Continuous variational convexity degree rolling mill back-up shaft

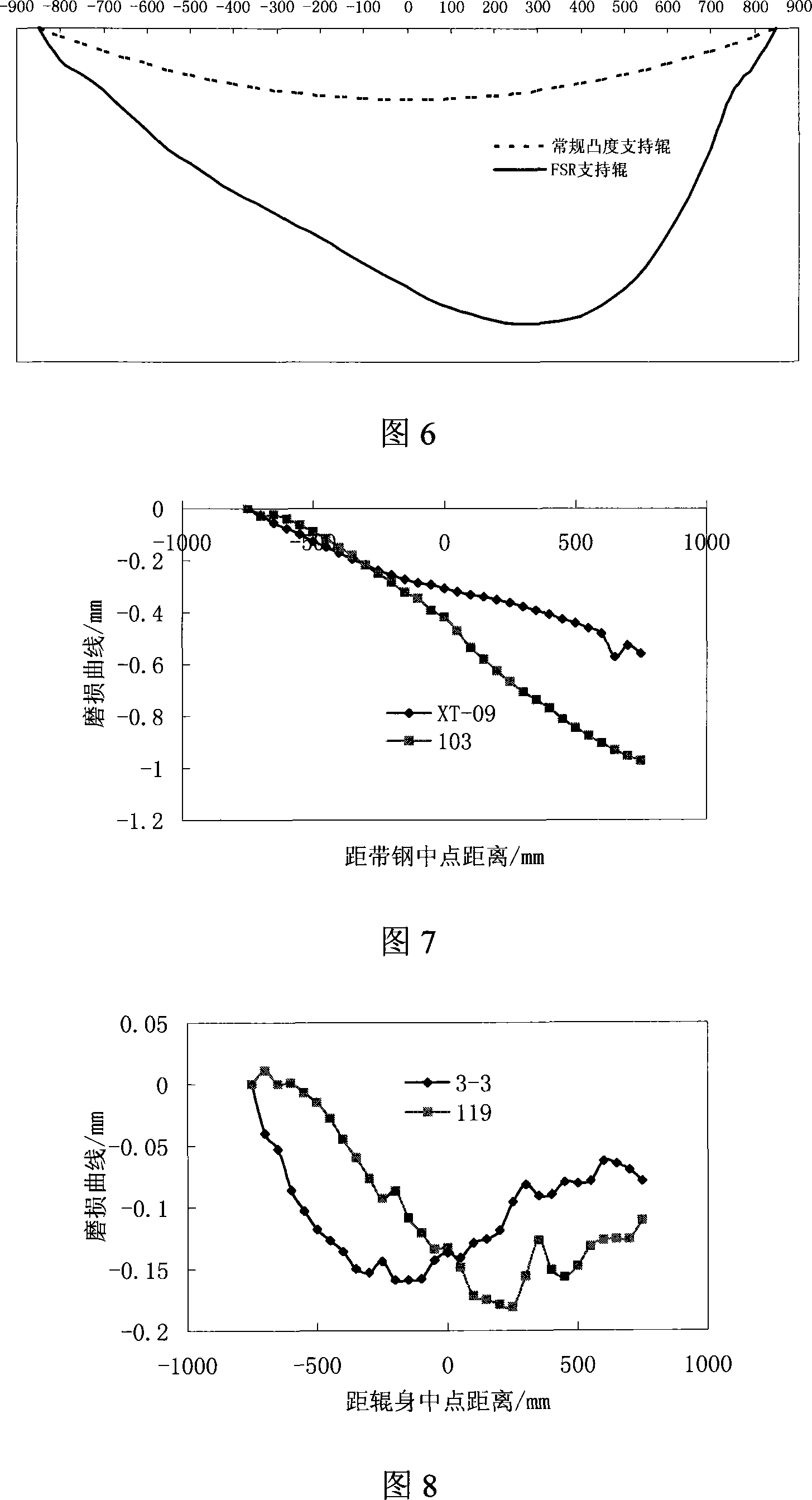

A back-up roll and variable crown technology, which is applied in metal rolling, metal rolling, metal processing equipment, etc., can solve the problem of uneven wear of crown back-up rolls, uneven pressure distribution between rolls, ringing strip shape quality, etc. problem, to achieve the effect of reducing the unevenness and peak value of the contact pressure distribution between the rollers, improving the uneven distribution of the pressure between the rollers, and improving the quality of the plate shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] This example discloses a support roll that matches the SmartCrown plus continuous variable crown work roll of the 1700 tandem cold rolling mill.

[0026] The implementation process of the support roller profile technology is as follows:

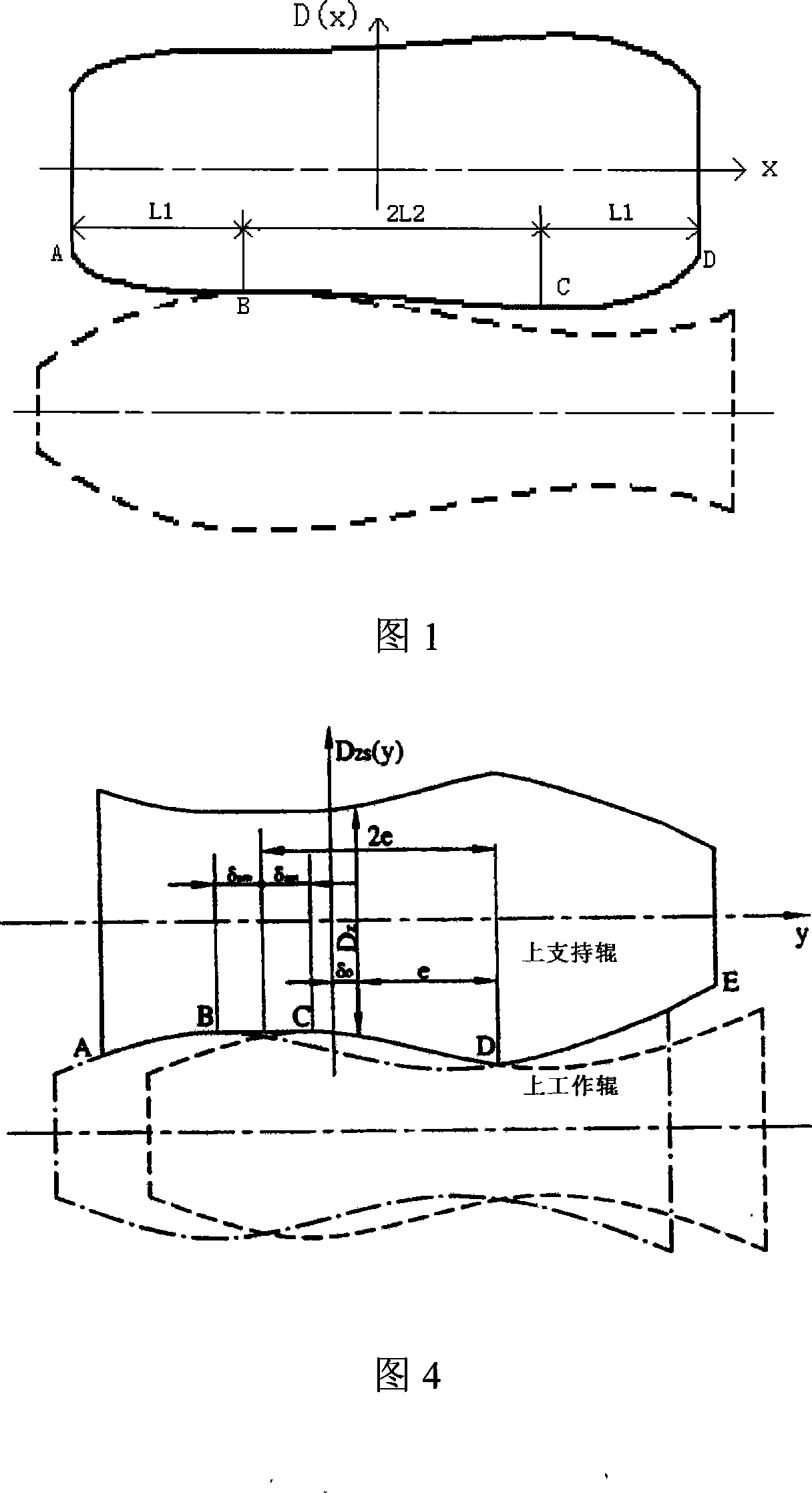

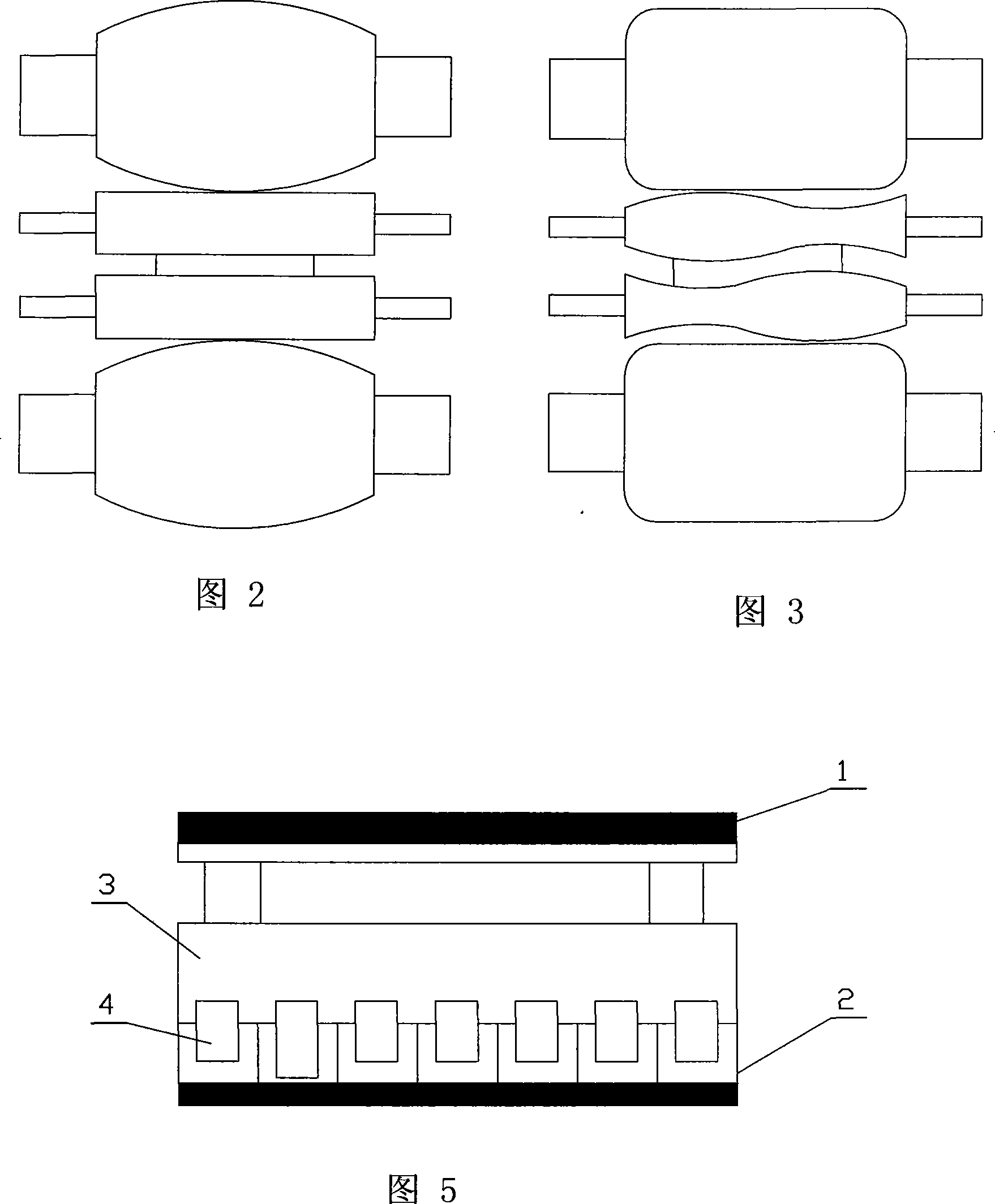

[0027] 1. According to the rolling mill technical parameters and the continuous variable crown work roll profile index, determine the support roll profile design parameters. Known continuous variable crown rolling mill work roll axial shift stroke range s∈[-s m , S m ], the corresponding roll gap convexity range is C W ∈[C 1 , C 2 ], work roll shape design and use length L b Take the sum of the maximum normal-rolled plate width and the roll shift stroke of the variable crown mill ~ the sum of the length of the support roll and the roll shift stroke of the variable crown mill, and set the work roll axial movement distance s to be 0, which The initial convexity of the roll gap is C 0 (Usually take C 0 =(C 1 +C 2 ) / 2), substituted into equati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com