Patents

Literature

405results about How to "Improve shape quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

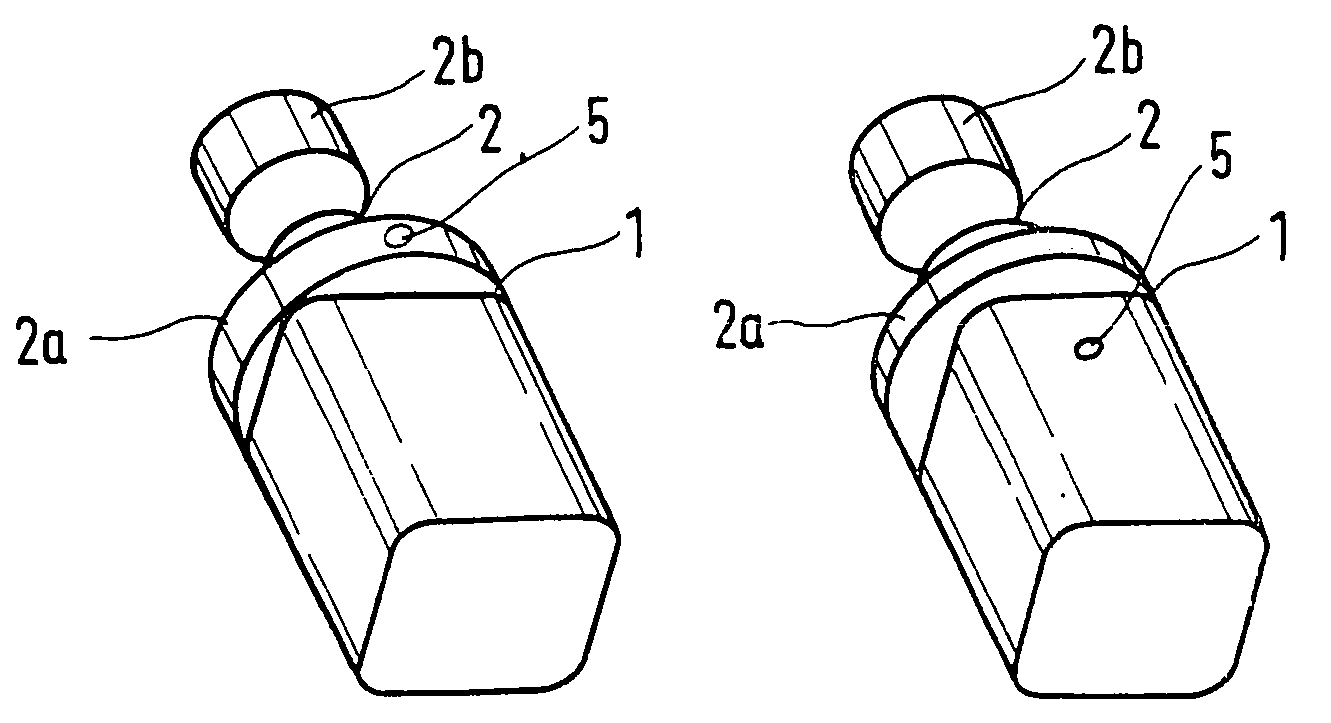

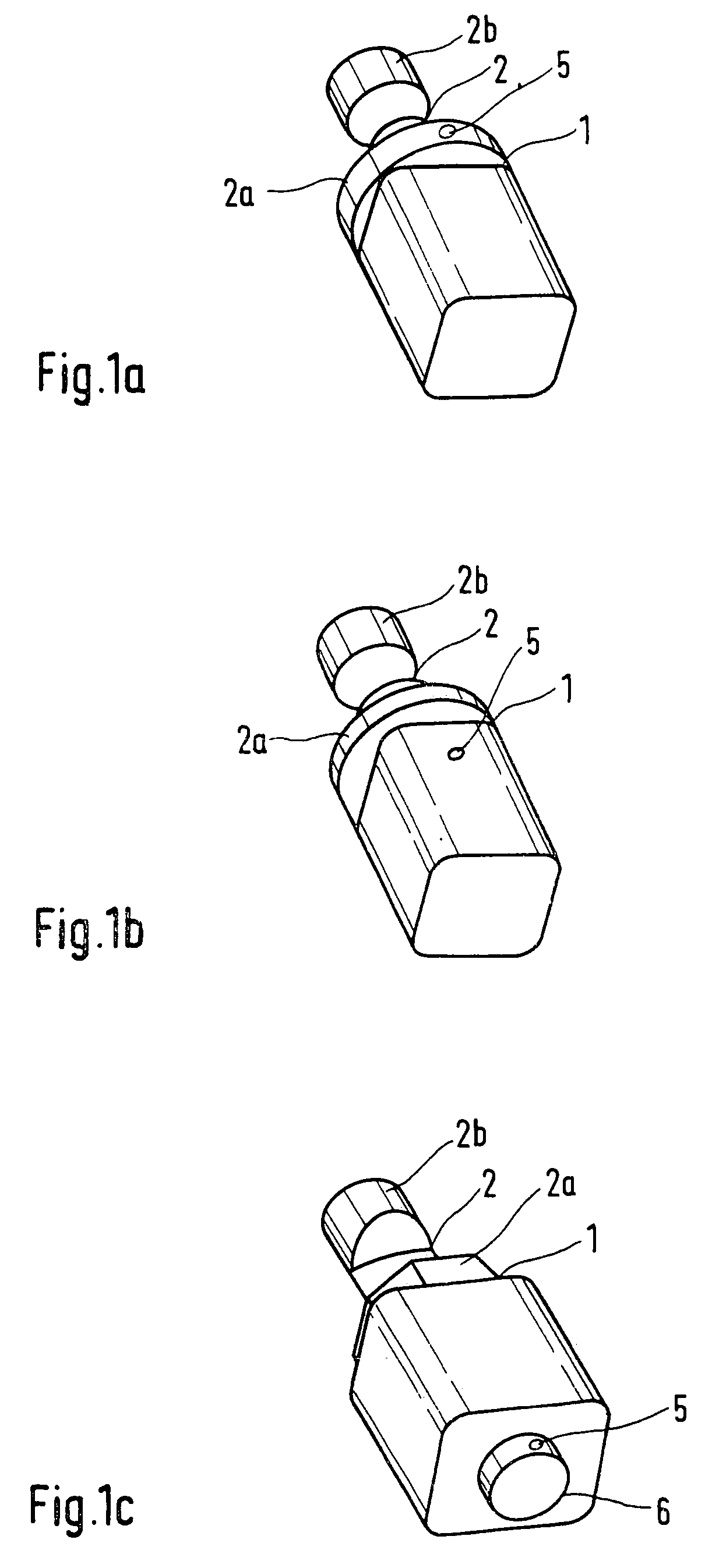

Blank for the production of a dental shaped body and method of producing said shaped body

ActiveUS7985119B2Considerable timeImprove shape qualityGrinding feed controlTooth crownsMaterial removalDental restorative materials

A blank and method for the production of dental shaped bodies in machining equipment having at least two tools located in the machining chamber of the machining equipment, including a corpus of tooth restoration material, from which the shaped body can be carved by means of at least one of at least two tools by material removal. The blank exhibits at least two gages, each of which is in the form of a recess, the geometry of which is such that the tool selected for the cutting operation can be recognized by means of at least one of the gages by reference to its outer contour, the at least two gages being disposed on the blank in such a way that they can be simultaneously engaged by the at least tools when the blank is clamped in the machining equipment for carving purposes.

Owner:SIRONA DENTAL SYSTEMS

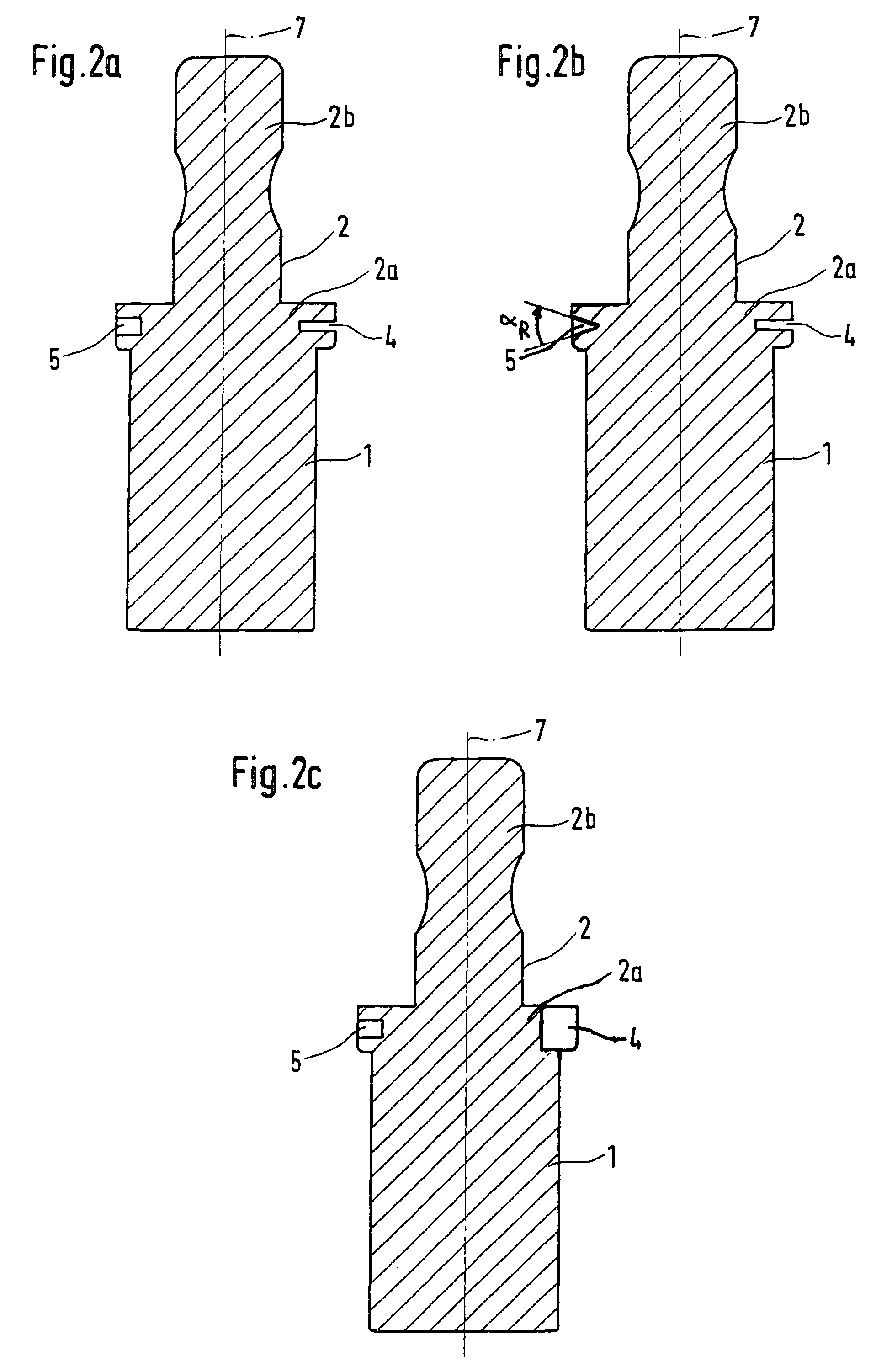

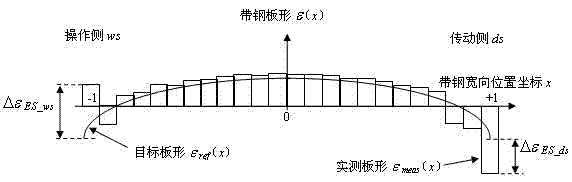

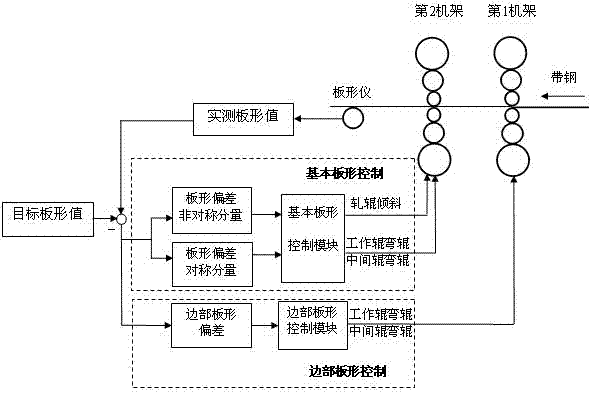

Control method of edge portion strip shape of cold rolling strip steel

The invention relates to a rolling method of cold rolling strip steel, in particular to a control method of edge portion strip shape of thin strip steel rolled by a cold continuous rolling mill or a two-stand temper mill. In a strip shape feedback control system centered on a last stand and on the basis of fundamental strip shape control function of major control for conventional edge waves and center waves, the method identifies the state of the edge portion strip shape of the strip steel based on the difference between the actual measured strip shape of strip steel edge portion together with the adjacent areas at the exit of last stand and an objective strip shape, and adjusts the corresponding strip shape executive mechanisms of the last stand and the rest stands according to the state of the edge portion strip shape to realize effective control for the edge portion strip shape of the strip steel, such as small edge waves and small side waves, thereby further improving the quality of the strip steel after cold rolling or temper rolling.

Owner:BAOSHAN IRON & STEEL CO LTD

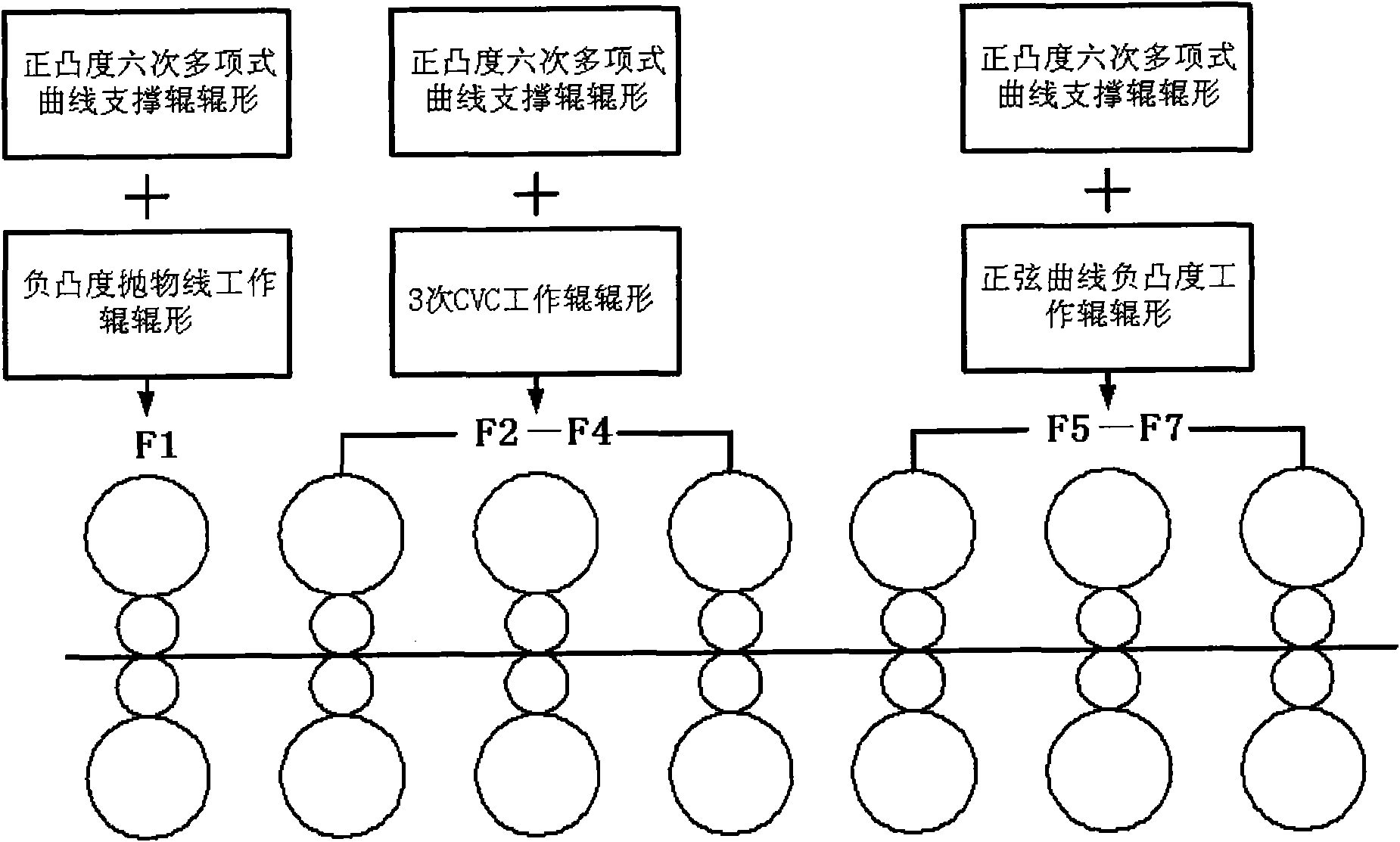

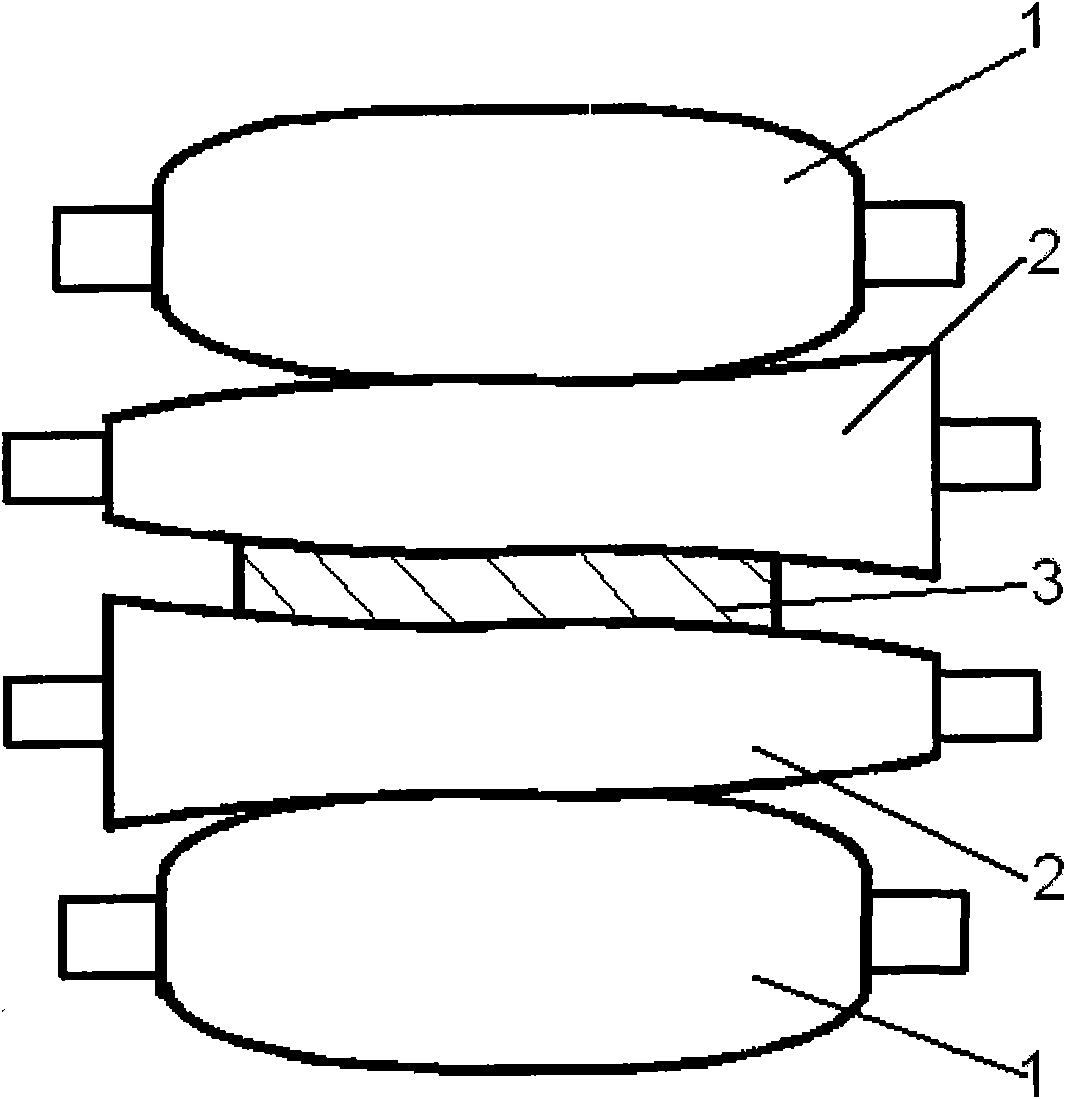

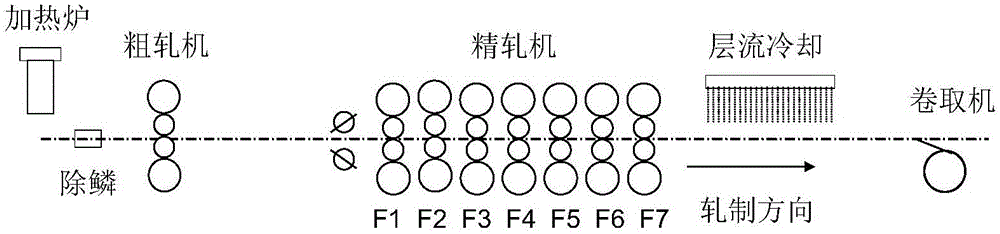

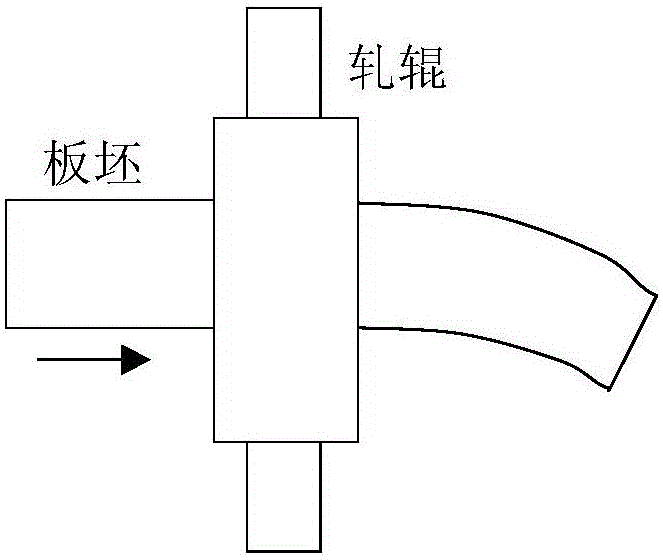

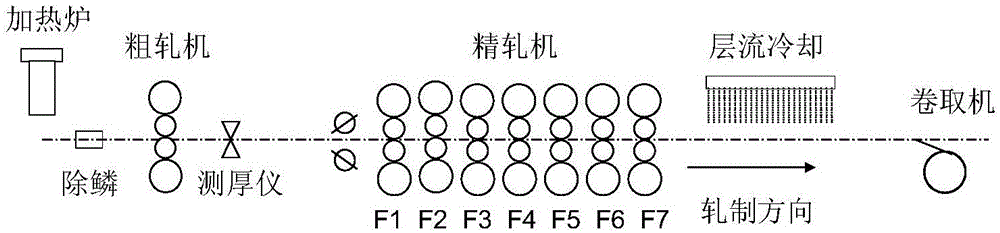

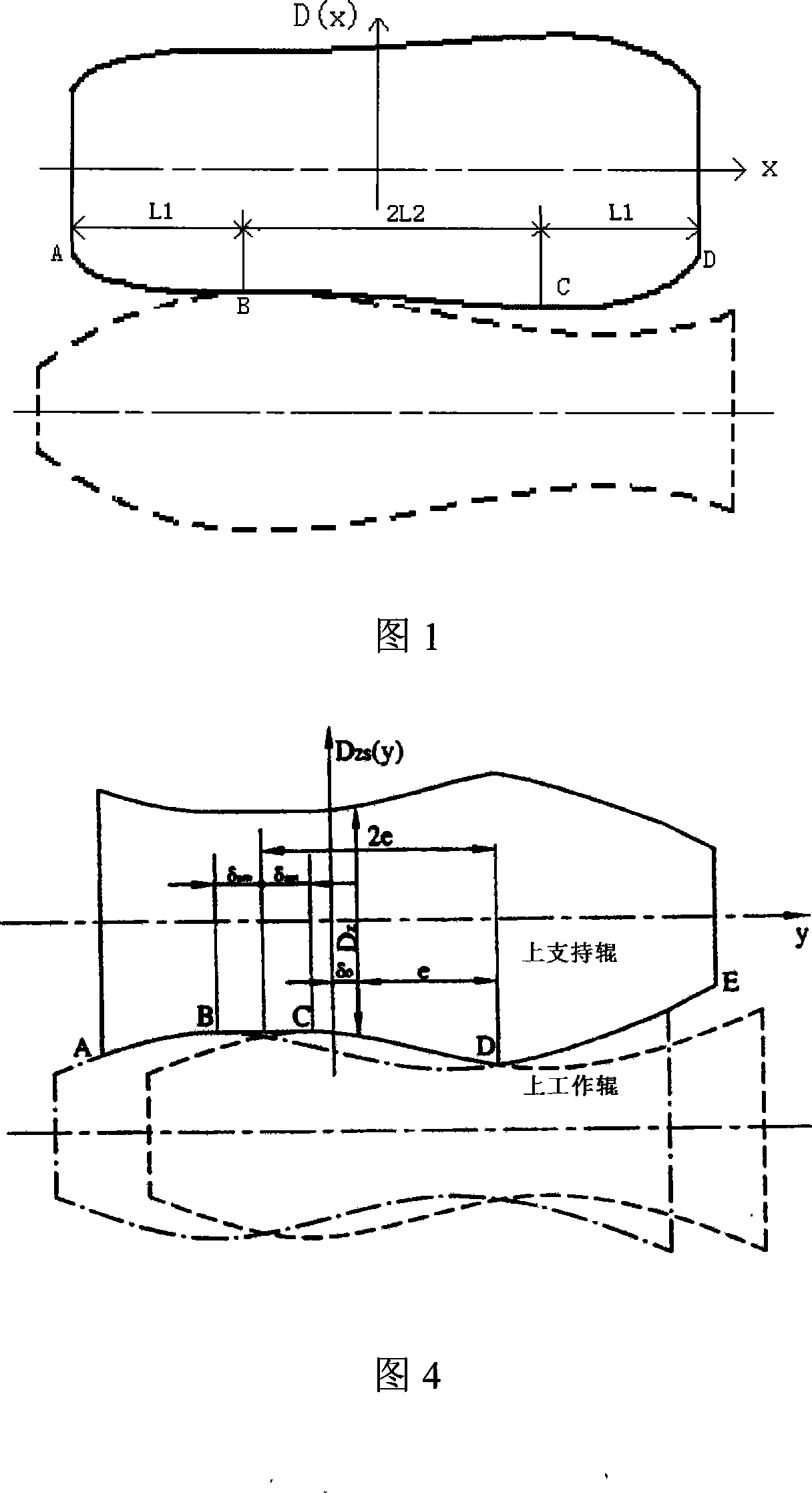

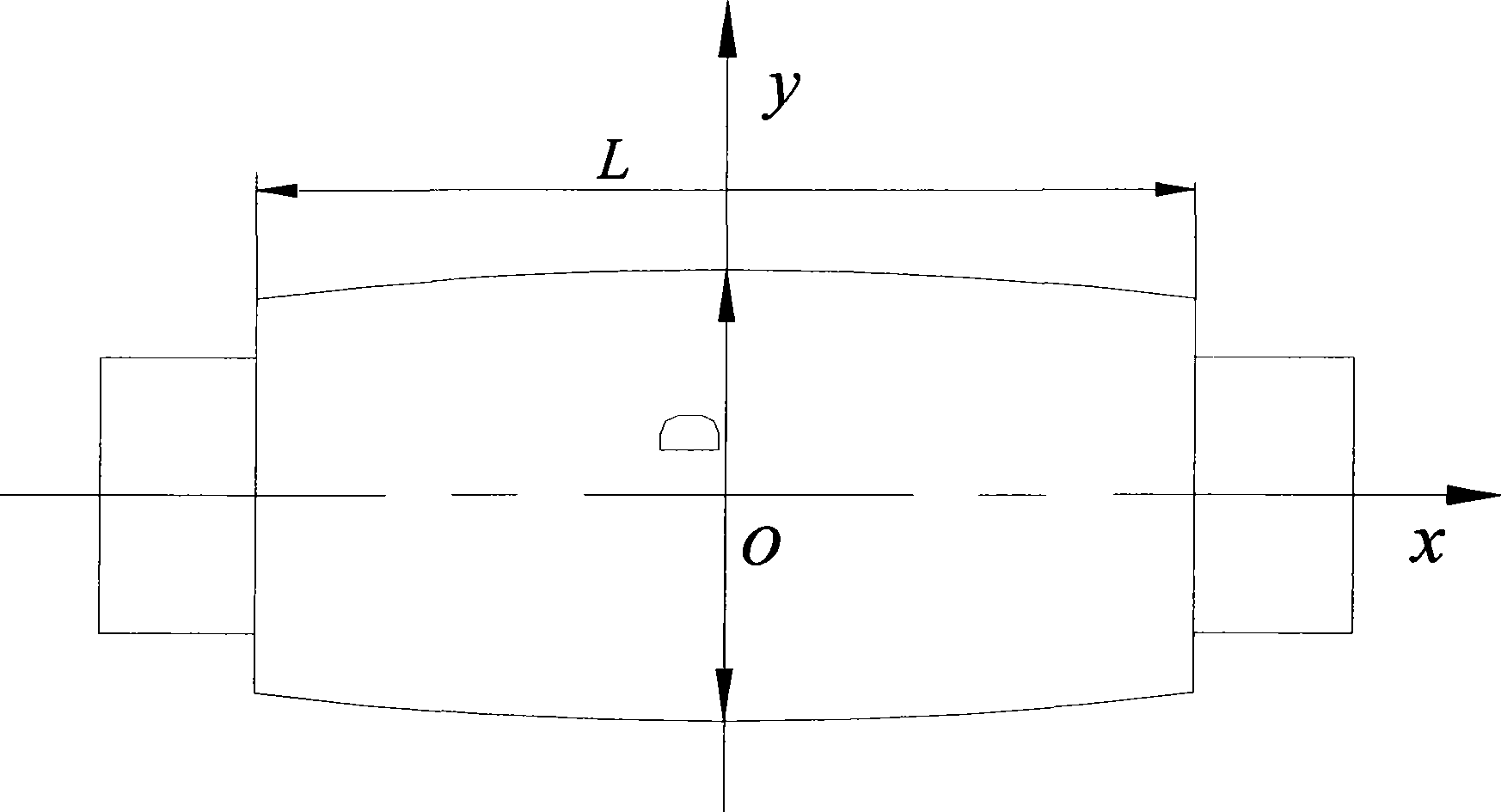

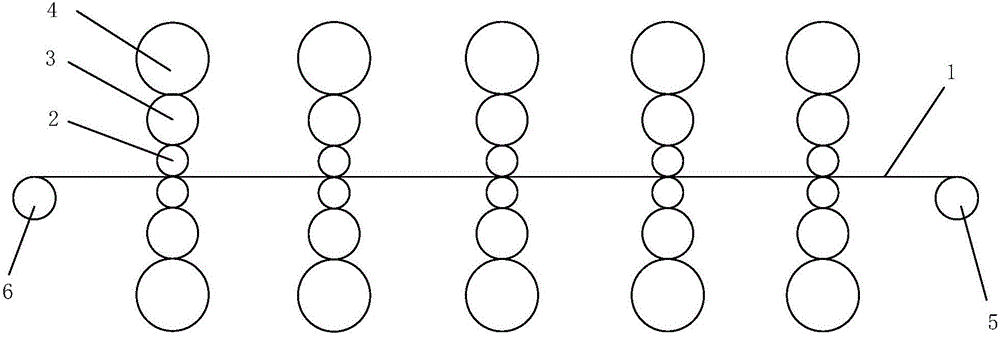

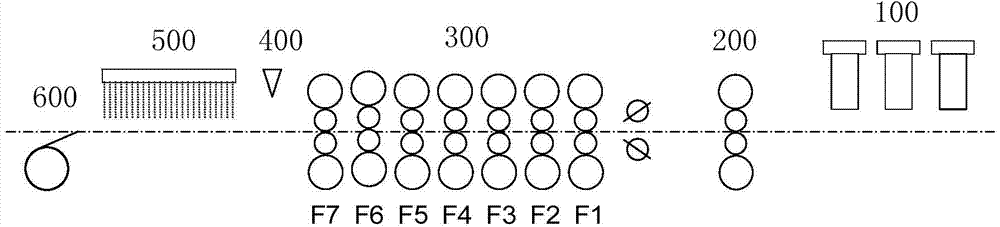

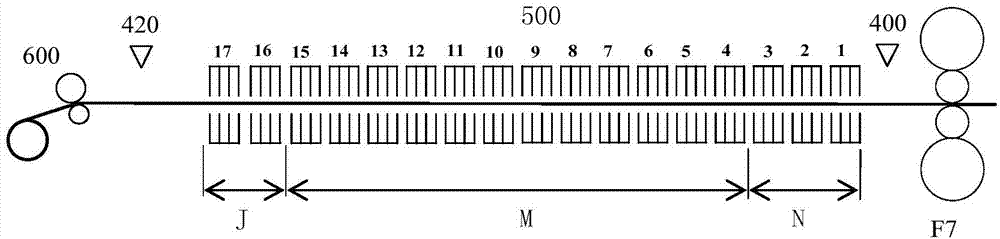

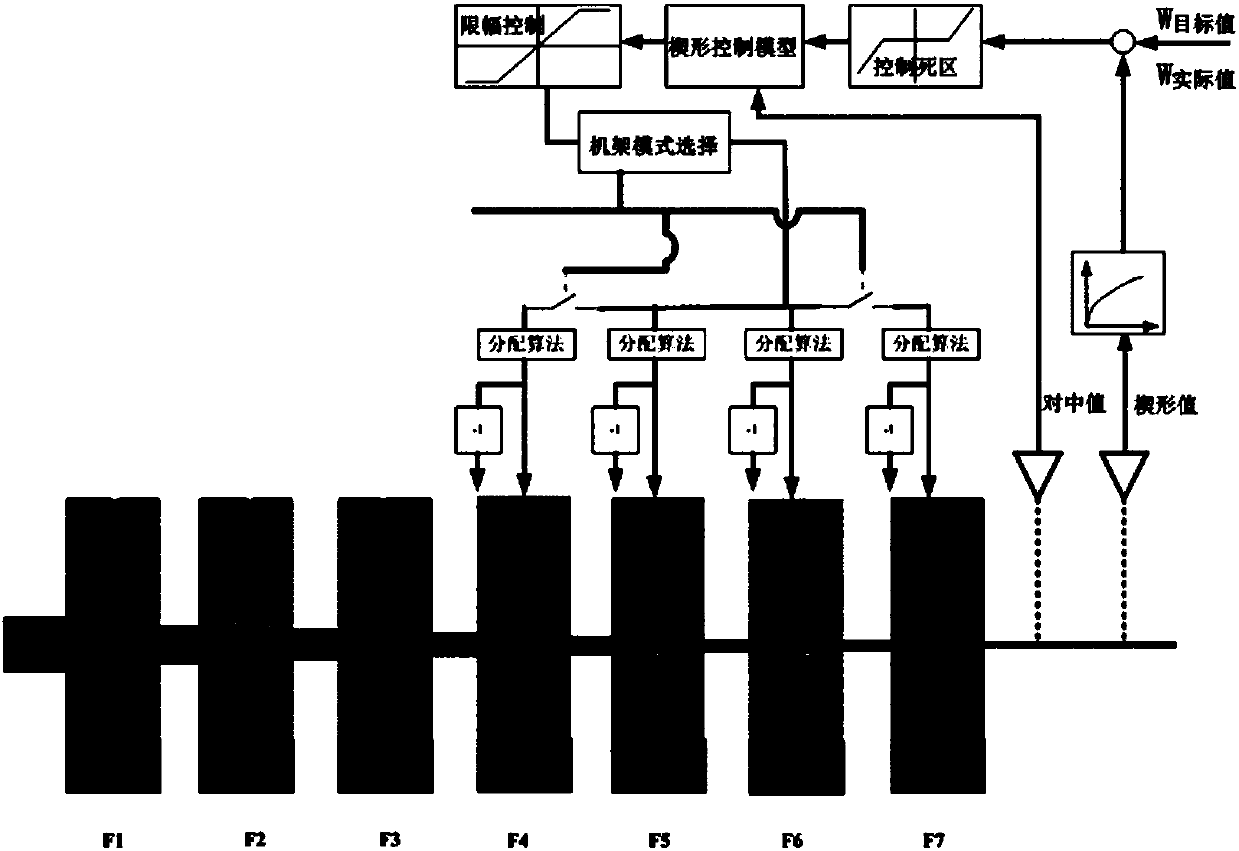

Complete roll forming configuring method for wide flat steel hot rolling finish mill set

ActiveCN101890429AReasonable configurationHigh precisionRollsMetal rolling arrangementsWork rollRoll forming

The invention relates to a complete roll forming configuring method for a wide flat steel hot rolling finish mill set. According to the characteristics that an upstream machine frame controls the convexity and a downstream machine frame controls the flatness in the seven-machine frame and four-roll hot rolling wide flat steel finish mill, a finish rolling inlet machine frame F1 adopts negative convexity working roll forming, a machine frame F2, a machine frame F3 and a machine frame F4 adopt cubic CVC working roll forming, and a machine frame F5, a machine frame F6, and a machine frame F7 adopt negative convexity working roll forming of sine curves and are matched with periodic roll shifting of the working roll with long stroke. The supporting rolls of all the machine frames of the finish mill set adopt positive convexity roll forming of sextic polynomes. The method improves the transverse rigidity of the machine frames of the finish mill, improves regulation and control efficiency of roll bending force of the working roll, and reduces flexibility deformation of the roll. The roll forming configuring method for the finish mill set improves stability of the wide flat steel rolling, reduces the deflection amount of the wide flat steel, prolongs the planned length for rolling and greatly improves profile shape control precision of the wide flat steel.

Owner:SHOUGANG CORPORATION

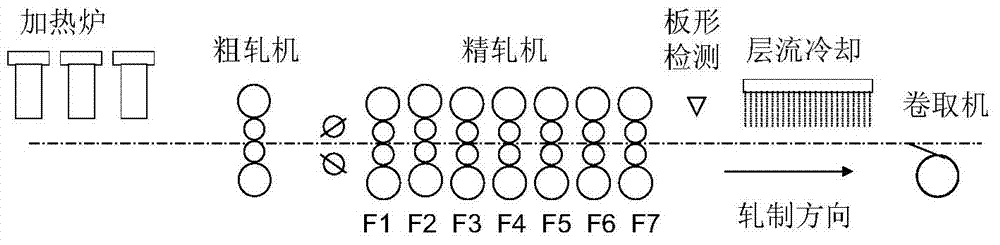

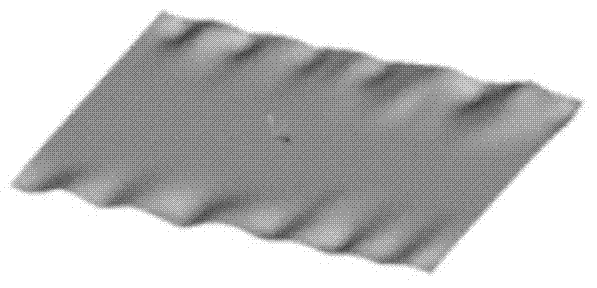

Slight center wave strip-shape control method of hot-rolled strip steel

ActiveCN104511484AFlat thickness distributionEasy to scratchProfile control deviceMartensitic stainless steelEngineering

The invention relates to a slight center wave strip-shape control method of hot-rolled strip steel. The method comprises the following steps: firstly, choosing a strip-shape feedback control frame; utilizing the adjusting manner of upstream frames, namely, adjusting the roll bending forces of the frames F2-F4 to realize the targeted slight center waves at a precision rolled outlet; secondly, controlling and adjusting the roll bending forces; detecting the flatness of the strip steel in real time by a strip-shape instrument and comparing it with a target value; if the deviation exists, adjusting the roll bending forces of the frames F2-F4. The slight center wave strip-shape control method of hot-rolled strip steel is applicable to overcoming strip-shape problems caused by the stages such as cooling and thermal treatment after hot rolling; the strip-shape quality of martensitic stainless steel strips is improved greatly and the scratching on the surface strip-shape in follow-up pickling and continuous annealing production is solved.

Owner:BAOSHAN IRON & STEEL CO LTD +1

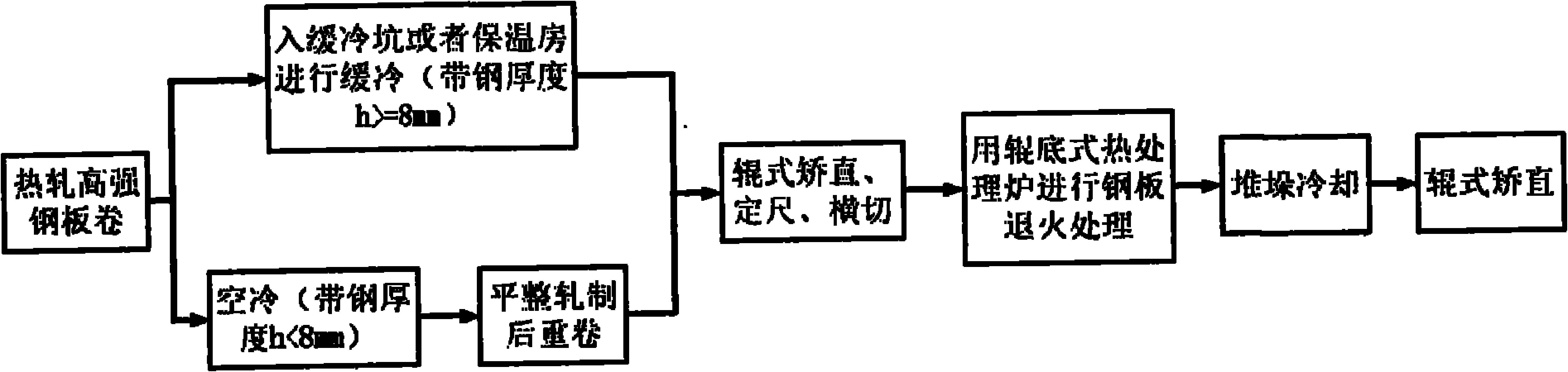

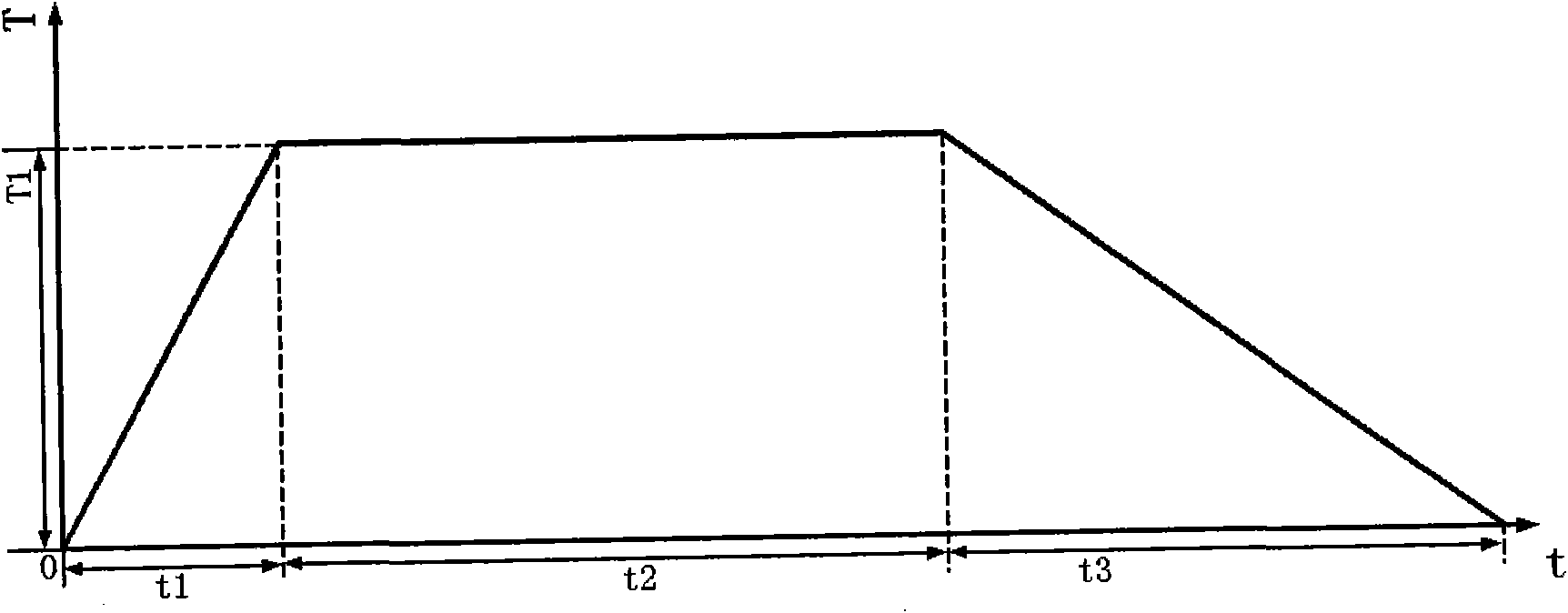

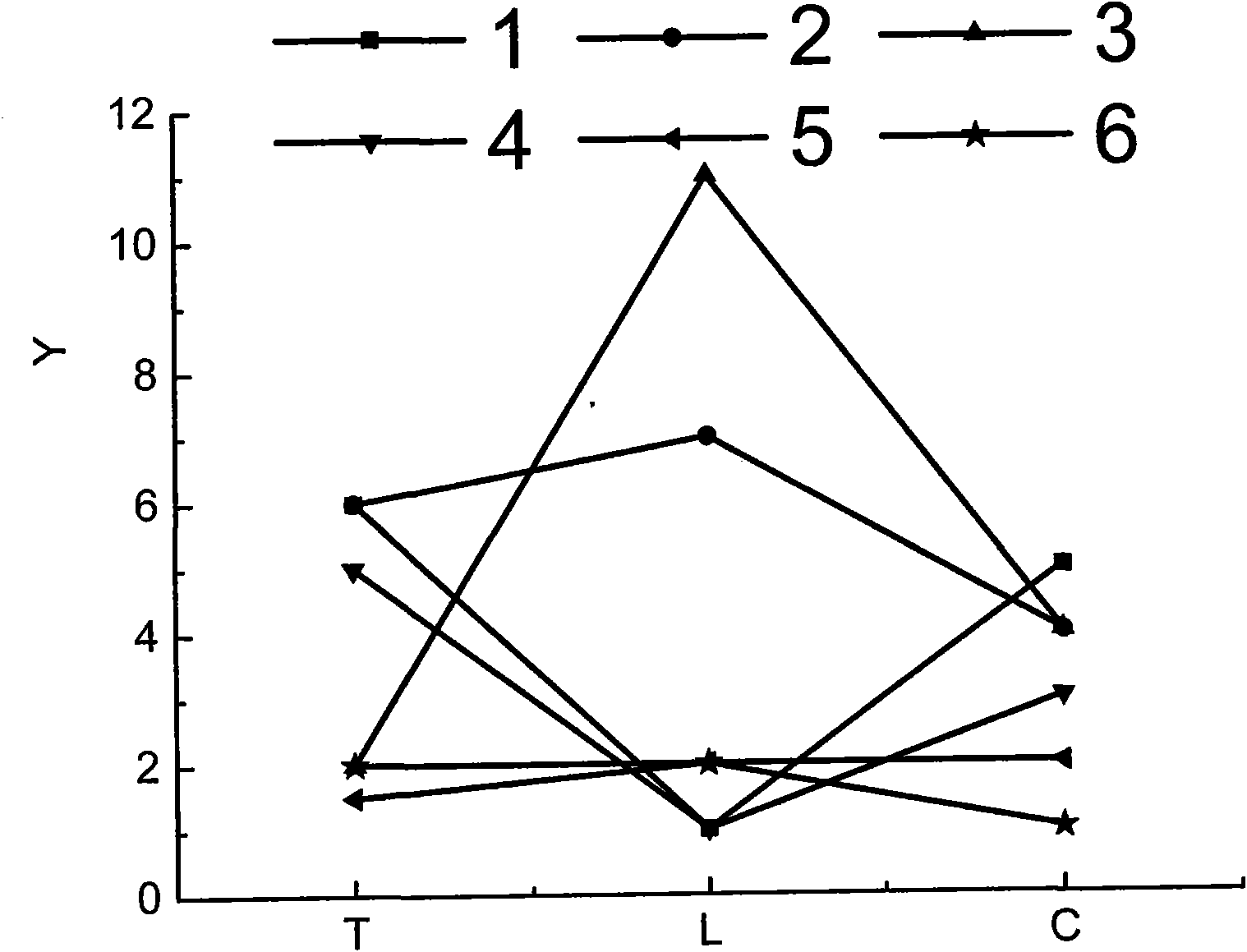

Method for removing residual stress of hot-rolling high-strength steel

ActiveCN101844162AAchieve development goalsImprove shape qualityFurnace typesProcess efficiency improvementCross cutStress relief

The invention relates to a method for removing residual stress of hot-rolling high-strength steel, which comprises the production flows of: (1) putting a steel coil of which the thickness is more than or equal to 8 millimeters into a slow cooling pit for slow cooling treatment; and (2) performing air cooling on a steel coil of which the thickness is less than 8 millimeters, and after the steel coil is cooled to reach room temperature, performing temper rolling and performing reeling again to form a coil. A roller-type straightening unit is adopted to perform straightening, flattening, dimensioning and cross-cut on the treated high-strength steel coil to form a steel plate. A roller-hearth heat treatment furnace is adopted to perform stress relief annealing on the flattened steel plate, so that the internal stress of the steel plate is eliminated; and after being tapped off, the steel plate is cooled slowly by adopting a stacking cooling mode, and finally the steel plate is straightened by using the straightening unit, so that the high-strength steel plate has the excellent plate shape stability and can meet the strict requirements of users on flatness of less than or equal to 2 mm / m of the high-strength steel plate. The conventional heat treatment furnace and roller-type straightening equipment can be utilized, so that the investment cost and machining cost are reduced, the annealing treatment time is shortened, and the effect of the plate shape improvement of hood-type annealing is achieved. Thus, the method has an important economic and social significance for the development of the high-strength steel.

Owner:SHOUGANG CORPORATION

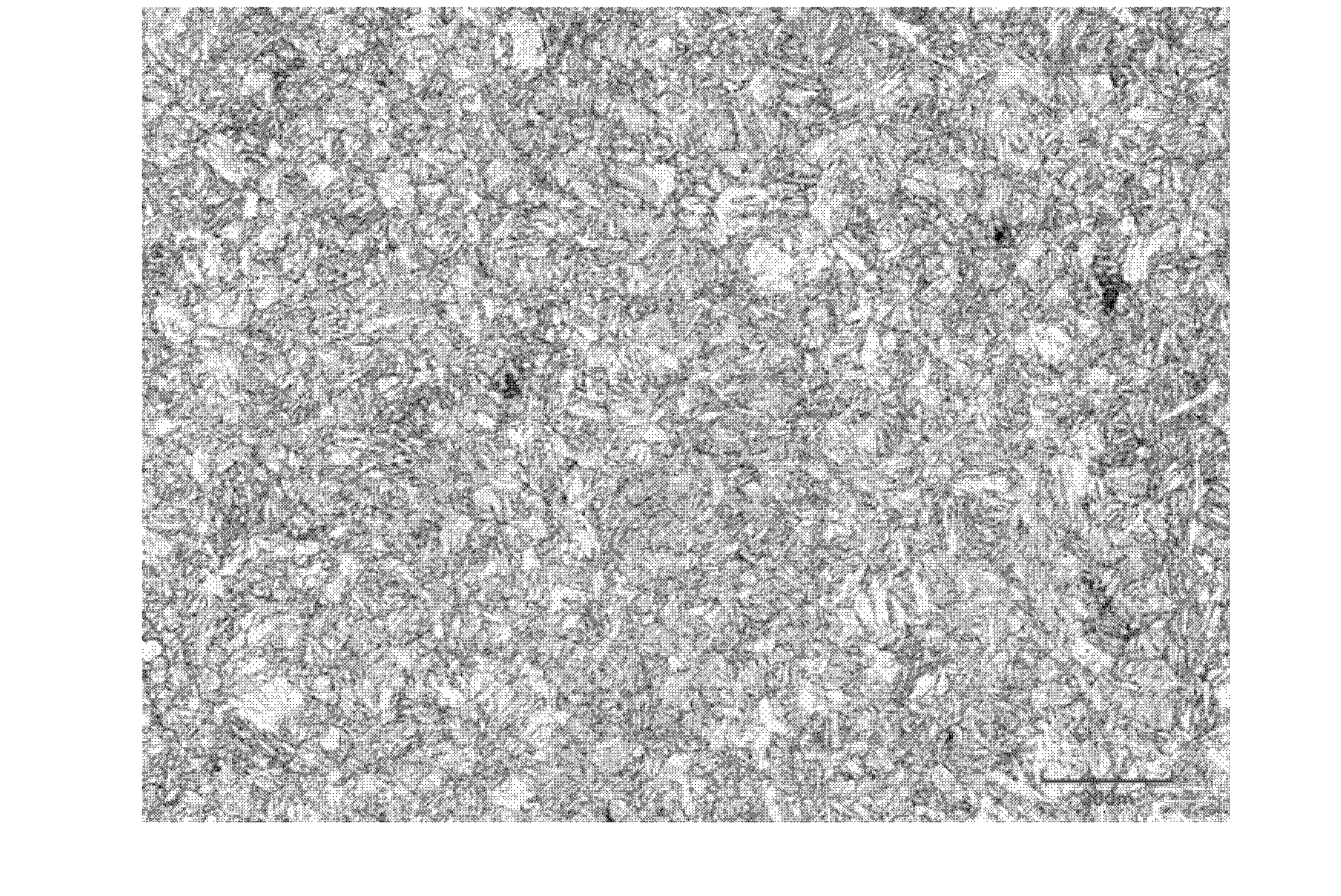

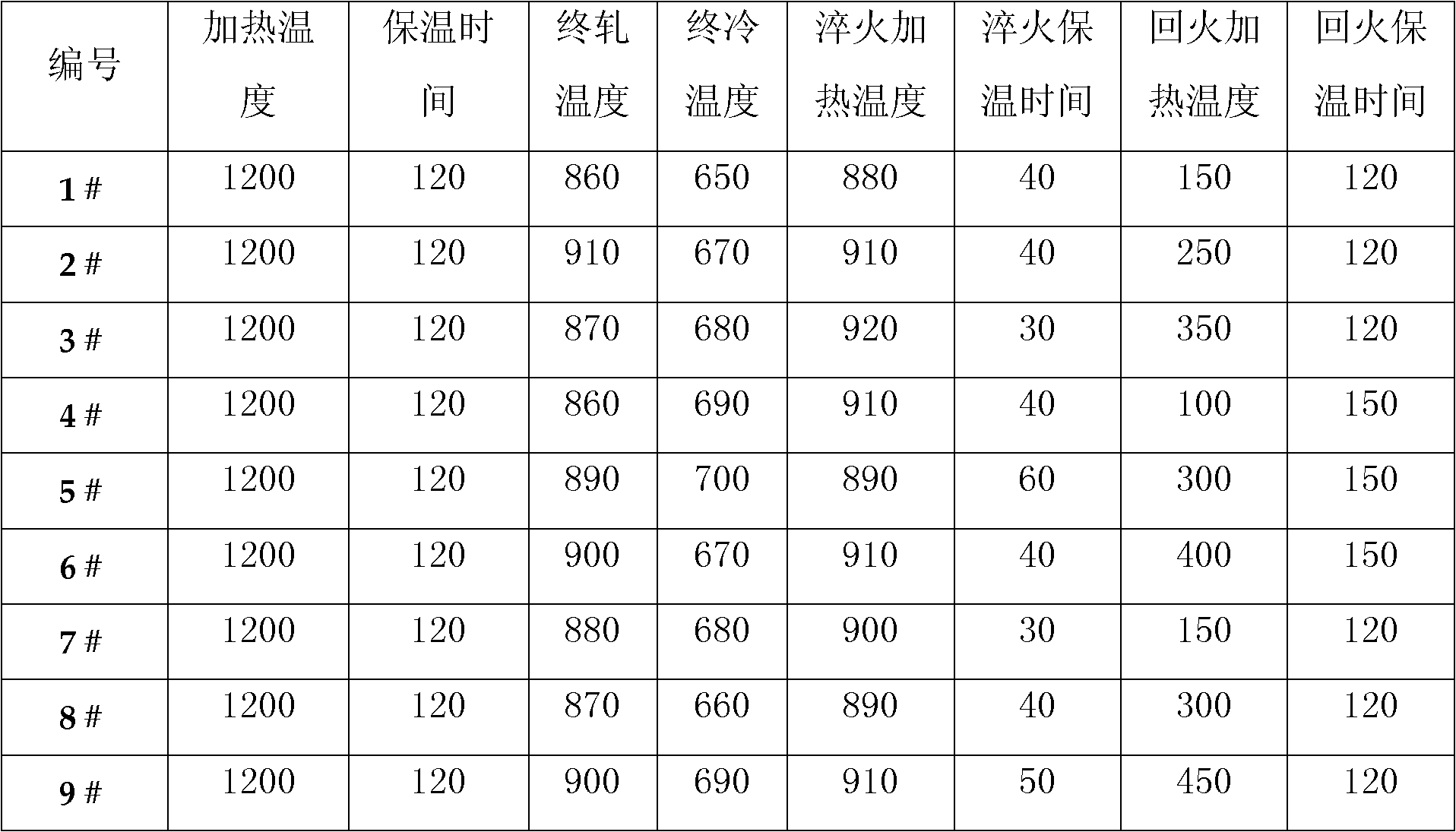

Ultra-high strength steel with yield strength level of 1100MPa-1200MPa and production method of steel

The invention provides ultra-high strength steel with yield strength level of 1100MPa-1200MPa and a production method of the steel. The chemical constituents (weight percentage) include: 0.15-0.18% of C, 0.20-0.25% of Si, 0.85-1.25% of Mn, 0.20-0.60% of Cr; and 0.45-0.65% of Mo, 0.035-0.060% of V, 0.015-0.020% of Nb, 0-0. 55% of Ni, 0-0.035% of Cu, 0.01-0.06% of Al, no more than 0.015% of P, no more than 0.01% of S, no more than 0.008% of N, the balance of Fe and unavoidable impurities. The production method includes: smelting and casting into casting blank; and heating the casting blank to 1150-1250 DEG C, wherein the final rolling temperature is 860-920 DEG C, the coiling temperature is 650-750 DEG C, the quenching heating temperature is 880-930 DEG C, the thermal insulation time is 20-90min, the tempering heating temperature is 100-450 DEG C, the thermal insulation time is over 90min. Slow cooling or air cooling is conducted to room temperature. For the steel plate produced with the constituents and the technology, the yield strength is 1150-1230MPa, the tensile strength is 1250-1340MPa, the elongation is 11-13.5%, and the impact power value at minus 40 DEG C is 21-34J.

Owner:SHOUGANG CORPORATION

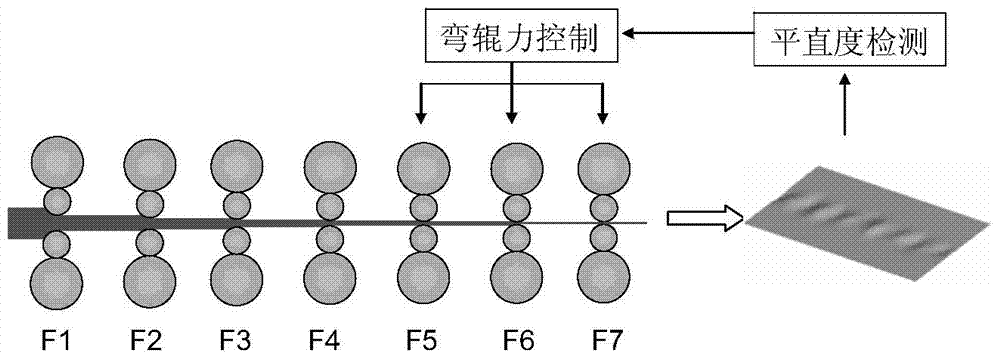

Method for improving plate shape quality of head portion or tail portion of hot rolling strip steel

ActiveCN103028613AImprove shape qualityQuality improvementProfile control deviceStrip steelEngineering

The invention relates to the field of plate shape control of hot rolling strip steel, in particular to a method for improving plate shape quality of a head portion or a tail portion of hot rolling strip steel. The method for improving the plate shape quality of the head portion or the tail portion of the hot rolling strip steel is characterized in that a balance state is switched to a roll bending state in advance according to time series of switch of the head portion before the head portion bites steel, and the roll bending state is switched to the balance state according to the time series of switch of the tail portion after the tail portion discharges the steel. Roll bending force which is set according to the plate shape of the head portion and the tail portion judges limitations in a switchover process. When the roll bending force exceeds a prescribed limitation, the roll bending force needs to be recalculated. A calculation principle is that the priority is given to maintaining glancing flatness of the head portion and the tail portion of the strip steel, the head portion and the tail portion of the strip steel are enabled to present micro edge waves, and the degree of convexity of the strip steel is preferably close to a target value. Compared with the prior art, the method for improving the plate shape quality of the head portion or the tail portion of the hot rolling strip steel has the advantages that calculation and judge of the roll bending force are respectively introduced to switchover time series of the head portion of the strip steel and the switchover time series of the tail portion of the strip steel, the plate shape quality of the head portion and tail portion of the strip steel is improved, ratios of steel clamping in the head portion in a finish rolling and a reeling area and steel drifting in the tail portion in the finish rolling area caused by bad shape of a tail plate are reduced.

Owner:ANGANG STEEL CO LTD

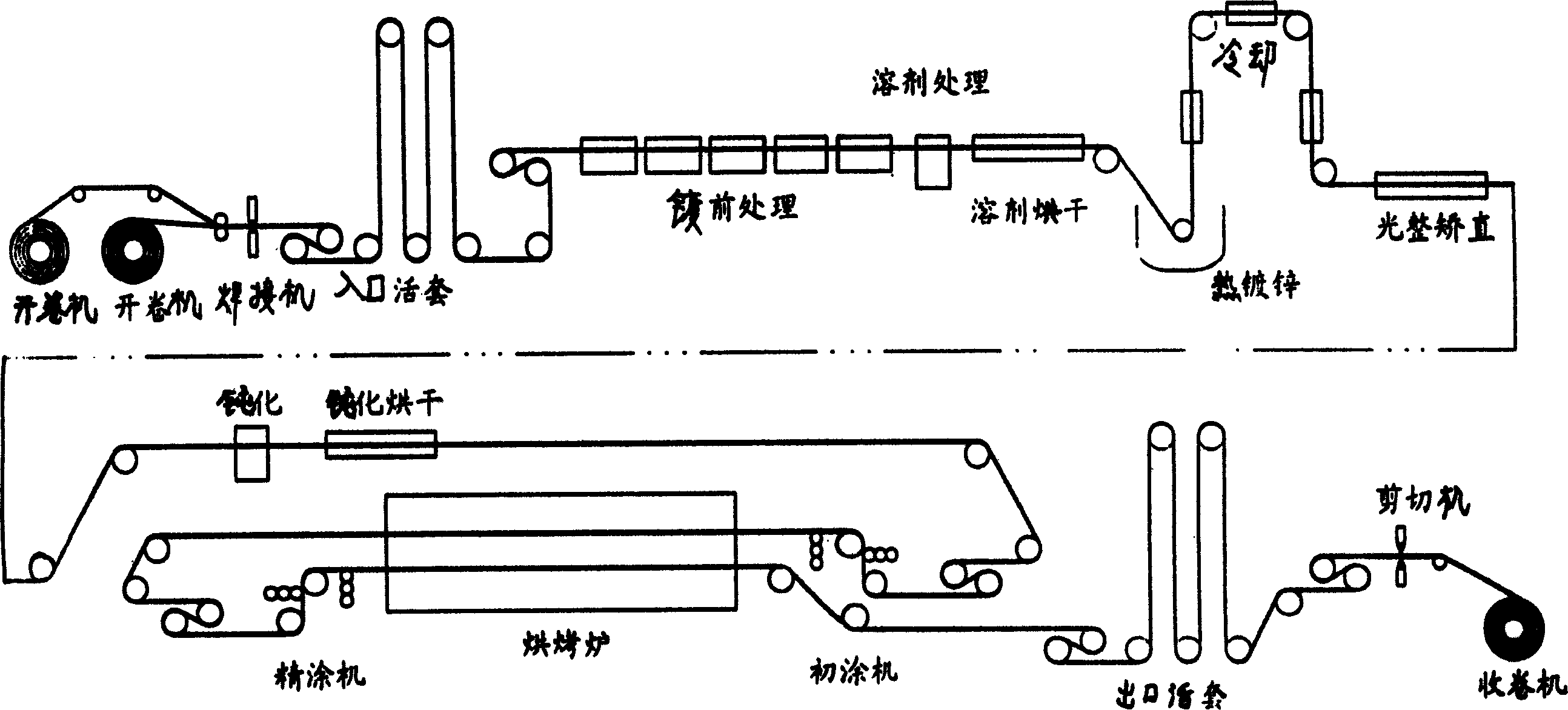

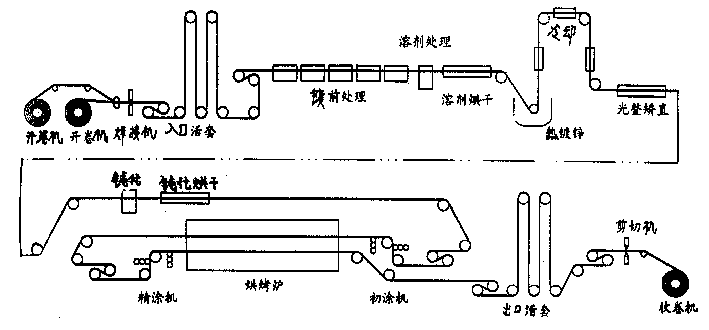

Method for continuous production of hot galvanizing color-painted steel strip

InactiveCN1594655ALow investment costSmall footprintHot-dipping/immersion processesLiquid surface applicatorsProduction lineSheet steel

The invention discloses a continuous hot galvanizing colorful coating steel plate production method, which combines the hot galvanizing and color coating into one assembly line. The inventive continuous hot galvanizing colorful coating steel plate production method can cut down auxiliary apparatus, reduce the assembly line investment cost by 30-40%, reduce the accommodation area by 50-60%. The inventive method has no need for oiling after hot galvanizing, also has no need for treatment before color coating, so diminish the damage to steel plate shape. The inventive method has no need for the unstable operation of galvanizing plate welding, can effectively save the steel strip.

Owner:ZHONGSHAN CHUANGZHI BUILDING MATERIALS TECHCO

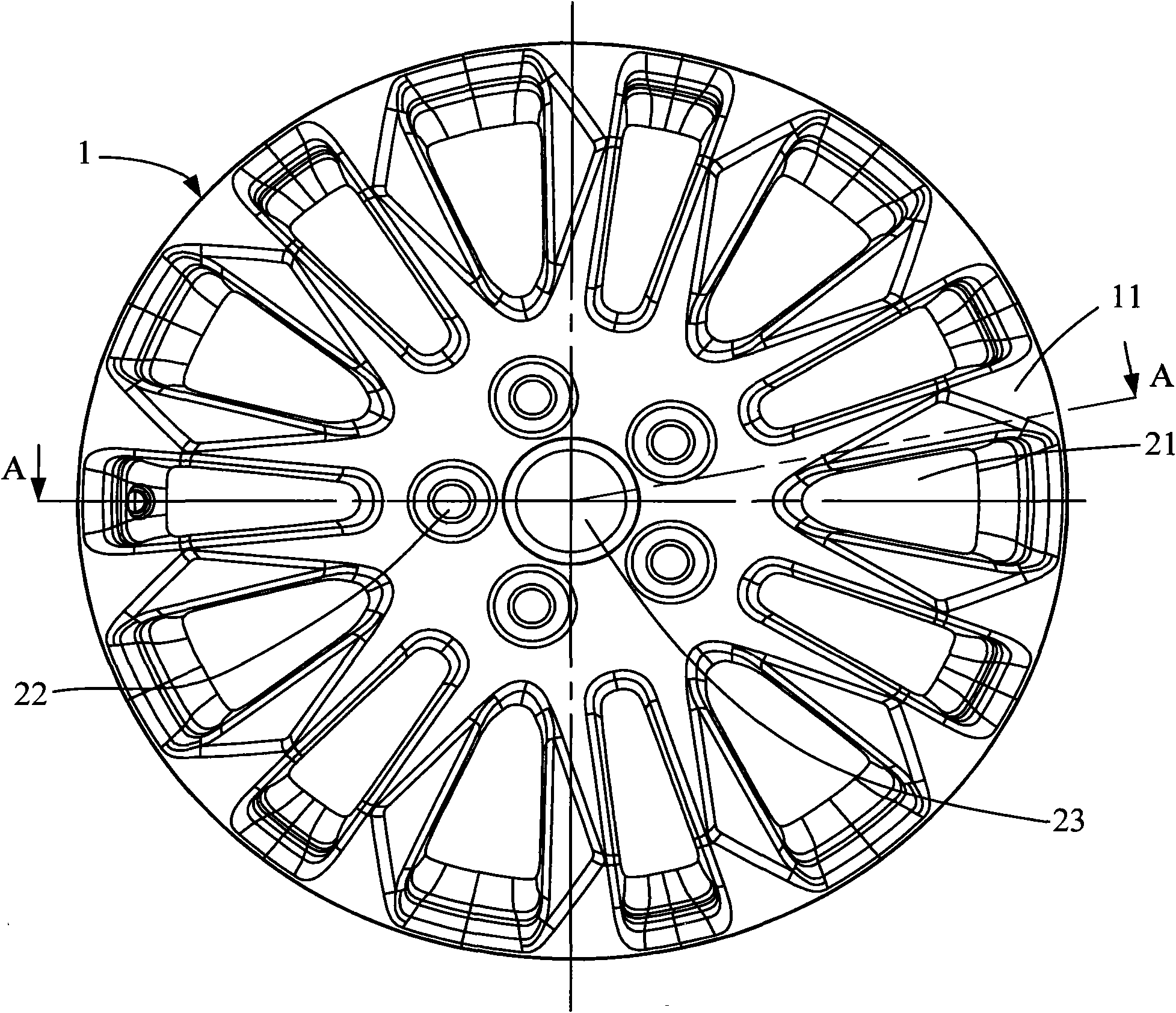

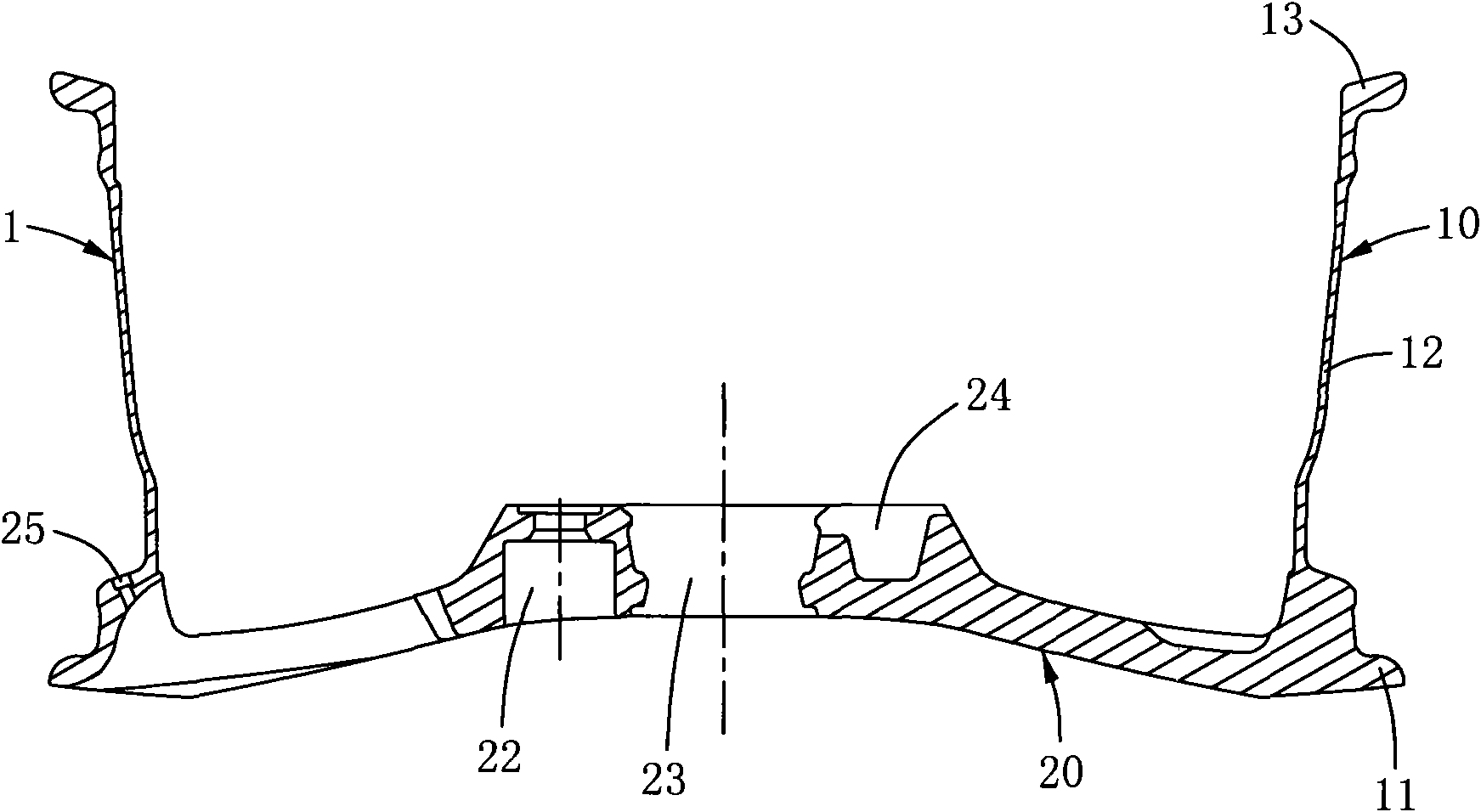

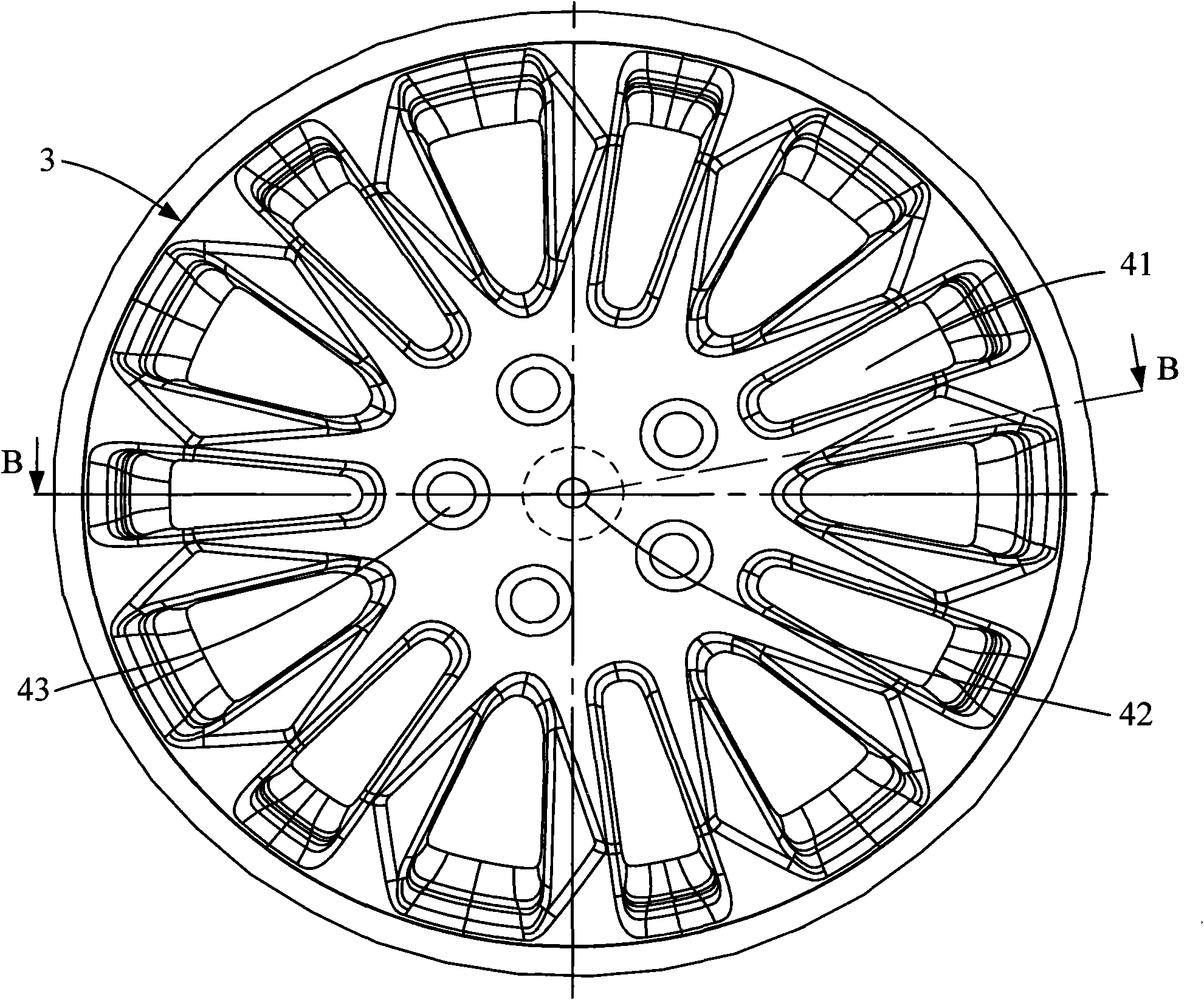

Manufacturing process of aluminum alloy wheel

The invention discloses a manufacturing process of an aluminum alloy wheel, which comprises the following steps: step 1) forming a casting blank in a low-pressure casting mode; step 2) forming a positioning hole on a spoke blank of the casting blank; step 3) preheating the casting blank by a first heating device; step 4) cooling the spoke blank of the casting blank; step 5) mounting the casting blank to a spinning machine; step 6) spinning a wheel rim blank of the casting blank by the spinning machine, heating the wheel rim blank by a second heating device to sufficiently ensure that the spinning temperature is not reduced and simultaneously the wheel rim blank keeps certain plasticity to control the deformation and the deforming speed of the wheel rim blank in the hot spinning process soas to obtain a crude product with good appearance and mechanical properties; and step 7) to step 9) performing heat treatment, mechanical processing and arrangement on the crude product so as to obtain the aluminum alloy wheel with low cost, light weight and good mechanical properties.

Owner:六和轻合金(昆山)有限公司 +1

Control method of rolling deflection of hot-rolled strip steel

ActiveCN106475424AImprove rolling stabilityImprove shape qualityRoll force/gap control deviceStrip millEngineering

The invention relates to a control method of rolling deflection of hot-rolled strip steel. The control method comprises the following steps that horizontal thickness distribution of an intermediate billet is measured in a real-time manner at a rough rolling outlet; and the wedge compensation of a finishing roller gap is calculated according to the horizontal thickness measured data of the roughly rolled intermediate billet, and the rolling reductions of two sides of finishing mills are reasonably set. Steel scraps generated due to rolling deflection are decreased, and the hot rolling stability and the strip shape quality of a strip steel product are improved. The problem that since the roughly rolled intermediate billet is wedged, the finish rolling deflection of the strip steel is caused is solved.

Owner:BAOSTEEL ZHANJIANG IRON & STEEL CO LTD +1

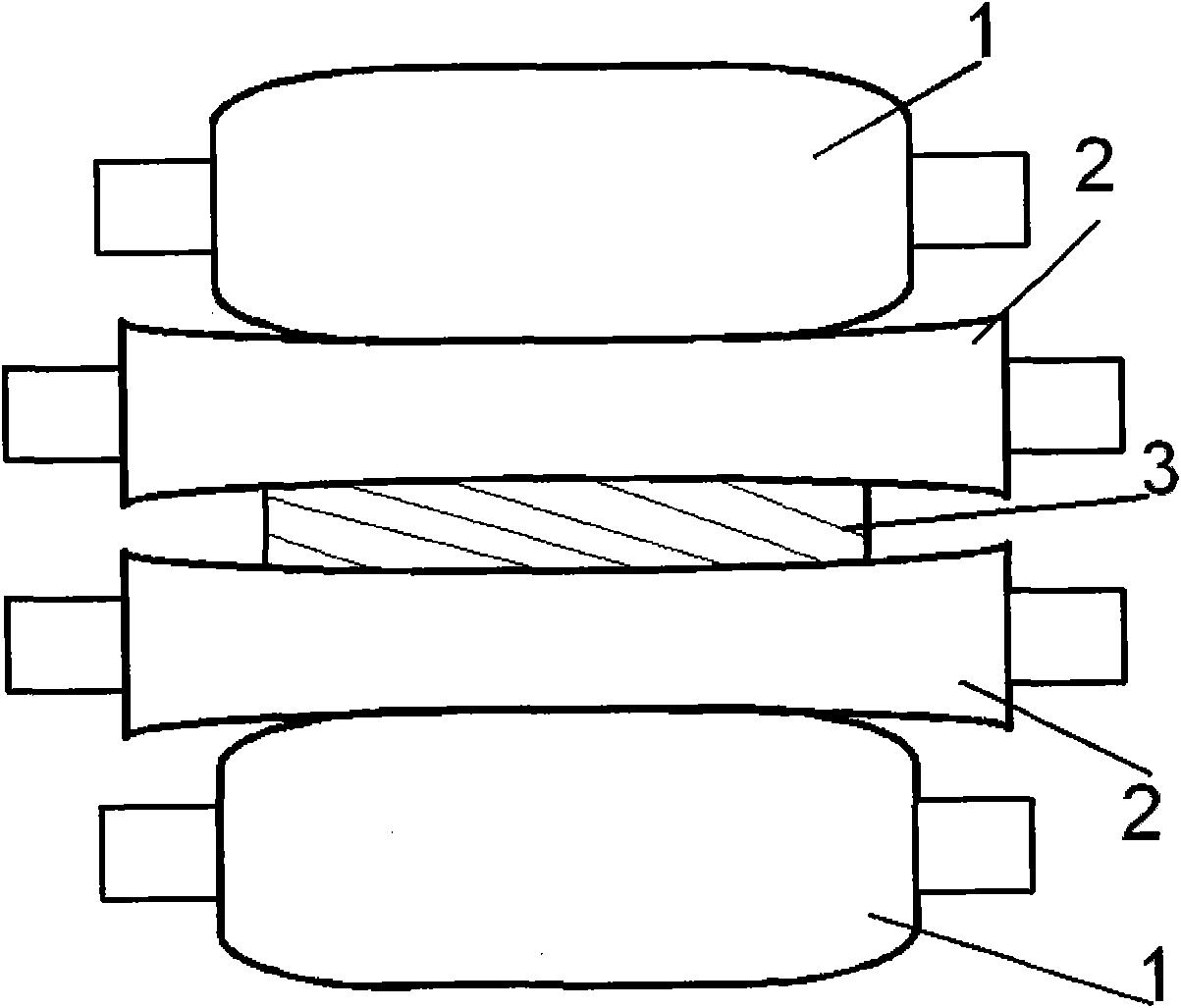

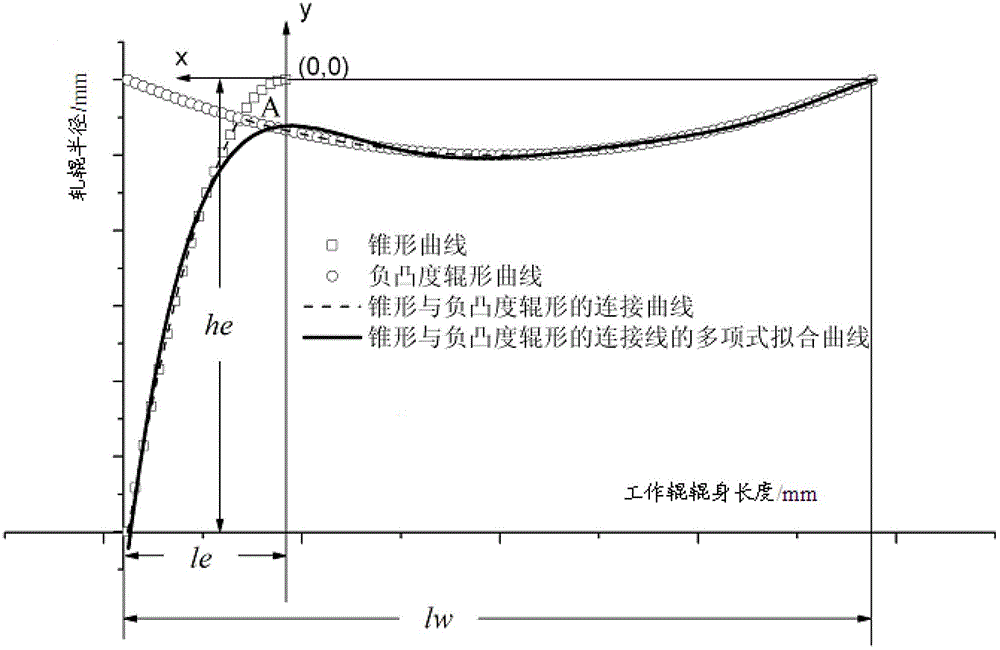

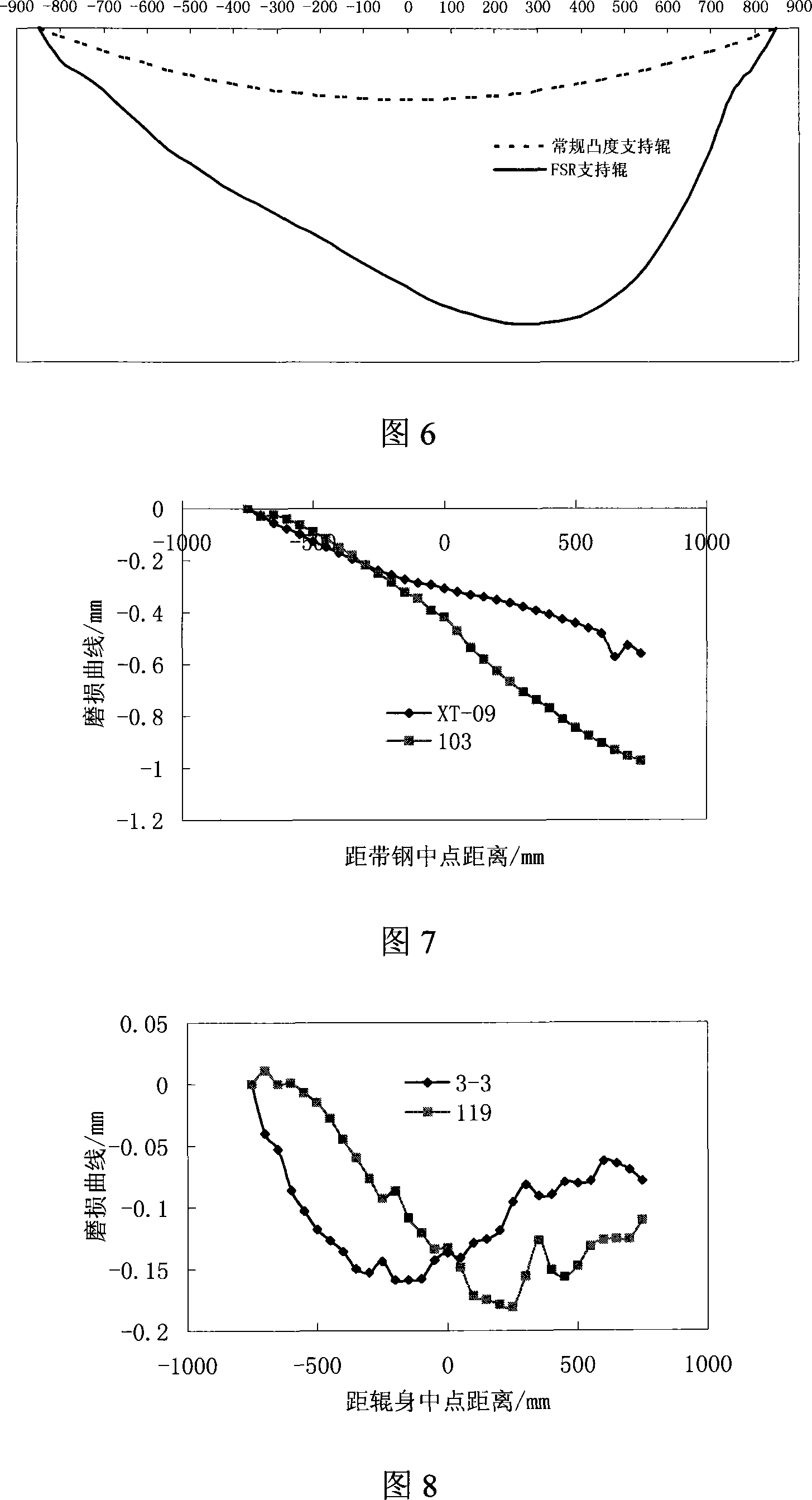

Working roller considering both convexity and edge drop control of strip steel and design method for roller shape of working roller

ActiveCN102744260AImprove shape qualityGood cross-sectional profile shapeRollsMetal rolling arrangementsProduction lineEngineering

The invention discloses a working roller considering both a convexity and an edge drop control of strip steel, belonging to the technical field of steel rolling. A curve equation of a roller shape of the working roller is that R(x)=b6x6+b5x5+b4x4+b3x3+b2x2+b1x+b0, x belong to [ 0,1w]. When the working roller is used for rolling silicon steel by the working roller on a downstream rack in a refine rolling set of a heat continuous rolling production line, a rolling hot convexity can be offset by a negative convexity segmentation of a parabolic curve, the edge drop of strip steel can be controlled by the segmentation of a conical curve, so that hot silicon steel is enabled to have a cross section with excellent profile and shape, a good board condition is provided for subsequent cold rolling, quality of silicon steel board shape is increased, edge-cutting quantity of a finished product of silicon steel is reduced, and the finished product rate is improved. Additionally, the invention further discloses a design method for a roller shape of the working roller.

Owner:SHOUGANG CORPORATION

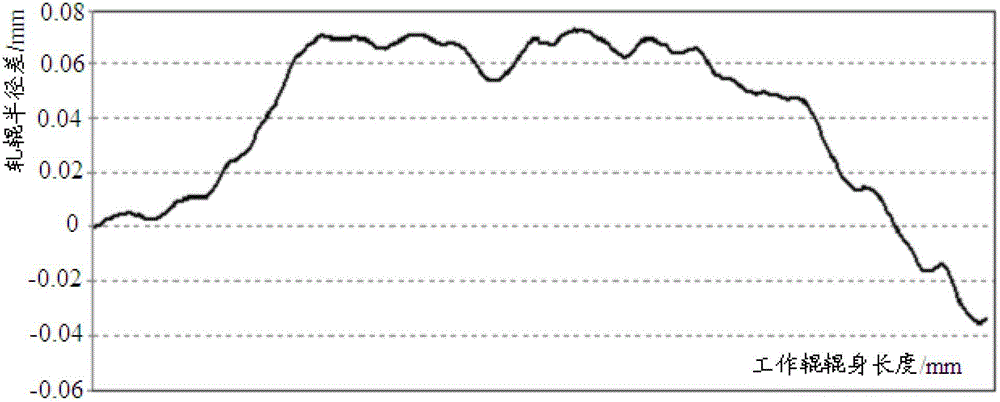

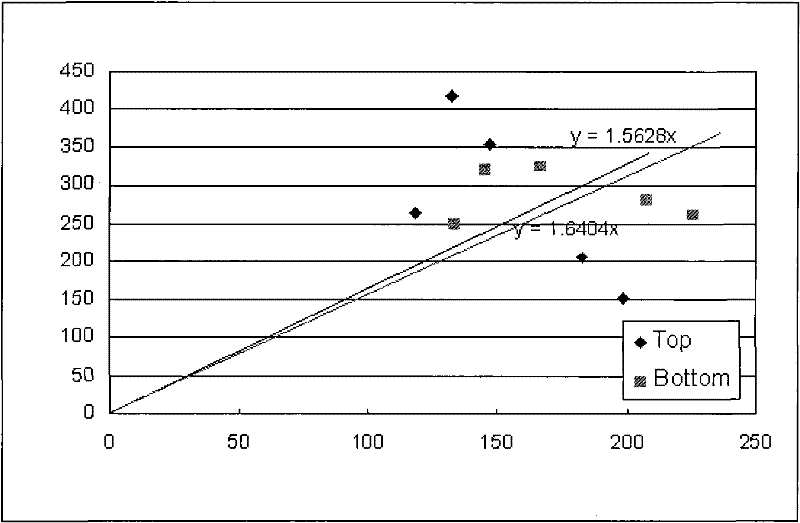

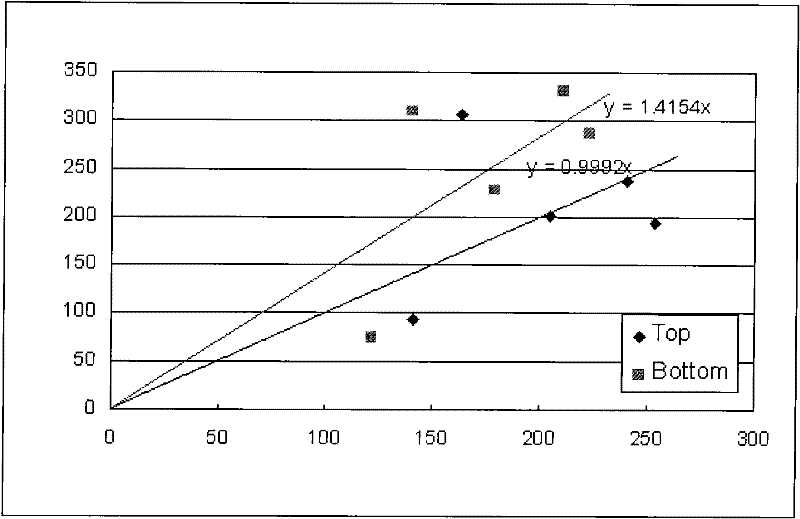

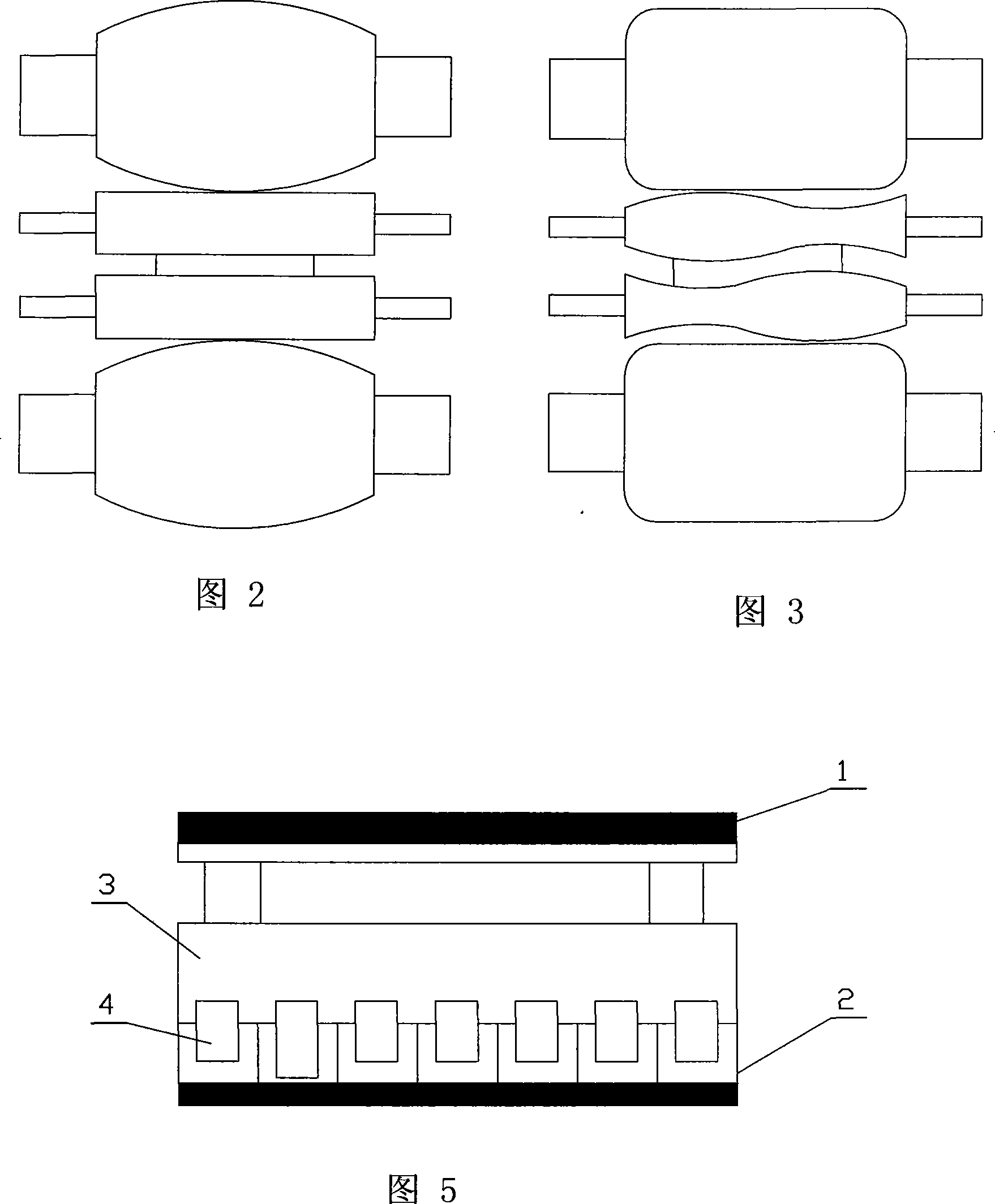

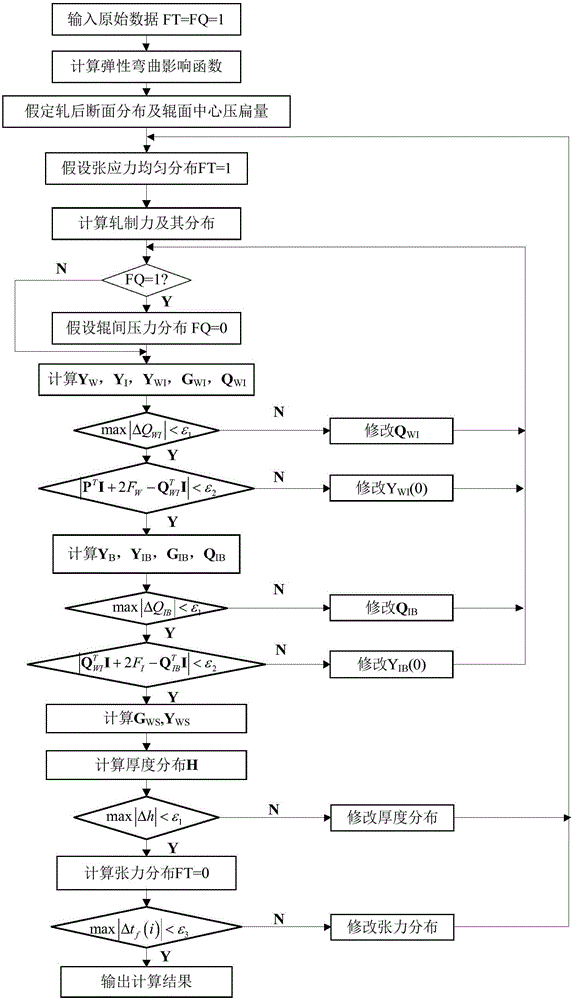

Roller wear optimization control method for improving quality of band steel

InactiveCN102236322AImprove calculation accuracyImprove shape qualityRoll force/gap control deviceProfile control deviceConversion factorMaterial type

The invention relates to a roller wear optimization control method for improving the quality of band steel. The method comprises the following steps of: 1, classifying rollers according to roller materials; 2, acquiring the roller shape and surface temperature data of working rollers of a front rack and a rear rack in more than two rolling periods for different roller materials; 3, performing optimization processing on the acquired data; and 4, performing roller wear computation and optimization control, namely performing the roller wear computation by using optimized wear conversion factors according to different roller classes to realize the optimization control over band steel profiles and roller gaps. In the optimization control method provided by the invention, parameter optimizationis performed according to different roller material types so as to improve the computational accuracy of a roller wear model and further improve band steel profile quality and roller gap control accuracy; moreover, measurement planning and parameter regulation processes are simple, operable and convenient to implement.

Owner:BAOSHAN IRON & STEEL CO LTD

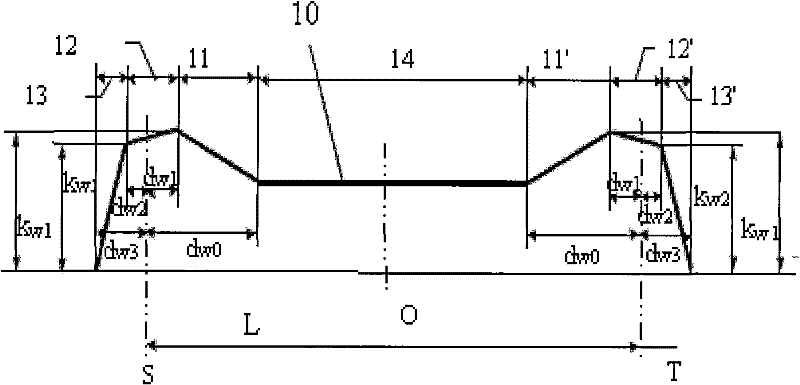

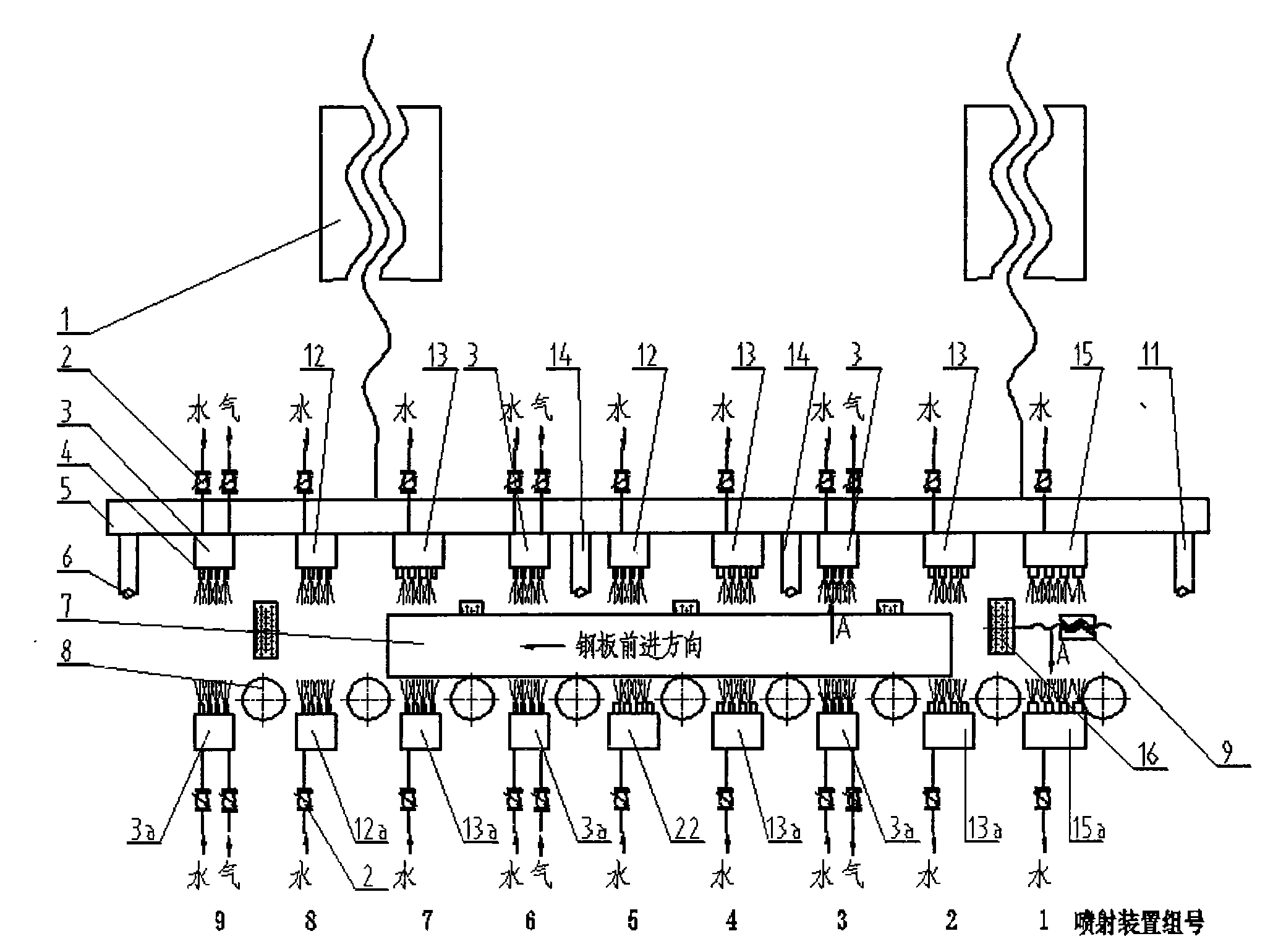

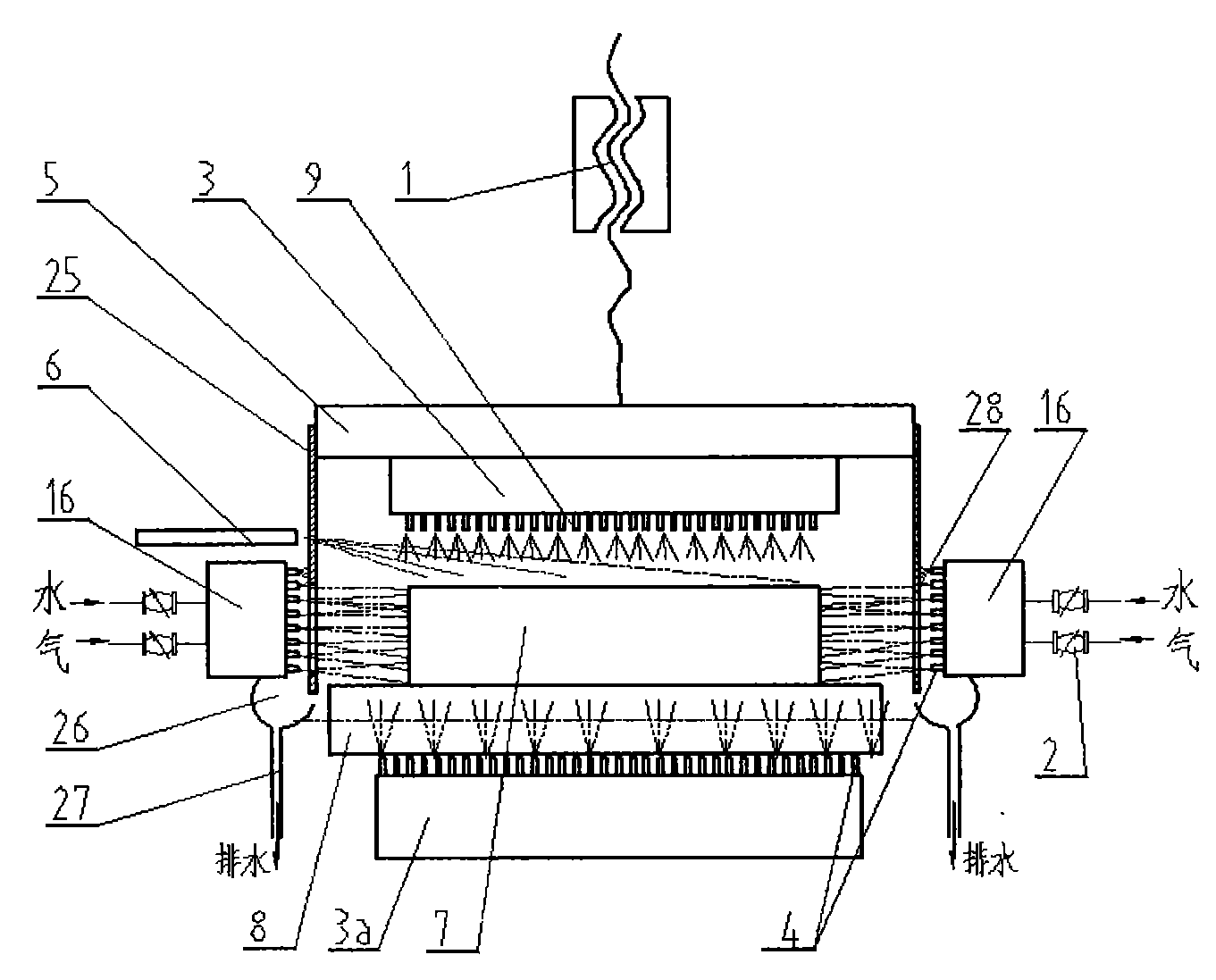

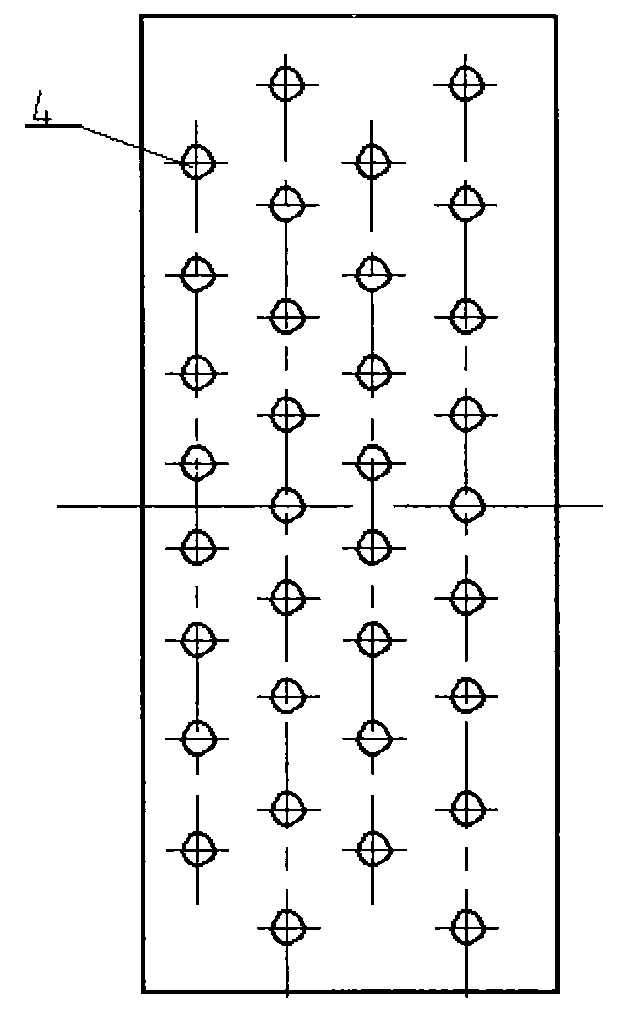

Square or flat material production line jet cooling system

ActiveCN102121063AFulfil requirementsImprove shape qualityFurnace typesHeat treatment furnacesProduction lineSpray nozzle

The invention relates to square or flat material production line jet cooling thermal treatment equipment, which mainly consists of upper and lower strong cold jet devices (15 and 15a), upper and lower medium cold jet devices (13 and 13a), upper and lower weak cold jet devices (12 and 12a), upper and lower aerosol jet devices (3 and 3a), side cold jet devices (16), front, middle and rear blowing devices (11, 14 and 6), a flow control device (2) and an upper jet device lifting device (1), wherein the upper strong, medium and weak jet devices (15, 13 and 12), the upper aerosol jet devices (3) and the front, middle and rear blowing devices (11, 14 and 6) can lift up and down together with the lifting device (1) so as to adapt to the requirements of square or flat materials of different thicknesses. The side cold jet devices (16) are arranged on two sides of a rail (8), and can quickly cool the thick square or flat materials. The cooling capacity of the cooling system can be regulated by opening the jet cooling devices of different groups and regulating the flow control device (2). Front and rear staggered nozzles dense in the middle and sparse on two sides are arranged so that the jet cooling system is uniform and the quenched square or flat materials have low deformation, unique texture and no cracking.

Owner:UNIV OF SCI & TECH BEIJING

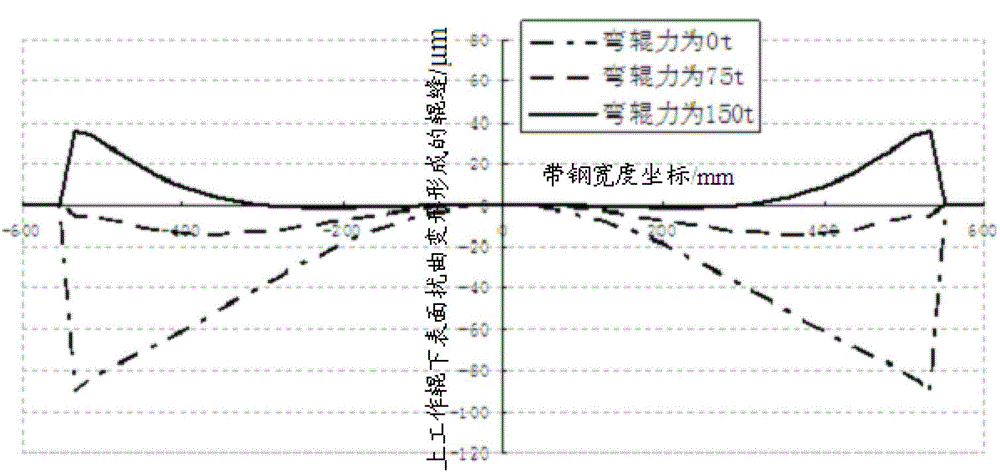

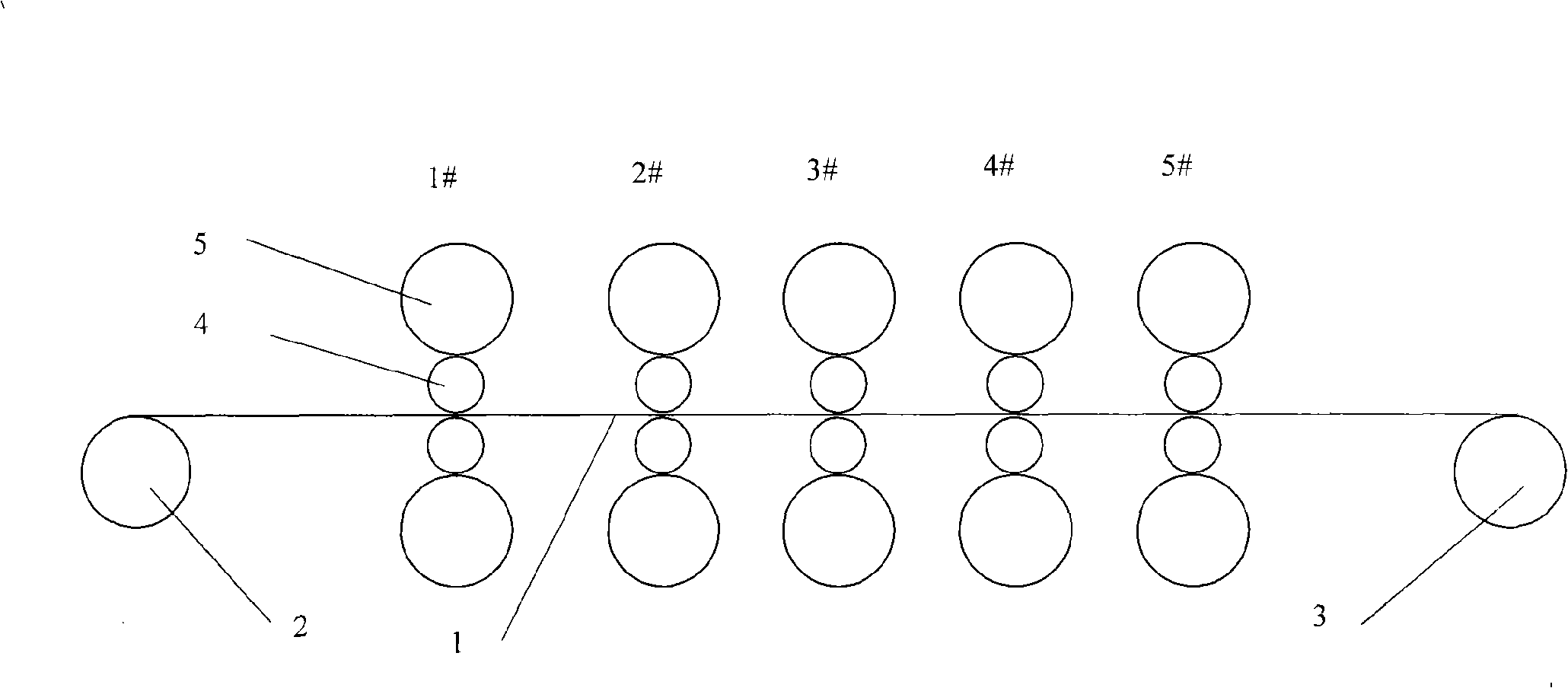

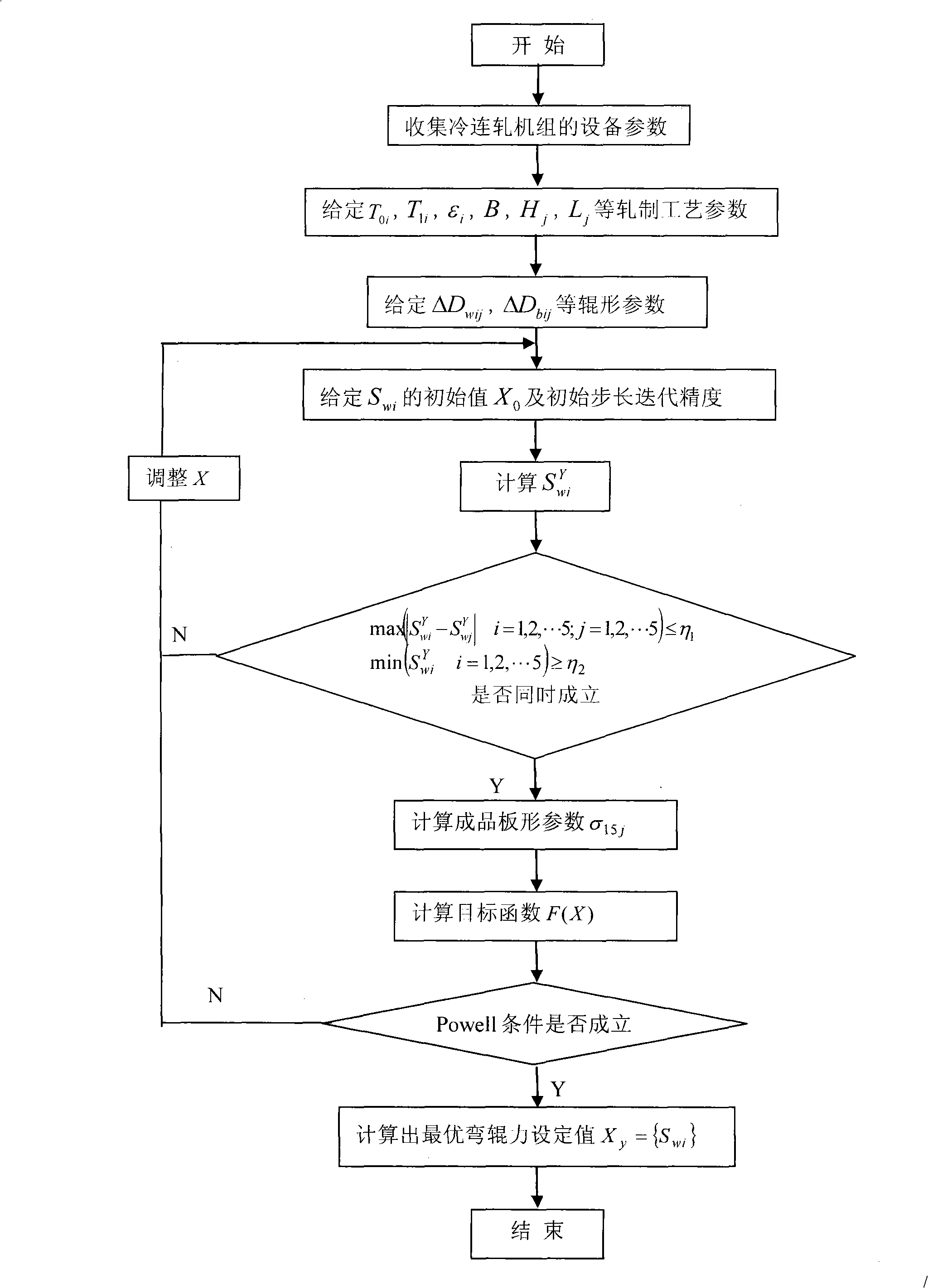

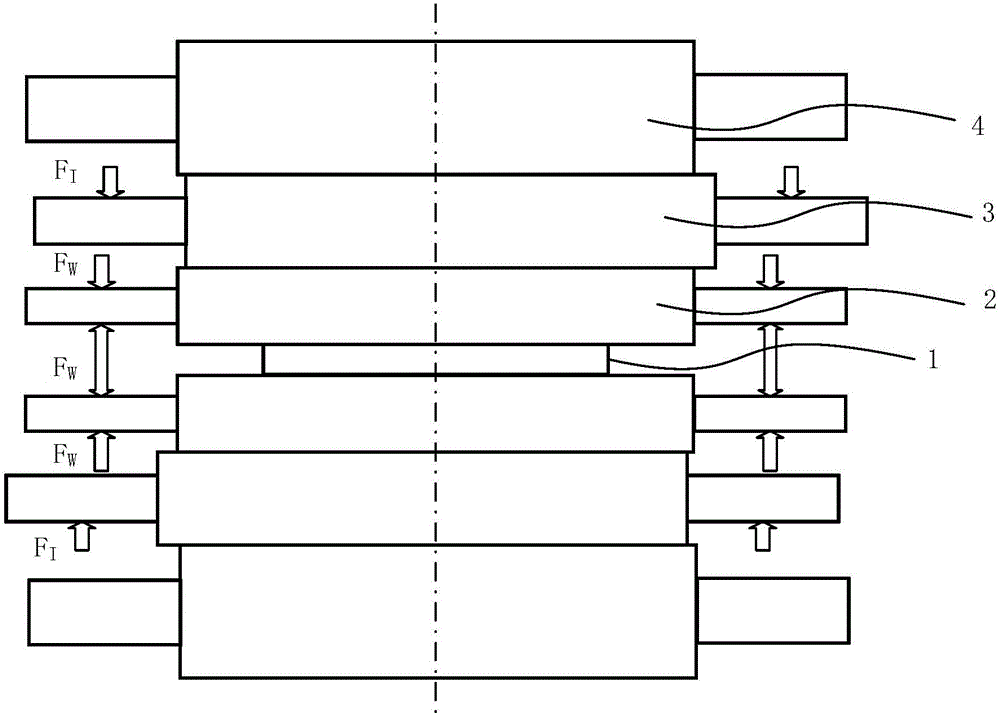

Synthetic setting technology of roll-bending force of five-frame four-roll cold continuous rolling device

InactiveCN101491814AImprove controlExtended service lifeProfile control deviceNumerical controlInequationEngineering

The invention relates to a roller bending force comprehensive setting method for a five-stand four-roller cold tandem rolling mill, and belongs to the technical field of strip cold rolling. The method can improve plate shape quality of finished products and prolong the service life of a roller bending cylinder. The method is characterized by comprising the following operation steps: (a) acquiring parameters of equipment of the mill; (b) acquiring key technological parameters; (c) setting a roller bending force initial setting value X0={Swi0 i=1, 2, 3, 4 and 5}, an iteration precision epsilon, an allowable maximum roller bending force allowance difference eta 1, and the minimum roller bending allowance eta 2; (d) calculating roller bending allowance of (No.1 to No.5) stands Swi; (e) judging whether inequations that max(absolute [Swi-Swj ] i=1, 2, 3, 4 and 5; j=1, 2, 3, 4 and 5) is less than or equal to eta 1 and min(Swi i=1, 2, 3, 4 and 5) is more than or equal to eta 2 come into existence at the same time, if so, entering (f), otherwise, entering (c), and setting the initial value until the inequations are met; (f) calculating a front pull transverse distribution value of the No.5 stand sigma 15j; (g) calculating a plate shape control objective function F(x)=(max(sigma15j)-min(sigma15j) / T15; and (h) judging whether Powell conditions come into existence, otherwise, changing the setting value and repeating the steps from (c) to (g) until the Powell conditions come into existence, and obtaining the optimal roller bending comprehensive setting value.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Semi-process cold-rolling non-oriented electrical steel and production process thereof

The invention discloses a semi-process cold-rolling non-oriented electrical steel and a production process thereof, which mainly solves the technical problems that the prior art is high in energy consumption, large in pollution and high in cost. According to the technical scheme, the semi-process cold-rolling non-oriented electrical steel is a special steel which comprises the following ingredients by mass: not more than 0.01% of C, not more than 0.015% of P, not more than 0.012% of S, not less than 0.4% and not more than 0.60% of Si, not less than 0.6% and not more than 0.8% of Mn, not less than 0.15% and not more than 0.25% of Al, and the balance of Fe. The production process comprises the following steps: smelting molten steel, continuous casting, hot-rolling, punching and annealing, and specifically comprises the following steps: pretreating molten iron, smelting in a rotary furnace, blowing argon over the whole process, conducting RH (Rockwell Hardness) fine smelting, conducting CSP (Cast Steel Plate) continuous casting, putting in a CSP heating furnace, conducting CSP hot-continuous-casting, pickling and cold-rolling and annealing, wherein in the smelting process in the rotary furnace, silicon iron, ferromanganese iron and an aluminum alloy are added to conduct alloying so as to manufacture an alloy steel. The semi-process cold-rolling non-oriented electrical steel is mainly used in a production process of a motor iron core.

Owner:HUNAN XUEBAO ELECTRIC APPLIANCE

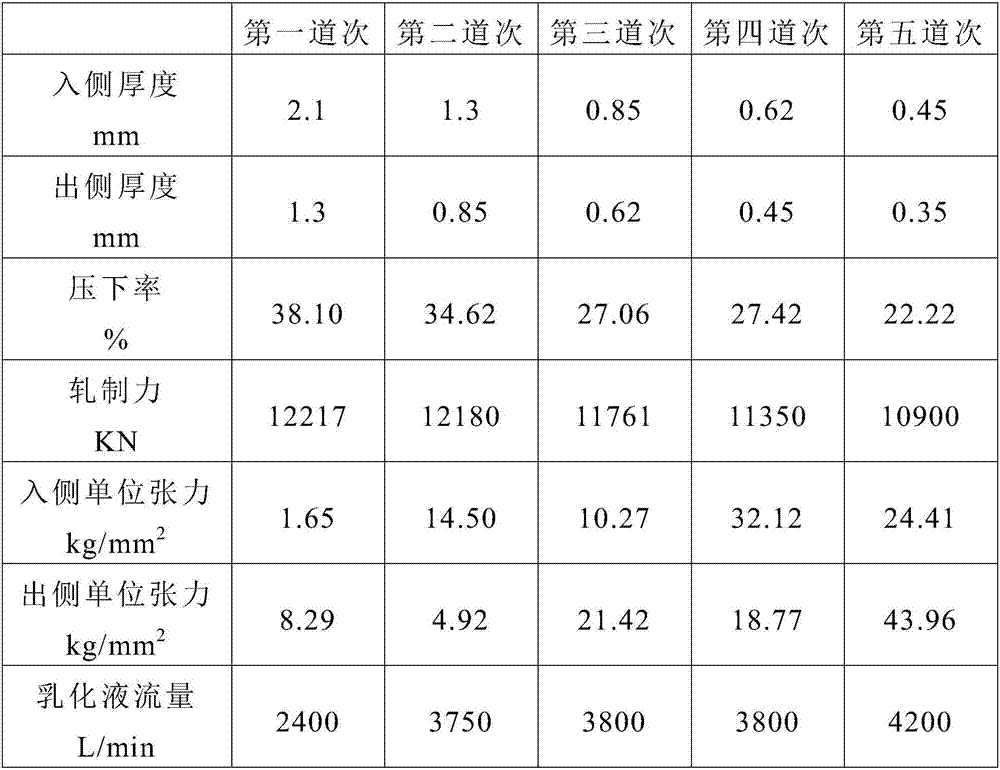

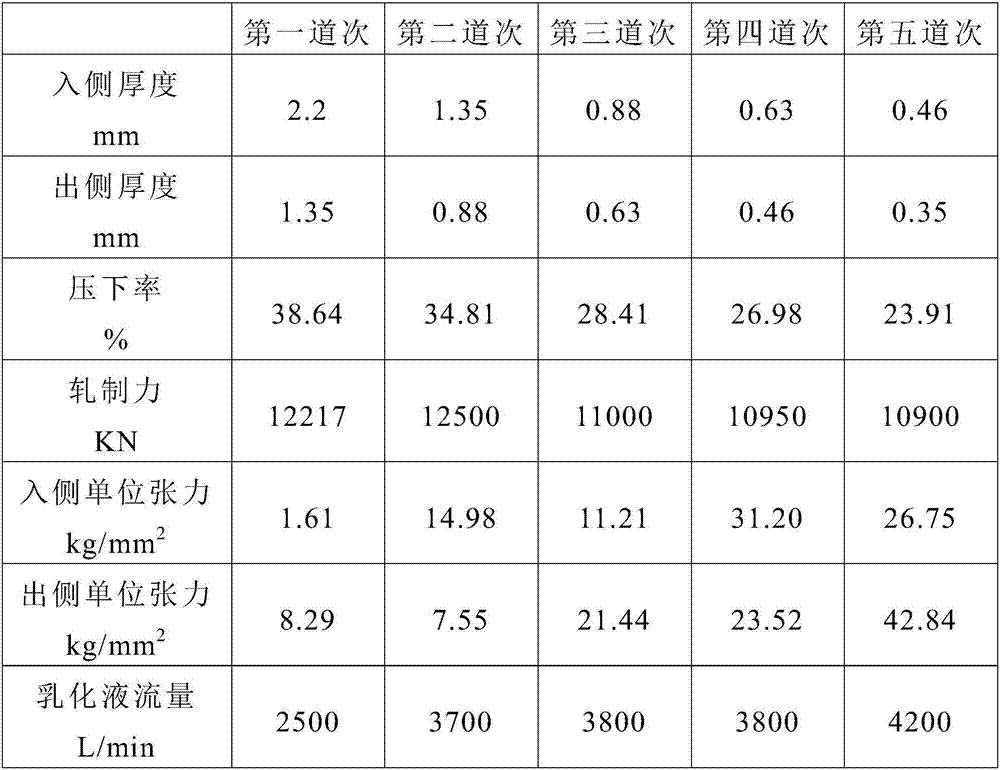

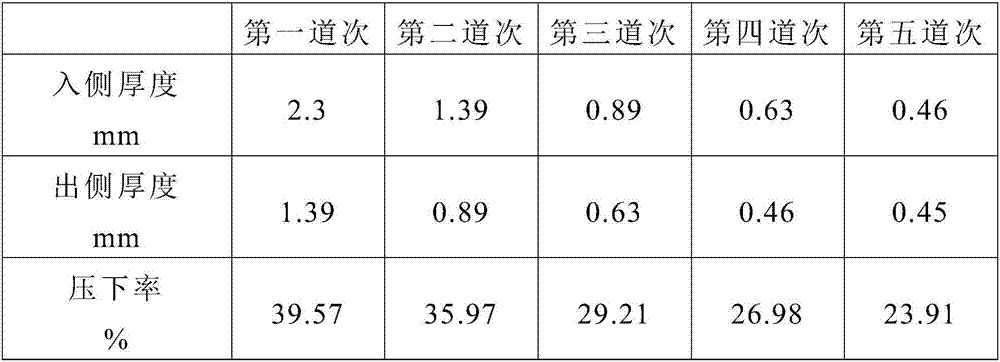

Cold rolling method for high grade non-oriented silicon steel through hot rolling, acid pickling and non-edge-cutting

ActiveCN107962075ALow costReduce resistanceRoll force/gap control deviceTemperature control deviceReduction rateThermal expansion

The invention relates to the field of silicon steel cold rolling, and discloses a cold rolling method for high grade non-oriented silicon steel through hot rolling, acid pickling and non-edge-cutting.The cold rolling method comprises the following steps that a steel coil is obtained, non-edge-cutting normalizing acid pickling is carried out, then a one-time cold rolling method is adopted for continuous reversible type five-pass cold rolling, the reduction rate, rolling force, entry side unit tension and exit side unit tension of each pass are controlled, emulsified liquid spraying is adoptedin rolling for process lubricating and cooling, thermal expansion adjustment steel coil plate shape of a working roll is controlled in a partitioned cooling mode, a rolled product is obtained, and then subsequent procedures are conducted conventionally. The cold rolling method for high grade non-oriented silicon steel through hot rolling solves the problems of poor rolling efficiency and poor finished product rate of high silicon content varieties.

Owner:武汉钢铁有限公司

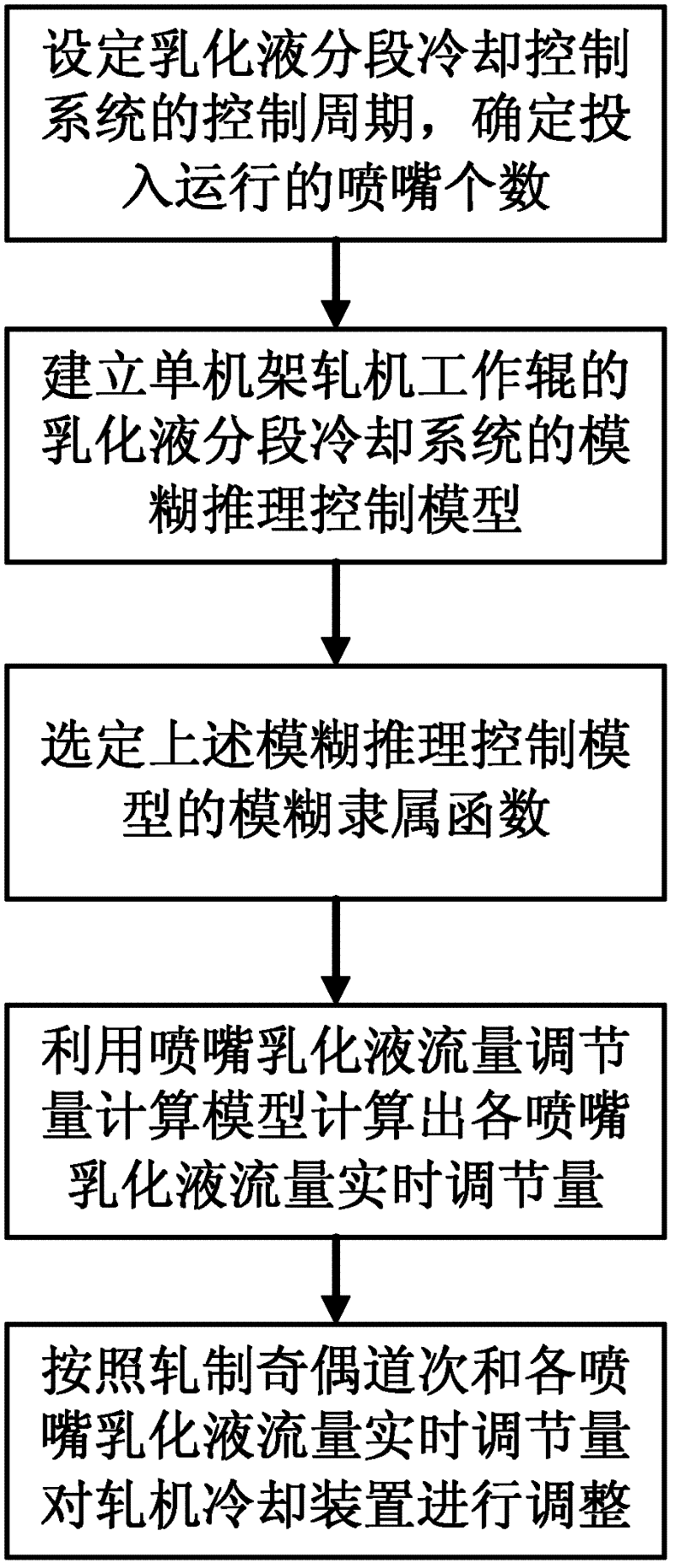

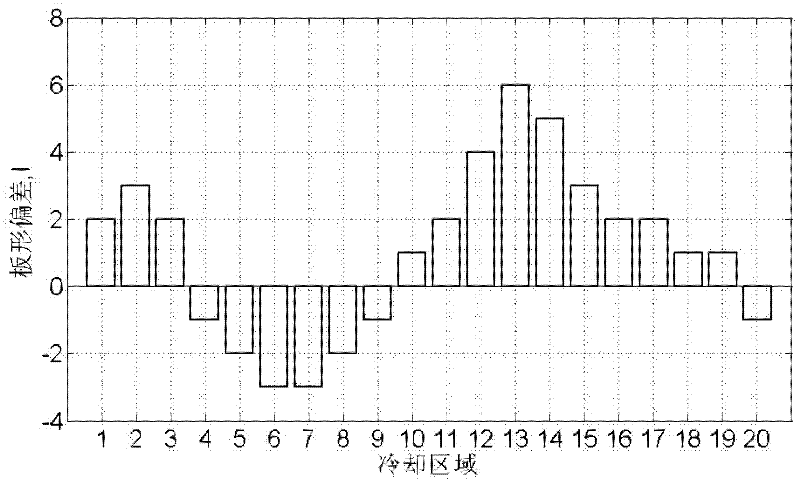

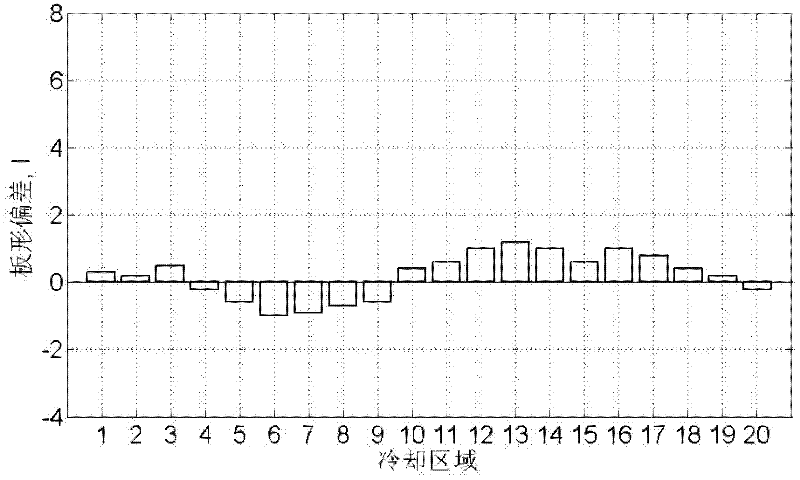

Sectional cooling control method for emulsion of working roller of single-frame rolling mill

InactiveCN102389902AOvercome technical problems that cannot be precisely controlledEliminate high order shape deviationRollsProfile control deviceTerra firmaEmulsion

The invention relates to a sectional cooling control method for an emulsion of a working roller of a single-frame rolling mill. Particularly, a fuzzy modeling method is used for establishing a quantitative relation among a plate-shape deviation, a previous regulating quantity of injected flow of the emulsion and a present regulating quantity of the injected flow of the emulsion, thereby realizinghigh-precision sectional cooling control of the emulsion of the working roller of the single-frame rolling mill. The method provided by the invention overcomes the technical problem that precise control cannot be realized because a long-time hysteresis phenomenon exists in an emulsion injecting cooling action mechanism; high-precision sectional cooling control of the emulsion of the working roller of the single-frame rolling mill is realized, thereby efficiently eliminating high plate-shape deviation of cold-rolling strip steel and promoting the quality of the plate shape of a cold-rolling strip steel product; the method is simple and practicable, fully meets a real-time demand of a sectional cooling control system and is characterized by effectiveness and practicability; and a firm foundation is established for high-precision plate-shape control of the cold-rolling strip steel.

Owner:WISDRI ENG & RES INC LTD

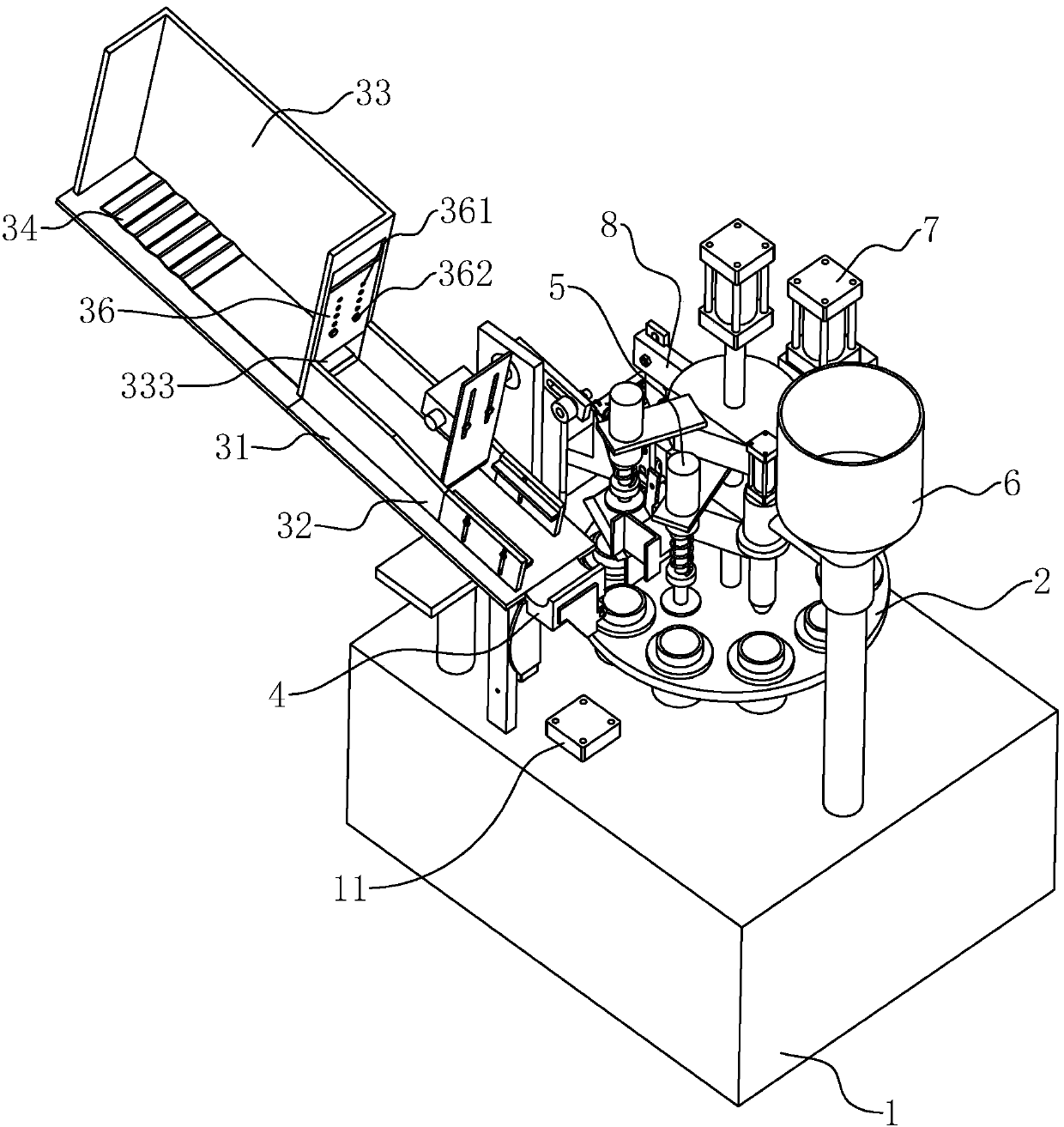

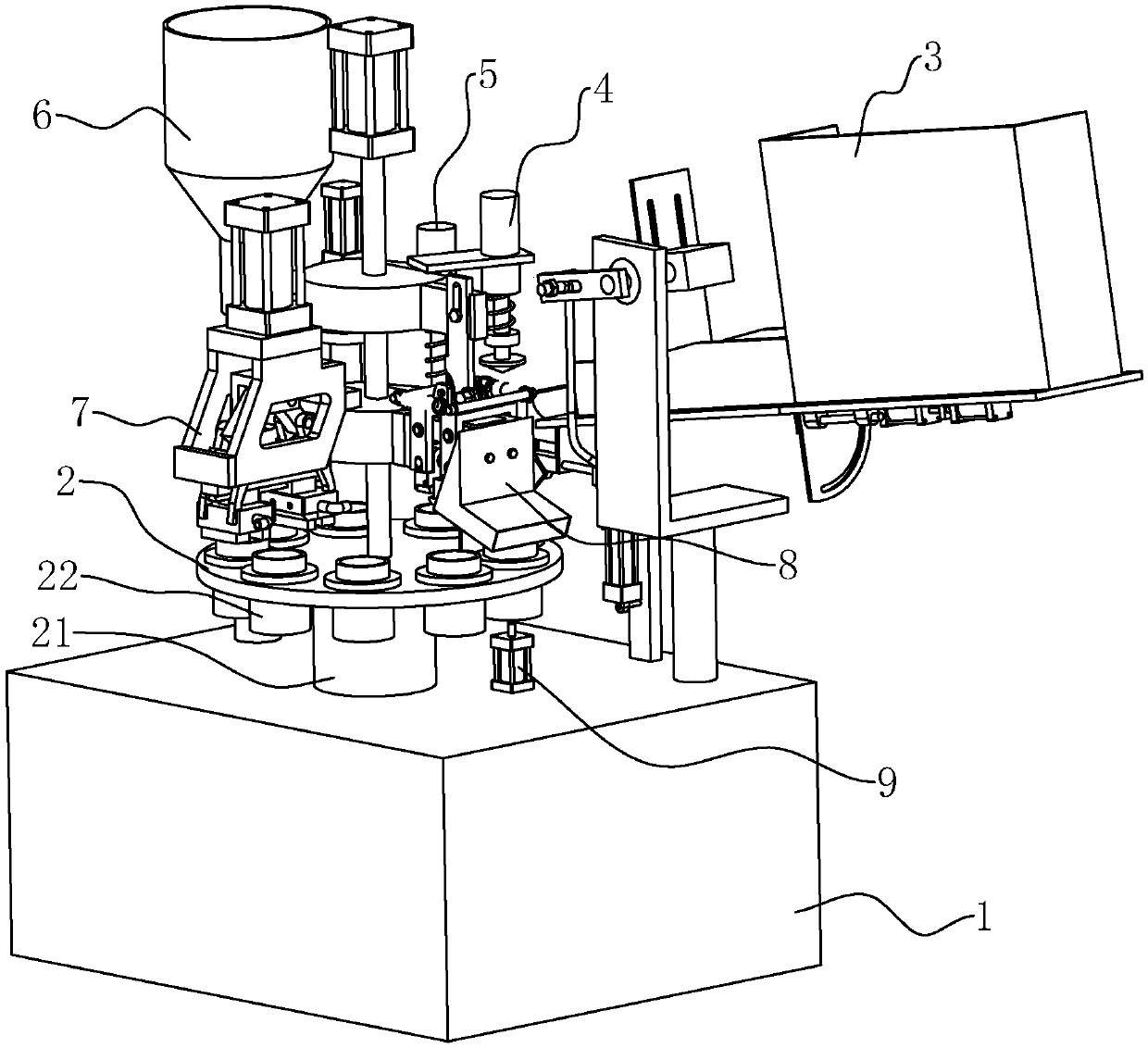

Fully-automatic flexible pipe filling and tail sealing machine

InactiveCN109515870AEasy to transportImprove stabilityWrapper twisting/gatheringEngineeringFully automatic

The invention discloses a fully-automatic flexible pipe filling and tail sealing machine, and relates to the technical field of flexible pipe filling and tail sealing machines. The fully-automatic flexible pipe filling and tail sealing machine is characterized in that a rack, a rotating disc arranged on the rack, and a driving mechanism used for driving the rotating disc to rotate on the rack areincluded; a plurality of pipe cups used for storing flexible pipes are arranged on the rotating disc; a feeding device, a pipe feeding device, a pipe pressing device, a filling device, a clamping heatsealing device, a tail cutting device, a pipe unloading device and a control device which are sequentially arranged on the rack are further included; the feeding device, the pipe feeding device, thepipe pressing device, the filling device, the clamping heat sealing device, the tail cutting device and the pipe unloading device are controlled through the control device, and the fully-automatic filling and tail sealing processes of the flexible pipes are achieved; and the effects that the automatic degree of flexible pipe filling is increased, the product quality is good, and the working efficiency is high are achieved.

Owner:温州市九亿机械有限公司

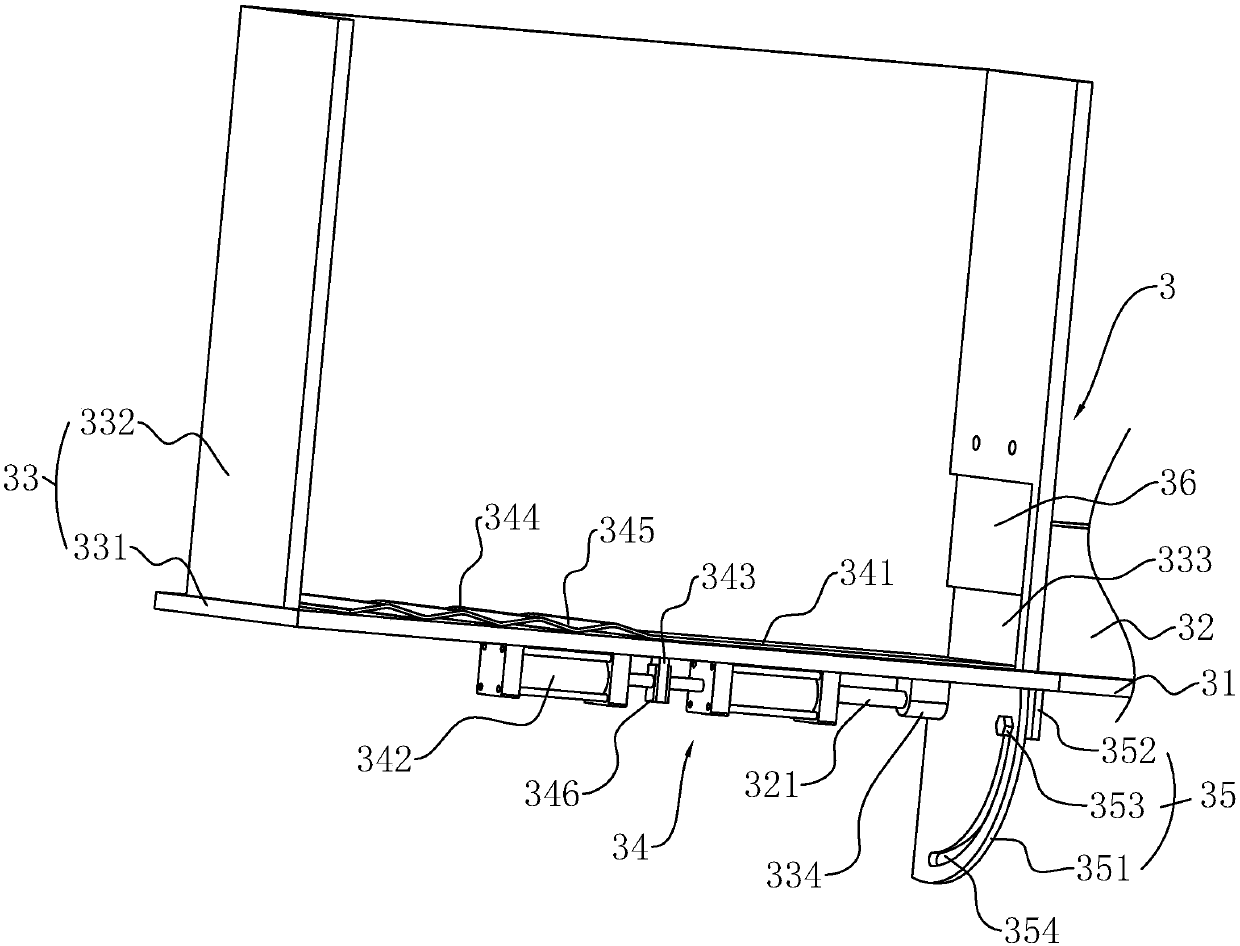

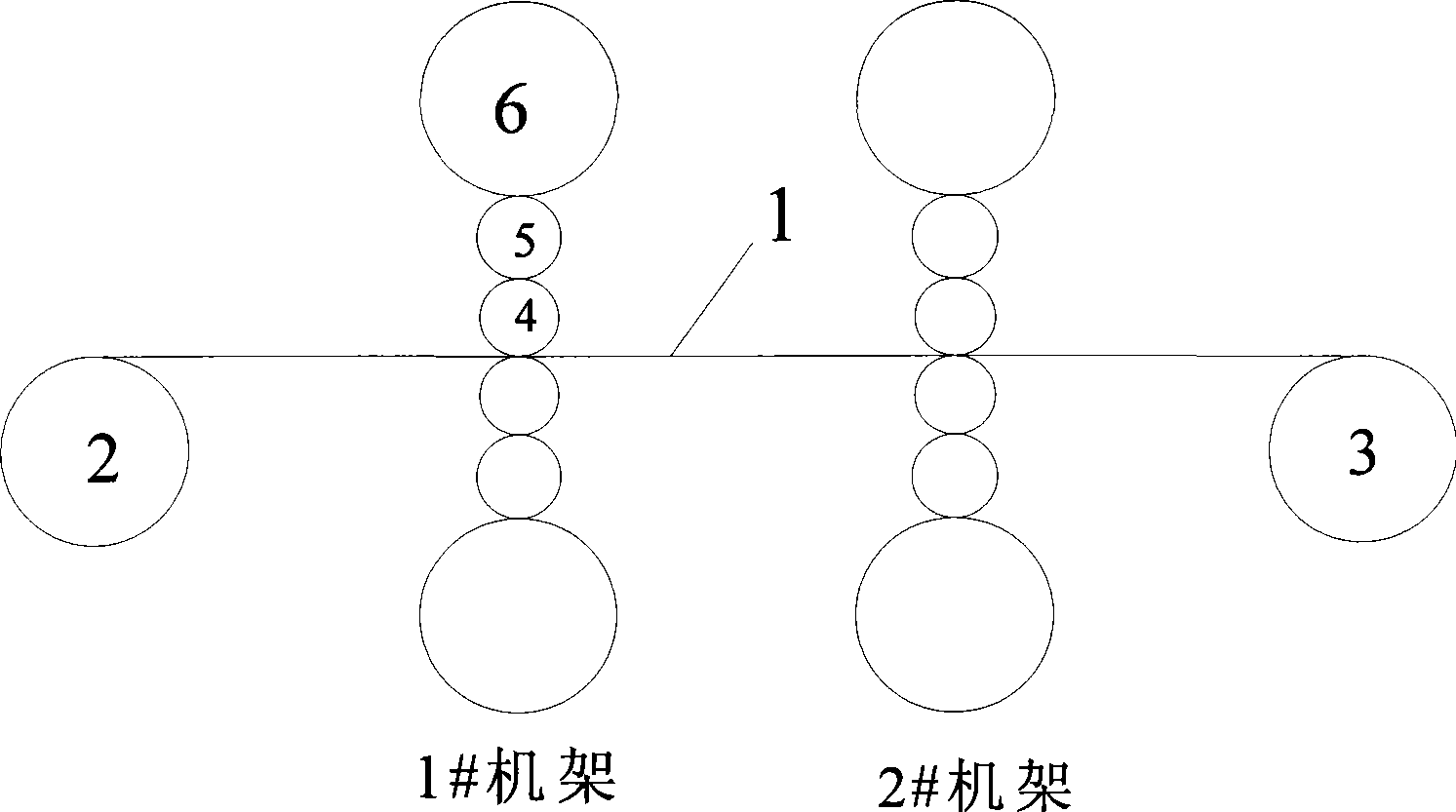

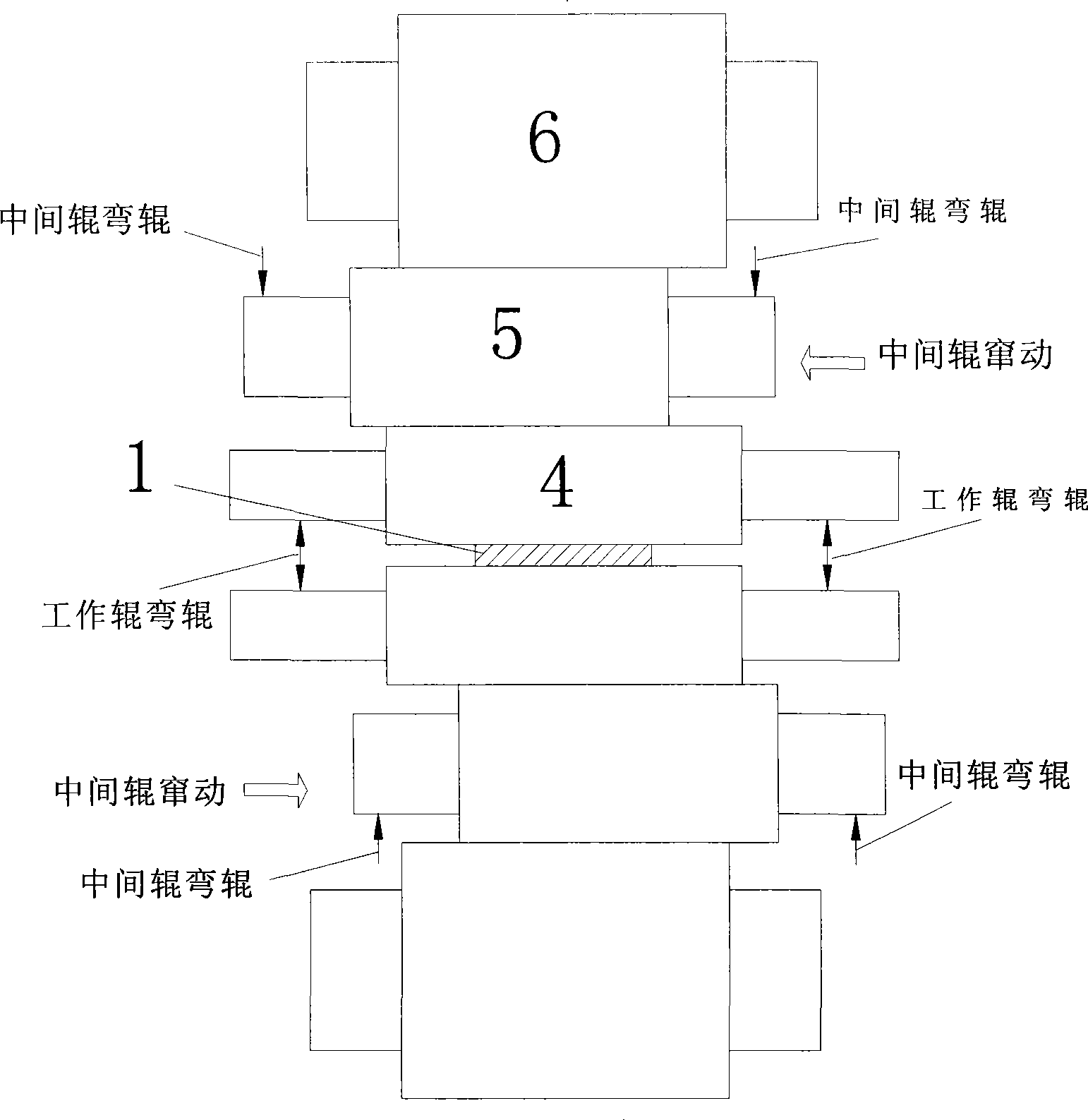

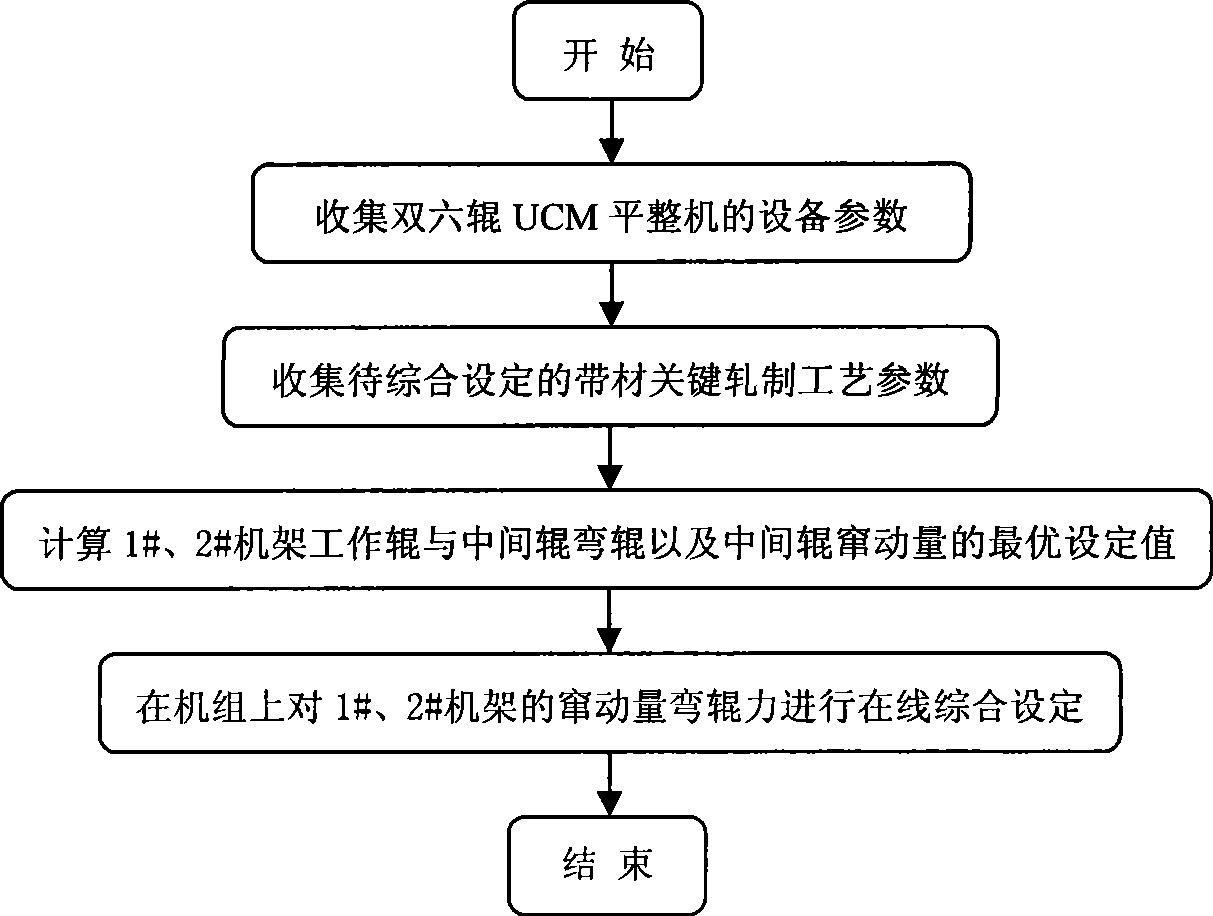

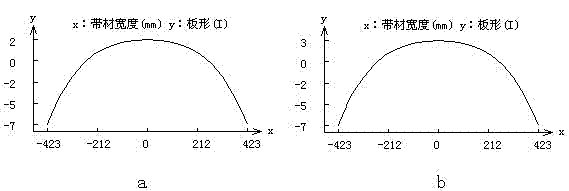

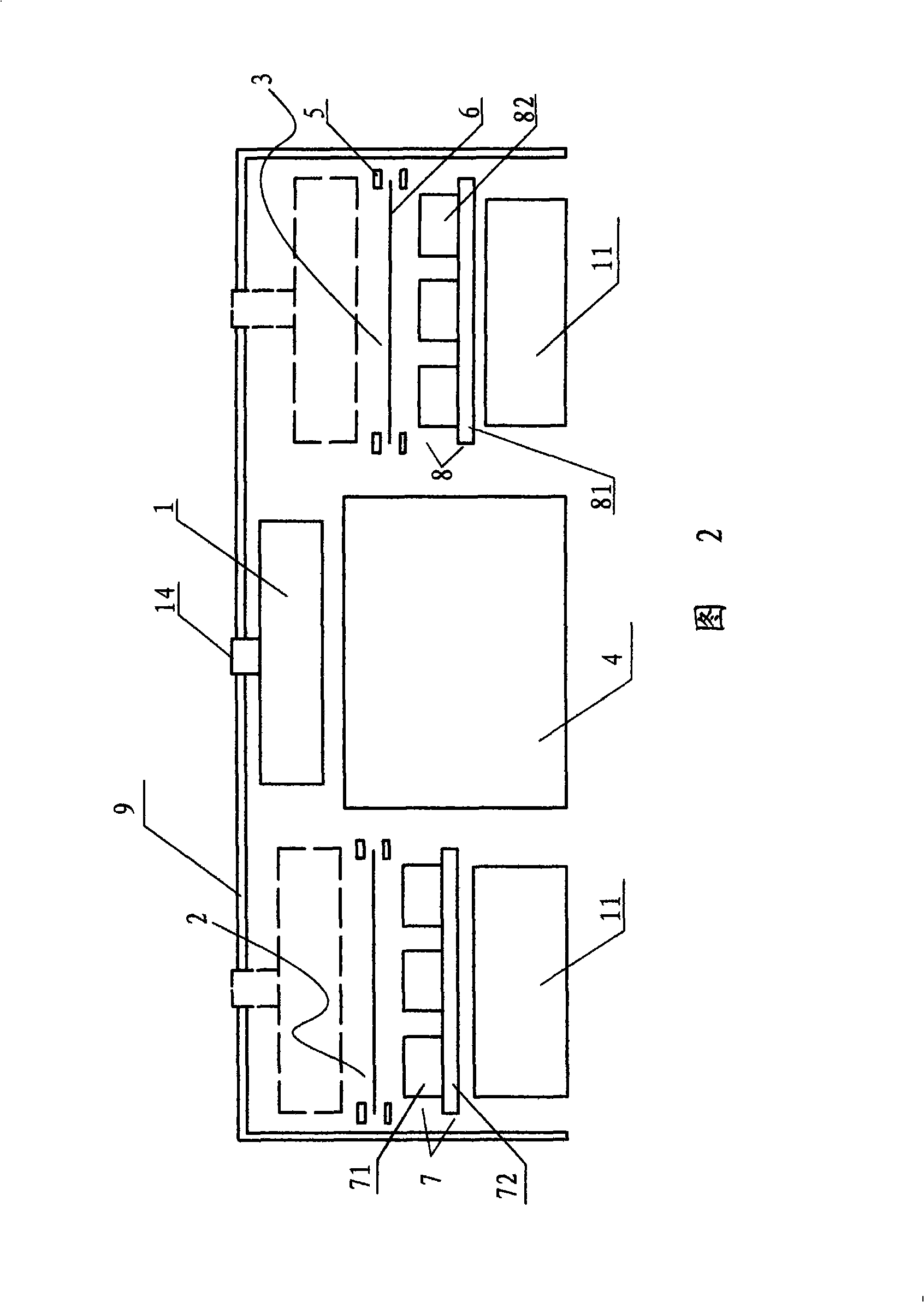

Integrated control method of double-six roller UCM type flattening machine group plate shape

InactiveCN101412043AGuaranteed Coordinated ControlExtended service lifeProfile control deviceNumerical controlWork rollEconomic benefits

The invention discloses a method for comprehensively controlling a plate shape of a double six-roller UCM model temper mill unit. The method is characterized by comprising the following steps: a. collecting equipment parameters of the double six-roller UCM model temper mill unit; b. collecting key rolling technology parameters of a strip material to be comprehensively set; c. calculating optimum setting values of working rolls of 1# frame and 2# frame, ,roll bending of an intermediate roll and movement of the intermediate roll; and d. carrying out comprehensive setting to roll bowing force of the movement of the 1# frame and the 2# frame on the unit according to calculated optimum movement and comprehensive setting value of the roll bowing force. The comprehensively controlling method provided by the invention not only can improve controllability to the plate shape by the roll bending of the working roll and the intermediate roll of the double six-roller UCM model temper mill unit, movement of the intermediate roll and other plate shape control modes, bring full play of roll bending and movement and improve the plate shape quality of a finished product, but also can improve the service life of a roller, and reduce roll consumption, so as to bring significant economic benefit for company.

Owner:YANSHAN UNIV

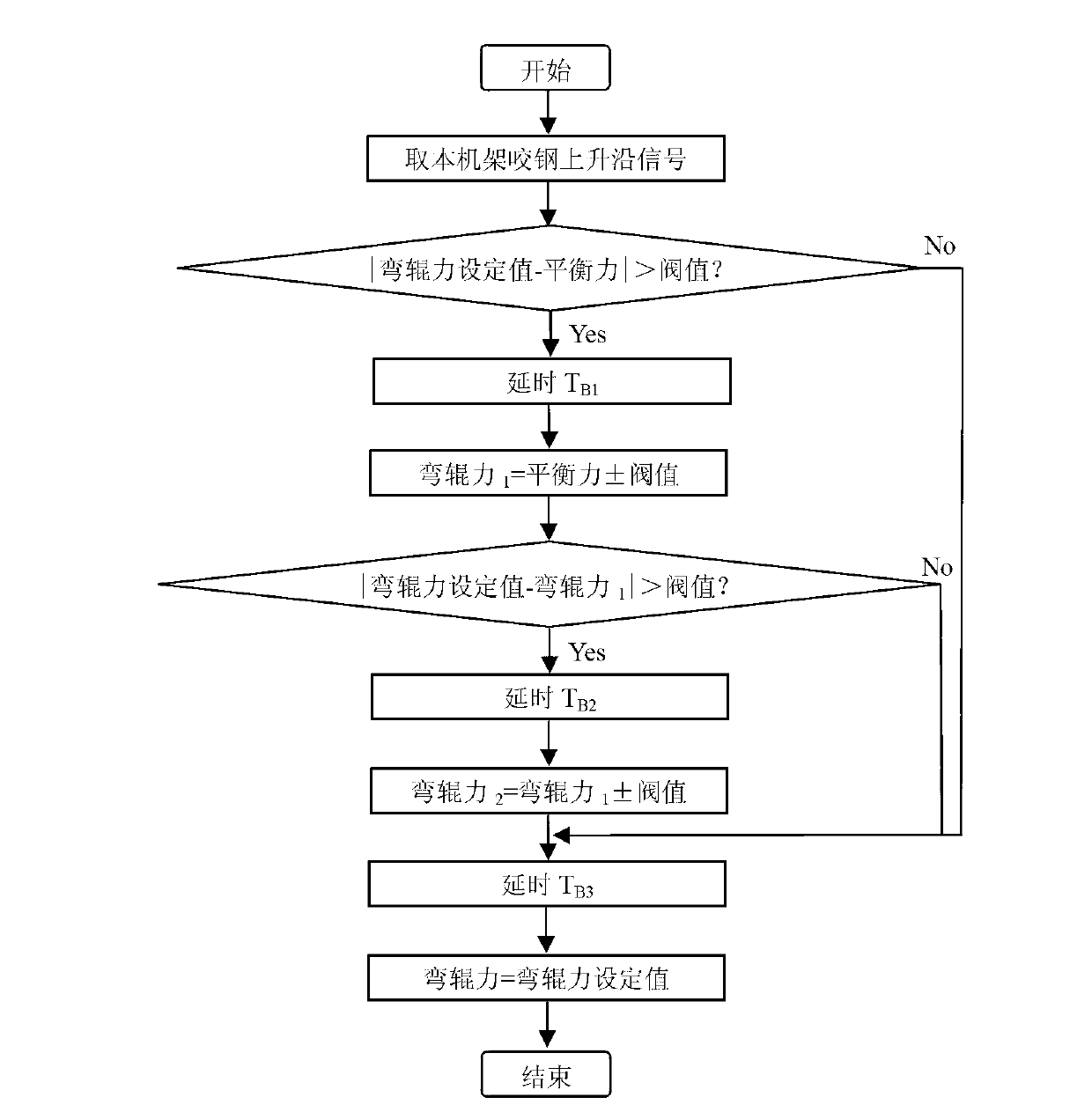

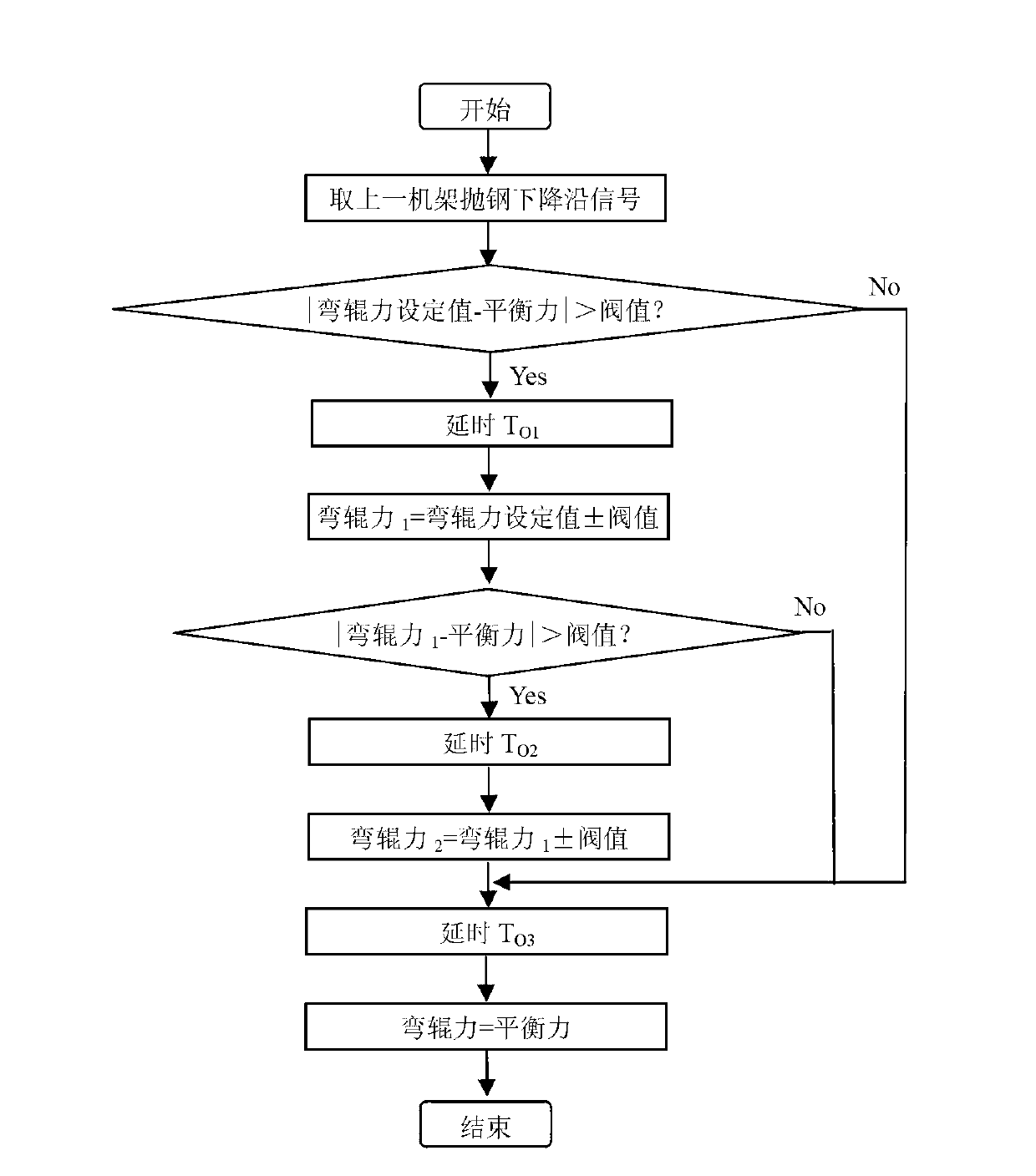

Method for controlling head and tail shapes of hot-rolled strip steel

ActiveCN102989787APrevent shape deterioration etc.Improve shape qualityRare end control deviceStructural engineeringStrip steel

The invention provides a method for controlling the head and tail shapes of hot-rolled strip steel. For the control on the head shape of strip steel, the smooth switching between the balancing and roll bending of a rack is controlled through a steel biting rising edge signal of the rack; and for the control on the tail shape of the strip steel, the smooth switching between the roll bending and balancing of a follow-up rack is controlled through a steel throwing falling edge signal of an upstream rack. According to the invention, through the reasonable design on a hydraulic balancing and roll bending control scheme of a working roll of a rear finishing mill, phenomena such as the head and tail shapes of strip steel are deteriorated due to the instantaneous switching between balancing and roll bending, and the like can be effectively prevented, thereby improving the quality of head and tail shapes of the strip steel, avoiding the occurrence of creasing and strip breakage accidents, and reducing the production cost.

Owner:ANGANG STEEL CO LTD

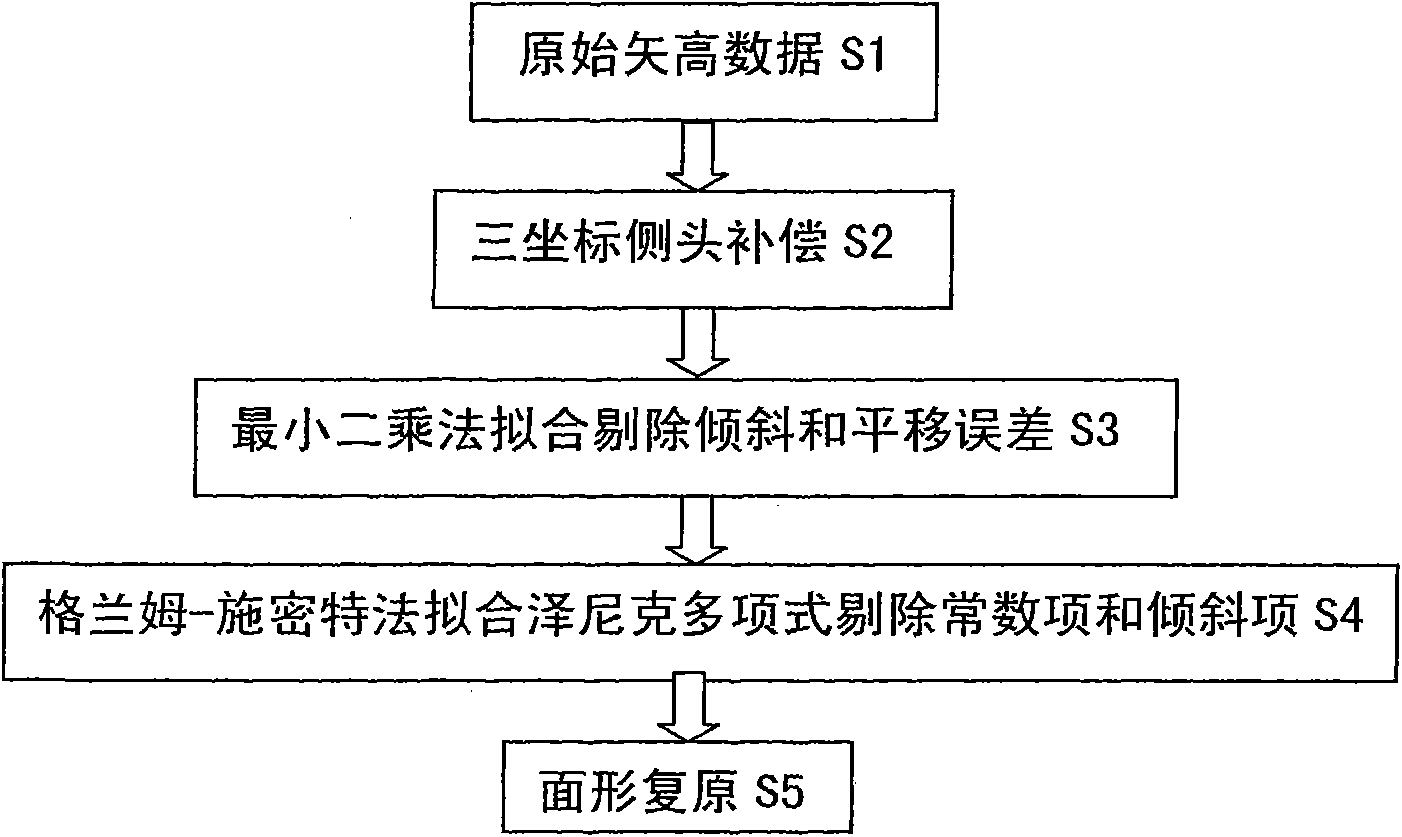

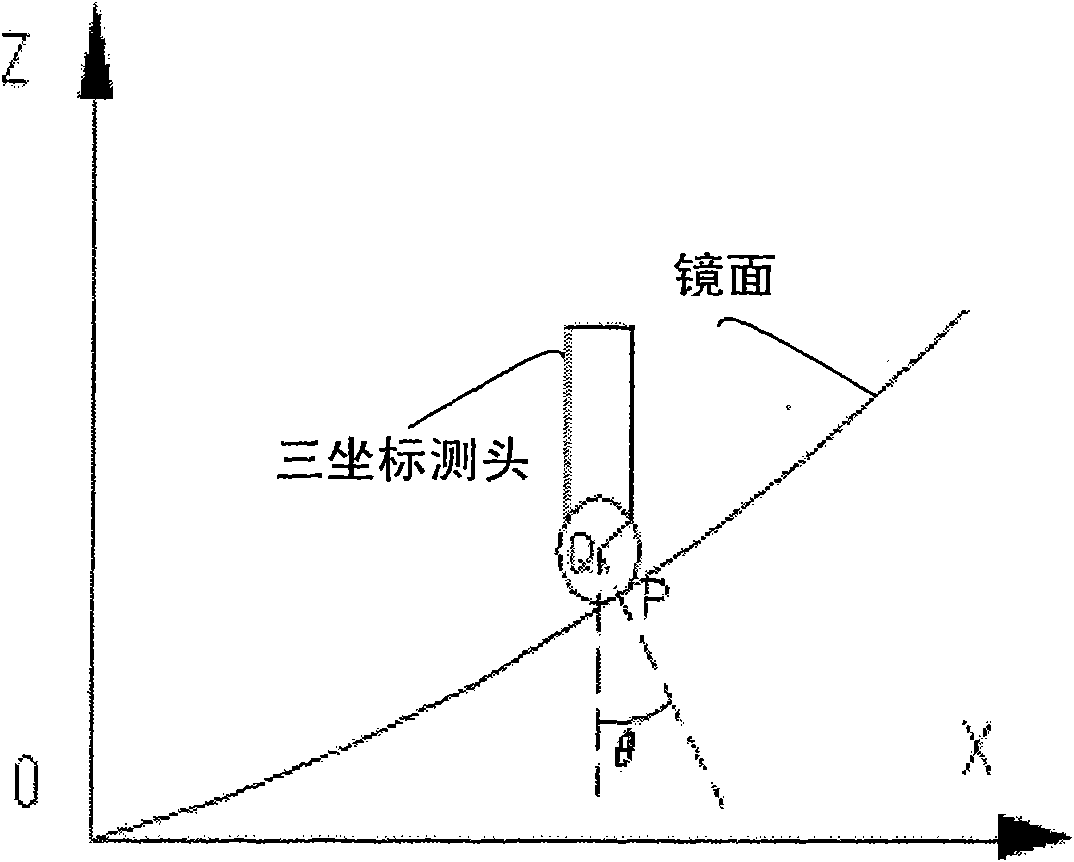

Method for detecting large-caliber aspheric optical element by utilizing three-coordinate measuring machine

InactiveCN101943559AAssess surface qualityImprove shape qualityMechanical measuring arrangementsInformation processingCoordinate-measuring machine

The invention relates to a method for detecting a large-caliber aspheric optical element by utilizing a three-coordinate measuring machine, which comprises the following steps of: processing the data obtained by the three-coordinate measuring machine by utilizing an information processing technology, carrying out error compensation on the measuring head of the three-coordinate measuring machine by adopting a method for compensation by utilizing the measuring head, eliminating the tilting and translation errors of detected data by utilizing a least square method, eliminating the constant term and the tilting term after surface shape data Zernike polynomial fitting by a Gram-Schmidt orthogonalization method, and restoring the surface shape of the detected large-caliber aspheric optical element to realize the purpose of high-precision three-coordinate measurement of the large-caliber optical element. The invention comprehensively considers the error source of the three-coordinate measuring machine of the detected large-caliber aspheric optical element, so that the surface shape quality of the optical element can be more truly and objectively evaluated. The invention is used for processing the surface shape measurement error of the optical element by adopting the measuring-head compensation and least square methods and has important application value for the surface shape detection of the high-precision large-caliber optical element.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Continuous variational convexity degree rolling mill back-up shaft

InactiveCN101229560AExtended service periodImprove roll gap lateral stiffness characteristicsCounter-pressure devicesMetal rolling arrangementsContact pressureWork roll

The invention provides a continuously variable crown mill support roll to be matched with a roll curve of a continuously variable crown work roll. The roll shape is skew asymmetrical curve which essentially consists of a roll gap whole line contact curve section in the range of the strip width at the middle of the roll body and a contact line variable curve section at two ends of the roll; and the roll shape curves of an upper support roll and a lower support roll are the same but are arranged reversedly in an angle of 180 degrees The continuously variable crown mill support roll with the roll shape curve and the mill roll system with the continuously variable crown work roll can not only reduce uneven distribution and peak of the contact pressure between the roll, reduce or eliminate side spalling of the continuously variable crown mill support roll with normal crown, improve service cycle and service life of the support roll and reduce roll consumption of the support roll, but also overcomes harmful contact zone outside the rolled strip width and improves roll gap lateral rigidity of the mill and plate shape control efficiency of bending force, thereby improving plate shape quality of the rolling strip.

Owner:武汉钢铁有限公司 +1

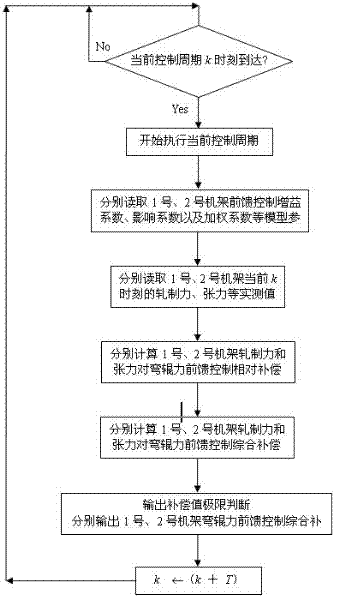

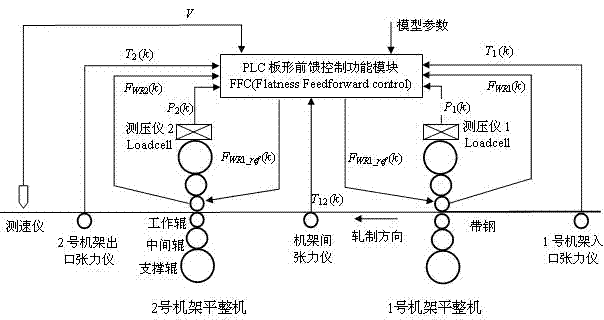

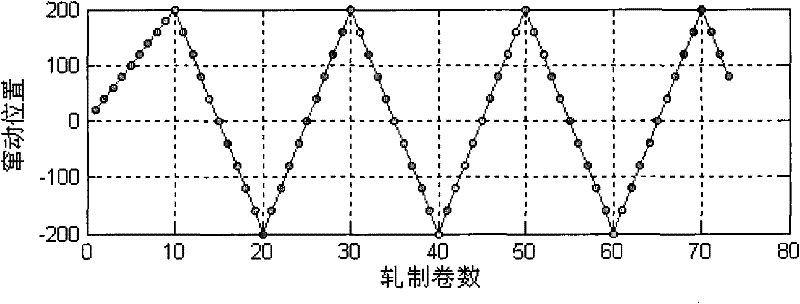

Control method for strip shape in rolling of cold-rolling strip steel by two-stand temper mill

The invention relates to a rolling method of cold-rolling strip steel, in particular to a feedforward control method of cold-rolling strip steel strip shape on a two-stand temper mill. A control method for the strip shape of the two-stand temper mill of the cold-rolling strip steel conducts feedforward control compensation for working roll bending force or intermediate roll bending force of two stands separately to reduce the combined impact of temper rolling force and tensile force on the strip steel strip shape in the processes of acceleration and deceleration on the basis of conventional strip shape feedback control centered on No. 2 stand, and based on the variation of the actual measured temper rolling force of the two stands, the tension of stand entry, the tension between stands and the tension of stand exit. The control method on the one hand improves the strip shape quality of the strip steel after the strip steel is rolled, and on the other hand enhances the stability in the process of temper rolling.

Owner:BAOSHAN IRON & STEEL CO LTD

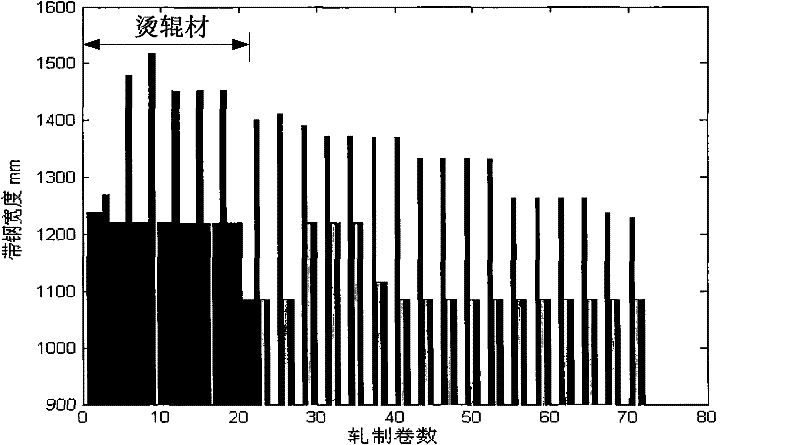

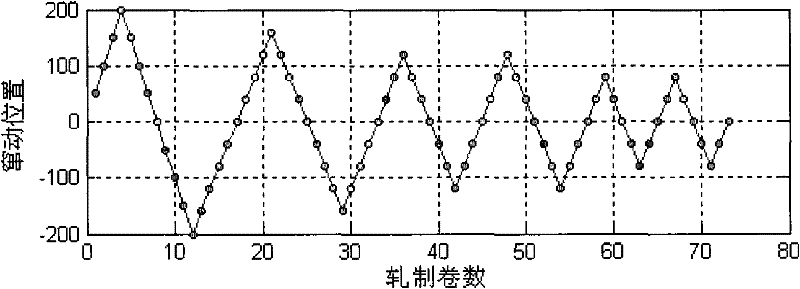

Hot rolling flat roller play control method

ActiveCN102161052AImprove shape qualityMetal rolling stand detailsRolling safety devicesStrip steelEngineering

The invention discloses a hot rolling flat roller play control method which provides more specific roller play strategies for different tandem rolling plans. The play control method includes the steps of classifying all strip steels of a rolling plan into two categories, a wide plate and a narrow plate, based on a critical width; as to the narrow plate, calculating the roller play positions of all the strip steels in a recursion mode, and then extracting the roller play position of the narrow plate; as to the wide plate, determining a permitted variation range of each roller play position, building an objective function for evaluating the sectional shape of the strip steel based on the rolling plan, and then optimally calculating the roller play position of the wide plate by employing the genetic algorithm. The hot rolling flat roller play control method breaks through the conventional roller play mode by providing more specific roller play strategies for different tandem rolling plans. The strip steels are classified into the wide plate and the narrow plate, and the narrow plate is calculated in a recursion mode, while the wide plate is optimally calculated by the genetic algorithm. Thus, the hot rolling flat roller play control method plays an active role in improving the quality of the strip shape of the tandem rolling strip steel.

Owner:BAOSHAN IRON & STEEL CO LTD

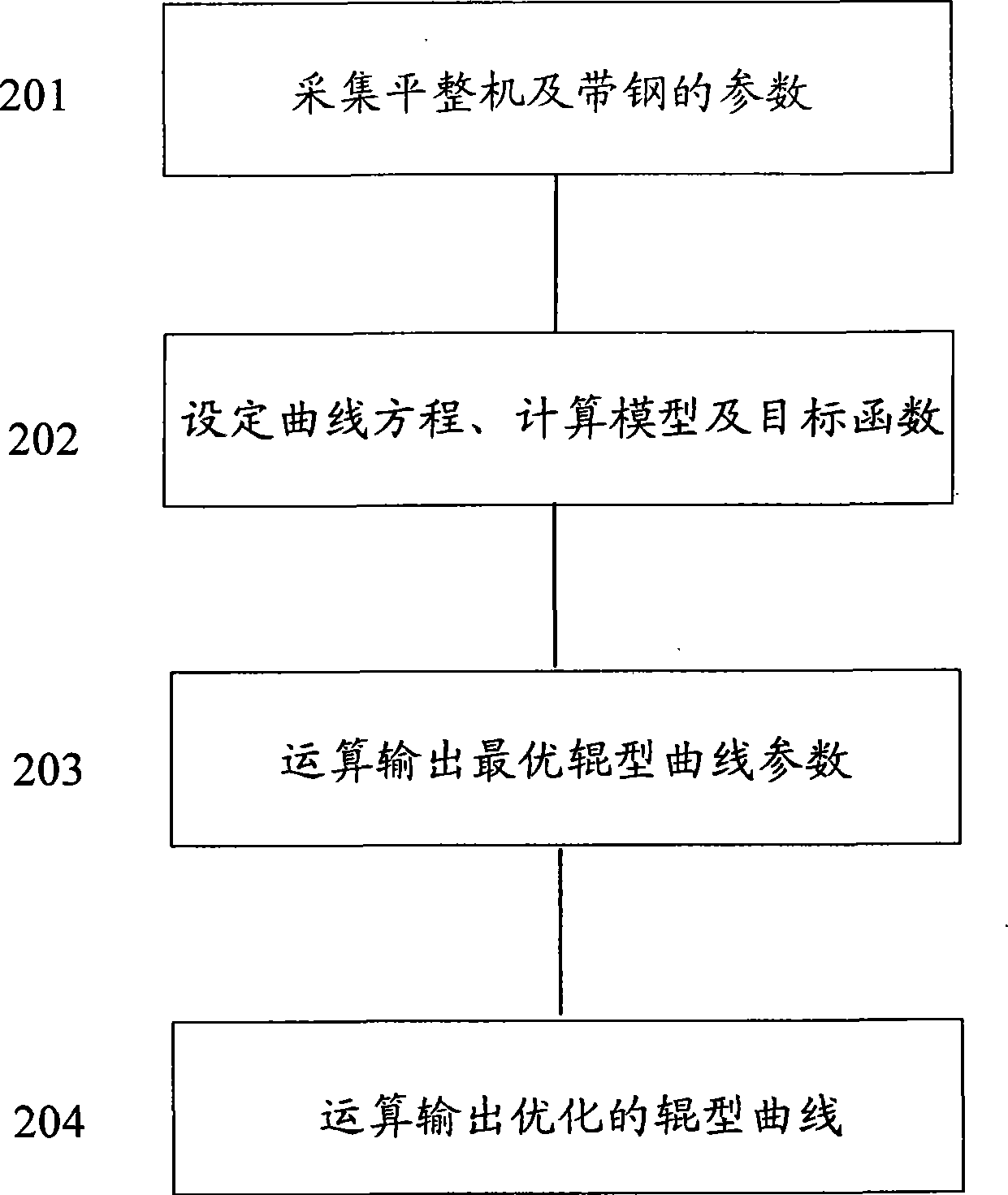

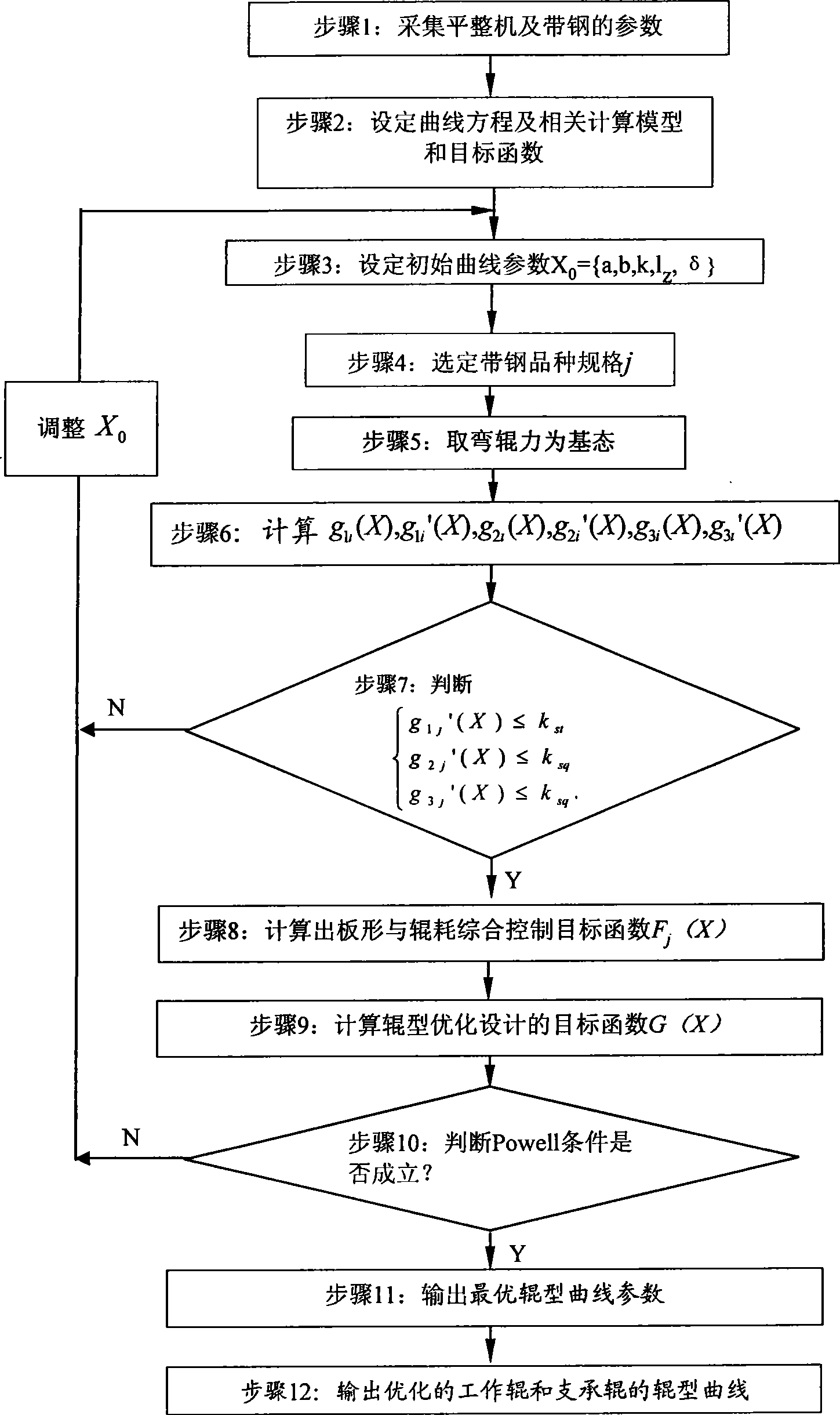

Roll-shaped curve design method of high-strength steel temper mill

ActiveCN101477579AImprove shape qualityReduce work roll consumptionSpecial data processing applicationsMathematical modelPeak value

The invention discloses a method for designing a roller curve of a high-strength steel leveling machine, which comprises the following steps: collecting parameters of steel in the leveling machine, setting a curvilinear equation and a related computation model and an objective function, inputting the related parameters into the curvilinear equation, the computation module and the objective function, obtaining the optimal parameters of the roller curve, and further obtaining the optimal roller curve of a working roller and a supporting roller. The method for designing the roller curve is characterized in that all the front tension, the rolling pressure and the pressure among rollers are transversely and evenly distributed and adopted as the optimal objective function at the first time, and peak values of the front tension, the rolling pressure and the pressure among rollers are restrained at the same time, a set of new mathematical models optimally designed of the curve of the high-strength steel roller is established, and applicable roller curves of the working roller and the supporting roller are designed; therefore, the quality of the shape of a plate and a strip after leveling is greatly improved, the roller loss of the working roller is reduced, the phenomena of 'gnawing shoulders' and 'losing weight' of the supporting roller are eliminated, and the occurrence probability of accidental roller replacement is reduced to the maximum.

Owner:BAOSHAN IRON & STEEL CO LTD

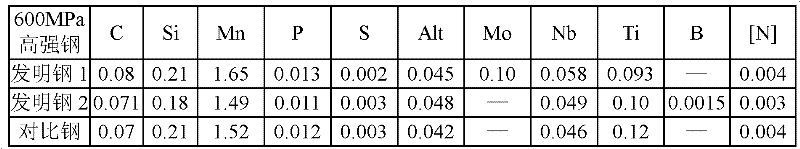

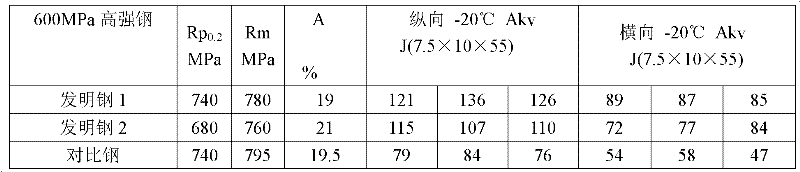

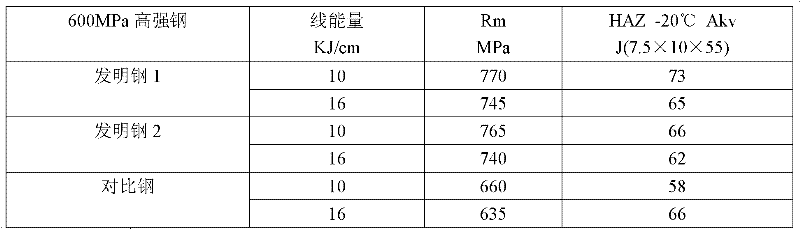

Low-temperature steel for engineering machinery and production method thereof

InactiveCN102409233AImprove high heat input welding performanceImprove toughnessTemperature control deviceHeat-affected zoneMechanical property

The invention relates to low-temperature steel for engineering machinery and a production method thereof. The steel is suitable for higher heat input welding and comprises the following chemical components by weight percent: 0.06-0.08% of C, 0.15-0.25% of Si, 1.6-1.9% of Mn, 0.05-0.07% of Nb, 0-0.30% of Mo, 0-0.0020% of B, 0.08-0.14% of Ti, 0.01-0.06% of Al, not more than 0.02% of P, not more than 0.010% of S, not more than 0.008% of N and the balance of Fe and inevitable impurities. The production method is characterized by controlling the heating temperature, precision rolling inlet temperature, finish rolling temperature, finished cooling temperature and annealing temperature. The material can ensure the transverse universal coiling impact energy at minus 20 DEG C to be more than 47J, and meanwhile, the HAZ (heat affected zone) strength and toughness of the steel plate can meet the mechanical property requirements of the base metal under 20KJ / cm welding property energy.

Owner:SHOUGANG CORPORATION

Setting method and device for roll bending force of six-roller cold-rolling mill

InactiveCN106216409AImprove setting calculation accuracyImprove shape qualityProfile control deviceEngineeringBending force

Owner:CISDI ENG CO LTD

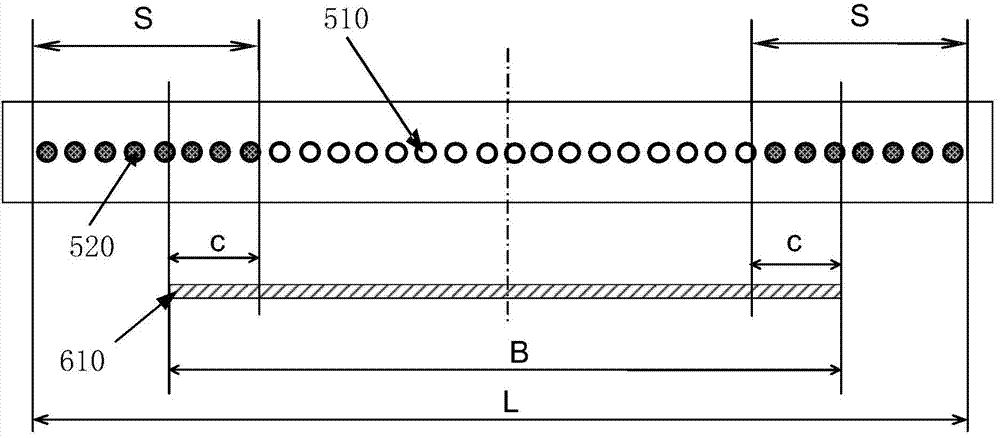

Method for controlling straightness of hot-rolling strip steel by changing spraying width of cooling water

ActiveCN104741389AChange spray widthControl flatnessWork cooling devicesProfile control deviceStrip millStrip steel

The invention discloses a method for controlling straightness of hot-rolling strip steel by changing the spraying width of cooling water, and relates to control equipment or a control method special for a metal rolling machine or a machined product of the metal rolling machine. The method is used for a laminar flow cooling system of a hot rolling line. The method comprises the following steps: according to the width B (unit mm), the edge wave width c (unit mm) and the equipment total cooling width L (unit mm) of a strip steel product, on the basis of a formula that S is equal to L-b+c, a single-side shelter width S is determined, and the spraying width of the cooling water is changed by blocking header nozzles of a corresponding cooling header. According to the method, nozzles on the two sides of the cooling header within a certain range are blocked, and the spraying width of the cooling water is changed; the straightness of the hot-rolling strip steel can be effectively controlled, and the method can adapt to changes of a product width; and the strip shape quality and the product yield are improved. The method is used for transformation of an existing hot rolling line, strip steel transverse temperature uniformity in the cooling process can be effectively improved, meanwhile, a heater or a baffle device can be omitted, and transformation cost of the hot rolling line is saved.

Owner:BAOSHAN IRON & STEEL CO LTD

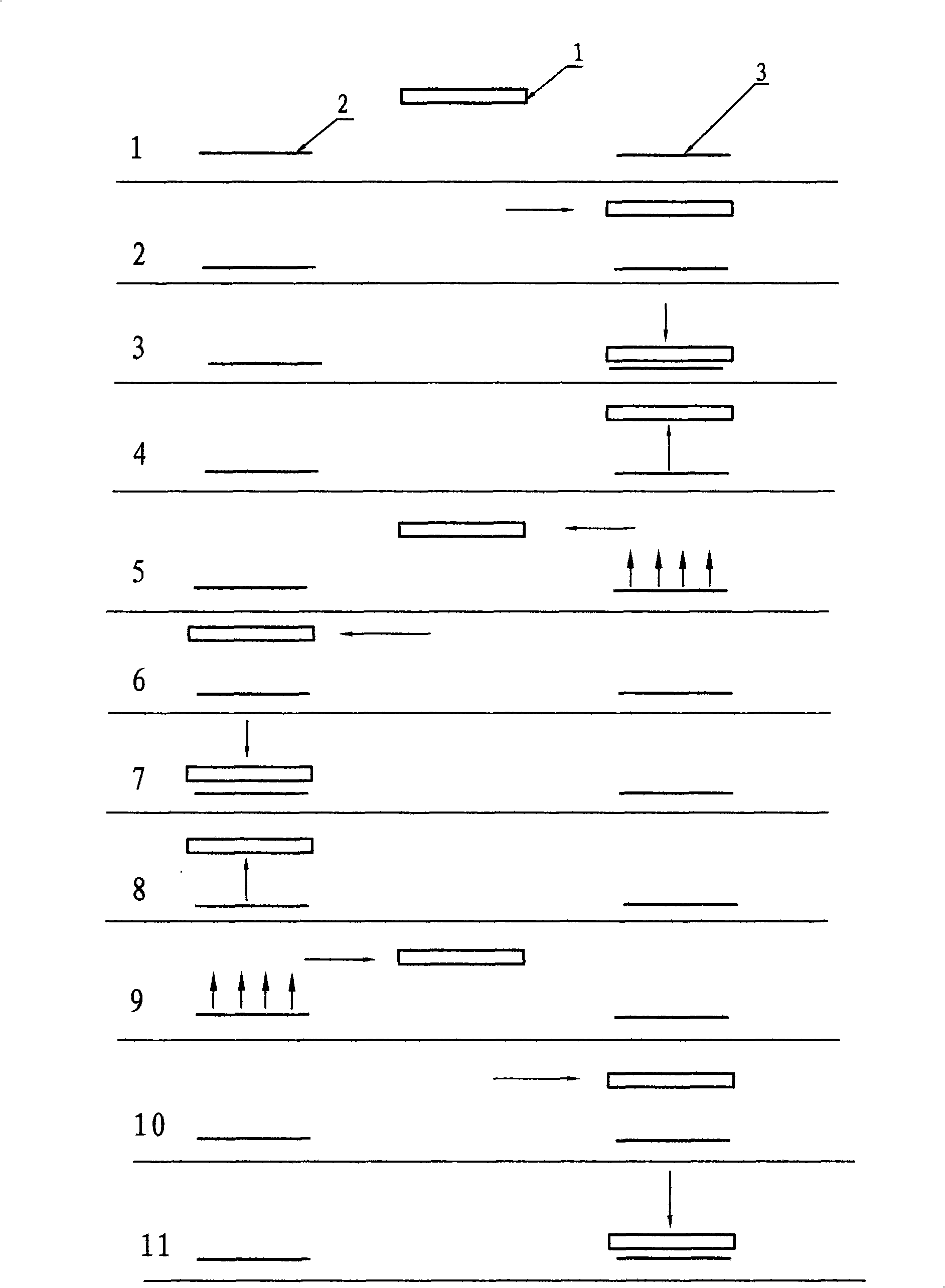

Efficient double-line suction plastic production method and device

The invention provides a high-efficiency dual-line plastic suction production method, comprising the steps as follows: 1) a bidirectional movable plastic suction heating furnace is arranged; the left side and the right side right below the plastic suction heating furnace are respectively provided with a set of vacuum forming processing line; 2) the plastic suction heating furnace is moved to the initial position and electrified to a given temperature, and the temperature is kept; 3) after the plastic suction heating furnace is transversely moved to one side right above the hot forming working position of the vacuum forming processing line, the plastic suction heating furnace vertically runs downwards to a given height H1 and remained for the time t1 so as to heat the material on the side of the processing line hot forming working position; 4) after the prearranged heating time t1 is reached, the plastic suction heating furnace runs upwards vertically and recovers transversely, and stops for a time t3; 5) the plastic suction heating furnace is moved to another processing line, runs downwards vertically by a height H2 and stops for a time t2; 6) the plastic suction heating furnace runs upwards vertically, transversely recovers and stops for a time t4; 7) the step 3) to step 6) are repeated. The invention also discloses a device which realizes the method of the invention.

Owner:DONGGUAN FUCAI PACKAGING PROD

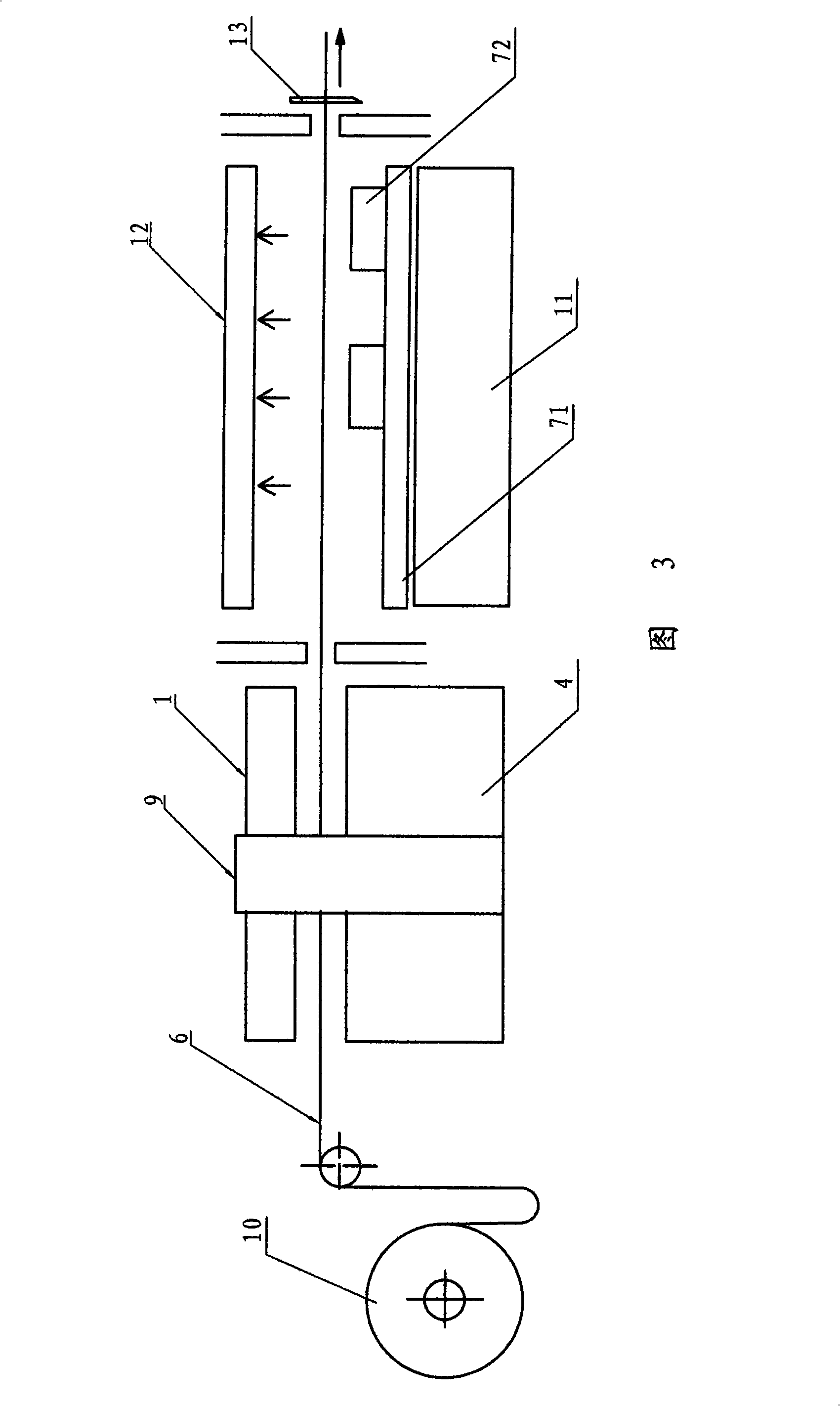

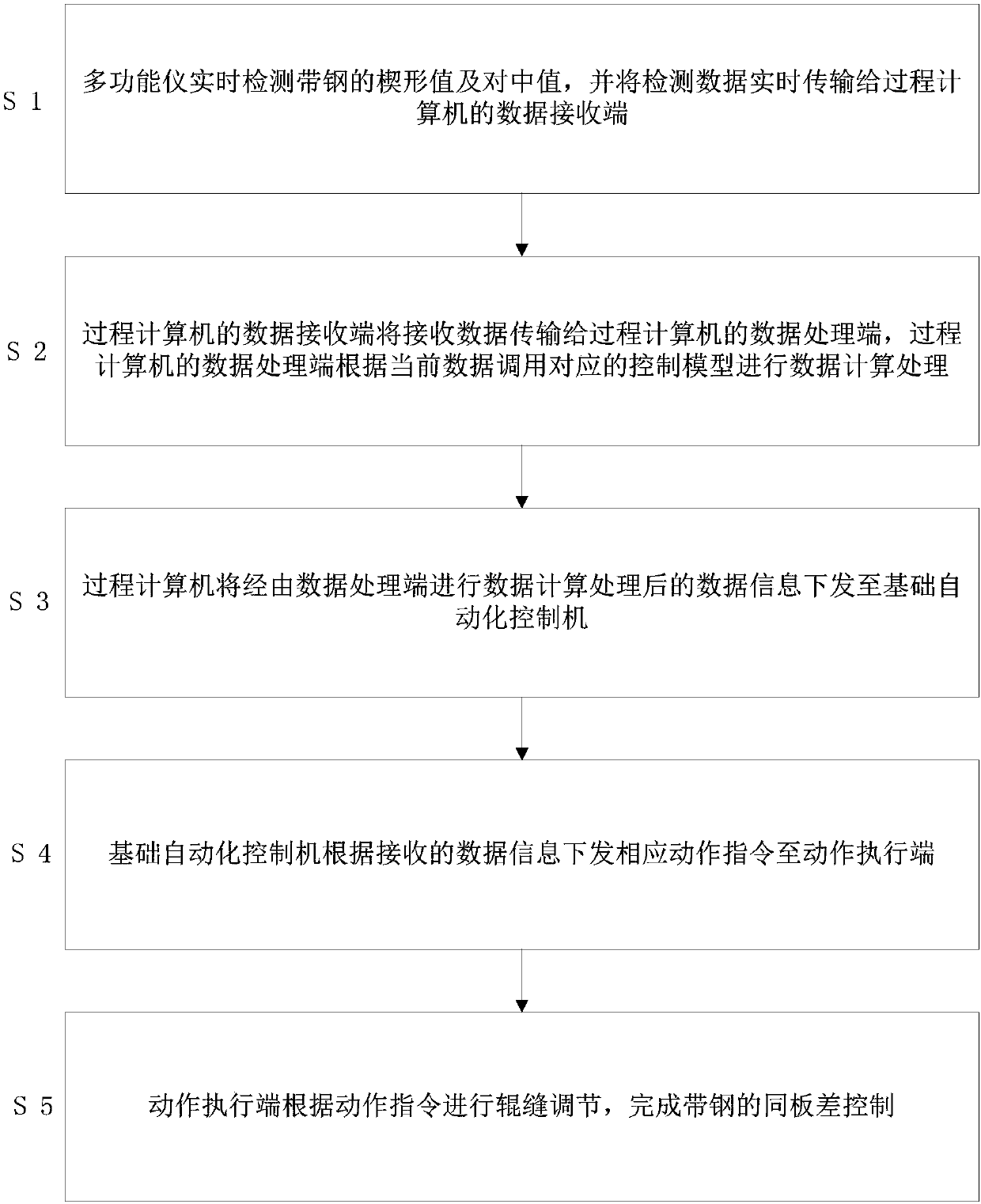

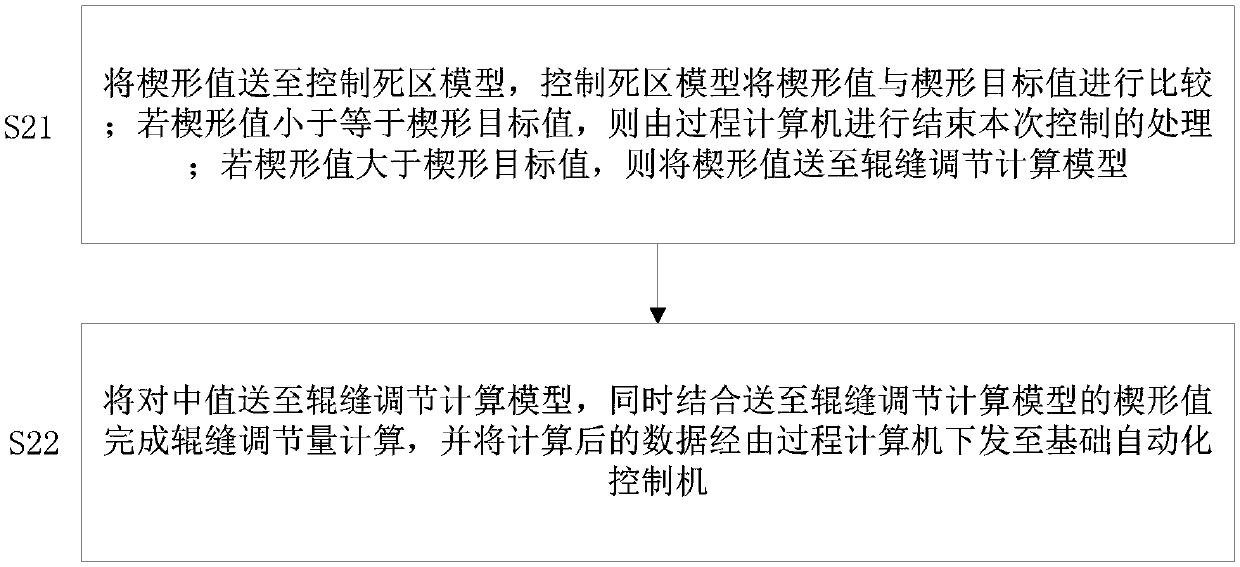

Wedge shape control system and method with off-tracking protection function

ActiveCN109570241AGuaranteed Full Length WedgeImprove stabilityRoll force/gap control deviceMetal rolling stand detailsAutomatic controlControl system

The invention provides a wedge shape control system and method with an off-tracking protection function. In order to control the intra-plate deviation in the rolling process of strip steel, through aprocess computer, a basic automatic control machine, a multifunctional instrument and a corresponding action executing end, roll gap control, with centering as the datum, of bending rolls is built forracks at a finish rolling outlet. According to the wedge shape control system and method with the off-tracking protection function, the single-side rolling reduction of all the finish rolling racks is real-timely dynamically adjusted according to the deviation between a wedge shape value detected by the multifunctional instrument, and a target wedge shape value to ensure that the overall-length wedge shape of the strip steel is in a certain interval; and meanwhile, in the real-time dynamic adjusting process, an adjusting model taking centering as the datum, synthesizing four elements of rolling mill rigidity, plastic deformation, thickness and width and constituted according to the regression thought is built by considering centering data of the finish rolling outlet, overall balance adjusting is carried out according to the model, wedge shape rolling and the final strip steel wedge shape are improved, and meanwhile rolling stability of hot rolling and plate shape quality of a strip steel product are improved.

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com