Integrated control method of cold-rolling strip steel flatness and lateral thickness difference

A cold-rolled strip, comprehensive control technology, applied in rolling mill control device, metal rolling, profile control, etc. Reduce the effect of manual intervention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

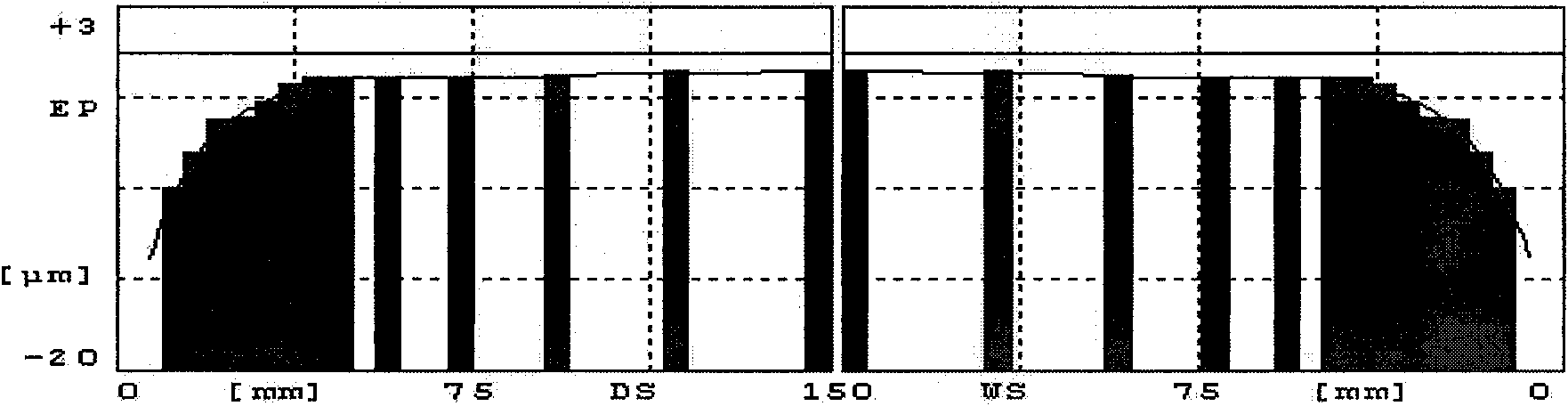

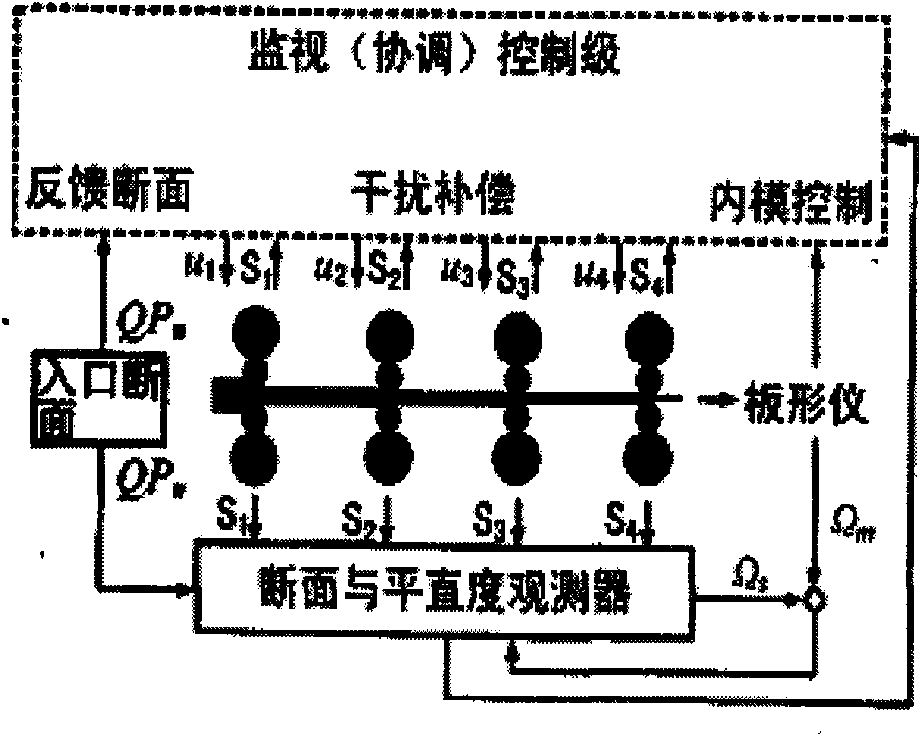

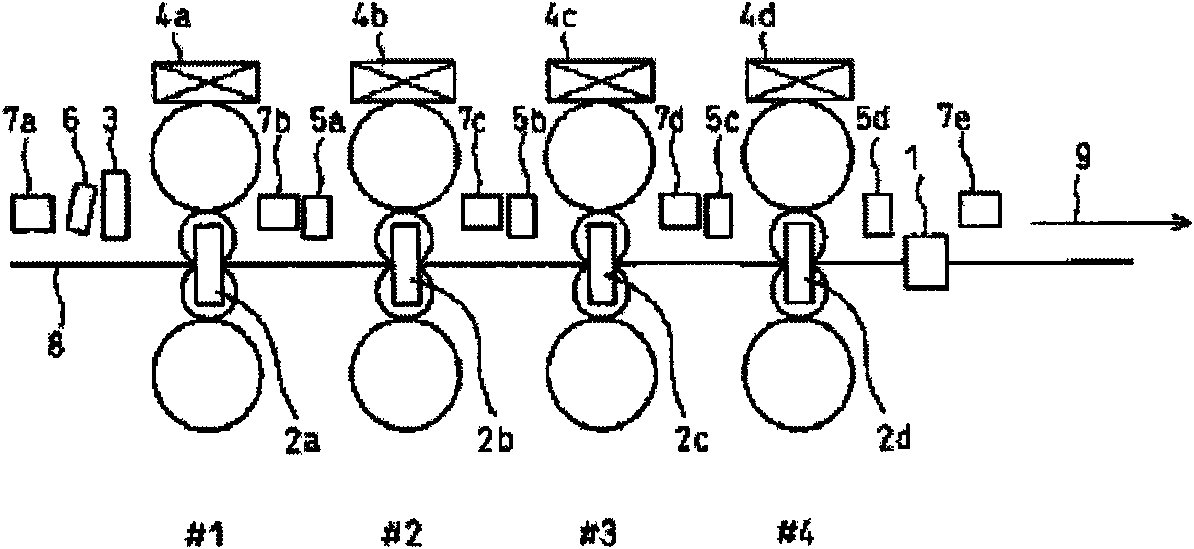

[0059] see Figure 4 , a method for comprehensively controlling the flatness and transverse thickness difference of cold-rolled strip steel, including moderately controlling the cross-sectional shape of the strip steel in the upstream stand of the cold rolling mill, and focusing on controlling the flatness of the strip steel in the downstream stand; Based on the actual measurement of the section shape and flatness of the hot-rolled incoming material by the profiler installed at the entrance of the No. The flatness meter installed at the exit of the cold rolling mill actually measures the flatness of the cold-rolled strip, and performs feed-forward control on the cross-sectional shape of the strip with the focus on the upstream stand, especially the No. 1 stand, and the downstream stand, especially the final stand. Feedback control of the flatn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com