Patents

Literature

124results about How to "Extended service period" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

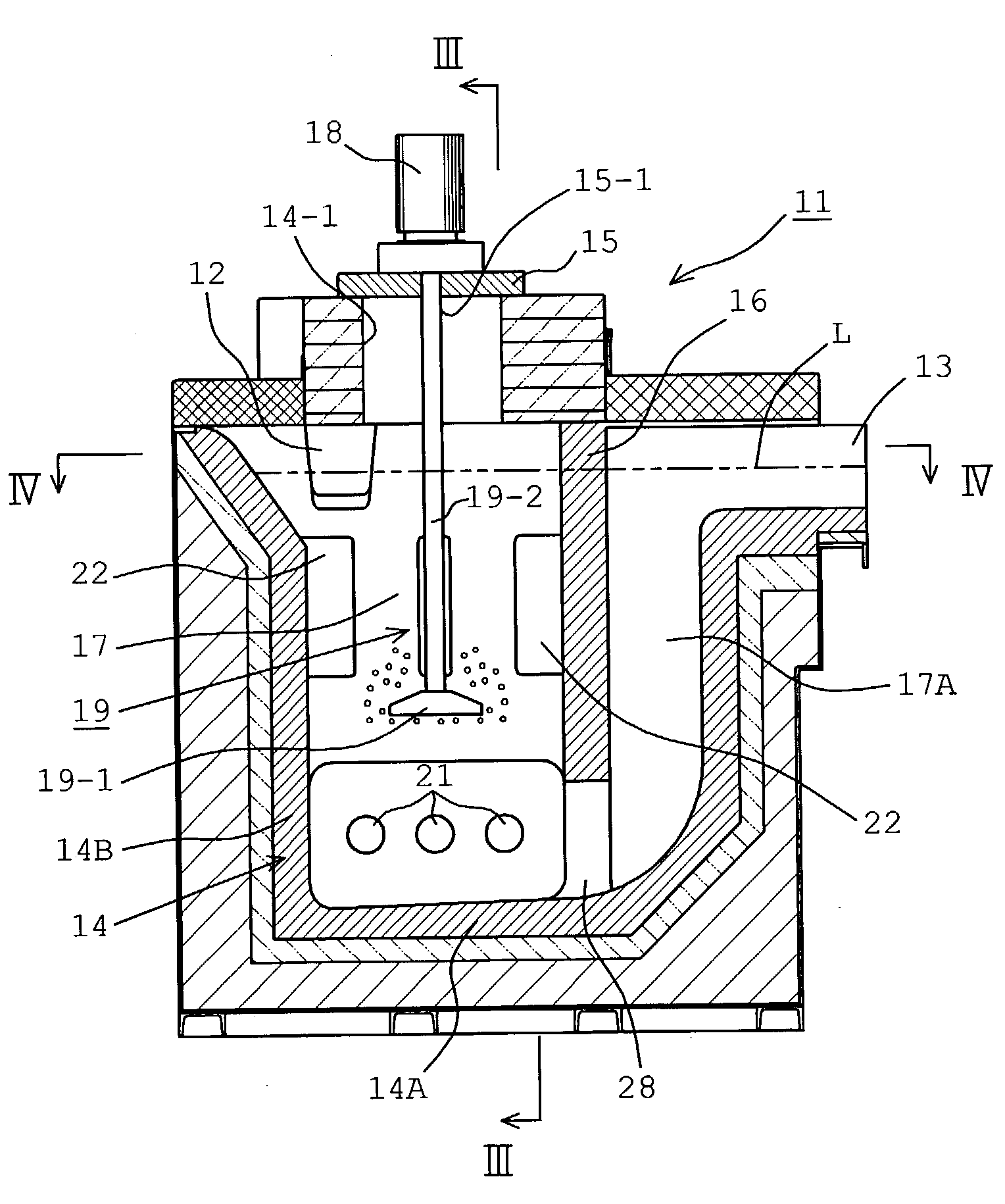

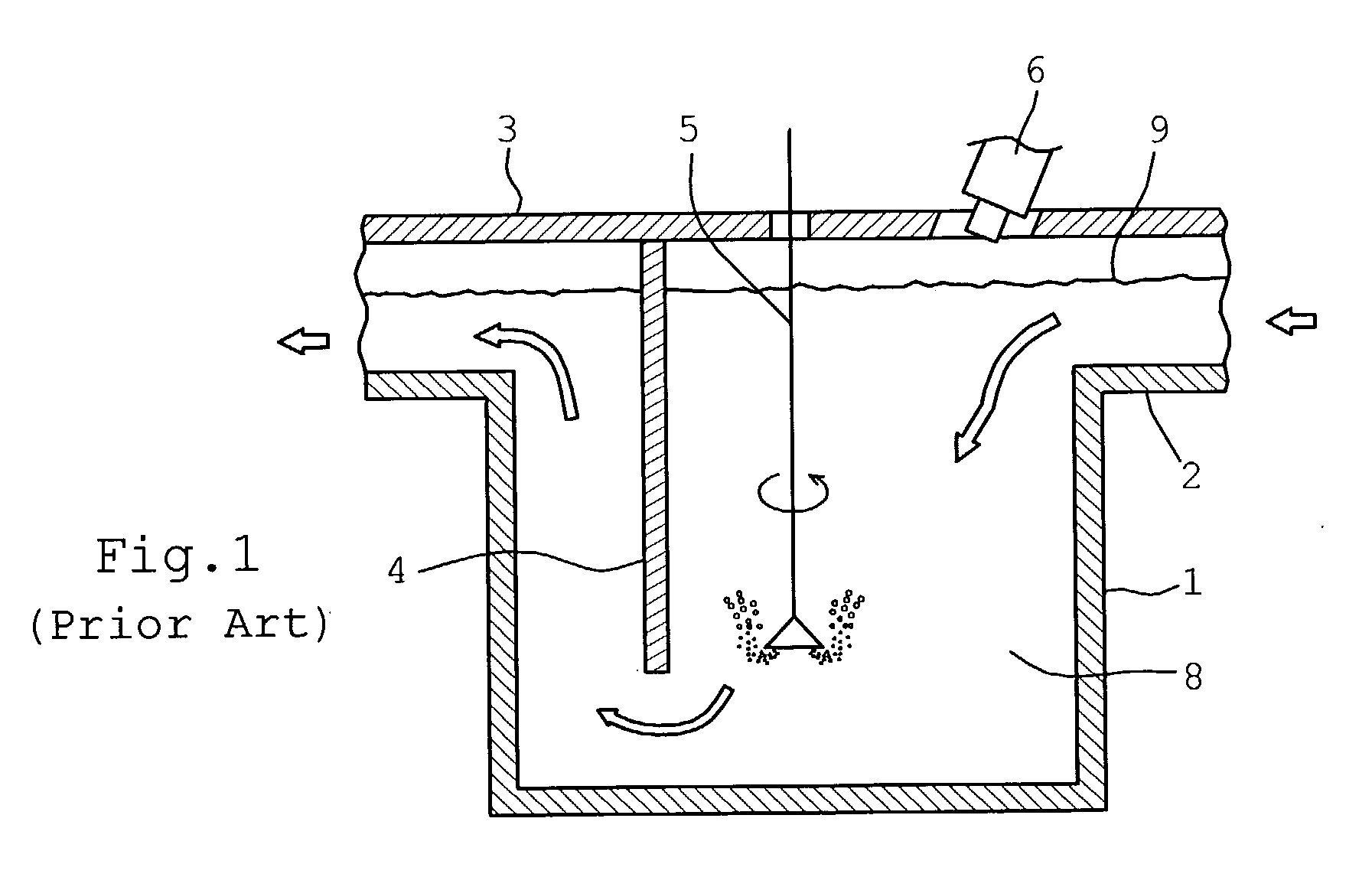

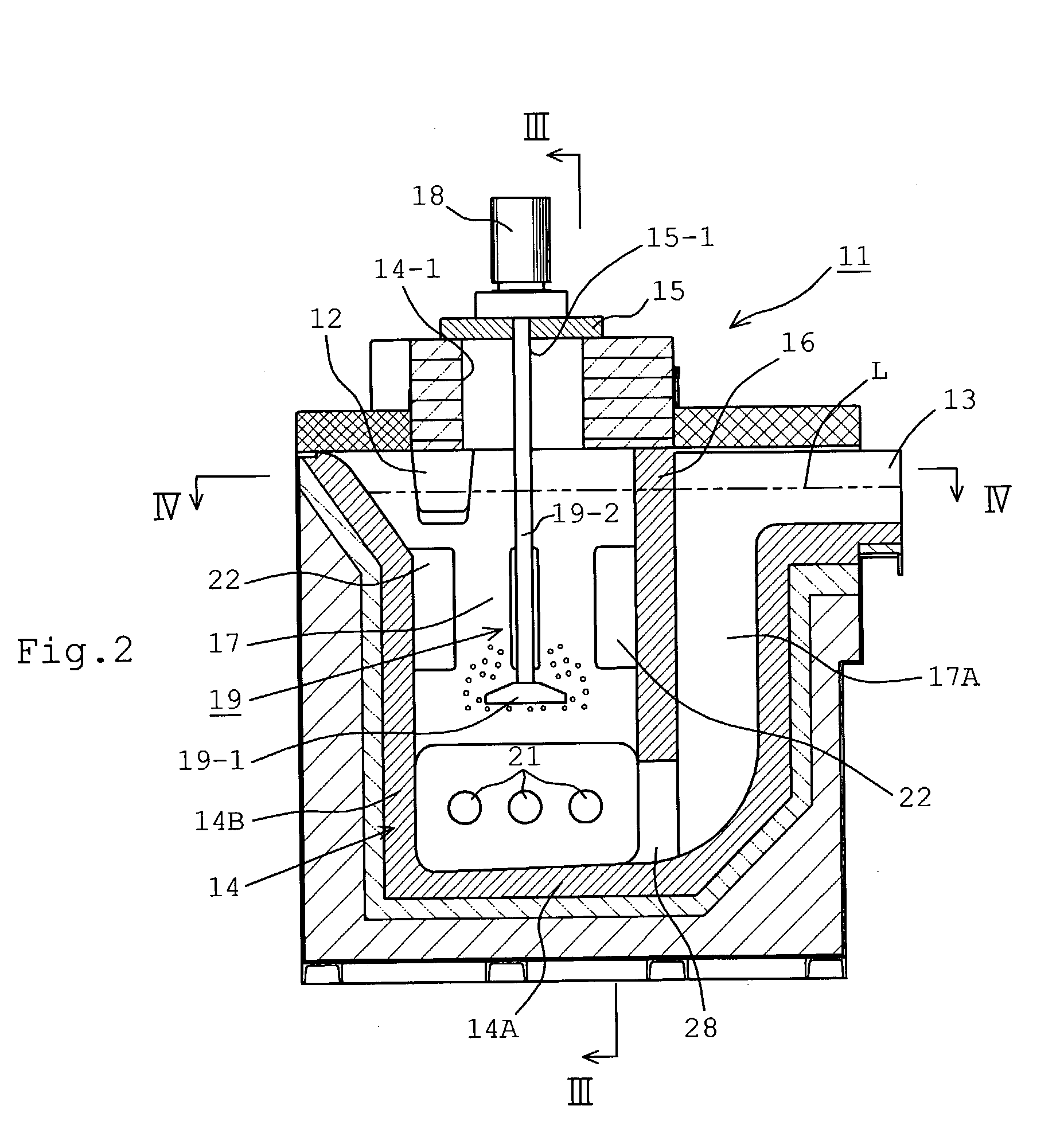

Inline degassing apparatus

InactiveUS20030151176A1Chance of damageExtended service periodMelt-holding vesselsStirring devicesNon-metallic inclusionsProduct gas

An inline degassing apparatus for removing solid solution gases as well as nonmetallic inclusions from molten metal in a degassing container, to which the molten metal is continuously introduced for degassing operation and from which the degassed molten metal is continuously removed. A rotary diffusing device is arranged in the degassing container for generating bubbles of inert gas diffused into the molten metal, thereby entrapping solid solution gases as well as nonmetallic inclusions into the bubbles, which are then floated and separated. Heaters are provided, which extend, in a cantilever fashion, from a side wall of container at a position adjacent the bottom wall of the container substantially parallel to the bottom wall.

Owner:PYROTEK JAPAN +1

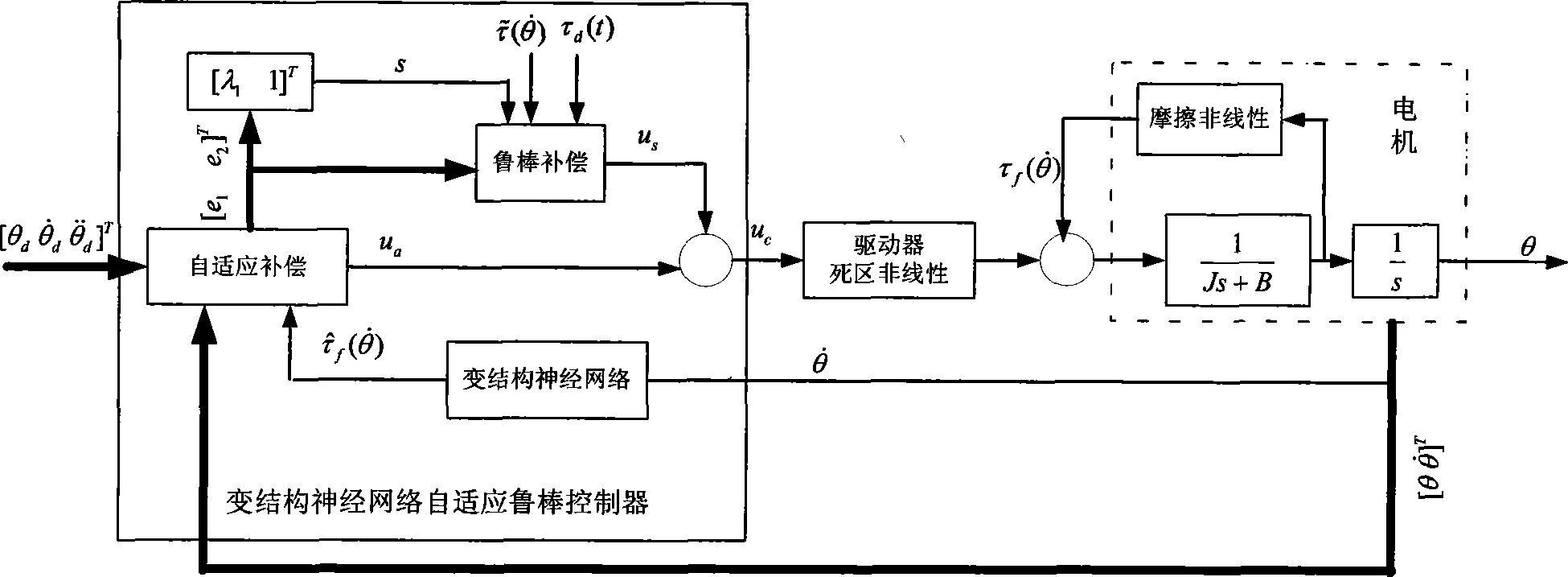

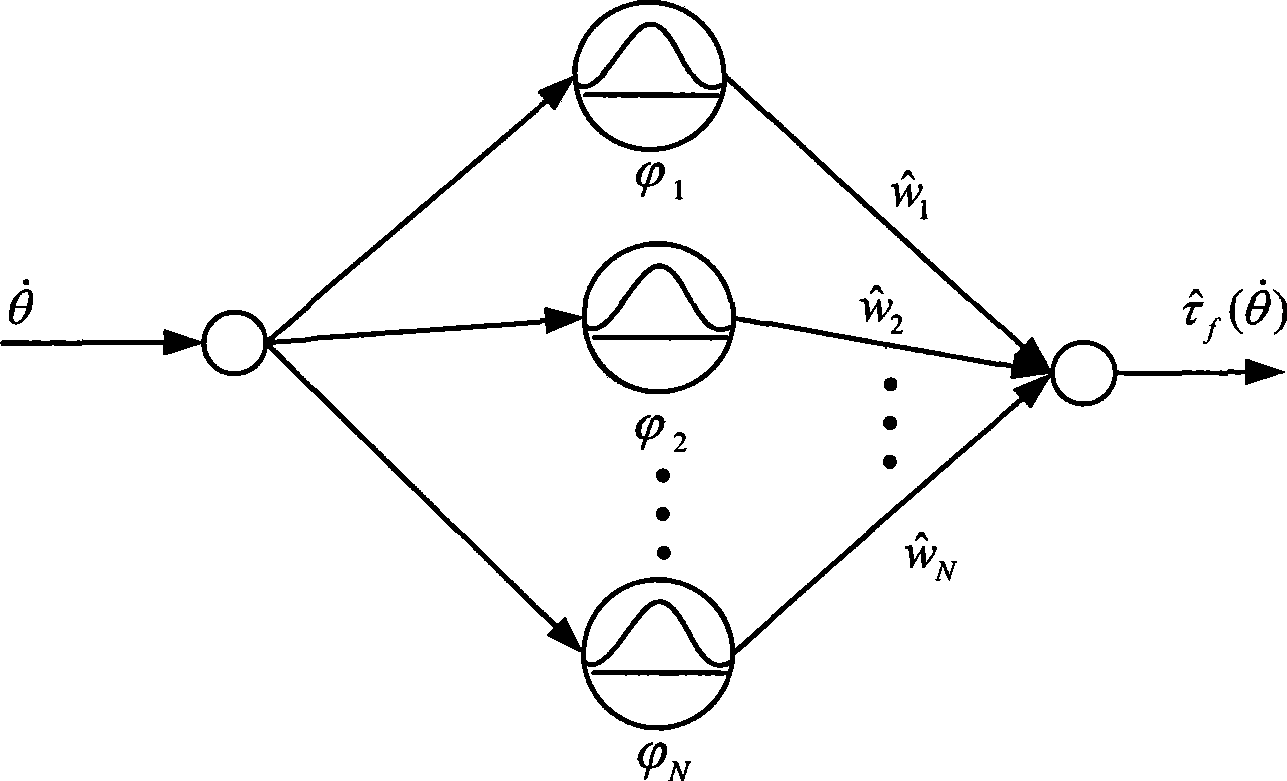

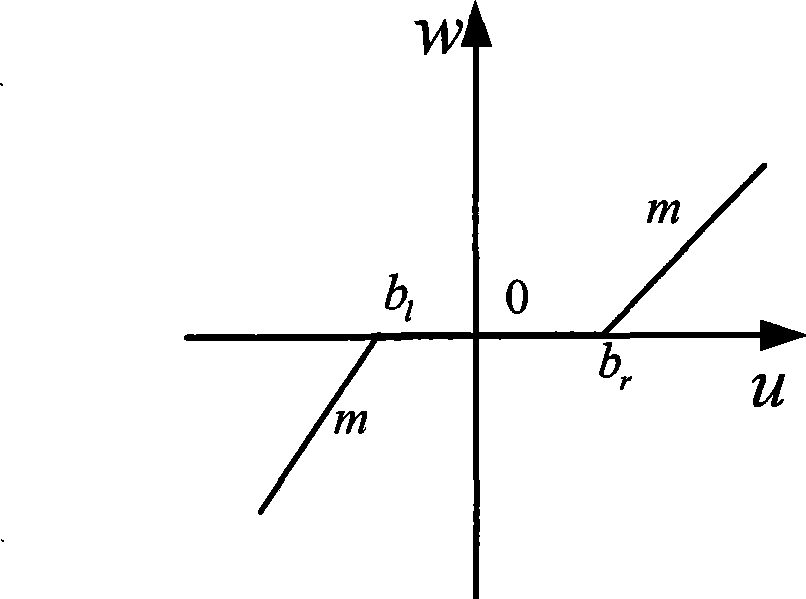

Essentially nonlinear compensation controller of servo system

InactiveCN101488010AImprove practicalityAchieve friction compensationAdaptive controlNetwork sizeDead zone nonlinearity

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

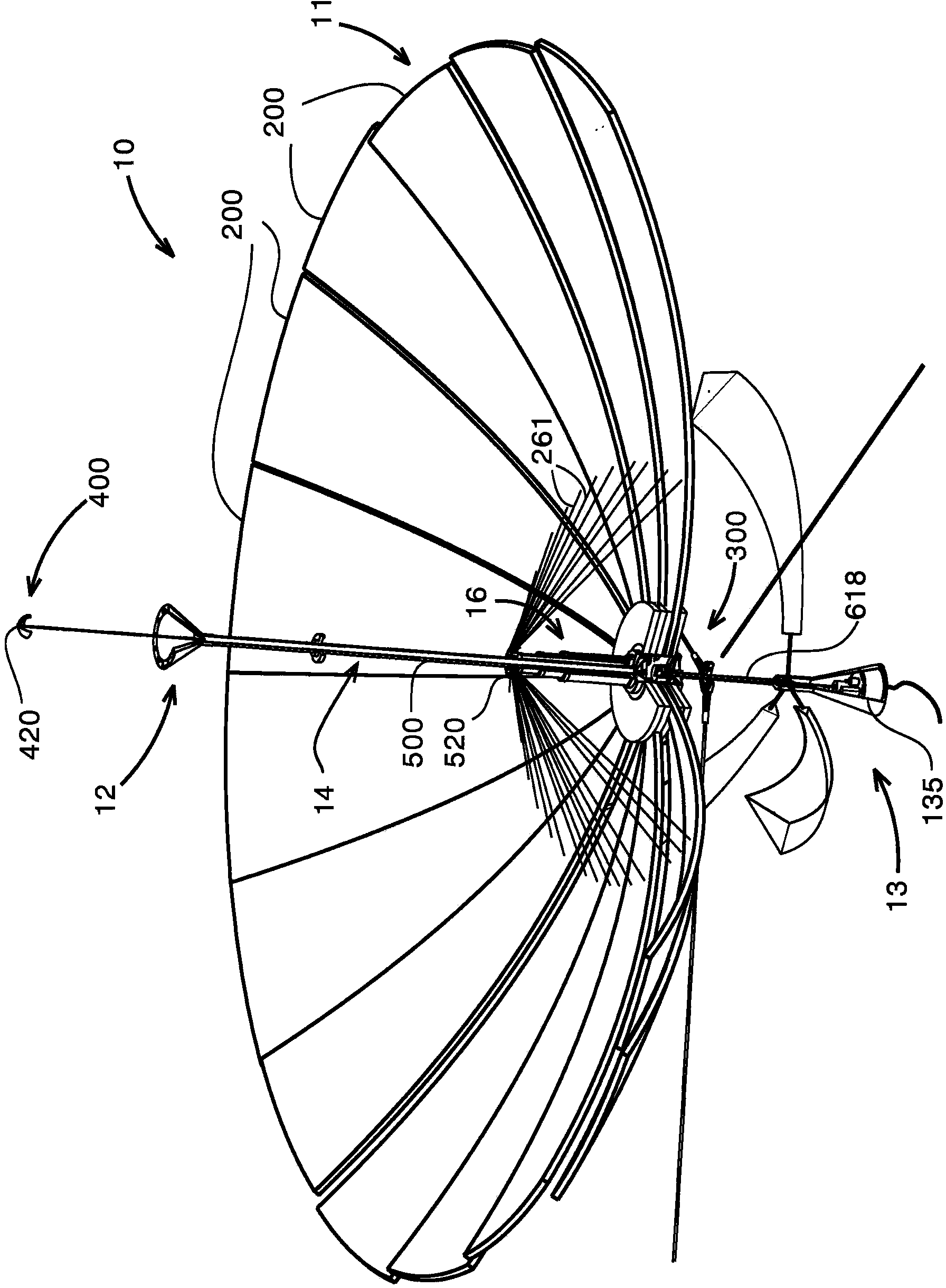

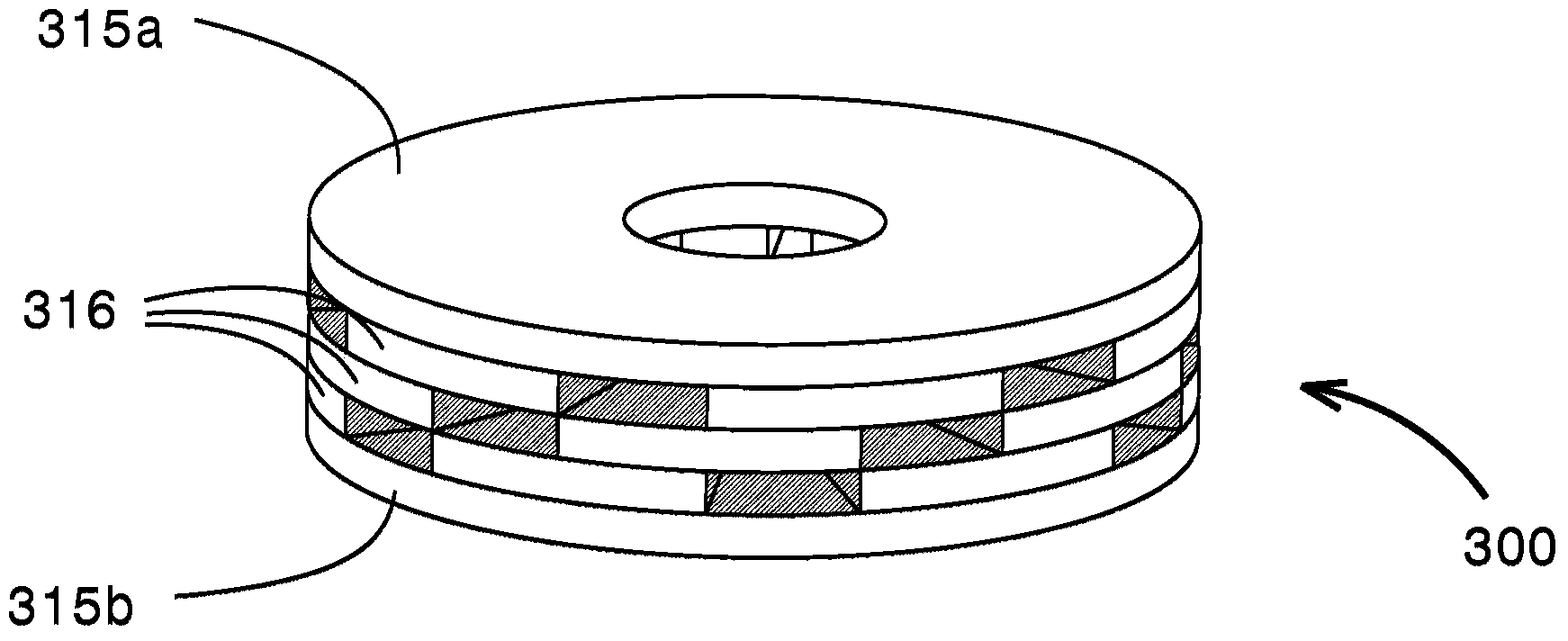

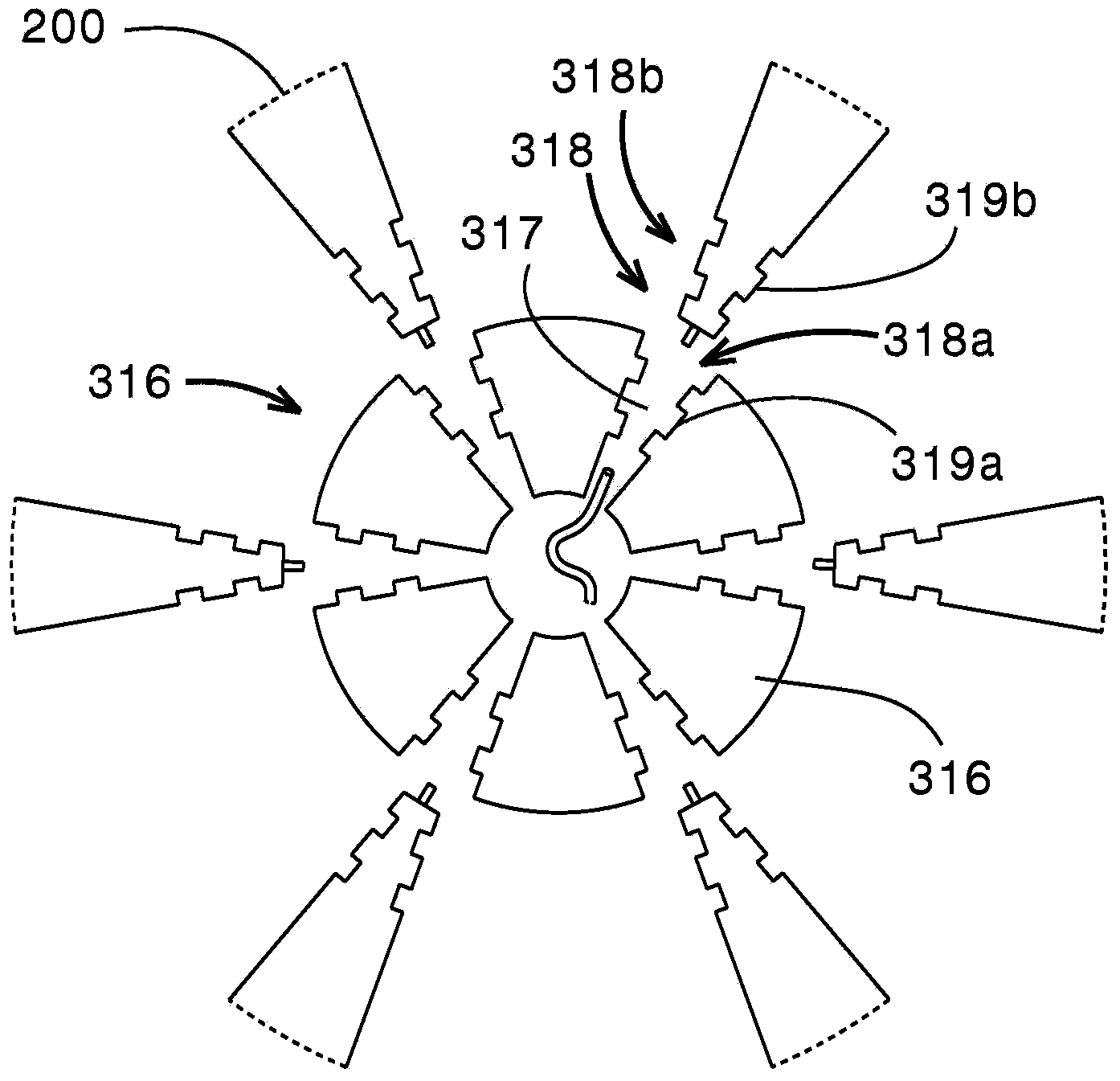

System and method for solar energy utilization

InactiveCN104114957AReduce usageEasy to replacePhotovoltaic supportsSolar heating energyEngineeringPosition of the Sun

A system for solar energy utilization is described. The system comprises a solar receiver, a solar energy concentrator mounted on a pole extending from the solar receiver along the main axis of the system, and a solar tracking system. The solar receiver is configured for receiving solar energy from the sun and concentrating the received solar energy at a predetermined spot area. The solar receiver includes a plurality of flexible mirrors independent of each other and radially arranged around a main axis of the system. The flexible mirrors are configured to be either deployed for operation or collapsed, for example for transportation or in the cases of possible damage of the system. The solar energy concentrator is located at the predetermined spot area in which the solar energy reflected from said plurality of flexible mirrors is concentrated, and configured for converting the concentrated reflected energy into electric energy. The solar tracking system is configured for sensing position of the sun and tilting the system for directing the solar receiver towards the sun to receive and reflect maximum sunlight onto the predetermined spot area.

Owner:OR HAMA ENERGY

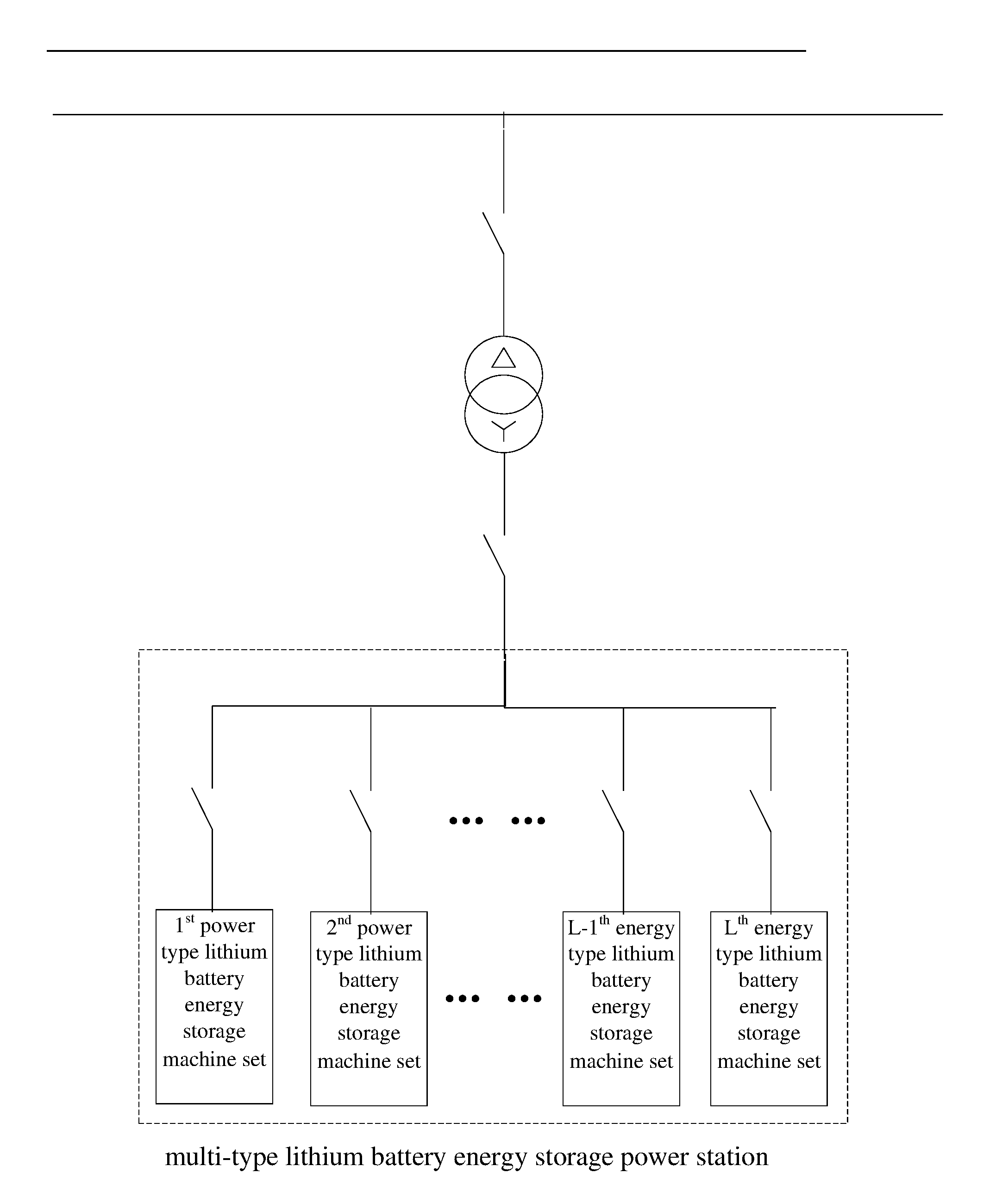

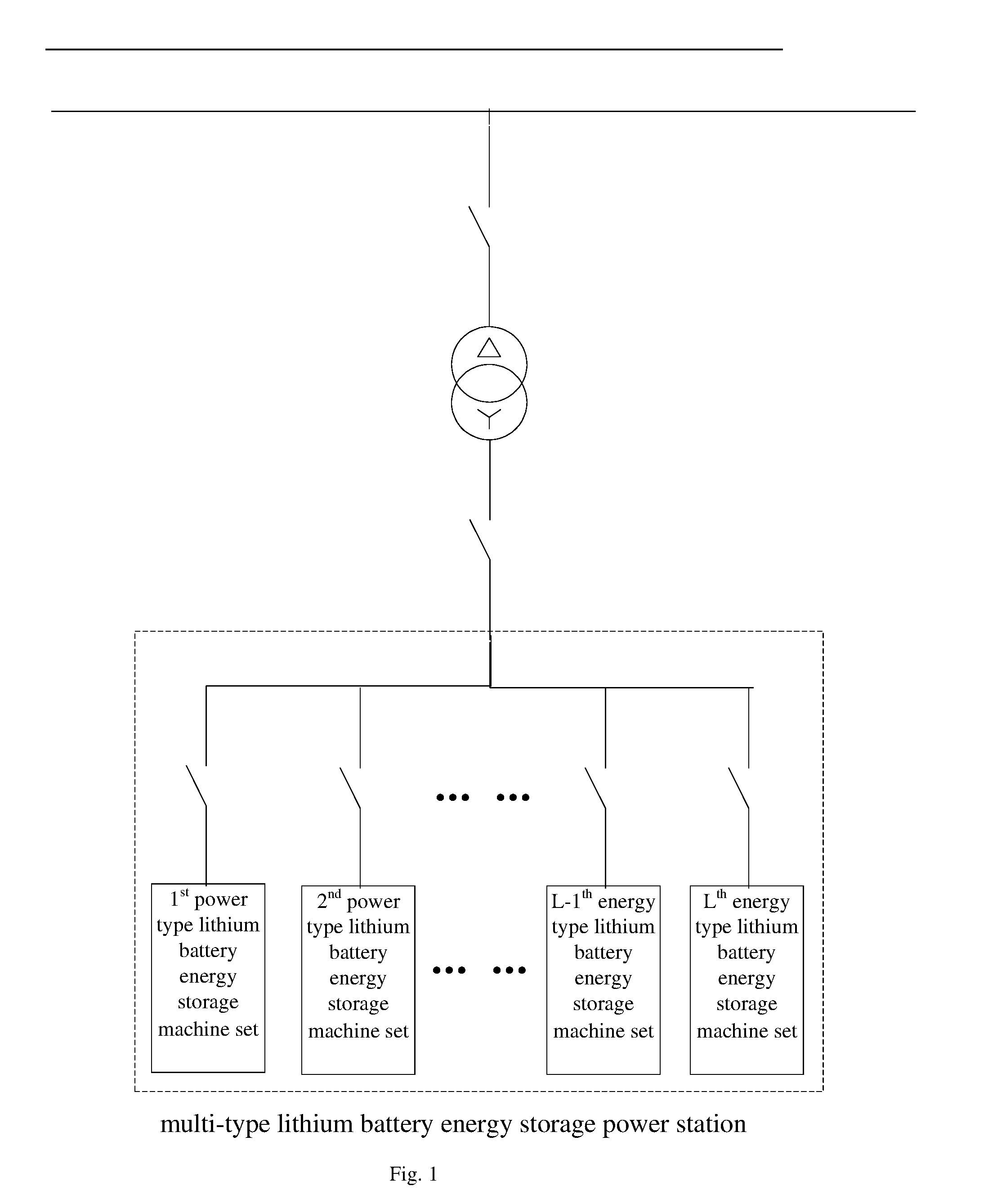

Energy management method of multi-type battery energy storage power station considering charge and discharge rates

ActiveUS20160197514A1Extended service lifeOptimizationMechanical power/torque controlLevel controlBattery storage power stationPower station

The present invention provides an energy management method of a multi-type battery energy storage power station considering charge and discharge rates, that includes: reading related data of the battery energy storage power station; calculating charge or discharge rate characteristic values of battery energy storage machine sets; calculating initial power command values of the battery energy storage machine sets; judging whether the initial power command values of the battery energy storage machine sets exceed the maximum allowable charge or discharge power of the machine sets in real time, if more than, online correcting and re-calculating the initial power command values of the battery energy storage machine sets; otherwise, setting the initial power command values of the energy storage machine sets as the power command values thereof; and summarizing the power command values of the battery energy storage machine sets, and outputting the same. With the reasonable control of the charge and discharge rates of the energy storage machines sets as target, the energy management method of the present invention is used for carrying out power coordinated control and energy management in the energy storage power station, and considering the service lives of energy storage batteries in the control strategy to achieve the functions of avoiding abuse of the energy storage batteries as much as possible, delaying battery aging and the like.

Owner:ZHANGJIAKOU WIND & SOLAR POWER ENERGY DEMONSTRATION STATION CO LTD +1

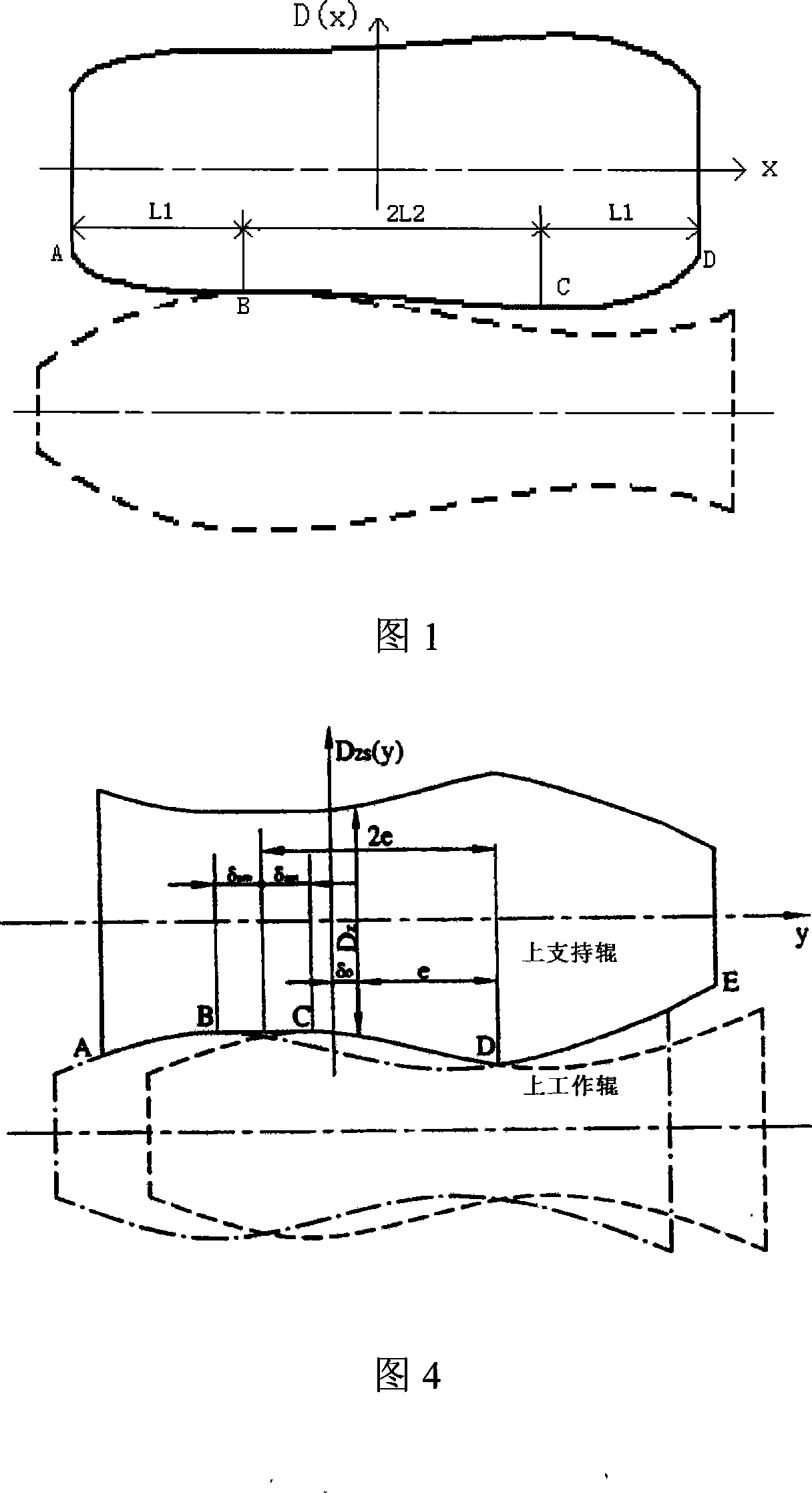

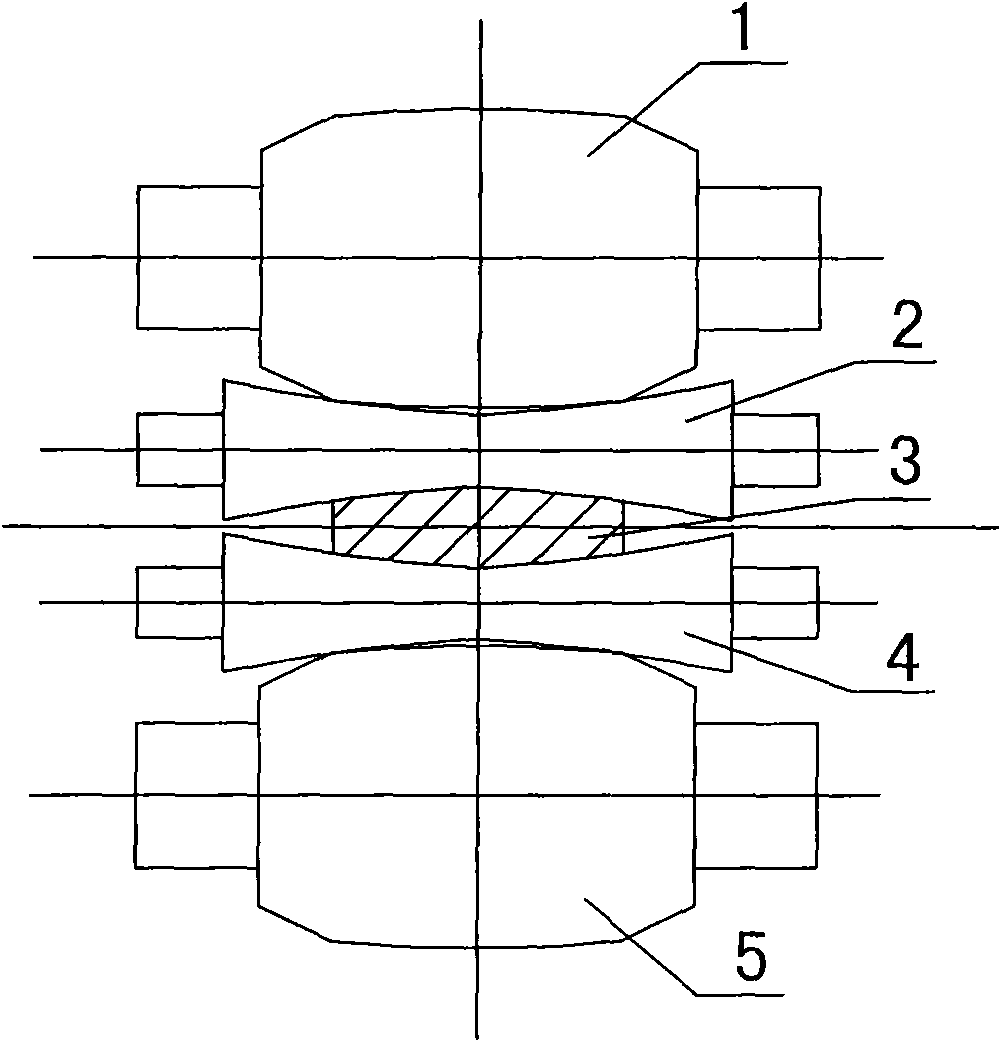

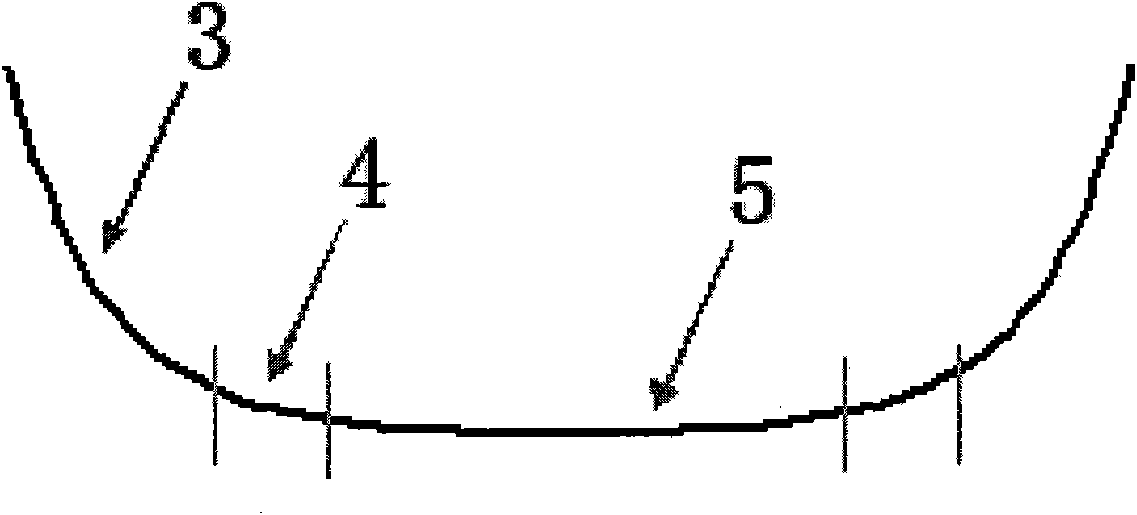

Continuous variational convexity degree rolling mill back-up shaft

InactiveCN101229560AExtended service periodImprove roll gap lateral stiffness characteristicsCounter-pressure devicesMetal rolling arrangementsContact pressureWork roll

The invention provides a continuously variable crown mill support roll to be matched with a roll curve of a continuously variable crown work roll. The roll shape is skew asymmetrical curve which essentially consists of a roll gap whole line contact curve section in the range of the strip width at the middle of the roll body and a contact line variable curve section at two ends of the roll; and the roll shape curves of an upper support roll and a lower support roll are the same but are arranged reversedly in an angle of 180 degrees The continuously variable crown mill support roll with the roll shape curve and the mill roll system with the continuously variable crown work roll can not only reduce uneven distribution and peak of the contact pressure between the roll, reduce or eliminate side spalling of the continuously variable crown mill support roll with normal crown, improve service cycle and service life of the support roll and reduce roll consumption of the support roll, but also overcomes harmful contact zone outside the rolled strip width and improves roll gap lateral rigidity of the mill and plate shape control efficiency of bending force, thereby improving plate shape quality of the rolling strip.

Owner:武汉钢铁有限公司 +1

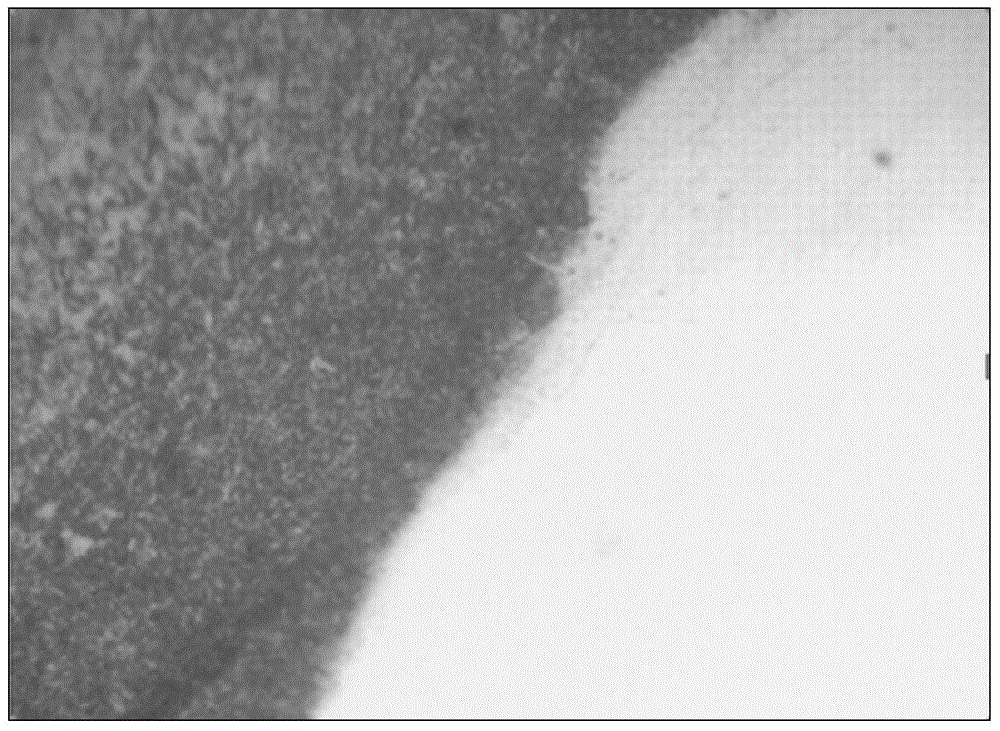

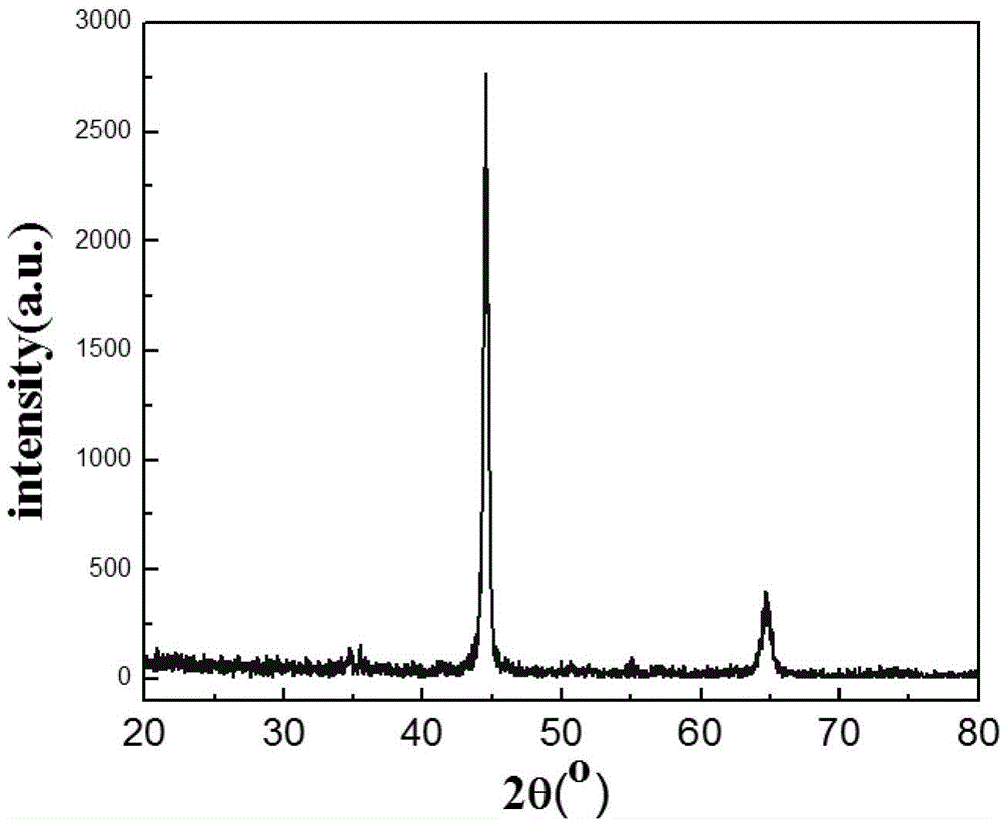

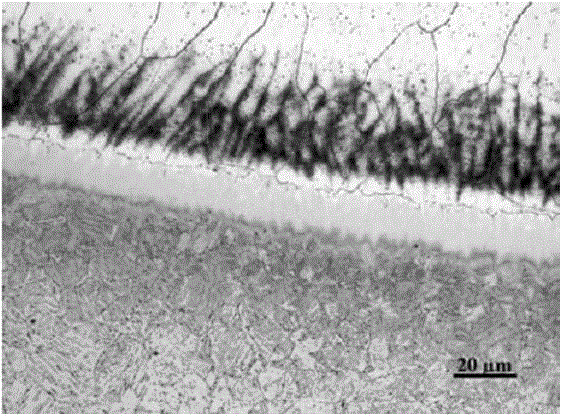

Iron-based non-crystalline composite coating for protecting heat exchange pipes in flue gas waste heat recovery system of power station boiler and laser re-melting and moulding technology thereof

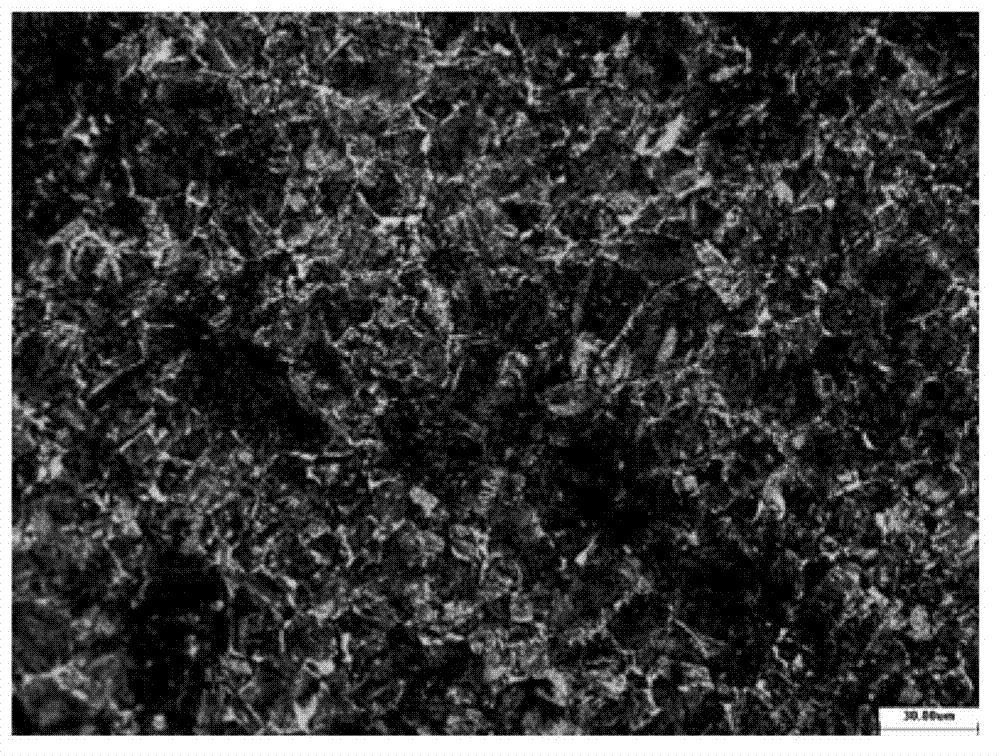

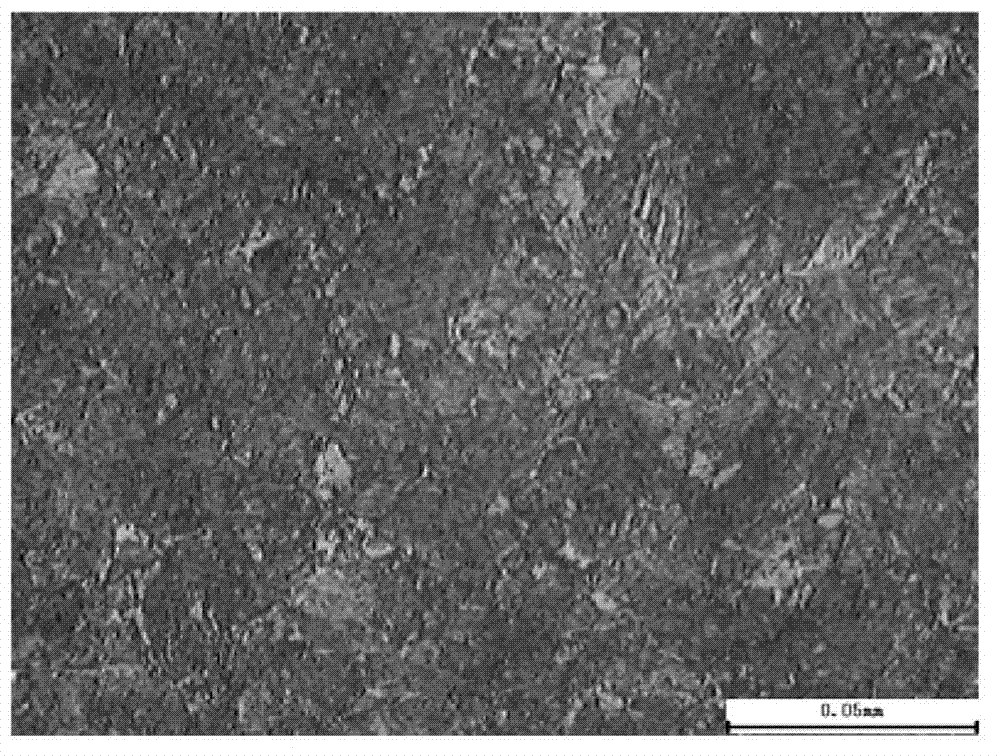

The invention discloses an iron-based non-crystalline composite coating for protecting heat exchange pipes in the flue gas waste heat recovery system of a power station boiler, and a laser re-melting and moulding technology thereof. The iron-based non-crystalline composite coating is composed of the following elements in percentage by weight: 55.1 to 66.2 wt% of Fe, 24.4 to 34.3 wt% of Cr, 2.4 to 3.4 wt% of B, 1.5 to 2.9 wt% of Si, 1.7 to 3.9 wt% of Mo, and 1.6 to 3.8 wt% of Nb. The moulding technology comprises the following steps: preparing iron-based non-crystalline cored wires, adopting an ultrasonic electric arc spraying method to prepare an iron-based thermally-sprayed alloy coating on the surface of a heat exchange pipe; and then adopting neodymium-doped yttrium aluminium garnet (YAG) laser as the heat source to carry out laser re-melting and moulding on the positions, which are prone to low-temperature acid dew point corrosion, on the thermally-sprayed coating so as to form compact iron-based non-crystalline composite coating; wherein the coating and the substrate are combine through metallurgy, and no crack and gap exists between the substrate and the coating. The provided coating prevents the transfer of the low-temperature acid dew point corrosion, thus prominently improves the service life of the flue gas waste heat recovery system, relieves the symptom of low-temperature acid dew point corrosion, and has a great application potential.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

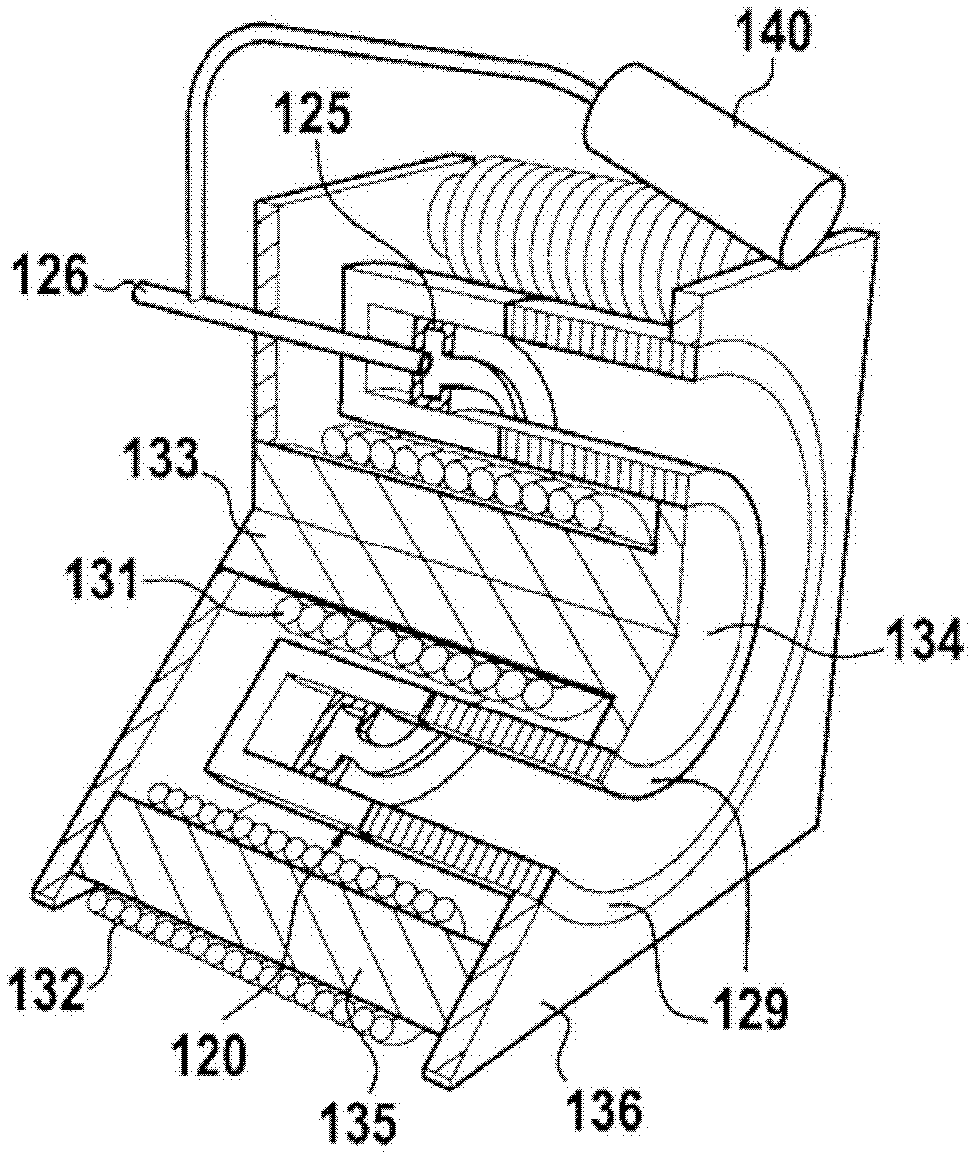

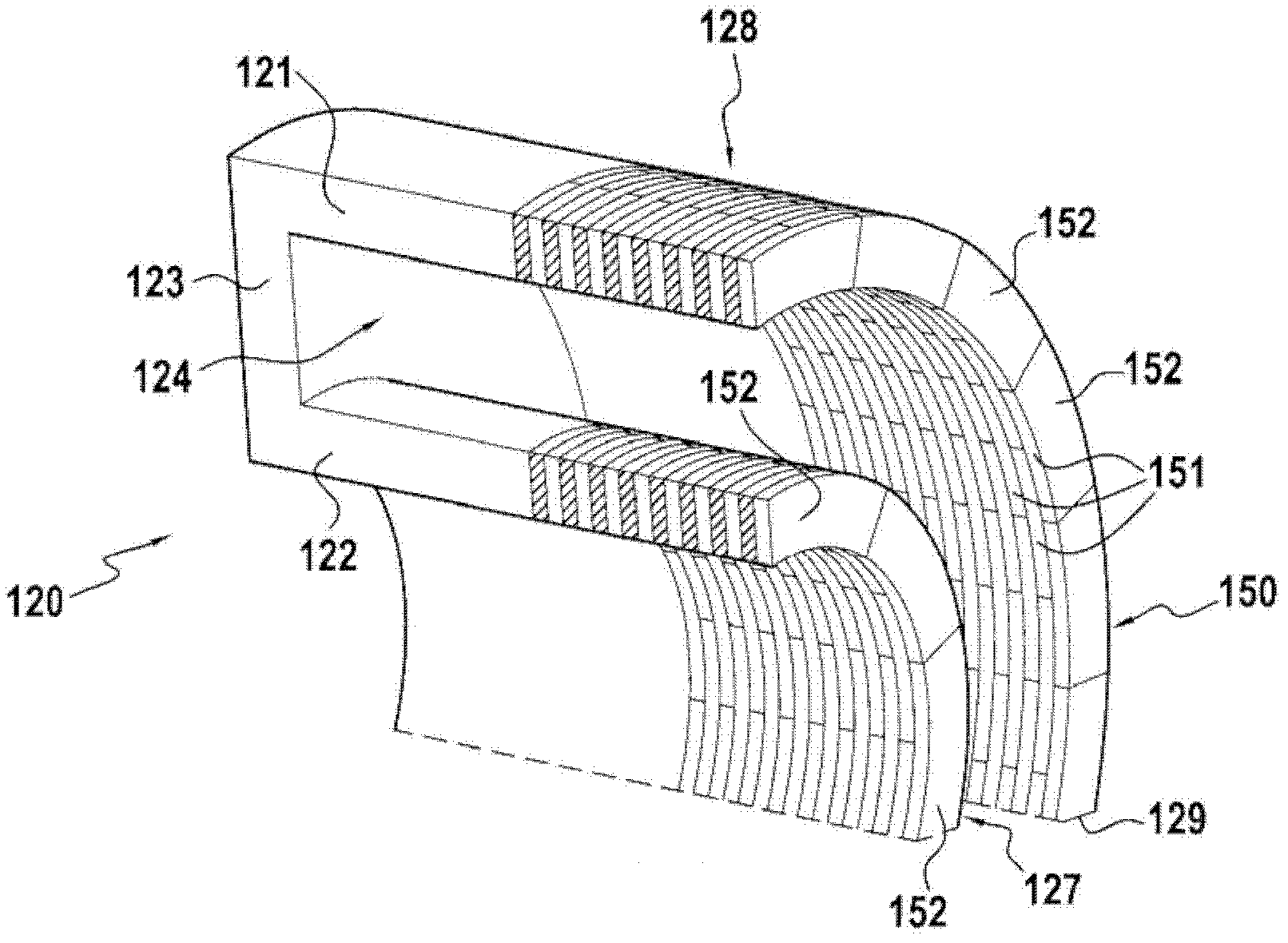

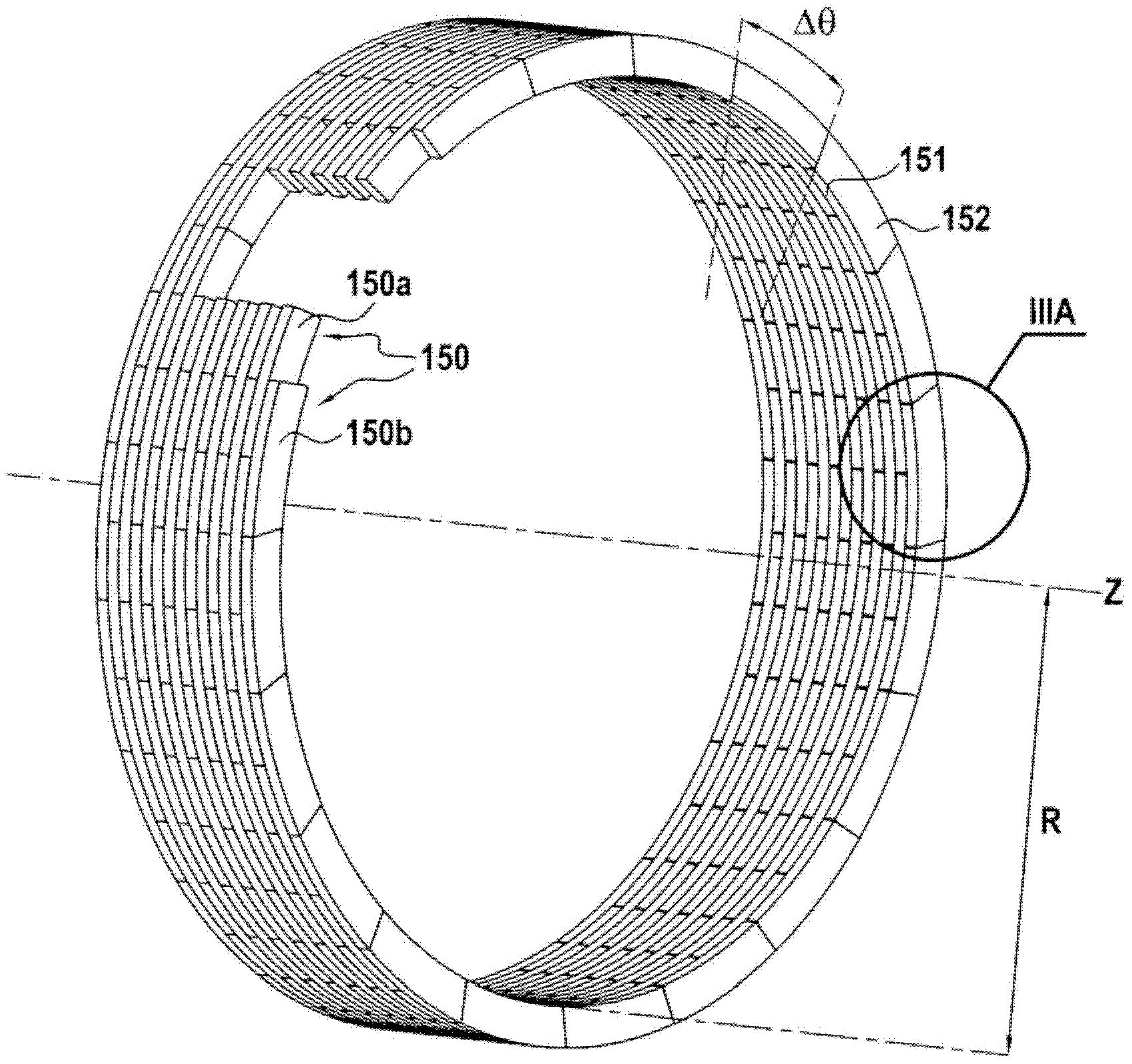

Hall effect plasma thruster

InactiveCN102439305ALow corrosion rateExtend your lifeMachines/enginesIon beam tubesElectrical conductorThin layer

The invention relates to a Hall effect plasma thruster including a main annular ionization and acceleration channel (120) having an open downstream end (129), at least one cathode, an annular anode that is concentric with the main annular channel (120), a pipe and a dispenser for feeding an ionizable gas into the channel (120), and a magnetic circuit for generating a magnetic field in the main annular channel (120). The main annular channel (120) includes portions of inner (127) and outer (128) annular walls located in the vicinity of the open end and (129) each including an assembly of conductive or semiconducting rings (150) juxtaposed in the form of blades separated by thin layers of insulation (152).

Owner:斯奈克码 +3

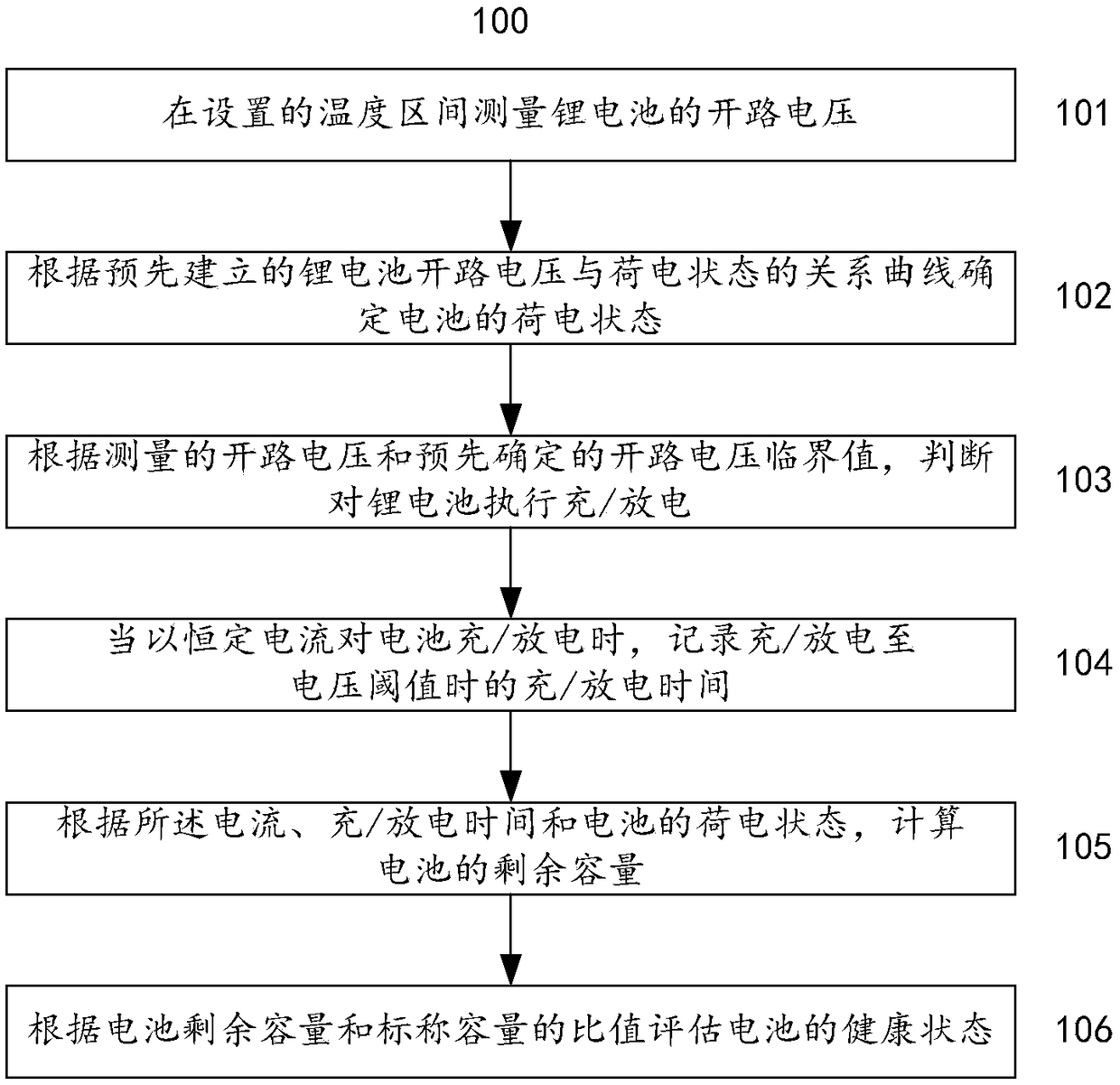

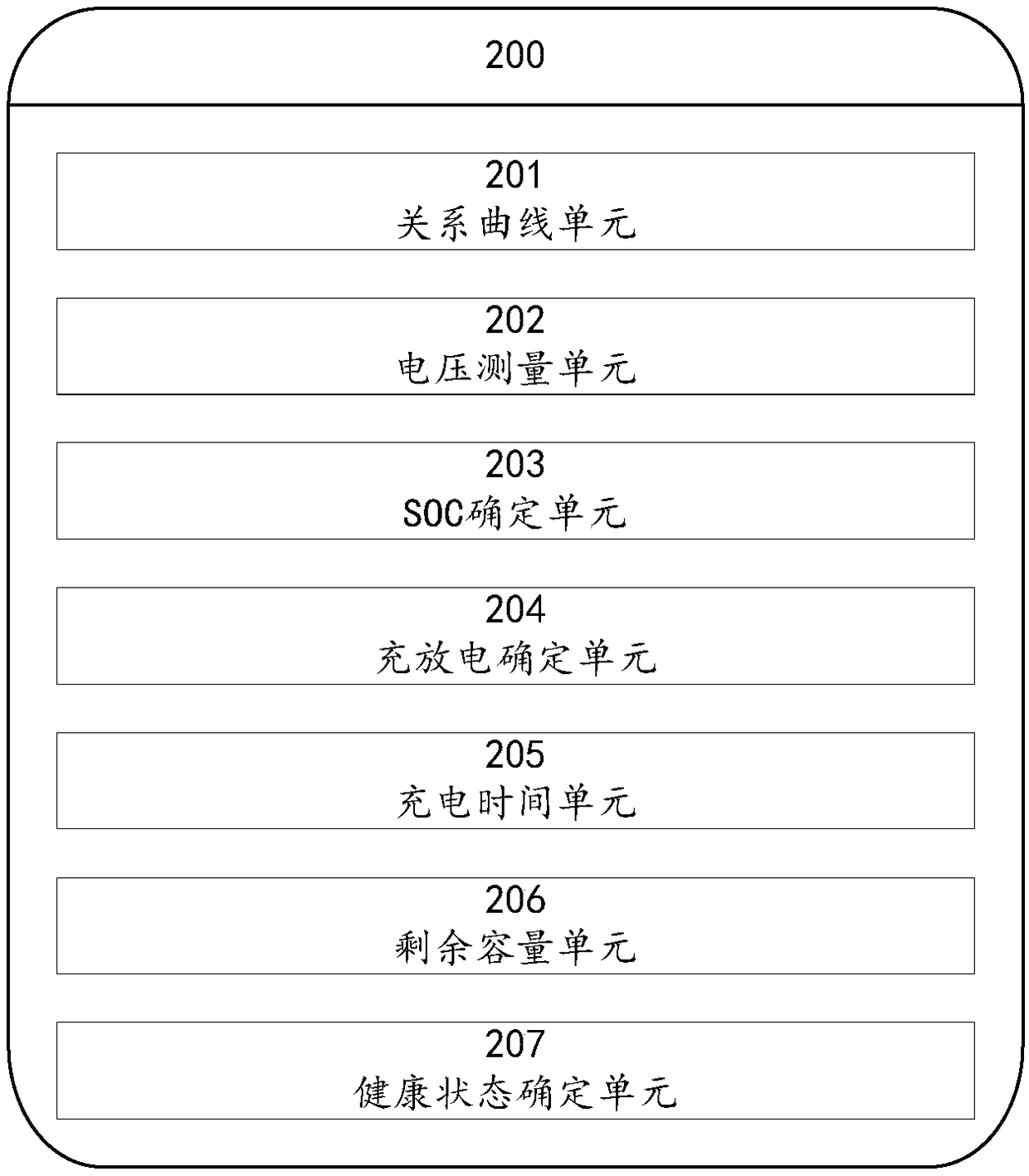

Method and system for evaluating health state of lithium battery

PendingCN108931738AExtended service periodLower life cycle costsElectrical testingLower limitResource utilization

The invention provides a method and a system for evaluating the health state of a lithium battery. The method comprises steps: open circuit voltage of the lithium battery is measured; according to theopen circuit voltage and in combination of upper and lower limit values of working voltage of different types of batteries and constant current charging / discharging time, the remaining capacity of the battery is calculated; and finally, according to the ratio of the remaining capacity of the battery to a nominal capacity, the health state of the battery is determined, and the larger the ratio is,the better the health state is. According to the method and the system for evaluating the health state of the lithium battery, the operation is simple and convenient, the speed is fast, scientific basis is provided for screening and grading combination of batteries in service, the service life of the lithium battery can be effectively prolonged, the whole life cycle cost of the lithium battery isreduced, and the effectiveness and the rationality of resource utilization are improved.

Owner:CHINA ELECTRIC POWER RES INST +1

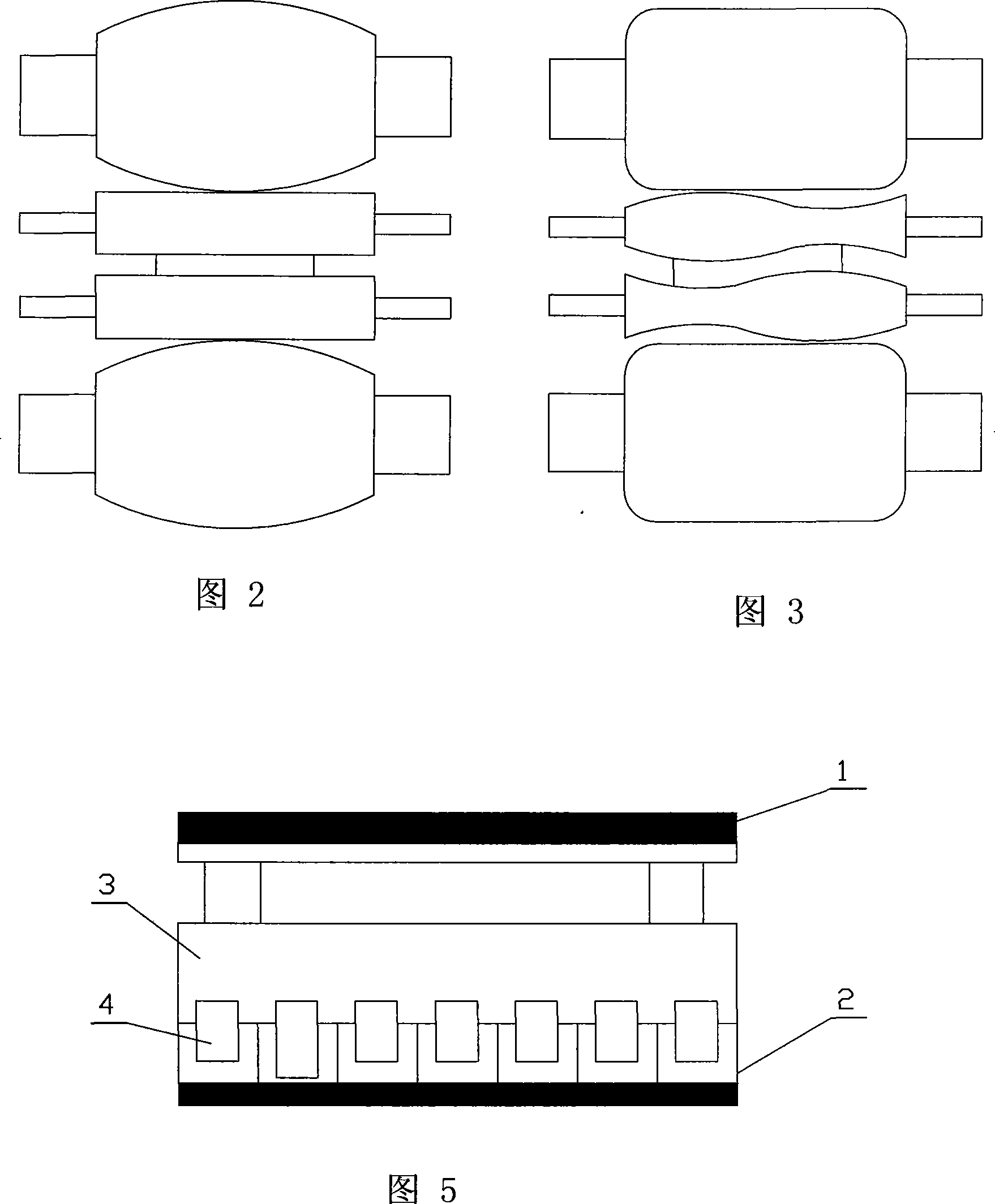

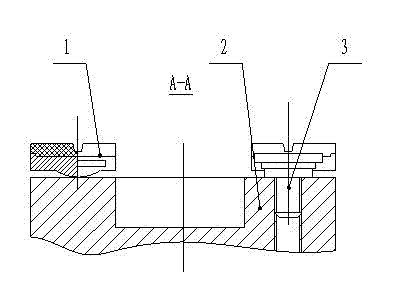

Roller of four-high rougher

InactiveCN101837369AExtended service periodImprove shape qualityCounter-pressure devicesRollsWork rollRoll forming

The invention relates to a roller of a four-high rougher, belonging to the technical field of a production process of hot rolled strips. The roller comprises two working rolls which symmetrically prop against a roughing mill and two supporting rolls which are in contact with the two working rolls, wherein the generatrix of the working rolls is a median-concave continuous curve determined by a curvilinear equation; and the generatrix of the supporting rolls comprises three sections, the middle section is a median-convex continuous curve determined by a polynomial equation, and the two end sections are symmetrical chamfer lines of an axial projected length L. The invention can inhibit the deviation of strip steel in the rough rolling process by the negative-convexity roll forming of the working rolls, equalize contact stresses among the rolls and eliminate the disadvantage of overlarge stress caused by the contact of the edges of the working rolls and supporting rolls, thereby prolonging the service cycle of the supporting rolls and improving the strip quality of an intermediate blank at the outlet of the roughing mill.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

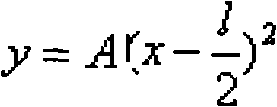

Permeable pavement structure with high strength and high permeability and paving method thereof

ActiveCN106351103AHigh strengthImprove permeabilityIn situ pavingsPaving gutters/kerbsChipsealHigh density

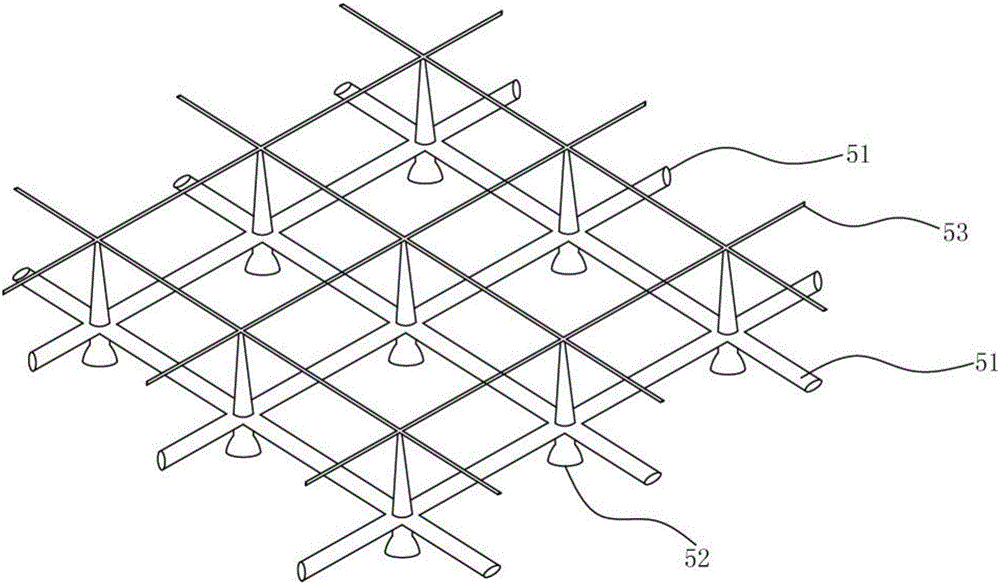

The invention discloses a permeable pavement structure with high strength and high permeability. The permeable pavement structure comprises a water isolating seal layer, a base layer and a surface layer which are sequentially arranged on a soil matrix; the surface layer comprises a permeable framework, and concrete positioned among pores of the permeable framework; the permeable framework comprises transverse vent pipes which are communicated with one another and vertical osmosis pipes vertically arranged on the transverse vent pipes; the base layer comprises rubble layer at the upper layer and a sand mat at the lower layer; and the water isolating seal layer comprises a water isolating membrane. The high-density concrete in the surface layer has the advantages of high strength and high durability, and the permeable framework in the concrete can guide rainfall into the base layer so as to prevent accumulation of rainfall on the pavement. Rubbles in the rubble layer are overlapped so as to form a flowing passage for rainfall, thus playing the role in delivering water and improving the strength of the base layer. Macadams in the sand mat can decelerate infiltration of the rainfall, thus playing the roles in storing water, discharging water and improving the strength of the base layer; and the water isolating membrane can prevent the rainfall from permeating into the soil matrix.

Owner:苏谦

High-strength anchor bolt and production method thereof

InactiveCN102876965AFast heatingOnline production is stableFurnace typesIncreasing energy efficiencyUltimate tensile strengthMechanical property

The invention provides a high-strength anchor bolt and a production method thereof. The high-strength anchor bolt comprises the following components in percentage by weight: 0.25 to 0.50 percent of C, 0.2 to 1.5 percent of Si, 0.5 to 2.0 percent of Mn, less than or equal to 0.03 percent of P, less than or equal to 0.03 percent of S and the balance of iron and inevitable impurities. The high-strength anchor bolt is subjected to continuous sensing heat treatment, wherein the mechanical properties of the high-strength anchor bolt are that the tensile strength sigma b is 830 to 1,220MPa, the shear strength is more than or equal to 0.7 sigma b, the percentage elongation after fracture is more than or equal to 14 percent, and ballistic work at the temperature of 20 DEG C is more than or equal to 60J. The high-strength anchor bolt has the advantages of high strength, high ductility and impact resistance, and can effectively solve the problem of brittle rupture.

Owner:CHINA IRON & STEEL RES INST GRP +1

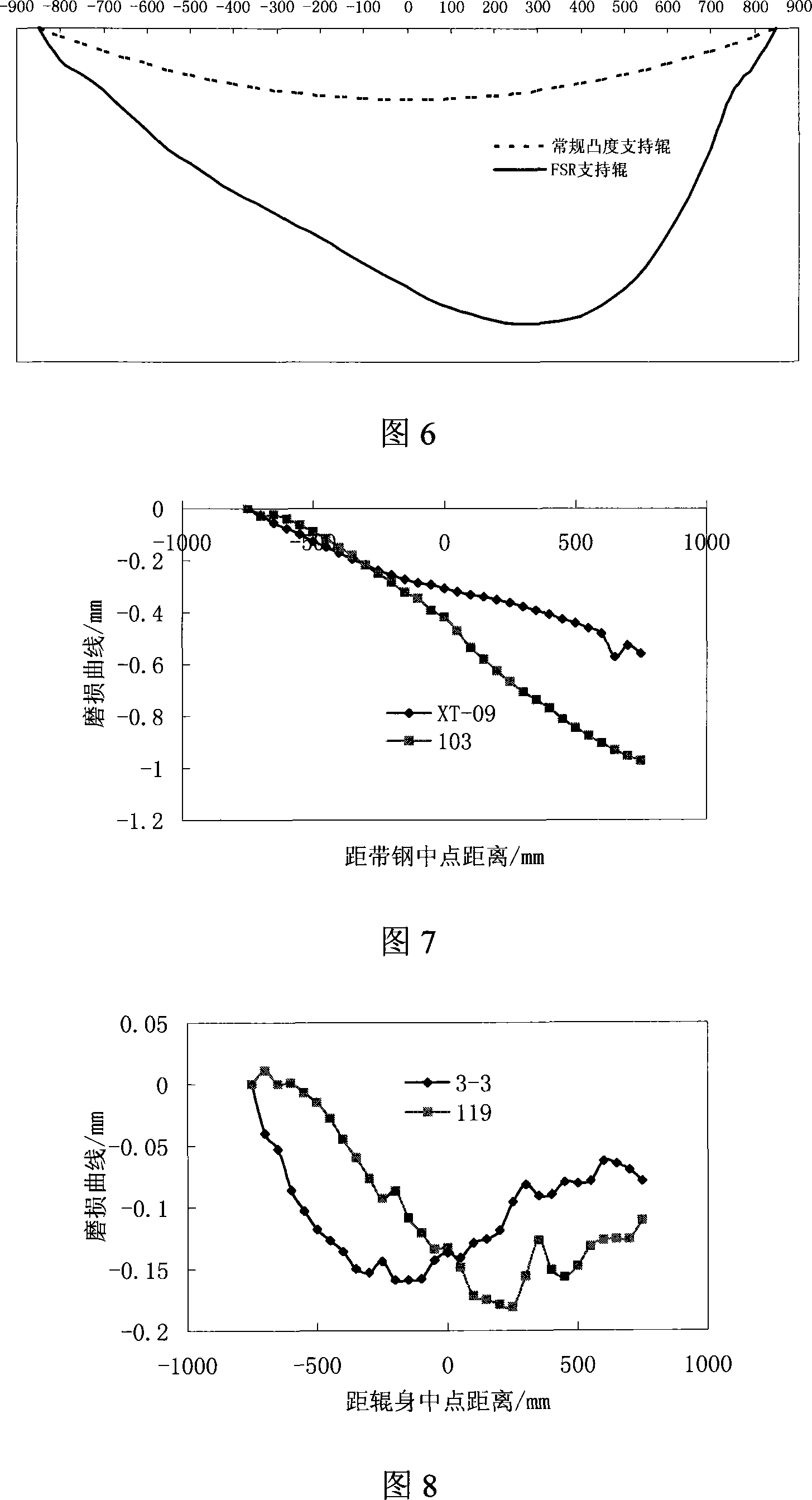

Method for controlling orange peel reticulate pattern defects on surface of strip steel

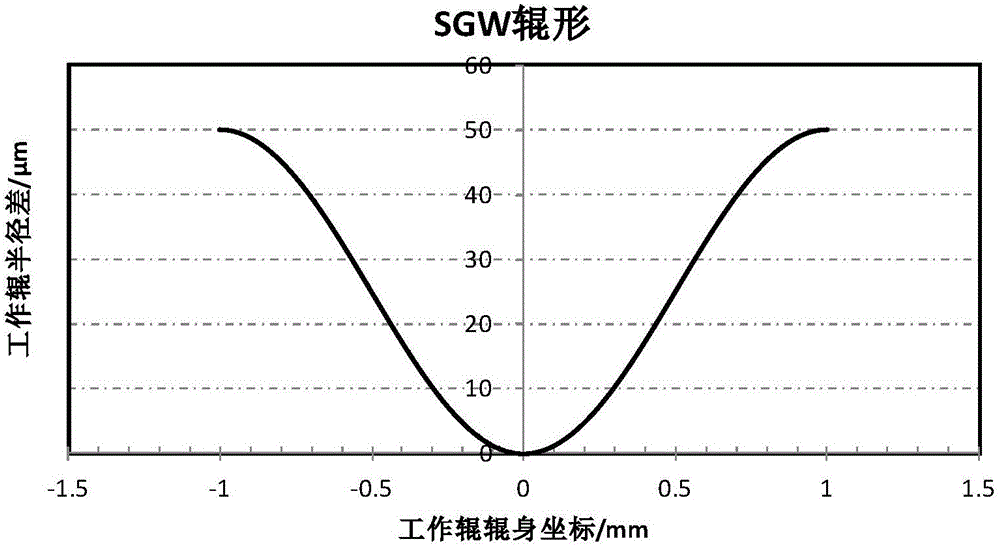

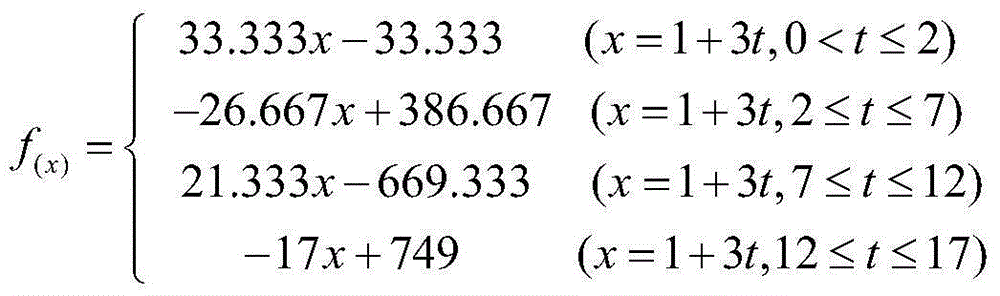

ActiveCN104998910AOrange Peel Defect ControlExtended service periodRollsProfile control deviceStrip steelMaterials science

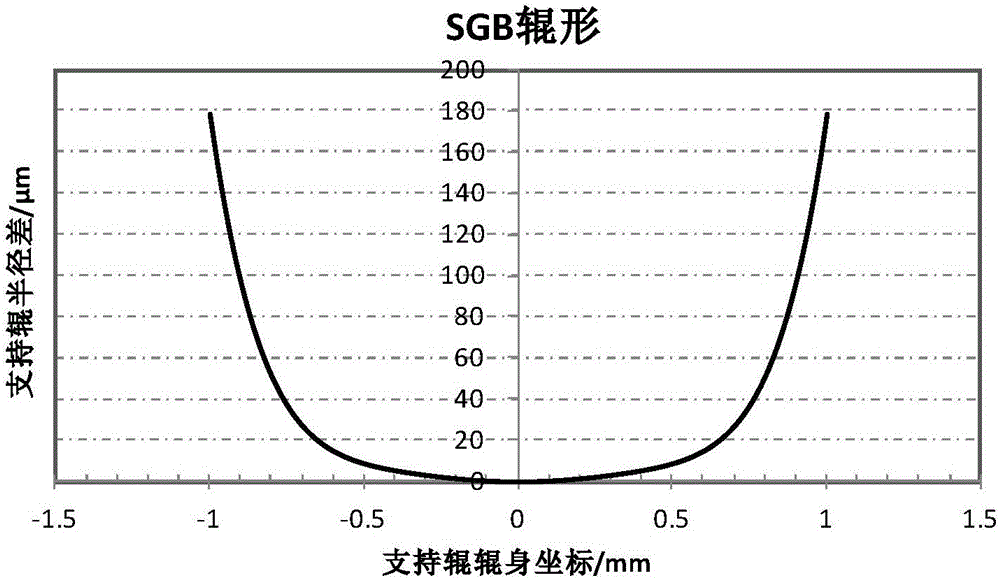

The invention belongs to the technical field of hot rolling, and discloses a method for controlling orange peel reticulate pattern defects on the surface of strip steel. The method is characterized by comprising the following steps: adopting an SGB roll profile curve on a supporting roller of a hot rolling temper mill; adopting an SGW roll profile curve on a working roller. The process parameters of the temper mill are set as the rolling force of 200-250 tons, the unwinding tension of 9-12 tons, and the winding tension of 20-23 tons, the rolling reduction of straightening rollers is used in a straightening machine group, and a roller shifting strategy with constant frequency, variable step sizes and variable stroke is adopted. According to the method, through the application of the SGB and SGW roll profile curves, a specific smoothing process and the roller shifting strategy, local wear of working rollers is greatly reduced, and orange peel reticulate pattern defects on the surface of the strip steel are effectively overcome.

Owner:SHOUGANG CORPORATION +1

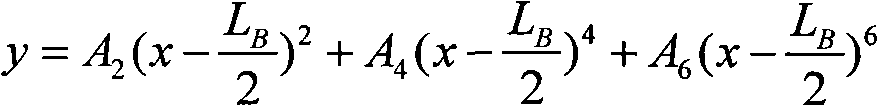

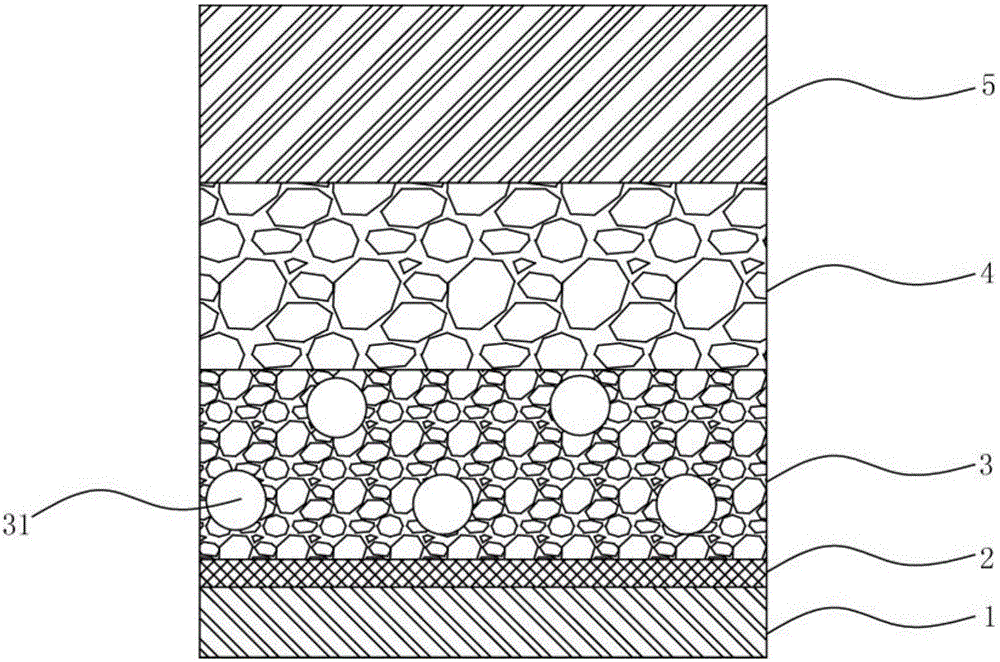

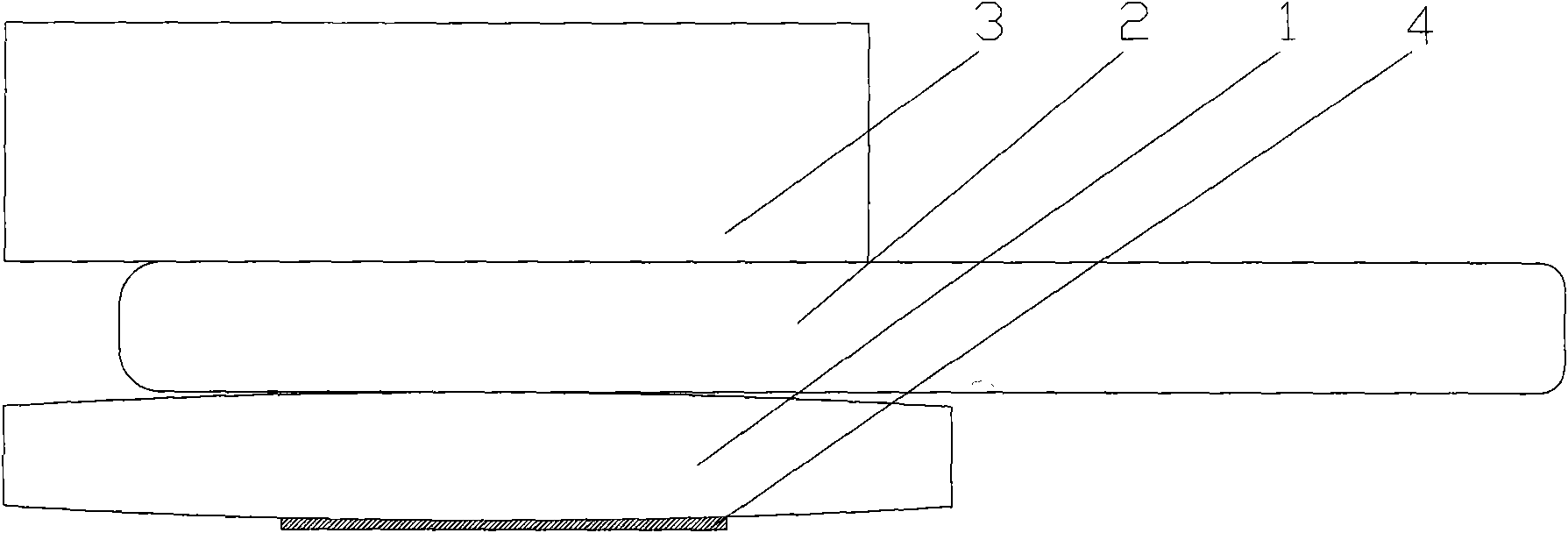

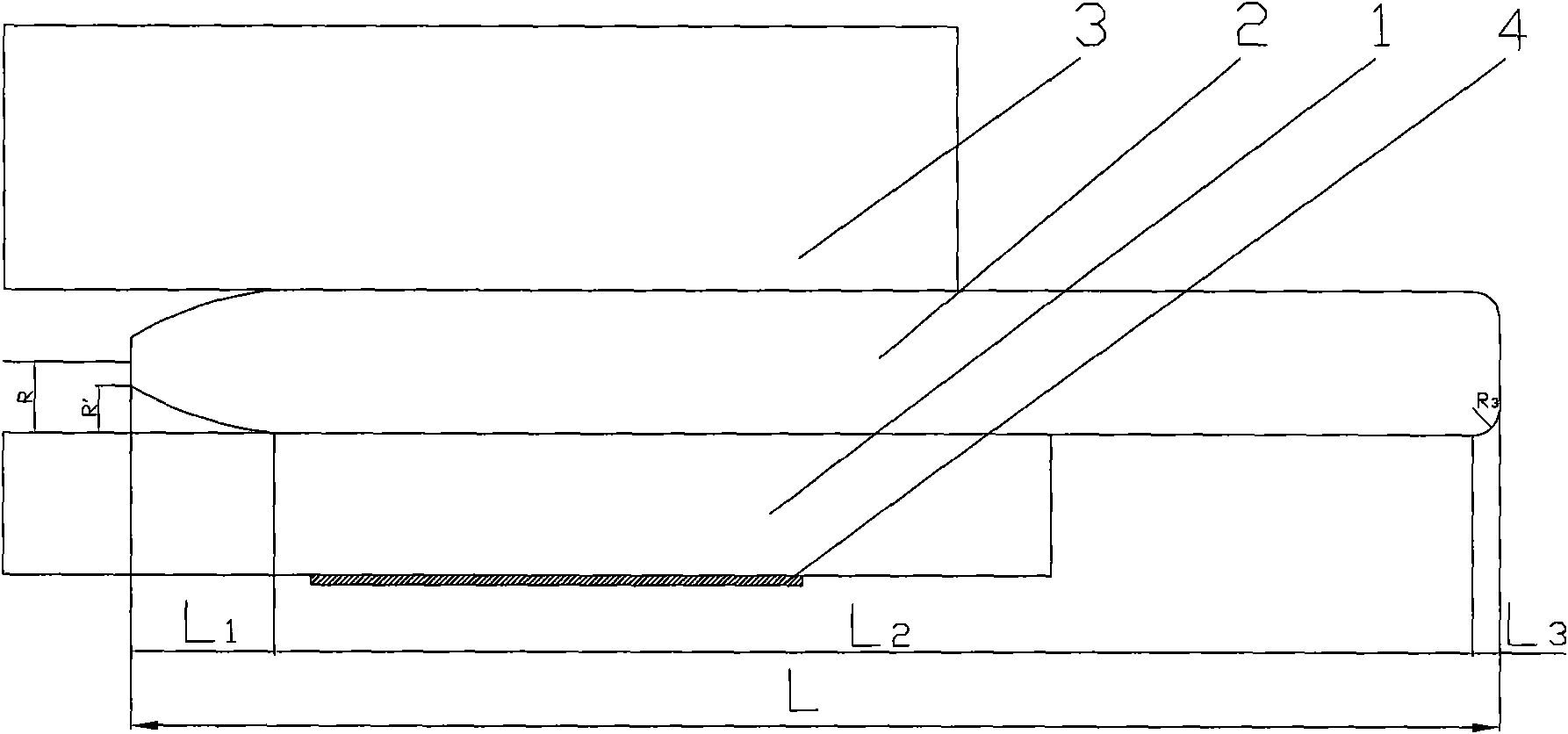

Intermediate roller contour of intermediate roller movable type convexity high-accuracy control temper mill

InactiveCN102107214AReduced contact pressure distributionUniform contact pressure distributionRollsMetal rolling arrangementsContact pressureMovable type

The invention relates to an intermediate roller contour, in particular to an intermediate roller contour of an intermediate roller movable type convexity high-accuracy control temper mill. The intermediate roller contour of the intermediate roller movable type convexity high-accuracy control temper mill consists of three continuous line segments, wherein a polynomial curve equation of a head roller contour is y=A2x<2>+A4x<4>+A6x<6>+A8x<8> by taking a crossing point of a head part and an intermediate segment as an origin of coordinates, axial direction of the intermediate roller as an X axis and radial direction of the intermediate roller as a Y axis; and in the equation, the origin of coordinates is the crossing point of the head roller contour and the intermediate segment, the axial direction of the intermediate roller is the X axis, the radial direction of the intermediate roller is the Y axis, R' is radius difference between roller bodies of two roller-shaped ends of the head, and L1 is more than 0 and less than or equal to L / 3 and the R' is more than 0 and less than R. Through the roller contour, a forced-contact condition is greatly relieved, contact pressure between rollers is uniformly distributed, a peak value of the contact pressure is greatly reduced, the improvement on the service periods of the rollers is facilitated, a set value of rolling force is reduced, the service life of the rollers is prolonged, and the risk of roller spalling is reduced.

Owner:BAOSHAN IRON & STEEL CO LTD +1

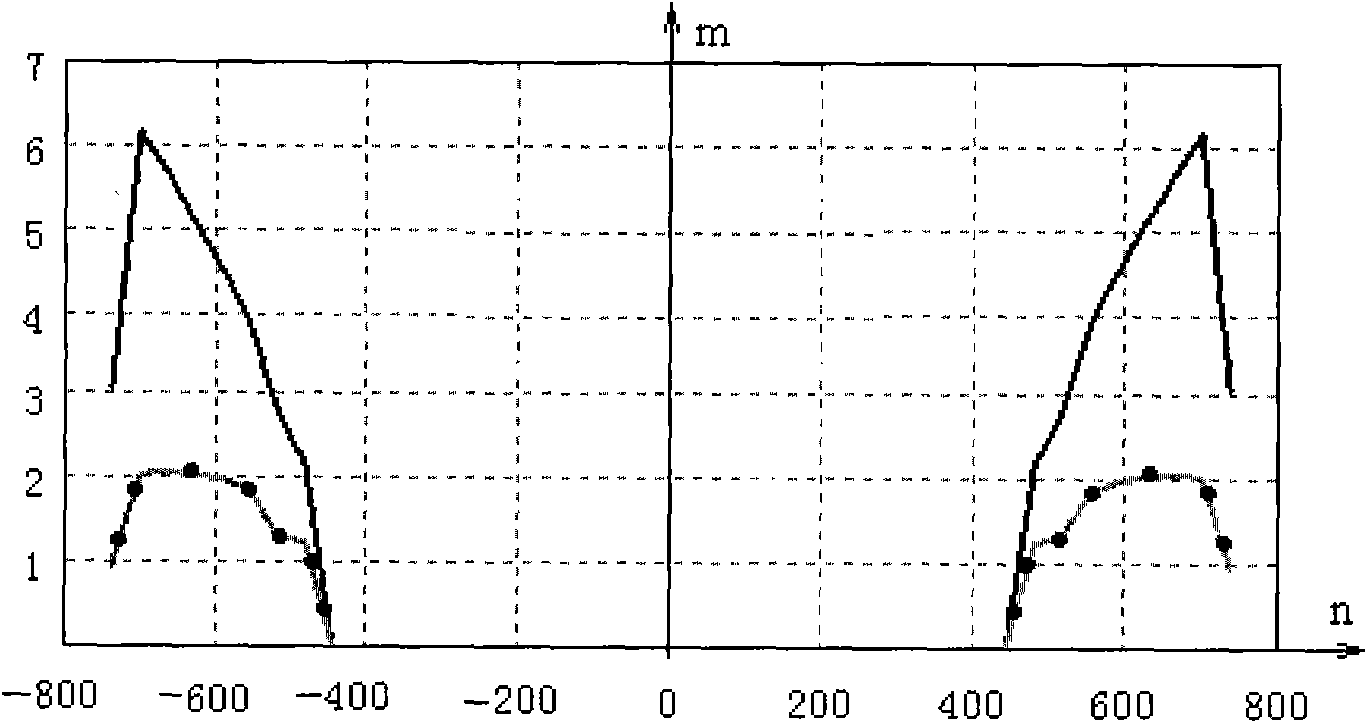

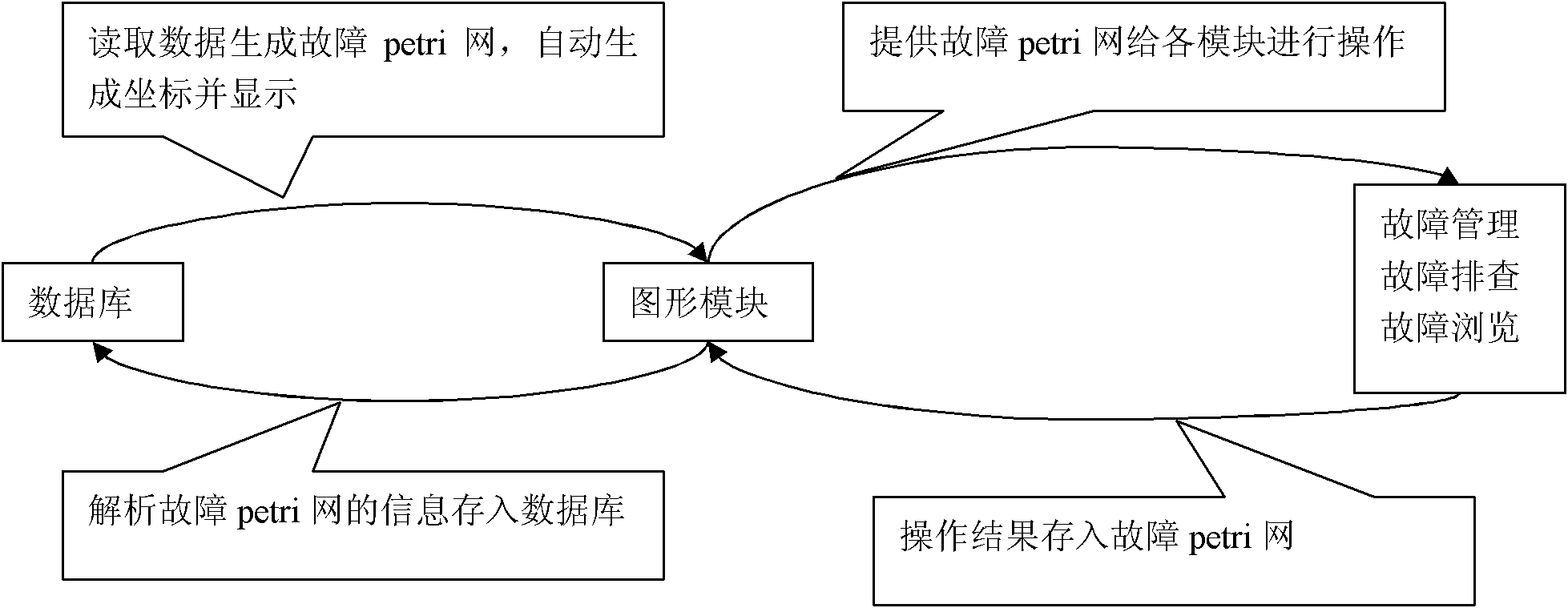

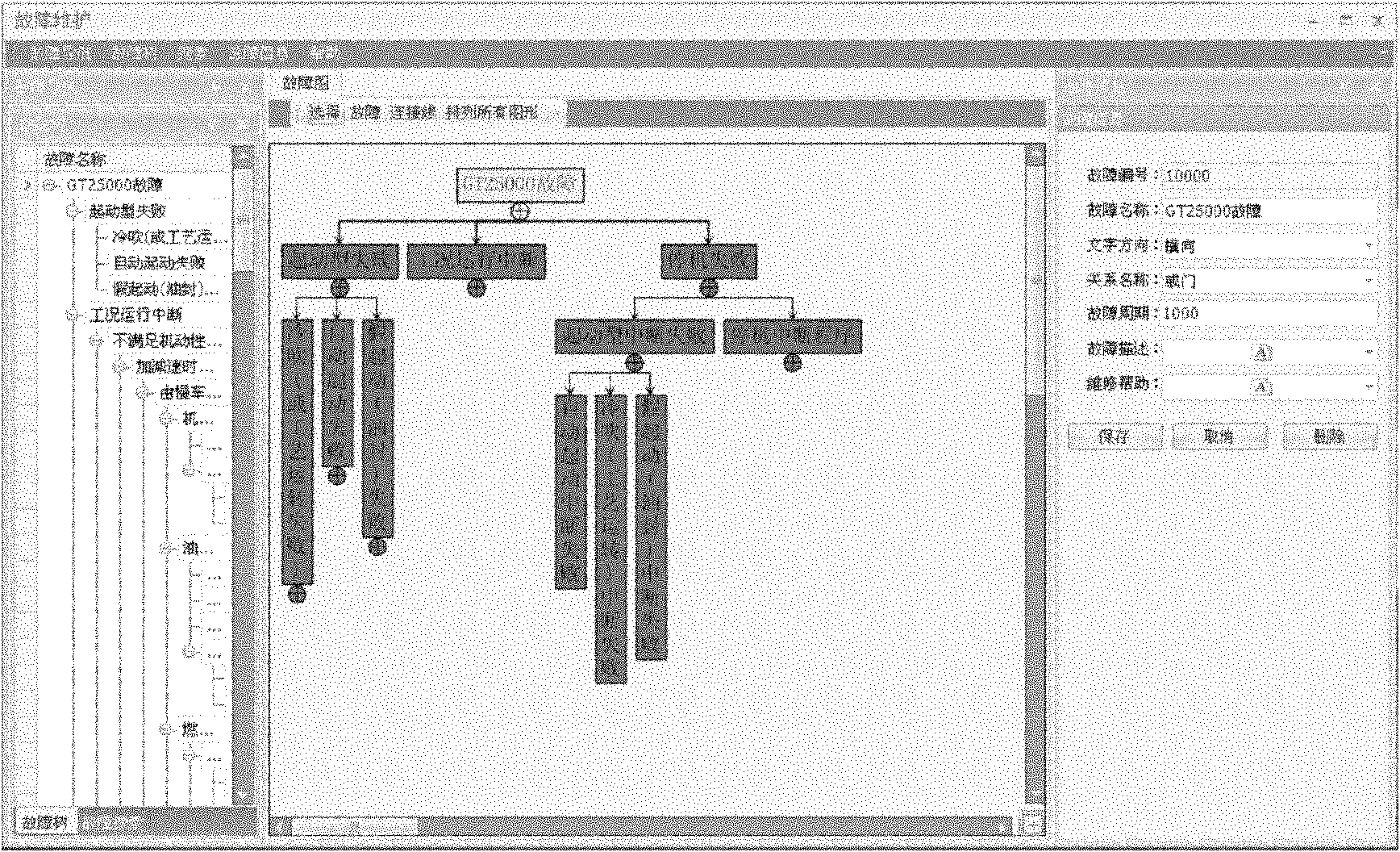

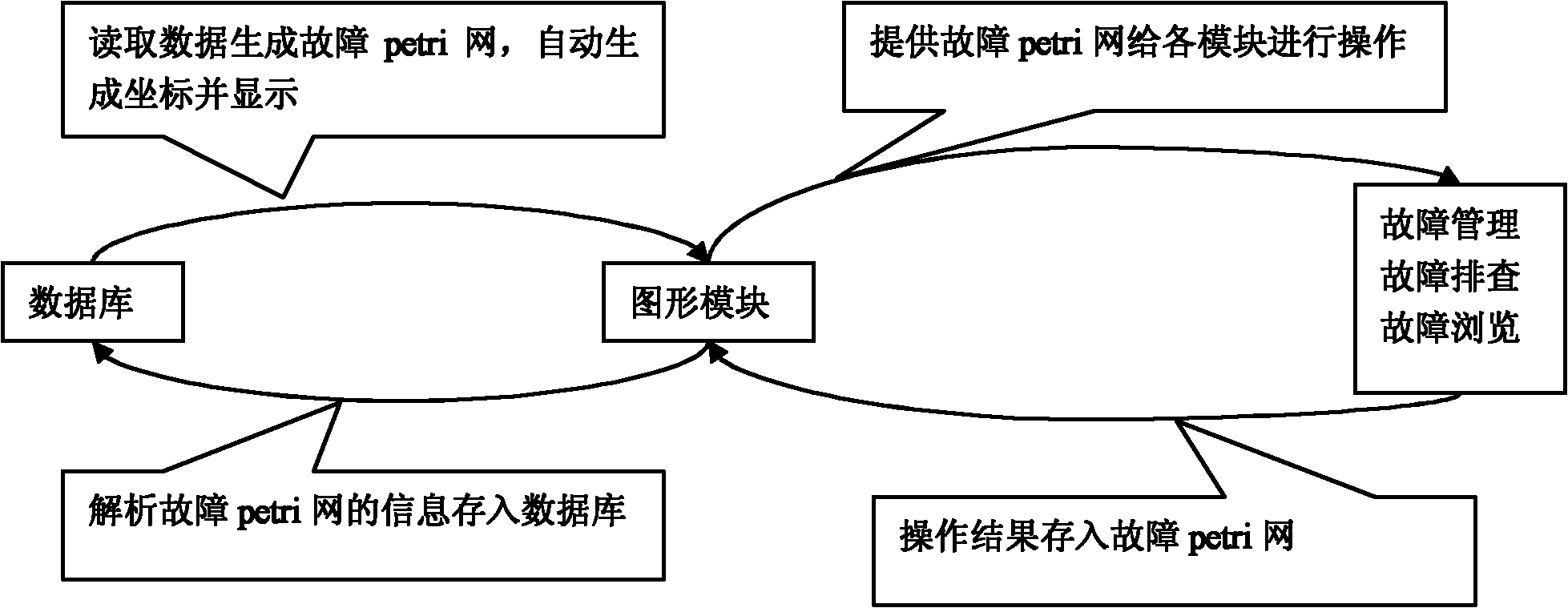

Method for patterning Petri network and application of method for patterning Petri network to diagnosis of fault of marine gas turbine

InactiveCN102146845AOvercome usabilityOvercome the disadvantage of inconvenienceGas turbine plantsJet propulsion plantsGraphicsNetwork generation

The invention provides a method for patterning a Petri network. The method comprises the following steps of: 1, reading out fault data from a database by using a fault Petri network generation algorithm, constructing a fault Petri network, automatically generating coordinates and displaying the coordinates on an interface; and 2, reading the data on the fault Petri network displayed in the form of a pattern and storing the data into the database so as to realize storage of fault information and diagnosis information. By the method, the shortcoming that most of the conventional fault diagnosissystems manage and diagnose the faults with a simple word mode and have no self-learning functions is overcome. By using a patterned fault diagnosis technology, a maintainer can find out abnormity inadvance and immediately determine a fault reason. Sudden events can be prevented, the service expiration and the service time of equipment can be prolonged, and the cost is saved. The invention also discloses application of the method for patterning the Petri network to diagnosis of the fault of a marine gas turbine.

Owner:NAVAL UNIV OF ENG PLA

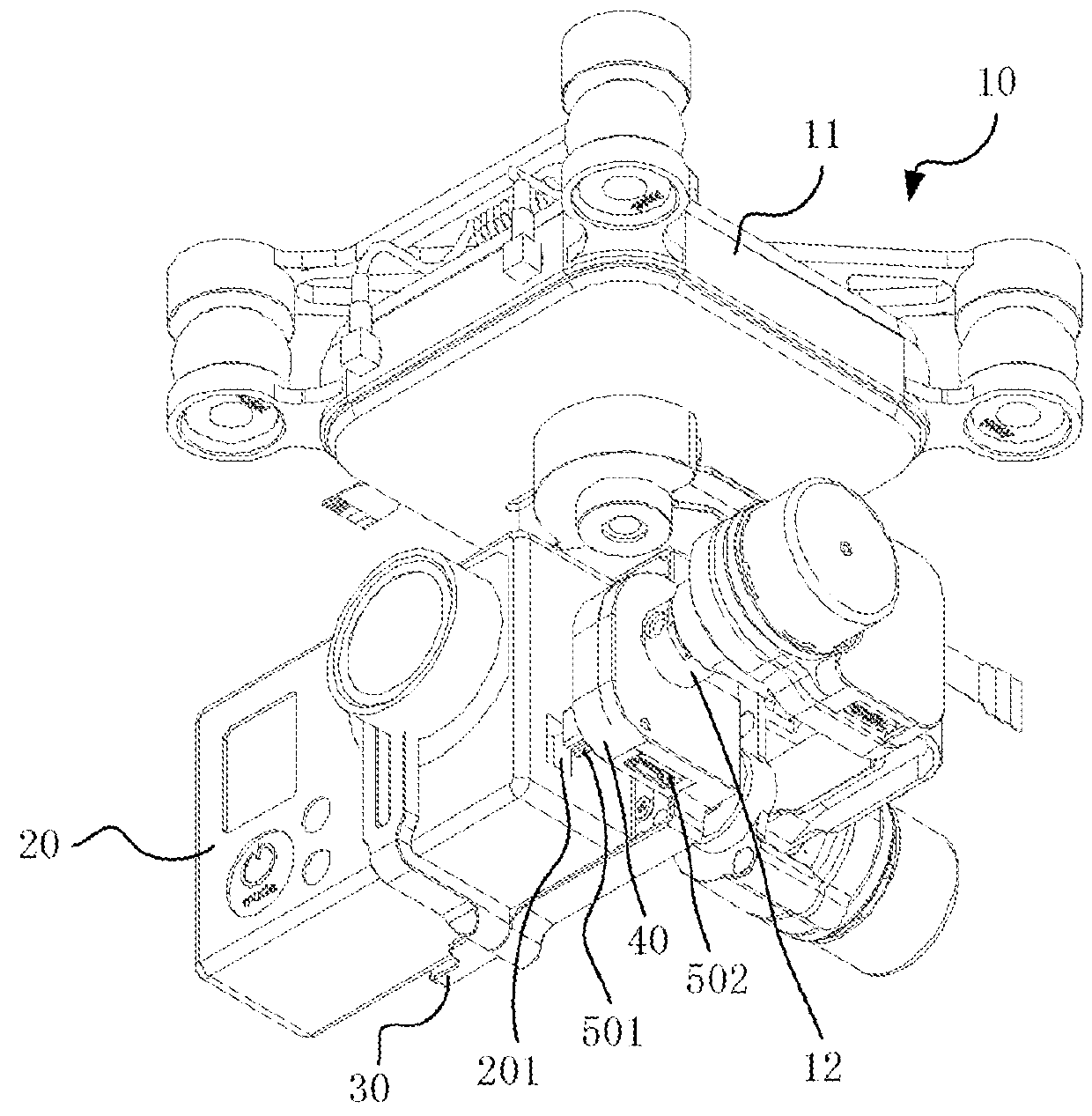

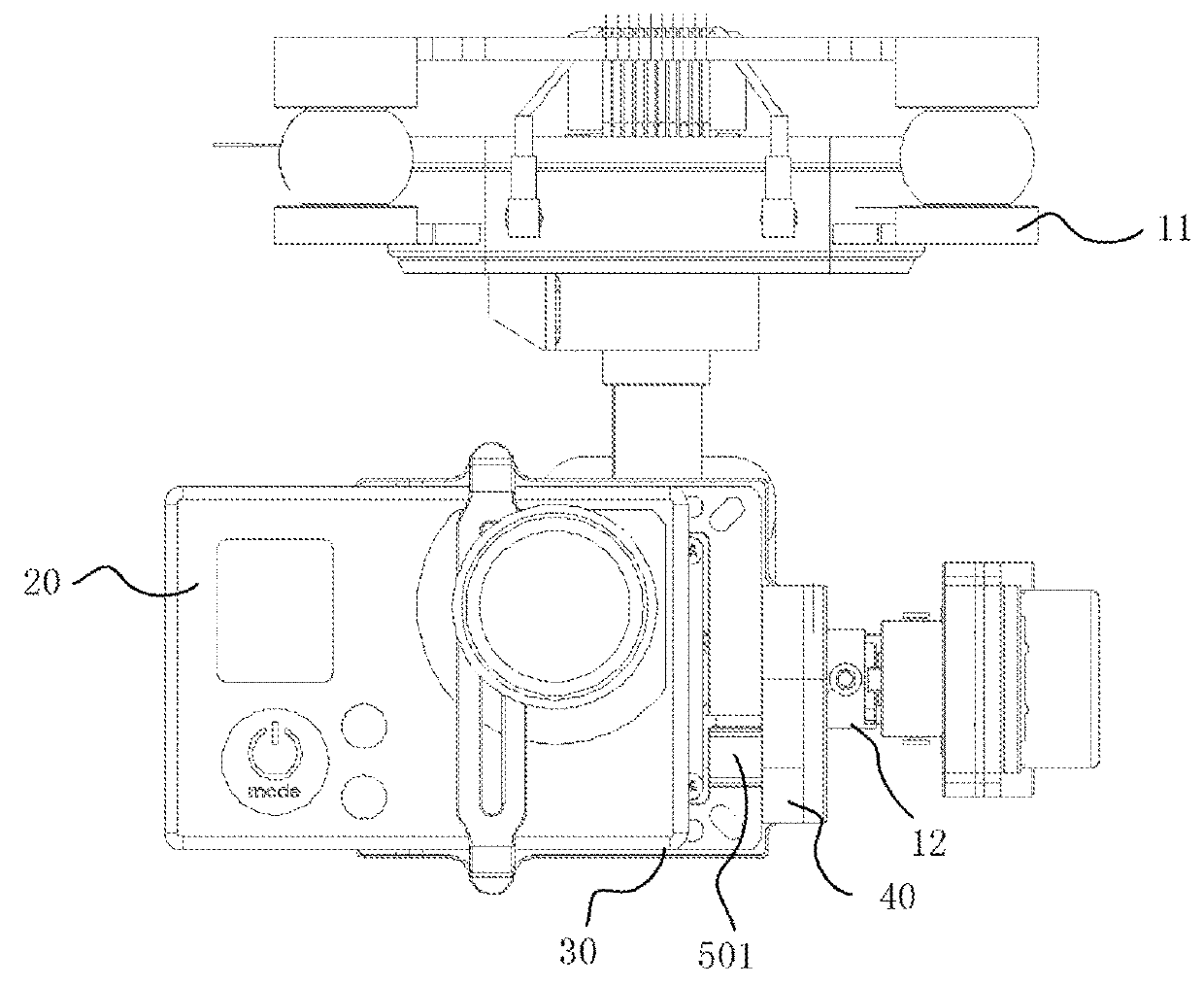

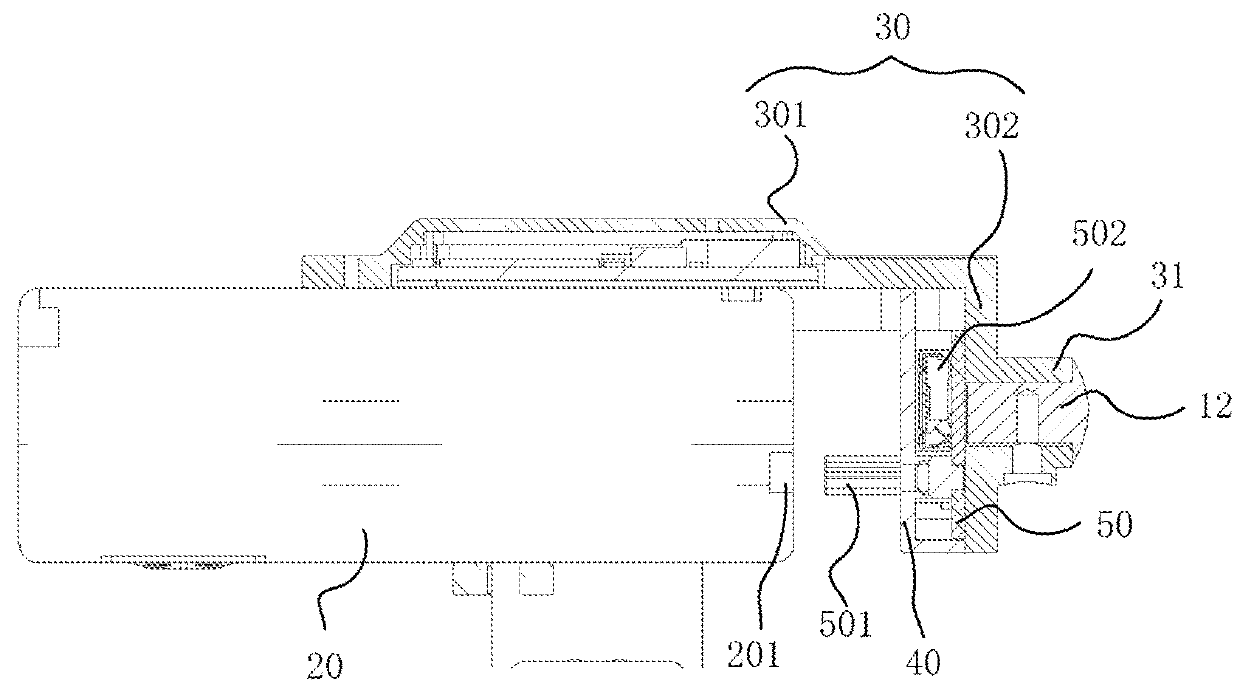

Unmanned aerial vehicle, image photographing apparatus and gimbal thereof

ActiveUS20180273203A1Reduced service lifeExtended service periodAircraft componentsUnmanned aerial vehiclesExternal storageData transmission

The present application relates to a gimbal configured to mount a photographing device. The gimbal includes a main body, a mounting shaft connected to the main body and a base disposed on the mounting shaft. The base is configured to fasten the photographing device. The gimbal further includes a fixing plate disposed on the base and a circuit board mounted between the fixing plate and the base. The circuit board is provided with a USB input interface and a USB output interface. The USB input interface is configured to form a data transmission connection to the photographing device. The USB output interface is configured to be connected to an external storage device. The present application further relates to an image photographing apparatus including the foregoing gimbal and an unmanned aerial vehicle including the foregoing image photographing apparatus.

Owner:SHENZHEN AUTEL INTELLIGENT AVIATION TECH CO LTD

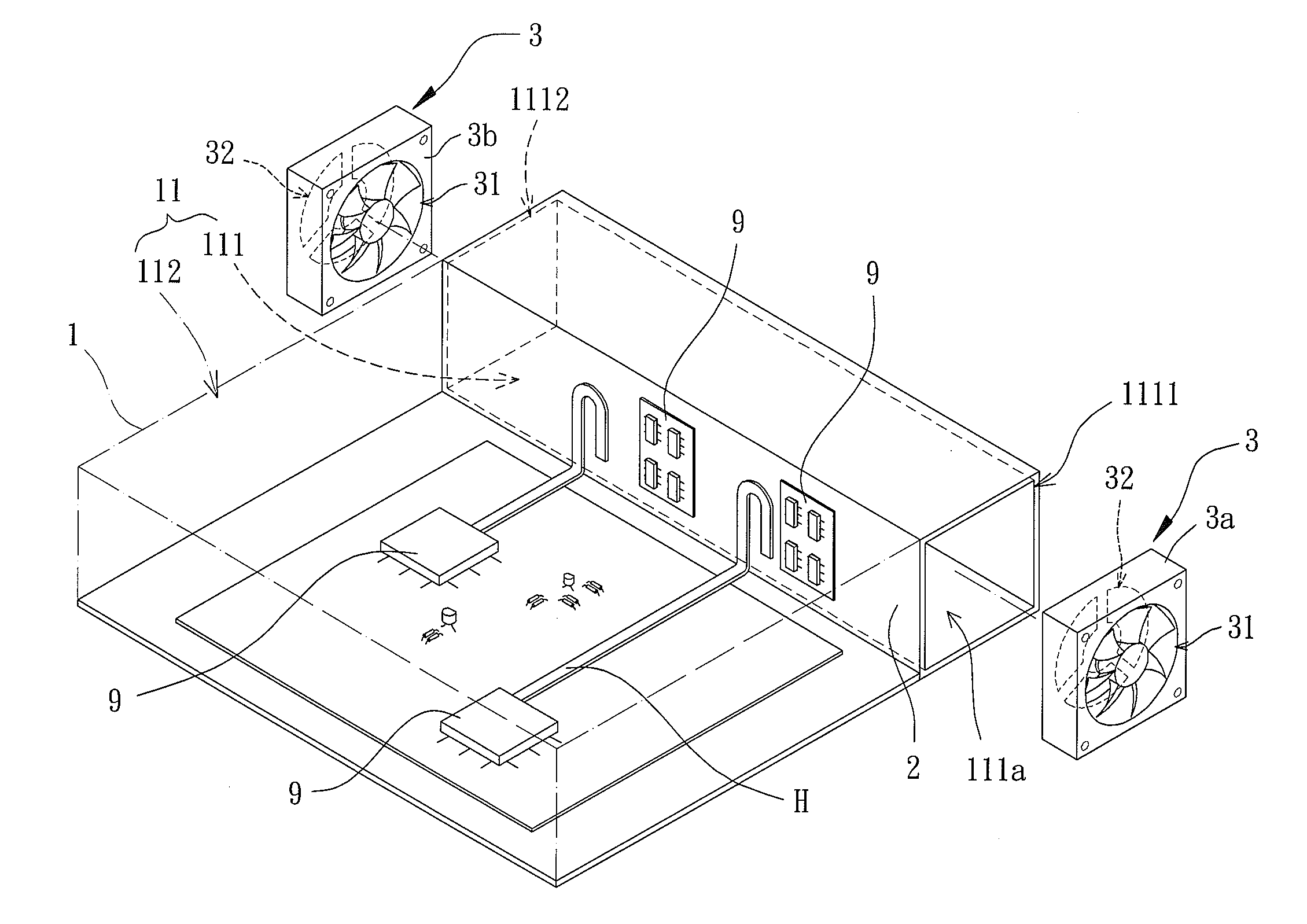

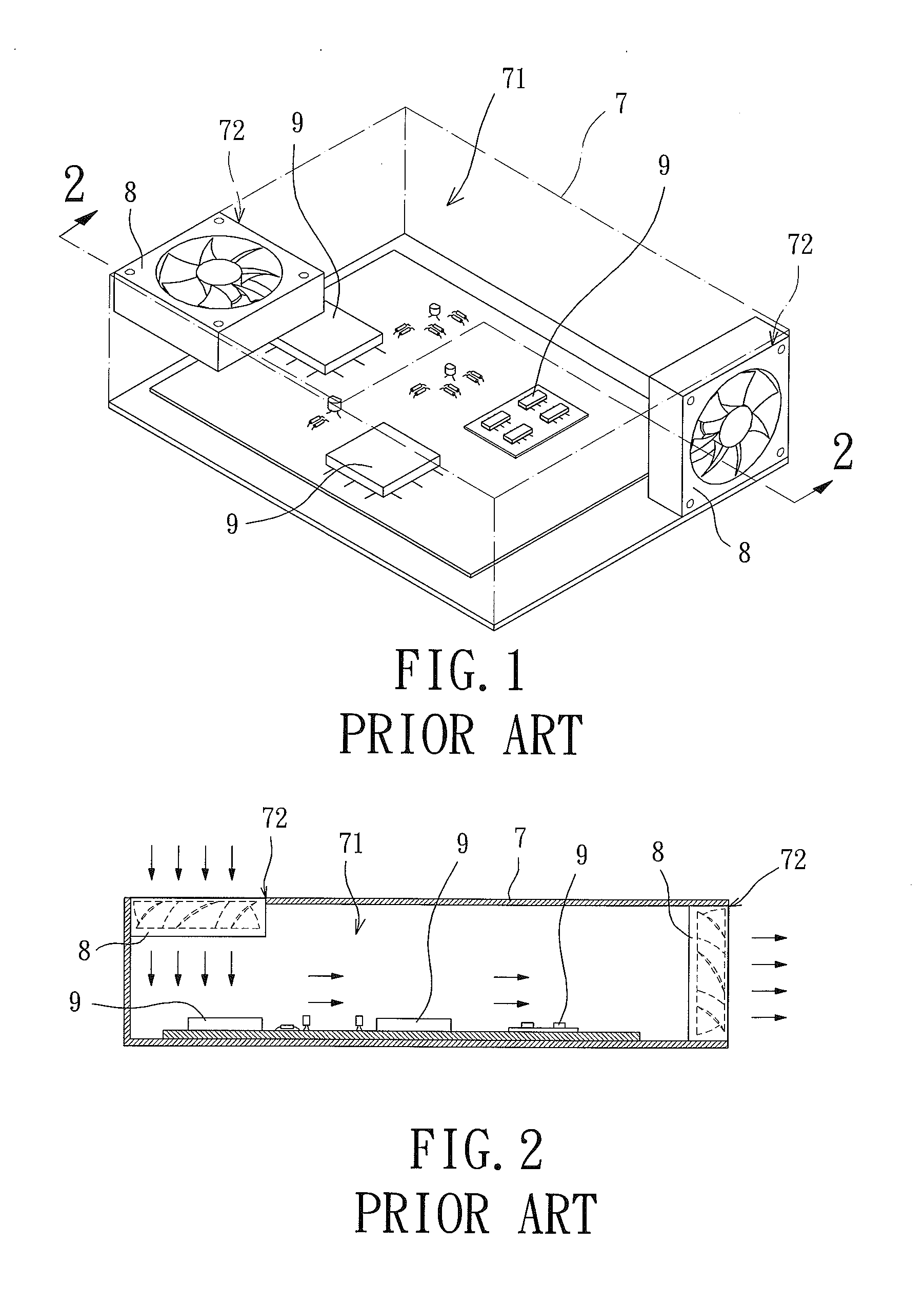

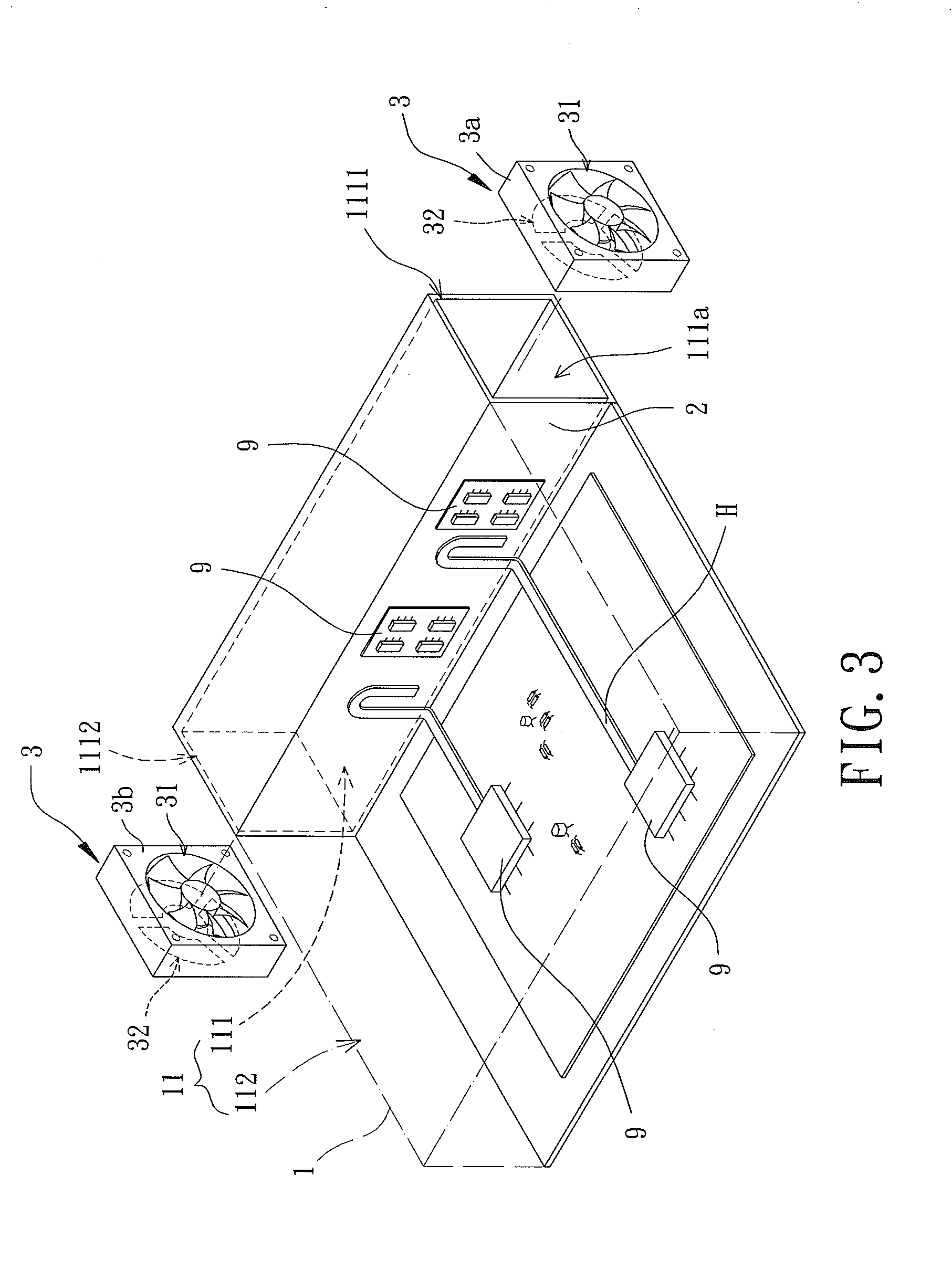

Electronic Product Including a Heat Dissipating Device

ActiveUS20140254095A1Extended service periodIncrease the heat exchange areaSemiconductor/solid-state device detailsSolid-state devicesHeat conductingElectronic component

An electronic product including a heat dissipating device is disclosed. The electronic product includes a casing, a heat conducting board, at least one fan unit and a plurality of electronic elements. The casing includes a compartment. The heat conducting board divides the compartment into first and second chambers. The first chamber includes a plurality of openings. The fan unit(s) includes an air inlet aligned with an opening of the openings, as well as an air outlet aligned with another opening of the openings. The first chamber defines at least one air channel each being in the form of a single air channel including two ends respectively in communication with the opening and the other opening. In one embodiment, the at least one fan unit includes first and second fan units. In another embodiment, the at least one air channel includes first and second air channels in communication with each other.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

Environment-friendly type transformer oil with high ignition point and preparation method of transformer oil

The invention discloses environment-friendly type transformer oil with a high ignition point and a preparation method of the transformer oil and belongs to the technical field of lubricating oil. The environment-friendly type transformer oil with the high ignition point comprises components in percentage by weight as follows: 99.5%-99.8% of high-oleic rapeseed oil, 0.1%-0.4% of an antioxidant and 0.1%-0.4% of a metal deactivator. The invention further provides a preparation method of the transformer oil. The preparation method comprises steps as follows: the high-oleic rapeseed oil is heated to 50-80 DEG C, the antioxidant and the metal deactivator are added sequentially, the materials are stirred and mixed for 1-5 h, and the transformer oil is obtained after cooling and refined filtration. The transformer oil adopts a simple process, does not contain harmful substances, is biodegradable and cannot damage the environment and the human body; the performance is stable, good stability is kept between different batches, the ignition point is high, and risks of fire disasters and explosions are effectively reduced; the addition quantity of the antioxidant is low, the service period is long, and the transformer oil has excellent physicochemical and dielectric properties and meets the requirement of national standard.

Owner:青岛中科润美润滑材料技术有限公司

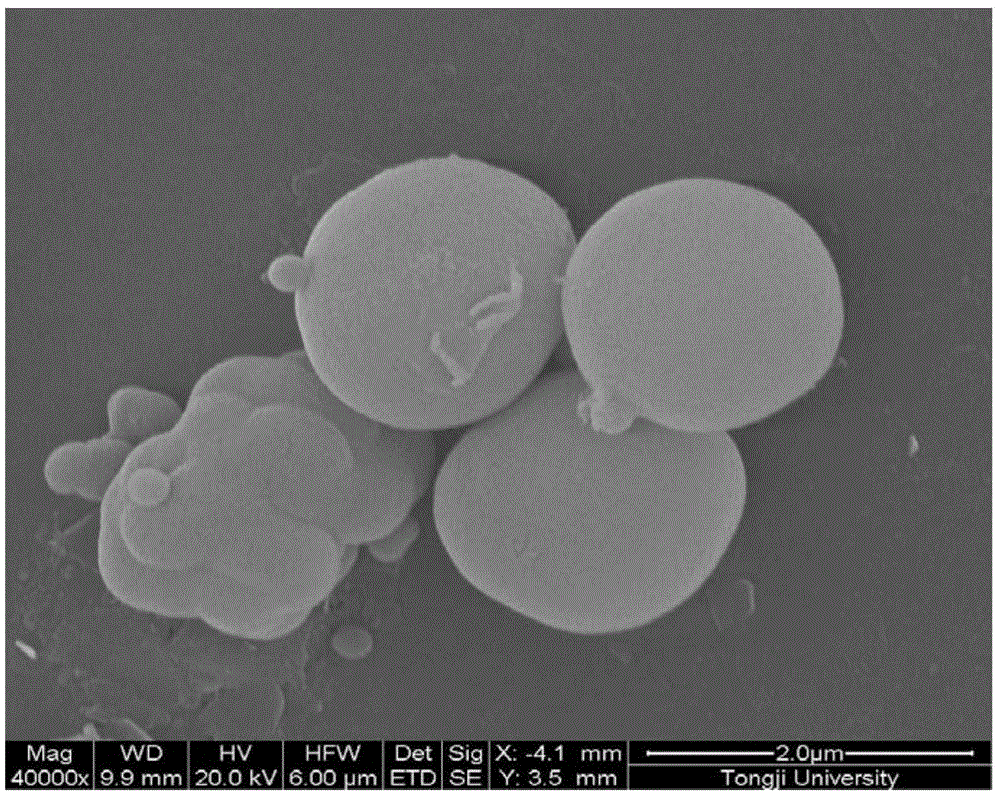

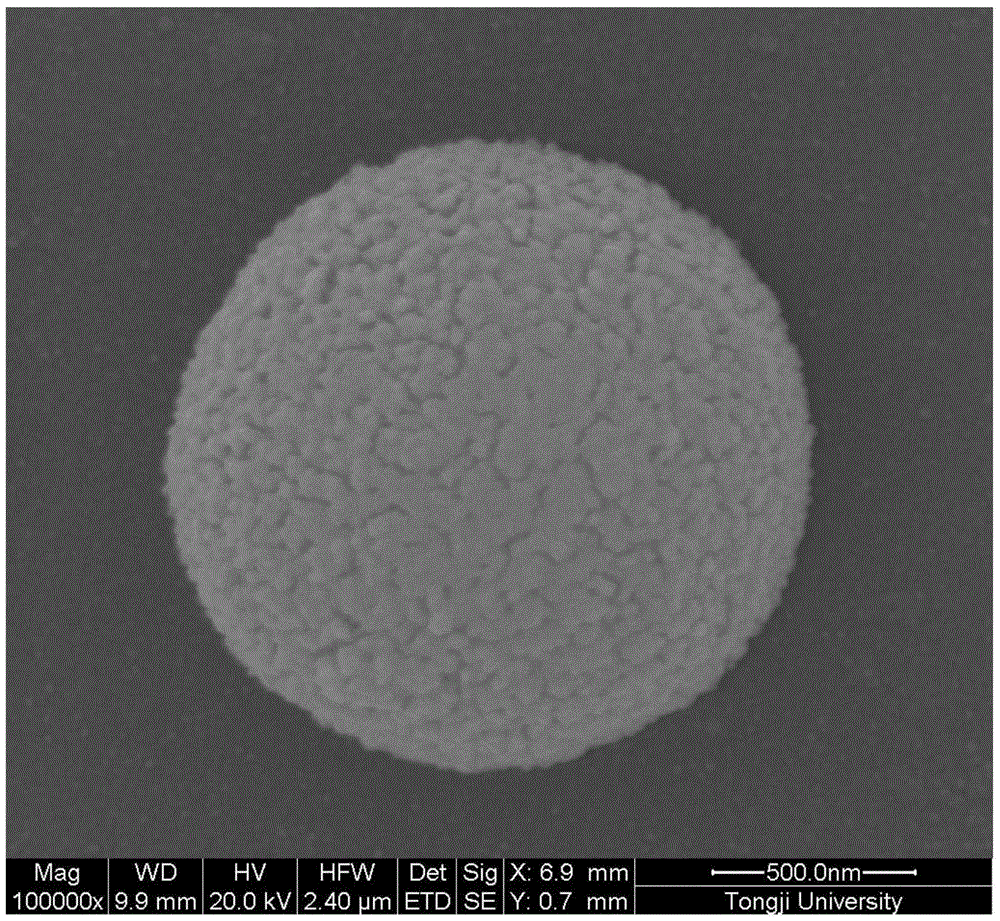

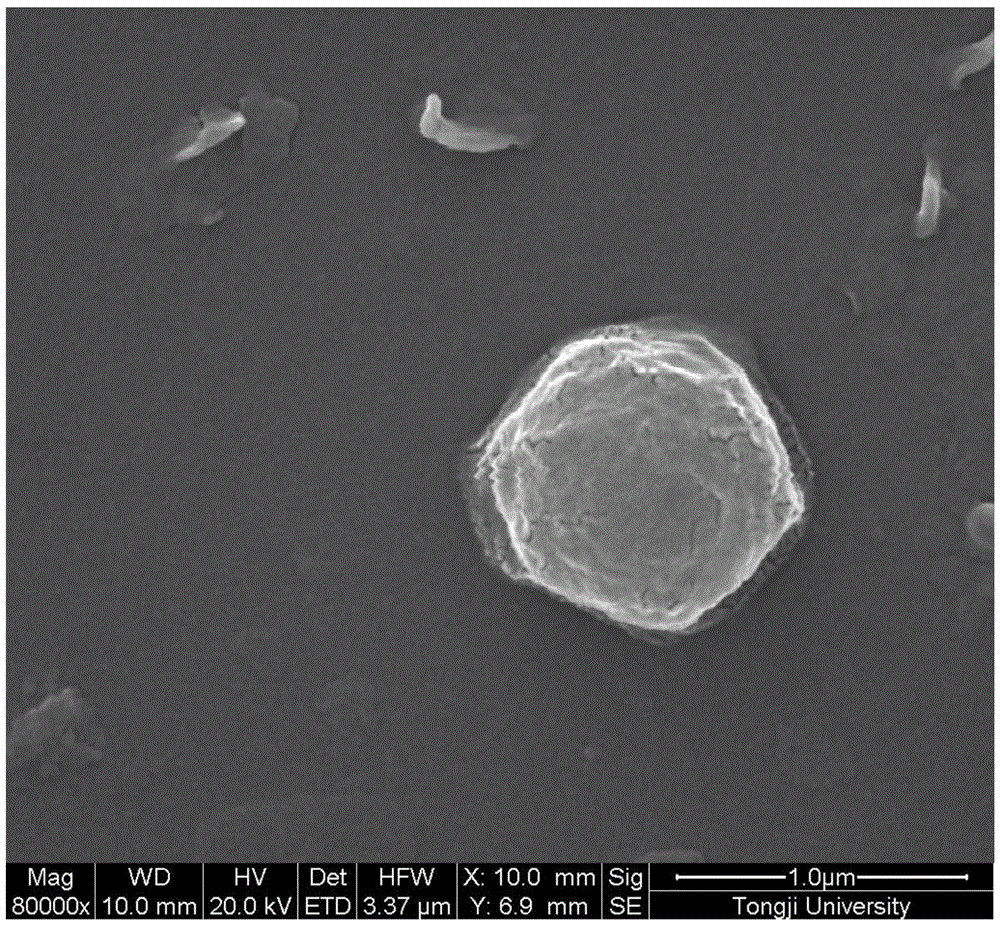

Concrete autolysis chemical sulfate corrosion resistance system in water environment

The invention relates to a concrete autolysis chemical sulfate corrosion resistance system in a water environment. The system comprises a concrete base and porous silicon dioxide microspheres arranged in the concrete base, wherein a sulfate-corrosion-resistant repair agent is carried on the porous silicon dioxide microspheres, and an autolysis protective film is coated on the surface. Compared with the prior art, the sulfate corrosion resistance system can be effective for a long time, can enhance the sulfate corrosion resistance of the concrete structure within a wide range, establishes an intelligent sulfate-corrosion-resistant substructure concrete system, enhances the safety and durability of the substructure, and prolongs the service life of the substructure.

Owner:TONGJI UNIV

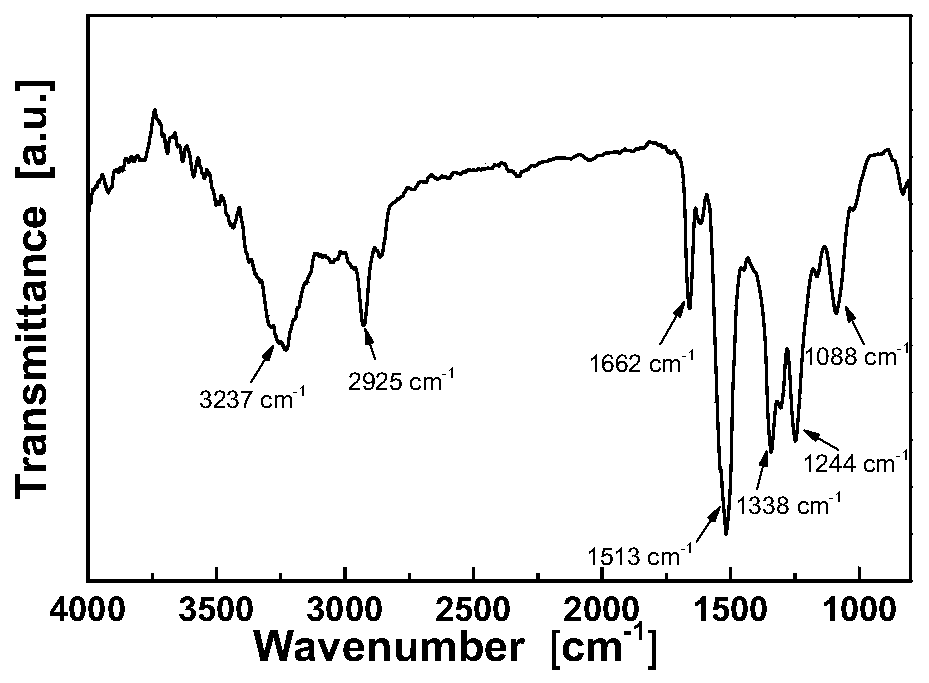

Intrinsic self-repairing and recyclable polythiourea polymer, and preparation method and application thereof

The invention relates to an intrinsic self-repairing and recyclable polythiourea polymer, and a preparation method and an application thereof. The polythiourea polymer is composed of the following components in parts by weight: 1.9 to 24.5 parts of a diamine monomer, 3.7 to 5.9 parts of a diisothiocyanate monomer and 0.07 to 2.2 parts of an amine monomer crosslinking agent; the functionality of the amine monomer crosslinking agent is greater than 2. The polythiourea polymer provided by the invention contains a characteristic dynamic reversible thiourea bond unit, and endows the polythiourea polymer material with thermotropic reversible self-repairing and solid crushing or solvent degradation recoquite properties, so that the use stability of the material is enhanced, and the service life of the material is prolonged. The preparation method provided by the invention is simple in process, the thermal reversible temperature range of thiourea bonds is wide (35-120 DEG C), and no additionalcatalyst is needed.

Owner:SUN YAT SEN UNIV

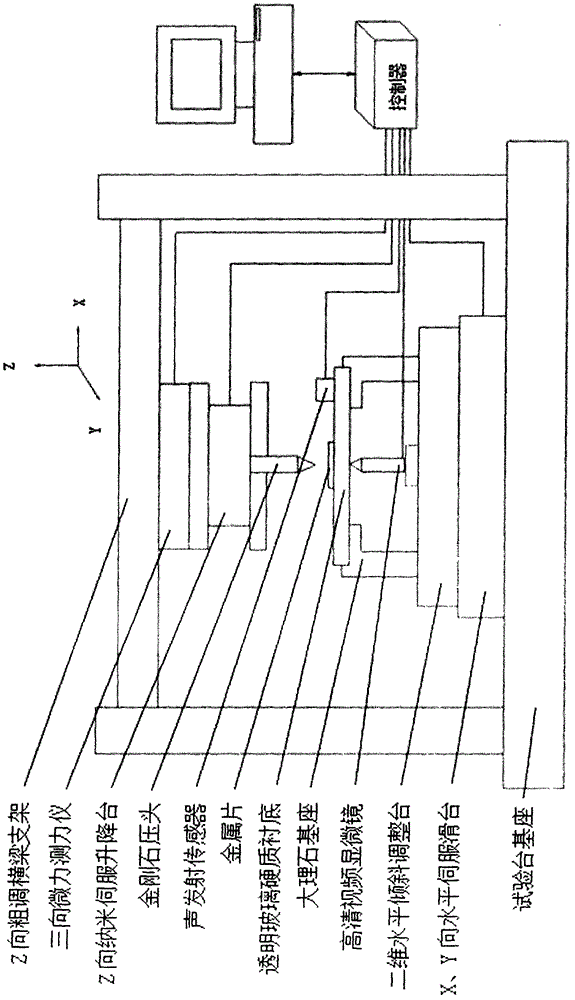

Nano-imprinting forming and pressure-print hole-forming method of metal sheet

InactiveCN104483393AExtended service periodReduce processing costsMaterial analysis using sonic/ultrasonic/infrasonic wavesMeasurement deviceSignal characteristic

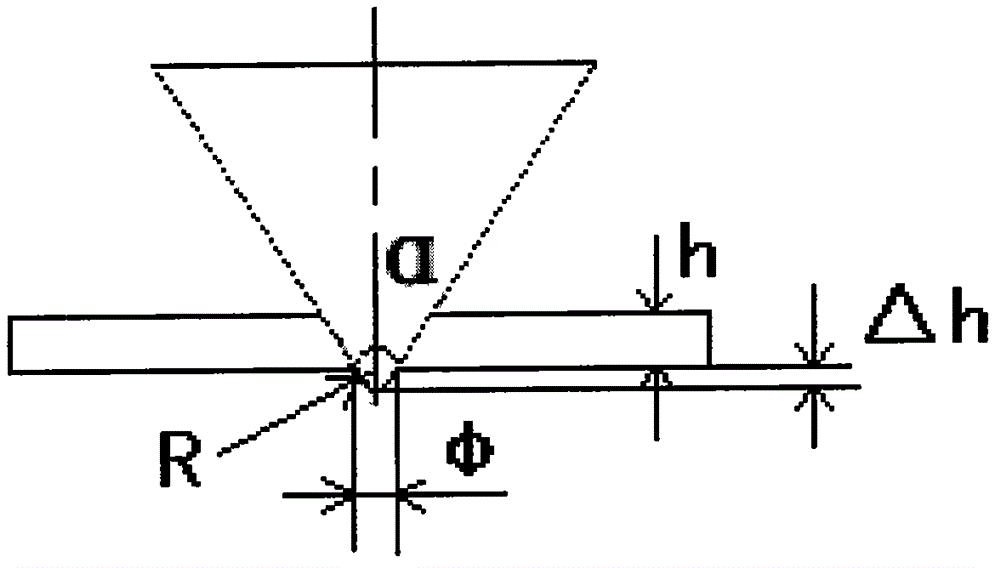

The invention discloses a nano-imprinting forming and pressure-print hole-forming method of a metal sheet. The method comprises the steps of grinding a taper angle a and a tip blunt circle radius R of a diamond pressure head according to indexes phi of different formed holes in the bottom of the metal sheet; judging a specific position, being contacted with the upper surface of the metal sheet, of the tip end of the diamond pressure head by utilizing a measurement device; controlling the diamond pressure head to press continuously through a Z-direction nano servo lifting platform, ensuring a material inside the metal sheet to do lateral plastic flow motion under the combined effect of the taper angle of the pressure head and a bottom hard glass substrate, forming the holes with the taper being the taper angle alpha, and breaking the bottoms of the holes to form a large hole; and accurately judging the hole-forming signal characteristic of the bottom of the thin metal sheet pressed by the diamond pressure head, and feeding back a continuous pressing quantity delta h of the Z-directional nano servo lifting platform.

Owner:CHANGCHUN UNIV OF SCI & TECH

Comprehensive control method for pressure position of hot continuous rolling rolled side guide plate

ActiveCN108714629AReduce wearExtended service periodTension/compression control deviceMetal rolling arrangementsCarbon steelService time

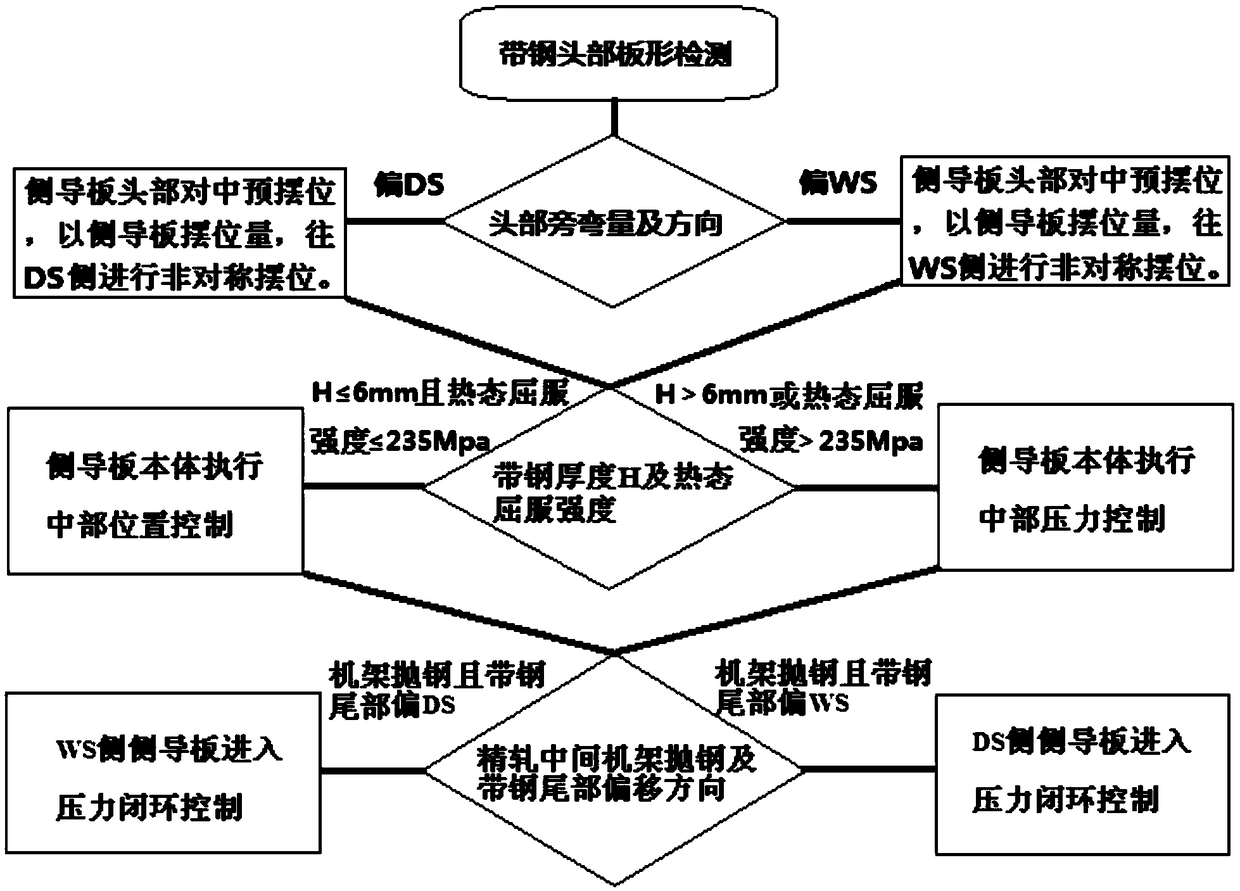

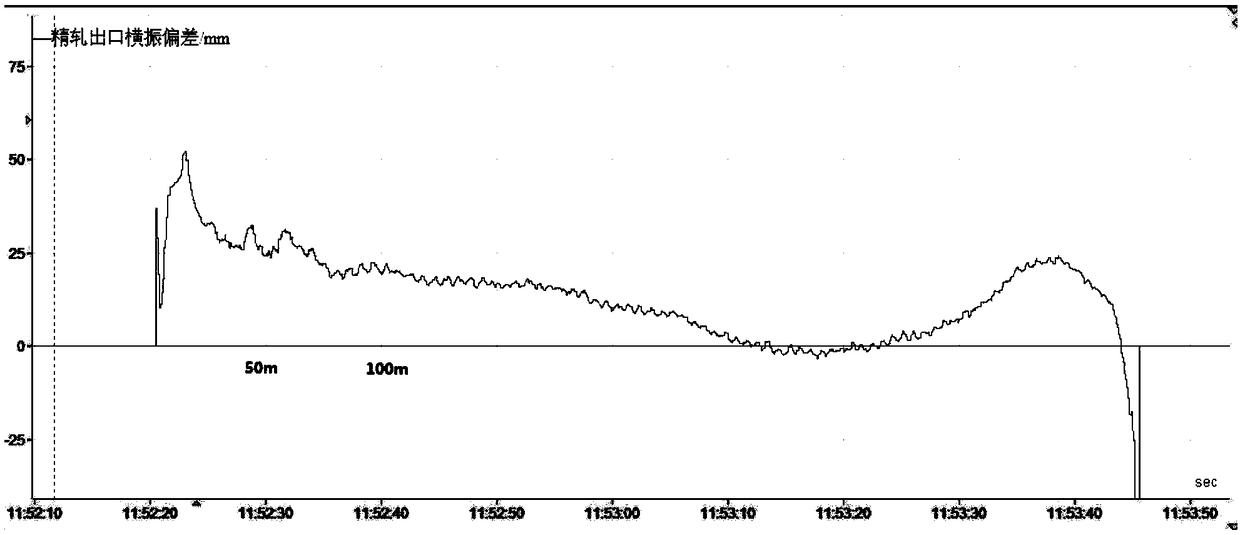

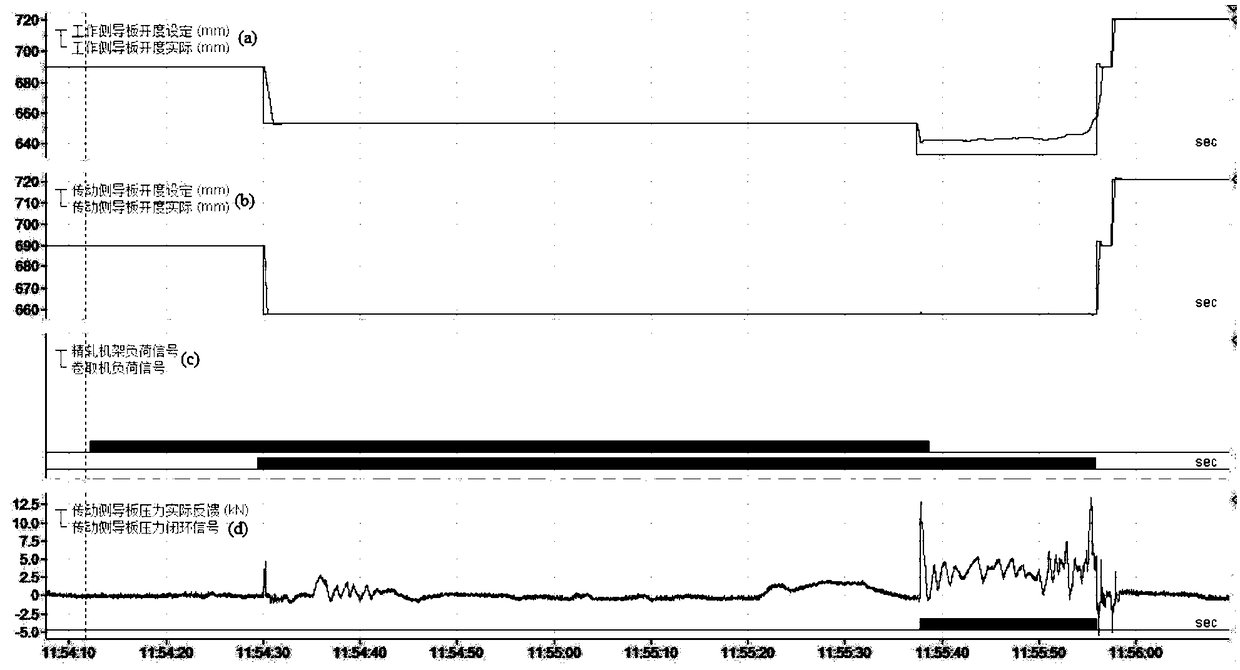

The invention discloses a comprehensive control method for the pressure position of a hot continuous rolling rolled side guide plate. At the head of all-variety strip steel, side guide plate head alignment pre-positioning control is conducted according to the finish rolling incoming material plate shape and the transverse vibration situation; for thin-specification plain carbon steel, the cold state width value is calculated at the corresponding rolling target temperature through an instrument, side guide plate middle position control is achieved; for thick-specification high-strength steel, side guide plate middle pressure closed-loop control is achieved; and at the tail of the all-variety strip steel, automatic side guide plate tail pressure closed-loop control is achieved according to the strip steel tail deflection direction. In the whole rolling period, the actual positions of the head and the tail of the strip steel are tracked in real time, and accordingly corresponding actionsare executed. Since the comprehensive control method is input, the on-machine service time of a rolled side guide plate is seven days; the cold-rolled raw material edge breaking material return rate is reduced to 0.46%, the thin-specification plain carbon steel roll head tower-form maximum value is reduced to 30 mm, and steel roll middle maximum roll-shaped sawteeth are reduced to 2 mm; and the abnormal roll shape occurrence rate is reduced to 1.52%.

Owner:武汉钢铁有限公司

Structure of an impurities collecting bucket for an air separator and purifier

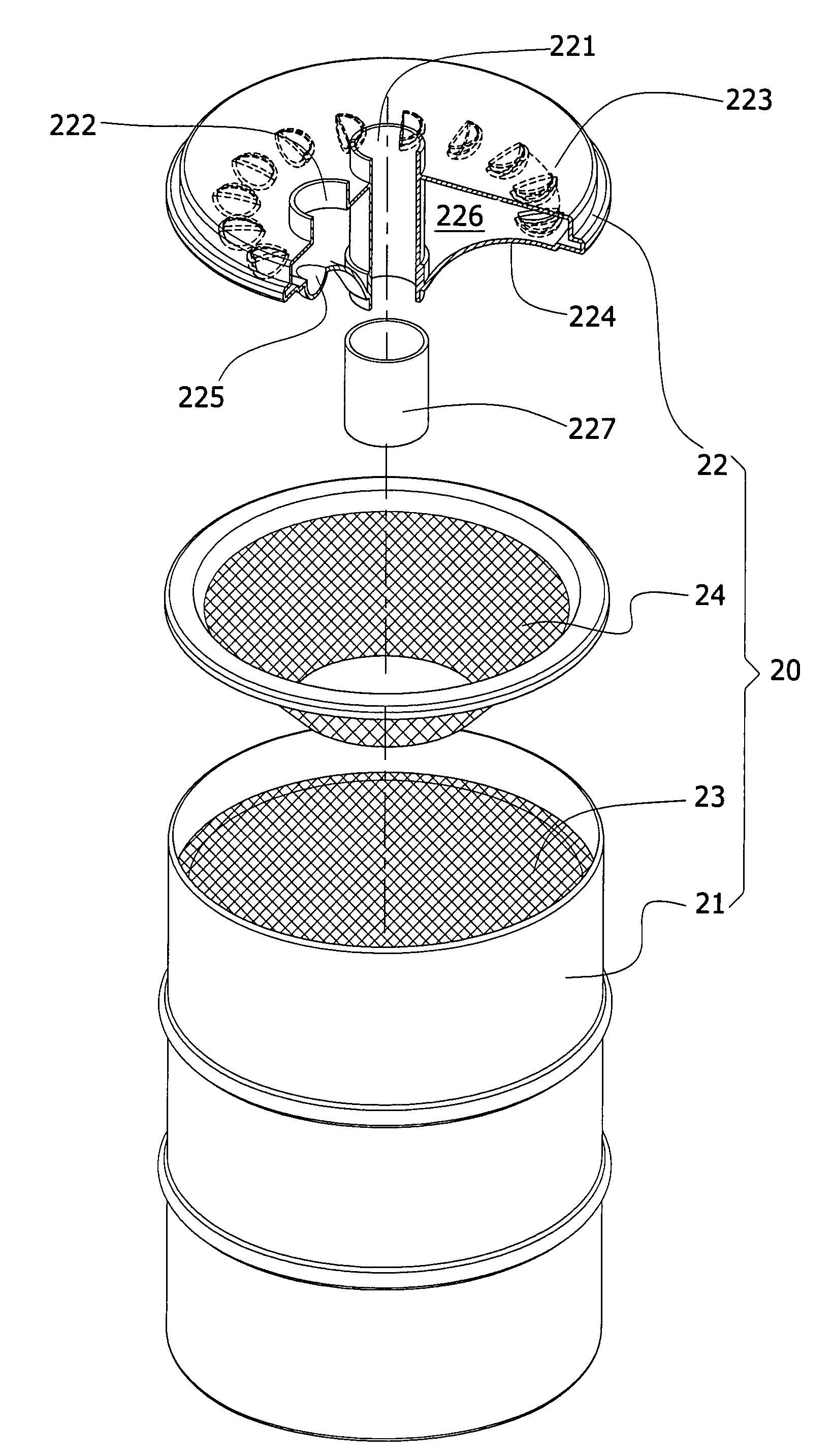

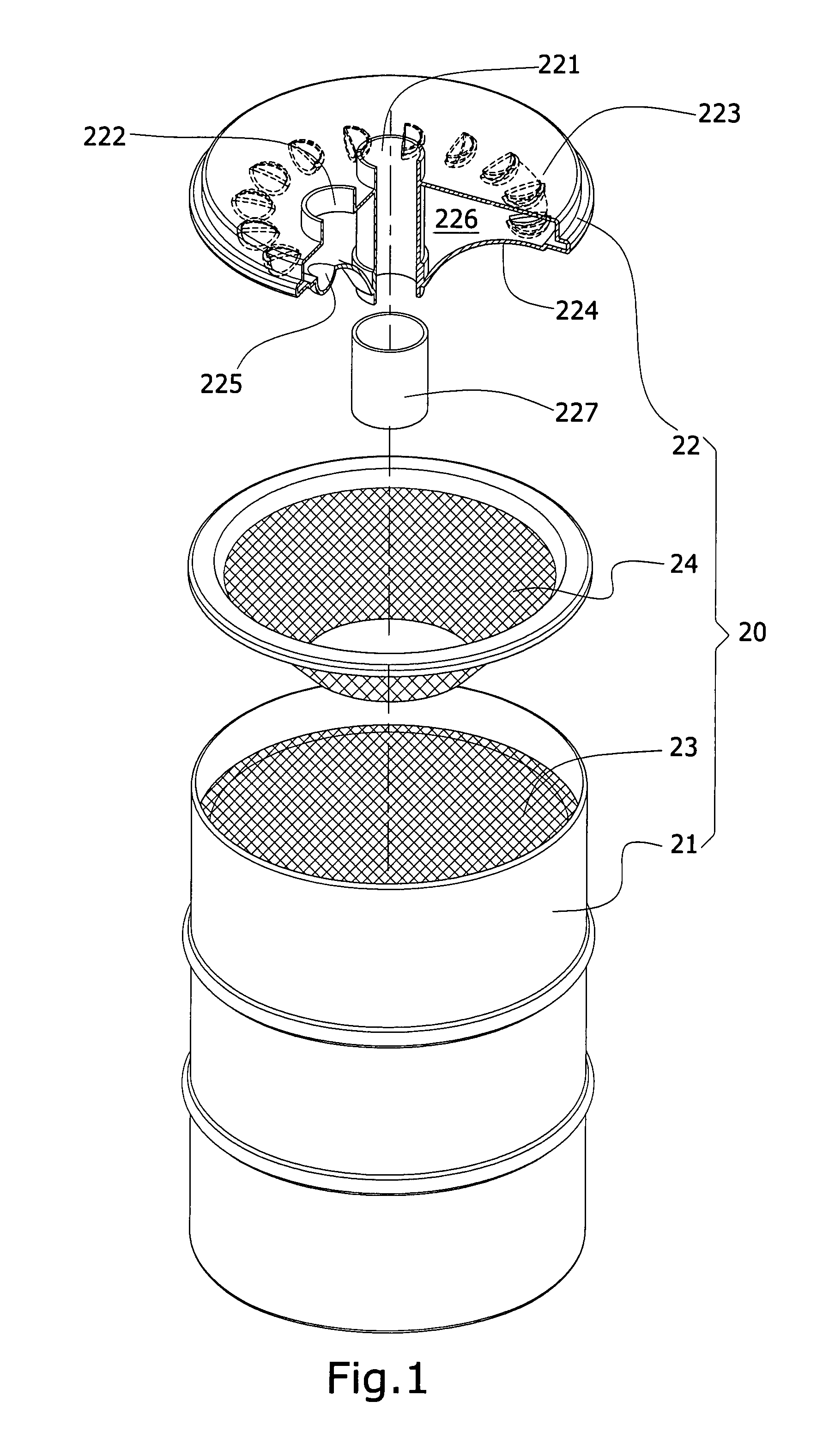

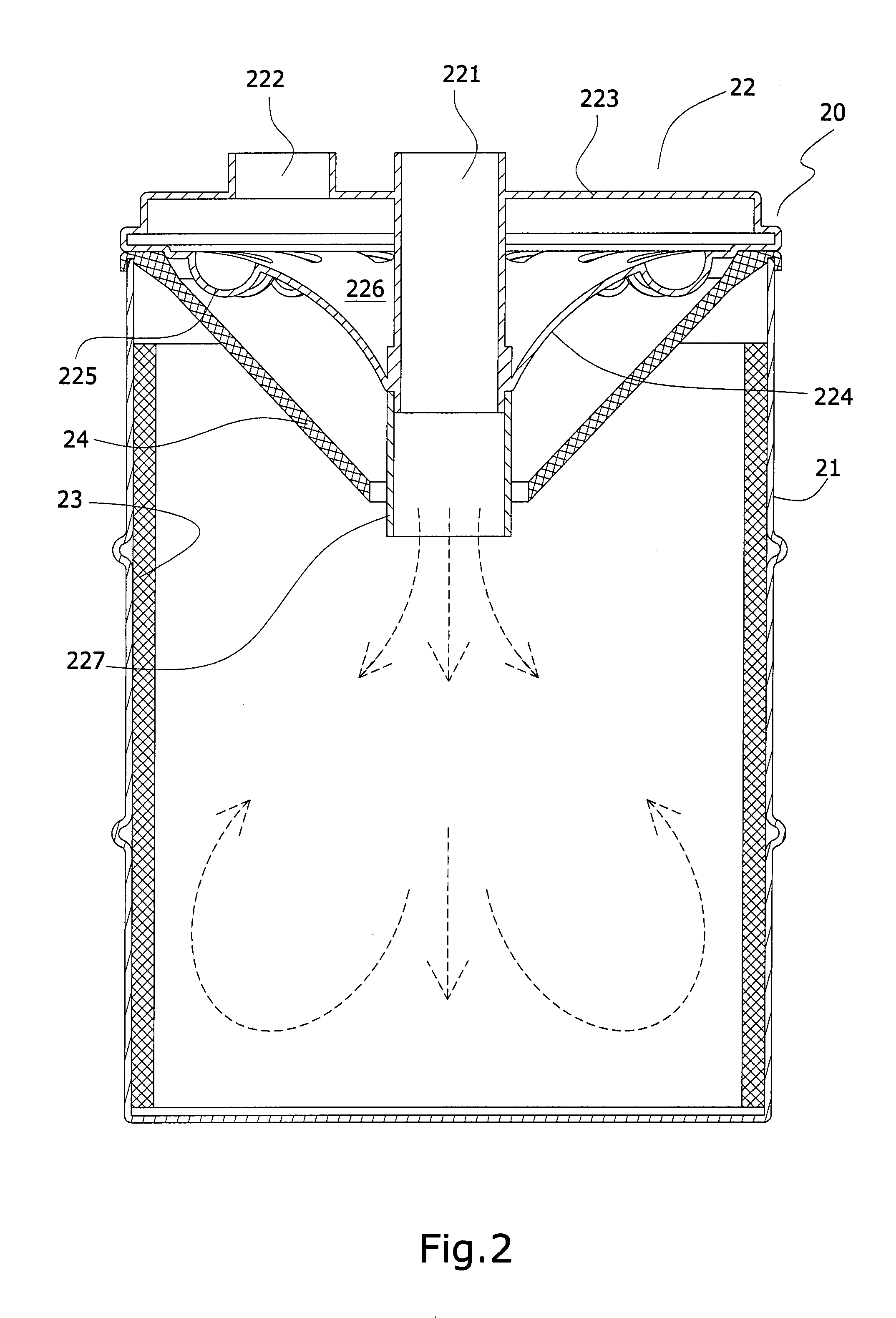

InactiveUS8012230B2Extended service periodImprove filtering effectCombination devicesAuxillary pretreatmentEngineeringImpurity

A structure of an impurities collecting bucket for an air separator and purifier, primarily structured from a bucket and an air guide cover, wherein the air guide cover covers an opening at an upper end of the bucket, and is provided with an air inlet and an air suction port. A guide pipe extends from the air inlet and connects to a work place, and another guide pipe connects the air suction port to an air inlet of an air separator and purifier for series operation.

Owner:LOCKHEED MARTIN CORP

Optimization design method for blade root of compound propeller blade

InactiveCN102930118AReduce development costsMeet the actual use requirementsSustainable transportationSpecial data processing applicationsStress distributionNavier stokes

The invention relates to an optimization design method for a blade root, in particular to the optimization design method for the blade root of a compound propeller blade, and aims to solve the problem that molded surfaces between adjacent propeller blades are often overlapped when a blade root connection form designed by the conventional design method is applied to a ship propeller, and the diameter of a propeller hub is relatively smaller, so that the propeller blades and the propeller hub cannot meet the use requirements. The optimization design method comprises the following steps: drawing a geometrical model of a compound propeller through a three-dimensional entity configuration software; calculating the hydrodynamic performance of the compound propeller by utilizing an RANS (Reynolds-Averaged Navier-Stokes) equation so as to build a geometrical model of the compound propeller blade with the wedge-shaped blade root; and calculating stress distribution of the propeller blade and the blade root through a finite element analysis software so as to finally finish optimization design of the blade root. The optimization design method is applied to transportation tools such as naval vessels.

Owner:HARBIN INST OF TECH

Coating structure of medical biodegradable zinc alloy stent and preparation method thereof

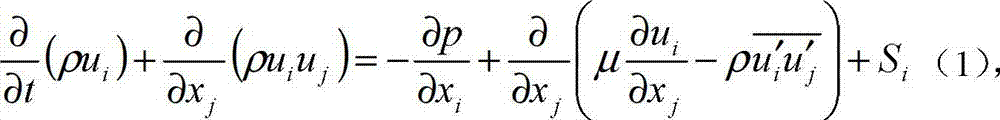

ActiveCN109939271AGood biocompatibilityNo side effectsSurgerySolid state diffusion coatingZinc alloysPolymer coatings

Provided are a coating structure of a medical biodegradable zinc alloy stent and a preparation method thereof. The stent consists of a coating covering the surface of a zinc alloy stent body (Zn), andcomprises three layers of S1, S2 and S3, the S1 is an oxide coating, the S2 is a polymer coating, and the S3 is a drug coating.

Owner:赵亚芳 +1

Polymer wax powder with self-repairing function, and preparation method thereof

ActiveCN110885458AHigh surface hardnessImprove stain resistanceAntifouling/underwater paintsPaints with biocidesPolyesterPolymer science

The invention relates to a polymer wax powder with a self-repairing function, and a preparation method thereof. The polymer wax powder is prepared from, by weight, 55-75 parts of polyethylene wax, 1-20 parts of allyl bisphenol A epoxy resin, 0.5-2 parts of hydroxyalkylamide, 0.5-5 parts of a silane coupling agent, 5-25 parts of carboxyl-terminated saturated polyester and 0.5-5 parts of an accelerant. The preparation method comprises the steps of ingredient mixing, melt extrusion, micronization, electron irradiation crosslinking and the like. The composite polymer wax micro-powder with the average particle size of 1-75 [mu]m can be prepared, and the wax micro-powder can be used as a polyester or epoxy polyester powder coating self-repairing functional additive to improve the surface hardness of a powder coating, enhance the stain resistance and make the coating material have the self-repairing function.

Owner:NANJING TIANSHI NEW MATERIAL TECH

Industrial intelligent optimization energy-saving system based on cement kiln fault diagnosis

PendingCN111158336AFailure prevention or eliminationImprove reliabilityProgramme controlEnergy industryStatistical analysisControl engineering

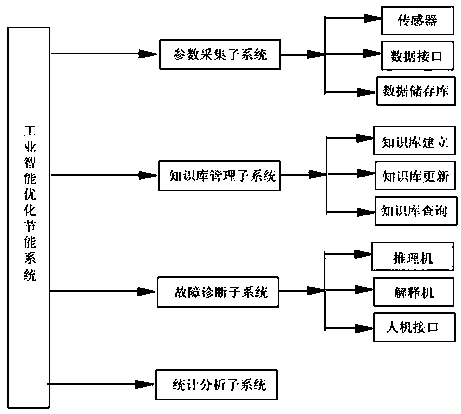

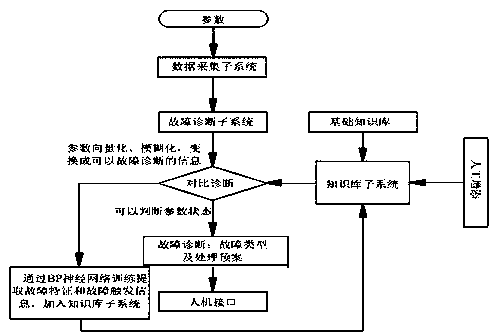

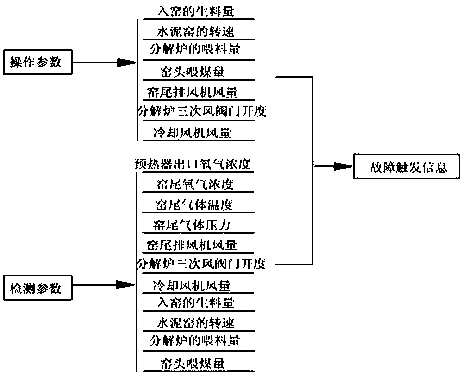

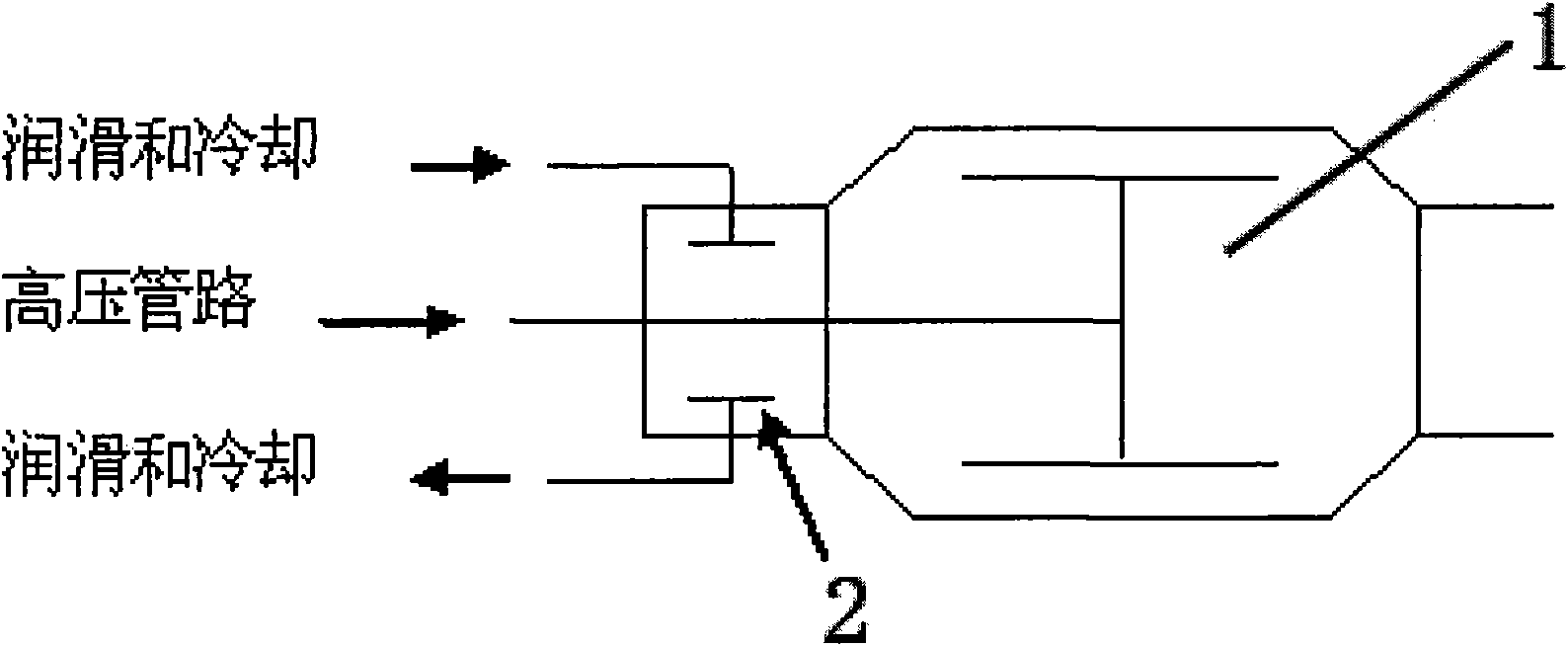

The invention discloses an industrial intelligent optimization energy-saving system based on cement kiln fault diagnosis, and belongs to the technical field of energy management and energy conservation. The method mainly solves the problems that an existing rotary kiln fault detection means excessively depends on experience, and the fault detection means is low in accuracy. The system is mainly characterized by consisting of a parameter acquisition subsystem, a knowledge base management subsystem, a fault diagnosis subsystem and a statistical analysis subsystem; the parameter acquisition subsystem comprises a sensor and a data interface; the knowledge base management subsystem has three functions of knowledge base establishment, knowledge base updating and knowledge base query; the fault diagnosis subsystem comprises an inference engine, an interpreter and a man-machine interface; and the statistical analysis subsystem is used for summarizing and counting fault information for a periodof time and analyzing fault abnormal points, so that a basis is provided for improving the intelligent degree of equipment inspection. The method has the characteristics of parameter information acquisition, fault diagnosis and statistical analysis, and is mainly used for fault diagnosis of the cement kiln.

Owner:万洲电气股份有限公司

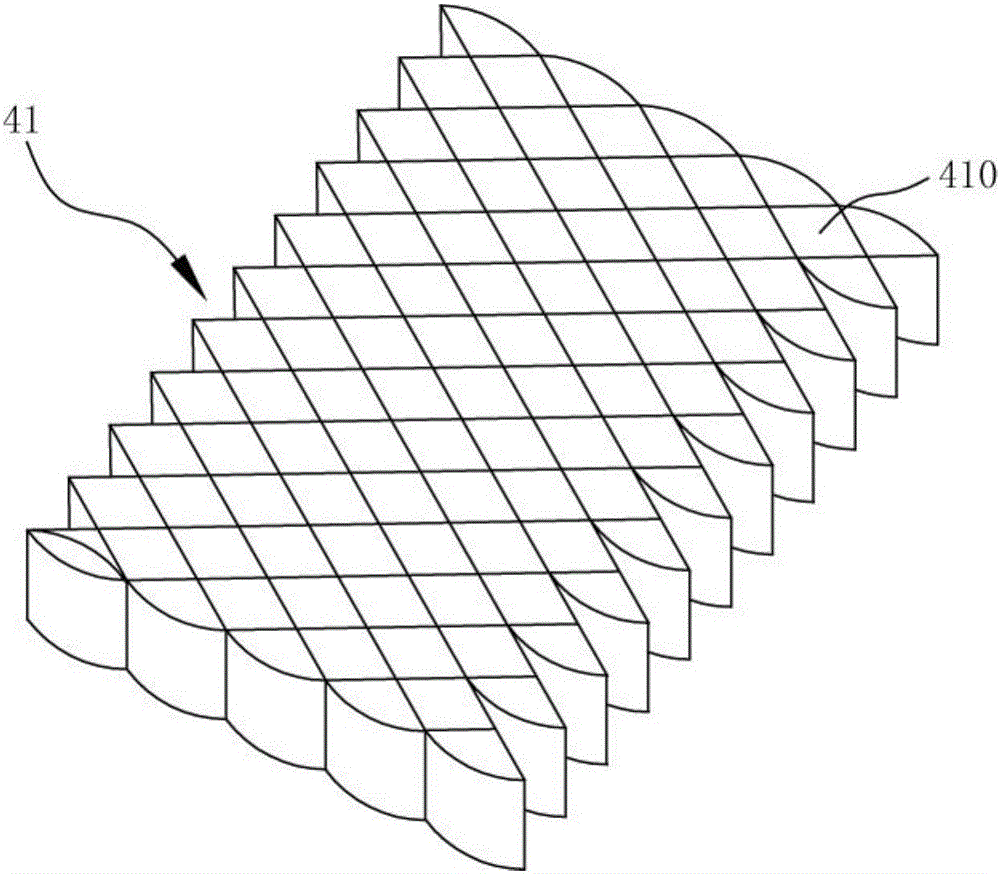

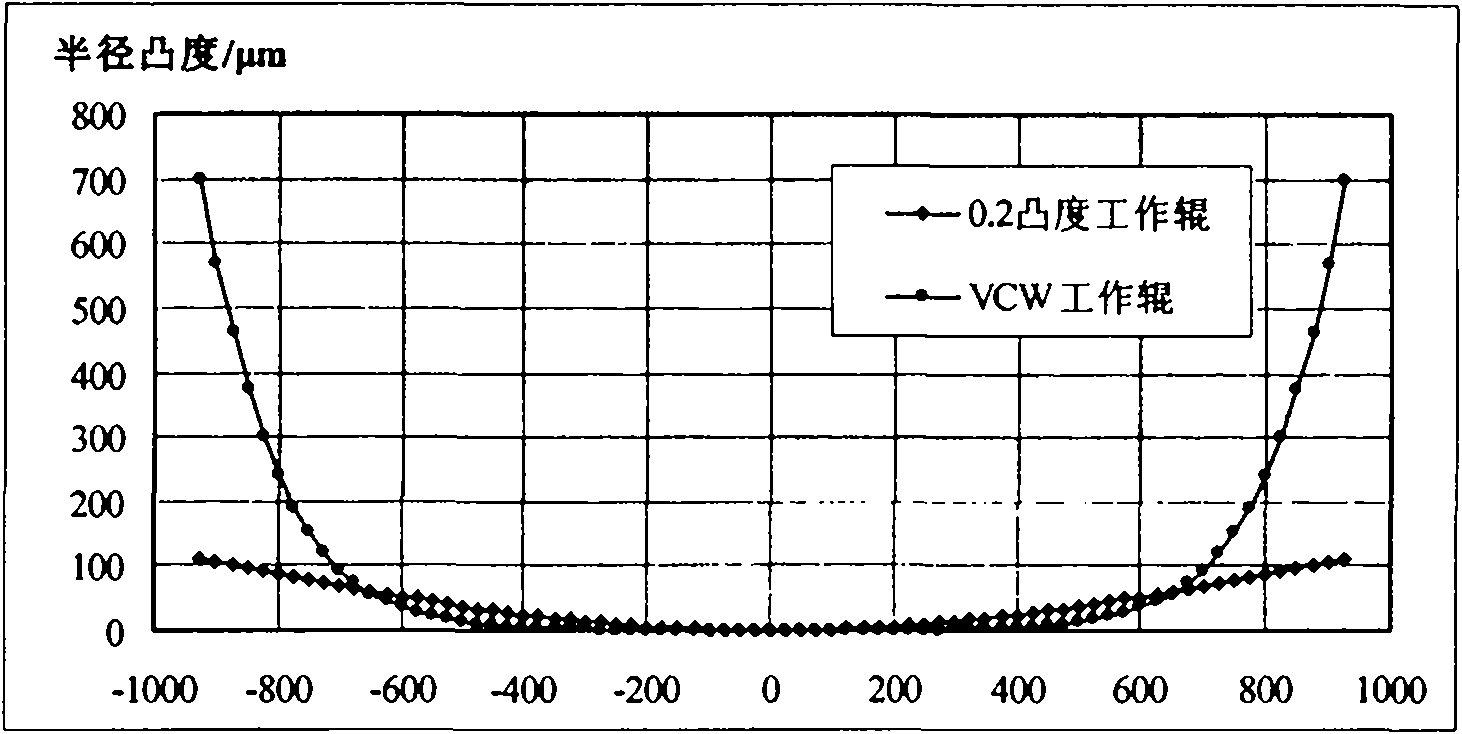

Method for forming variable crown working (VCW) roll shape for strip steel plate shape control

ActiveCN101992219AHas a quadratic convexity valueReduce asymmetric distributionProfile control deviceEngineeringStrip steel

The invention relates to a method for forming a variable crown working (VCW) roll shape for strip steel plate shape control, which is characterized in that a VCW roll shape curve of the VCW roll shape comprises a main carrying area, a transition area and a pressure reduction abutting area, wherein the main carrying area is defined in the strip steel width range of [-B / 2, B / 2], and B is maximal plate width; the transition area is in a range of [-LB / 2, -B / 2] and [B / 2, LB / 2] from the side of a support roll to the side of strip steel, and the roll diameter of the a transition area is smaller thanthat of the main carrying area; and the pressure abutting reduction area is in a range of [-LW / 2, -LB / 2] and [LB / 2, LW / 2] from the side of the working roll to the side of the support roll. The working roll of which the shaped needs to be formed by the method of the invention is just ground into the corresponding shape in a roll grinding workshop, and the invention has the advantages of convenientprocessing and low cost, can be conveniently popularized to a VC planishing mill, is suitable for producing a refrigerator plate with specific specification and has wide application prospect.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Self-aligning thrust bearing for submerged pump

ActiveCN102878105AIncrease contact surfaceRelieve pressurePump componentsPumpsMolecular materialsThrust bearing

The invention discloses a self-aligning thrust bearing for a submerged pump, which comprises a disc-shaped pedestal and at least two thrust bearing blocks uniformly distributed on the circumference of the pedestal; the thrust bearing bocks are composed of bases which are made of metal materials and friction sheets made of high molecular materials; at least one concave waterway is arranged on the surfaces of the friction sheets; a boss is arranged in the middles of the bottom surfaces of the bases; the boss is contacted with the pedestal; and the thrust bearing blocks are provided with clamping mechanisms to fix the thrust bearing blocks on the pedestal. The self-aligning thrust bearing aims at turning a fixing plane type thrust bearing into a self-aligning thrust bearing by changing the structure form of the original design; owing to the design of the boss at the bottom of the thrust bearing, the thrust bearing blocks are inclined to modify the matching precision, so as to remarkably increases the contact area of the thrust bearing blocks and reduce the pressure; the multiple movable friction blocks are synchronously abraded, thereby greatly prolonging the service life of the submerged electric pump. The processing part is simple and easy to realize and is comparatively low in cost; and with application of the self-aligning thrust bearing, the service life of the product is prolonged.

Owner:JINZHOU WATER PUMP FACTORY

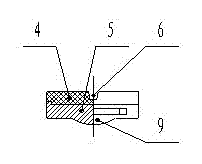

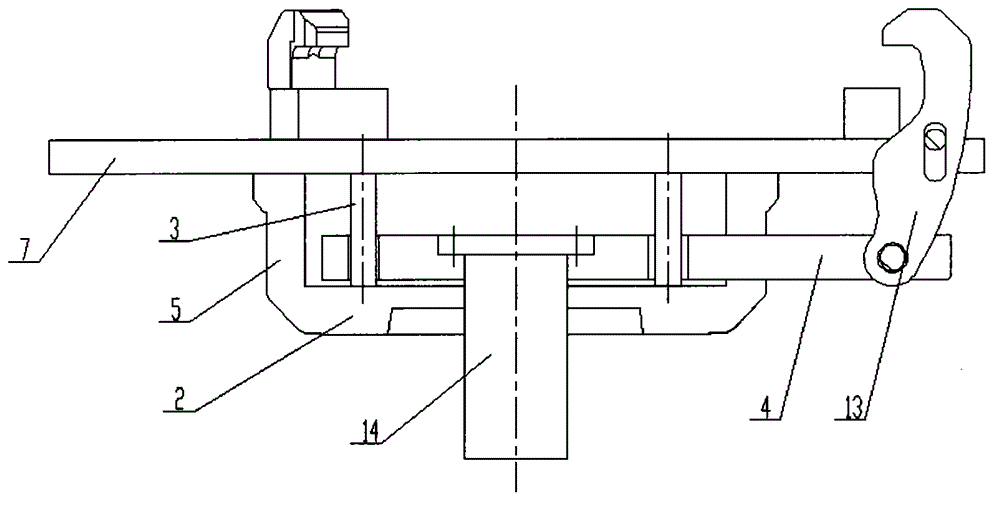

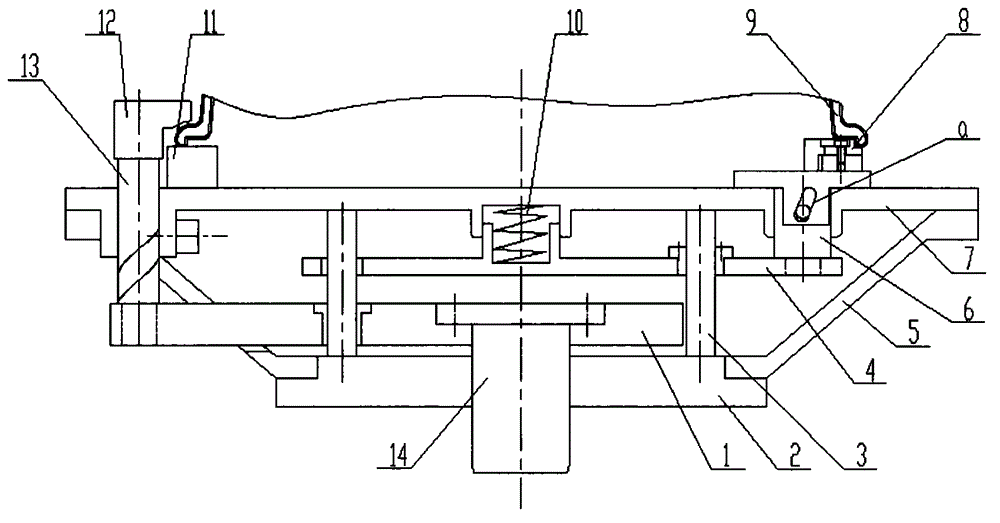

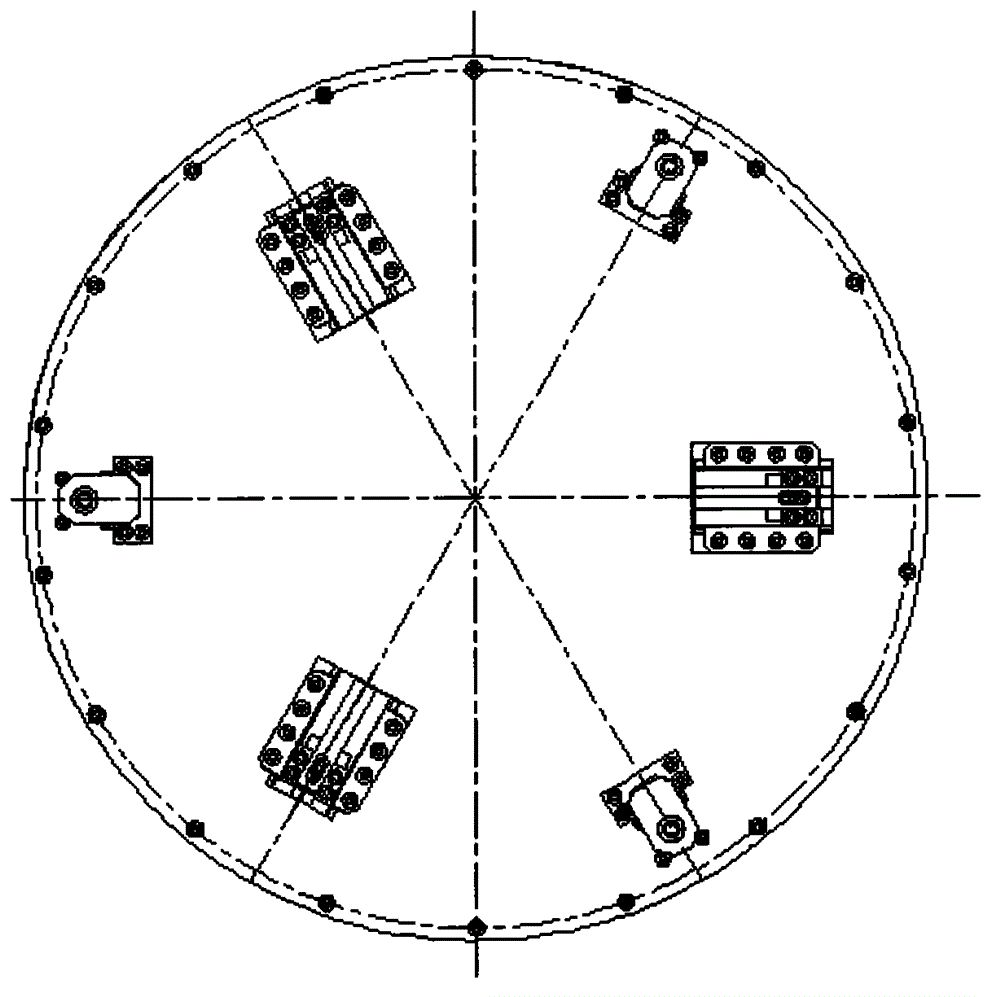

Power chuck for turning hub

The invention provides a power chuck for turning a hub which comprises a chassis, an upper plate, a support ring, a support guide rod, a pressing claw compression connecting rack, a central positioning rack, an axial compressing mechanism, a radial automatic positioning mechanism, a driving cylinder connecting shaft, a spring and the like. The power chuck has the characteristics that the annular conical support structure is adopted, so that the overall weight of the power chuck for turning the hub is greatly reduced, the main shaft load of a machine tool is reduced, the overhaul period and service life of the machine tool are prolonged and the utilization ratio of the machine tool is improved; furthermore, the rotation speed of the main shaft of the machine tool is favorably increased, so that the processing time of each hub can be shortened and the production efficiency is improved.

Owner:吴行飞

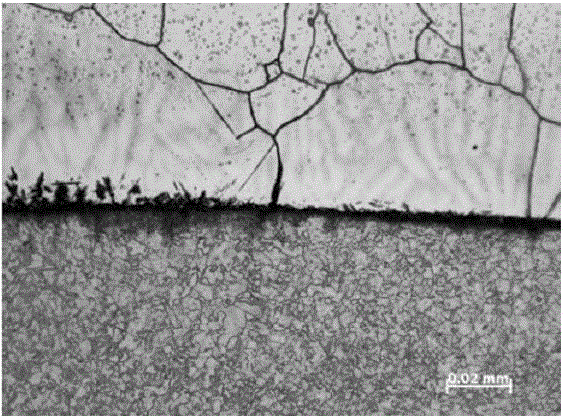

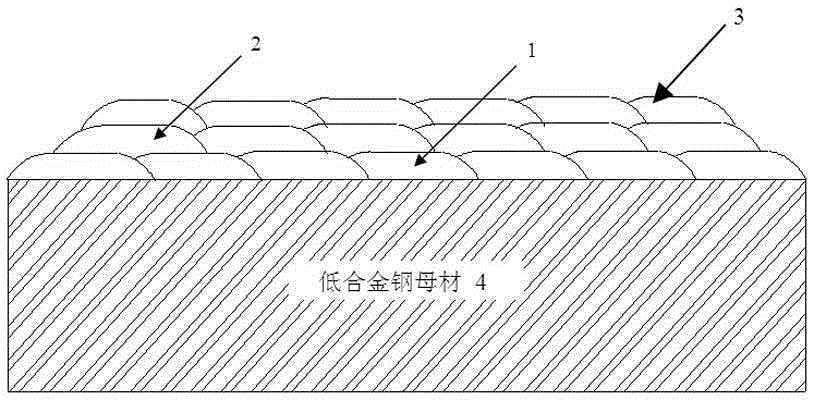

Method for performing stainless steel strip-electrode submerged-arc build-up welding on low-alloy parent steel

InactiveCN105234527AHigh bonding strengthImprove overall performanceArc welding apparatusWelding/cutting media/materialsAlloy steelWelding joint

The invention relates to a method for performing stainless steel strip-electrode submerged-arc build-up welding on low-alloy parent steel. The method comprises the following steps: S1, performing preheating before welding, and performing first-layer stainless steel strip-electrode submerged-arc build-up welding on a surface to be subjected to build-up welding, of the low-alloy parent steel, so as to form a first stainless steel build-up welding layer; S2, performing post-heating treatment; S3, performing second-layer stainless steel strip-electrode submerged-arc build-up welding and third-layer stainless steel strip-electrode submerged-arc build-up welding on the first stainless steel build-up welding layer so as to form a second stainless steel strip-electrode submerged-arc build-up welding layer and a third stainless steel strip-electrode submerged-arc build-up welding layer; and S4, performing postwelding heat treatment. According to the method, the thicknesses of hardening layers of transition regions of stainless steel strip-electrode submerged-arc build-up welding joints are effectively controlled by controlling preheating temperature, interlayer temperature, welding currents, welding voltages, welding speed, temperature of post-heating treatment, time of post-heating treatment, temperature of postwelding heat treatment and time of postwelding heat treatment, so that the thicknesses of the hardening layers are reduced by over 50%; the bonding strength of the build-up welding layers and the parent steel is improved; the problem that in the prior art, a stainless build-up welding layer on the low-alloy parent steel can crack, and even be stripped off, at a stainless steel strip-electrode submerged-arc build-up welding joint is solved.

Owner:SHANGHAI ELECTRIC NUCLEAR POWER EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com