Patents

Literature

1823results about "Profile control device" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for controlling planeness of cold-rolling strip steel

ActiveCN101618402ARealize coordinated controlAccurate detectionRare end control deviceTemperature control deviceAutomatic controlEngineering

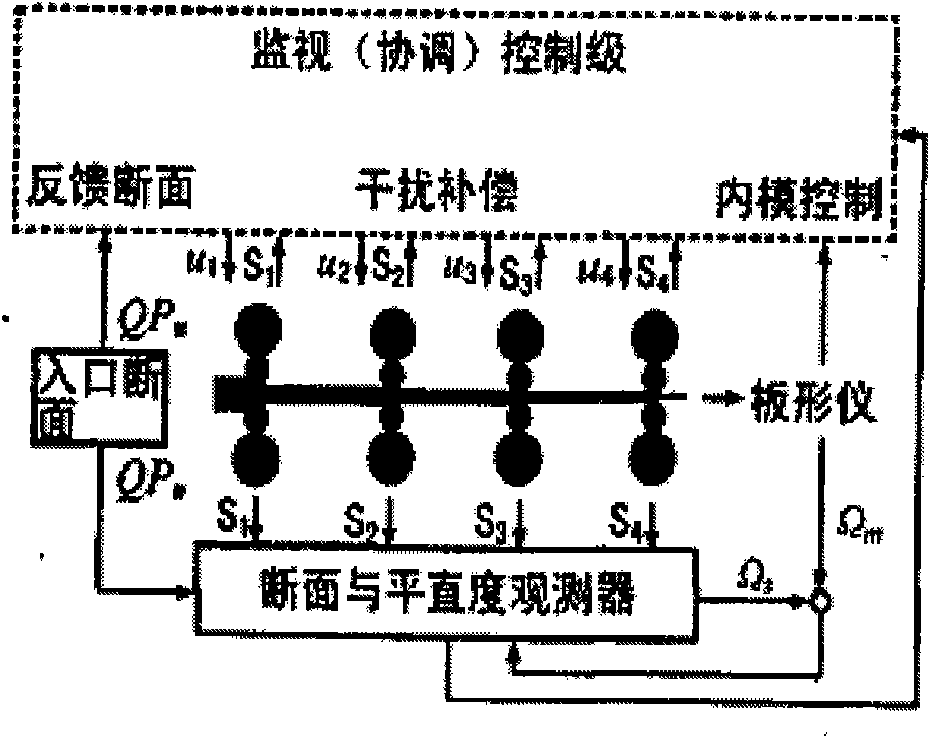

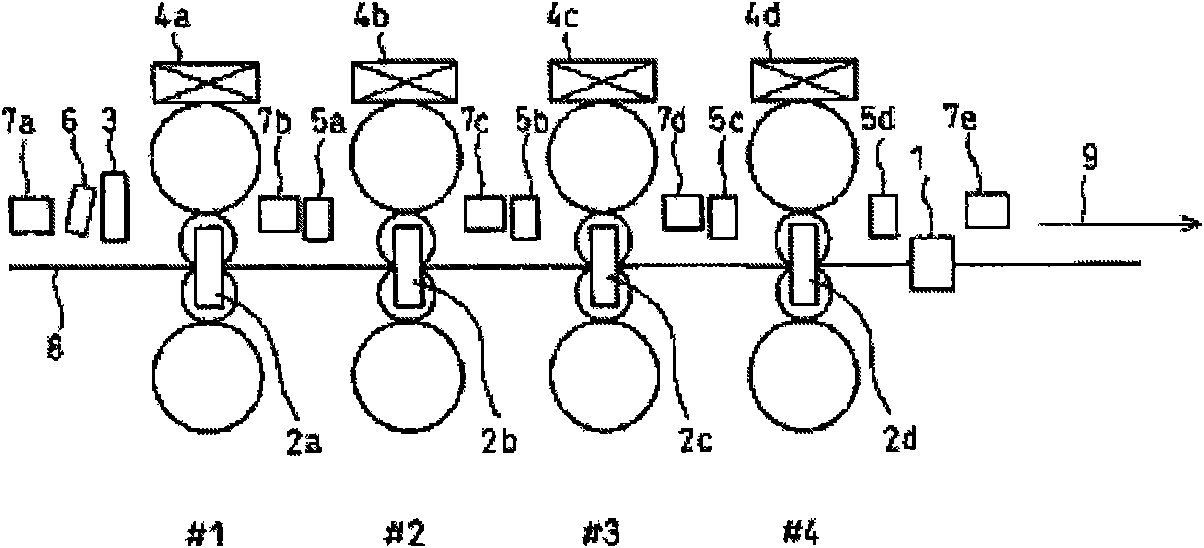

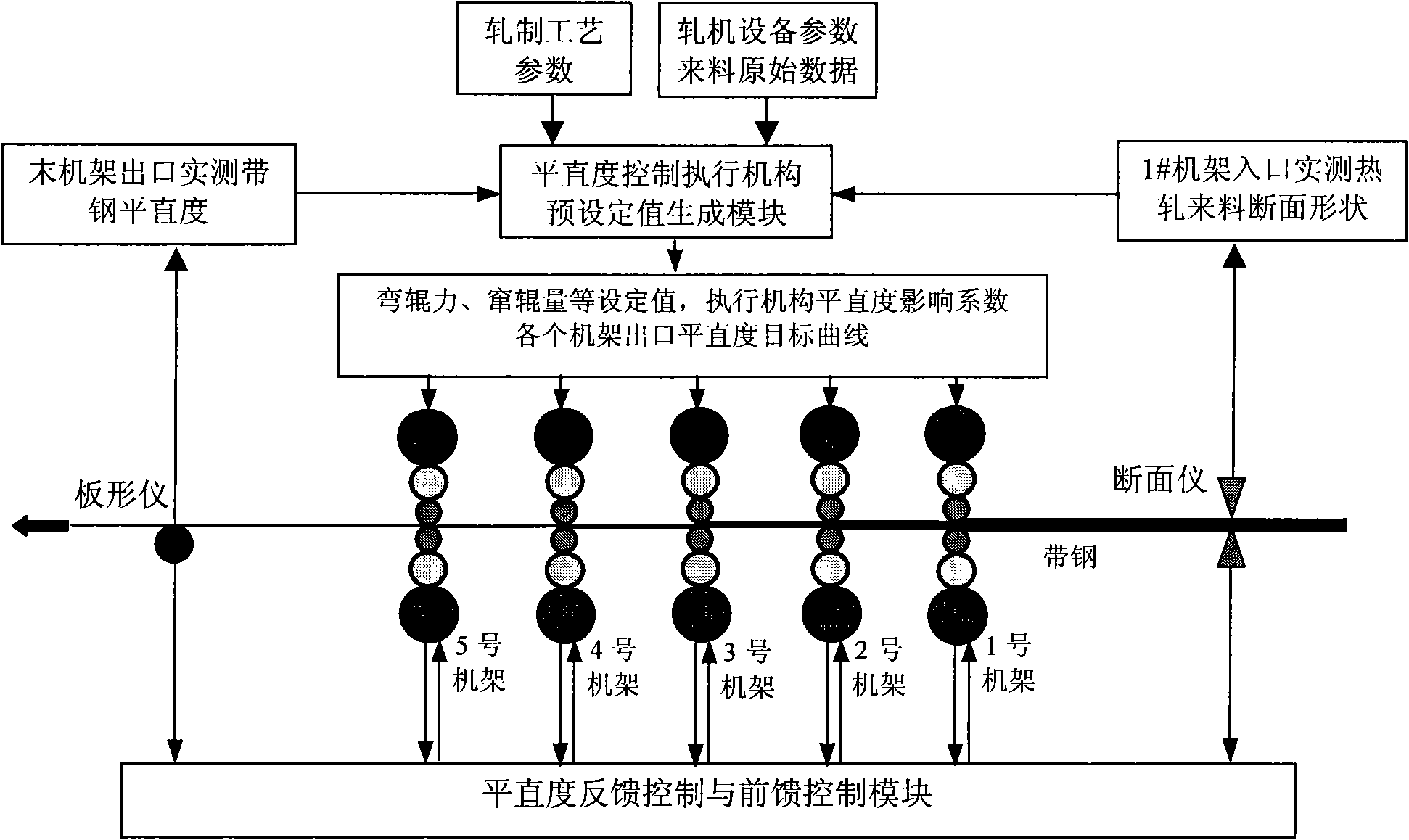

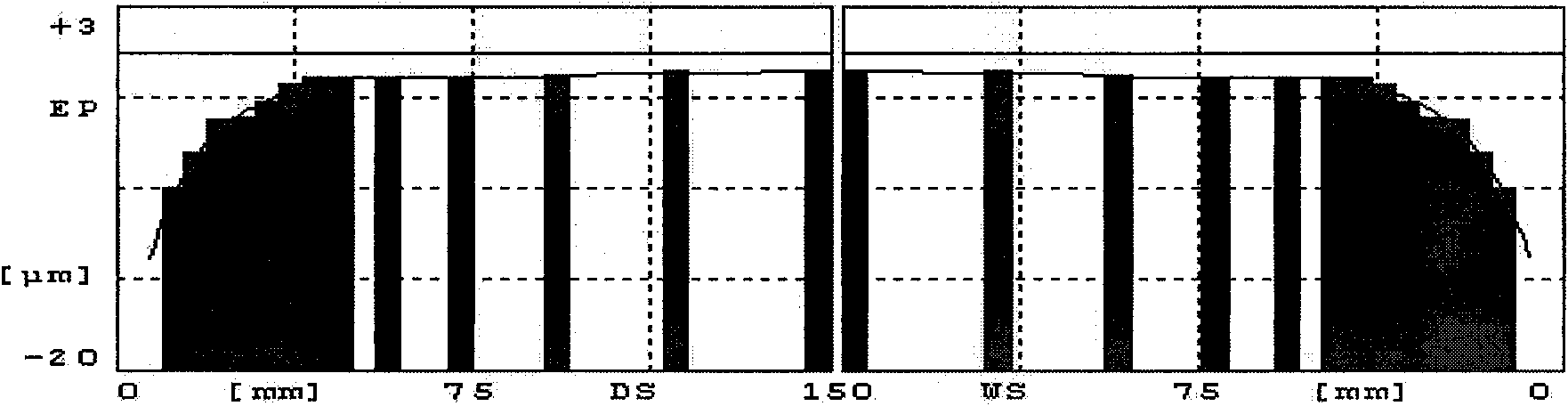

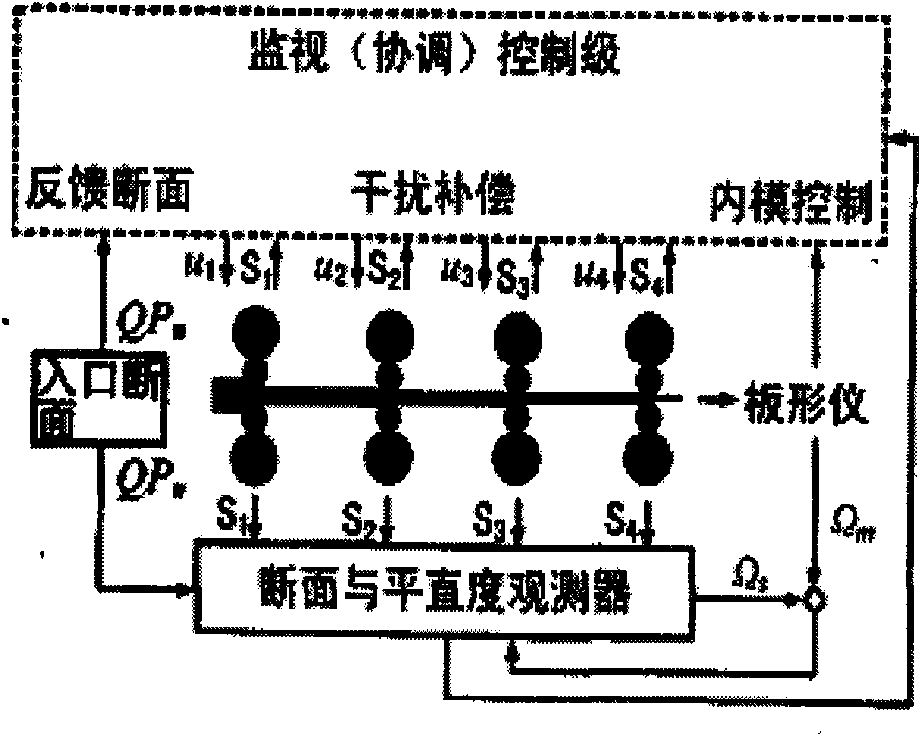

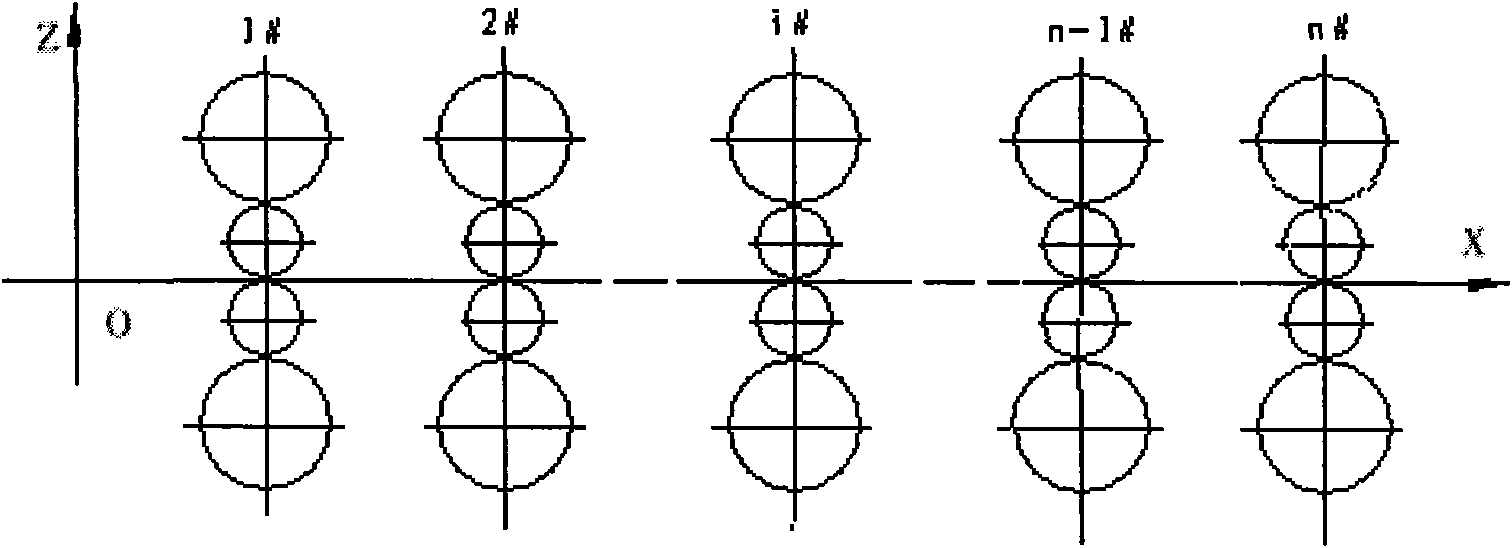

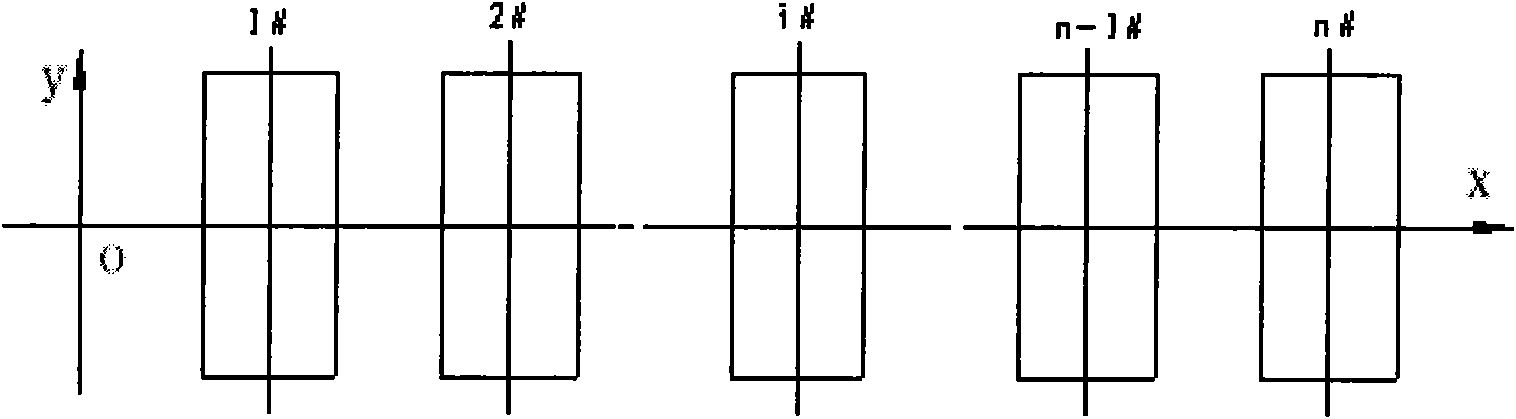

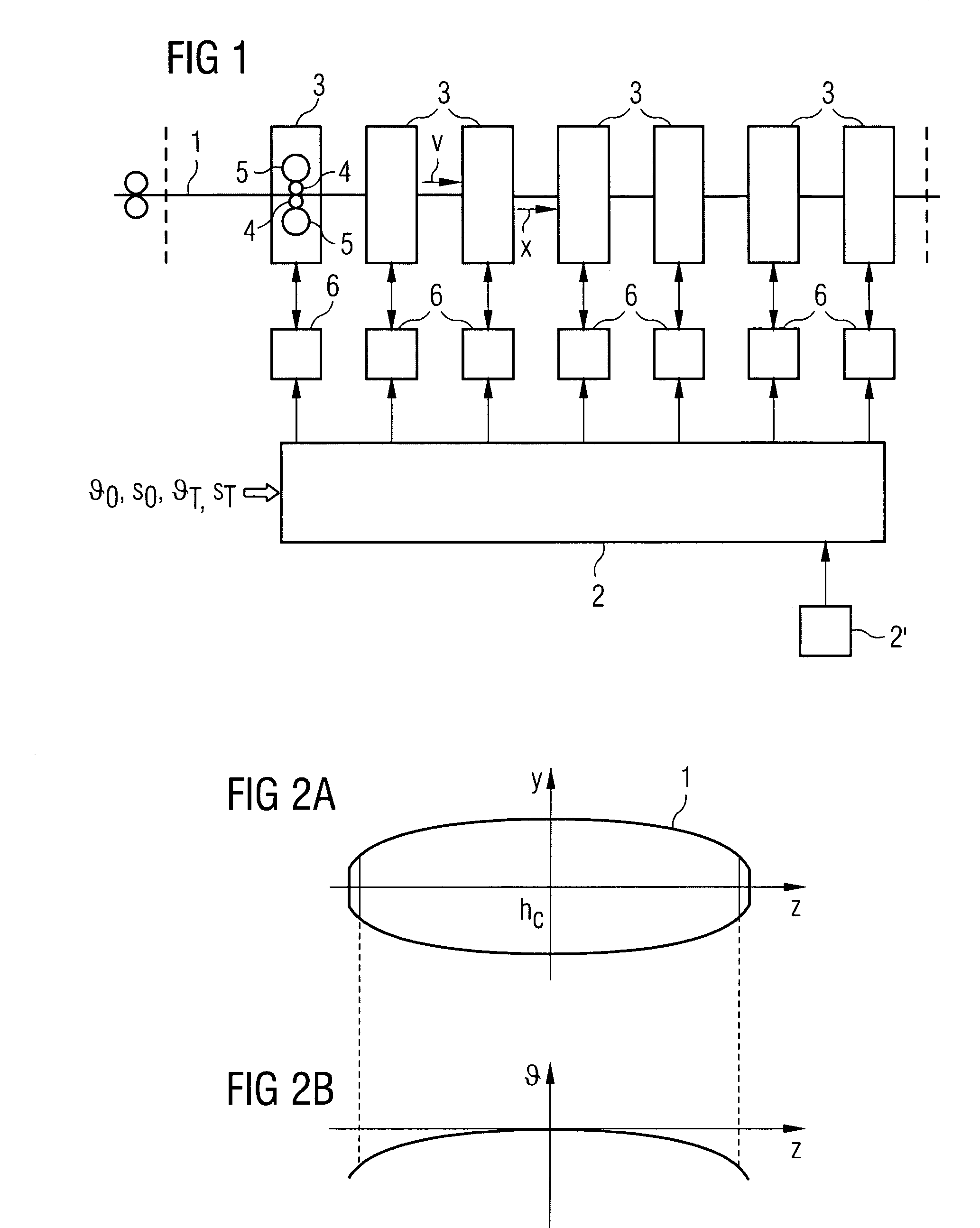

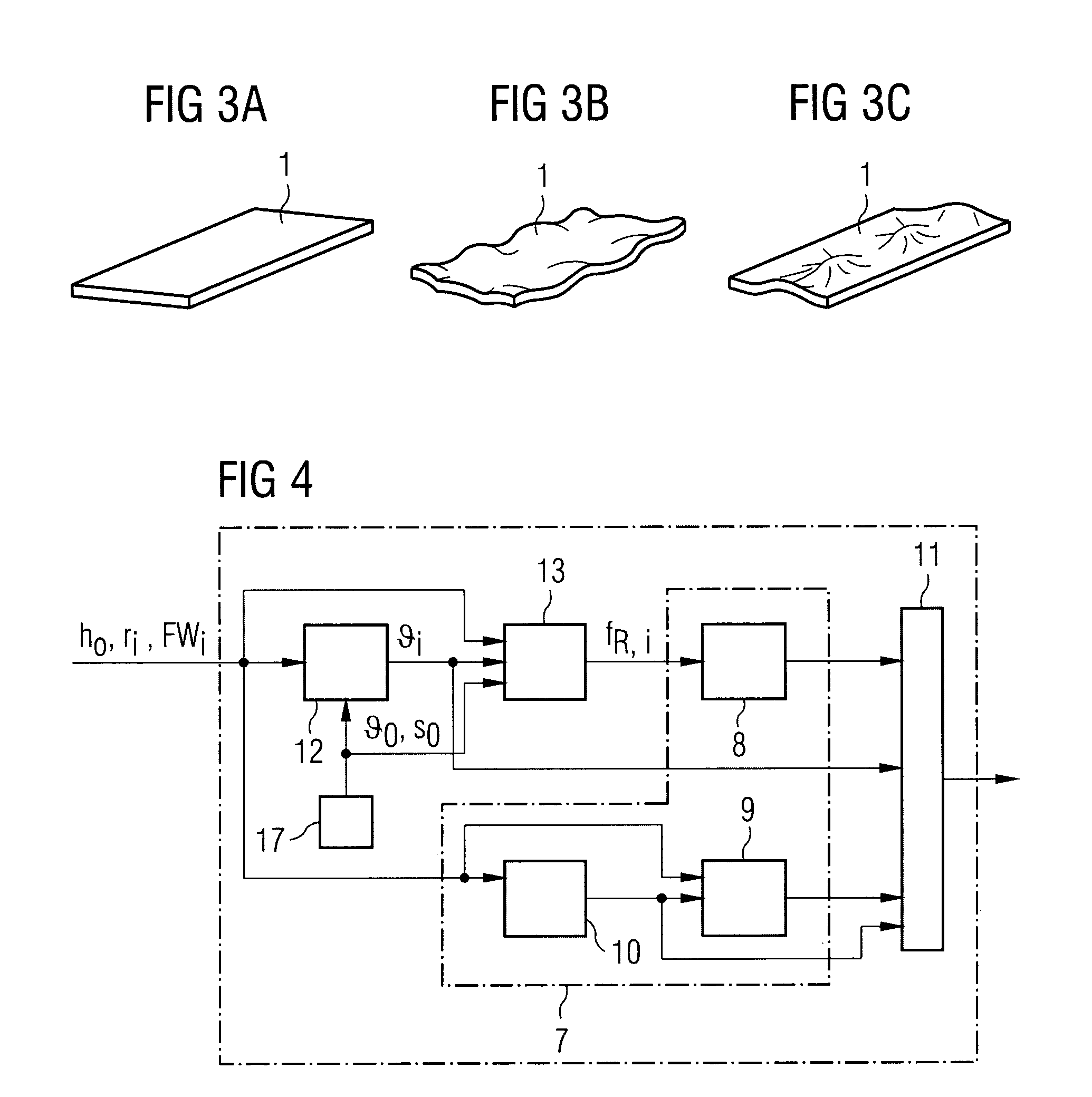

The invention discloses a method for controlling the planeness of cold-rolling strip steel, which comprises the following steps of: carrying out planeness feed-forward control, planeness feedback control and coordination control between both; detecting the cross-section shape and the planeness of a hot rolling incoming material, and actually-measured rolling technological parameters of each frame in real time based on a profiler configured on a No. 1 frame inlet, wherein the parameters comprise rolling force actually-measured values and plate shape adjusting mechanism actually-measured values, and carrying out the feed-forward control on the planeness of each frame outlet; and actually measuring the planeness of the cold-rolling strip steel based on a plate shape roller configured on an outlet of a cold rolling mill, and intensively carrying out the feedback control on the planeness of a final frame outlet. The method can eliminate the influences of the cross-section shape and the planeness of the hot rolling incoming material and fluctuations of the rolling technological parameters on the planeness of the final frame outlet to improve the planeness quality of the cold-rolling strip steel on the one hand, and can automatically control the planeness of each frame outlet, reduce incidence of abnormal conditions, such as fracture surfaces, deviation and the like, and improve the stability in the production process of tandem cold strip rolling on the other hand.

Owner:BAOSHAN IRON & STEEL CO LTD

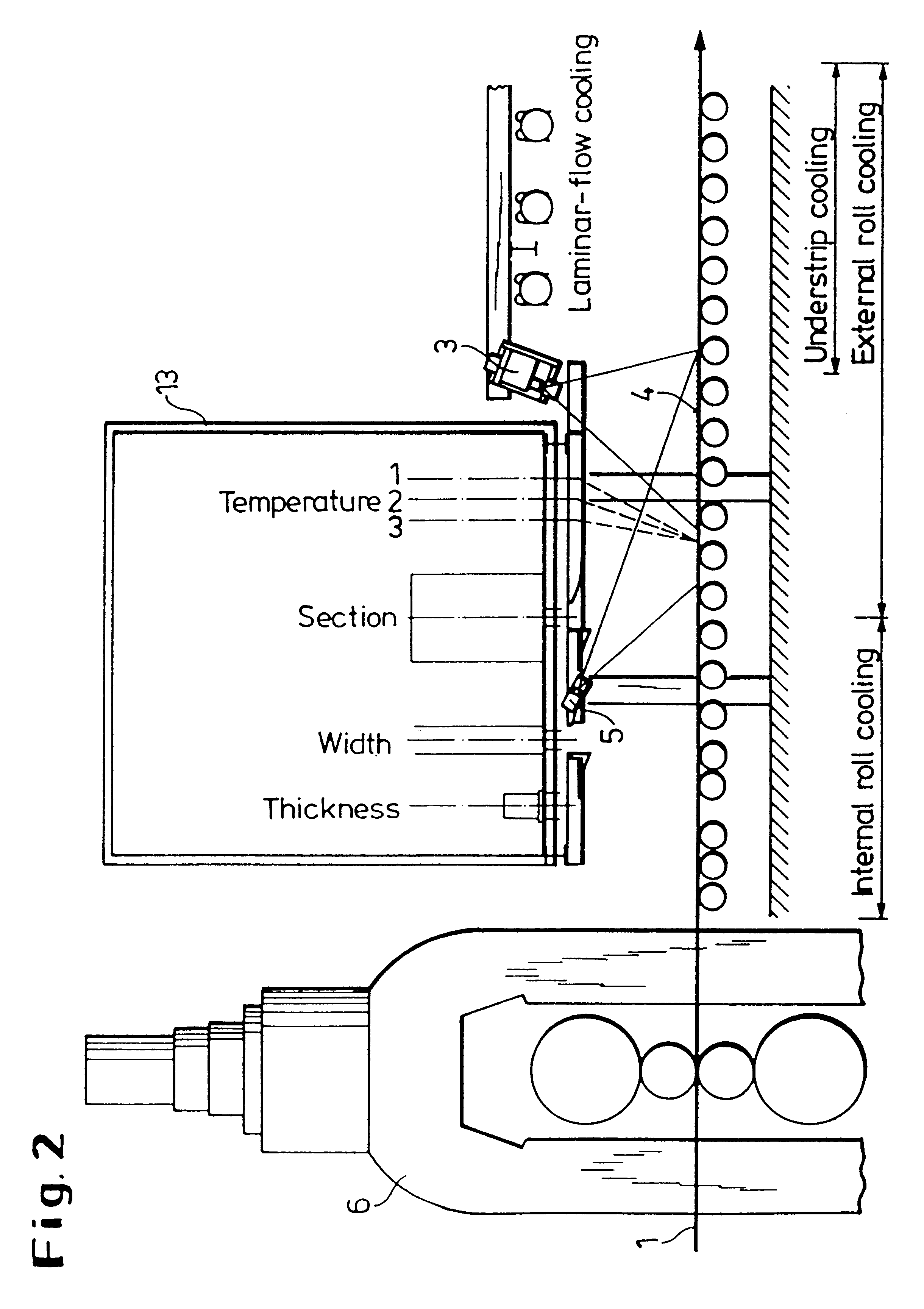

Integrated control method of cold-rolling strip steel flatness and lateral thickness difference

ActiveCN101683659AImprove stabilityGuaranteed stabilityMetal rolling arrangementsProfile control deviceStrip steelFeedback control

The invention discloses an integrated control method of cold-rolling strip steel flatness and lateral thickness difference, comprising: moderately and mainly controlling the shape of the strip steel section on the upstream rack of a cold-rolling mill, and mainly controlling strip steel flatness on the downstream rack; based on a profiler configured on a No.1 rack inlet of the cold-rolling mill, actually measuring and hot rolling incoming material section shape and flatness and rolling technological parameter measured values of each rack, wherein the rolling technological parameter measured values comprise rolling force and a plate shape regulating mechanism measured value; actually measuring the cold-rolling strip steel flatness on the basis of a shape meter configured on the cold-rollingmill outlet; performing feed-forward control to the shape of the strip steel section by taking the upstream rack, in particular the No. 1 rack as a key point; and performing feedback control to the strip steel flatness by taking the downstream rack, in particular an end rack as a key point to realize integrated control to the cold-rolling strip steel flatness and lateral thickness difference. Theinvention performs integrated coordination control by the strip steel flatness and section shape and reduces cold-rolling strip steel lateral thickness difference on the basis of further improving cold-rolling strip steel flatness quality.

Owner:BAOSHAN IRON & STEEL CO LTD

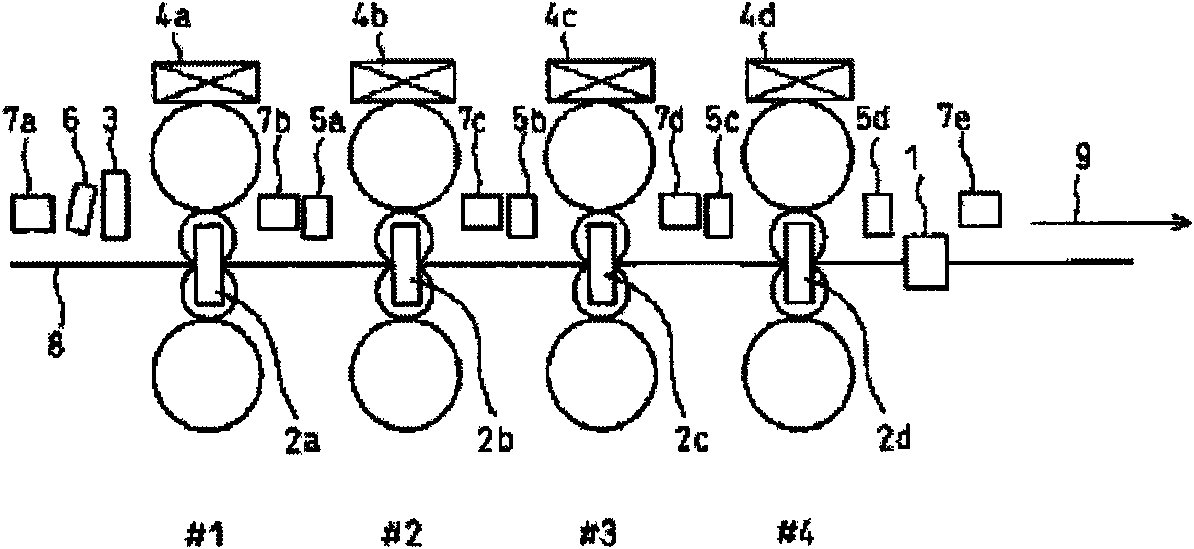

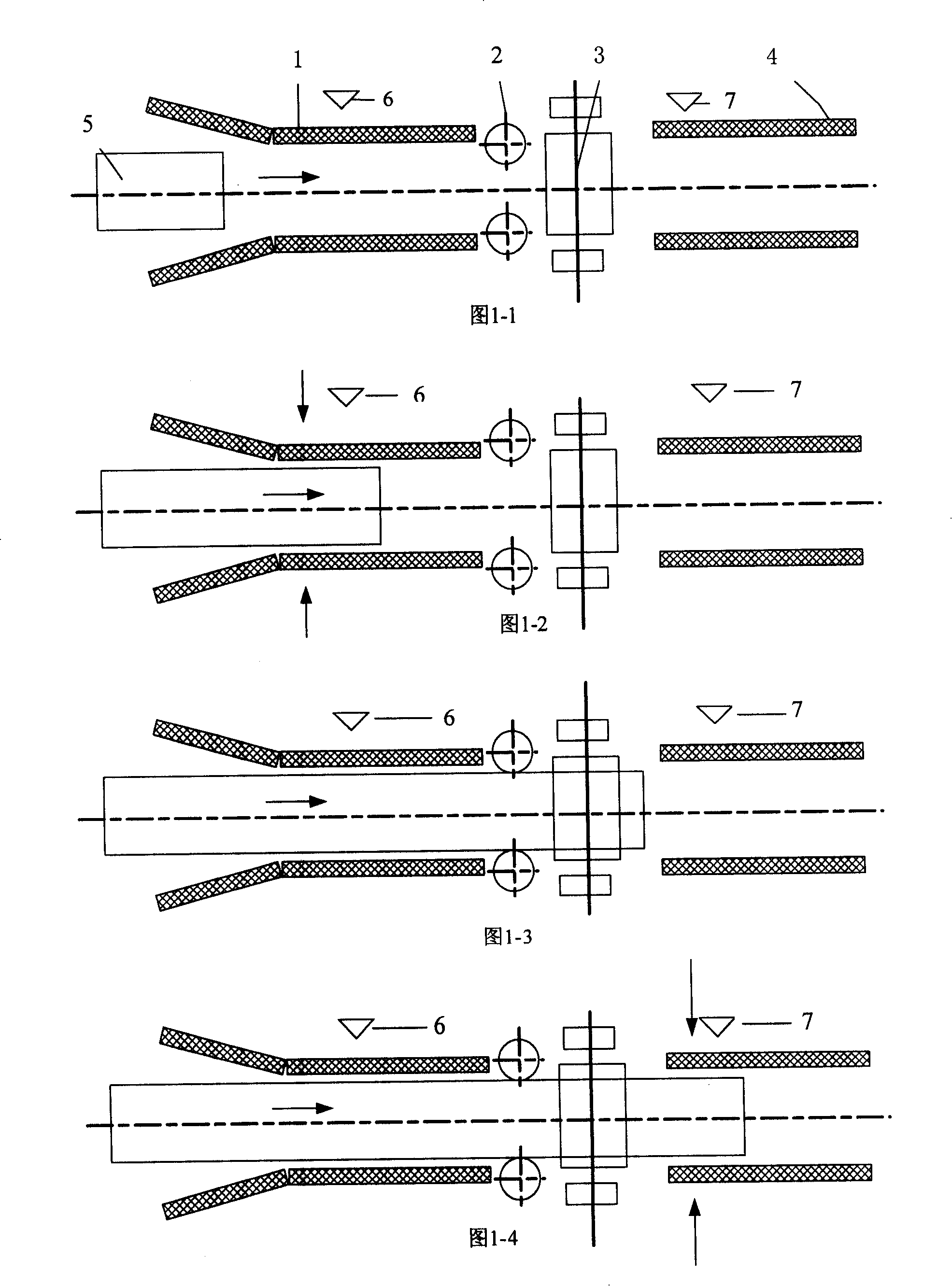

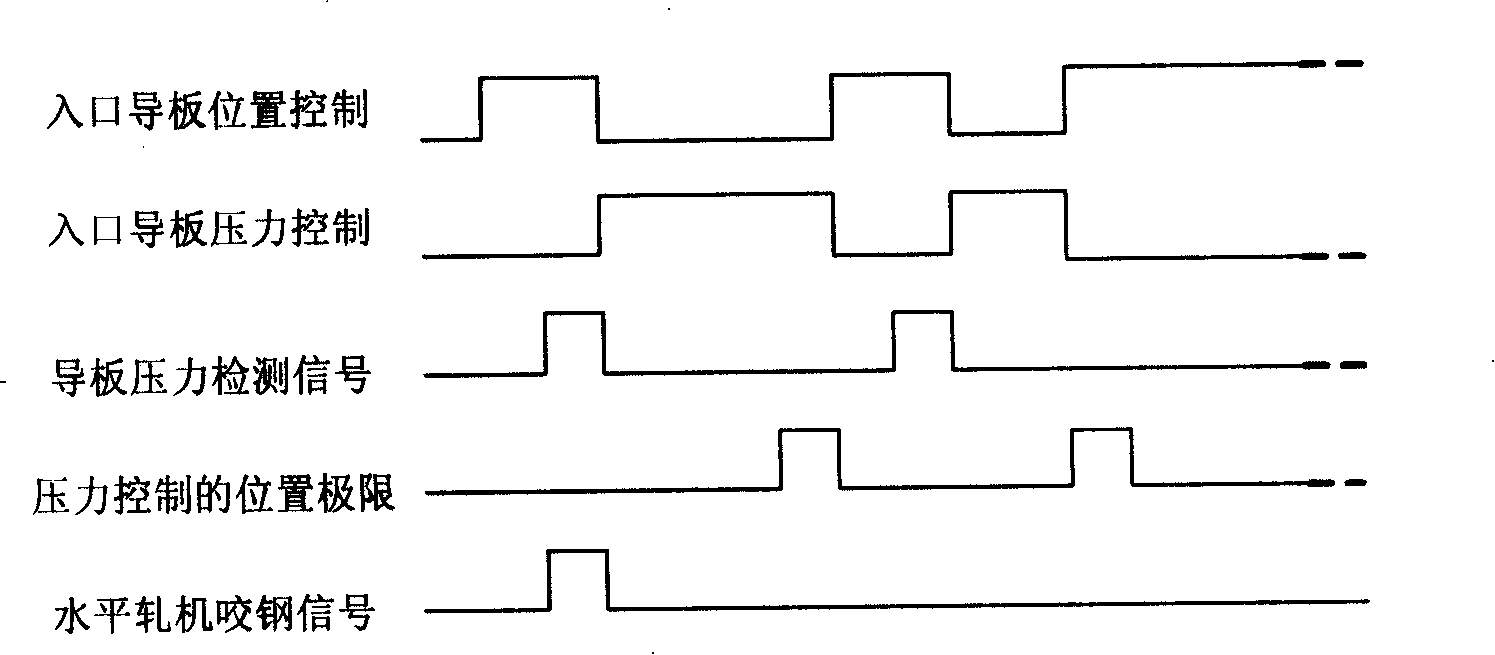

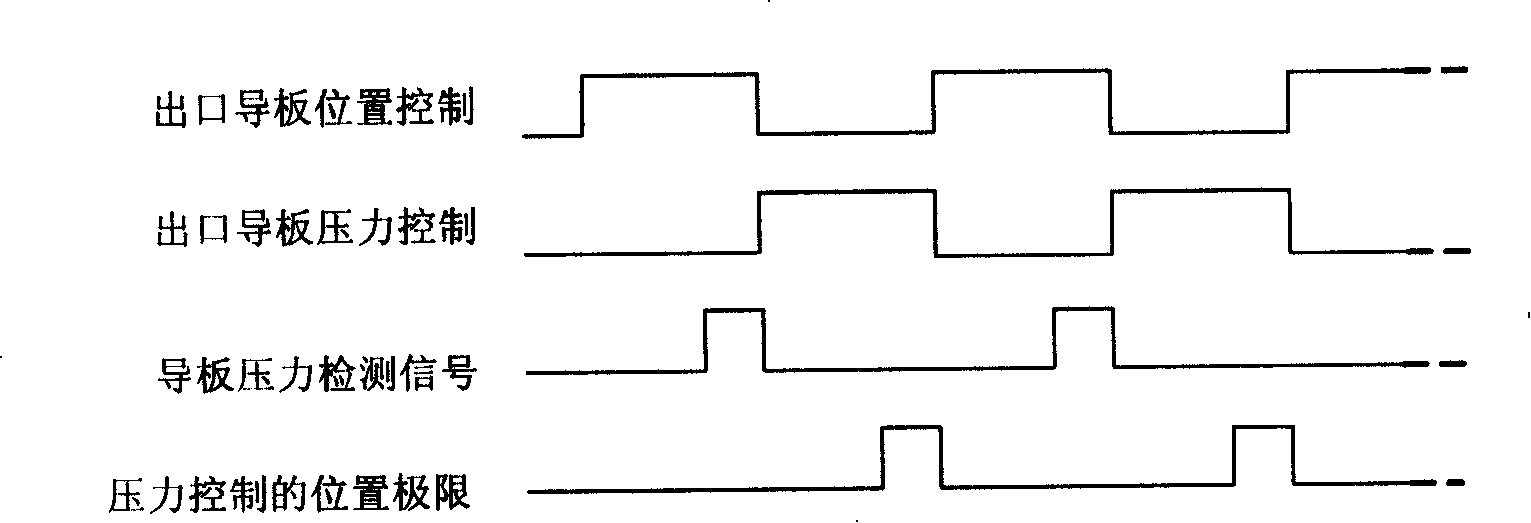

Controlling method of rough rolling breakdown bar camber

ActiveCN101224471APlay a guiding roleLow added valueGuiding/positioning/aligning arrangementsTension/compression control deviceAdditional valuesPosition control

The invention relate to a control technique of the rolling process of a rolling steel. The invention discloses a control method of a rough rolling intermediate billet camber. The control method combines a position control with a pressure control; in a multi-pass rolling of the positive-pass and reverse-pass of a roughing mill, the camber generation of the intermediate billet is restricted. The control method of the invention can reduce the additional value of the openness of a side guide plate, leads the flexible deformation of the intermediate billet between the inlet and the outlet of the roughing mill in the horizontal direction to be restricted by the side guide plate, reduces the camber of the intermediate billet, and prevents the severe abrasion which is caused by the long-term contact of the side guide plate and the intermediate billet.

Owner:BAOSHAN IRON & STEEL CO LTD

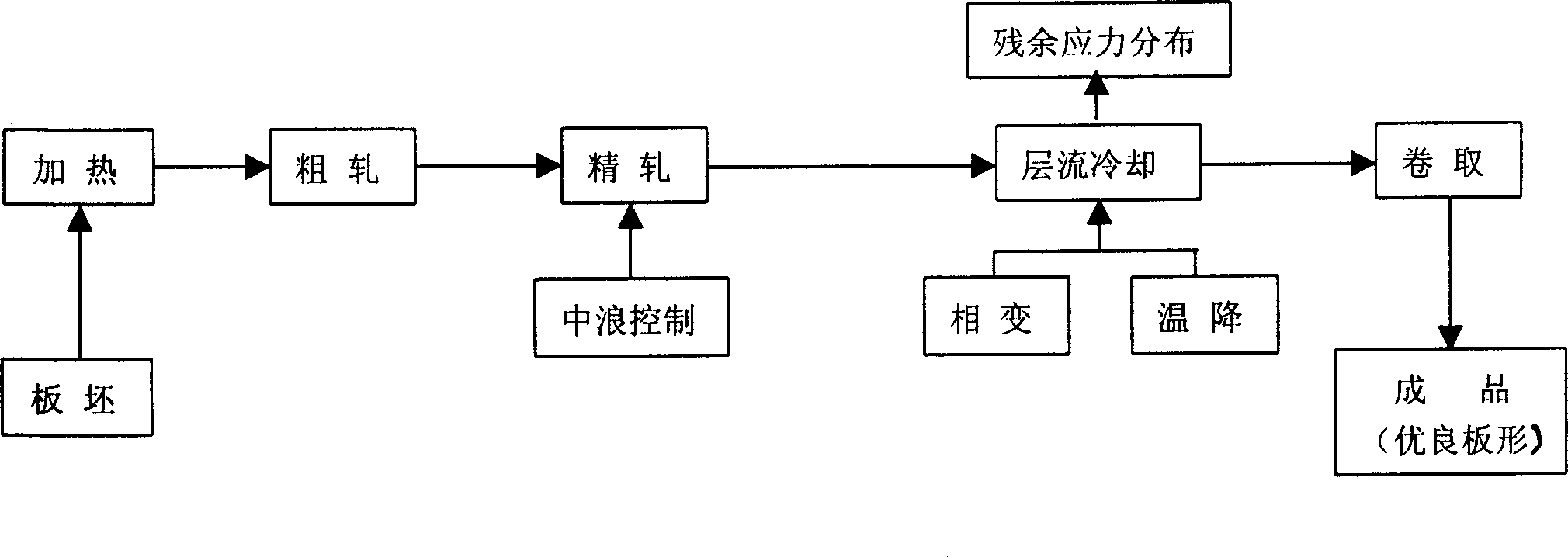

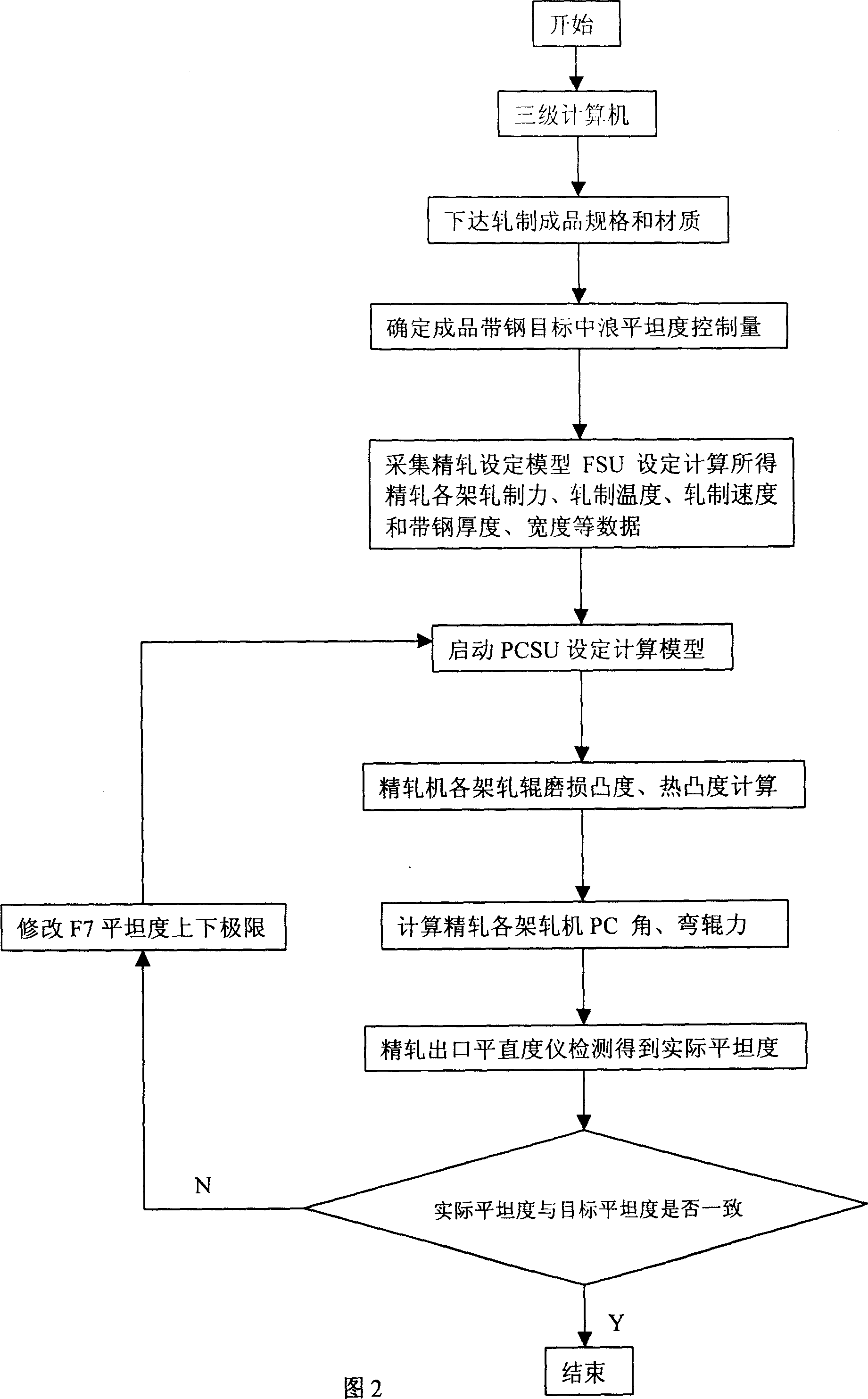

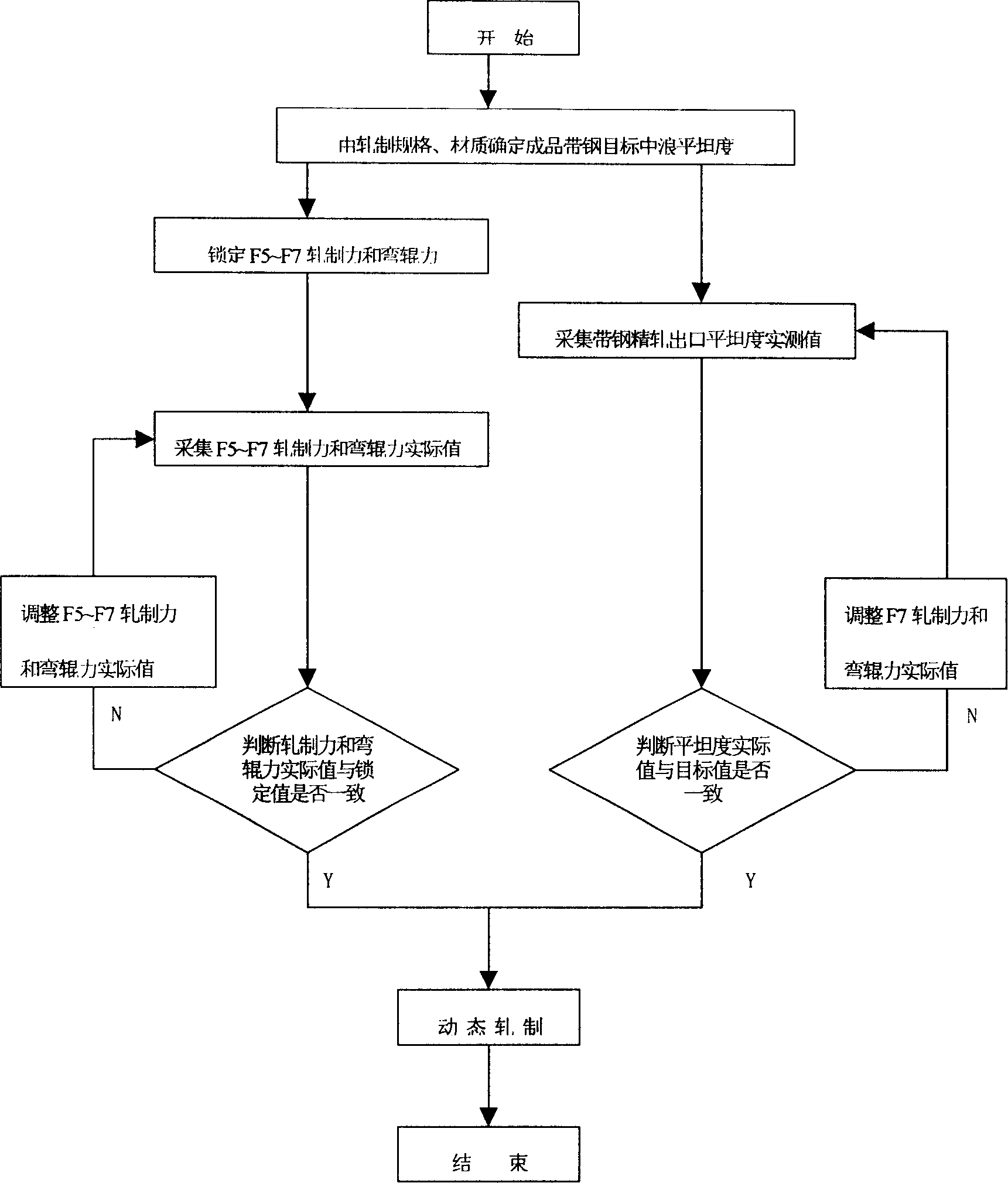

Hot-rolled strip steel moderate sea profile shape controlling method

A method of controlling moderate-sea strip shape of controlling strip steel. The head of strip steel is controlled by moderate-sea PCSU control, that is, PC setting control. The rear of strip steel is controlled by dynamically automatic strip shape moderate-sea control, which is dynamic ASC control. Determining the objective control degree of moderate-sea flatness of strip steel, calculating convexity of finish rolling strip steel, equivalent heat convexity of roller, coefficient of extension and flatness of strip steel. According to kinds, scales of steel, determining factors, constant terms, proportion factors in formulas, making moderate-sea control on flatness of exported finish rolling strip steel. Two-side sea in cooling could be effectively eliminated, which improves the quality ofstrip steel.

Owner:ANGANG STEEL CO LTD

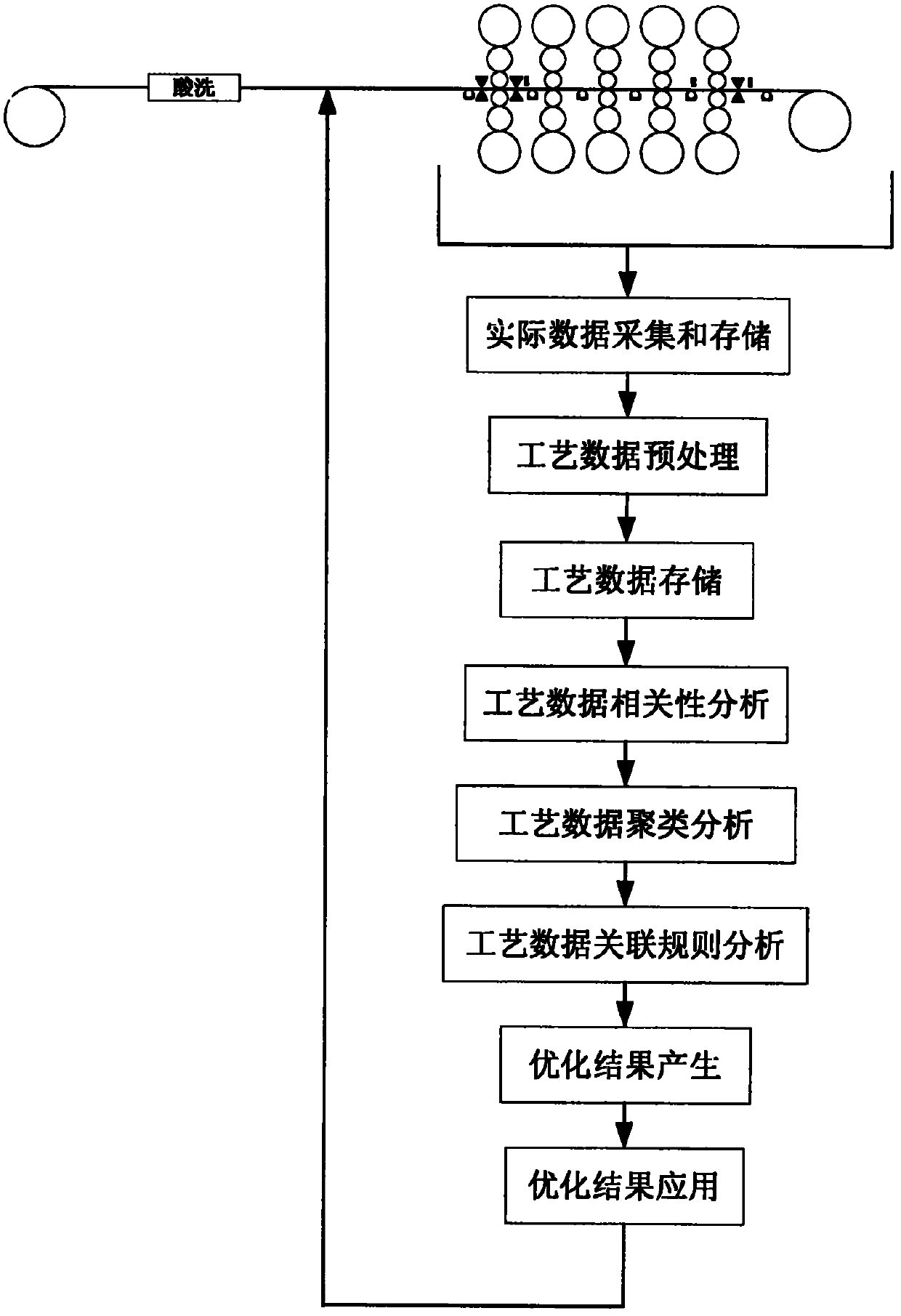

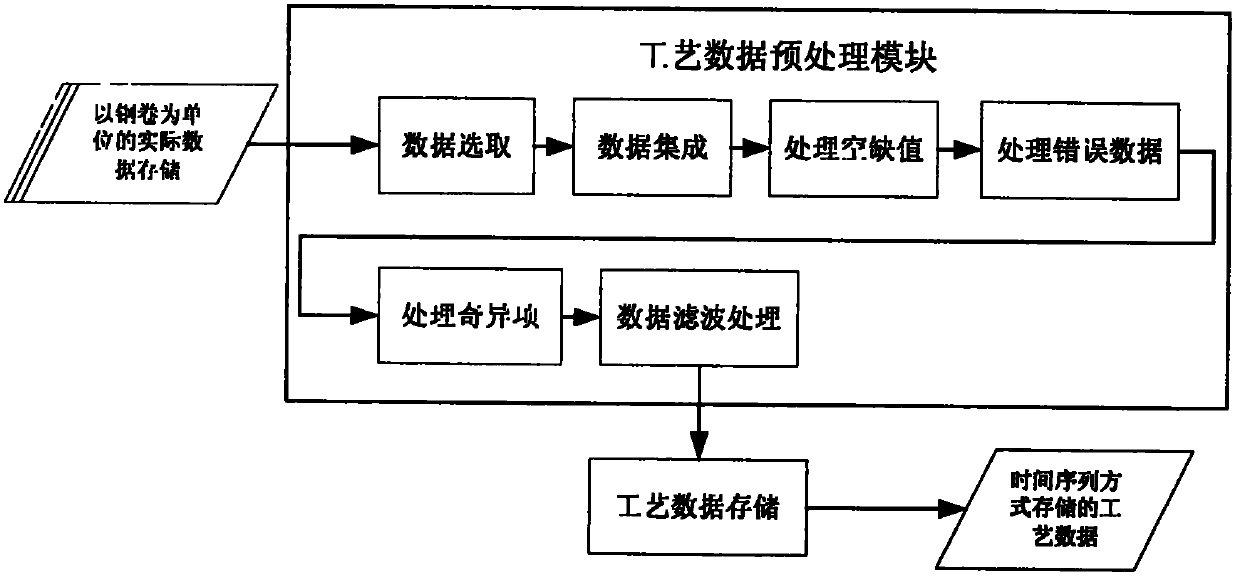

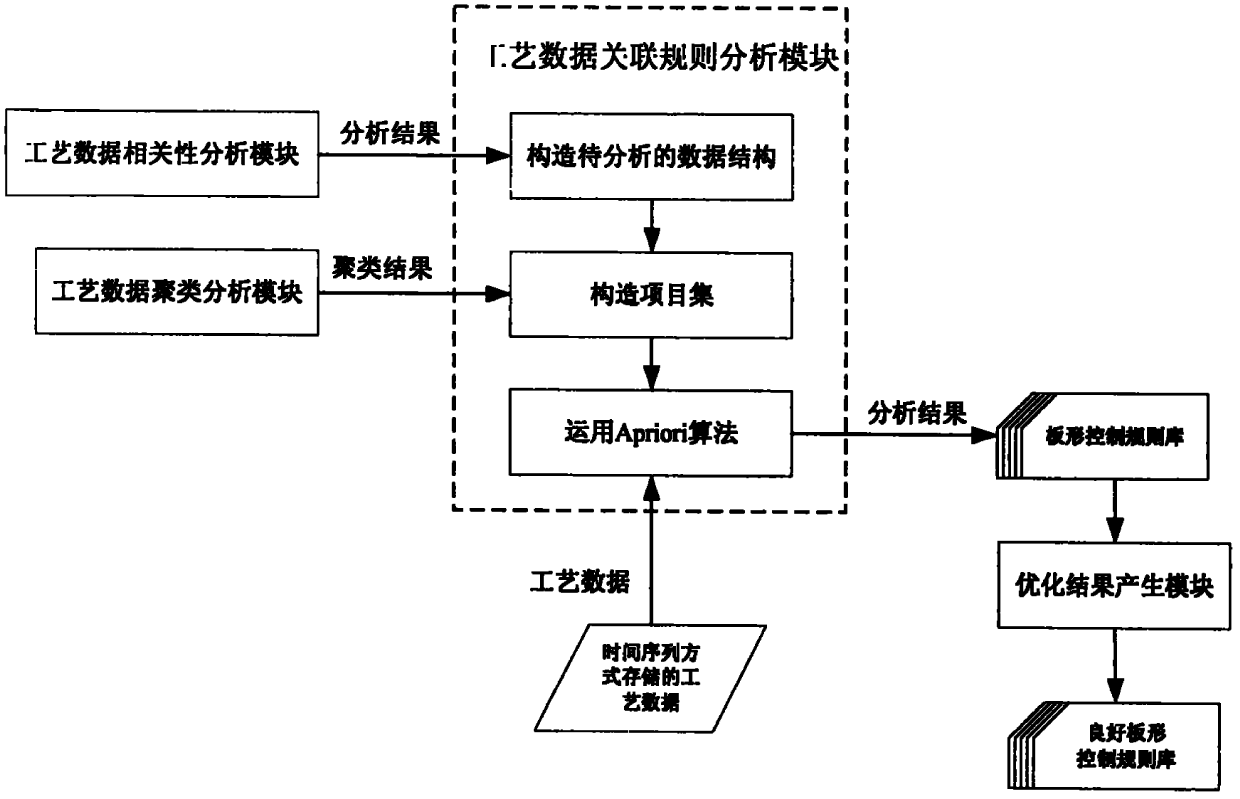

Data mining-based plate shape control key process parameter optimization system

ActiveCN102069094AImprove pass rateImprove the rate of successProfile control deviceAutomatic controlData acquisition

The invention relates to a data mining-based plate shape control key process parameter optimization system, and belongs to the technical field of automatic control of cold continuous rolling plate shape. The data mining method is adopted for acquiring key process parameter optimization settings which can meet the good cold continuous rolling plate shape. The system is characterized by comprising the following functional modules: an actual data acquisition and storage module, a process data pre-processing module, a process data storage module, a process data correlation analysis module, a process data clustering analysis module, a process data association rule analysis module, an optimization result generating module and an optimization result application module. The system has the advantage that the good plate shape can be obtained by applying the plate shape control system. The method avoids endless theoretical research on plate shape control and fully utilizes actual plate shape control process data containing successful operation experience of field operators, and the plate shape process parameter settings which can obtain the good plate shape are acquired by data mining, so the plate shape qualification rate and the finished product rate of cold continuous rolled strip steel are improved.

Owner:BEIJING SHOUGANG AUTOMATION INFORMATION TECH

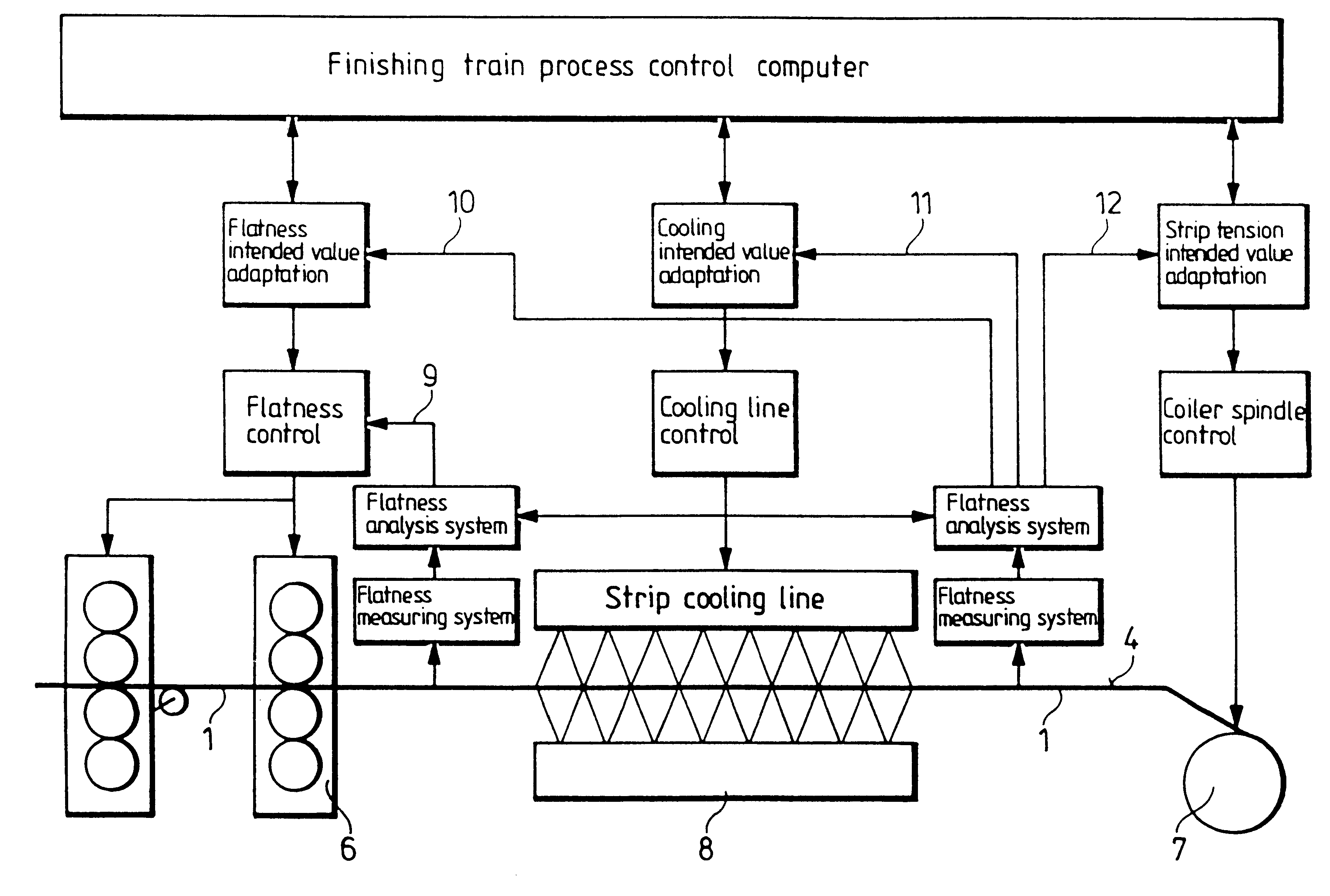

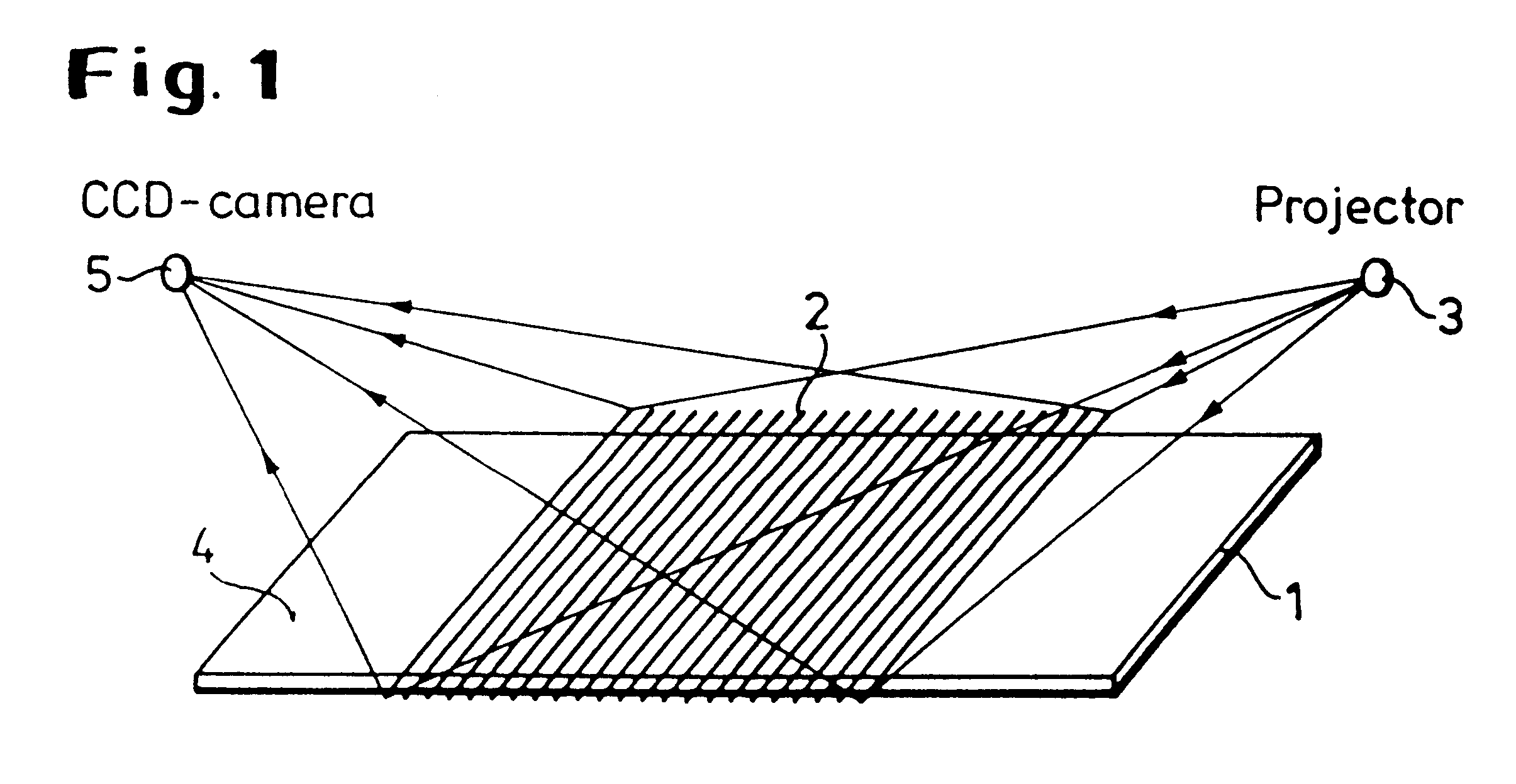

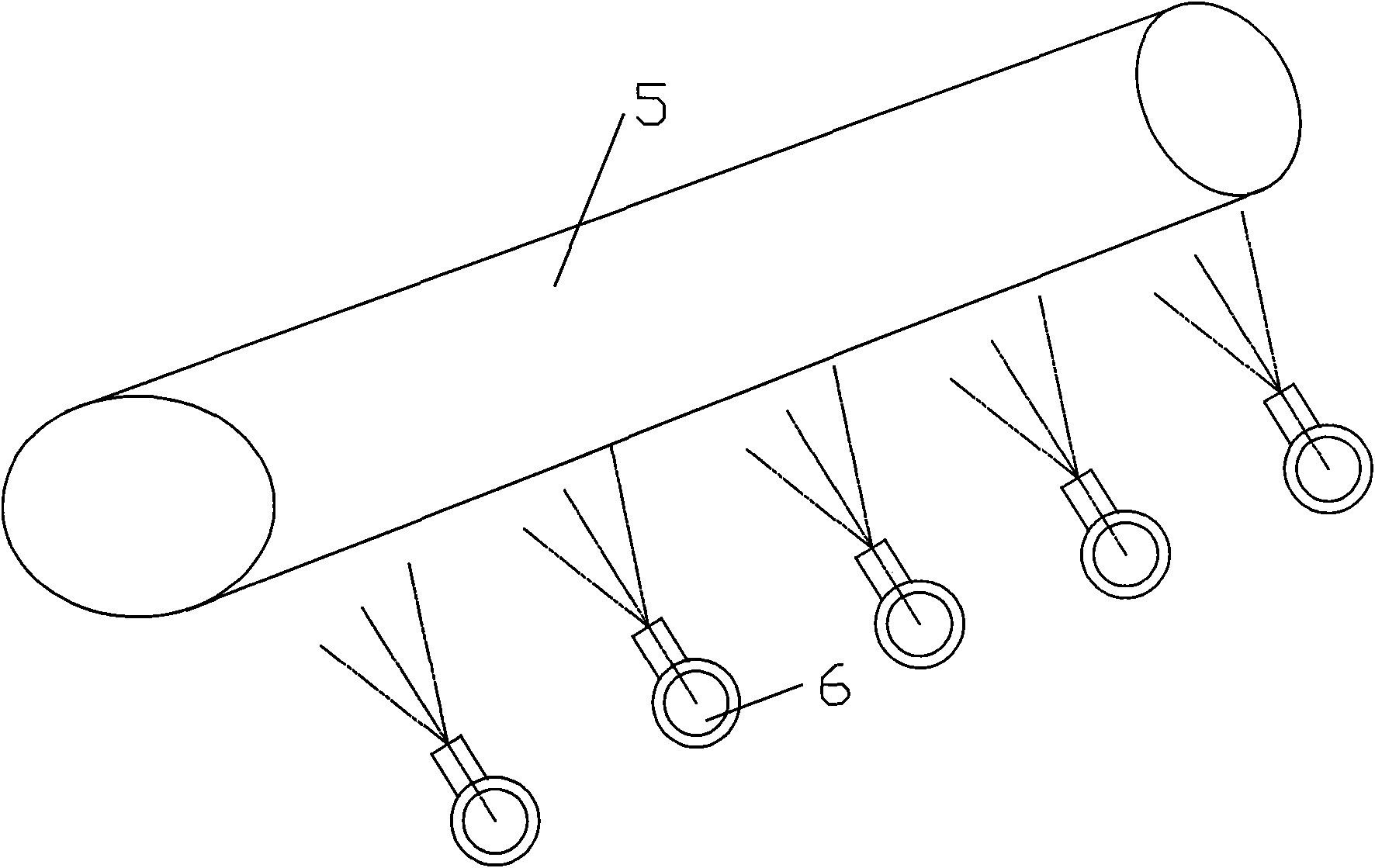

Flatness measurement system for metal strip

InactiveUS6286349B1Easy to measurePermit fine controlTemperature control deviceMeasuring devicesMetal stripsControl system

Owner:THYSSEN KRUPP STAHL AG +1

Control method of tandem cold rolling mill emulsion section cooling

The invention discloses a control method of tandem cold rolling mill emulsion section cooling, comprising the following steps: a. collecting the device parameter of a rolling mill and the key parameter of band steel to be rolled; b. collecting a technological lubrication institution parameter; c. giving emulsion section cooling flow distribution initial value and iteration precision; d. calculating corresponding work roll thermal crown; e. calculating the lateral distribution value of a slipping factor; f. comparing the slipping factor maximum value with a critical value; g. calculating the lateral distribution value of a slip injury index; h. comparing the maximum value of the slip injury index with the critical value; i. calculating the corresponding strip shape distribution value; j. calculating the function value of a strip shape objective function; and k. judging whether Powell condition is available, and obtaining the control curve of the optimal section cooling flow. The controlmethod of the invention combines device section condition with practical flow control precision to set the emulsion flow in sections, reduces problems of slipping, hot slip injury and the like causedby lubrication and ensures the strip shape and the surface quality index of chassis outlet strip steel rolled stock.

Owner:BAOSHAN IRON & STEEL CO LTD

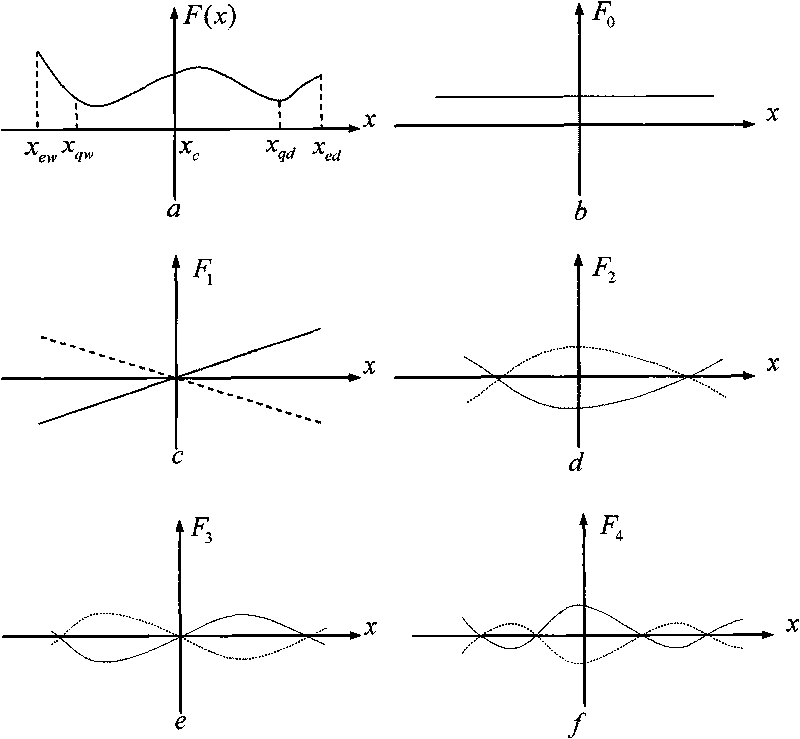

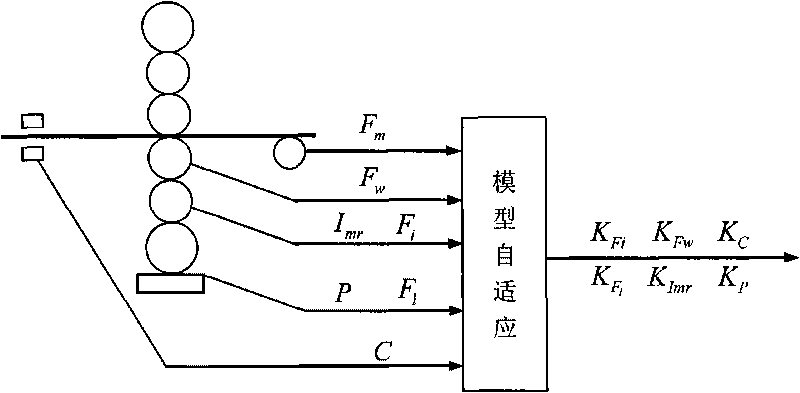

Model self-adapting sheet shape prediction and control method

ActiveCN101758084AEnsure consistencyHigh yieldProfile control deviceAdaptive controlTransmission time delayFeedback controller

The invention relates to a sheet shape control method for strip rolling. A model self-adapting sheet shape prediction and control method comprises the following steps: a sheet shape decomposition method and a sheet shape control model are given, and the input signals of the sheet shape control model include a rolling force and a crown of incoming material; then a sheet shape model which includes executing mechanism characteristics is obtained according to history sheet shape actual output data, the model is dynamically corrected according to real-time rolling parameters and corresponding actual sheet shape values, a correction model is used for accurately predicting the sheet shape and determining the optimal control quantity, and a feedback path, which removes transmission time-delay of strip steel between a frame and a measuring system, is established, thus carrying out regulation of a feedback controller in real time and ensuring rapid and dynamical sheet shape control. As the sheet shape control model is corrected in real time according to actual data, constantly changing actual conditions of the sheet shape model of a rolling mill are satisfied, thus predicting the sheet shape more accurately to increase the control accuracy of the sheet shape.

Owner:BAOSHAN IRON & STEEL CO LTD

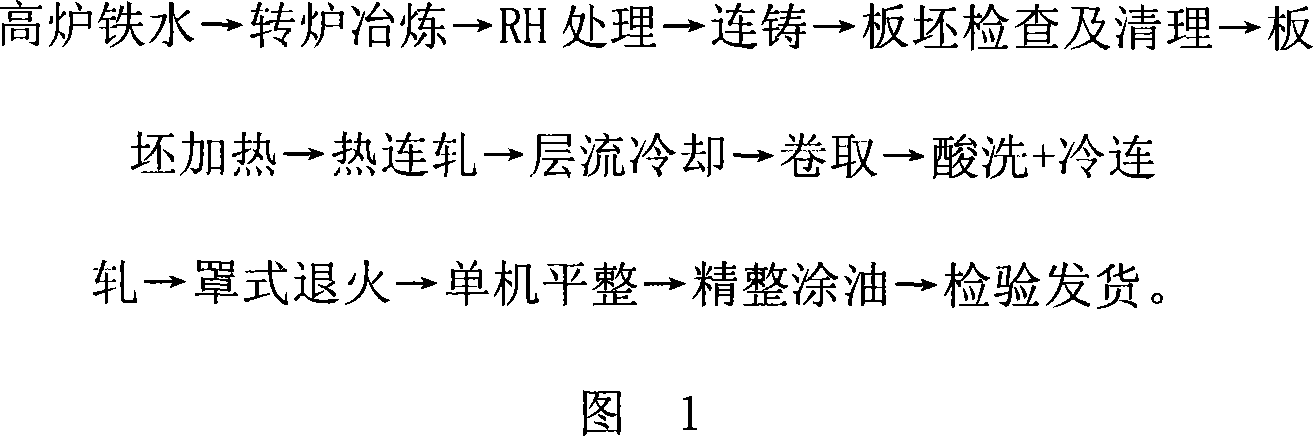

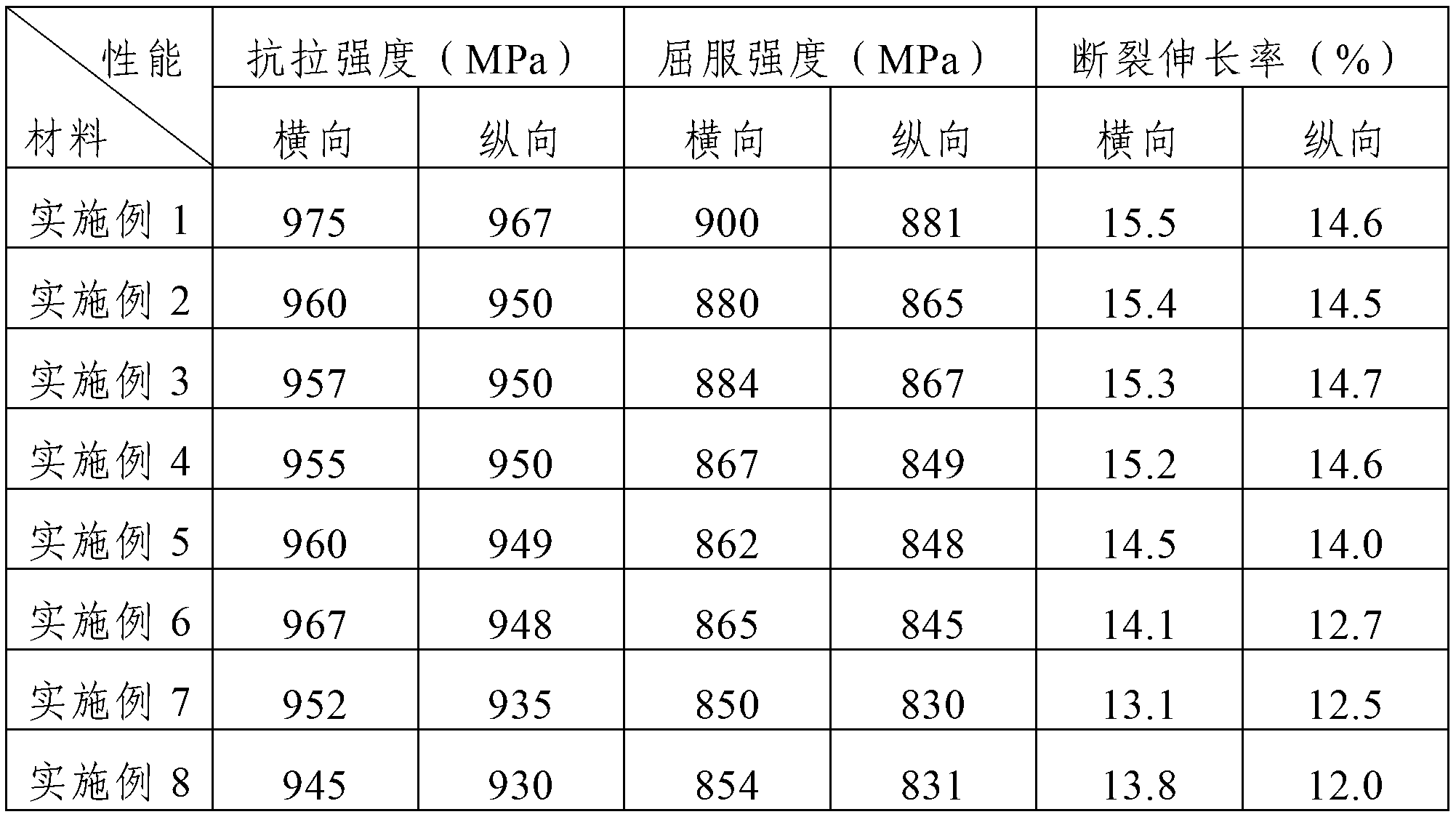

Ultra-low carbon cold-rolling deep-punching glassed steel and method of production

InactiveCN101082107ADoes not affect deep drawabilityImprove deep drawing performanceTemperature control deviceProfile control deviceChemical compositionPunching

The present invention relates to ultralow carbon cold rolled deep drawing glass-lined steel and its production process. The glass-lined steel has the chemical components including C 0.002-0.005 wt%, Si 0.004-0.020 wt%, Mn 0.08-0.13 wt%, P 0.006-0.020 wt%, S 0.01-0.035 wt%, Als 0.010-0.040 wt%, Ti 0.05-0.09 wt%, N not more than 0.004 wt%, and Fe and inevitable impurities for the rest. The steel of the present invention is superior to IF steel, and has raised Ti and S contents for effective separation of biphase Ti4C2S2 particle, and effective fixing of H atom to avoid scale burst of enamel. It has excellent deep drawing performance and excellent enameling performance.

Owner:武汉钢铁有限公司

Rolling method of TC4 titanium alloy wide cut medium-thickness plates

ActiveCN103230936AReduce anisotropyReal-time monitoring of rolling deformation temperatureTemperature control deviceProfile control deviceWork in processTitanium alloy

The invention provides a rolling method of TC4 titanium alloy wide cut medium-thickness plates. The rolling method includes the following steps: 1, first heating treatment is performed on TC4 titanium alloy plate blank with thickness ranging from 80mm to 150mm and length and width ranging from 800mm to 1200mm; 2, first rolling is performed on the TC4 titanium alloy plate blank to obtain semi-finished plate blank; 3, surface scale is removed after the semi-finished plate blank is sheared, and then second heating treatment is performed; and 4, second rolling is performed on the semi-finished plate blank to obtain TC4 titanium alloy wide cut medium-thickness plates with thickness ranging from 5mm to 30mm and width ranging from 1000mm to 2600mm. Through comprehensive control of rolling temperature, rolling heating number, heating number deformation and rolling directions, finally the TC4 titanium alloy wide cut medium-thickness plates with small anisotropism, high mechanical properties, strong plastic comprehensive matching are manufactured.

Owner:WESTERN METAL MATERIAL

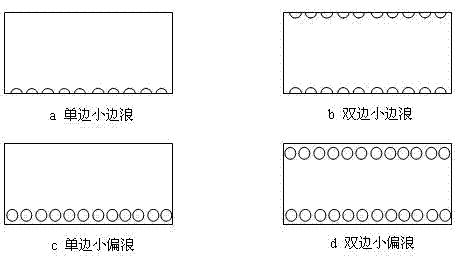

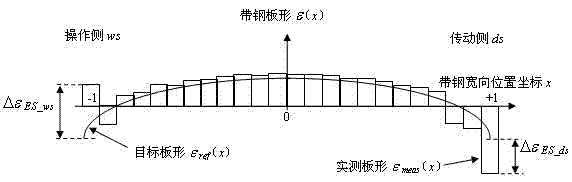

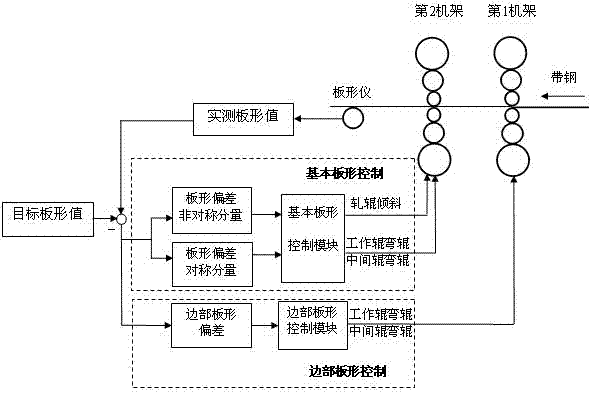

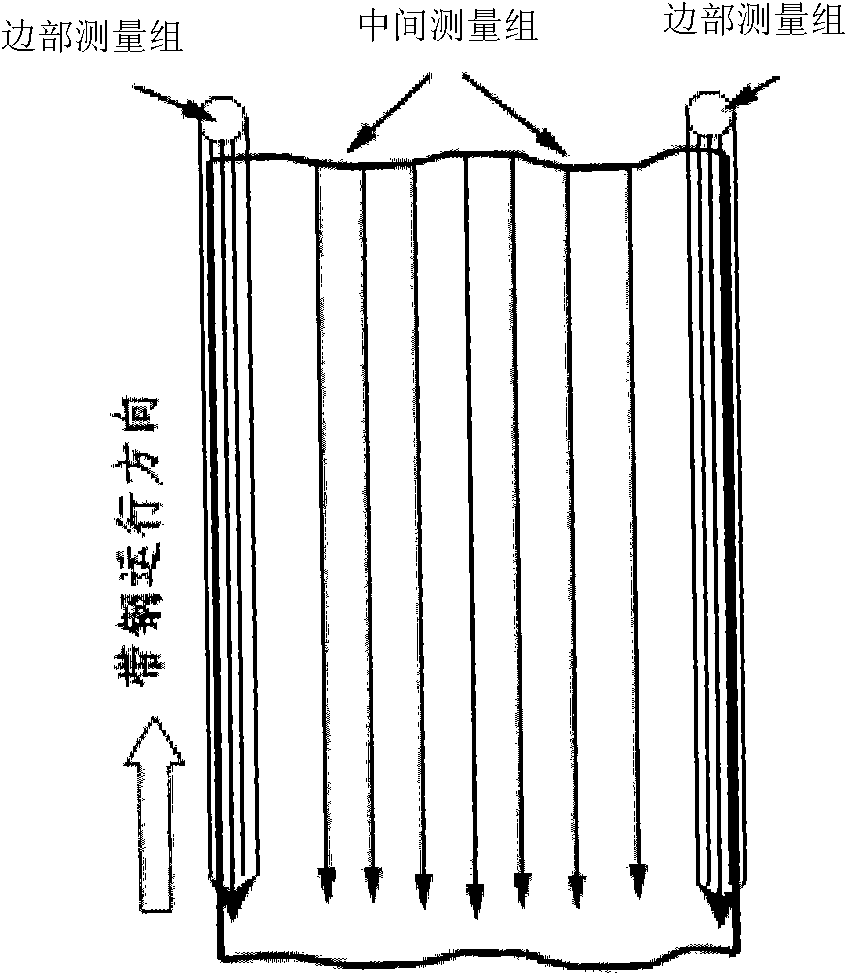

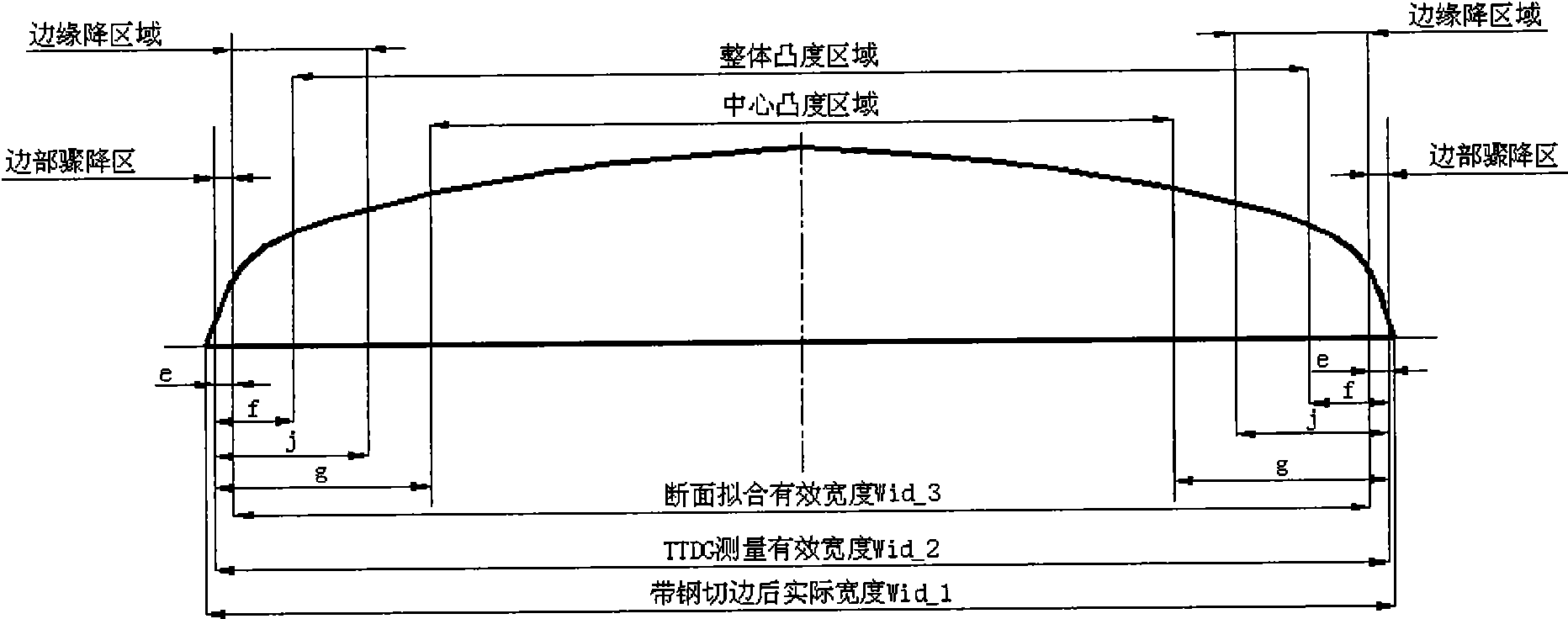

Control method of edge portion strip shape of cold rolling strip steel

The invention relates to a rolling method of cold rolling strip steel, in particular to a control method of edge portion strip shape of thin strip steel rolled by a cold continuous rolling mill or a two-stand temper mill. In a strip shape feedback control system centered on a last stand and on the basis of fundamental strip shape control function of major control for conventional edge waves and center waves, the method identifies the state of the edge portion strip shape of the strip steel based on the difference between the actual measured strip shape of strip steel edge portion together with the adjacent areas at the exit of last stand and an objective strip shape, and adjusts the corresponding strip shape executive mechanisms of the last stand and the rest stands according to the state of the edge portion strip shape to realize effective control for the edge portion strip shape of the strip steel, such as small edge waves and small side waves, thereby further improving the quality of the strip steel after cold rolling or temper rolling.

Owner:BAOSHAN IRON & STEEL CO LTD

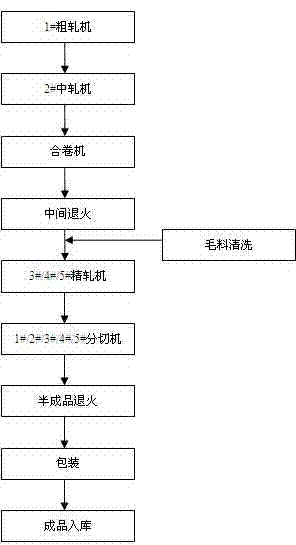

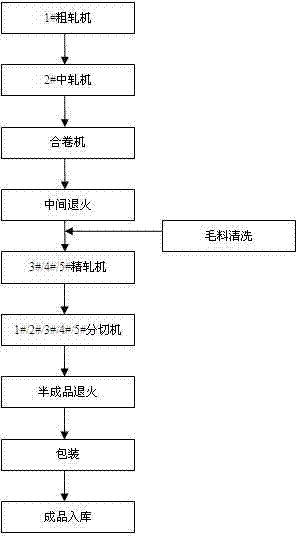

A production process for rolling double-zero aluminum foil

ActiveCN102284483AReduce the number of pinholesImprove mechanical propertiesMetal rolling arrangementsProfile control deviceSurface cleaningWork in process

The invention discloses a production process for rolling a light gauge aluminum foil, which comprises the following steps of: performing rough rolling, wherein the reduction per pass of the rough rolling is 0.3mm to 0.14mm to 0.07mm to 0.038mm; performing intermediate rolling, wherein the reduction per pass of the intermediate rolling is 0.038mm to 0.013mm; performing double rolling; performing intermediate annealing; cleaning a stock, namely performing surface cleaning on the aluminum foil stock by using rolling oil at a finish rolling inlet; performing finish rolling, wherein the reduction per pass of the finish rolling is 0.013mm to 0.005mm; slitting; annealing a semi-finished product; and packaging and warehousing. By adding the intermediate annealing and rolling oil cleaning processes for the aluminum foil, the mechanical property of the aluminum foil is improved while the thickness of the aluminum foil is reduced, and the breakage condition and a pinhole number in the rolling process are reduced.

Owner:JIANGSU ZHONGJI LAMINATION MATERIALS

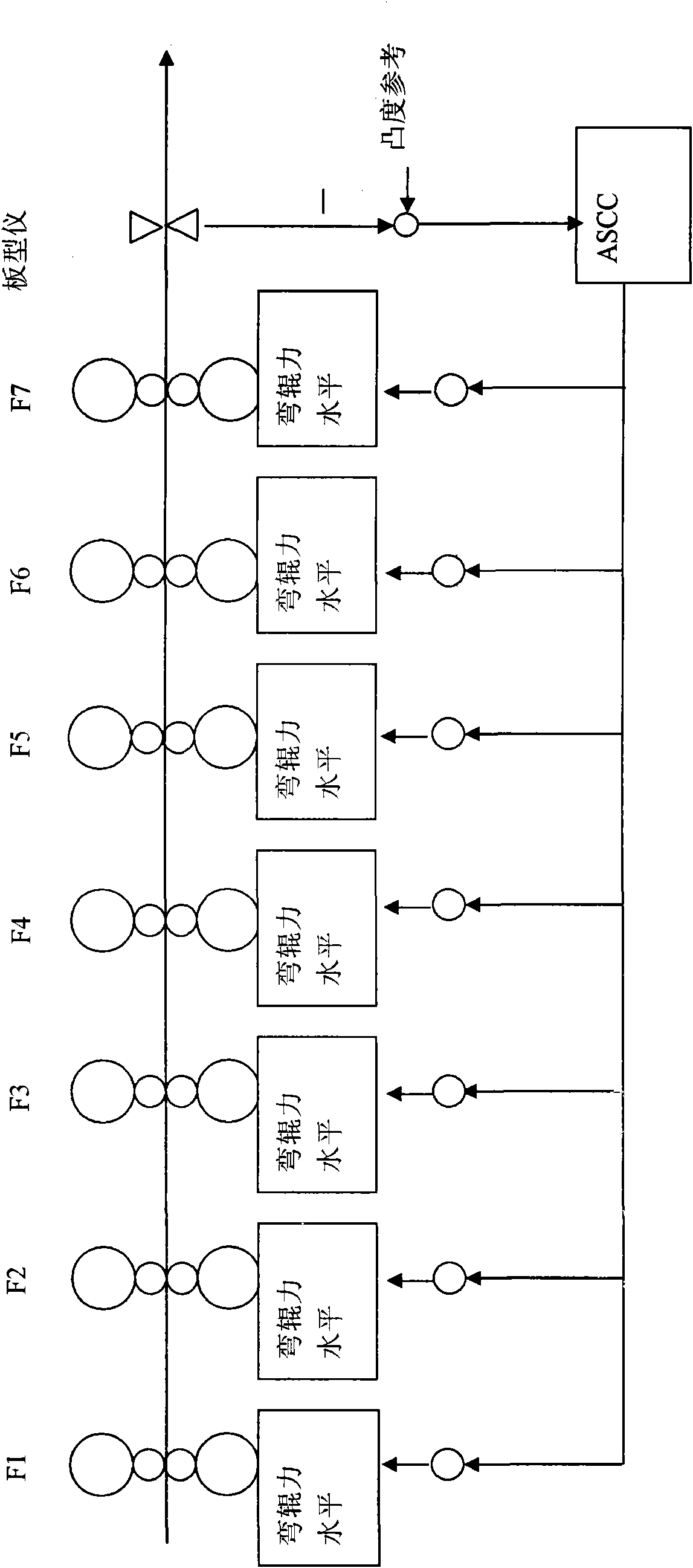

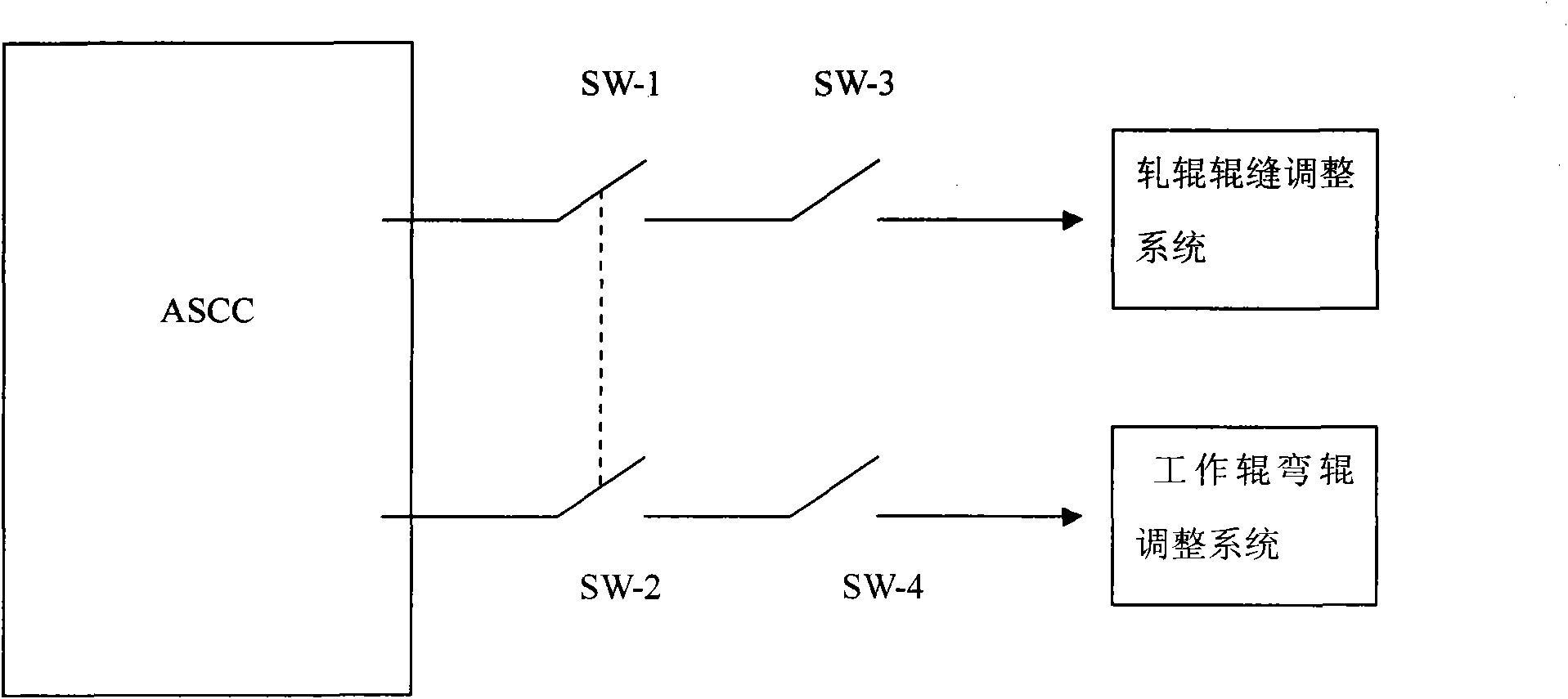

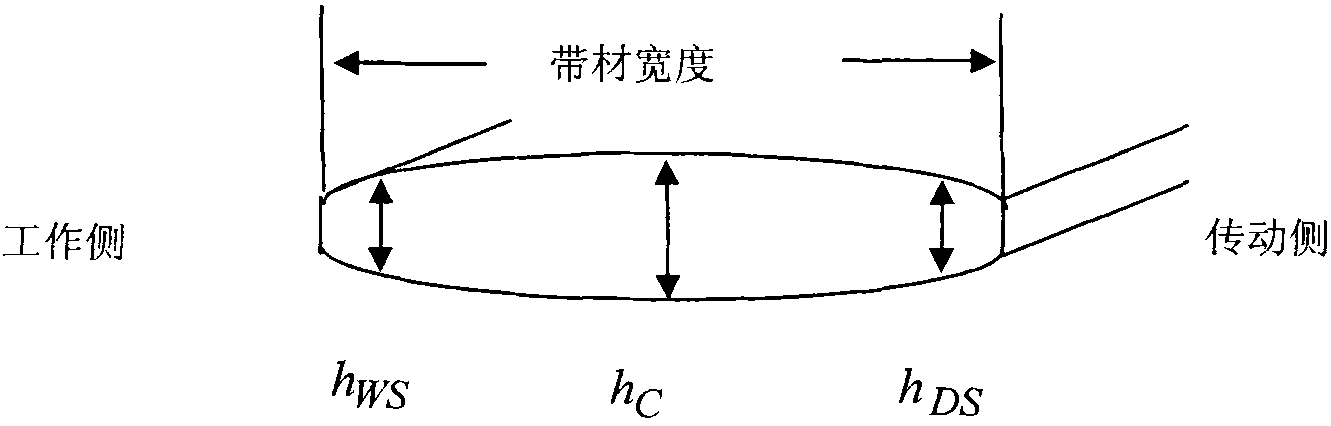

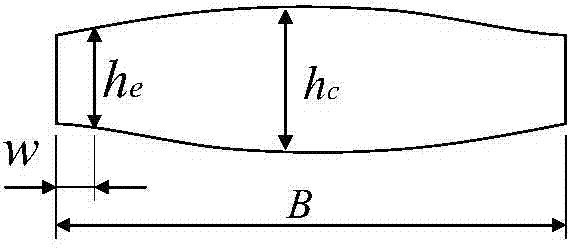

Method for automatically controlling convexity and/or wedge of hot rolled in series type rolling machine and system thereof

ActiveCN101890435AAvoid snaking motionEliminate single disadvantagesProfile control deviceAutomatic controlEconomic benefits

The invention relates to a method for automatically controlling the convexity and / or wedge of a hot rolled in series type rolling machine and a system (ASCC) thereof. The method comprises the following steps of: building feedback control for the bending of a working roll and the flattening of a roll gap from a first finishing mill stander to a final finishing mill stander in the hot rolled in series type rolling machine to automatically control the convexity (wedge) of strip steel, i.e. comparing the strip steel wedge which is detected by an ASCC model with the object wedge during rolling to obtain the difference; and correcting the difference through the comprehensive computation and the control method of the system to build a step type adjusting method. Therefore, the invention maximizes the response of the feedback control to correct the wedge and the convexity of the strip steel, guarantees the good flatness of products, prevents the strip steel to have snake-like motion in each stander, overcomes the defect that the existing convexity controlling method is single, and comprehensively balances the relationship between the convexity and the wedge. The invention can guarantee the convexity precision of the wedge along the long axis direction of the strip steel, improves the flatness, guarantees the product quality and the production safety, and can effectively improve the economic benefit of steel rolling factories.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

Hot rolled strip steel convexity control method

ActiveCN104511482AGuaranteed accuracyGuaranteed stabilityProfile control deviceAutomatic controlThermal expansion

A hot rolled strip steel convexity control method comprises the steps of according to original roll profiles, abrasion, thermal expansion of rollers and concrete rolling conditions (such as rolling force, plate width and plate thickness), utilizing a mathematic model to calculate plate shape setting and controlling parameters such as roll bending force and crossing angles of the rollers; after threading of a strip steel, carrying out automatic convexity control, which comprises roll bending force compensation for roller thermal convexity change, roll bending force compensation for rolling force change and actual measurement convexity feedback control; according to actual measurement strip steel convexity and target convexity, utilizing the mathematic model to carry out convexity self-learning so as to improve the setting precision of the next roll of strip steel. According to the hot rolled strip steel convexity control method, the strip steel convexity precision and the overall length convexity stability can be effectively guaranteed under the condition that deviation appears in the convexity setting or the rolling conditions drastically change.

Owner:BAOSHAN IRON & STEEL CO LTD +1

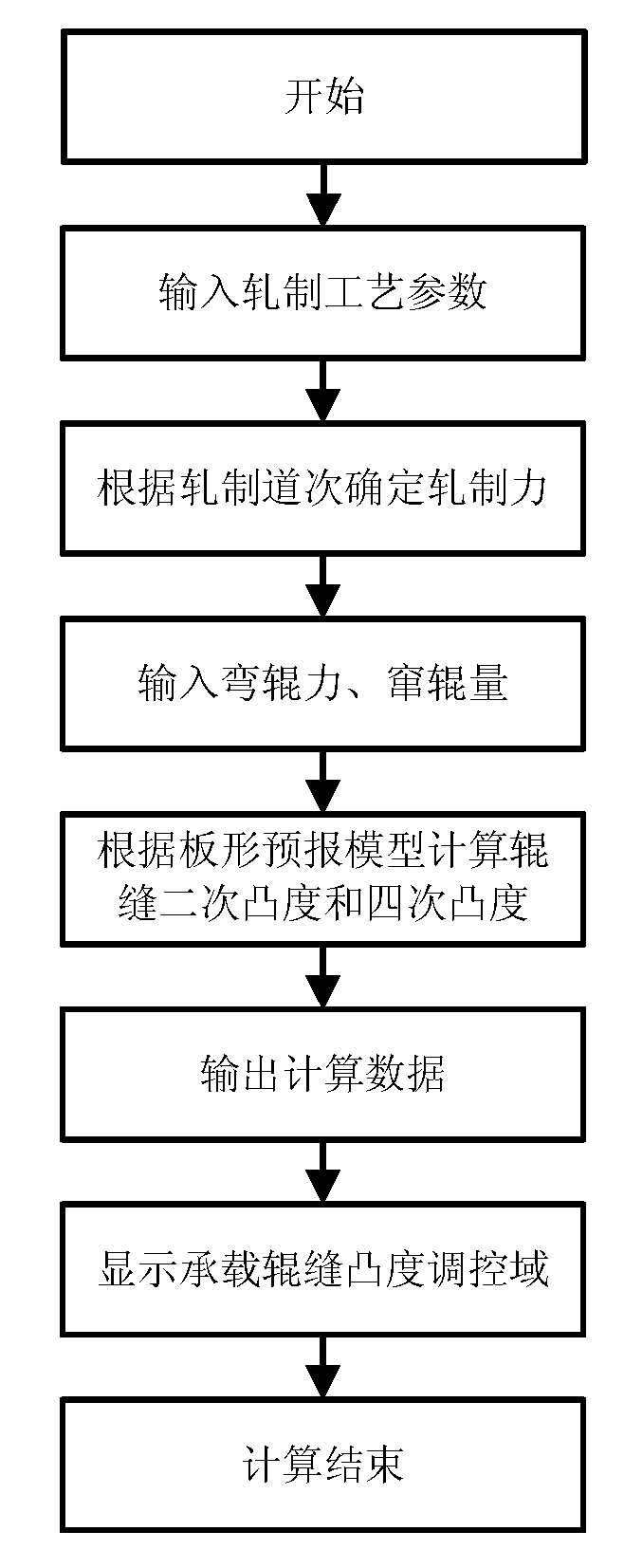

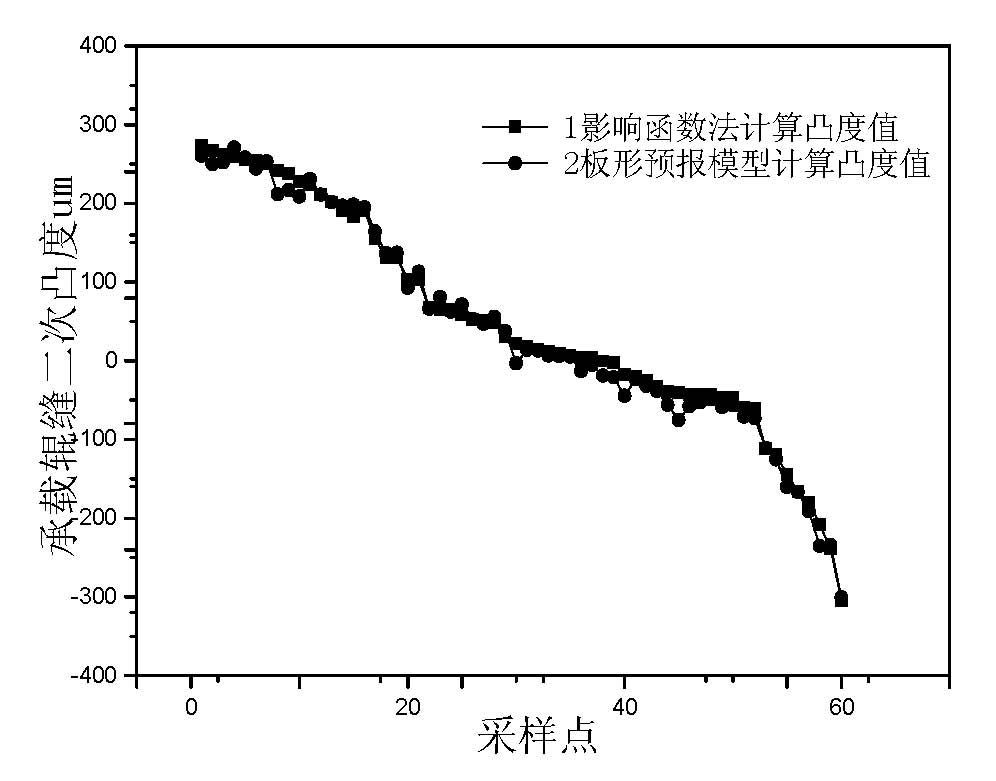

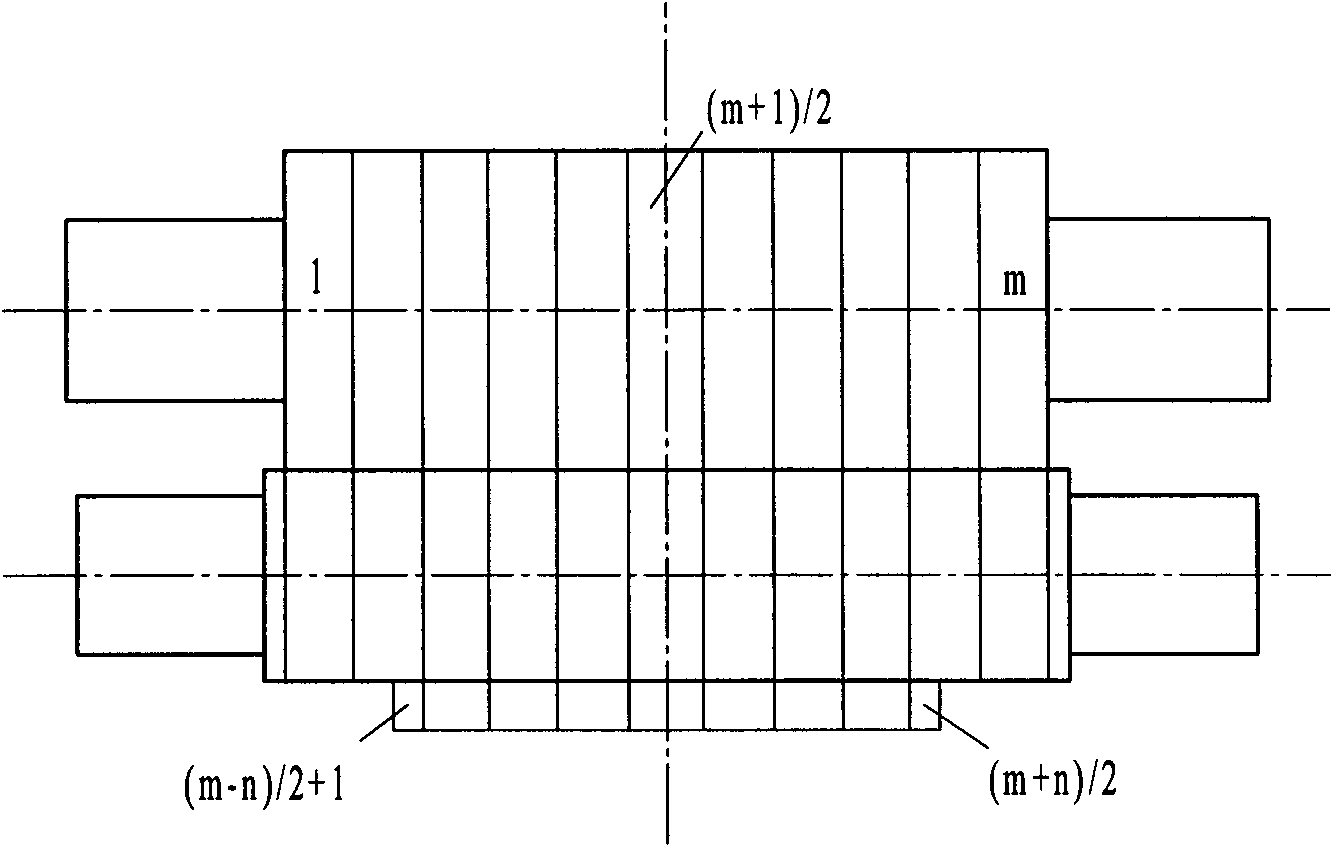

High-precision strip shape control prediction method for CVC (continuously variable crown) four-roll cold rolling mill

InactiveCN102601127AComposite wave in control sideHigh yieldMeasuring devicesProfile control deviceClassical mechanicsWave form

The invention relates to a high-precision strip shape control prediction method for a CVC (continuously variable crown) four-roll cold rolling mill. The high-precision strip shape control prediction method includes the steps: (1) building a strip shape prediction model for the CVC four-roll cold rolling mill; (2) determining parameters of the strip shape prediction model by means of regression; and (3) predicting a crown regulating domain of the CVC four-roll cold rolling mill in an online and real-time manner according to the regulating range of strip steel widths, roll radiuses, roll bending force and traversing positions under the condition of determined rolling force based on the strip shape prediction model. By the aid of the technical scheme, the strip shape prediction model is built, the secondary crown and the quaternary crown of a bearing roll gap can be accurately predicted, and the strip shape regulating capability of the rolling mill can be predicted in an online manner based on the strip shape prediction model. Besides, preset values of the roll bending force and roll shifting of the CVC four-roll cold rolling mill can be optimized, so that double waves or middle waves in a secondary wave form and edge and middle composite waves in a quaternary wave form can be effectively controlled, and the yield of a strip is improved.

Owner:WISDRI ENG & RES INC LTD

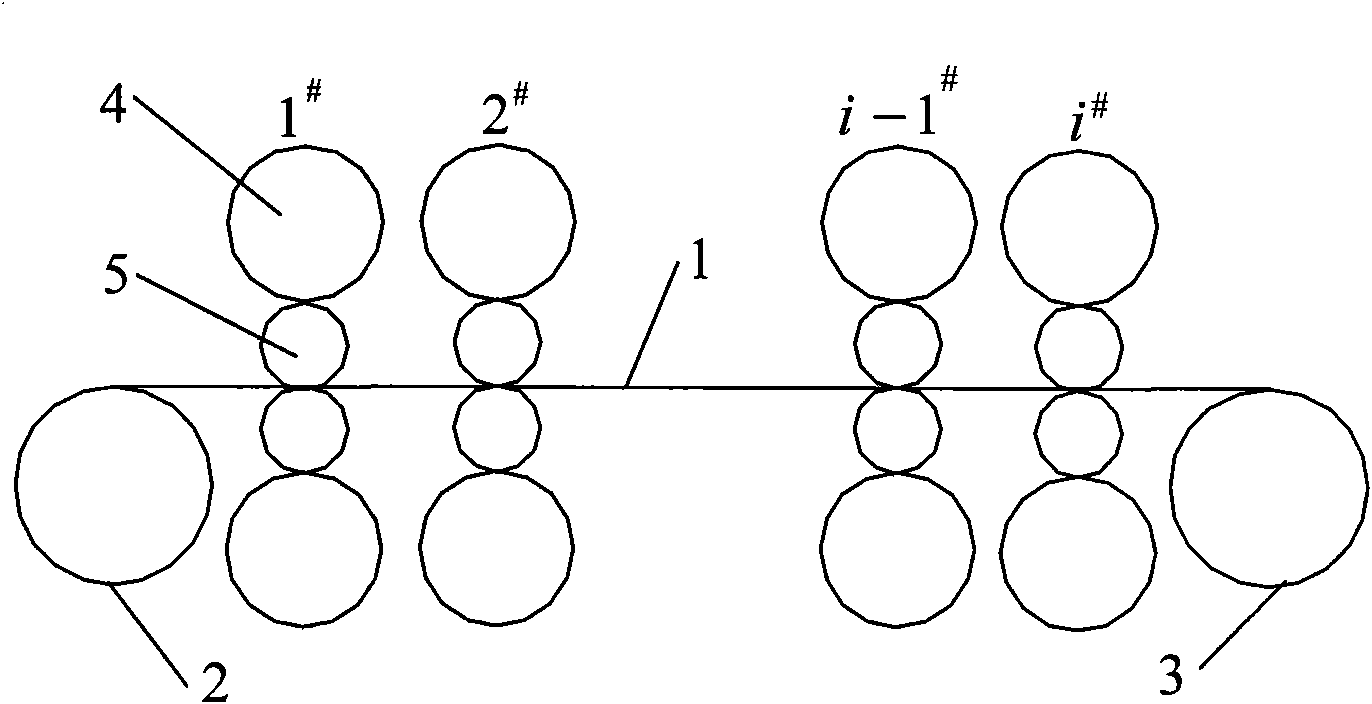

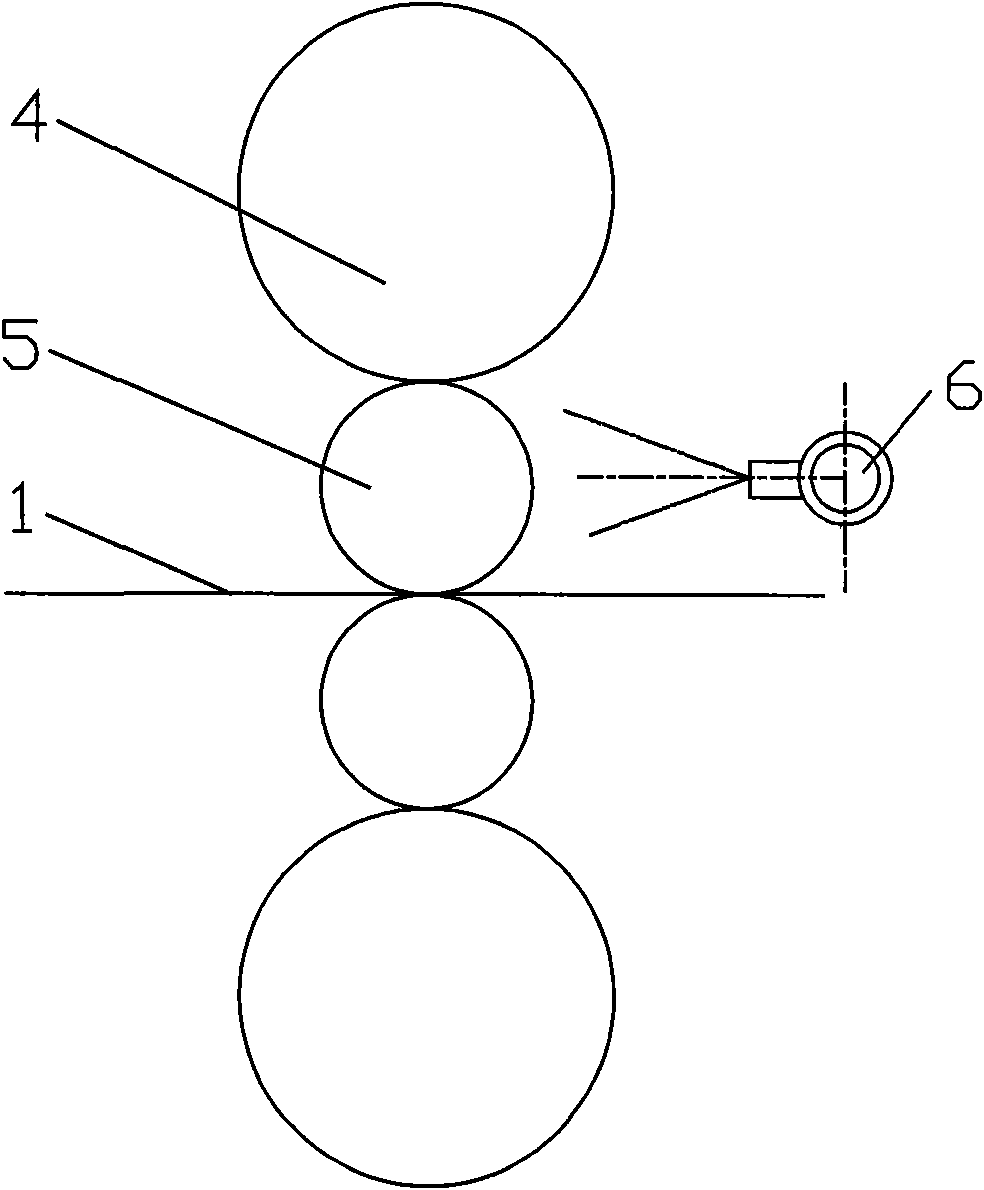

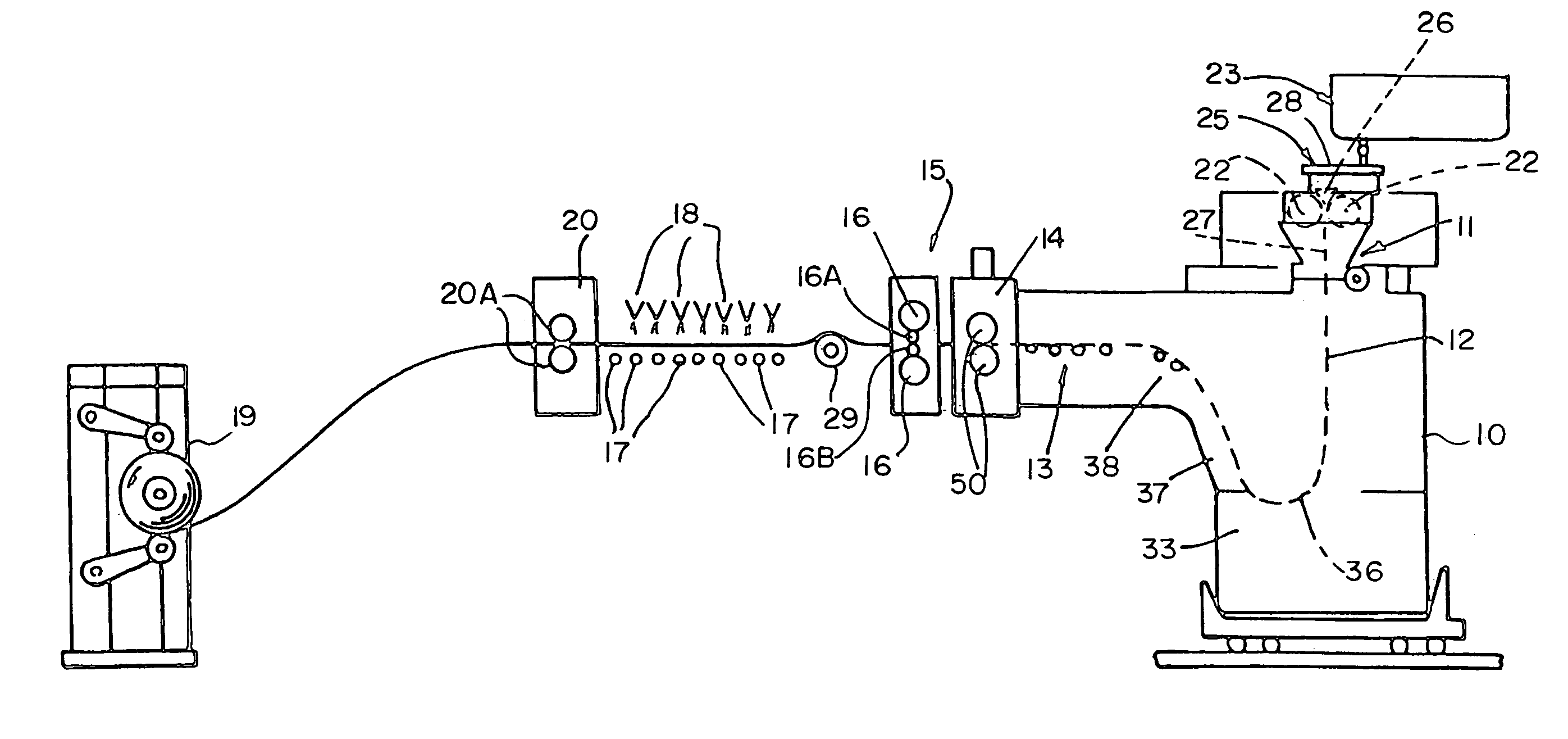

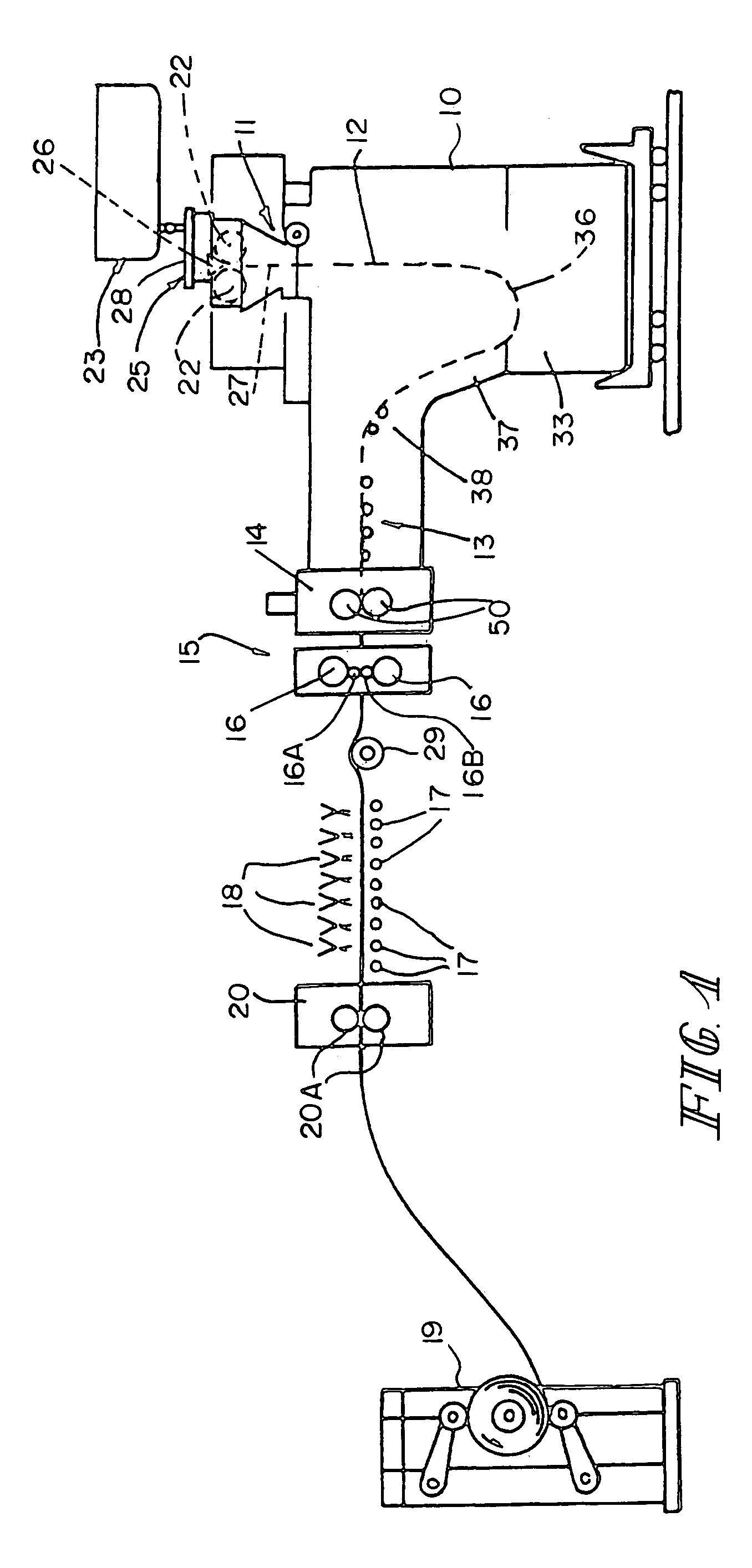

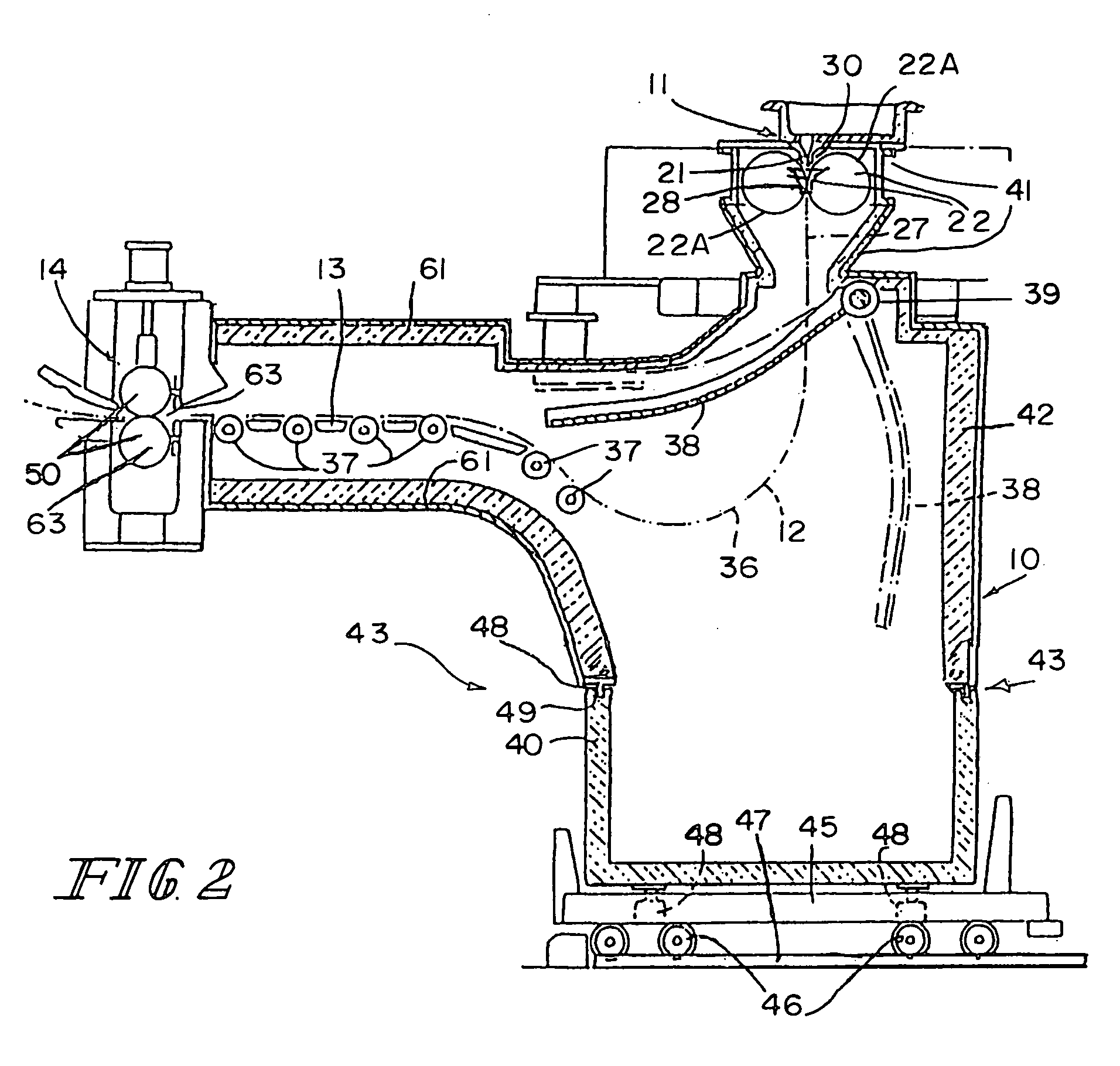

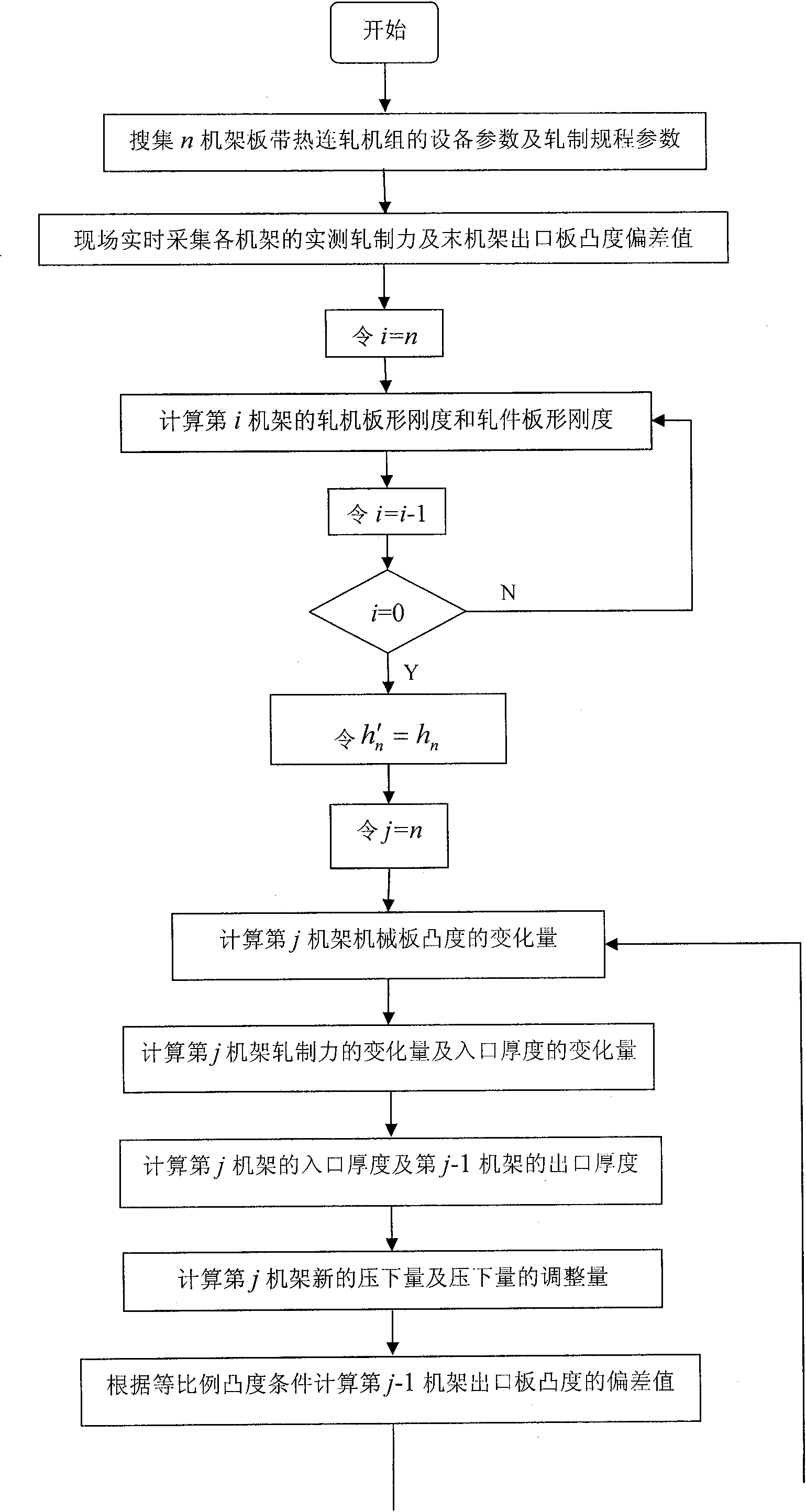

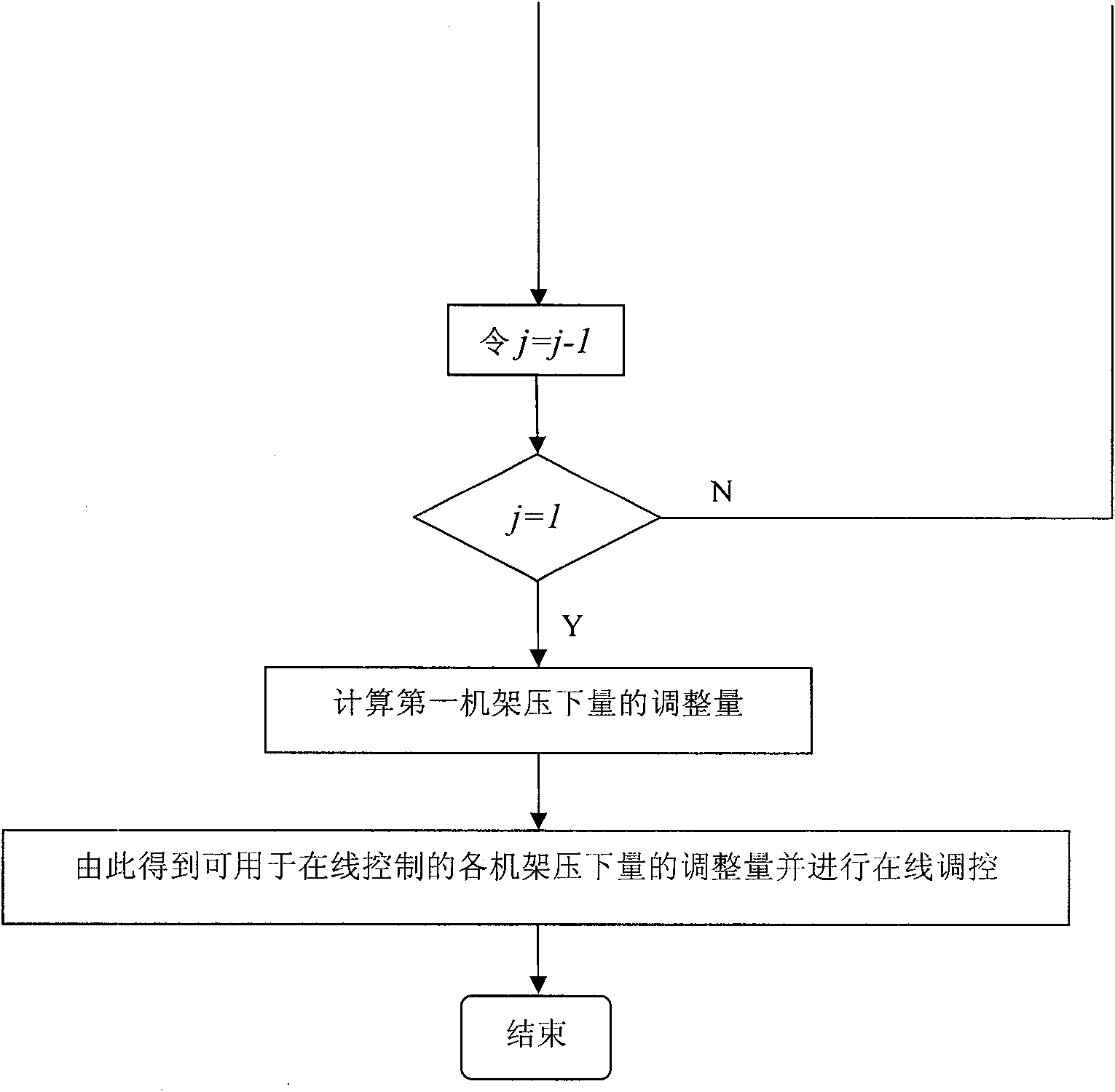

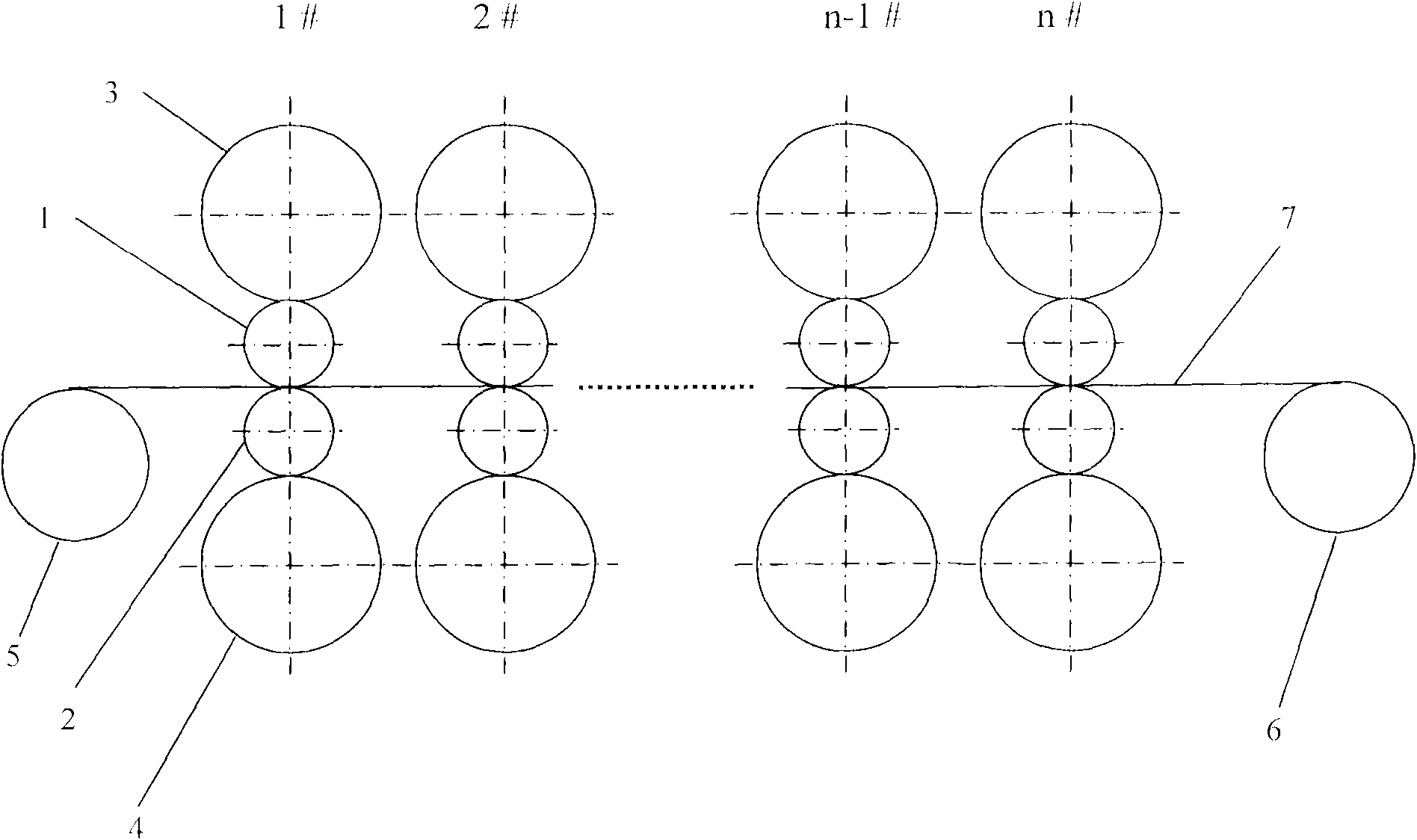

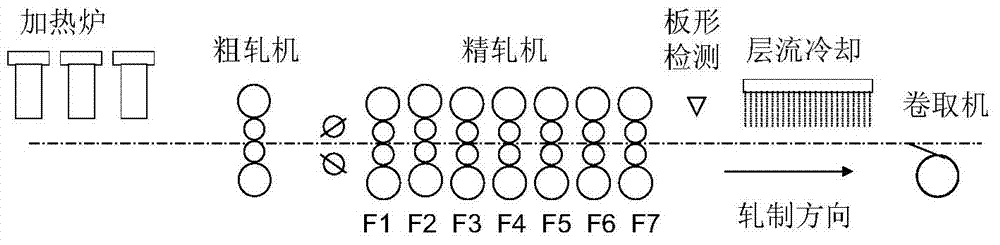

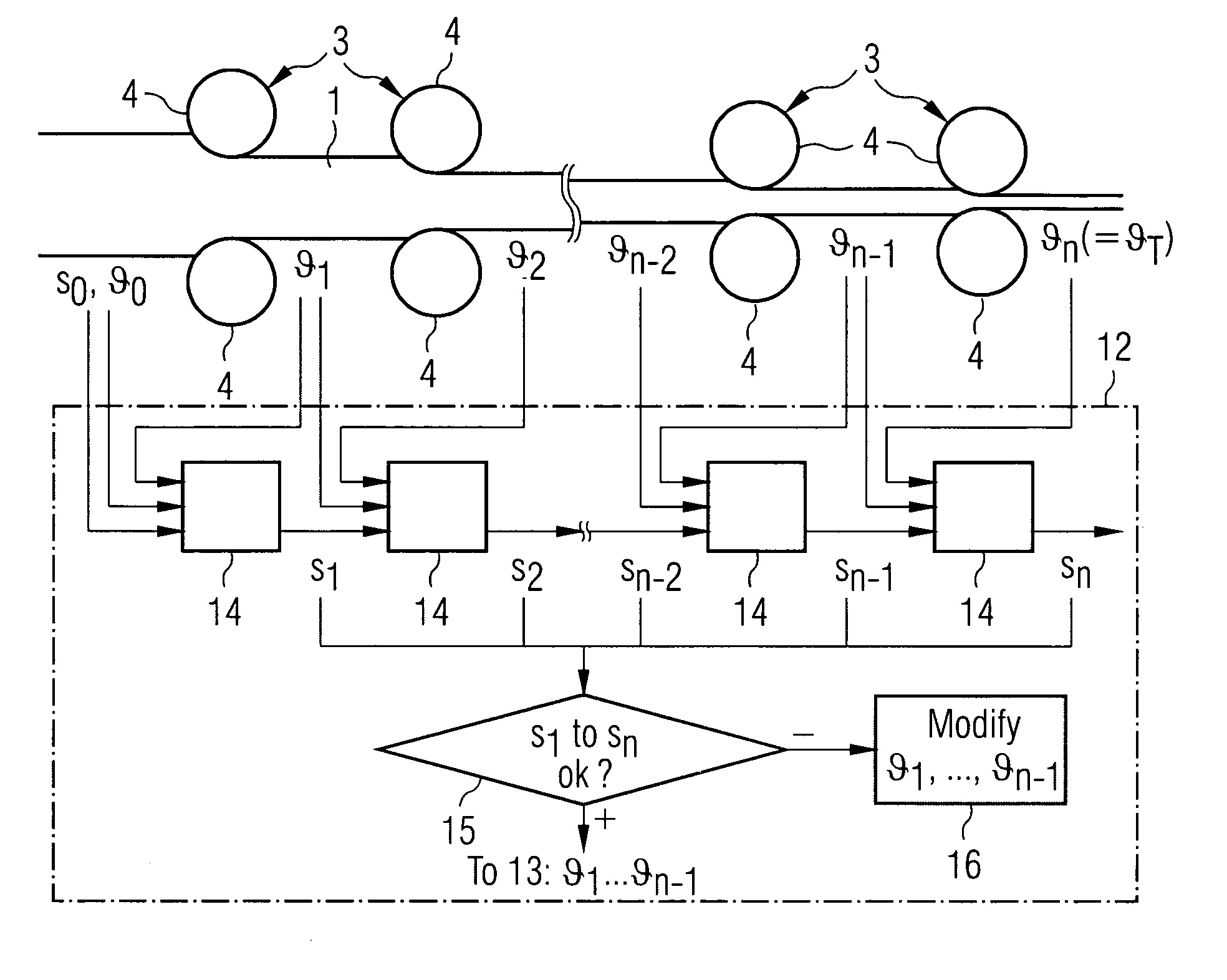

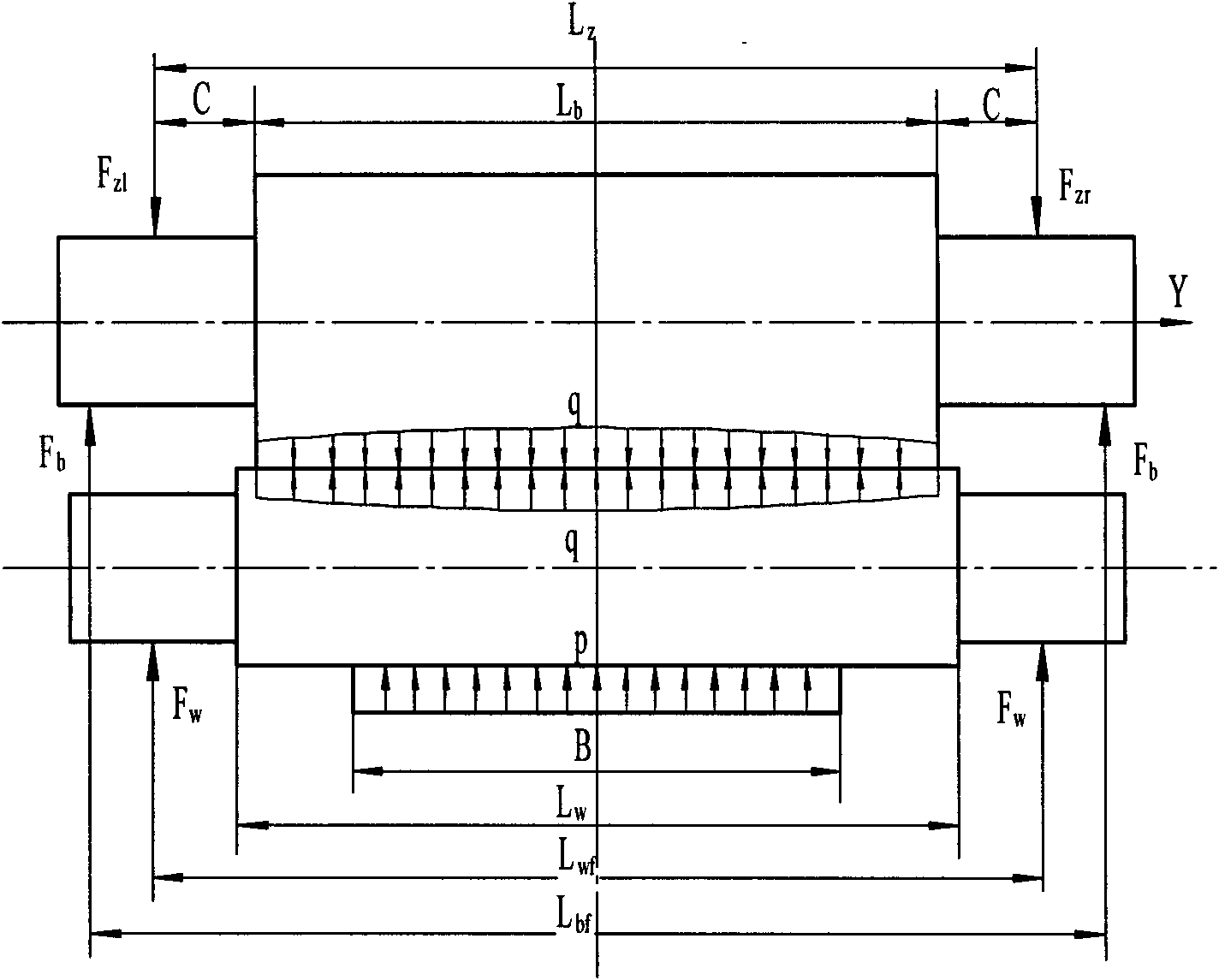

On-line coordination control method for plate shape and plate thickness of strip tandem hot continuous rolling mill

InactiveCN101890433ALower control costsSimple control methodRoll force/gap control deviceProfile control deviceSlice thicknessEngineering

The invention discloses an on-line coordination control method for the plate shape and plate thickness of a strip tandem hot continuous rolling mill, belonging to the technical filed of hot continuous rolling of sheets and strips. The method is characterized by comprising the following steps: (1) collecting n rack hot continuous rolling mill equipment and rolling schedule parameters; (2) collecting the roll force and the convexity offset value of a last rack plate in situ; (3) calculating the plate shape stiffness of each rack; (4) keeping the thickness of the outlet of the tail rack to be constant; (5) inversely calculating the convexity variable quantity of the mechanical plate of the i rack from the tail rack; (6) calculating the roll force and the variable quality of the thickness of the inlet of the i rack; (7) calculating the thickness of the new inlet and outlet of the i rack; (8) calculating the rolling reduction and adjusted quantity of the i rack; (9) calculating the convexity variable quantity of the outlet plate of the (i-1) rack according to the equi-proportional convexity condition; (10) repeating steps from (5) to (9) to obtain the rolling reduction and adjusted quantities of 2nd to n racks; (11) calculating the rolling reduction and adjusted quantity of the first rack; and (12) carrying out on-line coordination control according to the rolling reduction and adjusted quantities, thereby achieving the purpose of coordination control on the plate shape and plate thickness.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for controlling pitting on surface of medium steel plate

InactiveCN101704026AGuaranteed performanceReduce incidenceTemperature control deviceWork treatment devicesChemical compositionMetallurgy

The invention discloses a method for controlling pitting on the surface of a medium steel plate, which prevents the surface of the medium steel plate from generating the pitting by controlling the components of a billet and adopting different heating and descaling processes according to different components, wherein the billet comprises the following chemical components in percentage by mass: 0.08 to 0.20 percent of C, 0.13 to 0.20 percent of Si, 0.90 to 1.60 percent of Mn, less than or equal to 0.02 percent of P, less than or equal to 0.02 percent of S, 0 to 0.04 percent of Nb, 0 to 0.018 percent of Ti, 0.02 to 0.05 percent of Alt and the balance of Fe and impurities; for a steel type containing a microalloy, a method for reducing Si content, heating the steel at a high temperature, descaling at the high temperature and fast cooling the steel after rolling the steel is adopted; and for a steel type containing no microalloy, a method for reducing Si content, heating the steel at a low temperature, descaling at the low temperature and fast cooling the steel after rolling the steel is adopted. The method of the invention can substantially clear off primary scales on the surface of the medium steel plate, thereby greatly reducing the occurrence of the pitting on the surface of the medium steel plate, and reducing the energy consumption and production cost and improving the production efficiency and the economic benefit of enterprises while guaranteeing the properties of the steel plate. The method is suitable to be popularized on a national scale.

Owner:NANJING IRON & STEEL CO LTD

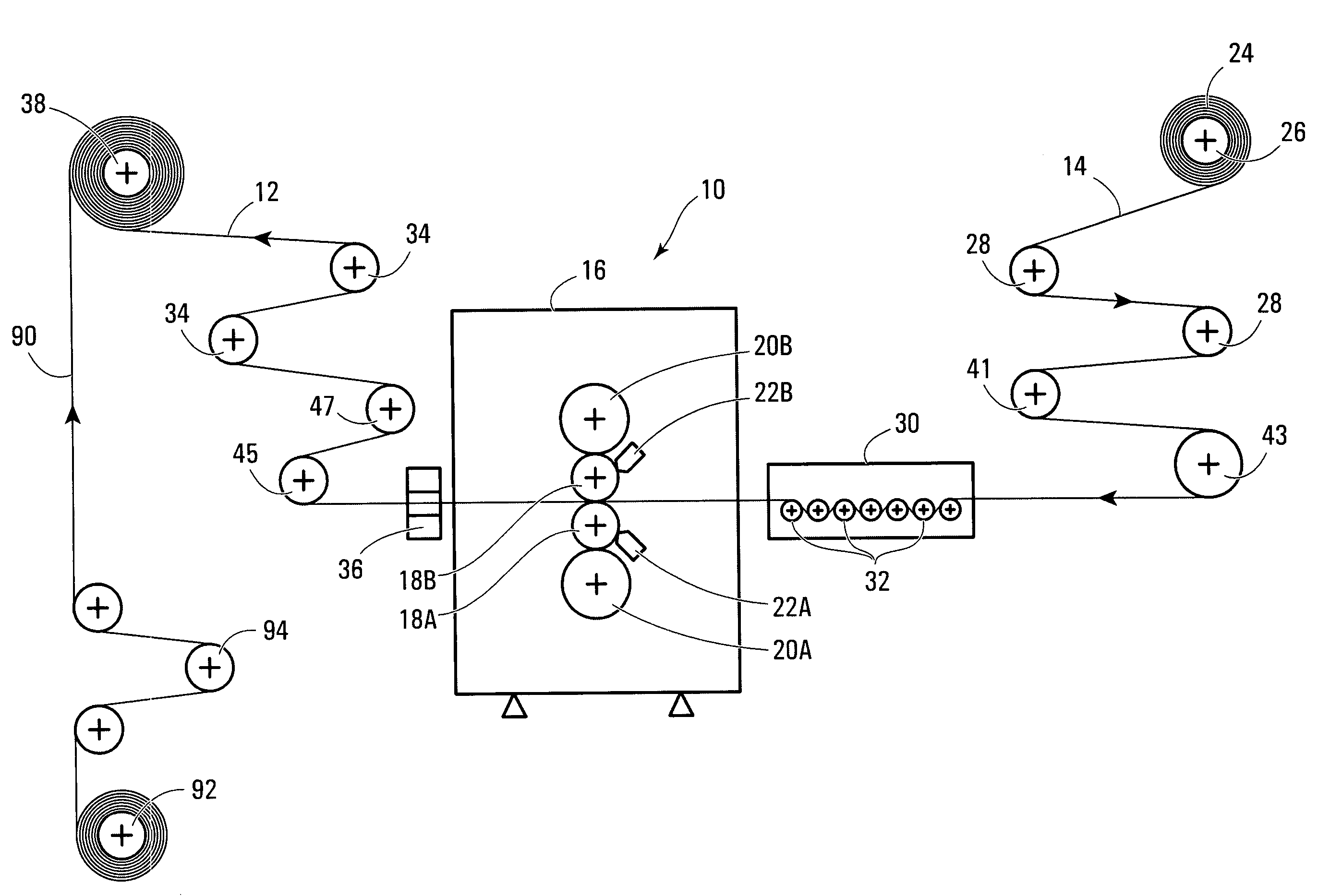

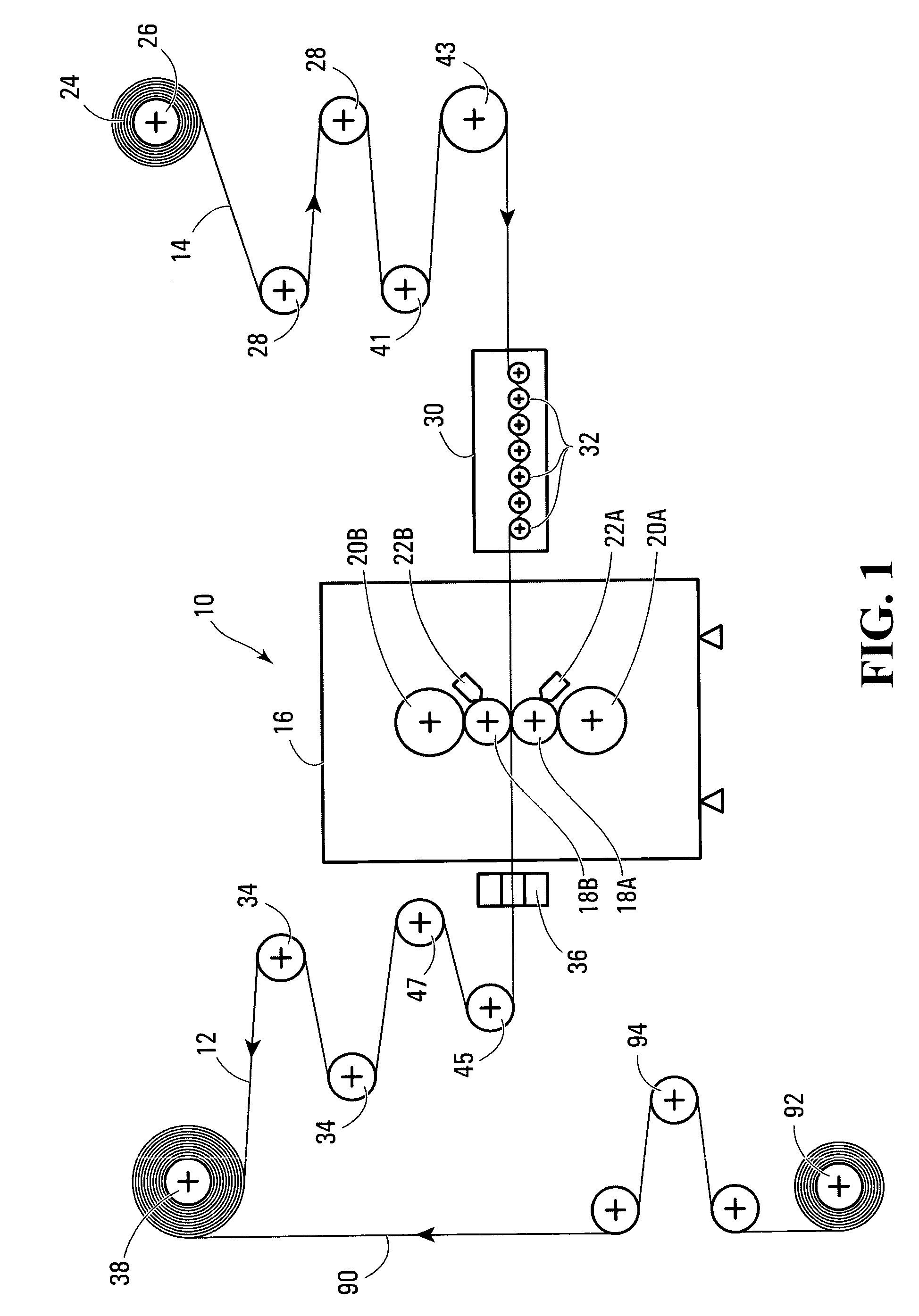

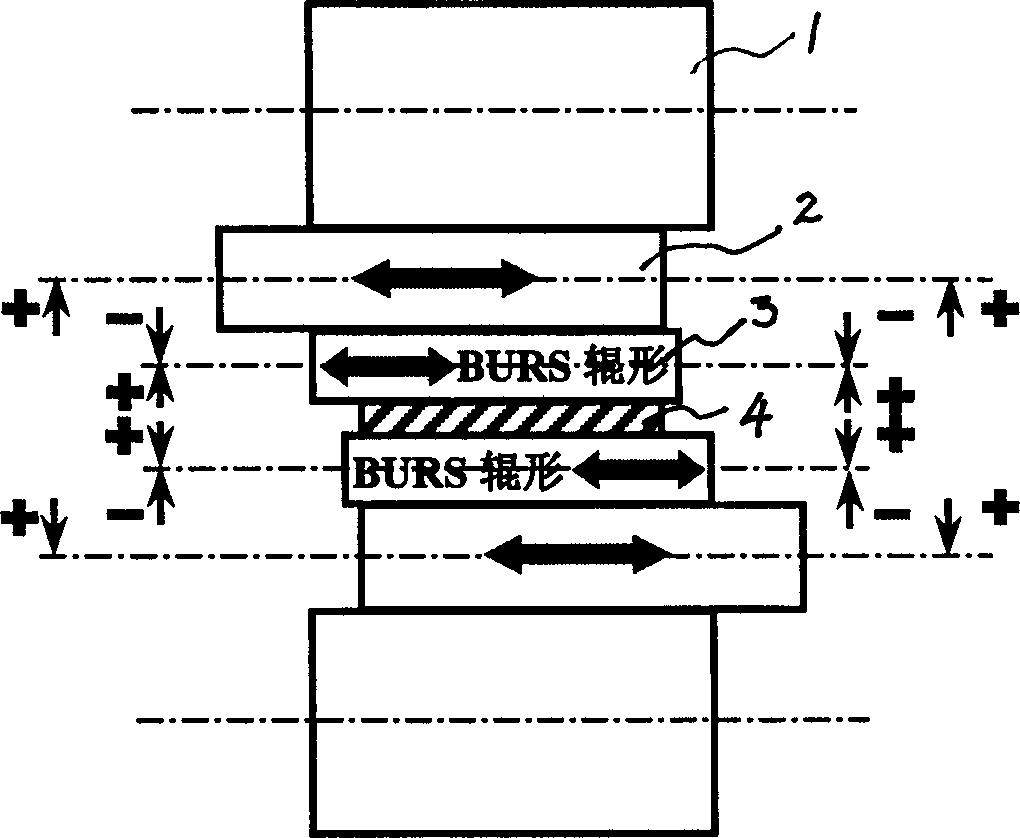

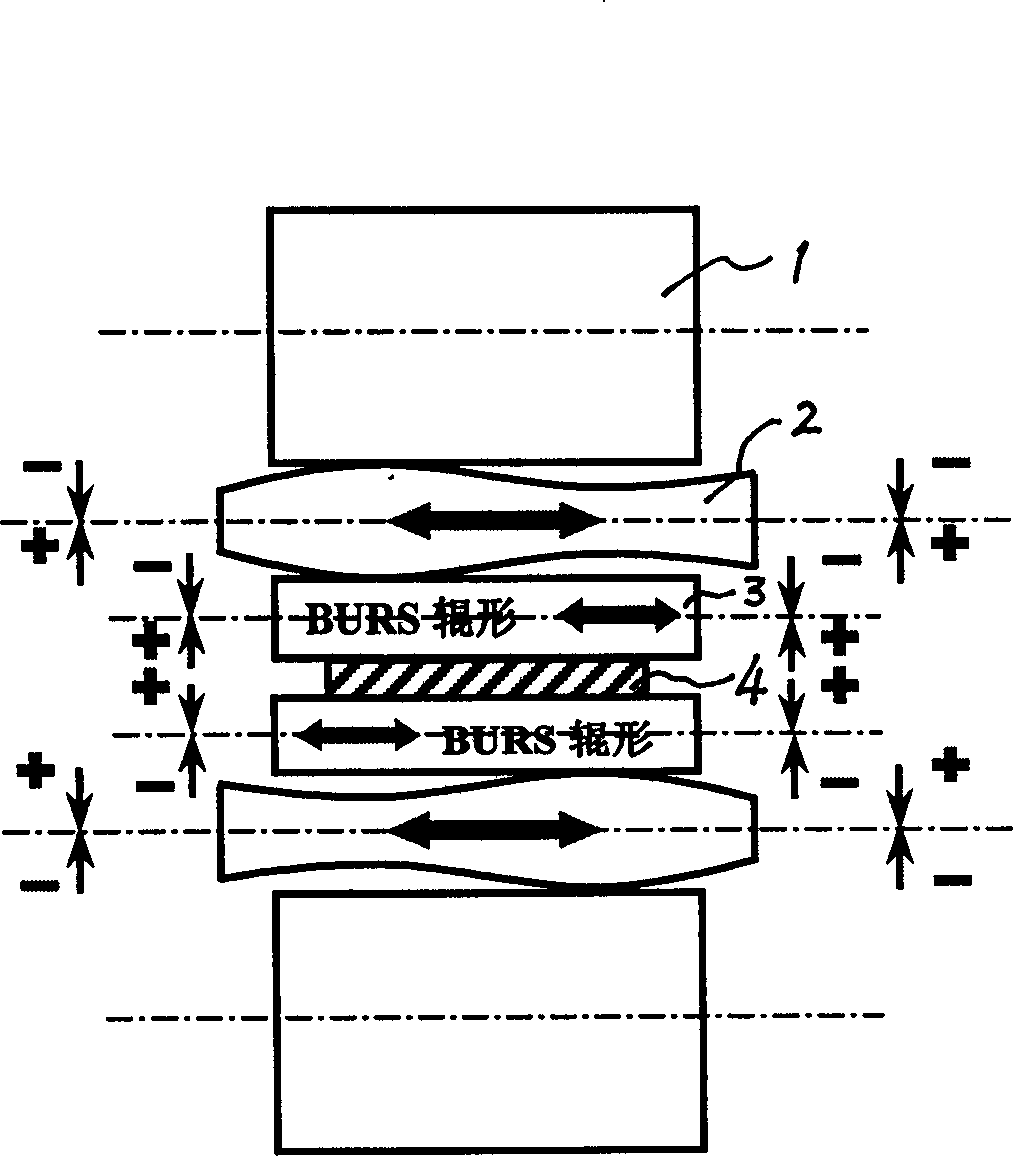

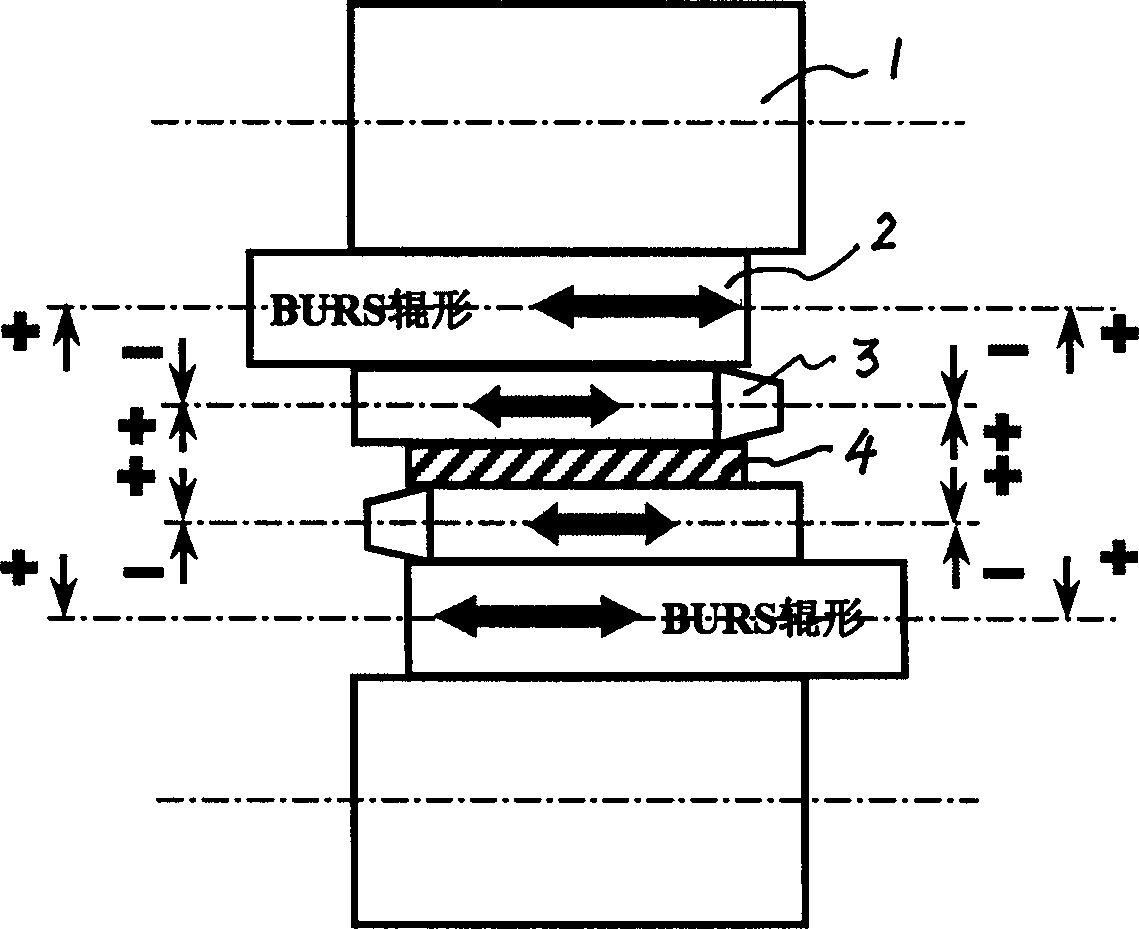

Lamination process and apparatus for alkali metals or alloys thereof

ActiveUS7513136B2Reduce thicknessElectrode rolling/calenderingRoll force/gap control deviceLithiumElectrical battery

An apparatus for and method of manufacturing lithium or lithium alloy anodes for electrochemical cells by a lamination process wherein a lithium or lithium alloy sheet is reduced into a thin lithium or lithium alloy film. The method and apparatus provide adjustments of the profile defined by the meeting surfaces of a pair of working rollers to compensate for thermal dilation of the working rollers or to compensate for irregular thickness of the lithium or lithium alloy sheet to control the shape and profile of the lithium or lithium alloy film being laminated.

Owner:BATHIUM CANADA

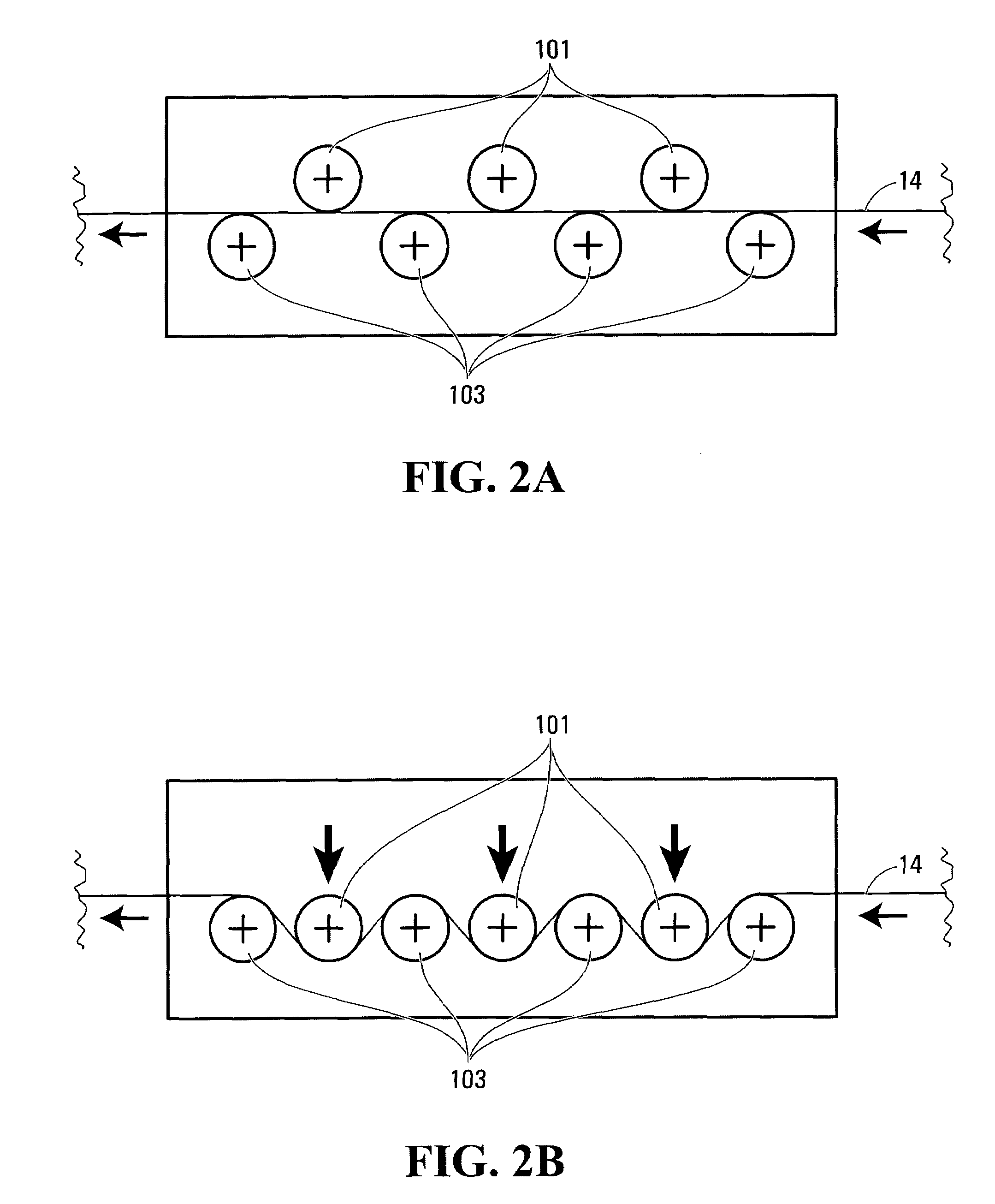

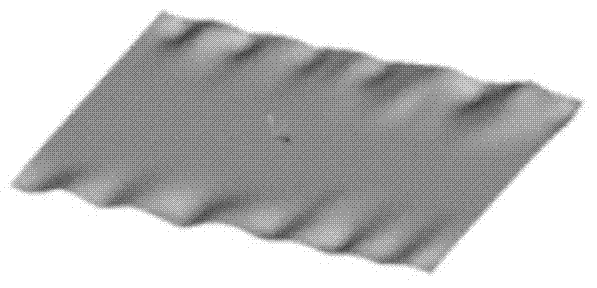

Rolling method for overcoming compound wave shape

A rolling method for overcoming the complex wave shape features that a rolling mill which has special pass configuration and contains at least 4 rollers (supporting roller and working rollers or intermediate rollers) and a plate shape control system are used. The plate shape controlling steps includes measuring plate shape data, processing to obtain plate shape signal, calculating plate shape deviation, and finding out the control signal of plate shape controller by polynomial fitting method or influence function method.

Owner:BAOSHAN IRON & STEEL CO LTD

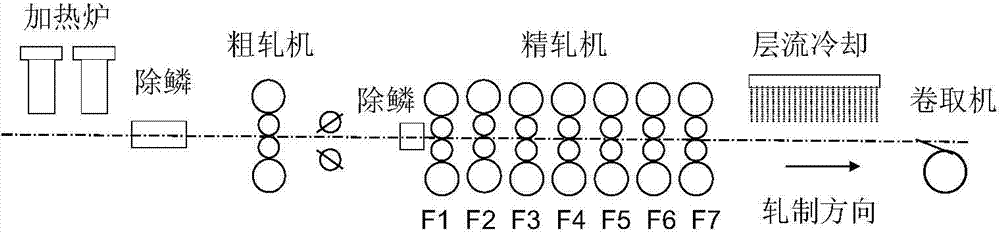

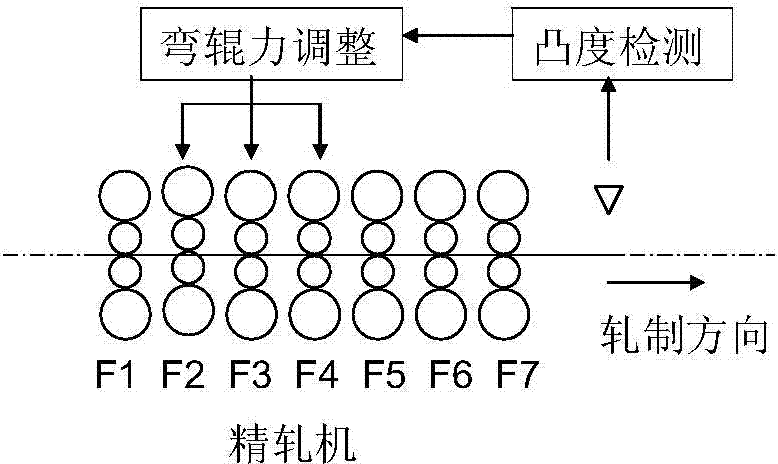

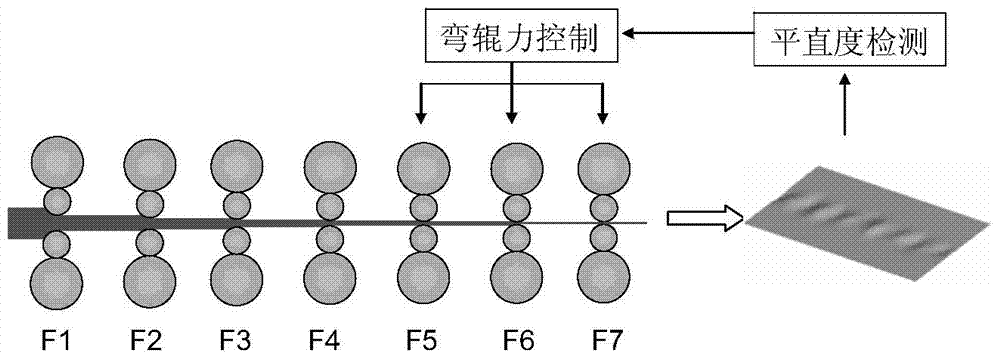

Slight center wave strip-shape control method of hot-rolled strip steel

ActiveCN104511484AFlat thickness distributionEasy to scratchProfile control deviceMartensitic stainless steelEngineering

The invention relates to a slight center wave strip-shape control method of hot-rolled strip steel. The method comprises the following steps: firstly, choosing a strip-shape feedback control frame; utilizing the adjusting manner of upstream frames, namely, adjusting the roll bending forces of the frames F2-F4 to realize the targeted slight center waves at a precision rolled outlet; secondly, controlling and adjusting the roll bending forces; detecting the flatness of the strip steel in real time by a strip-shape instrument and comparing it with a target value; if the deviation exists, adjusting the roll bending forces of the frames F2-F4. The slight center wave strip-shape control method of hot-rolled strip steel is applicable to overcoming strip-shape problems caused by the stages such as cooling and thermal treatment after hot rolling; the strip-shape quality of martensitic stainless steel strips is improved greatly and the scratching on the surface strip-shape in follow-up pickling and continuous annealing production is solved.

Owner:BAOSHAN IRON & STEEL CO LTD +1

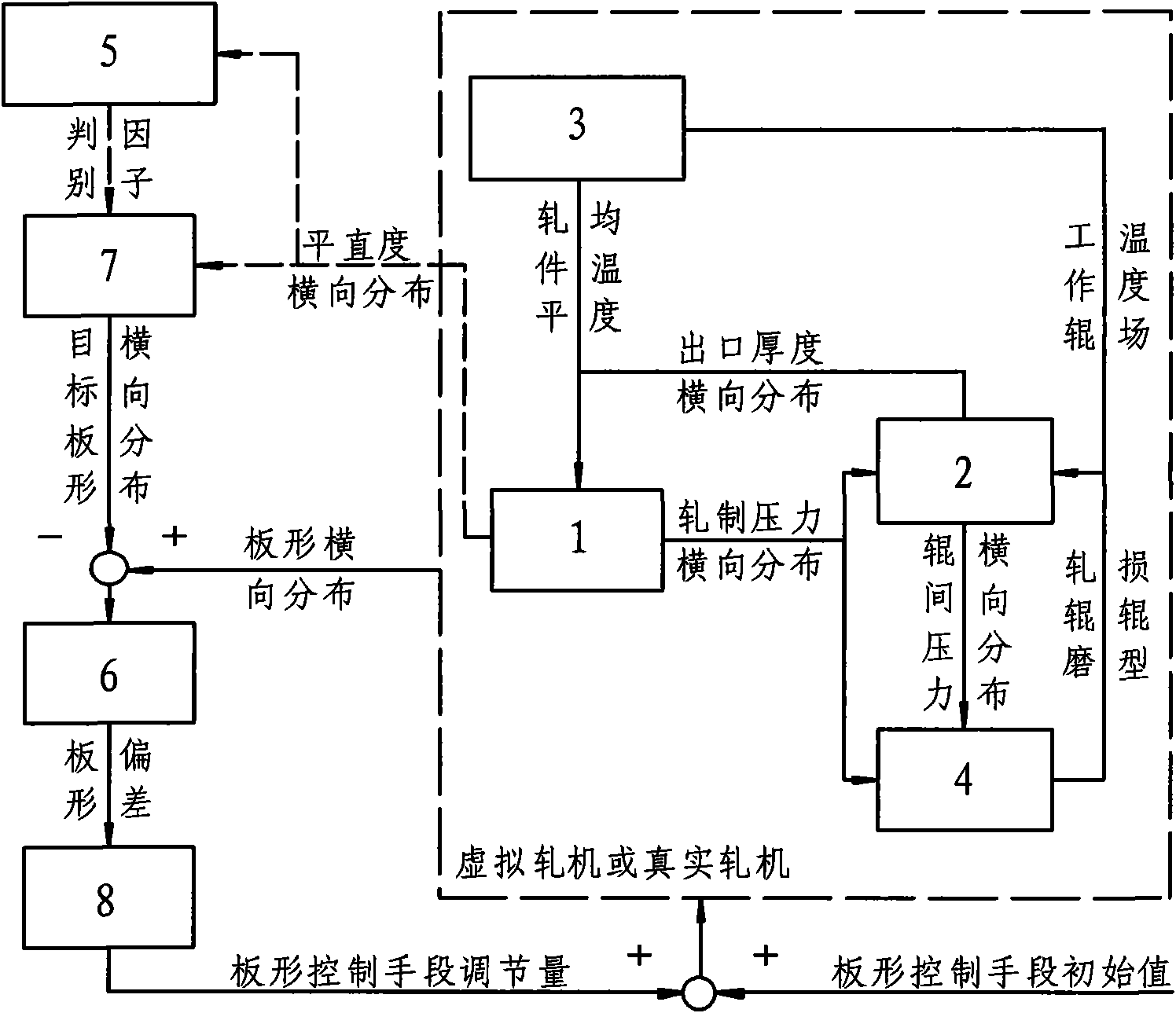

Plate-shape control integrated system and executing method thereof

ActiveCN101623708ASolve control problemsSave labor timeProgramme control in sequence/logic controllersProfile control deviceControl systemComputer module

The invention provides an integrated method of a plate-shape control system of a plate-strip cold and hot continuous rolling machine. The plate-shape control system comprises a rolled piece plastic-distortion module, a roller-system elastic-distortion module, a rolled piece and roller temperature field module, a roller-system abrasion module, a flatness well-recognition module, a plate-shaped mode recognition module, a plate-shape standard curve module and a plate-shape control module. The invention integrates all modules according to internal relations, can solve a plurality of plate-shape control problems comprehensively and optimally, adopts a set of calculating flows in actual application and effects saves the labor time.

Owner:YANSHAN UNIV

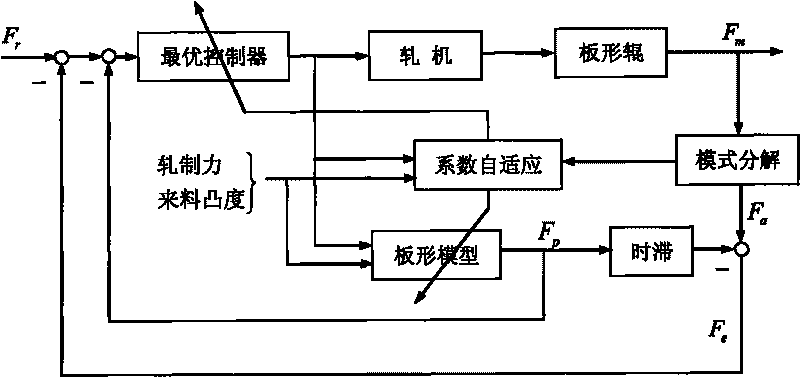

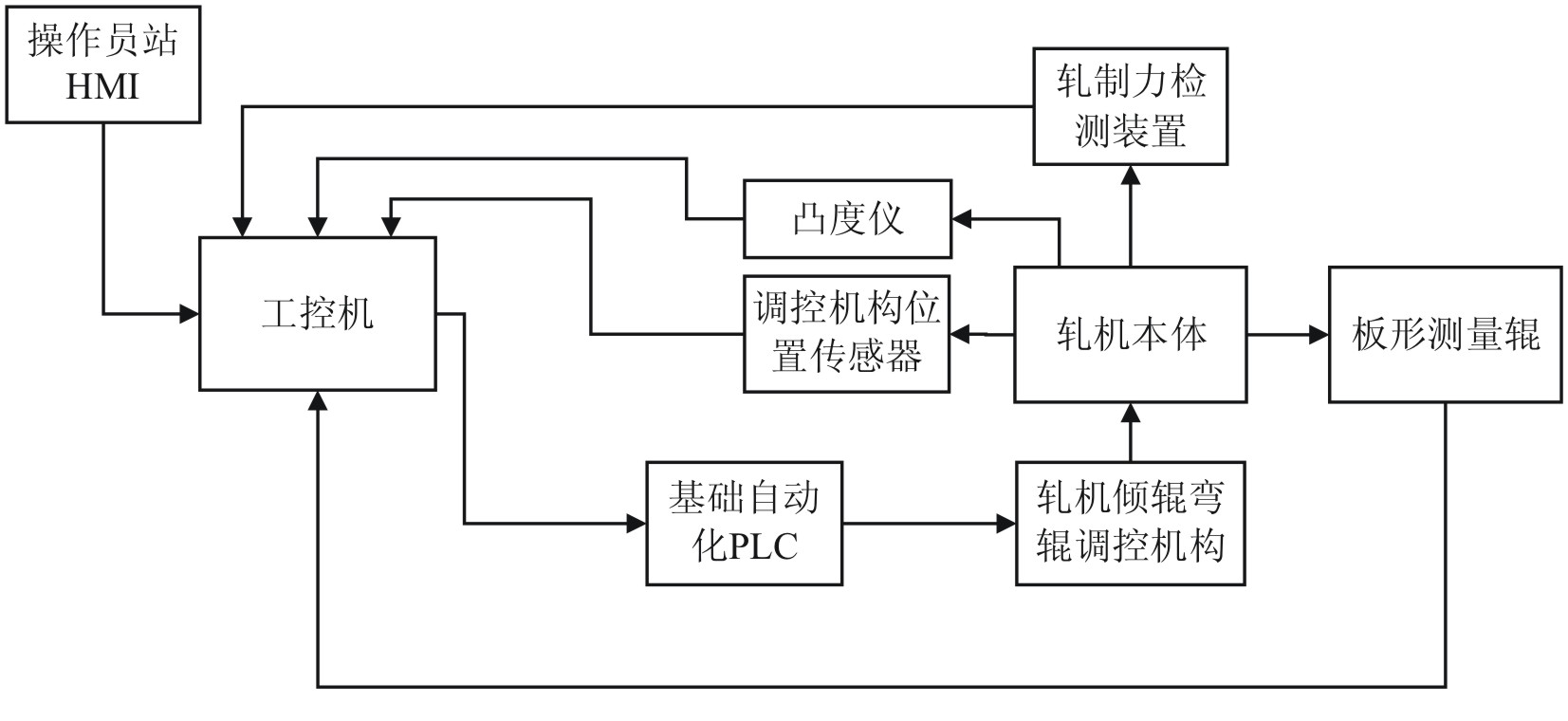

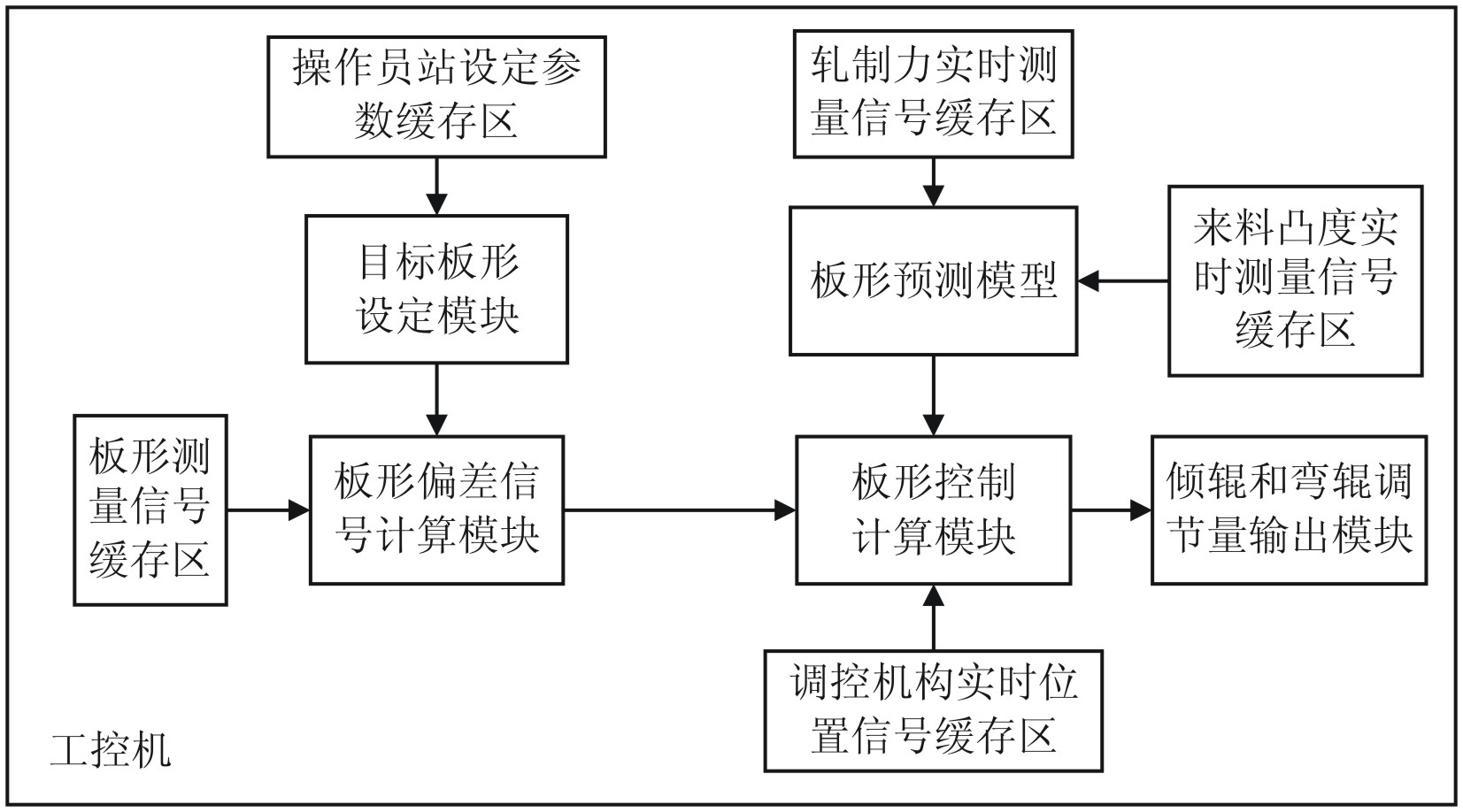

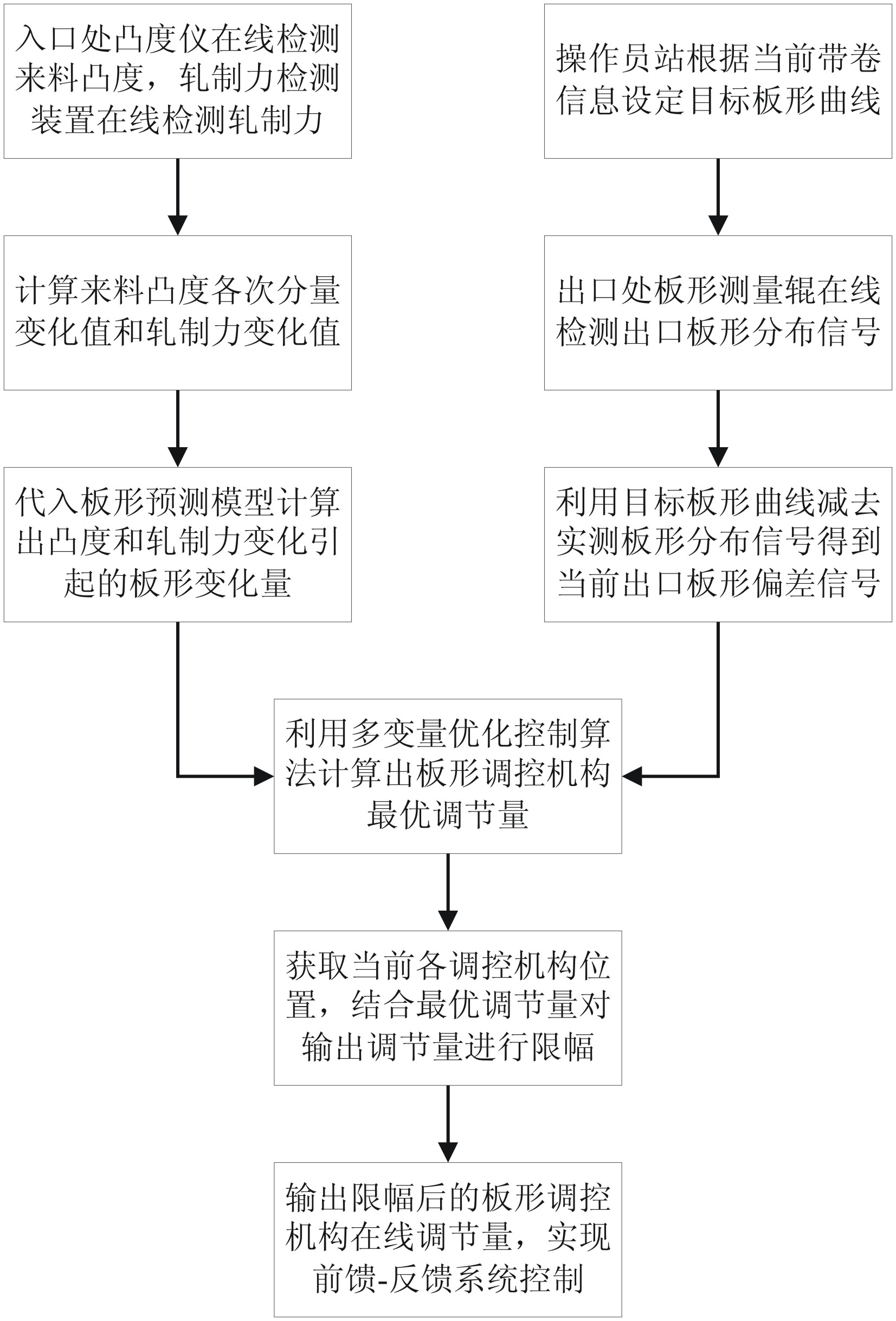

Cold-rolled strip steel plate shape control system and method

ActiveCN102632085AEliminate technical issues that degrade qualityEliminate shape defectsMeasuring devicesProfile control deviceAutomatic controlTime delays

The invention discloses a cold-rolled strip steel plate shape control system and method. An advanced feedforward-feedback cooperative control architecture is adopted and after a plate shape automatic control system is put into on-line operation, plate shape variation and outlet plate shape real-time deflection caused by changes of convexity and rolling force are jointly calculated out by calculating links of the plate shape variation and the outlet plate shape real-time deflection which are caused by the changes of the convexity and the rolling force; and then an on-line regulation variable for control of a cold-rolled strip steel plate shape is calculated out at an optimal regulation variable calculating and amplitude limit processing link of a plate shape control mechanism. The time-delay influence of strip steel in transmission between a rolling mill and a plate shape gauge is eliminated and the precision for estimating the plate shape is ensured; and the technical problem of outlet plate shape quality variation caused by practical factors such as the convexity change and the rolling force fluctuation of supplied materials during the rolling process can be solved, so that the quality of cold-rolled strip steel products is enhanced remarkably.

Owner:惠州市南钢金属压延有限公司

Rolling device for preparing high-toughness high-formability magnesium alloy sheet strip coil

ActiveCN102240676ARealize continuous temperature-controlled rollingImprove mechanical propertiesMeasuring devicesTension/compression control deviceMetallic materialsFeedback control

The invention relates to a rolling device for preparing a high-toughness high-formability magnesium alloy sheet strip coil and belongs to the field of metal material rolling. The rolling device provided by the invention comprises a rolling machine, an uncoiling machine, a left-right recoiling machine, a front online heating insulating device of the roll machine, a rear online heating insulating device of the roll machine, a straightening machine, a bending rectifying machine, a thickness measuring device, a steering tension roll, a guide roll, a roller heating and lubricating device and the like. In the invention, an online continuous heating device and an advanced PLC (programmable logic control) feedback control system are adopted, and continuous temperature control rolling on the magnesium alloy strip coil is realized. The rolling device provided by the invention has the advantages of uniform heating temperature, high heating efficiency and high temperature control accuracy, and high-quality thin wrought magnesium alloy strip coils are efficiently produced by virtue of a roller preheating insulating system, a technical lubricating system, a strip shape control system and a tension straightening device, thus the geometric quality and structure properties of rolled metal can meet operating requirements.

Owner:江苏永良镁业科技有限公司

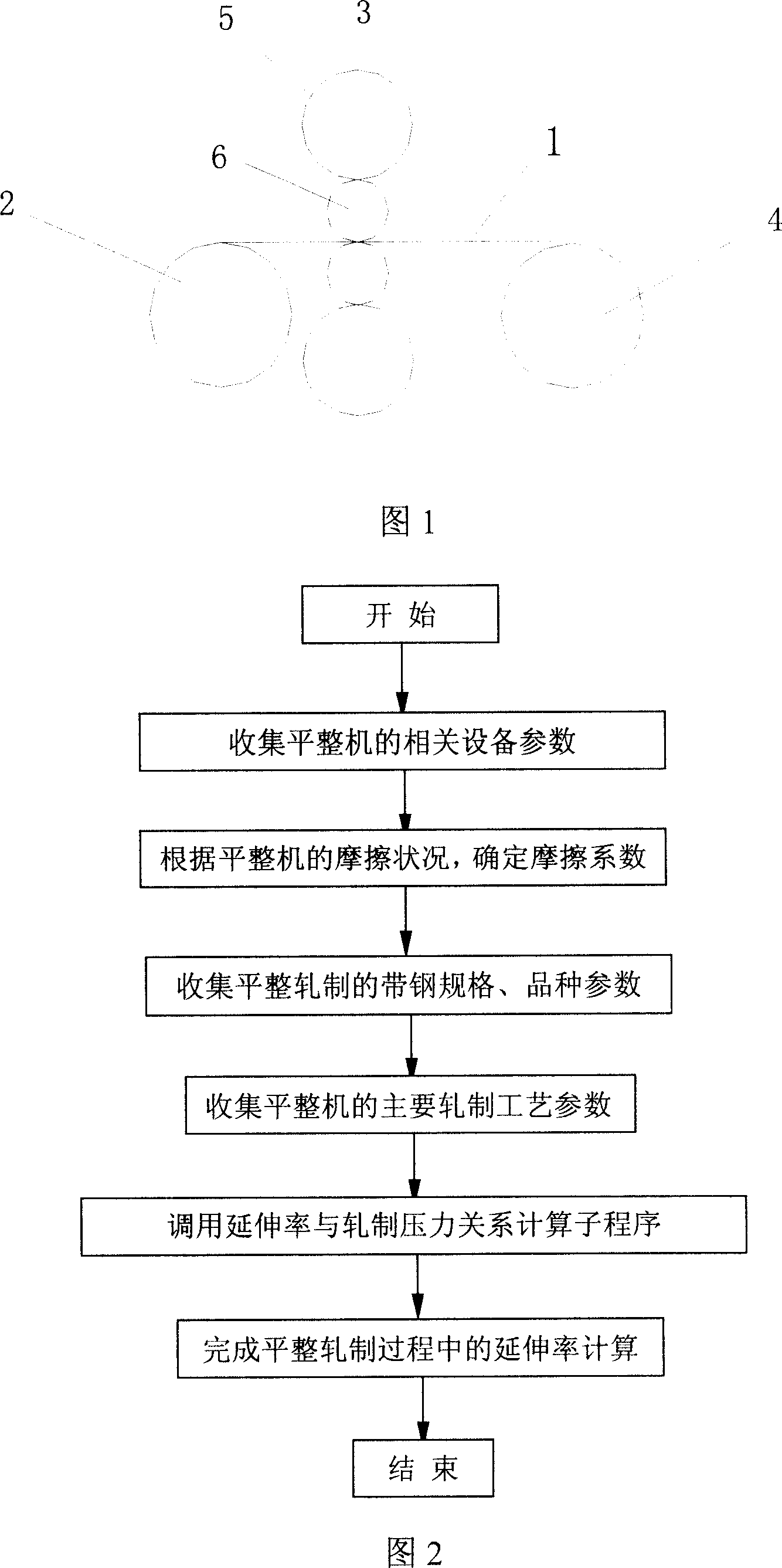

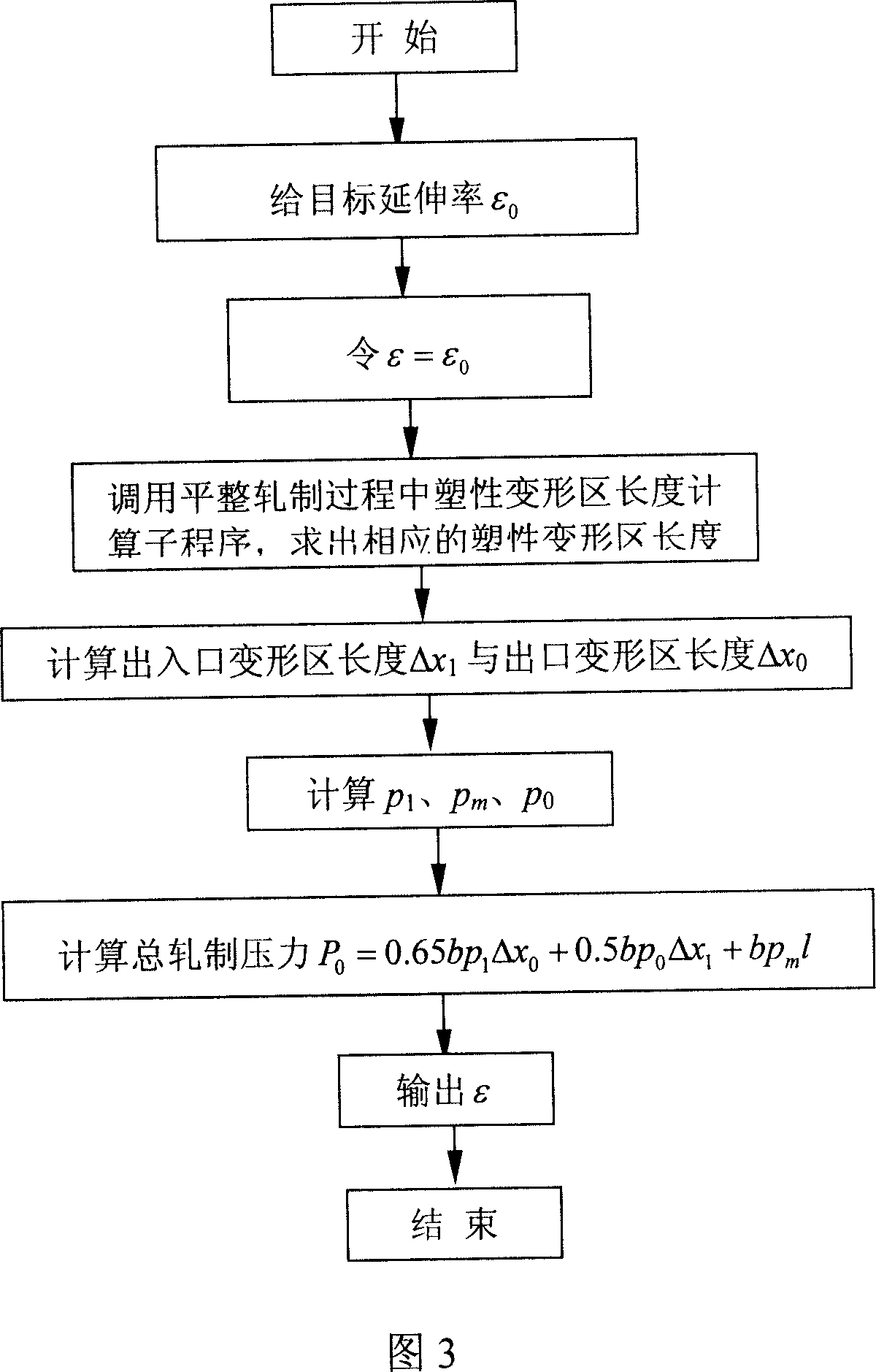

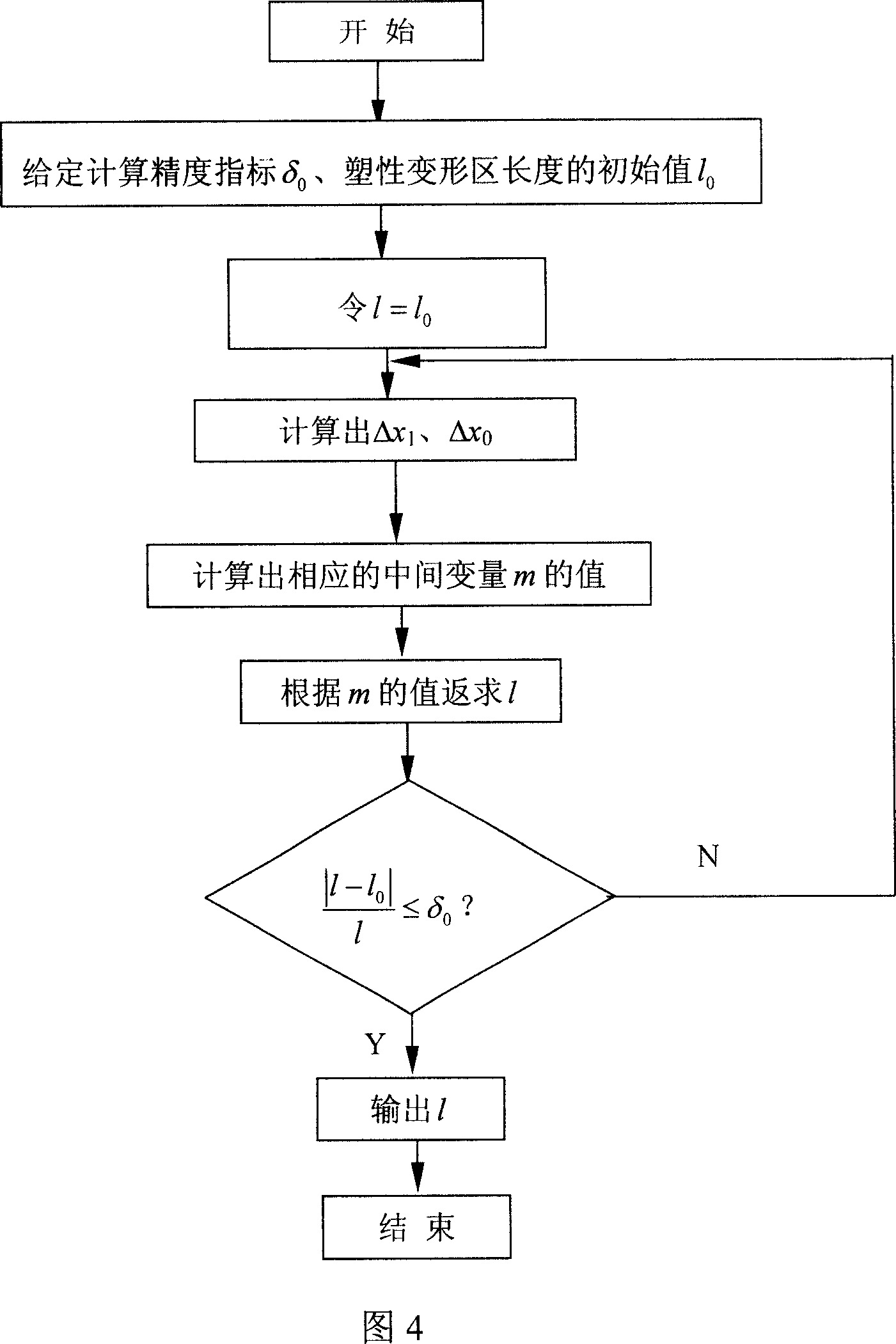

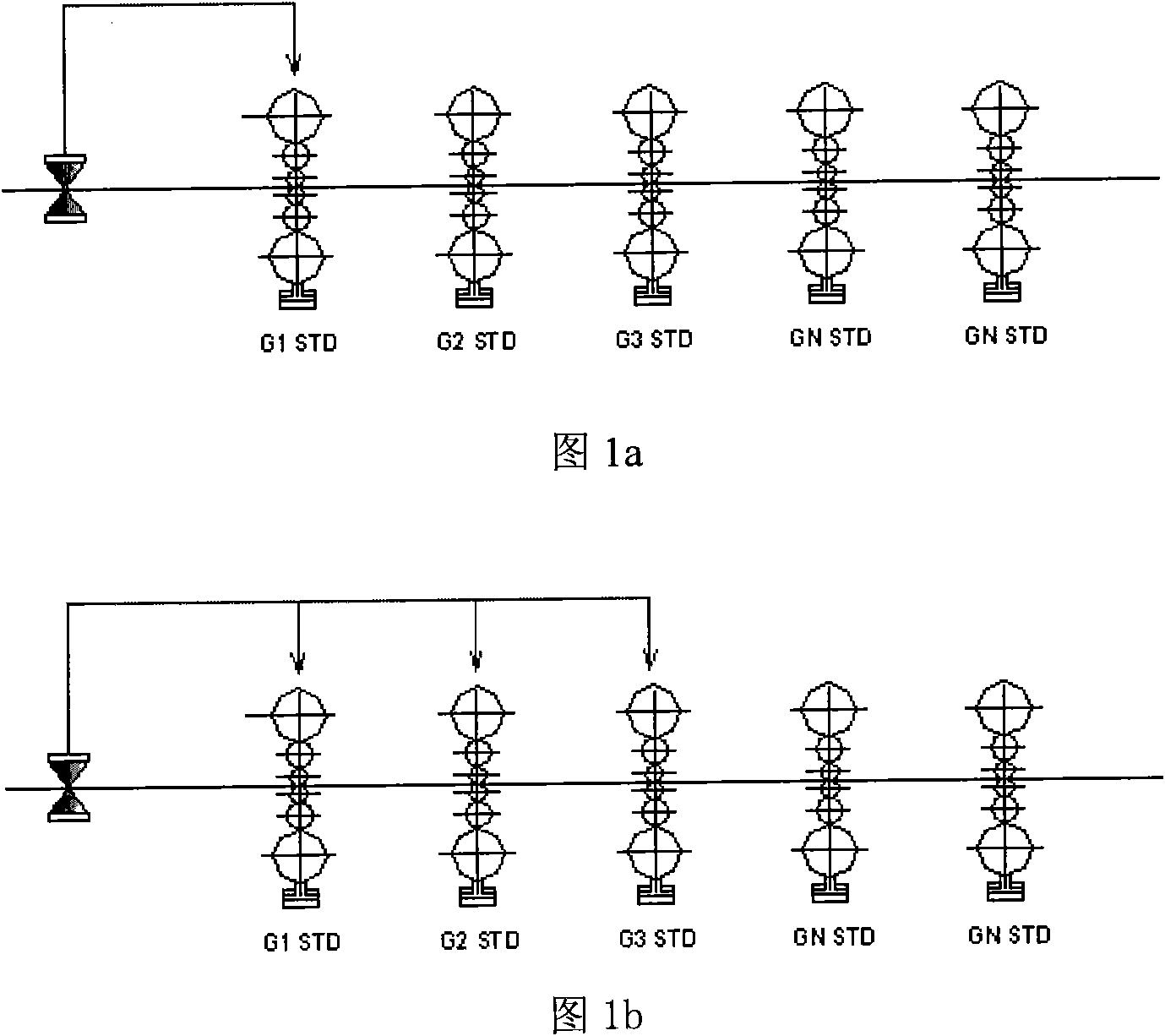

Method for comprehensive control of elongation coefficient and plate shape of steel band during even rolling process

InactiveCN101003063AImprove mechanical propertiesQuality improvementProfile control deviceMetal rolling arrangementsControl objectiveStrip steel

A method for controlling the elongation percentage, plate shape, etc in the skin rolling procedure of band steel features that an elongation percentage control unit, a plate shape control unit and an integrated control unit for both elongation percentage and plate shape are used, which use respectively three different optimizing algorithms to be used in a single iterative calculation procedure consisting of multiple optimizing calculation sub-procedures.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Control method of lateral thick difference of cold-rolling strip steels

ActiveCN102029294AReal-time acquisition of lateral thickness fluctuationsTimely responseRoll force/gap control deviceMeasuring devicesStrip steelEngineering

The invention discloses a control method of the lateral thick difference of cold-rolling strip steels, which realizes the feedforward control of the lateral thick difference of the cold-rolling strip steels by detecting the shapes of the profiles of hot-rolling supplied materials in real time on the basis of a profiler configured on an inlet of a No.1 rack. The control method mainly comprises thefollowing steps of: (1) configuring a strip steel profile shape detector on the inlet of the No.1 rack of a cold-rolling mill, and detecting the shapes of the profiles of the hot-rolling supplied materials in real time; (2) calculating to obtain the characteristic value vectors of the profiles of the cold-rolling strip steels positioned on the inlet of the No.1 rack through the measured values ofthe shapes of the profiles of the hot-rolling supplied materials; (3) respectively determining the compensation amount of a working bending roll, an intermediate bending roll, a supporting tilting roll, an upper shifting roll, a lower shifting roll and an intermediate shifting roll of the No.1 rack according to the difference of the actual values of the characteristic vectors of the profiles of the cold-rolling strip steels positioned on the inlet of the No.1 rack and the target values of the characteristic vectors; and (4) when the lateral thick difference is output in a controlling way, adopting the actual distribution of the flatness of a roll gap outlet as a constraint condition. The invention can further enhance the quality of the cold-rolling strip steels of cold-rolling mill products and ensure the stability of a cold-rolling production process.

Owner:BAOSHAN IRON & STEEL CO LTD

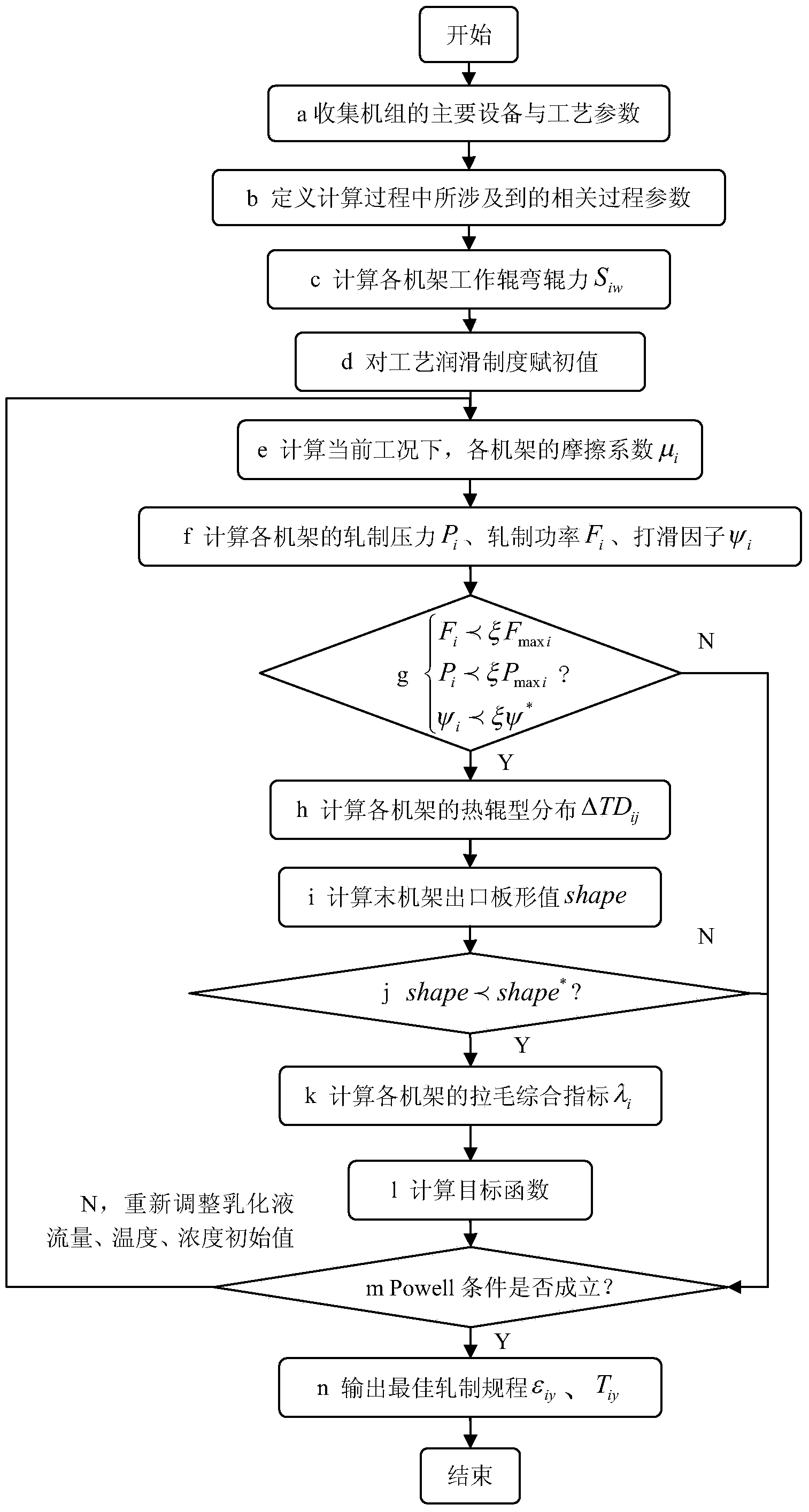

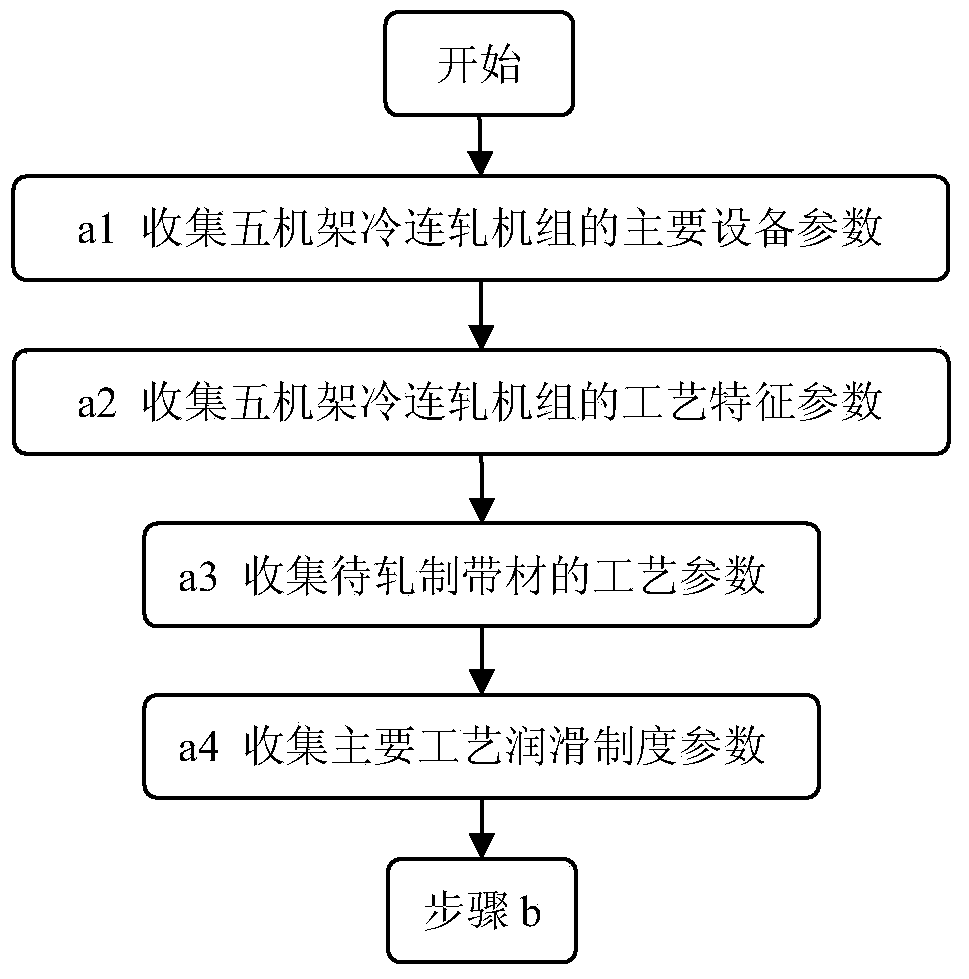

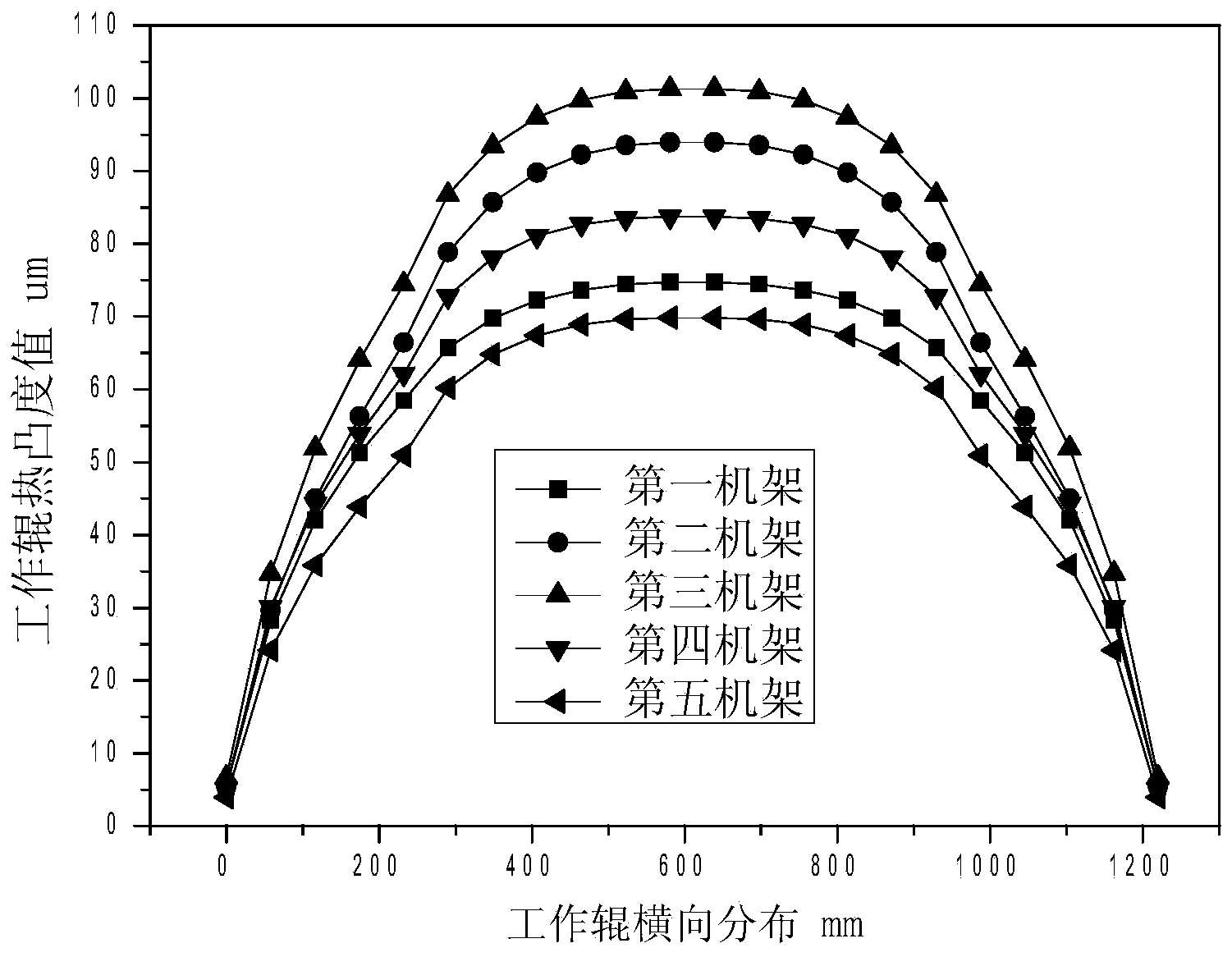

Optimization method of technological lubrication system taking galling prevention as objective for tandem cold mill

ActiveCN103611732AReduce picking defectsImprove surface qualityWork treatment devicesProfile control deviceDefined ProcedureEmulsion

Disclosed is an optimization method of a technological lubrication system taking galling prevention as an objective for a tandem cold mill. The method mainly comprises the following computer-executed steps: 1, collecting main equipment and technological parameters of a five-stand tandem cold mill; 2, defining procedure parameters related in the technological lubrication system optimization procedure; 3, giving initial values of emulsion flow, emulsion concentration and emulsion temperature of a first stand, a second stand, a third stand, a fourth stand and a fifth stand; 4, computing a friction coefficient mui of each stand in a current technological lubrication system and rolling schedule; 5, computing rolling pressure, rolling power and slip factors of each stand; 6, computing thermal crown distribution of a working roll of each stand; 7, computing an outlet flatness value of the tail stand; 8, computing a value of a comprehensive galling judgment index lambdai of each stand; 9, computing an optimization objective function in the current technological lubrication system; 10, completing optimal setting of the technological lubrication system, taking the galling prevention as the objective, of the tandem cold mill. By the method, galling defection occurrence probability of each stand is lowered, and outlet surface quality of strip steel is improved.

Owner:唐山市榕泽钢材加工有限公司

Method for improving plate shape quality of head portion or tail portion of hot rolling strip steel

ActiveCN103028613AImprove shape qualityQuality improvementProfile control deviceStrip steelEngineering

The invention relates to the field of plate shape control of hot rolling strip steel, in particular to a method for improving plate shape quality of a head portion or a tail portion of hot rolling strip steel. The method for improving the plate shape quality of the head portion or the tail portion of the hot rolling strip steel is characterized in that a balance state is switched to a roll bending state in advance according to time series of switch of the head portion before the head portion bites steel, and the roll bending state is switched to the balance state according to the time series of switch of the tail portion after the tail portion discharges the steel. Roll bending force which is set according to the plate shape of the head portion and the tail portion judges limitations in a switchover process. When the roll bending force exceeds a prescribed limitation, the roll bending force needs to be recalculated. A calculation principle is that the priority is given to maintaining glancing flatness of the head portion and the tail portion of the strip steel, the head portion and the tail portion of the strip steel are enabled to present micro edge waves, and the degree of convexity of the strip steel is preferably close to a target value. Compared with the prior art, the method for improving the plate shape quality of the head portion or the tail portion of the hot rolling strip steel has the advantages that calculation and judge of the roll bending force are respectively introduced to switchover time series of the head portion of the strip steel and the switchover time series of the tail portion of the strip steel, the plate shape quality of the head portion and tail portion of the strip steel is improved, ratios of steel clamping in the head portion in a finish rolling and a reeling area and steel drifting in the tail portion in the finish rolling area caused by bad shape of a tail plate are reduced.

Owner:ANGANG STEEL CO LTD

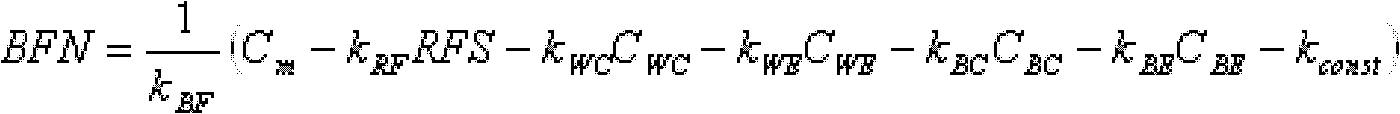

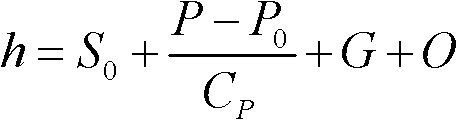

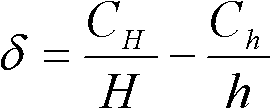

Computer-aided method for determining desired values for controlling elements of profile and surface evenness

InactiveUS7031797B2Reduce effortRoll force/gap control deviceSpecial data processing applicationsMetal stripsComputer-aided

Input variables, which describe a metal strip prior to and after the passage of a rolling stand, are fed to a material flow model. The material flow model determines online a rolling force progression in the direction of the width of the strip and fees said progression to a roller deformation model. The latter determines roller deformations from said progression and feeds them to a desired value calculator, which calculates the desired values for the controlling elements of profile and surface evenness using the calculated roller deformations and a contour progression on the runout side.

Owner:PRIMETALS TECH GERMANY

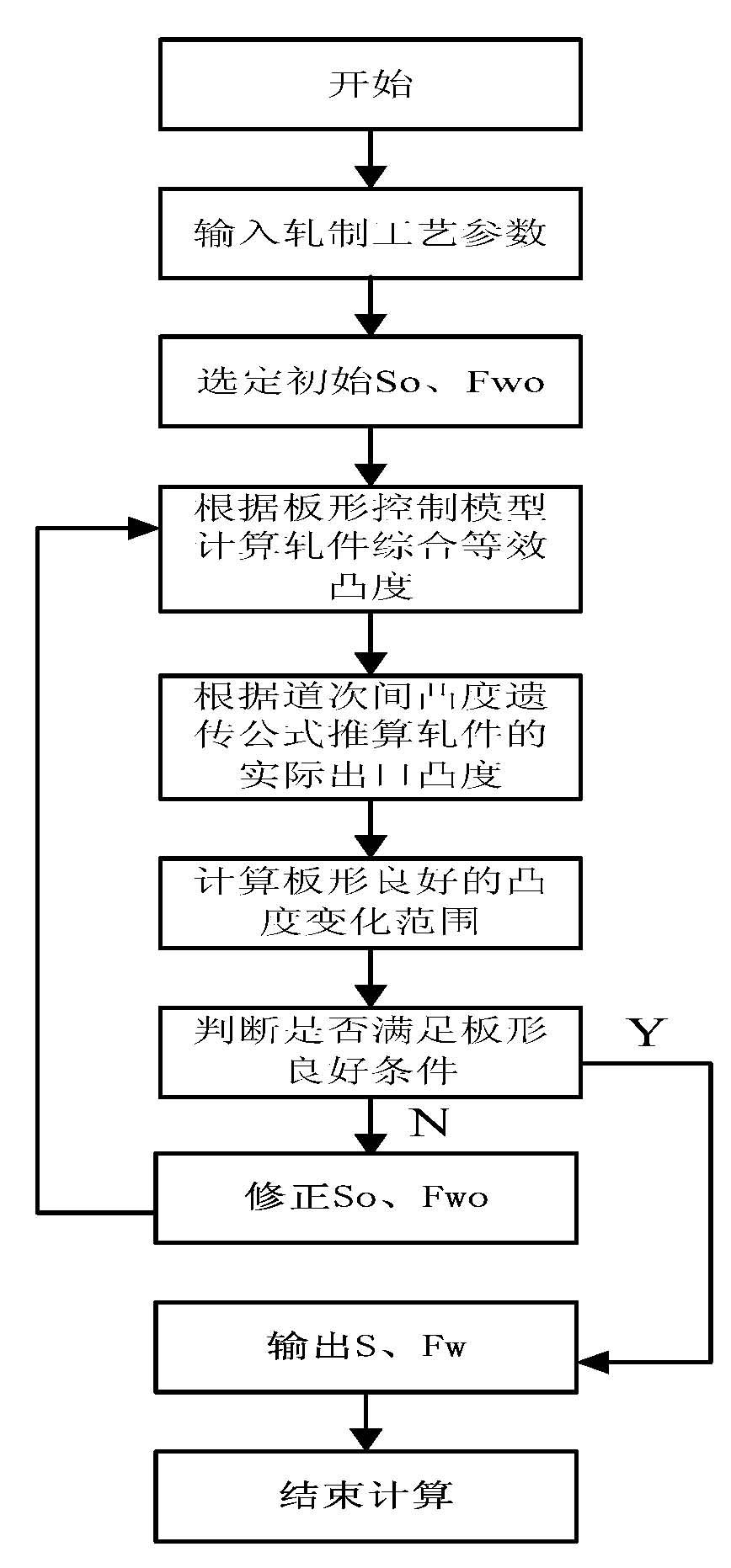

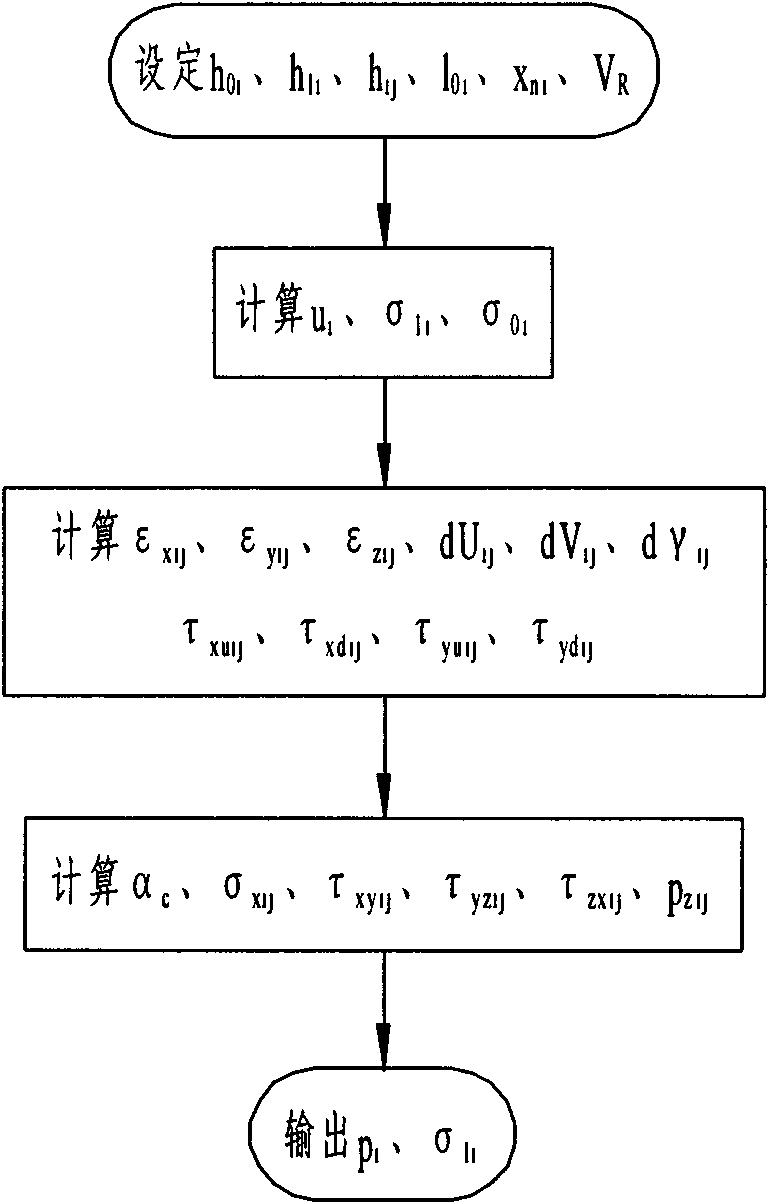

Method for setting plate shape and plate convexity off-line prediction of PC rolling mill

InactiveCN101648216AImproved shape controlImprove forecast accuracyProfile control deviceEngineeringBending force

The invention relates to a method for setting plate shape and plate convexity off-line prediction of a PC rolling mill, aiming at the rolling distinctiveness of the PC rolling mill and comprising thefollowing step: (a) collecting an actual equipment parameter and a technological parameter of the PC rolling mill; (b) discretizing a roll system and a roll piece; (c) setting an initial technologicalparameter; (d) computing transverse distribution values of the rolling pressure and front tensile stress of a unit length; (e) computing pressure among rollers and the distribution value of outlet thickness; (f) performing the convergence theorem by the maximum value of the transverse distribution variable quantity of the outlet thickness, if the not convergent, turning to the (d) step; and (g) judging plate shape condition to optimize a crossing angle and a roller bending force according to the distribution condition of plate convexity and the front tensile stress. The invention has high prediction precision of the rolling pressure and the plate convexity, computed crossing angle and roller bending force optimization and good rolling plate shape, not only enhances the plate shape controlcapability of the PC rolling mill but also achieves the industrial application precision requirement.

Owner:YANSHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com