Patents

Literature

2767results about How to "Degree of reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

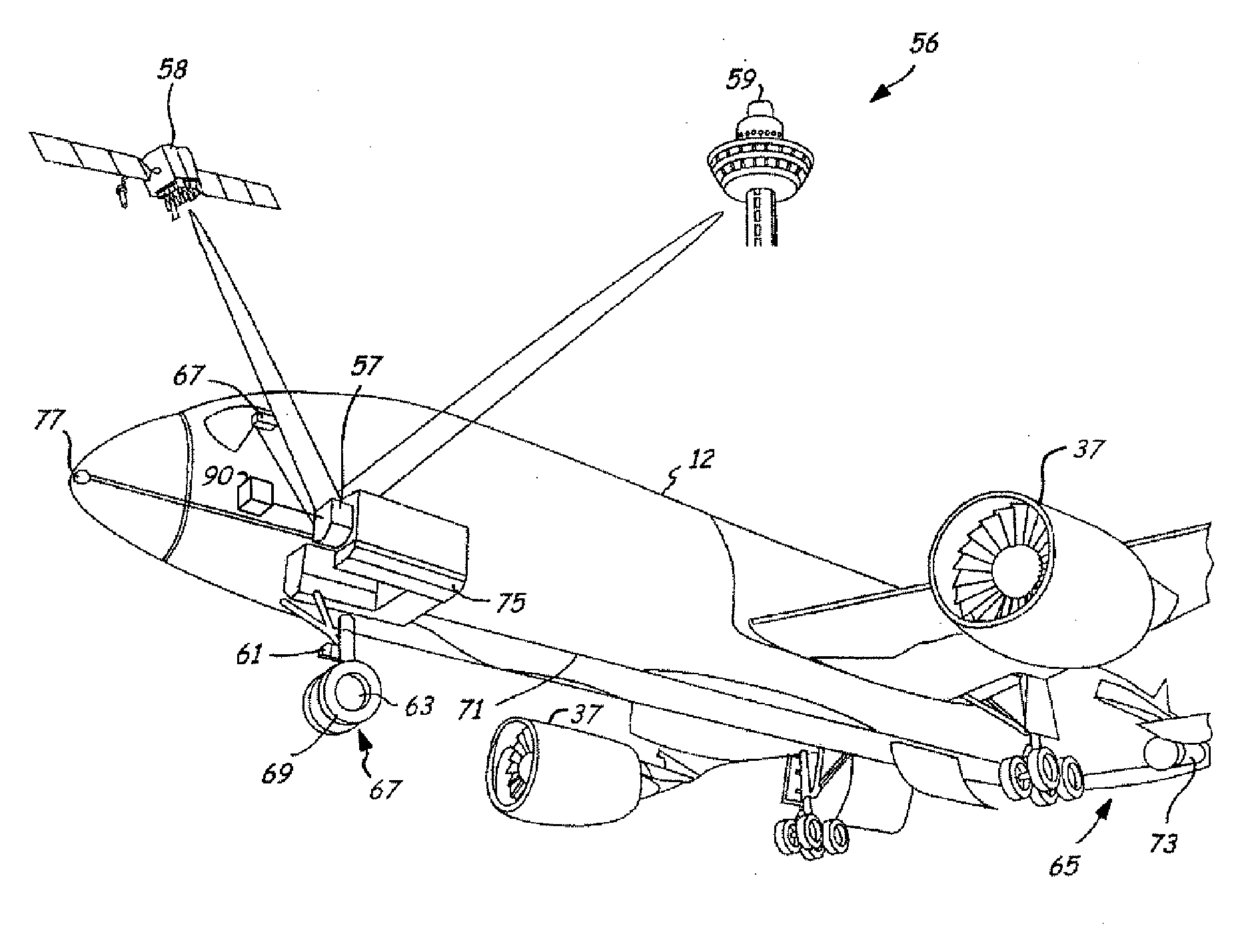

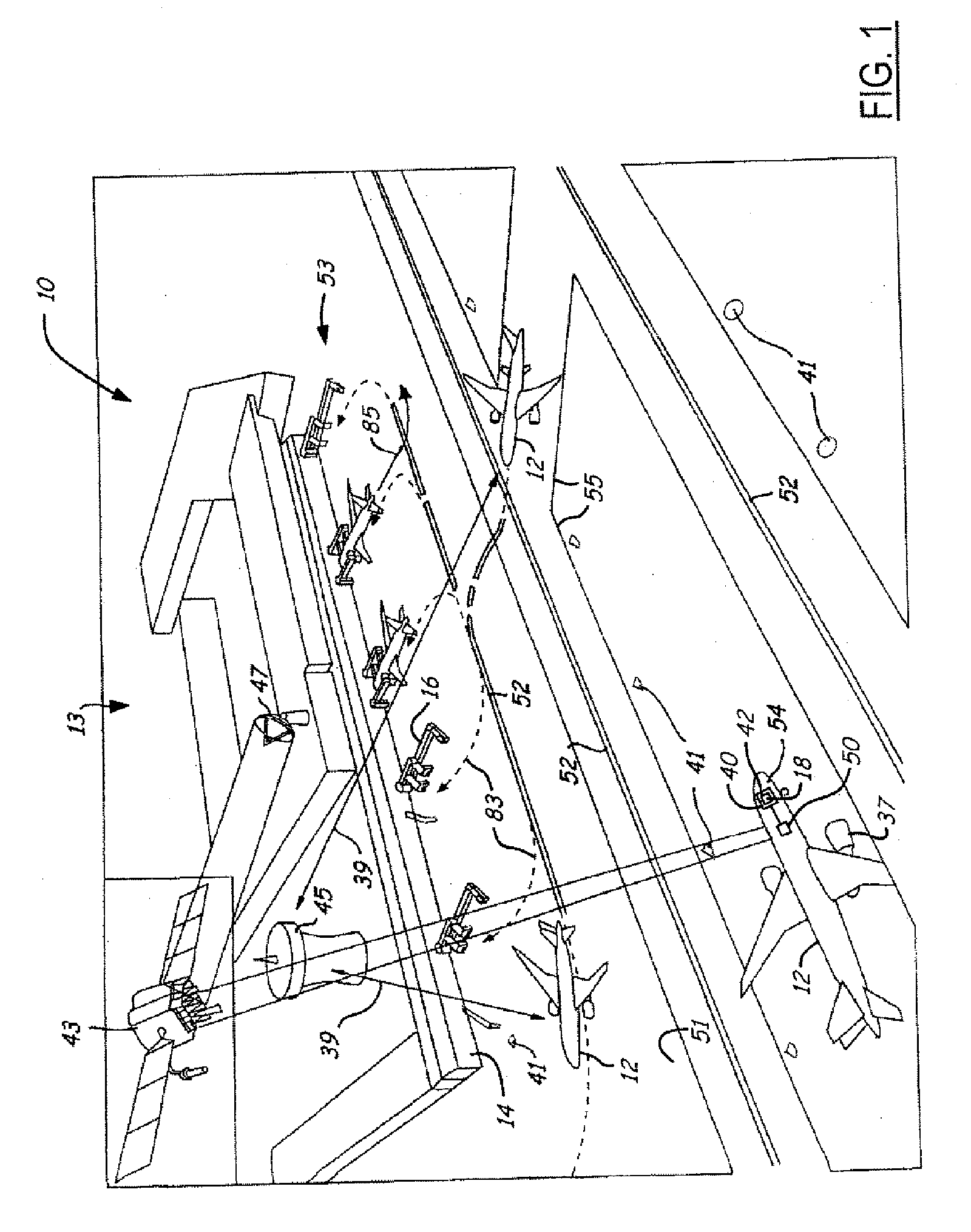

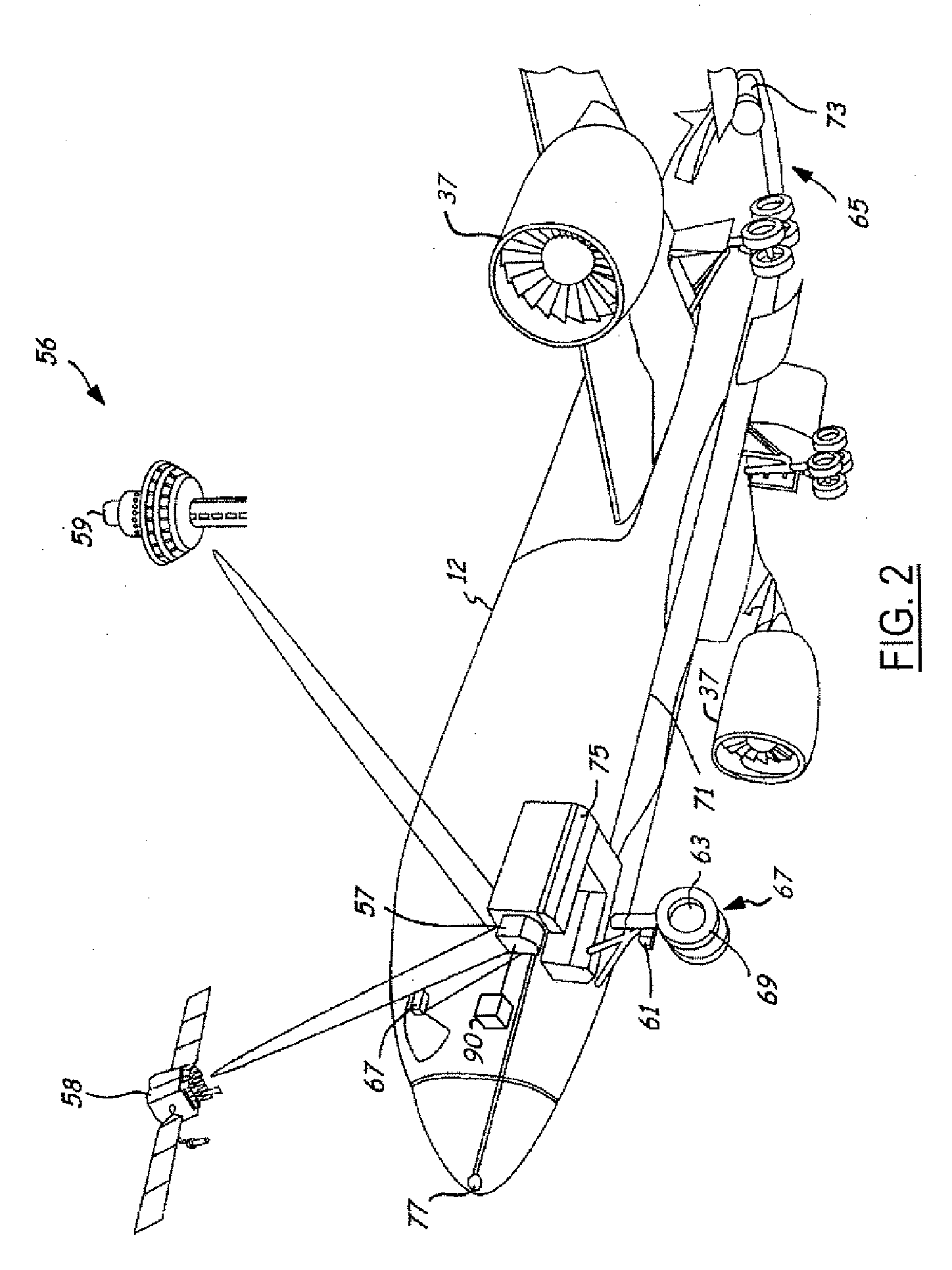

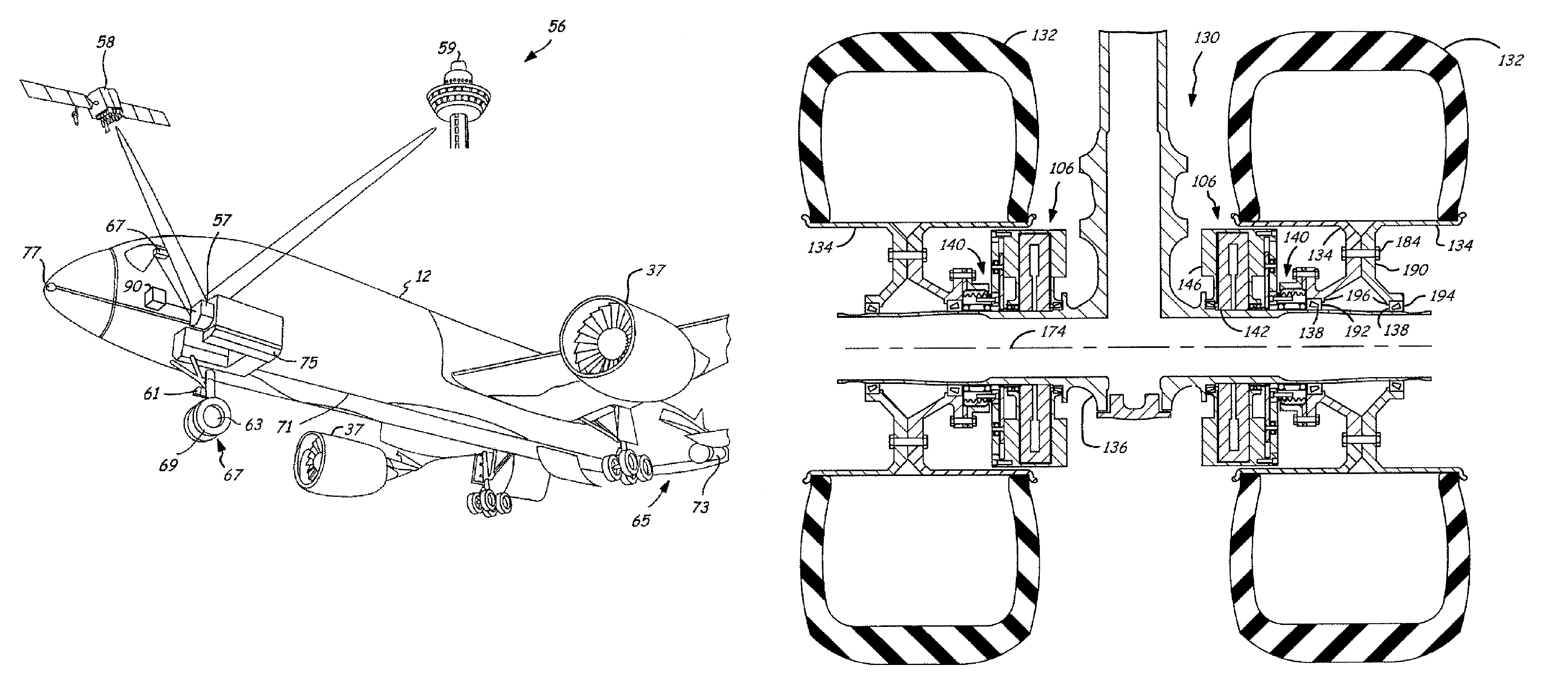

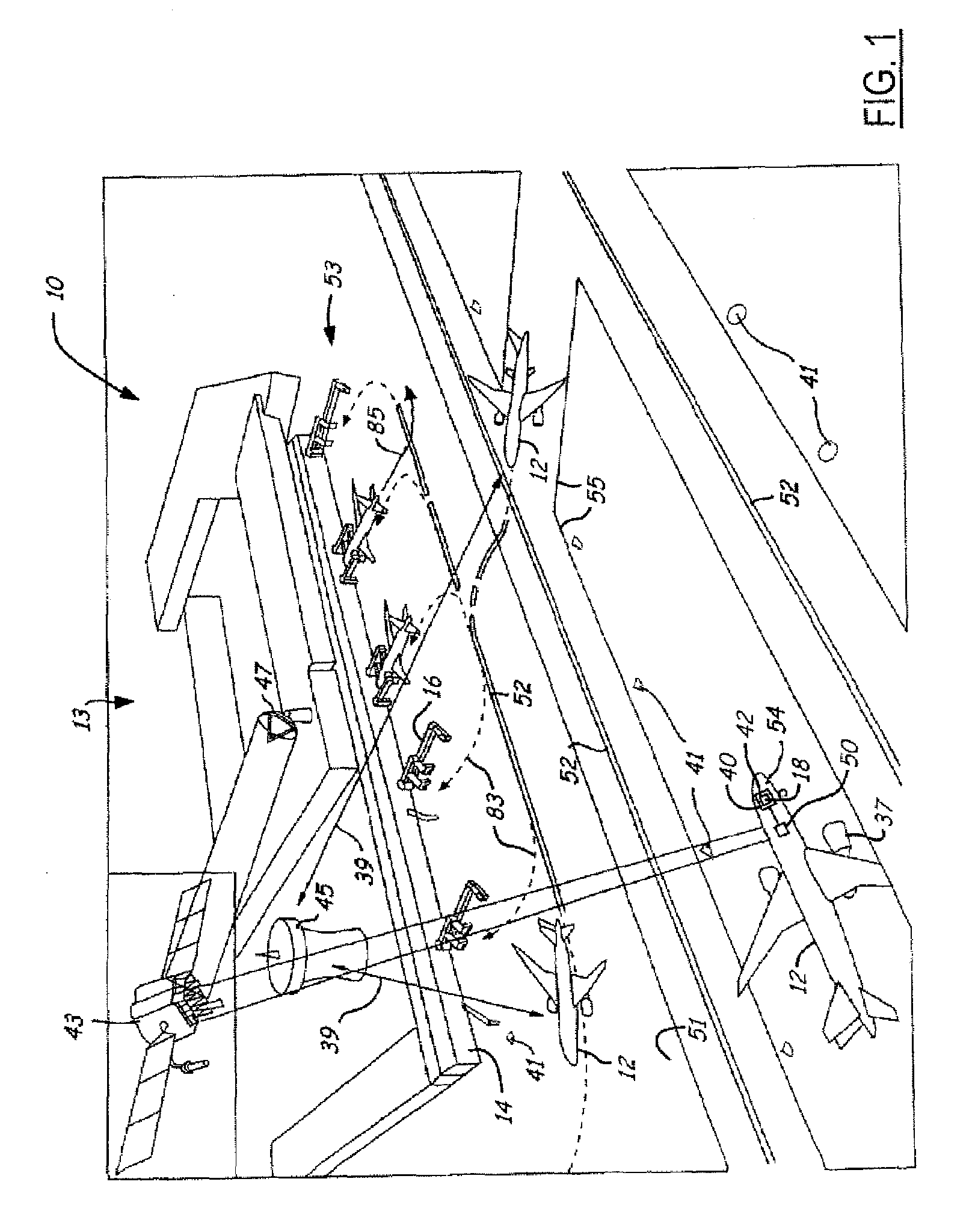

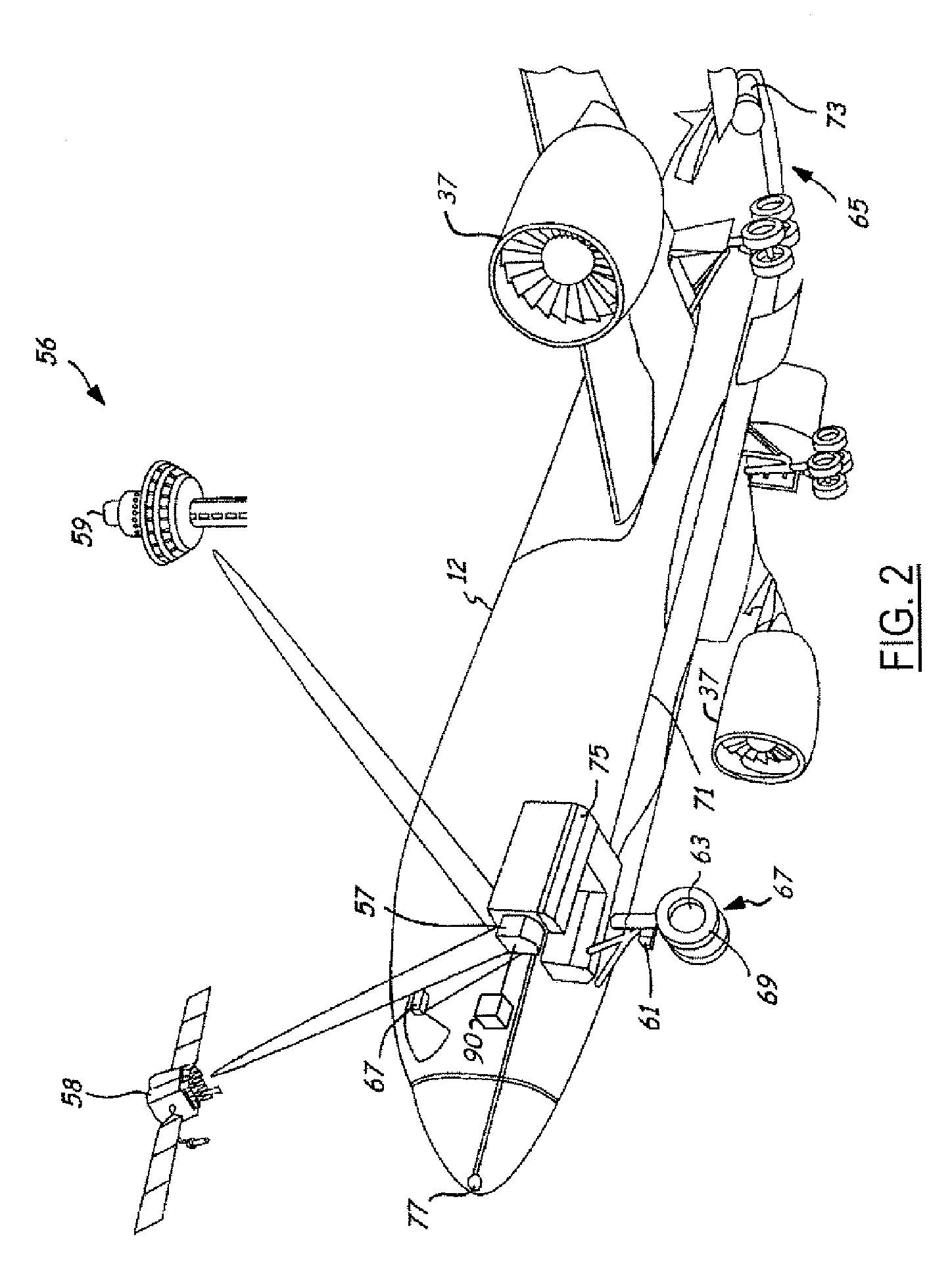

Powered nose aircraft wheel system

InactiveUS20060065779A1Improve productivityEfficiently useLiquid handling installationsEnergy efficient operational measuresAutomotive engineeringAirplane

A powered nose aircraft wheel system (130) for an aircraft (12) includes landing gear (104) that extends from the aircraft (12). A wheel axel (136) is coupled to the landing gear (104). A wheel (134) is coupled to the wheel axel (136). A wheel motor (106) is coupled to the wheel axel (136) and the wheel (134). A controller (120) is coupled to the wheel motor (106) and rotates the wheel (134). A method of taxiing an aircraft (12) includes permitting the wheel (134) of the aircraft (12) to freely spin during the landing of the aircraft (12). Power is transferred from an auxiliary power unit (73) of the aircraft (12) to the wheel motor (106). The wheel (134) is rotated via the wheel motor (106). The aircraft (12) is steered and the speed of the wheel (134) is controlled via one or more controllers selected from an onboard controller (18, 118, 120) and an offboard controller (45, 58, 59).

Owner:THE BOEING CO

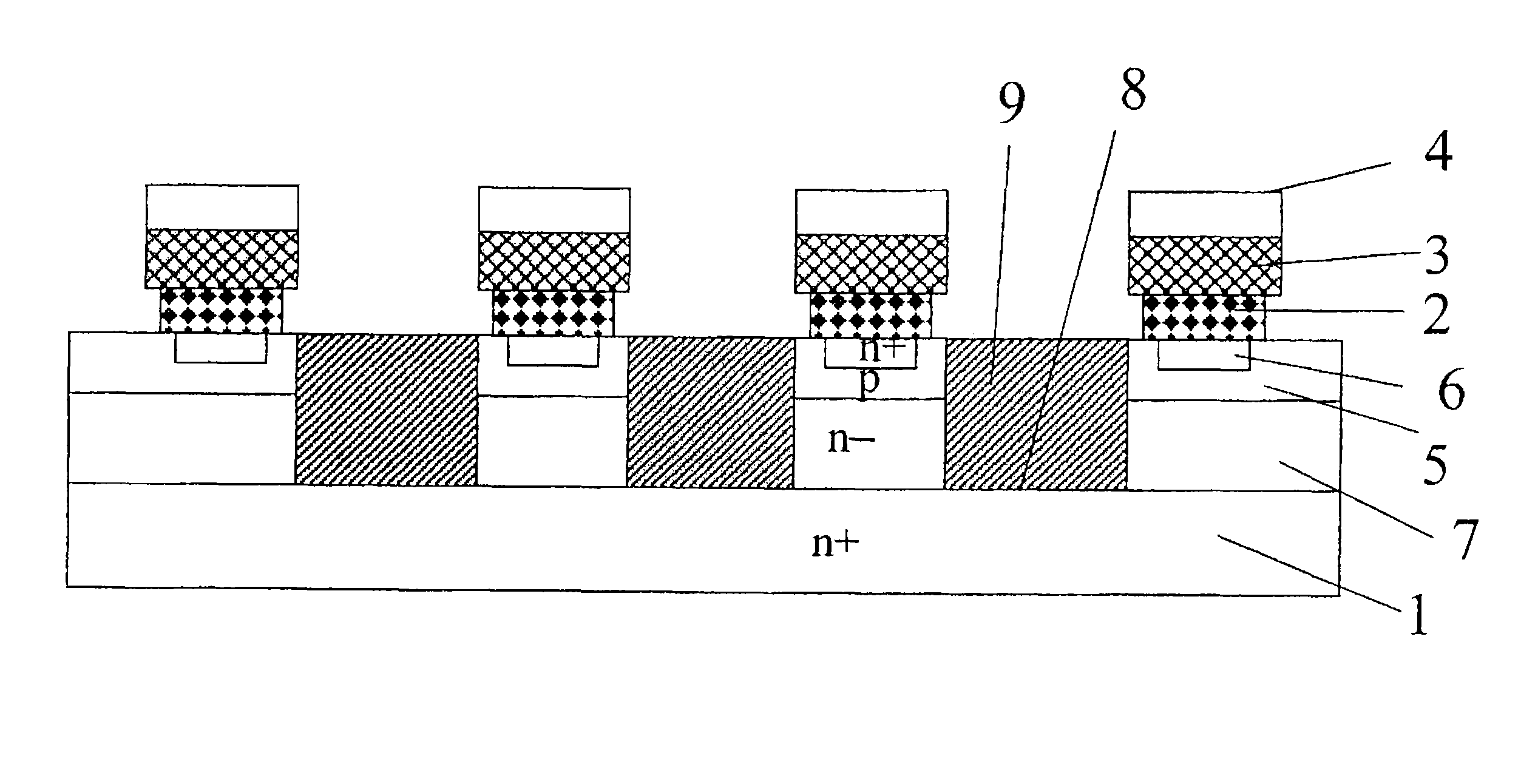

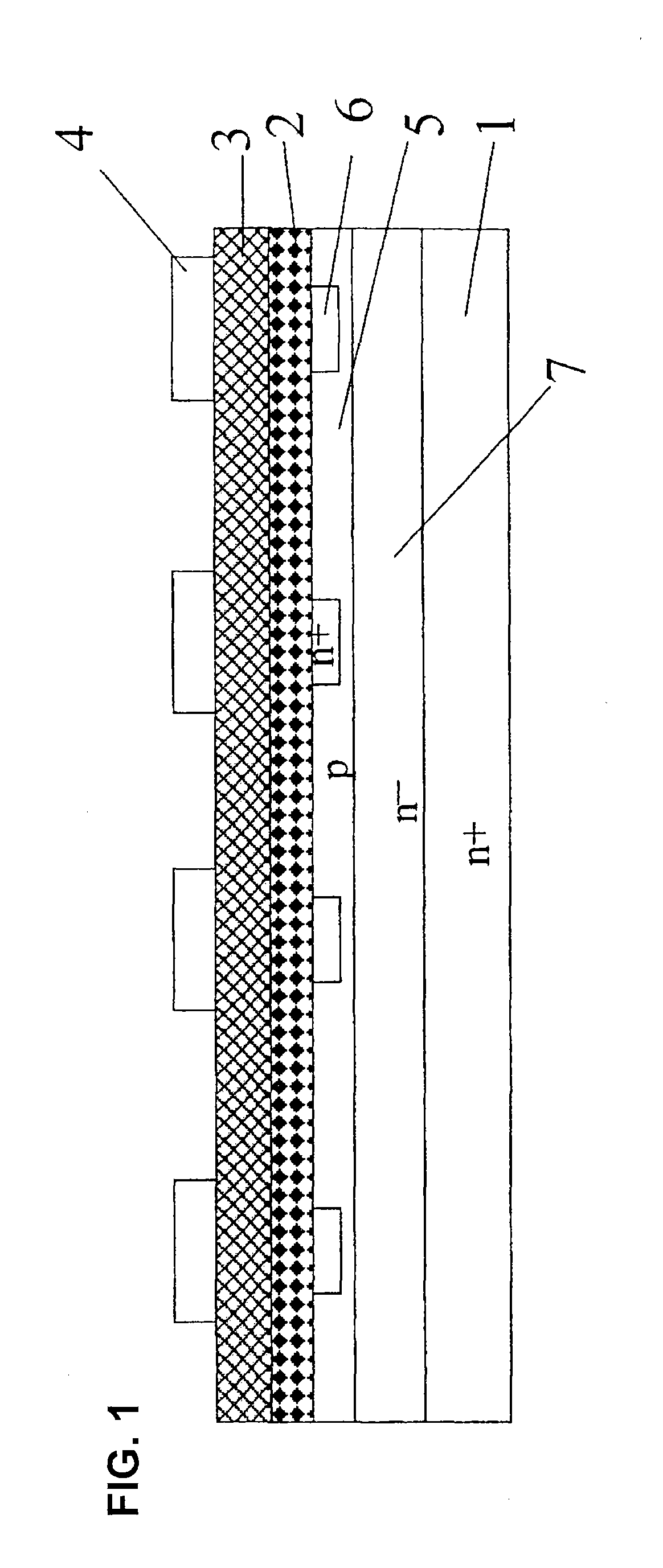

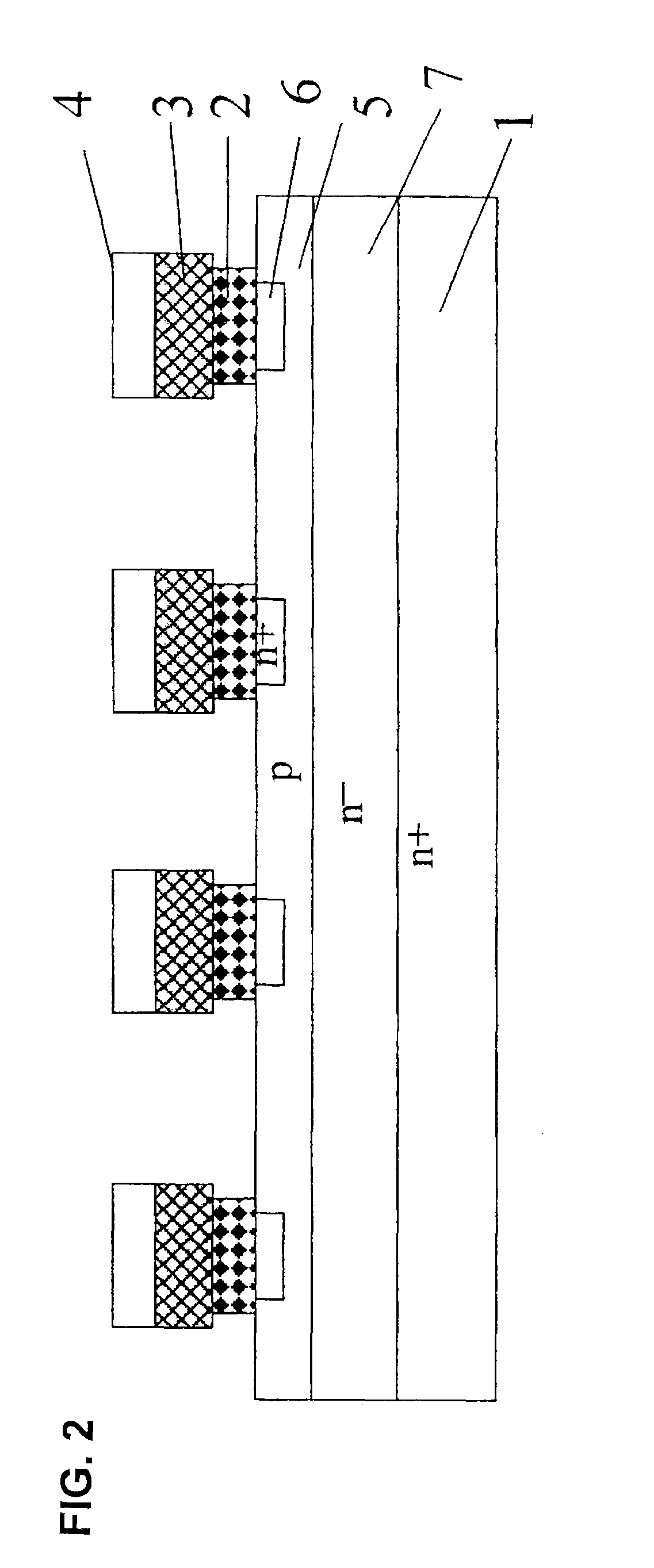

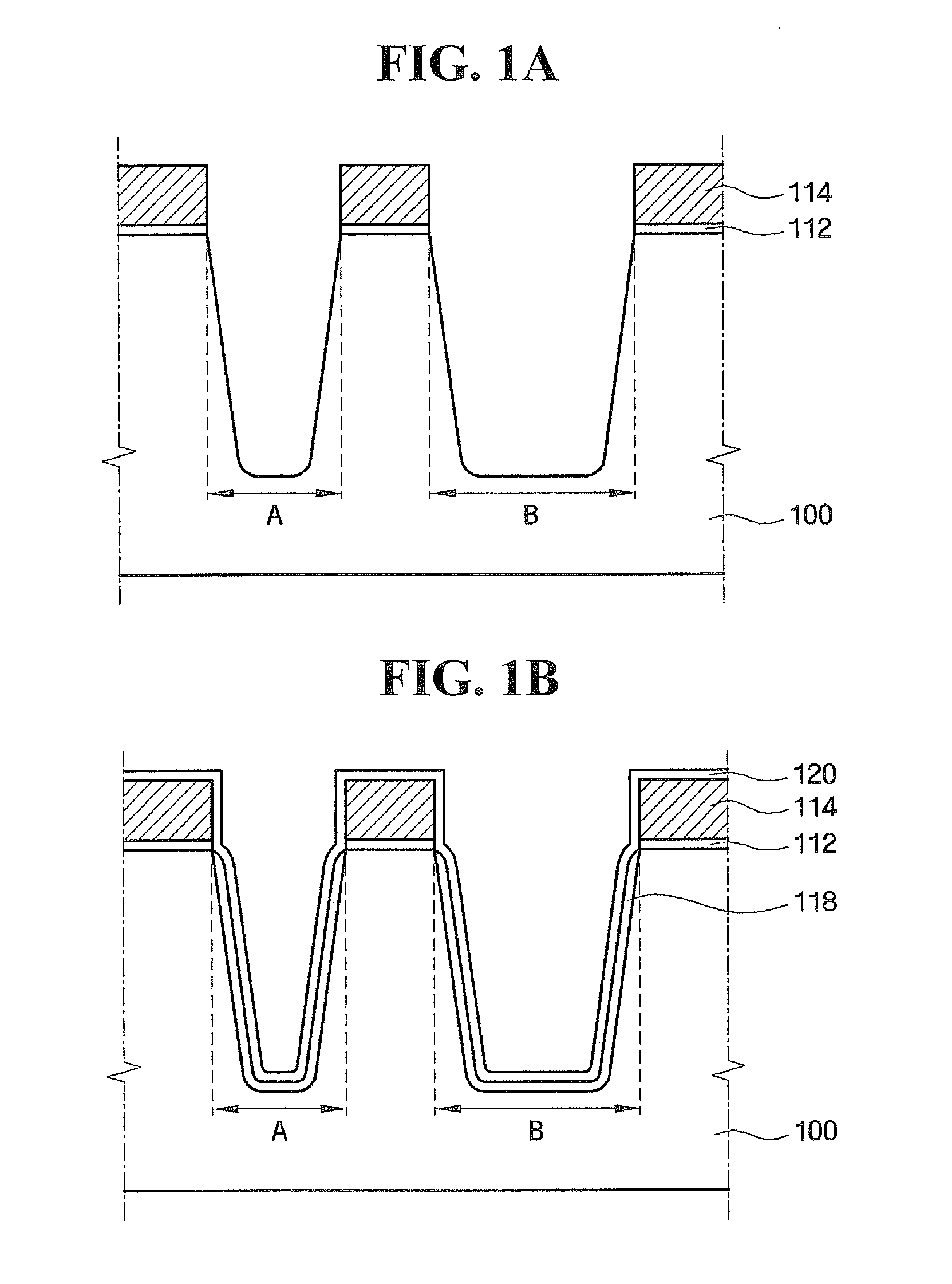

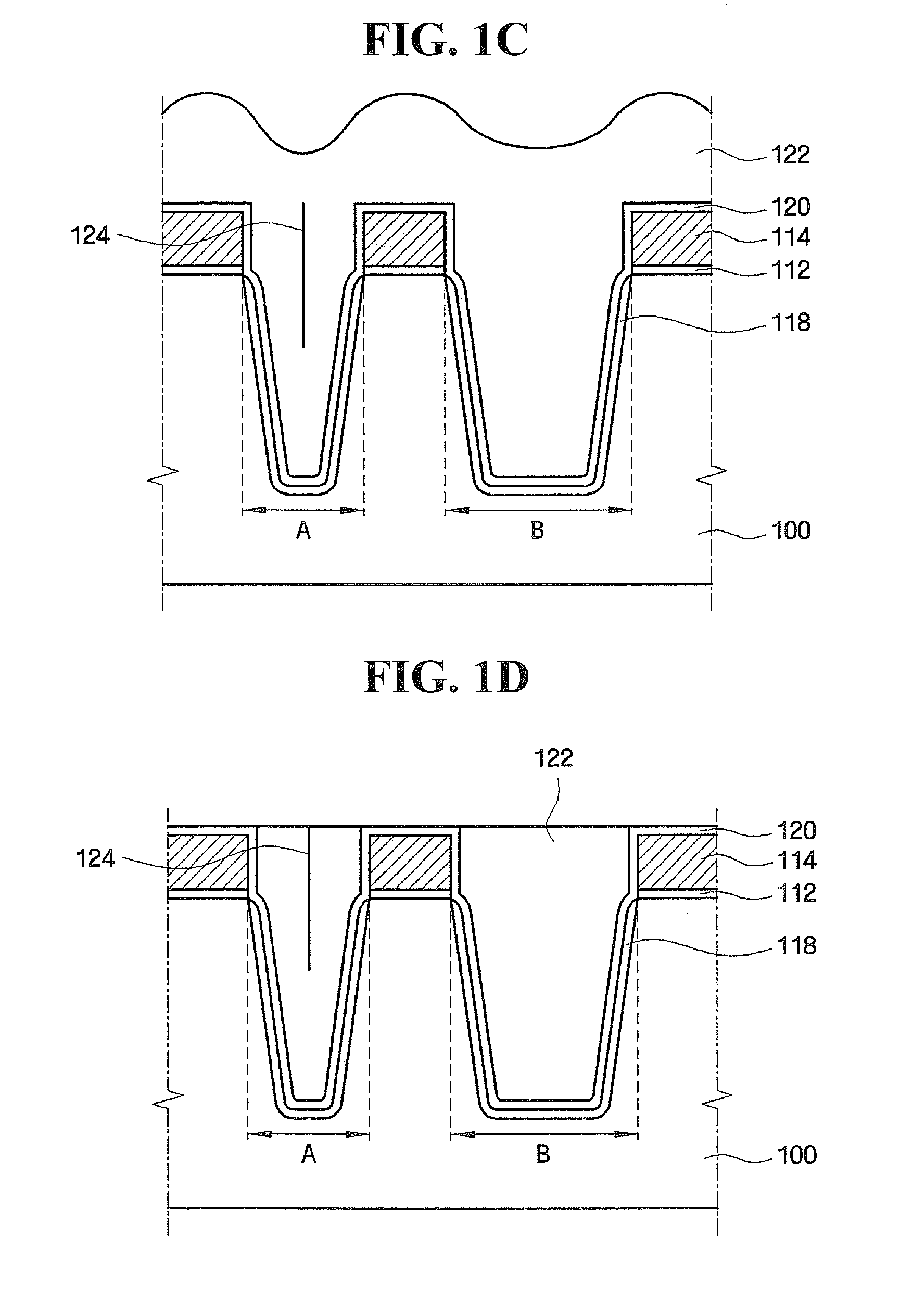

Manufacturing method of a silicon carbide semiconductor device

InactiveUS8071482B2Smooth curveImprove breakdown voltageSemiconductor/solid-state device detailsSolid-state devicesSemiconductorDry etching

A manufacturing method for a silicon carbide semiconductor device is disclosed. It includes an etching method in which an Al film and Ni film are laid on an SiC wafer in this order and wet-etched, whereby a two-layer etching mask is formed in which Ni film portions overhang Al film portions. Mesa grooves are formed by dry etching by using this etching mask.

Owner:FUJI ELECTRIC CO LTD

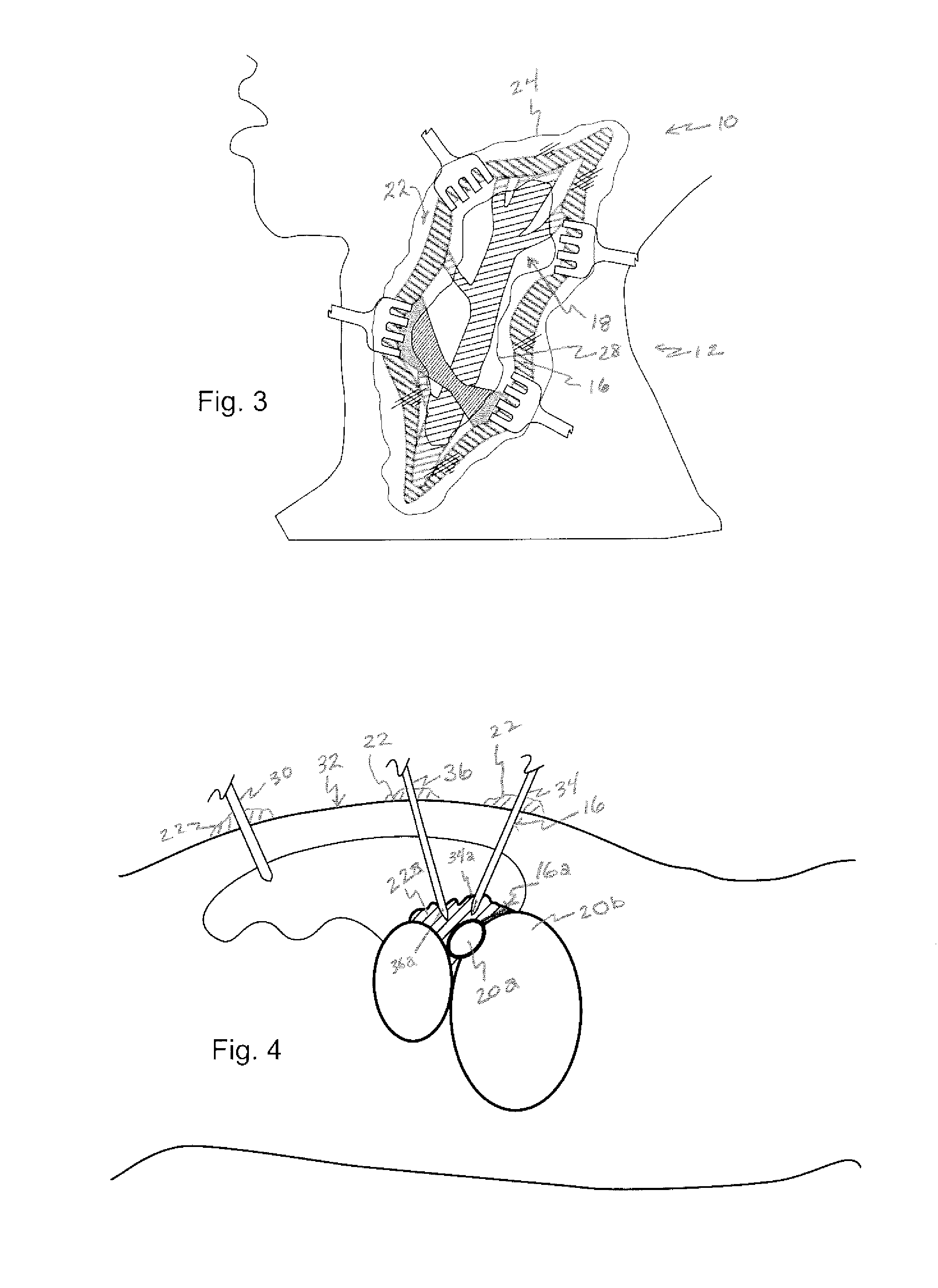

Powered nose aircraft wheel system

InactiveUS7445178B2Improves arrival and departure efficiency and productivityEasy to useLiquid handling installationsEnergy efficient operational measuresNoseAuxiliary power unit

A powered nose aircraft wheel system (130) for an aircraft (12) includes landing gear (104) that extends from the aircraft (12). A wheel axel (136) is coupled to the landing gear (104). A wheel (134) is coupled to the wheel axel (136). A wheel motor (106) is coupled to the wheel axel (136) and the wheel (134). A controller (120) is coupled to the wheel motor (106) and rotates the wheel (134). A method of taxiing an aircraft (12) includes permitting the wheel (134) of the aircraft (12) to freely spin during the landing of the aircraft (12). Power is transferred from an auxiliary power unit (73) of the aircraft (12) to the wheel motor (106). The wheel (134) is rotated via the wheel motor (106). The aircraft (12) is steered and the speed of the wheel (134) is controlled via one or more controllers selected from an onboard controller (18, 118, 120) and an offboard controller (45, 58, 59).

Owner:THE BOEING CO

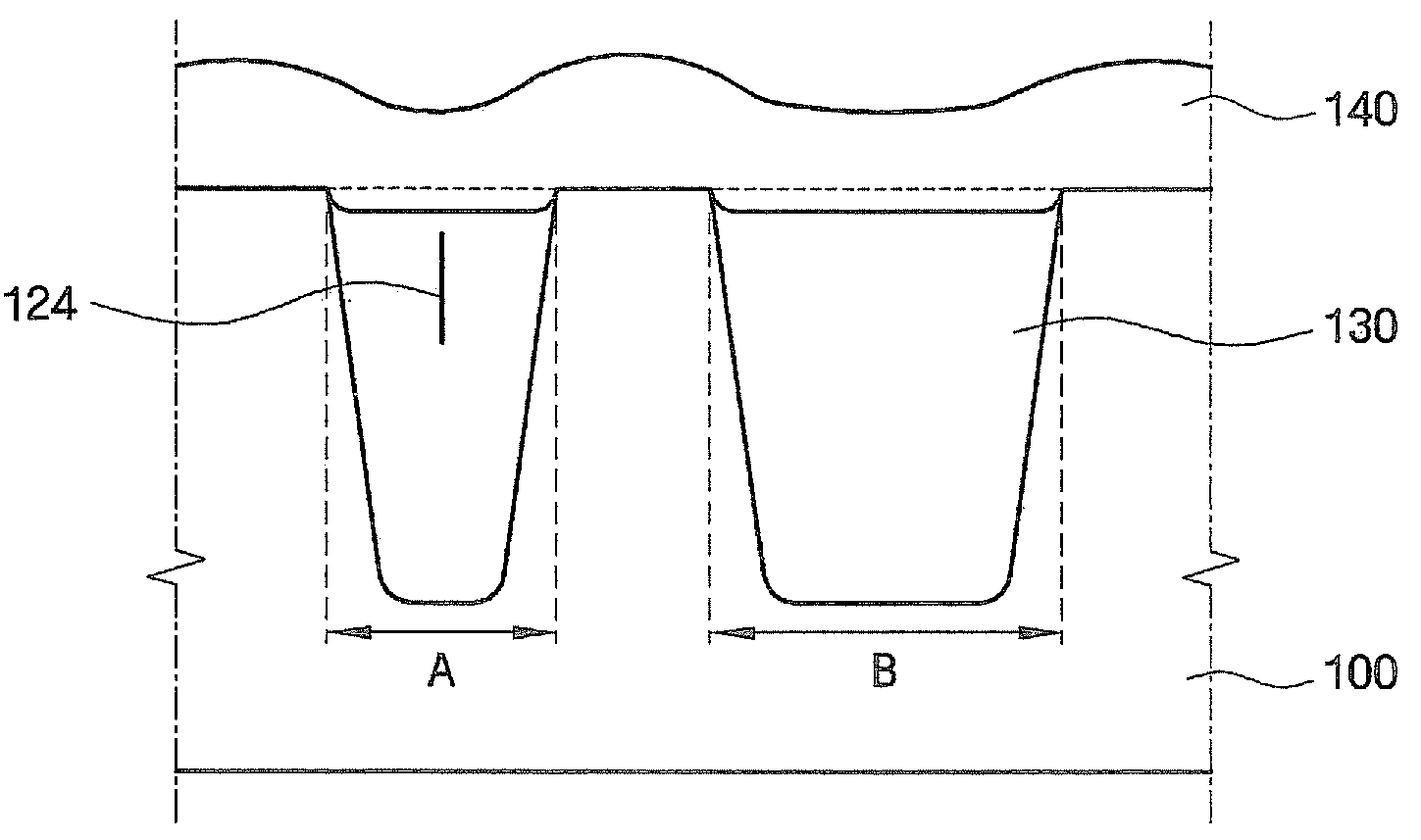

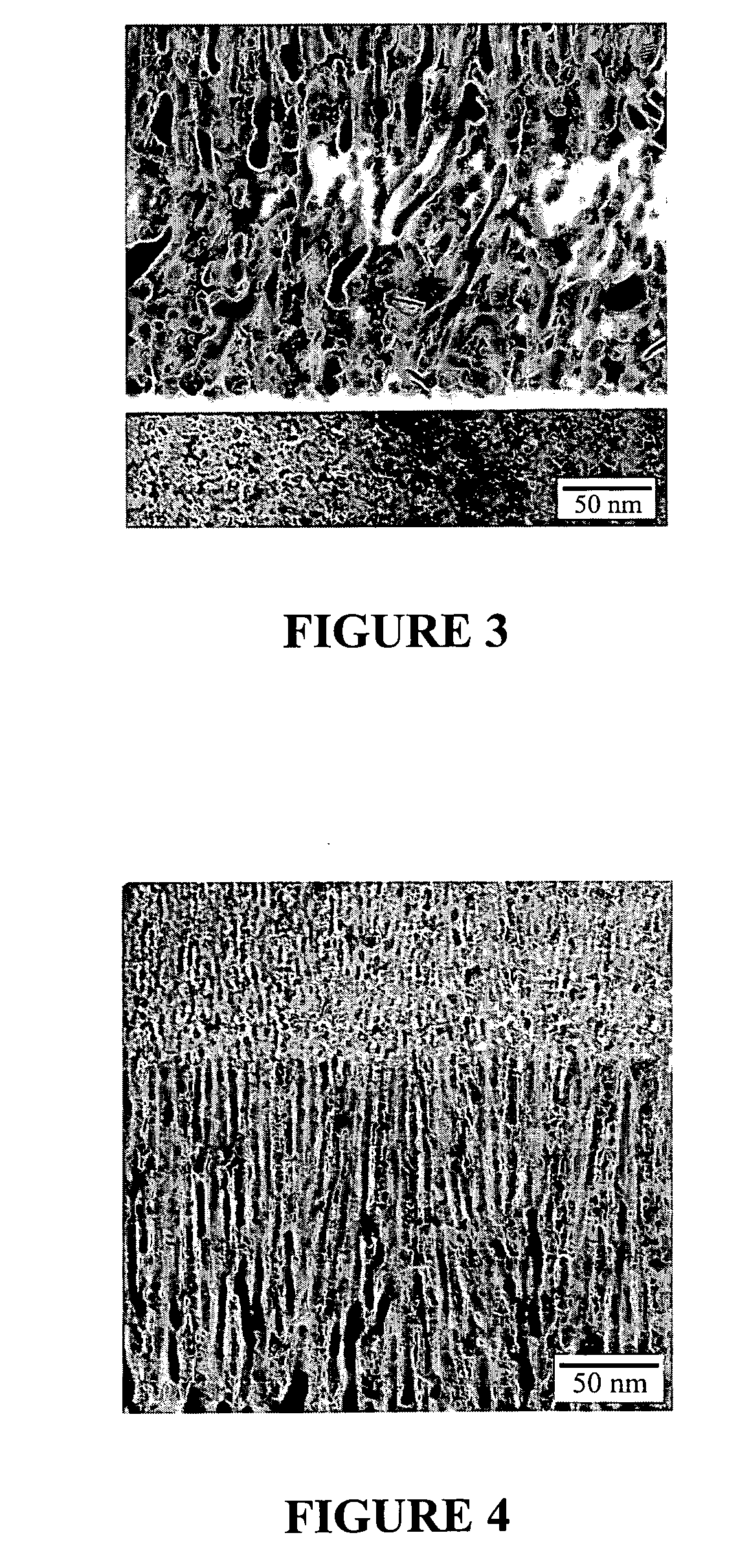

Methods of Forming Integrated Circuit Devices Having Ion-Cured Electrically Insulating Layers Therein

ActiveUS20090098706A1Quality improvementDegree of reductionSemiconductor/solid-state device manufacturingAtomic orderEngineering

Methods of forming integrated circuit devices include forming a trench in a surface of semiconductor substrate and filling the trench with an electrically insulating region having a seam therein. The trench may be filled by depositing a sufficiently thick electrically insulating layer on sidewalls and a bottom of the trench. Curing ions are then implanted into the electrically insulating region at a sufficient energy and dose to reduce a degree of atomic order therein. The curing ions may be ones selected from a group consisting of nitrogen (N), phosphorus (P), boron (B), arsenic (As), carbon (C), argon (Ar), germanium (Ge), helium (He), neon (Ne) and xenon (Xe). These curing ions may be implanted at an energy of at least about 80 KeV and a dose of at least about 5×1014 ions / cm2. The electrically insulating region is then annealed at a sufficient temperature and for a sufficient duration to increase a degree of atomic order within the electrically insulating region.

Owner:IBM CORP +2

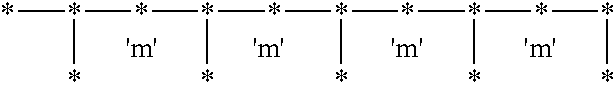

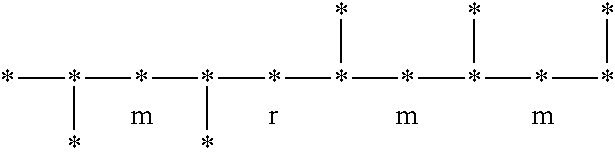

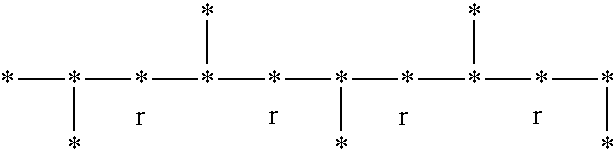

Syndiotactic rich polyolefins

Disclosed herein is a polymer comprising an amorphous syndiotactic rich polyolefin comprising greater than about 50 wt % C3-C40 alpha olefins and having about 50% to less than about 80% r dyads, based on the total number of r and m dyads present in the polymer; a heat of fusion of 10 joules / g or less according to the procedure described in ASTM E 794-85; and an ash content of 1 wt % or less. A functionalized amorphous syndiotactic rich polyolefin is also disclosed, along with methods to produce and a method to use the inventive polymer.

Owner:EXXONMOBIL CHEM PAT INC

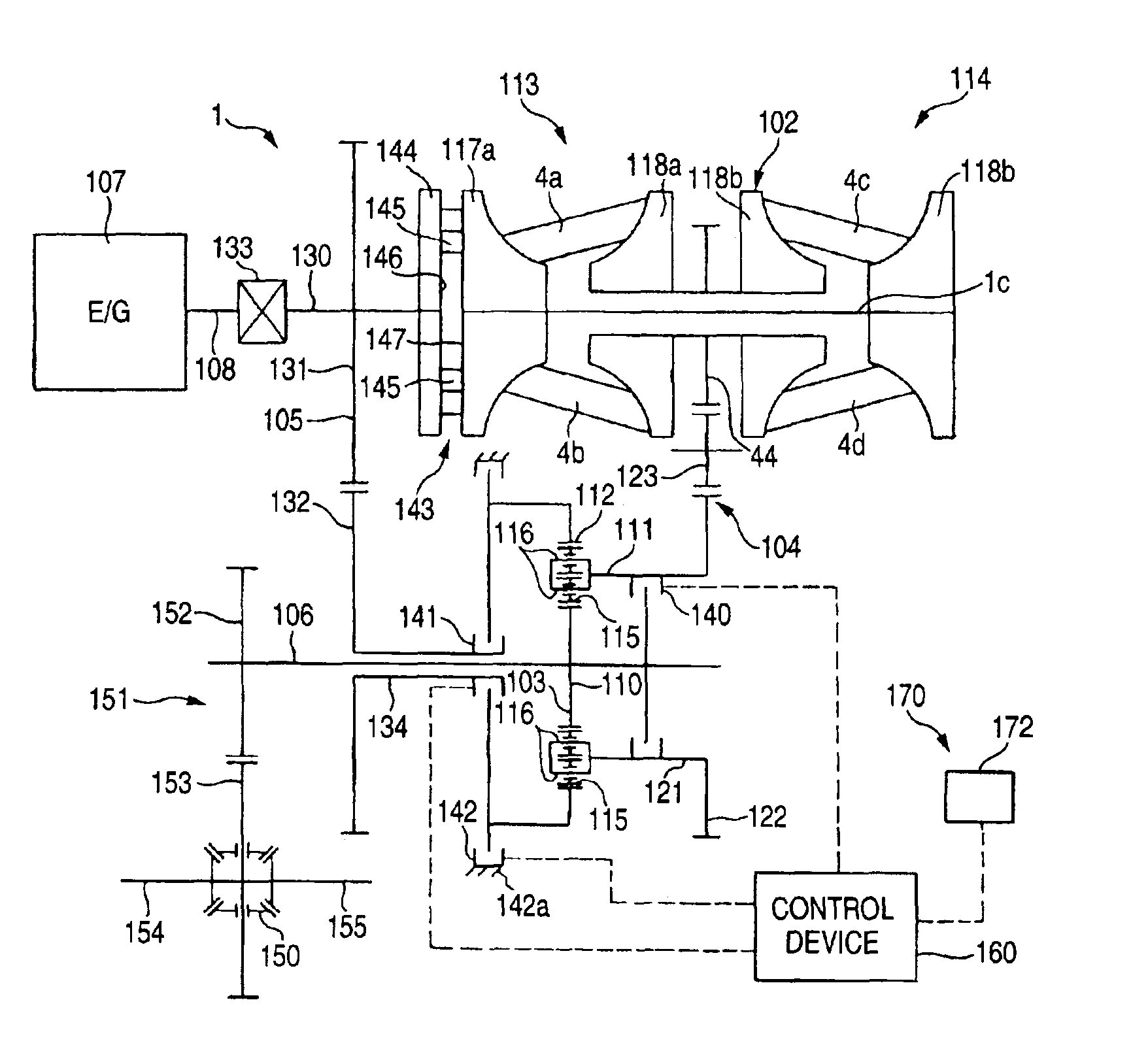

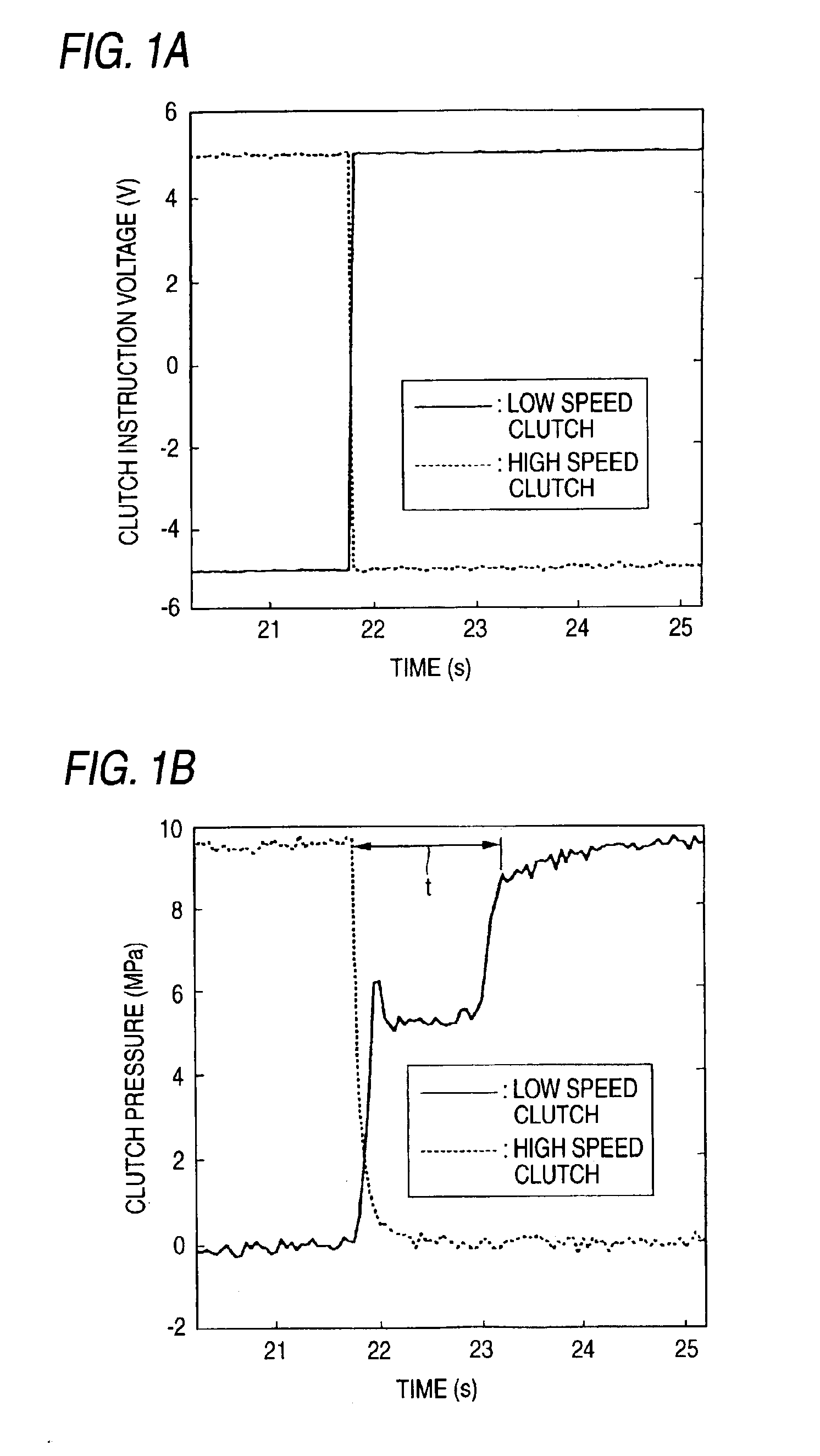

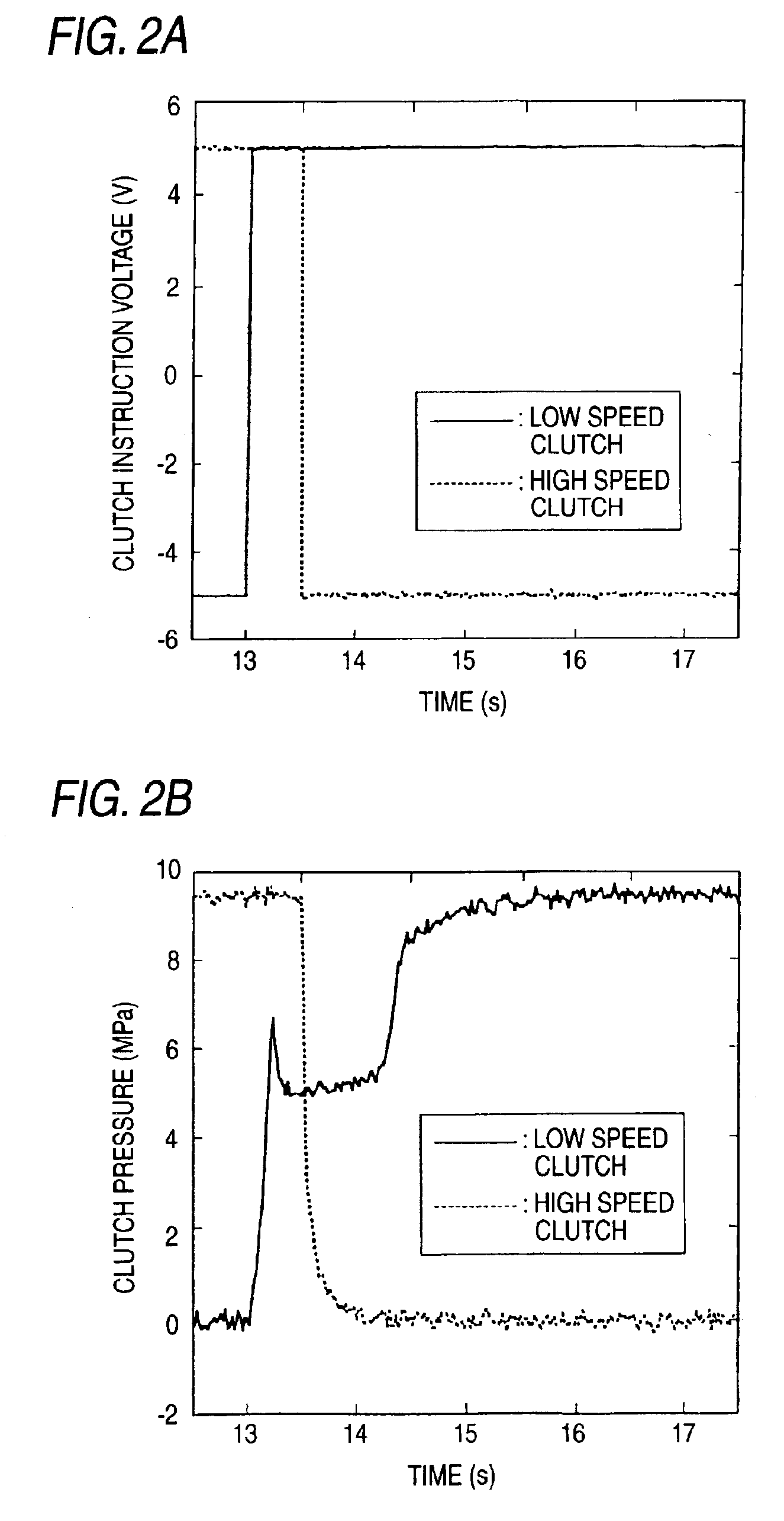

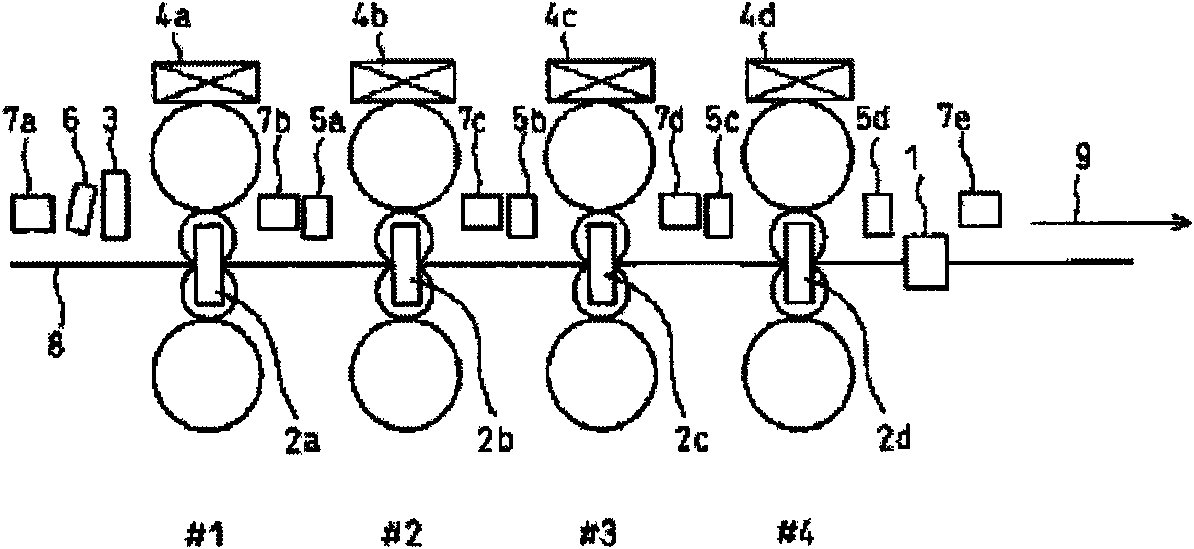

Continuously variable transmission apparatus

A continuously variable transmission apparatus has clutch device having a low speed clutch; a high speed clutch; and, a controller switching the transmission state into any one of a low speed mode and a high speed mode by connecting any one of the clutches, wherein timings for signaling by the controller for switching the connected and disconnected states of the clutches vary according to the switching directions of the low speed and high speed modes; and, a timing for signaling for connecting the low speed clutch with respect to the moment for signaling for cutting off the connection of the high speed clutch in order to switch the high speed mode over to the low speed mode is set earlier than a timing for signaling for connecting the high speed clutch with respect to the moment for signaling for cutting off the connection of the low speed clutch.

Owner:NSK LTD

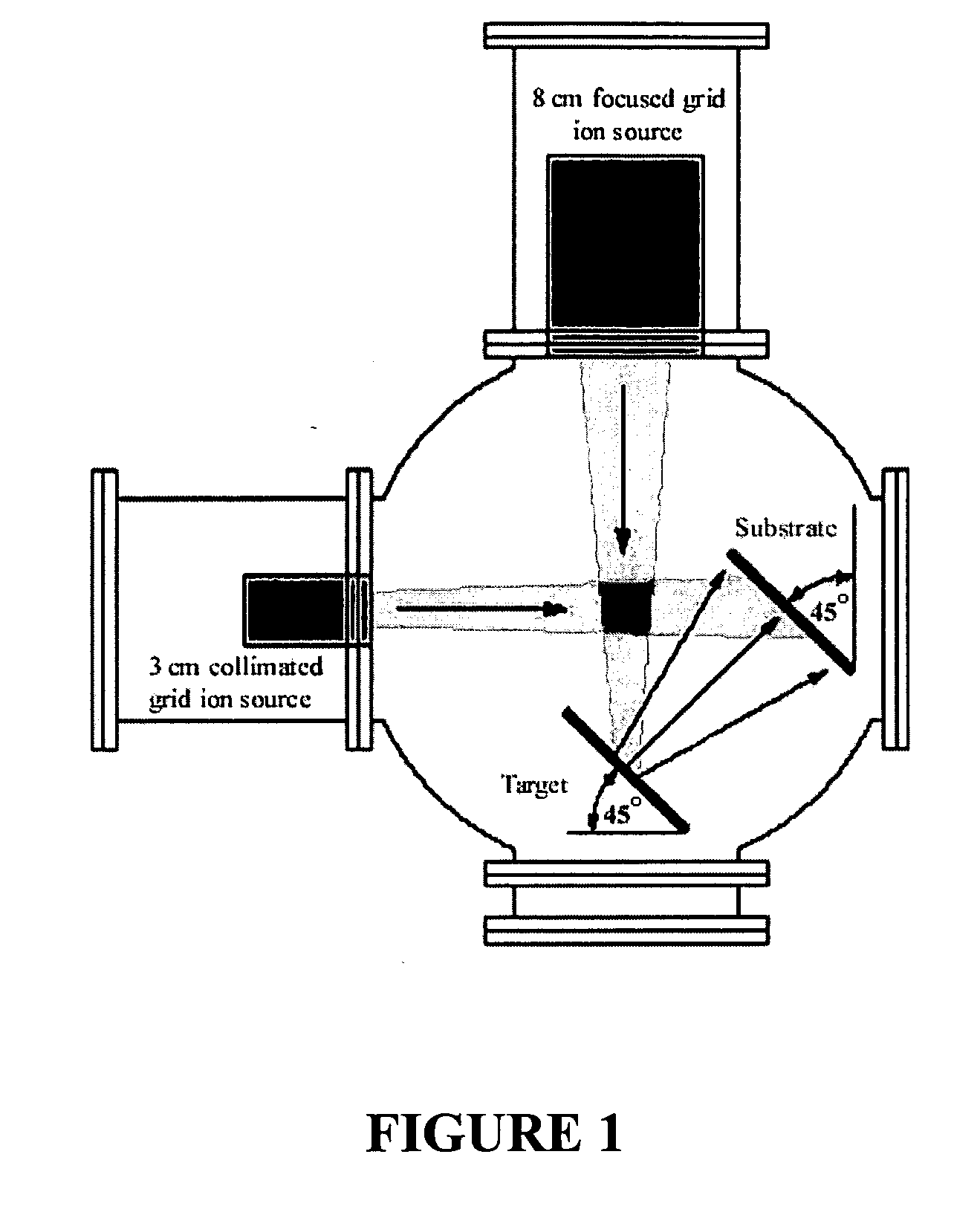

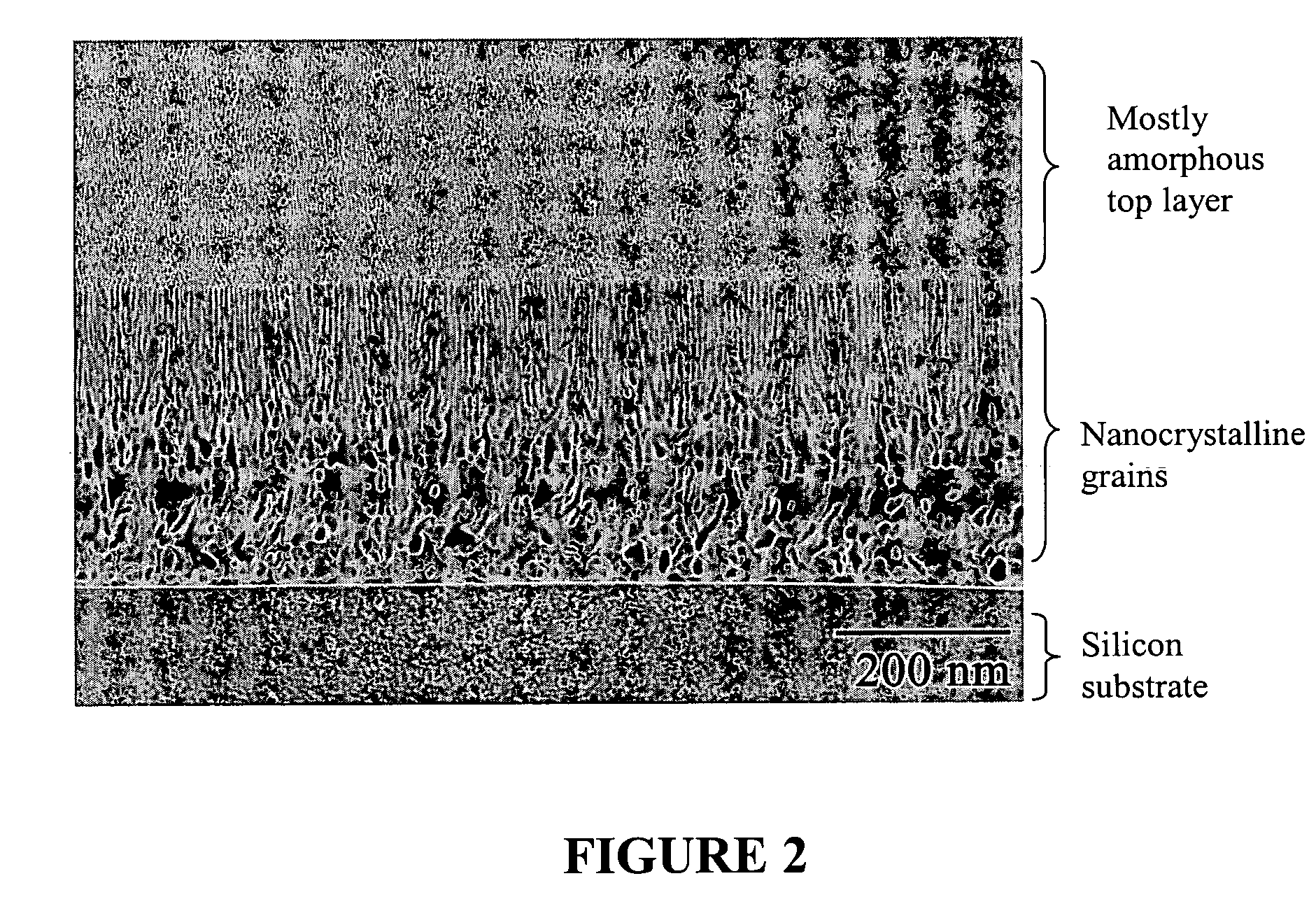

Functionally graded biocompatible coating and coated implant

ActiveUS20060210494A1Degree of reductionDental implantsCosmetic preparationsCalcium biphosphateCalcium phosphate coating

The present invention provides a biocompatible coating comprising calcium phosphate that is functionally graded across the thickness of the coating. The coating, which preferably includes hydroxyapatite, is particularly useful for coating implants, such as dental or orthopedic implants. The functionally graded coating is generally crystalline near the interface with the surface of the implant, with crystallinity and crystal diameter decreasing toward the outer layer of the coating. The invention further provides methods for preparing a coated implant comprising a functionally graded calcium phosphate coating thereon.

Owner:NORTH CAROLINA STATE UNIV

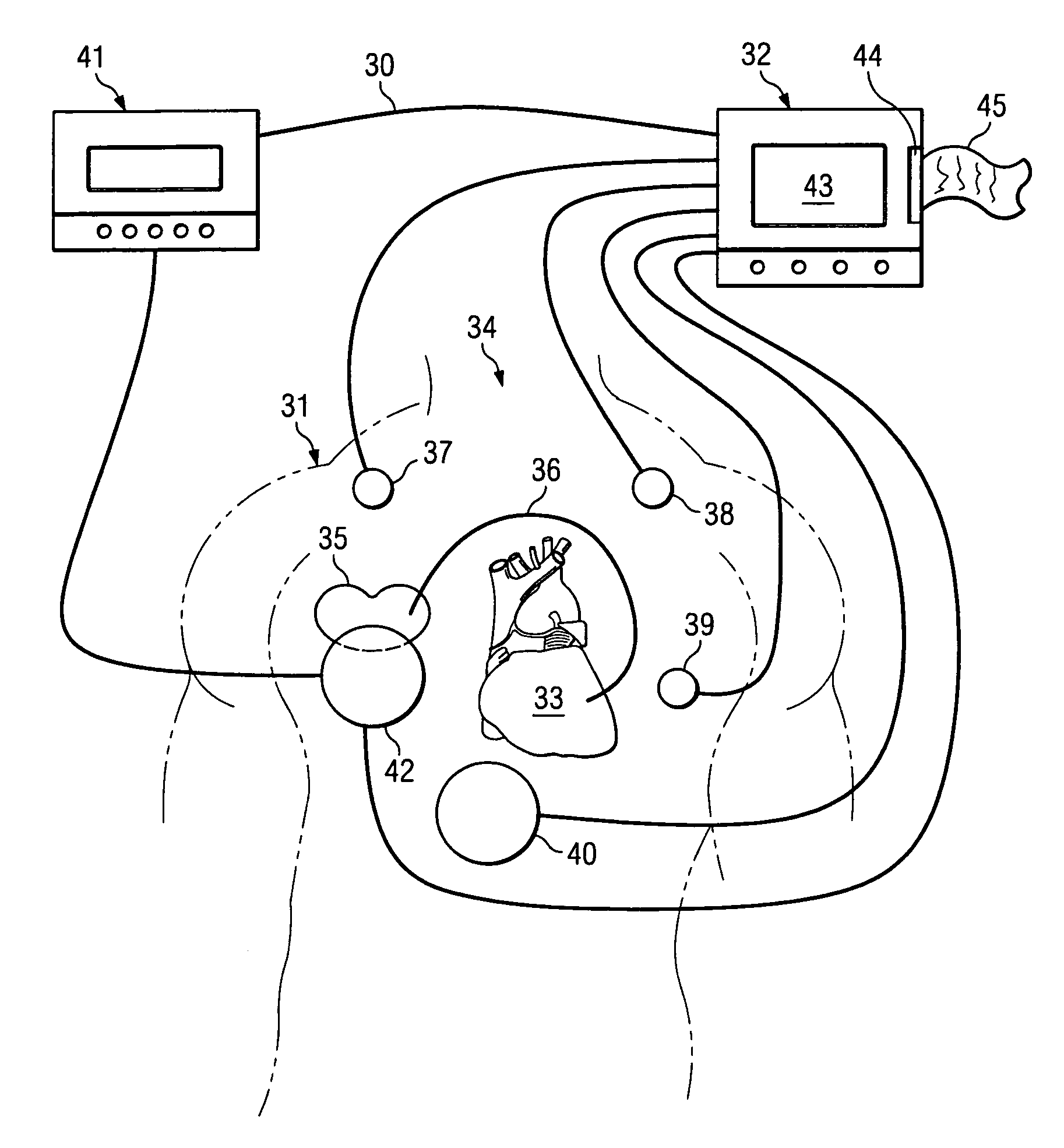

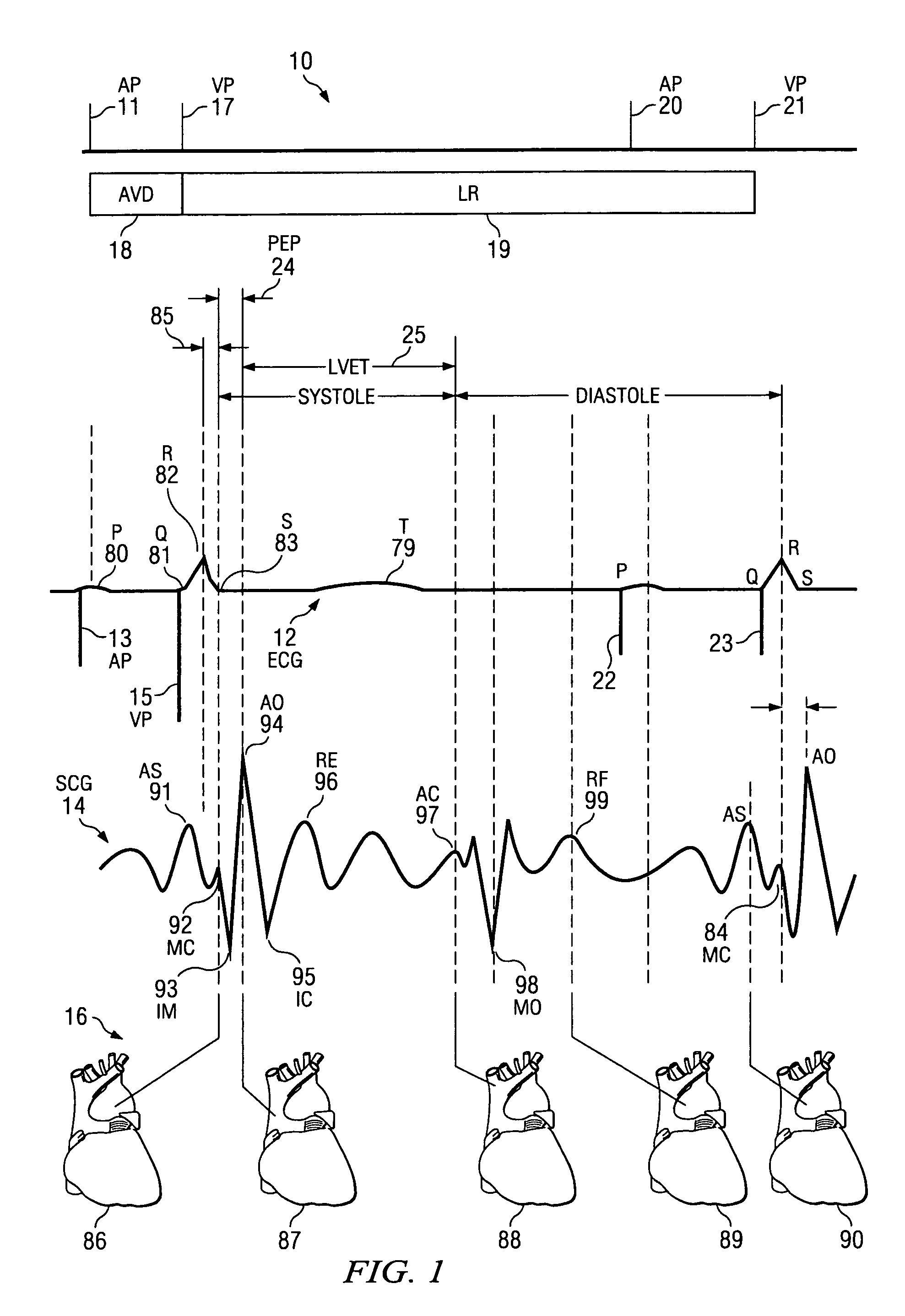

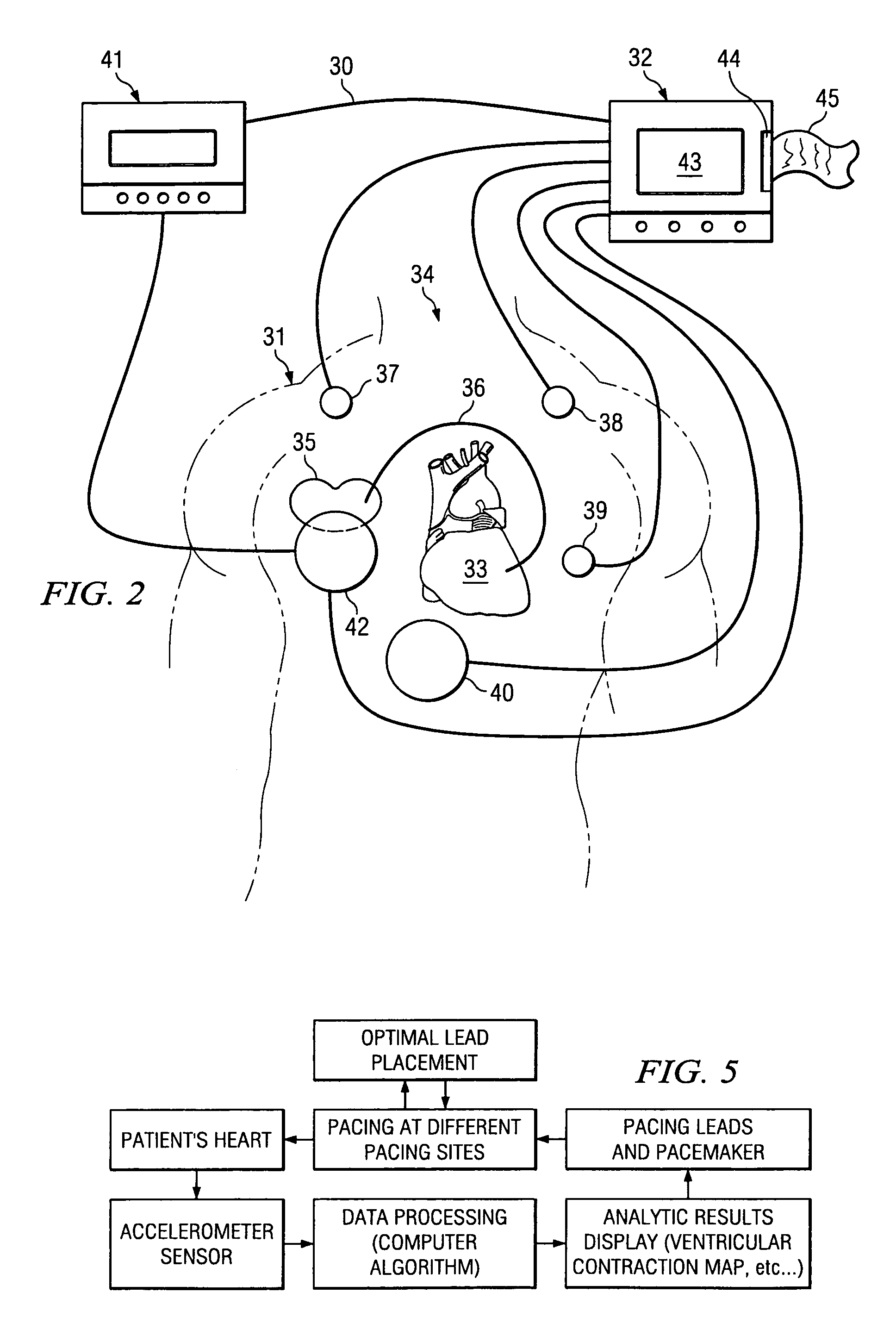

Optimization method for cardiac resynchronization therapy

ActiveUS6978184B1Shortening of pre-ejection periodIncrease in rate of contractionInternal electrodesHeart stimulatorsAccelerometerLeft ventricular size

The patterns of contraction and relaxation of the heart before and during left ventricular or biventricular pacing are analyzed and displayed in real time mode to assist physicians to screen patients for cardiac resynchronization therapy, to set the optimal A-V or right ventricle to left ventricle interval delay, and to select the site(s) of pacing that result in optimal cardiac performance. The system includes an accelerometer sensor; a programmable pace maker, a computer data analysis module, and may also include a 2D and 3D visual graphic display of analytic results, i.e. a Ventricular Contraction Map. A feedback network provides direction for optimal pacing leads placement. The method includes selecting a location to place the leads of a cardiac pacing device, collecting seismocardiographic (SCG) data corresponding to heart motion during paced beats of a patient's heart, determining hemodynamic and electrophysiological parameters based on the SCG data, repeating the preceding steps for another lead placement location, and selecting a lead placement location that provides the best cardiac performance by comparing the calculated hemodynamic and electrophysiological parameters for each different lead placement location.

Owner:HEART FORCE MEDICAL +1

Expandable microspheres for foam insulation and methods

InactiveUS20050079352A1Use in some applicationHigh of encapsulationLiquid surface applicatorsGlass/slag layered productsPolymer scienceFoaming agent

Hollow thermoexpandable particles or microspheres are provided that contain hydrocarbon blowing agents and have a shell polymer that can be softened at the onset of the expansion temperature and solidified at a higher temperature (thermoset) in an expanded state. Preferably, the microspheres have a shell of thermally expandable and thermally crosslinkable polymer and a hollow interior that contains a hydrocarbon liquid that boils at a temperature below the heat activated crosslinking temperature of the polymer shell. The crosslinking of the shell polymer during or after expansion, which is heat activated at an elevated temperature, can solidify the shell polymer and, then, maintain the expanded volume of the microspheres. The thermoexpandable thermoset polymer particles are useful in insulation, packaging, for making foam materials such as polyurethane or polyisocyanurate rigid foams. The invented thermoset microspheres can substantially improve the close cell percentage and compressive strength of the foam materials and make the foam manufacturing less hazardous.

Owner:IP RIGHTS +1

Method for the production of polypeptides

The present invention relates to a novel method for the production of short chain polypeptides, including polypeptides having up to 3 disulfide bonds and / or structures rich in basic amino acid residues, and open structured short chain polypeptides, e.g. glucagon, glucagon like peptides and their functional analogues, in genetically modified yeast cells, said genetically modified yeast cells, and a method for the preparation of said yeast cells.

Owner:NOVO NORDISK AS

Medicine for preventing and treating coronary heart disease and angina pectoris and its prepn and other use

InactiveCN1348815AGood curative effectLess frequent seizuresNervous disorderMetabolism disorderSalvia miltiorrhizaCoronary artery disease

The present invention relates to traditional Chinese medicine for treating coronary heart disease and stenocardia is made from (by wt.%) salvia root 50-97%, notoginseng 2-48% and borneol 0.2-3%, in which the salvia root and notoginseng and hot extracted with water, then filtering, concentrating, alcohol precipitating, standing still, recovering ethyl alcohol, concentrating, into extractum, further blended with borneol and adjuvant polyglycol-6000 to form into product.

Owner:TIANJIN TASLY PHARMA CO LTD

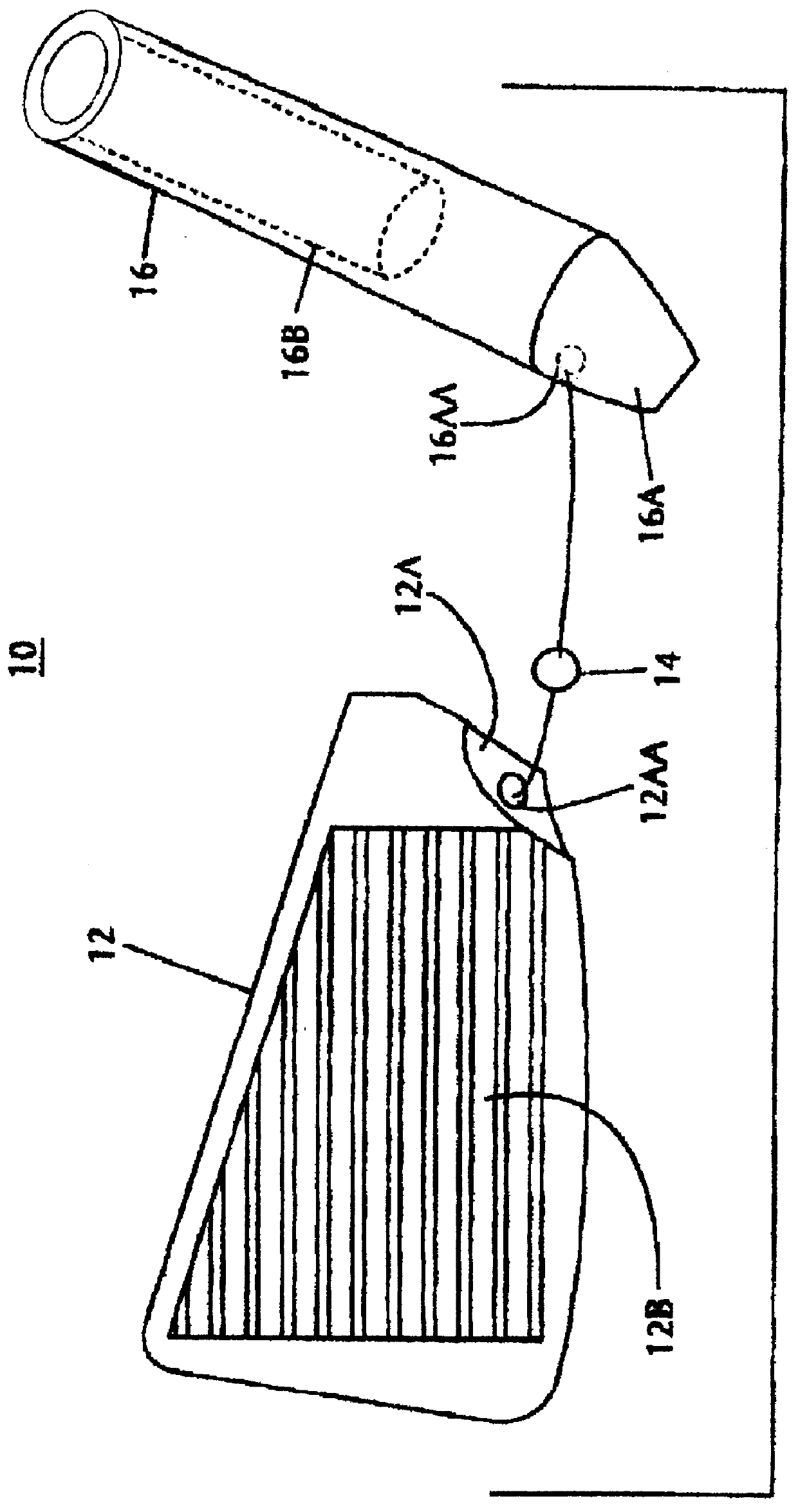

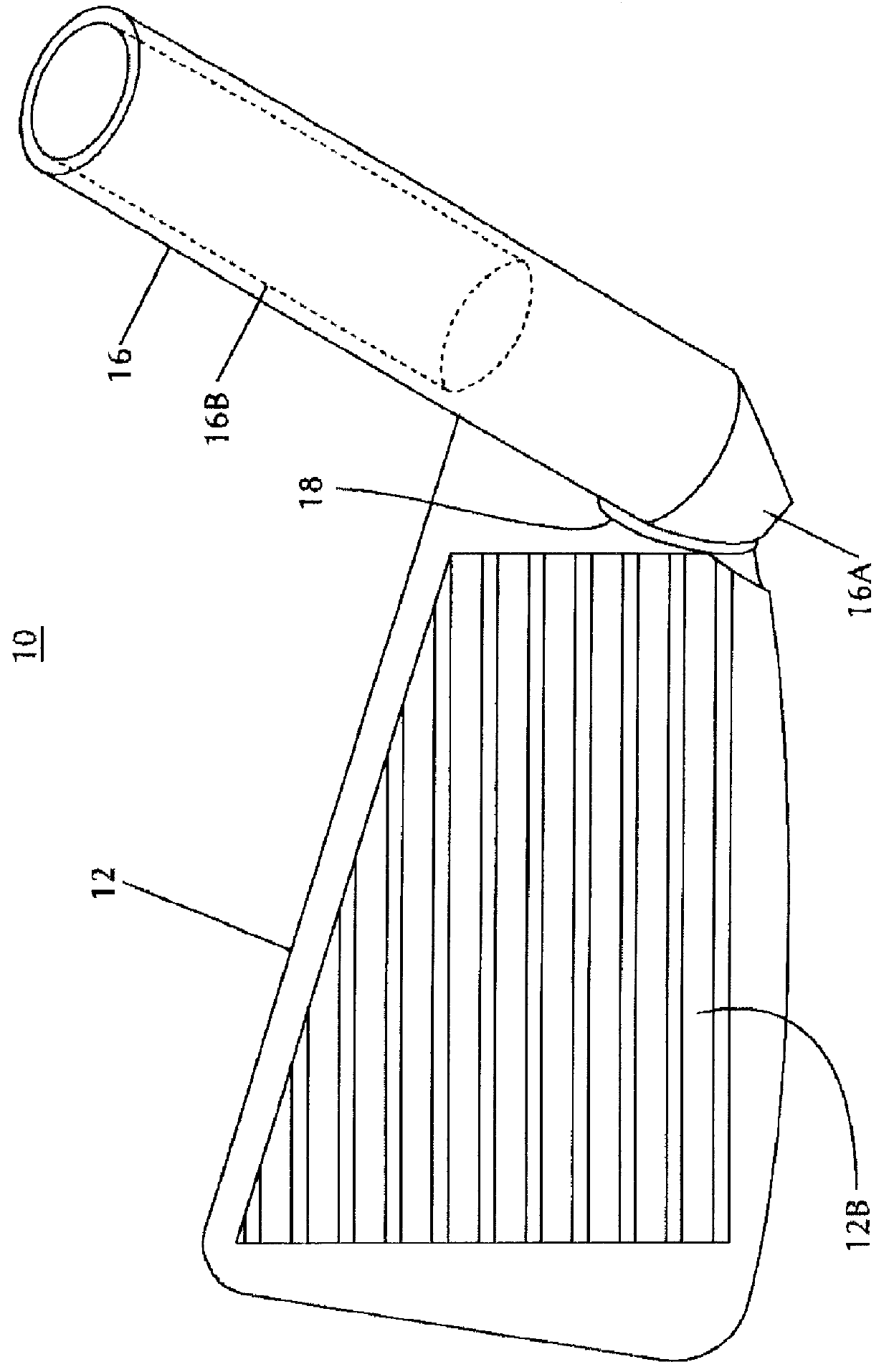

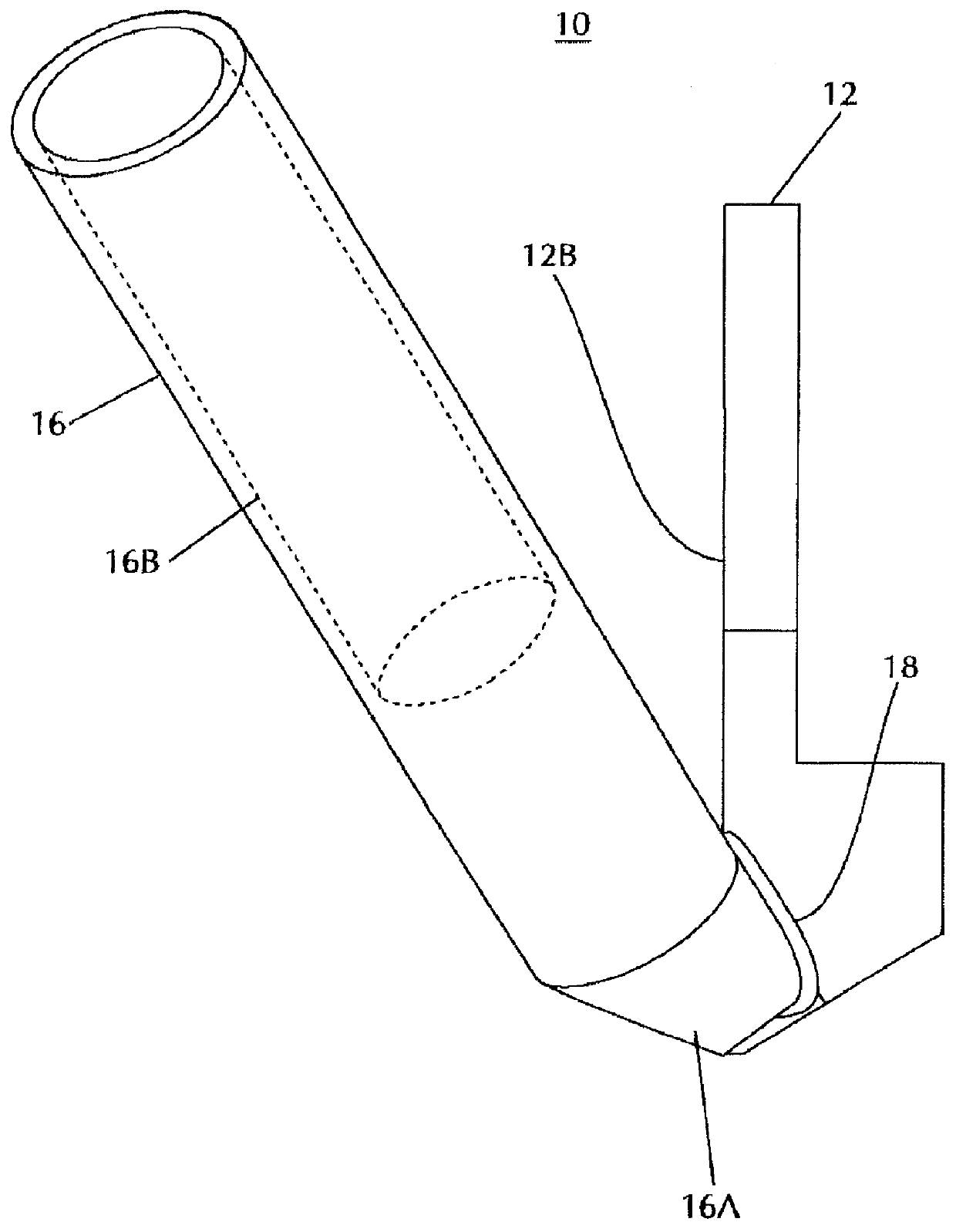

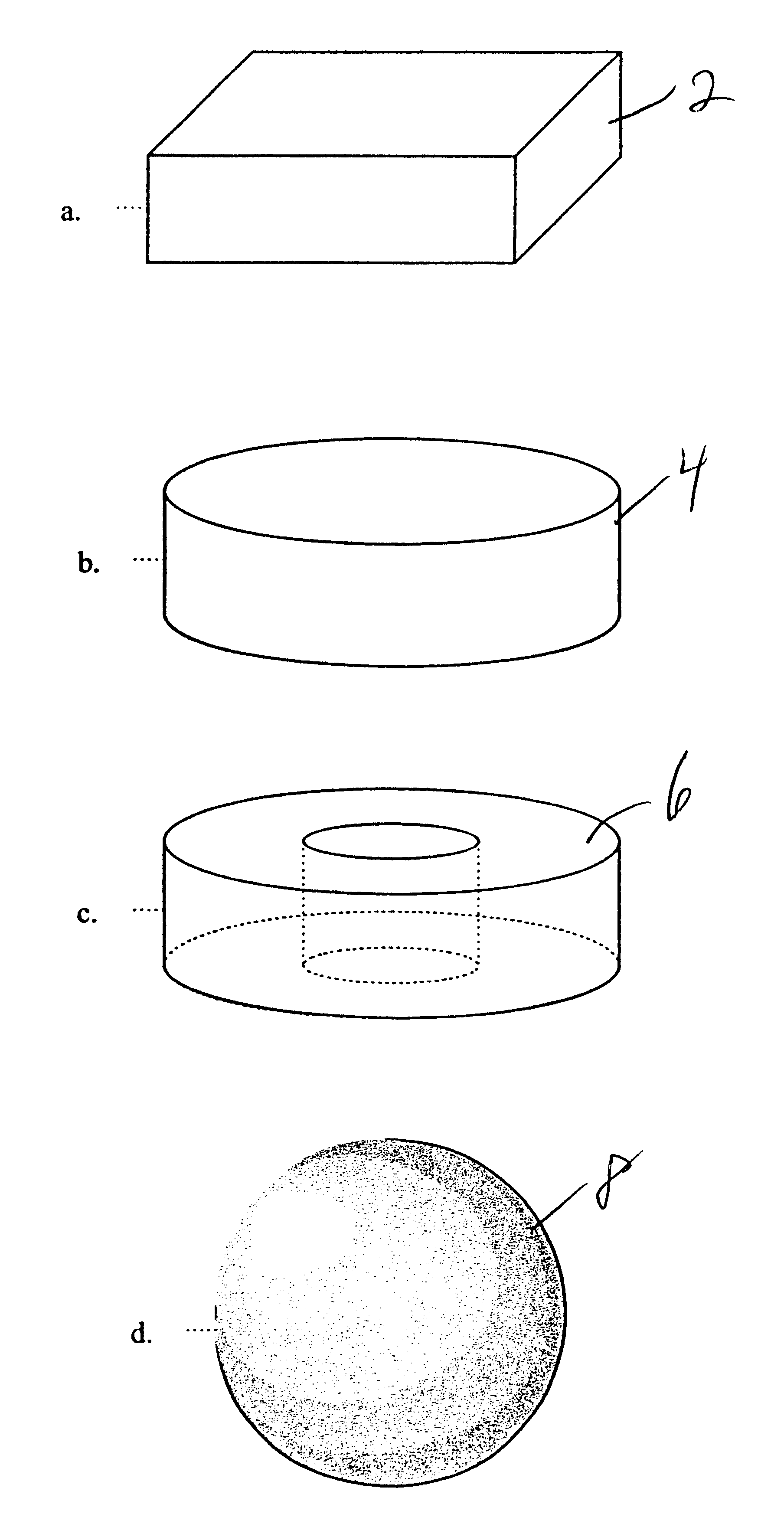

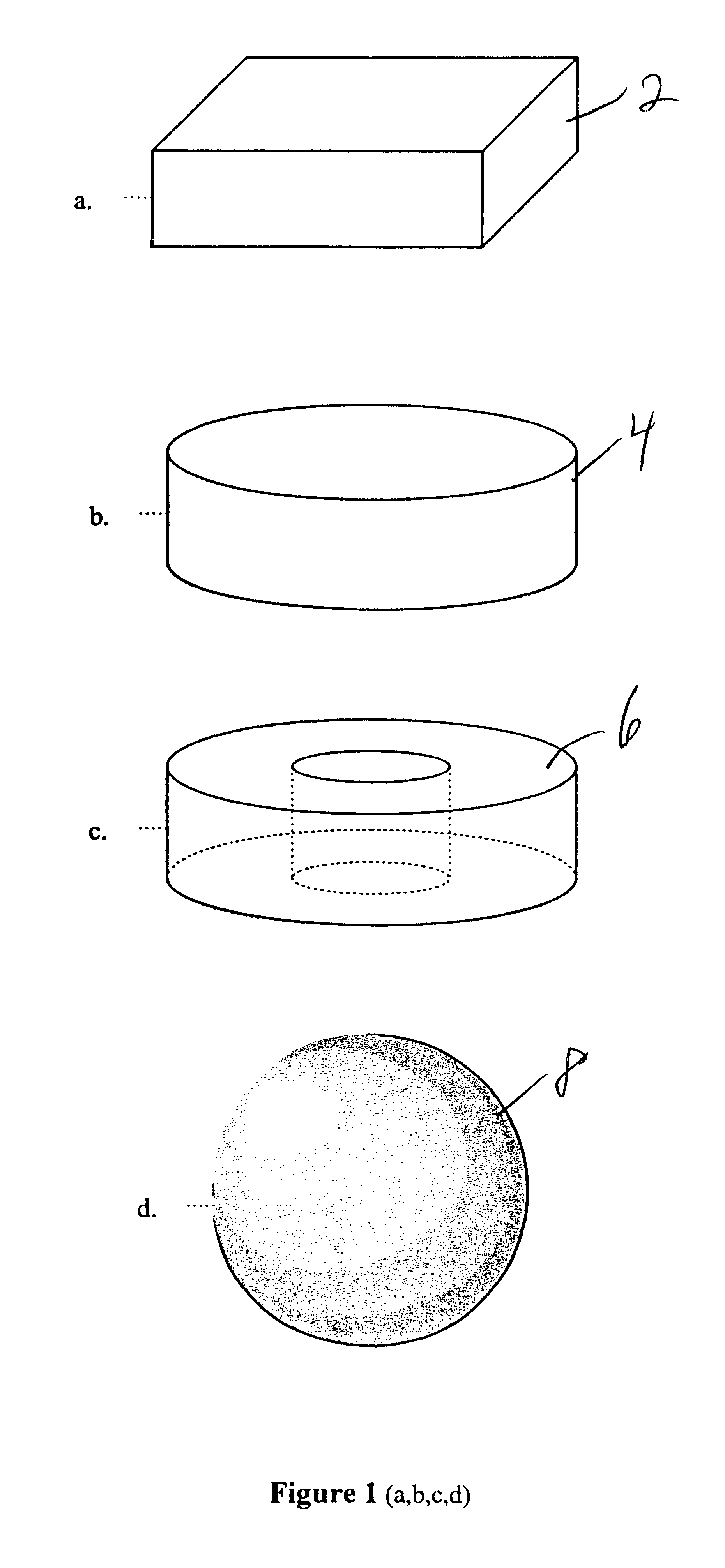

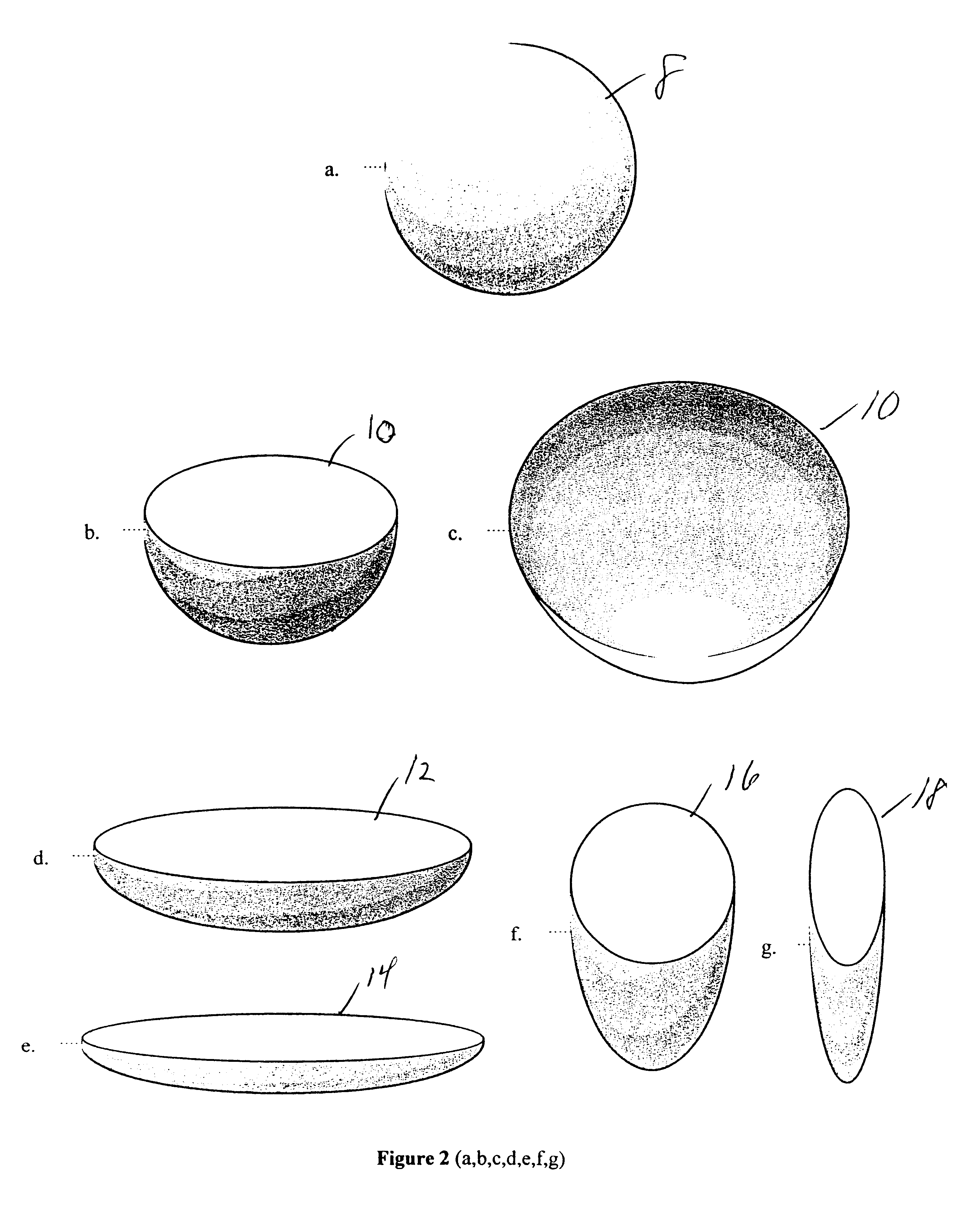

Custom-fabricated golf club device and method

InactiveUS6120384AWide rangeAccurate resolutionGolfing accessoriesGolf clubsManufacturing technologyCombined use

A custom-fabricated golf club device comprising a golf club head with a recessed portion located at the front heel portion of the head and machined therein, the recessed portion comprising a substantially semi-spherical aperture. A hosel assembly has a lower portion, having a substantially semi-spherical aperture that aligns with the aperture of the head recessed portion, the hosel assembly further having a recessed portion at an upper portion thereof. A steel ball is located securely within the aperture of head recessed portion and the aperture of the hosel assembly lower portion, functioning to provide positive location of the club head and hosel assembly. In the preferred mode, a permanent weldment functions to securely affix the lower portion of the hosel assembly to the club head at the heel portion of the club head. The device is utilized in conjunction with golf clubs of both the iron and wedge variety to provide a cost-effective and convenient way to custom-fabricate golf clubs to the unique physical characteristics of individual players. By taking advantage of machining, rather than forging or casting the components, a wide range of lie angles with precise resolution can be achieved. In addition, the manufacturing techniques of the present invention diligently conform to the USGA rule that clubs other than putters shall not be designed to be adjustable except for weight.

Owner:DRAKE STANLEY

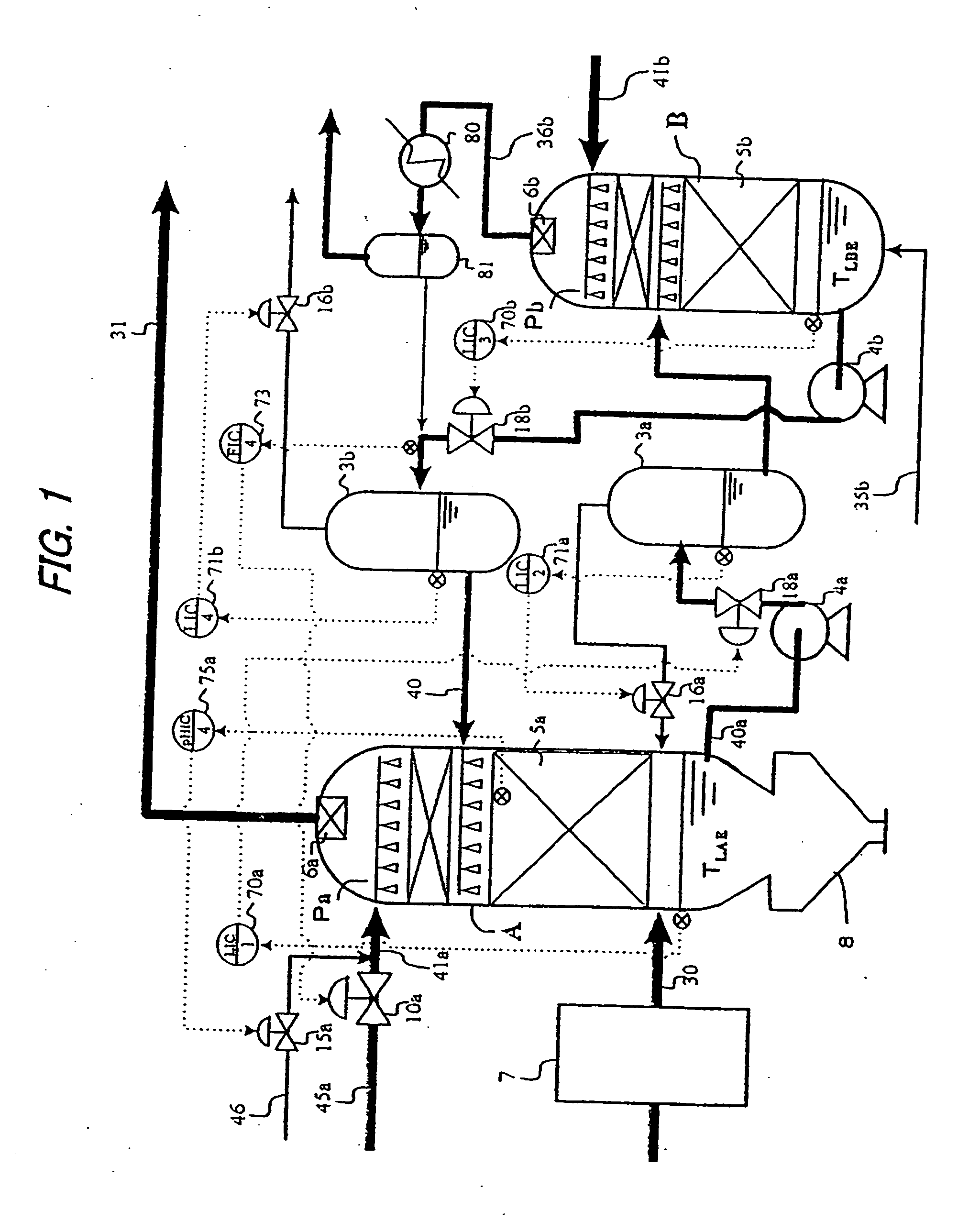

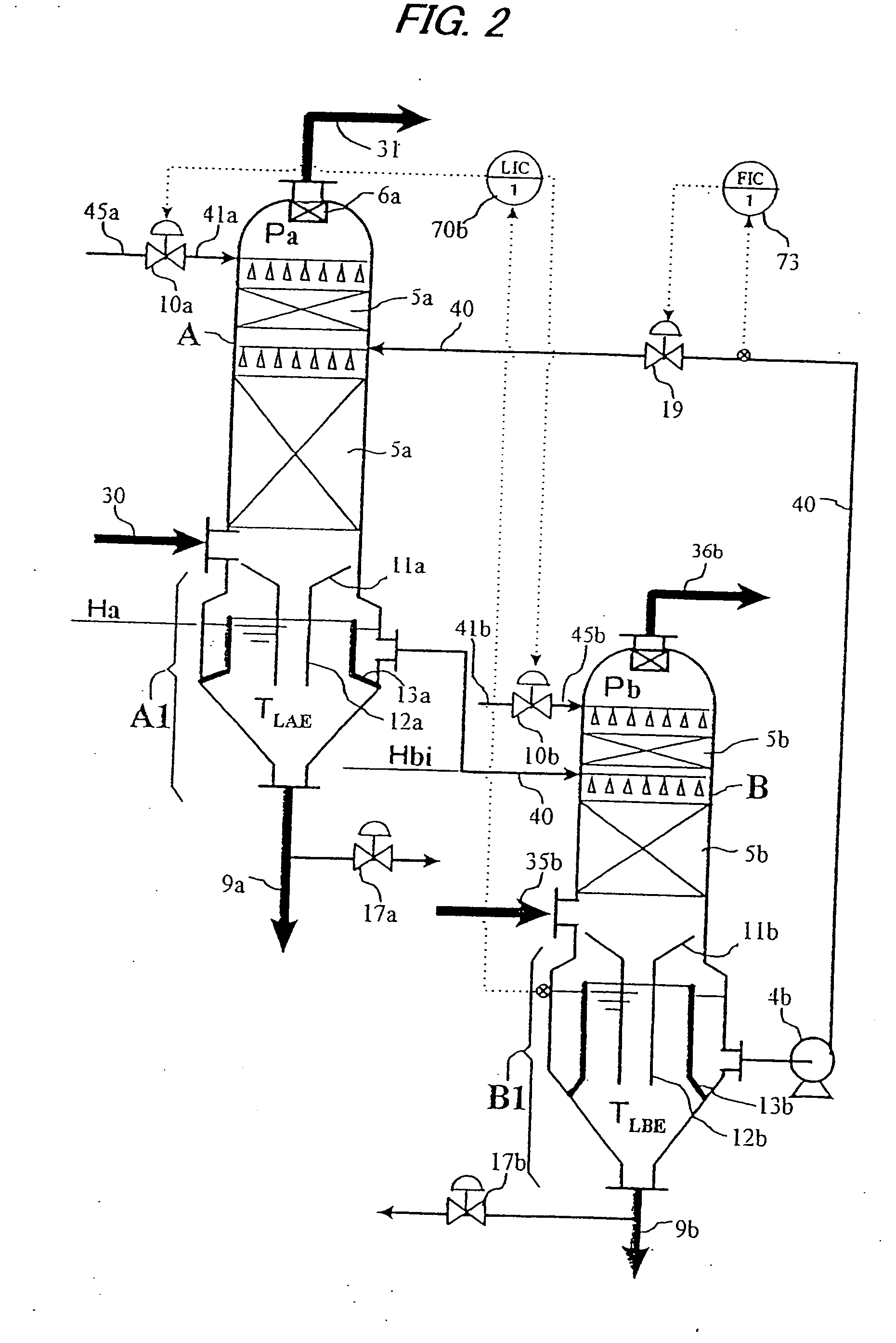

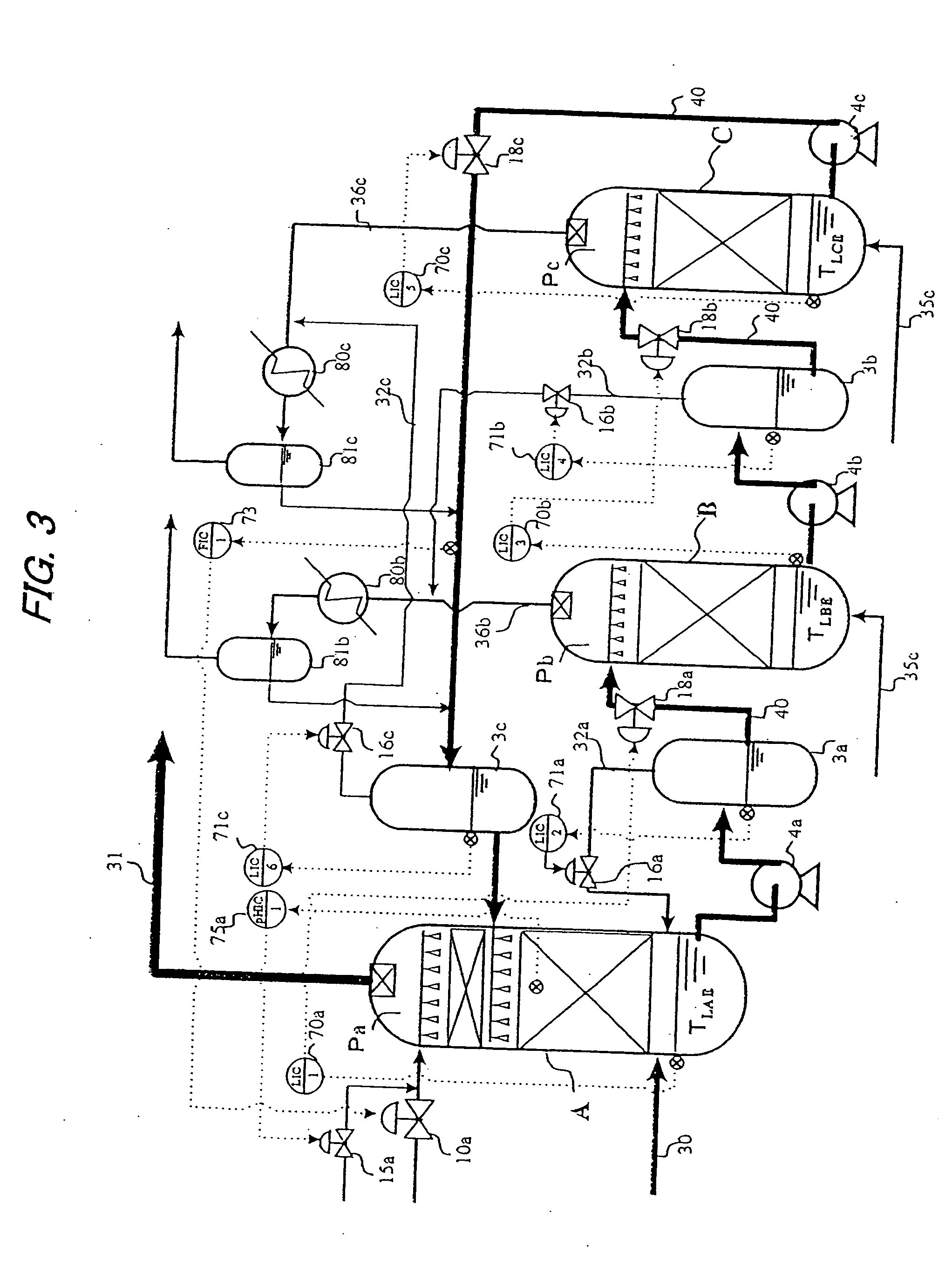

Acid gas scrubbing apparatus and method

InactiveUS20050132883A1Improve energy efficiencyImprove acid gas removal capabilityUsing liquid separation agentCombustible gas catalytic treatmentScrubberCarbon dioxide

An acid gas scrubbing apparatus and method brings a gas, to be scrubbed, containing carbon dioxide into contact with a gas scrubbing liquid containing alkaline agent and cooled, and acid gases in the gas are removed. A gas scrubber removes acid gases in a gas, to be scrubbed, containing carbon dioxide by bringing the gas to be scrubbed into contact with a gas scrubbing liquid containing alkaline agent. A scrubbing liquid regenerator regenerates and cools the gas scrubbing liquid by bringing the gas scrubbing liquid into contact with a regenerating gas having components different from the gas scrubbing liquid and the gas to be scrubbed. A circulating device is provided between the gas scrubber and the scrubbing liquid regenerator for circulating the scrubbing liquid.

Owner:SU QINGQUAN +4

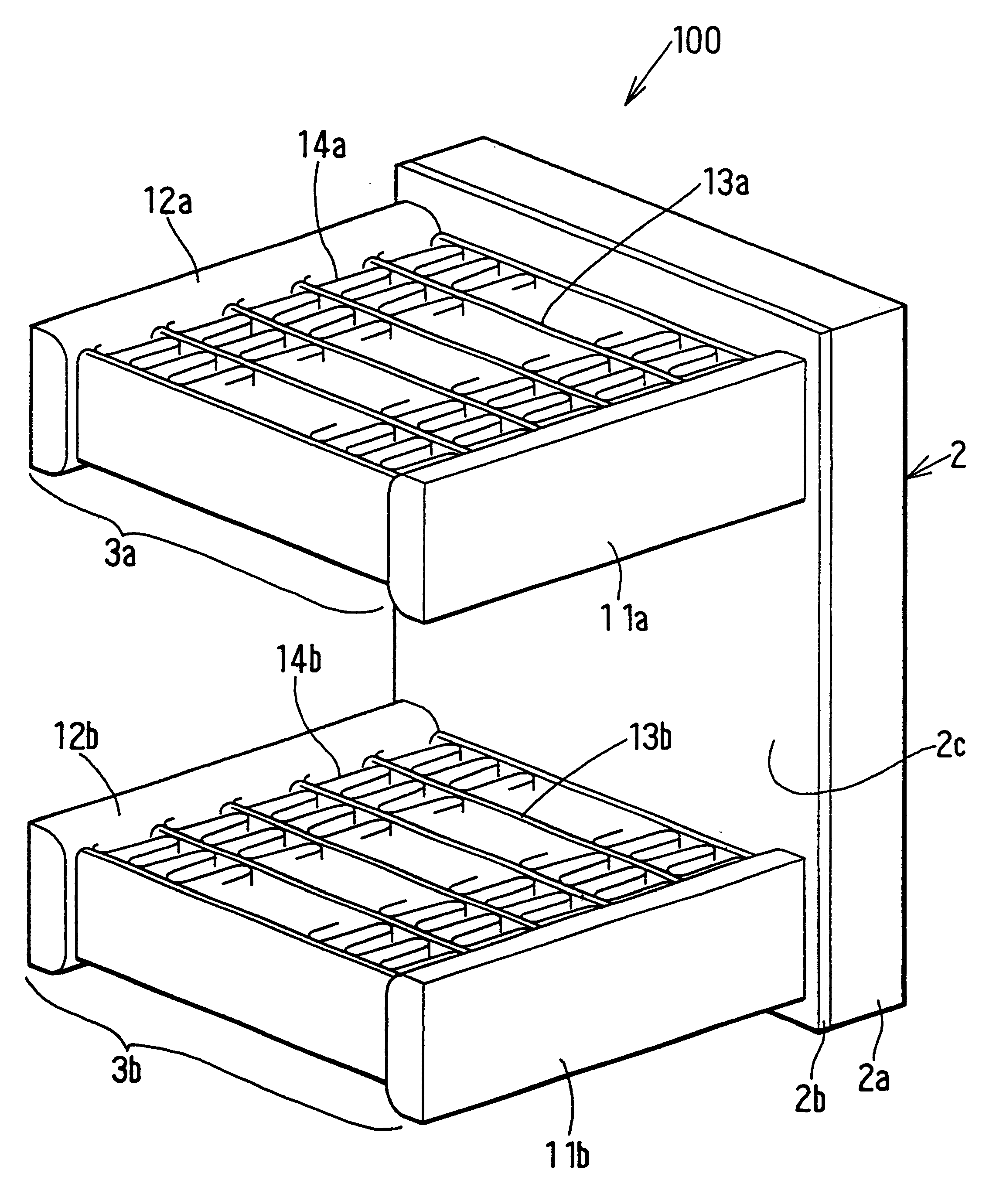

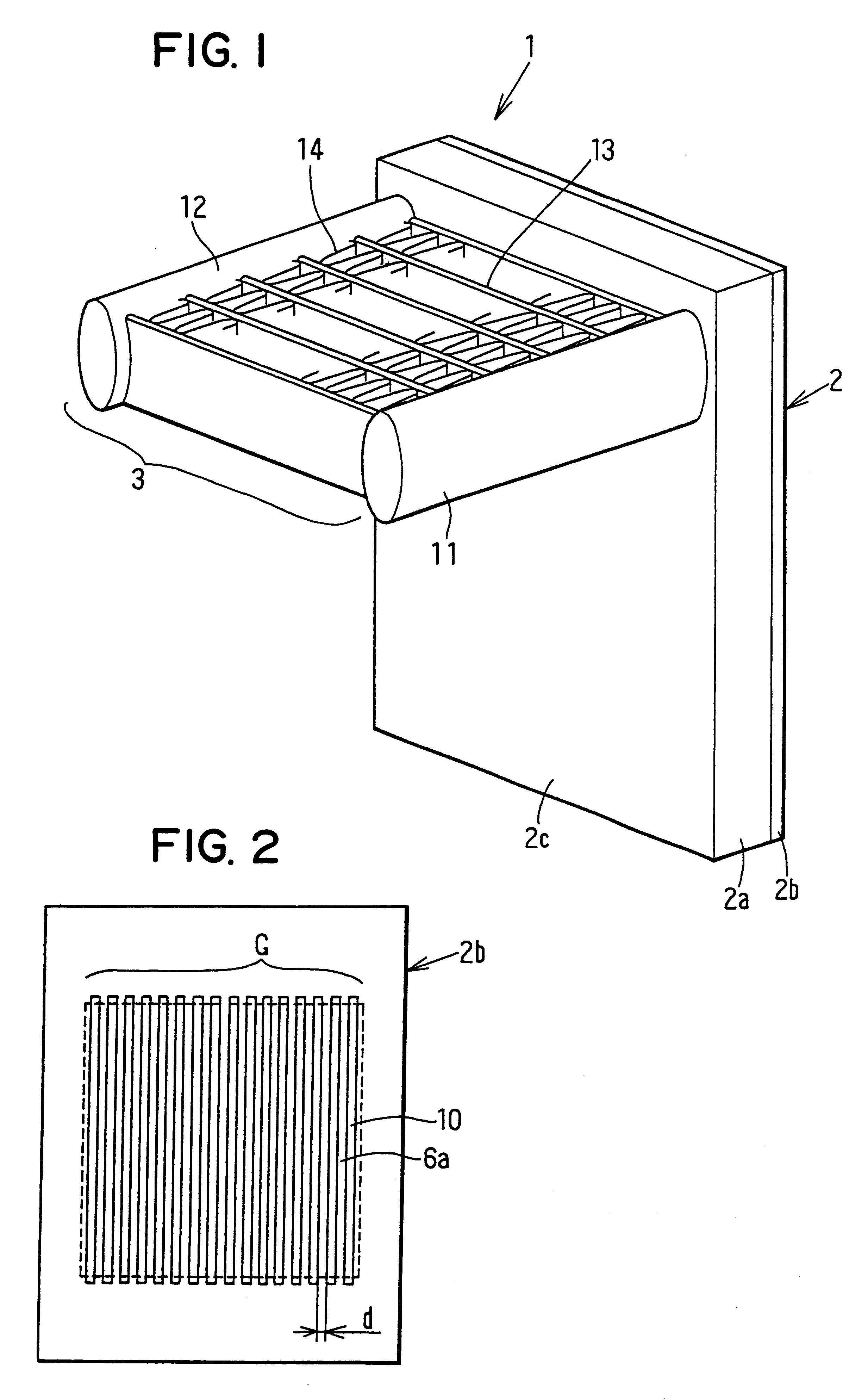

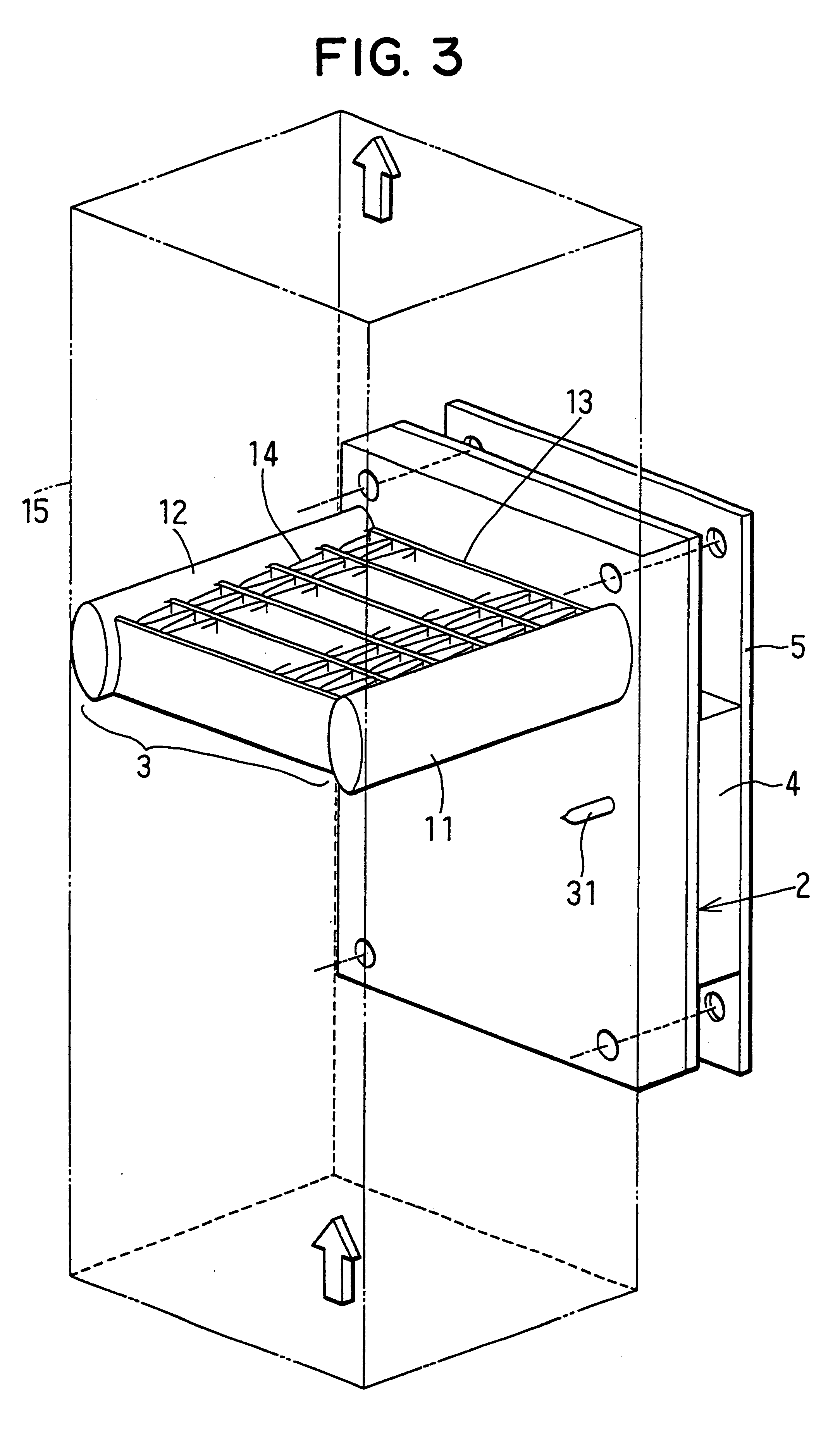

Cooling device boiling and condensing refrigerant

InactiveUS6360814B1Simple structureImprove performanceSemiconductor/solid-state device detailsSolid-state devicesEngineeringRefrigerant

A cooling device for cooling a heat-generating member includes a refrigerant tank for boiling liquid refrigerant by heat from the heat-generating member and a radiator for cooling and condensing gas refrigerant from the refrigerant tank. The refrigerant tank has therein a plurality of refrigerant passages defined by ribs which are integrally formed with any one of opposite wall parts of the refrigerant tank. The ribs continuously extend in an up-down direction to be slightly longer than an up-down dimension of a boiling surface of the refrigerant tank. In the cooling device, because each passage width of the refrigerant passages is set to be equal to or smaller than double Laplace length, an outer diameter of bubbles in the refrigerant passages becomes larger, and liquid refrigerant can be moved upwardly by bubbles. Accordingly, it can restrict liquid refrigerant surface from being lowered even when gas-generating amount is increased.

Owner:DENSO CORP

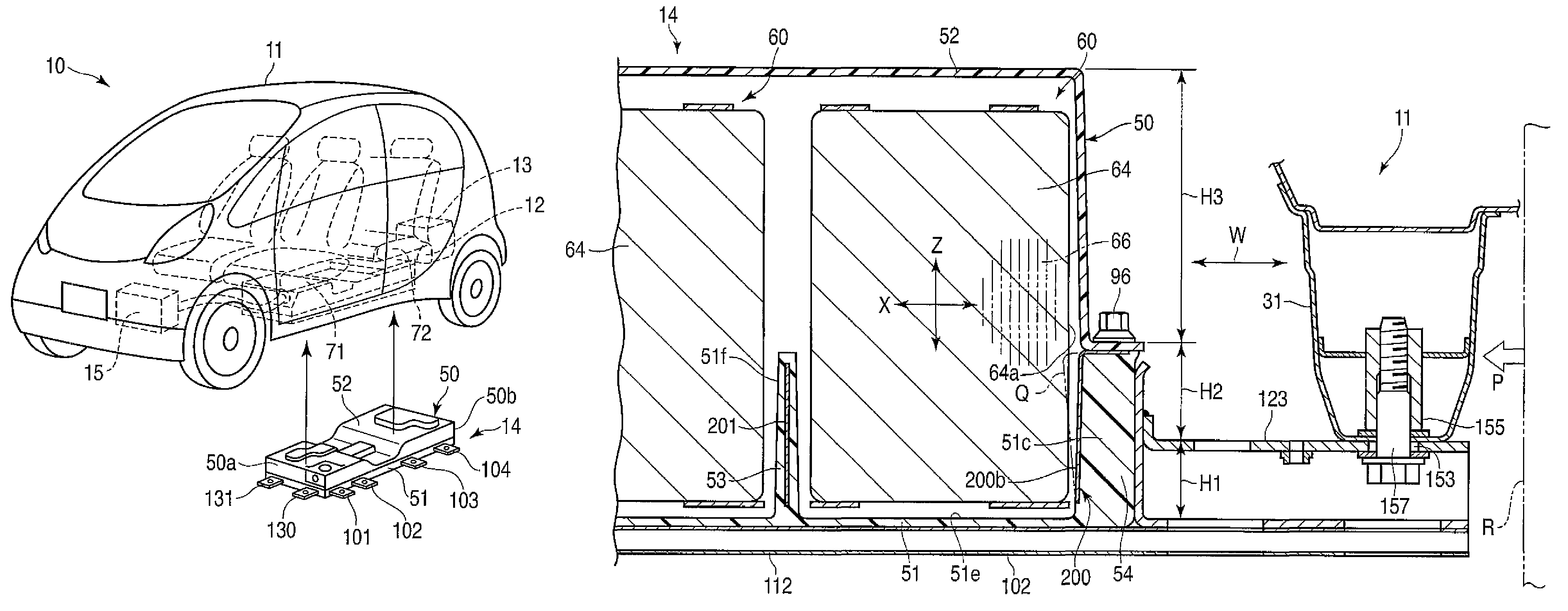

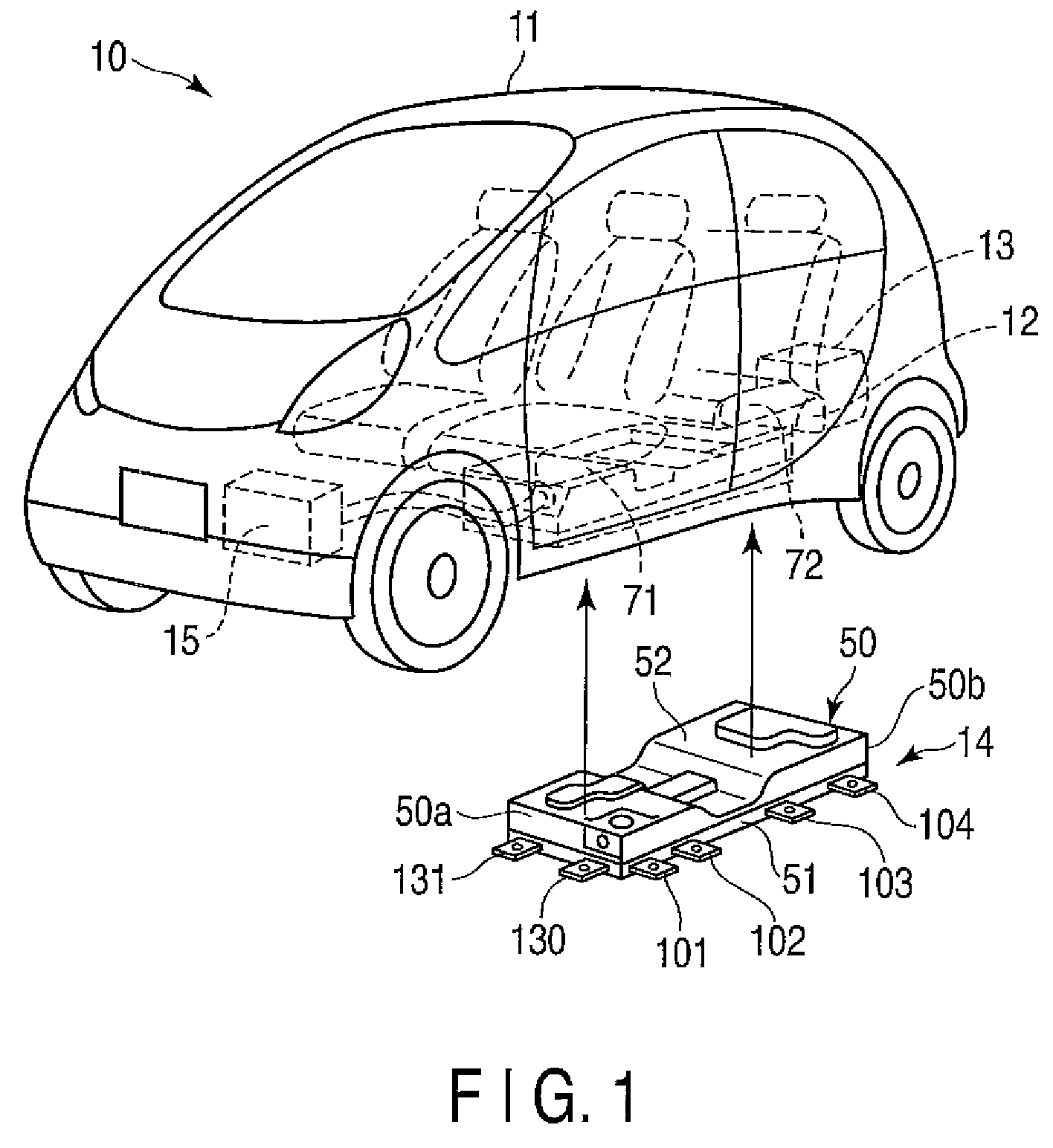

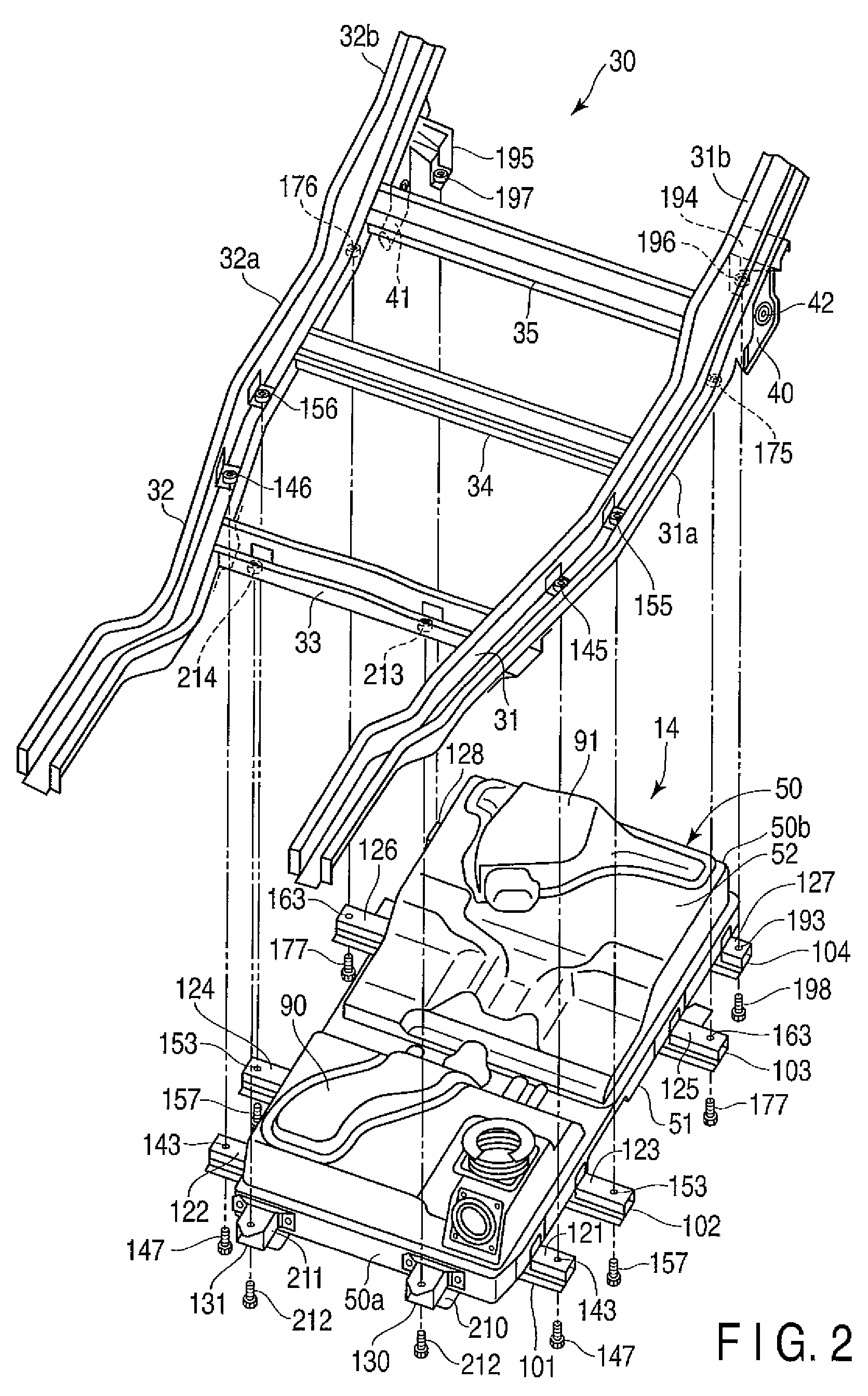

Electric vehicle

InactiveUS7654352B2Degree of reductionDegree can be loweredElectric propulsion mountingGas pressure propulsion mountingEngineeringElectric vehicle

A battery unit mounted in an electric vehicle is provided with a battery case and a plurality of battery modules. The battery case includes a tray member on the lower side and a cover member on the upper side. The tray member is fixed to side members by a beam member extending in a width direction of a vehicle body. Each battery module is composed of a plurality of cells. Among all the cells contained in the battery case, at least those cells on the outer peripheral side which are located near a flank of the vehicle body are located on the tray member so that a lamination direction of cell elements is coincident with the width direction of the vehicle body.

Owner:MITSUBISHI MOTORS CORP

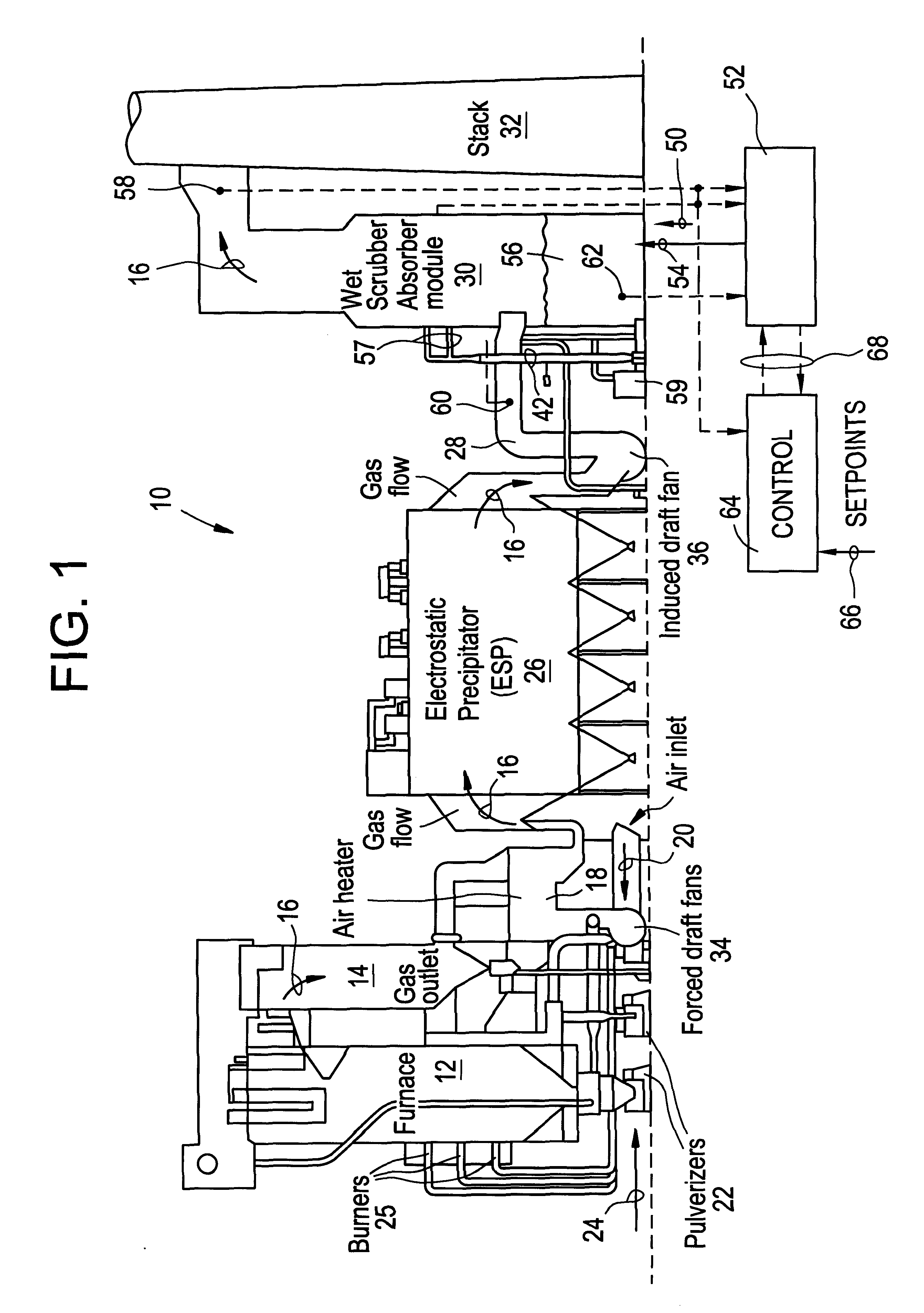

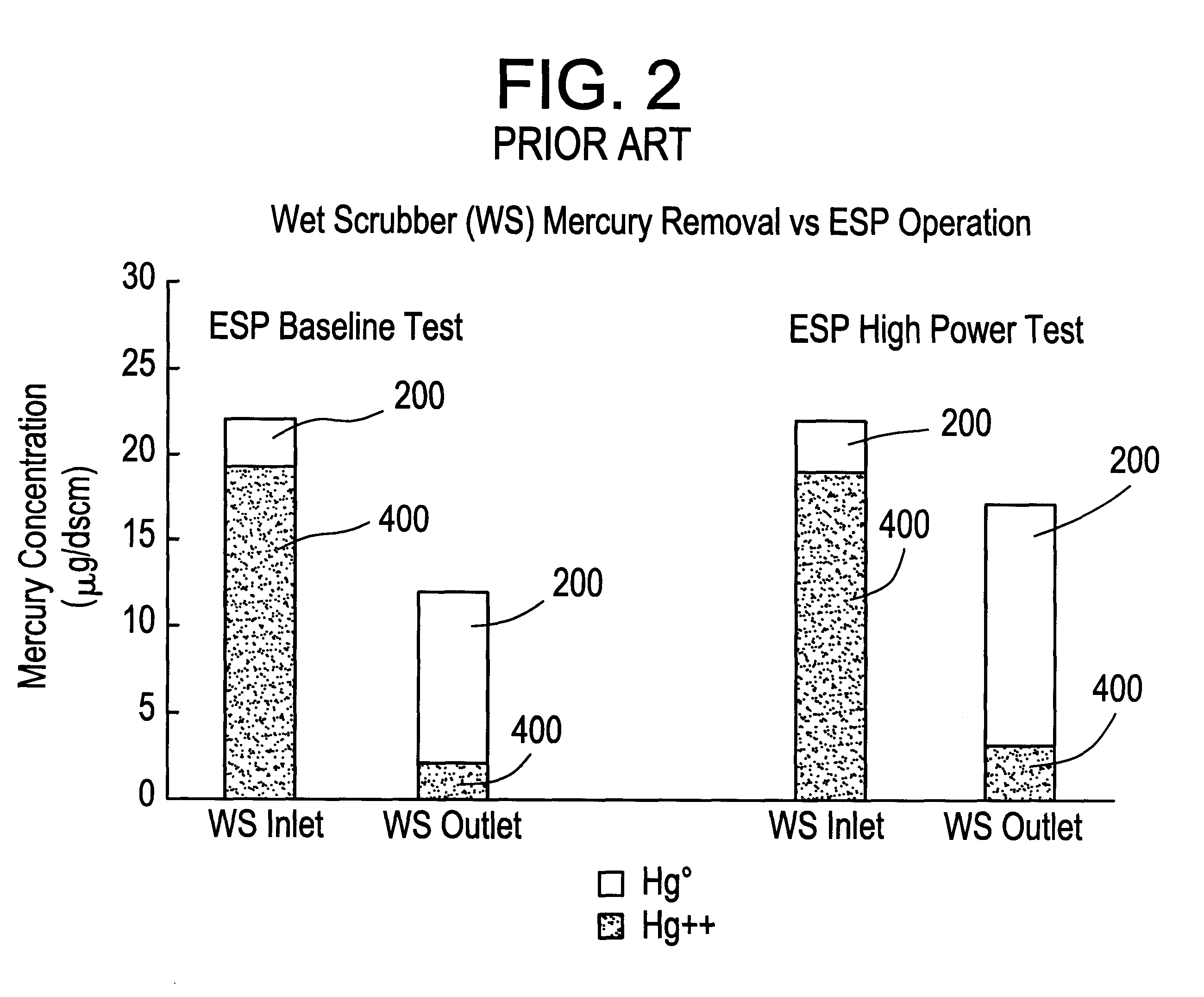

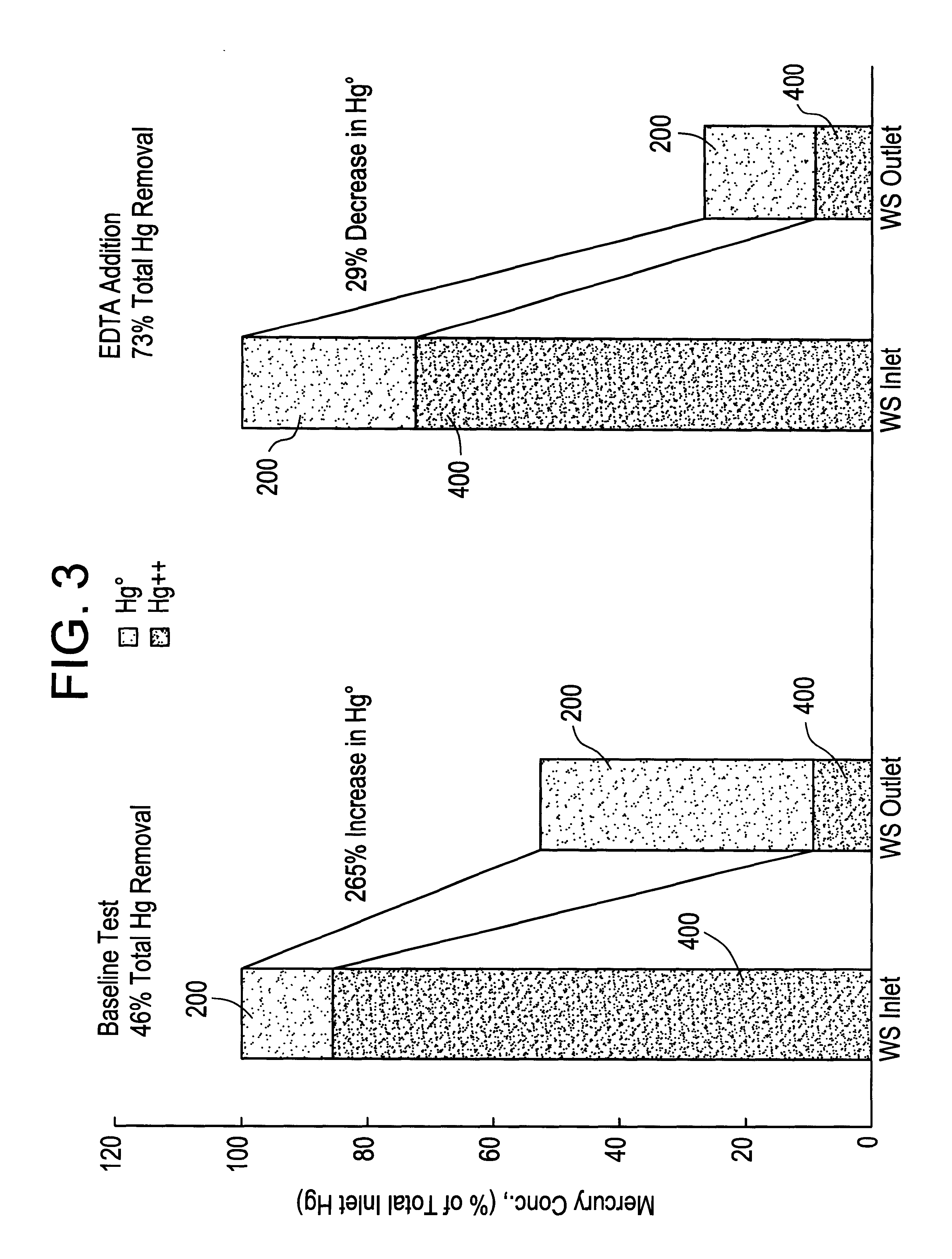

Mercury removal in utility wet scrubber using a chelating agent

InactiveUS6328939B1Degree of reductionReduce concentrationUsing liquid separation agentChemical/physical processesCombustionElemental mercury

A method for capturing and reducing the mercury content of an industrial flue gas such as that produced in the combustion of a fossil fuel or solid waste adds a chelating agent, such as ethylenediaminetetraacetic acid (EDTA) or other similar compounds like HEDTA, DTPA and / or NTA, to the flue gas being scrubbed in a wet scrubber used in the industrial process. The chelating agent prevents the reduction of oxidized mercury to elemental mercury, thereby increasing the mercury removal efficiency of the wet scrubber. Exemplary tests on inlet and outlet mercury concentration in an industrial flue gas were performed without and with EDTA addition. Without EDTA, mercury removal totaled 42%. With EDTA, mercury removal increased to 71%. The invention may be readily adapted to known wet scrubber systems and it specifically provides for the removal of unwanted mercury both by supplying S2- ions to convert Hg2+ ions into mercuric sulfide (HgS) and by supplying a chelating agent to sequester other ions, including but not limited to Fe2+ ions, which could otherwise induce the unwanted reduction of Hg2+ to the form, Hg0.

Owner:THE BABCOCK & WILCOX CO

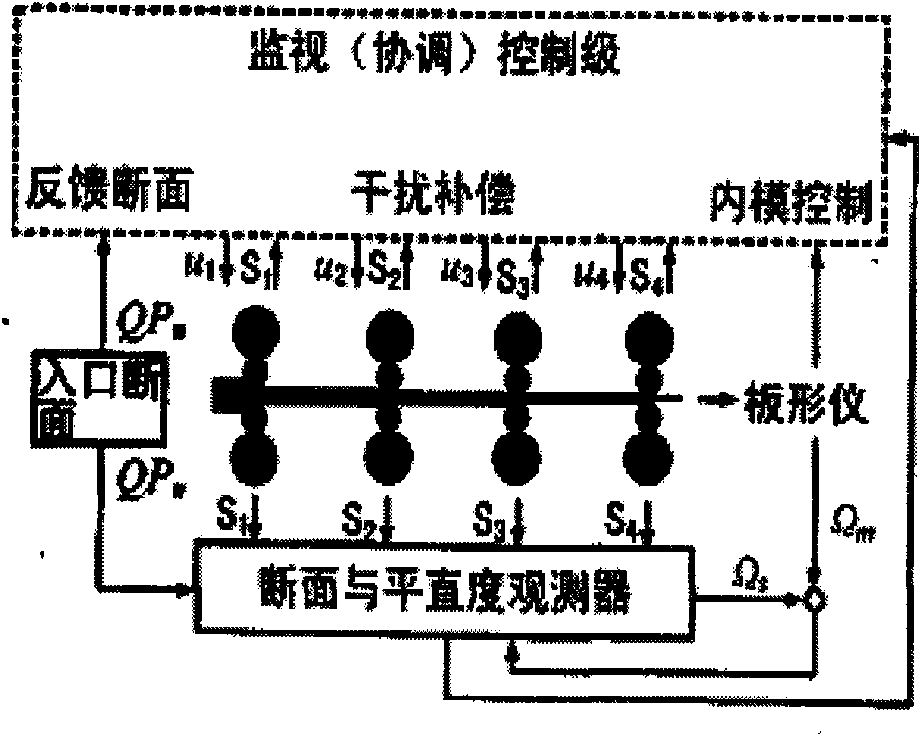

Integrated control method of cold-rolling strip steel flatness and lateral thickness difference

ActiveCN101683659AImprove stabilityGuaranteed stabilityMetal rolling arrangementsProfile control deviceStrip steelFeedback control

The invention discloses an integrated control method of cold-rolling strip steel flatness and lateral thickness difference, comprising: moderately and mainly controlling the shape of the strip steel section on the upstream rack of a cold-rolling mill, and mainly controlling strip steel flatness on the downstream rack; based on a profiler configured on a No.1 rack inlet of the cold-rolling mill, actually measuring and hot rolling incoming material section shape and flatness and rolling technological parameter measured values of each rack, wherein the rolling technological parameter measured values comprise rolling force and a plate shape regulating mechanism measured value; actually measuring the cold-rolling strip steel flatness on the basis of a shape meter configured on the cold-rollingmill outlet; performing feed-forward control to the shape of the strip steel section by taking the upstream rack, in particular the No. 1 rack as a key point; and performing feedback control to the strip steel flatness by taking the downstream rack, in particular an end rack as a key point to realize integrated control to the cold-rolling strip steel flatness and lateral thickness difference. Theinvention performs integrated coordination control by the strip steel flatness and section shape and reduces cold-rolling strip steel lateral thickness difference on the basis of further improving cold-rolling strip steel flatness quality.

Owner:BAOSHAN IRON & STEEL CO LTD

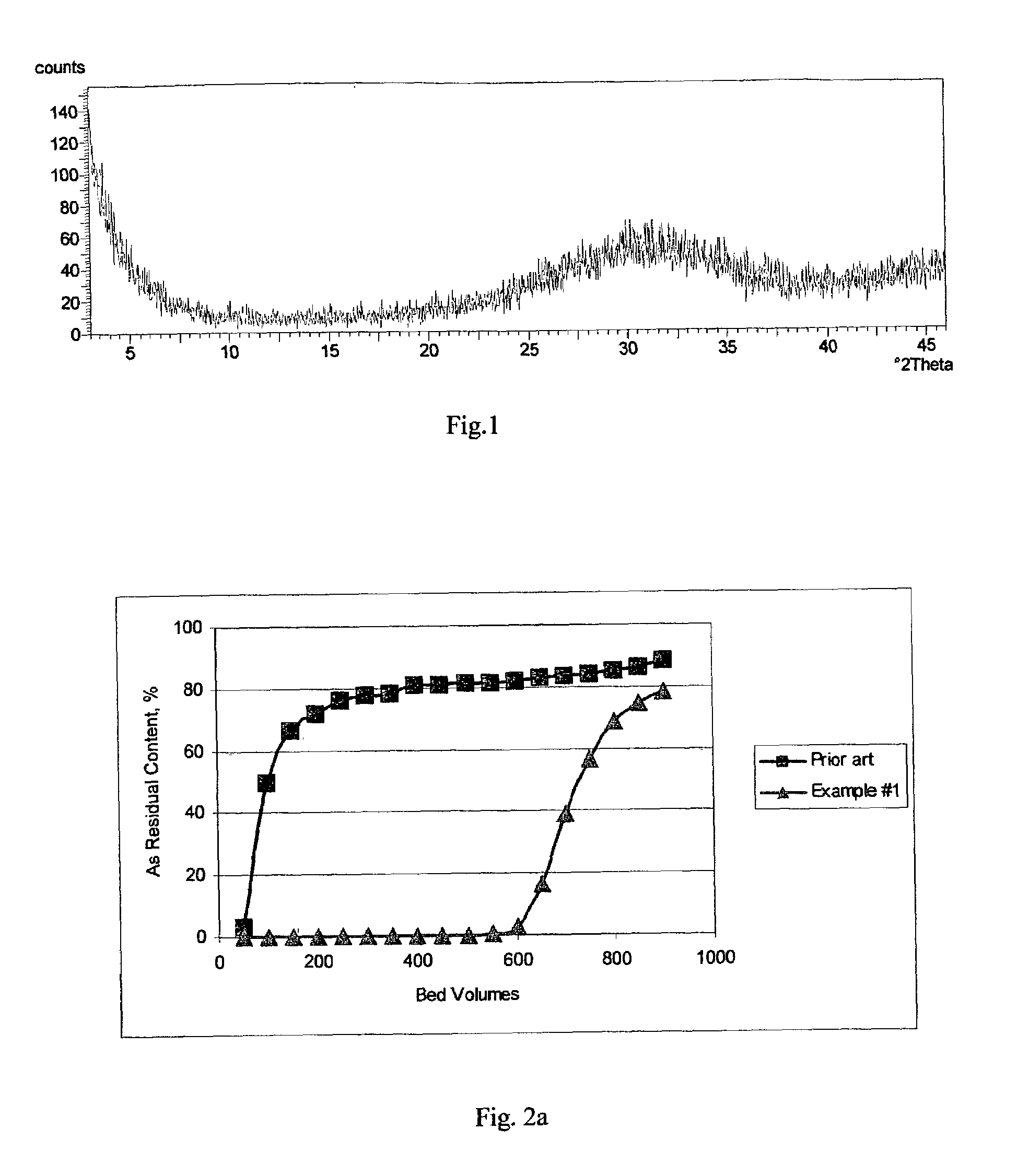

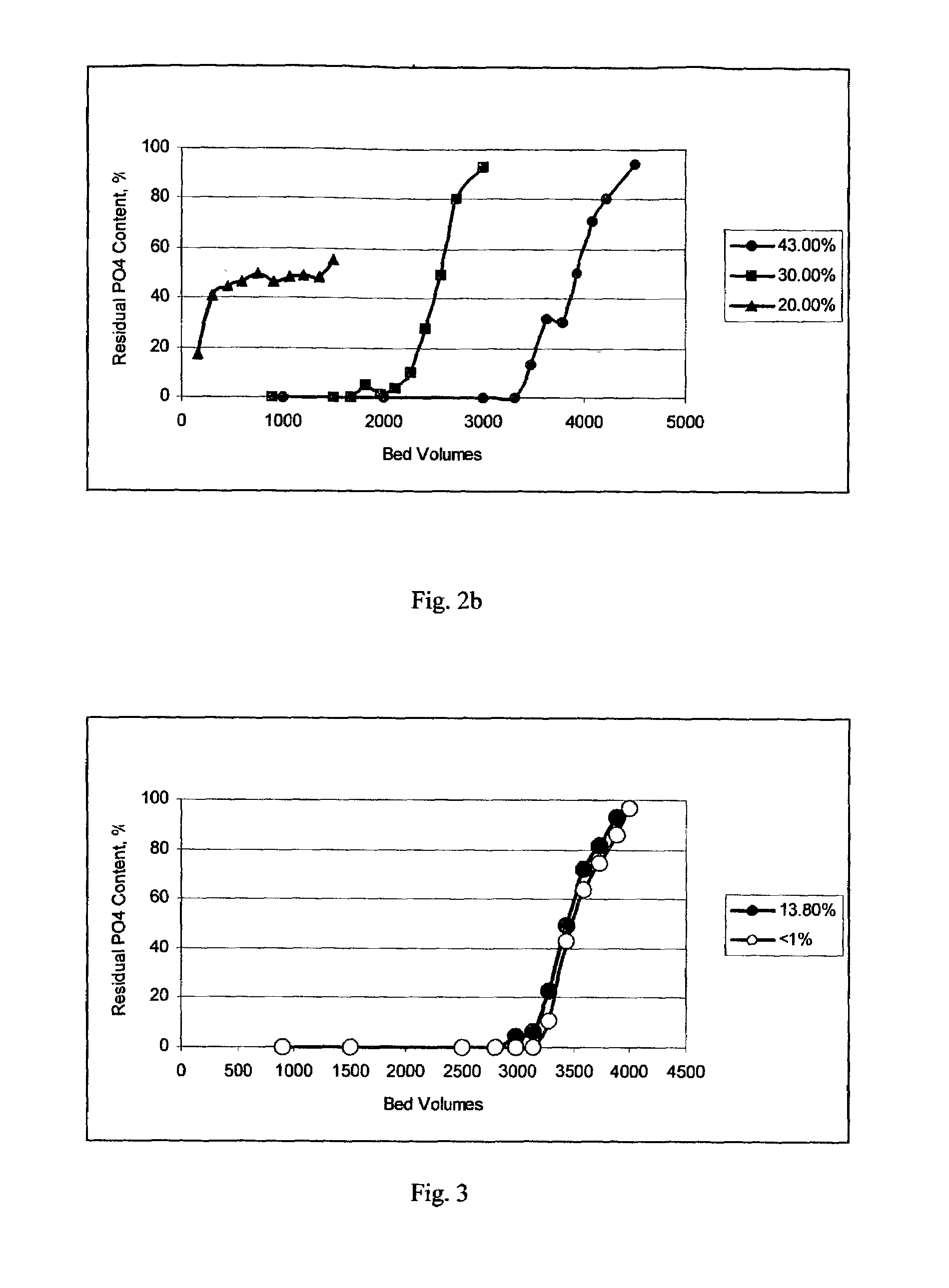

Hydrous zirconium oxide, hydrous hafnium oxide and method of making same

ActiveUS7252767B2Loss of stabilityDegree of reductionOther chemical processesSolid sorbent liquid separationIonIon exchange

The present invention features a method of making hydrous zirconium oxide having desirable properties, including resistance to moisture content, predetermined particle size, and developed porosity and surface area. The inventive material is suitable for use as an ion exchanger, a catalyst and a catalyst support. The process comprises providing a liquid comprising a zirconium compound and an alkali metal-containing reagent. The alkali metal-containing reagent may comprise a compound selected from the group consisting of MOH-M2SO4, MOH-M3PO4, and combinations thereof, where M is at least one of Li, Na and K. The zirconium compound may be treated with the alkali metal-containing reagent effective to form a mixture which achieves an uptake of alkali metal in an amount ranging from 0.5 to 2.5 meq / g. The mixture is reacted to form the hydrous zirconium oxide. A molar ratio of SO4 / Zr and PO4 / Zr in the mixture may range from 0.2-0.7:1. The mixture may be heated at a temperature ranging from 80 to 150° C. to produce a reaction product. The reaction product may be treated with acid having a pH ranging from 4 to 8 at a temperature ranging from 20 to 60° C. to form the hydrous zirconium oxide. Also featured is a method of making hydrous hafnium oxide. The inventive hydrous zirconium oxide and hydrous hafnium oxide are characterized by at least one of the following: stability against moisture loss, a particular surface area, a particular pore size distribution, an affinity towards anions including at least one of PO4, HPO4, H2PO4, AsO4, HAsO4, H2AsO4 and AsO3, oxoanions of Cr, Se, B, Mo,and W, and / or resistance against poisoning by SiO3 and SO4.

Owner:MEL CHEM

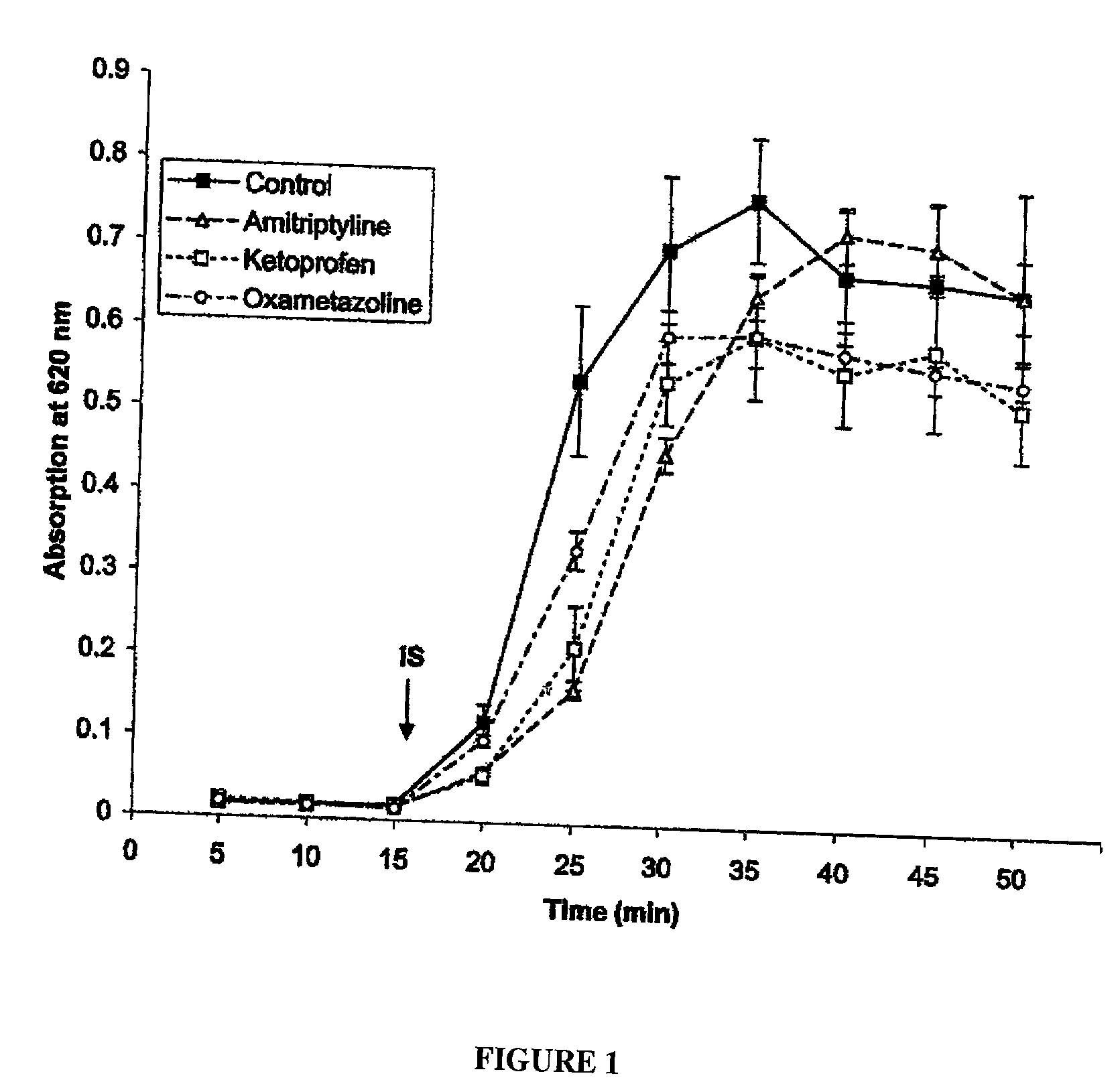

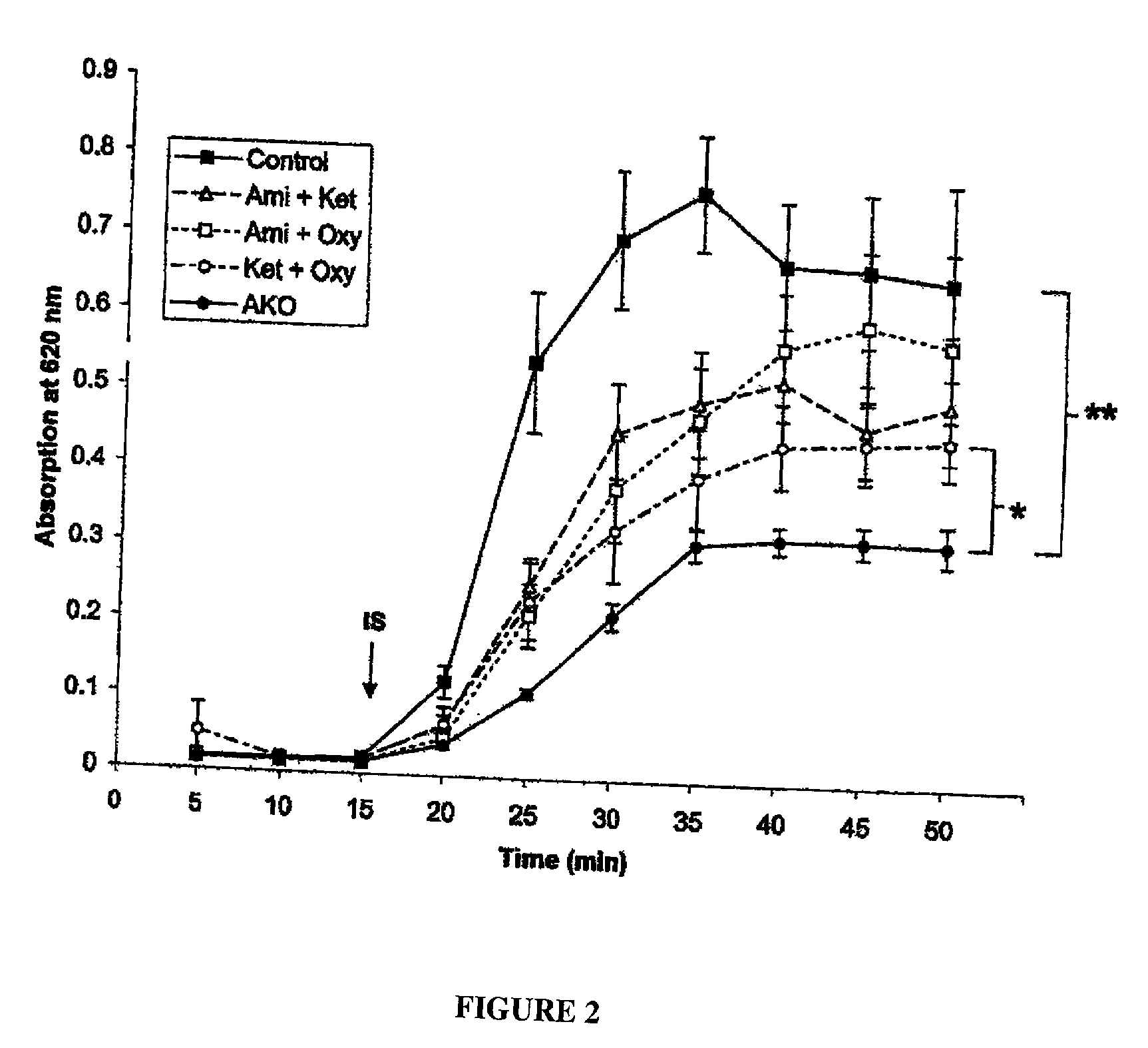

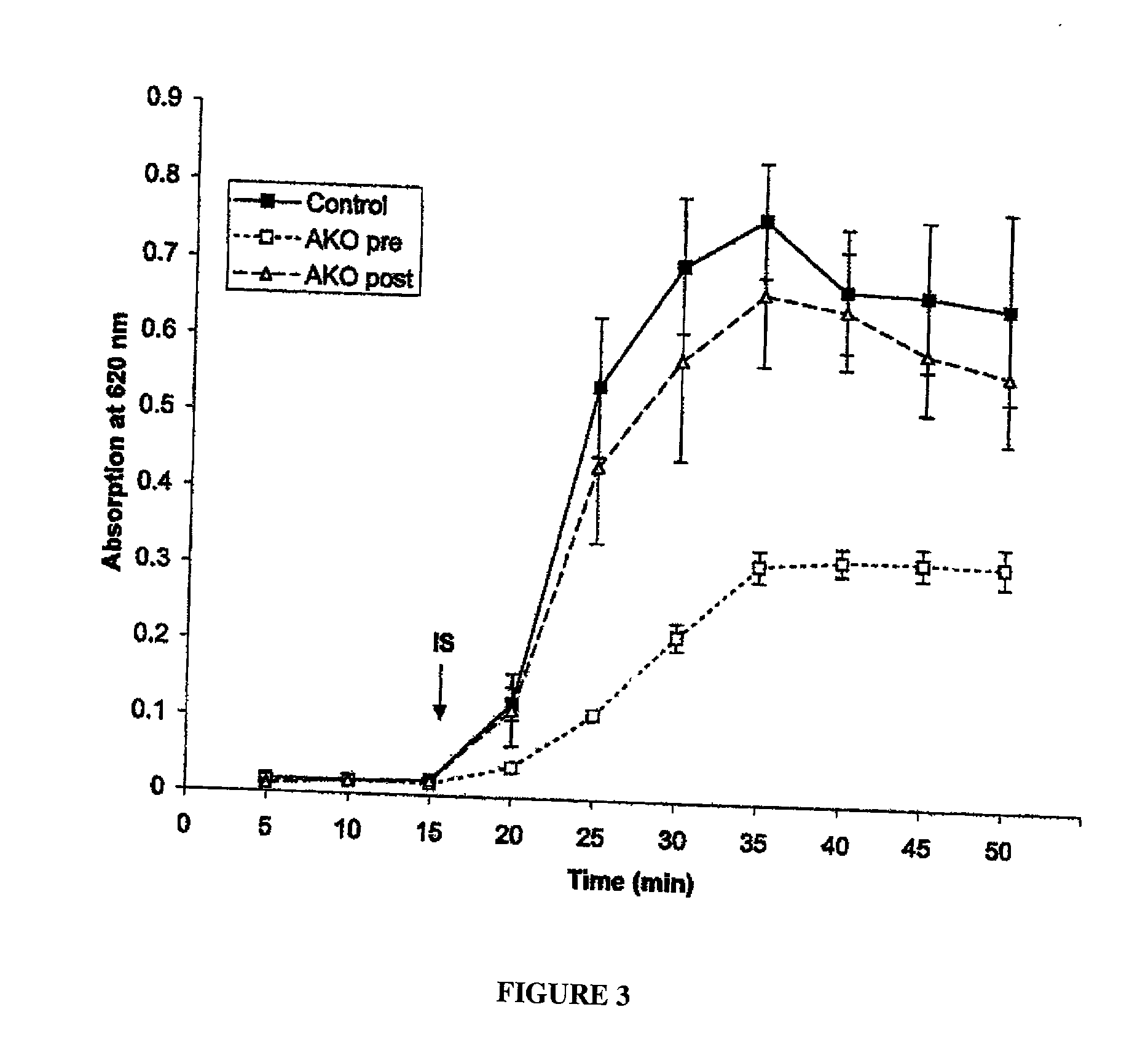

Arthroscopic irrigation solution and method for peripheral vasoconstriction and inhibition of pain and inflammation

InactiveUS20030087962A1Control inflammationPain controlBiocideKallidin/bradykinin ingredientsArteriolar VasoconstrictionInflammation Process

A method and solution for perioperatively inhibiting a variety of pain and inflammation processes during arthroscopic procedures. The solution preferably includes a vasoconstrictor that demonstrates substantial agonist activity at alpha adrenergic receptors and that is selected for peripheral (local) vasoconstriction and one or more additional pain and inflammation inhibitory agents at dilute concentration in a physiologic carrier, such as saline or lactated Ringer's solution. The solution is applied by continuous irrigation of a wound during a surgical procedure for peripheral vasoconstriction and inhibition of pain and / or inflammation while avoiding undesirable side effects associated with systemic application of larger doses of the agents.

Owner:OMEROS CORP

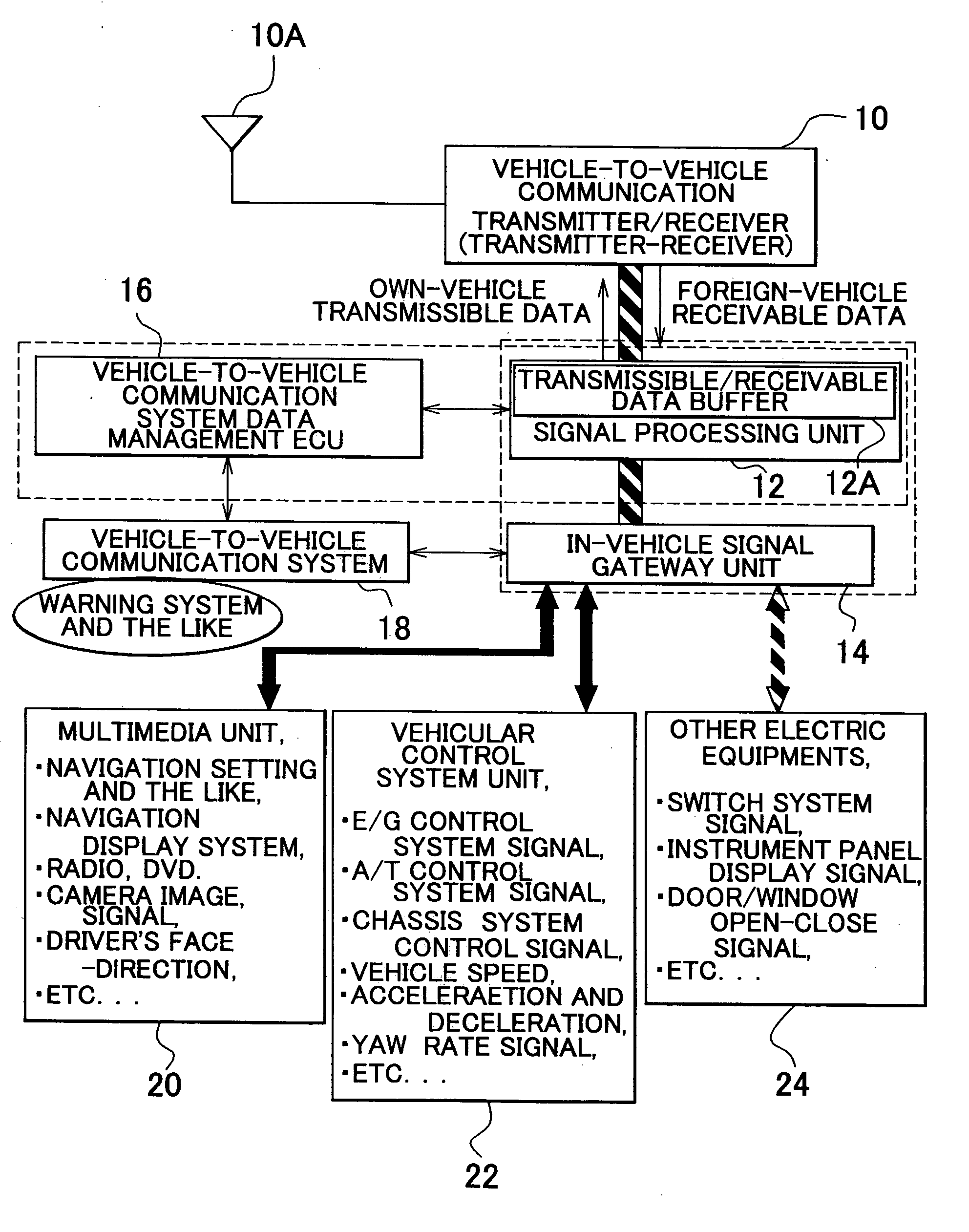

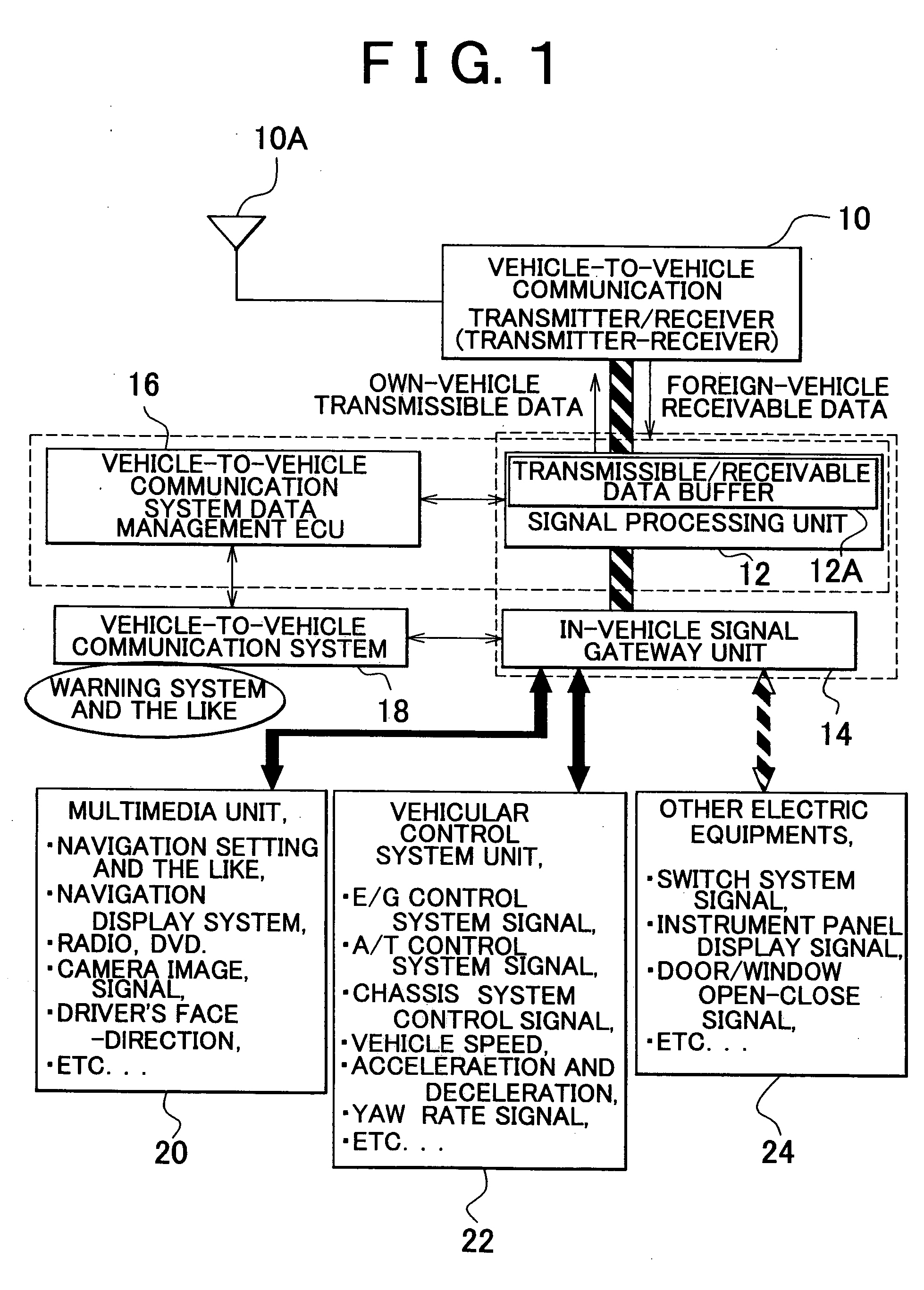

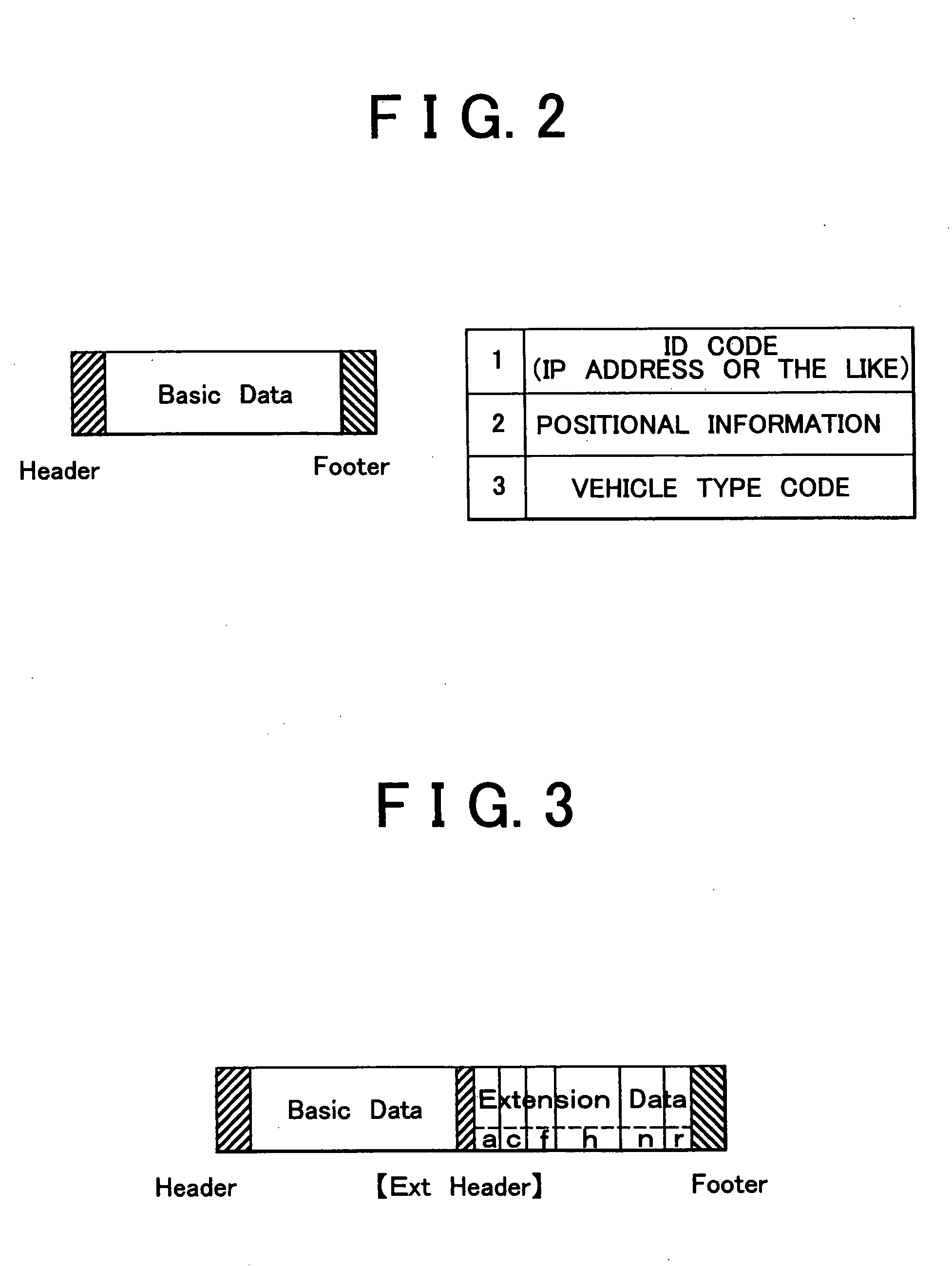

Communication apparatus

InactiveUS20040138809A1Degree of reductionImprove practicalityInstruments for road network navigationArrangements for variable traffic instructionsEngineeringE communication

A vehicular communication apparatus in accordance with the invention, which is installed in a vehicle and designed to establish bidirectional communication with a foreign moving object, comprises collection means for collecting a plurality of pieces of information obtained from the vehicle, selection means for selecting from the collected pieces of information those to be transmitted to the foreign moving object, and transmission means for transmitting only the selected pieces of information to the foreign moving object.

Owner:TOYOTA JIDOSHA KK

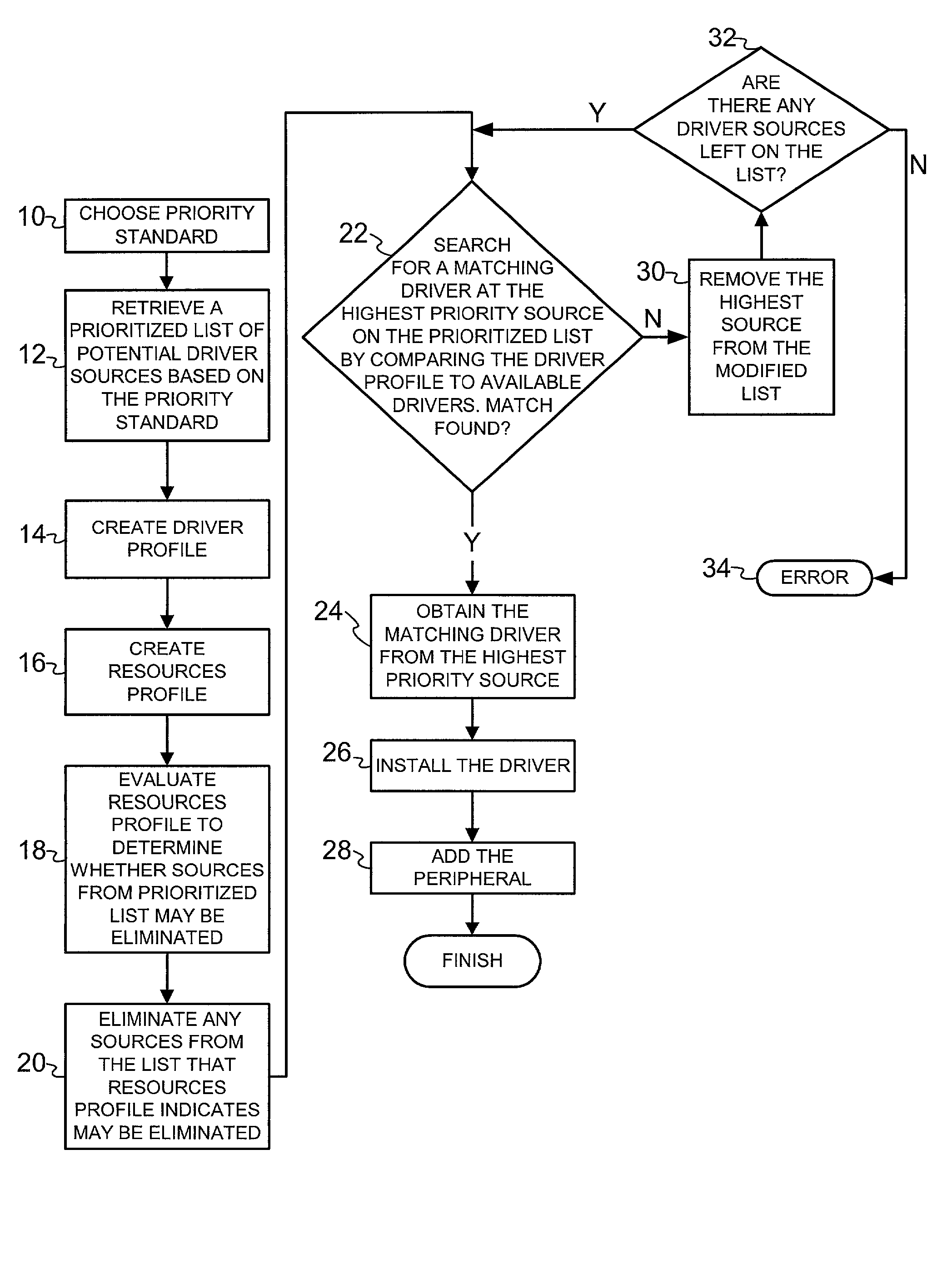

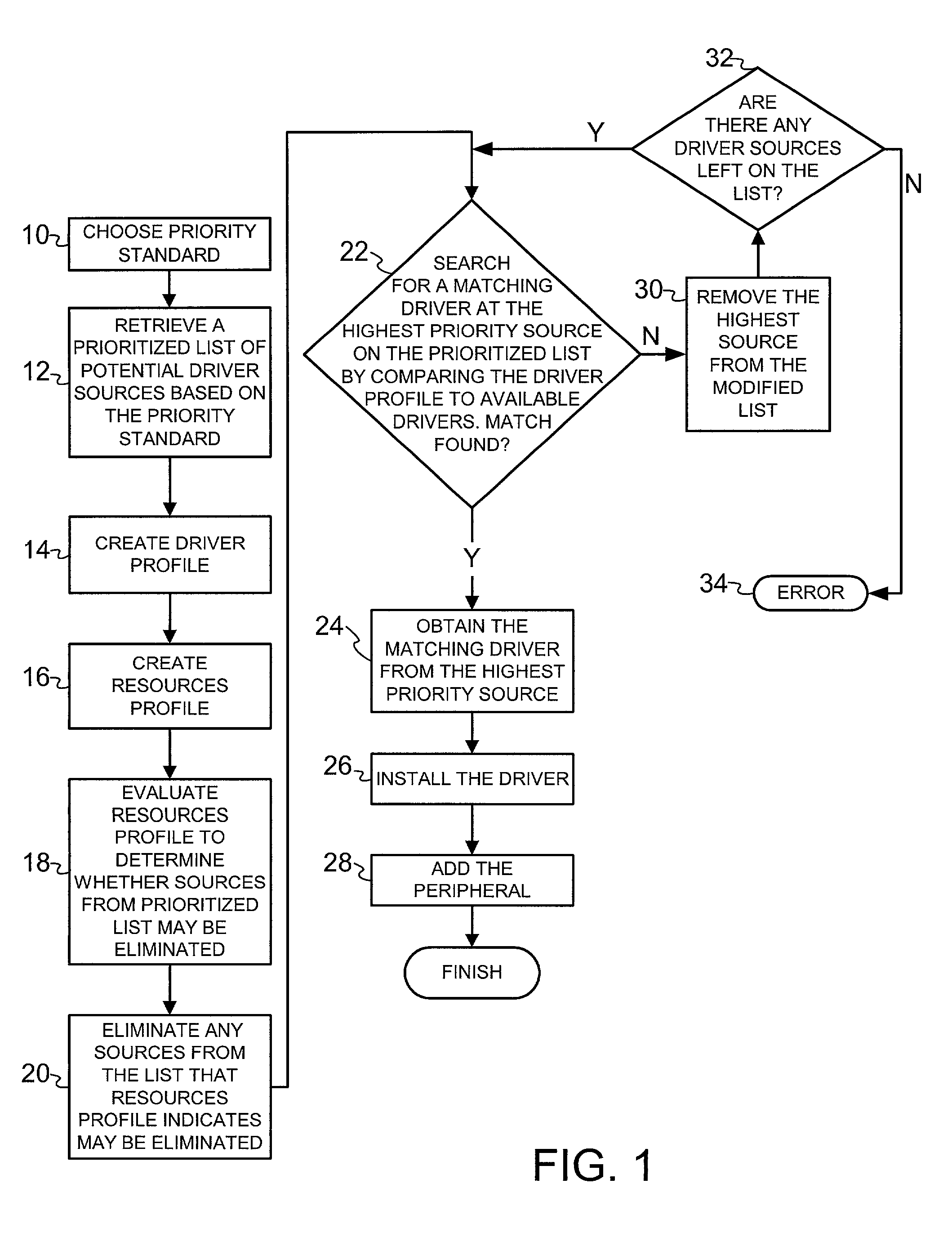

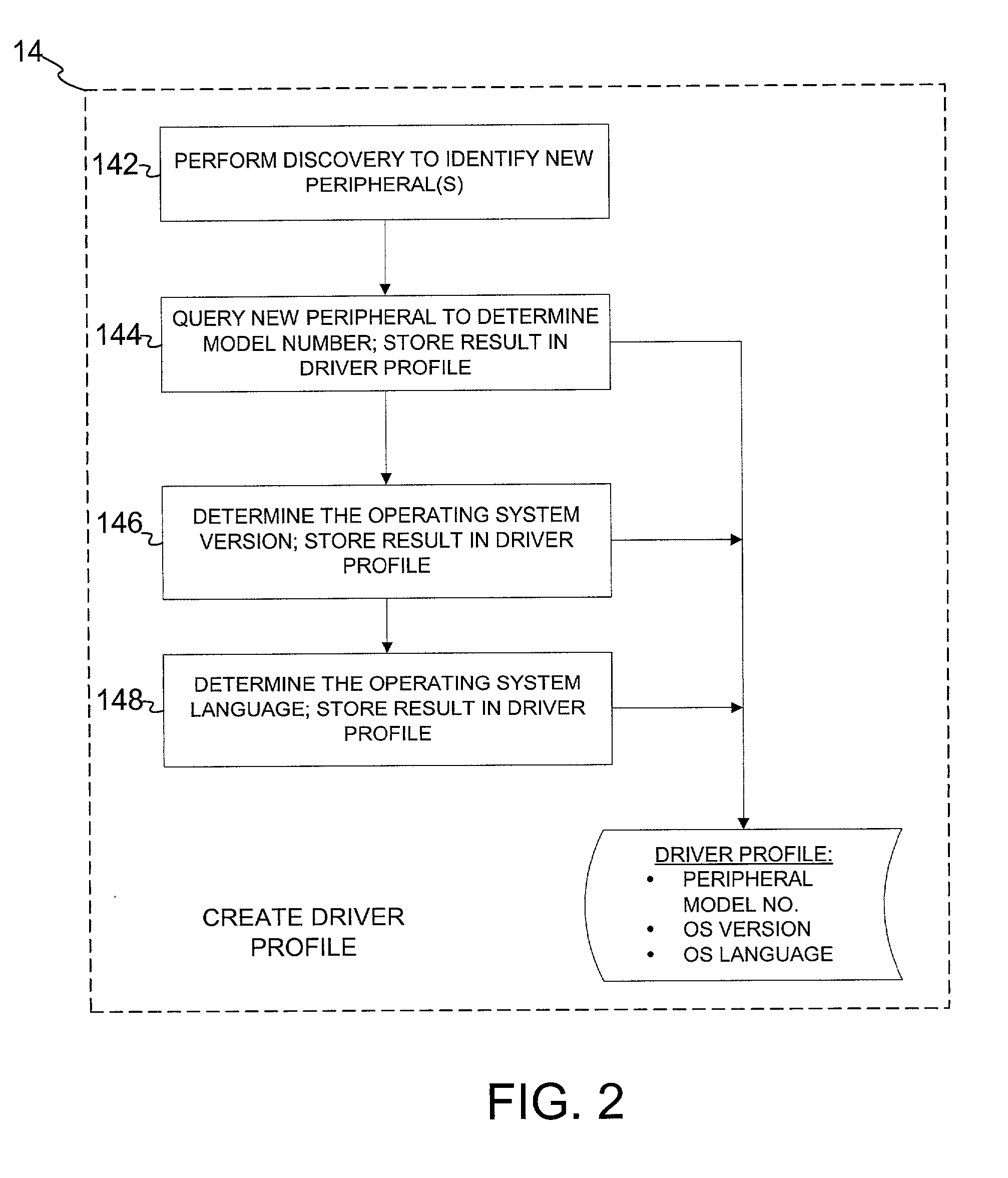

Peripheral driver installation method and system

InactiveUS20020129353A1Reduce degreeEfficiently placedProgram loading/initiatingMemory systemsPotential sourceOperating system

A method for locating and installing peripheral drivers has steps of creating a driver profile, creating a resources profile, and of looking to potential driver sources on a prioritized list for drivers that match the driver profile. The driver profile may comprise information such as the peripheral model number, the operating system version number, and the operating system language determined through automated queries. The resources profile generally describes the resources available to the operating system in terms of access to the potential driver sources on the list, and may be used to eliminate sources from the list that are not accessible. The remaining sources on the list are checked in descending priority order until a driver matching the driver profile is found. Once a matching driver is found, it is installed on the operating system.

Owner:HEWLETT PACKARD DEV CO LP

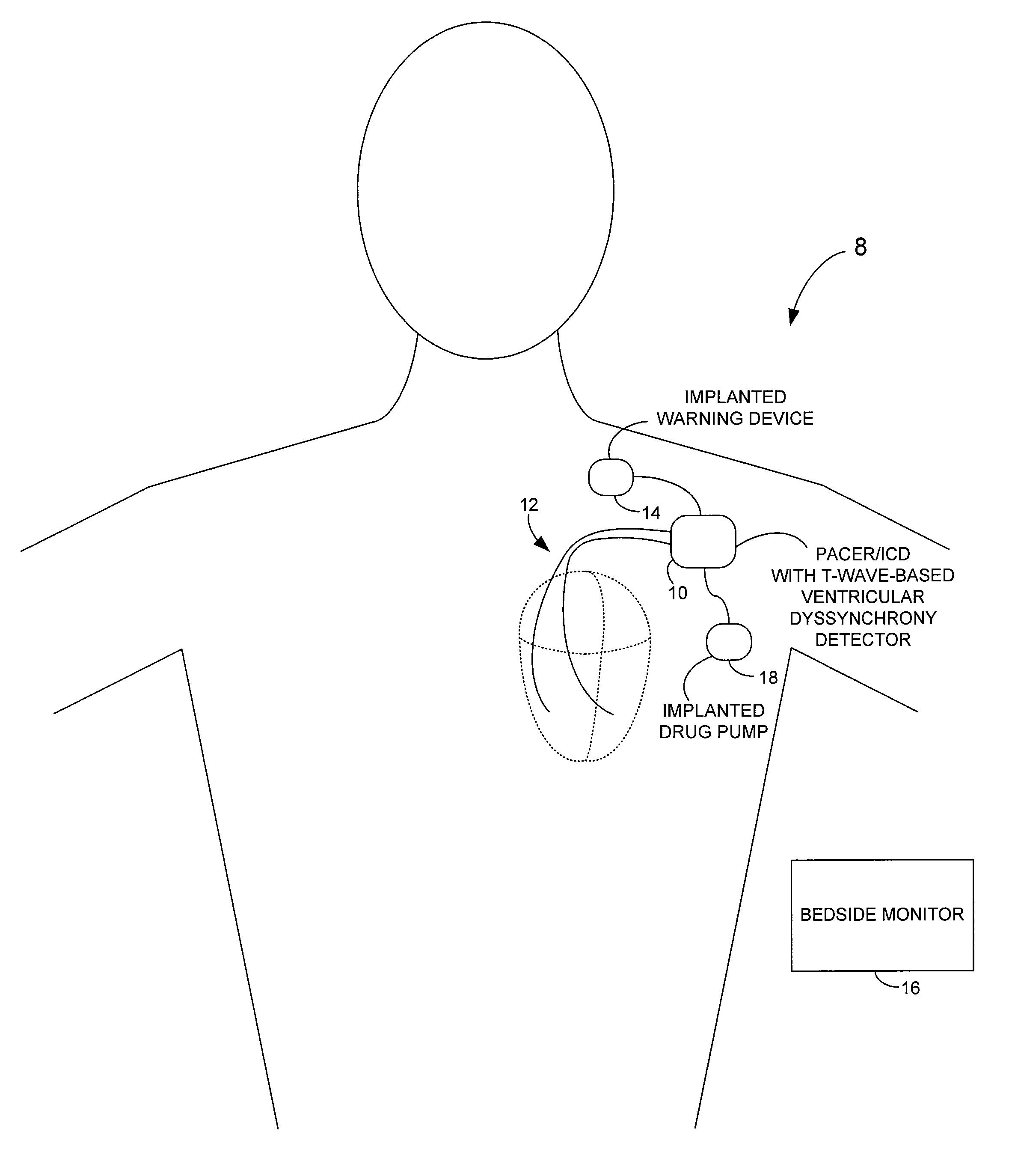

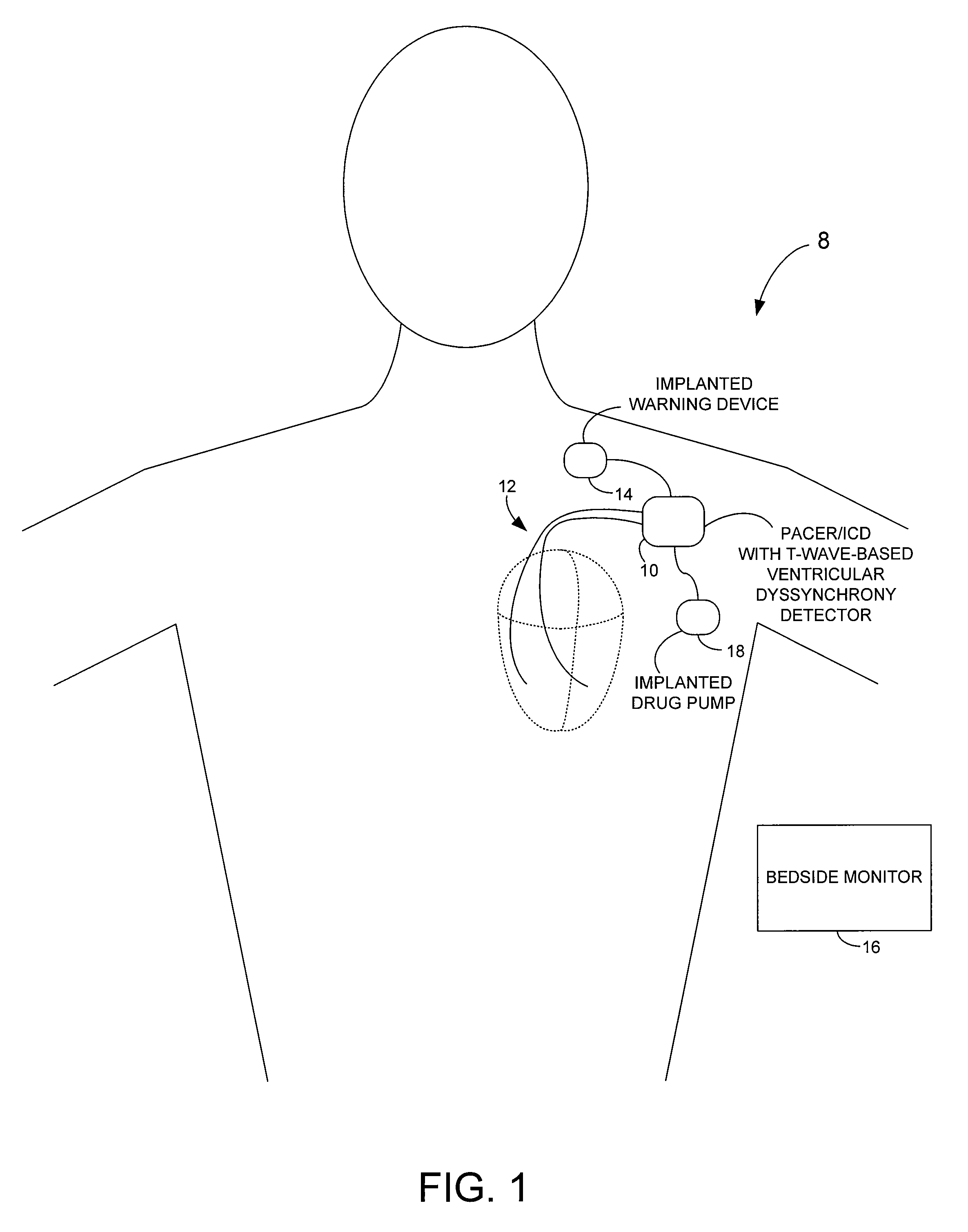

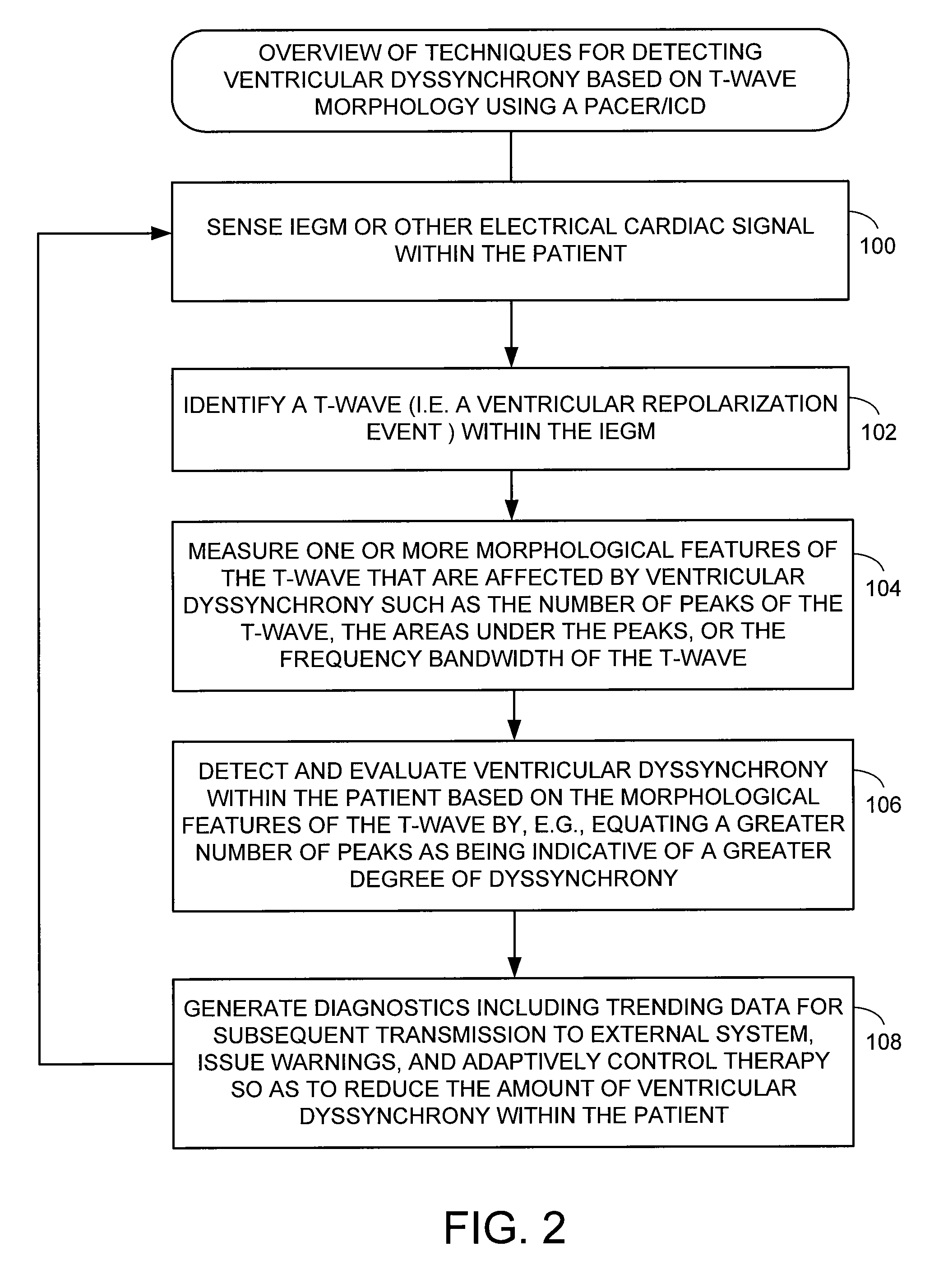

Systems and methods for use by an implantable medical device for evaluating ventricular dyssynchrony based on T-wave morphology

ActiveUS7676264B1Simple procedureReduce dyssynchronyElectrocardiographyHeart stimulatorsT waveSeverity/Intensity

Techniques are provided for detecting and evaluating ventricular dyssynchrony based on morphological features of the T-wave and for controlling therapy in response thereto. For example, the number of peaks in the T-wave, the area under the peaks, the number of points of inflection, and the slope of the T-wave can be used to detect ventricular dyssynchrony and evaluate its severity. As ventricular dyssynchrony often arises due to heart failure, the degree of dyssynchrony may also be used as a proxy for tracking the progression of heart failure. Pacing therapy is automatically and adaptively adjusted based on the degree of ventricular dyssynchrony so as to reduce the dyssynchrony and thereby improve cardiac function.

Owner:PACESETTER INC

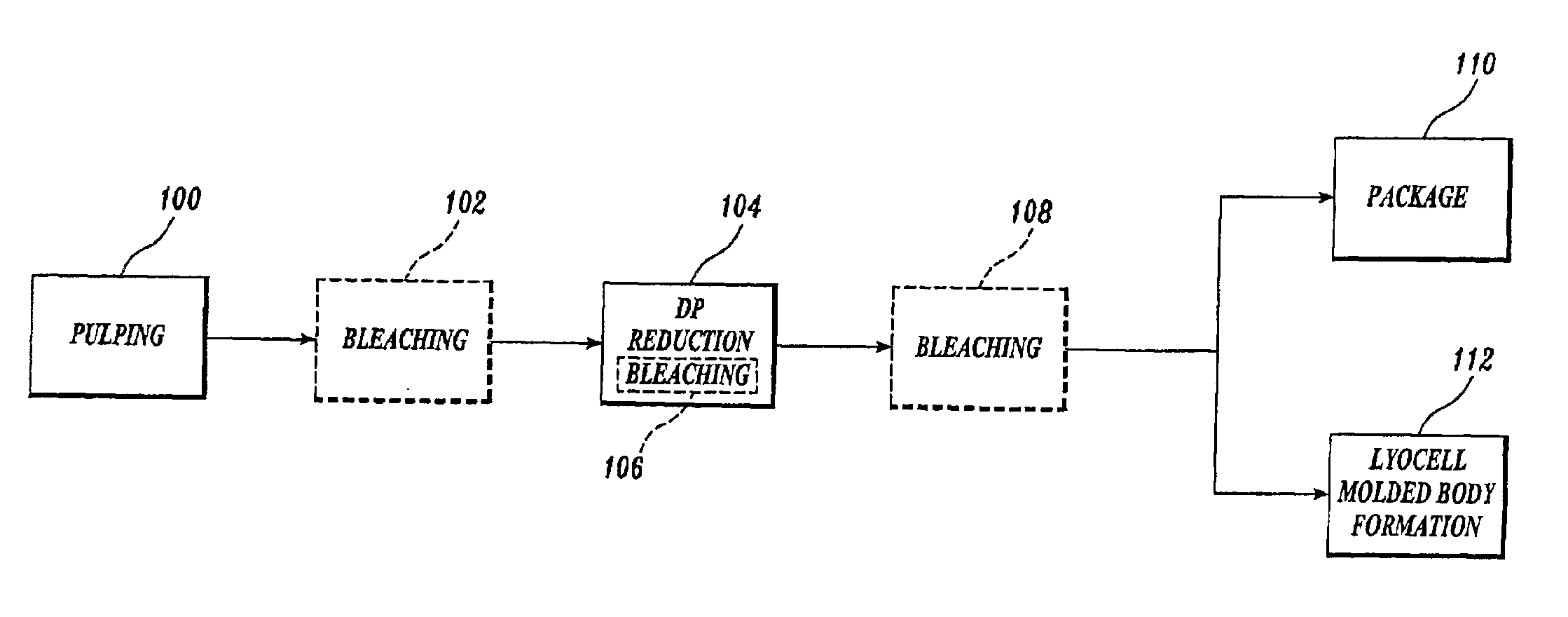

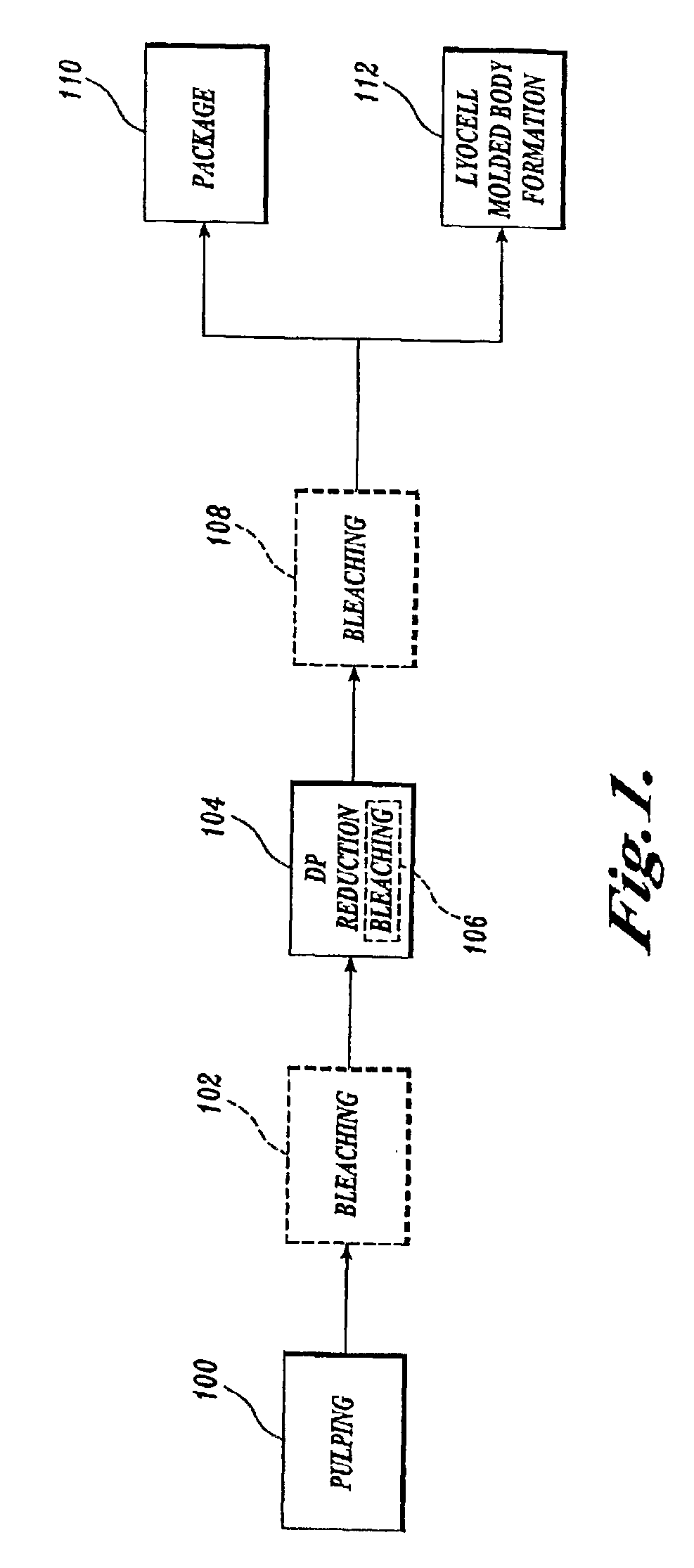

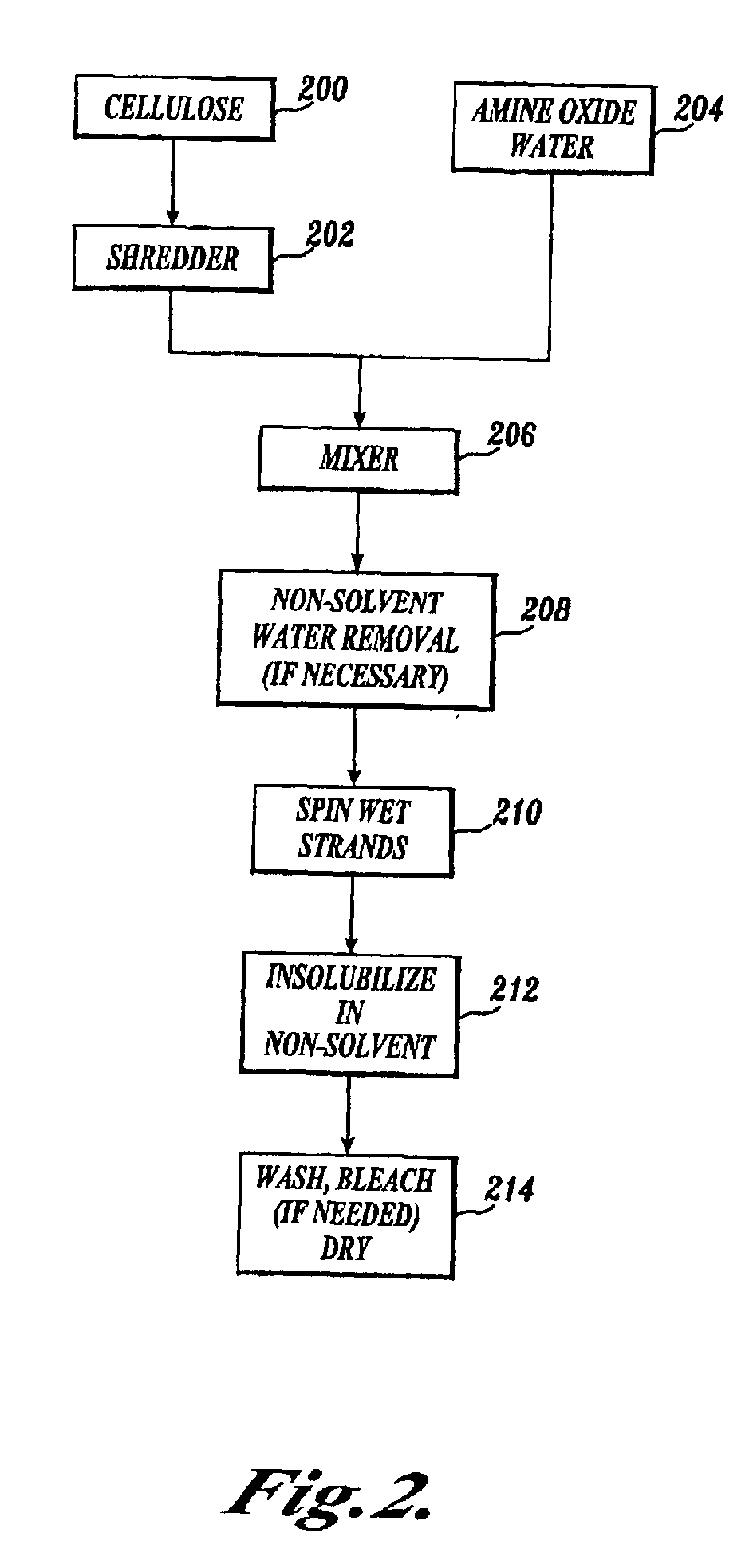

Process for making lyocell fiber from sawdust pulp

InactiveUS6861023B2Reducing average degree of polymerizationReduced hemicellulose contentPulp properties modificationArtificial filaments from cellulose solutionsCopperLyocell

A process for making lyocell fibers including the steps of pulping raw material in a digester to provide an alkaline pulp, wherein the raw material includes sawdust in an amount greater than 0% up to 100%; contacting the alkaline pulp including cellulose and at least about 7% hemicellulose under alkaline conditions with an amount of an oxidant sufficient to reduce the average degree of polymerization of the cellulose to the range of from about 200 to about 1100 without substantially reducing the hemicellulose content or substantially increasing the copper number of the pulp; and forming fibers from the pulp.

Owner:INT PAPER CO

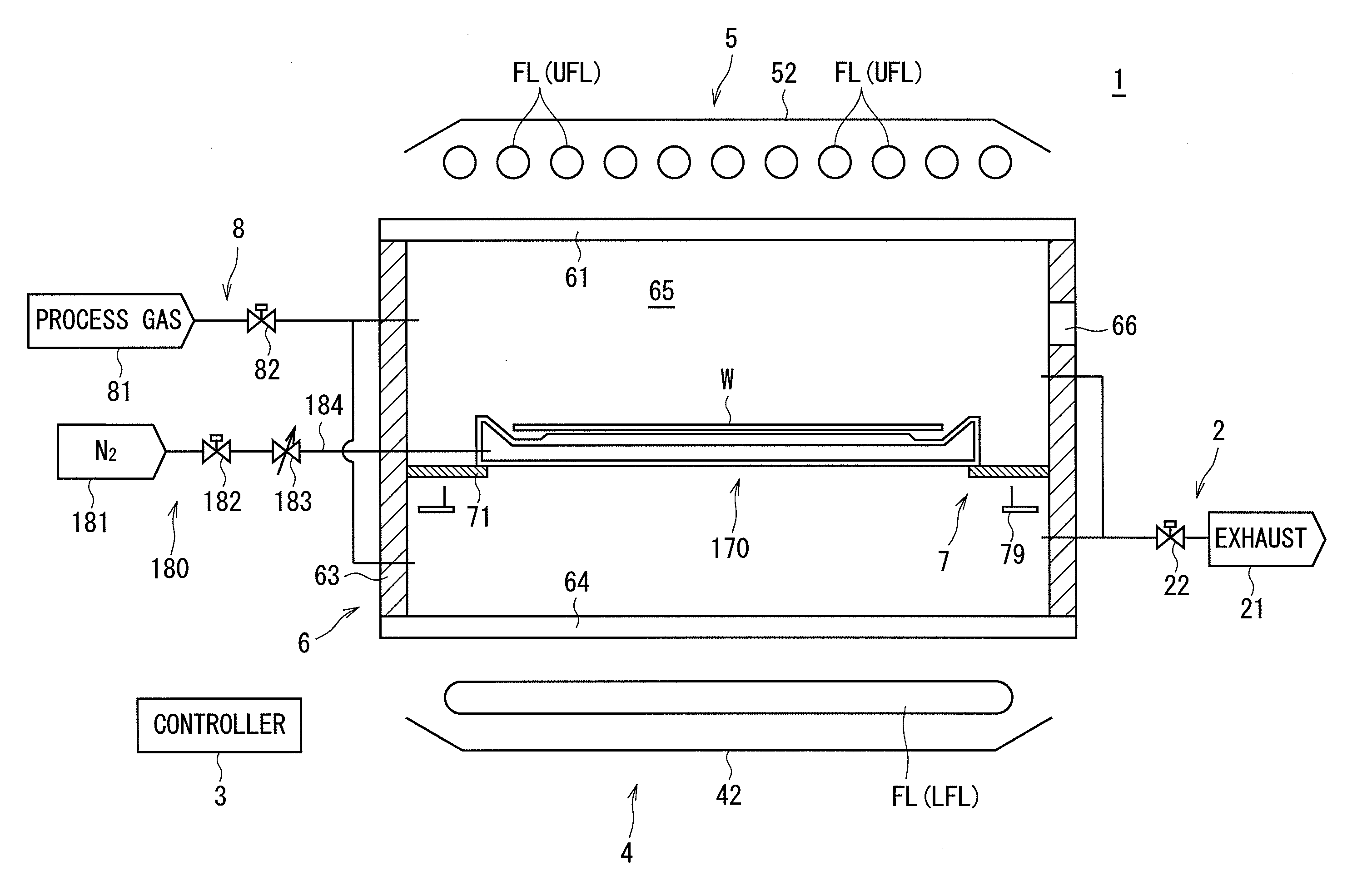

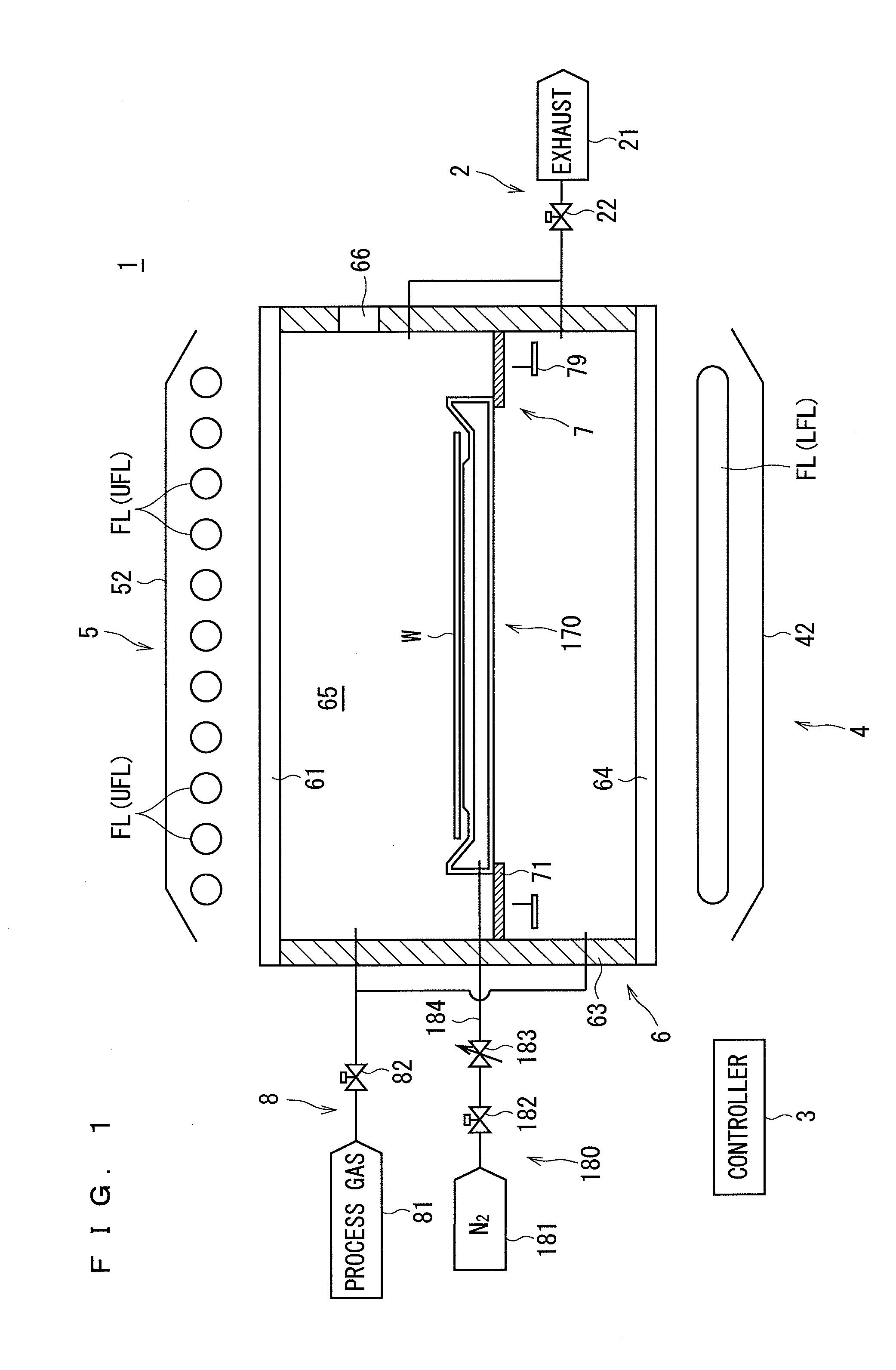

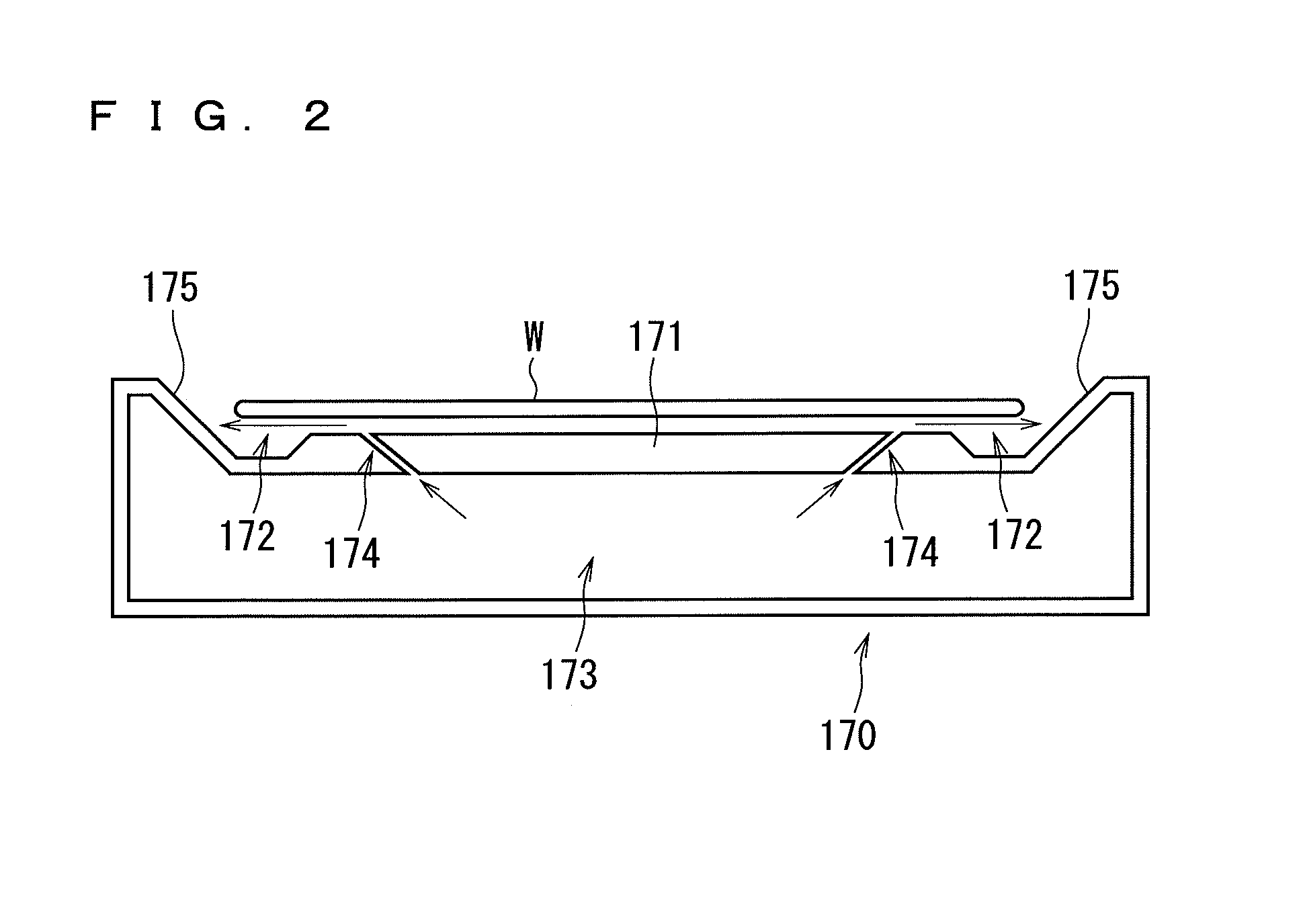

Heat treatment apparatus for heating substrate by irradiation with flashes of light, and heat treatment method

ActiveUS20130203269A1Degree of reductionAvoid crackingMuffle furnacesCharge supportsRoom temperatureEngineering

A first flash heating is performed in which a lower flash lamp irradiates a back surface of a semiconductor wafer with flashes of light, so that heat conduction from the back surface to a surface of the semiconductor wafer raises the temperature of the surface from the room temperature to an intermediate temperature. Then, a second flash heating is performed in which an upper flash lamp irradiates the surface of the semiconductor wafer with flashes of light, to raise the temperature of the surface of the semiconductor wafer from the intermediate temperature to a target temperature. Since only the irradiation with flashes of light emitted from the lower flash lamp and the upper flash lamp is used to cause the semiconductor wafer having the room temperature to reach the target temperature, all heat treatments can be completed in an extremely short time of one second or less.

Owner:DAINIPPON SCREEN MTG CO LTD

Method and apparatus for assisting or resisting postures or movements related to the joints of humans or devices

InactiveUS6846270B1Degree of reductionFunction increaseChiropractic devicesEye exercisersEngineeringStatic force

A process for accommodating, improving or transmuting random static and dynamic human functions to an object is provided. A device is selected which includes a proximal member and a distal member which articulate relative to one another at an interface. Energy is transmitted through the interface with a predetermined and variable efficacy. The interface is configured to permit static force to have perpendicular and parallel components relative to a primary plane of the interface and to permit a dynamic force to have a parallel component relative to the primary plane. An inertia at the interface is affected in terms of positive or negative affinity between the members and a proximity of the members to one another at the interface such that either the static or dynamic forces attract the members to one another at the interface, such that either the static or dynamic forces attract the members toward one another at the interface urging a contact whereby a tendency for a motion of one member relative to another at the interface is resisted and a tendency for the interface between the members to remain in a statically opposed position is assisted. Alternatively, the static and dynamic forces repel the members from one another at the interface urging a separation whereby a tendency for a motion of one relative to another at the interface is assisted and a tendency for the interface between the members to remain in a statically opposed position is resisted.

Owner:ETNYRE GRANT

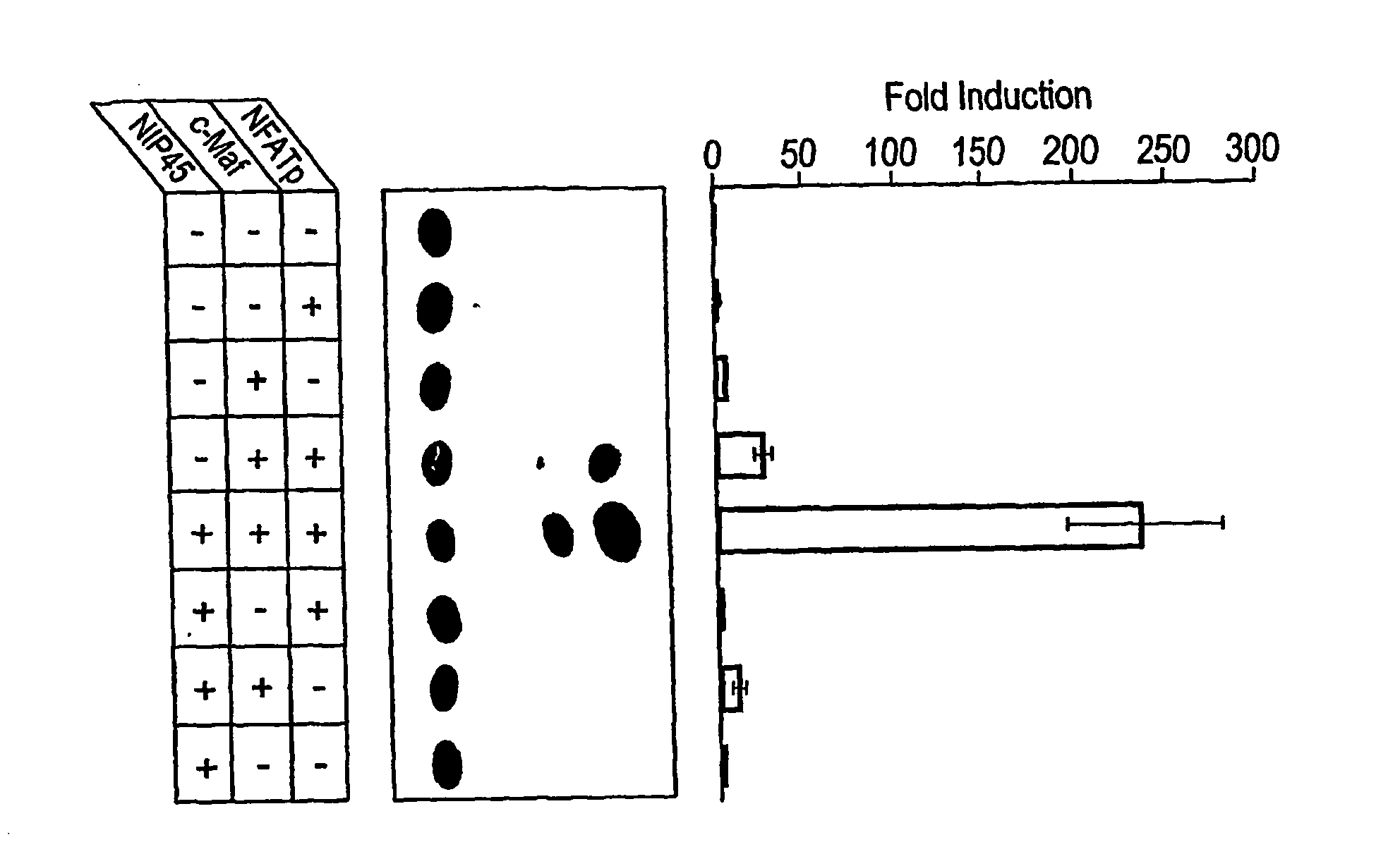

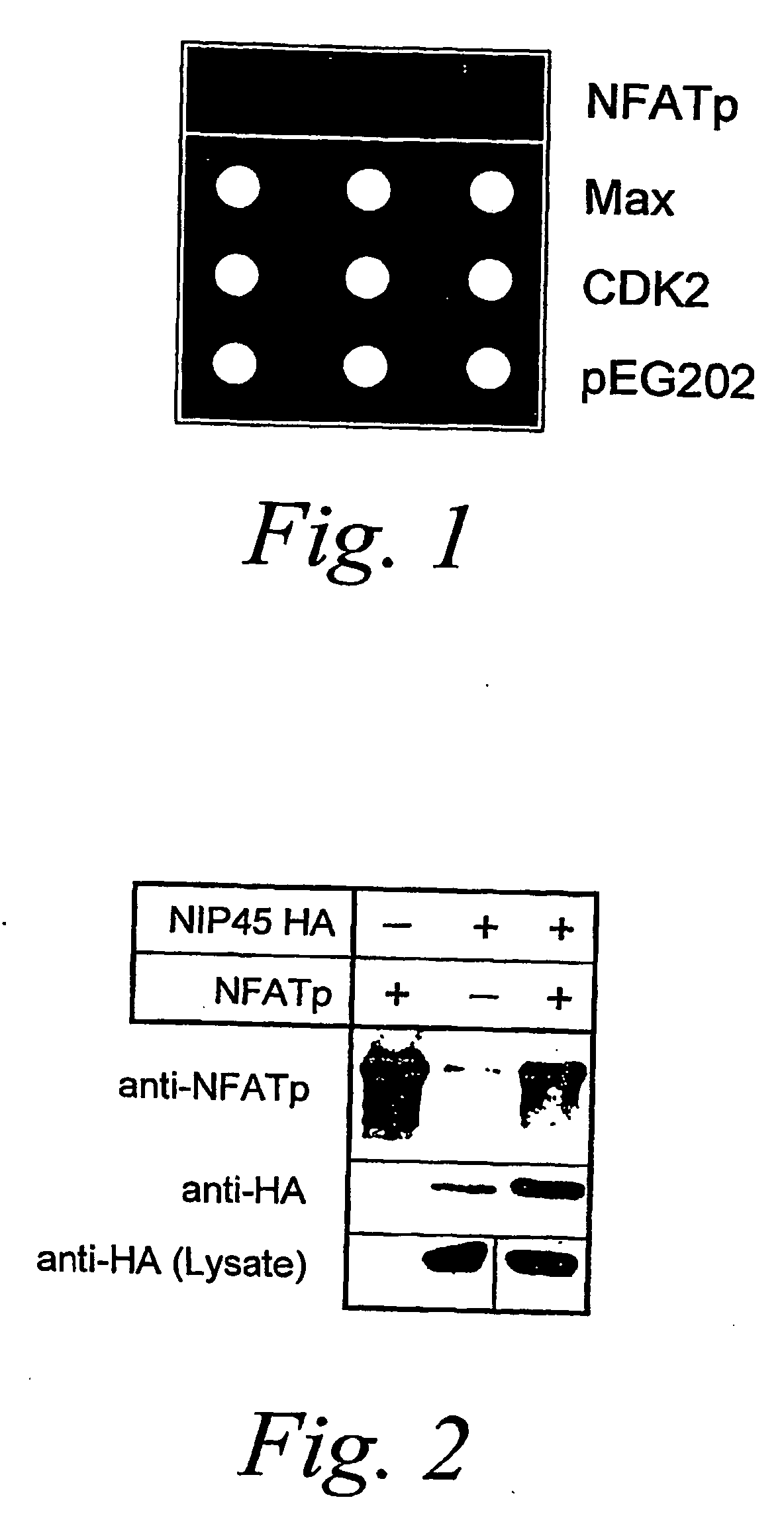

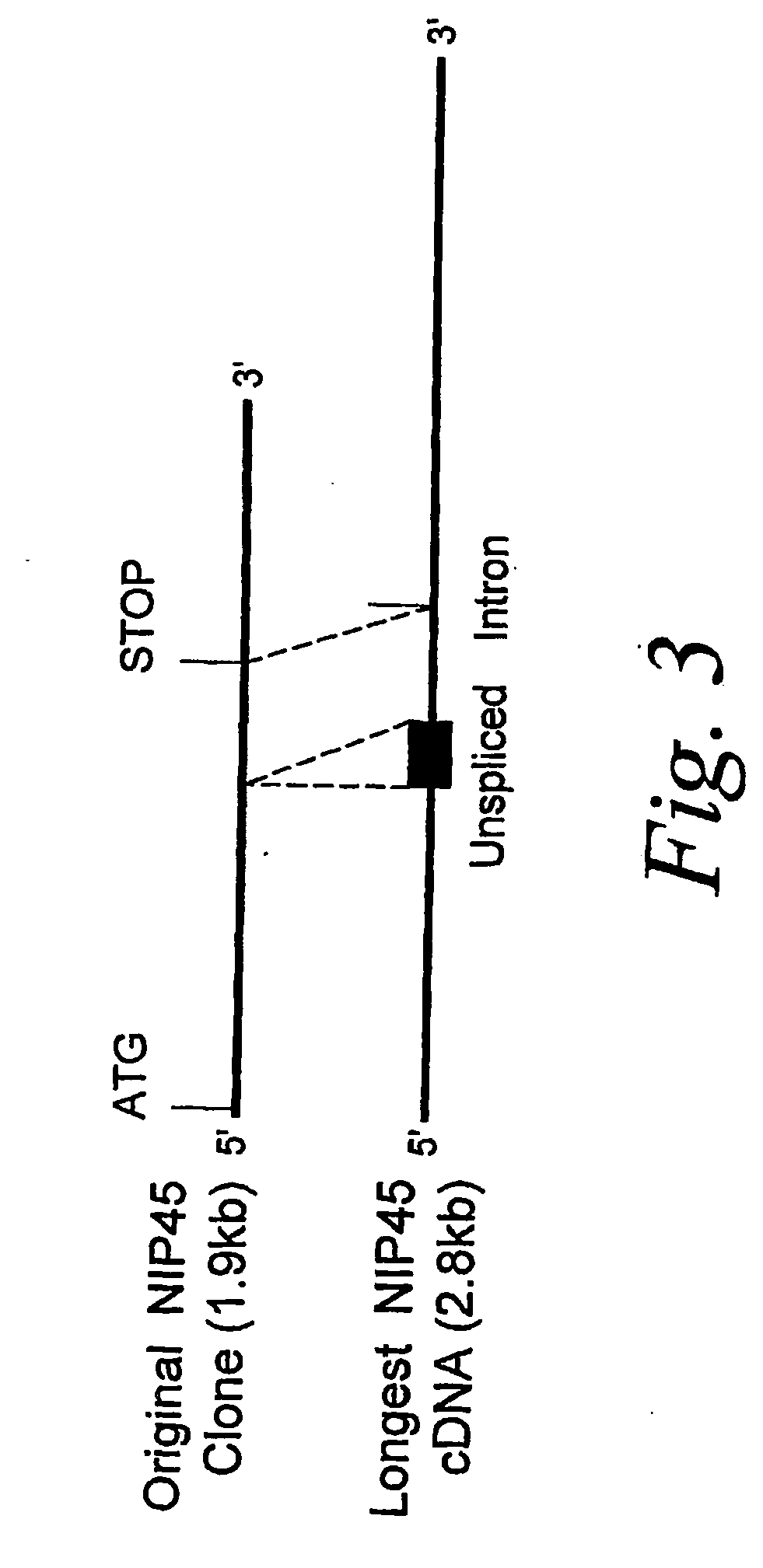

Modulation of immune system function by modulation of polypeptide arginine methyltransferases

InactiveUS20090048117A1Increase productionDegree of reductionMicrobiological testing/measurementLibrary screeningCytokineIMMUNOLOGIC CELLS

The instant invention pertains to, e.g., method of identifying a compound that modulates cytokine production or T cell receptor-mediated signaling, by identifying modulators of the expression and / or activity or PRMT polypeptides. The invention further pertains to methods for identifying a compound that modulates cytokine production in a non-T cell, by identifying compounds that modulate the expression and / or activity of NIP45. Methods for modulating cytokine production in cells by modulating the expression and / or activity of at least one molecule selected from the group consisting of: NIP45, PRMT1, and NFAT are also provided. The invention also pertains to methods for modulating the relative number of Th1 or Th2 cells is modulated and to methods of treating a subject that would benefit from the modulation of cytokine production comprising contacting an immune cell from the subject with an agent that modulates PRMT 1 expression and / or activity in the immune cell.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

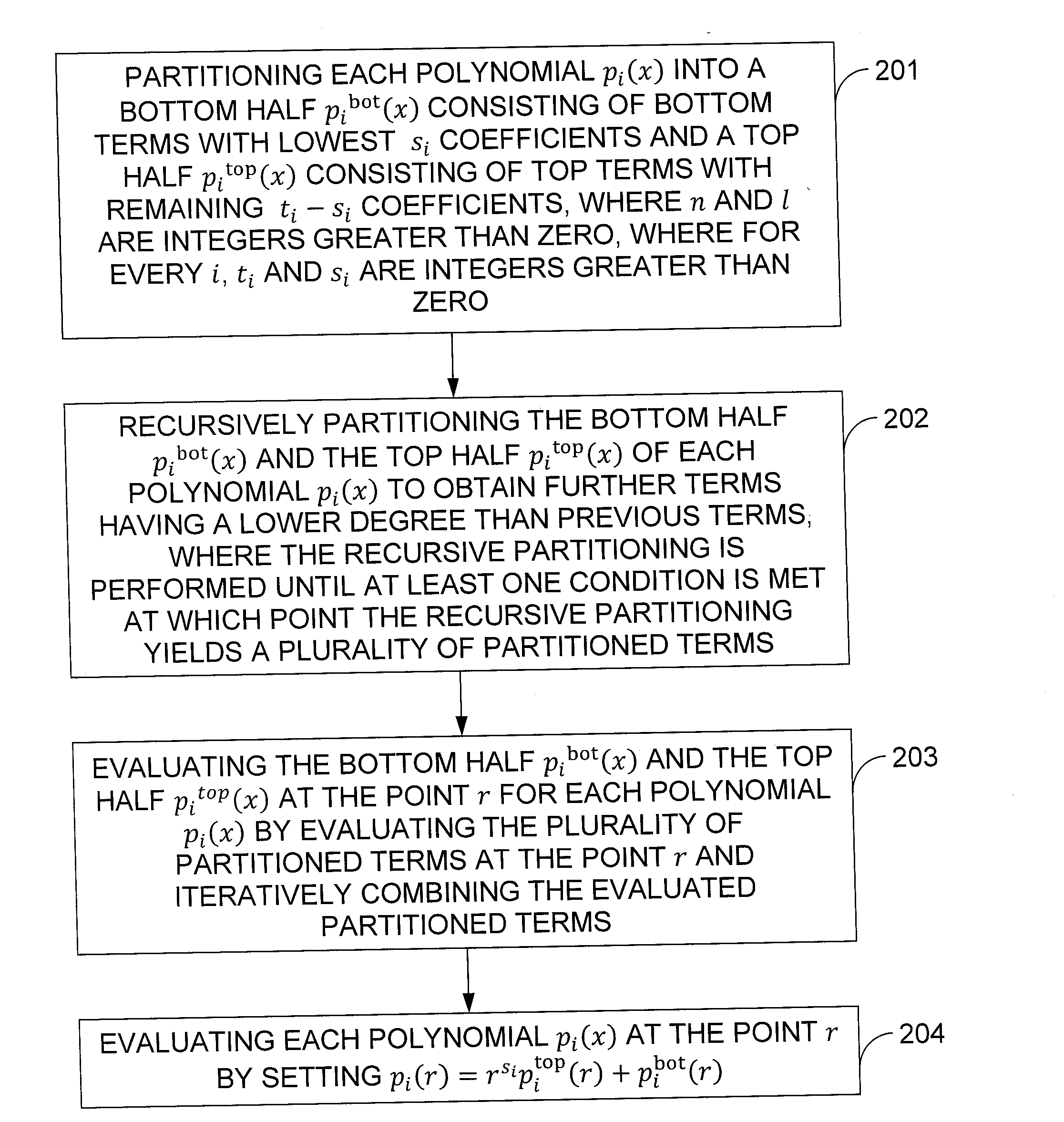

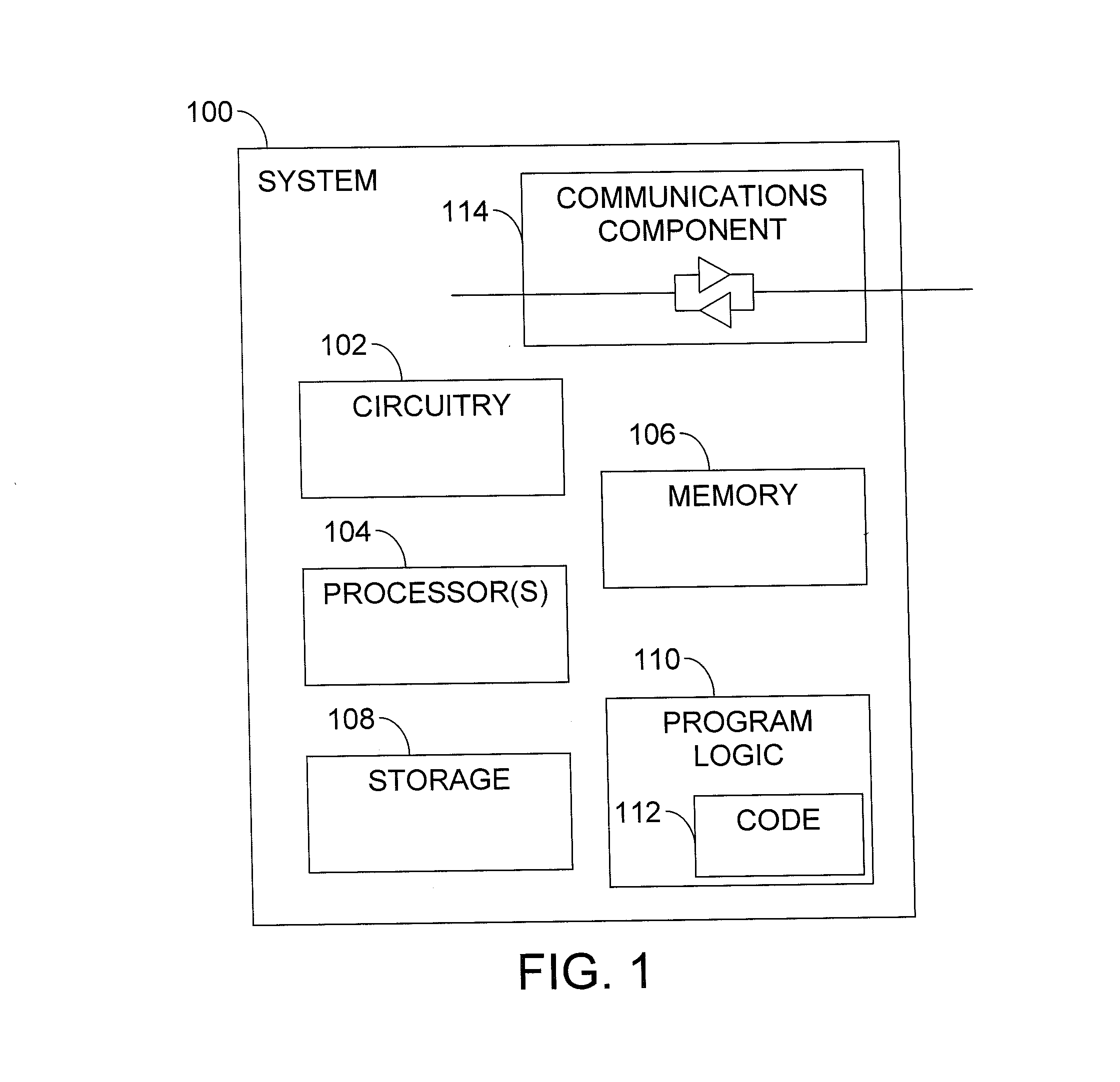

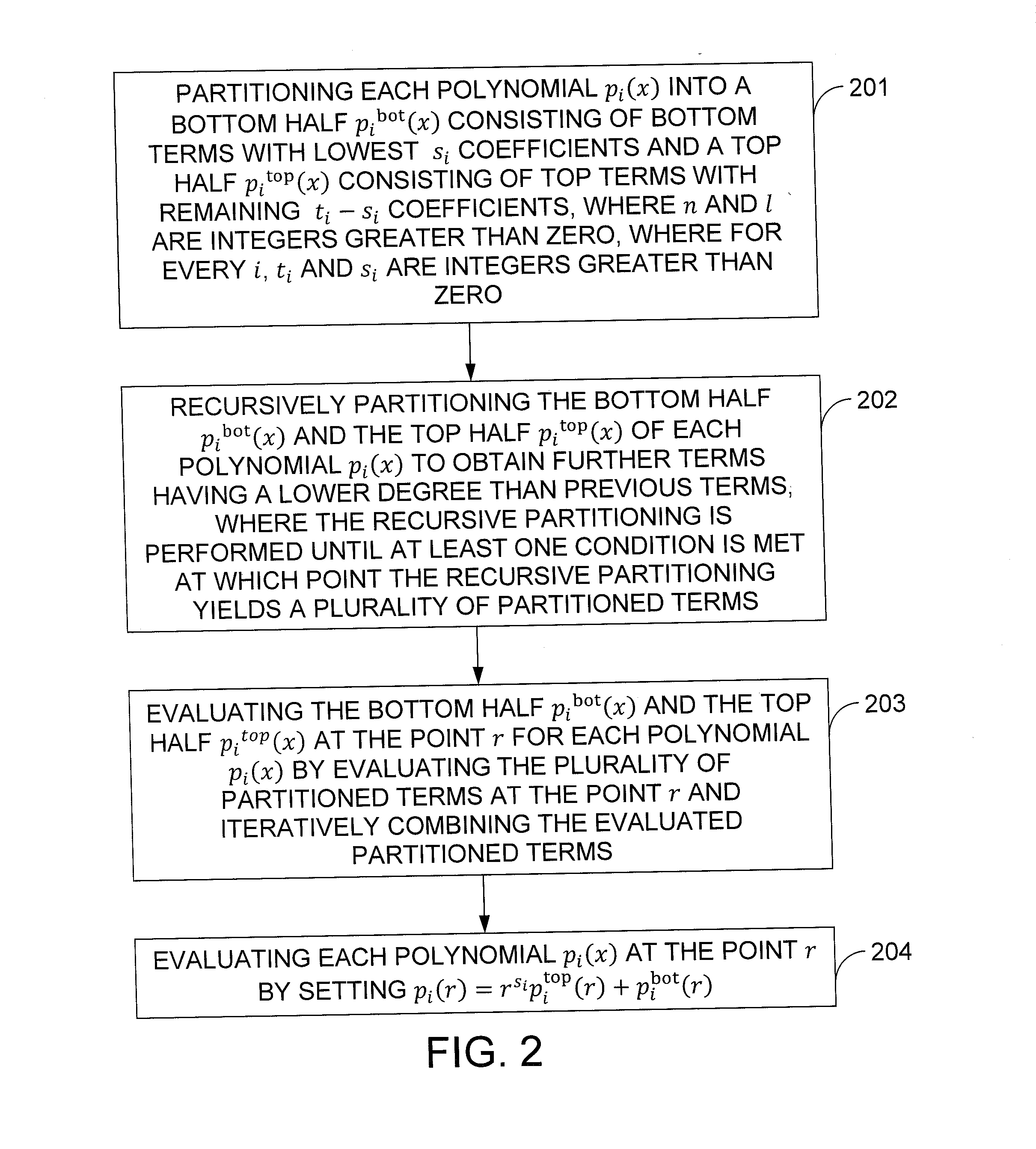

Fast Evaluation Of Many Polynomials With Small Coefficients On The Same Point

InactiveUS20120039463A1Degree of reductionSecret communicationCommunication with homomorphic encryptionComputational physicsRecursion

In one exemplary embodiment of the invention, a method for evaluating at point r one or more polynomials p1(x), . . . , pl(x) of maximum degree up to n−1, where the polynomial pi(x) has a degree of ti−1, the method including: partitioning each polynomial pi(x) into a bottom half pibot(x) with bottom terms of lowest si coefficients and a top half pitop(x) with top terms of remaining ti−si coefficients; recursively partitioning the bottom half pibot(x) and the top half pitop(x) of each polynomial pi(x) obtaining further terms having a lower degree than previous terms, performed until at least one condition is met yielding a plurality of partitioned terms; evaluating the bottom half pibot(x) and the top half pitop(x) at the point r for each polynomial pi(x) by evaluating the partitioned terms at the point r and iteratively combining the evaluated partitioned terms; and evaluating each polynomial pi(x) at the point r by setting pi(r)=rs<sub2>i< / sub2>pitop(r)+pibot(r).

Owner:IBM CORP

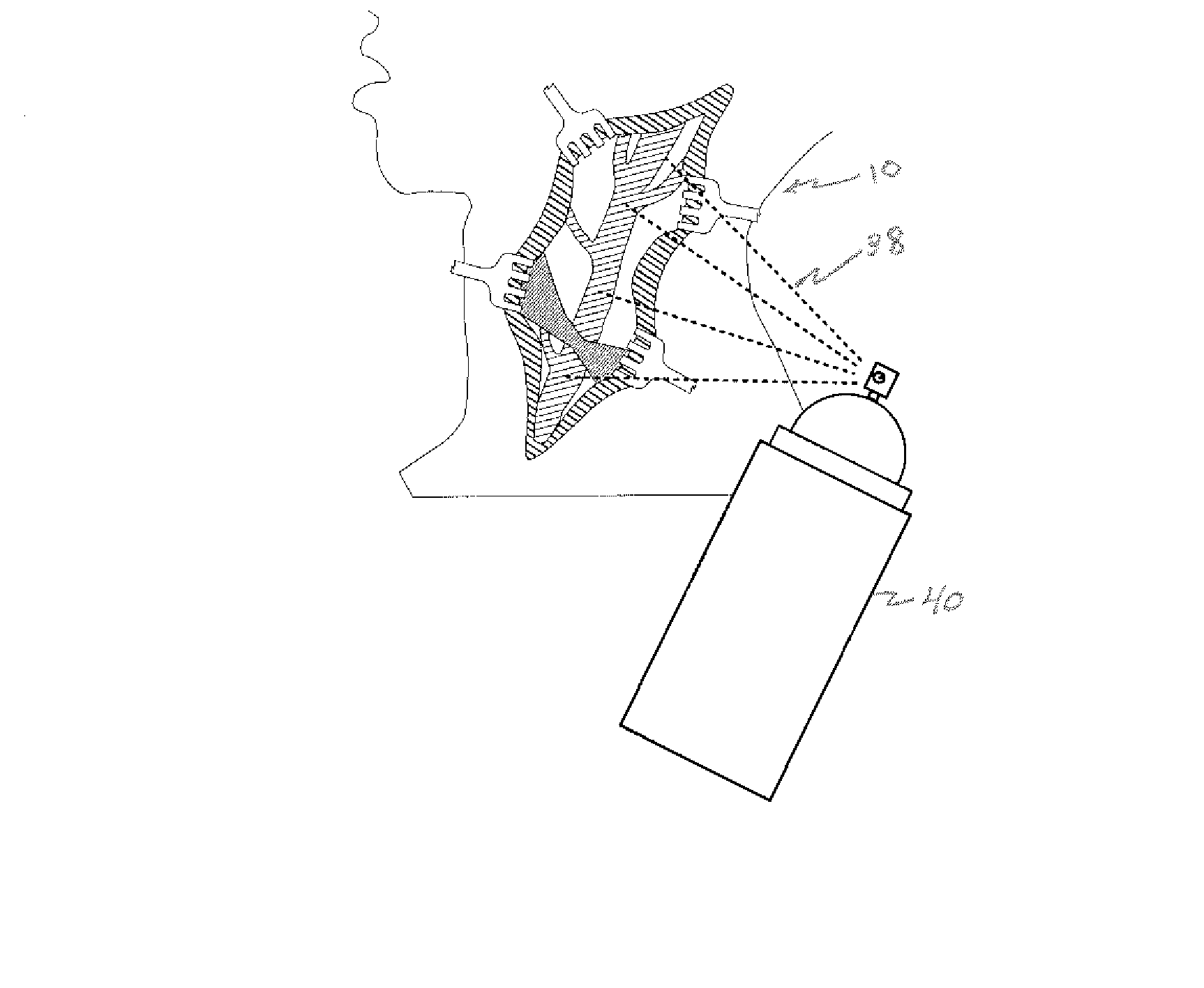

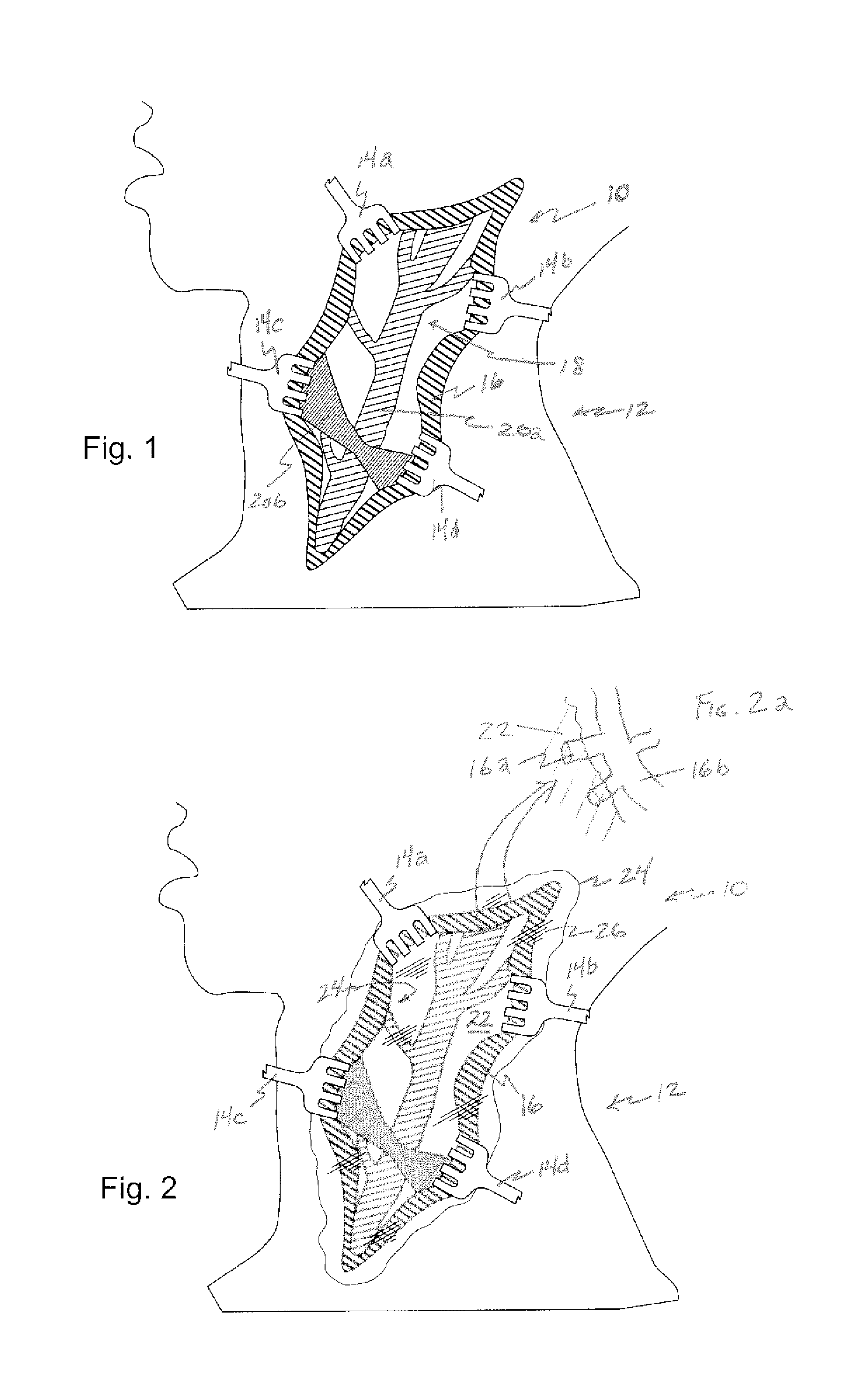

Method of inhibiting the formation of adhesions and scar tissue and reducing blood loss

InactiveUS20080069855A1Increased riskEasy to disassembleBiocideInternal osteosythesisWound siteBlood vessel

The present invention provides a method for inhibiting the formation of scar tissue and / or exogenous bone at a wound site in a body of a patient. The method includes administering an amount of a biologic agent to the wound site, wherein the biologic agent is synovial fluid or cerebrospinal fluid. A viscous substance applied to the wound site, advantageously incorporating the biologic agent, reduces the flow of blood from cut blood vessels, and contributes to a reduction in the formation of adhesions through action of the biologic agent, and through barrier properties introduced by the viscous substance.

Owner:P TECH

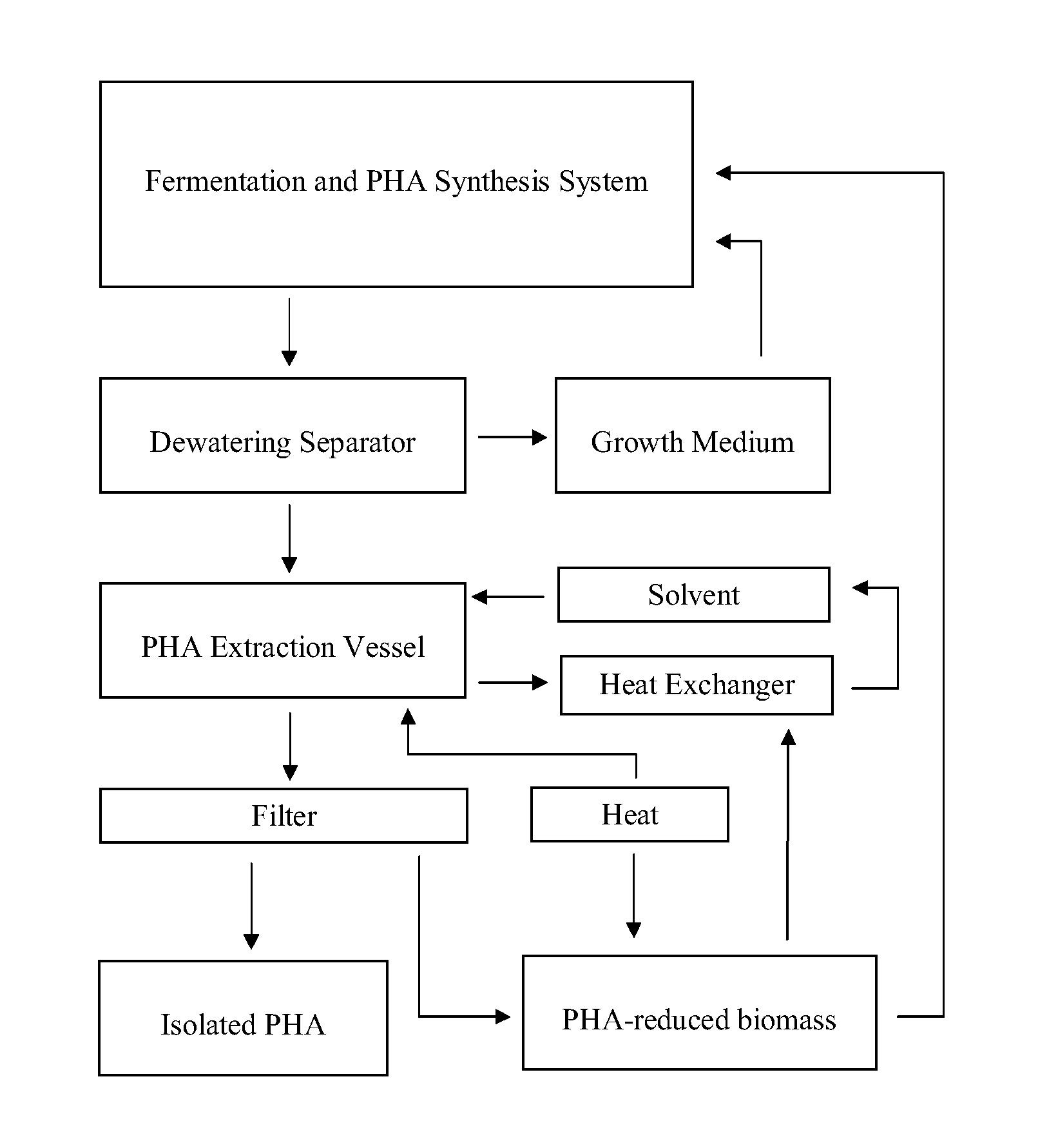

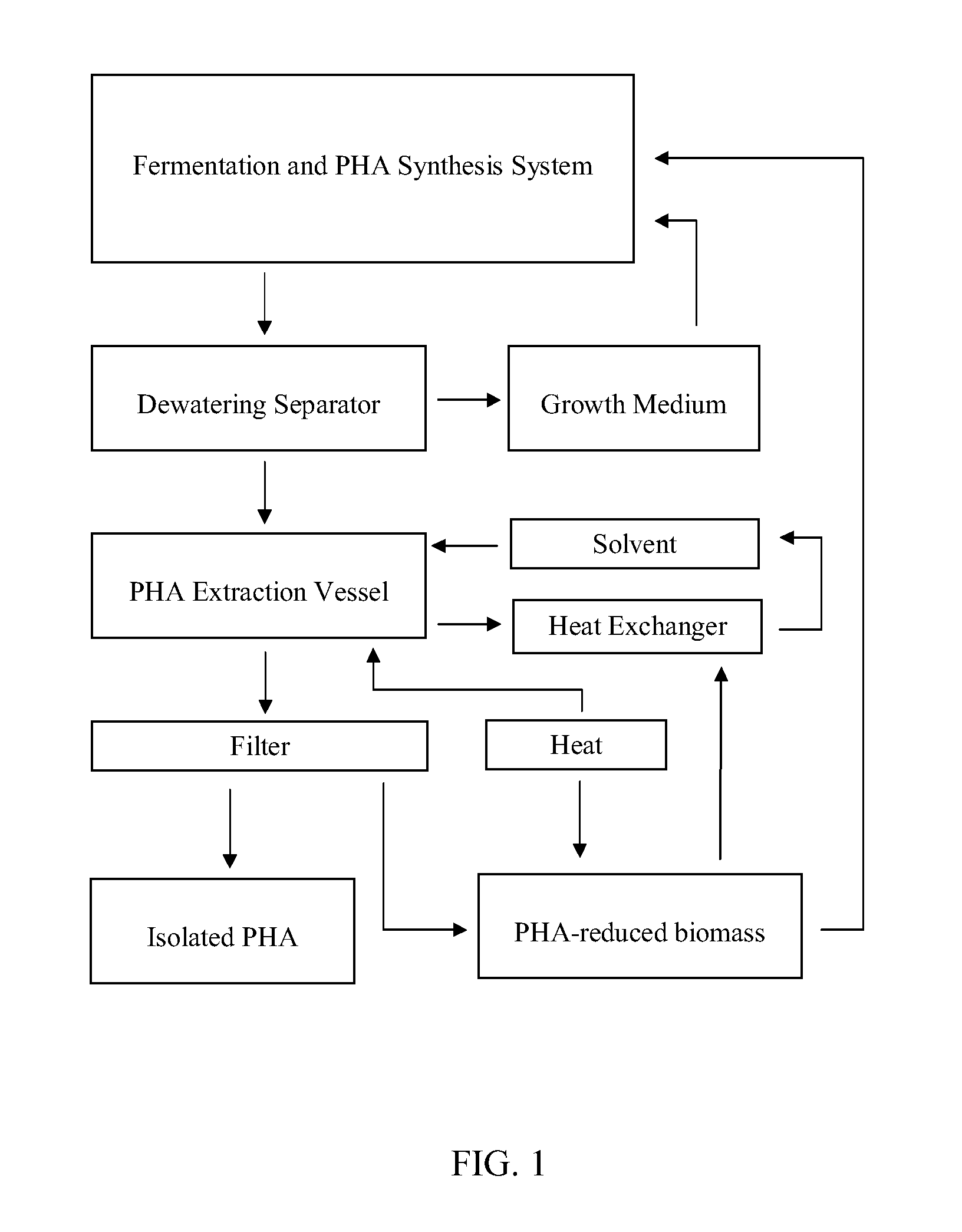

Polyhydroxyalkanoate production method

ActiveUS20130337516A1Reduce carbon input costWide availabilityFermentationCarbon sourceMaterials science

Provided are processes for the production and high efficiency processing of polyhydroxyalkanoates (PHA) from carbon sources comprising carbon-containing gases or materials.

Owner:NEWLIGHT TECH

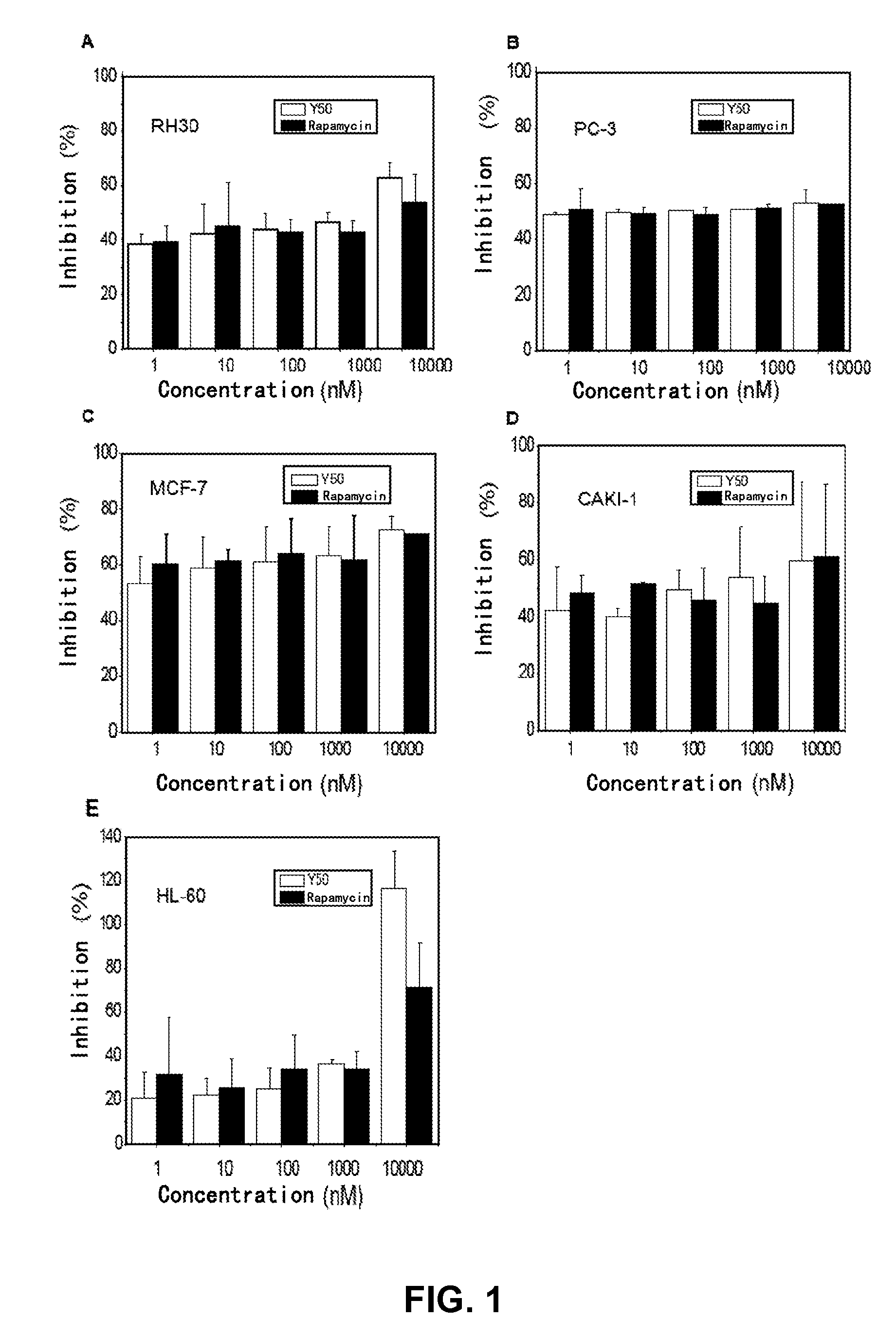

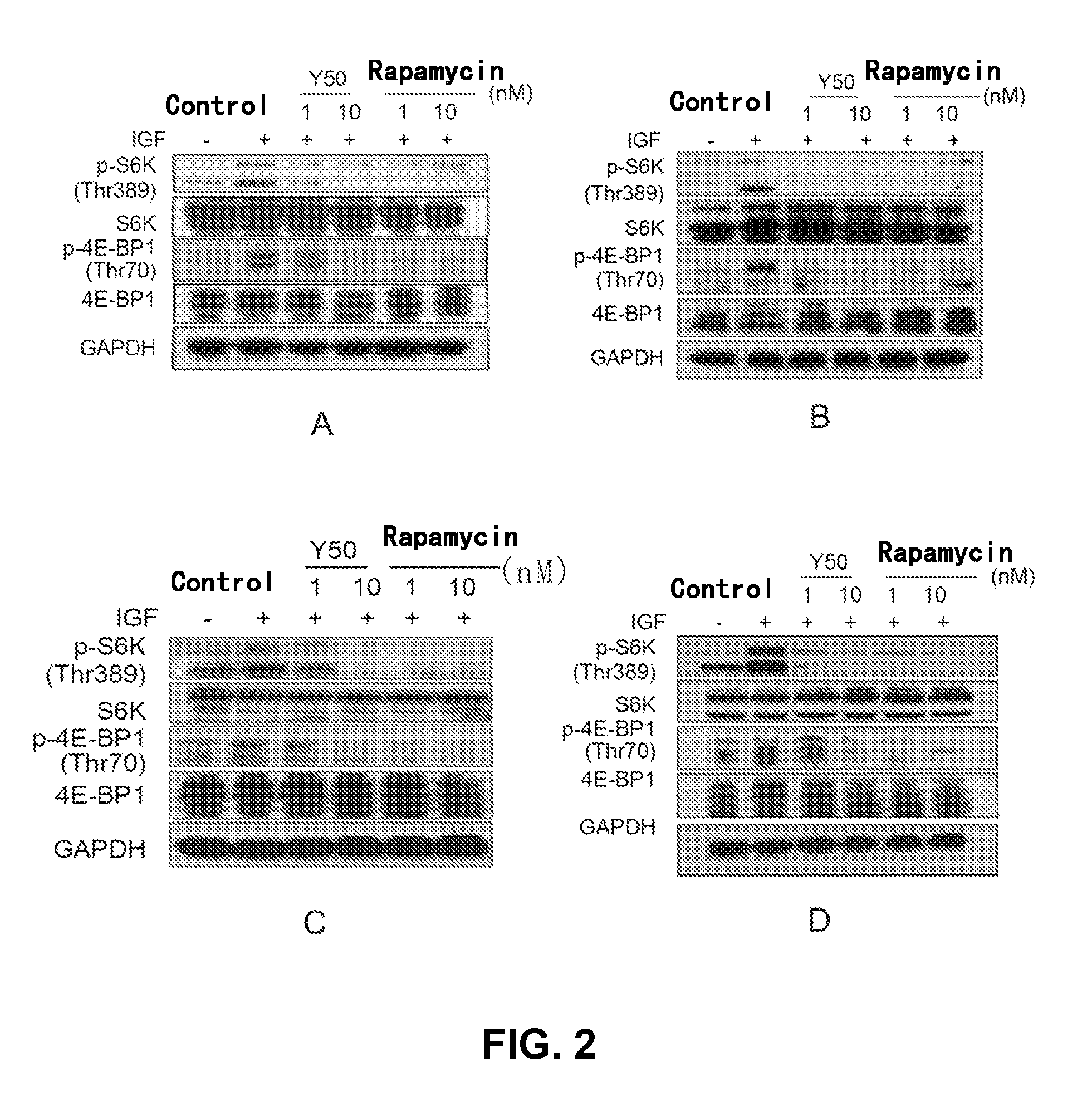

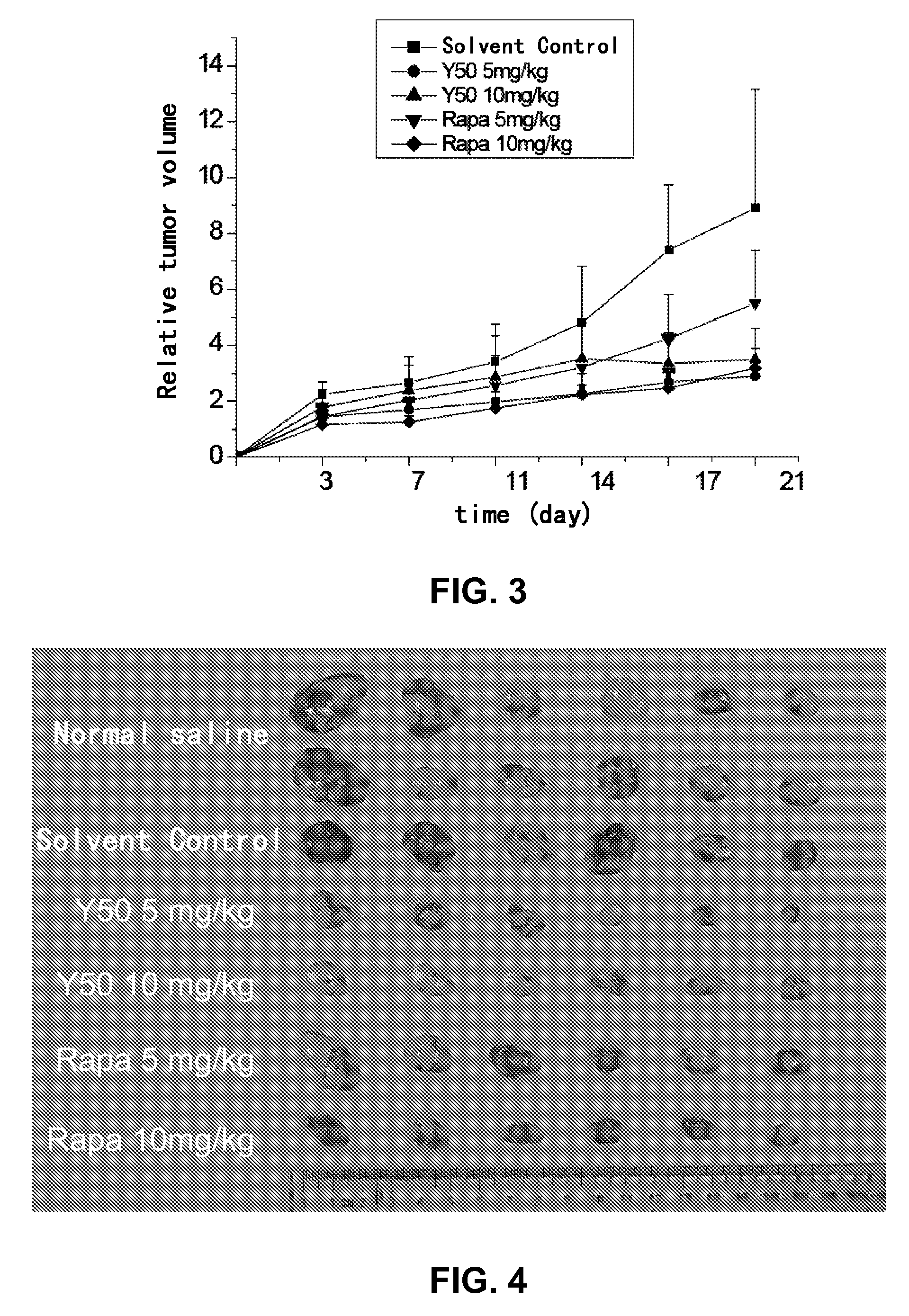

Rapamycin carbonic ester analogues, pharmaceutical compositions, preparations and uses thereof

InactiveUS8455510B2Superior anti-tumor and anti-cancer activitiesImproved pharmacokinetic propertiesBiocideOrganic chemistrySolubilityWater soluble

Rapalogs of formula I, pharmaceutically acceptable salts, pharmaceutical compositions, and preparation methods and uses thereof. The rapalogs have the structure of formula I and can be used as an anti-tumor medicament. Comparing with rapamycin, the rapalogs of the present invention exhibit enhanced water solubility, and improved pharmacological and pharmacokinetic properties by introducing a hydrophilic and polar group such as a hydroxyl.

Owner:SHANGHAI INST OF MATERIA MEDICA CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com