Turntable type quantitative discharging device

A quantitative discharge, turntable technology, applied in the direction of transportation, packaging, loading/unloading, etc., can solve the problems of long storage time, fast discharge speed, slow speed, etc., and achieve simple arch breaking principle and fast discharge speed , easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Below in conjunction with accompanying drawing, the present invention is further described.

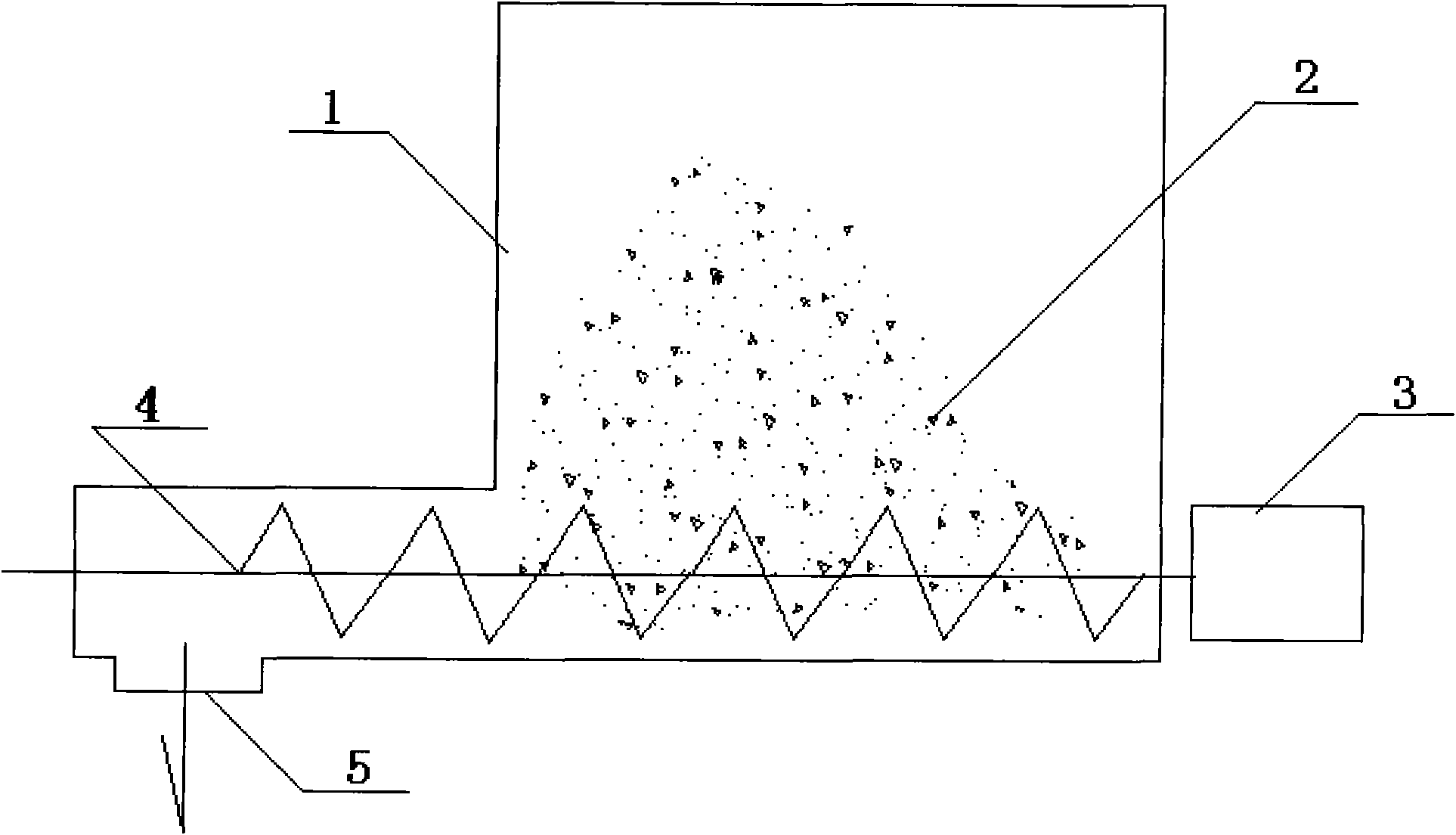

[0057] figure 1 Shown is the structural representation of the existing screw type discharge device. It can be seen from the figure that the powder and granular trace raw materials 2 in the raw material bin 1 are driven by the motor 3 to rotate the screw shaft 4, and the raw materials 2 are discharged from the discharge port 5. The discharge speed and precision cannot be taken into account, and the adaptability to materials is poor and the use is inconvenient.

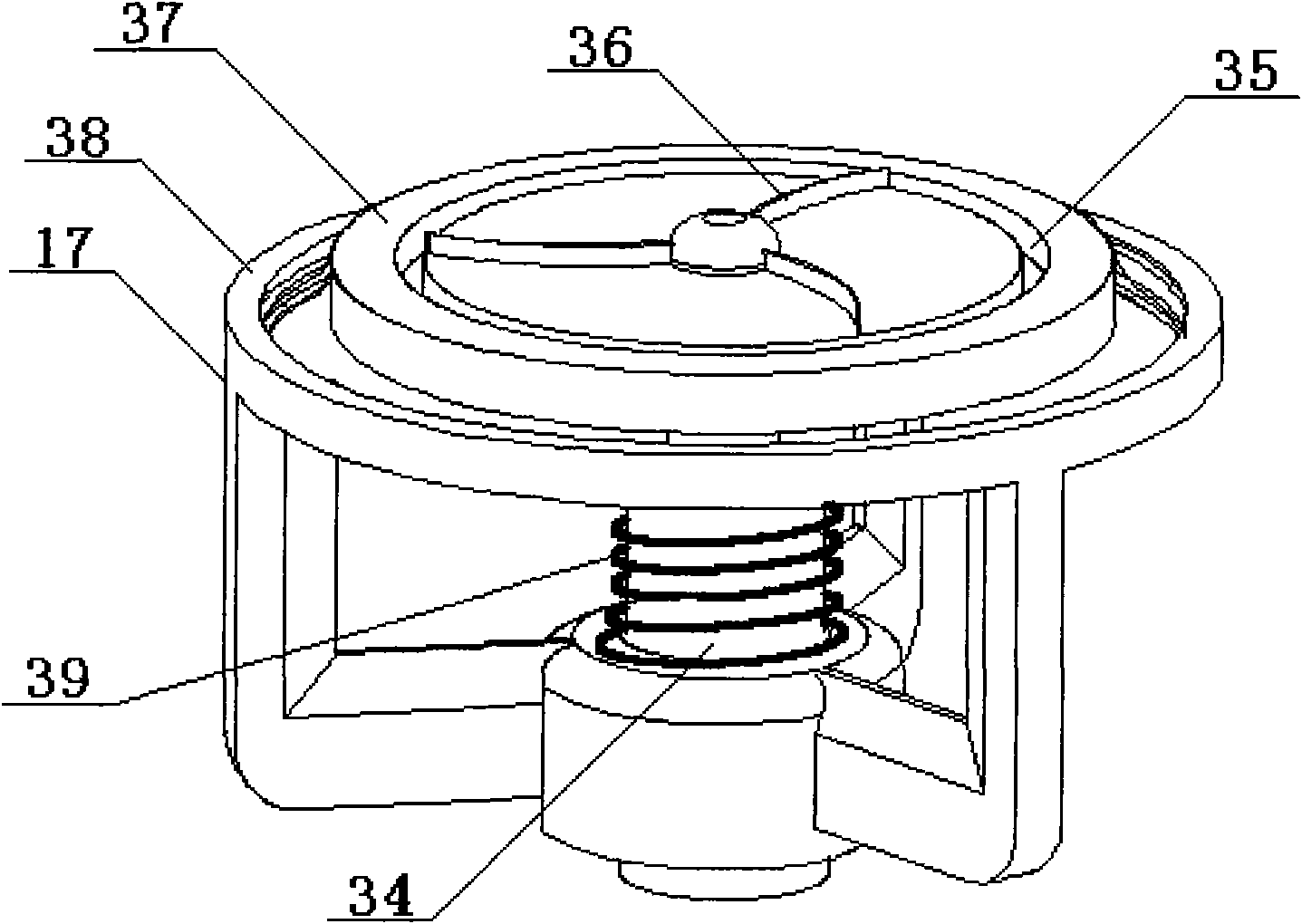

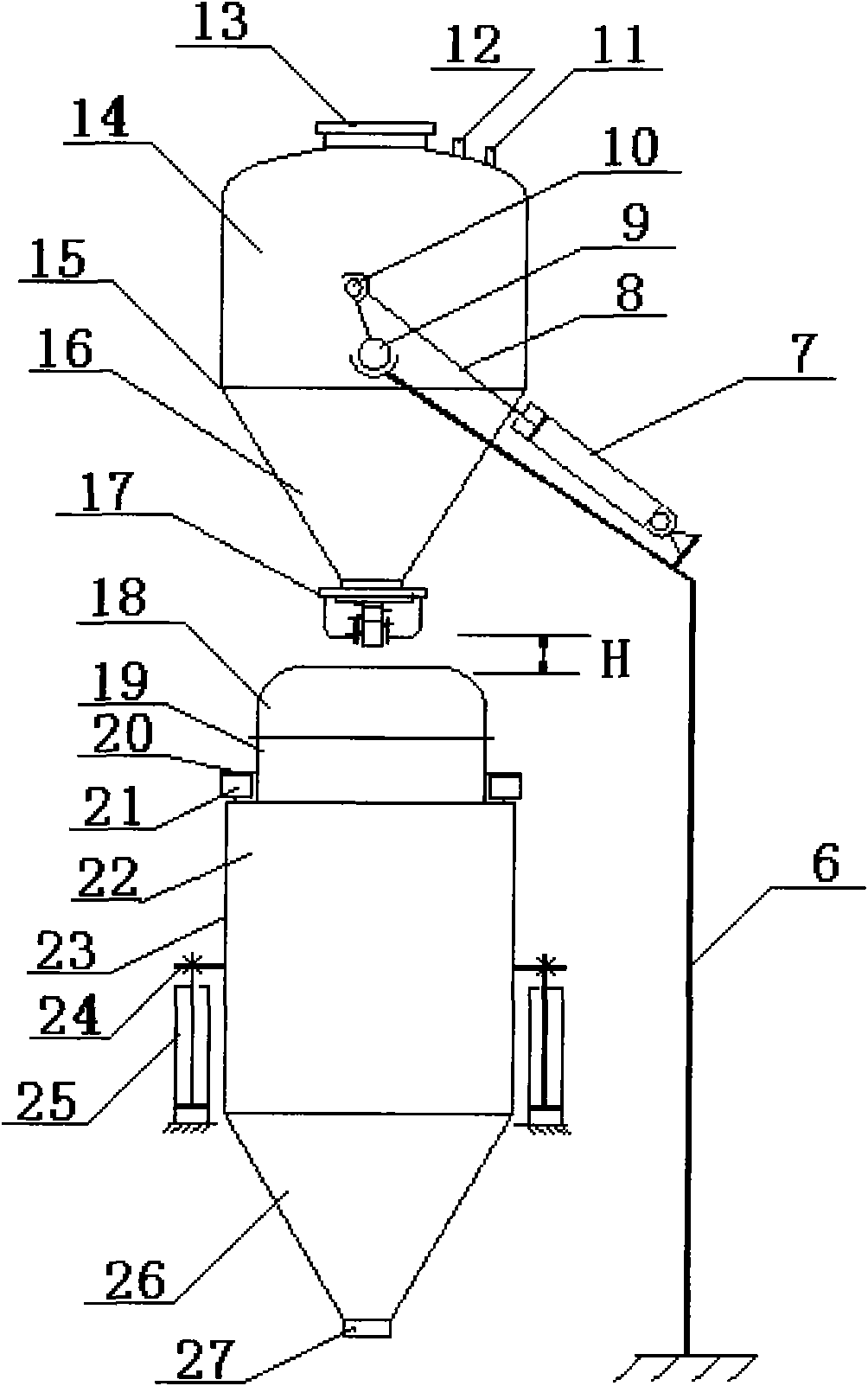

[0058] figure 2 Shown is the structural representation of the present invention. As can be seen from the figure, it includes upper and lower parts, the upper part includes a storage bin 15 composed of an upper cylinder 14 and a lower cone 16, a turntable assembly 17, a storage bin swing cylinder 7 and a bin bracket 6; The lower part includes a collection tank 23 formed by an upper cylinder 22 and a lower cone 26, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com