Patents

Literature

2134results about How to "Lower melting temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chemically toughened glasses

InactiveUS6518211B1Promote meltingNot affecting strain pointGlass/slag layered productsThin material handlingToughened glass

A glass composition capable of being chemically strengthened by ion-exchange within 100 hours to provide a glass with a surface compressive stress of greater then 400 MPa and an ion-exchange depth greater then 200 microns comprising: SiO2 58% to 70% (by weight), Al2O3 5% to 15%, Na2O 12% to 18%, K2O 0.1% to 5%, MgO 4% to 10%, CaO 0% to 1% with the provisos that the total of the Al2O3 and MgO is in excess of 13%, the total of the amounts of Al2O3 plus MgO divided by the amount of K2O is at least 3 and that the sum of the amounts of Na2O, K2O and MgO is at least 22%.

Owner:GKN AEROSPACE SERVICES LTD

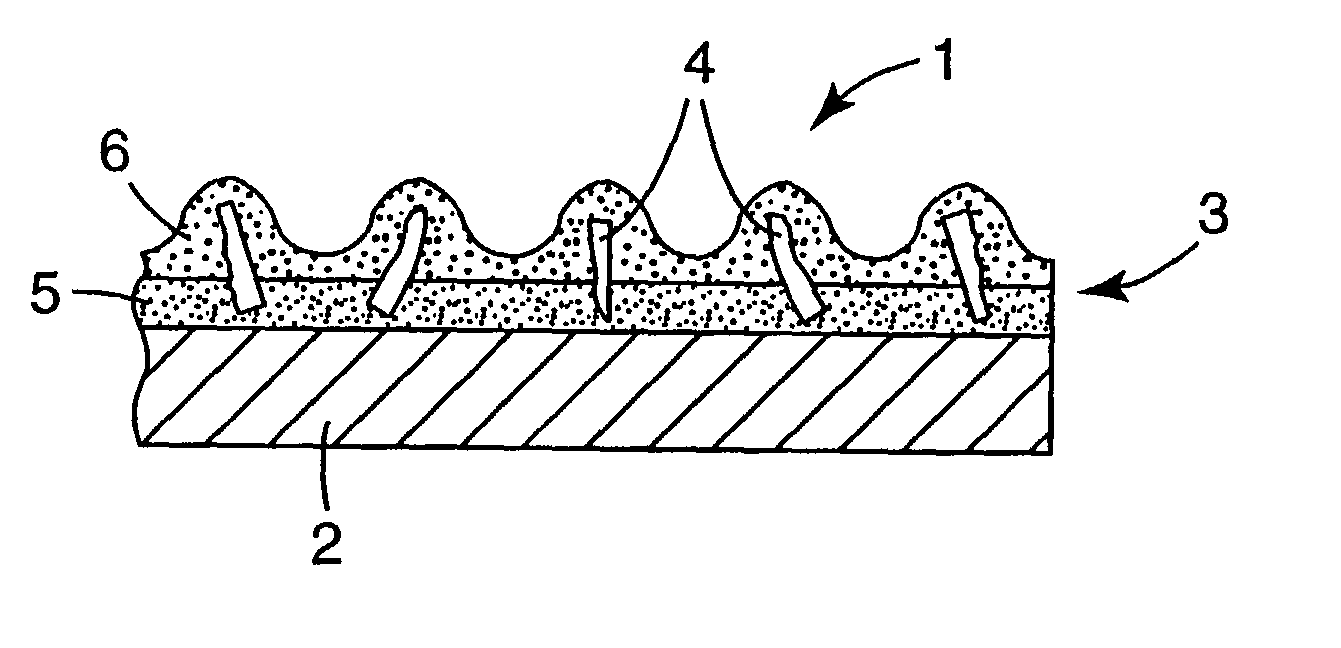

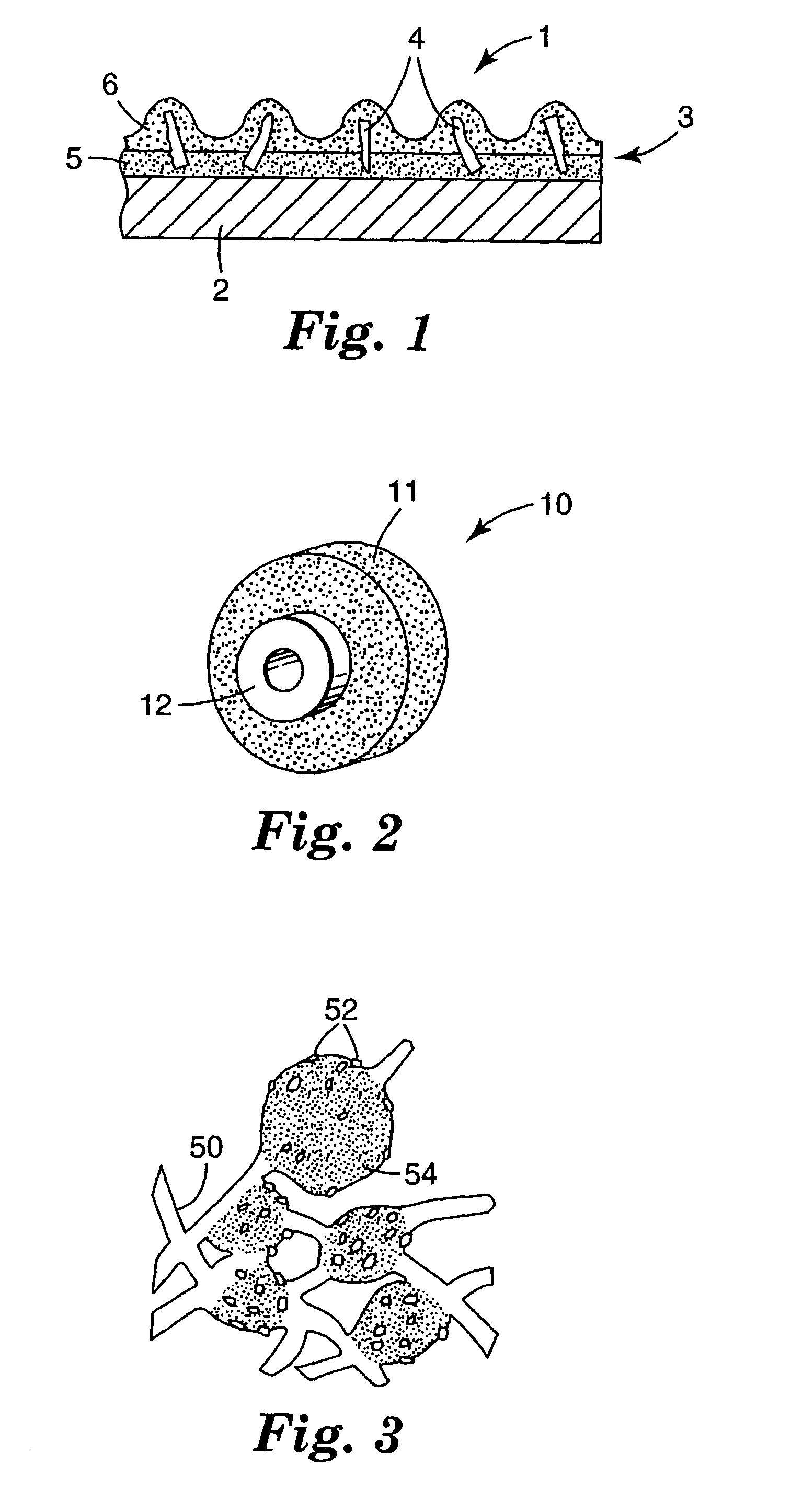

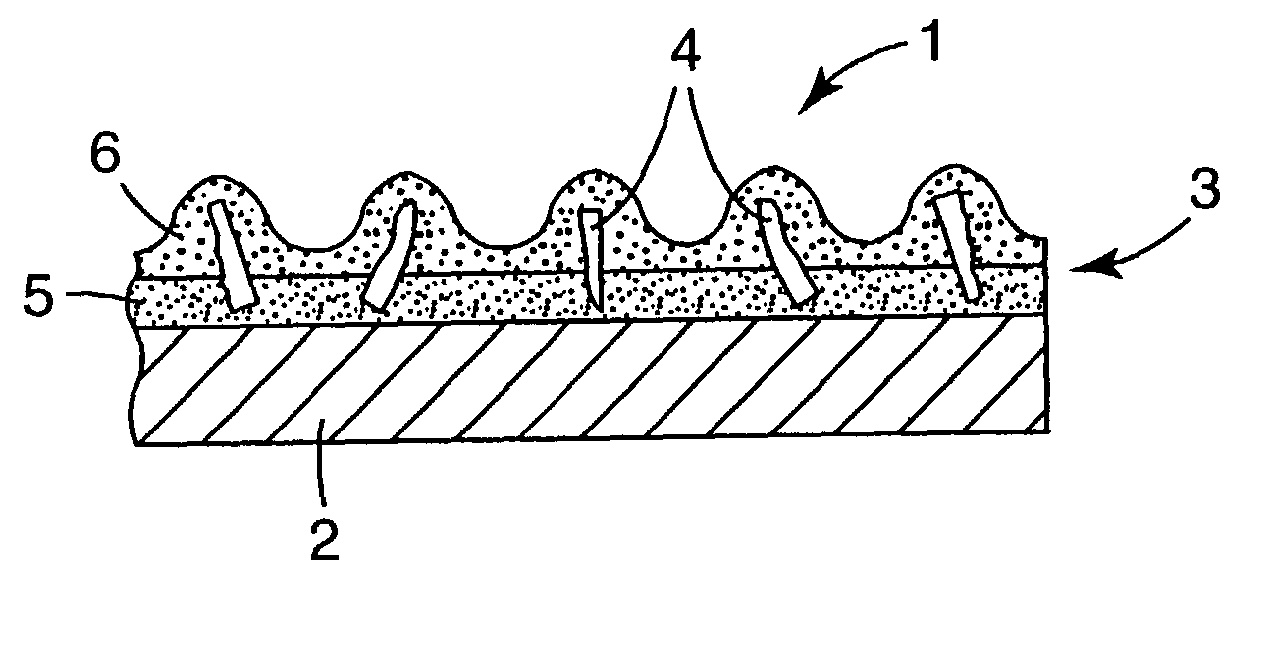

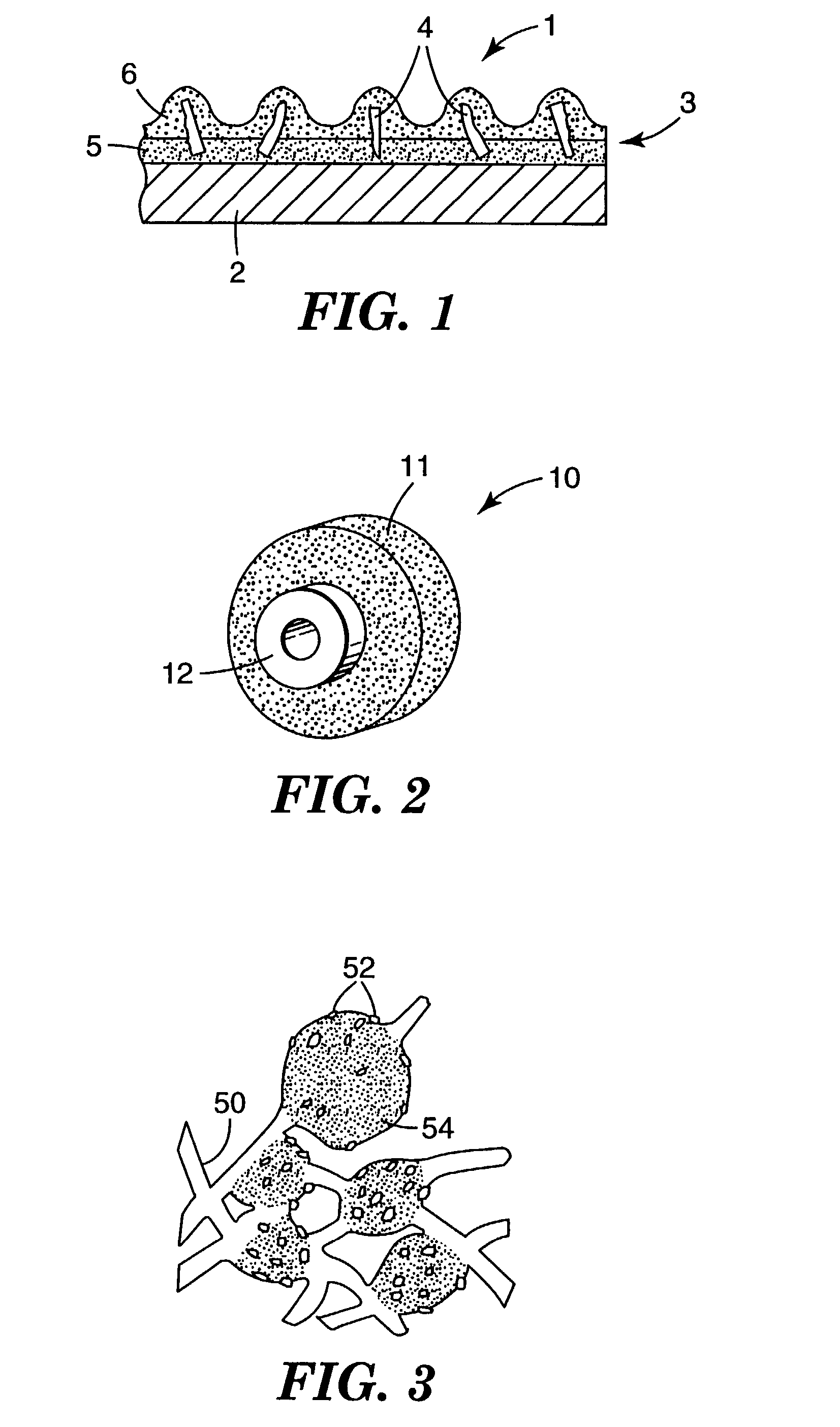

Abrasive particles, and methods of making and using the same

InactiveUS20030110707A1Facilitates formation and homogeneityOxide formationGlass drawing apparatusGlass forming apparatusAbrasive

Owner:3M INNOVATIVE PROPERTIES CO

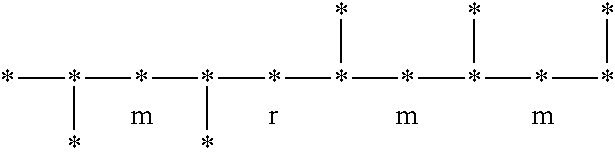

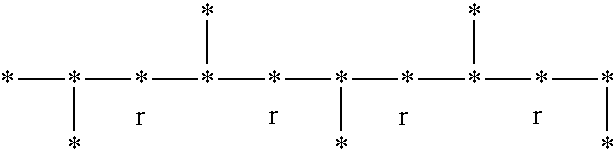

Syndiotactic rich polyolefins

Disclosed herein is a polymer comprising an amorphous syndiotactic rich polyolefin comprising greater than about 50 wt % C3-C40 alpha olefins and having about 50% to less than about 80% r dyads, based on the total number of r and m dyads present in the polymer; a heat of fusion of 10 joules / g or less according to the procedure described in ASTM E 794-85; and an ash content of 1 wt % or less. A functionalized amorphous syndiotactic rich polyolefin is also disclosed, along with methods to produce and a method to use the inventive polymer.

Owner:EXXONMOBIL CHEM PAT INC

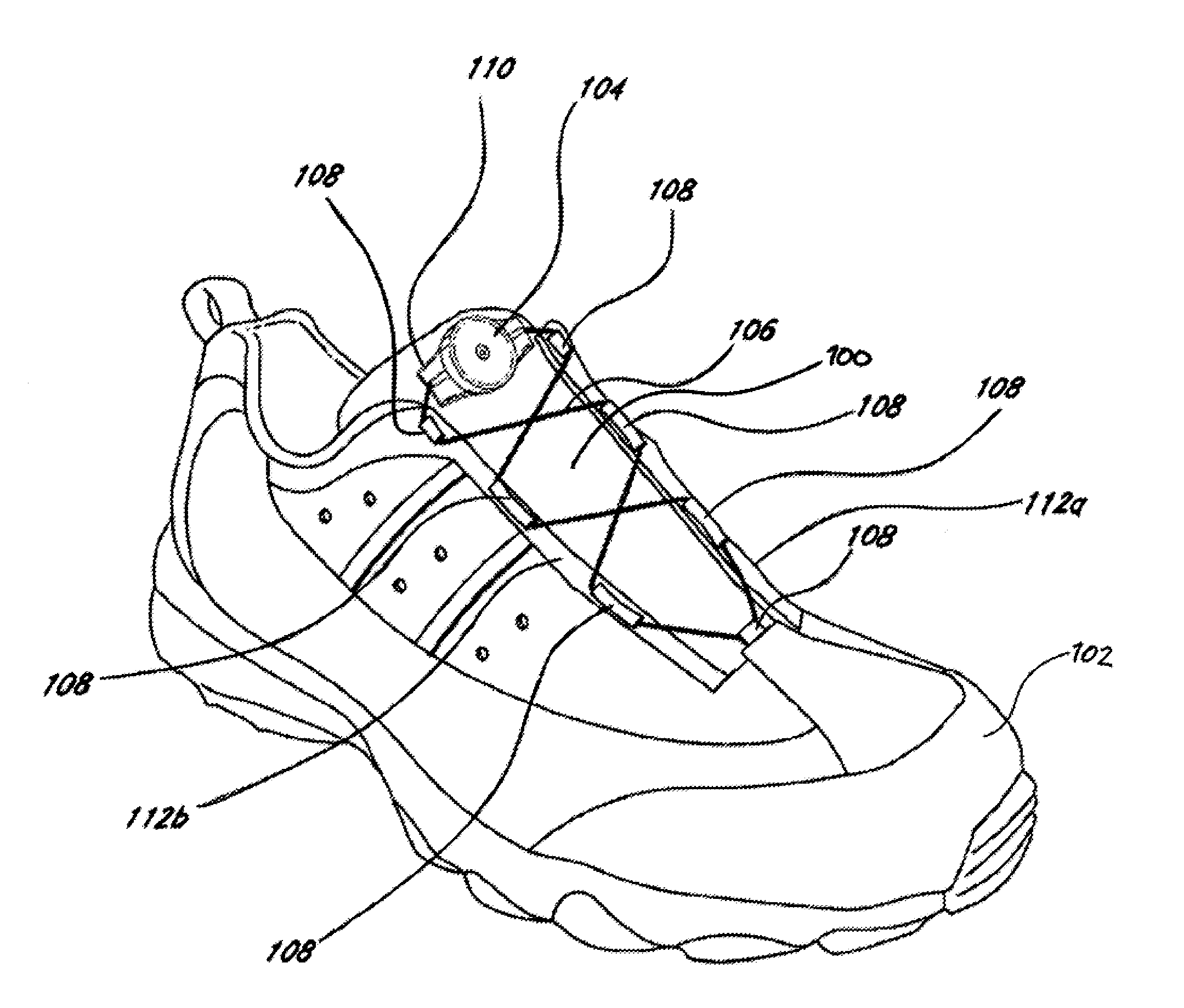

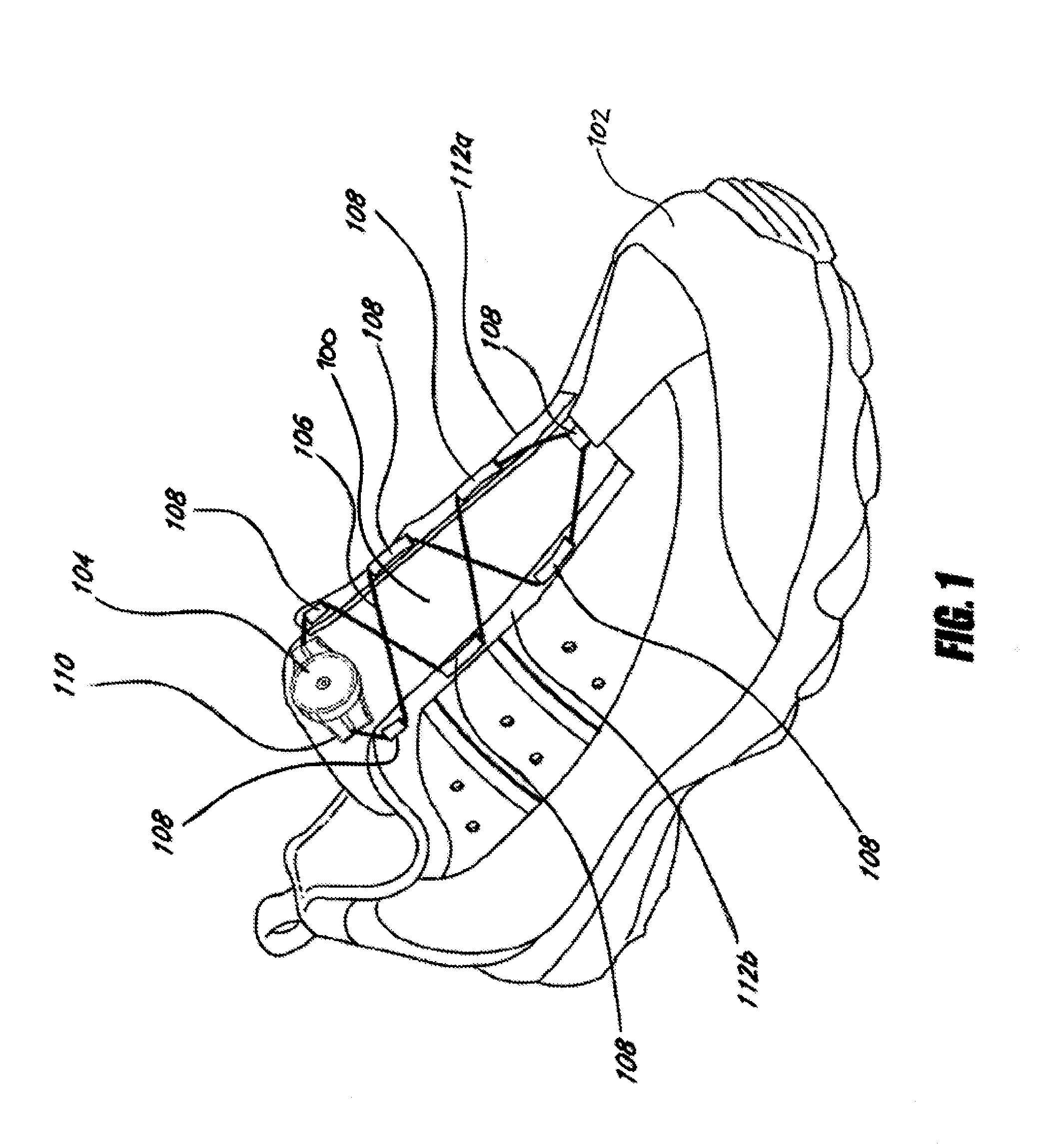

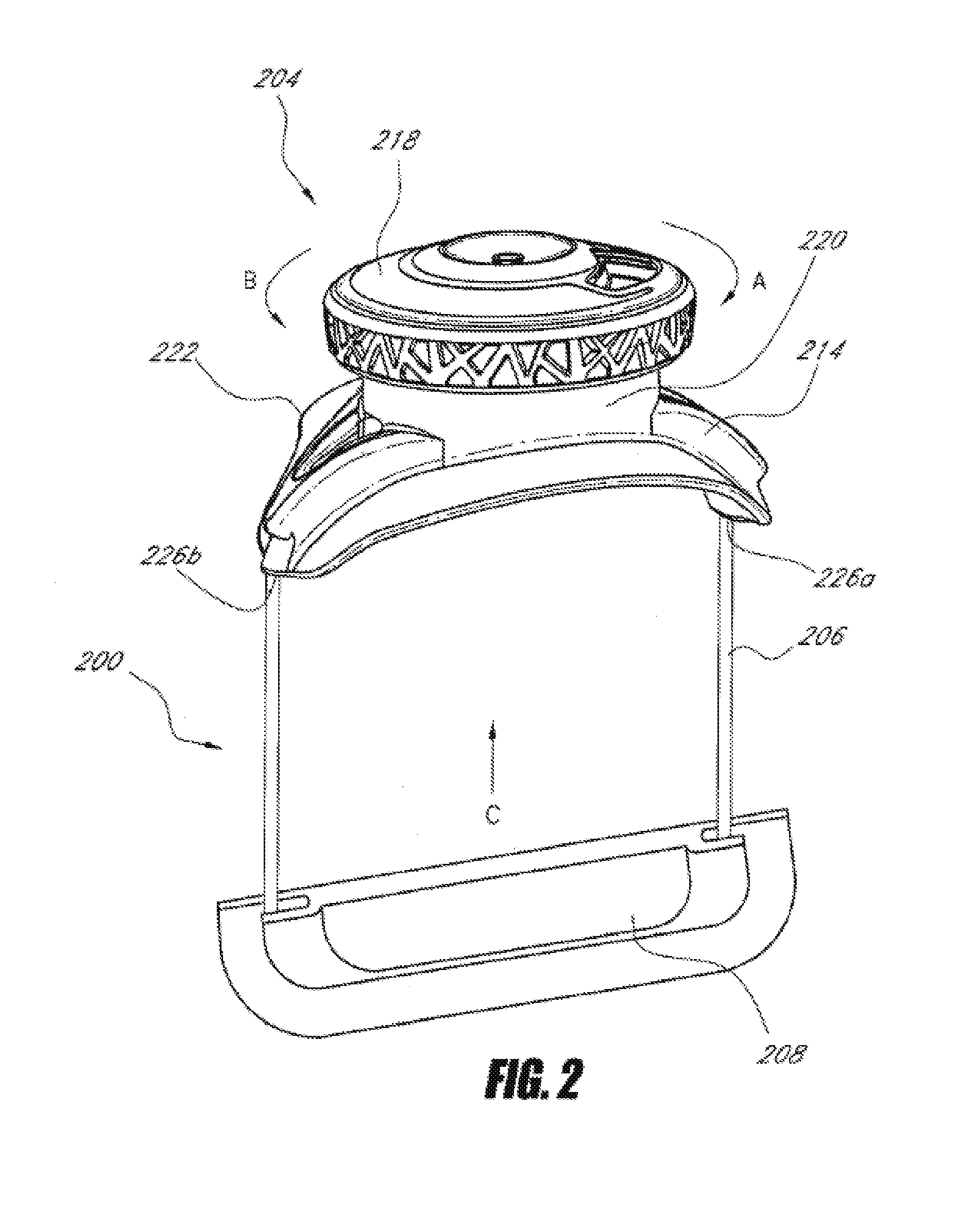

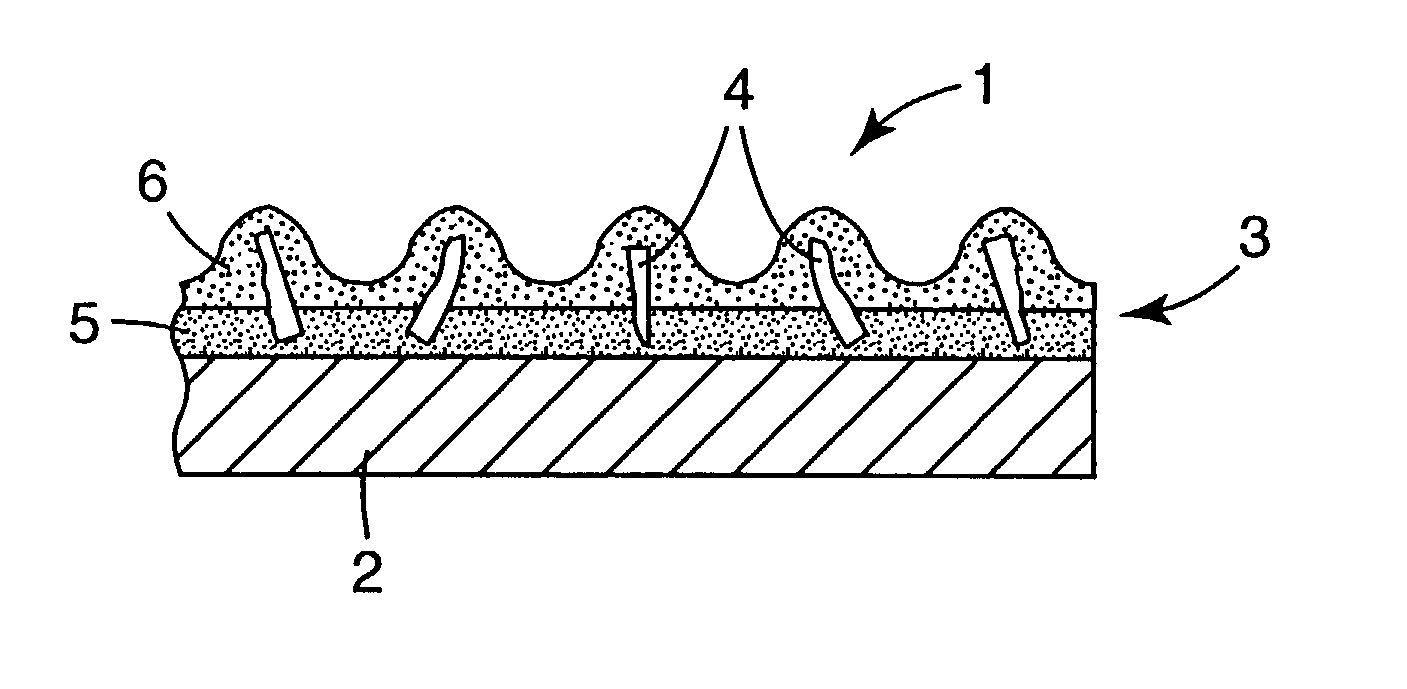

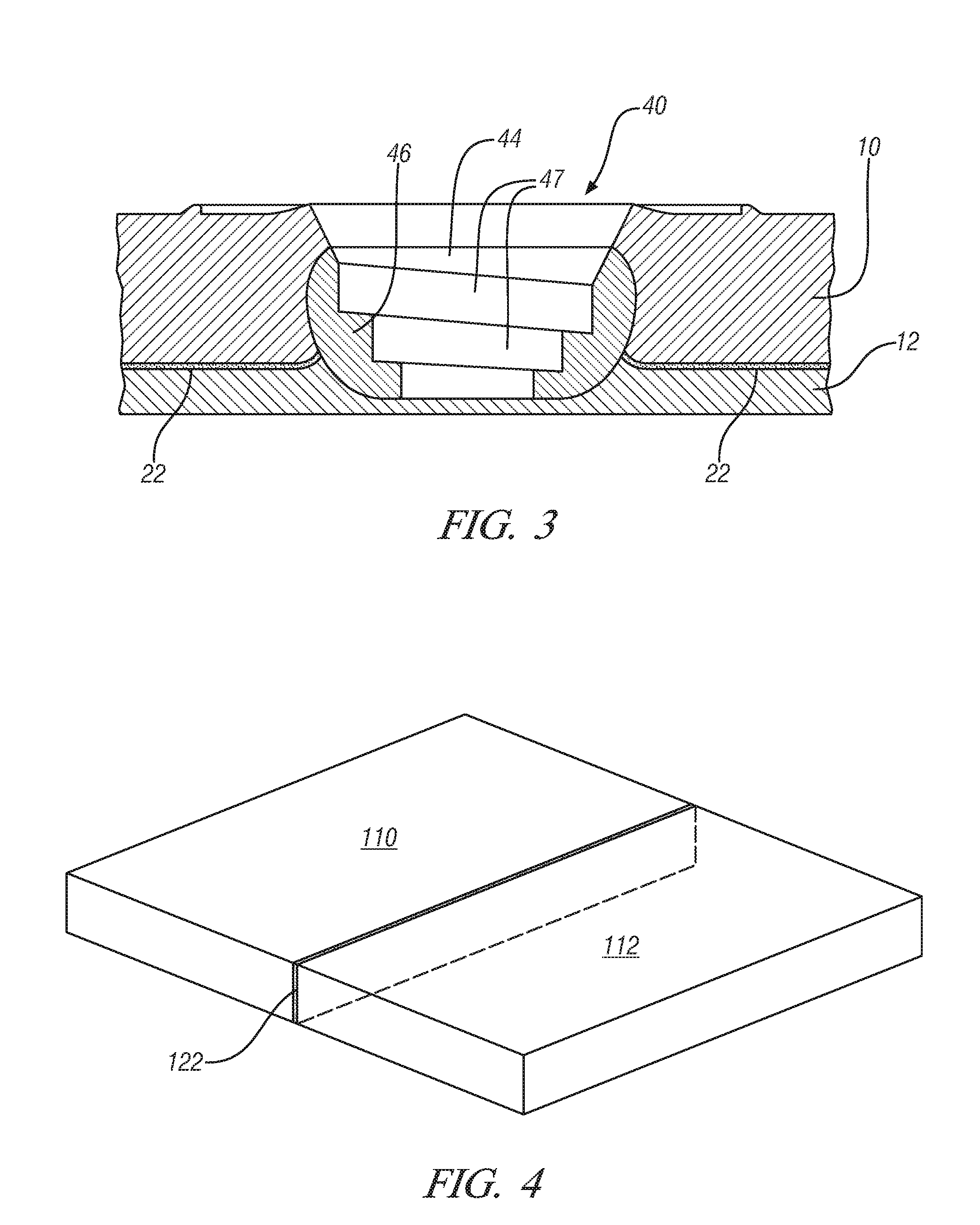

Guides and components for closure systems and methods therefor

ActiveUS20150059206A1Easily and conveniently coupledTighten shoeEyeletsLacing hooksThermoplastic elastomerEngineering

According to an embodiment, a component for attachment to an article includes an upper component that is made of a thermoplastic material having a first melting temperature and a flange member that is molded onto the upper component and made of a thermoplastic elastomer material having a second melting temperature that is lower than the first melting temperature of the upper component. The flange member extends laterally from a bottom end of the upper component so that a bottom surface of the flange member is flush with or positioned axially below a bottom surface of the upper component. The melting temperature of the thermoplastic elastomer material enables the flange member to be directly coupled to the article via heat welding and the like without substantially affecting the upper component.

Owner:BOA TECHNOLOGY

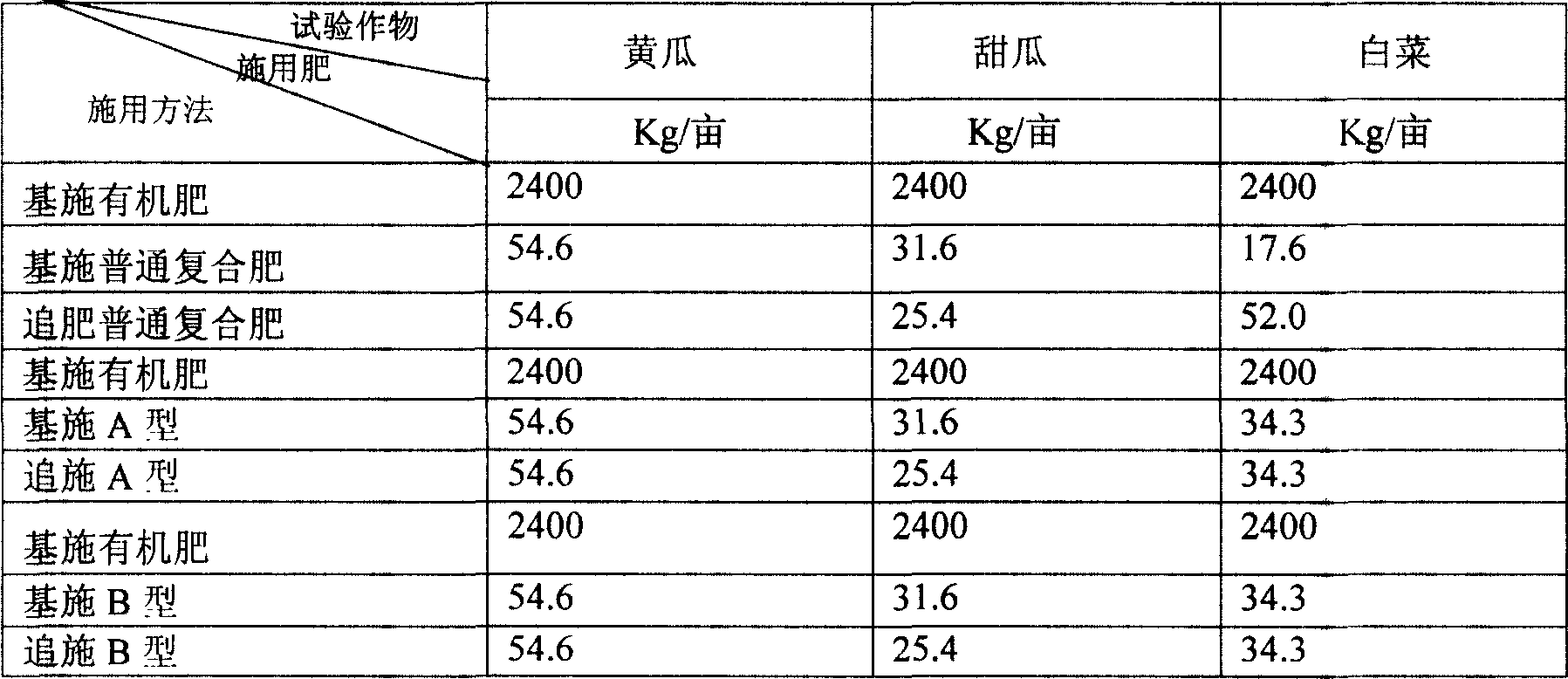

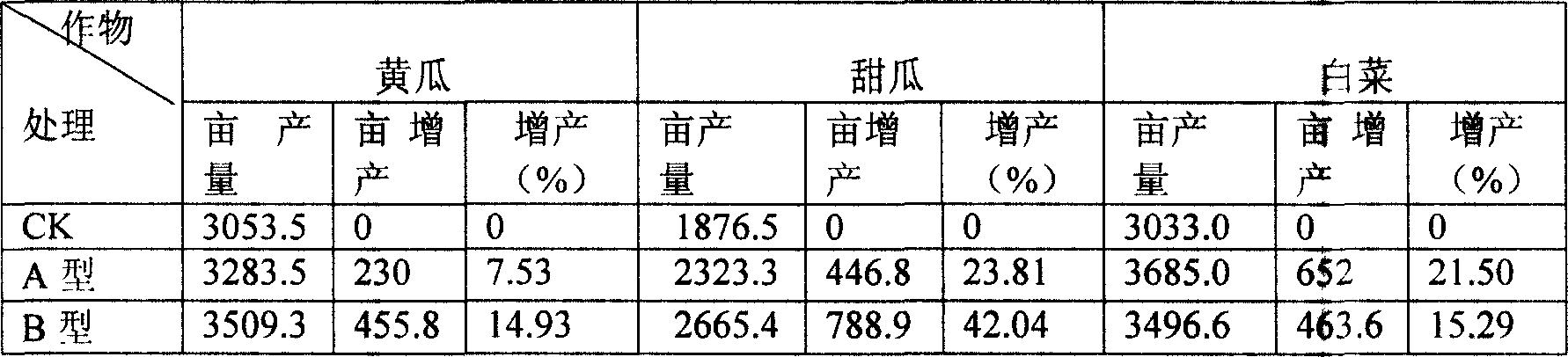

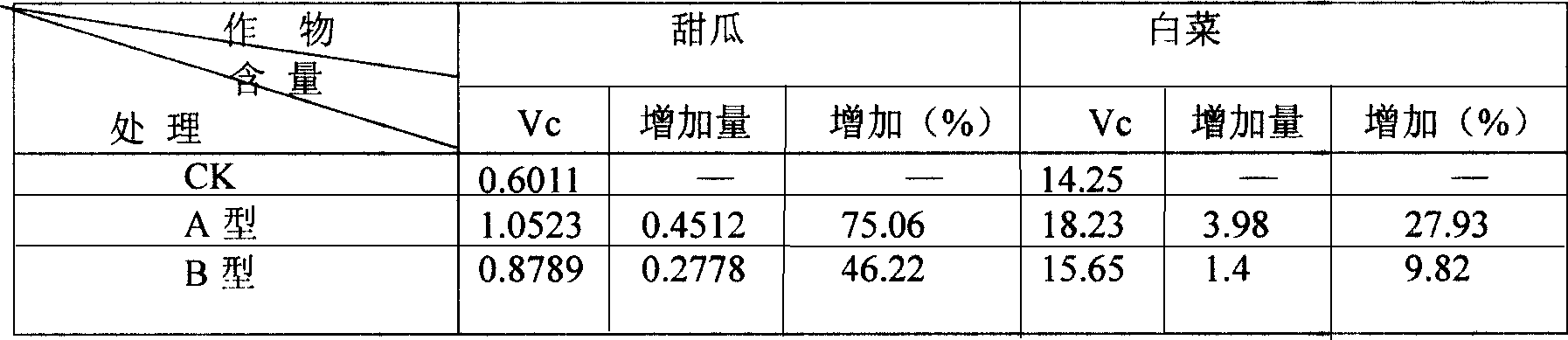

Humic acid composite material and preparation method thereof

InactiveCN101041600APromote absorptionGood water solubilityAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPhosphorNitrogen

The invention discloses a particle-typed composite fertilizer of humic acid and manufacturing method, which consists of dressing and karyosome, wherein the dressing contains nitrogen, phosphor and potassium. The manufacturing method comprises the following steps: graining humic acid; cladding; graining; solidifying fused fertilizer on the particle of humic acid; making the composite fertilizer dissolved into water without falling; fitting for large scale of agricultural product.

Owner:阴高鹏

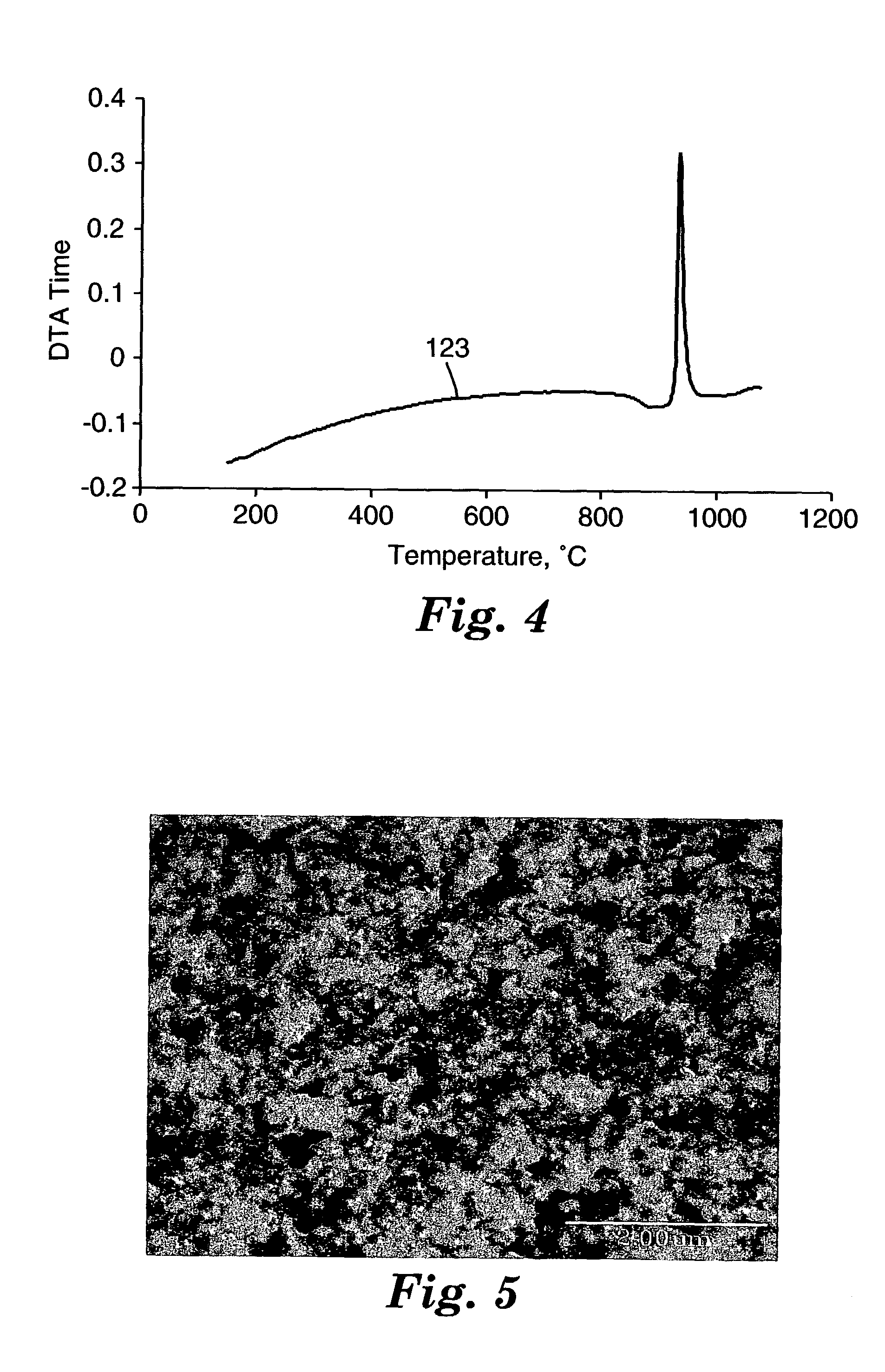

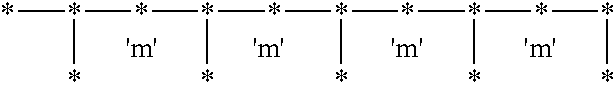

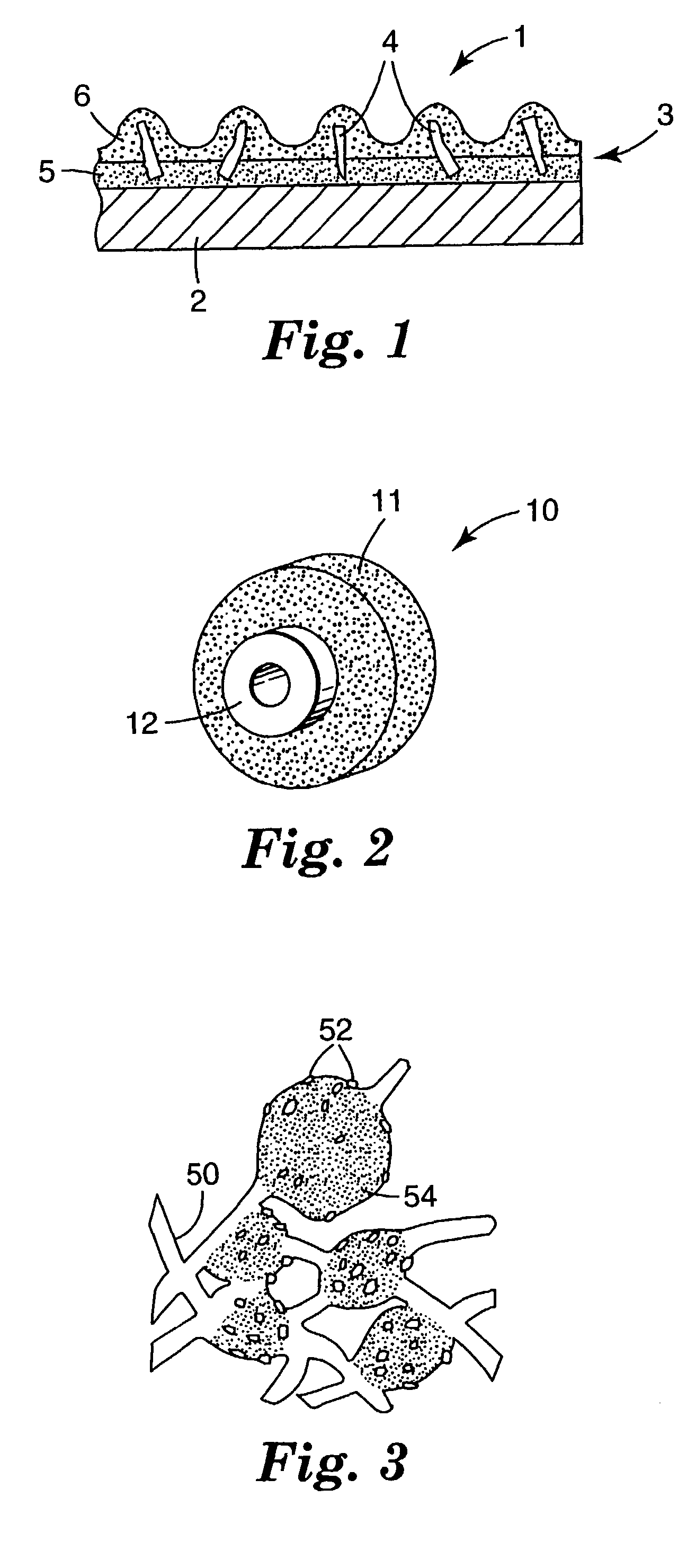

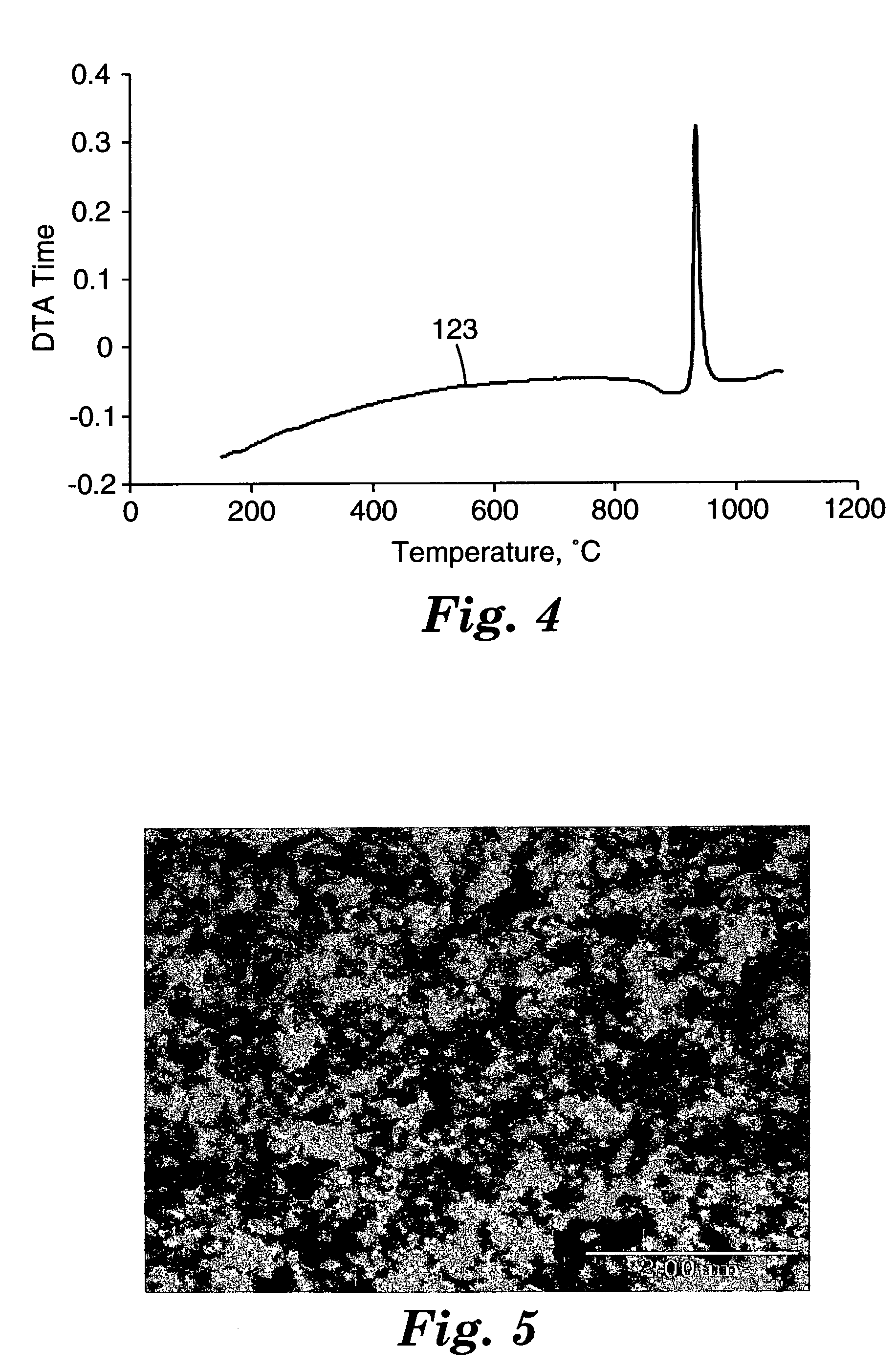

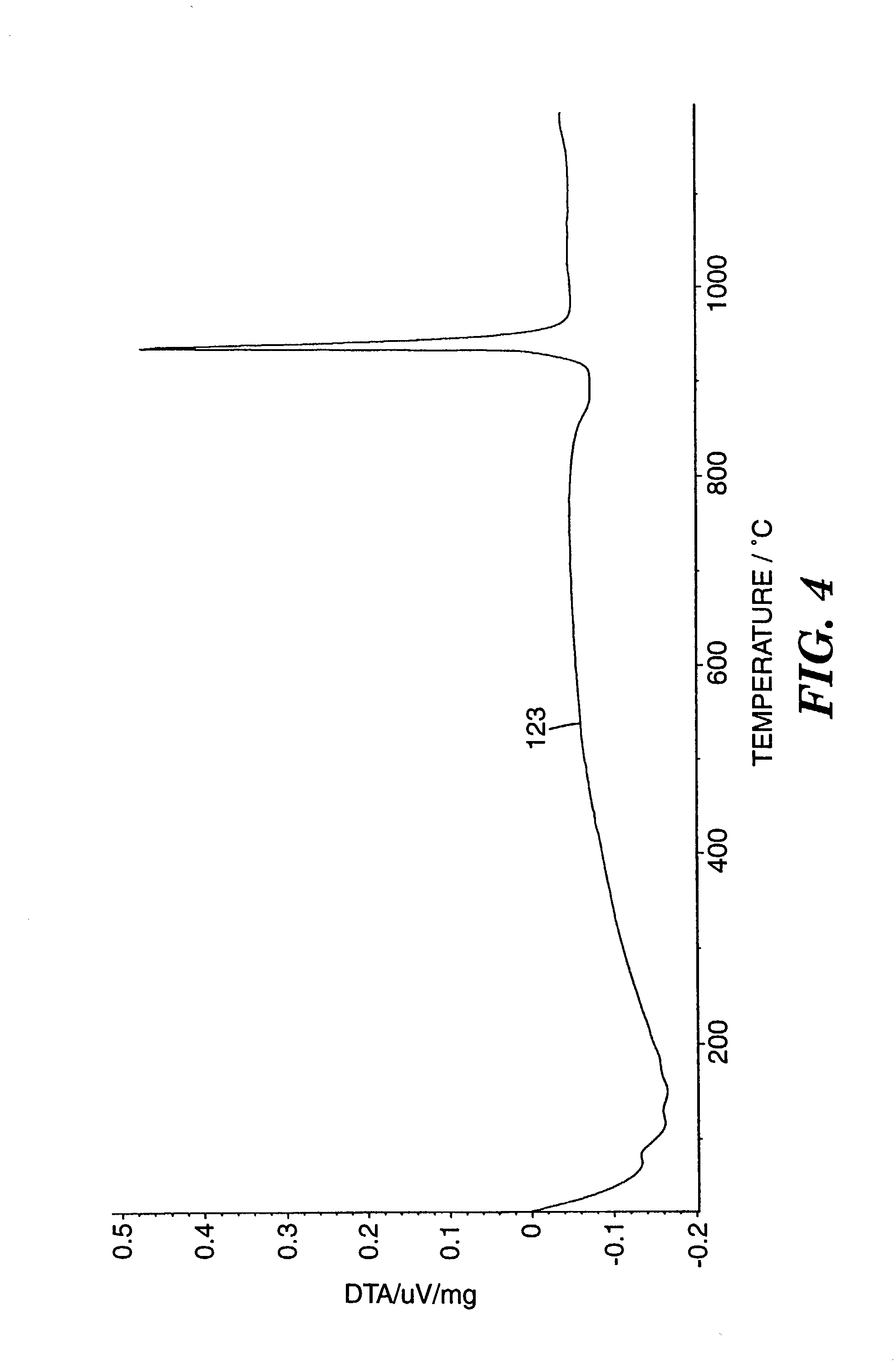

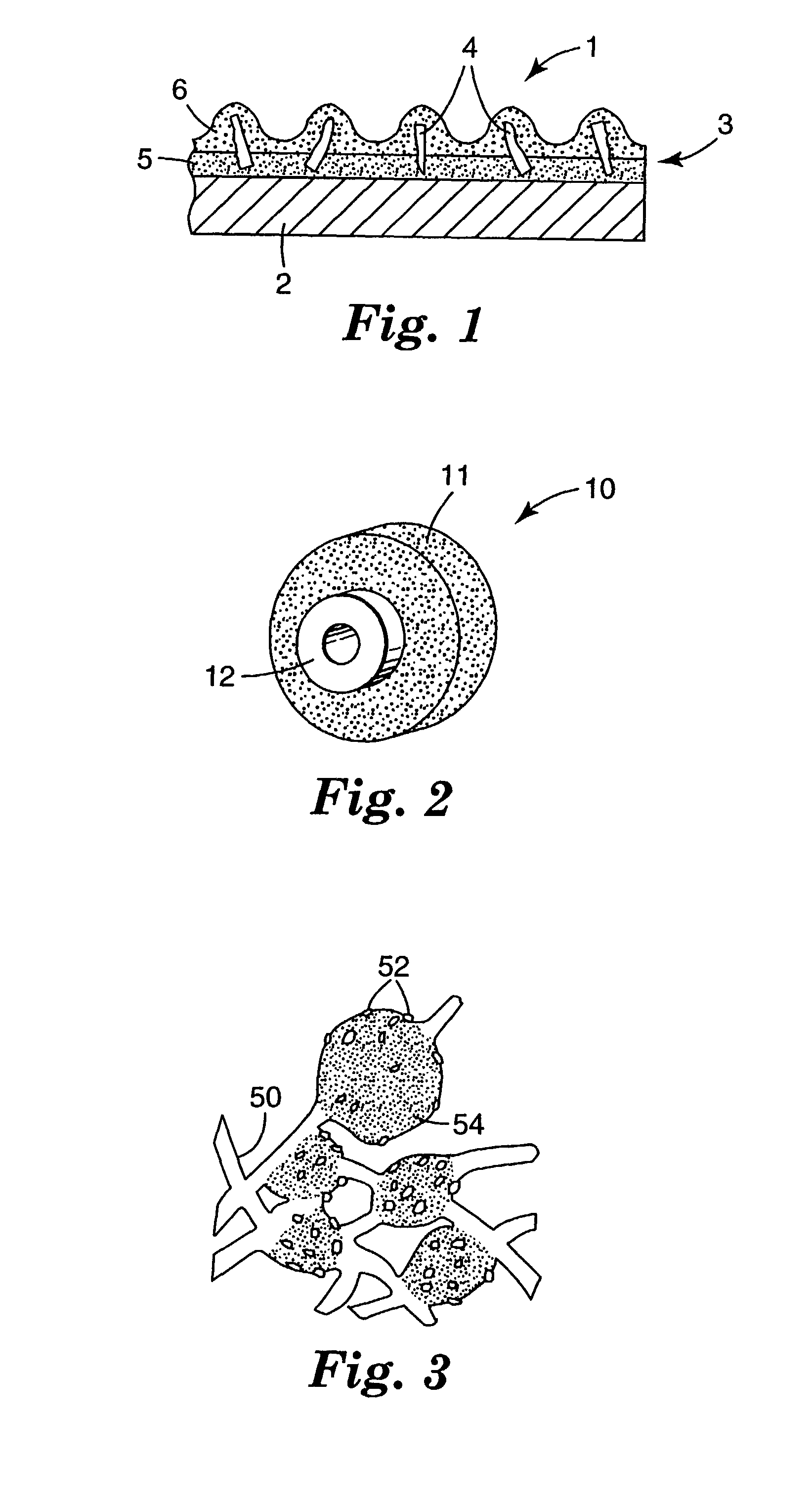

Al2O3-Y2O3-ZrO2/HfO2 materials, and methods of making and using the same

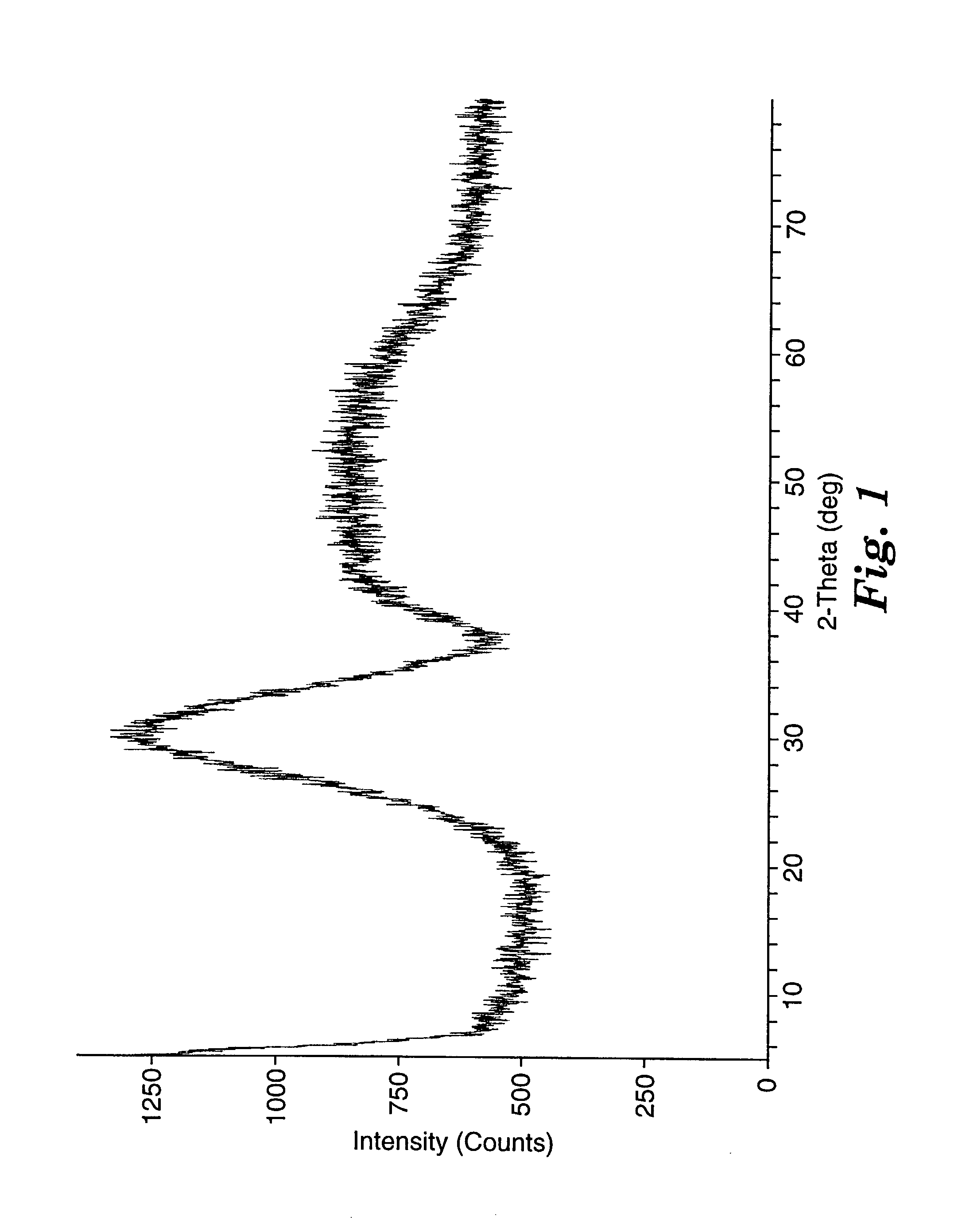

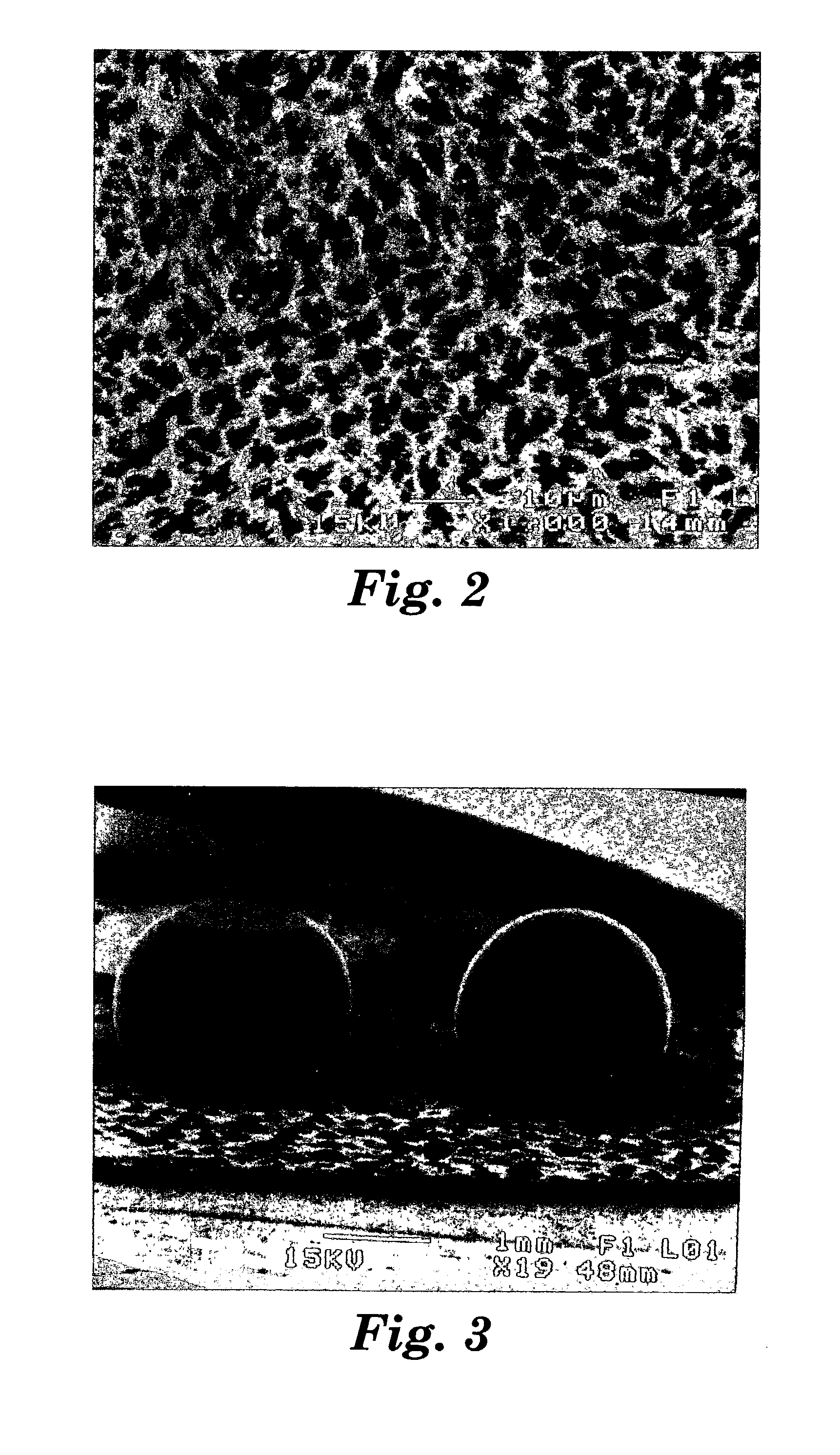

InactiveUS7507268B2Facilitates formation and homogeneityEliminates and minimizes heat transferPigmenting treatmentGlass drawing apparatusFiberThermal insulation

Al2O3—Y2O3—ZrO2 / HfO2 ceramics (including glasses, crystalline ceramics, and glass-ceramics) and methods of making the same. Ceramics according to the present invention can be made, formed as, or converted into glass beads, articles (e.g., plates), fibers, particles, and thin coatings. The particles and fibers are useful, for example, as thermal insulation, filler, or reinforcing material in composites (e.g., ceramic, metal, or polymeric matrix composites). The thin coatings can be useful, for example, as protective coatings in applications involving wear, as well as for thermal management. Certain ceramic particles according to the present invention can be are particularly useful as abrasive particles.

Owner:3M INNOVATIVE PROPERTIES CO

High-strength heat-resisting magnesium alloy and its preparing method

This invention is a high-intensive heat-fast magnesium alloy and its preparation method, and the magnesium alloy has the following components with their weight percentages: 6-15%Gd, 1-6%Y, 0.35-0.8%Zr, 0-1.5%Ca, and impurity elements Si, Fe, Cu and Ni with their gross less than 0.02%, and the rest percentage is Mg. while melting, add Gd, Y, Zr in the Mg melt in Mg-Gd, Mg-Y, Mg-Zr forms, then carry out solution treatment to the magnesium alloy under 450-500deg.C for 6-12 hours, squeeze in in 350-450deg.C, treat in time the squeezing stick for 10-16 hours in 225deg.C to improve its strength.

Owner:SHANGHAI JIAO TONG UNIV

Al2O3-Y2O3-ZrO2/HfO2 materials, and methods of making and using the same

InactiveUS20030110708A1Facilitates formation and homogeneityOxide formationPigmenting treatmentGlass drawing apparatusFiberThermal insulation

Al2O3-Y2O3-ZrO2 / HfO2 ceramics (including glasses, crystalline ceramics, and glass-ceramics) and methods of making the same. Ceramics according to the present invention can be made, formed as, or converted into glass beads, articles (e.g., plates), fibers, particles, and thin coatings. The particles and fibers are useful, for example, as thermal insulation, filler, or reinforcing material in composites (e.g., ceramic, metal, or polymeric matrix composites). The thin coatings can be useful, for example, as protective coatings in applications involving wear, as well as for thermal management. Certain ceramic particles according to the present invention can be are particularly useful as abrasive particles.

Owner:3M INNOVATIVE PROPERTIES CO

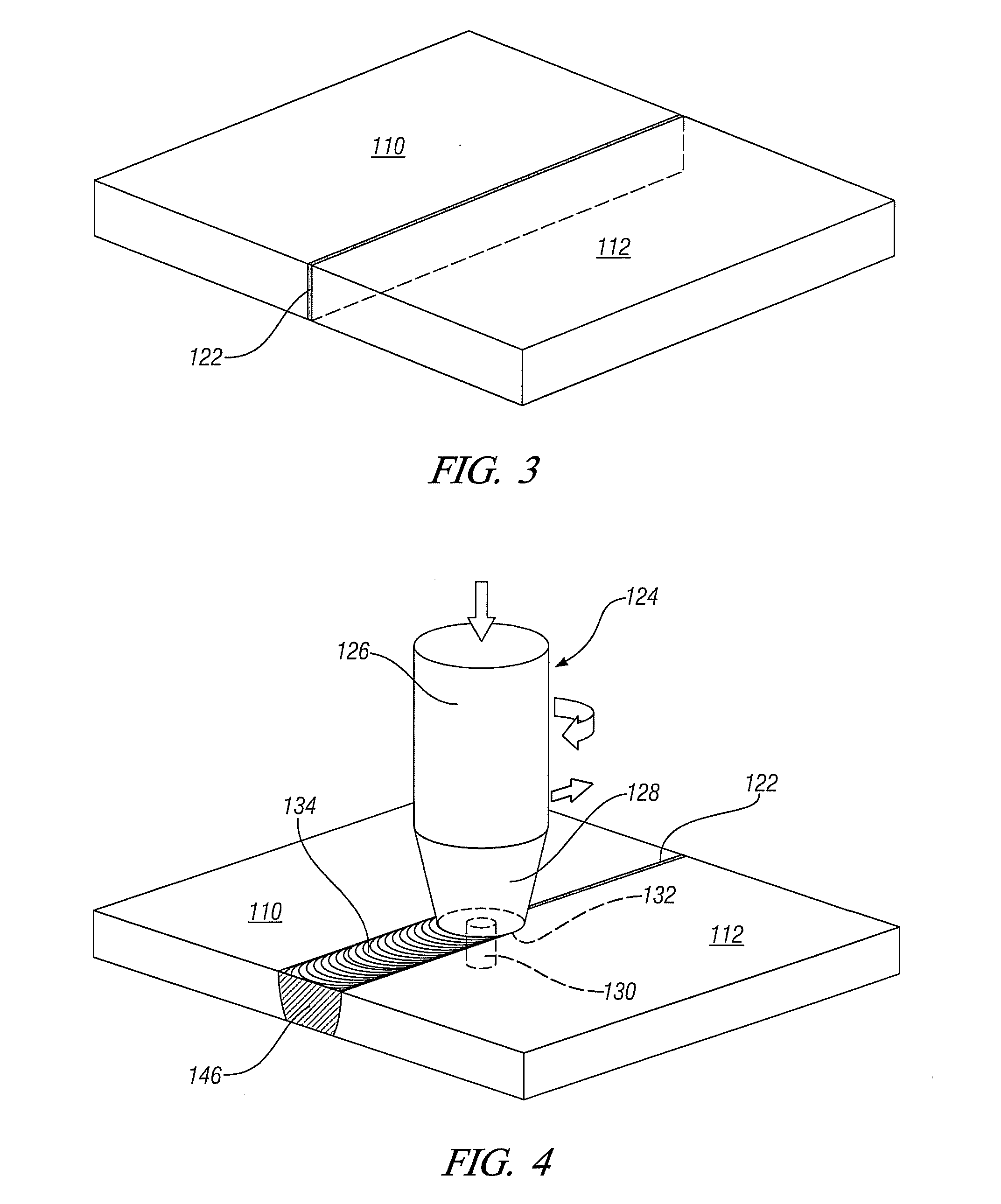

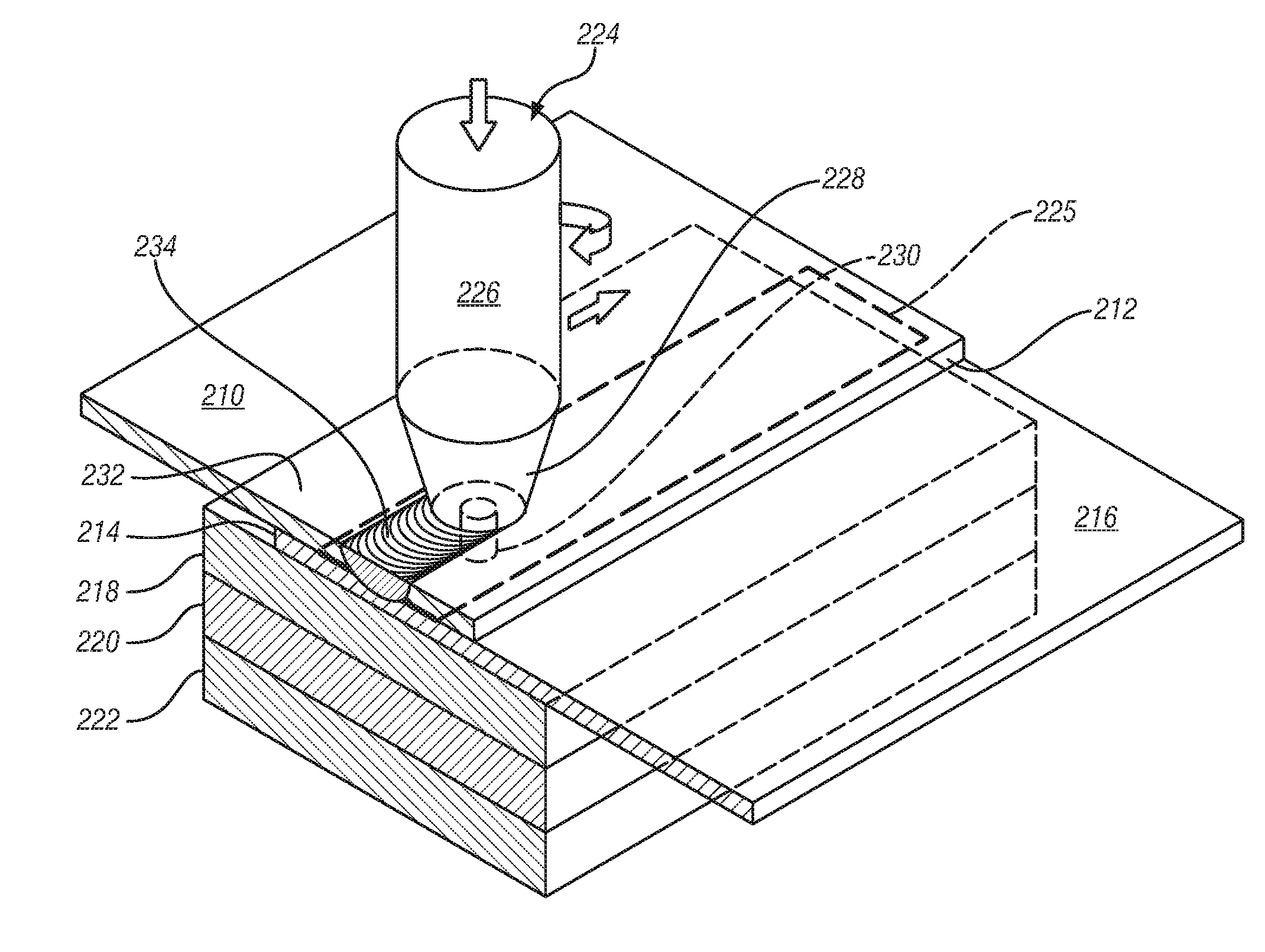

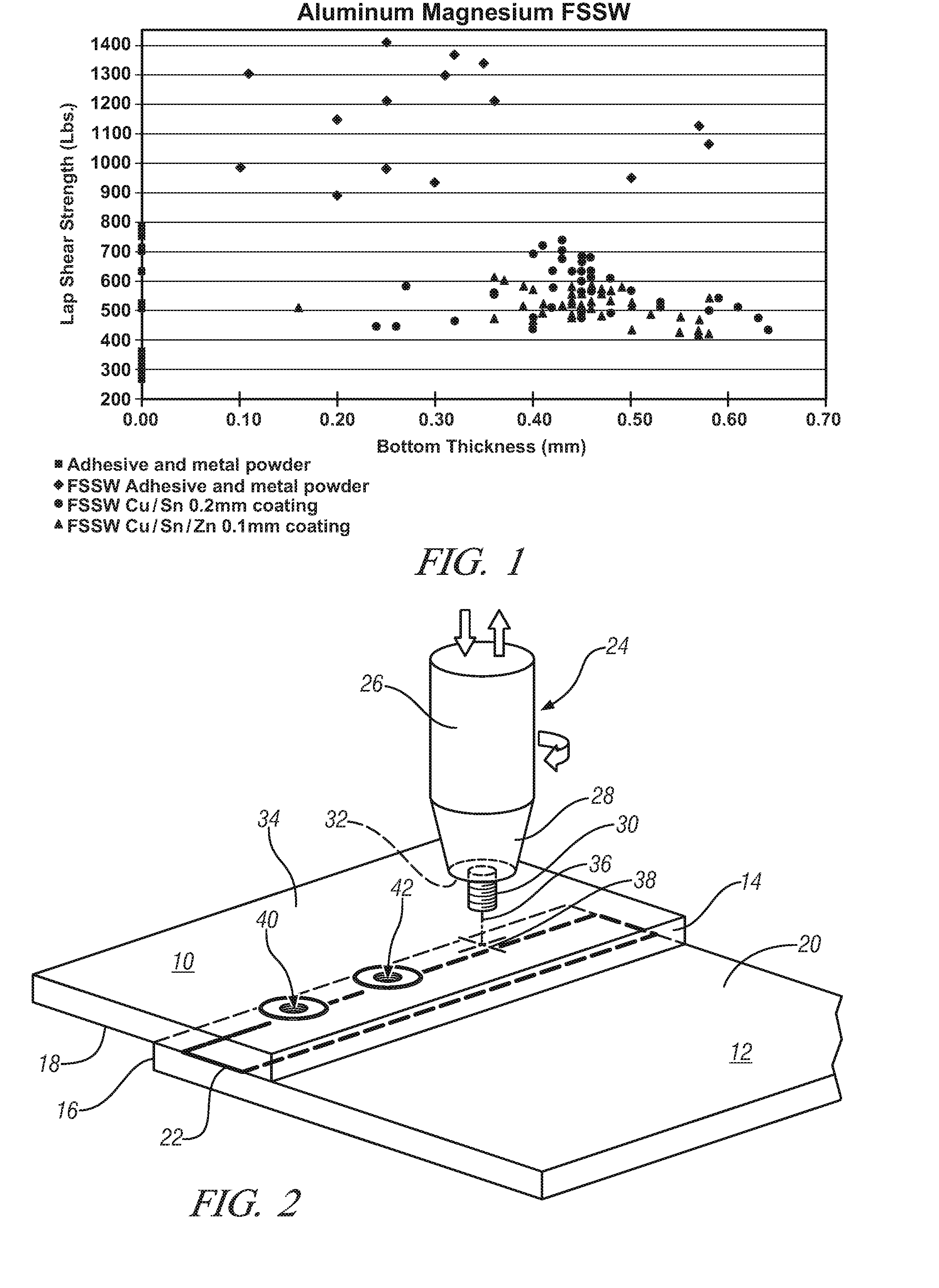

Friction stir welding of dissimilar metals

InactiveUS20100089977A1Improve mechanical propertiesHigh viscosityWelding/soldering/cutting articlesNon-electric welding apparatusFriction stir weldingTin

When a friction stir weld tool penetrates the interface of two workpieces of dissimilar metal alloy materials, the resultant weld of the different alloy materials may produce a weak weld joint. Such weak joints are often experienced, for example, when attempting to form spot welds or other friction stir welds between a magnesium alloy sheet or strip and an aluminum alloy sheet or strip. It is discovered that suitable coating compositions placed at the interface of assembled workpieces can alter the composition of the friction stir weld material and strengthen the resulting bond. In the example of friction stir welds between magnesium alloy and aluminum alloy workpieces, it is found that combinations of copper, tin, and zinc, and other powders can strengthen the magnesium-containing and aluminum-containing friction stir weld material.

Owner:GM GLOBAL TECH OPERATIONS LLC

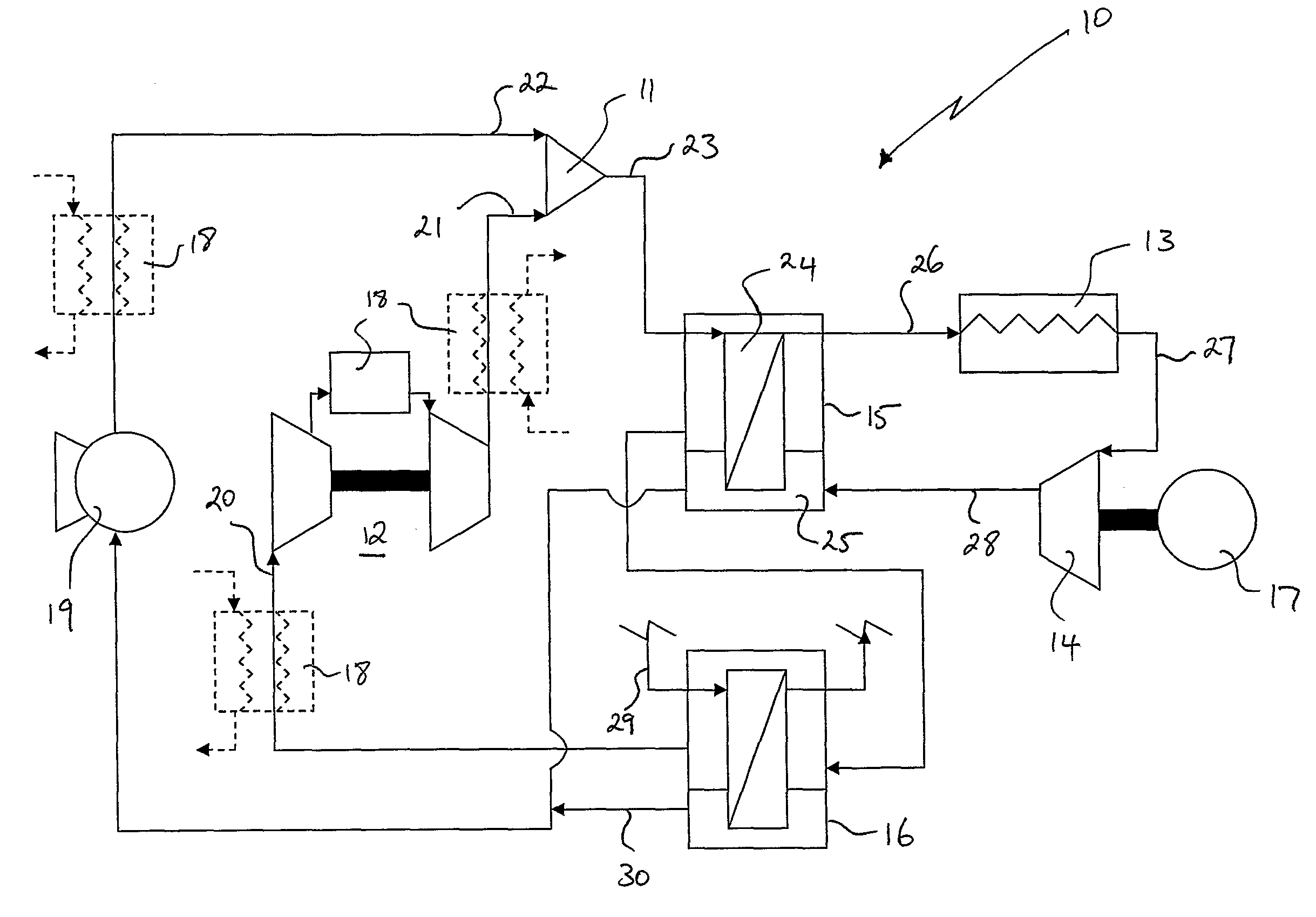

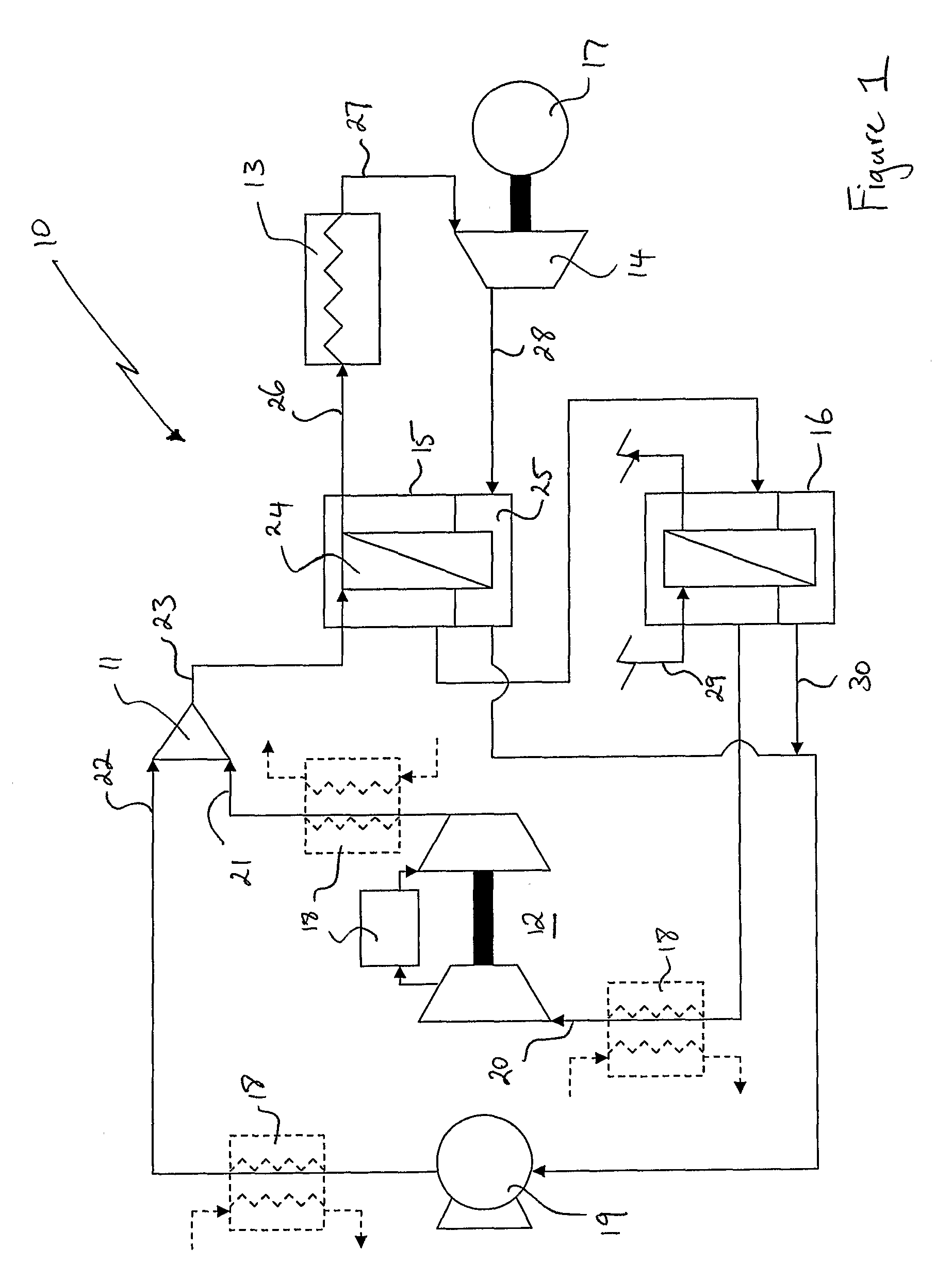

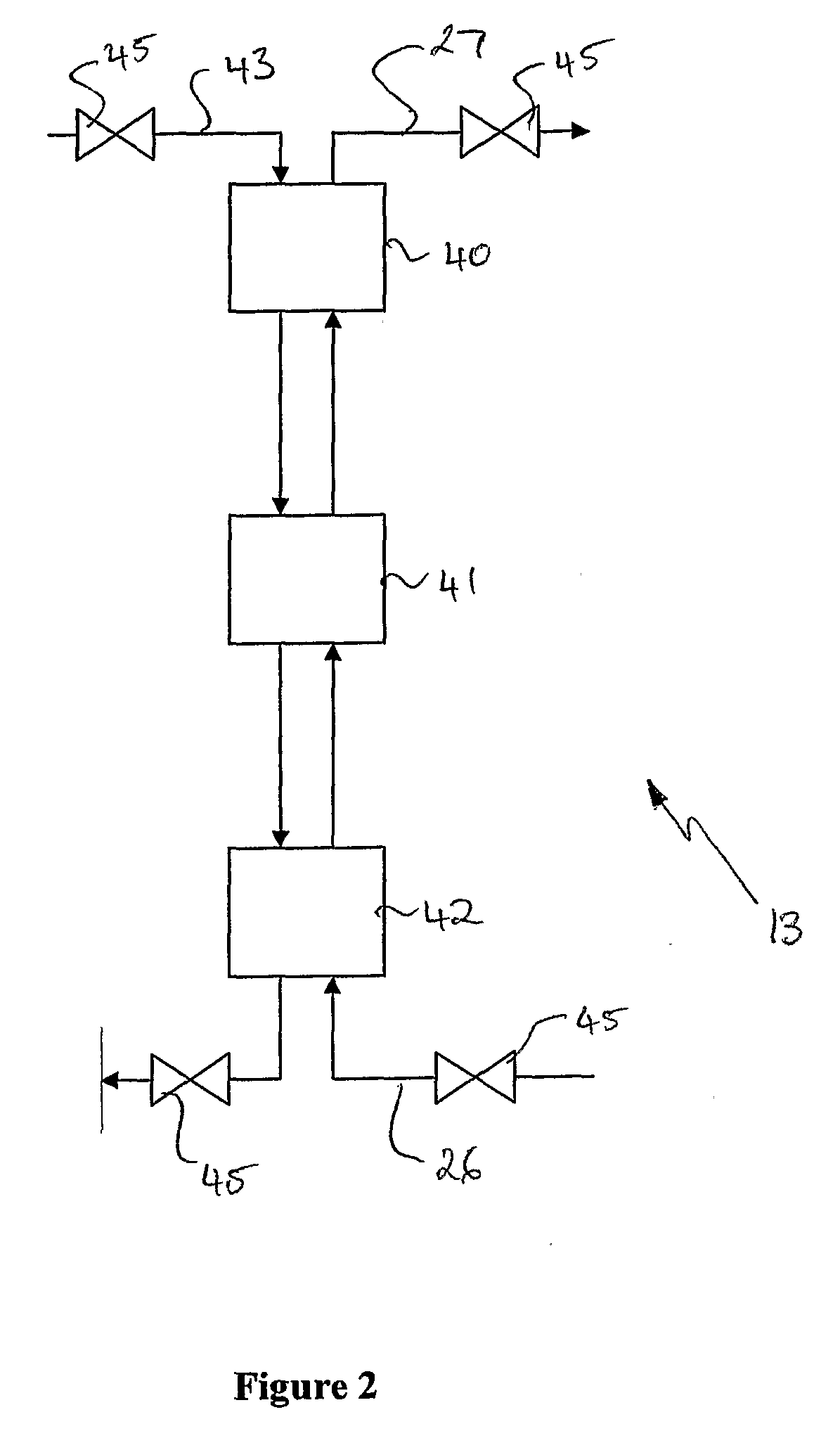

Heat Engine System

InactiveUS20100287934A1Increase temperatureImprove heat transfer performanceHeat storage plantsSteam useEnergy transferWorking fluid

A heat engine system for producing work by expanding a working fluid comprising first and second components, the system comprising, an apparatus for combining the second component of the working fluid as a liquid with the first component, the first component being a gas throughout the system, a compressor for compressing the first component, a pump for compressing at least most of the second component, a heater for heating the first and second components, an expander for expanding the first and second components to produce the work, and a recuperator for transferring at least some of the energy of the working fluid from the outlet of the expander, to the working fluid from the outlet of the apparatus, wherein a substantial portion of the energy transferred in the recuperator is at least a portion of the latent heat of the second component from the outlet of the expander.

Owner:COMMONWEALTH SCI & IND RES ORG +1

Films comprising biodegradable PHA copolymers

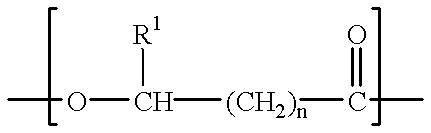

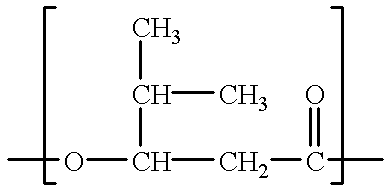

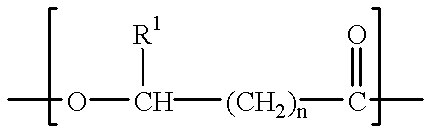

InactiveUS6174990B1High ratioSmall cross sectionFlexible coversWrappersBiodegradable copolymersMonomer

The present invention relates to biodegradable PHA copolymers comprising at least two randomly repeating monomer units. The present invention further relates to a plastic article comprising a biodegradable copolymer, wherein the biodegradable copolymer comprises at least two randomly repeating monomer units (RRMU) wherein the first RRMU has the structurewherein R1 is H, or C1 or C2 alkyl, and n is 1 or 2; the second RRMU has the structureand wherein at least 50% of the RRMUs have the structure of the first RRMU. The present invention further relates to an absorbent article comprising a liquid pervious topsheet, a liquid impervious backsheet comprising a film comprising a PHA of the present invention and an absorbent core positioned between the topsheet and the backsheet.

Owner:DANIMER IPCO LLC

Al2O3-rare earth oxide-ZrO2/HfO2 materials, and methods of making and using the same

InactiveUS20030126803A1Facilitates formation and homogeneityOxide formationPigmenting treatmentOther chemical processesFiberThermal insulation

Al2O3-rare earth oxide-ZrO2 / HfO2 ceramics (including glasses, crystalline ceramics, and glass-ceramics) and methods of making the same. Ceramics according to the present invention can be made, formed as, or converted into glass beads, articles (e.g., plates), fibers, particles, and thin coatings. The particles and fibers are useful, for example, as thermal insulation, filler, or reinforcing material in composites (e.g., ceramic, metal, or polymeric matrix composites). The thin coatings can be useful, for example, as protective coatings in applications involving wear, as well as for thermal management. Certain ceramic particles according to the present invention can be are particularly useful as abrasive particles.

Owner:3M INNOVATIVE PROPERTIES CO

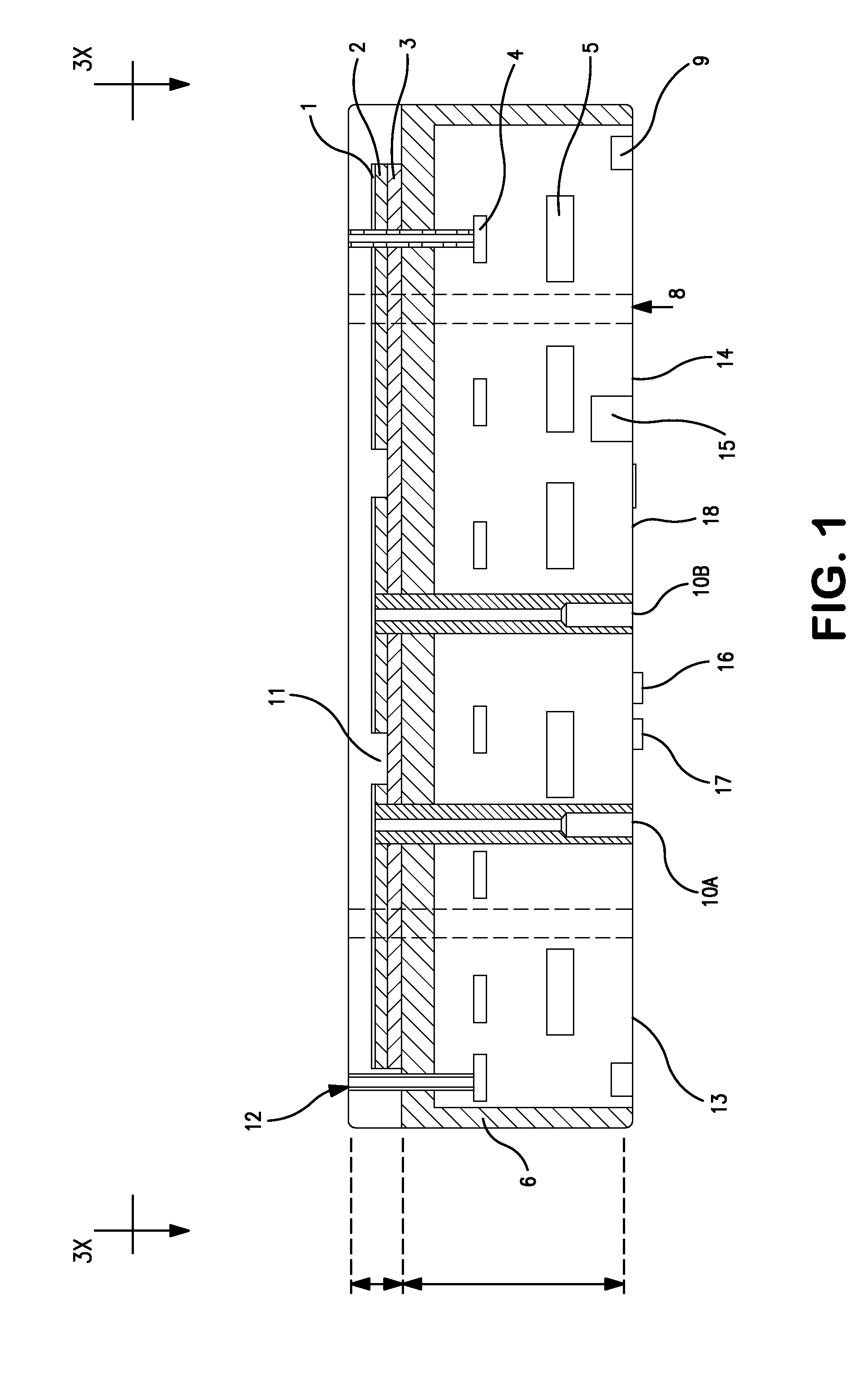

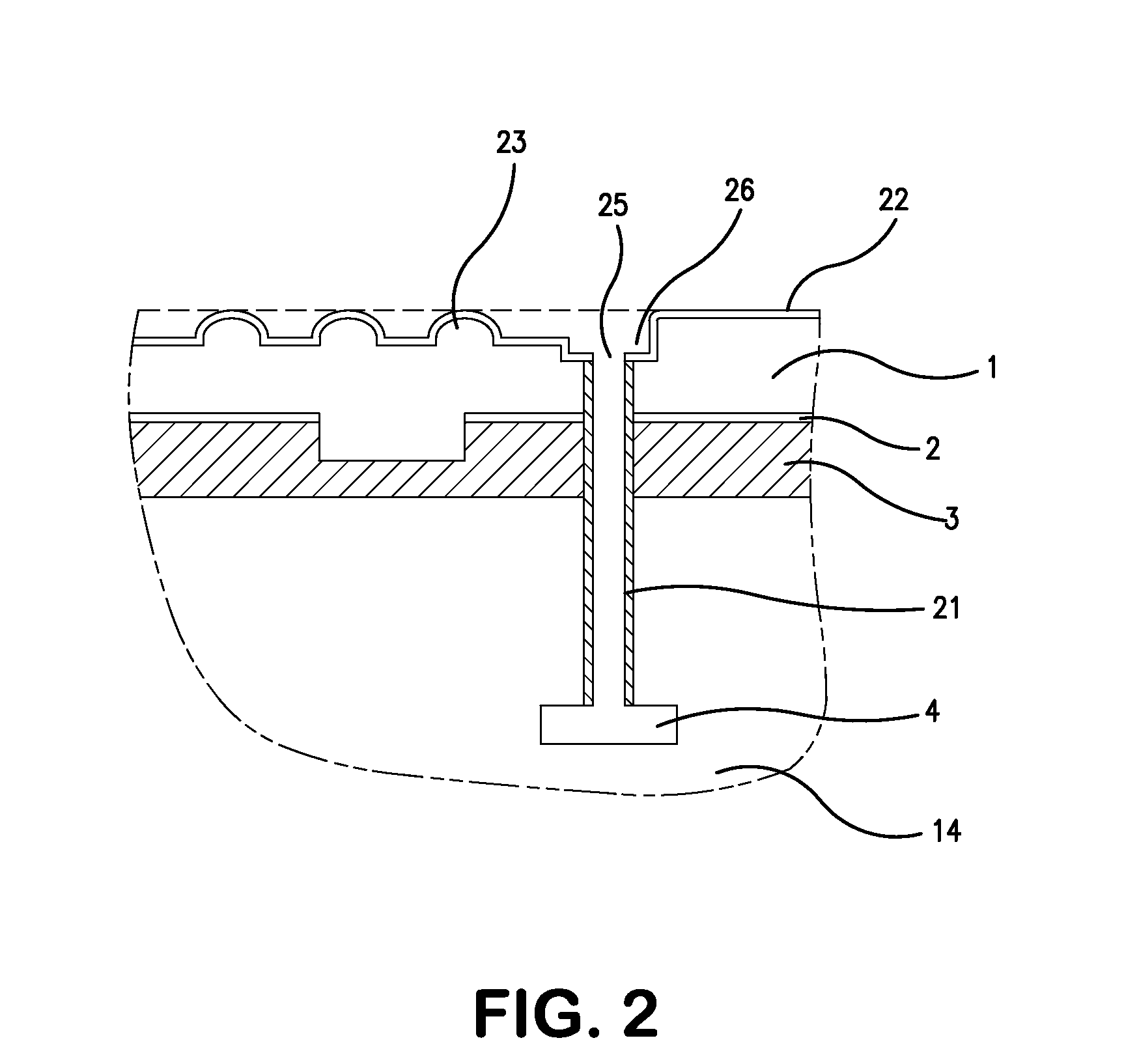

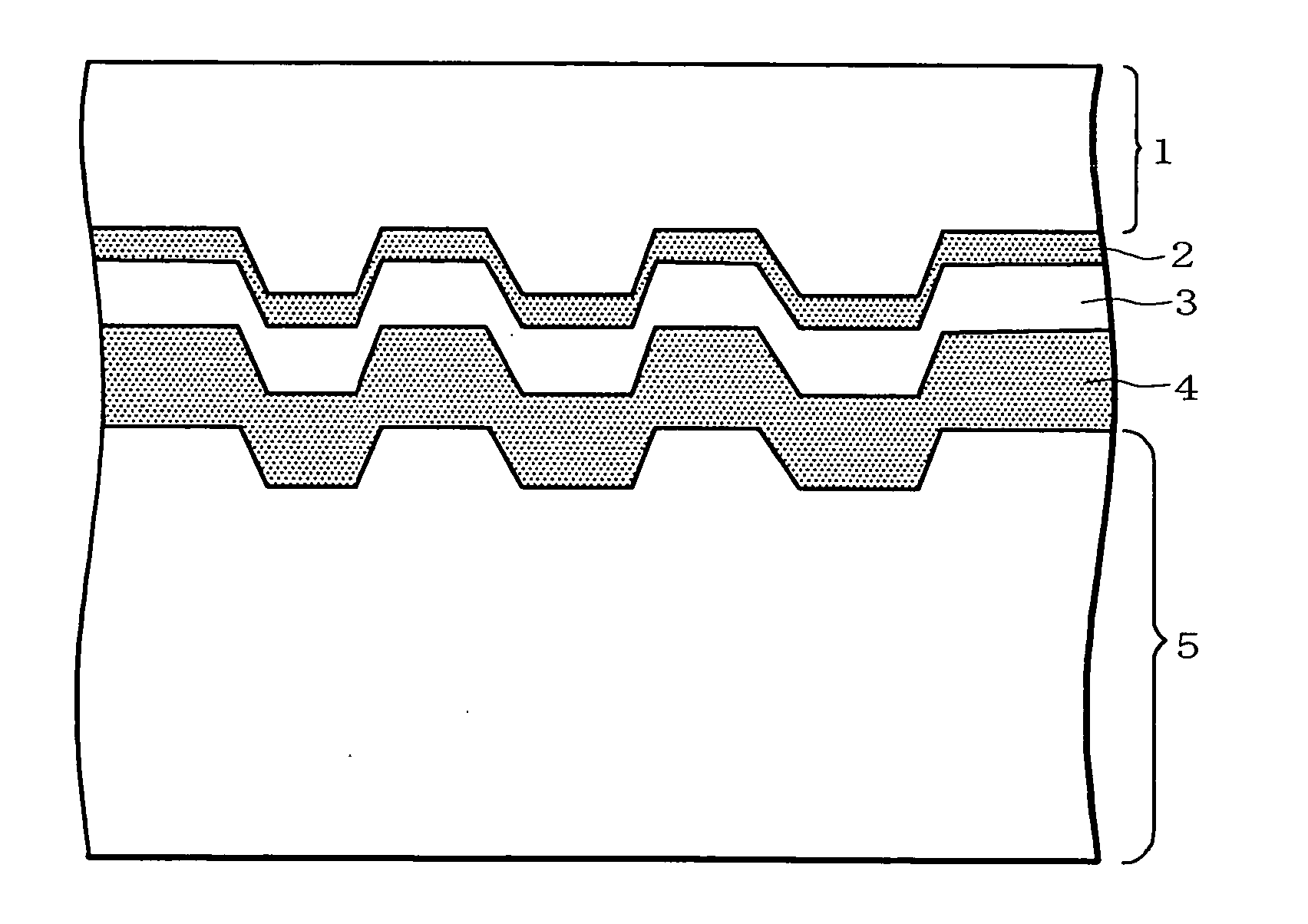

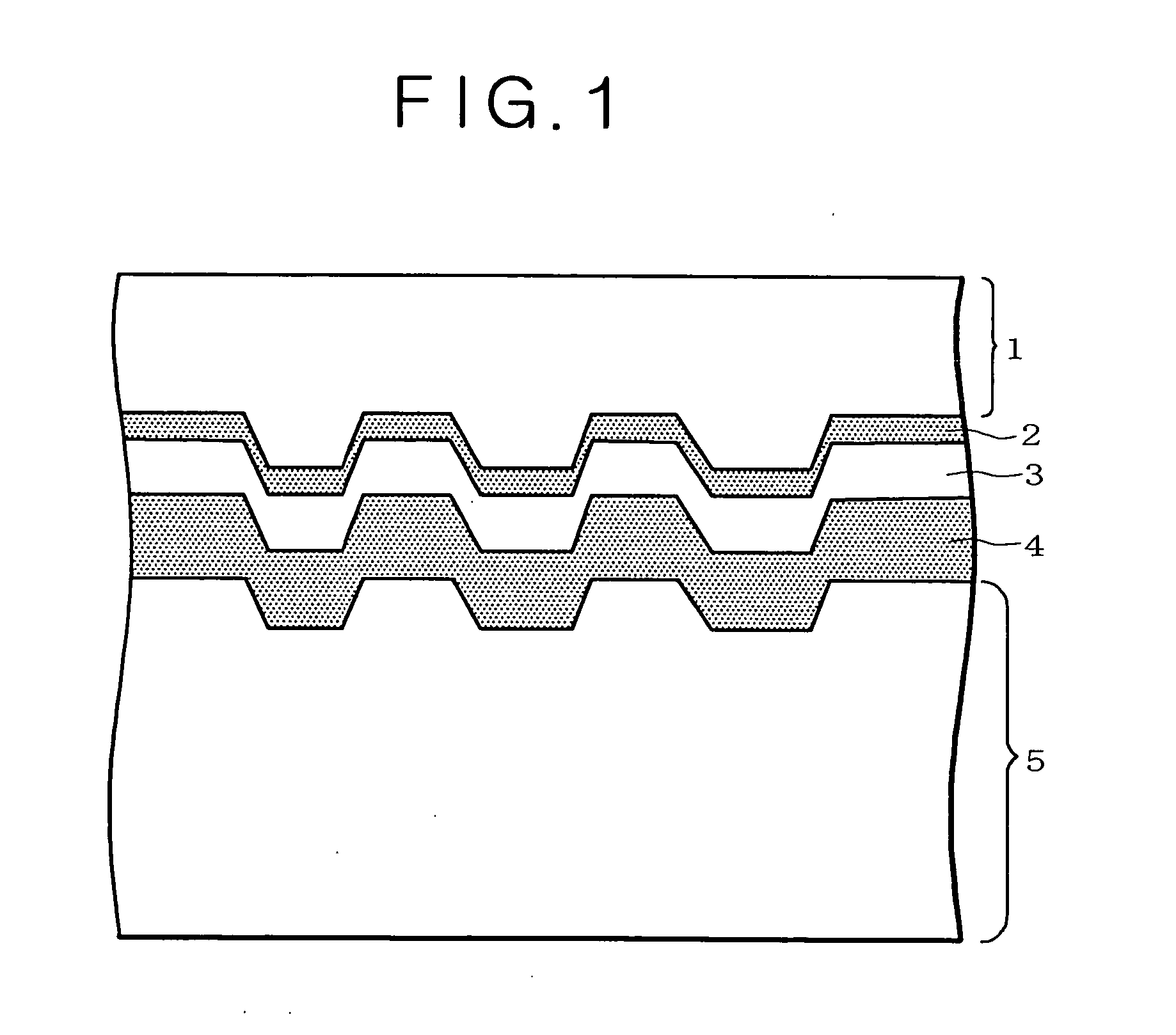

Polyceramic e-chuck

ActiveUS20090002913A1Reduce thermal stressEasy to controlSleeve/socket jointsElectric discharge tubesCapacitanceDielectric layer

The present invention discloses an electrostatic chuck for clamping work substrates, said chuck comprising three layers, where the dielectric constant of included non-conductive layers is selected to provide overall lower capacitance to the chuck. In the chuck assembly of the present invention, the top dielectric layer that is in contact with a substrate, such as, for example, a wafer, has a dielectric constant that is preferably greater than about 5, with a resistivity that is preferably greater than about 1E6 ohm.m, whereas the bottom dielectric layer has a dielectric constant that is preferably less than about 5 and a resistivity that is preferably greater than about 1E10 ohm.m. The intermediate layer preferably has a conductive layer where the resistivity is less than about 1 ohm.m. The electrostatic chuck may be bonded to heat sinks coated with anti-arc dielectrics. The heat sink can also be used as an RF electrode. The heat sink may have provisions for coolants and gas channels to feed a cooling gas to the backside of a wafer. The heat sink may have feed thrus to power the segmented electrodes in the electrostatic chuck. The passages for the feed thrus, gas feed holes and lift pins may be lined with ceramics or polymers to prevent any discharge to the heat sink. The electrostatic chuck is for clamping work substrates like Si, GaAs, SiO2, etc. used in semiconductor tools.

Owner:FM INDS

Ceramic materials, abrasive particles, abrasive articles, and methods of making and using the same

InactiveUS20030126802A1Facilitates formation and homogeneityOxide formationOther chemical processesInorganic pigment treatmentGlass-ceramicMaterials science

Owner:3M INNOVATIVE PROPERTIES CO

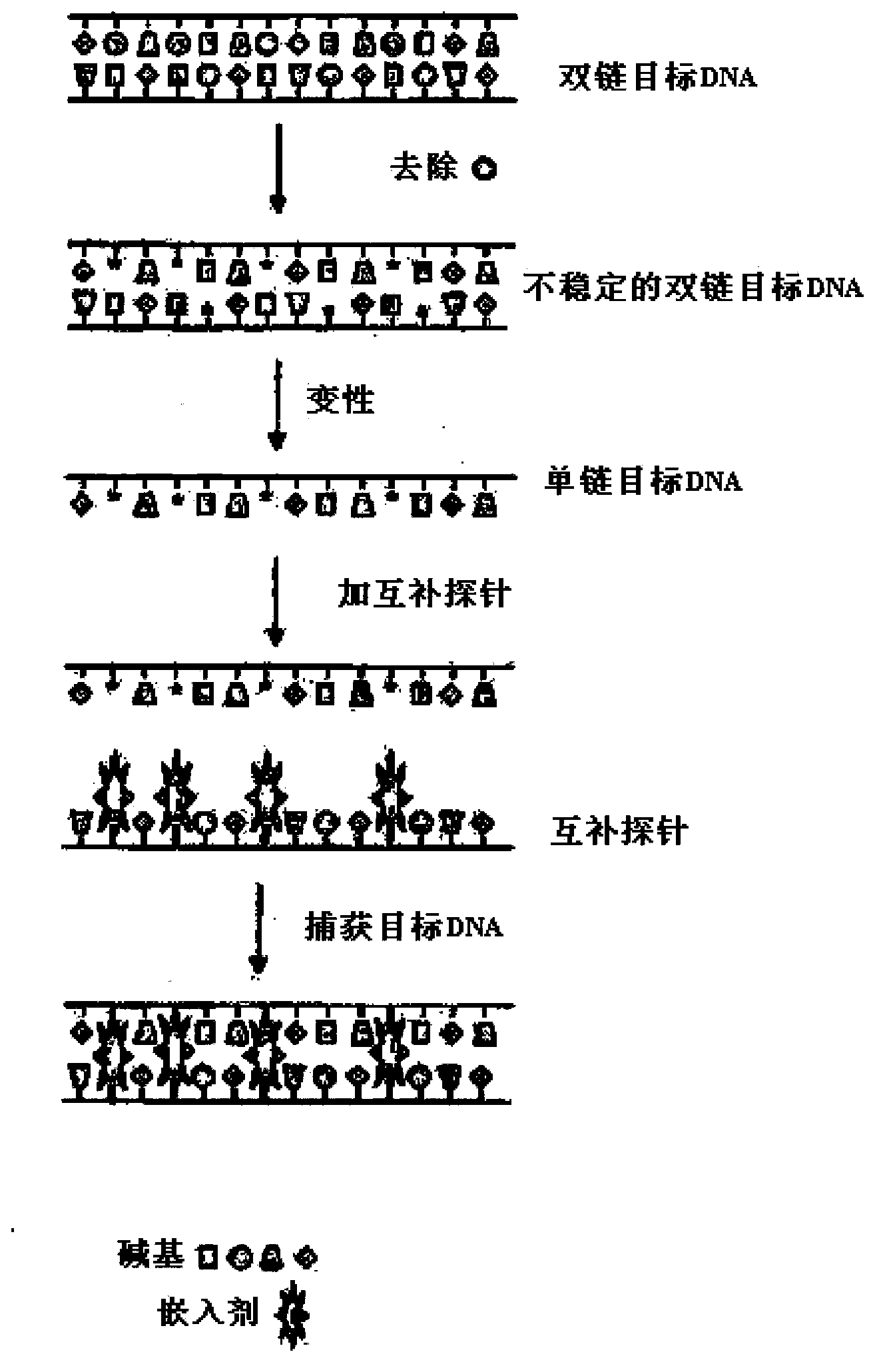

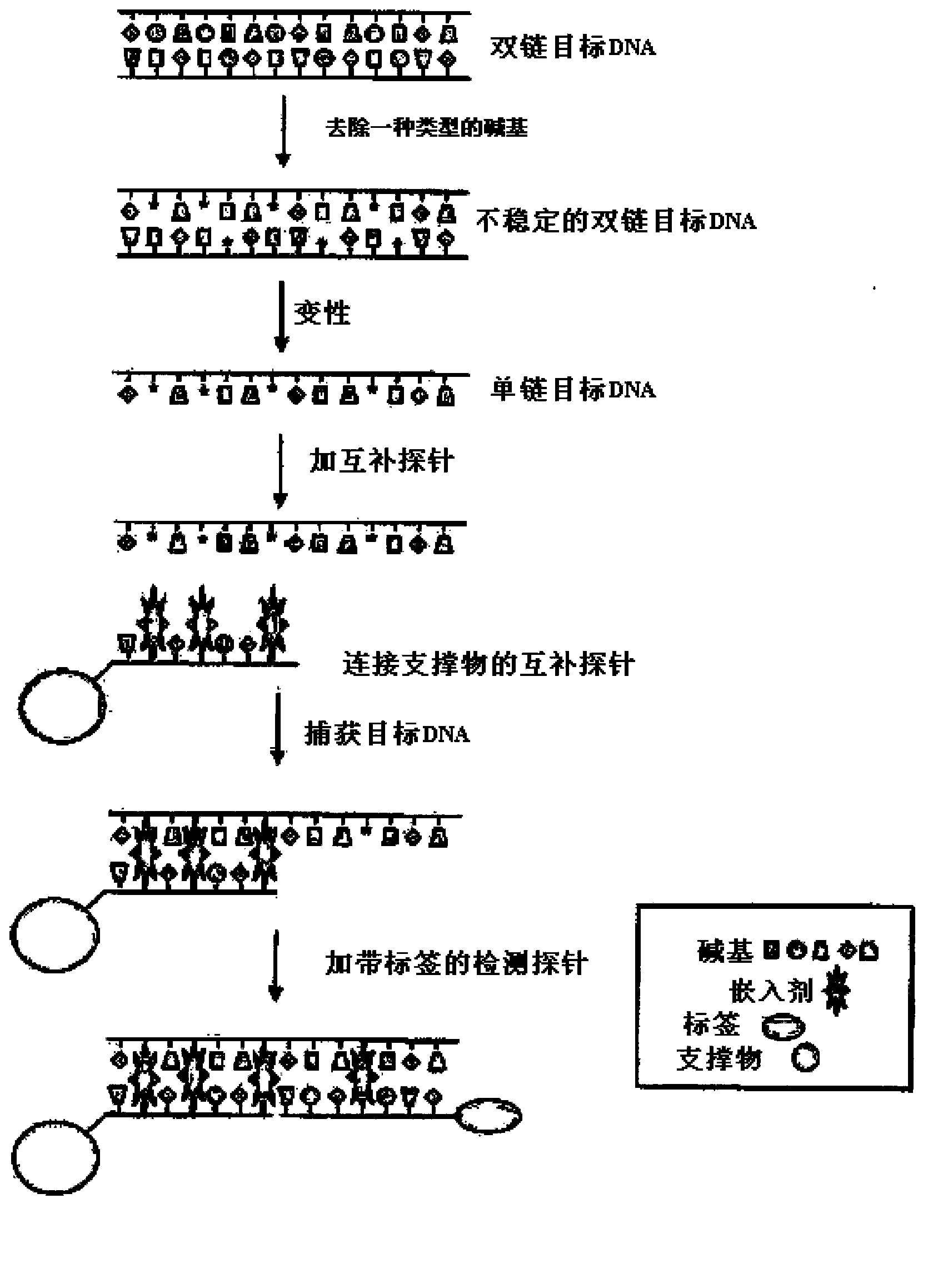

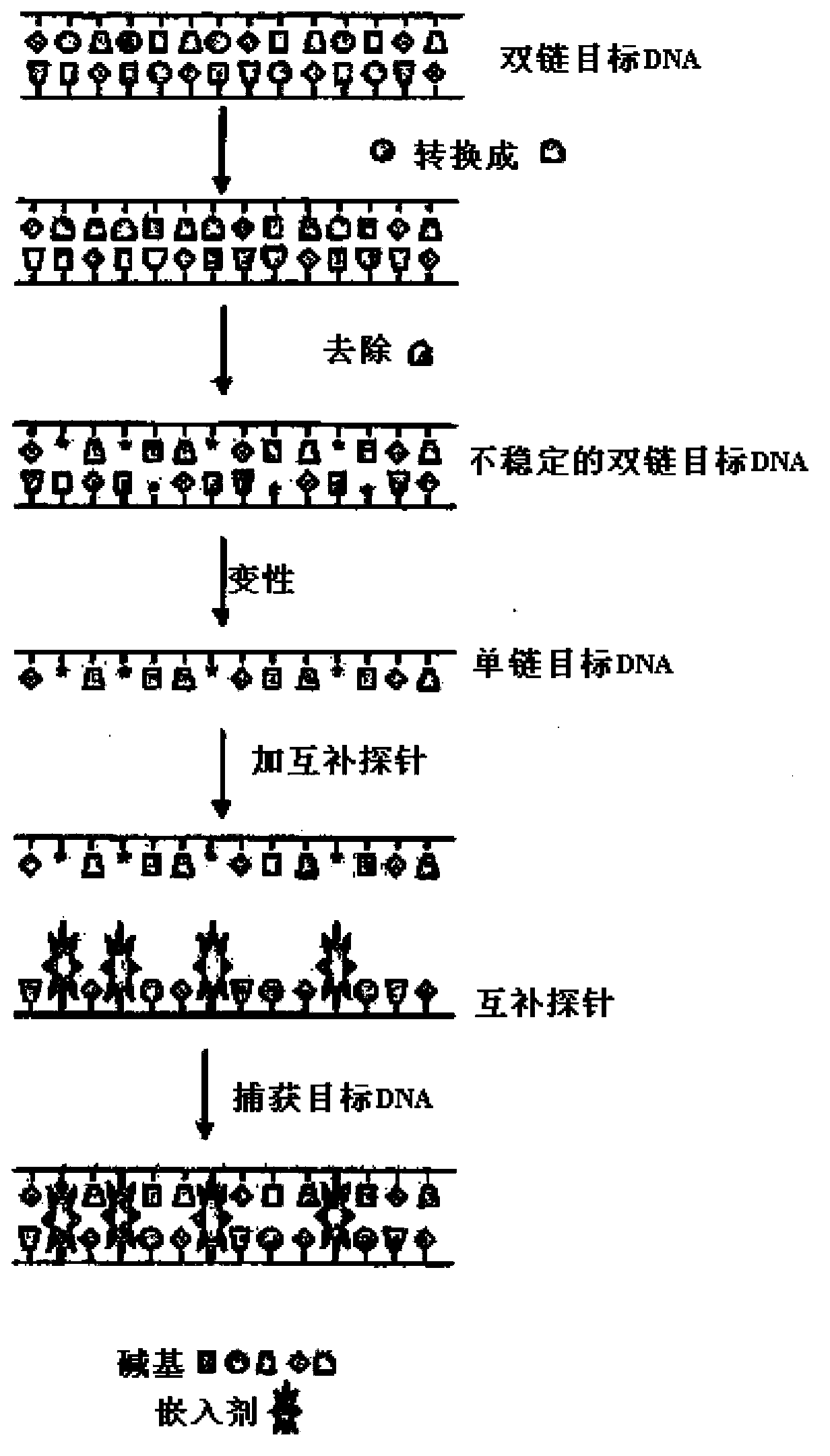

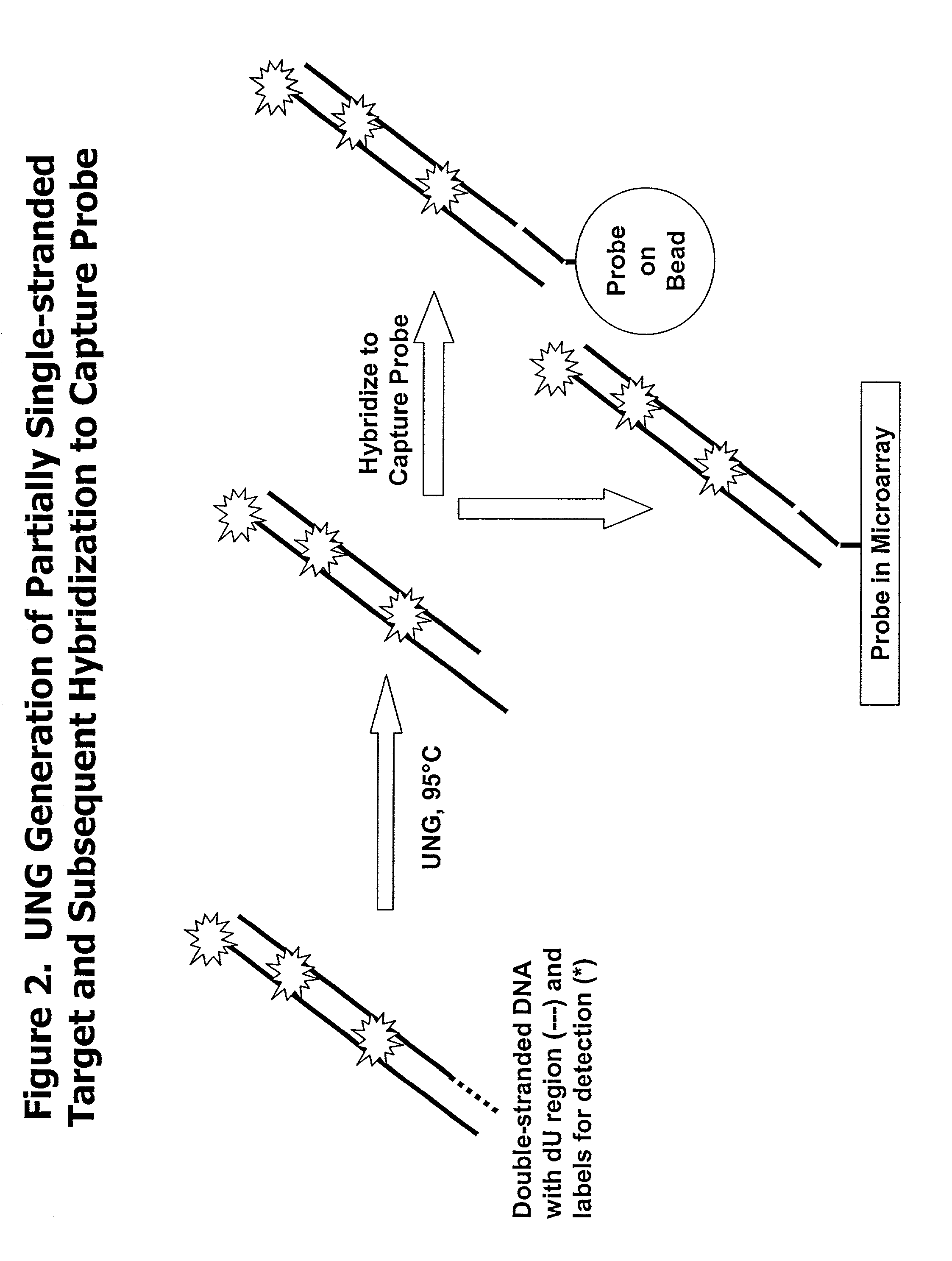

Capture of target DNA and RNA by probes comprising intercalator molecules

InactiveCN103517991AIncrease credibilityLower melting temperatureMicrobiological testing/measurementAgainst vector-borne diseasesNucleotidePolynucleotide

The present invention relates to a technology for specific capture of single stranded target Polynucleotide by a complementary probe comprising one or more intercalator molecules. The method further involves removal of one or more types of bases in the single stranded target Polynucleotide prior to interaction with the complementary probe. This results in generation of one or more abasic sites which can interact with and / or into where the intercalator molecule can be inserted.

Owner:QUANTIBACT AS

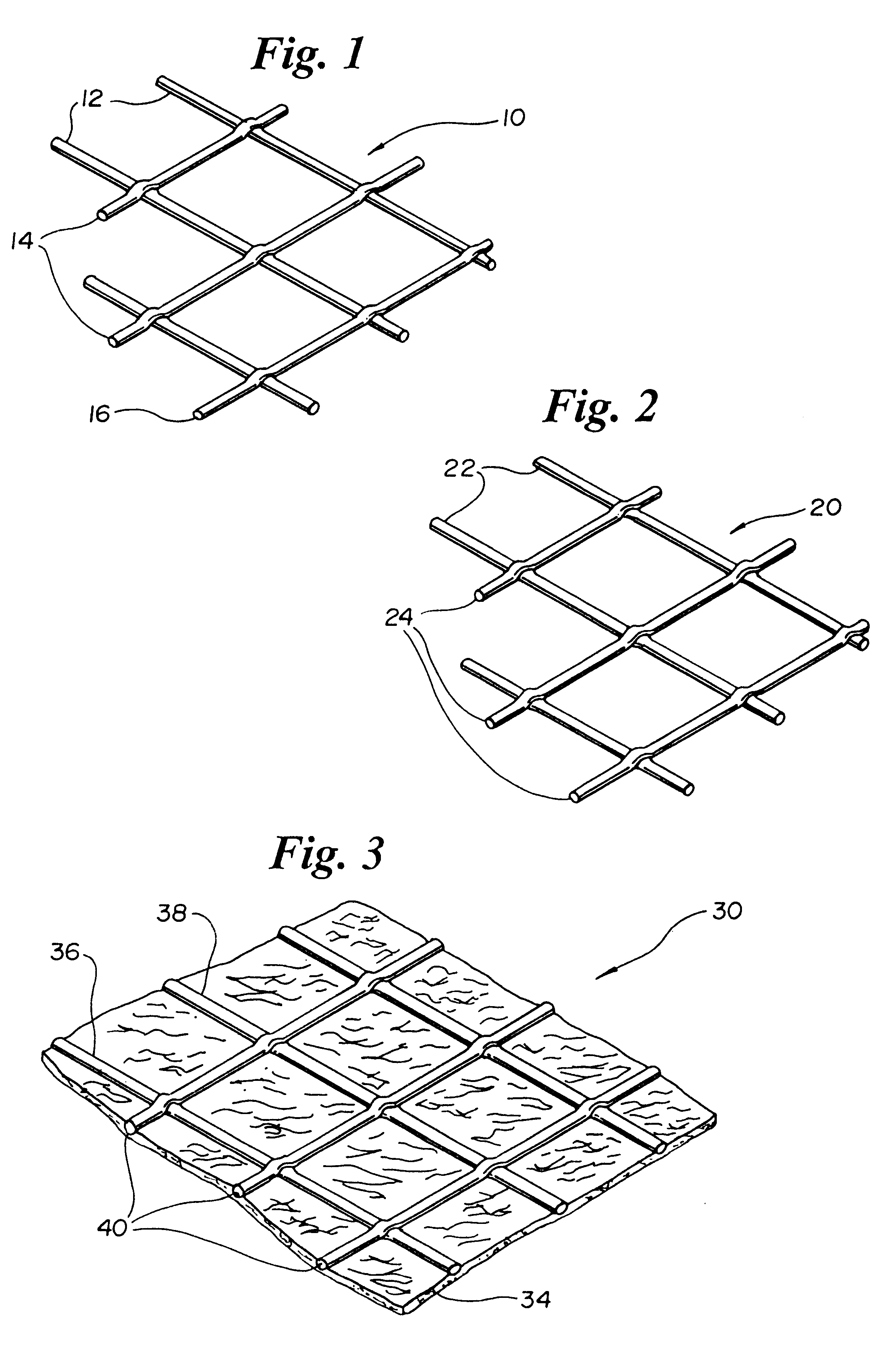

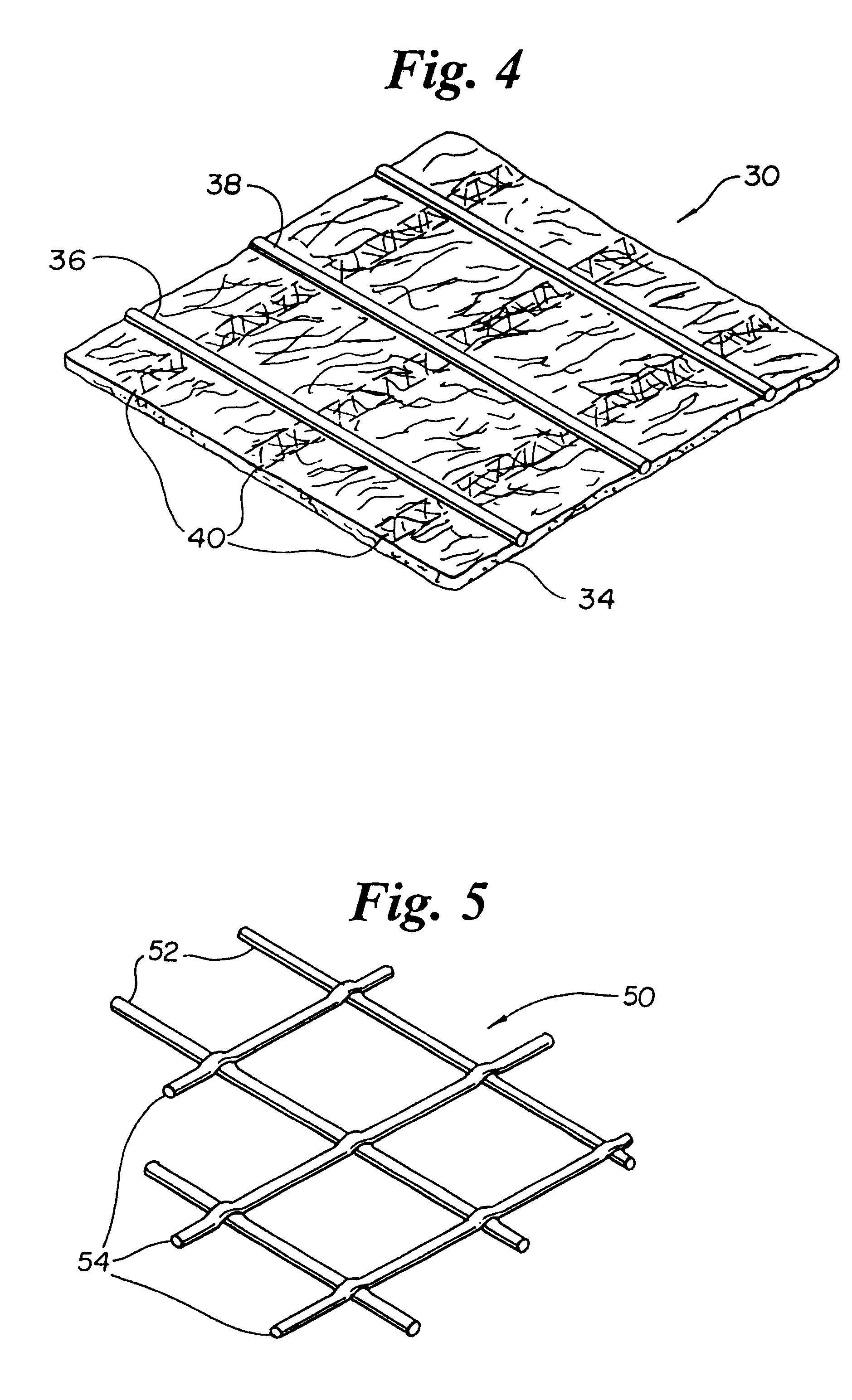

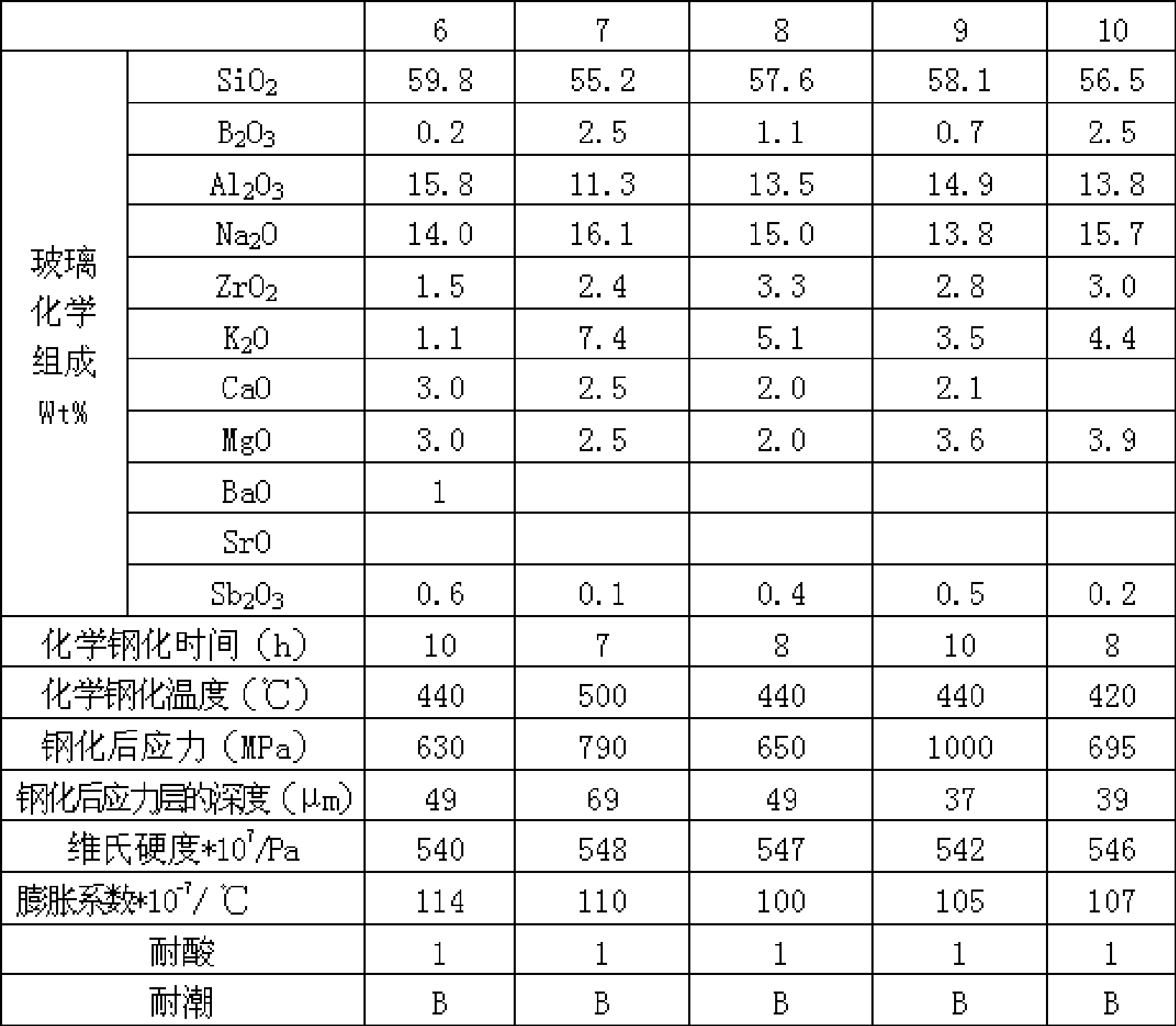

Extruded netting exhibiting stretch and bonding

InactiveUS6204207B1Easy to operateLow raw material costLaminationLamination apparatusAdhesiveMaterials science

Extruded net with at least some strands which melt away upon the application of heat while other strands maintain elastic, or other desirable, properties. This netting is advantageously combined with a fabric in which the low melting strands function as an adhesive, while the high melting strands maintain their designed properties in the final laminate product.

Owner:CONWED PLASTICS

Blast-furnace smelting method for vanadium titano-magnetite

InactiveCN101775451ARaise the gradeReduce tons of iron slagBlast furnace detailsMagnetiteBlast furnace smelting

The invention discloses a blast-furnace smelting method for vanadium titano-magnetite. The method is realized in a way that: vanadium titano-magnetite accounts for 30-60% of ferrous burden which is fed into a blast furnace, and the burden comprises 40-65% of agglomerate, 30-50% of pellet and 5-10% of lump ore; the diacidic basicities CaO / SiO2 of agglomerate, pellet and blast-furnace slag are respectively controlled at 1.6-2.5, 0.6-1.0 and 1.05-1.20; the content of MgO in blast-furnace slag is controlled at 7.5-9.0%; by adding two batches of ore and three batches of coke and using the charging operation of the development center, manganese oxide ore or sintered manganese ore powder, and fluorite are incorporated into injection coal and injected into the blast furnace along with the coal powder; and thus, the content of MnO in the slag and the content of CaF2 in the slag are respectively controlled at 1.0-4.5% and 0.50-2.0%, and the oxygen-enrichment percentage of the blast furnace is controlled at 2.0-4.0%. Compared with the smelting blast furnace using the same quality and structure of the burden, the comprehensive coke ratio of the invention is reduced by 20-50kg per ton of iron, the content of TFe in the slag is reduced by 50%, and the comprehensive cost per ton of iron is reduced by 30-50 yuan. The invention has wide prospects for popularization and application.

Owner:CENT SOUTH UNIV

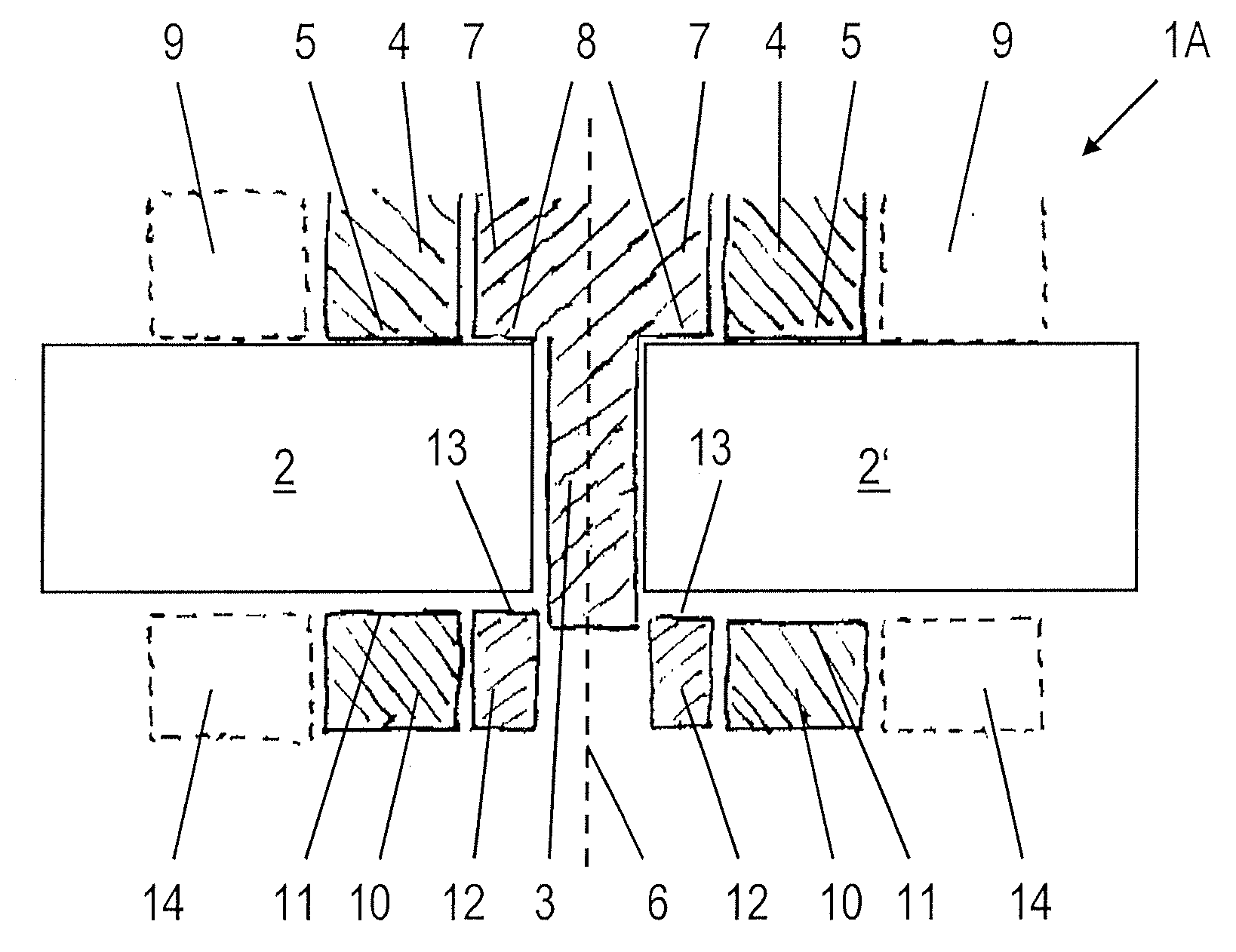

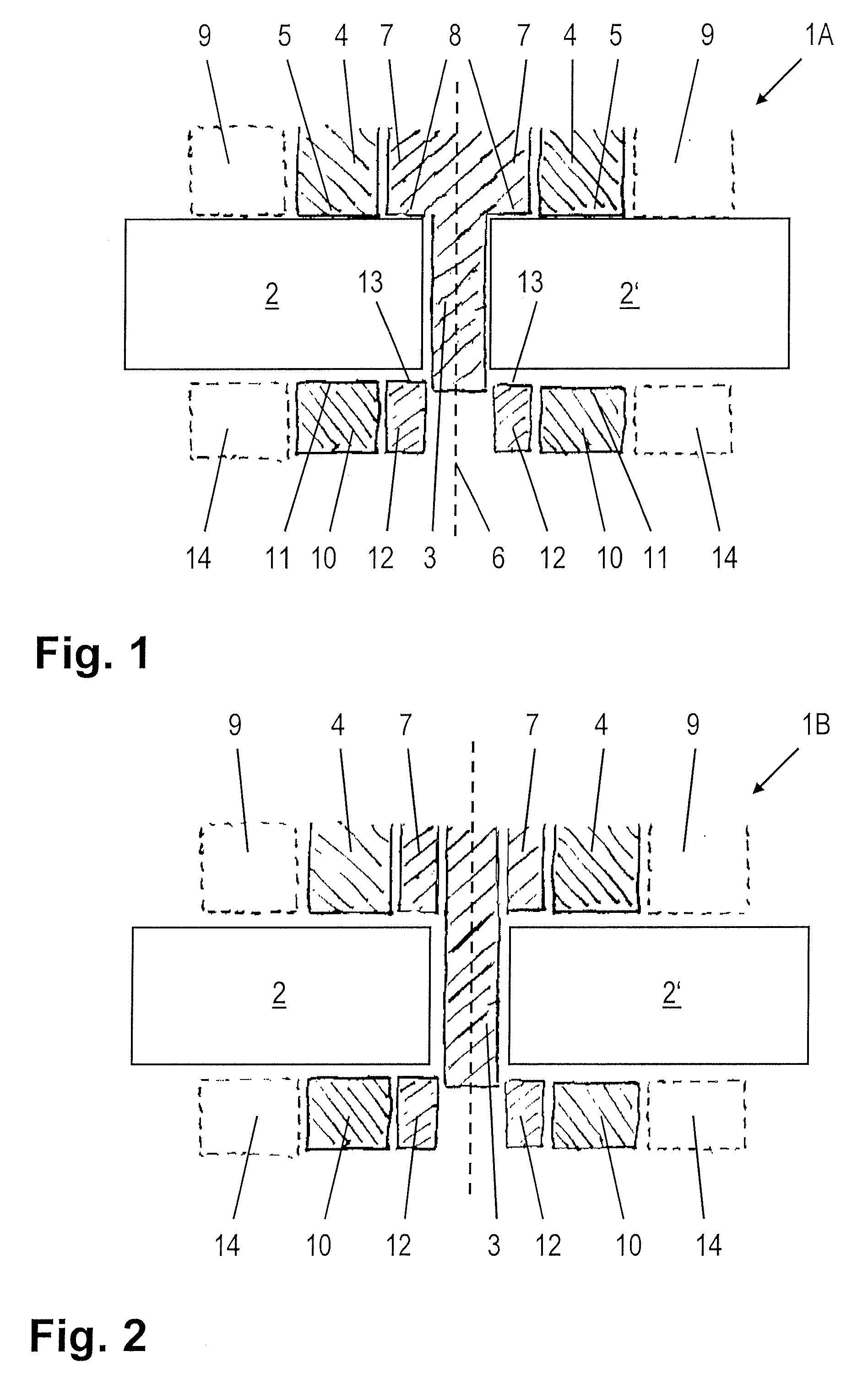

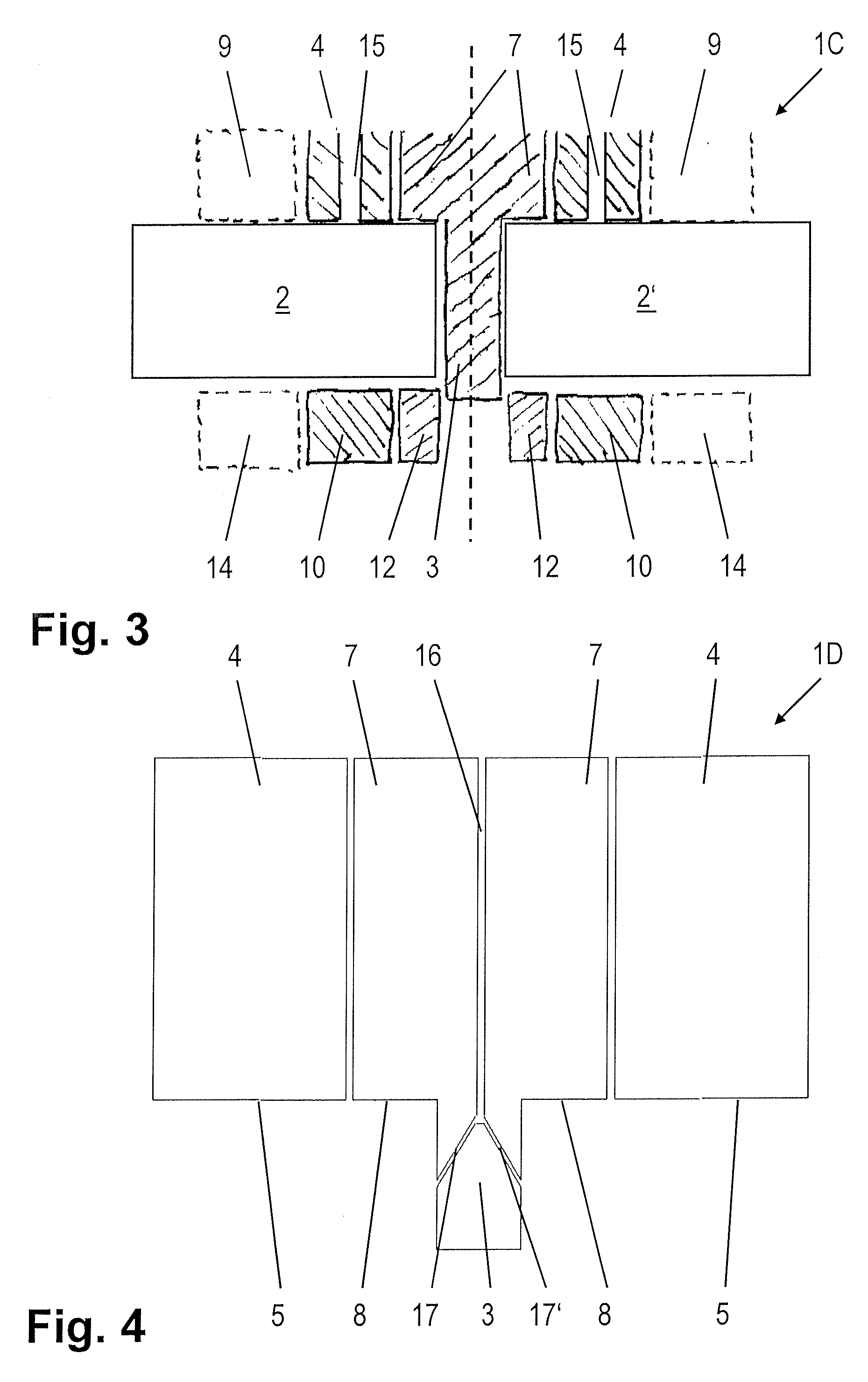

Friction stir welding appparatus

InactiveUS20060289604A1Small sizeMuch successWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention illustrates and describes an apparatus for friction stir welding, having a pin (3) and a first friction surface segment (4), the pin (3) and the first friction surface segment (4) being rotationally driven about an axis of rotation (6), and the first friction surface segment (4) having a first friction surface (5) for resting on a workpiece (2). The object of providing a friction stir welding apparatus which can be used to better set the energy which is introduced into the workpiece by way of the friction between pin and friction surface, on the one hand, and workpiece, on the other hand, is achieved by virtue of the fact that a first inner segment (7) is provided, having a first inner friction surface (8) for resting on a workpiece (2, 2′), that the first inner segment (7) surrounds the pin (3), that the first friction surface segment (4) surrounds the first inner segment (7), and that the first friction surface segment (4) is rotationally driven independently of the first inner segment (7).

Owner:GKSS FORSCHUNGSZENTRUM GEESTHACHT GMBH

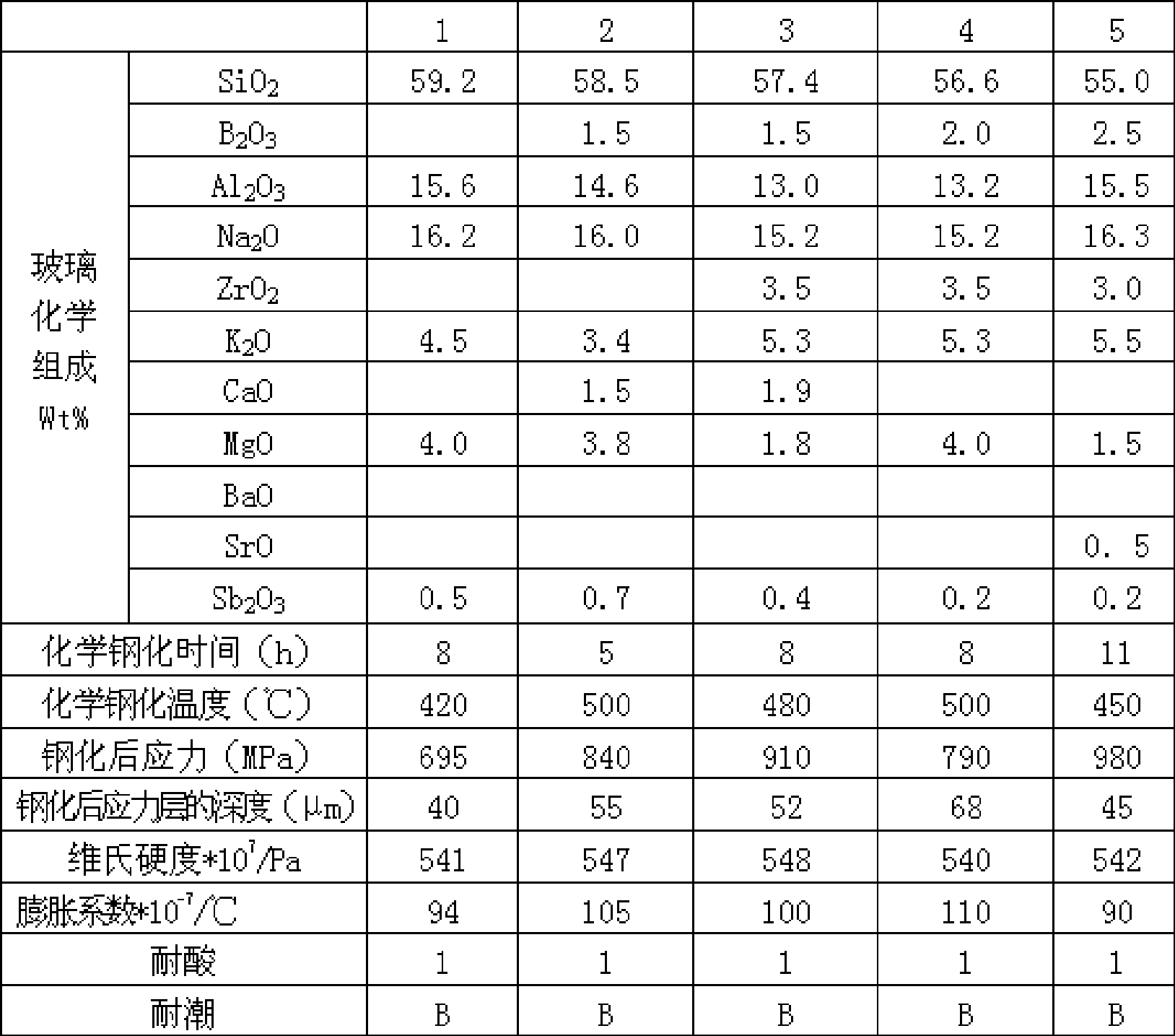

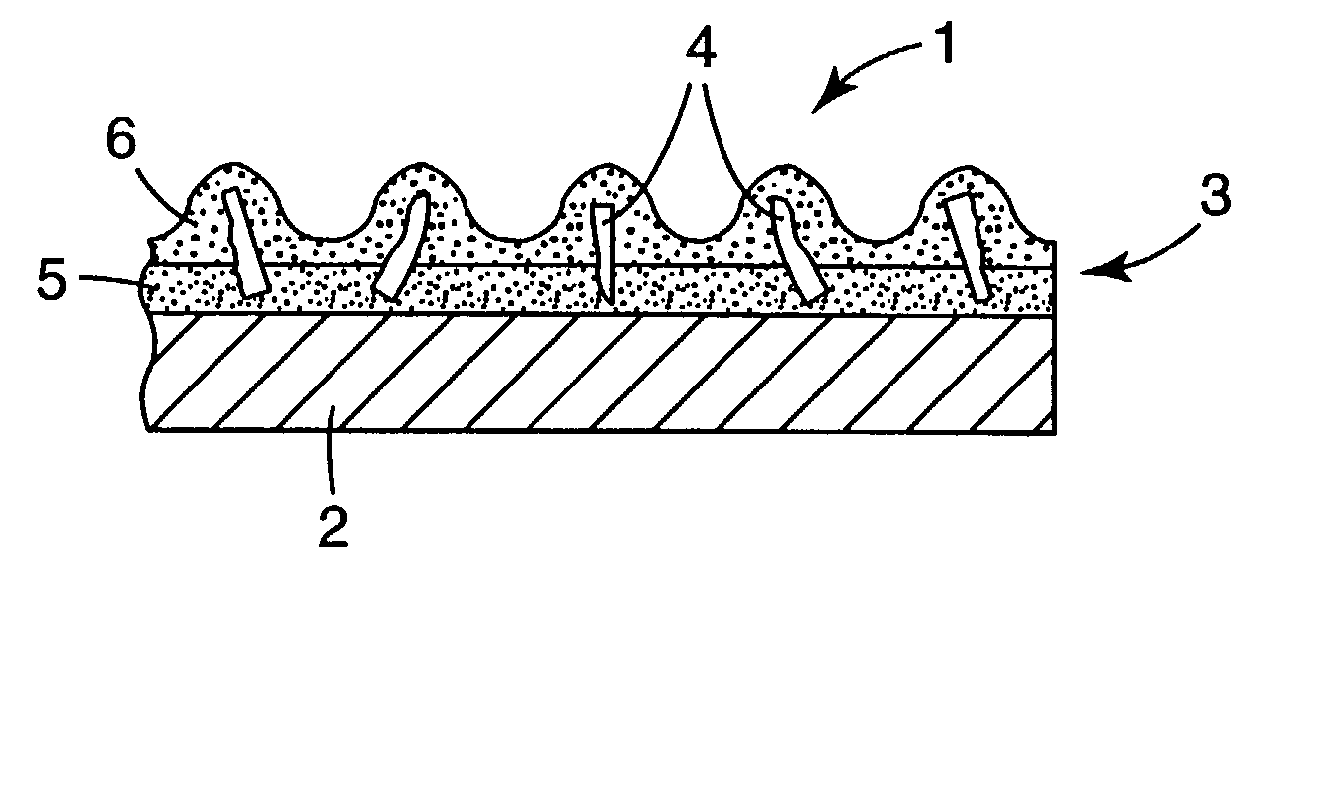

Glass suitable for chemically tempering and chemical tempered glass

ActiveCN101508524AReduce manufacturing difficultyLower melting temperatureGlass tempering apparatusThin material handlingProtective glassesIon exchange

The invention provides silica-alumina-sodium oxide glass which is suitable for a low-temperature ion exchange process and is easy to melt. The glass is suitable for chemical tempering, and comprises the following compositions in percentage by weight: 55 to 60 percent of SiO2, 0.1 to 2.5 percent of B2O3, 11 to 16 percent of Al2O3, 14 to 17 percent of Na2O, 1 to 8 percent of K2O, 0 to 8 percent of ZrO, 0 to 5 percent of CaO, 0 to 5 percent of MgO, and 0 to 1 percent of Sb2O3. The invention, by reasonably setting the compositions, reduces the manufacturing difficulty of the glass, obviously reduces the melting temperature of the glass, and is favorable for reducing energy consumption and improving the rate of finished products of products; and under the conditions that the tempering temperature of the glass is between 380 and 500 DEG C and the tempering time is between 4 and 12 hours, the surface compressive stress of the glass can reach between 610 and 1,100MPa, the depth of a stress layer can reach between 31 and 80 mu m, and the glass is strengthened and has good shock resistance. The glass has higher wear resistance, and is suitable for protective glass materials of high-grade electronic display products such as mobile phones, PDA and the like.

Owner:CDGM OPTICAL GLASS

Lead-free alloy solder containing rare-earth and more alloy components

InactiveCN1346728ALower melting temperatureAdjust mechanical propertiesWelding/cutting media/materialsSoldering mediaRare-earth elementChemical composition

A lead-free alloy solder containing rare-earth elements and multiple other elements for electronic package contains Ag (0.1-5 wt.%), Cu (0.1-1 wt.%), Bi (0.1-8 wt.%), In (0.1-7.5 wt.%), Sb (0-8 wt.%), the mixture of La and Ce or the mixture of La, Ce and one or both of Pr and Nd (0.01-2 wt.%) and Sn (the balance). It has liquidus temp less than 210 deg.c (even 190 deg.C or lower), less than 15 deg.c for liquidus and solidus temp difference, at least 60 MPa of yield strength, at least 18% of elongation percentage, excellent wetting ability, and high soldering quality.

Owner:DALIAN UNIV OF TECH

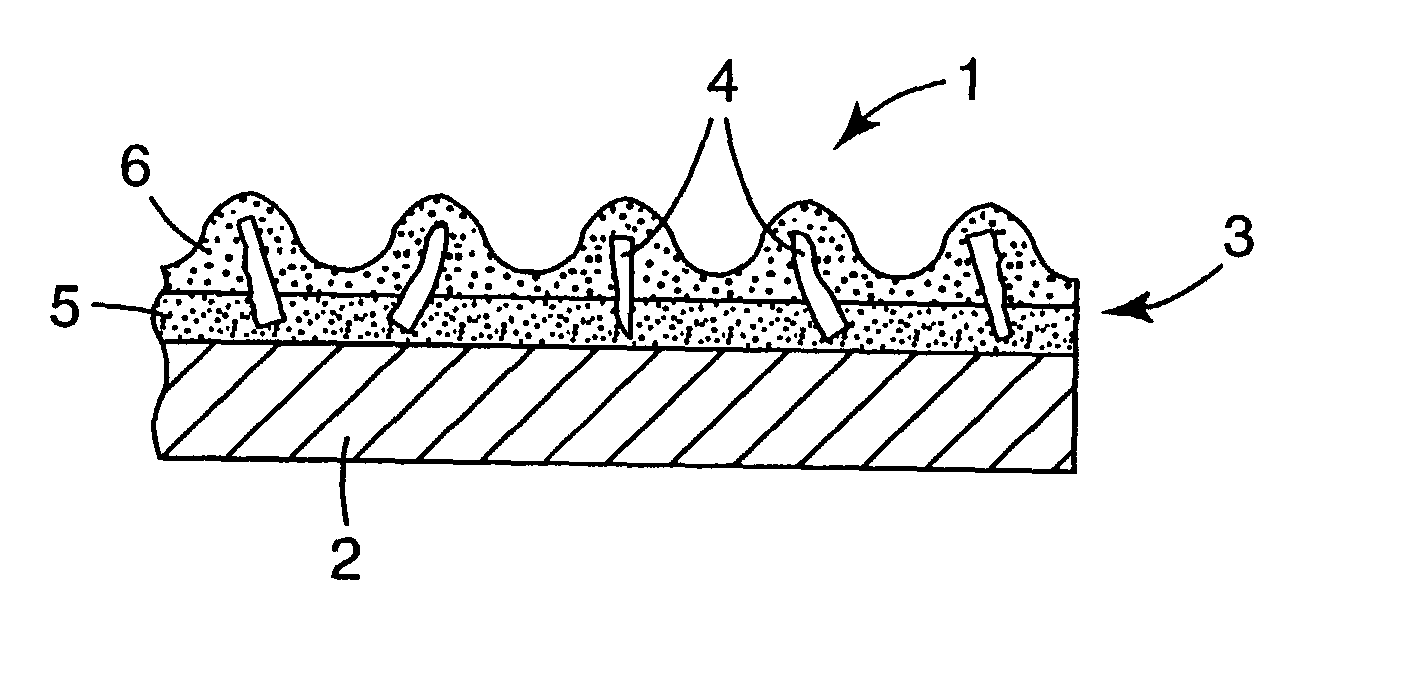

Abrasive particles and methods of making and using the same

InactiveUS20030110706A1Facilitates formation and homogeneityOxide formationPigmenting treatmentOther chemical processesOxideMetal

Abrasive particles comprising ceramic (including glasses, crystalline ceramics, and glass-ceramics) comprising (on a theoretical oxide basis) Al2O3 and at least one other metal oxide (e.g., REO and; REO and at least one of ZrO2 or HfO2) and methods of making the same. The abrasive particles can be incorporated into a variety of abrasive articles, including bonded abrasives, coated abrasives, nonwoven abrasives, and abrasive brushes.

Owner:3M INNOVATIVE PROPERTIES CO

Friction stir welding of dissimilar metals

InactiveUS20100089976A1Improve adhesionImprove joint strengthWelding/cutting media/materialsWelding/soldering/cutting articlesAdhesiveMaterials science

When a friction stir weld tool penetrates the interface of two workpieces of dissimilar metal alloy materials, the resultant weld of the different alloy materials may produce a weak weld joint. Such weak joints are often experienced, for example, when attempting to form spot welds or other friction stir welds between a magnesium alloy sheet or strip and an aluminum alloy sheet or strip. It is discovered that suitable coating compositions including an adhesive placed at the interface of assembled workpieces can alter the composition of the friction stir weld material and strengthen the resulting bond. In the example of friction stir welds between magnesium alloy and aluminum alloy workpieces, it is found that combinations of an adhesive with copper, tin, zinc, and / or other powders can strengthen the magnesium-containing and aluminum-containing friction stir weld material.

Owner:GM GLOBAL TECH OPERATIONS LLC

Abrasive particles, abrasive articles, and methods of making and using the same

InactiveUS20030115805A1Facilitates formation and homogeneityOxide formationOther chemical processesInorganic pigment treatmentAbrasive

Owner:3M INNOVATIVE PROPERTIES CO

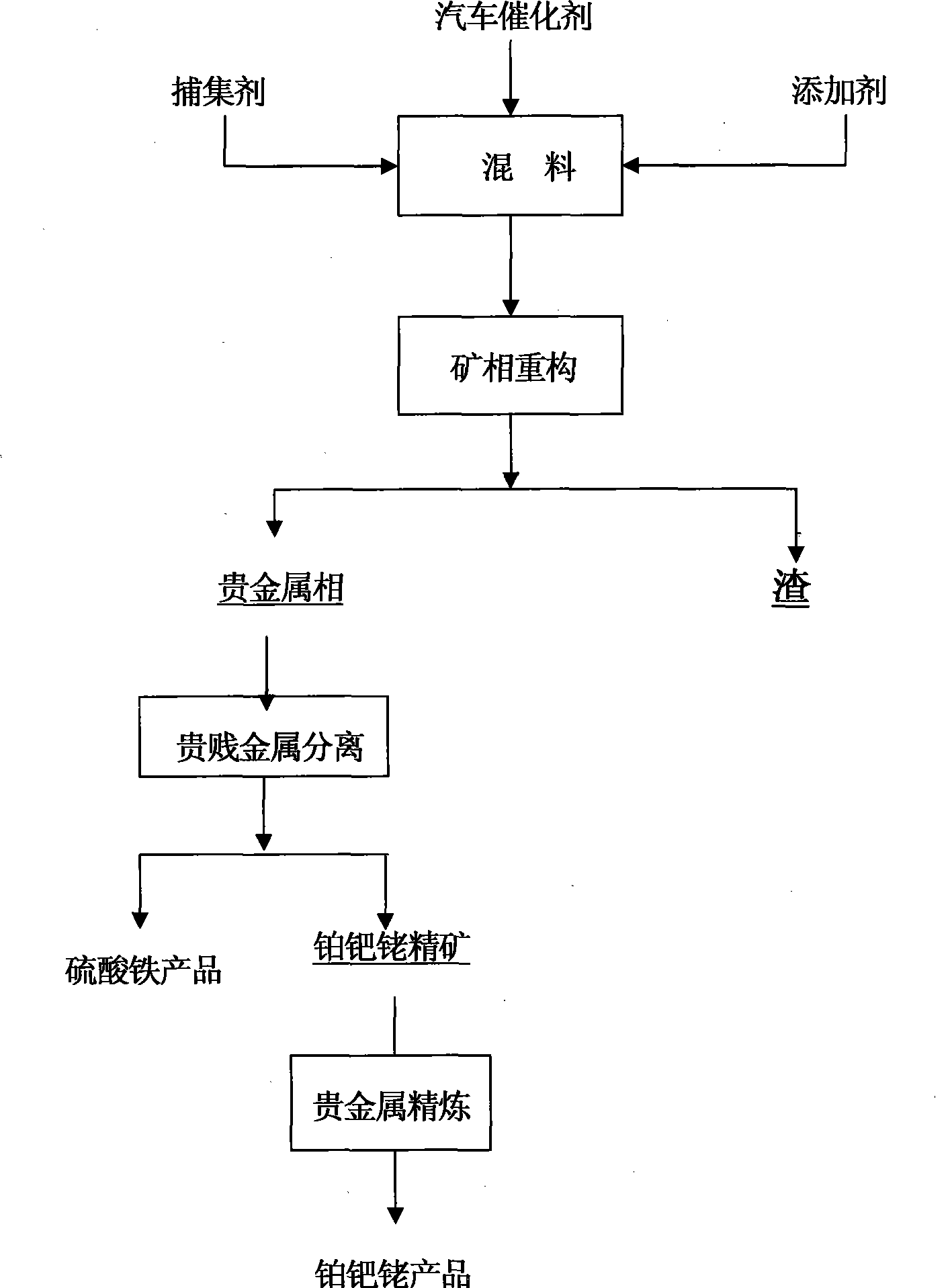

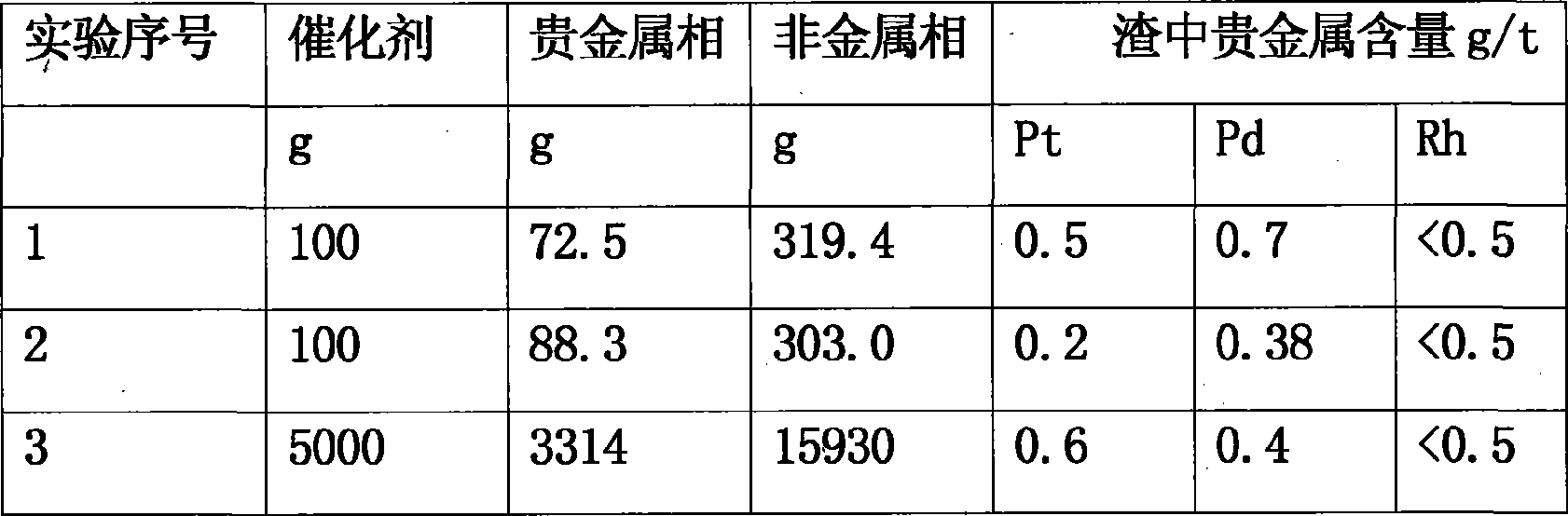

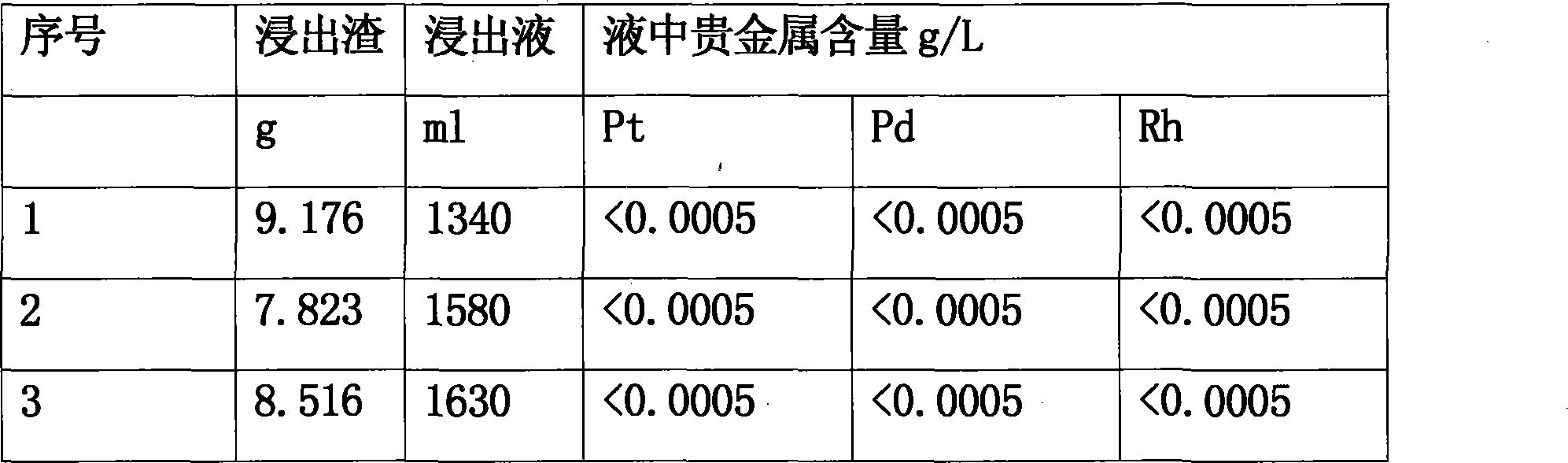

Method for extracting platinum, palladium, rhodium from automotive catalyst of ore phase reconstruction

InactiveCN101509077AEfficient captureReduce corrosionProcess efficiency improvementElectric arc furnaceSlag

The invention relates to a method for recovering noble metals from spent automotive exhaust catalysts, comprising the following processes: 1. mixing the spent automotive exhaust catalyst with a reducing agent, an additive and a trapping agent; 2. putting the mixed materials into a clay graphite crucible, and putting the clay graphite crucible into an electric furnace or an electric arc furnace for smelting, thus obtaining a noble metal phase; 3. selectively leaching base metals from the noble metal phase, thus obtaining the enrichment of the noble metal, refining the enrichment of the noble metal to produce platinum, palladium and rhodium products. The method is characterized by simple process flow and high recovery rates of noble metals. The platinum, palladium and rhodium in the waste slag are less than 1g / t and the product purity is 99.95%.

Owner:KUNMING INST OF PRECIOUS METALS

Syndiotactic rich polyolefins

Disclosed herein is a polymer comprising an amorphous syndiotactic rich polyolefin comprising greater than about 50 wt % C3-C40 alpha olefins and having about 50% to less than about 80% r dyads, based on the total number of r and m dyads present in the polymer; a heat of fusion of 10 joules / g or less according to the procedure described in ASTM E 794-85; and an ash content of 1 wt % or less. A functionalized amorphous syndiotactic rich polyolefin is also disclosed, along with methods to produce and a method to use the inventive polymer.

Owner:EXXONMOBIL CHEM PAT INC

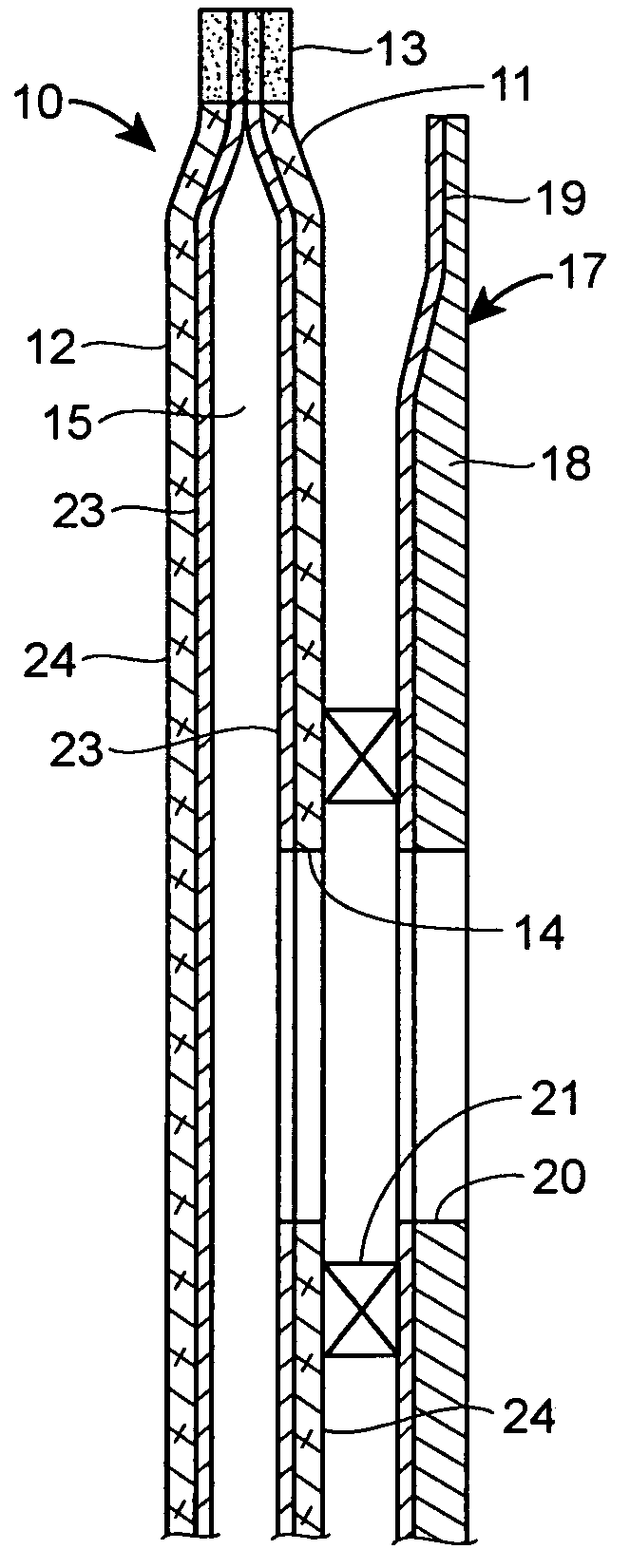

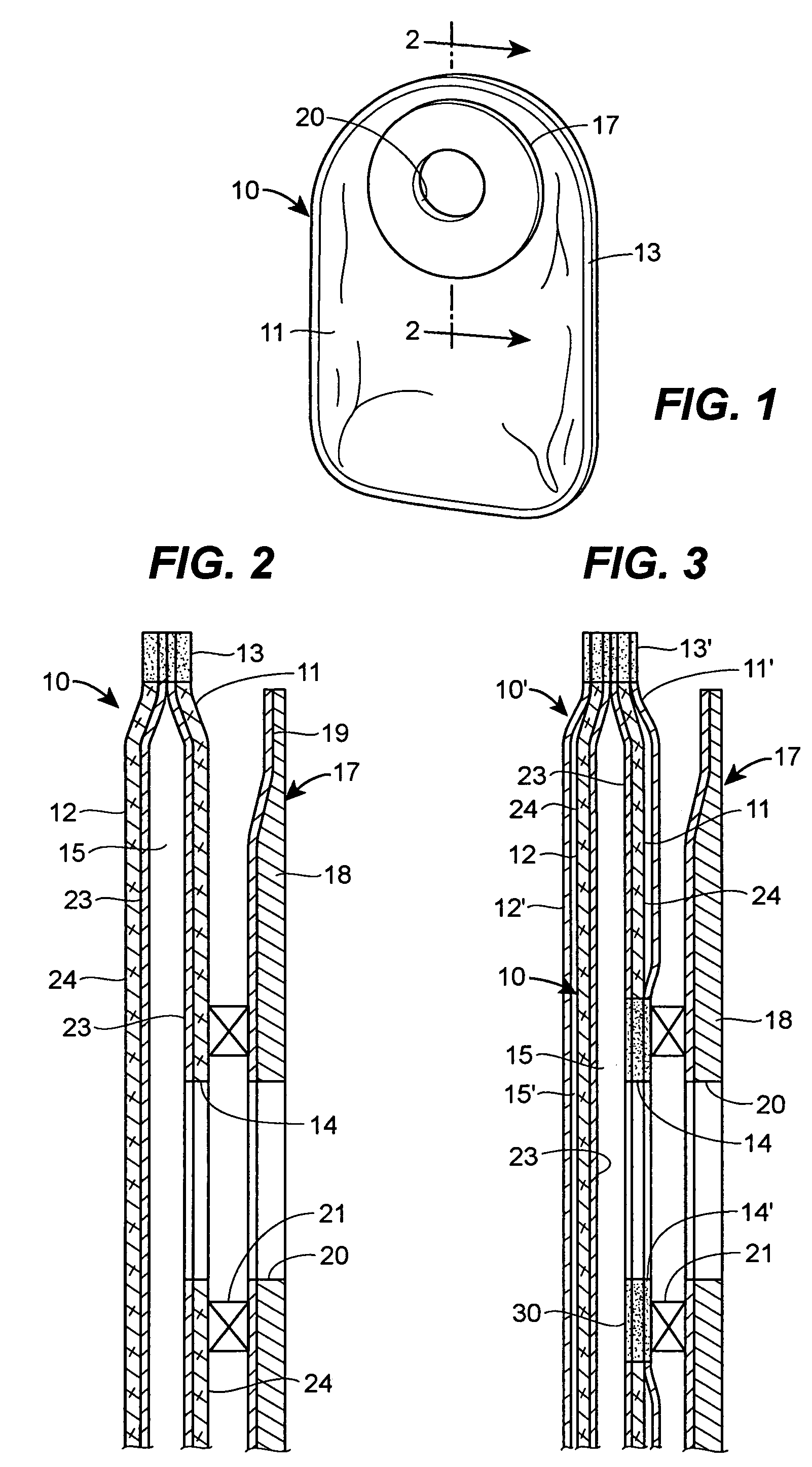

Flushable body waste collection pouch, pouch-in-pouch appliance using the same, and method relating thereto

InactiveUS7179245B2Limited biodegradabilityReduce noiseSynthetic resin layered productsNon-surgical orthopedic devicesFiberPolymer science

A biodegradable and toilet-flushable body waste collection pouch, and an appliance in which such pouch constitutes the inner pouch of a peelably separable pouch-in- pouch system, are disclosed. The walls of the inner pouch are composed of an ultra-thin, heat-sealable film impermeable to body wastes comprising a plasticized biodegradable polyester or copolyester externally covered by a soft, porous, water-disintegratable cover layer of biodegradable and water-dispersible fibers.

Owner:HOLLISTER INCORPORAED

Aluminum-alloy reflection film for optical information-recording, optical information-recording medium, and aluminum-alloy sputtering target for formation of the aluminum-alloy reflection film for optical information-recording

InactiveUS20050112019A1Lower melting temperatureImprove corrosion resistanceVacuum evaporation coatingSputtering coatingSputteringRare-earth element

There are provided an aluminum-alloy reflection film for optical information-recording, having low thermal conductivity, low melting temperature, and high corrosion resistance, capable of coping with laser marking, an optical information-recording medium comprising the reflection film described, and an aluminum-alloy sputtering target for formation of the reflection film described. The invention includes (1) an aluminum-alloy reflection film for optical information-recording, containing an element Al as the main constituent, 1.0 to 10.0 at. % of at least one element selected from the group of rare earth elements, and 0.5 to 5.0 at. % of at least one element selected from the group consisting of elements Cr, Ta, Ti, Mo, V, W, Zr, Hf, Nb, and Ni, (2) an optical information-recording medium comprising any of the aluminum-alloy reflection films described as above, and (3) a sputtering target having the same composition as that for any of the aluminum-alloy reflection films described as above.

Owner:KOBE STEEL LTD

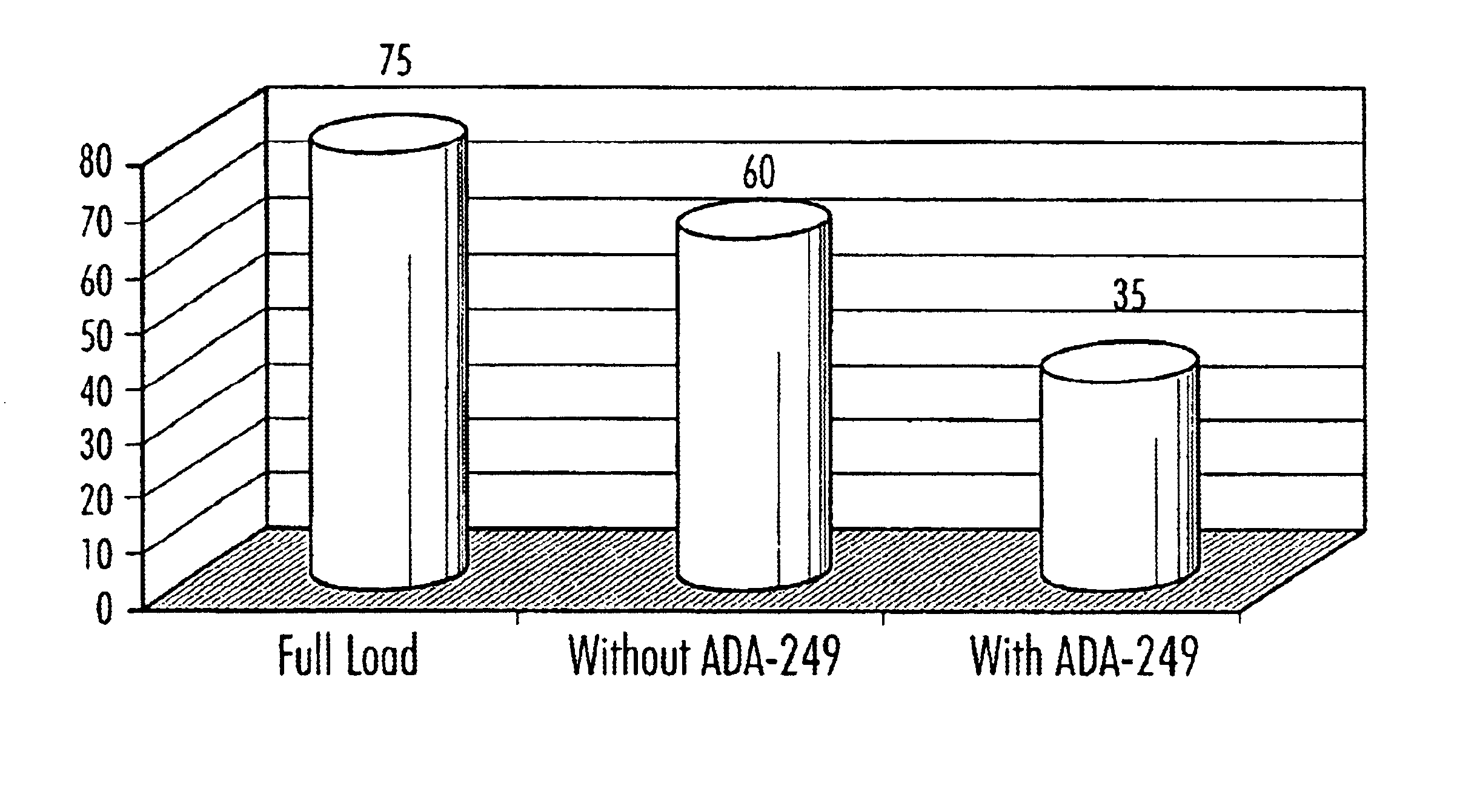

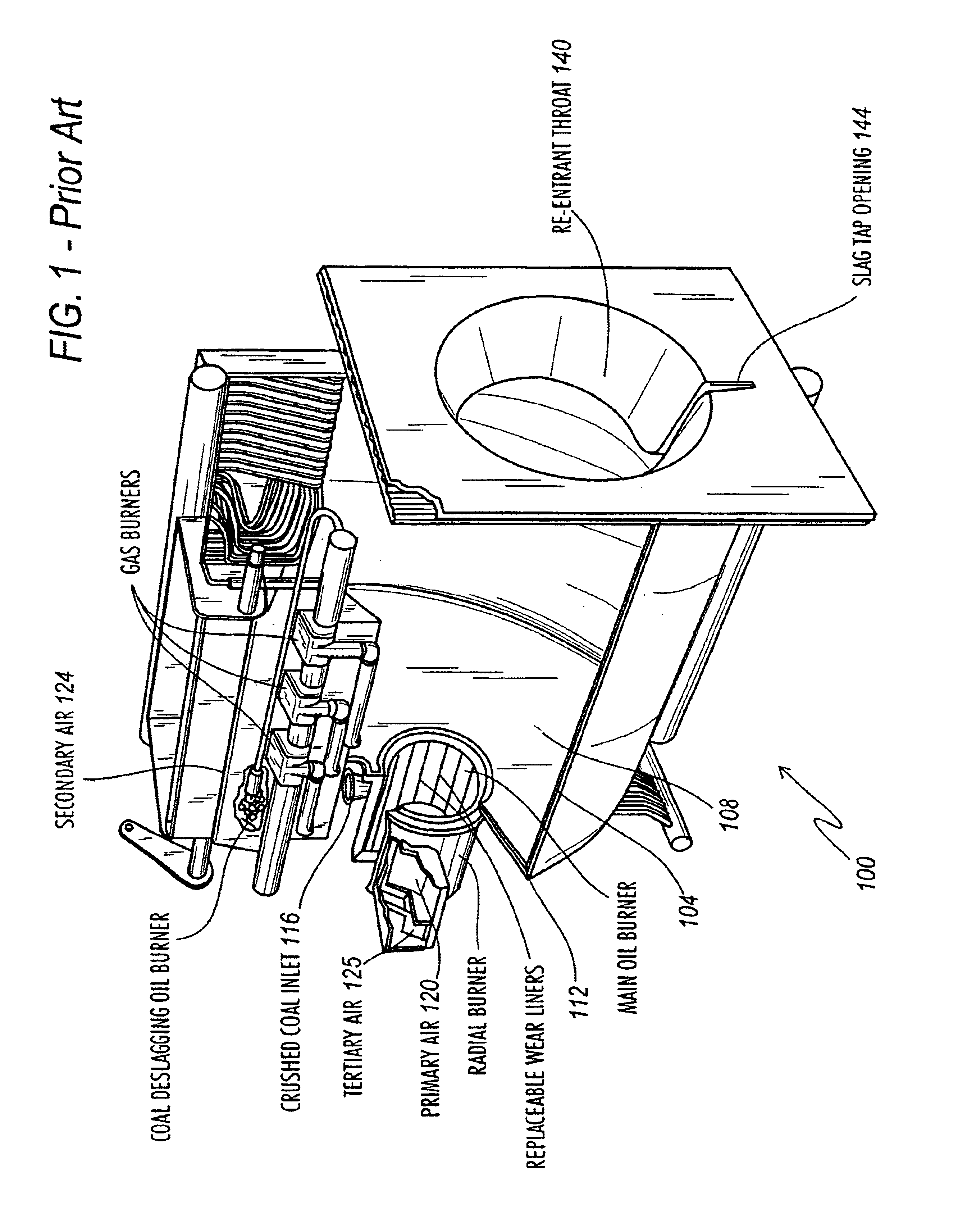

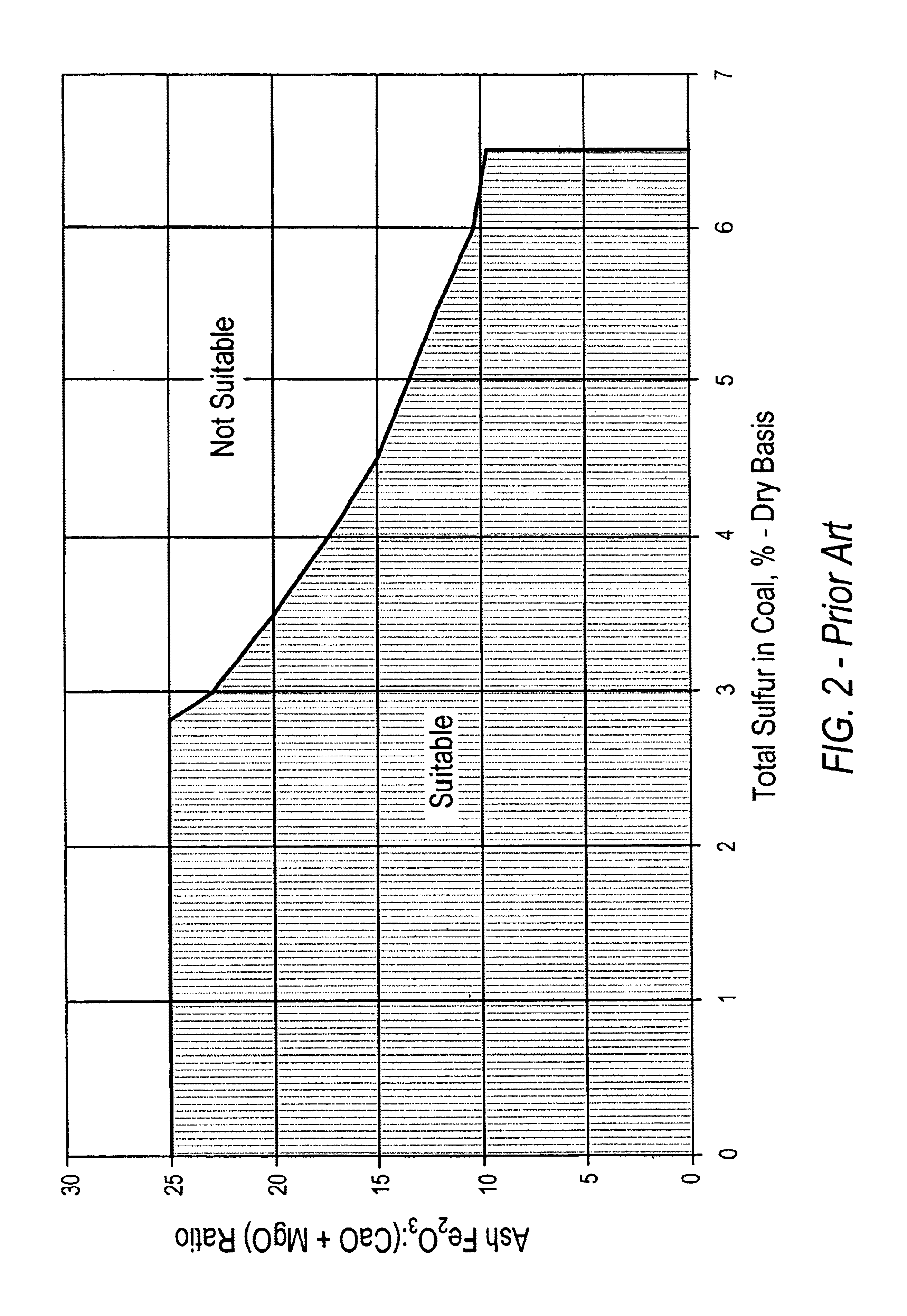

Low sulfur coal additive for improved furnace operation

InactiveUS7332002B2Improve featuresLower melting temperatureSolid fuel pretreatmentSolid fuelsSlagMelt temperature

The present invention is directed to additives for coal-fired furnaces, particularly furnaces using a layer of slag to capture coal particles for combustion. The additive(s) include iron, mineralizer(s), handling aid(s), flow aid(s), and / or abrasive material(s). The iron and mineralizers can lower the melting temperature of ash in low-iron, high alkali coals, leading to improved furnace performance.

Owner:ADA ES

Absorbent articles comprising biodegradable PHA copolymers

InactiveUS6160199AProtect and promote and control plant growthRaise the ratioSynthetic resin layered productsBaby linensBiodegradable copolymersPolymer chemistry

The present invention relates to biodegradable PHA copolymers comprising at least two randomly repeating monomer units. The present invention further relates to a plastic article comprising a biodegradable copolymer, wherein the biodegradable copolymer comprises at least two randomly repeating monomer units (RRMU) wherein the first RRMU has the structure wherein R1 is H, or C1 or C2 alkyl, and n is 1 or 2; the second RRMU has the structure and wherein at least 50% of the RRMUs have the structure of the first RRMU. The present invention further relates to an absorbent article comprising a liquid pervious topsheet, a liquid impervious backsheet comprising a film comprising a PHA of the present invention and an absorbent core positioned between the topsheet and the backsheet.

Owner:DANIMER IPCO LLC

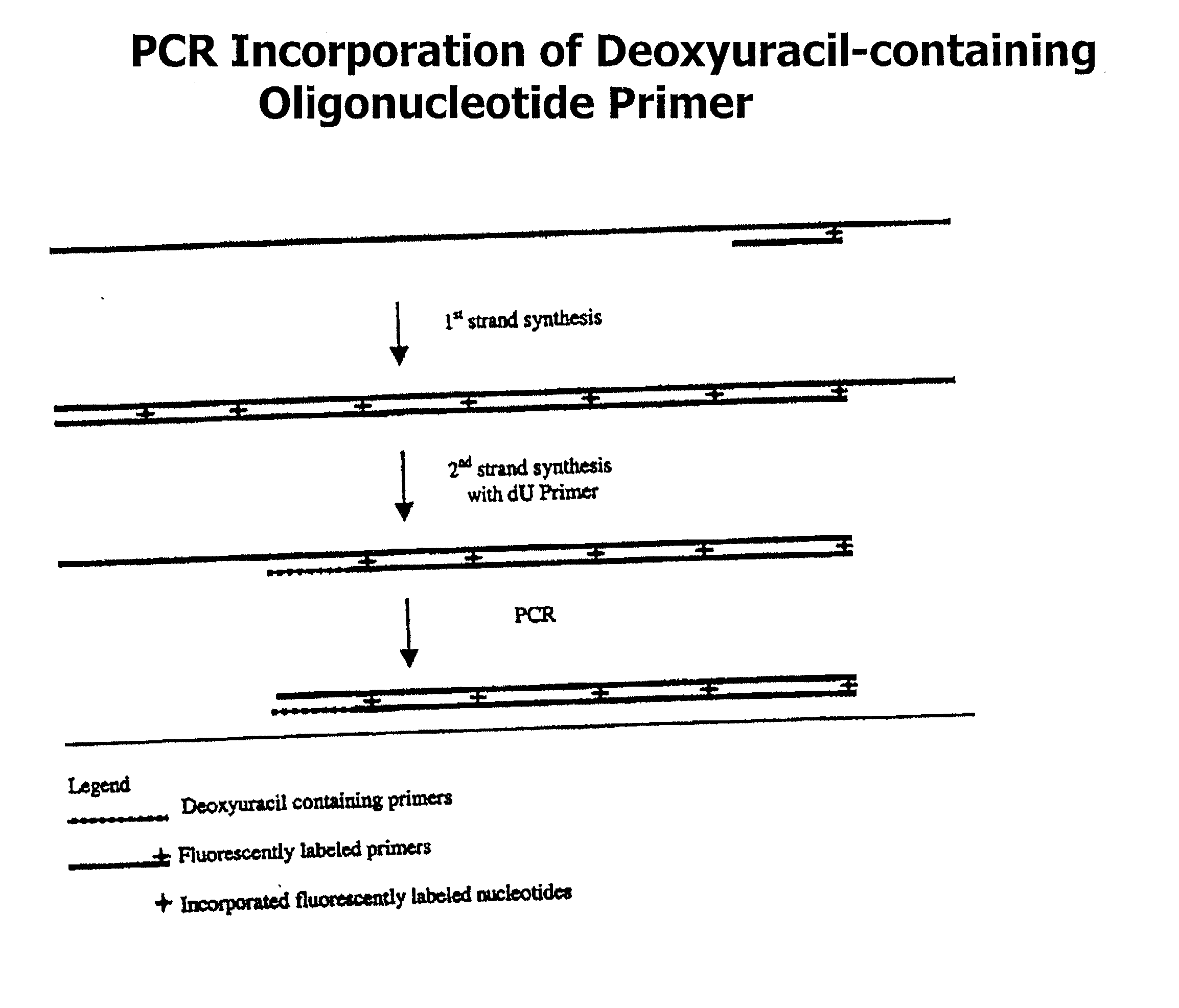

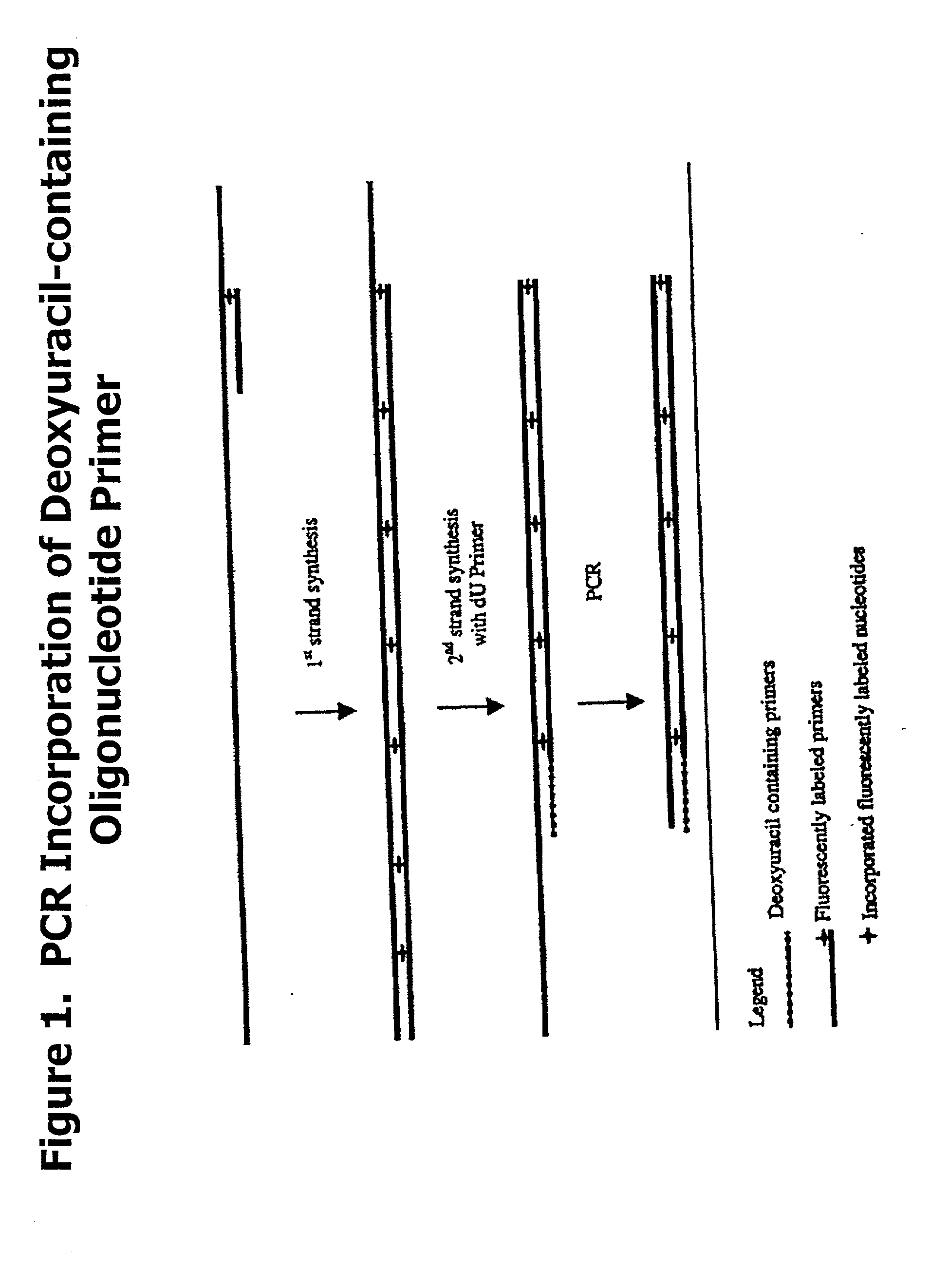

Partially double-stranded nucleic acids, methods of making, and use thereof

InactiveUS20020127575A1Accurate comparisonLower melting temperatureMicrobiological testing/measurementFermentationNucleic acid sequencingSingle strand

A process is disclosed for generating at least one partially double-stranded target nucleic acid, which contains at least one single-stranded region at a terminal end. The process comprises the steps of (a) providing at least one primer, P1, containing at least one labile nucleotide; (b) combining at least one target nucleic acid sequence with P1 to generate a double-stranded polynucleotide containing at least one labile nucleotide; (c) exposing the double-stranded polynucleotide to conditions that promote single-strand cleavage of the polynucleotide at the site of the at least one labile nucleotide of primer P1; and (d) exposing the cleaved polynucleotide to conditions that promote the dissociation of the cleaved portions of primer P1 from a terminal end. The labile nucleotide may be dUTP, wherein the single-stranded cleavage of the polynucleotide at the site of the labile nucleotide occurs by treatment with uracil N-glycosylase.

Owner:HOKE GLENN +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com