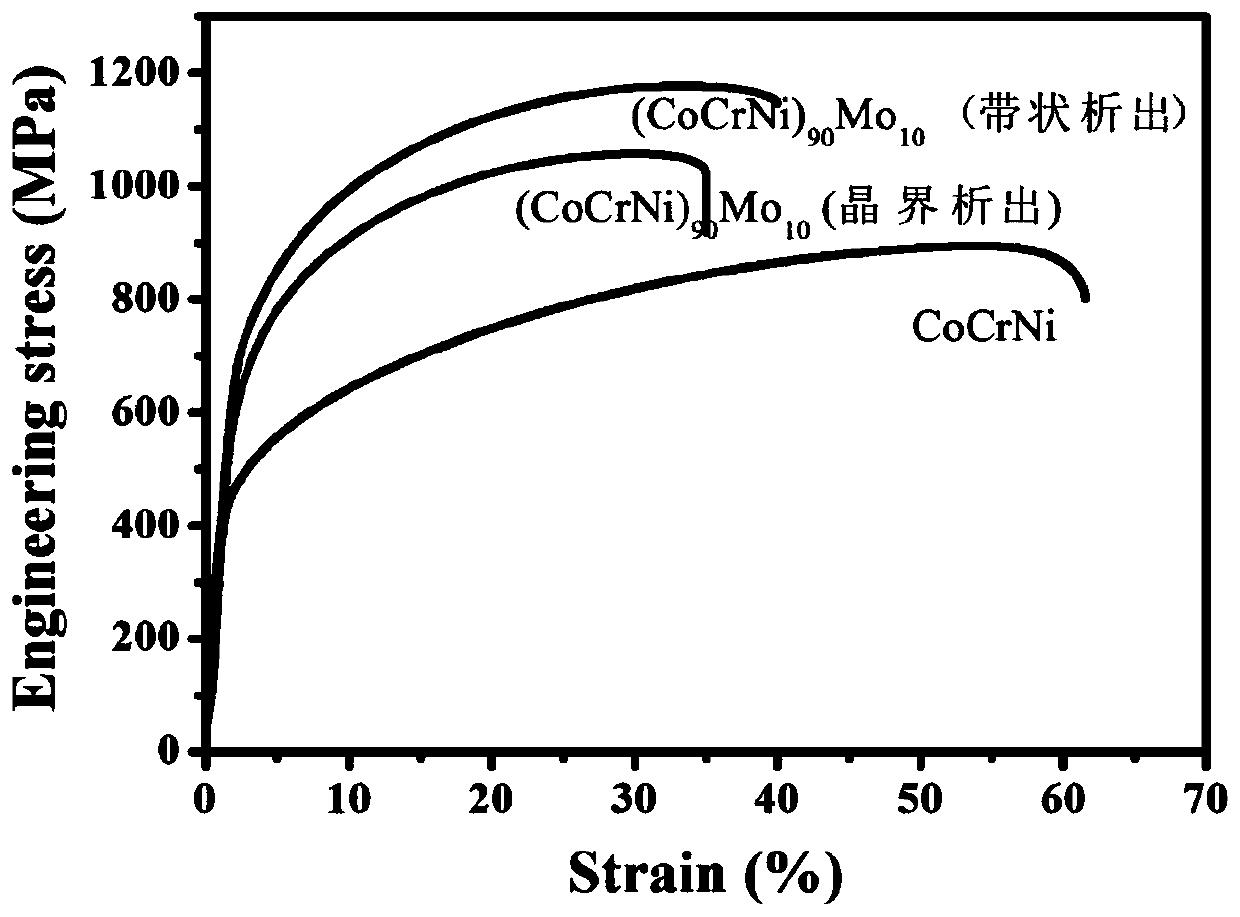

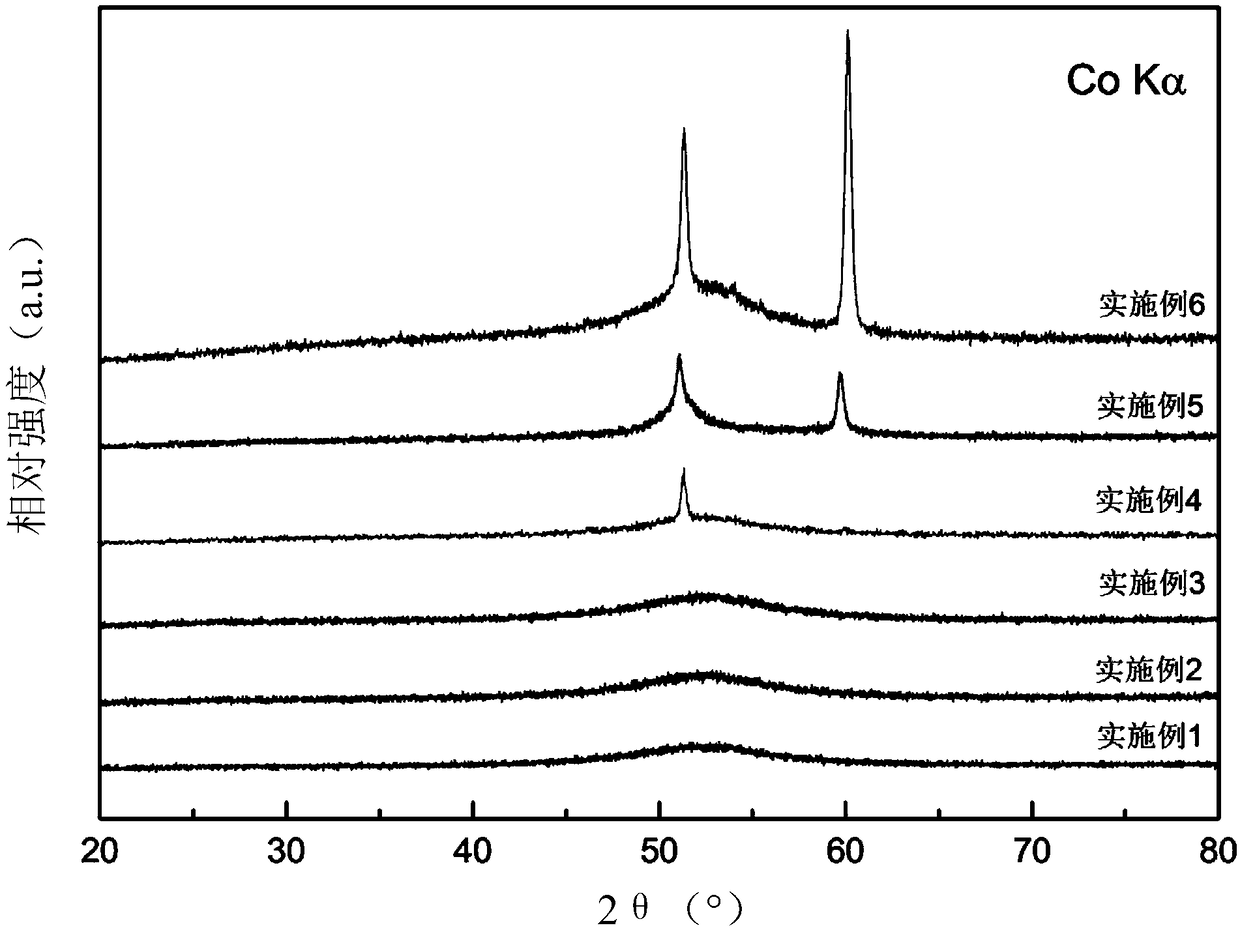

High-entropy alloy with banded precipitated phase and preparation method thereof

ActiveCN110106428AGood room temperature tensile propertiesImprove solid solution strengtheningHigh entropy alloysMo element

The invention discloses a high-entropy alloy with a banded precipitated phase. The high-entropy alloy consists of Co, Cr, Ni and Mo elements, wherein the atomic percent of Co is 25-35%, the atomic percent of Cr is 25-35%, the atomic percent of Ni is 25-35%, the atomic percent of Mo is 5-15%, and the sum of atomic percents of the components is 100%. The phase composition of the high-entropy alloy with the banded precipitated phase comprises a face-centered cubic phase and a sigma precipitated phase, wherein the sigma precipitated phase accounts for 40-60%. In the preparation method, the non-uniform precipitation of the Mo-rich phase is achieved through the combination of hot processing, solid solution processing, cold processing and annealing process, and the high-entropy alloy with the banded precipitated phase is obtained. The alloy can ensure excellent strength and toughness matching, and has application prospects in the fields of cutter materials, aerospace materials and the like.

Owner:HEBEI UNIV OF TECH

Zn-Al-Mg composite anticorrosive coating and manufacturing method thereof for cast-iron pipelines

ActiveCN103375658AWide range of ingredientsMeet diversityMolten spray coatingCorrosion preventionPorosityMg composite

The invention discloses a Zn-Al-Mg composite anticorrosive coating and a manufacturing method thereof for cast-iron pipelines and relates to the technical field of corrosion prevention technology for metal materials. The Zn-Al-Mg composite anticorrosive coating comprises a Zn-Al-Mg alloy or Zn-Al-Mg pseudo alloy, and is characterized in that the Zn-Al-Mg alloy comprises, by weight, 90-97% of Zn, 2.0-9.5% of Al, 0.2-2.0% of Mg; the Zn-Al-Mg pseudo alloy comprises, by weight, 50-70% of Zn, 28-50% of Al and 1.5-5.0% of Mg; the Zn-Al-Mg alloy or Zn-Al-Mg pseudo alloy is prepared by electric arc spraying. The Zn-Al-Mg is mainly used for corrosion prevention for outer surfaces of the cast-iron pipelines and / or pipe fittings. The anticorrosive coating has advantages of high adhesion, low porosity, excellent corrosion resistance and low cost; the manufacturing method is simple, easy to operate and wide in material sources; therefore, economical benefit is good.

Owner:XINXING DUCTILE IRON PIPES CO LTD

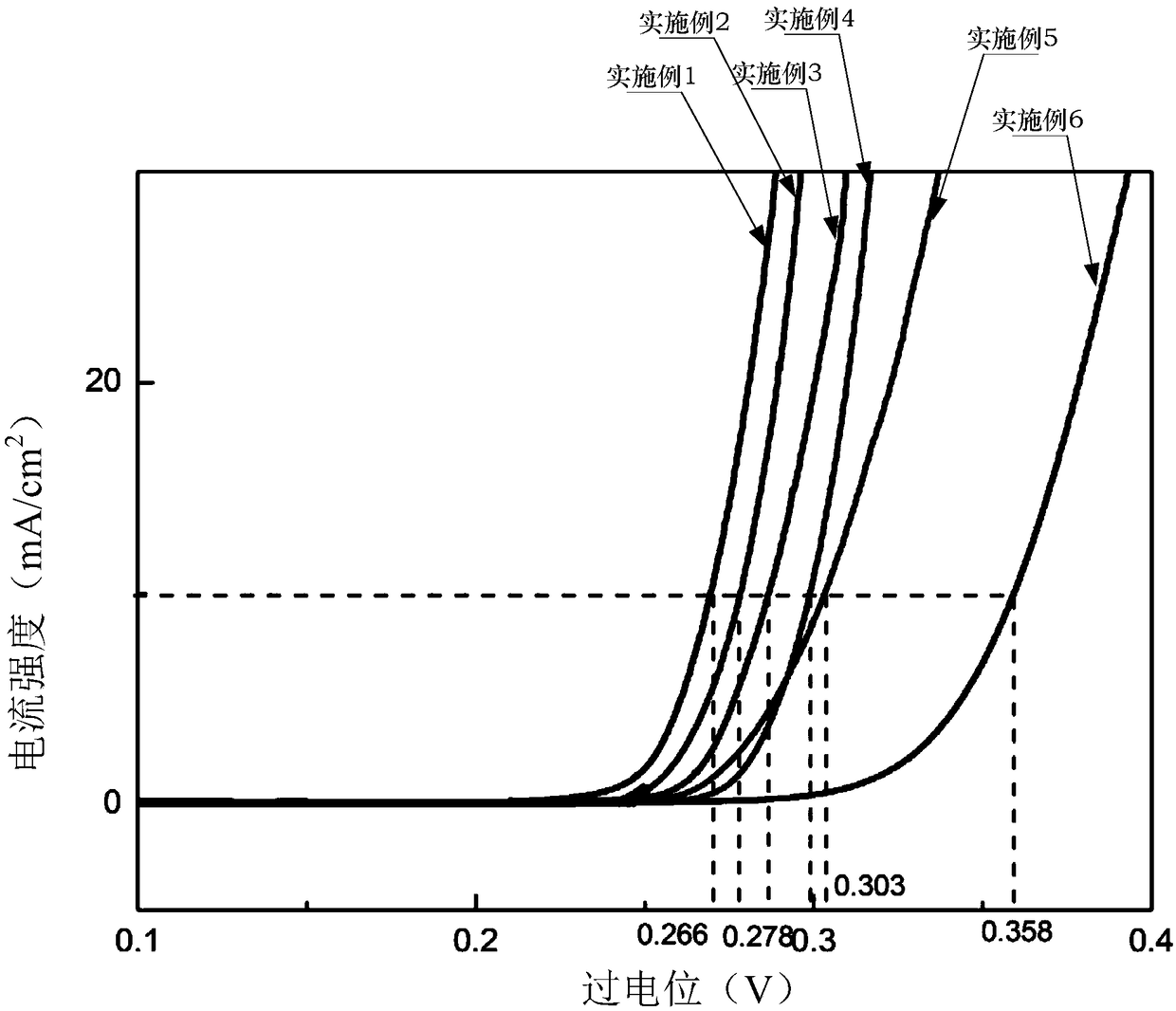

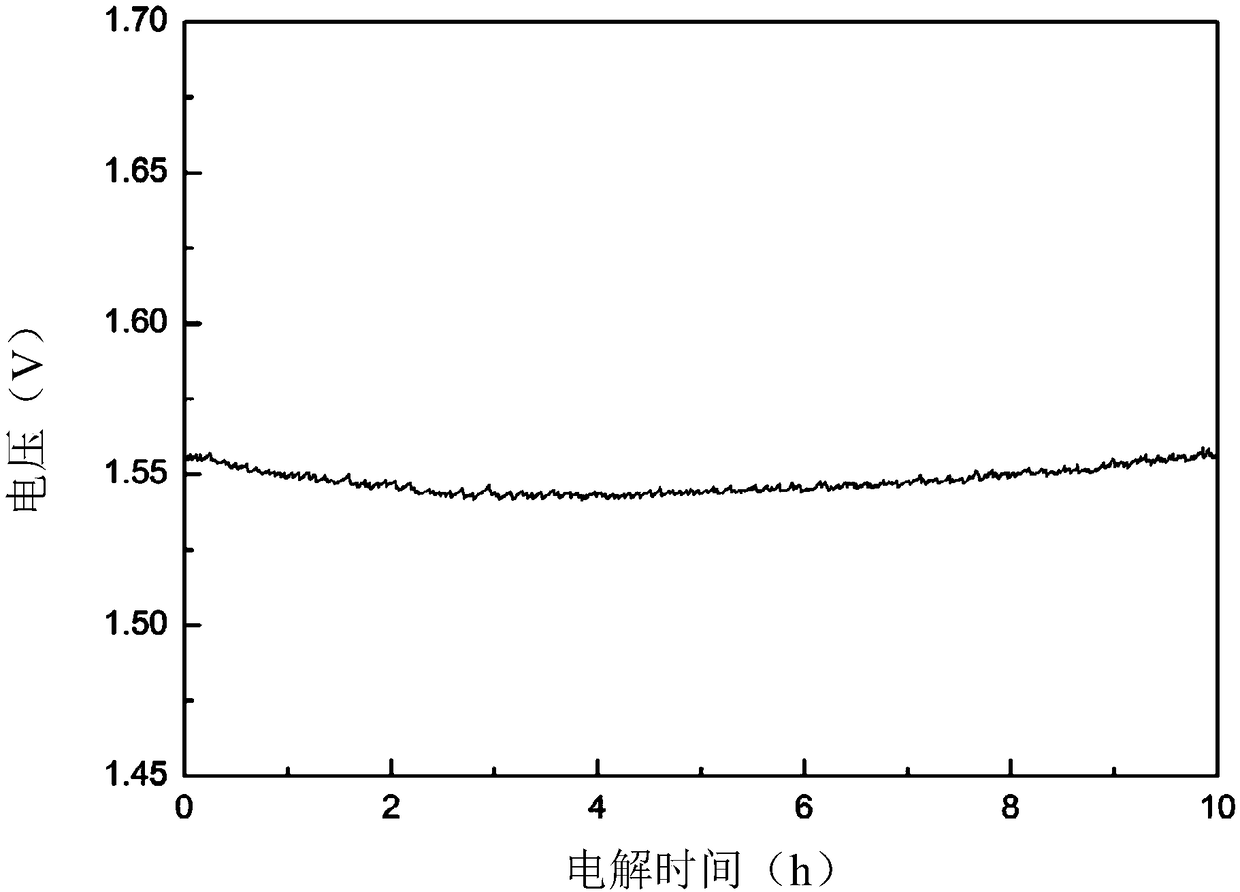

(FeaCobNic)xMyRz oxygen evolution catalytic material and application to anode oxygen evolution electrode

ActiveCN108660474AIncrease contact areaImprove the hydrogen evolution efficiency of electrolyzed waterElectrodesAlloyOxygen

The invention discloses a (FeaCobNic)xMyRz oxygen evolution catalytic material and an application to an anode oxygen evolution electrode. The atomic percent of the (FeaCobNic)xMyRz oxygen evolution catalytic material is that a plus b plus c is equal to 1, wherein a is larger than or equal to 0.5 and is less than or equal to 0.94, b is larger than or equal to 0.01 and is less than or equal to 0.9,c is larger than or equal to 0.5 and is less than or equal to 0.94, x is larger than or equal to 50 and is less than or equal to 95, y is larger than or equal to 5 and is less than or equal to 35, z is larger than or equal to 0.5 and is less than or equal to 15, M is one of or more than one of B, Si, C and P, and R is one of or more than one of Nb, Cr, Mn, Ru, Mo, Zr, Cu, Y and La. The (FeaCobNic)xMyRz oxygen evolution catalytic material is prepared into strips by adopting electric arc melting and induction melting so as to obtain alloy strips of which the thickness is 0.05 to 500 mum.(FeaCobNic)xMyRz is directly used as a working electrode to be applied to electrolyzed water, and the overpotential is 220 mV to 360 mV in the condition that the current density is 10 mA cm<-2>.

Owner:北京自然天空科技发展有限公司

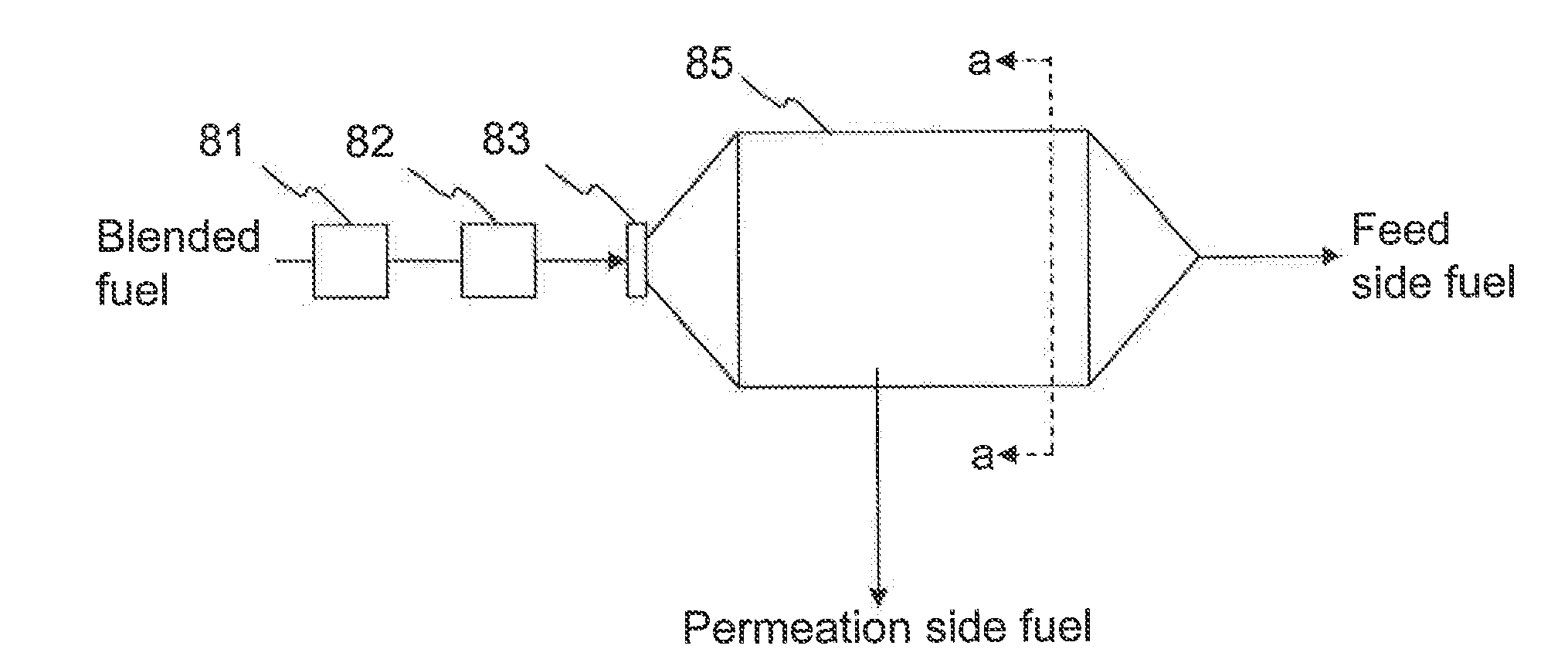

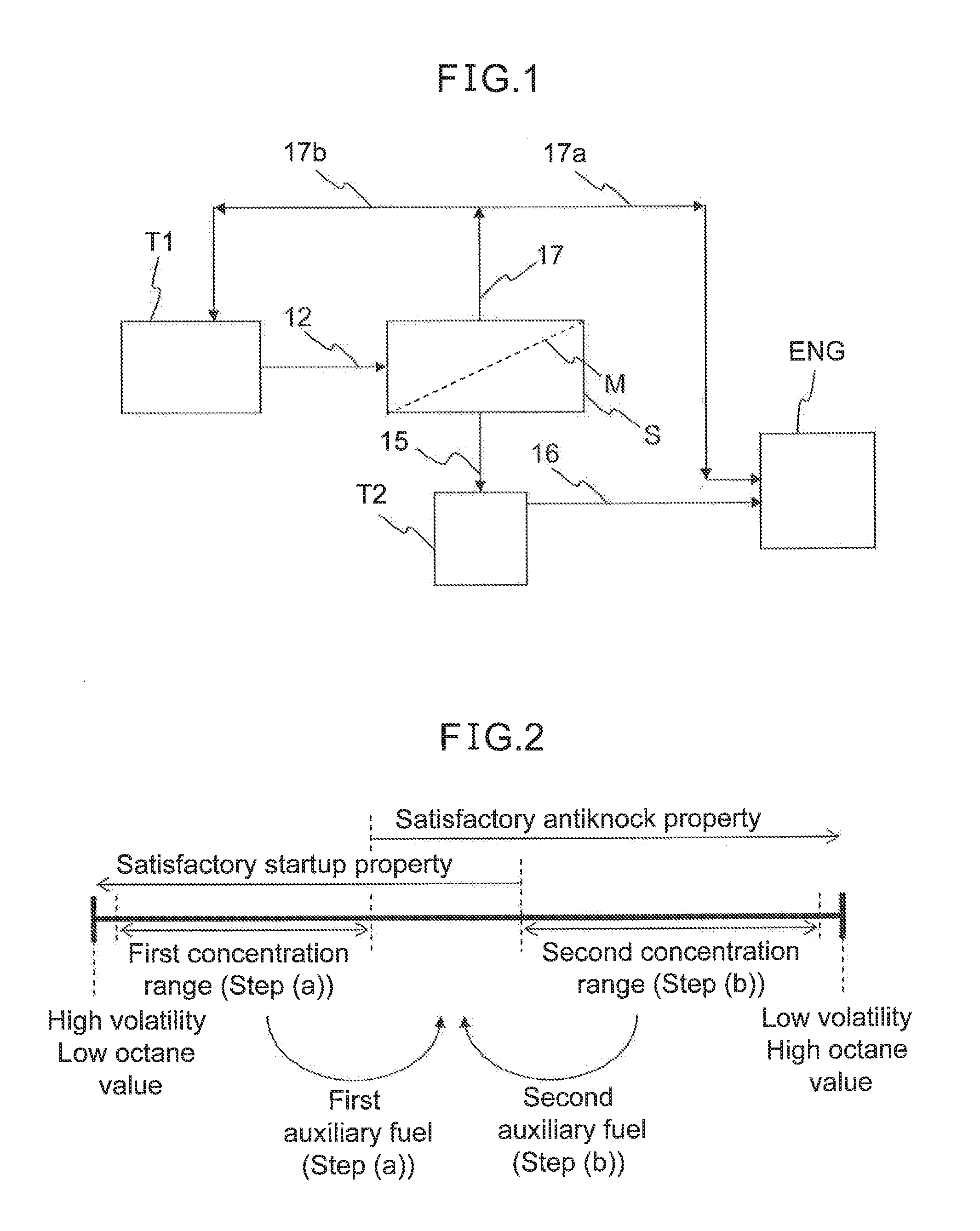

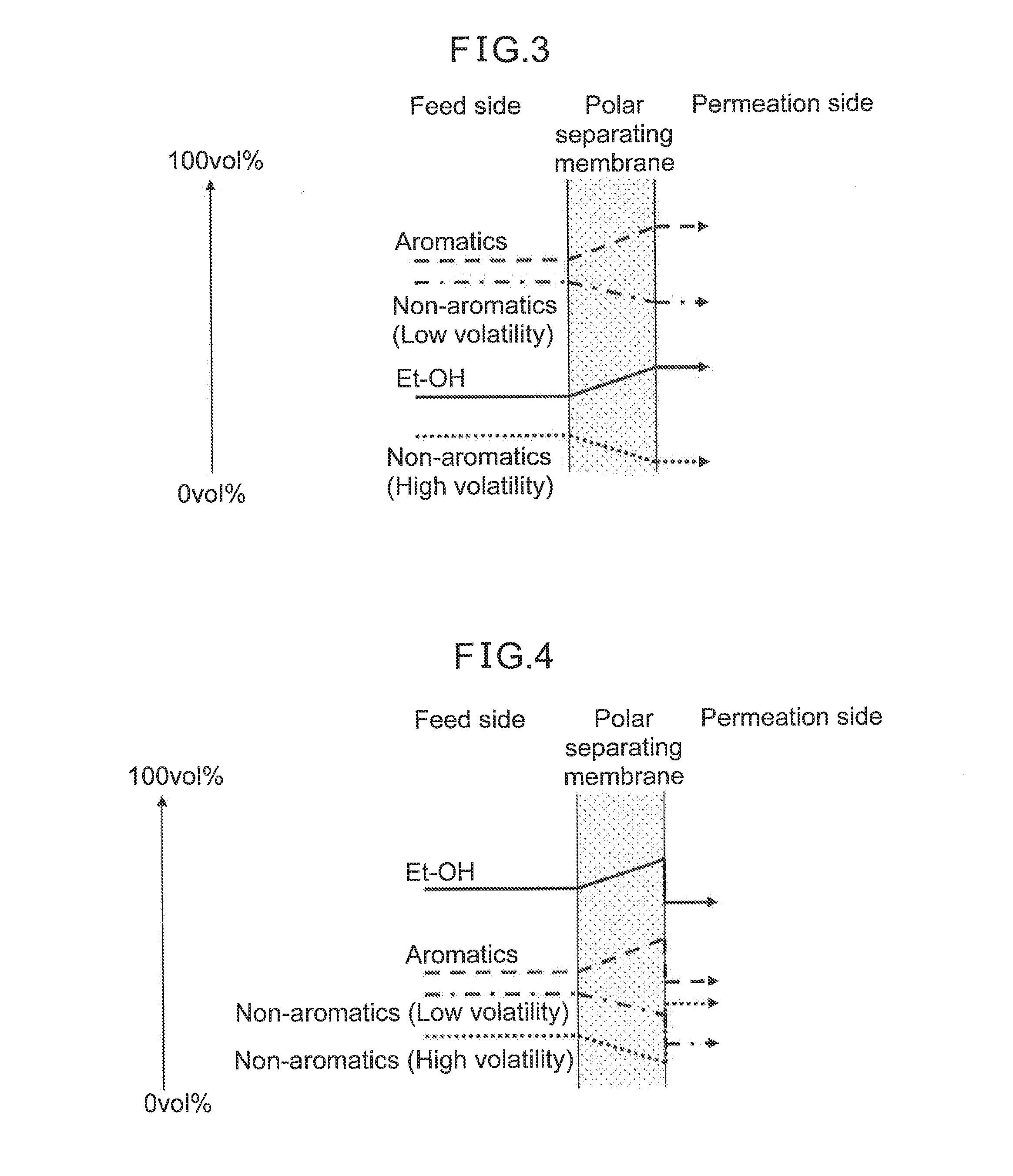

Fuel separation method

InactiveUS20150353853A1Wide range of ingredientsMembranesSemi-permeable membranesGasoline fuelProcess engineering

A fuel separation method by which auxiliary fuel is separated from blended gasoline fuel for a flexible fuel vehicle capable of using ethanol-blended gasoline fuel, the method including the following steps (a) and (b): (a) a step in which, when the ethanol concentration is low, the blended gasoline fuel is separated by a polar separating membrane member at a relatively high separation temperature to obtain, at the permeation side of the membrane, a first auxiliary fuel enriched with the aromatic gasoline components and ethanol component, and (b) a step in which, when the ethanol concentration is high, the blended gasoline fuel is separated by a polar separating membrane member at a relatively low second separation temperature to obtain, at the permeation side of the membrane, a second auxiliary fuel enriched with the non-aromatic high-volatile gasoline components.

Owner:TOYOTA JIDOSHA KK +2

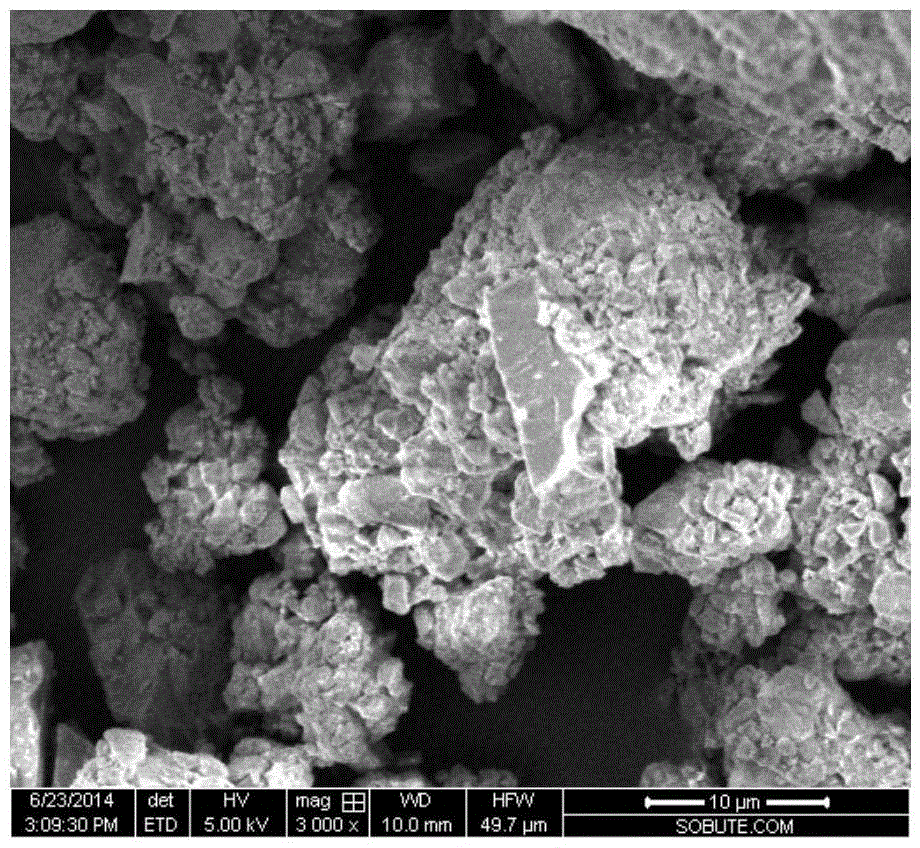

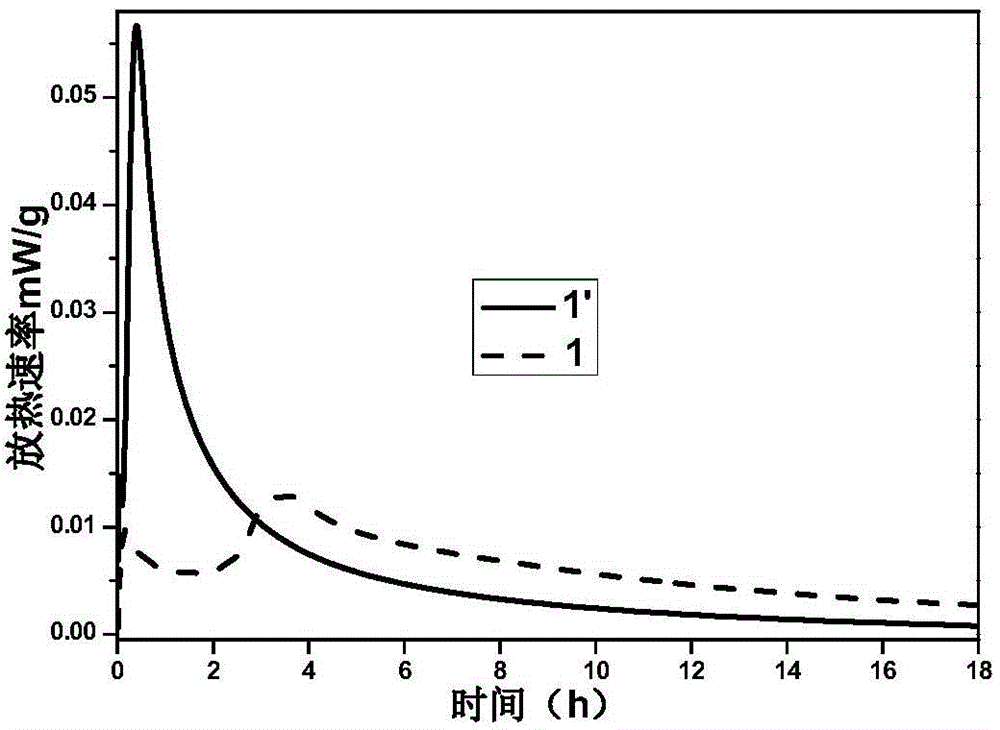

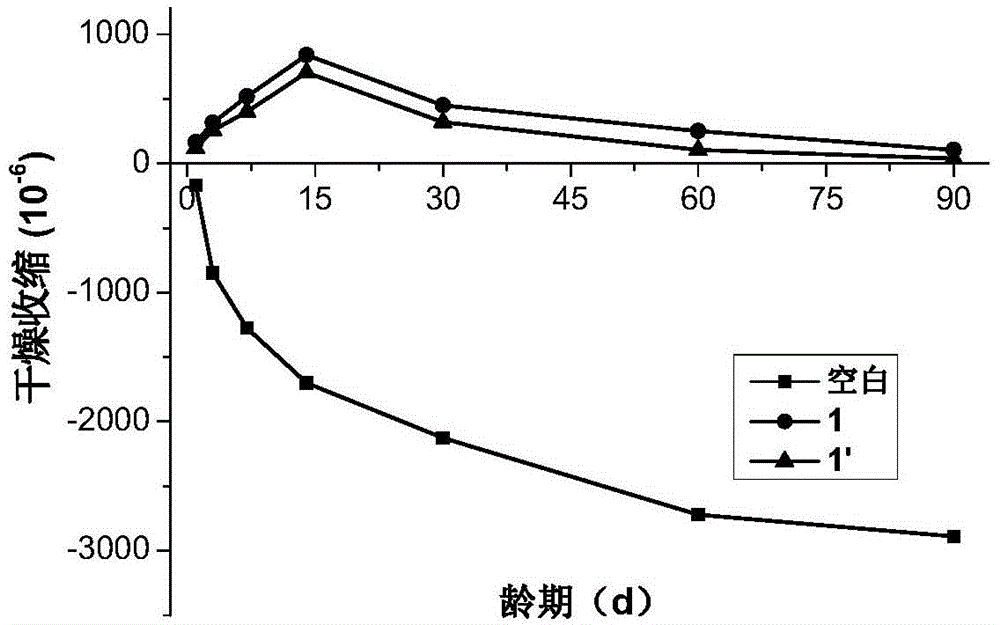

Modified calcium oxide expansion agent for cement concrete and preparation method of modified calcium oxide expansion agent

The invention provides a modified calcium oxide expansion agent for cement concrete. The modified calcium oxide expansion agent for the cement concrete has the specific surface area of 100-600m<2> / kg and is prepared from a degradable high polymer and calcium oxide expansion clinker. According to the modified calcium oxide expansion agent for the cement concrete, provided by the invention, the invalid hydration of calcium oxide at a plastic stage of concrete is reduced, the hardened expansion quantity is increased, and the shelf life of the product can be further prolonged; the expansion agent can be applied to the crack resisting and seepage prevention of a concrete structure and can be used for greatly improving the durability of the concrete.

Owner:JIANGSU SOBUTE NEW MATERIALS

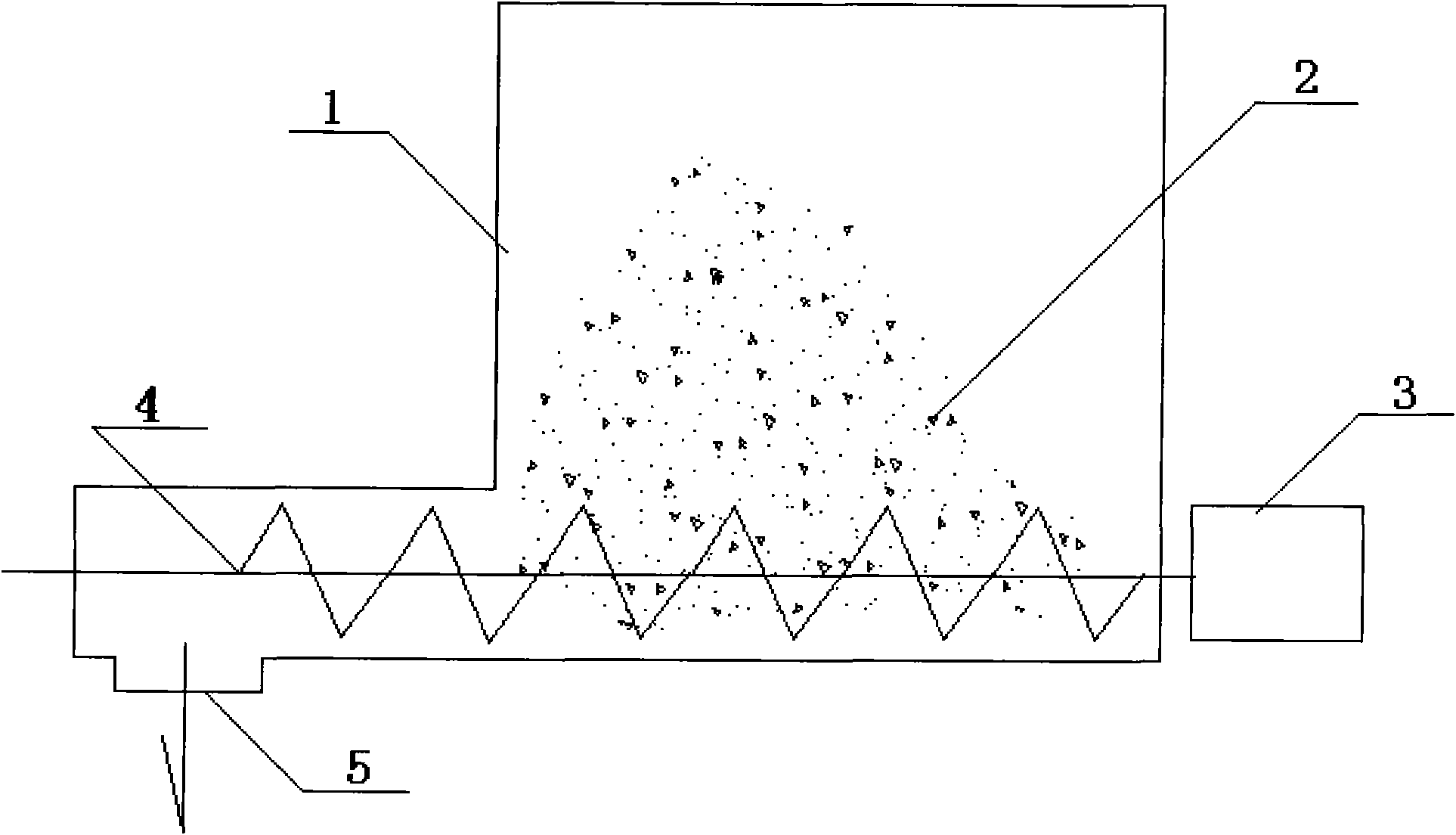

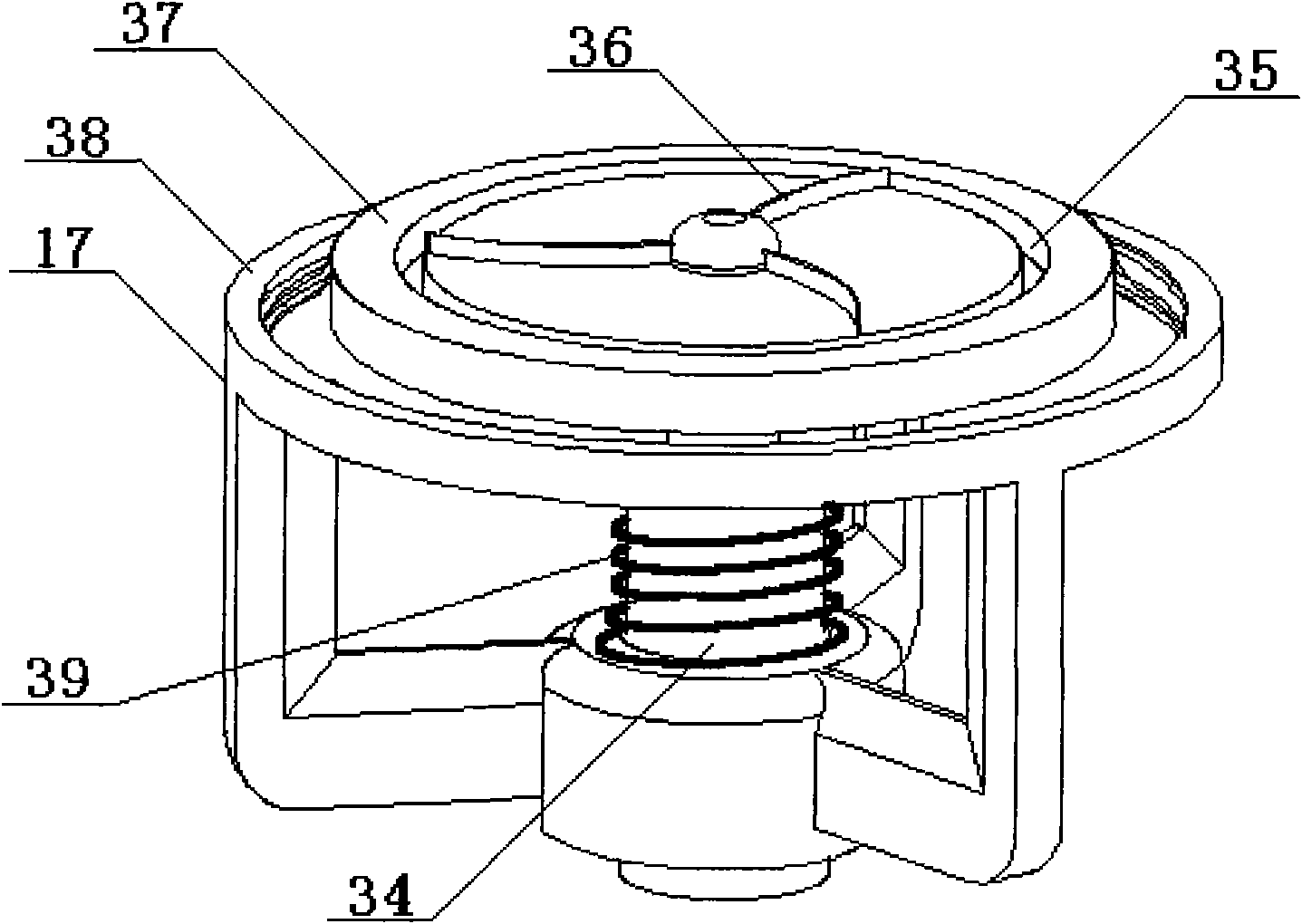

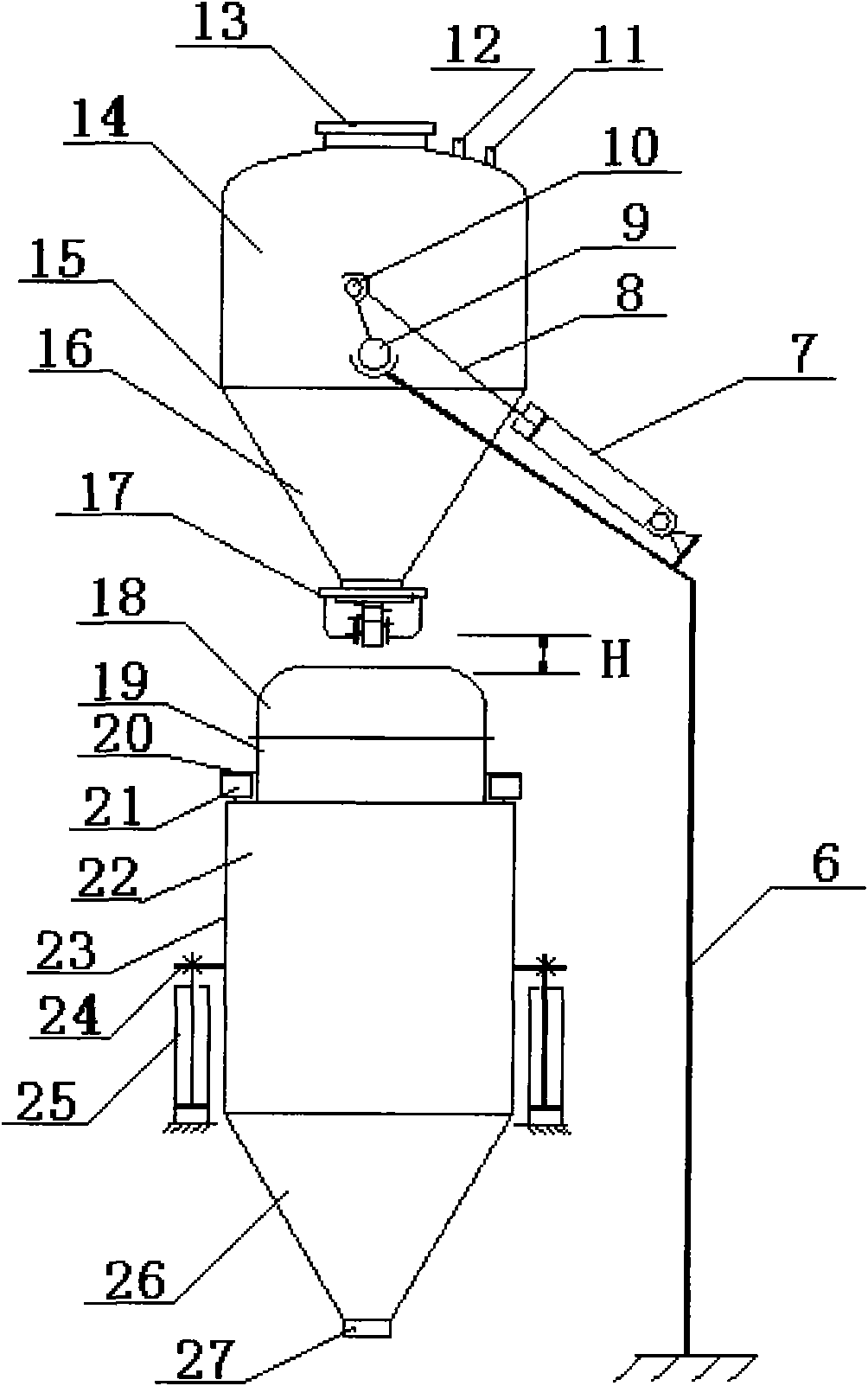

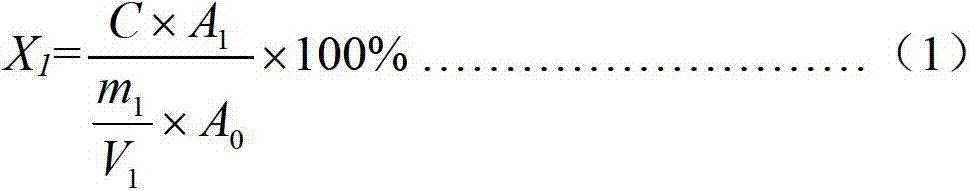

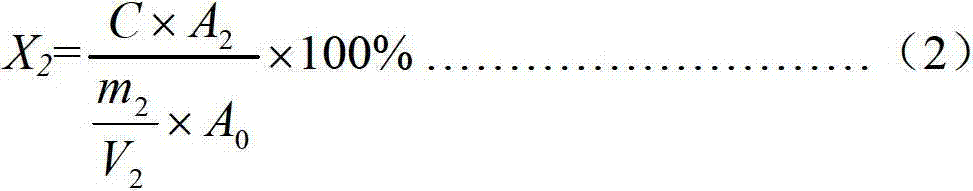

Turntable type quantitative discharging device

The invention discloses a turntable type quantitative discharging device, which comprises a storage bin. The turntable type quantitative discharging device is characterized in that the storage bin is a barrel with a circular upper part and a conical lower part, the lower edge of the lower conical part of the barrel is fixedly connected with a discharging pipe provided with a serrated bottom edge, and the outer side of the discharging pipe is fixedly provided with a bin bottom flange plate with external threads. The turntable type quantitative discharging device also comprises a cylinder which supports a supporting point outside of the storage bin so that the storage bin can rotate; a turntable assembly which is connected with the threads of the bin bottom flange plate through threads and comprises a three-claw turntable seat, a turntable arranged in the middle of the turntable seat and a rotating beam barrel; a collecting tank which is arranged below the turntable assembly and is a barrel with an upper circular part and a lower conical part; a driving host which is arranged in the middle upper part of the collecting tank; and a weighing scale which is arranged in the middle upper part of the collecting tank. The device has the advantages of simple structure, stable discharge and easy use and cleaning, can realize the smooth, accurate, rapid and automatic quantitative discharging of trace raw materials, and is applicable to the mixing and production with multiple types of powdered and particular trace raw materials and high weighing precision.

Owner:广西南宁市真唯特自动化设备有限公司

Novel culture medium for producing pulullan and method for fermenting and producing pulullan

InactiveCN103243135ALow costWide range of ingredientsMicroorganism based processesFermentationInorganic saltsSucrose

The invention relates to a novel culture medium and production technique for fermenting and producing pulullan. The formula of the culture medium is as follows: sucrose is used as a carbon source, the concentration of the sucrose is 60-120g / L, urea is used as a nitrogen source, and the concentration of the urea is 2-4g / L; K2HPO4, MgSO4.7H2O, and FeSO4.7H2O are used as inorganic salts, the concentration of the NaCl is 2-4g / L, the concentration of the K2HPO4 is 3-10g / L, the concentration of the MgSO4.7H2O is 0.3-0.5g / L, the concentration of the FeSO4.7H2O is 25-100mg / L, and the pH ranges from 6 to 7. The culture medium has clear ingredients, the ingredients of the fermented product are simple, and the following extraction production cost can be lowered; and the culture medium is wide for ingredient source, easy to buy and lower in cost.

Owner:天津北洋百川生物技术有限公司

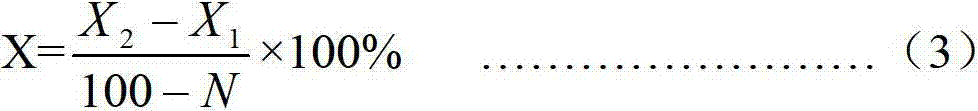

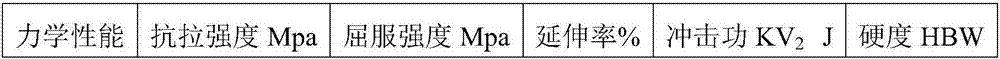

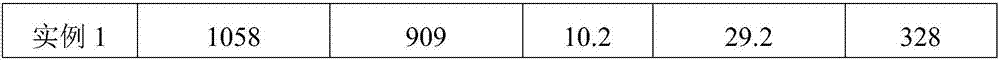

Alloy steel material for high speed train brake disc and preparation method of alloy steel material

ActiveCN107058883AReduce contentImprove purityElectric furnaceProcess efficiency improvementCrack resistanceNiobium

The invention relates to an alloy steel material for a high speed train brake disc and a preparation method of alloy steel material. The technical problem that elongation, impact energy, anti-fatigue performance, and crack resistance of existing materials need to be further improved is solved. The alloy steel material comprises the chemical components of carbon, silicon, manganese, chromium, nickel, molybdenum, vanadium, titanium, niobium, tungsten, aluminum, copper, zirconium, cobalt, phosphorus, sulfur, oxygen, nitrogen, hydrogen, iron and trace impurities. The preparation method of the alloy steel material is disclosed simultaneously. The alloy steel material for the high speed train brake disc and the preparation method thereof can be widely applied to the field of preparation of alloy steel materials for high speed train brake discs.

Owner:SHANDONG HAOAN GOLDTECH NEW MATERIALS

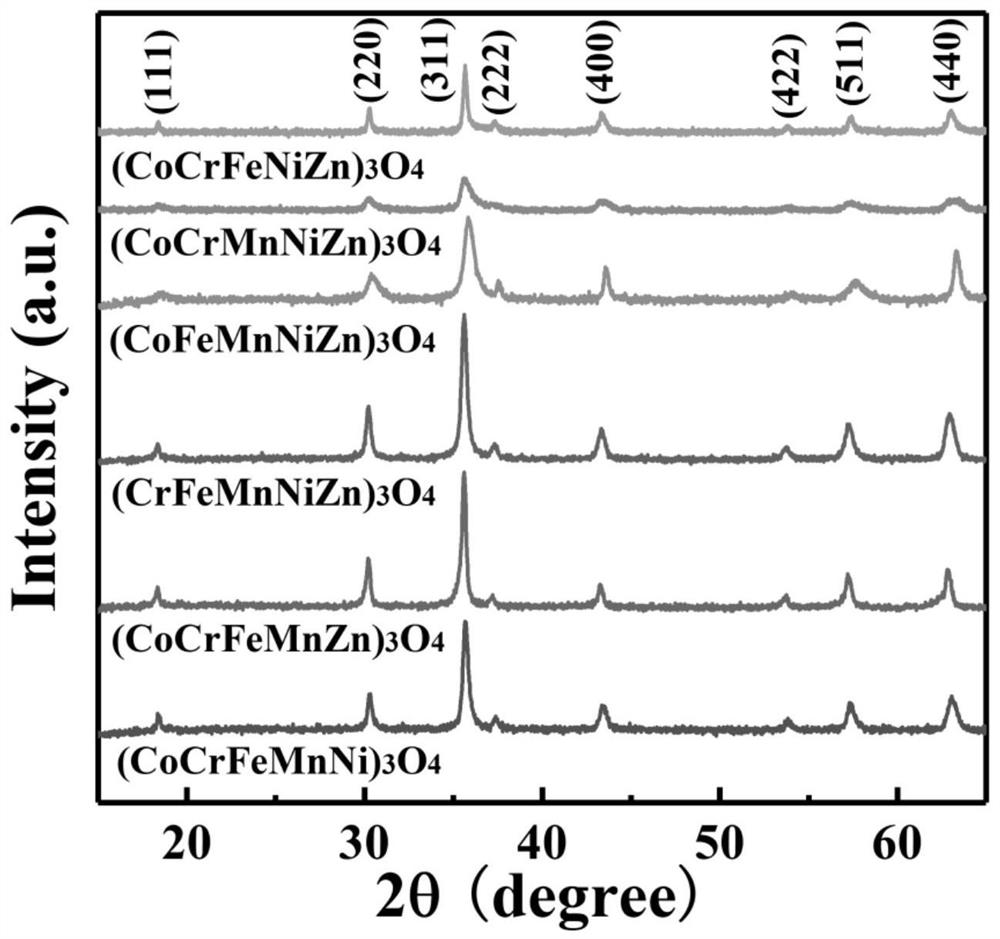

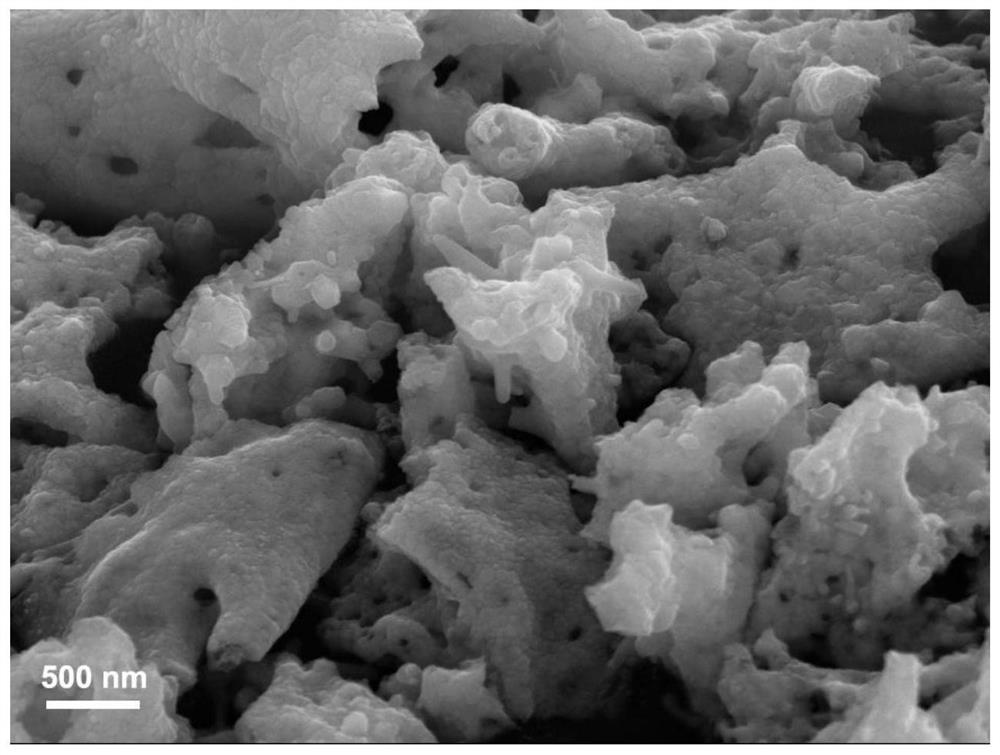

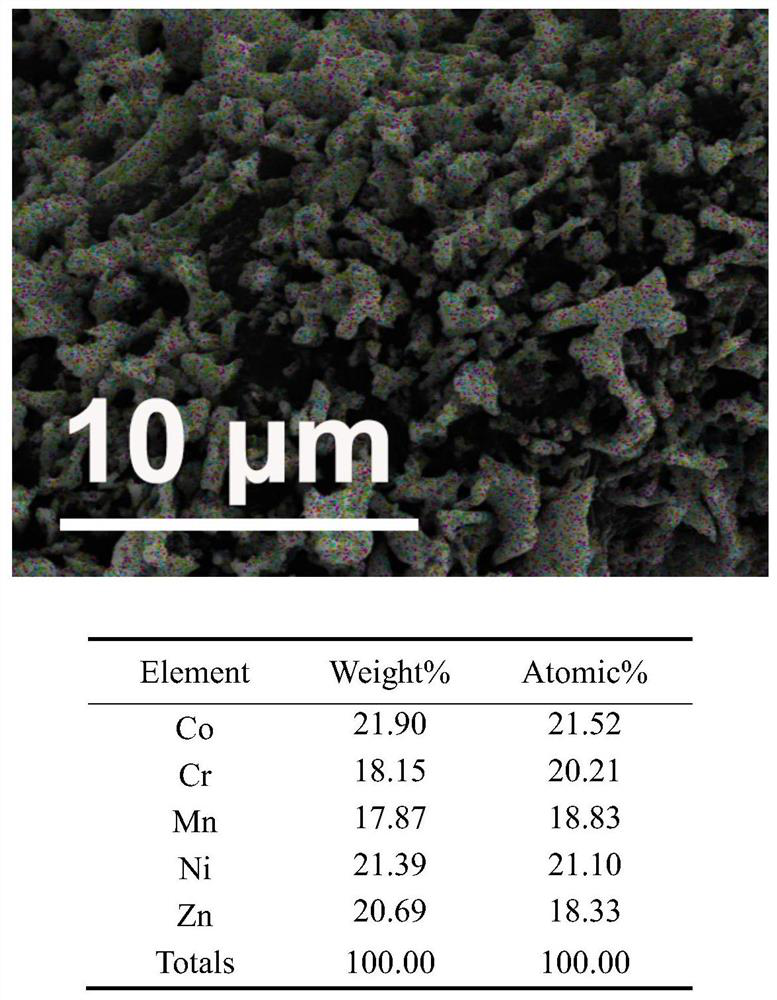

Single-phase spinel type high-entropy oxides as well as preparation method and application thereof

ActiveCN112340787AWide range of ingredientsNo pollution in the processCobalt compoundsCoatingsPhysical chemistryThin membrane

The invention belongs to the technical field of high-entropy oxide materials, and particularly relates to a plurality of single-phase spinel type high-entropy oxides as well as a preparation method and application thereof. According to the invention, expansion is carried out on the basis of an existing spinel-type (CoCrFeMnNi)3O4 high-entropy oxide material to prepare the single-phase spinel-typehigh-entropy oxide of a new system, the component range of the spinel-type high-entropy oxide is expanded, the application of the prepared single-phase spinel-type high-entropy oxide of the new systemin the field of electrochromism is discovered and proposed, and the application field of the single-phase spinel type high-entropy oxides are further expanded. According to the invention, the component range of the spinel type high-entropy oxides is expanded; single-phase spinel type high-entropy oxide powder materials prepared by a sol-gel combustion method are high in purity, small in particlesize and uniform in element distribution; a spin-coating method is adopted, so process is simple, and prepared single-phase spinel type high-entropy oxide film materials are good in uniformity; and meanwhile, the application of the single-phase spinel type high-entropy oxides as electrochromic materials is provided, so the application field of the single-phase spinel type high-entropy oxides are further expanded.

Owner:东北大学秦皇岛分校

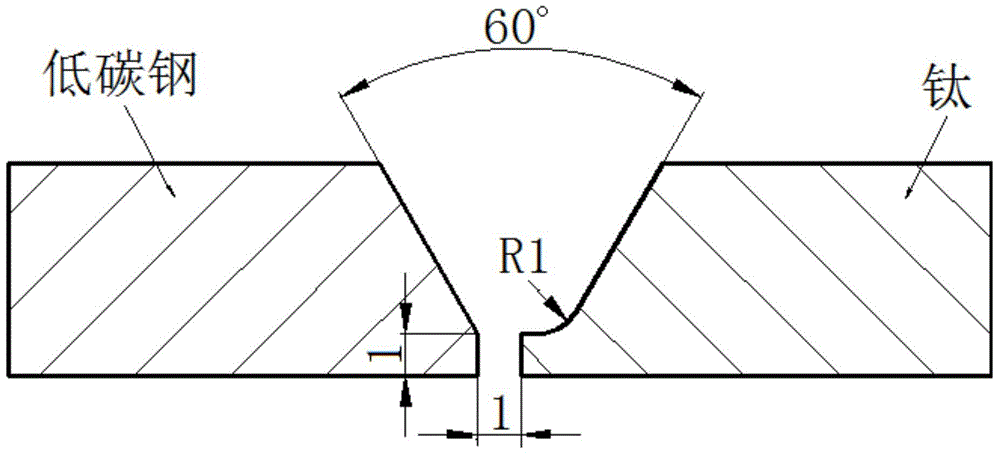

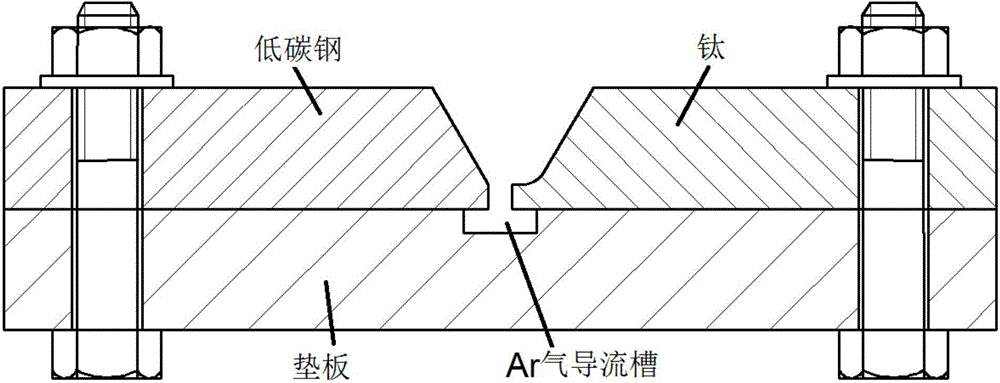

High-entropy alloy welding wire for welding titanium/low-carbon steel in TIG (Tungsten Inert Gas) mode and application

InactiveCN104476011AImprove toughnessImprove corrosion resistanceArc welding apparatusWelding/cutting media/materialsHigh entropy alloysTitanium

The invention discloses a high-entropy alloy welding wire for welding titanium / low-carbon steel in a TIG (Tungsten Inert Gas) mode. The high-entropy alloy welding wire is formed by the following components in atomic percent with the total percent of 100 percent: 5 percent of Ti, 2 percent to 15 percent of Fe, 25 percent to 35 percent of Ni, 23 percent to 30 percent of Cu, and 25 percent to 35 percent of V. The invention also discloses a method for applying the high-entropy alloy welding wire to welding the titanium / the low-carbon steel in the TIG mode. The welding material cost is low, the preparation is simple, the welding method is convenient and easy to implement, the adaptability is wide, and the obtained titanium / low-carbon steel welded joint is good in formation of weld, free of cracks, high in intensity and good in toughness.

Owner:XIAN UNIV OF TECH

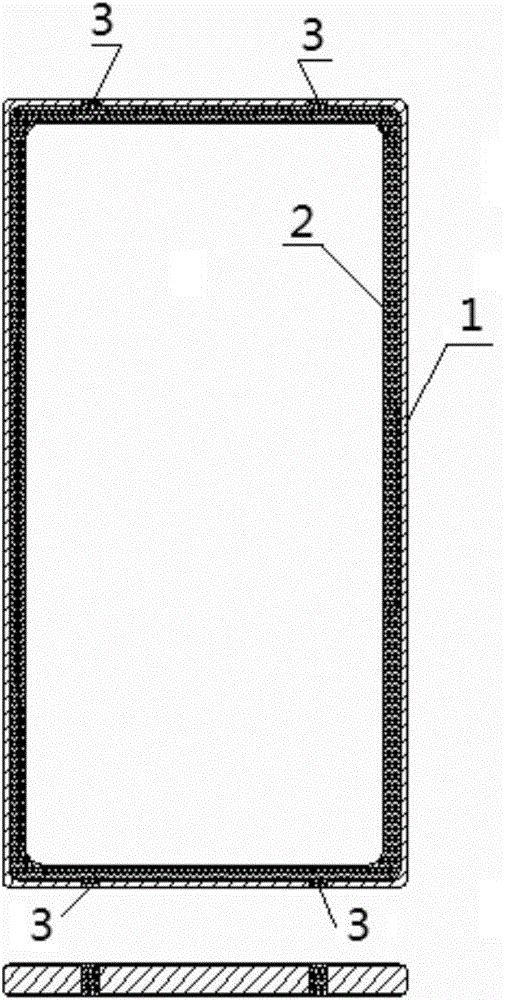

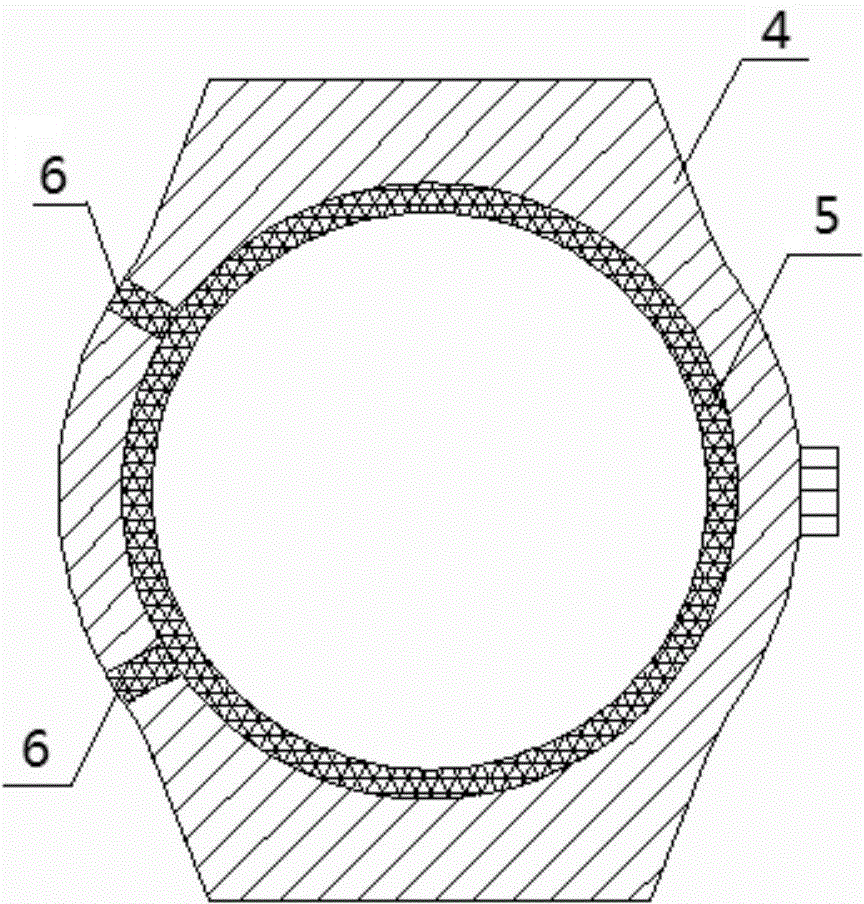

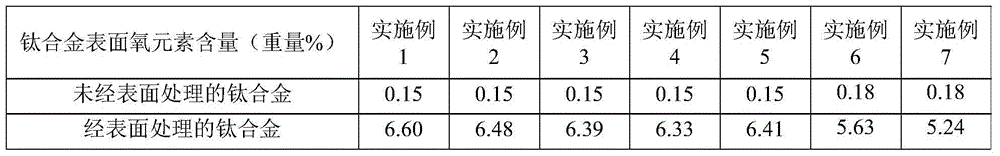

Metal-resin composite as well as preparation method thereof and electronic product shell

ActiveCN105522684AImprove bindingNot easy to fall offAnodisationLamination ancillary operationsOxygenTitanium alloy

The invention discloses a metal-resin composite and a preparation method thereof. The metal is titanium or a titanium alloy; the composite comprises a metal substrate and a resin layer which is attached to at least partial surface of the metal substrate; pits are distributed in the surface of the metal substrate attached with the resin layer; part of resin in the resin layer downwards extends, the pits are filled with the resin, and content of an element oxygen in the surface layer of the metal substrate accounts for more than 1wt%. The preparation method comprises the following steps: soaking the metal substrate into an etching solution comprising at least one alkali metal hydroxide, and forming pits in the surface of the metal substrate; and injecting resin into the surface of the metal substrate subjected to surface treatment to form the resin layer. The binding force between the metal substrate and the resin layer in the metal-resin composite is high, so that the resin layer is not easily dropped from the surface of the metal substrate, and therefore, the metal-resin composite is suitable for being used an electronic product shell. The etching solution used by the preparation method is low in toxicity and is small in volatility, so that the operation safety is high, and the pollution to the environment is small.

Owner:BYD CO LTD

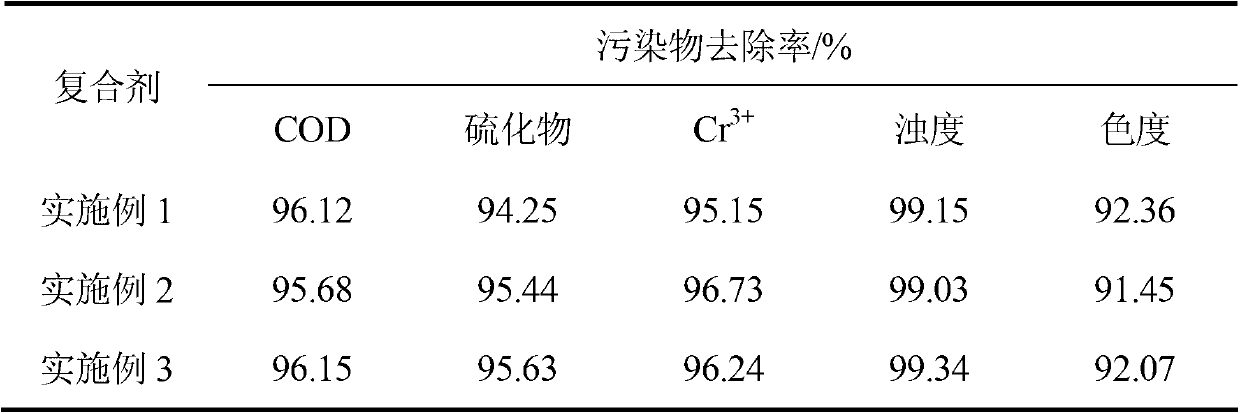

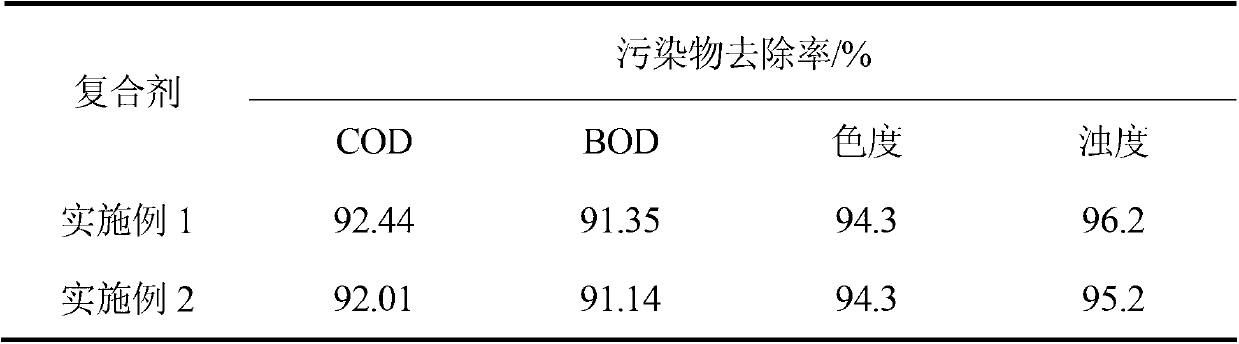

Water treatment compound agent based on potassium ferrate and preparation method of water treatment compound agent

InactiveCN103121745AEasy to handleReduce cost inputWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionBiocompatibility TestingTherapeutic effect

The invention discloses a water treatment compound agent based on potassium ferrate. The water treatment compound agent comprises the following components by mass percent: 8-35 percent of potassium ferrate, 25-50 percent of polymeric ferric sulfate, 20-40 percent of diatomite, 5-20 percent of calcium hydroxide and 3-8 percent of sodium hydroxide. A preparation method of the water treatment compound agent comprises the following steps of: adding the components into a dry vessel one by one, introducing dry inert gas to carry out protection, uniformly mixing under the condition of room temperature, and storing a mixture in the inert gas environment and a sealed and dark position without water. With the adoption of the water treatment compound agent, the cost investment in the water treatment process is effectively lowered, and the water treatment effect of potassium ferrate can also be further improved; and the water treatment compound agent is wide in component source and good in biocompatibility, has low cost, does not have environmental toxicity and accords with the requirement of greening of water treatment.

Owner:XIJING UNIV

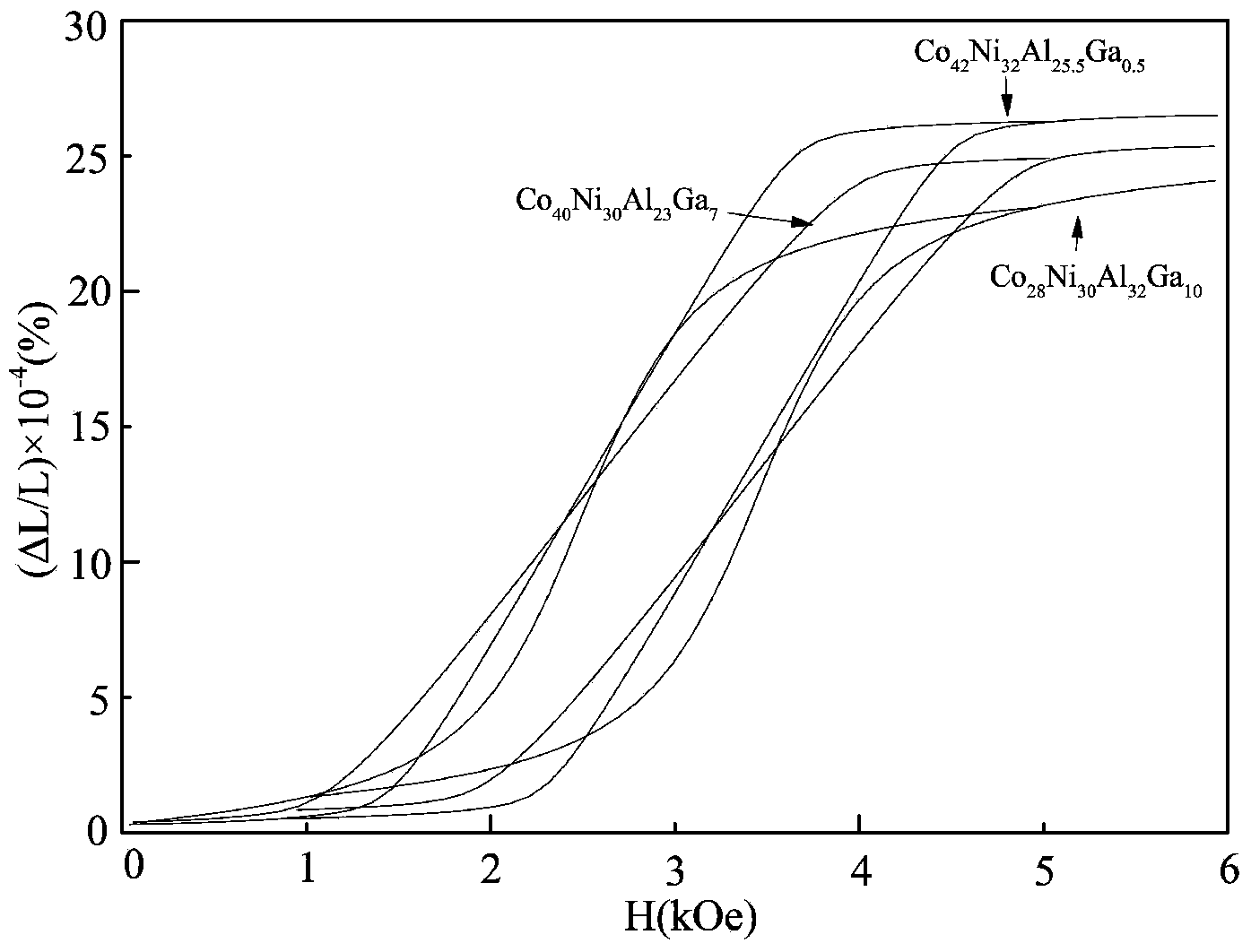

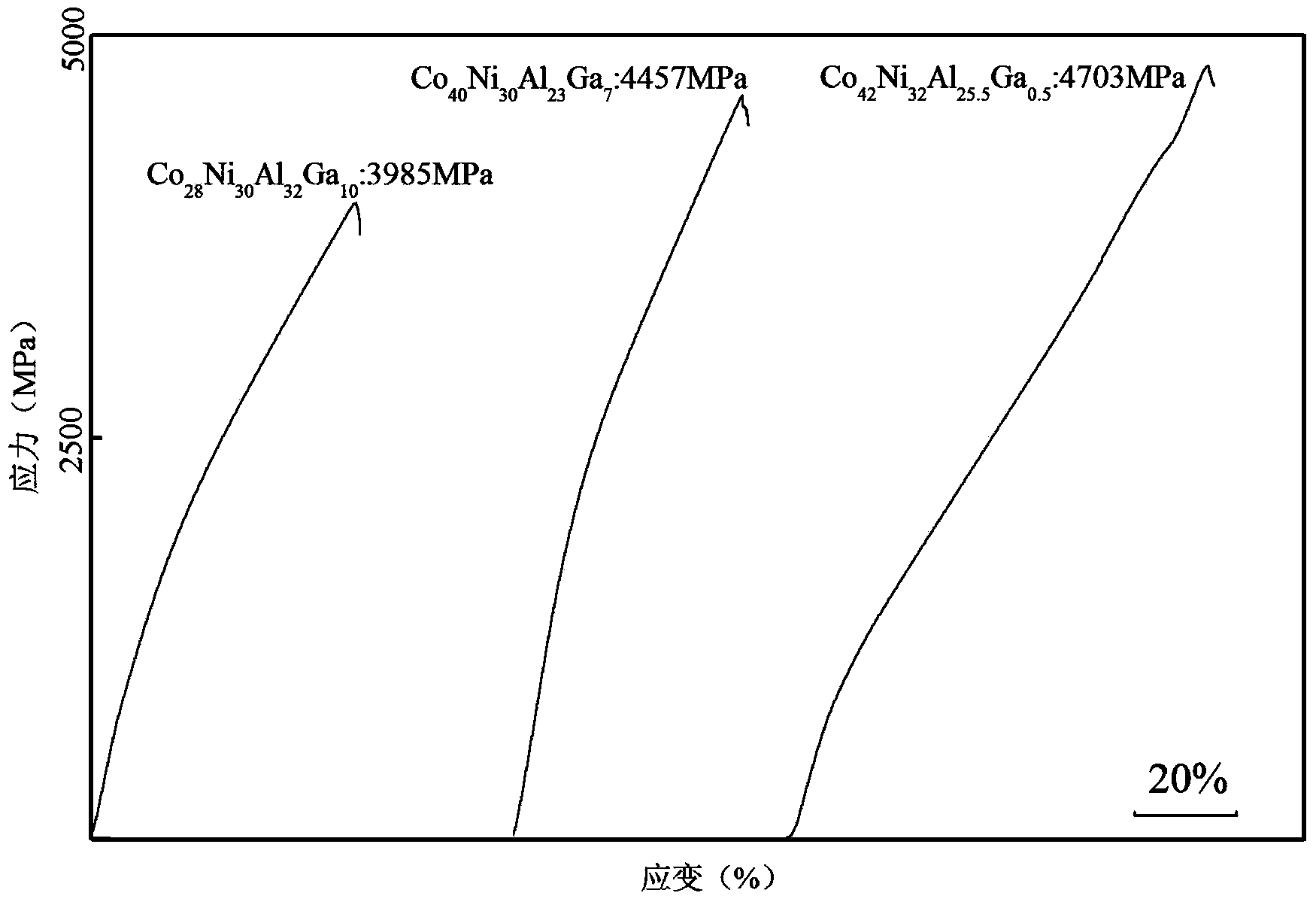

Magnetic material with magnetic field for driving martensite twin crystal rearrangement and preparation method thereof

The invention discloses a magnetic material with a magnetic field for driving martensite twin crystal rearrangement and a preparation method thereof. The material has ferromagnetism and a two-way shape memory effect, and is a novel magnetically controlled shape memory alloy capable of driving martensite twin crystal rearrangement to generate macro-strain by an outer magnetic field, wherein the chemical component is CoxNiyAlzGaj, x is less than or equal to 42 and greater than or equal to 28; y is less than or equal to 32 and greater than or equal to 25, z is less than or equal to 35 and greater than or equal to 23, j is less than or equal to 10 and greater than or equal to 0.5, x+y+z+j =100, and x, y, z and j represent the molar percentage content. Compared with the existing alloy, the magnetically controlled shape memory alloy CoxNiyAlzGaj disclosed by the invention has large magnetic strain, a wide martensite phase transformation temperature range and good mechanical property, and has important application to the field such as a high-power underwater sonar, a micro positioner, vibration and noise control, a linear motor, a microwave device, a robot and the like.

Owner:SOUTHEAST UNIV

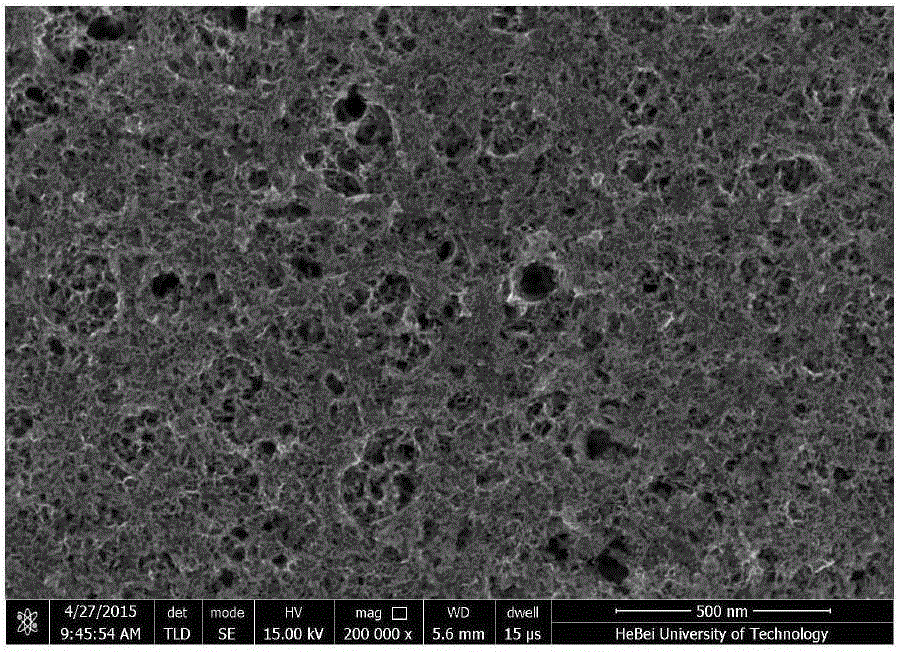

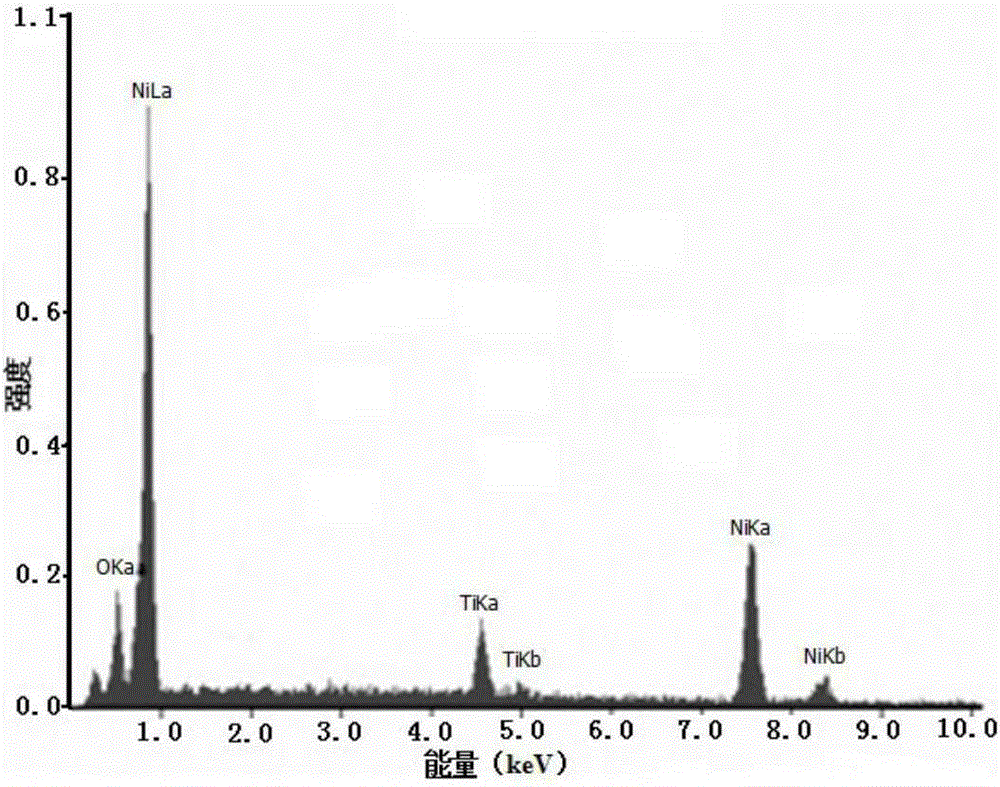

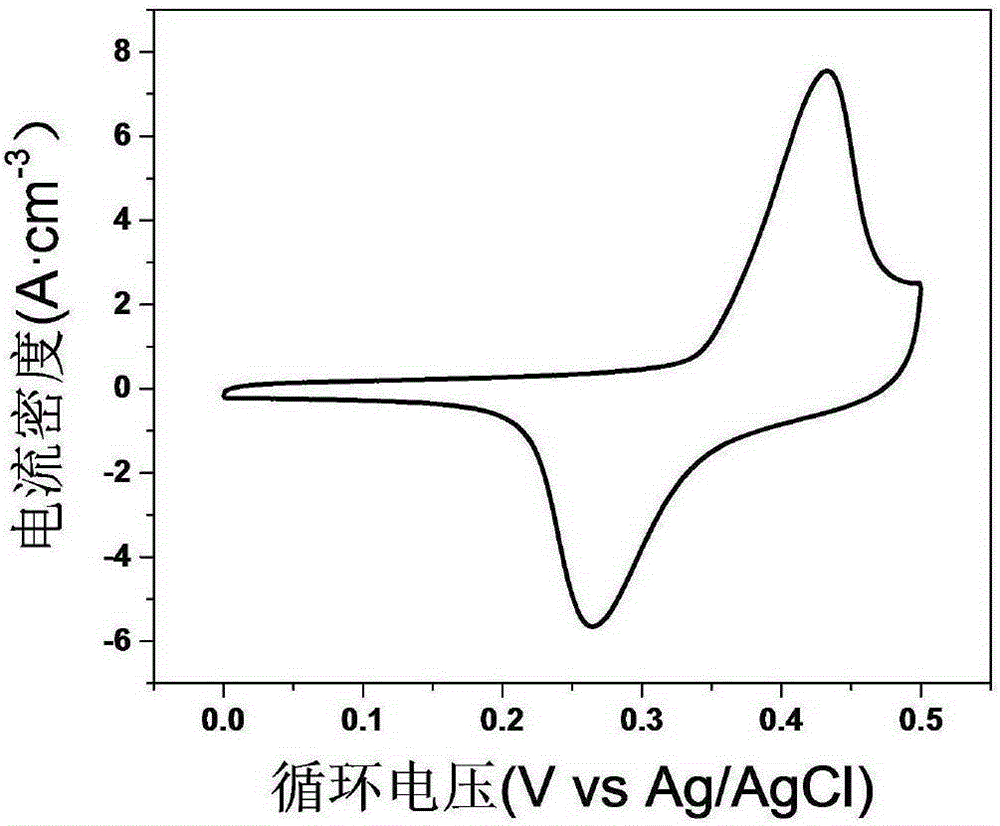

Preparation method of flexible nano porous nickel/nickel oxide composite electrode plate

ActiveCN105261491AHighlight substantive featuresGood flexibilityHybrid capacitor electrodesHybrid/EDL manufactureAcid etchingComposite electrode

The invention discloses a preparation method of a flexible nano porous nickel / nickel oxide composite electrode plate. The method comprises the following steps: (1) preparing a Ni-Ti precursor amorphous alloy ribbon, selecting high-purity Ni and Ti metals according to the atomic percentage ratio of Ni to Ti being (35+x):(65-x), wherein x is 0 to 10, carrying out melting by an arc-melting furnace to prepare a Ni-Ti alloy ingot, removing a surface scale cinder of the Ni-Ti alloy ingot, and preparing the Ni-Ti amorphous alloy ribbon by vacuum melt-spinning equipment, so as to prepare the Ni-Ti amorphous alloy ribbon with the thickness of 25-30 microns; and (2) carrying out a free dealloying treatment on the Ni-Ti amorphous alloy ribbon obtained in the previous step in an acid etching solution at a room temperature for 40-100 minutes, and washing the obtained nano porous ribbon with deionized water, so as to obtain the nano porous nickel / nickel oxide composite electrode plate. The composite electrode material prepared by the method shows excellent flexibility and simultaneously has good electrochemical properties.

Owner:HEBEI UNIV OF TECH

Method for preparing aluminum-titanium-carbon intermediate alloy

One Al-Ti-C intermediate alloy preparation method, involves a kind to use in the aluminum alloy production crystal grain thin Al-Ti-C intermediate alloy production method. Its characteristic lies in with the calcium carbide does carbon source, the production craft completely dissolves after the aluminum, melts the body fever to join the electricity stone powder hydrofluotitanic acid armor the mixture, elevates temperature to 950deg.C~~1000deg.C, guarantees the wet 10~~30 minute, after melt body surface liquid state dregs casting.The invention characteristic is the raw material unites is easy, alloy production craft simple, production cost low, produces the alloy thin medicinal preparation thin crystal grain with this craft is incubation period short, specially suits outside the stove is continuously thin.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Aluminum-scandium alloy target with high scandium content and preparation method thereof

ActiveCN111455327ASmall grain sizeHigh densityVacuum evaporation coatingSputtering coatingMetallic aluminumThermal deformation

Owner:HUNAN RARE EARTH METAL MATERIAL RES INST

Indoor air purifying agent

The invention relates to a formula of an indoor air purifying agent and belongs to the technical field of chemical processing. The indoor air purifying agent is prepared by uniformly mixing the following components in parts by weight: 40-70 parts of modified zeolite, 15-35 parts of activated carbon, 2-8 parts of sodium percarbonate and 5-10 parts of dichlorobenzene, wherein modified zeolite is obtained by uniformly mixing inorganic acid in certain concentration and volume with a certain mass of zeolite and drying, and sodium percabonate is obtained by carrying out reaction on a certain mass of sodium carbonate with hydrogen peroxide in certain volume. The indoor air purifying agent has the advantages of available raw material components, low cost, good capability of adsorbing inorganic matters and organic matters and especially effective absorption of ammonia gas and hydrogen sulphide in the air, so that the effect of purifying the air is realized.

Owner:DOSHAN NEW STRATEGY INTPROP CULTURECO

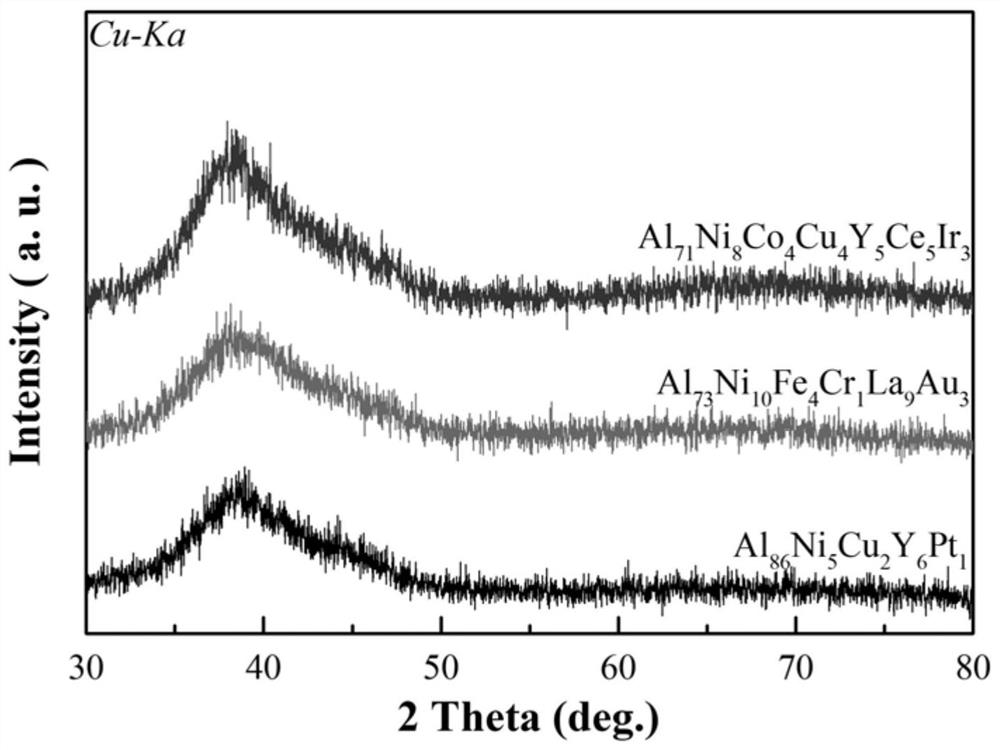

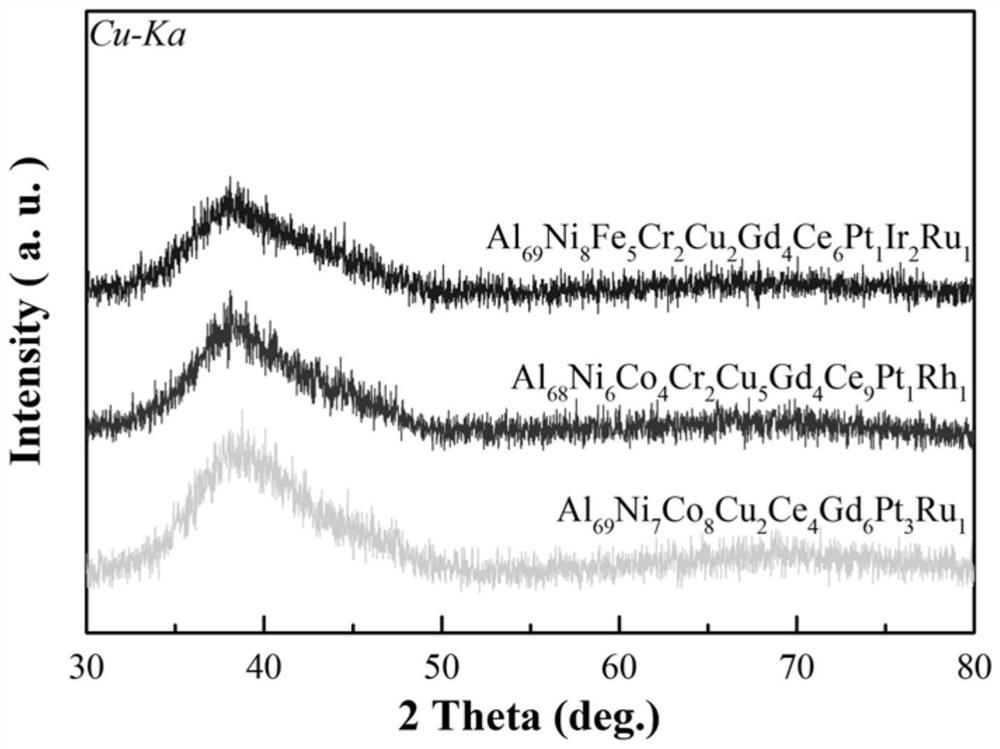

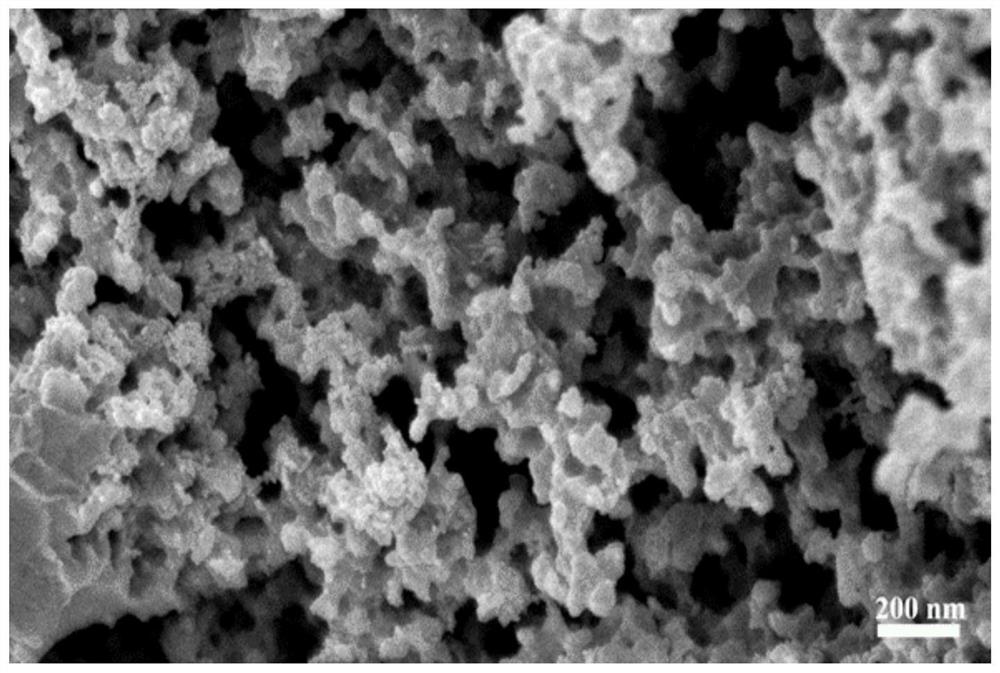

Nano-porous Al-Ni-M-RE-R amorphous alloy used as hydrogen evolution catalytic electrode, and preparation method thereof

ActiveCN112064058AWide range of ingredientsSolve the problem of difficult preparation of nanoporous structuresElectrode shape/formsRare-earth elementElectrolysis

The invention discloses a nano-porous Al-Ni-M-RE-R amorphous alloy used as a hydrogen evolution catalytic electrode, wherein a transition metal element M is Fe, Co, Cr and Cu, a rare earth element REis Y, La, Gd and Ce, a precious metal R is Pt, Ru, Pd, Rh, Au and Ir, and a hydrogen evolution catalytic electrode comprises the following components in percentage by mass: Al, 2-12% of Ni, 1-13% of M, 2-13% of RE, and 0.2-7% of R, and is treated by adopting a constant current method, a corrosion method or a pulse corrosion current method, so that the prepared nano porous amorphous alloy is stablein structure, large in specific surface area, adjustable in component, structure and morphology and high in catalytic activity. According to the invention, when the nano-porous amorphous alloy hydrogen evolution electrode is used as a water electrolysis hydrogen evolution catalytic electrode, the hydrogen evolution overpotential is 40-65 mV and the Tafel slope is 10-60 mV / dec under the current density of 10 mA.cm<-2>, so that the nano-porous amorphous alloy hydrogen evolution electrode has excellent hydrogen evolution catalytic activity.

Owner:BEIHANG UNIV

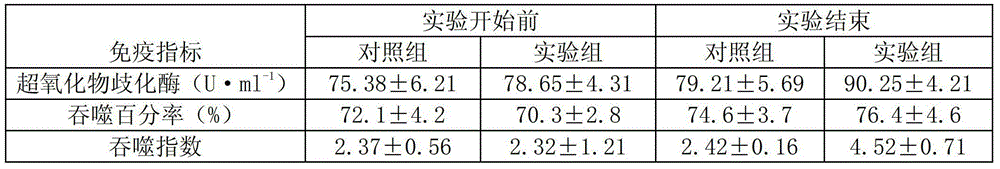

Composite feed for improving immunity of herring and preparation method thereof

InactiveCN103330083AWide range of ingredientsWide variety of sourcesFood processingAnimal feeding stuffBiotechnologyMultivitamin

The invention discloses a composite feed for improving immunity of herring. The feed comprises the following components by weight portion: 3-6 parts of a fish meal, 15-25 parts of a soybean meal, 2-5 parts of a meat and bone meal, 4-6 parts of wheat bran, 4-8 parts of rice chaff and 5-10 parts of compound vitamin; and the feed also comprises 5-15 parts of Chitosan Oligosaccharide and 10-20 parts of konjac mannan oligosaccharide. The feed provided by the invention has effects of enhancing body function and immunity of herring, and the effects are reflected in the significantly increased immune indexes including superoxide dismutase, phagocytic percentage and phagocytic index of herring; and the feed provided by the invention has extensive component sources and low price, and is suitable for large-scale cultivation.

Owner:JURONG CITY GUOZHUANG TOWN NANHE FARM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com